Patents

Literature

4566 results about "Inlet manifold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In automotive engineering, an inlet manifold or intake manifold (in American English) is the part of an engine that supplies the fuel/air mixture to the cylinders. The word manifold comes from the Old English word manigfeald (from the Anglo-Saxon manig [many] and feald [repeatedly]) and refers to the multiplying of one (pipe) into many.

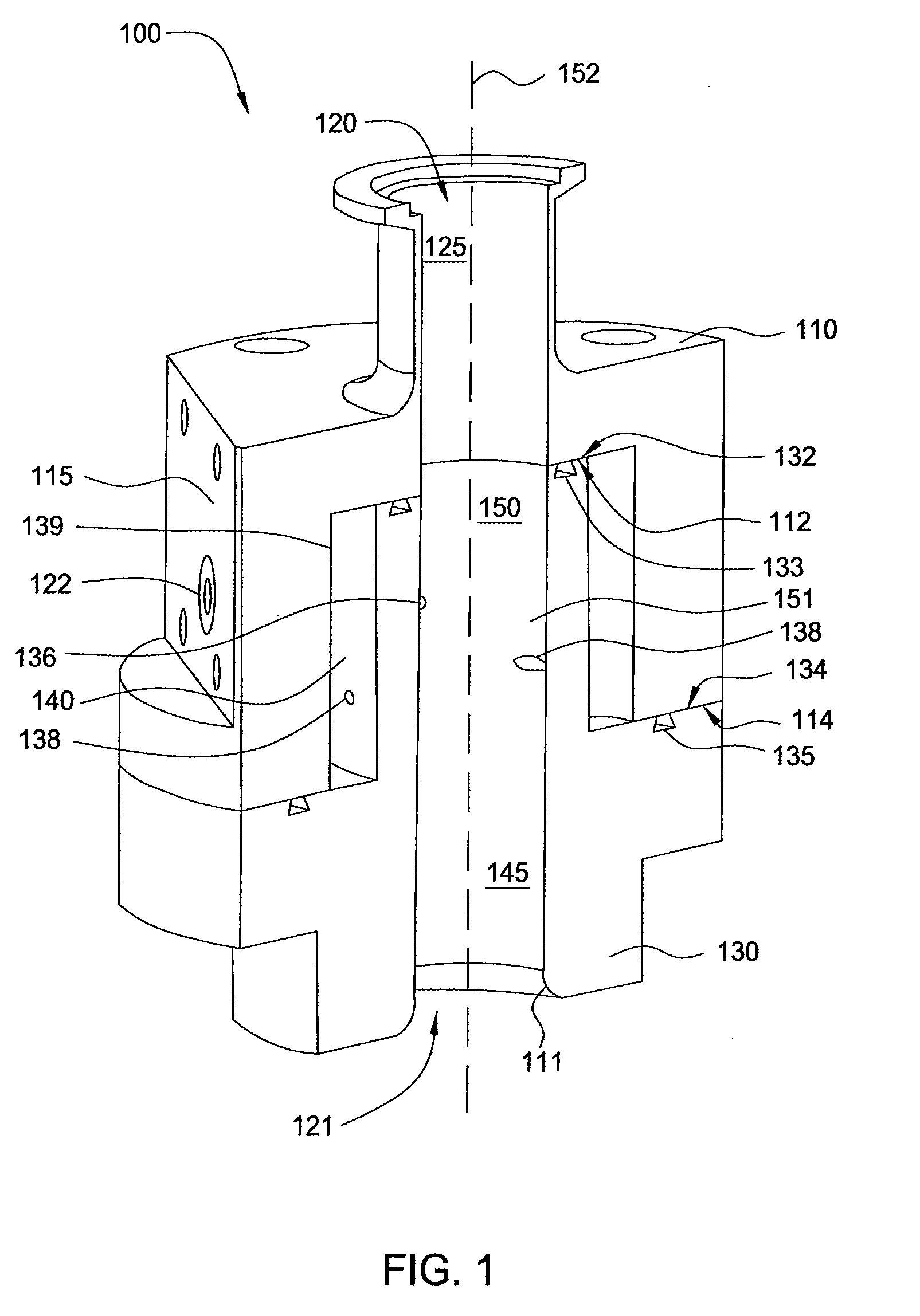

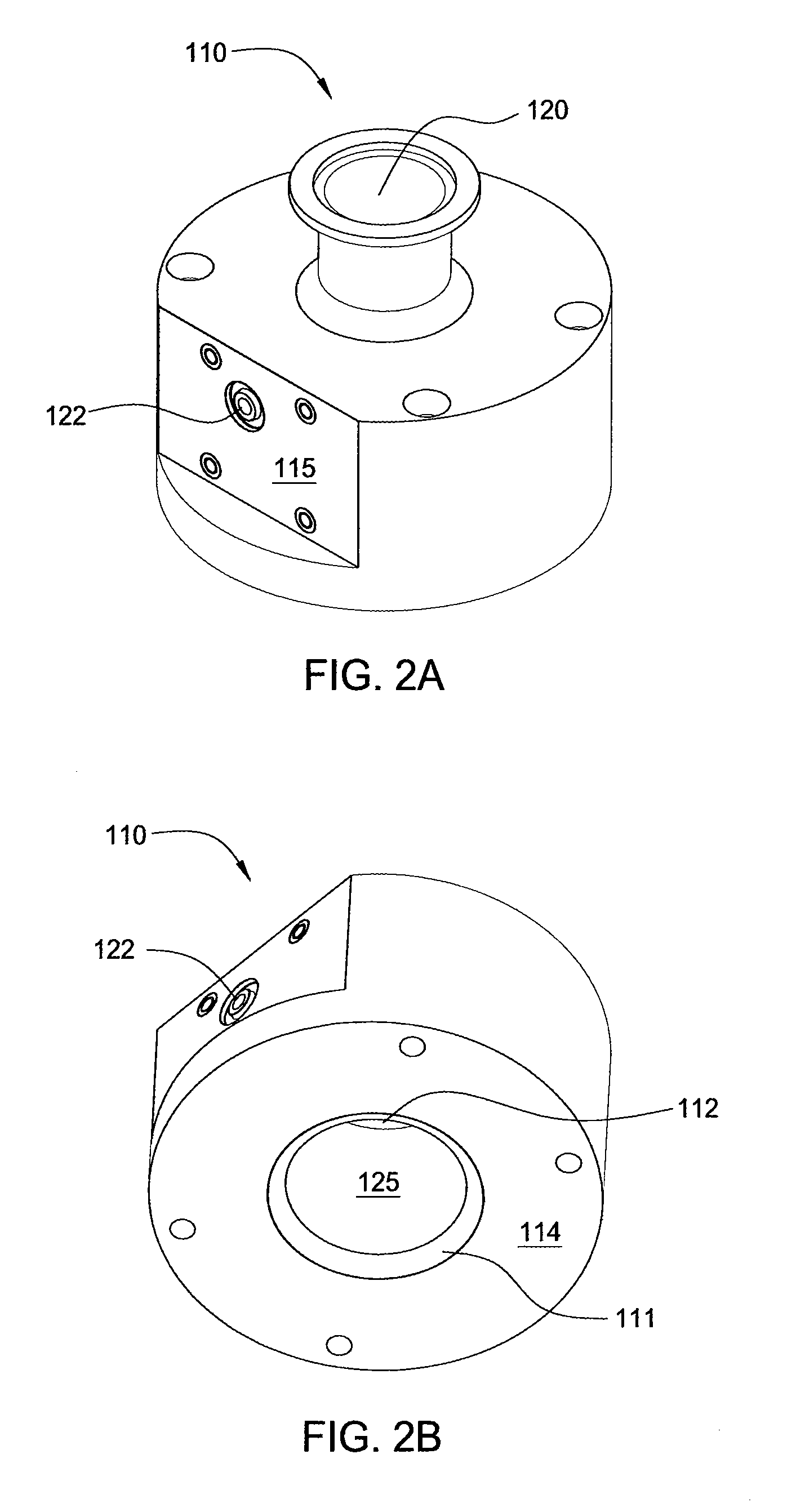

Apparatuses and methods for atomic layer deposition

ActiveUS20100003406A1Hole densityHigh hole densityElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaAtomic layer deposition

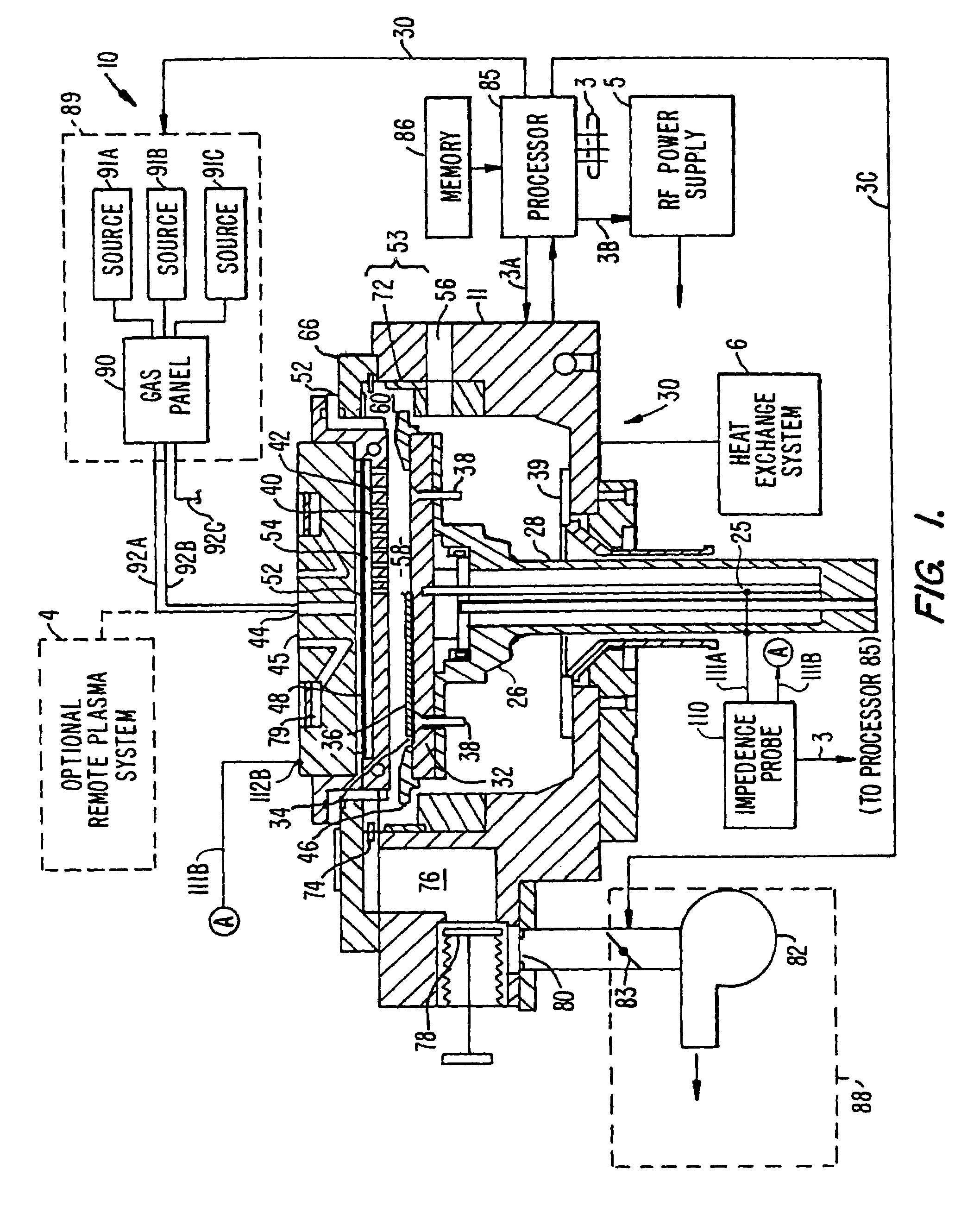

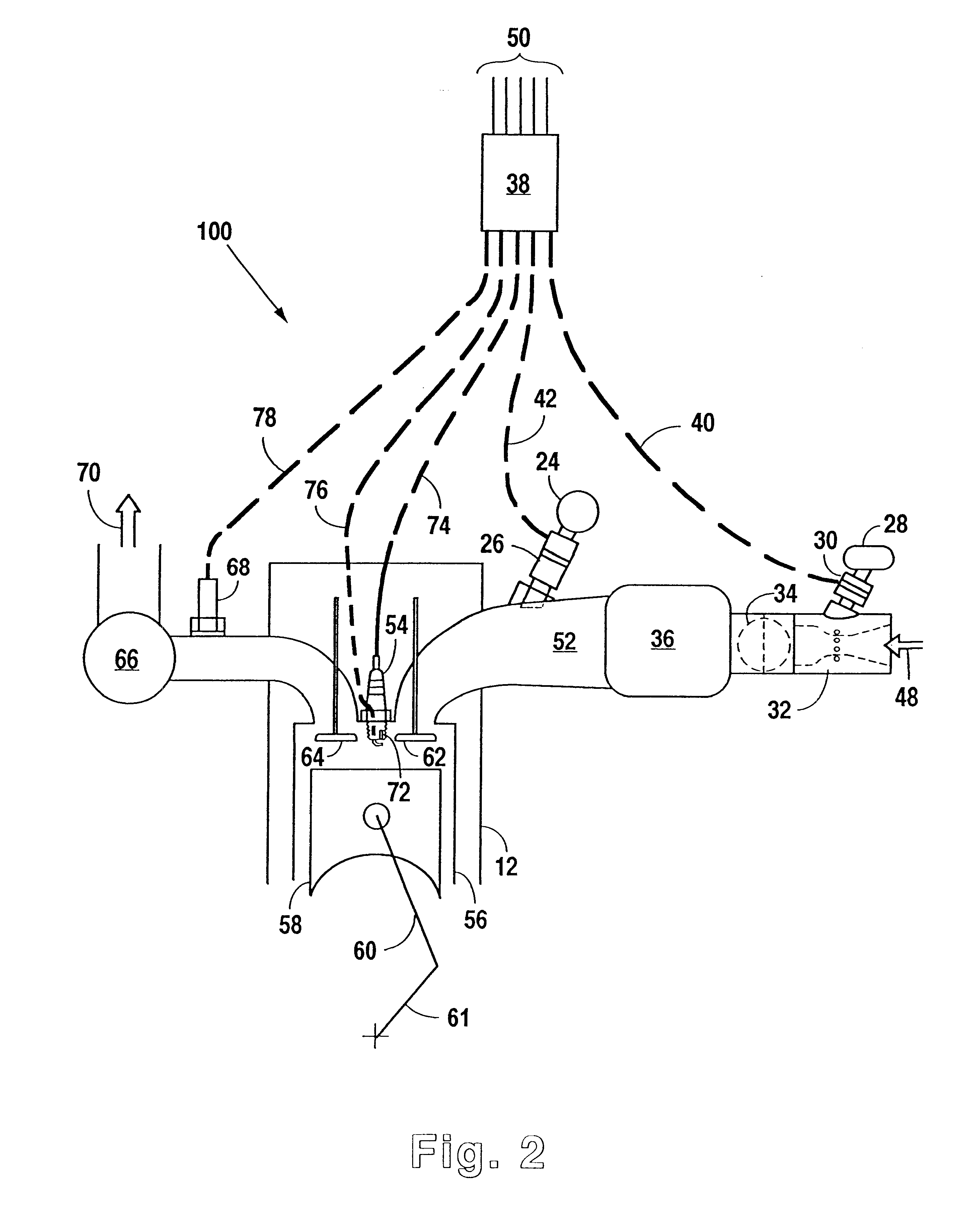

Embodiments of the invention provide apparatuses and methods for atomic layer deposition (ALD), such as plasma-enhanced ALD (PE-ALD). In some embodiments, a PE-ALD chamber is provided which includes a chamber lid assembly coupled with a chamber body having a substrate support therein. In one embodiment, the chamber lid assembly has an inlet manifold assembly containing an annular channel encompassing a centralized channel, wherein the centralized channel extends through the inlet manifold assembly, and the inlet manifold assembly further contains injection holes extending from the annular channel, through a sidewall of the centralized channel, and to the centralized channel. The chamber lid assembly further contains a showerhead assembly disposed below the inlet manifold assembly, a water box disposed between the inlet manifold assembly and the showerhead assembly, and a remote plasma system (RPS) disposed above and coupled with the inlet manifold assembly, and in fluid communication with the centralized channel.

Owner:APPLIED MATERIALS INC

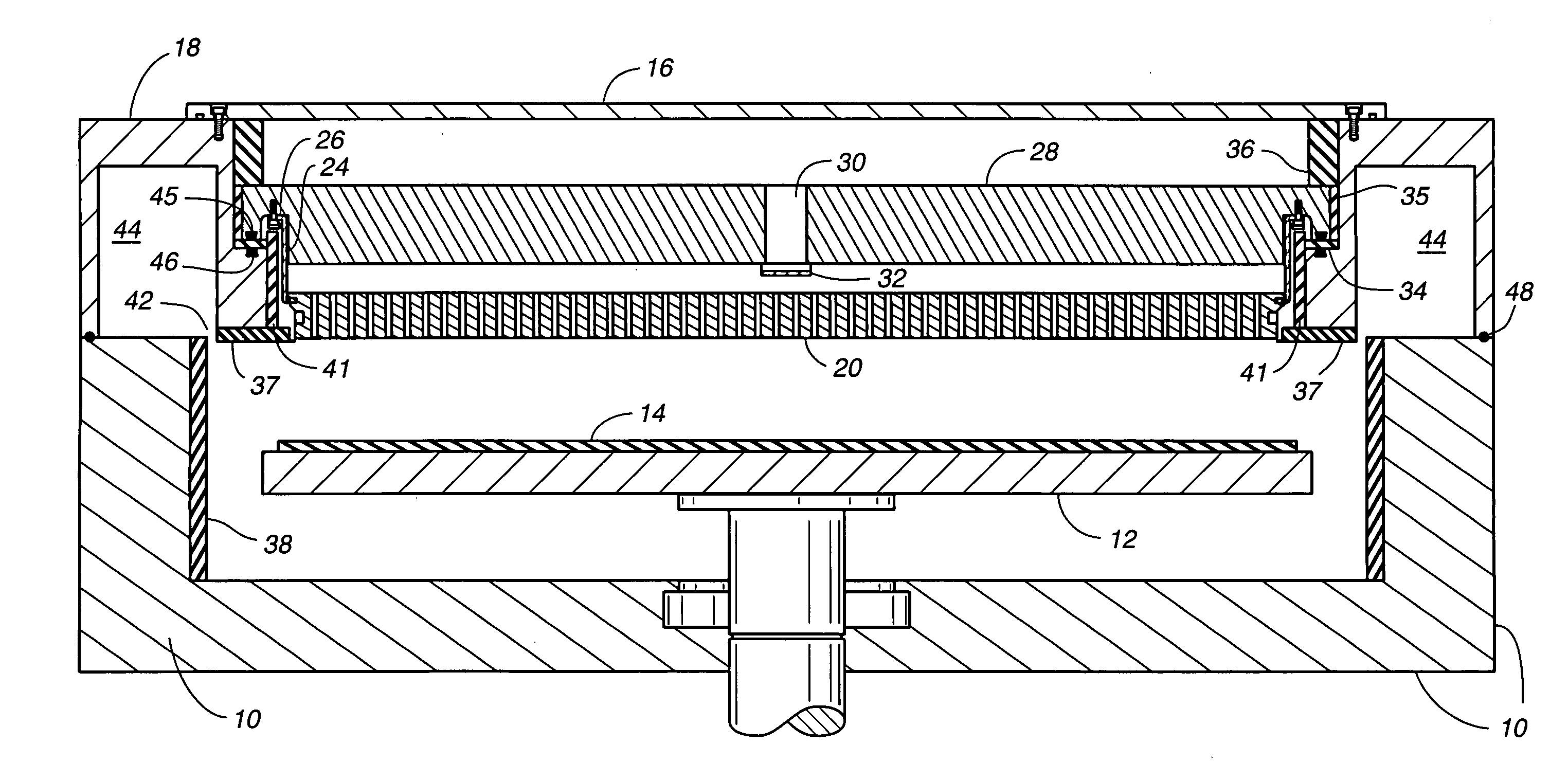

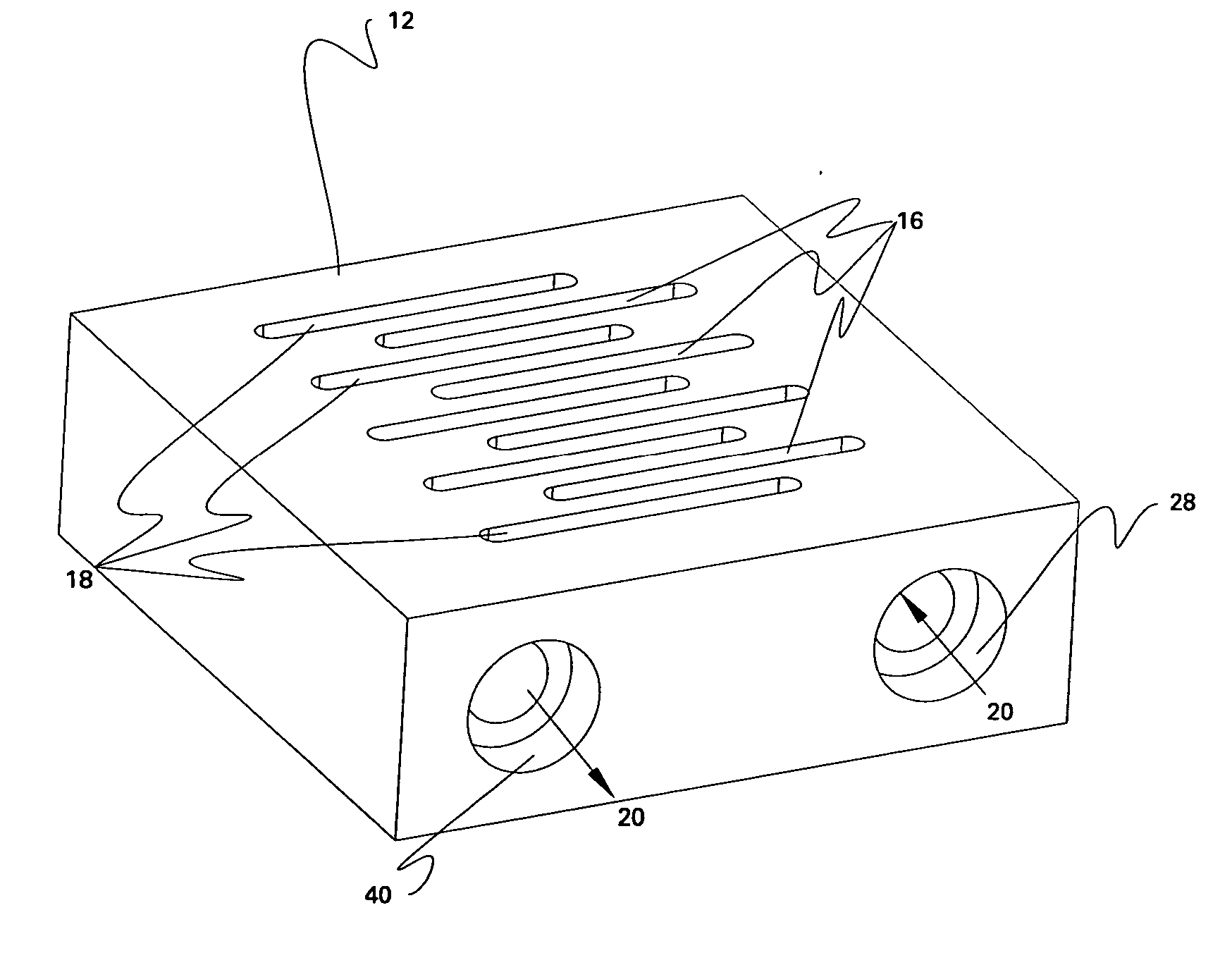

Suspended gas distribution plate

InactiveUS7017269B2Avoid distortionAvoid crackingElectric discharge tubesSemiconductor/solid-state device manufacturingThermal isolationEngineering

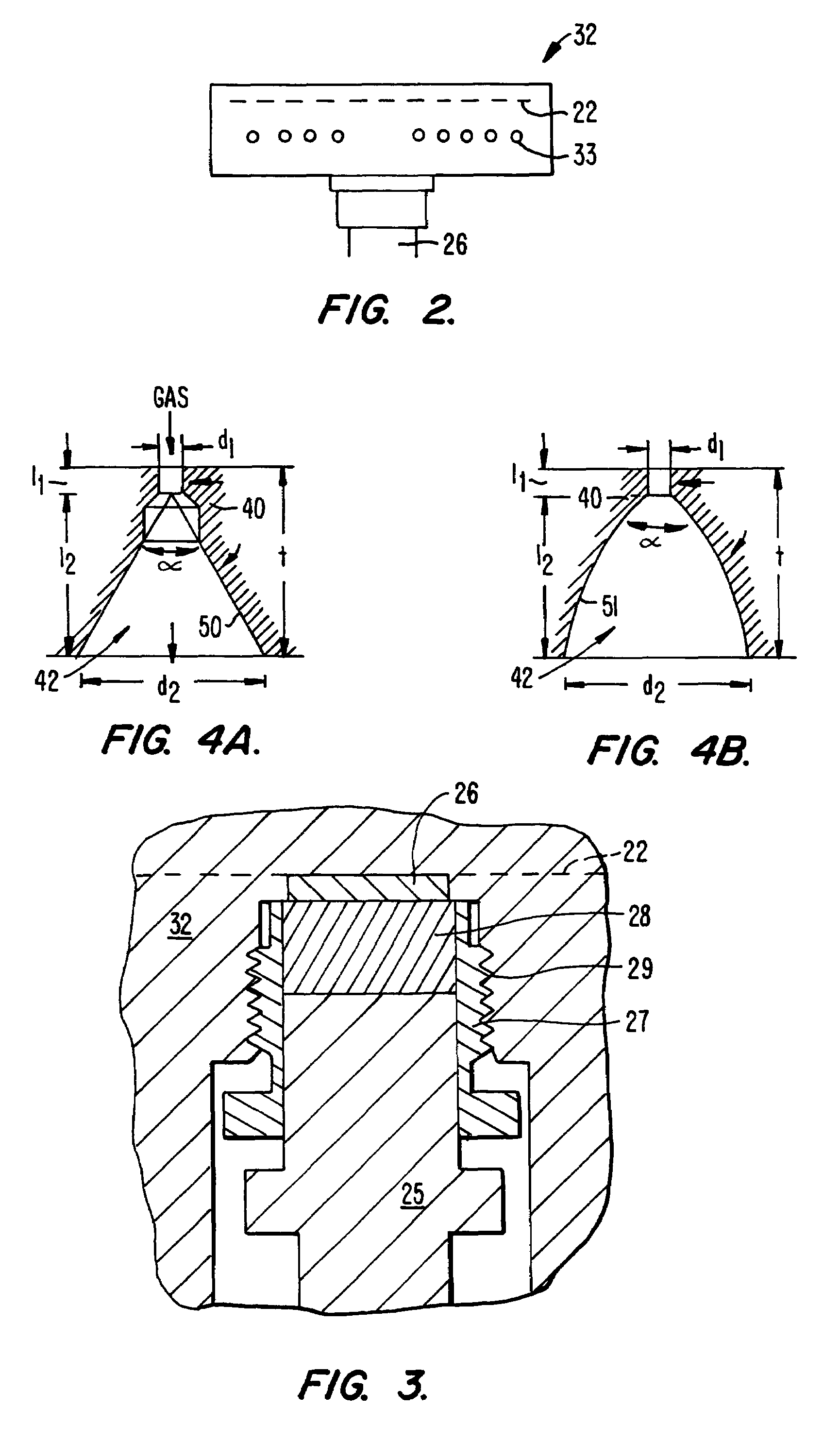

A gas inlet manifold for a plasma chamber having a perforated gas distribution plate suspended by flexible side walls. The flexible suspension minimizes mechanical stress due to thermal expansion of the gas distribution plate. In another aspect, the suspension provides thermal isolation between the gas distribution plate and other components of the chamber.

Owner:APPLIED MATERIALS INC

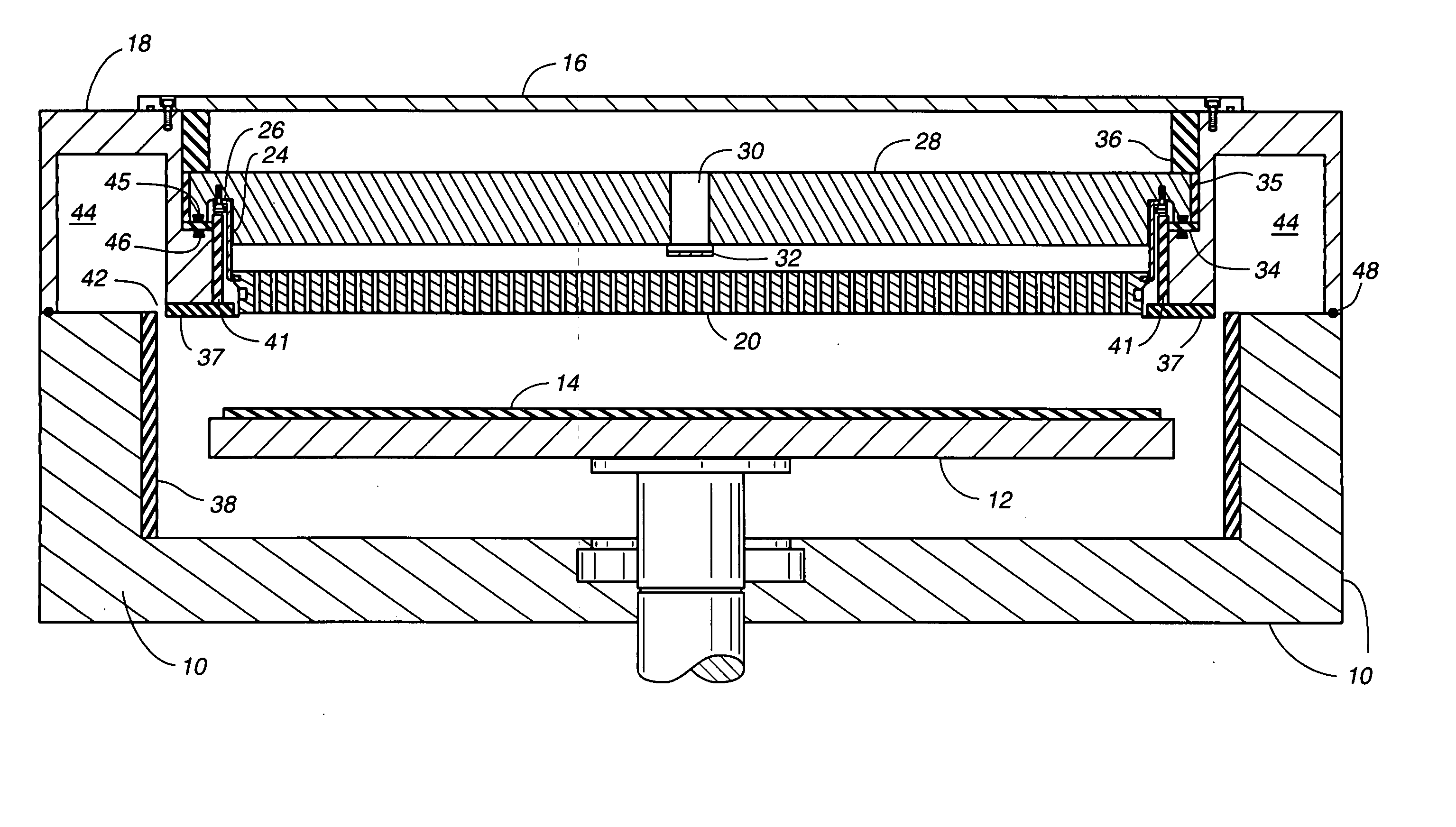

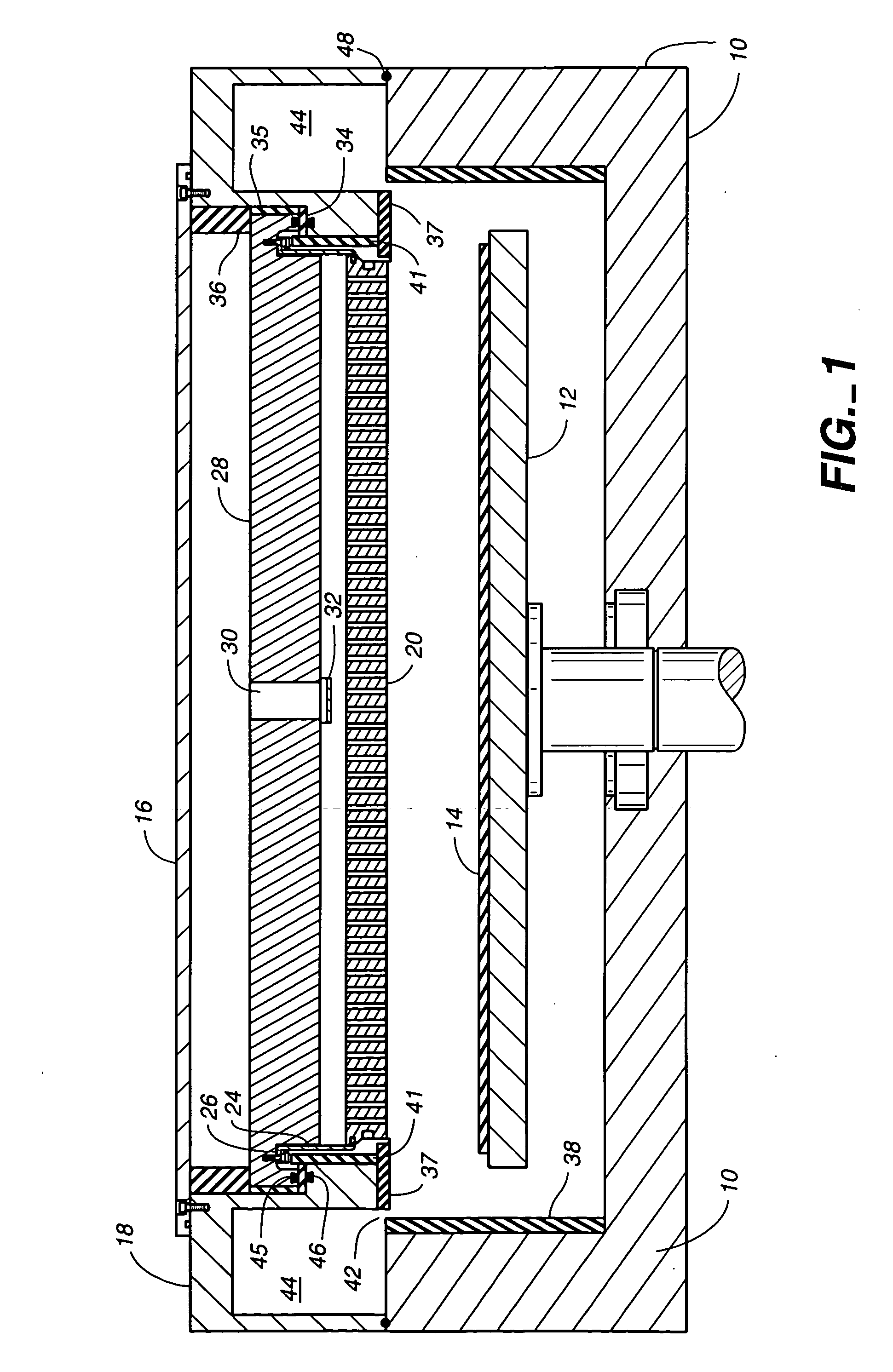

Suspended gas distribution manifold for plasma chamber

InactiveUS7484473B2Avoiding distortion and crackingImprove spatial uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingThermal isolationProduct gas

Owner:APPLIED MATERIALS INC

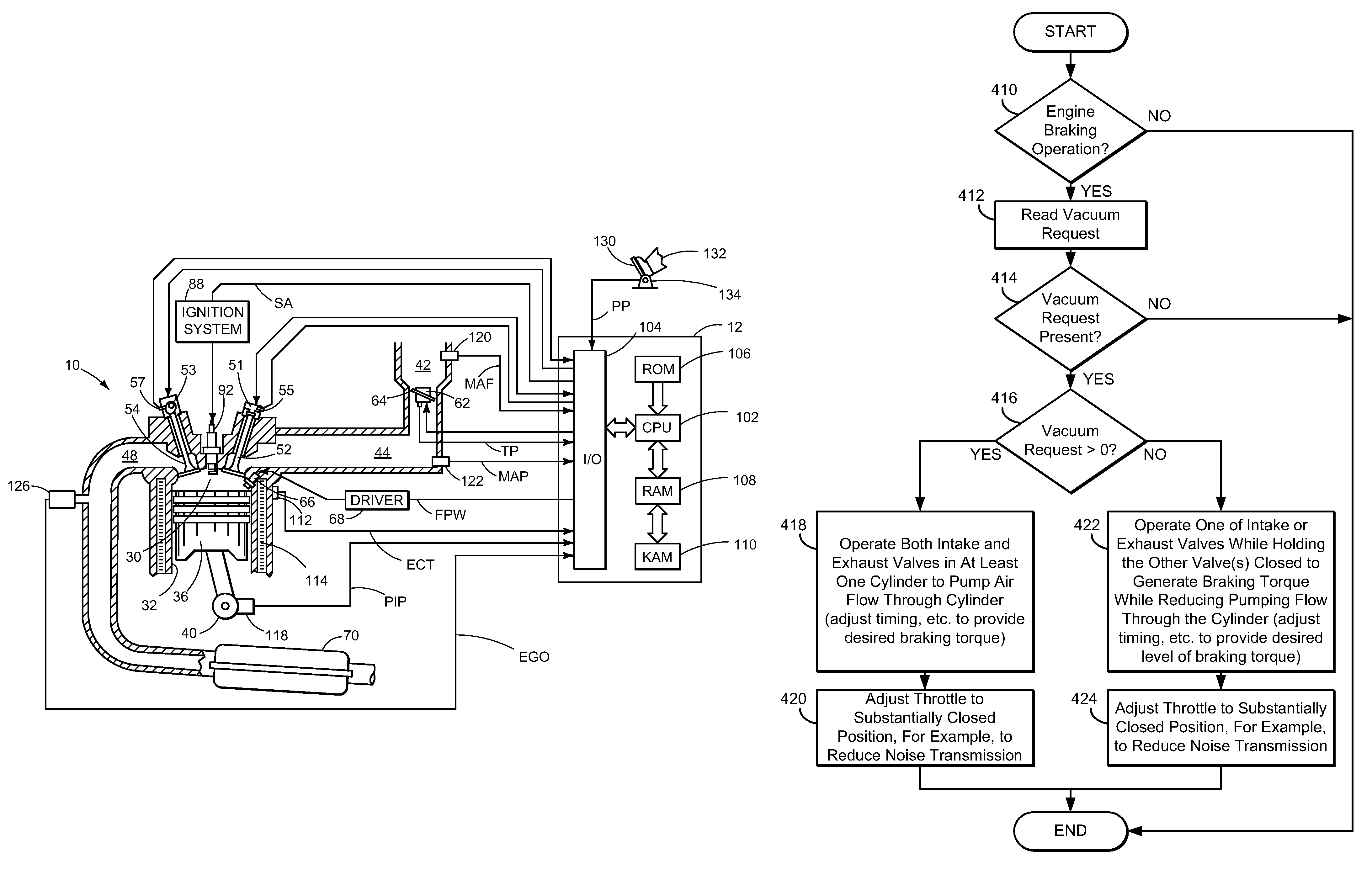

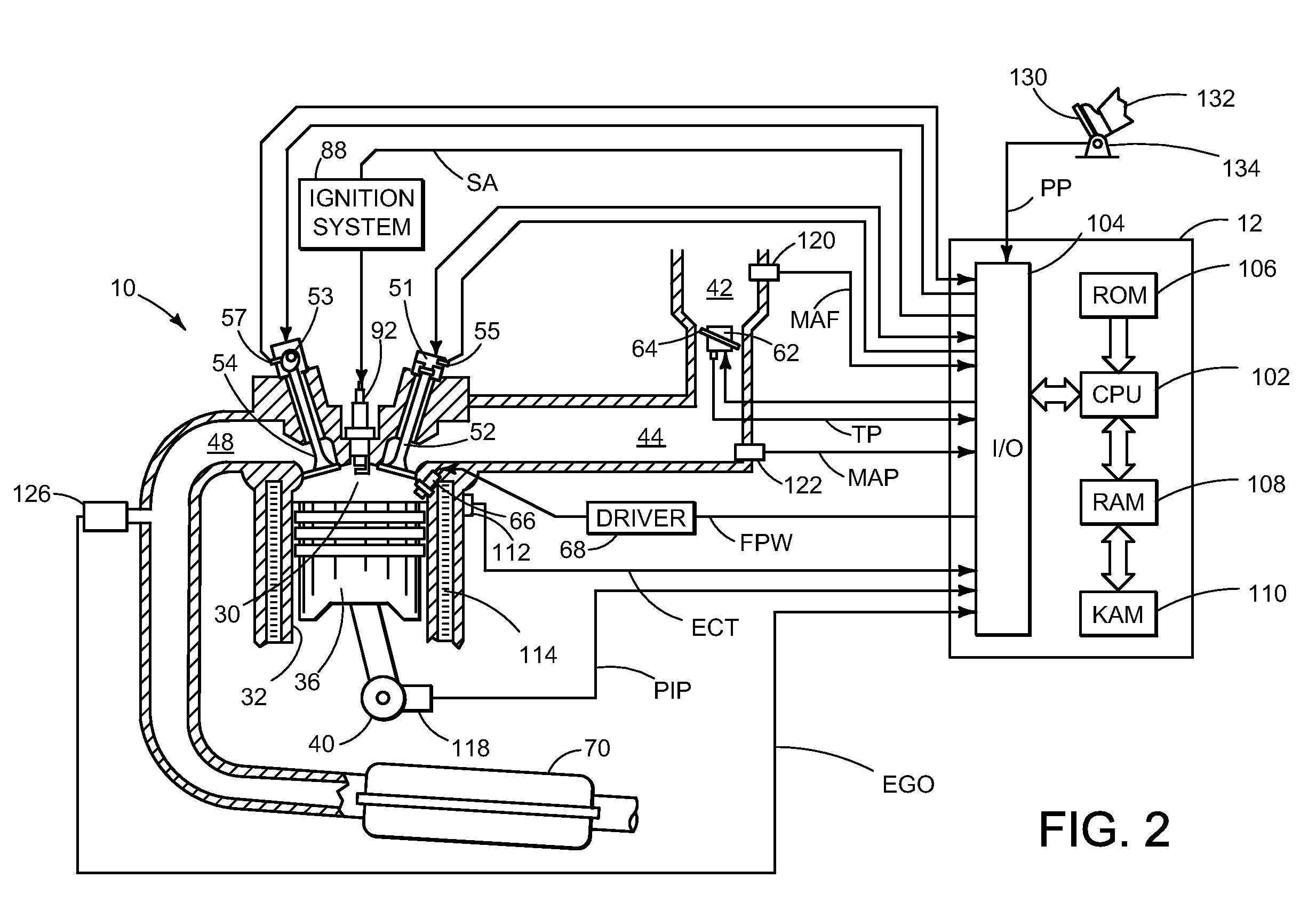

Vehicle braking control

ActiveUS7930087B2Reduced effectivenessImprove fuel economyElectrical controlInternal combustion piston enginesExhaust valveInlet valve

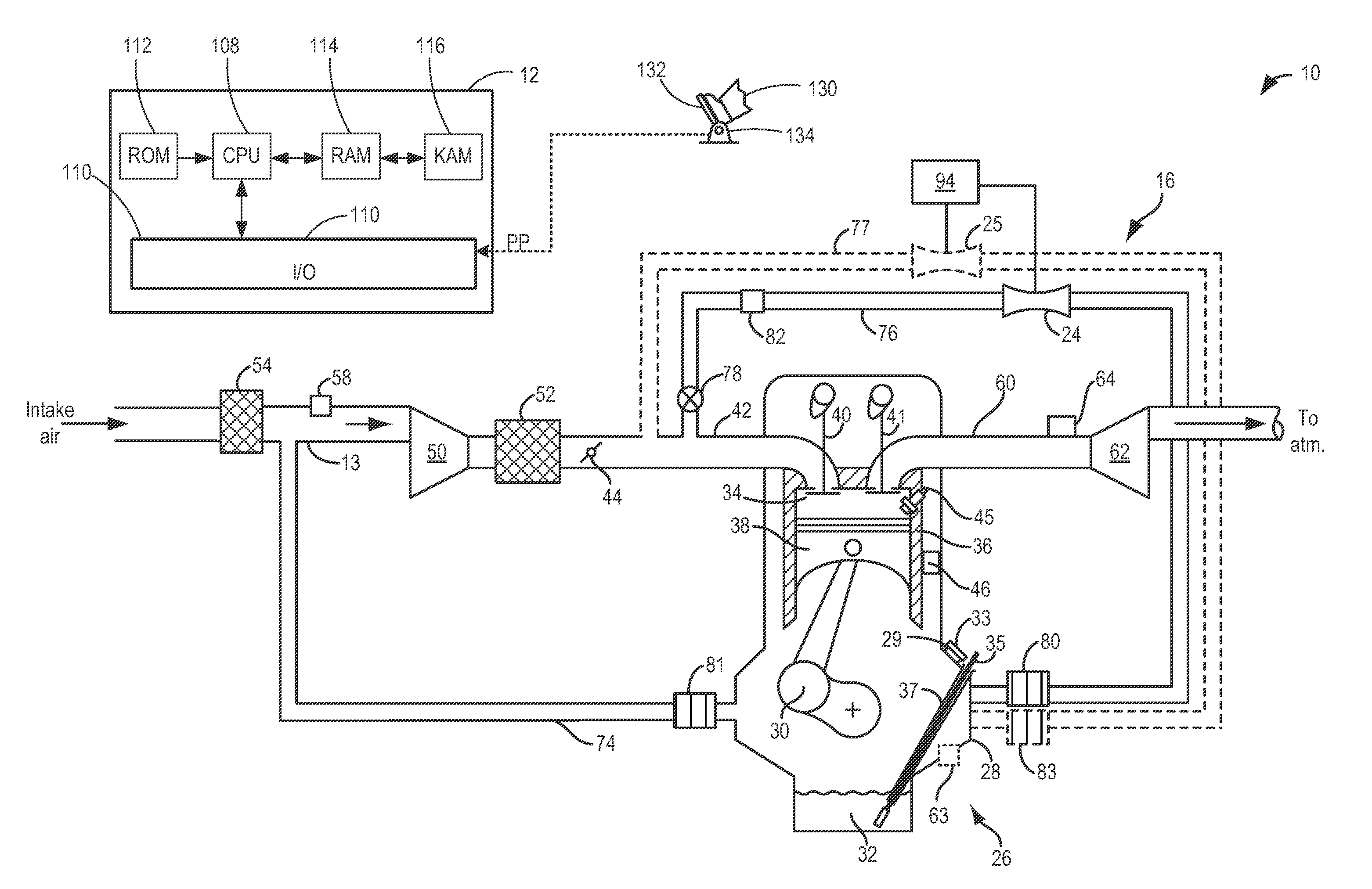

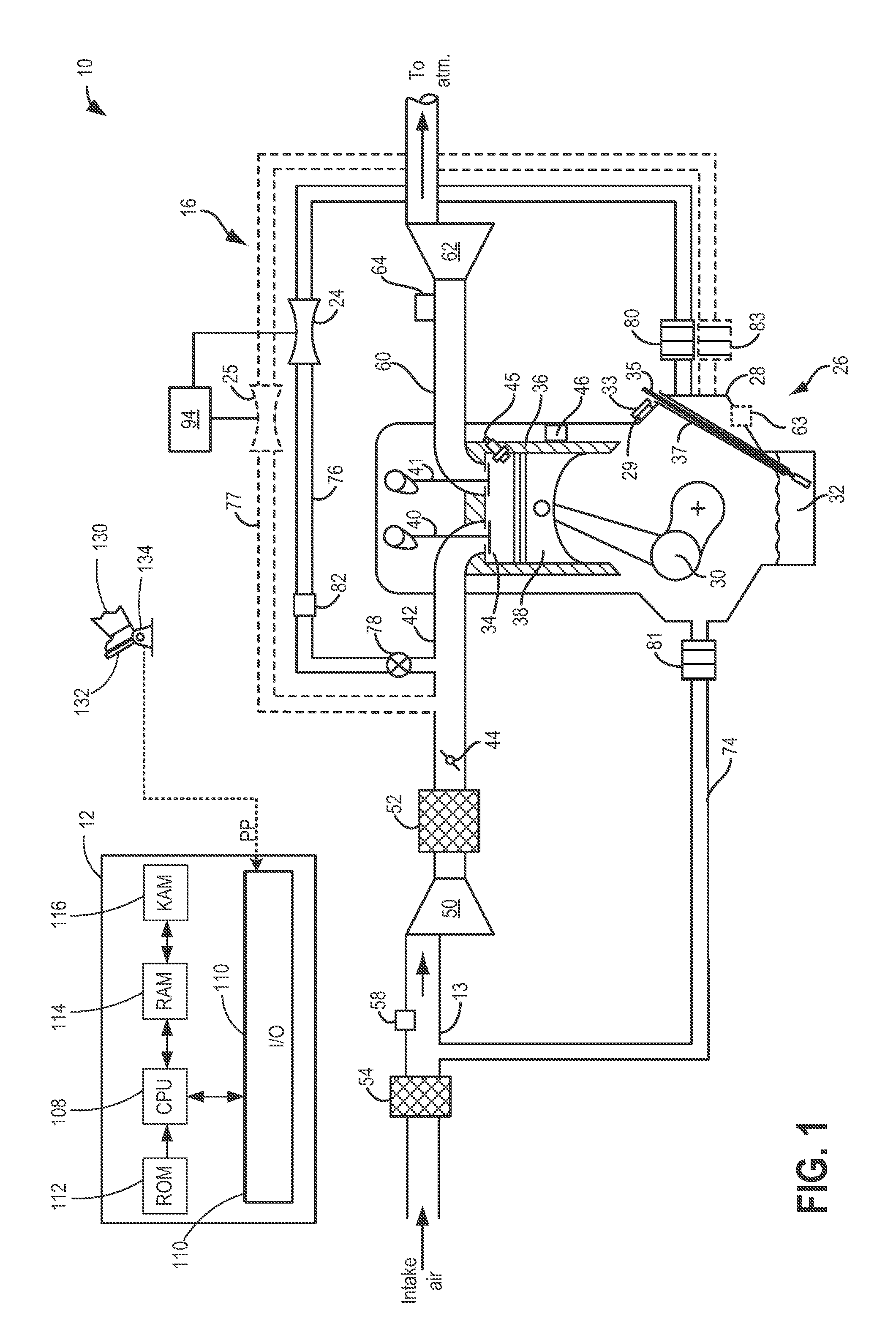

A method of operating an engine for a vehicle having at least a first cylinder, the method comprising of operating the first cylinder to provide at least one of compression braking and expansion braking by holding one of an intake valve and an exhaust valve of the first cylinder closed while opening, closing, and opening the other of the intake valve and the exhaust valve during a cycle of the first cylinder and during a first vacuum level of an intake manifold upstream of the first cylinder; and operating the first cylinder to provide at least one of compression braking and expansion braking by operating both the intake valve and the exhaust valve of the first cylinder during a cycle of the first cylinder to allow at least some air to flow through the first cylinder during a second vacuum level of the intake manifold.

Owner:FORD GLOBAL TECH LLC

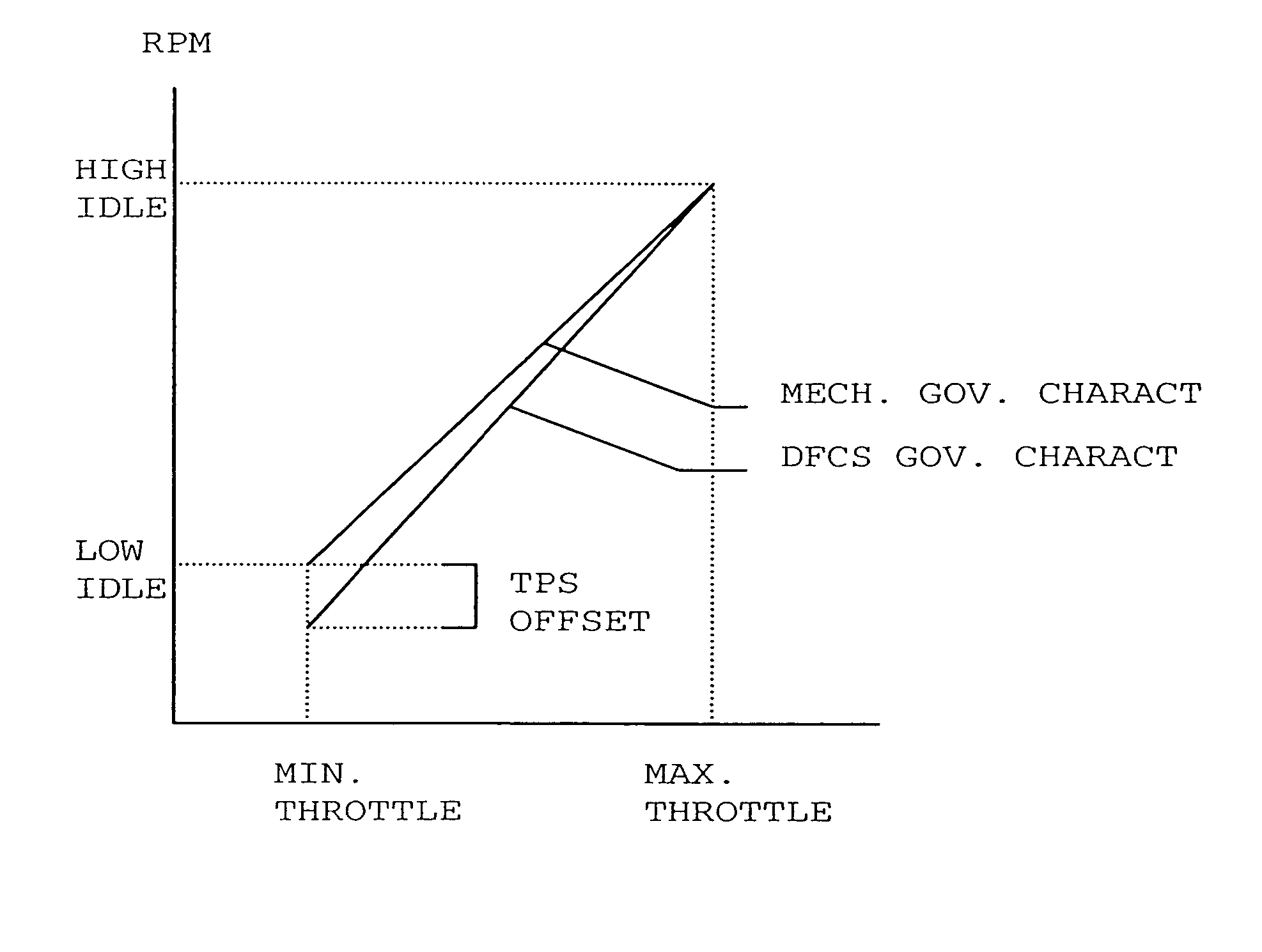

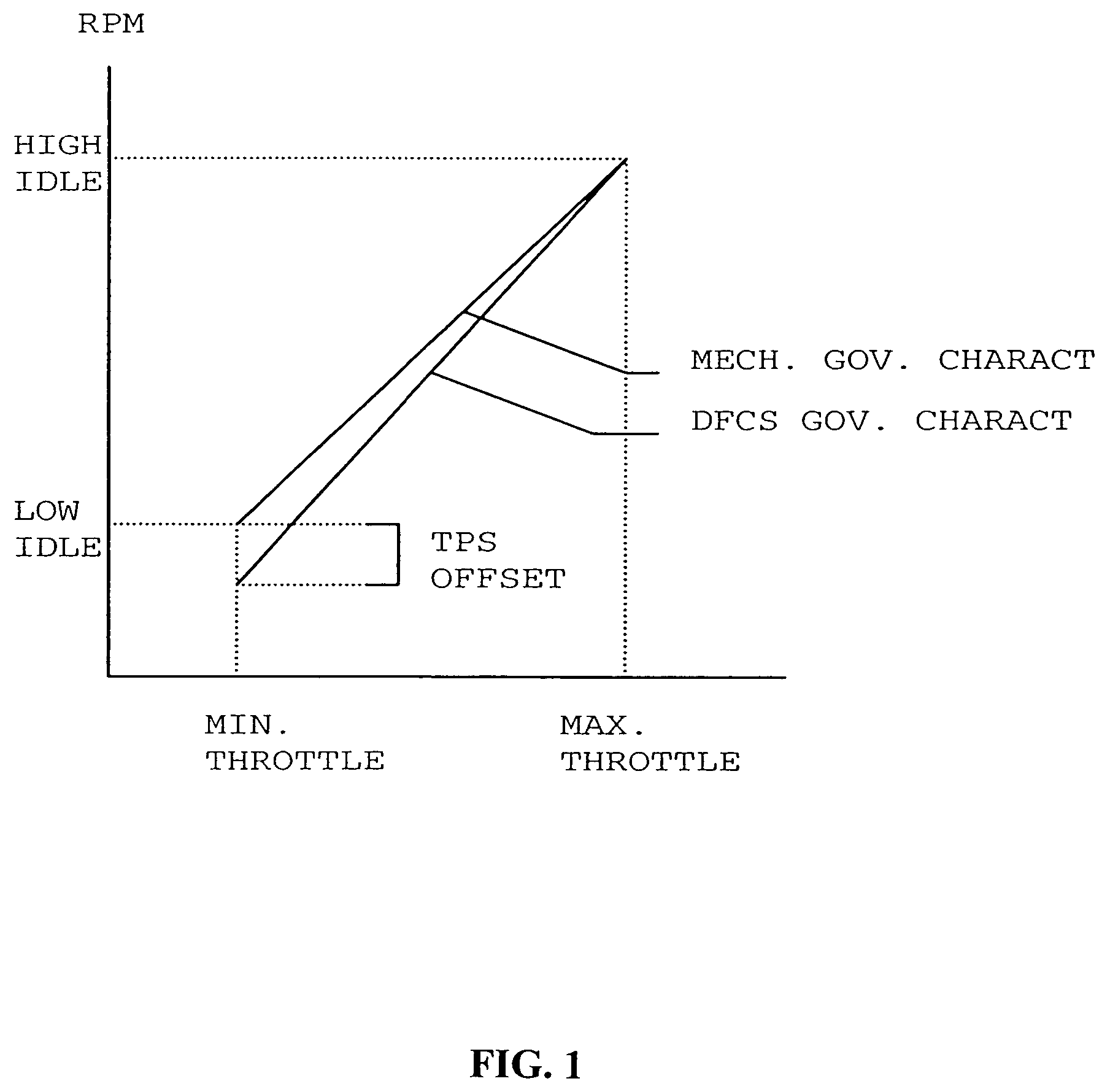

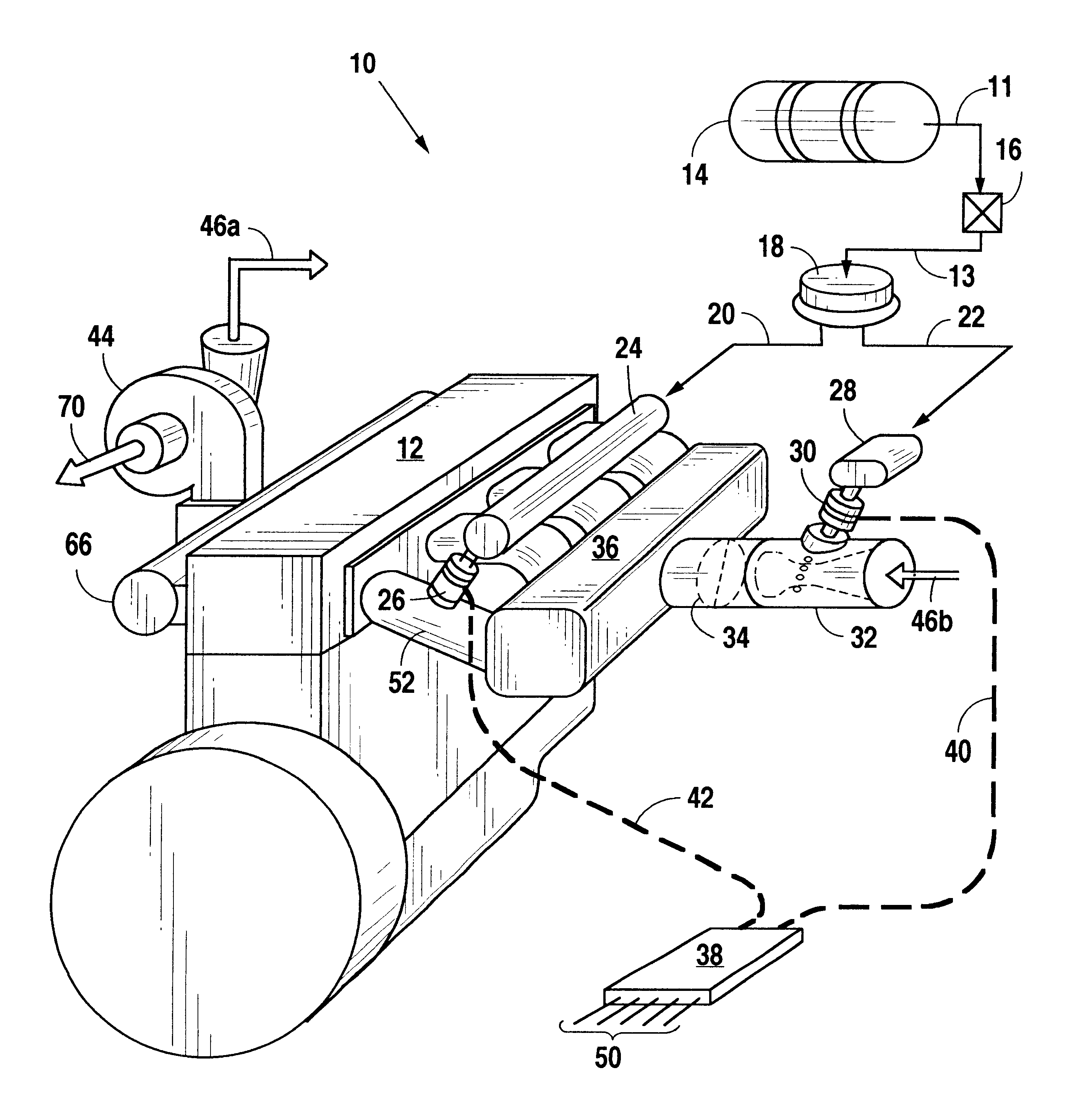

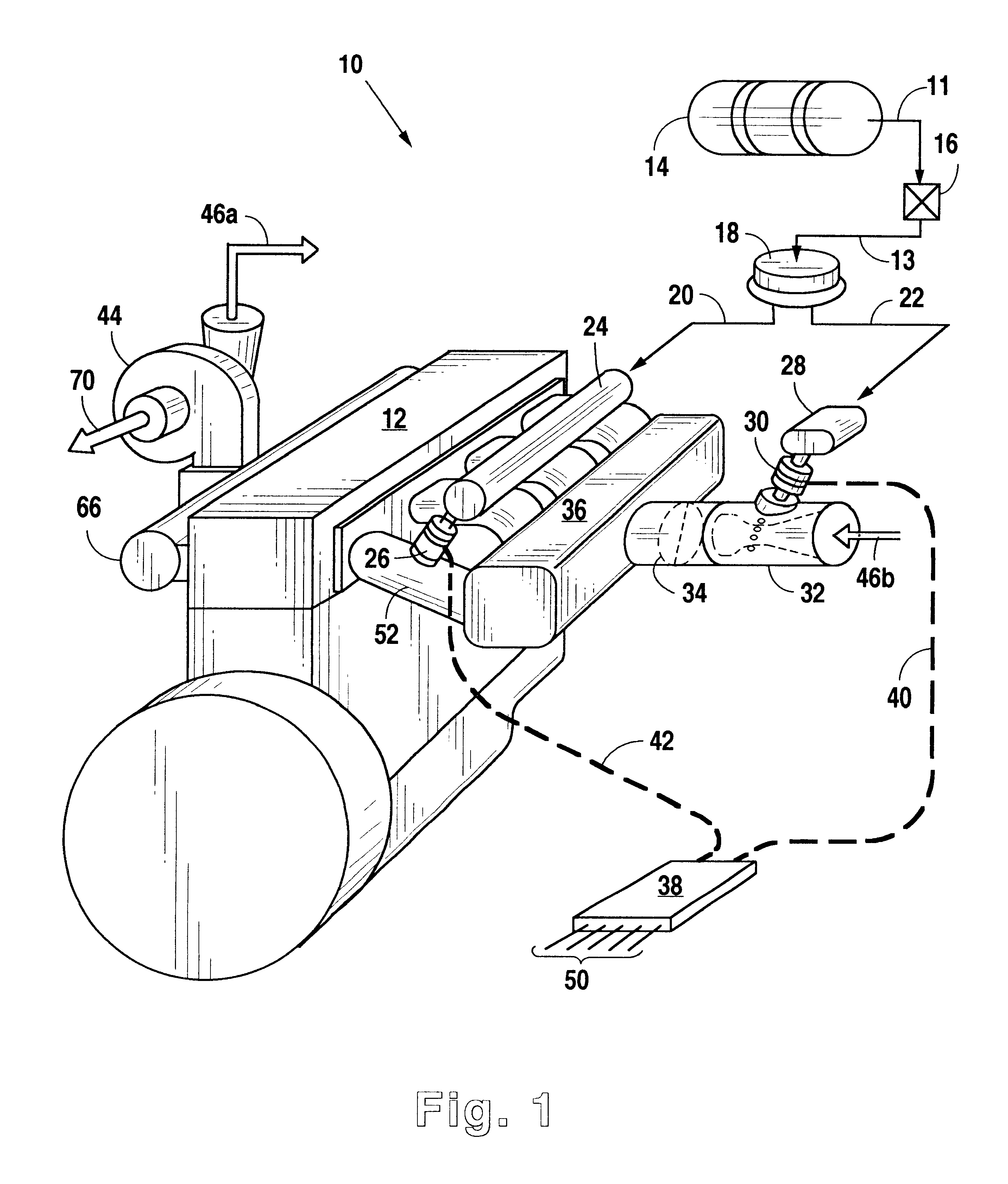

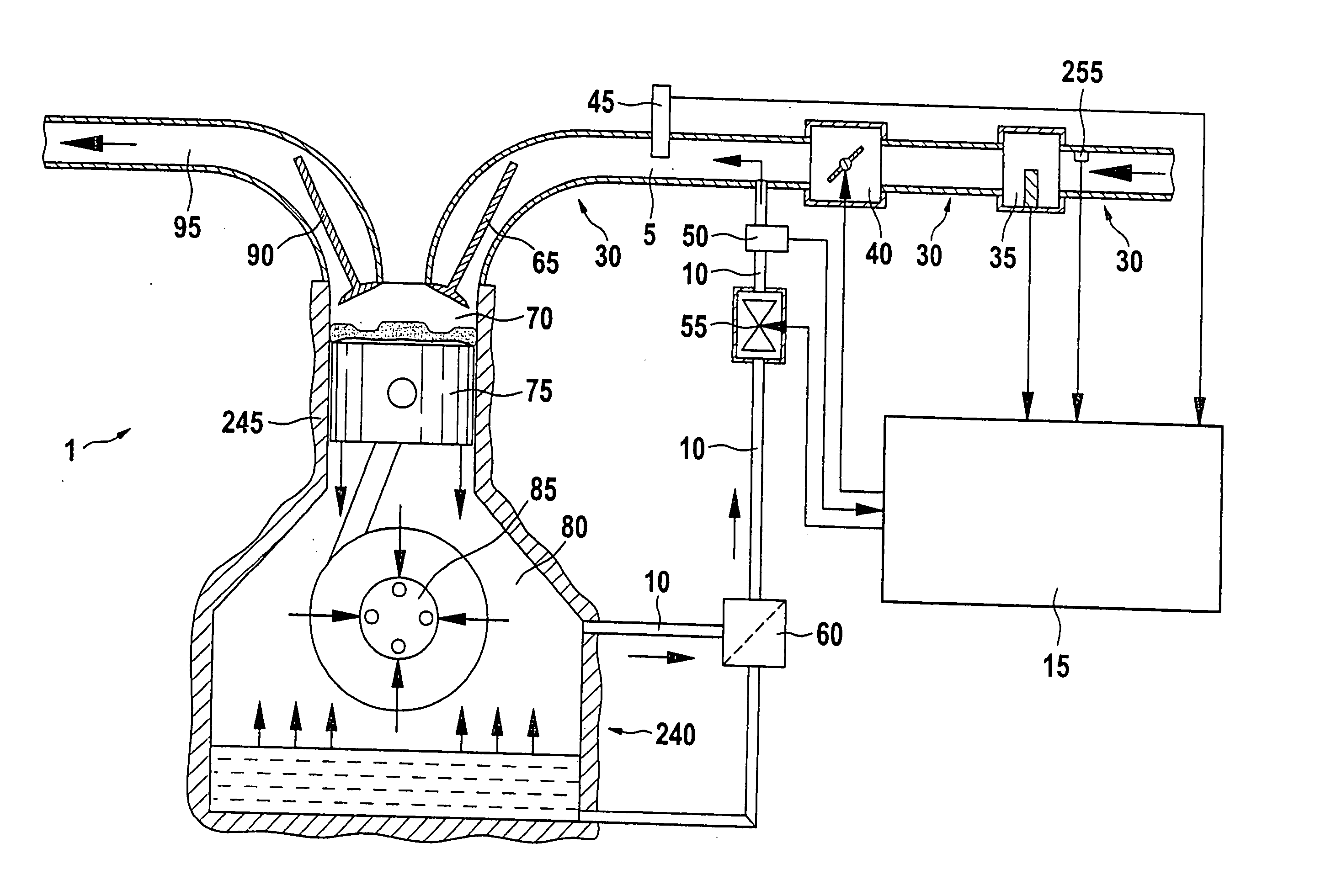

Methods and apparatus for operation of multiple fuel engines

Methods and apparatus are disclosed for operation of a multiple fuel engine, which runs on a combination of two or more fuels. An electronic control unit (ECU) may be connected to the existing components of an engine system in order to control operation of the multiple fuel engine. The engine system may be mechanically governed or electronically controlled. The ECU inputs operating characteristics of the engine system, determines governing characteristics for multiple fuel operation based on the operating characteristics, and controls the amounts of fuel delivered to the engine based on the governing characteristics. In a preferred embodiment, a dual fuel engine operates using diesel as a first fuel and natural gas as a second fuel. The operating characteristics may include engine speed, throttle position, engine exhaust temperature, gas pressure of the second fuel, gas temperature of the second fuel, boost pressure of an intake manifold, or engine coolant temperature.

Owner:2FUEL TECH INC +1

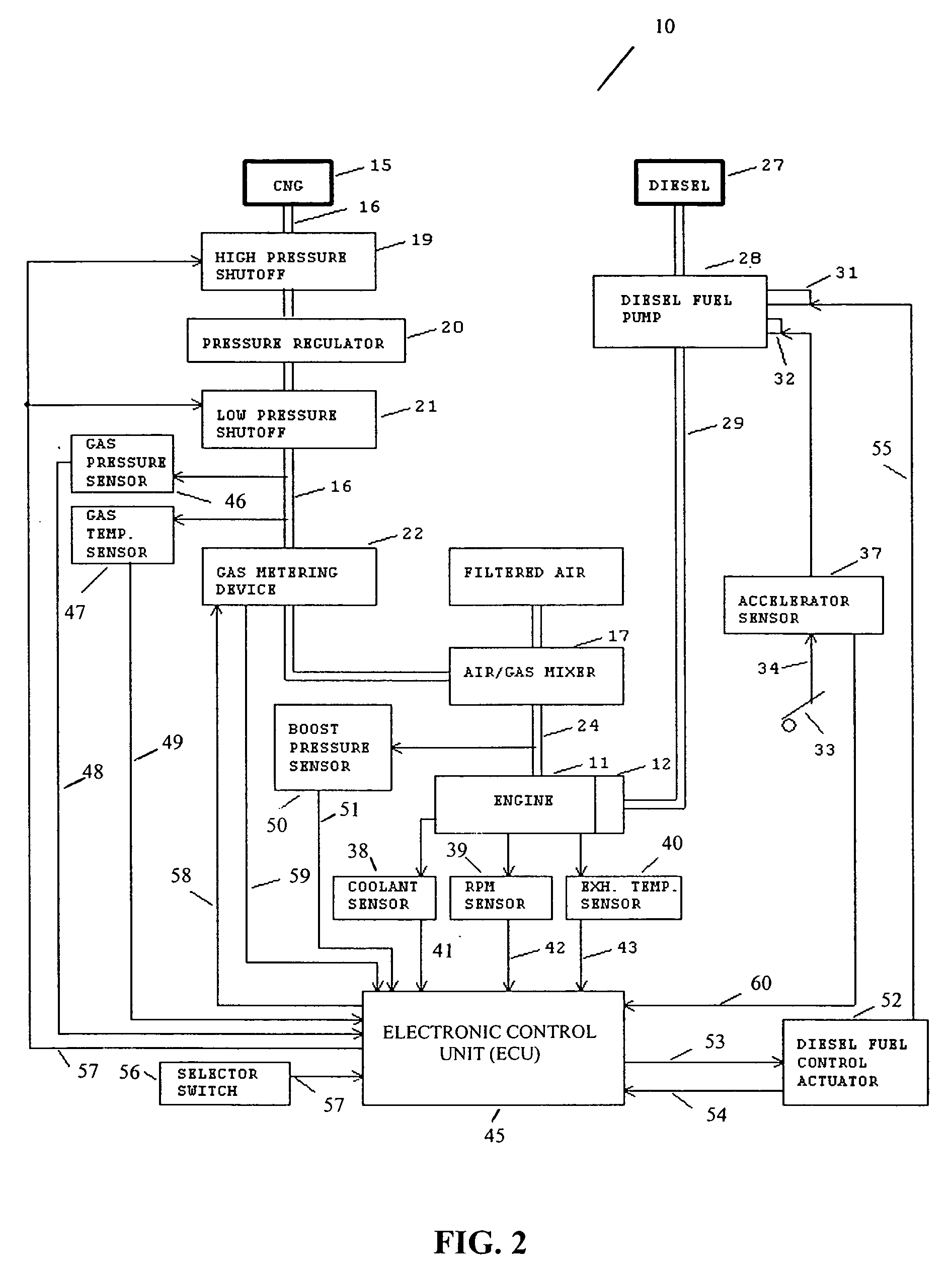

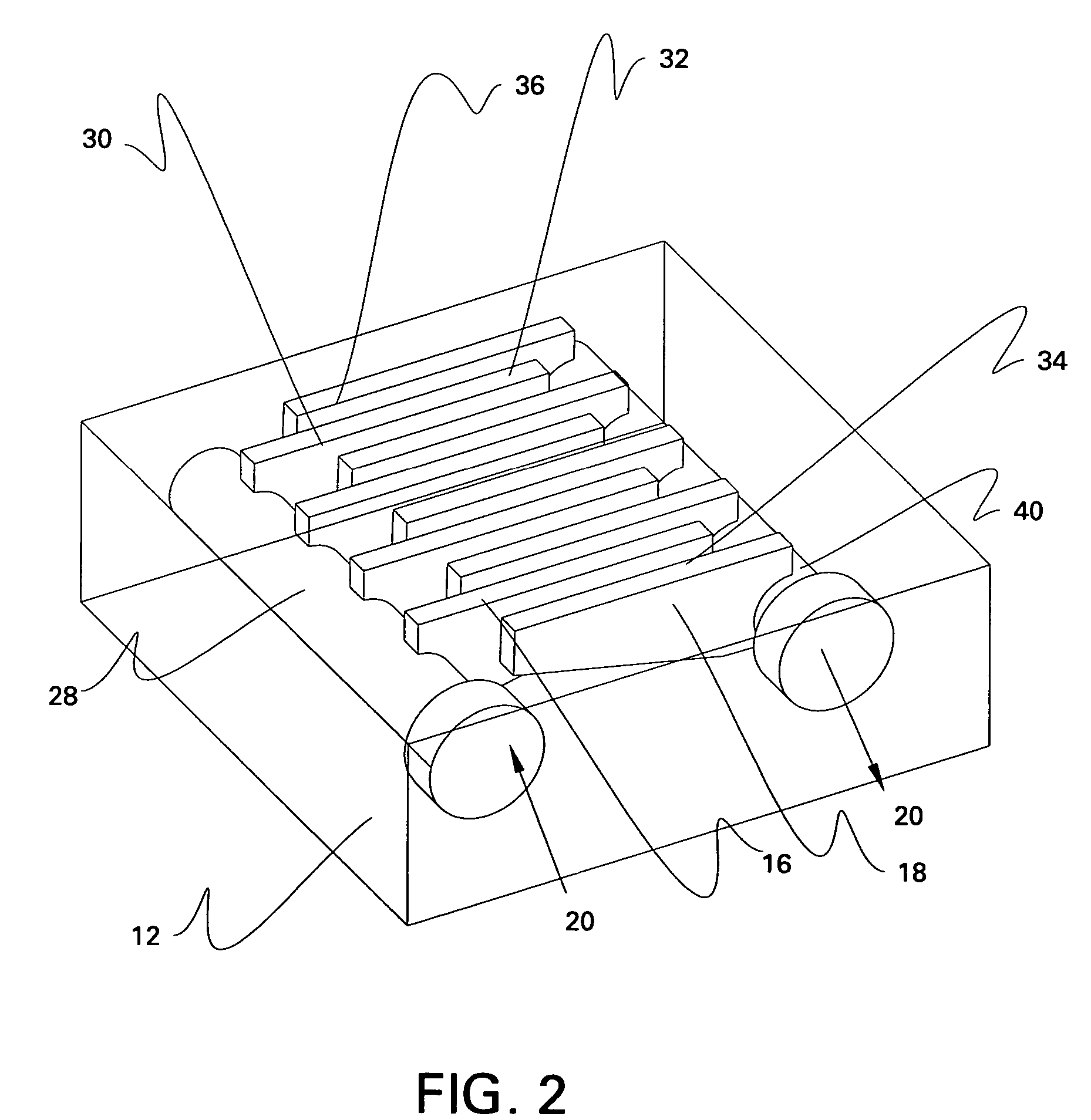

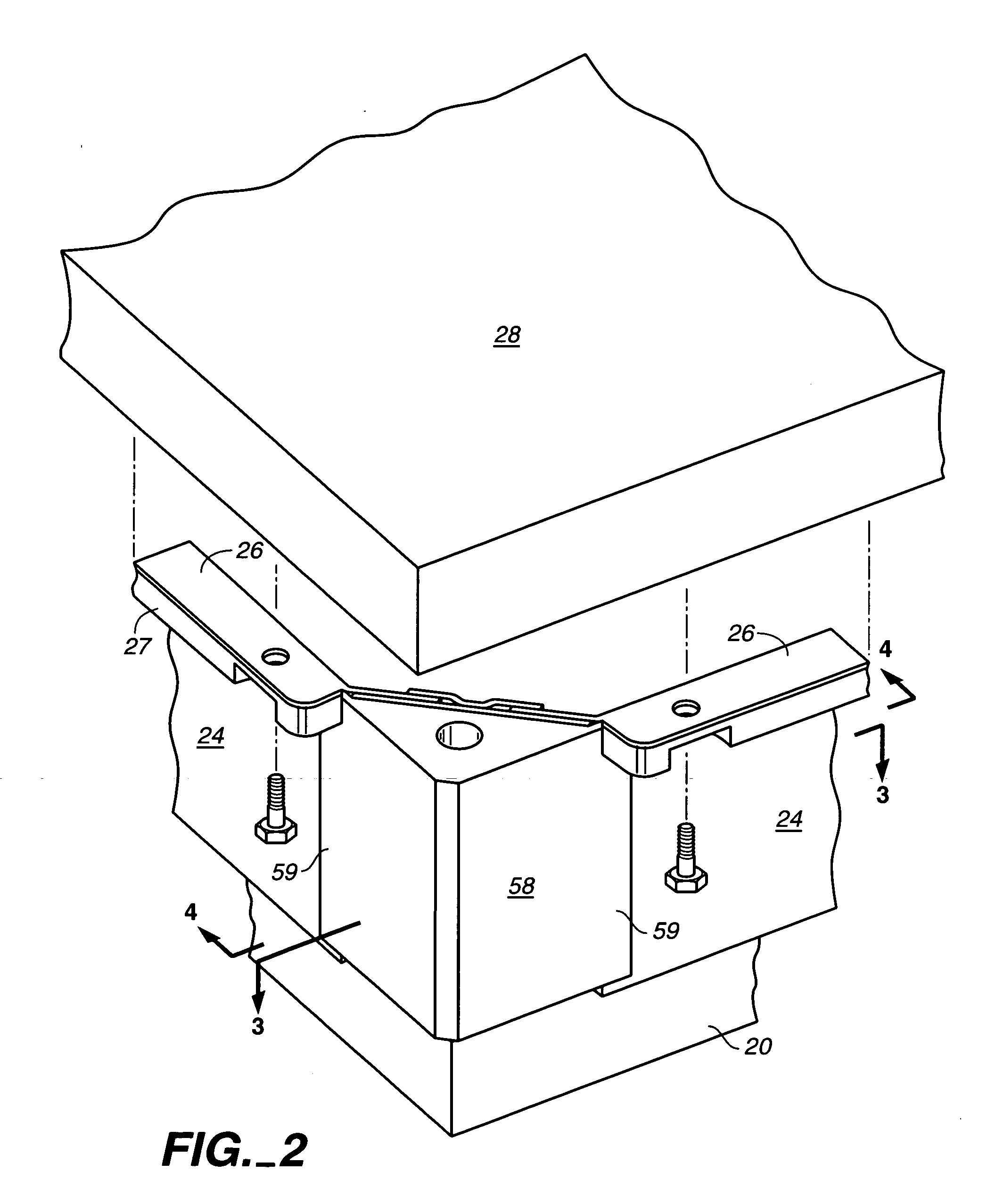

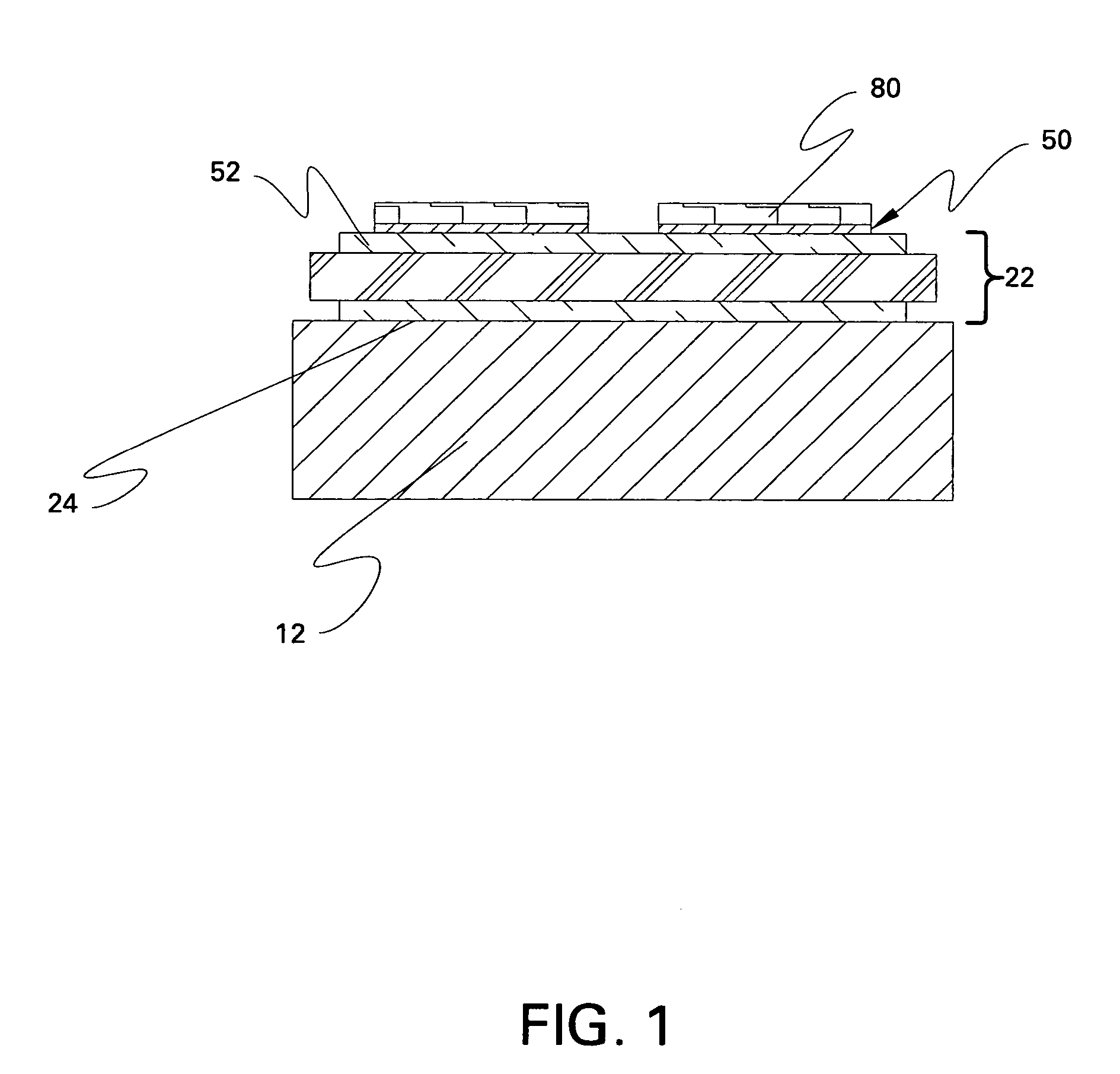

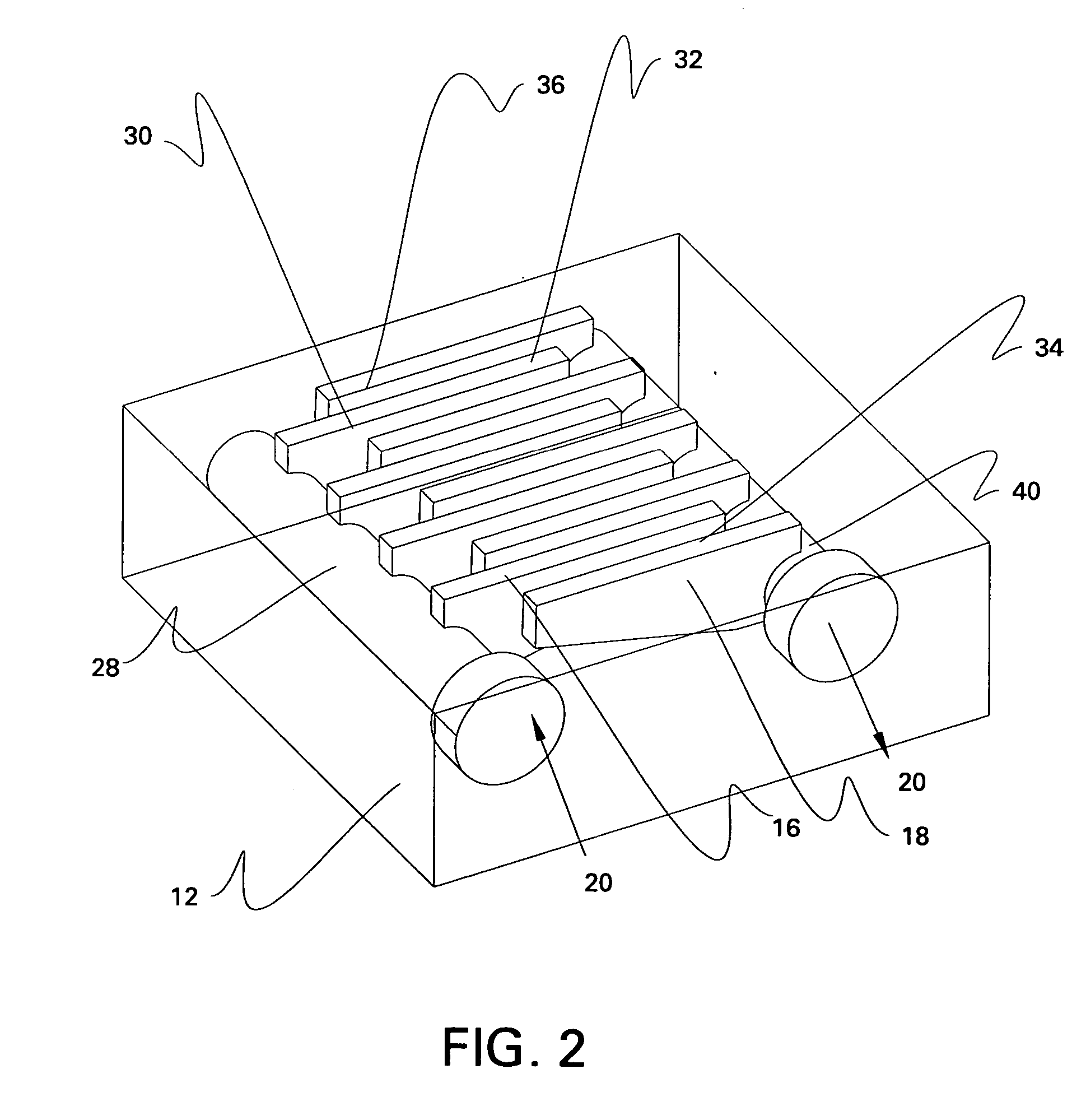

Multi-level microchannel heat exchangers

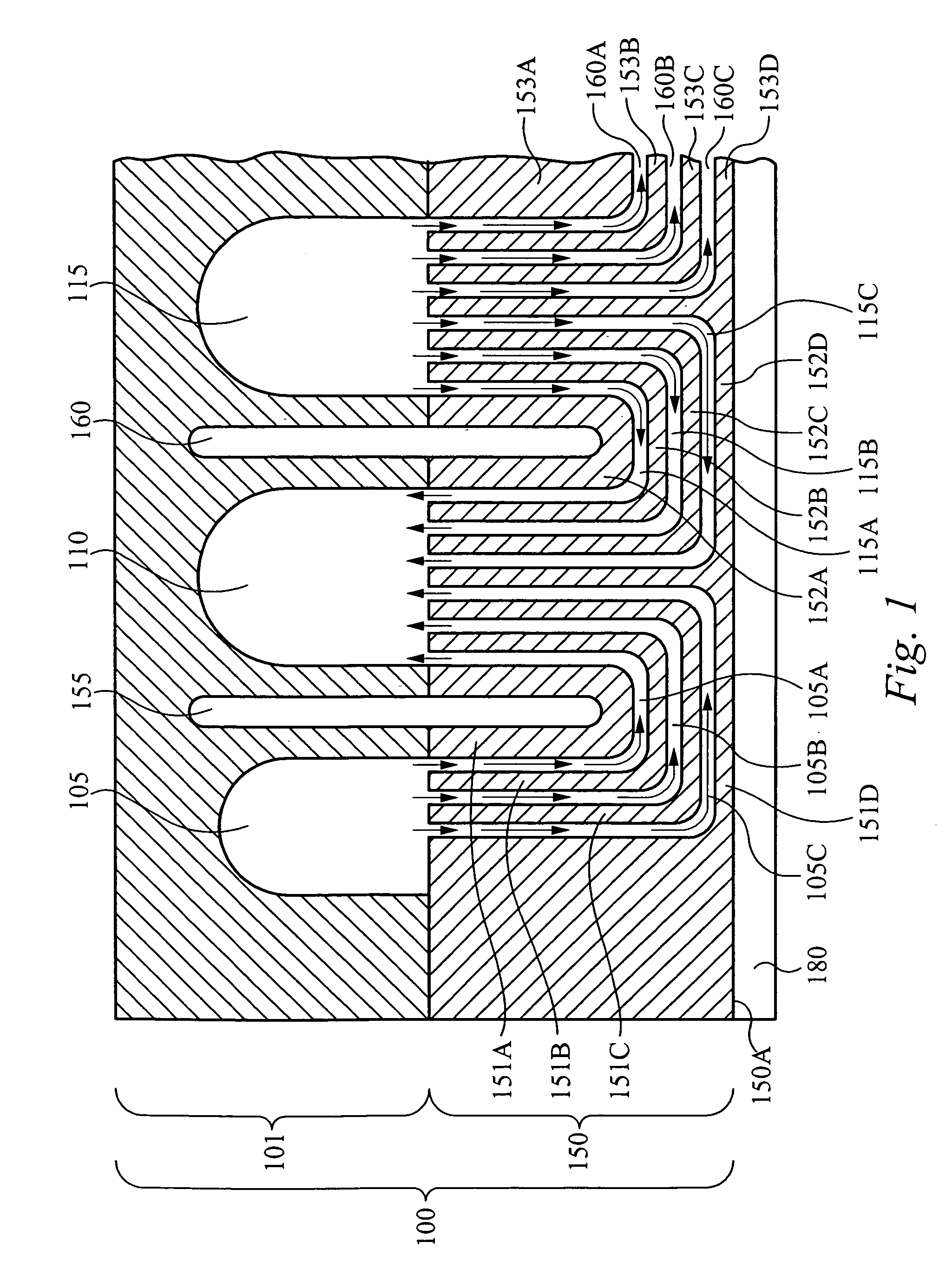

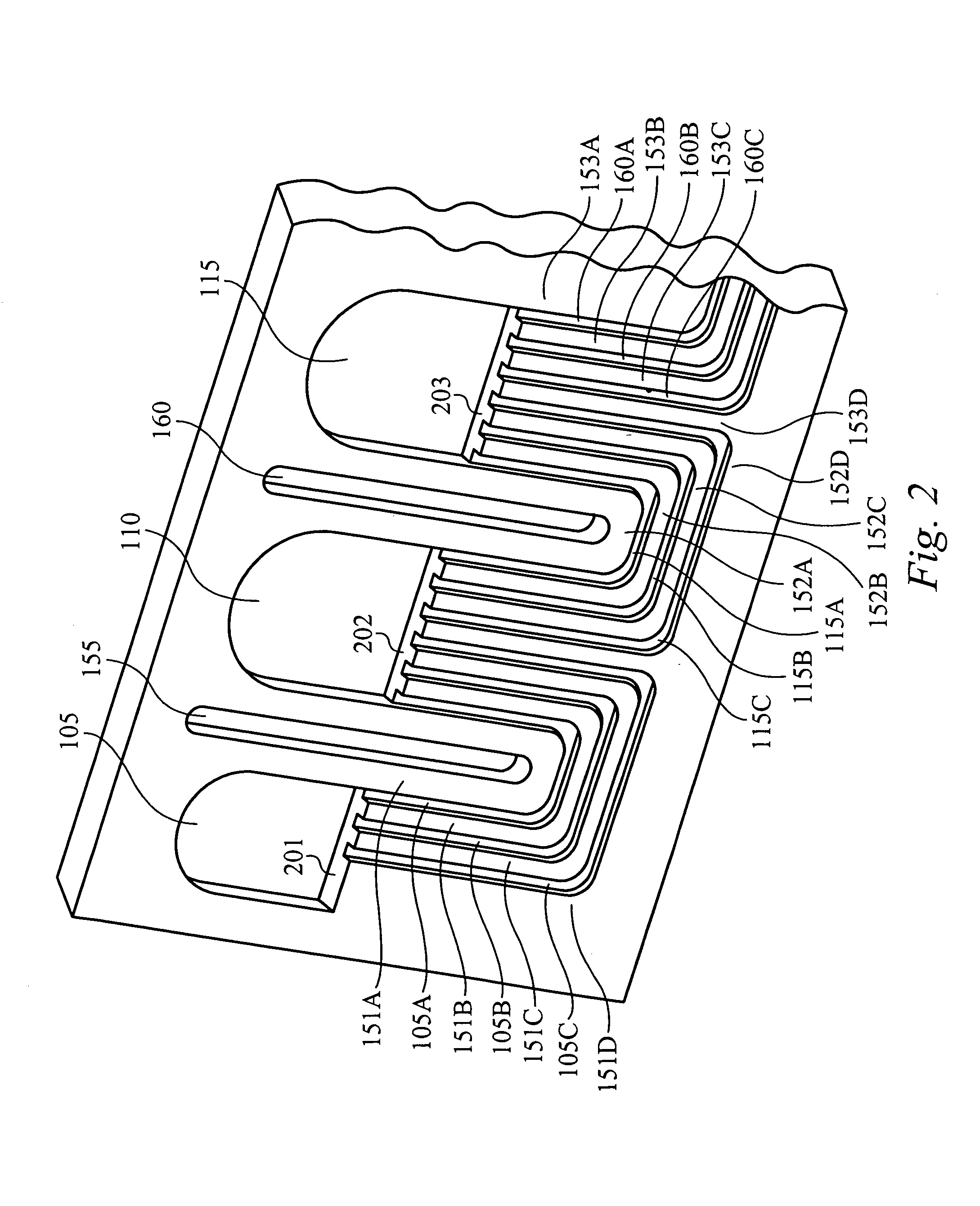

ActiveUS7156159B2Uniform pressure flowAccurate concentrationThermal insulationSemiconductor/solid-state device detailsInterface layerInlet manifold

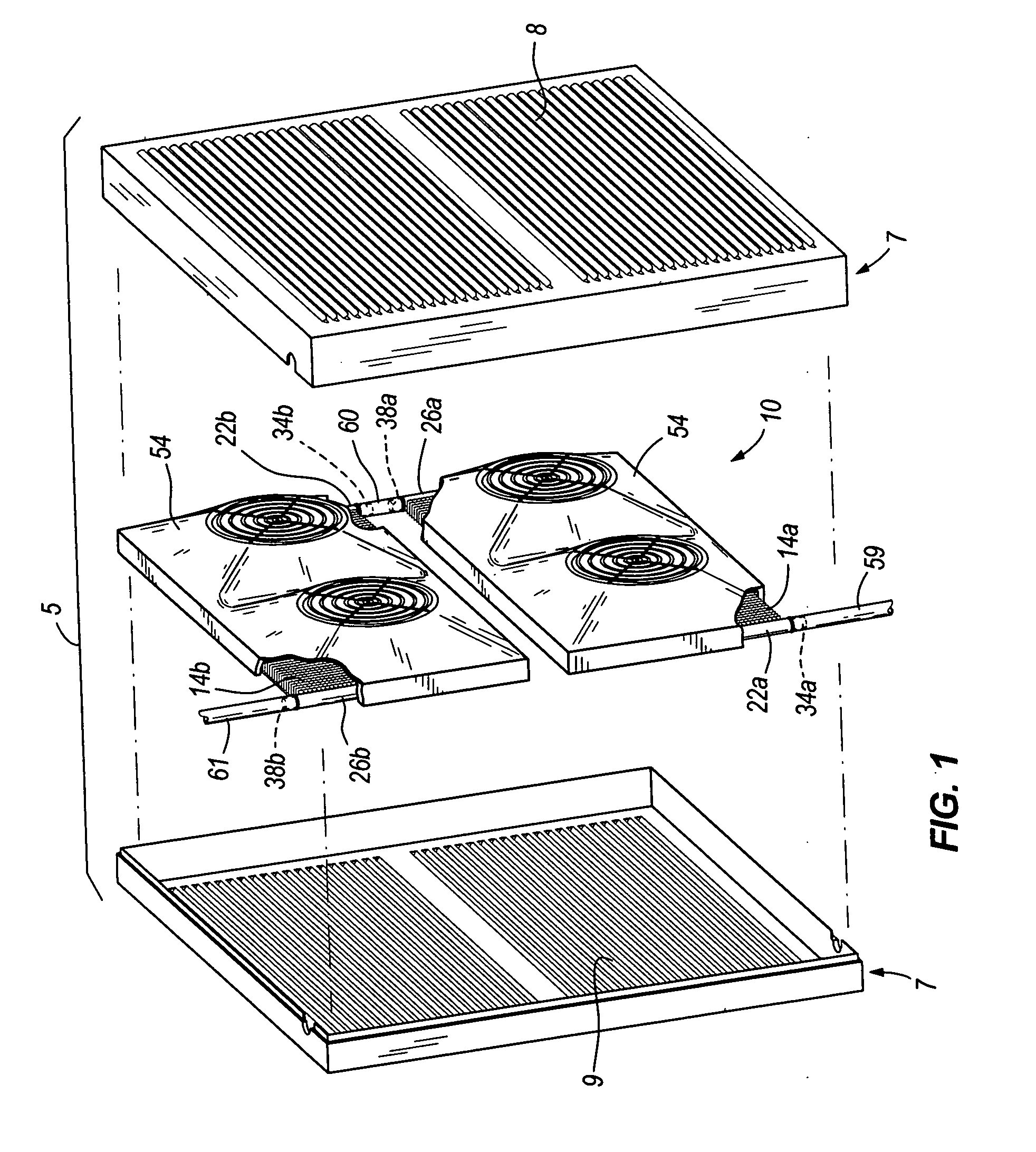

An apparatus and method of circulating a heat-absorbing material within a heat exchanger. The apparatus comprises a manifold layer coupled to an interface layer. The manifold layer comprises an inlet manifold and an outlet manifold. The interface layer comprises a plurality of channels that extend from the inlet manifold, toward a heat-exchanging plane, and turn away from the heat-exchanging plane, terminating at the outlet manifold. The plurality of channels are stacked in a plane non-parallel to the heat-exchanging plane. Each of the channels is adjacent to another, thus allowing heat radiated from a heat-generating device to be conducted to a cooling material circulating within the channels, away from the heat-generating device. Preferably, each of the channels has a U-shape or an elongated U-shape.

Owner:VERTIV CORP

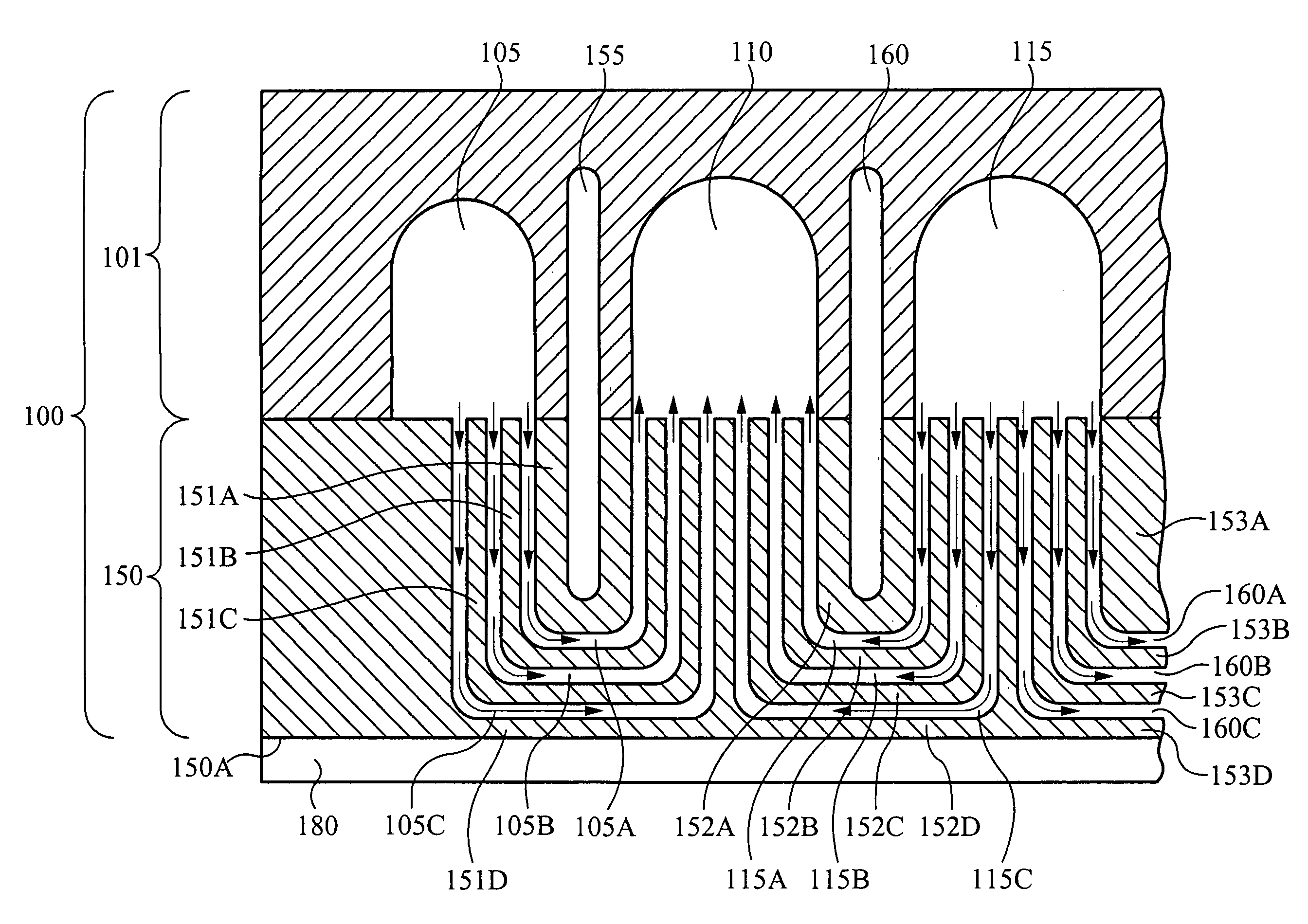

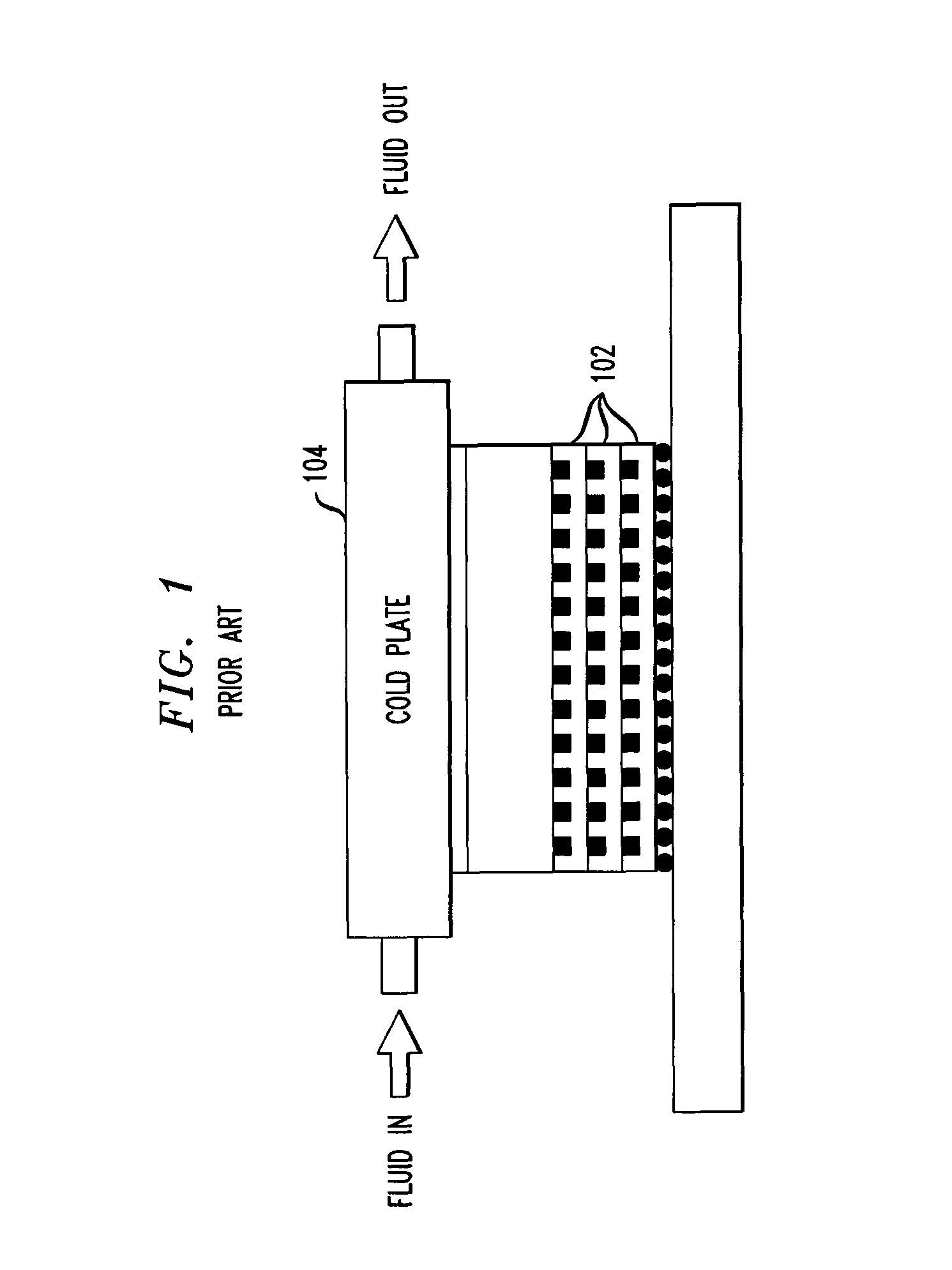

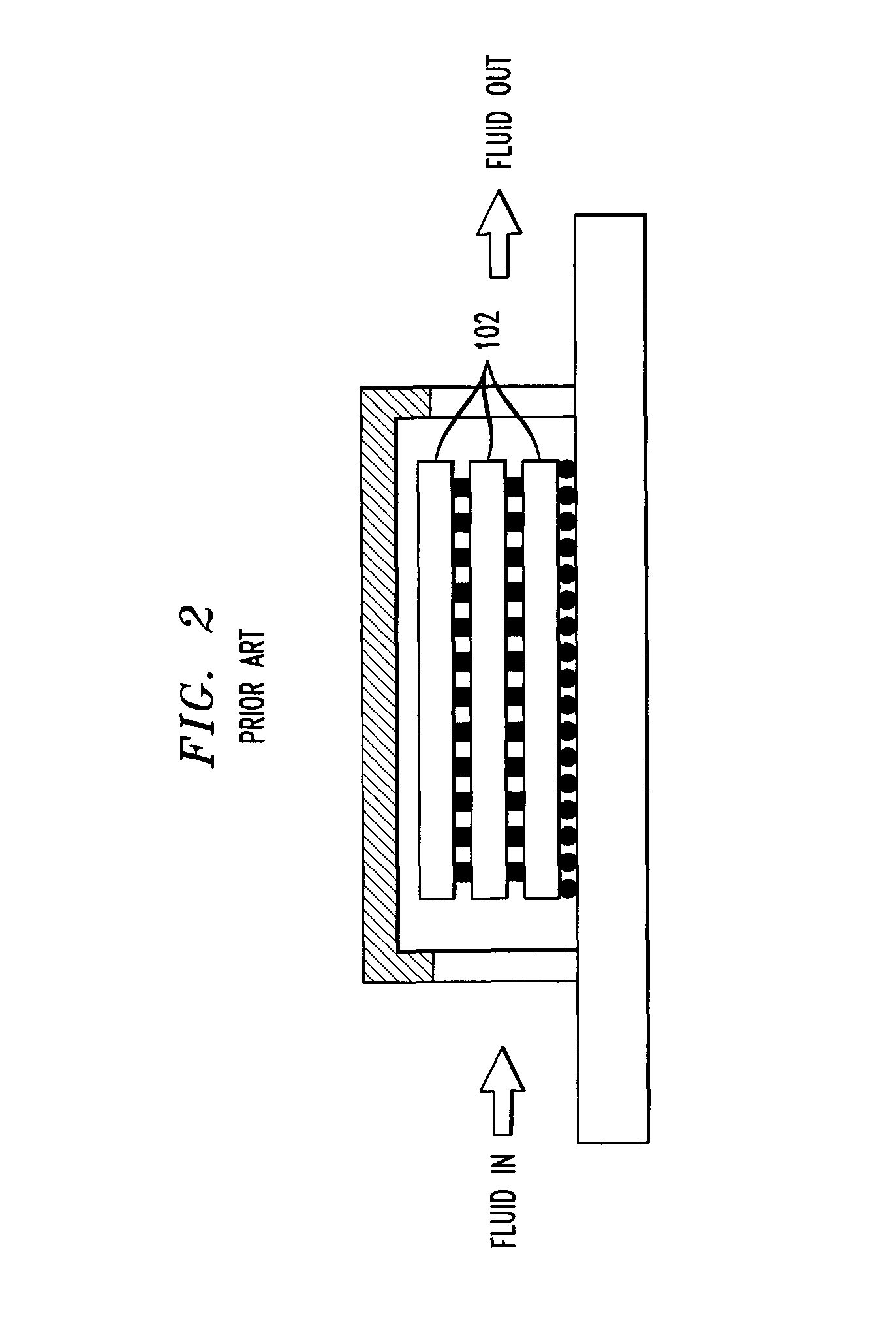

Heat sink with microchannel cooling for power devices

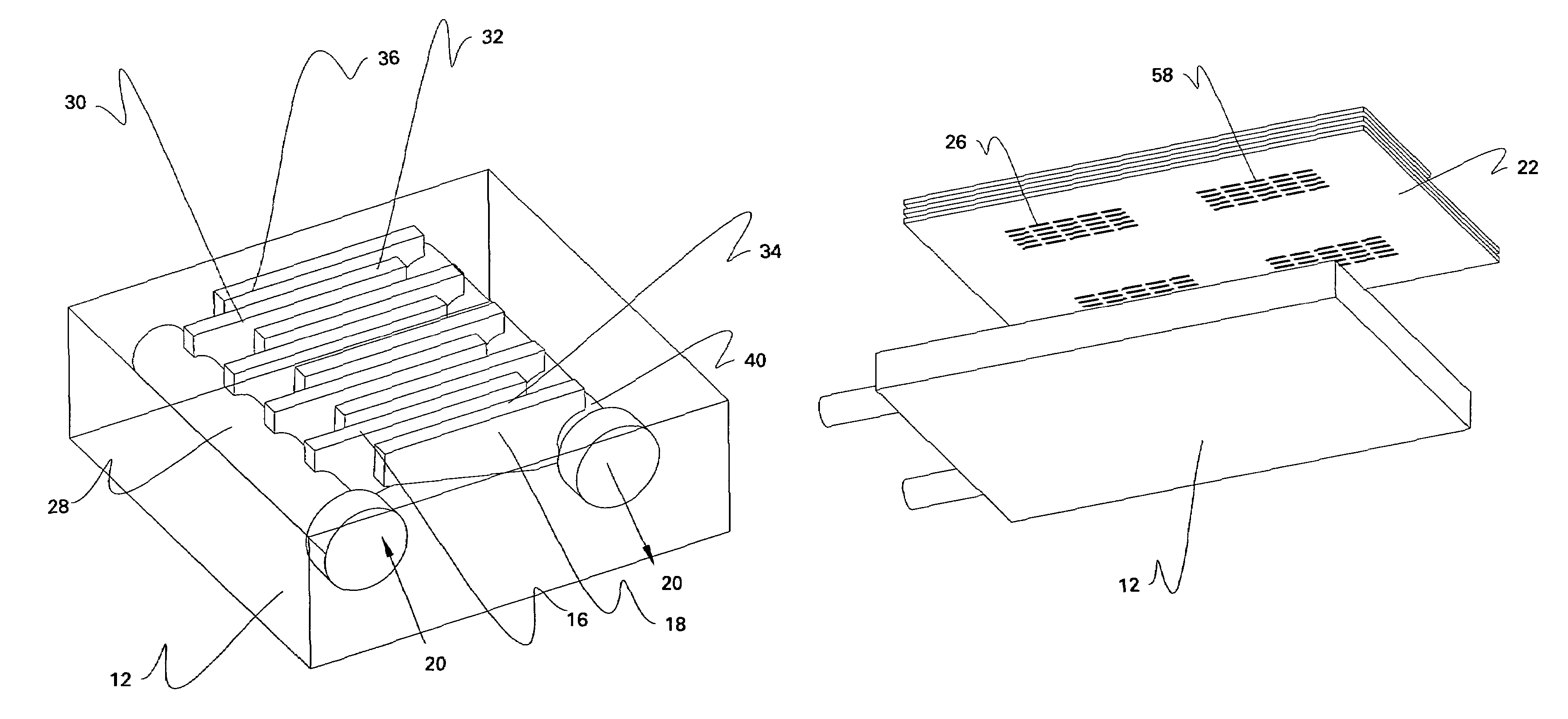

InactiveUS7353859B2Semiconductor/solid-state device detailsSolid-state devicesEngineeringThermal contact

An apparatus for cooling at least one heated surface includes a base plate defining a number of inlet and outlet manifolds. The inlet manifolds are configured to receive a coolant, and the outlet manifolds exhaust the coolant. The inlet and outlet manifolds are interleaved. The apparatus also includes at least one substrate having inner and outer surfaces. The inner surface is coupled to the base plate and defines a number of microchannels that receive the coolant from the inlet manifolds and deliver the coolant to the outlet manifolds. The microchannels are oriented substantially perpendicular to the inlet and outlet manifolds. The outer surface is in thermal contact with the heated surface. The apparatus also includes an inlet plenum that supplies the coolant to the inlet manifolds, and an outlet plenum that exhausts the coolant from the outlet manifolds. The inlet plenum and outlet plenum are oriented in a plane of the base plate.

Owner:GENERAL ELECTRIC CO

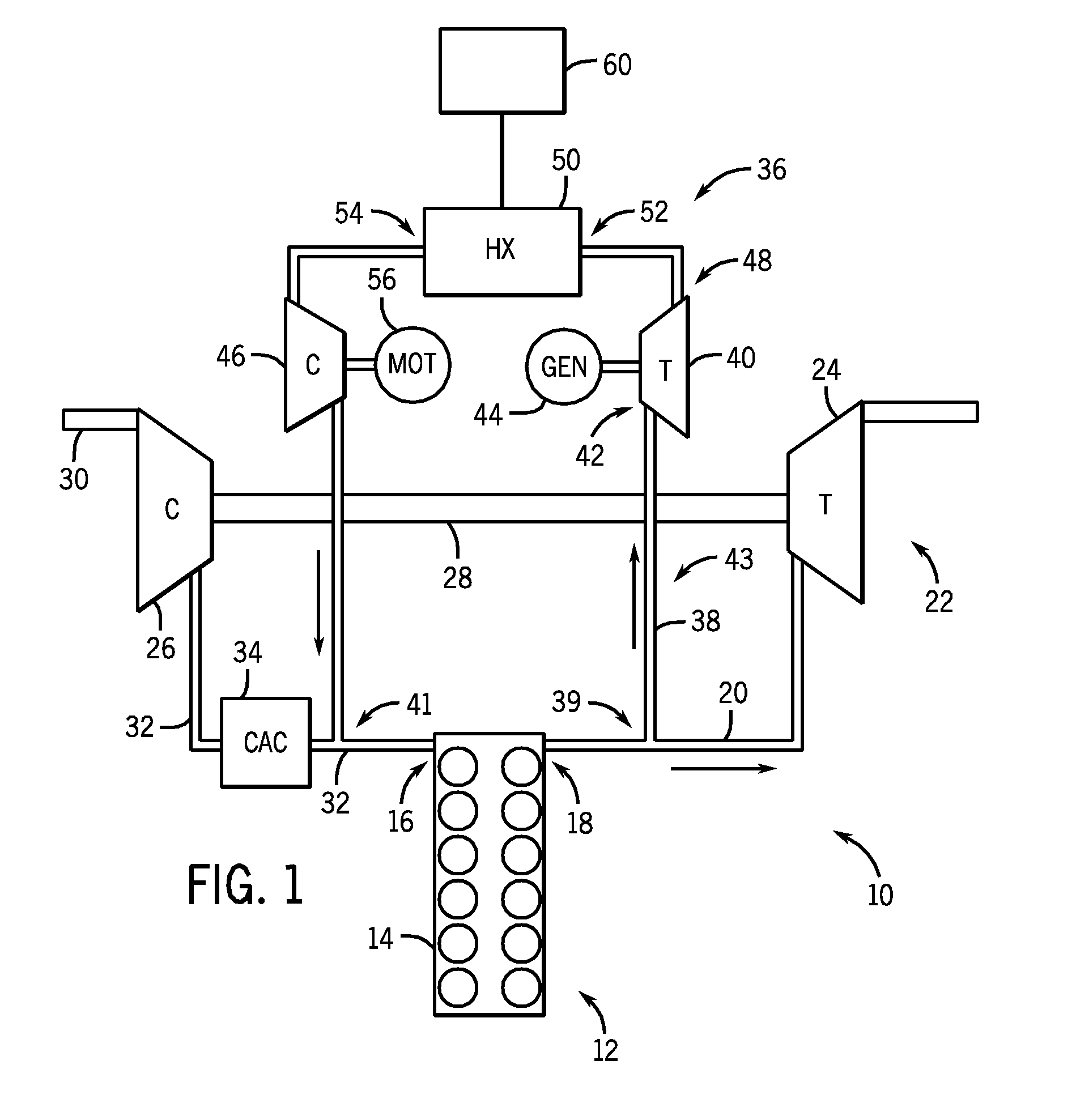

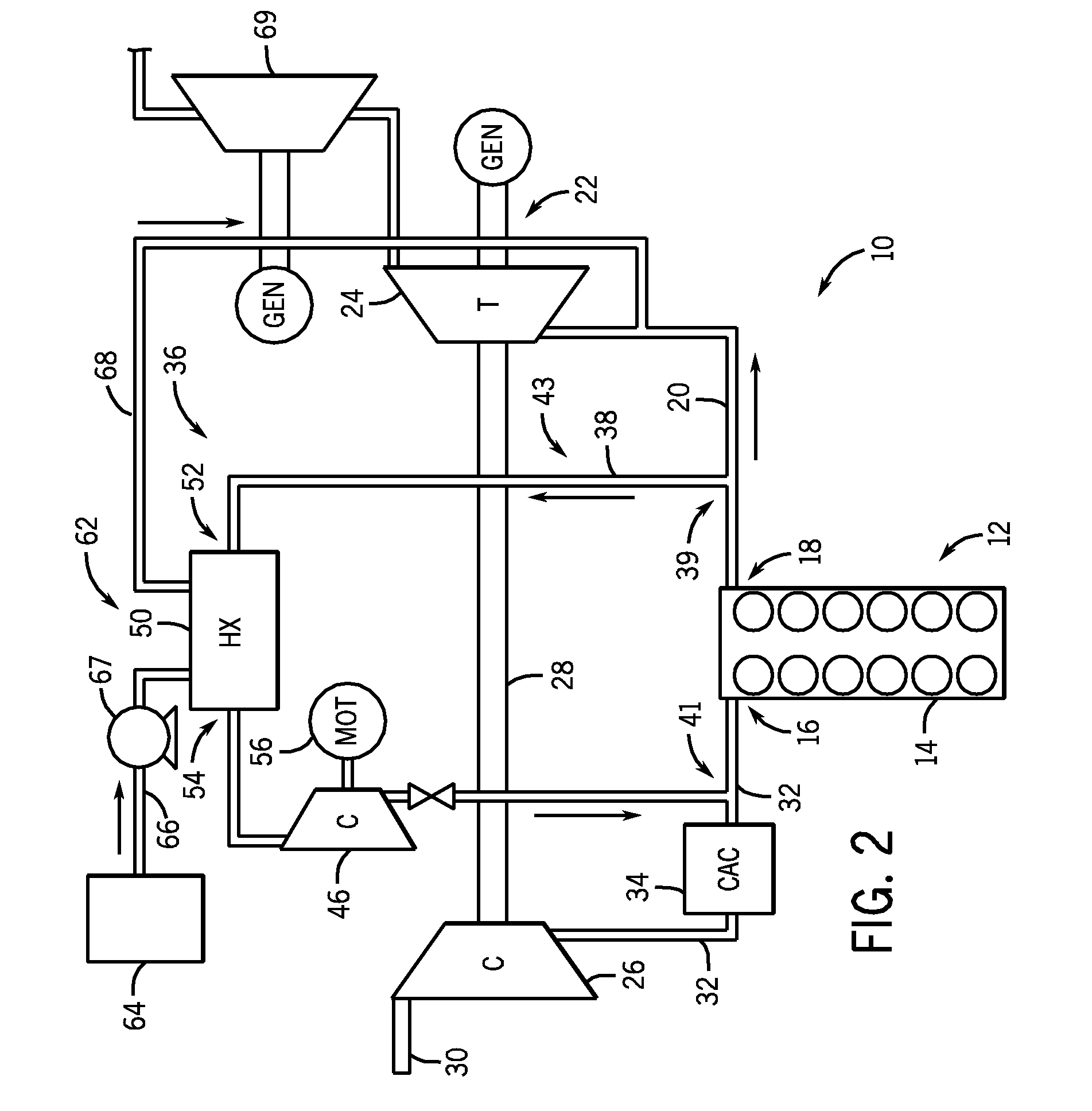

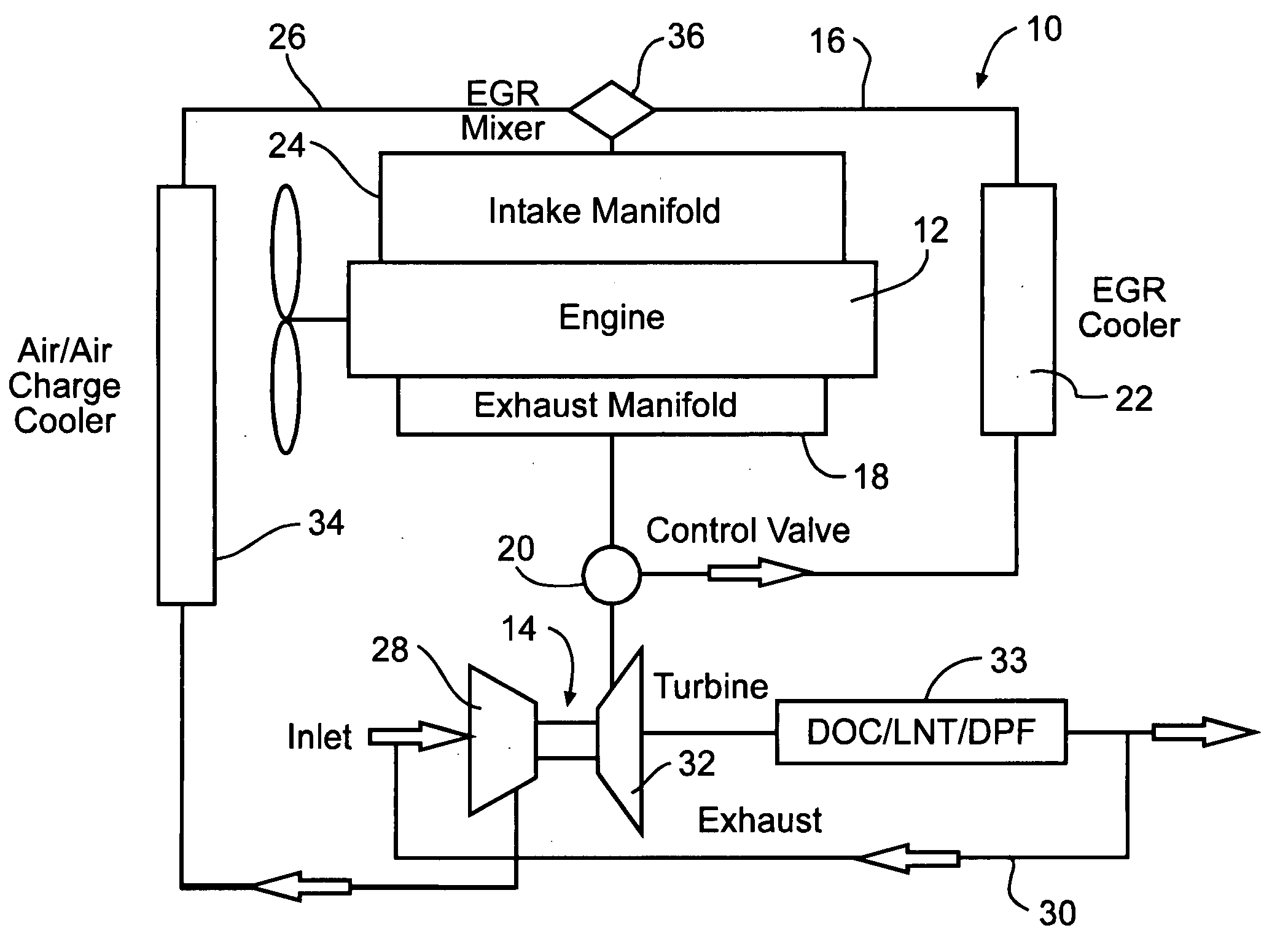

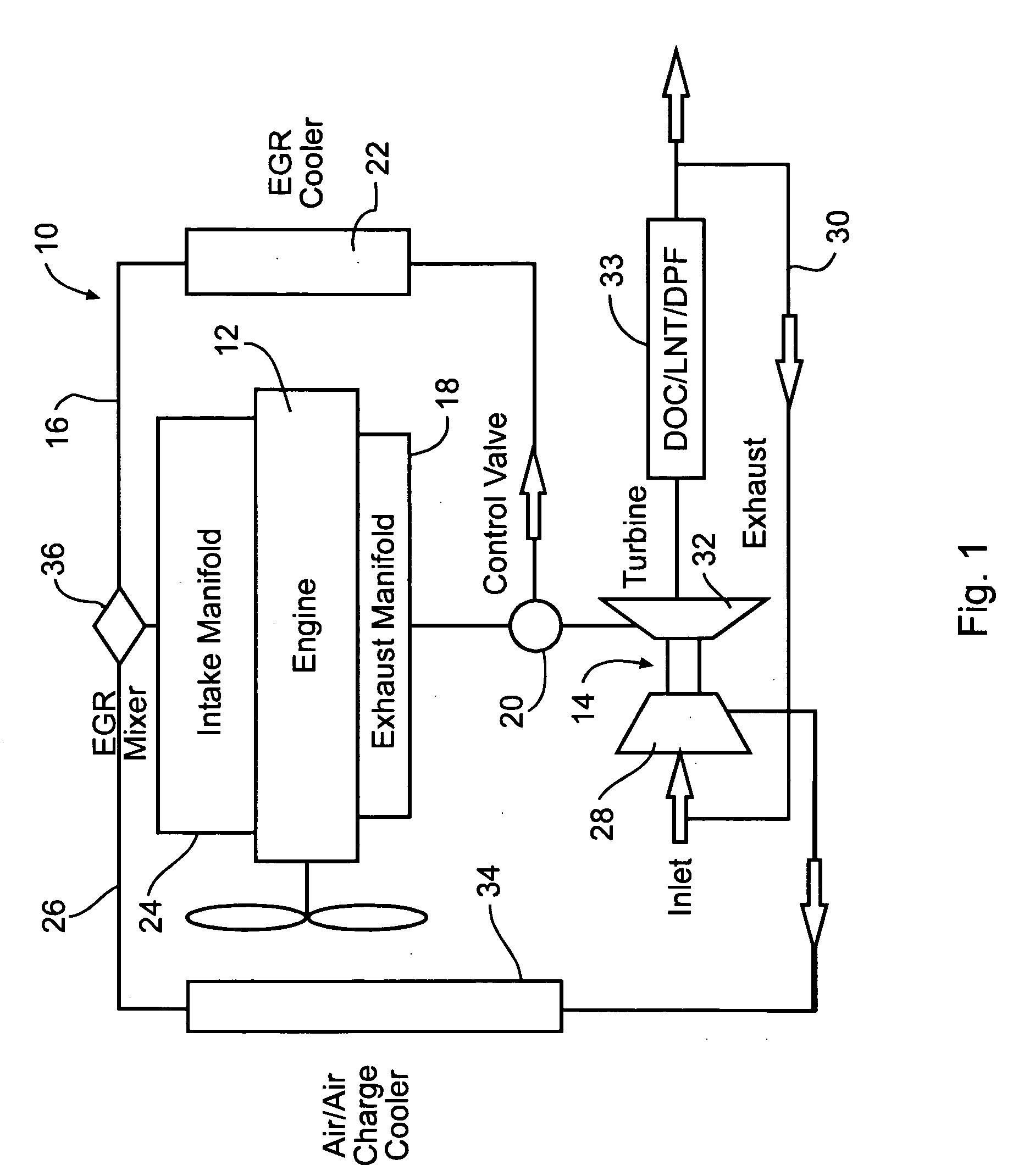

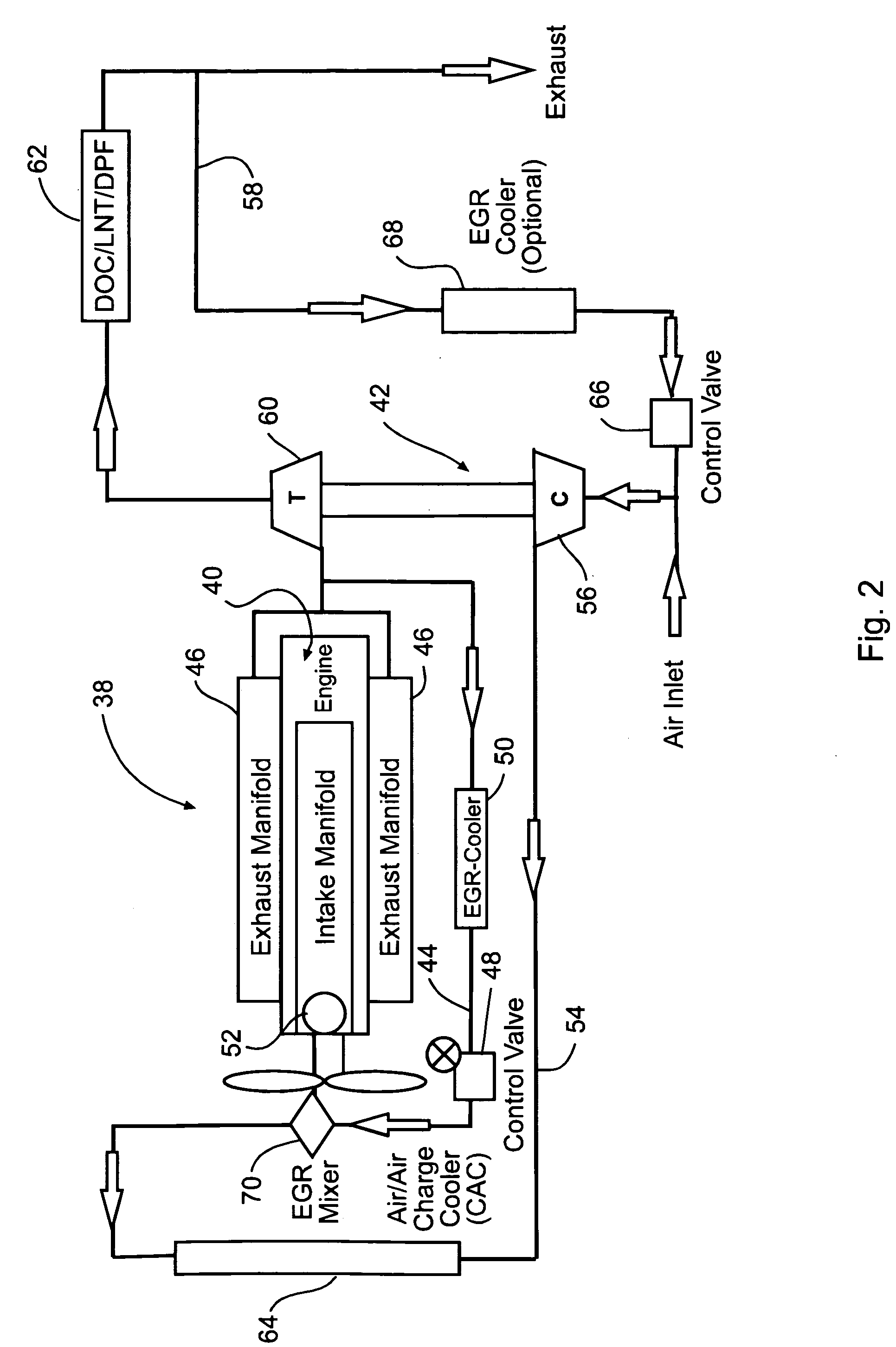

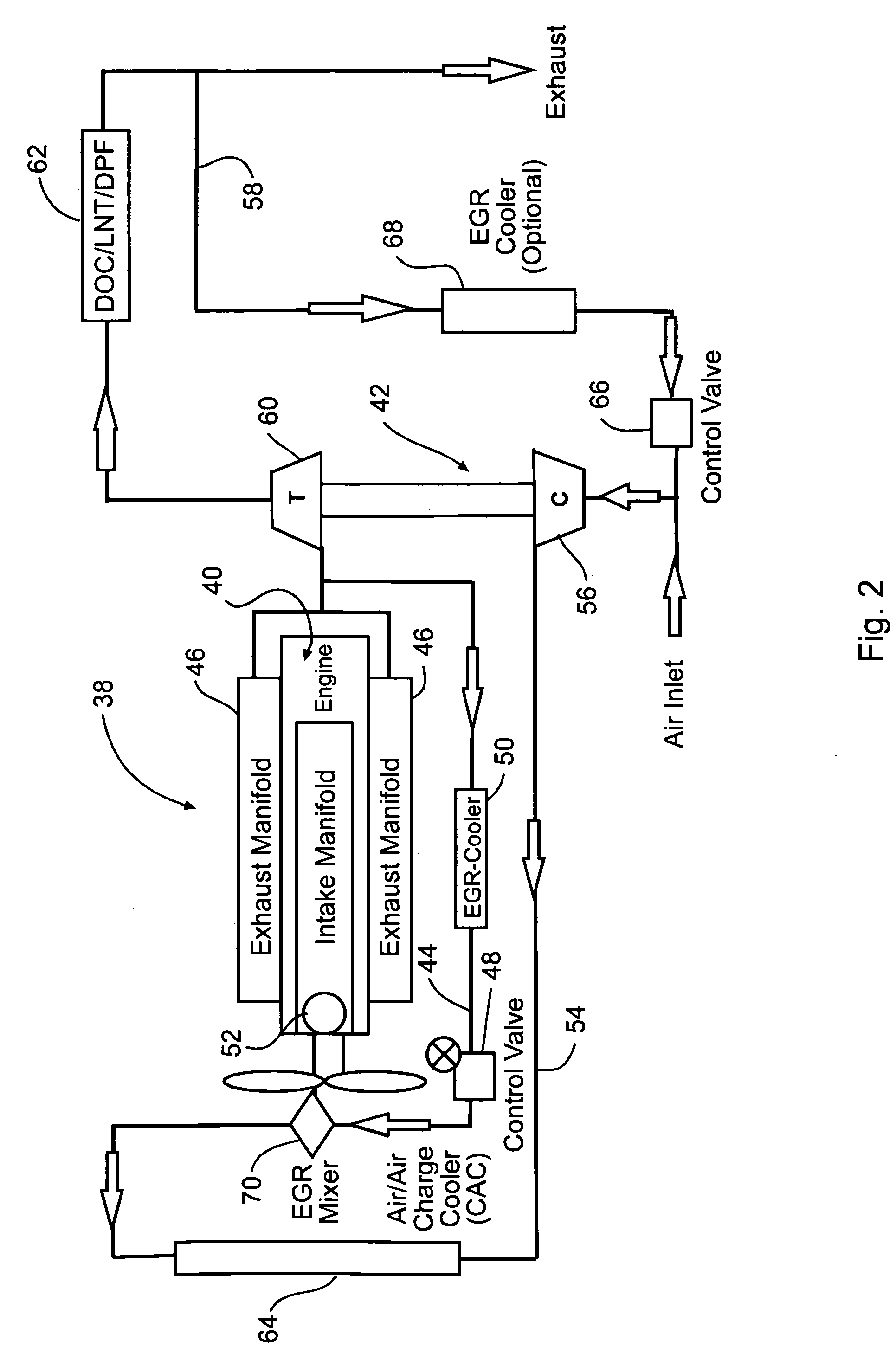

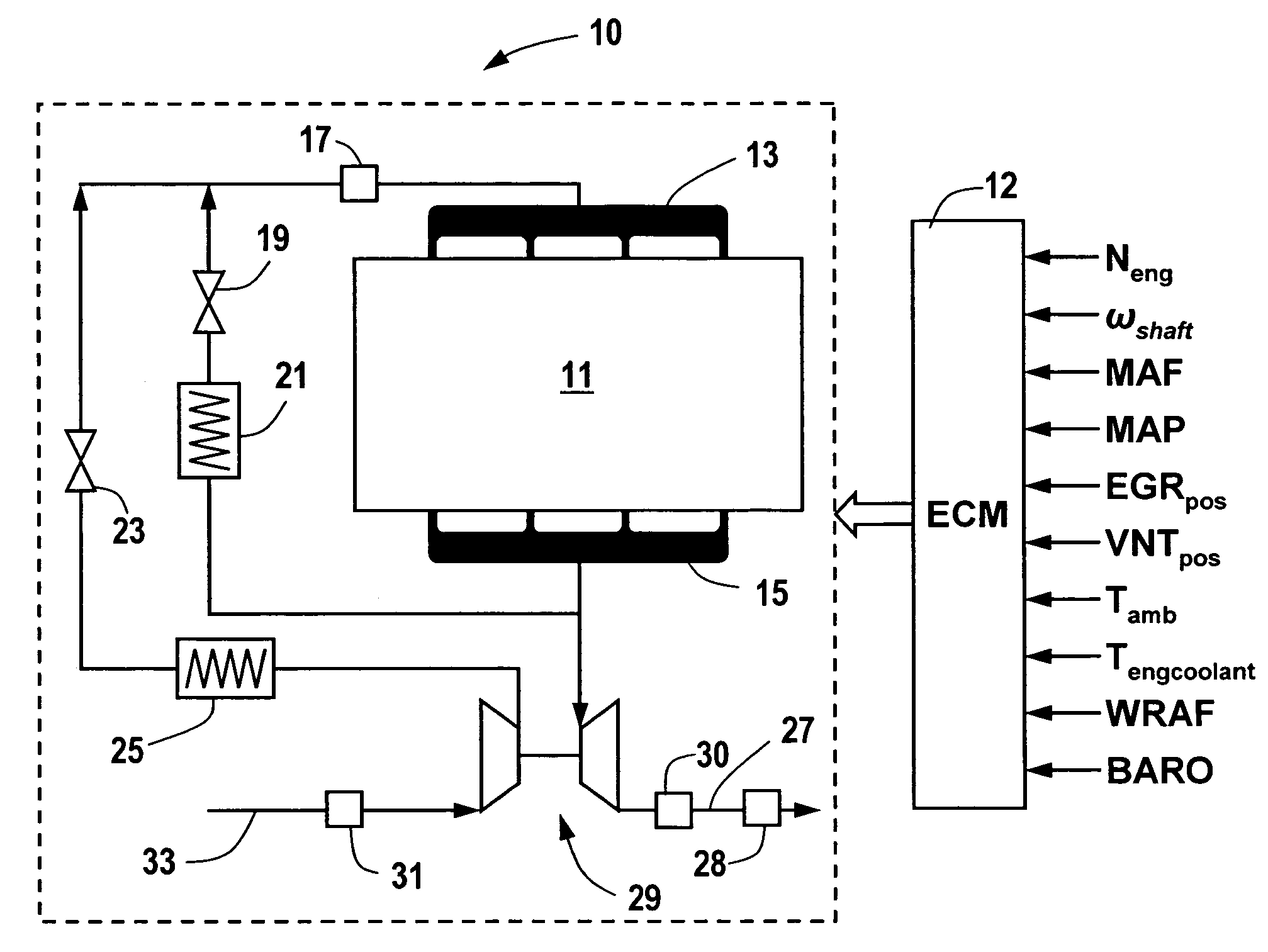

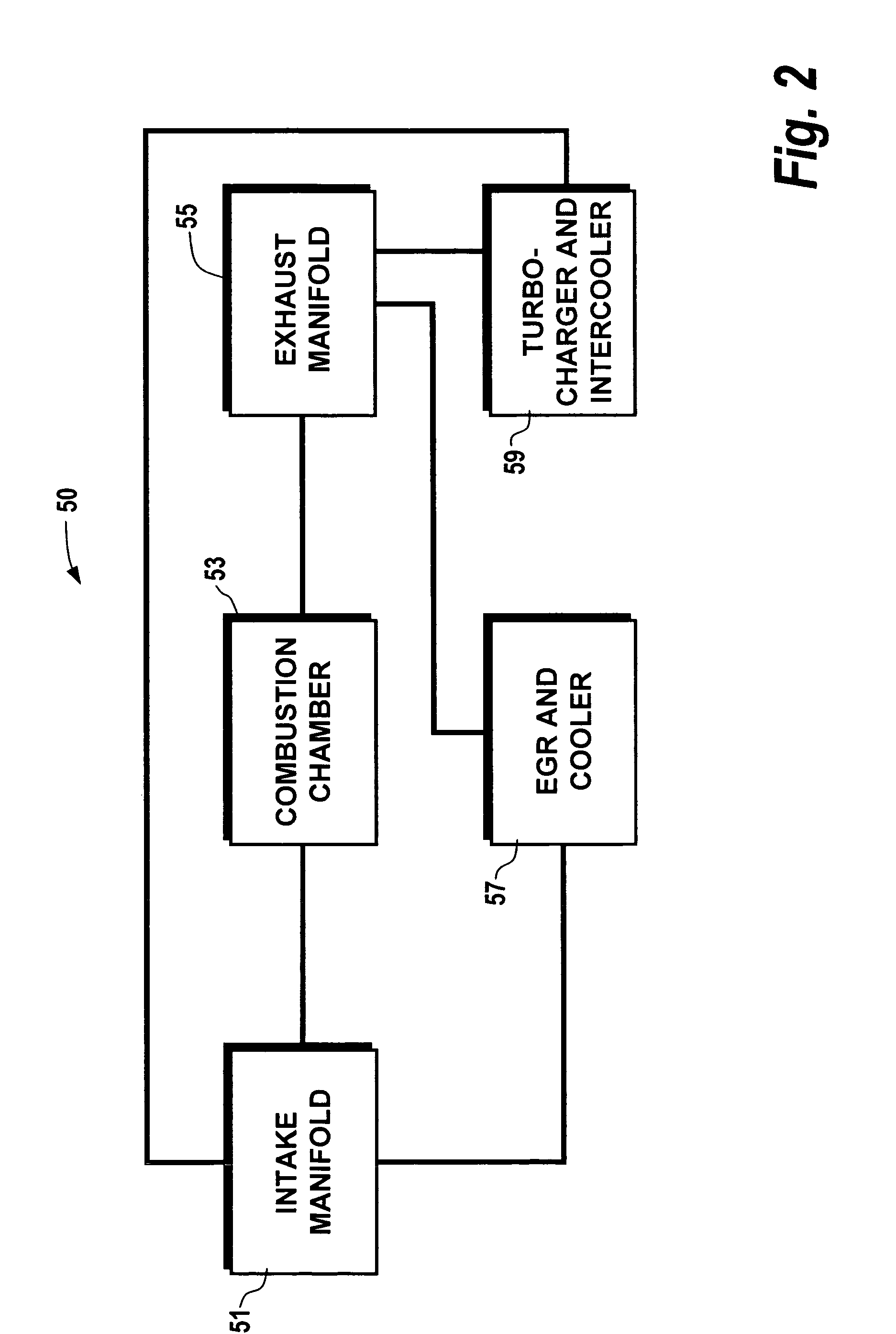

System and method for waste heat recovery in exhaust gas recirculation

InactiveUS20110209473A1Liquid degasificationInternal combustion piston enginesTurbochargerExhaust fumes

A system and method for waste heat recovery in exhaust gas recirculation is disclosed. The system includes an engine having an intake manifold and an exhaust manifold, an exhaust conduit connected to the exhaust manifold, and a turbocharger having a turbine and a compressor, the turbine being connected to the exhaust conduit to receive a portion of the exhaust gas from the exhaust manifold. The system also includes an EGR system connected to the exhaust conduit to receive a portion of the exhaust gas, with the EGR system including an EGR conduit that is connected to the exhaust conduit to receive a portion of the exhaust gas, a heat exchanger connected to the EGR conduit and being configured to extract heat from the exhaust gas, and a waste heat recovery system connected to the heat exchanger and configured to capture the heat extracted by the heat exchanger.

Owner:GENERAL ELECTRIC CO

Suspended gas distribution manifold for plasma chamber

InactiveUS20050000432A1Minimize gas leakagePermit some movementElectric discharge tubesSemiconductor/solid-state device manufacturingThermal dilatationThermal isolation

A gas inlet manifold for a plasma chamber having a perforated gas distribution plate suspended by a side wall comprising one or more sheets. The sheets preferably provide flexibility to alleviate stress in the gas distribution plate due to thermal expansion and contraction. In another aspect, the side wall provides thermal isolation between the gas distribution plate and other components of the chamber.

Owner:APPLIED MATERIALS INC

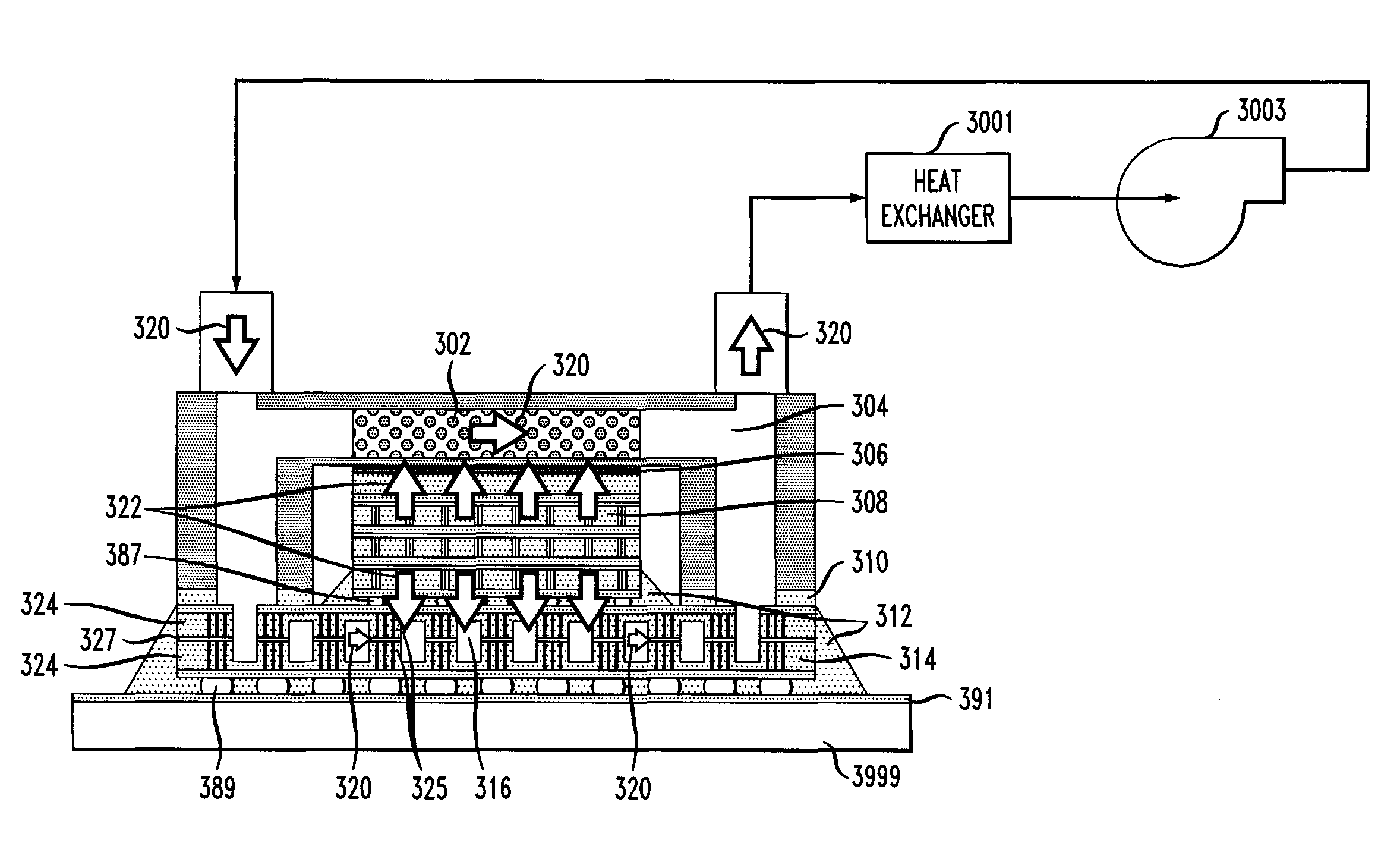

Double-face heat removal of vertically integrated chip-stacks utilizing combined symmetric silicon carrier fluid cavity and micro-channel cold plate

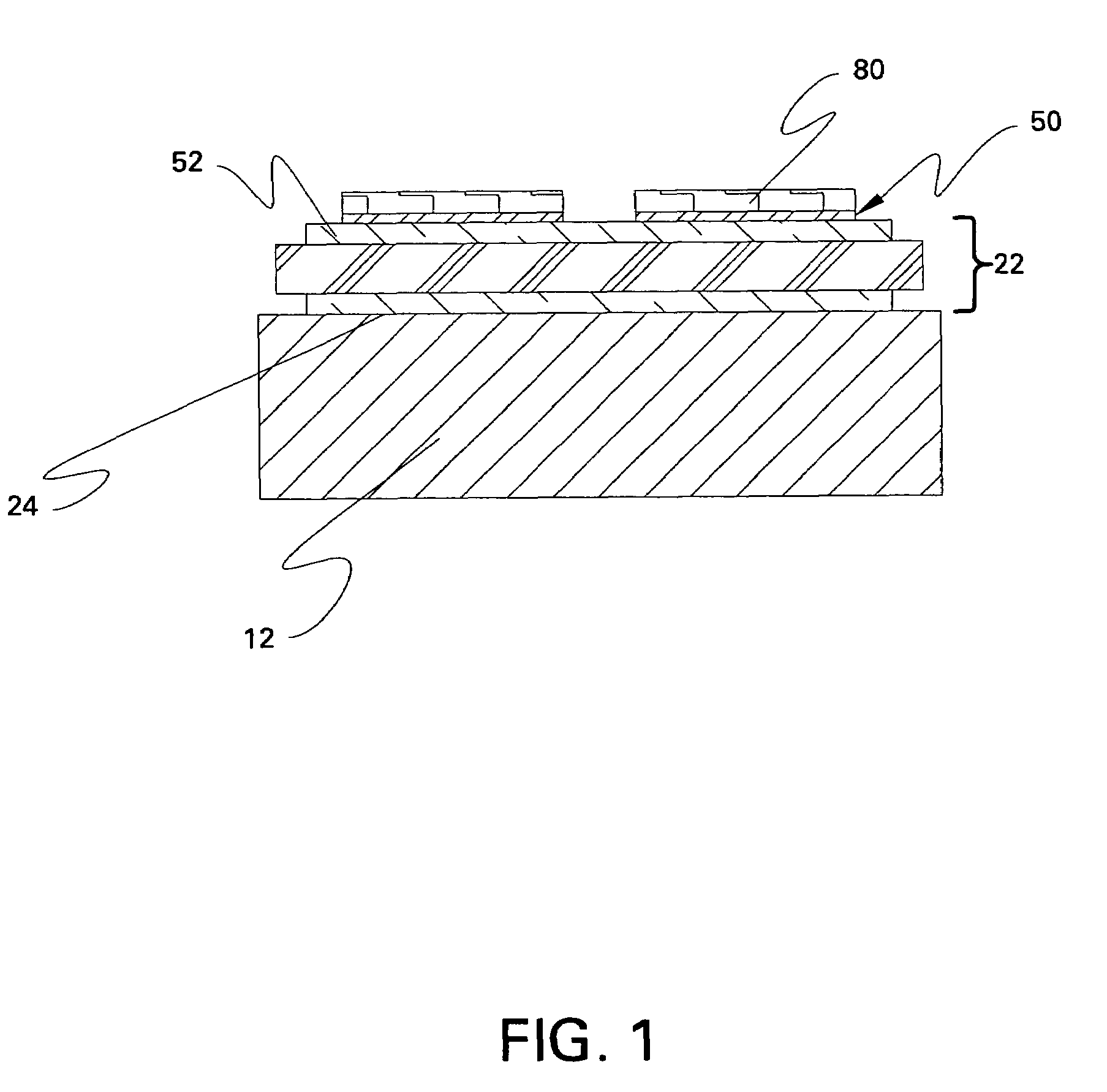

ActiveUS7990711B1Simple actionSemiconductor/solid-state device detailsSolid-state devicesElectricityCarrier fluid

A plurality of heat-dissipating electronic chips are arranged in a vertical chip stack. The electronic chips have electronic components thereon. A cold plate is secured to a back side of the chip stack. A silicon carrier sandwich, defining a fluid cavity, is secured to a front side of the chip stack. An inlet manifold is configured to supply cooling fluid to the cold plate and the fluid cavity of the silicon carrier sandwich. An outlet manifold is configured to receive the cooling fluid from the cold plate and the fluid cavity of the silicon carrier sandwich. The cold plate, the silicon carrier sandwich, the inlet manifold, and the outlet manifold are configured and dimensioned to electrically isolate the cooling fluid from the electronic components. A method of operating an electronic apparatus and a method of manufacturing an electronic apparatus are also disclosed. Single-sided heat removal with double-sided electrical input-output and double-sided heat removal with double-sided electrical input-output are also disclosed.

Owner:GLOBALFOUNDRIES US INC

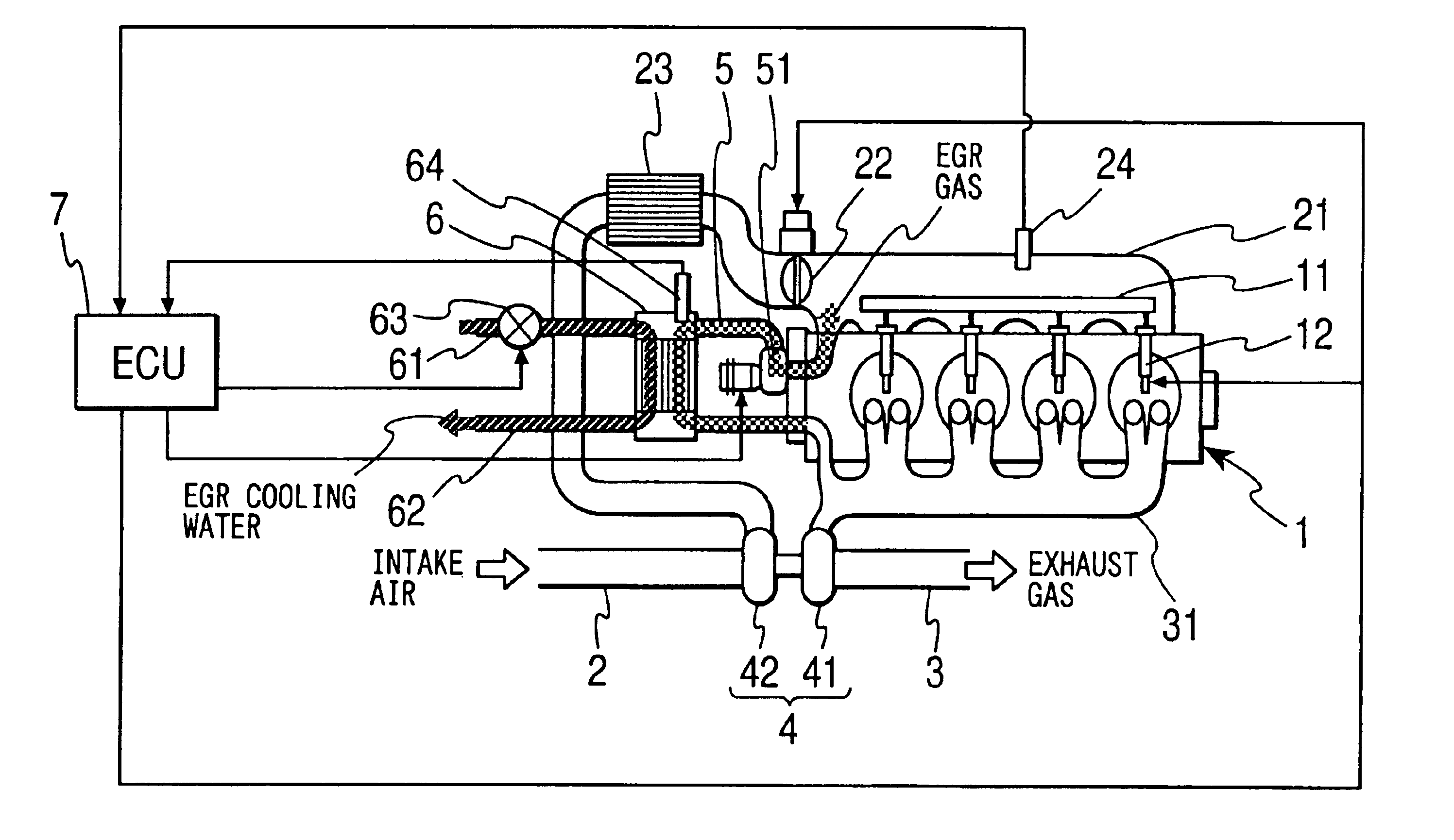

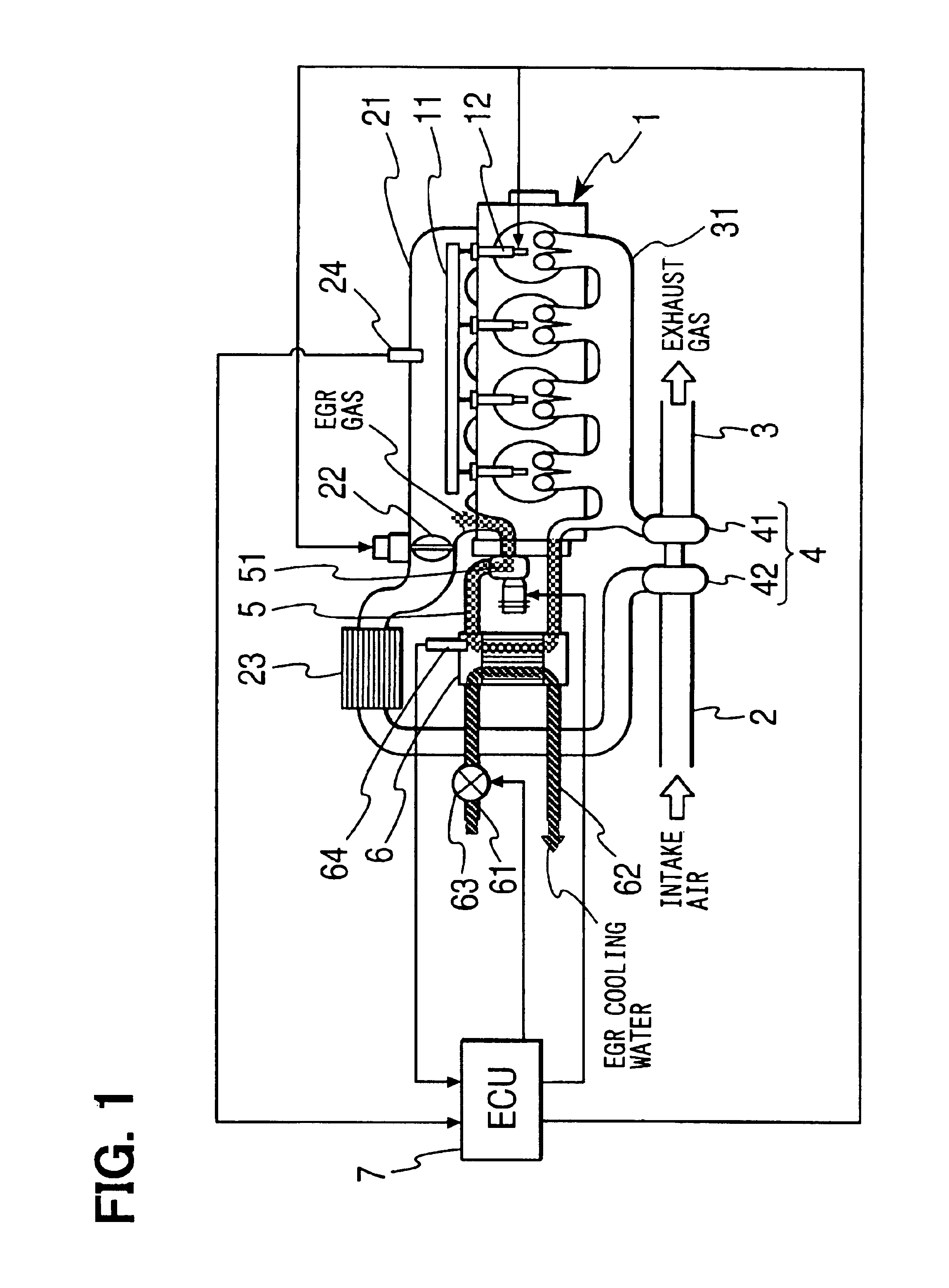

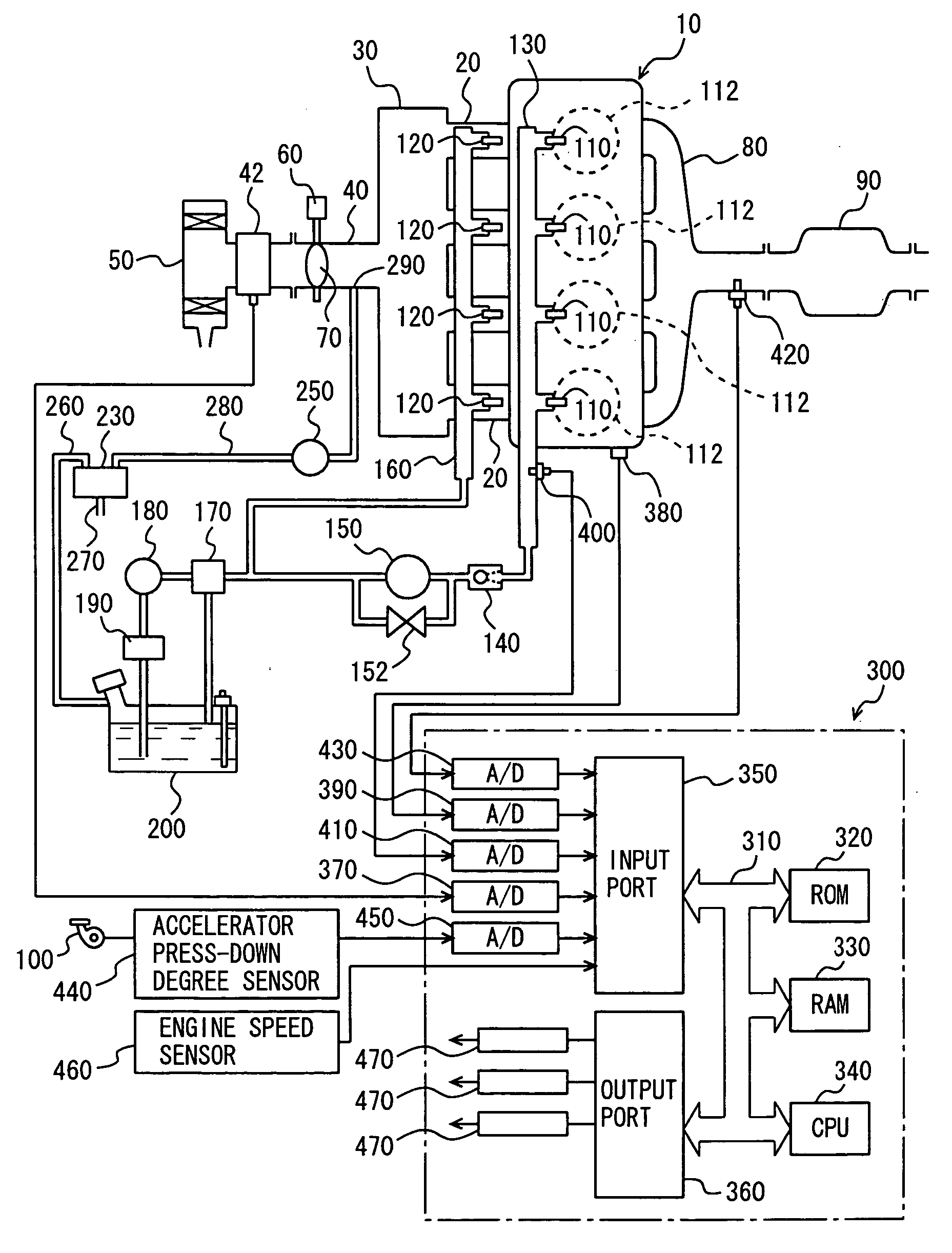

Exhaust gas recirculation system having cooler

InactiveUS6826903B2Improve heat transfer effectElectrical controlNon-fuel substance addition to fuelExhaust fumesExhaust gas recirculation

An exhaust gas recirculation (EGR) system of an internal combustion engine has an EGR cooler in an EGR passage connecting an exhaust manifold with an intake manifold. The EGR cooler cools EGR gas recirculated through the EGR passage. Cooling performance detecting means included in an electronic control unit (ECU) determines that cooling performance of the EGR cooler is degraded when intake pressure measured by an intake pressure sensor is lower than a normal intake pressure by at least a predetermined value. When the degradation of the cooling performance is detected, cooling performance regeneration controlling means included in the ECU increases the temperature inside the EGR cooler by heating the exhaust gas to eliminate soot or unburned hydrocarbon by oxidization. Thus, the cooling performance of the EGR cooler is regenerated.

Owner:DENSO CORP

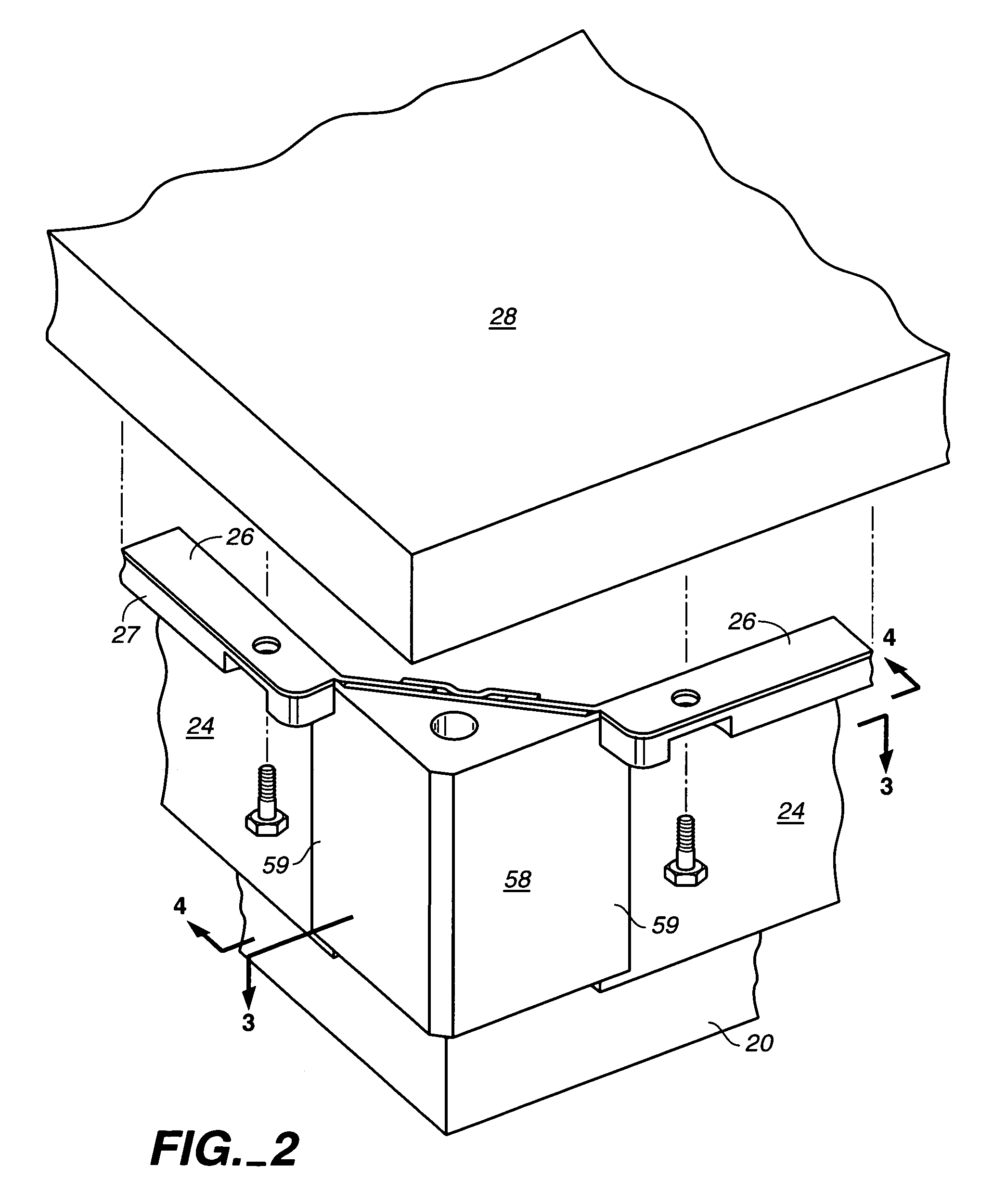

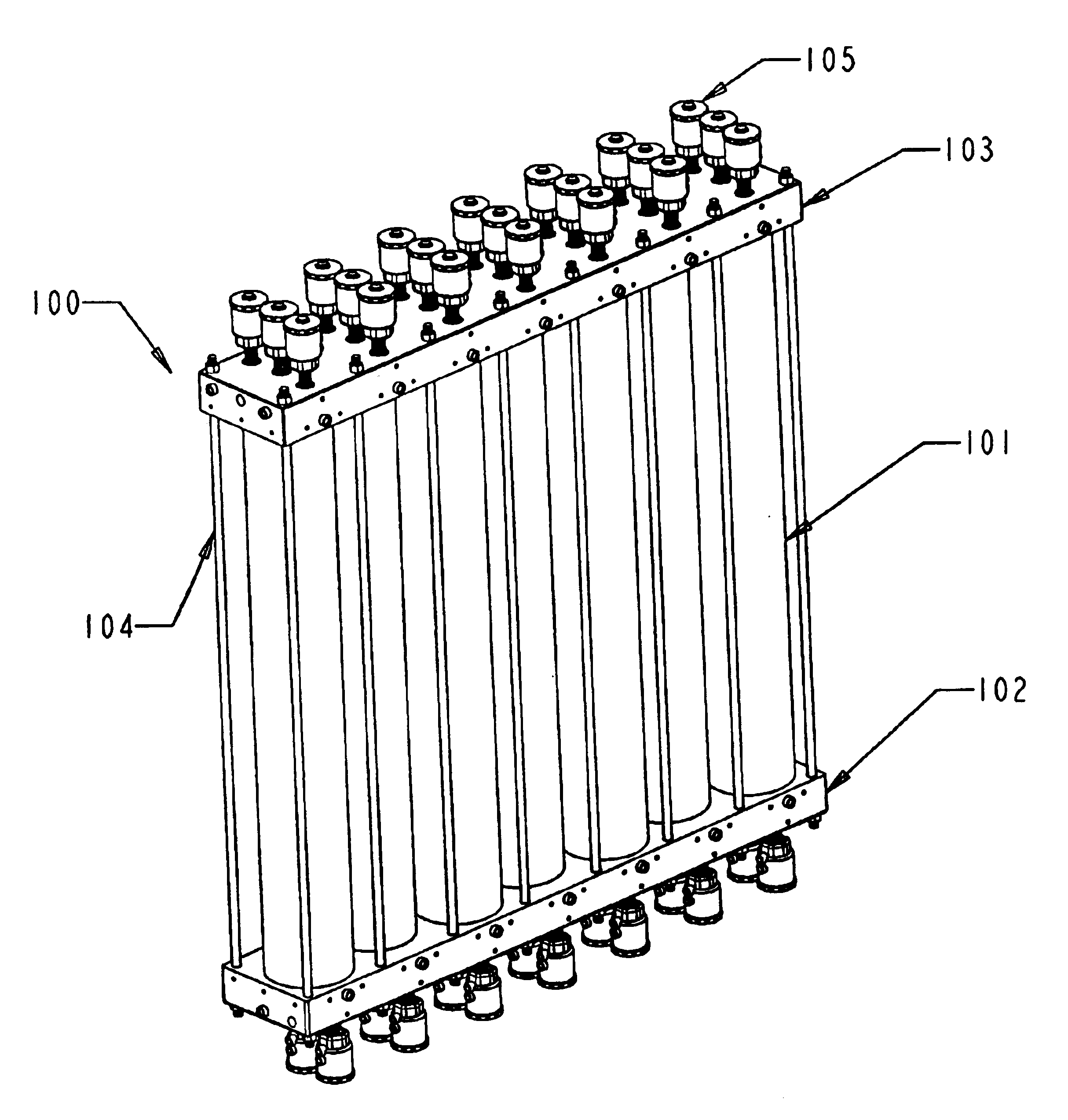

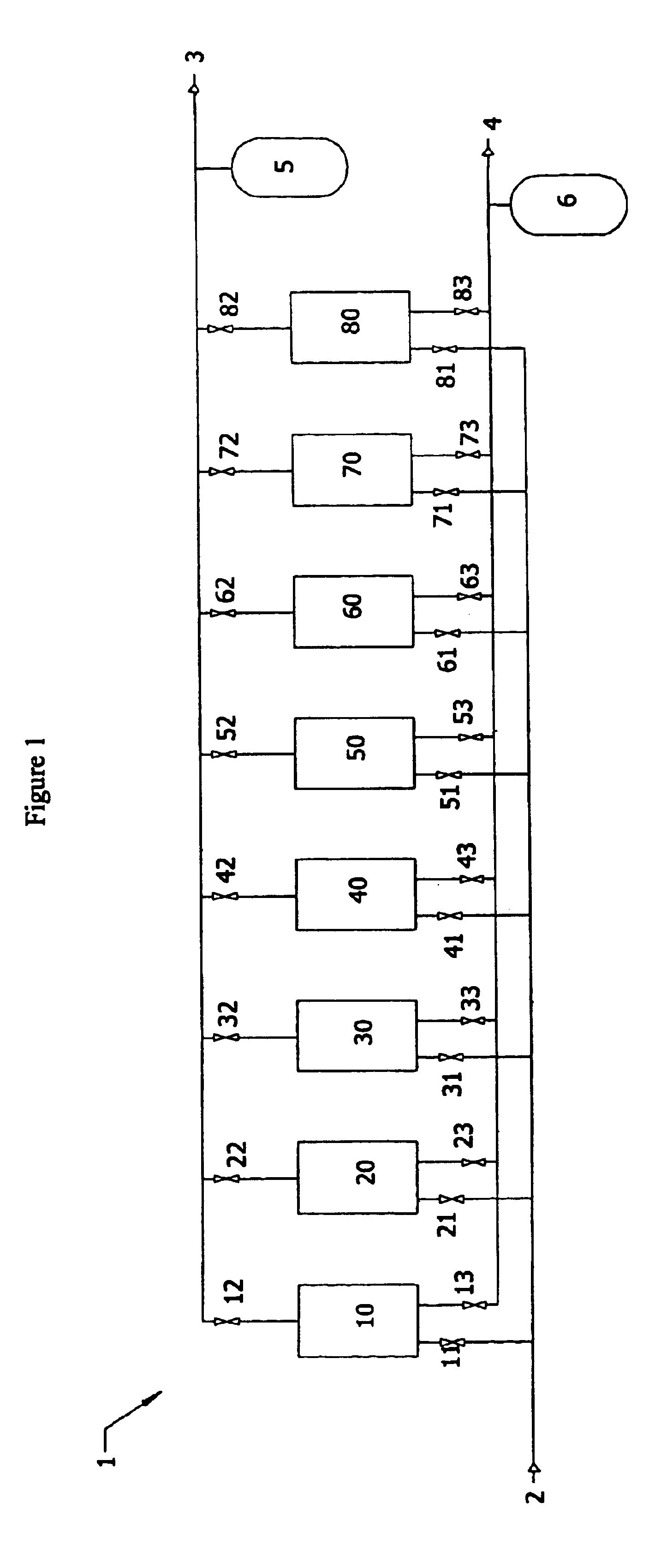

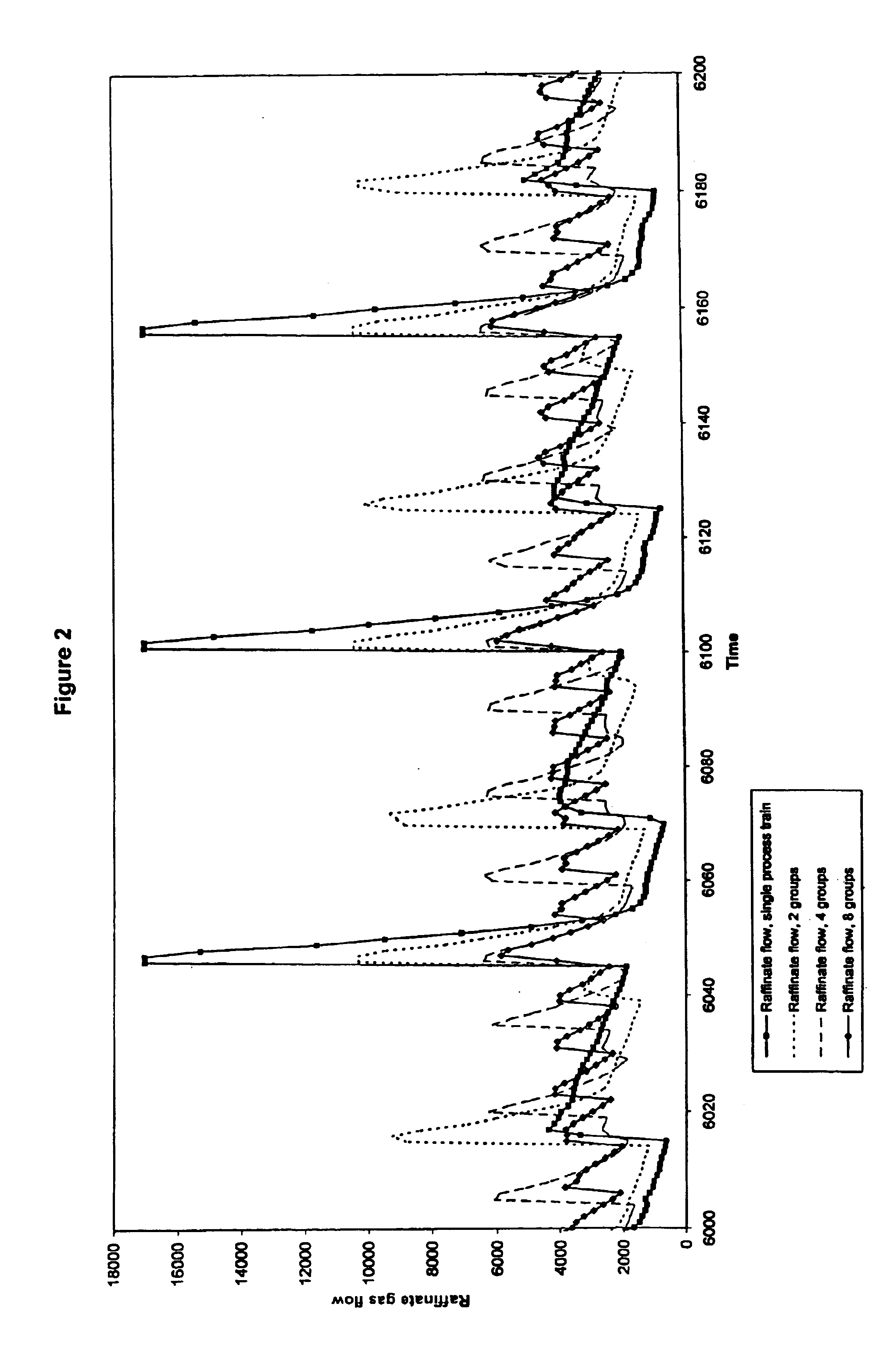

Modular pressure swing adsorption process and apparatus

InactiveUS6918953B2Reduce flowImprove reliabilityGas treatmentWaste based fuelProcess engineeringRigid structure

A pressure swing adsorption (PSA) system including a first group of PSA modules having a plurality of first PSA modules, and a second group of PSA modules having a plurality of second PSA modules. The system includes a feed gas manifold, a product manifold, and a waste manifold connected to the first PSA modules and the second PSA modules. Each first PSA module operates on a first PSA cycle in synchronization with the other first PSA modules, and each second PSA module operates on a second PSA cycle in synchronization with the other second PSA modules. The first PSA cycle is offset from the second PSA cycle. The PSA modules include a plurality of pressurized adsorbent chambers, an inlet manifold, and an outlet manifold. A rigid structure is provided that connects the inlet manifold to the outlet manifold, and structurally joins the inlet and outlet manifolds to the adsorbent chambers.

Owner:LUMMUS TECH INC

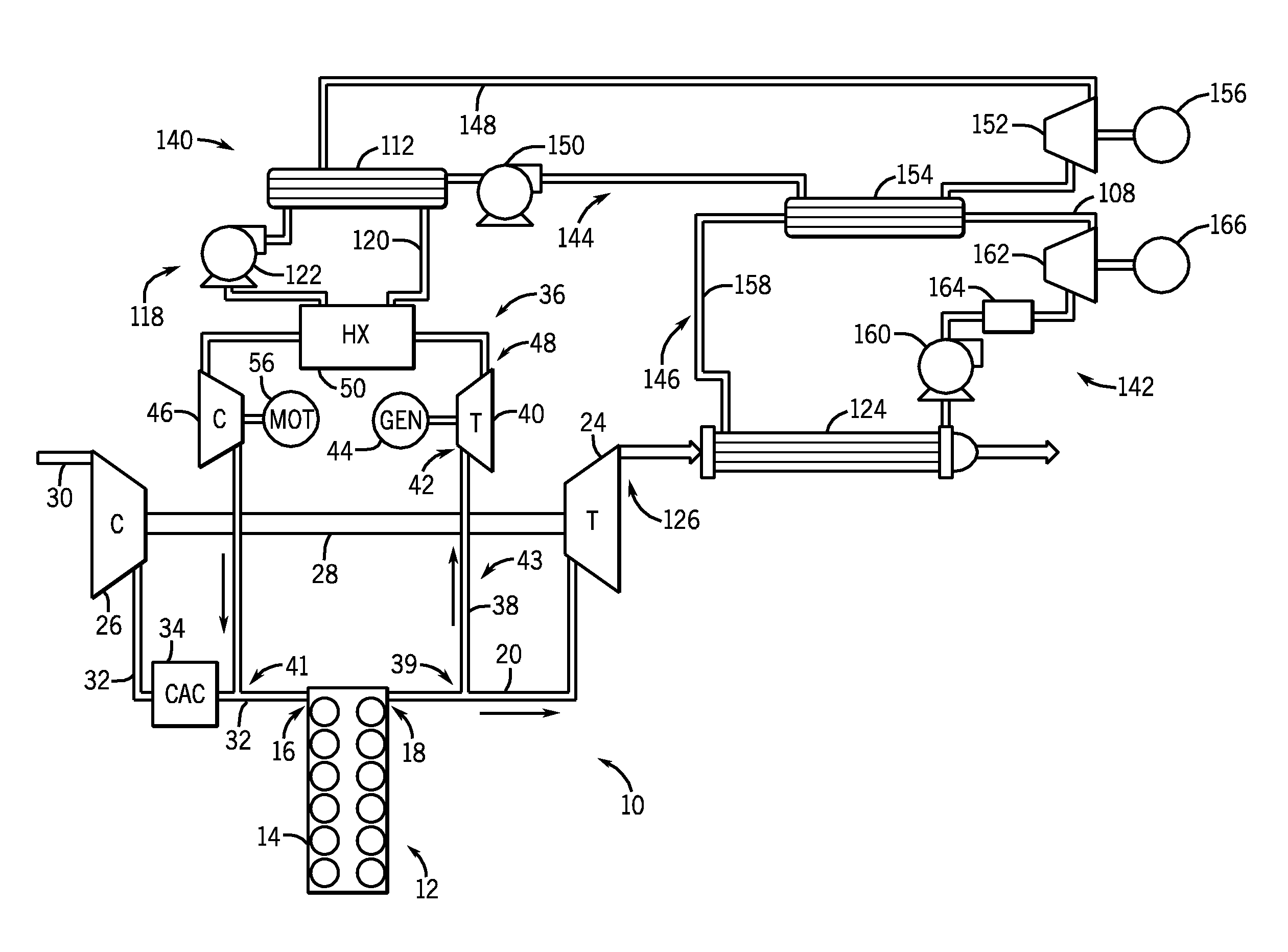

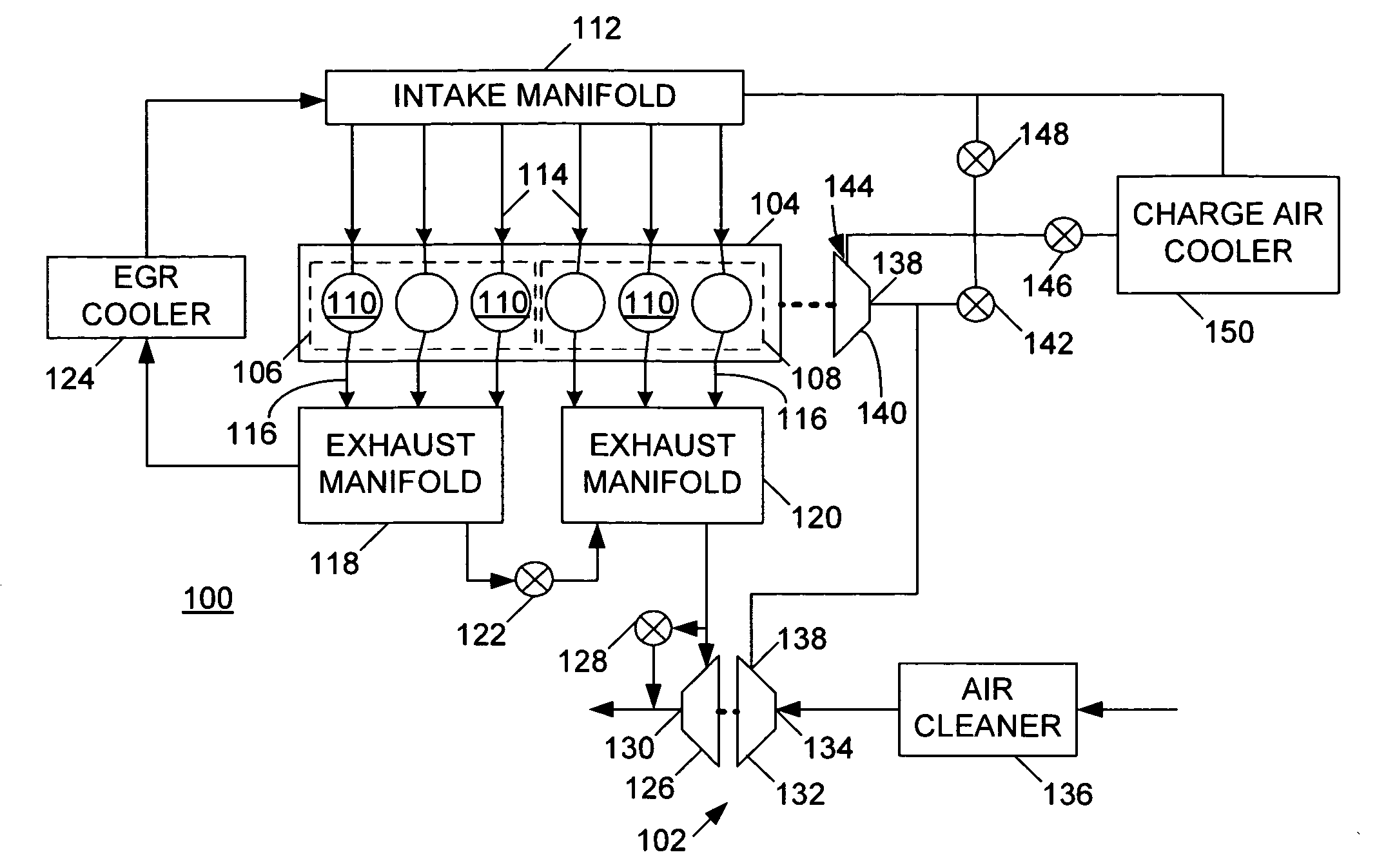

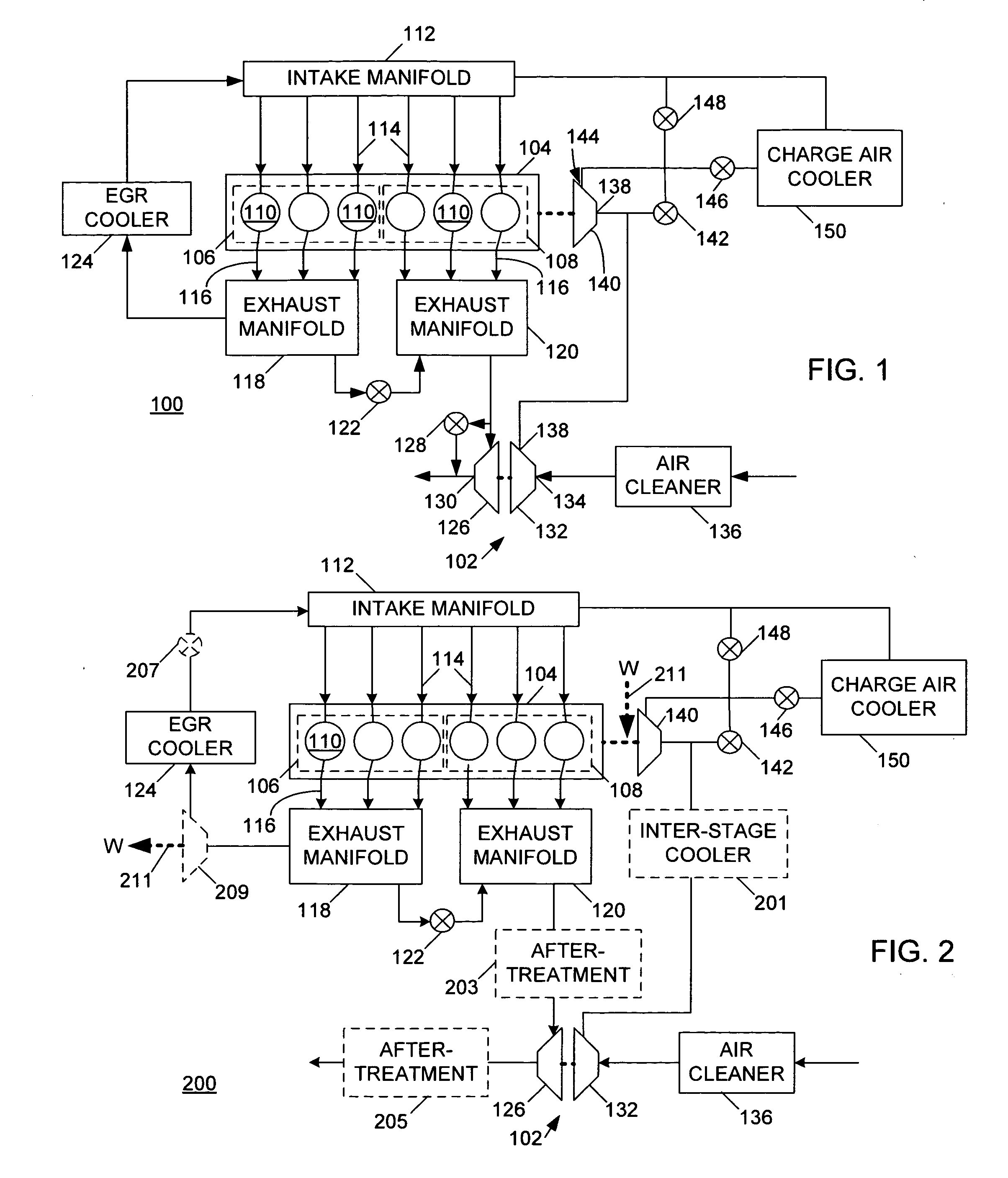

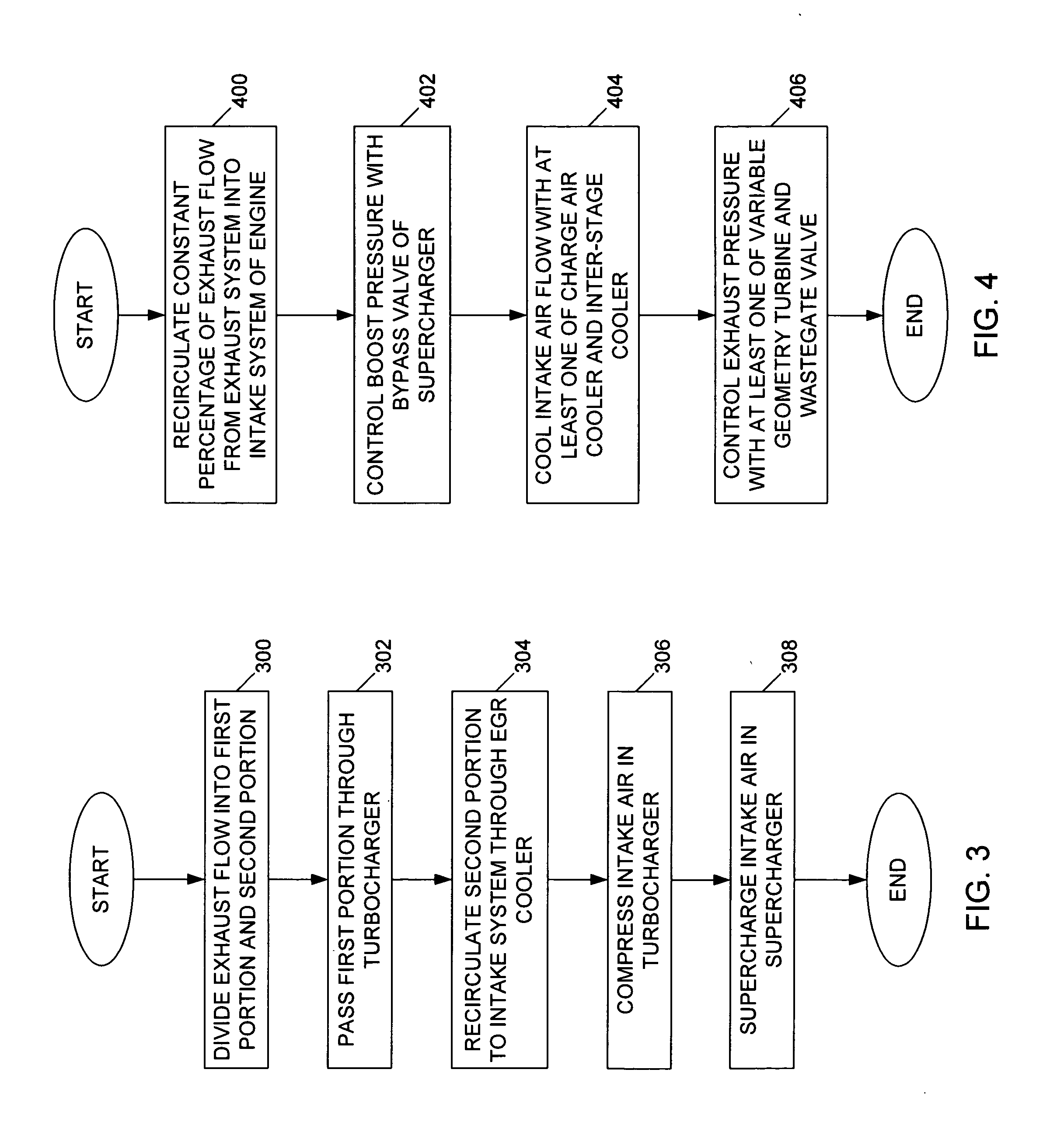

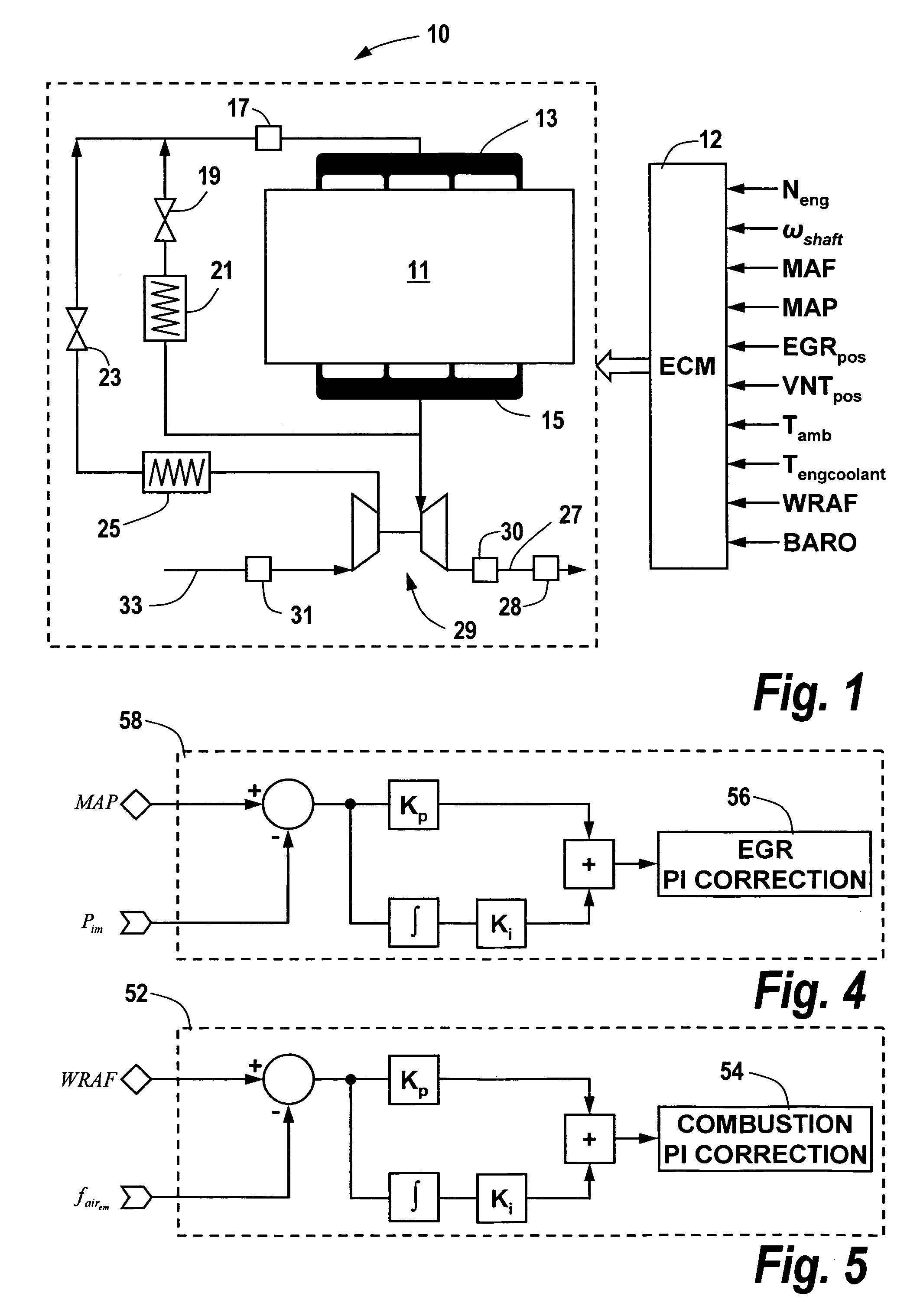

Constant EGR rate engine and method

ActiveUS20070175215A1Non-fuel substance addition to fuelInternal combustion piston enginesExhaust valveTurbocharger

An internal combustion engine (100) includes a first exhaust manifold (120), and a second exhaust manifold (118) fluidly connected to the first exhaust manifold (120) through an exhaust valve (122). An exhaust gas recirculation (EGR) cooler (124) constantly fluidly connects the second exhaust manifold (118) with an intake manifold (112). A turbocharger (102) has a turbine (126) in fluid communication with the first exhaust manifold (120), and a compressor (132) in fluid communication with a supercharger (140). A charge air cooler (150) fluidly connects the supercharger (140) with the intake manifold (112).

Owner:INT ENGINE INTPROP CO LLC

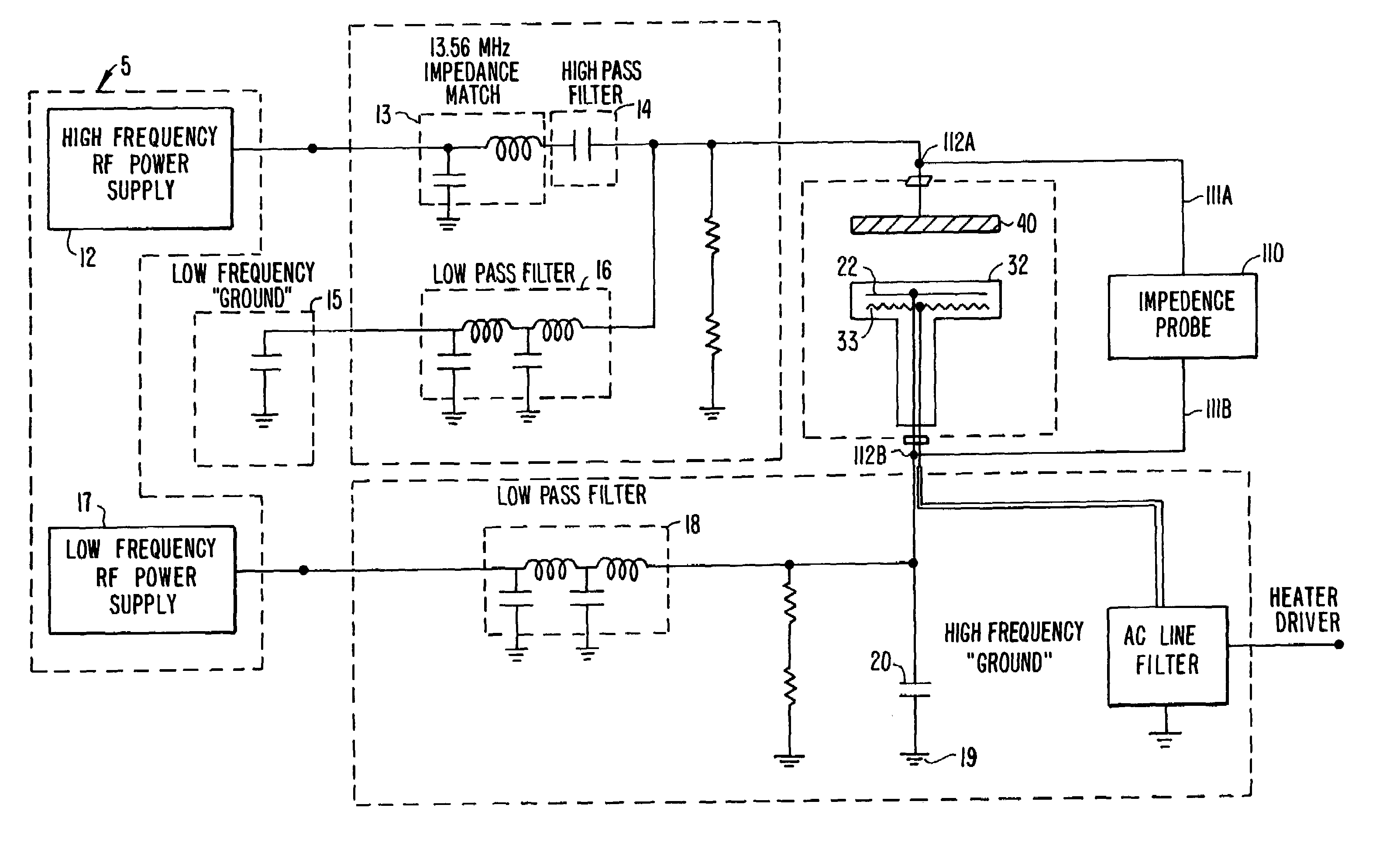

Method and apparatus for monitoring and adjusting chamber impedance

InactiveUS7004107B1Minimize phase interferencePotential for arcing is greatly reducedLiquid surface applicatorsElectric discharge tubesElectricityControl system

A substrate processing system that includes a deposition chamber having a reaction zone, a substrate holder that positions a substrate in the reaction zone, a gas distribution system that includes a gas inlet manifold for supplying one or more process gases to said reaction zone, a plasma power source for forming a plasma from a process gas introduced into the reaction zone of the deposition chamber and an impedance monitor that is electrically coupled to the deposition chamber to measure an impedance level of the plasma. In a preferred embodiment, the substrate holder is a first electrode and the gas inlet manifold is a second electrode and RF power is supplied by the plasma power source to either the first or second electrodes to form the plasma. In another preferred embodiment, the processing system further includes a computer processor that is communicatively coupled to the impedance monitor and to other control systems of the processing system so that the computer processor can adjust the impedance of the deposition chamber during the course of an extended wafer run if the impedance drifts outside of a predetermined tolerance range.

Owner:APPLIED MATERIALS INC

Microchannnel evaporator assembly

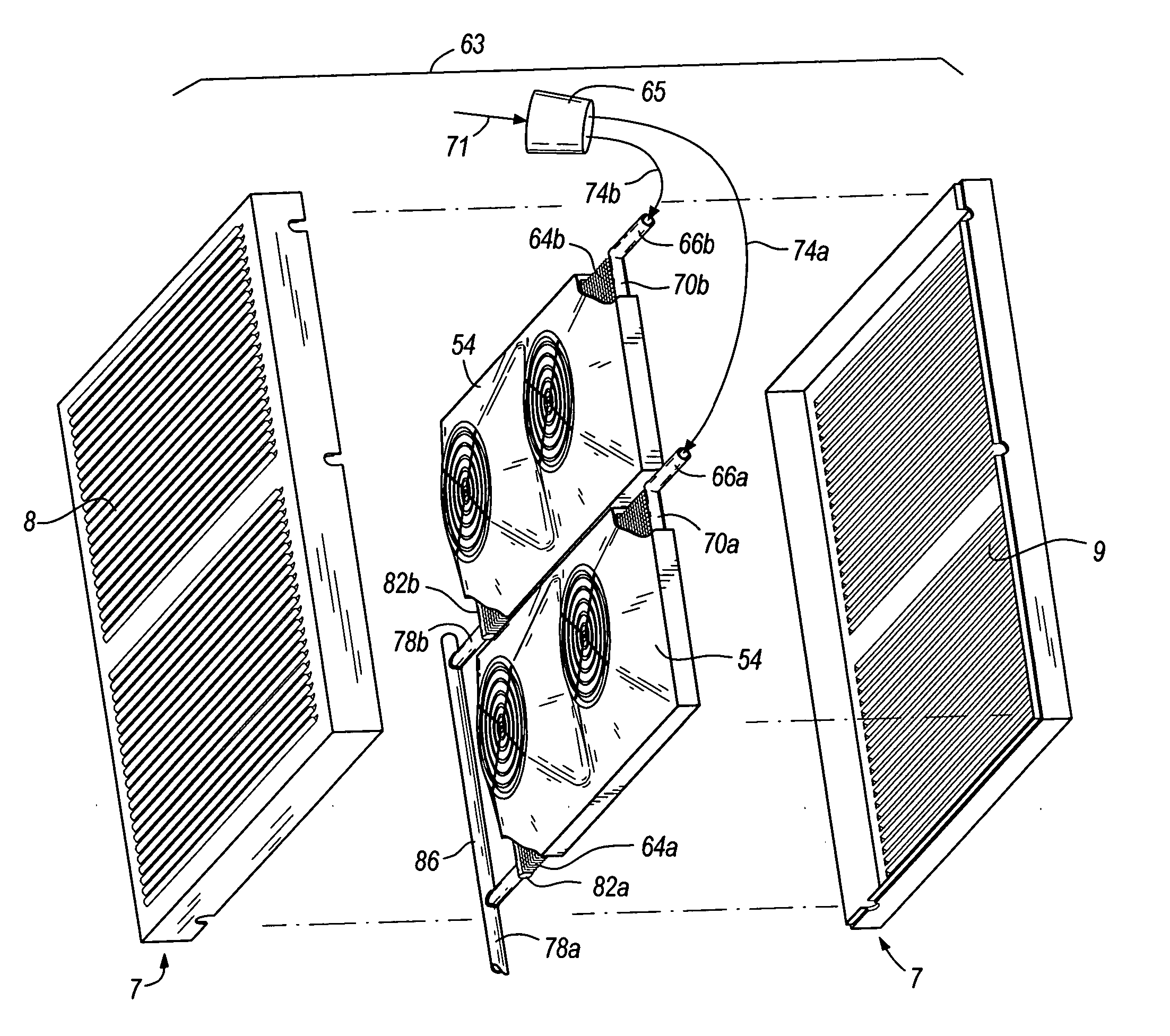

The present invention provides a unit cooler adapted for use in a refrigerated environment. The unit cooler includes a housing adapted to be positioned within the refrigerated environment and at least one microchannel evaporator coil supported by the housing. The at least one microchannel evaporator coil includes an inlet manifold and an outlet manifold. The inlet manifold has an inlet port for receiving refrigerant, and the outlet manifold has an outlet port for discharging the refrigerant.

Owner:HUSNN

Vacuum enhancing check valve

InactiveUS20060016477A1Reducing vehicle 's costReduce complexityBraking action transmissionRatio controlEngineeringCheck valve

A vacuum enhancing check valve for direct connection to a vehicle brake booster which increases the partial vacuum provided thereto and restricts possible air back flow into the brake booster. The valve comprises a venturi for reducing the pressure of air induced to flow between a first air inlet and an air outlet by a partial vacuum at a vehicle engine's intake manifold. By significantly reducing the air pressure, the valve enhances the partial vacuum available for provision to the brake booster. The venturi is also in air communication with a second air inlet directly attachable to the brake booster such that the air pressure at the second air inlet tends toward the enhanced partial vacuum within the venturi. A valve seat and seal member within the valve are cooperative to allow air flow from the second air inlet toward the venturi, but not in the reverse direction.

Owner:FORD GLOBAL TECH LLC

Heat sink with microchannel cooling for power devices

InactiveUS20060108098A1Semiconductor/solid-state device detailsSolid-state devicesEngineeringThermal contact

An apparatus for cooling at least one heated surface includes a base plate defining a number of inlet and outlet manifolds. The inlet manifolds are configured to receive a coolant, and the outlet manifolds exhaust the coolant. The inlet and outlet manifolds are interleaved. The apparatus also includes at least one substrate having inner and outer surfaces. The inner surface is coupled to the base plate and defines a number of microchannels that receive the coolant from the inlet manifolds and deliver the coolant to the outlet manifolds. The microchannels are oriented substantially perpendicular to the inlet and outlet manifolds. The outer surface is in thermal contact with the heated surface. The apparatus also includes an inlet plenum that supplies the coolant to the inlet manifolds, and an outlet plenum that exhausts the coolant from the outlet manifolds. The inlet plenum and outlet plenum are oriented in a plane of the base plate.

Owner:GENERAL ELECTRIC CO

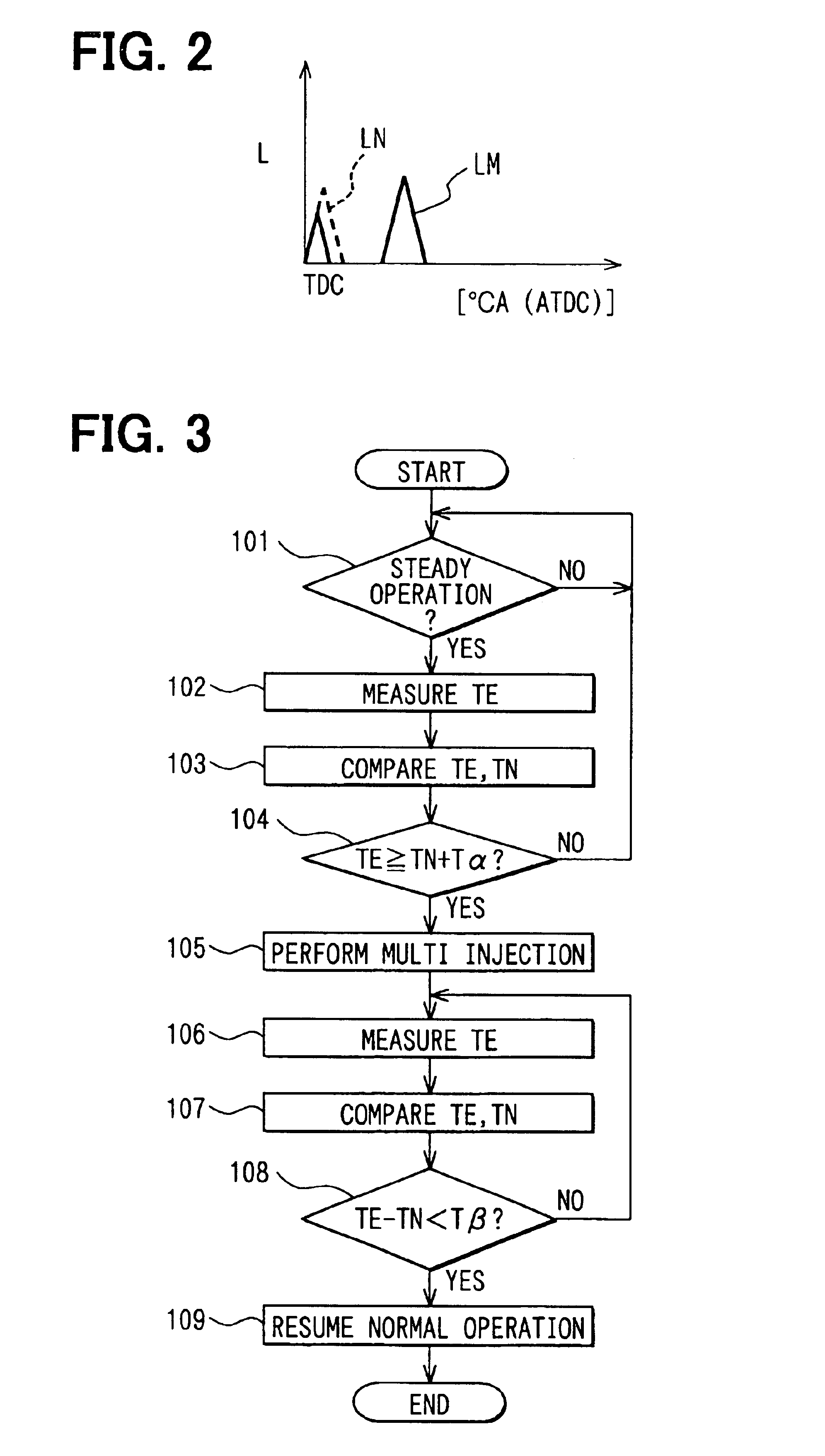

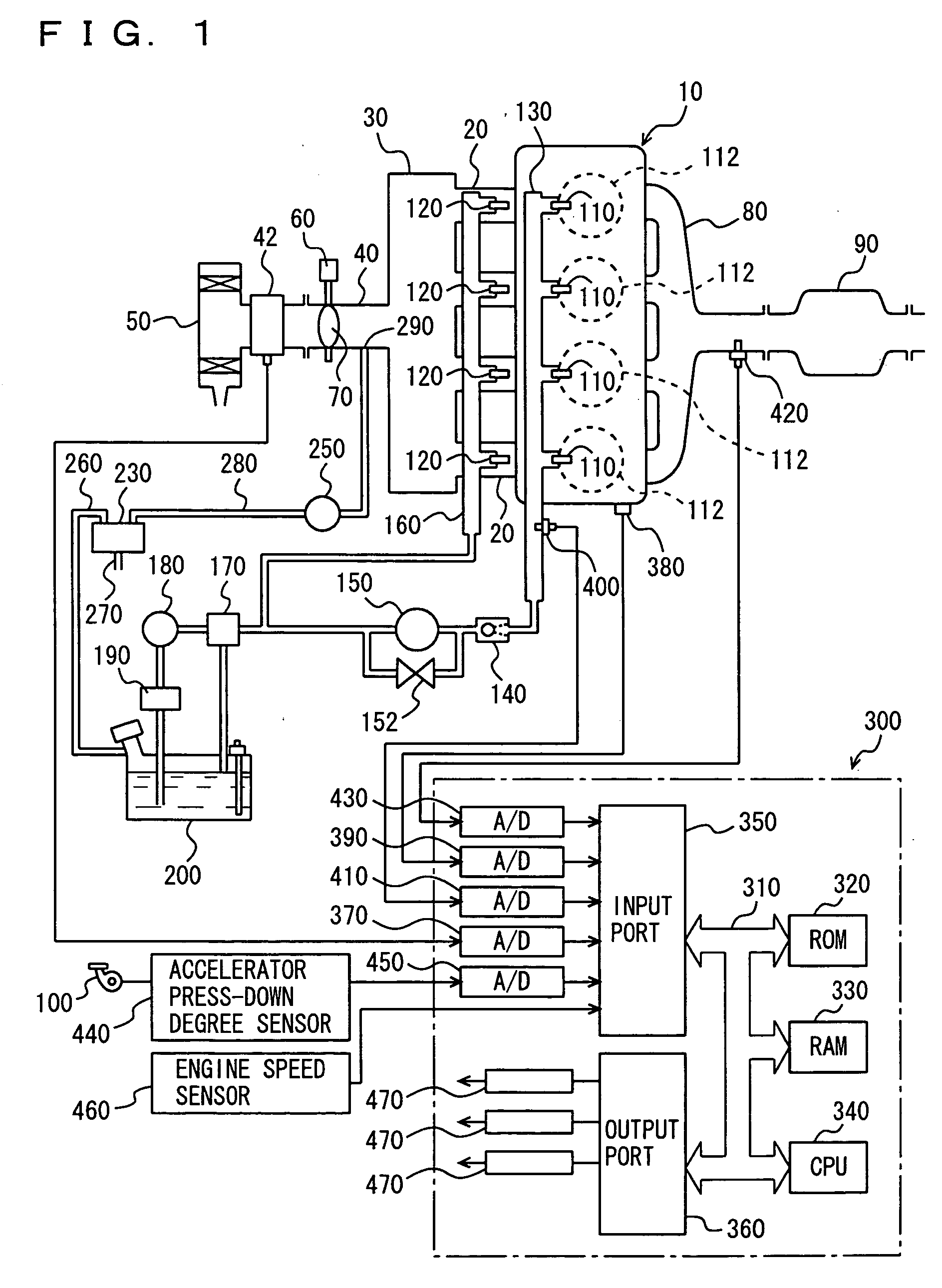

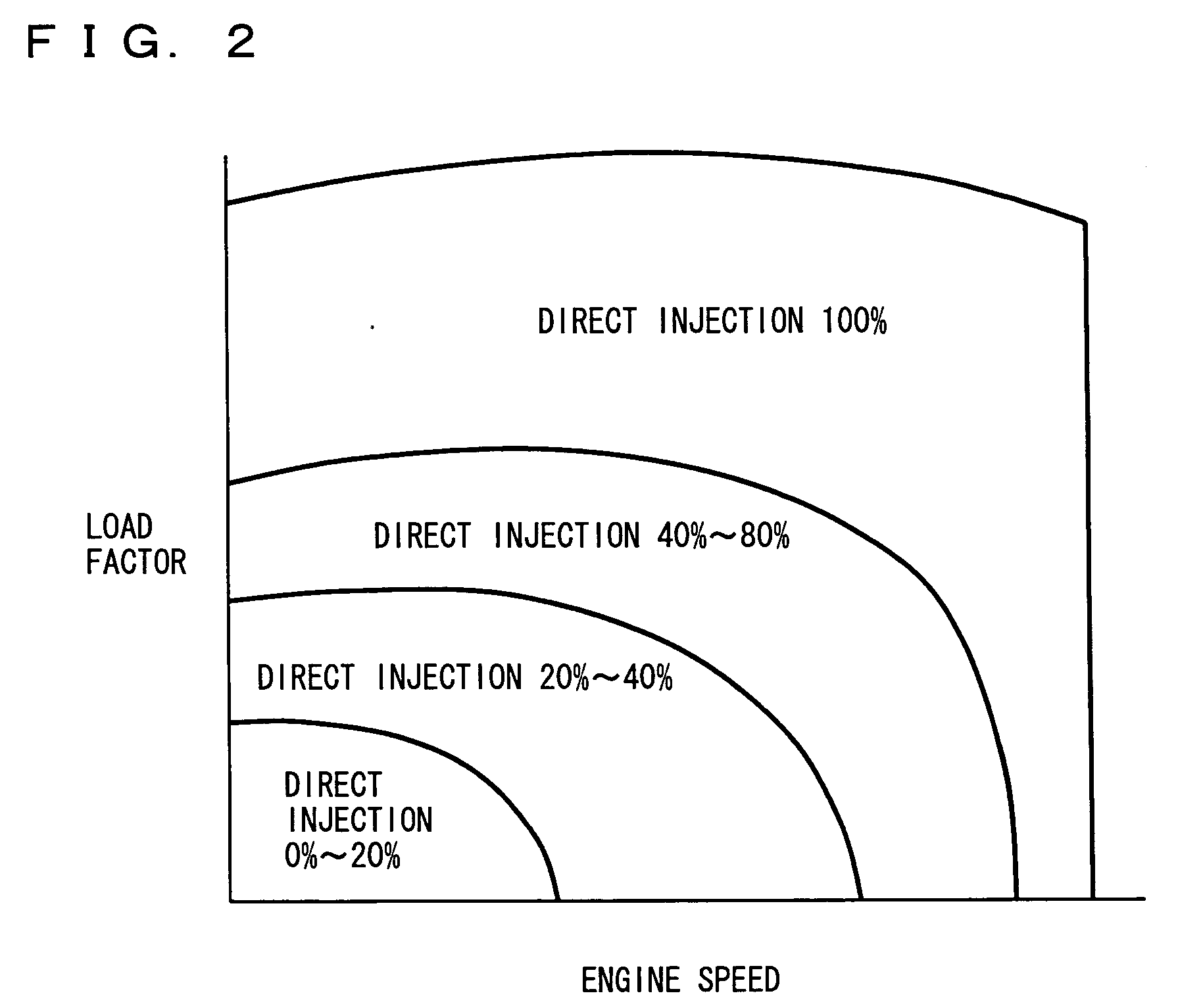

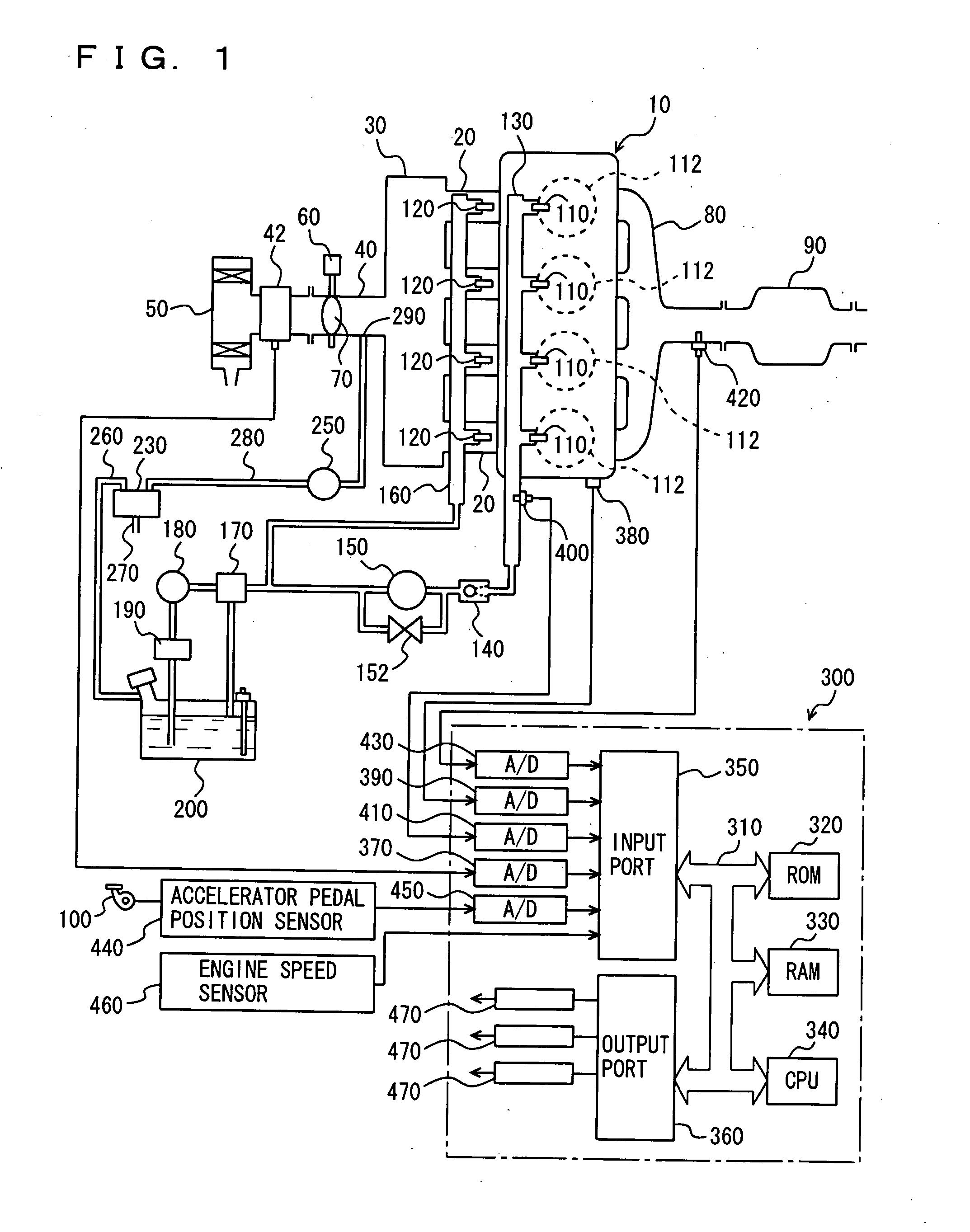

Control device of internal combustion engine

ActiveUS20050274353A1Avoid volatilityLowering of of emissionElectrical controlCombustion enginesInlet manifoldFuel injection

When an injection sharing ratio r is neither 0 nor 1, an engine ECU executes a program including a step of calculating a purge reduction amount of an in-cylinder injector as fpg×r and calculating a purge reduction amount of an intake manifold injector as fpg×(1-r) when performing purge processing according to a current fuel injection sharing ratio of the injectors, and a step of calculating a correction fuel injection amount of the in-cylinder injector by raising the fuel injection amount to a minimum fuel injection amount, and calculating a correction fuel injection amount of the intake manifold injector by subtracting the raised amount from the fuel injection amount of the intake manifold injector when the fuel injection amount of the in-cylinder injector calculated by using the purge reduction amount is lower than the minimum injection amount.

Owner:TOYOTA JIDOSHA KK

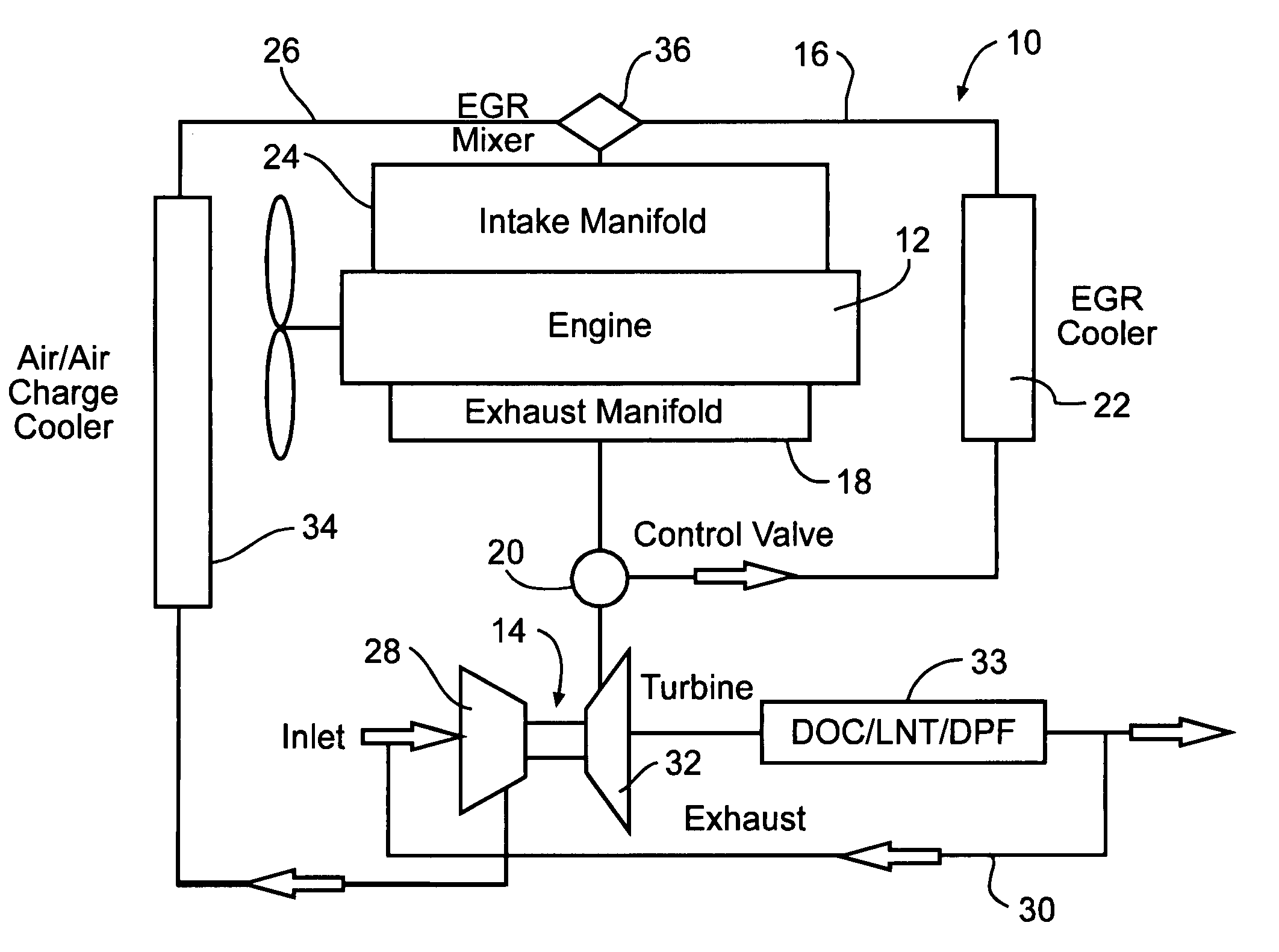

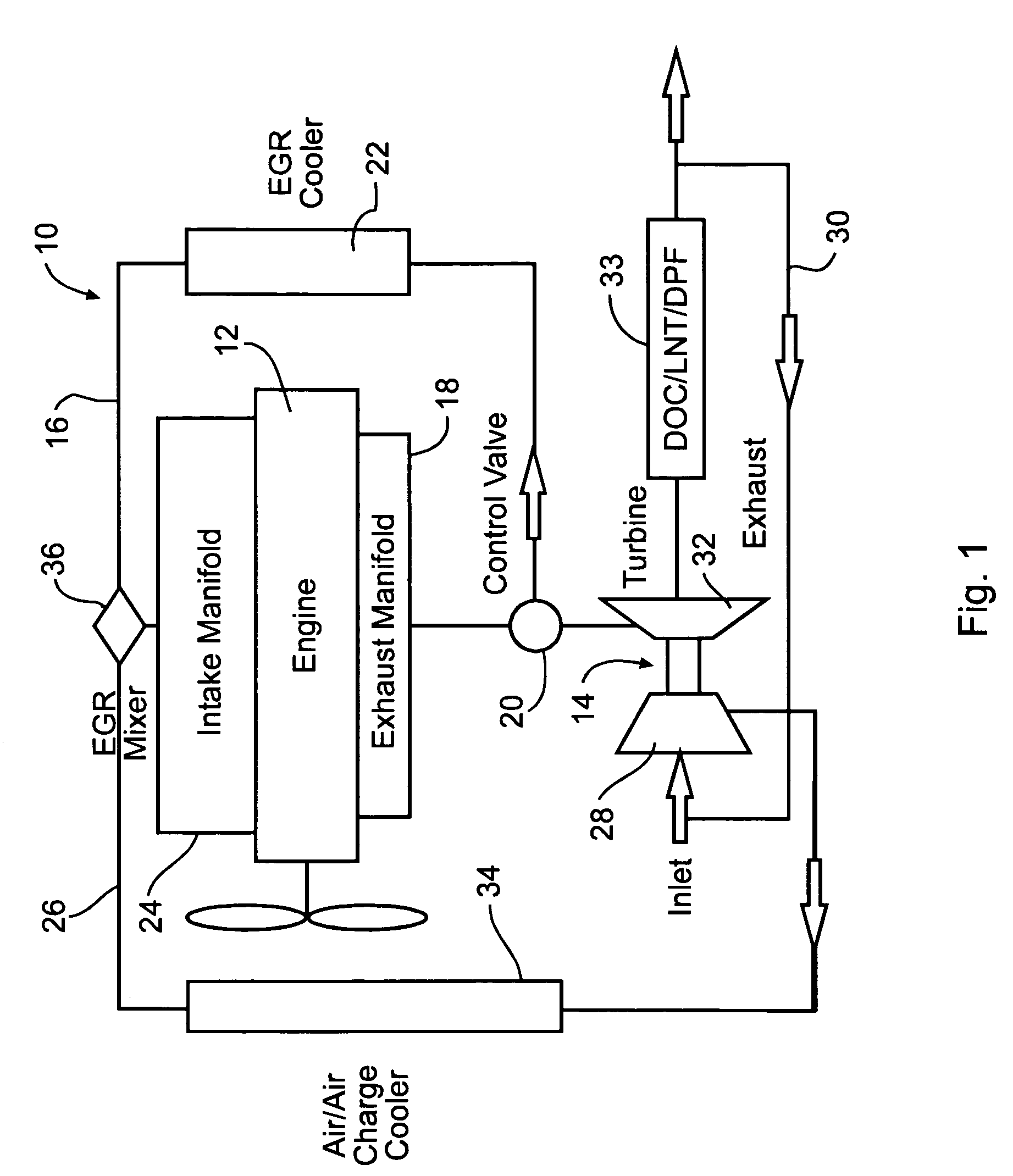

Dual and hybrid EGR systems for use with turbocharged engine

ActiveUS20050103013A1Non-fuel substance addition to fuelInternal combustion piston enginesSingle stageTurbocharger

EGR systems for an internal combustion engine configured to operate using multiple-staged turbochargers, or a pair of single stage turbochargers, to provide exhaust gas recirculation to meet emissions requirements while not affecting engine performance. One or two EGR loops operating at low, intermediate, or high pressures may be employed. EGR exhaust gases may be taken directly from the exhaust manifold, or after the exhaust stream has passed through a turbocharger turbine. EGR exhaust gases may be injected at an intermediate pressure between stages of a multiple stage turbocharger, or alternatively between a low pressure turbocharger compressor and high pressure turbocharger compressor, before being boosted to a pressure high enough to ensure the desired mass flow to the engine and delivered to the intake manifold. Intake air may be pressurized prior to mixing with the EGR exhaust gases.

Owner:GARRETT TRANSPORATION I INC

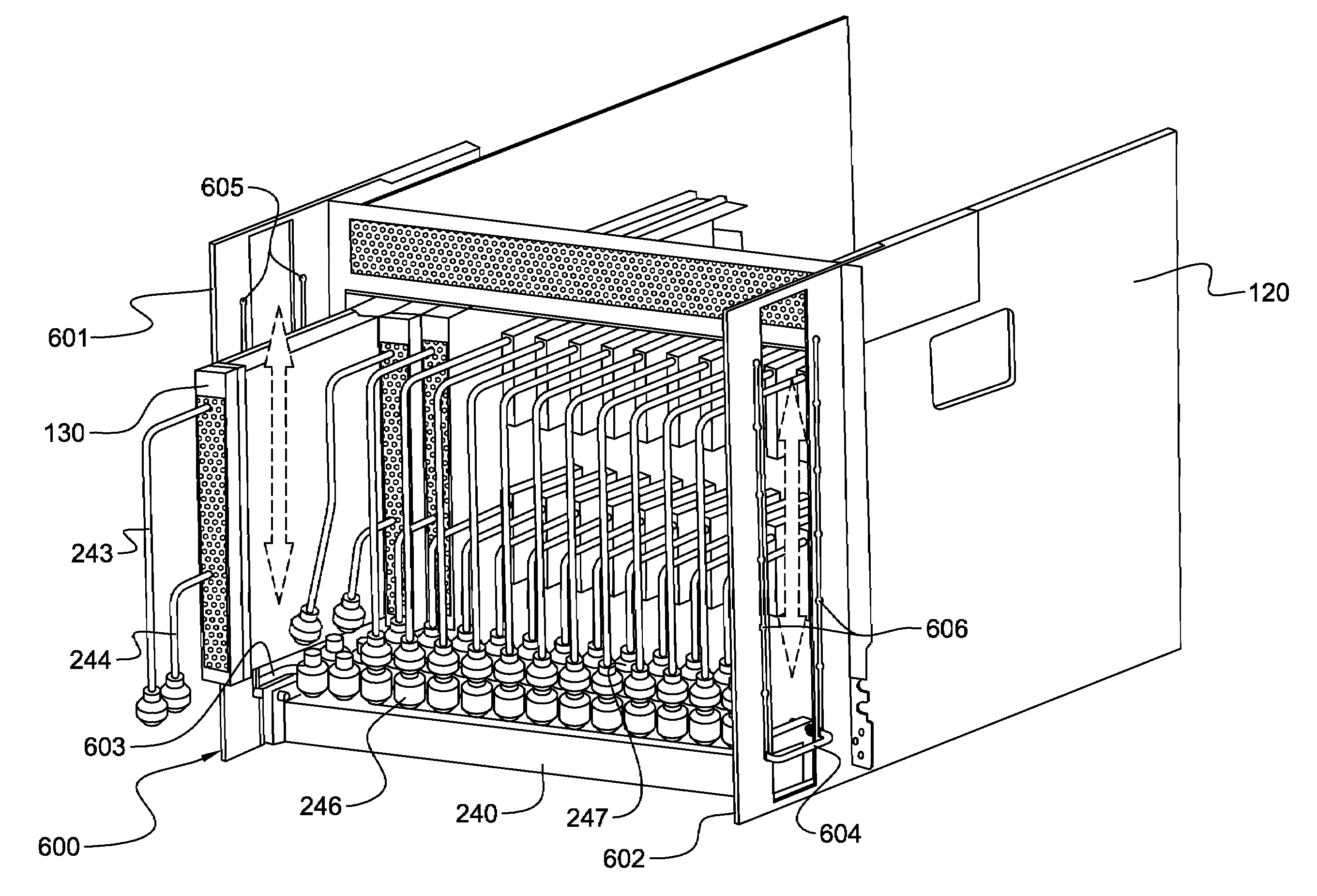

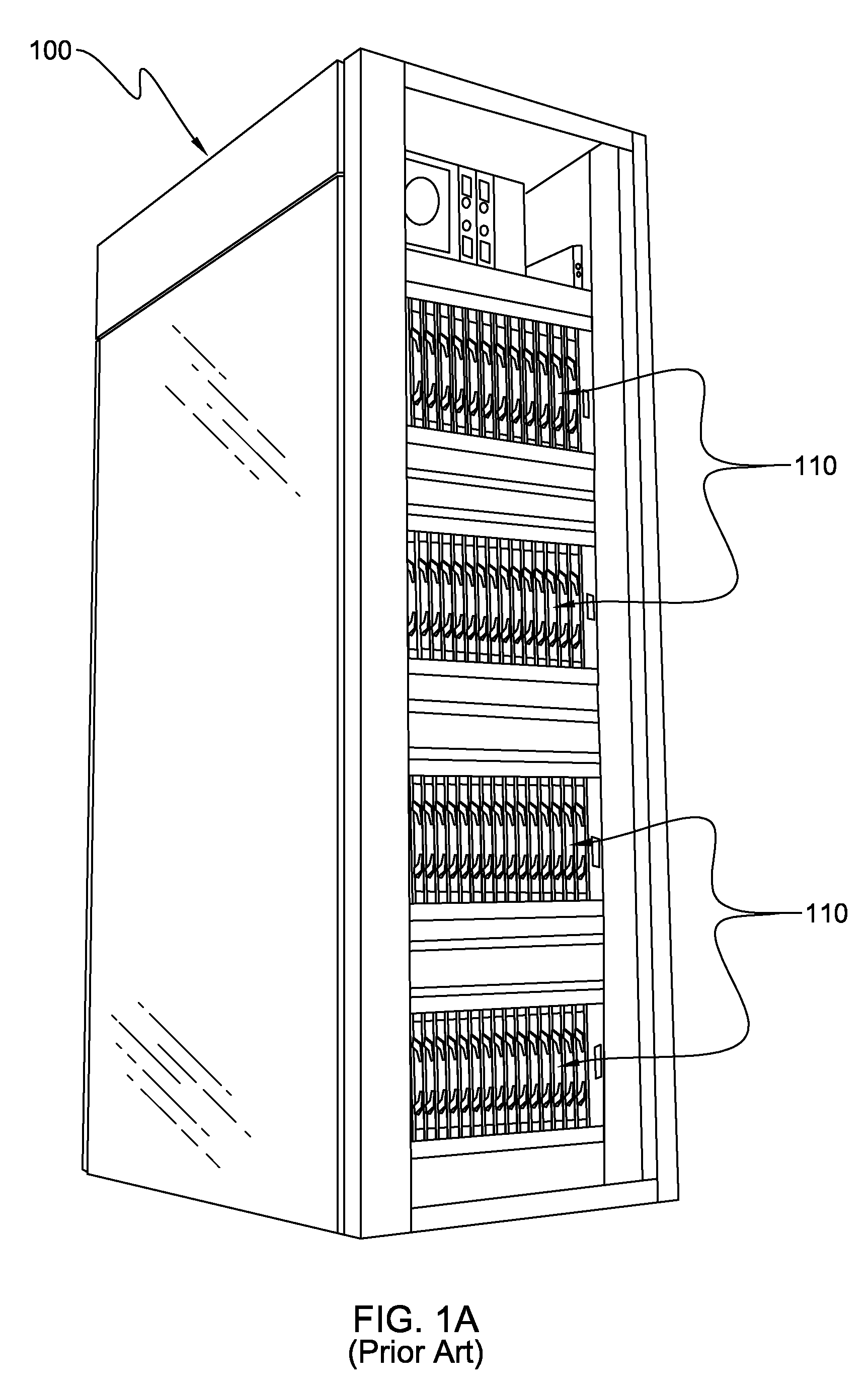

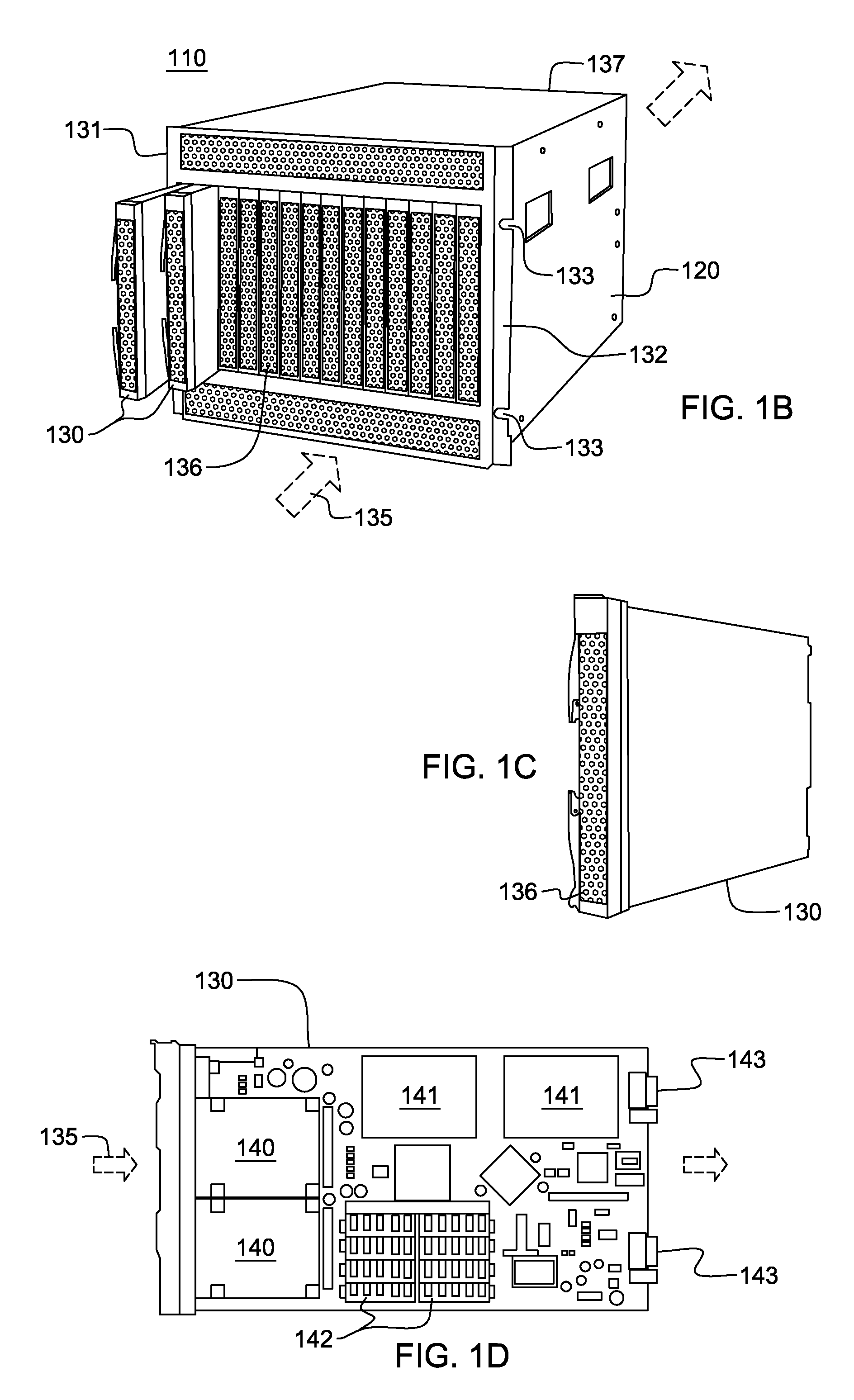

Liquid cooling apparatus and method for facilitating cooling of an electronics system

InactiveUS7639499B1Easy accessOvercomes shortcomingDomestic cooling apparatusSemiconductor/solid-state device detailsElectronic systemsInlet manifold

Apparatus and method are provided for facilitating liquid cooling one or more components of an electronic subsystem chassis disposed within an electronics rack. The apparatus includes a rack-level coolant manifold assembly and at least one movable chassis-level manifold subassembly. The rack-level coolant manifold assembly includes a rack-level inlet manifold and a rack-level outlet manifold, and each movable chassis-level manifold subassembly includes a chassis-level coolant inlet manifold coupled in fluid communication with the rack-level inlet manifold, and a chassis-level coolant outlet manifold coupled in fluid communication with the rack-level outlet manifold. The chassis-level manifold subassembly is slidably coupled to the electronics rack to facilitate access to one or more removable components of the electronic subsystem chassis. In one embodiment, the electronics subsystem chassis is a multi-blade center system having multiple removable blades, each blade being an electronics subsystem.

Owner:IBM CORP

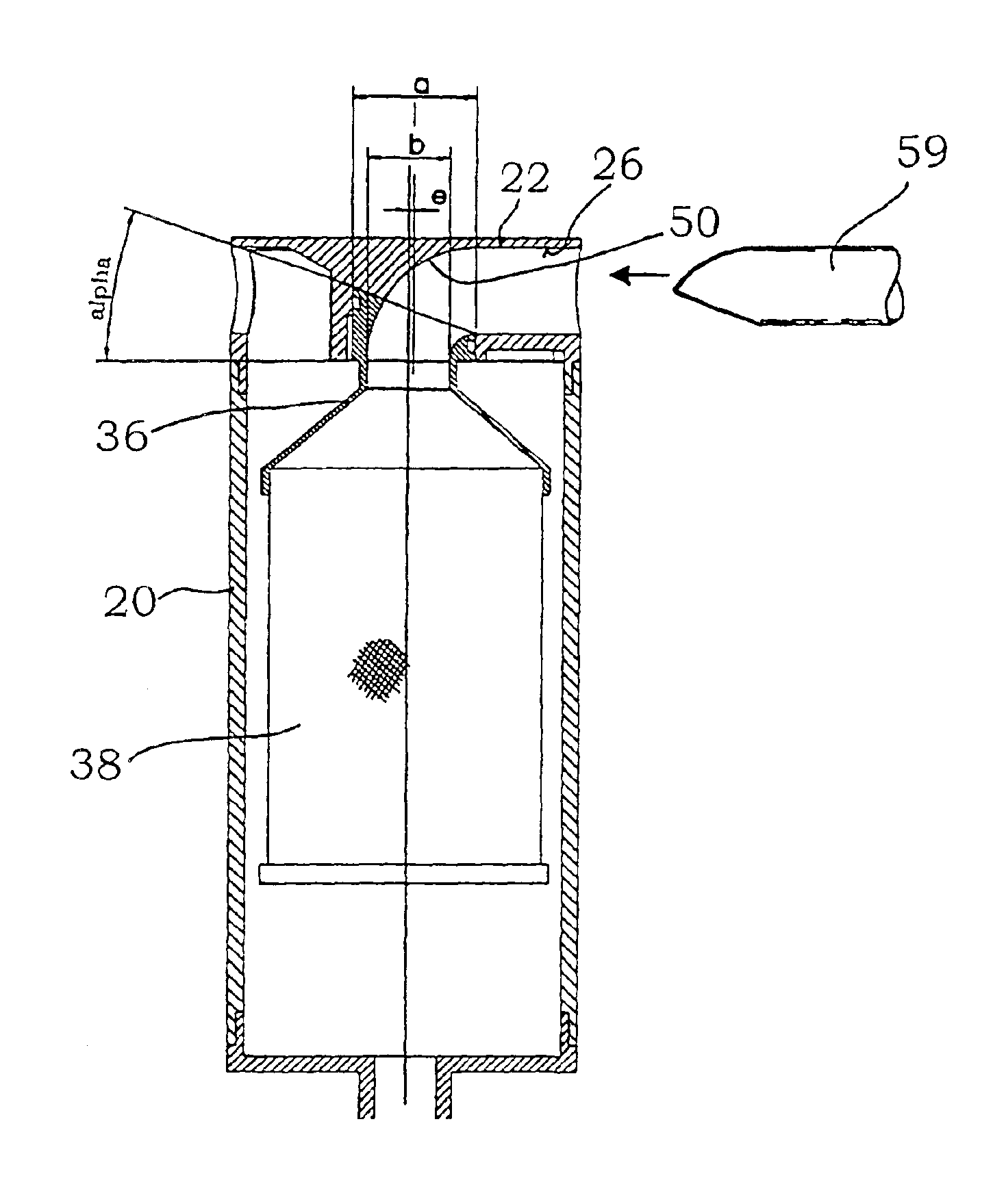

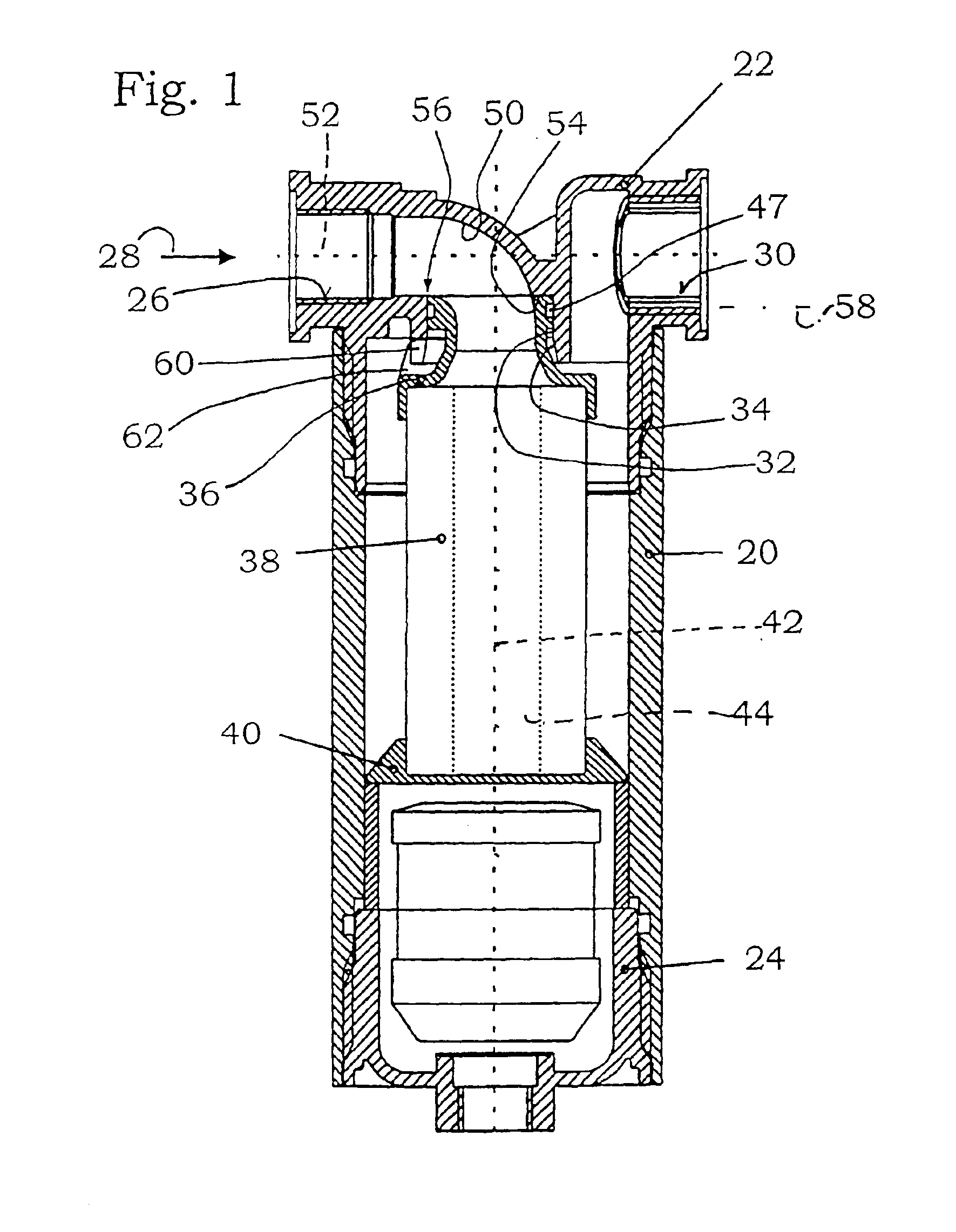

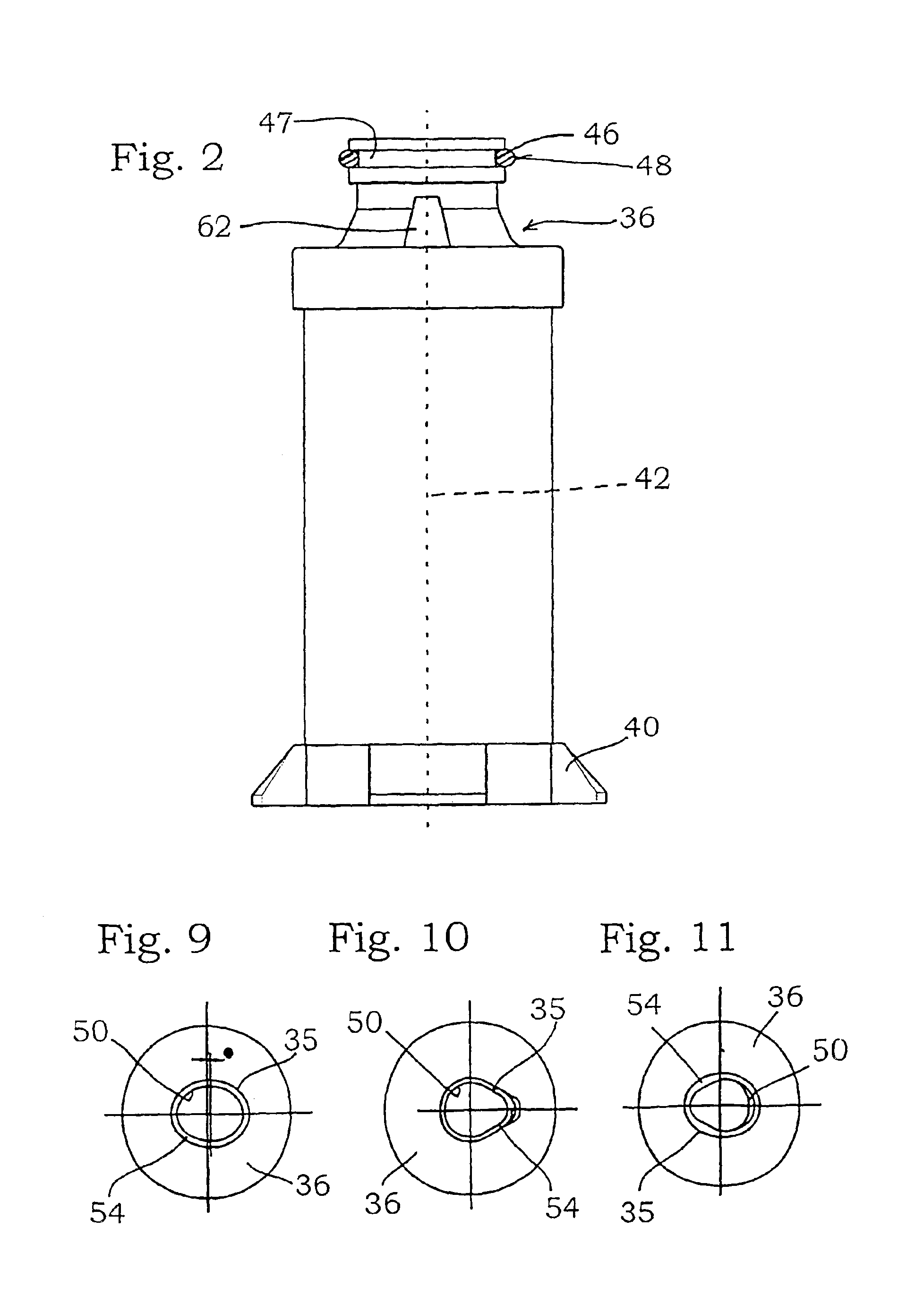

Filter for the separation of contaminants from gas stream

InactiveUS6936084B2Easy to manufactureEasy to useCombination devicesDispersed particle filtrationEngineeringCentral element

A filter for separating contaminants from a gas stream, including (a) a housing having a housing body and a housing head, the housing head having an inlet for the gas stream to be purified, an outlet and a first sealing surface, and (b) a filter element accommodated in the housing, having an element head and an element body having a central element axis and an element interior. The element head has a second sealing surface which cooperates with the first sealing surface. A curved inlet manifold is formed between the inlet and the element interior. The inlet manifold is embodied partly in the housing head and partly in the element head such that the first and second sealing surfaces contact in a sealing plane at a 90° to 60° angle to the element axis. A radially arranged seal is provided on the sealing plane, forming one of the sealing surfaces.

Owner:BEKO TECHNOLOGIES GMBH

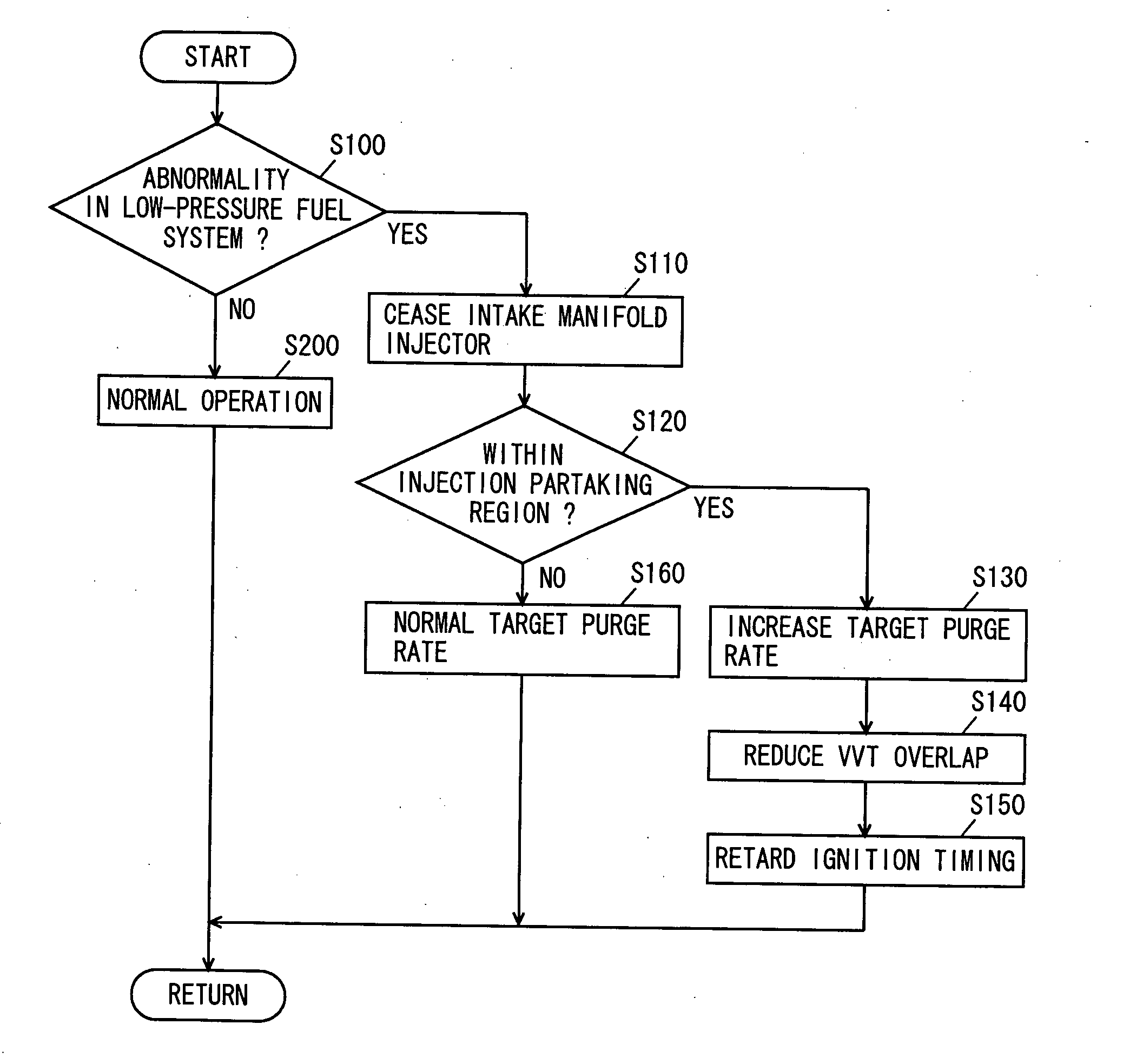

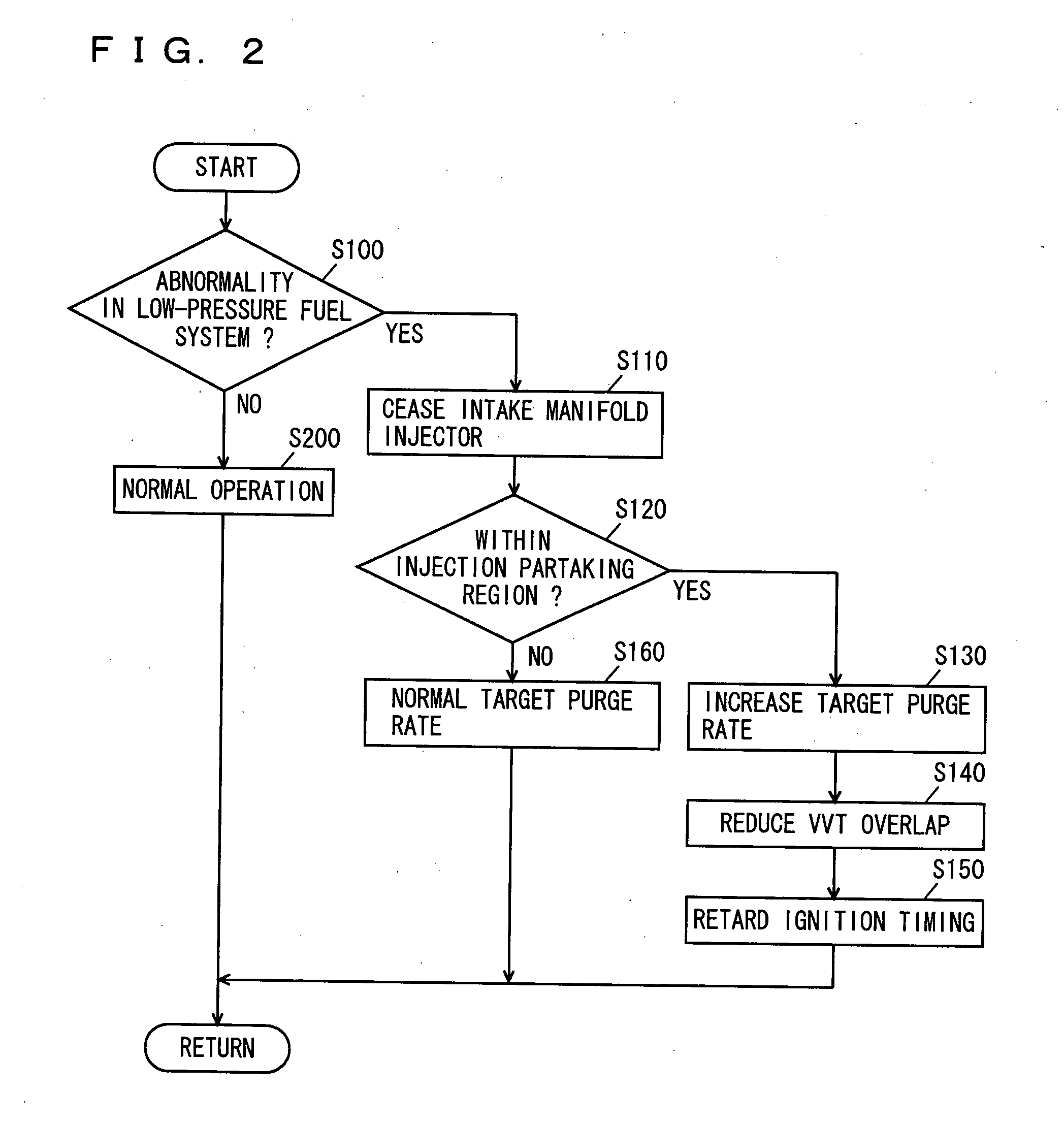

Control apparatus for internal combustion engine

InactiveUS20060090732A1Increasing purge rateVariation can be suppressedValve arrangementsElectrical controlIgnition timingInlet manifold

An engine ECU executes a program including the steps of: determining presence of abnormality in a low-pressure fuel system; ceasing an intake manifold injector when determination is made of abnormality in the low-pressure fuel system; increasing the target purge rate when the engine operation state attains an injection partaking state between an in-cylinder injector and an intake manifold injector; reducing the VVT overlap; and retarding the ignition timing.

Owner:TOYOTA JIDOSHA KK

Dual and hybrid EGR systems for use with turbocharged engine

InactiveUS7013879B2Non-fuel substance addition to fuelInternal combustion piston enginesSingle stageTurbocharger

EGR systems for an internal combustion engine configured to operate using multiple-staged turbochargers, or a pair of single stage turbochargers, to provide exhaust gas recirculation to meet emissions requirements while not affecting engine performance. One or two EGR loops operating at low, intermediate, or high pressures may be employed. EGR exhaust gases may be taken directly from the exhaust manifold, or after the exhaust stream has passed through a turbocharger turbine. EGR exhaust gases may be injected at an intermediate pressure between stages of a multiple stage turbocharger, or alternatively between a low pressure turbocharger compressor and high pressure turbocharger compressor, before being boosted to a pressure high enough to ensure the desired mass flow to the engine and delivered to the intake manifold. Intake air may be pressurized prior to mixing with the EGR exhaust gases.

Owner:GARRETT TRANSPORATION I INC

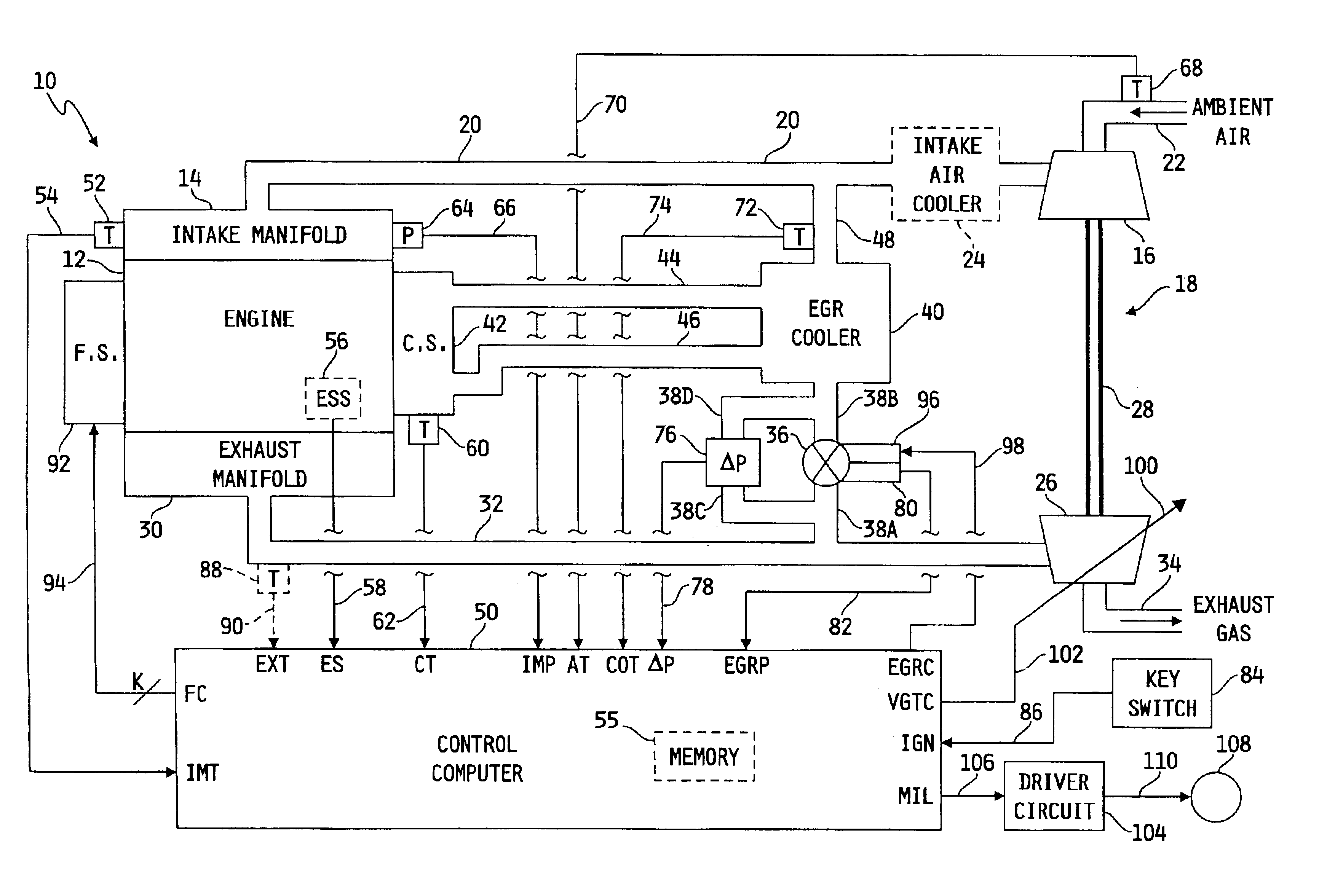

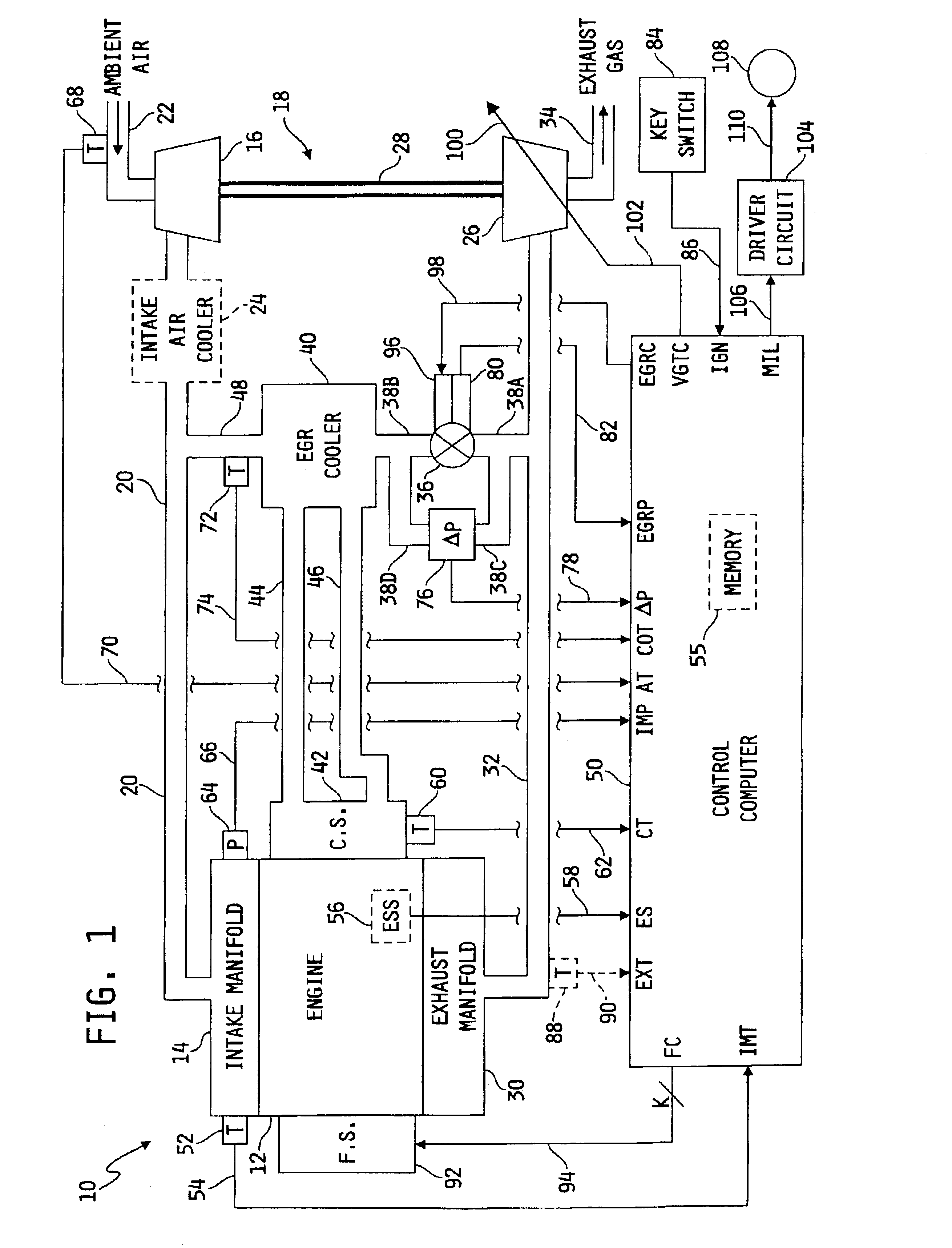

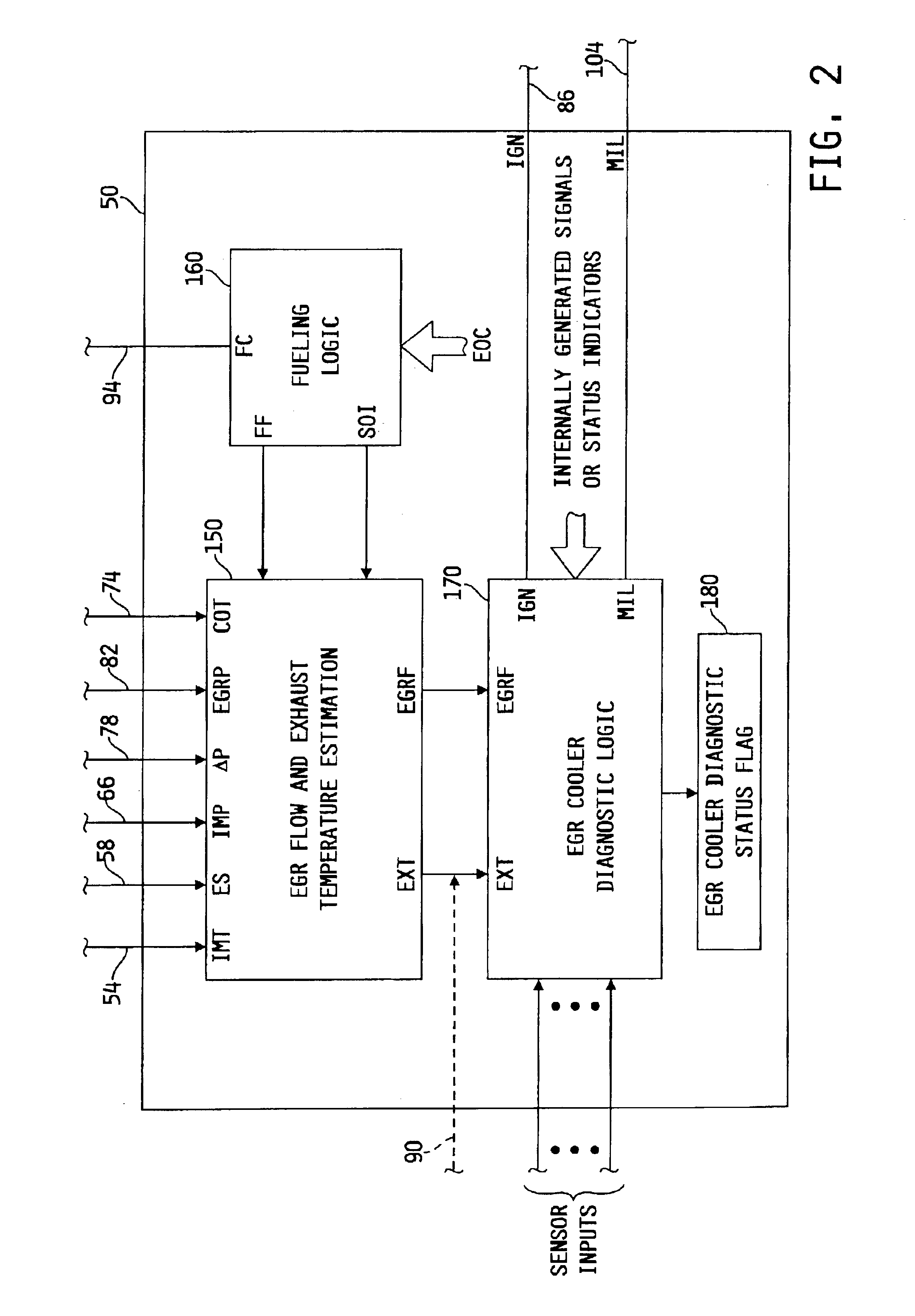

System for diagnosing operation of an EGR cooler

InactiveUS6848434B2Internal combustion piston enginesNon-fuel substance addition to fuelCoolant flowEngineering

A system is disclosed for diagnosing operation of an EGR cooler disposed in-line with an EGR conduit fluidly coupled between an intake manifold and an exhaust manifold of the engine such that exhaust gas flowing through the EGR conduit also flows through the EGR cooler. The EGR cooler is coupled to an engine cooling system such that coolant fluid circulating through the engine also circulates through the EGR cooler. Means are provided for determining a temperature of exhaust gas produced by the engine, a temperature of exhaust gas exiting the EGR cooler, a temperature of the coolant fluid and a flow rate of exhaust gas through the EGR conduit. A control computer is configured to diagnose operation the EGR cooler as a function of the temperature of exhaust gas produced by the engine, the EGR cooler outlet temperature, the engine coolant temperature and the EGR flow rate.

Owner:CUMMINS INC

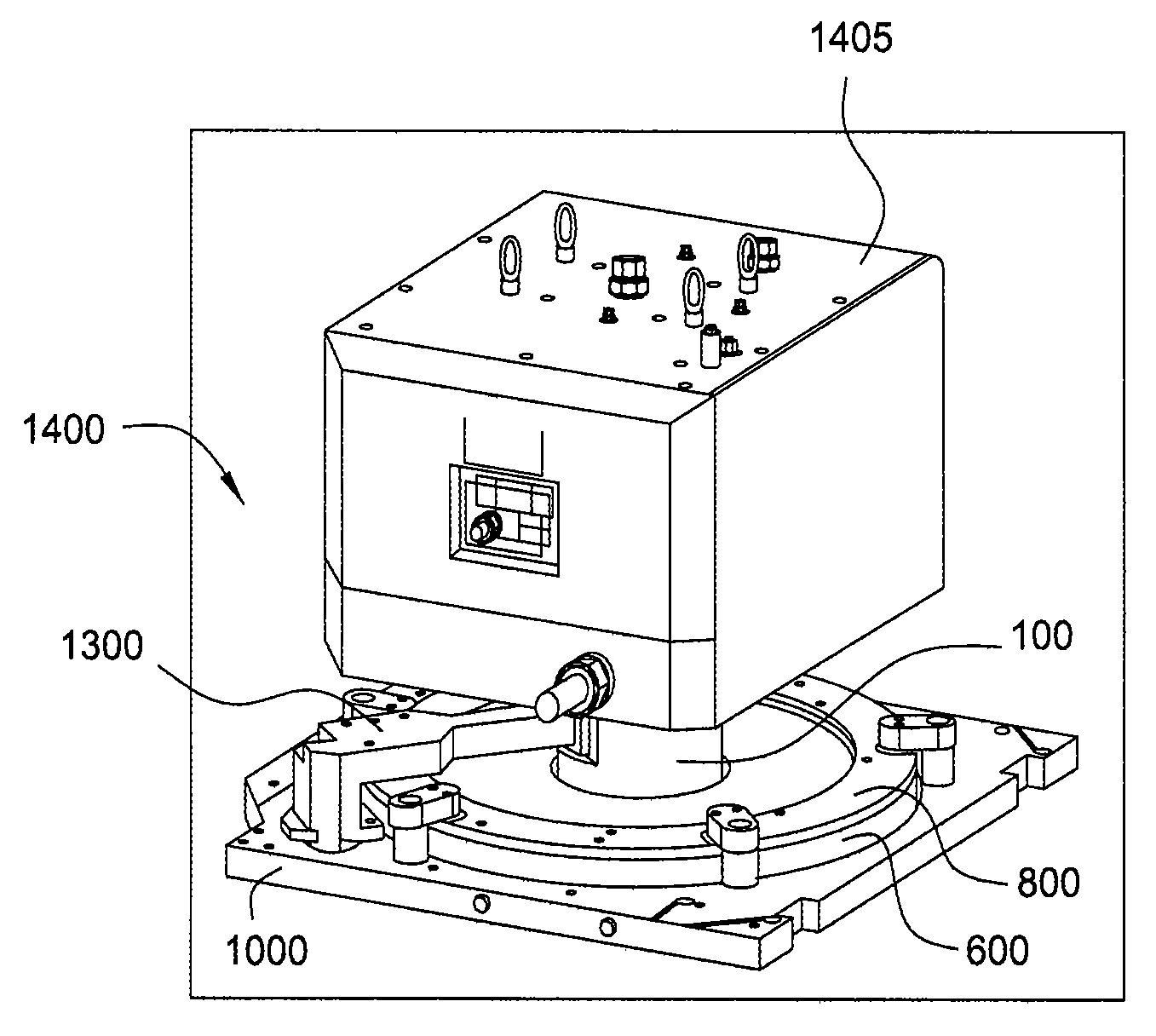

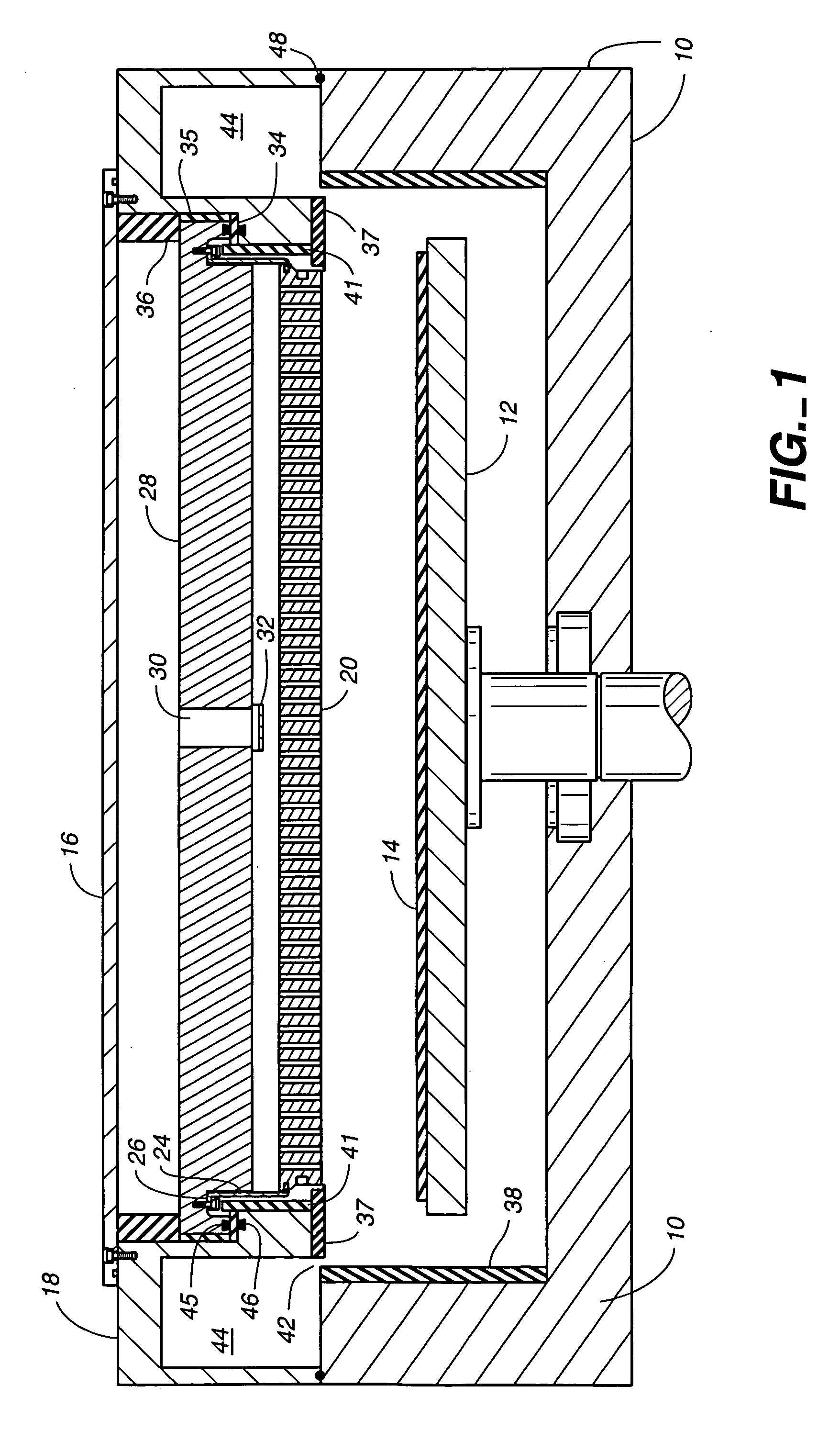

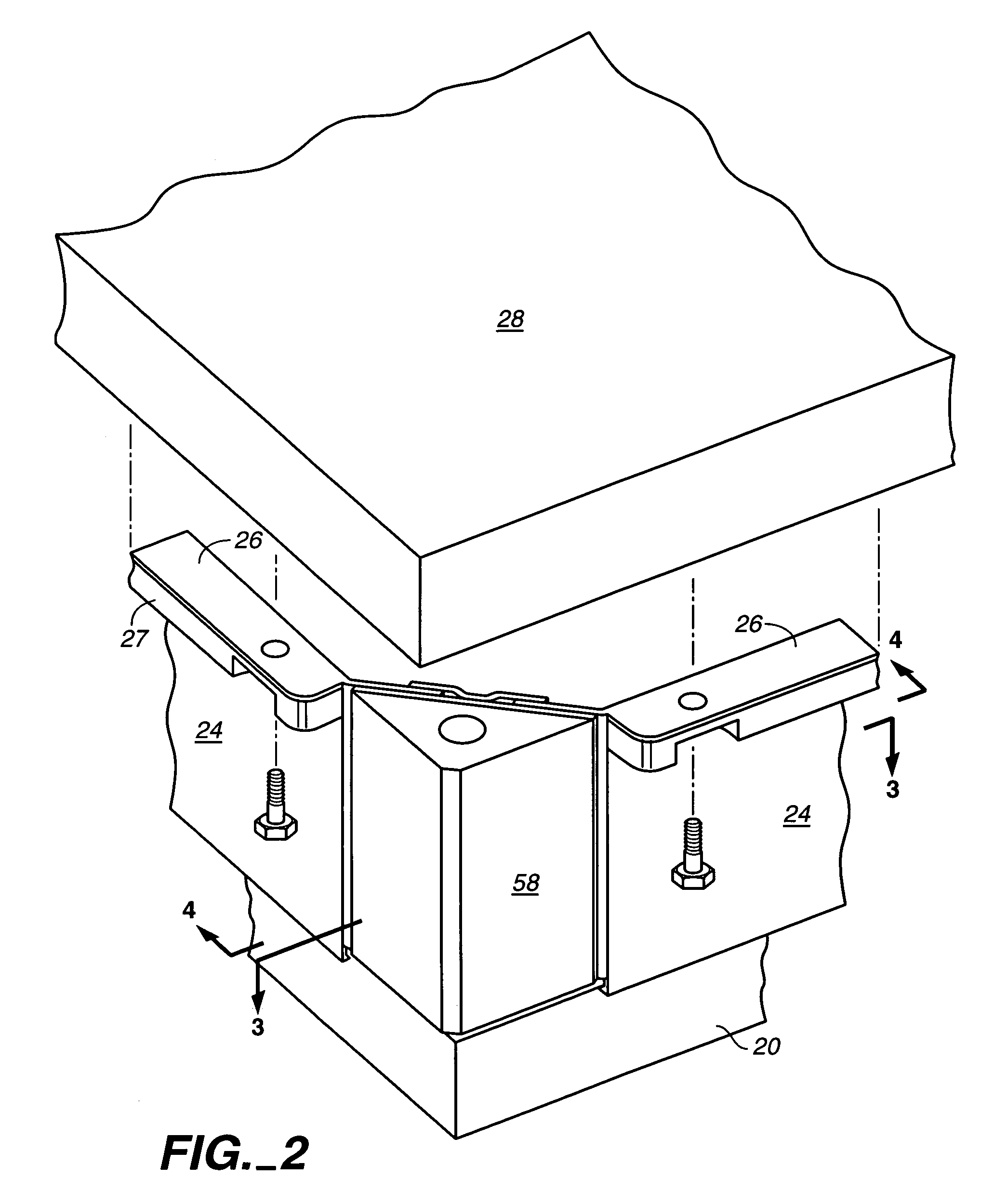

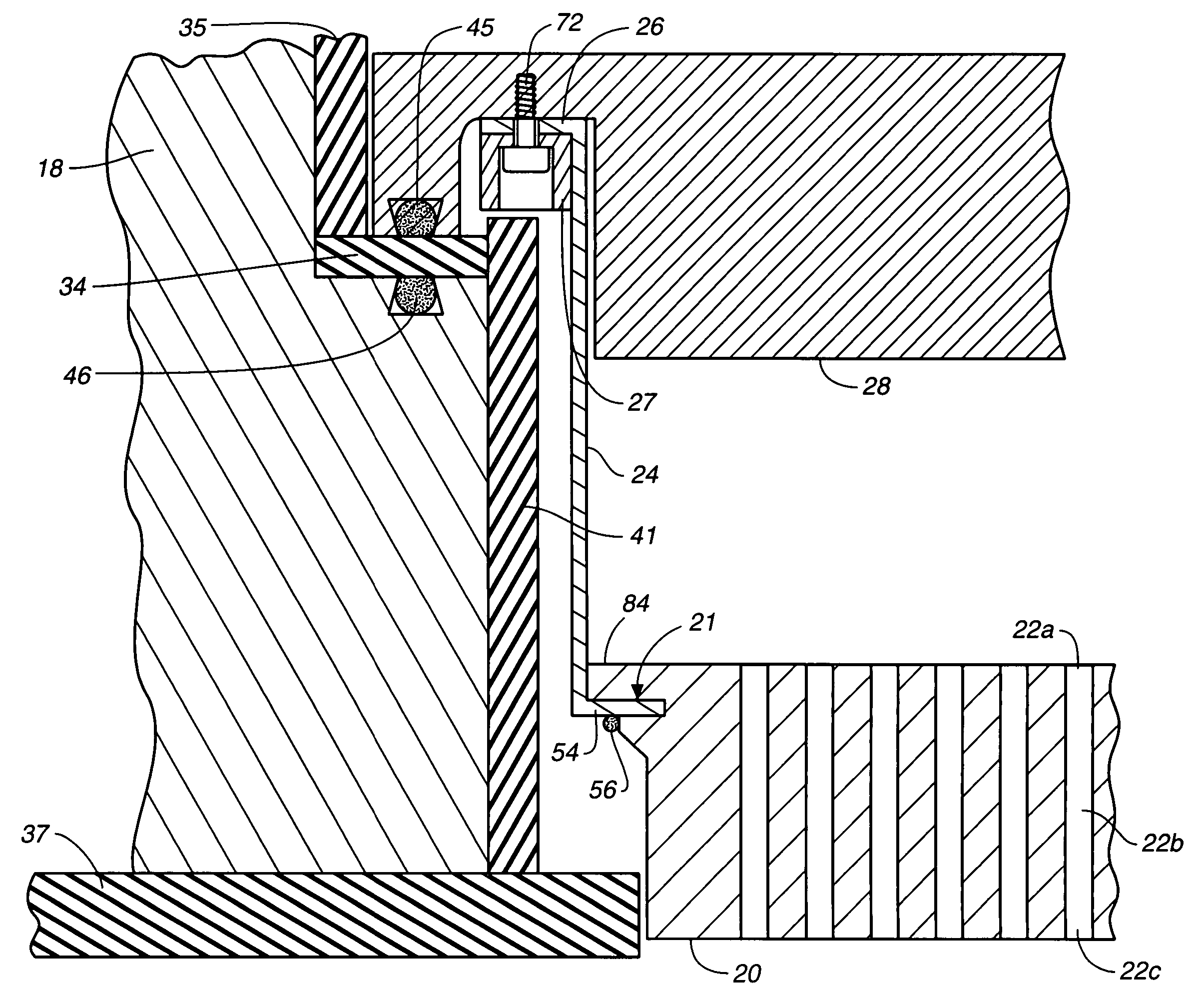

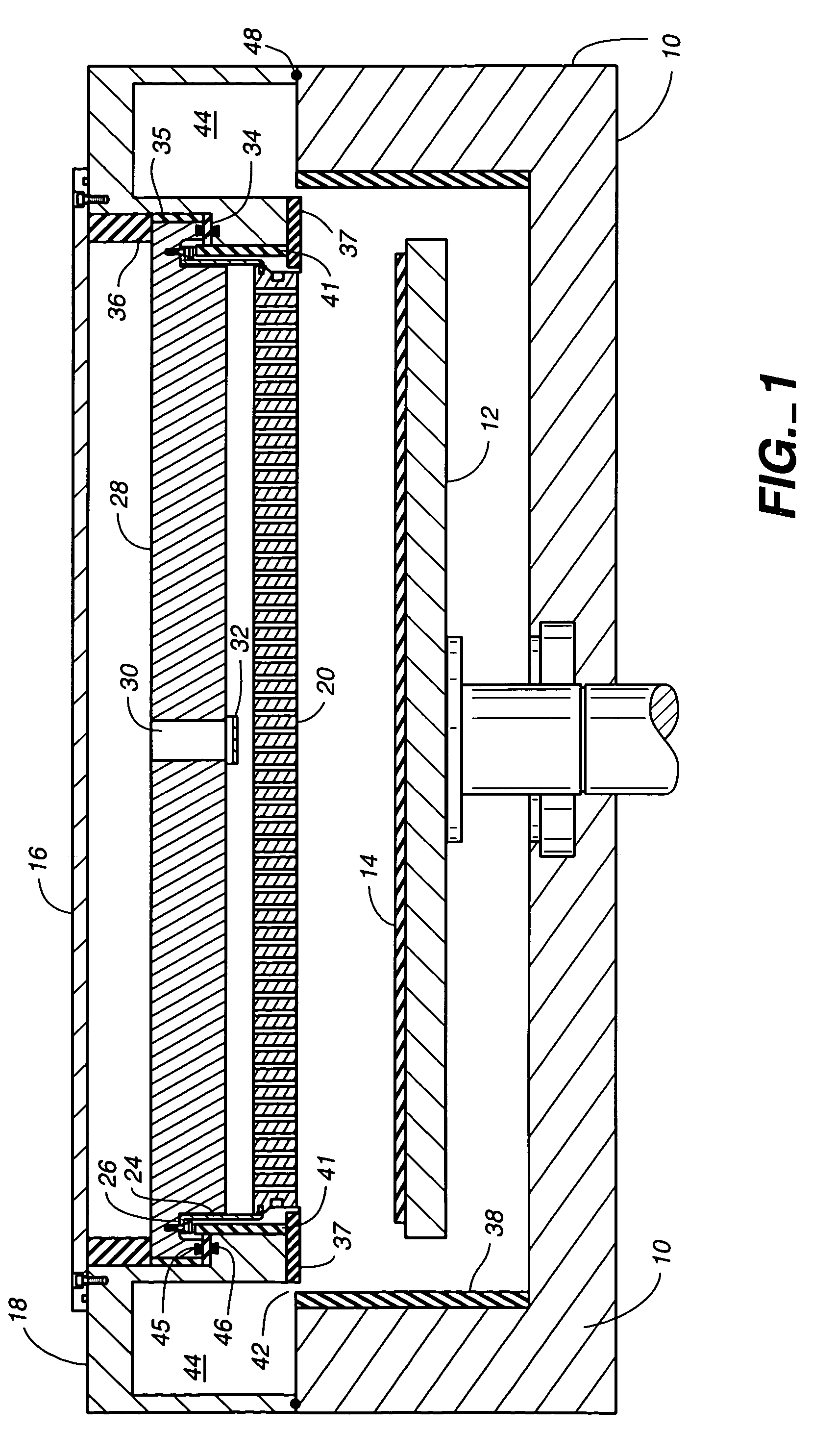

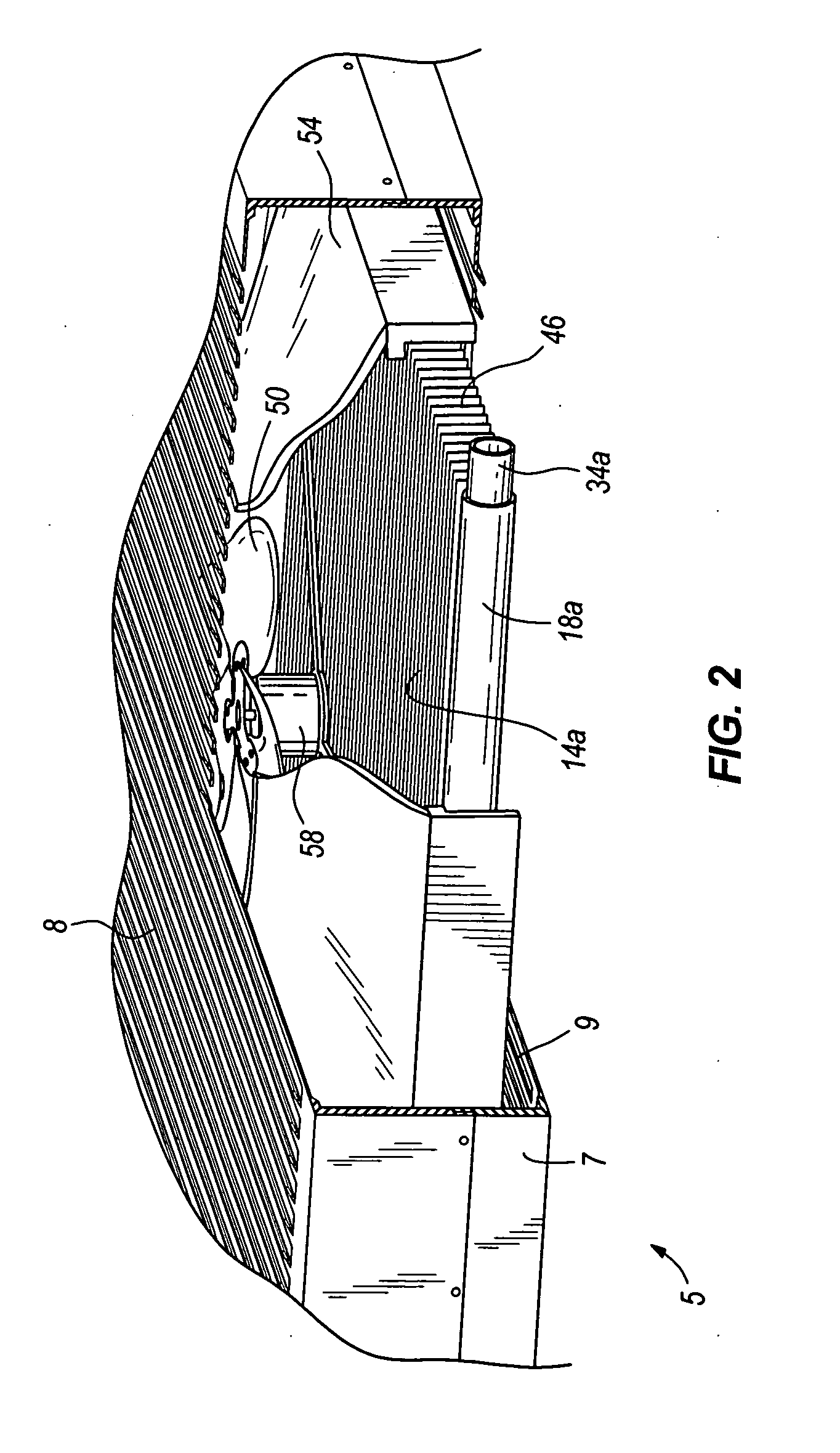

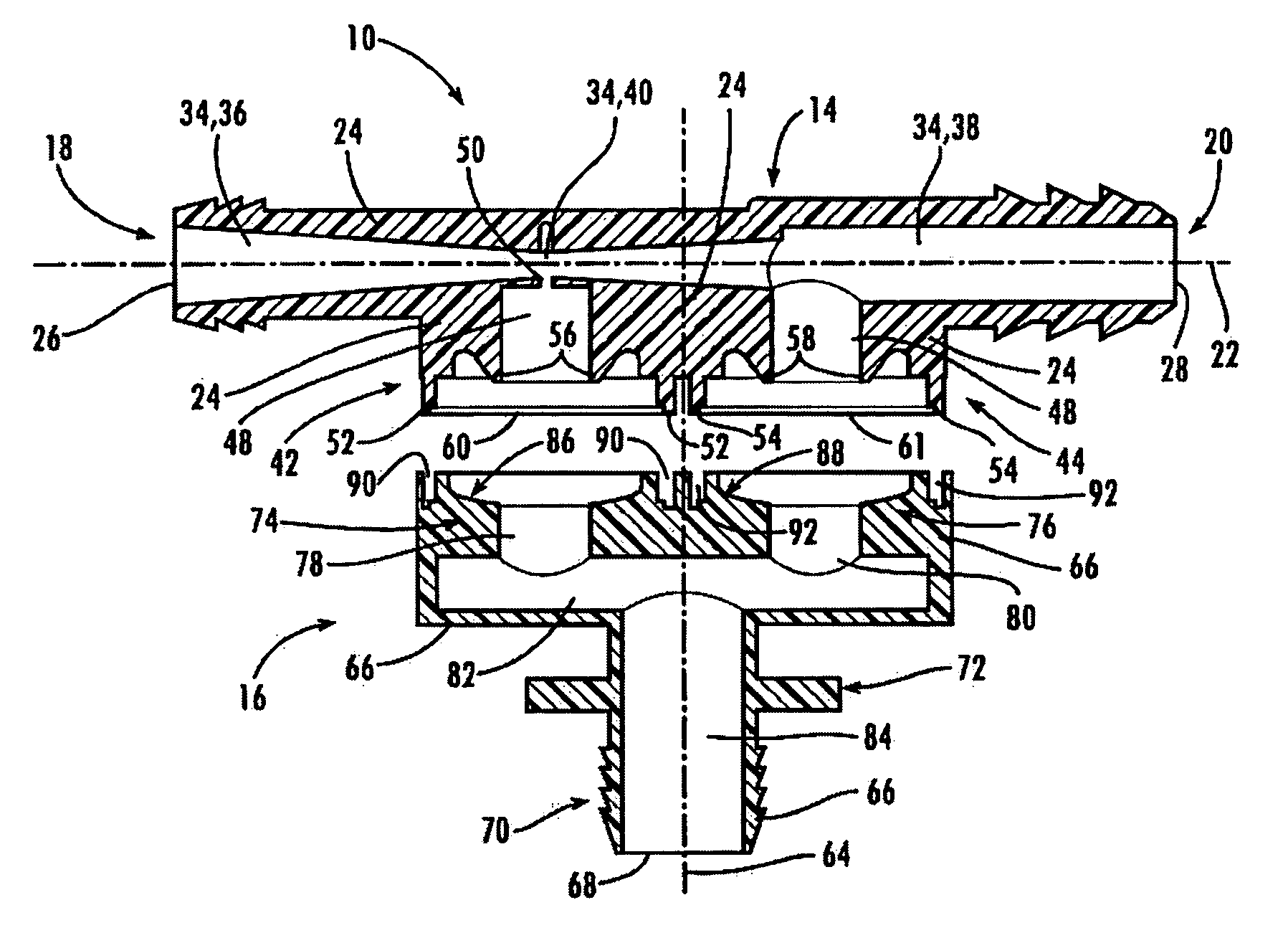

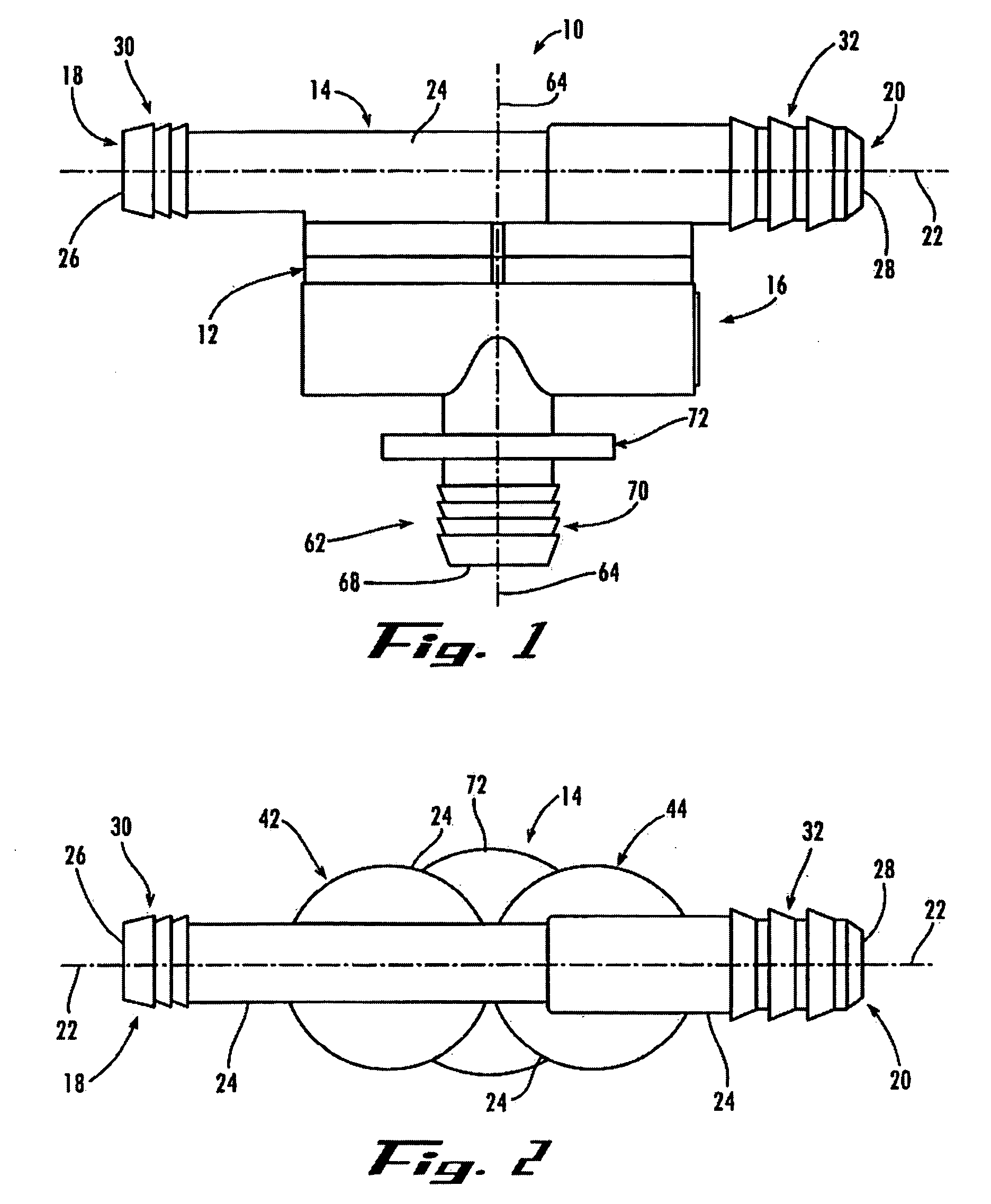

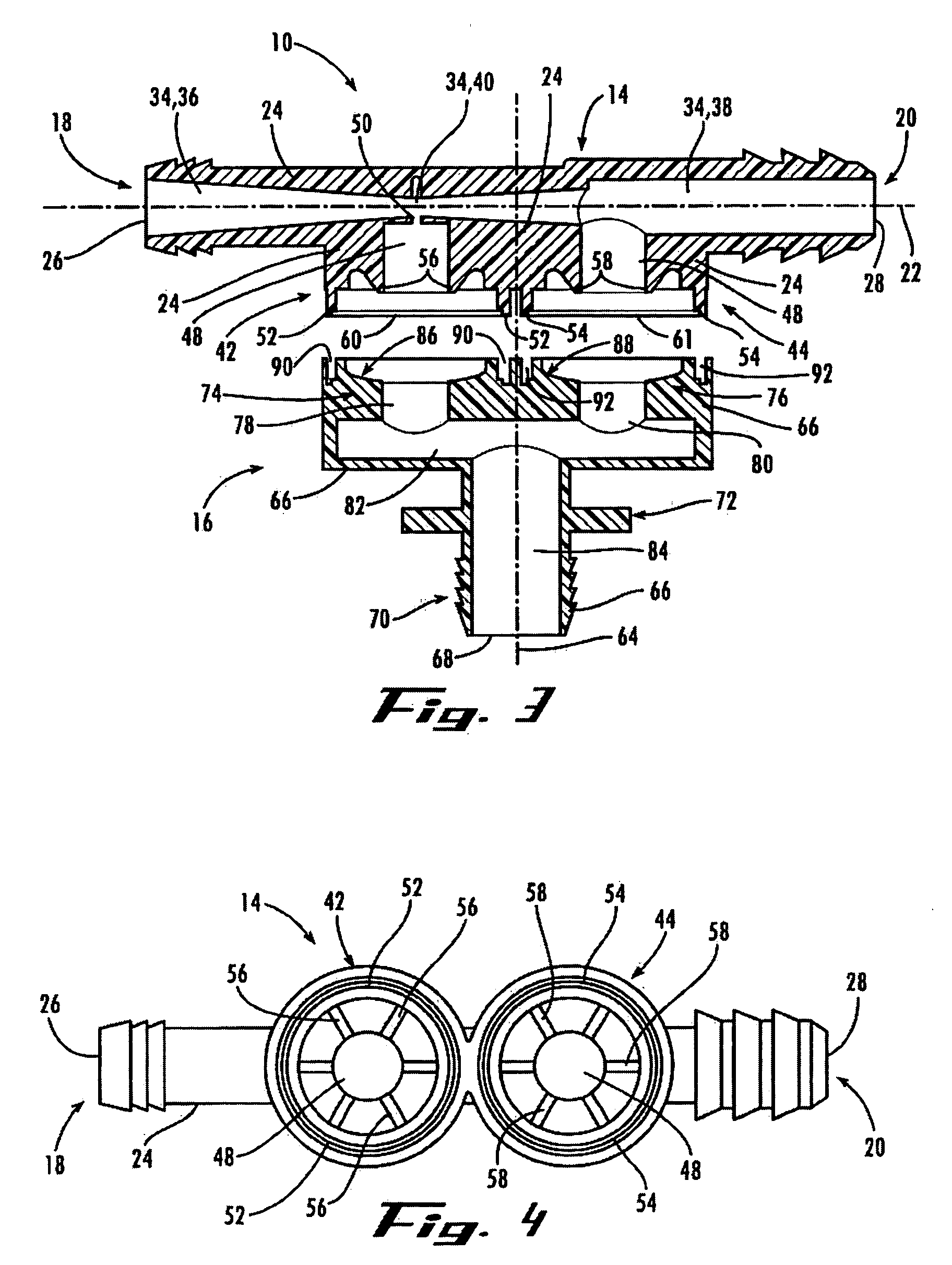

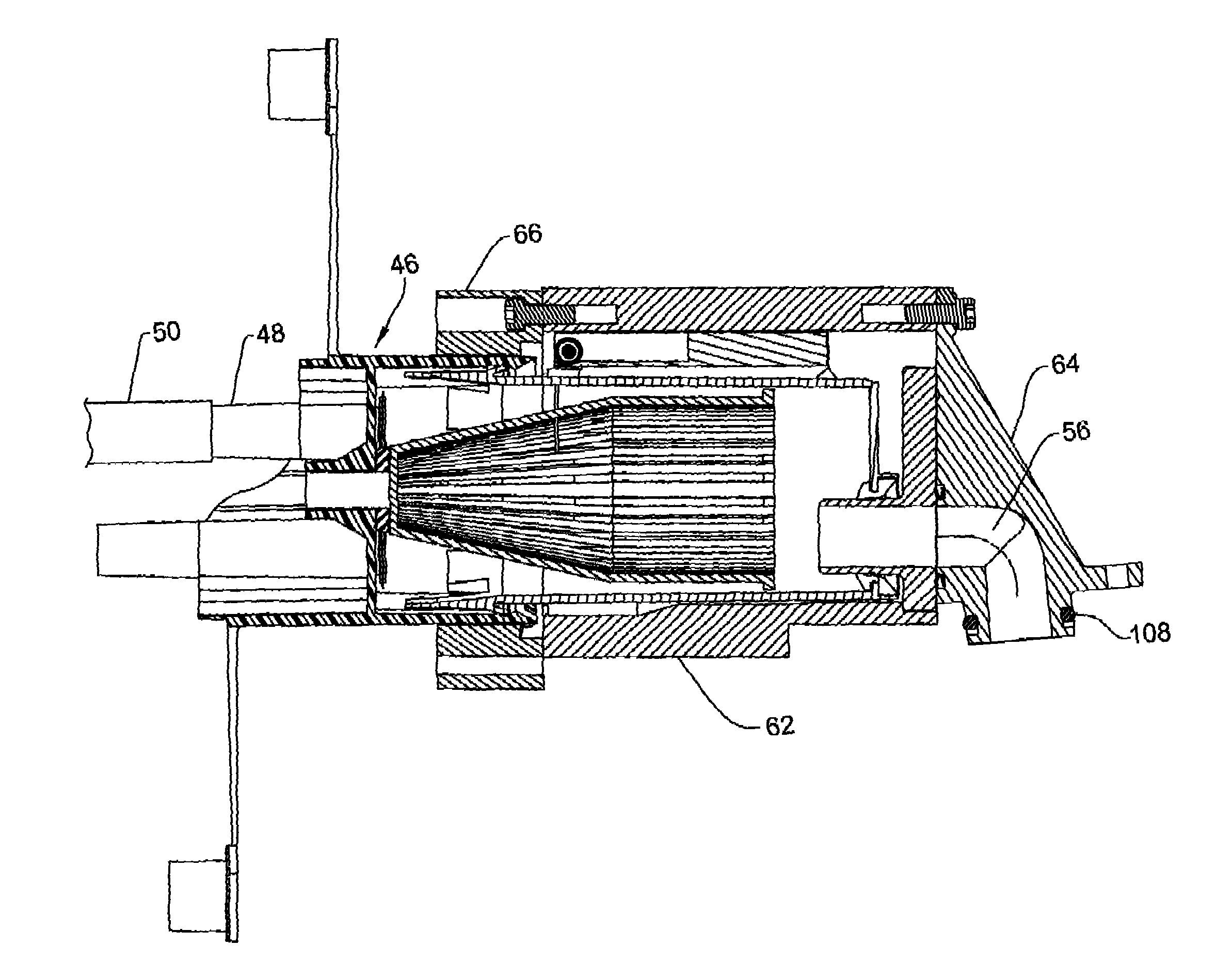

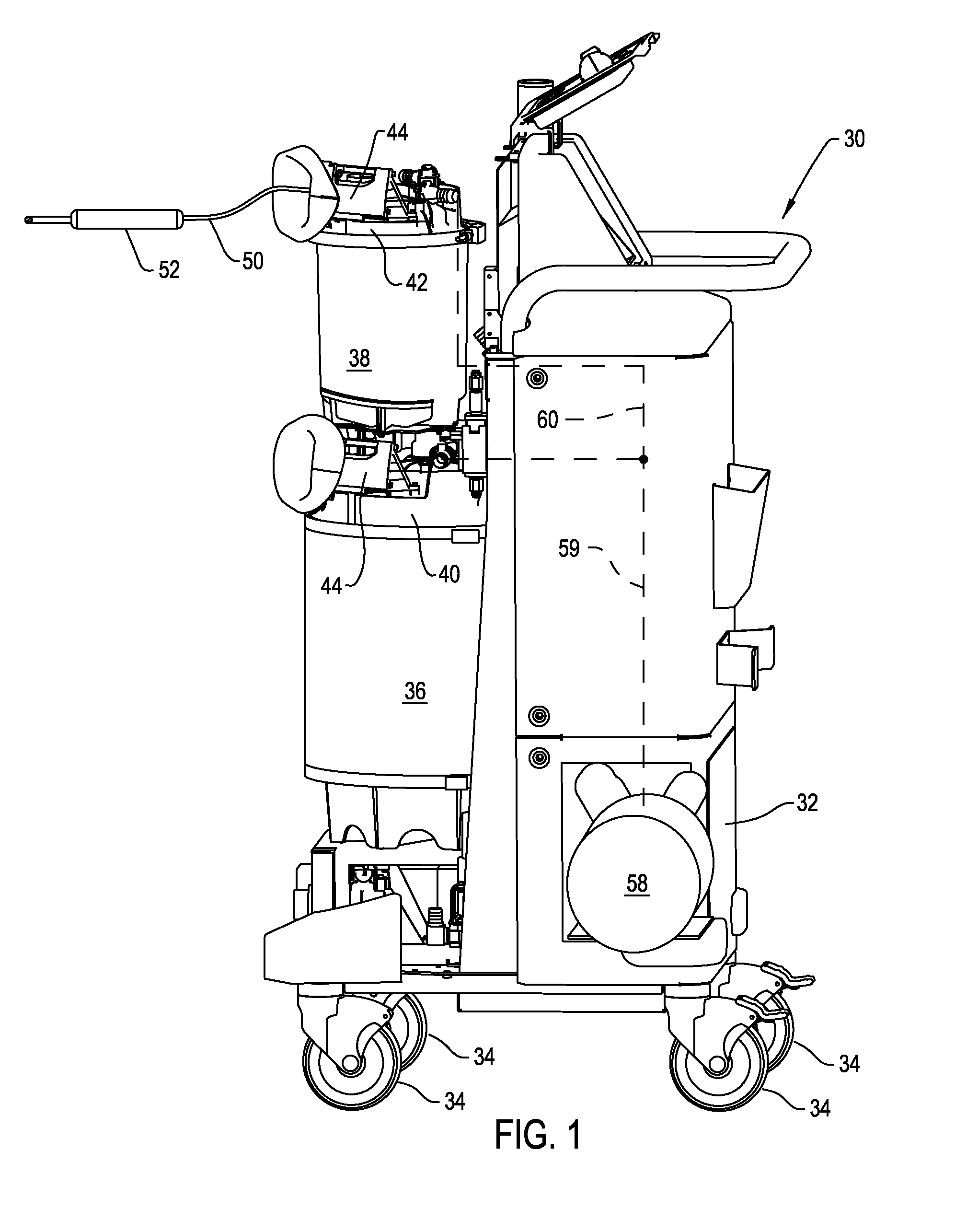

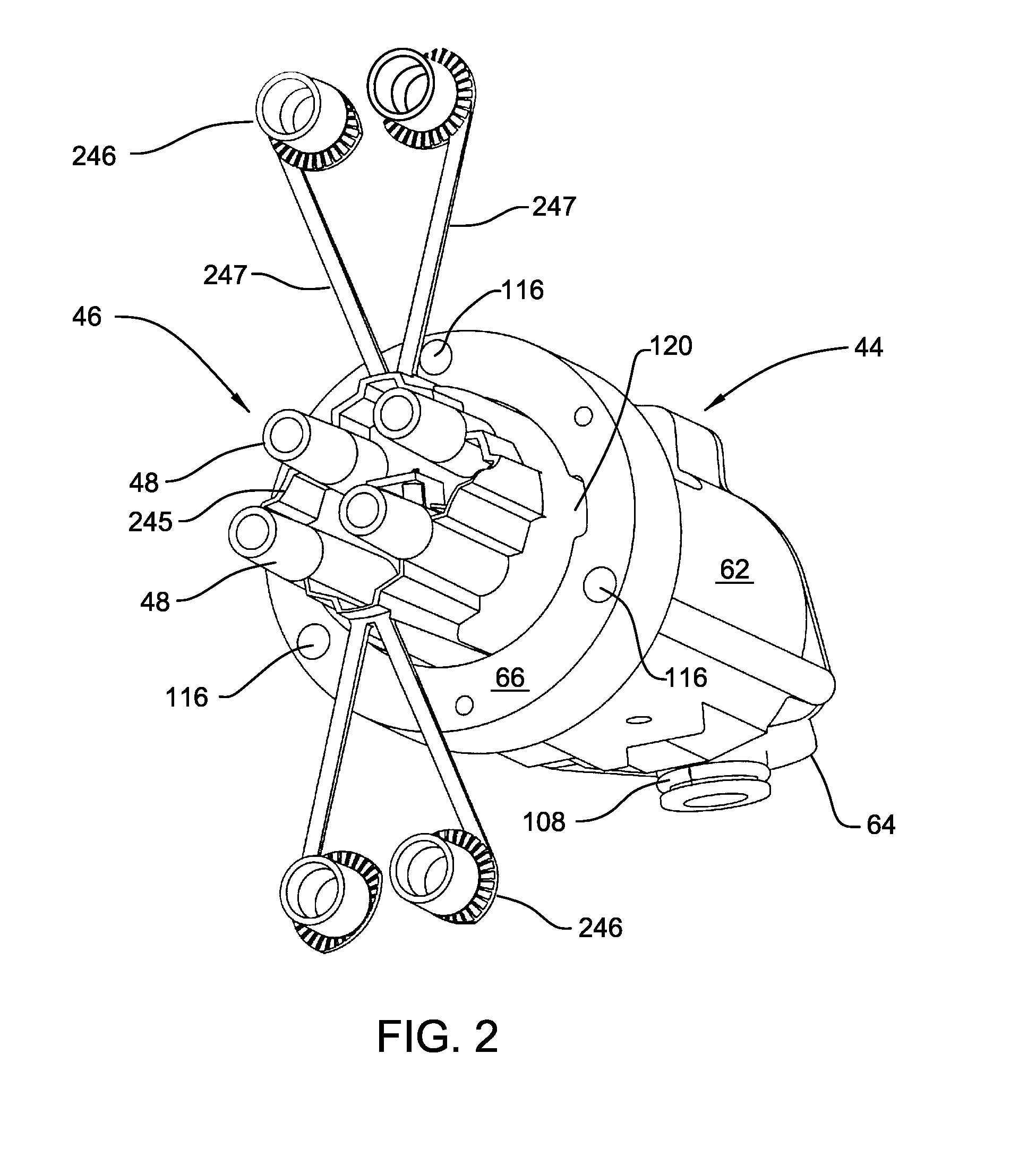

Removable inlet manifold for a medical/surgical waste collection system, the manifold including a driver for actuating a valve integral with the waste collection system

ActiveUS7615037B2Minimize releasePrevent leakageSurgical furnitureDiagnosticsCollection systemWaste collection

A removable manifold for a medical / surgical waste collection system. The manifold is dimensioned to be mounted to a receiver integral with the system. The manifold includes a driver for engaging a complementary valve internal to the receiver. The valve regulates flow between the receiver and the down line components of the waste collection system. The valve is normally closed. When the manifold is fitted to the receiver the driver engages the valve so as move the valve to the open position. This allows fluid flow from the manifold and receiver to the downstream components of the system.

Owner:STRYKER CORP

Intake oxygen estimator for internal combustion engine

ActiveUS7117078B1Electrical controlDigital data processing detailsExternal combustion engineExhaust gas recirculation

An internal combustion engine system includes an intake manifold, a combustion chamber, an exhaust manifold and exhaust gas recirculation apparatus for recirculating a portion of the exhausted gases from the exhaust manifold to the intake manifold. An estimate intake manifold oxygen concentration is determined from the air fraction within the intake manifold which is determined from an engine system model that provides interdependent air mass fractions at various locations within the engine system.

Owner:GM GLOBAL TECH OPERATIONS LLC

Fuel system with dual fuel injectors for internal combustion engines

InactiveUS6371092B1Reduce startup timeElectrical controlInternal combustion piston enginesCombustionInlet valve

This invention is directed to an apparatus and method for providing improved control of fuel, preferably gaseous fuel, to an internal combustion engine such that each cylinder of the engine will operate within a predetermined tolerance off of its lean misfire limit. The disclosed system introduces fuel to the engine at two locations: (1) upstream of the intake manifold to provide premixing of a majority of the fuel with air, and (2) near the intake valve of each cylinder for tailoring the fuel flow to each cylinder to achieve that fuel-to-air ratio which is necessary to maintain each cylinder at the desired tolerance from the lean misfire limit. Several calibration and control methods are described to maximize performance of the fuel system, including the use of a misfire detection technique to determine the lean misfire limit of each cylinder to allow the respective port fuel injector to provide a specified margin from lean misfire. The present invention enhances engine performance and driveability while reducing exhaust emissions.

Owner:ECONTROLS LLC

Crankcase ventilation and vacuum generation

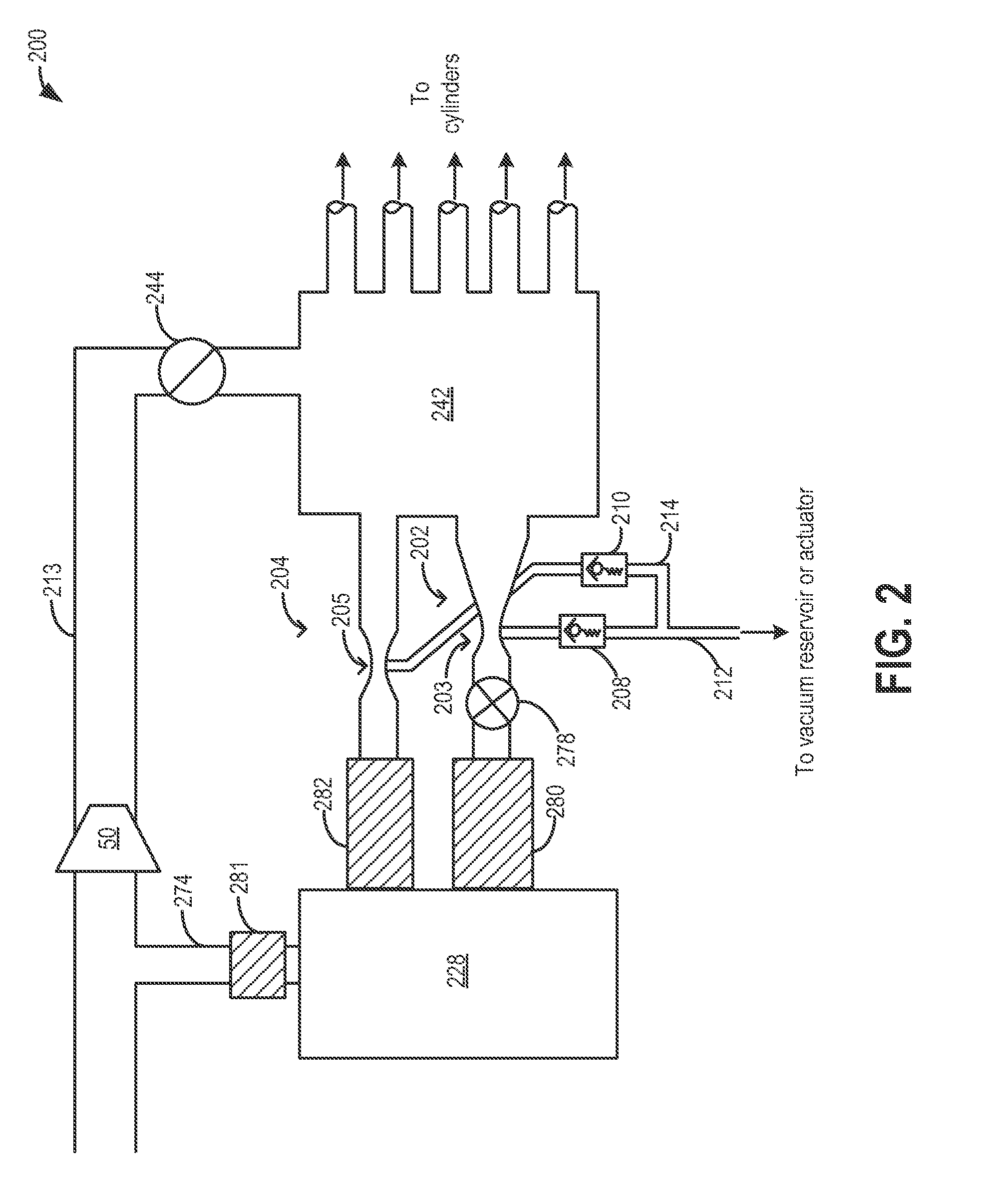

InactiveUS20130340732A1Increase vacuum generationImprove power generation efficiencyInternal combustion piston enginesNon-fuel substance addition to fuelInspiratorProcess engineering

Methods and systems are provided for generating vacuum from crankcase ventilation flow. During both directions of gas flow between an engine intake manifold and a crankcase, gases are directed through one or more aspirators to produce vacuum. The drawn vacuum may then be used to operate various engine vacuum actuators.

Owner:FORD GLOBAL TECH LLC

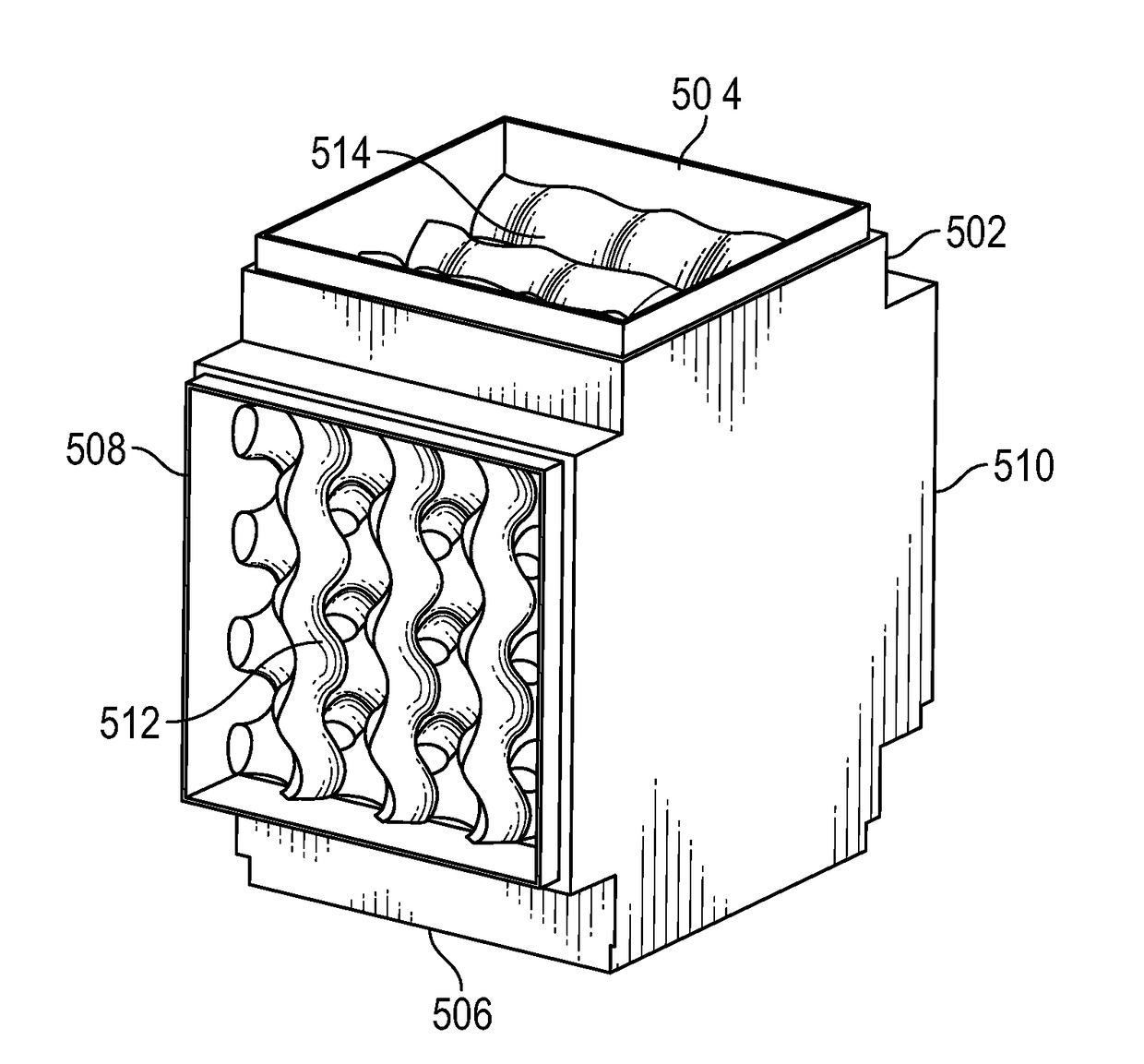

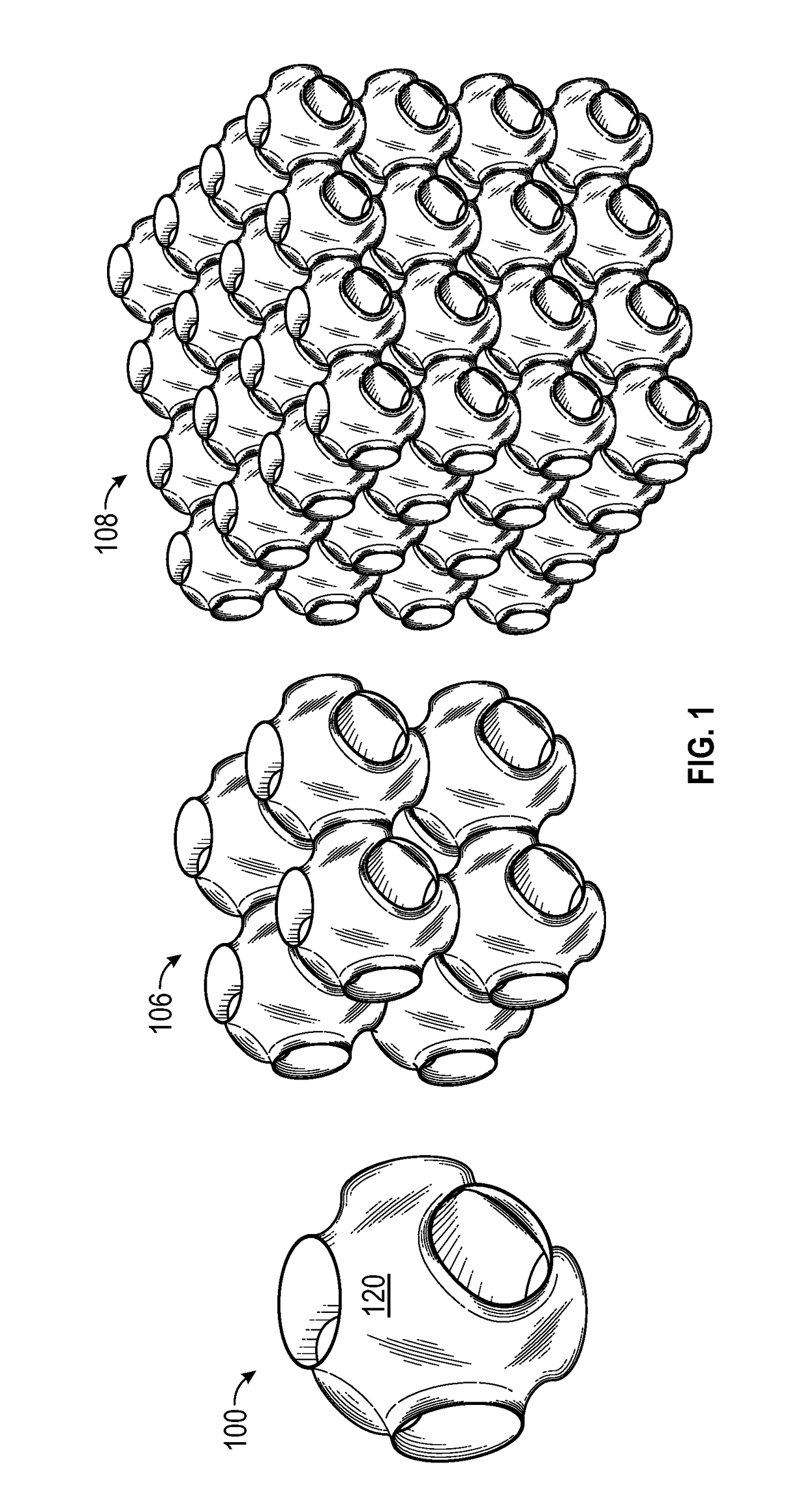

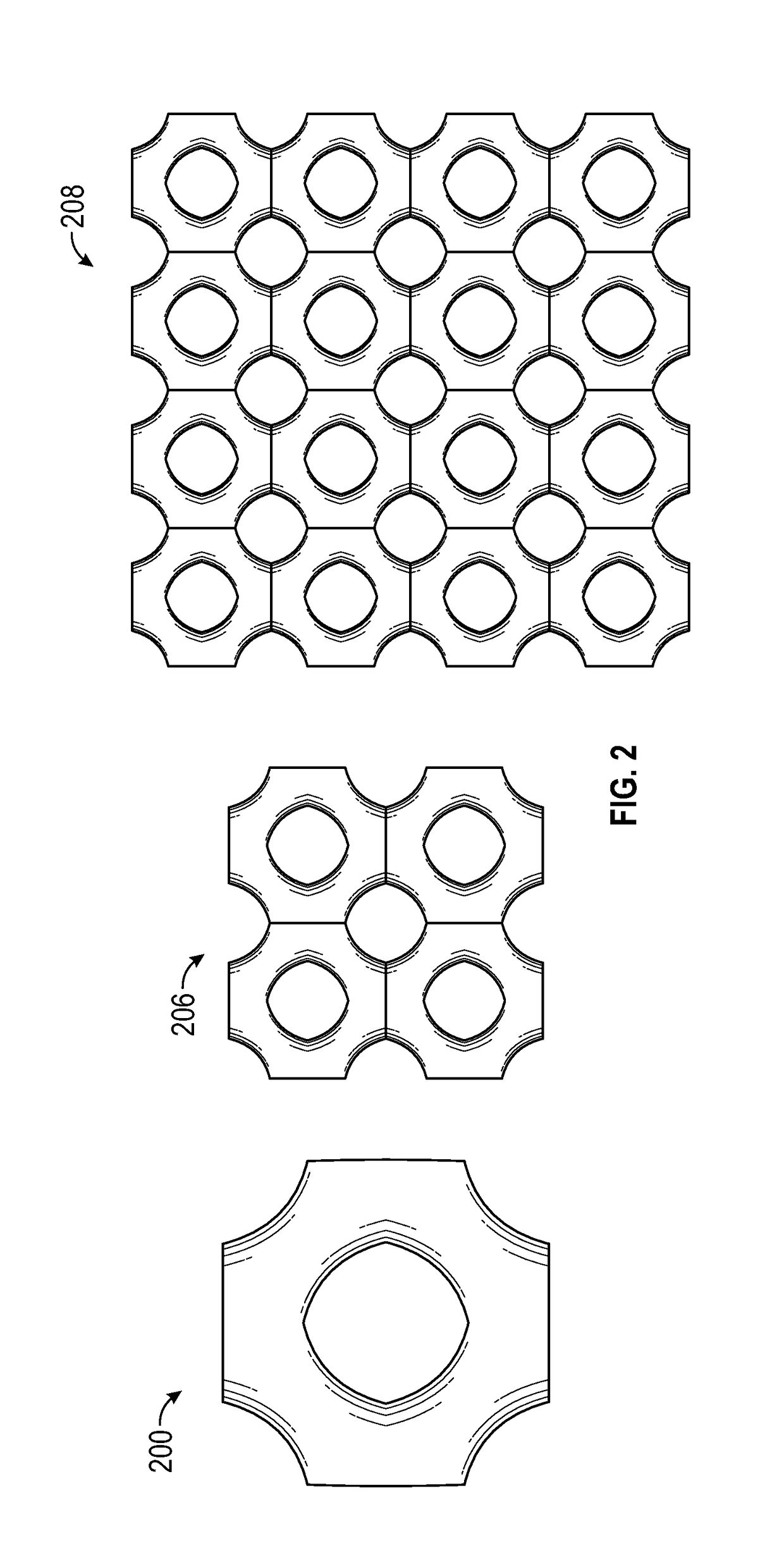

Monolithic Bicontinuous Labyrinth Structures and Methods For Their Manufacture

ActiveUS20180187984A1Efficiently manufacturableInhibition featureAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringInlet manifold

A heat exchanger includes a core comprising a single piece continuous boundary having a first surface defining a first labyrinth, and an opposing second surface defining a second labyrinth; a first inlet manifold connected to the first labyrinth and configured to supply a first fluid to the first labyrinth; and a second inlet manifold connected to the second labyrinth and configured to supply a second fluid to the second labyrinth; wherein the core comprises a plurality of identical three dimensional unit cell structures replicated in three orthogonal spatial dimensions.

Owner:TITAN TENSOR LLC

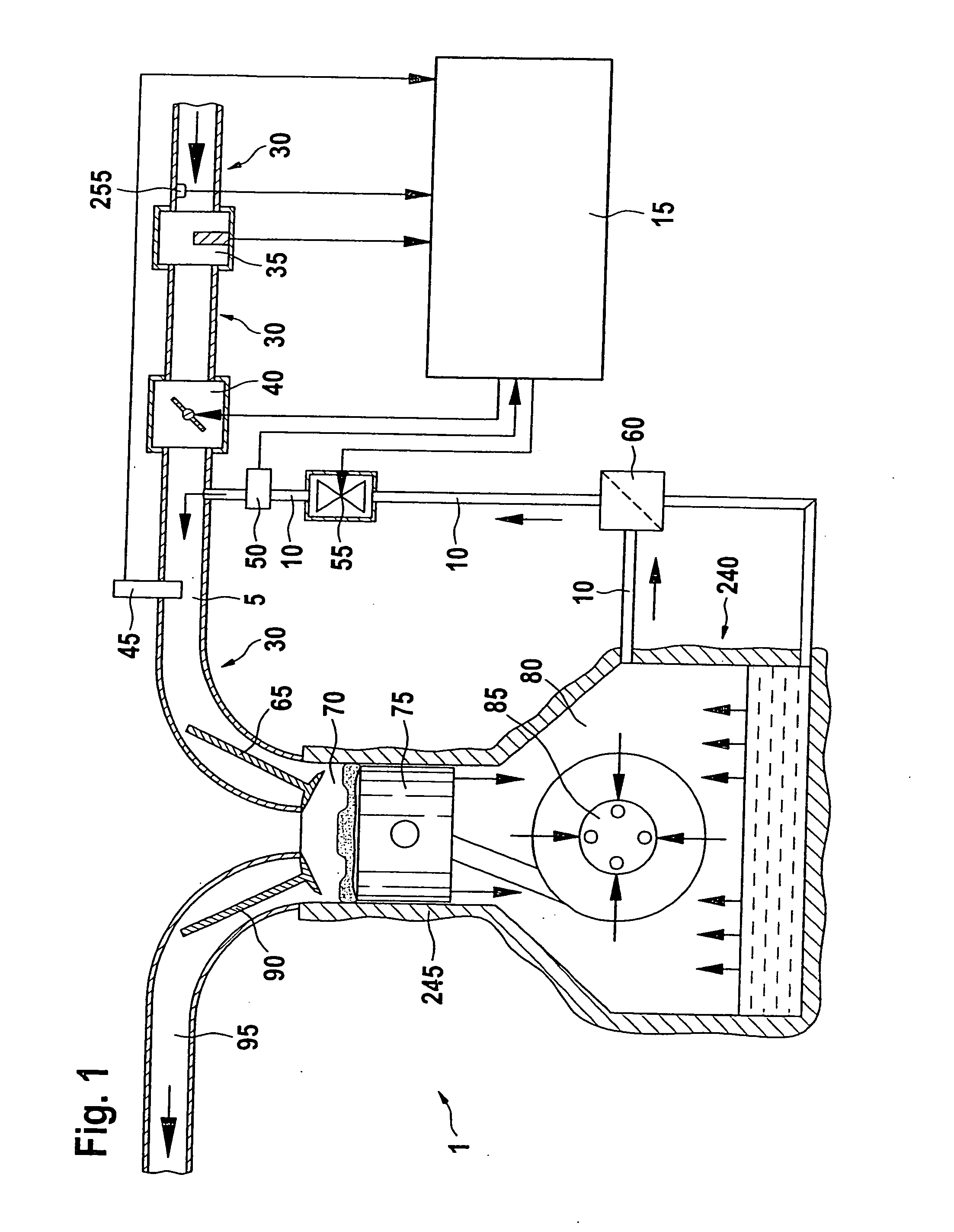

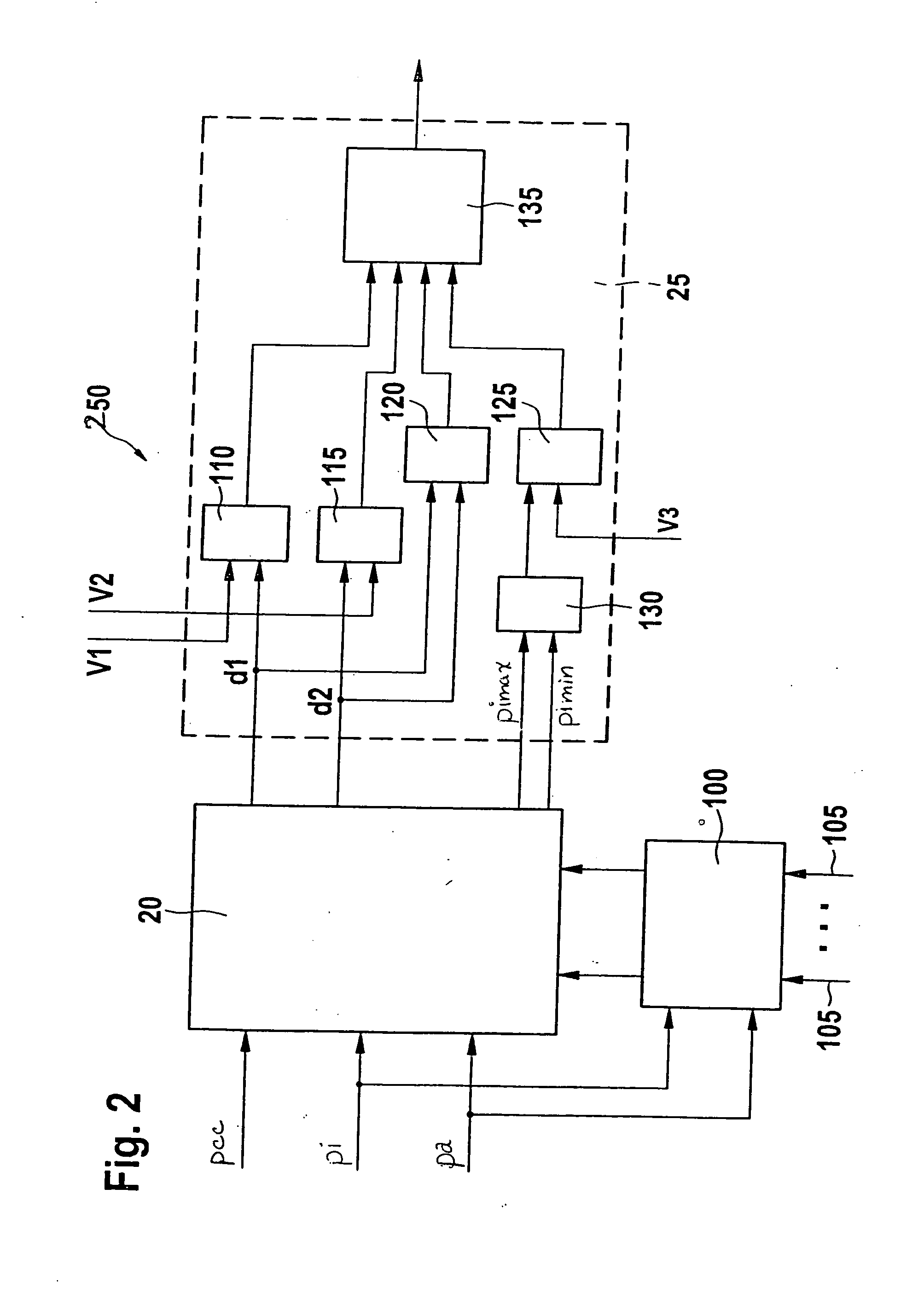

Method and device for operating an internal combustion engine

InactiveUS20050022795A1Reliable detectionReduce riskEngine pressureElectrical controlFuel tankAmbient pressure

A method and a device for operating an internal combustion engine having an intake manifold and a ventilation system may allow a reliable and fault-free diagnosis of a fault in the ventilation. The ventilation system may be a tank ventilation or a crankcase ventilation. The ventilation duct is conducted to the intake manifold of the internal combustion engine. At least one pressure differential may be determined between an intake-manifold pressure or an ambient pressure, on the one hand, and a pressure in the ventilation duct, on the other hand. A fault in the ventilation may be diagnosed as a function of the at least one pressure differential.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com