Patents

Literature

1638 results about "Coolant temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

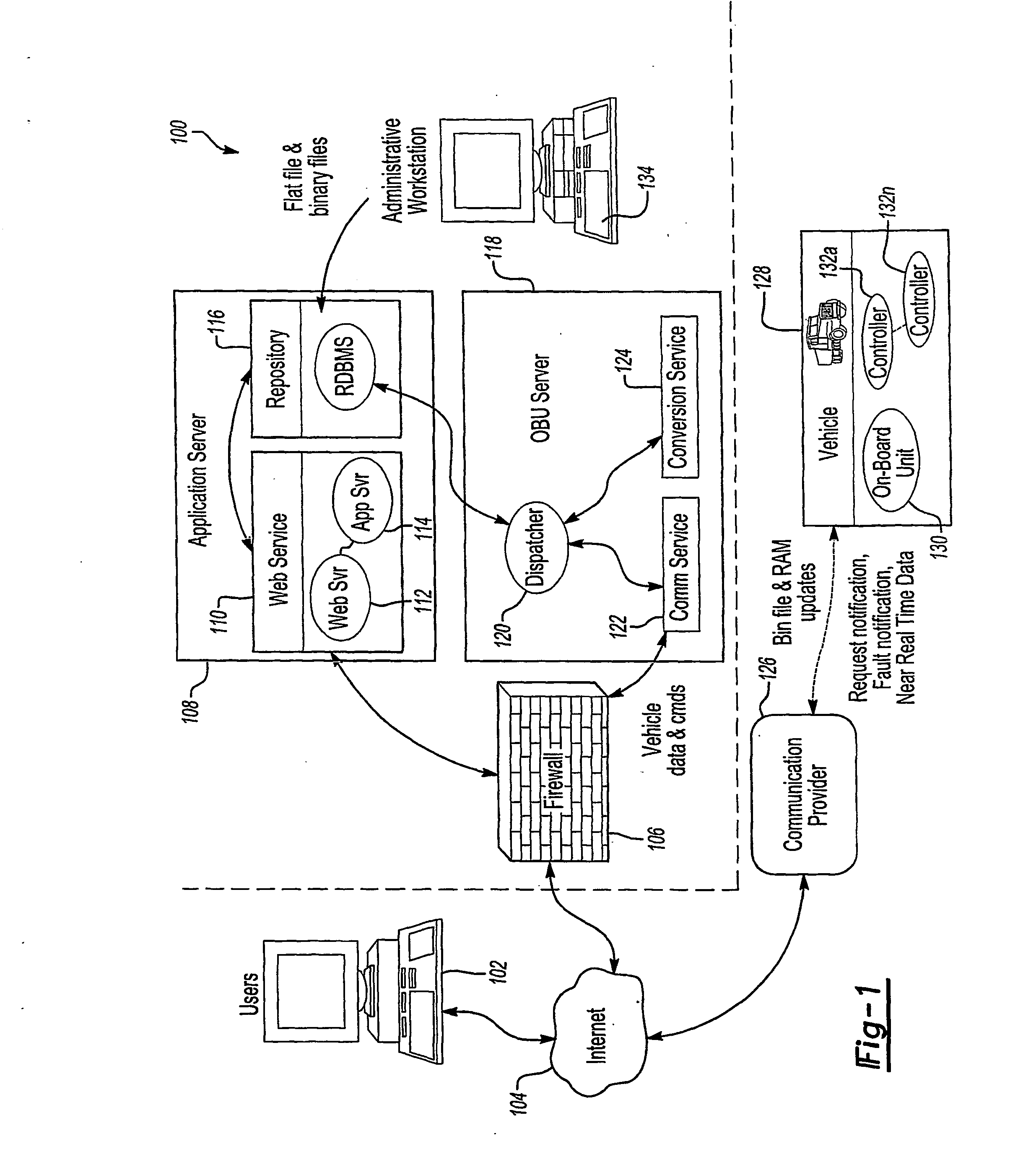

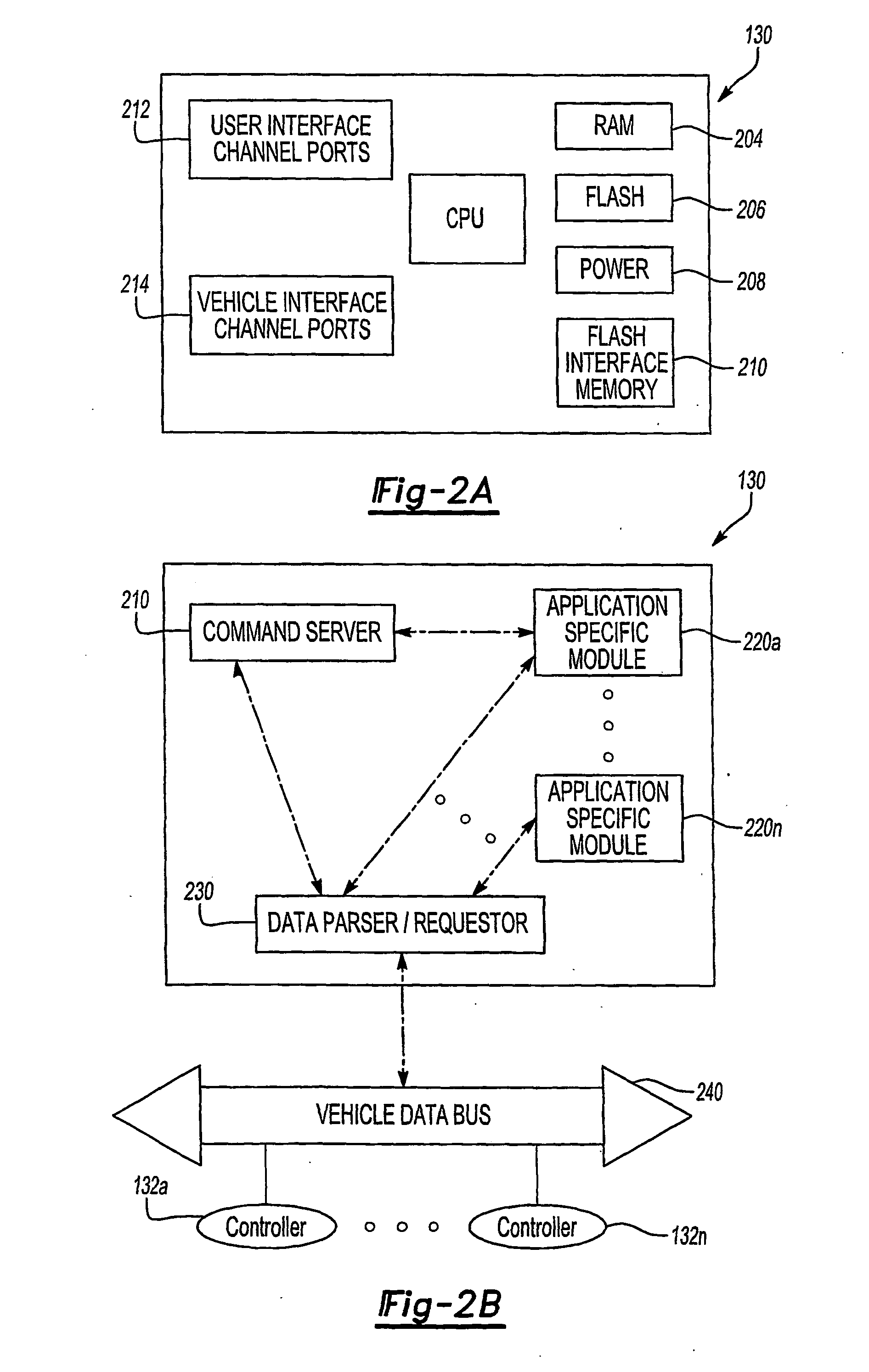

System, method and computer program product for remote vehicle diagnostics, monitoring, configuring and reprogramming

InactiveUS7155321B2Eliminate needVehicle testingRegistering/indicating working of vehiclesFleet managementLogistics management

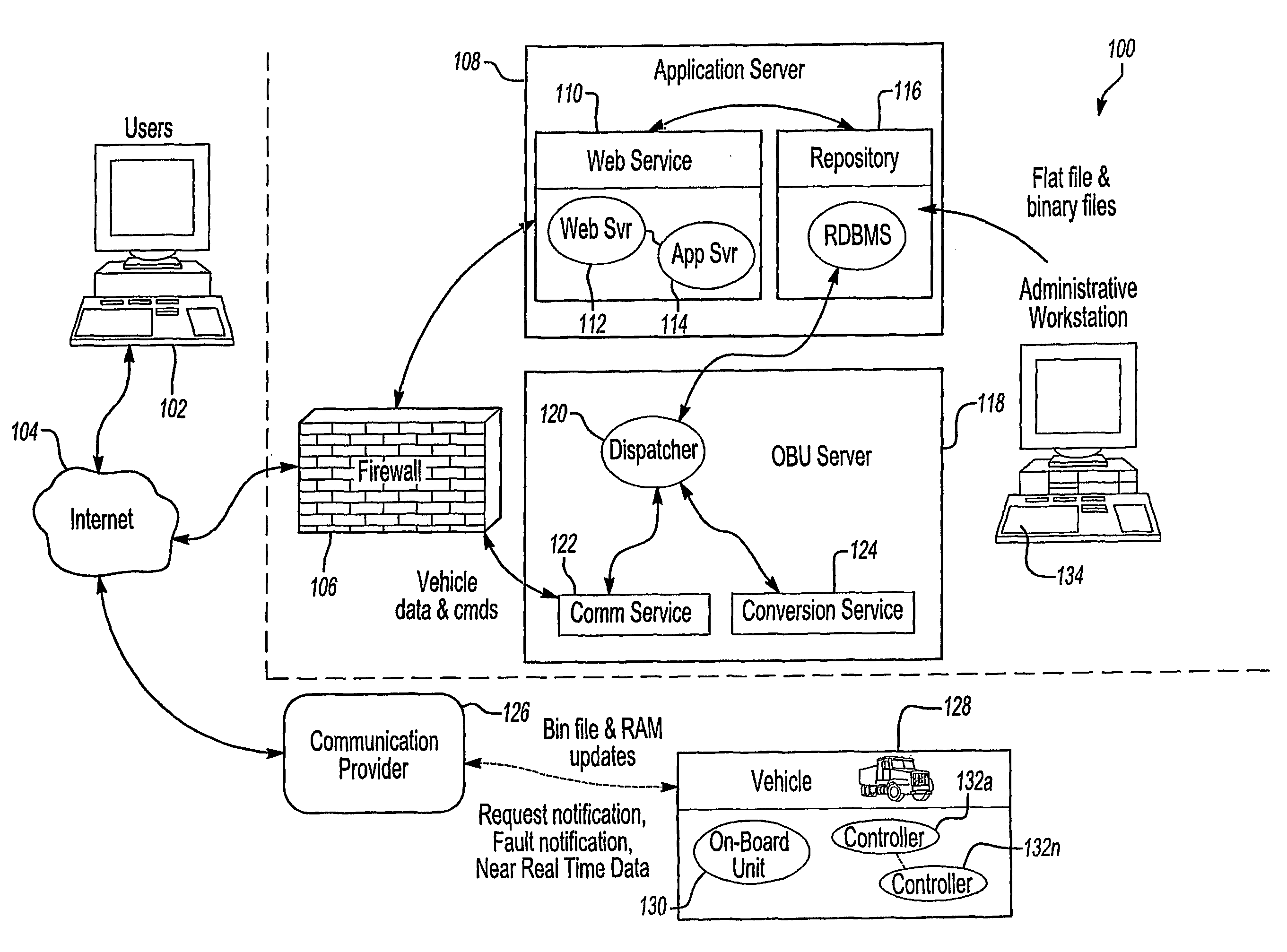

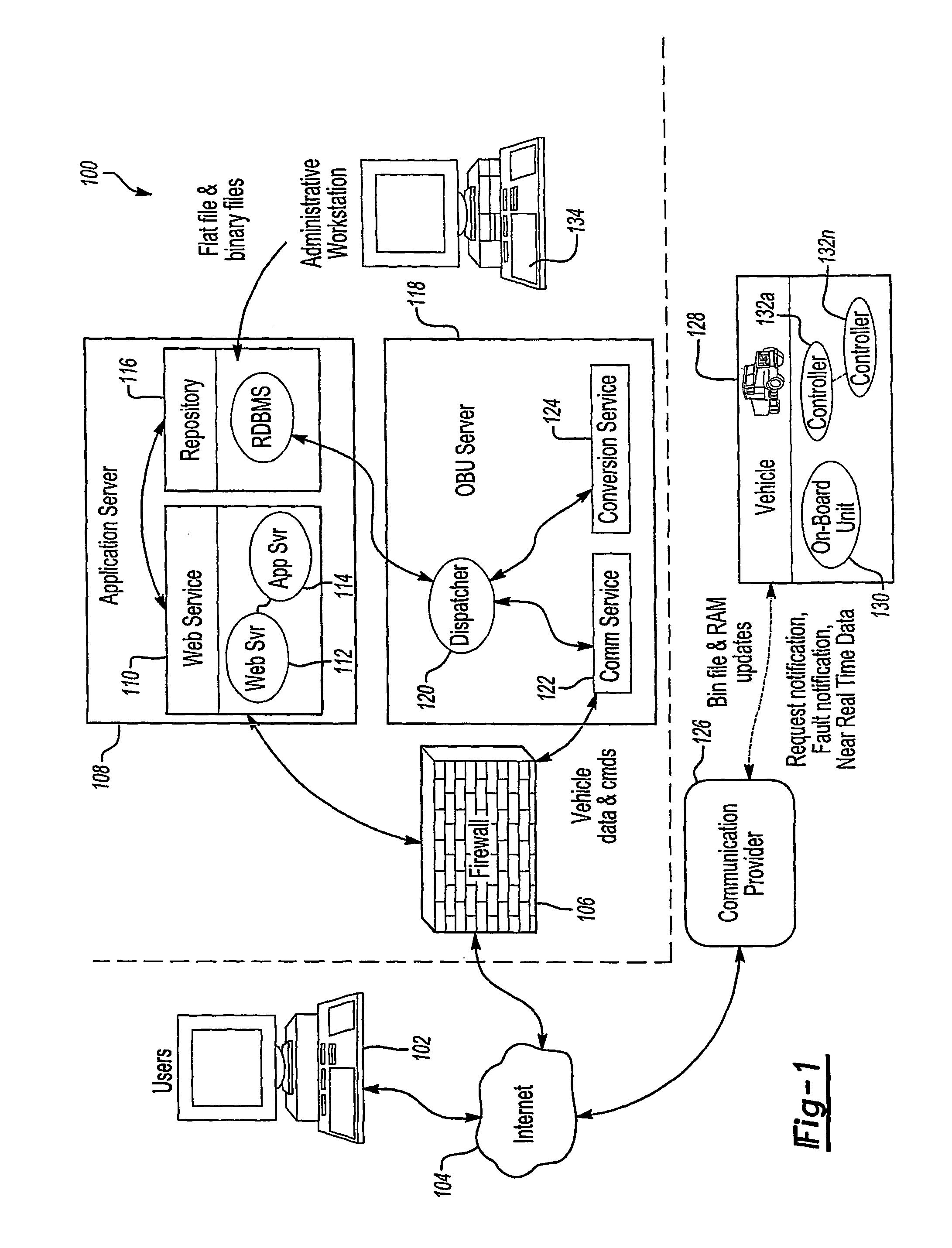

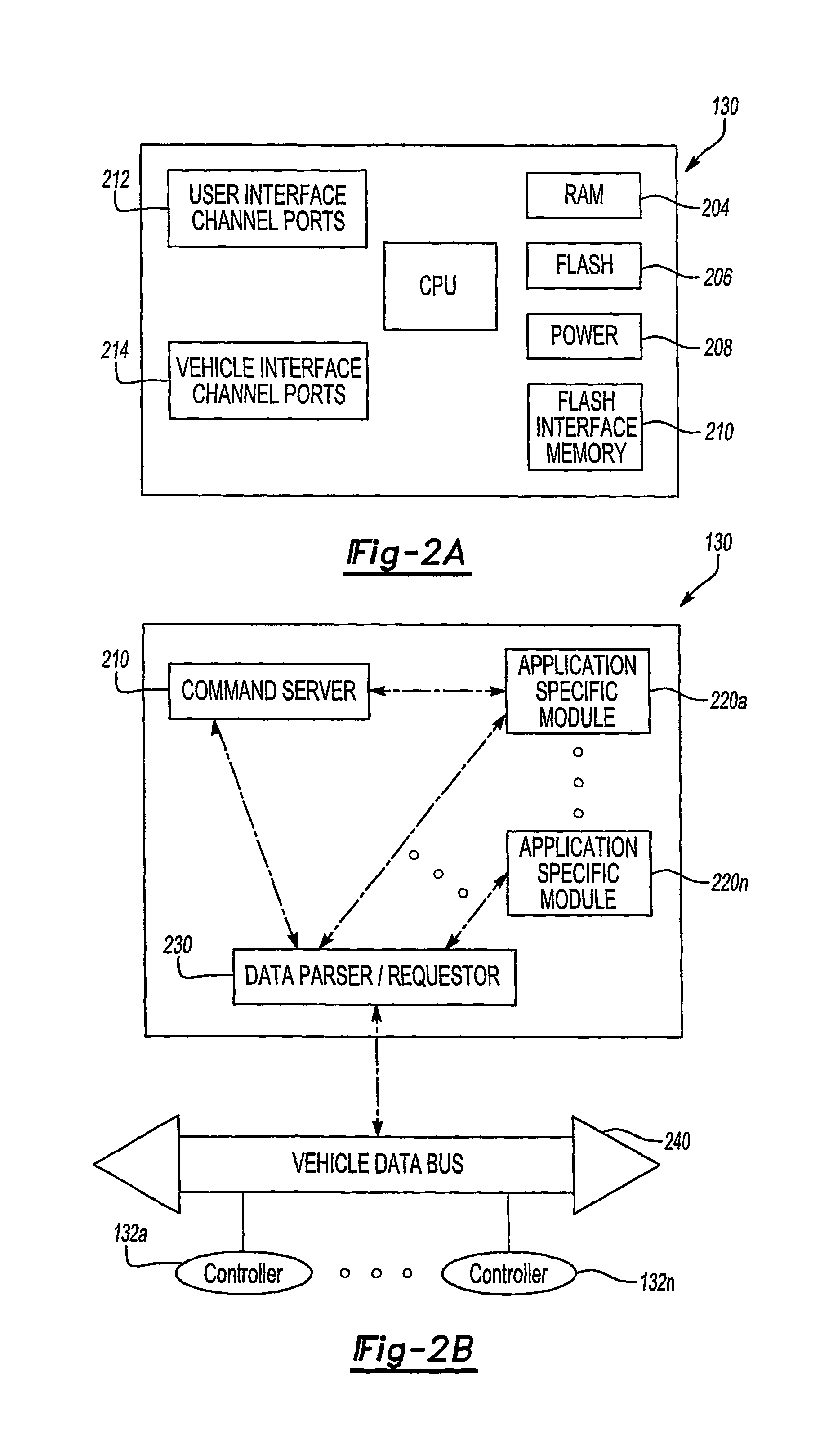

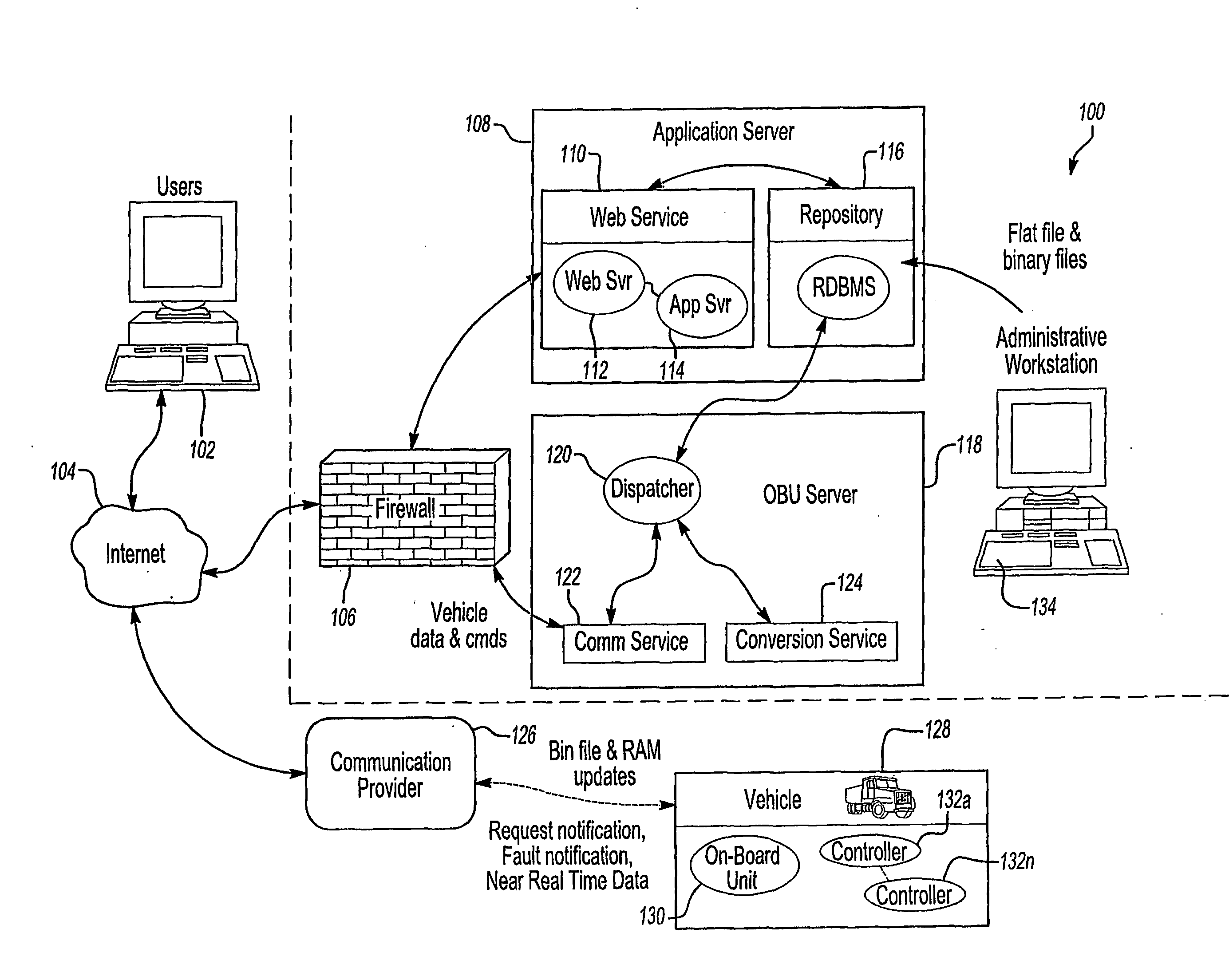

A remote vehicle diagnostics, monitoring, configuration and reprogramming tool is provided. The system includes a fleet of vehicles equipped with wireless mobile communications means that enable fleet managers to remotely diagnose, monitor and reprogram vehicles in their fleet via an Internet Web-based browser environment. Each vehicle within the fleet is equipped with a smart device that is coupled to the data bus within each vehicle. Date commands relating to the vehicle's parameters (e.g., diagnostic parameters such as max road speed, engine RPM, coolant temperature, air inlet temperature, etc.) are sent and received using satellite and terrestrial wireless communications technology. The invention allows users to remotely perform total fleet logistics and eliminates (or reduces) the need to physically bring fleet vehicles to a repair, maintenance or configuration facility.

Owner:IDSC HLDG

System, method and computer program product for remote vehicle diagnostics, monitoring, configuring and reprogramming

InactiveUS20040167689A1Vehicle testingRegistering/indicating working of vehiclesFleet managementLogistics management

A remote vehicle diagnostics, monitoring, configuration and reprogramming tool is provided. The system includes a fleet of vehicles equipped with wireless mobile communications means that enable fleet managers to remotely diagnose, monitor and reprogram vehicles in their fleet via an Internet Web-based browser environment. Each vehicle within the fleet is equipped with a smart device that is coupled to the data bus within each vehicle. Date commands relating to the vehicle's parameters (e.g., diagnostic parameters such as max road speed, engine RPM, coolant temperature, air inlet temperature, etc.) are sent and received using satellite and terrestrial wireless communications technology. The invention allows users to remotely perform total fleet logistics and eliminates (or reduces) the need to physically bring fleet vehicles to a repair, maintenance or configuration facility.

Owner:IDSC HLDG

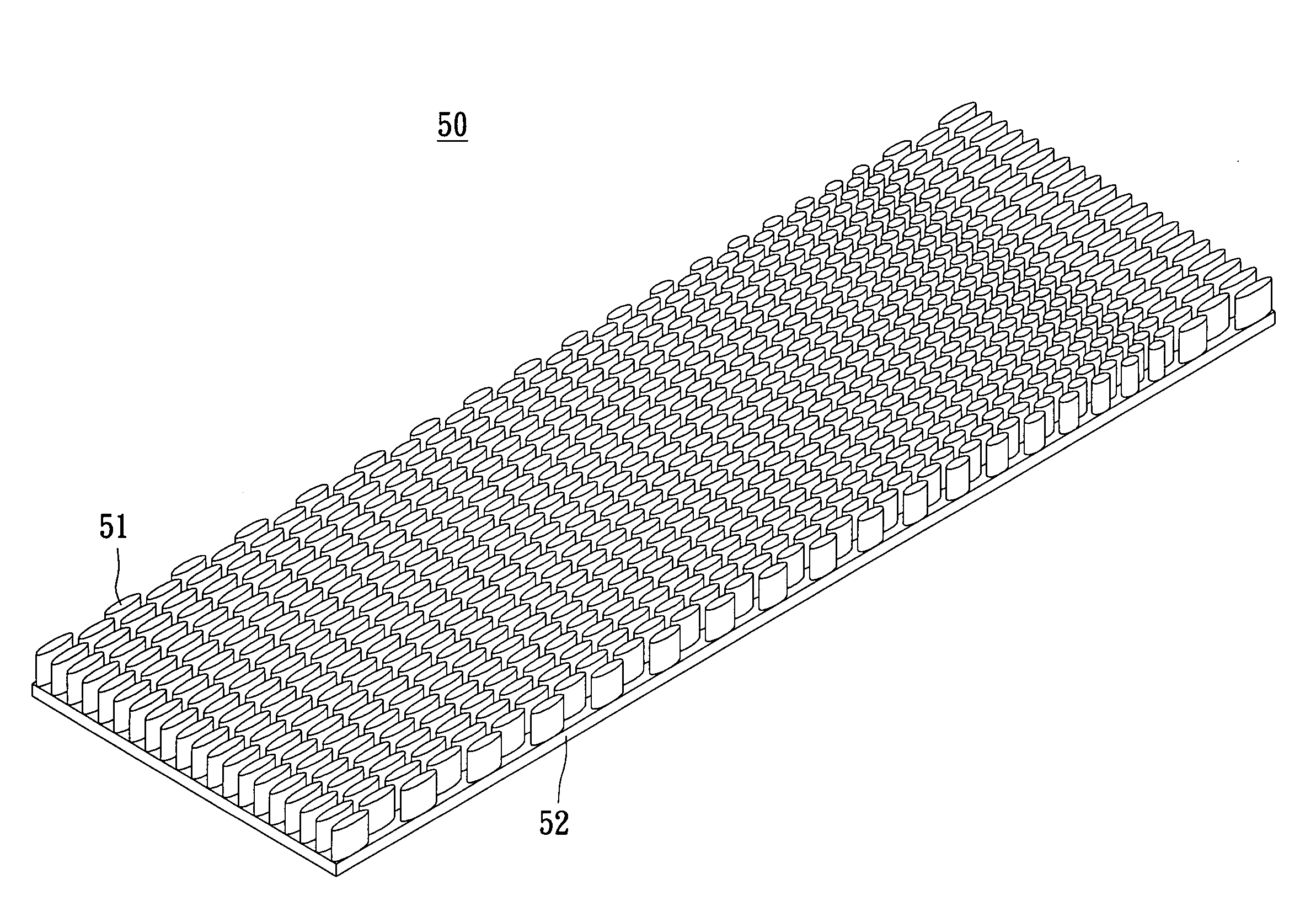

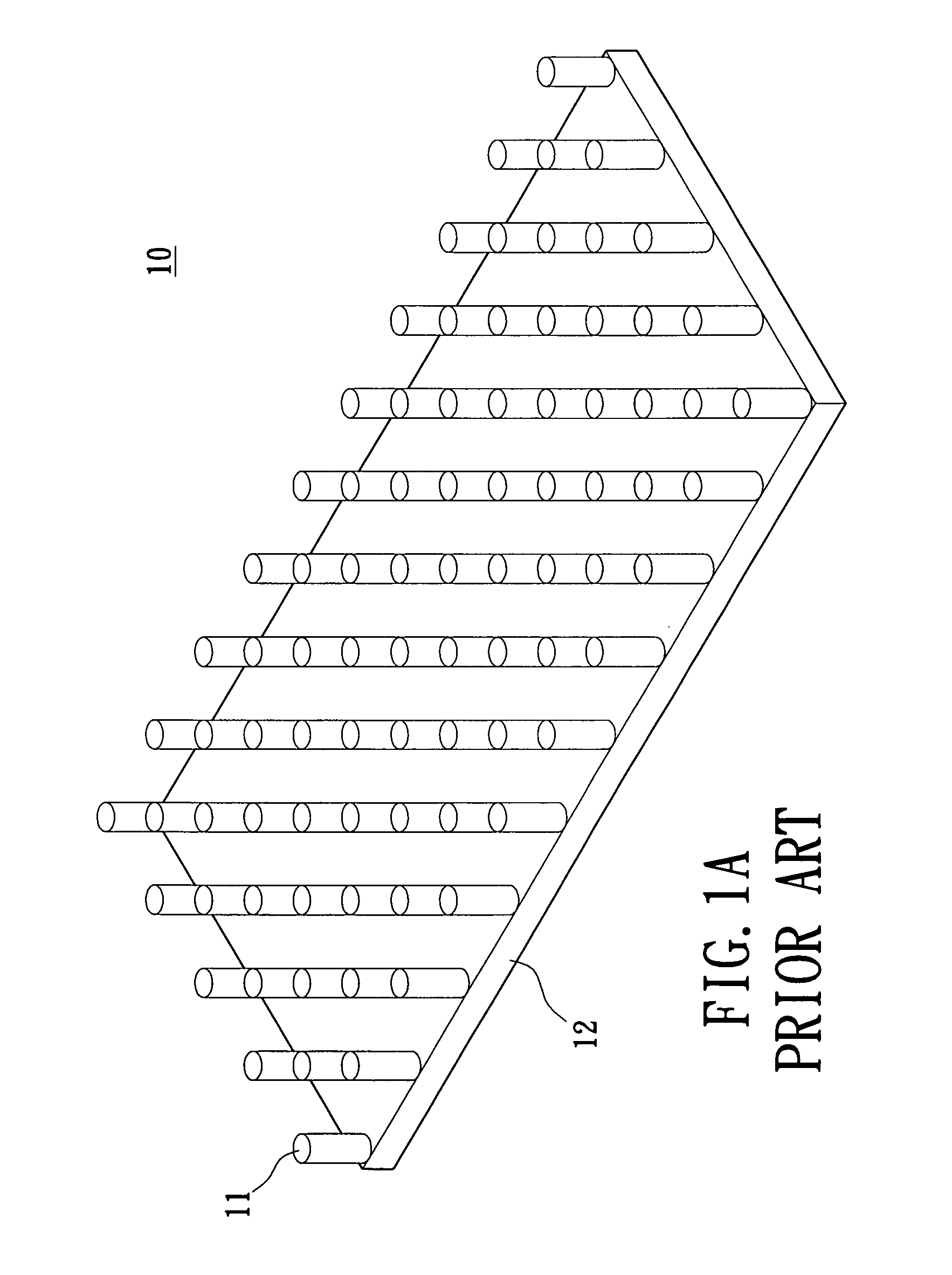

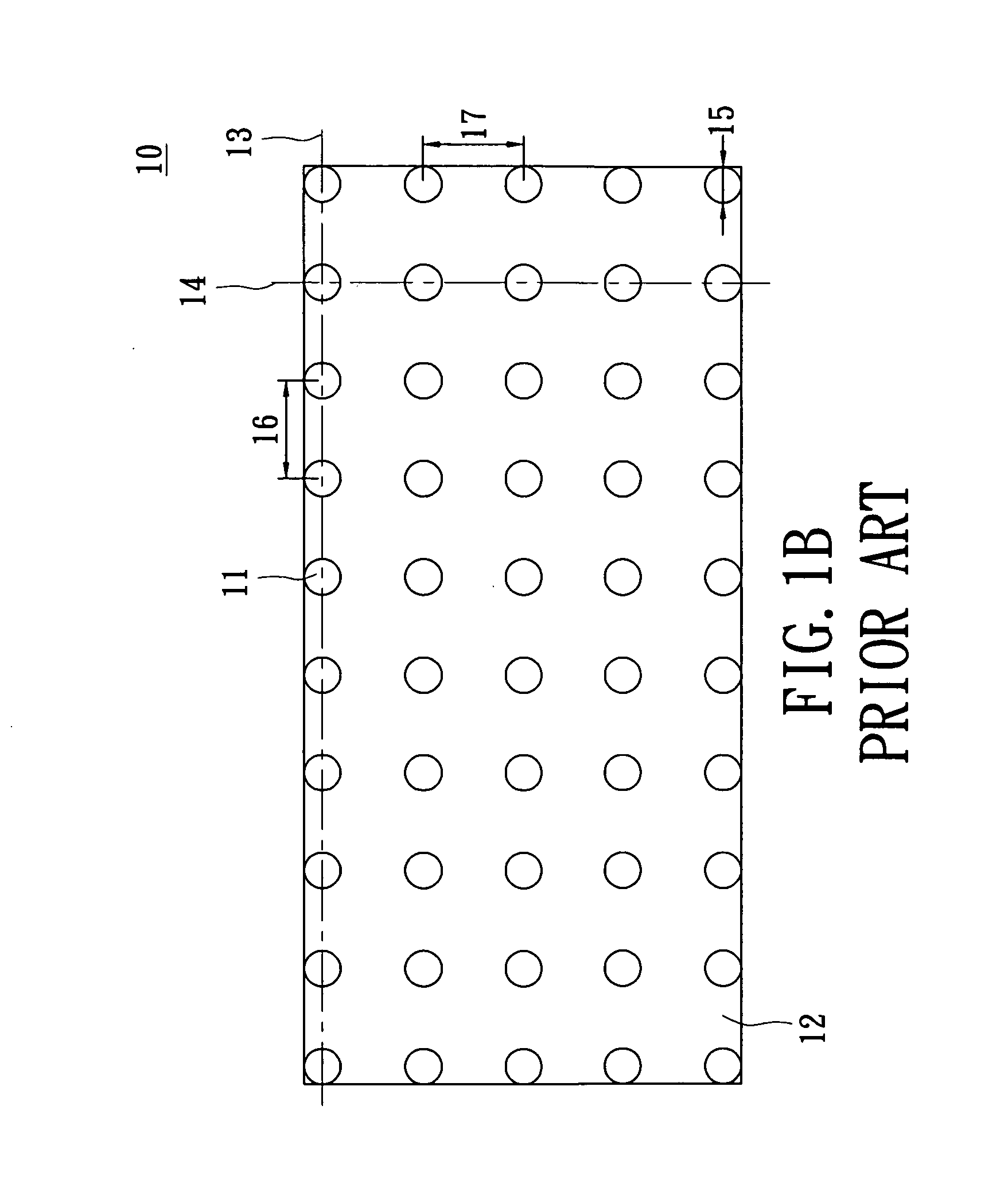

Non-linear fin heat sink

InactiveUS20090145581A1Improve power densityDissipating/removing heatSemiconductor/solid-state device detailsSolid-state devicesCoolant flowEngineering

A non-linear fin heat sink is provided for dissipating / removing heat uniformly from a device, where the heat generation is non-uniform over that device, while also providing a small and relatively lightweight heat sink. The heat sink has extended surface protrusions that are optimally shaped in recognition of convective heat transfer, conductive heat transfer, and flow resistance allowing the heat sink to offset the temperature rise of a coolant media and provide enhanced cooling for the coolant temperature, deliver optimized cooling efficiency per the local physical properties of the coolant media, be used with a fluid for effectuating heat transfer; either liquid coolant, gas coolant or a combination thereof. Furthermore the heat sink features turbulence enhancement of the coolant stream by a pin array through which coolant stream passes, such fin array featuring a non-linear shape, spacing, and height pattern to provide optimal cooling while simultaneously reducing volume and flow resistance.

Owner:THERMAL TECH

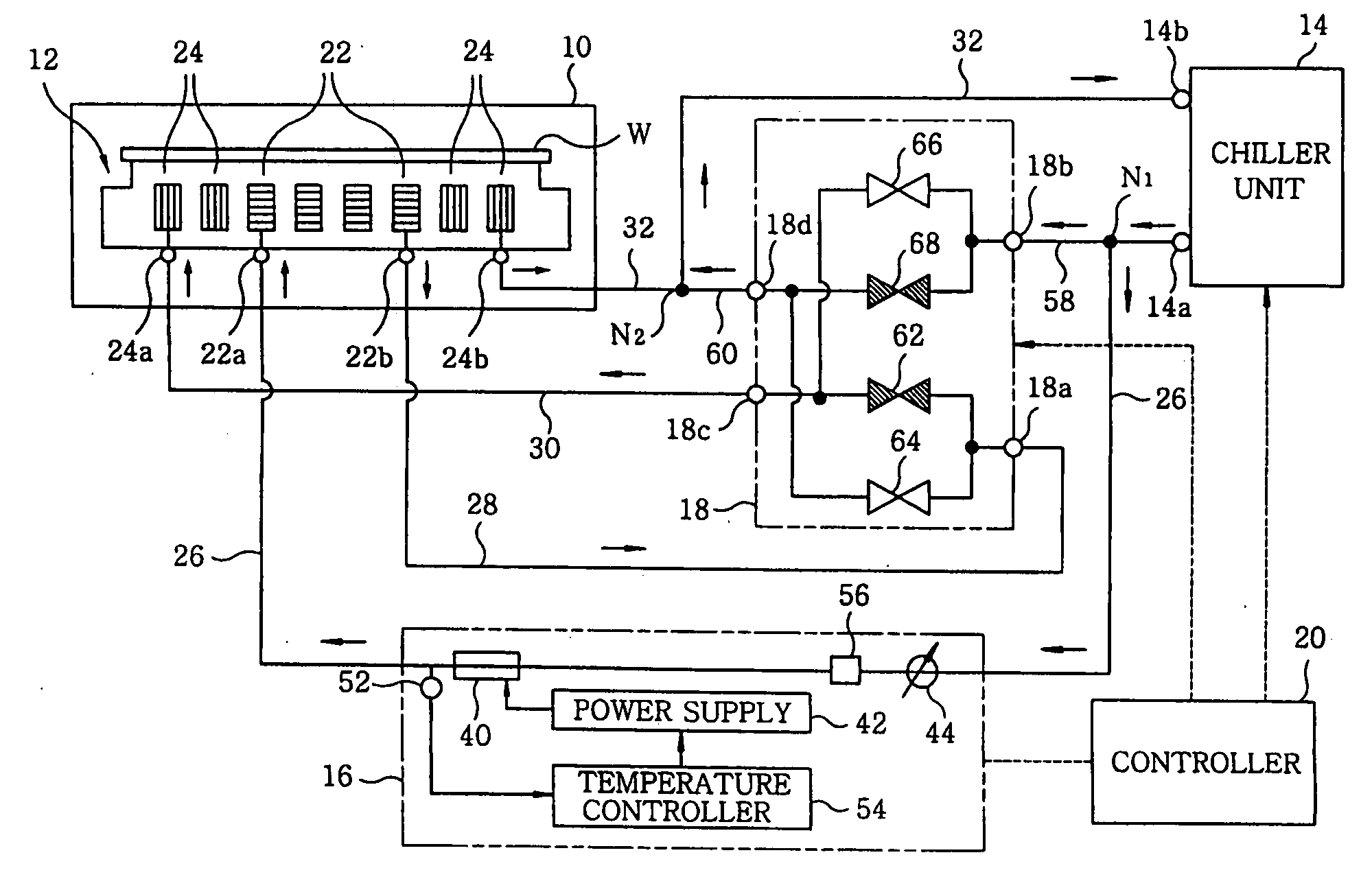

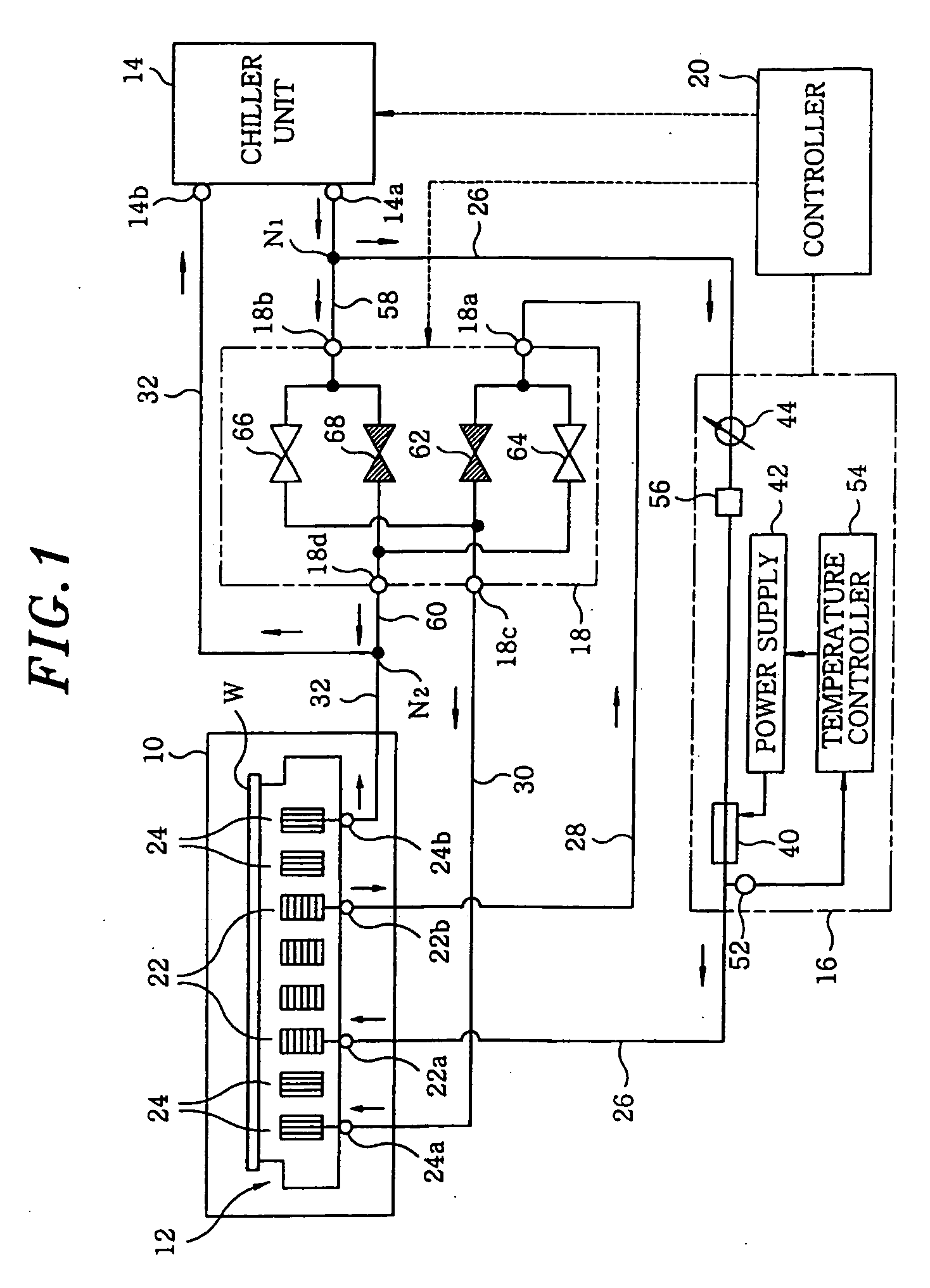

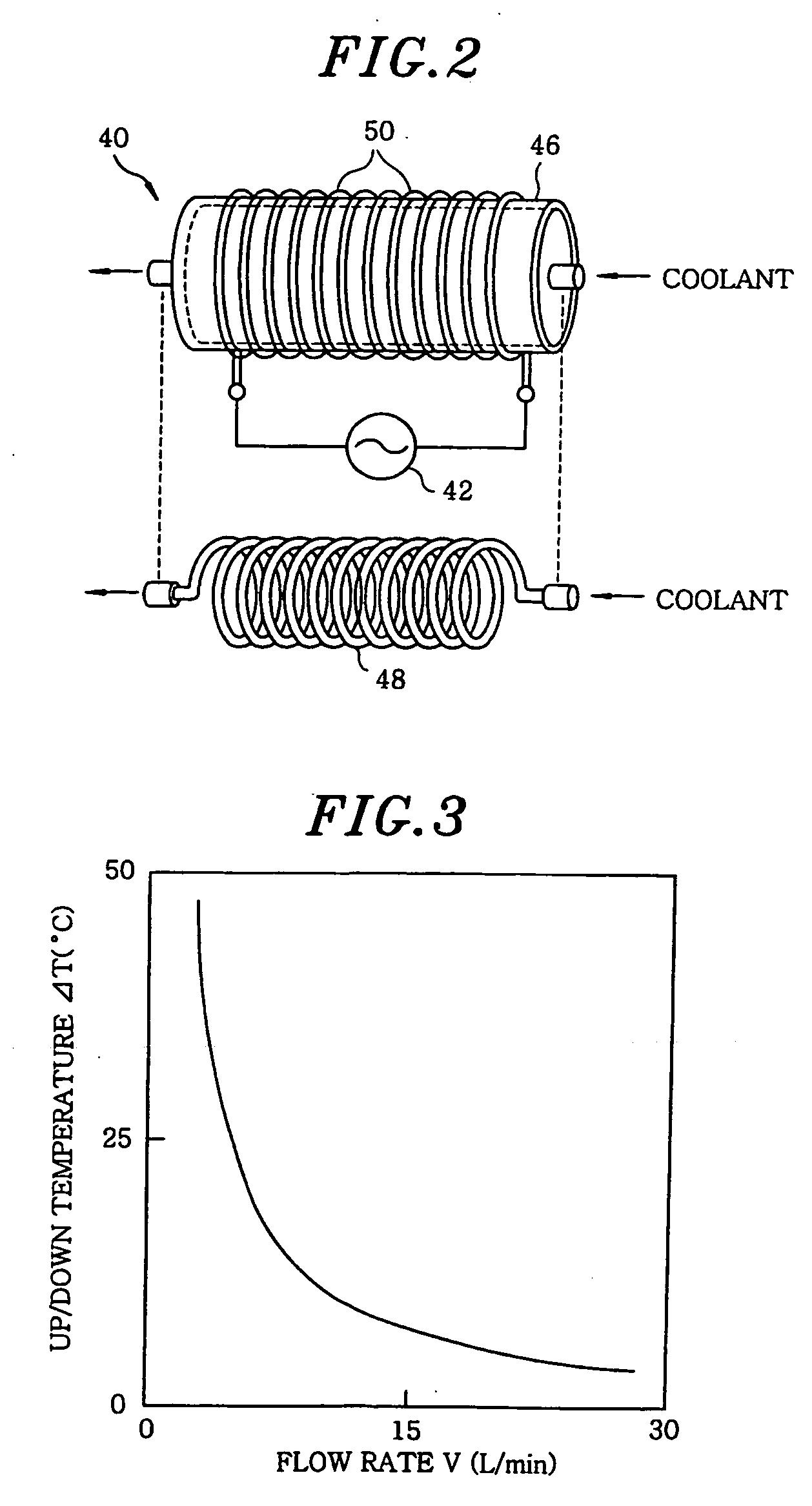

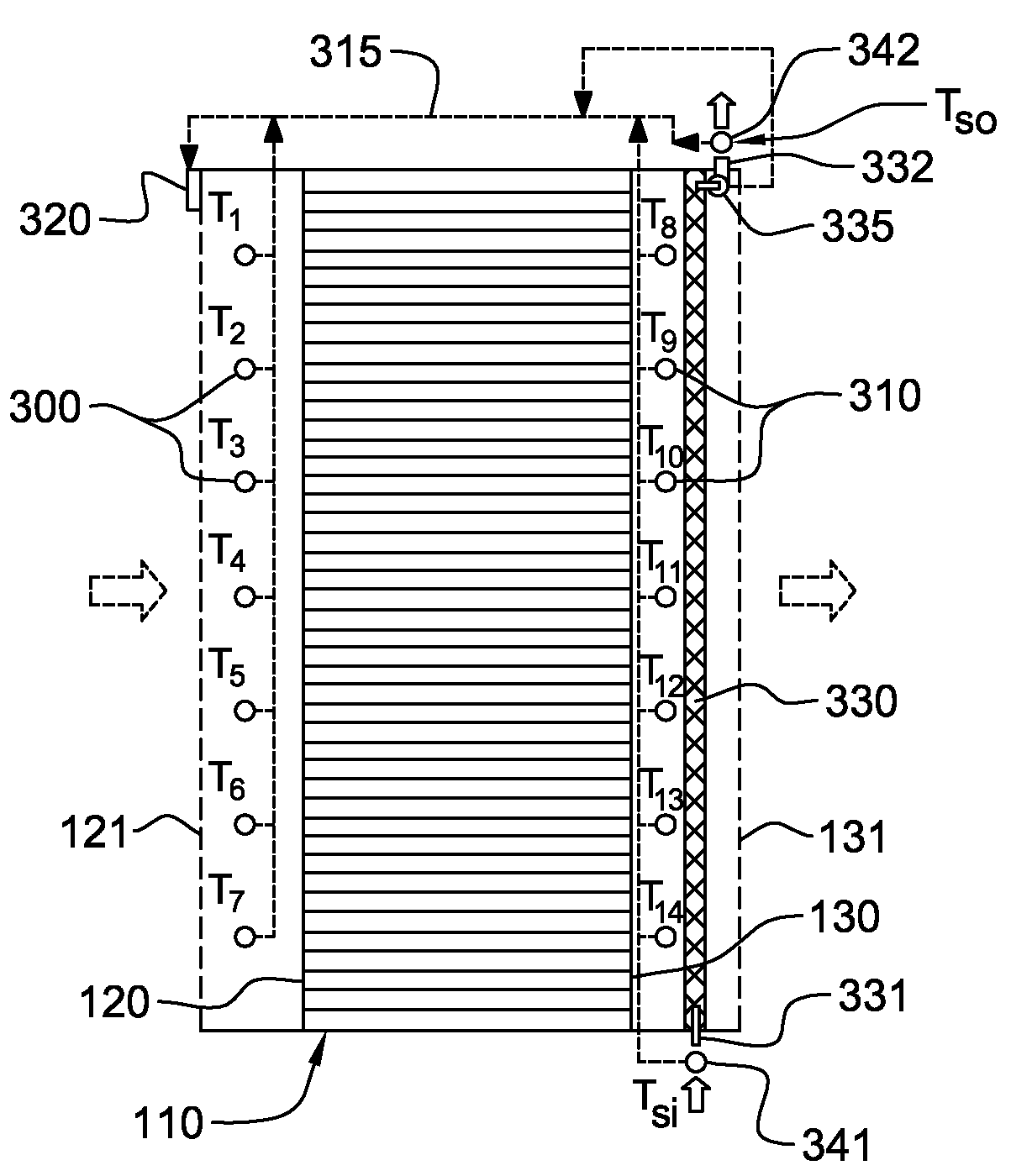

Device and method for controlling temperature of a mounting table, a program therefor, and a processing apparatus including same

ActiveUS20060219360A1Small-scaledImprove accuracyElectric discharge tubesTemperatue controlTemperature controlMode control

A device for controlling a temperature of a mounting table for mounting thereon a target object includes a first and a second coolant passageway provided at the mounting table, a coolant circulator for circulating a coolant in the first and the second coolant passageway, channels, a coolant temperature controller for raising or lowering the temperature of the coolant, a channel switching unit for connecting, blocking and changing the channels among a first to a fourth port; and a channel controller. Various modes for controlling a temperature of the mounting table can be obtained by combining an ON / OFF state of the heating operation in the coolant temperature controller with ON / OFF states of opening / closing valves in the channel switching unit under the control of the channel controller.

Owner:TOKYO ELECTRON LTD

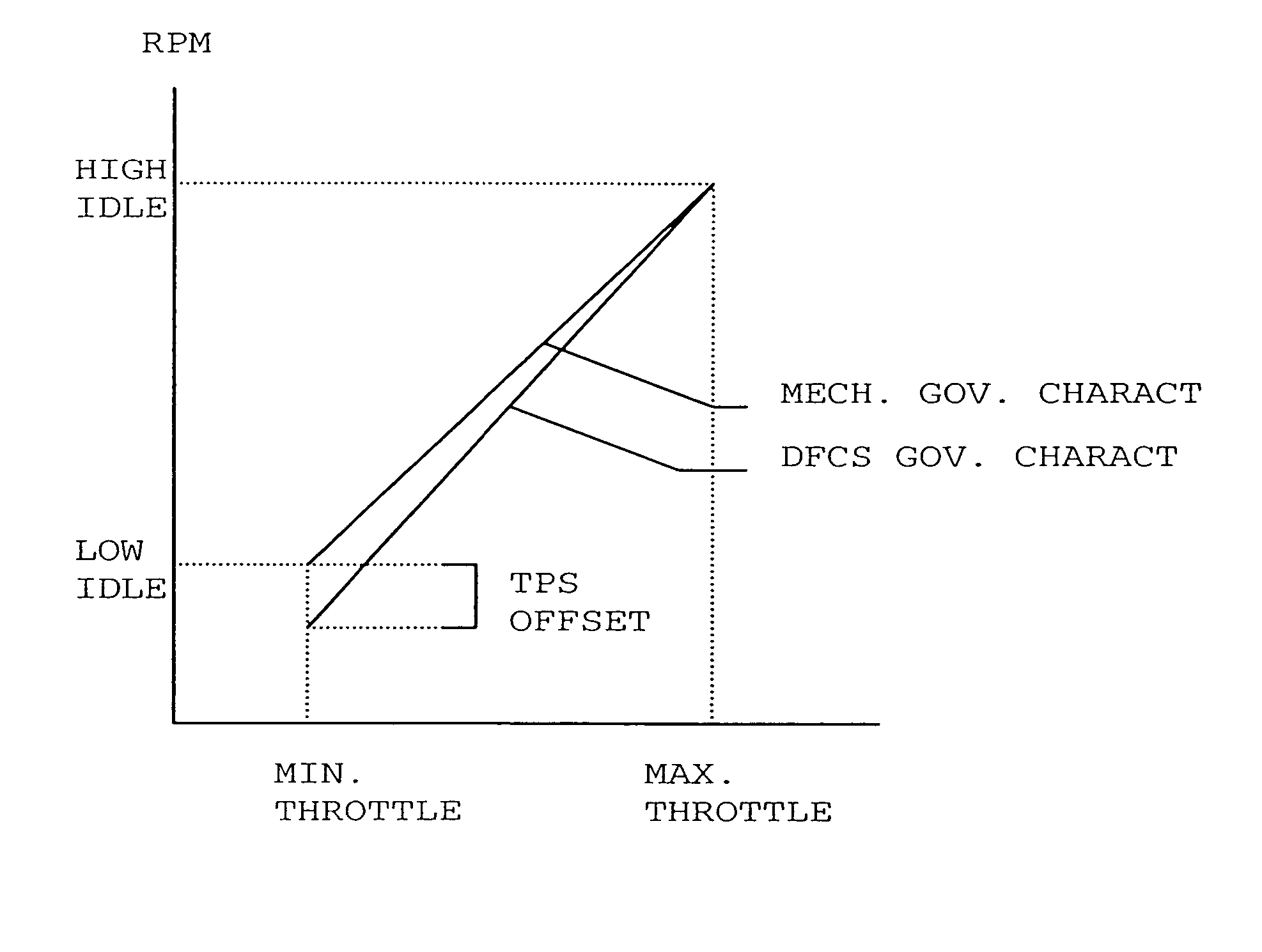

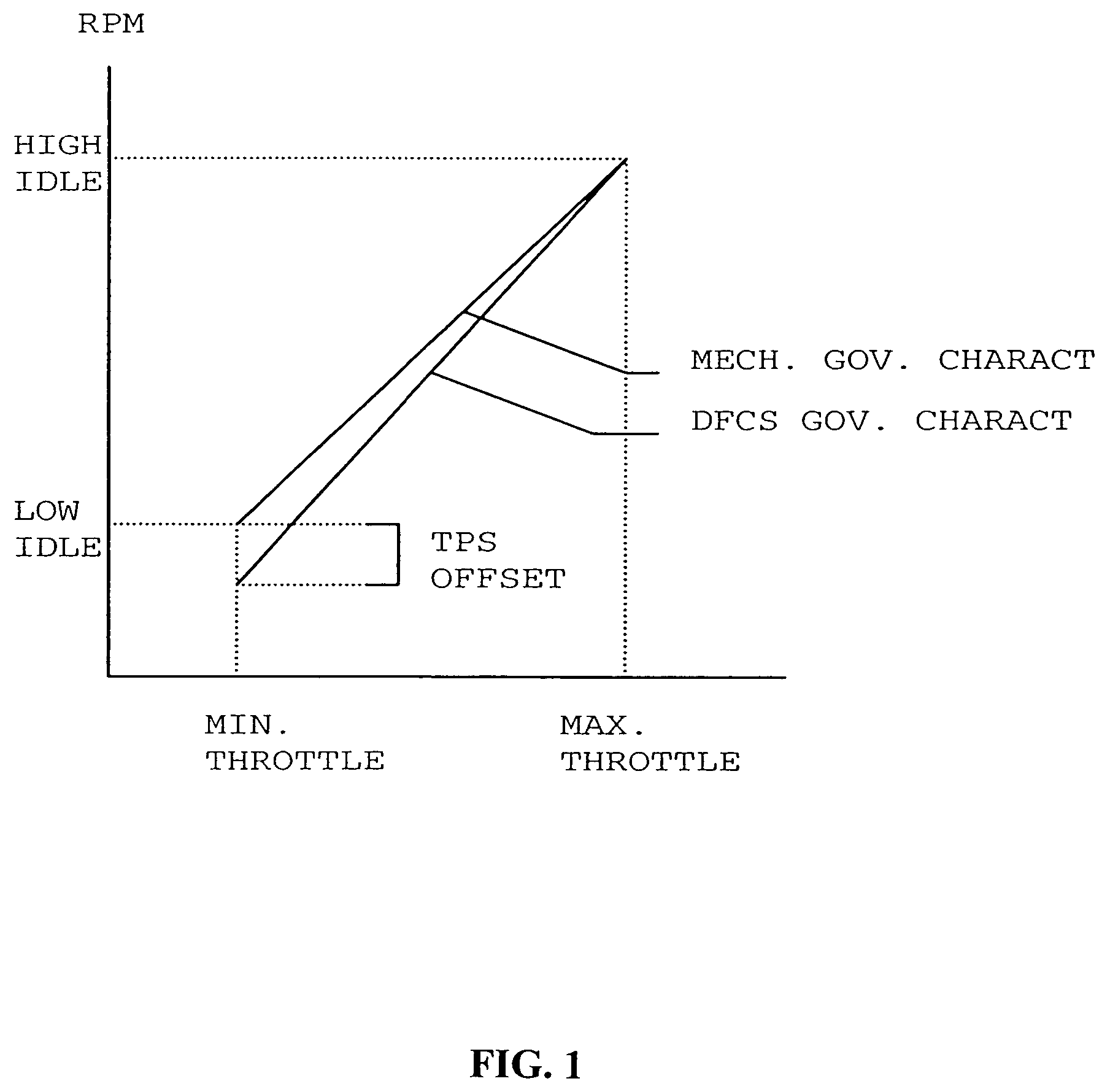

Methods and apparatus for operation of multiple fuel engines

Methods and apparatus are disclosed for operation of a multiple fuel engine, which runs on a combination of two or more fuels. An electronic control unit (ECU) may be connected to the existing components of an engine system in order to control operation of the multiple fuel engine. The engine system may be mechanically governed or electronically controlled. The ECU inputs operating characteristics of the engine system, determines governing characteristics for multiple fuel operation based on the operating characteristics, and controls the amounts of fuel delivered to the engine based on the governing characteristics. In a preferred embodiment, a dual fuel engine operates using diesel as a first fuel and natural gas as a second fuel. The operating characteristics may include engine speed, throttle position, engine exhaust temperature, gas pressure of the second fuel, gas temperature of the second fuel, boost pressure of an intake manifold, or engine coolant temperature.

Owner:2FUEL TECH INC +1

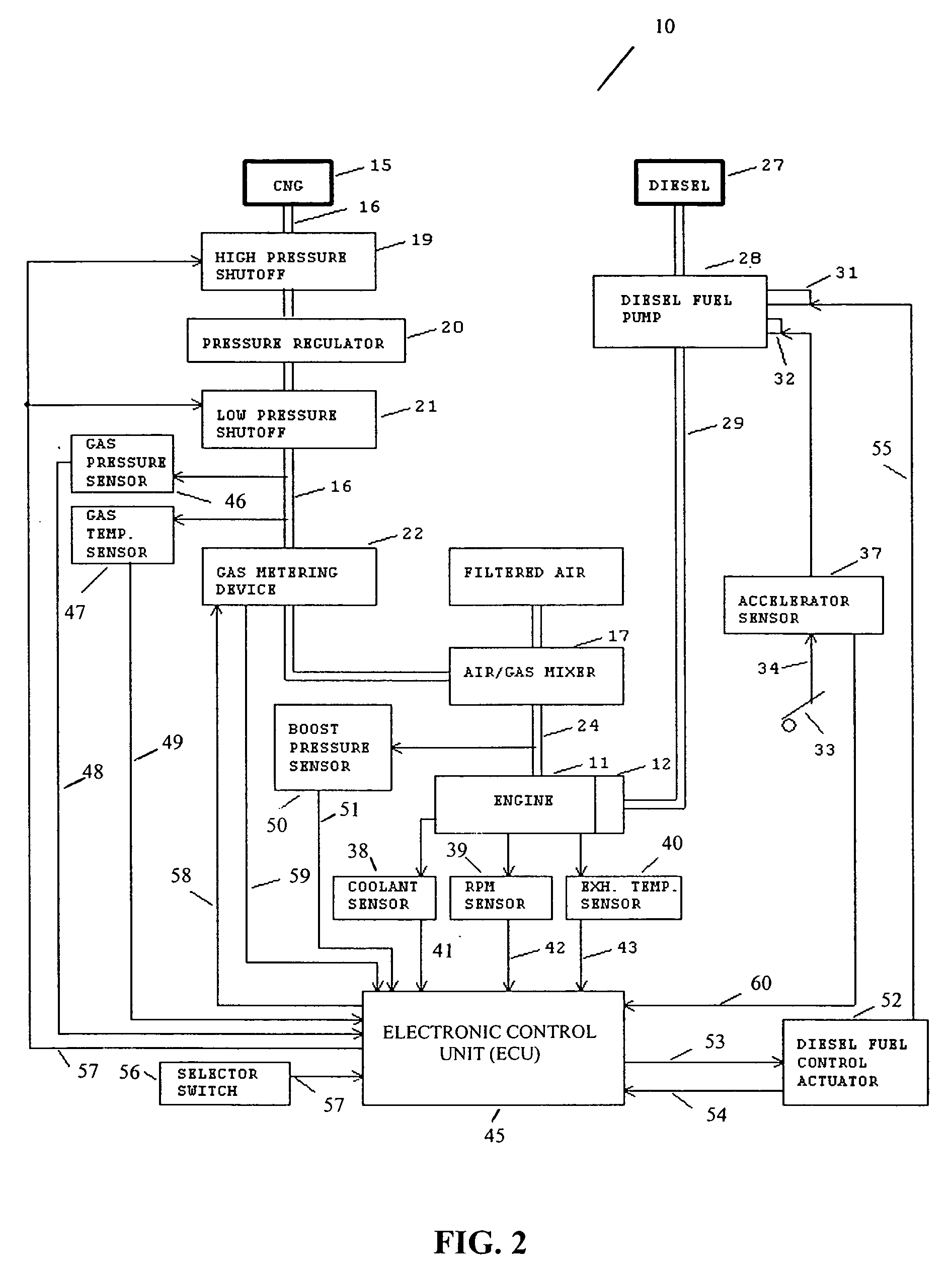

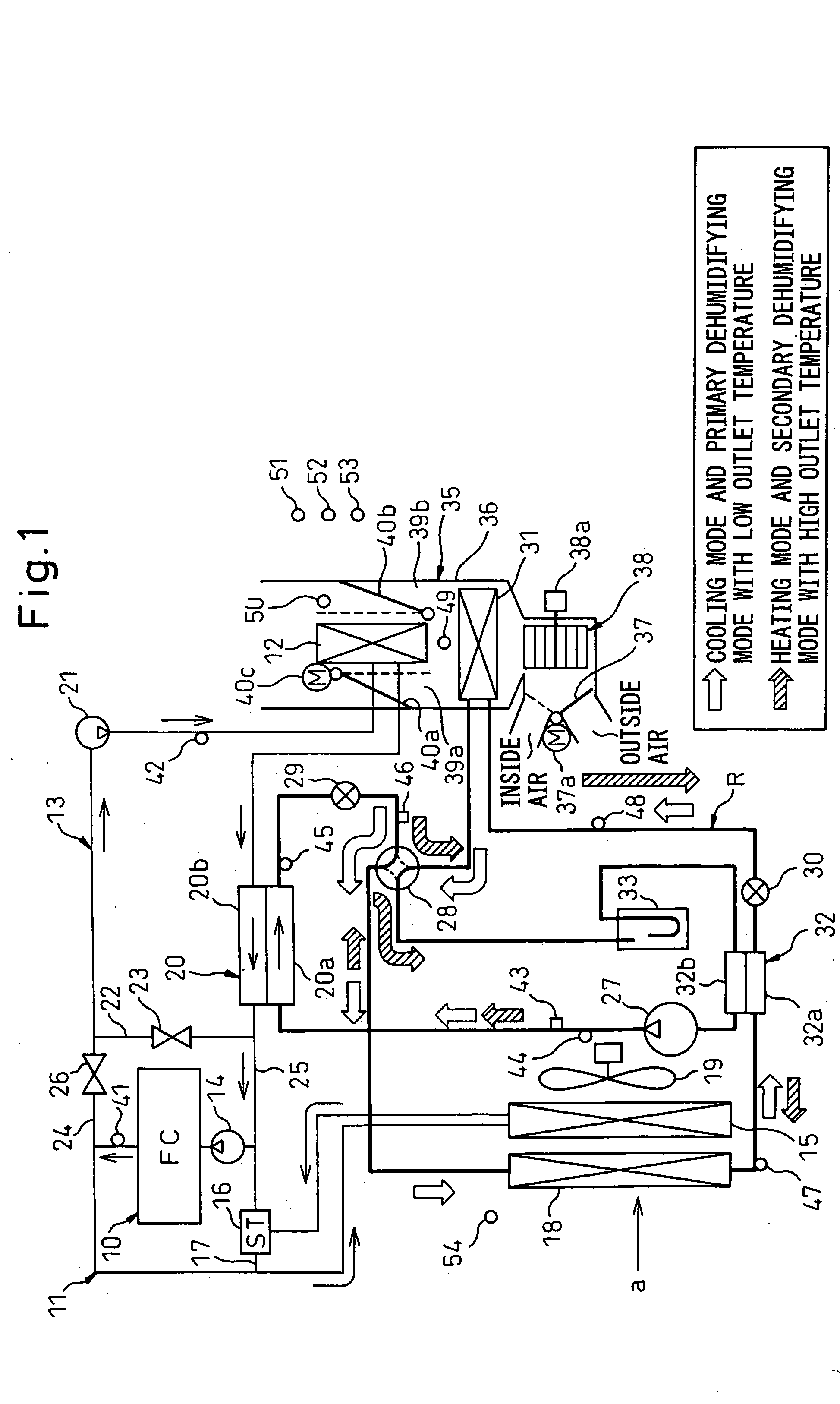

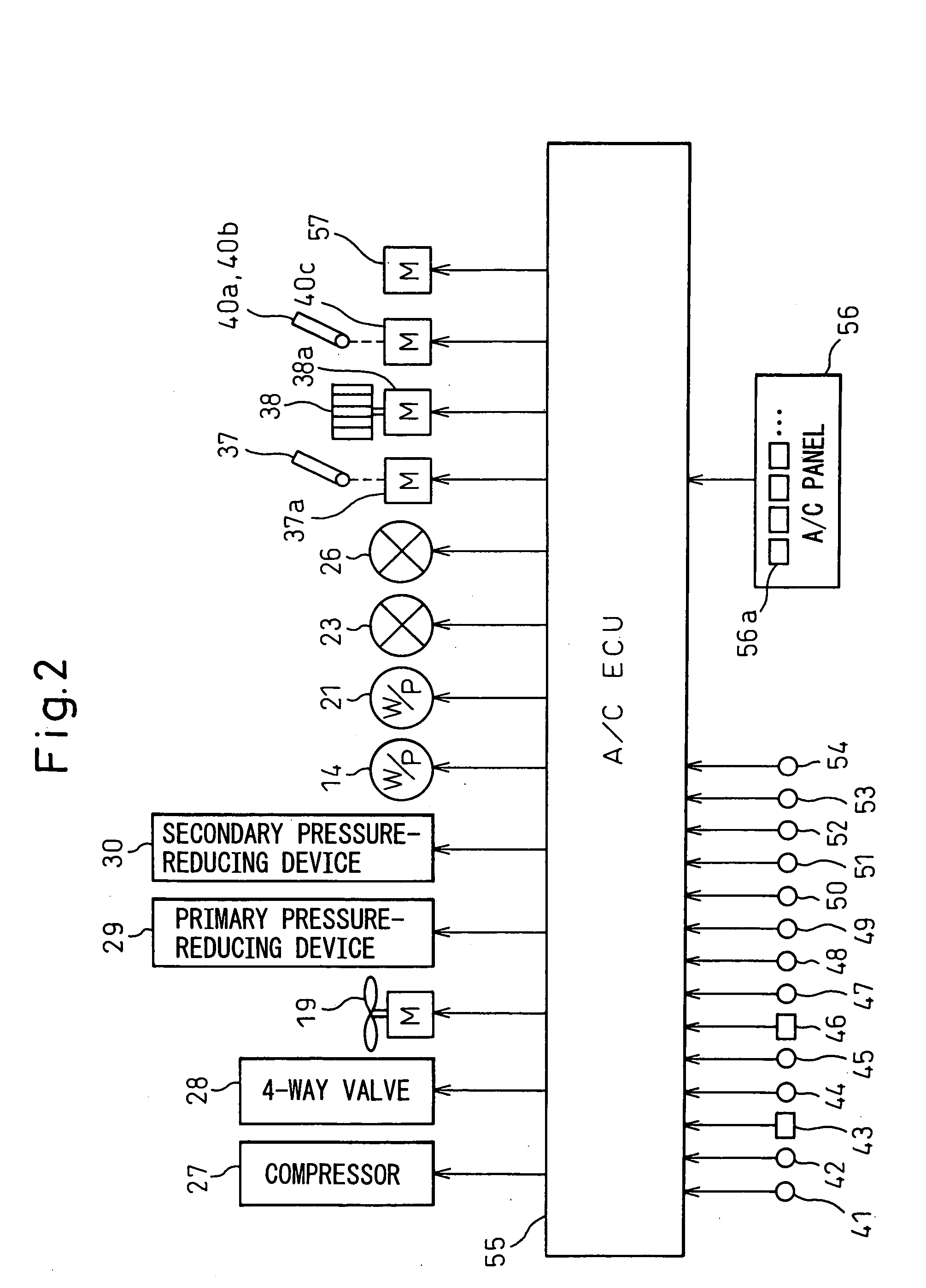

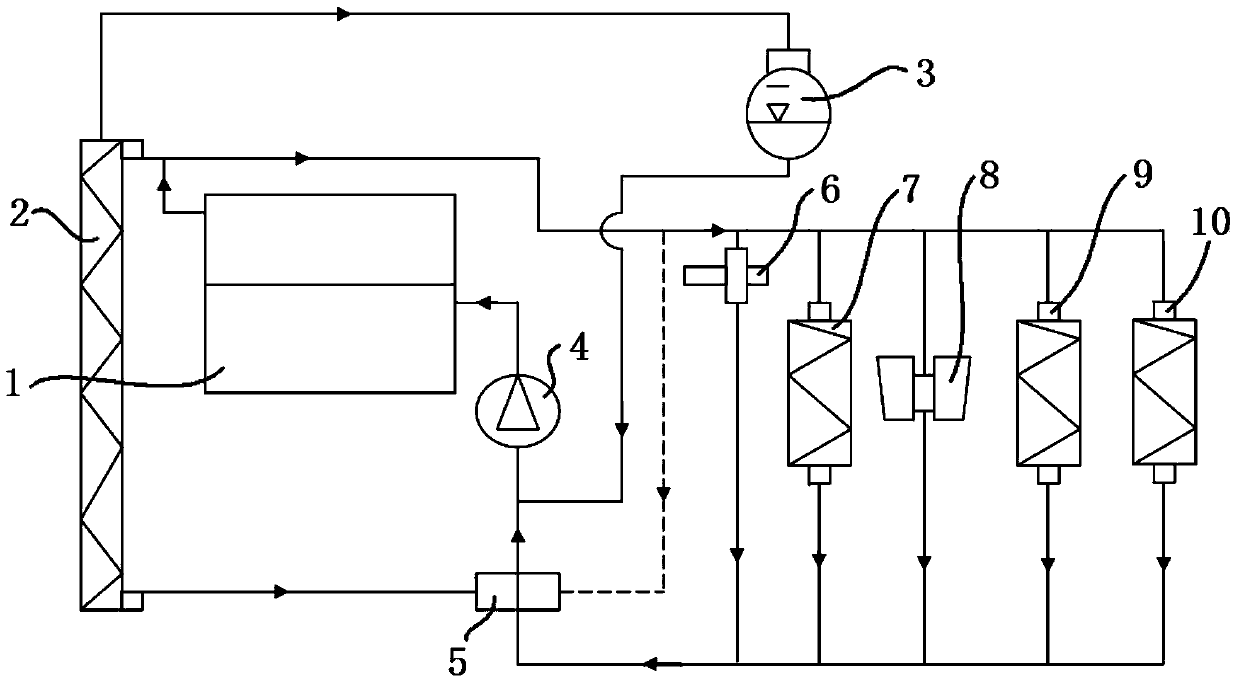

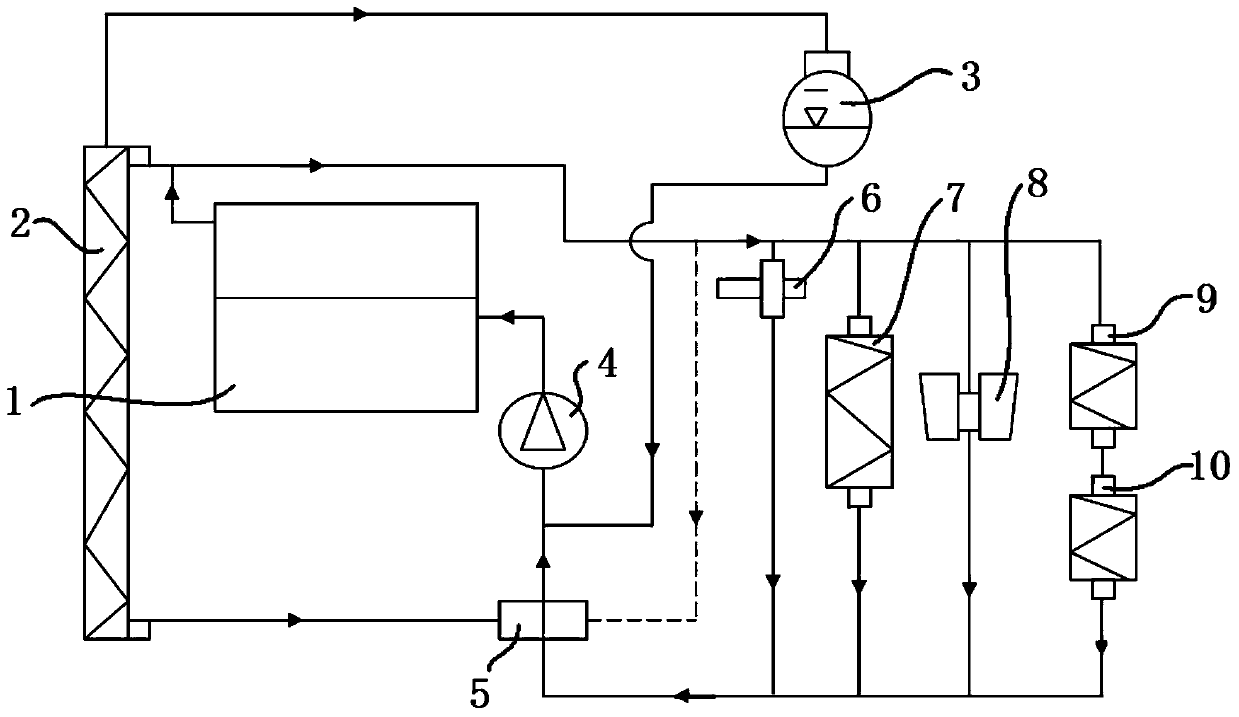

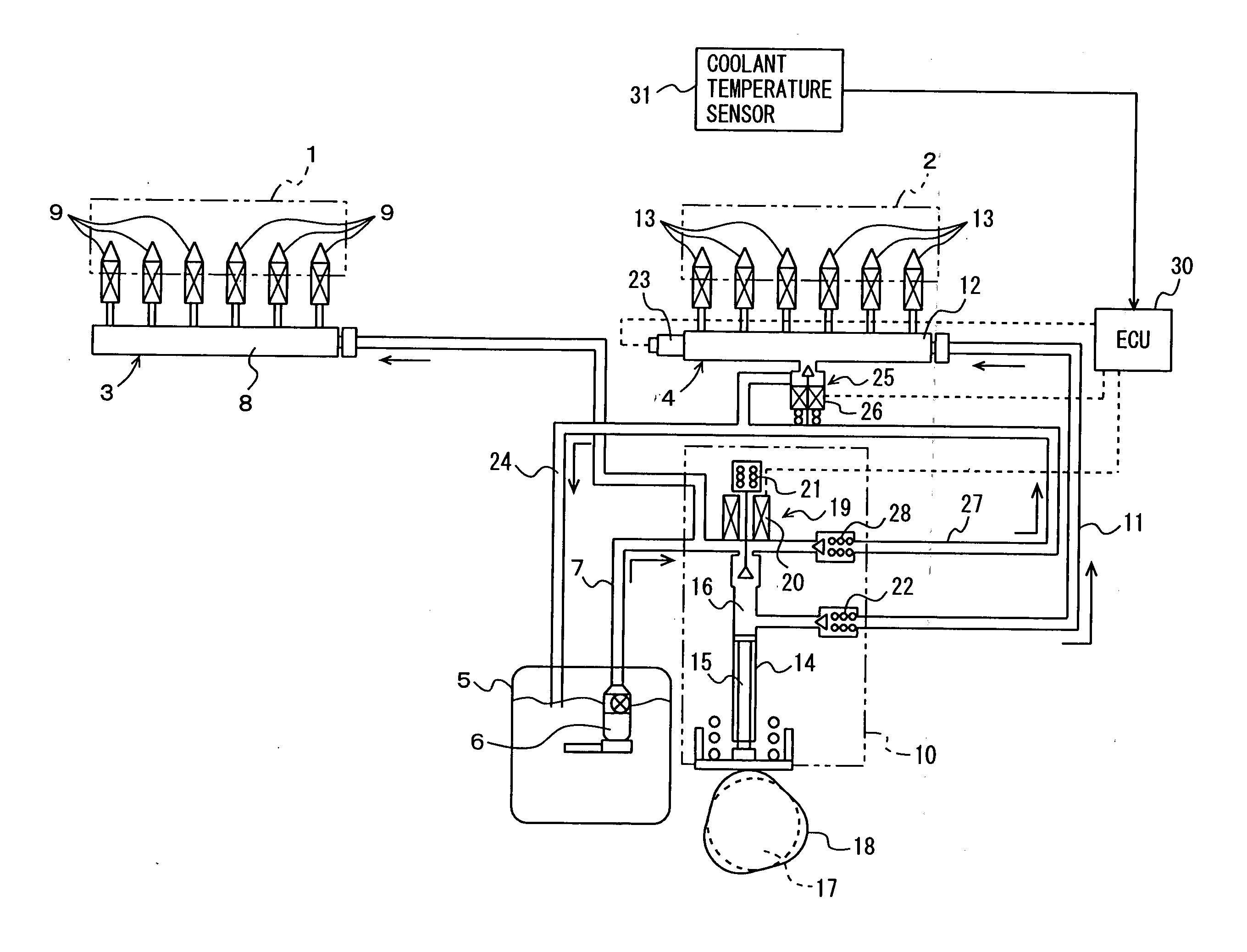

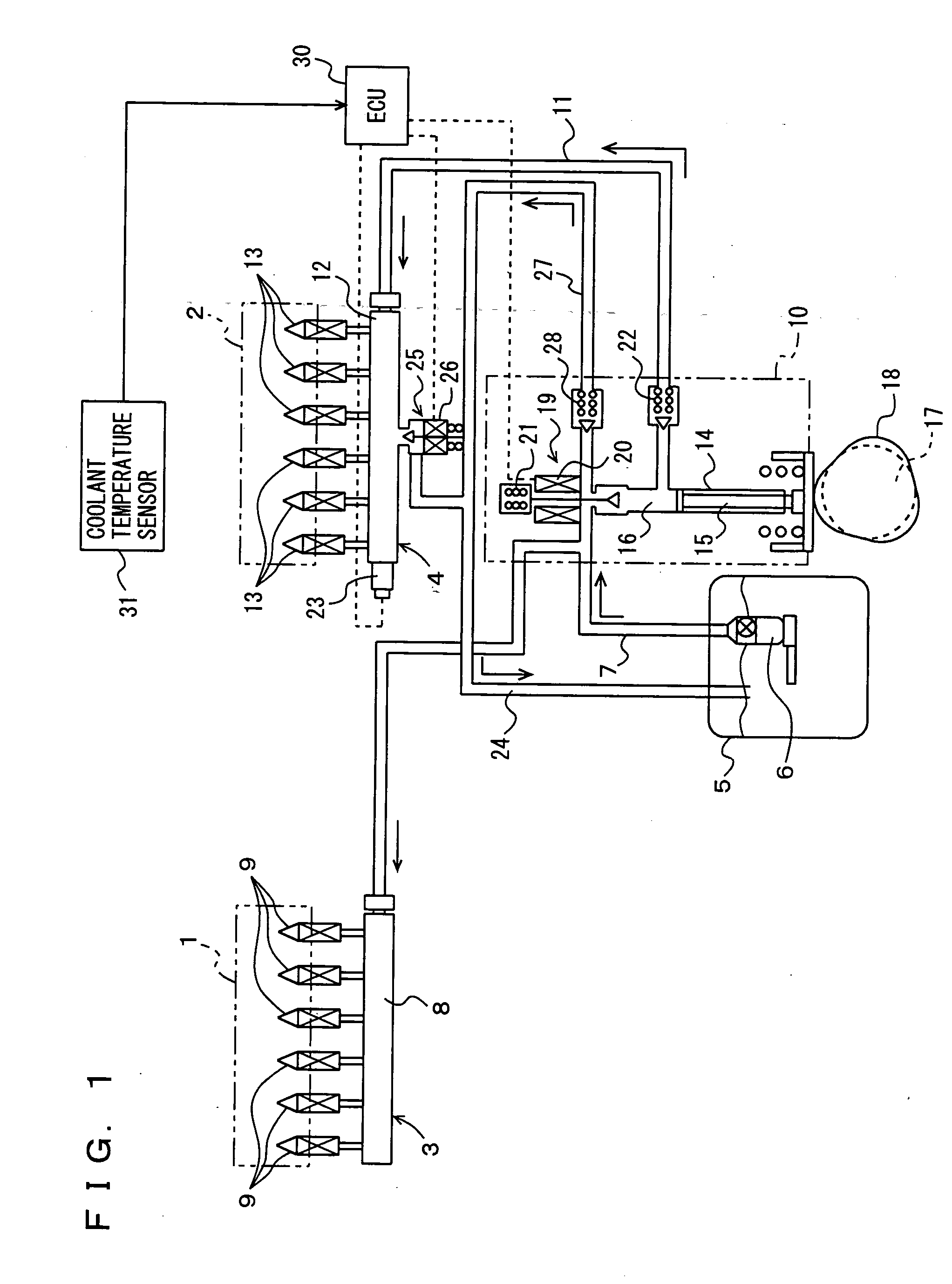

Automotive air conditioning system

InactiveUS20050178523A1Increase immediate effect of heating performanceImprove immediacyPower to auxillary motorsEmergency protection arrangementsEngineeringCoolant temperature

An automotive air conditioning system has a primary hot water circuit 11 located on a side where a vehicle installed heat generator 10 is located and a secondary hot water circuit 13 which includes a hot water type heater core 12 for heating passenger compartment outlet air, whereby when in a heating mode, in the event that a coolant temperature TW1 of the primary hot water circuit is lower than a coolant temperature TW2 of the secondary hot water circuit 13, an opening and closing valve 26 is closed, whereas an opening and closing valve 23 is opened, so that a state is created in which the hot water circuits 11, 13 are separated from each other. On the other hand, in the event that the coolant temperature TW1 of the primary hot water circuit becomes higher than the coolant temperature TW2 of the secondary hot water circuit 13, the opening and closing valve 26 is opened, whereas the opening and closing valve 23 is closed, so that a state is created in which the hot water circuits 11, 13 are connected to each other.

Owner:DENSO CORP

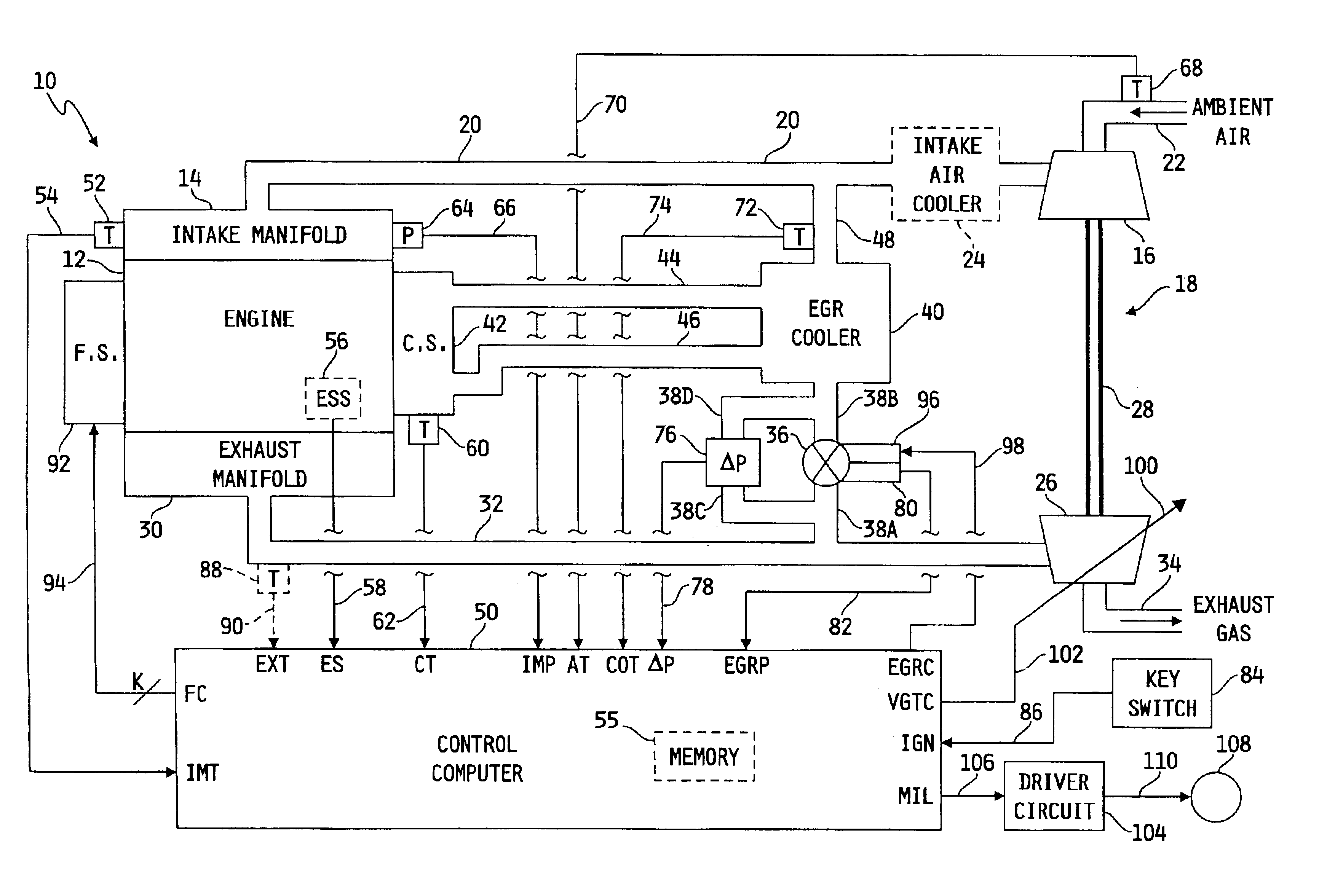

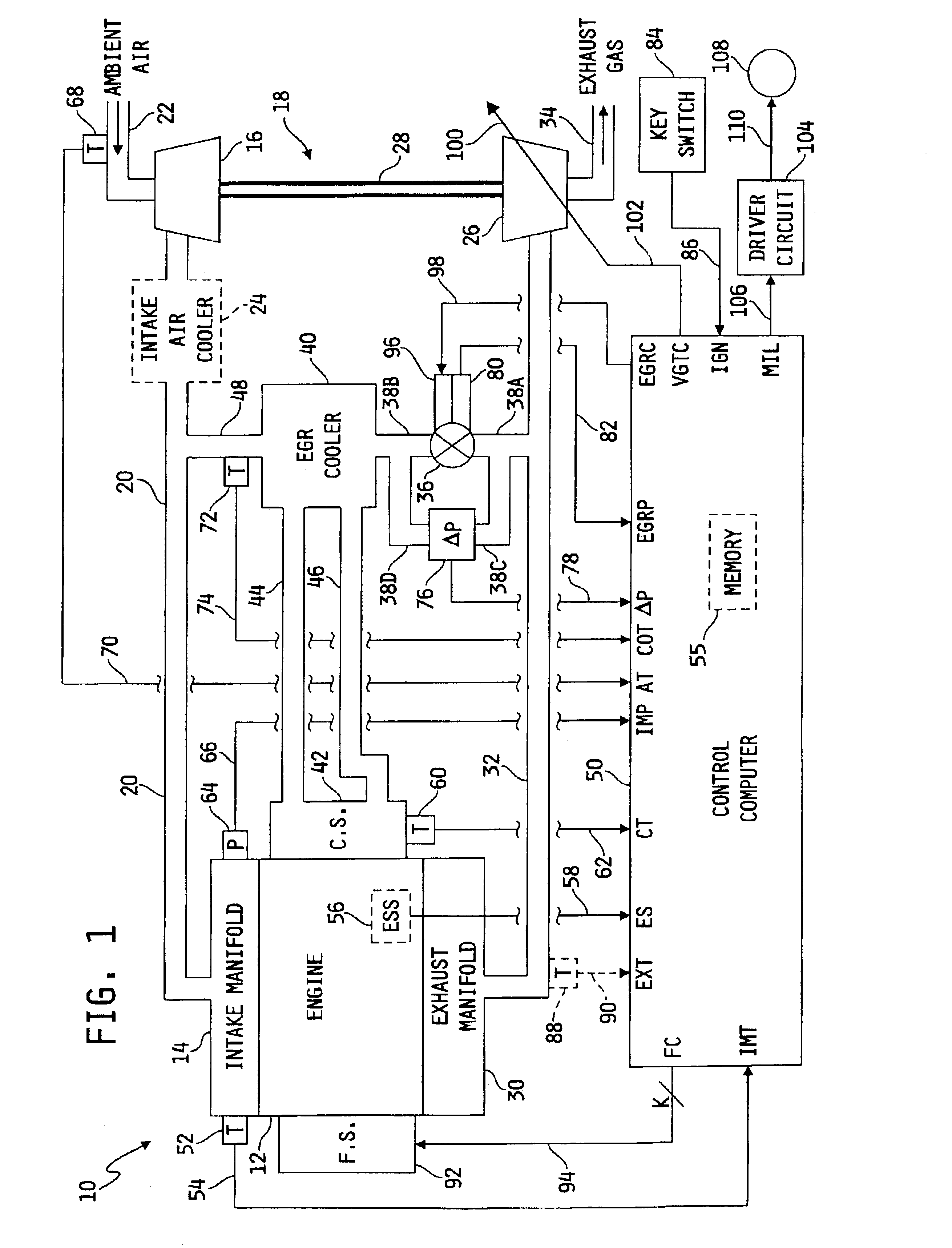

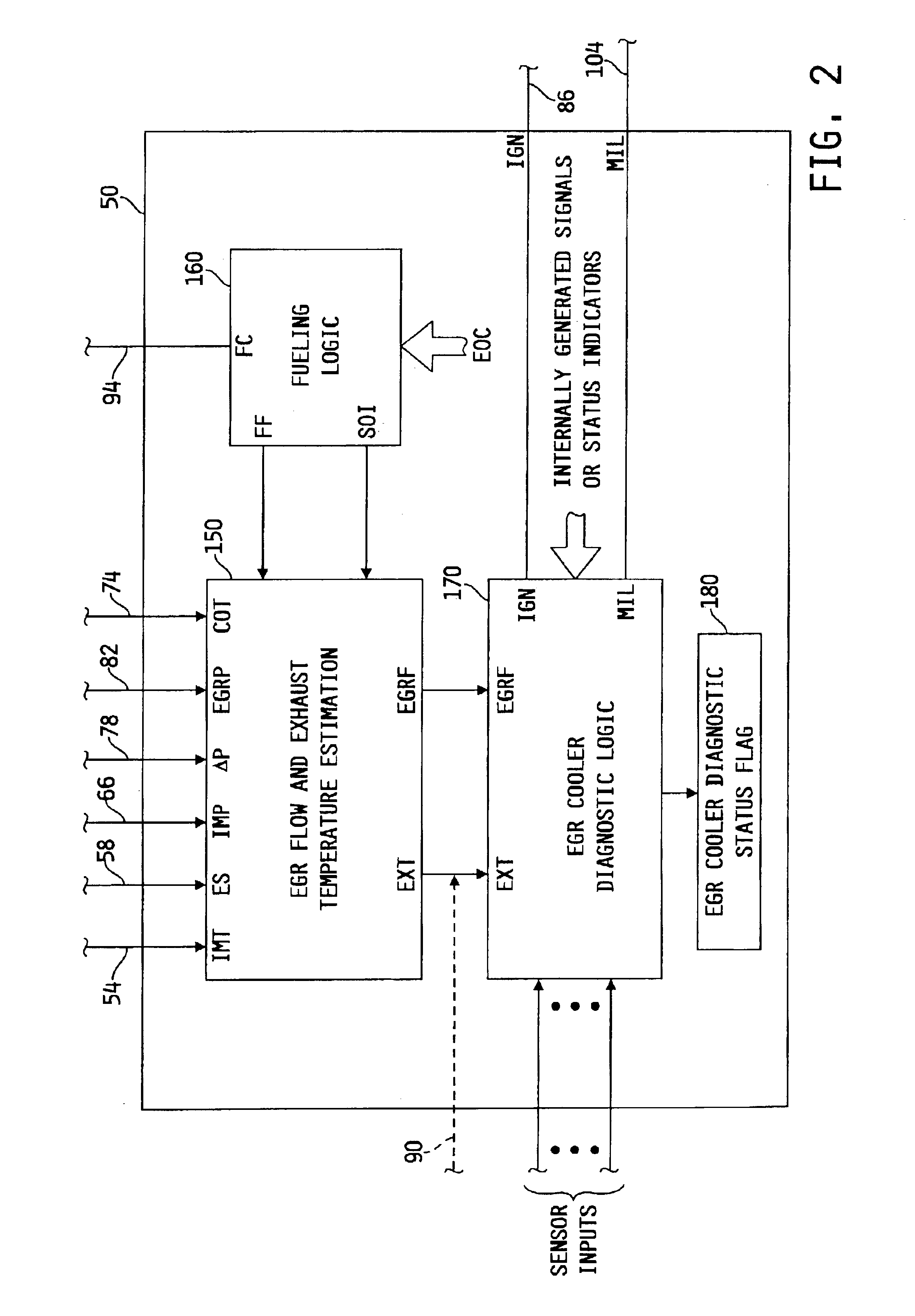

System for diagnosing operation of an EGR cooler

InactiveUS6848434B2Internal combustion piston enginesNon-fuel substance addition to fuelCoolant flowEngineering

A system is disclosed for diagnosing operation of an EGR cooler disposed in-line with an EGR conduit fluidly coupled between an intake manifold and an exhaust manifold of the engine such that exhaust gas flowing through the EGR conduit also flows through the EGR cooler. The EGR cooler is coupled to an engine cooling system such that coolant fluid circulating through the engine also circulates through the EGR cooler. Means are provided for determining a temperature of exhaust gas produced by the engine, a temperature of exhaust gas exiting the EGR cooler, a temperature of the coolant fluid and a flow rate of exhaust gas through the EGR conduit. A control computer is configured to diagnose operation the EGR cooler as a function of the temperature of exhaust gas produced by the engine, the EGR cooler outlet temperature, the engine coolant temperature and the EGR flow rate.

Owner:CUMMINS INC

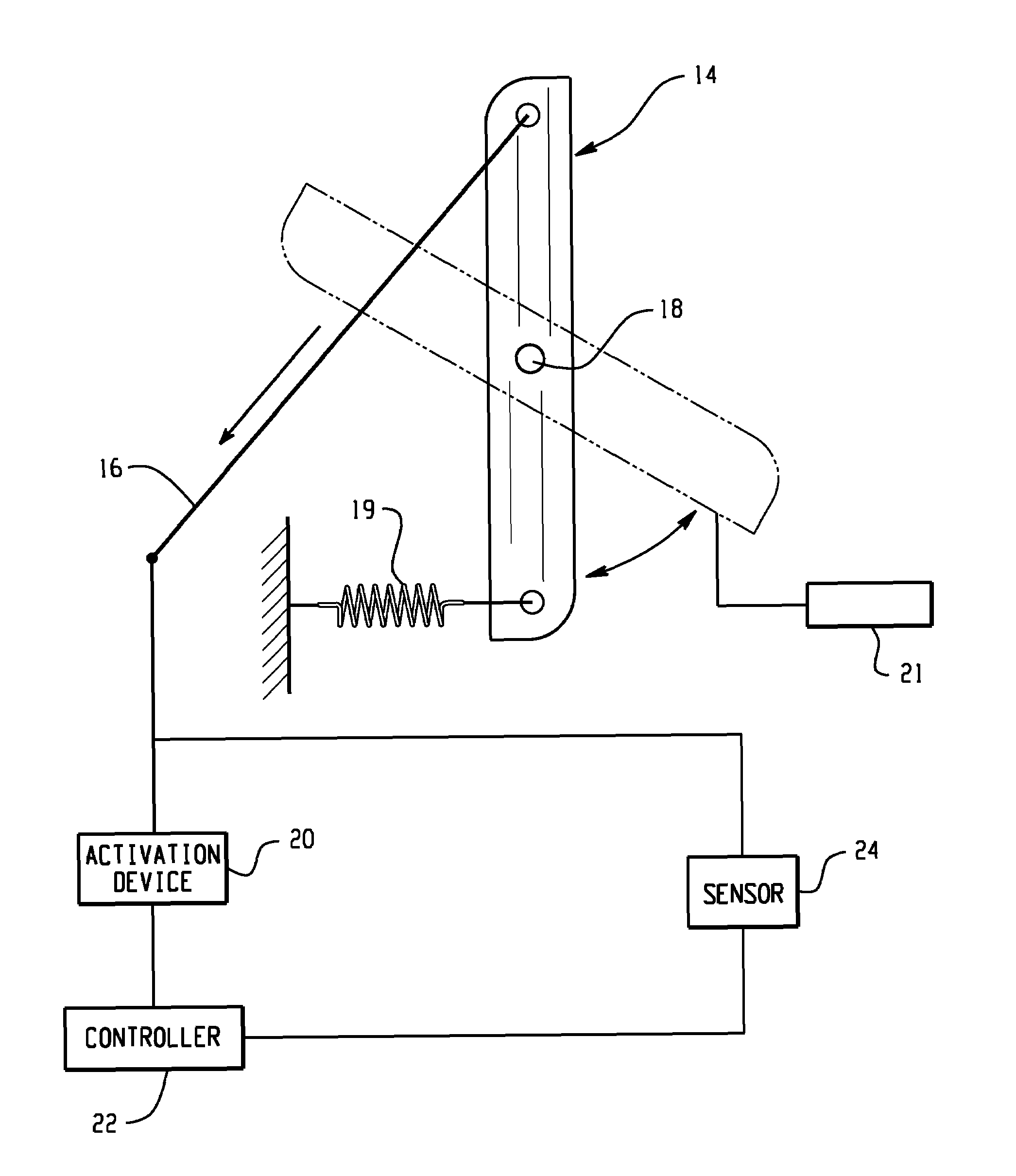

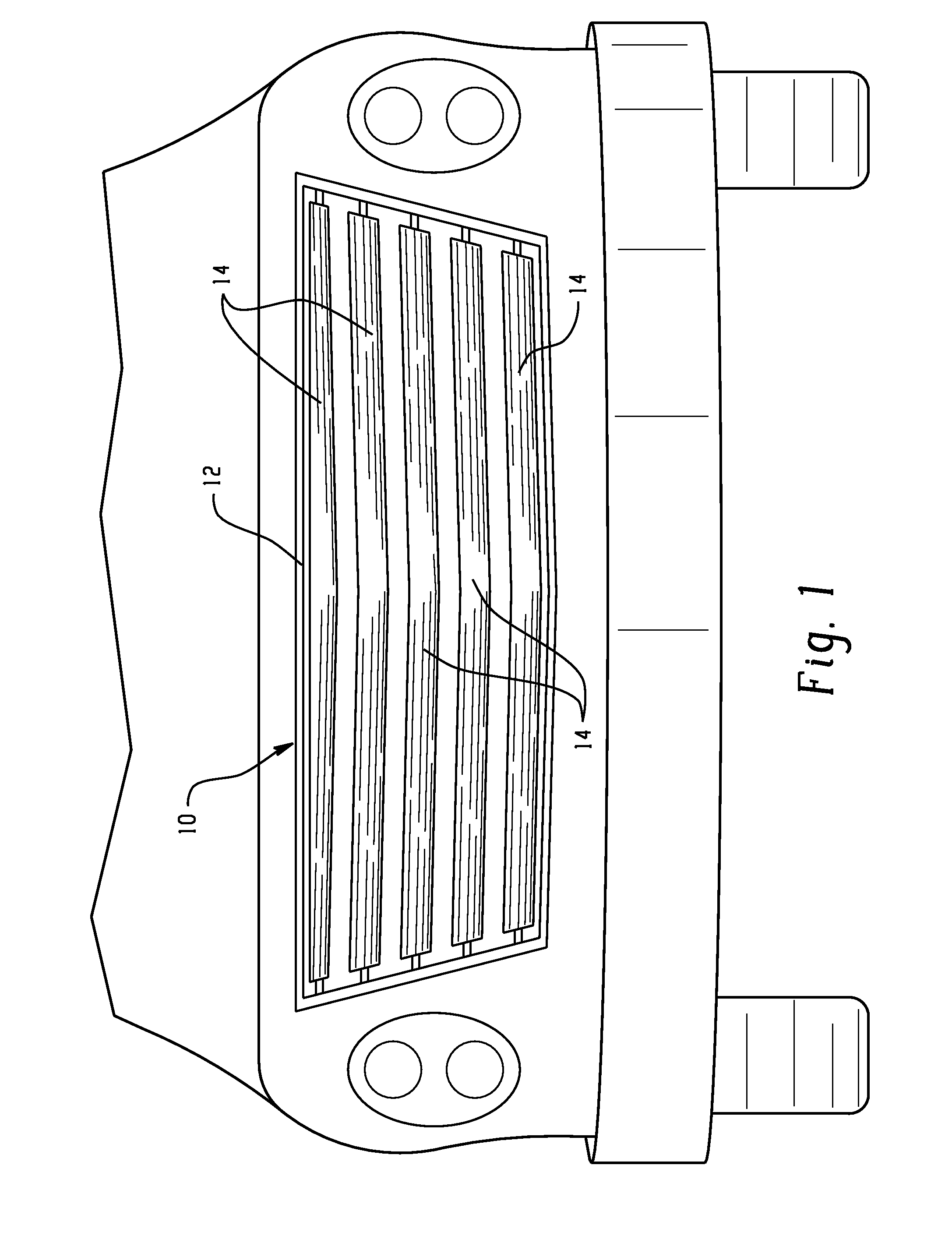

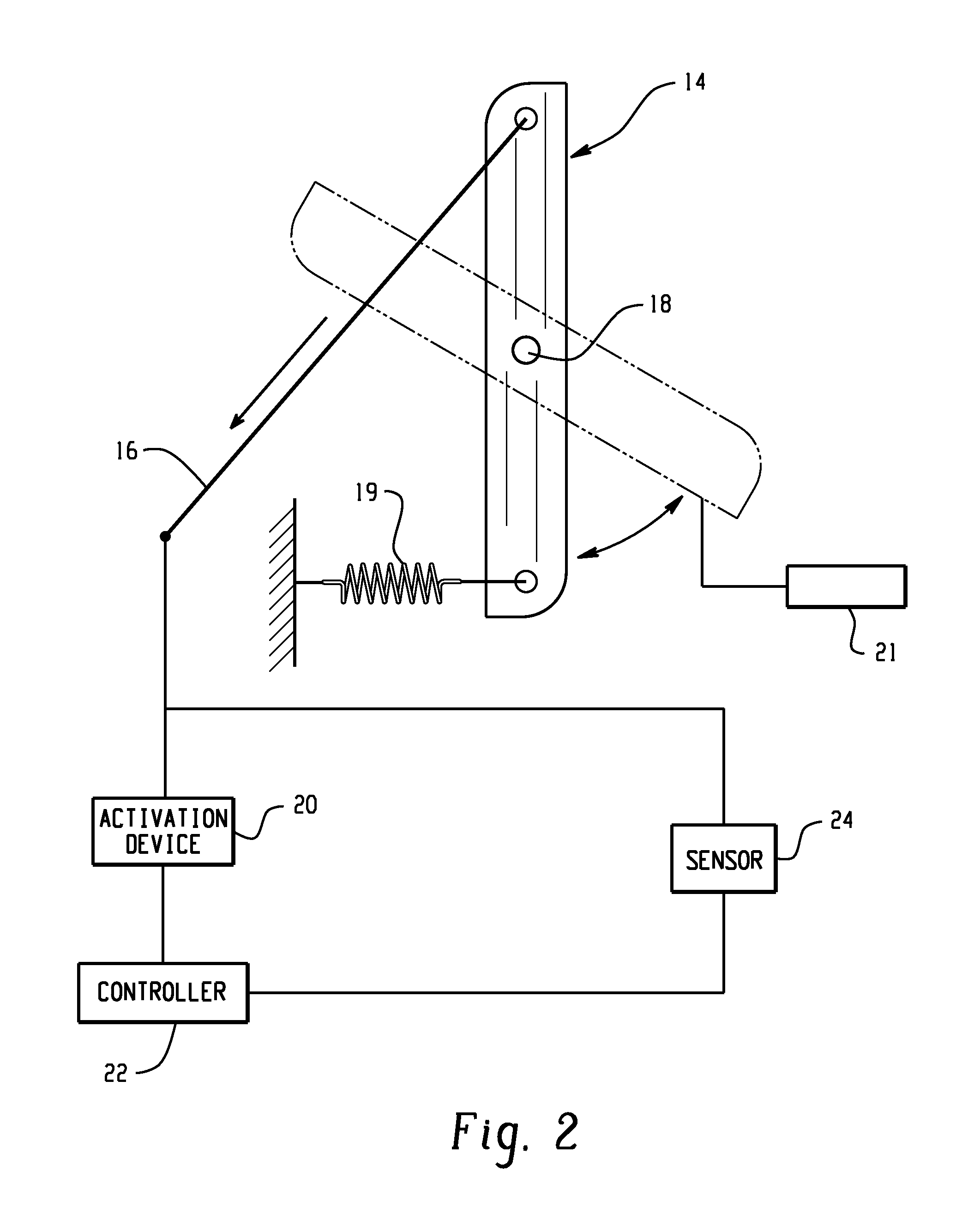

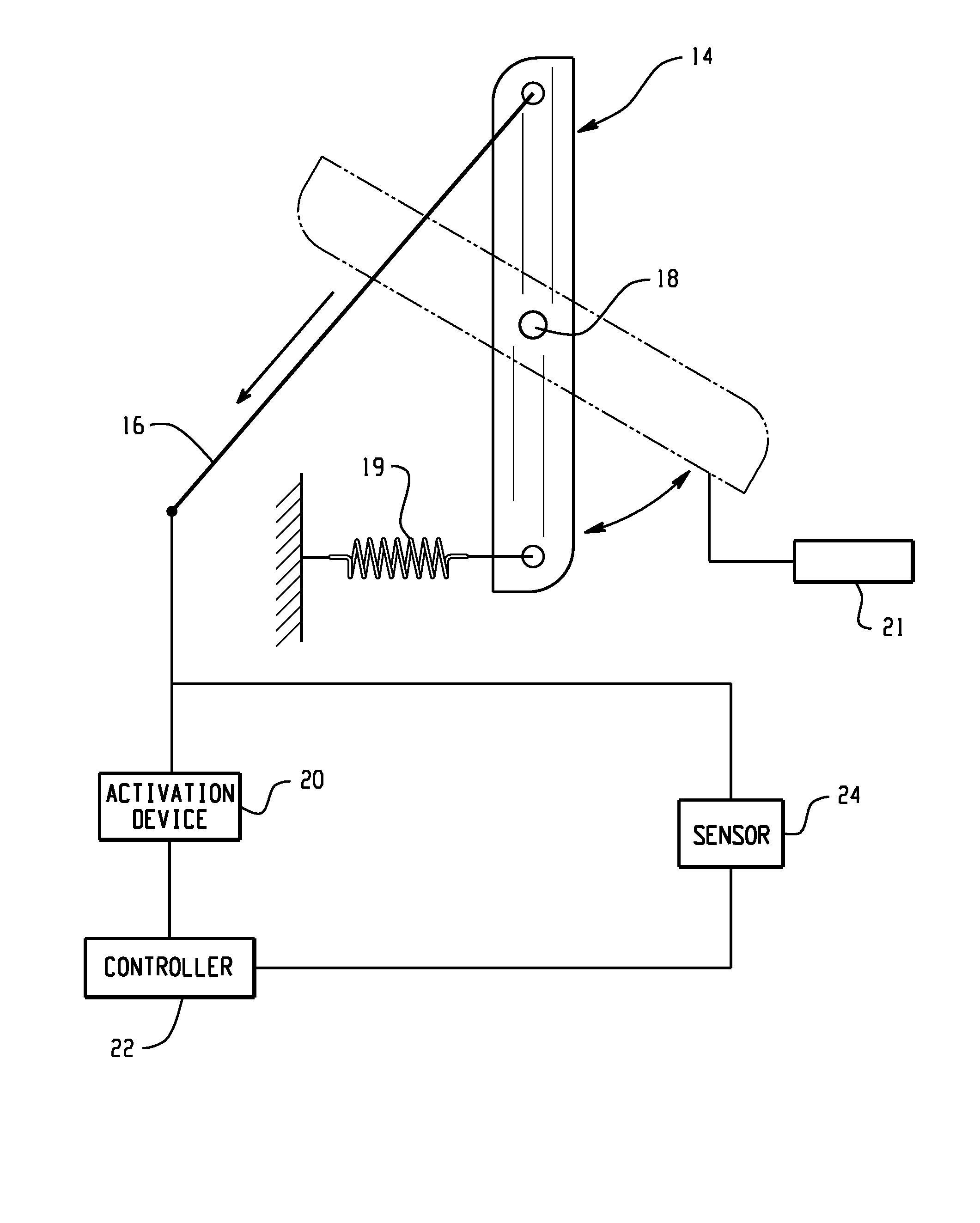

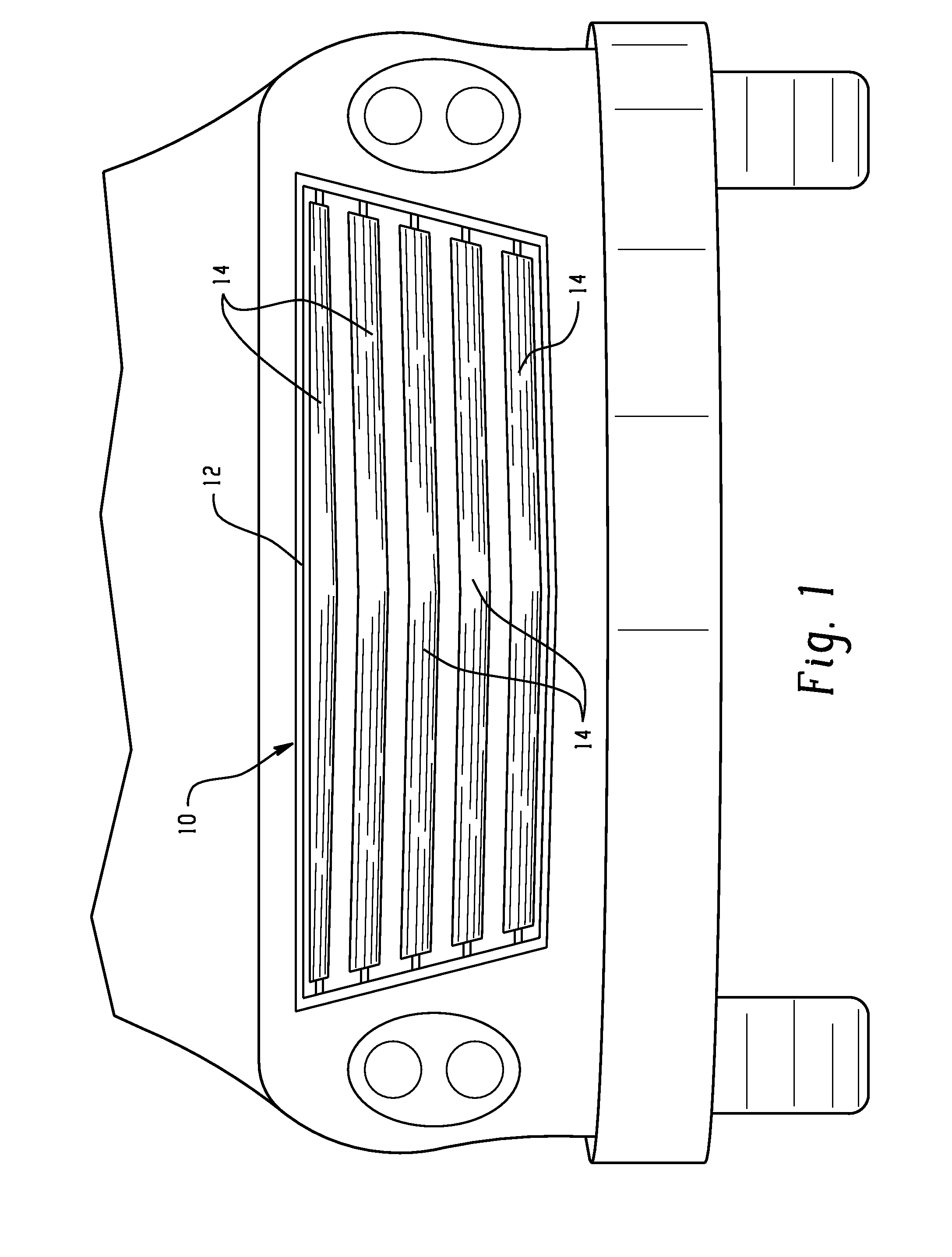

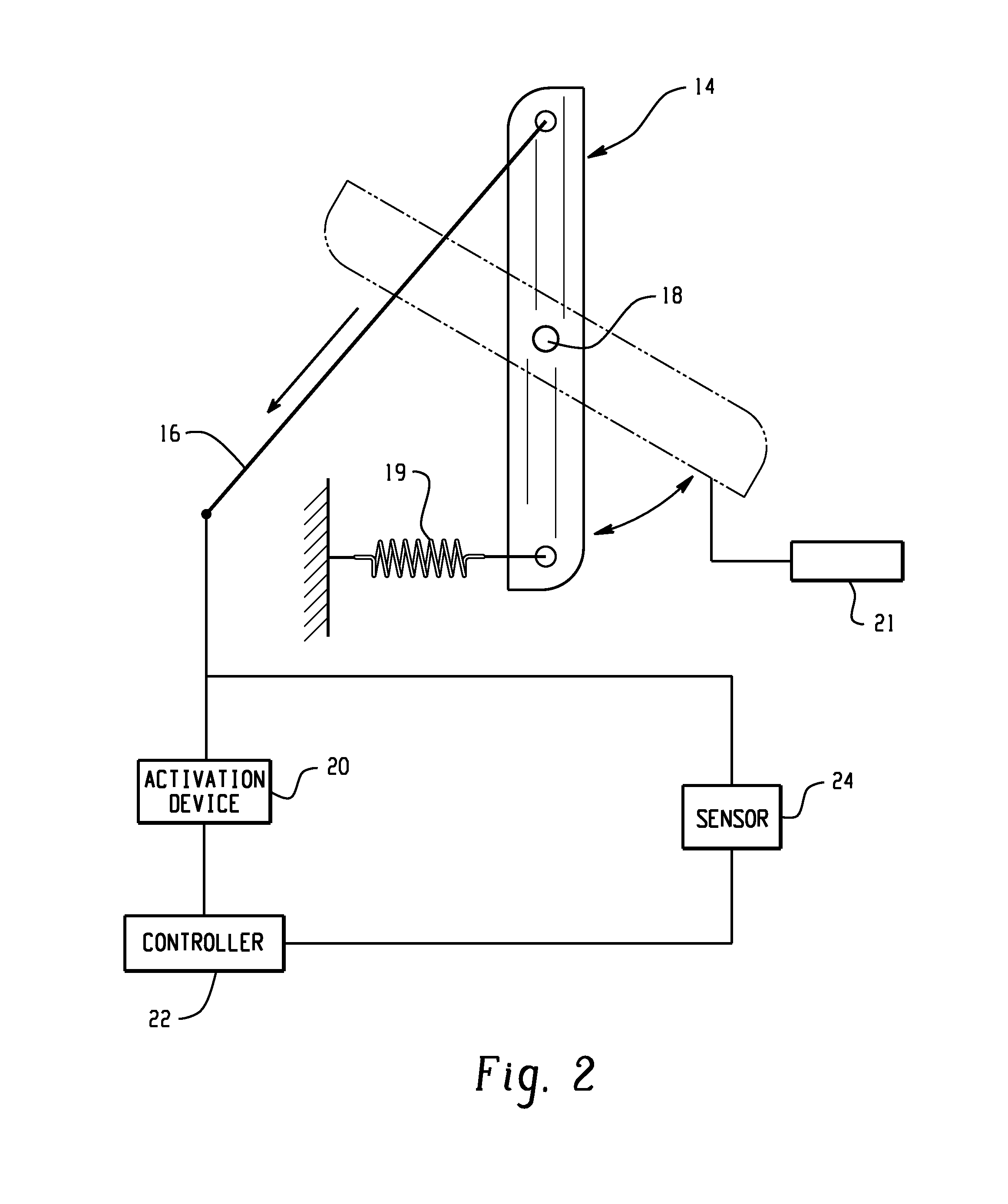

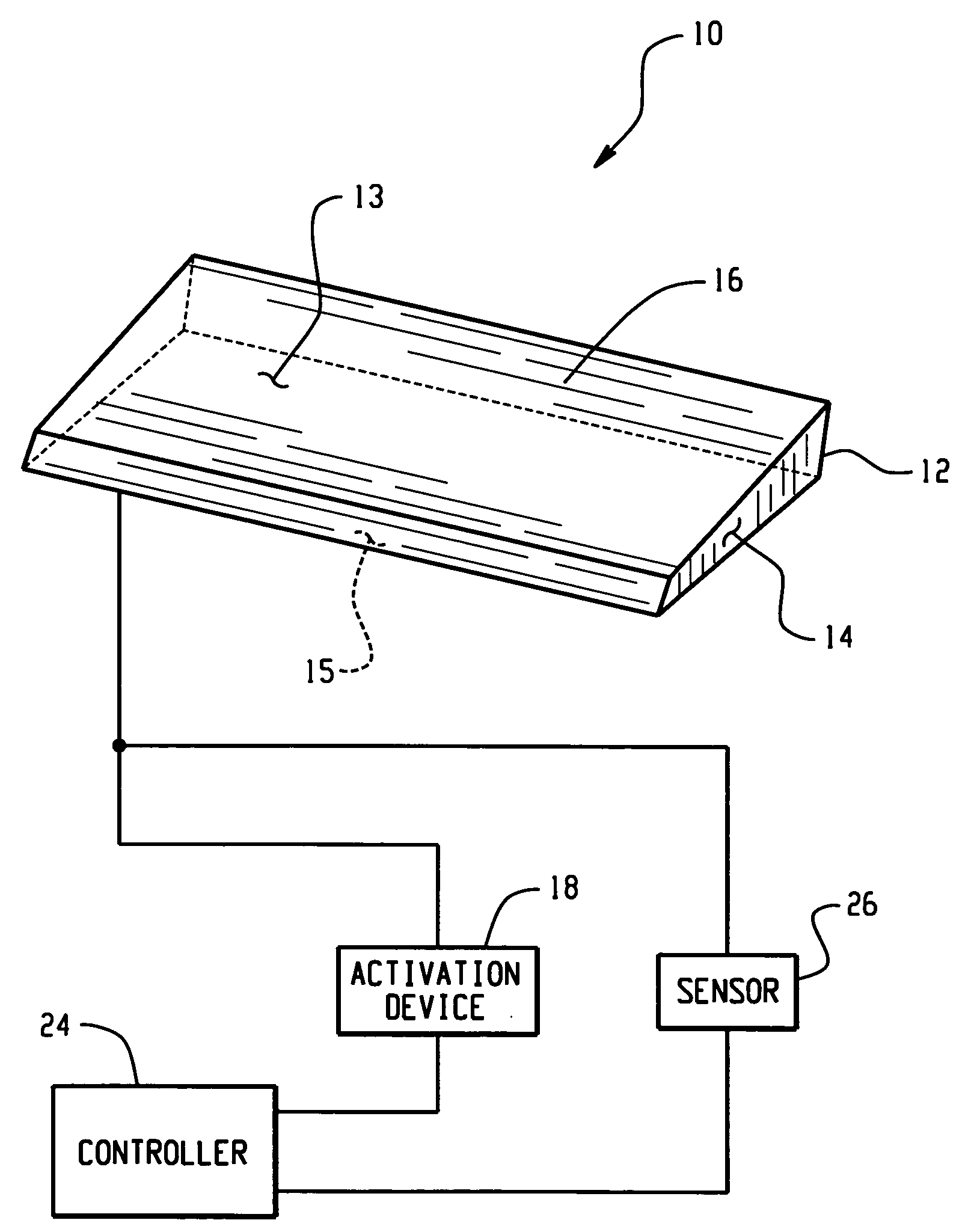

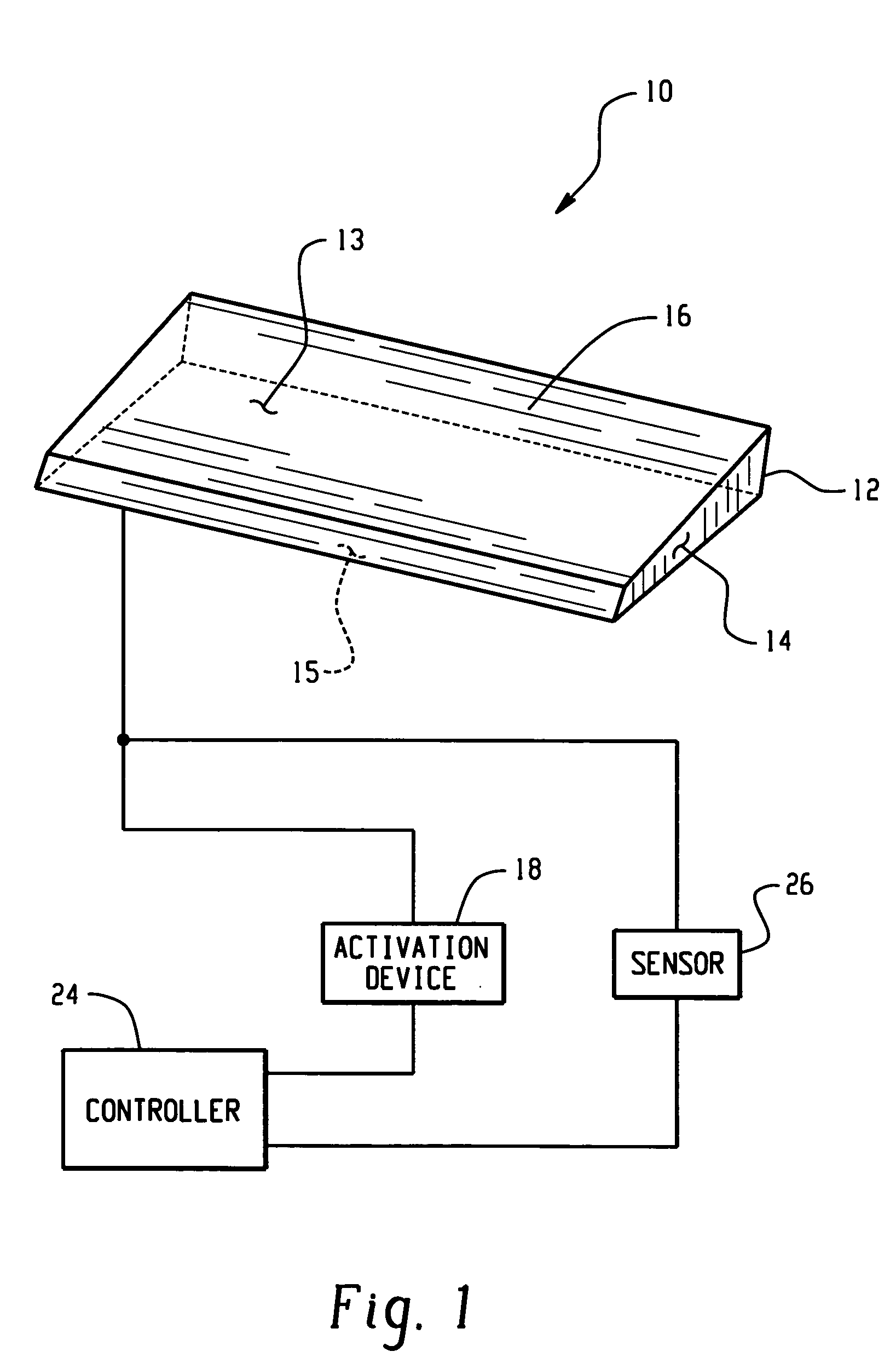

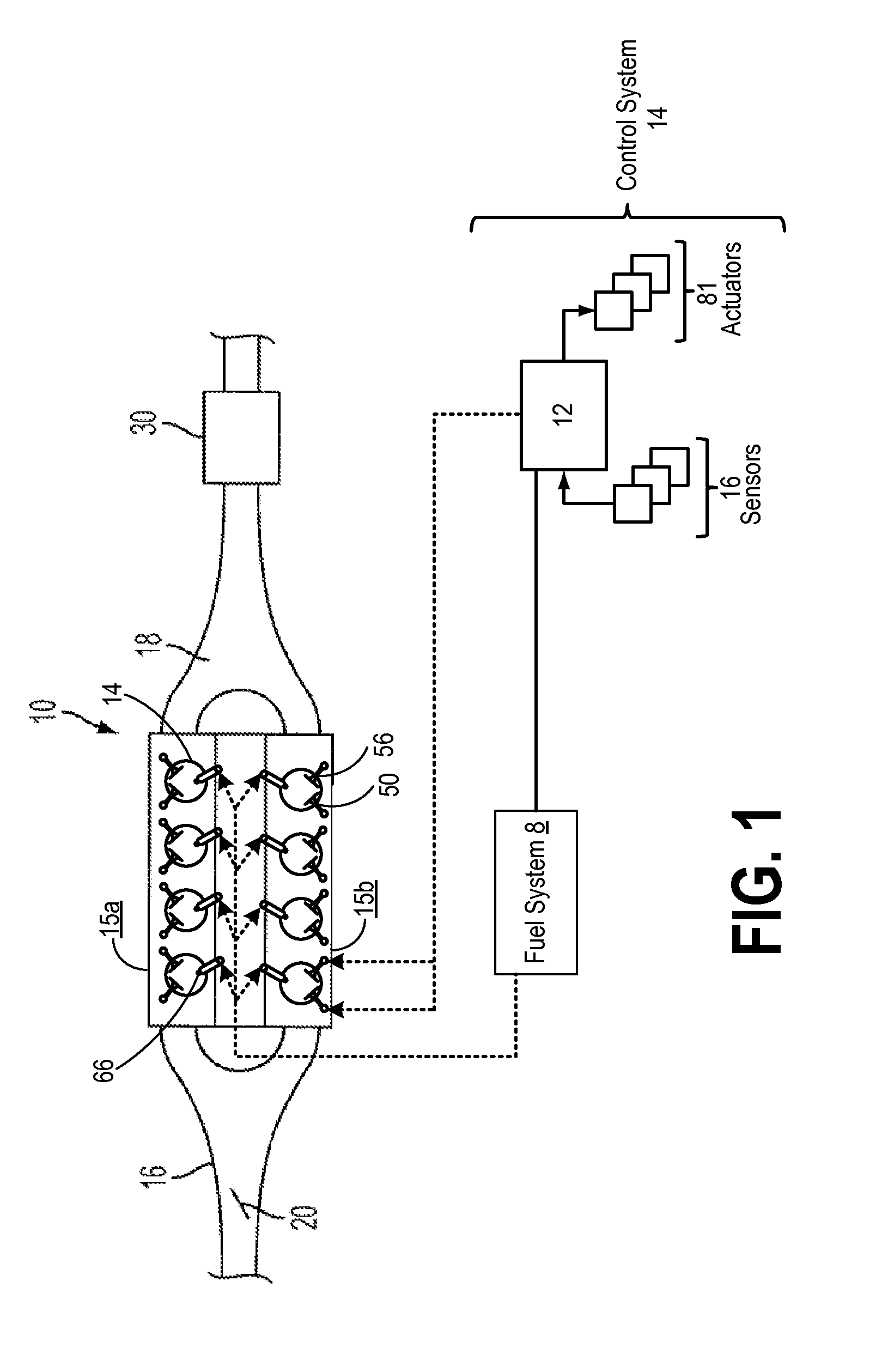

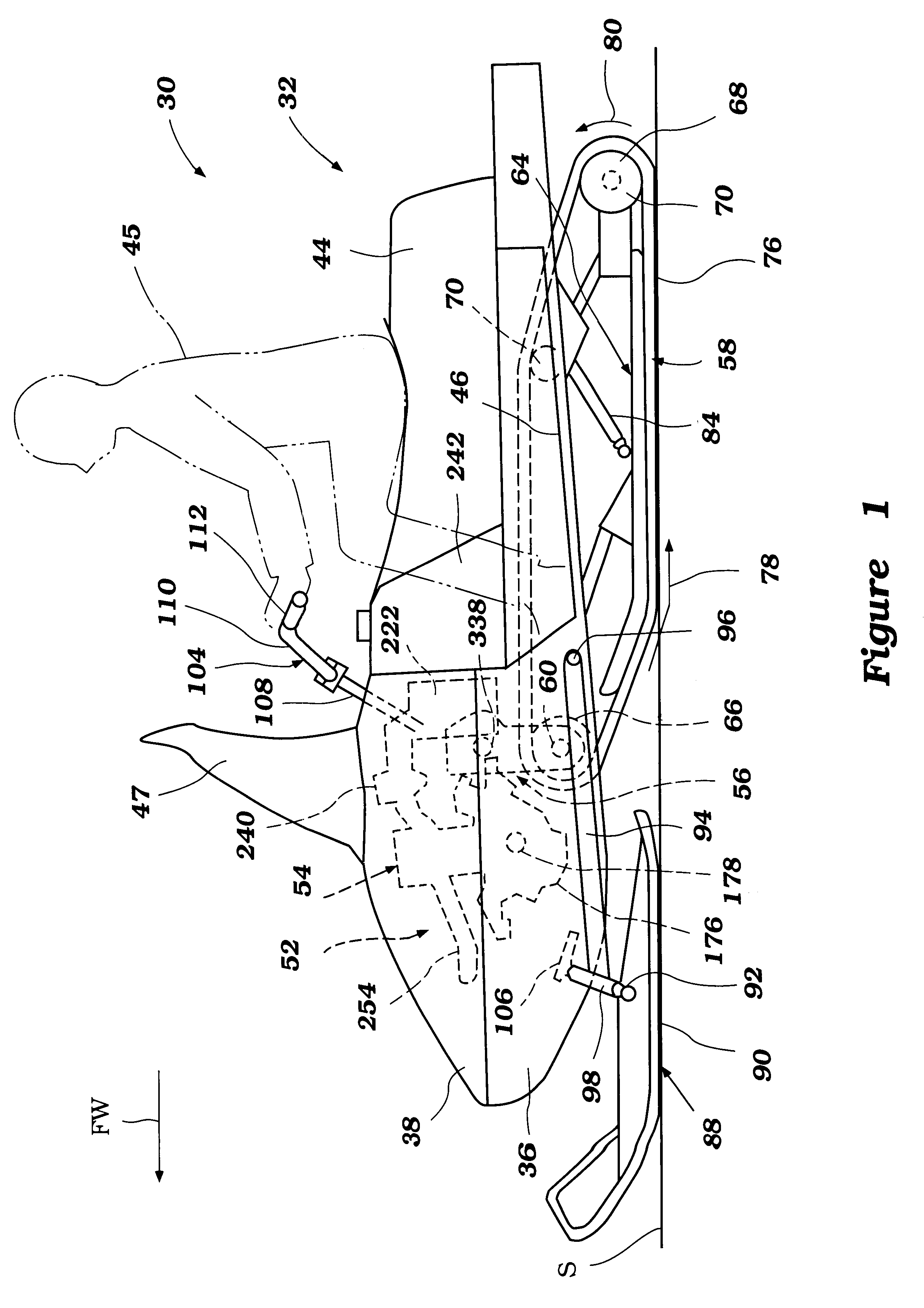

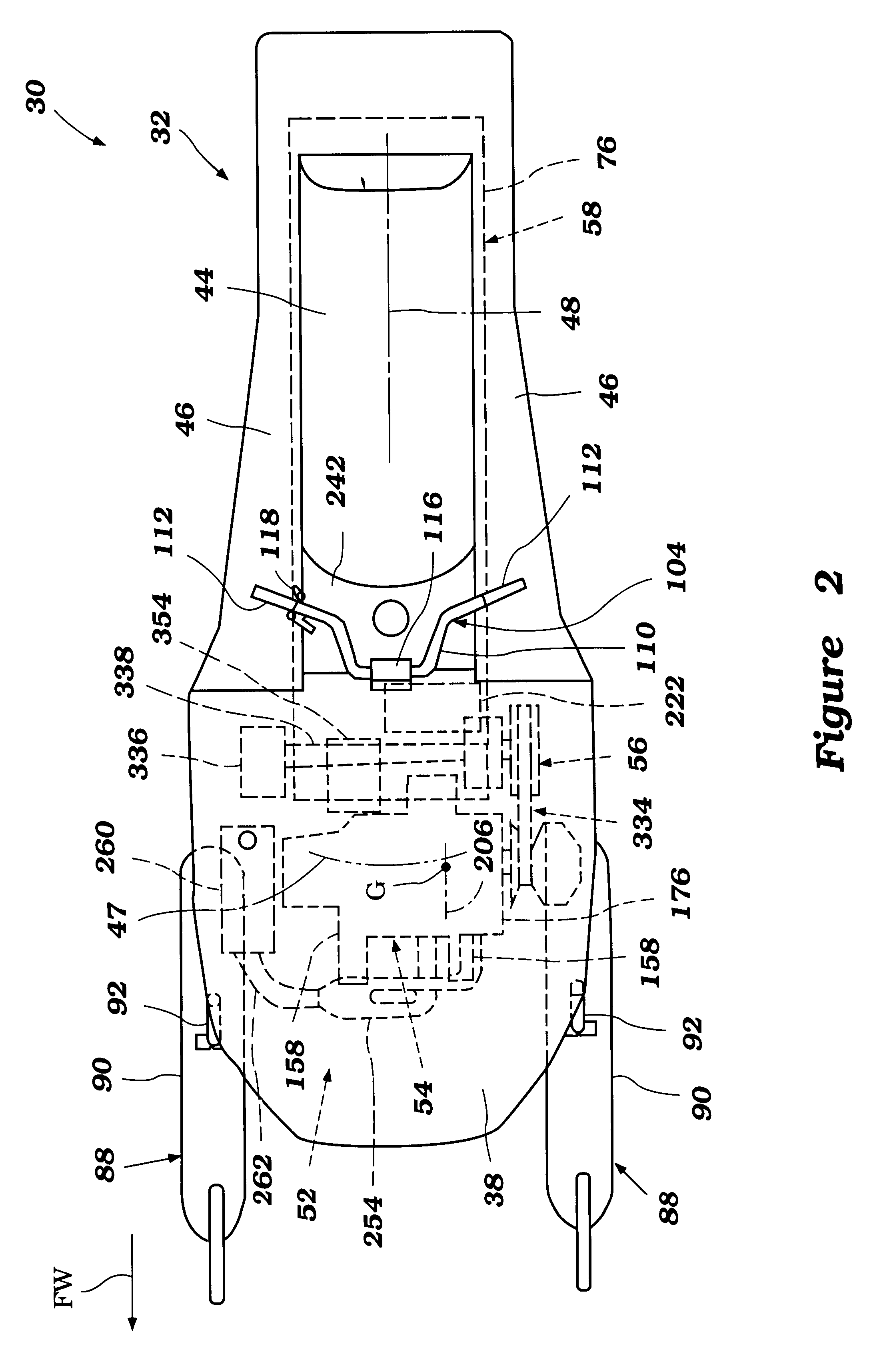

Reversibly opening and closing a grille using active materials

An active grille comprises a plurality of blades and an active material in operative communication with the blades. The active material is in operative communication with the blades and is operative to change at least one attribute in response to an activation signal, wherein fluid flow through the grille changes with the change in the at least one attribute of the active material. By way of example, in vehicle applications, the blades of a grille disposed in front of an engine compartment can be selectively positioned to provide increased airflow through the radiator due to increases in engine coolant temperature. As such, the active grille can be configured to improve vehicle fuel economy while maintaining proper engine cooling. An activation device, controller and sensors may be employed to further control the change in at least one feature of the active grille.

Owner:GM GLOBAL TECH OPERATIONS LLC

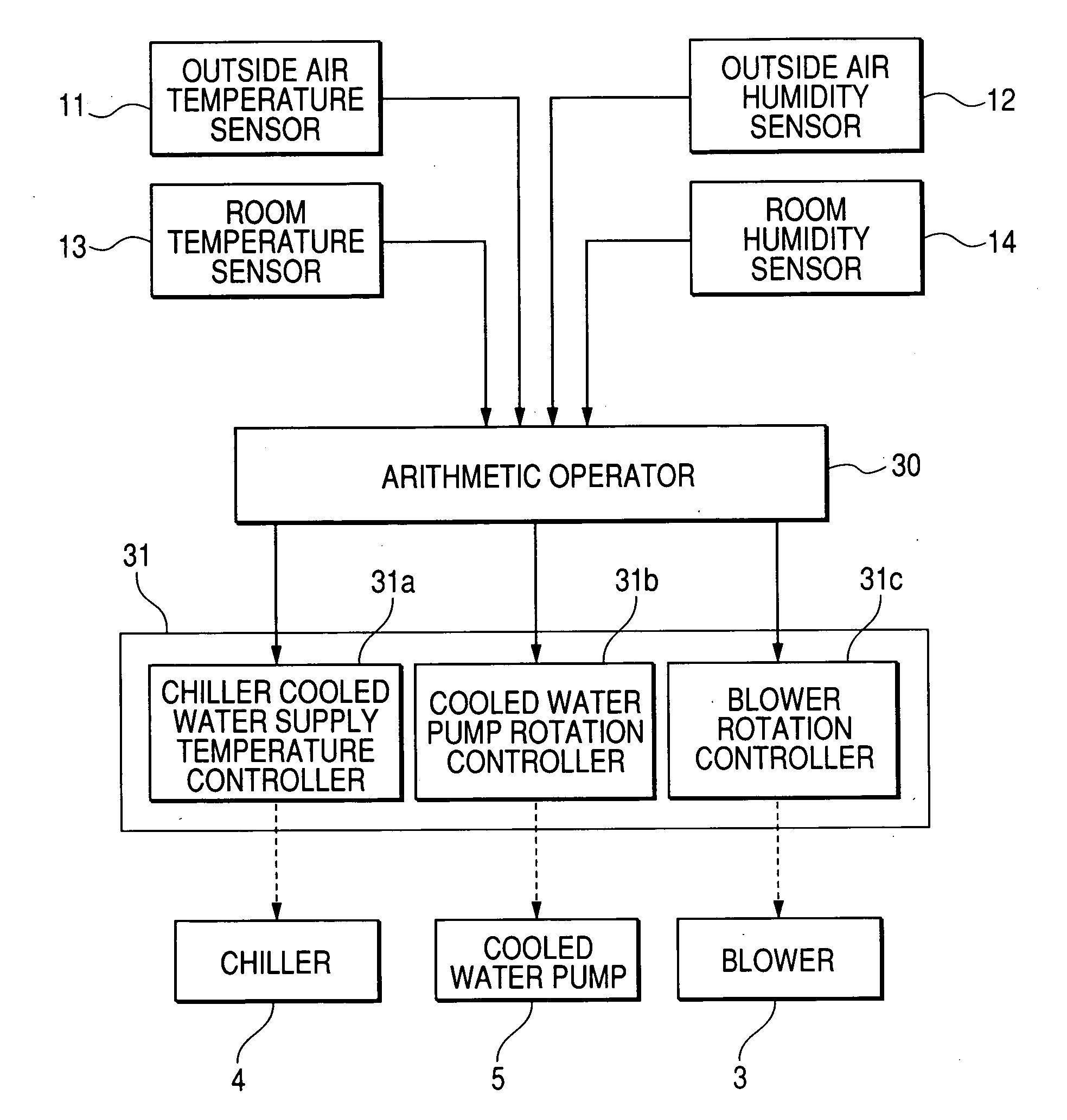

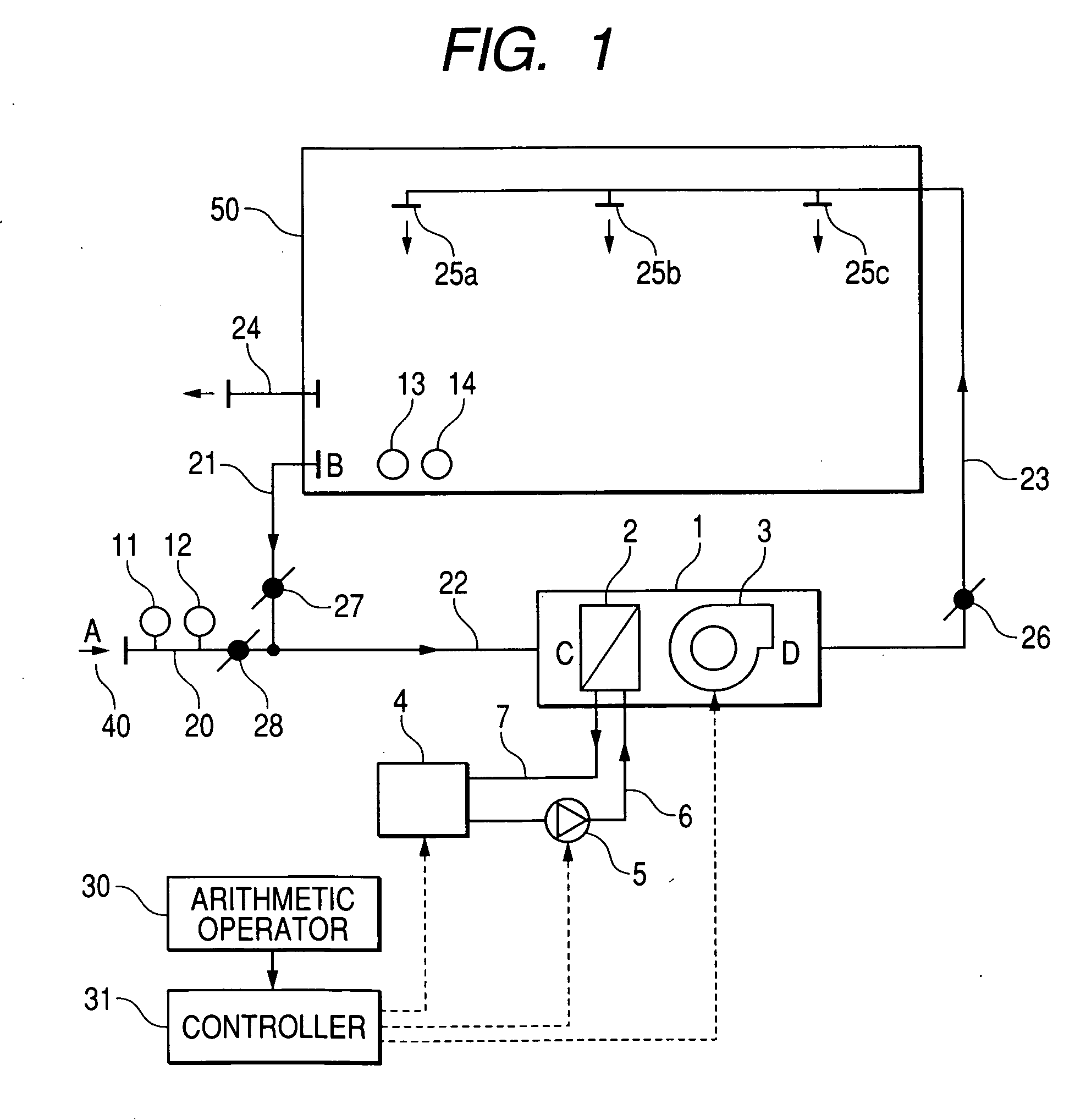

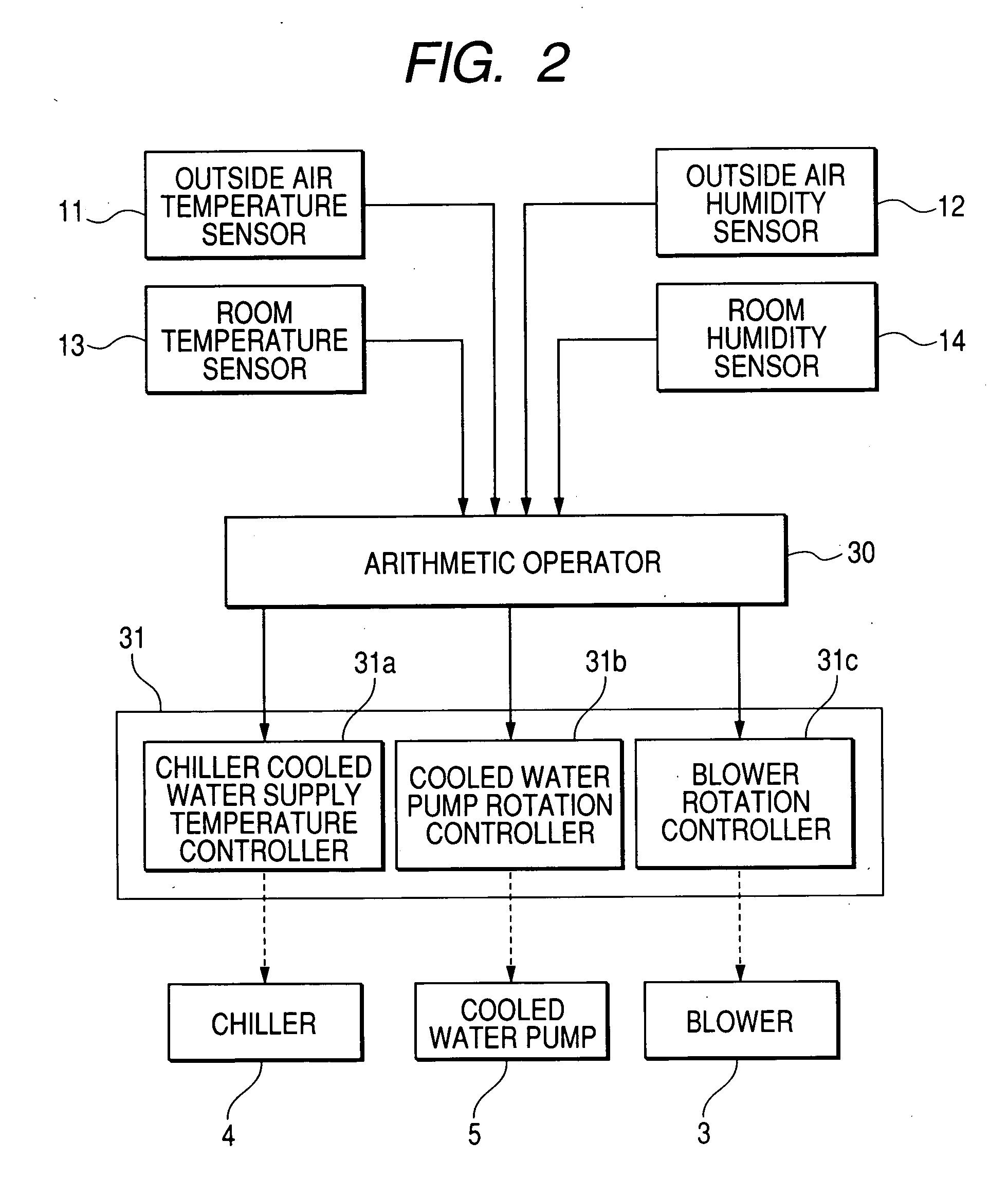

Air conditioning apparatus

InactiveUS20070107450A1Increase in chiller load can be preventedQuantity minimizationMechanical apparatusSpace heating and ventilation safety systemsAir volumeCoolant flow

An air conditioning apparatus comprises an air-conditioning unit including at least a cooling coil as a heat exchanger, a blower, a chiller, and a coolant pump for conducting air-conditioning, wherein the coolant pump pumps the coolant cooled by the chiller to the cooling coil, the cooling coil cools the air through heat exchange of the coolant and the air, the blower supplies the cooled air into a room. Coolant temperature of the chiller, the coolant flow rate of the coolant pump, and the air flow rate of the blower are calculated in accordance with the set points of the indoor temperature and the indoor humidity, and the chiller, coolant pump, and blower are controlled on the basis of the arithmetic calculation results. Thereby, the indoor temperature and indoor humidity are independently controlled in the central air-conditioning system.

Owner:HITACHI LTD

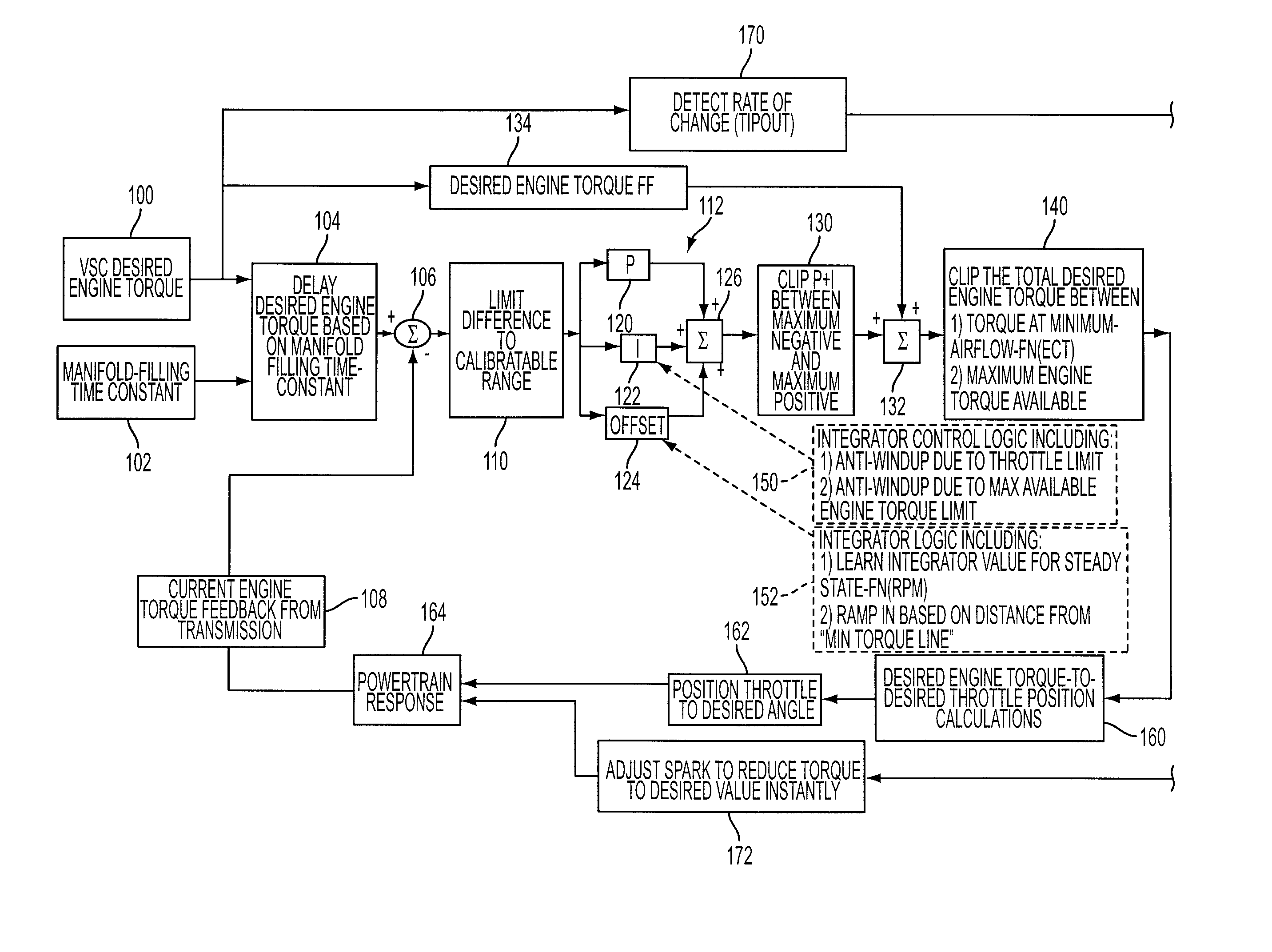

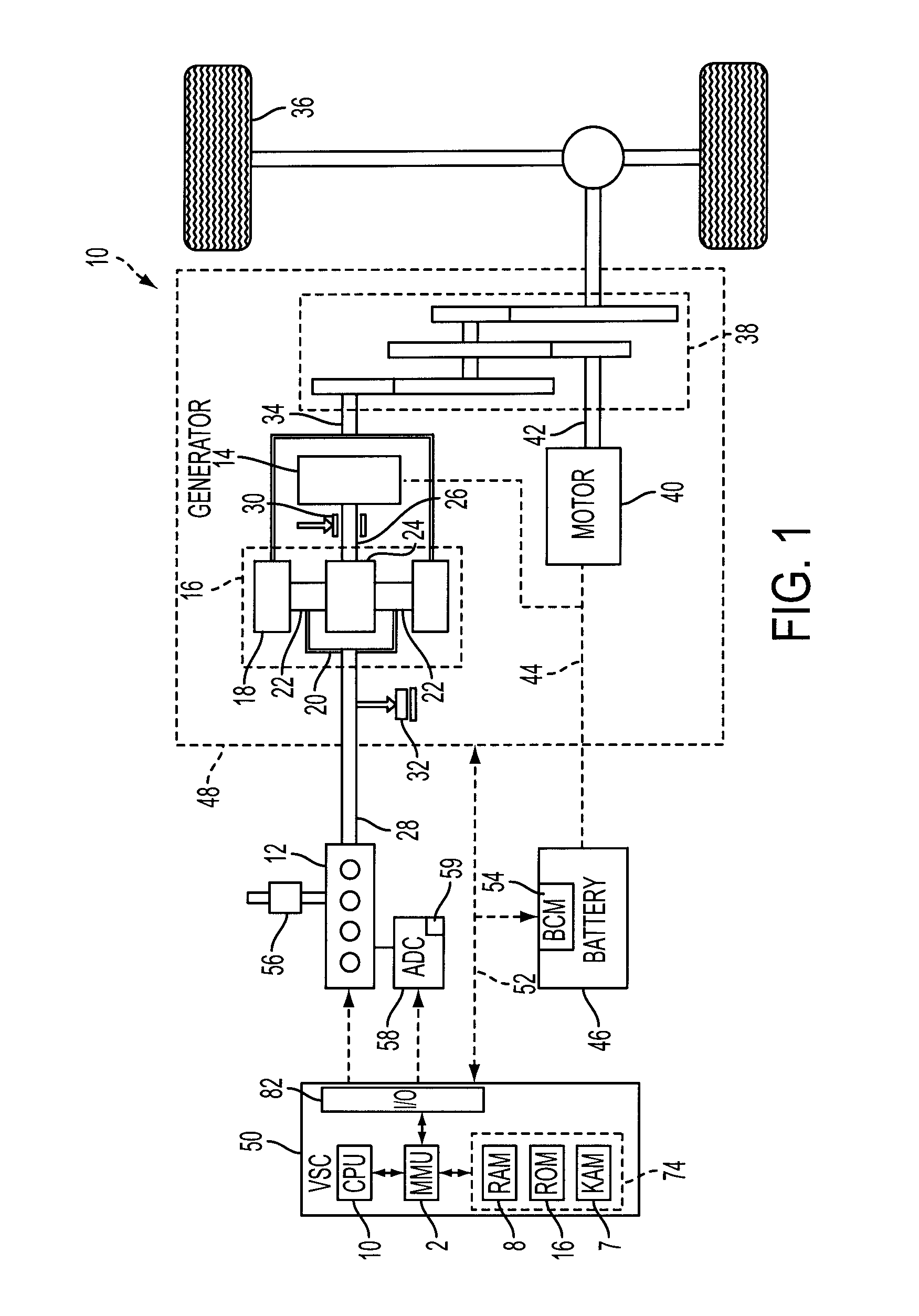

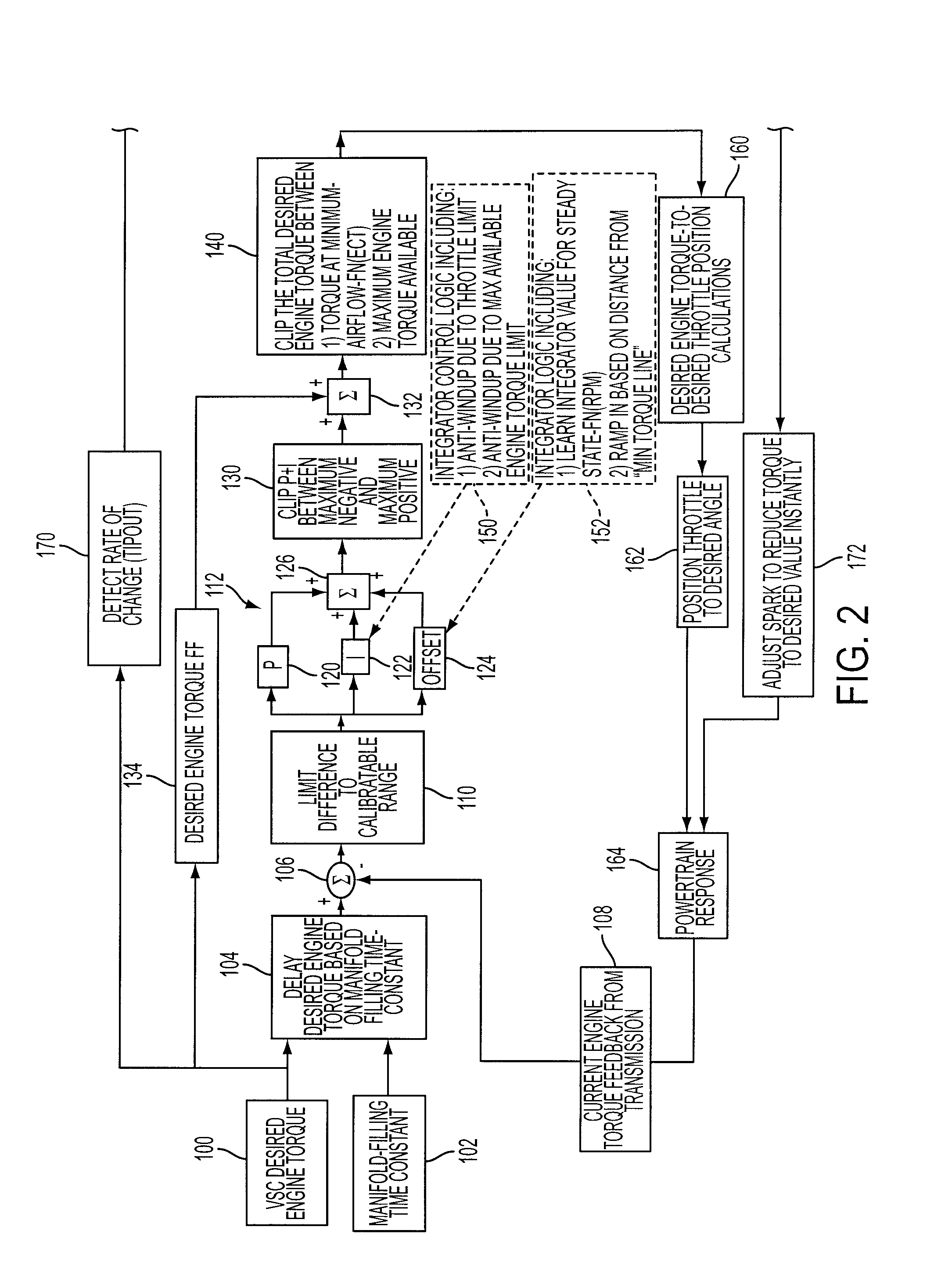

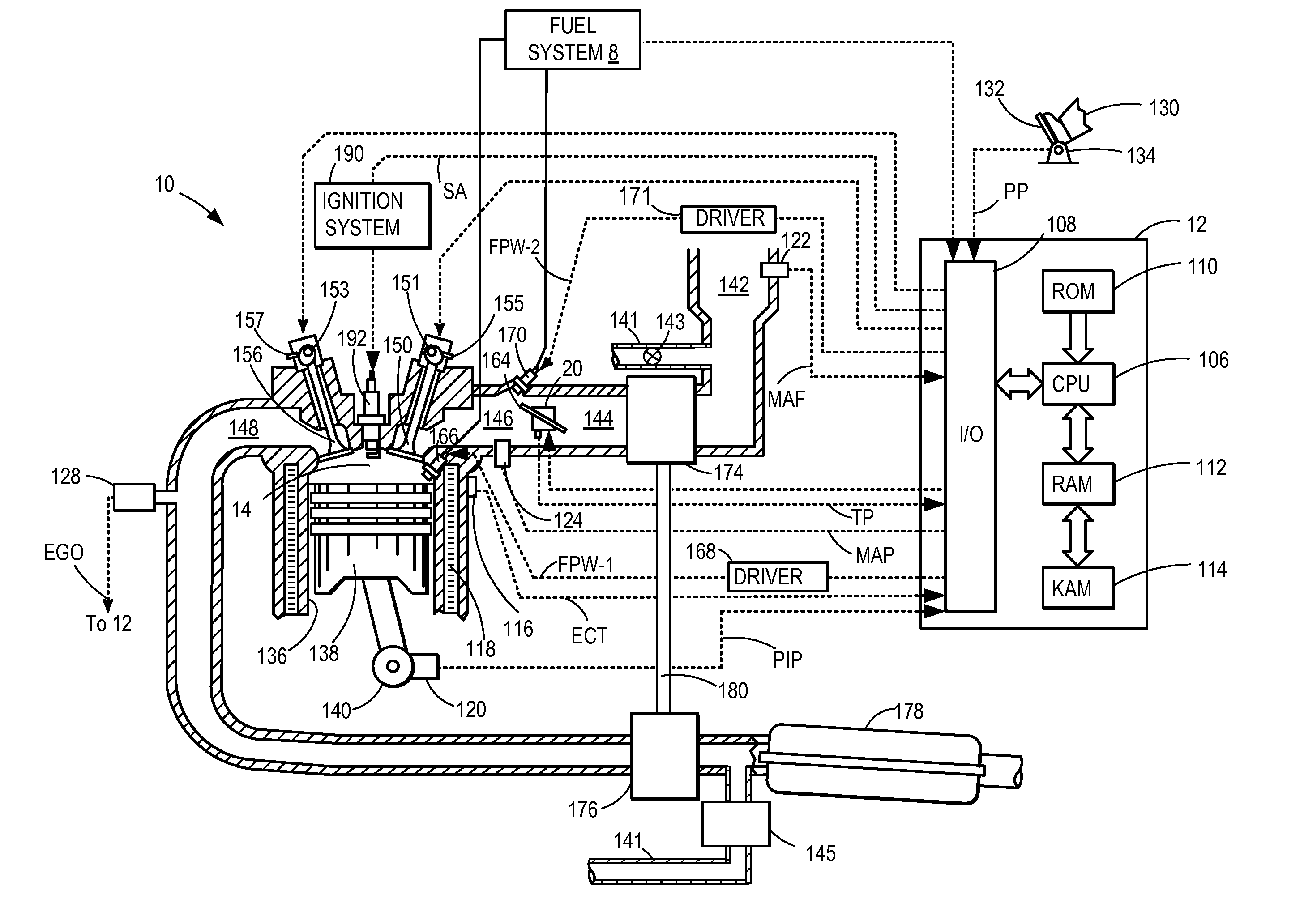

Torque-based powertrain control for vehicles

ActiveUS7275518B1Prevent over-chargingImproved torque controlElectrical controlInternal combustion piston enginesEngineeringPowertrain control

A system and method for controlling a vehicle powertrain having an internal combustion engine include determining a difference between a desired engine torque and a current engine torque, adjusting the difference based on a stored torque offset corresponding to a current engine speed, and controlling the engine to produce a torque corresponding to the adjusted torque difference. The stored torque offset is adjusted when the engine is operating in a predetermined engine speed range based on a steady-state difference between the desired and current engine torque to reduce the steady-state difference to zero. The adjusted torque difference may be limited by a maximum-engine-torque-available parameter and a minimum-engine-torque-available parameter, which is based on an operating temperature, such as the engine coolant temperature. The system and method may also include controlling spark to rapidly reduce current engine torque to the adjusted torque difference value.

Owner:FORD GLOBAL TECH LLC

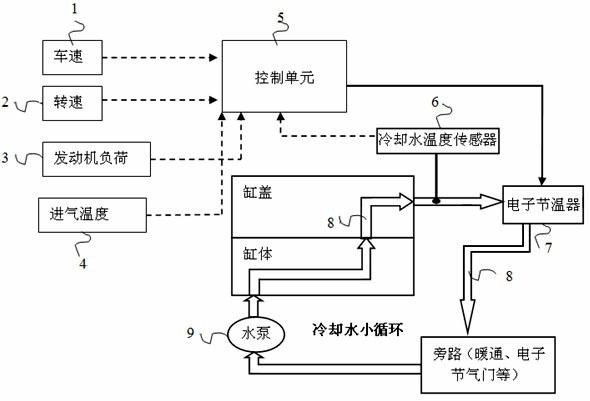

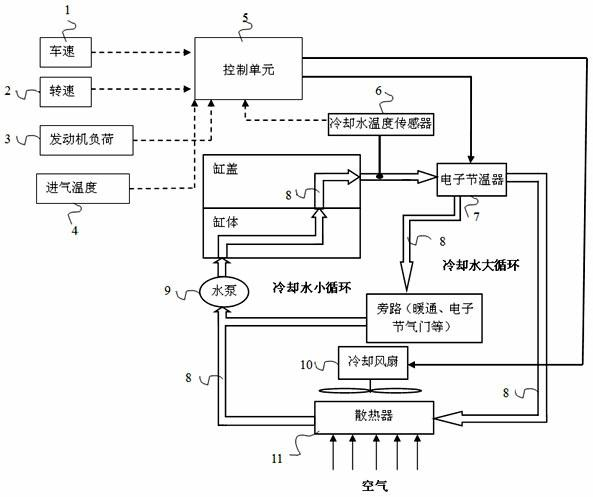

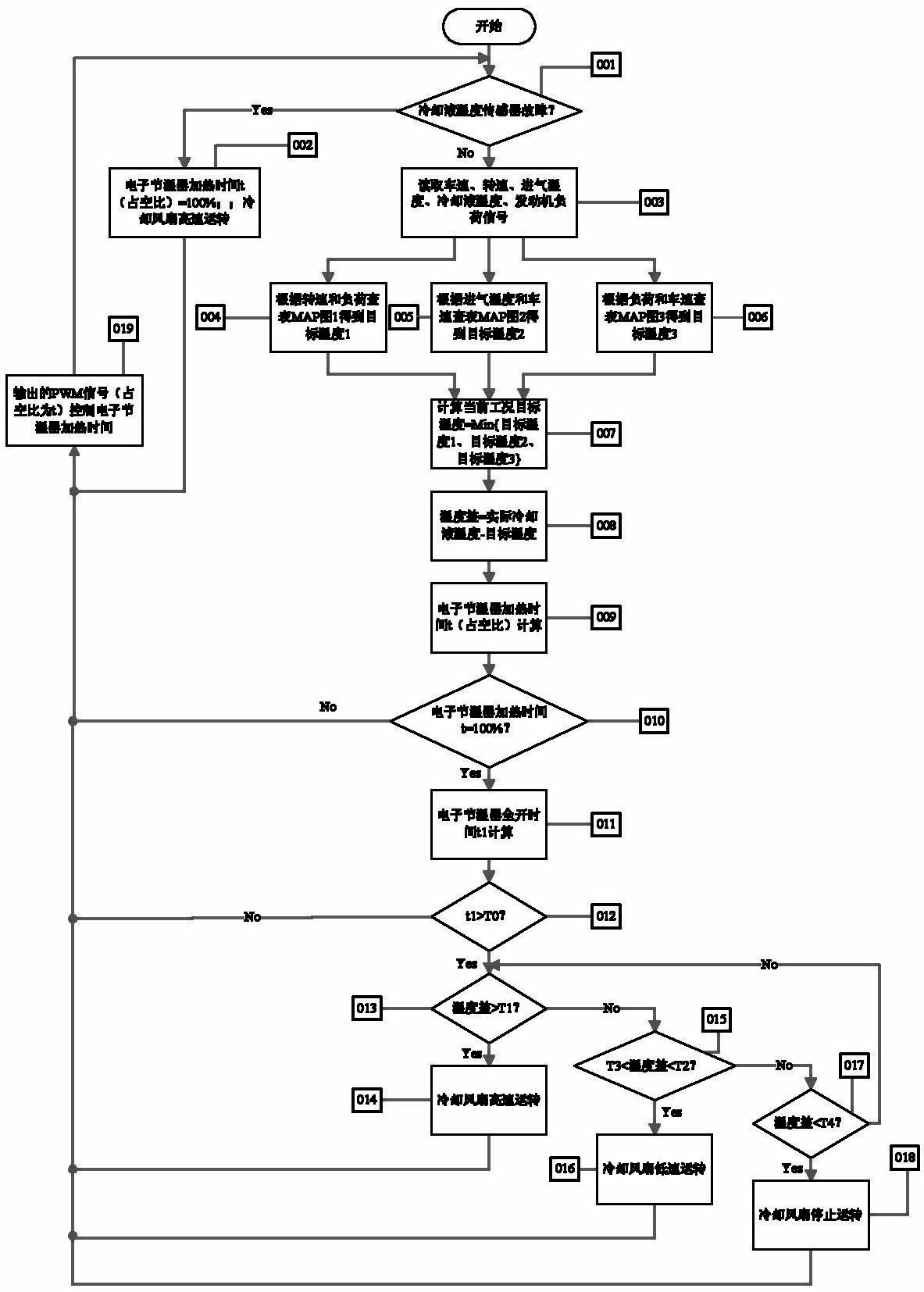

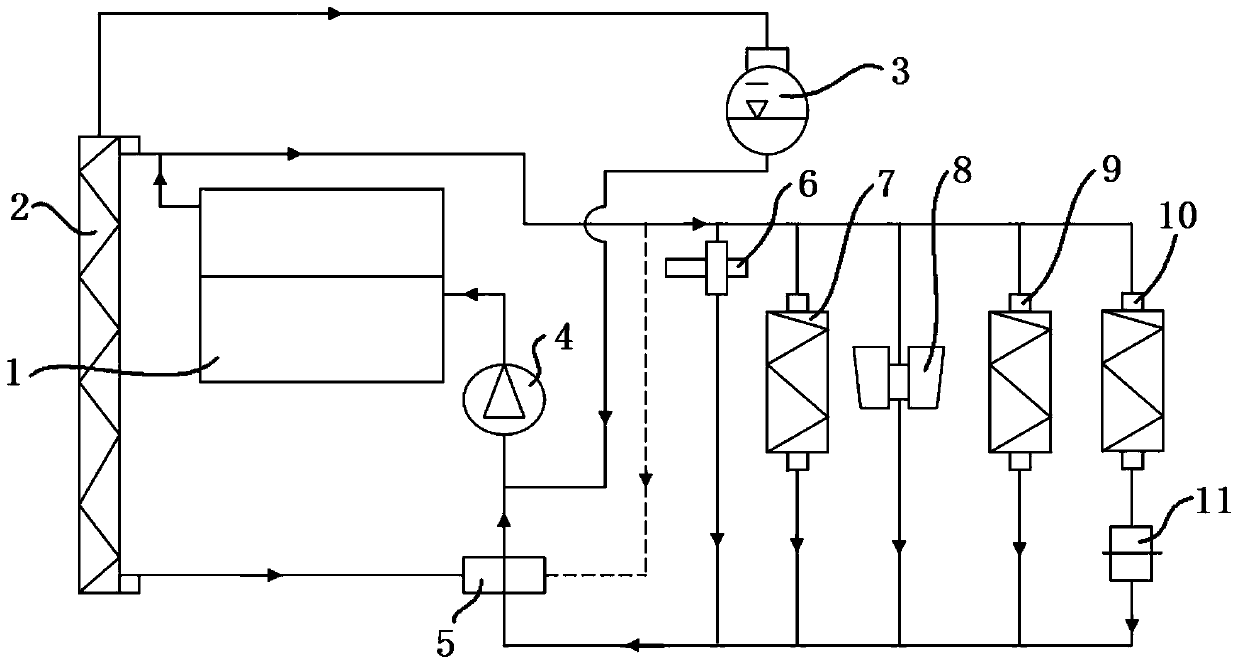

Engine cooling system and temperature control method of cooling liquid thereof

ActiveCN102182540AEmission reductionReduce turn-on timeCoolant flow controlMachines/enginesLow speedLiquid temperature

The invention discloses an engine cooling system and a temperature control method of cooling liquid thereof. The engine cooling system comprises a heat radiator, a water pump, a circulating water jacket, an electronic thermostat, a cooling fan, a cooling liquid temperature sensor and an engine control unit, wherein the control unit determines the cooling liquid target temperature of an engine under the current operation working condition according to acquired signals, such as engine rotating speed, load, speed, air inlet temperature, and the like and ensures that the engine works under the optimal cooling liquid temperature condition by controlling the heating time of the electronic thermostat and the high and low speed running of the cooling fan.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Reversibly opening and closing a grille using active materials

An active grille comprises a plurality of blades and an active material in operative communication with the blades. The active material is in operative communication with the blades and is operative to change at least one attribute in response to an activation signal, wherein fluid flow through the grille changes with the change in the at least one attribute of the active material. By way of example, in vehicle applications, the blades of a grille disposed in front of an engine compartment can be selectively positioned to provide increased airflow through the radiator due to increases in engine coolant temperature. As such, the active grille can be configured to improve vehicle fuel economy while maintaining proper engine cooling. An activation device, controller and sensors may be employed to further control the change in at least one feature of the active grille.

Owner:GM GLOBAL TECH OPERATIONS LLC

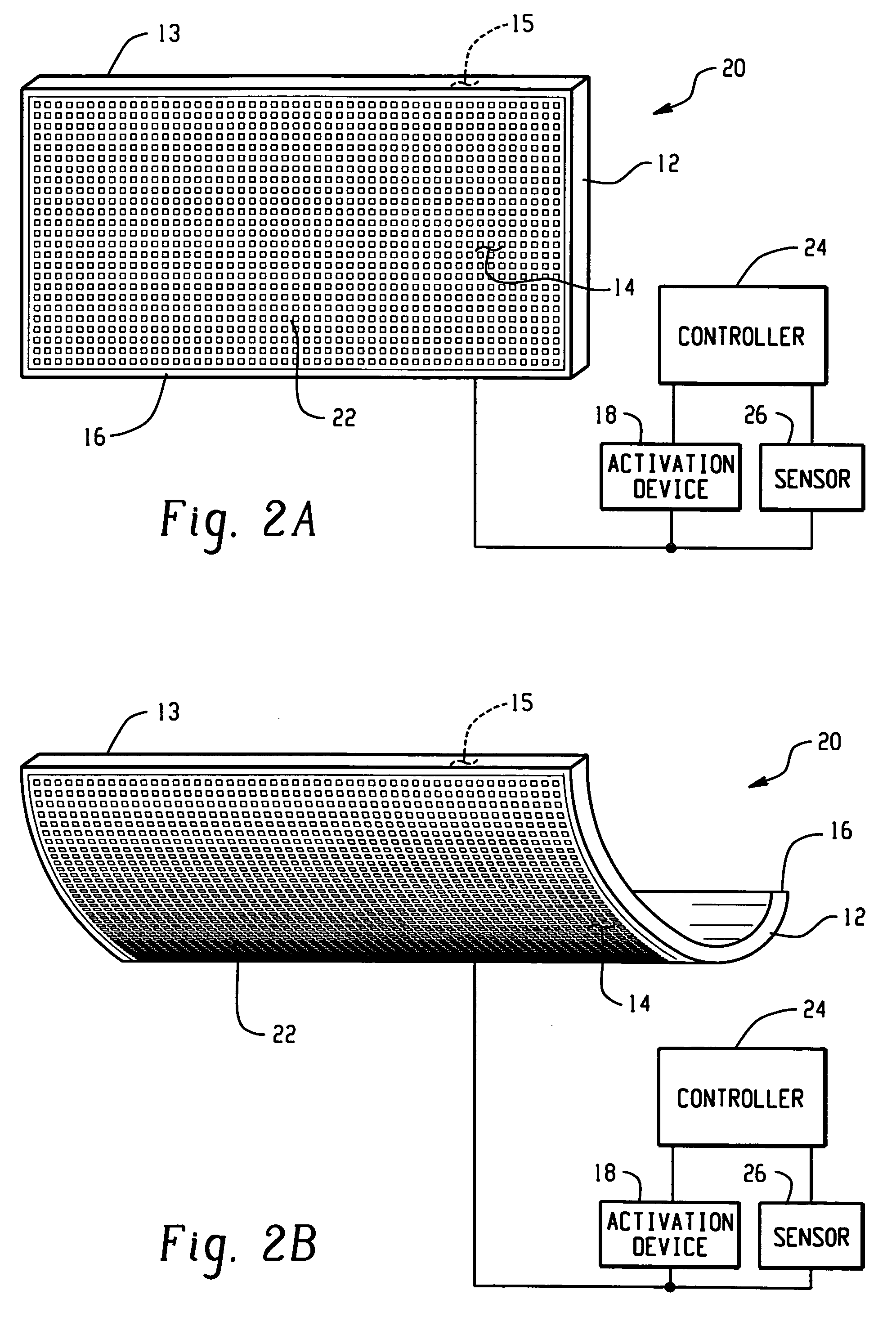

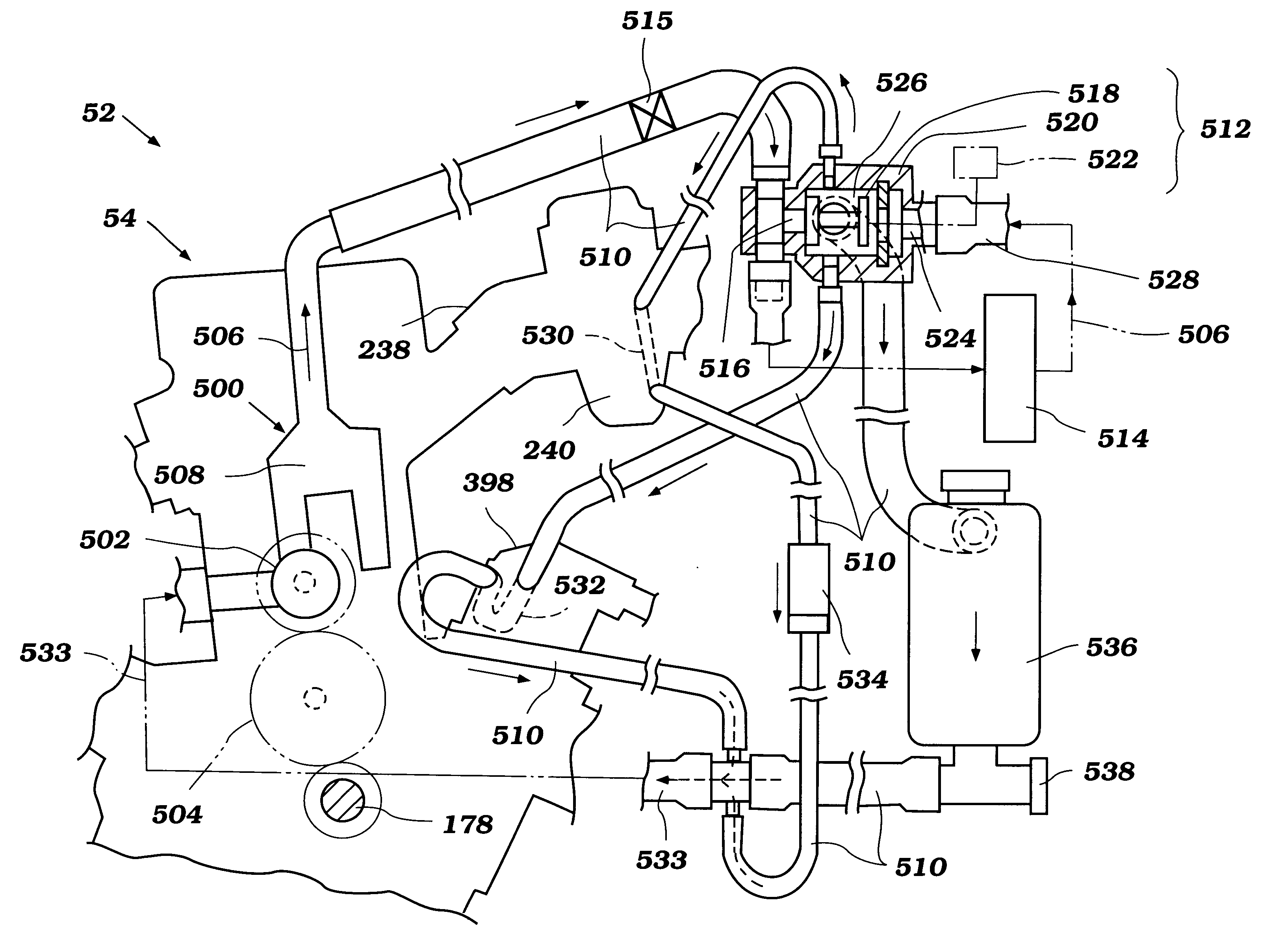

Airflow control devices based on active materials

ActiveUS20050121240A1Vehicle seatsVehicle body stabilisationBiological activationCoolant temperature

An airflow control device comprises a body and an active material in operative communication with the body. The active material, such as a shape memory material, is operative to change at least one attribute in response to an activation signal. The active material can change its shape, dimensions and / or stiffness producing a change in at least one feature of the airflow control device such as shape, dimension, location, orientation, and / or stiffness to control vehicle airflow to better suit changes in driving conditions such as the need for increased airflow through the radiator due to increases in engine coolant temperature. As such, the device improves vehicle fuel economy while maintaining proper engine cooling. An activation device, controller and sensors may be employed to further control the change in at least one feature of the airflow control device such as shape, dimension, location, orientation, and / or stiffness of the device. A method for controlling vehicle airflow selectively introduces an activation signal to initiate a change of at least one feature of the device that can be reversed upon discontinuation of the activation signal.

Owner:GM GLOBAL TECH OPERATIONS LLC

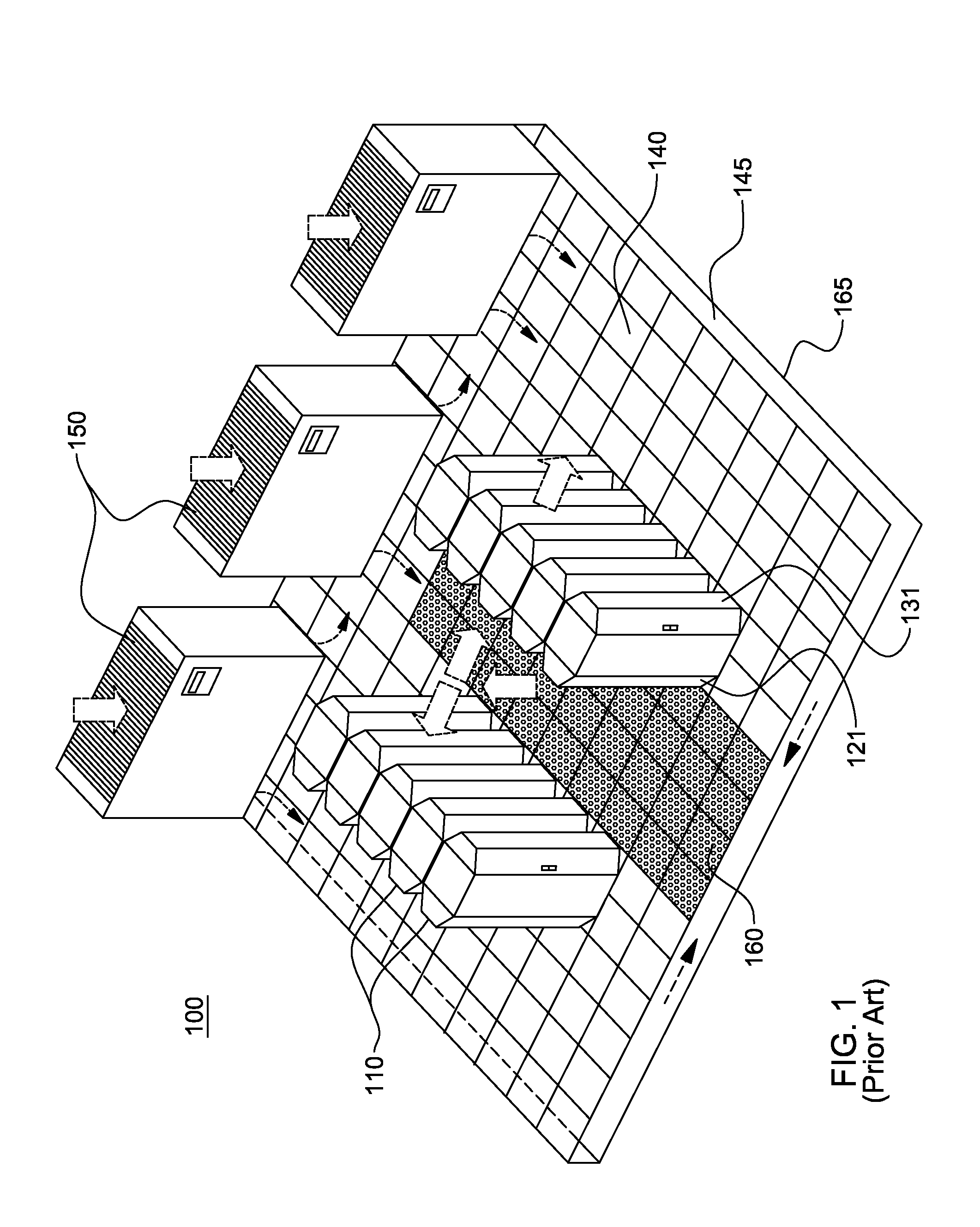

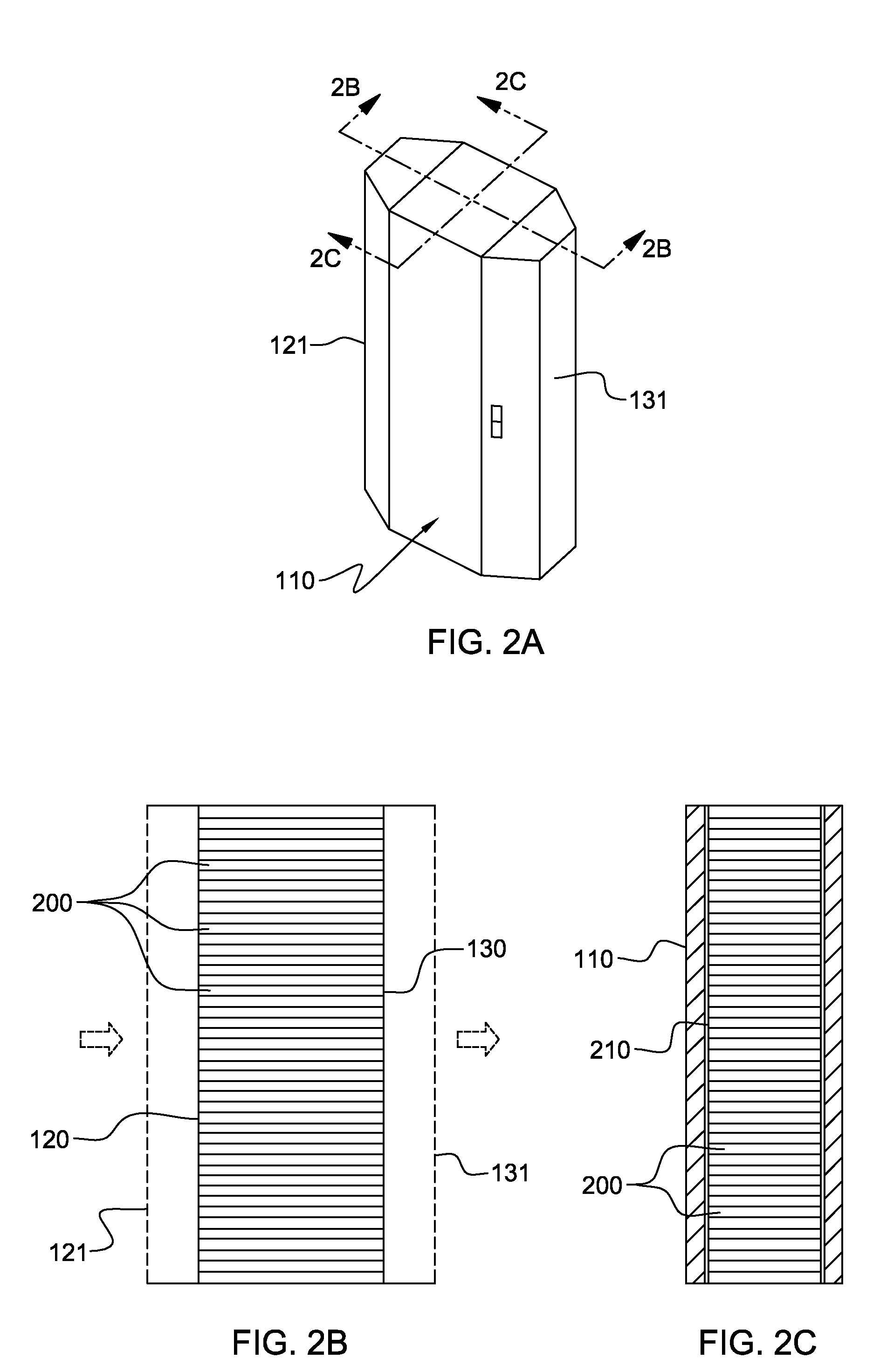

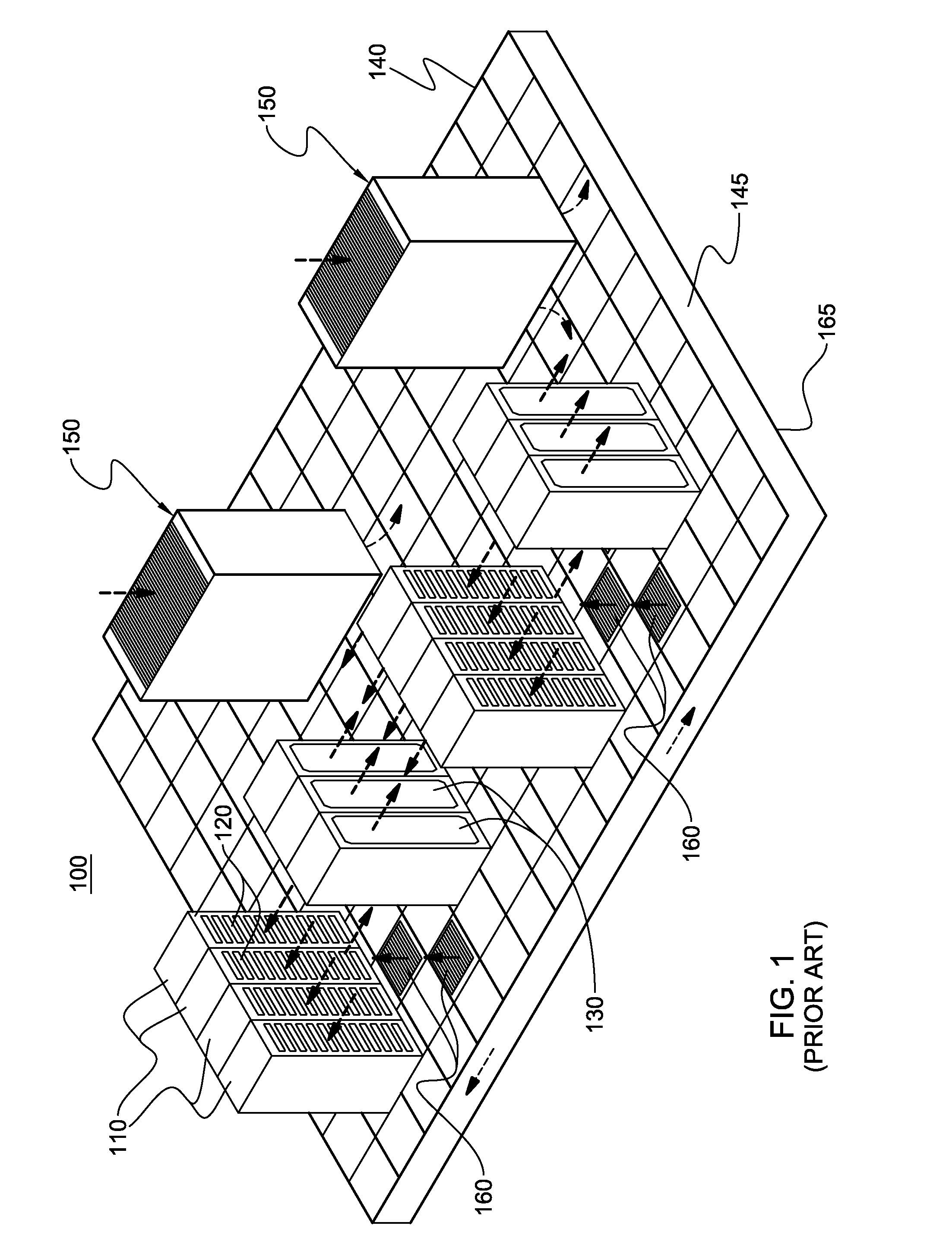

Monitoring method and system for determining rack airflow rate and rack power consumption

ActiveUS20090205416A1Volume/mass flow by thermal effectsVolume flow proportion measurementEngineeringCoolant temperature

Monitoring method and system are provided for dynamically determining rack airflow rate and rack power consumption employing a heat exchanger disposed at an air outlet side of the electronics rack. The method includes: sensing air temperature at the air outlet side of the electronics rack, sensing coolant temperature at a coolant inlet and coolant temperature at a coolant outlet of the heat exchanger, and determining airflow rate through the electronics rack; and outputting the determined airflow rate through the electronics rack. The determining employs the sensed air temperature at the air outlet side of the rack and the sensed coolant temperatures at the coolant inlet and outlet of the heat exchanger. In one embodiment, the heat exchanger is an air-to-air heat exchanger, and in another embodiment, the heat exchanger is an air-to-liquid heat exchanger.

Owner:LENOVO GLOBAL TECH INT LTD

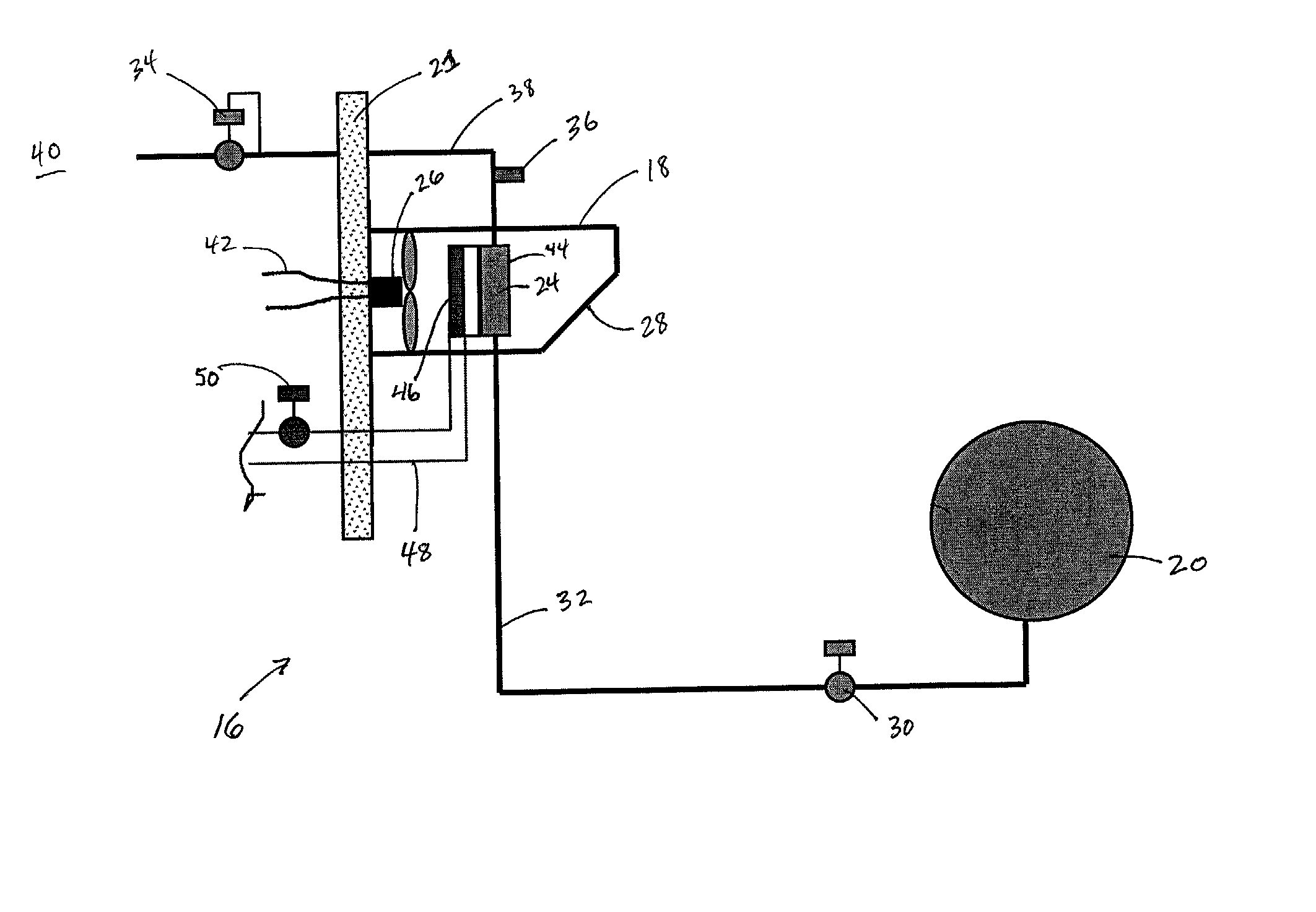

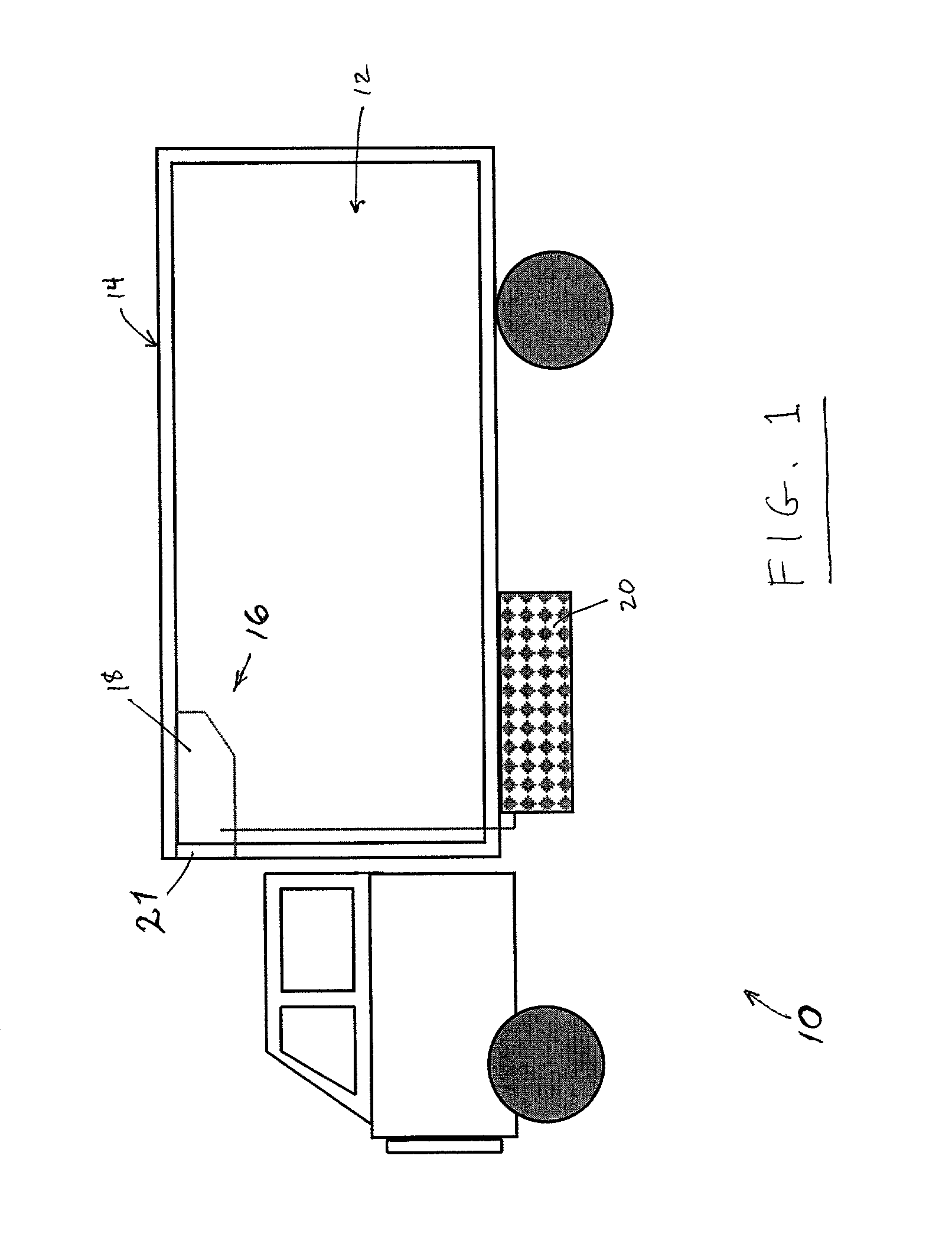

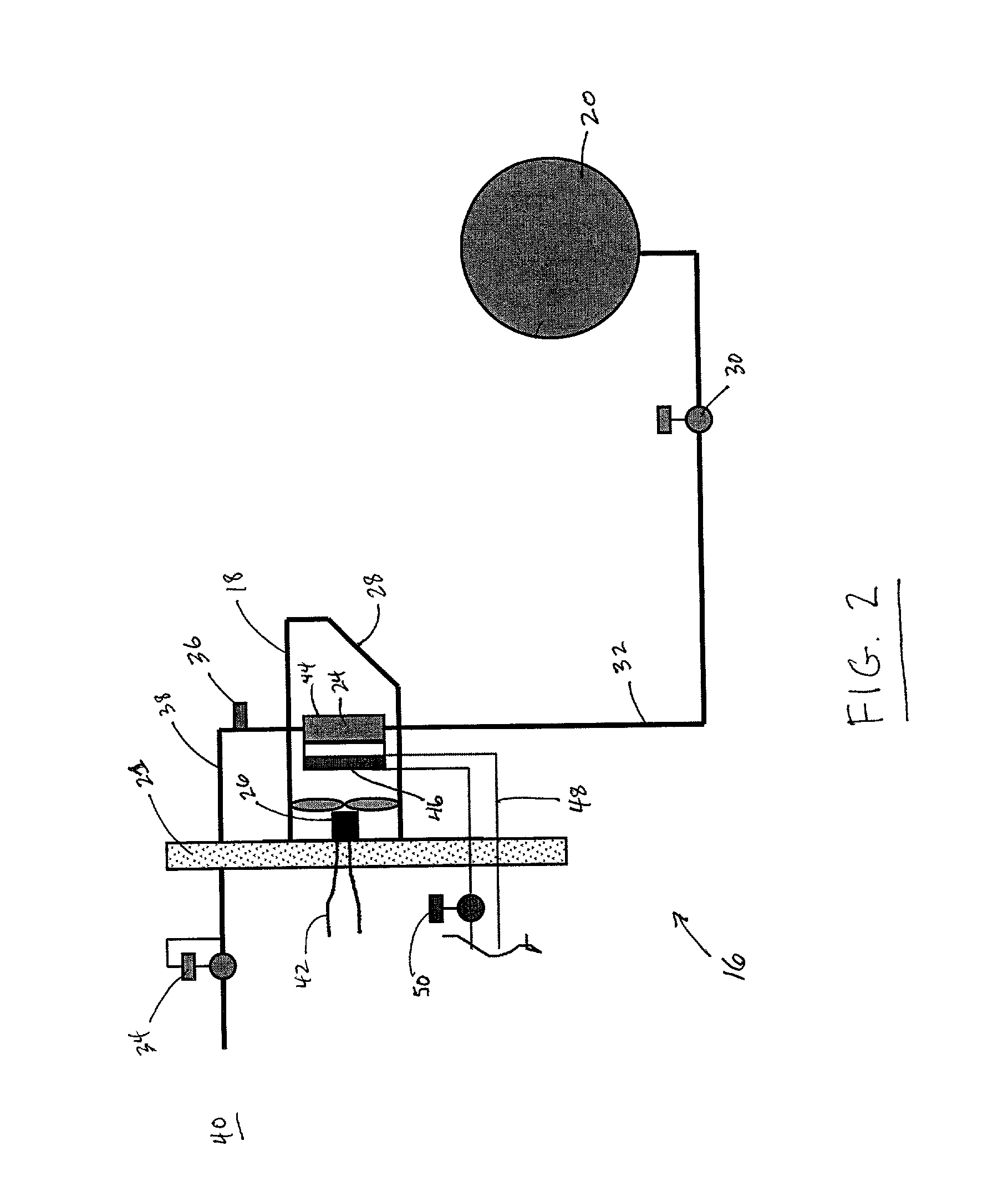

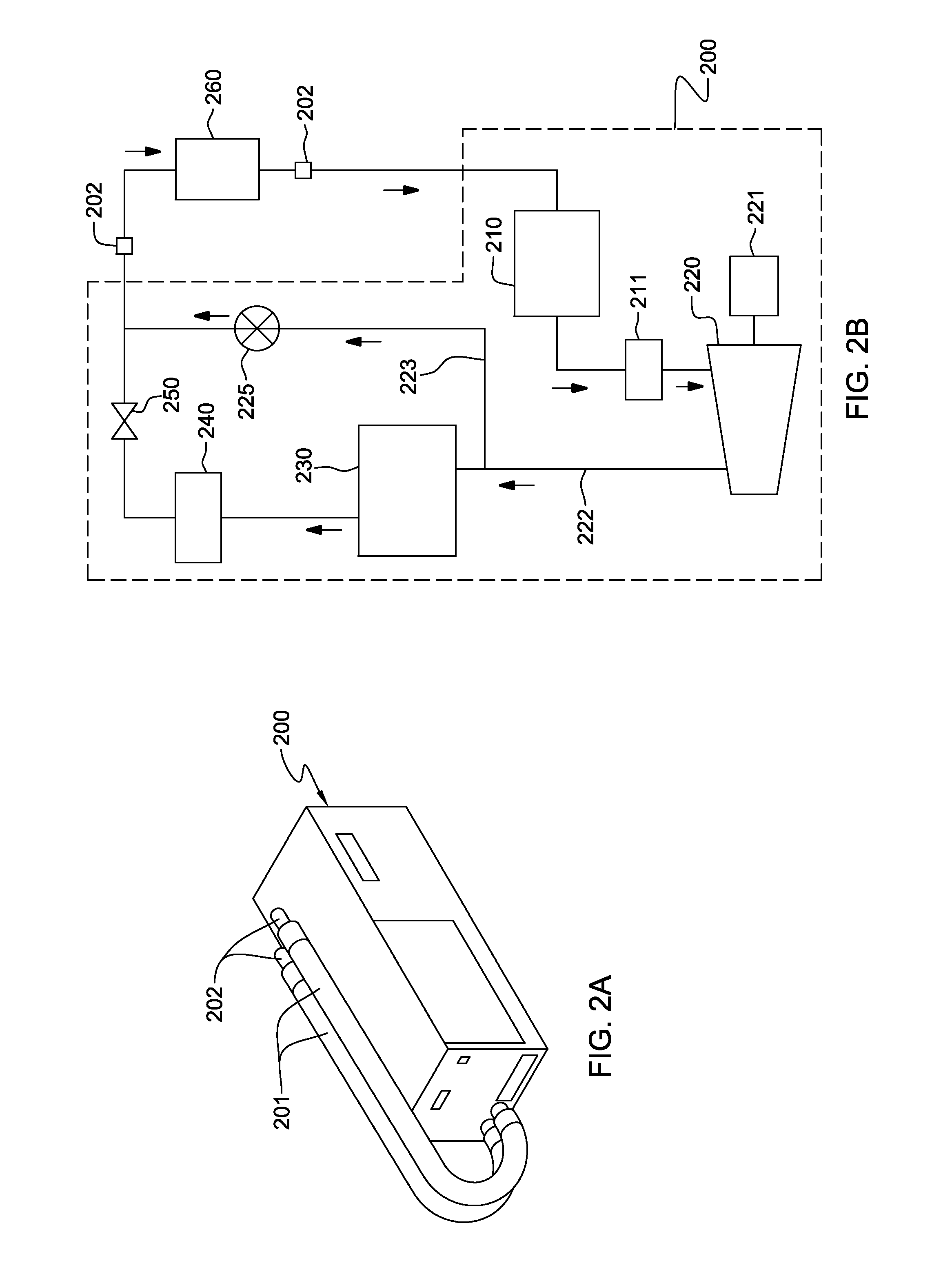

Cryogenic refrigeration unit suited for delivery vehicles

InactiveUS20020129613A1Reduce the temperatureNot contaminate atmosphereAir-treating devicesRefrigerated goods vehicleAir cycleDelivery vehicle

An apparatus to refrigerate the cargo space of delivery vehicles. It provides an environmentally friendly alternative to conventional mechanical a / c and refrigeration units. Cooling is provided by controlled evaporation of a liquefied gas such as CO.sub.2 or nitrogen. Defrost and heating requirements, if needed, are provided by hot engine coolant or by electric heaters powered from the vehicle electrical system. Airflow for the evaporator and for circulation in the temperature controlled space is provided by a blower which is mechanically or electrically driven from vehicle power. This invention can also be applied to multi-temperature control applications. The apparatus is compact and is particularly suited for small inner city delivery vehicles. FIG. 1: The sketch shows an inner city delivery truck for which this invention is most suitable. Refrigerated goods are placed in roller cages that are designed to maximize cargo hauled by use of roller cages that extend to within 2 inches of the ceiling. The evaporator section of this invention is mounted at or near the front wall of the truck and is separated from the cargo by a vertical bulkhead. The conditioned air is delivered at the bottom of the truck to avoid top freeze of perishable cargo that is in close proximity to the ceiling. FIG. 2: This shows the piping schematic and is similar to the invention described in U.S. Application Serial No. 60 / 238,929 (the '929 application) incorporated herein by reference. FIG. 2 shows the engine coolant coil located ahead of the CO.sub.2 coil in the direction of airflow. This prevents the coldest air from coming in contact with the engine coolant--in the cooling mode the air leaving the CO.sub.2 coil can be as low as -50.degree. F. for frozen load applications and this may cause the engine coolant to start freezing. Arrangements must be made to circulate air between the two coils in defrost mode. One means to accomplish this is to place a damper at the outlet of the evaporator section and run the fans. The damper would be closed during defrost. Another method is to place the engine coolant coil on the discharge side of the CO.sub.2 coil and use a cut-out switch if the engine coolant temperature drops below a predetermined value. In this arrangement there is no need for the damper arrangement as the heat will rise to melt any frost on the CO.sub.2 coil. If electric heat is used for defrost and heating freezing of the engine coolant is not a concern and the heaters can be fastened to the discharge side of the CO.sub.2 coil. An electric stand-by mode can be provided to power the system for cooling, heating and defrost when the vehicle is parked with the engine off. A plug-in electrical cable can provide the power needed for the controls, the fans and for heating and defrost. The figure shows the electric heaters attached on the discharge side of the CO.sub.2 coil. Operation: Detailed description is in the '929 application except for the following: The evaporator section is designed for vertical installation to maximize cargo space. Air is discharged at the bottom but may be a conventional top discharge if needed for specific applications. Conventional methods can be used to provide defrost and heating. If engine coolant is used for a heat source, it is preferable to thermally isolate the CO.sub.2 coil from the engine coolant coil to avoid freezing the coolant. The evaporator blower may be located on the inlet side of the coils rather than as shown in the figures. Unique Features: 1. Absence of a conventional condensing section on the exterior of the vehicle makes this an ideal refrigeration unit for small inner city delivery vehicles. Many of the truck cabs are now almost full height (same as the truck body) and there is limited space for the condensing section. 2. Cold plates can be used and still maximize cargo cube. However, this invention has 30-40% less weight than comparable "cold plate" systems. 3. Other features are described in the '929 application.]

Owner:THERMO KING CORP

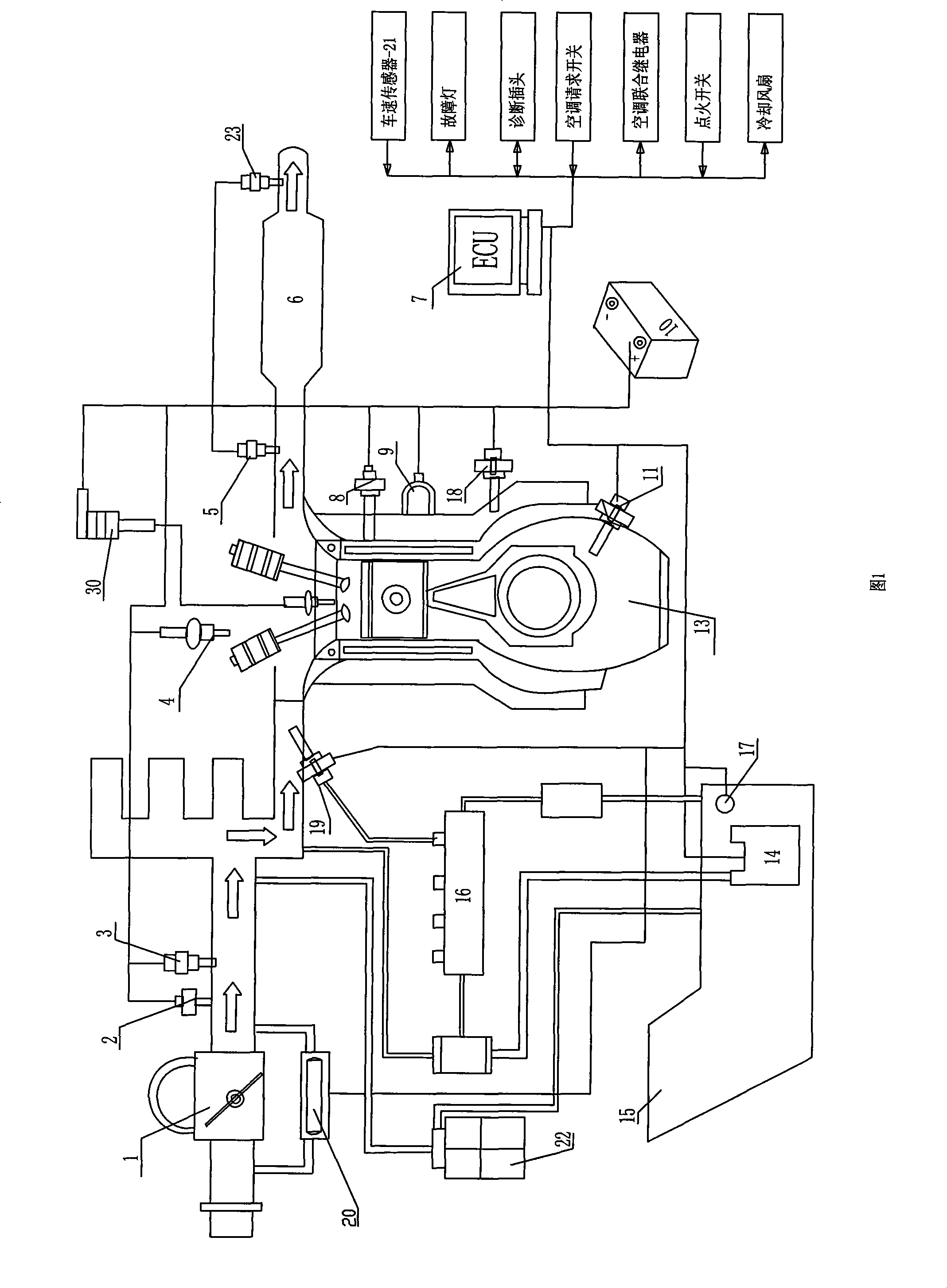

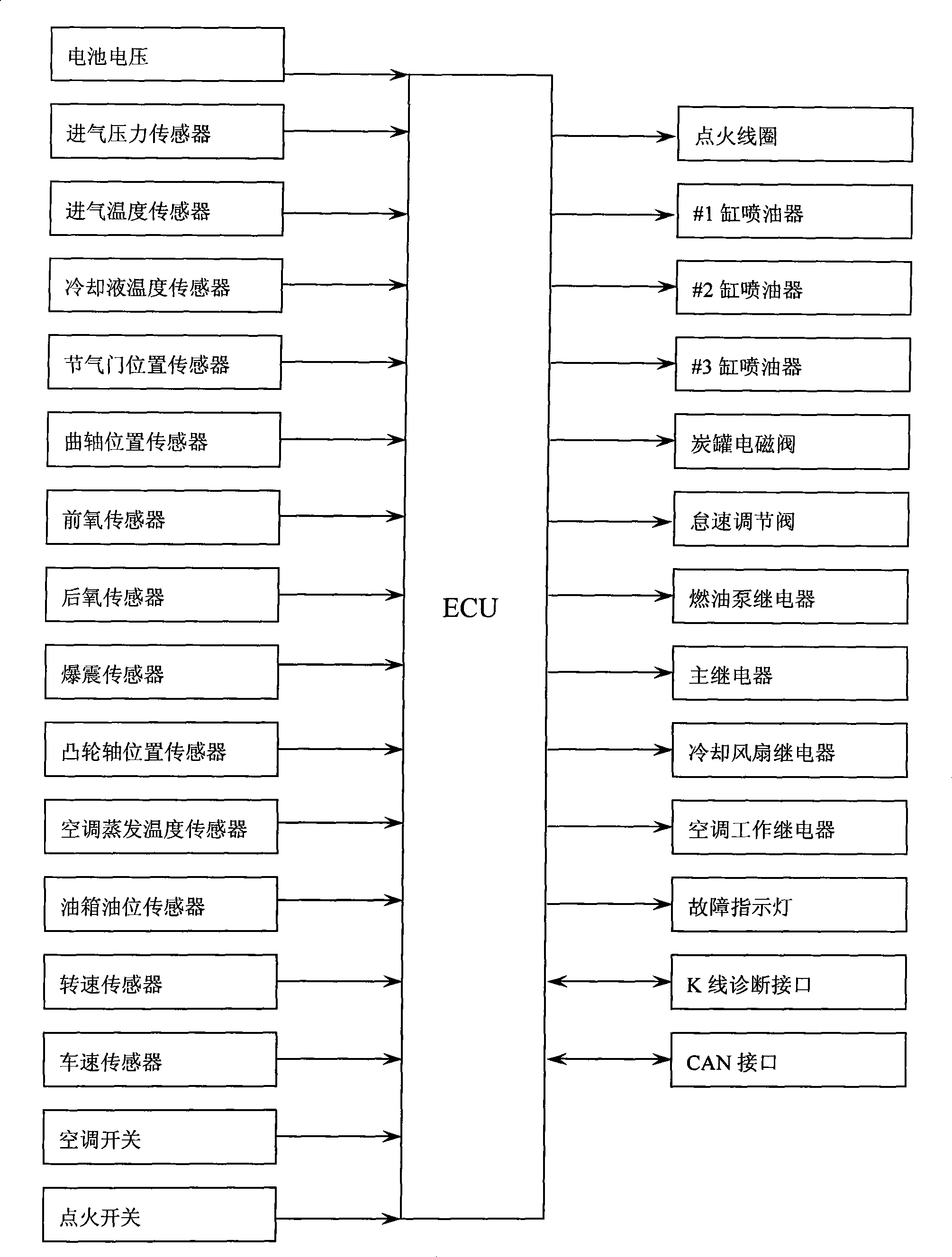

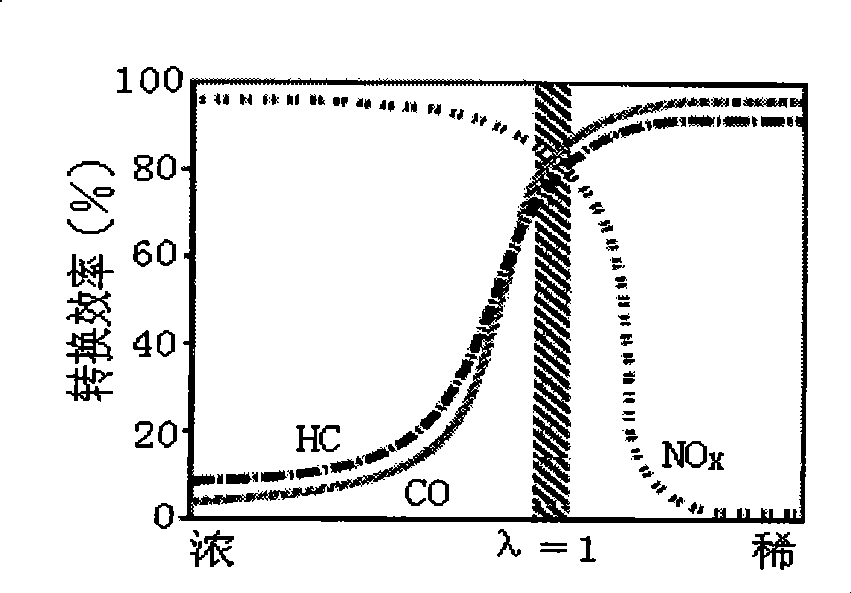

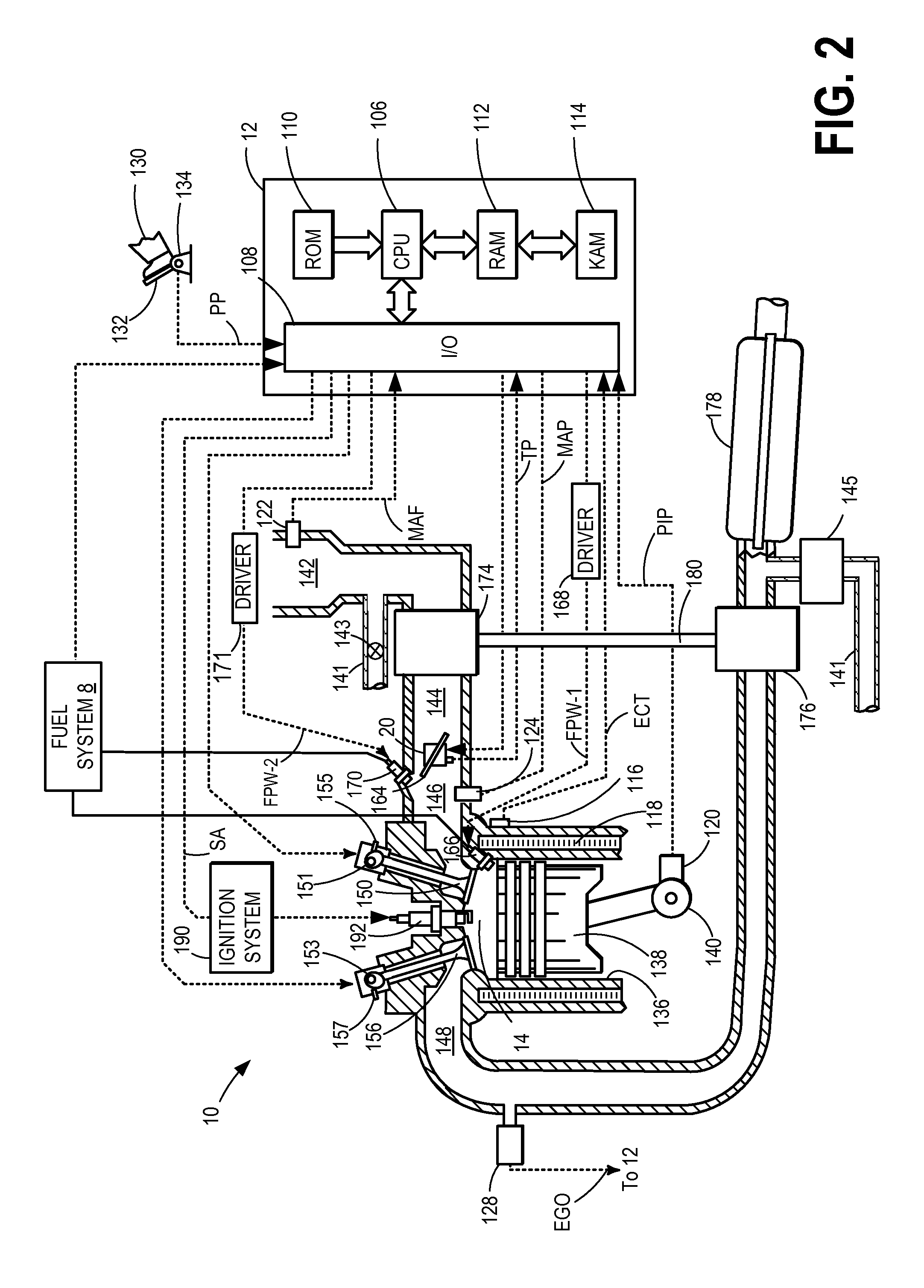

Electric-controlled petrol engine work system

InactiveCN101363380ARich control functionsGood control function integration performanceElectrical controlMachines/enginesIdle speed controlIgnition coil

The invention provides a work system of an electronically controlled gasoline engine, comprising an air intake system, a fuel oil supply system, an ignition system as well as an electronic control system; the electronic control system consists of a sensor section, an electronic control unit ECU and an actuator section, wherein, the sensor section includes a throttle position sensor, an intake pressure and temperature sensor and an intake temperature sensor which are arranged on an intake pipe of an intake system, a camshaft position sensor, a coolant temperature sensor and a crankshaft position sensor which are arranged on the engine, a front oxygen sensor arranged in front of a three-way catalyst converter on an exhaust pipe of the engine, and the components of the sensor section are all connected with the ECU, and the actuator section consists of an electric fuel pump, an oil sprayer, an idle speed regulating valve and an ignition coil; the components of the actuator section are all connected with the ECU, and the ECU includes a fuel injection control program, an ignition control program and an idle speed control program; the system adopts reasonable control strategy and has comprehensive control function, good integrated performance of control function and fine system portability.

Owner:张和君 +1

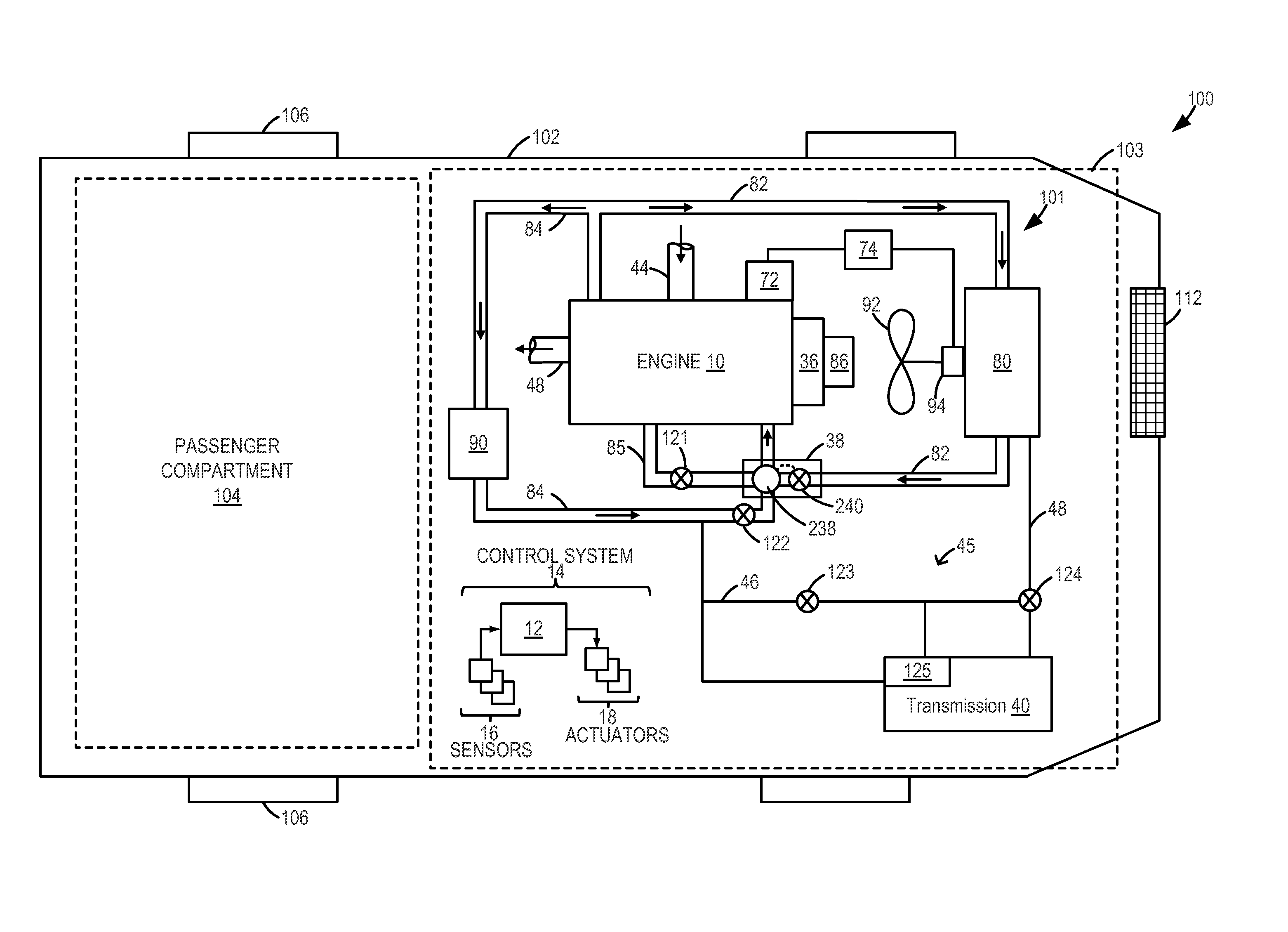

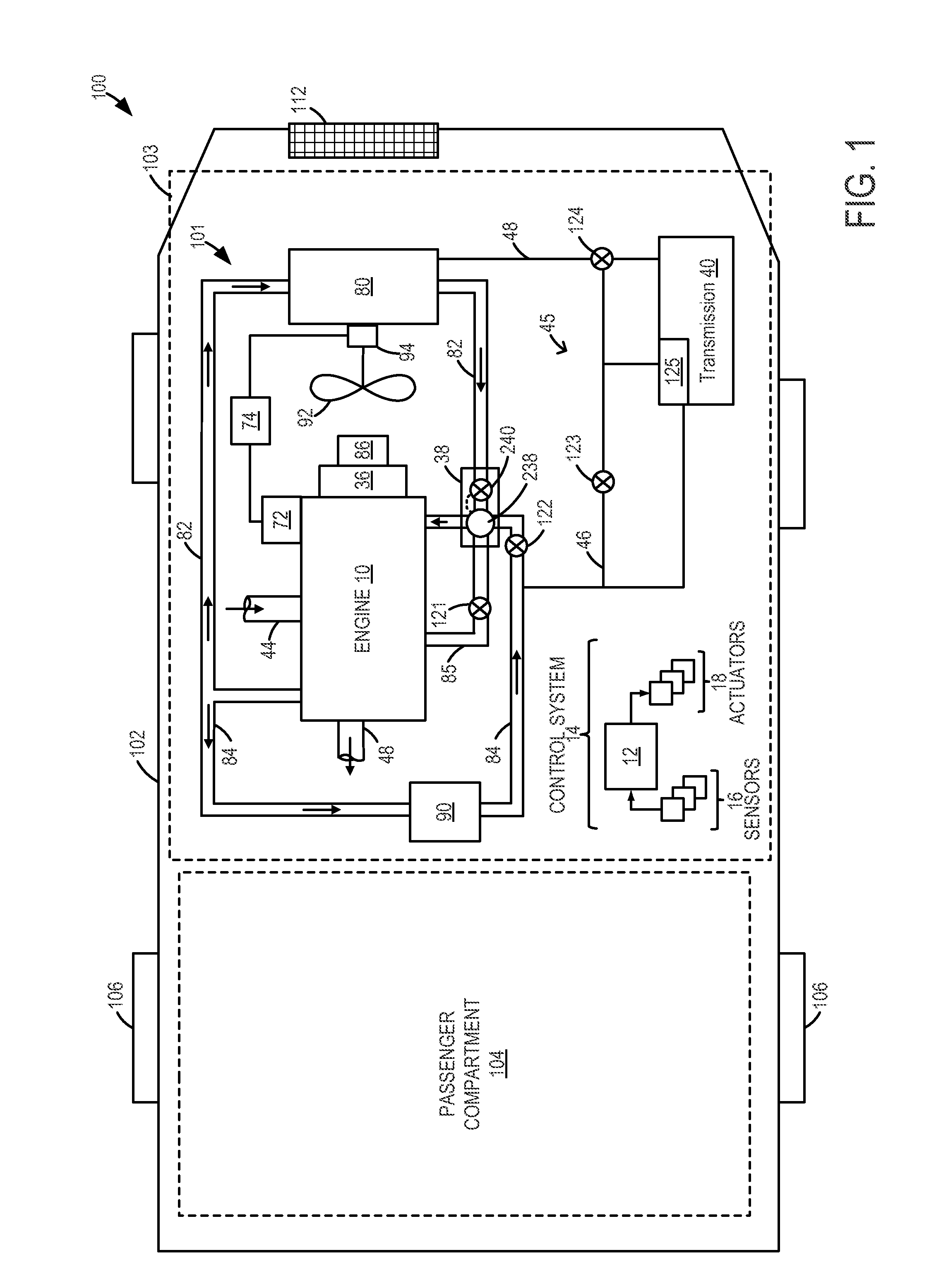

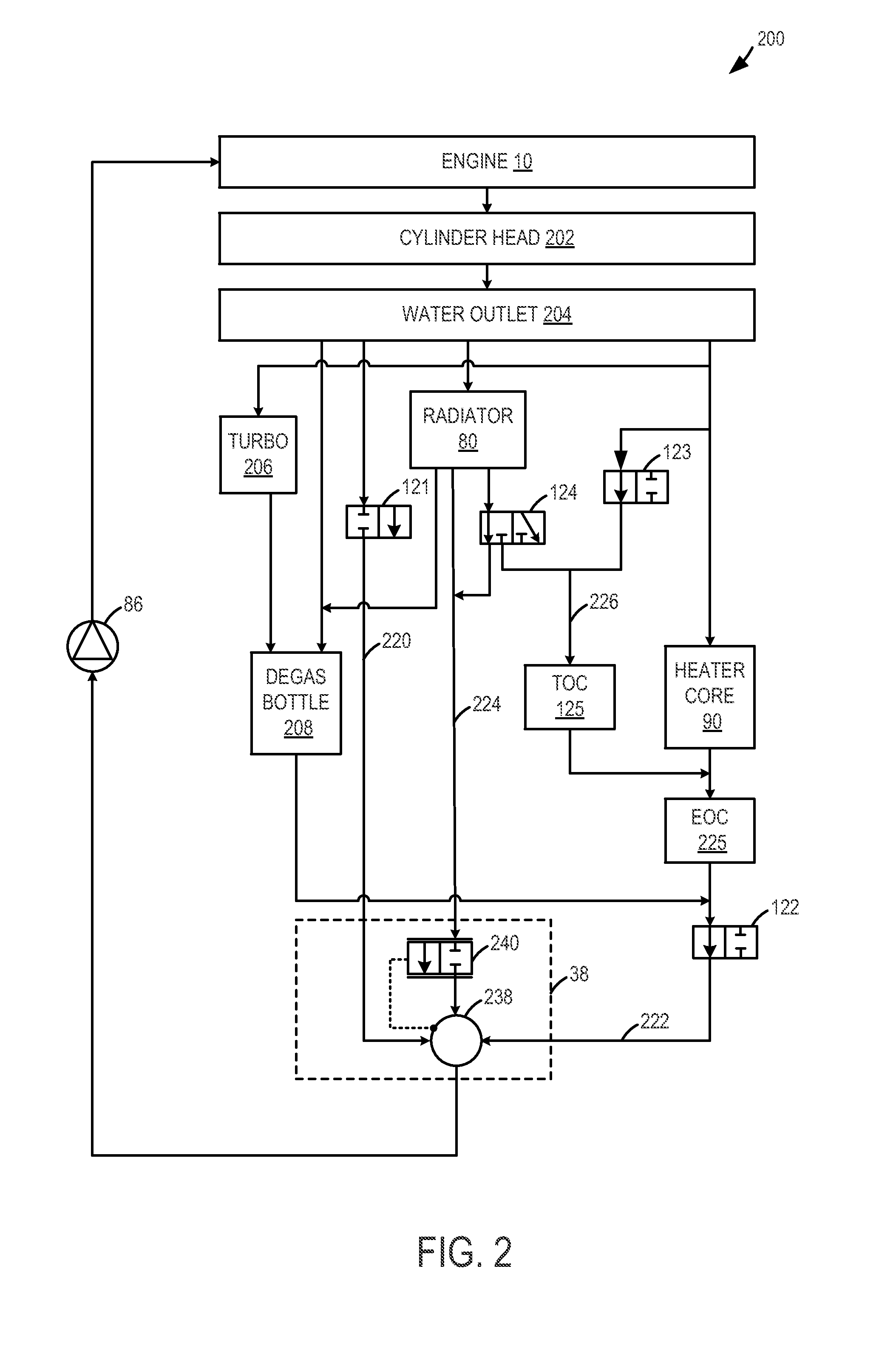

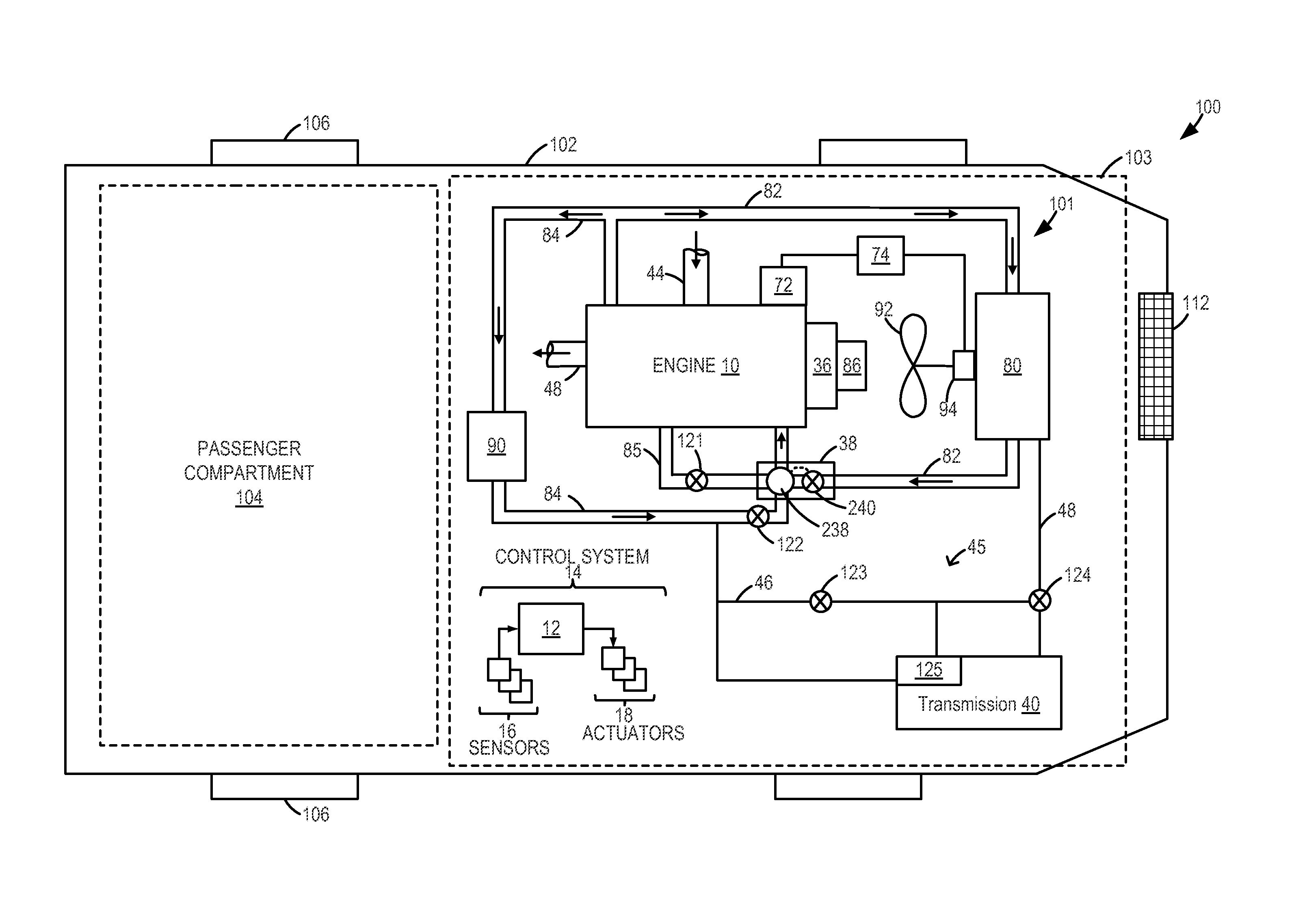

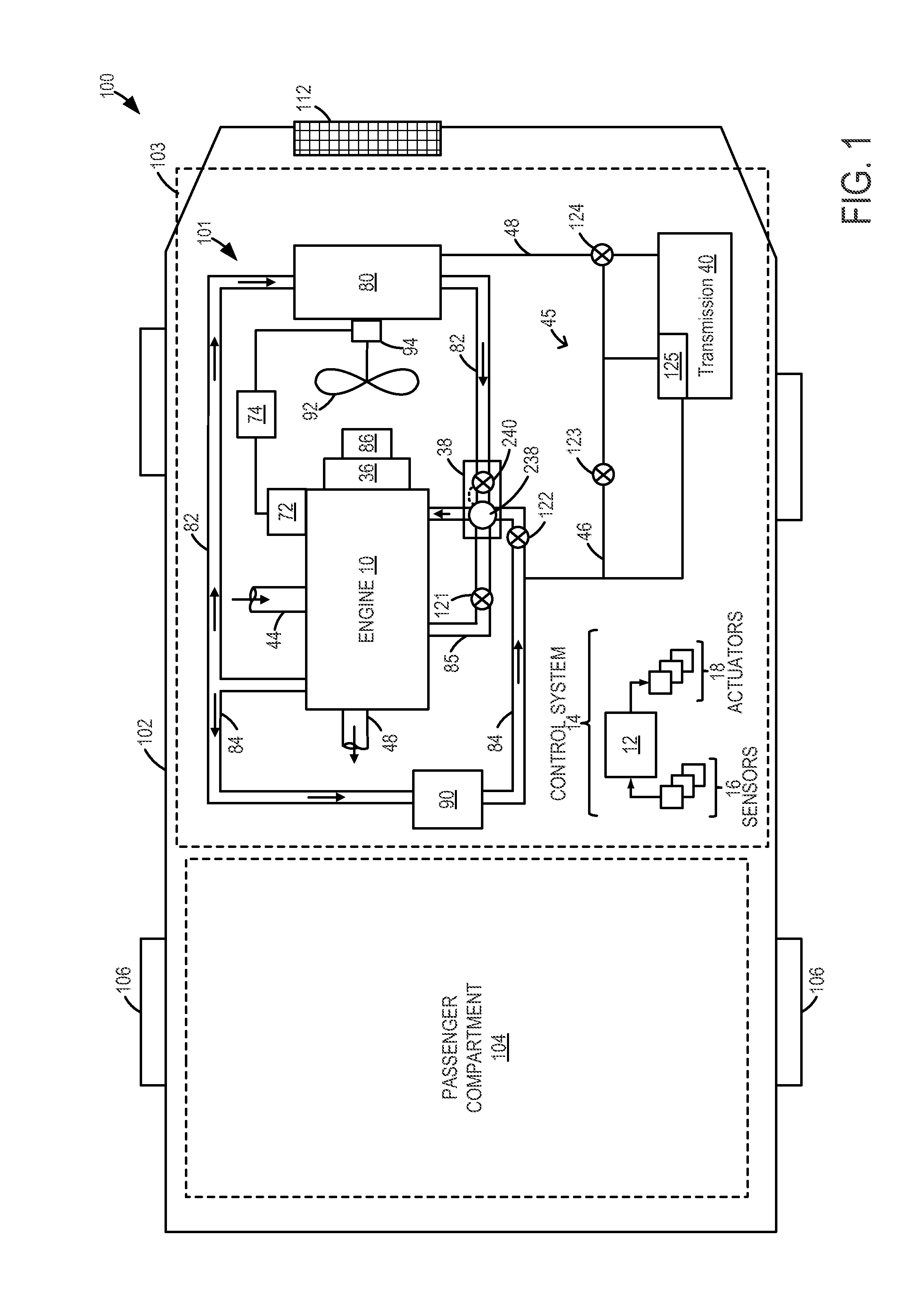

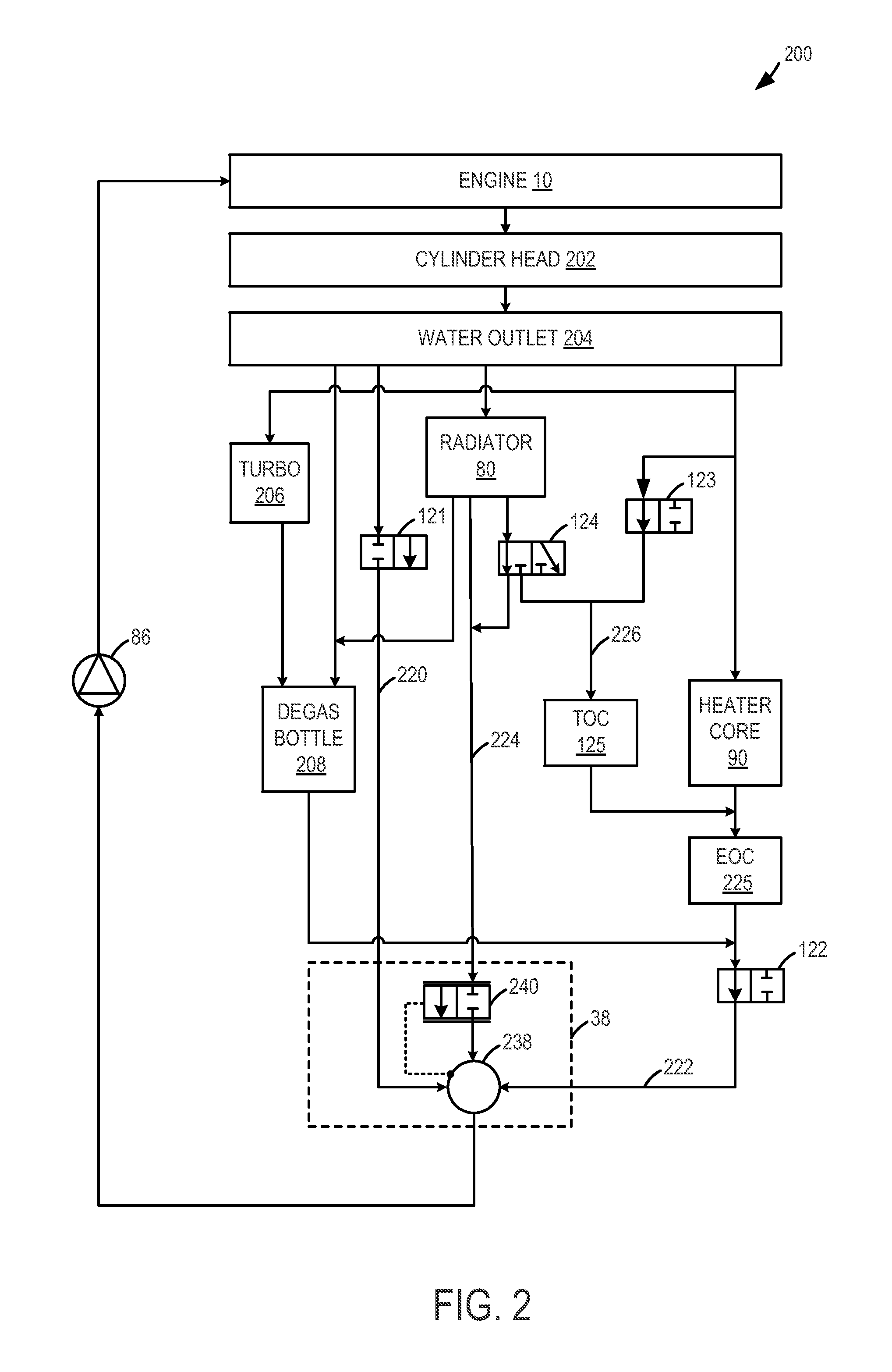

Engine cooling system control

ActiveUS20130255605A1Accurate valueReduce the possibilityLiquid coolingCoolant flow controlCoolant temperatureWarming up

Methods and systems are provided for diagnosing each of a plurality of engine cooling system components including various valves and grill shutters. Each valve may be individually closed and opened for a specified duration, and corresponding changes in coolant temperature may be monitored. If all the components are functional, the various valves may be adjusted to stagnate coolant at the engine and expedite engine warm-up during a cold-start.

Owner:FORD GLOBAL TECH LLC

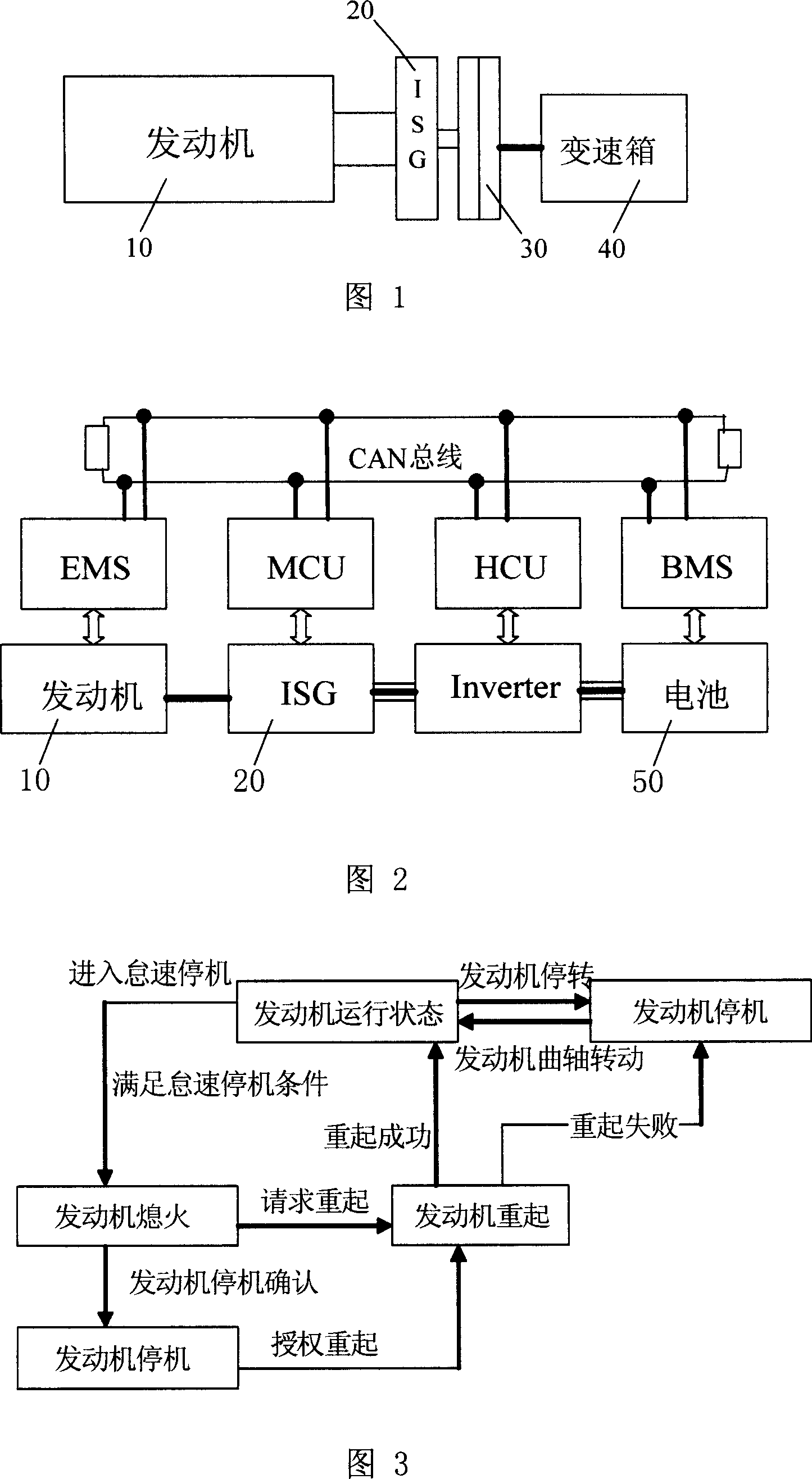

Engine on-off control method for mixed power automobile

InactiveCN1986307AWith vacuumStart fastHybrid vehiclesGas pressure propulsion mountingMotor driveIdle speed

The present invention relates to engine on-off control method for mixed power automobile. In condition of engine coolant temperature higher than preset value, automobile speed lower than the preset idle speed, air conditioner in off state, no treading on the accelerator pedal, auxiliary braking vacuum pump with certain vacuum degree, etc., the engine will be in idle stop state and may be re-started only after the EMS receiving starting signal. The present invention realizes the idle stop of the engine by means of the EMS, controls the fast starting of the engine with the EMS to control the motor, and makes the engine to jet oil and ignite after the motor drives the engine to certain rotation speed. The said control method can start the engine fast and raise the starting exhaust performance of the engine.

Owner:CHERY AUTOMOBILE CO LTD

Engine cooling system control

InactiveUS20130255604A1Improve economyInternal-combustion engine testingCoolant flow controlEngineeringCoolant temperature

Methods and systems are provided for diagnosing each of a plurality of engine cooling system components including various valves and grill shutters. Each valve may be individually closed and opened for a specified duration, and corresponding changes in coolant temperature may be monitored. If all the components are functional, the various valves may be adjusted to stagnate coolant at the engine and expedite engine warm-up during a cold-start.

Owner:FORD GLOBAL TECH LLC

Method and system for particulate matter control

ActiveUS20160115878A1Extending cylinder deactivation benefitImprovement in PM emissionElectrical controlSpeed sensing governorsParticulatesCoolant temperature

Methods and systems are provided for particulate matter control in an engine configured for skip-fire operation. A cylinder pattern selected for selective cylinder deactivation, including a total number of deactivated / active cylinders as well as individual deactivated cylinder identities, may be adjusted based on an engine soot load, or a parameter indicative of engine soot load such as engine coolant temperature. In addition, reactivated engine cylinders may be transiently operated with split fuel injection to raise combustion surface temperatures.

Owner:FORD GLOBAL TECH LLC

Engine cooling system

The invention discloses an engine cooling system which comprises a coolant pump, an engine water jacket, a first thermostat, a radiator, and a transmission cooler, wherein a circulation loop of a coolant in the coolant pump comprises a large circulation loop going through the water jacket, the thermostat and the radiator and a small circulation loop going through the water jacket and the thermostat, the transmission cooler is connected in parallel with the small circulation loop, the first thermostat is provided with a main valve whose opening changes along with the change of the temperature of the coolant and an auxiliary valve whose opening changes along with the change of the temperature of the coolant, the main valve of the first thermostat is connected with the radiator to control the coolant flow in the large circulation loop, the auxiliary valve of the first thermostat is connected with the coolant pump to control the coolant flow in the small circulation loop, the engine cooling system further comprises a second thermostat, the second thermostat is connected in series with the transmission cooler to control the coolant flow passing by the transmission cooler, and a branch comprising the transmission cooler and the second thermostat is connected in parallel with the small circulation loop.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

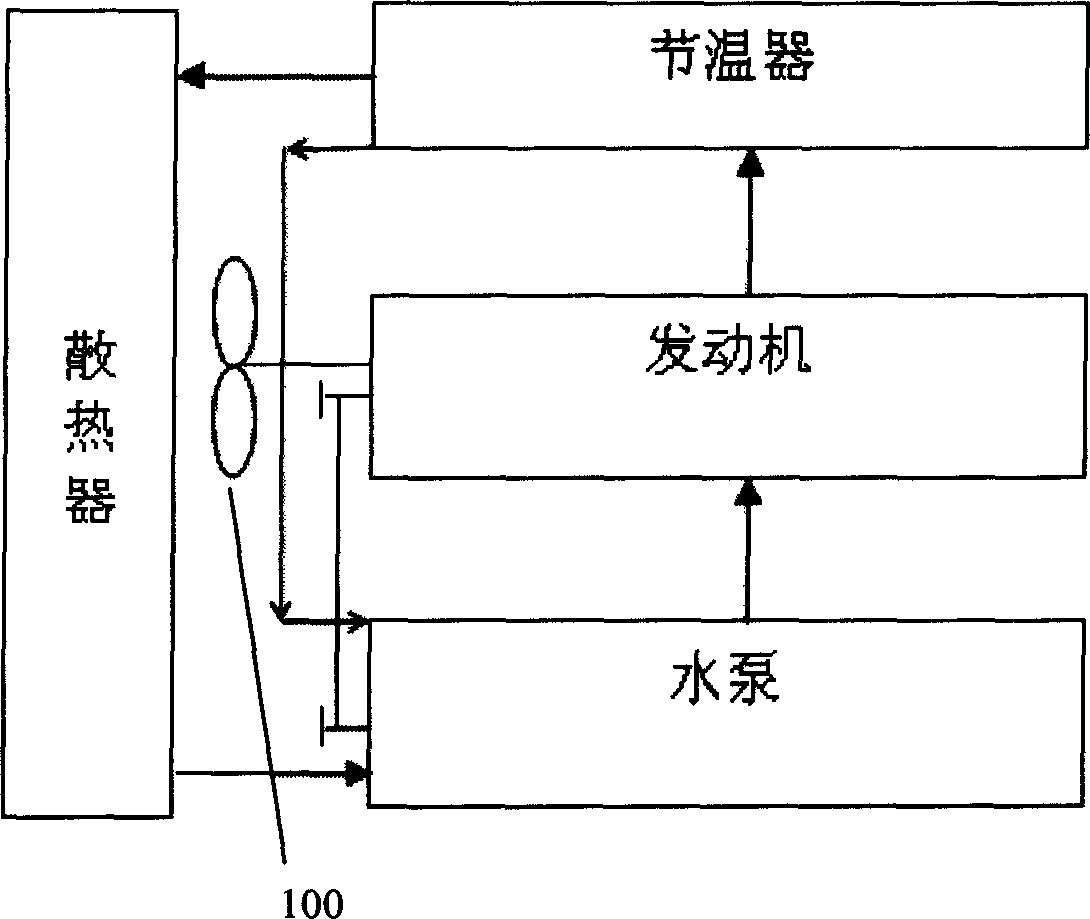

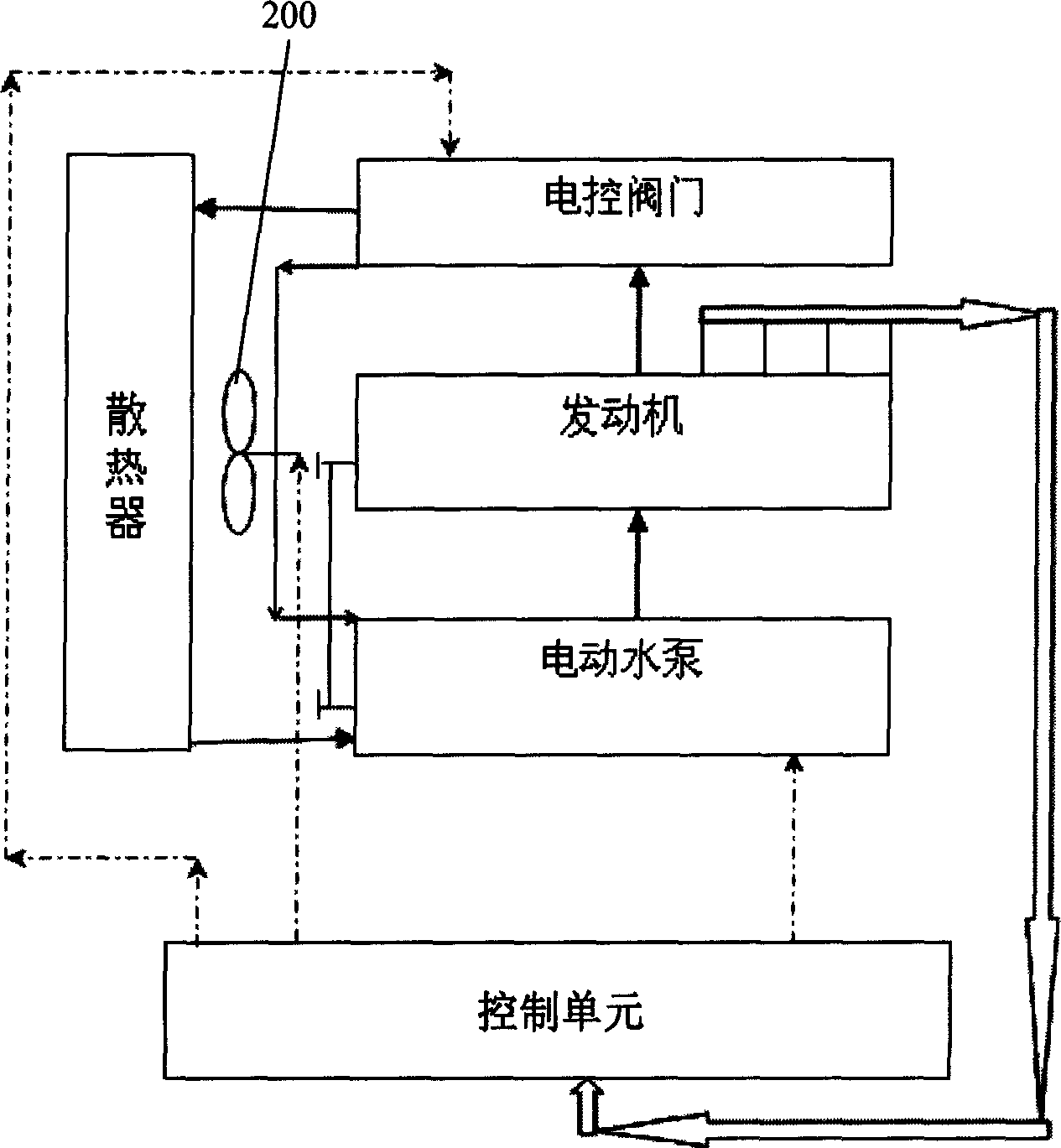

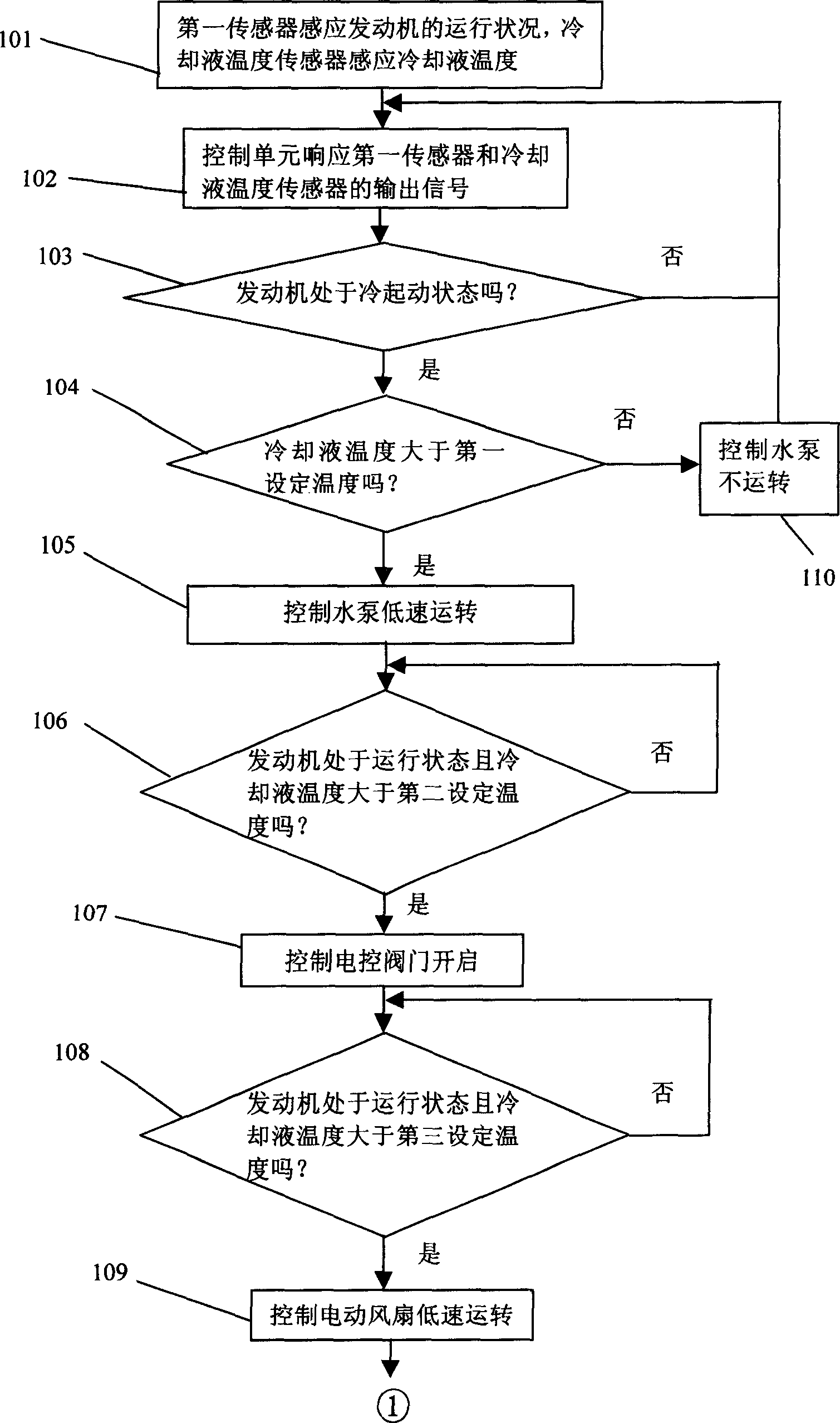

Water cooling system of engine and cooling method thereof

InactiveCN1884804AIncrease starting speedReduce exhaust pollutionLiquid coolingCoolant flow controlLiquid temperatureEngineering

The invention relates to an engine water cooling system and relative cooling method, wherein the first sensor senses the working condition of engine; the cooling liquid temperature sensor senses the temperature of cooling liquid inside the engine; the control unit responds the signals of first sensor and the cooling liquid temperature sensor, to control the electric water pump to operate when the temperature of cooling liquid is higher than the first preset temperature when the engine starts, to drive the cooling liquid to cool the engine, to improve the starting property of engine and the discharging property of heating machine; and the electric controller based on the operation parameter of engine and the temperature of cooling liquid, controls the switch of electric valve, the electric water pump and the rotation speed of electric fan, to control the circulation and the flux of cooling liquid, and the cooling ability of cooling fan, to improve the property of engine.

Owner:BYD CO LTD

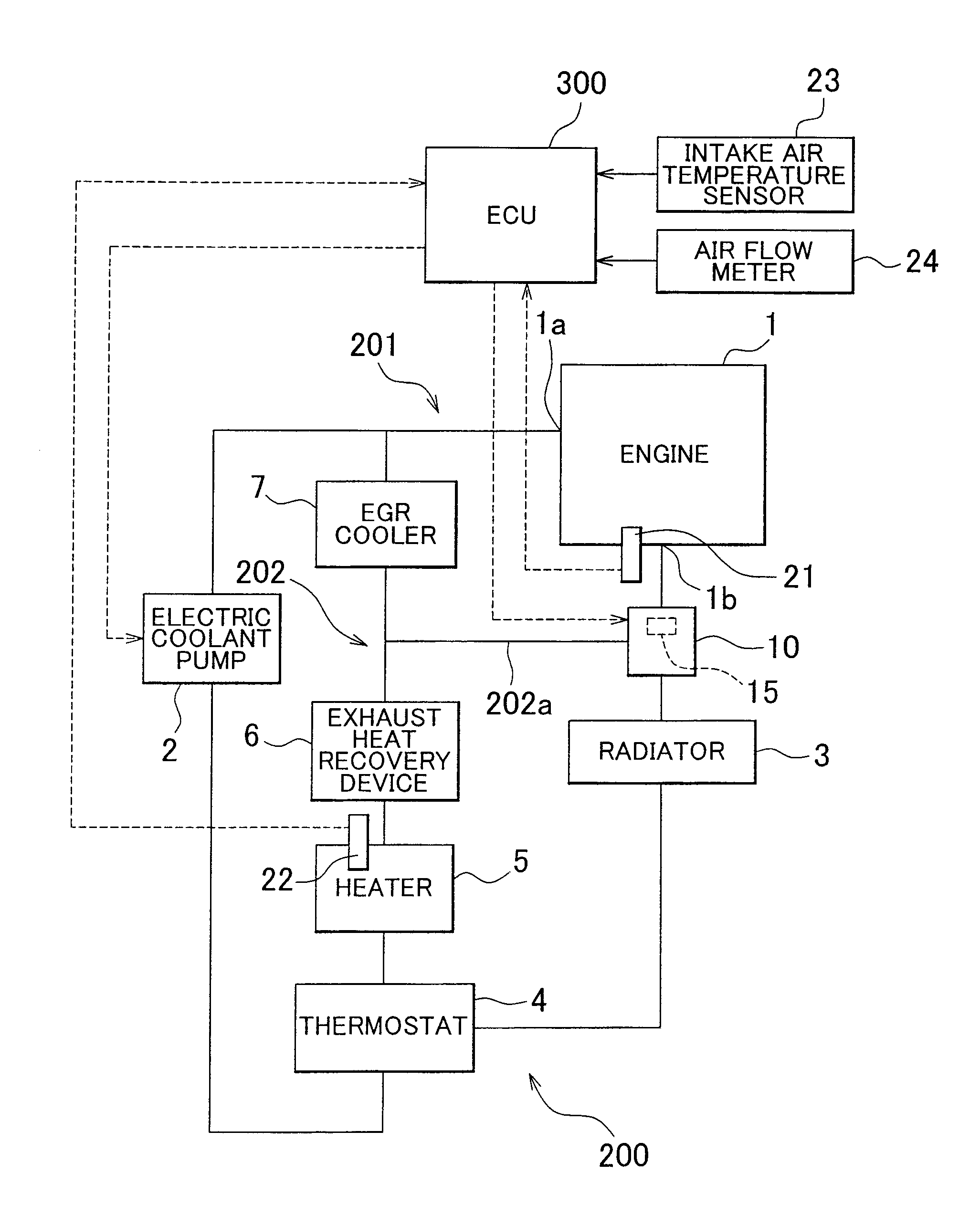

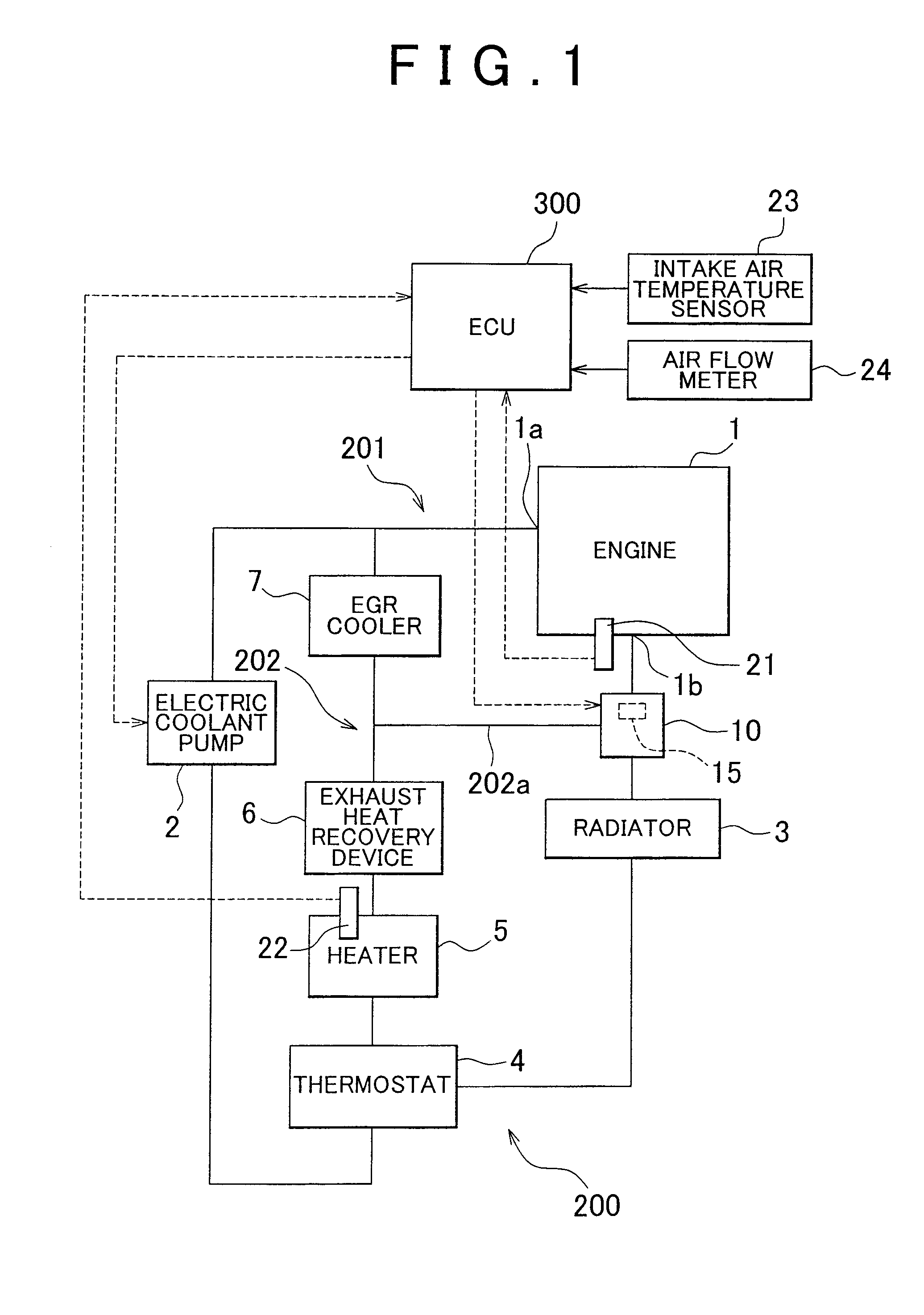

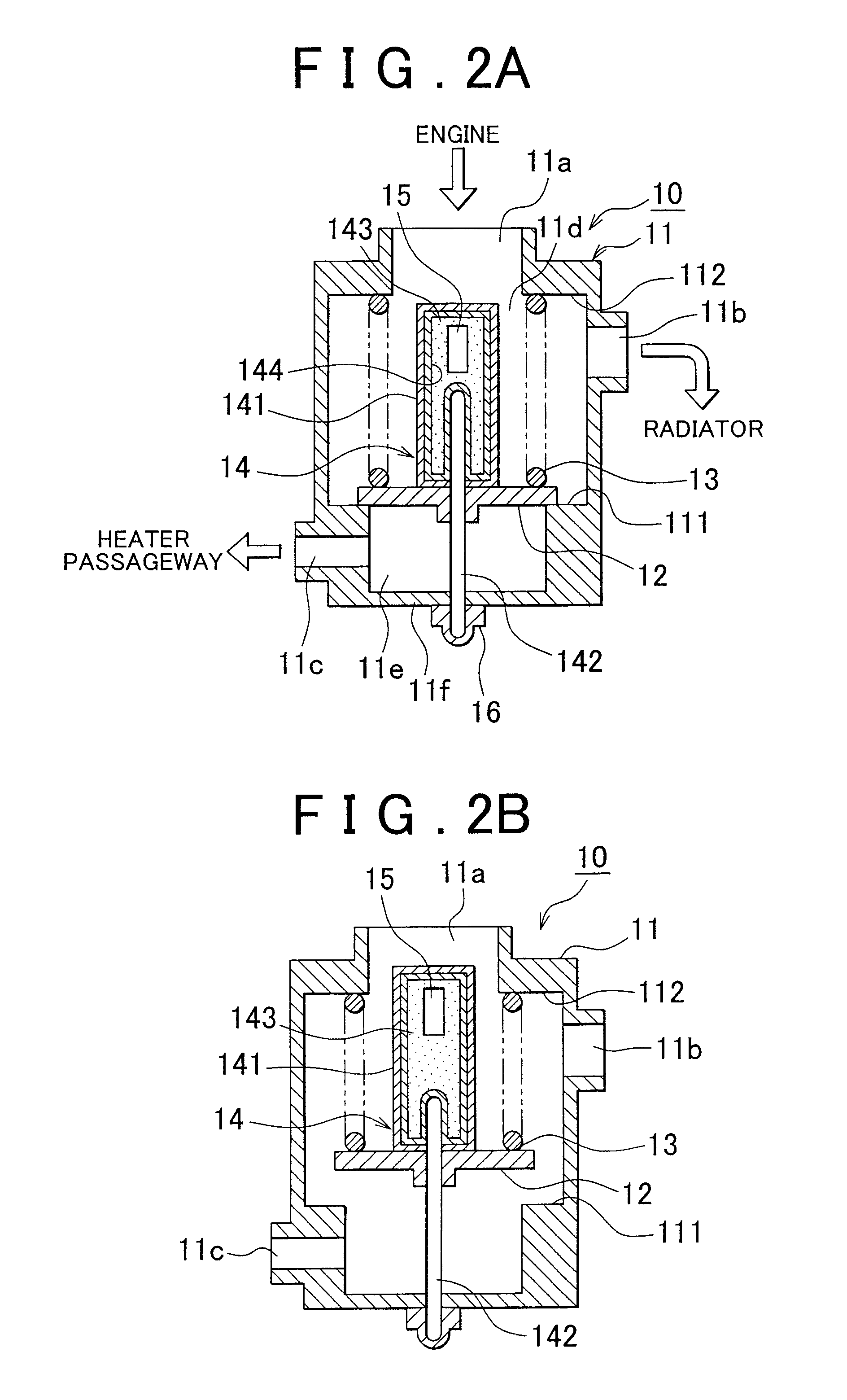

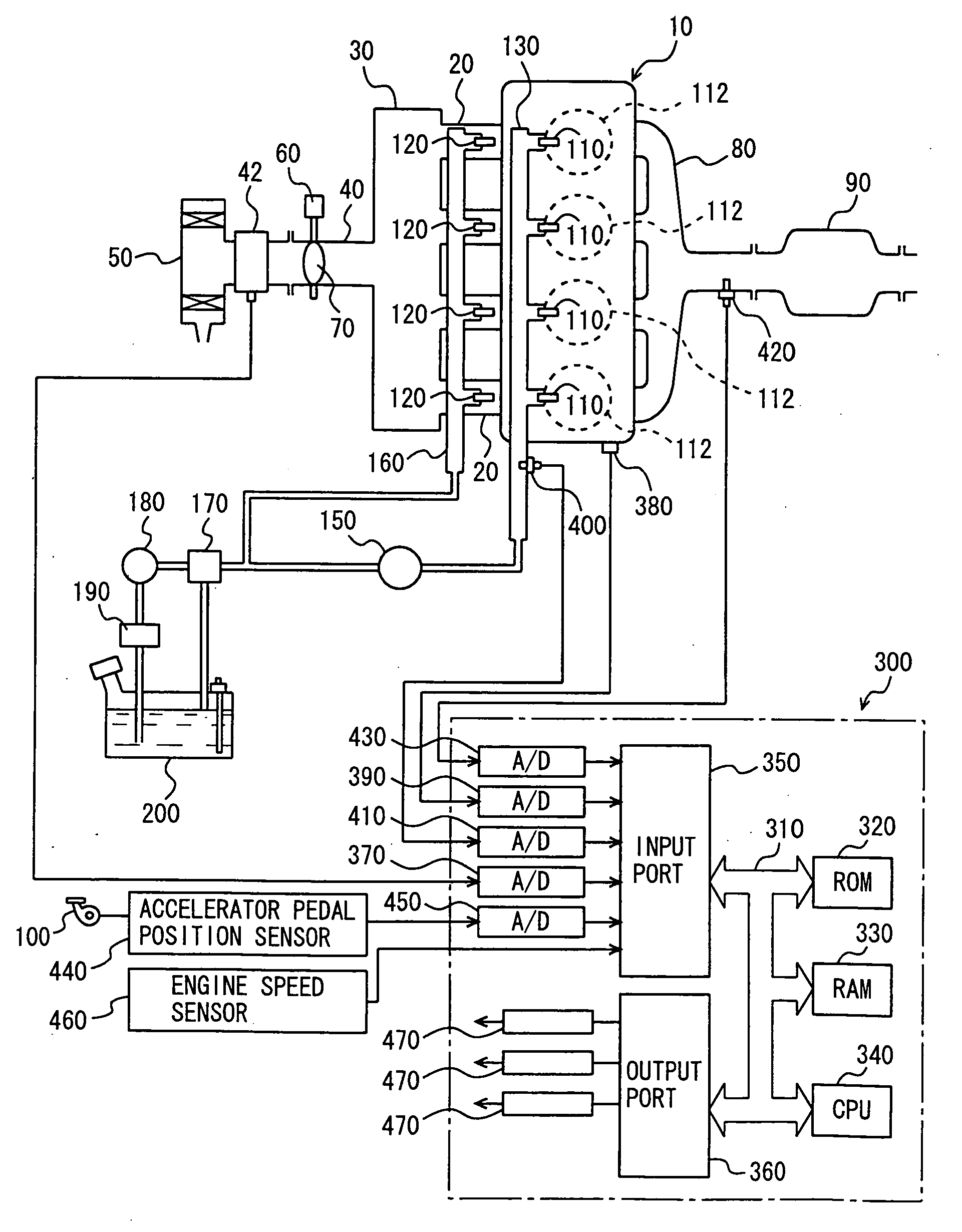

Abnormality determination apparatus and abnormality determination method for coolant temperature sensor, and engine cooling system

InactiveUS20130213600A1Increase temperatureAccurately determineAir-treating devicesCoolant flow controlCoolant temperatureChangeover

A coolant temperature sensor abnormality determination apparatus opens a changeover valve to increase the temperature of a coolant in a heater passageway if the amount of increase of the detected heater inlet coolant temperature value obtained when the intake air amount of an engine becomes equal to or greater than a predetermined value is small. Then, if the amount of increase in the detected heater inlet coolant temperature value after the changeover valve opens is greater than or equal to the predetermined value, the apparatus determines that the heater inlet coolant temperature sensor is normal. If the amount of increase in the detected heater inlet coolant temperature value is smaller than the predetermined value, the apparatus determines that the heater inlet coolant temperature sensor is abnormal.

Owner:TOYOTA JIDOSHA KK

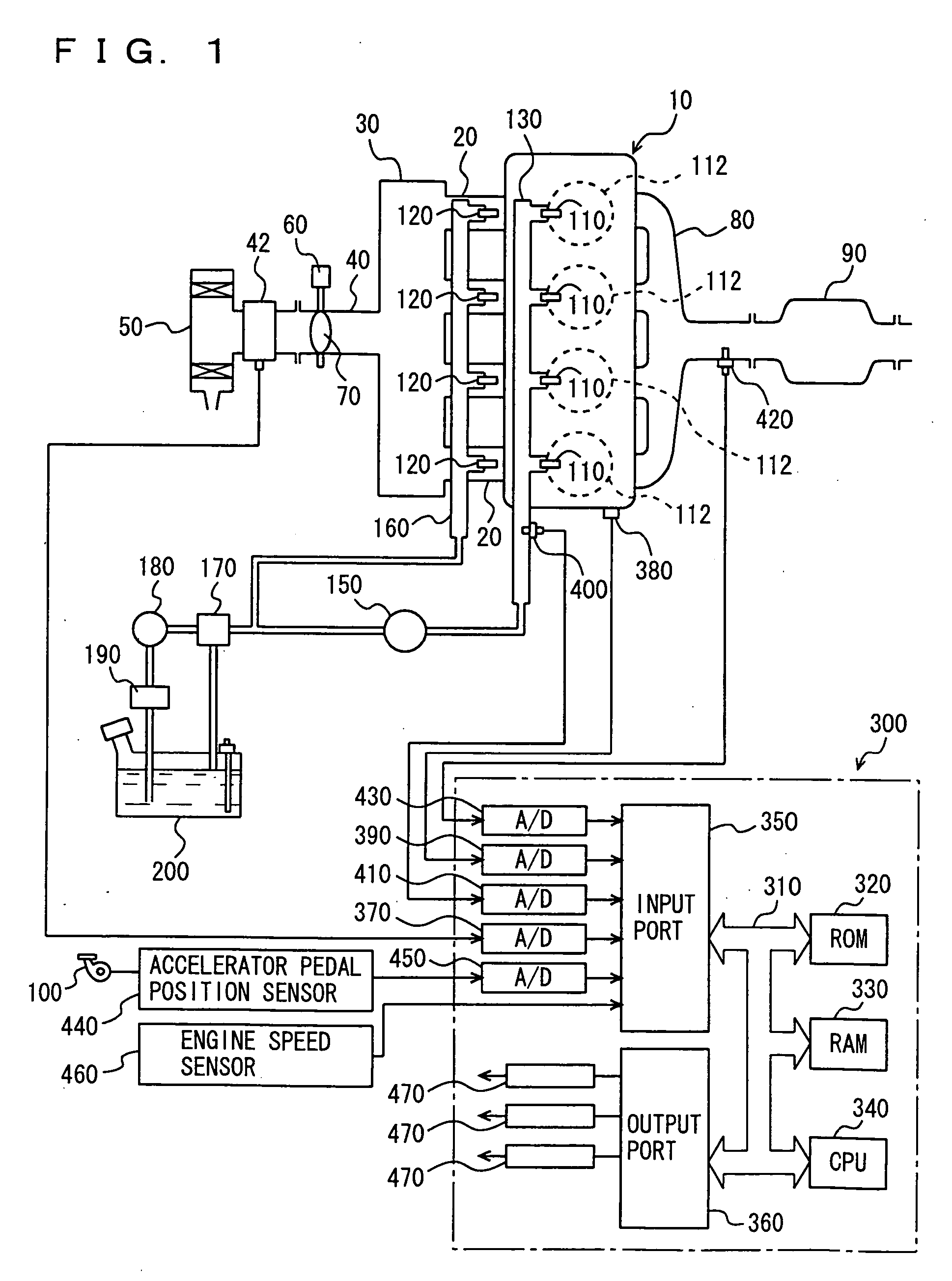

Control apparatus for internal combustion engine

InactiveUS20070000478A1Suppress generationStable combustionElectrical controlDigital data processing detailsTransitional RegionIdle speed

An engine ECU executes a program including the steps of: detecting an engine speed NE, engine load, and engine coolant temperature (S100, S110, S115); when determination is made of being in an idle region (YES at S120), determining whether in a cold idle region, a transitional region, or a warm idle region (S130); injecting fuel from an intake manifold injector alone when in the cold idle region (S140); injecting fuel from the intake manifold injector and injecting fuel from an in-cylinder injector at the feed pressure when in the transitional region (S150); and injecting fuel from the in-cylinder injector at the feed pressure when in the warm idle region (S160).

Owner:TOYOTA JIDOSHA KK

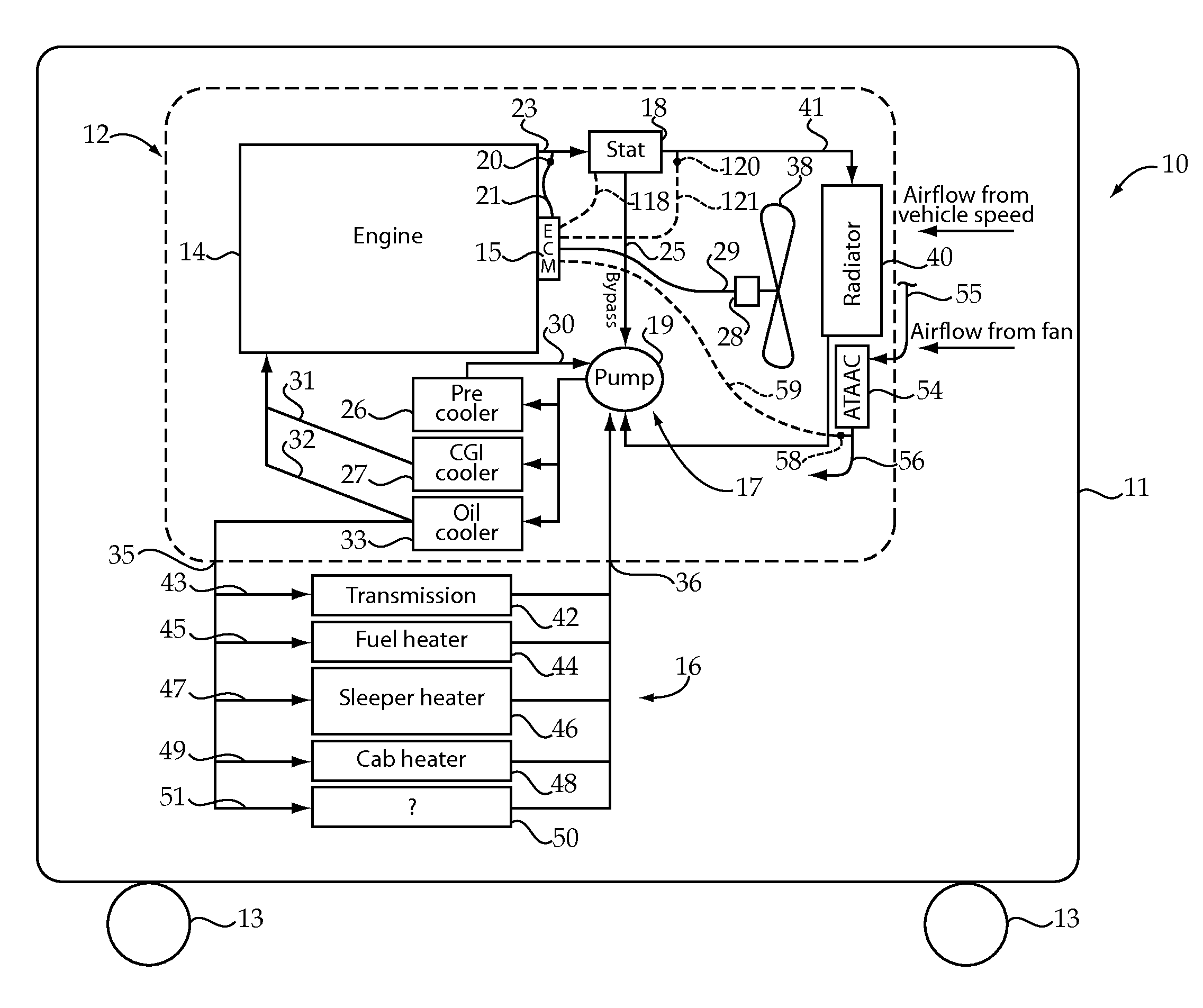

Cooling system for land vehicles

A land vehicle comprises an engine having a closed loop cooling system. The cooling system includes a heat exchanger and a switching valve arrangement. The valve arrangement allows coolant to bypass the heat exchanger until the coolant temperature has exceeded a preset temperature.

Owner:YAMAHA MOTOR CO LTD

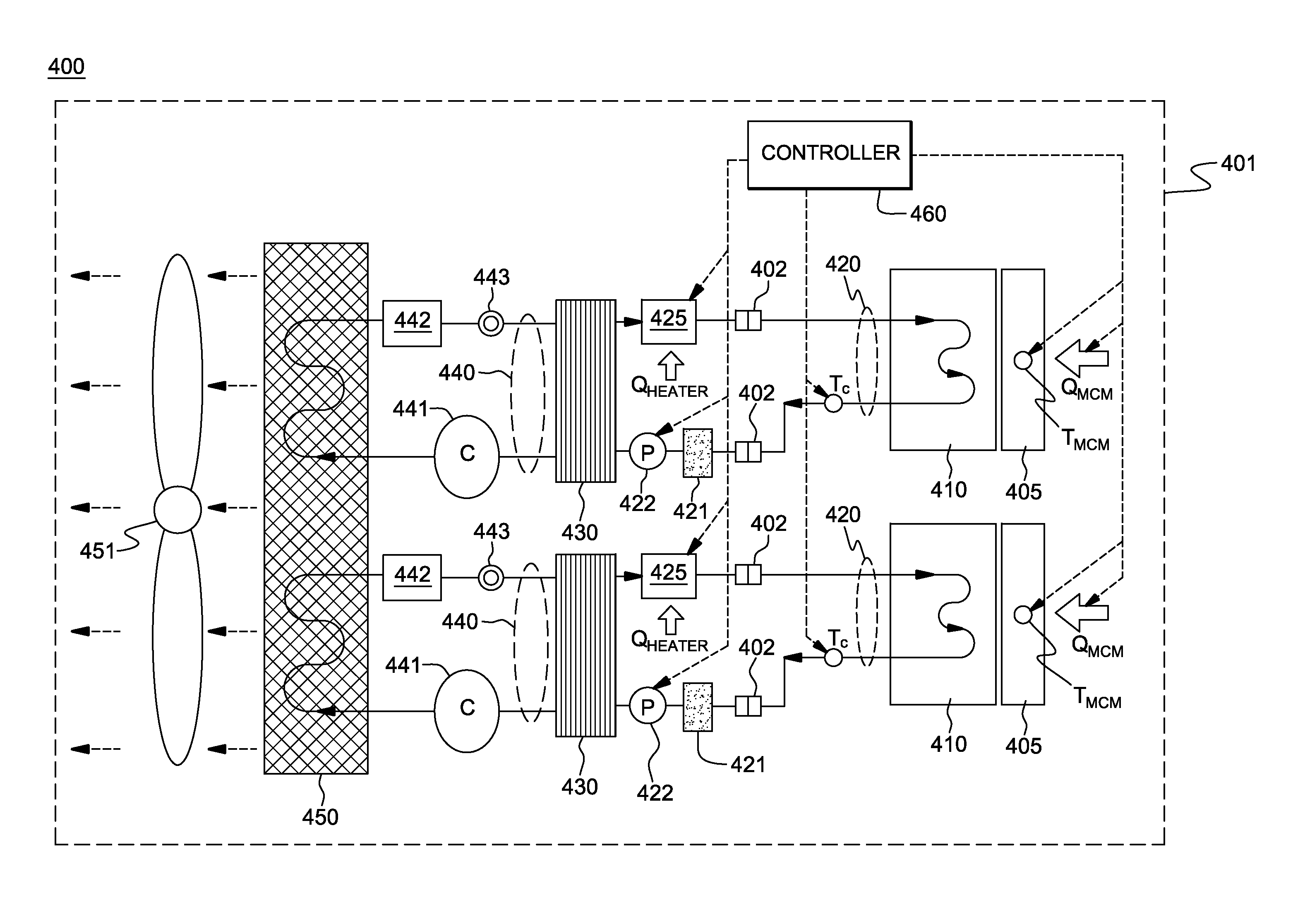

Coolant-buffered, vapor-compression refrigeration with thermal storage and compressor cycling

ActiveUS20120111036A1Improve cooling effectSuppress swingHeat storage plantsCompression machines with non-reversible cycleThermal energy storageEngineering

Owner:IBM CORP

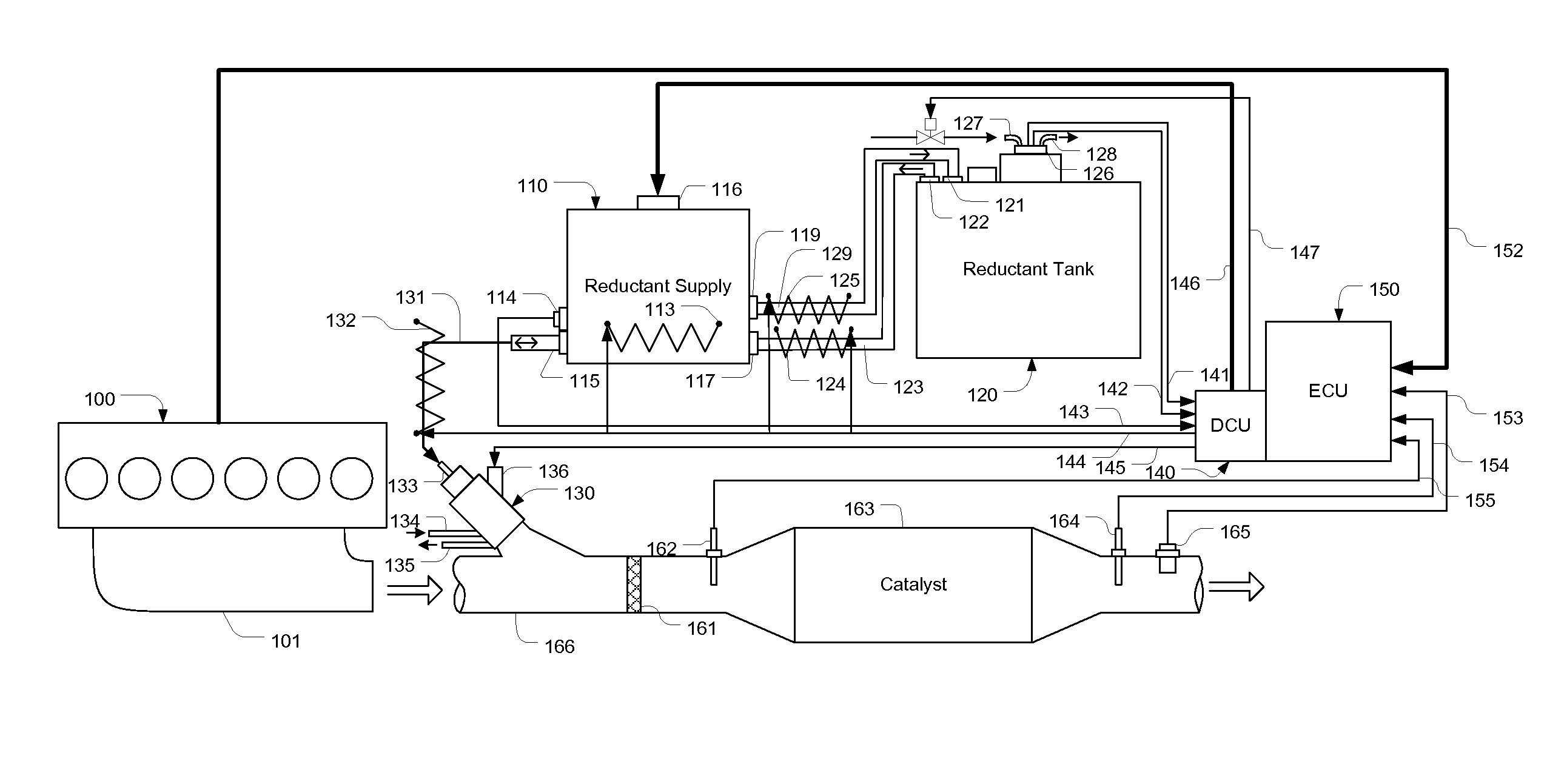

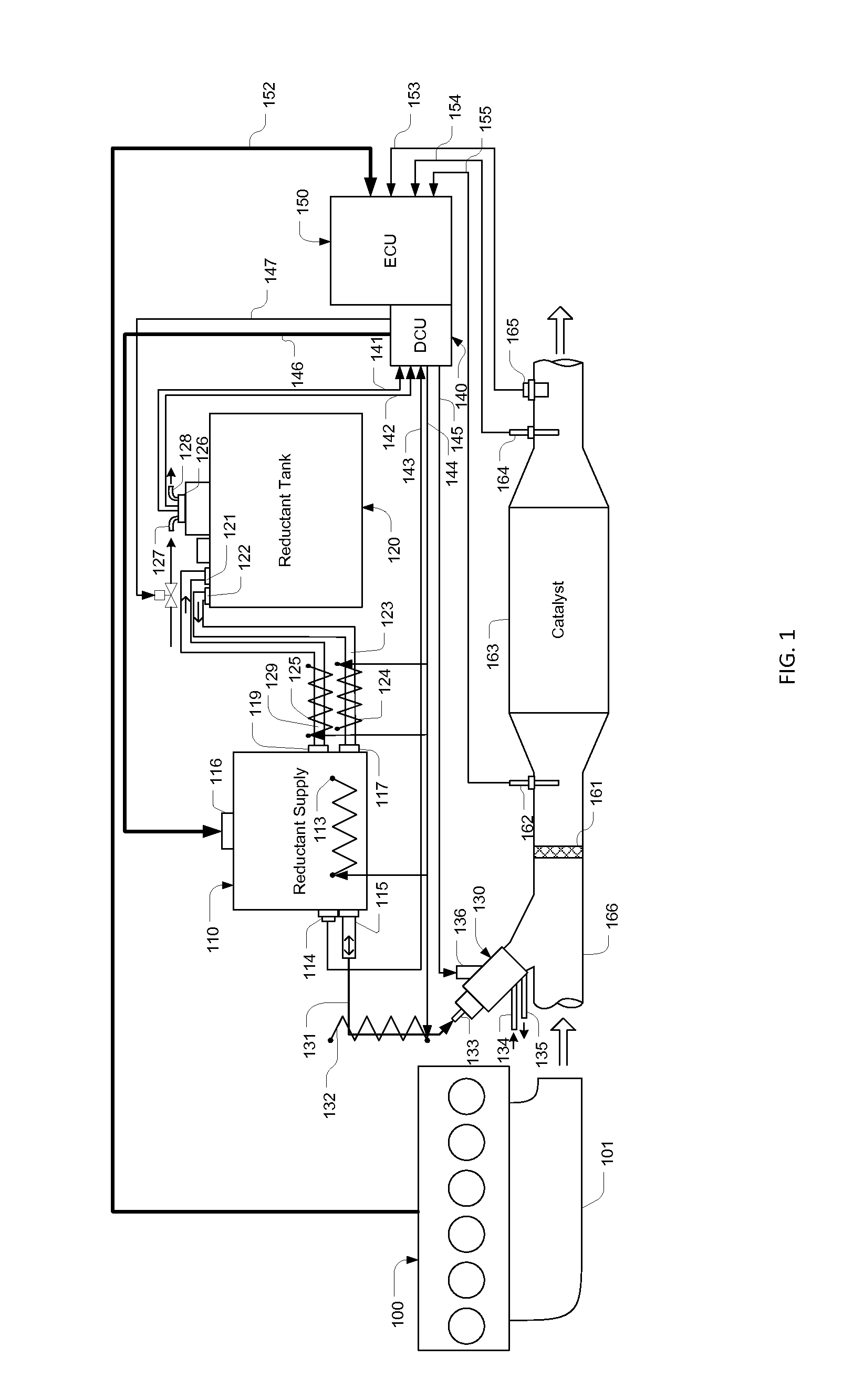

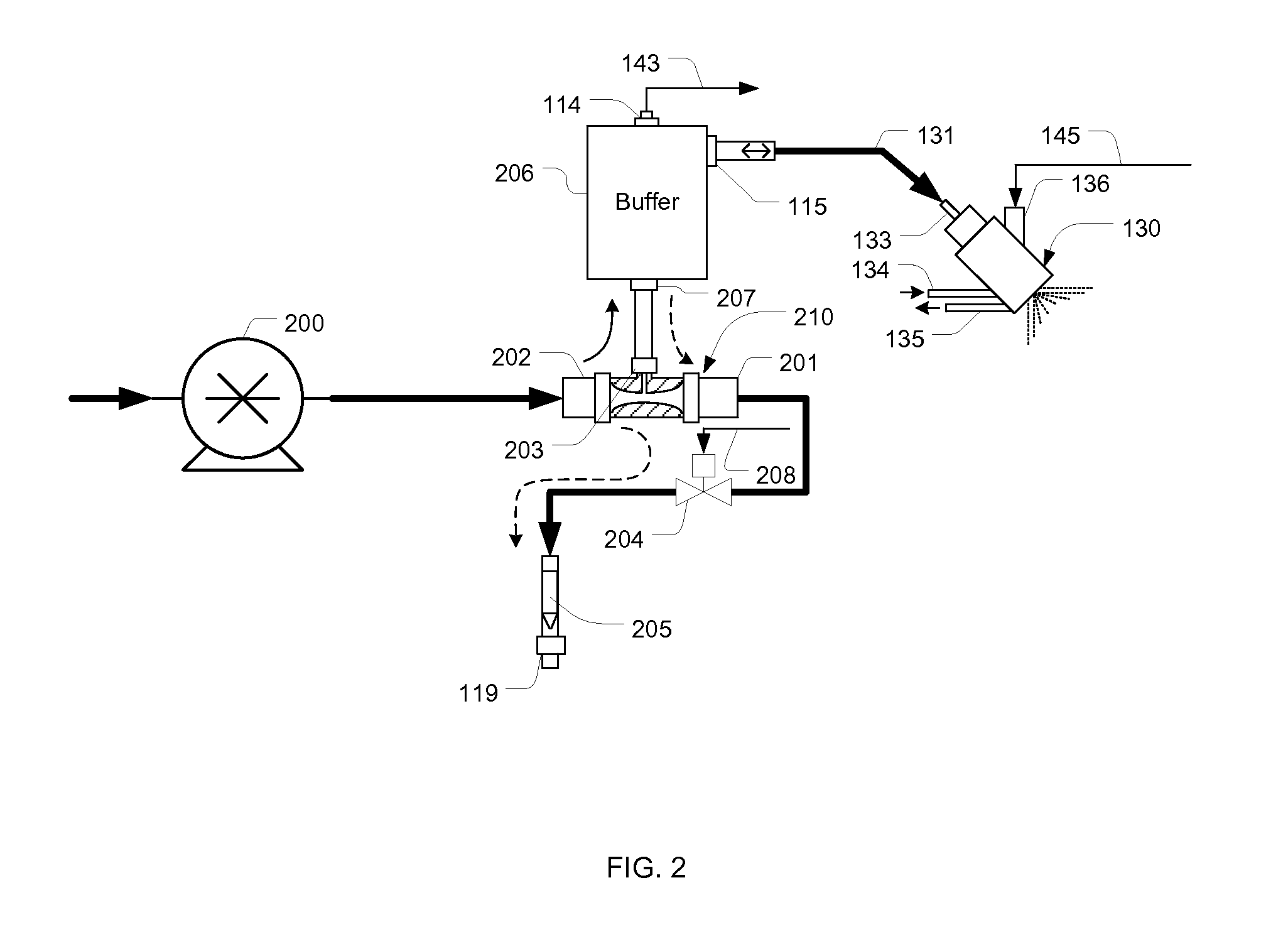

Reductant delivery apparatus with purging means

InactiveUS20130055701A1Improve emission effectRelieve stressInternal combustion piston enginesExhaust apparatusControl flowStream flow

A dosing apparatus with purging means for delivering reductant into an exhaust gas treatment system of an internal combustion engine. The apparatus includes a first Venturi T connector with two high pressure ports and a low pressure port, and a purge control valve for switching from normal dosing to purging by controlling flow through the two high pressure ports. The apparatus may also include a second Venturi T connector and a reductant supply chamber for purging reductant residue in its pump and reductant passage lines. The apparatus may further include a purging controller that triggers a purging event according to engine oil or coolant temperature and controls the purging process after a dosing process completes.

Owner:YAN MI +1

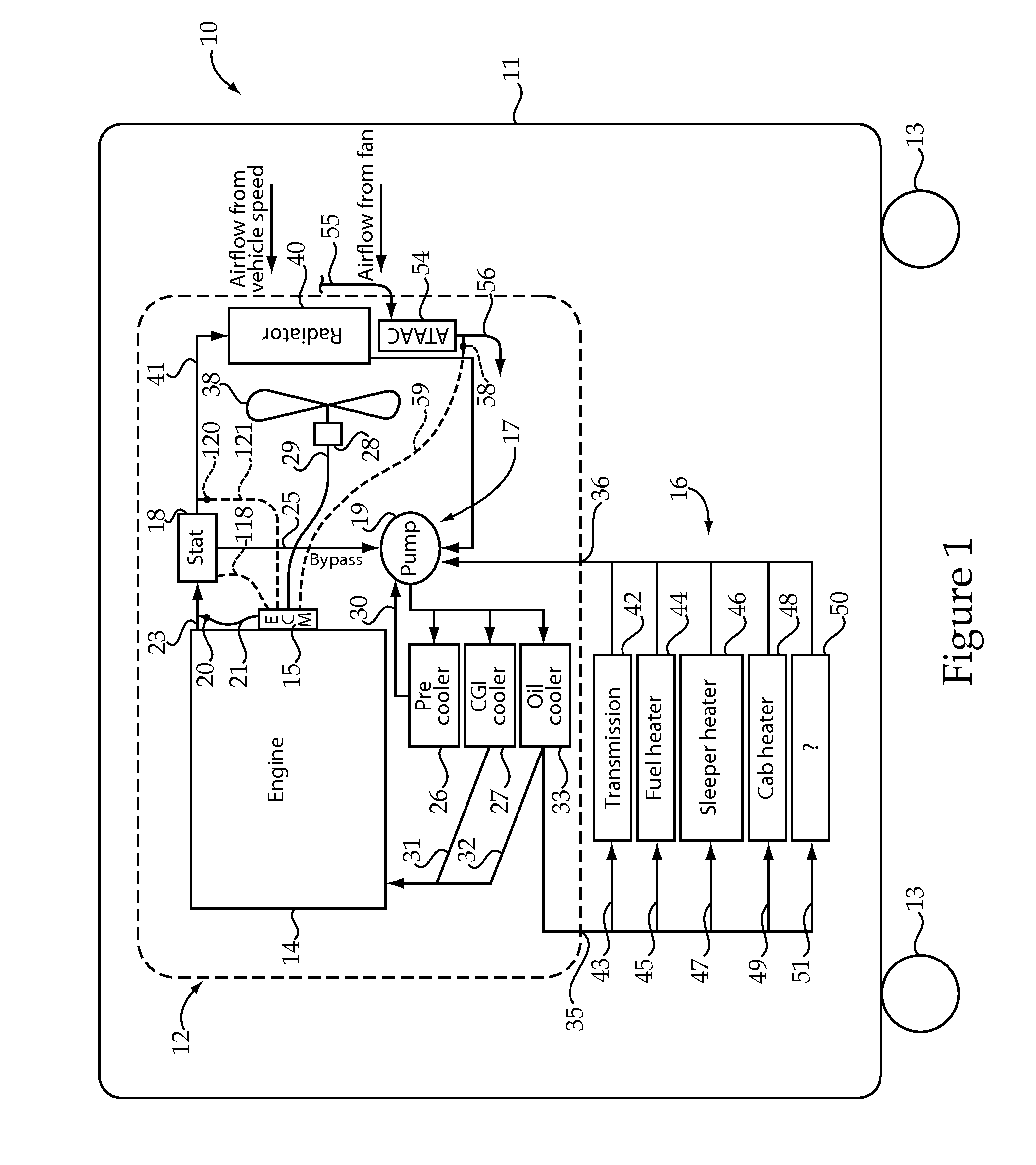

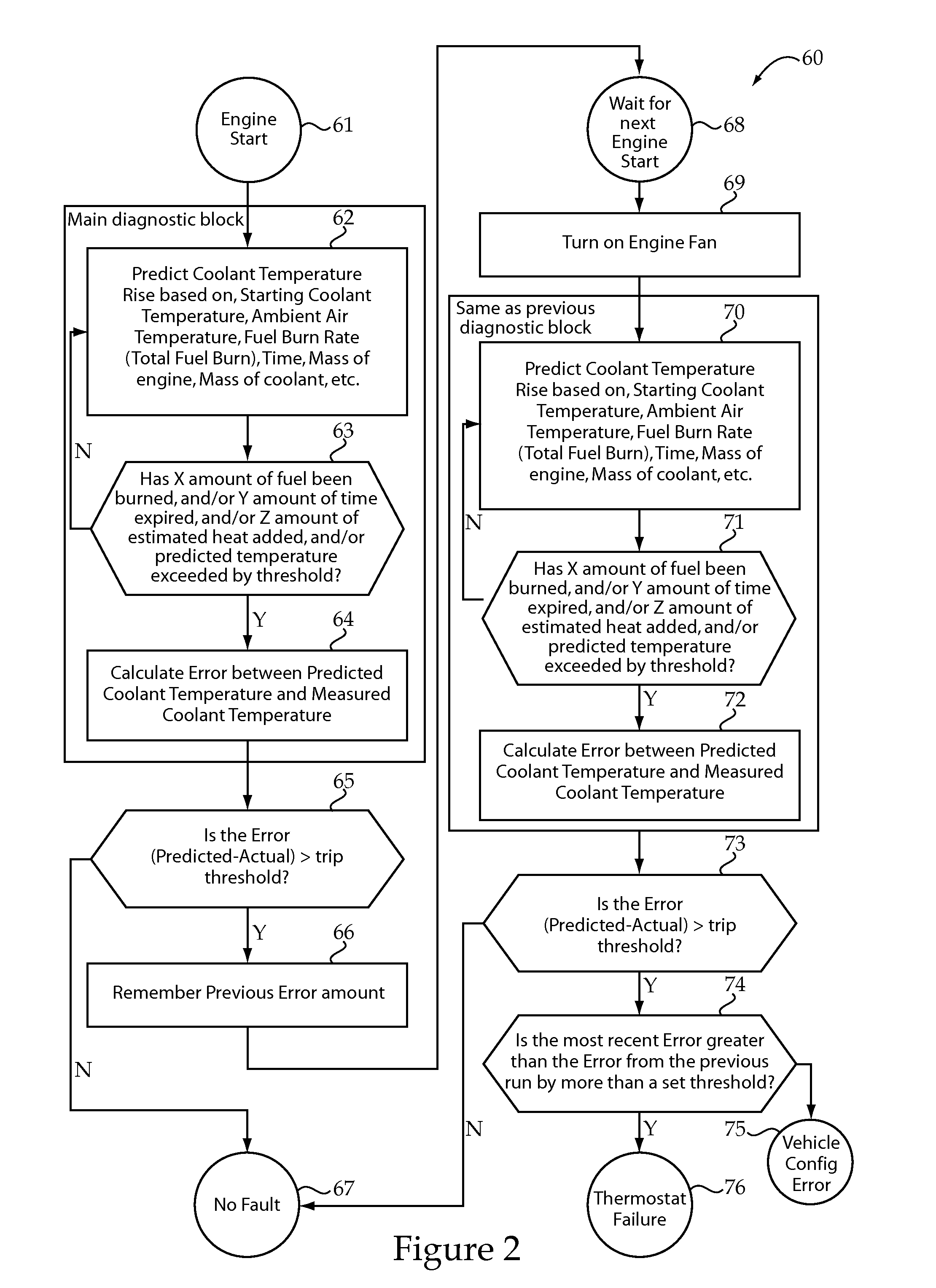

Engine cooling system onboard diagnostic strategy

An onboard cooling system diagnostic strategy utilizes at least one temperature sensor fluidly positioned between an electronically controlled engine and a thermostat. The diagnostic algorithm operates by monitoring coolant temperature during engine startup. By comparing the actual coolant temperature during engine start-up to a predicted coolant temperature that should occur if no cooling system error is present, a cooling system fault condition may be identified. If a cooling system fault is detected, the diagnostic logic may activate the engine cooling fan or intrusively open an electrically controlled thermostat while monitoring the coolant temperature response to the intrusive action. If there is a substantial change in coolant temperature responsive to the intrusive action, this phenomenon can be utilized to correctly distinguish between a thermostat failure and a vehicle configuration error corresponding to an overcooled vehicle. The present disclosure also can utilize a similar strategy to diagnose problems associated with other vehicle fluid coolers that exchange heat with ambient air moved by a circulation fan.

Owner:CATERPILLAR INC

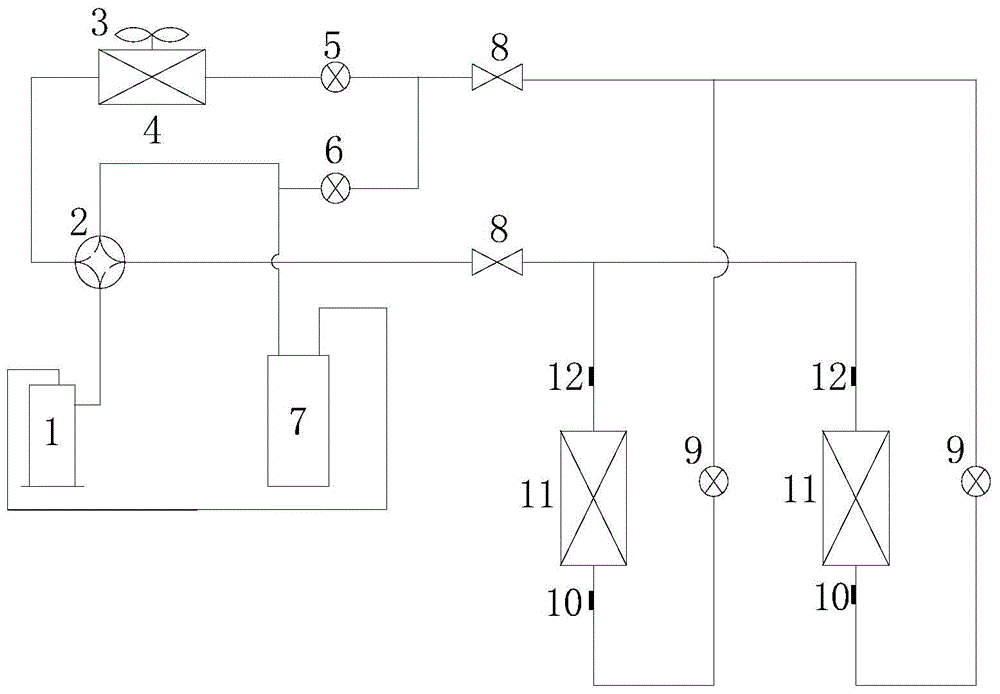

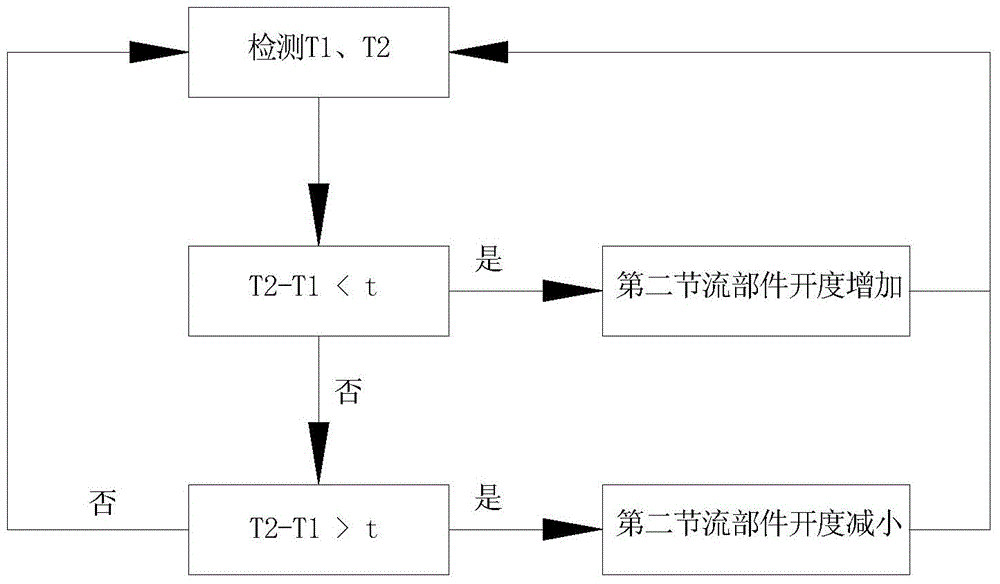

Multi-split air conditioner and control method thereof

InactiveCN104807229AStable superheatMechanical apparatusSpace heating and ventilation safety systemsVapor–liquid separatorEvaporation

The invention belongs to the technical field of a multi-split air conditioner, and discloses a multi-split air conditioner and a control method thereof. A compressor is respectively communicated with an inlet of an outdoor heat exchanger and an outlet of a gas-liquid separator; an indoor evaporation unit is arranged between an outlet of the outdoor heat exchanger and an inlet of the gas-liquid separator; the outlet of the outdoor heat exchanger and the inlet of the gas-liquid separator are communicated through a second throttling component; the indoor evaporation unit comprises a plurality of groups of indoor evaporators in parallel connection, and an inlet temperature sensing bag and an outlet temperature sensing bag are respectively arranged on a branch at which each indoor evaporator is located. The coolant temperature at the outlet and the inlet of the indoor evaporator is detected, and the overheat degree is obtained through calculation and is compared with a set value, so the opening degree of the second throttling component is regulated according to the result, and the goal of regulating the total quantity of the coolant entering the indoor evaporation unit is achieved, and the frequent starting and stopping of an outdoor unit is avoided, the use comfort degree of a user is improved, and the stability of an air conditioner system is ensured.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

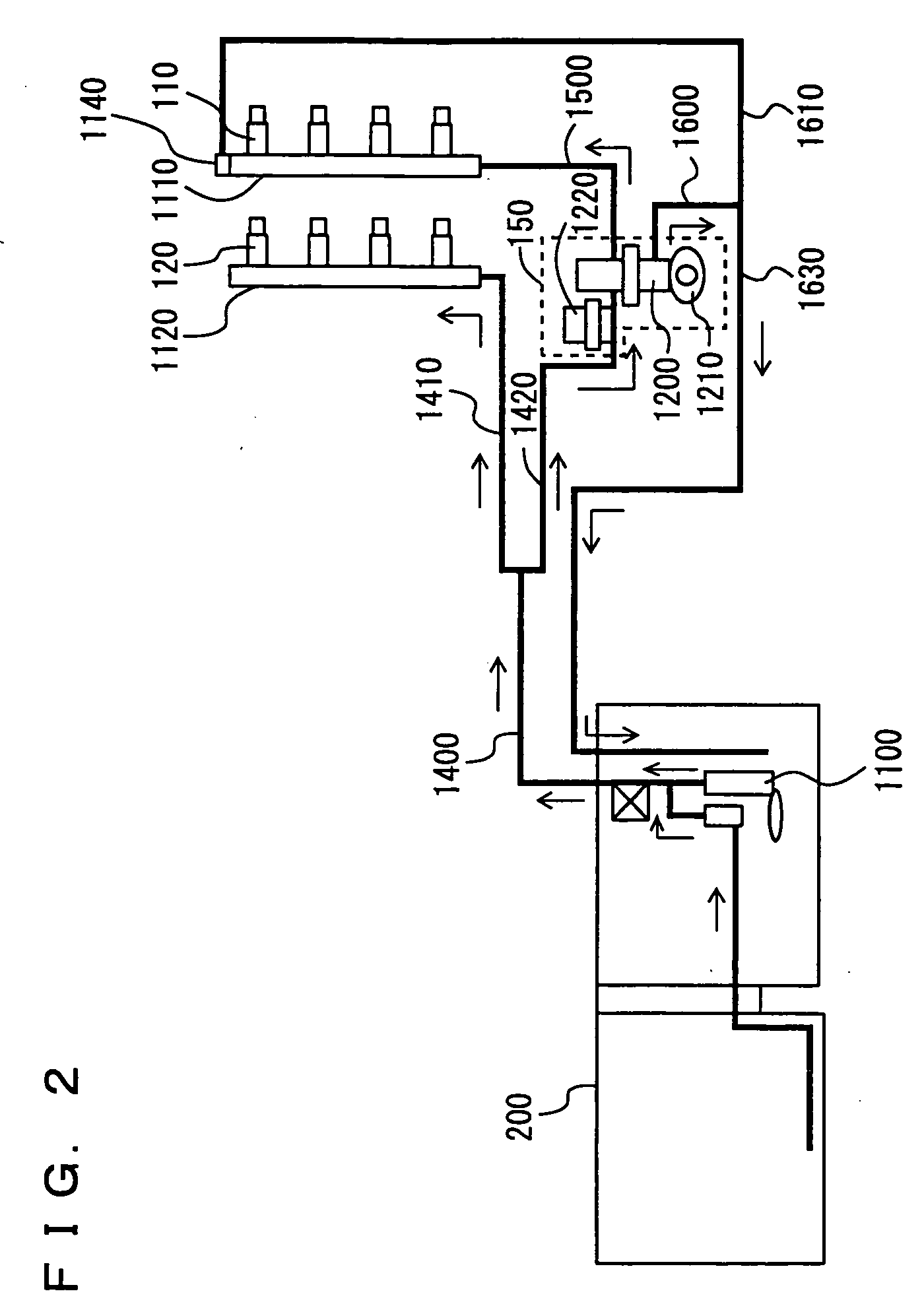

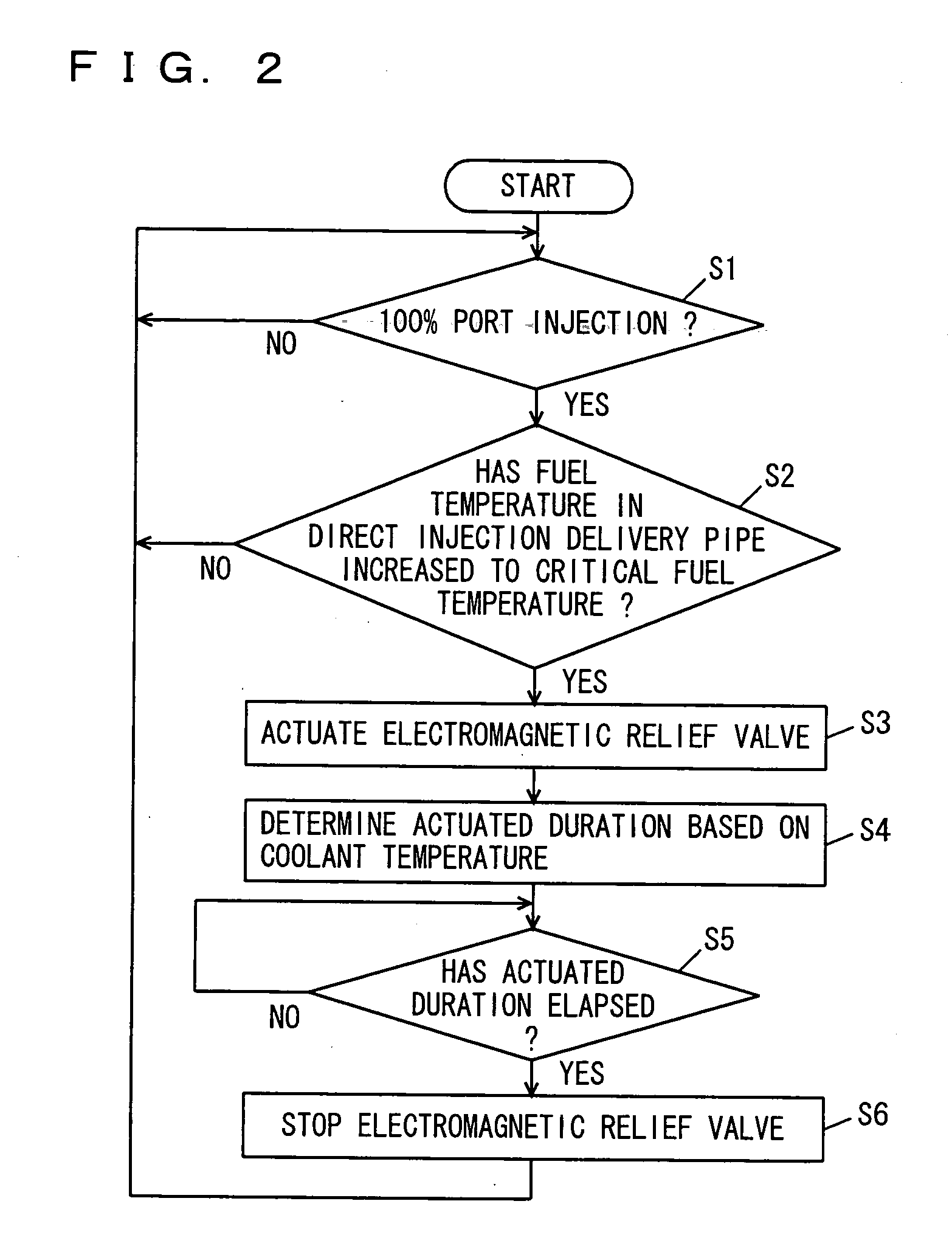

Fuel supply apparatus for internal combustion engine

InactiveUS20060075992A1Suppress mutationImprove the state of combustionElectrical controlInternal combustion piston enginesHigh pressureCoolant temperature

The engine ECU executes a program including the step of detecting an engine coolant temperature, the step of detecting an engine speed and an engine load, the step of estimating a temperature at a tip end of an in-cylinder injector based on the engine coolant temperature, the engine speed and the engine load, and, when the temperature at the tip end is greater than a guaranteed temperature, the step of calculating a drive duty of a high-pressure fuel pump that ensures a decrease of the temperature at the tip end of the in-cylinder injector to the guaranteed temperature, and the step of controlling the high-pressure fuel pump using the drive duty.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com