Abnormality determination apparatus and abnormality determination method for coolant temperature sensor, and engine cooling system

a technology of abnormality determination and abnormality determination, which is applied in the field of abnormality determination apparatus and abnormality determination method of coolant temperature sensor, and engine cooling system, which can solve problems such as coolant temperature sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

of Determination Process

[0058]An example of the abnormality determination process for the heater inlet coolant temperature sensor 22 will be described with reference to a flowchart shown in FIG. 5. The process routine shown in FIG. 5 is executed by the ECU 300.

[0059]The process routine shown in FIG. 5 is started at the time point (IG-ON) when the ignition switch is turned on. When the process routine shown in FIG. 5 is started, the ECU 300, firstly in step ST101, picks the heater inlet coolant temperature thw2 occurring at the time of start of the engine from the output signal of the heater inlet coolant temperature sensor 22. Next, in step ST102, the ECU 300 reads in an abnormality determination value α (° C.) for use in the determination processes of step ST105 and step ST110 that are described later. This abnormality determination value a may be a constant value (e.g., α=5° C.), or may also be variably set according to the coolant temperature occurring at the time of start of the...

example 2

of Determination Process

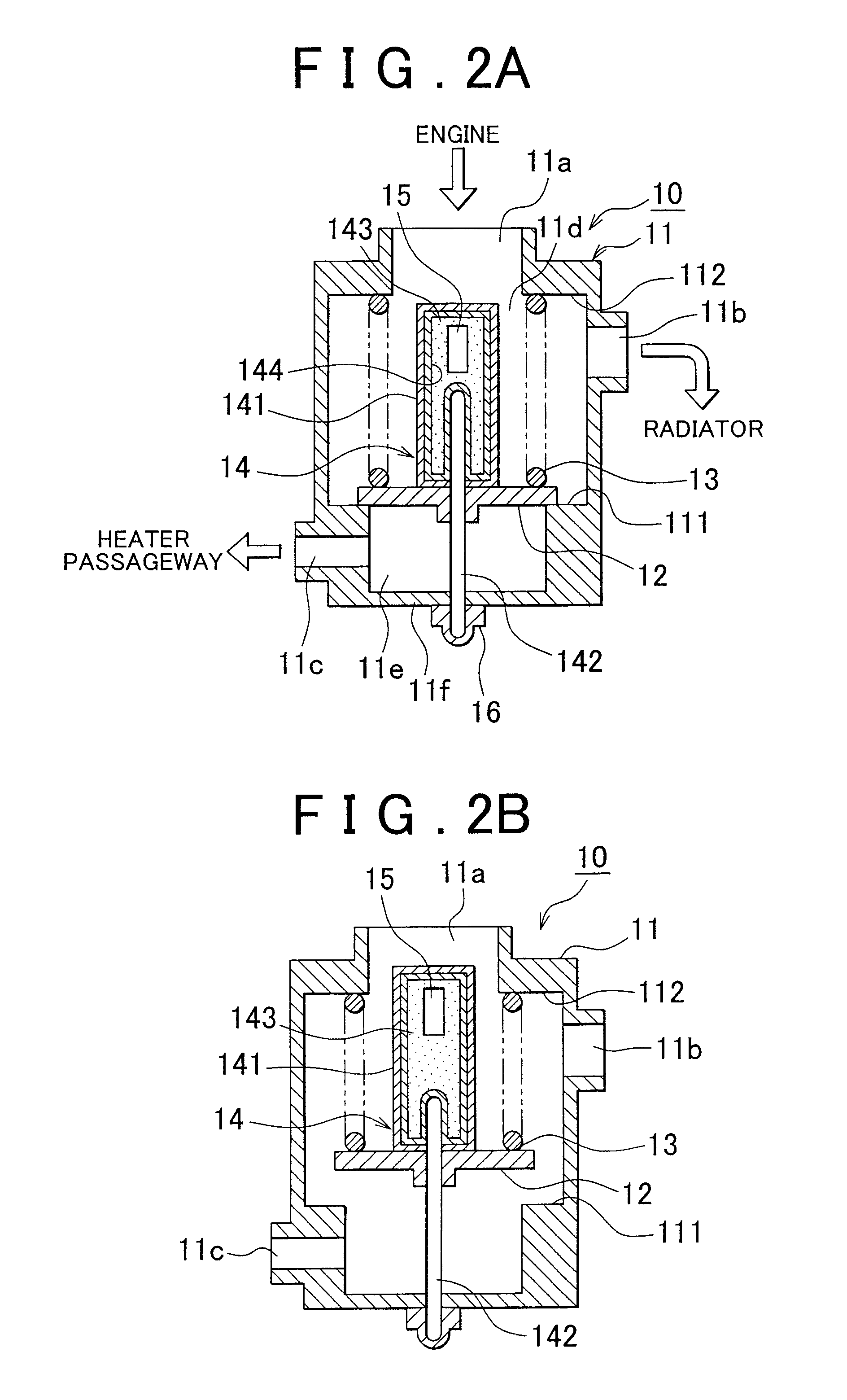

[0079]Although in the example 1 of the determination process, it is determined that the changeover valve 10 has opened, at the time point when a certain time (time time 1) elapses following the start of electrification of the electric heater 15 of the changeover valve 10, it is also permissible to estimate the ambient coolant temperature Tvw of the temperature sensitive portion 14 of the changeover valve 10, and determine whether the changeover valve 10 has opened on the basis of the estimated value of the changeover valve's ambient coolant temperature Tvw.

[0080]Concretely, using the engine coolant temperature thw1 detected by the engine coolant temperature sensor 21, the ECU 300 estimates the changeover valve's ambient coolant temperature Tvw on the basis of a map or a calculation expression. At the time point when the estimated value of the changeover valve's ambient coolant temperature Tvw reaches the valve-opening temperature (70° C.) of the changeover va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com