Patents

Literature

23001 results about "Polyolefin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A polyolefin is a type of polymer produced from a simple olefin (also called an alkene with the general formula CₙH₂ₙ) as a monomer. For example, polyethylene is the polyolefin produced by polymerizing the olefin ethylene. Polypropylene is another common polyolefin which is made from the olefin propylene.

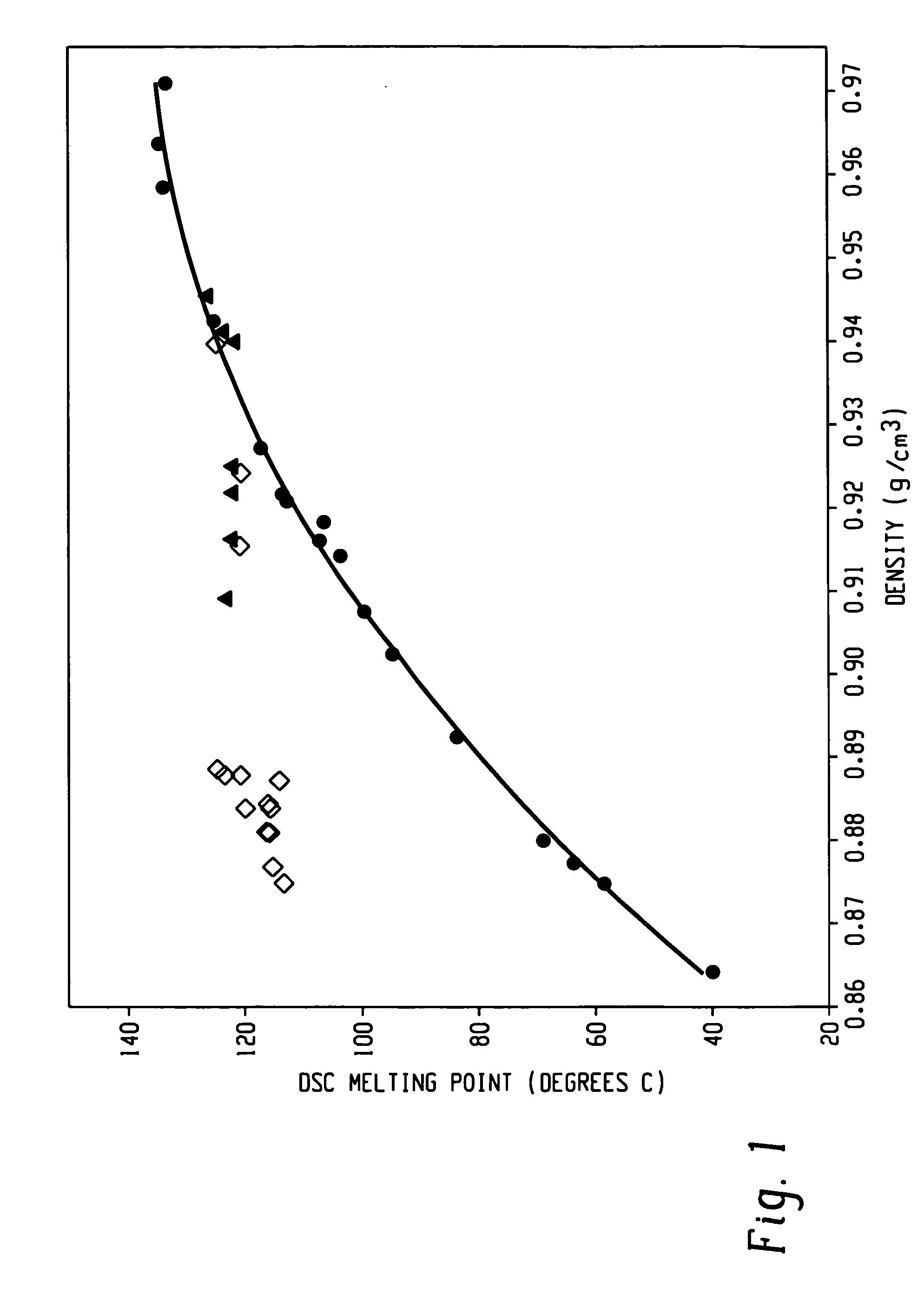

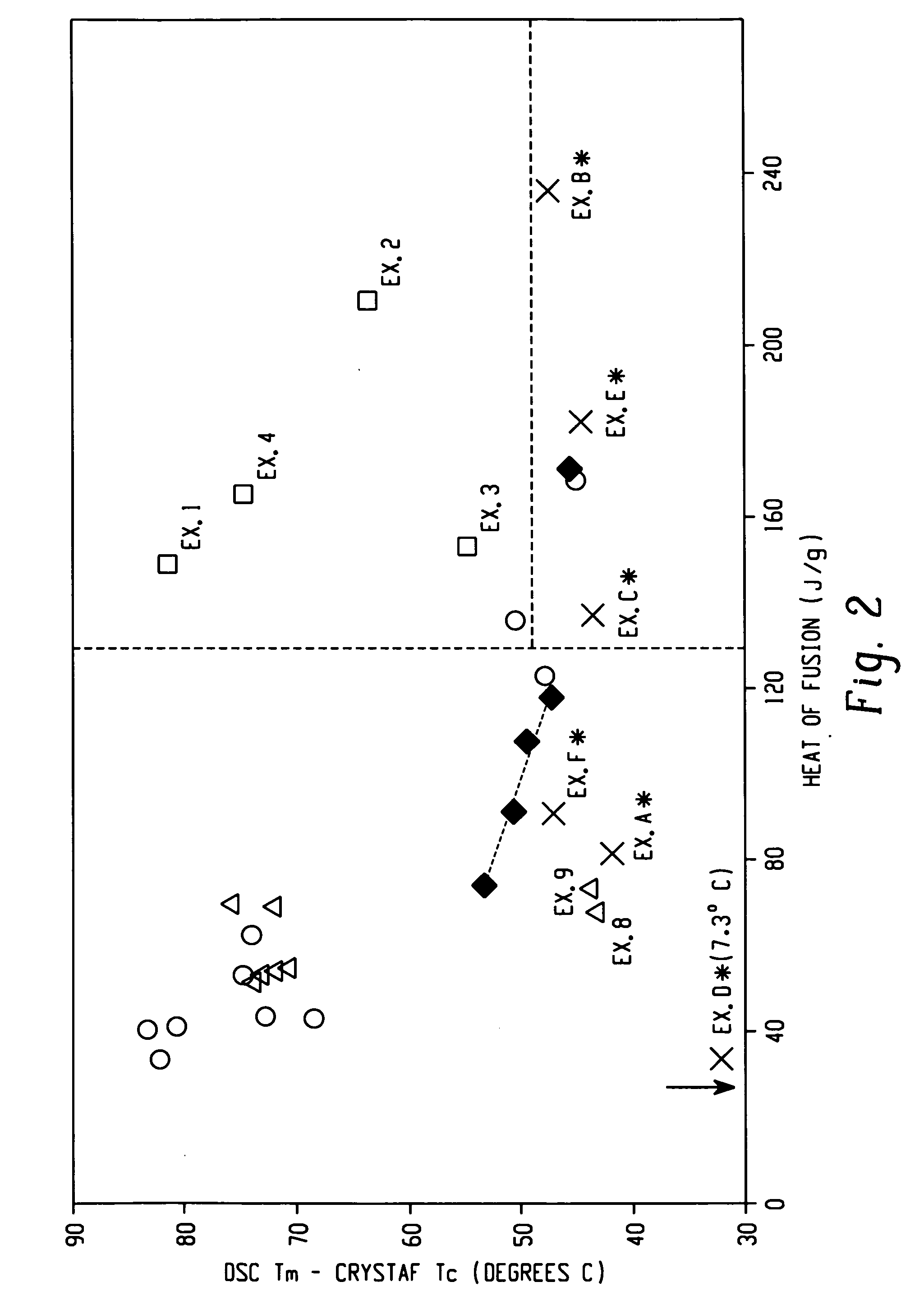

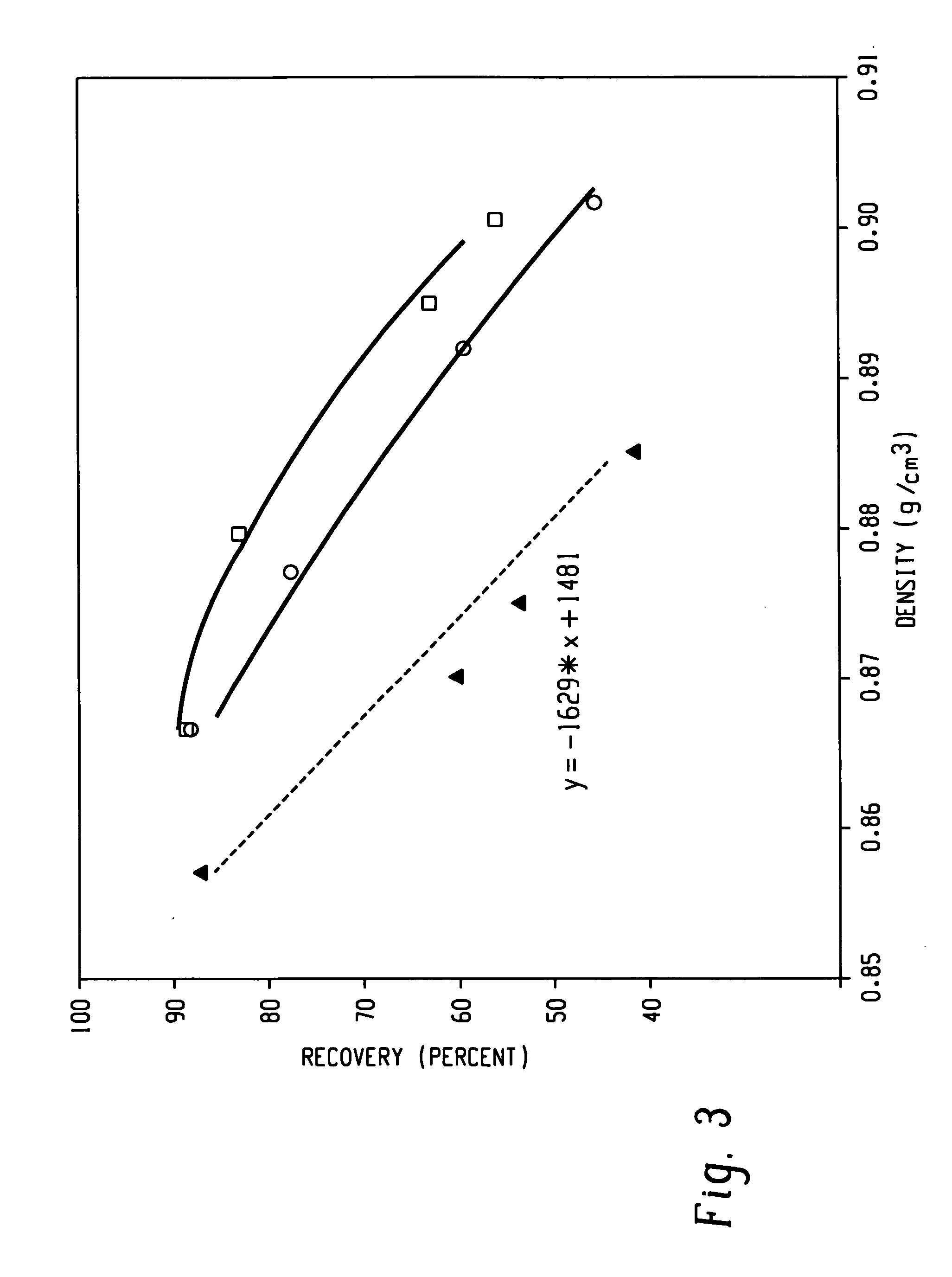

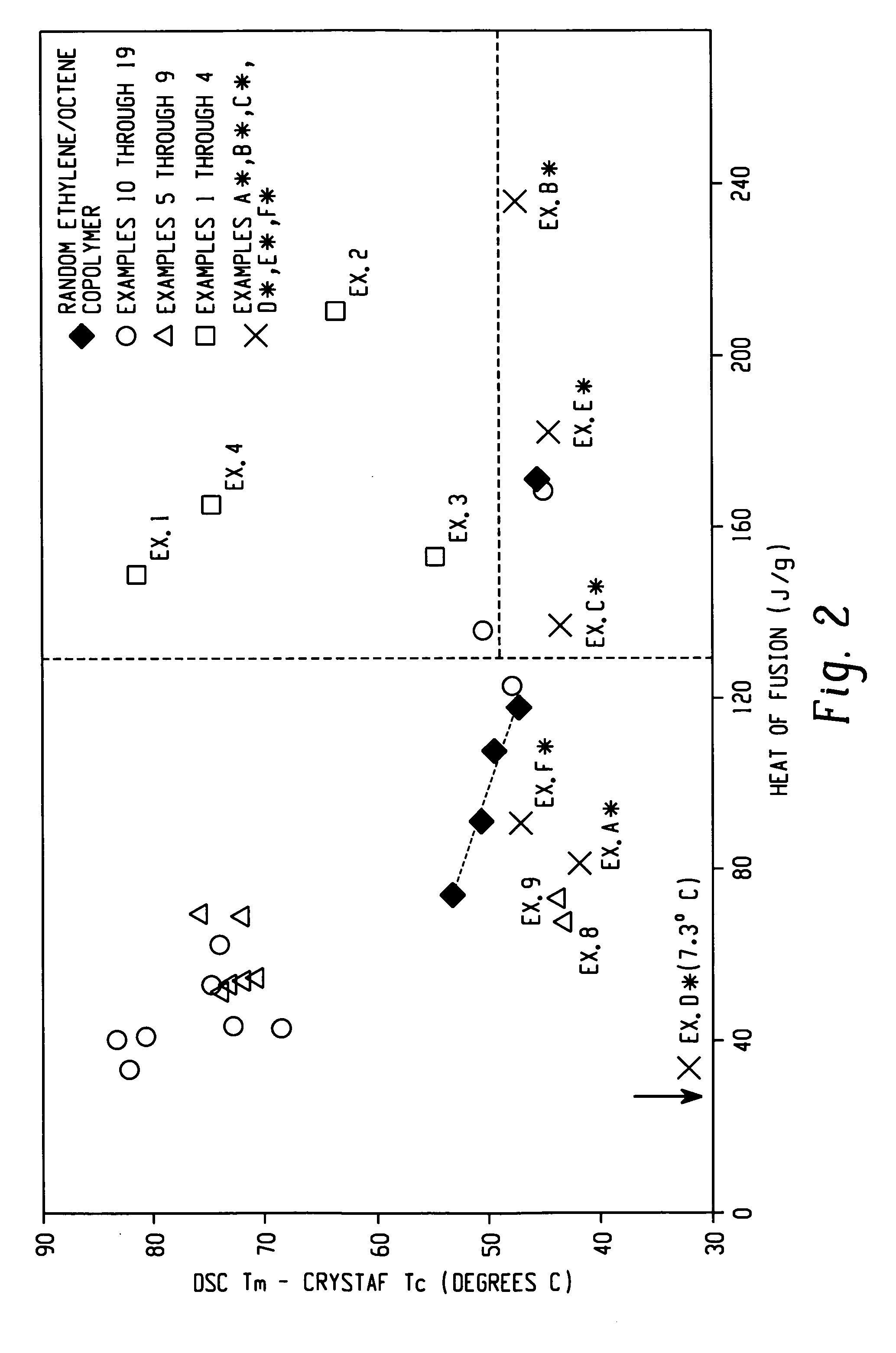

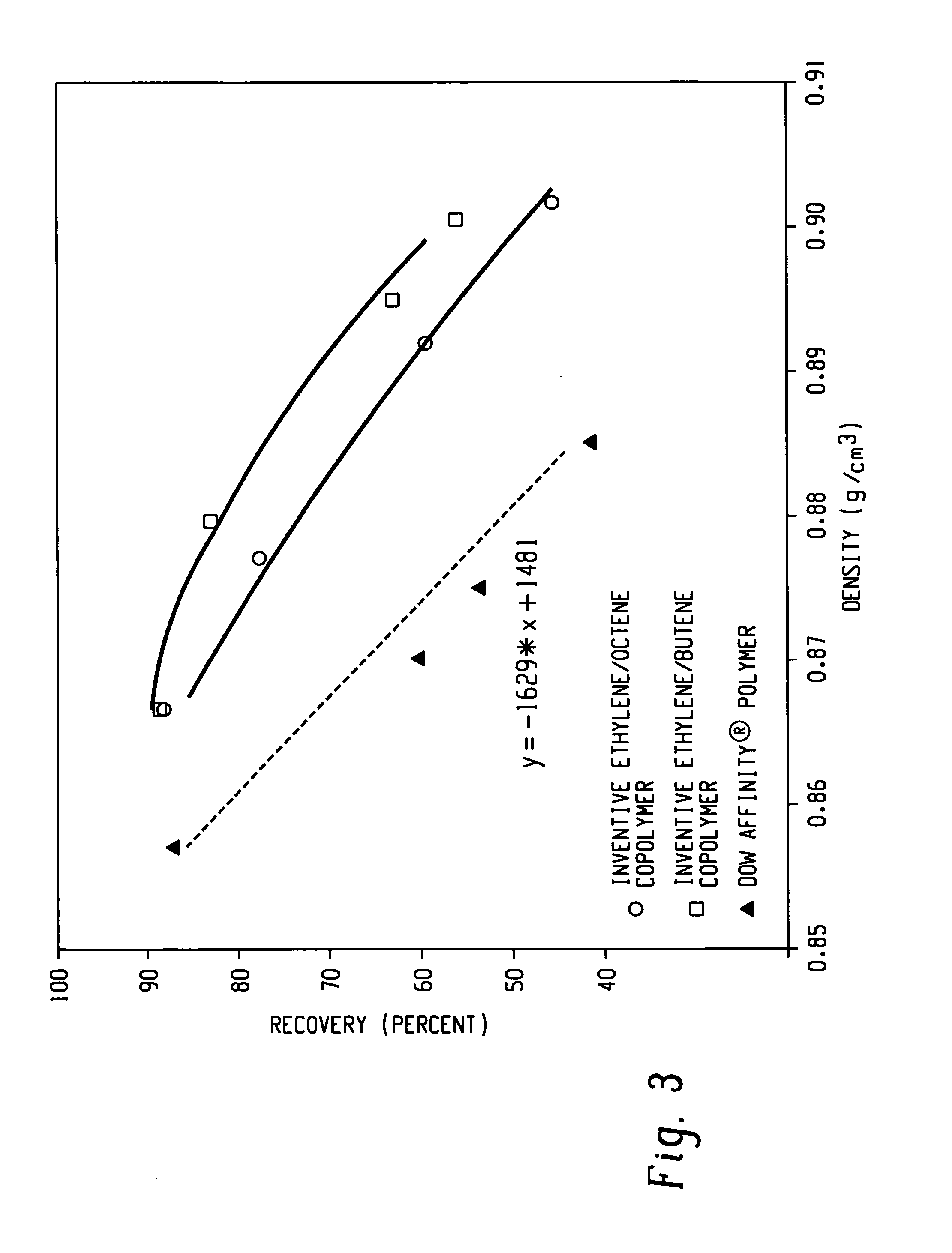

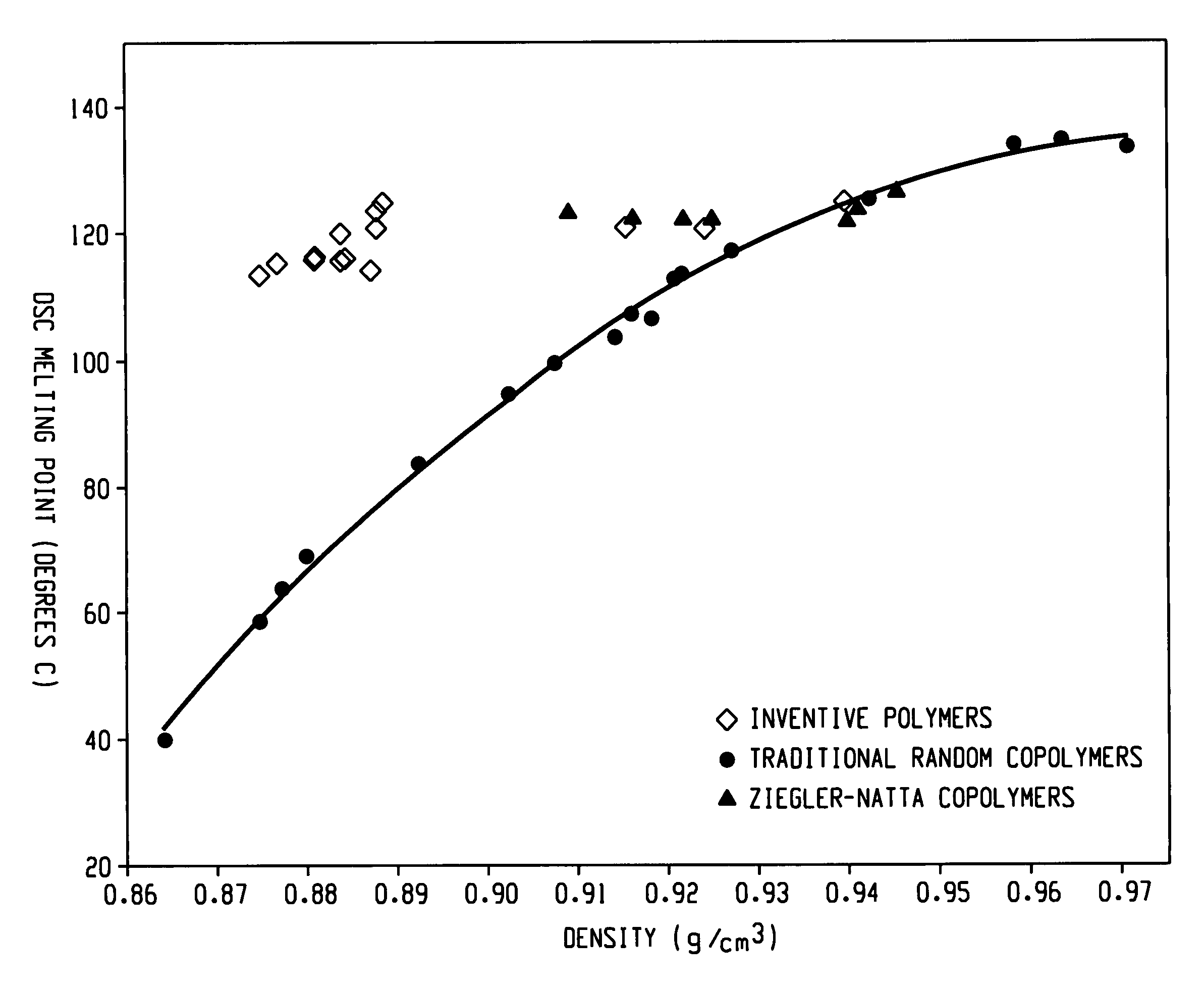

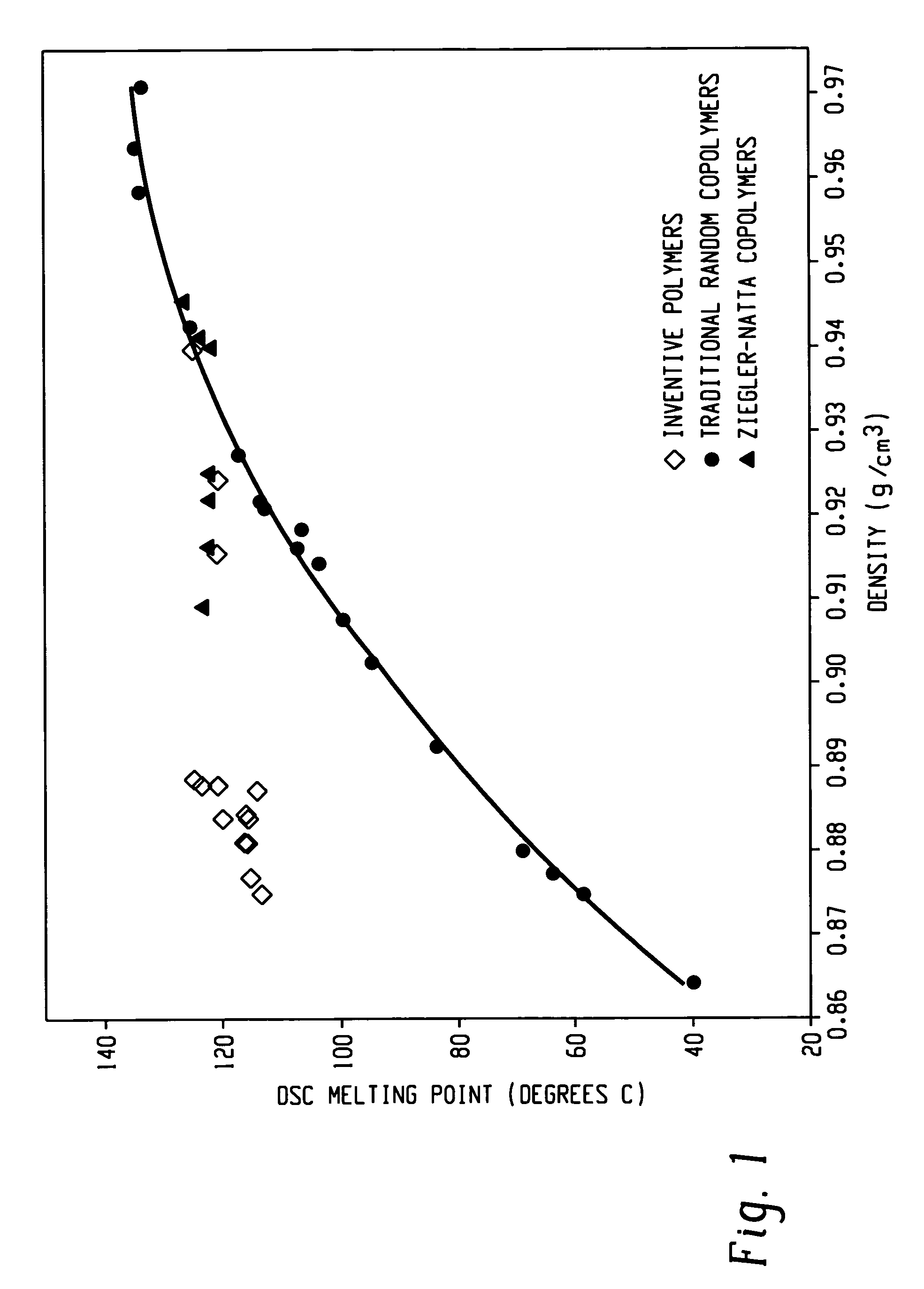

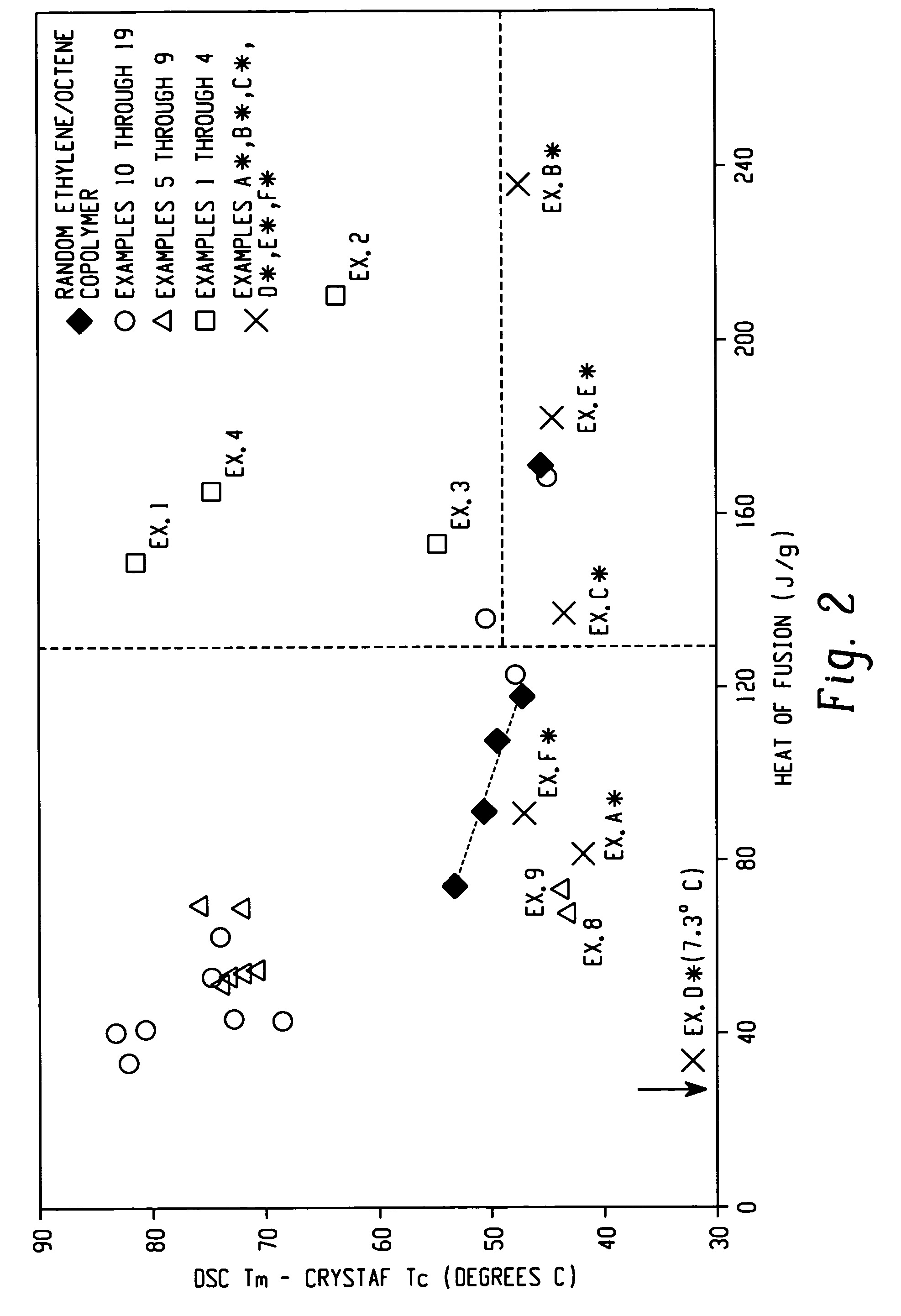

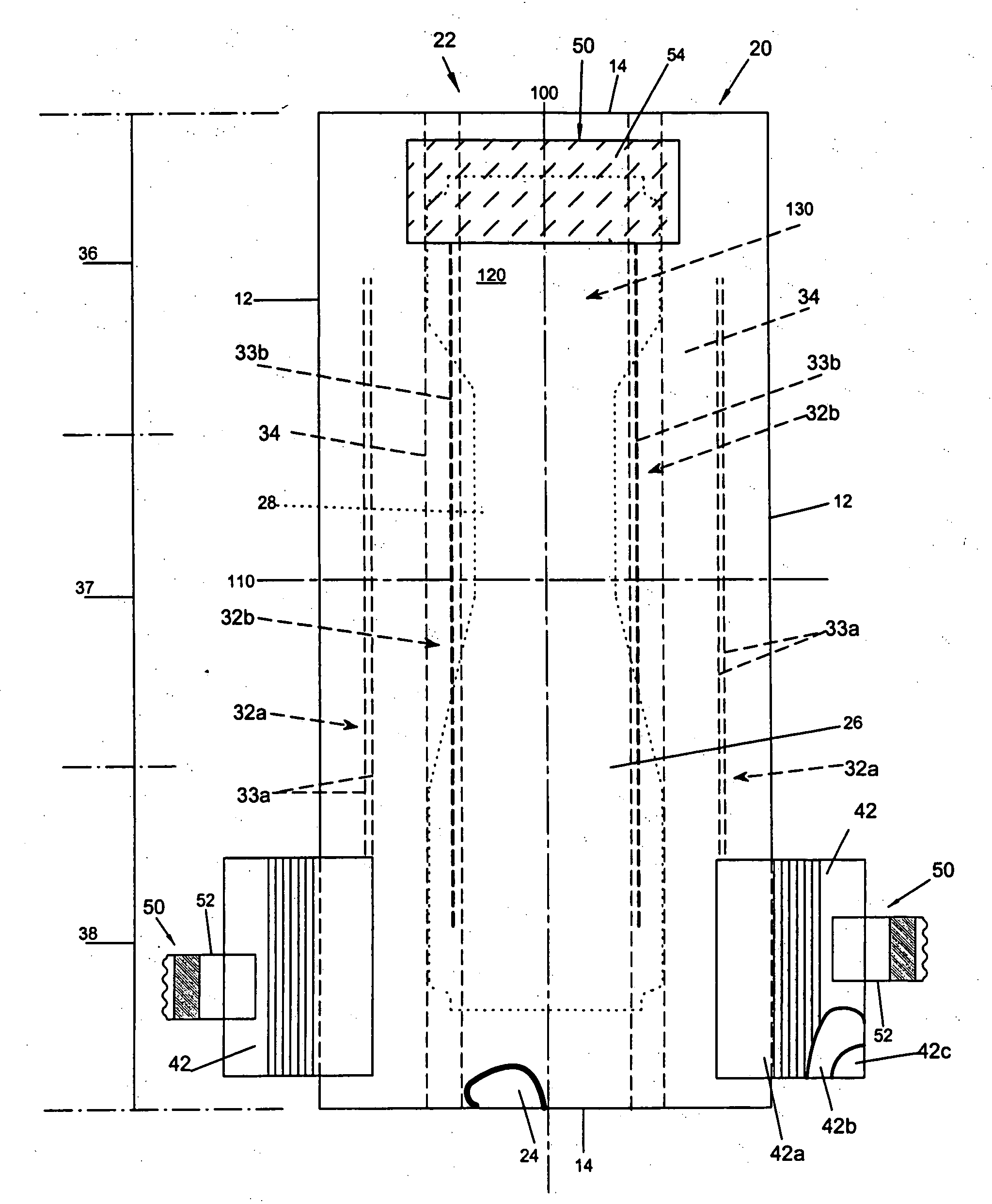

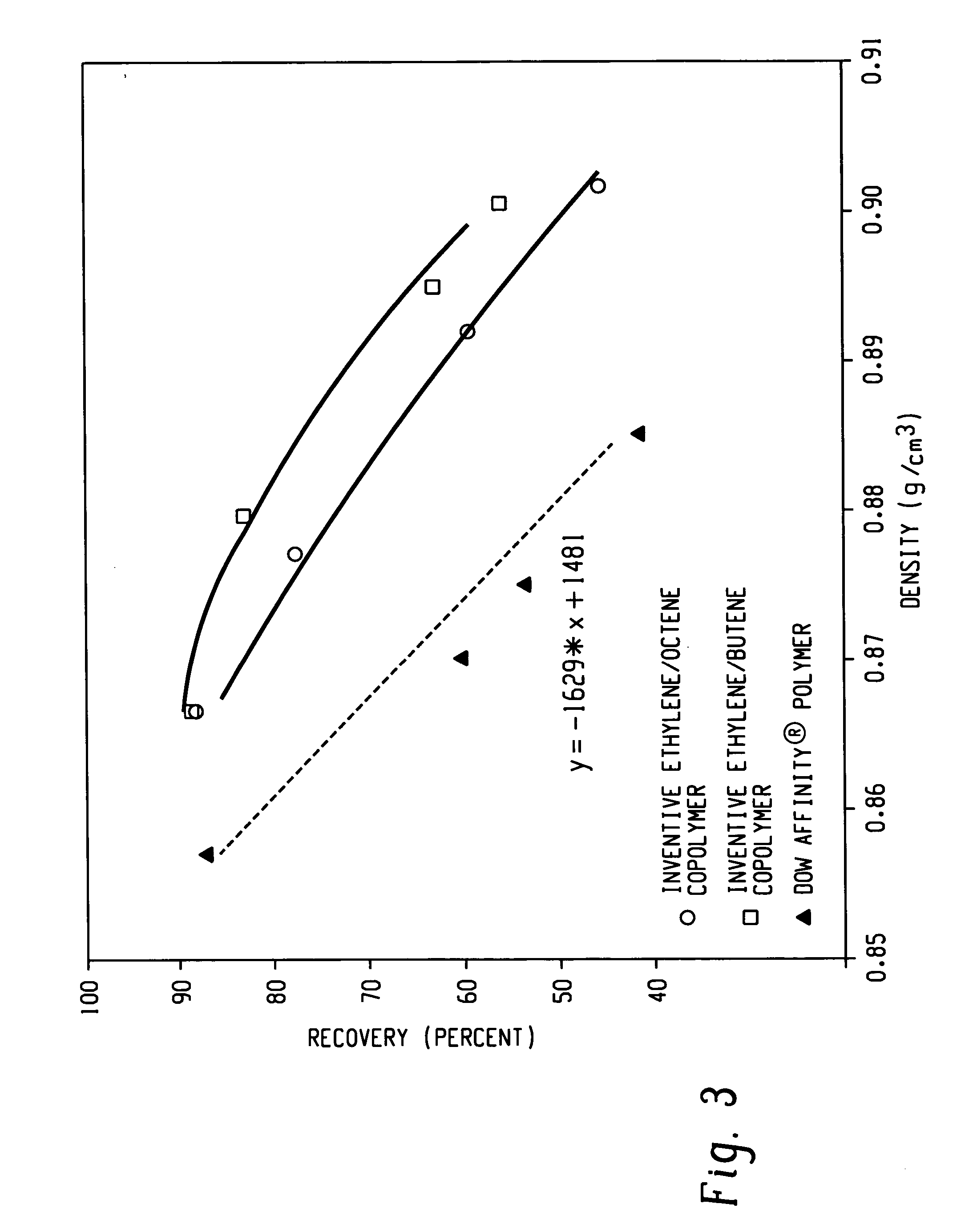

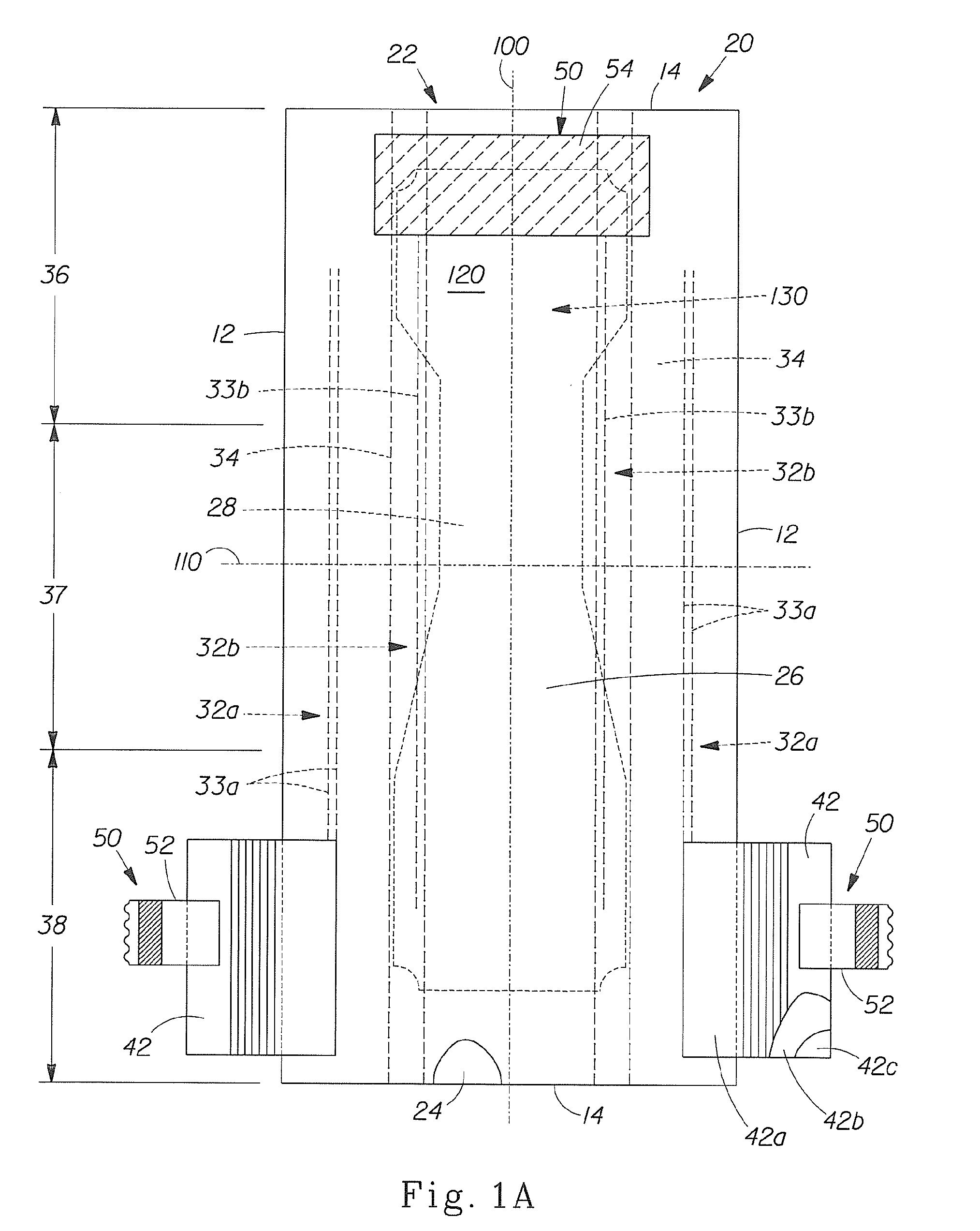

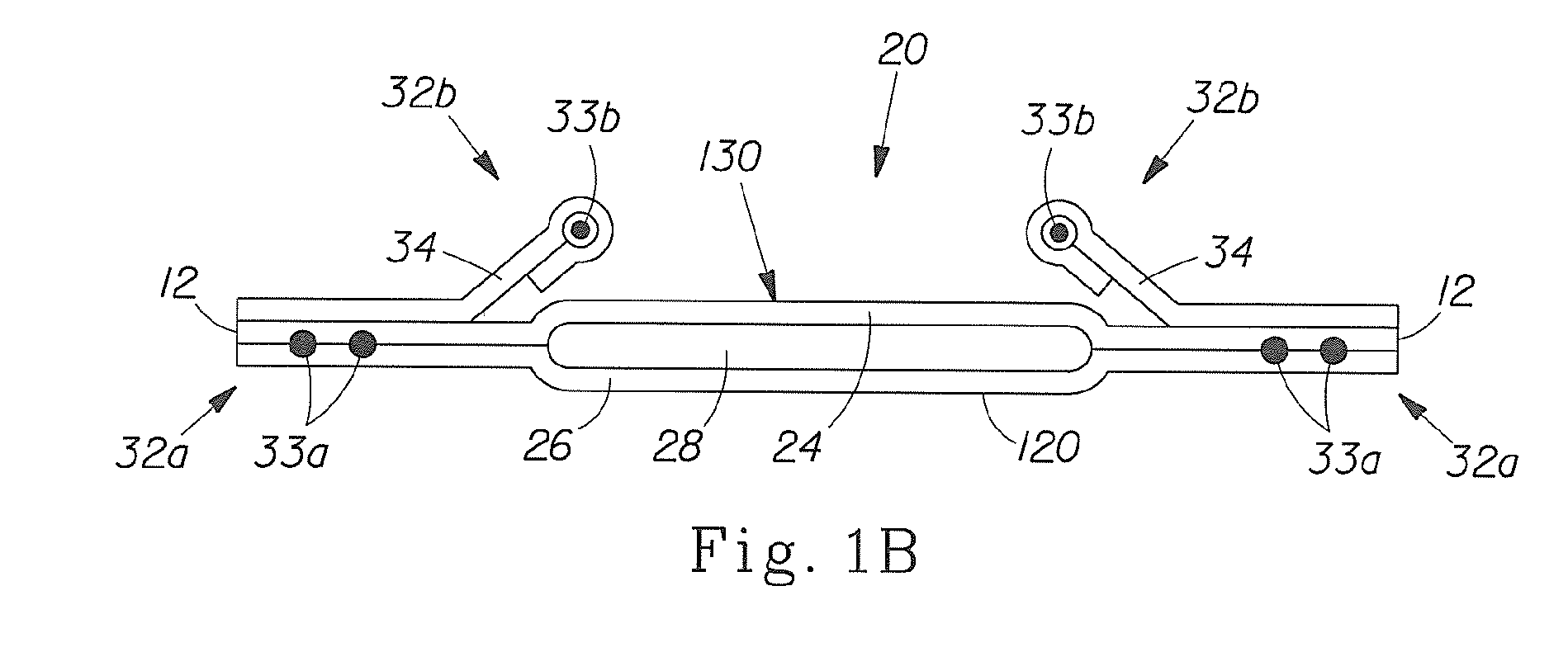

Compositions of ethylene/alpha-olefin multi-block interpolymer for elastic films and laminates

Owner:DOW GLOBAL TECH LLC

Absorbent article comprising a synthetic polymer derived from a renewable resource and methods of producing said article

An absorbent article is disclosed having a topsheet, a backsheet joined with the topsheet, an absorbent core disposed between the topsheet and the backsheet, and a synthetic superabsorbent polymer derived from a first renewable resource via at least one intermediate compound, wherein said superabsorbent polymer exhibits a defined Saline Flow Conductivity value and Absorption Against Pressure value. Alternately, an absorbent article is disclosed having a synthetic polyolefin derived from a first renewable resource via at least one intermediate compound. The synthetic polyolefin exhibits defined performance characteristics making the polyolefin particularly useful in certain components of the absorbent article. Methods for making the aforementioned absorbent articles are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

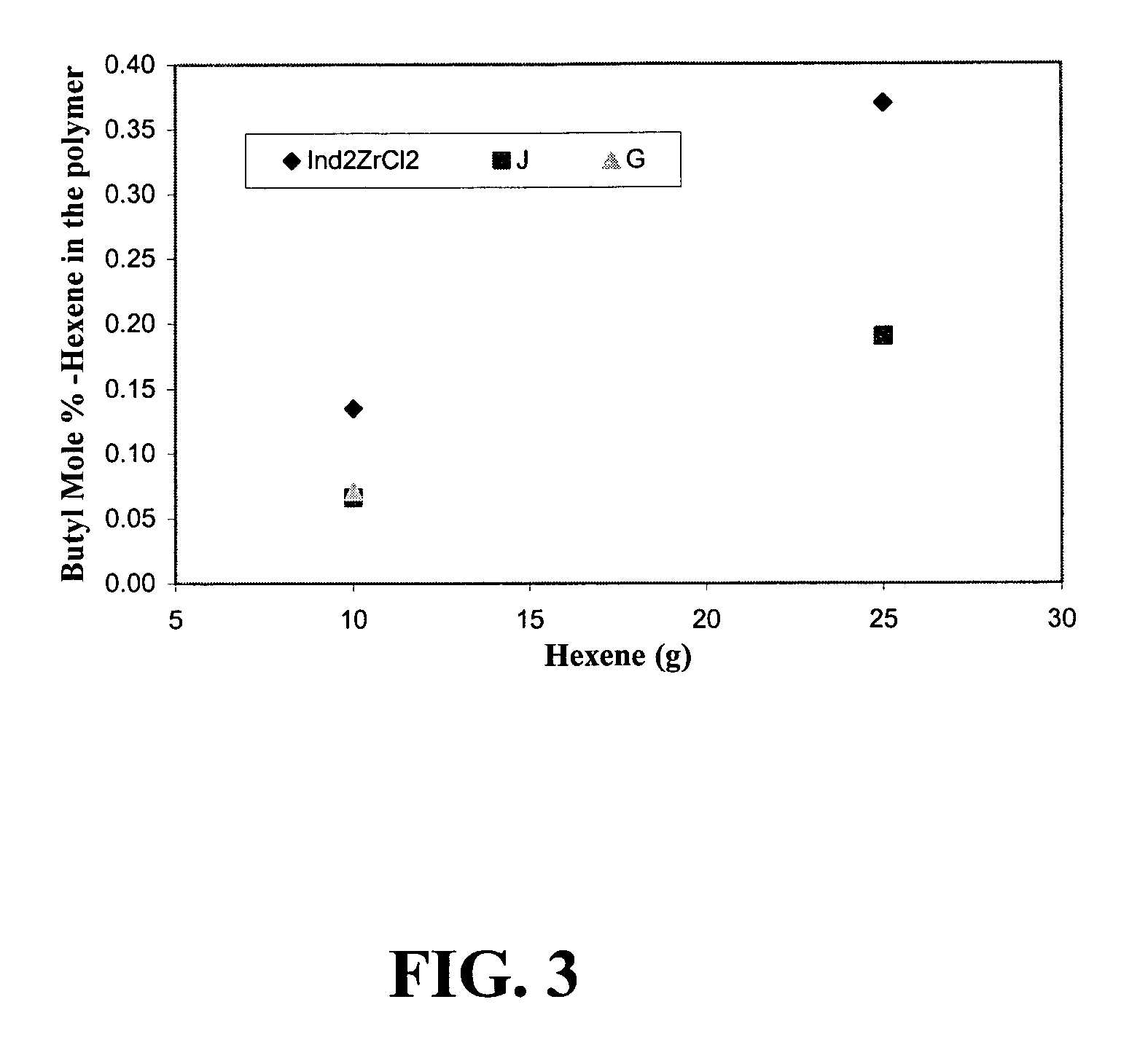

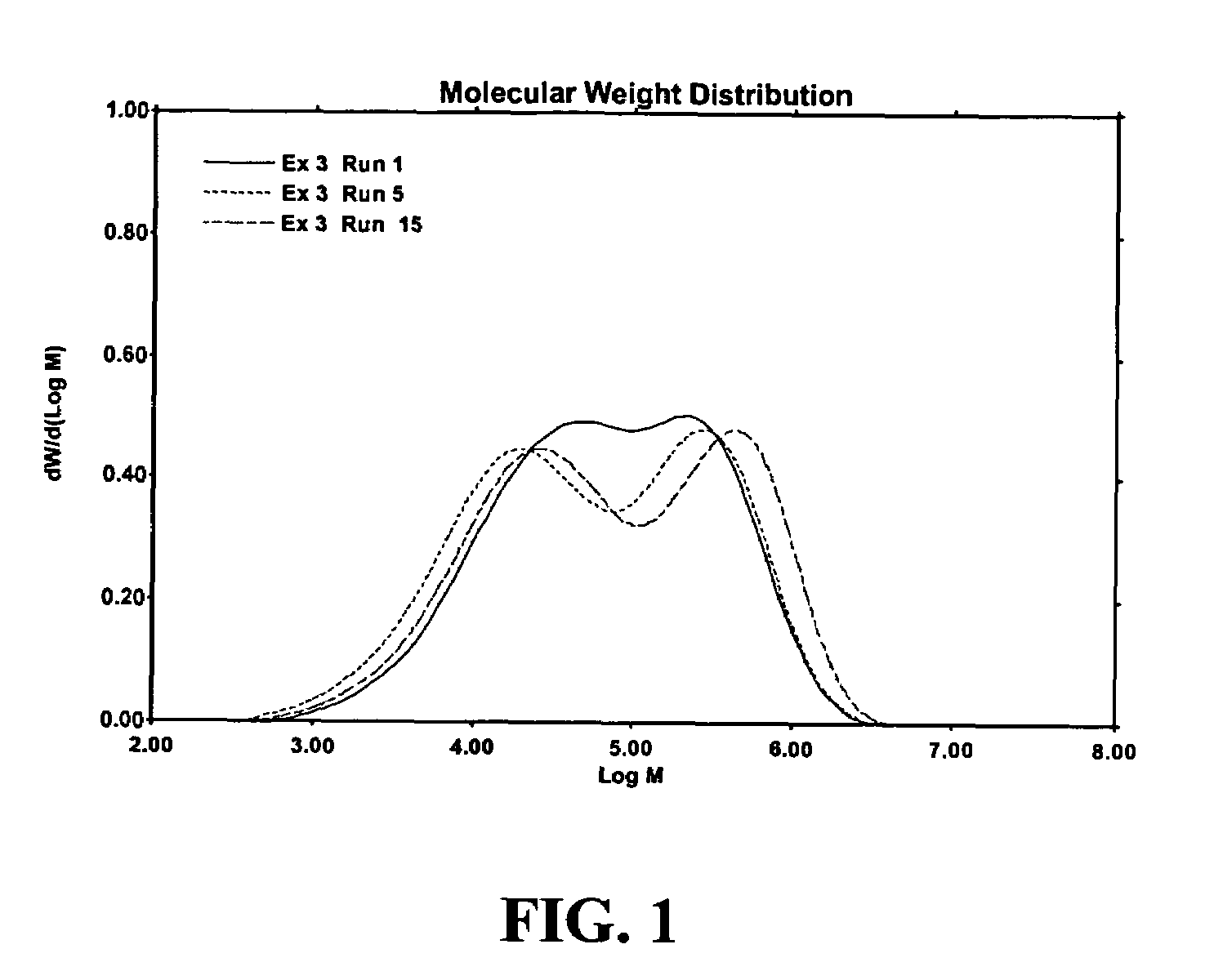

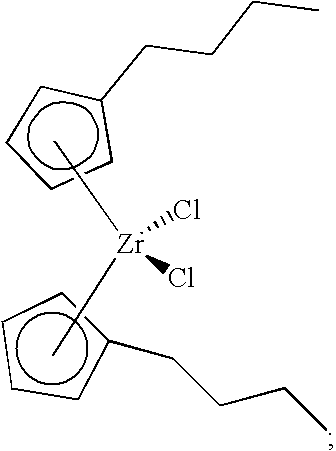

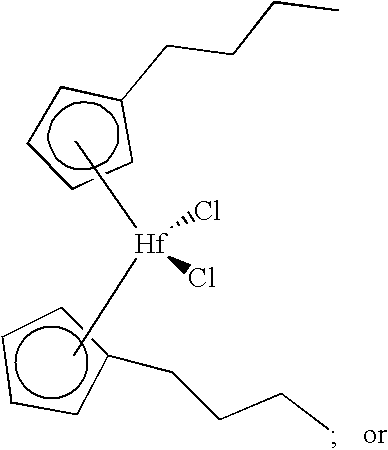

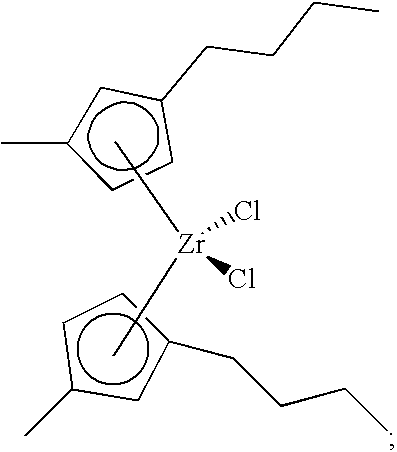

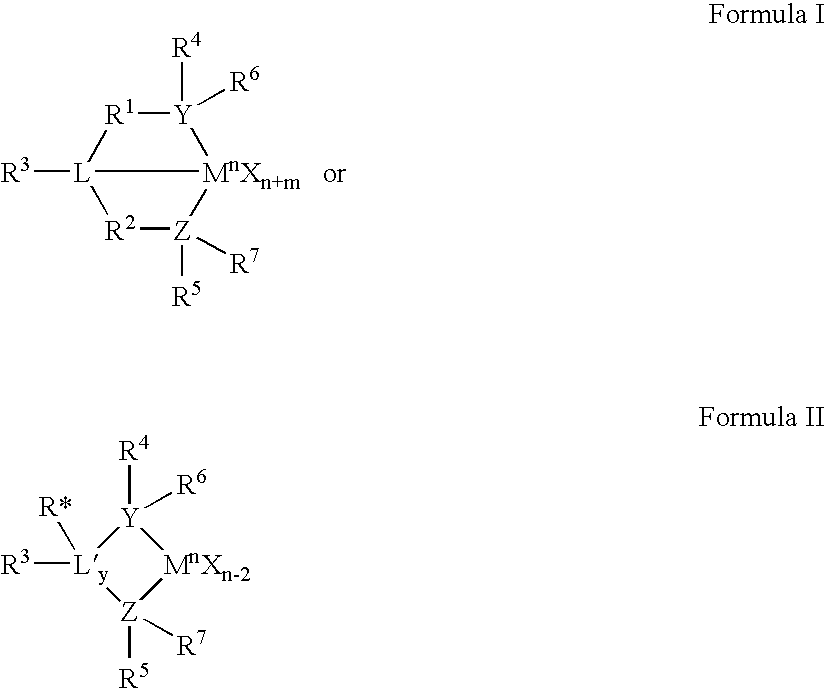

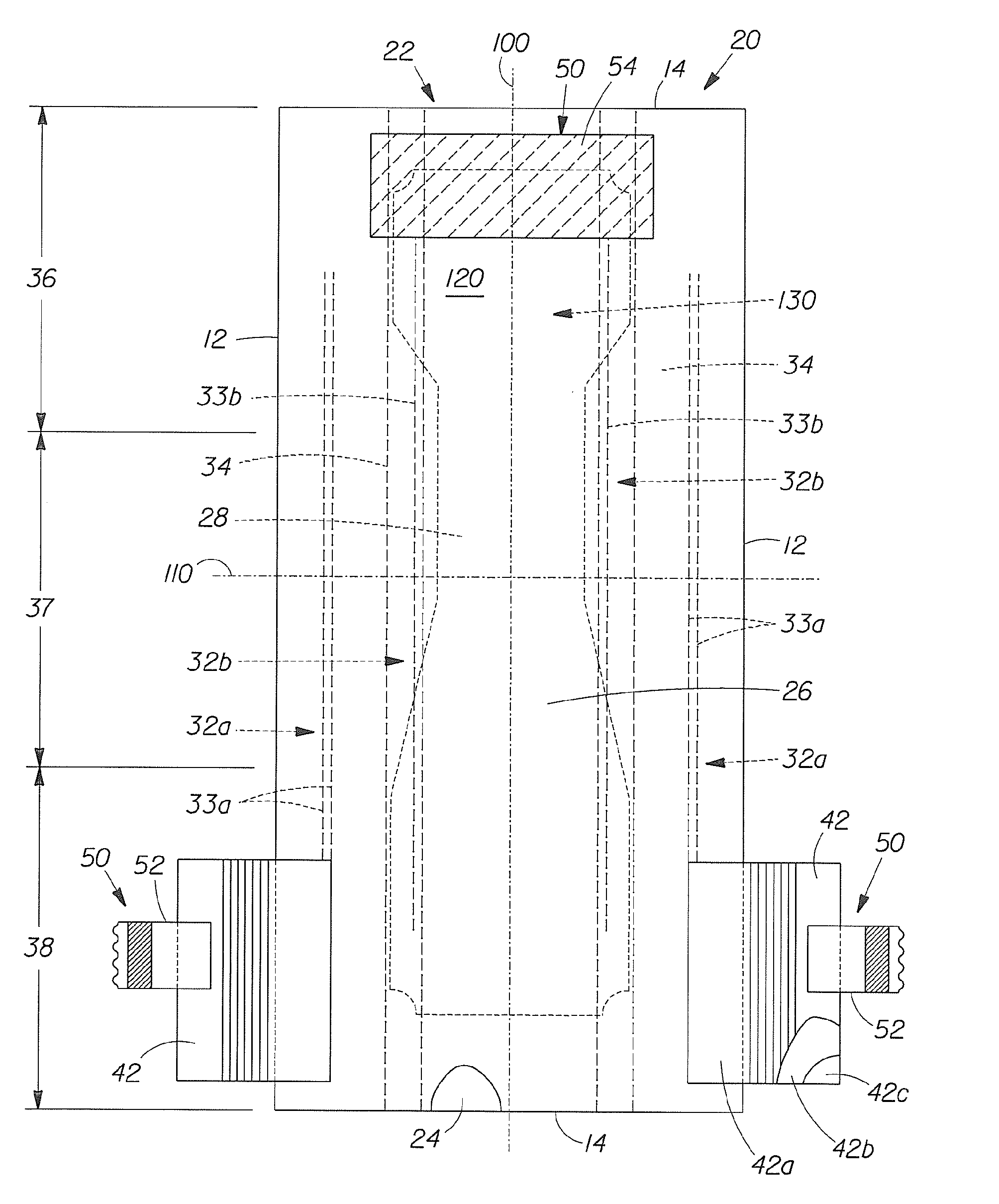

Polymerization catalysts and process for producing bimodal polymers in a single reactor

ActiveUS7226886B2Outstanding balance of stiffnessHigh impact strengthOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyolefinImproved method

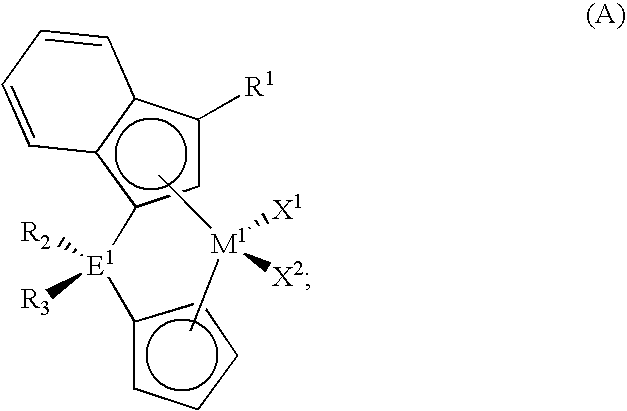

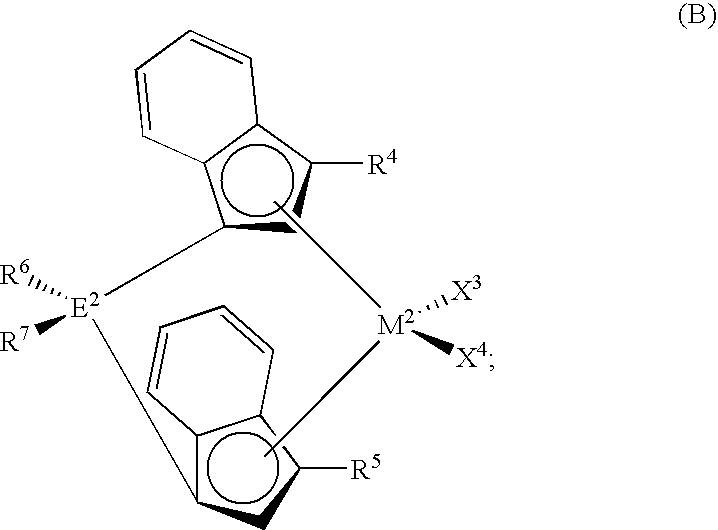

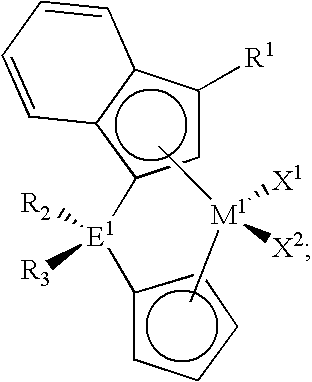

Catalyst compositions comprising a first metallocene compound, a second metallocene compound, an activator-support, and an organoaluminum compound are provided. An improved method for preparing cyclopentadienyl complexes used to produce polyolefins is also provided.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Polymerization catalysts and process for producing bimodal polymers in a single reactor

ActiveUS7312283B2Outstanding balance of stiffnessHigh impact strengthOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyolefinEthylene Polymers

Catalyst compositions comprising a first metallocene compound, a second metallocene compound, an activator-support, and an organoaluminum compound are provided. Methods for preparing and using such catalysts to produce polyolefins are also provided. The compositions and methods disclosed herein provide ethylene polymers having a HLMI of from about 0.5 to about 25, a polymer density of from about 0.920 to about 0.965, and a polydispersity of from about 3.0 to about 30.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

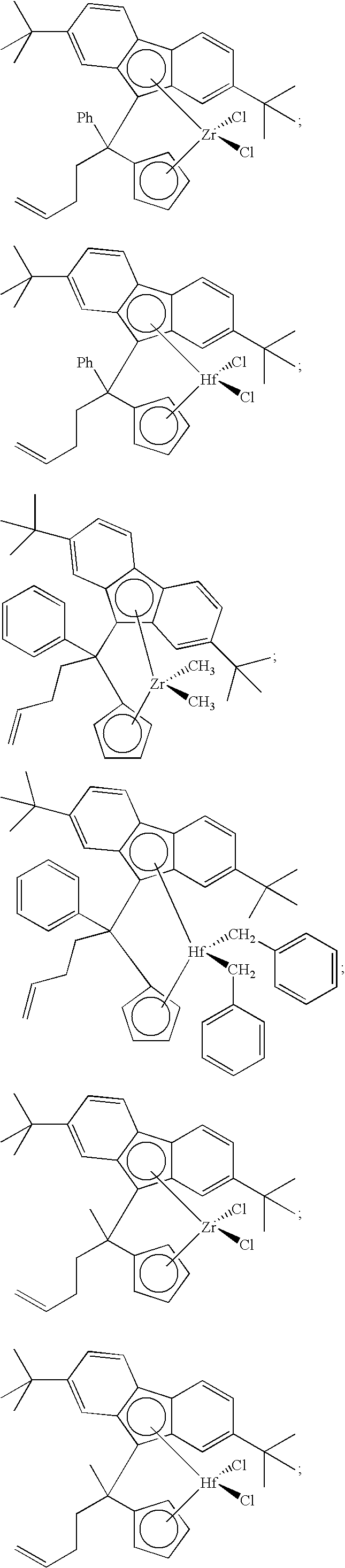

Polymerization catalysts for producing high melt index polymers without the use of hydrogen

ActiveUS7026494B1High porositySilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPolyolefinHydrogen

Various catalyst compositions including the contact product of at least one ansa-metallocene compound, at least one organoaluminum compound, and at least one activator-support are disclosed. Processes for forming such compositions and for forming polyolefins with such compositions are also disclosed. Metallocene compounds are also presented.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Absorbent Article Comprising A Synthetic Polymer Derived From A Renewable Resource And Methods Of Producing Said Article

Owner:HIRD BRYN +1

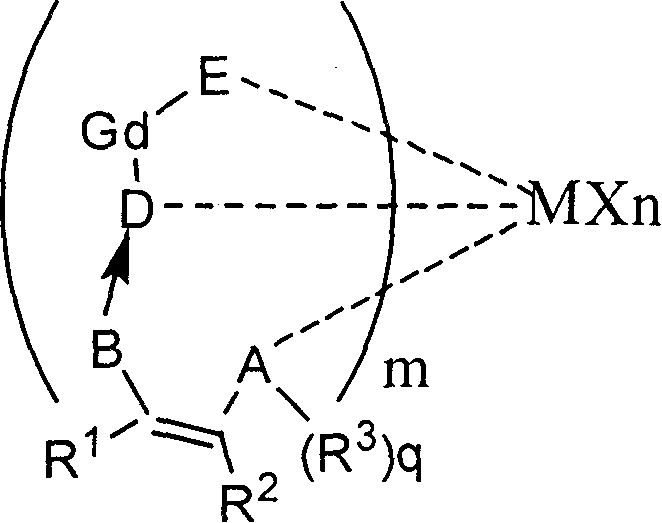

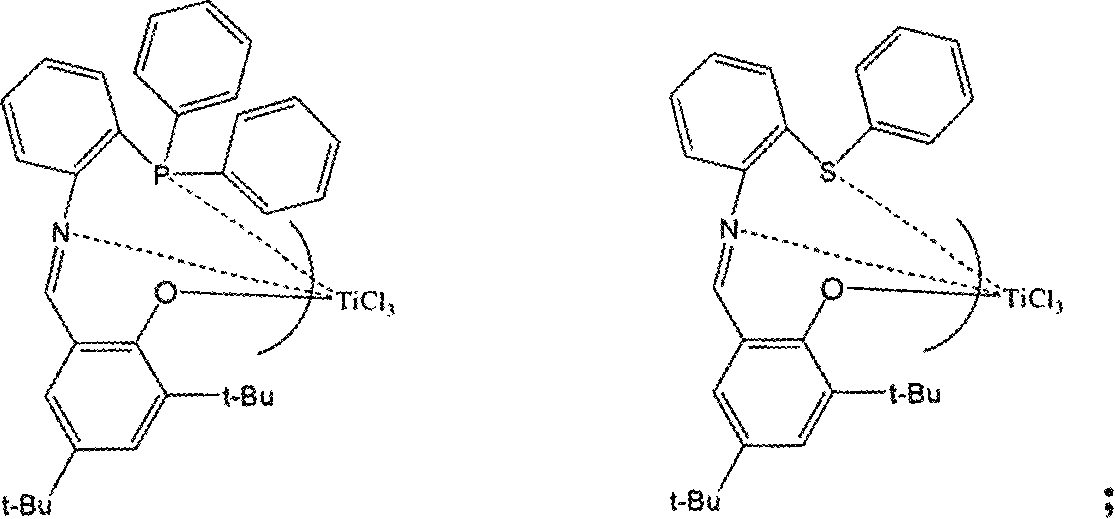

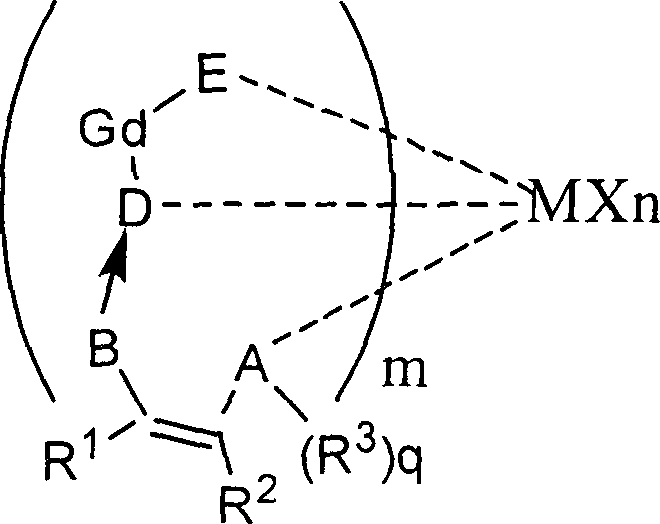

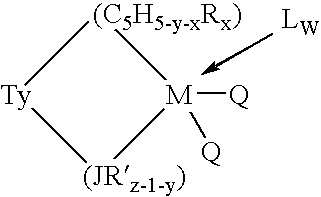

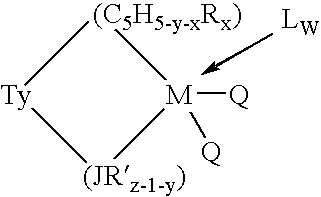

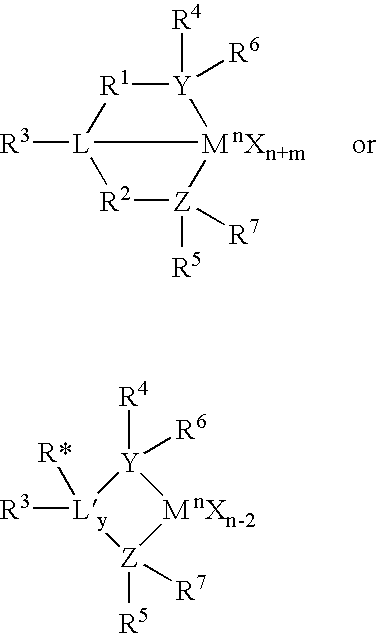

Aluminum-free monocyclopentadienyl metallocene catalysts for olefin polymerization

ActiveUS7163907B1Organic-compounds/hydrides/coordination-complexes catalystsMetallocenesPolymer sciencePolyolefin

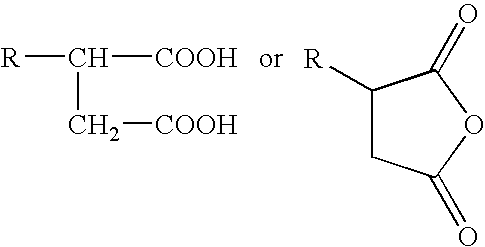

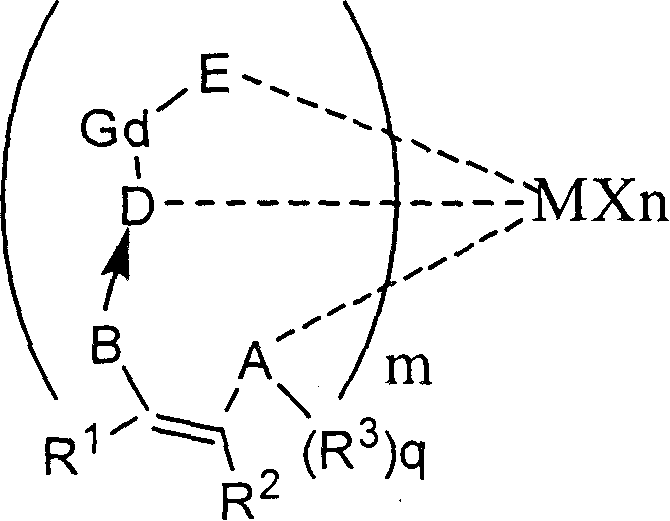

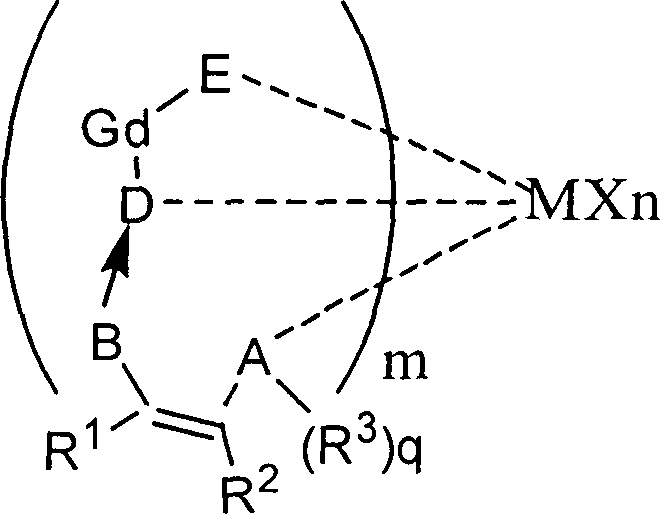

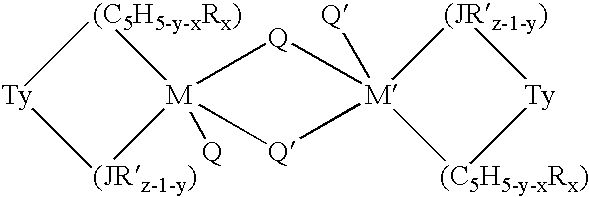

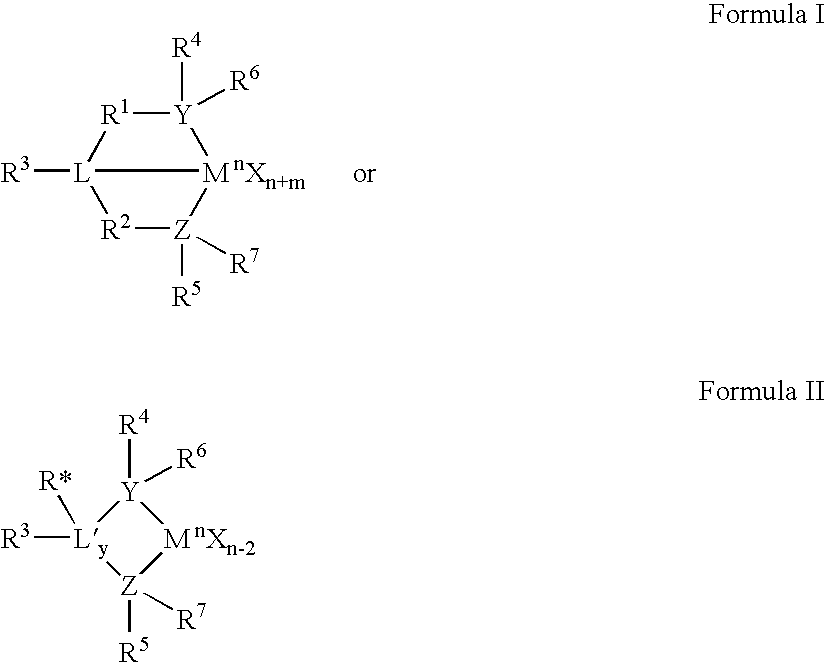

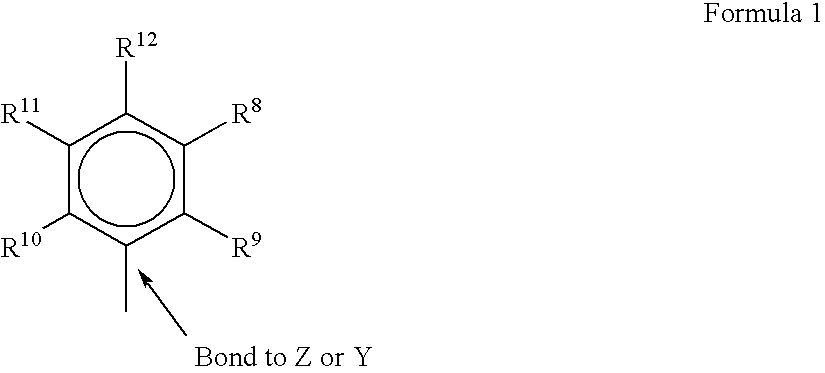

This invention relates to a catalyst system for the production of polyolefins comprising:(A) a Group IV B transition metal component represented by one of the two general formulaewherein(C5H5-y-xRx) is a cylopentadienyl ring(JR′z-l-y) is a heteroatom ligand in which J is an element with a coordination number of three from Group V-A or an element with a coordination number of two rom Group VI-A of the Periodic Table of Elements,each Q is independently, hydride, C1—C20 hydrocarbyl radicals, substituted hydrocarbyl radials wherein one or more hydrogen atoms is replaced by an electron withdrawing group, or C1—C20 hydrocarbyl-substituted metalloid radicals wherein the metalloid is selected from the group consisting of germanium and silicon, provided that Q is not a substituted or unsubstituted cyclopentadienyl ring, or both Q together may be an alkylidene, olefin, acetylene or a cyclometallated hydrocarbyl;“y” is 0 or 1; when “y” is 1, T is a covalent bridging group containing a Group IV-A or V-A element;L is a neutral Lewis base; and “w” is a number from 0 to 3;(B) an activator compound comprising (1) a cation; and (2) a compatible noncoordinating anion.

Owner:EXXONMOBIL CHEM PAT INC

Absorbent Article Comprising A Synthetic Polymer Derived From A Renewable Resource And Methods Of Producing Said Article

An absorbent article is disclosed having a topsheet, a backsheet joined with the topsheet, an absorbent core disposed between the topsheet and the backsheet, and a synthetic superabsorbent polymer derived from a first renewable resource via at least one intermediate compound, wherein said superabsorbent polymer exhibits a defined Saline Flow Conductivity value and Absorption Against Pressure value. Alternately, an absorbent article is disclosed having a synthetic polyolefin derived from a first renewable resource via at least one intermediate compound. The synthetic polyolefin exhibits defined performance characteristics making the polyolefin particularly useful in certain components of the absorbent article. Methods for making the aforementioned absorbent articles are also disclosed.

Owner:HIRD BRYN +1

Absorbent Article Comprising A Synthetic Polymer Derived From A Renewable Resource And Methods Of Producing Said Article

An absorbent article is disclosed having a topsheet, a backsheet joined with the topsheet, an absorbent core disposed between the topsheet and the backsheet, and a synthetic superabsorbent polymer derived from a first renewable resource via at least one intermediate compound, wherein said superabsorbent polymer exhibits a defined Saline Flow Conductivity value and Absorption Against Pressure value. Alternately, an absorbent article is disclosed having a synthetic polyolefin derived from a first renewable resource via at least one intermediate compound. The synthetic polyolefin exhibits defined performance characteristics making the polyolefin particularly useful in certain components of the absorbent article. Methods for making the aforementioned absorbent articles are also disclosed.

Owner:HIRD BRYN +1

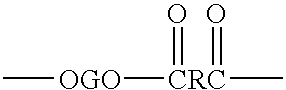

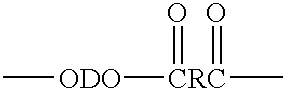

Oxygen scavenging condensation copolymers for bottles and packaging articles

Compositions for scavenging oxygen are disclosed. These compositions comprise condensation copolymers comprising predominantly polyester segments and an oxygen scavenging amount of polyolefin oligomer segments. The polyester segments comprise segments derived from typical bottling and packaging polyesters such as PET and PEN. The copolymers are preferably formed by transesterification during reactive extrusion and typically comprise about 0.5 to about 12 wt % of polyolefin oligomer segments. The copolycondensates are capable of absorbing at least 0.4 cc of oxygen per gram of copolymer in the solid state at ambient temperatures and are typically used as layers in films, liners, cups, wraps, bottles, etc. Use of these oxygen scavenging compositions in bottles provides a clear and rigid bottle similar in appearance to unmodified polyester bottles. In a series of preferred embodiments, bottles fabricated with the oxygen scavenging copolycondensates of this invention are over 99.4 wt % polyester and suitable for recycle with other polyester bottles.

Owner:COLORMATRIX HLDG

Resins that yield low haze films and the process for their production

ActiveUS7199073B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemical treatmentPolyolefin

Catalyst compositions comprising a first metallocene compound, a second metallocene compound, a third metallocene compound, a chemically-treated solid oxide, and an organoaluminum compound are provided. Methods for preparing and using the catalyst and polyolefins are also provided. The compositions and methods disclosed herein provide ethylene polymers having decreased haze while minimizing impact on other properties, such as dart impact.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

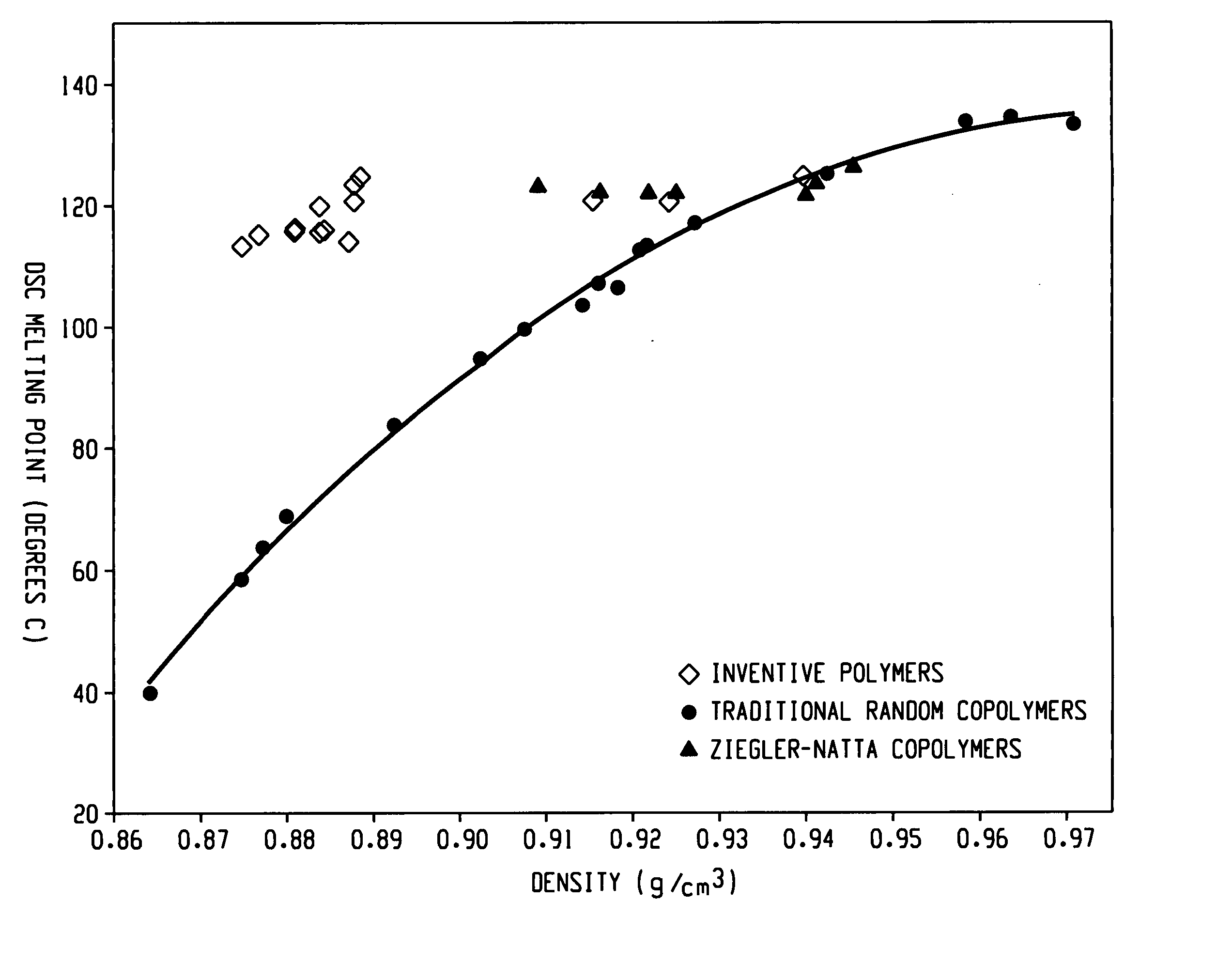

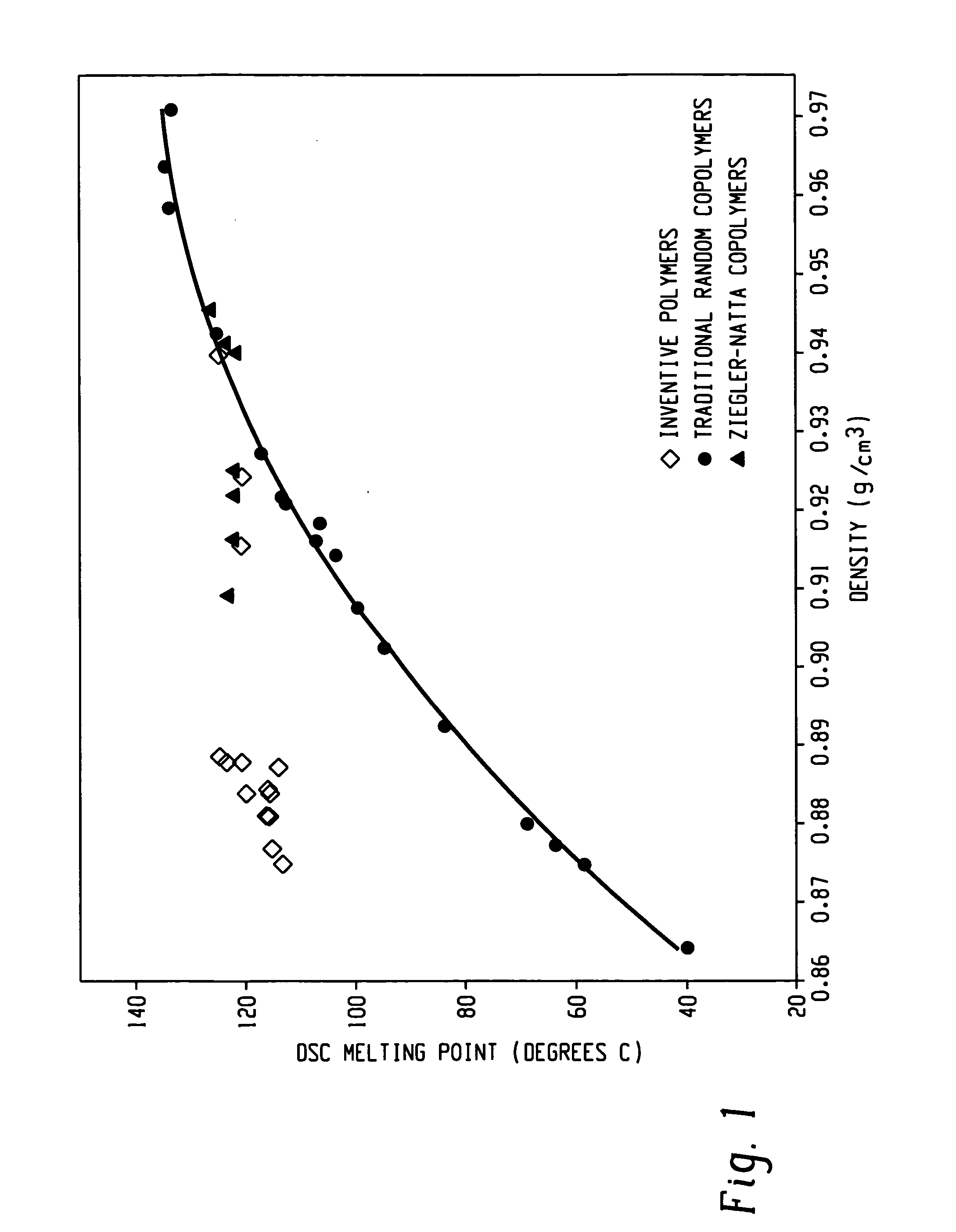

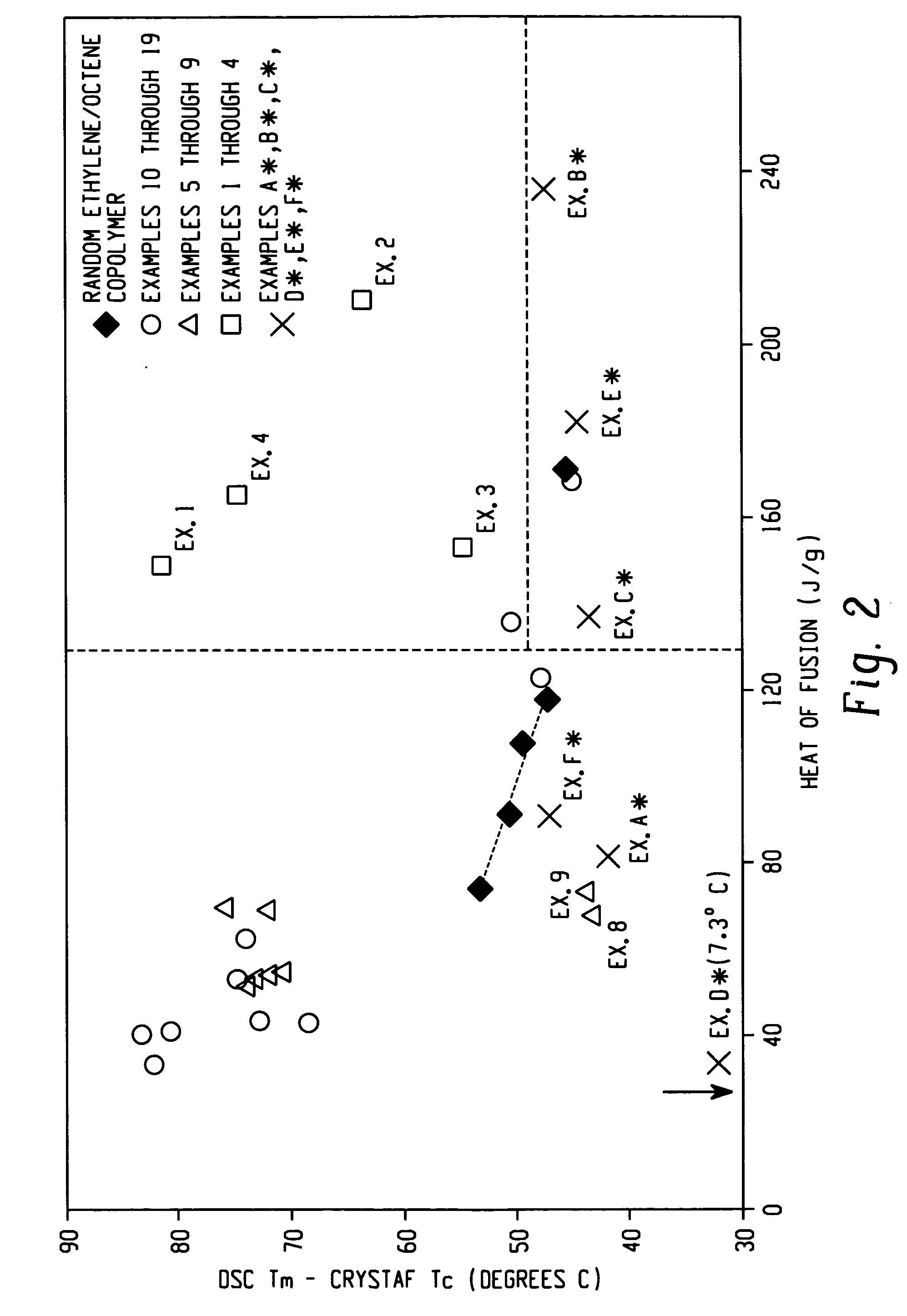

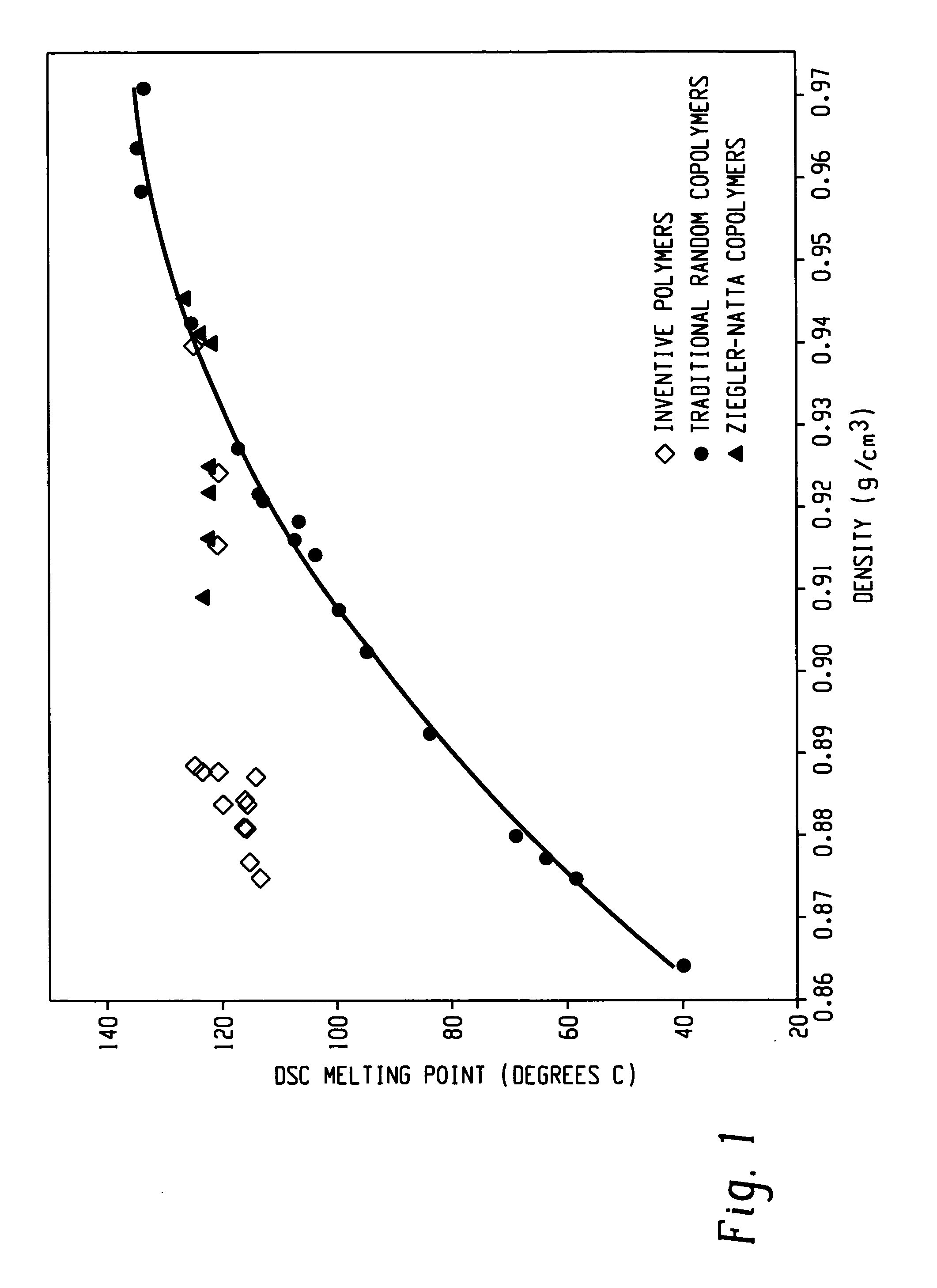

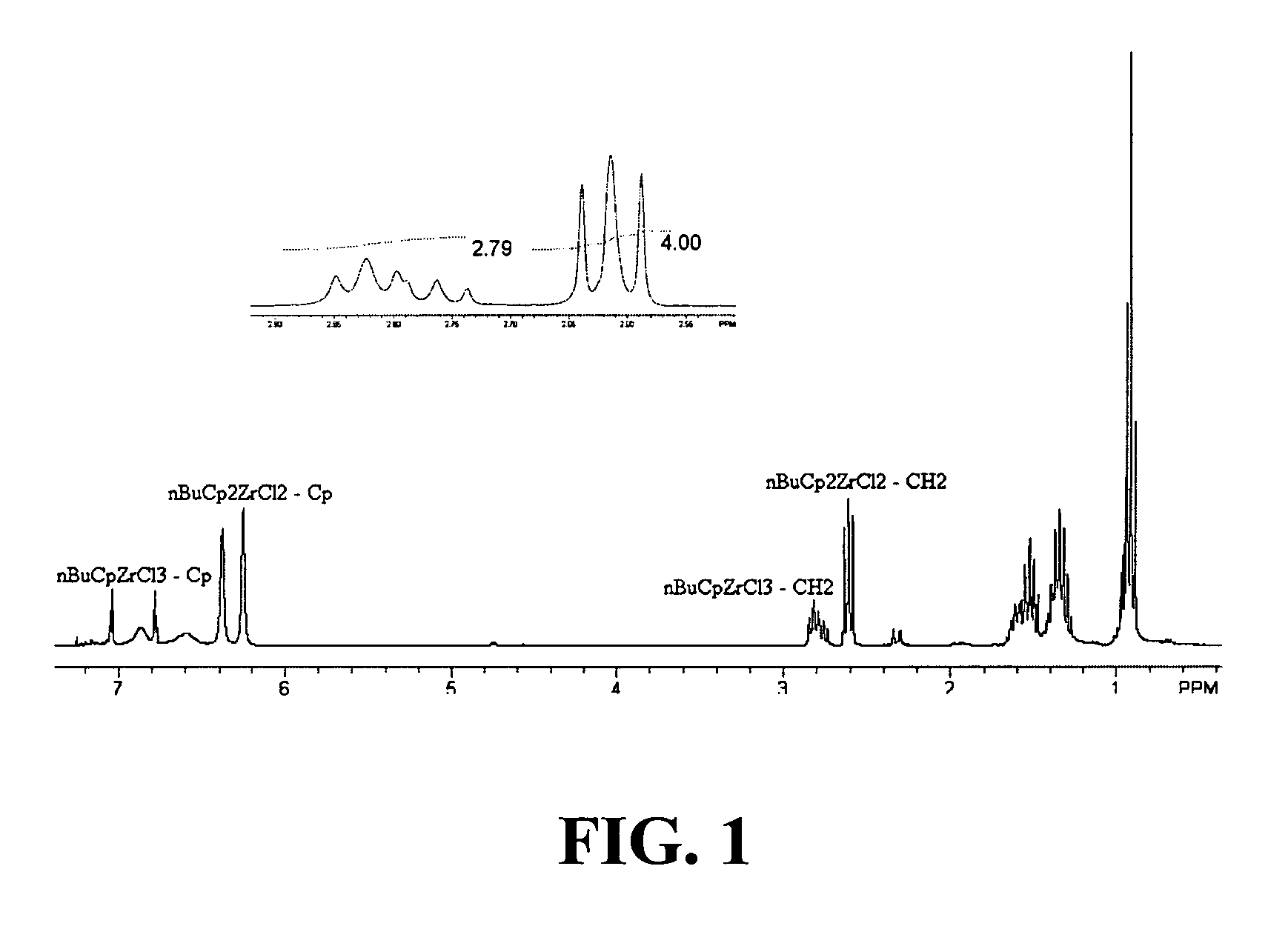

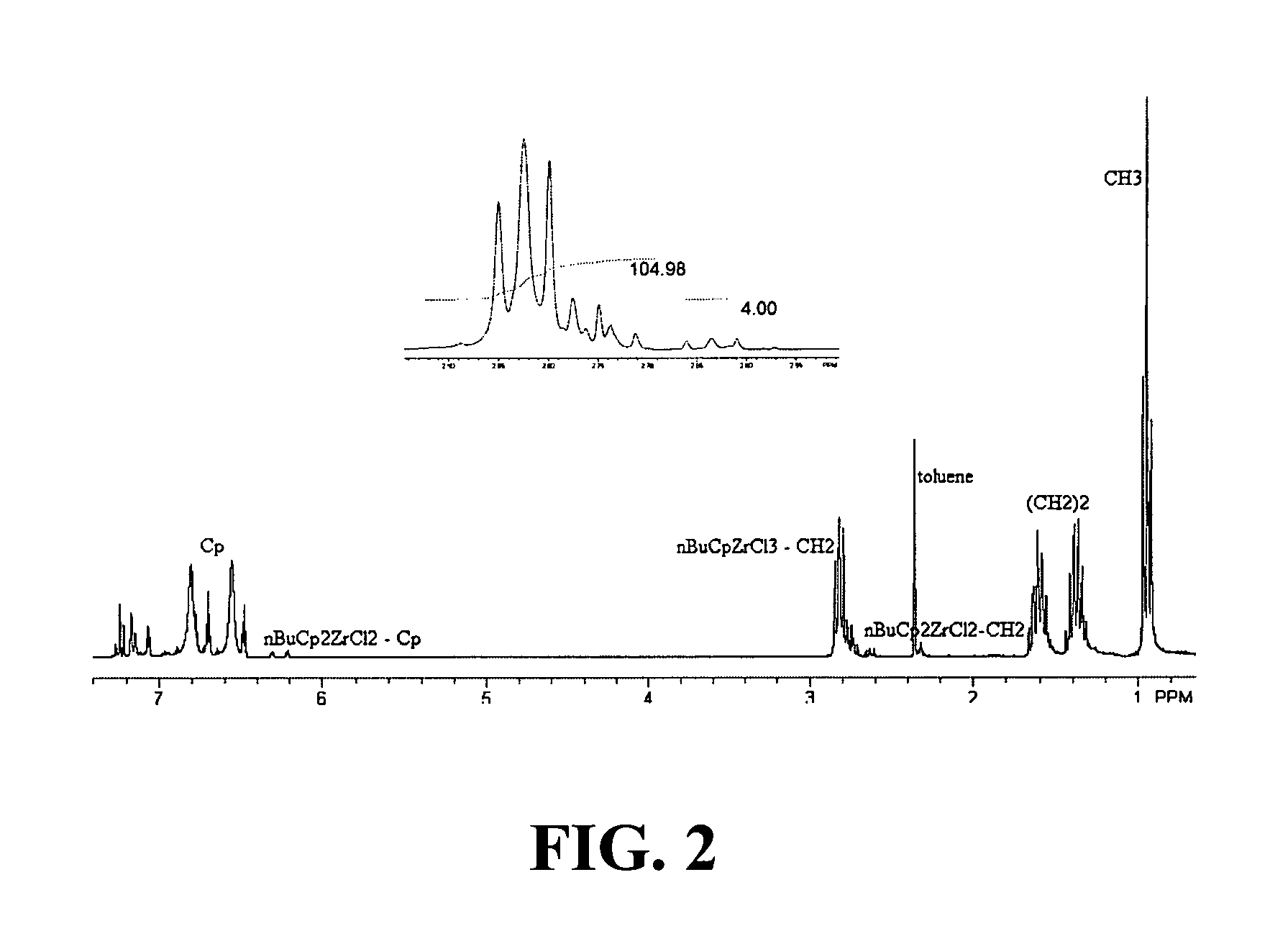

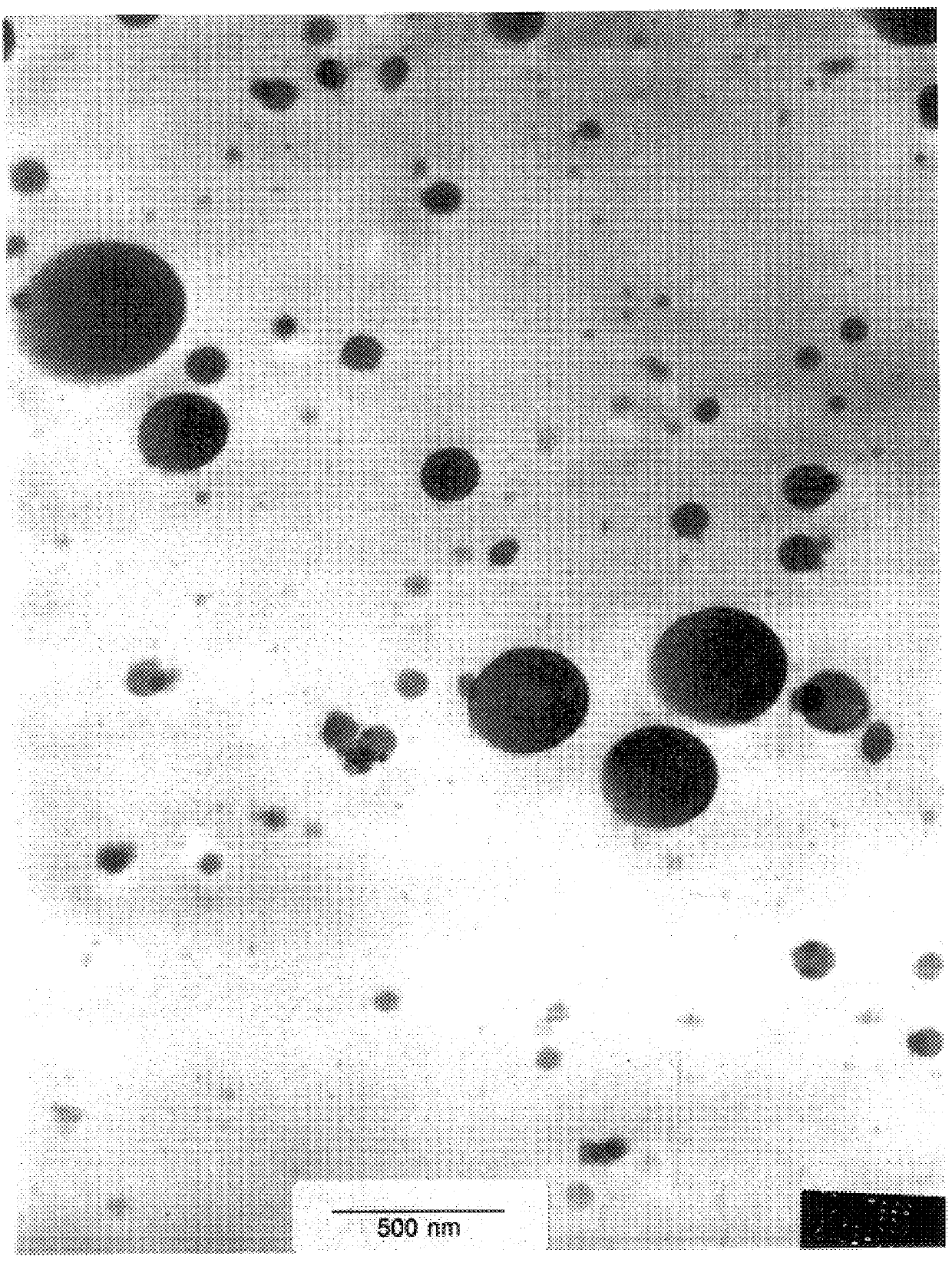

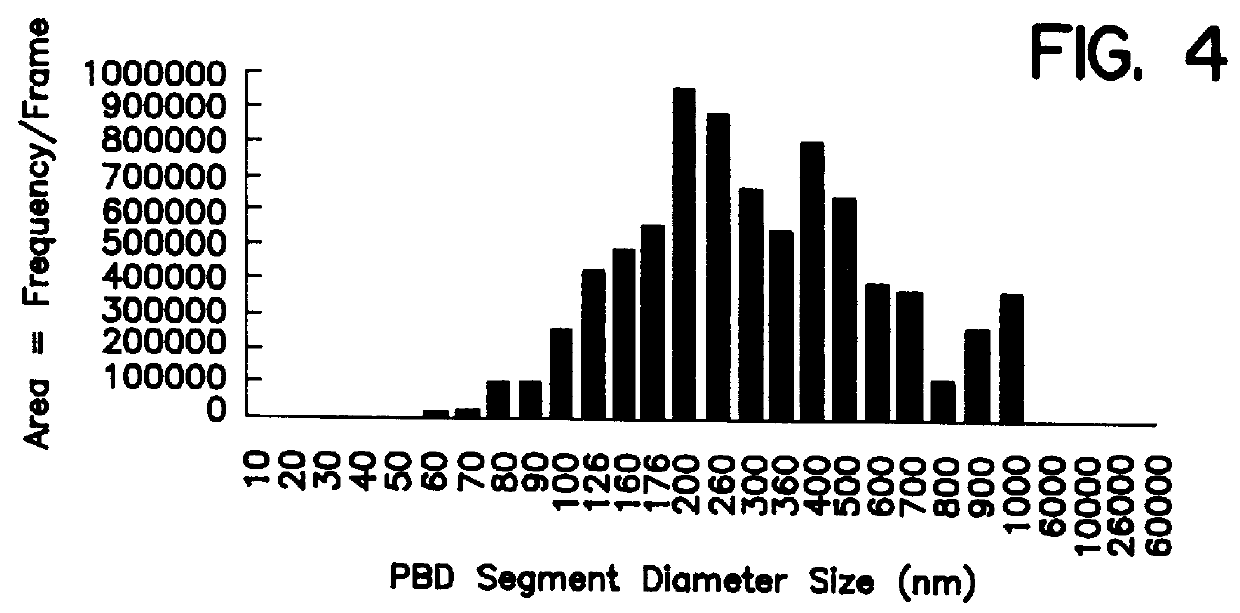

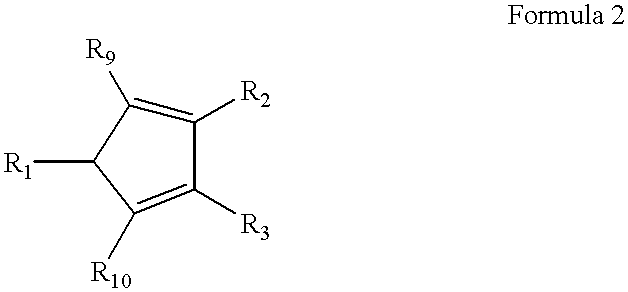

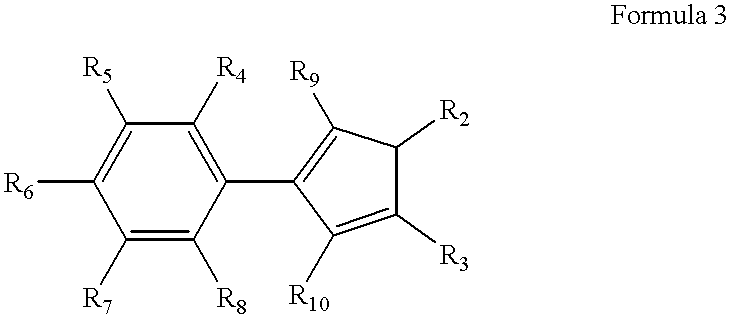

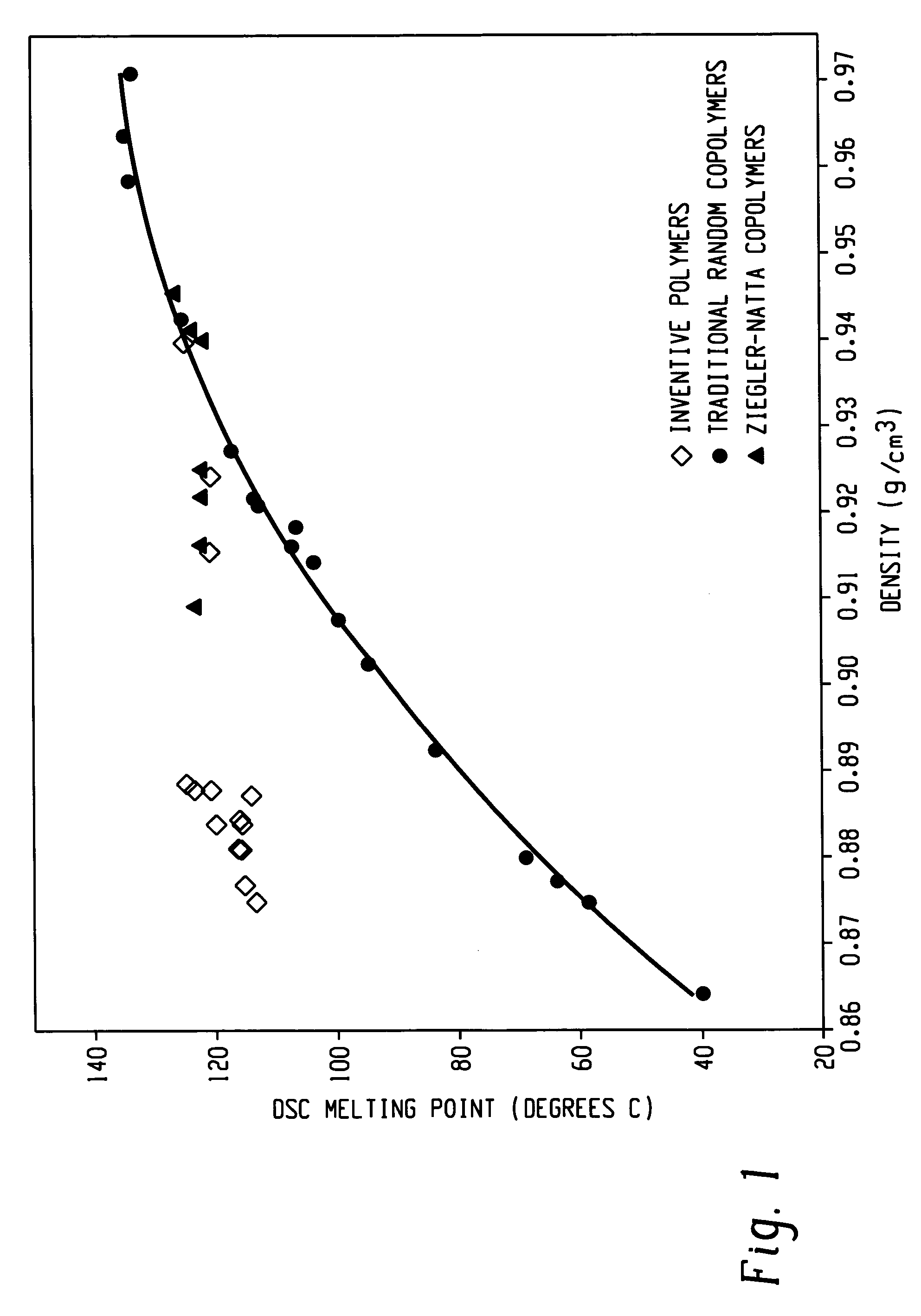

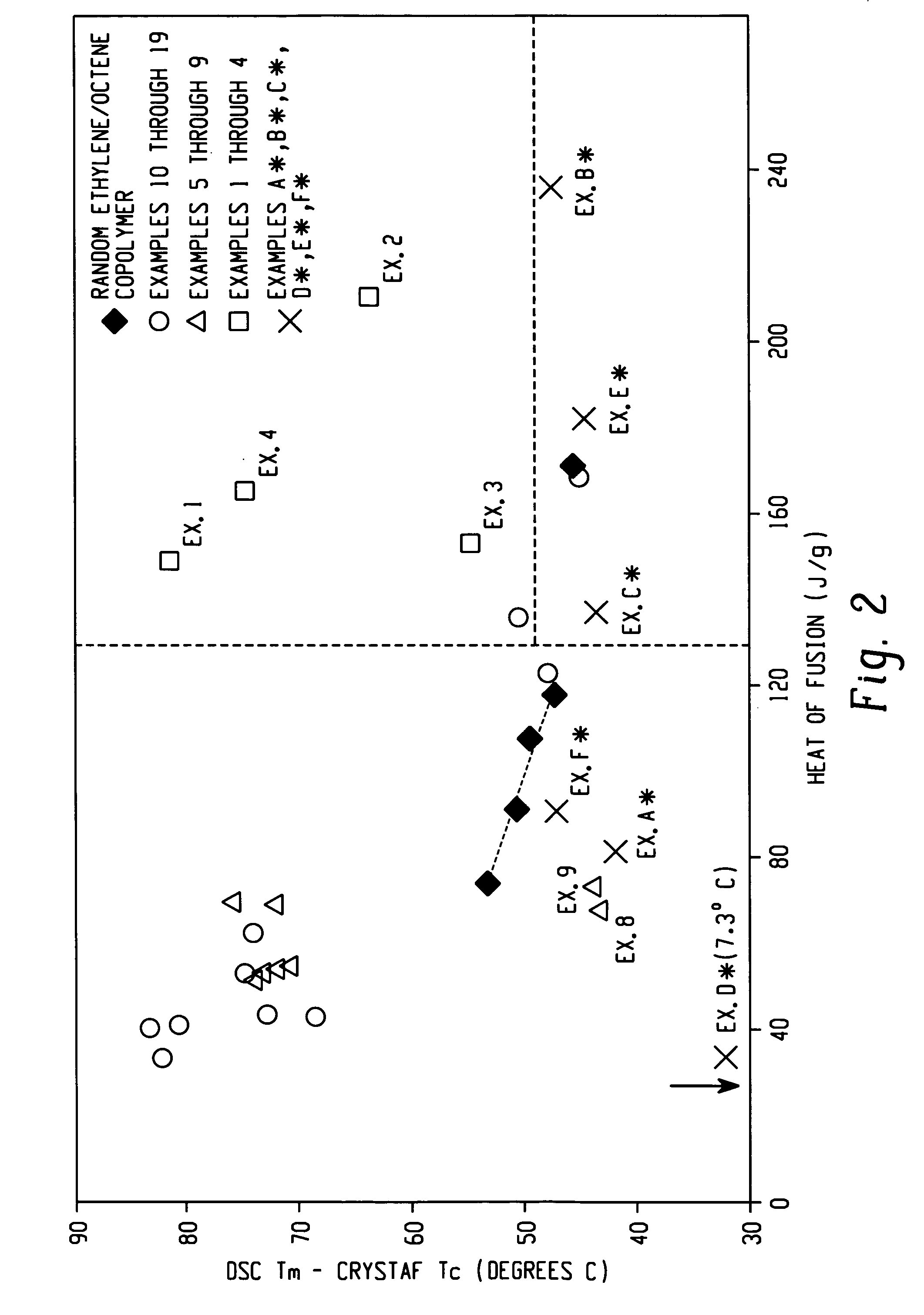

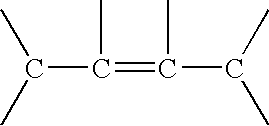

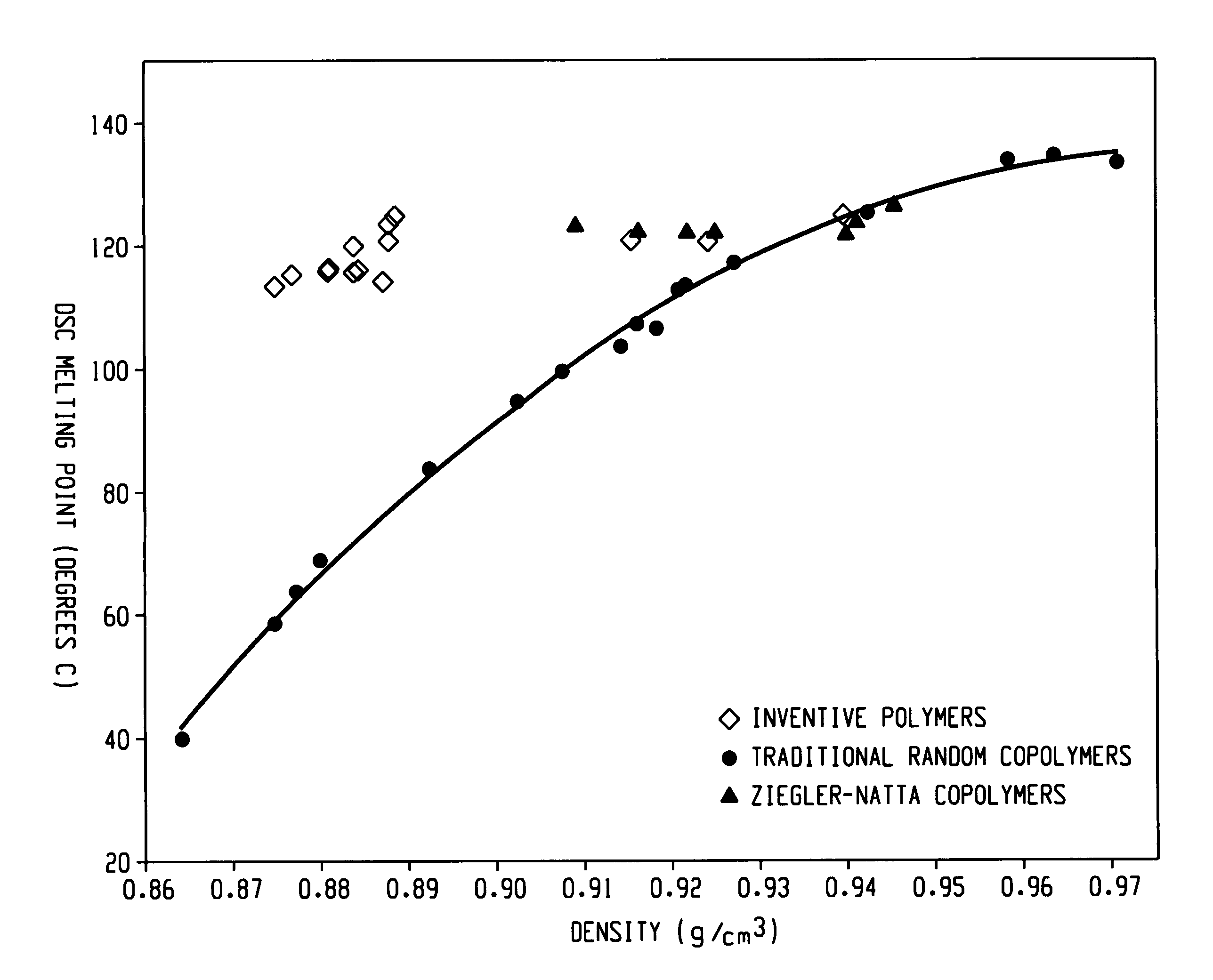

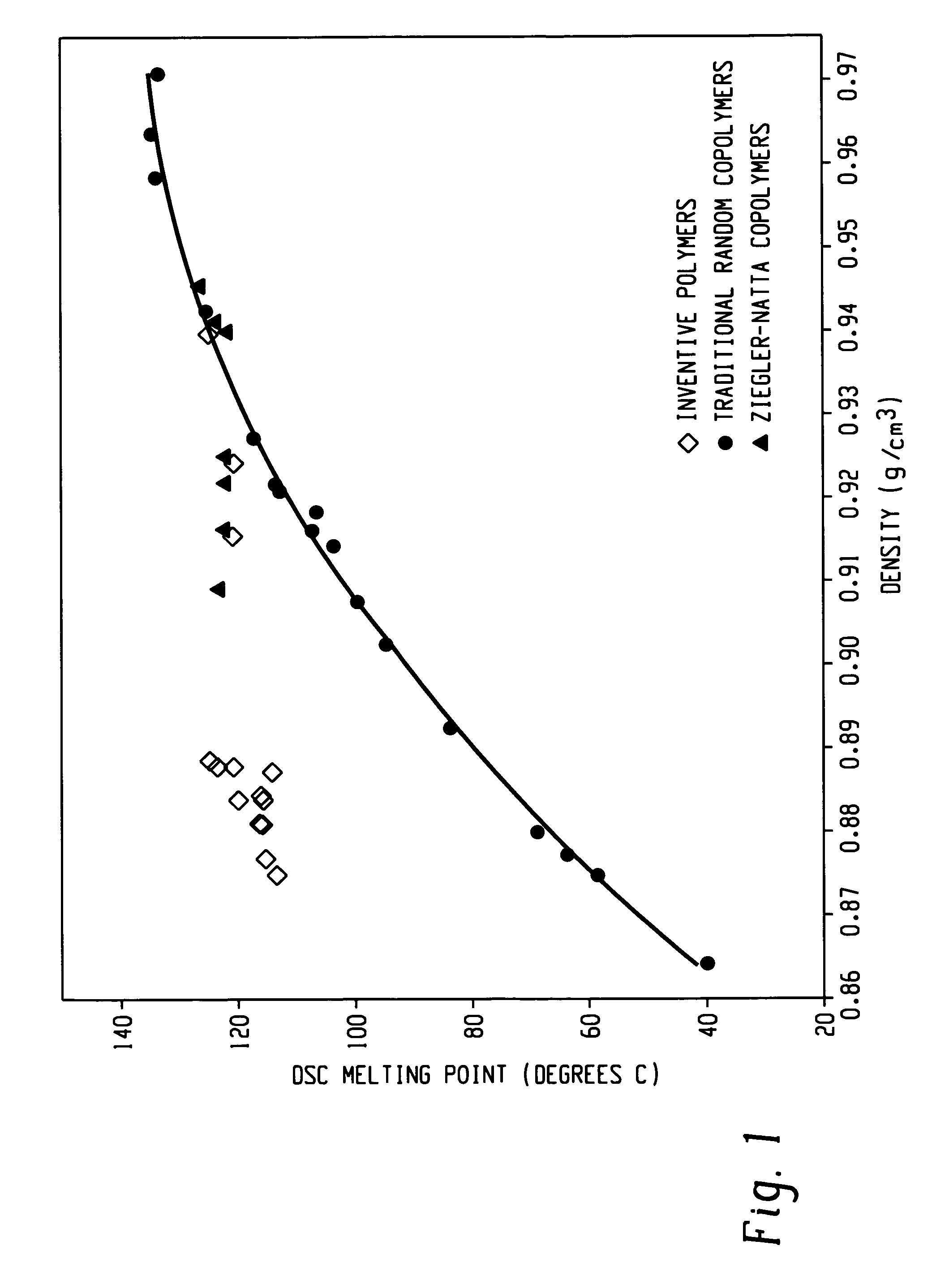

High-melting polyolefin copolymer elastomers, catalysts and methods of synthesis

InactiveUS6169151B1Property is limitedOrganic-compounds/hydrides/coordination-complexes catalystsElastomerPolymer science

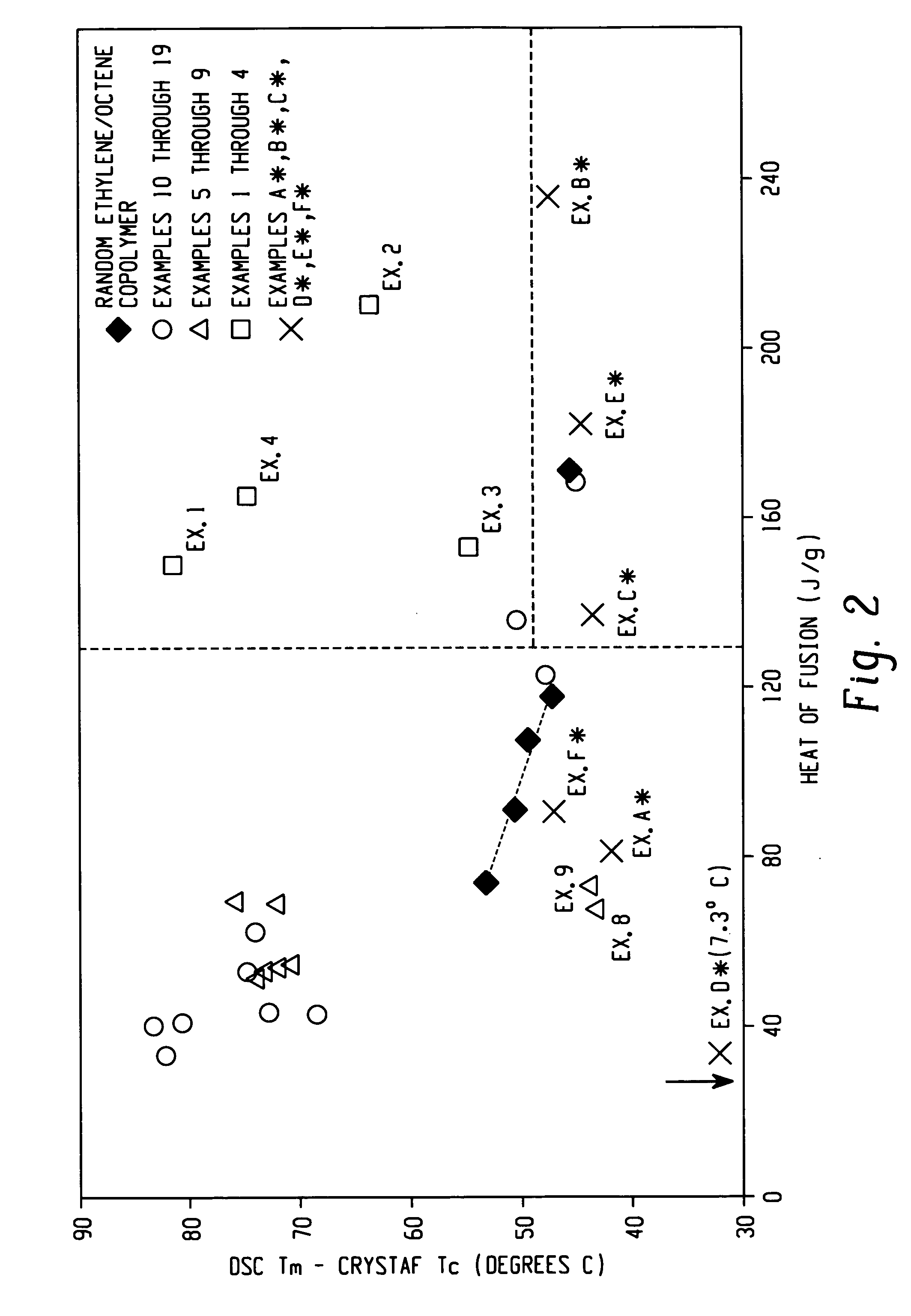

This invention relates to high melting polyolefin copolymers suitable as thermoplastic elastomers and catalysts and methods for their synthesis. These elastomeric olefin copolymers are characterized by a mole fraction of crystallizable component Xc from about 30 to about 99%; low glass transition temperatures, below -20° C., and typically below -50° C.; melting points above about 90° C.; high molecular weights; a molecular weight distribution MW / Mn< / =10; and a narrow composition distribution between chains of < / =15%. The novel copolymers of the invention range from reactor blends to multiblock copolymers that can be sequentially fractionated into fractions of differing crystallinities, which fractions nevertheless show compositions of comonomers which differ by less than 15% from the parent polymer (reactor product). The invention also relates to a process for producing such copolymers by utilizing an unbridged, substituted or unsubstituted cyclopentadienyl metallocene catalyst that is capable of interconverting between states with different copolymerization characteristics, which interconversion is controlled by selecting the substituents of the cyclopentadienyl ligands so that the rate of interconversion of the two states is within several orders of magnitude of the rate of formation of a single polymer chain. Where ri>rf the polymer can be characterized as multiblock; where ri<rf, the result is a polymer blend and where ri / rf is close to 1, the resulting polymer is a mixture of blend and multiblock. The metallocene catalysts of the invention are able to interconvert between more than two states, with embodiments of four states being shown in FIG. 2.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Catalyst composition, method of polymerization, and polymer therefrom

Owner:UNIVATION TECH LLC

Cap liners, closures and gaskets from multi-block polymers

A polymer composition comprises at least an ethylene / α-olefin interpolymer and at least one other polymer. The other polymer can be selected from a second ethylene / α-olefin interpolymer, an elastomer, a polyolefin, a polar polymer, and an ethylene / carboxylic acid interpolymer or ionomer thereof. The ethylene / α-olefin interpolymer is a block copolymer having at least a hard block and at least a soft block. The soft block comprises a higher amount of comonomers than the hard block. The block interpolymer has a number of unique characteristics disclosed here. Also provided are gaskets, bottle cap liners, and closures that comprise or obtained from a compositon comprising at least one ethylene / α-olefin interpolymer and at least one polyolefin. The gaskets are capable of compression sealing various containers, without contaminating the contents. Liquid containers particularly benefit from the use of the novel gasket materials disclosed herein.

Owner:DOW GLOBAL TECH LLC

Quaternary Ammonium Salt of a Polyalkene-Substituted Amine Compound

InactiveUS20080113890A1Organic compound preparationTransportation and packagingCompound aQuaternary ammonium cation

A quaternary ammonium salt detergent made from the reaction product of the reaction of: (a) polyalkene-substituted amine having at least one tertiary amino group; and (b) a quaternizing agent suitable for converting the tertiary amino group to a quaternary nitrogen and the use of such quaternary ammonium salt detergents in a fuel composition to reduce intake valve deposits.

Owner:THE LUBRIZOL CORP

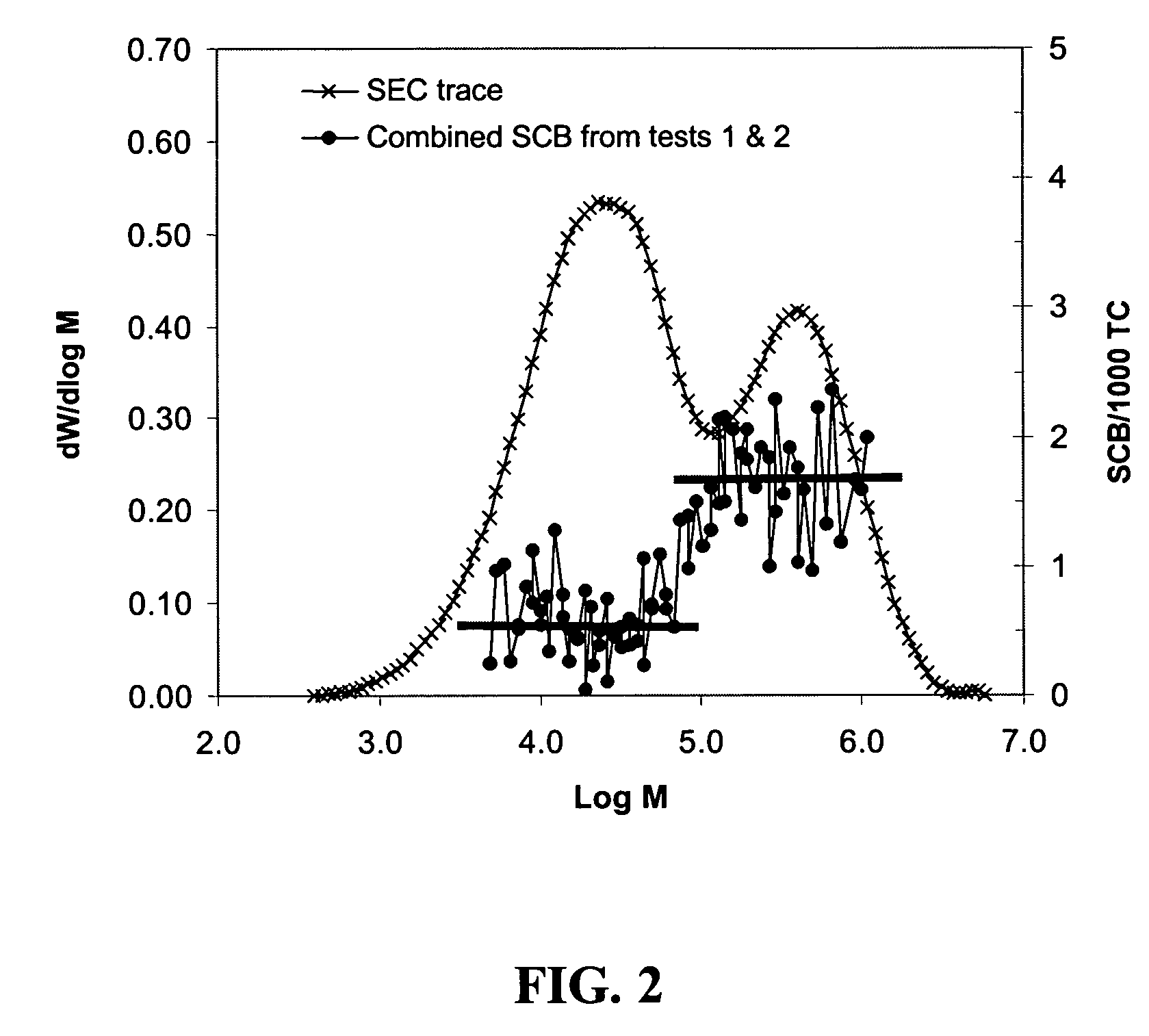

Catalyst composition, method of polymerization, and polymer therefrom

InactiveUS6841631B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyolefinMetal

Catalyst compositions and methods, useful in polymerization processes, utilizing at least two metal compounds are disclosed. At least one of the metal compounds is a Group 15 containing metal compound and the other metal compound is preferably a bulky ligand metallocene-type catalyst. The invention also discloses a new polyolefin, generally polyethylene, particularly a multimodal polymer and more specifically, a bimodal polymer, and its use in various end-use applications such as film, molding and pipe.

Owner:UNIVATION TECH LLC

Absorbent Article Comprising A Synthetic Polymer Derived From A Renewable Resource And Methods Of Producing Said Article

An absorbent article is disclosed having a topsheet, a backsheet joined with the topsheet, an absorbent core disposed between the topsheet and the backsheet, and a synthetic superabsorbent polymer derived from a first renewable resource via at least one intermediate compound, wherein said superabsorbent polymer exhibits a defined Saline Flow Conductivity value and Absorption Against Pressure value. Alternately, an absorbent article is disclosed having a synthetic polyolefin derived from a first renewable resource via at least one inteimediate compound. The synthetic polyolefin exhibits defined performance characteristics making the polyolefin particularly useful in certain components of the absorbent article. Methods for making the aforementioned absorbent articles are also disclosed.

Owner:HIRD BRYN +1

Polymer blends from interpolymers of ethylene/alpha-olefins and flexible molded articles made therefrom

Polymer blends comprises 1) at least one ethylene / α-olefin interpolymer and 2) at least one polyolefin, or at least one styrenic block copolymer, or a combination thereof. Such polyolefins include, but are not limited to, high melt strength high density polyethylene and high melt strength polypropylene. The ethylene / α-olefin interpolymers are random block copolymers comprising at least a hard block and at least a soft block. The polyolefins can be homopolymers or interpolymers. The resulting polymer blends can be used to make flexible molded articles.

Owner:DOW GLOBAL TECH LLC

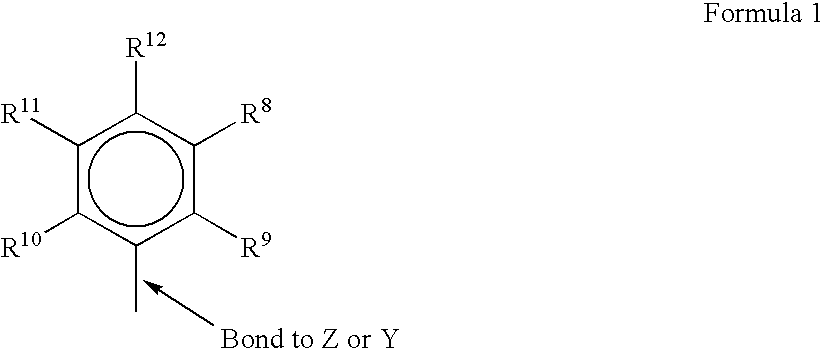

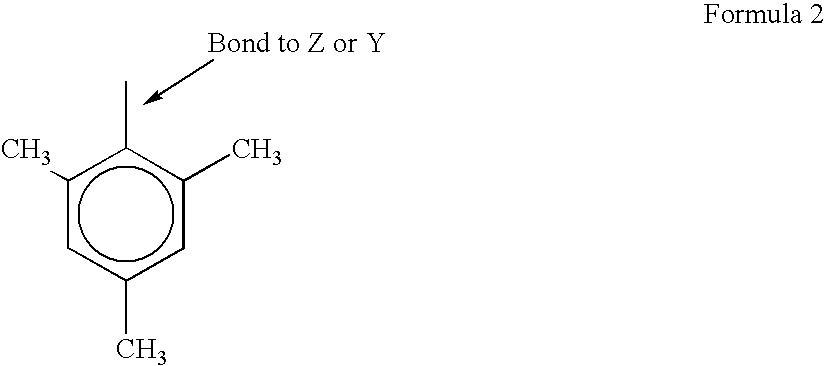

Bicyclo[2.2.1]heptane dicarboxylate salts as polyolefin nucleators

InactiveUS6465551B1Exceptional nucleation efficacyExcellent calcium stearate compatibilityOrganic chemistryOrganic compound preparationChemistryPolyolefin

Compounds and compositions comprising specific metal salts of bicyclo[2.2.1 ]heptane dicarboxylate salts in order to provide highly desirable properties within polyolefin articles are provided. The inventive salts and derivatives thereof are useful as nucleating and / or clarifying agents for such polyolefin, provide excellent crystallization temperatures, stiffness, and calcium stearate compatibility within target polyolefin. Also, such compounds exhibit very low hygroscopicity and therefore excellent shelf stability as powdered or granular formulations. Polyolefin additive compositions and methods of producing polyolefin with such compounds are also contemplated within this invention.

Owner:MILLIKEN & CO

Polymer blends from interpolymers of ethylene/alpha-olefin with improved compatibility

Disclosed herein are polymer blends comprising at least one ethylene / α-olefin interpolymer and two different polyolefins which can be homopolymers. The ethylene / α-olefin interpolymers are block copolymers comprising at least a hard block and at least a soft block. In some embodiments, the ethylene / α-olefin interpolymer can function as a compatibilizer between the two polyolefins which may not be otherwise compatible. Methods of making the polymer blends and molded articles made from the polymer blends are also described.

Owner:DOW GLOBAL TECH LLC

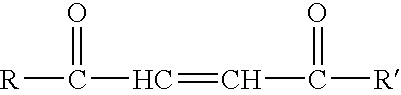

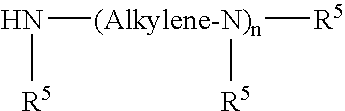

Low-chlorine, polyolefin-substituted, with amine reacted, alpha-beta unsaturated carboxylic compounds

A composition of matter comprising an amine acylated with a hydrocarbyl group substituted carboxylic acylating agent containing an average of from 1.3 to 1.6 groups derived from α,β-unsaturated carboxylic compounds per Mn of the hydrocarbyl group, wherein the hydrocarbyl group has Mn determined by GPC ranging from 1500 to 3000, the amine comprises polyamine bottoms and said acylated amine has total base number (TBN) ranging from 17 to 35. A method for preparing the composition, lubricating oils containing the composition and, in another embodiment, lubricating oil compositions of this invention further comprising a metal overbased sulfonate detergent.

Owner:THE LUBRIZOL CORP

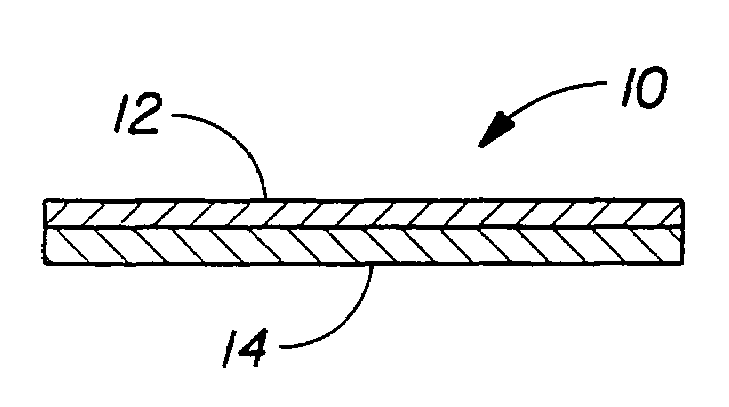

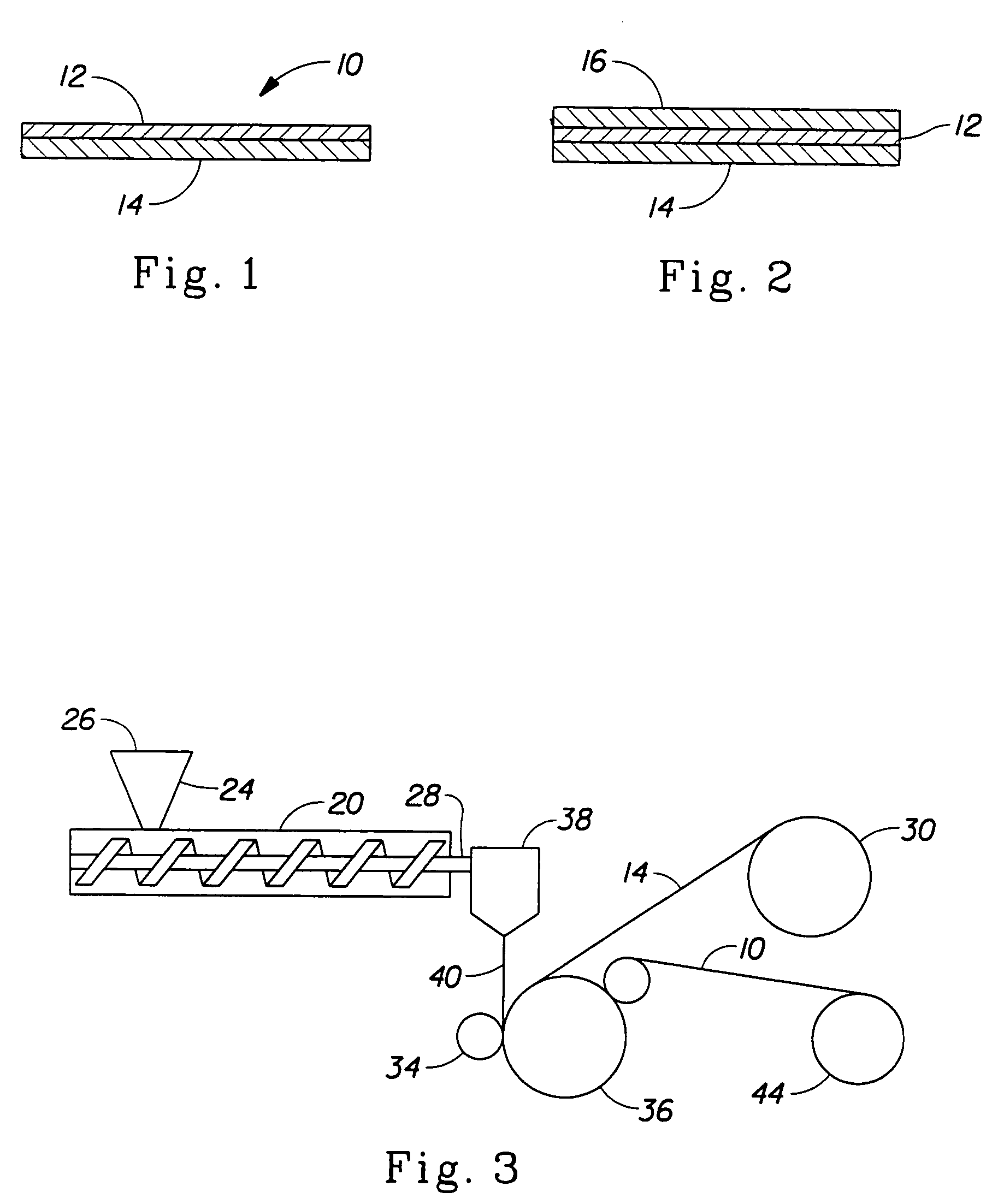

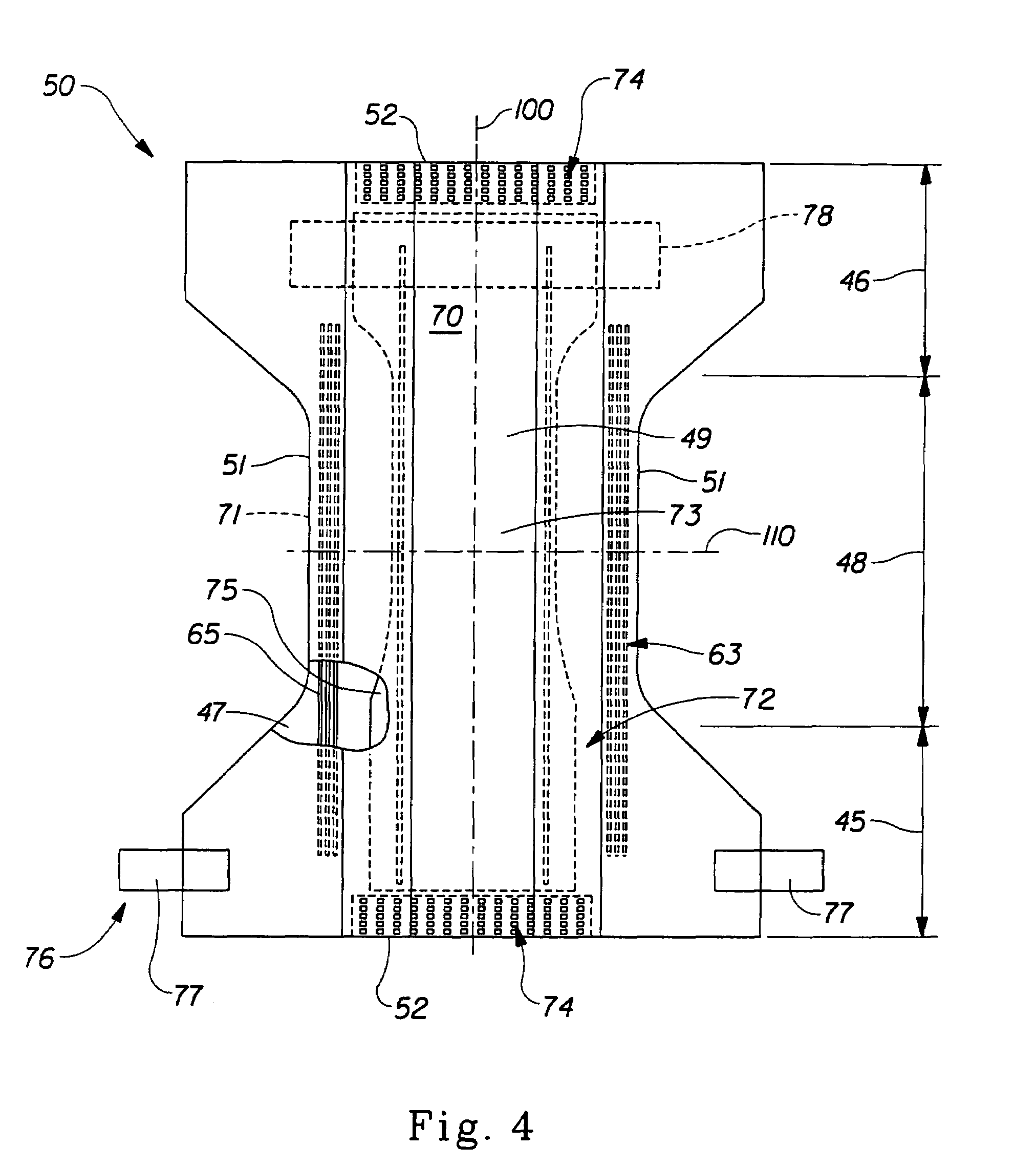

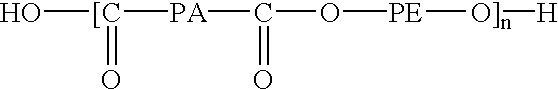

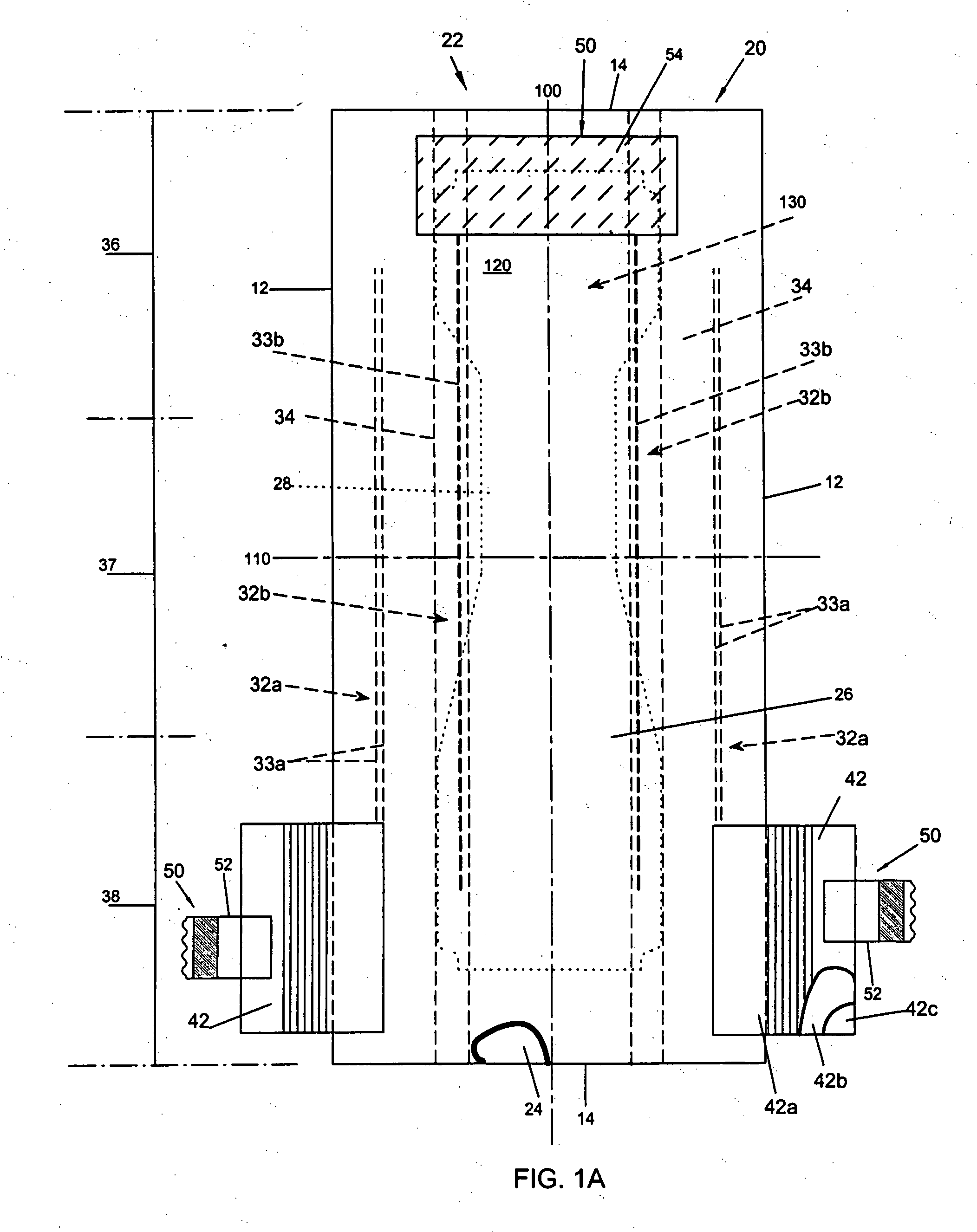

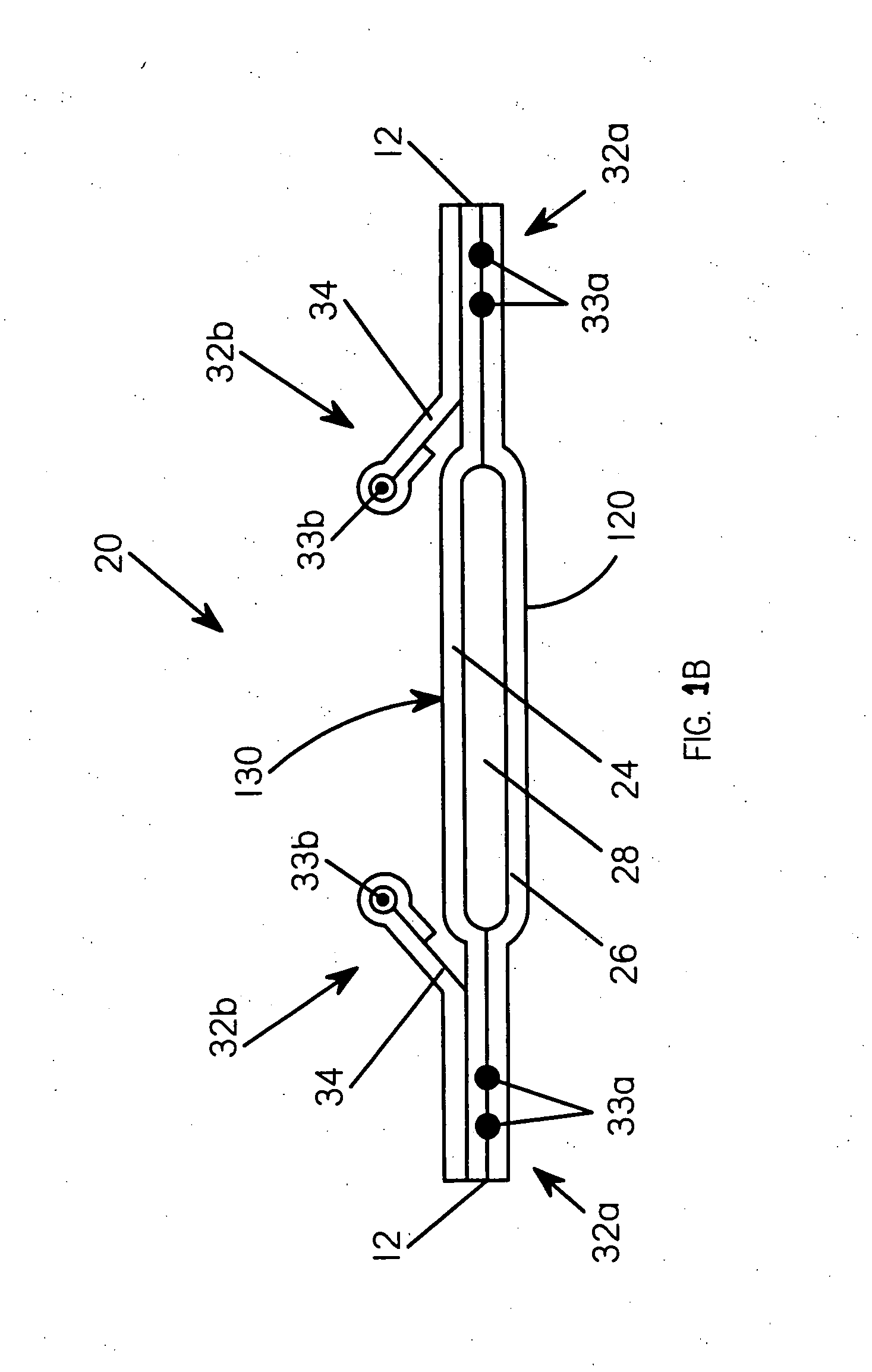

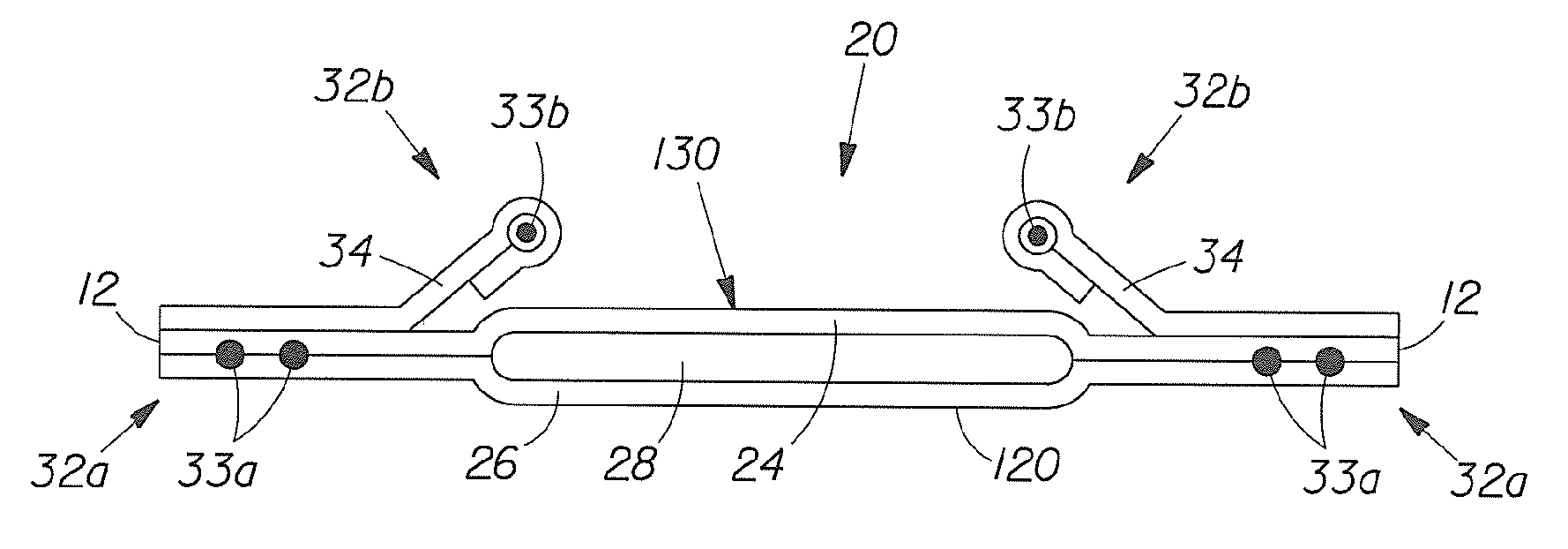

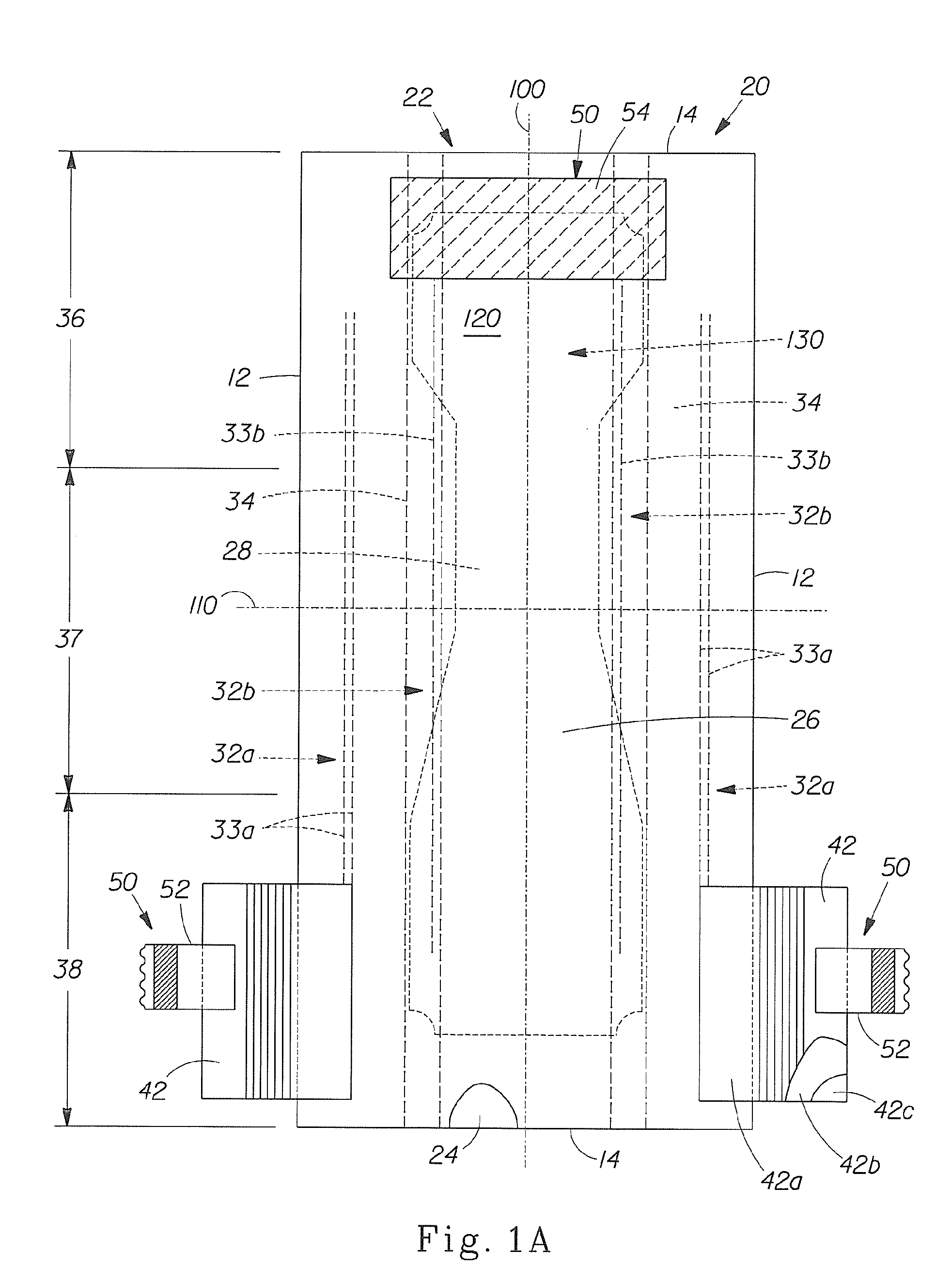

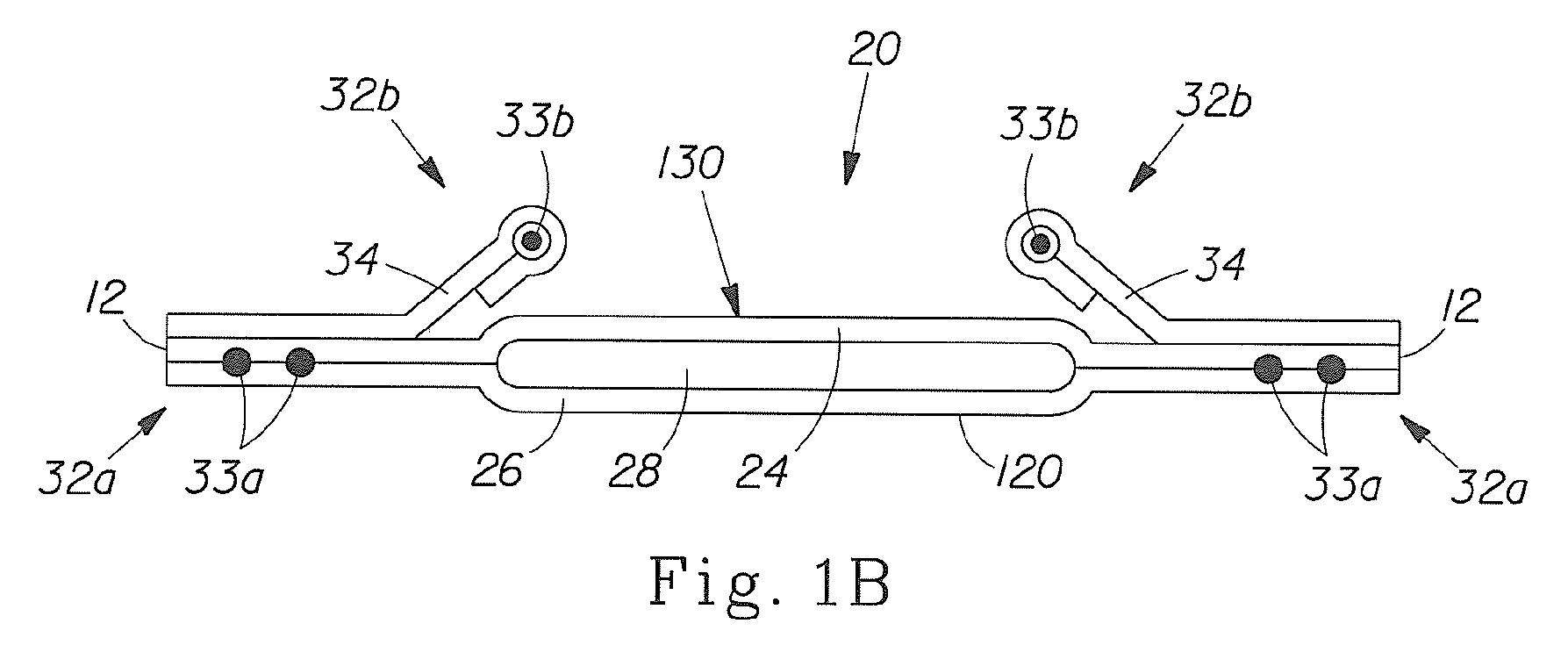

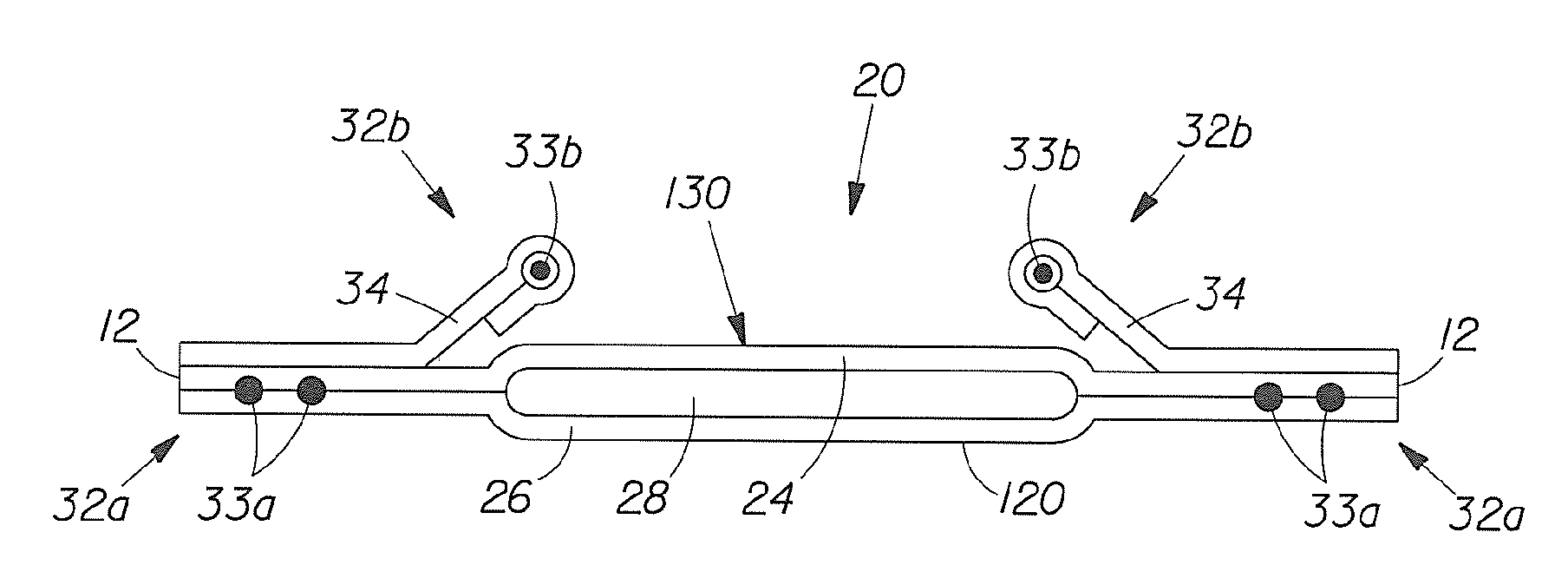

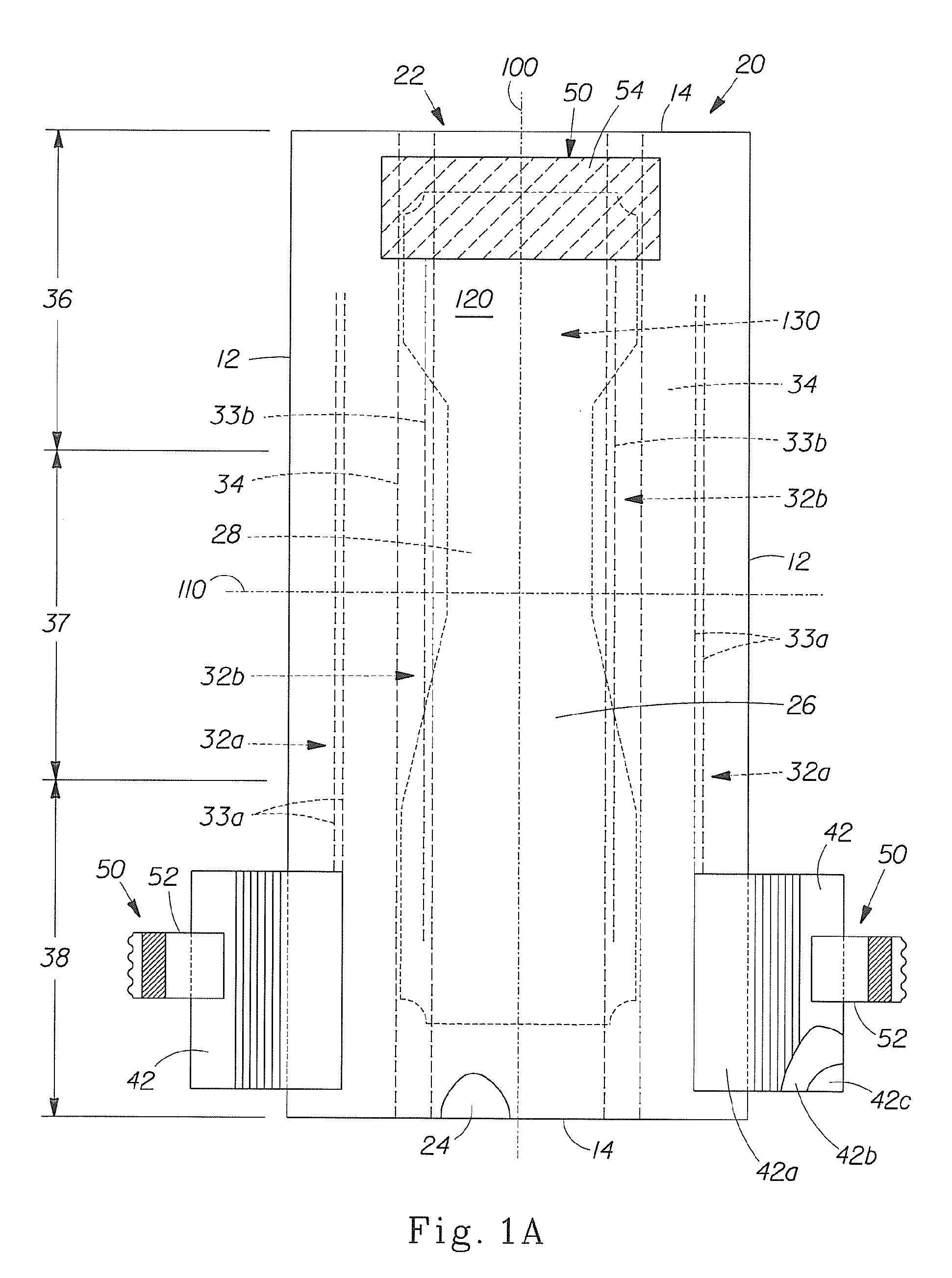

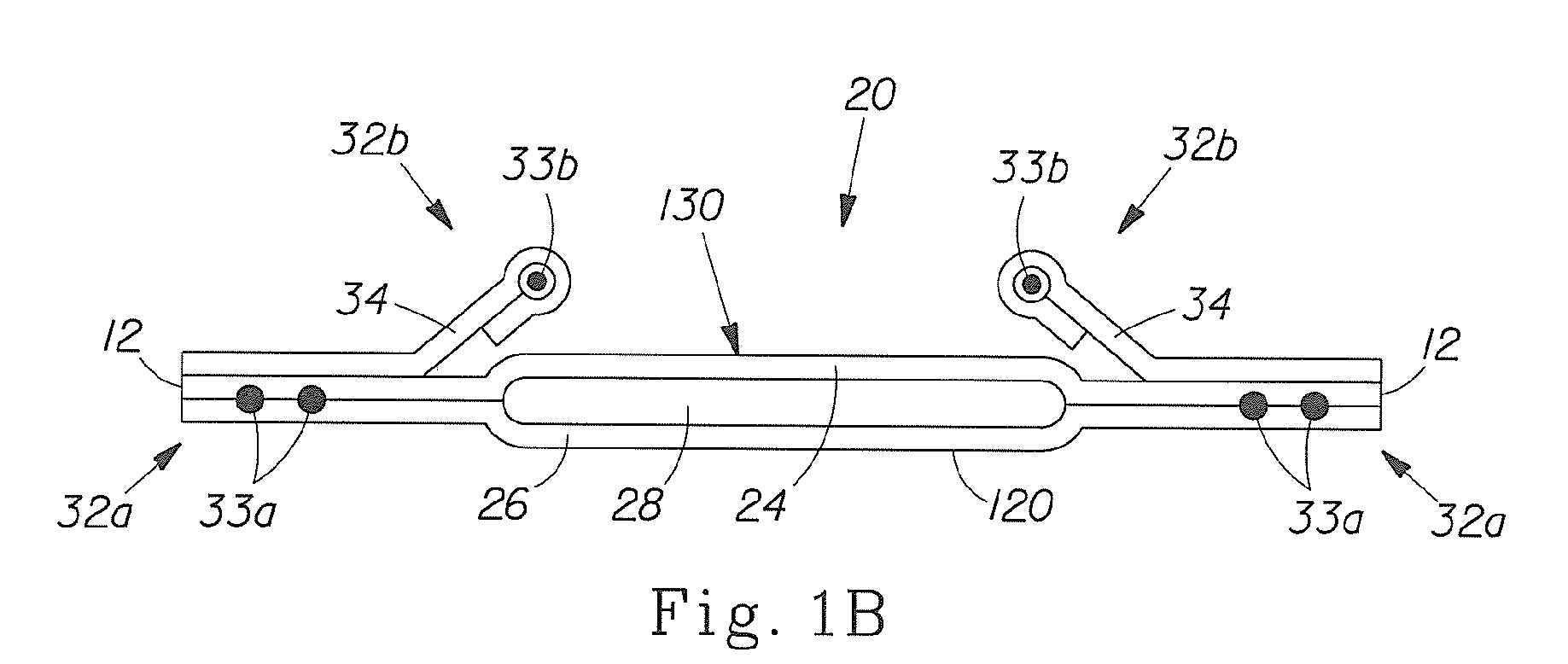

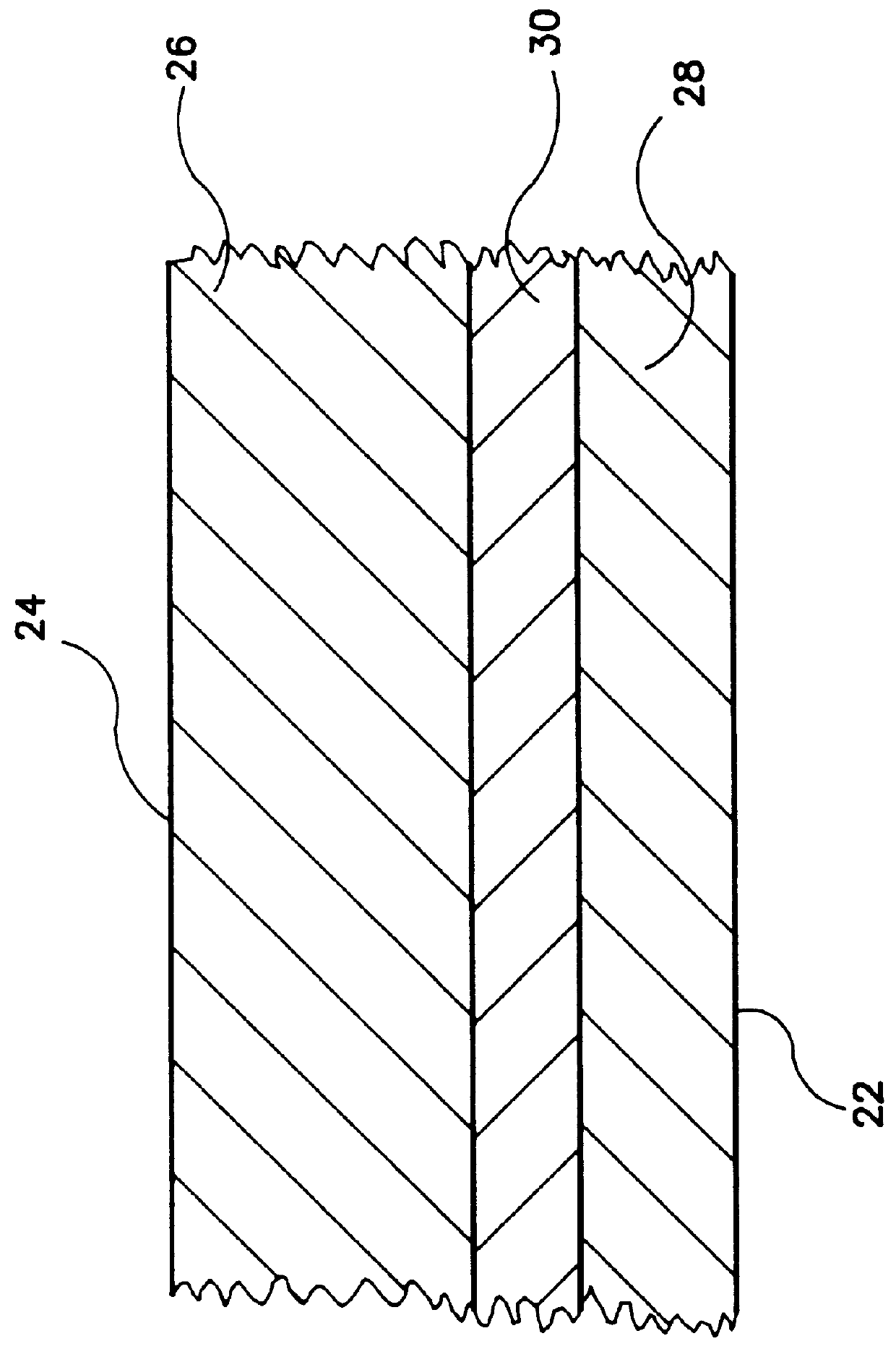

Breathable composite sheet structure and absorbent articles utilizing same

A breathable composite sheet material, a method for making such a sheet material, and an absorbent article utilizing the sheet material are provided. The composite sheet material is comprised of a thermoplastic film adhered directly to a fibrous substrate. The thermoplastic film comprises at least 50% by weight of a polymer material from the group of block copolyether esters, block copolyether amides and polyurethanes. The substrate comprises a fibrous web of at least 50% by weight of polyolefin polymer synthetic fibers. The composite sheet exhibits a peel strength of at least 0.1 N / cm, a dynamic fluid transmission of less than about 0.75 g / m2 when subjected to an impact energy of about 2400 joules / m2, and a moisture vapor transmission rate, according to the desiccant method, of at least 1500 g / m2 / 24 hr. The absorbent article comprises (a) a topsheet; (b) a backsheet; and (c) an absorbent core located between the topsheet and the backsheet; wherein the backsheet comprises the non-porous, substantially fluid impermeable, moisture vapor permeable composite sheet material described above. The composite sheet material is oriented such that the film layer of the composite sheet material faces toward the absorbent core. The absorbent article may comprise a disposable diaper.

Owner:THE PROCTER & GAMBLE COMPANY

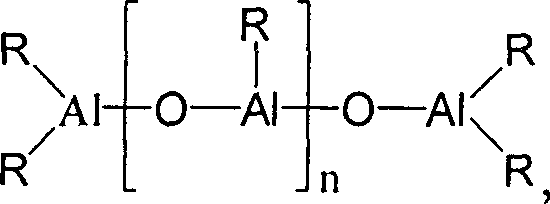

Application of supported non-metallocene catalyst in ethene polymerization process by slurry method

The invention discloses an application of load non- metallocene catalyst in the slurry process for vinyl polymerying, the load non- metallocene catalyst and catalyst promoter forming the catalytic system, the alkene polymerization comprising: vinyl homopolymerization, combined polymerization of vinyl with propylene, butylenes, hexane, octane or norbornene; the catalyst carrier being chosen from: inorganic oxide of metallic oxide from IIA, IIIA, IVA, and IVB groups, or oxided mixture and mixing oxide; the catalyst promoter being chosen from: methylaluoxane, ethylaluoxane, isobutylaluoxane, trimethylaluminum,triethylaluminum,triisobutylaluminum,methylaluoxane-trimethylaluminum or methylaluoxane-triethylaluminum; the mole proportion between the catalyst promoter and catalyst being Al / Ti= 1:1-500. The inventioin is characterized by the less methylaluoxane consumption, stable reaction, easy-to-control polymerization temperature and non still-sticking phenomenon. The produced polyolefine possesses perfect granual shape, and the maximum polymer clamp density can reach 0.385 g / ml.

Owner:SINOPEC YANGZI PETROCHEM

Rheology modification of interpolymers of ethylene/alpha-olefins and articles made therefrom

Rheology modification of an ethylene / α-olefin interpolymer is achieved by blending the interpolymer with at least one branched polyolefin. The polyolefins can be homopolymers or interpolymers and have a branching index of less than 1. The ethylene / α-olefin interpolymer is a block copolymer having at least a hard block and at least a soft block. The soft block comprises a higher amount of comonomers than the hard block. The block interpolymer has a number of unique characteristics disclosed here. Rheology-modified ethylene / α-olefin interpolymer, i.e., the resulting polymer blends, can be extruded or molded into many useful articles, such as films, sheets, profiles, gaskets, foams, etc.

Owner:DOW GLOBAL TECH LLC

Highly active supporting method of non-metallocene catalyst

A method of non- metallocene catalyst loading with high active: the carrier and chemical activating agent reacting with each other to get the modification carrier; dissolving the magnesium compounds into the tetrahydrofuran-alcohol mixing system to form solution, adding the modification carrier into the solution for reaction, filtering, washing, drying and sucting to get the composite carrier; dissolving the non- metallocene catalyst for lkene polymerization into the dissolvent, then reacting with the composite carrier and through process of washing, filtering and drying to get the load non- metallocene catalyst. It can also be: proceeding heating activating treatment before the reaction of carrier with the chemical activating agent; the composite carrier reacting with chemical additive before reacting with catalyst to get the modification composite carrier, the modification composite carrier reacting with catalyst to get the load non- metallocene catalyst. The load catalyst produced in this invention is high active; the load catalyst of high property can be produced with less methylaluoxane; the polyolefine produced with the catalyst prepared in this invention possesses sound granual shape.

Owner:SINOPEC YANGZI PETROCHEM

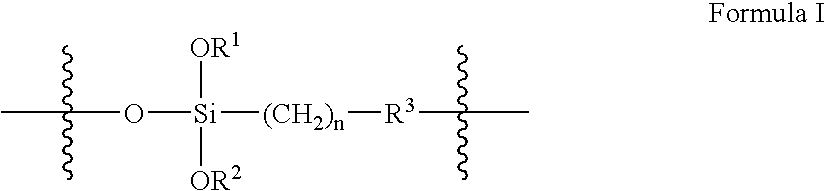

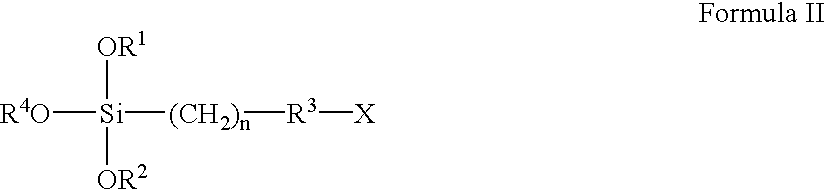

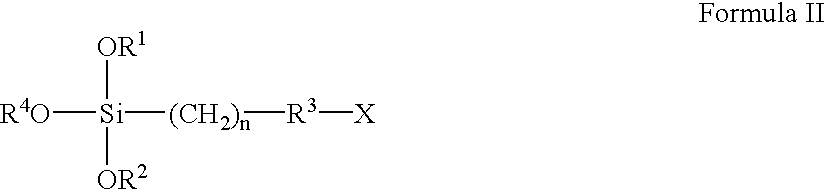

Functionalized porous substrate for binding chemical and biological moieties

The invention relates to porous polymeric materials, methods of making them, and applications in medical devices. A specific embodiment of the invention encompasses a material comprising a porous polyolefin substrate containing inclusions of a material to which chemical or biological moieties are attached directly or via a spacer.

Owner:POREX TECHNOLOGIES CORP

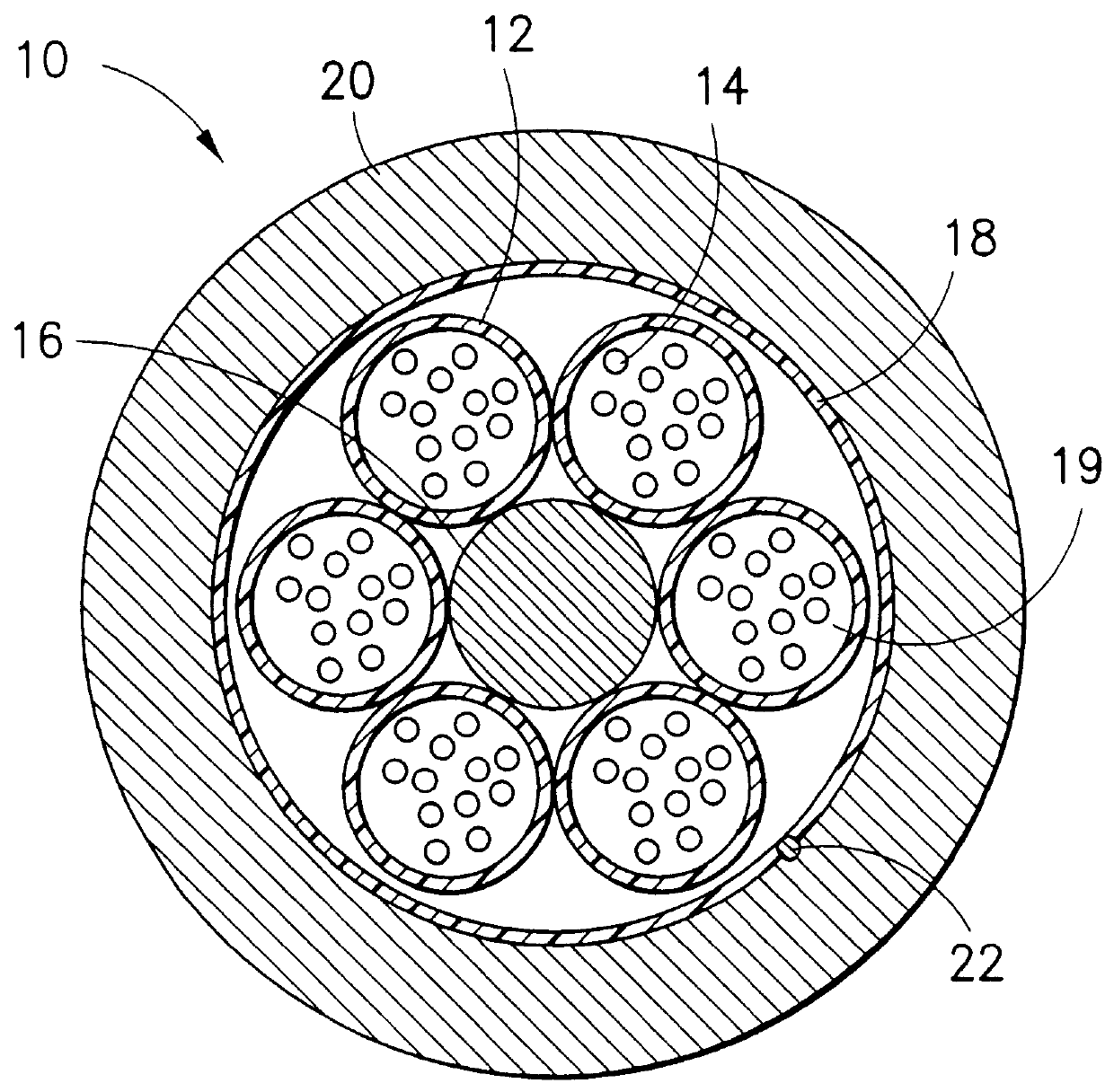

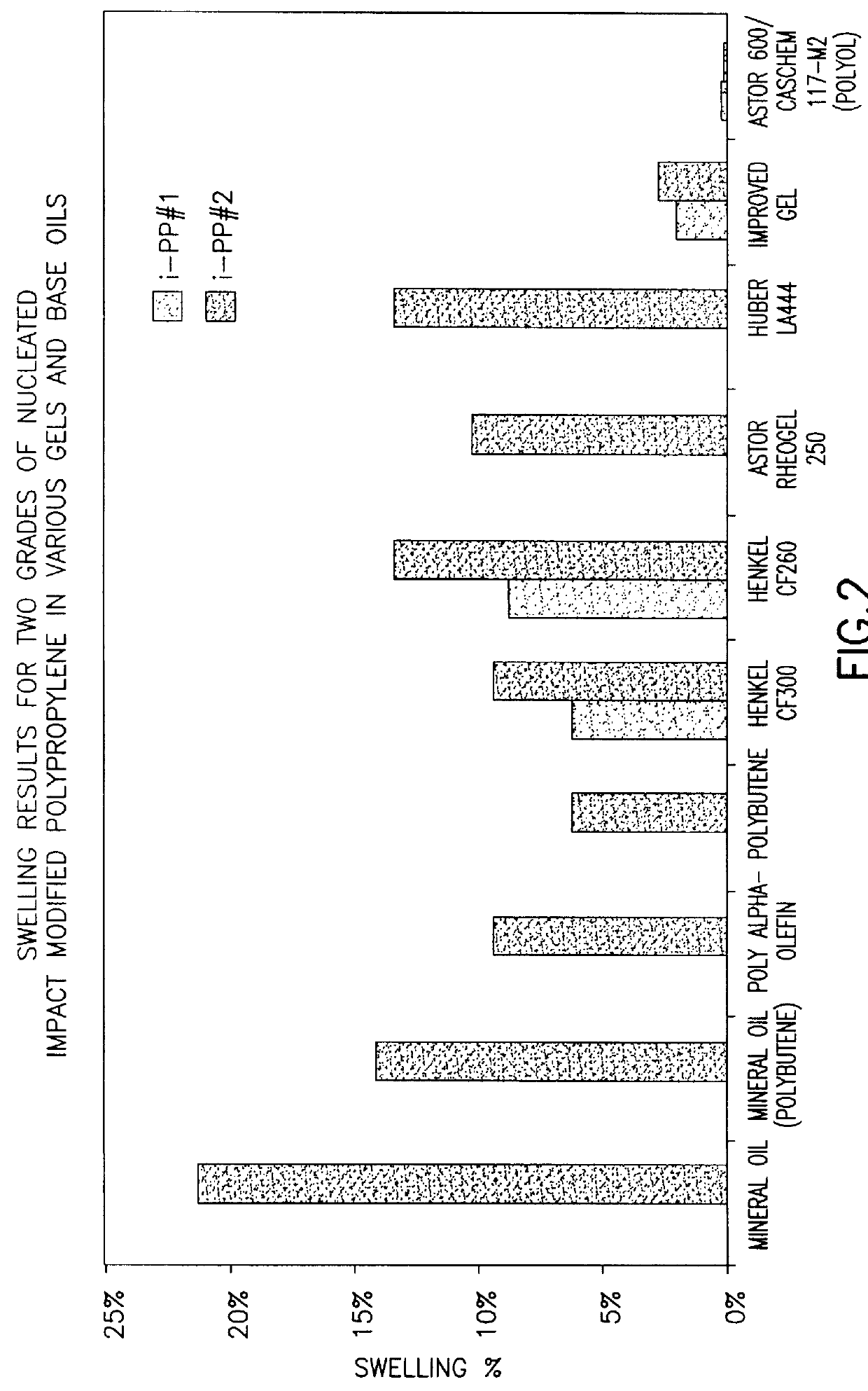

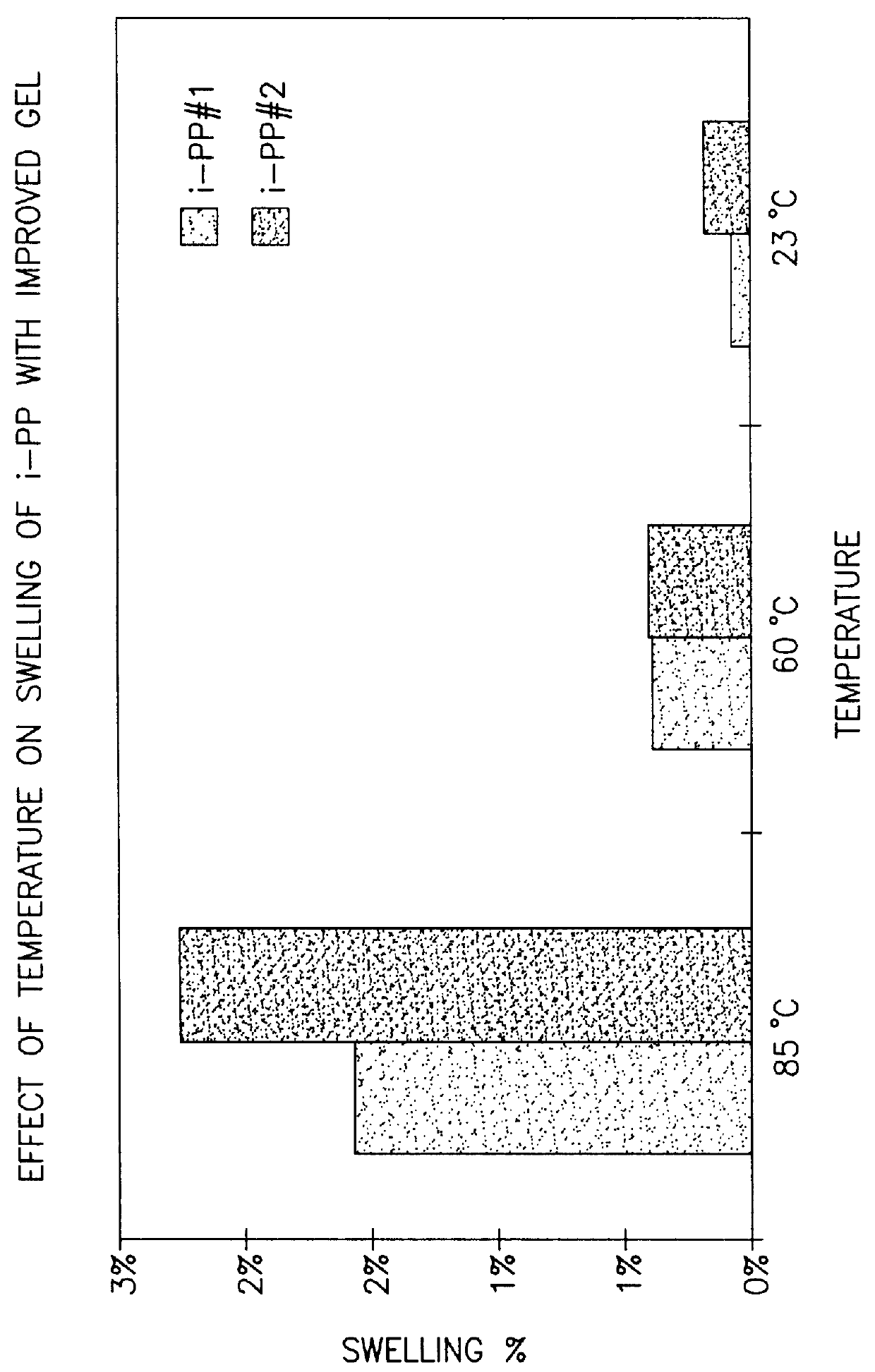

Water blocking gels compatible with polyolefin optical fiber cable buffer tubes and cables made therewith

A water blocking gel which is compatible with polyolefin optical fiber cable buffer tubes is disclosed. The water blocking gel comprises a polyolefin oil, wherein only a very small fraction of the polyolefin species have a molecular weight below about 2000. The gel also includes a thixotropic agent, and a thermal oxidation stabilizer. The gel is relatively low cost, does not cause substantially swelling of the polyolefin buffer tubes in contact therewith and does not degrade the buffer tube's physical properties.

Owner:ALCATEL LUCENT SAS

Interpolymers of ethylene/a-olefins blends and profiles and gaskets made therefrom

Polymer blends comprise at least an ethylene / α-olefin interpolymers and at least one polyolefin. The polyolefins can be homopolymers or interpolymers and have a melt strength of at least about 6 cN. The ethylene / α-olefin interpolymer is a block copolymer having at least a hard block and at least a soft block. The soft block comprises a higher amount of comonomers than the hard block. The block interpolymer has a number of unique characteristics disclosed here. The polymer blends can be profiled extruded to make profiles, gaskets, and other products.

Owner:DOW GLOBAL TECH LLC

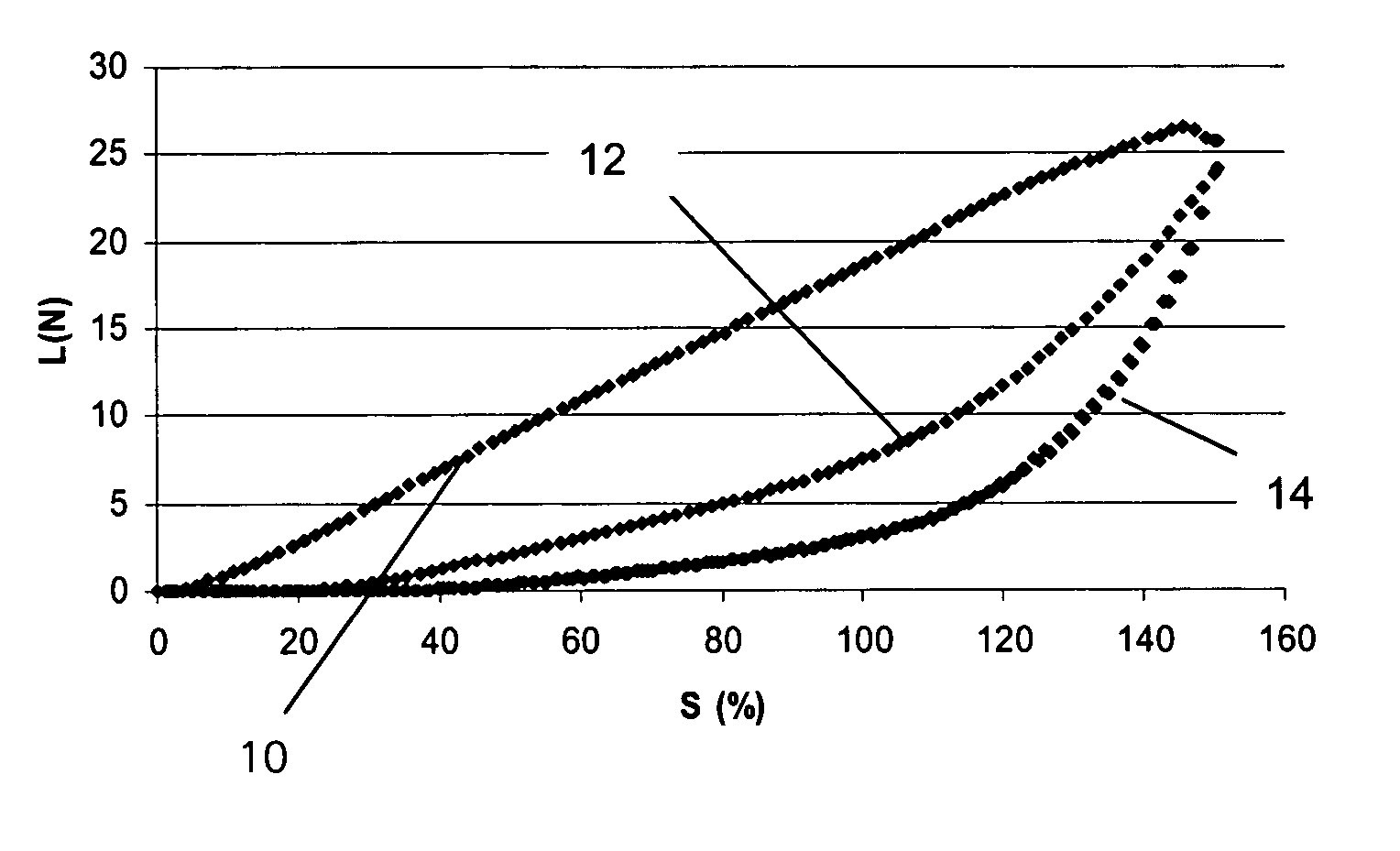

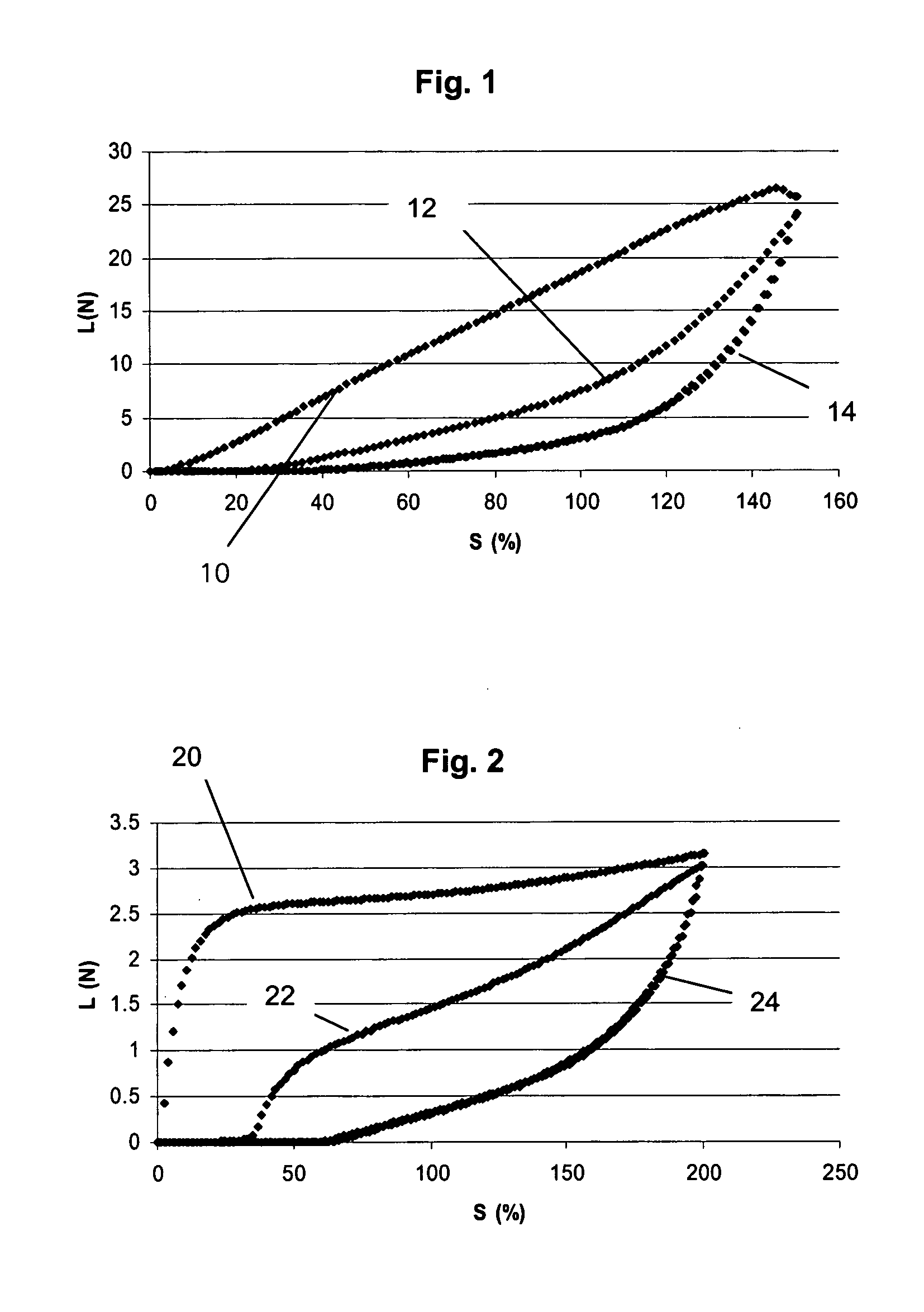

Web materials having both plastic and elastic properties

An extruded web is disclosed. The extruded web can be either a nonwoven material of a films. The web comprises a plasto-elastic material where the plasto-elastic material is a combination of a first polyolefin and a second polyolefin (either a polymeric blends or a polymeric mixture). The claimed combination of polyolefins results in a material that has substantially plastic properties when a sample taken from said web is subjected to an initial strain cycle (such that the web is provided with a set of at least 30% by an initial strain cycle) and substantially elastic properties when a sample taken from the web is subjected to at least a second strain cycle.

Owner:THE PROCTER & GAMBLE COMPANY

Highly-resilient thermoplastic elastomer compositions

A thermoplastic composition of (a) an acid copolymer, (b) a salt of a high molecular weight, monomeric organic acid; (c) a thermoplastic polymer selected from copolyetheresters, elastomeric polyolefins, styrene diene block copolymers, elastomeric polyolefins thermoplastic polyurethanes and copolyetheramides; (d) cation source; and (d) optionally a filler. Also included is use of such compositions in components of one-, two- and three-piece golf balls or multi-layered golf balls made therefrom.

Owner:EI DU PONT DE NEMOURS & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Bicyclo[2.2.1]heptane dicarboxylate salts as polyolefin nucleators Bicyclo[2.2.1]heptane dicarboxylate salts as polyolefin nucleators](https://images-eureka.patsnap.com/patent_img/7d258cb1-9493-44a8-9f4d-3c287732759f/US06465551-20021015-C00001.png)

![Bicyclo[2.2.1]heptane dicarboxylate salts as polyolefin nucleators Bicyclo[2.2.1]heptane dicarboxylate salts as polyolefin nucleators](https://images-eureka.patsnap.com/patent_img/7d258cb1-9493-44a8-9f4d-3c287732759f/US06465551-20021015-C00002.png)

![Bicyclo[2.2.1]heptane dicarboxylate salts as polyolefin nucleators Bicyclo[2.2.1]heptane dicarboxylate salts as polyolefin nucleators](https://images-eureka.patsnap.com/patent_img/7d258cb1-9493-44a8-9f4d-3c287732759f/US06465551-20021015-C00003.png)