Patents

Literature

970 results about "Ethylene Polymers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Group of common polymers made from ethylene monomer. Includes low-density polyethylene, high-density polyethylene and medium- density polyethylene plus copolymers like ethylene- propylene-diene rubber.

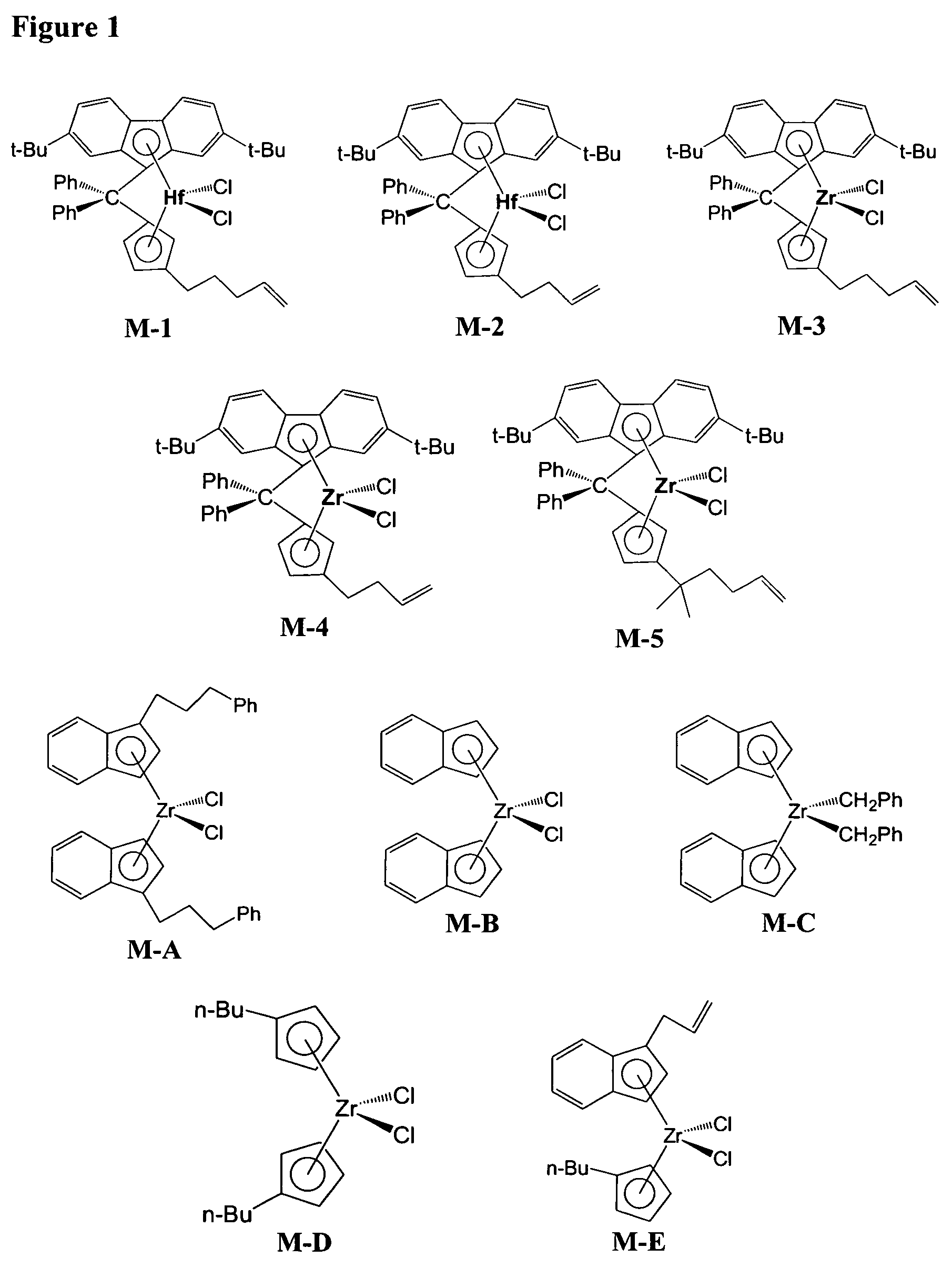

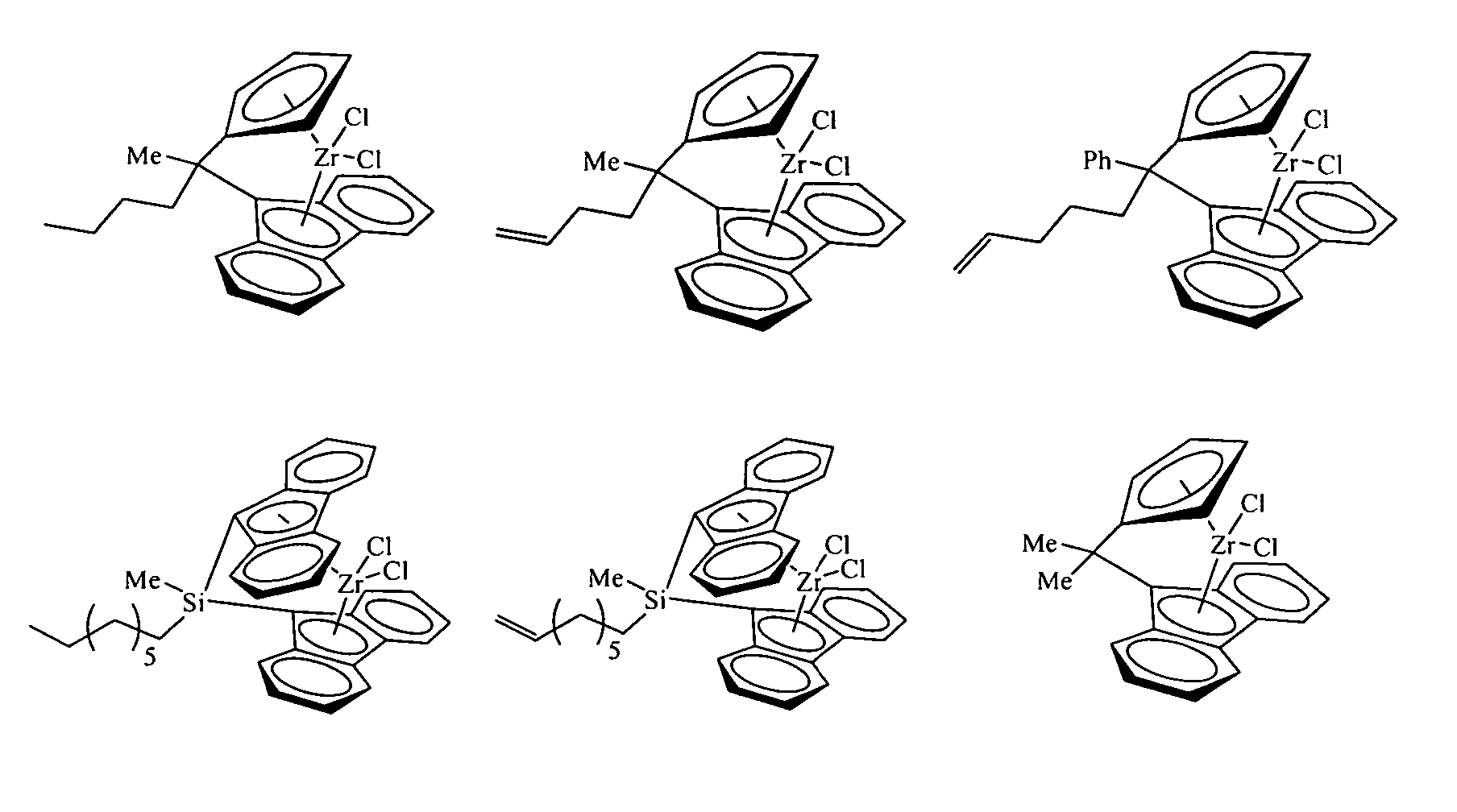

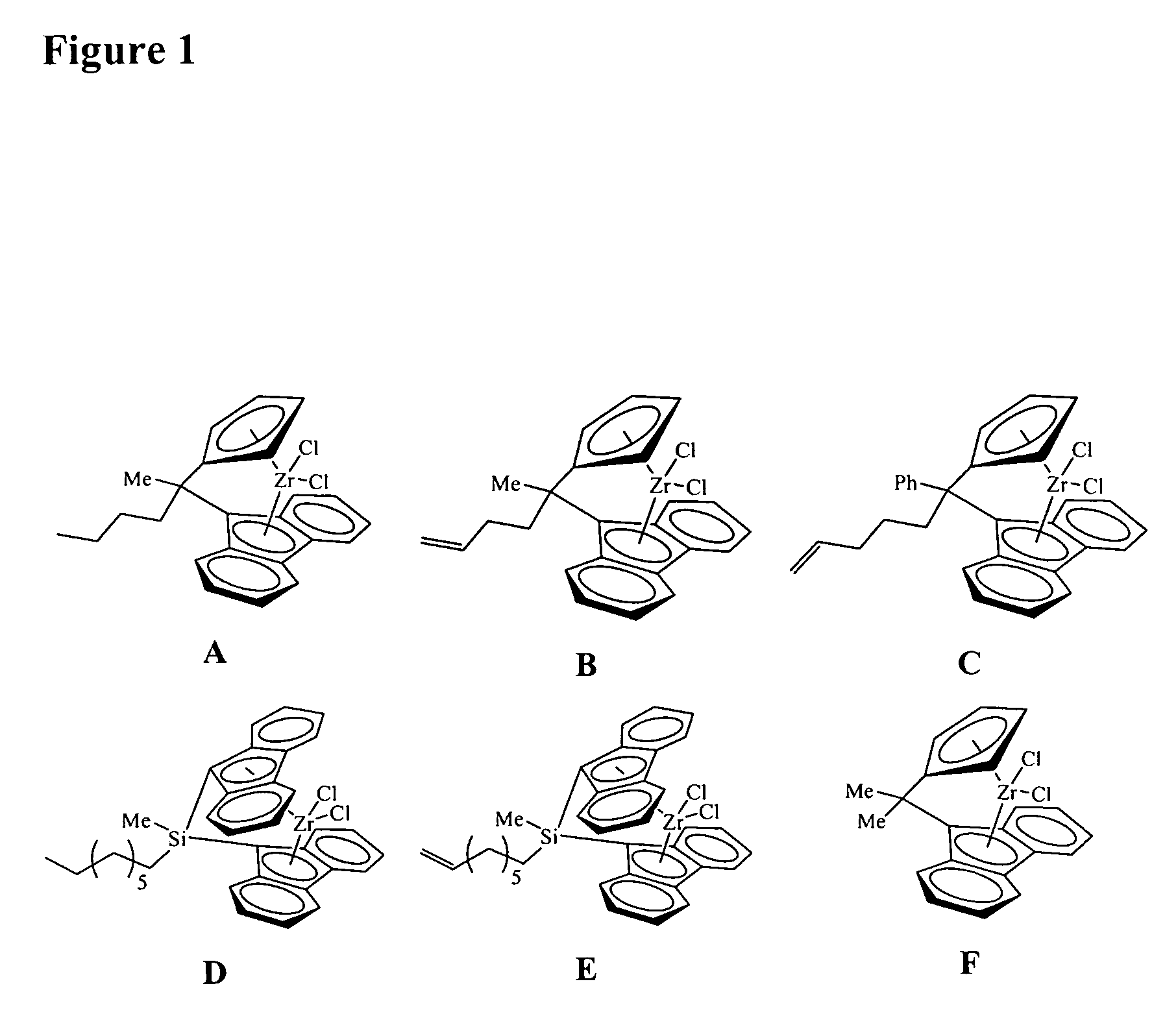

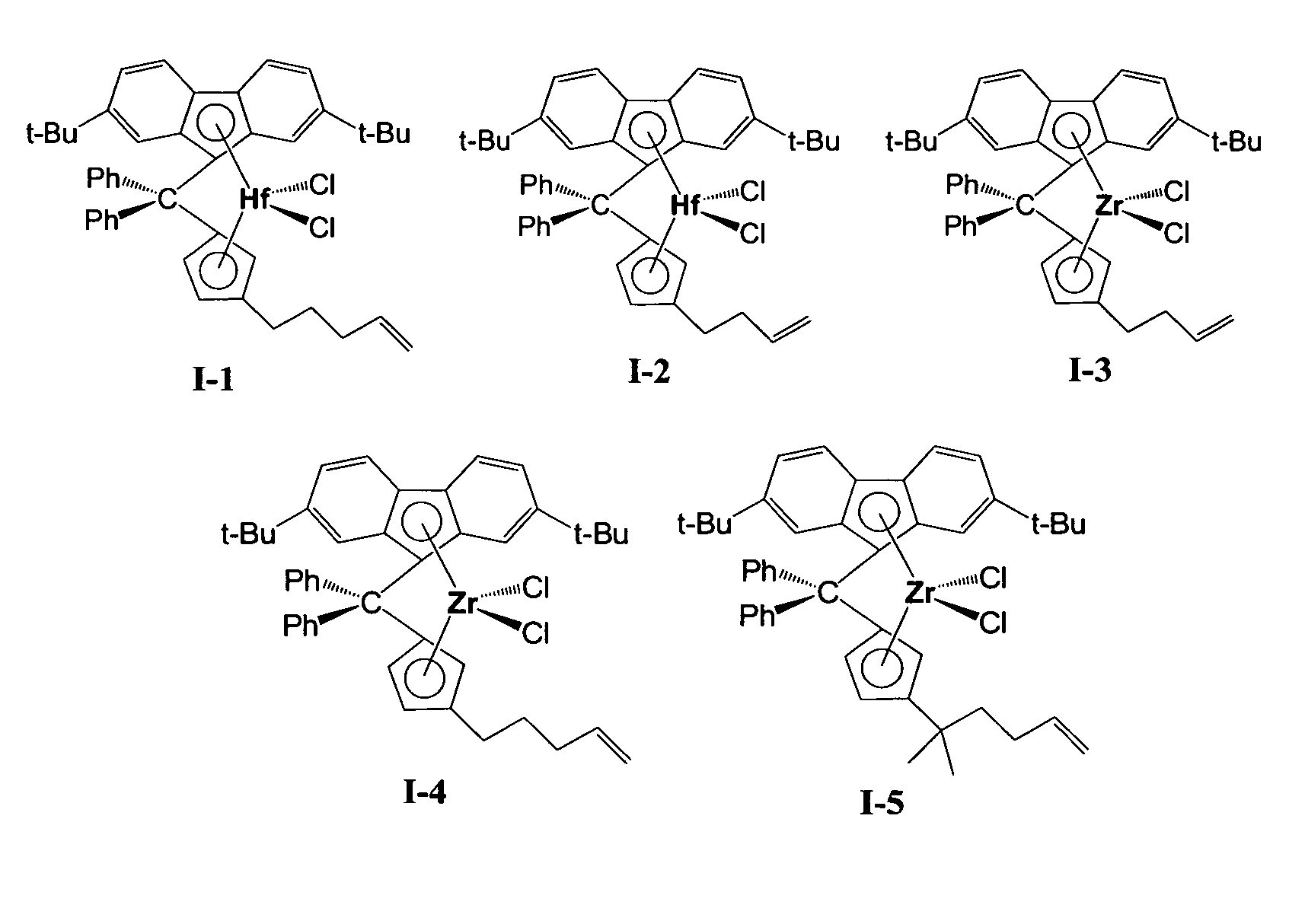

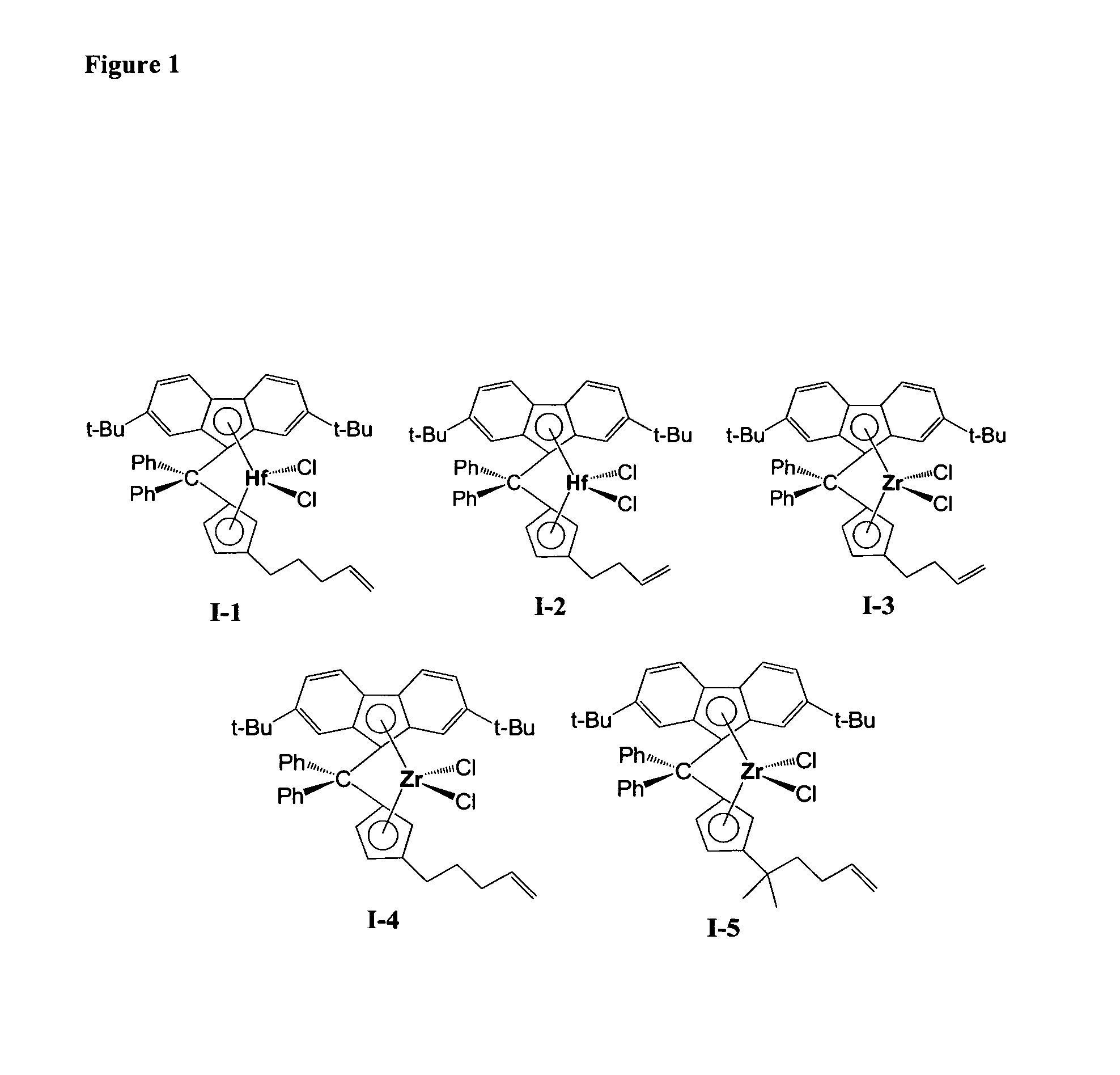

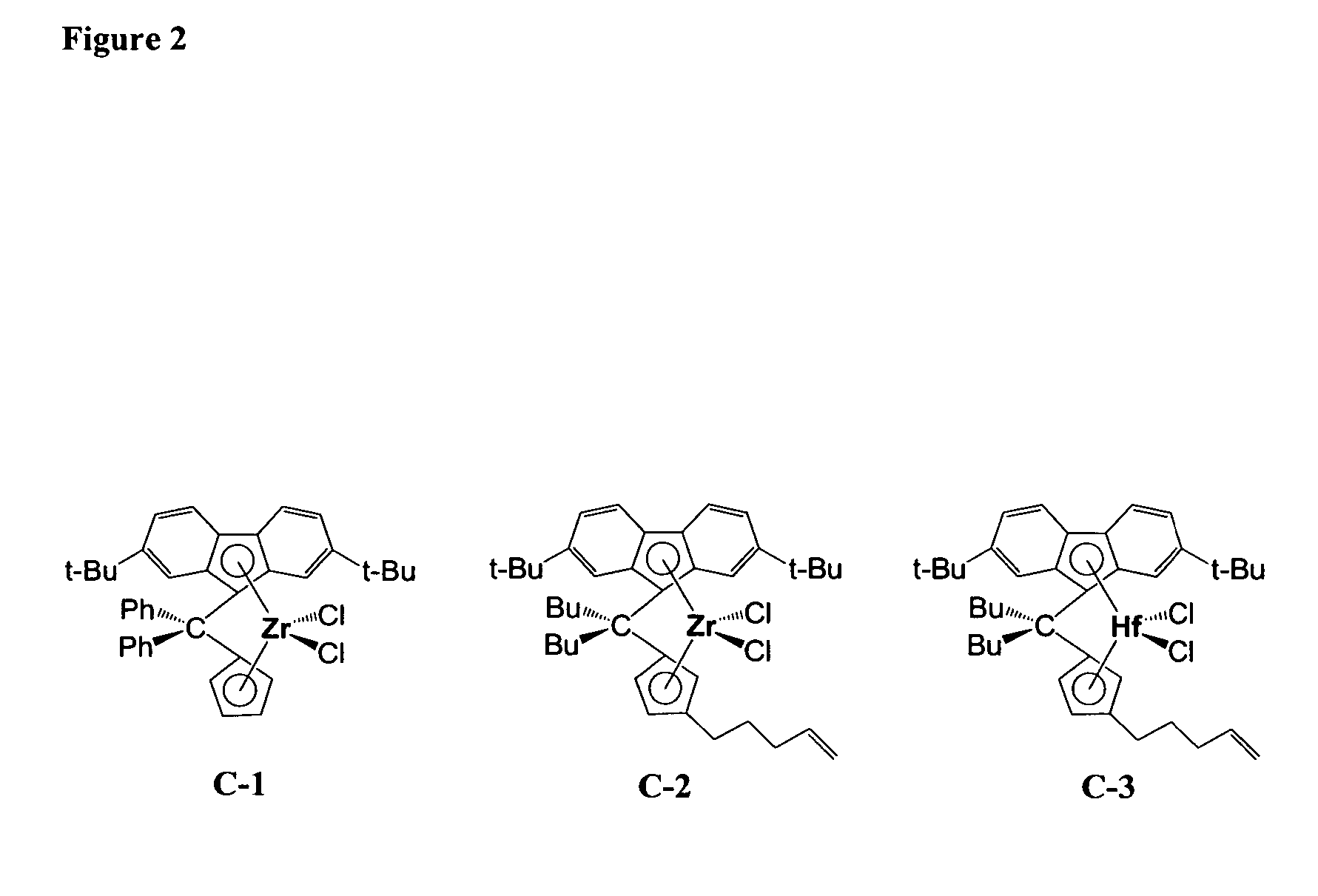

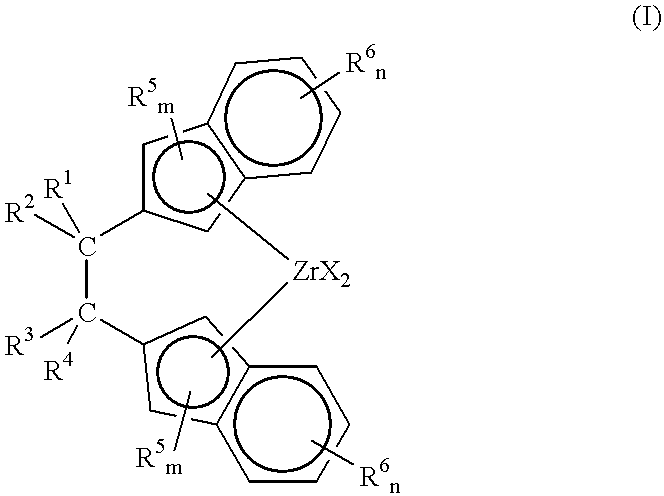

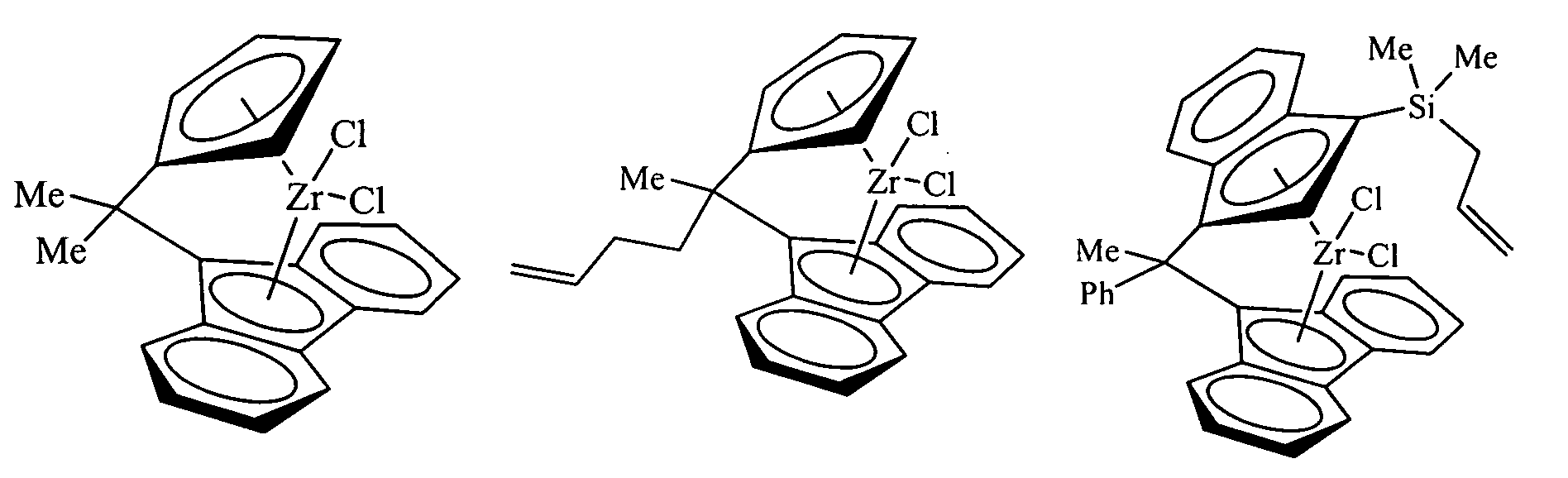

Dual metallocene catalysts for polymerization of bimodal polymers

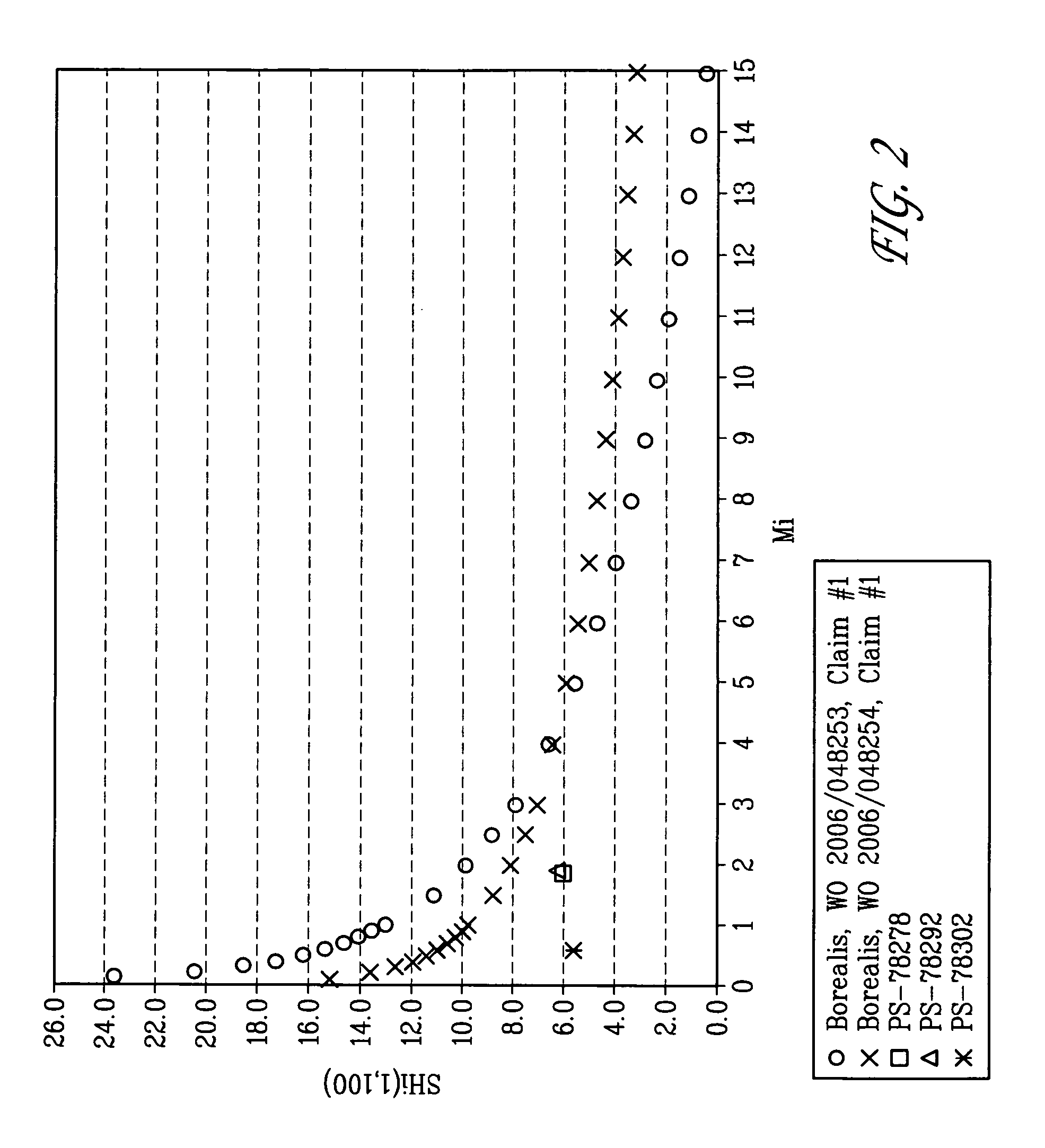

ActiveUS7619047B2Good balance of stiffnessHigh impact strengthGroup 8/9/10/18 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsEthylene PolymersEthylene

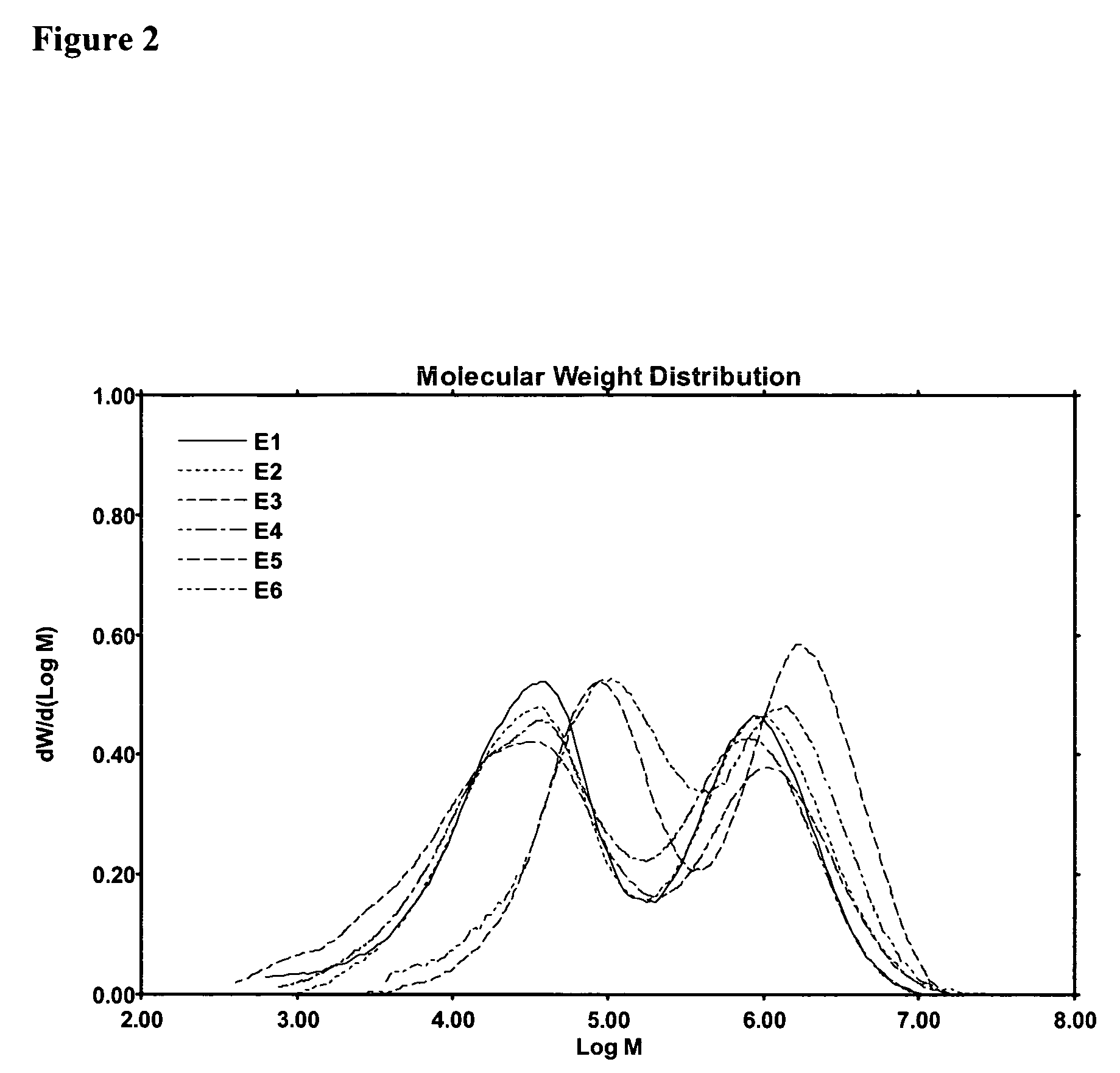

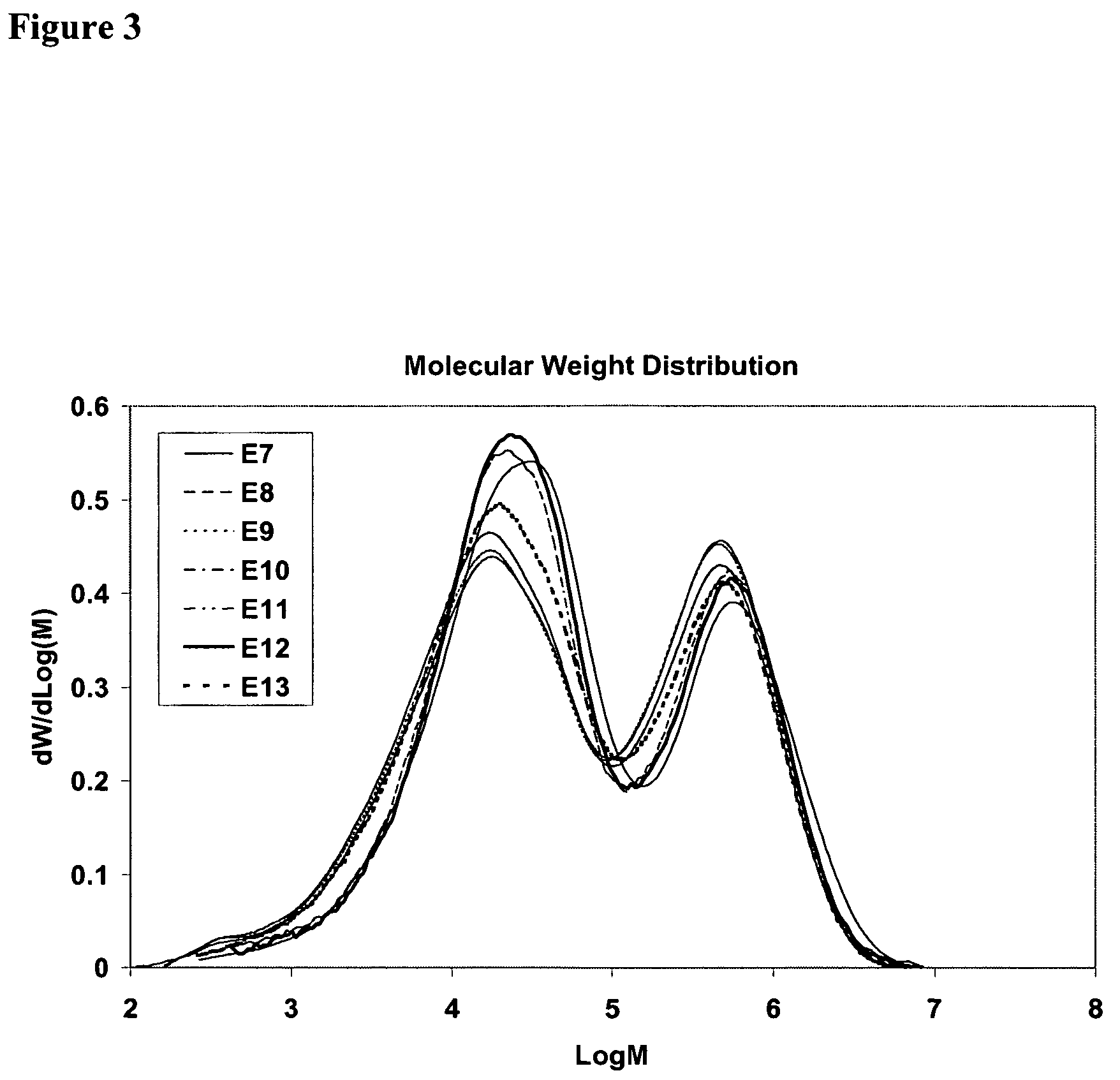

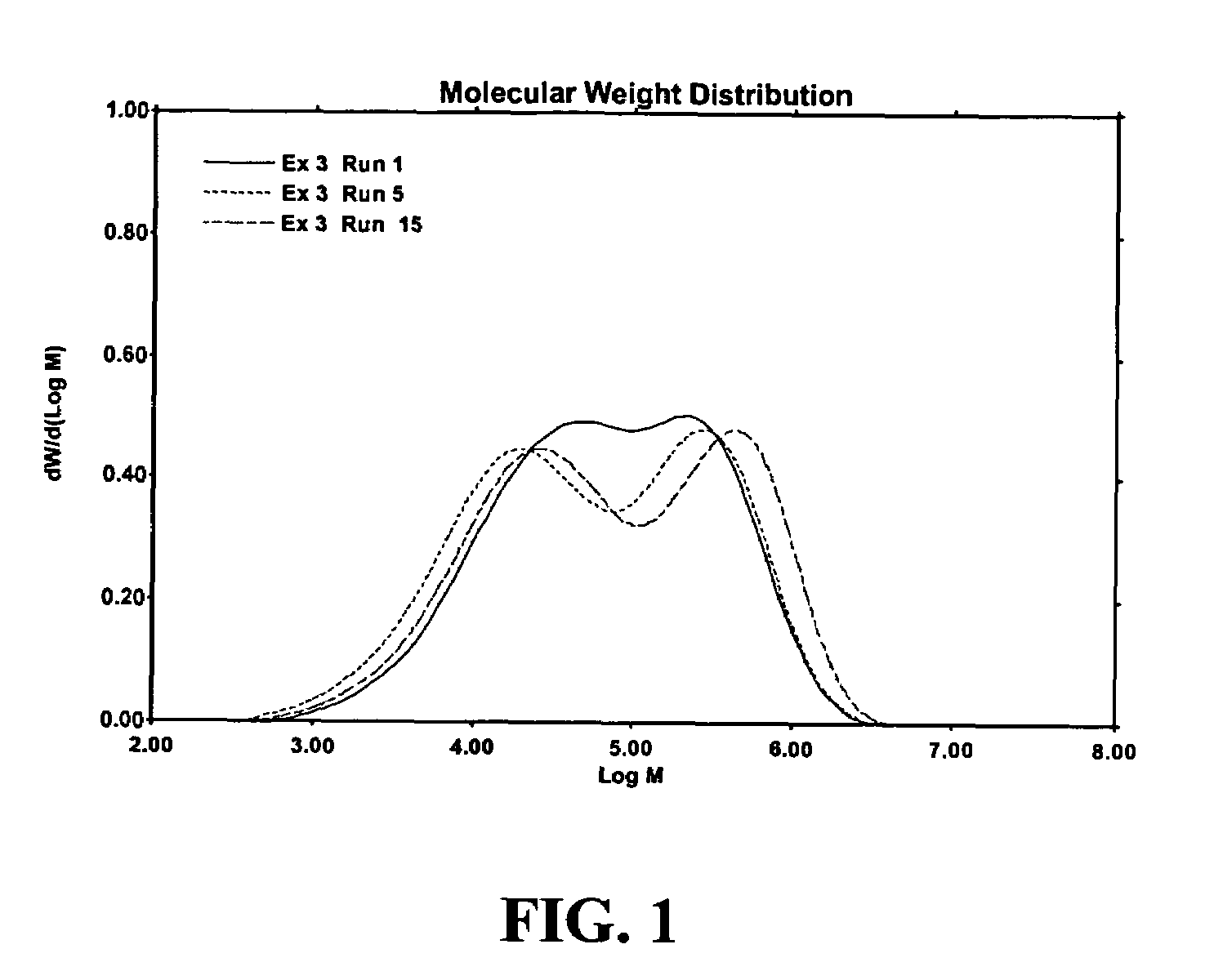

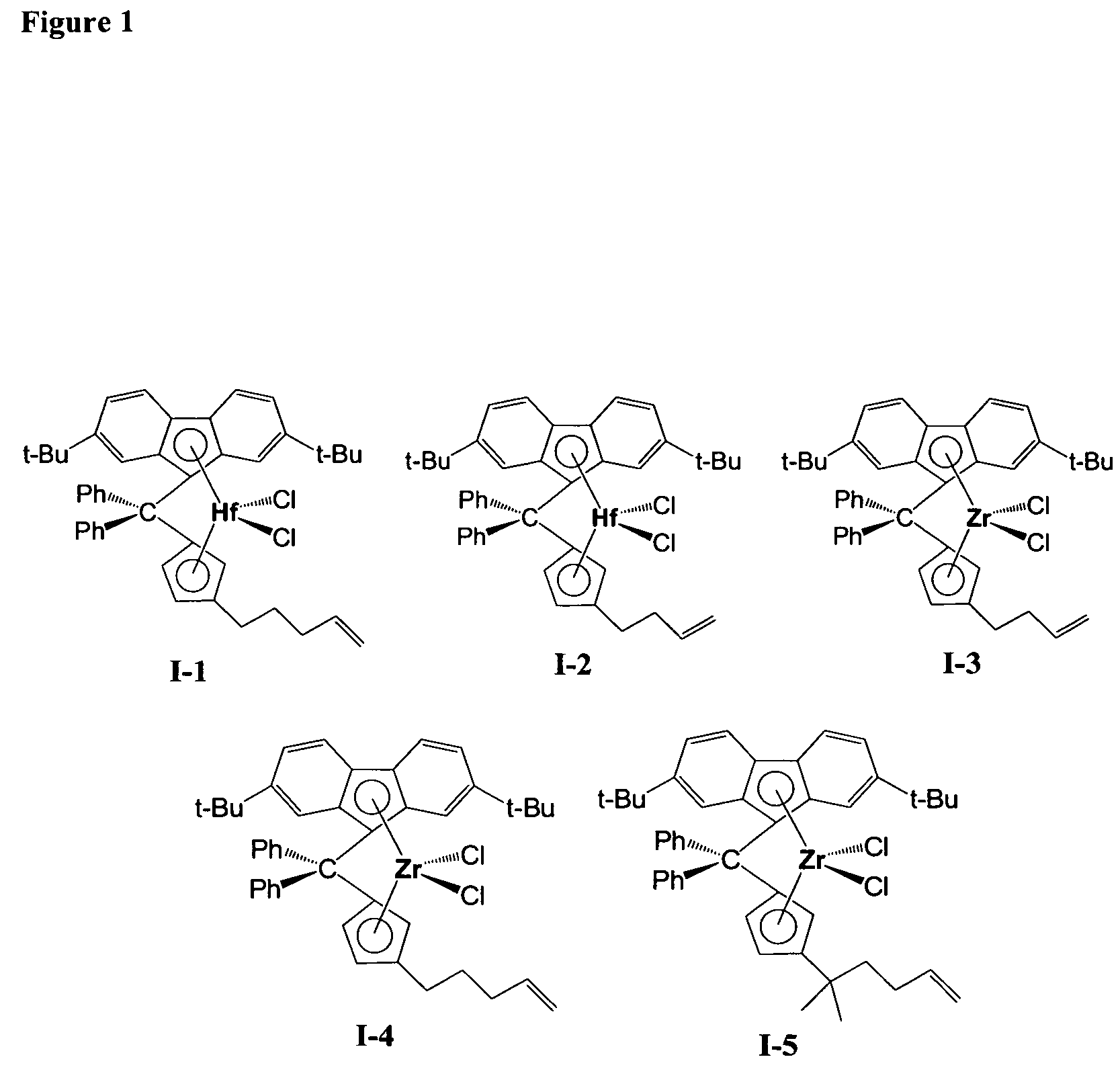

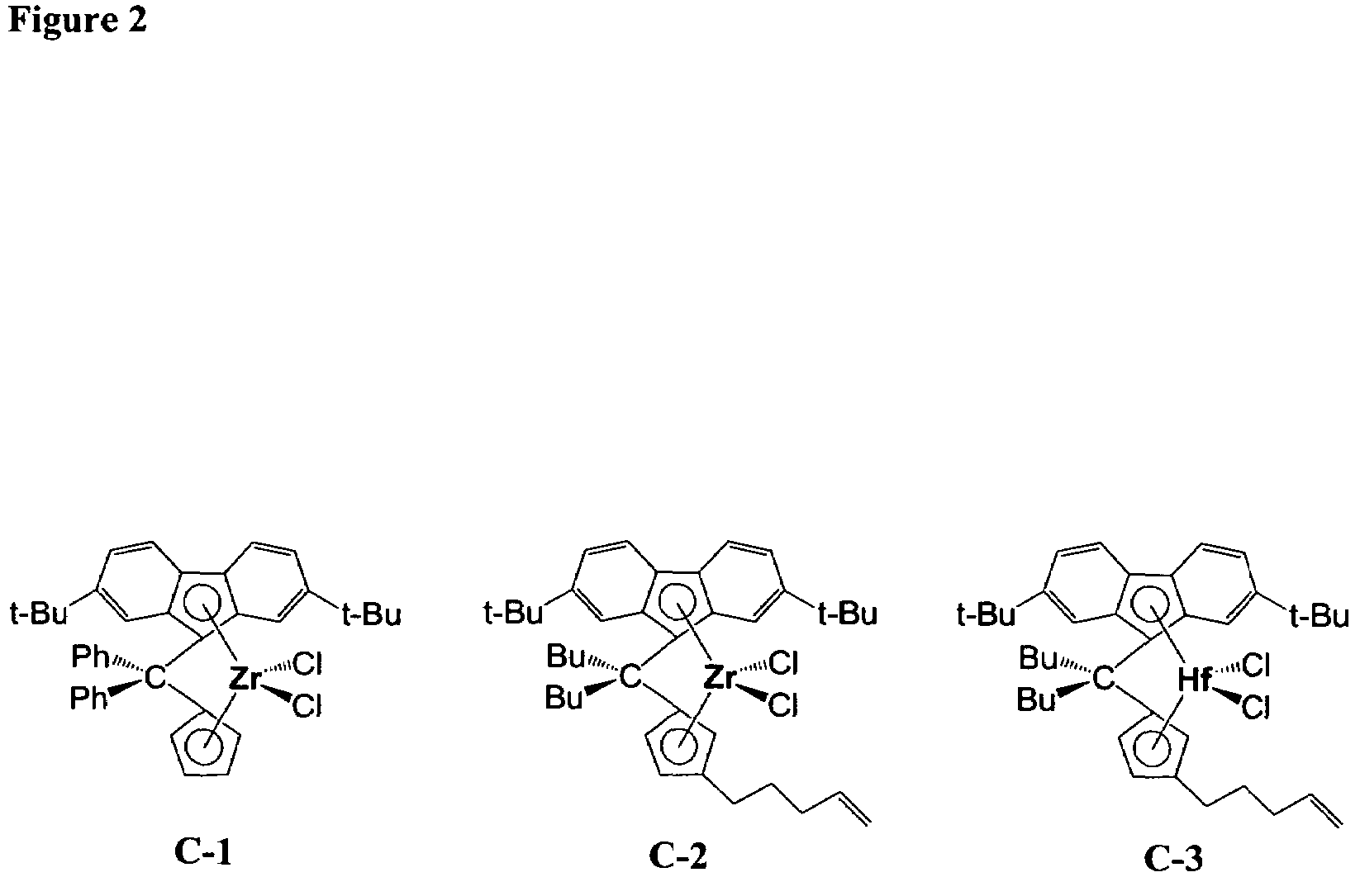

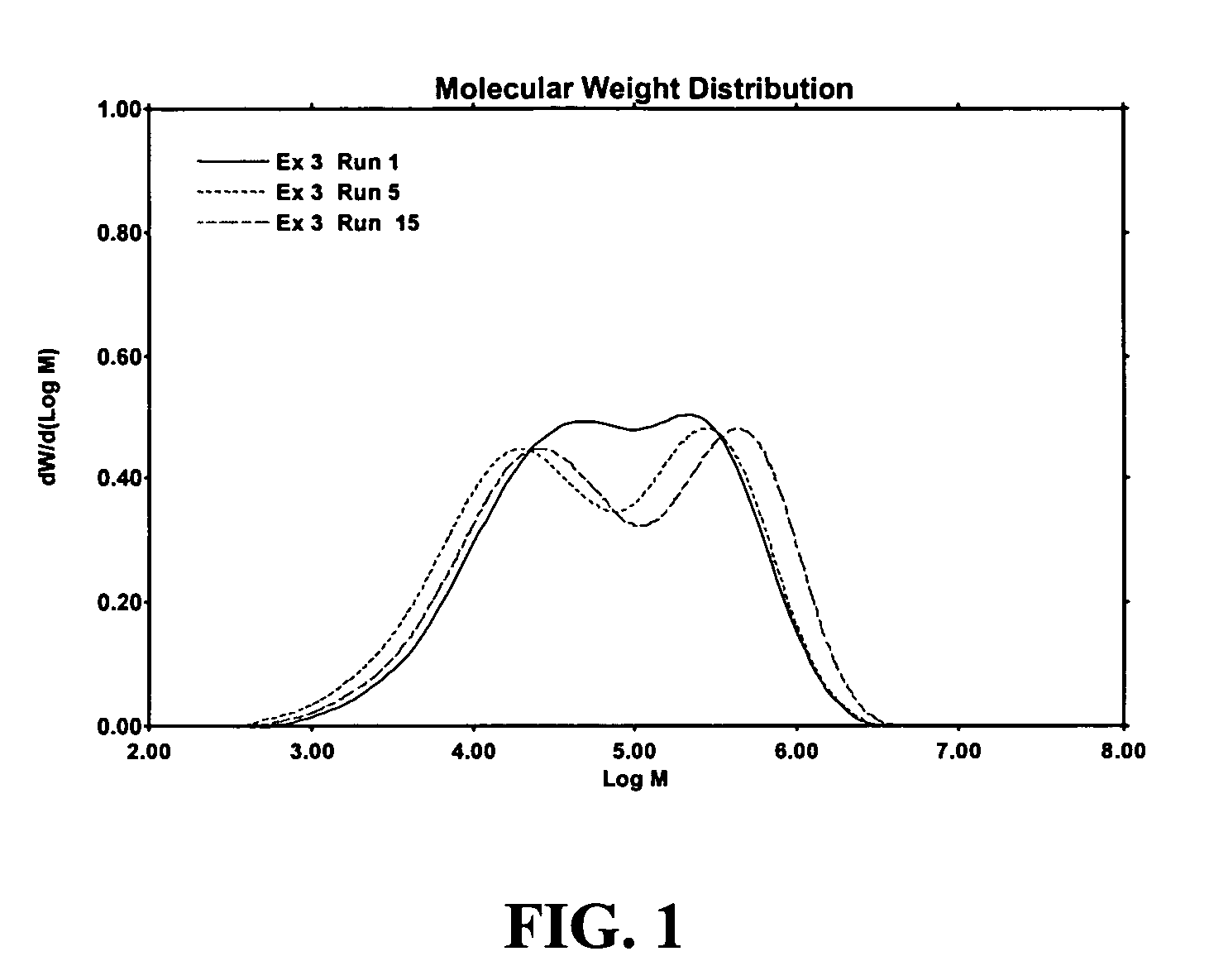

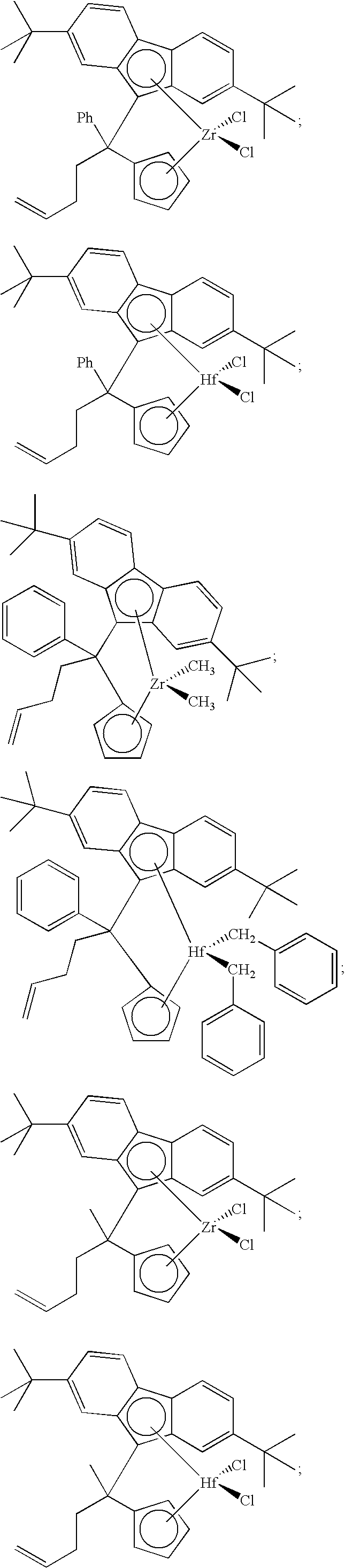

This invention relates to catalyst compositions, methods, and polymers encompassing at least one first Group 4 metallocene compound comprising bridging η5-cyclopentadienyl-type ligands, in combination with at least one second Group 4 metallocene with non-bridging η5-cyclopentadienyl-type ligands, typically in combination with at least one cocatalyst, and at least one activator. The compositions and methods disclosed herein provide ethylene polymers with a bimodal molecular weight distribution.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Polymerization catalysts and process for producing bimodal polymers in a single reactor

ActiveUS7312283B2Outstanding balance of stiffnessHigh impact strengthOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyolefinEthylene Polymers

Catalyst compositions comprising a first metallocene compound, a second metallocene compound, an activator-support, and an organoaluminum compound are provided. Methods for preparing and using such catalysts to produce polyolefins are also provided. The compositions and methods disclosed herein provide ethylene polymers having a HLMI of from about 0.5 to about 25, a polymer density of from about 0.920 to about 0.965, and a polydispersity of from about 3.0 to about 30.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

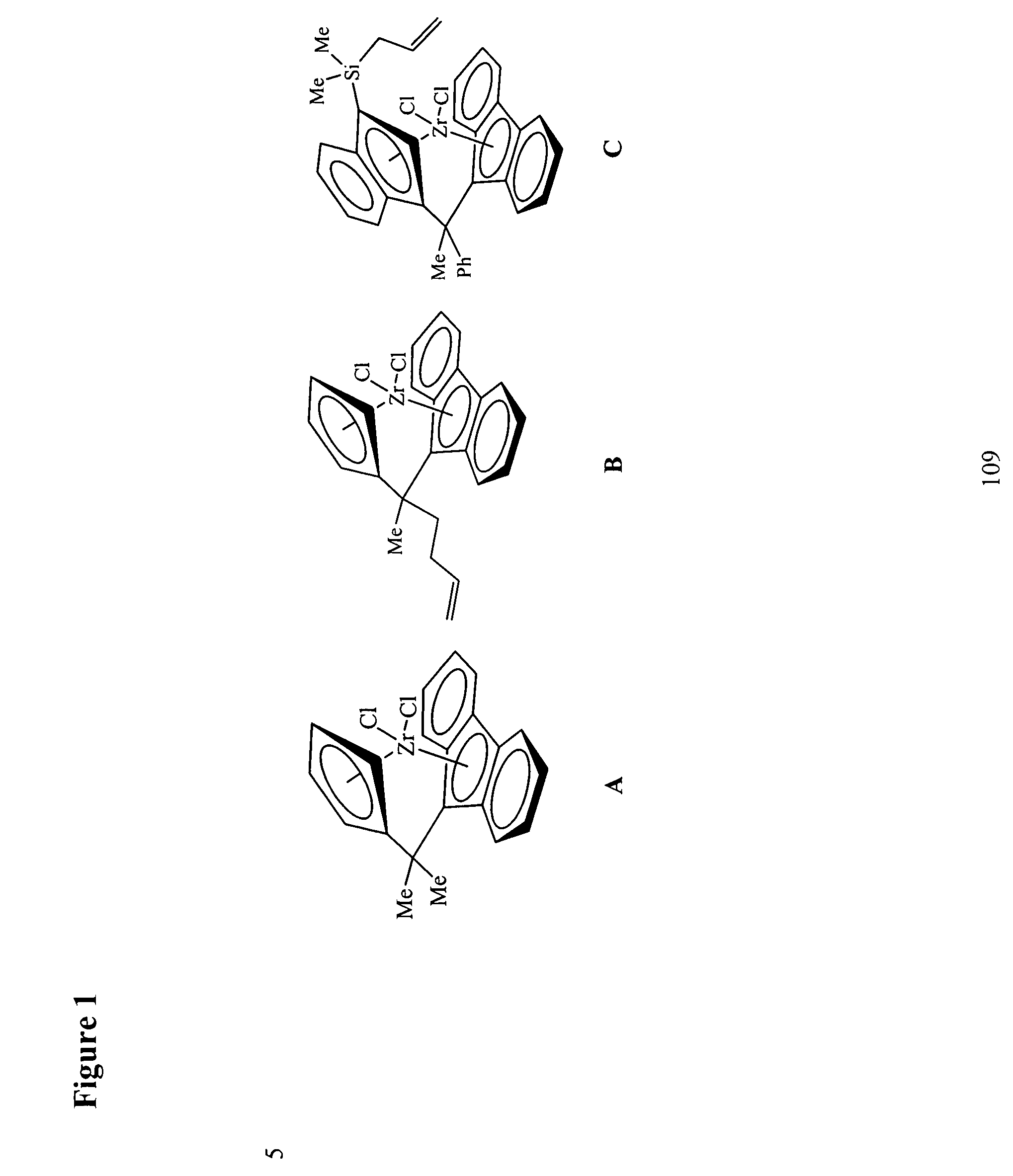

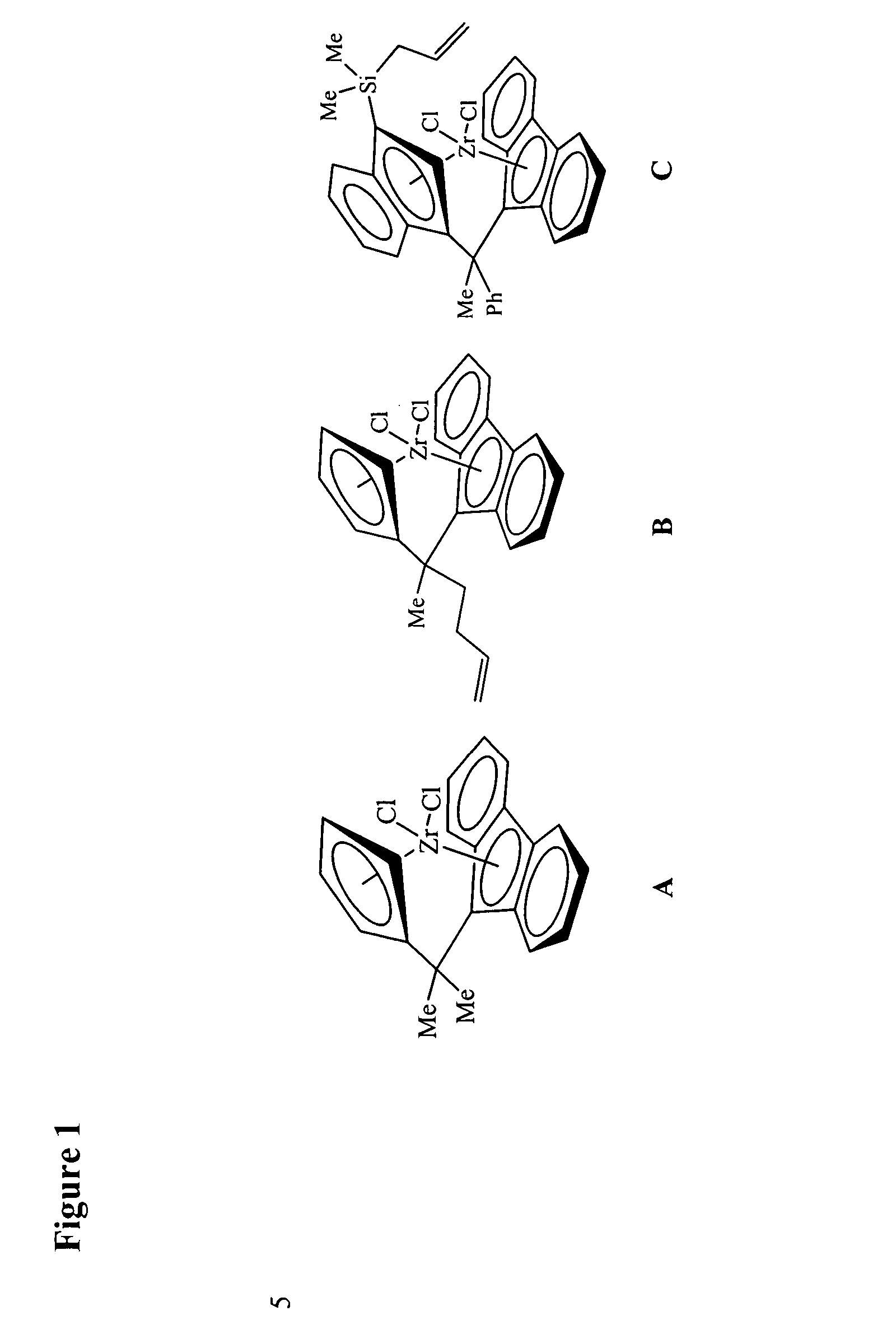

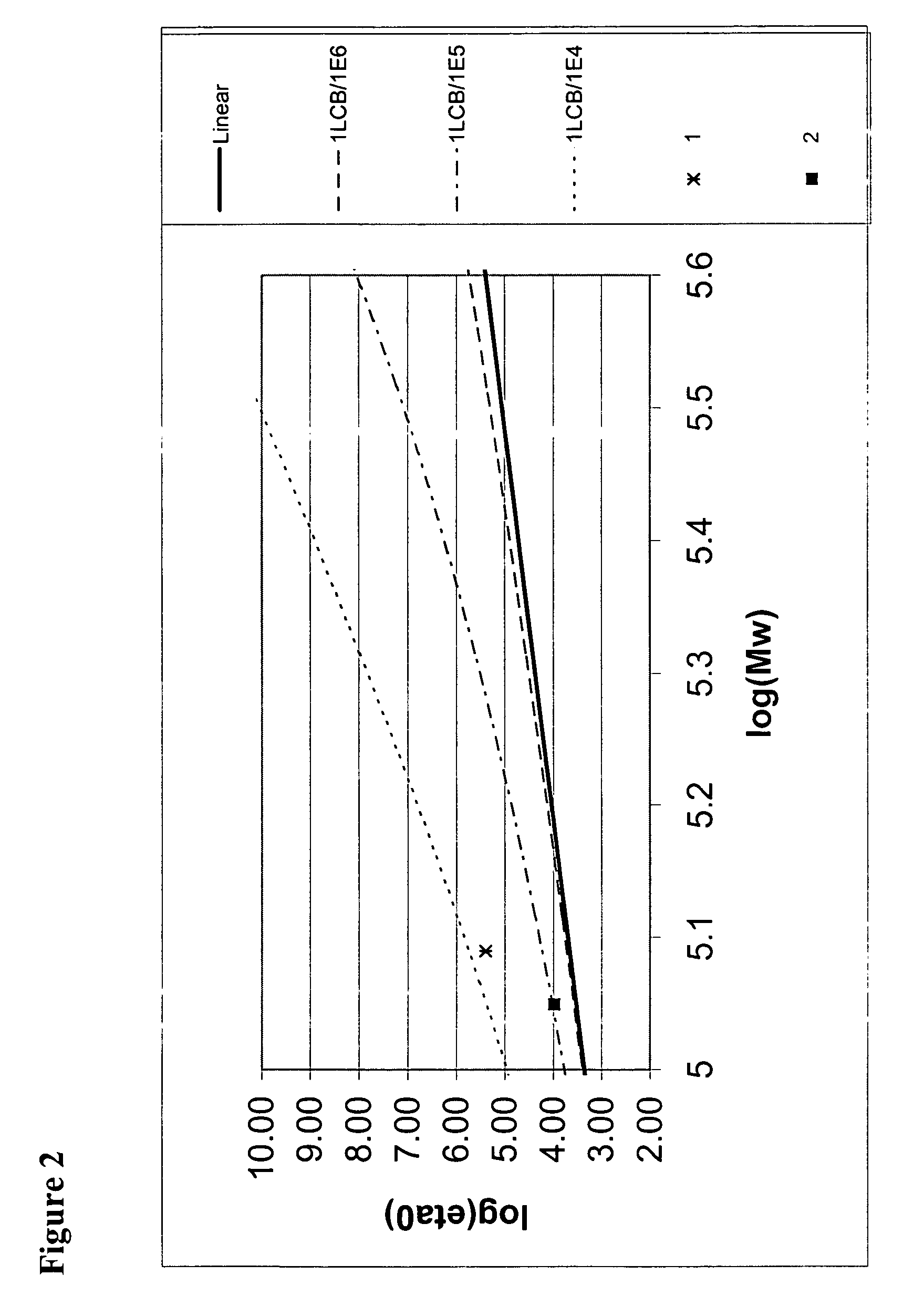

Polymerization catalysts for producing high molecular weight polymers with low levels of long chain branching

ActiveUS7517939B2High catalytic activityHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsGroup 8/9/10/18 element organic compoundsHigh molecular massEthylene Polymers

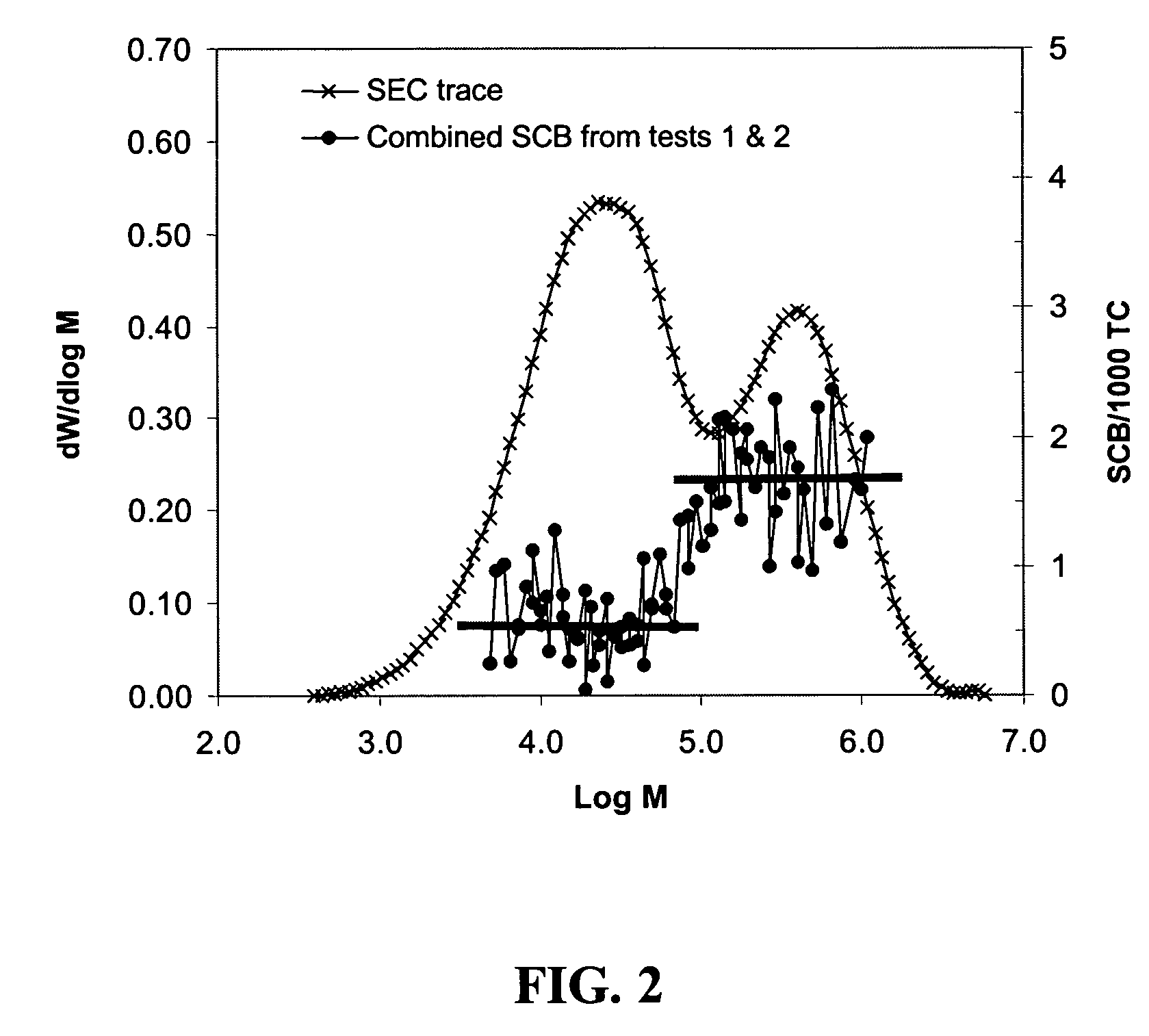

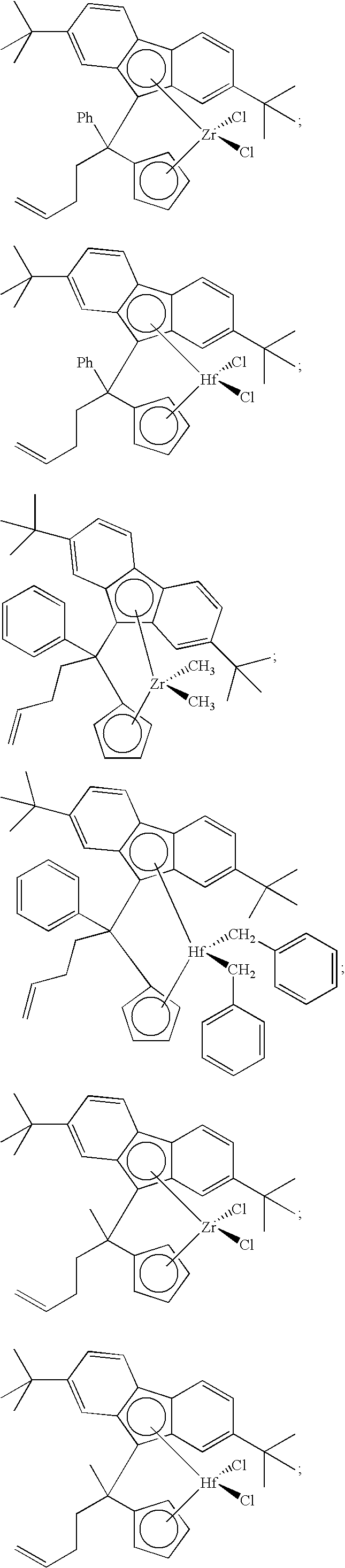

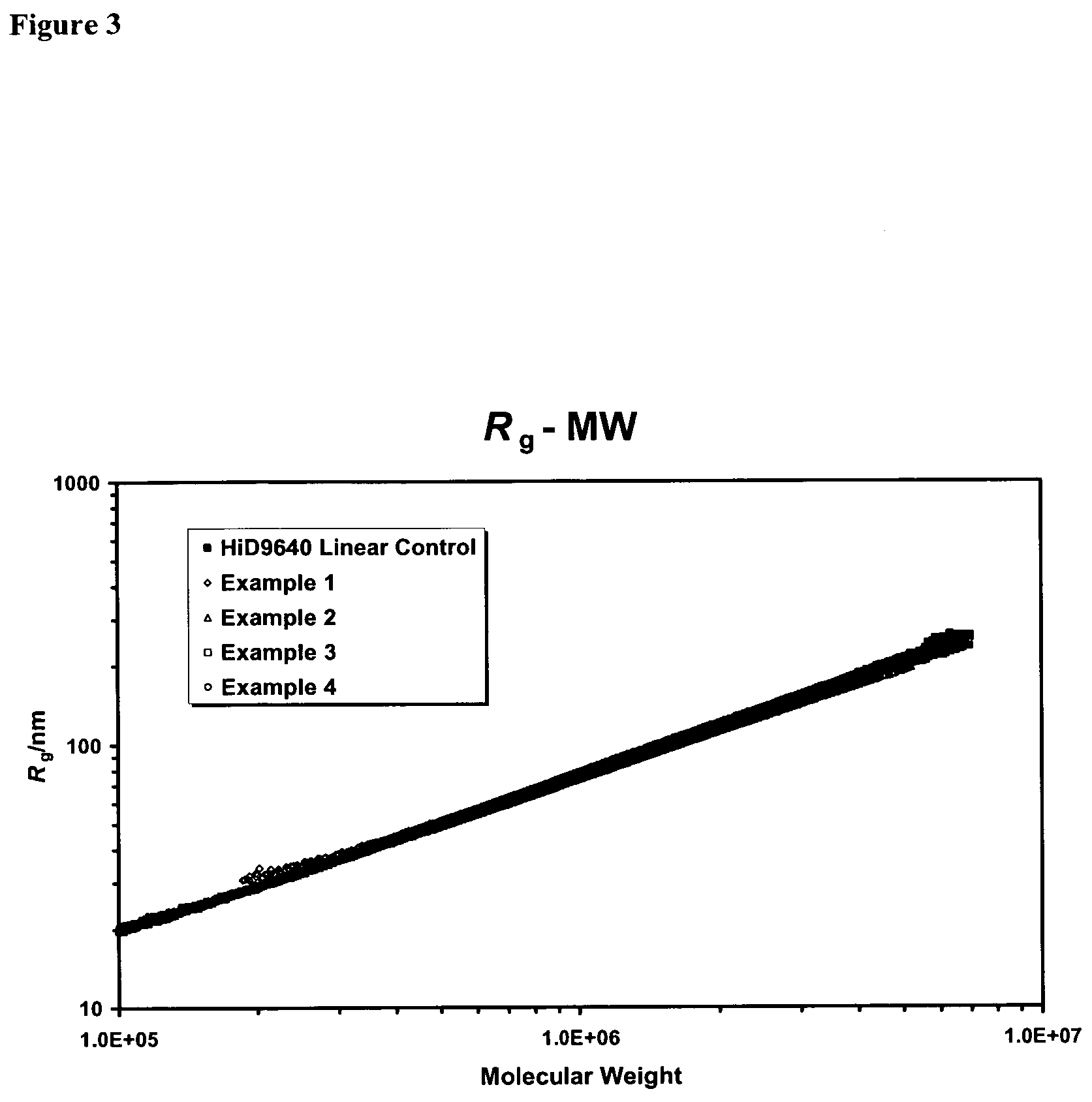

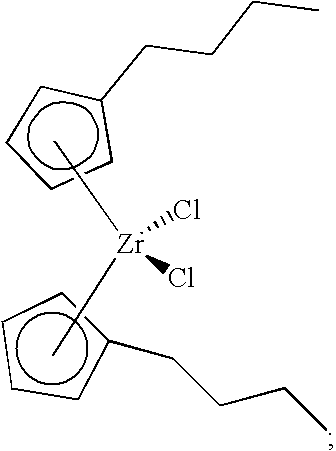

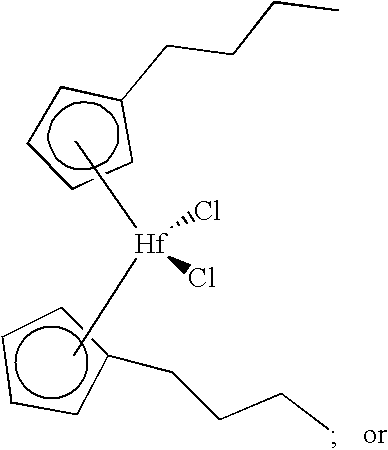

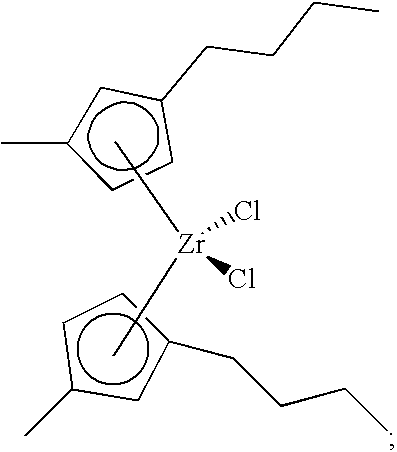

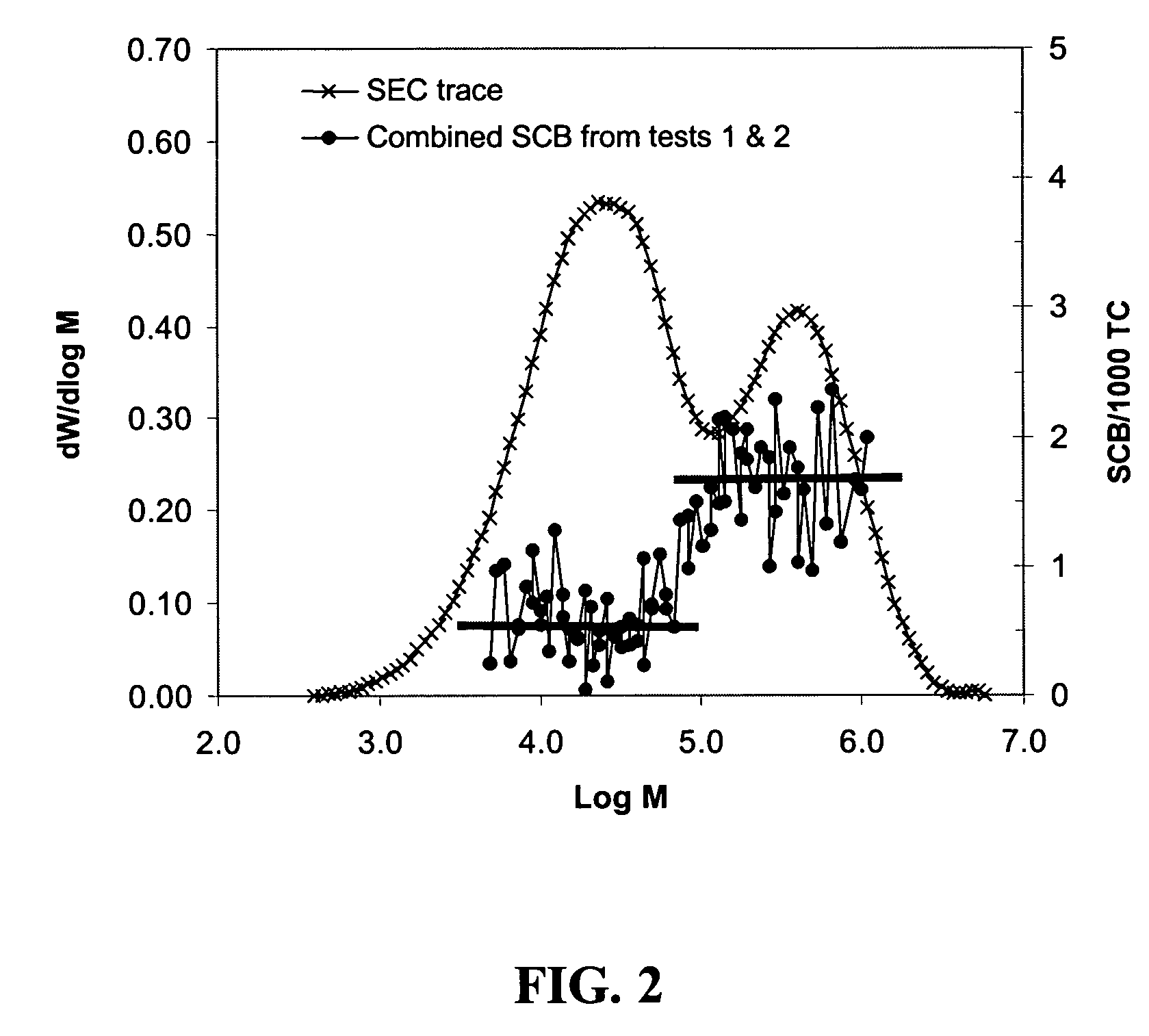

This invention relates to catalyst compositions, methods, and polymers encompassing at least one Group 4 metallocene compound comprising bridging η5-cyclopentadienyl-type ligands, typically in combination with at least one cocatalyst, and at least one activator. The compositions and methods disclosed herein provide ethylene polymers with low levels of long chain branching.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

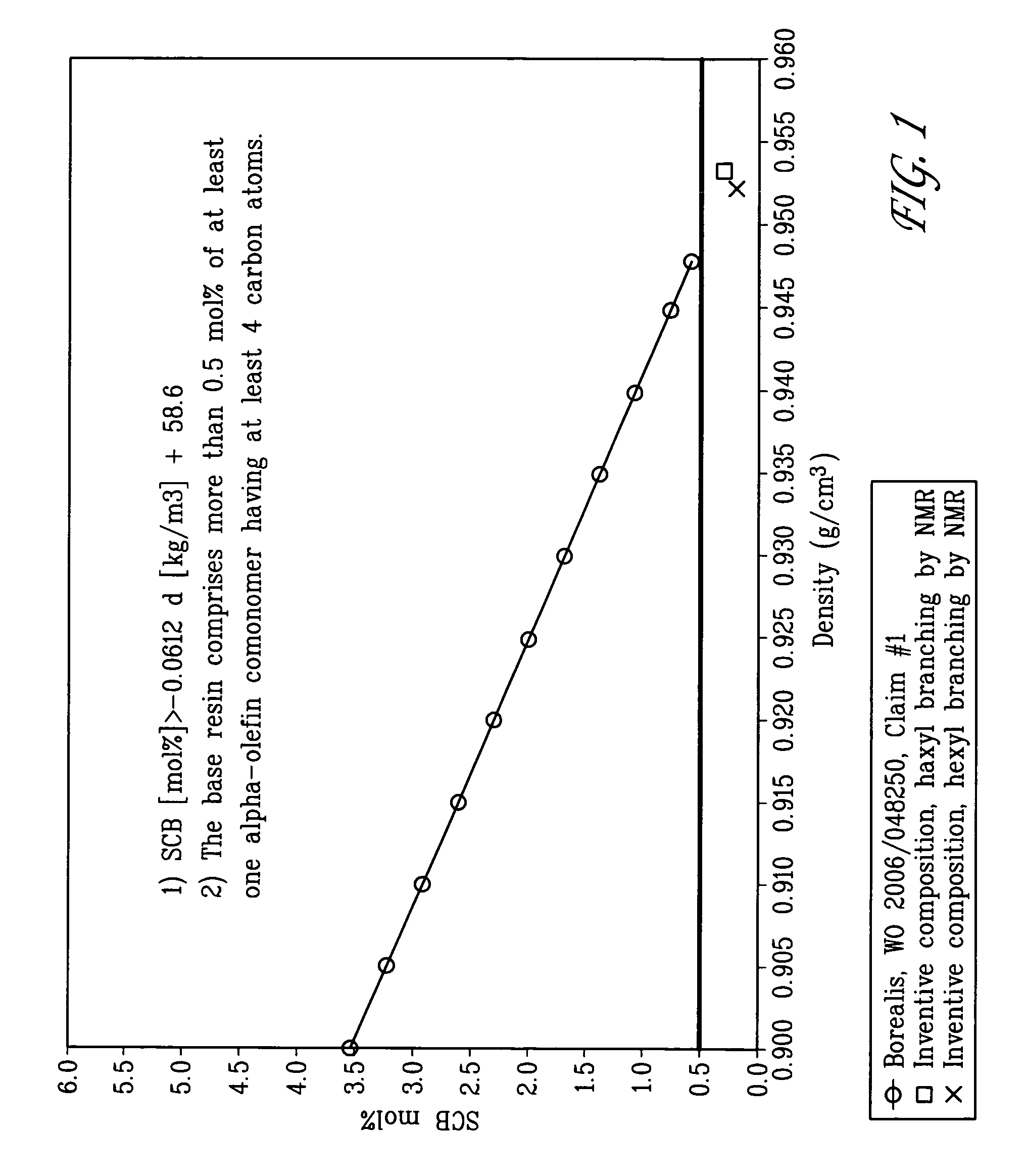

Resins that yield low haze films and the process for their production

ActiveUS7199073B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemical treatmentPolyolefin

Catalyst compositions comprising a first metallocene compound, a second metallocene compound, a third metallocene compound, a chemically-treated solid oxide, and an organoaluminum compound are provided. Methods for preparing and using the catalyst and polyolefins are also provided. The compositions and methods disclosed herein provide ethylene polymers having decreased haze while minimizing impact on other properties, such as dart impact.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

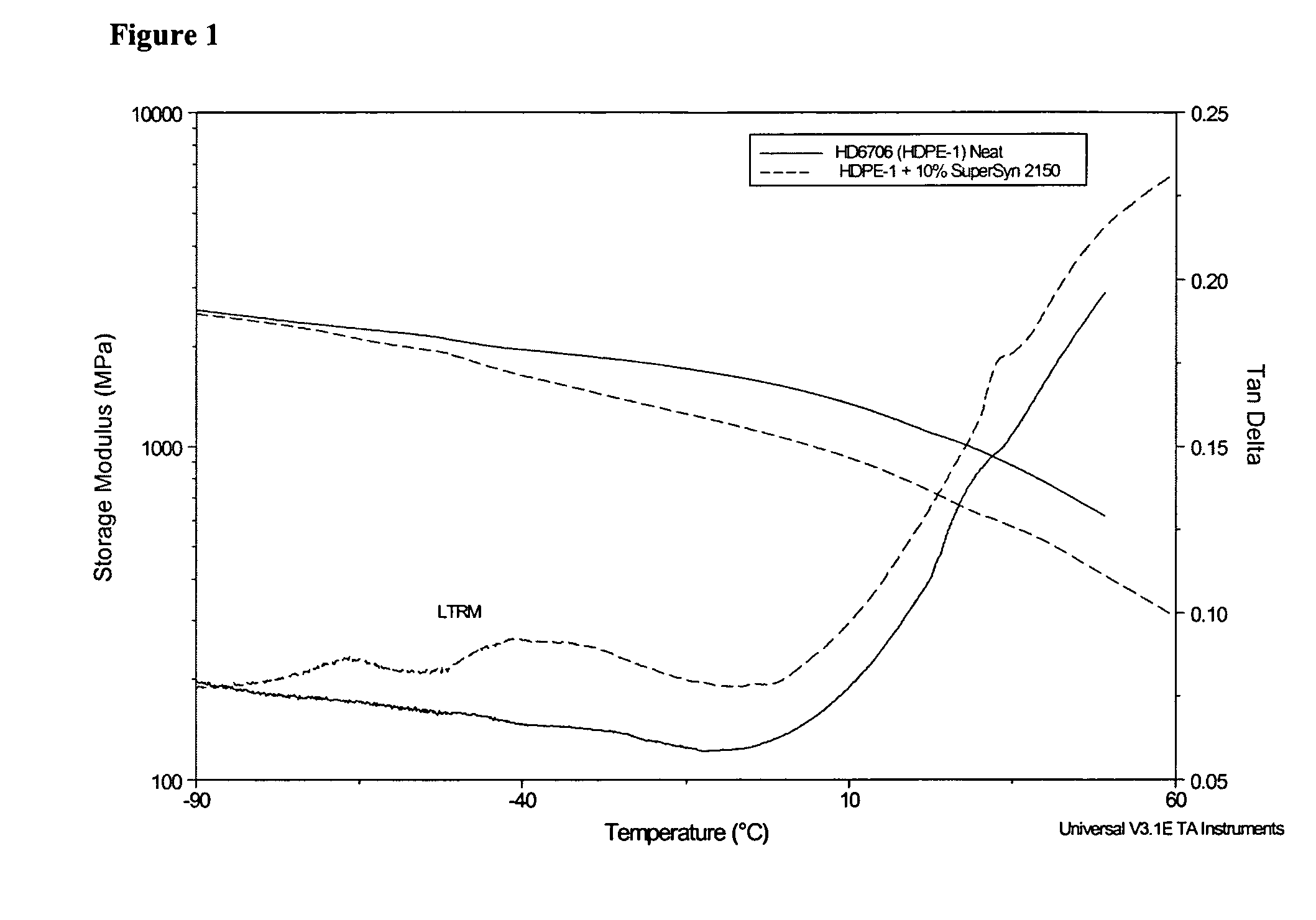

Modified polyethylene compositions

The present invention relates to a composition comprising more than 25 weight % (based on the weight of the composition) of one or more ethylene polymers having an Mw of 20,000 g / mole or more and at least 0.1 weight % of a liquid hydrocarbon modifier where the modifier has: 1) a viscosity index of 120 or more, and 2) an kinematic viscosity of 3 to 3000 cSt at 100° C., and 3) a pour point of −10° C. or less, and 4) a flash point of 200° C. or more; and wherein the modifier contains less than 5 weight % of functional groups selected from hydroxide, aryls, substituted aryls, halogens, alkoxys, carboxylates, esters, acrylates, oxygen, nitrogen, and carboxyl, based upon the weight of the modifier.

Owner:EXXONMOBIL CHEM PAT INC

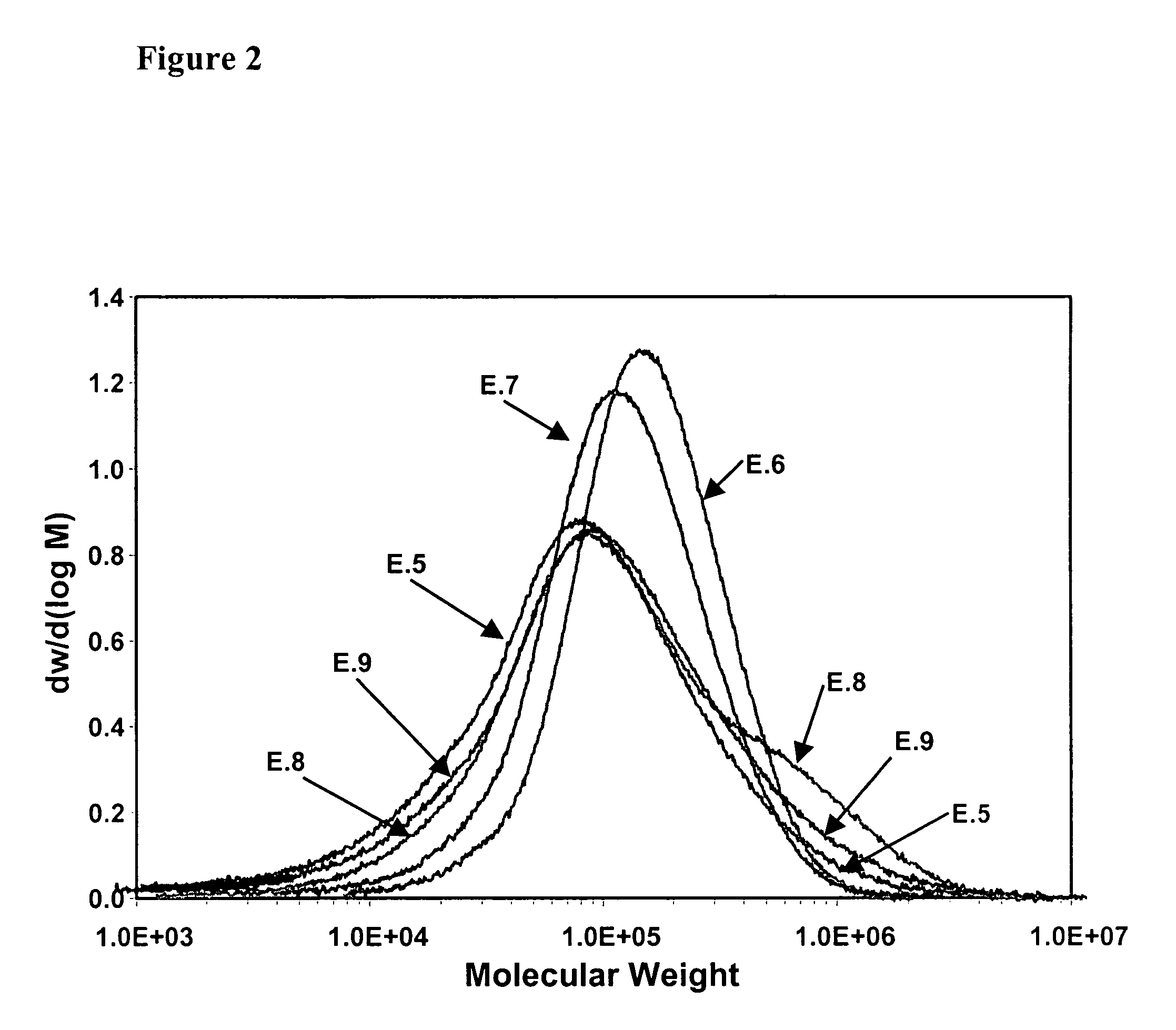

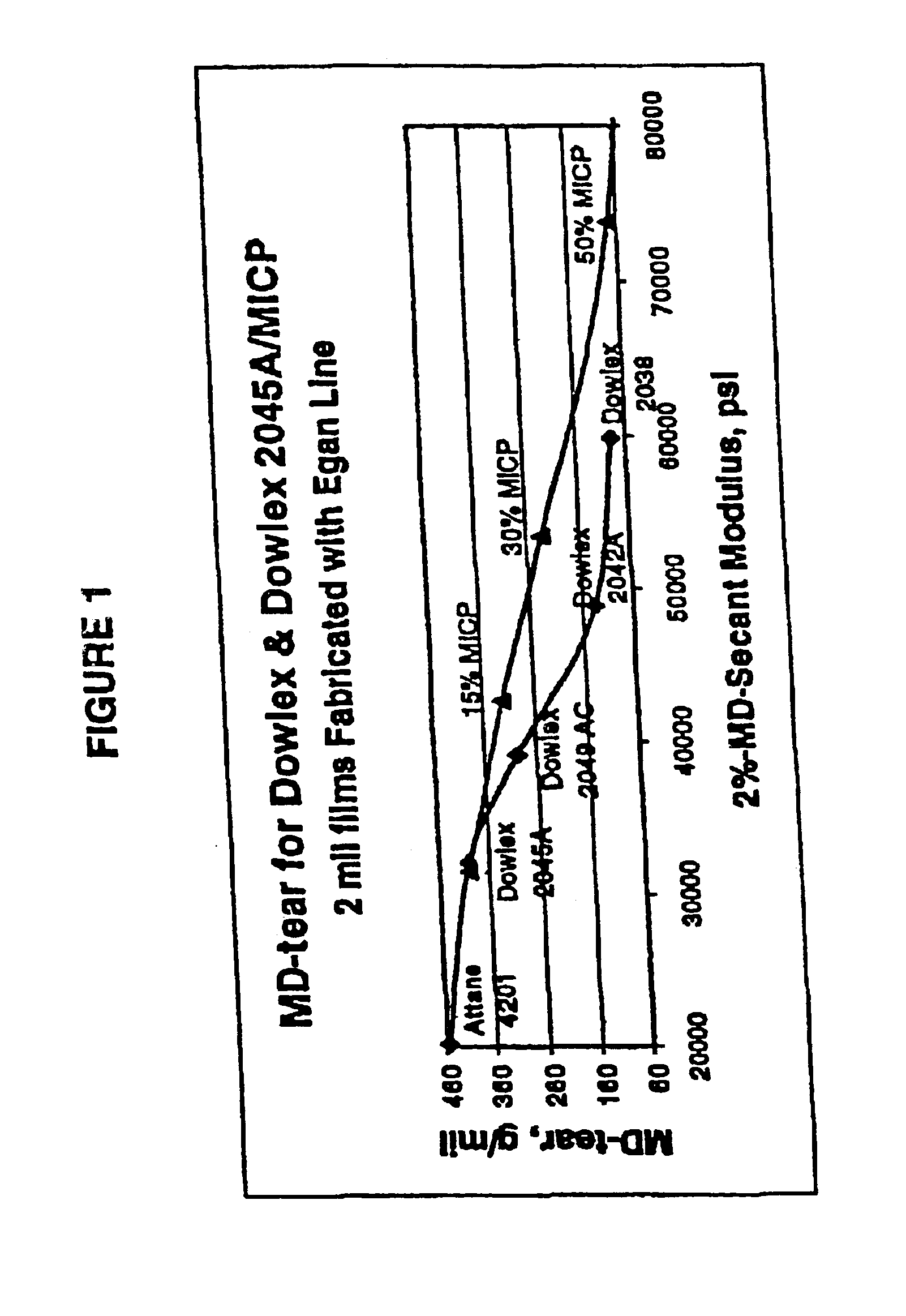

Dual metallocene catalyst for producing film resins with good machine direction (MD) elmendorf tear strength

ActiveUS7119153B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemical treatmentPolyolefin

This invention relates to catalyst compositions comprising a first metallocene compound, a second metallocene compound, at least one chemically-treated solid oxide, and at least one organoaluminum compound. This invention also relates to methods to prepare and use the catalyst compositions and new polyolefins. The compositions and methods disclosed herein provide ethylene polymers and copolymers with lower MI, increased melt strength, and good MD tear properties.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Polymerization catalysts for producing polymers with low levels of long chain branching

ActiveUS7148298B2High catalytic activityHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationEthylene PolymersPolymerization catalysts

This invention relates to catalyst compositions, methods, and polymers encompassing a Group 4 metallocene with bridging η5-cyclopentadienyl-type ligands, in combination with a cocatalyst and an activator-support. The compositions and methods disclosed herein provide ethylene polymers with low levels of long chain branching.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Polymerization catalysts for producing polymers with low levels of long chain branching

InactiveUS20050288461A1Improve productivityHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationEthylene PolymersPolymerization catalysts

This invention relates to catalyst compositions, methods, and polymers encompassing a Group 4 metallocene with bridging η5-cyclopentadienyl-type ligands, in combination with a cocatalyst and an activator-support. The compositions and methods disclosed herein provide ethylene polymers with low levels of long chain branching.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

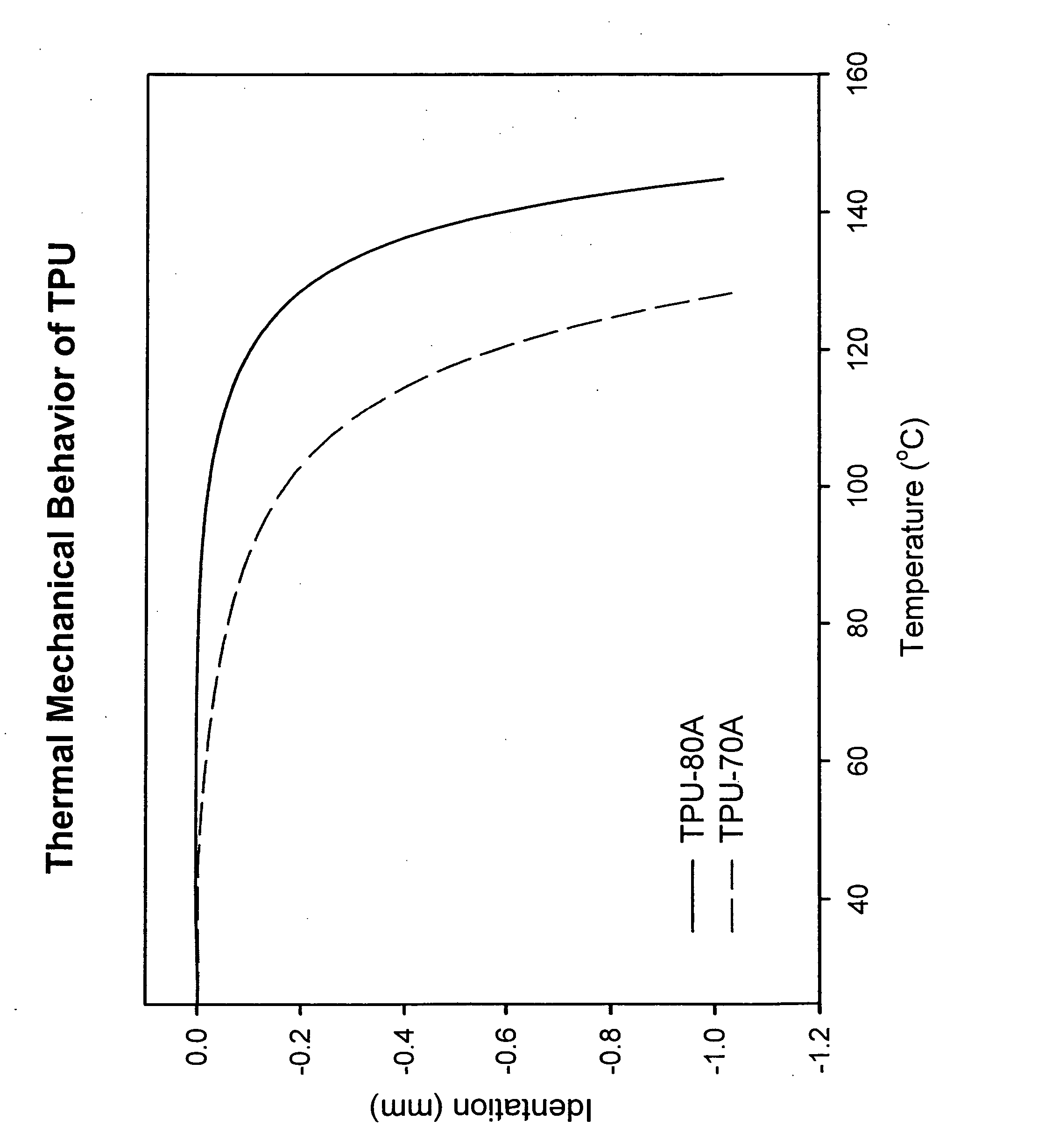

Closures for bottles

ActiveUS8022143B2Improved balance of Theological and processing and organoleptic propertyCompression moldingPolymer science

A dual reactor solution process gives high density polyethylene compositions containing a first ethylene polymer and a second ethylene polymer which have a good balance of processability, toughness, and environmental stress crack resistance combined with good organoleptic properties. The polyethylene compositions are suitable for compression molding or injection molding applications and are particularly useful in the manufacture of caps and closures for bottles.

Owner:NOVA CHEM (INT) SA

Polymerization catalysts and process for producing bimodal polymers in a single reactor

ActiveUS20070043176A1Outstanding balance of stiffnessHigh impact strengthOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyolefinEthylene Polymers

Catalyst compositions comprising a first metallocene compound, a second metallocene compound, an activator-support, and an organoaluminum compound are provided. Methods for preparing and using such catalysts to produce polyolefins are also provided. The compositions and methods disclosed herein provide ethylene polymers having a HLMI of from about 0.5 to about 25, a polymer density of from about 0.920 to about 0.965, and a polydispersity of from about 3.0 to about 30.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Polymerization catalysts for producing high molecular weight polymers with low levels of long chain branching

ActiveUS20070179044A1High catalytic activityHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsGroup 8/9/10/18 element organic compoundsPolymer scienceEthylene Polymers

This invention relates to catalyst compositions, methods, and polymers encompassing at least one Group 4 metallocene compound comprising bridging η5-cyclopentadienyl-type ligands, typically in combination with at least one cocatalyst, and at least one activator. The compositions and methods disclosed herein provide ethylene polymers with low levels of long chain branching.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Mitigation of Biomolecular Adsorption with Hydrophilic Polymer Additives

ActiveUS20090280251A1Reduce surface tensionInhibit bindingSludge treatmentVolume/mass flow measurementHydrophilic polymersPhenyl Ethers

Molecular adsorption to the microfluidic device surfaces can be passively and actively mitigated by mixing certain hydrophilic polymers (organic polymers with repeating hydrophilic groups—the preferred polymers being amphipathic surfactants—with the sample liquid during or prior to relevant microfluidic operations. Nonionic surfactants such as polyoxyethylene sorbitan monooleate and polyoxyethylene octyl phenyl ether are especially effective. High molecular weight polyethylene polymers are also effective. The hydrophilic polymers appear to prevent binding of the fouling molecules to the microfluidic by occupying the surface sites in place of the fouling molecules or by interacting with the fouling molecules to prevent binding of the fouling molecules the surface. When surface adsorption is thus mitigated, microfluidic devices can readily handle samples containing biomolecules to enable active sample concentration, filtering, washing, transport, mixing and other sample handling operations.

Owner:ADVANCED LIQUID LOGIC

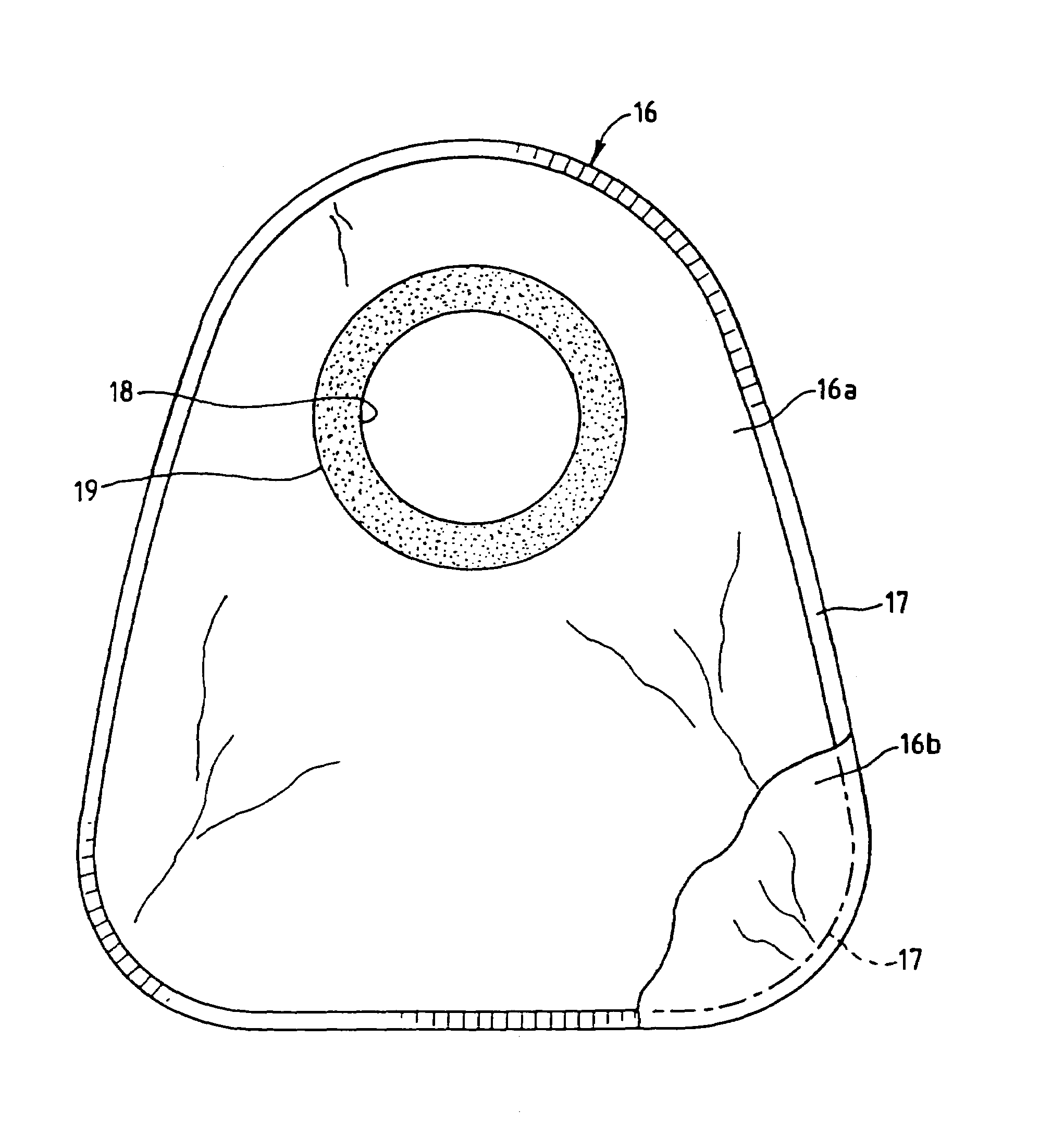

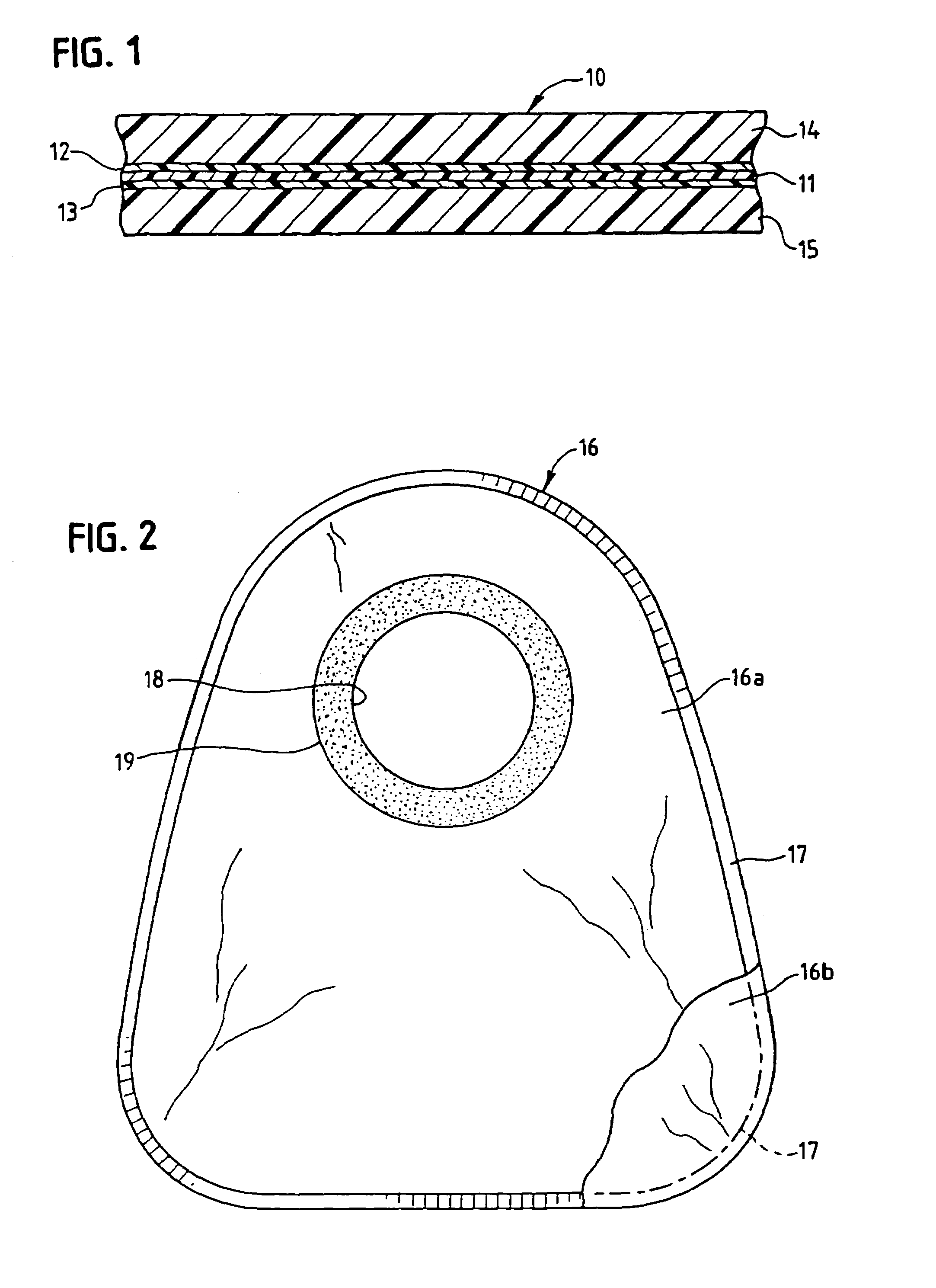

Multilayer chlorine-free film with barrier layer of a polyamide blend and ostomy pouches formed therefrom

InactiveUS7270860B2Good odor barrier propertyMinimal noiseEnvelopes/bags making machineryLayered product treatmentPolyamideEthylene Polymers

A multilayer heat-sealable chlorine-free odor barrier film having relatively low modulus, high interlaminar strength, and low noise upon flexing is provided. The film comprises an odor barrier layer of an amorphous polyamide resin blended with an anhydride-modified olefinic polymer or copolymer. The film also includes at least one heat-sealable skin layer, preferably two such skin layers on opposite sides of said odor barrier layer, composed of an ethylene polymer or copolymer. Pouches formed of such multilayer films are also disclosed.

Owner:HOLLISTER INCORPORAED

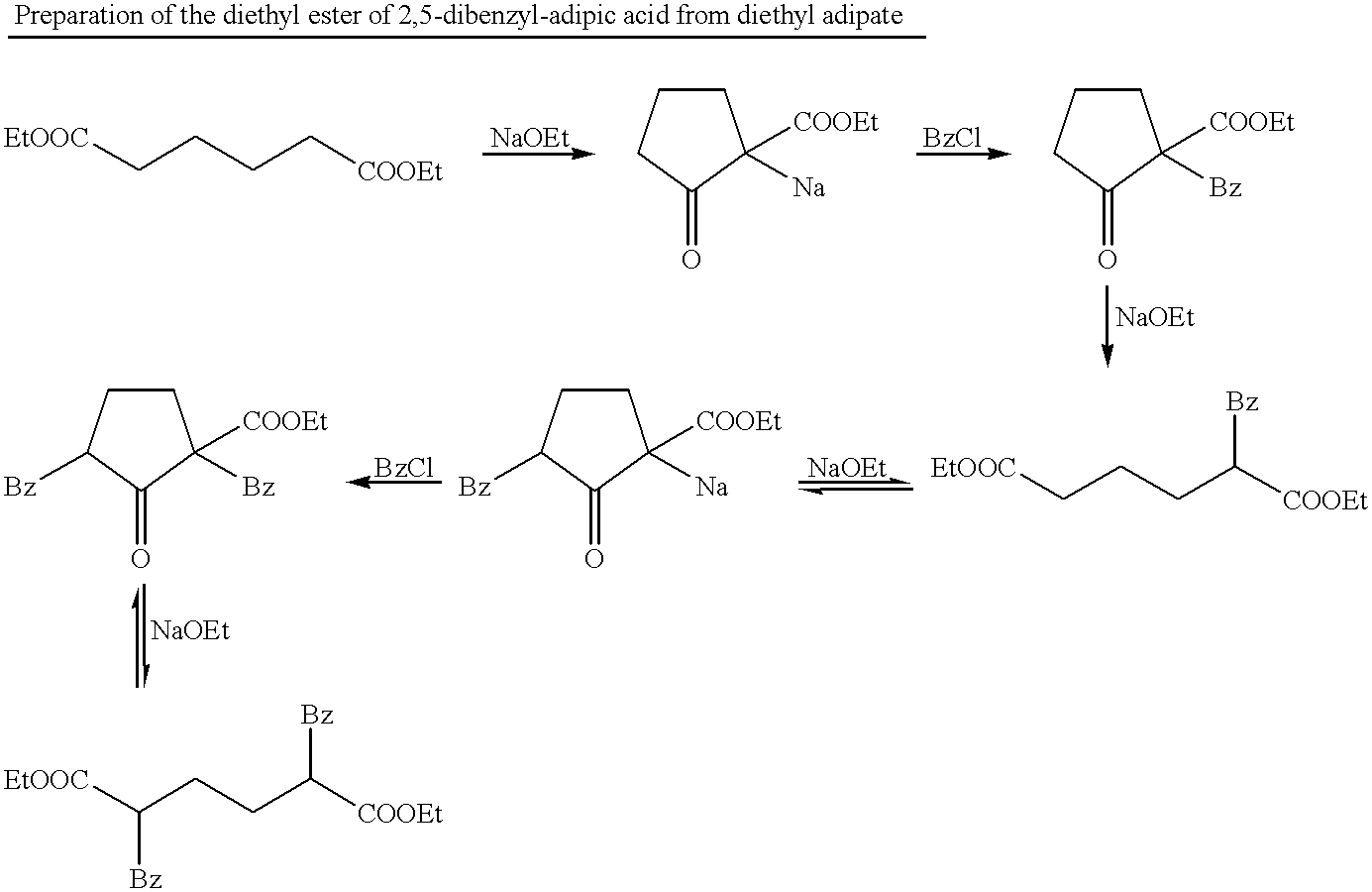

Multi-stage process for the polymerization of olefins

A multi-stage process for preparing ethylene (co)polymers having broad molecular weight distributions is disclosed, said process comprising:(A) a first polymerization stage in which, in the presence of a Ti or V catalyst, a first ethylene polymer is prepared;(B) a treatment stage in which the catalyst used in the first stage is deactivated and in which a bridged bis-2-indenyl zirconocene is supported on the ethylene polymer produced in stage (A), optionally in the presence of a suitable cocatalyst; and(C) a second polymerization stage in which ethylene is polymerized in the presence of the product obtained from stage (B).Furthermore, polyethylene obtainable by the above process is disclosed, having intrinsic viscosity ranging from 0.5 to 6 dl / g, Mw / Mn>8 and cold xylene solubility<1.2% wt.

Owner:MONTELL TECH CO BV

Adhesive polyethylene compositions and multi-layer laminated films using the same

InactiveUS6210765B1Improve adhesion strengthHigh heat sealing strength heatWrappers shrinkageShrinkage connectionsElastomerPolyamide

Disclosed is a specific adhesive polyethylene composition comprising [1] a modified ethylene / alpha-olefin copolymer resin or elastomer obtained by modifying a specific ethylene / alpha-olefin copolymer resin or elastomer, each of which comprises ethylene and an alpha-olefin of 3 to 20 carbon atoms, with an unsaturated carboxylic acid or anhydride, ester, amide, imide or metallic salt derivative of a unsaturated carboxylic acid thereof, [2] an unmodified ethylene / alpha-olefin copolymer resin and / or an unmodified ethylene / alpha-olefin copolymer elastomer and [3] a tackifier. Also disclosed is a multi-layer laminated film of 3 or more layers in which a layer of the above composition is interposed between an ethylene polymer layer and either a polyamide resin layer, an ethylene / vinyl alcohol copolymer layer or a layer of a mixture of polyamide resin and ethylene / vinyl alcohol copolymer. The adhesive polyethylene composition shows excellent adhesion strength to ethylene polymers, polyamide resins and ethylene / vinyl alcohol copolymers, high heat-sealing strength and heat resistance. The multi-layer laminated film shows excellent strength, heat resistance and gas barrier properties, and besides this film has heat shrinkability, so that the film is suitably used as a shrink film.

Owner:MITSUI CHEM INC

Polyethylene Molding Powder and Porous Articles Made Therefrom

The present invention relates to a new molding powder comprising polyethylene polymer particles. The molecular weight of the polyethylene polymer is within the range of from about 600,000 g / mol to about 2,700,000 g / mol as determined by ASTM 4020. The average particle size of the particles of the polyethylene polymer is within the range of from about 5 microns to about 1000 microns and the polyethylene has a powder bulk density in the range of from about 0.10 to about 0.30 g / cc. Also disclosed is a process for molding a shape from a molding powder comprising the inventive polyethylene polymer particles, as well as porous articles made in accordance with the process. The articles have excellent porosity and good strength for porous and porous filtration applications.

Owner:TICONA LLC

Polymerization catalysts for producing polymers with low levels of long chain branching

ActiveUS20050288462A1Improve productivityHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationEthylene PolymersPolymerization catalysts

This invention relates to catalyst compositions, methods, and polymers encompassing a Group 4 metallocene with bridging θ5-cyclopentadienyl-type ligands, in combination with a cocatalyst and an activator-support. The compositions and methods disclosed herein provide ethylene polymers with low levels of long chain branching.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Method for producing expandable polystyrene particles

A process for preparing expandable particulate styrene polymers wherein from 5 to 50% by weight of expanded graphite and also, if desired, from 2 to 20% by weight of a phosphorus compound, are present as flame retardants, by suspension polymerization of styrene in the presence of the flame retardants.

Owner:BASF AG

Elastic, heat and moisture resistant bicomponent and biconstituent fibers

Owner:DOW GLOBAL TECH LLC

Polyethylene rich/polypropylene blends and their uses

InactiveUS6939919B2Good blocking performanceHigh modulusFlexible coversWrappersPropylene PolymersEthylene Polymers

The present invention includes a blend composition comprising at least one coupled propylene polymer and at least 55 weight percent of at least one ethylene polymer, based on the total weight of the coupled propylene polymer and the ethylene polymer. The invention also includes methods for making the coupled propylene polymer and methods for making the blend composition. The present invention further includes films made from the blend composition.

Owner:DOW GLOBAL TECH LLC

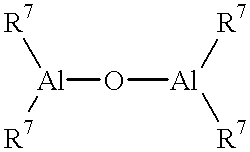

Method for making polyolefins

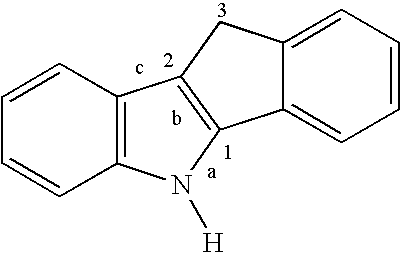

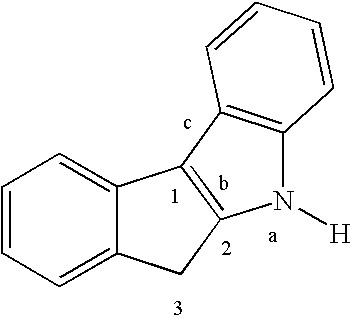

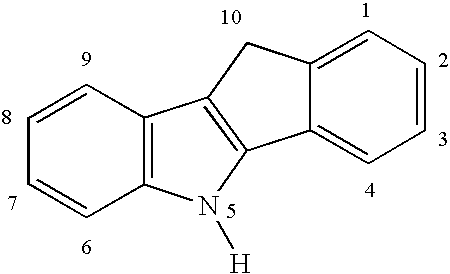

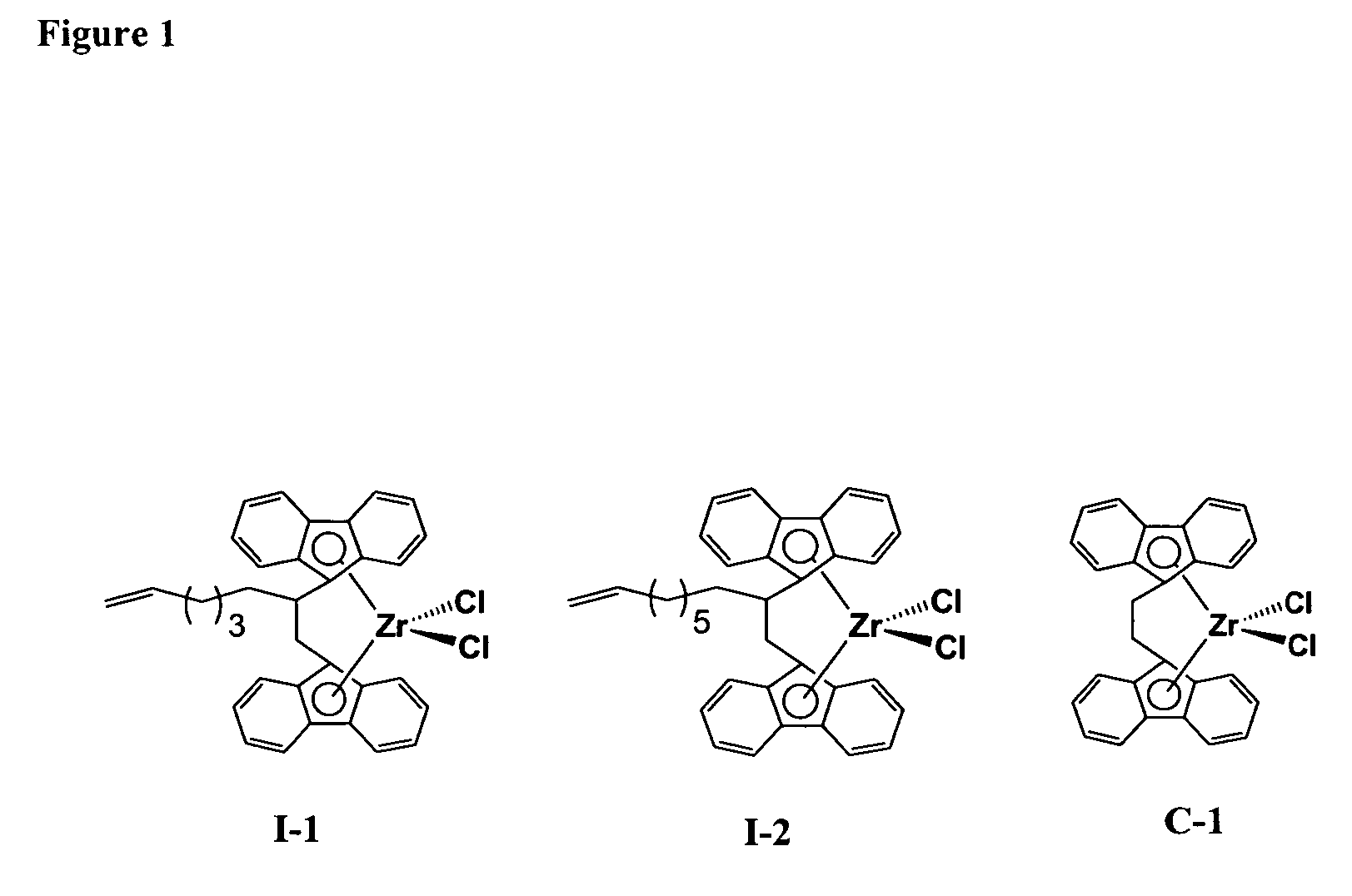

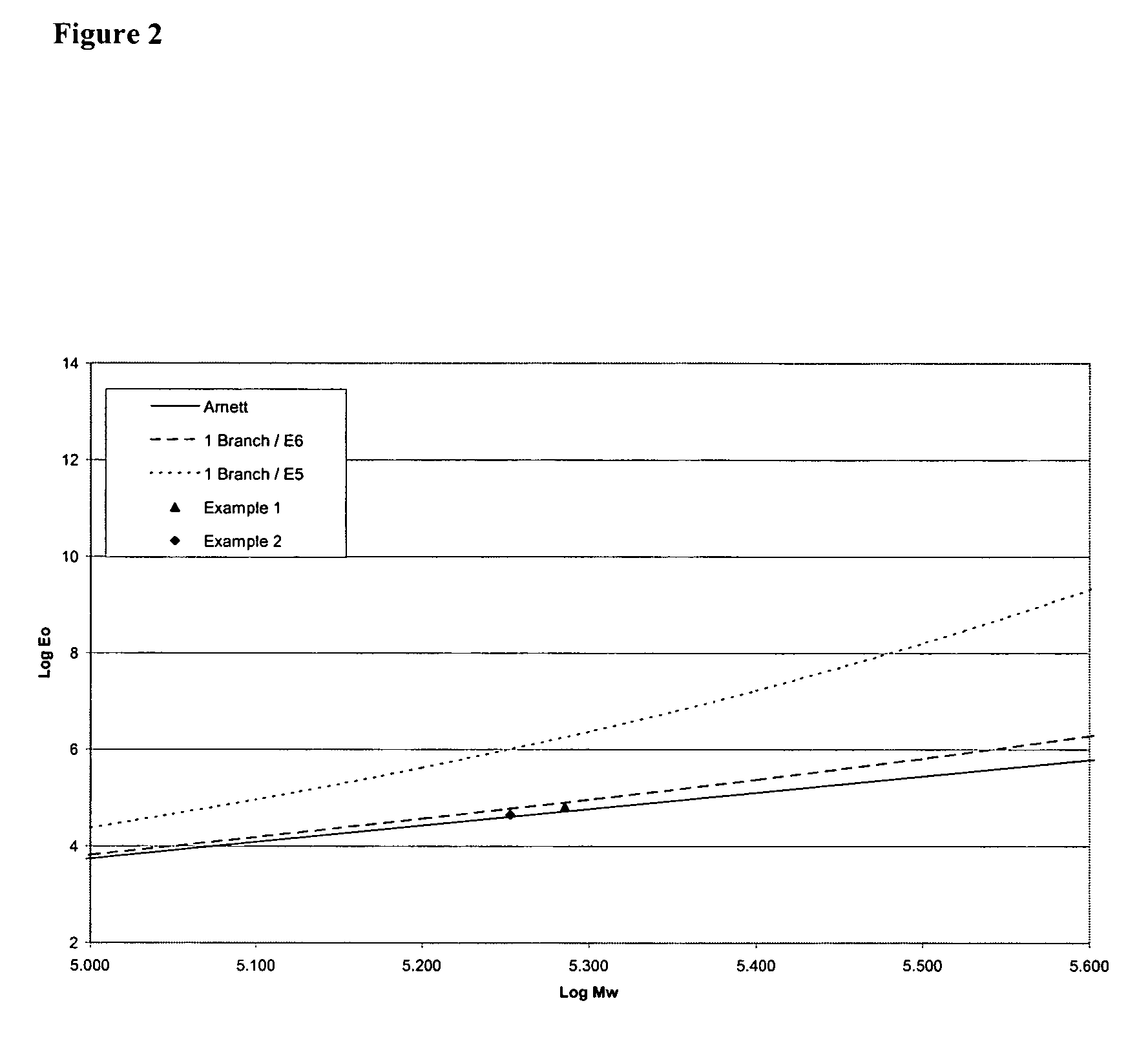

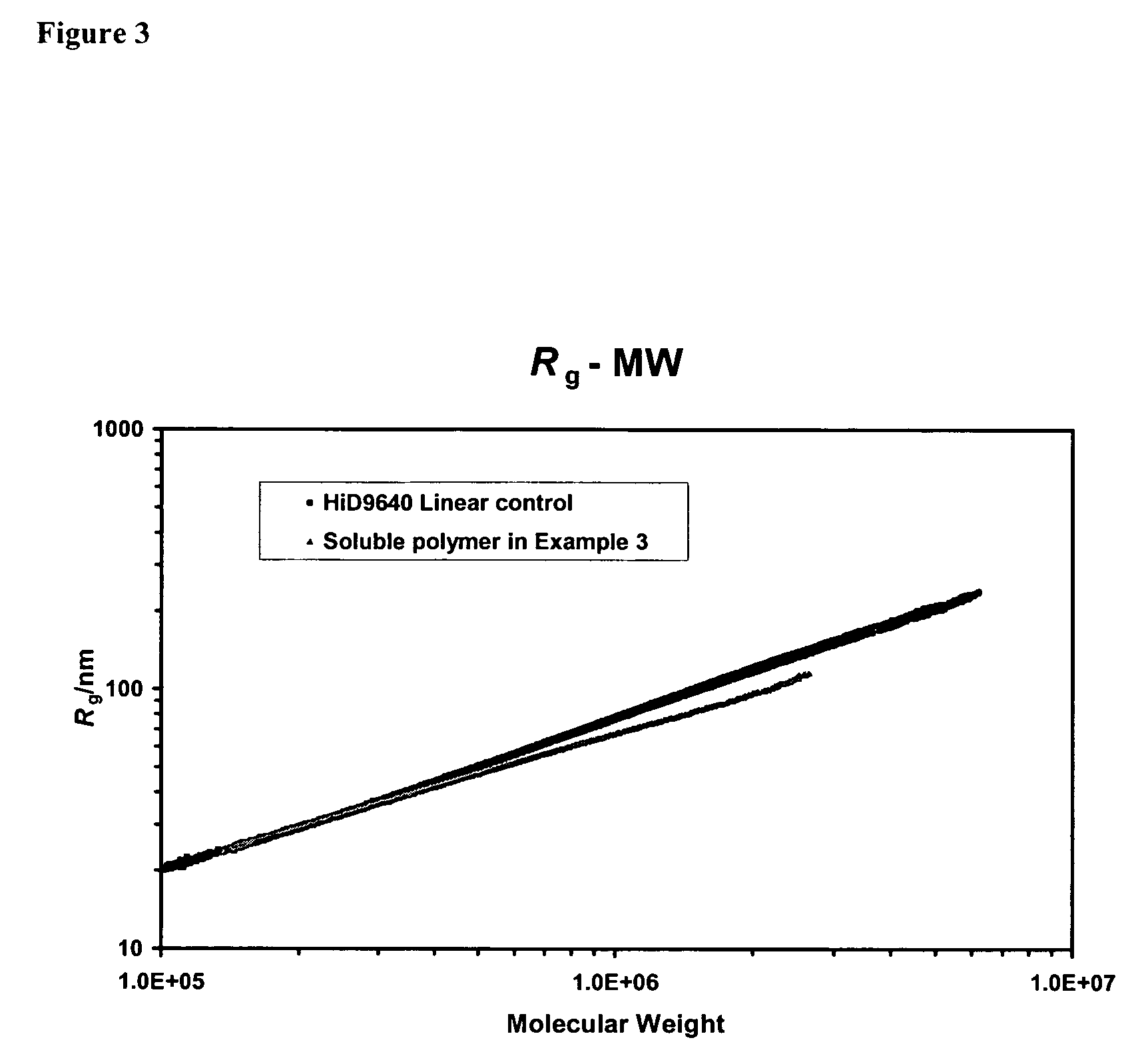

A method for making ethylene polymers and copolymers is disclosed. The method uses a catalyst system comprising a low level of an aluminum-containing activator, a bridged indenoindolyl transition metal complex, and a treated silica support. The method enables economical preparation of ethylene copolymers having very low density. The silica-supported, bridged complexes incorporate comonomers efficiently and are valuable for a commercial slurry loop process. Use of a bridged indeno[2,1-b]indolyl complex provides exceptionally efficient comonomer incorporation, and gives polymers with a substantial and controlled level of long-chain branching. The method facilitates the production of a wide variety of polyolefins, from HDPE to plastomers.

Owner:EQUSR CHEM LP

Polymerization catalysts for producing polymers with low levels of long chain branching

ActiveUS7576163B2High catalytic activityHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationEthylene PolymersPolymerization catalysts

This invention relates to catalyst compositions, methods, and polymers encompassing at least one Group 4 metallocene compound comprising bridging η5-cyclopentadienyl-type ligands, typically in combination with at least one cocatalyst, and at least one activator. The compositions and methods disclosed herein provide ethylene polymers with low levels of long chain branching.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

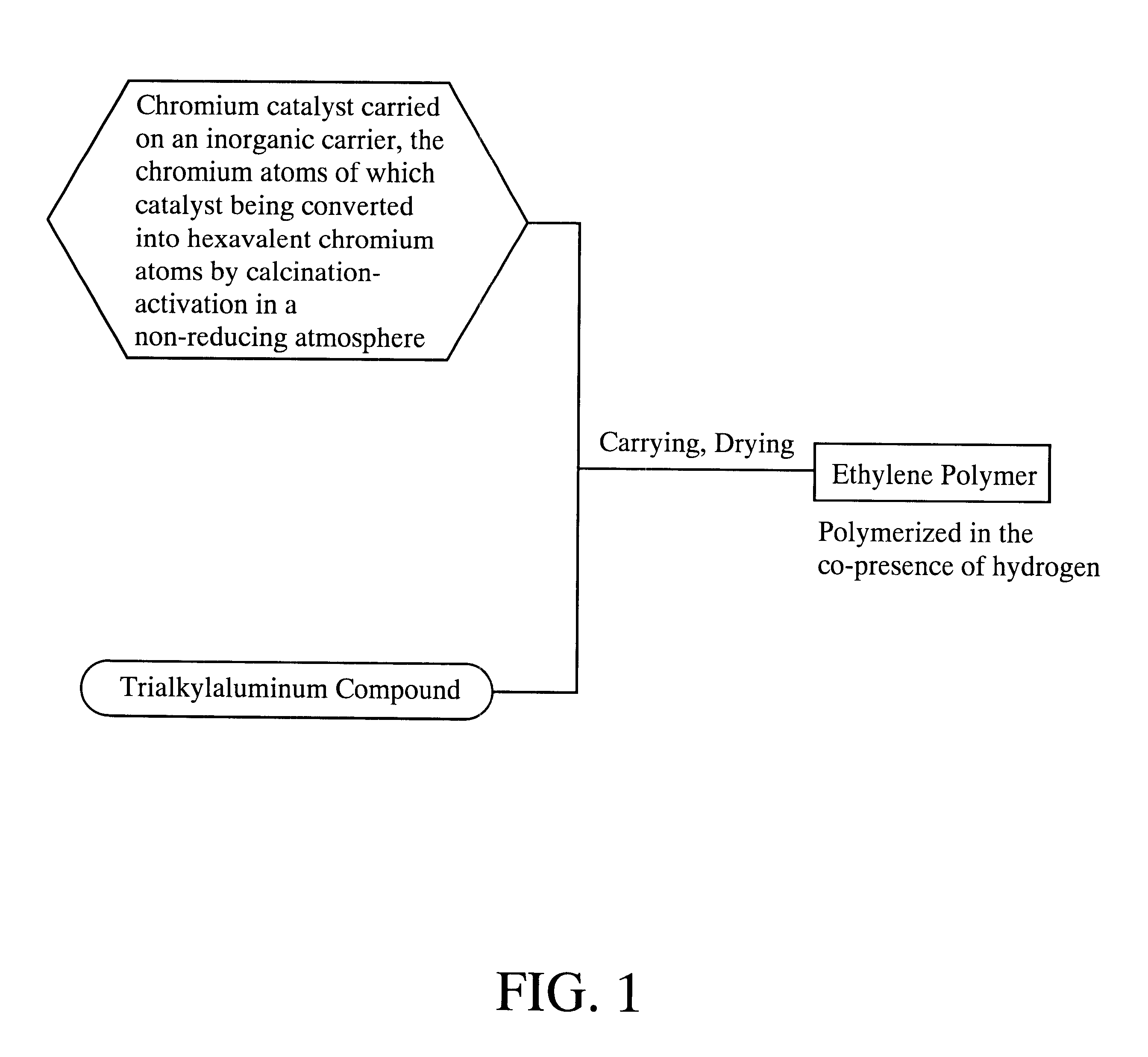

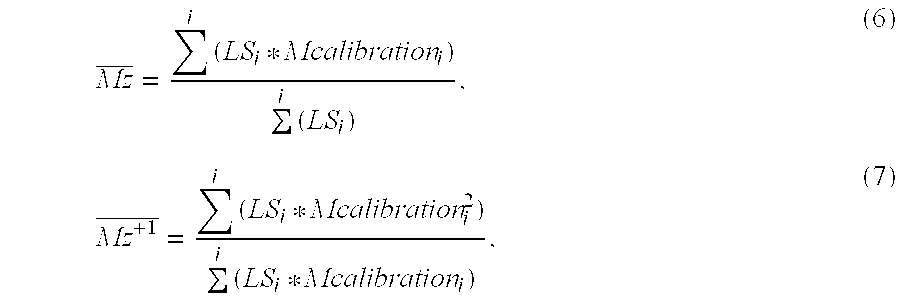

Ethylene polymers and method for producing the same

InactiveUS6646069B2Improve impact resistanceImprove balanceOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChromium CompoundsCrack resistance

The invention relates to a method for producing an ethylene polymer, comprising performing polymerization of ethylene in co-presence of hydrogen using a trialkylaluminum compound-carried chromium catalyst, wherein the chromium catalyst is obtained by calcination-activating a chromium compound that is carried on an inorganic oxide carrier in a non-reducing atmosphere to convert chromium atoms in the chromium compound into hexavalent chromium atoms for at least a portion thereof, and treating with a trialkylaluminum compound in an inert hydrocarbon solvent to carry thereon and removing to dry the solvent so that the chromium atoms are not over-reduced by the trialkylaluminum compound, and to an ethylene polymer suitable for blow molded articles obtained by the production method. The ethylene polymer of the invention have improved environment stress crack resistance (ESCR) and impact resistance in a good balance and are suitable for molded blow articles, in particular large size blow molded articles.

Owner:JAPAN POLYOLEFINS CO LTD

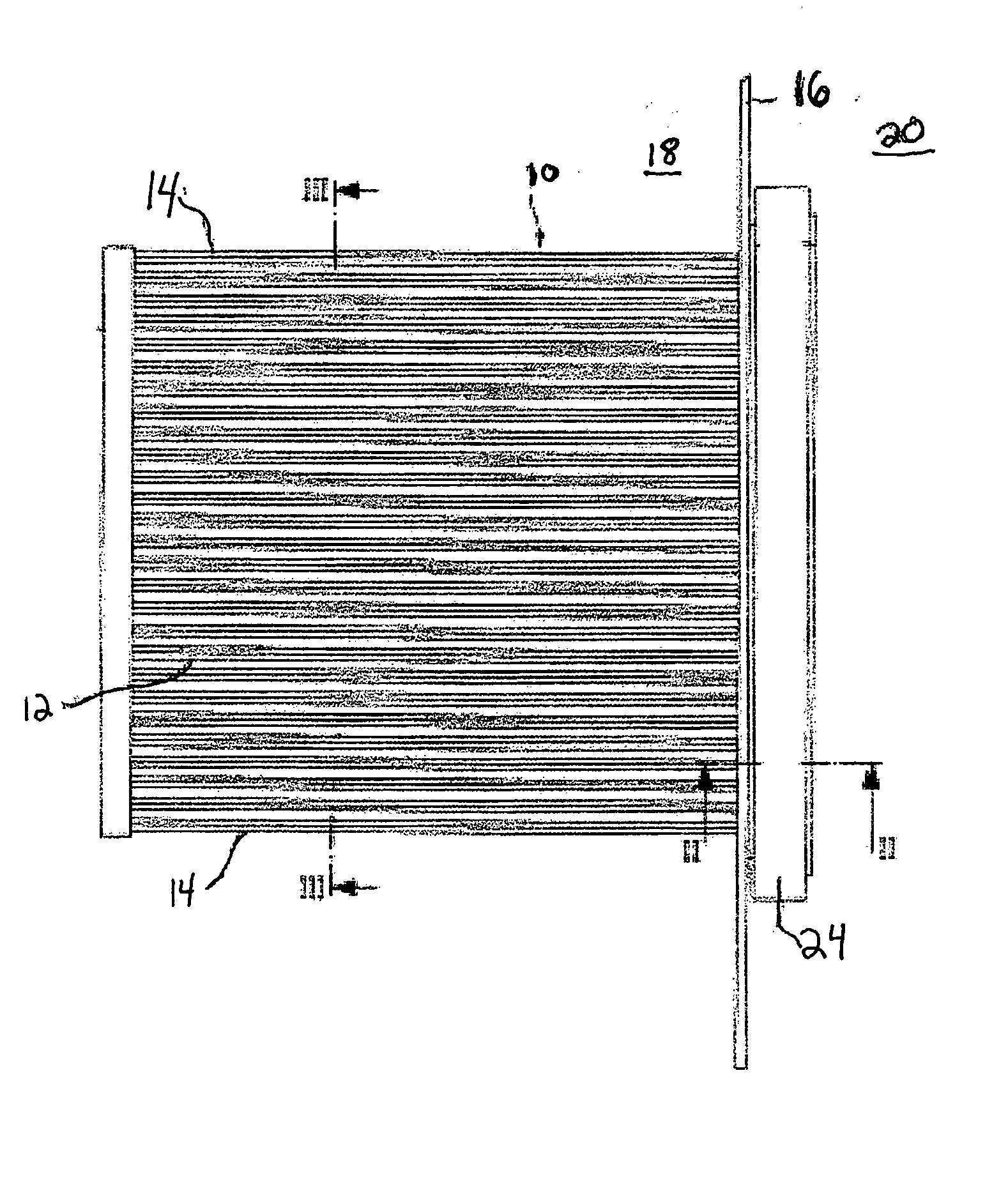

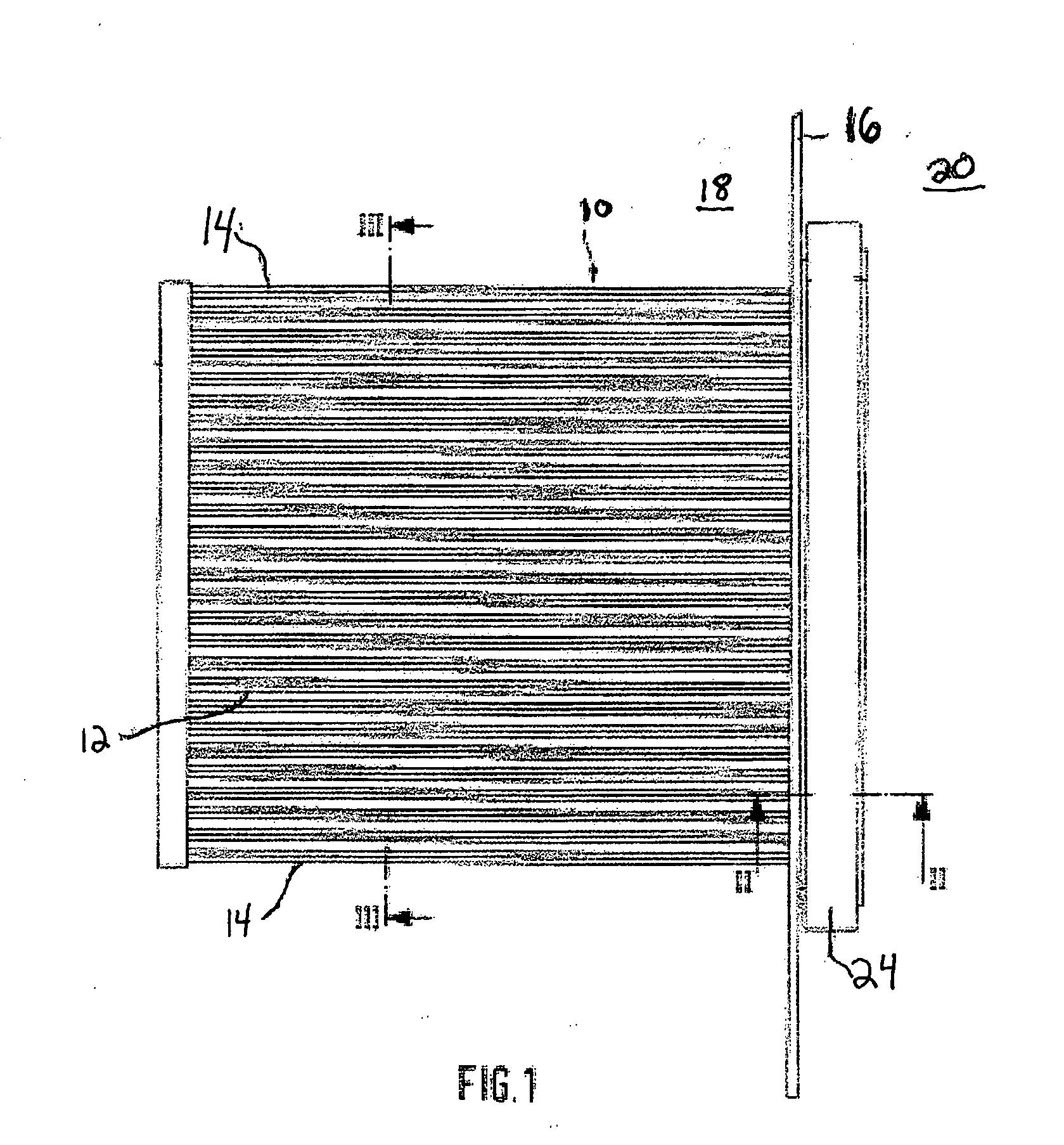

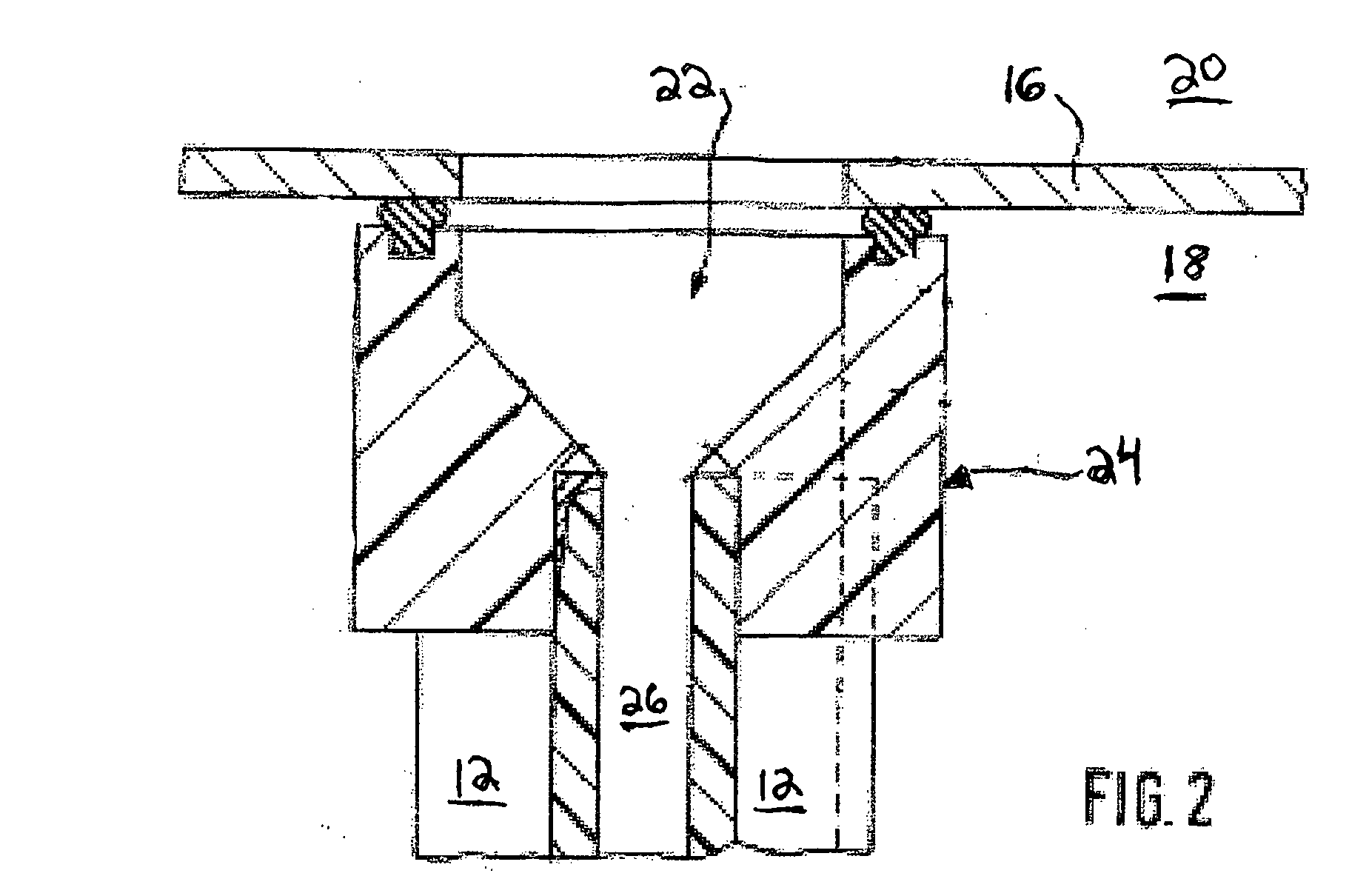

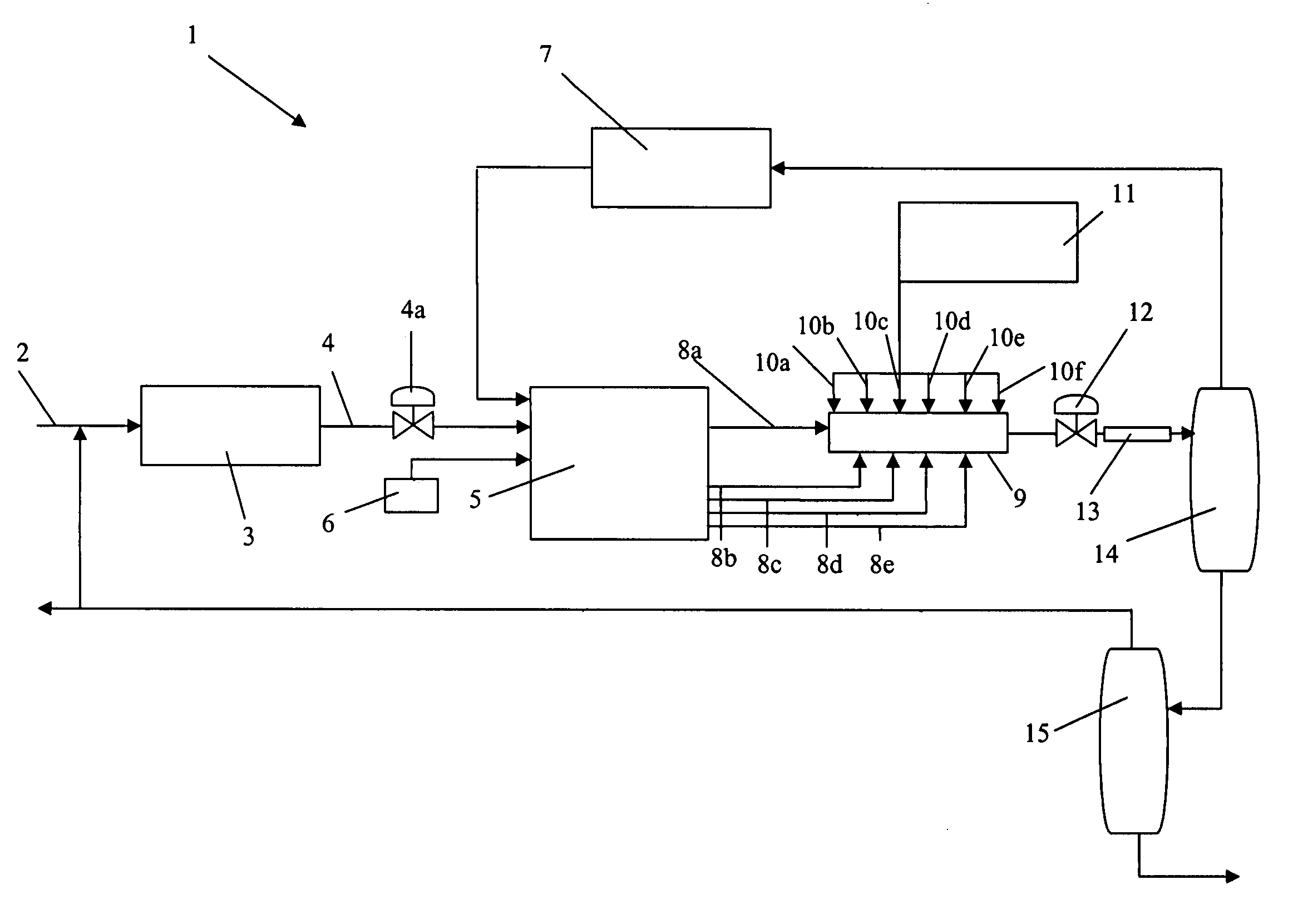

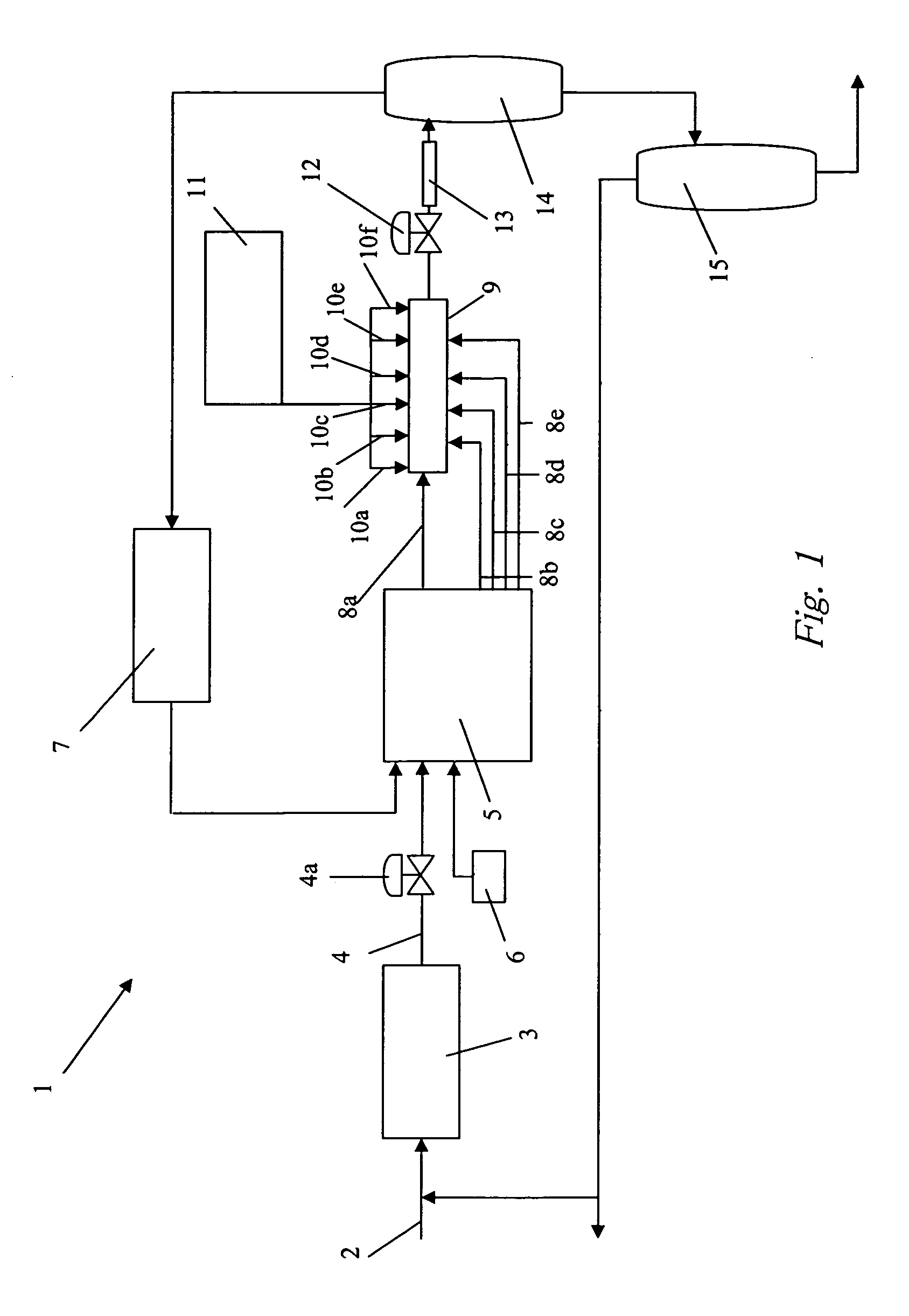

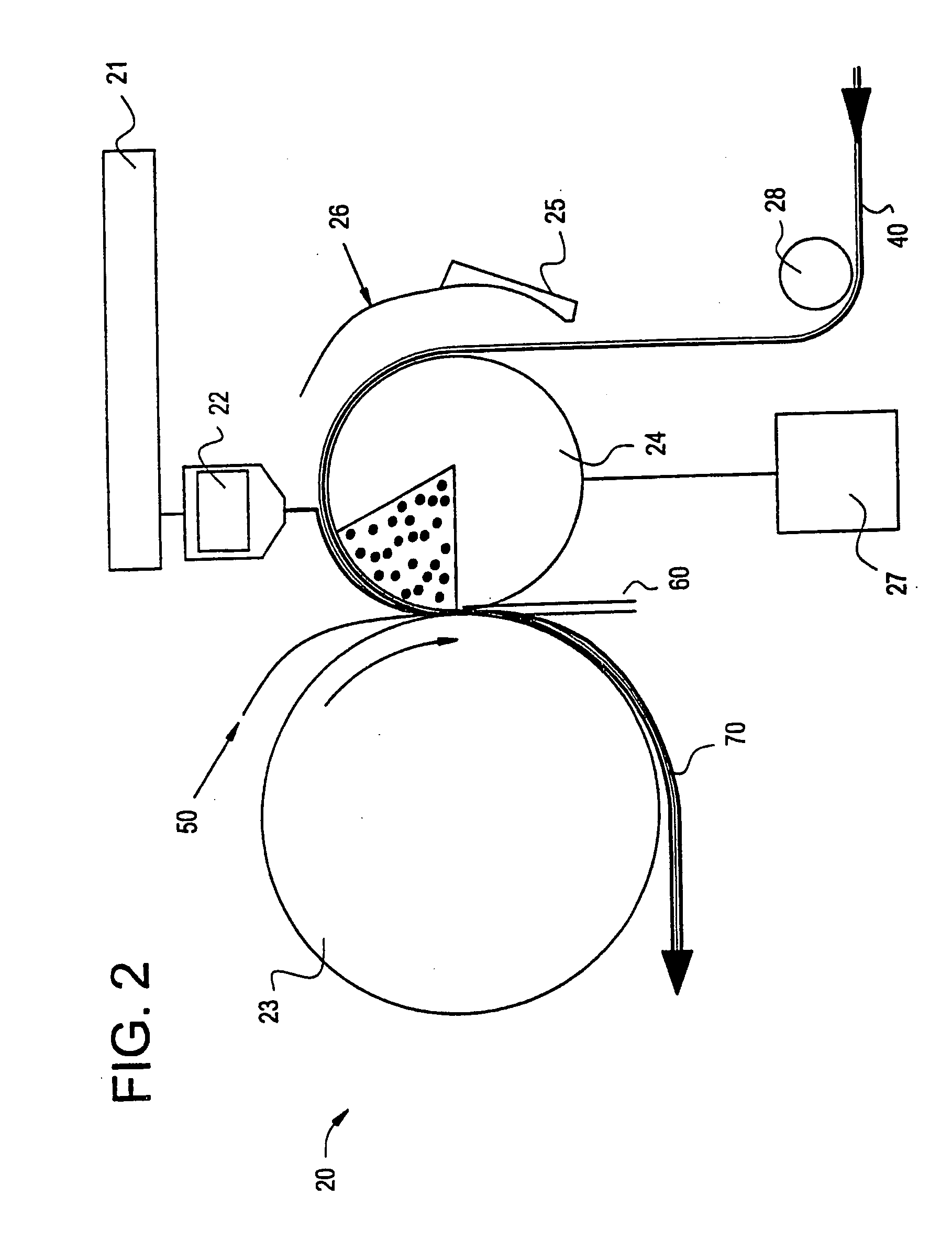

Process and apparatus for manufacturing ethylene polymers and copolymers

InactiveUS7582709B2Reliable and efficient method of manufactureEfficient heat dissipationEthylene productionChemical/physical/physico-chemical stationary reactorsPolymer scienceReaction zone

The invention relates to a process for the manufacture of ethylene polymers and copolymers in which ethylene is compressed in a primary compressor at a throughput of at least 55 tonnes / hour, mixed with recycled ethylene and further compressed in a two-stage reciprocating secondary compressor having at least 14 cylinders to a pressure of at least 2300 bar at a throughput of at least 120 tonnes / hour, heating at least a portion of that ethylene to a temperature of at least 95° C. and introducing it into a tubular reactor of diameter at least 65 mm and a length of at least 1500 m, introducing initiator in at least three reaction zones to give a conversion of at least 28% and maintaining a pressure drop over the reactor to maintain a flow velocity of at least 6 m / s.

Owner:EXXONMOBIL CHEM PAT INC

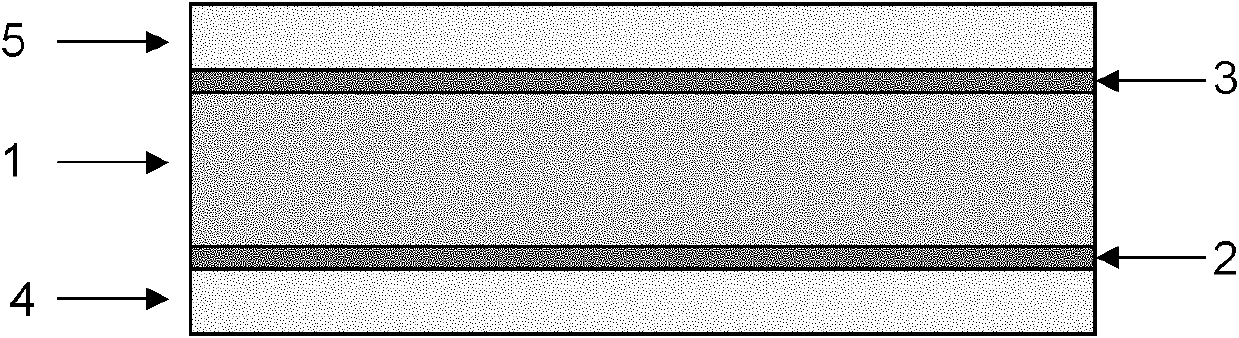

Polymer back panel of solar battery assembly and manufacture method of polymer back panel

ActiveCN102569452AExtend your lifeHigh bonding strengthSynthetic resin layered productsCoatingsPolymer alloyPolyethylene terephthalate glycol

The invention provides a polymer back panel of a solar battery assembly. The polymer back panel comprises a base film layer, binding layers on both sides of the base film layer, a fourth thin film layer and a fifth thin film layer on the other two sides of the binding layers, wherein the base film layers contain at least one of the following components: polyamide polymers, polypropylene and acrylic polymers, polyethylene and ethylene polymers, polyvinylidene chloride, styrene polymers, ABS (acrylonitrile butadiene styrene) resins, liquid crystal polymers, acrylic acid polymers, polyphenyl ether, polycarbonate and polymer alloy of polycarbonate and poly(C2-6 alkal terephthalate). In addition, the invention also provides a manufacture method of the back panel. By adopting a thin film structure made of one or more of the above polymers to substitute for the conventional PET (polyethylene terephthalate) layer, the polymer back panel has excellent processing formation performance, material mechanical performance, barrier performance and anti-aging performance; and a back panel laminated film can be prepared by molten co-extrusion or extrusion composite process, with the advantages of significantly improved bonding strength between the films and simplified production process.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

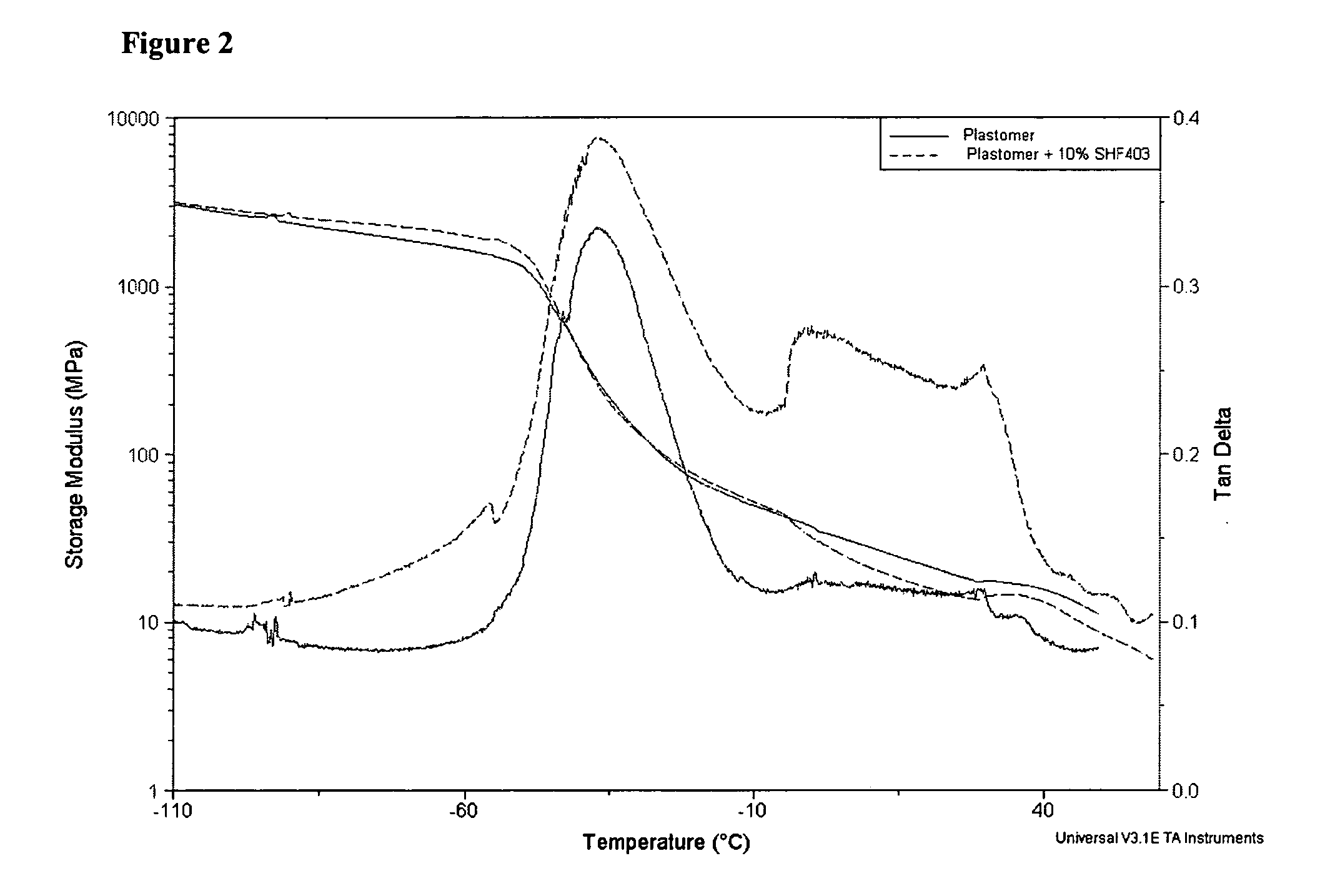

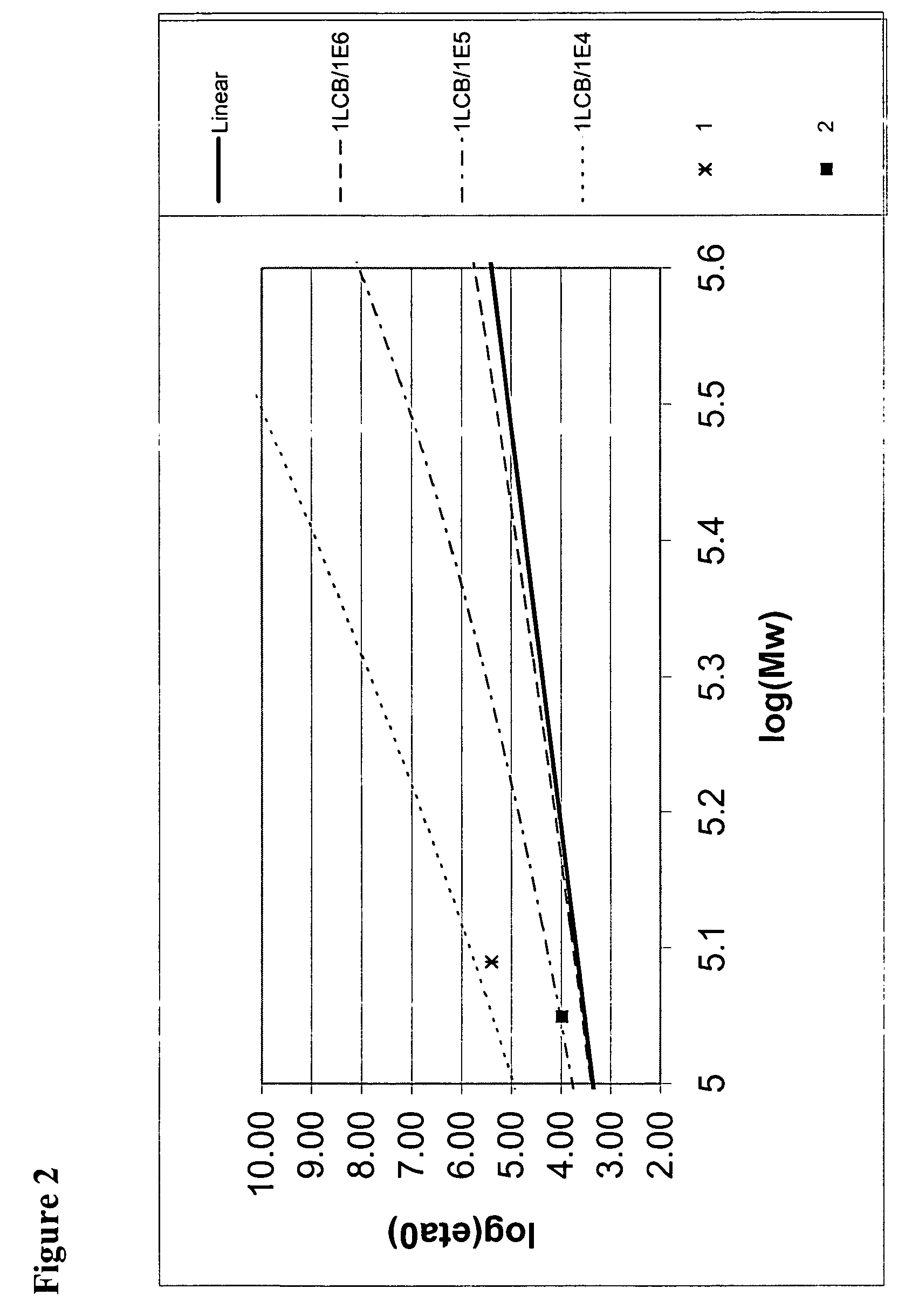

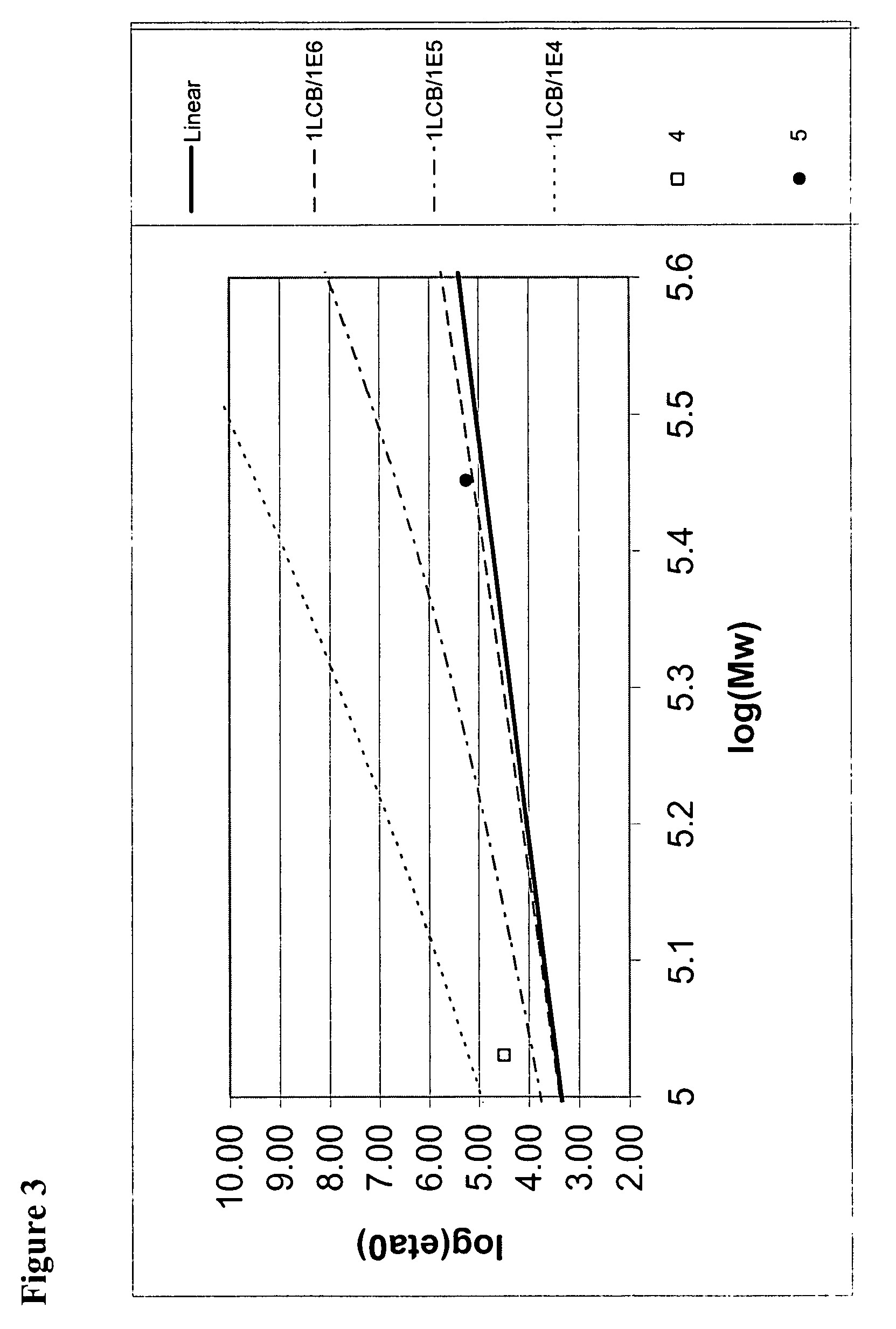

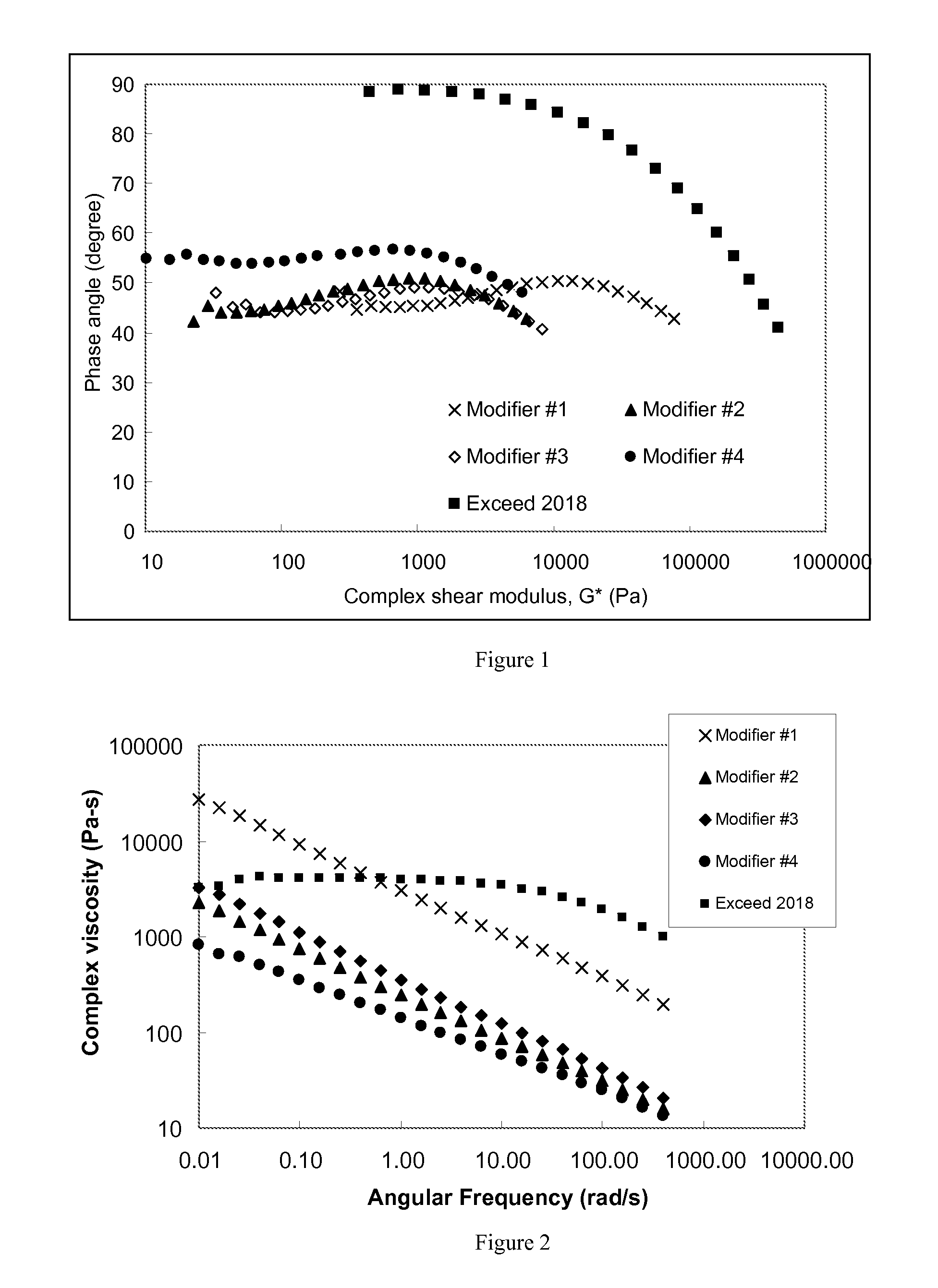

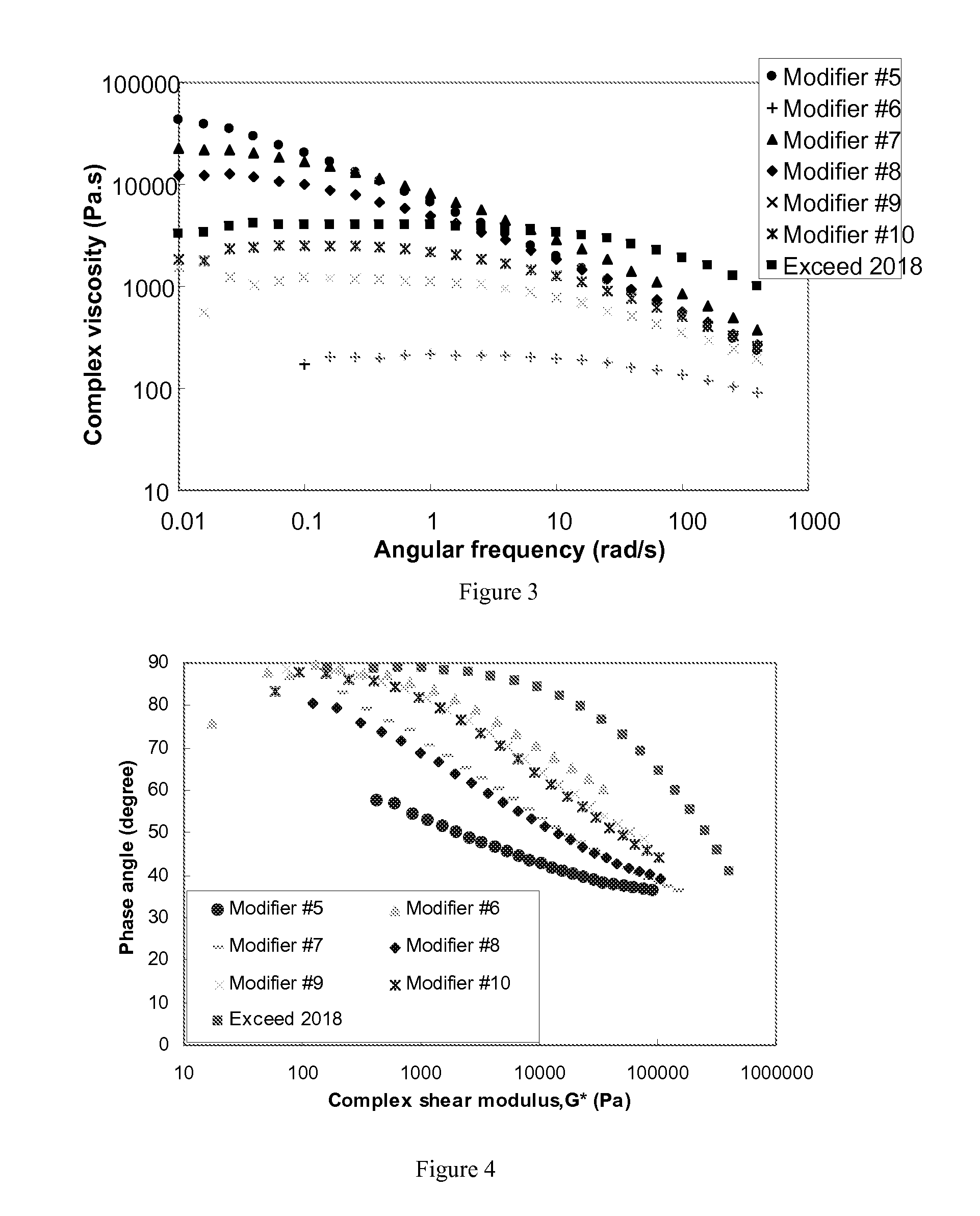

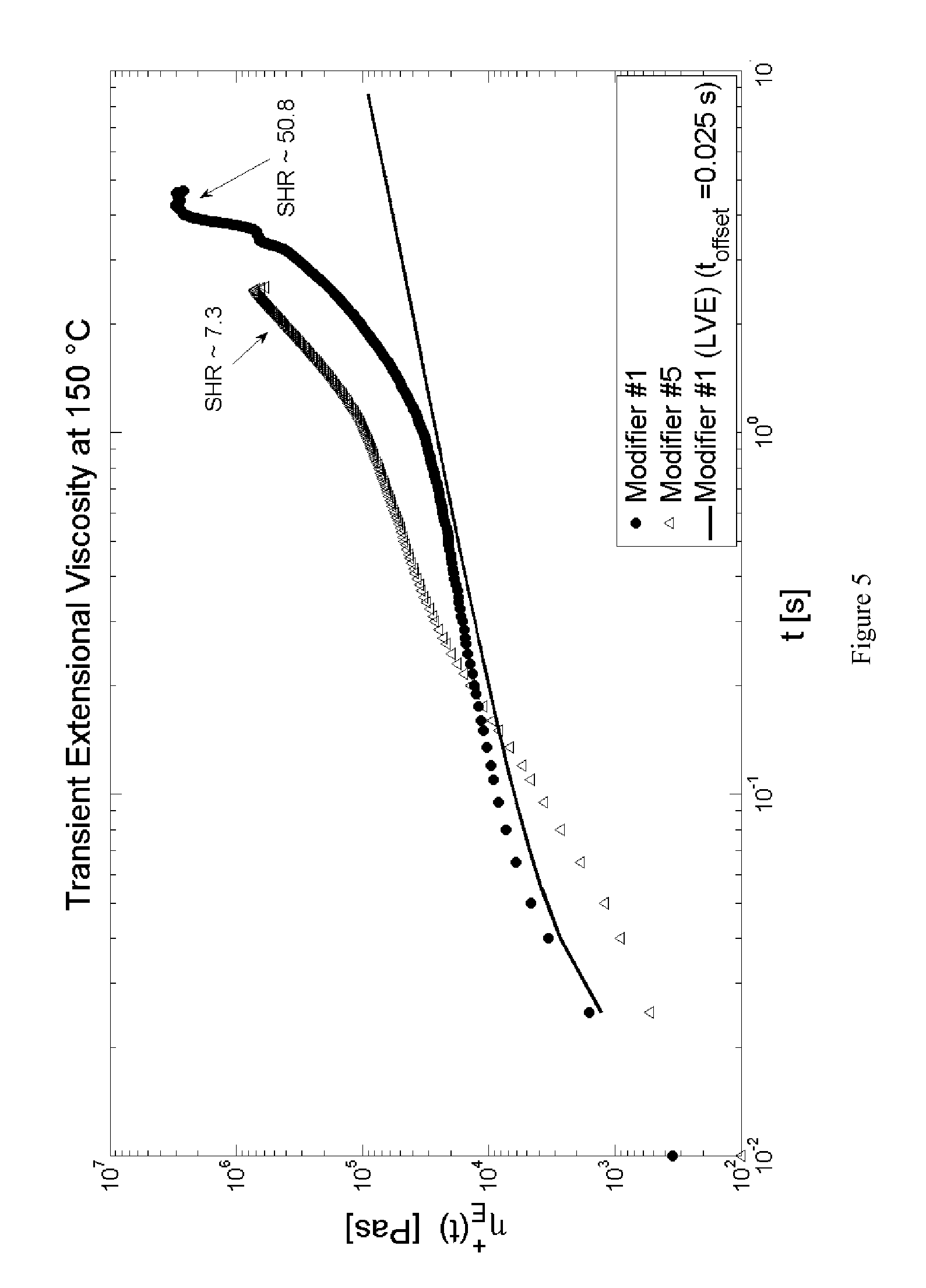

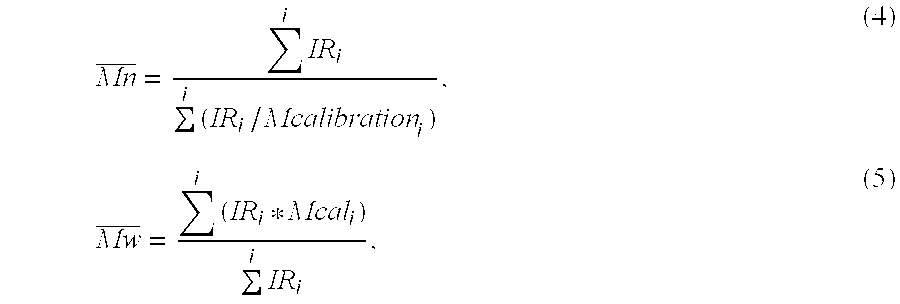

Modified Polyethylene Compositions

The present invention relates to a branched modifier and a composition comprising more than 25 wt % (based on the weight of the composition) of one or more linear ethylene polymers having a g′vis of 0.97 or more and an Mw of 20,000 g / mol or more and at least 0.1 wt % of a branched modifier where the modifier has a g′vis of less than 0.97, wherein the ethylene polymer has a g′vis of at least 0.01 units higher than the g′vis of the branched modifier.

Owner:EXXONMOBIL CHEM PAT INC

Polyolefin compositions, articles made therefrom and methods for preparing the same

ActiveUS8129472B2Excellent balance of stiffnessIncrease resistanceHollow wall articlesBlow moldingPolyolefin

The invention provides compositions for blow molding applications and other applications, where such compositions comprise a high molecular weight ethylene interpolymer and a low molecular weight ethylene polymer, and where the high molecular weight ethylene interpolymer has a density from 0.920 g / cm3 to 0.950 g / cm3, and an I21 from 0.05 to 1 dg / min, and where the low molecular weight ethylene polymer has density from 0.965 g / cm3 to 0.985 g / cm3, and an I2 from 600 to 2000 dg / min. The composition has a density from 0.950 g / cm3 to 0.970 g / cm3, and comprises greater from 45 to 80 weight percent of the high molecular component, and from 20 to 55 weight percent of the low molecular weight component, based on the sum weight of the high molecular weight component and the low molecular weight component. The invention also provides for methods of preparing said compositions and for articles prepared from the same.

Owner:DOW GLOBAL TECH LLC

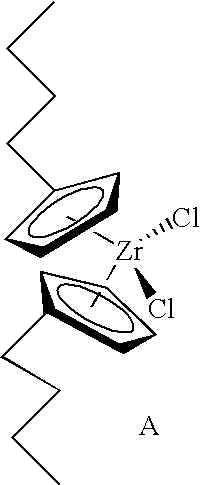

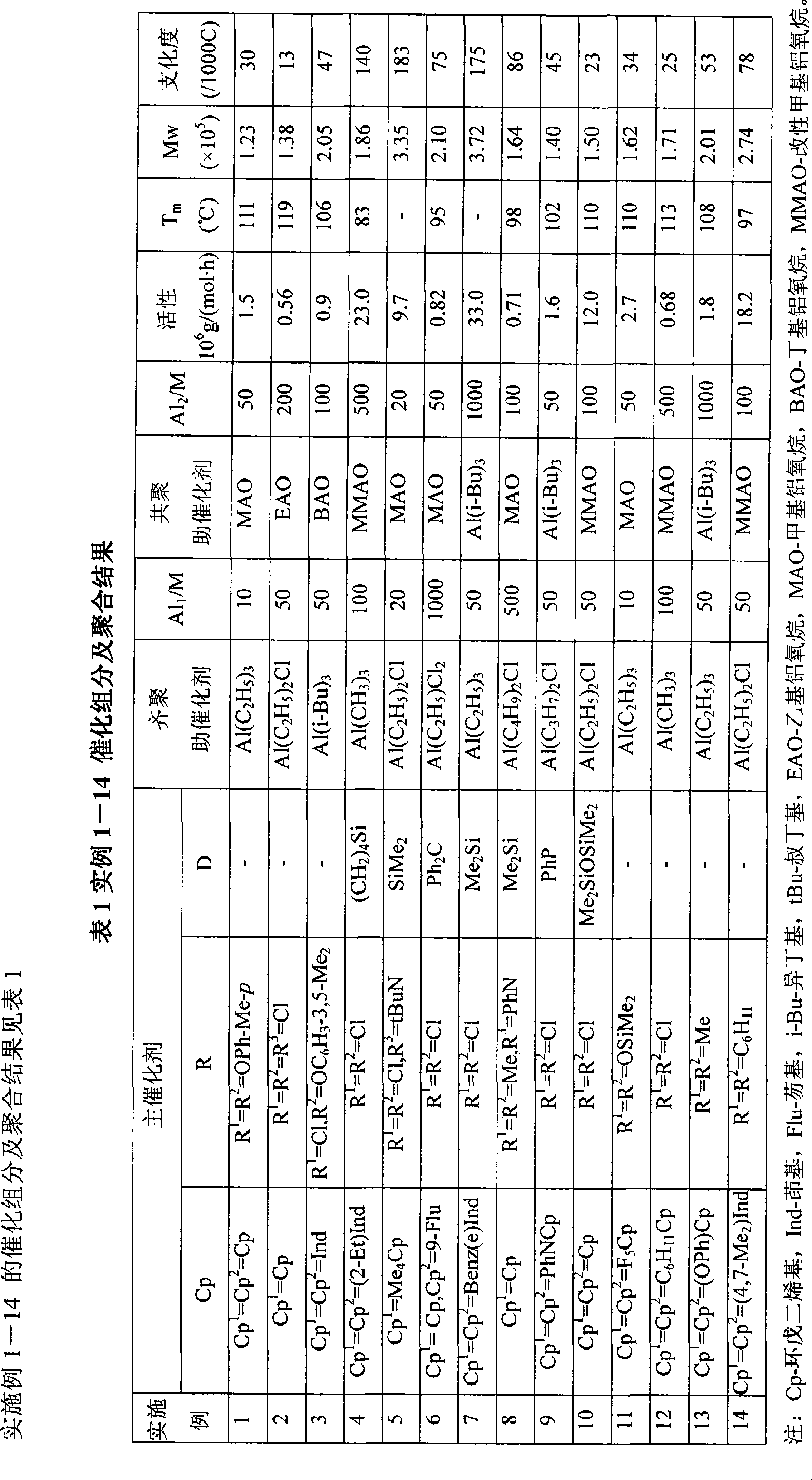

Metallocene domino catalytic system for preparing branched polyethylene using ethylene as only monomer and use thereof

InactiveCN101392036ALower synthesis costAchieve the effect of molecular tailoringTriisobutylaluminiumStructural formula

The invention discloses a domino catalyzing system of a primary metallocene catalyst, which takes ethane as a sole monomer to prepare branched polyethylene, and the application thereof, which relates to vinyl copolymer. the catalyzing system is a compound catalyzing system consisting of the single primary metallocene catalyst and two different catalyst promoters, wherein, the primary catalyst is a metallocene catalyst with a structural formula of Cp<1>MR<1>R<2>R<3>, Cp<1>Cp<2>MR<1>R<2> or Cp<1>-D-Cp<2>MR<1>R<2>; alkyl aluminium acts as an oligomerization catalyst promoter; methylaluminoxane or triisobutyl aluminium or triethyl aluminum that is not used together with the oligomerization catalyst promoter acts as a copolymerization catalyst promoter; the mole ratio between the oligomerization catalyst promoter and the primary catalyst is 10-1000 to 1, and the mole ratio between the copolymerization catalyst promoter and the primary catalyst is 20-1000 to 1. The catalytic activity of the metallocene domino catalyzing system for preparing the branched polyethylene is 5 multiplied by 10<5> to 5 multiplied by 10<7>gPE / (molM per hour), the degree of branching is 10-200 / 1000C, the molecular weight of the branched polyethylene prepared under the effect of the catalyzing system ranges from 1 multiplied by 10<5> to 4 multiplied by 10<5> and the melting point is below 120 DEG C or even no melting point exists.

Owner:HEBEI UNIV OF TECH

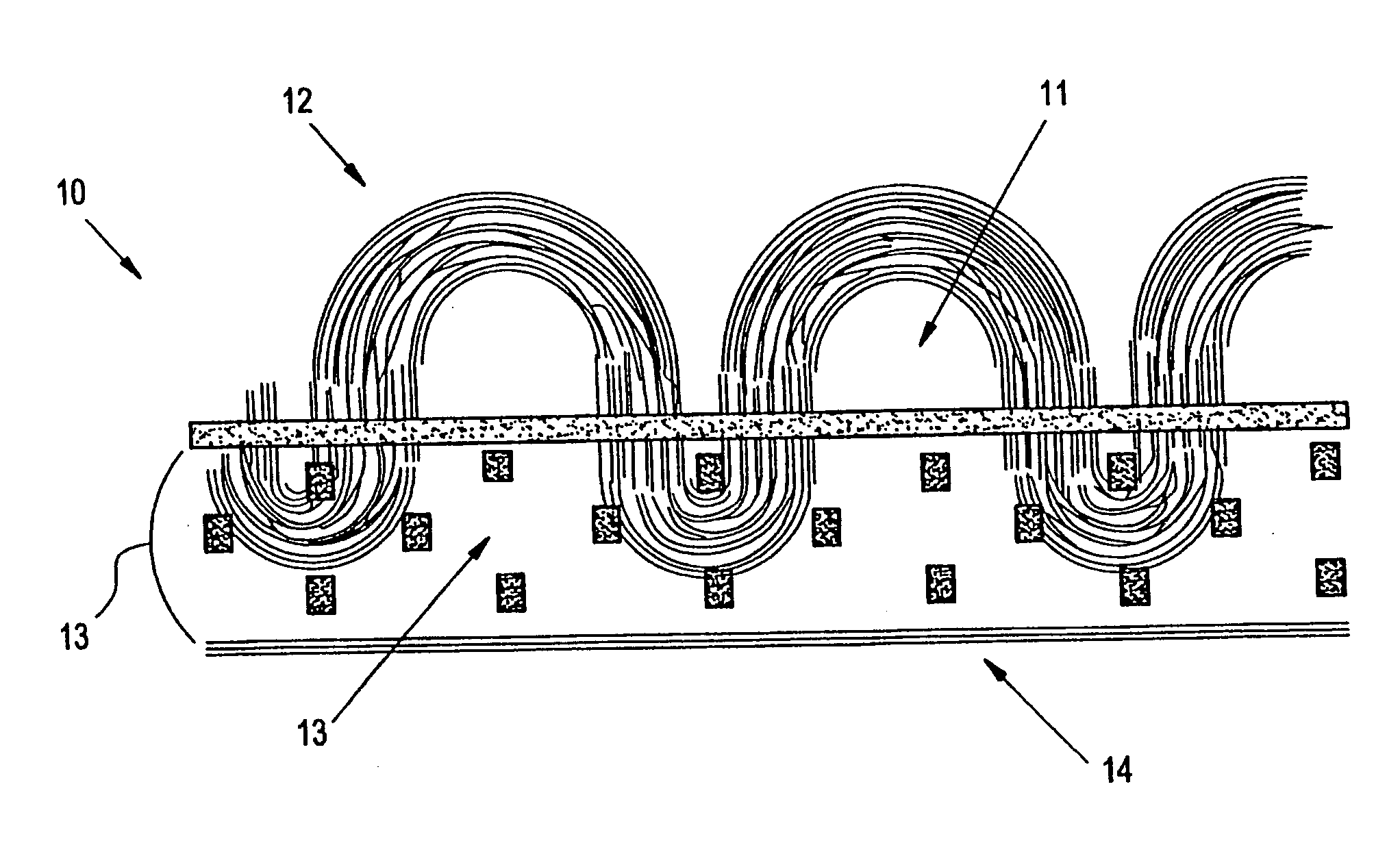

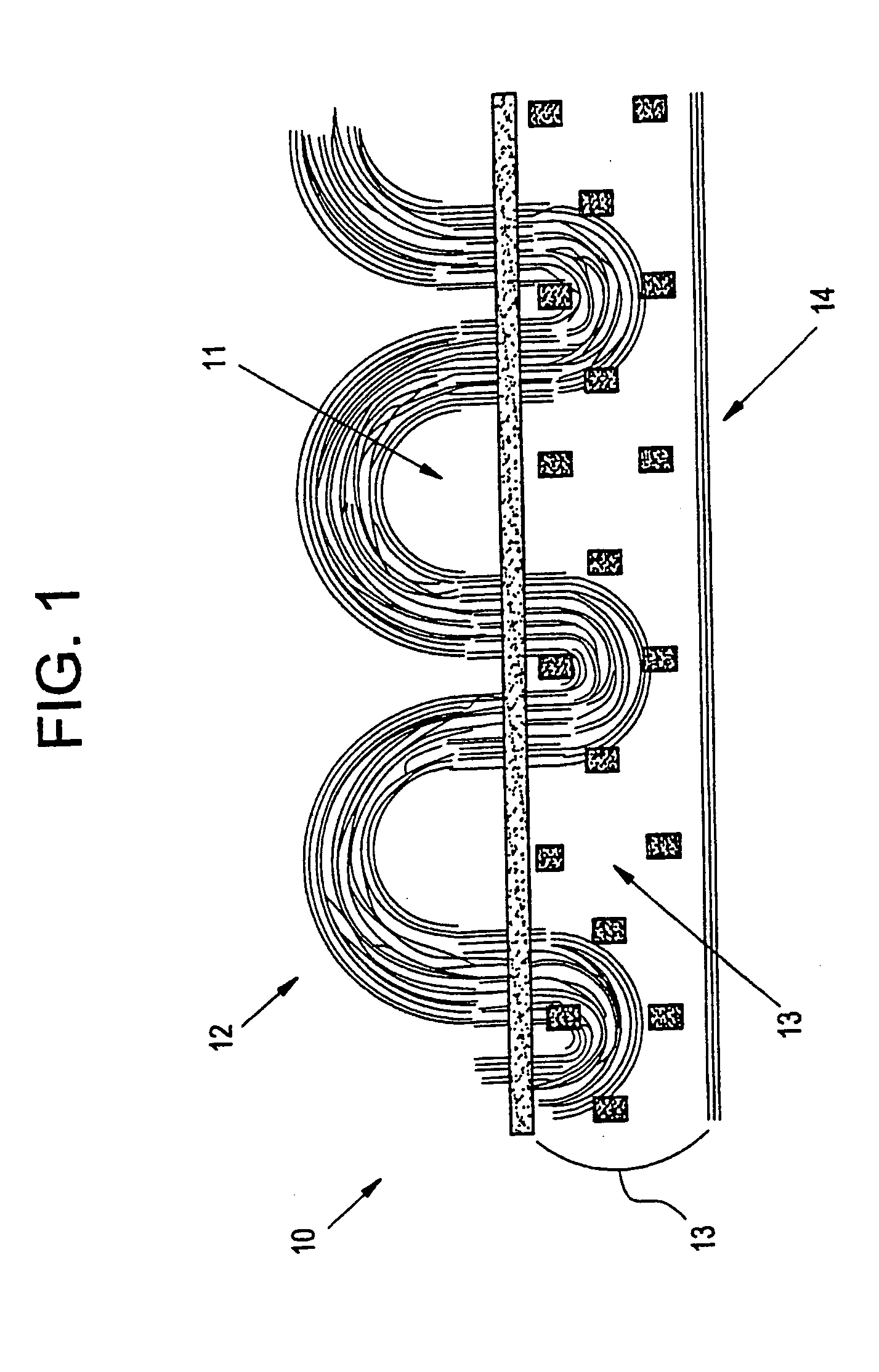

Carpet, carpet backings and methods

The present invention pertains to carpet and method of making it. In one aspect, the carpet includes (a) a primary backing which has a face and a back surface, (b) a plurality of fibers attached to the primary backing and extending from the face of the primary backing and exposed at the back surface of the primary backing, (c) an adhesive backing, (d) an optional secondary backing adjacent to the adhesive backing, and (e) at least one homogeneously branched linear ethylene polymer. The method includes extrusion coating at least one homogeneously branched linear ethylene polymer onto the back surface of a primary backing to provide an adhesive backing. The method can include additional steps or procedures, either separately or in various combinations. Additional steps and procedures include preheating the primary backing prior the extrusion step, multilayer adhesive backings, washing or scouring the primary backing prior the extrusion step, and utilizing adhesive polymeric additives, high heat content fillers, blowing agents and / or implosion agents. The constructions and methods described herein are particularly suited for making carpet tile.

Owner:BRUMBELOW JULIE +7

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com