Polymer back panel of solar battery assembly and manufacture method of polymer back panel

A technology of solar cells and polymers, applied in electrical components, chemical instruments and methods, circuits, etc., can solve problems such as difficult packaging, poor barrier properties, and poor heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

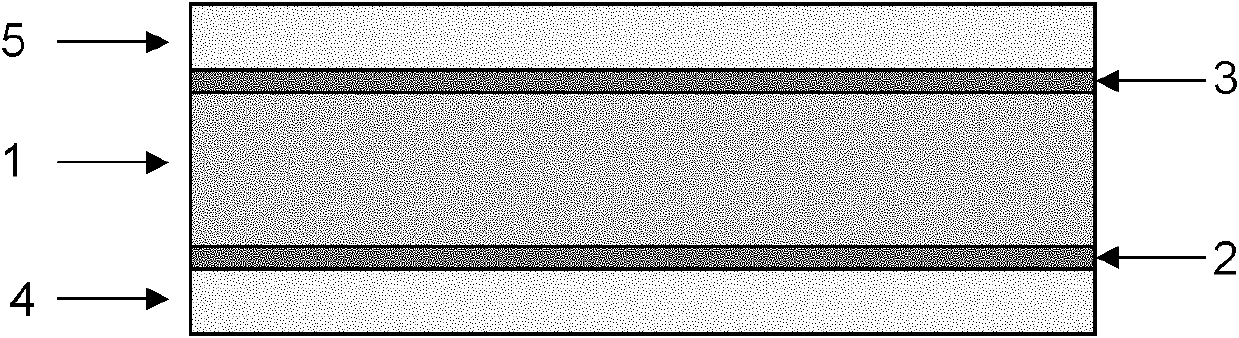

[0079] Using ordinary extrusion-grade polyvinylidene fluoride PVDF plastic particles, adding 15% polymethyl methacrylate PMMA and 5% surface-treated titanium dioxide TiO 2 , Extrude, mix and granulate through a twin-screw extruder at a temperature of about 200°C to obtain PVDF mixture plastic particles. Use ethylene-butyl acrylate EBA as the first adhesive layer, add 5% of titanium dioxide, 1% of silane coupling agent, and 0.5% of light stabilizer and anti-aging agent and mix uniformly in a common mixer to obtain an EBA mixture. Common nylon 12 is used as the base material.

[0080] The mixture of PVDF, nylon 12 and EBA is melted and co-extruded through a multi-layer extruder, and the extrusion temperature is 270°C, thereby obtaining a four-layer laminated film of PVDF / EBA / Nylon12 / EBA, and the thickness of the four layers is 20 / 20 / 200 / 80 microns.

[0081] The PVDF / EBA / Nylon12 / EBA solar cell module back sheet thus produced has a total thickness of 320 microns.

[0082] The ...

Embodiment 2

[0088] Using ordinary extrusion-grade polyvinylidene fluoride PVDF plastic particles, adding 5% polymethyl methacrylate PMMA and 5% surface-treated titanium dioxide TiO 2 , Extrude, mix and granulate through a twin-screw extruder at a temperature of about 200°C to obtain PVDF mixture plastic particles. Ethylene-butyl acrylate EBA and polymethyl methacrylate are used as the adhesive layer, and nylon 12 and Nylon12 are used as the base material.

[0089] Four extruders of PVDF, PMMA, EBA and Nylon12 were melted and co-extruded, and the extrusion temperature was 270°C, thereby obtaining a seven-layer laminated film of PVDF / PMMA / EBA / Nylon12 / EBA / PMMA / EBA / PVDF, and the thickness of the seven layers was respectively For 20 / 20 / 20 / 200 / 20 / 20 / 20 microns. The PVDF / PMMA / EBA / Nylon12 / EBA / PMMA / EBA / PVDF back sheet of the solar cell module thus produced has a total thickness of 320 microns.

[0090] The peel strength between the PVDF and nylon 12 layers in the back sheet was tested, and the r...

Embodiment 3

[0096] Common extrusion-grade tetrafluoroethylene and hexafluoroethylene copolymer FEP plastic particles are used, and 5% of surface-treated titanium dioxide TiO2 is added to extrude the cast film through a twin-screw extruder at a temperature of about 360°C. The thickness is 20 microns. The thermoplastic polyurethane TPU mixture is used as the adhesive layer, 1% of silane coupling agent, 30% of ethylene-butyl acrylate EBA, and 0.5% of light stabilizer and anti-aging agent are added to TPU, mechanically mixed in an ordinary mixer, and extruded by twin-screw Machine extrusion compounding granulation to obtain TPU mixture.

[0097] Nylon 12 is melt-blended with 50% polypropylene PP, and 5% maleic anhydride grafted polypropylene MAH-PP is added as a compatibilizer, and the nylon blend is obtained by compounding and granulating through a twin-screw extruder.

[0098] Melt and co-extrude the three-layer film TPU / Nylon12 / TPU onto the FEP film through a multi-layer extruder to melt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com