Patents

Literature

4359 results about "Tetrafluoroethylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tetrafluoroethylene (TFE) is a fluorocarbon with chemical formula C₂F₄. It is the simplest perfluorinated alkene. This gaseous species is used primarily in the industrial preparation of polymers.

Copolymers of tetrafluoroethylene

ActiveUS7531611B2Synthetic resin layered productsThin material handlingBreaking strengthTetrafluoroethylene

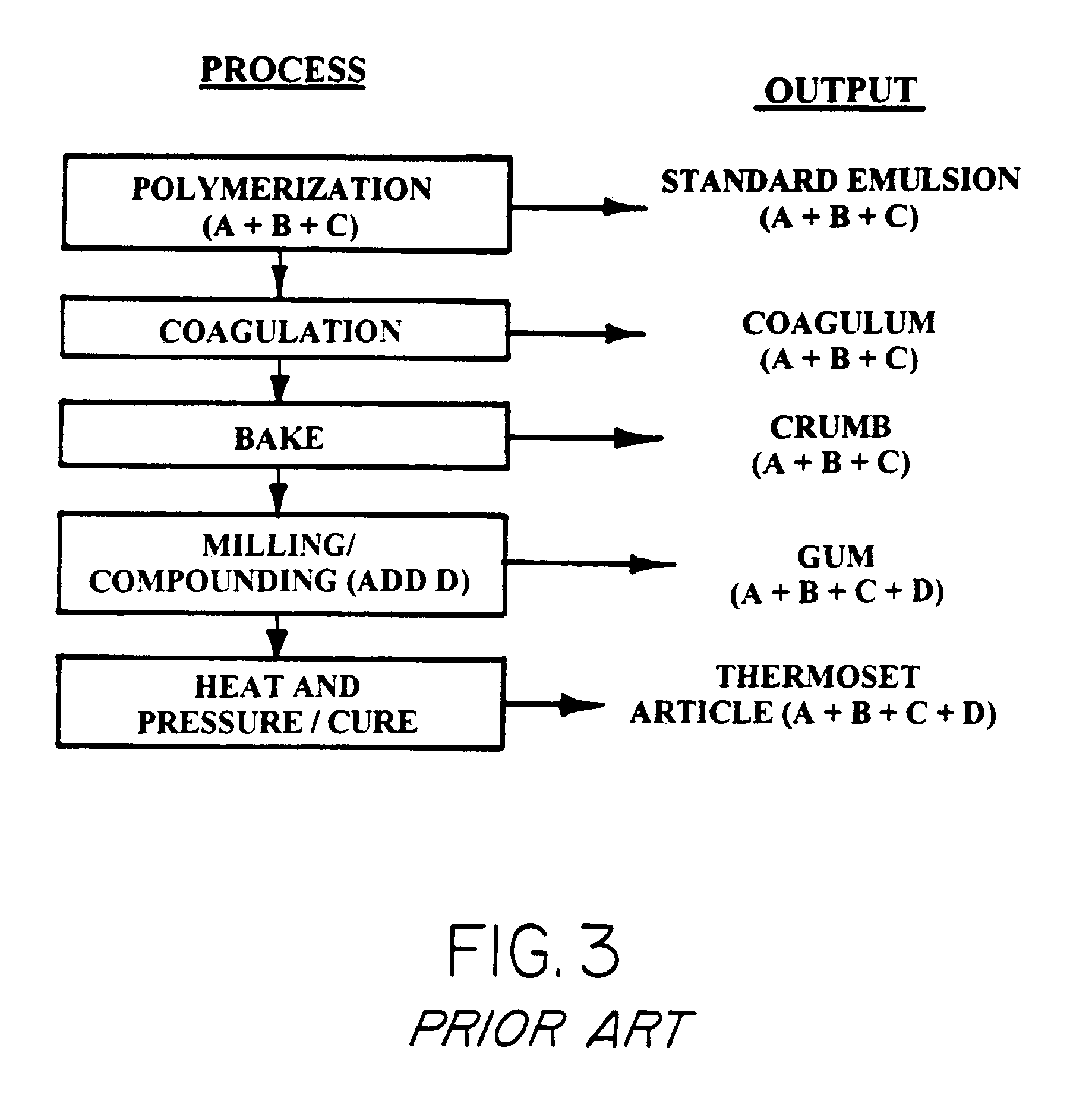

A polymerization process for producing a tetrafluoroethylene copolymer, and the copolymer produced thereby, are provided. The copolymer is of the dispersion / fine powder type and contains polymerized tetrafluoroethylene monomer units and co-polymerized higher homologous comonomer units having the formula (CnF(2n+1))CH═CH2, wherein 6≦n<10, in which the primary particles are believed to have a core and shell structure and the polymerized comonomer units are present in an amount from 0.01 mol % to 0.3 mol %, based upon total copolymer composition. The copolymer has a raw dispersion primary particle size (RDPS) of less than 0.210 microns coupled with a standard specific gravity (SSG) of less than 2.143. Preferably the copolymer has comonomer units present in an amount from 0.05 mol % and 0.25 mol % and the RDPS is within the range between 0.178 microns and 0.200 microns, coupled with a SSG of less than 2.140. Copolymers produced according to the invention, (perfluorohexyl)ethylene (PFHE) and (perfluorooctyl)ethylene (PFOE), may be shaped into the form of 0.1 inch diameter expanded beading, which expanded beading can have a break strength of at least 10.0 lbs, and which may exceed 13.0 lbs.

Owner:WL GORE & ASSOC INC

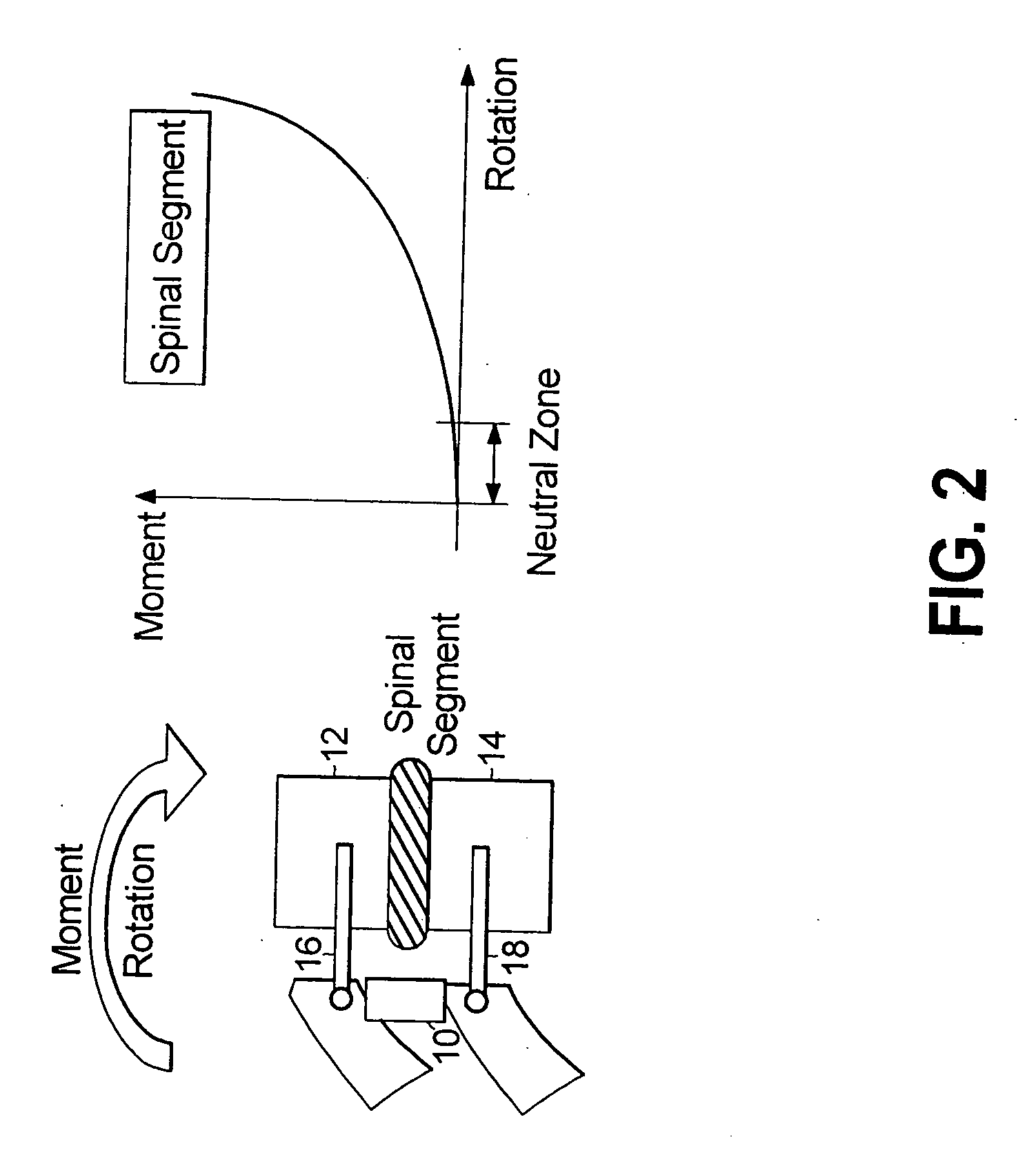

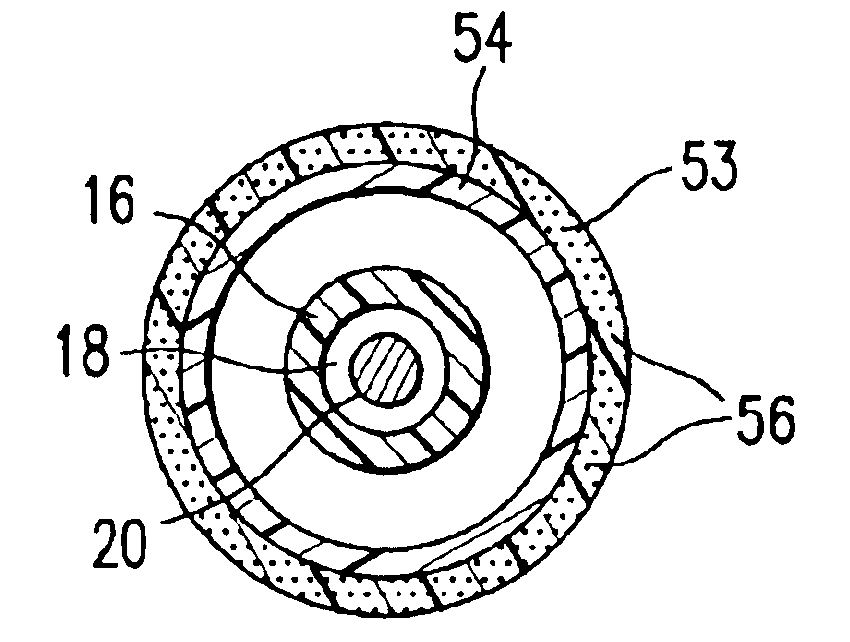

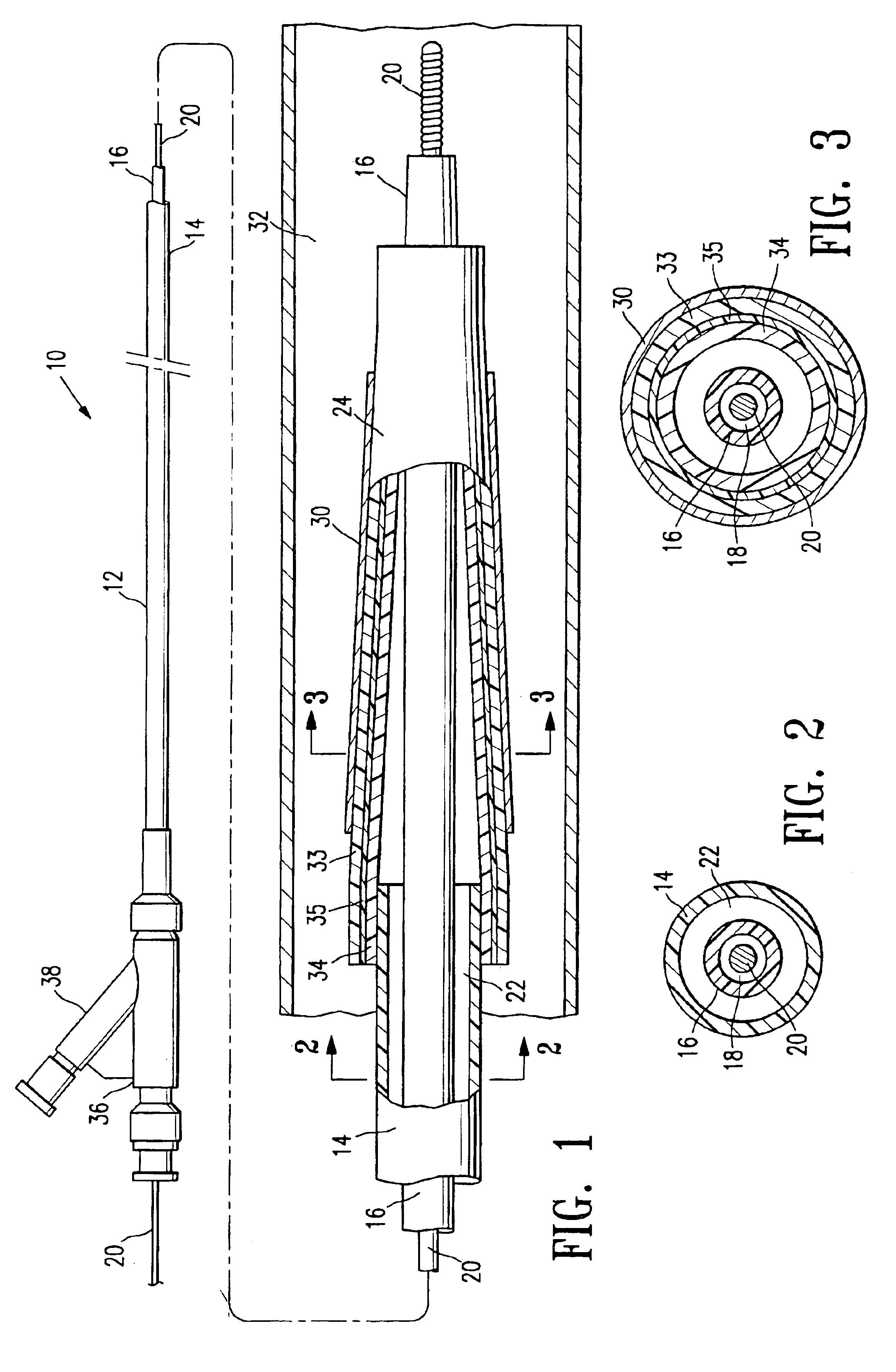

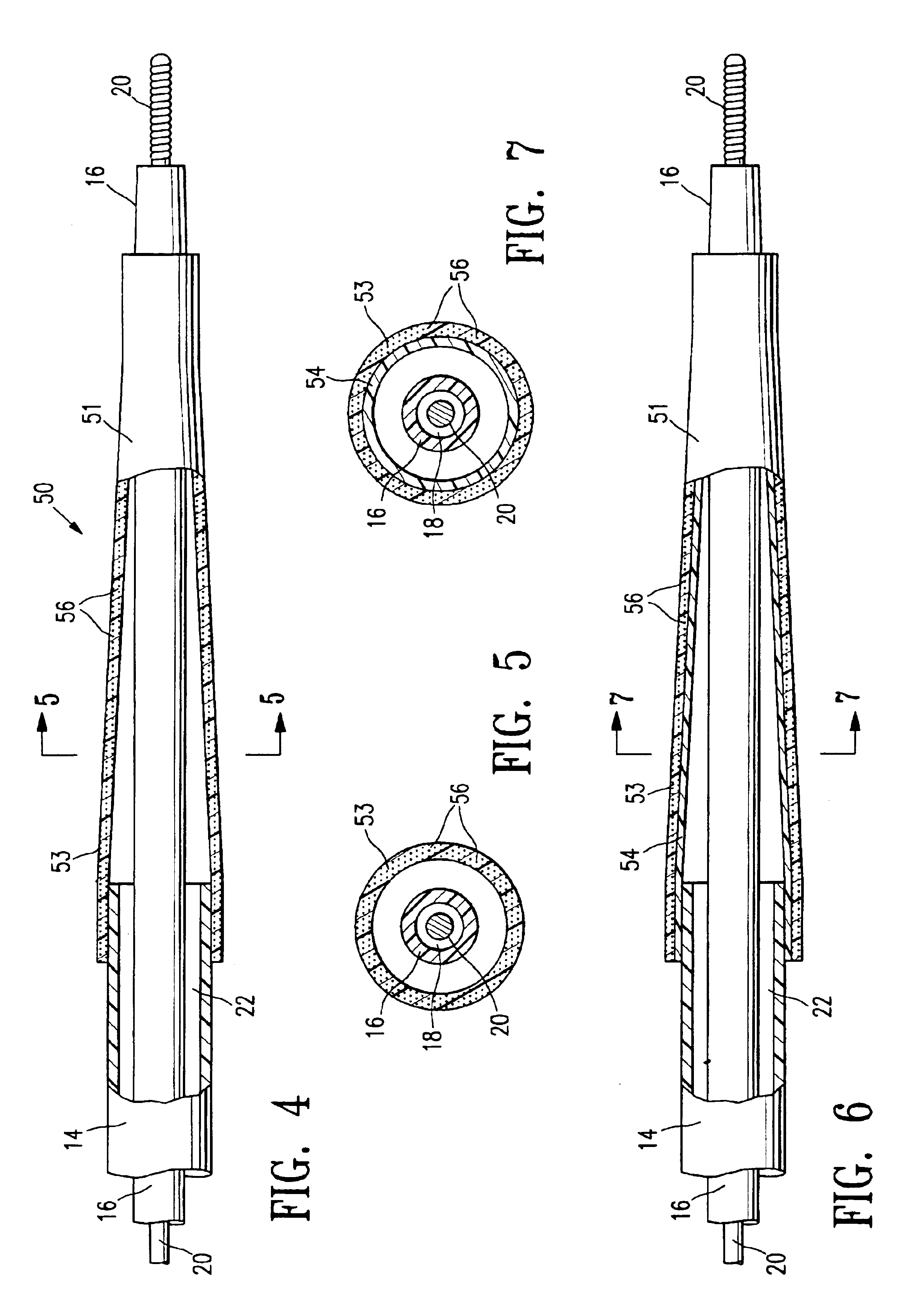

Surgical implant devices and systems including a sheath member

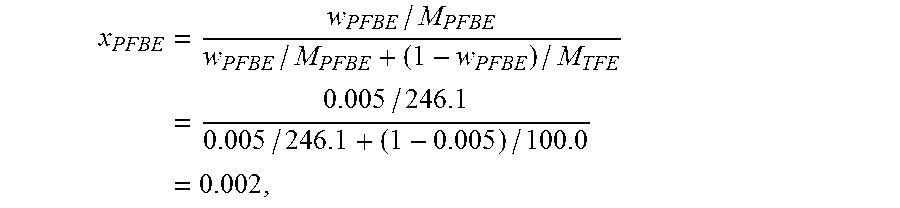

InactiveUS20050177156A1Easy to installImprove clinical outcomesSuture equipmentsInternal osteosythesisAnatomical structuresSpinal column

A surgical implant is provided that includes first and second abutment surfaces between which are positioned a force imparting mechanism. A sheath is positioned between the first and second abutment surfaces, and surrounds the force imparting mechanism. The sheath is fabricated from a material that accommodates relative movement of the abutment members, while exhibiting substantially inert behavior relative to surrounding anatomical structures. The sheath is generally fabricated from expanded polytetrafluoroethylene, ultra-high molecular weight polyethylene, a copolymer of polycarbonate and a urethane, or a blend of a polycarbonate and a urethane. The force imparting member may include one or more springs, e.g., a pair of nested springs. The surgical implant may be a dynamic spine stabilizing member that is advantageously incorporated into a spine stabilization system to offer clinically efficacious results.

Owner:RACHIOTEK

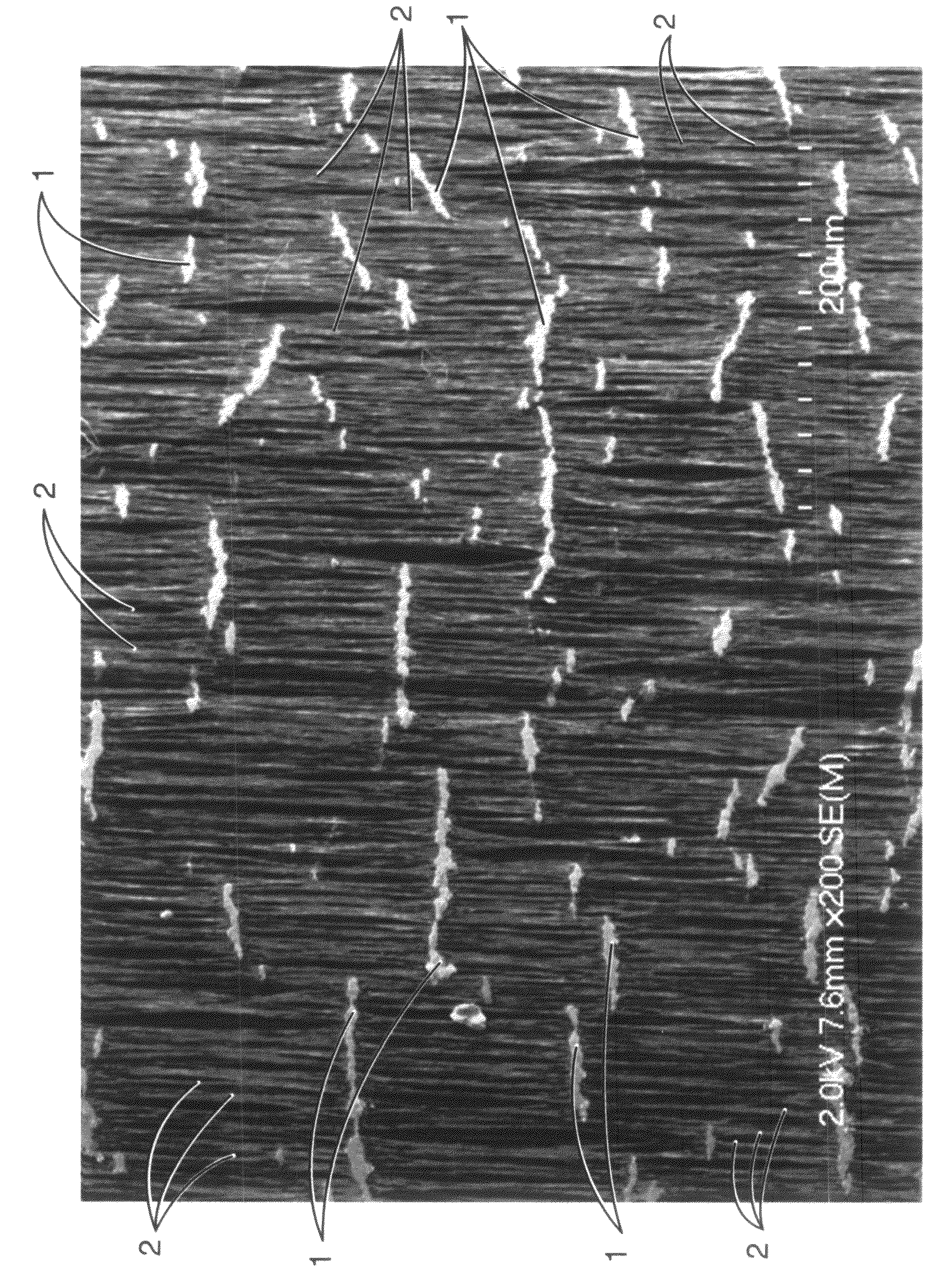

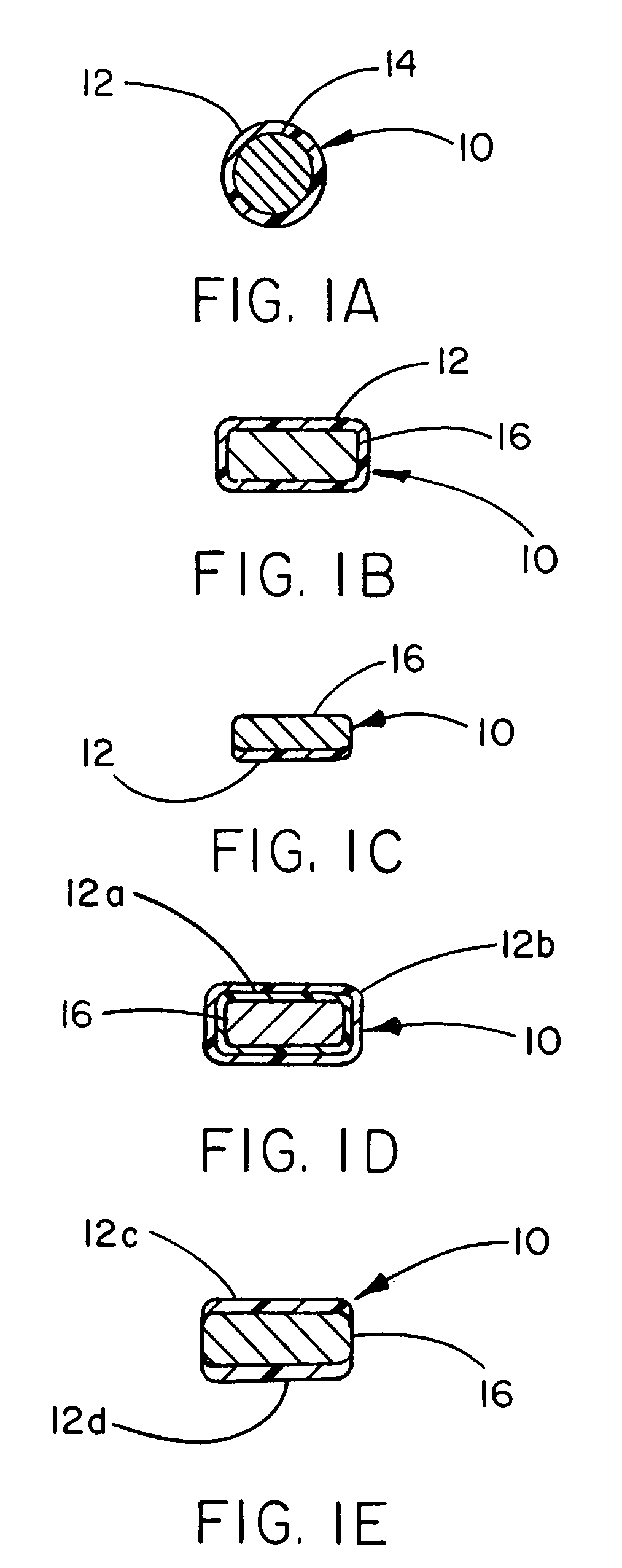

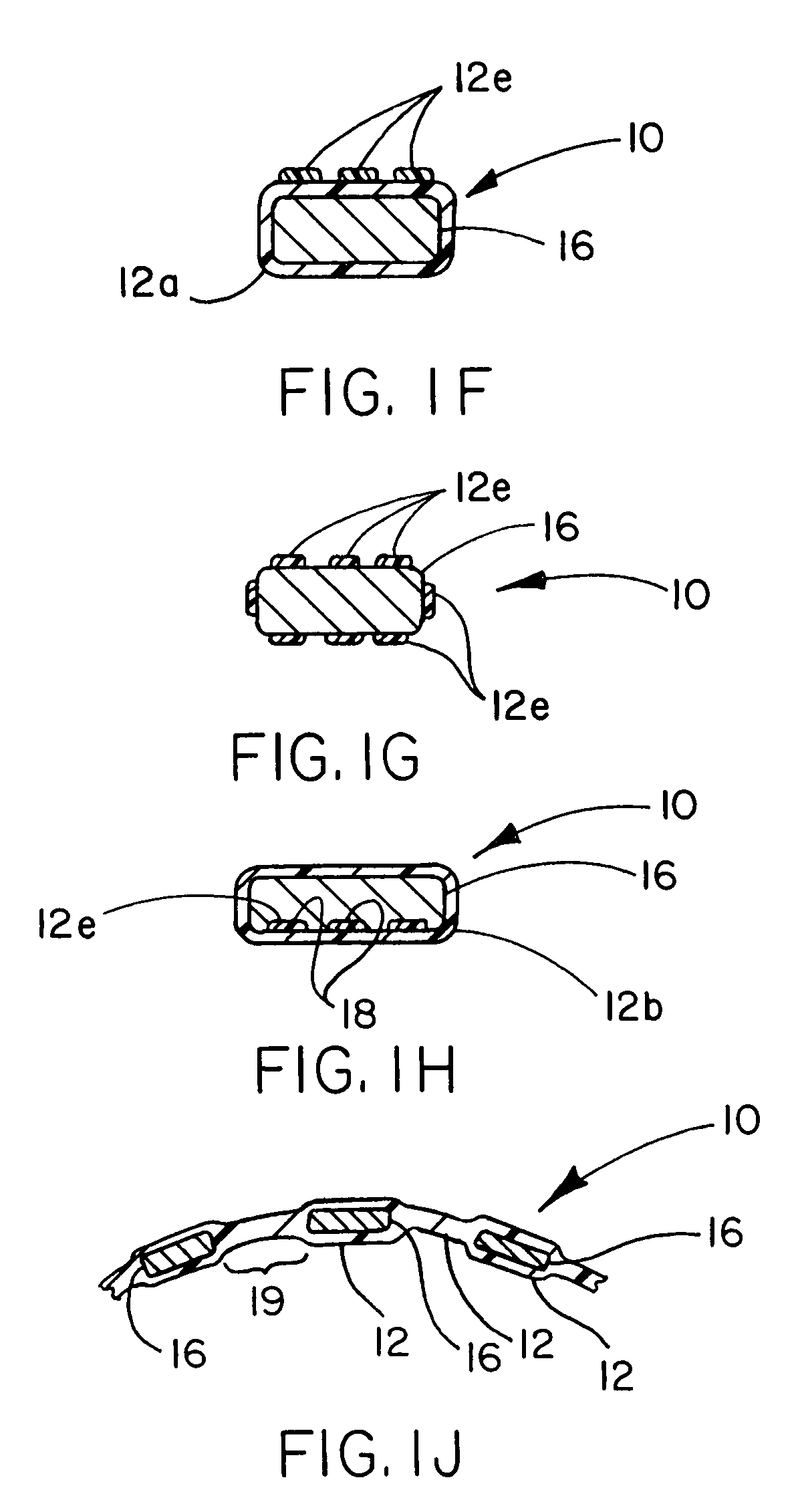

Expandable TFE copolymers, method of making, and porous, expended articles thereof

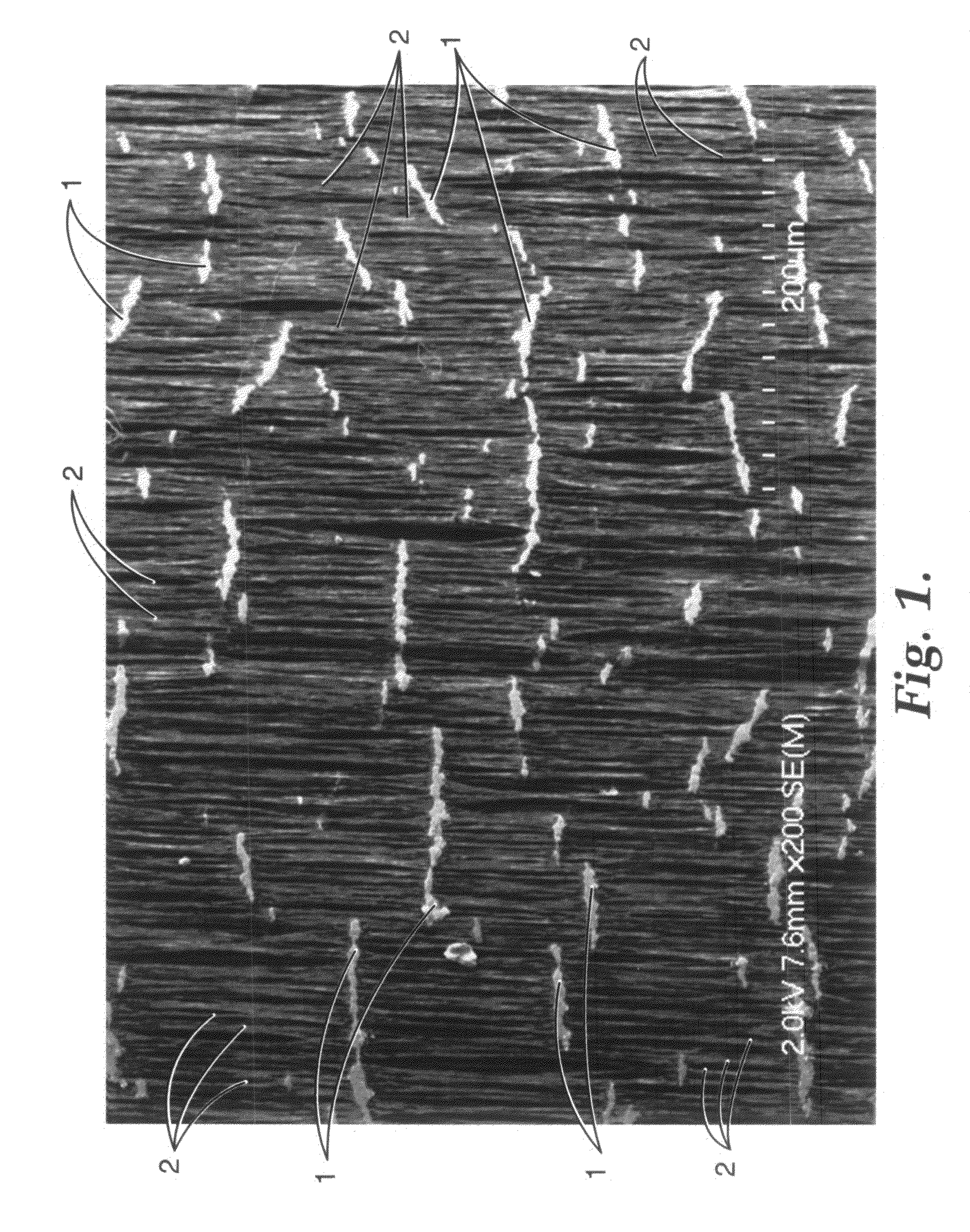

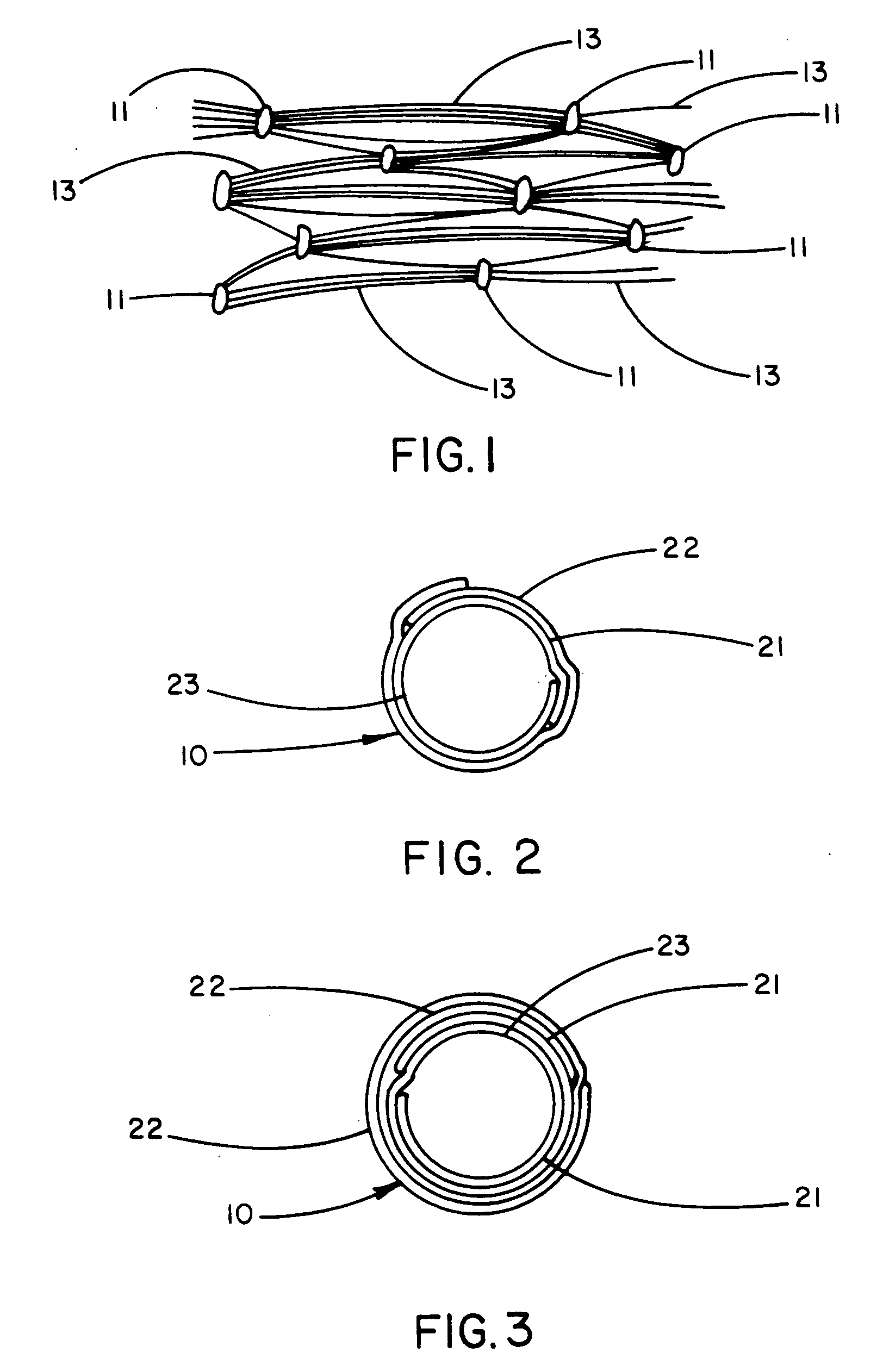

A process for the polymerization of a true tetrafluoroethylene (TFE) copolymer of the fine powder type is provided, wherein the copolymer contains polymerized comonomer units of at least one comonomer other than TFE in concentrations of at least or exceeding 1.0 weight percent, and which can exceed 5.0 weight percent, wherein the copolymer is expandable, that is, the copolymer may be expanded to produce strong, useful, expanded TFE copolymeric articles having a microstructure of nodes interconnected by fibrils.

Owner:WL GORE & ASSOC INC

Expandable TFE copolymers, method of making, and porous, expended articles thereof

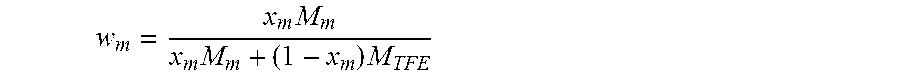

ActiveUS20090093602A1Improve the extrusion effectStretch smoothlyThin material handlingFiberTetrafluoroethylene

A process for the polymerization of a true tetrafluoroethylene (TFE) copolymer of the fine powder type is provided, wherein the copolymer contains polymerized comonomer units of at least one comonomer other than TFE in concentrations of at least or exceeding 1.0 weight percent, and which can exceed 5.0 weight percent, wherein the copolymer is expandable, that is, the copolymer may be expanded to produce strong, useful, expanded TFE copolymeric articles having a microstructure of nodes interconnected by fibrils.

Owner:WL GORE & ASSOC INC

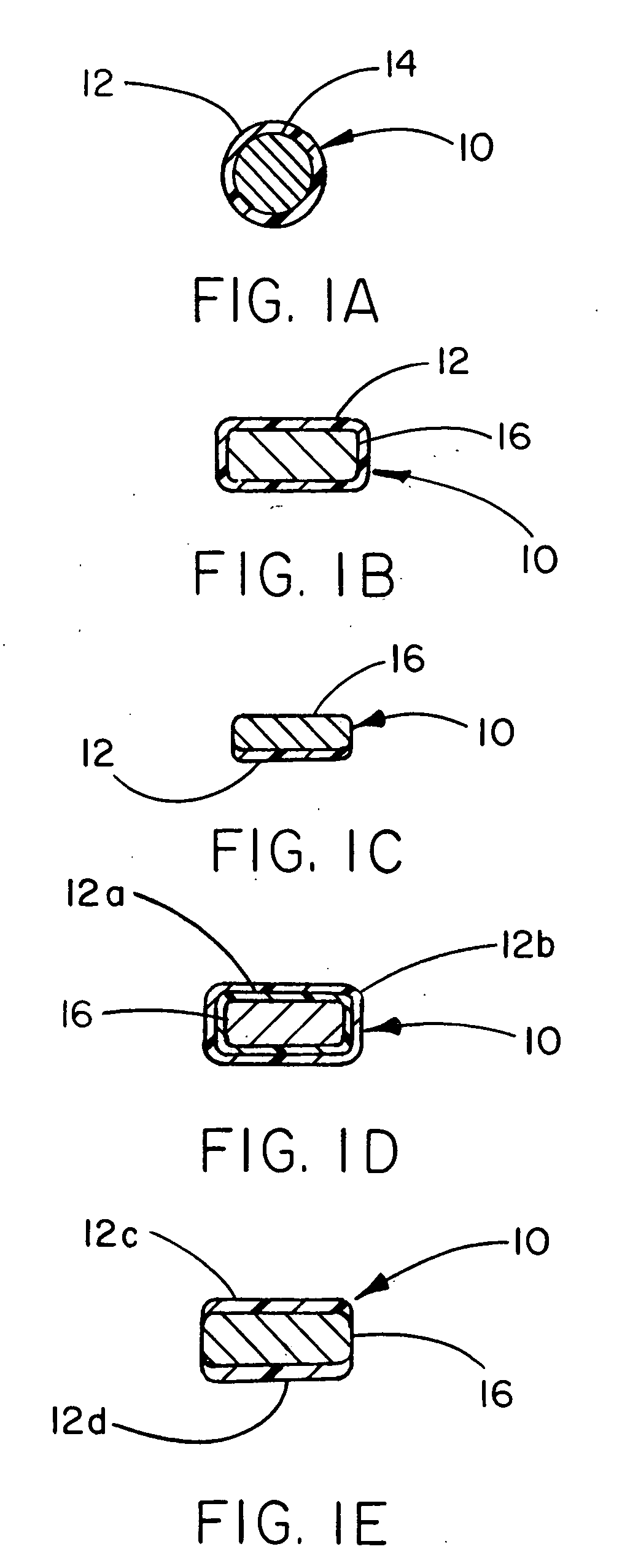

Thermoplastic copolymer of tetrafluoroethylene and perfluoromethyl vinyl ether and medical devices employing the copolymer

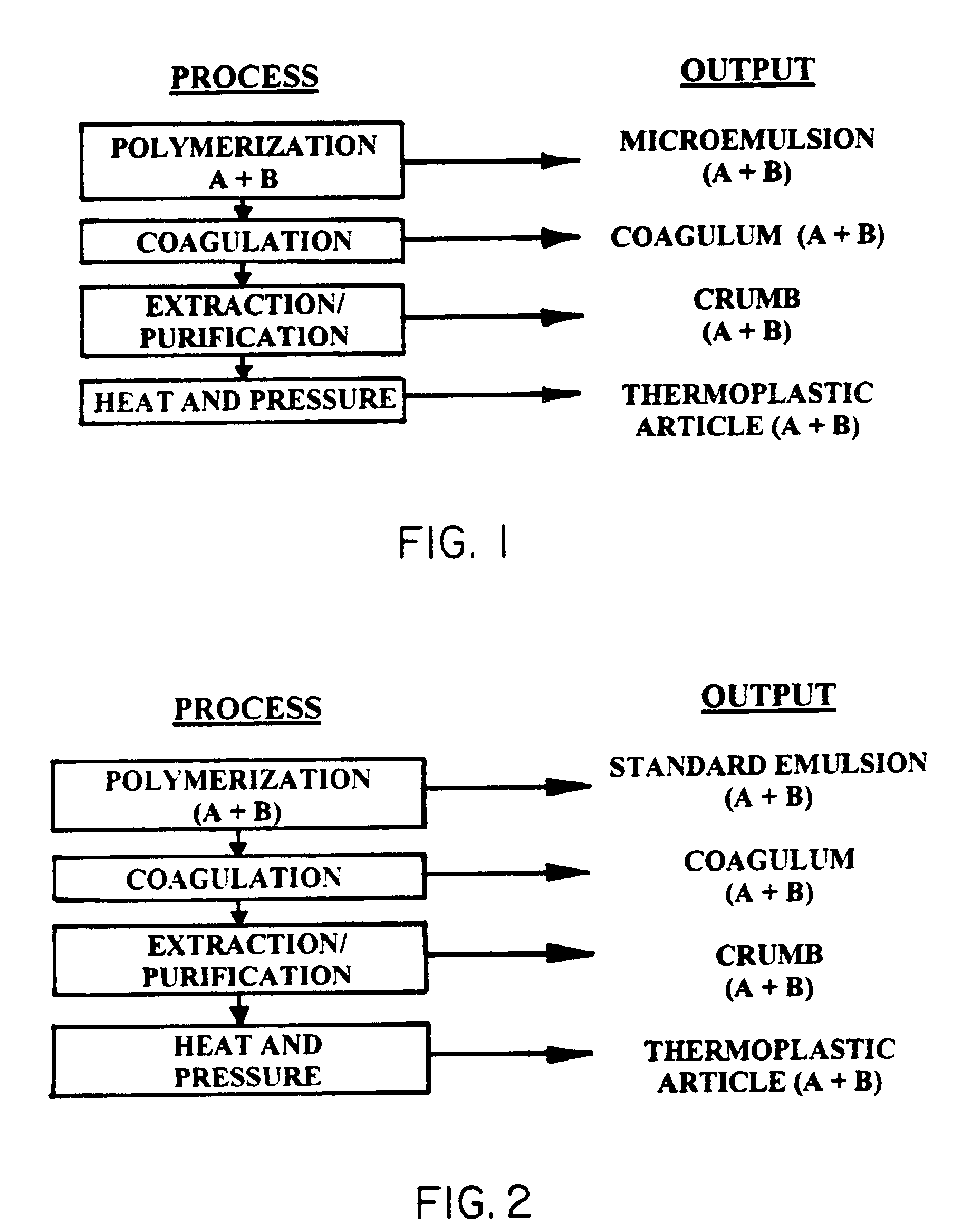

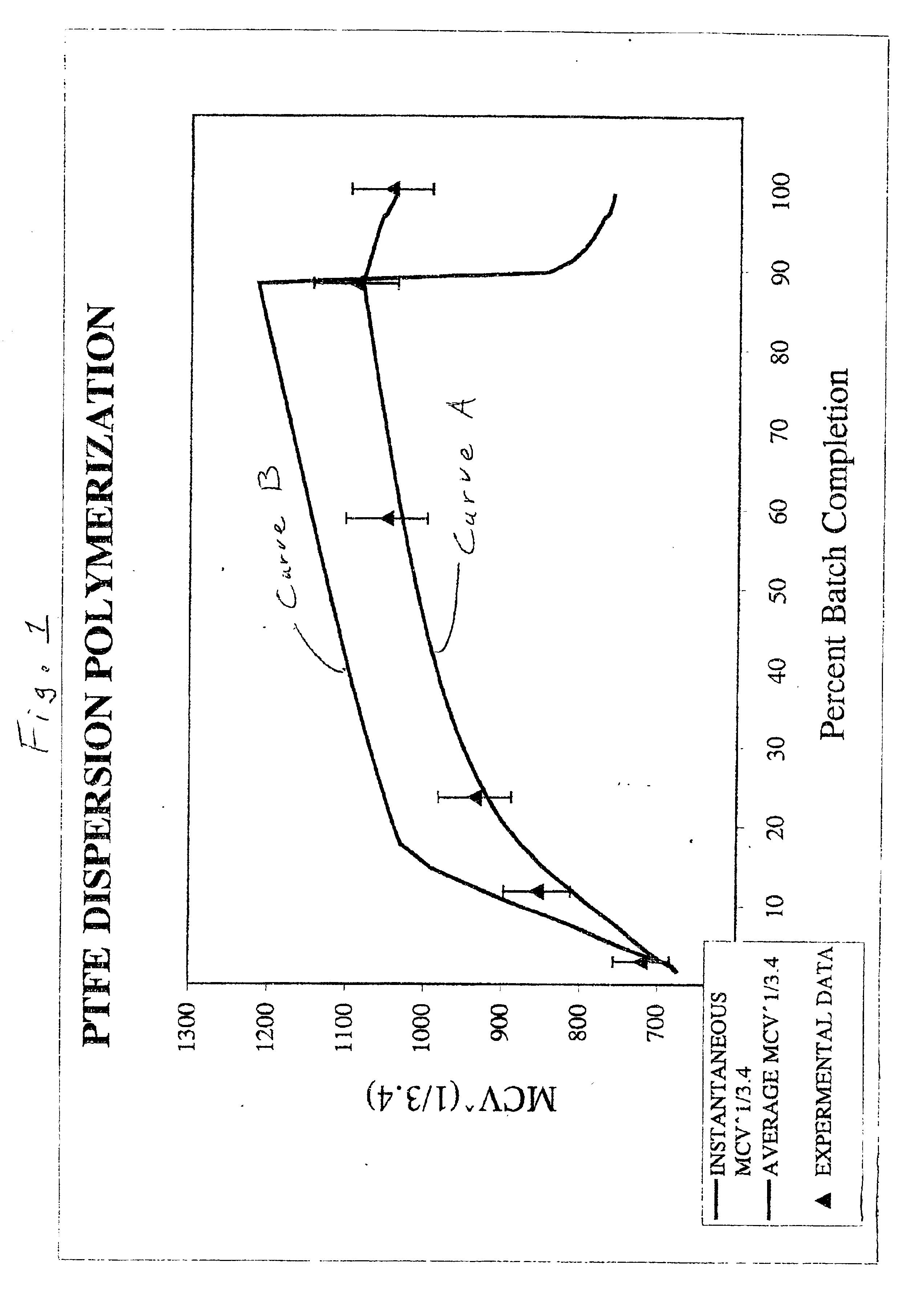

An improved elastomeric material is described comprising an essentially noncross-linkable amorphous copolymer of tetrafluoroethylene (TFE) and perfluoromethyl vinyl ether (PMVE) which is both a thermoplastic and exhibits exceptional mechanical properties. This material is particularly suitable for use in ultra-clean environments, and particularly for use in an implantable device, since it does not contain contaminants that previous thermoset TFE / PMVE copolymers have required. Among the improved properties of the present invention are excellent biocompatibility, high matrix tensile strength, high clarity, high abrasion resistance, high purity, adequate elasticity, and ease of processing due to the thermoplastic, and noncross-linkable structure of the copolymer. The material of the present invention is also a high strength bonding agent particularly suited for bonding porous PTFE to itself or to other porous substances at room or elevated temperatures.

Owner:WL GORE & ASSOC INC

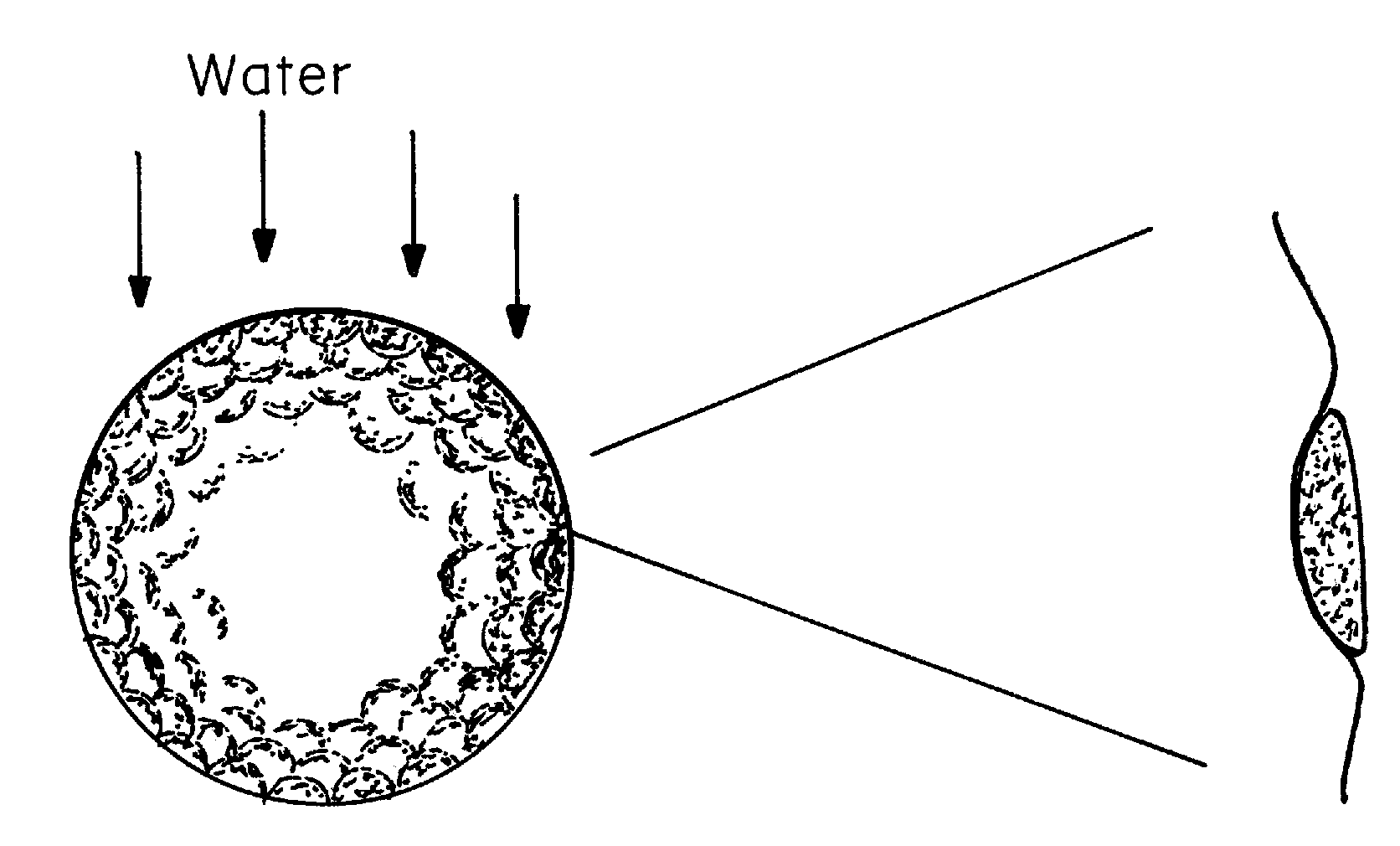

Core-shell fluoropolymer dispersions

InactiveUS6841594B2High shear stabilityExtend elastic lifeSynthetic resin layered productsCellulosic plastic layered productsTetrafluoroethylenePolymer science

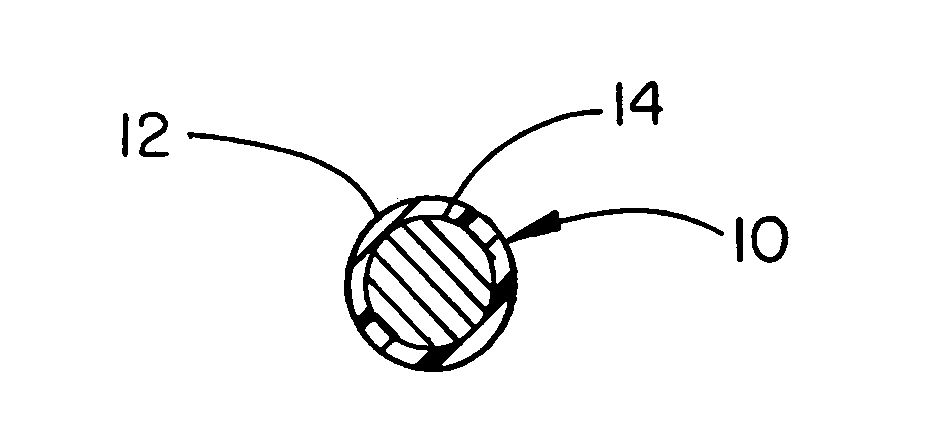

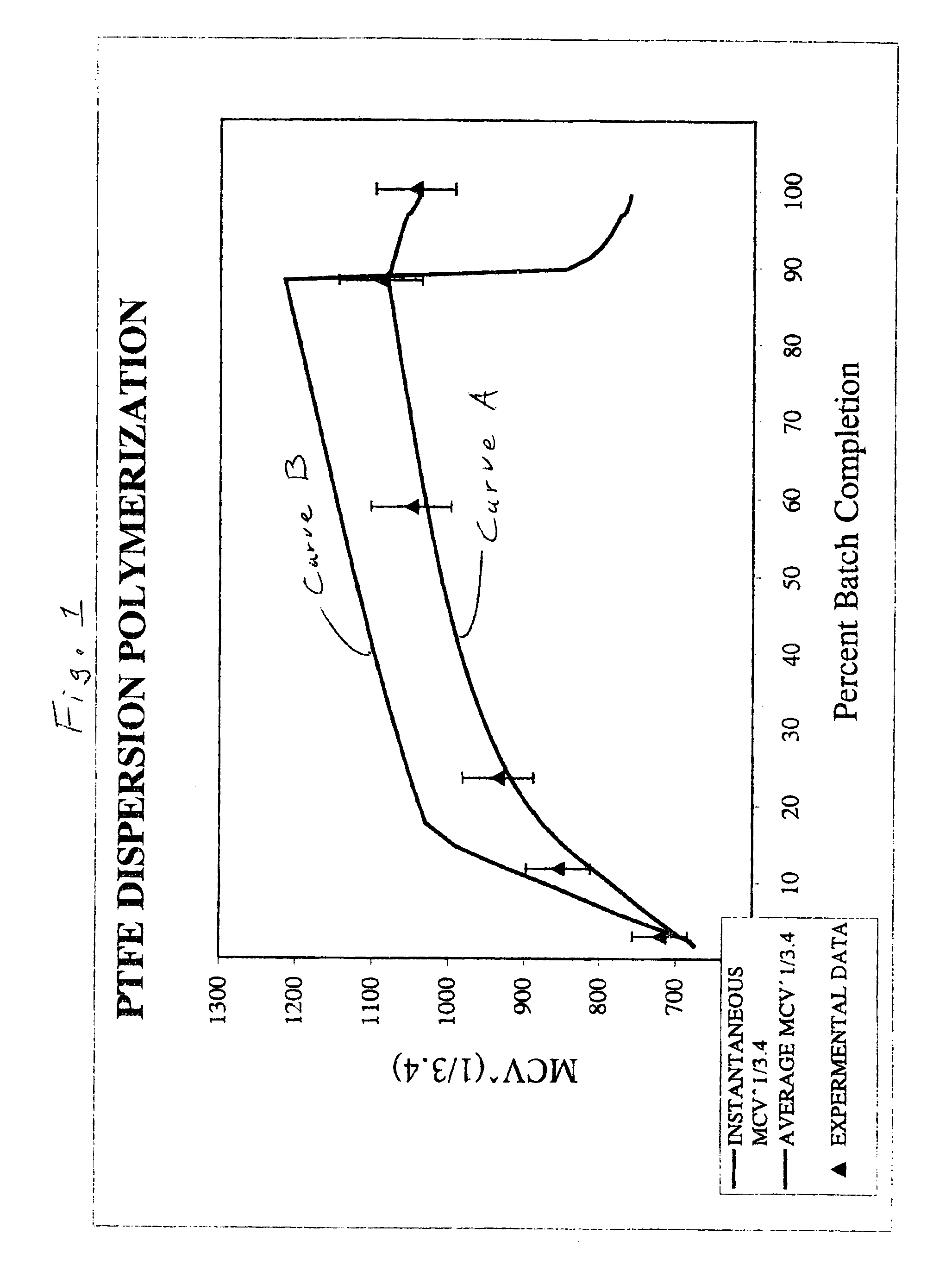

A dispersion of non-melt-processible fluoropolymer particles having an SSG of less than about 2.225 in aqueous medium. The fluoropolymer particles comprise a core of high molecular weight polytetrafluoroethylene having an average melt creep viscosity greater than about 1.5×1010 Pa·s and a shell of lower molecular weight polytetrafluoroethylene or modified polytetrafluoroethylene. The shell has an average melt creep viscosity greater than about 9×109 Pa·s and comprises about 5 to about 30% by weight of the particles. The fluoropolymer in the dispersion of the invention is fibrillating.

Owner:THE CHEMOURS CO FC LLC

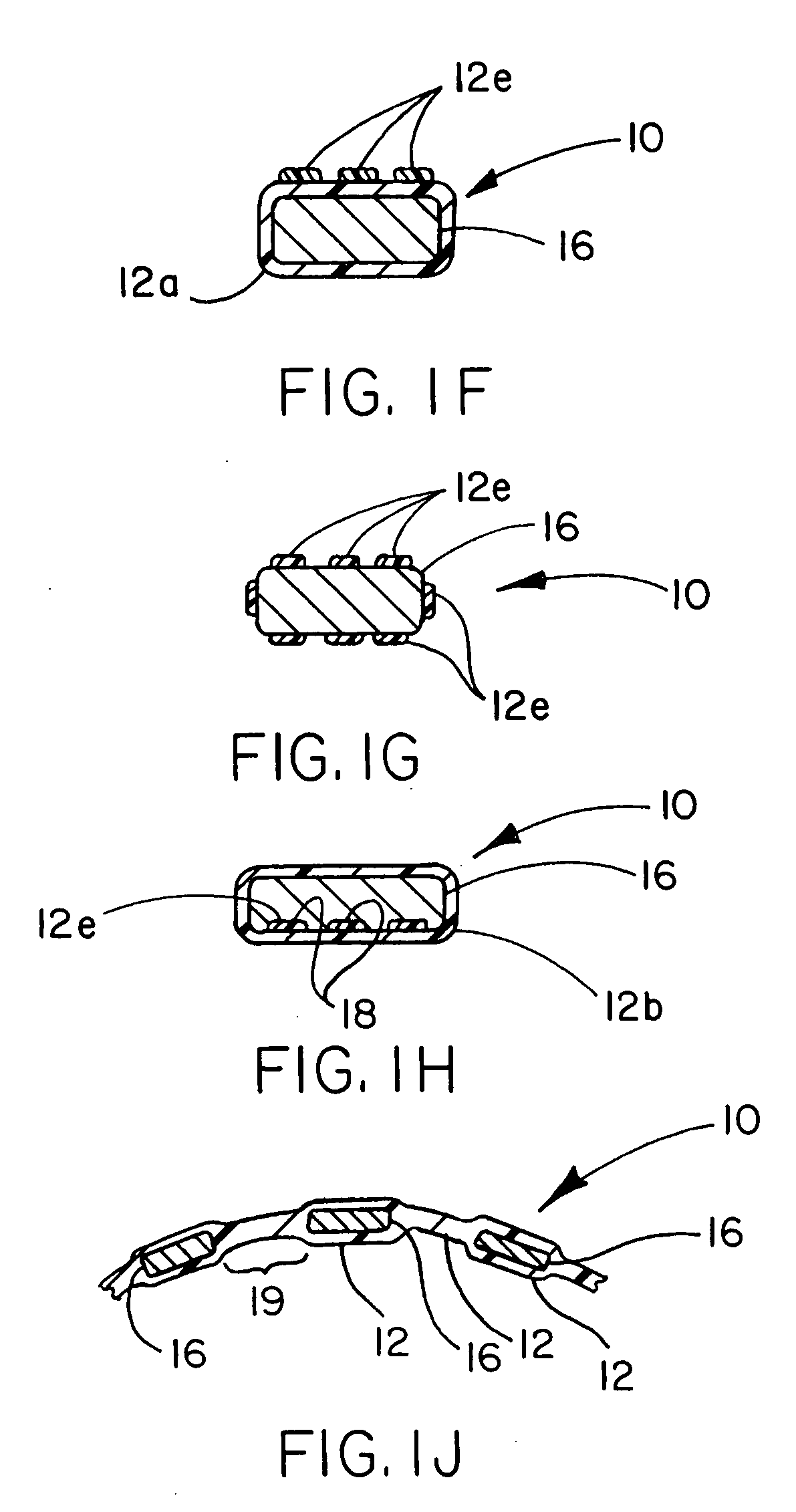

Thermoplastic fluoropolymer-coated medical devices

A medical device provided with at least a partial surface coating of a thermoplastic copolymer of tetrafluoroethylene and perfluoroalkylvinylether that is free of cross-linking monomers and curing agents. The fluoropolymer coating is preferably an amorphous thermoplastic, is highly inert and biocompatible, has elastomeric characteristics that provide desirable mechanical properties such as good flexibility and durability. These characteristics allow the coating to be considered “functionally transparent” because it withstands mechanical deformations required for the assembly, deployment, expansion, and placement of medical devices, without any adverse effect on the mechanical and biological functionality of the coated device. Further, its inertness, derived from the perfluorocarbon structure, contributes to its functionally transparent nature. The coating can be provided with various liquid or solid additives, can be loaded with large quantities of additives including a wide range of therapeutic agents, and has excellent drug elution characteristics when elutable additives are used. The desirable mechanical characteristics are surprising given the absence of cross-linking monomers and curing agents that would otherwise render such materials inadequately biocompatible. The perfluoroalkylvinylether may be perfluoromethylvinylether, perfluoroethylvinylether or perfluoropropylvinylether.

Owner:WL GORE & ASSOC INC

Aqueous tetrafluoroethylene polymer dispersion,process for producing the same, tetrafluoroethylene polymer powder,and molded tetrafluoroethylene polymer

InactiveUS20070060699A1Excellent in moldability/processabilityIncrease concentrationFibre treatmentTetrafluoroethylenePolymer science

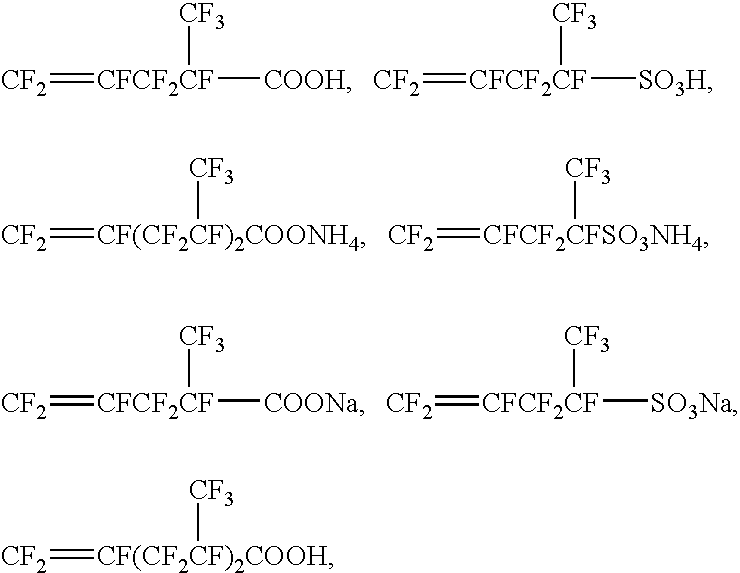

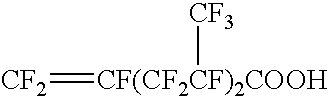

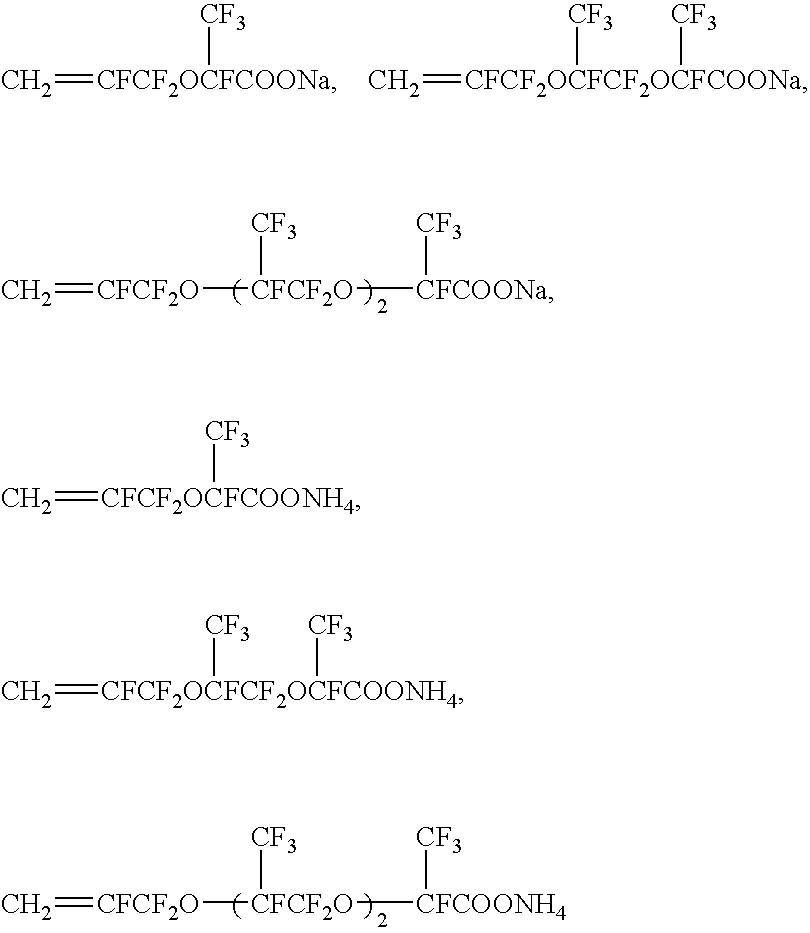

The present invention provides a tetrafluoroethylene polymer aqueous dispersion obtained by carrying out a TFE polymerization in an aqueous medium in the presence of a fluorovinyl group-containing emulsifier, wherein the TFE polymer aqueous dispersion contains a particle comprising a TFE polymer dispersed in the aqueous medium, the fluorovinyl group-containing emulsifier comprises a fluorovinyl group-containing compound, and the TFE polymer aqueous dispersion has a fluorine-containing surfactant content of not higher than 1000 ppm by mass.

Owner:DAIKIN IND LTD

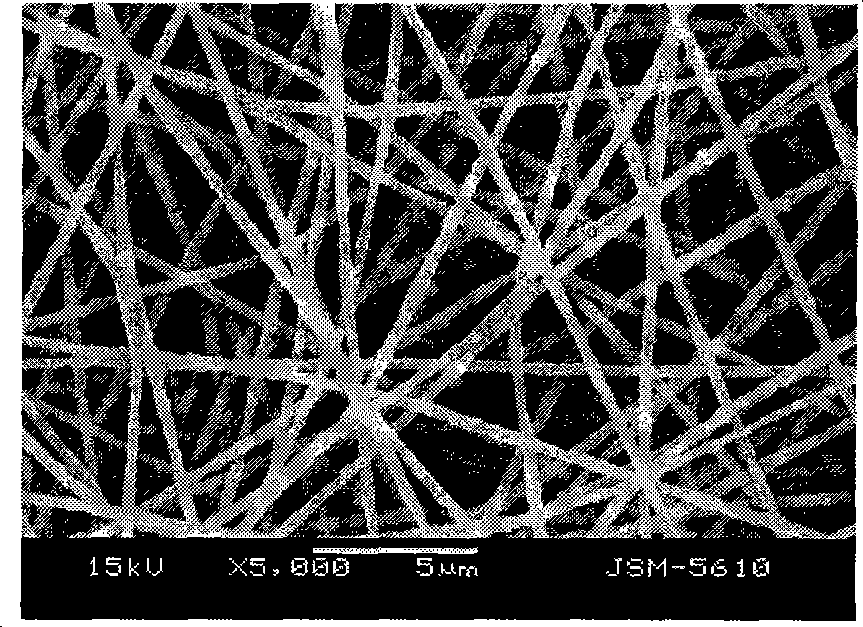

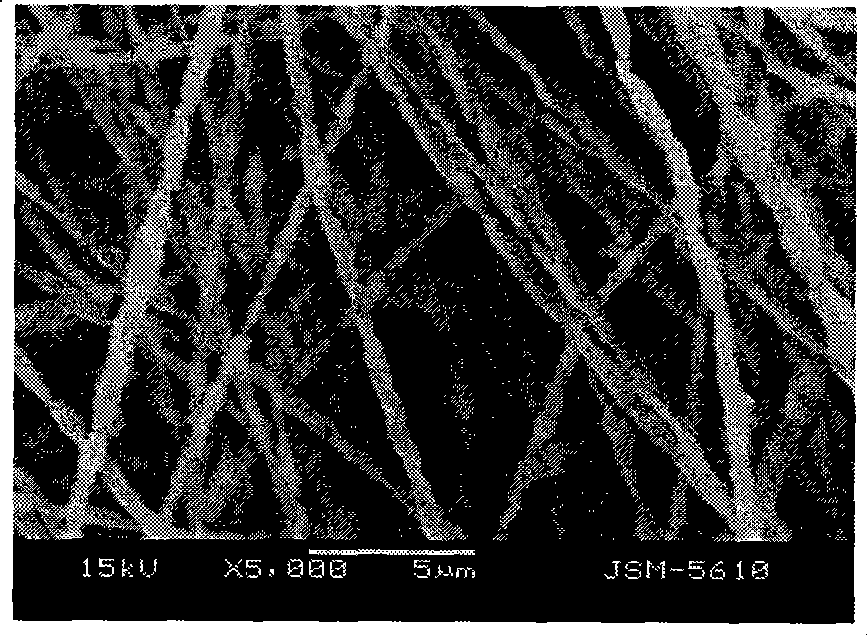

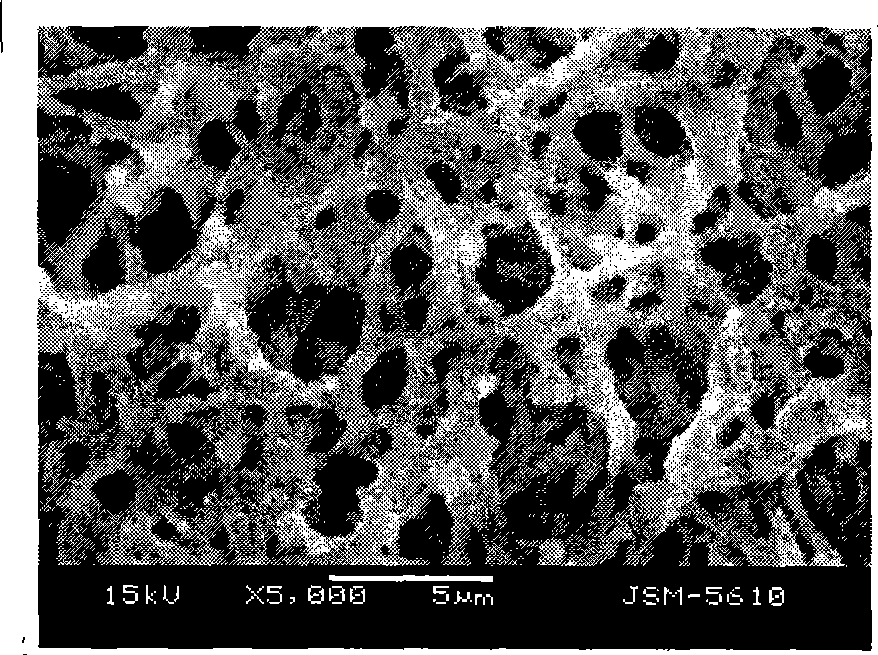

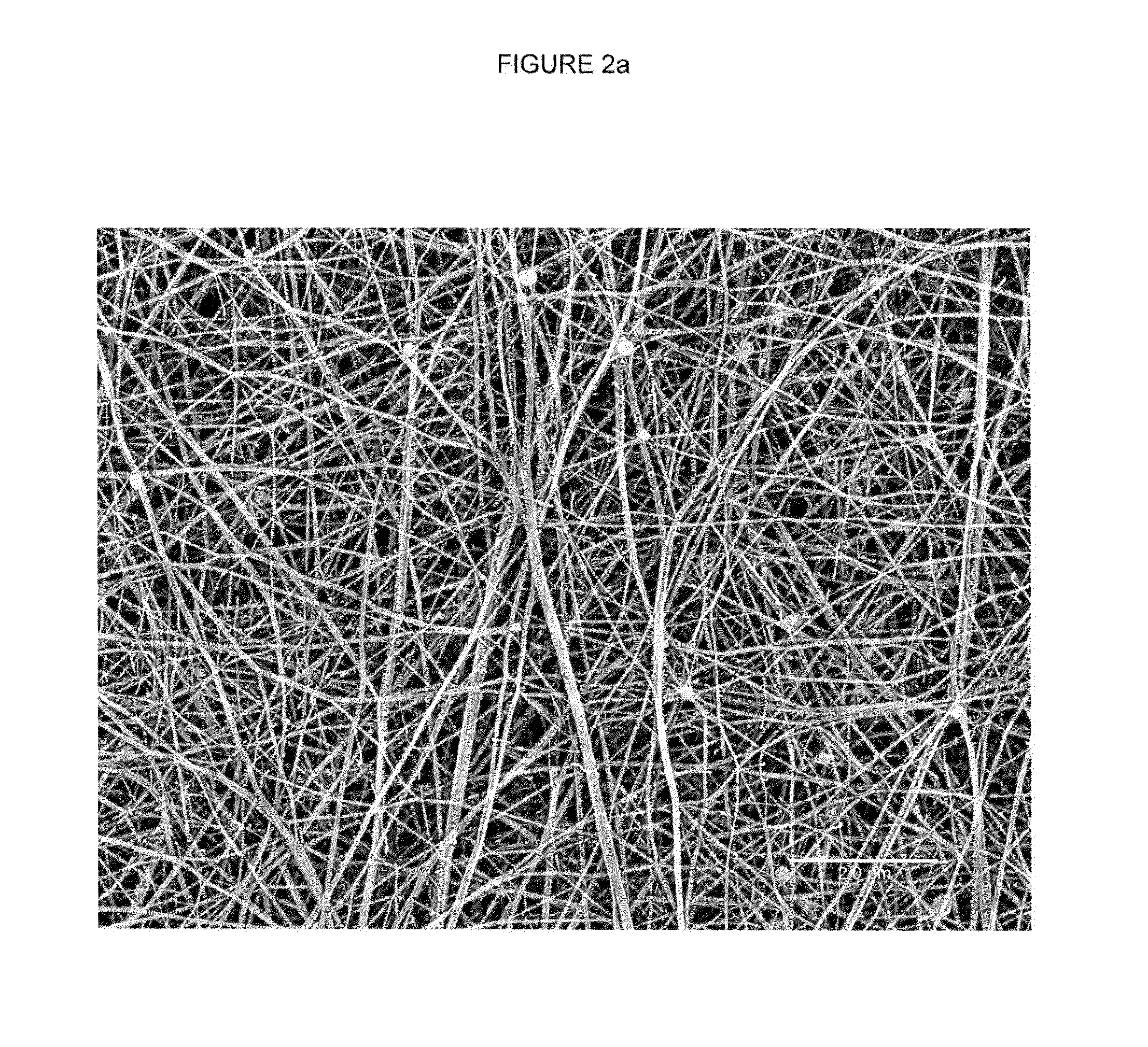

Preparation method of polytetrafluoroethylene superfine fiber porous membrane

InactiveCN101530750AUniform pore sizeHigh porositySemi-permeable membranesHigh concentrationVoid ratio

The invention discloses a preparation method of polytetrafluoroethylene superfine fiber porous membrane. In the method, high concentration polytetrafluoroethylene aqueous emulsion is mixed with matrix polymer uniformly to prepare spinning solution. With the effect of high voltage electric field, polytetrafluoroethylene / matrix polymer composite superfine fiber porous membrane with the diameter of 100 nm to 2 [mu]m is obtained by electrostatic spinning, and then polytetrafluoroethylene superfine fiber porous membrane is formed at the conditions of sintering temperature being 330 to 500 DEG C and the sintering time lasting 30s to 5min so that the aperture diameter is 100 nm to 10 [mu]m and the porosity is 50% to 80%. The polytetrafluoroethylene superfine fiber porous membrane prepared by using the method has uniform aperture diameter and high porosity, and can be widely applied to filter material. Compared with the existing technology, the preparation method has the characteristics of simple processing technology, short process and low cost.

Owner:ZHEJIANG SCI-TECH UNIV

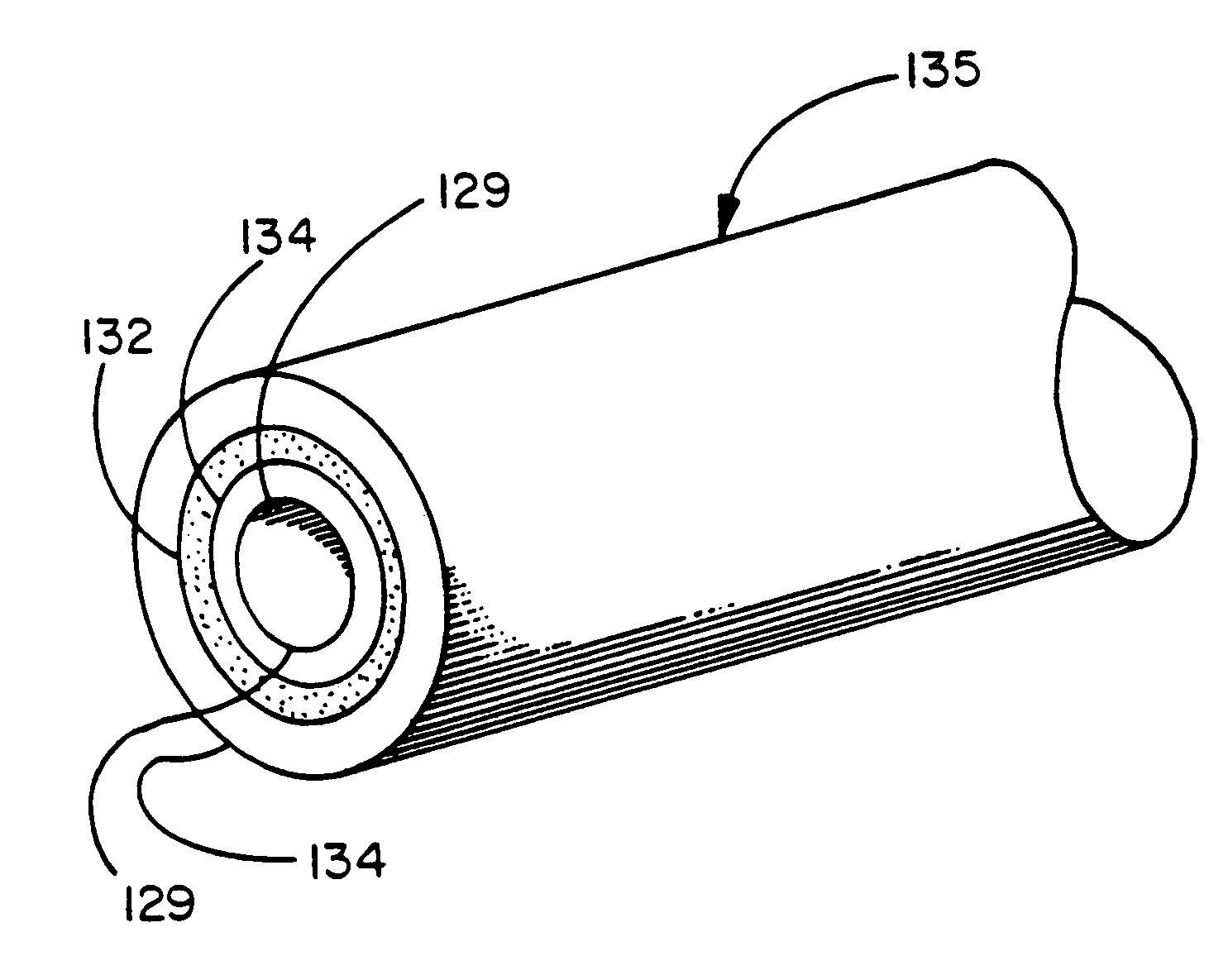

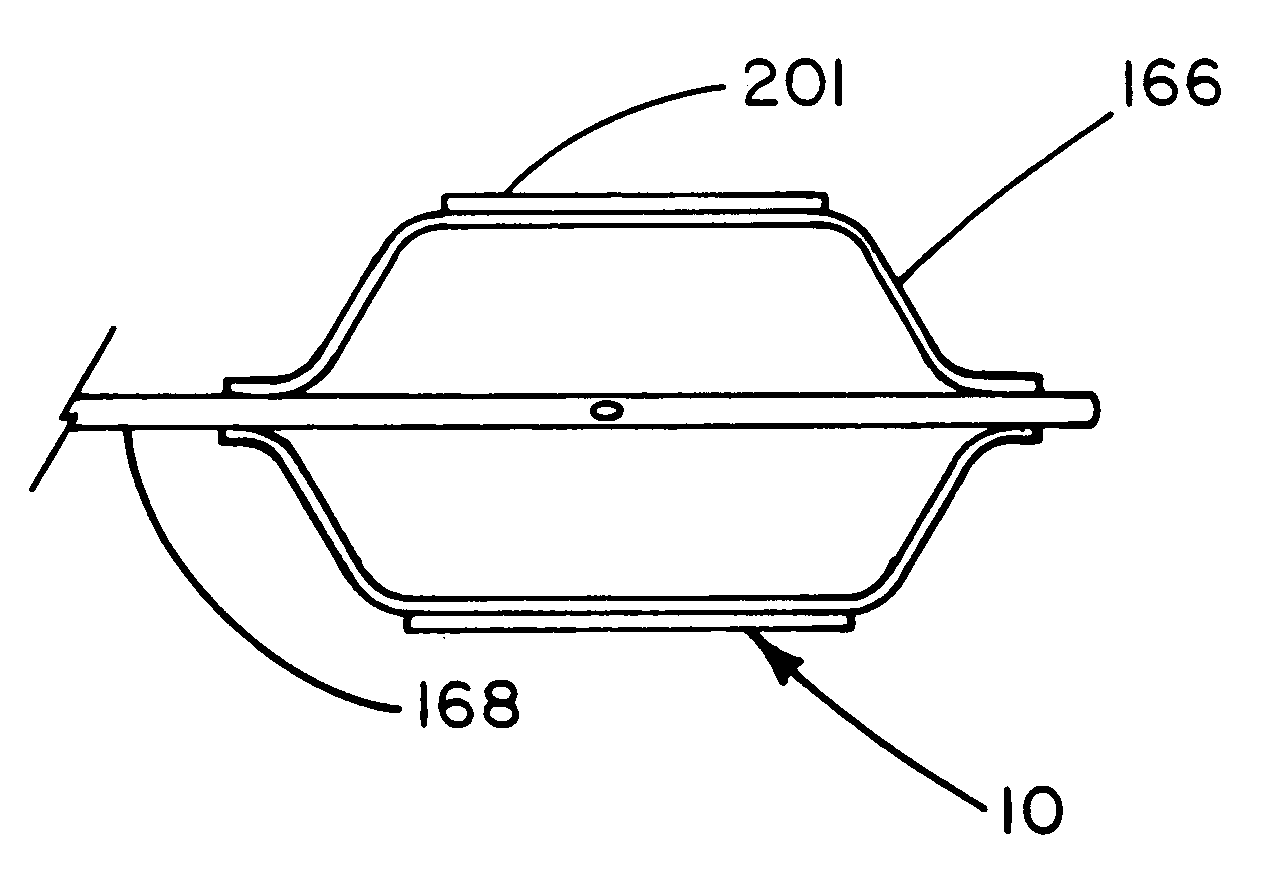

Catheter balloon formed of ePTFE and a diene polymer

InactiveUS6946173B2Improve performanceImprove adhesionEnvelopes/bags making machineryMouldsElastomerTetrafluoroethylene

A catheter balloon formed of a polymeric material such as expanded polytetrafluoroethylene (ePTFE) bonded to a second layer formed of a low tensile set polymer and / or impregnated with a low tensile set polymer. In a presently preferred embodiment, the low tensile set polymer is a silicone-polyurethane copolymer elastomer or a diene polymer elastomer. The low tensile set polymer has high strength, low modulus, high elongation, and low tensile set. The diene or silicone-polyurethane has a low tensile set, which facilitates deflation of the balloon to a low profile deflated configuration. One aspect of the invention provides improved attachment of the diene to the ePTFE. In one embodiment, the second layer is formed of a diene mixed with a bonding promoter such as a vulcanizing agent which is covalently bonded to the diene.

Owner:ABBOTT CARDIOVASCULAR

Thin-wall polytetrafluoroethylene tube

A thin-wall PTFE (polytetrafluoroethylene) tube in the form of a tube of porous expanded PTFE film wherein the porous PTFE film has a microstructure containing a multiplicity of fibrils. The thin-wall tube is used in a non-porous embodiment as the balloon portion of a balloon catheter. The thin-wall tube is not elastomeric; however, because of the thinness, strength and flexibility of the tube, it may be inserted into a body conduit in a collapsed state and then deployed from a catheter and inflated up to the maximum diameter of the thin-wall tube. The porous PTFE film is provided with a continuous layer of adhesive to provide the non-porous tube; the adhesive is preferably a thermoplastic and more preferably a thermoplastic fluoropolymer such as fluorinated ethylene propylene.

Owner:GORE ENTERPRISE HLDG INC

Thermoplastic fluoropolymer-coated medical devices

A medical device provided with at least a partial surface coating of a thermoplastic copolymer of tetrafluoroethylene and perfluoroalkylvinylether that is free of cross-linking monomers and curing agents. The fluoropolymer coating is preferably an amorphous thermoplastic, is highly inert and biocompatible, has elastomeric characteristics that provide desirable mechanical properties such as good flexibility and durability. These characteristics allow the coating to be considered “functionally transparent” because it withstands mechanical deformations required for the assembly, deployment, expansion, and placement of medical devices, without any adverse effect on the mechanical and biological functionality of the coated device. Further, its inertness, derived from the perfluorocarbon structure, contributes to its functionally transparent nature. The coating can be provided with various liquid or solid additives, can be loaded with large quantities of additives including a wide range of therapeutic agents, and has excellent drug elution characteristics when elutable additives are used. The desirable mechanical characteristics are surprising given the absence of cross-linking monomers and curing agents that would otherwise render such materials inadequately biocompatible. The perfluoroalkylvinylether may be perfluoromethylvinylether, perfluoroethylvinylether or perfluoropropylvinylether.

Owner:WL GORE & ASSOC INC

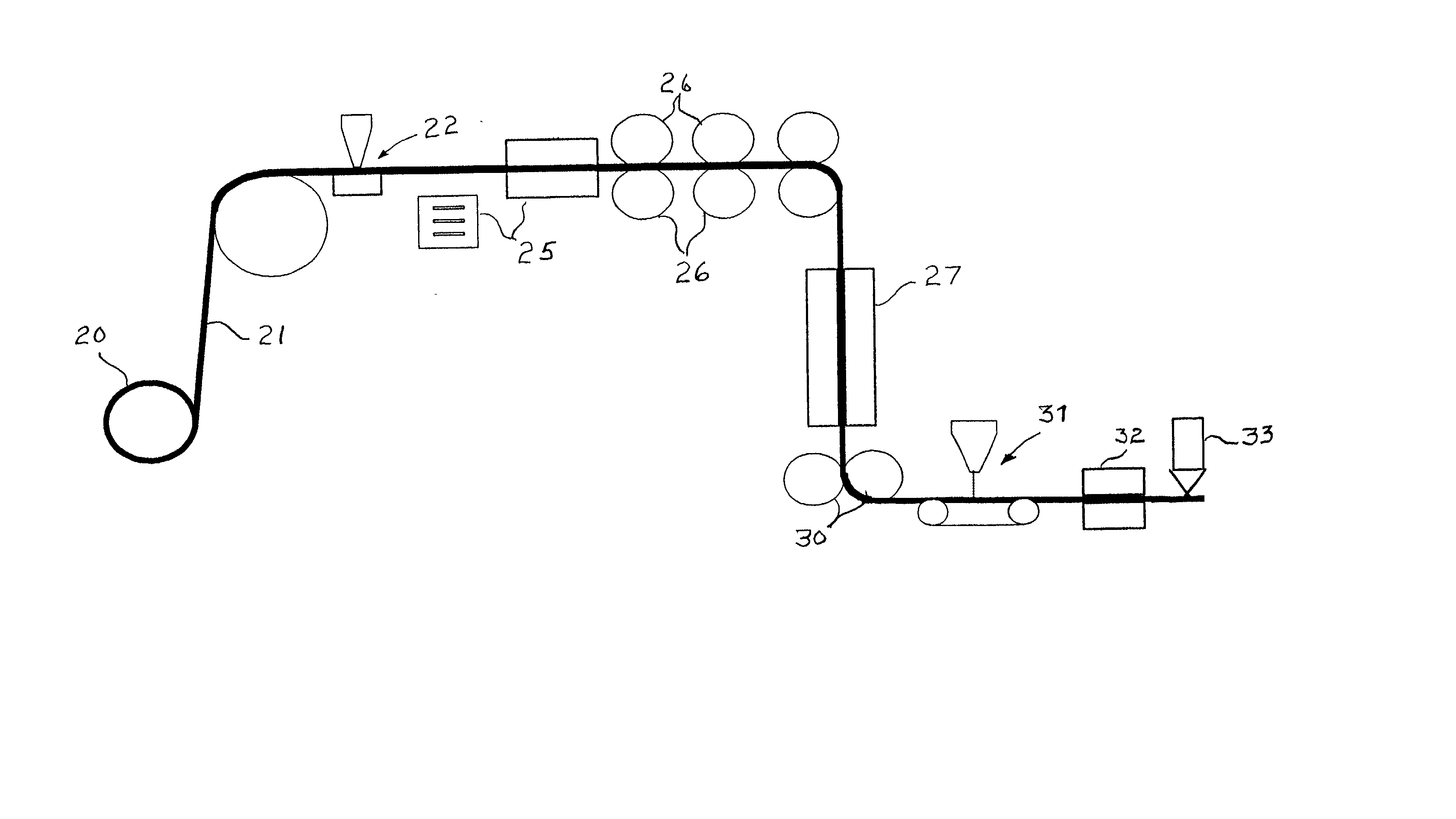

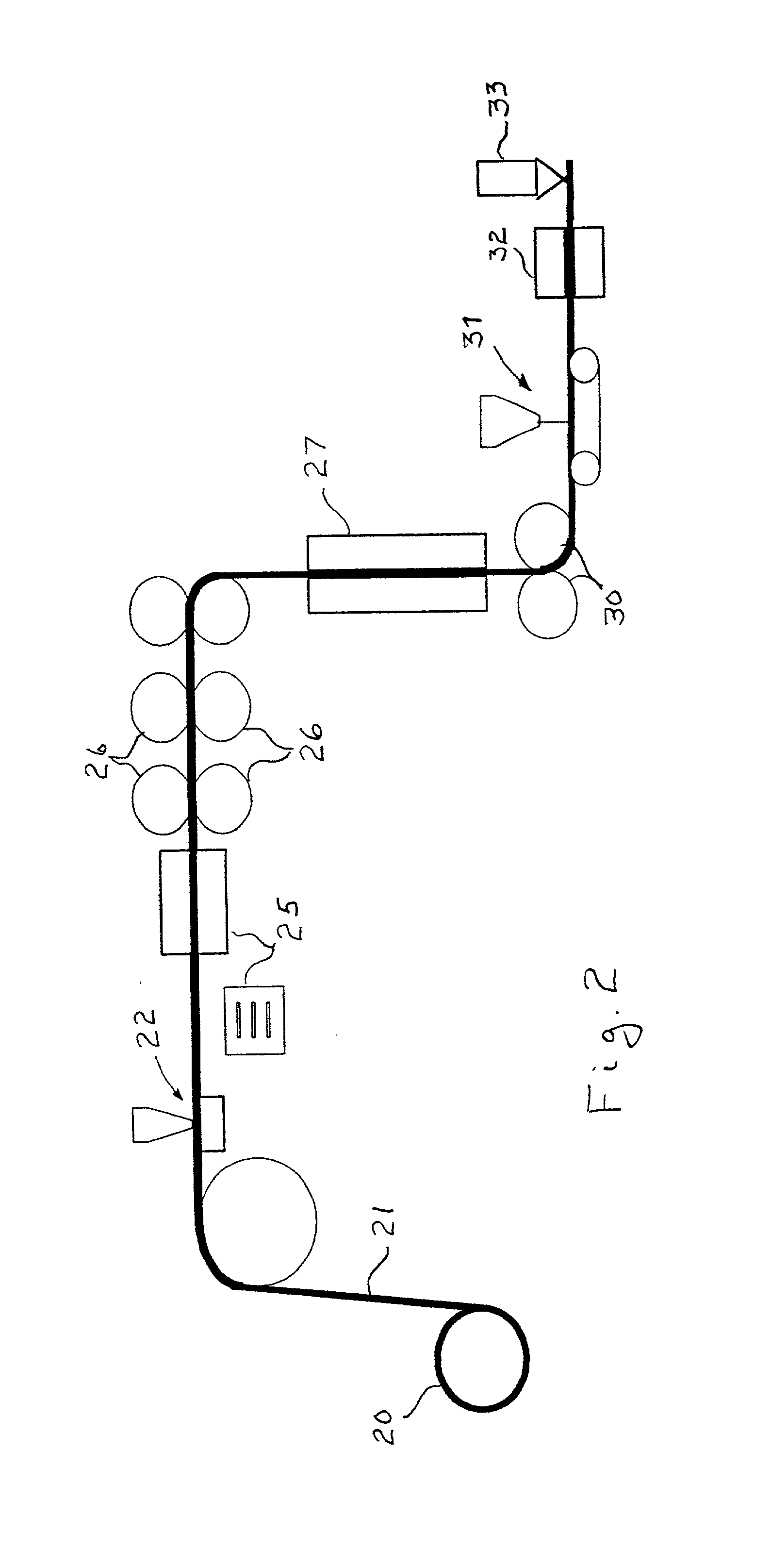

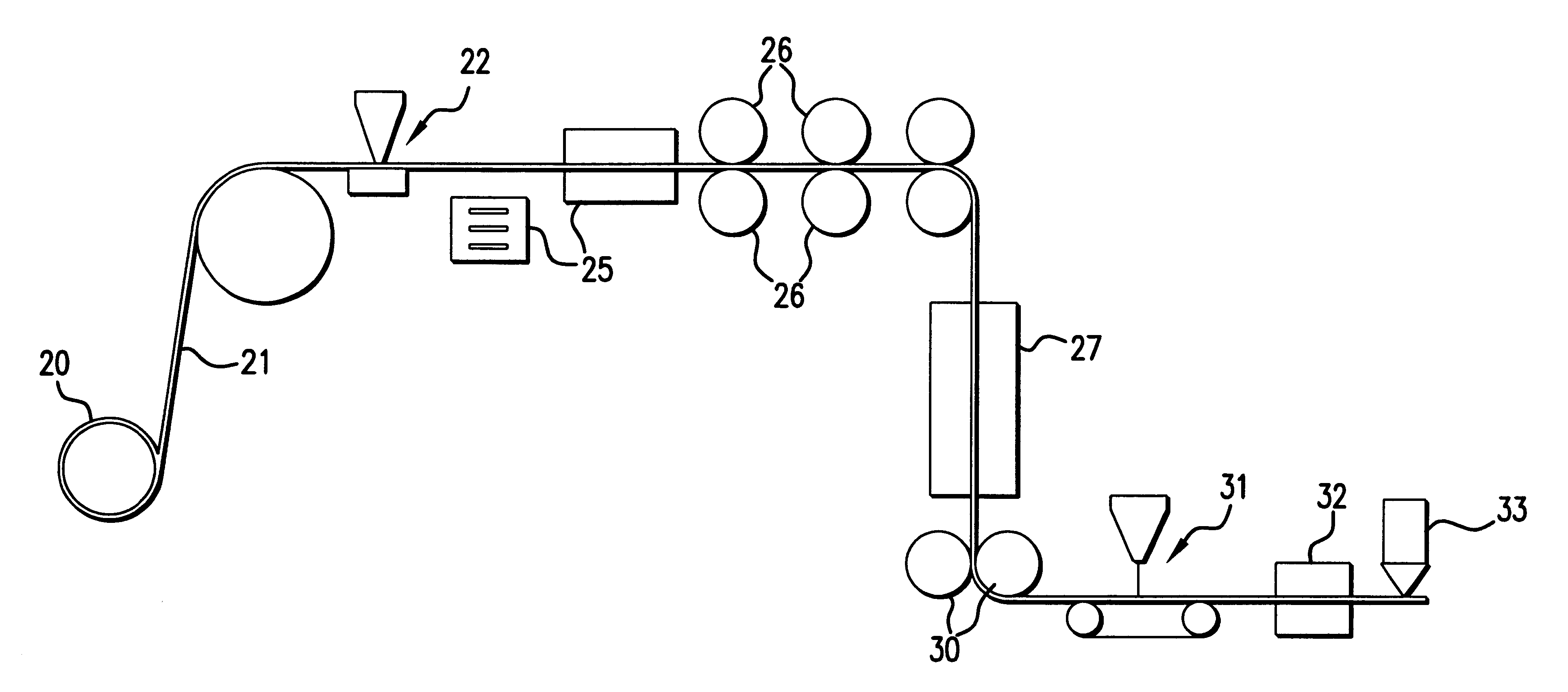

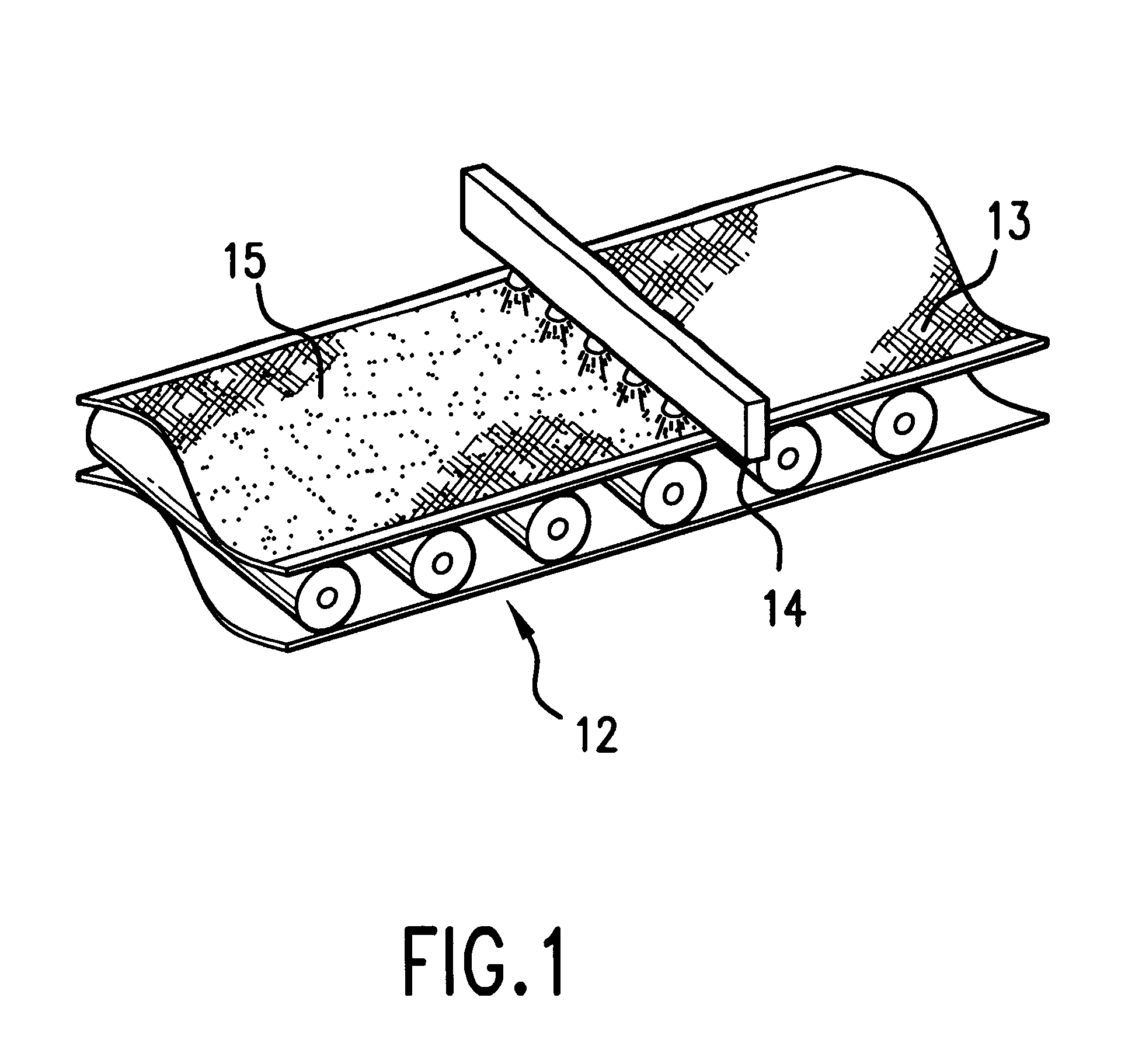

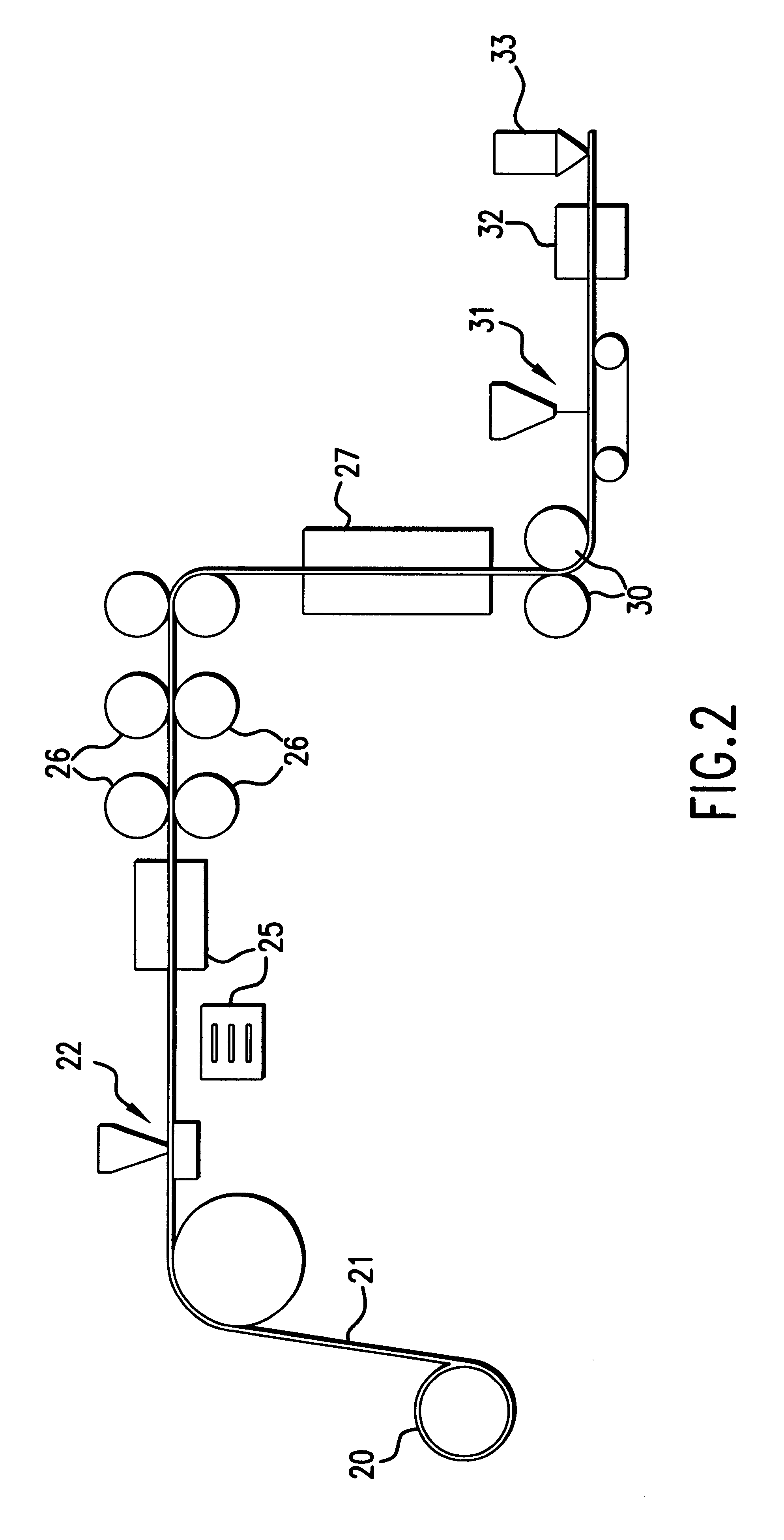

Gas diffusion electrode manufacture and MEA fabrication

InactiveUS20020134501A1Final product manufactureAdhesive processes with surface pretreatmentTetrafluoroethyleneEmulsion

A method for producing a gas diffusion electrode in which a slurry of carbon black, alcohol, water and a tetrafluoroethylene emulsion is applied as a layer a non-Teflonized carbon cloth substrate, which is then heated to remove water. The dried coated carbon cloth is then rolled followed by heating to remove wetting agents present in the tetrafluoroethylene emulsion. The coated carbon cloth is then cooled and rolled again to produce the final end product.

Owner:GAS TECH INST

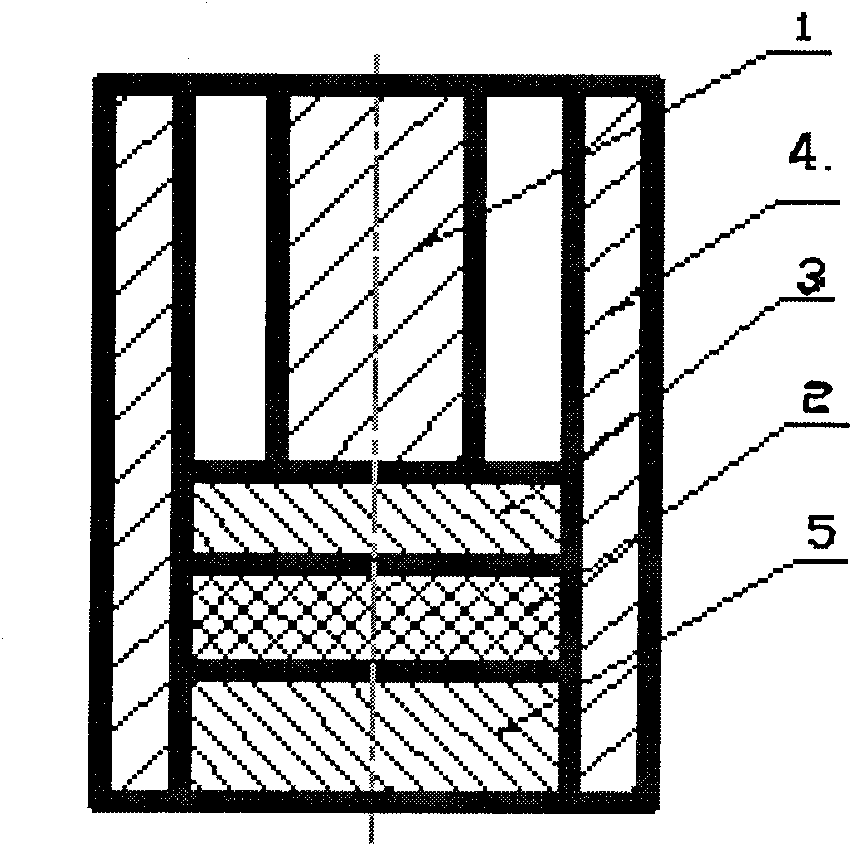

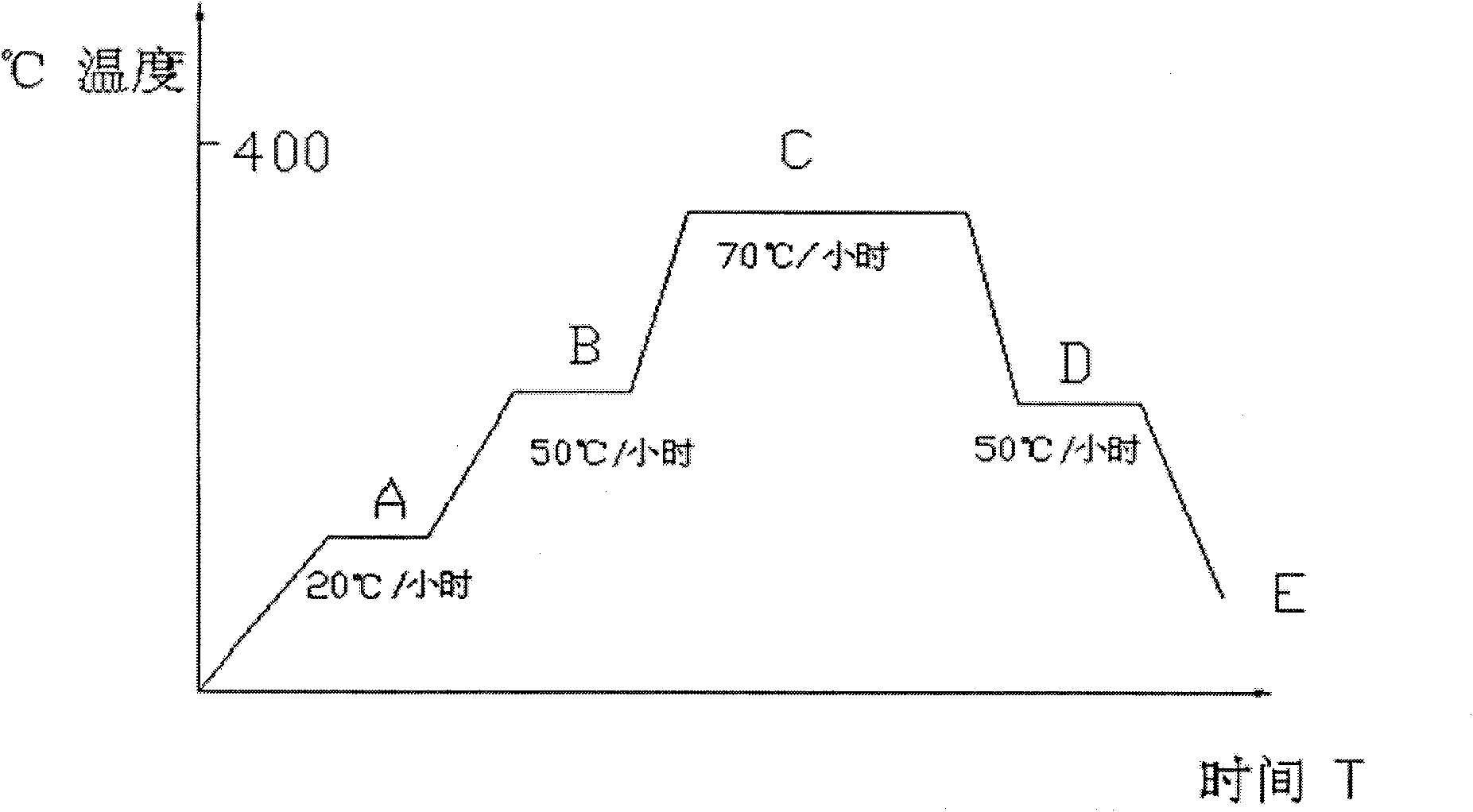

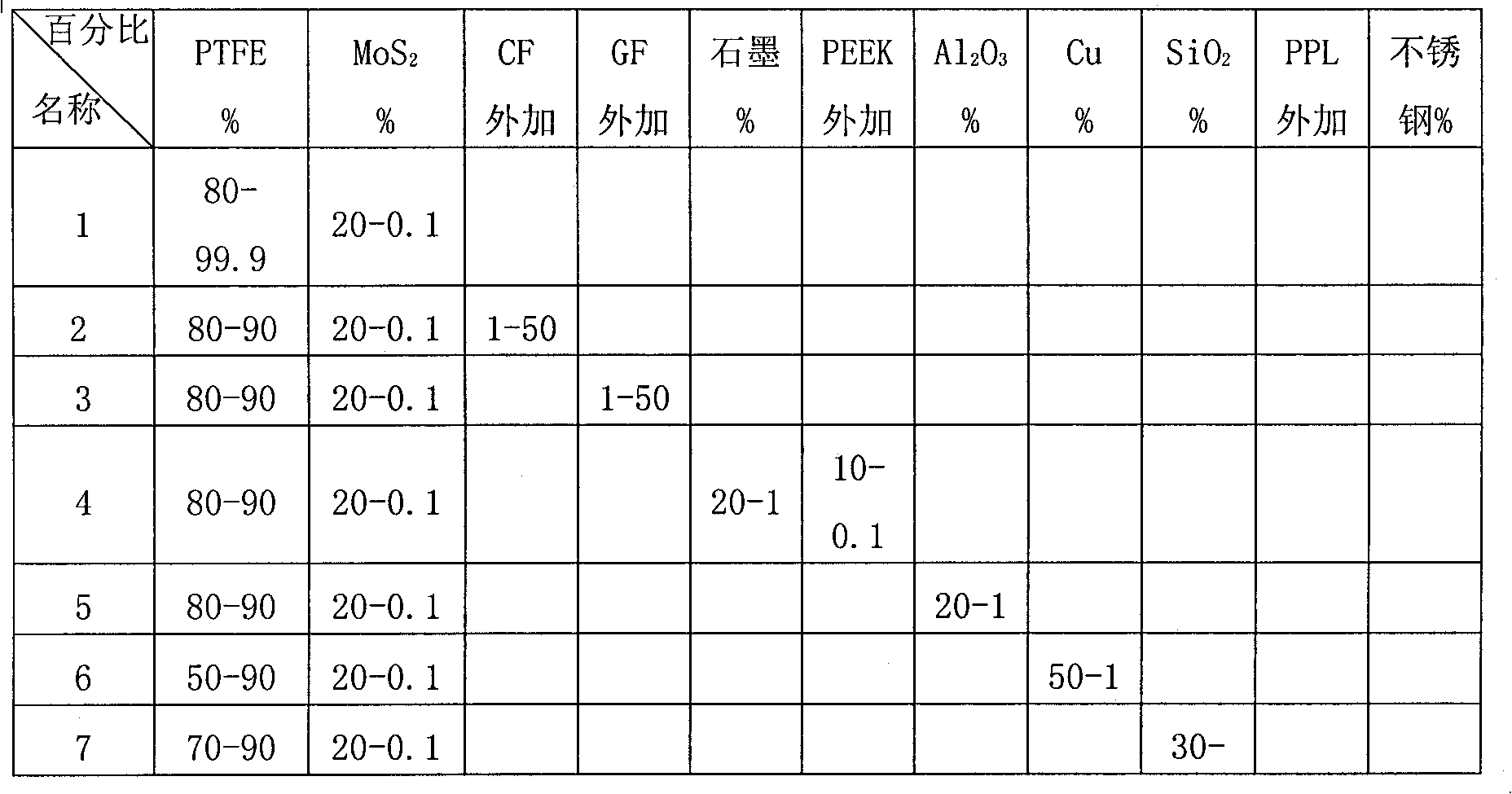

Polytetrafluoroethylene composite material and product preparation method thereof

ActiveCN101775186AImprove thermal conductivityImproved ball compressive strengthFiberTetrafluoroethylene

The invention discloses a polytetrafluoroethylene composite material, which comprises one or more of molybdenum disulfide, aluminum sesquioxide, copper powder, graphite, silicon dioxide and stainless steel powder and polytetrafluoroethylene, wherein the polytetrafluoroethylene composite material is a binary polytetrafluoroethylene composite material, which comprises 80 to 99.9 weight percent of the polytetrafluoroethylene, and the balance of other components. A product preparation method for the material comprises the following steps: compounding the materials of polytetrafluoroethylene (PTFE), molybdenum disulfide (MoS2), aluminium oxide (Al2O3), Cu powder, silicon dioxide (SiO2), polyphenylester (PPL), stainless steel powder, carbon fiber (CF), glass fiber (GF) and the like, molding the materials by a mold pressing sintering method, and then mechanically machining the materials to form an L-shaped sealing element.

Owner:NANJING COMPTECH MATERIALS

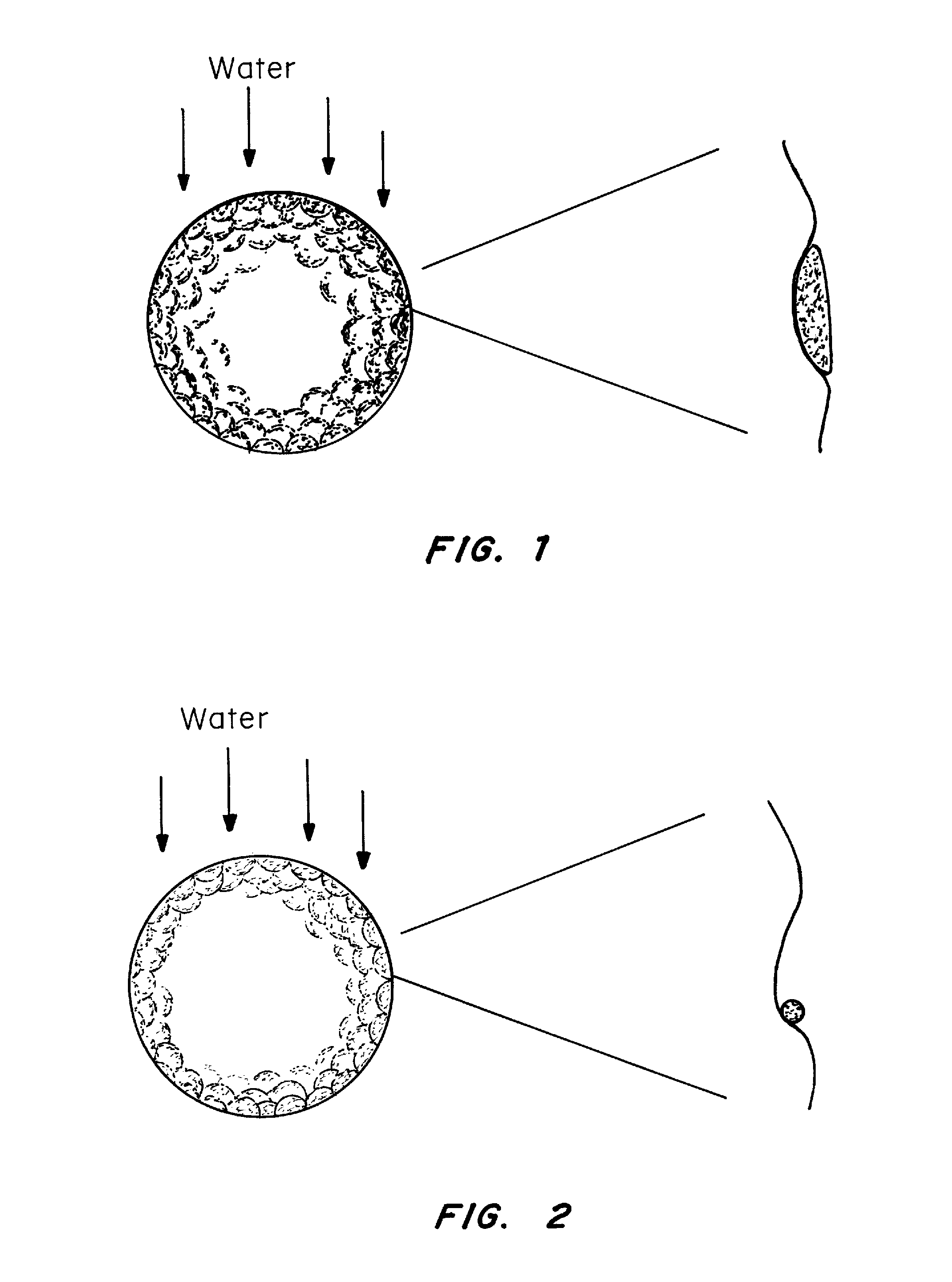

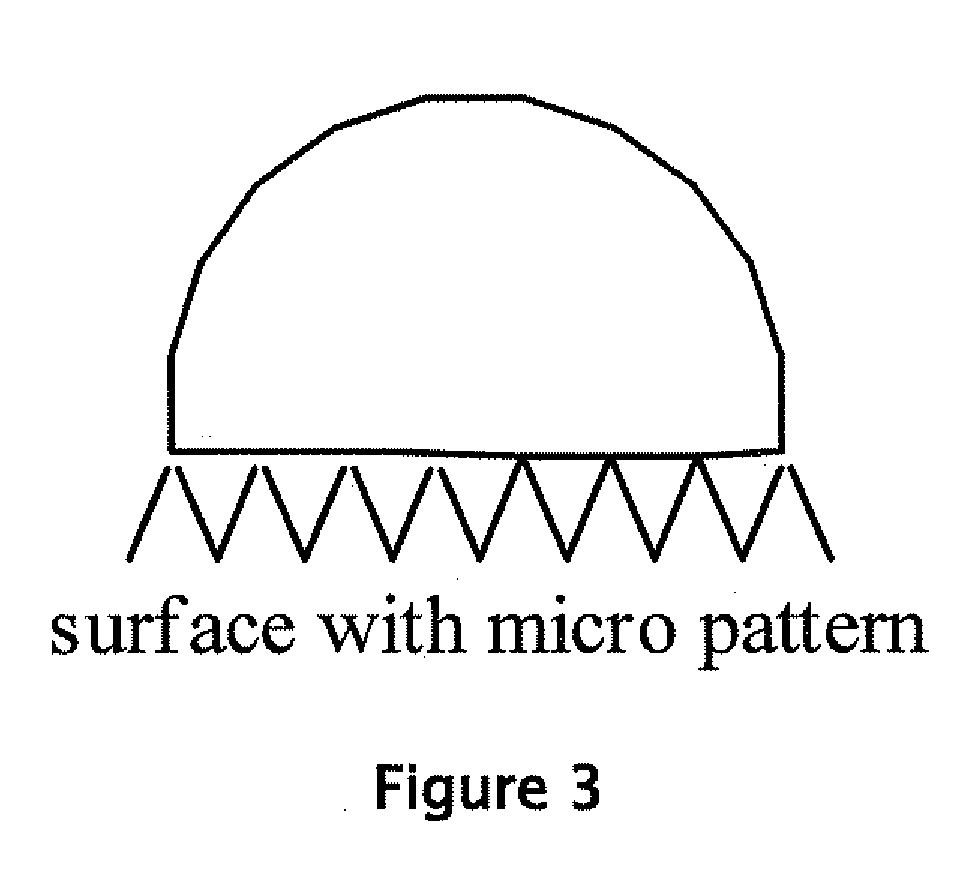

Water Repellant Golf Balls Containing a Hydrophobic or Superhydrophobic Outer Layer or Coating

InactiveUS20080280699A1Improve performanceSynthetic resin layered productsPaper coatingPolymer sciencePolyethylene glycol

Water-repellant, self-cleaning coatings and methods of making and using thereof are described herein. In one embodiment, a hydrophobic or super hydrophobic coating is applied to the surface of a golf ball to make the golf-ball water-repellant and self-cleaning. Suitable coating materials include silicone compounds, silicone compounds, nanoparticles, silanes, fluorocarbon polymers, perfluoroalkyl ethyl methacrylate (PPFEMA) coated polycaprolactone, hydrocarbons, polymer mats made of polystyrene and poly[tetrafluoroethylene-co-(vinylidene fluoride)-co-propylene] (PTVFP); polyethylene glycol with glucose and sucrose in conjunction with a hydrophobic substance; combinations of nanoparticles with polyethylene or polypropylene; high density polyethylene, technical waxes; films of rough particles of metal oxides, polymer binder layers containing a plurality of porous protrusions, and combinations thereof. Suitable coating techniques include, but are not limited to, spraying, dipping, painting, brushing, or wiping (such as applying the coating from a towel or sponge). The coating material or the outer layer of the golf ball may be modified to create nano- or micro roughness or patterns on the surface of the golf ball, which can induce the lotus effect. This roughness or pattern can be created using a variety of techniques known in the art including, but not limited to, etching, top / down methodologies, bottom / up methodologies, or combinations thereof.

Owner:JARVHOLM ERIK JONAS

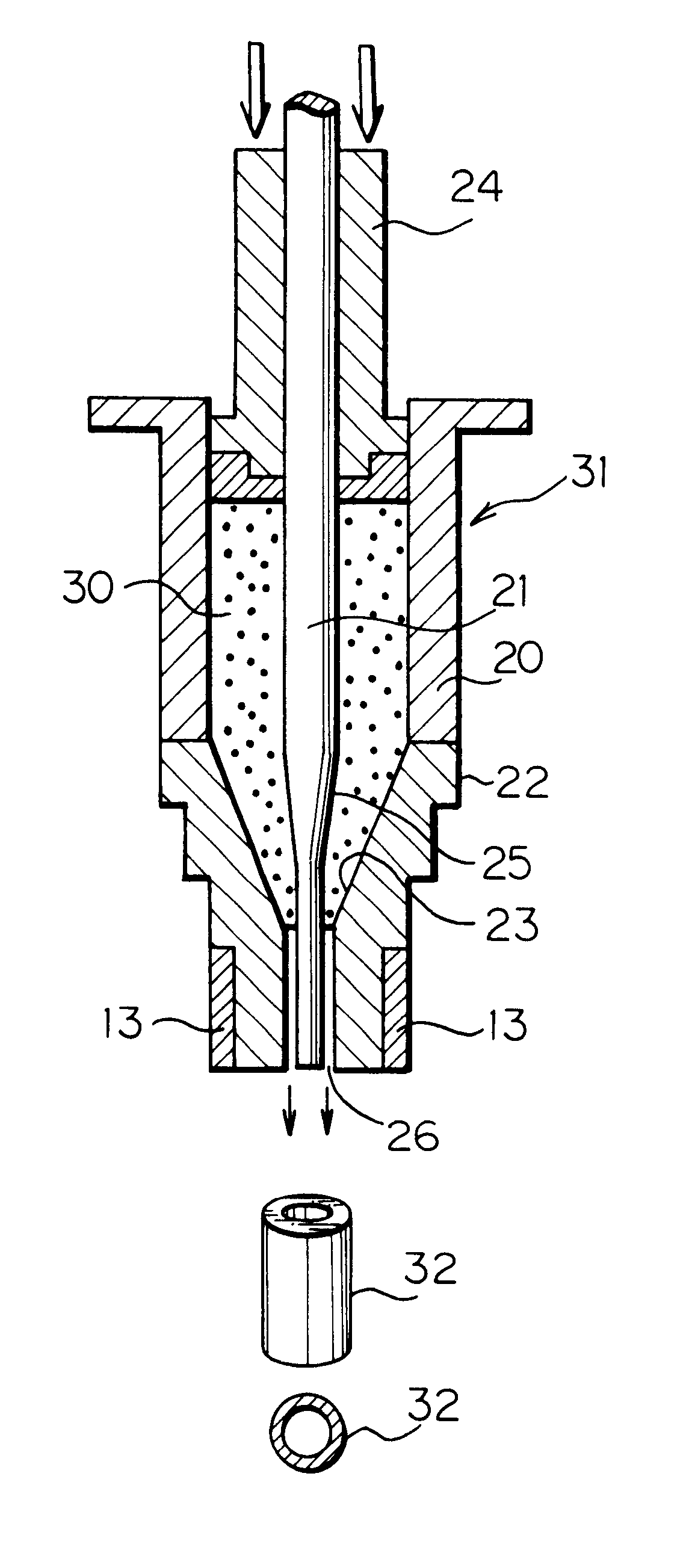

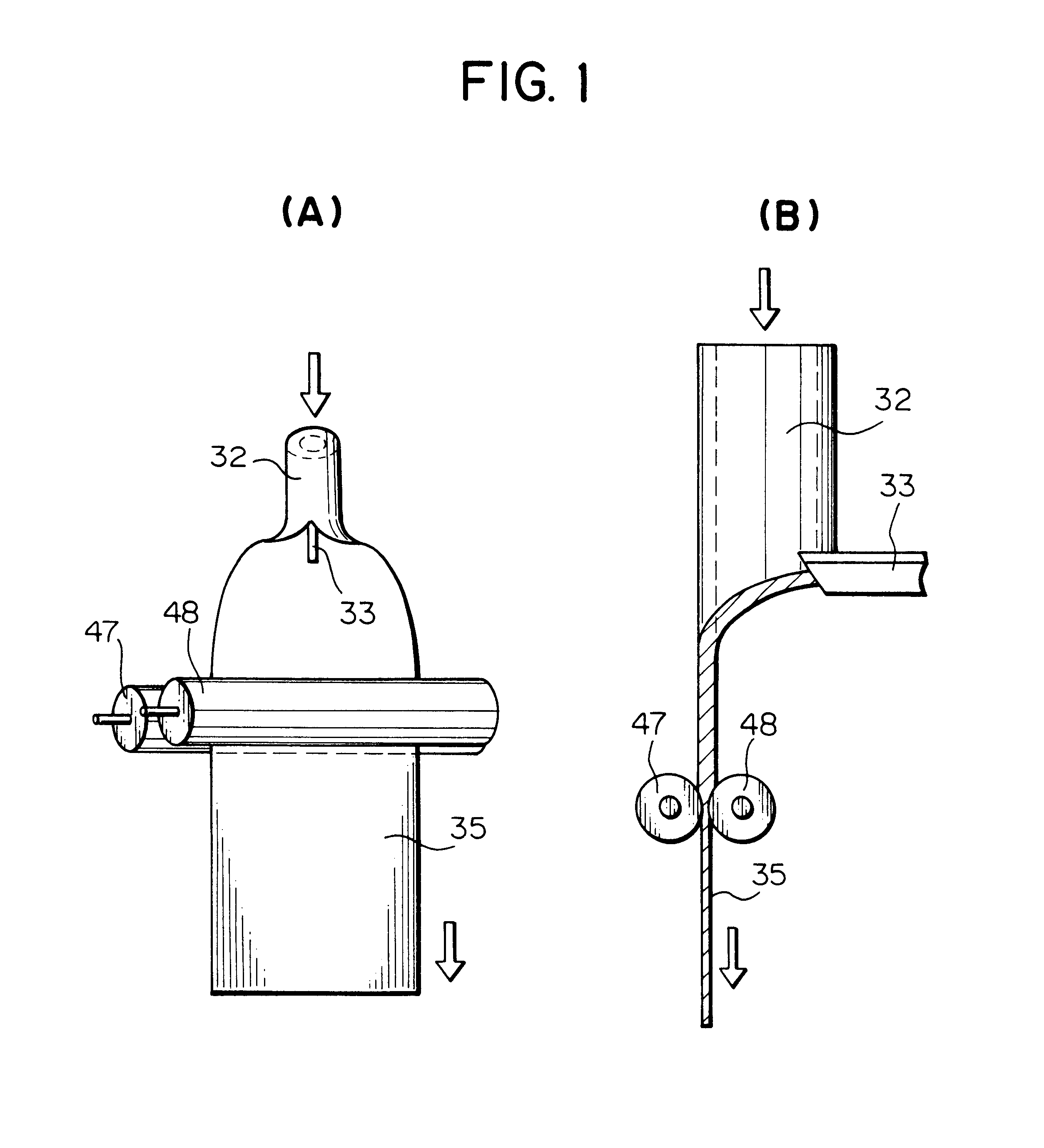

Manufacturing method of a highly conductive polytetrafluoroethylene sheet

InactiveUS6270707B1Electrode manufacturing processesActive material electrodesTetrafluoroethyleneMaterials science

This invention concerns a method of manufacturing a highly conductive polytetrafluoroethylene sheet; a method of manufacturing a highly conductive unsintered polytetrafluoroethylene sheet: and a method of manufacturing a highly conductive sintered sheet. In the first method, a paste of polytetrafluoroethylene powder admixed with conductive substance and extrusion lubricant is extruded to preform an unsintered tube-like material, and at least one place on the circumference of this extruded material, the material is cut open longitudinally and the resulting sheet is calendered if necessary. The second method includes a sintering process for the sheet. This invention also concerns a highly conductive polytetrafluoroethylene sheet having a wide-width and long-length, which is obtained by the above-mentioned method. This sheet is not less than 170 mm in width and has variance of volume resistivity (conductivity) in the longitudinal direction, 10% or less, preferably 7% or less in the cross direction. This invention can provide a highly conductive wide-type PTFE sheet whose conductivity in the longitudinal direction is nearly uniform in the cross direction.

Owner:DAIKIN IND LTD

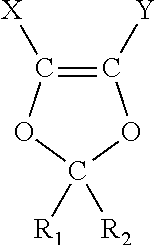

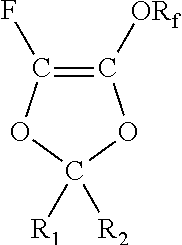

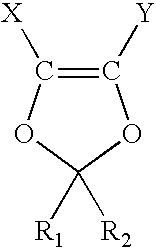

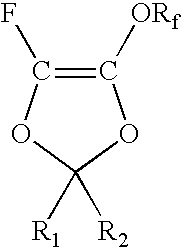

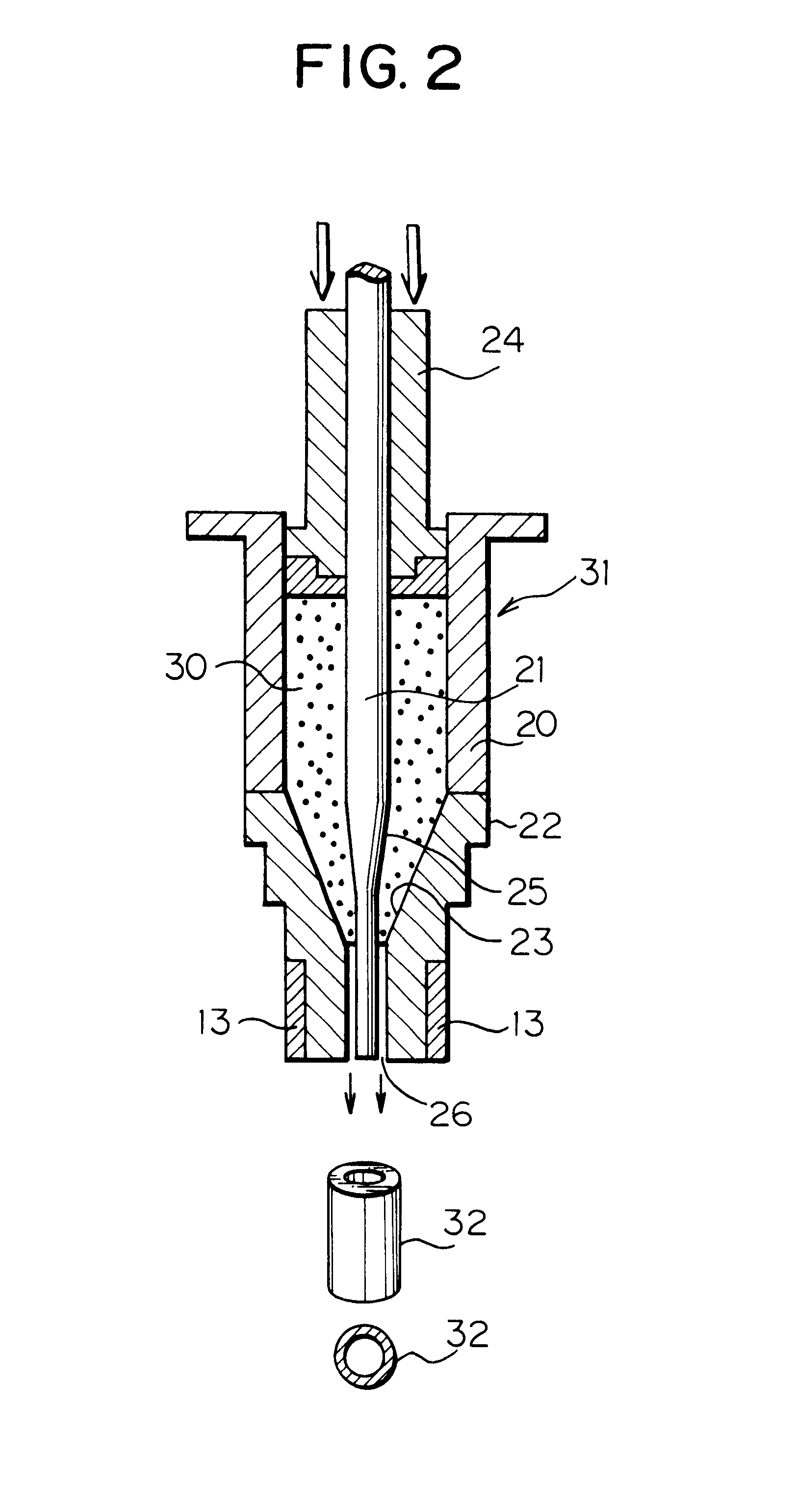

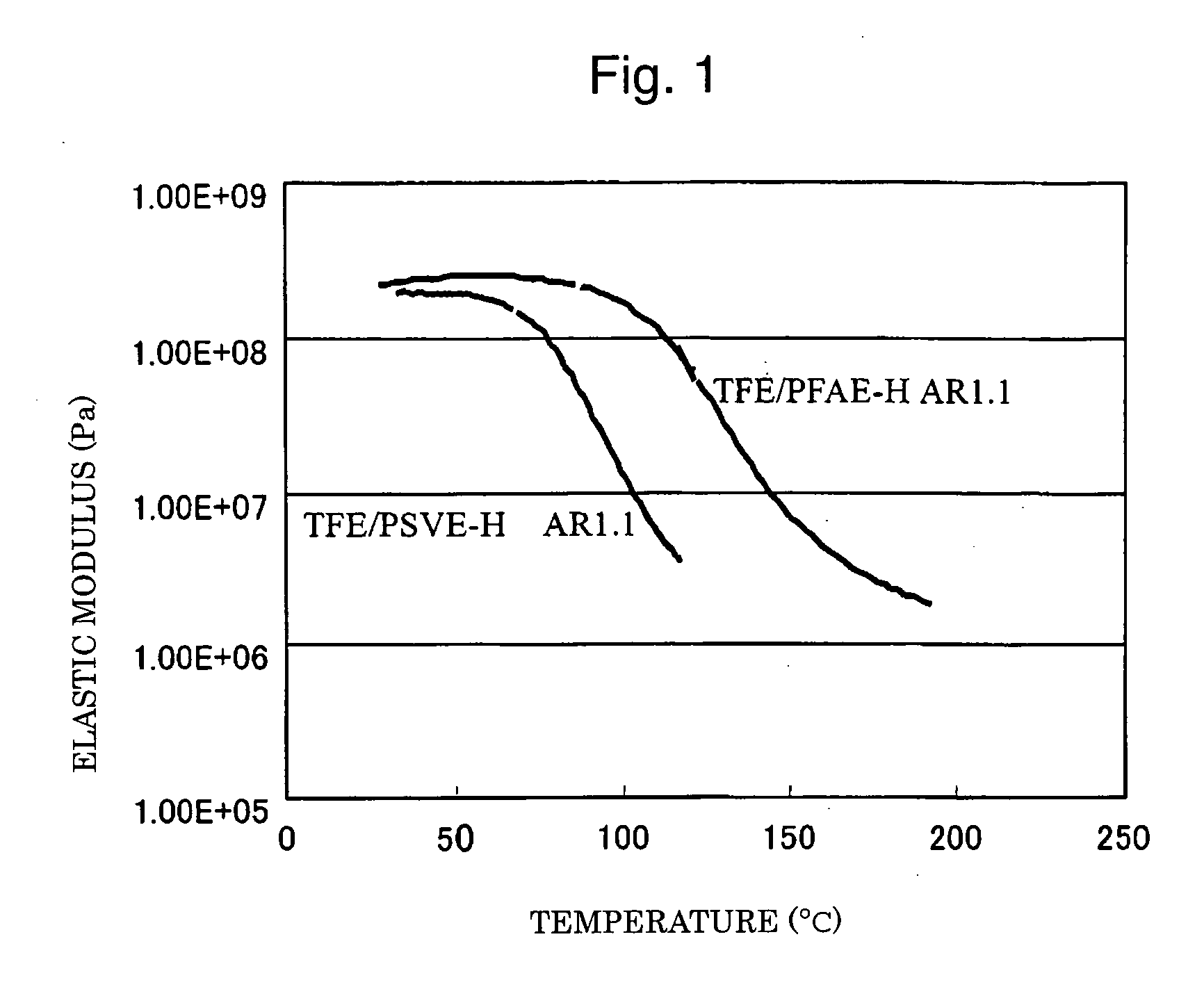

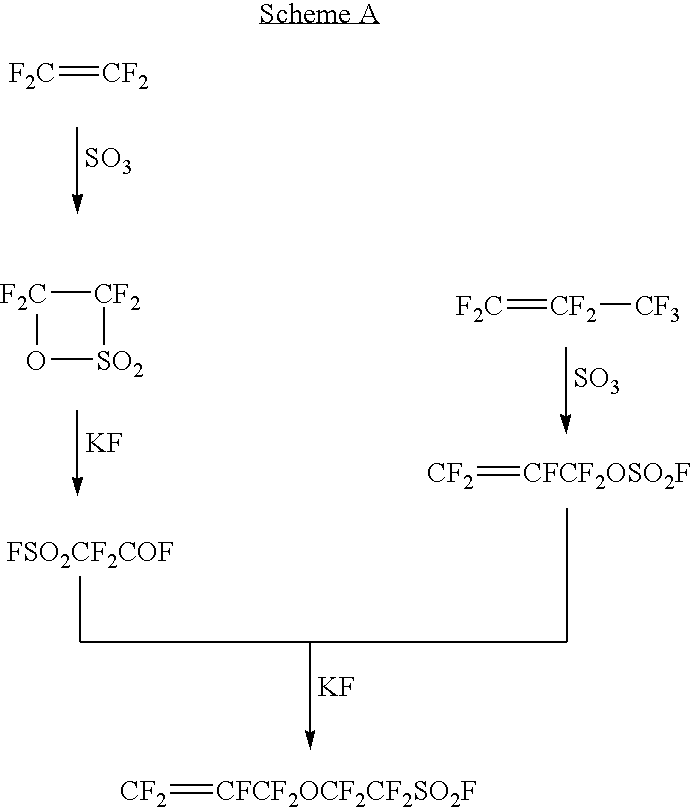

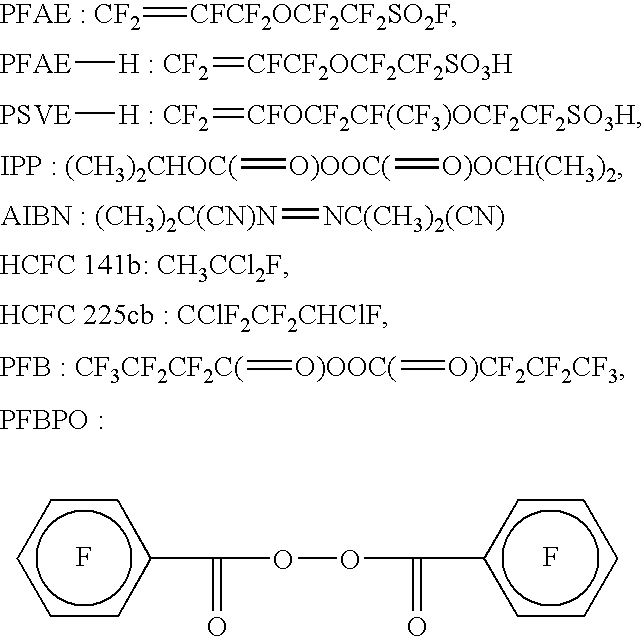

Polymer electrolyte fuel cell, electrolyte material therefore and method for its production

InactiveUS20050037265A1Easy to synthesizeSufficient molecular weightSolid electrolytesCell electrodesTetrafluoroethyleneFuel cells

An electrolyte material for a polymer electrolyte fuel cell, which is made of a copolymer comprising repeating units based on CF2═CFCF2OCF2CF2SO3H and repeating units based on tetrafluoroethylene and which has an ion exchange capacity of from 0.9 to 1.5 (meq / g dry resin). This electrolyte material has ion conductivity and durability equal to conventional electrolyte material, is easy to synthesize, has a softening point higher than electrolyte material heretofore widely used for application to fuel cells and is suitable for operation of a polymer electrolyte fuel cell at a temperature higher than the conventional material.

Owner:ASAHI GLASS CO LTD

Process for applying fluoropolymer powder coating as a primer layer and an overcoat

InactiveUS20060110601A1Superior and durable adhesionIncrease temperatureSynthetic resin layered productsPackagingTetrafluoroethylenePolymer science

The invention relates to use of a tetrafluoroethylene / perfluoroolefin copolymer applied as a primer powder in conjunction with a powder overcoat of tetrafluoroethylene / perfluoro (vinyl alkyl ether) copolymer, also known as perfluoroalkoxy polymer (PFA), which when baked onto a substrate gives superior and more durable adhesion of the coating system to the substrate. The quality of the adhesion is measured by a boiling water peel test.

Owner:THE CHEMOURS CO FC LLC

Surface hydrophilic modification method for polytetrafluoroethylene bulked membrane

InactiveCN101890314ASimple processEfficient treatment processSemi-permeable membranesWater layerLow pressure plasma

The invention relates to a surface hydrophilic modification method for a polytetrafluoroethylene bulked membrane, which is characterized by comprising the steps of: pretreating a polytetrafluoroethylene membrane by adopting low-pressure glow discharge plasma to make the surface of the polytetrafluoroethylene membrane generate active groups, and grafting acrylic acid to form a relatively stable hydrophilic layer. The method has the advantages that: the active groups are generated on the surface of the polytetrafluoroethylene membrane by low-pressure plasma treatment, and the relatively stable hydrophilic layer can be formed on the surface of the membrane by acrylic acid grafting treatment, so that the hydrophilicity of the polytetrafluoroethylene membrane is effectively improved, and the effect is lasting; and the polytetrafluoroethylene membrane is treated by the low-pressure plasma induction and acrylic acid grafting, so the treatment method is simple, high-efficiency, water and energy-saving, and suitable for industrialized production.

Owner:DONGHUA UNIV

High vinyl ether modified sinterable polytetrafluoroethylene

InactiveUS6870020B2Improve the level ofEasy to processPigmenting treatmentSynthetic resin layered productsVinyl etherTetrafluoroethylene

Modified polytetrafluoroethylene powder of a sinterable copolymer of tetrafluoroethylene containing about 0.5 to about 10 weight % of fluorinated vinyl ether, the copolymer having a melt creep viscosity of greater than about 1×106 Pa·S. In preferred embodiments, the sinterable copolymer has a melt creep viscosity of greater than about 1×107 Pa·S and fluorinated vinyl ether content of from about 1 to about 7 weight %. The polymer has a combination of a high level of fluorinated vinyl ether and a melt creep viscosity which is high enough to enable the fabrication of articles by sintering.

Owner:THE CHEMOURS CO FC LLC

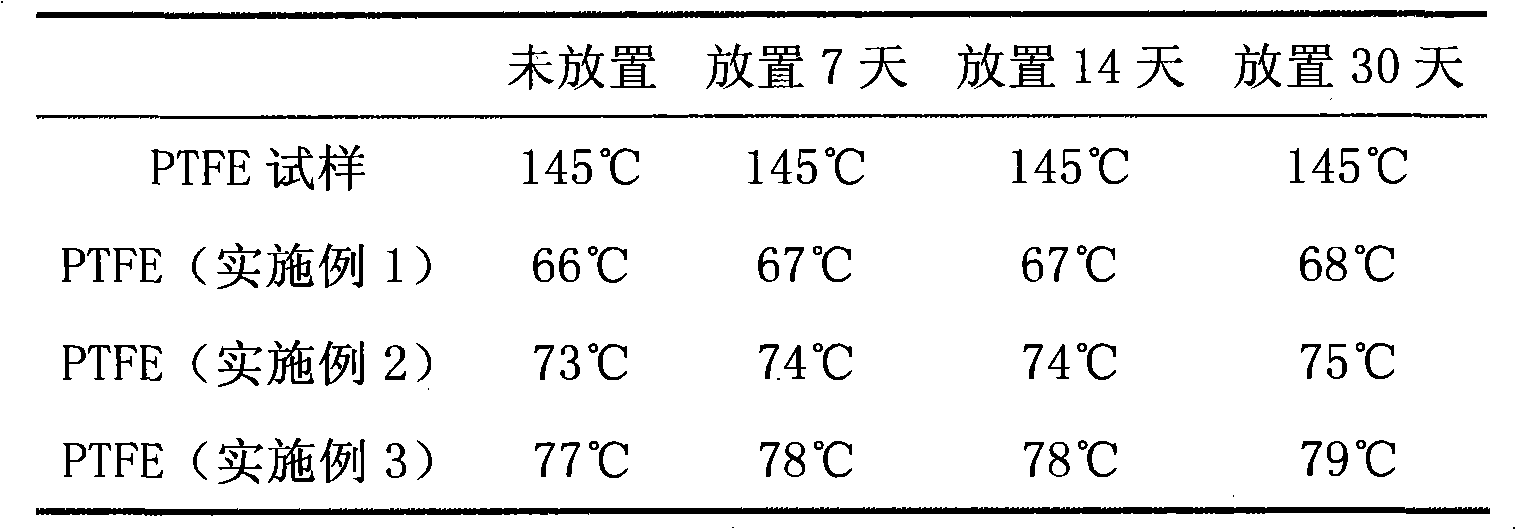

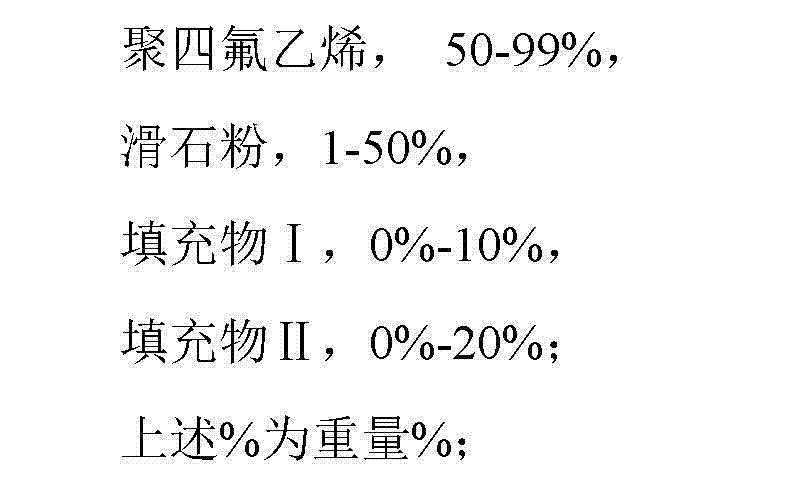

Preparation method of talc filled PTFE composite material

The invention discloses a preparation method of a talc filled PTFE (polytetrafluoroethylene) composite material. The method comprises the following steps in order: 1) conducting burdening with 50-99 wt% of PTFE, 1-50 wt% of talc powder, 0 wt%-10 wt% of filler I, and 0 wt%-20 wt% of filler II; 2) mixing the mixture obtained in step 1) uniformly, then carrying out cold pressing molding under a pressure of 25-40 MPa, and maintaining the pressure for 3-10 minutes; 3) putting the molded product obtained in step 2) into a high temperature sintering furnace, heating the product to a temperature of 360-380DEG C at a heating rate of 30-100DEG C / h, then preserving the heat for 0.5-2h; and 4) leaving the sintered product obtained in step 3) to natural cooling to room temperature, thus obtaining the talc filled PTFE composite material. The talc filled PTFE composite material prepared by the method of the invention has excellent performances and a wide application range.

Owner:ZHEJIANG UNIV

Concentrated fluoropolymer dispersions

InactiveUS6956078B2High shear stabilityFilm/foil adhesivesFibre treatmentTetrafluoroethylenePolymer science

An aqueous dispersion composition of about 30 to about 70 weight % non-melt-processible fluoropolymer particles having a standard specific gravity (SSG) of less than 2.225 and about 2 to about 11 weight % surfactant based on the weight of said fluoropolymer comprising a compound or mixture of compounds of the formula:R(OCH2CH2)nOHwherein R is a branched alkyl, branched alkenyl, cycloalkyl, or cycloalkenyl hydrocarbon group having 8-18 carbon atoms and n is an average value of 5 to 18. The fluoropolymer particles of the dispersion comprise a core of high molecular weight polytetrafluoroethylene and a shell of lower molecular weight polytetrafluoroethylene or modified polytetrafluoroethylene. Preferably, the aqueous dispersion composition comprises about 45 to about 65 weight % non-melt-processible fluoropolymer particles.

Owner:THE CHEMOURS CO FC LLC

High temperature resistant P.T.F.E. coated filter material

ActiveCN1768912AAvoid cloggingExcellent "surface filter" characteristicsSemi-permeable membranesSynthetic resin layered productsTetrafluoroethyleneGlass fiber

The invention relates to a high temperature-resistant polytetrafluoroethylene tectorial filter material, belonging to the improvement on present polytetrafluoroethylene composite filter material, which comprises a glass fiber base cloth and a polytetrafluoroethylene surface film. It is characterized in that: first using after-treatment agent to process the dipping process on the glass fiber base cloth, then processing the high-temperature heat compression on the polytetrafluoroethylene surface film. The invention uses film forming emulsifier, fluorine silane coupling agent and fluoroplymer emulsion to form a film on the glass fiber base cloth, which can improve the effects of anti-soil, oil-proof and preservation, and it can have fusion combination with expanded micro-pore polytetrafluoroethylene film in the condition of high-temperature heat compression, to effectively solve the problem of hard fusion combination between inorganic material of glass fiber and organic inertia material of polytetrafluoroethylene to significantly improve the fastness between them.

Owner:中材科技膜材料(山东)有限公司

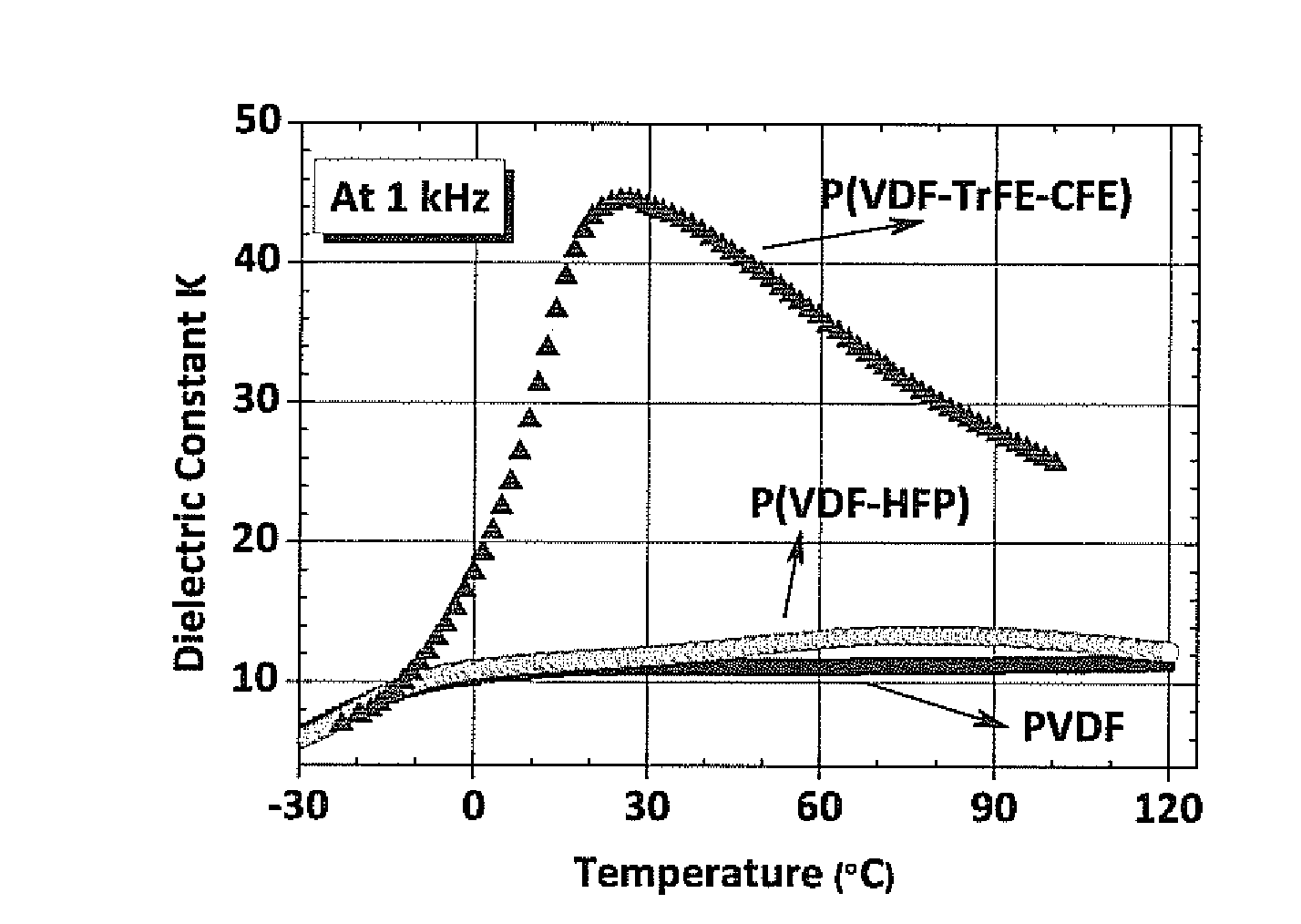

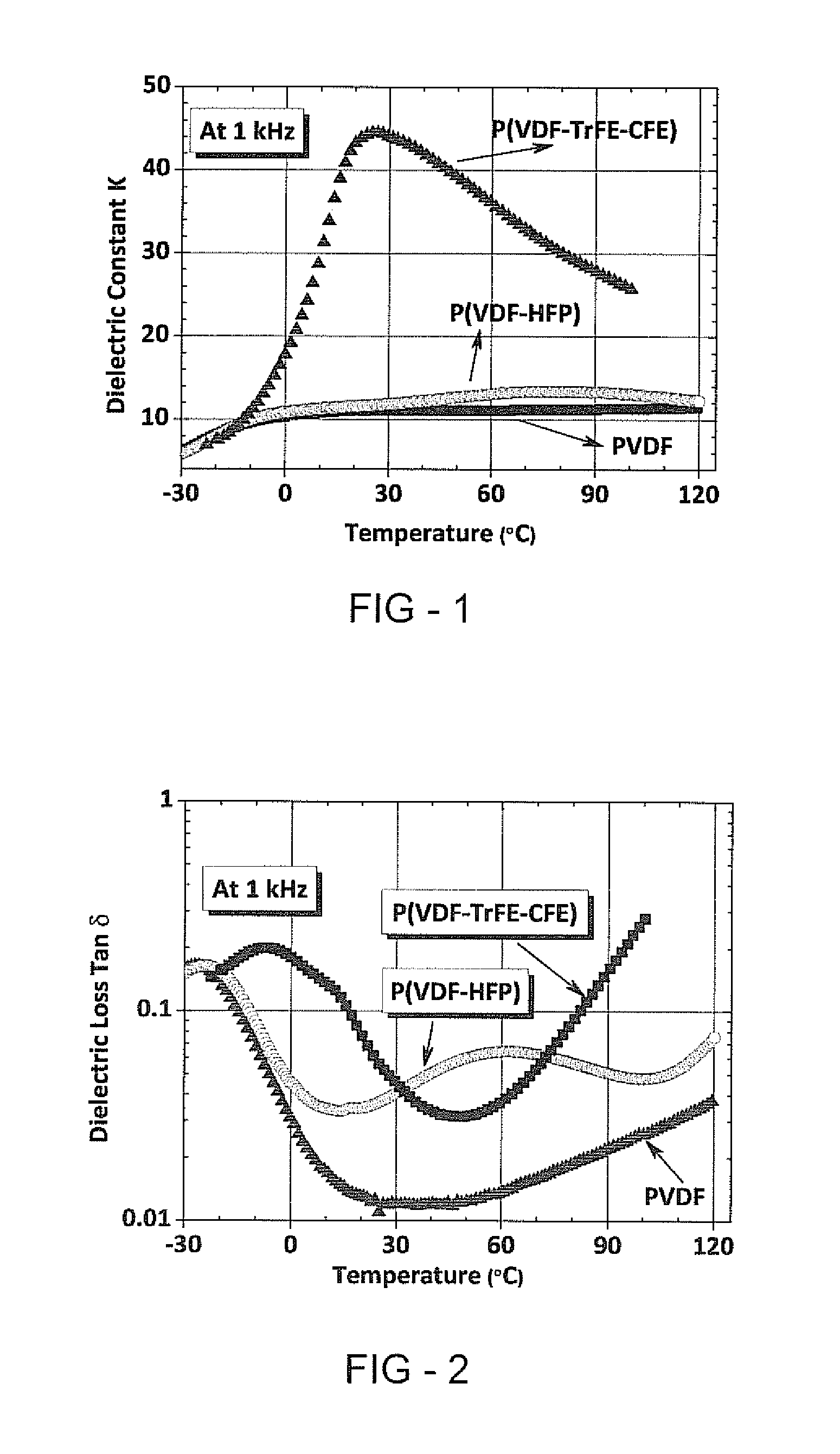

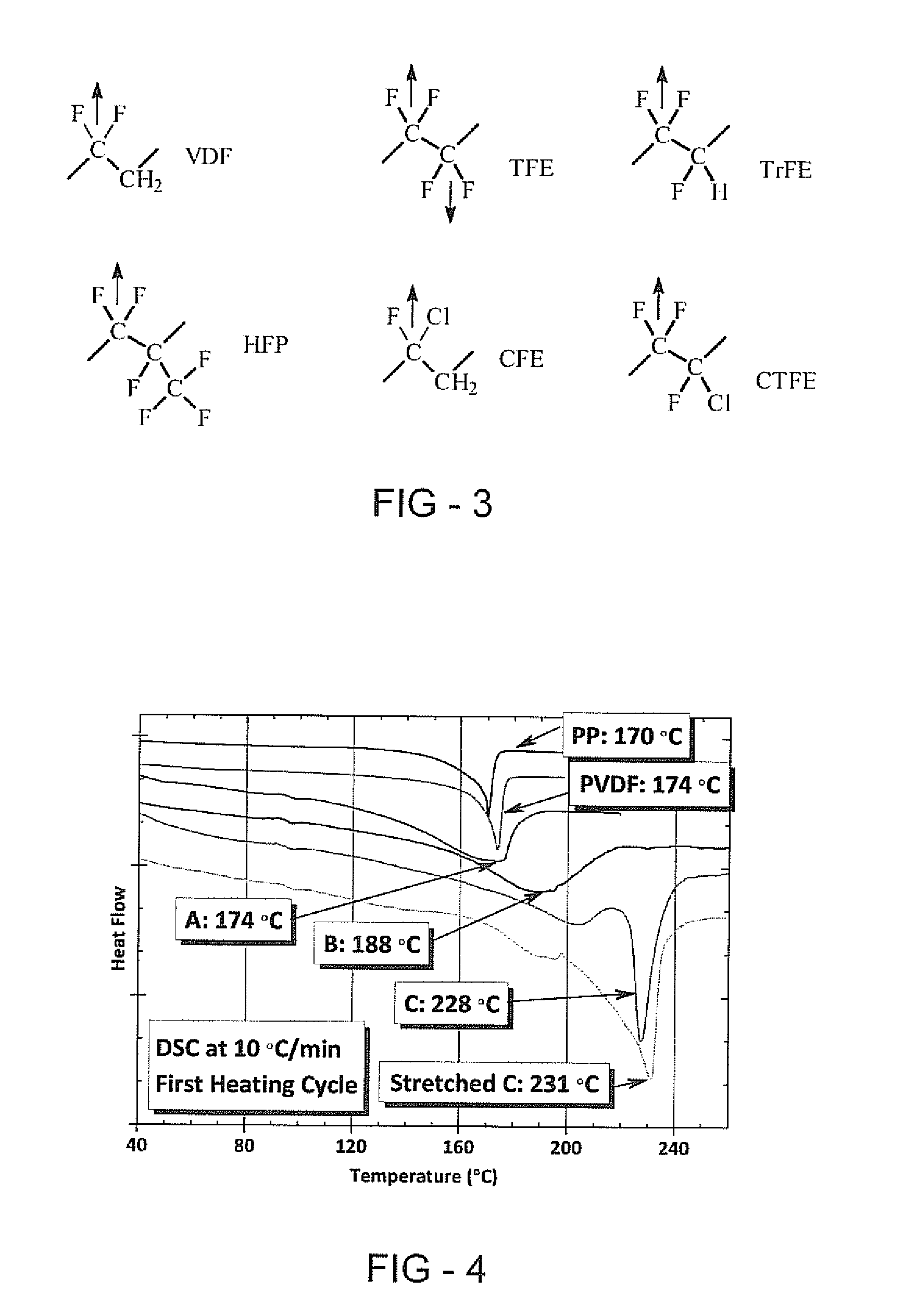

Capacitor having high temperature stability, high dielectric constant, low dielectric loss, and low leakage current

InactiveUS20110228442A1Physical improvementGood chemical propertiesFixed capacitor dielectricStacked capacitorsMetal foilPolymer thin films

Examples of the present invention include high electric energy density polymer film capacitors with high dielectric constant, low dielectric dissipation tangent, and low leakage current in a broad temperature range. More particularly, examples include a polymer film capacitor in which the dielectric layer comprise a copolymer of a first monomer (such as tetrafluoroethylene) and a second polar monomer. The second monomer component may be selected from vinylidene fluoride, trifluoroethylene or their mixtures, and optionally other monomers may be included to adjust the mechanical performance. The capacitors can be made by winding metallized films, plain films with metal foils, or hybrid construction where the films comprise the new compositions. The capacitors can be used in DC bus capacitors and energy storage capacitors in pulsed power systems.

Owner:NOVASENTIS +1

Curable perfluoroelastomer composition

Perfluoroelastomer compositions comprising perfluoroelastomers having copolymerized units of tetrafluoroethylene, a perfluoro(vinyl ether), and a nitrile-containing cure site monomer are cured with certain nitrogen-containing nucleophilic compounds. The nucleophilic compounds also act as dual curatives in perfluoroelastomer compositions which incorporate other curing agents.

Owner:DUPONT POLYMERS INC

Fluororesin mixture, copper-clad plate prepared therefrom and manufacturing method thereof

ActiveCN101838431AImprove dipping qualityUniform glue contentGlass/slag layered productsMetal layered productsVinyl etherGlass fiber

The invention relates to a fluororesin mixture, a copper-clad plate prepared therefrom and a manufacturing method thereof. The fluororesin mixture contains the following two substances as necessary components in 100 parts by weight of an organic solid substance: 90-99 parts of polytetrafluoroethylene (PTFE) emulsions and 1-10 parts of polytetrafluoroethylene perfluoroalkyl vinyl ether (PFA) emulsions. The copper-clad plate prepared from the fluororesin mixture comprises a plurality of superimposed varnished cloths and copper foil coating one or two surfaces of the varnished cloths, and each varnished cloth comprises a glass fiber cloth and the fluororesin mixture attached to the dipped and dried glass fiber cloth. The fluororesin mixture is prepared by using the PTFE emulsions as main resins and can dip the glass fiber cloths many times under the condition that the PTFE sintering temperature is330 DEG C to prepare the vanished cloths, and the vanished cloths prepared from the fluororesin mixture has the advantages of good gum dipping quality, level surface, flexibility and easy operation; and besides, the copper-clad plate made from the fluororesin mixture has excellent dielectric performance which meets the dielectric performance requirement of the high-frequency communication field for a base plate material, and has simple making method and process and is beneficial to industrial continuous production.

Owner:GUANGDONG SHENGYI SCI TECH

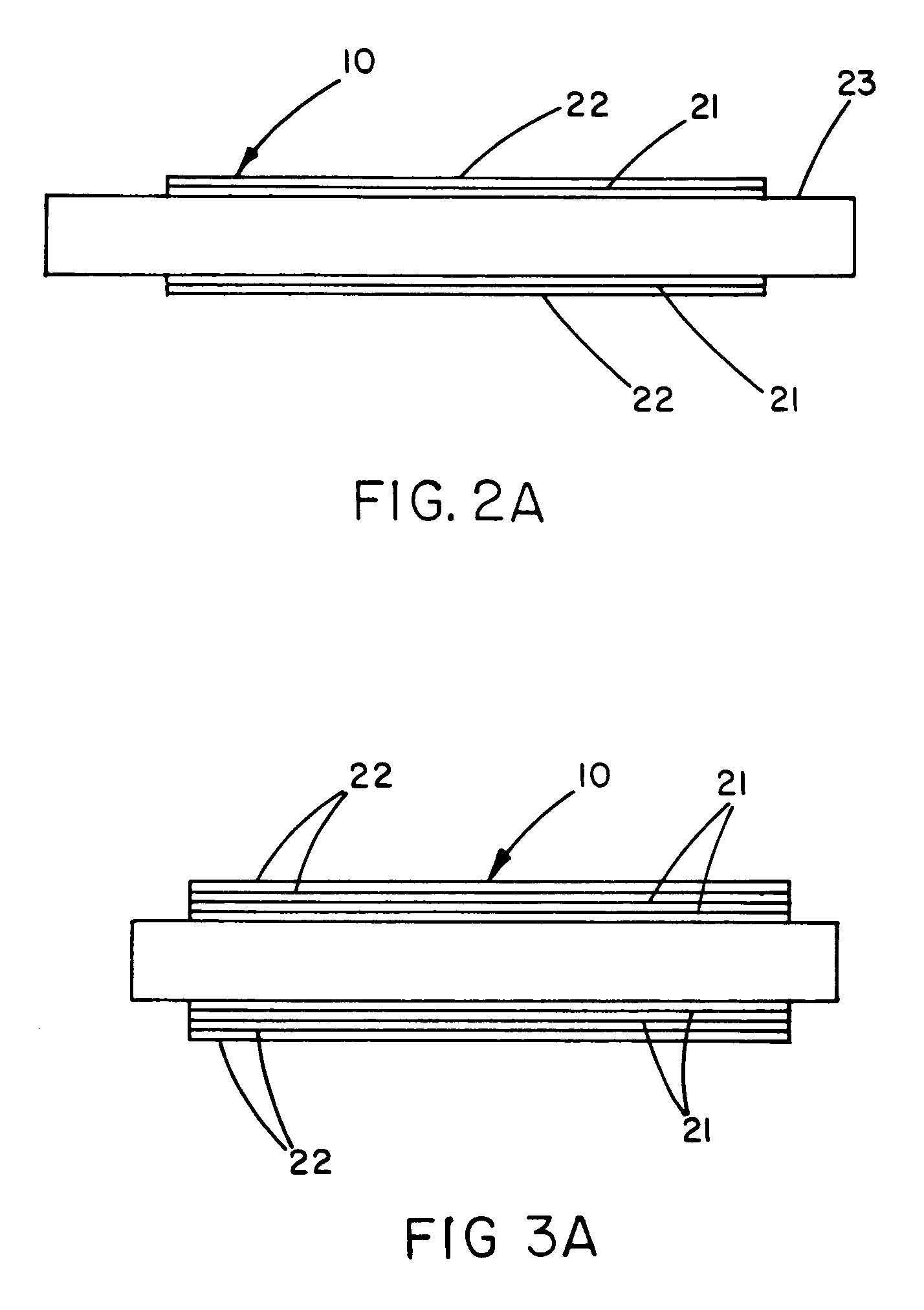

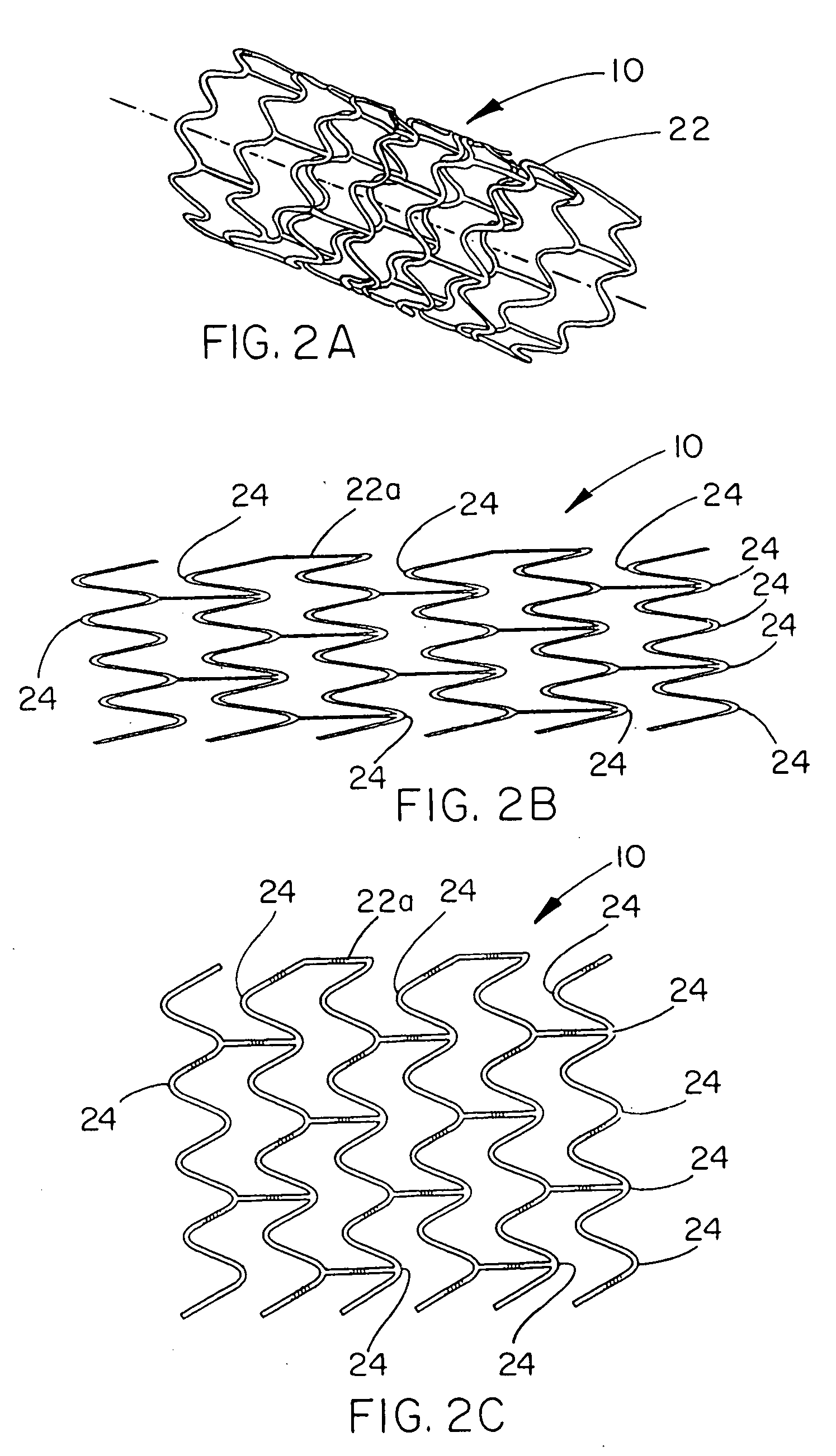

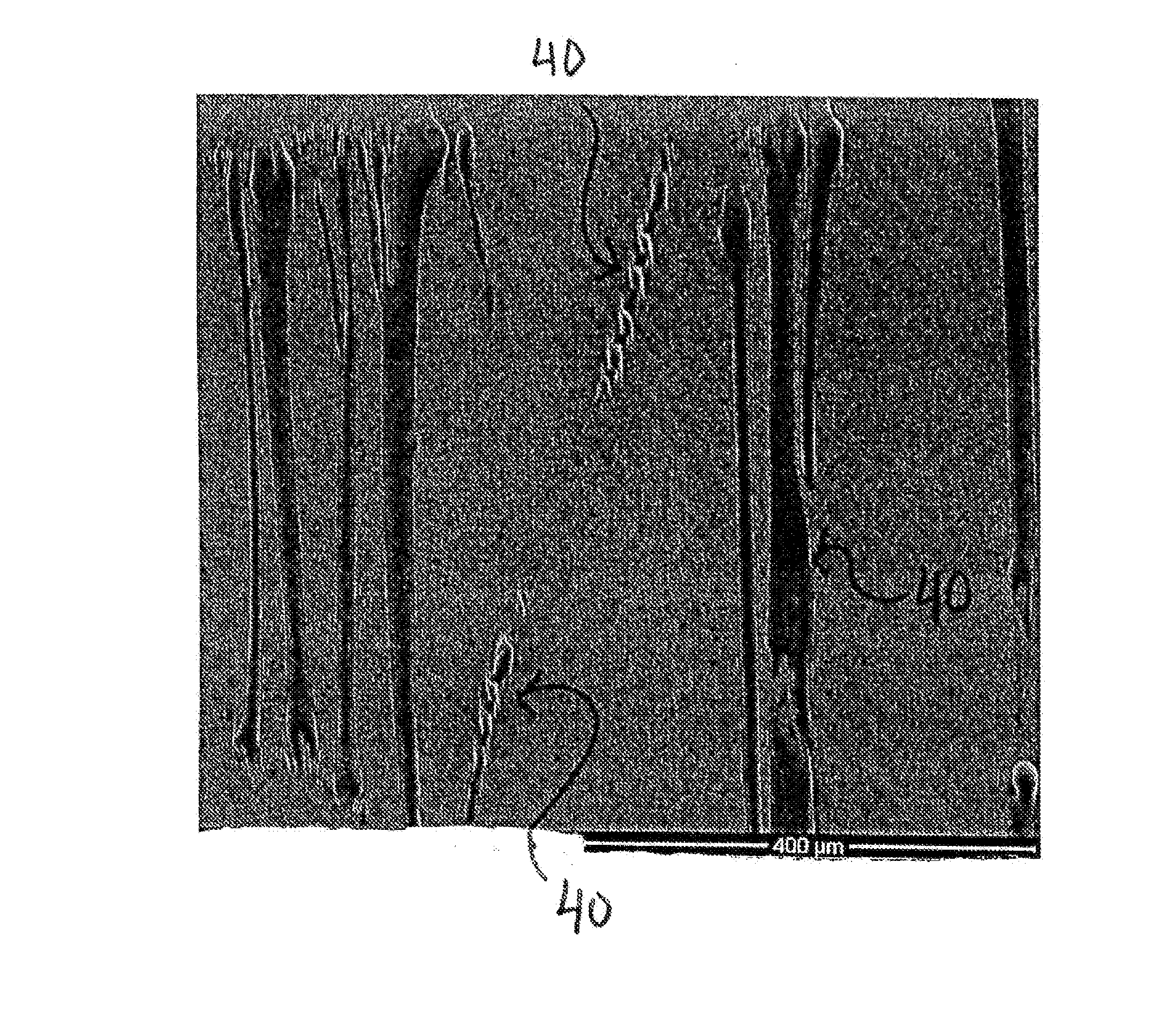

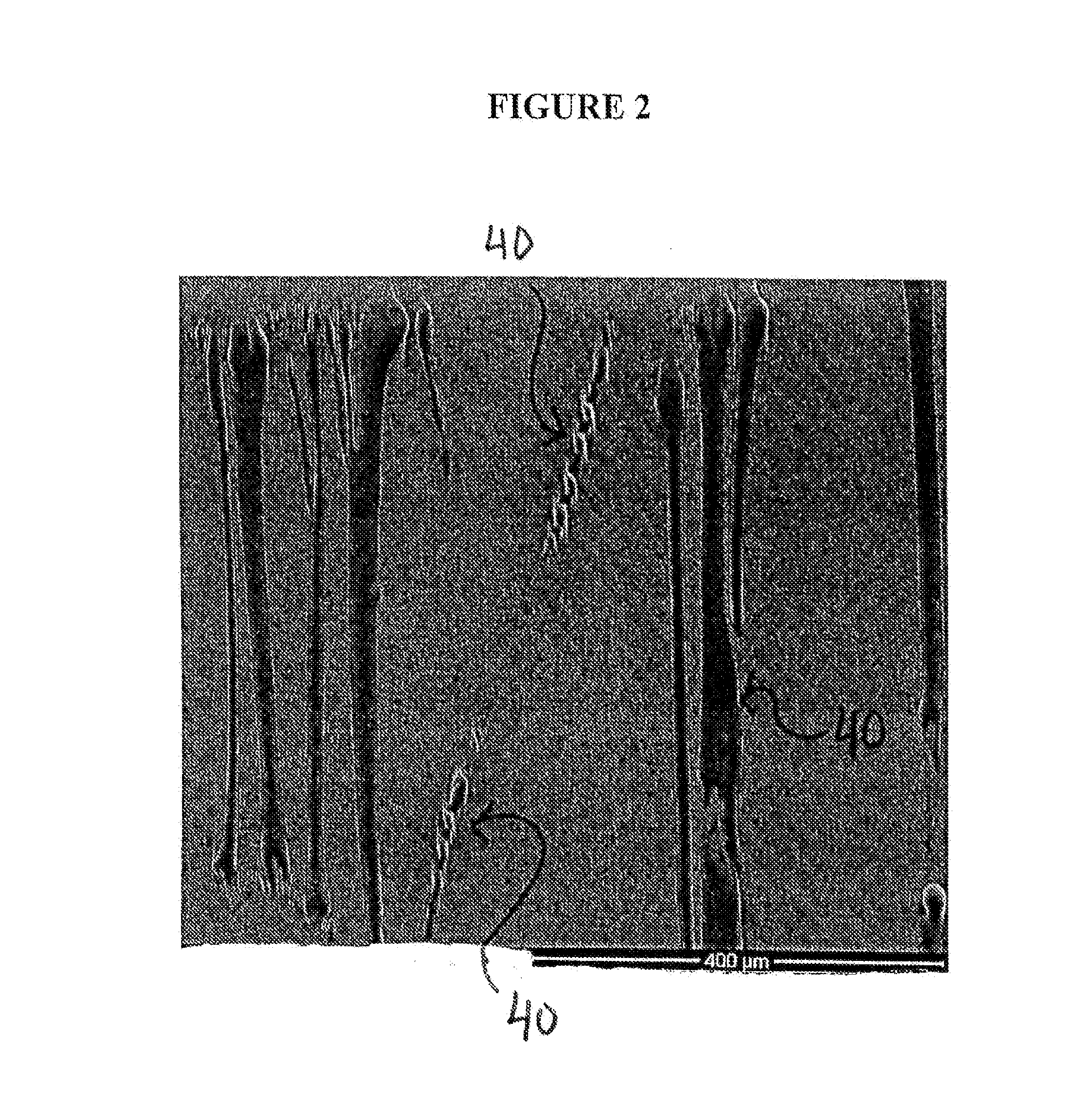

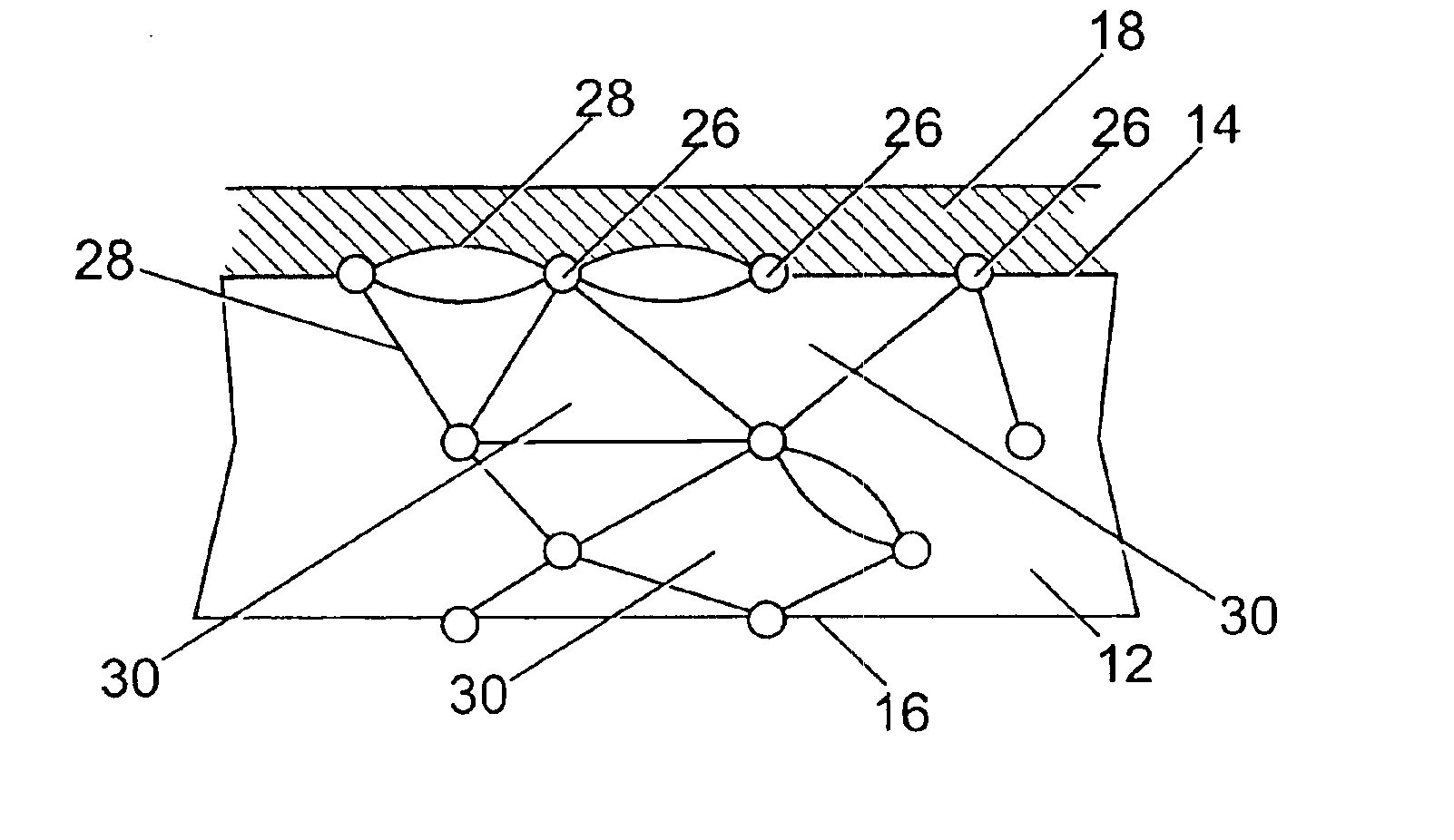

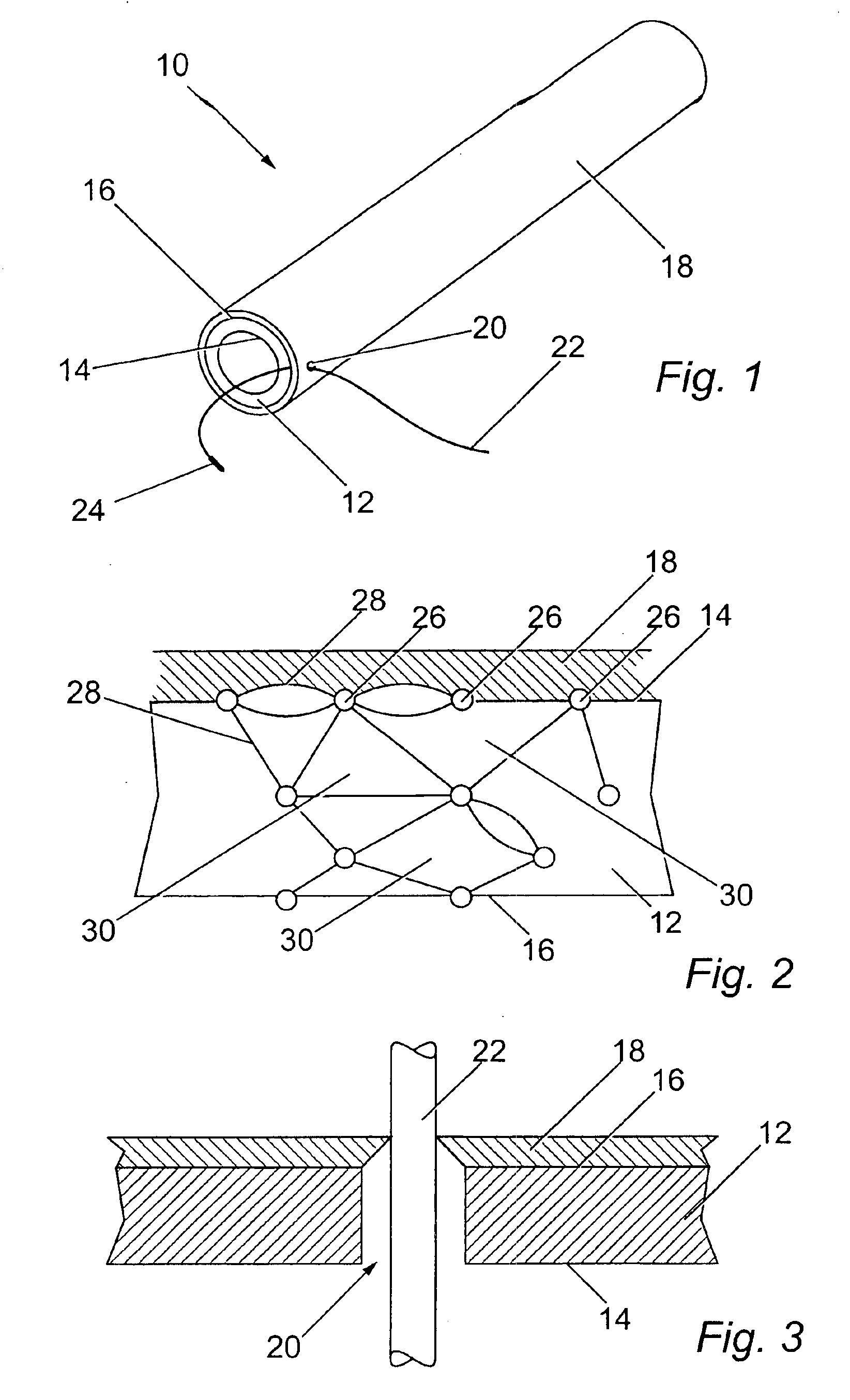

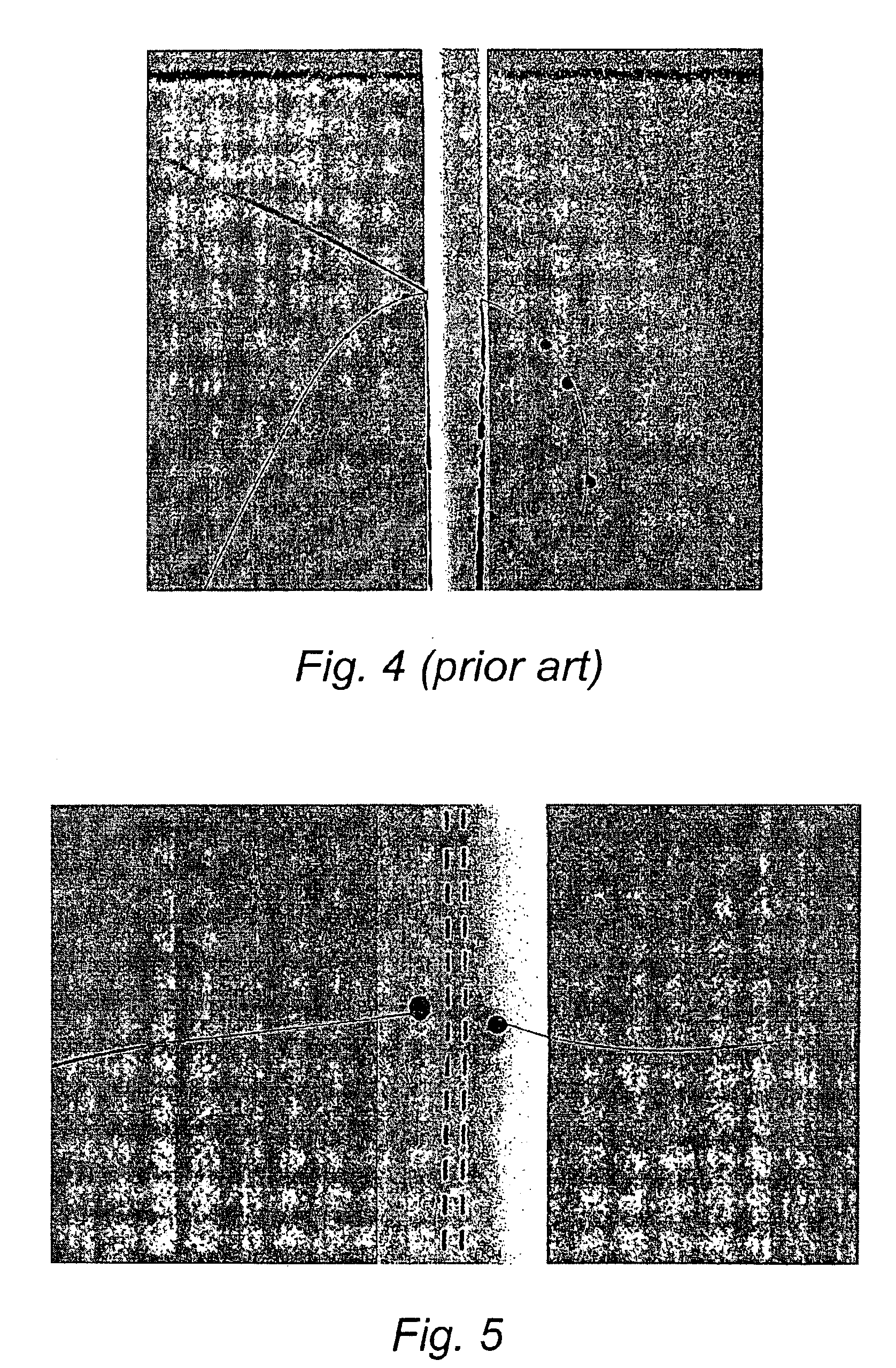

Articles including expanded polytetrafluoroethylene membranes with serpentine fibrils

InactiveUS20130183515A1High elongationSynthetic resin layered productsCeramic shaping apparatusElastomerFiber

Articles including expanded fluoropolymer membranes having serpentine fibrils are provided. The fluoropolymer membranes exhibit high elongation while substantially retaining the strength properties of the fluoropolymer membrane. The membrane may include a fluoropolymer and / or elastomer. Additionally, the article has an elongation in at least one direction of at least about 100% and a matrix tensile strength of at least about 50 MPa. The article may be formed by (1) expanding a dried, extruded fluoropolymer tape in at least one direction to produce an expanded fluoropolymer membrane and (2) retracting the expanded fluoropolymer membrane in at least one direction of expansion by applying heat or by adding a solvent. The application of a tensile force at least partially straightens the serpentine fibrils, thereby elongating the article. The expanded fluoropolymer membrane may include a microstructure of substantially only fibrils. The membranes may be imbibed with an elastomeric material to form a composite.

Owner:WL GORE & ASSOC INC

Articles Including Expanded Polytetrafluoroethylene Membranes with Serpentine Fibrils and Having a Discontinuous Fluoropolymer Layer Thereon

ActiveUS20130184807A1High elongationIncrease stiffnessDecorative surface effectsLighting elementsFiberTetrafluoroethylene

Articles comprising an expanded polytetrafluoroethylene membrane having serpentine fibrils and having a discontinuous coating of a fluoropolymer thereon are provided. The fluoropolymer may be located at least partially in the pores of the expanded fluoropolymer membrane. In exemplary embodiments, the fluoropolymer is fluorinated ethylene propylene. The application of a tensile force at least partially straightens the serpentine fibrils, thereby elongating the article. The expanded polytetrafluoroethylene membrane may include a microstructure of substantially only fibrils. The articles can be elongated to a predetermined point at which further elongation is inhibited by a dramatic increase in stiffness. In one embodiment, the articles are used to form a covered stent device that requires little force to distend in the radial direction to a first diameter but is highly resistant to further distension to a second diameter (stop point). A large increase in diameter can advantageously be achieved prior to reaching the stop point.

Owner:WL GORE & ASSOC INC

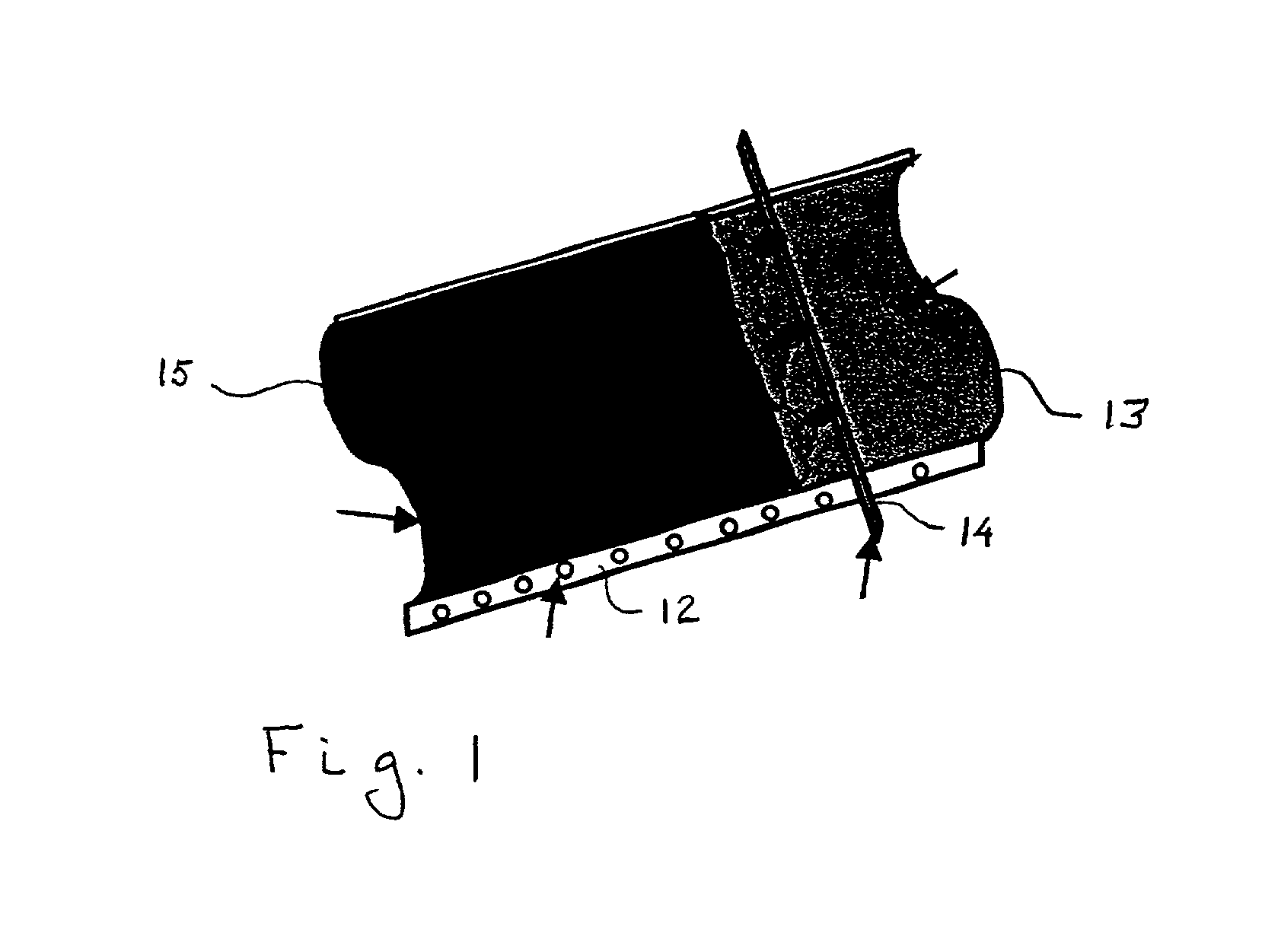

Expanded polytetrafluoroethylene vascular graft with coating

A vascular graft comprised of a tubular polytetrafluoroethylene (ePTFE) sheet is provided. The ePTFE sheet has a substantially uniform coating of bioresorbable gel material, for example gelatin, on a surface thereof. The coating minimises bleeding through suture holes in the ePTFE sheet and provides an increase in longitudinal extensibility.

Owner:VASCUTEK

Gas diffusion electrode manufacture and MEA fabrication

InactiveUS6627035B2Increase internal resistanceReduce hydrophobicityFinal product manufactureAdhesive processes with surface pretreatmentTetrafluoroethyleneEmulsion

A method for producing a gas diffusion electrode in which a slurry of carbon black, alcohol, water and a tetrafluoroethylene emulsion is applied as a layer a non-Teflonized carbon cloth substrate, which is then heated to remove water. The dried coated carbon cloth is then rolled followed by heating to remove wetting agents present in the tetrafluoroethylene emulsion. The coated carbon cloth is then cooled and rolled again to produce the final end product.

Owner:GAS TECH INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com