Patents

Literature

183 results about "Ptfe composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

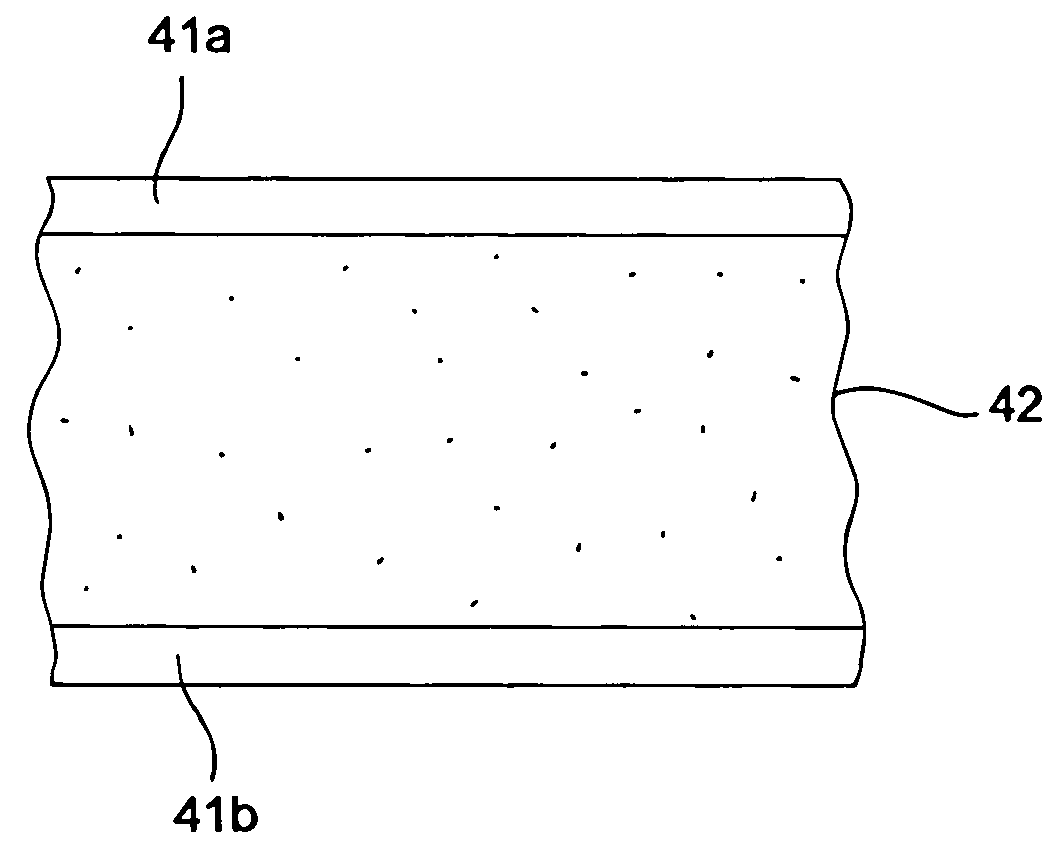

Aerogel/PTFE composite insulating material

ActiveUS20050100728A1Increase flexibilityHigh strengthDigital data processing detailsAdhesive articlesInto-structureMaterials science

A material comprising aerogel particles and a polytetrafluoroethylene (PTFE) binder is formed having a thermal conductivity of less than or equal to 25 mW / m K at atmospheric conditions. The material is moldable or formable, having little or no shedding of filler particles, and may be formed into structures such as tapes or composites, for example, by bonding the material between two outer layers. Advantageously, composites may be flexed, stretched, or bent without significant dusting or loss of insulating properties.

Owner:WL GORE & ASSOC INC

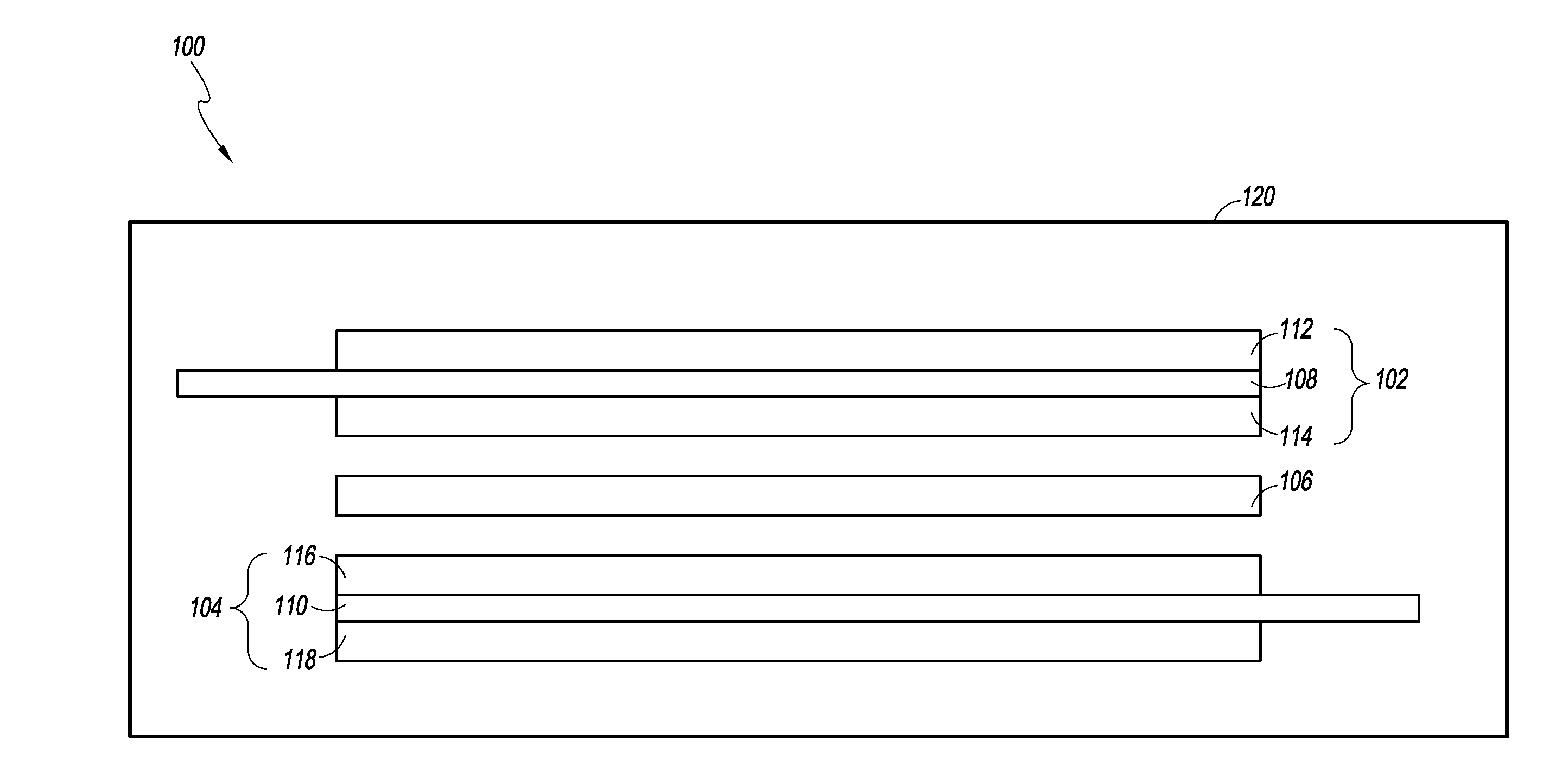

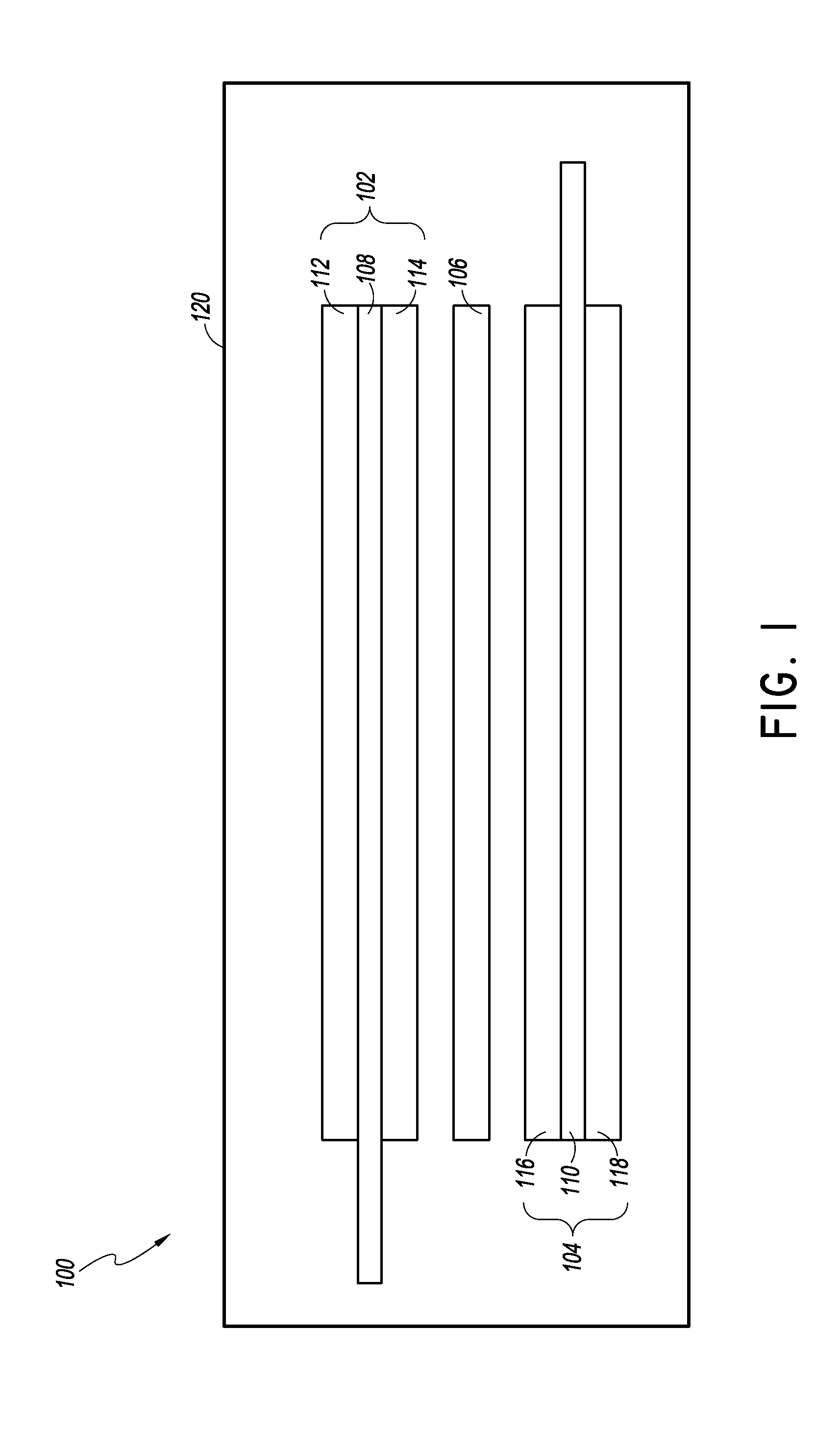

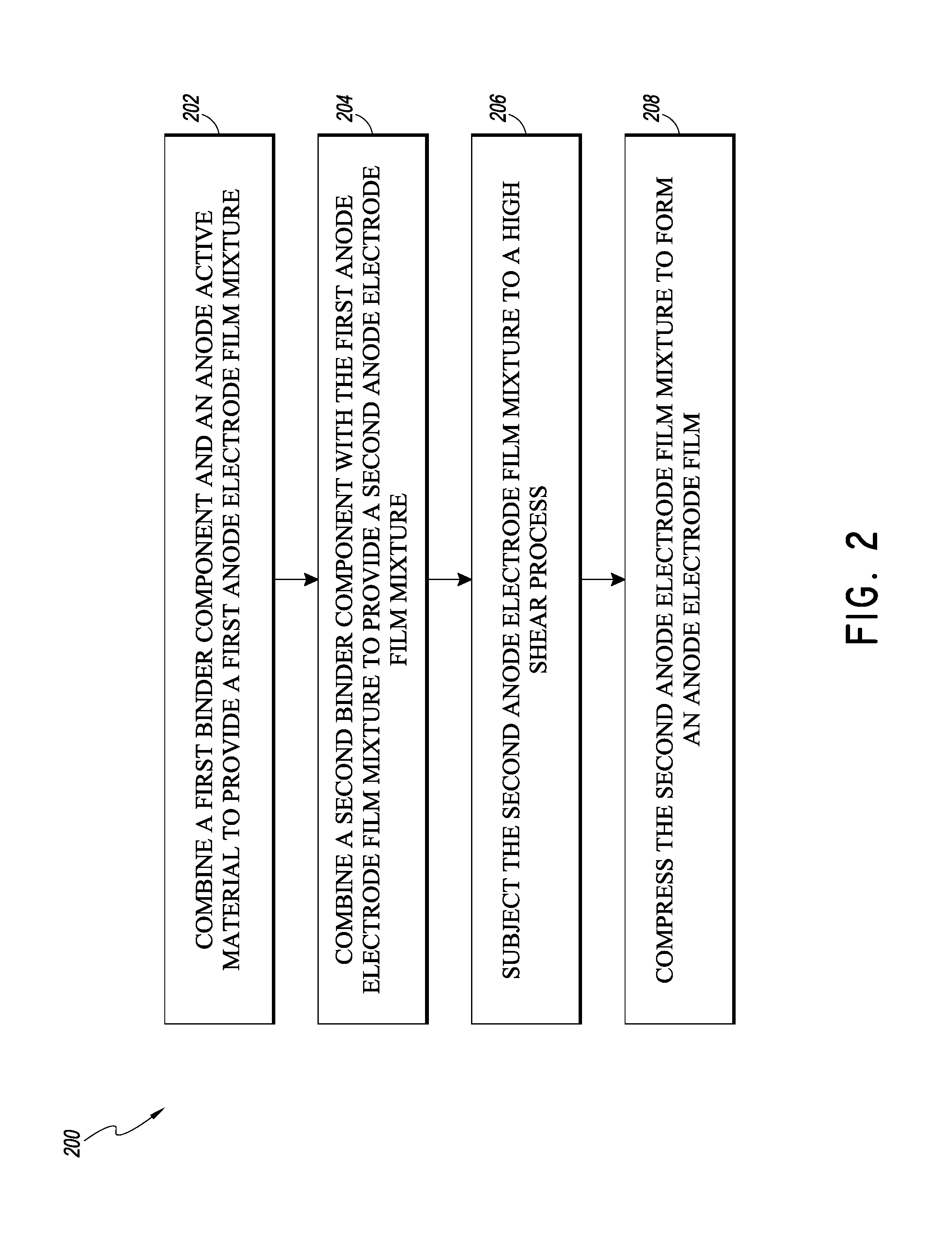

Dry energy storage device electrode and methods of making the same

ActiveUS20150303481A1Electrode rolling/calenderingSolid electrolytic capacitorsEthylene oxidePolyvinylidene difluoride

An energy storage device can include a cathode and an anode, where at least one of the cathode and the anode are made of a polytetrafluoroethylene (PTFE) composite binder material including PTFE and at least one of polyvinylidene fluoride (PVDF), a PVDF co-polymer, and poly(ethylene oxide) (PEO). The energy storage device can be a lithium ion battery, a lithium ion capacitor, and / or any other lithium based energy storage device. The PTFE composite binder material can have a ratio of about 1:1 of PTFE to a non-PTFE component, such a PVDF, PVDF co-polymer and / or PEO.

Owner:TESLA INC

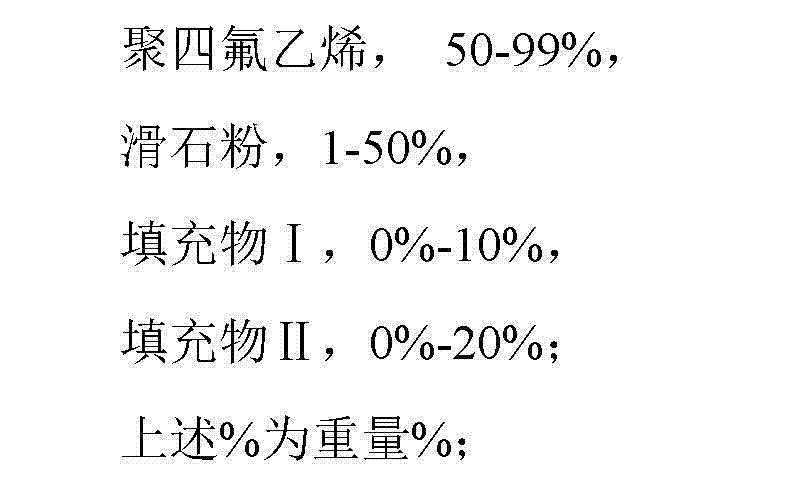

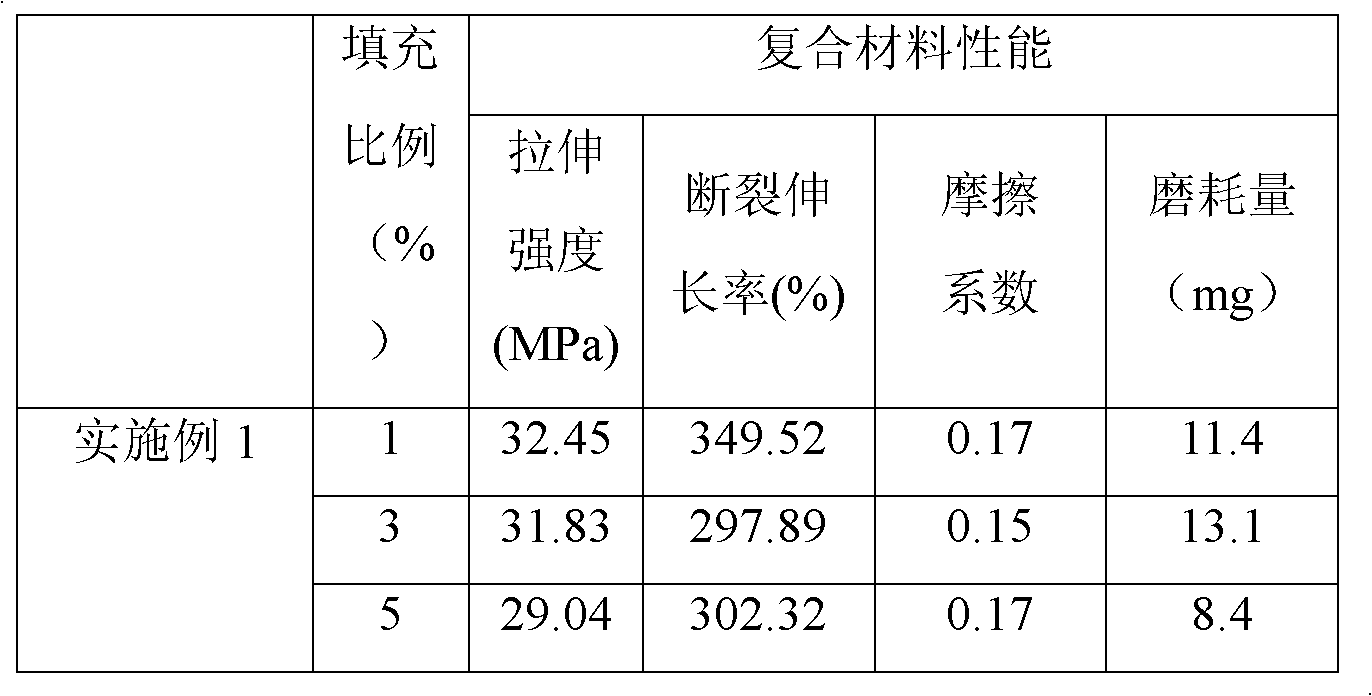

Preparation method of talc filled PTFE composite material

The invention discloses a preparation method of a talc filled PTFE (polytetrafluoroethylene) composite material. The method comprises the following steps in order: 1) conducting burdening with 50-99 wt% of PTFE, 1-50 wt% of talc powder, 0 wt%-10 wt% of filler I, and 0 wt%-20 wt% of filler II; 2) mixing the mixture obtained in step 1) uniformly, then carrying out cold pressing molding under a pressure of 25-40 MPa, and maintaining the pressure for 3-10 minutes; 3) putting the molded product obtained in step 2) into a high temperature sintering furnace, heating the product to a temperature of 360-380DEG C at a heating rate of 30-100DEG C / h, then preserving the heat for 0.5-2h; and 4) leaving the sintered product obtained in step 3) to natural cooling to room temperature, thus obtaining the talc filled PTFE composite material. The talc filled PTFE composite material prepared by the method of the invention has excellent performances and a wide application range.

Owner:ZHEJIANG UNIV

Preparing method of PTFE (polytetrafluoroethylene) composite material filled with nano particles

InactiveCN102604282AImprove mechanical propertiesImprove wear resistanceTetrafluoroethyleneOrganic solvent

The invention discloses a preparing method of a PTFE (polytetrafluoroethylene) composite material filled with nano particles. The method comprises the following steps of: (1) carrying out surface modification on nano particles by virtue of a coupling agent to obtain modified nano particles; (2) carrying out coarse mixing on PTFE and the modified nano particles to obtain premixing powder, wherein the weight content of the modified nano particles in the premixing powder is 0.1%-50%; (3) adding organic solvent in the premixing powder, carrying out ultrasonic agitation, filtering and drying to obtain PTFE composite powder with uniformly dispersed nano particles, wherein the weight ratio of the organic solvent to the premixing powder is 50-1000%; and (4) carrying out mould-pressing and sintering on the PTFE composite powder to obtain the PTFE composite material filled with nano particles. The PTFE composite material filled with nano particles, prepared by the method, has the characteristics of high mechanical property, high wear-resisting property, low frictional factor and the like.

Owner:ZHEJIANG UNIV

Preparation method of polytetrafluoroethylene (PTFE) composite dielectric substrate

ActiveCN104175686AViscosity is easy to controlEasy to coat and moldSynthetic resin layered productsLaminationEmulsionMicrowave

The invention relates to the field of a high-frequency copper-clad plate of a polytetrafluoroethylene (PTFE) dielectric substrate, and in particular relates to a preparation method of a polytetrafluoroethylene (PTFE) composite dielectric substrate used for a microwave circuit. The method comprises the steps of firstly, mixing fluororesin emulsion, inorganic filler and a thickening agent to prepare stable and uniform dispersion liquid; after that, enabling a release type base material to be coated with the dispersion liquid, and then baking; after baking, carrying out release type separation on a resin layer and the base material; cutting and overlapping the separated resin layer according to the thickness and the size of the substrate; covering the two sides of the resin layer with copper foils, and carrying out high-temperature lamination sintering to obtain the PTFE composite dielectric substrate covered by the copper foils at the double sides. After the preparation method is used, the formation of a hole in the composite dielectric substrate and the residue of an organic auxiliary agent are effectively reduced; the preparation method has the advantages of being simple and convenient in technology, beneficial to large scale production, etc.

Owner:GUANGDONG SHENGYI SCI TECH

Preparation method of hydrophilic PTFE (polytetrafluoroethylene) composite microporous membrane

ActiveCN104353370AImprove hydrophilicityImprove adsorption stabilitySemi-permeable membranesPolymer scienceOrganic chemistry

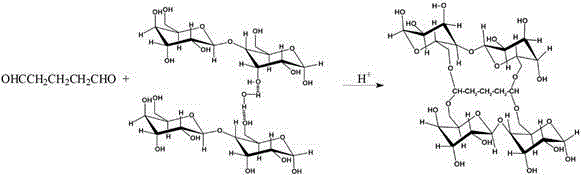

The invention relates to a preparation method of a hydrophilic PTFE (polytetrafluoroethylene) composite microporous membrane. The preparation method comprises the following steps: 1, adding inorganic nano particles in the formula of a PTFE raw material, uniformly mixing and stretching to obtain a PTFE composite microporous membrane; 2, adding a polyhydroxy compound and a couping agent to water to prepare a modified water solution, soaking the PTFE composite microporous membrane obtained in the step 1 until the membrane is transparent, then dipping into the modified water solution, taking out and drying; and 3, dipping the dried PTFE composite microporous membrane in a pentanedial solution, and after taking out, washing and drying to obtain the hydrophilic PTFE composite microporous membrane. The preparation method has the advantages that after the PTFE composite microporous membrane is treated by the modifying method, the hydrophilic property of the membrane is remarkably improved; persistence of the hydrophilic property is obviously improved while the hydrophilic property is ensured; the preparation process is easy and feasible, is low in cost and is suitable for industrial production.

Owner:中材科技膜材料(山东)有限公司

Method for preparing ultrafine zeolite powder filling PTFE (polytetrafluoroethylene) composite material

The invention discloses a method for preparing an ultrafine zeolite powder filling PTFE (polytetrafluoroethylene) composite material. The method comprises the steps of 1) proportioning materials, i.e. mixing polytetrafluoroethylene, ultrafine zeolite powder, a filler I and a filler II according to the ratio; 2) uniformly mixing the mixture proportioned and then carrying out cold press forming under the pressure of 20-40 Mpa; 3) putting the formed object obtained in the step 2) into a high temperature sintering furnace, heating to 330-380 DEG C with the speed of 30-100 DEG C / hour and preserving heat for 0.5-2 hours; and 4) naturally cooling sintering products obtained in the step 3) to the room temperature to obtain the ultrafine zeolite powder filling PTFE (polytetrafluoroethylene) composite material. The ultrafine zeolite powder filling PTFE (polytetrafluoroethylene) composite material prepared according to the method has excellent performance, the wear resistance of the composite material is improved upon the premise of not remarkably reducing the matrix friction coefficient of PTFE, and the application range of the composite material is wide.

Owner:ZHEJIANG UNIV

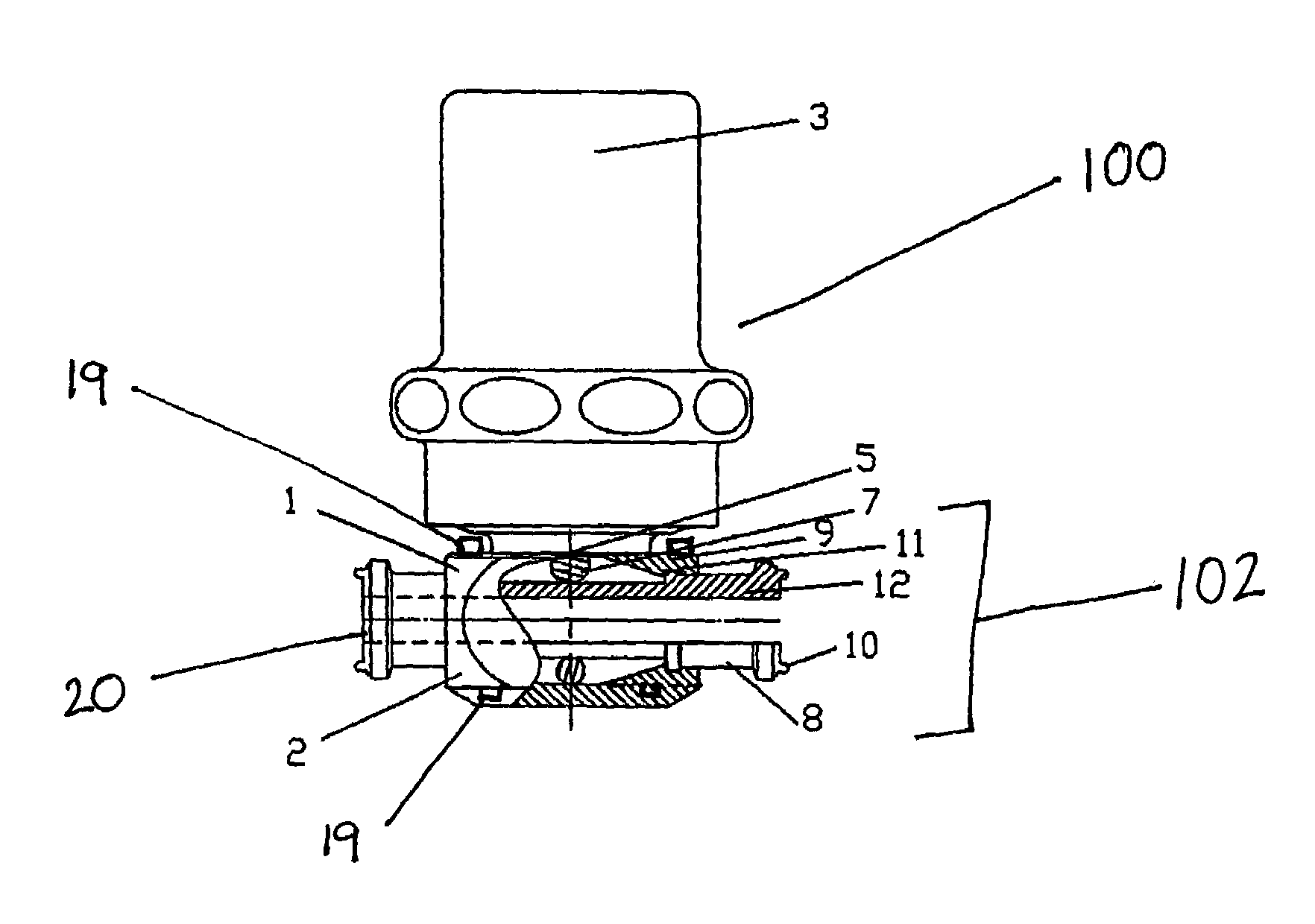

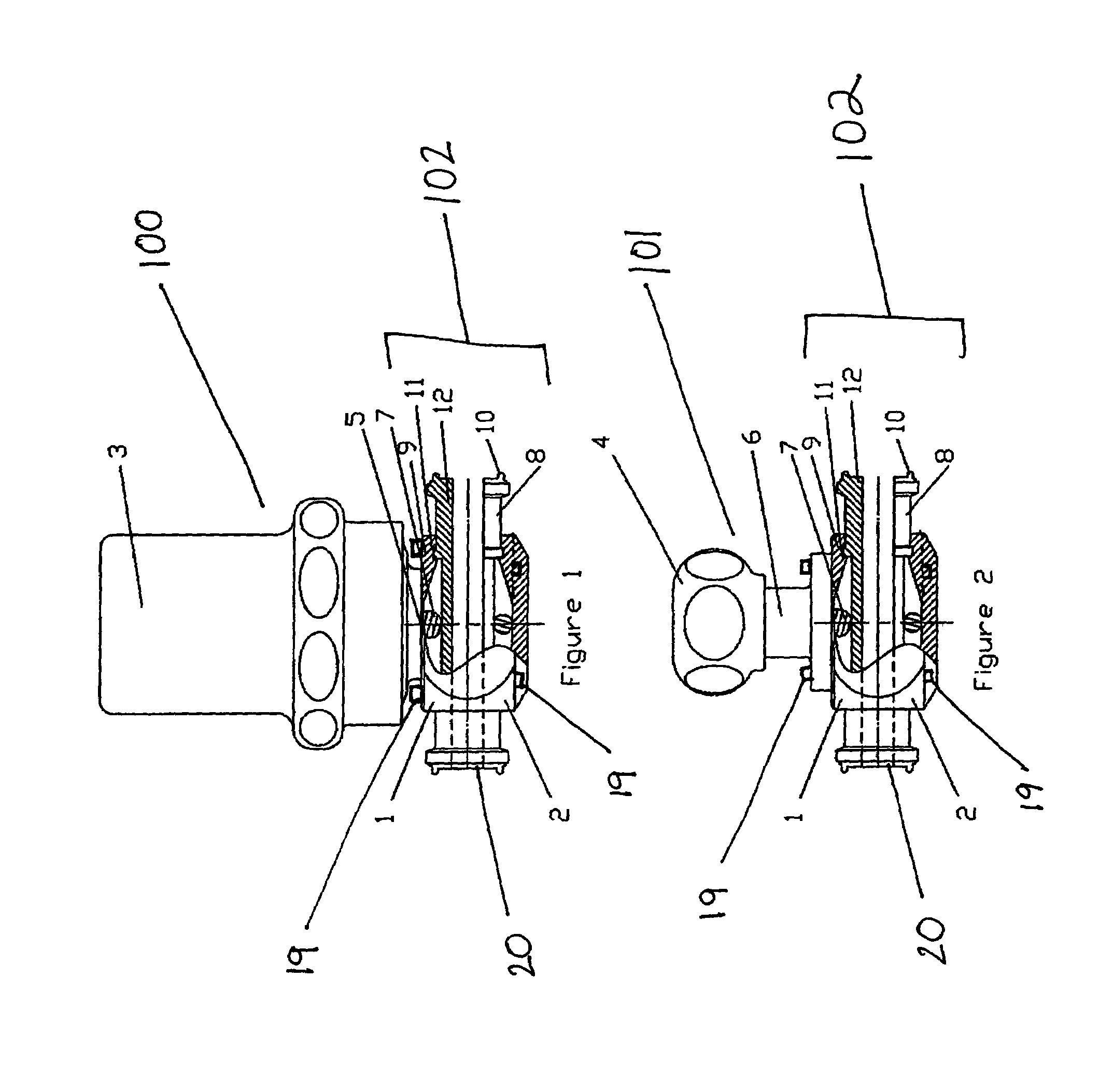

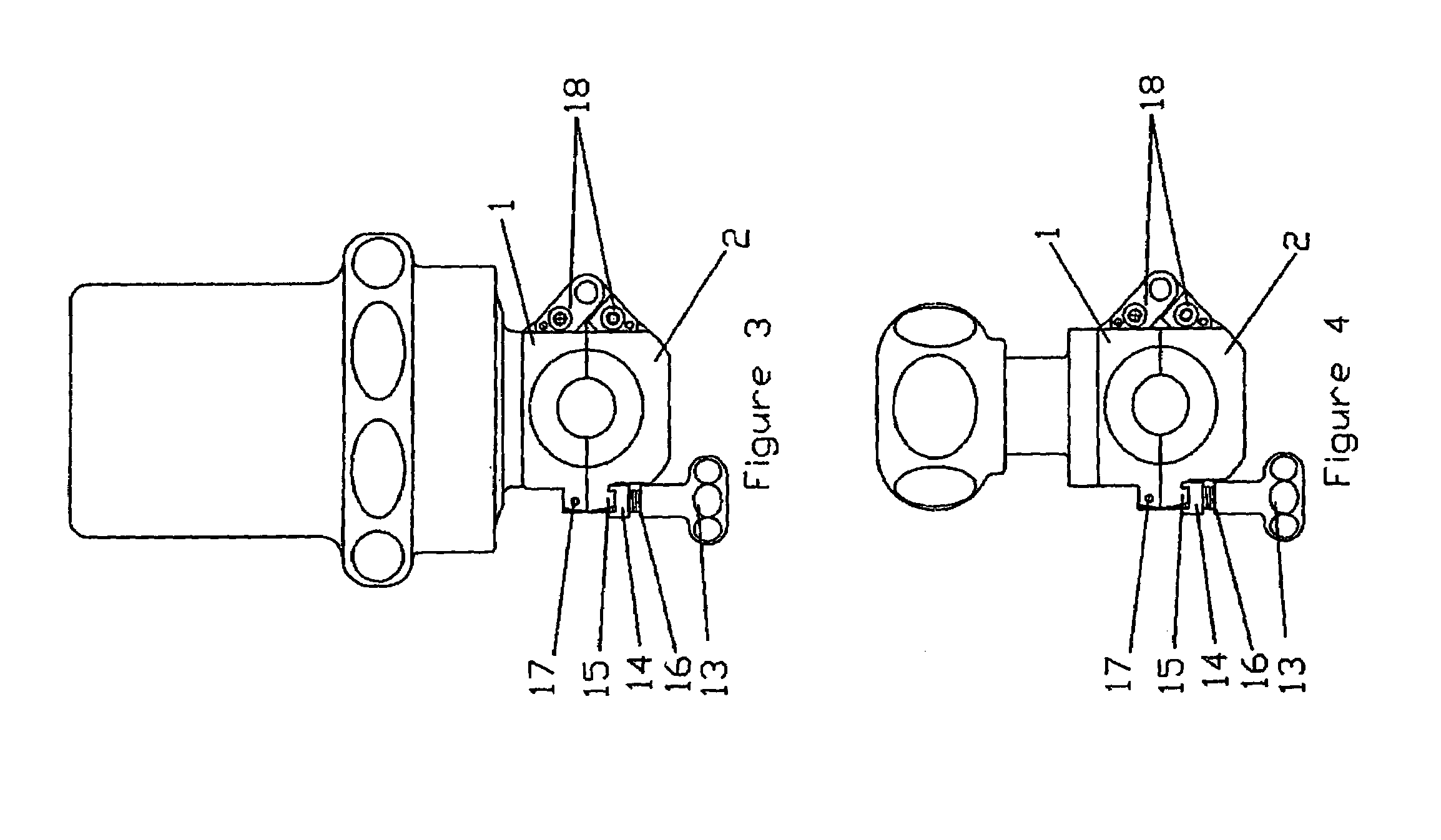

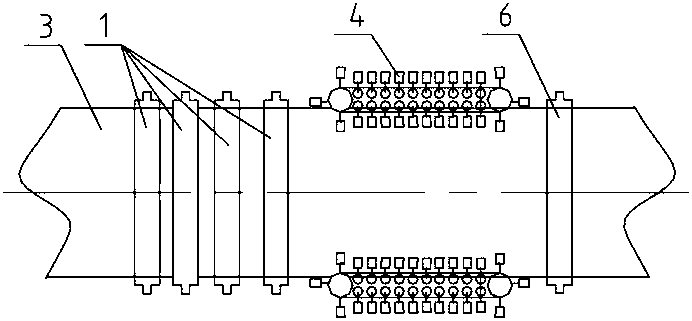

Free flow valve and element

ActiveUS6976664B2Reducing and eliminating operationEliminate needDiaphragm valvesEngine diaphragmsPinch valveFree flow

A gasketless, straight-through bore fluid flow pinch valve and flexible, removable tubing element for improved sanitary conditions in production facilities. The valve casing is joined by fittings that enable separation of the casing to remove and replace the flexible element, which includes all wetted surfaces. The fittings may be one or more hinges to permit partial separation of the valve casing, which permits the element to remain on-line while maintenance is performed on the valve. The flexible element is a silicone or PTFE-composite which is in an axially compressed state when locked into the valve by rigid, tolerance-fitted backup cups on the molded ends of the element, which increases the process life of the element.

Owner:PARKER INTANGIBLES LLC

High-wearing polytetrafluoroethylene composite material and method for making same

The invention discloses polytetrafluoroethylene composite material with high wear resistance, which is characterized in that polytetrafluoroethylene, monomer, initiator and organic solvent are reacted and polymerized to form the composite material with the structure of a core and a shell; wherein, the content for the core part of polytetrafluoroethylene fine particle is 50% to 80%; the shell part occupies 20% to 50%; the weight ratio for raw material component is as below: 1% to 35% of PTFE micropowder (granularity ranges from 30 to 300 mesh), 45% to 705 of water, 1% to 30% of monomer, 0.1% to 1% of initiator (occupying rate among monomer), 0.2% to 4% of dispersing agent, 0 to 0.5% of stabilizing agent, 0.2% to 2% of surface-active material and little organic solvent. The preparation method comprises the steps that: firstly, mixed reaction polymerization; secondly, rinsing; thirdly, dehydration; fourthly, sieving; fifthly, packing. The invention has the advantages of high wear resistance for producing PTFE composite material and other advantages.

Owner:丁永津

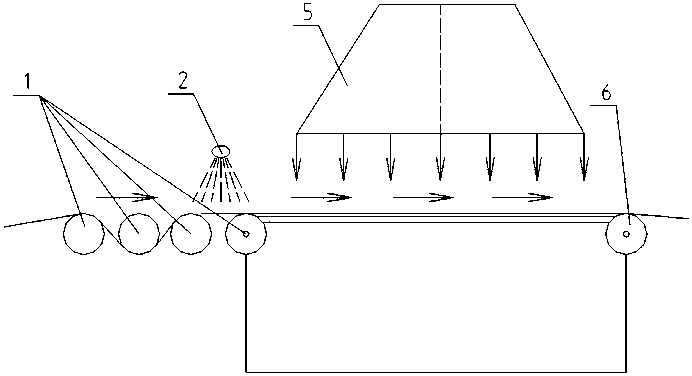

Preparation method for multifunctional PTFE composite film

ActiveCN103272497AImprove filtration efficiencyStrong resistance to water penetrationSemi-permeable membranesEmulsionUltimate tensile strength

The invention relates to a preparation method for PTFE, and particularly relates to a preparation method for a multifunctional PTFE composite film. The preparation method mainly solves the technical problems that a polytetrafluoroethylene film prepared by a conventional technology can not filter small particles and has poor resistance to water permeability and poor strength. The preparation method comprises the steps of preparing a blank by mixing materials; base-band shaping; stretching to form a film; then conveying the surface of the prepared PTFE biaxial stretching microporous film to an expansion roller; coating a fluorine resin suspended emulsion on the surface of the PTFE biaxial stretching microporous film by a spraying device; sending the surface of the PTFE biaxial stretching microporous film to an infrared or hot wind heating device by a roller cloth clamper to carry out drying and high temperature rapid calcinations, so as to make the fluorine resin coated on the surface melt; and finally winding into the film by a winding roller to obtain the multifunctional PTFE composite film.

Owner:浙江国泰萧星密封材料股份有限公司

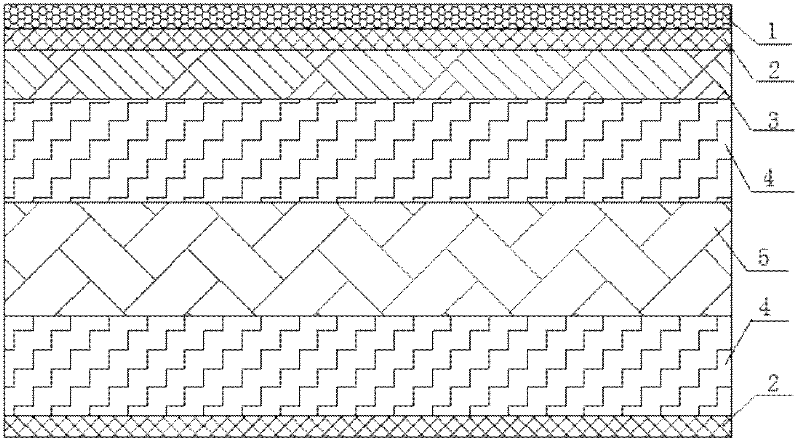

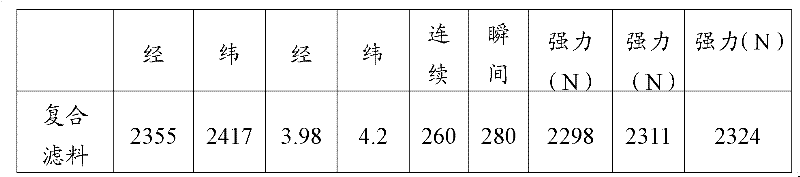

PTFE (polytetrafluoroethylene) composite filtering material and its manufacturing method

ActiveCN102357321AHigh tensile strengthAccelerated corrosionSynthetic resin layered productsGlass/slag layered productsGlass fiberSurface layer

The invention provides a PTFE composite filtering material with good comprehensive performances and low cost, as well as its manufacturing method. From a dust contact face, the PTFE composite filtering material of the invention comprises in order: a PTFE microporous membrane layer, a PTFE dipping treatment layer, a PTFE superfine surface layer, a glass fiber layer, a sewing thread base cloth layer, a glass fiber and a PTFE dipping treatment layer. The PTFE composite filtering material provided in the invention has extremely high tensile strength and corrosion resistance, good filtering performance, low operation resistance, low production cost and long service life, and is suitable for dust filtration in complicated working conditions like high operation temperature, strong corrosion, great dust content, high filtration accuracy requirement, thus being a novel filtering material of high cost performance.

Owner:昆山万瑞达工业纺织品有限公司

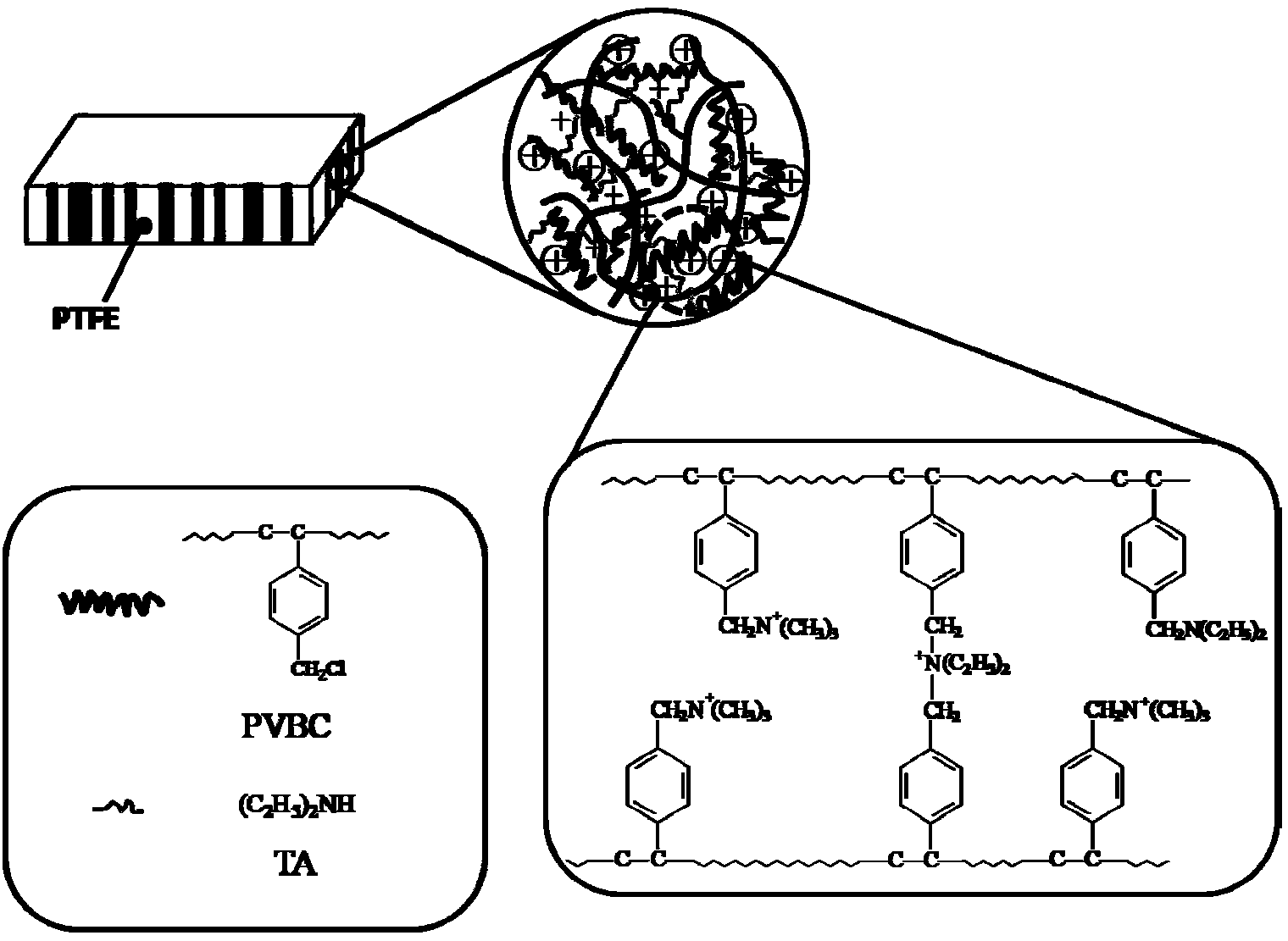

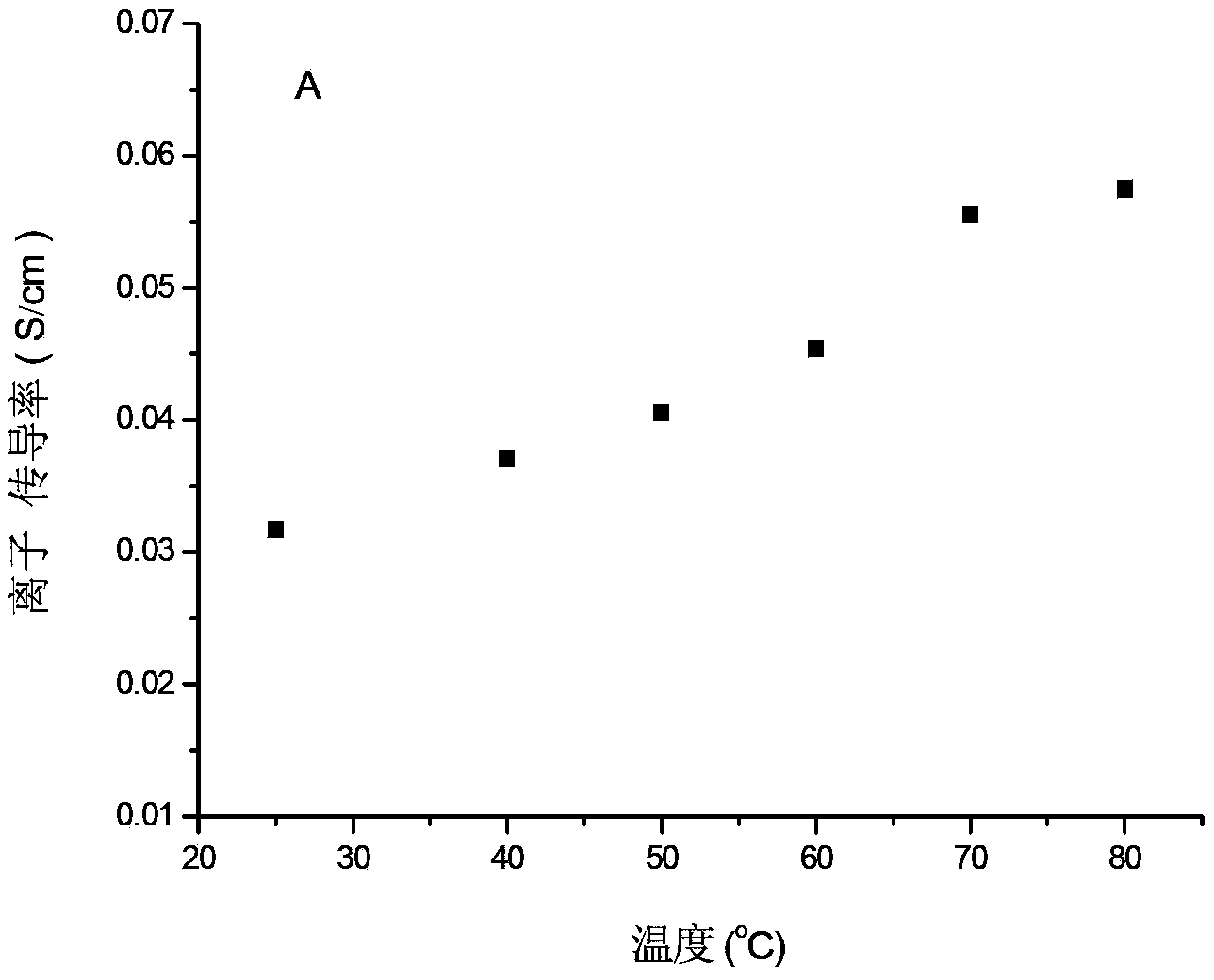

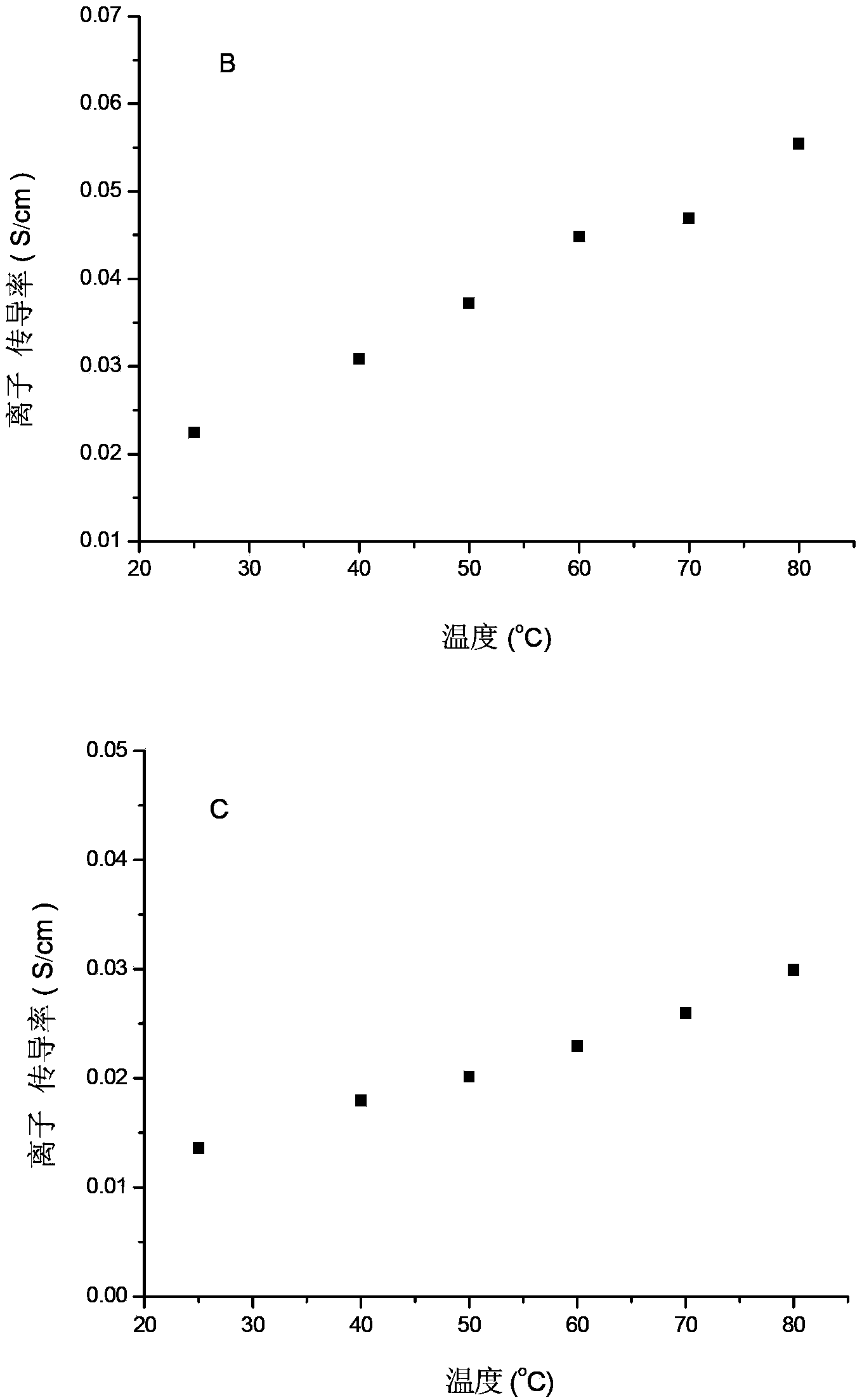

Preparation method of cross-linking type composite anion-exchange membrane

ActiveCN103387690AEfficient responseImprove ionic conductivityCell seperators/membranes/diaphragms/spacersFuel cell detailsCross-linkPolymer dissolution

A preparation method of a cross-linking type composite anion-exchange membrane comprises the following steps: soaking a (polytetrafluoroethylene) PTFE porous membrane in an ethanol solution for removing organic matters on the surface of the PTFE porous membrane; dissolving a chloromethylated polymer in an organic solvent, and adding a lower secondary amine reagent for configuration of a partly tertiary aminated polymer solution (a cross-linking precursor solution); letting in a lower tertiary amine reagent for quaternization; casting to prepare a PTFE composite membrane by a phase transformation method; immersing the prepared composite membrane in the lower tertiary amine reagent for the quaternization to obtain the anion-exchange membrane based on PTFE. The preparation method of the cross-linking type composite anion-exchange membrane is simple and efficient, and the prepared anion-exchange membrane has high ion-exchange capacity, high ionic conductivity and good dimensional stability and has wide application prospect in the alkaline fuel cells.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Polytetrafluoroethylene (PTFE) composite material and preparation method thereof

InactiveCN101613511AGood anti-friction and self-lubricating propertiesImprove wear resistanceTetrafluoroethylenePolyether ether ketone

The invention relates to a polytetrafluoroethylene (PTFE) composite material and a preparation method thereof. The composite material comprises the following components by mass percentage: 5 to 20% of polyether ether ketone (PEEK) powder and 78-94.5% of PTFE powder of which the average particle sizes are less than or equal to 100 microns, and 0.5-2.0% of nano-diamond powder of which the average particle size is less than or equal to 20 nm. The preparation method utilizes the mass percentage of the composite material of the invention and the following processes: 1. using a stirring ball mill to disperse the nano-diamond powder and dispersing agent polyvinylpyrrolidone (PVP) in ethanol medium, milling the mixture into zirconia balls being 0.2-1.0mm in the condition of rotating speed being 500-600 r / min and stirring time being 2-5h, screening the zirconia balls after even dispersion to obtain nano-diamond dispersal liquid; and the mass ratio of nano-diamond powder and dispersing agent being 10:1; 2. adding PEEK powder and PTFE powder into nano-diamond dispersal liquid and then stirring for 1-3h, drying the stirred mixture at a temperature of 70-90 DEG C after even mixing to obtain mixed powder; 3. cold press molding; and 4. high-temperature sintering to obtain the PTFE composite material.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method of high-filler-filling-amount polytetrafluoroethylene composite film material

The invention provides a preparation method of a high-filler-filling-amount polytetrafluoroethylene composite film material. According to the main content of the preparation method, by means of high-speed mixing, cold pressing blank formation, sintering formation, turning film formation and calendaring aftertreatment, the polytetrafluoroethylene composite film material with the filling amount of inorganic filler as high as 20wt% or over is prepared; and besides, through design of the dispersion states of multiple kinds of inorganic filler with different functions and adjustment of the preparation technology, the inorganic filler / polytetrafluoroethylene composite film material which is controllable in film structure and excellent in mechanical performance, electrical conductivity, heat conductivity and wear resistance can be prepared. The high-filler-filling-amount polytetrafluoroethylene composite film material has the advantages of being controllable in film structure, excellent in mechanical performance, flexible and adjustable in functionality, simple in preparation technology and equipment and suitable for industrialization. The high-filler-filling-amount polytetrafluoroethylene composite film material has remarkable research value and application prospect in the field of high-performance high-functionality PTFE composite film materials.

Owner:SICHUAN UNIV

High-load-bearing low-friction polytetrafluoroethylene friction material and its manufacturing process

InactiveCN102276951AHigh mechanical strengthReduce coefficient of frictionOther chemical processesHigh loadBasalt fiber

The invention which relates to a PTFE friction material with high bearing and a low friction coefficient and a manufacturing process thereof belongs to the field of materials with high bearing and low friction coefficients and manufacturing processes thereof. The PTFE friction material which mainly comprises components of PTFE, poly-p-hydroxybenzoate, expanded graphite, a basalt fiber, a silane or titanate coupling agent and the like is manufactured by adopting a mixing technology of ultrasonic vibration-swirling and the manufacturing process of vacuum cold press sintering or vacuum hot pressing molding. The mechanical strength of the PTFE composite material is obviously increased, the friction coefficient of the PTFE composite material is reduced, and the PTFE composite material which has obvious progresses in aspects of tensile strength, ball indentation hardness, wear resistance and the like allows application demands of harsh industrial fields and transport fields of railway freight car bogies, slide slewing bearings and the like to be satisfied. The PTFE friction material of the invention has the advantages of low friction coefficient, and good bearing performance and corrosion resistance, and the manufacturing process of the PTFE friction material has the advantages of simplicity, low cost, and wide practicality.

Owner:CHINA UNIV OF MINING & TECH +1

Aerogel/PTFE composite insulating material

ActiveUS20050143515A1Increase flexibilityHigh strengthDigital data processing detailsSemiconductor/solid-state device detailsInto-structureThermal conductivity

A material comprising aerogel particles and a polytetrafluoroethylene (PTFE) binder is formed having a thermal conductivity of less than or equal to 25 mW / m K at atmospheric conditions. The material is moldable or formable, having little or no shedding of filler particles, and may be formed into structures such as tapes or composites, for example, by bonding the material between two outer layers. Advantageously, composites may be flexed, stretched, or bent without significant dusting or loss of insulating properties.

Owner:WL GORE & ASSOC INC

Superfine kaoline filled PTFE composite material and preparation method thereof

InactiveCN103509300AWide range of applicationsSimple preparation processTetrafluoroethyleneSURFACTANT BLEND

The invention provides a superfine kaoline filled PTFE composite material and a preparation method thereof. The composite material mainly comprises the following raw materials in parts by weight: 80 to 95 parts of teflon, 5 to 20 parts of superfine kaoline, 0.01 to 1 part of a filler, and 0.005 to 0.1 part of a surfactant. The superfine kaoline filled PTFE composite material provided by the invention has the advantages that as superfine kaoline is low in cost, wide in application range and soft, can be dispersed in suspended water, and has good plasticity, high cohesiveness and excellent electric insulation property, the composite material is simple in preparation technology, is economical and practical, and has high market competitiveness.

Owner:ZHEJIANG UNIV

Potassium hexatitanate whisker reinforced PTFE composite material

InactiveCN1401699AImprove performanceImprove wear resistanceHeat deflection temperaturePolymer science

A teflon composite material reinforced by the crystal whisker of potassium hexatitanate, which has 0.5-2 microns of diameter and whose surface has been treated by silane or titanate coupling agent, is disclosed. Its advantages are high impact strength, high temp for thermal deformation, high elongation for break, high tension strength and high antiwear nature.

Owner:NANJING UNIV OF TECH

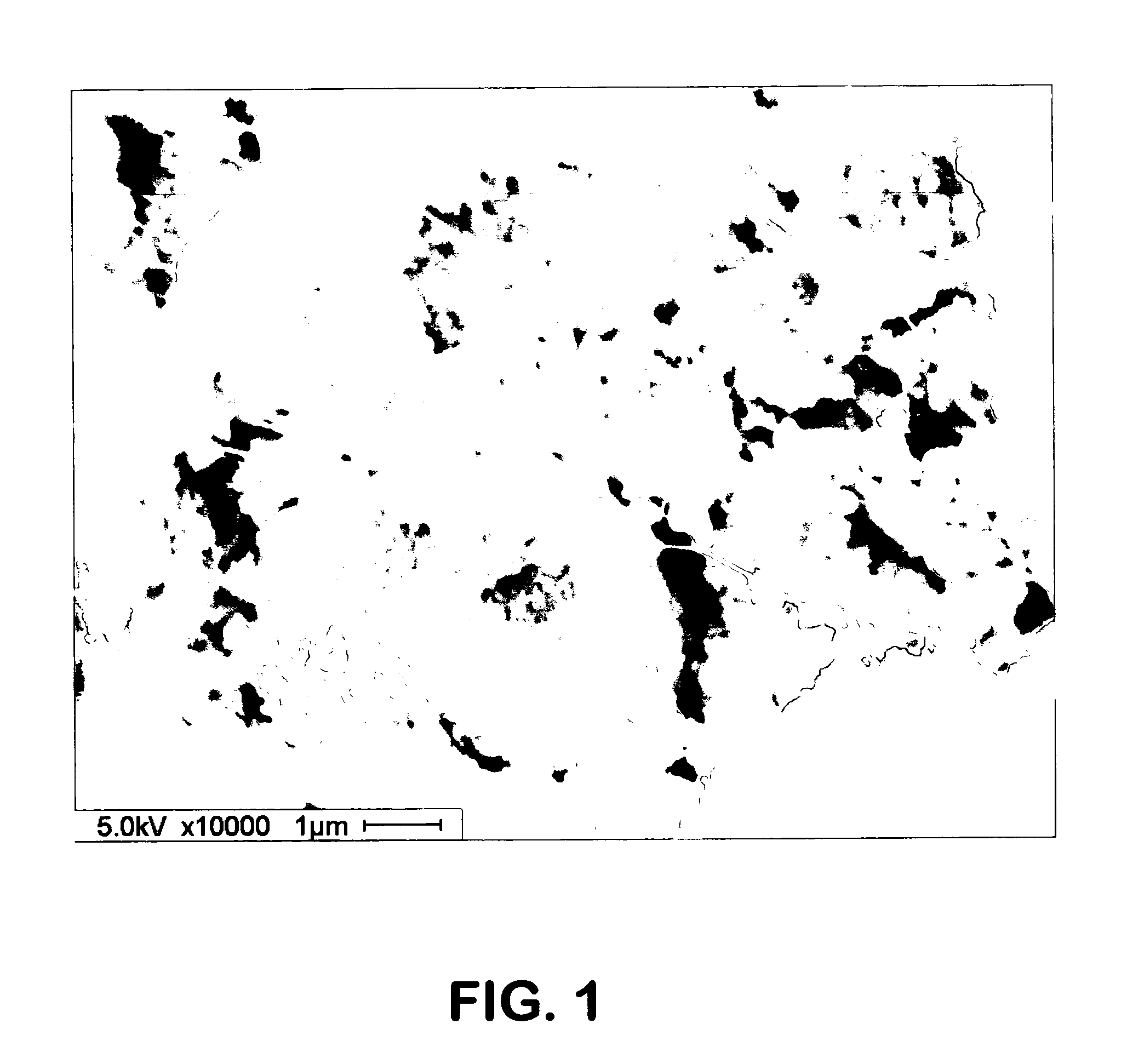

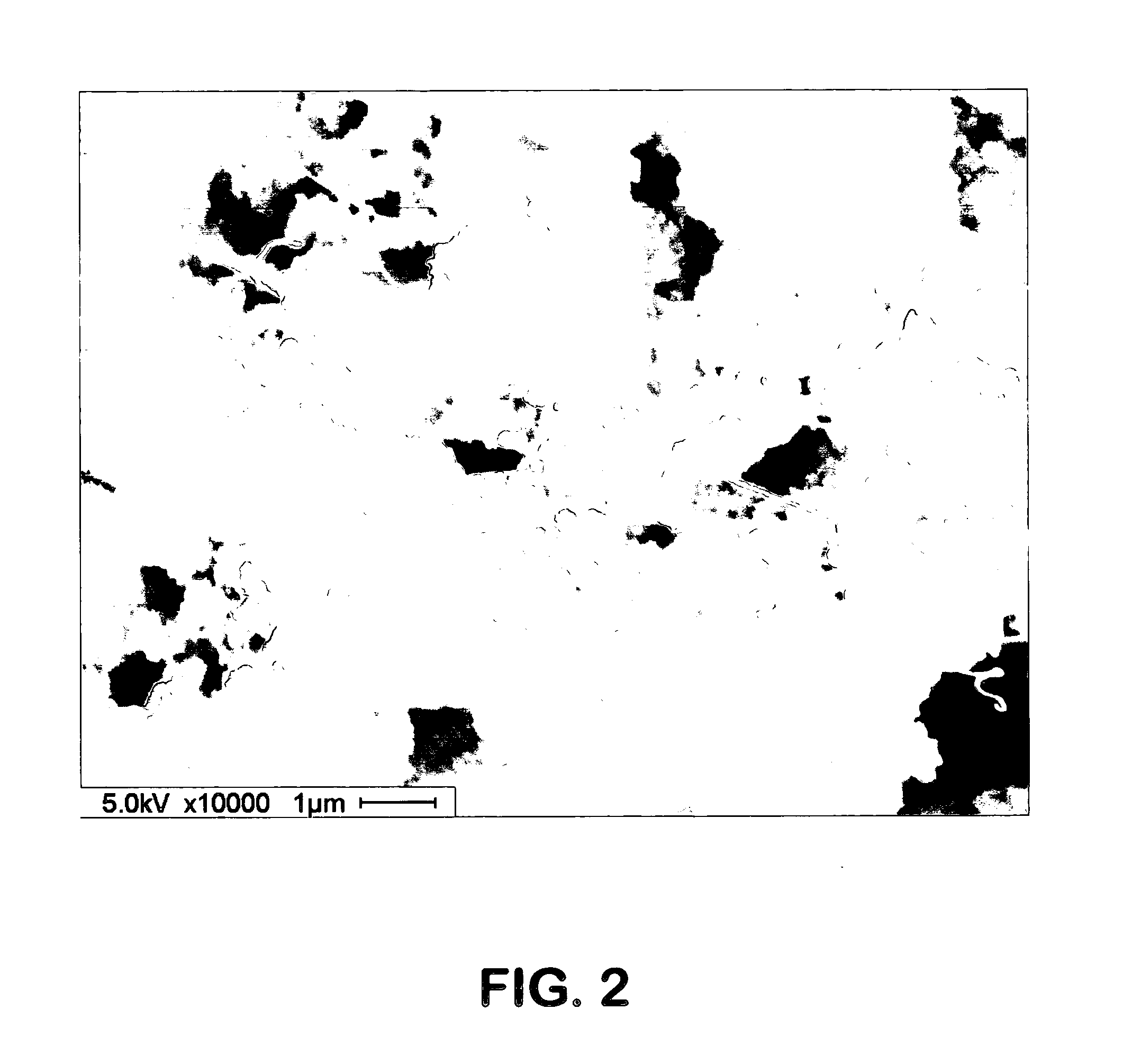

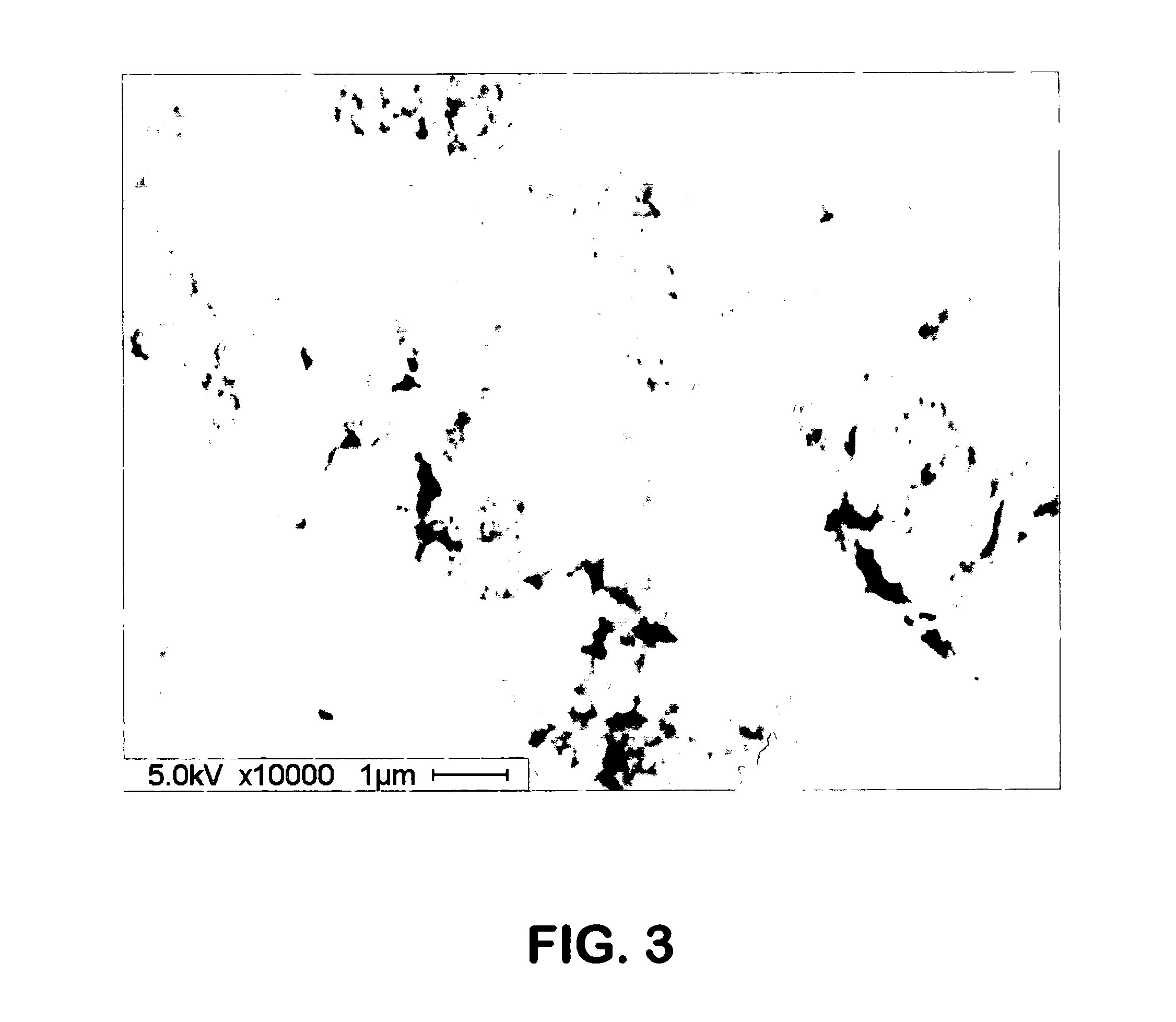

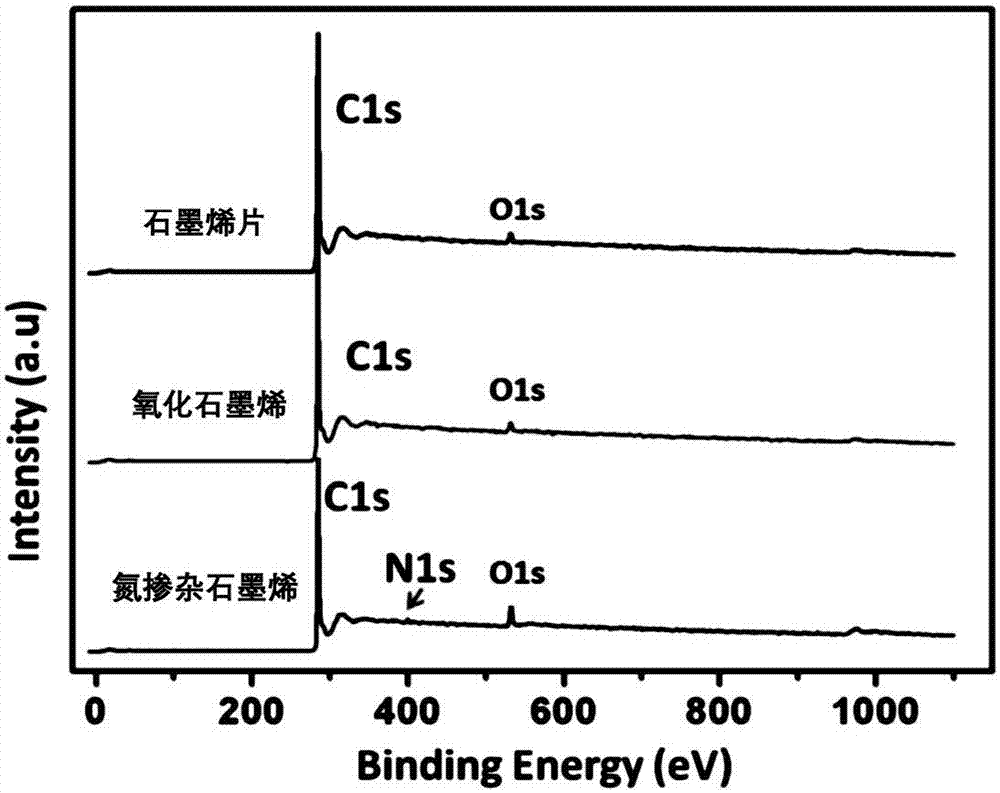

Preparation method of nitrogen-doped graphene/polytetrafluoroethylene (PTFE ) composite material

The invention relates to a preparation method of a nitrogen-doped graphene / polytetrafluoroethylene (PTFE) composite material. The preparation method comprises the following steps: treating a graphene sheet with strong acid to prepare a nitrogen-doped graphene precursor; or carrying out amino acid chemical reaction on graphene oxide to prepare nitrogen-doped graphene; uniformly mixing one of the prepared nitrogen-doped graphene precursor or the nitrogen-doped graphene with PTFE powder and an auxiliary agent, wherein the weight ratio of the materials is that the nitrogen-doped graphene precursor or the nitrogen-doped graphene to the PTFE to the auxiliary agent is 1 to (100 to 200) to (10 to 25) and the auxiliary agent is prepared from the components according to a weight ratio: carbon fiber to copper powder to glass fiber to cuprous chloride to a silane coupling agent to nano zinc oxide powder to silicon carbide of (5 to 12) to (10 to 40) to (3 to 7) to (2 to 4) to 1 to (3 to 9) to (1 to 5); carrying out die pressing and carrying out temperature control sintering to obtain the nitrogen-doped graphene / PTFE composite material. The nitrogen-doped graphene / PTFE composite material has the advantages of high temperature resistance and better friction and abrasion performances.

Owner:GREATOO INTELLIGENT EQUIP INC +1

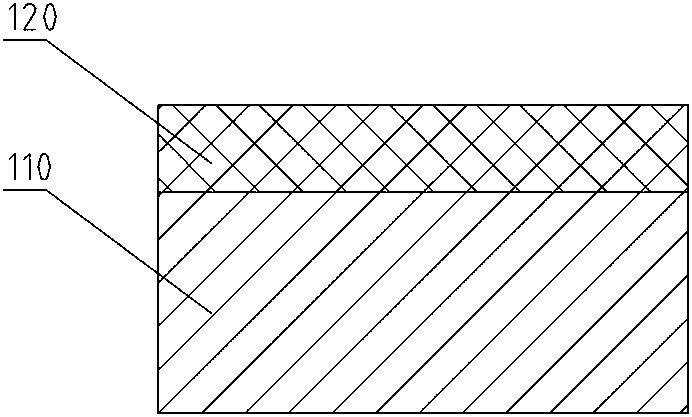

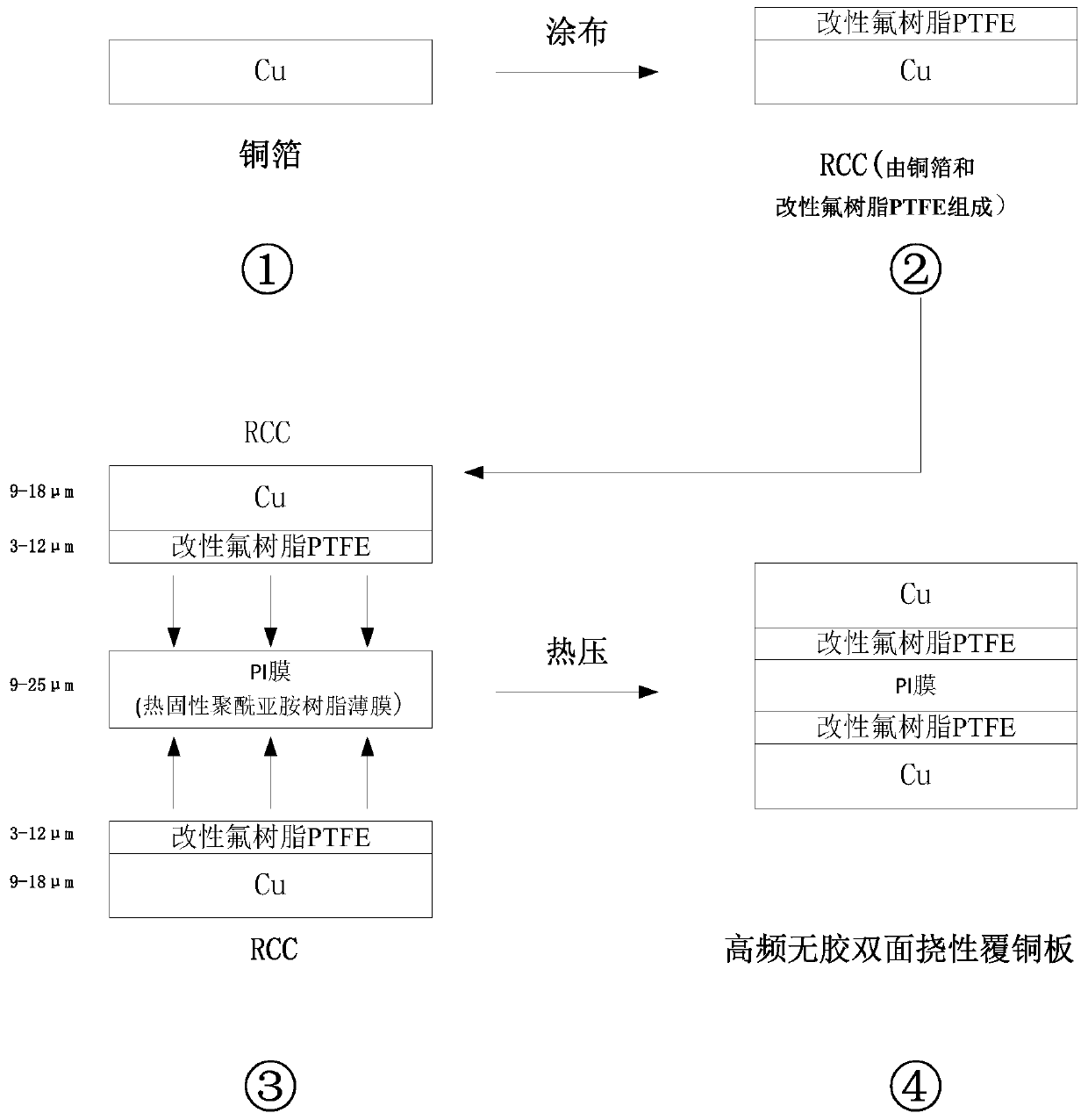

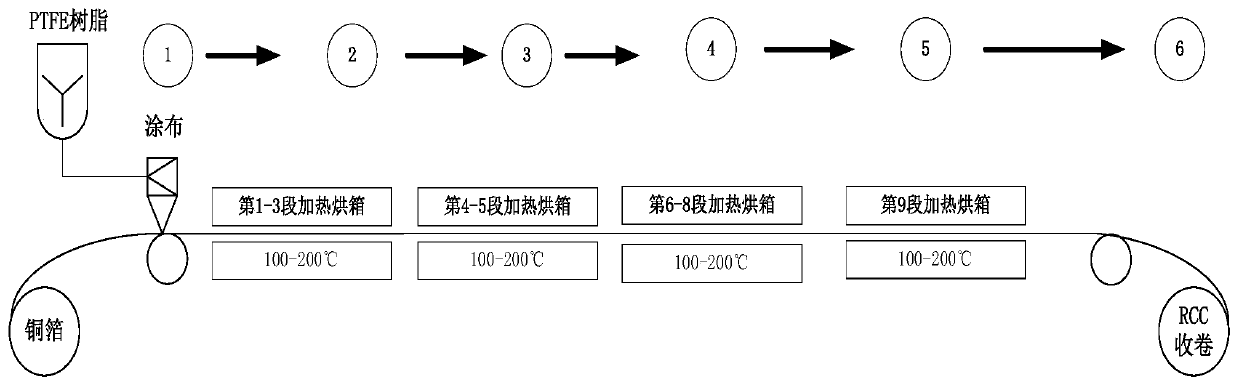

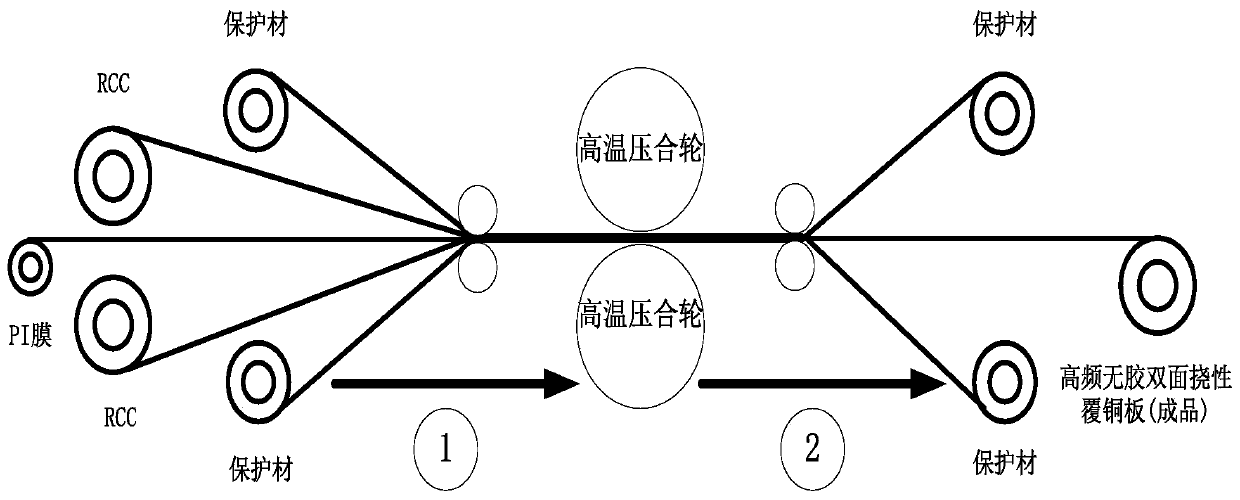

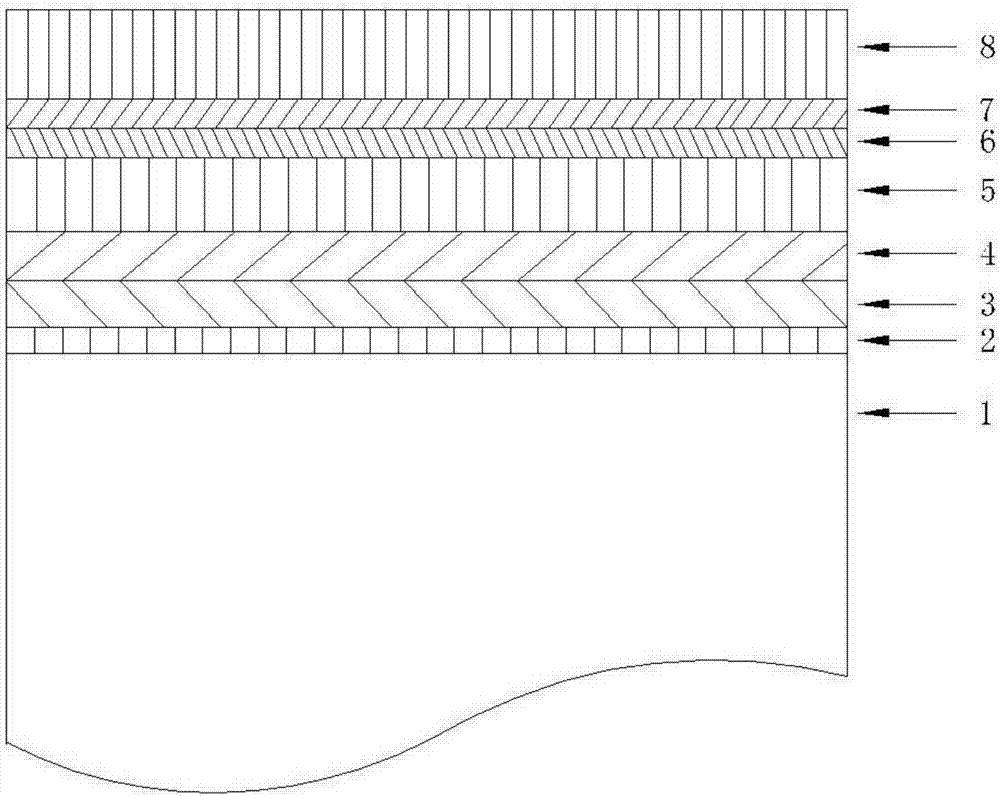

High-frequency glue-free double-sided flexible copper clad laminate and preparation method thereof

InactiveCN110181904ATransmission signal loss is smallHigh peel strengthLamination ancillary operationsSynthetic resin layered productsAdhesion forceDielectric loss

The invention discloses a high-frequency glue-free double-sided flexible copper clad laminate, which comprises an upper layer copper foil, a lower layer copper foil and an insulating layer sandwichedbetween the two copper foil layers, wherein the insulating layer is a PTFE / PI / PTFE composite film comprising a thermosetting polyimide resin film positioned in the middle and a modified fluororesin PTFE positioned on the upper side and the lower side of the thermosetting polyimide resin film PI. The invention further provides a preparation method of the high-frequency glue-free double-sided flexible copper clad laminate, wherein the preparation method comprises a coating process and a pressing process. According to the present invention, the PI film is subjected to plasma surface treatment toatomize the surface so as to increase the adhesion force after the hot pressing, and the roughness of the copper foil is low, such that the prepared copper clad laminate has characteristics of good peel strength, low impedance, low dielectric constant, low dielectric loss and low signal loss.

Owner:曾瑾

Scale-inhibiting copper-based heat exchange surface and manufacturing method thereof

ActiveCN101956185AHas non-wetting propertiesImprove wettabilityLiquid/solution decomposition chemical coatingCopperMetal

The invention discloses a copper-based heat exchange surface. A Ni-P-PTFE composite clad layer covers on the surface of a copper-based material and has the excellent coefficients of heat conductivity, and simultaneously, can reduce the surface energy of the copper-based material to fulfill the aim of inhibiting scale. In addition, the invention also discloses a manufacturing method of the copper-based heat exchange surface. The copper-based heat exchange surface and the method have the advantages that Ni-P-PTFE is plated on the surface of the copper-based material, and water molecules cannot moisten the surface of PTFE fully so as to form attached scale deposits by utilizing the characteristic of low PTFE surface wettability; the surface energy of the material is reduced on the premise ofensuring the excellent coefficients of heat conductivity so as to fulfill the aim of inhibiting scale; in order to improve the heat conductivity of the surface of red copper, basic plating solution containing metal Ni is adopted in a chemical composite plating method, and the heat conductivity is high; and the copper-based heat exchange surface has the low surface energy and low adsorptive capacity on scaling crystal nuclei, and simultaneously, has the nonwetting characteristic and is not favorable for depositing and aggregating the scale deposits.

Owner:广东高而美制冷设备有限公司

Preparation method of PTFE composite nanofiltration membrane for water filtration purification

InactiveCN110449038APlay a secondary interception roleDecreased skeletal reinforcementSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisCross-linkFiltration

The invention relates to the technical field of water treatment, and discloses a preparation method of a PTFE composite nanofiltration membrane for water filtration purification. The preparation method comprises the following steps of 1) immersing a hydrophobic polytetrafluoroethylene ultrafiltration base membrane in a carboxymethyl chitosan solution to obtain a hydrophilic modified polytetrafluoroethylene ultrafiltration base membrane; 2) immersing the hydrophilic modified polytetrafluoroethylene ultrafiltration base membrane into a sodium alginate solution, adding rod-shaped nano zinc oxide,and dropwise adding a calcium chloride solution for a reaction to obtain an intermediate polytetrafluoroethylene ultrafiltration base membrane; 3) immersing the intermediate polytetrafluoroethylene ultrafiltration base membrane into a polyethyleneimine solution, taking out the base membrane, and immersing the base membrane in a trimesoyl chloride solution for an interfacial polymerization reaction to obtain a nascent-state composite nanofiltration membrane; 4) placing the nascent-state composite nanofiltration membrane in an oven for heating, curing and cross-linking to obtain the PTFE composite nanofiltration membrane. According to the preparation method, the polytetrafluoroethylene base membrane is not severely shrunk under heating conditions, and the reduction of the binding force of acomposite nanofiltration membrane retaining layer and the base membrane is avoided.

Owner:陈圆圆

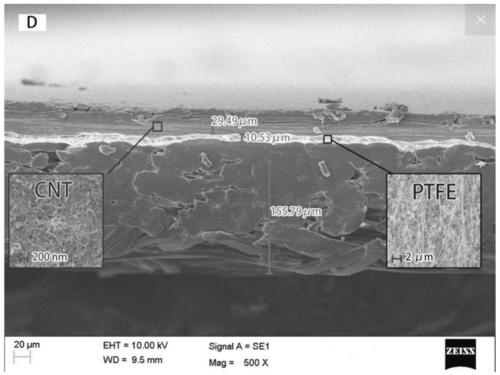

Porous gas diffusion layer and preparation method thereof

InactiveCN104779399AFacilitate the commercialization processImprove performanceCell electrodesFuel cell detailsEmulsionDiffusion resistance

The invention provides a preparation method of a porous gas diffusion layer. The preparation method comprises the following steps: adding a pore forming agent into PTFE emulsion to obtain PTFE composite emulsion; loading the composite emulsion onto a conductive supporter to form a coating-modified conductive supporter; sintering the coating-modified conductive supporter; and soaking the sintered coating-modified conductive supporter in a pore-forming-agent-removing agent to etch off the pore forming agent so as to obtain the porous gas diffusion layer with a porous structure. The invention further provides a porous gas diffusion layer. In the provided porous gas diffusion layer, a three-dimensional channel structure is formed in PTFE through a technical design, and thus the gas diffusion resistance is reduced. The provided porous gas diffusion layer can prominently improve the performance of a metal-air battery under a high power (namely high current discharge) condition.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

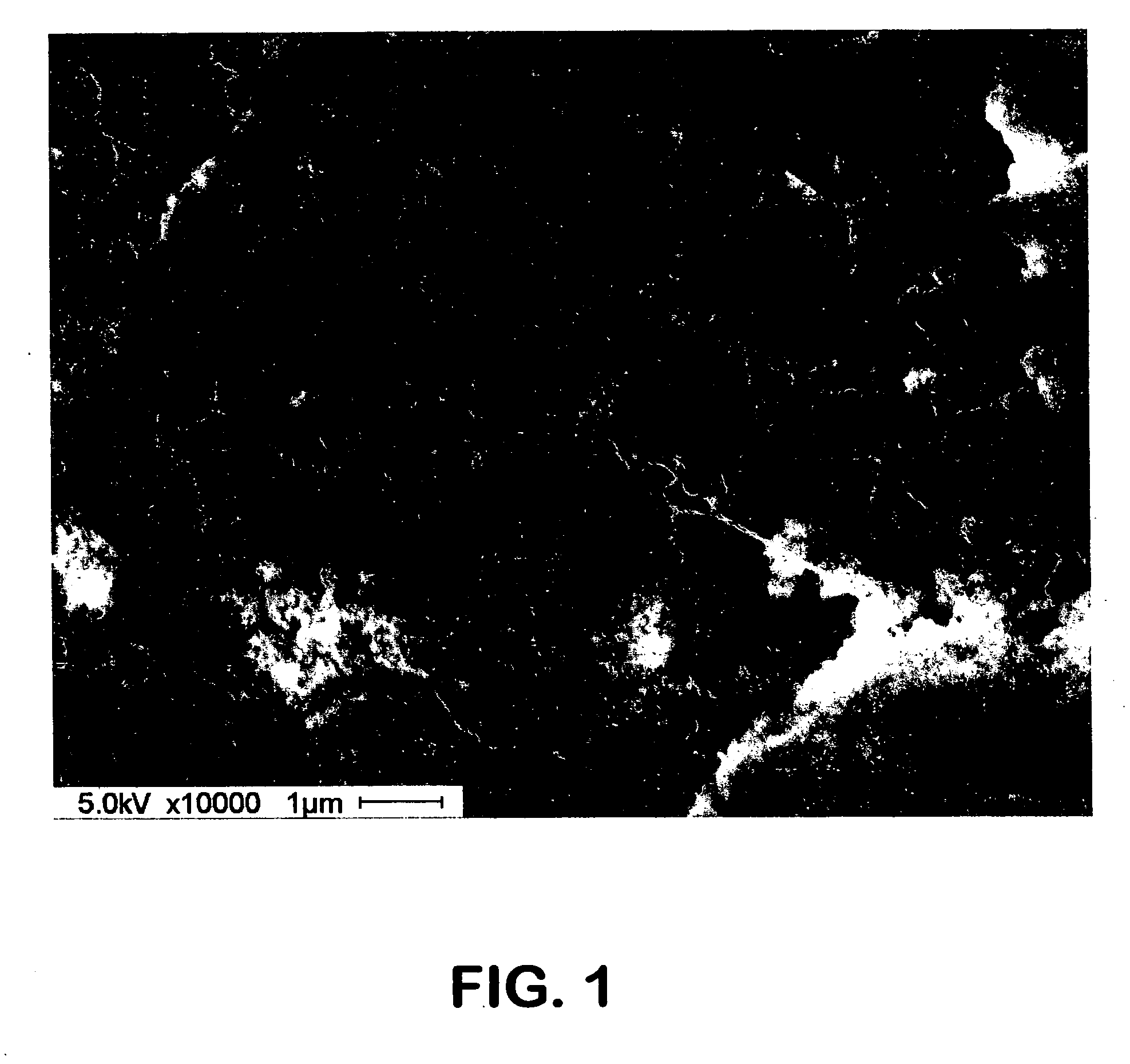

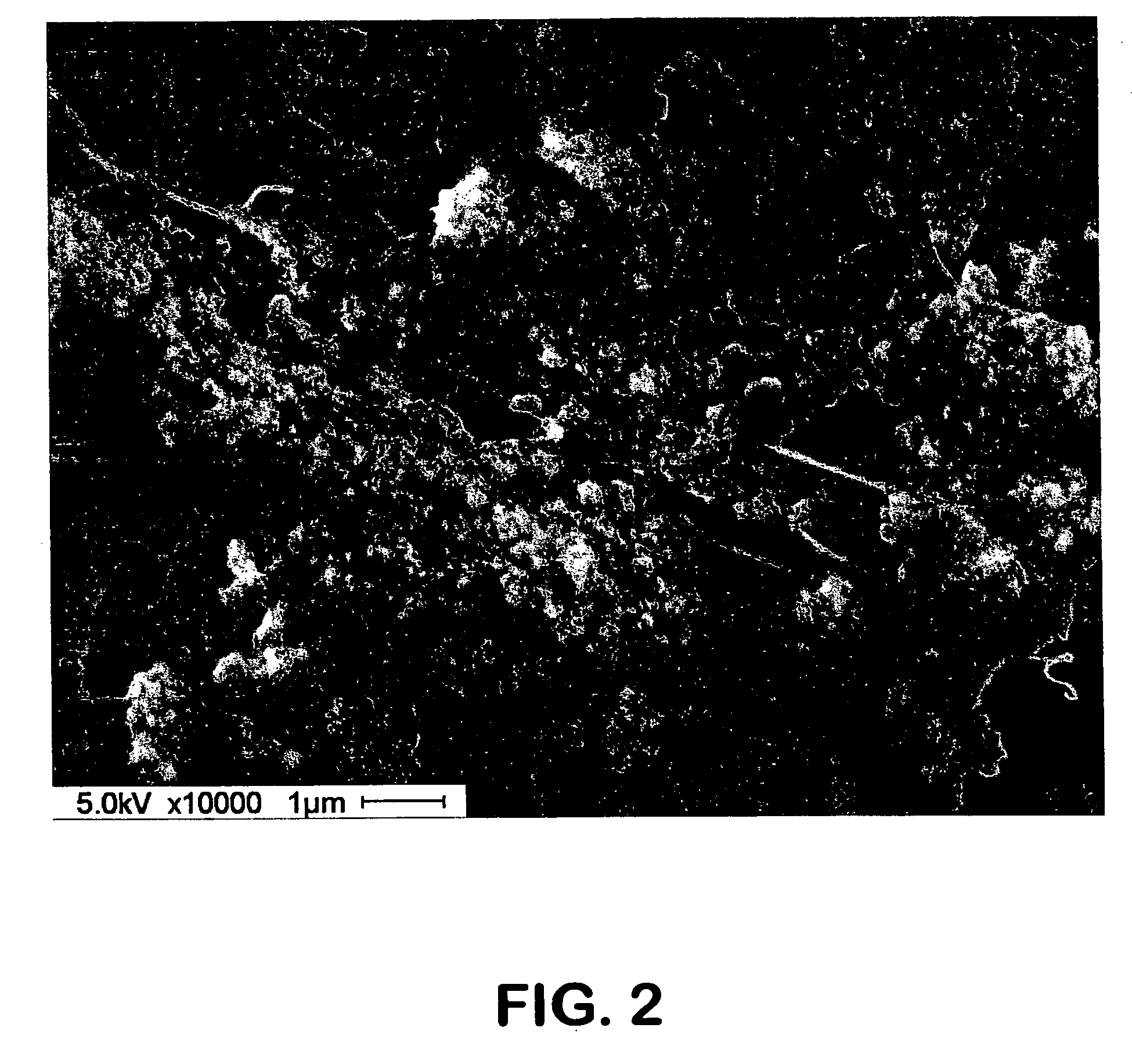

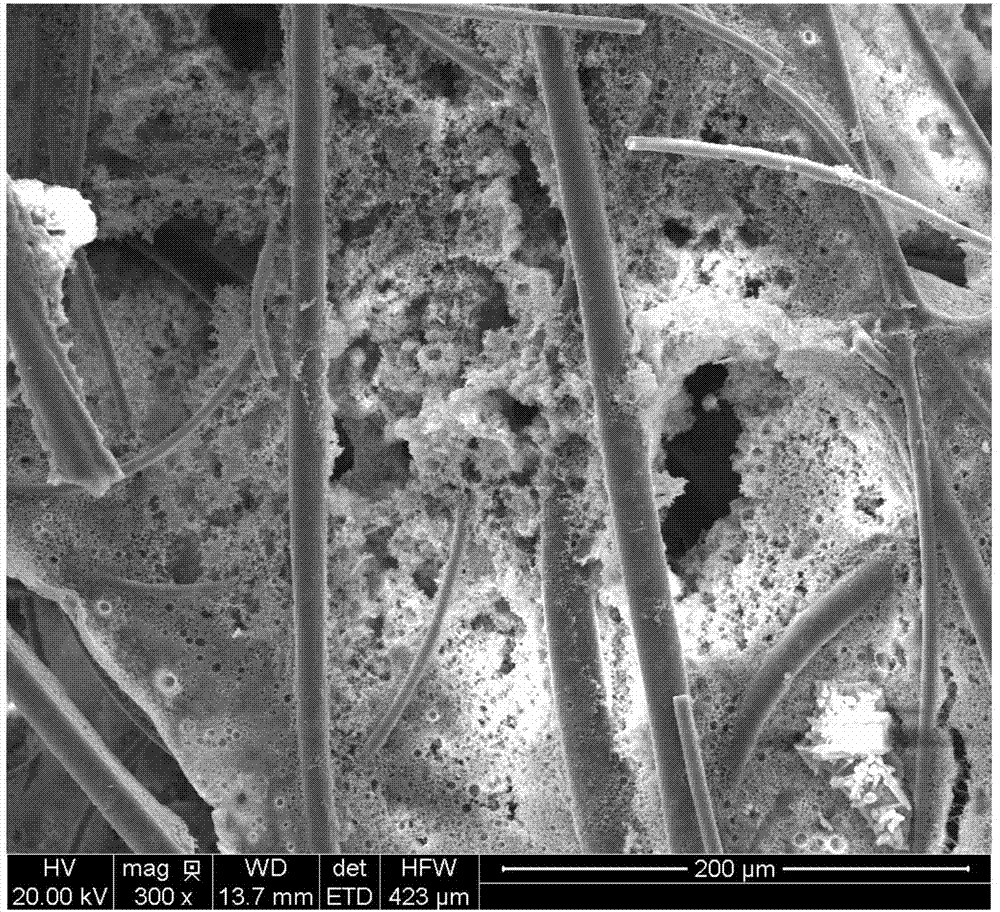

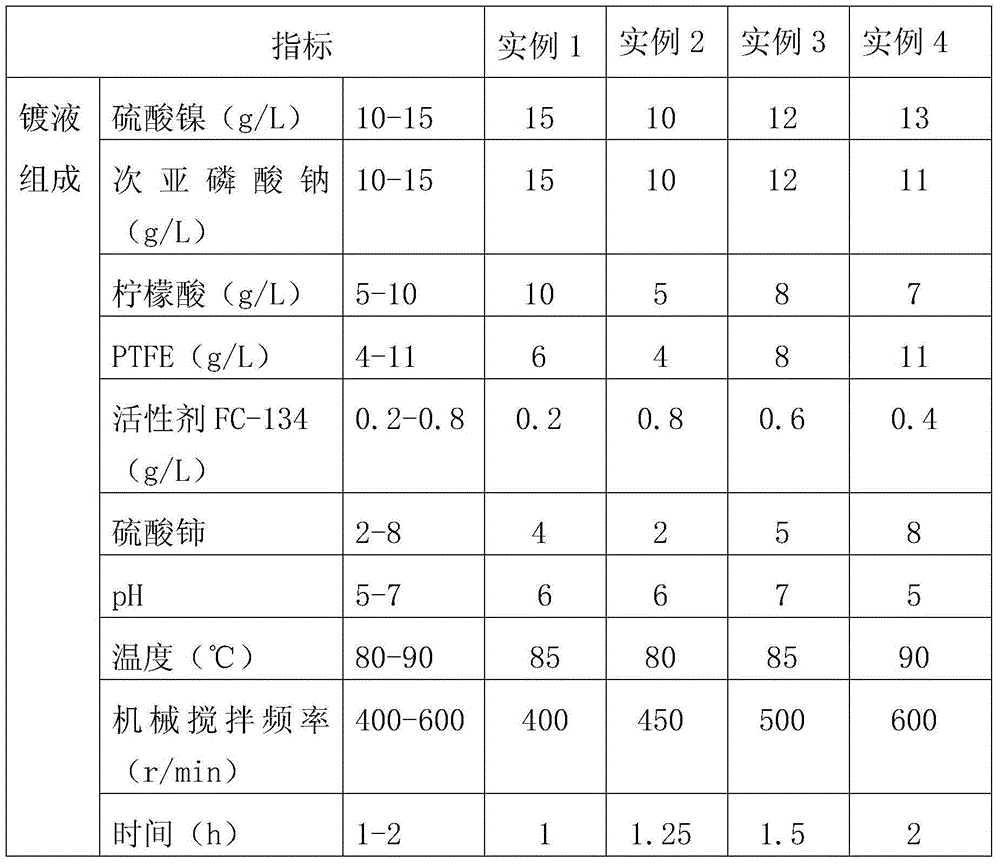

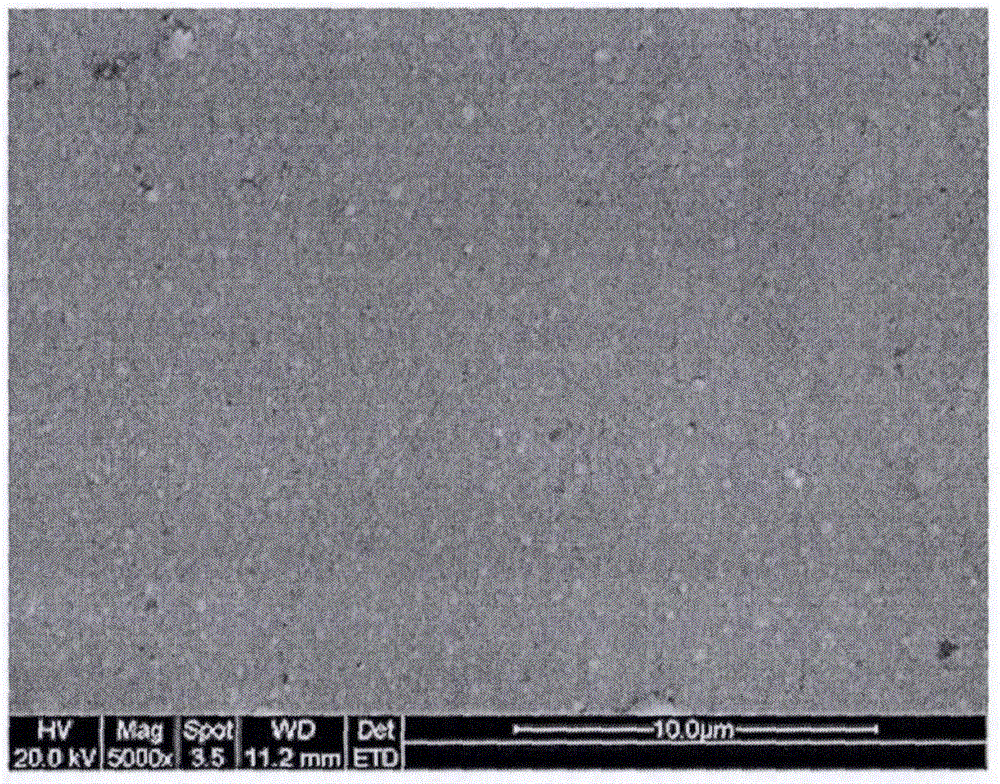

Preparation process of chemical plating rare earth cerium Ni-P-PTFE (Polytetrafluoroethylene) composite coating

ActiveCN104419919ASimple processLow costLiquid/solution decomposition chemical coatingActive agentPtfe composite

The invention relates to a preparation method of a chemical sedimentation rare earth cerium Ni-P-PTFE (Polytetrafluoroethylene) composite coating. Based on a chemical Ni-P-PTFE composite plating process and the characteristics of a rare earth cerium atom, the Ni-P-PTFE composite coating is prepared on a steel 20 matrix by virtue of a mechanical stirring method. The method comprises the following specific steps of pretreating a sample; preparing a plating solution containing 10-15g / L nickel sulfate, 10-15g / L sodium hypophosphite, 5-10g / L citric acid and 2-8g / L cerium sulfate; preparing a mixed solution of 4-11g / L PTFE emulsion and 0.2-0.8g / L an active agent FC-134; mixing the plating solution with the mixed solution; cleaning the sample; activating with hydrochloric acid; washing with water; plating; and washing with water and drying. The Ni-P-PTFE composite coating prepared by the preparation method, which is disclosed by the invention, has the advantages of small friction coefficient, good wear resistance and antifouling property and the PTFE particles in the coating are evenly distributed.

Owner:PETROCHINA CO LTD +1

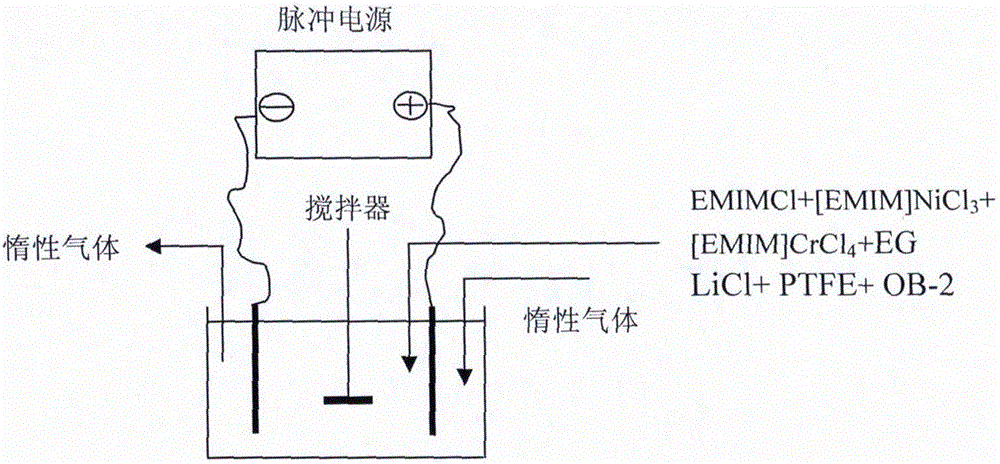

Method for electroplating Ni-Cr-PTFE composite coating in ionic liquid

InactiveCN105862093AEvenly distributedImprove anti-friction performanceElectrolytic coatingsImpulse frequencyAverage current

The invention discloses a method for electroplating a Ni-Cr-PTFE composite coating in ionic liquid. In a non-water system and an inert-gas atmosphere, [BMIM]NiCl3 liquid containing nickel ions, [BMIM]CrCl4 liquid containing chromium ions, LiCl, PTFE and N,N-dimethyldodecylamine oxide (OB-2) are added into a certain amount of mixed solvent of 1-ethyl-3-methylimidazolium chlorine (EMIMCI) and ethylene glycol (EG), mechanical stirring and ultrasonic wave stirring are conducted for a certain time until the mixture is mixed evenly, and electroplate liquid is obtained; a cathode electrode and an anode electrode are placed into an electroplating bath, a certain space between the electrodes, temperature, impulse frequency, pulse duty factor, deposition period and average current density are kept, pulse electroplating is conducted at a certain stirring speed, and after electroplating, washing and drying are conducted, and the Ni-Cr-PTFE composite coating is obtained, wherein a pretreated matrix serves as the cathode electrode, and a platinum sheet or graphite serves as the anode electrode. Due to the fact that the PTFE and Cr are added, the antifriction performance and hardness of the coating are obviously improved, the process procedure is simple, the equipment investment is low, and the method is environmentally friendly and economical.

Owner:ANQING NORMAL UNIV

Composite Separators for Li-ion Batteries

InactiveCN102270756AIntegrity guaranteedQuick breakCell component detailsPorous membranePolypropylene

The invention discloses a polytetrafluoroethylene composite diaphragm for a lithium ion battery. It includes a diaphragm, the diaphragm is formed by the upper polypropylene microporous membrane and the lower polypropylene microporous membrane or the upper polyethylene microporous membrane and the lower polyethylene microporous membrane, characterized in that the upper polypropylene microporous membrane A polytetrafluoroethylene microporous membrane is arranged between the porous membrane and the lower polypropylene microporous membrane or between the upper polyethylene microporous membrane and the lower polyethylene microporous membrane. The polytetrafluoroethylene composite diaphragm for lithium ion battery of the present invention not only has the low closed cell temperature of the lithium ion battery diaphragm, but also has the performance of high membrane rupture temperature, and effectively guarantees the safety and reliability of the lithium ion battery during use sex. The polytetrafluoroethylene composite separator for the lithium ion battery of the present invention can be used as a separator between the positive electrode and the negative electrode of the lithium ion battery.

Owner:LINGQI ENVIRONMENTAL PROTECTION EQUIP FACTORY SHANGHAI

Preparation technology of chemical plating Ni-P-PTFE composite coating

InactiveCN106958013AGood chemical stabilityGood chemical propertiesLiquid/solution decomposition chemical coatingChemical platingWear resistance

The invention discloses a preparation technology of a chemical plating Ni-P-PTFE composite coating, and belongs to the technical field of metal surface treatment. The preparation technology comprises the following steps: (1) a low-carbon steel heat exchange surface is subjected to preliminary treatment; (2) Ni-P-PTFE composite coating liquid is prepared, and a Ni-P-PTFE composite coating is prepared on the low-carbon steel heat exchange surface by employing the prepared Ni-P-PTFE composite coating liquid; and (3) the microbial fouling inhibition and alleviation performances of the Ni-P-PTFE composite coating are evaluated. The abrasive resistance and the drainage effect of the surface of the Ni-P-PTFE composite coating can be improved effectively, so that the Ni-P-PTFE composite coating can adapt to multiple complex environments. The form and stable Ni-P-PTFE composite coating is formed on a Q235 carbon steel base material, a plating solution is stable in a plating application process, and the uniform and stable Ni-P-PTFE composite coating can be obtained nearly without mixing.

Owner:NORTHEAST DIANLI UNIVERSITY

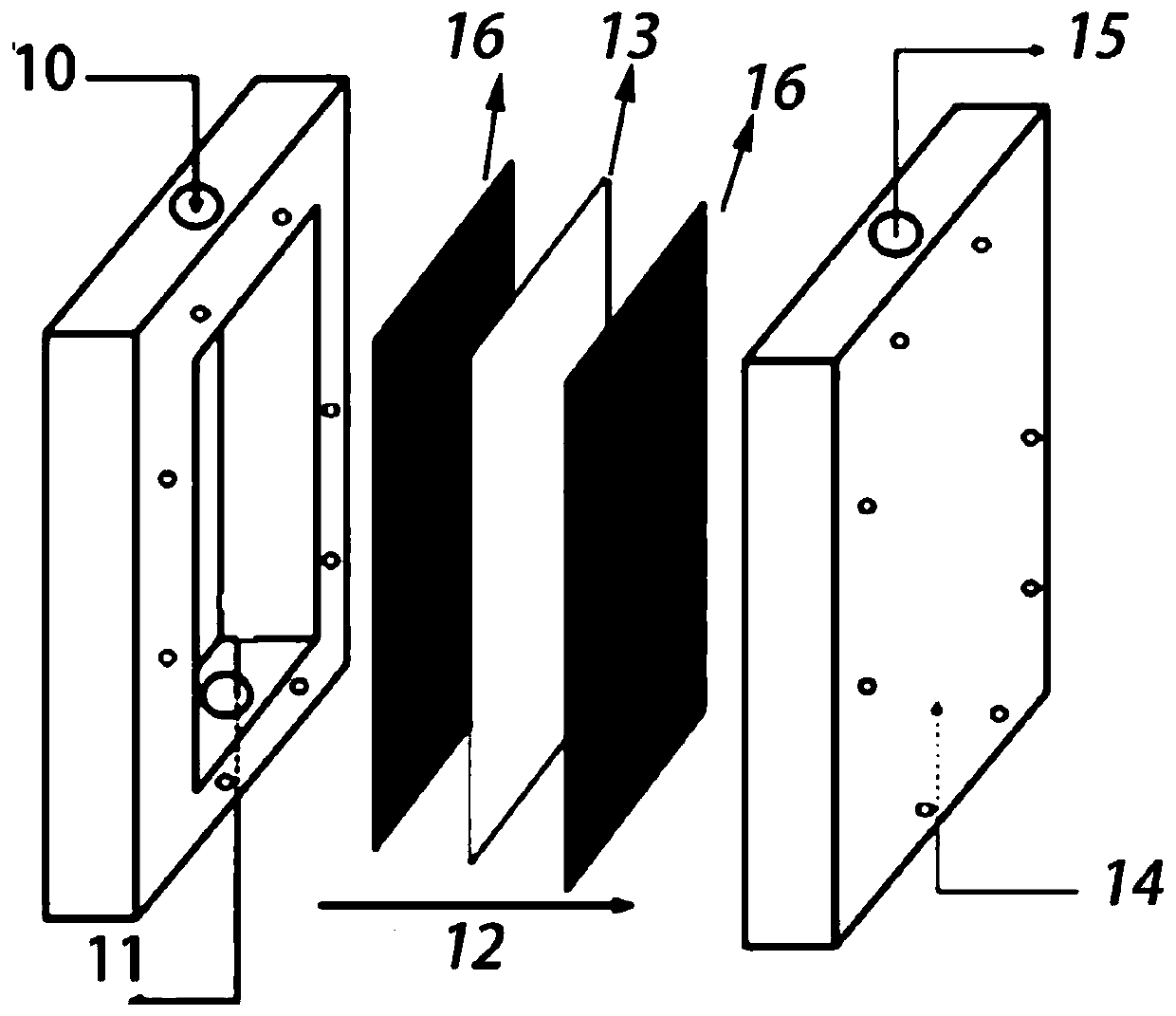

Soft and hard composite coating woodworking tool and preparing method thereof

ActiveCN107151786AEffective response to shocksImprove chip resistanceVacuum evaporation coatingSputtering coatingHardnessChemical stability

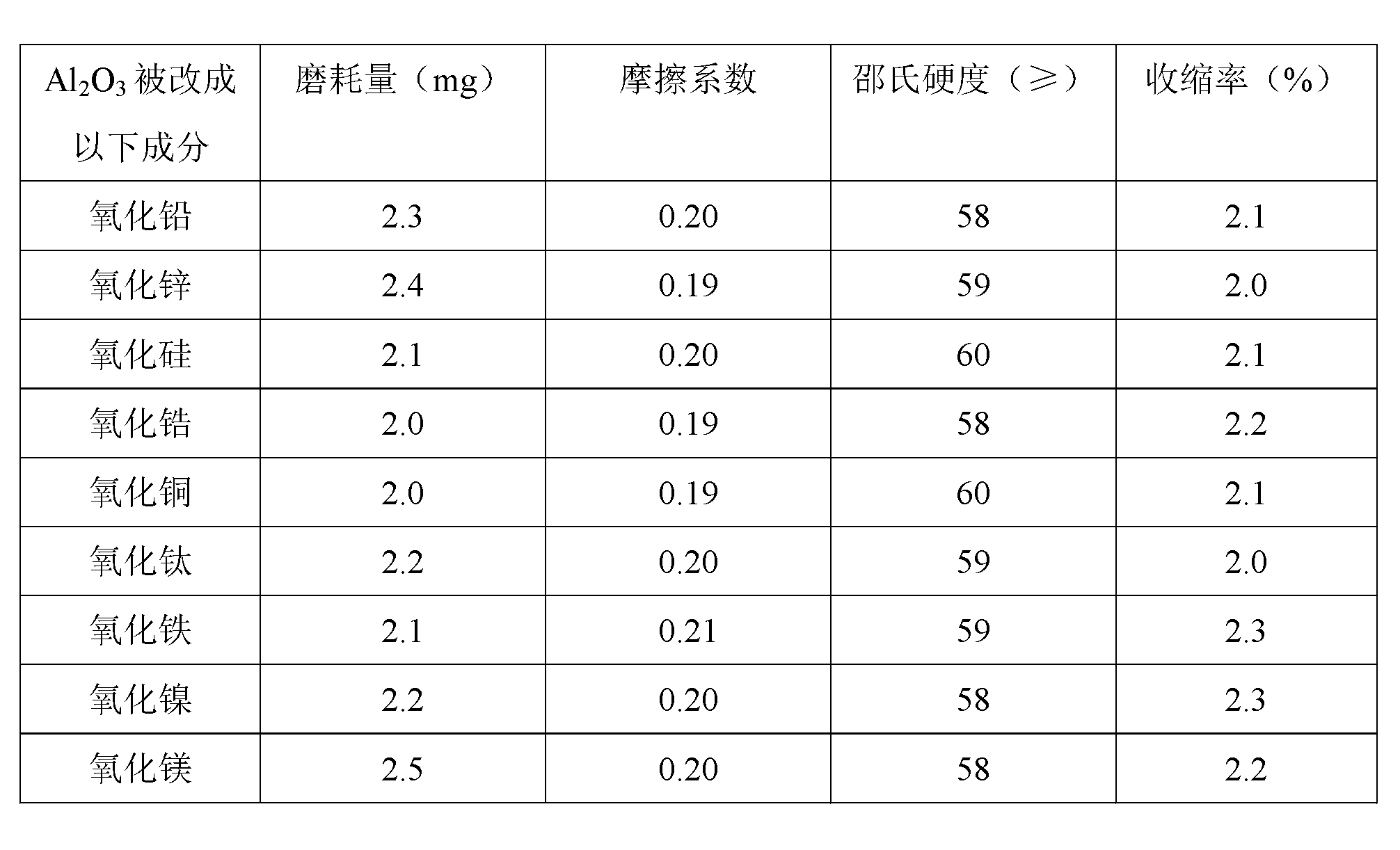

The invention provides a soft and hard composite coating woodworking tool and a preparing method thereof. The soft and hard composite coating woodworking tool comprises a tool base body and a tool coating arranged on the outer surface of the tool base body. The tool coating sequentially comprises a Cr transition layer, a CrN hard coating, a CrCN hard coating, a CrN / WS2 middle buffering layer, a CrN transition layer, a Cr / Ni transition layer and a Ni / Al2O3 / PTFE composite coating from interior to exterior. The coating tool integrates characteristics of high hardness and high abrasion resistance of the CrN / CrCN hard coating, self-lubricating performance and good bonding performance of the CrN / WS2 middle buffering layer and good abrasion resistance and chemical stability and low friction coefficient of the Ni / Al2O3 / PTFE composite coating, and the woodworking tool shows better cutting performance during wood and wood composite material cutting.

Owner:泰州市龙洋木业有限公司

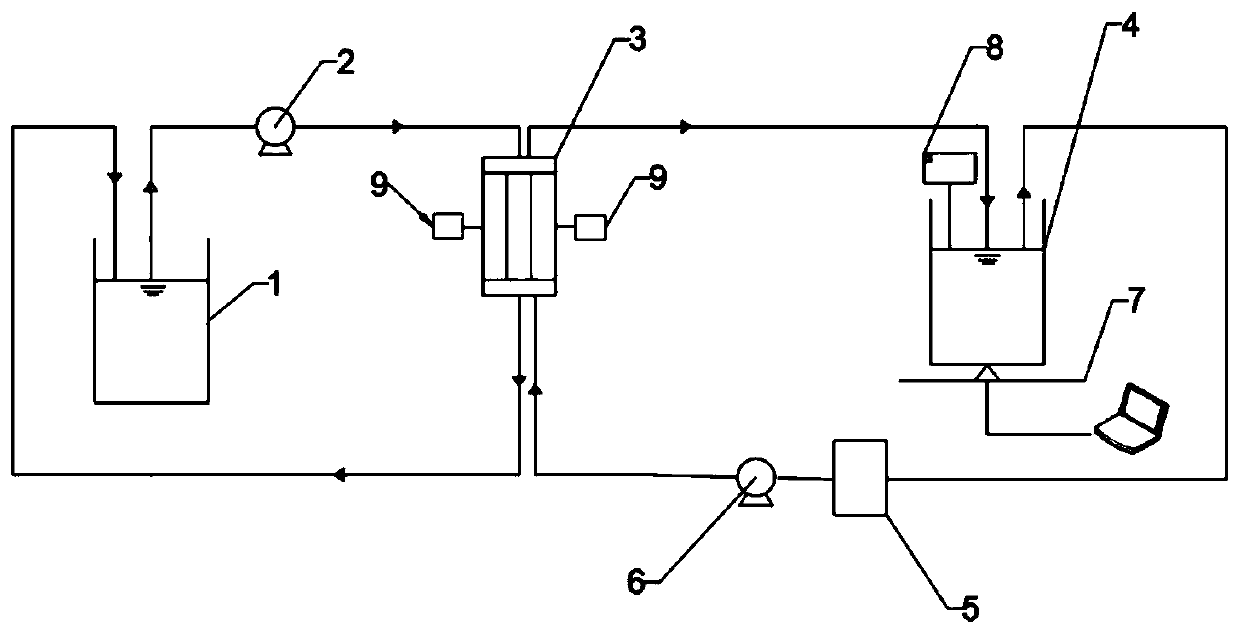

Membrane distillation device with electrified self-heating function

InactiveCN109956527AHigh porosityImprove electrochemical performanceWater/sewage treatment bu osmosis/dialysisWater/sewage treatment by heatingPeristaltic pumpCarbon nanotube

The invention discloses a membrane distillation device with an electrified self-heating function. The device comprises two loops which are a heat circulation loop and a cold circulation loop, whereinthe heat circulation loop is powered by a hot side peristaltic pump, and forms a loop with a feed water tank and a membrane module. The cold circulation loop is powered by a cold side peristaltic pump, and forms a loop together with the membrane module, a distilled water tank and a condensation tank, the real-time mass change of the distilled water tank is measured by a balance and measurement software to determine the membrane flux change, a conductivity meter is used to monitor the electric conductivity change of a distilled liquid in real time, the feeding side membrane surface in the membrane module is connected with electrodes and a power supply, a membrane used in the invention is a carbon nanotube-PTFE composite membrane, and the device can release a large amount of heat after beingelectrified, and automatically heats the liquid flowing through the module. The composite membrane can alleviate the original membrane pollution and membrane wetting phenomena of the PTFE membrane, also can greatly reduce the energy consumption, and has a very good development prospect.

Owner:HOHAI UNIV

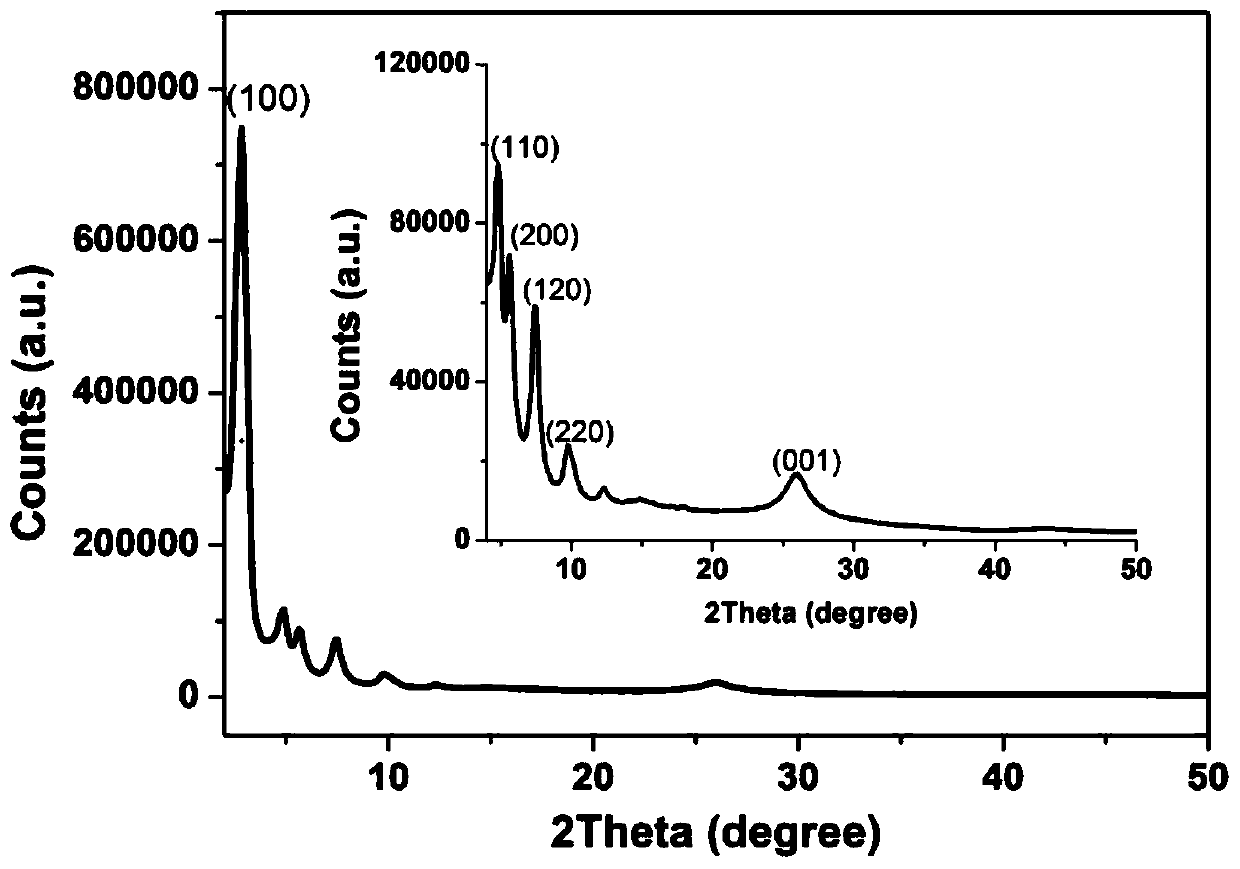

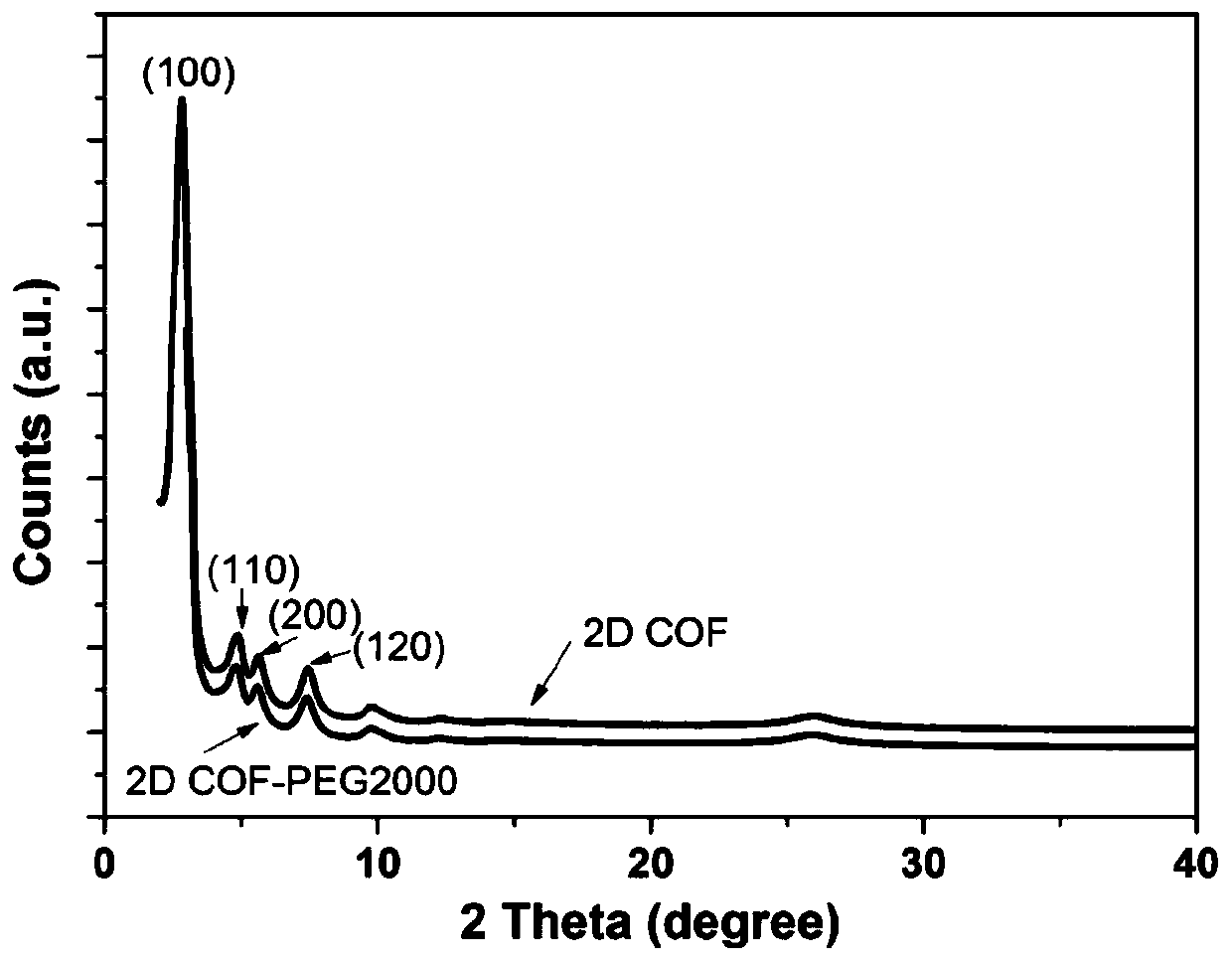

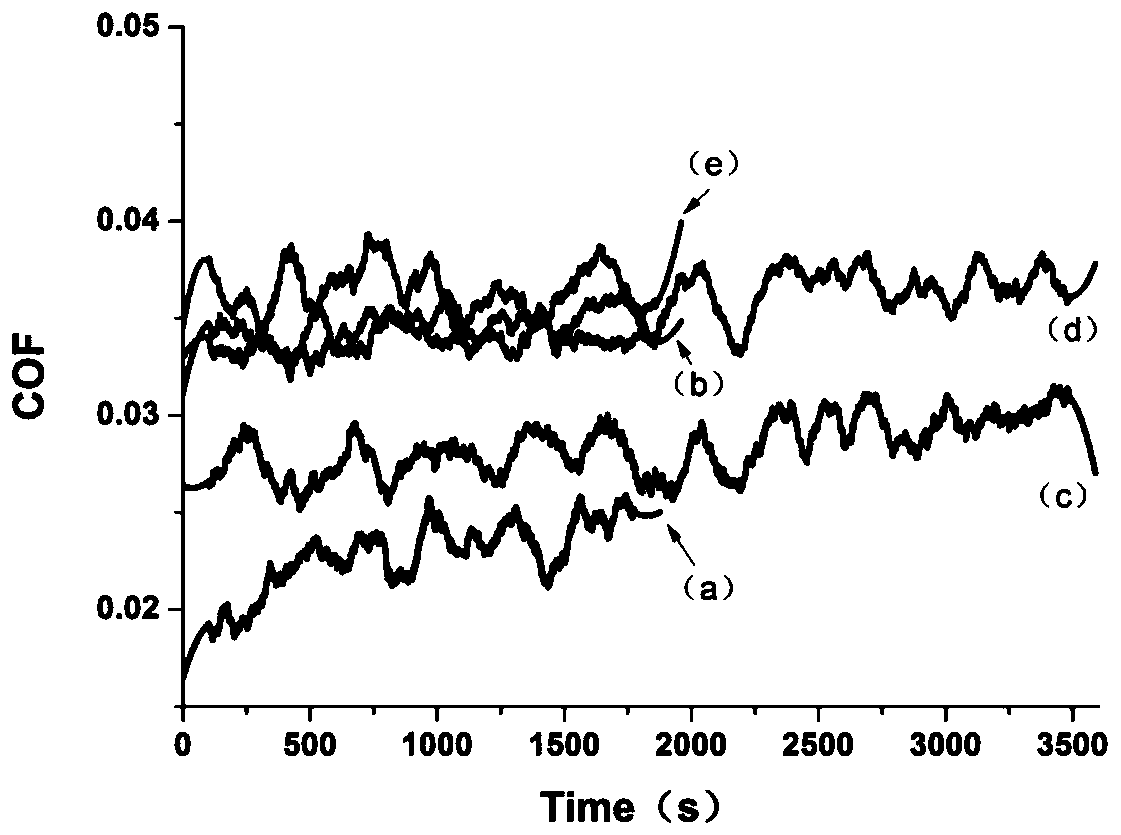

Two-dimensional covalent organic framework modified flexible fiber fabric and preparation method thereof

ActiveCN110904685AHigh mechanical strengthOscillating friction torque reductionFibre typesPolymer sciencePolymer chemistry

The invention provides a two-dimensional covalent organic framework modified flexible fiber fabric and a preparation method thereof, and belongs to the field of fabrics. The modified flexible fiber fabric prepared by the method can be used for antifriction processing between the inner and outer spherical surfaces of a large self-lubricating rod end joint bearing, and the solid / oil composite lubrication effect is effectively achieved. On the premise that the flexibility and deformability of the PTFE composite fiber fabric is not lost, the surface friction coefficient of the PTFE composite fiberfabric and the swing friction torque between the inner and outer spherical surfaces of the rod end joint bearing are further reduced.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com