Membrane distillation device with electrified self-heating function

A membrane distillation and self-heating technology, used in heating water/sewage treatment, pervaporation, membrane technology, etc., can solve the problems of insufficient chemical stability and thermal stability, low membrane distillation effluent flux, and decreased effluent quality. Good electrochemical performance, reducing membrane fouling and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

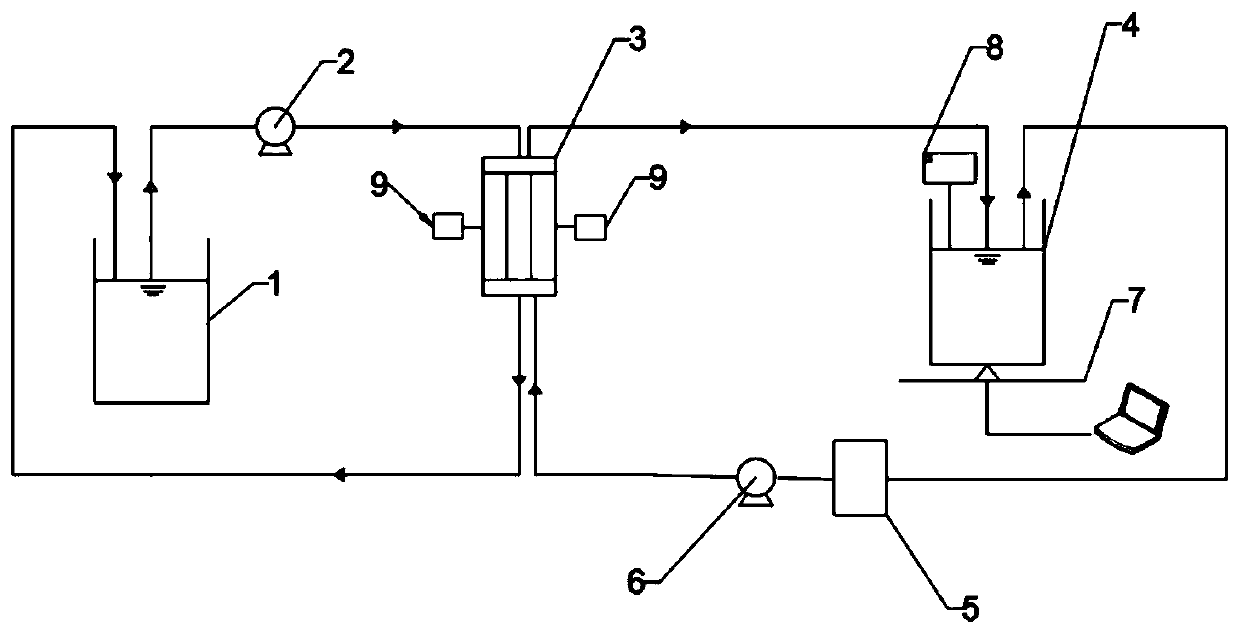

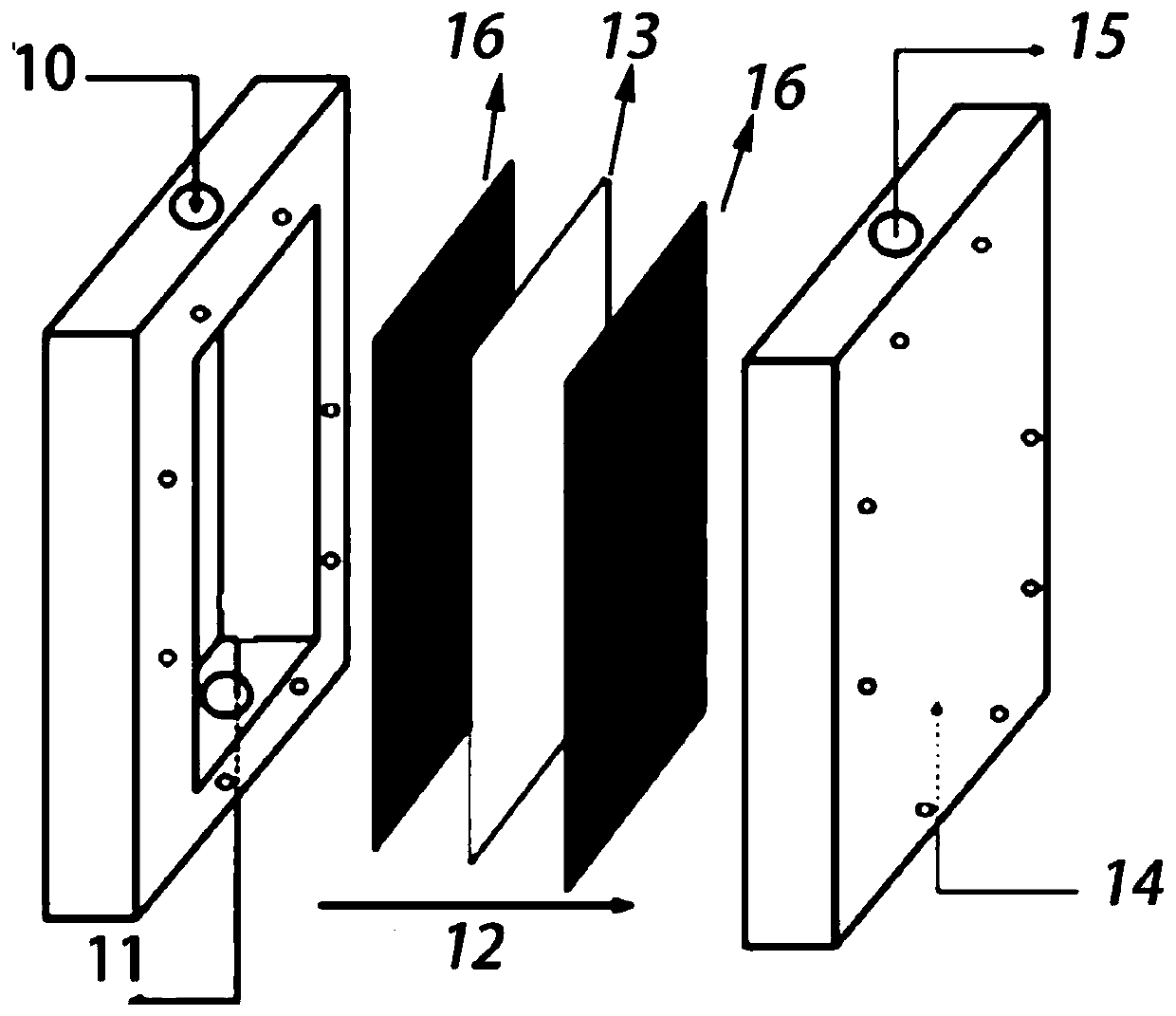

Method used

Image

Examples

Embodiment Construction

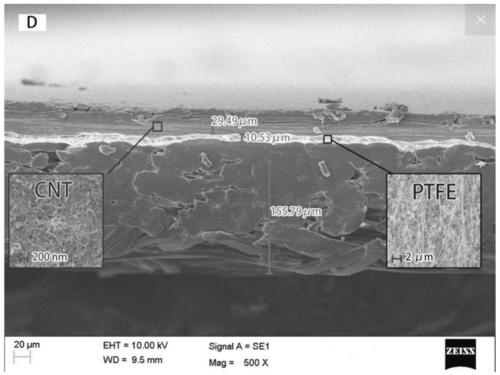

[0026] In recent years, carbon nanotubes have developed rapidly. Due to their hollow structure and capillary force in the structure, carbon nanotubes can not only provide channels for water molecule transmission, increase the effective mass transfer surface area of the membrane, but also absorb water vapor, enhance The permeability and selectivity of the membrane, the composite membrane composed of carbon nanotubes and traditional membranes are superior to the original membranes in terms of antifouling and stability. In addition, carbon nanotubes have a high thermal conductivity. Doping a small amount of carbon nanotubes in the distillation membrane can reduce the temperature gradient in the membrane pores, weaken the temperature difference polarization during the membrane distillation process, and prevent the reduction of the mass transfer driving force from affecting the membrane. Flux is adversely affected.

[0027] Carbon nanotubes will release a large amount of heat aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com