Patents

Literature

113results about How to "Reduce wetting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of all-solid polymer electrolyte through in-situ ring opening polymerization of epoxy compound, and application of the all-solid polymer electrolyte in all-solid lithium battery

ActiveCN105914405AIncrease contactImprove interface compatibilityFinal product manufactureLi-accumulatorsEpoxySolid state electrolyte

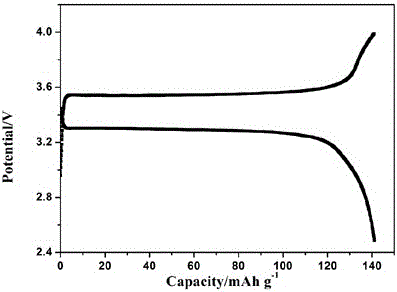

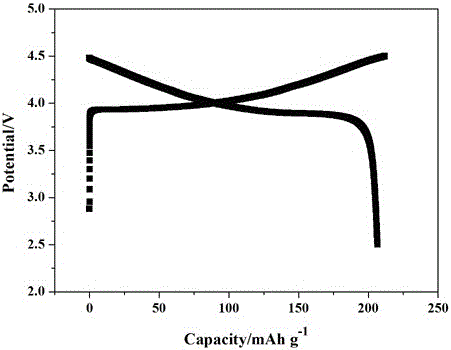

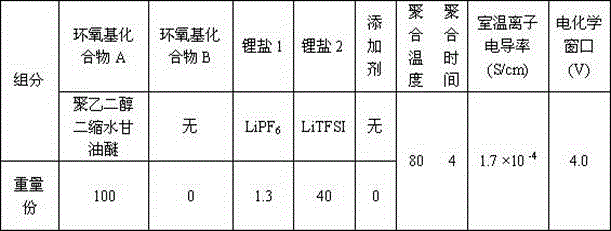

The invention discloses a preparation method of an all-solid polymer electrolyte through in-situ ring opening polymerization of an epoxy compound, and an application of the all-solid polymer electrolyte in an all-solid battery. The preparation method is characterized in that a liquid-state epoxy compound, a lithium salt, a battery additive and the like are employed as precursors and are injected into between a positive pole sheet and a negative pole sheet of the battery, and under a heating condition, in-situ polymerization solidification is carried out to form the all-solid polymer electrolyte, and furthermore, the all-solid battery is produced. The ionic conductivity at room temperature of the all-solid polymer electrolyte can reach from 1*10<-5> S / cm to 9*10<-3> S / cm and electric potential window is 3.5-5 V. The all-solid polymer electrolyte is prepared through the in-situ copolymerization method, so that the all-solid polymer electrolyte has excellent contact with electrodes, thereby greatly improving interface compatibility of the solid-state battery, reducing interface wetting and modification steps of the solid-state battery, reducing production cost of the solid-state battery and improving performances of the solid-state battery. The invention also discloses an all-solid polymer lithium battery assembled from the all-solid polymer electrolyte.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

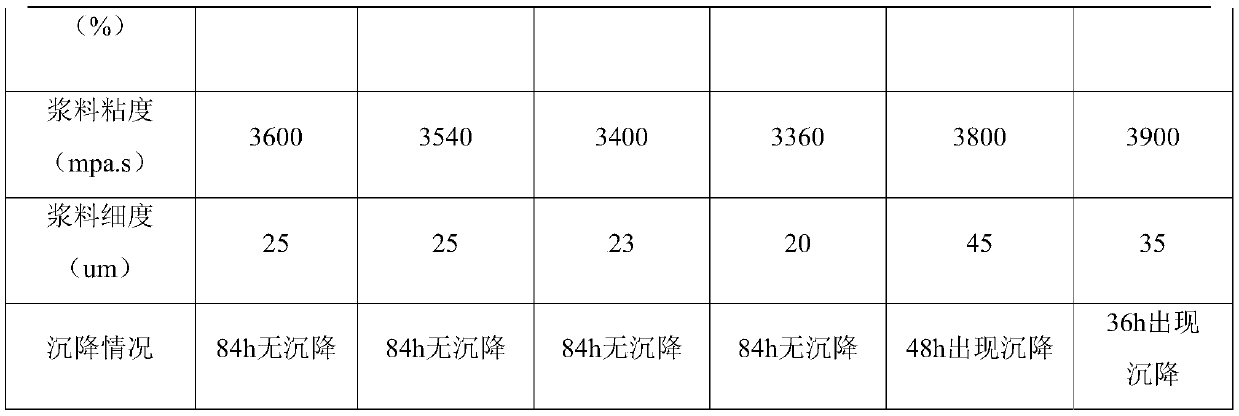

Negative pole slurry of lithium ion battery, rapid preparation method thereof and negative pole piece of lithium ion battery

ActiveCN107293706AImprove stabilityEasy to spreadElectrode thermal treatmentSecondary cellsAdhesivePole piece

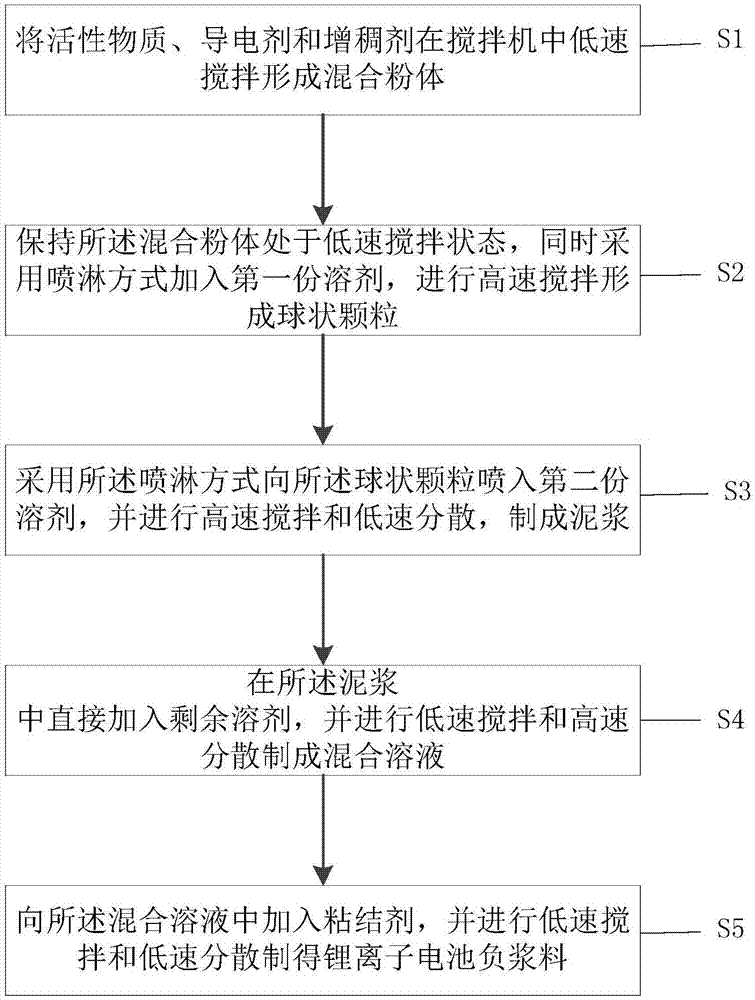

The invention discloses negative pole slurry of a lithium ion battery, a rapid preparation method thereof and a negative pole piece of the lithium ion battery. The preparation method comprises the following steps: stirring an active substance, a conducting agent and a thickening agent in a stirring machine at a low speed to form mixed powder, then in the state that low-speed stirring of the mixed powder is maintained, adopting a spraying manner to add a first solvent, carrying out high-speed stirring to form spherical particles, then adopting the spraying manner again to inject a second solvent into the spherical particles, carrying out high-speed stirring and low-speed dispersion to prepare slurry, then directly adding remaining solvent, carrying out low-speed stirring and high-speed dispersion to prepare a mixed solution, finally adding an adhesive, and carrying out low-speed stirring and low-speed dispersion to prepare the negative slurry of the lithium ion battery. The addition of the solvents adopts stirring and spraying manners, and the power is rapidly moistened to form the uniform spherical particles, so that the total mixing time is reduced, the production efficiency is improved, and the equipment energy consumption is reduced. The negative pole slurry of the lithium ion battery prepared by the method has high stability, and the negative pole piece dried and prepared by the negative pole slurry coated on a current collector is relatively attractive in appearance.

Owner:HUIZHOU TOPBAND ELECTRICAL TECH CO LTD

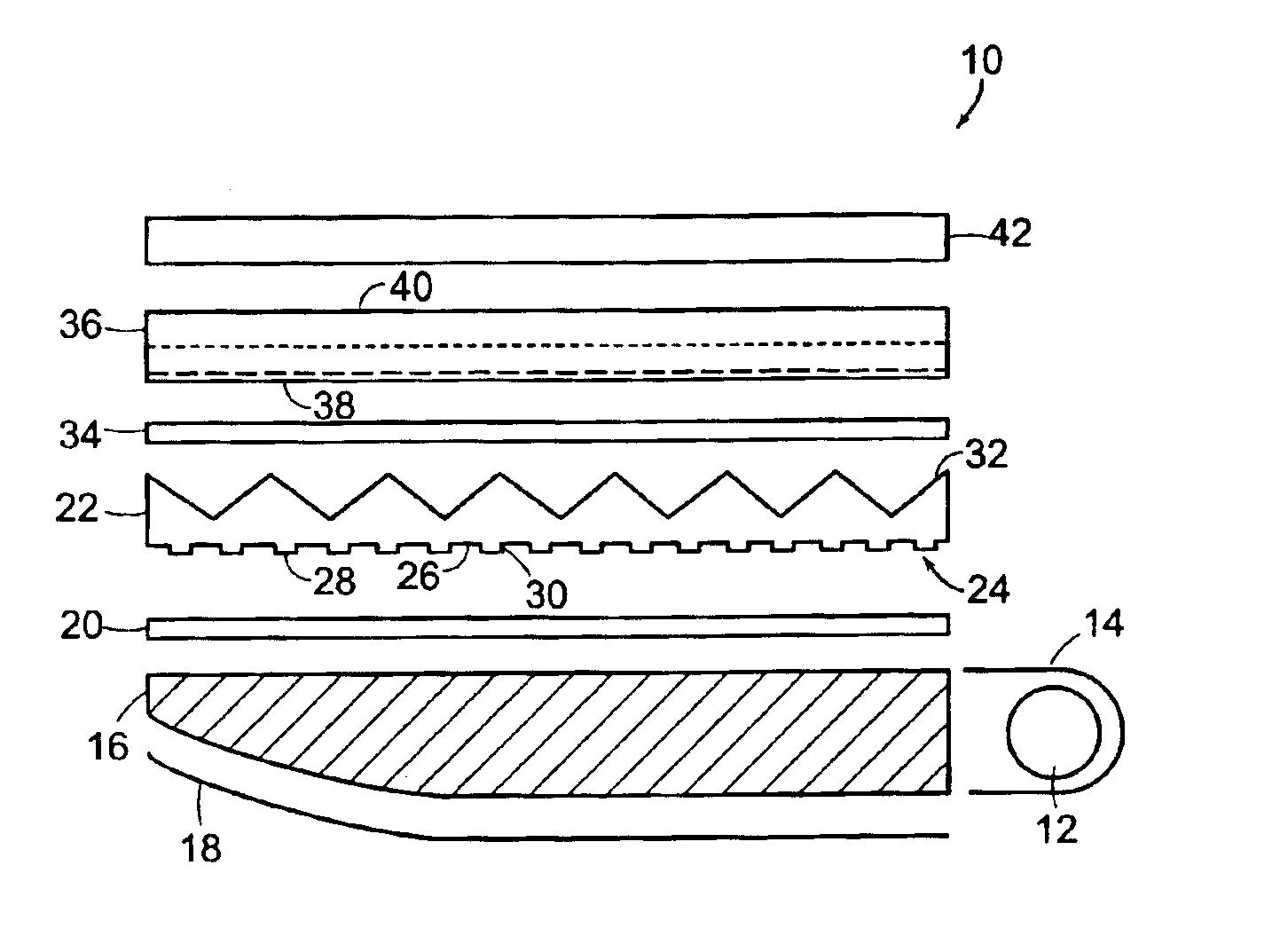

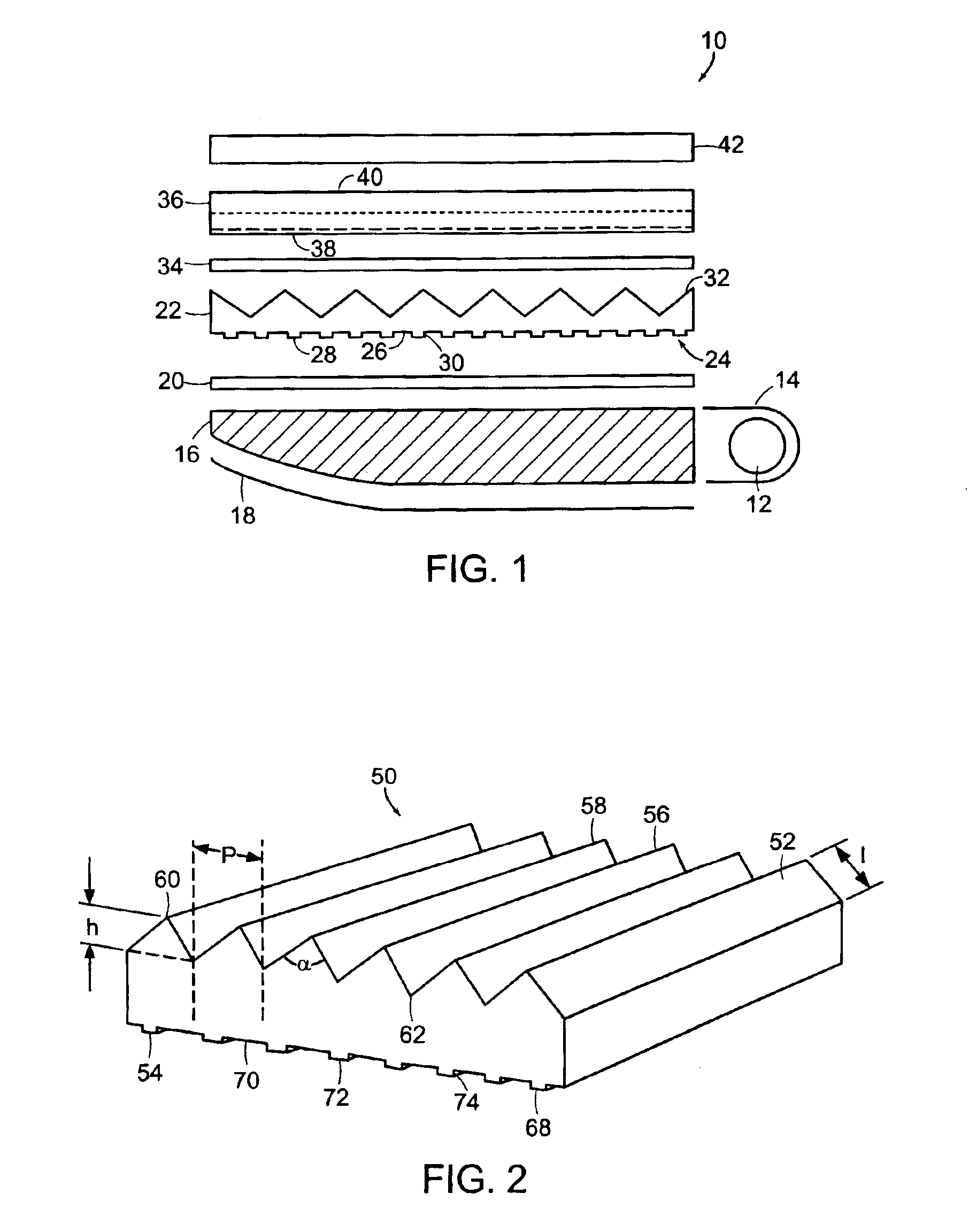

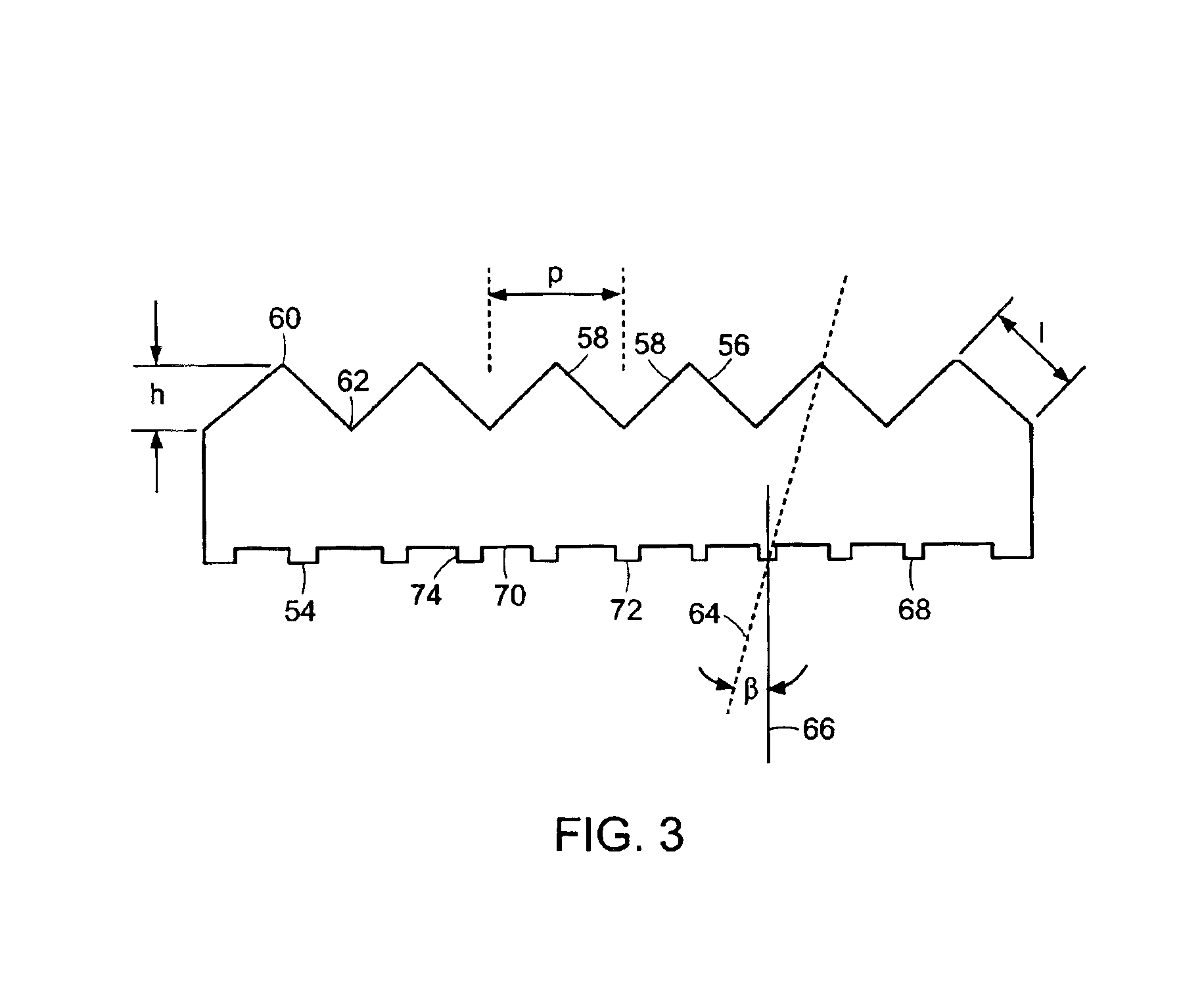

Grooved optical microstructure light collimating films

Owner:ORAFOL AMERICAS

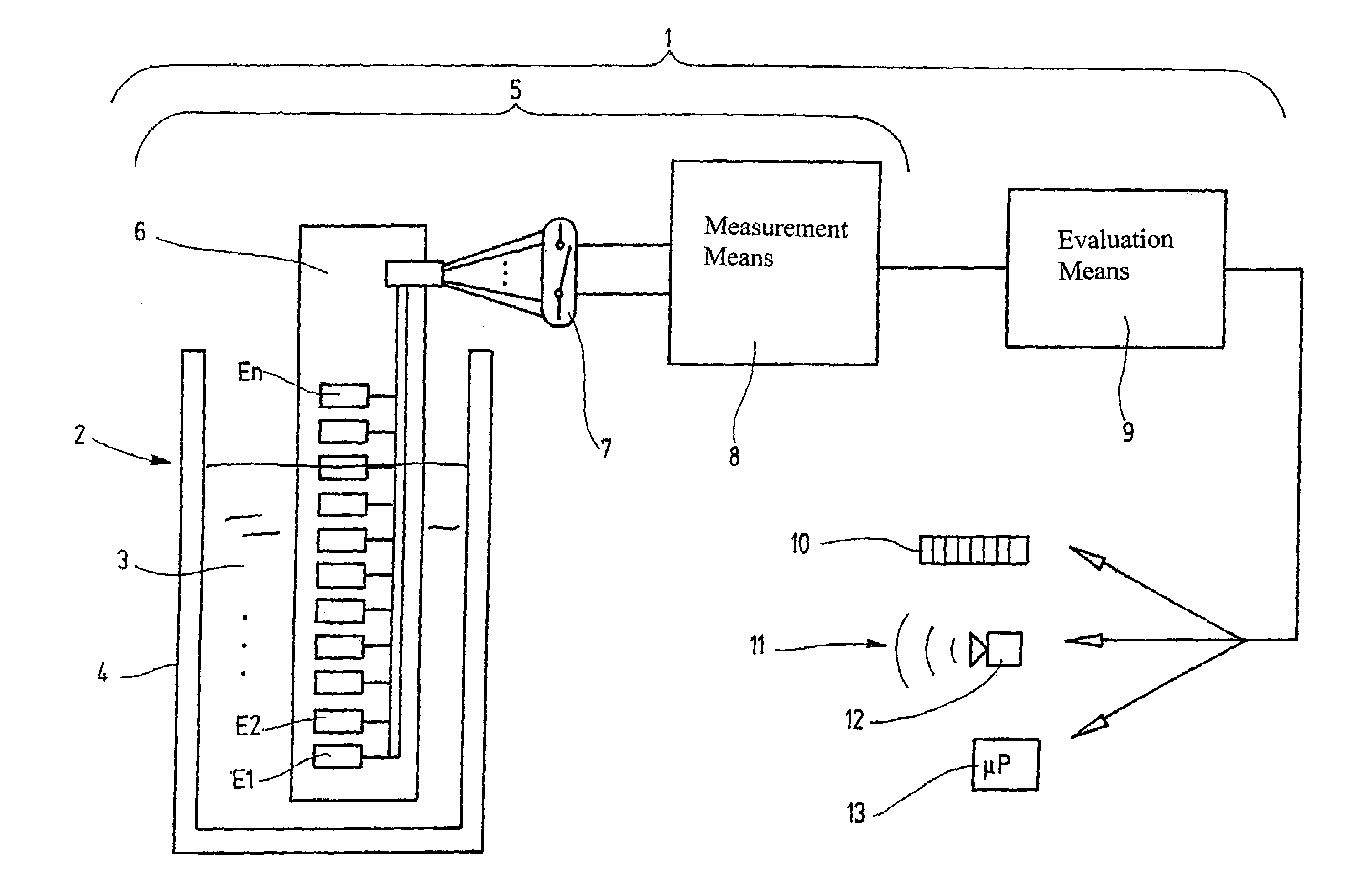

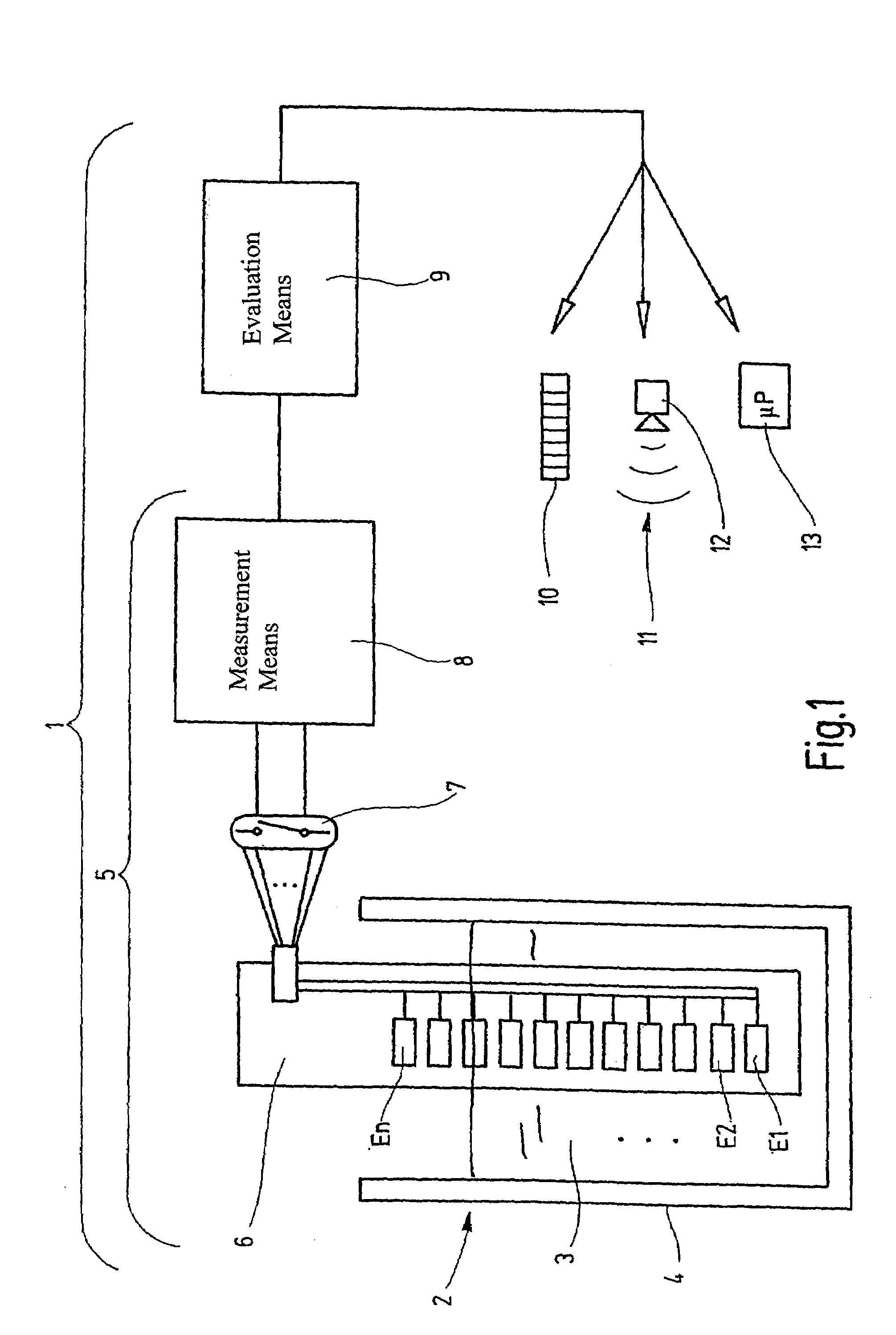

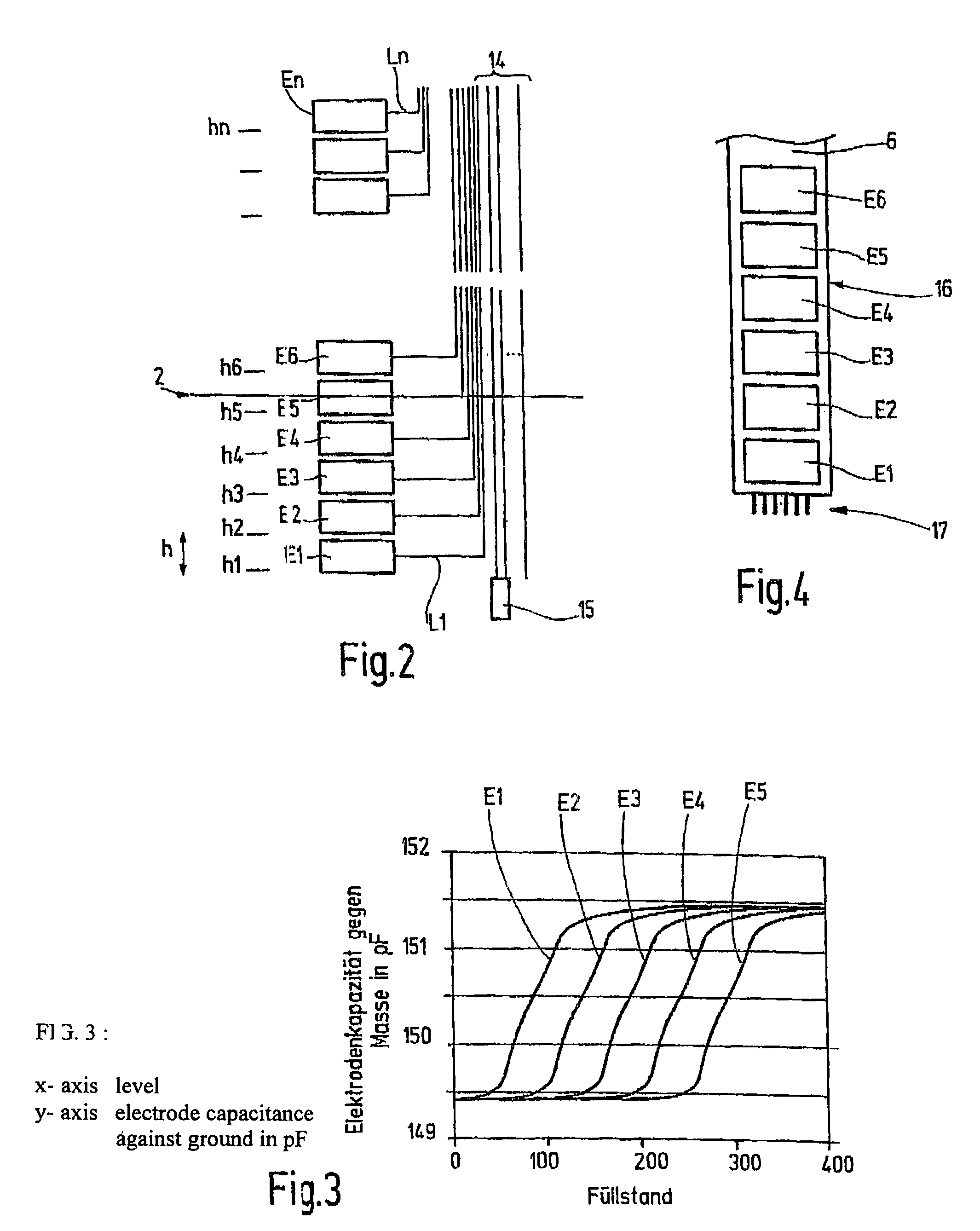

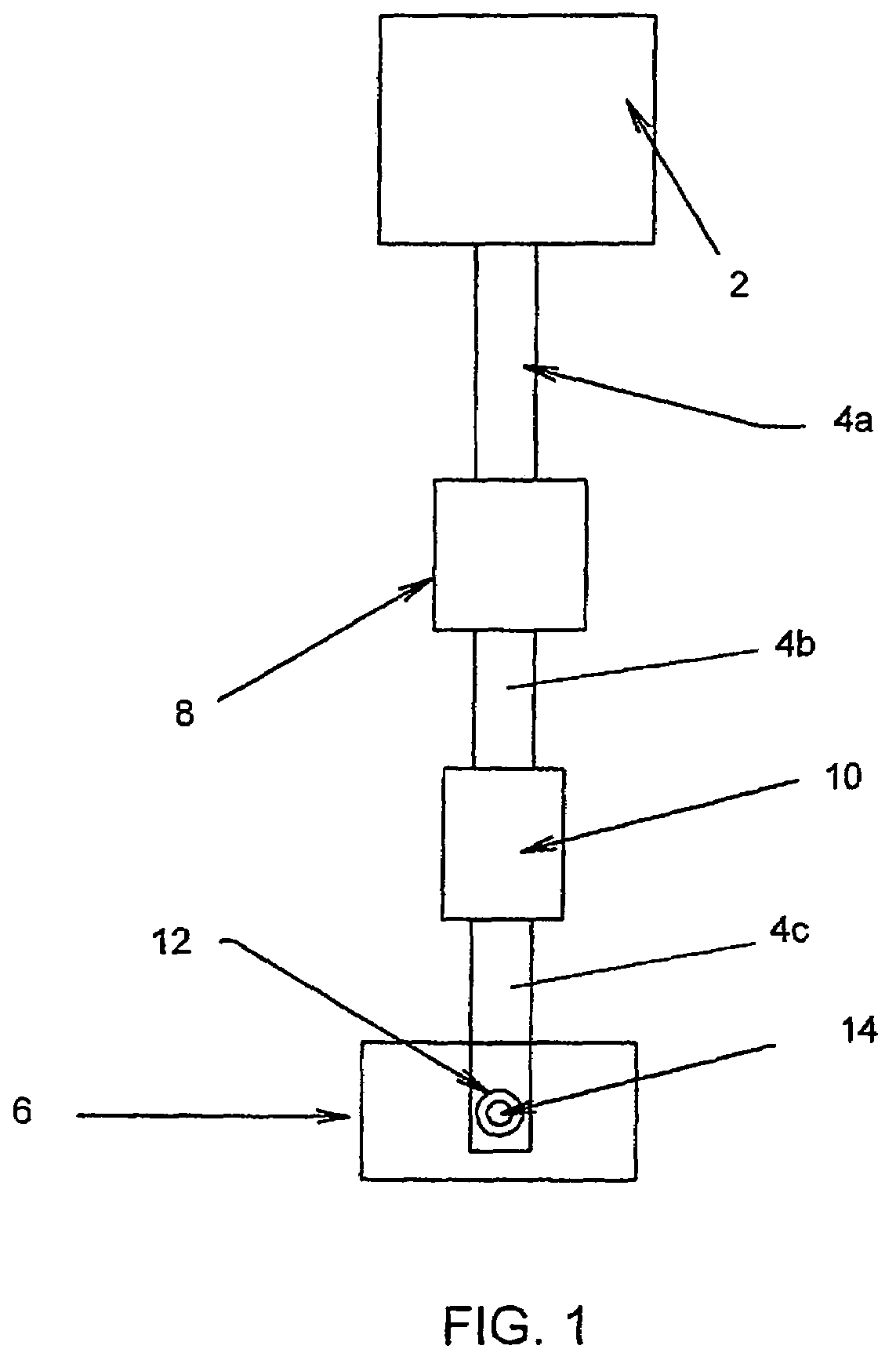

Device and method for measuring capacitance and device for determining the level of a liquid using one such device

InactiveUS7161361B2Economical to produce and installGuaranteed uptimeResistance/reactance/impedenceMachines/enginesCapacitanceMeasurement device

A device (5) measures capacity, and includes an electrode arrangement with a plurality of electrodes (E1, E2, . . . , En) which are adjacently and / or successively arranged on a carrier (6). An intrinsic measuring device (8) measures the capacitance between a first electrode (E2), in the form of a measuring electrode, and a second electrode (E1), in the form of a counter-electrode. A controllable switching device (7) connects the electrodes (E1, E2, . . . , En), in the form of first and second electrodes (E2, E1), to the measuring device (8) in such a way that they can be switched in a pre-determinable manner. Each electrode (E1, E2, . . . , En) of the electrode arrangement can be switched in a controlled, alternate manner by the switching device (7), in the form of a measuring electrode, and respectively at least one of the other electrodes (E1, E2, . . . , En), in the form of a counter-electrode, can be switched to a pre-determinable reference potential. An associate method and a device (1) determine the level (2) of a liquid (3) using one such device (5).

Owner:HYDAC ELECTRONICS GMBH

Special water-based cutting fluid for diamond wire saw

The invention relates to a special water-based cutting fluid for diamond wire saw comprising the following components in percentage by weight: 0.01% of dispersing agent, 0.01-3% of wetting agent, 0.05% of defoaming agent, 0.01% of corrosion inhibitor, 0.01% of chelating agent, 0.01% of bactericide, 0.01% of penetrating agent and the balance of water. The invention has the advantages of extremely lower viscosity, good cooling property and good chip suspension and diffusivity; in addition, silicon grains of chip grains can be greatly wetted, the diamond wire saw is cleaned clearly, has low foaminess, is not sensitive to metal ions and can not be combusted. The special water-based cutting fluid disclosed by the invention is stable during use at high temperature and has longer service life and higher cutting efficiency; and in addition, the cutting fluid left on the silicon chips is easy to be removed, and the recovery of silicon powder turns to be very easy.

Owner:JIANGSU KAIXING PLASTICS

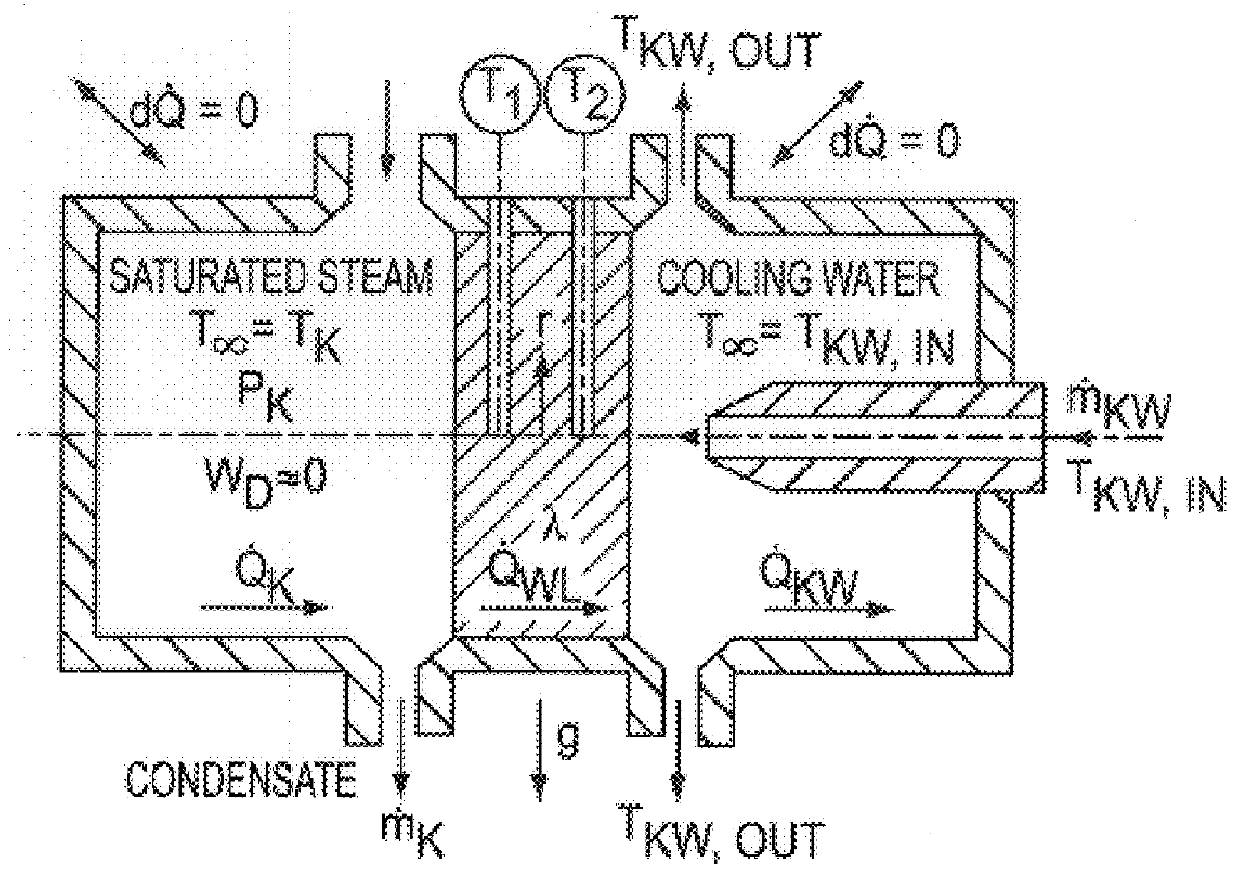

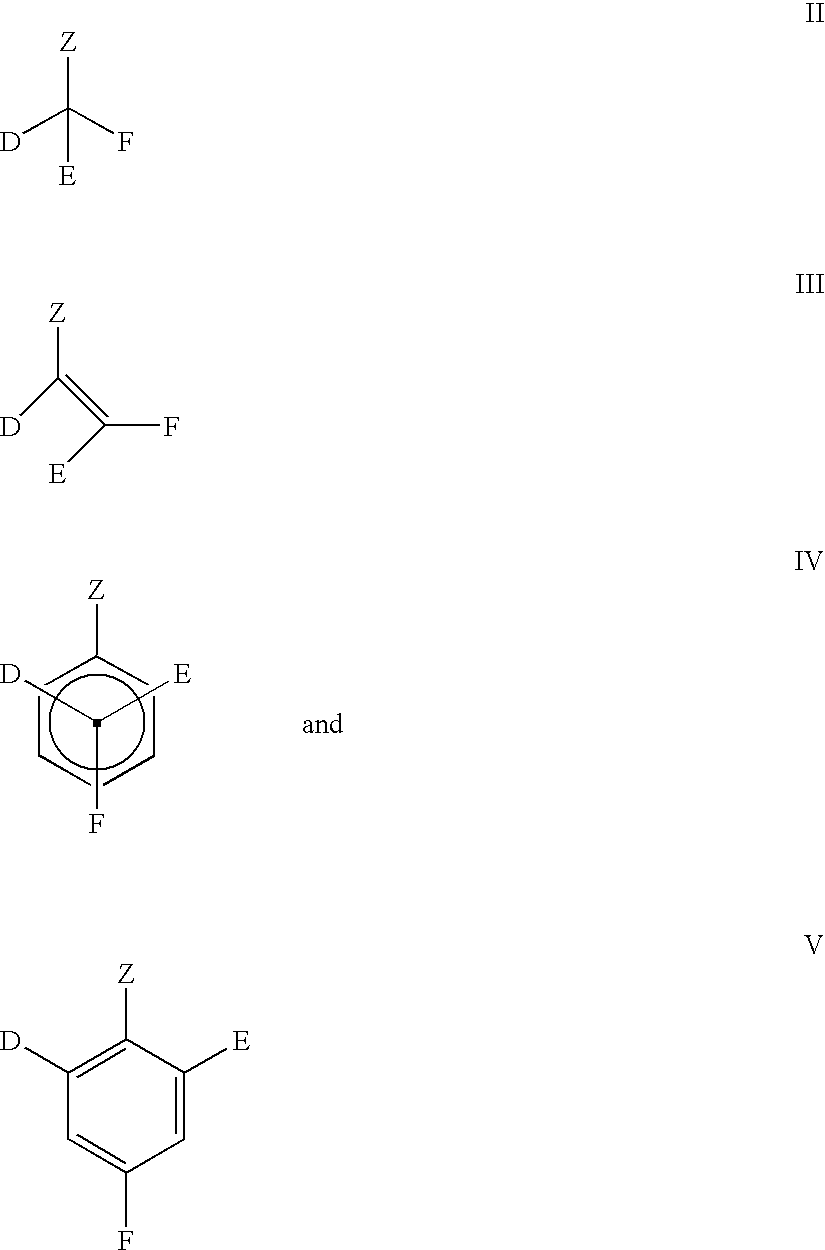

Use of plasma polymer layer sequences as functional layers in material transport or heat exchanger systems

InactiveUS6192979B1Reduction factorImproved wear behaviorTemperatue controlHeat transfer modificationWettingEngineering

A material transport or heat exchanger system. The material transport or heat exchange system includes at least one component including a base material. The at least one component includes a top functional layer capable of adjusting wetting behavior of the base material. The top functional layer includes carbon and hydrogen, and at least one of a non-metallic element and a semi-metallic element selected from the group consisting of 3rd, 4th, 5th, 6th, and 7th main group of the periodic table of elements, and mixtures thereof. A process for treating a surface of at least one component including a base material of a material transport or heat exchanger system. The process includes forming a top functional layer on at least a portion of the at least one component which is capable of adjusting wetting behavior of the base material. The top functional layer includes carbon and hydrogen, and at least one of a non-metallic element and a semi-metallic element selected from the group consisting of 3rd, 4th, 5th, 6th, and 7th main group of the periodic table of elements, and mixtures thereof.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

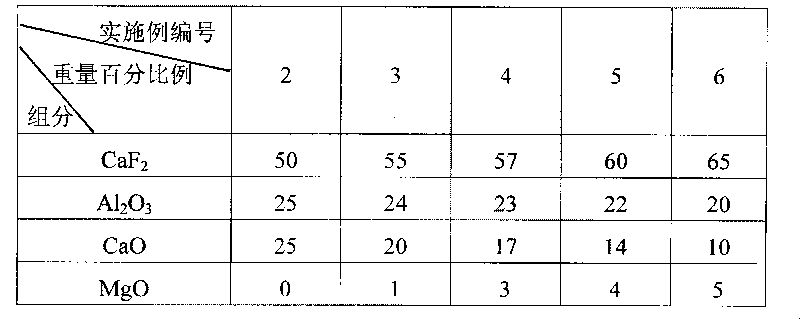

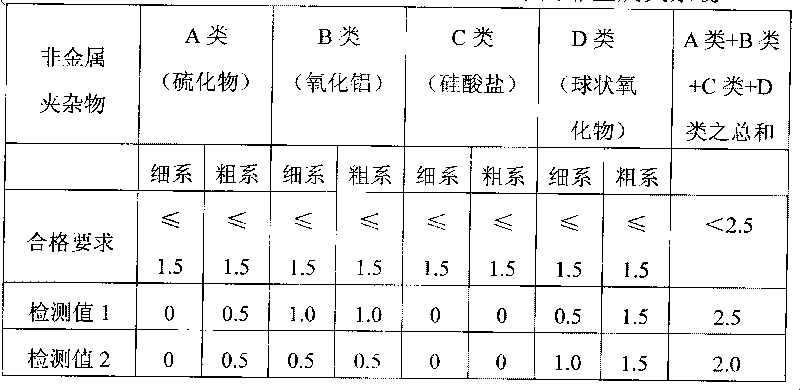

Electroslag remelting quaternary slag system for preparing high-purity stainless steel

The invention discloses an electroslag remelting quaternary slag system for preparing high-purity stainless steel. The electroslag remelting quaternary slag system is characterized by comprising the following compositions in percentage by weight: 50 to 65 percent of CaF2, 20 to 25 percent of Al2O3, 10 to 25 percent of CaO and 0 to 5 percent of MgO. The quaternary slag system is adopted for electroslag remelting, can effectively reduce the non-metallic inclusion content of the steel and improves the purity of the steel under the condition of non-protective atmosphere and has the characteristics of little investment, low use cost and easy realization.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

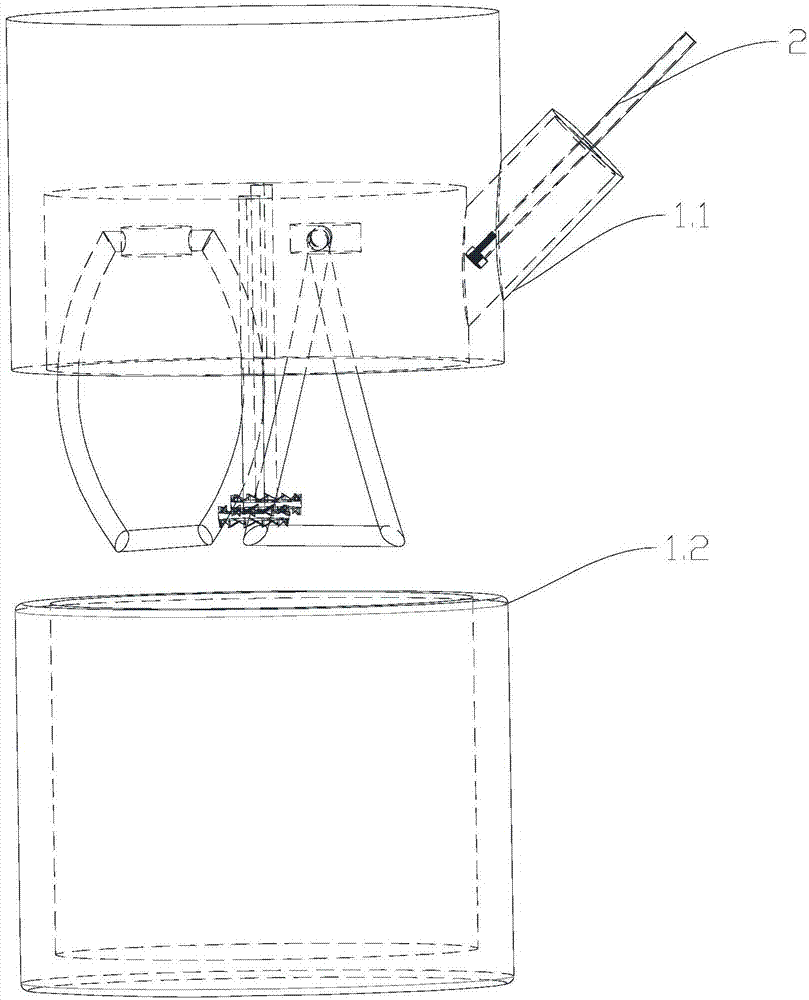

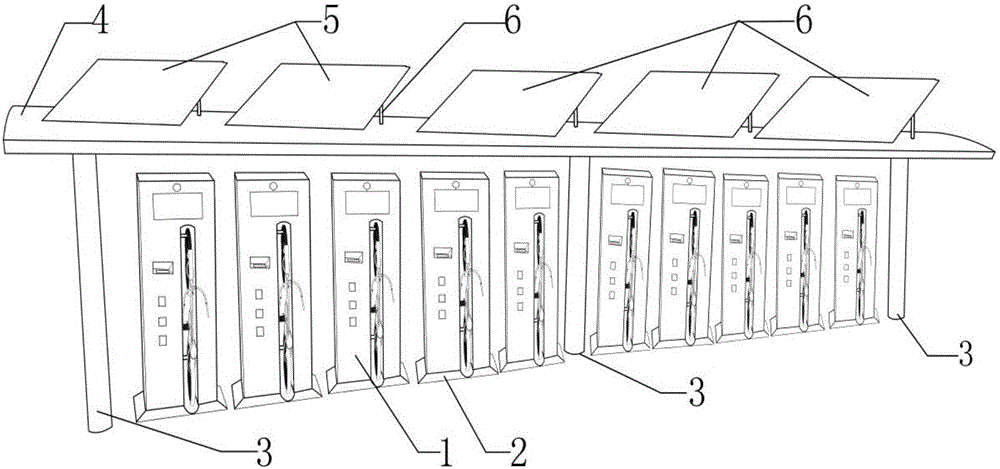

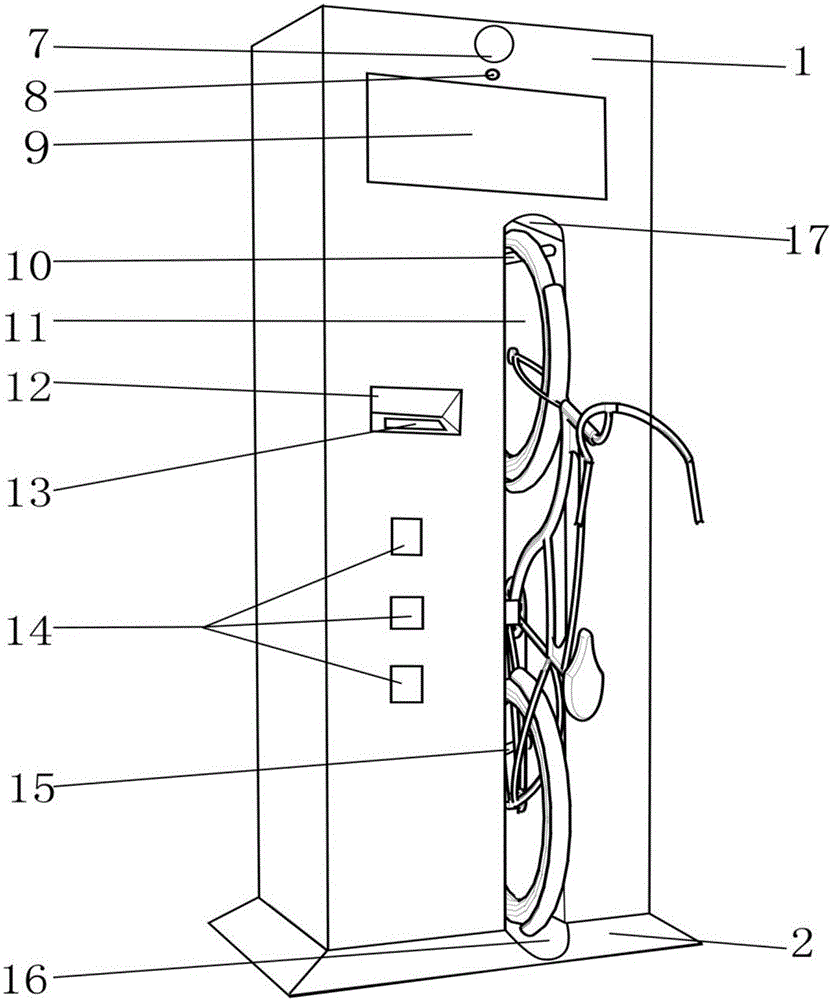

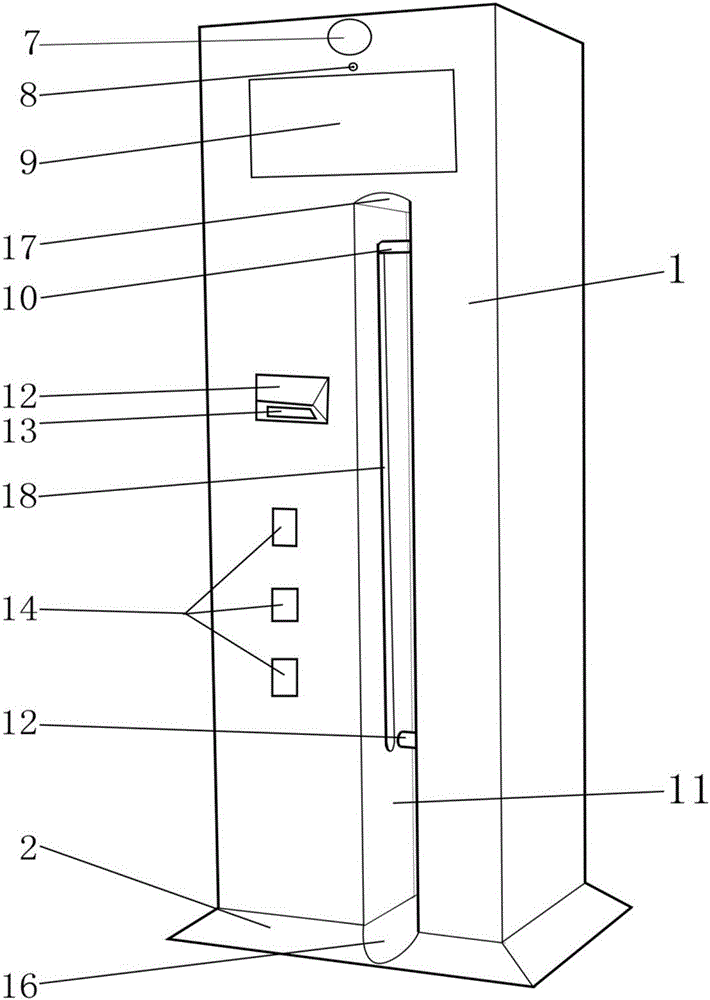

Energy-saving suspension-type public bicycle parking station

The invention relates to a suspension-type public bicycle frame, and discloses an energy-saving suspension-type public bicycle parking station. The energy-saving suspension-type public bicycle parking station comprises a suspension-type frame main body, a canopy and a solar power generation panel, wherein the frame main body is fixed on a base, a U-shaped oblique groove is formed in the middle of the base, a bicycle storage wall is arranged above the U-shaped oblique groove, a first track cavity and a fixing lock outlet are formed in the left side of the bicycle storage wall, and a second track cavity, a lifting lock hole and a fixing lock hole are formed in the right side of the bicycle storage wall; a first supporting seat, a second supporting seat, a hydraulic lifting rod, a first casing pipe, a second casing pipe, a first electronic push-pull rod, a second electronic push-pull rod, a lifting lock and a fixing lock are installed inside the frame main body; a convex monitoring camera, an infrared detector, an LED touch screen, a card punching groove, a card read chip and an indicator lamp are installed at the outer side of the frame main body; the canopy is fixed on stand columns, and the solar power generation panel is installed on the canopy by virtue of a rotatable supporting seat. By utilizing the energy-saving suspension-type public bicycle parking station, not only can the energy conservation and environmental protection be realized, but also the floor occupation space is reduced, bicycles are protected, and the bicycles are convenient for travelers to borrow and return.

Owner:李鑫磊

Oily sludge recycling and treatment method

InactiveCN107253813AImprove extraction efficiencyAvoid separation and recycling inefficientWaste water treatment from quariesSludge treatmentChemistryUltrasonic oscillation

The invention discloses an oily sludge recycling and treatment method. The oily sludge recycling and treatment method comprises the following steps: mixing oily sludge, water and an extracting agent in a mass ratio of 1:2:(0.3-0.7), wherein the extracting agent is a mixture containing a low-boiling-point organic solvent, a dispersing agent and an anionic surfactant; carrying out ultrasonic oscillation on the mixture in the step S1, and forming an oily sludge extracting agent mixed solution; carrying out solid-liquid centrifugal separation on the oily sludge extracting agent mixed solution, so that deoiled sludge and oil-water extracting agent mixed solution are obtained; and carrying out water separation and oil purification and recycling on the oil-water extracting agent mixed solution. The oily sludge recycling and treatment method provided by the invention is low in separation cost and high in efficiency and can realize extraction and recycling of petroleum in oily sludge, so that resources are utilized again.

Owner:湖南云平环保科技有限公司

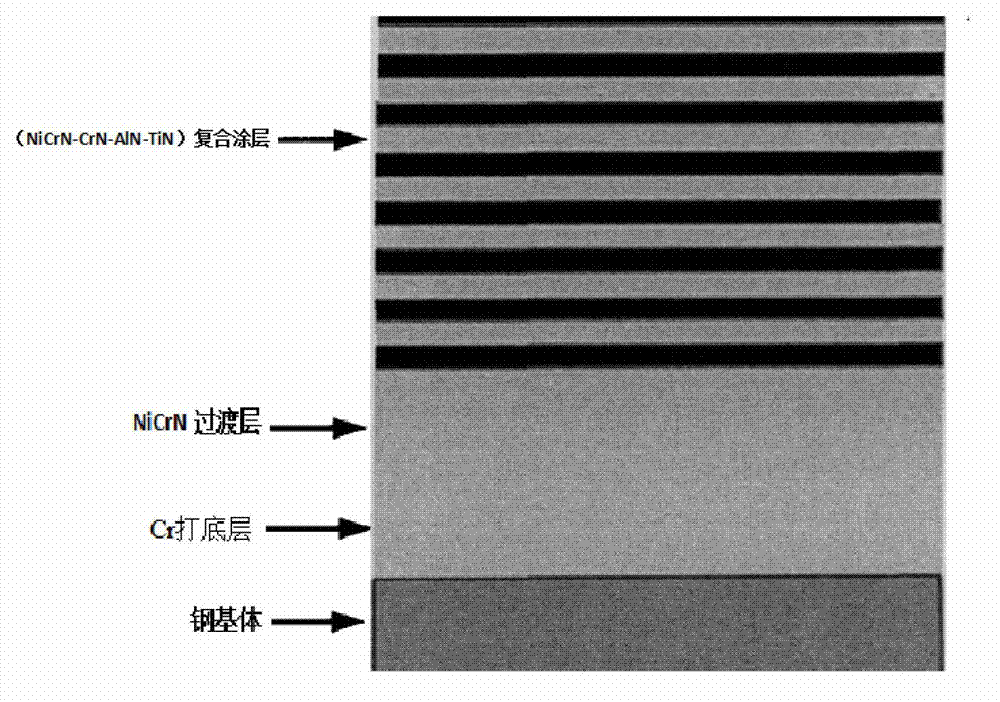

Product containing NiCrN ternary coating and preparation method thereof

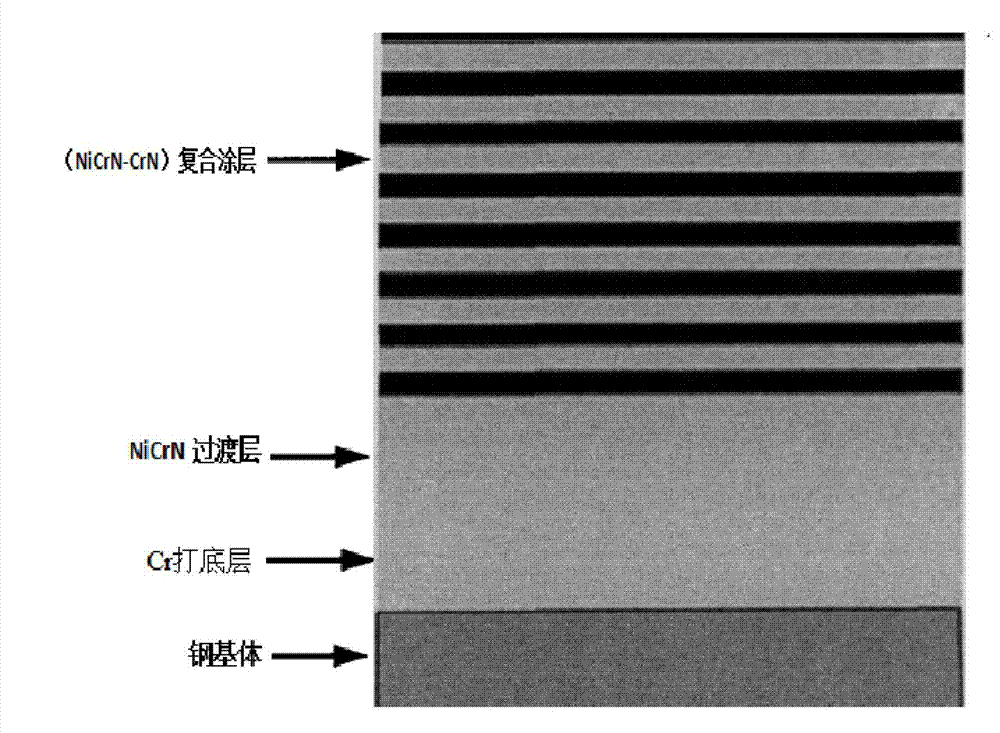

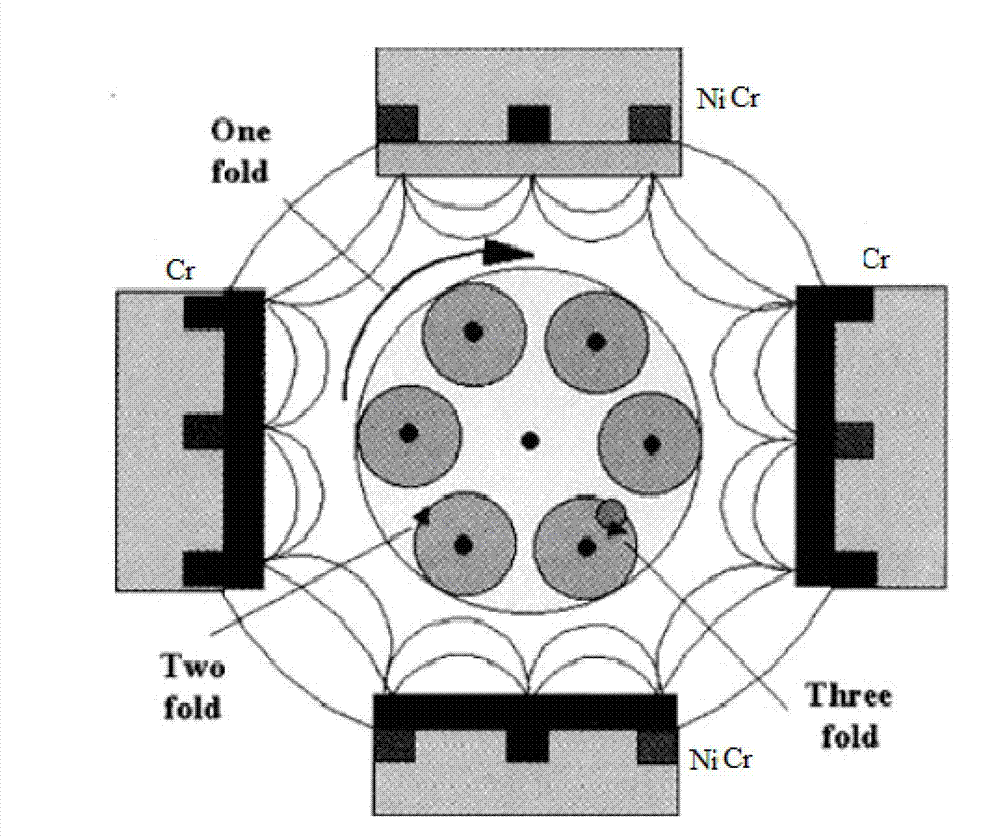

ActiveCN103029366AHigh bonding strength of membrane baseImprove toughnessVacuum evaporation coatingSputtering coatingOrganic solventCritical load

The invention discloses a product containing an NiCrN ternary coating. On the product, a Cr layer is used as a bottom layer, an NiCrN layer is used as a transition layer, and a plurality of NiCrN-CrN composite coatings are deposited on the NiCrN transition layer, so that the thickness of the composite coating reaches 2-5 mu m. By adopting the multilayer gradient design and nitriding technique before filming, the invention greatly enhances the film-base bonding strength of the coating. The critical load of the gradient coating prepared by the invention in a scarification test is up to 75N which is much higher than that of a related coating prepared by any other method or technique; and the hardness of the product containing an NiCrN ternary coating can reach 2780HV. The invention greatly enhances the shock resistance, abrasion resistance, friction resistance and heat stability on the surface of a mold or cutter, and greatly lowers the friction factor and weight loss rate by abrasion. The NiCrN ternary coating greatly enhances the wetting angle of mold steel for organic solvents, which indicates that the coating can greatly improve the demoldability of the mold.

Owner:郎溪品旭科技发展有限公司

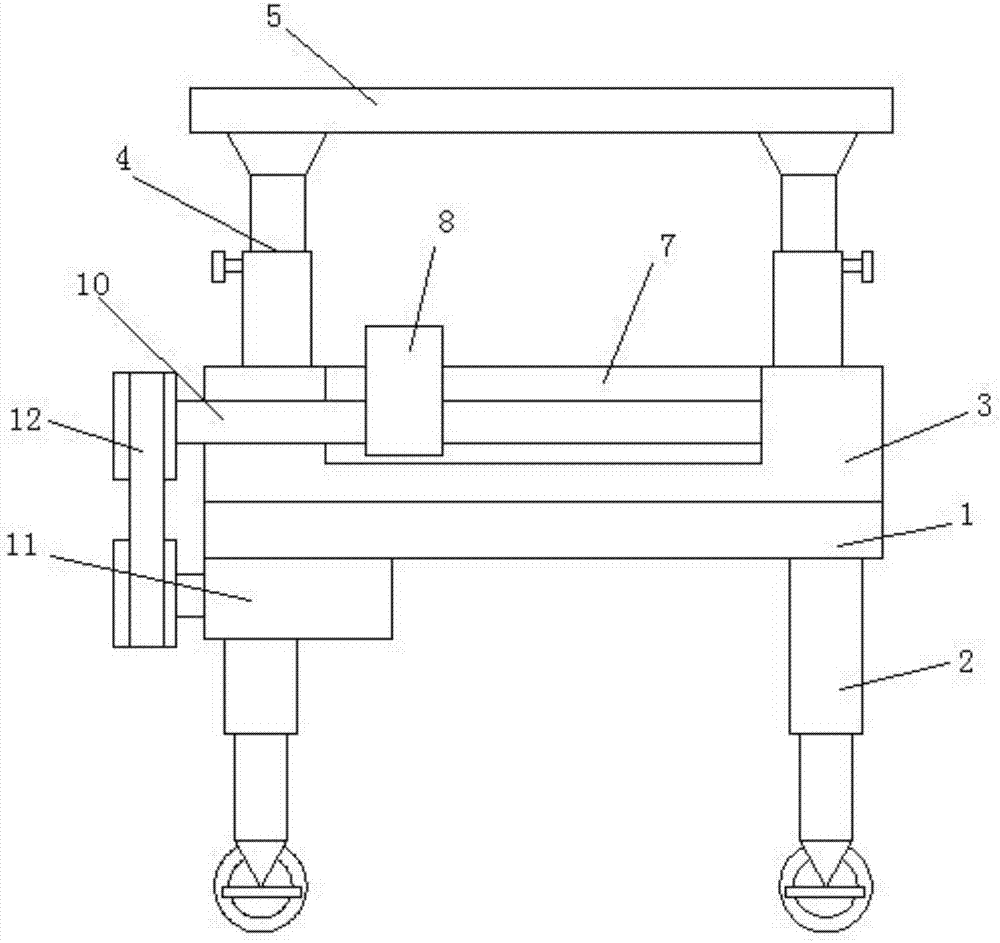

Grain tedding device and use method thereof

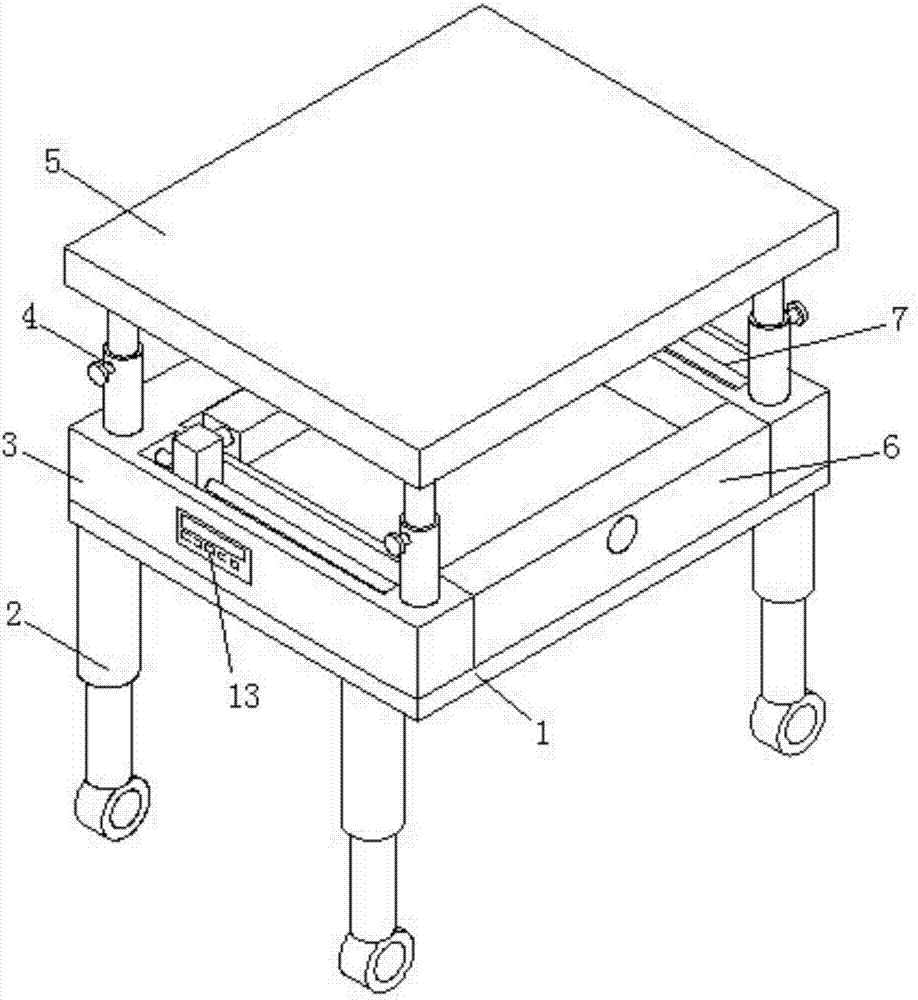

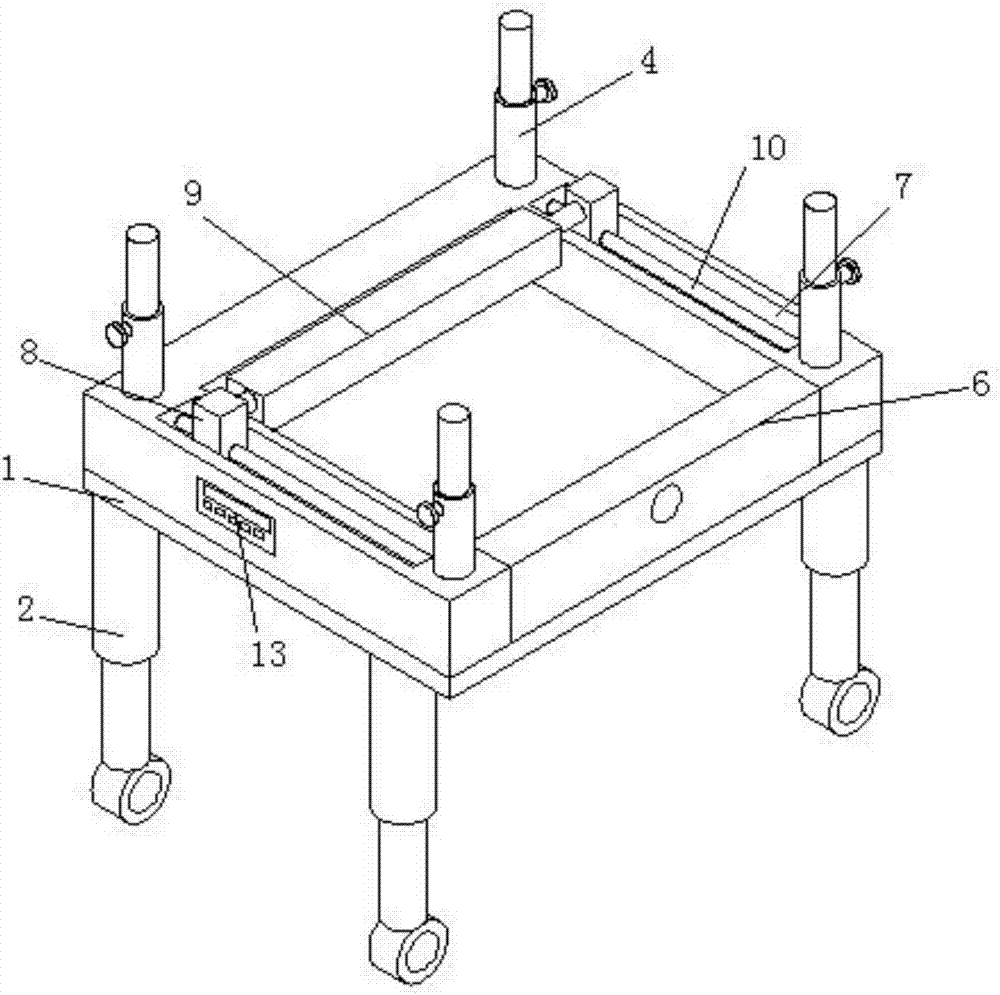

InactiveCN107270668AImprove sufficiencyImprove uniformityFood processingClimate change adaptationEngineeringGlass sheet

The invention discloses a grain tedding device and a use method thereof. The grain tedding device comprises a base; four groups of jack bodies are symmetrically mounted on corners of the bottom of the base; a protecting plate is welded on the outer side of the top of the base; four groups of telescopic rods are symmetrically inlaid on corners of the top of the protecting plate; the tops of the telescopic rods are fixedly connected with a transparent glass plate through suction cups; sliding grooves are formed in two sides of the top of the protecting plate; sliding blocks are glidingly connected in the sliding grooves; a pushing plate is fixedly mounted between the sliding blocks through a connecting rod; a forward-and-reverse-rotation motor is fixedly mounted in the middle of the back end of the bottom of the base; screw rods are fixedly mounted in the sliding grooves through rolling bearings; and one end of each screw rod penetrates through the corresponding sliding block and the protecting plate to be in transmission connection with the forward-and-reverse-rotation motor through a belt pulley. The grain tedding device is simple and reasonable in structural design, convenient to operate, capable of saving time and effort, convenient to move, diversified in function, good in tedding effect, safe, stable, wide in application range and beneficial to promotion and popularization.

Owner:合肥朝霞机械科技有限公司

Hydroscopic polymer gels for easier cleaning

InactiveUS20050245428A1Reduce adhesionEasy to cleanOrganic detergent compounding agentsFibre treatmentProtonationPolymer science

Hydroscopic polymer gels can be formed by applying a polymer to a surface and allowing water to be sequestered from the atmosphere into the polymer. The polymer gels are formed using methods and compositions employing water soluble or water dispersible copolymers having: (i) a first monomer that is acidic and is capable of forming an anionic charge in the composition; (ii) a second monomer that is amphipathic; (iii) optionally, a third monomer that is hydrophobic; and (iv) optionally, a fourth monomer that that has a permanent cationic charge or that is capable of forming a cationic charge on protonation. The polymer gels are particularly substantive and effective at modifying surfaces such as glass and hydrophobic polymeric substrates to provide soap scum and soil resistance, and easier next time cleaning benefits.

Owner:THE CLOROX CO

Displacement Sensor with Reduced Hysteresis

InactiveUS20120266470A1Reduce and eliminate hysteresisReduce hysteresisIncline measurementMotion resistanceEngineering

A method and apparatus are provided for reducing hysteresis in displacement sensors by reducing the resistance to motion between components in the sensing units that move relative to each other.

Owner:EKCHIAN JACK A

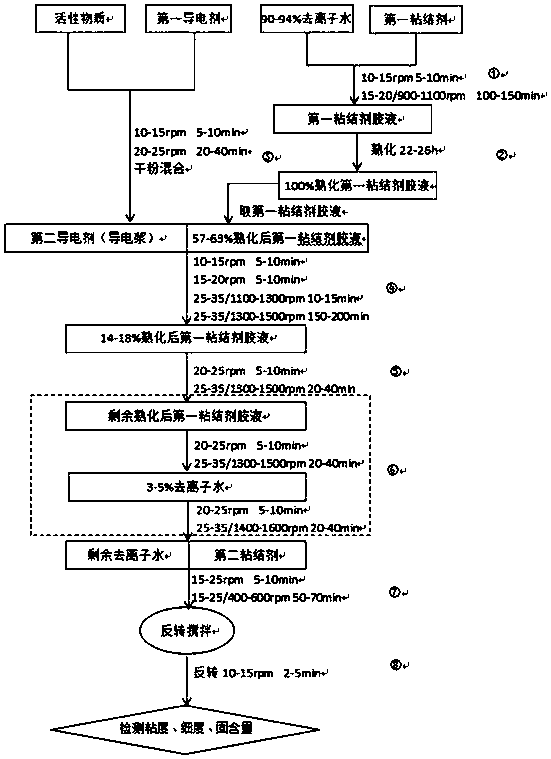

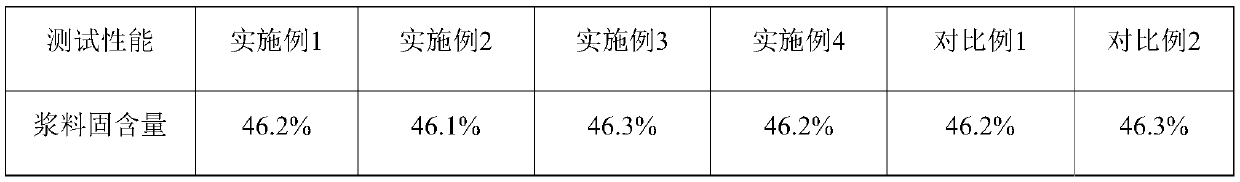

Preparation method of negative electrode slurry

ActiveCN111370672AAdvantages of preparation methodImprove dispersion uniformityCell electrodesSecondary cellsElectrical batterySlurry

The invention provides a preparation method of negative electrode slurry. The preparation method comprises the following steps: (1) preparing a glue solution; (2) curing the glue solution; (3) mixingdry powder; (4) carrying out high-viscosity mixing; (5) carrying out first high-speed dispersion; (6) carrying out second high-speed dispersion; (7) adjusting the viscosity; (8) carrying out reverse stirring; according to the preparation method of the negative electrode slurry, the dispersion uniformity, the stability and the rheological property of the slurry can be improved, the production efficiency of a coating process is improved, and the coating appearance and the coating thickness uniformity are improved, so that the electrical performance and the safety performance of a lithium ion battery are improved. And on the premise of ensuring the performance of the slurry, the stirring time of the slurry is shortened, large-scale application is facilitated, and great production practice significance is achieved.

Owner:TIANJIN ENERGIES

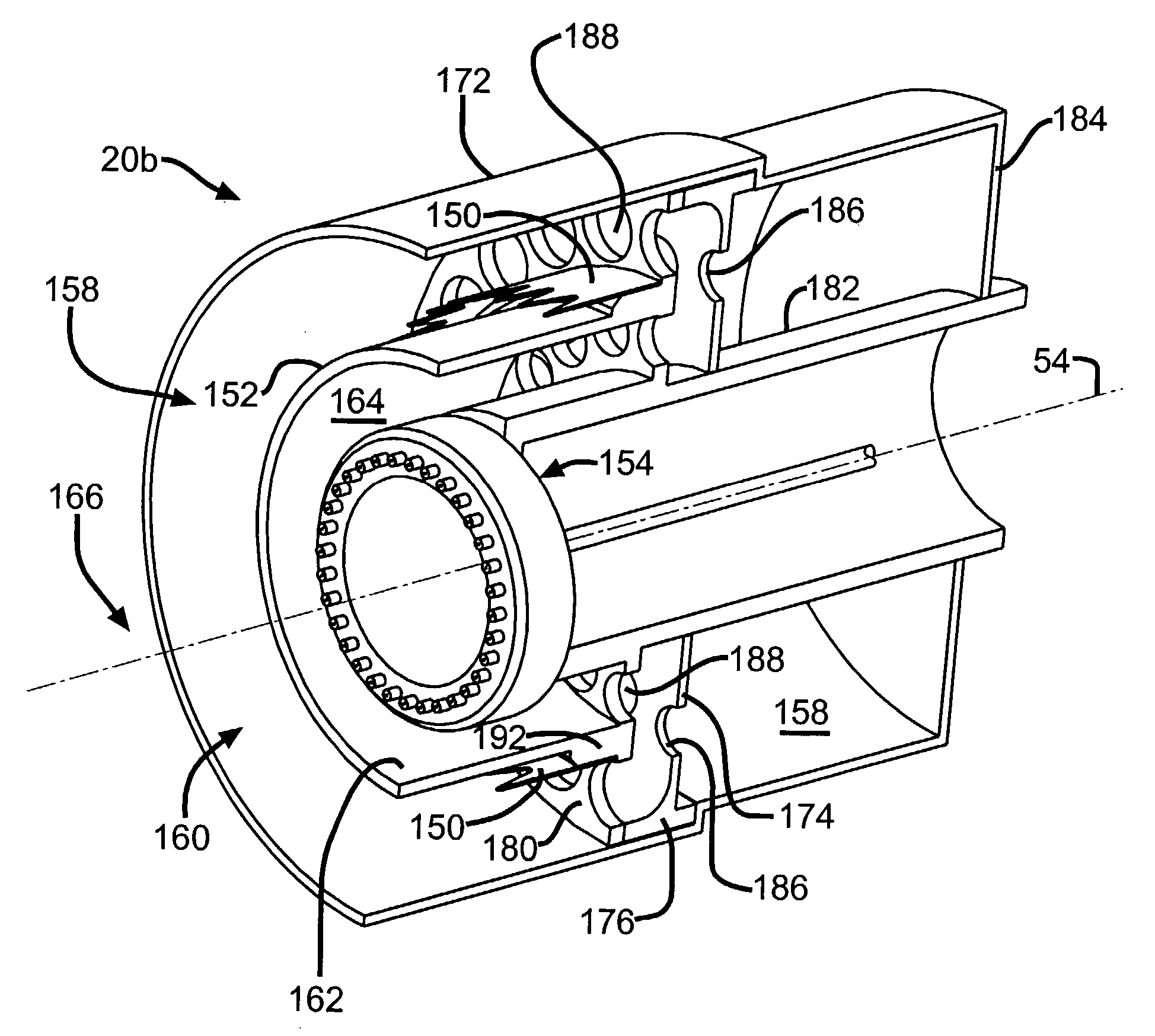

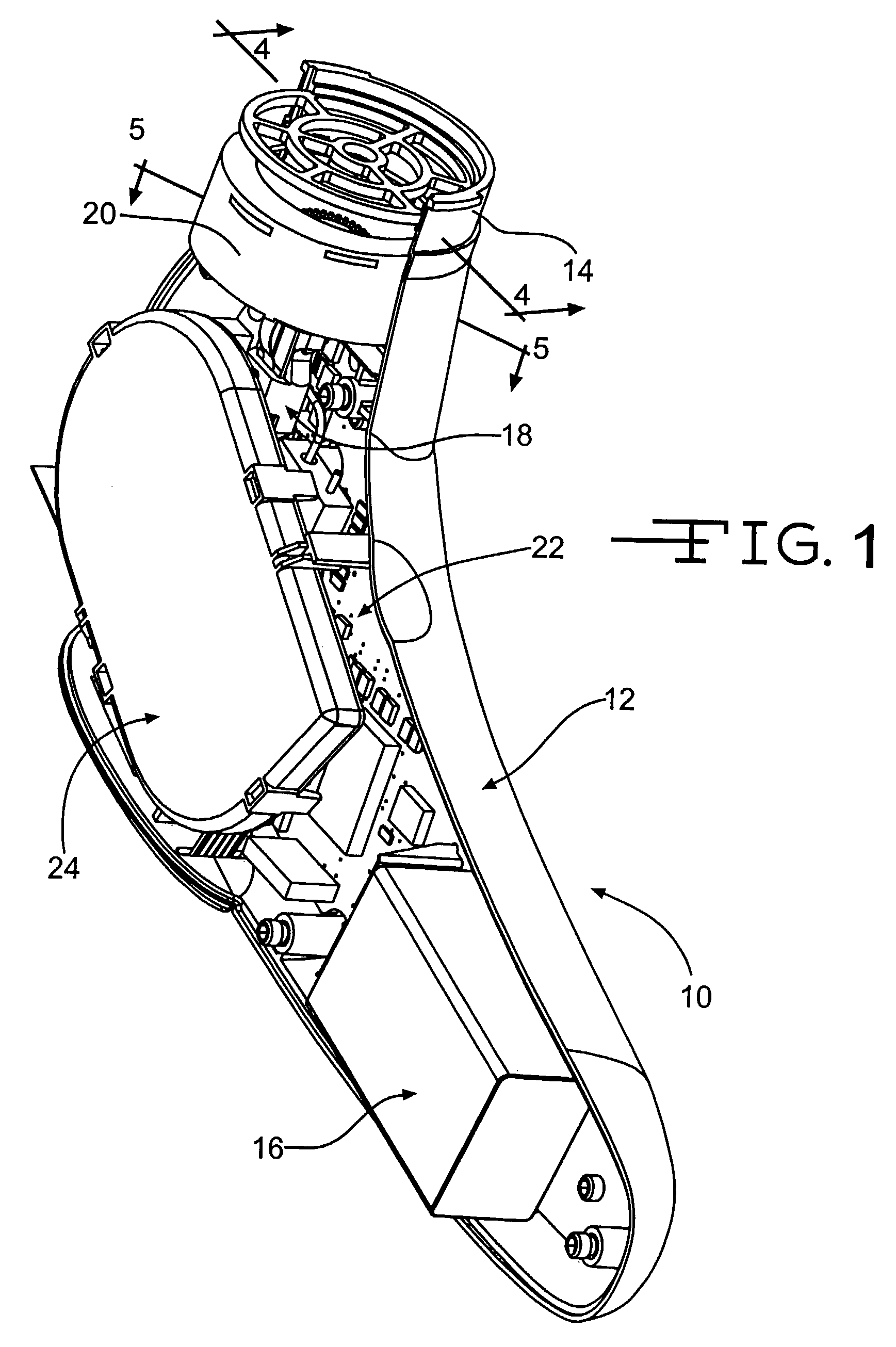

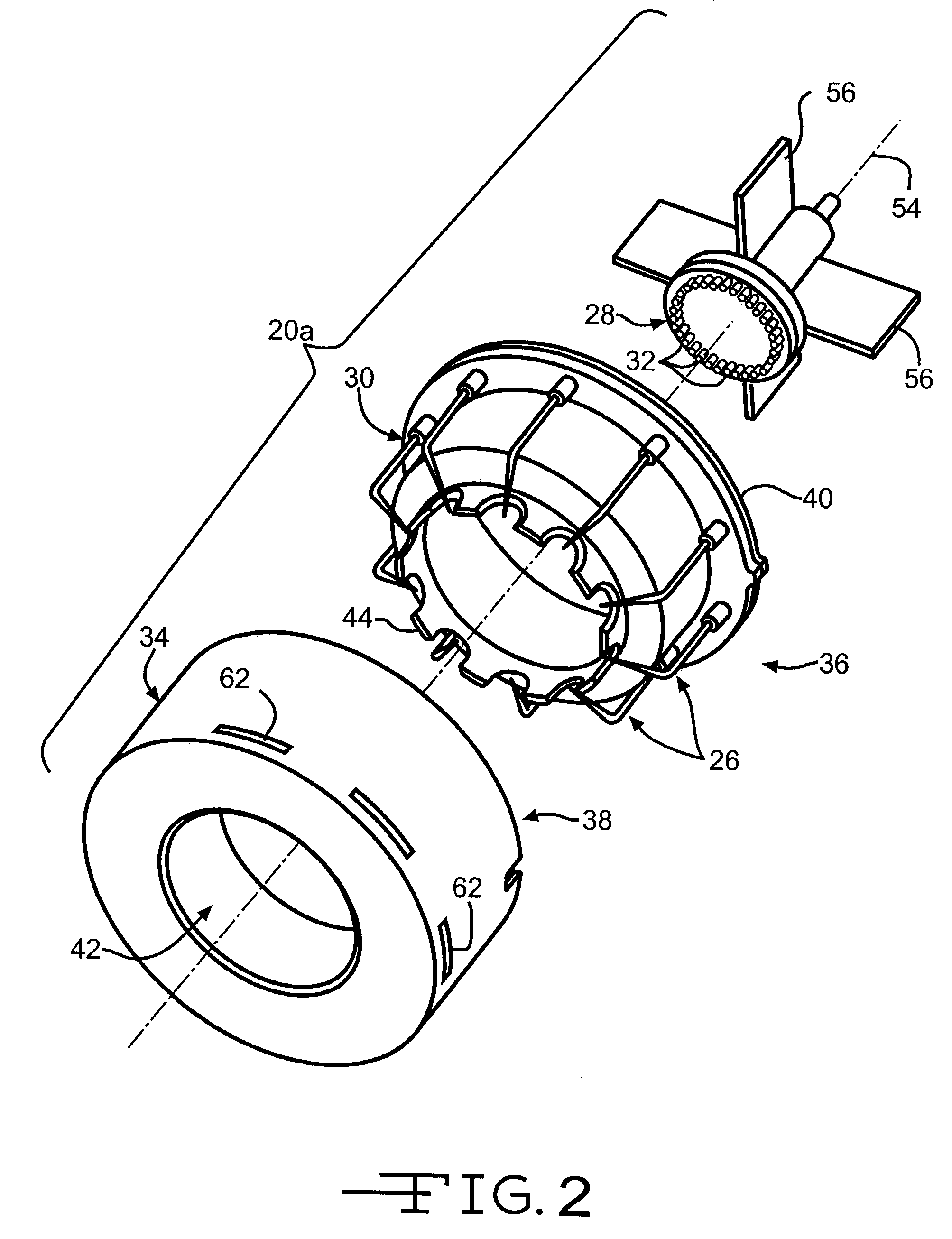

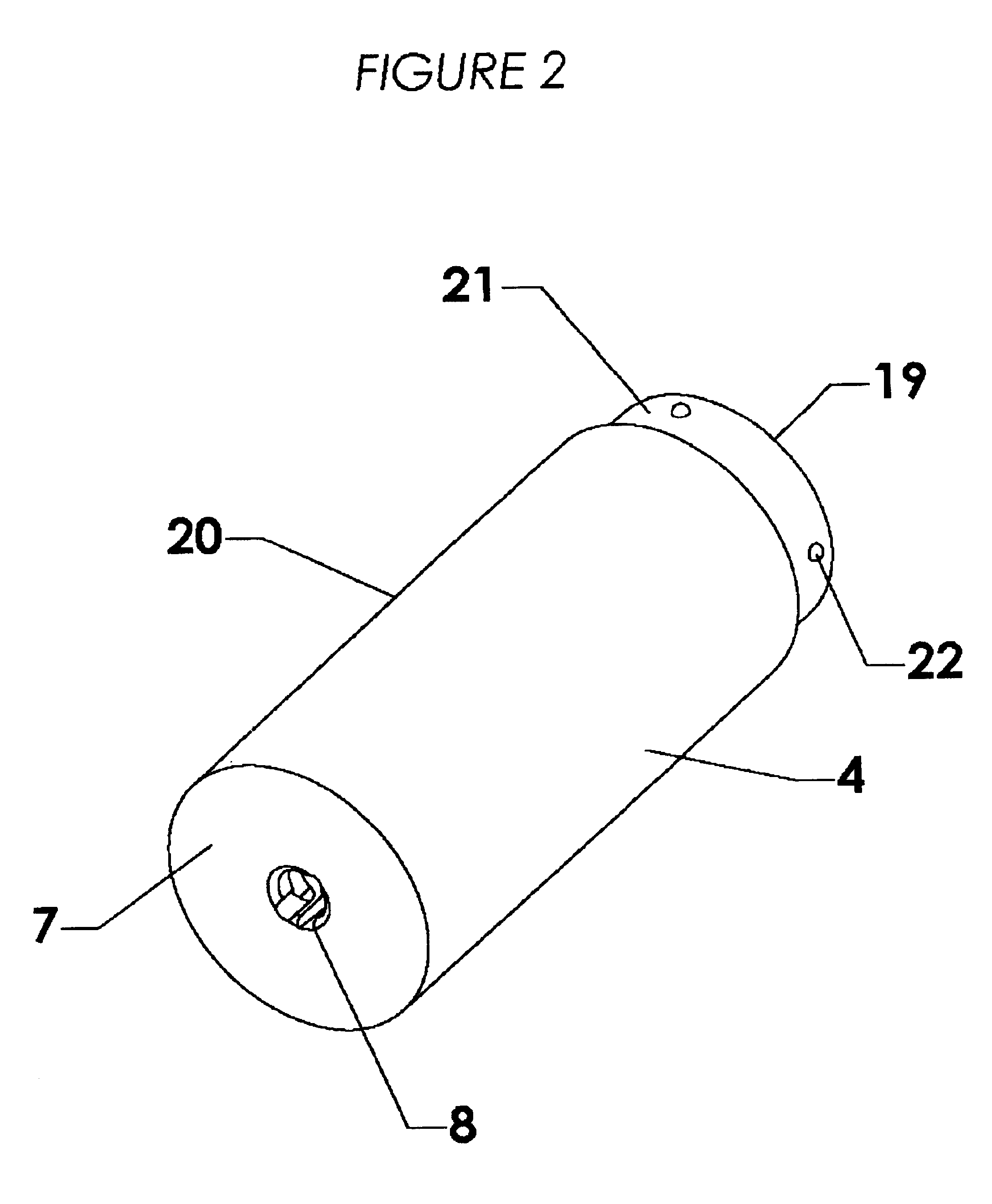

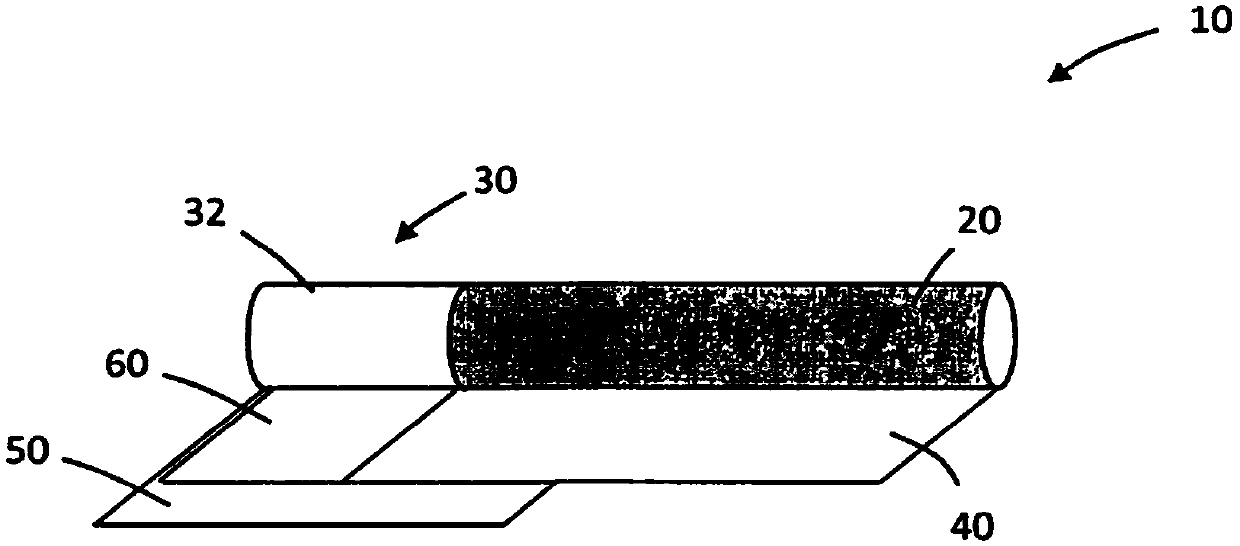

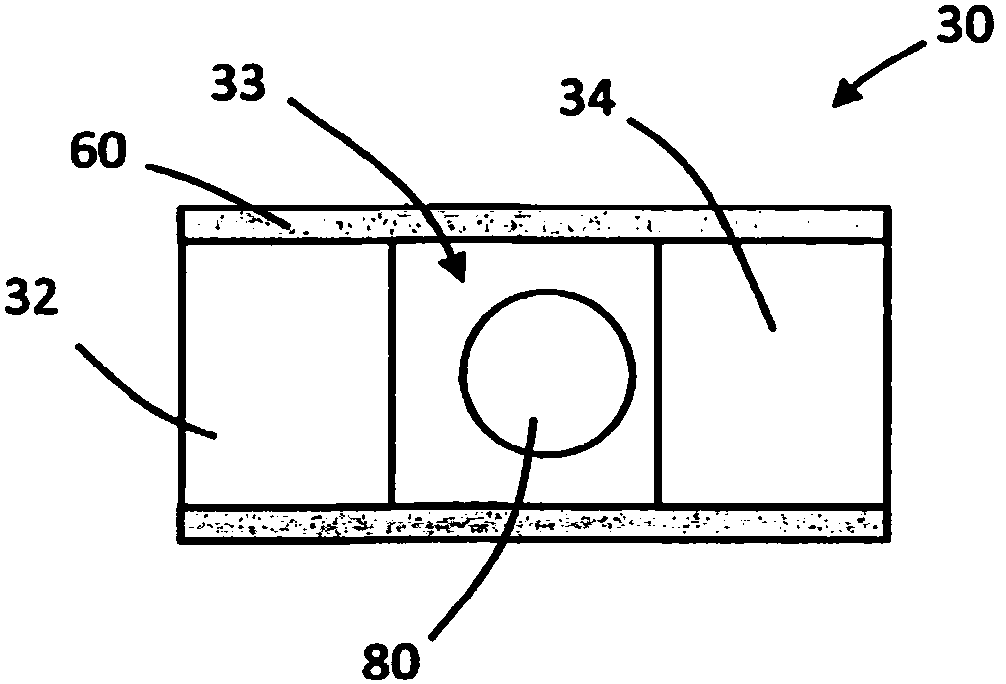

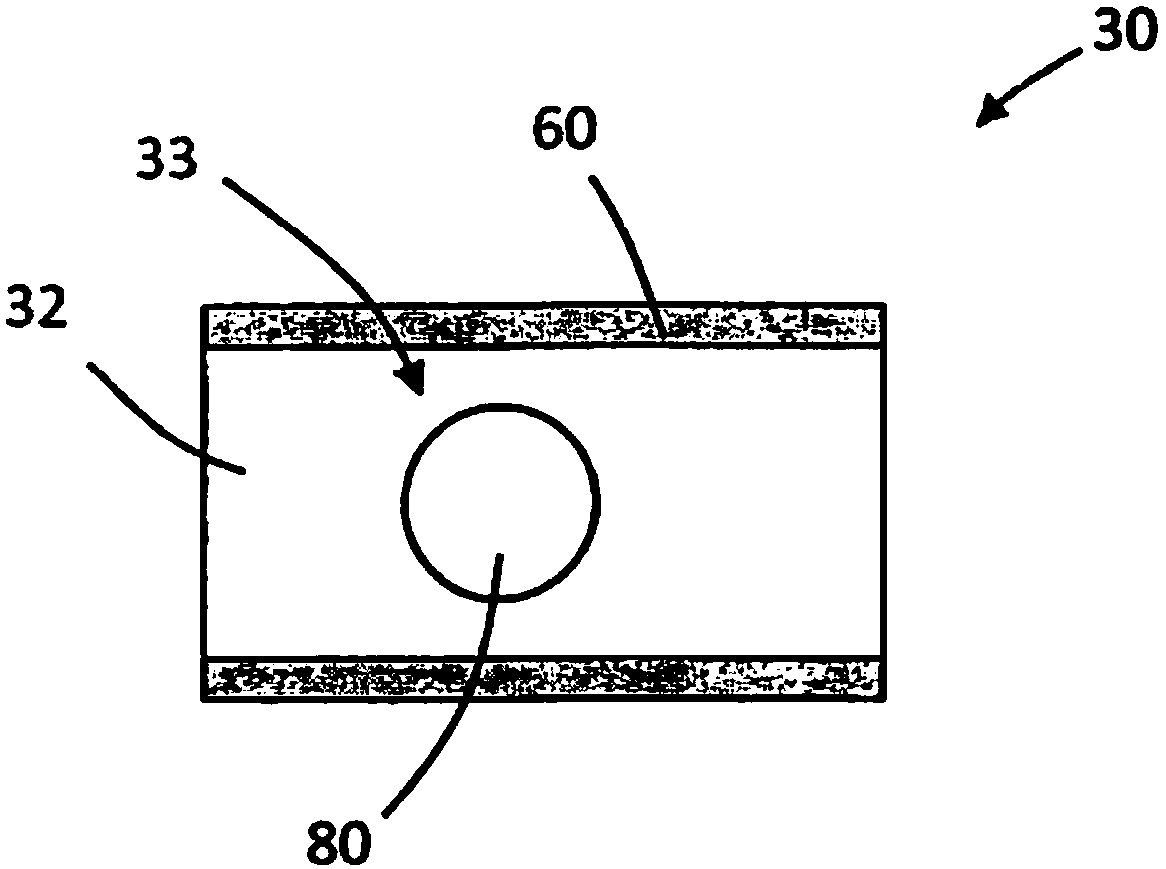

Nozzle for handheld pulmonary aerosol delivery device

An improved Electrohydrodynamic (EHD) nozzle particularly suitable for a handheld pulmonary aerosol inhaler increases the consistent and efficient dispensing of therapeutic liquids by reducing or eliminating wetting through shielding of discharge electrodes. Some versions further eliminate wetting while enhances neutralization of the aerosol through presentation of a corona wind of ions annularly surround the aerosol. Incorporation of improved liquid distribution with consistent pressure drops to each EHD nozzle tip allows horizontal dispensing, and by using dielectric nozzle tips with low surface energy to thereby avoid wicking between dispenses and to advantageously reduce achievable particle size when dispensing. Some versions feature enhanced snap-fit assembly and other manufacturability advantages. One of the unique features of the EHD nozzles is achieved high dose rate (microliters / minute) with low wetting and small particle size (1.0-5 microns), although these properties tend to be mutually exclusive. Furthermore, these attributes are incorporated into a conveniently small, handheld device.

Owner:EFIELD INNOVATIONS

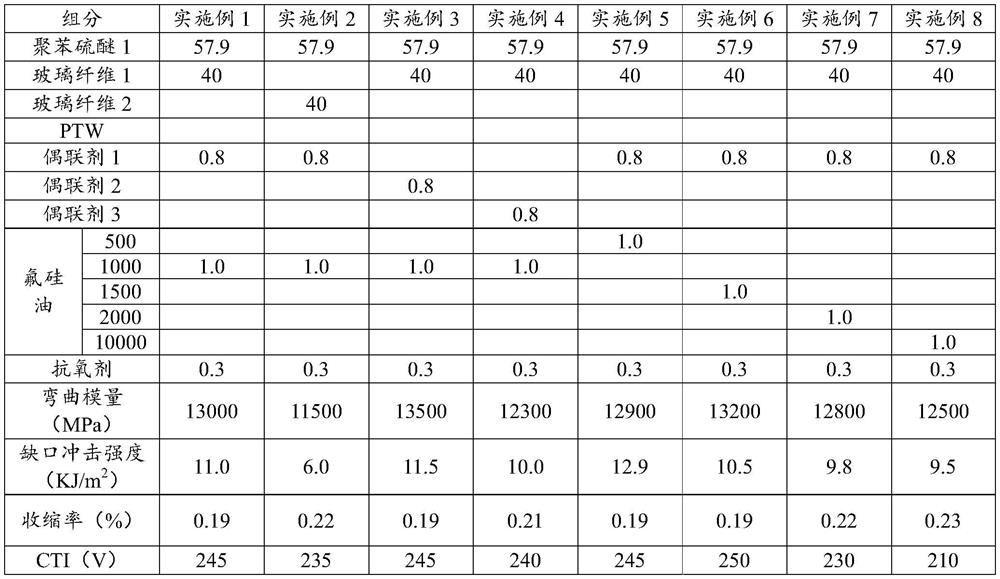

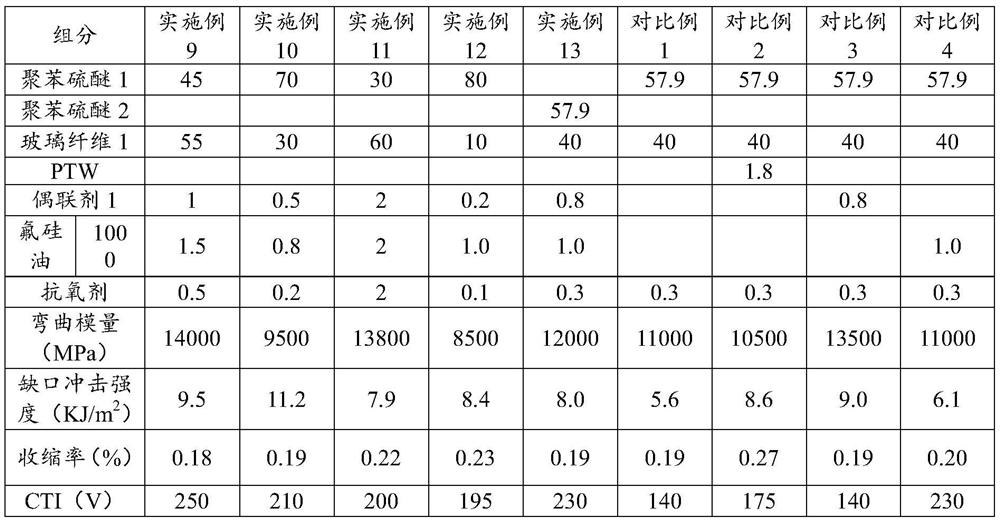

Hydrophobic high-CTI polyphenylene sulfide composition as well as preparation method and application thereof

The invention discloses a hydrophobic high CTI polyphenylene sulfide composition. The composition comprises the following components in parts by weight: 30-80 parts of polyphenylene sulfide, 10-60 parts of glass fibers, 0.2-2 part of a coupling agent, 0.2-2 part of fluorosilicone oil and 0.1-2 part of an antioxidant. According to the hydrophobic high CTI polyphenylene sulfide composition, the compatibility of PPS and a glass fiber material is improved through the coupling agent, the rigidity and the toughness of the material are further improved, meanwhile, the fluorosilicone oil is added, andthe characteristics of low surface energy and super-hydrophobicity of the fluorosilicone oil are utilized, in the injection molding process, due to the low surface energy, the composition is gatheredon the material surface, and the influence on the rigidity of the material is small. Meanwhile, after the fluorosilicone oil is gathered on the surface, the wetting of the PPS by the electrolyte canbe greatly reduced due to the super-hydrophobic characteristic, and the CTI of the PPS material can be obviously improved.

Owner:KINGFA SCI & TECH CO LTD

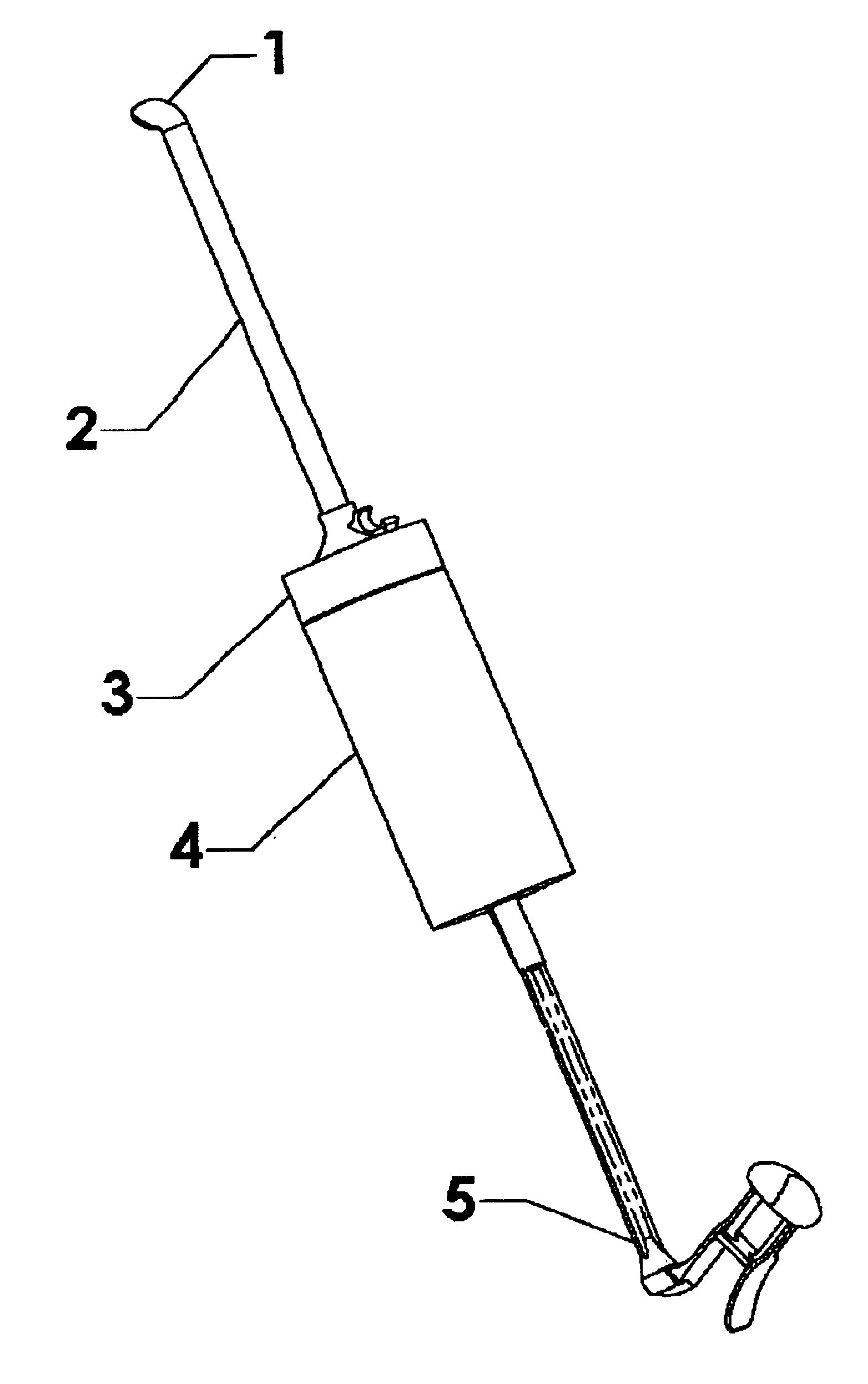

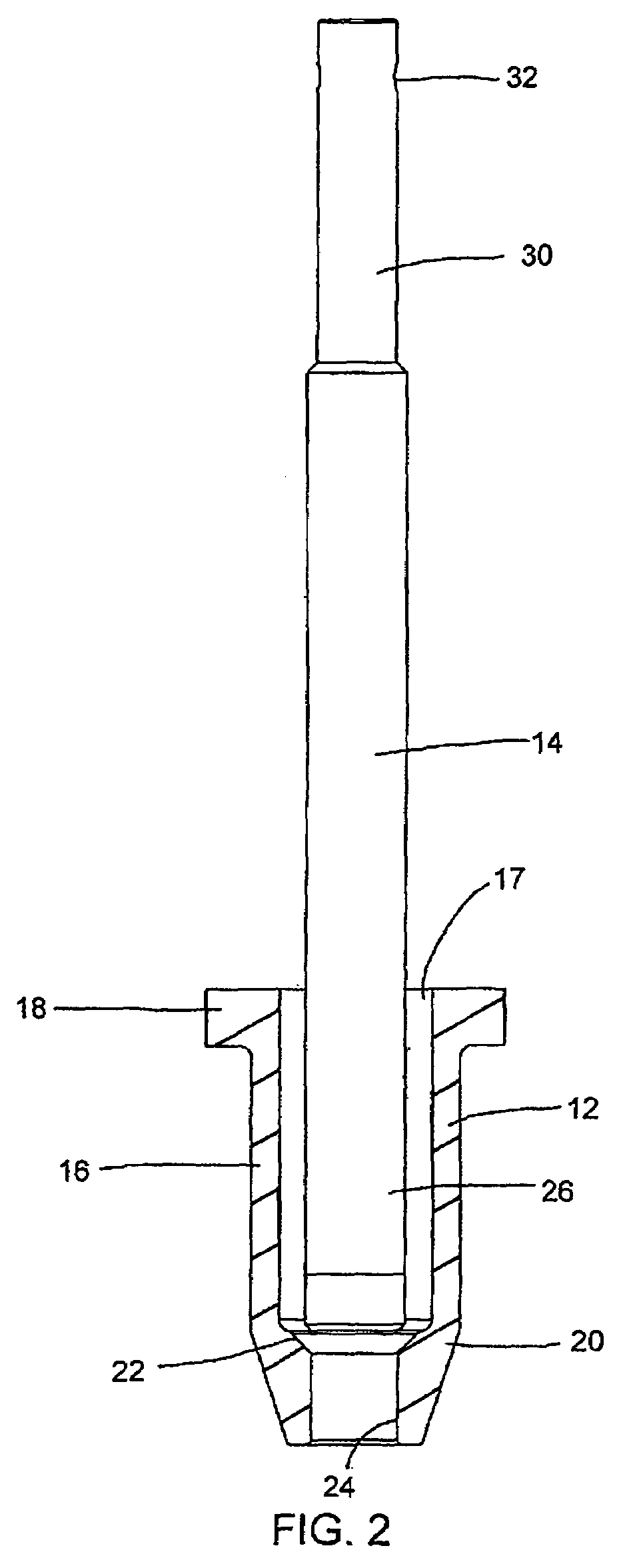

Disposable perineum cleaning device

InactiveUS6955662B2Reduce wettingEasy to disassembleBathroom accessoriesMedical devicesHand heldHand held devices

The present invention relates to a hand-held device that enables persons of limited mobility to clean their perineal areas, and comprises a liquid reservoir that can be squeezed with gentle pressure, a spraying portion that generates a directed stream of liquid droplets towards the patient, and a tissue holder portion through which the user can grab, use and dispose of cleaning tissue.

Owner:MO BILITY 1NC

Control pin

InactiveUS7278464B2Safely withdrawn and replacedBreakage of the control pin and blocking of the pouring spout is therefore preventedMelt-holding vesselsMolten metal pouring equipmentsFiberComposite ceramic

A control pin for controlling the flow of liquid metal in a casting process includes an elongate body member, the body member being made at least partially of a composite ceramic material that includes a fibrous reinforcing material embedded within a ceramic matrix, and a failsafe element embedded within the composite ceramic material.

Owner:PYROTECK INC

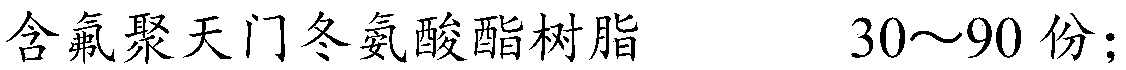

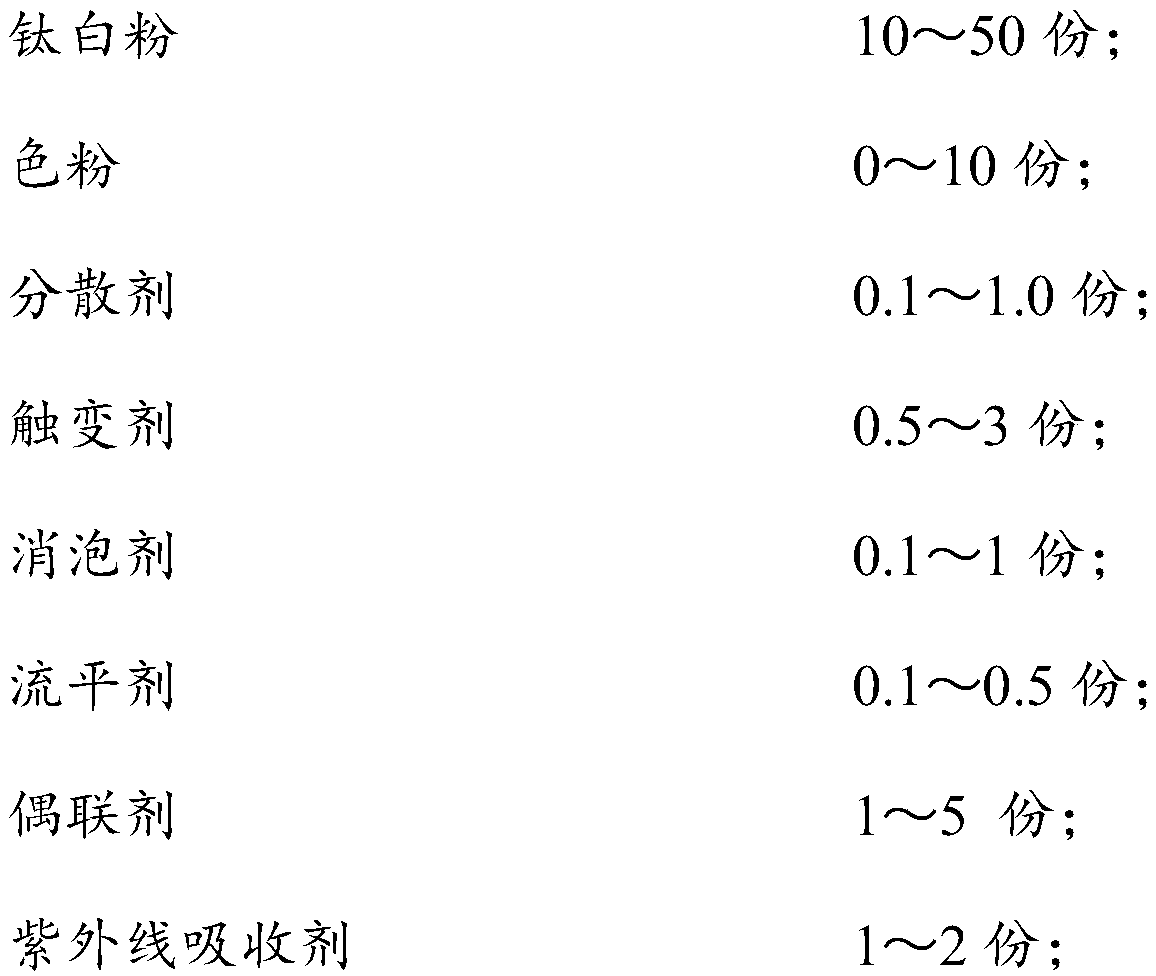

Fluorine modified aspartic polyurea coating and preparation method thereof

ActiveCN109207039AIncrease resistanceImprove high temperature resistancePolyurea/polyurethane coatingsGlass transitionPolyurea

The invention discloses a fluorine-modified aspartic polyurea coating and a preparation method thereof, and relates to the technical field of synthetic coatings. The fluorine-modified aspartic polyurea coating is prepared by creatively combining the advantages of aspartic polyurea and a fluorocarbon coating, the fluorine-modified aspartic polyurea coating prepared from fluorine-modified fluorine-containing polyaspartic acid ester resin can be applied wind power blades, can significantly improve the glass transition temperature, improves the high temperature resistance of a coating film, and further improves the anti-aging, anti-light loss an d anti-tarnish properties at high temperature, the water contact angle of the coating surface is reduced, the wetting and erosion of water to the coating film can be reduced, the resistance to the water is improved, and the ability to resist ice coating is improved when the wind turbine blades are operated in a low temperature and high humidity environment.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

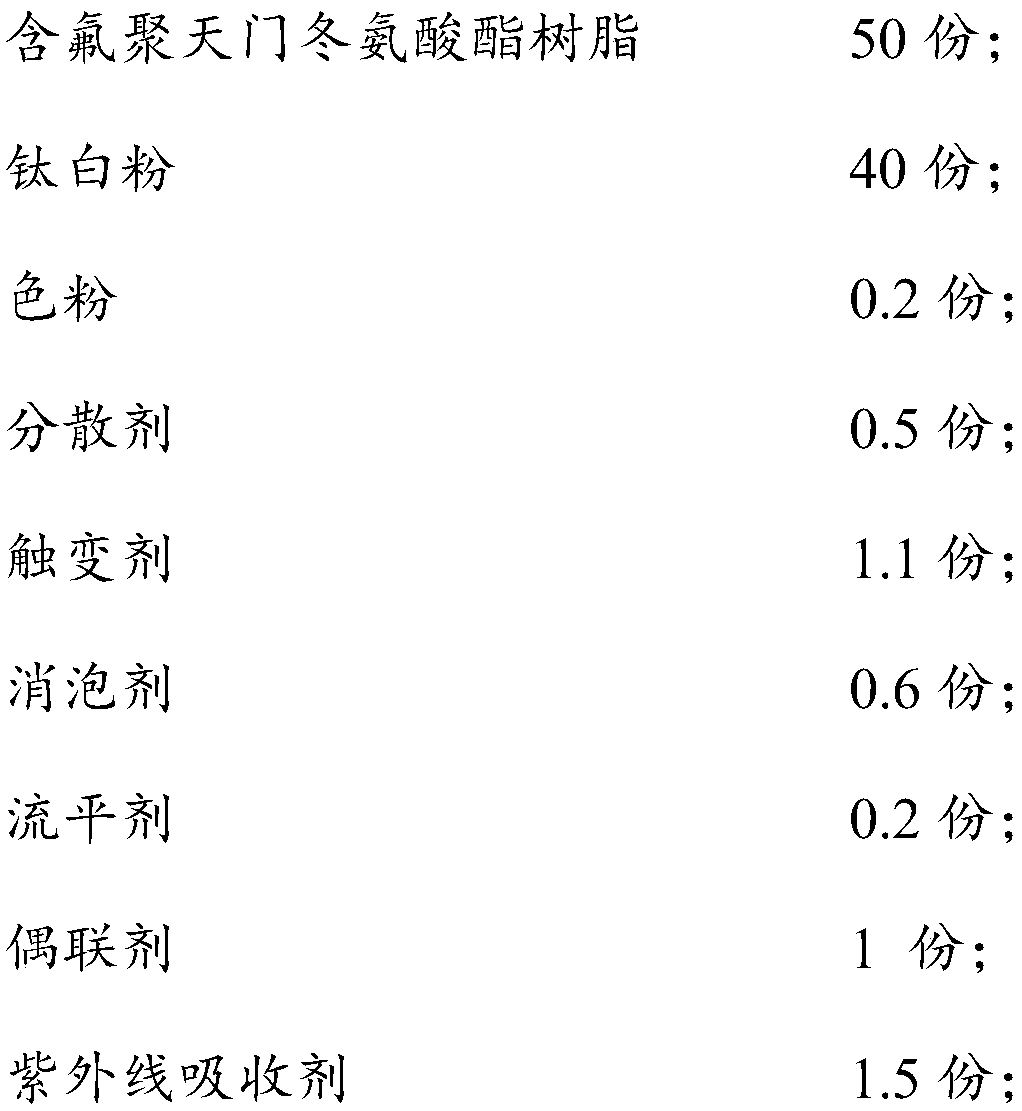

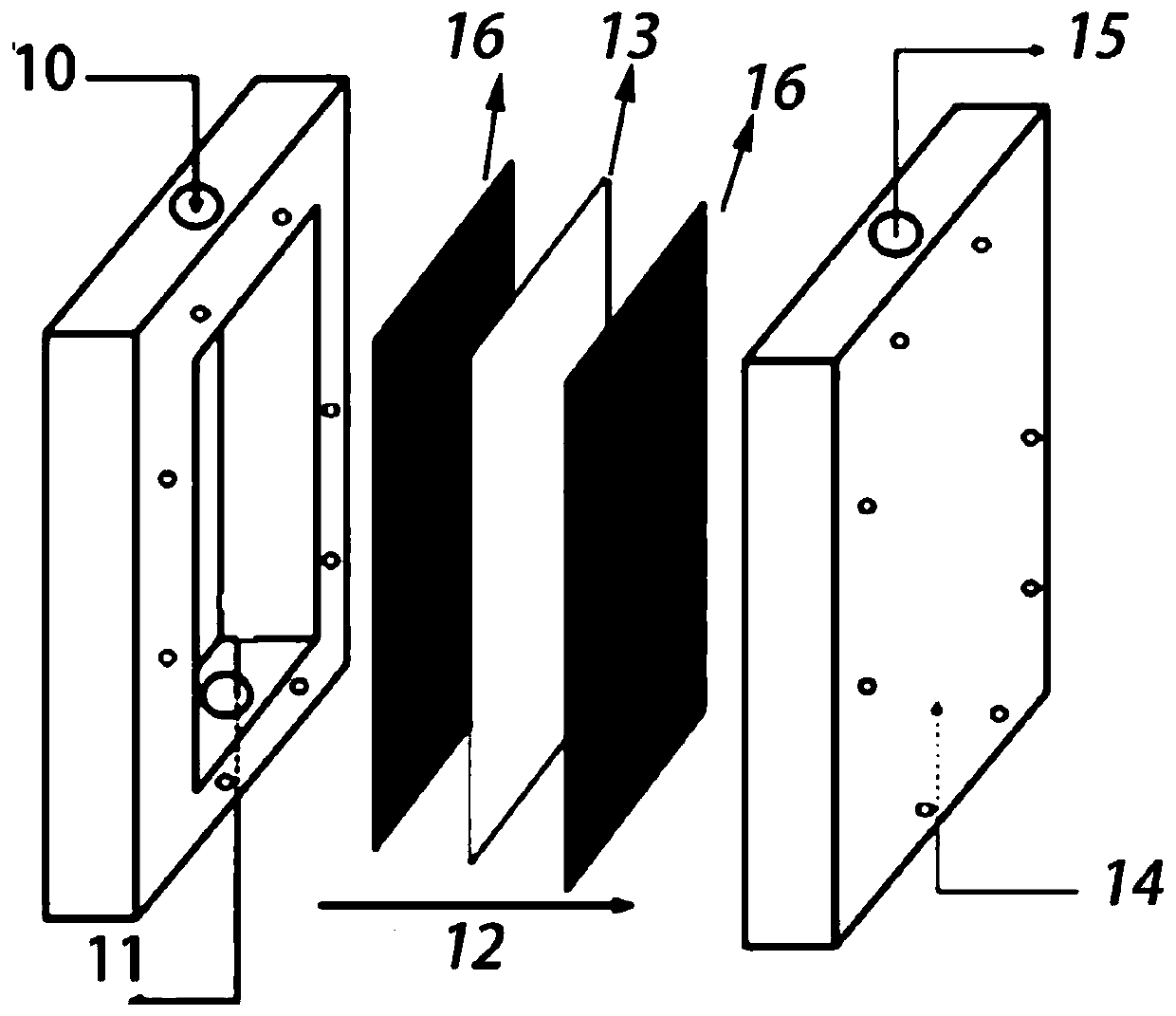

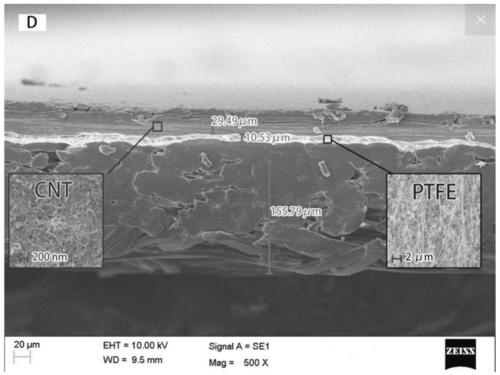

Membrane distillation device with electrified self-heating function

InactiveCN109956527AHigh porosityImprove electrochemical performanceWater/sewage treatment bu osmosis/dialysisWater/sewage treatment by heatingPeristaltic pumpCarbon nanotube

The invention discloses a membrane distillation device with an electrified self-heating function. The device comprises two loops which are a heat circulation loop and a cold circulation loop, whereinthe heat circulation loop is powered by a hot side peristaltic pump, and forms a loop with a feed water tank and a membrane module. The cold circulation loop is powered by a cold side peristaltic pump, and forms a loop together with the membrane module, a distilled water tank and a condensation tank, the real-time mass change of the distilled water tank is measured by a balance and measurement software to determine the membrane flux change, a conductivity meter is used to monitor the electric conductivity change of a distilled liquid in real time, the feeding side membrane surface in the membrane module is connected with electrodes and a power supply, a membrane used in the invention is a carbon nanotube-PTFE composite membrane, and the device can release a large amount of heat after beingelectrified, and automatically heats the liquid flowing through the module. The composite membrane can alleviate the original membrane pollution and membrane wetting phenomena of the PTFE membrane, also can greatly reduce the energy consumption, and has a very good development prospect.

Owner:HOHAI UNIV

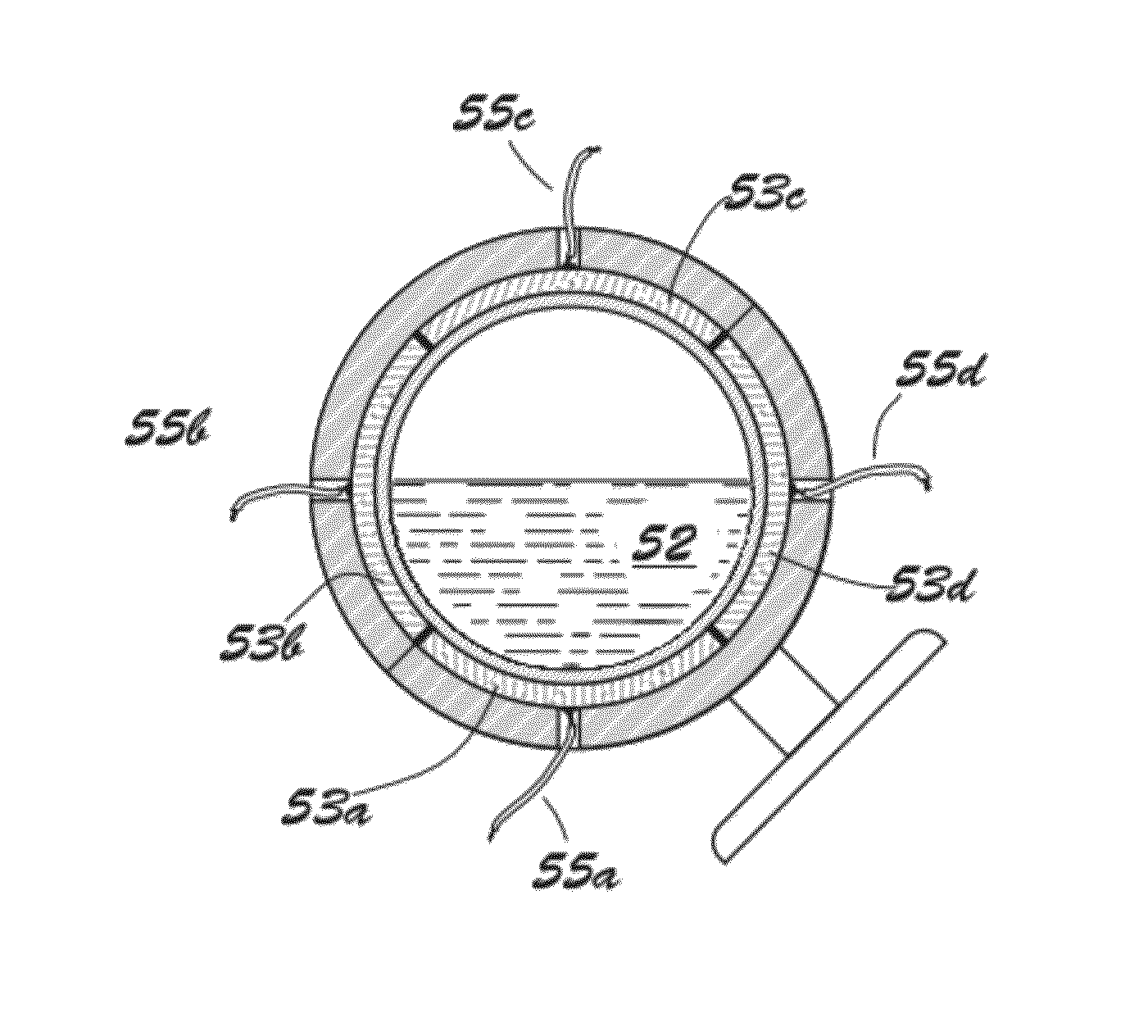

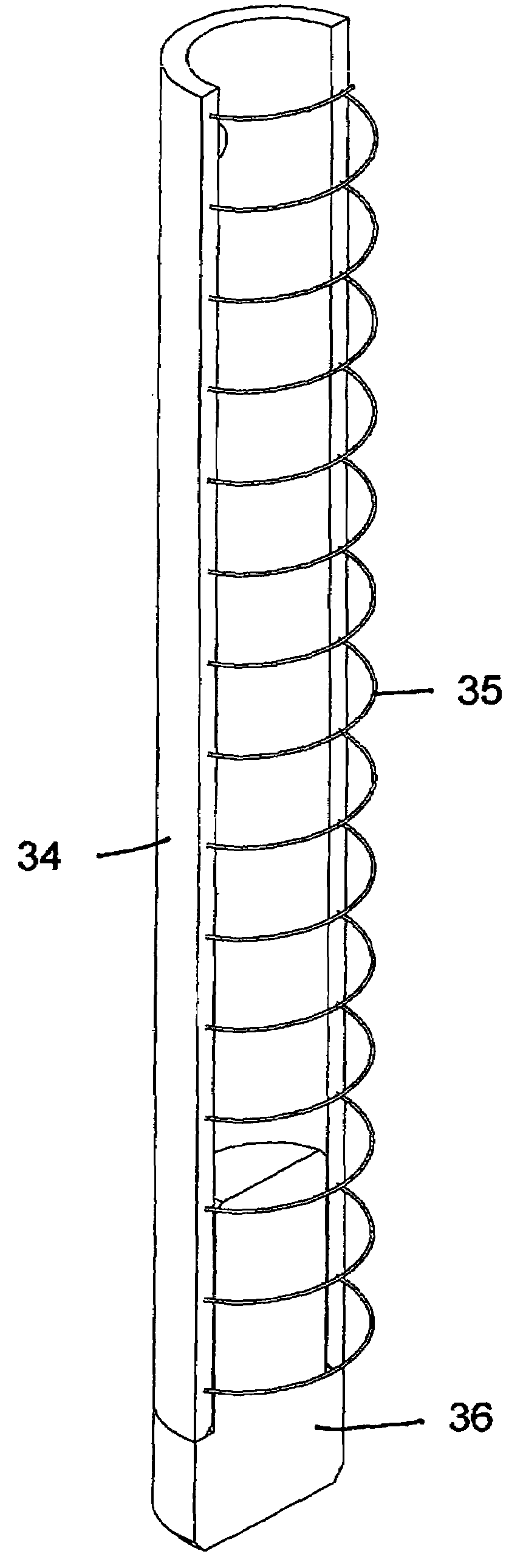

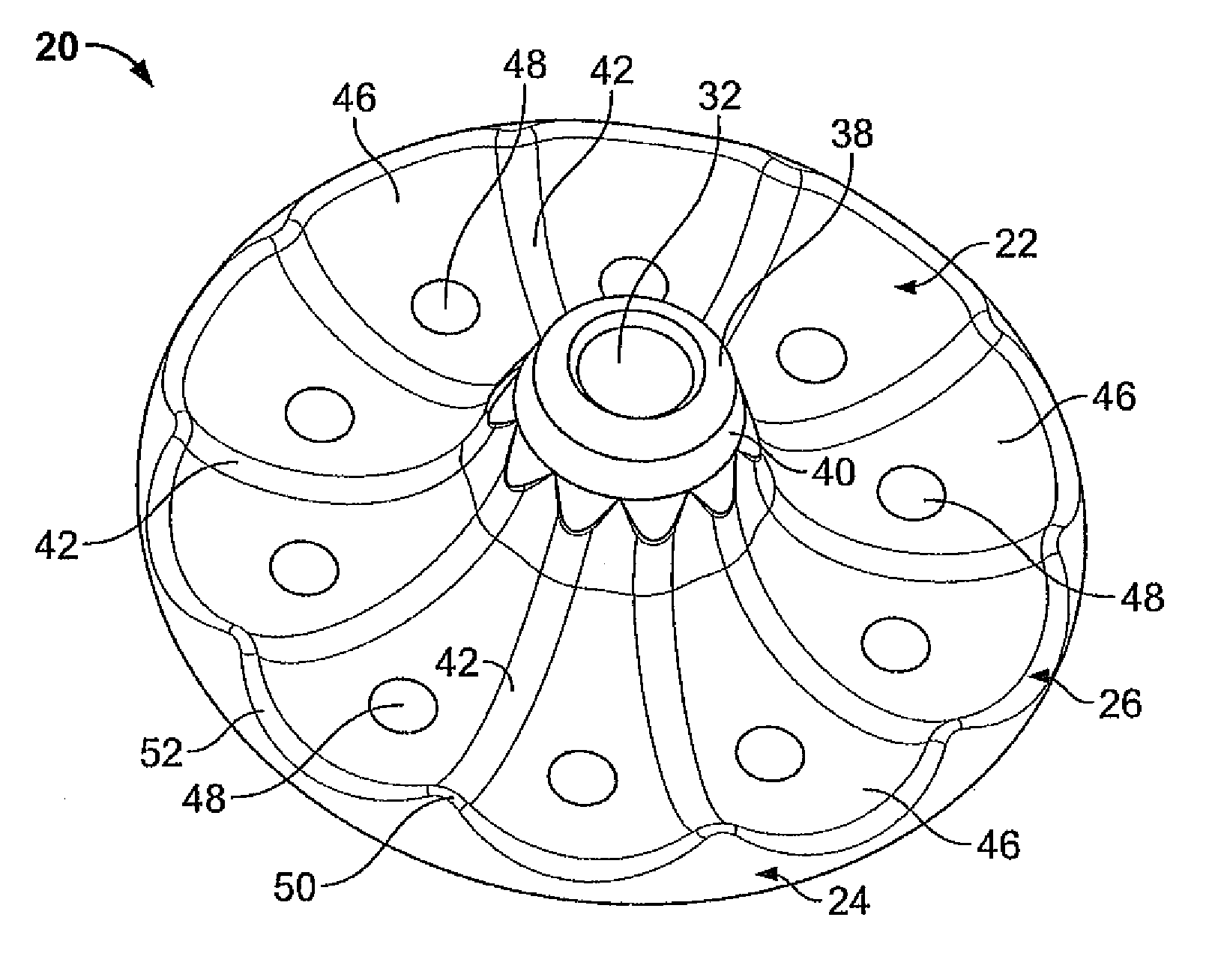

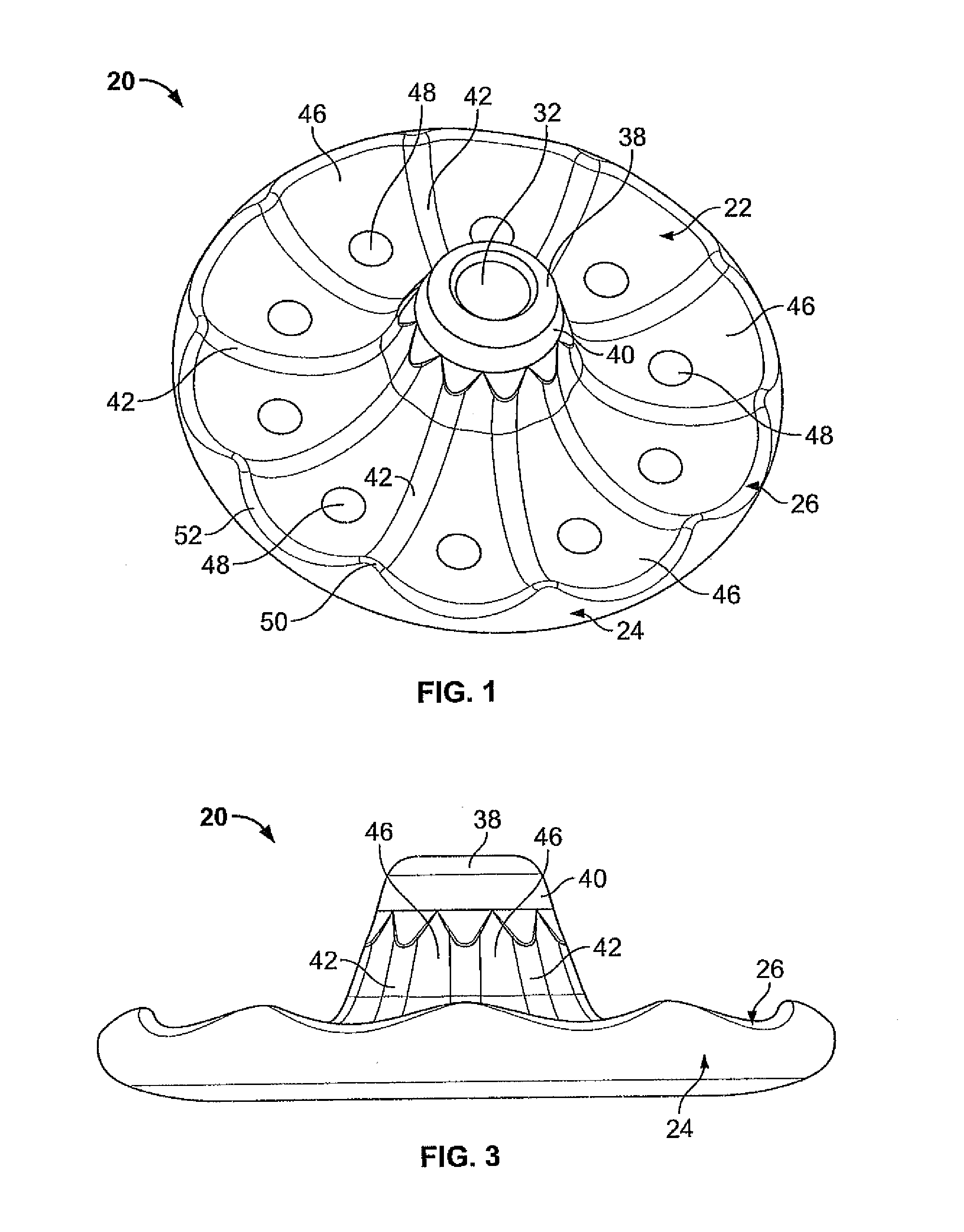

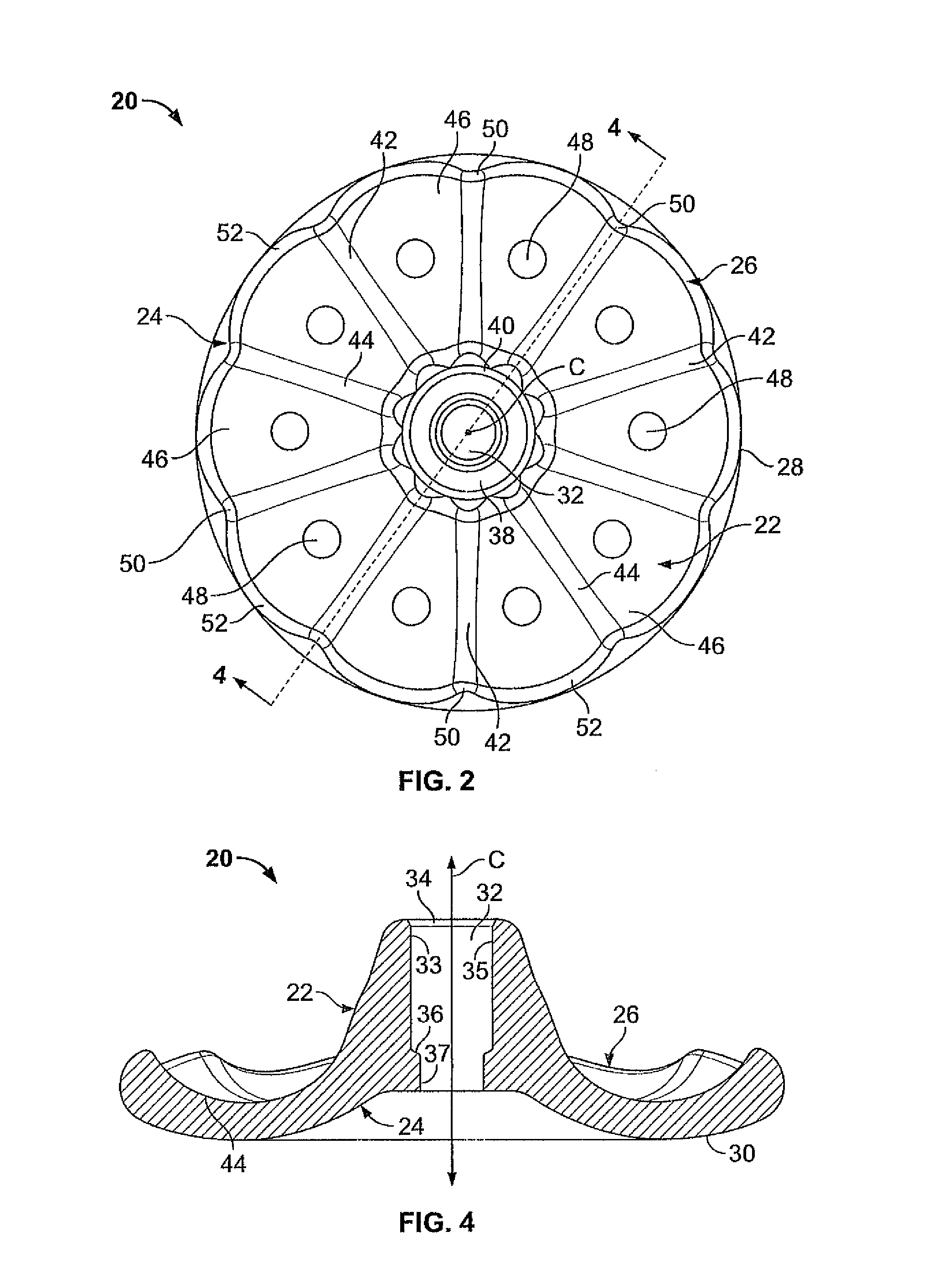

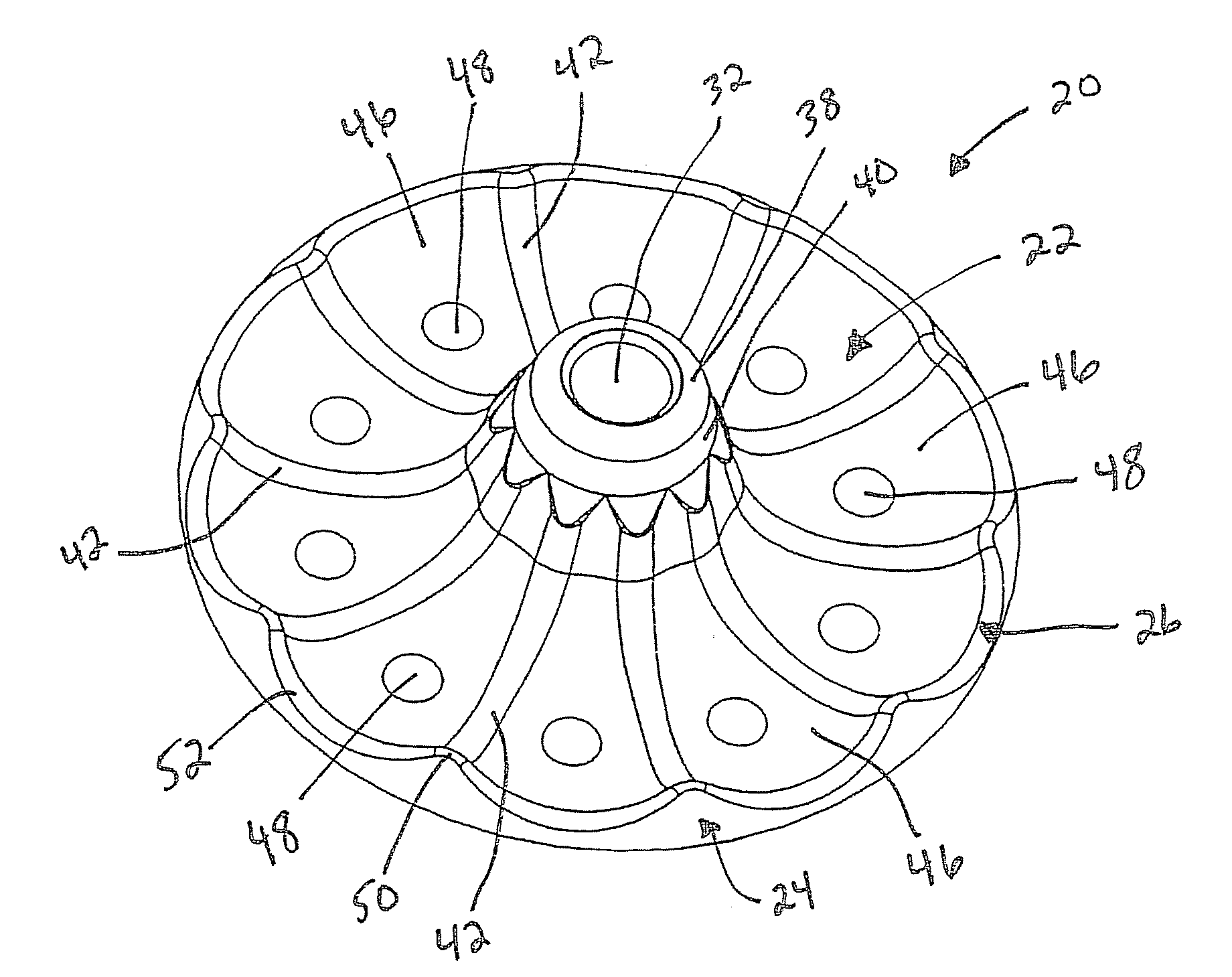

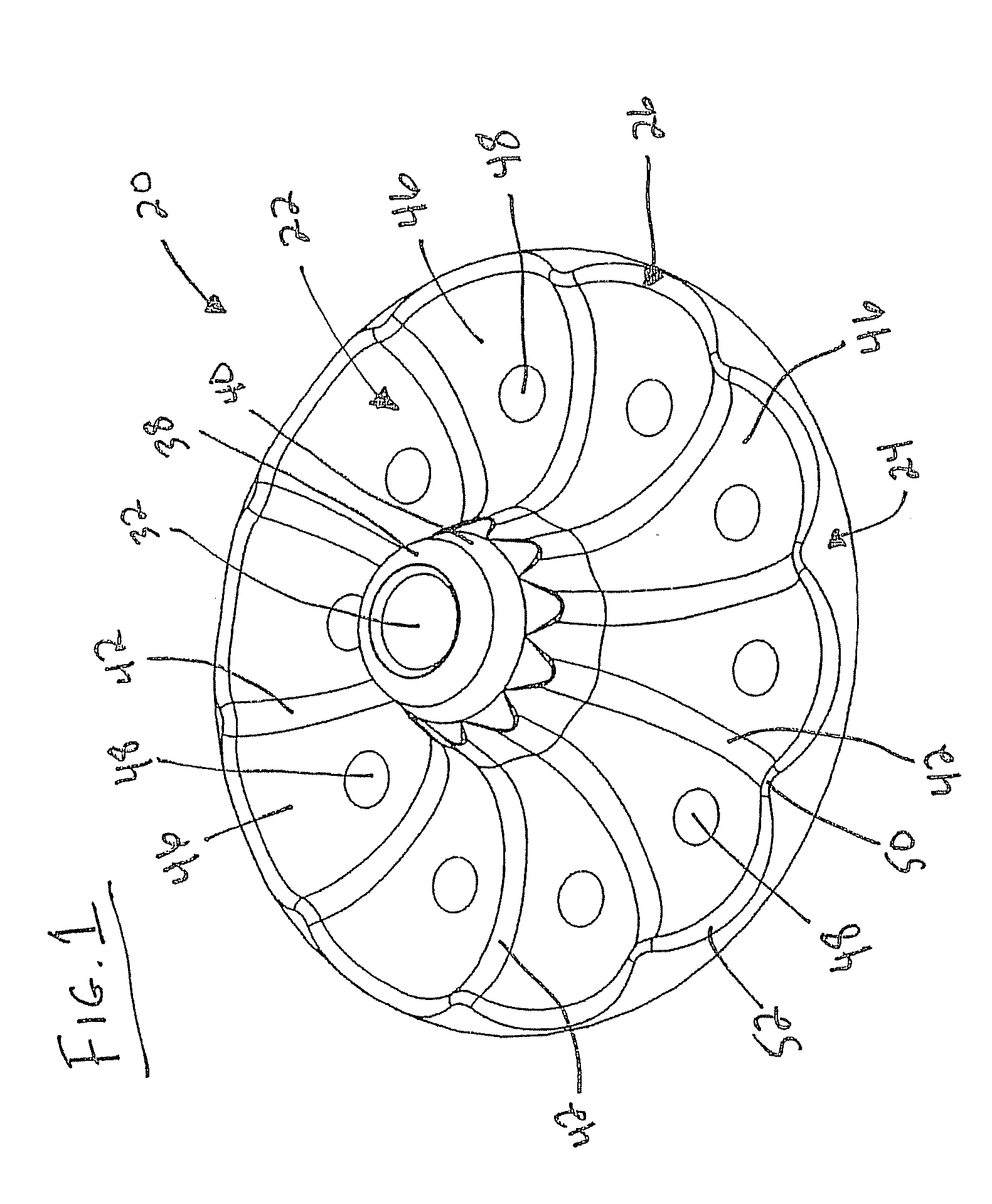

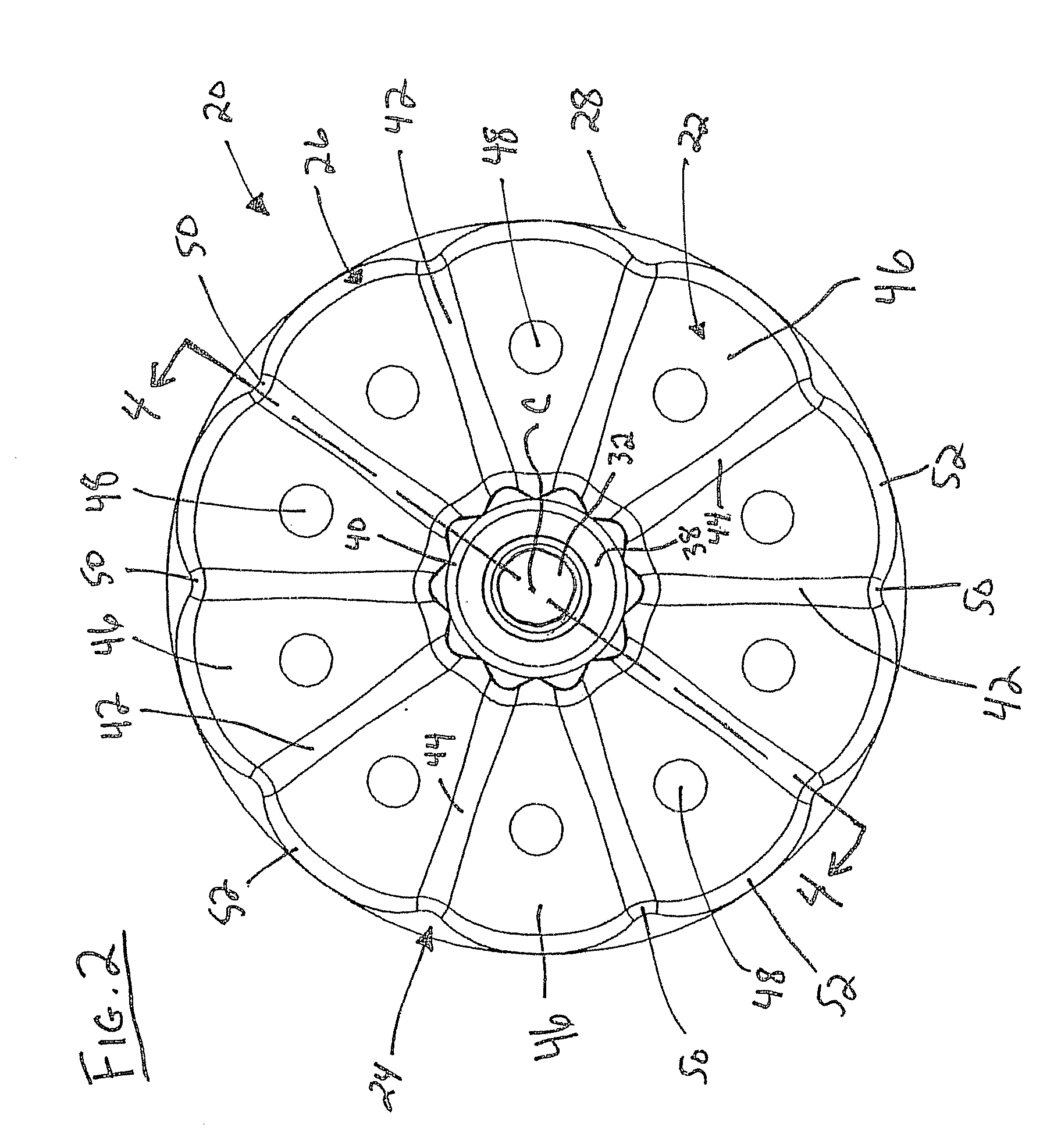

Watering device for poultry

ActiveUS7681526B2Prevent spillageAvoid wastingAnimal watering devicesAvicultureLine tubingEngineering

A watering disc for use in a nipple assembly of a watering line system has an outer rim portion and an upper surface extending inwardly from said outer rim portion to an aperture provided through a center of the watering disc. The upper surface defines a plurality of separators and a plurality of individual compartments in an alternating manner about a circumference of the watering disc. The plurality of separators generally extend from proximate the center of the watering disc to the outer rim portion in order to define each individual compartment between the outer rim portion and two adjacent separators. Each individual compartment is substantially formed in a concave manner and are configured to receive and retain water from the watering line system. The watering disc is formed of plastic and has reflective particles integrally formed therein for attracting poultry to the watering disc.

Owner:CTB INC

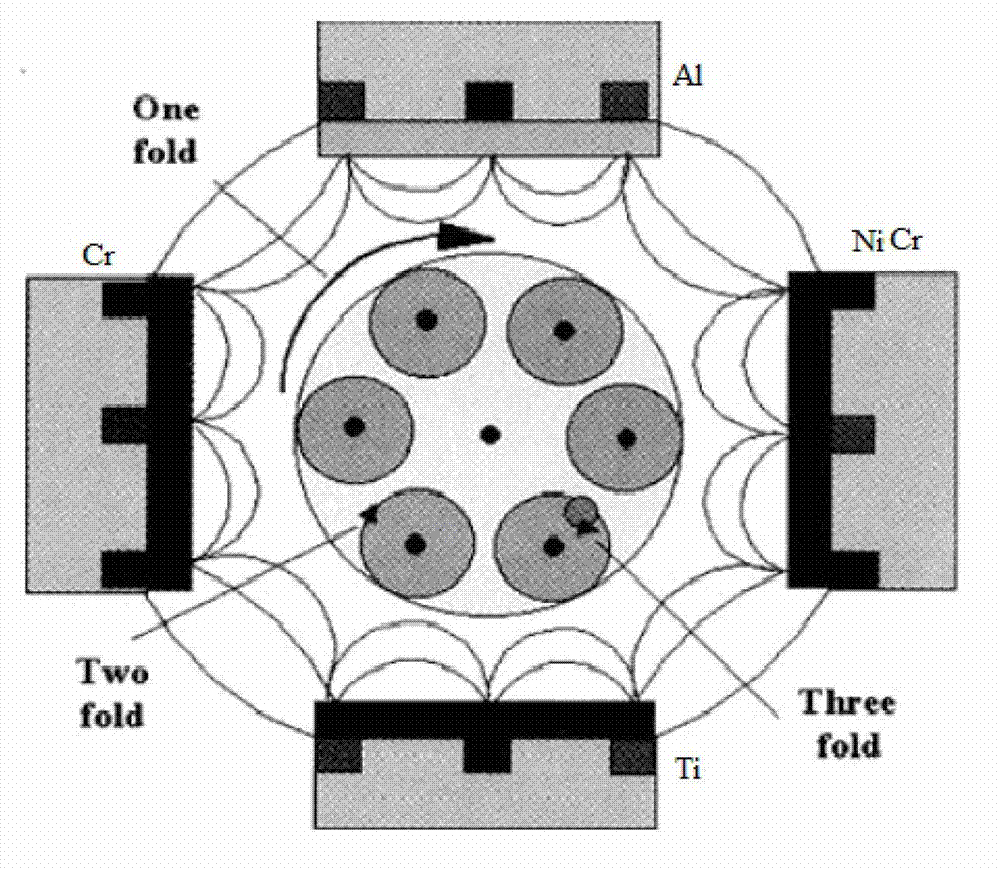

Product containing CrNiTiAlN quinary coating and preparation method thereof

ActiveCN103045998AHigh bonding strength of membrane baseImprove toughnessVacuum evaporation coatingSputtering coatingOrganic solventCritical load

The invention discloses a product containing a CrNiTiAlN quinary coating. The product takes a Cr layer as a bottom layer and takes an NiCrN layer as a transition layer, wherein a plurality of NiCrN-CrN-AlN-TiN composite coatings with the thickness are deposited on the NiCrN layer, and the thickness of the composite coatings can achieve 2-5 mu m; and according to the product disclosed by the invention, a multi-layer gradient design and a nitriding process before film plating are adopted, so that a coating-substrate bonding strength is greatly improved, and the critical load of the prepared gradient coatings in a scratch test is as high as 68N, which is relatively higher than related plated layers prepared by other methods and processes. The hardness of the product containing the CrNiTiAlN quinary coating can achieve 2880HV; the anti-impact, wear-resistant and anti-friction performances and the thermal stability of the surfaces of a mold and a cutter are greatly improved, and the friction coefficient and the rate of weight loss caused by wear are greatly reduced; and the wetting angle of mold steel to an organic solvent is improved, thereby showing that the coating can be used for greatly improving the demolding performance of the mold.

Owner:郎溪品旭科技发展有限公司

Flavor capsules for smoking articles

PendingCN107846971AReduce contaminationReduce wettingTobacco treatmentTobacco smoke filtersFood flavorChemistry

A smoking article includes a smokable material and a filter downstream of the smokable material. The filter comprises a capsule having a core and a breakable shell. The core has a mixture including one or more lipid compounds and one or more humectants. The lipid compounds account for 50% or more of the weight of the mixture. At least one of the one or more humectants is capable of interacting with one or more smoke constituents to reduce the concentration of the one or more smoke constituents in mainstream smoke.

Owner:PHILIP MORRIS PROD SA

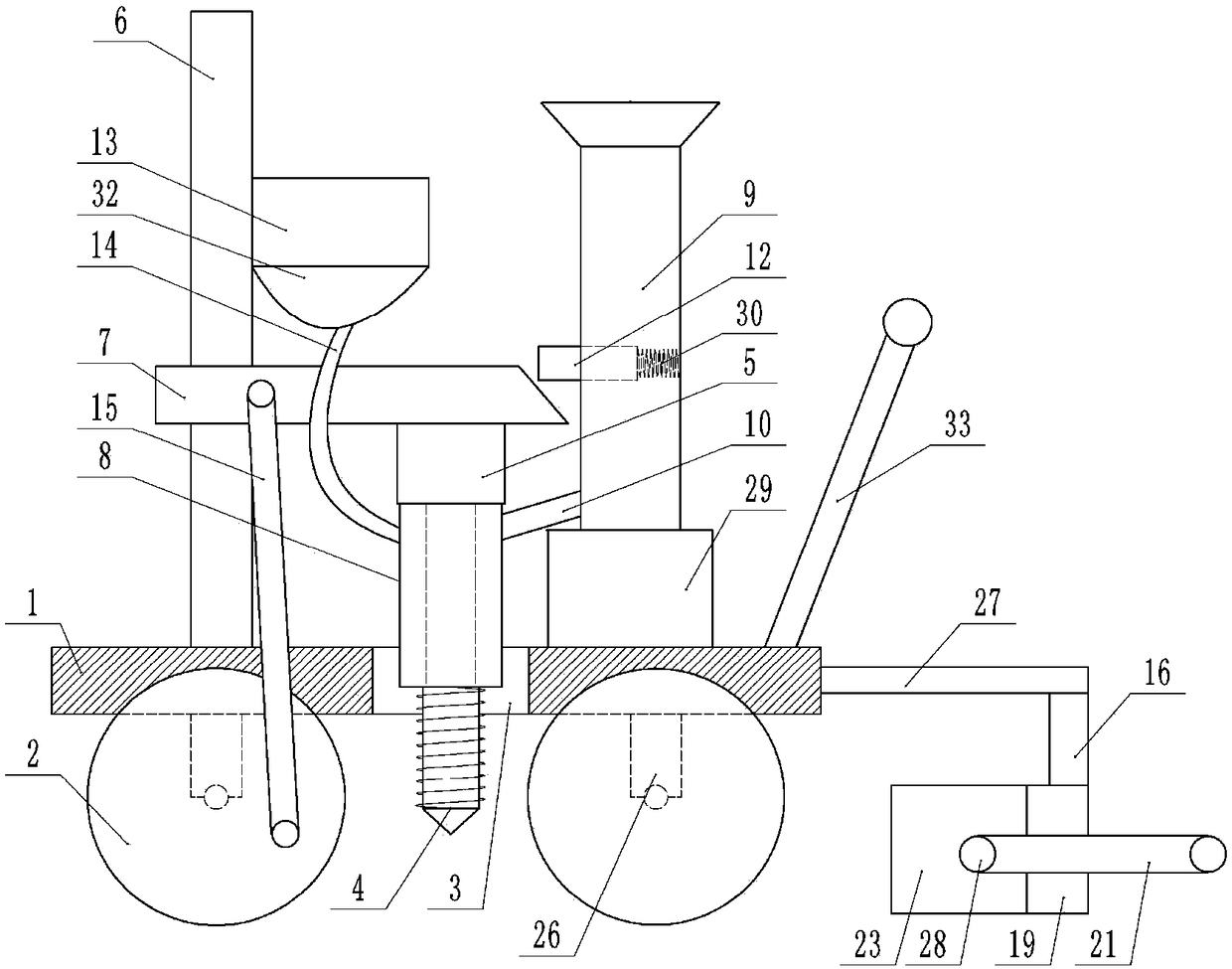

Planting equipment used for cassia obtusifolia

The invention belongs to the technical field of plant planting equipment, and particularly discloses planting equipment used for cassia obtusifolia. The equipment comprises a base board, rollers are arranged on the lower part of the base board, a supporting rod and a placement barrel are arranged on the base board, a supporting board is arranged on the supporting rod, a motor is arranged on the supporting board, a drill is arranged on the output shaft of the motor, a guiding barrel is arranged on the motor, a discharging port is formed in the guiding barrel, a baffle is arranged on the placement barrel, a first spring is arranged between the baffle and the placement barrel, a placement pipe is arranged on the bottom of the placement barrel, a strut is hinged to the part, located in an eccentric position, of the roller, and the end, away from the roller, of the strut is hinged to the supporting board. The equipment is mainly used for planting the cassia obtusifolia, so that the problemis solved that during cassia obtusifolia sowing, the emergence rate is affected due to inconsistent seed placement numbers.

Owner:凤冈县万福食品有限责任公司

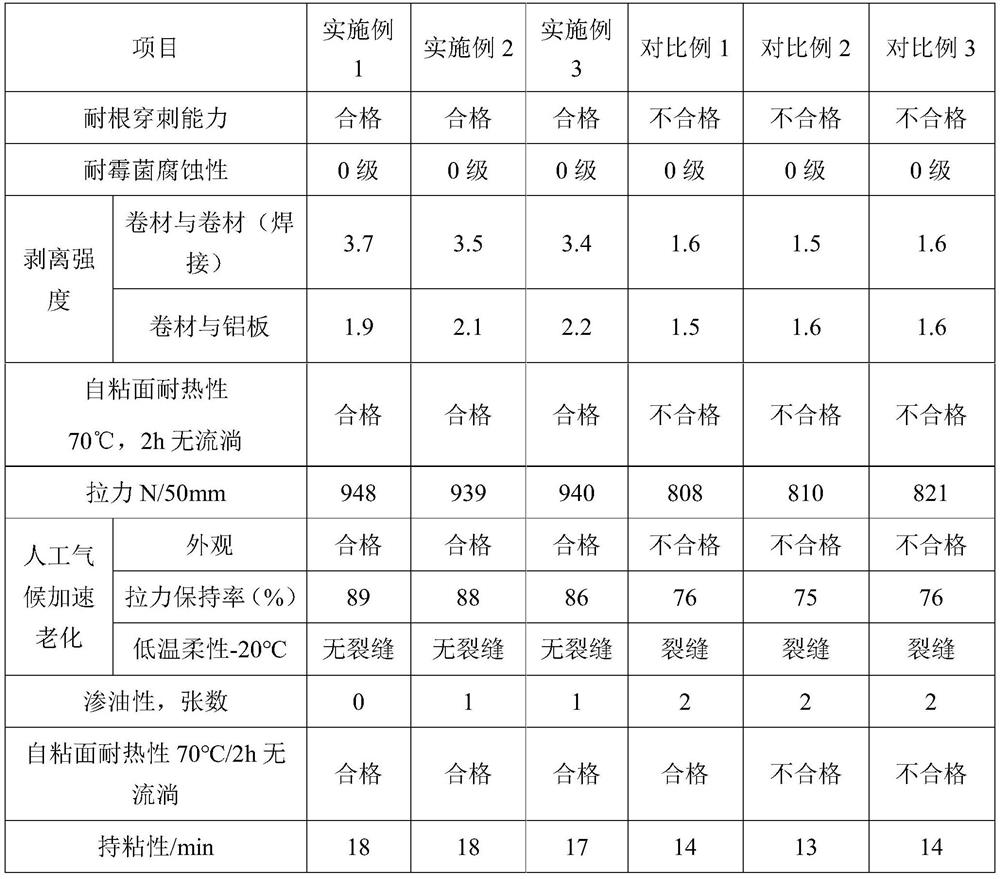

Modified asphalt waterproof coiled material with self-adhesive layer and preparation method of modified asphalt waterproof coiled material

ActiveCN113025224AReduce the effect of swellingExtend effective lifeRoof improvementRoof covering using flexible materialsPolyesterPolymer science

The invention relates to the technical field of waterproof coiled materials, and provides a modified asphalt waterproof coiled material with a self-adhesive layer, wherein the modified asphalt waterproof coiled material comprises a polyethylene film, a modified asphalt coating material layer, a silica gel modified asphalt fully-impregnated polyester base layer, a modified asphalt coating material layer, a multi-layer casting co-extrusion film, a high-molecular hot-melt pressure-sensitive adhesive layer and a polyethylene isolating film which are arranged in sequence. By means of the technical scheme, the problems that in the prior art, the service life is short, and the mechanical property is poor are solved.

Owner:远大洪雨(唐山)防水材料有限公司

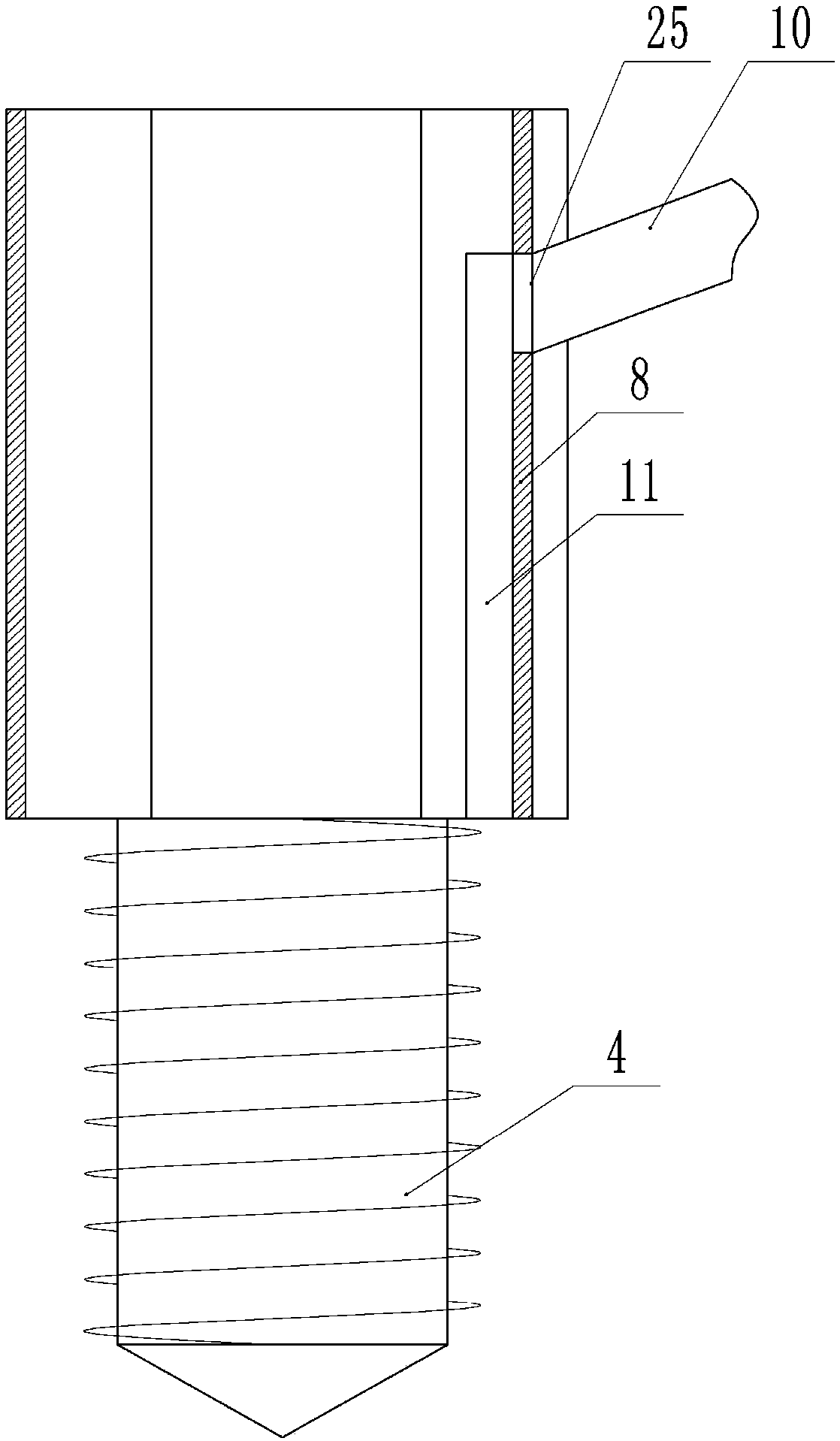

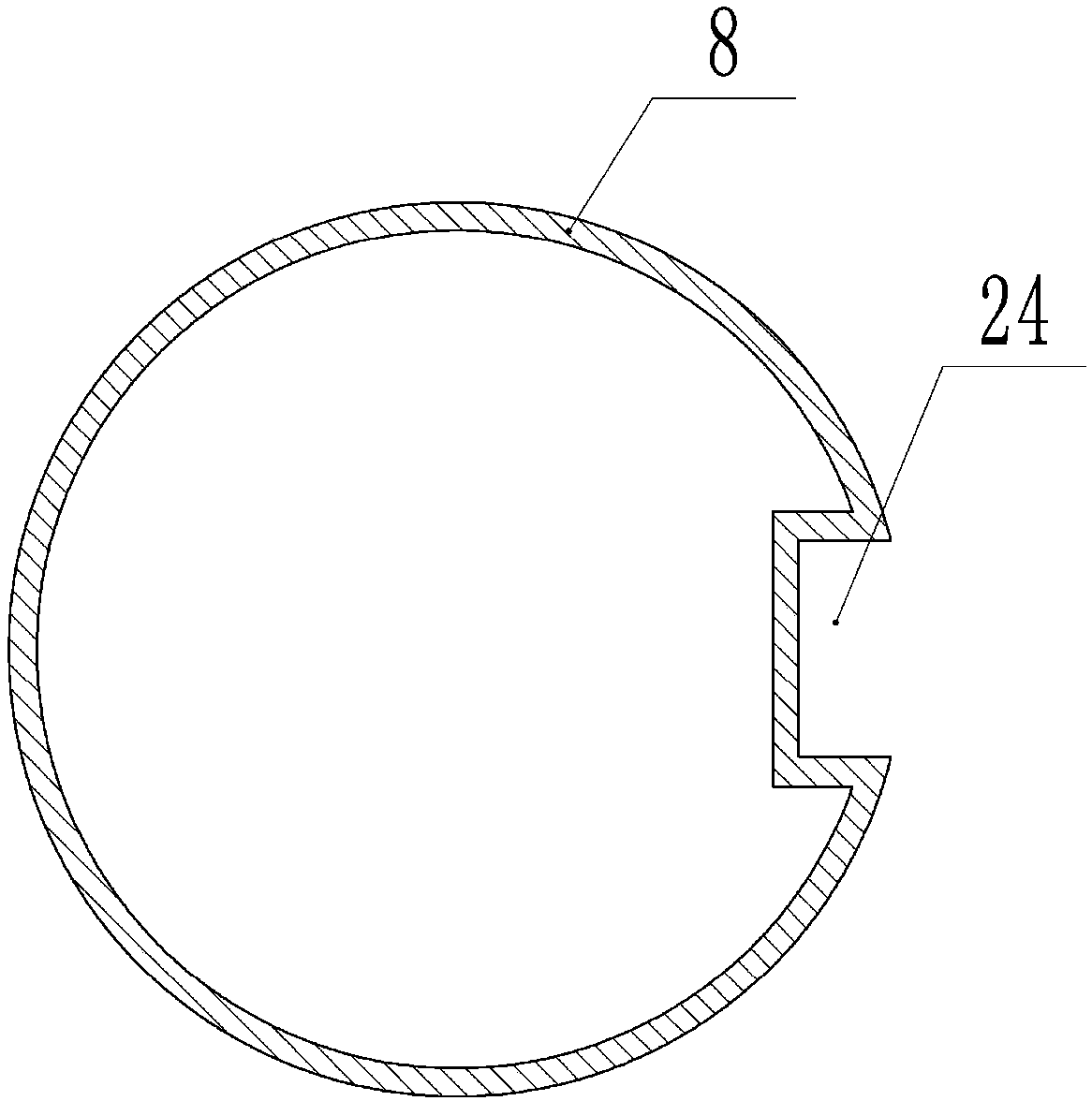

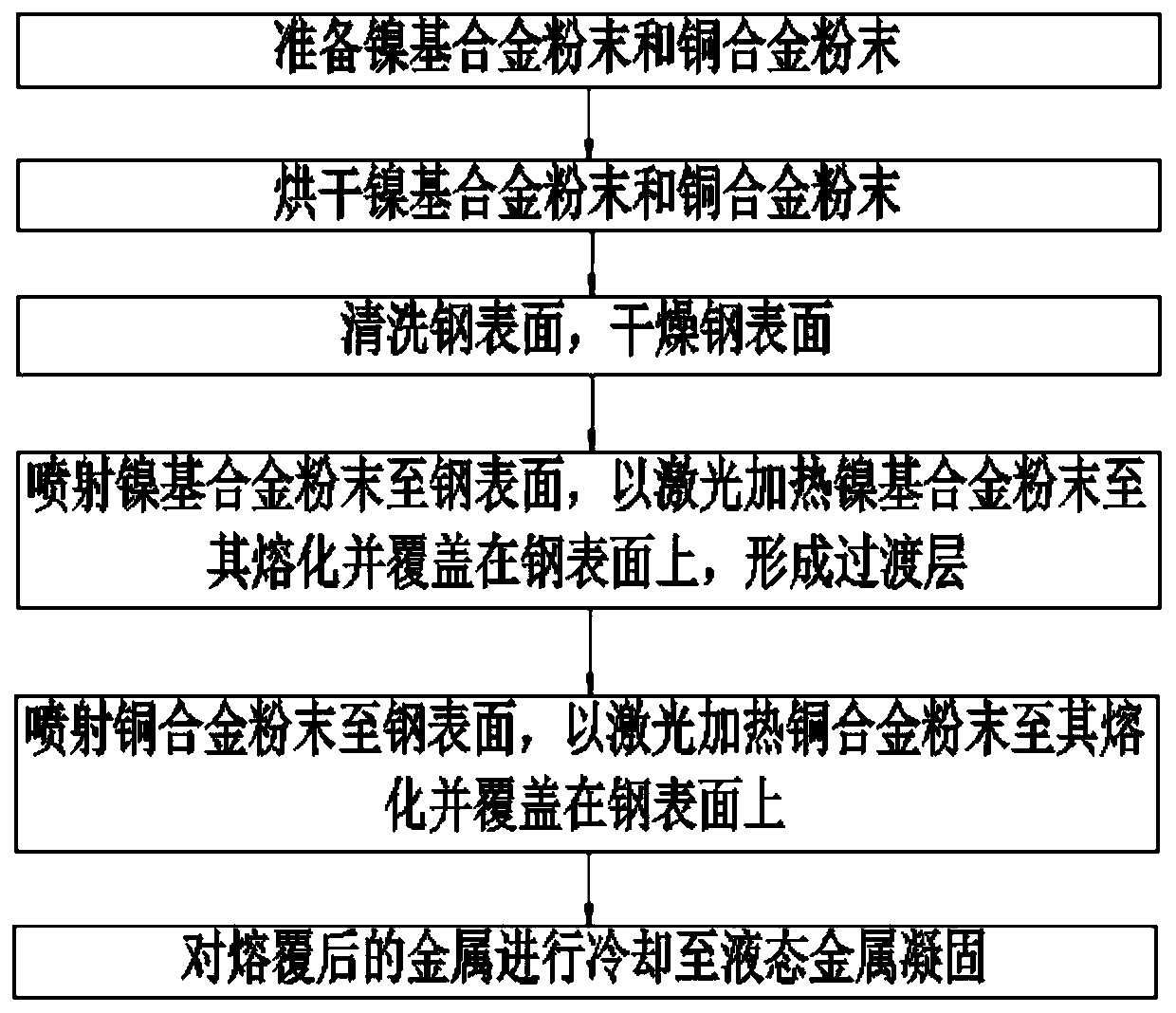

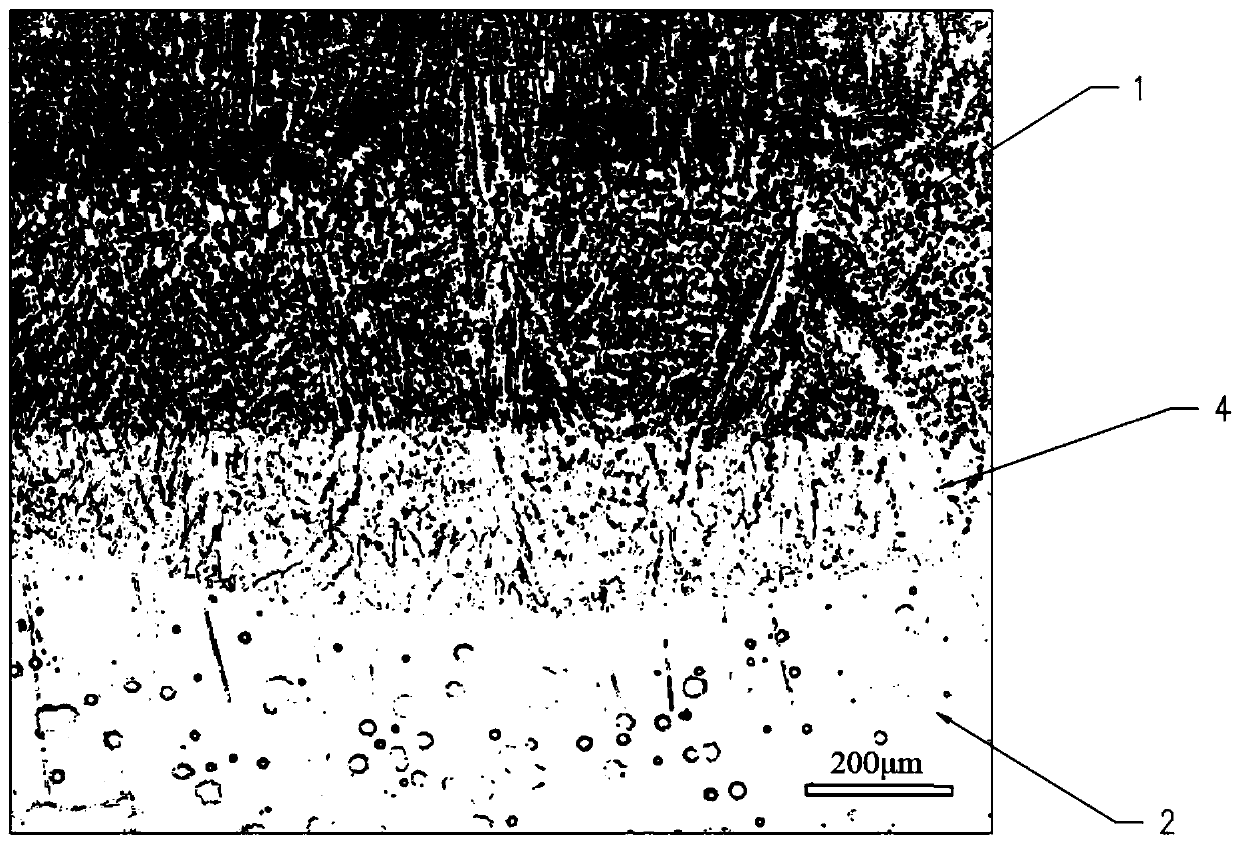

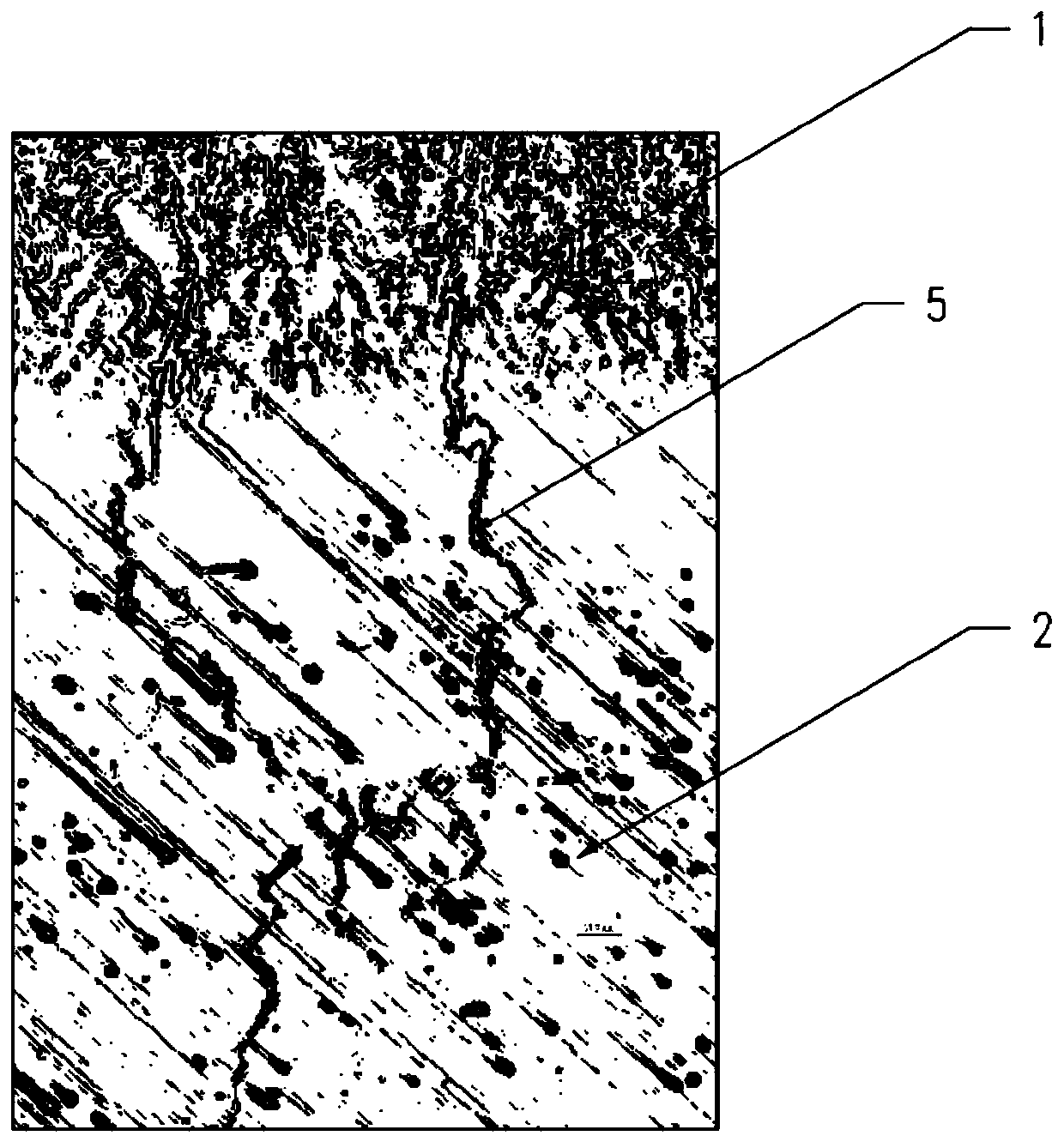

Laser cladding method used for controlling producing of copper permeating cracks

ActiveCN109778180ASolve the technical problems that are prone to copper penetration cracksPenetration Crack ControlMetallic material coating processesLiquid stateLiquid metal

The invention provides a laser cladding method used for controlling producing of copper permeating cracks. The method is used for solving the technical problem that copper permeating cracks are proneto being produced during copper / steel laser heterogenous welding in the prior art. The method comprises the steps that firstly, materials are prepared, specifically, nickel base alloy powder and copper alloy powder are prepared; secondly, drying is performed, specifically, the nickel base alloy powder and the copper alloy powder are dried; thirdly, a steel surface is pretreated, specifically, thesteel surface is cleaned and dried; fourthly, a transition layer is subjected to cladding, specifically, the nickel base alloy powder is sprayed to the steel surface and heated through laser to be melted so as to cover the steel surface, and the transition layer is formed; fifthly, copper alloy is subjected to cladding, the copper alloy powder is sprayed to the steel surface and heated through laser to be melted so as to cover the steel surface; and sixthly, cooling and solidifying are performed, specifically, cladding metal is cooled to be in a liquid state and solidified. By means of the technical scheme provided by the embodiment of the invention, the technical effects that the corrosion resistance and abrasion resistance of the cladding layer are improved, and the copper permeating cracks are controlled can be achieved.

Owner:上海岳乾激光科技有限公司

Watering device for poultry

ActiveUS20080156271A1Prevent spillageAvoid wastingAnimal watering devicesAvicultureLine tubingEngineering

A watering disc for use in a nipple assembly of a watering line system has an outer rim portion and an upper surface extending inwardly from said outer rim portion to an aperture provided through a center of the watering disc. The upper surface defines a plurality of separators and a plurality of individual compartments in an alternating manner about a circumference of the watering disc. The plurality of separators generally extend from proximate the center of the watering disc to the outer rim portion in order to define each individual compartment between the outer rim portion and two adjacent separators. Each individual compartment is substantially formed in a concave manner and are configured to receive and retain water from the watering line system. The watering disc is formed of plastic and has reflective particles integrally formed therein for attracting poultry to the watering disc.

Owner:CTB INC

In-situ polymerization electrolyte, method for preparing in-situ all-solid-state battery by adopting in-situ polymerization electrolyte and in-situ all-solid-state battery

PendingCN113299982AImprove interface compatibilityImprove performanceFinal product manufactureSecondary cells servicing/maintenanceElectrolytic agentIn situ polymerization

The invention relates to the technical field of all-solid-state batteries, and particularly discloses an in-situ polymerization electrolyte, a method for preparing an in-situ all-solid-state battery by adopting the in-situ polymerization electrolyte and the in-situ all-solid-state battery. The in-situ polymerization electrolyte comprises polymerizable liquid crystal, lithium salt and a polymerization initiator, the polymerizable liquid crystal is acrylic ester containing cyano groups, and the viscosity of the in-situ polymerization electrolyte is 1-1000 cps. The method for preparing the in-situ all-solid-state battery by adopting the in-situ polymerization electrolyte comprises the following steps: injecting the in-situ polymerization electrolyte serving as a prepolymer between a positive electrode and a negative electrode of the assembled battery, and performing heating and curing to convert the in-situ polymerization electrolyte into a solid polymer electrolyte. The preparation method of the in-situ all-solid-state battery can share a lithium ion battery production line with the liquid electrolyte, the investment of newly added equipment is low, and the commercialization process of the solid-state battery can be greatly promoted.

Owner:GUANGZHOU TINCI MATERIALS TECH

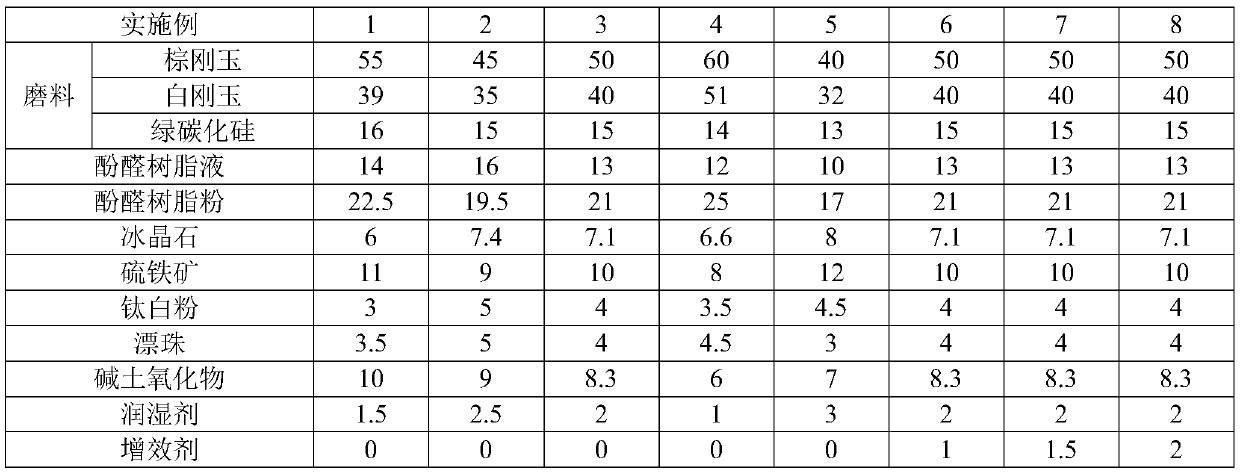

Resin grinding wheel and preparation method thereof

ActiveCN110977793AFull responseFully associativeAbrasion apparatusCompressive resistanceAlkaline earth oxides

The invention relates to a resin grinding wheel and a preparation method thereof, and belongs to the technical field of resin grinding wheel production, and the resin grinding wheel comprises the following raw materials of an abrasive, phenolic resin liquid, phenolic resin powder, cryolite, pyrite, titanium dioxide, floating beads, alkaline earth oxide and a wetting agent. According to the resin grinding wheel, the raw materials are cooperated, under the conditions that the polished surface of a workpiece is glossy and free of black spots, the resin grinding wheel has high workpiece abrasion loss and grinding ratio and low grinding wheel loss, the service life of the resin grinding wheel is prolonged, meanwhile, the resin grinding wheel further has high compressive strength and hardness, and the resin grinding wheel has a good using effect. According to the preparation method of the resin grinding wheel, by adding the annular magnetic field, twice mechanical pressing and twice curing,the raw materials are fully reacted and self-combined, the density and bonding strength of the resin grinding wheel are improved, the resin grinding wheel shows good comprehensive performance, and meanwhile the preparation method has the advantage of being convenient to control.

Owner:郑州九天工贸有限公司

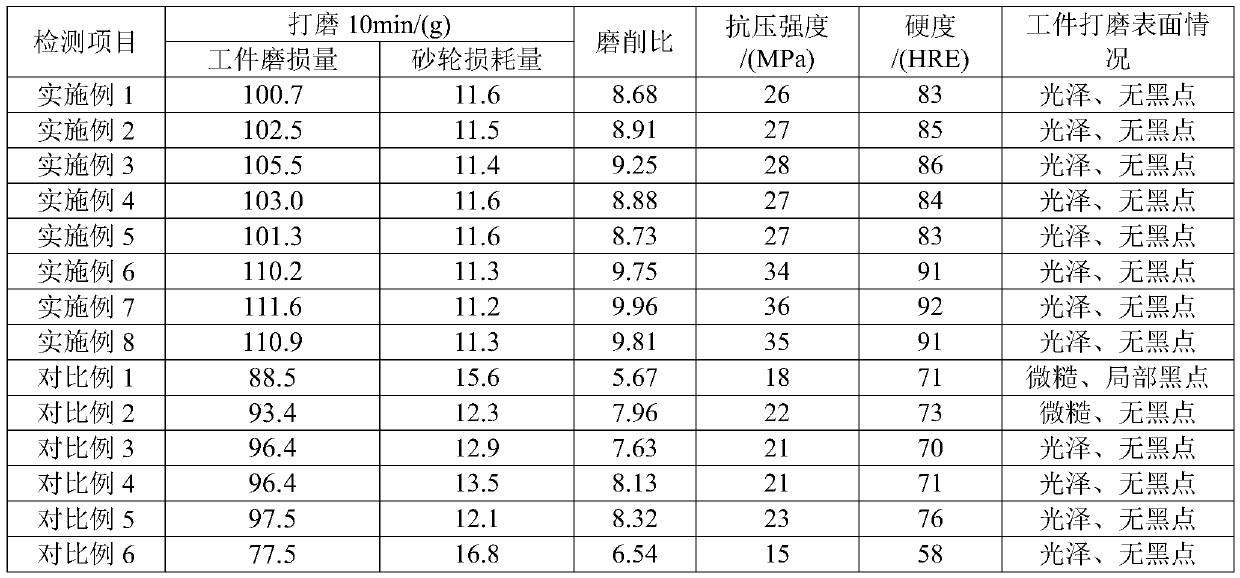

Substation with alarming and anti-seepage functions

InactiveCN106025879ASimple structureEasy to useSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringInfrared detector

The invention provides a substation with alarming and anti-seepage functions, relates to the field of transformer protection box bodies and solves the problem that an existing substation mounted outdoors is easy to cause accidents in thunderstorm weather. The substation comprises a base, a box body, a rain-proof table, a plurality of infrared detectors and an alarm device; the box body is fixed on the base; the rain-proof table is arranged above the box body and used for preventing rain; the rain-proof table is a cover body of a V-shaped ridge structure; the plurality of infrared detectors are fixed on the periphery of the rain-proof table, and the induction signal output end of each infrared detector is connected with a data signal input end of the alarm device; an unidirectional air outlet is formed in one side surface of the box body, and air can be prevented from flowing back into the box body. The substation with the alarming and anti-seepage functions is mainly used for protecting transformer equipment.

Owner:国网黑龙江省电力有限公司牡丹江供电公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com