Patents

Literature

205 results about "Fluorosilicone oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

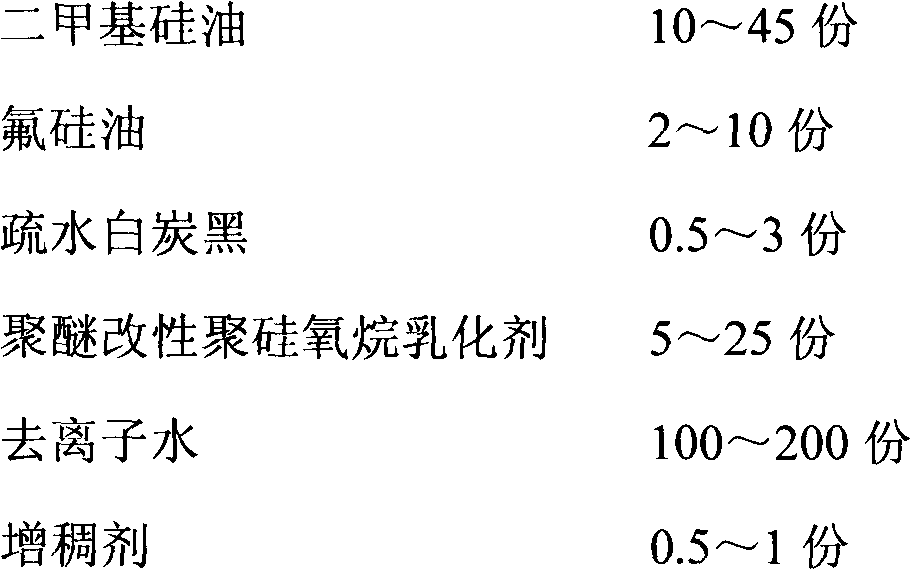

High-efficiency antifoaming agent

InactiveCN102949867AGood anti-foam performanceStrong antifoam performanceFoam dispersion/preventionAdditive ingredientBULK ACTIVE INGREDIENT

The invention relates to a high-efficiency antifoaming agent which comprises the following raw materials based on parts by weight: 10-45 parts of simethicone, 2-10 parts of fluorosilicone oil, 0.5-3 parts of hydrophobic white carbon black, 5-25 parts of polyether-modified polysiloxane emulgator, 100-200 parts of deionized water and 0.5-1 part of thickening agent. The antifoaming agent takes composition of the simethicone and the fluorosilicone oil as a main antifoaming active ingredient; and after the fluorosilicone oil is added, the surface tension of an antifoaming agent system can be reduced, and the antifoaming and foam-inhibiting performances can be improved. According to the polyether-modified polysiloxane emulgator, not only can the antifoaming active ingredients be emulsified, but also the effect enhancing action can be achieved due to the fact that the high-efficiency antifoaming agent further has good antifoaming ingredients. The antifoaming agent is high in antifoaming capacity, long in foam-inhibiting time, wide in application range, capable of being applied to various foam systems, and suitable for antifoaming and foam-inhibiting under severe conditions, i.e. high acid-base, high temperature and the like.

Owner:TIANJIN SCIPHARMACN

Preparation method of addition type liquid fluorinated silicone rubber

The invention relates to a preparation method of addition type liquid fluorinated silicone rubber. D3F, ViD4 and MM with the purity larger than 99.5% are adopted as raw materials and evenly mixed according to a certain ratio, and vinyl fluorosilicone oil is obtained; the vinyl fluorosilicone oil is used as base gum, a reinforcement agent, a cross-linking agent and a catalyst are added in the vinyl fluorosilicone oil, kneading, grinding, tabletting and other technologies are performed, and the liquid fluorinated silicone rubber (FSR) is obtained; the insulation performance, hydrophobic property, the high-temperature resistance and the like of the LSR are better than that of liquid silicone rubber (LSR) with the same technology and formula. The preparation method is short in production period, the product has the good heat tear resistance, demolding is convenient, various machining ways of mold pressing, extrusion, injection molding and the like can be achieved, and automatic production materials can be achieved.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +1

Antibacterial corrosion-resistant ceramic coating of non-stick pan and preparation method of coating

ActiveCN103483885AImprove mechanical propertiesImprove performanceAntifouling/underwater paintsPaints with biocidesEpoxyPolyester

The invention relates to an antibacterial corrosion-resistant ceramic coating of a non-stick pan and a preparation method of the coating, and belongs to the technical field of ceramic machining. The antibacterial corrosion-resistant ceramic coating comprises the components in parts by weight as follows: 35-40 parts of silicon oxide sol, 5-9 parts of aluminum oxide sol, 1-3 parts of zirconium oxide sol, 5-8 parts of a water soluble polyester modified epoxy resin, 1-3 parts of black iron oxide, 5-8 parts of spherical ceramic micro powder, 8-12 parts of absolute ethyl alcohol, 1-3 parts of silver nitrate, 1-3 parts of aluminum nitrate, 1-3 parts of and fluoride silicone oil and 10-15 parts of deionized water. The preparation method comprises the steps as follows: the materials are mixed according toin the ratio, stirred for 4-6 h in a sealing manner at a temperature of 35-42 DEG C and a rotating speed of 300-350 rpm (revolutions per minute), and then calcinated at a high temperature of 300-350 DEG C; and composite ceramic material powder is composited. The coating of the non-stick pan has good mechanical property, is high in strength, high-temperature-resistant, abrasion-resistant and scratch-resistant, and has an antibacterial function; and the preparation technology is simple, and the coating is non-toxic and harmless to the environment.

Owner:浙江飞哲科技股份有限公司

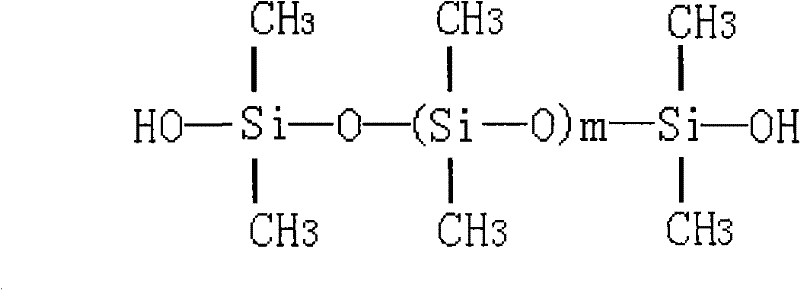

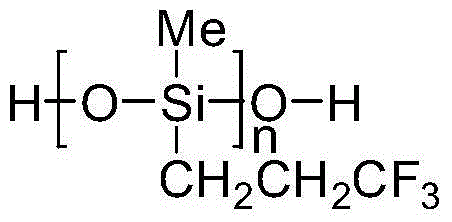

Method for synthesizing low molecular weight hydroxy-terminated fluorine silicon oil

InactiveCN101948481AEasy to operateHigh yieldSilicon organic compoundsPtru catalystMethyl palmoxirate

The invention relates to a method for synthesizing low molecular weight hydroxy-terminated fluorine silicon oil, which is characterized by comprising the following steps of: adding a certain amount of 3,3,3-trifluoropropylmethyl ring trisiloxane into three flasks, starting stirring, and then adding a certain amount of polar solvent, capping agent and catalyst into the flasks; slowly heating the mixture to between 50 and 80 DEG C till reflux appears, and maintaining the reaction till the reaction is complete; then cooling the mixture to room temperature, adding a certain amount of magnesium oxide and kieselguhr for filtration, and washing the filter cakes by using the same part of solvent; and transferring the filtrate to the three flasks, adjusting the temperature and pressure to evaporate the solvent, and then removing low-boiling substances to obtain a required product. The method has the advantages of simple and quick operation, economy, applicability, high yield, clarity, transparency and low viscosity of the obtained product and the like.

Owner:新元化学(山东)股份有限公司

Organosilicon release agent with ultra-light release force and preparation method thereof

ActiveCN110819261AWith ultra-light release forceReduce release forceCoatingsFilm/foil adhesive release linersPolymer scienceMethyl palmoxirate

The invention provides a formula and a preparation method of an organosilicon release agent with ultra-light release force. Vinyl silicone oil, methyl fluorosilicone oil and amino silicone oil are respectively used as a main agent, a light stripping agent and an anti-migration agent and are matched with other materials to obtain the organosilicon release agent; an organosilicon release film with ultra-light release force is obtained by coating a polymer film (PET, PP, PE, PI and the like) with the organosilicon release agent, the release force of the organosilicon release film is greatly reduced, a high residual rate is ensured, and the release film surface obtained by the formula has a film surface effect with uniform color. The product can meet the requirement for ultra-light release force of a release film on the market, and the application field of a traditional organosilicon release agent is further widened.

Owner:SUZHOU SHIHUA NEW MATERIAL TECH

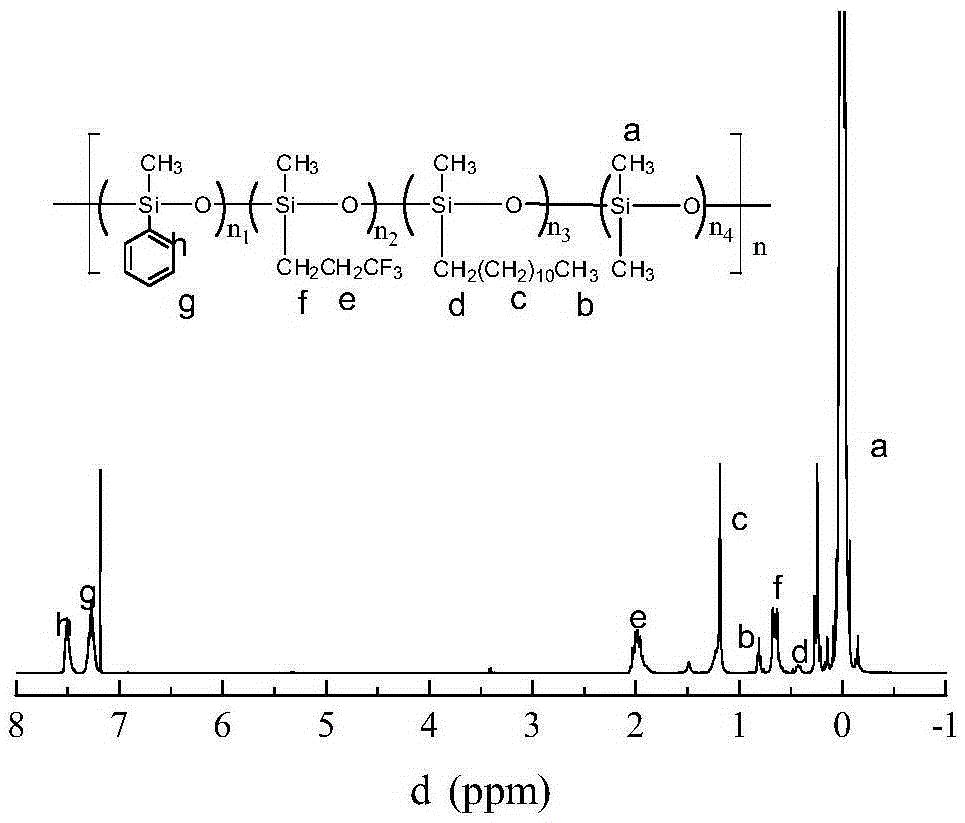

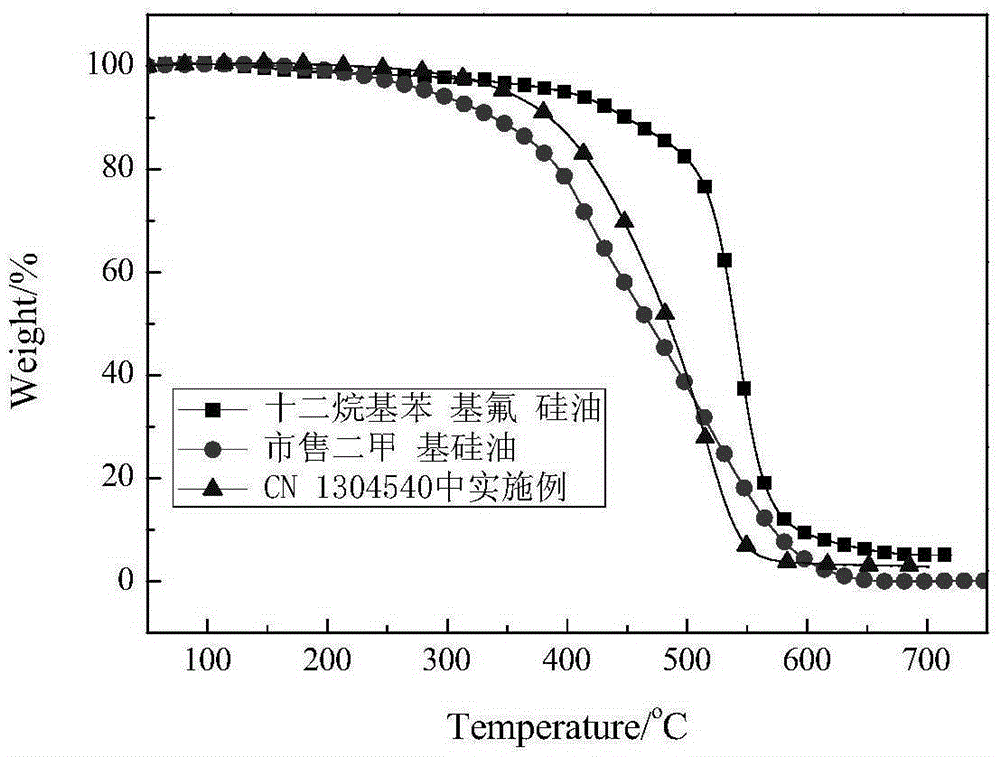

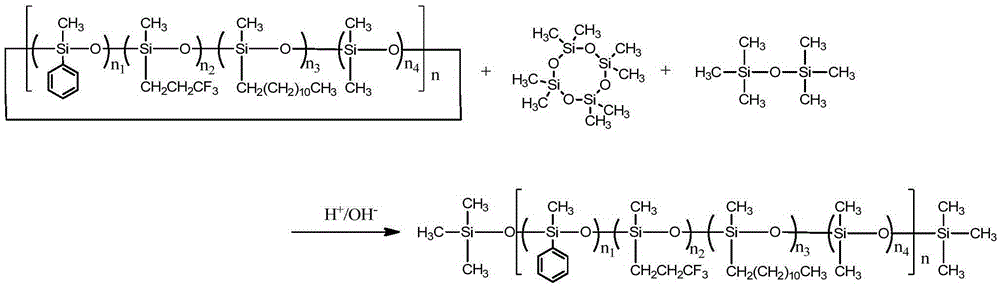

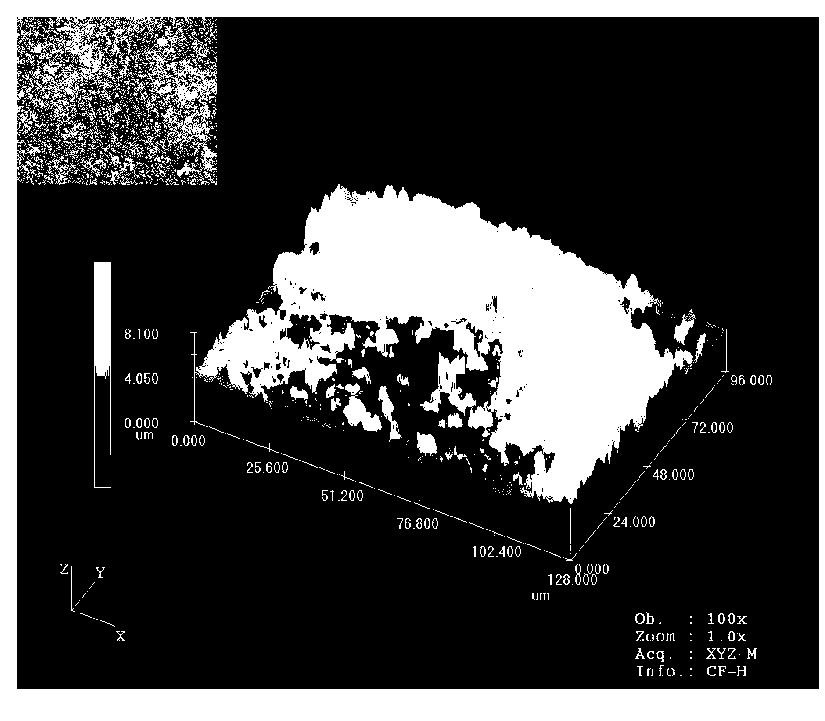

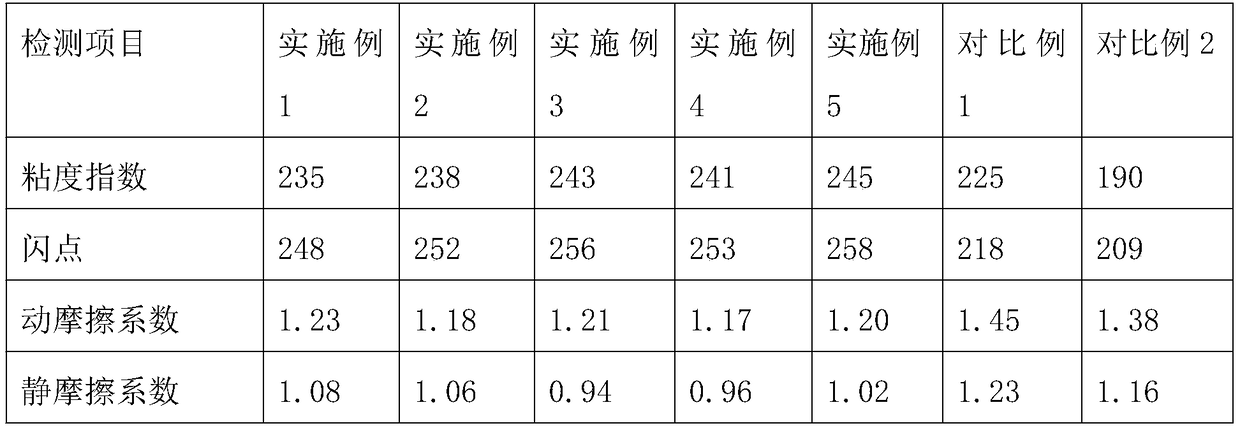

Long-chain alkyl phenyl fluorosilicone oil and preparation method thereof

The invention discloses long-chain alkyl phenyl fluorosilicone oil and a preparation method thereof. The preparation method comprises the following steps: under the protection of inert gas, a self-made polyfunctional group substituted hybrid siloxane ring body is used as a reaction raw material, a corresponding end-capping reagent is added, and a strong acid or strong base ring-opening reaction is carried out to prepare high-molecular-weight long-chain alkyl phenyl fluorosilicone oil. The preparation method is low in cost and mild in reaction condition, the molecular structure and organic group content of the product are easy to control, the organic group in the synthesized product is more uniform in distribution, the synthesized product is low in viscosity and good in heat resistance, and the lubricating property requirements within a wide temperature range are met; at the same time, the long-chain alkyl phenyl fluorosilicone oil can be used as an additive and used in a compounding manner with the synthetic oil or mineral oil, so that the lubricating properties of the synthetic oil or mineral oil are improved.

Owner:ZHEJIANG UNIV

Organic fluorine oxosilane nanometer freezing sticky resistant coating and preparation process thereof

InactiveCN102838923AReduce bond strengthExtended service lifePolyurea/polyurethane coatingsFrostPlasticizer

The invention discloses an organic fluorine oxosilane nanometer freezing sticky resistant coating and a preparation process of the organic fluorine oxosilane nanometer freezing sticky resistant coating. A coating layer comprises a fluorine oxosilane solution and / or hydroxyl-terminated fluorine contained silicone oil, a catalytic agent, polyvinyl acetal, a diluent, a curing agent, a plasticizer, a dispersing agent, an antifoaming agent and nanometer powder. A synthetic process: adding 15-20% of the fluorine oxosilane solution and / or the hydroxyl-terminated fluorine contained silicone oil and 30-36% of the polyvinyl acetal into the 16-30% diluent, adding 0.5-1% of the catalytic agent, adding 2-5% of the plasticizer and 1-2% of the nanometer grade inorganic powder, 0.5-10% of the dispersing agent and 0.5-2% of the antifoaming agent, reacting for 2-4 hours at the temperature of 90 DEG C for ball milling, finally adding 10-20% of the curing agent, and evenly stirring and coating on a surface of a workpiece for room temperature curing. The coating layer can obviously reduce bonding strength between frost and a metal substrate, and can effectively reduce or restrain formation of the frost.

Owner:JILIN UNIV

Addition type liquid fluorosilicone rubber composition and preparation method thereof

ActiveCN108976816AIncrease responsivenessImprove mechanical propertiesUltraviolet lightsPhotoinitiator

The invention relates to the field of liquid fluorosilicone rubber, in particular to an addition type liquid fluorosilicone rubber composition and a preparation method thereof. The liquid fluorosilicone rubber is prepared from the following components in percentage by weight: 100 parts of vinyl fluorosilicone oil, 70 to 120 parts of mercaptopyl fluorosilicone oil, 5 to 10 parts of a photoinitiator, 0 to 100 parts of filler, high vinyl fluorosilicone oil, and 0 to 15 parts of an auxiliary agent. The vinyl fluorosilicone oil and the mercaptopyl fluorosilicone oil provided by the invention are irradiated with ultraviolet light by the photoinitiator, and are subjected to addition and crosslinking to obtain the liquid fluorosilicone rubber. The method provided by the invention is simple, does not need to be heated, and does not need to use expensive precious metal catalysts, and the liquid fluorosilicone rubber having different oil resistance can be obtained by adjusting the content of trifluoropropyl group in the fluorosilicone oil.

Owner:福建拓烯新材料科技有限公司

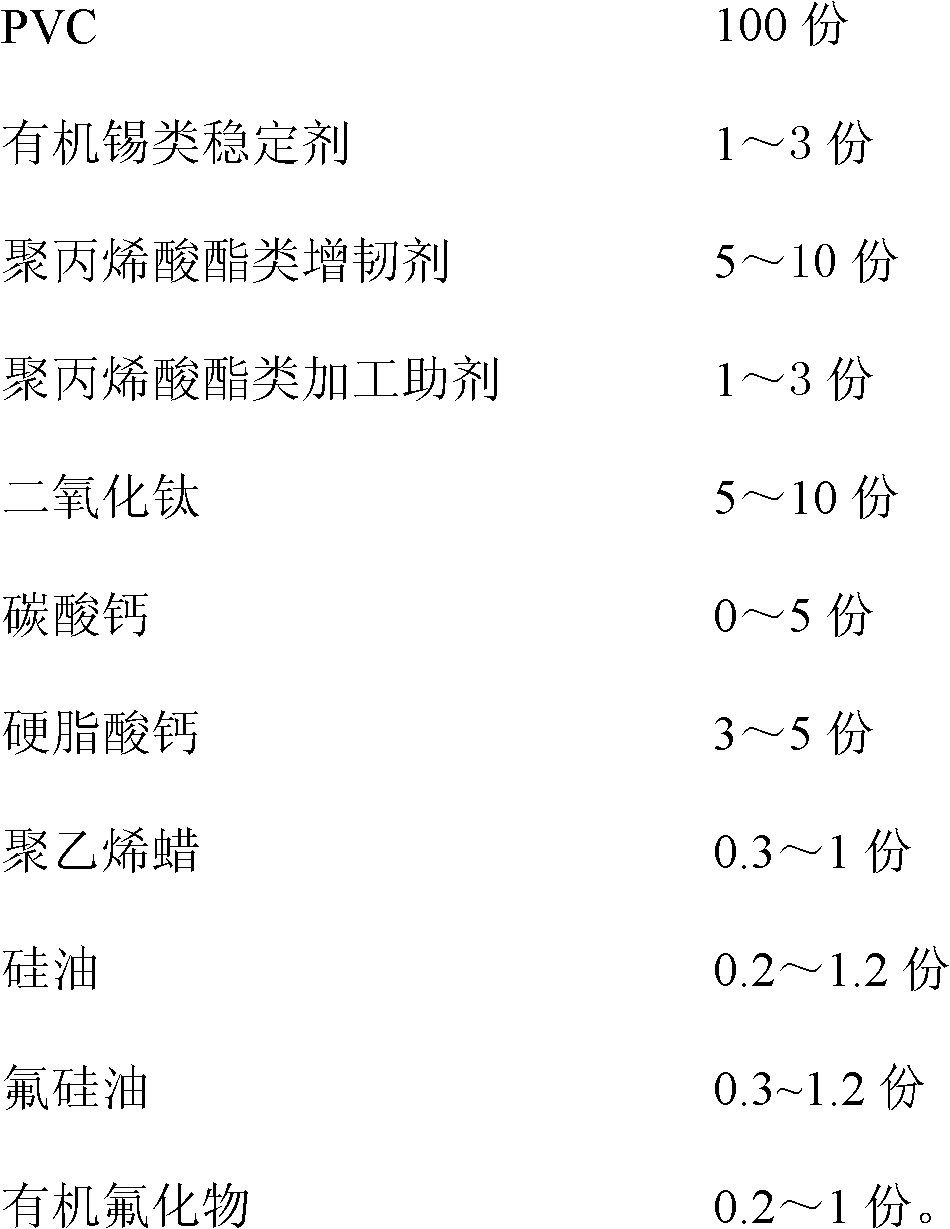

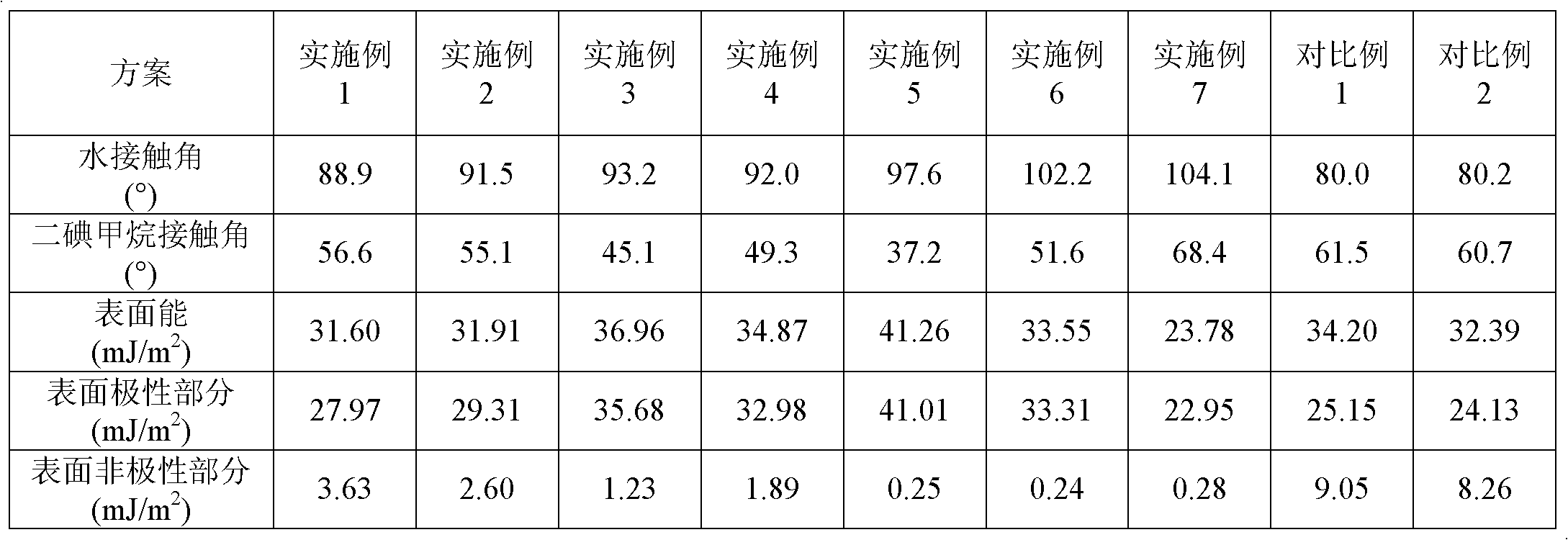

Base station antenna polyvinyl chloride (PVC) profile housing with surface self-cleaning function and preparation method thereof

ActiveCN102174234AImprove processing fluidityImproves UV resistanceRadiating element housingsUltraviolet lightsPolyvinyl chloride

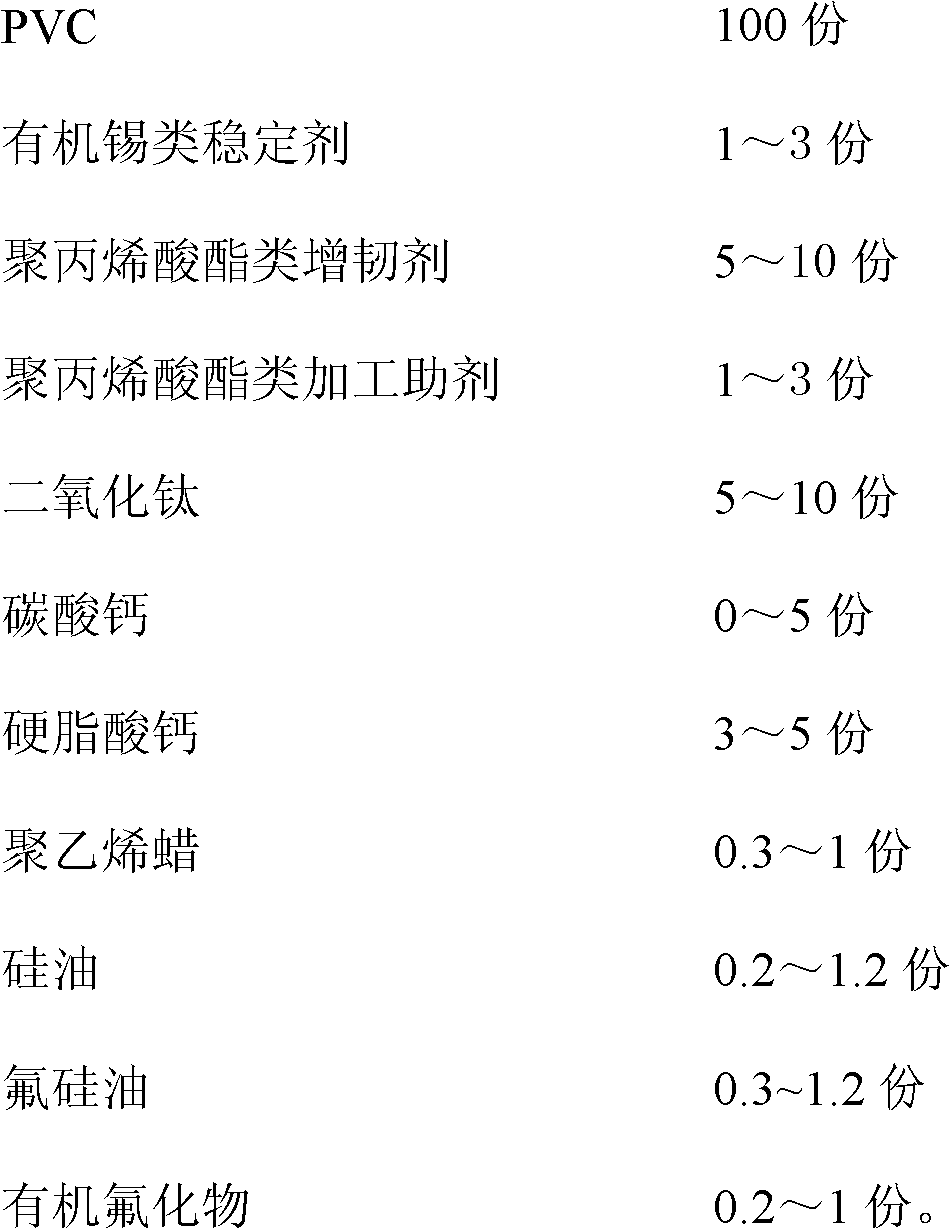

The invention discloses a base station antenna polyvinyl chloride (PVC) profile housing with a surface self-cleaning function. The mechanical properties of the PVC profile housing are improved, the ultraviolet light resistance is greatly increased; and moreover, the non-polarity of the surface energy of the profile is significantly increased, thus the surface water contact angle of the profile is significantly increased, the hydrophobicity is increased and the surface self-cleaning function can be achieved. The base station antenna PVC profile housing with the surface self-cleaning function is prepared from the following raw materials in parts by weight: 100 parts of PVC, 1-3 parts of organotin stabilizer, 5-10 parts of polyacrylate toughening agent, 1-3 parts of polyacrylate processing aid, 5-10 parts of titanium dioxide, 0-5 parts of calcium carbonate, 3-5 parts of calcium stearate, 0.3-1 part of polyethylene wax, 0.2-1.2 parts of silicone oil, 0.3-1.2 parts of fluorosilicone oil and 0.2-1 part of organic fluoride.

Owner:NANJING TECH UNIV +1

Fluorinated polysiloxane sealant for sealing integral fuel tank of airplane

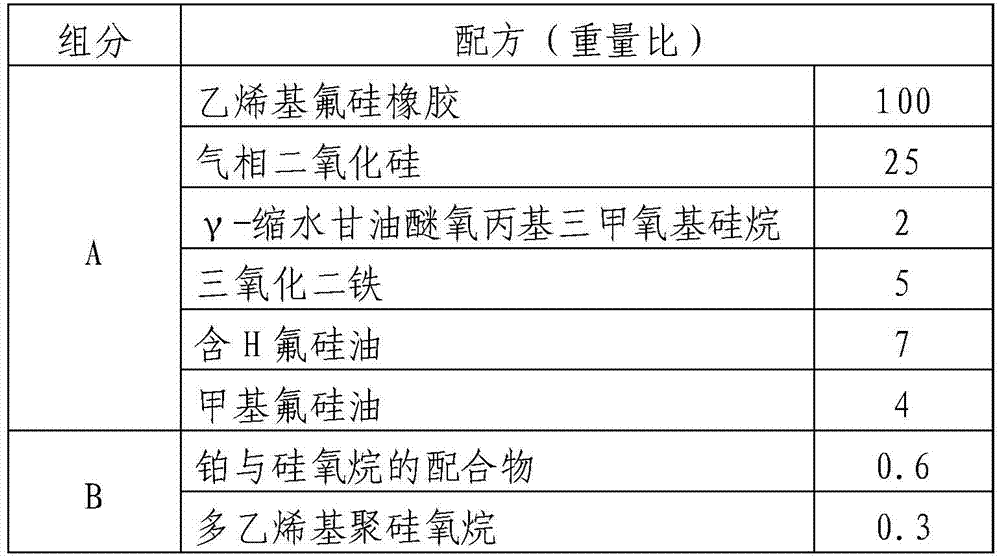

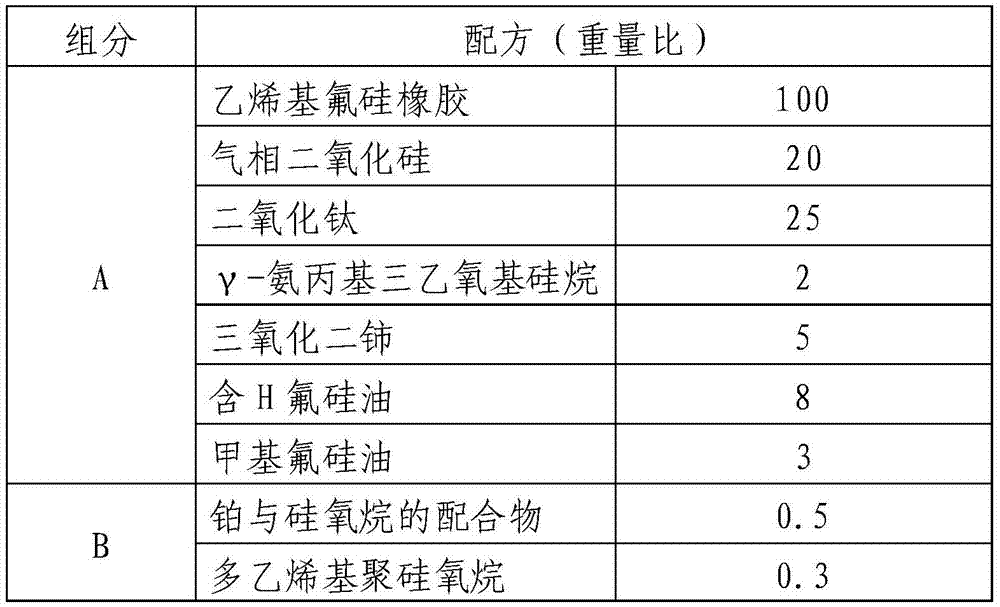

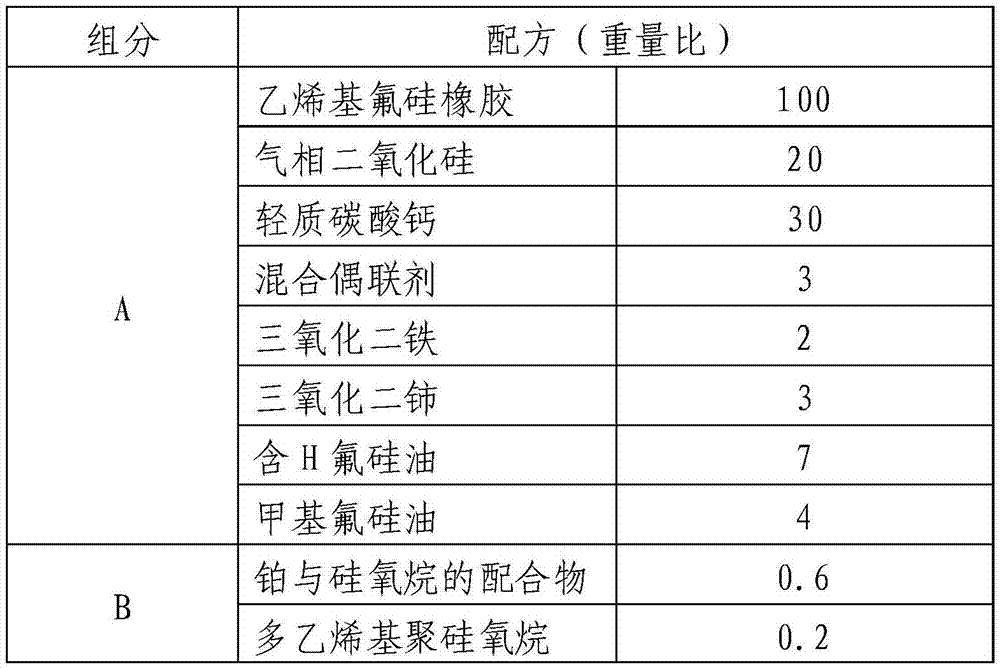

ActiveCN105441020AMeet sealing requirementsHigh temperature resistanceNon-macromolecular adhesive additivesOther chemical processesPlatinumFuel tank

The invention belongs to the technical field of preparation of sealants, and relates to a high-temperature-resistant fluorinated polysiloxane sealant for sealing an integral fuel tank of an airplane. The high-temperature-resistant fluorinated polysiloxane sealant is prepared from a component A and a component B. The component A is prepared from vinyl end capped liquid fluorinated silicone rubber, filler, a heat resisting agent, a coupling agent, H containing fluorosilicone oil and methyl fluorosilicone oil. The component B is prepared from a complex of platinum and siloxane and an inhibitor. According to the fluorinated polysiloxane sealant for sealing the integral fuel tank of the airplane, the temperature resisting grade of the integral fuel tank sealant is improved, the sealing effect is guaranteed, and the requirement for sealing the integral fuel tank of the high-speed airplane is met.

Owner:BAIMTEC MATERIAL CO LTD

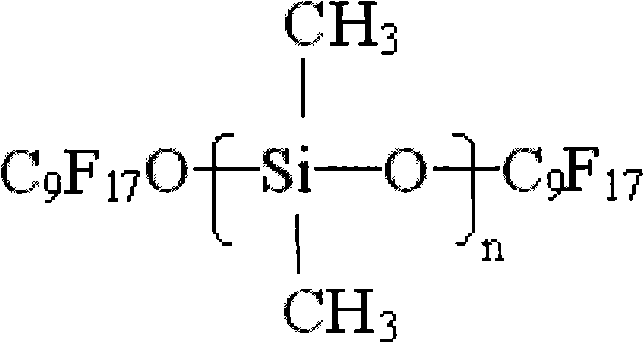

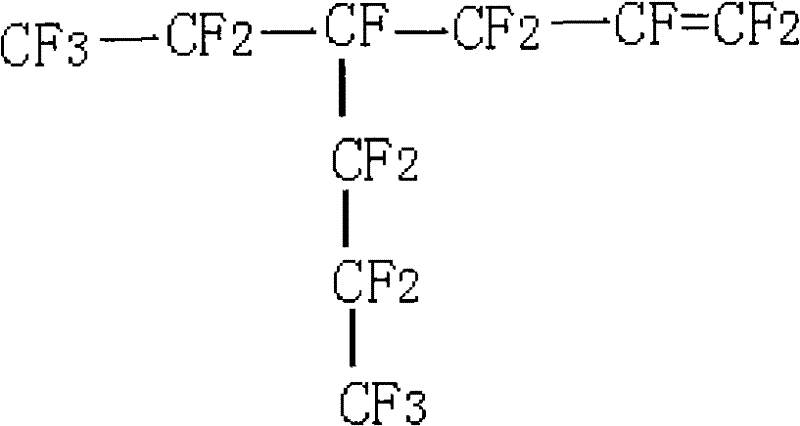

Fluorosilicone oil and preparation method of fluorosilicone oil

InactiveCN102558560AGood high and low temperature resistanceGood viscosity and temperatureBase-materialsSolventSpecial property

The invention discloses fluorosilicone oil and preparation method of the fluorosilicone oil. The fluorosilicone oil has ether and silicon bonds, its fluorocarbon chain is C9 branched chain or C6 straight chain, and the silicone part is hydroxy-containing organic silicon oligomer. The method is simple, environmentally friendly, and easy to realize. The fluorosilicone oil prepared by introducing long-chain fluorohydroxy to silicone molecular structure combines the properties of silicone and fluorocarbon, not only maintains the inherent excellent high and low temperature resistance and viscosity-temperature property of silicone oil, but also improves waterproof performance, oil resistance and solvent resistance, and is endowed with special properties.

Owner:方舟(佛冈)化学材料有限公司

Hydrophobic and oleophobic coating composition and preparation method thereof

InactiveCN112210293AHydrophobicImprove oleophobic propertiesAntifouling/underwater paintsPaints with biocidesPolymer scienceOrganosolv

The invention relates to the technical field of hydrophobic and oleophobic coatings, and particularly discloses a hydrophobic and oleophobic coating composition and a preparation method thereof. The hydrophobic and oleophobic coating composition comprises the following components in parts by weight: 10-25 parts of methyl hydrogen-containing silicone oil; 5-15 parts by weight of hydroxyl-terminatedsilicone oil; 2-8 parts by weight of amino silicone oil; 0.1 to 2 parts by weight of perfluorosilicone oil; 3-10 parts by weight of organic solvent type silica sol; and 40-80 parts by weight of organic solvent. According to the invention, methyl hydrogen-containing silicone oil, hydroxyl-terminated polydimethylsiloxane and amino silicone oil undergo a condensation reaction to form a three-dimensional network structure, and perfluorosilicone oil is combined to further improve the oleophobic effect of the system; and by adding the solvent type silica sol, inorganic silicon oxide particles in the silica sol and organopolysiloxane are hybridized, and a uniform system is formed, so that the formed coating has excellent hydrophobic and oleophobic effects and good wear resistance, the product islow in production cost, long in shelf life, simple in preparation method and suitable for industrial production, and industrial production and wide application are facilitated.

Owner:FOSHAN SITECH CHEM TECH

Modified polypropylene material and preparation method thereof

InactiveCN106566070AImprove low temperature performanceHigh impact strengthPolymer scienceAntioxidant

The invention discloses a modified polypropylene material. The modified polypropylene material comprises, by weight, 80-140 parts of polypropylene, 30-40 parts of a styrene-butadiene-styrene block polymer, 20-30 parts of polyurethane resin, 5-10 parts of hydroxyl-terminated hyperbranched polyester, 8-15 parts of chlorinated polyethylene, 1-2 parts of iron powder, 3-8 parts of fluorosilicone oil and 1-3 parts of an antioxidant. The polyurethane resin and the hydroxyl-terminated hyperbranched polyester added to raw materials are blended with the polypropylene and the styrene-butadiene-styrene block polymer to make the modified polypropylene material have improved wear resistance, ageing resistance and toughness, and the addition of the chlorinated polyethylene and the iron powder makes the modified polypropylene material have good sound insulation performance, so the modified polypropylene material can be used in the building field as a sound insulation assisting material of doors and windows, and the use of the modified polypropylene material is developed.

Owner:GUANGXI TEACHERS EDUCATION UNIV

Wear-resistant fireproof modified coating for building interior wall

InactiveCN105925095AGood wear resistance and fire resistanceImprove wear resistanceFireproof paintsWear resistantGlass microsphere

The invention discloses a wear-resistant fireproof modified coating for a building interior wall. The wear-resistant fireproof modified coating for the building interior wall is prepared from organosilicone-modified epoxy acrylate, vinyl acetate homopolymer emulsion, pure acrylic emulsion, styrene-acrylate copolymer emulsion, silica sol, nano-zinc borate, nano-magnesium hydroxide, sepiolite, expanded vermiculite, expanded perlite, wood fibers, hollow glass microspheres, talcum powder, aluminum tripolyphosphate, nano-barium sulfate, fluorosilicone oil, sodium hexametaphosphate, dimethylbenzene, propylene glycol, an organosilicon defoamer, hydroxyethyl cellulose, a polyurethane thickener, a titanate coupling agent NDZ-201, nonylphenol polyoxyethylene ether and water. The coating for the interior wall has excellent wear resistance and fireproofness.

Owner:梁冬

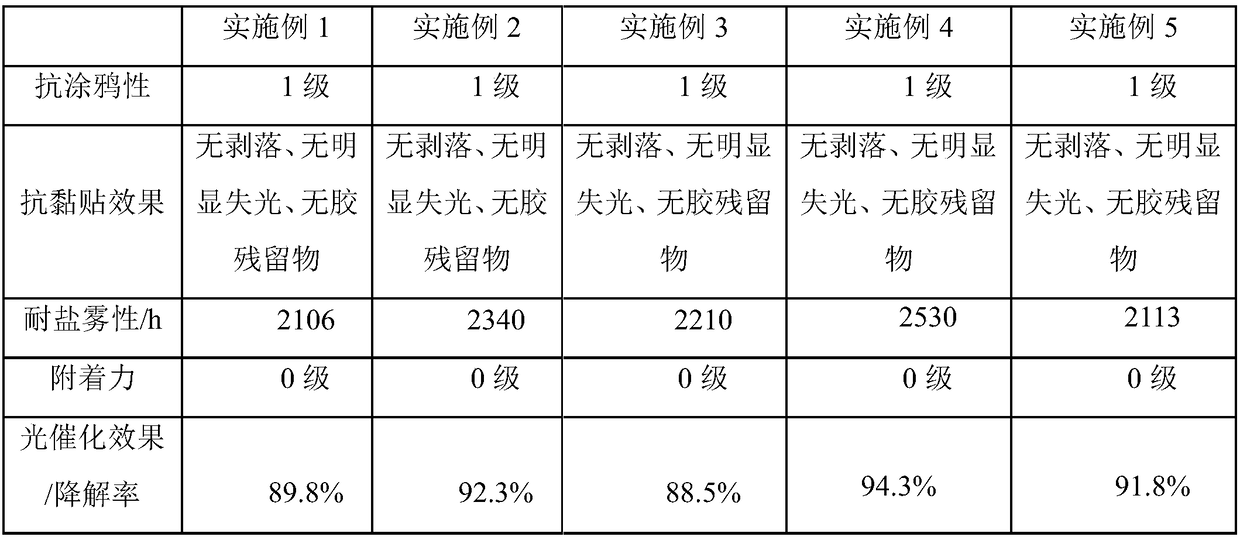

Anti-doodling paint and preparation method thereof

InactiveCN109401616AHigh transparencyExcellent low surface energyAntifouling/underwater paintsPaints with biocidesAnti-graffiti coatingStain

The application provides anti-doodling paint and a preparation method thereof. The anti-doodling paint provided by the application is prepared from the following components: modified organic-inorganichybrid resin obtained by modifying an organosilicon material with hydroxyl-fluorosilicone oil, titanate, nano-titanium dioxide, a nano-cerium oxide, a dispersant, an antifoaming agent and a couplingagent; a film formed by the anti-doodling paint is high in transparency, excellent in low surface energy performance, good in anti-doodling effect and excellent in stain resistance, has an enhanced anti-corrosion effect, and has a good photocatalytic decomposition effect on oil stain bonded to the film formed by the paint. By adopting the preparation method of the anti-doodling paint, the anti-doodling paint with high transparency, good anti-doodling effect and excellent stain resistance can be obtained.

Owner:深圳市溯元科技有限公司

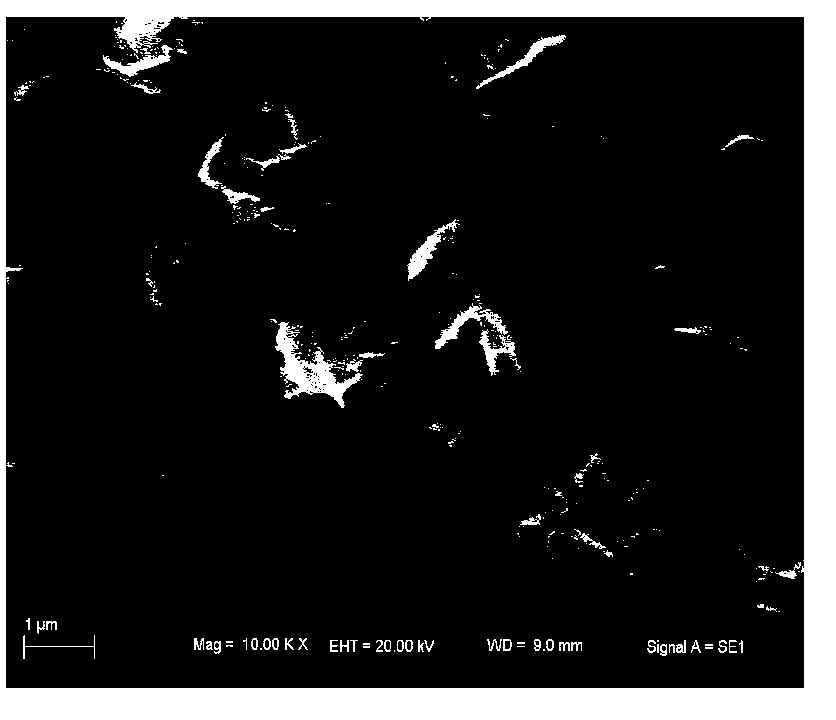

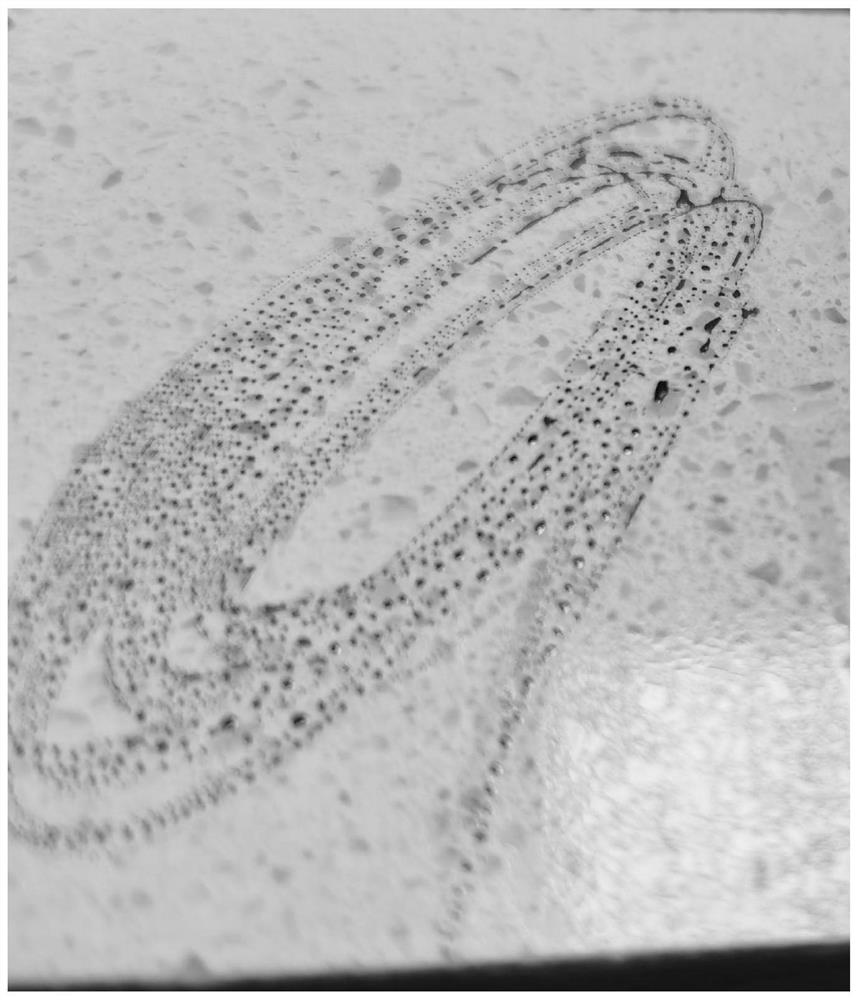

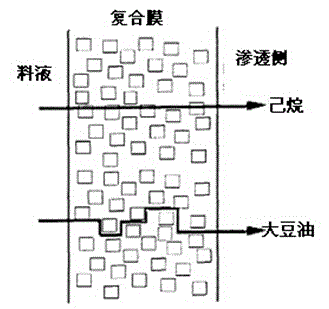

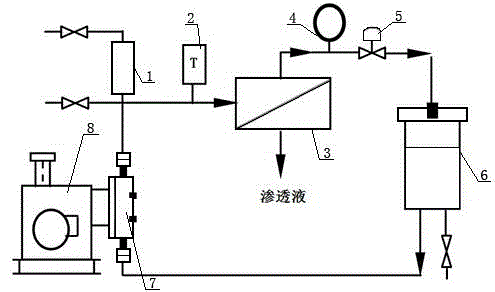

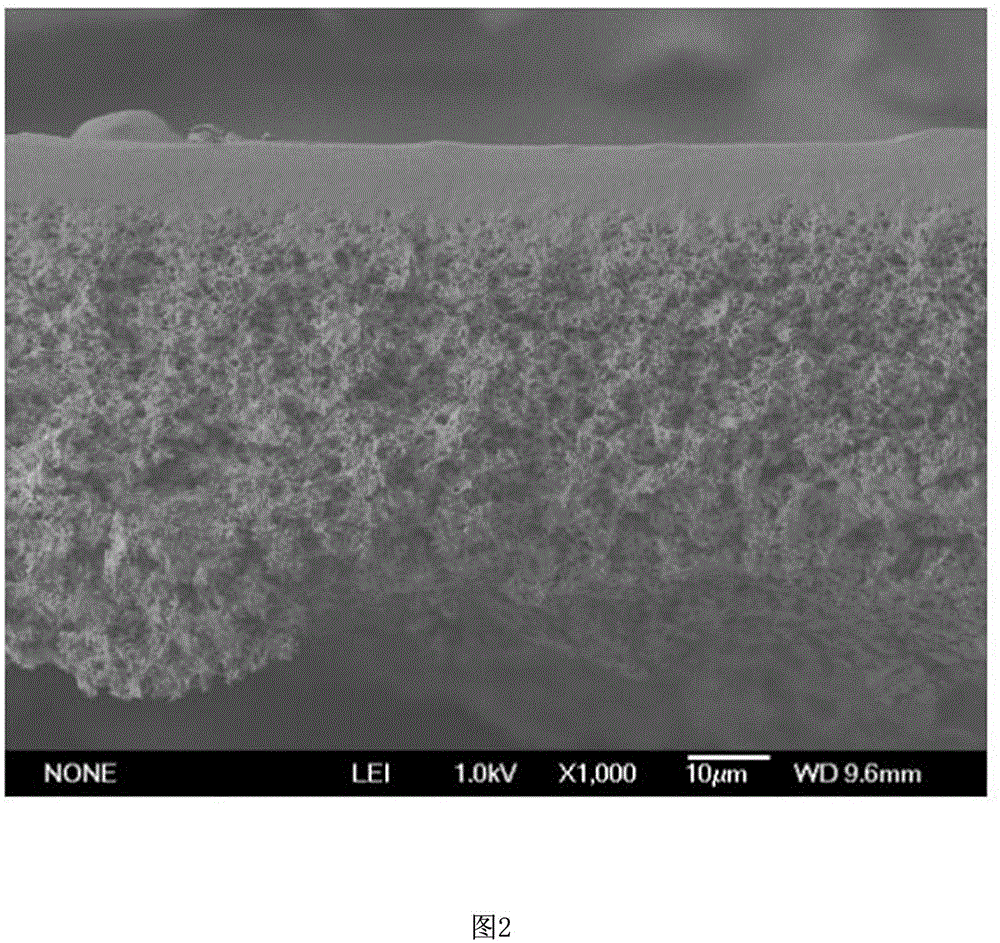

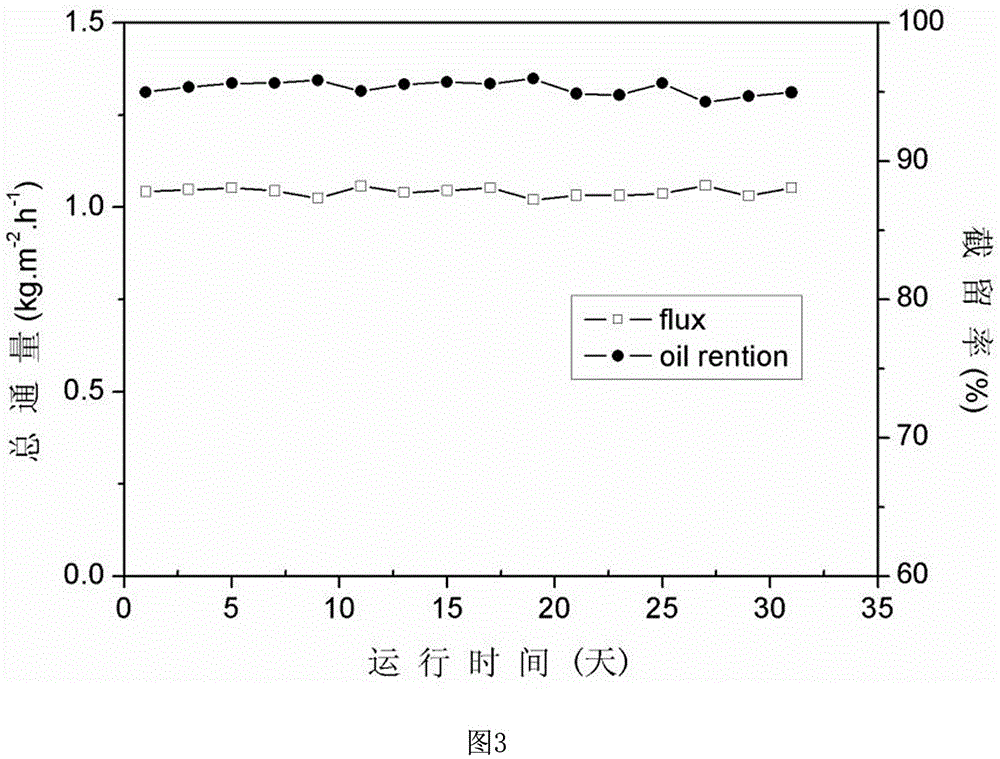

Preparation method of microporous molecular sieve filled solvent resistant composite film

ActiveCN104383819AEvenly dispersedTightly boundSemi-permeable membranesMolecular sieveOrganic solvent

The invention discloses a preparation method of a microporous molecular sieve filled solvent resistant composite film. The preparation method comprises the following steps: preparing fluorosilicone oil, a microporous molecular sieve, a crosslinking agent, a catalyst and a solvent into a film casting solution, uniformly coating the film casting solution on a base film by using a solvent resistant ultra-filtration film as the base film, further heating to enable the film casting solution to deeply crosslink with the base film after the solvent is evaporated and solidified so as to obtain the microporous molecular sieve filled solvent resistant composite film. Through the composite film prepared by using the method disclosed by the invention, the molecular sieve is uniformly dispersed in a separation layer, and meanwhile, the separation layer is tightly combined with a support layer; the composite film has good swelling resistance in the organic solvent, and is excellent in separation effect and high in stability when being used for recycling low-molecular weight solvent from an oil mixture, and the separation performance can be stably maintained in long-term operation.

Owner:TSINGHUA UNIV

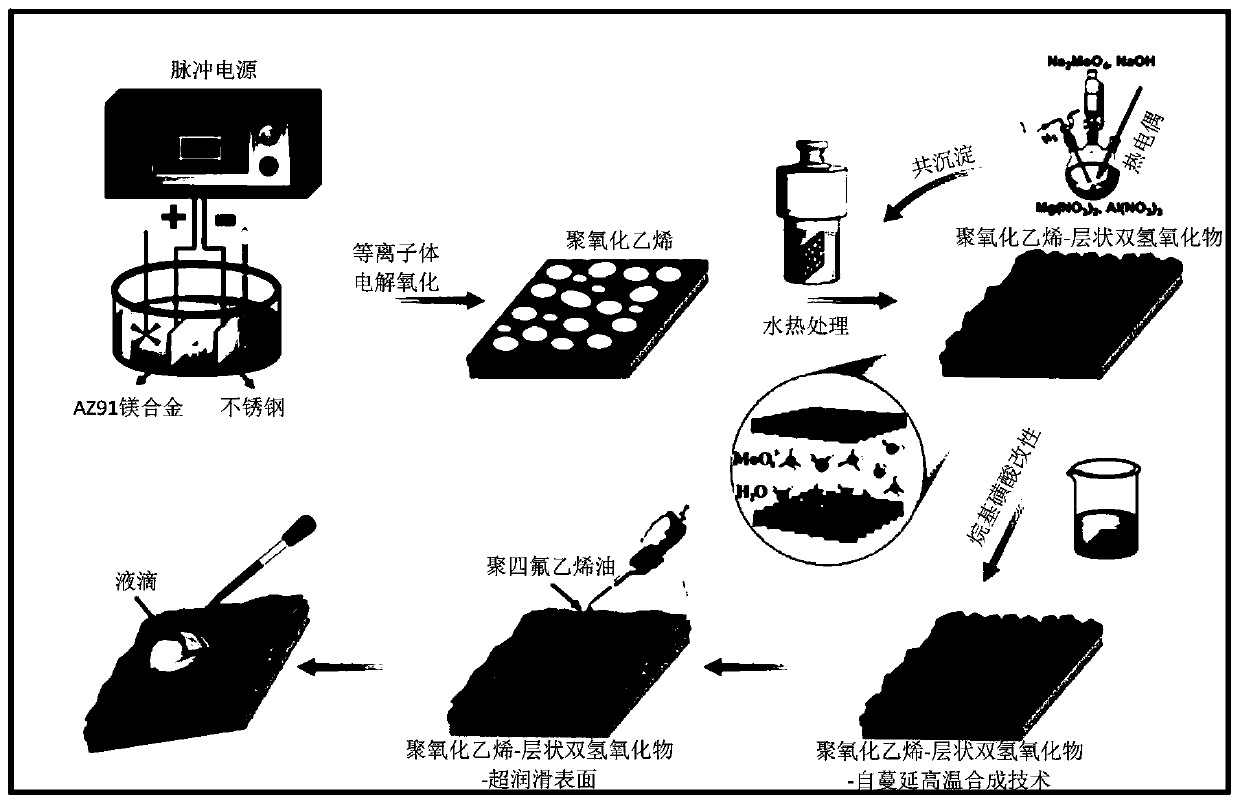

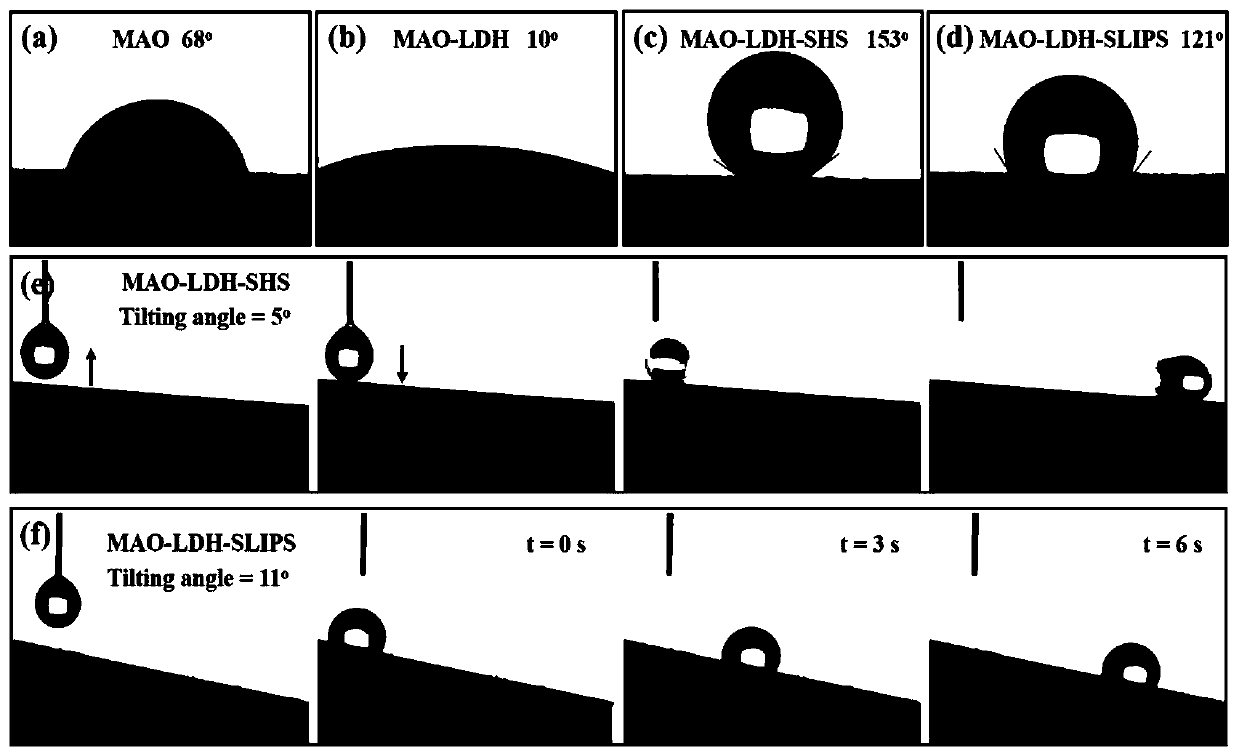

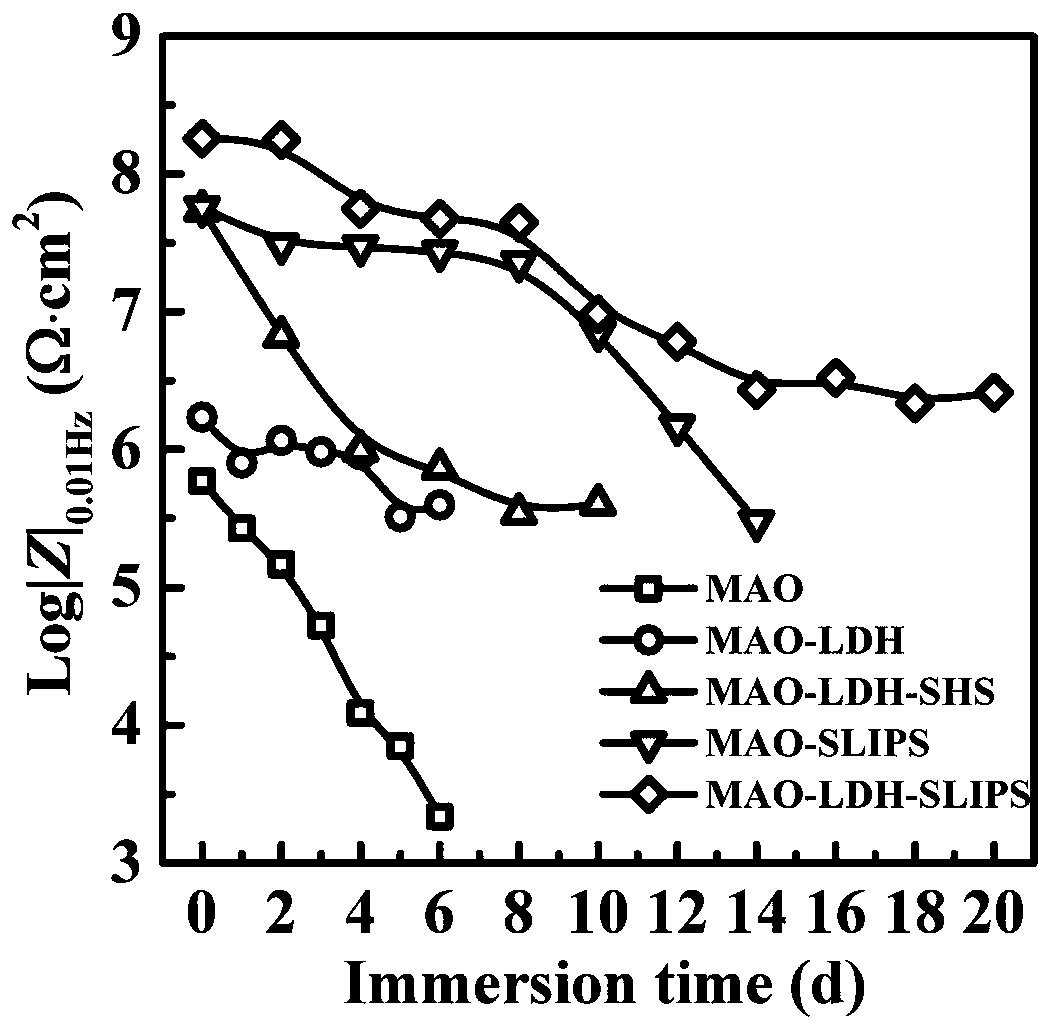

Preparation method of bionic super-lubricating composite anti-corrosion coating with self-restoration function

InactiveCN111593393AAchieve self-healingLow affinityAnodisationLiquid/solution decomposition chemical coatingSuperhydrophobePhysical chemistry

The invention discloses a preparation method of a bionic super-lubricating composite anti-corrosion coating with a self-restoration function. A micro-arc oxidation (MAO) film and a corrosion inhibition particle intercalated lamellar hydroxide (LDH) film are prepared on the surface of a magnesium-aluminum alloy, fluorine-containing silicone oil is injected, and therefore the functions such as surface super-lubricating and coating restoration are achieved. In the disclosed composite coating, WO4<2->, MoO4<2-> and other corrosion inhibition particles are intercalated into an MAO generated magnesium-aluminum lamellar hydroxide (MgAl-LDH) film, the corrosion inhibition particles mixed in intercalation can be released in a corrosive medium containing Cl<-> in a response manner, inspersed Cl<-> is captured through anion exchange, corrosive anions are released, and self-restoration of the corrosion resistance of the coating is achieved. Meanwhile, the fluorine-containing silicone oil on the surface can heal surface scratches through self-leveling under the condition without the help of external force, and therefore the capacity of self-restoration, super-superhydrophobicity and long-time corrosion resistance of the composite coating is achieved.

Owner:ELECTRIC POWER SCI & RES INST OF STATE GRID TIANJIN ELECTRIC POWER CO +2

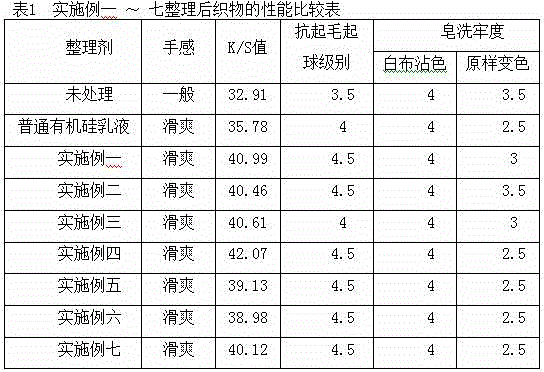

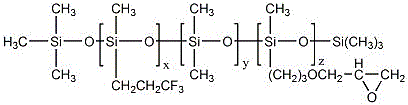

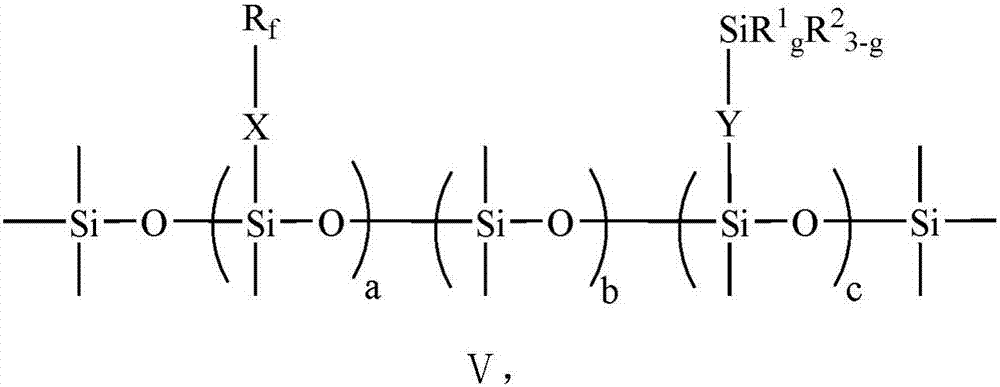

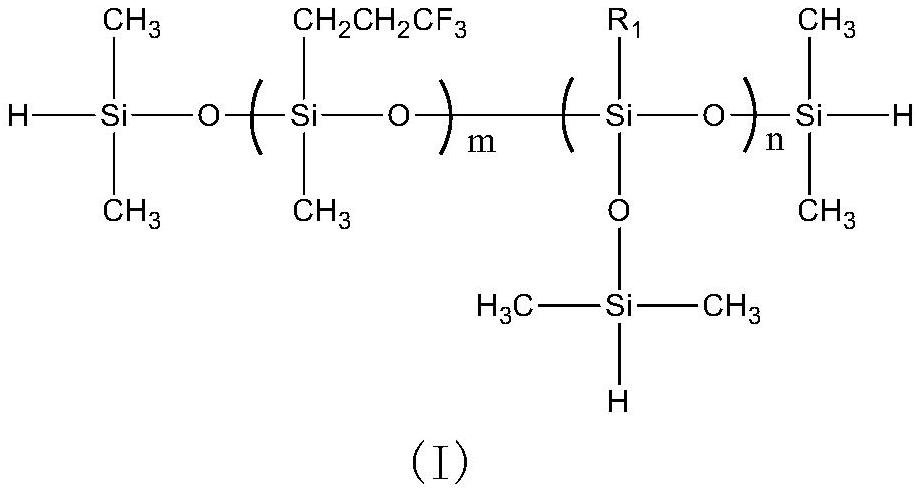

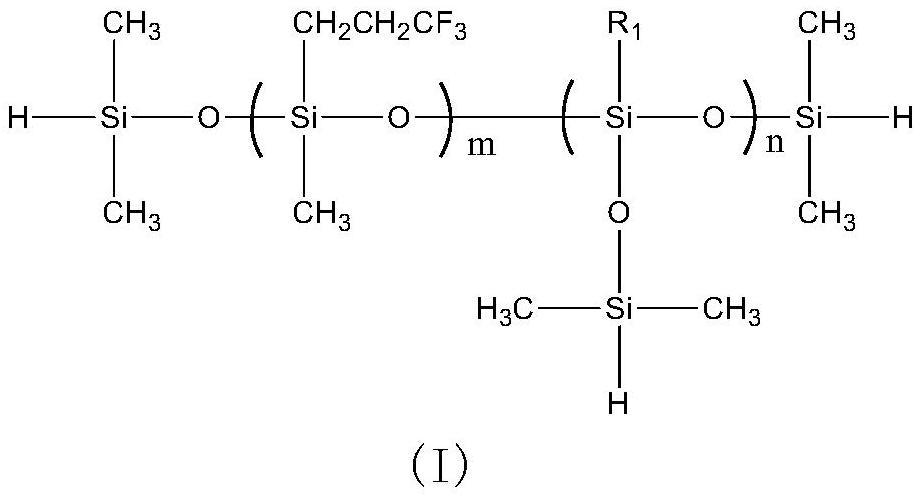

Epoxy-based organic fluorosilicone oil emulsion darkening finishing agent and preparation method thereof

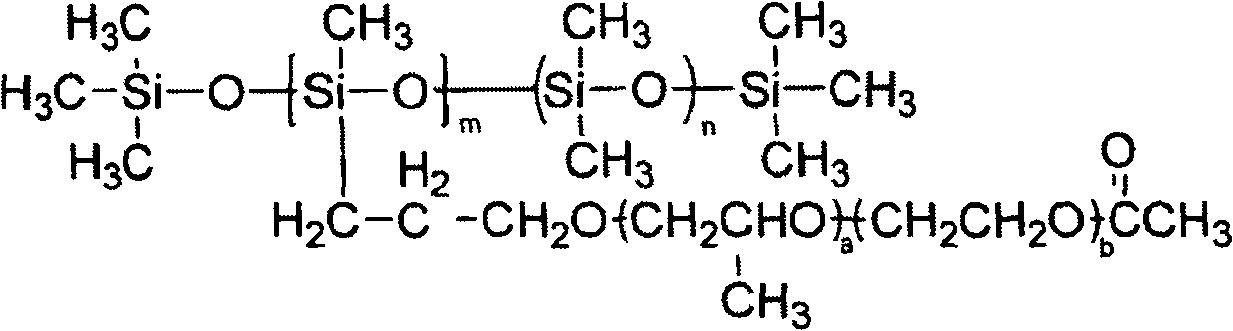

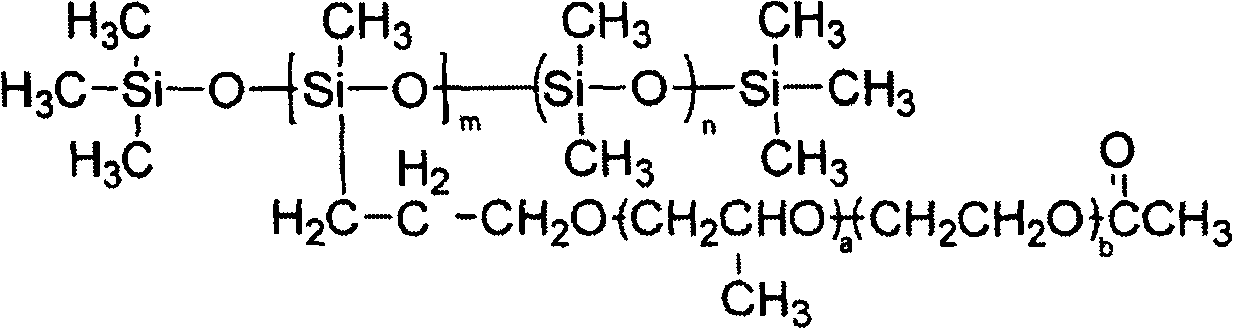

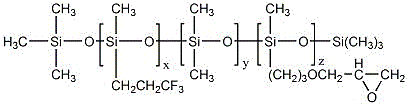

The invention discloses an epoxy-based organic fluorosilicone oil emulsion darkening finishing agent, made from, by weight, 5-35% of octamethylcyclotetrasiloxane, 0.5-10% of 1,3,5-tris(3,3,3-trifluoropropyl)methylcyclotrisiloxane, 0.1-6% of 3-[(2,3)-epoxypropyl]propylmethyldimethoxysilane, 0.001-0.1% of a terminator, 0.001-0.1% of a high-alkality catalyst, 0.1-2% of an emulsifier, and the balance of deionized water; the epoxy-based organic fluorosilicone oil emulsion darkening finishing agent has a following structural formula, wherein X equals to 10-100, Y equals to 80-1000, Z equals to 8-80, and all X, Y and Z are integers; a preparation method of the darkening finishing agent is simple, the reaction process is easy to perform, an obtained emulsion is stable, the darkening finishing agent has significant darkening effect when applied to darkening post-finishing of dark fabric, and washing fastness and handle of textile fabrics can be improved.

Owner:SHANGHAI UNIV

Tough heat-conductive antibacterial non-stick coating

InactiveCN105348882AImprove antibacterial propertiesImprove mechanical propertiesAntifouling/underwater paintsPaints with biocidesWater basedPolyester

The invention discloses a tough heat-conductive antibacterial non-stick coating which is prepared from, by weight, 1-2 parts of graphene powder, 10-20 parts of nano SiO2 dispersion liquid, 10-15 parts of aluminum oxide sol, 10-15 parts of zirconium oxide sol, 2-4 parts of bentonite, 1-3 parts of black iron oxide, 8-10 parts of polyimide, 30-50 parts of polytetrafluoroethylene water-based resin, 5-20 parts of acrylic acid, 5-8 parts of water-soluble polyester modified epoxy resin, 1-3 parts of fluorosilicone oil, 1-2 parts of silver nitrate, 1-2 parts of aluminum nitrate and 3-5 parts of butyl cellosolve. The coating is good in ductility, high in toughness, resistant to wear, not prone to cracking and high in heat conductivity, has the antibacterial function and can be widely applied to kitchen cookware and tableware.

Owner:无锡大塘复合材料有限公司

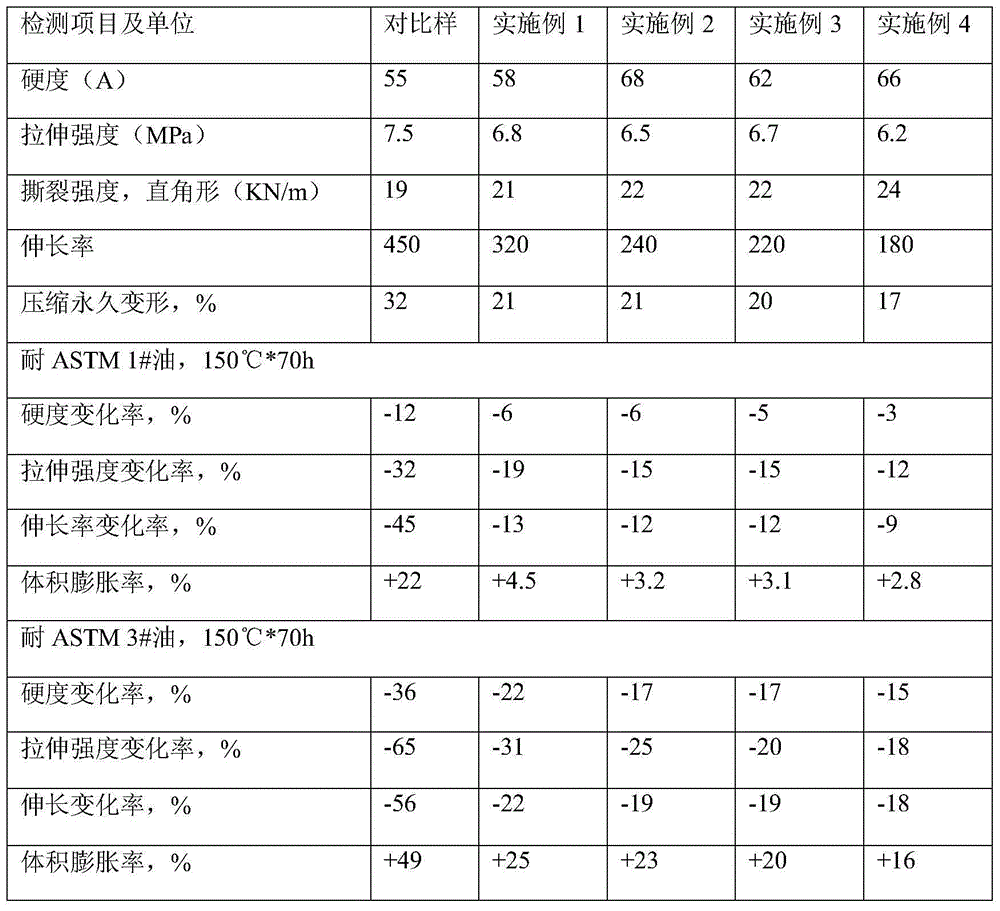

Oil-resistant silicone rubber composite and preparation method thereof

The invention discloses an oil-resistant silicone rubber composite. The components of the composite include fluorine-containing copolymer silicone rubber, hydroxy terminated fluorosilicone oil, simethicone, wollastonite and mica. Compared with the existing oil-resistant rubber, the composite has the advantages that the fluorine-containing copolymer silicone rubber and the hydroxy terminated fluorosilicone oil are adopted, the oil resistance is improved greatly, and the fine oil resistant effect is achieved; furthermore, the wollastonite and mica are adopted, the oil resistance is improved, the cost is lowered, and the market application value is provided. Compared with conventional oil-resistant rubber prepared through vinyl silicone rubber, the oil-resistant rubber prepared through fluorine-containing copolymer silicone rubber has the advantages of better oil resistance and physical properties and higher stability. The oil resistance is detected according to the GB / T1690-2006 standard, and the volume change rate is not greater than 25%.

Owner:DONGJUE SILICONE NANJING CO LTD

Wear-resisting and weather-resisting modified paint

InactiveCN107266989AExcellent wear resistance and weather resistanceHigh hardnessCoatingsCyclohexanoneAcrylic resin

The invention discloses a wear-resistant and weather-resistant modified coating. The raw materials include fluorocarbon resin, caprolactone modified acrylic resin, styrene-acrylic emulsion, polyvinyl chloride resin, modified composite filler, modified adhesive, polyurethane, ortho Dioctyl phthalate, modified nano-montmorillonite, nano-titanium dioxide, sericite powder, magnesium hydroxide, ultrafine silica, calcined kaolin, kaolin, alumina, butyl acetate, sodium persulfate, fluorosilicone oil, Xylene, cyclohexanone, defoamer, silane coupling agent KH‑560, dispersant, silane coupling agent KH‑570, wetting agent and water. The modified coating of the invention has excellent wear resistance and weather resistance.

Owner:TIANCHANG JULONG TRAVEL PAINT

Lubricating oil for mechanical equipment and preparation method thereof

InactiveCN108822934AHigh viscosityImprove the lubrication effectLubricant compositionAntioxidantMechanical equipment

The invention discloses lubricating oil for mechanical equipment and a preparation method thereof, and relates to the field of lubricating oil. The lubricating oil for the mechanical equipment comprises the following raw materials in parts by weight: 30-40 parts of polyalphaolefin, 15-20 parts of fluorosilicone oil, 1.5-4 parts of pentaerythritol ester, 2-5 parts of modified nanodiamond, 1-3 partsof castor oil, 3-6 parts of grapheme, 1-3 parts of molybdenum disulfide, 0.4-0.8 part of Tween, 0.5-1.2 parts of sorbitol monooleate, 0.2-0.6 part of an antioxidant, 0.4-0.8 part of a demulsifying agent and 0.7-1.5 parts of a viscosity index improver. Through cooperation of the raw materials, the lubricating oil has good viscosity, lubricity and antioxidation; the lubricating oil forms a curing protection layer on the surface of the mechanical equipment; meanwhile, the lubricating oil has good wear resistance and durability.

Owner:合肥博创机械制造有限公司

Preparation method of perfluoropolyfluoroether fluorosilane with plurality of hydrolytically-active end groups

ActiveCN107216459ARaw materials are easy to getMild process conditionsAntifouling/underwater paintsPaints with biocidesSilanesEnd-group

The invention relates to a preparation method of perfluoropolyfluoroether fluorosilane with a plurality of hydrolytically-active end groups. The preparation method comprises the following steps: performing an addition reaction of vinyl-terminated perfluoropolyether and dialkoxyfluorosilane in the presence of a fluorine-containing solvent and a catalyst to obtain perfluoropolyether fluoroalkyl silane; performing a hydrolysis reaction on the perfluoropolyether fluoroalkyl silane to obtain a perfluoropolyether fluoroalkyl silane hydrolysate; reacting the perfluoropolyether fluoroalkyl silane hydrolysate with polyvinylsilicone oil in the presence of an alkali catalyst to obtain vinyl perfluoropolyether fluorosilicone oil; performing an addition reaction of the vinyl perfluoropolyether fluorosilicone oil and trialkoxyhydrosilane in the presence of a fluorine-containing solvent and a catalyst to obtain the perfluoropolyfluoroether fluorosilane. The preparation method has the advantages of adoption of readily-available raw materials and mild and safe process conditions; the defects that raw materials are difficult to obtain and are flammable and combustible in the prior art are overcome.

Owner:太仓中化环保化工有限公司

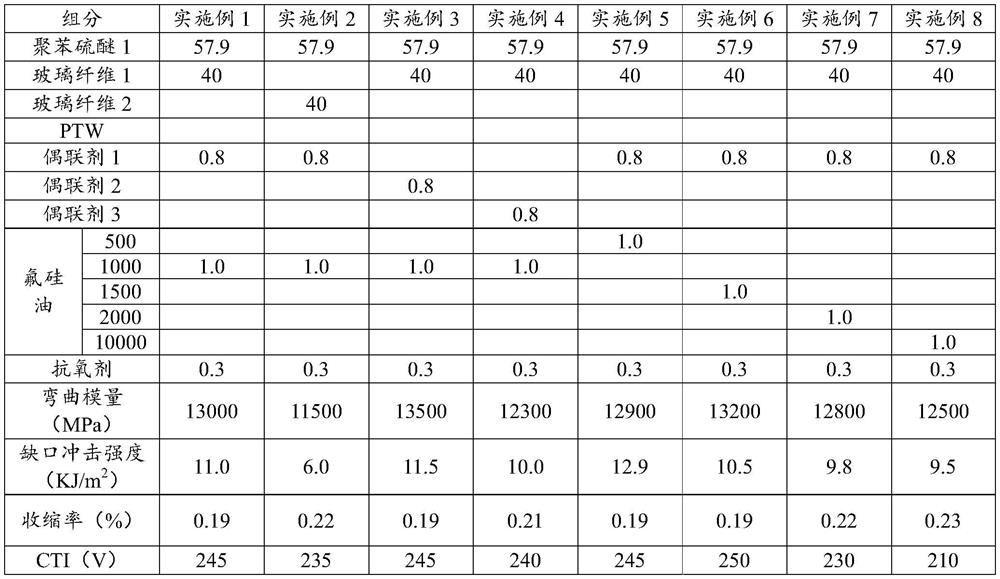

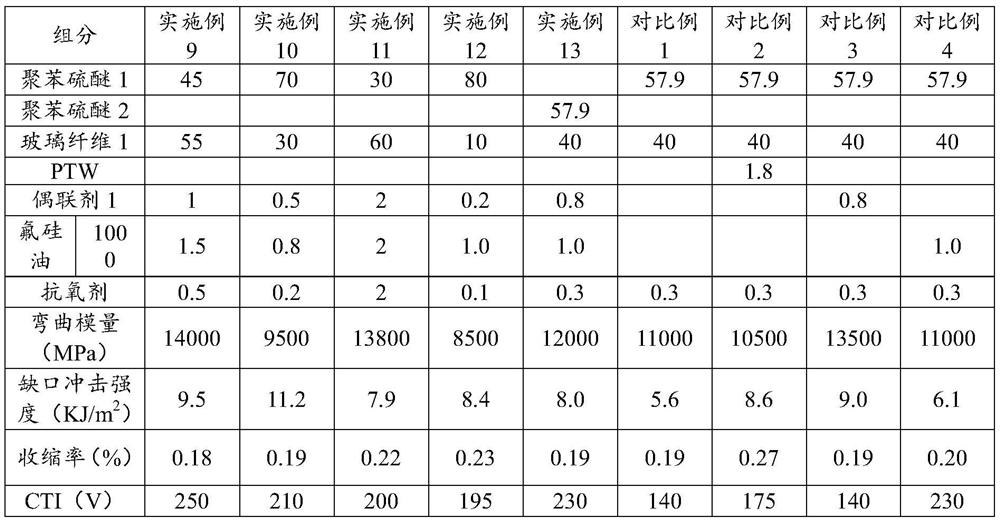

Hydrophobic high-CTI polyphenylene sulfide composition as well as preparation method and application thereof

The invention discloses a hydrophobic high CTI polyphenylene sulfide composition. The composition comprises the following components in parts by weight: 30-80 parts of polyphenylene sulfide, 10-60 parts of glass fibers, 0.2-2 part of a coupling agent, 0.2-2 part of fluorosilicone oil and 0.1-2 part of an antioxidant. According to the hydrophobic high CTI polyphenylene sulfide composition, the compatibility of PPS and a glass fiber material is improved through the coupling agent, the rigidity and the toughness of the material are further improved, meanwhile, the fluorosilicone oil is added, andthe characteristics of low surface energy and super-hydrophobicity of the fluorosilicone oil are utilized, in the injection molding process, due to the low surface energy, the composition is gatheredon the material surface, and the influence on the rigidity of the material is small. Meanwhile, after the fluorosilicone oil is gathered on the surface, the wetting of the PPS by the electrolyte canbe greatly reduced due to the super-hydrophobic characteristic, and the CTI of the PPS material can be obviously improved.

Owner:KINGFA SCI & TECH CO LTD

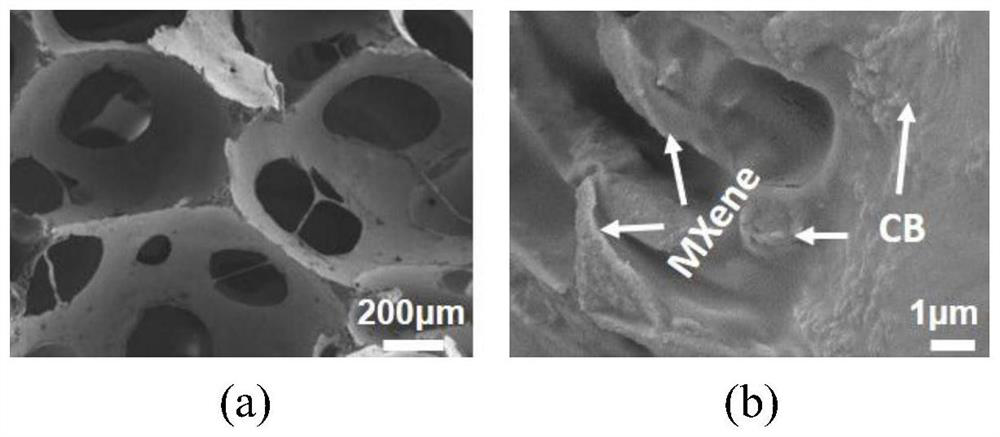

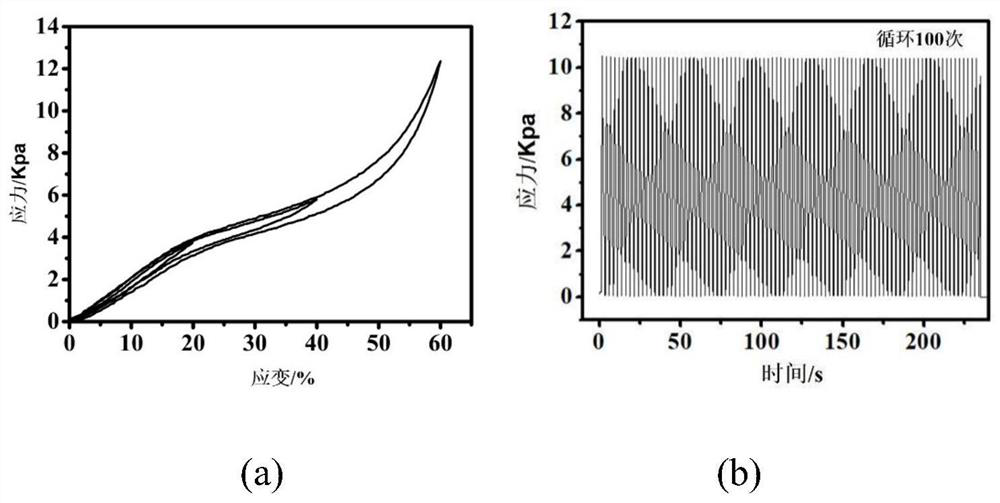

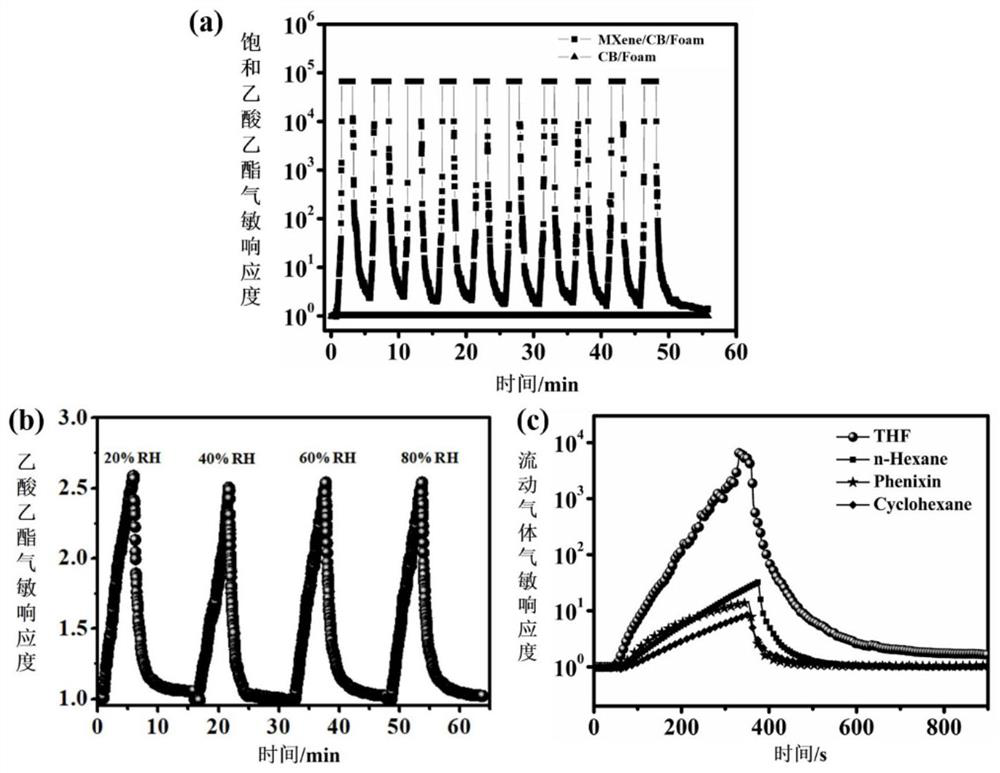

Conductive fluorinated silicone rubber foam composite material as well as preparation method and application thereof

ActiveCN113150358AWell mixedEnvironmentally friendly manufacturing processMaterial analysis by electric/magnetic meansOrganic solventFoaming agent

The invention discloses a conductive fluorinated silicone rubber foam composite material, a preparation method thereof and application of the conductive fluorinated silicone rubber foam composite material in the field of gas-sensitive detection. The preparation method comprises the following steps: ultrasonically dispersing carbon conductive particles in an organic solvent which is volatile at normal temperature to obtain conductive particle dispersion liquid; stirring perfluorosilicone oil, hydrogen-containing fluorosilicone oil and conductive particle dispersion liquid in an organic solvent until the organic solvent is completely volatilized, then adding a foaming agent and an inhibitor, performing uniform mixing to obtain a component A, and uniformly mixing perfluorosilicone oil and a platinum catalyst to obtain a component B; mixing the component A and the component B, performing uniform stirring, reacting at room temperature for 5-30 minutes, and crosslinking and curing the obtained product at 50-125 DEG C for 10-60 minutes to obtain the conductive fluorinated silicone rubber foam composite material.

Owner:HANGZHOU NORMAL UNIVERSITY +1

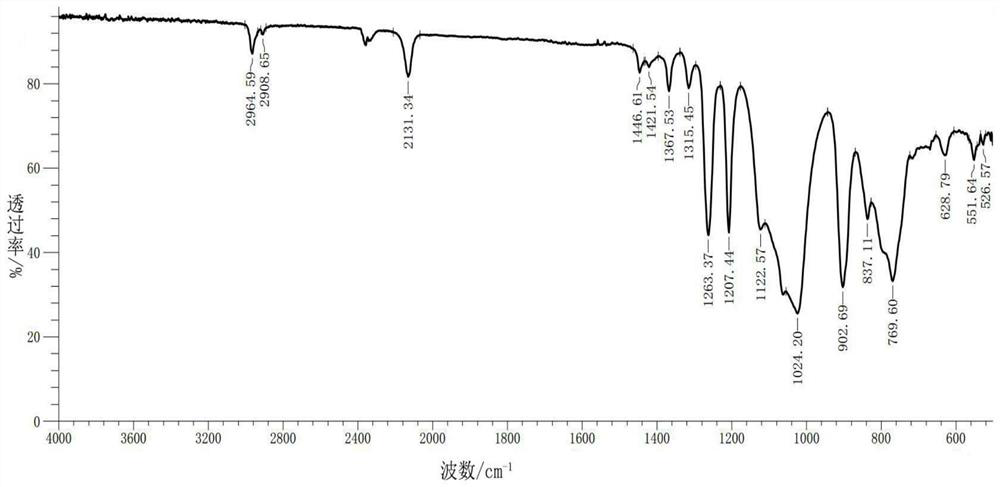

Fluorine-contained phenyl hydrogen-contained silicone oil cross-linking agent and preparing method thereof

The invention belongs to the technical field of cross-linking agents and discloses a fluorine-contained phenyl hydrogen-contained silicone oil cross-linking agent and a preparing method thereof. According to the method, a base catalyst is added into low-viscosity methyl silicone oil, phenyl cyclosiloxane and fluorosilicone oil, the mixture is mixed uniformly, temperature is raised, the mixture is stirred at constant temperature and cooled, an acid catalyst and hydrogen-contained silicone oil are sequentially added into the mixture, a balanced reaction is carried out, and follow-up treatment is carried out after the reaction is finished, so that the colorless and transparent fluorine-contained phenyl hydrogen-contained silicone oil cross-linking agent is obtained. According to the preparing method, methyl cyclosiloxane and an end-capping agent do not needed to be added, the technology is simplified, and the product quality and stability are improved; the adopted raw materials do not contain chlorine or alkoxy, and therefore introduction of chloride ions and residues of alkoxy are avoided; as no solvent is adopted, harm to the human body and pollution to the environment are avoided; the yield of the prepared cross-linking agent is high.

Owner:SOUTH CHINA UNIV OF TECH

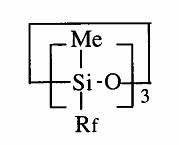

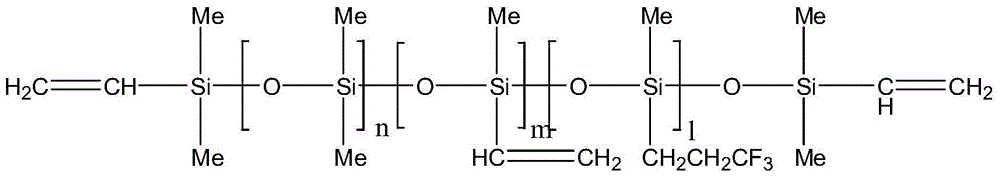

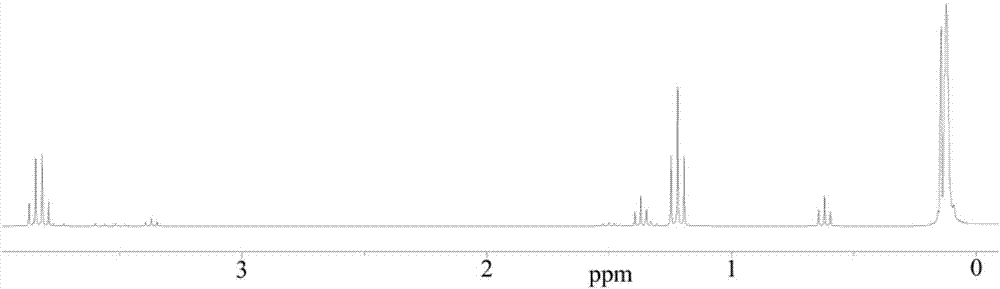

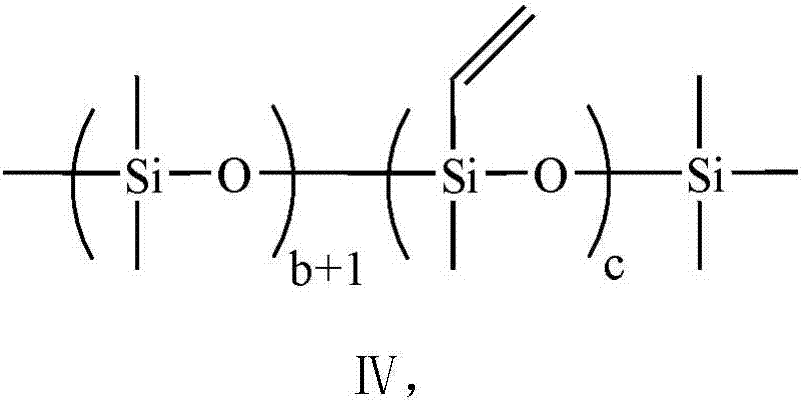

High-activity hydrogen-containing fluorosilicone oil cross-linking agent and preparation method thereof

The invention discloses a high-activity hydrogen-containing fluorosilicone oil cross-linking agent and a preparation method thereof. The molecular structure of the cross-linking agent is shown in thespecification, a dimethyl silicon-oxygen chain link exists between the side hydrogen and the main chain silicon-oxygen chain link; compared with a structure in which side group hydrogen in a conventional hydrogen-containing fluorosilicone oil structure is directly connected to a silicon atom of a main chain, according to the structure, the steric hindrance effect of trifluoropropyl is reduced, theshielding influence of trifluoropropyl on silicon hydrogen is reduced, the reaction activity of silicon hydrogen on a main chain is improved, a good vulcanization effect can be achieved by adding a small amount of additive fluorosilicone rubber in a vulcanization system of the additive fluorosilicone rubber, and the mechanical property of the fluorosilicone rubber is improved.

Owner:威海新元新材料有限公司 +1

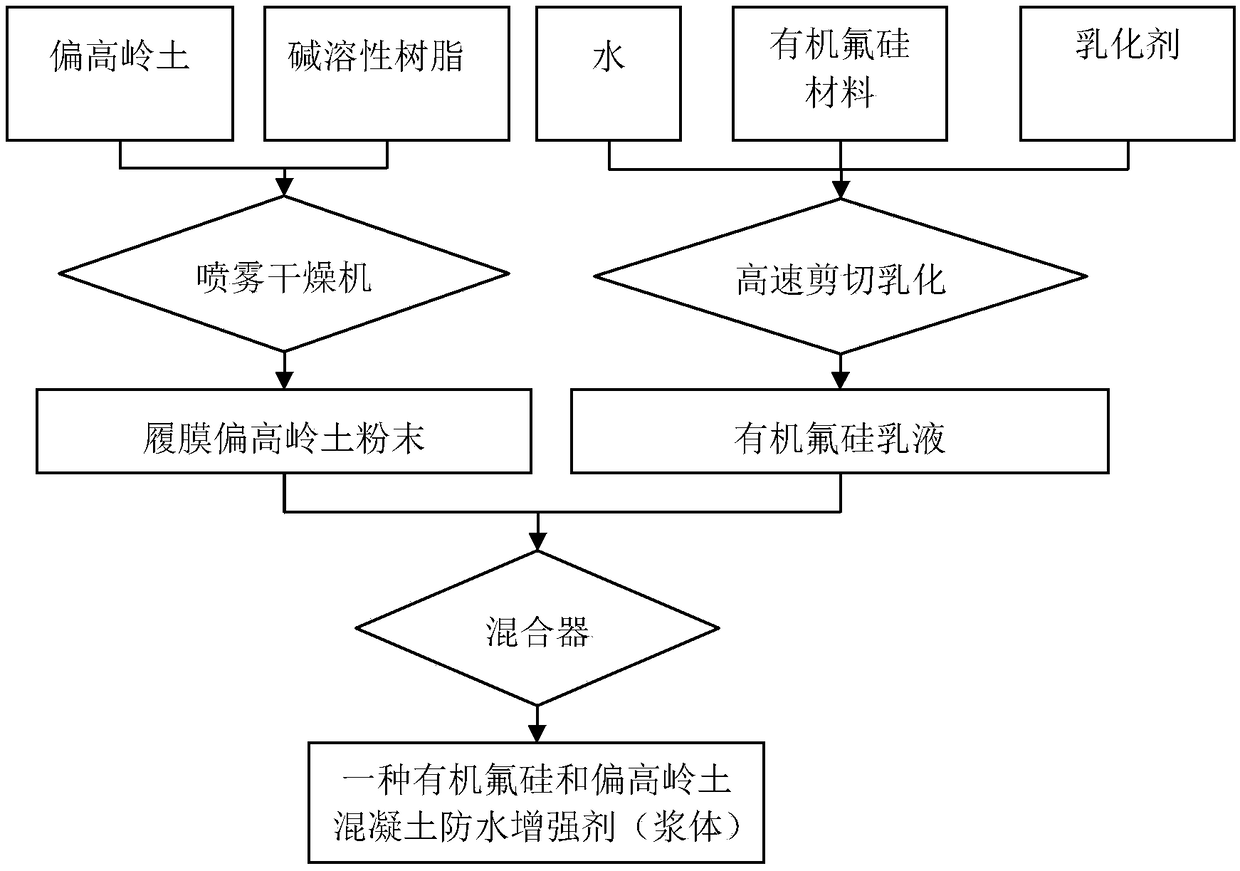

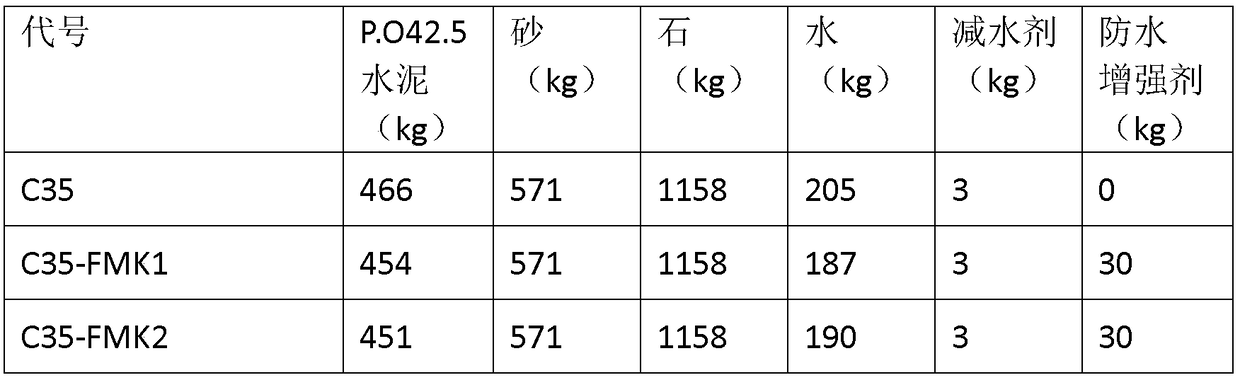

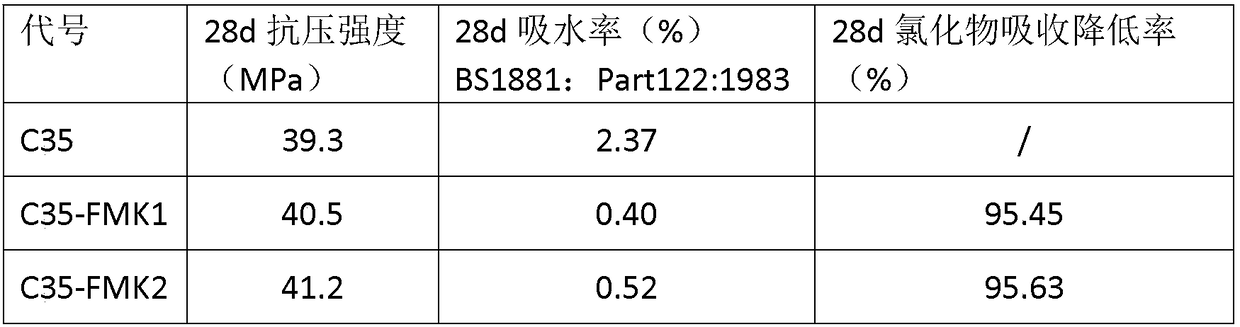

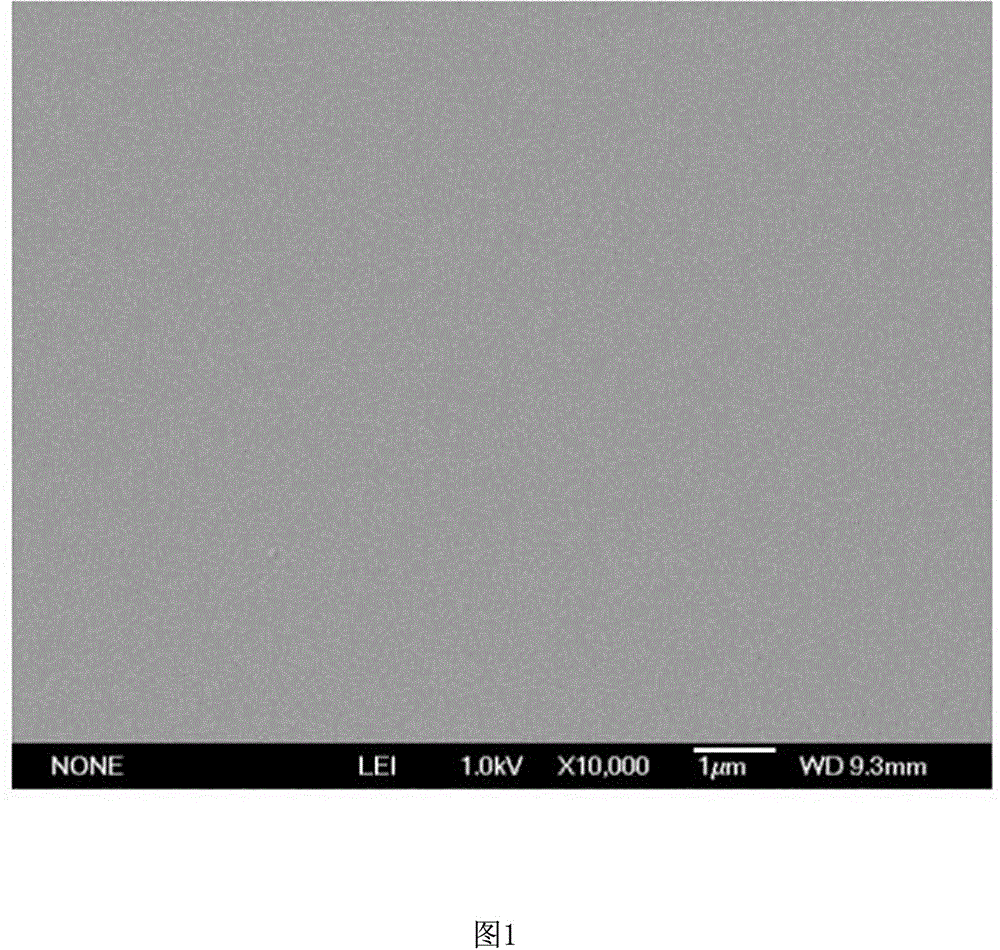

Organic fluorosilicone and metakaolin concrete waterproofing fortifier and preparation method and application thereof

The invention discloses an organic fluorosilicone and metakaolin concrete waterproofing fortifier and a preparation method and application thereof. The organic fluorosilicone and metakaolin concrete waterproofing fortifier contains the following ingredients (by weight): 30-50% of metakaolin, 3-5% of alkali-soluble resin, 5-15% of an organic fluorosilicone hydrophobic component, 0.1-1.0% of an emulsifier, 0.5-1.0% of a pH regulator and 30-50% of water, wherein the metakaolin is made into metakaolin powder with an alkali-soluble protective adhesive film. By mixing the metakaolin powder with thealkali-soluble protective adhesive film into an organic fluorosilicone oil-in-water emulsion with pH value being neutral, the organic fluorosilicone and metakaolin concrete waterproofing fortifier isprepared. Concrete with the application of the organic fluorosilicone and metakaolin concrete waterproofing fortifier as an additive has the following advantages: water absorption is obviously reduced; chloride absorption reduction rate, sulfate corrosion resistance and freezing and thawing cycle resistance of the concrete are remarkably raised; and durability of the concrete is obviously enhanced.

Owner:CCCC FOURTH HARBOR ENG INST +2

Preparation method of solvent resistant nanofiltration membrane

InactiveCN104437141AEasy to separateStrong toleranceSemi-permeable membranesPolymer sciencePtru catalyst

The invention discloses a preparation method of a solvent resistant nanofiltration membrane. The preparation method comprises the steps of dissolving fluorosilicone oil, a cross-linking agent and a catalyst in a solvent, fully stirring to prepare a casting solution, filtering, defoaming, controlling the thickness, uniformly coating a base membrane by the casting solution, placing at room temperature until the solvent is volatized and solidified preliminarily, and further crosslinking at certain room temperature to obtain the fluorinated silicone rubber solvent resistant nanofiltration membrane. The prepared solvent resistant nanofiltration membrane is used for recycling hexane from soybean oil / hexane mixed oil, has excellent separation property, can overcome the disadvantage that the common silicone rubber has organic solvent intolerance, has excellent swelling resisting behavior, and can keep stable separating property after long-time operation.

Owner:TSINGHUA UNIV

Durable waterproof engineering coating and preparation method thereof

InactiveCN110862736AEasy to prepareEasy to operateFireproof paintsAnti-corrosive paintsEpoxyPolymer science

The invention discloses a durable waterproof engineering coating, and is characterized in that the durable waterproof engineering coating is prepared from the following raw materials in parts by weight: 25-30 parts of an allylthiourea / 3-amino-3-(2-pyridine)acrylonitrile / 1-vinyl-1,2,4-triazole / titanium triisopropoxide methacrylate copolymer, 2-4 parts of epoxy modified 2,4,6-triphenylborazine, 20-30 parts of amino-terminated polyurethane, 1-4 parts of asphalt, 2-5 parts of vinyl-terminated fluorosilicone oil, 0.5-1.5 parts of a photoinitiator, 15-20 parts of a filler, 1-3 parts of a defoaming agent, 1-3 parts of a dispersing agent, 1-3 parts of an emulsifying agent and 20-30 parts of an organic solvent. The invention also provides a preparation method of the durable waterproof engineering coating. The durable waterproof engineering coating disclosed by the invention is remarkable in waterproof effect, good in comprehensive performance and excellent in weather resistance, mechanical property, heat resistance and wear resistance.

Owner:HUNAN CHENLI NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com