High-efficiency antifoaming agent

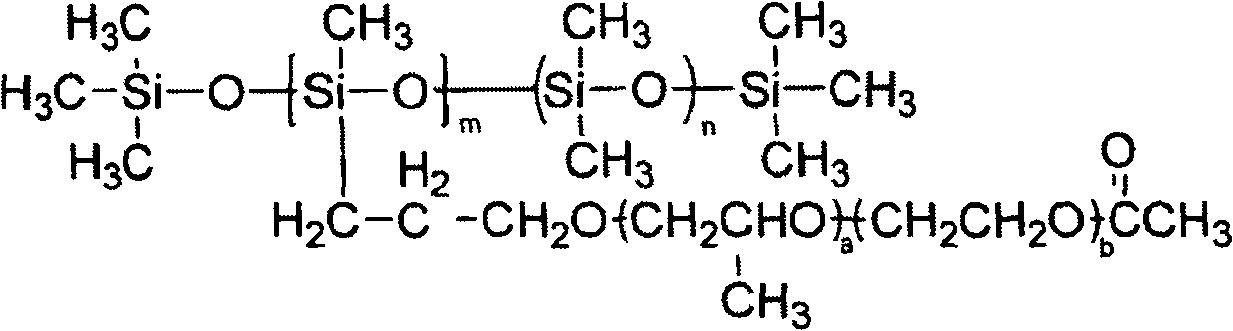

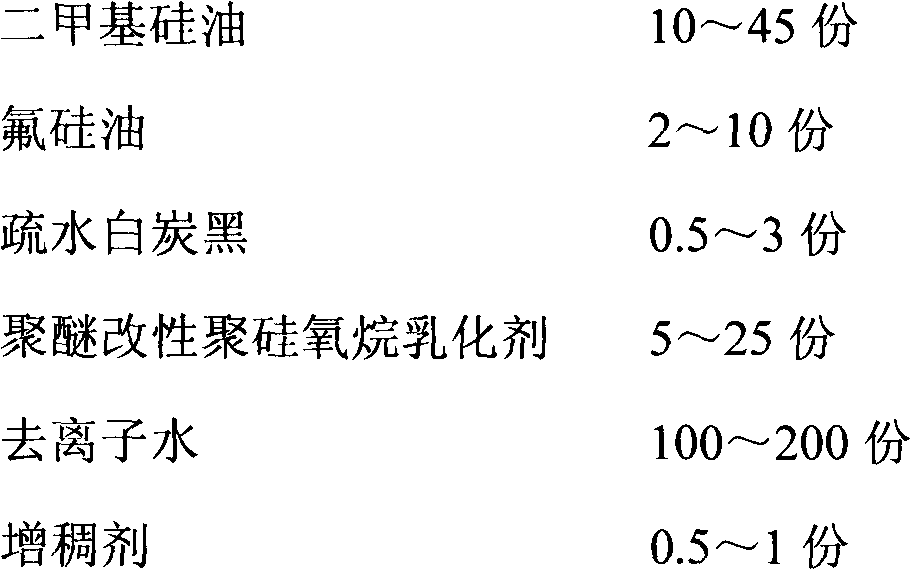

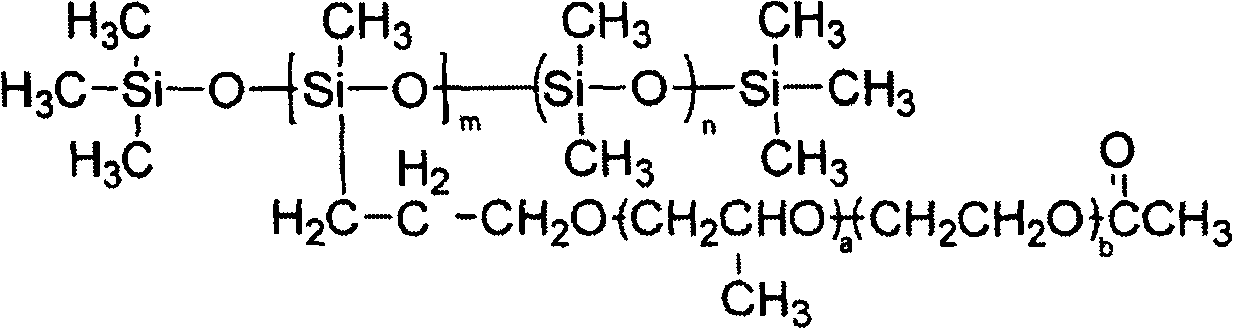

A defoamer and high-efficiency technology, applied in the field of fine chemical preparations, can solve the problem of single compounding technology, the inability of the defoamer to exert the high temperature resistance, acid and alkali resistance of polyether modified polysiloxane, and the defoamer elimination and inhibition. Poor foam performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 20Kg of 500cst simethicone oil, 20Kg of 1000cst simethicone oil, 5Kg of methyl fluorosilicone oil, and 3Kg of hydrophobic white carbon black into the reaction kettle, keep it warm at 200°C for 8 hours, and grind the obtained product through a colloid mill; mix 40Kg of the above product with poly Mix 17Kg of ether-modified polysiloxane emulsifier thoroughly. At 70°C, add water to the oil to undergo phase inversion. When adding water, keep the emulsification temperature constant. After adding water, cool to room temperature and pass through a colloid mill before adding thickener. Aqueous solution Dilute this product to 20% emulsion.

Embodiment 2

[0026] Add 20Kg of 500cst simethicone oil, 20Kg of 1000cst simethicone oil, 5Kg of vinyl fluorosilicone oil, and 3Kg of hydrophobic white carbon black into the reaction kettle. Mix 17Kg of ether-modified polysiloxane emulsifier thoroughly. At 70°C, add water to the oil to undergo phase inversion. When adding water, keep the emulsification temperature constant. After adding water, cool to room temperature and pass through a colloid mill before adding thickener. Aqueous solution Dilute this product to 20% emulsion.

Embodiment 3

[0028] Add 20Kg of 500cst simethicone oil, 20Kg of 1000cst simethicone oil, 10Kg of methyl fluorosilicone oil, and 4Kg of hydrophobic white carbon black into the reaction kettle, keep it warm at 200°C for 8 hours, and grind the obtained product through a colloid mill; mix 50Kg of the above product with poly Mix 15Kg of ether-modified polysiloxane emulsifier thoroughly. At 70°C, add water to the oil for phase inversion. Keep the emulsification temperature constant when adding water. After adding water, cool to room temperature and pass through a colloid mill before adding thickener. Aqueous solution Dilute this product to 20% emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com