Patents

Literature

2723results about "Foam dispersion/prevention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

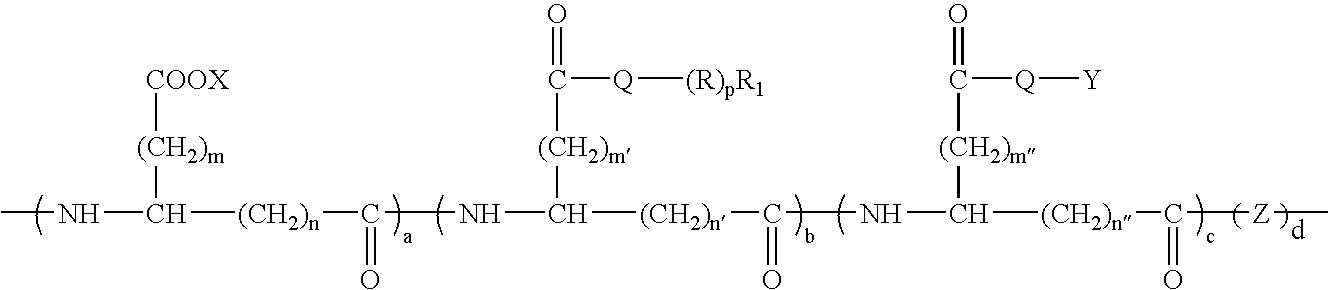

Acid thickeners and uses thereof

InactiveUS7060661B2Improve thermal stabilityOther chemical processesFluid removalHydrogenSURFACTANT BLEND

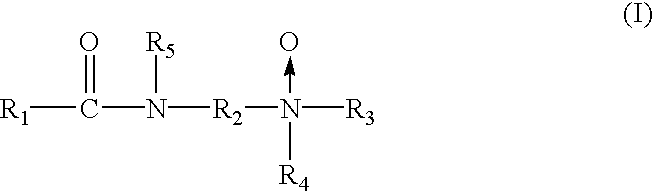

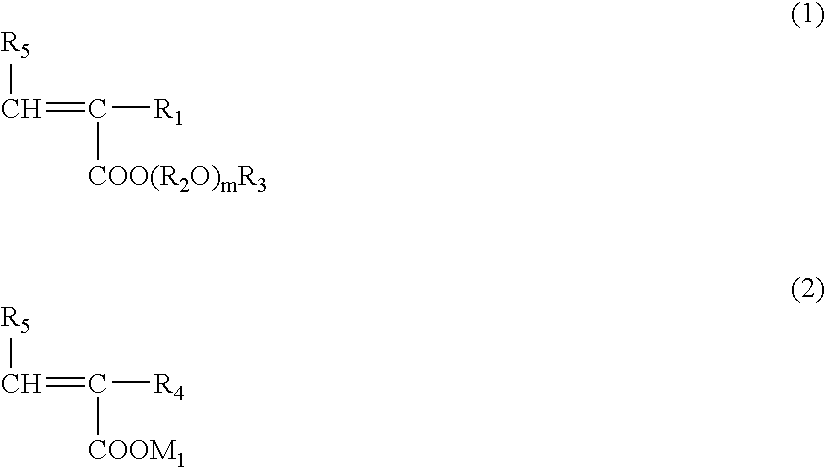

The present invention generally relates to aqueous, acidic compositions thickened with an amidoamine oxide gelling agent and / or viscoelastic surfactant of the general formula I:wherein R1 is a saturated or unsaturated, straight or branched chain aliphatic group of from about 7 to about 30 carbon atoms, R2 is a divalent alkylene group of 2–6 carbon atoms which may be linear or branched, substituted or unsubstituted, and R3 and R4 are independently C1–C4 alkyl or hydroxyalkyl groups or together they form a heterocyclic ring of up to six members, and R5 is hydrogen or a C1–C4 alkyl or hydroxyalkyl group. The aforementioned gelling agents advantageously provide gels that do not undergo phase separation over extended periods of time and exhibit high heat stability. The thickened acid gels of the invention have applications in household and industrial cleaners and degreasers, oilfield stimulation applications and the like.

Owner:AKZO NOBEL CHEM INT BV

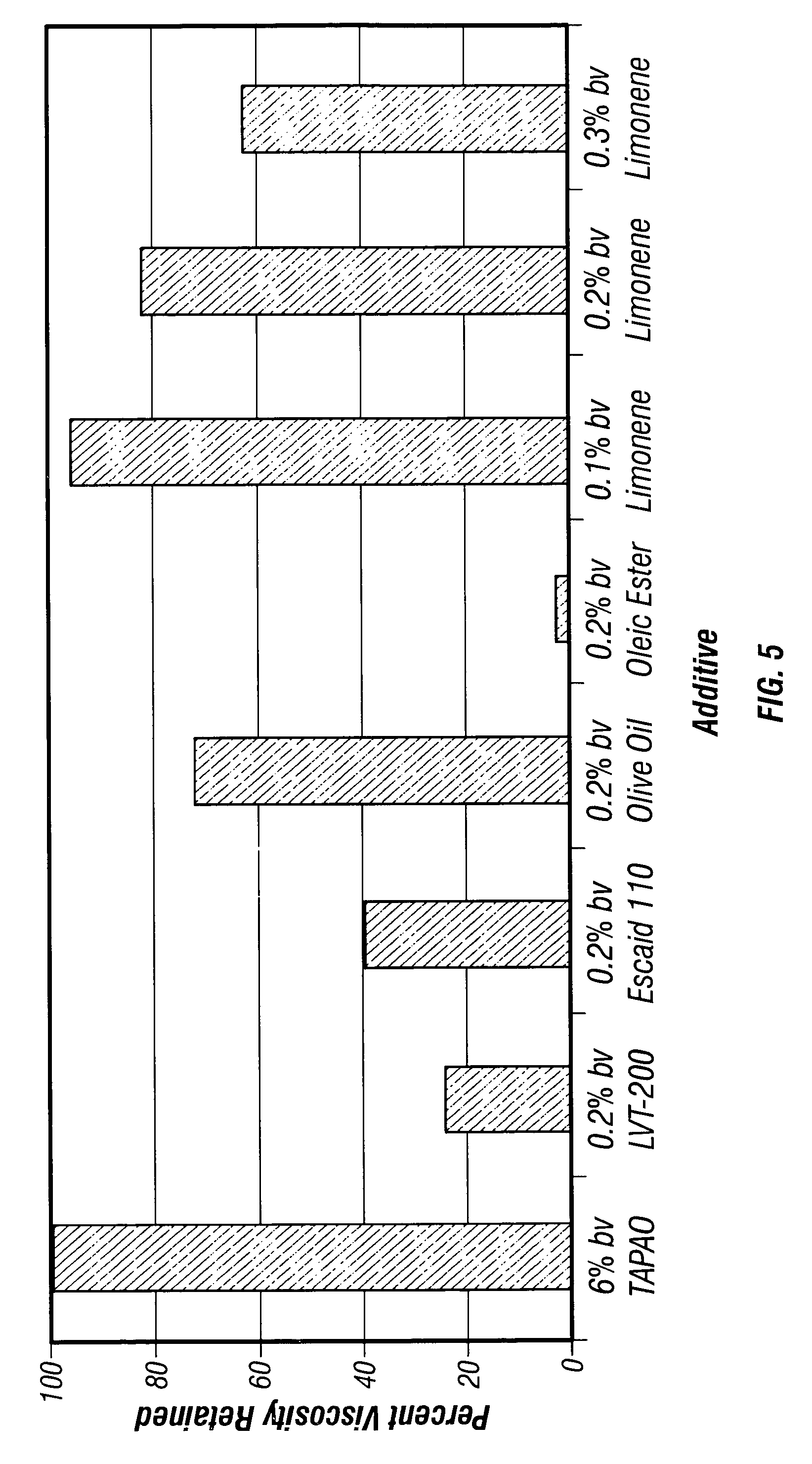

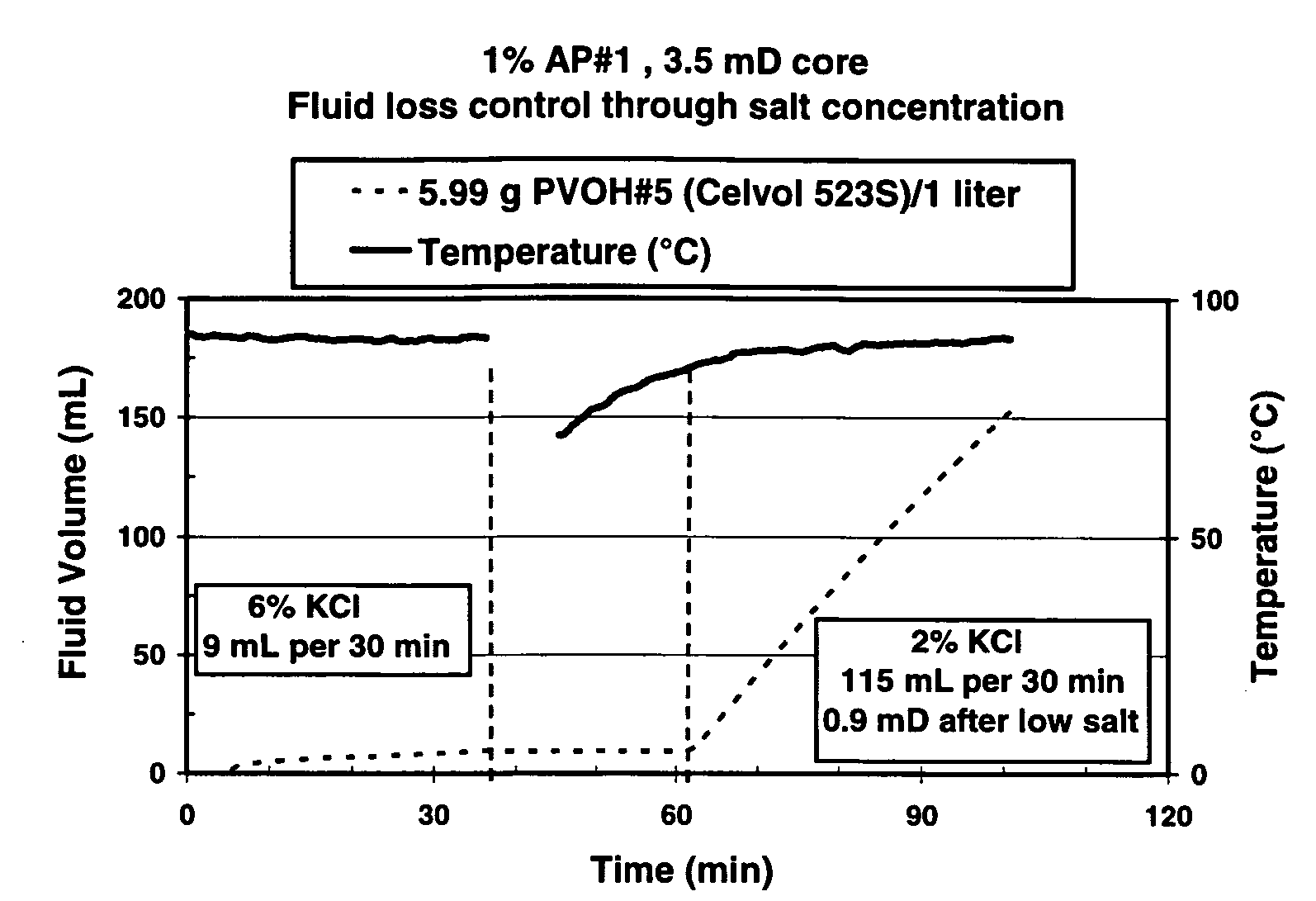

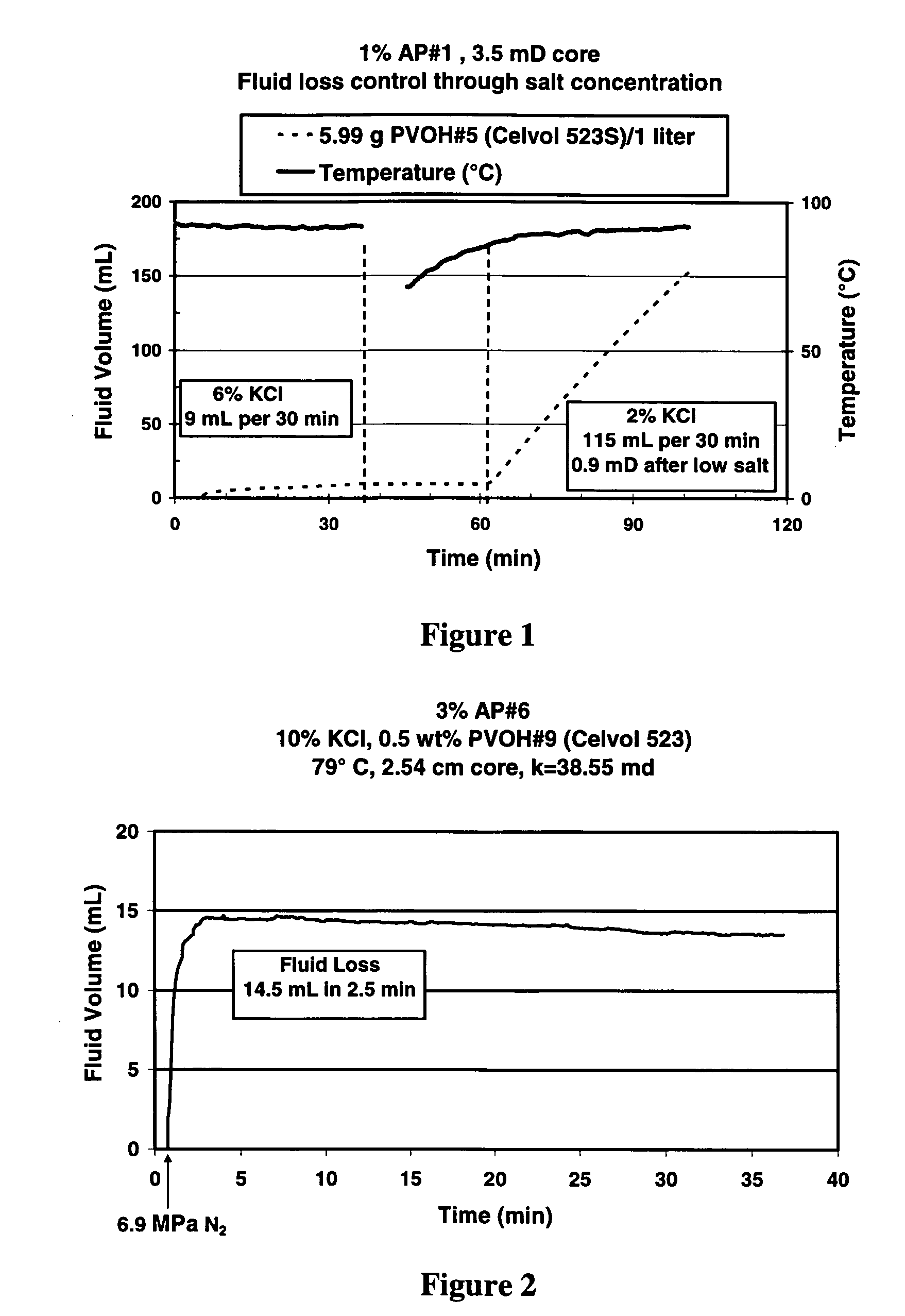

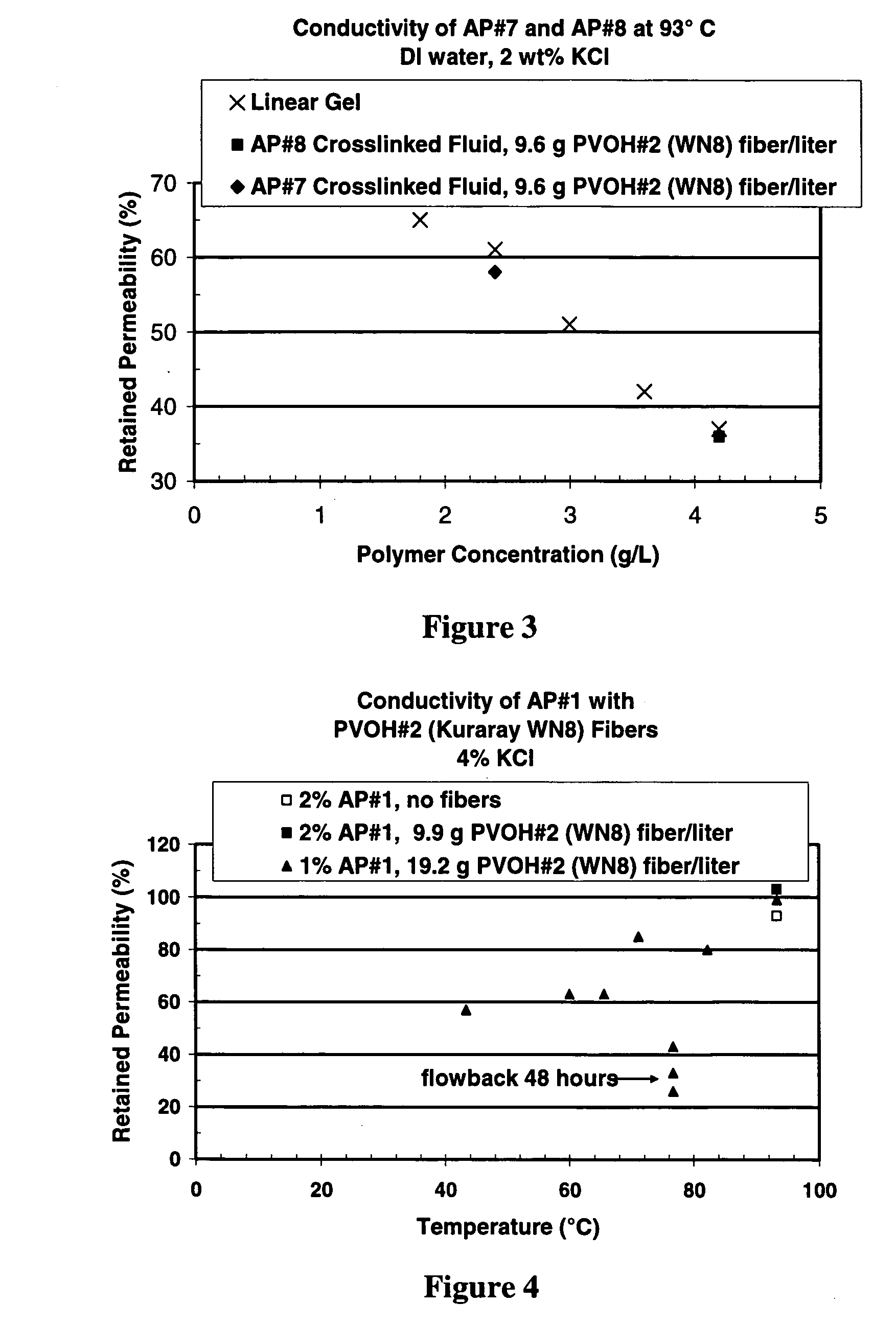

Well treatment with dissolvable polymer

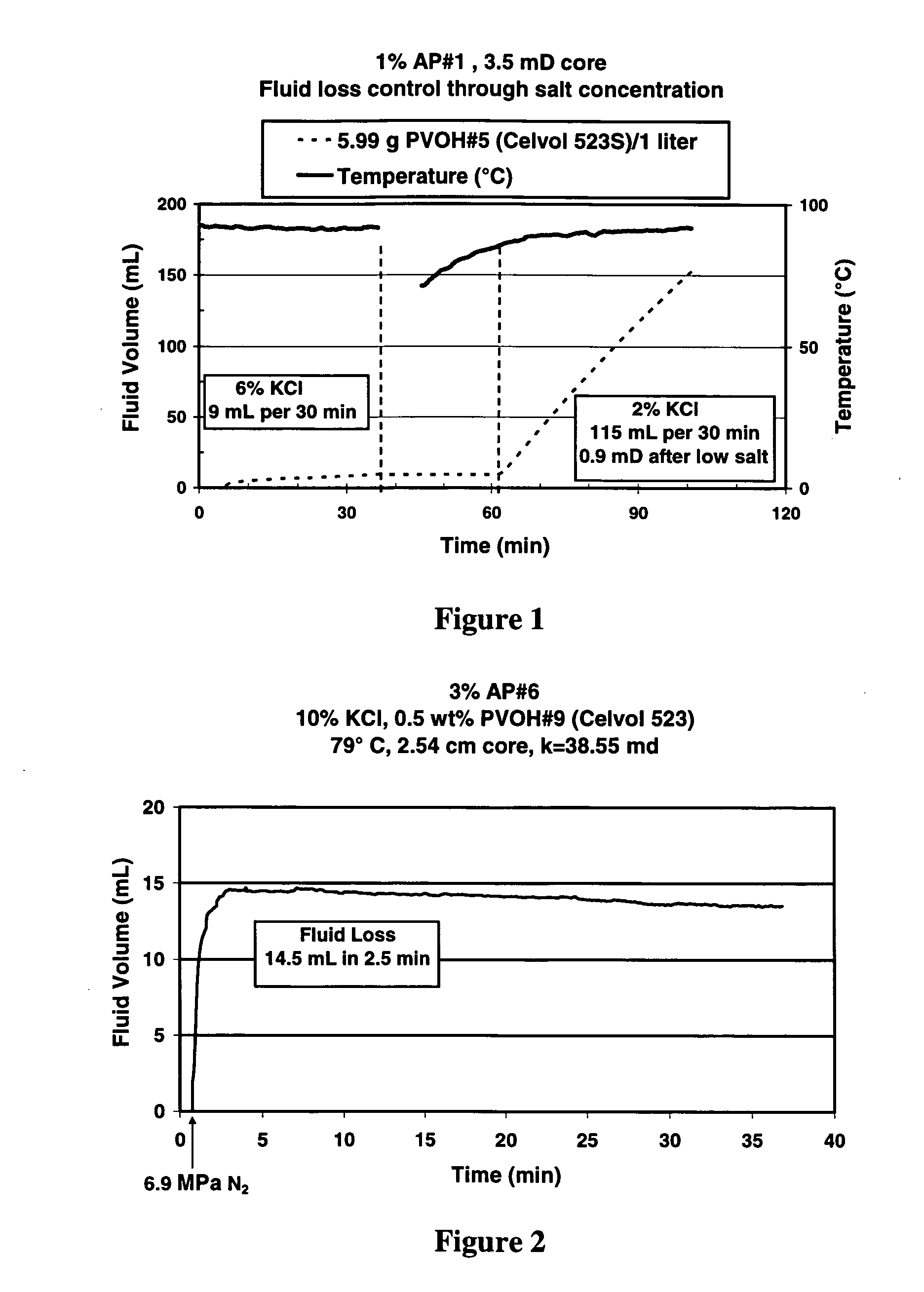

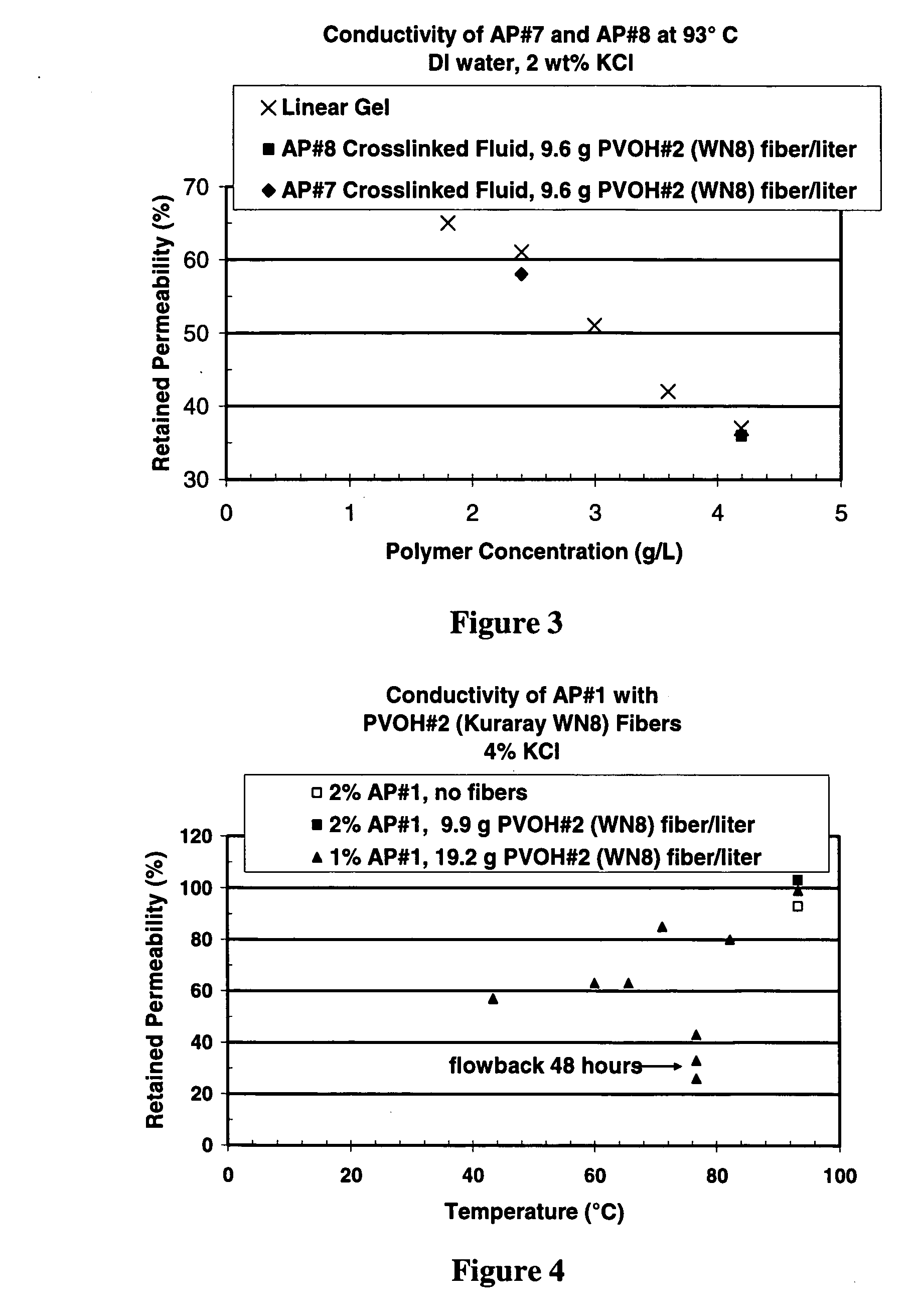

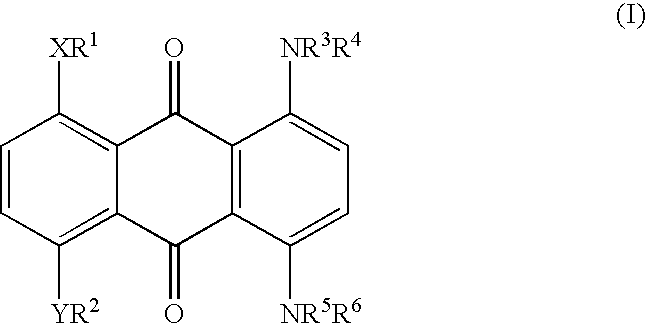

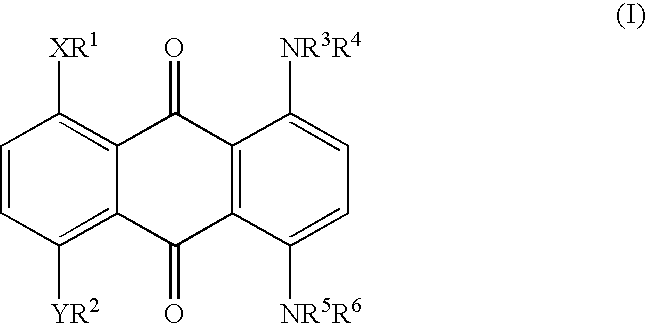

InactiveUS20060157248A1Ease and flexibility for subsequent completion processEasy to processInsulationLiquid/gas jet drillingPolyvinyl alcoholDissolution

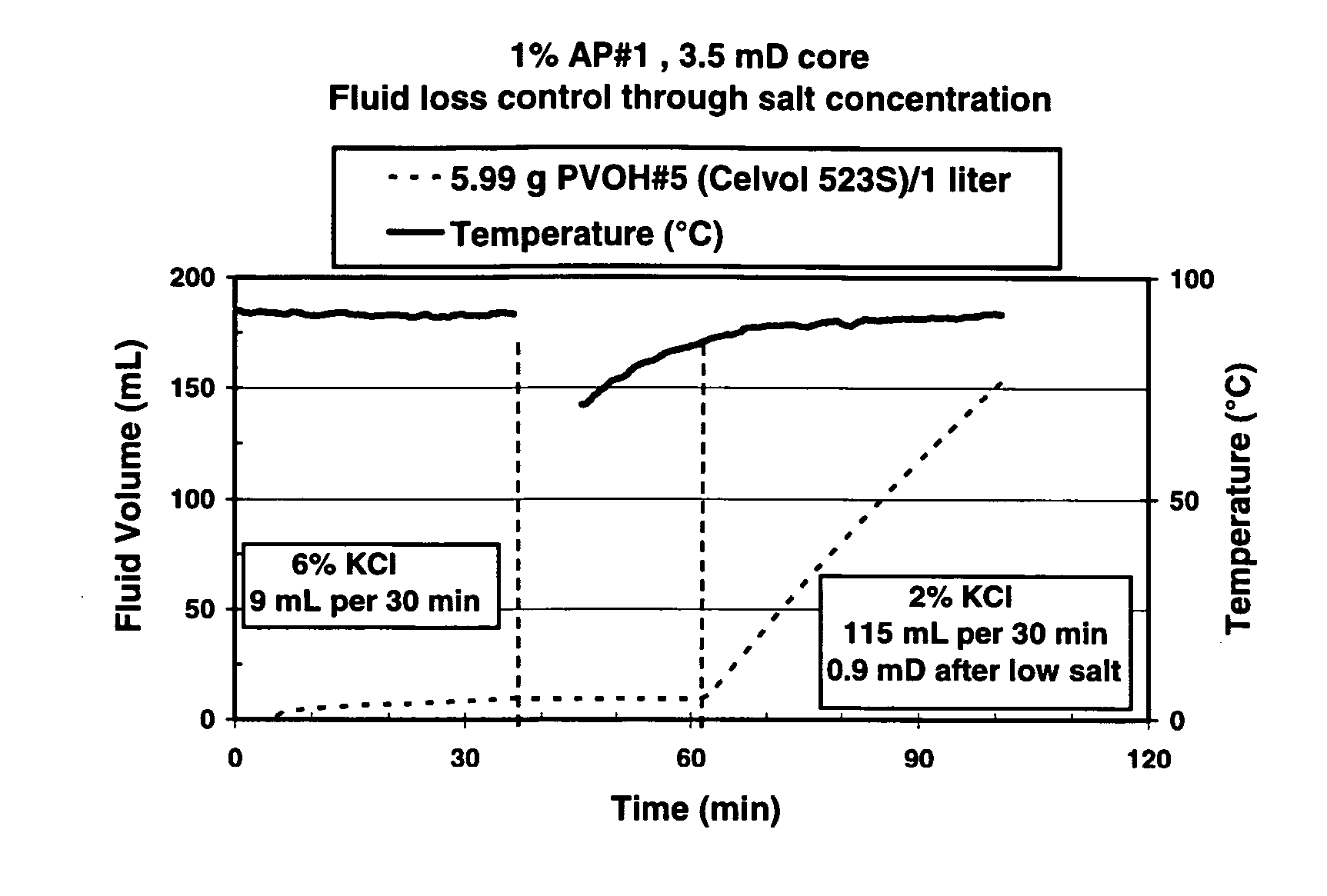

Well treatment is disclosed that includes injecting a well treatment fluid with insoluble polyol polymer such as polyvinyl alcohol (PVOH) dispersed therein, depositing the insoluble polymer in the wellbore or an adjacent formation, and thereafter dissolving the polymer by reducing salinity and / or increasing temperature conditions in the environment of the polymer deposit. The method is disclosed for filter cake formation, fluid loss control, drilling, hydraulic fracturing and fiber assisted transport, where removal of the polyol at the end of treatment or after treatment is desired. The method is also disclosed for providing dissolved polyol as a delayed breaker in crosslinked polymer viscosified systems and viscoelastic surfactant systems. Also disclosed are well treatment fluids containing insoluble amorphous or at least partially crystalline polyol, and a PVOH fiber composition wherein the fibers are stabilized from dissolution by salinity.

Owner:SCHLUMBERGER TECH CORP

Method for marking hydrocarbons with substituted anthraquinones

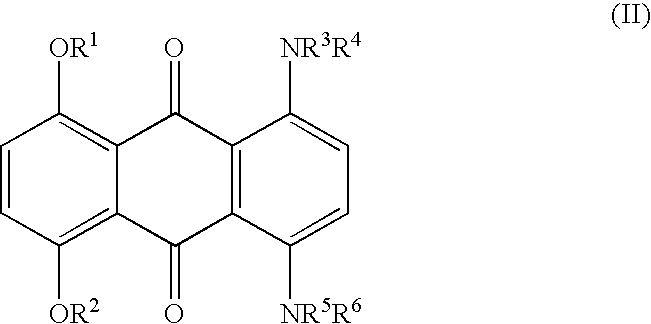

ActiveUS20040250469A1Lower levelFacilitates quantitative spectrophotometric determinationEarth material testingLiquid carbonaceous fuelsArylAnthranil

A method for marking a liquid petroleum hydrocarbon. The method comprises adding to the liquid petroleum hydrocarbon at least one substituted anthraquinone dry having formula (I) wherein X is O or S; Y is O, NR<7 >or S; R<1 >and R<2 >independently are hydrogen, alkyl, aryl, aralkyl, heteroalkyl, heterocyclic or alkanoyl; R<3 >and R<5 >independently are alkyl, aryl, aralkyl, heteroalkyl or heterocyclic; R<4 >and R<6 >independently are hydrogen or alkyl; R<7 >is hydrogen or alkyl; and wherein the substituted anthraquinone dye(s) has an absorption maximum in the range from 600 nm to 750 nm.

Owner:ROHM & HAAS CO

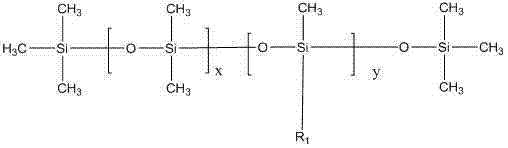

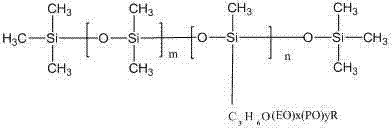

Organopolysiloxanes for defoaming aqueous systems

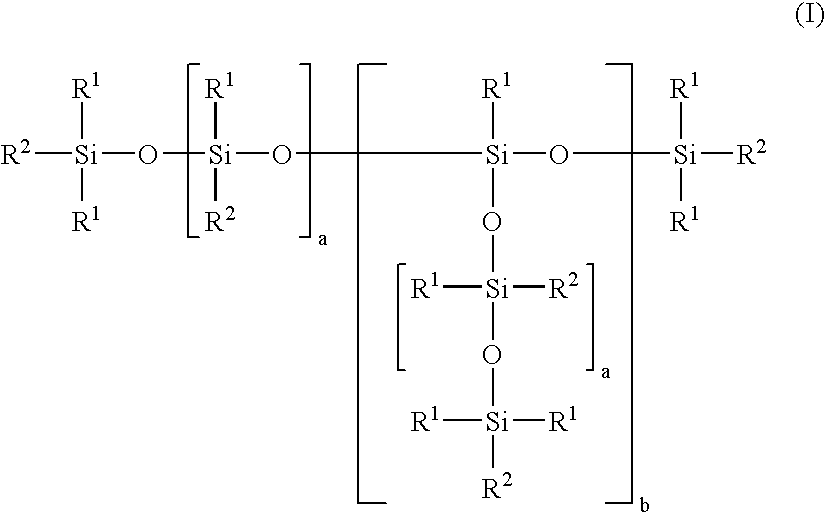

InactiveUS6858663B2Improve balanceRapid foam collapseGroup 4/14 element organic compoundsOther chemical processesWater insolublePrinting ink

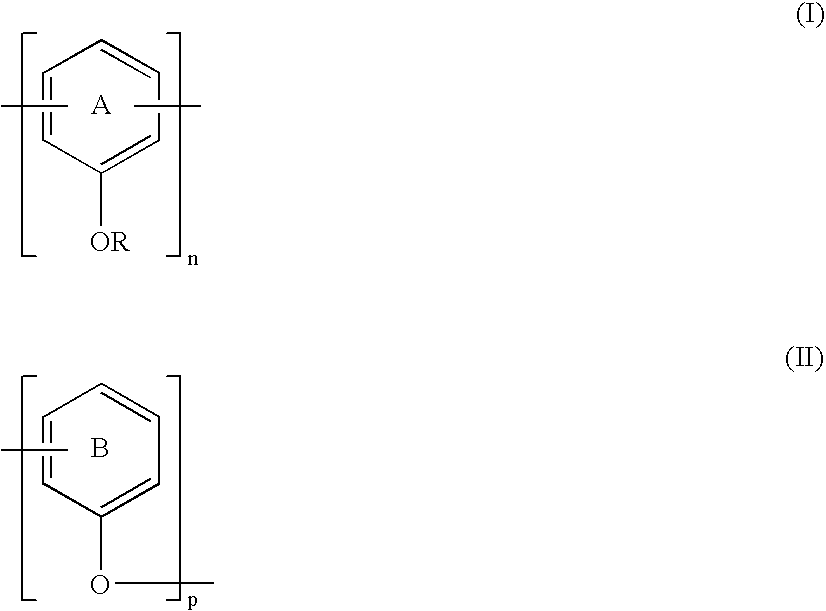

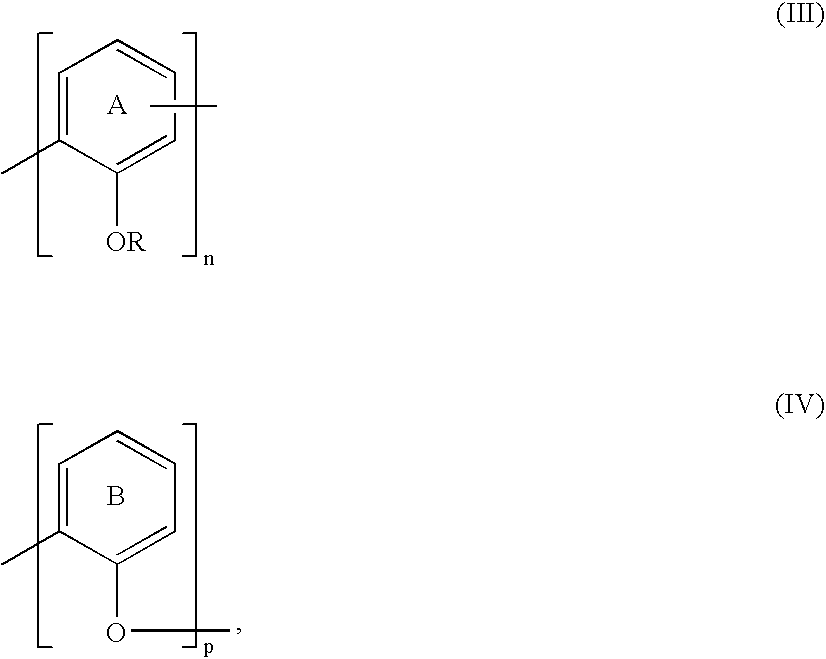

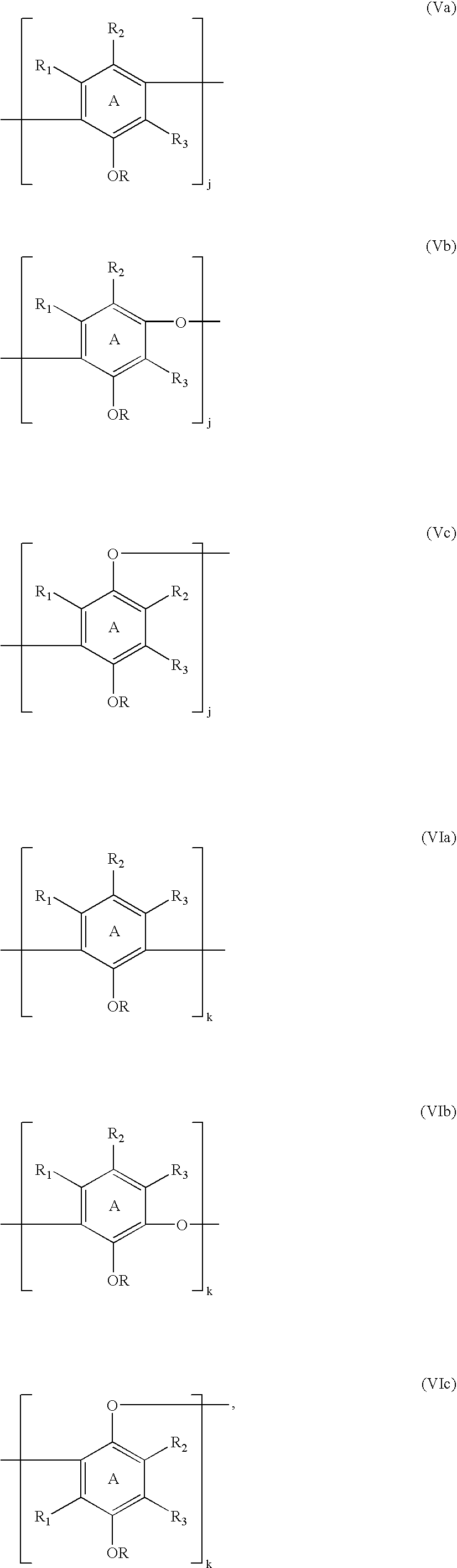

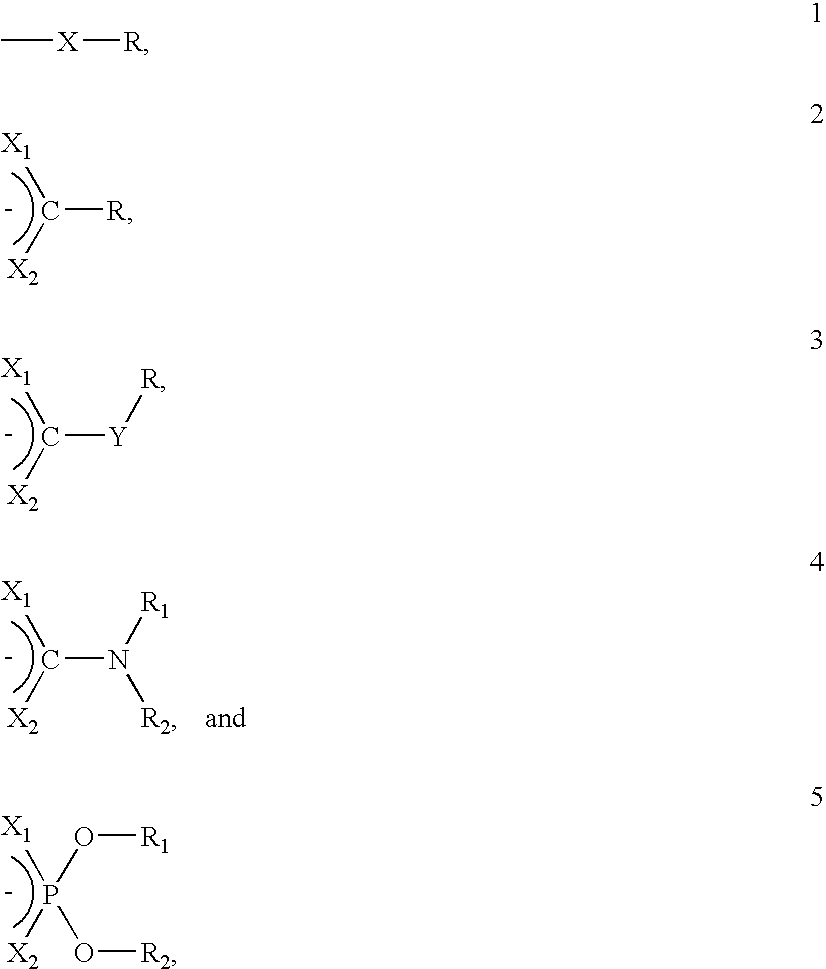

The invention relates to the use of water-insoluble organopolysiloxane derivatives of the general formula (I) in which the radicalsR1 are alkyl radicals, preferably having 1 to 4 carbon atoms or aryl radicals, but at least 80% of the radicals R1 are methyl radicals, andR2 at least once in the molecule has the definition (a) for defoaming aqueous media, especially printing inks and paints.

Owner:EVONIK DEGUSSA GMBH

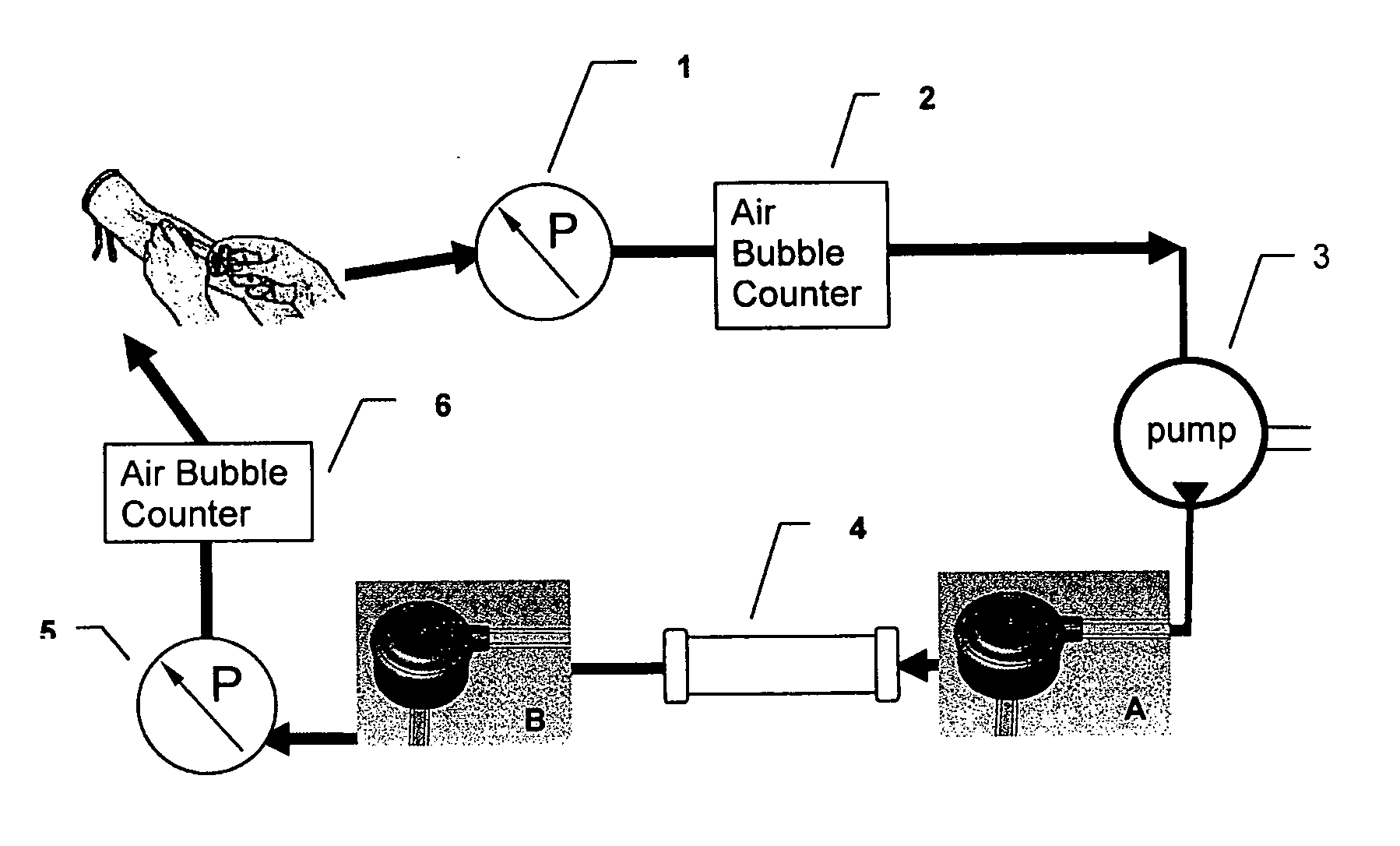

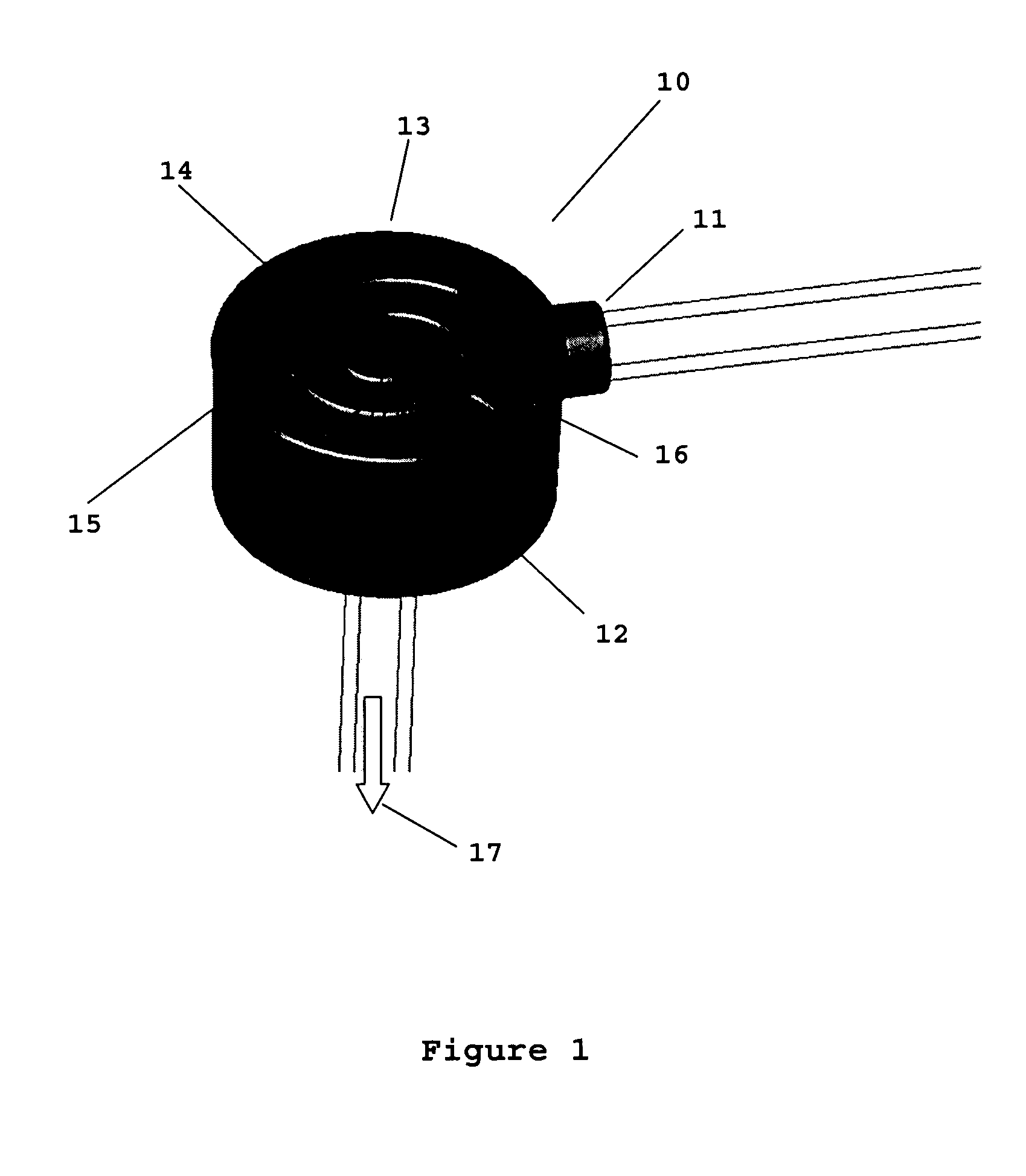

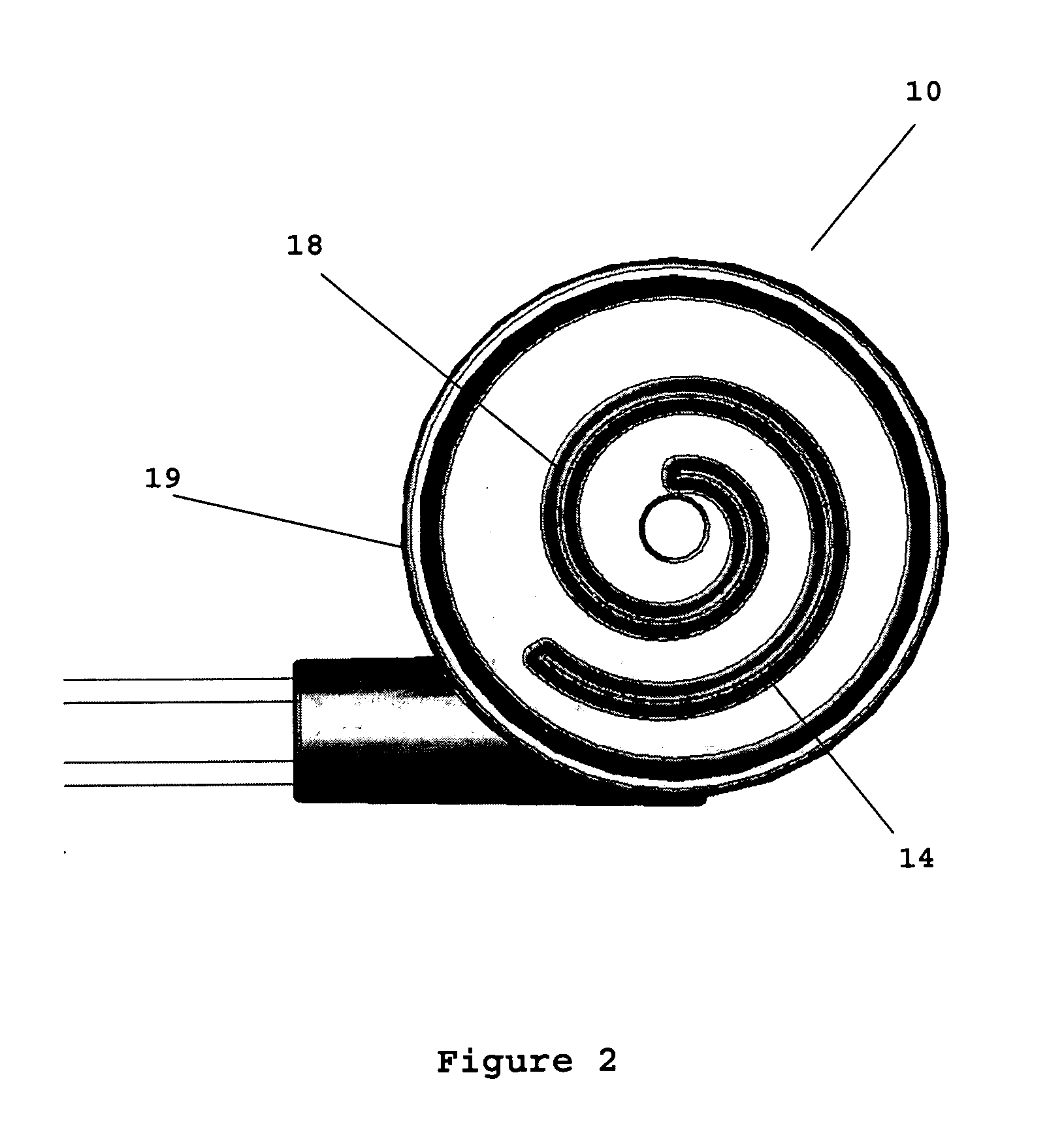

Degassing device

ActiveUS20110092875A1Maximize advantageReduced effectivenessDialysis systemsMedical devicesHaemodialysis machineEngineering

Owner:GAMBRO LUNDIA AB

Lubricating oil

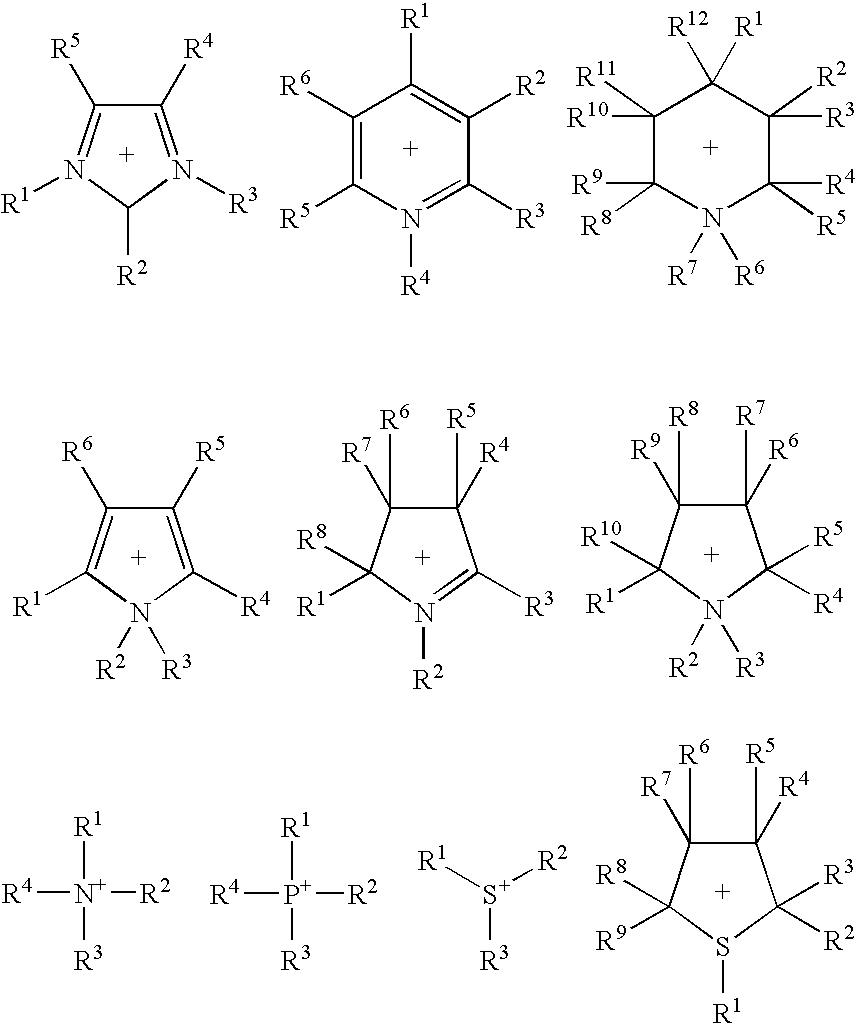

InactiveUS20070027038A1Low vapor pressureImprove heat resistanceOrganic chemistryProtective coatings for layersHeat resistanceBase oil

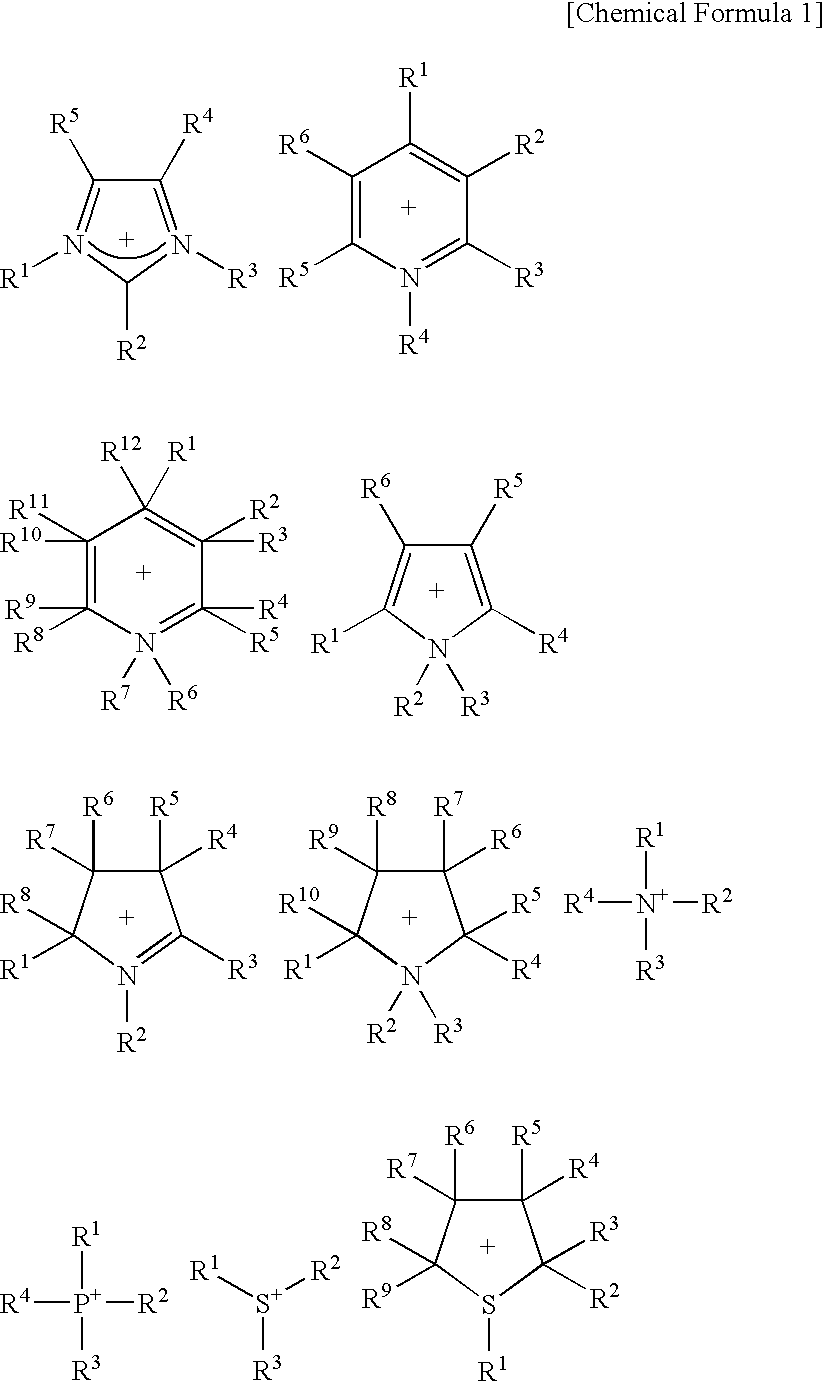

The invention provides a lube oil which exhibits low vapor pressure despite having low viscosity, is non-flammable, exhibits excellent heat resistance, has tribological characteristics equivalent to those of conventional hydrocarbon-based lube oils, and can be used for a long time under very severe conditions such as high temperature and vacuum. The lube oil contains, as a base oil, an ionic liquid formed of a cation and an anion and having an ion concentration of 1 mol / dm3 or more.

Owner:IDEMITSU KOSAN CO LTD +1

Bacteria-based and enzyme-based mechanisms and products for viscosity reduction breaking of viscoelastic fluids

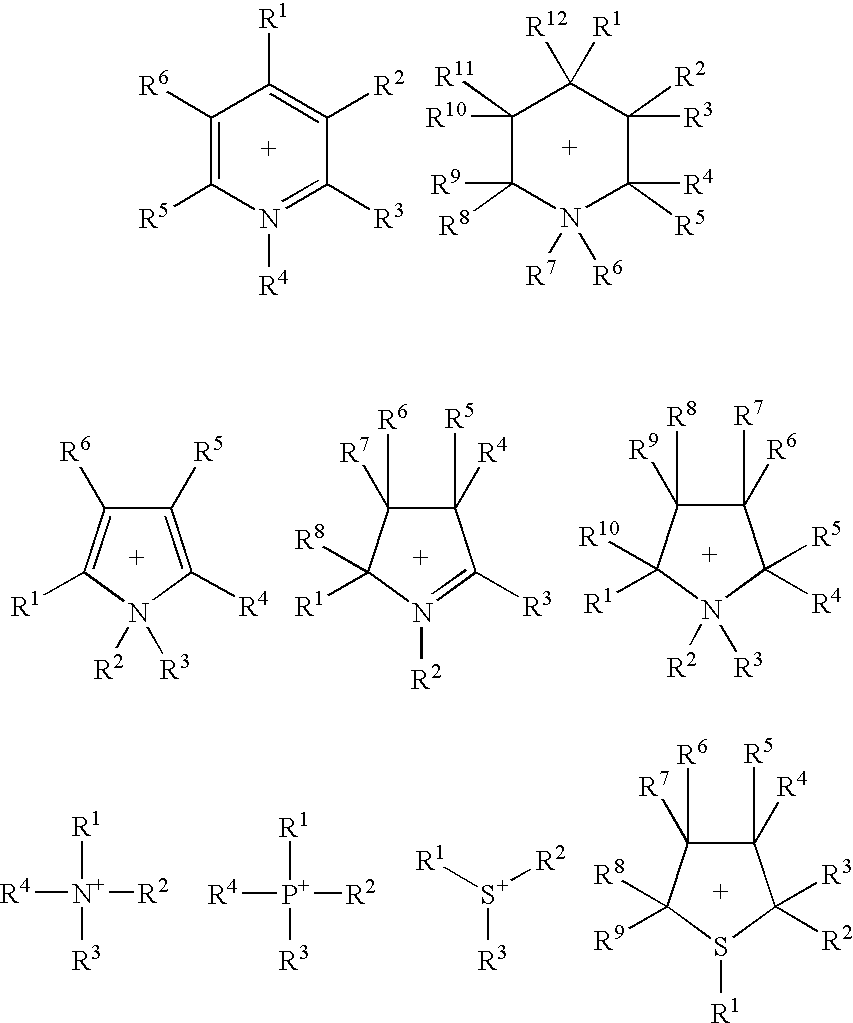

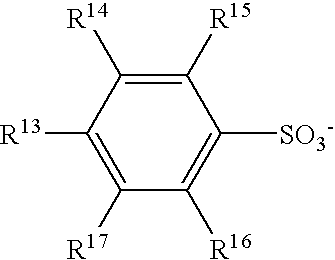

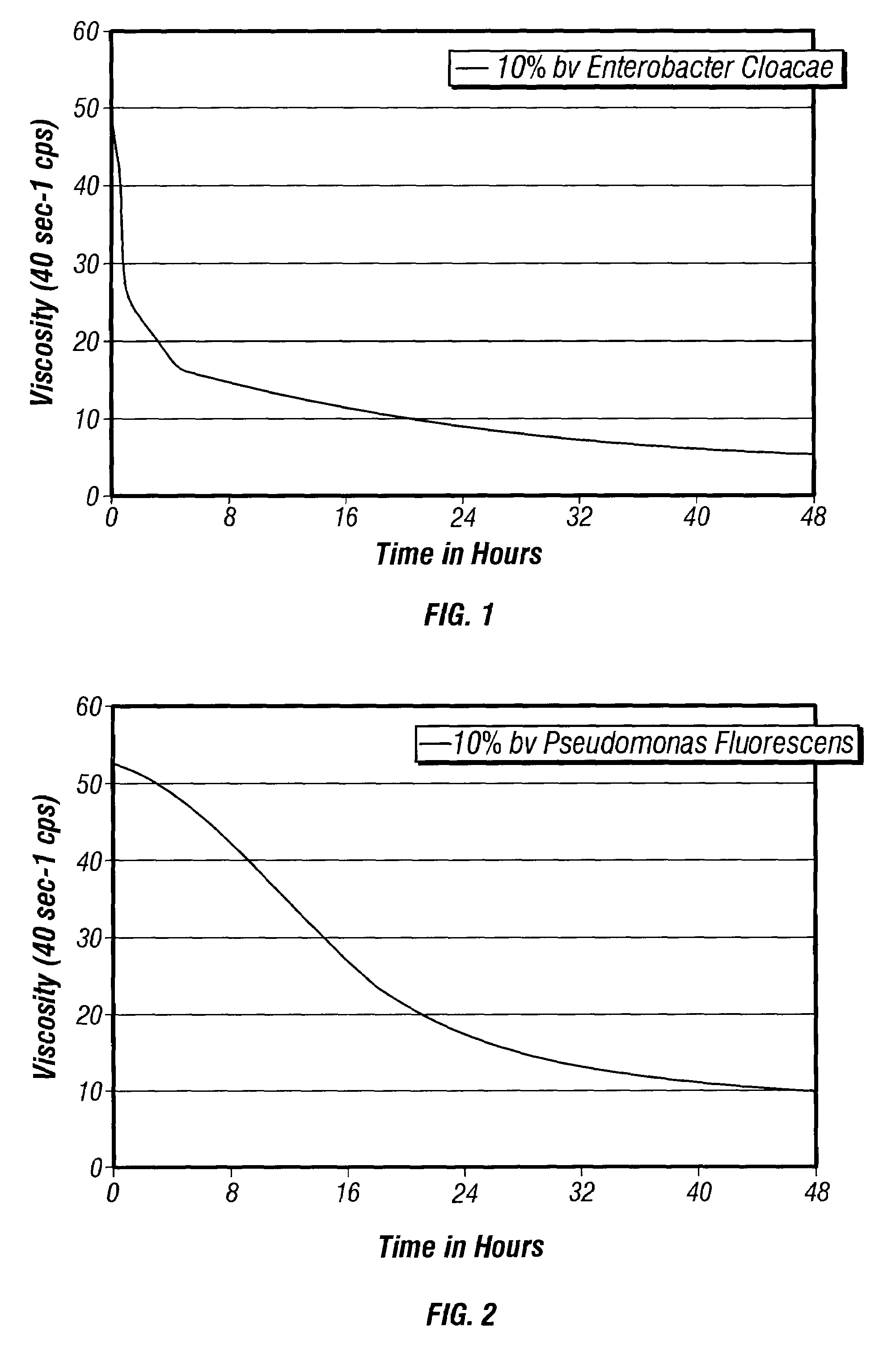

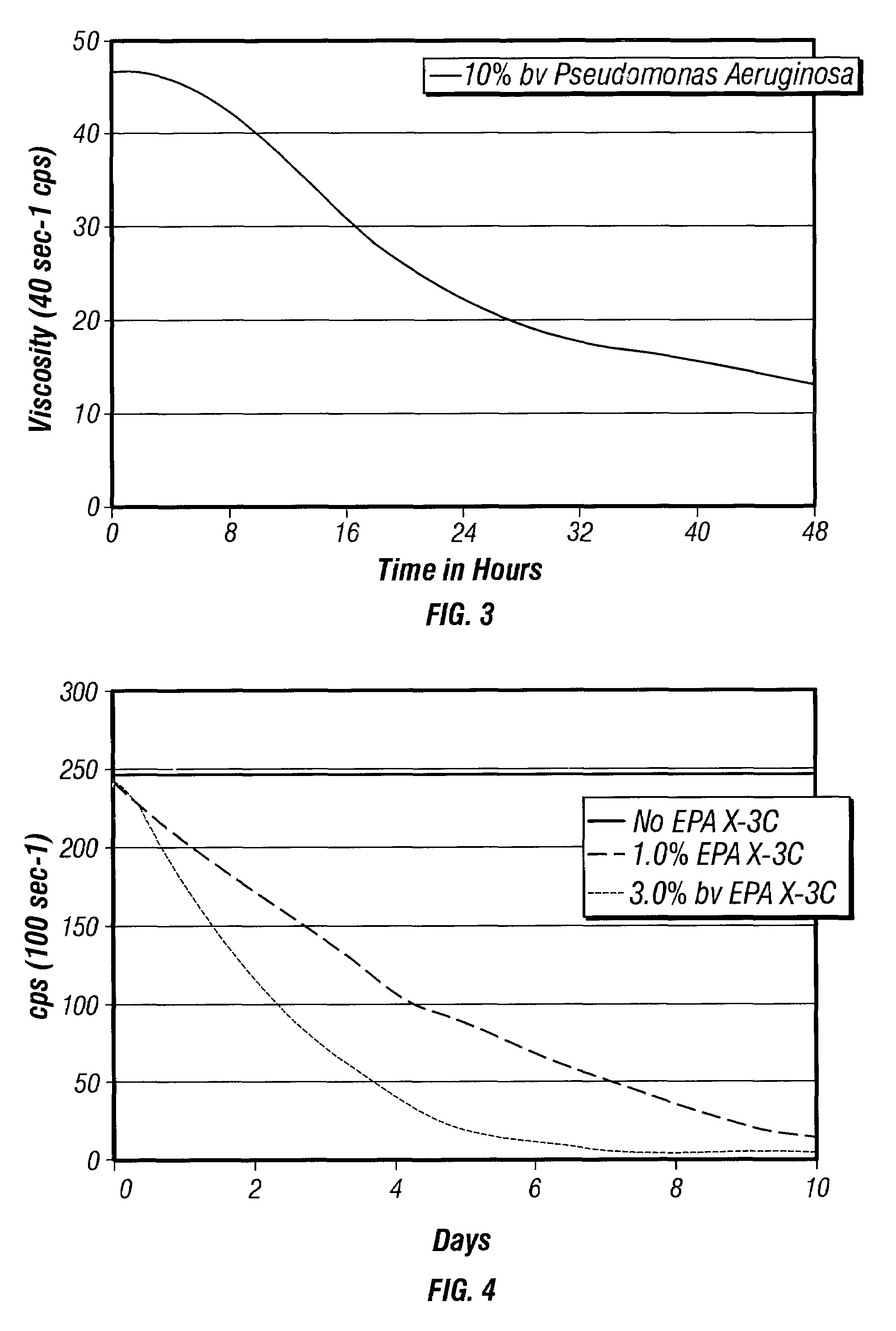

ActiveUS7052901B2Low viscosityBreak viscosityDeodrantsFlushingIndirect actionPseudomonas fluorescens

It has been discovered that fluids viscosified with viscoelastic surfactants (VESs) may have their viscosities reduced (gels broken) by the direct or indirect action of a biochemical agent, such as bacteria, fungi, and / or enzymes. The biochemical agent may directly attack the VES itself, or some other component in the fluid that produces a by-product that then causes viscosity reduction. The biochemical agent may disaggregate or otherwise attack the micellar structure of the VES-gelled fluid. The biochemical agent may produce an enzyme that reduces viscosity by one of these mechanisms. A single biochemical agent may operate simultaneously by two different mechanisms, such as by degrading the VES directly, as well as another component, such as a glycol, the latter mechanism in turn producing a by-product (e.g. an alcohol) that causes viscosity reduction. Alternatively, two or more different biochemical agents may be used simultaneously. In a specific, non-limiting instance, a brine fluid gelled with an amine oxide surfactant can have its viscosity broken with bacteria such as Enterobacter cloacae, Pseudomonas fluorescens, Pseudomonas aeruginosa, and the like.

Owner:BAKER HUGHES INC

Well treatment with dissolvable polymer

InactiveUS7398826B2Easy to processRestore permeabilityInsulationLiquid/gas jet drillingPolyvinyl alcoholDissolution

Well treatment is disclosed that includes injecting a well treatment fluid with insoluble polyol polymer such as polyvinyl alcohol (PVOH) dispersed therein, depositing the insoluble polymer in the wellbore or an adjacent formation, and thereafter dissolving the polymer by reducing salinity and / or increasing temperature conditions in the environment of the polymer deposit. The method is disclosed for filter cake formation, fluid loss control, drilling, hydraulic fracturing and fiber assisted transport, where removal of the polyol at the end of treatment or after treatment is desired. The method is also disclosed for providing dissolved polyol as a delayed breaker in crosslinked polymer viscosified systems and viscoelastic surfactant systems. Also disclosed are well treatment fluids containing insoluble amorphous or at least partially crystalline polyol, and a PVOH fiber composition wherein the fibers are stabilized from dissolution by salinity.

Owner:SCHLUMBERGER TECH CORP

Dispersant and foaming agent combination

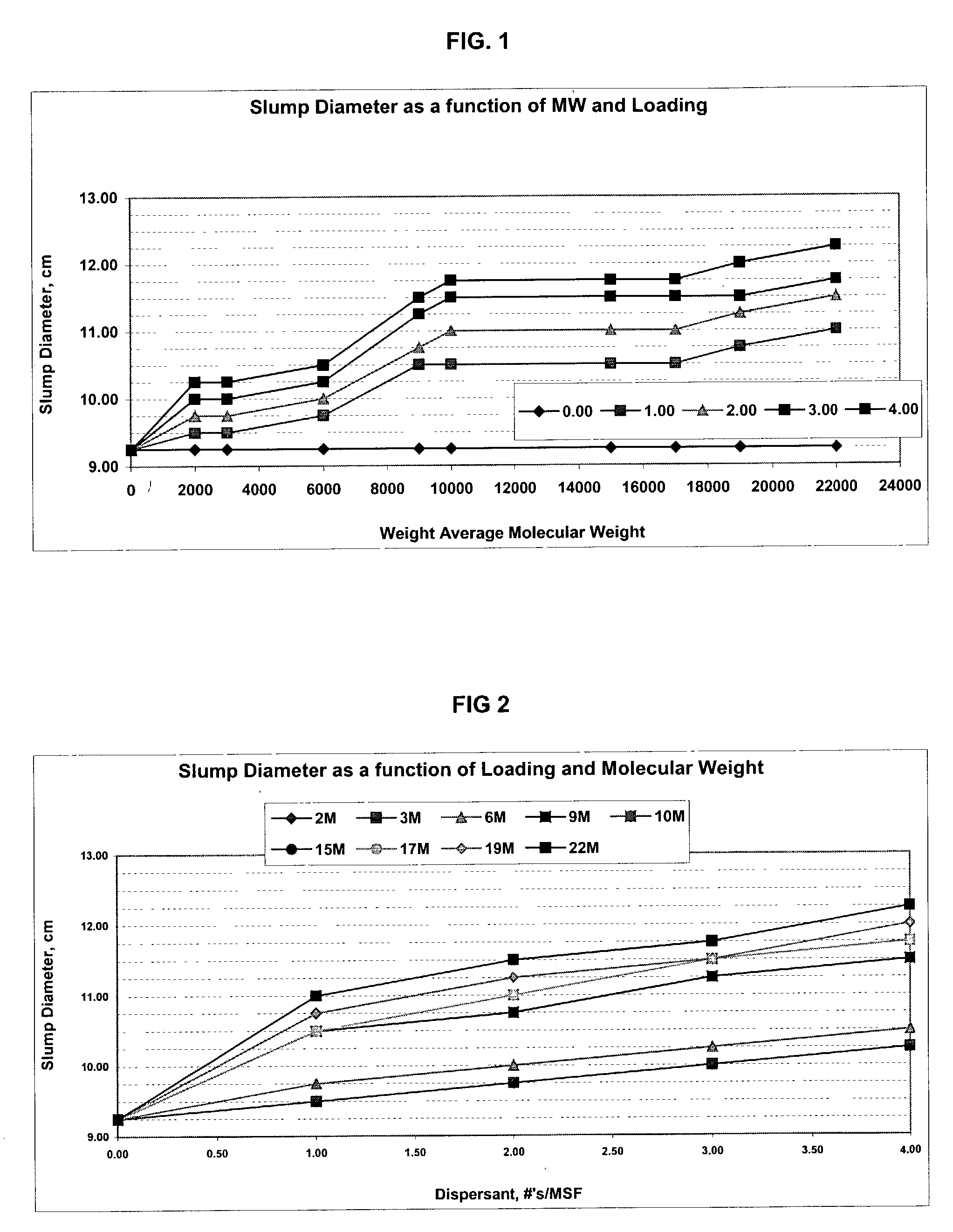

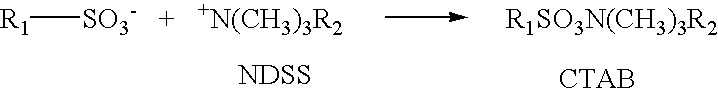

InactiveUS20040028956A1Low densityReduce weightConstruction materialOther chemical processesAlkaline earth metalAir entrainment

The present invention provides a dispersant and foaming agent combination that is useful in the production of gypsum wallboard and other aqueous cementitious products, a method of forming a gypsum wallboard and a gypsum wallboard. The dispersant in the combination according to the invention is a naphthalene sulfonate-aldehyde condensate alkali salt polymer having a weight average molecular weight of from about 17,000 to about 47,000. The alkali is preferably an alkali metal and / or an alkaline earth metal. The aldehyde is preferably formaldehyde. The foaming agent used in the combination according to the invention is a soap, preferably an alkali salt of an alkyl ether sulfate and / or an alkyl sulfate. The combination of a high molecular weight dispersant and a foaming agent produces a gypsum wallboard core effect that more efficiently entrains air (i.e., creates void space), thereby lowering overall board weight without detrimentally affecting strength. A gypsum wallboard formed using the dispersant and foaming agent combination according to the invention exhibits a higher nail pull value than gypsum wallboard formed using a conventional dispersant and a foaming agent at the same solids loading ratio.

Owner:GEO SPECIALTY CHEM

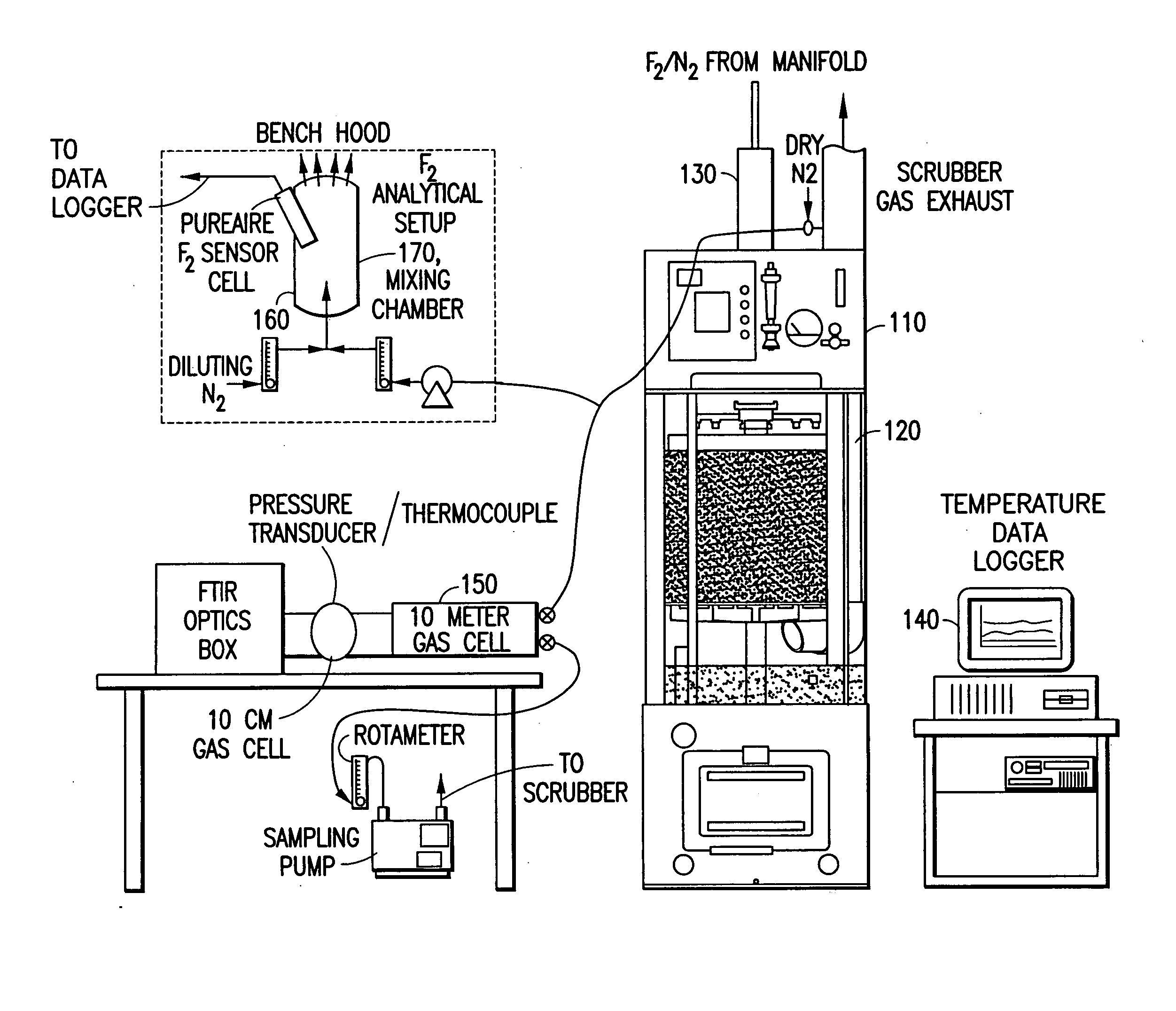

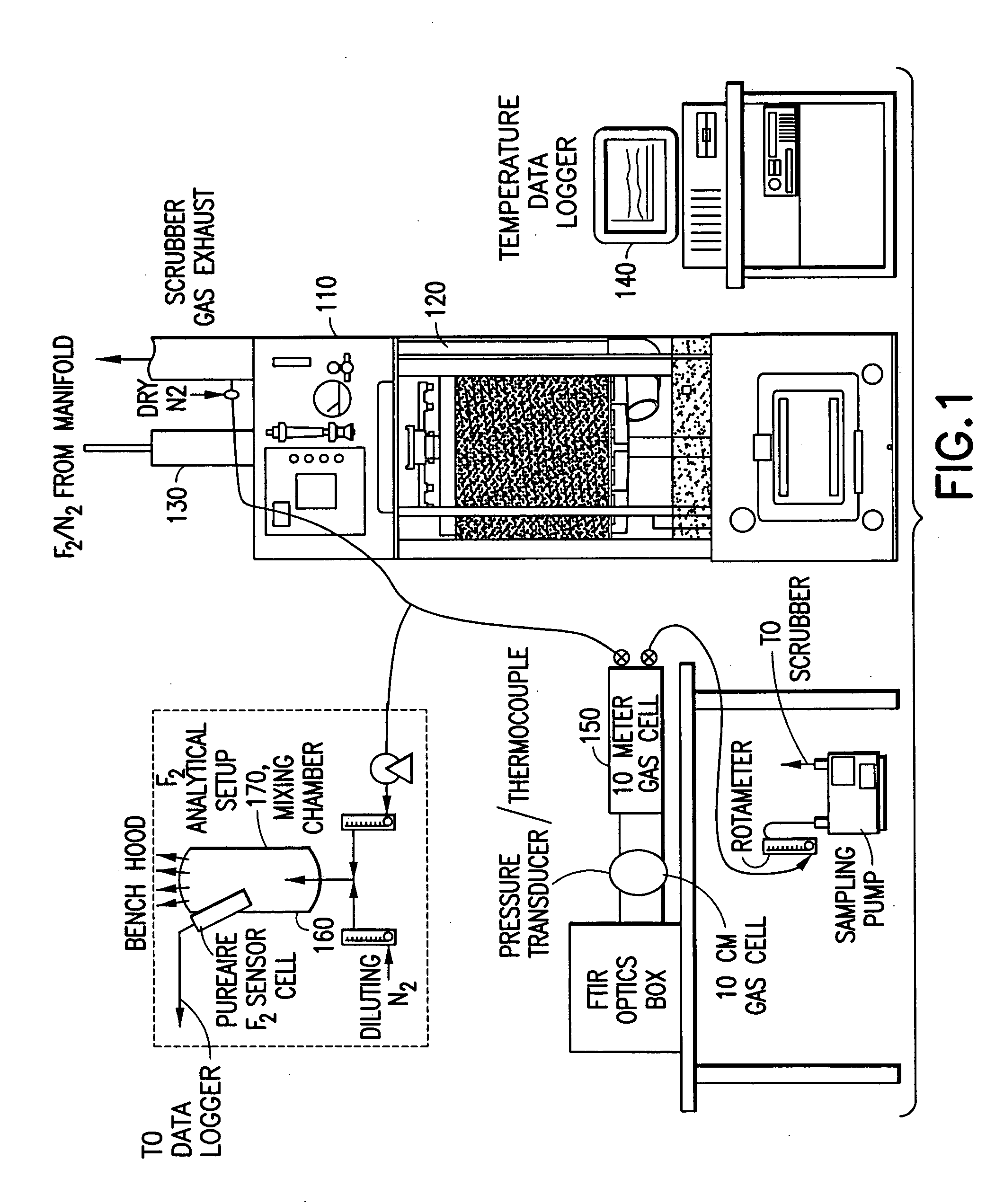

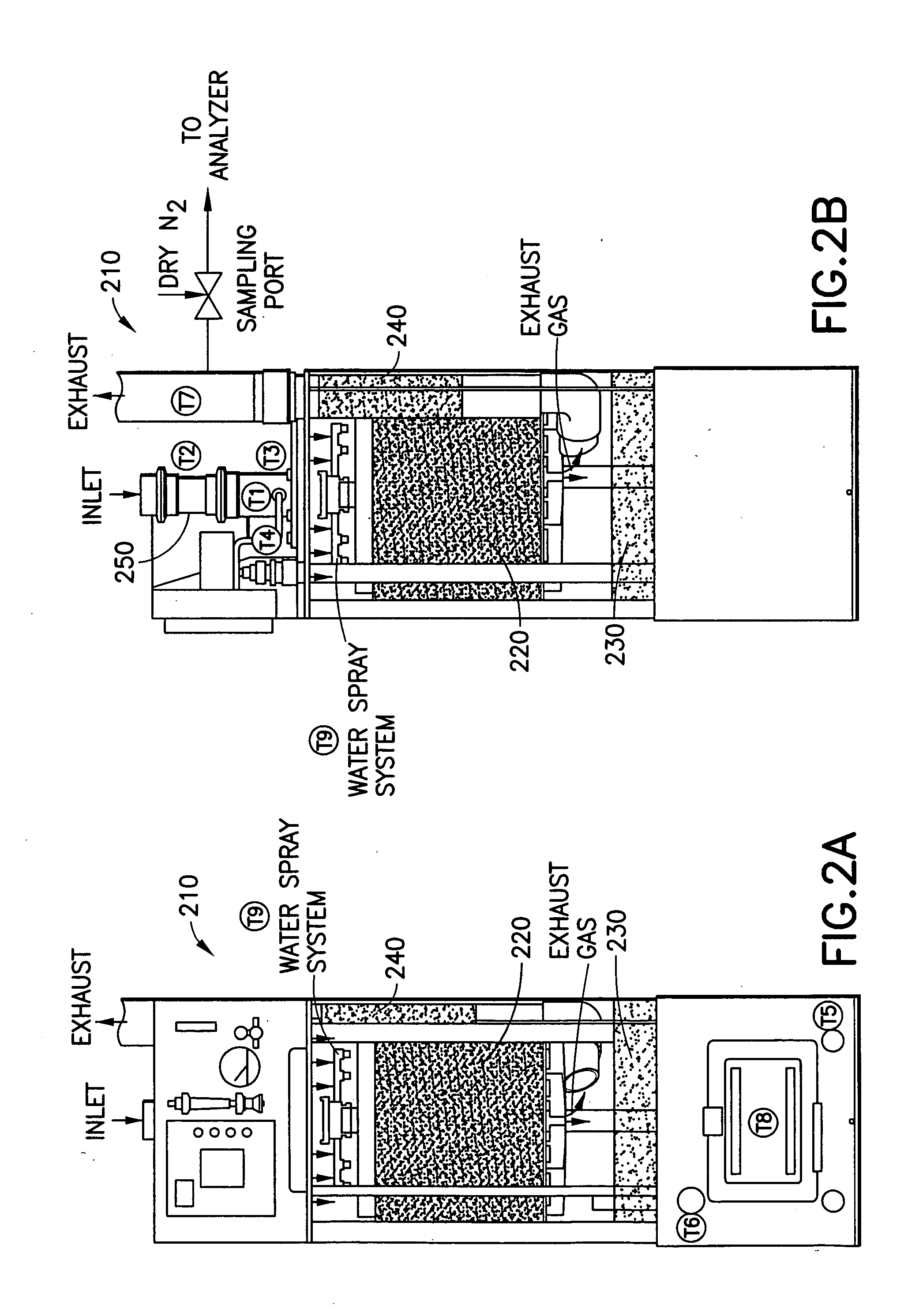

Apparatus and method for point-of-use treatment of effluent gas streams

InactiveUS20040213721A1Highly efficient mannerReduce foaming in the scrubbing systemProcess control/regulationHydrogenSilanesChlorofluorocarbon

A system for abating undesired component(s) from a gas stream containing same, such as halocompounds, acid gases, silanes, ammonia, etc., by scrubbing of the effluent gas stream with an aqueous scrubbing medium. Halocompounds, such as fluorine, fluorides, perfluorocarbons, and chlorofluorocarbons, may be scrubbed in the presence of a reducing agent, e.g., sodium thiosulfate, ammonium hydroxide, or potassium iodide. In one embodiment, the scrubbing system includes a first acid gas scrubbing unit operated in cocurrent gas / liquid flow, and a second "polishing" unit operated in countercurrent gas / liquid flow, to achieve high removal efficiency with low consumption of water. The scrubbing system may utilize removable insert beds of packing material, packaged in a foraminous containment structure. The abatement system of the invention has particular utility in the treatment of semiconductor manufacturing process effluents.

Owner:APPLIED MATERIALS INC

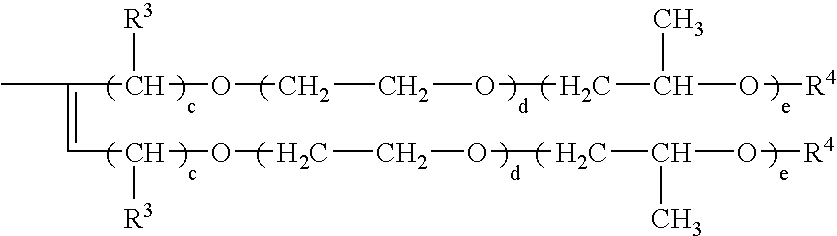

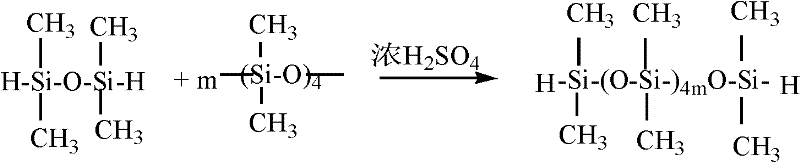

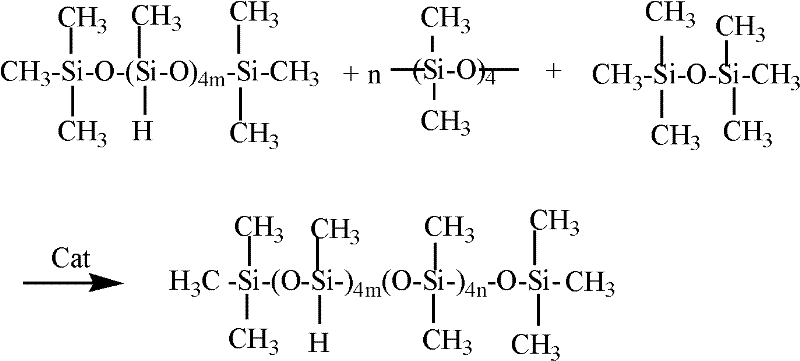

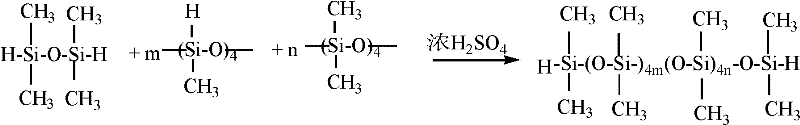

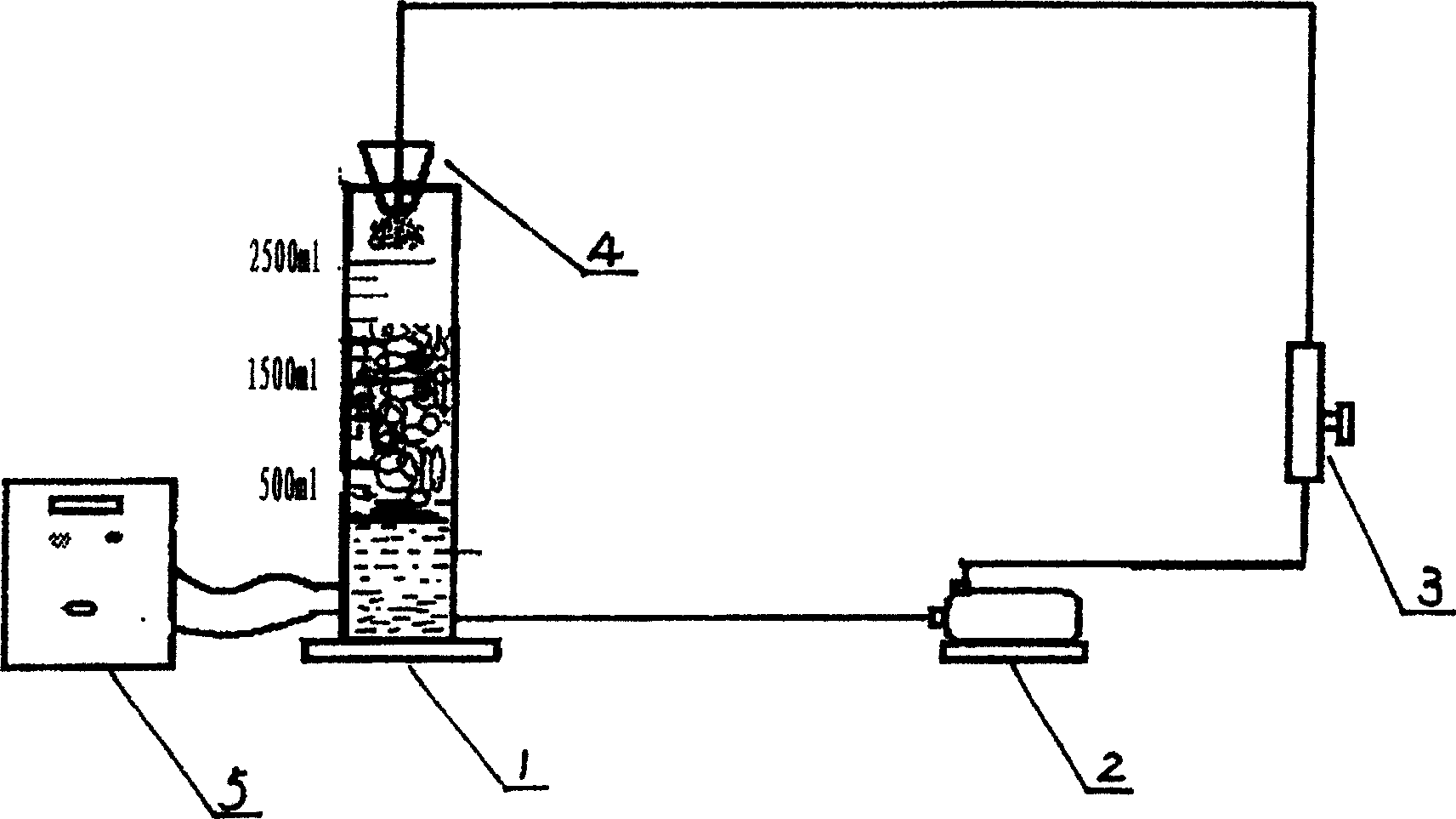

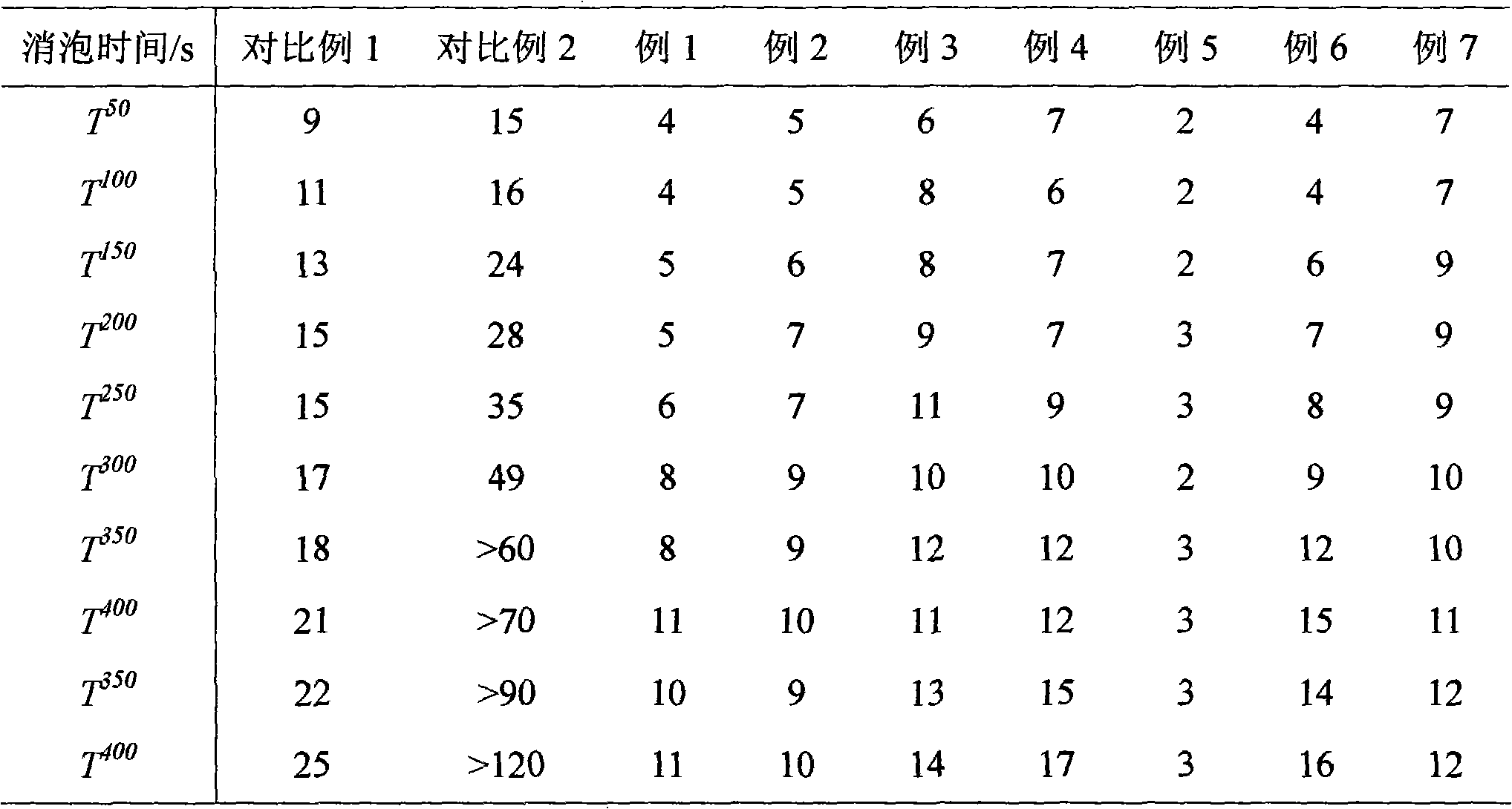

A kind of water-soluble polyether modified silicone defoamer and its preparation and compounding method

The invention relates to a water-soluble polyether modified silicone defoamer. The preparation method of the polyether-modified silicone defoamer comprises the following steps: firstly, adding terminal allyl polyoxyalkylene ether into a container for stirring, removing water; then adding solvent and low hydrogen-containing silicone oil into the above solution and stirring; then The catalyst is added to carry out stirring and heating reaction under N2 atmosphere and reflux condensation conditions; after the reaction is completed, the solvent and low boilers are removed to obtain the water-soluble polyether modified silicone. The invention also provides a compounding method of the water-soluble polyether modified silicone defoamer prepared by the above preparation method. The defoaming agent solves the problems that polysiloxanes are difficult to dissolve in water, have poor high temperature resistance and strong alkali resistance, and polyether defoaming agents have unsatisfactory defoaming speed and foam suppression time. The compounding method of water-soluble polyether-modified silicone defoamer solves the problems of incomplete emulsification of simethicone-type defoamer, demulsification when used, low temperature resistance and poor foam suppression ability.

Owner:黄山市强力化工有限公司

Prepn process of active defoaming agent composition

The present invention is one kind of active defoaming composition suitable for eliminating harmful foams under high temperature and strong alkaline condition in high efficiency, and may be used in washing paper pulp, treating metal surface and other fields. The active defoaming composition is prepared with organic siloxane, silicone resin, inorganic oxide particle, hydrophobic treating agent, catalyst and other material. The preparation process includes the following steps: 1. mixing organic siloxane, silicone resin and catalyst, and heating the mixture to 80-200 deg.c for controllable polymerization; 2. adding inorganic oxide particle and hydrophobic treating agent; and 3. further heating to reaction at 80-200 deg.c temperature and 0.01-0.08 MPa vacuum for 2-10 hr, and cooling to room temperature to obtain white polymer as the active defoaming composition.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Lubricant oil compositions

InactiveUS20070161522A1Extended shelf lifeImprove performanceLiquid carbonaceous fuelsAdditivesAntioxidantLubricant

Compositions comprise first antioxidants and first additives, such as, a surface additives, performance enhancing additives and lubricant protective additives and optionally second additives and / or second antioxidants. The compositions are useful to improve lubricants, lubricant oils and other lubricant materials. The compositions and methods generally provide longer shelf lives, increased oxidative resistance, improved quality and / or enhanced performance to lubricants or lubricant oils.

Owner:POLNOX CORP

Lubricating oil compositions

Lubricating oil compositions having a sulfated ash content of no more than 1.0 mass %, which contain a major amount of oil of lubricating viscosity, a minor amount of calcium salicylate detergent, an amount of a magnesium-based detergent providing at least 200 ppm of magnesium, and a basic, low molecular weight, nitrogen-containing dispersant, which compositions provide improved top ring wear protection in internal combustion engines.

Owner:INFINEUM INT LTD

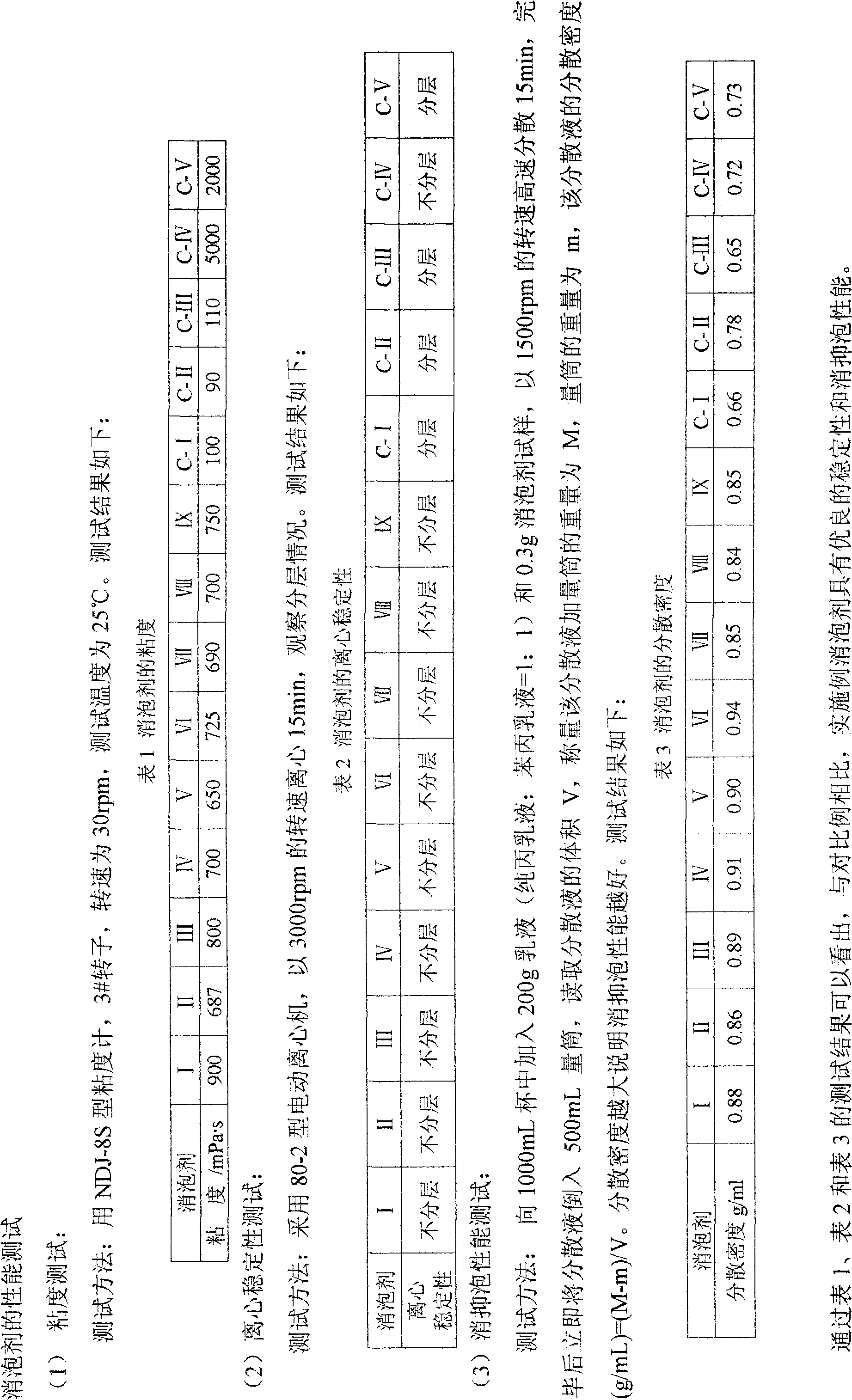

Mineral oil defoaming agent and preparation method thereof

ActiveCN101991975AImprove performanceGood defoaming performanceFoam dispersion/preventionBlack liquorSewage

The invention provides a mineral oil defoaming agent comprising mineral oil, a fatty acid metal soap, fatty acid amide, white carbon black, a defoaming auxiliary agent and an emulsifying agent. The invention has the technical scheme that the fatty acid metal soap, the fatty acid amide and the white carbon black are simultaneously selected as defoaming substances and a method mixing the defoaming substances into the mineral oil is changed, thus the stability and the foam removing and depressing properties of the mineral oil defoaming agent are improved. The mineral oil defoaming agent has better foam removing and depressing effects in the processes of papermaking black liquor, coating, sewage treatment, latex, cleaning, and the like.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

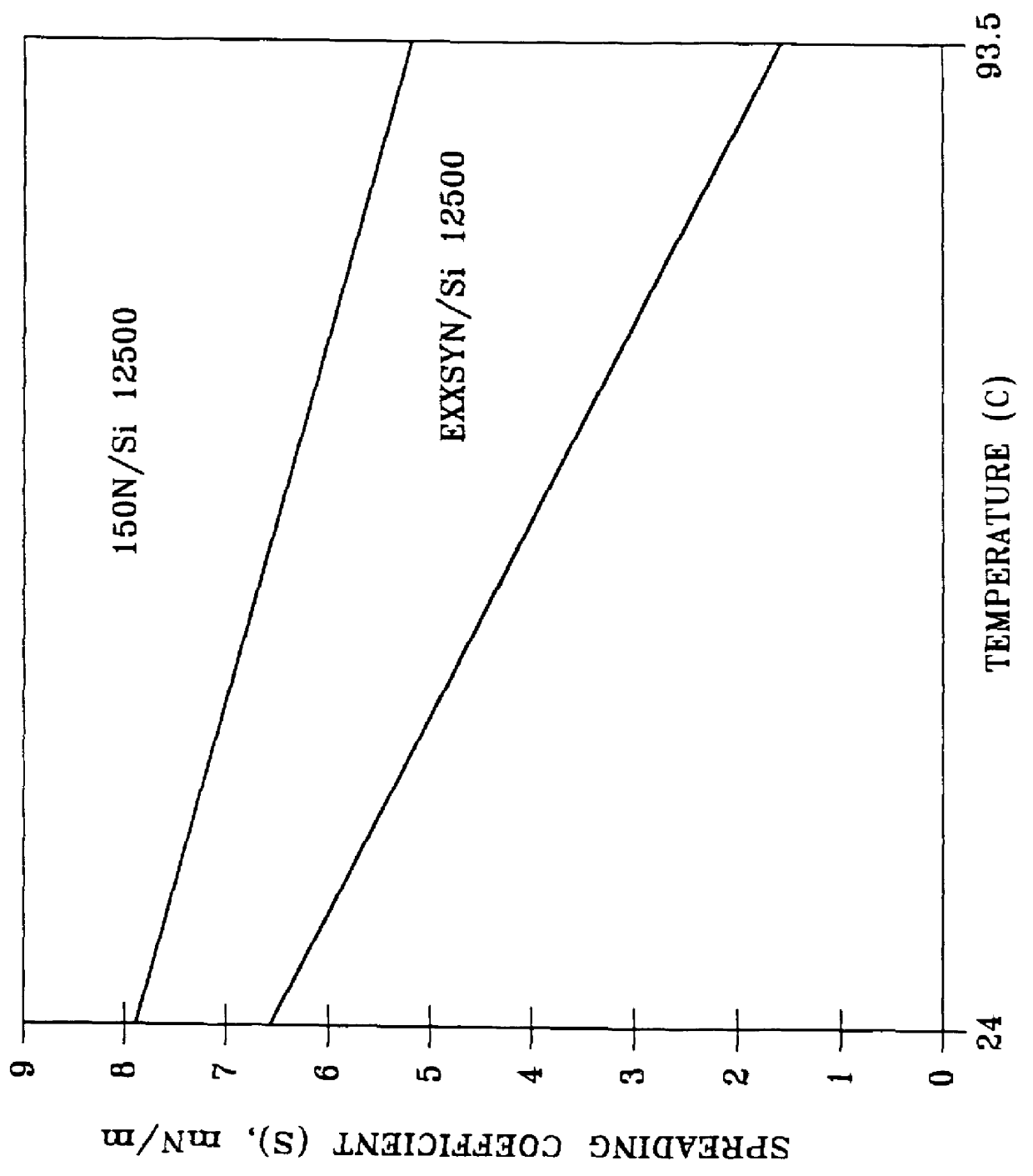

Method for reducing foaming of lubricating oils

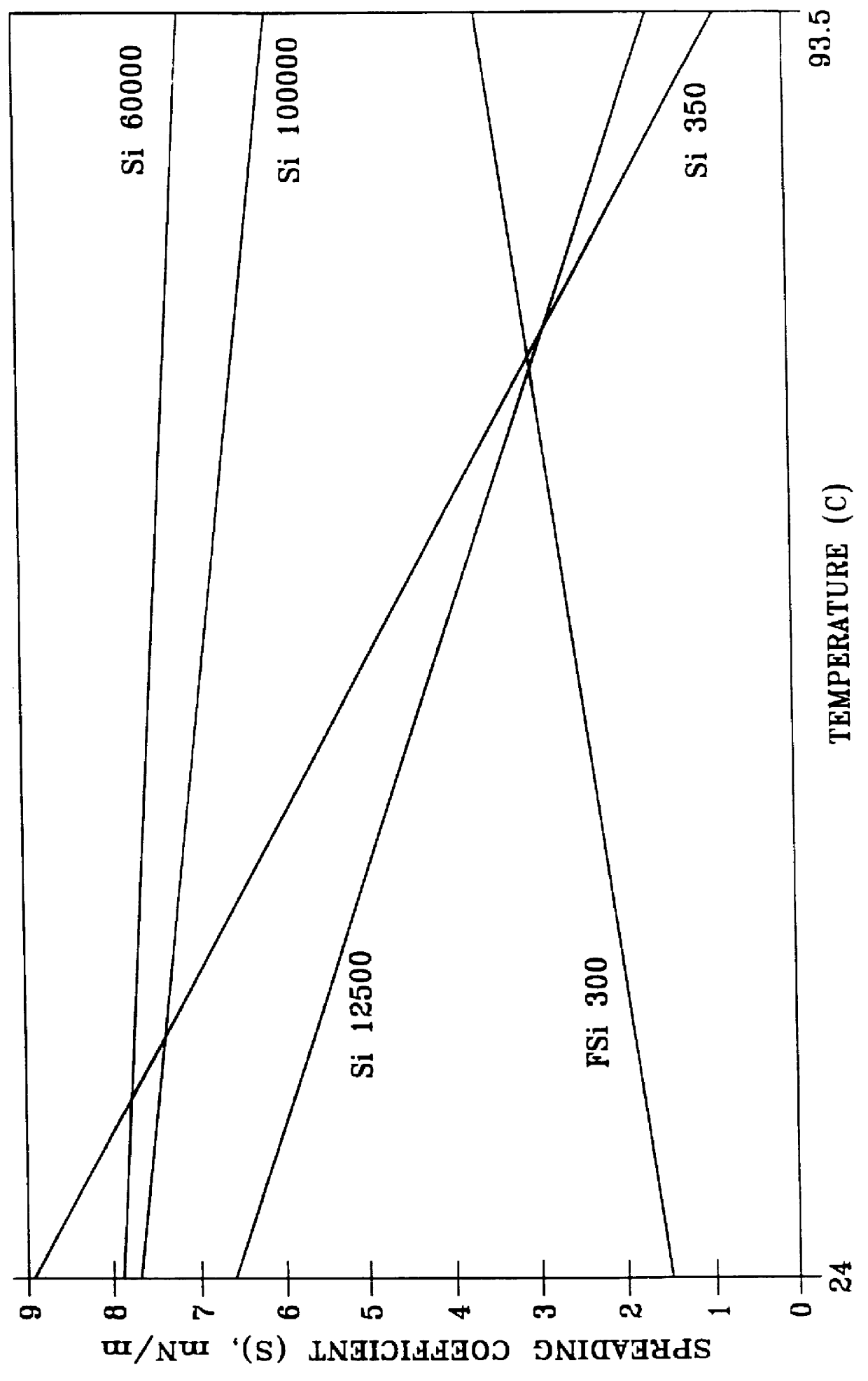

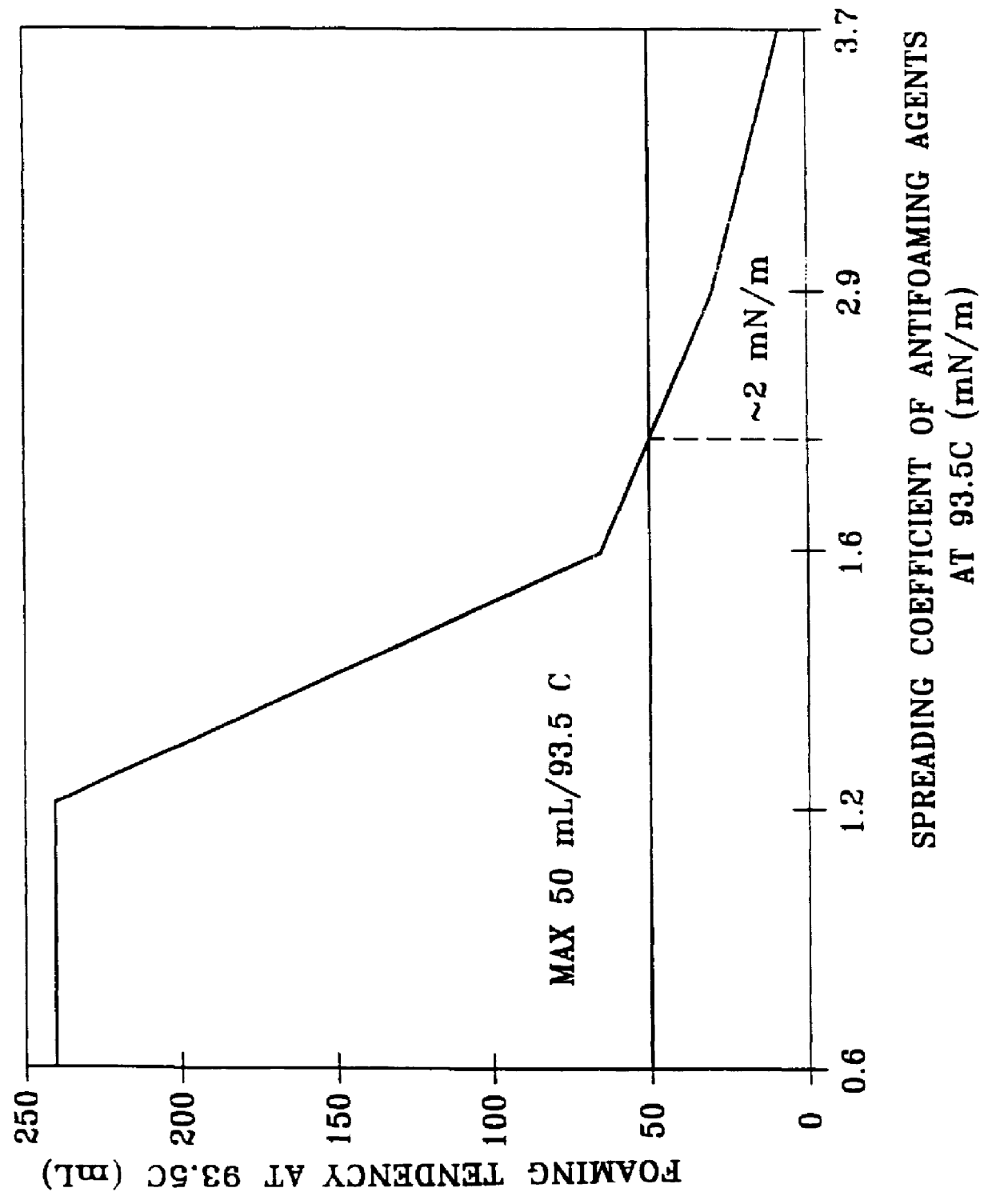

Foaming of a lube oil comprising a base stock derived from wax isomeration and an additive package is effectively reduced to within specification limits of 50 ml / ml over a temperature range of from at least 24 DEG C. to 93.5 DEG C. by adding to the oil an effective amount of an antifoamant exhibiting a spreading coefficient of at least about 2 mN / m. This has been found to be particularly effective in reducing foaming of lube oils containing a mixture of a wax isomerate oil and a petroleum oil fraction. Antifoamants typically used with conventional lube oils containing one or more petroleum fraction base stocks, but which do not exhibit a spreading coefficient of at least 2 mN / m with the wax isomerate containing oil, have been found not to be effective in reducing the foaming of the oil.

Owner:EXXON RES & ENG CO

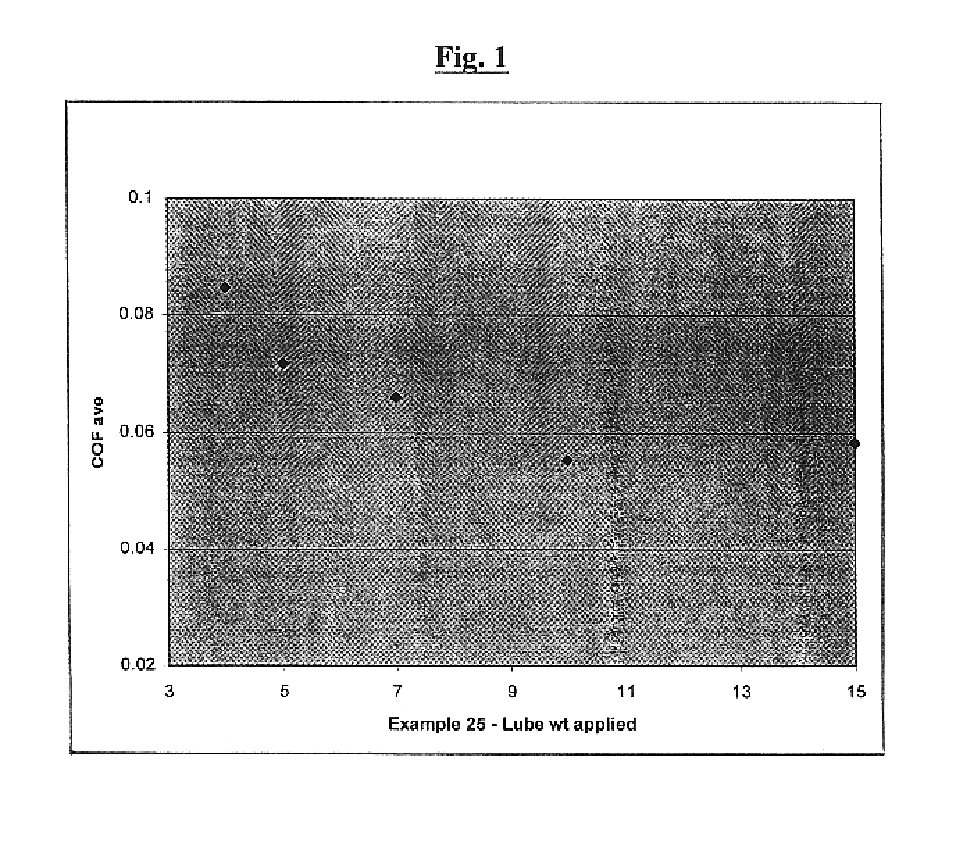

Container, such as a food or beverage container, lubrication method

A process for lubricating a container, such as a beverage container, or a conveyor for containers, by applying to the container or conveyor, a thin continuous, substantially non-dripping layer of a liquid lubricant. The process provides many advantages compared to the use of a conventional dilute aqueous lubricant.

Owner:ECOLAB USA INC

Efficient silicone defoaming agent

InactiveCN102343165AGood anti-foam performanceGood dispersionFoam dispersion/preventionDispersityEmulsion

The invention discloses an efficient silicone defoaming agent, which mainly comprises a silicone grease mixture, a synergistic agent, a polyether silicone oil emulsifier, an assistant emulsifier, a thickening agent, preservative and water, wherein in an emulsifier emulsion, the silicone grease mixture and the polyether silicone oil emulsifier account for 70-90 percent of the amount of active matters; the active matters account for 5-30 percent of the amount of the emulsion; and water serves as another medium. In the efficient silicone defoaming agent, the foam inhibiting performance is enhanced by using the silicone grease mixture, the defoaming performance and dispersity are improved by using the polyether silicone oil emulsifier, and the silicone grease viscosity and compatibility are lowered and the emulsifying effect is improved by adding the synergistic agent. The efficient silicone defoaming agent has the characteristics of application to waterborne systems, high defoaming speed, good foam inhibiting effect, low using dosage, high chemical inertness, nontoxicity, capability of acting under severe conditions and low cost.

Owner:山东大易化工有限公司

Solubilized defoamers for cementitious compositions

InactiveUS6875801B2Long-term storage stabilitySolid waste managementTransportation and packagingWater insolubleSolvent

Amine solubilizing agents are mixed with water insoluble defoamers and optionally a dispersant for cementitious compositions to provide an admixture for cementitious compositions that is stable over time. A cementitious composition is provided that includes cementitious material, water, a water insoluble defoamer, optionally a dispersant for cementitious compositions, and an amine solubilizing agent that solubilizes the water insoluble defoamer. A method is provided for making a cementitious composition that includes mixing cementitious material, water, a water insoluble defoamer, an amine solubilizing agent that solubilizes the water insoluble defoamer, and optionally a dispersant for cementitious compositions.

Owner:MBT HLDG +1

High-whiteness, non-heat-treated hydrophobic precipitated silica

InactiveUS6899951B2High whitenessImprove reinforcementSilicaGlass/slag layered productsDouble bottomSilicon dioxide

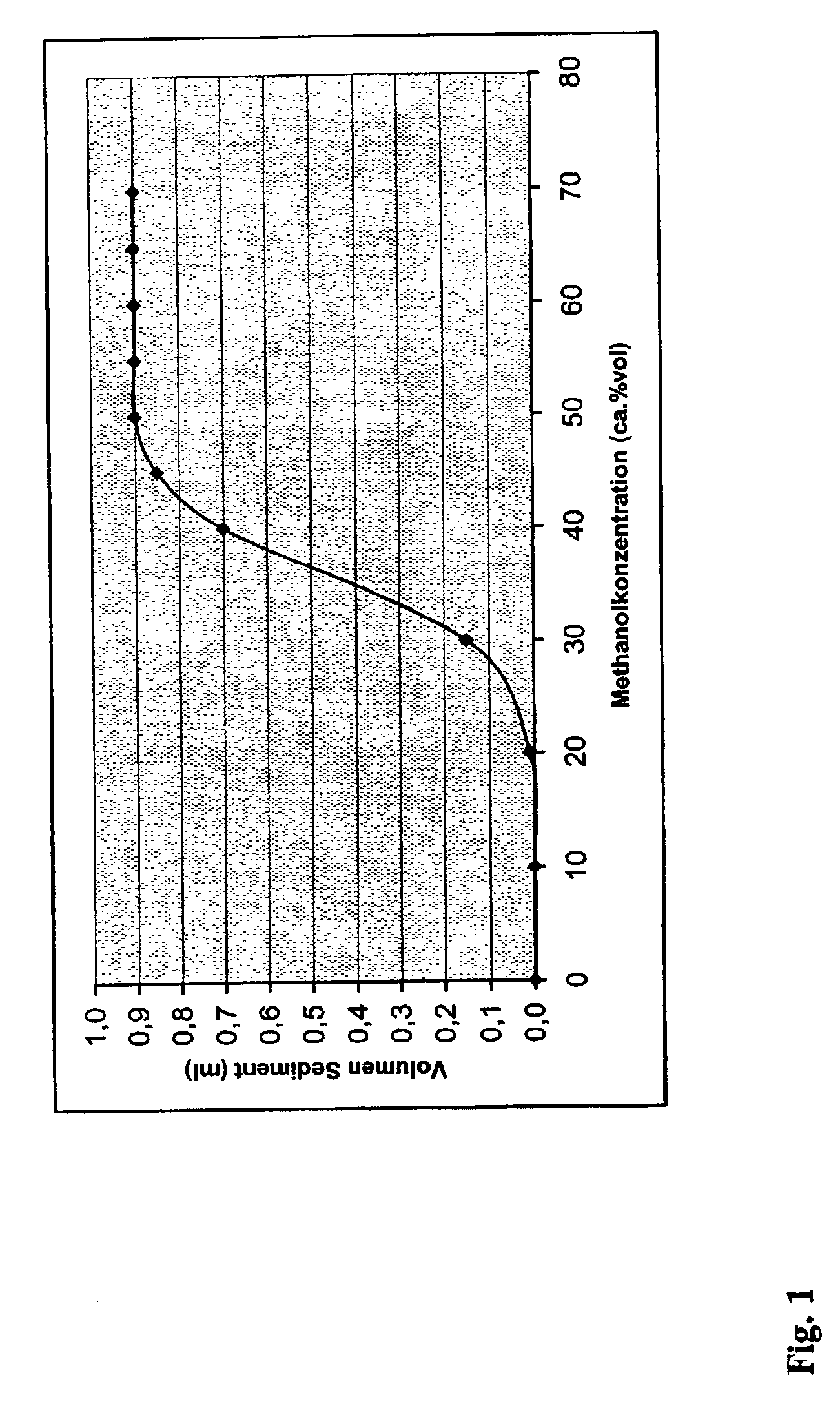

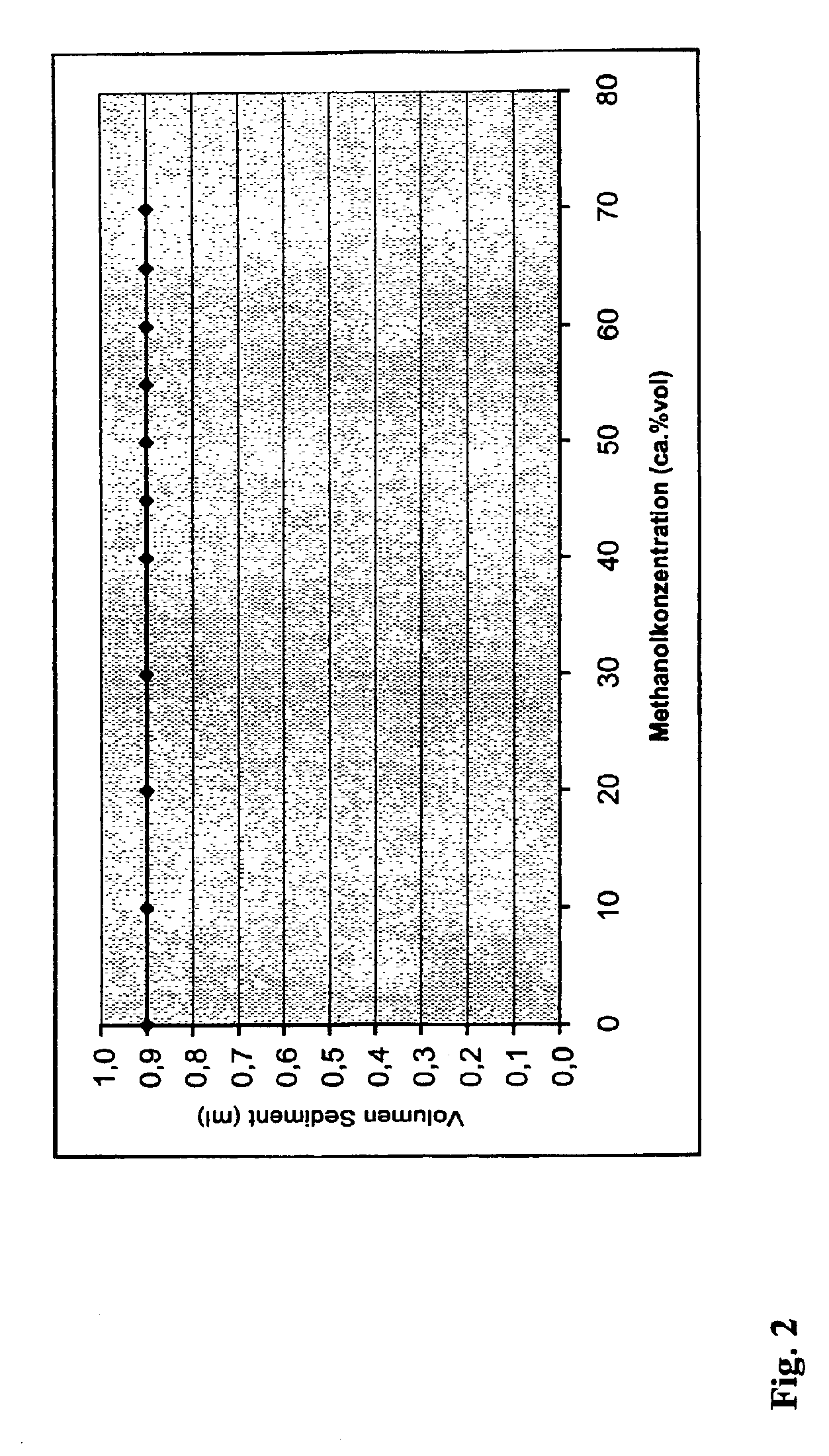

The present invention provides a hydrophobic precipitated silica having the following properties:carbon content1.0-8.0%methanol wettability 20-55%reflectance>94%BET / CTAB ratio ≦1DBP absorption<250 g / 100 gBET surface area 50-110 m2 / gCTAB surface area100-150 m2 / gSears number<13.The present invention also provides methods for making and using the hydrophobic precipitated silica and articles and compositions which include the same.

Owner:EVONIK DEGUSSA GMBH

Method for handling oil refining alkaline residue

InactiveCN1485409AGood entrainment effectEmission complianceWater/sewage treatment by heatingHydrocarbon oils refiningAlcoholEvaporation

A method of processing alkali wastes in oil refinement comprises: evaporating alkali wastes in oil refinement containing an evaporation accelerating agent, the evaporated gas-phrase condensate is recycled, introducing the concentrated alkali wastes into a burning oven, and producing sodium carbonate and sodium sulfate at 750í½950degree C. The evaporation accelerating agent comprises: 30í½85úÑ polymer of polyoxypropylen-polyoxyethylene, 5í½23úÑlow-carbon alcohol, 5í½55úÑ water.

Owner:CHINA PETROLEUM & CHEM CORP +1

Antiadhesive high temperature layers

ActiveUS20060159909A1Easy to slideGood adhesionFireproof paintsMaterial nanotechnologySolid particleBoron nitride

Owner:INST FUR NEUE MATERIALIEN GEMEINNUTZIGE GMBH

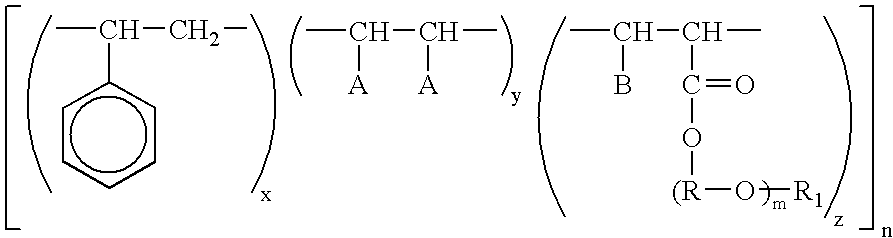

Silicone dispersions

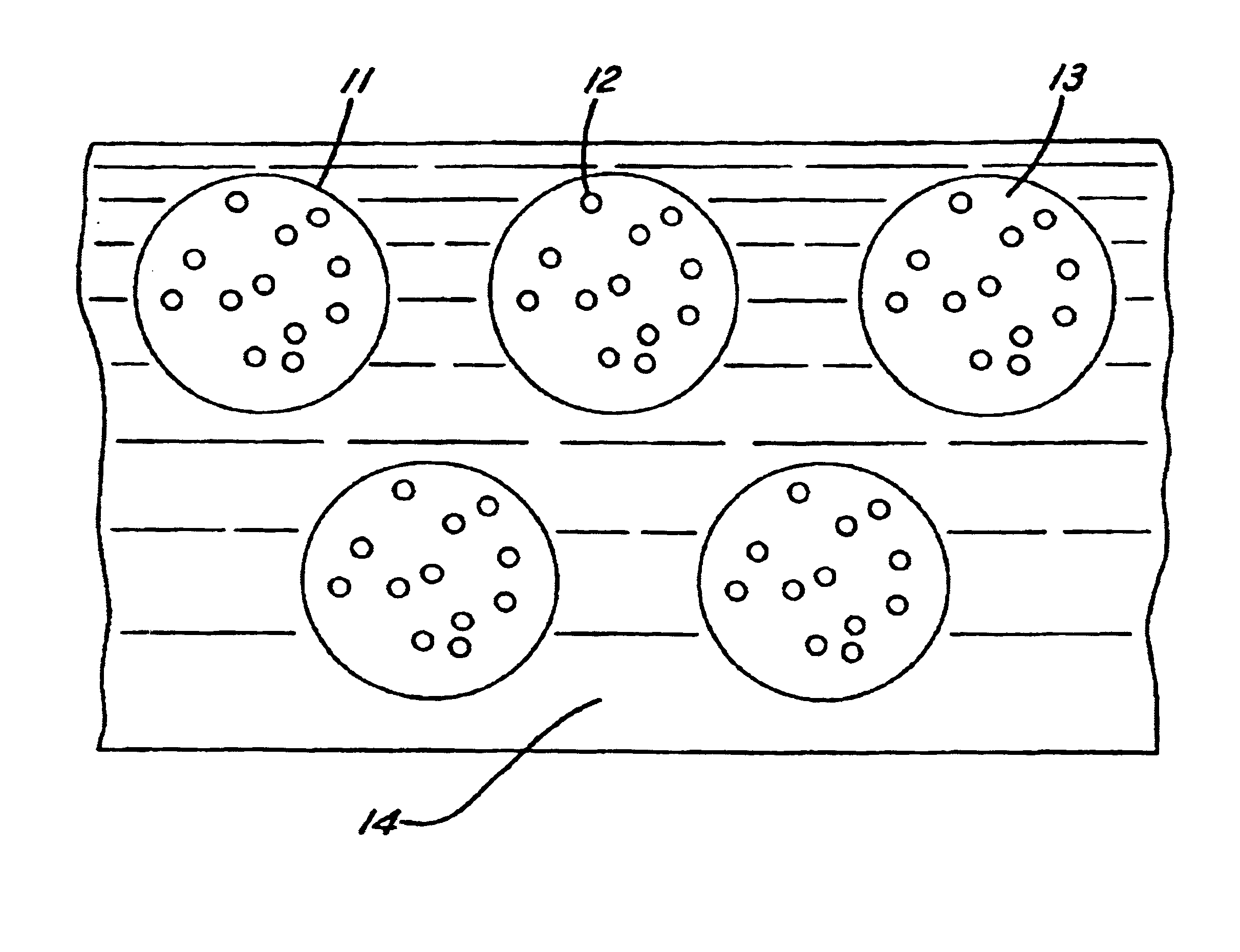

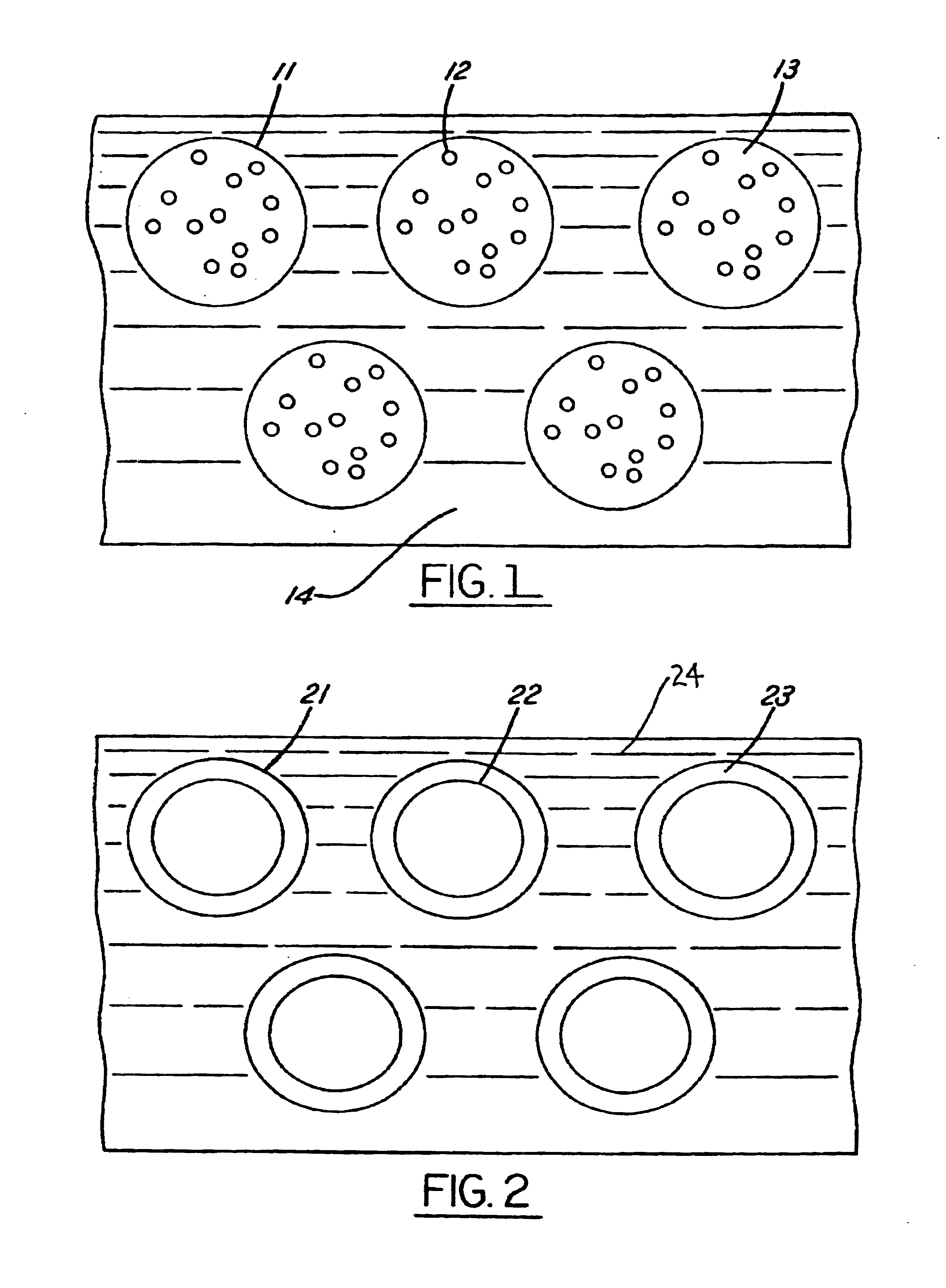

InactiveUS6656975B1Improve efficiencyReduce rateNon-fibrous pulp additionNatural cellulose pulp/paperSilica gelSilicone

A silicone composition having a continuous phase of a polar organic liquid including particles of a silicone active material encapsulated within an organic encapsulating material which is a solid at 25° C. The silicone active material is sparingly soluble in the polar organic liquid at 25° C., but is substantially dissolved in the polar organic liquid at temperatures of from 40 to 100° C. The three phase contact angle between the organic encapsulating material, the silicone antifoam, and the polar organic liquid is below 130° C., with the angle measured through the silicone.

Owner:DOW SILICONES CORP

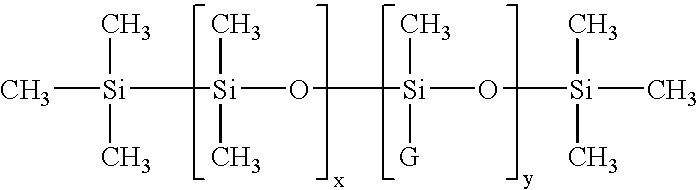

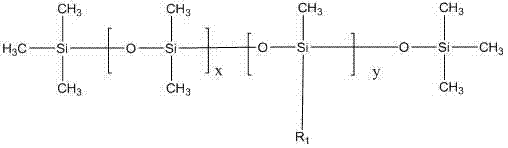

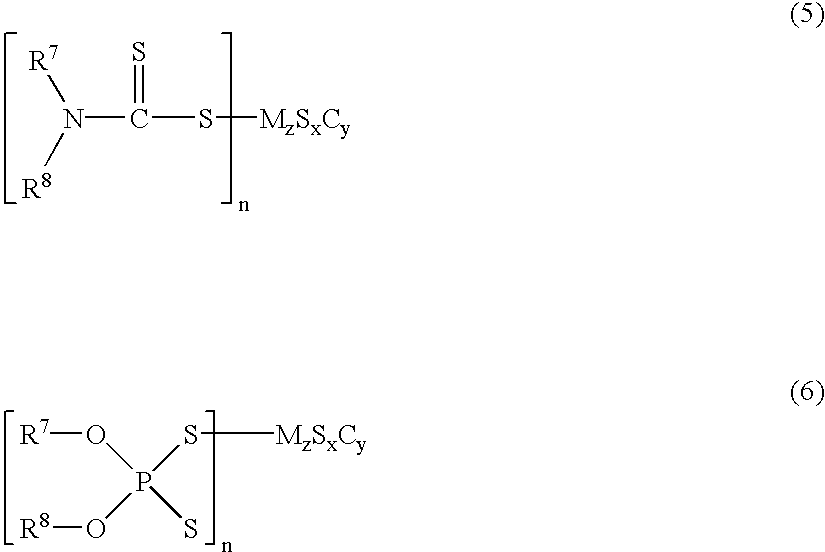

Method for preparing defoaming agent composition

The invention discloses a method for preparing a defoaming agent composition, belonging to the technical field of fine chemical preparation. The invention provides a defoaming agent composition widely used for removing harmful foams in industrial production. The defoaming agent composition comprises the following components: (1) polysiloxane RaSiO(4-a) / 2; (2) a coupling agent; (3) fine filler particles such as silicon dioxide and the like; (4) organic silicon resin; (5) polyether modified polysiloxane MDx(CH3GSiO)yM, wherein M is chain link R'2SiO1 / 2, D is chain link R'2SiO2 / 2, G is polyether radical-(CH2)z(EO)g(PO)hR'' and (6) an alkaline catalyst. The preparation method comprises the following steps: (1) heating the polysiloxane and the coupling agent together in a stirring machine, adding the alkaline catalyst to carry out a polymerization reaction at the temperature of 40-140 DEG C; (2) after crosslinking the mixture, adding the organic silicon resin and the polyether modified polysiloxane, carrying out a reaction again for 1-7 h at the temperature of 80-140 DEG C, and then adding the fine filler particles to mix uniformly, carrying out a reaction for 1-6 h at temperature of 90-180 DEG C; (3) after finishing the reaction, keeping the mixture for 0.1-1.5 h at the vacuum degree of -0.01 to -0.08 MPa, and finally, cooling to the room temperature to obtain white active materials that are defoaming agent compositions.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Preparation method of high-viscosity organic silicon defoamer

InactiveCN104069654AIncrease the molecular chain lengthGood defoaming performanceFoam dispersion/preventionRoom temperatureOil phase

The invention discloses a preparation method of a high-viscosity organic silicon defoamer. The preparation method comprises the following steps of preparing a silicon grease by using organopolysiloxane, dewatering particles, catalysts and silicon resin under 180-240 DEG C, and stirring and uniformly mixing the silicon grease, polyether modified silicone oil and an emulsifying agent under 72-78 DEG C so as to obtain an oil phase mixture, dissolving a dispersing thickening agent in water; then adding a sodium hydroxide solution to uniformly stir to obtain emulsifying thickening water, adding the emulsifying thickening water into an oil-phase mixture, and carrying out emulsifying stir on the oil-phase mixture under 72-78 DEG C to obtain a coarse emulsifying object; and homogenizing the coarse emulsifying object under 50-55 DEG C to obtain a fine emulsifying object, adding residue water into the fine emulsifying object, stirring and uniformly mixing the fine emulsifying object under room temperature so as to obtain the high-viscosity organic silicon defoamer. The preparation method provided by the invention has the advantages that high-viscosity simethicone is utilized as an emulsifying main raw material, and thus, the obtained high-viscosity organic silicon defoamer has an ultra-strong defoaming speed and an anti-foam effect.

Owner:道尔达(西安)新材料有限公司

Lubricant for oil retaining bearing

InactiveUS20090069204A1Low vapor pressureImprove heat resistanceAssociation with grounding devicesShaftsHeat resistanceEngineering

A lubricant for an oil retaining bearing containing 1 to 100% by mass of an ionic liquid. The lubricant has a low vapor pressure, low flammability, excellent heat resistance and ability to suppress the emanation of low volatile components and decomposed gases during use, or a lubricant for an oil retaining bearing which has antistatic property and is capable of grounding the static electricity generated by flow charging of the lubricant.

Owner:IDEMITSU KOSAN CO LTD

Preparation method of mineral oil defoaming agent

InactiveCN102120158AGood dispersionGood defoaming effectTransportation and packagingMixingWaxColloid

The invention discloses a preparation method of a mineral oil defoaming agent, comprising the following steps: adding mineral oil to a reaction container; adding wax, white carbon black, an emulsifying agent and oleic acid in sequence when dispersing at a high speed; after finishing adding, dispersing until the system is basically and uniformly dispersed at a high speed; turning to a colloid grinder and grinding and dispersing for 4-6 times; checking; and after the material is qualified, discharging the material. In the preparation method of a mineral oil defoaming agent in the invention, a proper variety of wax or modified wax is selected so that the mineral oil defoaming agent has perfect dispersing and defoaming effects and storage stability; the prepared mineral oil defoaming agent is a novel water defoaming agent, and has the characteristics of environmental protection, safety, excellent performance, and the like; the preparation method perfects the sorts of the products in the domestic market; and the preparation method has a simple manufacturing process and is easy to produce in a large scale.

Owner:SUZHOU BONA CHEM TECH

Rolling bearing

InactiveUS20030040442A1Reaction can be suppressedImprove fatigue strengthLiquid carbonaceous fuelsThickenersAlternatorRolling-element bearing

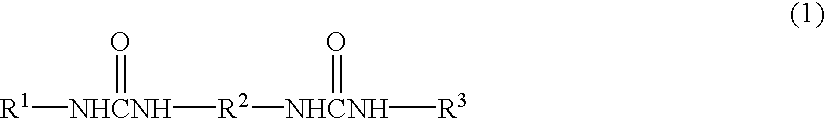

The invention aims to provide a rolling bearing that secures a sufficient bearing life economically even when used under such conditions that water from the outside or water formed by moisture condensation may seep into the lubricant or the bearing is affected by the vibrations, and particularly a rolling bearing suited to the electric parts and accessaries of au automobile engine, such as an alternator. To accomplish the object, the hydrogen ion exponent pH of the grease sealed into the inside of the bearing is adjusted in a range of from 7 to 13. For the same purpose, the hydrogen ion exponent pH of the grease is adjusted in a range of from 5 to 13 where a prescribed amount of an organic metal salt or ADTC is added to the grease, where a prescribed amount of an inorganic compound having an average particle size of 2 squarem or smaller is added to the grease, or where a diurea compound containing an aromatic amine or a mixture of the diurea compound is added to the grease as a thickener.

Owner:NSK LTD

Defoamer

To provide a defoaming agent causing less cissing. The defoaming agent contains an aluminum carboxylate (A) and hydrocarbon oil (B), but contains no alkaline earth metals, wherein (A) is an aluminum di-carboxylate (A2) or a mixture of an aluminum mono-carboxylate (A1) and an aluminum di-carboxylate (A2), the content, by weight, of (A) is 0.1-60% and the content of (B) is 40-99.9% based on the weight of (A) and (B), and the content of A(1) is <=40% based on the total weight of (A1) and (A2). In addition, the defoaming agent contains free fatty acid (FA) and the content of (FA) is preferably 1-30% based on the weight of (A1) and (A2). In addition, the defoaming agent contains hydrocarbon oil (B) containing aromatic carbon (BA), and the content of (BA) is preferably 1-30% by number based on the total number of carbons of (B).

Owner:日本诺普科助剂有限公司

Surfactant Additives Used to Retain Producibility While Drilling

InactiveUS20120000708A1Reduce surface tensionHigh viscosityLiquid/gas jet drillingDrilling compositionWell drillingSURFACTANT BLEND

Of the many embodiments provided herein, one embodiment includes a method comprising: providing a drilling fluid comprising: an aqueous fluid; and a surfactant; and drilling a well bore in a subterranean formation comprising an oleaginous fluid using the drilling fluid, wherein the surfactant forms a micelle within the well bore; and removing an oil block in the formation.

Owner:HALLIBURTON ENERGY SERVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com