Method for handling oil refining alkaline residue

A treatment method, a technology of refining alkali residue, applied in the direction of heating water/sewage treatment, petroleum industry, refined hydrocarbon oil, etc., can solve the problems of mist entrainment, inability to recycle chemical raw materials, and inability to solve sewage discharge, etc., to achieve treatment Low cost, saving construction investment, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

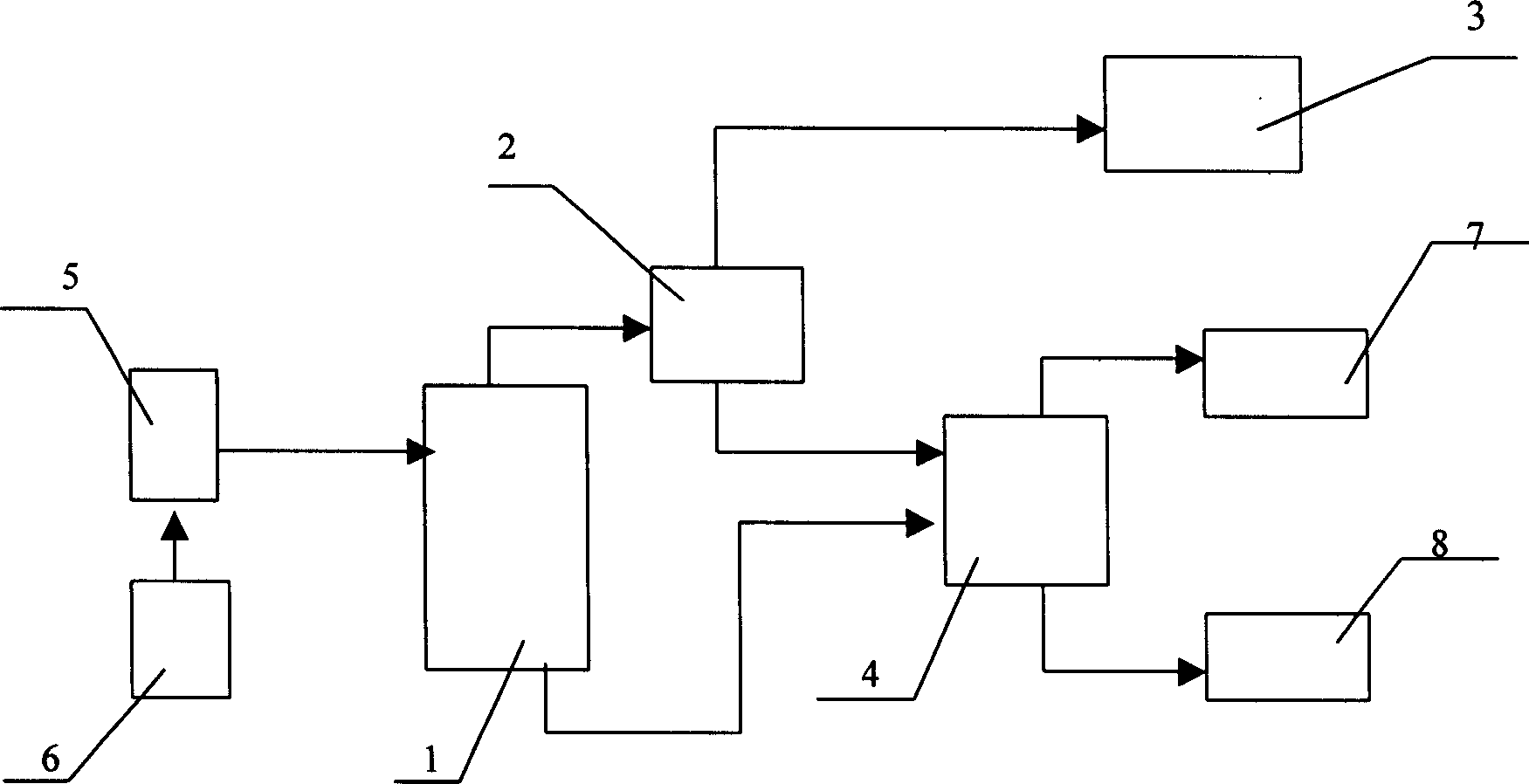

Method used

Image

Examples

Embodiment 1

[0024] The alkali refined alkali slag of atmospheric distillation overhead fraction contains COD 23317mg / l; volatile phenol 835mg / l; sulfide 3375mg / l; pH value is 14; solid content 10%. Components of the evaporation accelerator: polyoxypropylene polyoxyethylene polymer (molecular weight about 9500) accounts for 60%, ethanol accounts for 21%, and water accounts for 19%.

[0025] Add the evaporation accelerator to the alkali slag at a concentration of 60 μg / g (the flow rate of the alkali slag is 1 ton per hour), and use a rising film evaporator to evaporate at normal pressure and 108°C, and return the evaporated gas phase condensate to the atmospheric and vacuum device to replace the process Inject water. Noncondensable gas and concentrated alkali slag (solid content 47%) are incinerated under the combustion of heavy oil to generate Na 2 CO 3 、Na 2 SO 4 , At the same time recovery of combustion heat, steam production, combustion conditions 810 ℃, -85Pa. 60% of the combustio...

Embodiment 2

[0028] Catalytic gasoline alkali residue contains COD 335750mg / l; volatile phenol 10000mg / l; sulfide 26150mg / l; pH value 14; solid content 35%. Components of the evaporation accelerator: polyoxypropylene polyoxyethylene polymer (molecular weight about 7500) accounts for 71%, methanol accounts for 16%, and water accounts for 13%.

[0029] Add the evaporation accelerator to the alkali slag with a flow rate of 0.5 tons / hour at a concentration of 80 μg / g, and evaporate it at normal pressure and 104°C with a steaming ball, and the evaporated gas phase condensate is used as process water. The solid content of concentrated alkali slag is 45%, and it is burned together with non-condensable gas under the combustion of heavy oil to generate Na 2 CO 3 、Na 2 SO 4 , At the same time recovery of combustion heat, by-product steam, combustion conditions 880 ℃, -75Pa. 70% of the combustion products are solid and the rest are molten.

[0030] The COD content of the discharged sewage is 180...

Embodiment 3

[0032] Liquid hydrocarbon alkali residue contains COD33071mg / l; volatile phenol 2134mg / l; sulfide 1189mg / l; pH value is 14. Components of the evaporation accelerator: polyoxypropylene polyoxyethylene polymer (molecular weight about 11500) accounts for 43%, ethanol accounts for 10%, and water accounts for 47%.

[0033] The evaporation accelerator is added into the liquid hydrocarbon alkali slag at a flow rate of 300 kg / h at a concentration of 60 μg / g, the flow rate of the alkali slag is 300 kg / h, and the solid content is 15%. Use a rising film evaporator to evaporate at normal pressure and 109°C, and the evaporated gas phase condensate (about 120 kg / hour) returns to the atmospheric and vacuum device to replace the process water injection. The solid content of concentrated alkali slag is 46%. It is incinerated with non-condensable gas under the combustion of heavy oil to generate Na 2 CO 3 、Na 2 SO 4 , At the same time recovery of combustion heat, steam production, combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com