Patents

Literature

785results about How to "Emission compliance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

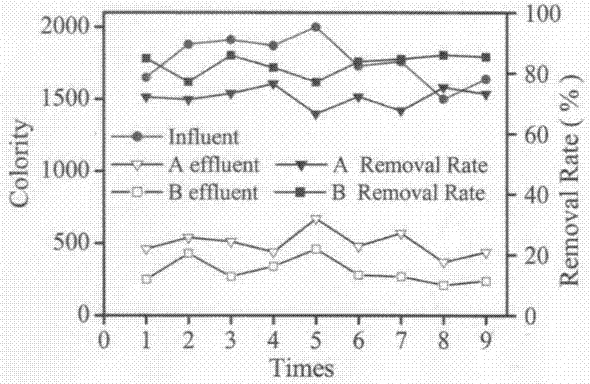

Textile dyeing wastewater advanced treatment recycling technology

InactiveCN102145965AReduce chromaImproved BioprocessingMultistage water/sewage treatmentWater/sewage treatment by neutralisationTextile fiberChemical treatment

The invention discloses a textile dyeing wastewater advanced treatment recycling technology. The technology comprises the following steps: filtering to remove textile fibers; cooling; neutralizing, degrading organic matters and decomposing, replacing or degrading (cracking) the chormophoric groups of the organic matters to reduce the chroma of the wastewater; performing biochemical treatment with the biomembrane; precipitating to ensure that the precipitated sludge enters a sludge treatment system and the supernatant enters a flocculation pool; performing chemical treatment, namely adding a medicament in the flocculation pool to remove the suspended matter (SS), CODcr (chemical oxygen demand), BOD (biochemical oxygen demand) and chroma of the water; performing secondary precipitation to ensure that the free SS is precipitated and the wastewater is decolored further; separating to remove and degrade the chloride ions of the reuse water; performing secondary biochemical treatment to further reduce the concentrations of the SS, CODcr and BOD in wastewater; performing ozone oxidation treatment, decoloring, degrading organic matters; performing chemical treatment to remove insoluble dye materials and SS and reduce the COD and chroma; and performing secondary filtration, and forming an ozone / activated carbon system to ensure that the hydroxyl radicals of activated carbon are used and the organic reaction in wastewater is adopted to decolor and degrade organic matters. The invention overcomes the defects of the existing physical method, chemical method and chemical method treatment technologies; and the technology has been used in many enterprises, and the good treatment effects are obtained.

Owner:李斌 +2

Silicon-containing wastewater treatment method

ActiveCN101746907AEmission complianceSolve SiO

<sub>2</sub>

easy gel problemMultistage water/sewage treatmentWater/sewage treatment by neutralisationChemistrySilicate

The invention relates to a silicon-containing wastewater treatment method. The silicon-containing wastewater treatment method provided by the invention comprises: adding a nucleation coagulant aid to silicon-containing wastewater and mixing the silicon-containing wastewater with the nucleation coagulant aid, wherein the nucleation coagulant aid is an insoluble solid which serves as a growing core capable of allowing granular micro-substances that are suspended in water and not easy to coagulate to aggregate, grow up and settle; and regulating the pH of the silicon-containing wastewater between 3.5 and 9. The treatment method provided by the invention has the advantages of applicability to silicate wastewater discharged in various processes, capability of thoroughly solving the problem that SiO2 in the silicon-containing wastewater is easy to gel, mild using conditions, simple operation process and capability of enabling treated wastewater to reach discharge standards.

Owner:CHINA PETROLEUM & CHEM CORP +1

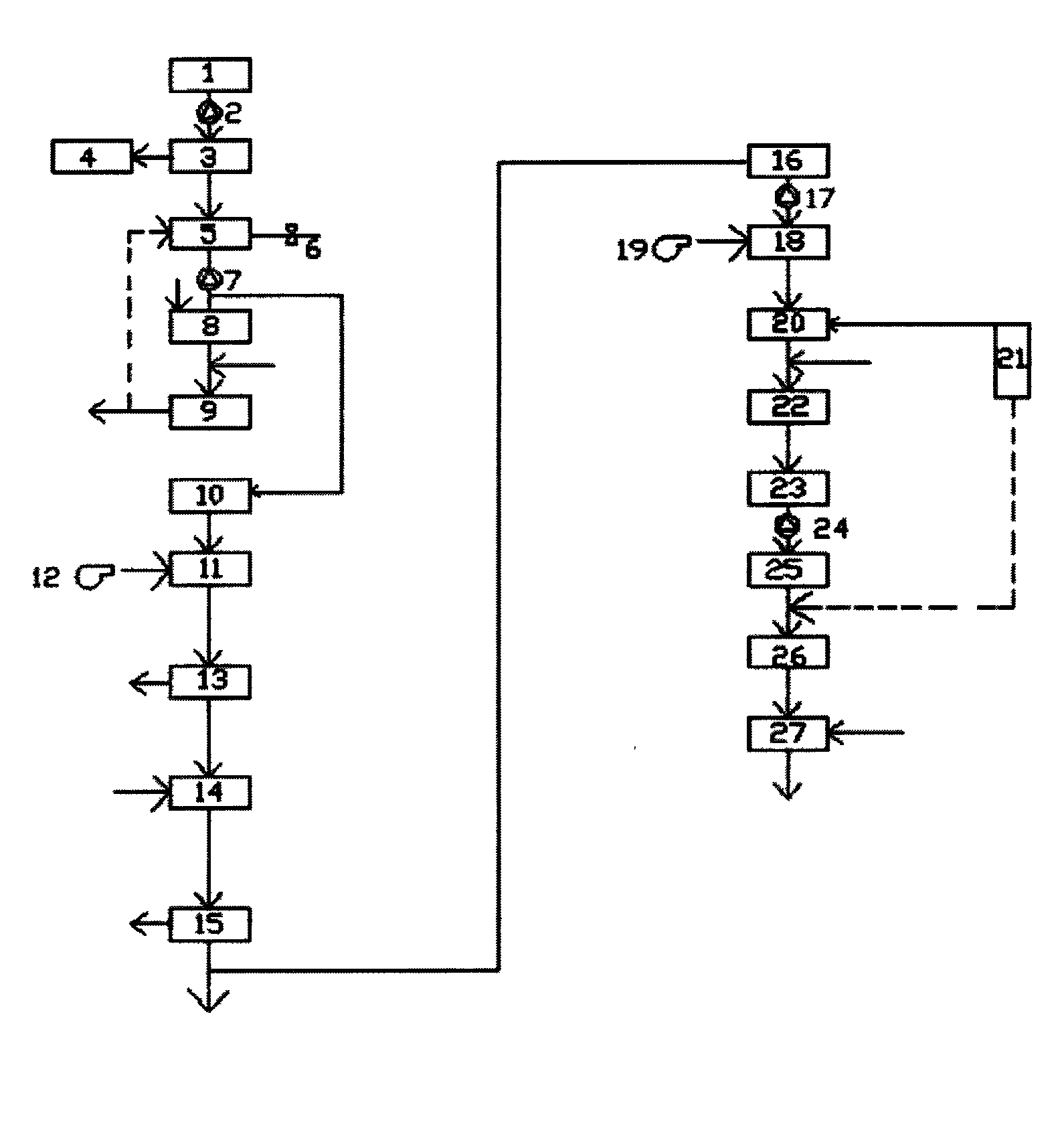

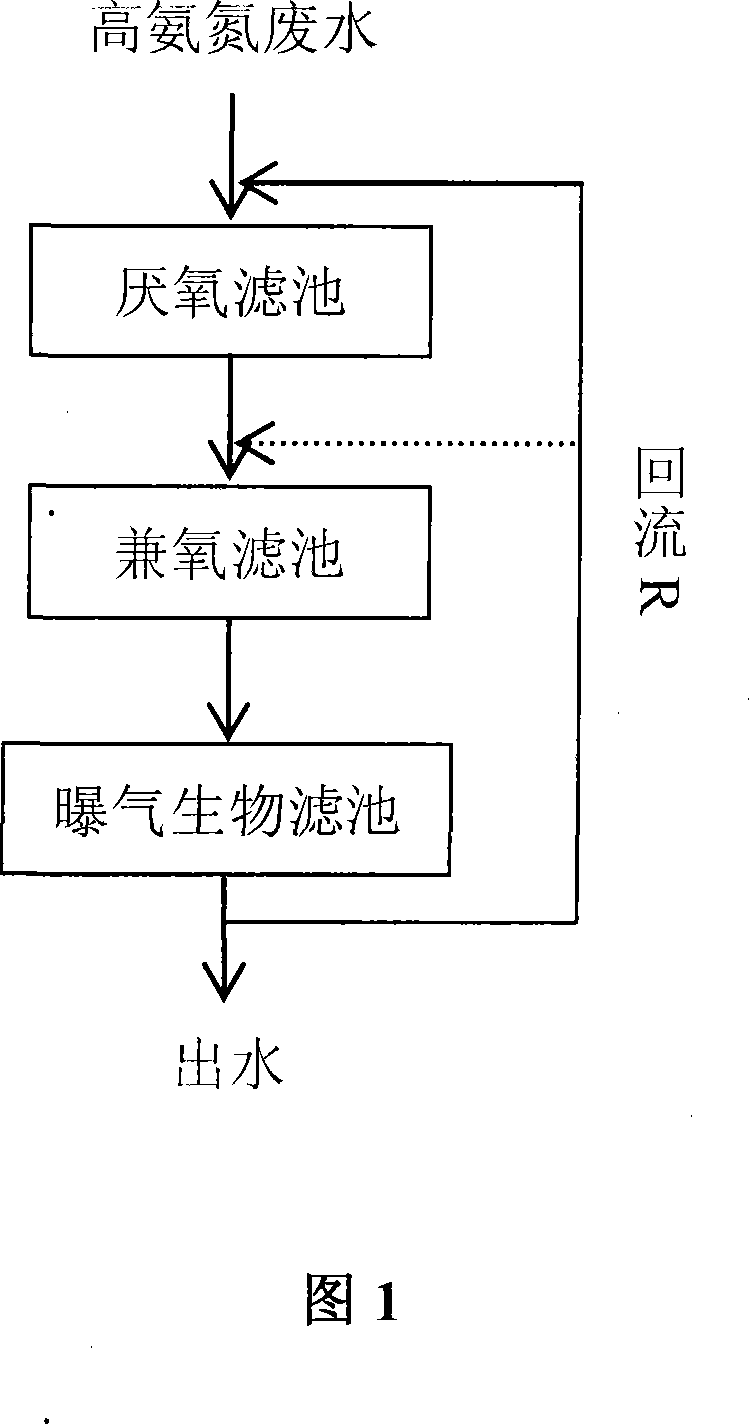

Intensified biological treatment method for high strength ammonia wastewater

InactiveCN101229944AIncrease loadNot easy to loseTreatment using aerobic processesTreatment with anaerobic digestion processesBioaugmentationChemistry

The invention relates to a bioaugmentation treatment method of high ammonia nitrogen, belonging to a sewage treatment technology field which adopts the combined process of anaerobic-hypoxia-aerobic. All the used reactors are biology filtering pool reactor and the inner of the reactor is filled with a macroporous poly urethano carrier. In the domestication and culture process of the biology filtering pool biology membrane, compound microorganism of a high efficiency is added. The high ammonia nitrogen water is processed by a strengthening immobilization technology. The detail functions of each unit are referred to the specification. The invention has the advantages that the two kinds of technologies of biology filtering and the bioaugmentation are combined with the strengthening immobilization technology; the carbon and nitrogen pollution in the leachate are removed. As an effective combined biology treatment method, the invention also has the advantages of high removal efficiency of nitrogen and non-need additional organic carbon source; the high efficiency of bacteria fixedly growing on the carrier, reducing the inhibition effect of the high ammonia nitrogen to the biology, avoiding the draining of the bacteria in the traditional method, having the strong ability of bearing the water inlet pollutants load changes and ability of resisting the system impact. Therefore, the invention is.

Owner:PEKING UNIV

Method and process for advanced treatment of well drilling effluent

InactiveCN102139971AEasy to handleProcessing speedEnergy based wastewater treatmentMultistage water/sewage treatmentAmmonium sulfateChemistry

The invention relates to a method and processes for the advanced treatment of well drilling effluent. The method comprises the following processes of: chemically-enhanced solid-liquid separation, mechanical dehydration, treatment by the advanced oxidation technology and the like. The method comprises: adding 2 to 16 g / L of polyaluminium chloride into the well drilling effluent, stirring quickly and uniformly, adding 50 to 200 mg / L of cationic polyacrylamide, stirring at low speed for 10 to 15 minutes, so that the drilling waste liquid destabilized and agglutinated, and dehydrating in a centrifugal mode; and performing advanced oxidation treatment on the well drilling waste liquid from which solids are separated, regulating the pH value of the well drilling waste liquid to be 4, performing a reaction by taking hydrogen peroxide and ammonium persulfate as a composite oxidizing agent and ferrous sulfate as a catalyst under the condition of daylight or simulated daylight for 120 to 150 minutes, regulating the pH value of the well drilling waste liquid to be between 8 and 9 by using lime milk, clarifying, and discharging or performing the treatment in other modes. By the method, indexes such as the suspended solids, chromaticity, chemical oxygen demand (CODCr) and the like in the well drilling waste liquid are reduced substantially, so the method has a bright application prospect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

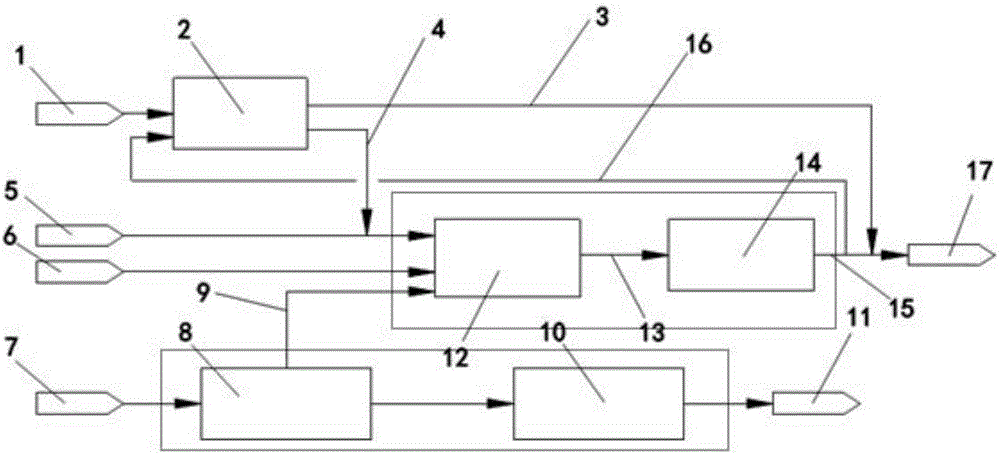

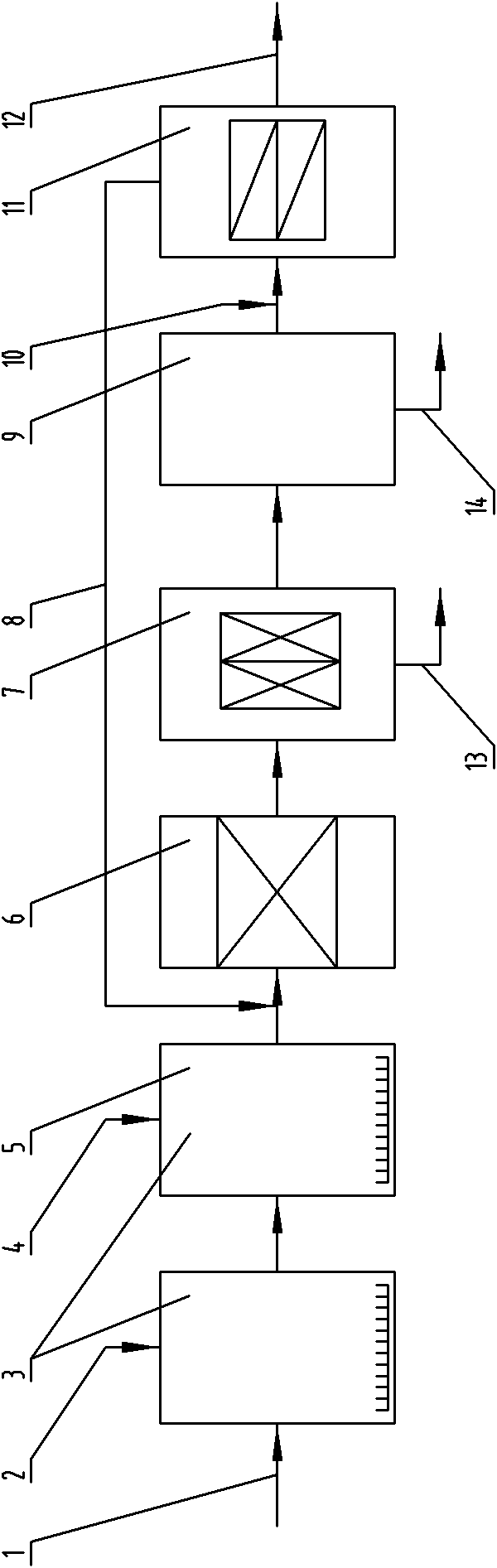

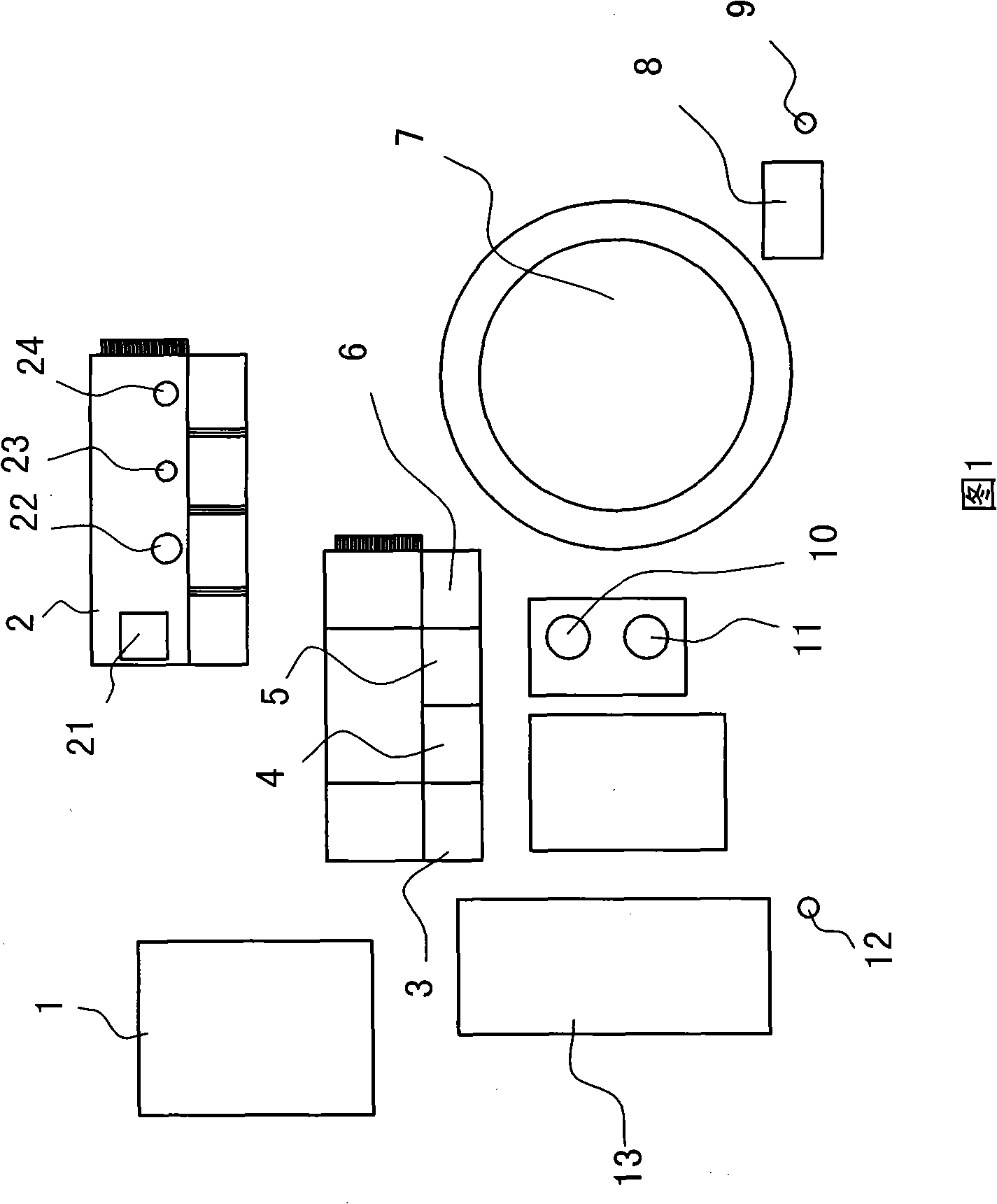

Method and system for treating VOCs gas in sewage treatment plant

InactiveCN105757688ASimultaneous processingReduce usageIncinerator apparatusHigh concentrationDesorption

The invention provides a method and a system for treating a VOCs gas in a sewage treatment plant, and is based on a VOCs gas absorption-desorption system, a combustion and waste heat recycling system and a wastewater treatment system. The method comprises the following specific steps: feeding a low-concentration VOCs gas in the sewage treatment plant through the VOCs gas absorption-desorption system so as to obtain a concentrated VOCs gas; combining the concentrated VOCs gas with a high-concentration VOCs gas and gases output from an anaerobic treatment unit in the sewage treatment plant to be introduced into the combustion and waste heat recycling system; introducing a certain amount of fuel and a waste gas methane generated in the wastewater treatment system so as to sufficiently combust the VOCs gas; after combustion, recycling the heat by using a waste heat boiler, feeding a part of cleaned fume at an outlet to the VOCs gas absorption-desorption system to desorb the low-concentration VOCs gas, and combining the other part of the cleaned fume with tail gases of an absorption-desorption device to be fed into a chimney for discharge.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

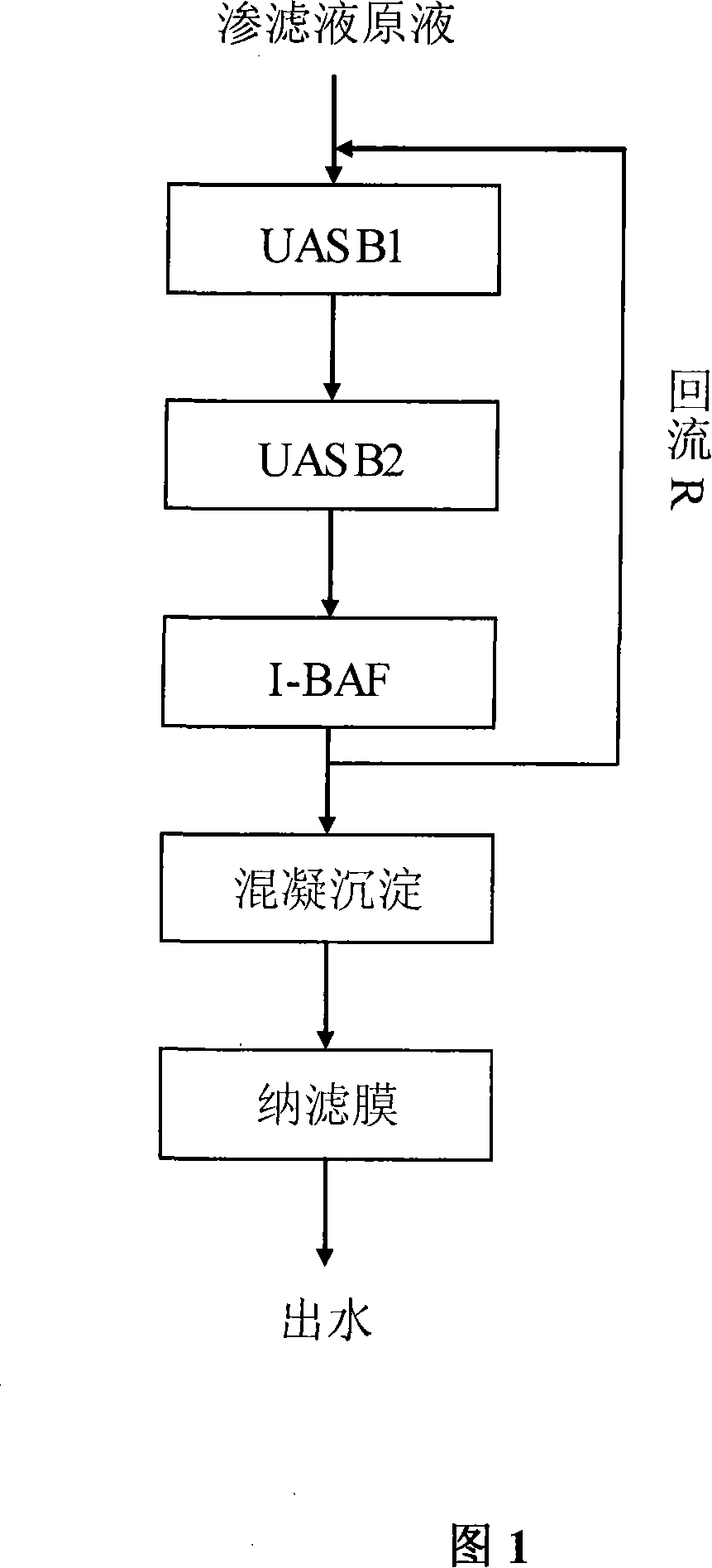

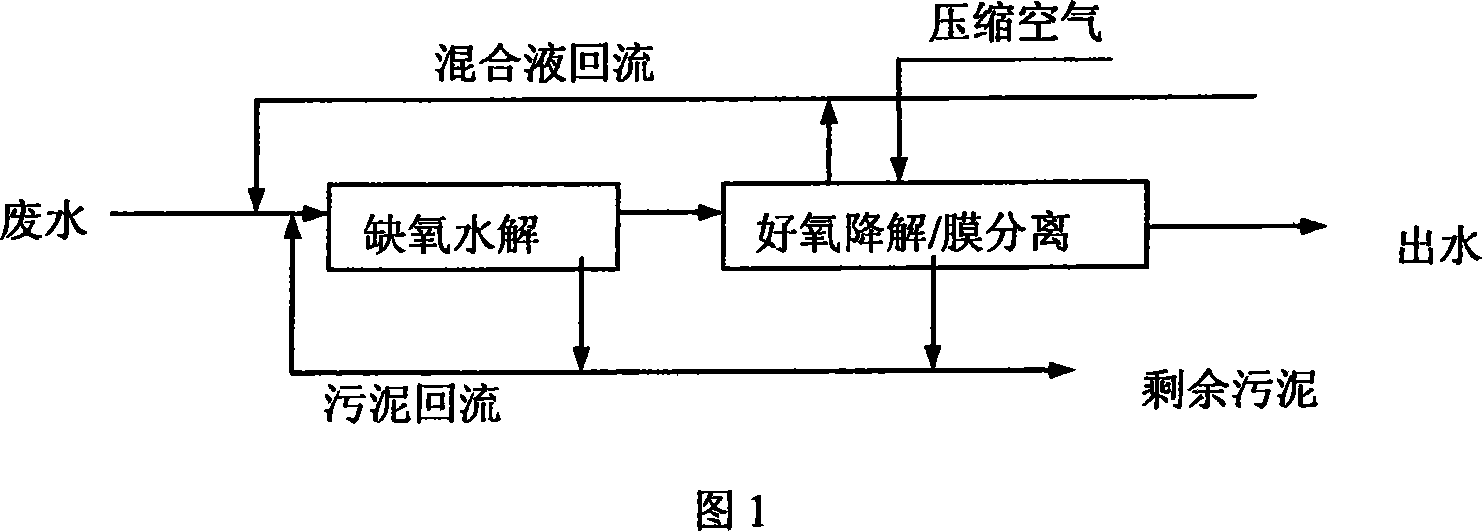

Anaerobic-aerobic-film processing technique for urban domestic refuse percolate

InactiveCN101148307AEfficient removalWater safetyTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisWater qualityOxygen

The present invention is the anaerobic treatment, aerobic treatment and membrane treatment process of domestic garbage percolate, and belongs to the field of sewage treating technology. The combined treating process is completed in four units including a two-stage upwards flowing anaerobic sludge bed, an immobilized microbial biological aeration filter, a coagulating and settling pond and a nanometer filtering membrane. The present invention has the advantages of simultaneous elimination of carbon, nitrogen and other pollutants, high treating effect, high load impact resistance and high stability. The present invention may be also applied in treating other waste water with high ammonia nitrogen content, high organic pollutant concentration and great water quality fluctuation.

Owner:北京盖雅环境科技有限公司

Method for producing tribasic copper chloride

The invention discloses a method for producing tribasic copper chloride. The method for producing the tribasic copper chloride includes the following steps of: (1) removing impurities from an acidic etching waste solution; (2) adding clean water or a tirbasic copper chloride production mother solution to a synthesis reactor, performing preheating, and then, preheating the acidic etching waste solution whose impurities have been removed and an alkaline solution of sodium hydroxide and mixing the two solutions for a reaction with the pH value and temperature of the reaction being controlled so as to gradually form the tribasic copper chloride, and discharging partial materials after a certain amount of reaction time; (3) filtering the materials discharged from the reaction system, and performing washing, suction filtration, centrifugation and drying on the filtrated residues to obtain the tribasic copper chloride; and (4) performing ammonia nitrogen removal treatment on filtrated liquid. By adopting the method for producing the tribasic copper chloride in the invention, continuous production can be achieved and the tribasic copper chloride with large particle size and high purity can be produced; further, production cost can be reduced and overall process can be integrated; and the method for producing the tribasic copper chloride is advantaged in simple ultimate steps of ammonia nitrogen removal, easiness in operation as well as reduced difficulty and cost of ammonia nitrogen treatment.

Owner:GUANGZHOU KECHENG ENVIRONMENTAL PROTECTION TECH

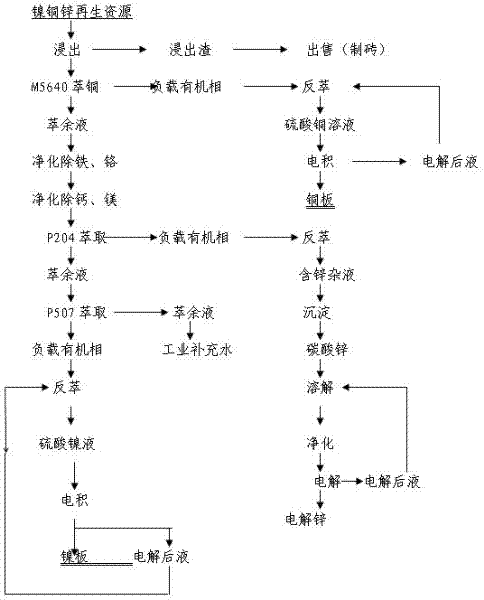

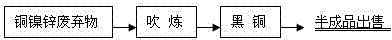

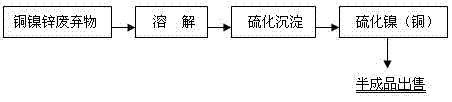

A method for directly producing electrolytic nickel with copper-nickel renewable resources

InactiveCN102260795AHigh recovery rateEmission compliancePhotography auxillary processesProcess efficiency improvementSlagChemistry

The invention relates to a method for directly producing electrolytic nickel with copper-nickel renewable resources, which includes the following steps: (1) pulping the copper-nickel renewable resources through ball milling, pumping them into a closed leaching tank, and adjusting the acidity of the pulp with sulfuric acid to make The pH reaches 0.5-3.5, and react at normal pressure and temperature at 60-70°C for 30 minutes to obtain a liquid containing NiSO4 and CuSO4; (2) obtain a liquid containing NiSO4 and CuSO4 from the slurry discharged from the leaching tank, Adjust the PH value to 2.0 with alkali in the atmospheric kettle and filter it with a plate and frame filter press; (3) Purify and remove impurities from the liquid after extracting copper; (4) After the reaction in the third step is completed, the Slag liquid separation by filter press filtration; (5) electrolytic copper; (6) electrolytic nickel. By adopting the invention, the comprehensive recovery rate is high; the treatment process does not pollute the environment, and the waste residue can be directly used for making bricks; the waste water can be recycled; the production cost is low and the economic benefit is good.

Owner:四川省尼科国润新材料有限公司

Method for comprehensively reclaiming arsenic caustic dross and sulfur dioxide flue gas in antimony pyrometallurgical smelting

ActiveCN101899574AEmission complianceSimple processDispersed particle separationProcess efficiency improvementSulfite saltEmission standard

The invention discloses a method for comprehensively reclaiming arsenic caustic dross and sulfur dioxide flue gas in antimony pyrometallurgical smelting. The method comprises the following steps: arsenic containing caustic dross in the antimony smelting process is leached; waste gas sulfur dioxide in the antimony-containing alkaline solution is absorbed; vulcanizer is used for dearsenizing; ferric sulfate is used for further dearsenizing; and purification, concentration and drying are performed; and the like. Therefore, the hard treated arsenic caustic dross and low content sulfur dioxide of the waste gas, which are generated in the antimony smelting process, can be treated completely, wherein the antimony reclaiming rate reaches 99 percent, arsenic removal rate is over 90 percent, sulfur dioxide removal rate is over 95 percent through absorption, so that the gas reaches emission standard, and alkali is transformed into sodium sulfite. The method has the advantages of simple technical process, small equipment investment, remarkable economic benefit and environmental benefit, completely solves the arsenic caustic dross and waste gas sulfur dioxide in the antimony smelting process, and cleans the antimony smelting process. Water solution in the whole process is circulated in a closed loop without wastewater discharge, and the waste gas is qualified to be exhausted to air, so the method is a clean and environment-friendly process.

Owner:锡矿山闪星锑业有限责任公司

Regeneration treatment method for waste cathode carbon blocks of aluminum electrolytic cell

The invention discloses a regeneration treatment method for waste cathode carbon blocks of an aluminum electrolytic cell and belongs to the technical field of solid waste treatment in the aluminum electrolysis industry. The main treatment process comprises the steps of crushing, screening, toxicity inhibition, batching and pressure-controlled heat treatment. After waste cathode carbon block materials of the aluminum electrolytic cell are crushed and screened, toxic inhibitors of hydrogen peroxide, potassium permanganate, hypochlorite and the like are added, then carbonaceous materials of anthracite, calcined petroleum coke, waste anode carbon blocks, anode scraps and the like are blended to serve as furnace-in raw materials, and the furnace-in raw materials are placed in a resistance furnace to be subjected to heat treatment at the ordinary pressure (1200-1800 DEG C) or the control pressure (1000-1600 DEG C and 0.01-0.5 atm). Fluoride volatilized from flue gas can be used for producingfluoride salt electrolytes after being cooled and crystallized, treated materials do not contain any contaminant, the carbon content is up to 99%, the conductivity is good, the specific surface areais large, the treated materials can be used for producing various carbon products, waste is turned into wealth, and environment-friendly resource application of overhaul of the waste cathode carbon blocks of the aluminum electrolytic cell is achieved.

Owner:UNIV OF SCI & TECH BEIJING

Deep stage treatment method for industrial wastewater

ActiveCN102616962AInfluent water quality requirements are lowReduce energy consumptionDispersed particle separationWater softeningWater qualityReverse osmosis

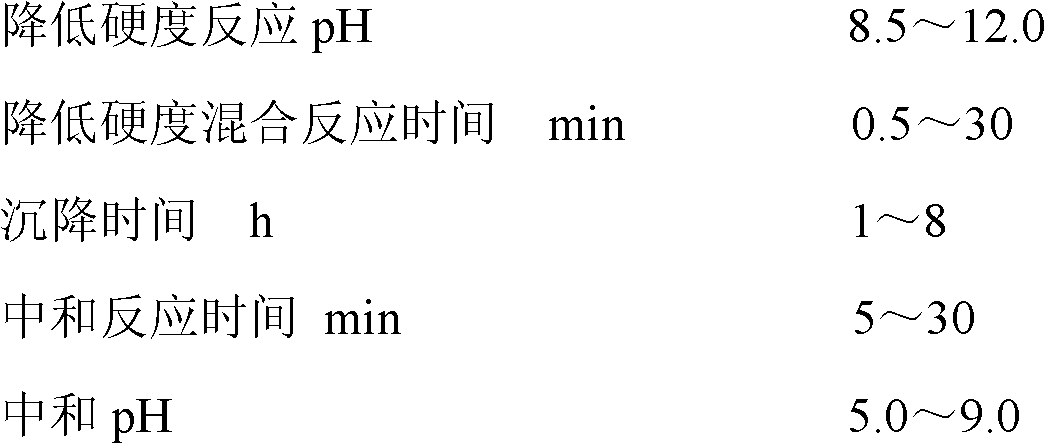

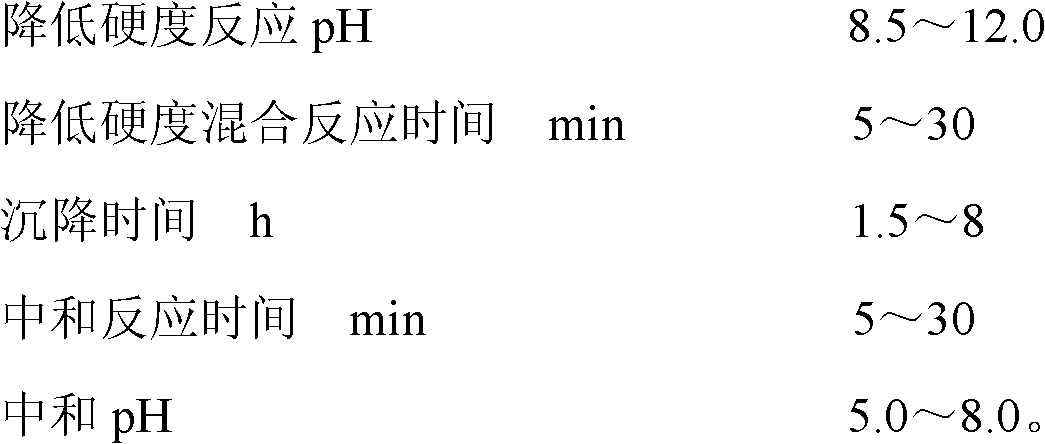

The invention discloses a deep stage treatment method for industrial wastewater. The method comprises the following steps of: 1, primarily reducing hardness, settling, and neutralizing; 2, filtering; 3, performing electro-adsorption to appropriately remove salt; and 4, performing reverse osmosis to deeply remove salt. According to deep stage treatment method for the industrial wastewater, the water quality application range is wide, a process can run stably, salt can be deeply removed by the method, and a small amount of sewage which is produced by a treatment system and meets the standard is discharged, and secondary pollution is avoided; and the treated industrial wastewater can be used as industrial circulating water, industrial circulating cooling water, and boiler water. The problems that a reverse osmosis membrane is easy to pollute, and reverse osmosis concentrated water which does not meet standard is discharged, and the problem of low running stability are solved; all the discharged sewage which is discharged meets the standard; and the produced water has various water qualities, and the recycling range is widened.

Owner:CHINA PETROLEUM & CHEM CORP

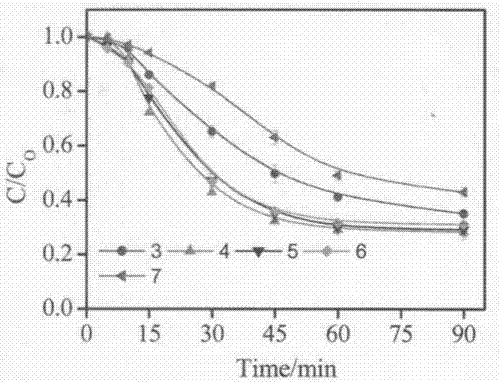

Method for oxidative degradation of organic pollutants in water by compounding heterogeneous iron-based material with sulfite under aeration condition

InactiveCN107311291AIncrease profitEmission complianceWater/sewage treatment by oxidationSulfate radicalsWater source

The invention relates to a method for oxidative degradation of organic pollutants in water by compounding a heterogeneous iron-based material with sulfite under an aeration condition. According to the invention, the oxygen content of a water body is increased through air aeration or oxygen aeration of the water body; the iron-based material and sulfite are added into the water body; and a series of reactions are carried out so as to produce active oxidizing agents like free sulfate radicals, free hydroxyl radicals and free monopersulfate radicals for degradation of organic pollutants. The method provided by the invention is efficient, economic, green, simple and wide in an application scope, ensures standard-reaching discharge of refractory organic wastewater produced in industrial production, and can guarantee water supply safety for aquatic products with organic contaminated water as a water source.

Owner:安徽同新源科技有限公司

Treatment method of arsenic wastewater

ActiveCN103112974AShort process routeShort construction periodMultistage water/sewage treatmentFlocculationResource recovery

The invention discloses a treatment method of arsenic wastewater. The treatment method comprises the following steps: optionally adding acid liquor into the arsenic wastewater to adjust the pH value to 0-5; introducing the arsenic wastewater into a reaction unit, continuously removing arsenic by adding sulfide in multistage manner; carrying out solid-liquid separation on the effluent after reaction, recycling the separated arsenic slag; adding alkali into the separated effluent to perform electrochemical advanced treatment, wherein the electrochemical advanced treatment includes an electrolytic coagulation step, an electrolytic flotation step and an electrolytic oxidation reduction step, in the electrolytic coagulation, cations are generated by the electrolyzation of a soluble anodic iron plate for flocculation; carrying out aerated oxidation on the effluent after flocculation to generate floc and micelle sediment including ferric ions, and then carrying out solid-liquid separation, wherein the liquid supernatant after separation can be recycled or reach the standard and drain outwards. The treatment method of arsenic wastewater has the advantages of simple technology, low investment, low cost and high resource recovery and recycling rate, and being green and environment-friendly, and being capable of treating continuously and the like.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

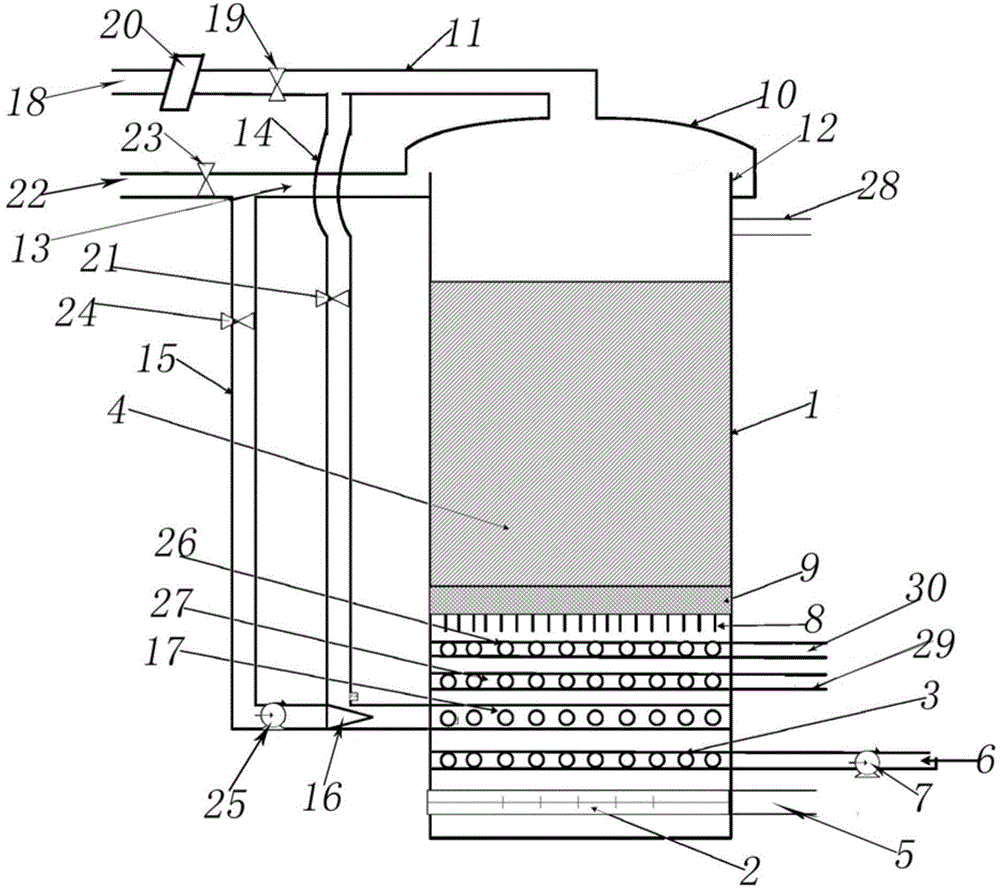

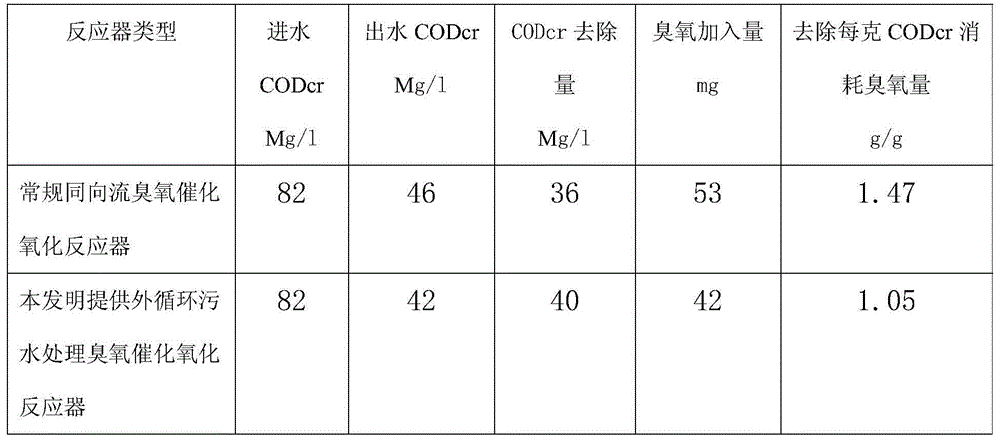

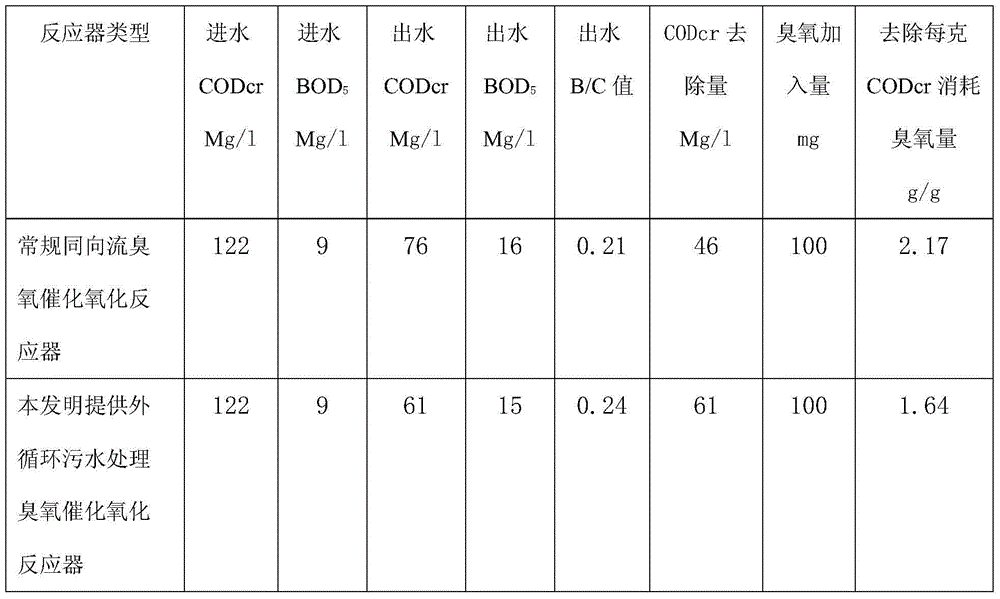

Catalytic ozonation reactor for treatment of external circulating wastewater and wastewater treatment method

ActiveCN104478066AImprove processing depthEmission complianceWater treatment compoundsWater/sewage treatment apparatusExhaust gasSewage

The invention discloses a catalytic ozonation reactor for treatment of external circulating wastewater. A tail gas pipe and a wastewater outlet pipe are arranged on a reactor, and are provided with reflux pipes; a tail gas reflux pipe and a wastewater reflux pipe are respectively communicated to a gas-phase inlet and a water-phase inlet of a water ejector; and an outlet of the water ejector is communicated with the inside of a reactor through a pipeline. The invention also discloses a wastewater treatment method. By virtue of the catalytic ozonation reactor for treatment of the external circulating wastewater, processed wastewater and tail gas are refluxed; and the ozone dissolved in the wastewater and the residual ozone in the tail gas are fully utilized to carry out catalytic oxidization reaction again, so that the wastewater treatment depth is improved; the ozone utilization rate is greatly improved; and the wastewater treatment depth is improved.

Owner:ZHEJIANG CATHAYRIPE ENVIRONMENTAL ENG

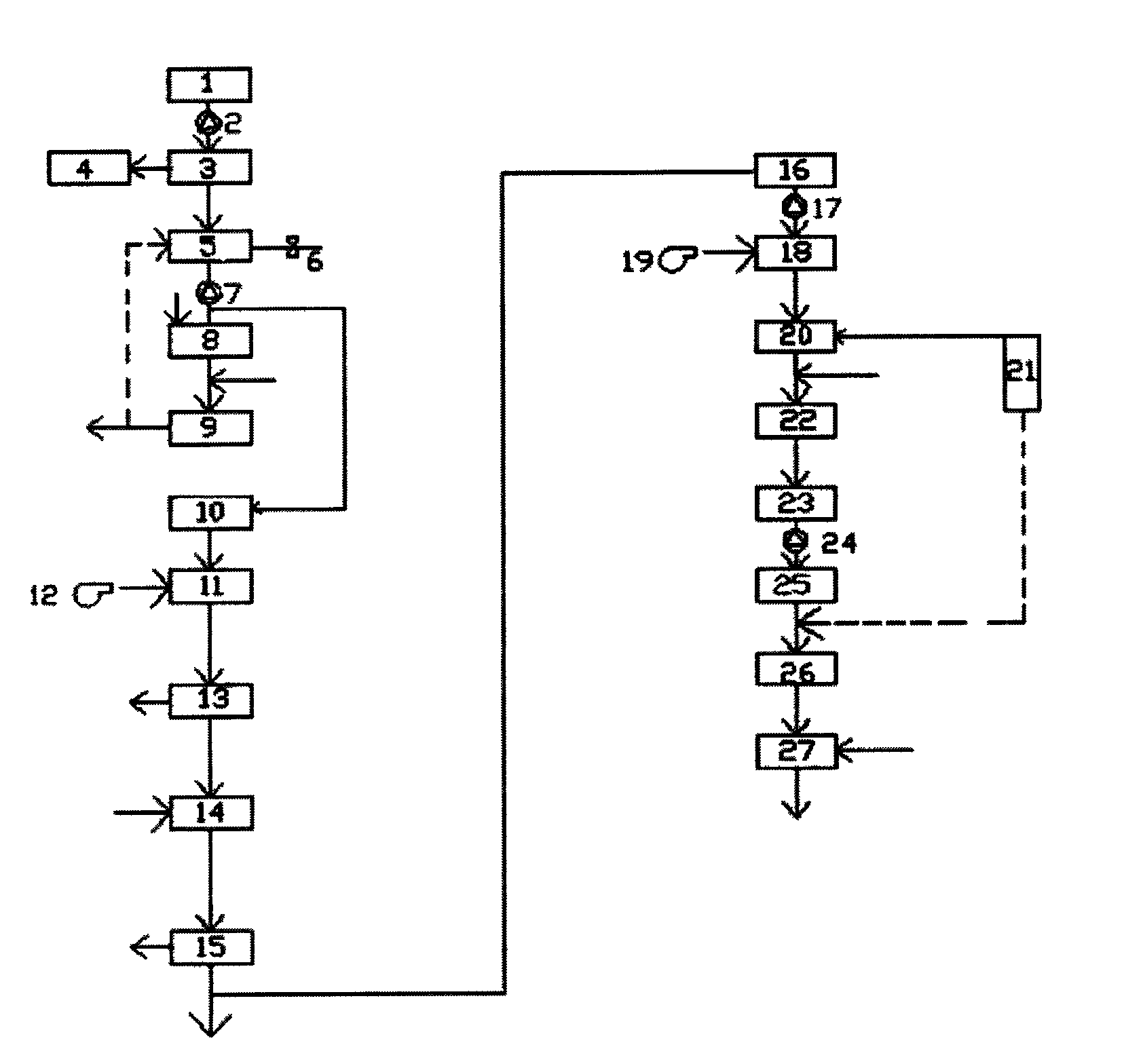

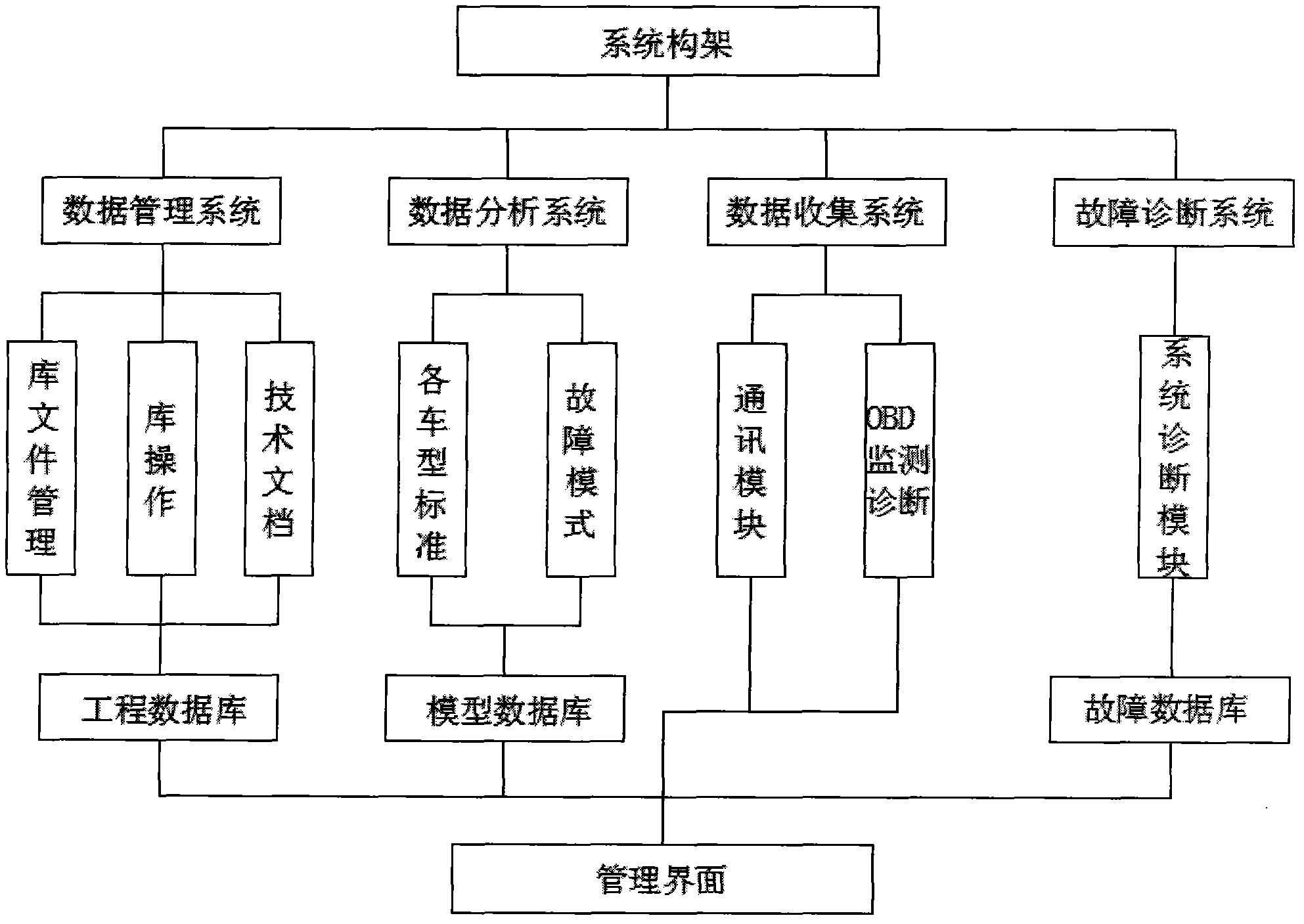

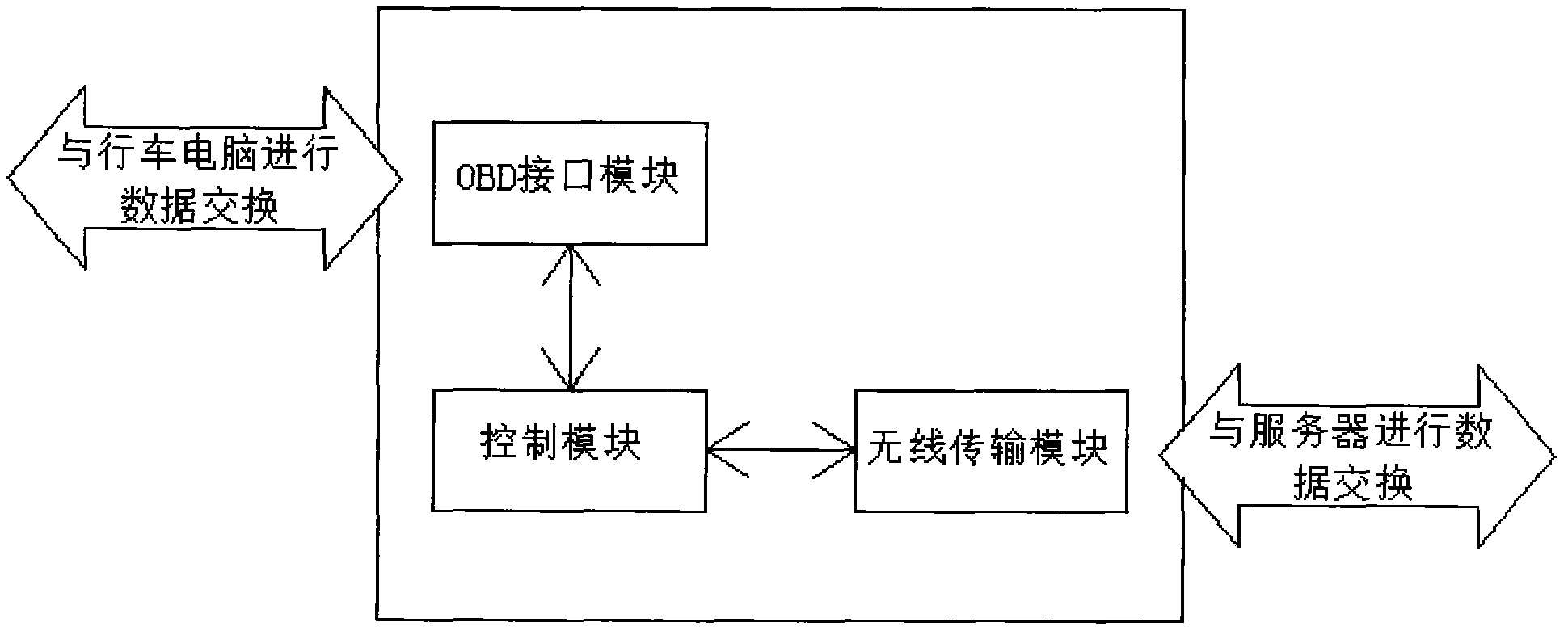

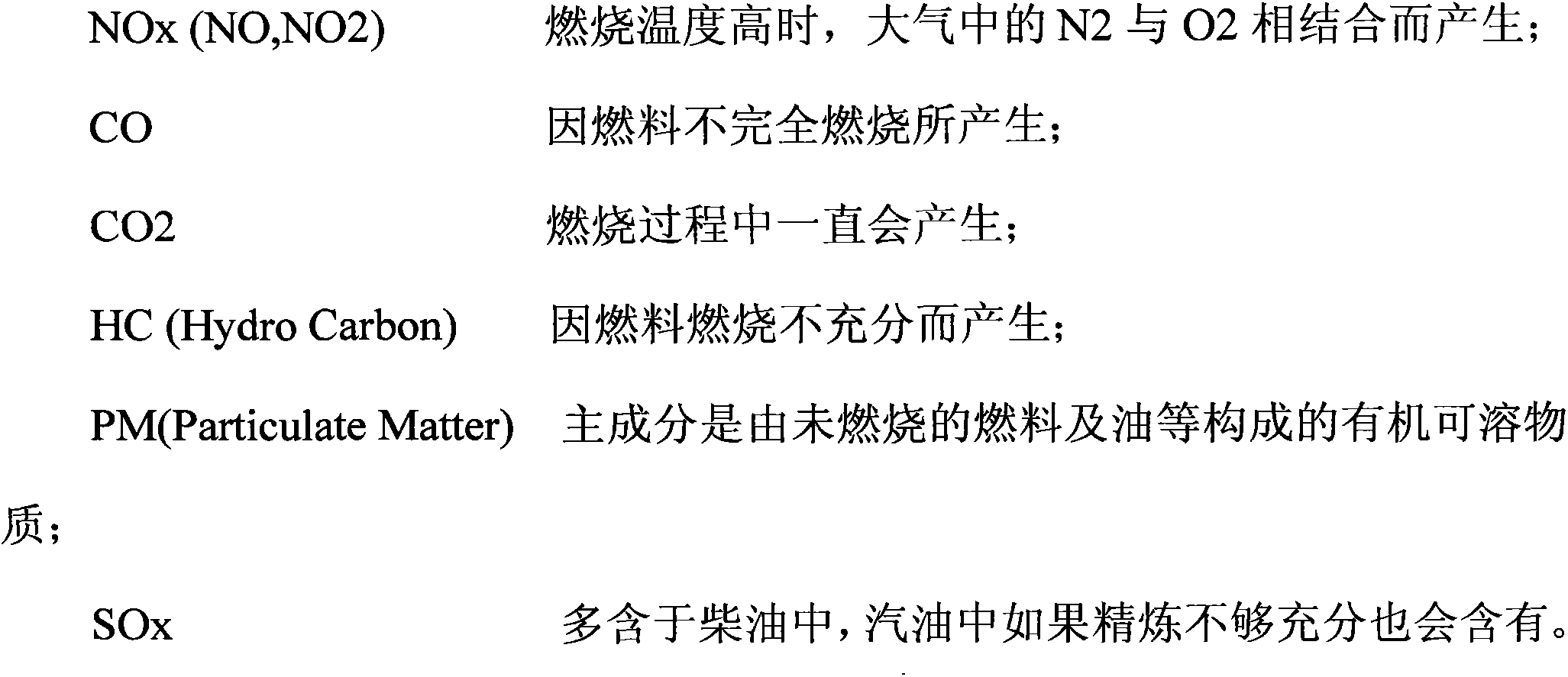

Monitoring system and method for the pollutants produced by automobile exhaust emissions in the air pollutants

InactiveCN104074580AEmission complianceEasy to track in timeInternal combustion piston enginesExhaust apparatusProper timeAtmospheric pollution

The invention discloses a monitoring system and method for the pollutants produced by automobile exhaust emissions in the air pollutants. The standard emission database of all automobile types is established, OBD monitoring and diagnosis devices are mounted on all automobiles for transmitting automobile emission data, and a remote-control data monitoring center monitors automobile exhaust by analyzing the automobile data and notifies a driver the emission is excessive. Compared with the prior art, the method and system has the advantages that the automobile exhaust emission situation is analyzed through the engine data during driving, the automobile exhaust emission can be monitored in real time, emission of the automobiles with the OBD monitoring and diagnosis devices are monitored for 7*24 hours in an uninterrupted manner, emission data can be counted, automobiles with abnormal emission can be found and necessarily controlled in proper time, the automobile owner can be contacted timely to repair the automobiles according to the problems, and the atmosphere pollution caused by automobile abnormity can be prevented.

Owner:孙磊

Aqueous hammer paint

The present invention relates to a paint material, in particular to a waterborne hammer paint. The present invention is characterized by comprising water, waterborne aluminum silver paste, film forming additive, antifreeze, anti-corrosion fungicide, defoaming agent, dispersant, regulator, waterborne bi-crosslinking acrylic emulsion, epoxy acrylic emulsion, paint sizing agent, thickening agent, flow agent, hammer tone agent, antitarnish agent and hardening agent. After being evenly stirred, the mixture is emulsified mechanically, the speed is reduced to between 400 and 600 rounds per minute; the waterborne bi-crosslinking acrylic emulsion is added and thickened after PH valve is adjusted between 8 and 9 with the regulator; after viscosity reaches between 80 and 160 seconds (T-4 / 23 DEG C) the waterborne hammer tone agent, antitarnish agent and hardening agent are added, and the paint sizing agent is added according to requirements, stirred evenly, filtered by a filter and then discharged to be packed into products. The present invention has the advantages of smooth appearance of paint film, vivid flower pattern and excellent antifouling, water and chemical resistant performances. The product can be widely applied to motors, machine tools, machinery, household electrical appliances and inside and outside building decoration. Compared with unctuous paint, the product has long life-span and durability and meets requirements of various environmental protection indexes. The product is nontoxic, harmless, noncombustible, nonexplosive and safe and reliable in storage and transportation.

Owner:王敏吉

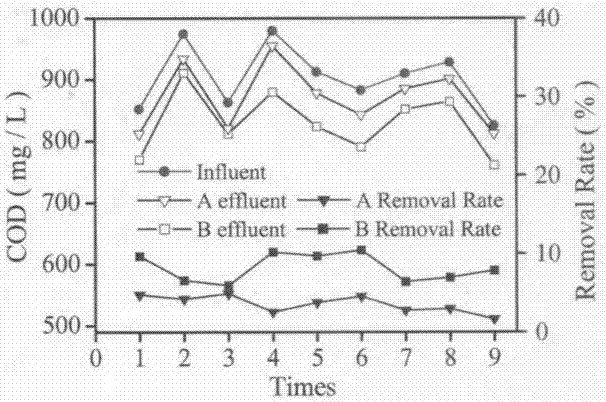

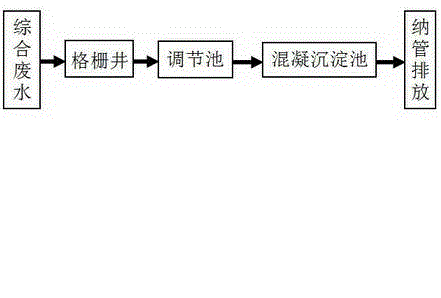

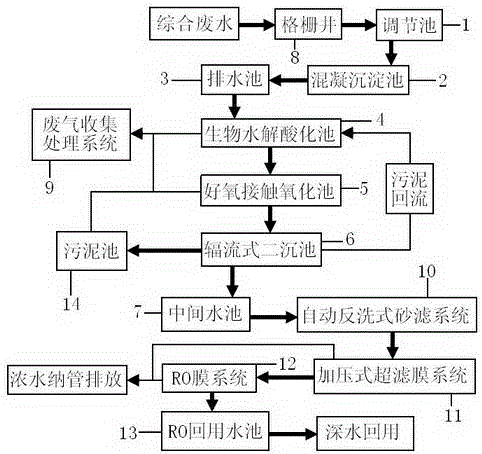

Printing and dyeing wastewater processing system

InactiveCN102616978ASolve the problem of exceeding the standardIncrease water reuseSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentWater dischargeSludge

The invention discloses a printing and dyeing wastewater processing system. The printing and dyeing wastewater processing system comprises a comprehensive wastewater preprocessing system, a depth reuse processing system and a sludge processing system, wherein the sludge processing system comprises a sludge pool; the comprehensive wastewater preprocessing system comprises an adjustment pool, a coagulative precipitation pool, a water discharging pool, a biological hydrolysis-acidification pool, an aerobic contact oxidation pool, a radial flow type secondary sedimentation pool and an intermediate water pool which are sequentially connected; the depth reuse processing system comprises an automatic backwashing sand filtration system, a pressure type ultrafilter membrane system, an RO membrane system and an RO reuse water pool which are sequentially connected; the sludge outlet of the radial flow type secondary sedimentation pool is communicated with the sludge pool; and the water outlet of the intermediate water pool is communicated with the automatic backwashing sand filtration system. According to the invention, the quality of the depth reuse water reaches outlet water quality standards; and the deepwater reuse can saves the water resource, and COD discharge is reduced year by year, so the content of discharged ammonia nitrogen can reach standards.

Owner:SHANGHAI ZHANGHUA FILM PURIFICATION

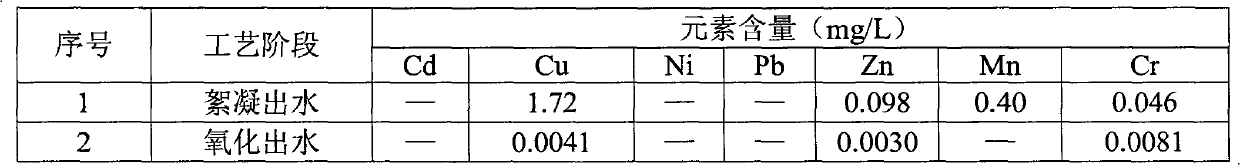

Method for treating mixed waste water of electroplating industry

InactiveCN101811806ALow biological toxicityReduce processing costsTreatment using aerobic processesWaste water treatment from metallurgical processChemistryHeavy metals

The invention discloses a method for treating the mixed waste water of the electroplating industry, which comprises the following steps of: firstly, reacting ferrous salt and the mixed waste water of the electroplating industry, then adding sodium hydroxide or lime, regulating the pH value to 6.5 to 7.5 and precipitating for 1.5 to 2h, wherein the concentration of the ferrous salt in the mixed waste water of the electroplating industry is 2000 to 4000mg / L; after precipitating the waste water, carrying out aerobic biochemical treatment on the obtained supernatant liquid by an aerobic biochemical treatment system filled with ceramsite with the detention time of 4 to 8h and removing the COD value and the residual cyanogen in the mixed waste water; and adding a chemical oxidant of sodium hypochlorite into the treated waste water, further oxidizing the cyanogen in the waste water, regulating the pH value of the waste water to 7 to 8.5 and precipitating again for 1.5 to 2h. The method has relatively low treatment cost, not only heavy metal and cyanide reach the standard, but also the COD value in the waste water can be obviously lowered, and the treated waste water reaches a novel discharge standard.

Owner:SOUTH CHINA UNIV OF TECH

Cleaning method of diamond wire cut silicon wafer

InactiveCN102294332AEfficient removalMeet surface requirementsCleaning using liquidsMetallurgySolar battery

Owner:江西金葵能源科技有限公司

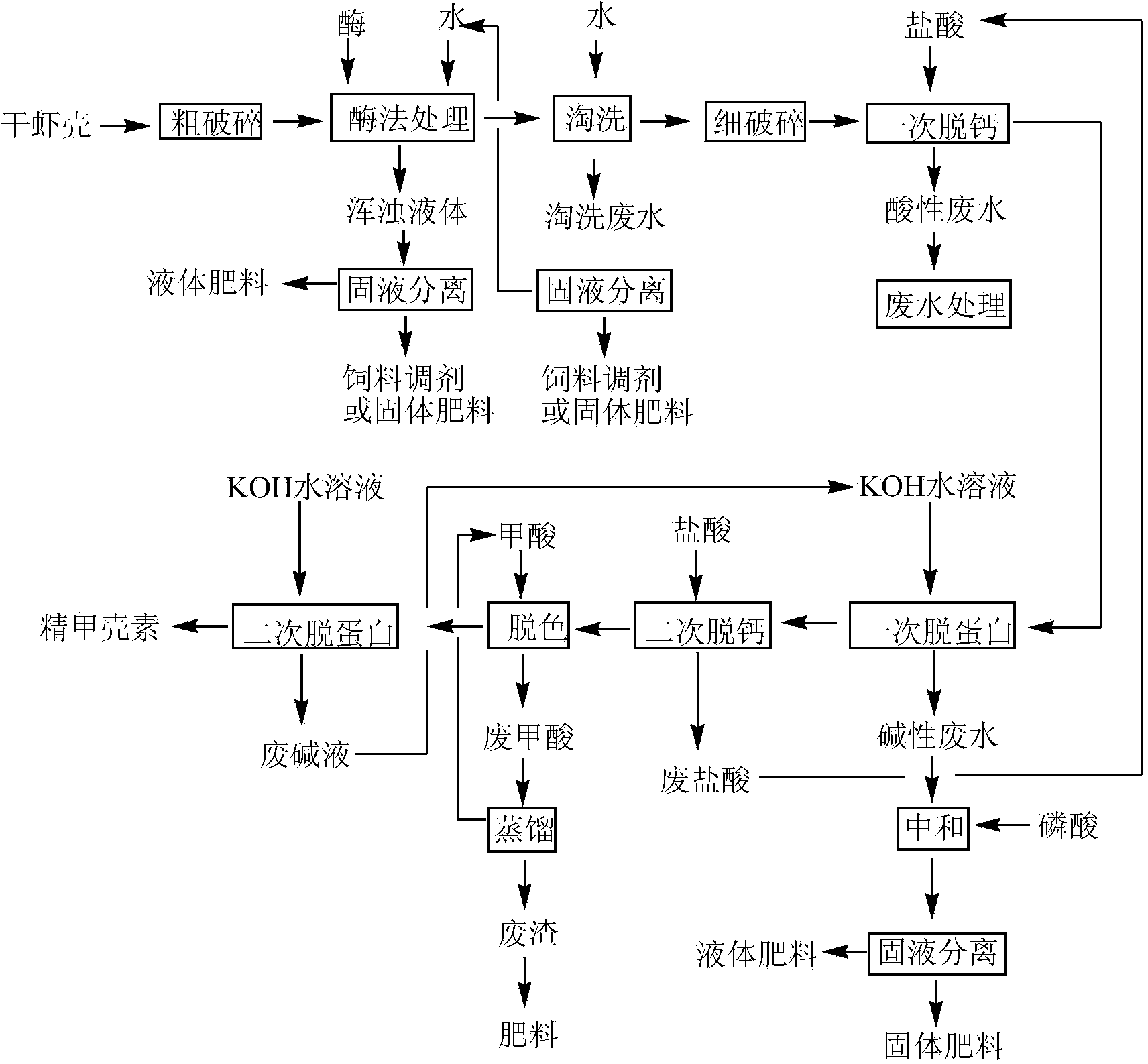

Method for extracting chitin from dried shrimp shells

The invention provides a method for extracting chitin from dried shrimp shells and belongs to the technical field of comprehensive utilization of aquatic product processing wastes. In order to solve the problem of difficulty in treatment of a large amount of manganese-containing wastewater generated in decolorizing with potassium permanganate during the conventional chitin extraction process, small-molecule organic acid decolorization is applied in extraction of chitin. The method comprises the following steps: firstly roughly crushing the dried shrimp shells, carrying out enzymatic hydrolysis on crushed dried shrimp shells with a protease, deeply cleaning, adding hydrochloric acid for decalcification and then deproteinizing with a potassium hydroxide solution, finally decolorizing with small-molecule organic acid to obtain a solid and cleaning the solid to obtain decolorized chitin. When decolorization is carried out in the method, the molecular chain of chitin cannot be destroyed, the pollution is small and after the decolorization is carried out with the small-molecule organic acid and waste acid obtained by the solid-liquid separation is subjected to reduced pressure distillation and can be recycled for decolorization.

Owner:TAIZHOU INST OF SCI &TECH NUST

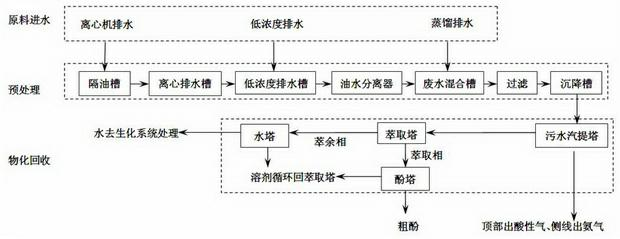

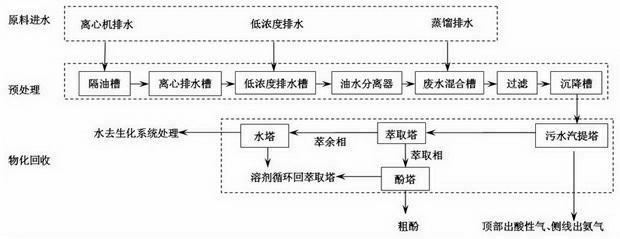

Separation treatment method for waste water in coal tar machining process

InactiveCN102674609AEasy to handleEmission complianceMultistage water/sewage treatmentWater/sewage treatment by heatingWastewaterProcess engineering

The invention discloses a separation treatment method for waste water in a coal tar machining process. The separation treatment method mainly comprises the following steps of: at first, pre-treating the waste water in the coal tar machining process to remove free oil and emulsified oil, and then entering a waste mixing groove; secondly, further removing oil matter by filtering and entering a subside for removing depositions through settling, so as to obtain oil-removed waste water; removing hydrogen sulfide and amine after the oil-removed waste water enters a sewage steam stripping tower, and extracting after acid-removed and amine-removed waste water enters an extraction tower; recovering crude carbolic acid and an extracting agent after an extract phase enters a phenol tower; separating the extracting agent from water after a residual extract phase enters a water tower; and processing after the water enters a follow-up biochemical system. The separation treatment method provided by the invention firstly removes acid and anime of the waste water, provides a good acid-alkali condition for follow-up solvent extraction and dephenolization, and has no need of adding a great amount of the acid and alkali in a treatment process. Meanwhile, byproducts, such as the crude carbolic acid, the anime, the hydrogen sulfide and the like, can be recovered. The water quality of the treated waste water can meet the water inlet requirements of the normal biochemical treatment.

Owner:SOUTH CHINA UNIV OF TECH

Method for treating high-fluorine sewage water

InactiveCN101402493AEmission complianceRapid precipitation separationMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSludgeTreated water

The invention provides a method for treating highly fluorine-contained wastewater, wherein four reaction tanks orderly overflowed are used, according to the weight ratio of calcium to fluorine of 3 to 1, the wastewater is fully mixed with calcium hydroxide solution with the concentration of 5 percent in the No. 1 reaction tank; in the No. 2 reaction tank, the overflowed water of the No. 1 reaction tank is fully mixed with calcium chloride solution of calcium hydroxide emulsion of which the concentration is 8 percent and the weight is 40 percent of the weight of the overflowed water of the No. 1 reaction tank; in the No. 3 reaction tank, the overflowed water of the No. 2 reaction tank is mixed with polyaluminum solution of which the concentration is 1 percent and the weight is 40 mg for each liter of the overflowed water of the No. 2 reaction tank; in the No. 4 reaction tank, the overflowed water of the No. 3 reaction tank is mixed with the polyacrylamide solution of which the concentration is 10 percent and the weight is 20 mg for each liter of the overflowed water of the No. 3 reaction tank; and the treated water from the No. 4 reaction tank is sent in a radial flow type sedimentation tank, and the supernatant of the radial flow type sedimentation tank is discharged into a clear water tank, and lower layer sludge is pumped in a sludge thickener for further sedimentation and separation. The fluoride concentration of the industrial wastewater is reduced to below 10 mg / L after being treated, thereby meeting the national pollution discharge standards.

Owner:浙江汉盛氟化学有限公司

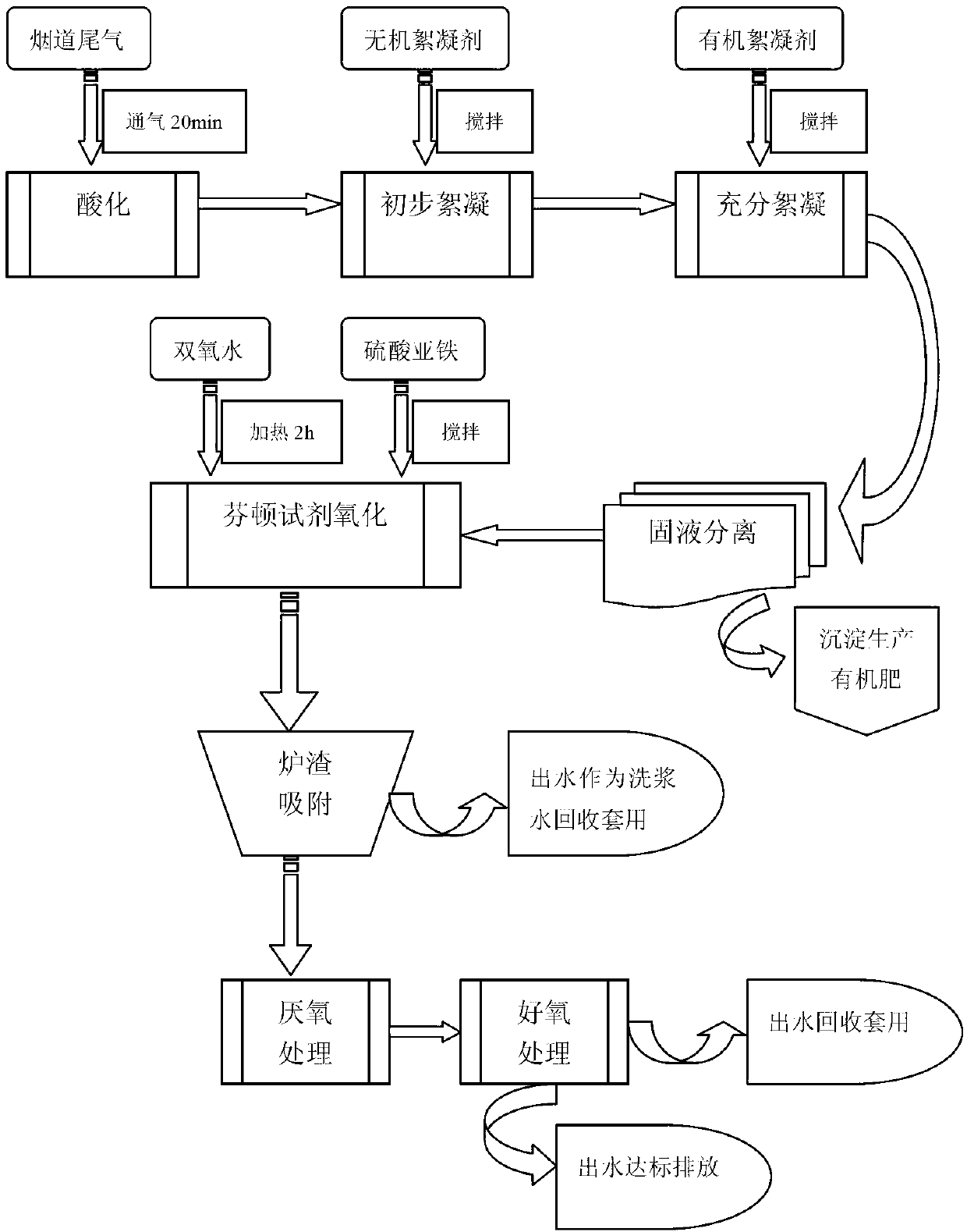

Method for comprehensively treating and utilizing dissolving pulp black liquor

ActiveCN102992553AEmission reductionEliminate ChromaTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentChemical oxygen demandSlag

The invention belongs to the technical field of biochemical environmental protection and provides a method for comprehensively treating and utilizing dissolving pulp black liquor. The method comprises the steps of (1) acidification, (2) flocculation, (3) oxidation, (4) adsorption and (5) biochemical treatment and further achieves sewage discharge up to the standard. By means of the method for comprehensively treating and utilizing the dissolving pulp black liquor, flue tail gas, slag and other wastes can be completely utilized, treatment cost is saved remarkably while emission of the three wastes is reduced, flocculated precipitate can serve as a raw material for producing organic fertilizers, considerable economic benefit is produced, chemical oxygen demand (COD) of water subjected to adsorption treatment is reduced by more than 85%, chroma is reduced by more than 99%, and the water can be recycled and can be subjected to biochemical treatment and then discharge up to the standard. The method is reasonable in process, low in cost and easy to implement, and has good economic benefit, environmental benefit and social benefit.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

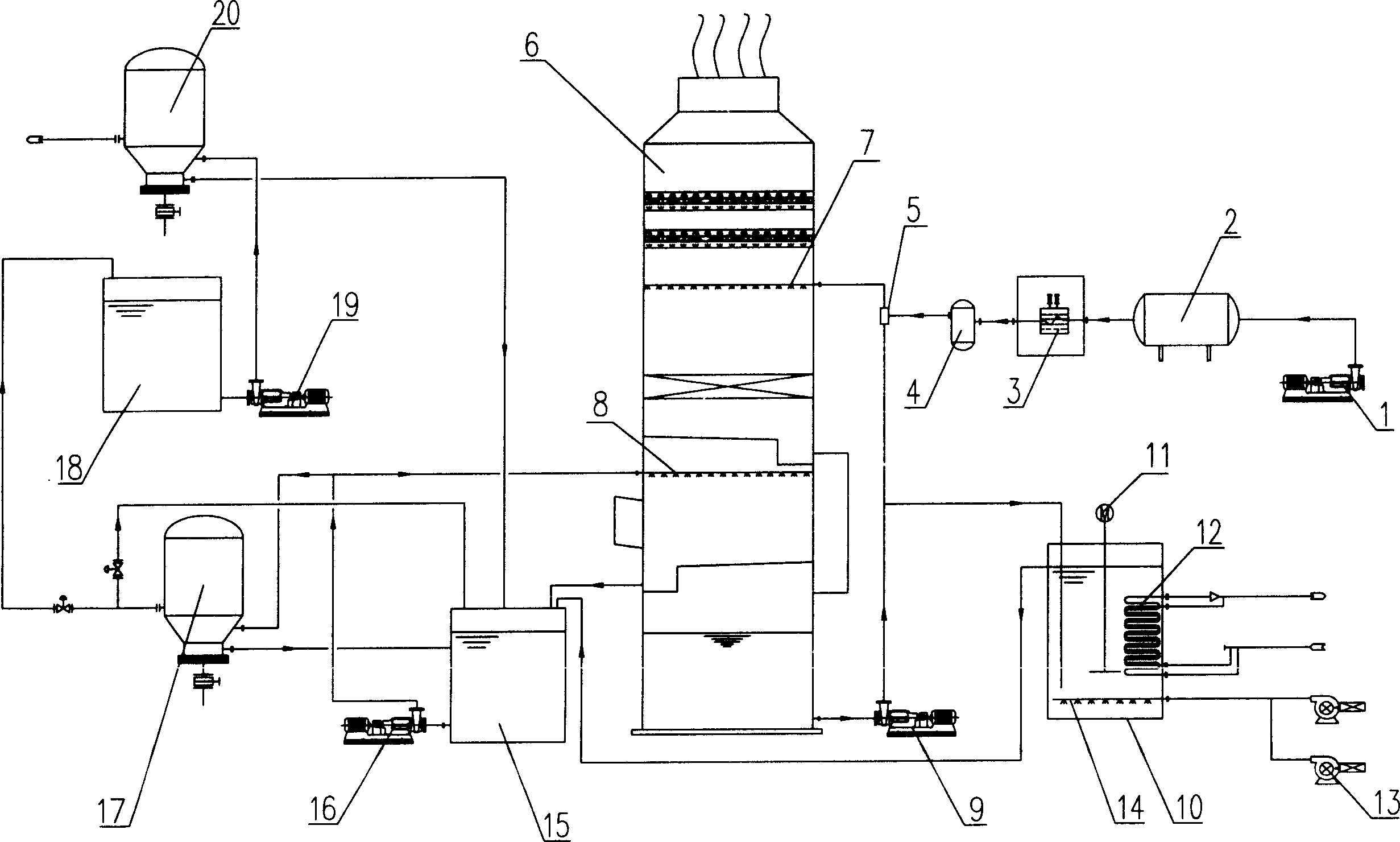

Sintering flue gas ammonia method desulfurizing system

ActiveCN101053760AReasonable processEmission complianceDispersed particle separationFurnace typesHigh concentrationCarbonization

The invention relates to an ammonia desulfurization system for sintering flue gas, and the system comprises a gasifying equipment, a absorbing equipment, an oxidation equipment, a concentration equipment and filter equipment etc. The ammonia desulfurization system for sintering flue gas of the invention can removes the SO2 in the flue gas effectively, but also can desulfurizate by reacting with SO2 in the flue gas using carbonization waste water (liquid ammonia gasified). The product of ammonium sulfite is oxidated in a low concentration at the common pressure, and then is concentrated by evaporation by the quantity of heat of the flue gas to greatly save the heat dissipation of concentration by evaporation to arrive at the aim of economize on energy. The ammonia sulfate solution in high concentration is filtrated, and then is send to the ammiaonia sulfate plant to produce chemical fertilizer. The flue gas desulfurization system of the invention has a reasonable process, makes the discharge of the flue gas reach the standard, forms without secondary pollution, treatment the waste gas by waste carbonization waste water, and produces the byproduct-chemical fertilizer.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

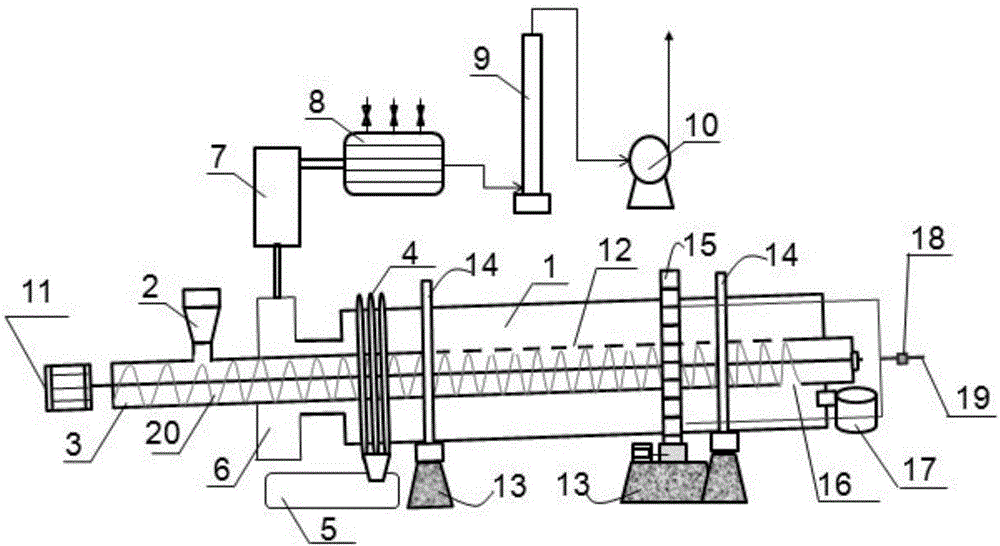

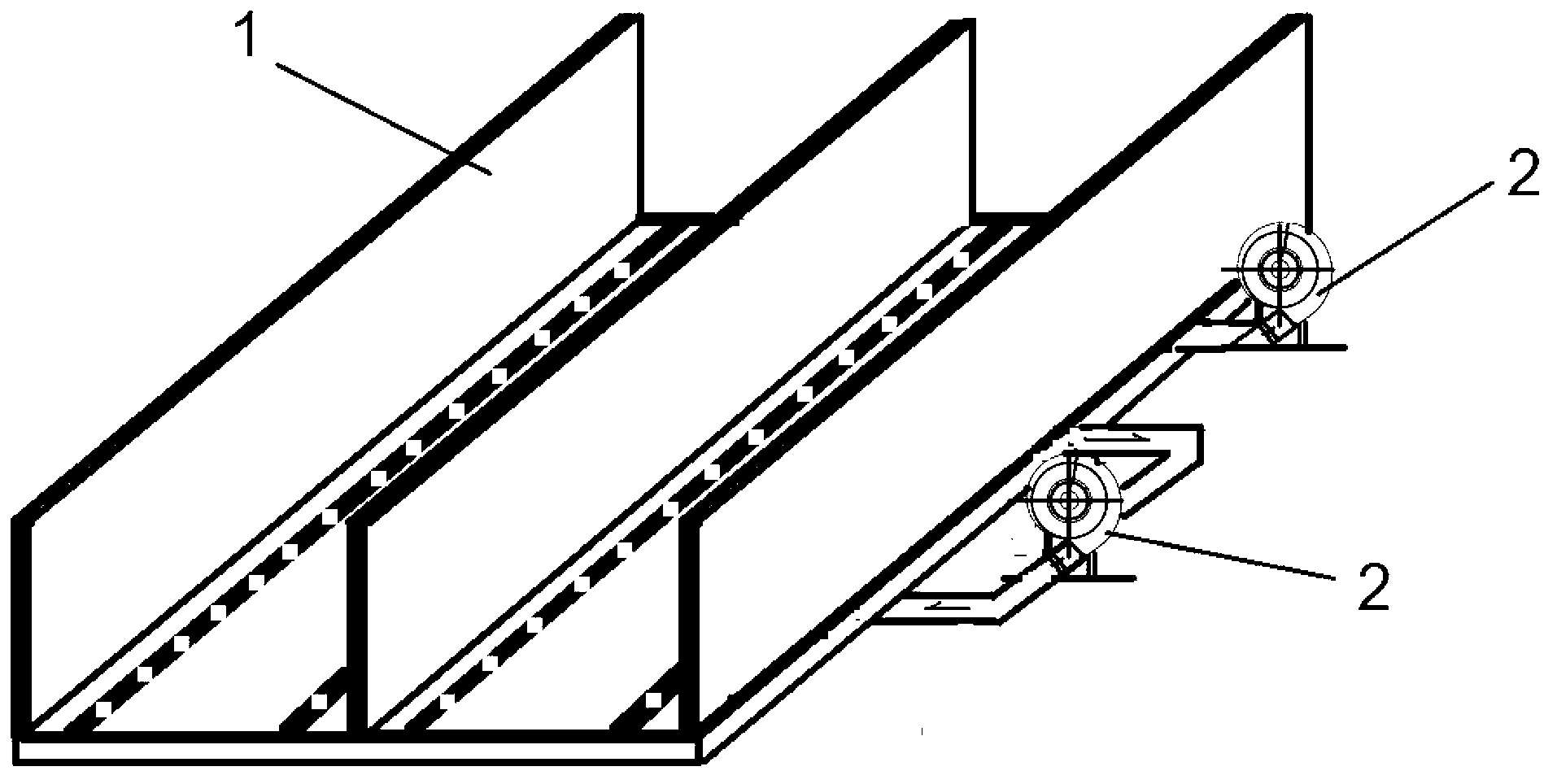

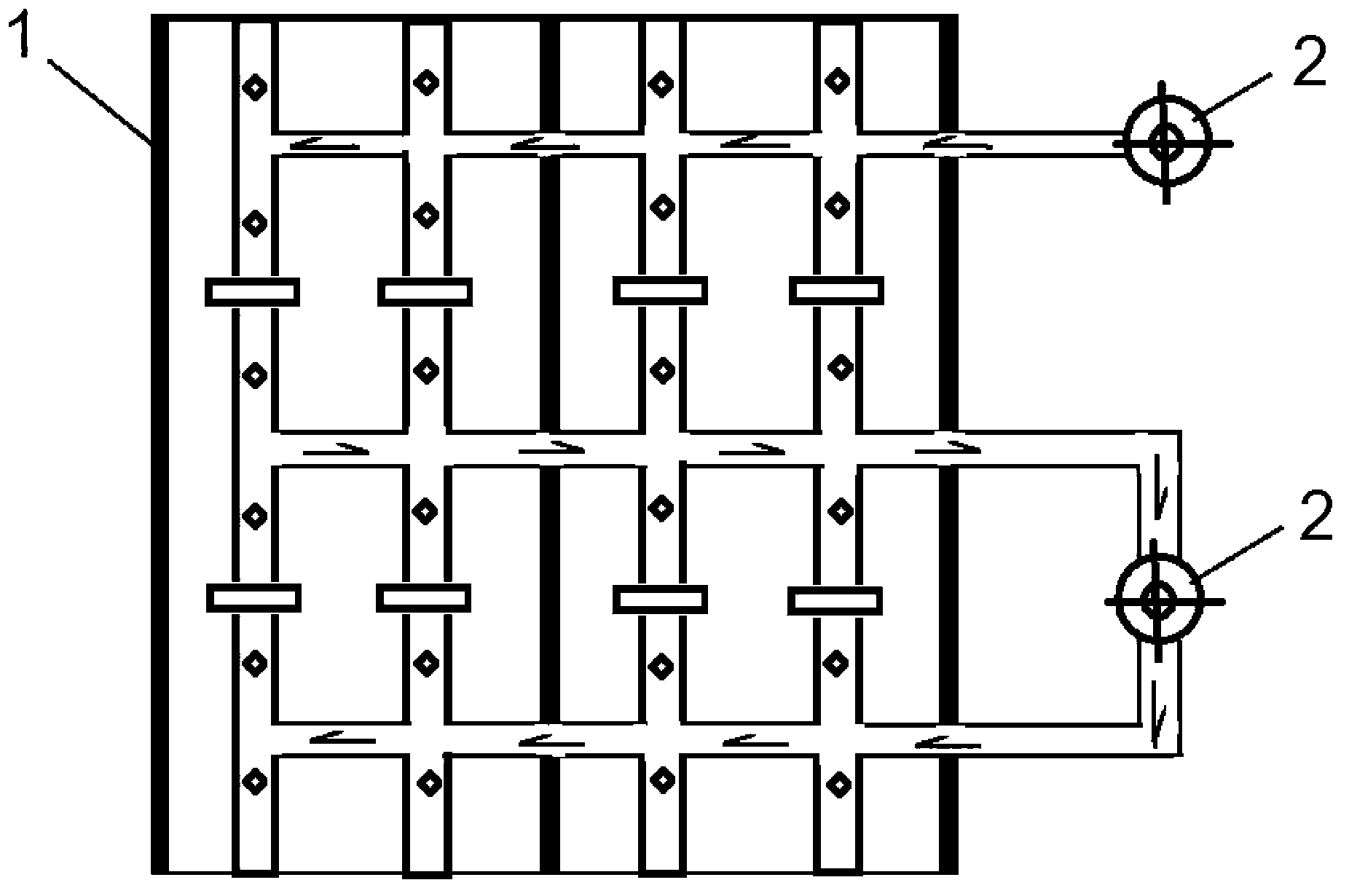

Carbonization and activation integrated processing device and processing method thereof

ActiveCN106044767ARealize continuous processing and productionRealize self-heatingCarbon compoundsEnergy inputActivated carbonCarbonization

The invention relates to a carbonization and activation integrated processing device and a processing method thereof; the device integrates raw material drying, carbonization and activation into one furnace body, and activated carbon is produced through self-heating type continuous processing production. The device is compact in structure design, realizes the integration of carbonization and activation processes, is stable in device operation, can be stably operated without external heat supply, and has the advantages of energy saving and environmental protection; and moreover, activated carbon processed by applying the device has good quality.

Owner:KETAN XIAMEN NEW CARBON MATERIAL CO LTD

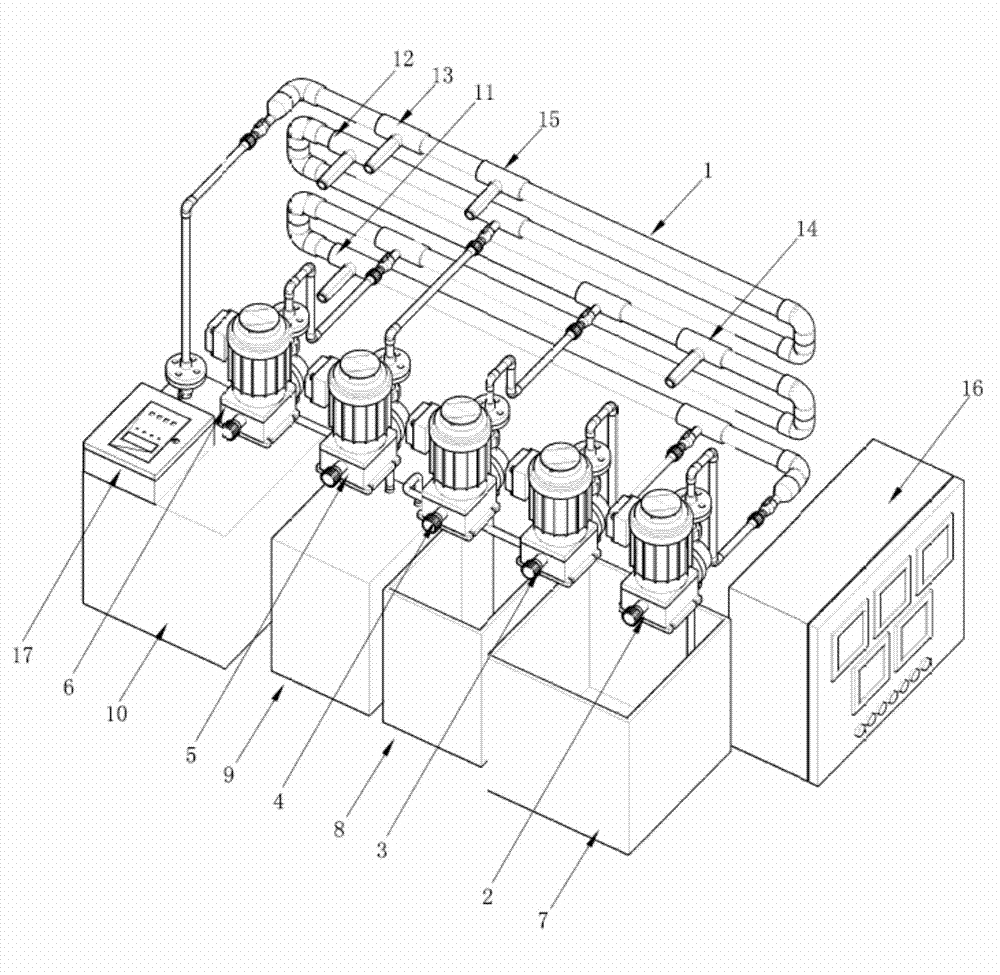

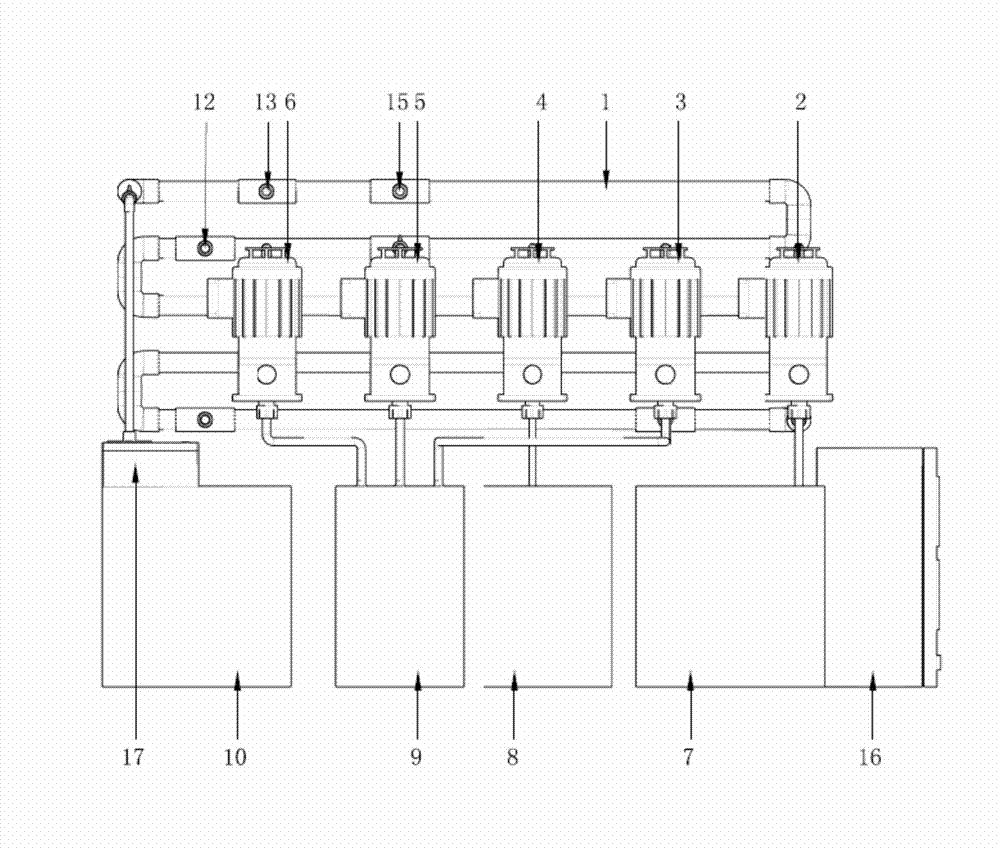

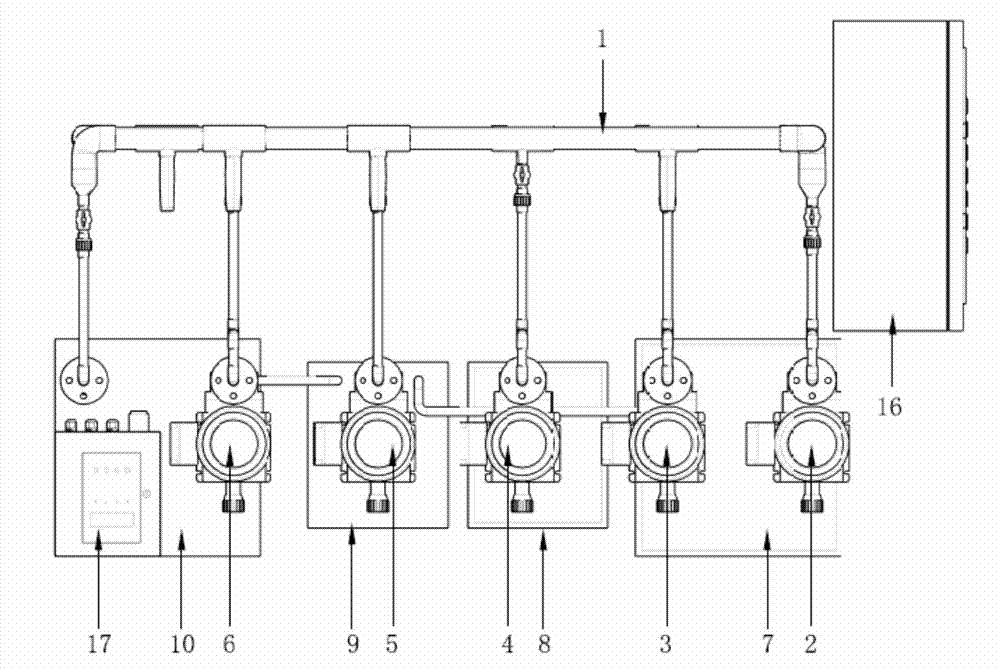

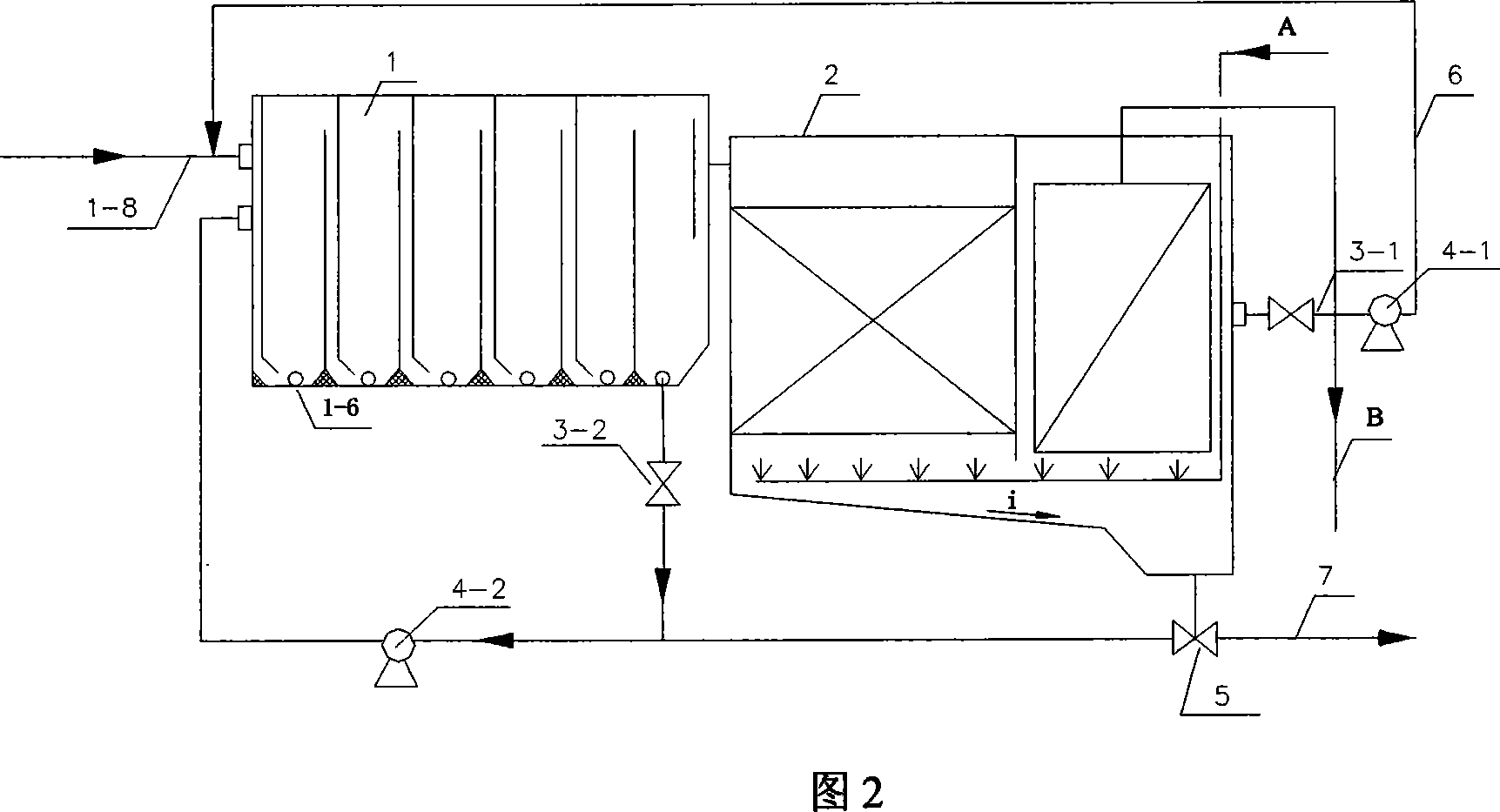

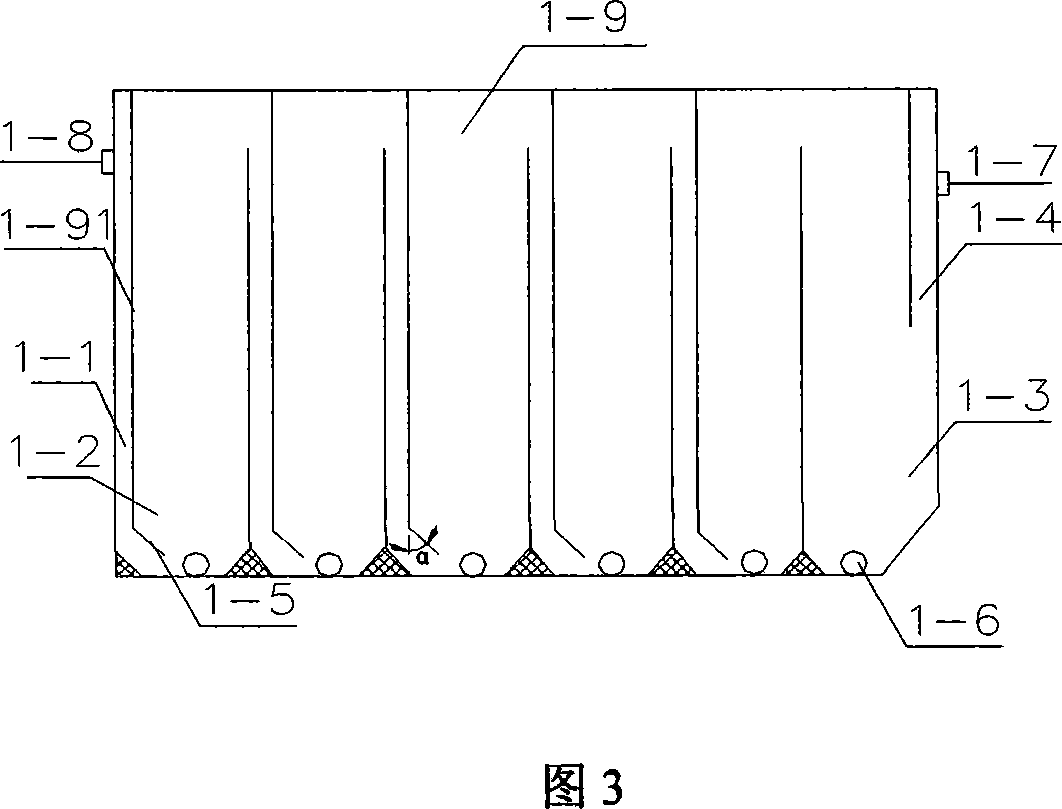

Equipment and method for treating wastewater difficult to be degraded by biology method of hydrolysis composite membrane

InactiveCN101050042AEnsure processing performanceClear functionWater contaminantsWater/sewage treatment bu osmosis/dialysisSludgeWastewater

This invention relates to apparatus and method for treating wastewater by hydrolysis-composite membrane biological method. The apparatus comprises: a multi-grid hydrolysis reactor and a composite membrane bioreactor. The method comprises: (1) introducing wastewater into the multi-grid hydrolysis reactor, and hydrolyzing in an anaerobic condition; (2) introducing the hydrolyzed wastewater into the contact oxidation region of the composite membrane reactor, and performing aerobic biological treatment; (3) introducing wastewater into the membrane separation region of the composite membrane bioreactor, and performing further aerobic biological treatment; (4) returning the sludge produced in the multi-grid hydrolysis reactor and the composite membrane bioreactor to the flow-guide region.

Owner:SOUTHEAST UNIV

Method for treating ammonia nitrogen waste water

ActiveCN101190809ALess side effectsIncrease profitMultistage water/sewage treatmentWater/sewage treatment by neutralisationMagnesium ammonium phosphatePhosphoric acid

A treatment method for waste water with ammonia nitrogen is characterized in that the waste water is divided into two parts, part A and part B, wherein, magnesium salt precipitant is added to the waste water of part A and the pH value thereof is adjusted to 7.0-10.5; phosphoric acid precipitant is added to the waste water of part B and the pH value thereof is adjusted to 1-4.0; then the waste water of the two parts is mixed and the pH value of the mixed waste water is adjusted to 8-10; after sedimentation the sediment of magnesium ammonium phosphate and supernatant liquor with ammonia nitrogen removed are obtained. The method of the invention improves the utilization rate of the precipitant and has high ammonia nitrogen removal efficiency; the obtained MAP is easy to deposit and separate and the turbidity is dramatically reduced, thereby reducing the difficulty of following flocculation treatment with short reaction sedimentation.

Owner:CHINA PETROLEUM & CHEM CORP +1

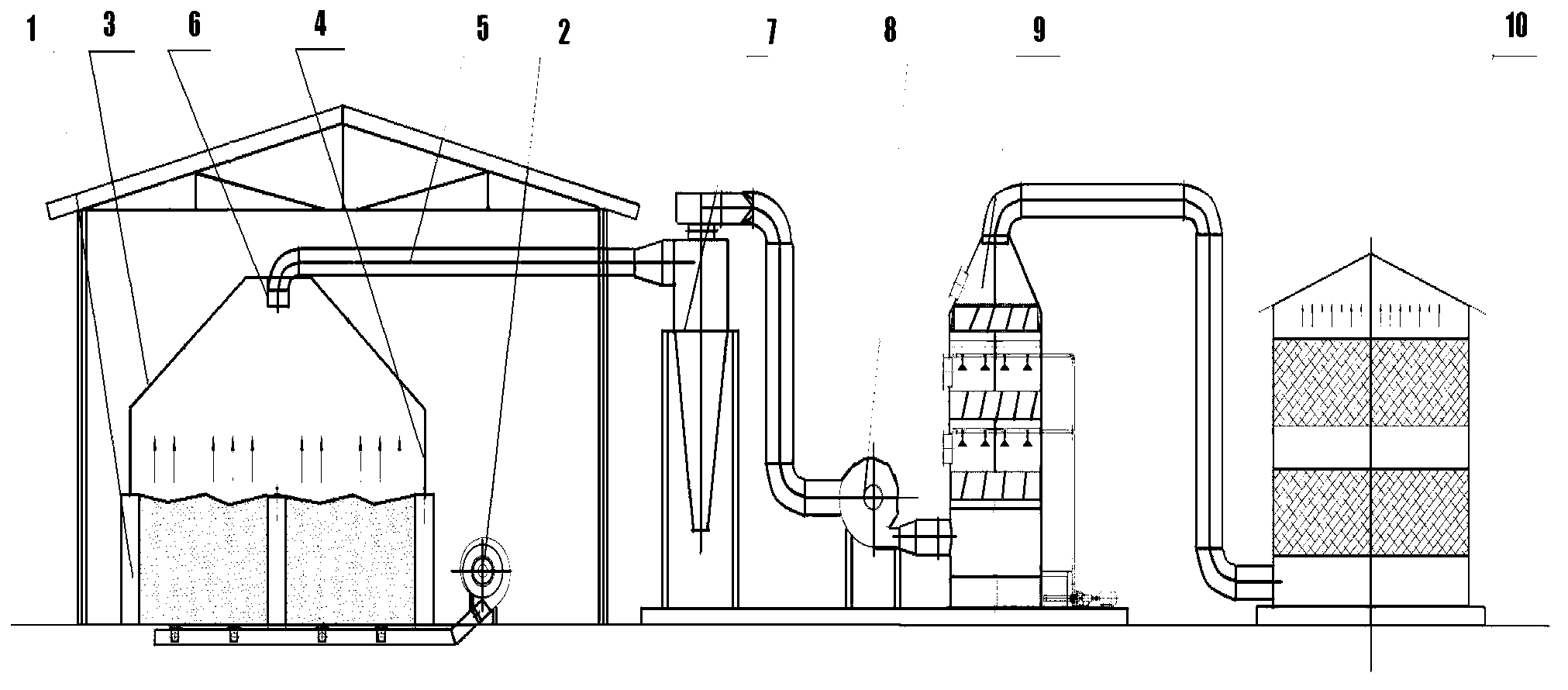

Emission reduction, collection and processing method for trough-type aerobic composting odors

ActiveCN103242073AEmission reductionHeating up fastClimate change adaptationOrganic fertiliser preparationEngineeringTower

The invention discloses an emission reduction, collection and processing method for trough-type aerobic composting odors. The method comprises the steps that composting raw materials are added to composting troughs, and odors produced by the composting troughs are collected by a gas collecting hood under the sheltering of a roller shutter, are led into a wind pipe through a draught fan, enter a cyclone dust remover so as to be subjected to dust removal, enter a deodorization tower and then enter a biofilter after the odors are processed by the deodorization tower. The method disclosed by the invention has the advantages that the odor emission can be effectively reduced, and the composting efficiency can be increased; and odor ingredients can be better collected and removed in an open aerobic composting environment.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT GUANGDONG ACADEMY OF AGRI SCI

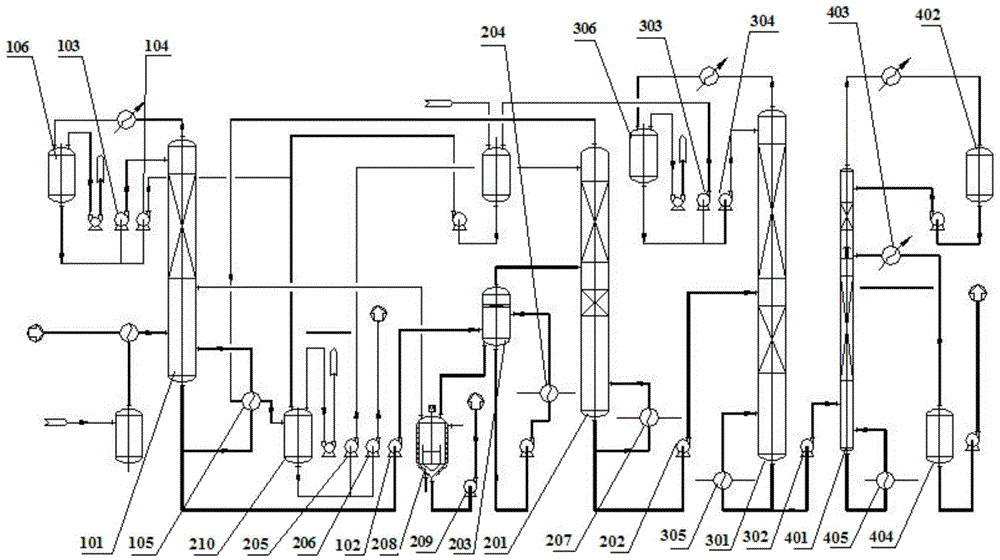

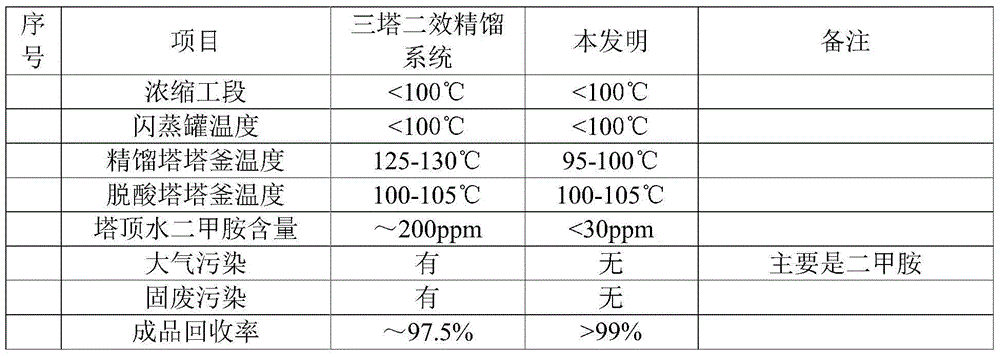

DMAC (dimethylacetamide) or DMF (dimethyl formamide) waste liquid four-tower double-effect rectification system and recovery method thereof

ActiveCN104815447ASolve pollutionSolve water pollutionCarboxylic acid amide separation/purificationFractional distillationRecovery methodDistillation

The invention discloses a DMAC (dimethylacetamide) or DMF (dimethyl formamide) waste liquid four-tower double-effect rectification system which comprises a first concentration tower, a second concentration tower, a rectification tower and a deacidifying tower. The invention further discloses a recovery method of the DMAC or DMF waste liquid four-tower double-effect rectification system. The method includes the steps: recovering and treating DMAC or DMF waste liquid; recovering and treating high-boiling objects and solid objects; recycling water; recycling steam. According to the invention, the DMAC or DMF waste is concentrated at the temperature less than 100 DEG C, distillation is performed at the temperature less than 100 DEG C, deacidification is performed at the temperature less than 105 DEG C, the whole process is completely performed at the low temperature, the DMAC or the DMF is not basically decomposed, and the finished product recovery rate of the DMAC or the DMF is higher than 99%. The four-tower double-effect rectification system solves the problems of solid waste pollution and air pollution and creates fine economic benefits, and environments are protected.

Owner:常州冀德环保科技有限公司

Municipal solid waste incineration fly ash resource utilization method

ActiveCN103128005ARealize resource utilizationMeet harmless requirementsFlotationBrickResource utilization

The invention provides a municipal solid waste incineration fly ash resource utilization method and relates to municipal solid waste treatment. The method includes a first step of mixing fly ash and water in a floatation tank, adding in sodium sulphide and stirring the mixture so as to enable salt in the fly ash to be dissolved into the water, and enabling heavy metal such as plumbum (Pb) and zinc (Zn) in an oxidation state in the fly ash to achieve vulcanizing to generate plumbum sulfide (PbS) and zinc sulfide (ZnS), a second step of adding collecting agents into the floatation tank again and stirring so as to enable the collecting agents to fully contact with the fly ash and enable the collecting agents to be adsorbed on the surfaces of vulcanized heavy metal, a third step of adding foaming agents and terpenic oil in the floatation tank, carrying out flotation separation and centrifugal dewatering, adding cement, sand, water, exciting agents, namely sodium delicate, and alum into the obtained fly ash and stirring, filling stirred samples into a trial mould, compacting the stirred samples, placing and maintaining the stirred samples and then demoulding to obtain cement blocks, and a fourth step of carrying out centrifugal dewatering on floating objects in the floatation tank, sending the floating objects into a household garbage incineration plant, and carrying out high-temperature processing on dioxin, wherein the dioxin can be completely resolved under an environment with the temperature larger than 850 DEG C and smoke stay time more than 2 hours (s), and smoke reaches the standard and is exhausted.

Owner:XIAMEN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com