Patents

Literature

36results about How to "Bright pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous hammer paint

The present invention relates to a paint material, in particular to a waterborne hammer paint. The present invention is characterized by comprising water, waterborne aluminum silver paste, film forming additive, antifreeze, anti-corrosion fungicide, defoaming agent, dispersant, regulator, waterborne bi-crosslinking acrylic emulsion, epoxy acrylic emulsion, paint sizing agent, thickening agent, flow agent, hammer tone agent, antitarnish agent and hardening agent. After being evenly stirred, the mixture is emulsified mechanically, the speed is reduced to between 400 and 600 rounds per minute; the waterborne bi-crosslinking acrylic emulsion is added and thickened after PH valve is adjusted between 8 and 9 with the regulator; after viscosity reaches between 80 and 160 seconds (T-4 / 23 DEG C) the waterborne hammer tone agent, antitarnish agent and hardening agent are added, and the paint sizing agent is added according to requirements, stirred evenly, filtered by a filter and then discharged to be packed into products. The present invention has the advantages of smooth appearance of paint film, vivid flower pattern and excellent antifouling, water and chemical resistant performances. The product can be widely applied to motors, machine tools, machinery, household electrical appliances and inside and outside building decoration. Compared with unctuous paint, the product has long life-span and durability and meets requirements of various environmental protection indexes. The product is nontoxic, harmless, noncombustible, nonexplosive and safe and reliable in storage and transportation.

Owner:王敏吉

High-strength artificial quartz stone plate and production process thereof

The invention discloses a high-strength artificial quartz stone plate and a production process thereof. The high-strength artificial quartz stone plate is made from, by weight, 40-60 parts of 4- to 10-mesh quartz sand, 25-35 parts of 400- to 600-mesh quartz powder, 30-40 parts of binder, 10-20 parts of cullet, 5-10 parts of aluminum silicate fiber, 10-15 parts of organic bentonite, 20-25 parts of zirconia ceramic powder, 30-40 parts of sodium silicate, 15-20 parts of fly ash, 0.5-1 part of isopropyl tri(dioctylpyrophosphate) titanate, and 0.2-0.3 part of pigment. The artificial quartz stone plate produced by the production process has the advantages of light weight, uniform density, bright color, rich pattern, high impact resistance, high wear resistance, fine heat resistance, fine weatherability, deformation resistance, scratch resistance, aging resistance, coloring resistance, environment friendliness, no pollution and the like, has high performance indexes in terms of acid and alkali resistance, slat spray resistance, gasoline resistance and the like in organic solvents, and is durable and fully as effective as simulation natural stone.

Owner:安徽瑞翔石英制品有限公司

Artificial quartz stone sheet material with linear patterns and production technology thereof

The invention discloses an artificial quartz stone sheet material with linear patterns and a production technology thereof. The sheet material comprises a main material with an A color and a pattern material with a B color. The main material comprises a granular raw material with a size of 0.075 to 5 mm, quartz powder with a size of 0.005 to 0.045 mm; color pigment, a silane coupling agent, unsaturated polyester resin, and a curing agent. The pattern material comprises an inorganic pigment, or comprises an inorganic pigment and quartz powder with a size of 0.045 to 0.212 mm. The granular raw material is quartz particles or glass particles. The artificial quartz stone, which is produced by mixing two materials, has the advantages of beauty, distinctive patterns, and unique color. The species and patterns of artificial quartz stone are enriched, at the same time, the production efficiency is high, the reject rate is effectively reduced, and the sheet material can be massively produced.

Owner:GUANGDONG BANNER NEW MATERIAL TECH

Bulk pattern artificial quartz stone plate and production process thereof

The invention discloses a bulk pattern artificial quartz stone plate and a production process thereof.The plate is prepared from a main material with color A and a pattern material with color B.The main material with color A is prepared from a particle raw material with granularity of 0.075-5 mm, quartz powder with granularity of 0.005-0.045 mm, colored pigment, silane coupling agent, unsaturated polyester resin and curing agent.The pattern material with color B is prepared from inorganic pigment or inorganic pigment and quartz powder with granularity of 0.045-0.212 mm, wherein the particle raw material is quartz particles or glass particles or the mixture of quartz particles and glass particles.The pattern material with color B is scattered in the main material with color A, the dry pattern material with color B can be attached to the wet main material with color A to form a color-mixed material, bulk patterns are displayed on the surface of the plate after stirring and pressing, and the larger the stirring frequency is, the more pattern bulks are formed; in addition, the pattern material is simplex inorganic pigment, namely, the mixed material of inorganic pigment and quartz powder, the prepared patterns are good in effect, clear in color and finer, the type and pattern of artificial quartz stone are enriched, production efficiency is high, the reject ratio of the product is effectively decreased, and mass production can be achieved.

Owner:GUANGDONG BANNER NEW MATERIAL TECH

Compound-color artificial quartz quartzite board having flowability and production process thereof

The invention provides a compound-color artificial quartz quartzite board having flowability and a production process thereof / .The board comprises a main material and two or more auxiliary colors, and the main material and the two or more auxiliary colors each comprises particle raw materials with the diameter ranging from 0.075 mm to 5 mm, quartz powder with the diameter ranging from 0.005 mm to 0.045 mm, colored pigment, a silane coupling agent, unsaturated polyester resin and a curing agent, wherein the particle raw materials are quartz particles or glass particles or a mixture of the quartz particles and the glass particles; the main material is different from auxiliary resin in proportion, the dry degree and wet degree of the materials are greatly different, the main material is mixed with auxiliary materials, dry materials can adhere to wet materials, a color-mixed material is obtained, and after the color-mixed material is stirred and compressed, flowability appear on the surface of the board.Obtained artificial quartzite is attractive in modeling, bright in pattern, and unique in color, the varieties and pattern forms of the artificial quartzite are enriched, meanwhile, production efficiency is high, the defective ratio of products is effectively lowered, and mass production can be conducted.

Owner:GUANGDONG BANNER NEW MATERIAL TECH

Digital printing advertisement base material and preparation method thereof

ActiveCN105017548ASame protective effectImprove the degree of automated productionMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesDigital printingHot-melt adhesive

The invention provides a digital printing advertisement base material and a preparation method thereof. The preparation method comprises the steps: preparing anti-ultraviolet hot melt glue for digital printing and putting a base layer on a coil-feeding rack of a coating machine for corona treatment; coating the anti-ultraviolet hot melt glue and drying the base layer at 60-120 DEG C, wherein the thickness of the cooled hot melt glue is 20-100 [mu]m; coating a 10-50 [mu]m thick ink-receptive coating on the cooled anti-ultraviolet hot melt glue, and printing a pattern; carrying out hot press, wherein the pressure is 1-5 kg, the temperature is 120-200 DEG C, the time is 2-50 seconds, and the anti-ultraviolet hot melt glue is melted and permeates among particles of the ink-receptive coating and the printed pattern and covers above and quickly congeals to a film to form a protective layer; and cooling and rolling. The advertisement base material prepared by the invention is bright in pattern, smooth and level, rainproof and sun-proof and strong in anti-ultraviolet ability, and is free of yellowing phenomenon if being used outdoors for one year.

Owner:ZHEJIANG FULAI NEW MATERIAL CO LTD

High-temperature-resistant artificial quartz stone plate and production process thereof

The invention discloses a high-temperature-resistant artificial quartz stone plate and a production process thereof. The high-temperature-resistant artificial quartz stone plate comprises, by weight, 40-50 parts of 20-40-mesh quartz sand, 20-30 parts of 400-600-mesh quartz powder, 30-40 parts of adhesives, 10-15 parts of blast furnace slag, 5-10 parts of ceramic fiber, 10-15 parts of attapulgite, 15-25 parts of nano wollastonite, 20-30 parts of sodium silicate, 15-20 parts of potassium feldspar powder, 0.5-1 part of double (pyrophosphate dioctyl oxygen radicals) ethylene ester titanate, and 0.2-0.3 part of pigments. The quartz stone plate is lightweight, even in density, bright in color, rich in pattern, high in strength, high-temperature-resistant, high in impact resistance, good in wear resistance, good in weather resistance, less prone to deformation, scratch-resistant, aging-resistant, less prone to dying, environment-friendly, pollution-free, durable and the like. In addition, the quartz stone plate is quite high in various organic solvent performance indexes such as acid-base resistance, salt-mist resistance and petroleum resistance, and the effect of high-simulation natural stone is completely achieved.

Owner:安徽瑞翔石英制品有限公司

Invariant color oil-based ink containing abelmoschus manihot extract and preparation method of ink

The invention discloses invariant color oil-based ink containing an abelmoschus manihot extract and a preparation method of the ink. The oil-based ink has anti-discoloration and anti-fading effects, and not only can guarantee bright color of newly printed patterns but also can keep bright patterns of printed matters still fresh after being placed for long time, giving a feeling that the color of the patterns is not changed.

Owner:苏州科德教育科技股份有限公司

Production method of satin color jean fabric

The invention relates to a production method of a satin colored jean plus material that is used for producing the satin colored jean plus material and belongs to textile technology. The satin colored jean material is produced through ball warping, dyeing, warp separating, slashing and driving shaft, weaving of a weaving workshop, sanforized finishing, water rinsing, millstone milling and subsequent finishing. The satin colored jean material is characterized in that the yarns after the warp balling are dyed in two parts with a first part directly entering an indigo dyeing slot through an oxidizing shelf and a second part firstly entering a dyeing slot of a vulcanized dye and then entering the indigo dyeing slot through the oxidizing shelf, and the yarns in the second part are dyed indigo synchronously with the yarns in the first part, and then the yarns are water rinsed, parched, warp separated, slashed, woven, sanforizing finished, water rinsed and millstone milled, thus being produced into fabric piece goods. The produced jean plus material is fashionable and has rich color, specific style, clear texture, burly fabric body, linear fabric edge, genuine color, fresh and vivid pattern, clear color luster of front and back surfaces, wash resistance, rich stereoscopic impression, good decorative effect and high quality.

Owner:SHANDONG LANJUN GROUP

Self-enhanced ceramic cold glaze and preparation method thereof

The artificial quartz stone plate with pearlescent dyeing particles according to the present invention, its raw materials include: 0.075-5mm granular raw material, 0.07-0.7mm decorative colored pearl powder, 0.005-0.045mm quartz powder, colored pigment, silane coupling agent, unsaturated Polyester resin, curing agent, accelerator. Among them, the raw material of the particles is quartz particles or glass particles, or a mixture of the two, which has beautiful shapes, bright patterns, and unique colors, which enriches the types and patterns of artificial quartz stones. At the same time, the production efficiency is high, and the defective rate of products is effectively reduced. Can be mass produced.

Owner:GUANGDONG BANNER NEW MATERIAL TECH

Three-color calacatta pattern artificial quartz plate and production process thereof

The invention discloses a three-color calacatta pattern artificial quartz plate and a production process thereof. The three-color calacatta pattern artificial quartz plate comprises a main material in color A, a filler material in color B and a pattern spraying material in color C. The main material in color A is prepared from 0.075-1mm particle materials, 0.005-0.045mm quartz powder, colored pigments, a silane coupling agent, unsaturated polyester resin and a curing agent. The filler material in color B is prepared from 0.005-0.045mm quartz powder, colored pigments, the silane coupling agent, unsaturated polyester resin and the curing agent. The pattern spraying material in color C is prepared from inorganic pigments or organic pigments, the silane coupling agent, unsaturated polyester resin and the curing agent. The particle materials are quartz particles or glass particles or mixture of the quartz particles and the glass particles. The manufactured artificial quartz is attractive in structure, bright and clear in pattern and unique in color and pattern forming; any patterns can be made through moulds in different shapes; by production stagger combination, high production efficiency is achieved, product reject ratio is effective decreased, and batch production can be realized.

Owner:GUANGDONG BANNER NEW MATERIAL TECH

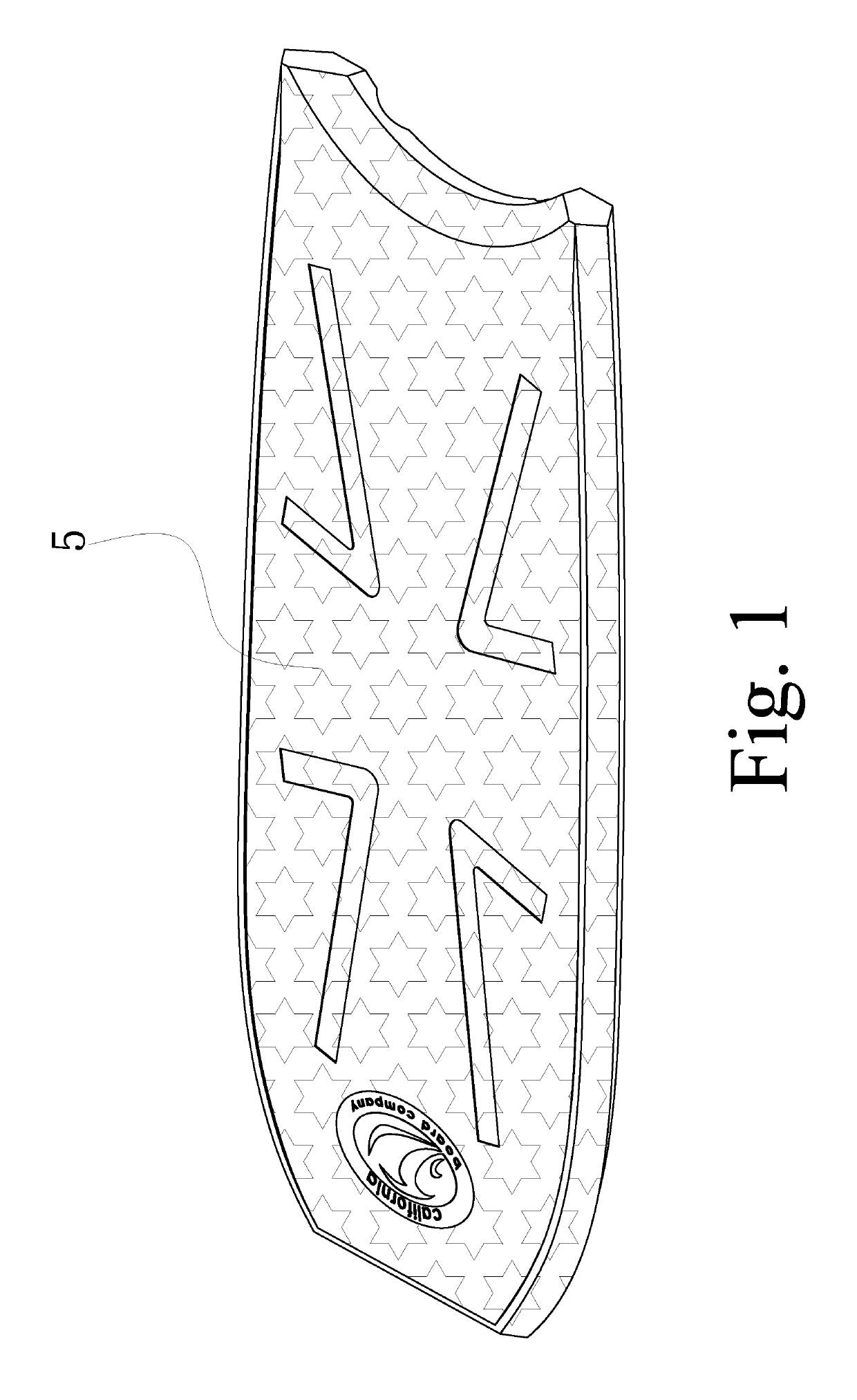

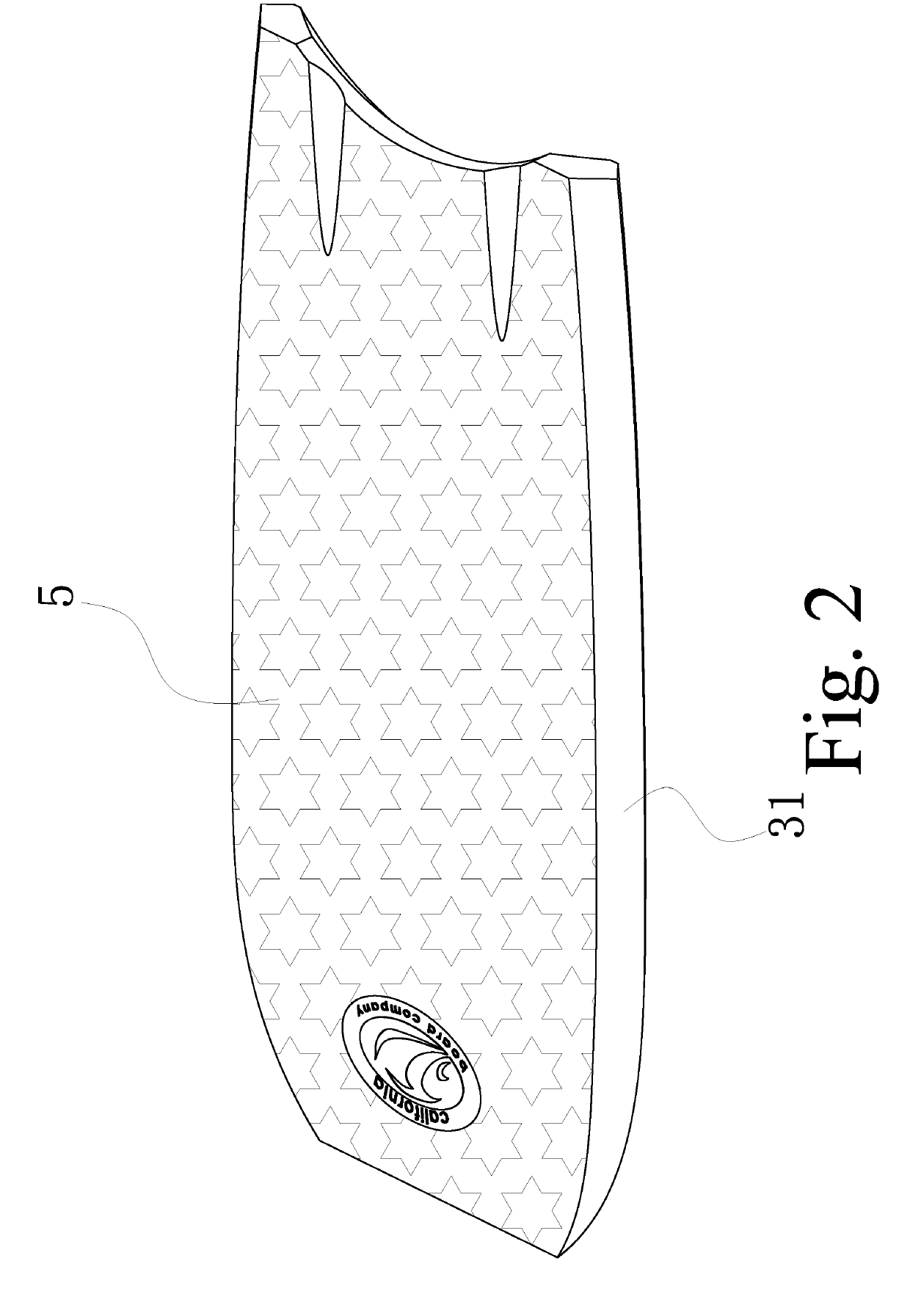

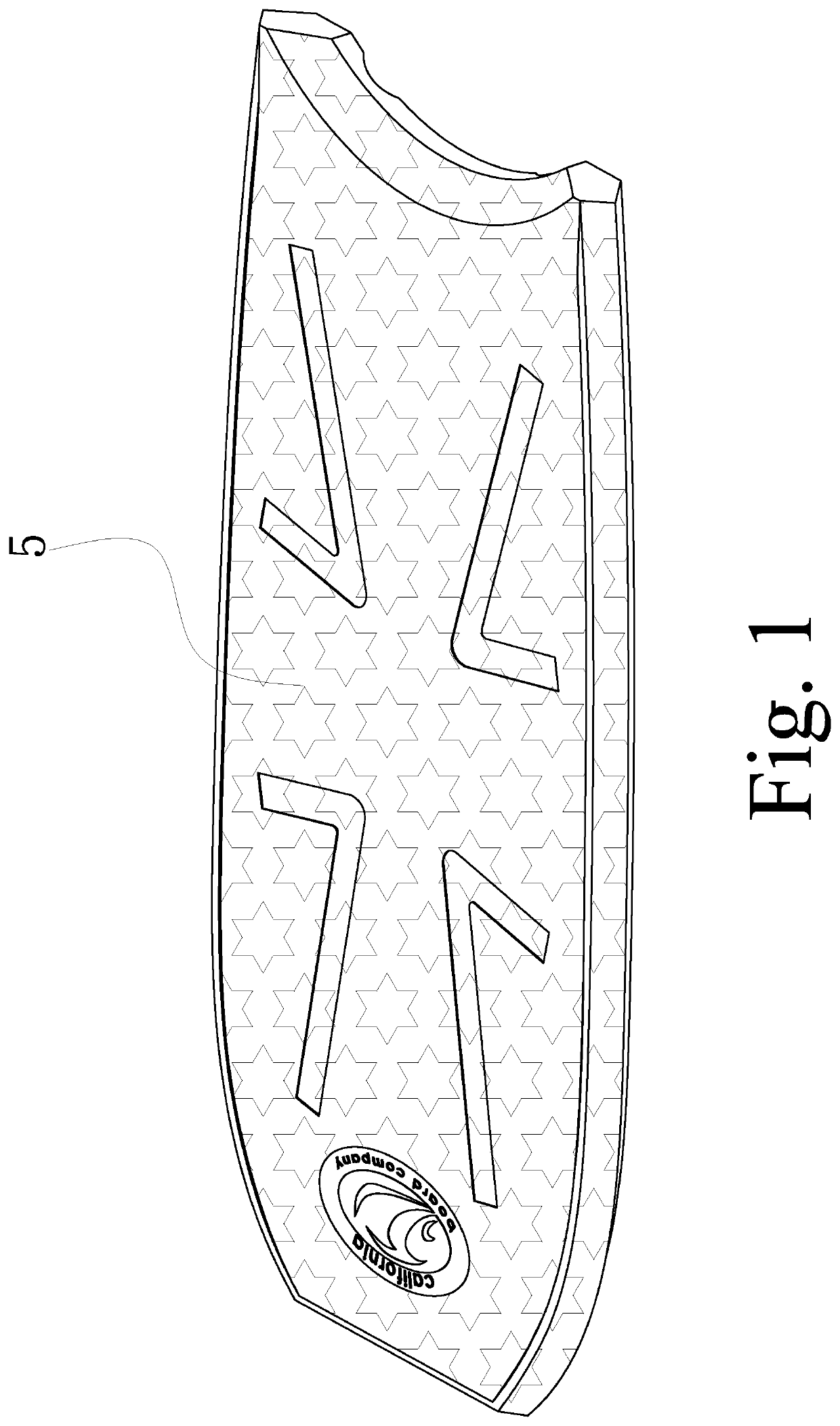

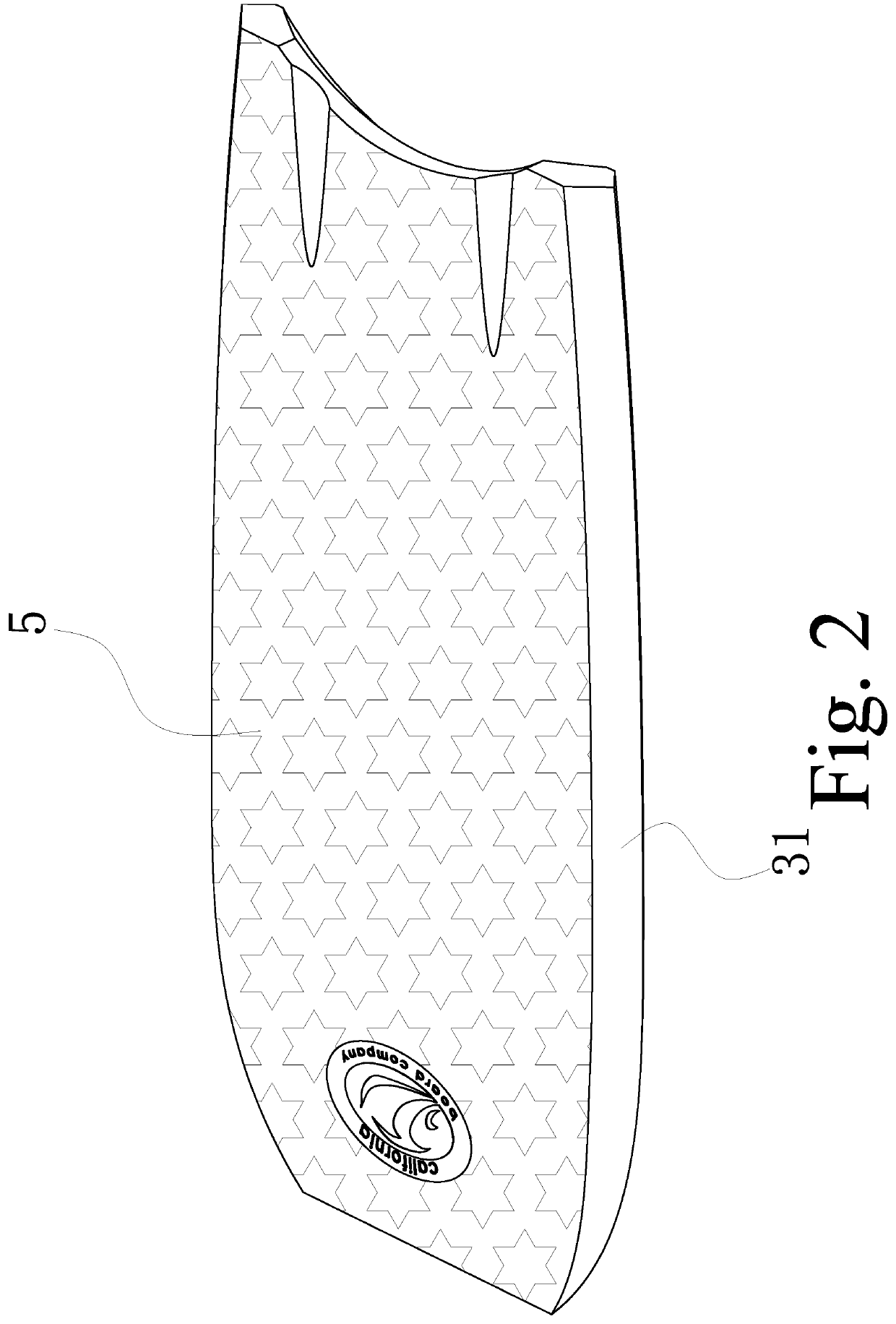

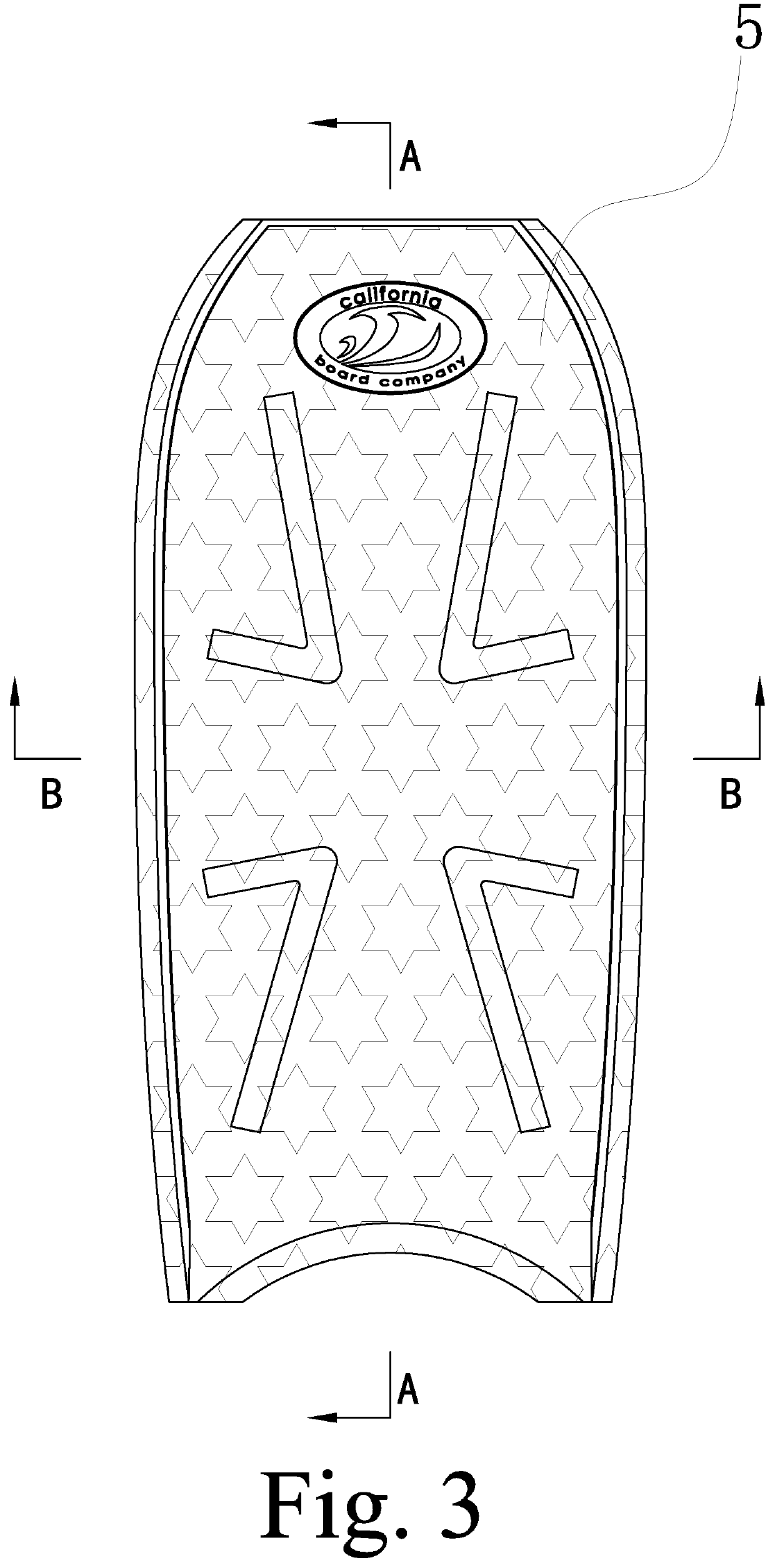

Method for manufacturing skateboard

ActiveUS20190308088A1Light weightReduce manufacturing costWood working apparatusDomestic articlesPlastic filmOrganic polymer

A method for manufacturing a skateboard, includes steps of: foaming an organic polymer material with steam with a temperature at a range of 160-180° C. to produce a foam board as the internal core board; sending the organic polymer material into an oven for heating to 190-210° C. to perform foam molding; cutting the foam board into an internal core layer; cutting the foam board into an upper surface layer and a lower surface layer; and then adhering the upper surface layer and the lower surface layer with the internal core layer together by EVA resin, and wrapping the internal core layer between the upper surface layer and the lower surface layer; printing a pattern layer on a surface of the plate body by laser printing; and casting a layer of the plastic film.

Owner:SHEN AIFU

Method for processing high-performance artificial quartz stone

InactiveCN105776951AImprove wear resistanceImprove overall performanceWeather resistanceOrganic solvent

The invention discloses a method for processing high-performance artificial quartz stone.The high-performance artificial quartz stone is prepared from, by weight, 8% of 721-3 resin, 19% of 800-mesh quartz powder, 11% of 400-mesh quartz powder, 13% of 80-mesh quartz sand, 17% of 60-mesh quartz sand, 8% of 80-mesh glass, 6% of 10-mesh glass, 18% of 40-mesh white glass and 2% (resin content) of coupling agent.An artificial quartz stone panel produced with the method has the advantages of being light, uniform in density, colorful, rich in pattern style, high in strength, resistant to high temperature, high in impact resistance, wearing resistance and weather resistance, not prone to deformation, resistant to scratching and aging, not prone to color change, environmentally friendly, free of pollution and the like, performance indexes in acid-base resistance, salt mist resistance and gasoline and other organic solvent resistance are high, durability is high, and the effect of high-simulation natural stone is completely realized.

Owner:HARBIN RUNDE WEIYE TECH DEV

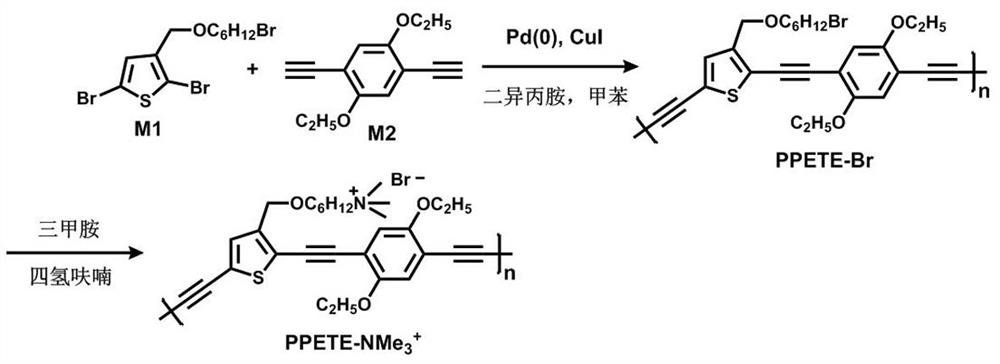

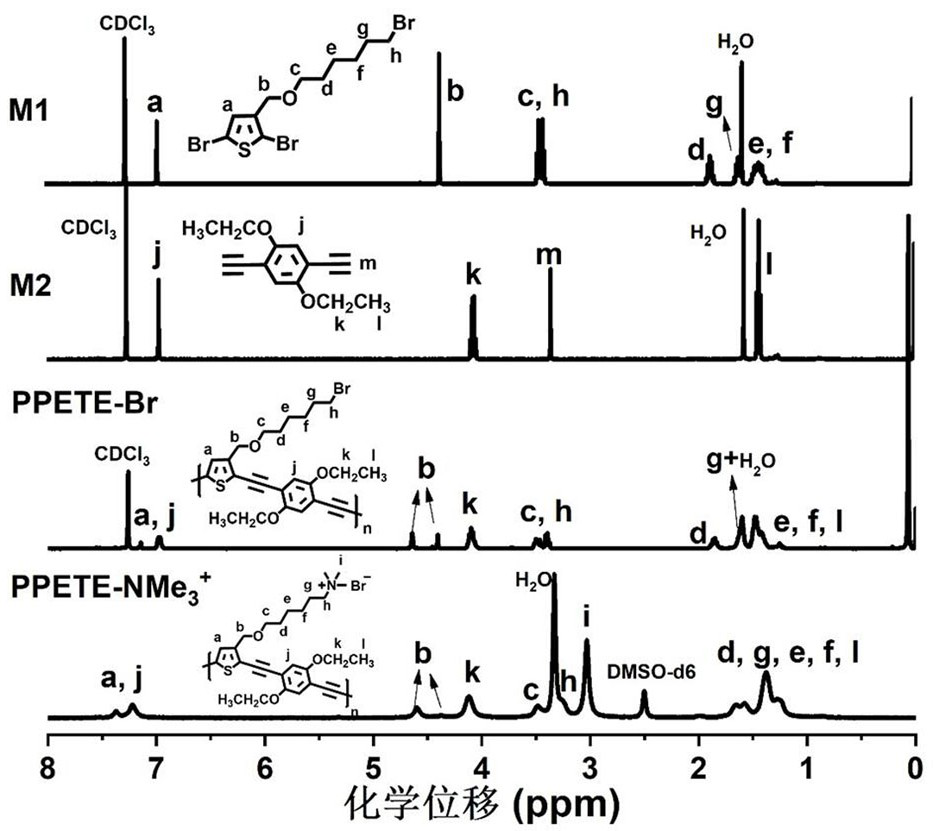

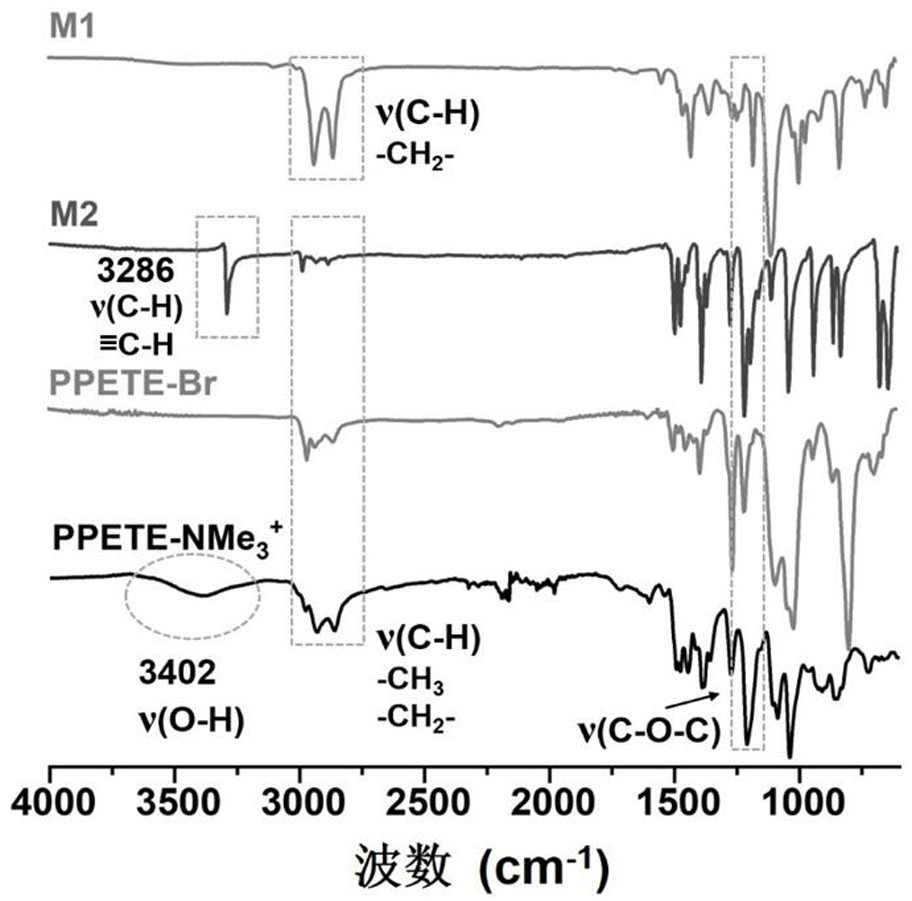

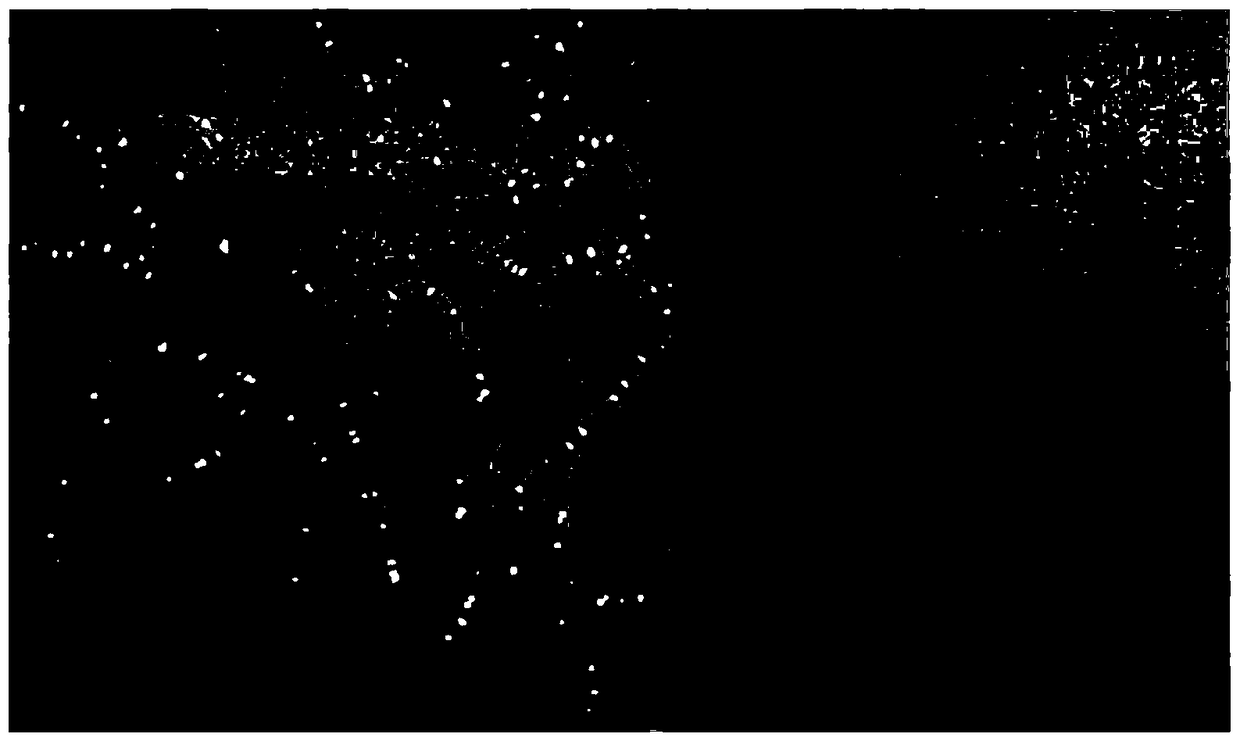

Fluorescent conjugated polymer, preparation method and application in development of grease fingerprints and blood fingerprints

ActiveCN113087878AFingerprint lines are clearBright patternDiagnostic recording/measuringSensorsUltraviolet lightsSubstitution reaction

The invention relates to a fluorescent conjugated polymer, a preparation method and an application of the fluorescent conjugated polymer in development of grease fingerprints and blood fingerprints. The preparation method comprises the following steps: synthesizing a cationic polyphenyleneethynylene thienyl fluorescent conjugated polymer through a Sonogashira coupling reaction and a subsequent substitution reaction, and dissolving the cationic polyphenyleneethynylene thienyl fluorescent conjugated polymer in a solvent to obtain the fingerprint developing liquid. The fingerprint developing liquid provided by the invention is effective for grease fingerprints and blood fingerprints, after a proper amount of developing liquid is dropwise added to an object and incubated together with the fingerprints for a period of time, and redundant developing liquid is absorbed and naturally aired, the bright fingerprint streaklines can be observed under 365 nm ultraviolet light. The fingerprint development liquid based on the cationic polyphenyleneethynylene thienyl fluorescent conjugated polymer provided by the invention can overcome the interference of background patterns, can develop grease fingerprints and blood fingerprints on different objects, and has the characteristics of simple preparation process and convenient development operation.

Owner:SUZHOU UNIV

Dazzling white glass artificial quartz stone plate and production process thereof

The invention discloses a dazzling white glass artificial quartz stone plate. The dazzling white glass artificial quartz stone plate comprises the following raw materials: white glass: 6 to 8 meshes, 8 to 16 meshes, 16 to 30 meshes, 30 to 50 meshes and 50 to 80 meshes, quartz sand: 4 to 6 meshes, 6 to 8 meshes, 16 to 26 meshes and 20 meshes, 325-mesh quartz powder, a silane coupling agent, a curing agent, an adhesive and colored pigment. The manufactured artificial quartz stone disclosed by the invention is attractive in appearance, bright in patterns, unique in colors and high in production efficiency, and further effectively lowers the reject ratio of the product, separates colors mutually and can be produced in batches.

Owner:GUANGDONG BANNER NEW MATERIAL TECH

Highly-weatherable allochroic synthetic wood plastic section bar and preparation technology thereof

InactiveCN103289276AStrong wood feelingSimple production processSynthetic resin layered productsEngineeringInorganic pigments

The invention discloses a highly-weatherable allochroic synthetic wood plastic section bar. The raw material of the plastic section bar is obtained through extruding mixed resin particles and an inorganic pigment, and the mixed resin particles are composed of ASA resin particles and ABS resin particles. The disadvantages of the prior art are overcome in the invention, the weatherable allochroic synthetic wood plastic section bar has a bright color and pattern for a long term, can be widely used in floors, window frames, furniture and guardrails, and has the advantages of strong wood sensation, synthetic wood texture appearance, and simple production technology.

Owner:ANHUI MEILUO BUILDING MATERIALS

Fluorescent artificial quartz stone plate and preparation method thereof

The invention relates to a fluorescent artificial quartz stone plate and a preparation method thereof. Inorganic oxide coated phosphor powder is used as a fluorescent filler, so as to inhibit the hydrolysis of the phosphor powder during the preparation of quartz stones. A coating layer is uniform, continuous, compact, firm and thin and reduces the loss of luminous intensity. The artificial quartz stones prepared by the method have the advantages of beautiful appearance, bright patterns and unique colors, greatly enrich the varieties and patterns of the artificial quartz stones, can be used for a variety of decorative occasions, and have a wide scope of application.

Owner:FOSHAN LANRUI OUTE INFORMATION SERVICES CO LTD

Colorful artificial quartzite board with sea sand and process for producing colorful artificial quartzite board

The invention relates to a colorful artificial quartzite board with sea sand. The colorful artificial quartzite board comprises sea sand with the size of 6-10 meshes, 10-20 meshes, 20-40 meshes and 40-120 meshes, quartz sand with the size of 40-70 meshes and 70-100 meshes, quartz powder with the size of 325 meshes, quartz powder with the size of 1250 meshes, silane coupling agents, curing agents, adhesive and colored pigment. The colorful artificial quartzite board has the advantages that manufactured artificial quartzite has attractive appearance, clear patterns and unique colors and is high in production efficiency, the reject ratio of the colorful artificial quartzite board can be effectively reduced, the colors are separated from one another, and the colorful artificial quartzite board can be produced on a large scale.

Owner:GUANGDONG BANNER NEW MATERIAL TECH

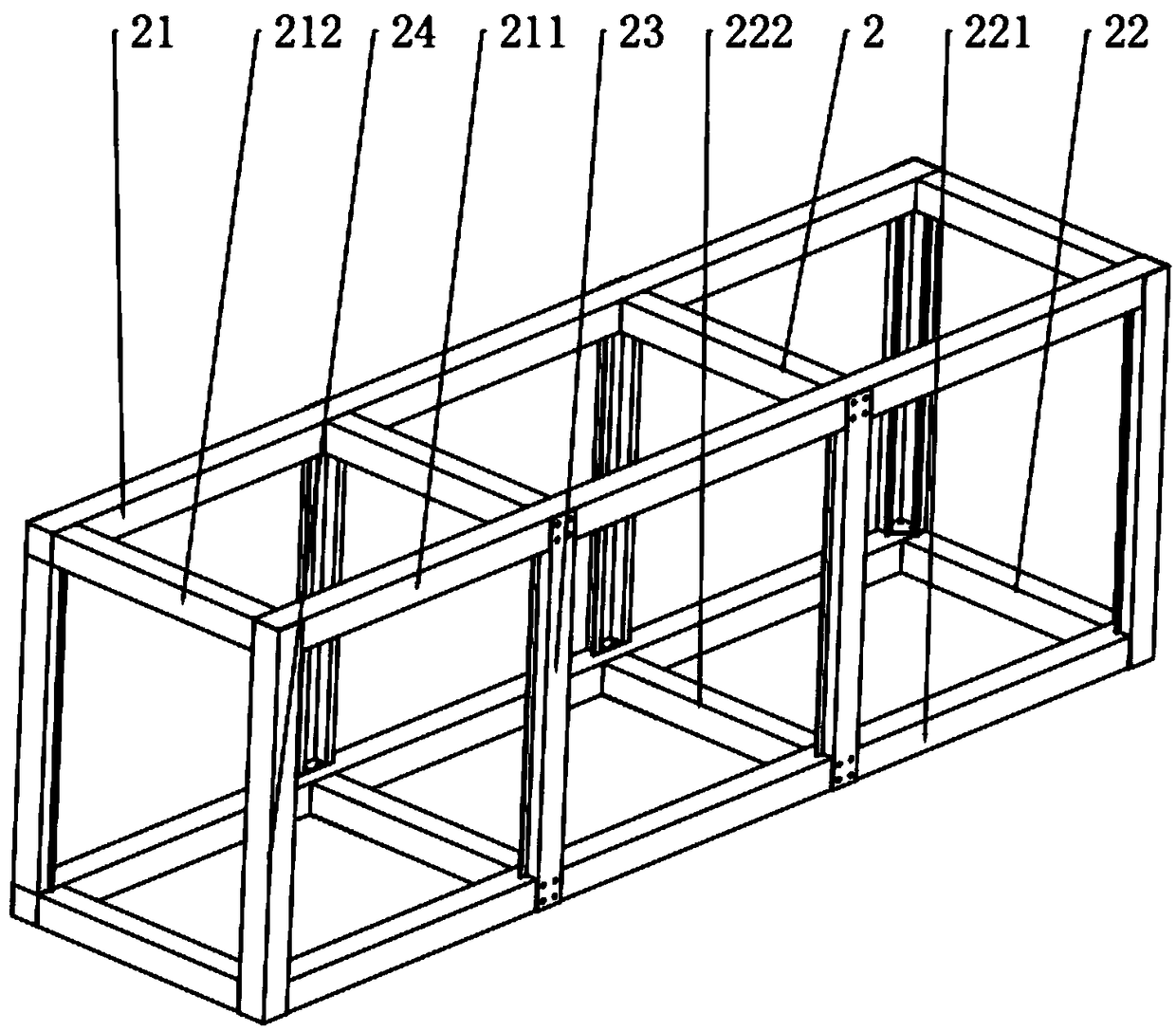

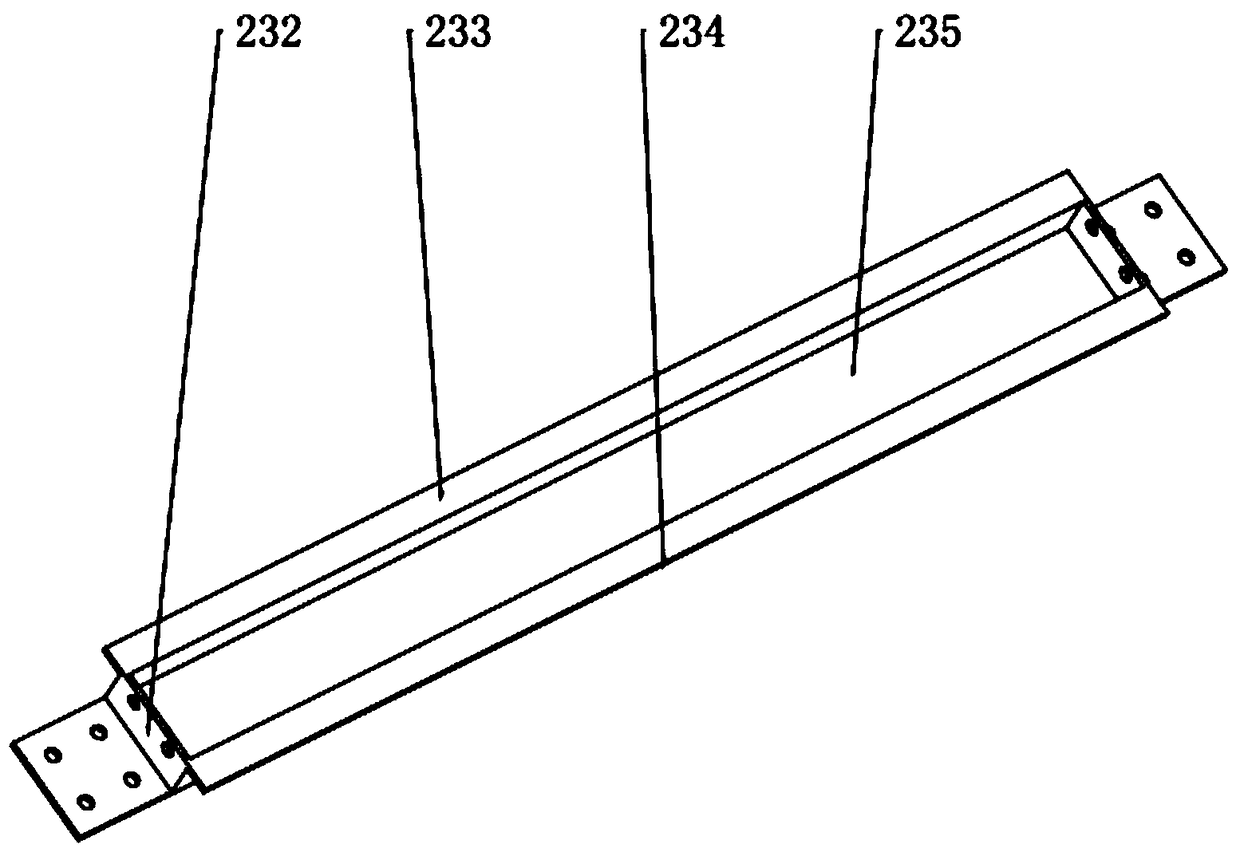

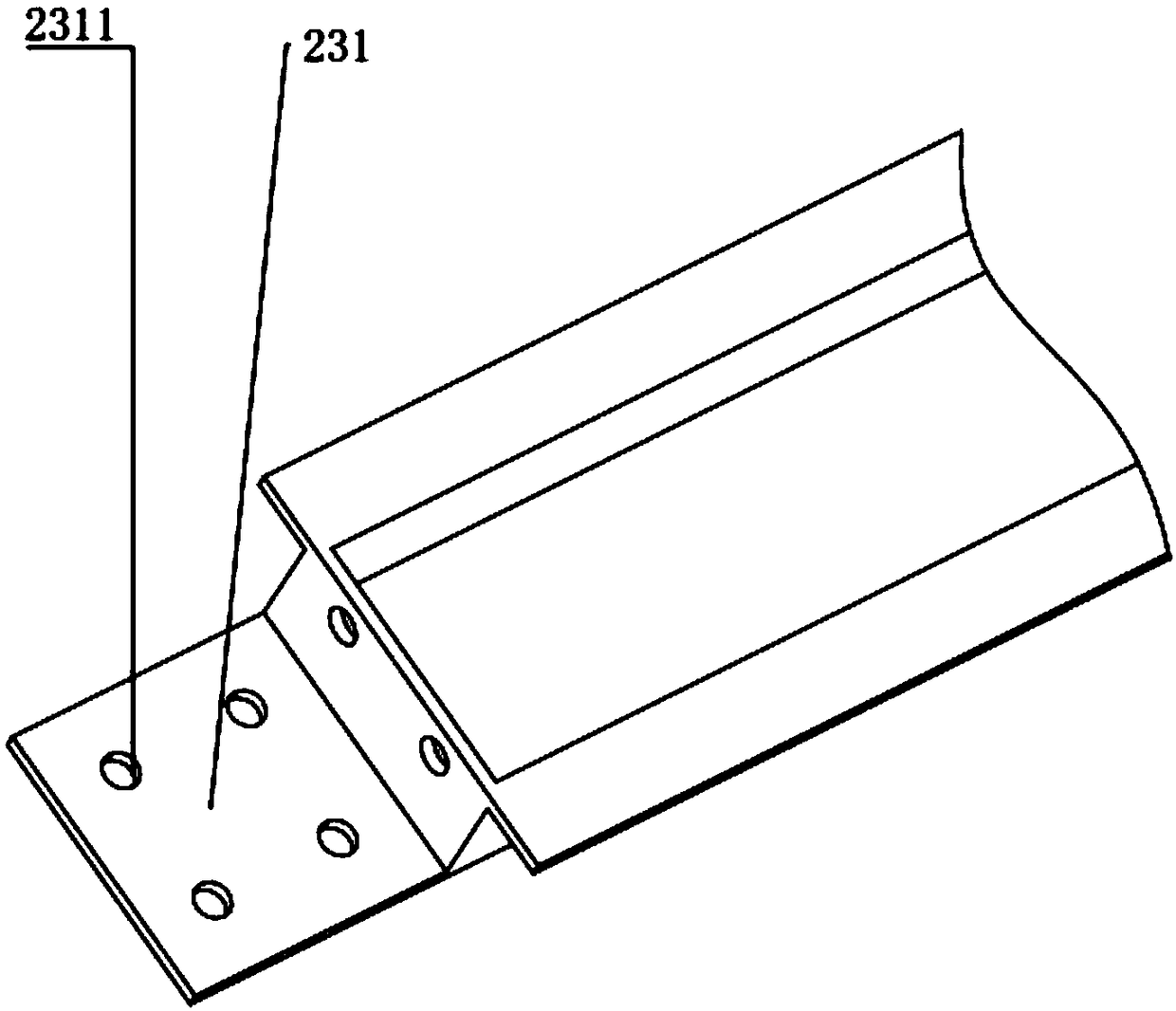

Combination type substation

InactiveCN108359355AImprove machining accuracy and machining efficiencyAvoid labor costs and welding costsSubstation/switching arrangement detailsDistribution substationsVolatile organic compoundToluene

The invention discloses a combination type substation. The combination type substation comprises a chassis, a box and a top cover, wherein the box comprises an upper bracket, a lower bracket, stand columns and corner columns; the top cover is arranged at the upper part of the box; the chassis is arranged at the lower part of the box; zinc-rich paint is sprayed to the inner walls of the chassis, the box and the top cover; an anti-corrosion material layer is sprayed to the surface of the zinc-rich paint; the anti-corrosion material is prepared from raw materials in parts by weight as follows: 55-75 parts of waterborne resin, 10-20 parts of zinc tripolyphosphate, 6-10 parts of toluene sulphonic acid, 6-9 parts of etidronic acid, 7-10 parts of an XR-424 auxiliary, 2-5 parts of fumaric acid, 1-3 parts of dimethyl sulfoxide and 15-25 parts of deionized water; after spraying of the anti-corrosion material layer is finished, the whole equipment is left under the condition of hot air at 45-55 DEG C for 3-4 h. According to the combination type substation, processing precision and processing efficiency of parts are improved, and content of VOC (volatile organic compounds) in exhausted hot airis greatly reduced.

Owner:SHOUGUANG JUNENG ELECTRIC

Preparation method of synthetic quartz jade

The invention relates to a preparation method of synthetic quartz jade. The preparation method comprises steps as follows: 1, a color concentrate, resin, an OT oxidizing agent, a normal-temperature curing agent, a coupling agent, UV531 and quartz sand are uniformly mixed in a stirring kettle in proportion and marked; 2, industrial pigments are taken and sufficiently and uniformly mixed in proportion, and raw stripe materials are prepared; 3, raw materials prepared in the step 1 and the raw stripe materials prepared in the step 2 are uniformly mixed in proportion and marked; 4, raw materials prepared in the step 3 are taken in sequence and discharged in a grouped manner; 5, discharging and charging are performed according to corresponding modes and respective regulated number of layers, and the synthetic quartz jade is obtained after compression. The prepared synthetic quartz jade is high in hardness and wear-resistance and corrosion-resistant, and the raw materials are non-toxic and additive-free and meet food-grade process requirements; by means of the unique charging mode, multiple stripes are formed under the condition of saving of manpower and resources, varieties and patterns of the synthetic quartz jade are enriched to the great extent, and the product application range is broadened.

Owner:HENAN YADU NEW MATERIAL CO LTD

Penetrating non-color-sticky digital printing paste

The invention relates to the technical field of a paste, and particularly relates to a penetrating non-color-sticky digital printing paste. The penetrating non-color-sticky digital printing paste comprises the following preparation raw materials in percentage by mass: 0.1 to 0.8% of sodium alginate, 0.1 to 0.5% of polypropylene glycol, 0.01 to 0.1% of acetic acid, 0.1 to 1% of sodium sulfate and the balance of methyl cellulose. The penetrating non-color-sticky digital printing paste has good penetrability, is not color-sticky, and has an excellent printing effect hand feeling, high color yieldand definition and a long storage period.

Owner:广州海邻新材料有限公司

Burnt-out T-shirt

This invention relates to a burnt-out printing T-shirt. Currently, the common T-shirt is made of cotton fiber or chemical fiber, the burnt-out printing can not be used in the manufacturing process which limits the manufacture and use of the T-shirt. The invention uses polyester filament as centre yarn, uses zein fiber as core spun yarn of external packing fiber, and can carry out the burnt-out printing conveniently, thus solving the problems. The invention has the advantages of ventilation property, bright pattern and good stability, etc.

Owner:张寿祥

Quartz countertop with double-color pattern and preparation process thereof

InactiveCN107129194ASolve the shortcomings of uneven artificial mixingIncrease productivityRadioactive contaminationHigh intensity

The invention discloses a quartz countertop with a double-color pattern and a preparation process thereof. The quartz countertop is natural in transition, uniform in board density, excellent in mechanical properties and high in strength and is a repeatedly-usable environment-friendly novel countertop without radioactive pollution and with scratch resistance, fouling resistance and high-temperature resistance. Raw materials of both a material A and a material B for the quartz countertop are composed of quartz sand with a size of 8 to 16 meshes, quartz sand with a size of 40 to 70 meshes, colorless glass with a size of 8 to 16 meshes, colorless glass with a size of 16 to 30 meshes, quartz powder with a size of 400 meshes, high-strength transparent unsaturated resin, a medium-temperature curing agent and a coupling agent. The material A is a main material and further comprises colorless glass with a size of 6 to 8 meshes and mirror glass with a size of 8 to 16 meshes; and the material B is a pattern material and accounts for 1 / 8 of the usage amount of the material A. The preparation process comprises the following steps: batch mixing via a feed mixer; crushing via screw crusher and remixing; sieving with a screen with a size of 15 mm and mixing; and uniform dispersion of the mud material of the material B into the mud material of the material A, wherein the material B is allowed to be naturally fused into the material A so as to realize double color fusion and present both nebulous impression and spot effect. The quartz countertop provided by the invention has a stable and uniform pattern and a distinct and unique color, can be produced in mass and is applicable as a countertop.

Owner:GUANGDONG BANNER NEW MATERIAL TECH

Preparation method of black stain-bleeding ink for ceramic inkjet printing

The invention discloses a preparation method of a black stain-bleeding ink for ceramic inkjet printing, wherein the black stain-bleeding ink is composed of the following components by the weight percentage: 10%-30% of a ruthenium metal complex, and 70%-90% of an organic solvent. The prepared black stain-bleeding ink has the advantages of high yield, high ruthenium content, homogenous phase of theink, no secondary treatment, narrow particle size distribution, no sedimentation, no clogging of printer nozzles, pure black after being printed and colored on a ceramic surface, and distinct patterns.

Owner:SUN YAT SEN UNIV

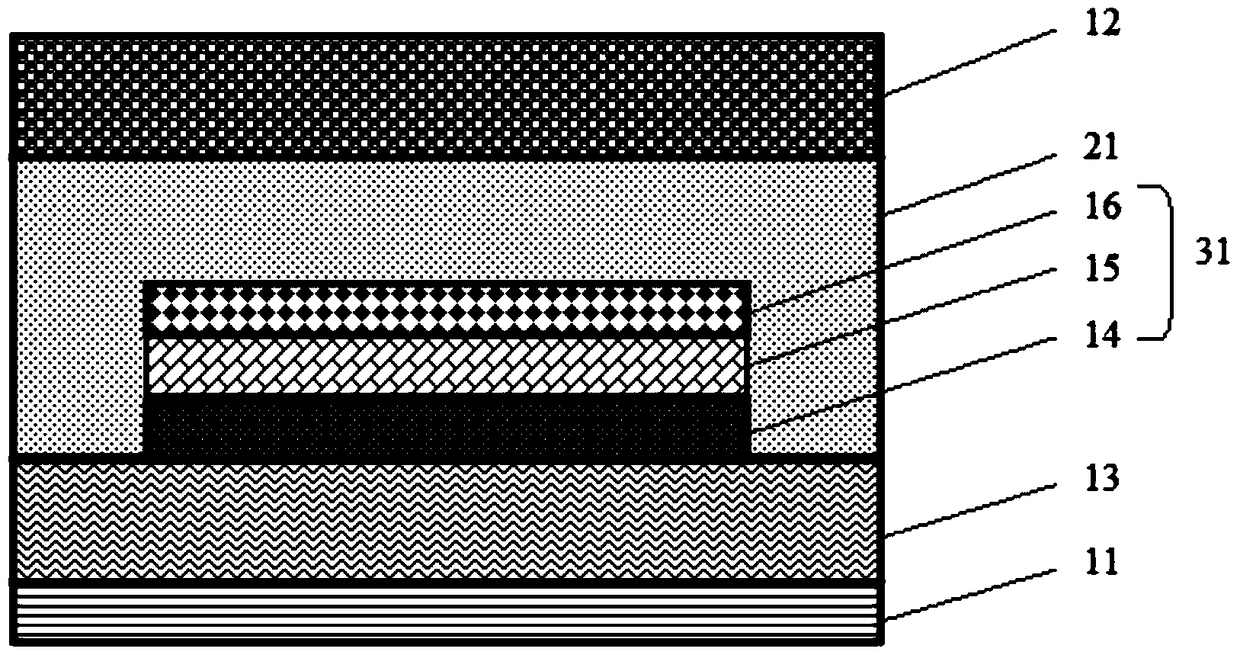

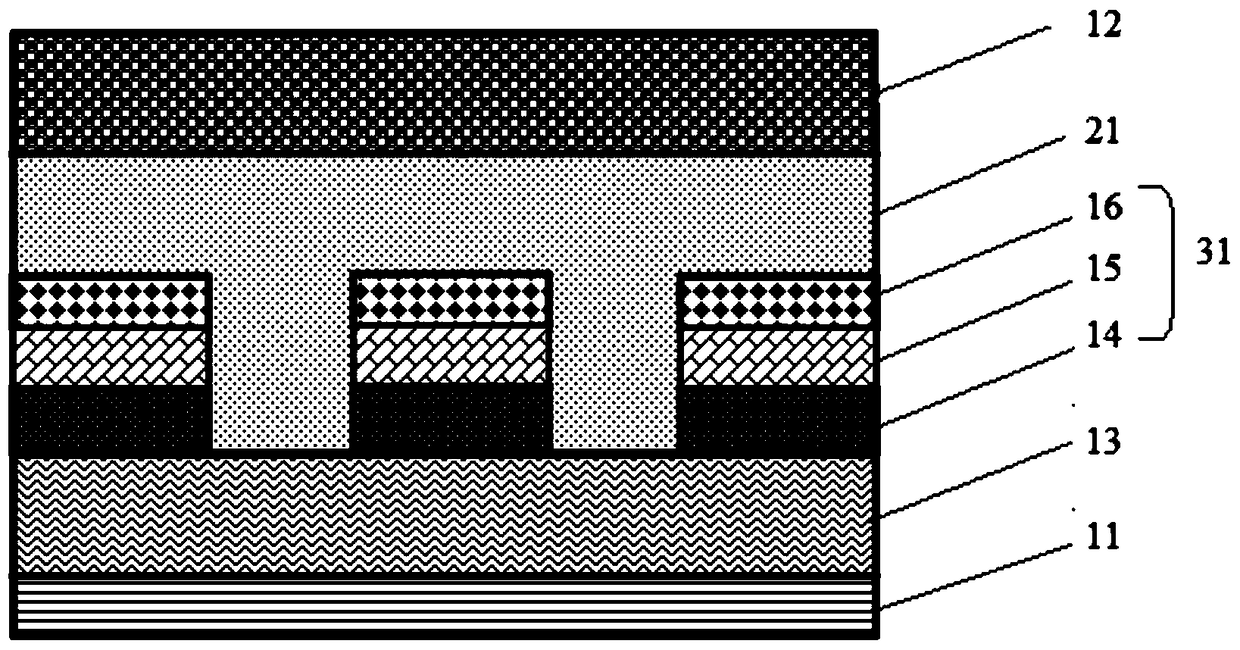

A Partial Mirror-like Metal Composite Film

ActiveCN105799284BBright patternImprove visual effectsSynthetic resin layered productsLaminationComposite filmMetal

The invention discloses a partially mirror-imitating metal composite film. The film includes a surface hardening coating layer, a transparent film layer, a raised composite layer, a composite adhesive layer and a base film layer stacked on each other in turn; the composite adhesive layer is arranged on the raised composite layer above and completely cover the transparent film layer; wherein, the raised composite layer sequentially includes a vacuum aluminum layer, a shielding oil layer and a color ink printing layer stacked on each other; the vacuum aluminum layer 1. The shielding oil layer and the color ink printing layer are in a corresponding relationship; the corresponding relationship means that the patterns and areas are the same. The partial mirror-like metal composite film of the present invention has a pattern of mirror-like metal texture, bright and beautiful, strong contrast, outstanding visual effect, and has a rather unique aesthetic and decorative effect; it has good industrial value and application prospect.

Owner:SHANGHAI RADIX VACUUM METALIZING

Method for manufacturing skateboard

ActiveUS10953310B2Light weightReduce manufacturing costWood working apparatusDomestic articlesPlastic filmOrganic polymer

A method for manufacturing a skateboard, includes steps of: foaming an organic polymer material with steam with a temperature at a range of 160-180° C. to produce a foam board as the internal core board; sending the organic polymer material into an oven for heating to 190-210° C. to perform foam molding; cutting the foam board into an internal core layer; cutting the foam board into an upper surface layer and a lower surface layer; and then adhering the upper surface layer and the lower surface layer with the internal core layer together by EVA resin, and wrapping the internal core layer between the upper surface layer and the lower surface layer; printing a pattern layer on a surface of the plate body by laser printing; and casting a layer of the plastic film.

Owner:SHEN AIFU

Ceramic stained paper in color change glaze, production process and application method of ceramic stained paper

The invention relates to ceramic stained paper in color change glaze, a production process and an application method of the ceramic stained paper, and belongs to the technical field of ceramic stainedpaper. The technical scheme includes that a high-melting object is added into a pigment at some printing position and used for heightening the calcination temperature of the pigment at the position,a low-melting object is added into a pigment at some printing position and used for lowering the calcination temperature of the pigment at the position, the printing position without adding the high-melting object and the low-melting object keeps the calcination temperature of the pigment, and the calcination temperatures of the pigments at the positions of the prepared ceramic stained paper are different. The ceramic stained paper has the advantages that prepared ceramic products are lively in tone, bright in pattern, high in stereoscopic sensation, wide in pattern and color change range andunexpected in artistic effect.

Owner:TANGSHAN PERMANENT AUSPICIOUS PORCELAIN IND LIMITED

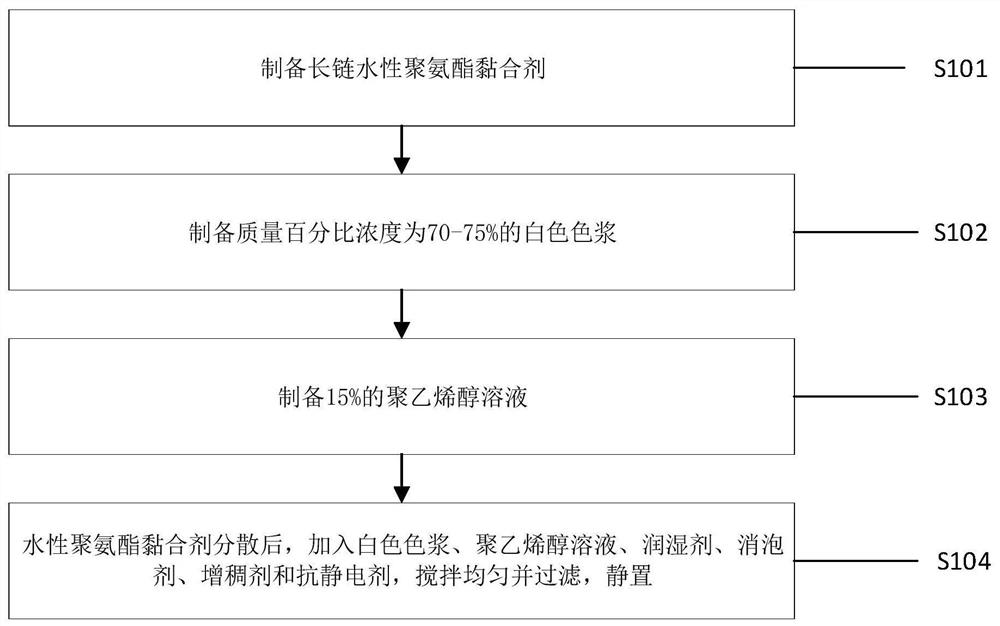

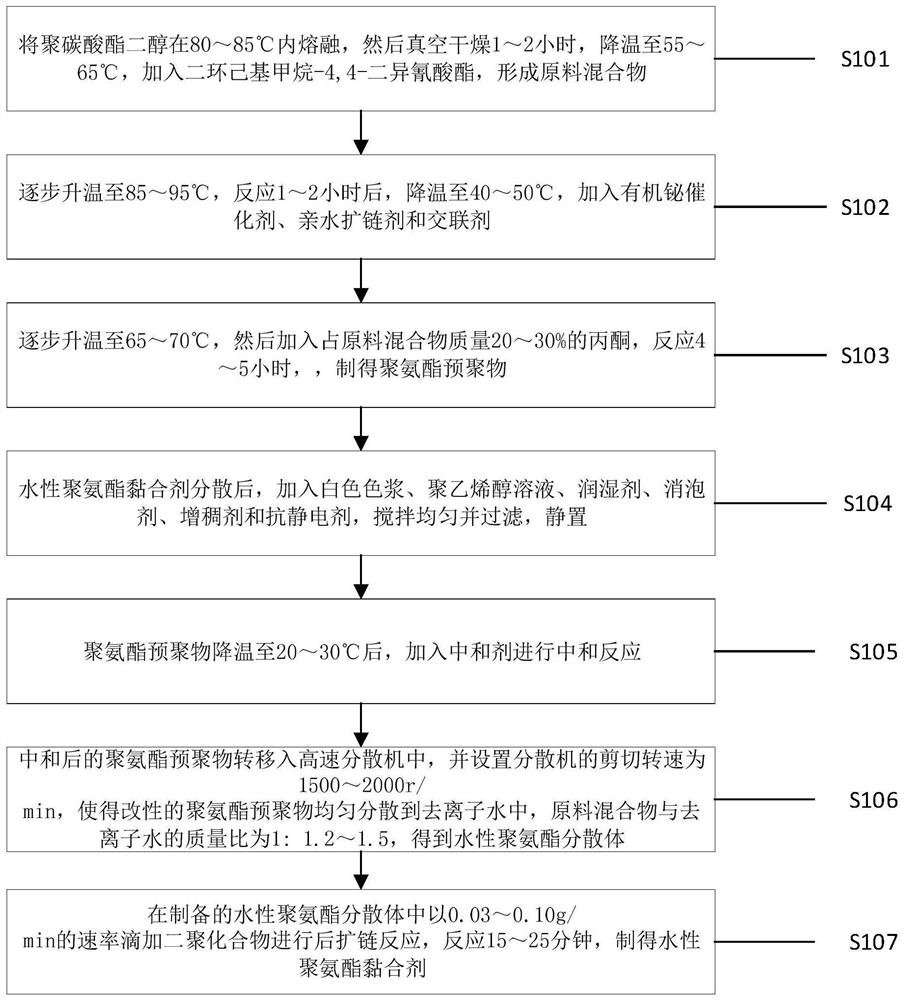

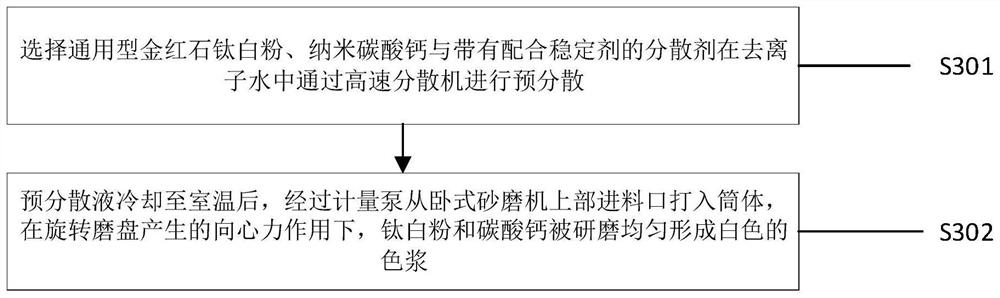

Preparation method and device of whitewashing agent suitable for color card base printing material

InactiveCN112920757AConsistent performanceMeet the physical and chemical performance testing standardsProcess control/regulationProductsPolymer sciencePolyurethane adhesive

The invention discloses a preparation method and device of a whitewashing agent suitable for a color card base printing material. The preparation method comprises the following steps: preparing a long-chain waterborne polyurethane adhesive; preparing white color paste with the mass percent concentration of 70-75%; preparing a 15% polyvinyl alcohol solution; after the waterborne polyurethane adhesive is dispersed, adding the white color paste, the polyvinyl alcohol solution, the wetting agent, the defoaming agent, the thickening agent and the antistatic agent, uniformly stirring, filtering and standing. The method has the advantages of low preparation cost, good whitening effect and the like, so that the color card base printing material has better covering effect and surface printing effect, the production process is simple, the product is easy to coat, the solid content can reach 64-66%, and the color card base printing material is suitable for coating PVC or PETG card base printing materials with various colors.

Owner:JIANGSU HUAXIN NEW MATERIAL

High-wear-resistance artificial quartz stone plate and production process thereof

The invention discloses a high-wear-resistance artificial quartz stone plate and a production process thereof. The high-wear-resistance artificial quartz stone plate is made from, by weight, 45-55 parts of 5- to 20-mesh quartz sand, 20-30 parts of 200- to 400-mesh quartz powder, 30-40 parts of binder, 10-20 parts of mullite sand, 5-10 parts of high silica glass fiber, 10-15 parts of activated clay, 15-20 parts of nano-barite, 20-30 parts of sodium silicate, 15-20 parts of fly ash, 0.5-1 part of tetraisopropyl di(dioctylphosphate) titanate, and 0.2-0.3 part of pigment. The artificial quartz stone plate produced by the production process has the advantages of light weight, uniform density, bright color, rich pattern, high impact resistance, high wear resistance, fine heat resistance, fine weatherability, deformation resistance, scratch resistance, aging resistance, coloring resistance, environment friendliness, no pollution and the like, has high performance indexes in terms of acid and alkali resistance, slat spray resistance, gasoline resistance and the like in organic solvents, and is durable and fully as effective as simulation natural stone.

Owner:安徽瑞翔石英制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com