Patents

Literature

424results about How to "Thicken" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

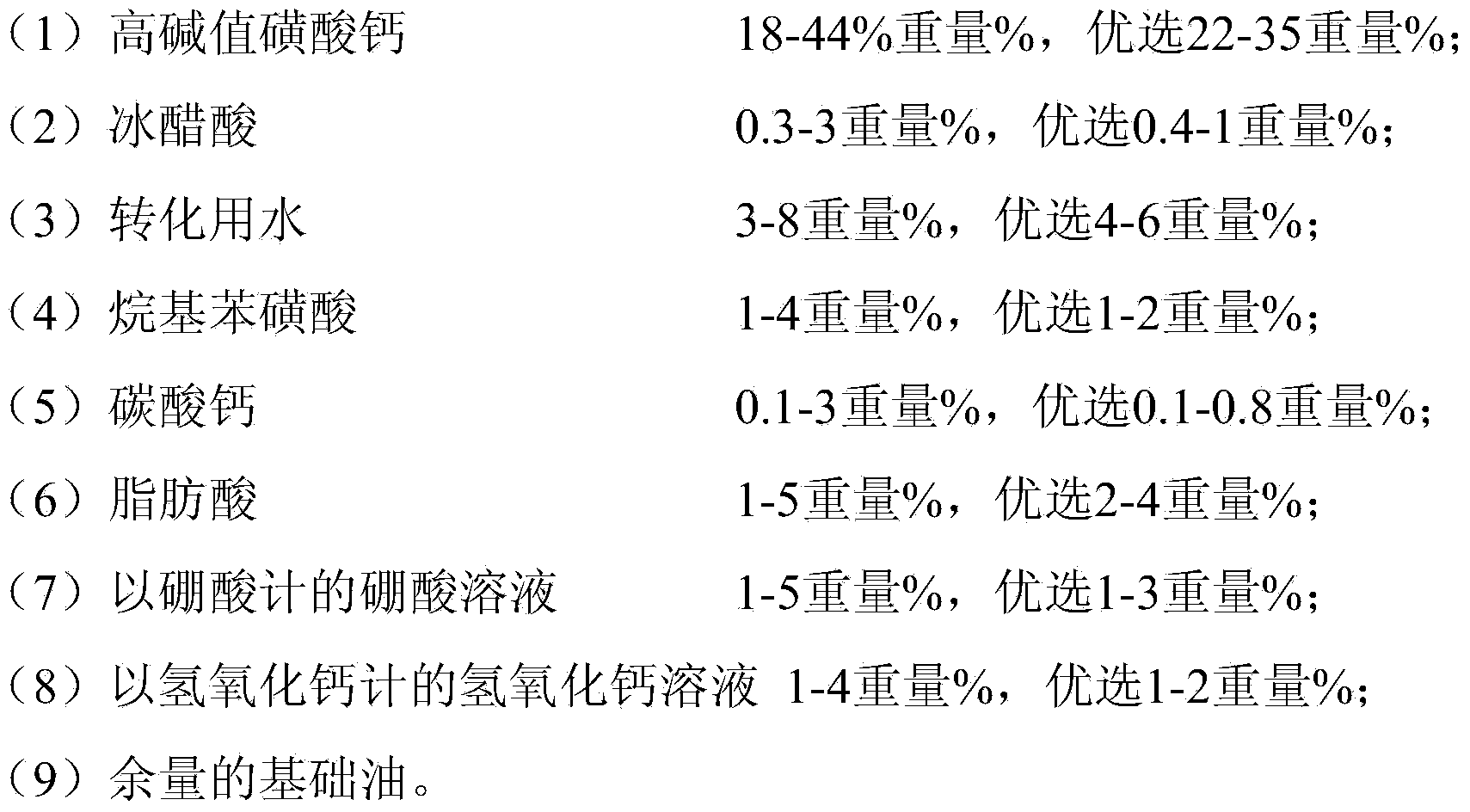

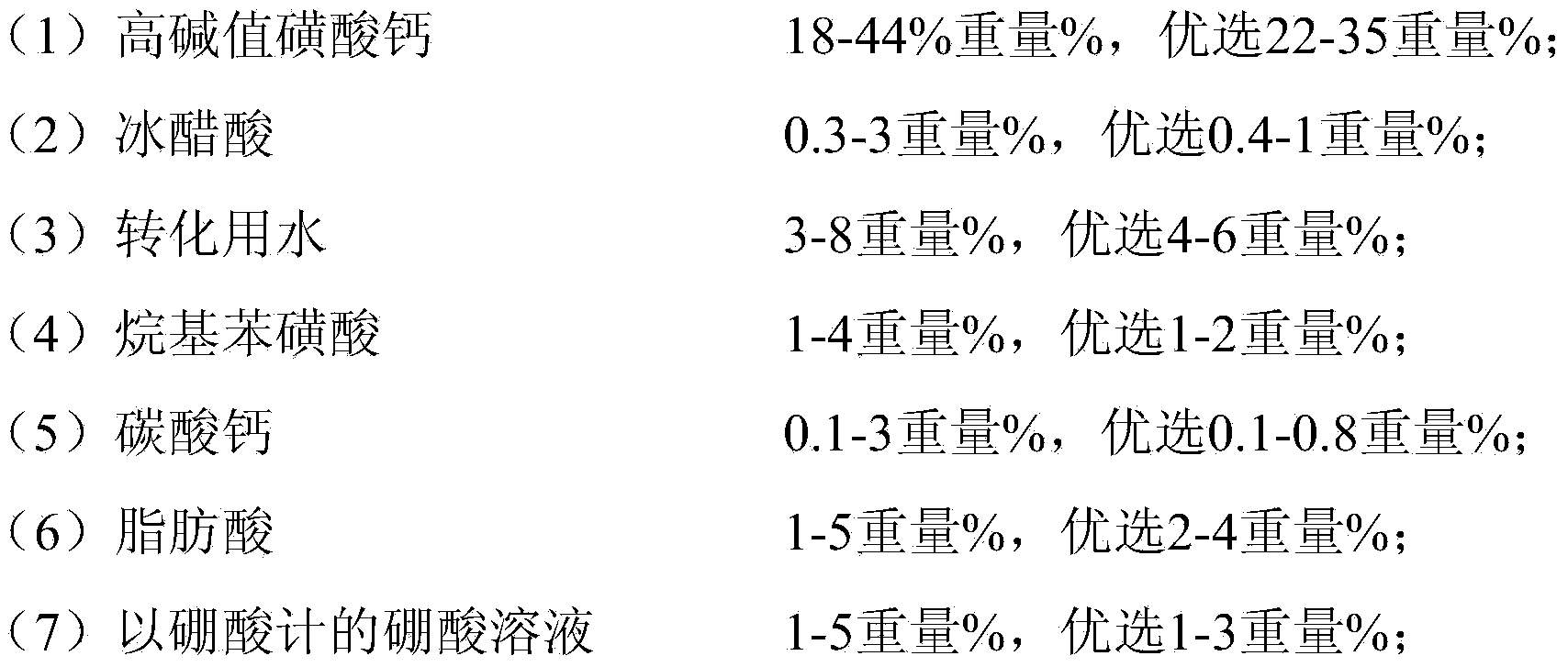

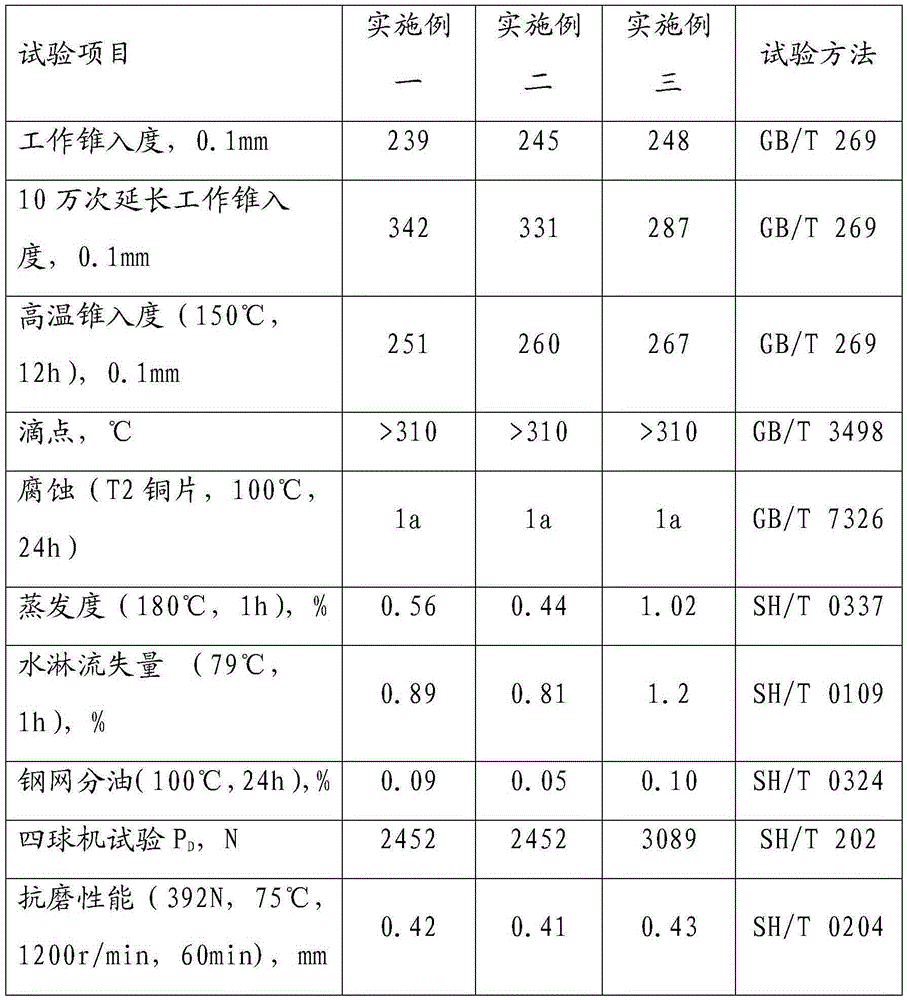

Composite calcium sulfonate lubricating grease composition and preparation method thereof

ActiveCN103740435ADrop point highGood extreme pressure and anti-wear propertiesThickenersChemistryBenzene

The invention relates to a composite calcium sulfonate lubricating grease composition and a preparation method thereof. The composite calcium sulfonate lubricating grease composition is prepared from the following raw materials in percentage by weight: 18 to 44 percent of high-base-number calcium sulfonate, 0.3 to 3 percent of glacial acetic acid, 3 to 8 percent of water for conversion, 1 to 4 percent of alkyl benzene sulfonic acid, 0.1 to 3 percent of calcium carbonate, 1 to 5 percent of fatty acid, 1 to 5 percent of a boric acid solution counted by using boric acid, 1 to 4 percent of a calcium hydroxide solution counted by using calcium hydroxide and the balance of base oil. The composite calcium sulfonate lubricating grease composition has the advantages of high dropping point, good extreme pressure antiwear property, excellent colloid stability and mechanical stability, and has a wide application range. The invention further relates to the preparation method for the composite calcium sulfonate lubricating grease composition.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

Geopolymer composite material for 3D printing and preparation method and application thereof

ActiveCN106082898ASave energyEnvironmentally friendlyAdditive manufacturing apparatusSolid waste managementAdditive ingredientSlag

A geopolymer composite material for 3D printing and a preparation method and application thereof are disclosed. The geopolymer composite material comprises the following ingredients (by weight): 20-25% of water-quenched granulated blast furnace slag powder, 10-15% of ground steel slag, 0-5% of fly ash, 33-45% of tailings machine-made sand, 3-5% of a composite activator, 2.5-3% of a high-molecular polymer, 1-3% of a volume stabilizer, 1-2% of a thixotropic agent, 0.05-0.1% of an antifoaming agent and 13.9-12.45% of mixing water. The above ingredients are fully and uniformly stirred and then the mixture is subsequently pumped into a 3D printer for construction. The geopolymer composite material has good caking property, strong stability and has good pump-out morphology maintaining capability and bond property. Printed buildings have good morphology and volume stability, and houses and buildings have good overall stability and use security.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Health-care food with function of enhancing immunity and memory

ActiveCN103315299AImprove actual functionsImprove immunityFood preparationDocosahexaenoic acidWhey protein

The invention discloses a health-care food with a function of enhancing immunity and memory. The food comprises the following components in percentage by weight: 60-85% of pea albumen powder, 10-20% of whey protein powder, 1.5-10% of DHA (Docosahexaenoic Acid) algae oil, 1-10% of phosphatidylserine and 0.5-1% of phospholipid. According to the invention, pea albumen and whey protein are mixed by a certain proportion by means of a complementarity principle of animal and vegetable proteins, so that the structural proportion and number of amino acids better meet the demand of human body to the benefit of improving the immunity of human body and promoting synthesis of cerebral proteins. Meanwhile, pea albumen and phospholipid are matched in used to improve blood environment and prevent and treat lapse of memory caused by insufficient oxygen and blood supply to the brain. DHA and phosphatidylserine compounded have the correlating and prompting effect in the metabolic process of the brain of human body so as to enhance the memory and the like, so that the health-care food disclosed by the invention has the function of enhancing the immunity of human body and improving the memory of human body.

Owner:BEIJING DAWN AEROSPACE BIO TECH

Fire extinguishing coagulant-thickener of caustic sludge colloid

InactiveCN1887381AImprove suspensionImprove the fire extinguishing effect of groutingFire extinguisherScrapIndustrial waste

The present invention belongs to the field of fire extinguishing technology, and is especially one kind of fire extinguishing coagulant-thickener of caustic sludge colloid. The fire extinguishing coagulant-thickener consists of superfine caustic sludge powder, linear polymer material containing hydrophobic hydroxyl group or carboxyl group, and inorganic silica and alumina material. The fire extinguishing coagulant-thickener is mixed with fire extinguishing base material to form colloid, and may swell after being mixed with water to form mixture slurry with great heat absorption and high heat stability. It has excellent use effect in preventing spontaneous ignition of coal bed and extinguishing fire of coal bed. The present invention uses industrial waste as main material and has rich material source and low cost.

Owner:FUDAN UNIV

Emulsion explosive and preparation method thereof

InactiveCN102173967ALow viscosityThickenNon-explosive/non-thermic compositionsEmulsion explosiveOil phase

The invention relates to an emulsion explosive which is formed by mixing a latex substrate and a sensitizing agent in a weight ratio of (95-97): (3-5) and sensitizing, wherein the latex substrate is formed by emulsifying 90-95 wt% of oil phase and 5-10 wt% of water phase; and the oil phase is prepared from 28-40 wt% of emulsifier and 60-72 wt% of oil phase material, wherein the emulsifier consists of 40-60 wt% of surfactant and 40-60 wt% of wetting and stabilizing agent, and the surfactant contains high hydroxyl S-80 which is prepared by a method comprising the following steps of: mixing oleic acid with sorbierite in an equivalent molar ratio, adding KOH the weight of which accounts for 0.1-0.15% of the total weight of reaction mixture, and effectively reacting for 3-7 hours at the temperature of 200-250 DEG C and the negative pressure of 0.05-0.1MPa. The emulsion explosive disclosed by the invention has a sensitization effect superior to emulsion explosive obtained by using the prior art. The invention further provides a preparation method of the emulsion explosive.

Owner:GUANGDONG HONGDA BLASTING

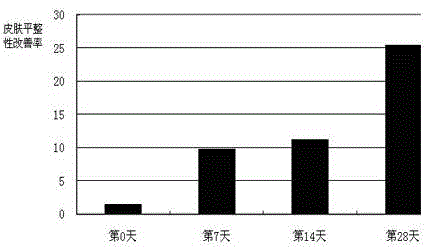

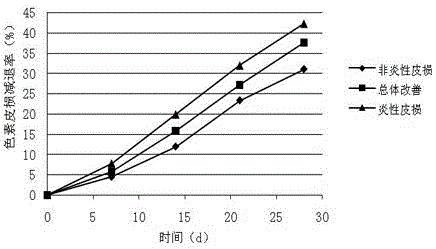

Beautifying and nursing essence and preparation method thereof

InactiveCN103908424AAvoid allergic reactionsNo side effectsCosmetic preparationsToilet preparationsCuticleUmbilical cord tissue

The invention discloses a beautifying and nursing essence and a preparation method thereof. The essence is prepared from an epidermis cell nutrient solution and contains a plurality of cell growth factors, amino acids and vitamins. The essence mainly comprises an epidermal growth factor, a fibroblast growth factor, collagen type I, a stem cell growth factor, a horn cell growth factor and amino acids and vitamins including gamma-aminobutyric acid, coenzyme Q, medical vitamin C, medical vitamin B5 and medical vitamin E. The preparation method for the essence comprises the following steps: acquisition of epidermis of umbilical cord tissue of a newborn; cell culture; collection of a cell nutrient solution; filtration sterilization; condensation of a volume; addition of active components; addition of glycerin and hyaluronic acid; etc. The beautifying and nursing essence provides a plurality of endogenous nutritional ingredients with physiological activity for the skin, can promote metabolism of epidermis cells and repair damaged cells, has a moisture retention effect and is applicable to skin beautifying and nursing.

Owner:奥思达干细胞有限公司

Single-component silane modified polyether sealant composition and sealant and preparation method thereof

ActiveCN108795360AGood weather resistanceIncreased durabilityNon-macromolecular adhesive additivesPolyether adhesivesSilanesUv absorber

The invention relates to the field of high molecular sealing materials and discloses a single-component silane modified polyether sealant composition and a sealant prepared from the single-component silane modified polyether sealant composition. The single-component silane modified polyether sealant composition disclosed by the invention is prepared from silane modified polyether resin, alkoxy terminated polydimethylsiloxane, a plasticizing agent, reinforcing filler, a water removal agent, a light stabilizing agent, an ultraviolet absorbent, a coupling agent and a catalyst. The sealant disclosed by the invention has the advantages of good smell, good ageing resistance, high recovery rate and the like.

Owner:浙江中天东方氟硅材料股份有限公司

Method for extracting high-purity beta-glucosan from oat bran

The invention discloses a method for extracting high-purity beta-glucosan from oat bran. According to the method, oat bran powder is sequentially treated by adopting the following steps: (1) carrying out ethyl alcohol reflux and enzyme deactivation; (2) stirring and extracting in hot water; (3) centrifuging and collecting supernatant; (4) carrying out enzymolysis and isoelectric precipitation; (5) carrying out alcohol precipitation; (6) centrifuging, collecting and precipitating; (7) carrying out ammonium sulfate precipitation; (8) dialyzing and removing impurities; and (9) carrying out freeze drying, so that the oat beta-glucosan is obtained. The high-purity oat beta-glucosan is obtained by adopting a mild water extraction method through extraction and treatment steps such as enzymolysis, isoelectric precipitation, alcohol precipitation, ammonium sulfate precipitation and dialysis. The high-purity oat beta-glucosan has a certain antioxidation effect on oil and can be added to yoghourt so as to improve the texture characteristics and nutritional ingredients of the yoghourt.

Owner:常州毅博生物科技有限公司

Special ultralow temperature cured laser etching conductive silver paste for mobile phone touch screen

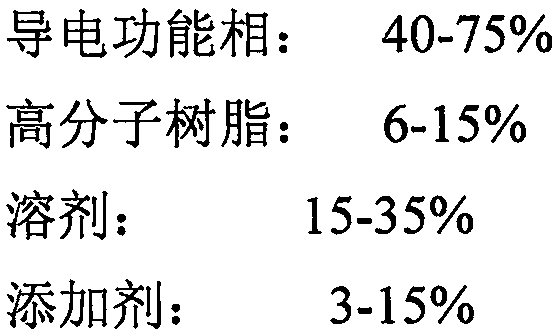

ActiveCN108022669AAchieve solidificationStable storageNon-conductive material with dispersed conductive materialMetal/alloy conductorsSilver pasteLaser etching

The invention relates to a special ultralow temperature cured laser etching conductive silver paste for a mobile phone touch screen. The conductive silver paste mainly comprises the following components: 40%-75% of a conductive function phase, 6-15% of macromolecule resin, 15-35% of a solvent and 3-15% of an additive. The preparation of the silver paste comprises the steps of macromolecule regioncarrier preparation, conductive silver paste preparation and conductive silver paste post-processing. The conductive silver paste can be completely cured under the condition of an ultralow temperatureof 80-110 DEG C, the temperature is reduced by 20-50 DEG C compared with a curing condition of 130 DEG C of the existing conductive silver paste, and shrinkage, folding and deformation of a substratemembrane material during high-temperature curing are reduced. The paste has excellent laser etching performance, and a clear pattern with the line width / line spacing being 30 microns / 30 microns can be etched; the paste has good adhesion on PET, an ITO film, a silver nanowire conductive film, TIO glass and ordinary glass, the pencil hardness is above 2H, and the square resistance can reach up to 20m[Omega] / square@1mil. In addition, the conductive silver paste is sintered and molded at an ultralow temperature, low in production cost, energy-saving and free of halogen, thereby being an environment-friendly product.

Owner:NANO TOP ELECTRONICS TECH

Preparation method of high-strength corrugated paper

InactiveCN102226322AImprove water resistanceImprove liquid repellencyInorganic compound additionPaper-making machinesCooking & bakingPulp and paper industry

The invention relates to a preparation method of corrugated paper, which comprises the following steps: pulping 20-30 parts of corn starch, 1-5 parts of ammonium persulfate and 4-8 parts of aluminum sulfate, thickening, and carrying out water-repellent treatment, primary baking, surface sizing and secondary baking to obtain the finished corrugated paper product. In the invention, the starch sizing agent is coated on the surface of the semi-finished corrugated paper product, and the corrugated paper is subjected to secondary baking and is completely aged, thereby effectively enhancing the liquid-repellent performance of the final corrugated paper product and enhancing the water repellence of the corrugated paper.

Owner:蓟县东赵乡福利造纸厂

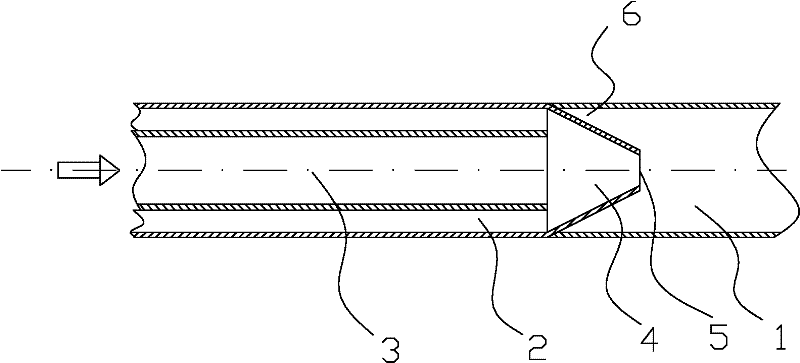

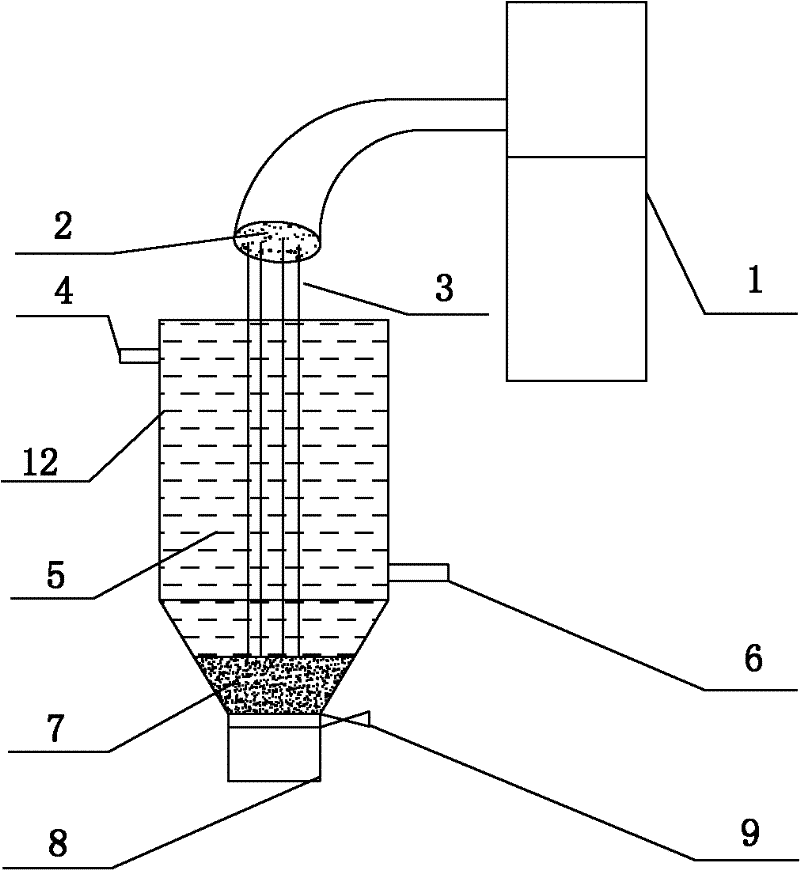

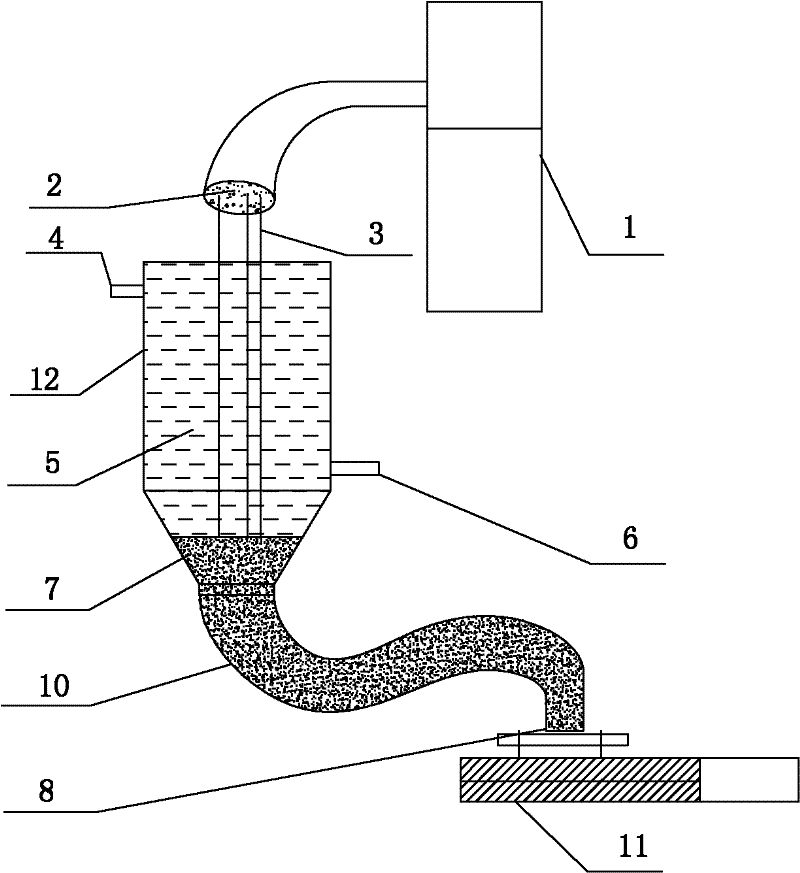

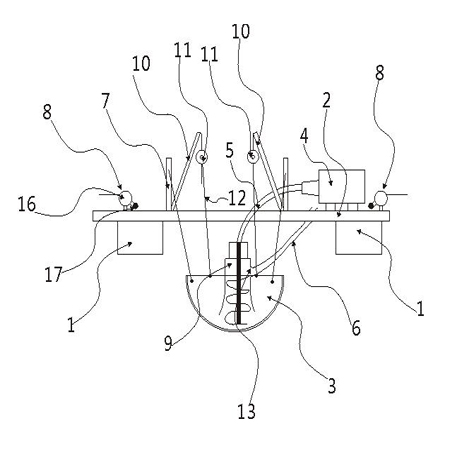

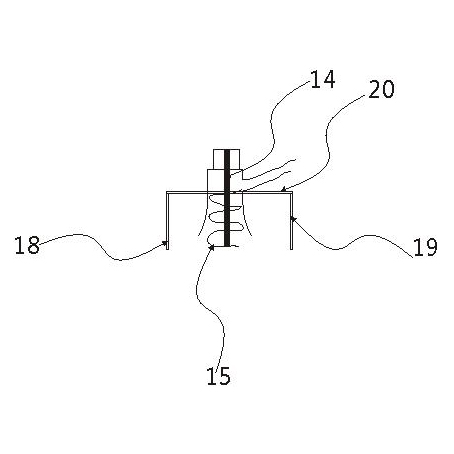

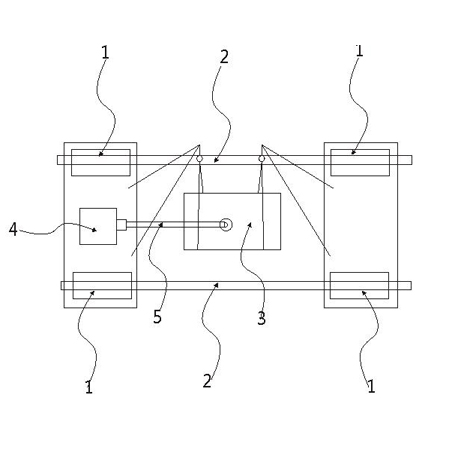

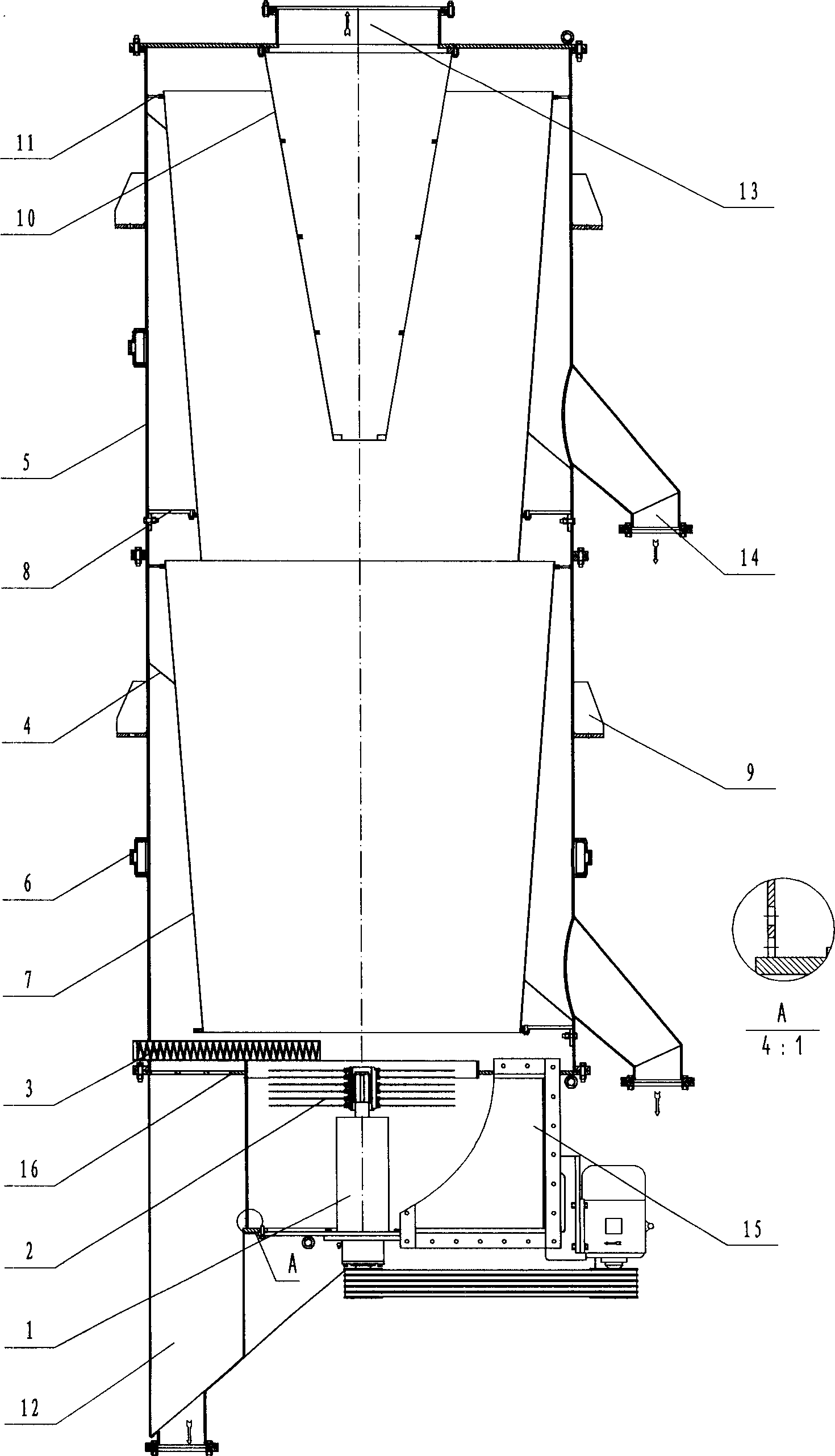

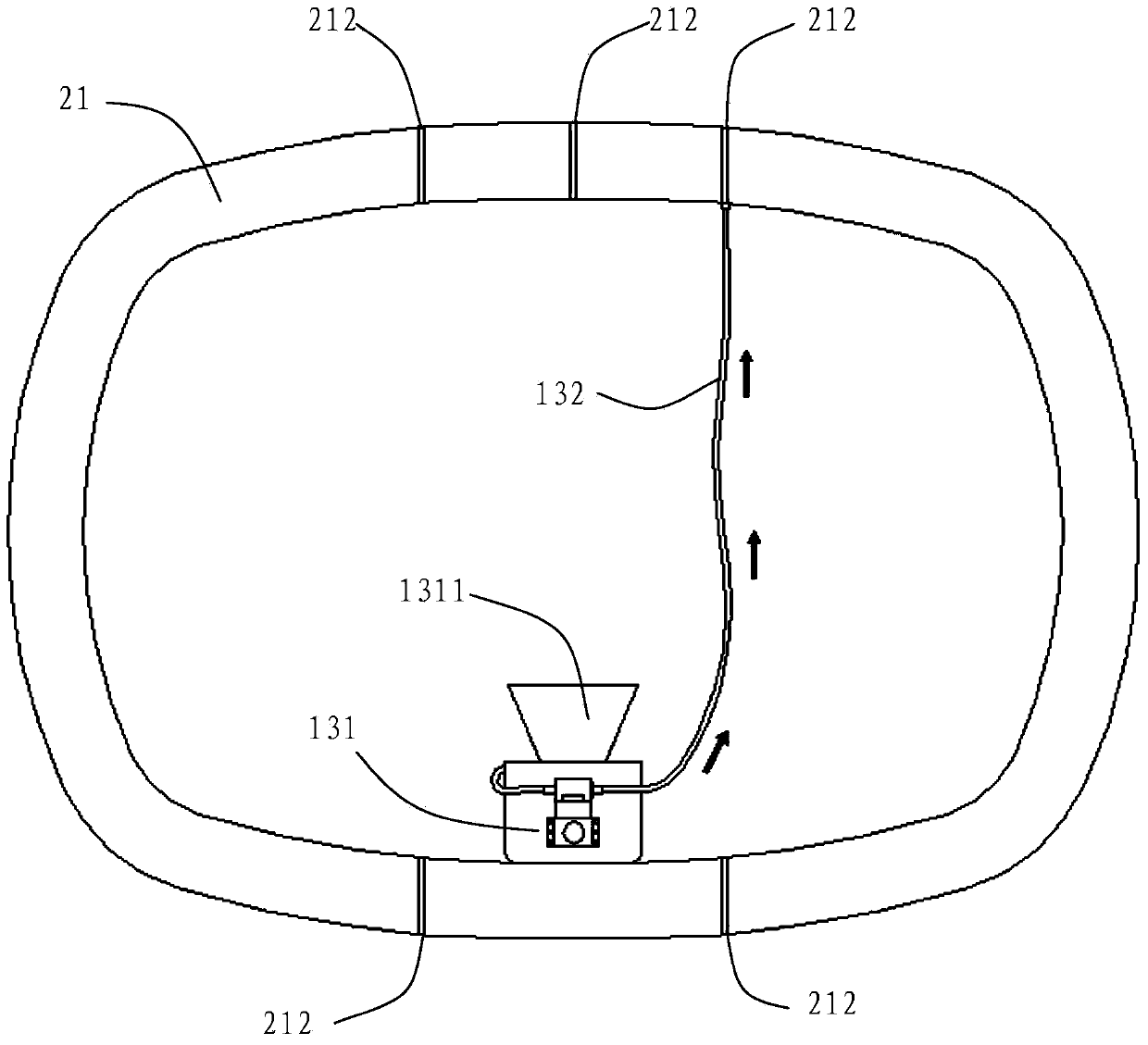

Silt extraction machine

The invention discloses a silt extraction machine. The silt extraction machine comprises a whole fixing platform, wherein the whole fixing platform is arranged on a floating body and is convenient to operate. The silt extraction machine is characterized in that: the whole fixing platform is provided with a power machine; the whole fixing platform is provided with a bracket acting on a silt collection box; the bracket is provided with a gourd pendant which is connected to the silt collection box through a chain; the silt collection box is provided with a screw device; the whole screw device is in a horn shape with a smaller upper side and a larger lower side, and a screw shaft is arranged in the screw device; the power machine directly acts on the screw shaft of the screw device through a power transmission shaft; a screw blade is also arranged in the screw device; the screw blade surrounds the screw shaft and is in a screw shape; and the upper part of the screw device is provided with a silt outlet which is externally connected with a slurry output pipe. By arranging the screw device on the silt collection box, the screw blade on the screw device can fast soften firm silt under the action of the power machine, and the silt with extremely high consistence can be delivered outside by screw extrusion. The silt extraction machine solves the problems that the slit with high consistence and high impurity content is difficultly extracted by the conventional silt machine and is difficult to stack and use.

Owner:张建平

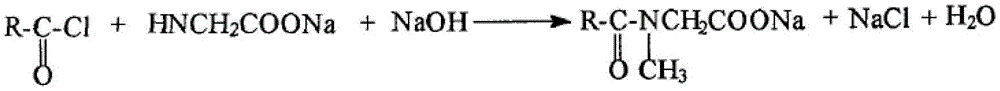

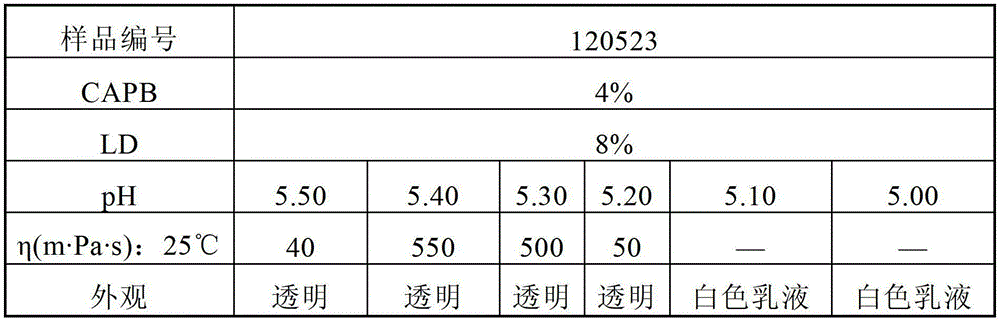

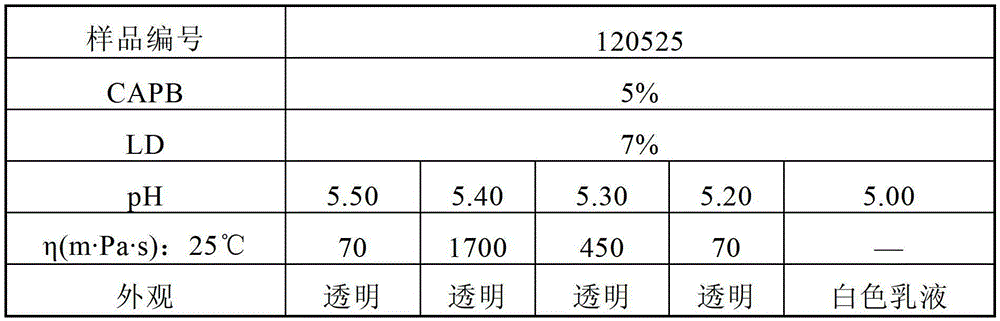

Amino-acid-type surfactant self-thickening composition

ActiveCN104095771AThickenCosmetic preparationsHair cosmeticsOLEAMIDOPROPYL BETAINECocamidopropyl betaine

The invention discloses an amino-acid-type surfactant self-thickening composition, and a preparation method and application thereof. The self-thickening composition comprises cocamidopropyl betaine and sodium lauroylsarcosinate as thickening agents, wherein the weight ratio of cocamidopropyl betaine to sodium lauroylsarcosinate is 1:2-3:1, and pH of the composition is 4.0-5.6. The invention also discloses application of the composition to personal cleaning products.

Owner:SHANGHAI JAHWA UNITED

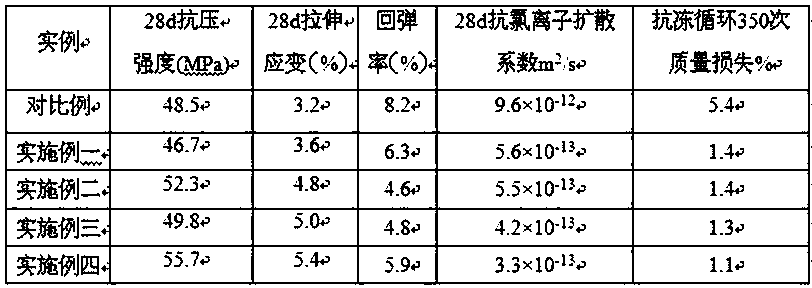

Ultrahigh-toughness alkali-activated shotcrete and preparation method thereof

The invention discloses ultrahigh-toughness alkali-activated shotcrete and a preparation method thereof. The shotcrete consists of the following components in parts by mass: 200 to 400 parts of ultrafine lithium slag powder, 100 to 200 parts of slag powder, 50 to 100 parts of stone powder waste, 30 to 60 parts of Portland cement, 10 to 70 parts of sodium hydroxide solution, 15 to 50 parts of sodium silicate solution, 1 to 10 parts of aluminum sulfate, 1 to 5 parts of nanometer aluminum oxide, 400 to 900 parts of nickel slag sand, 300 to 600 parts of copper slag sand, 3 to 6 parts of a thickening agent, 1 to 20 parts of fiber, 3 to 10 parts of a water-reducing agent and 200 to 350 parts of water. The problems that the existing ordinary ultrahigh-property shotcrete has large use amount of cement and low durability are effectively solved.

Owner:南京绿色增材智造研究院有限公司

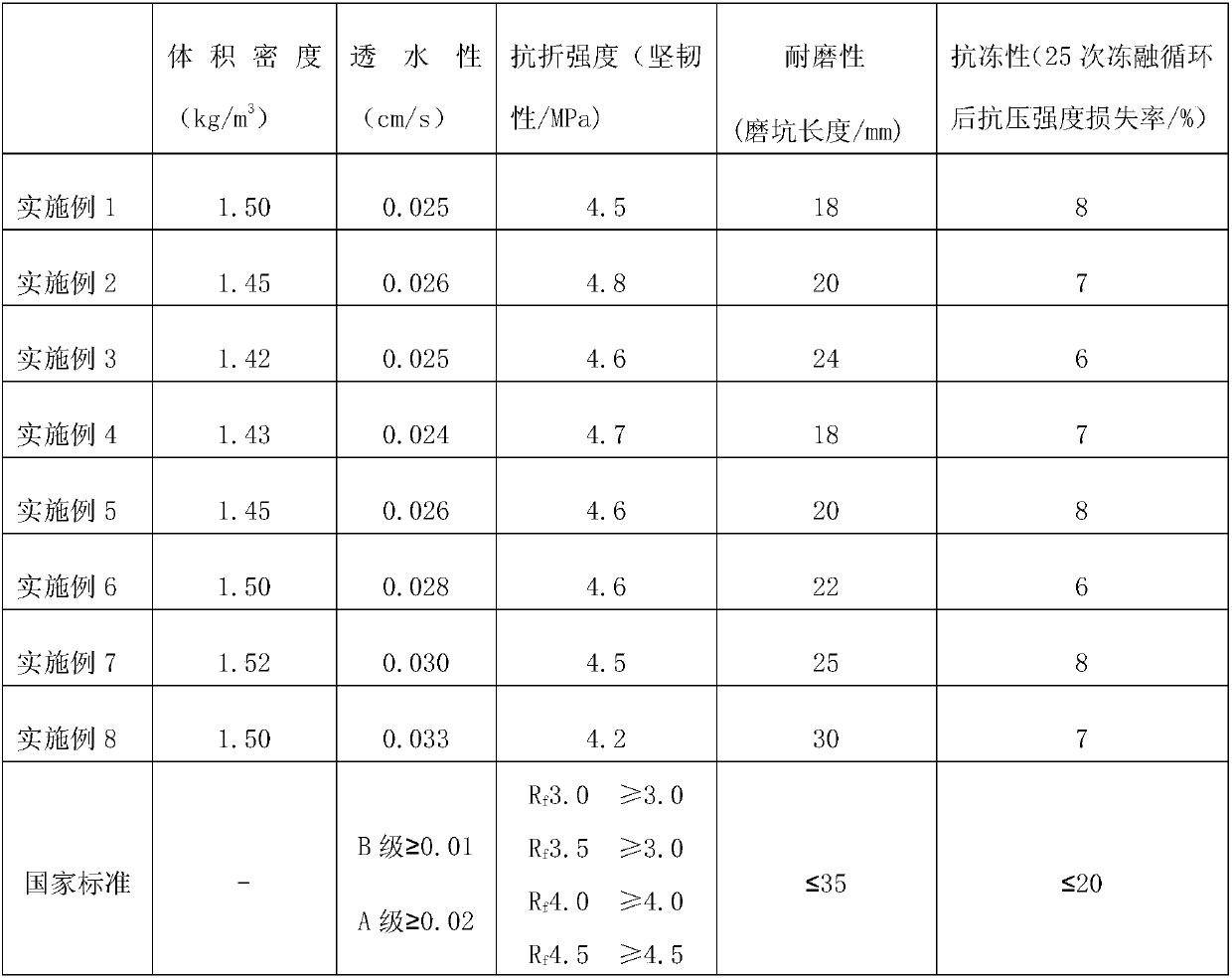

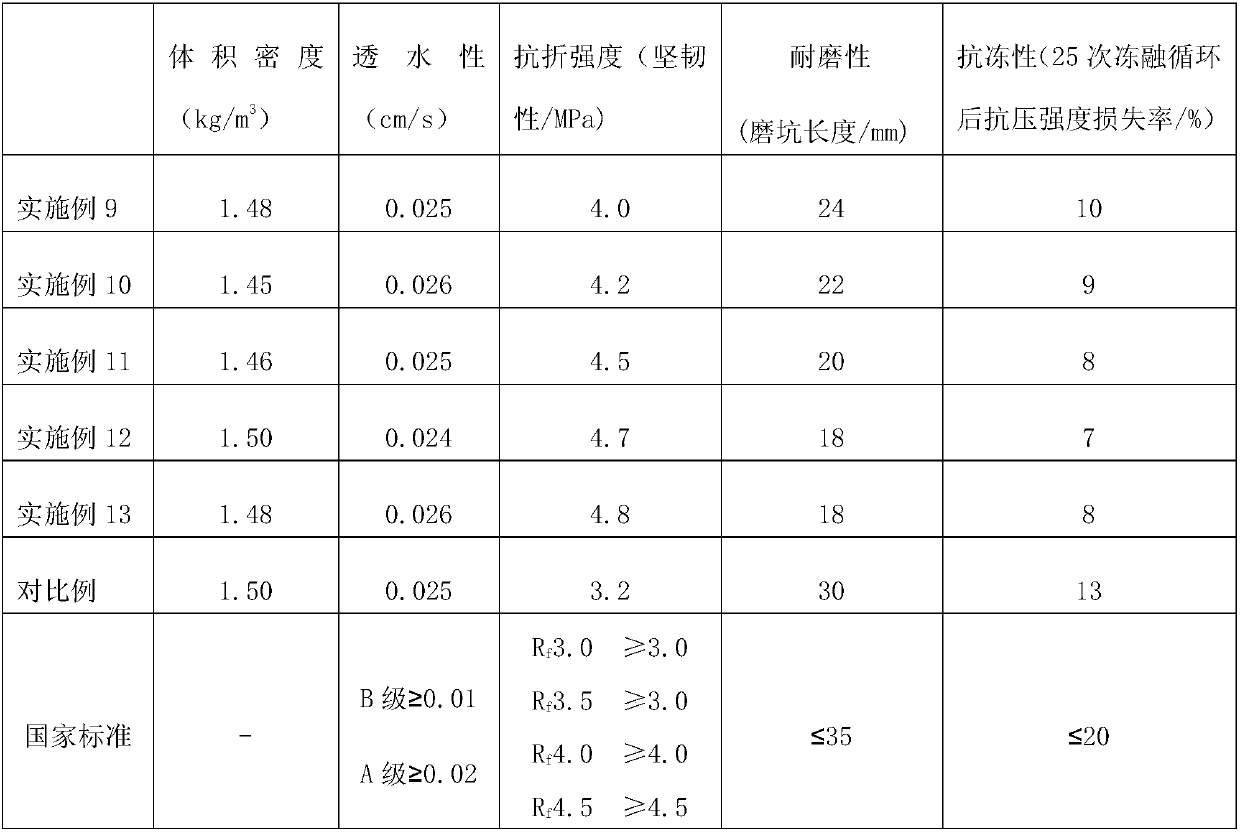

Water permeable brick based on graphene and solid wastes and preparation method thereof

ActiveCN107602072AHigh strengthImprove high temperature resistanceCeramic materials productionCeramicwareSodium BentoniteBrick

The invention provides a water permeable brick based on graphene and solid wastes. The water permeable brick is prepared from municipal sludge, municipal waste soil, construction waste, coal ash, nonmetal tailings, graphene, bentonite, sodium silicate, pore forming substance and hydroxypropyl methyl cellulose. The water permeable brick with excellent performances is acquired in the manner of utilizing the construction waste, coal ash, graphene and nonmetal tailings as aggregates and utilizing the municipal sludge, municipal waste soil, bentonite and sodium silicate to bond the aggregate grainsand thus is endowed with the performances, such as, high strength, high temperature resistance and high wearing resistance. A large amount of municipal sludge, municipal waste soil and construction waste are effectively utilized and the recycling of the coal ash and the nonmetal tailing waste resources is realized, so that the environment protection is benefited, the industrial and regional economy and the development of urbanization are promoted.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

Low-water-absorption foamed concrete and preparation method thereof

InactiveCN104150951AShort initial setting timeReduced open porosityCeramicwareFoam concreteAluminate

The invention relates to a low-water-absorption foamed concrete and a preparation method thereof. The low-water-absorption foamed concrete is prepared from ordinary Portland cement, sulphoaluminate cement, raw material soil, water, a thickening agent, a water-reducing agent, a foam-stabilizing agent, an accelerator and a foaming agent. Through addition of the sulphoaluminate cement and the accelerator which can accelerate coagulation of the ordinary Portland cement, break of bubbles during an initial setting time is reduced and an opening porosity and water absorption of the foamed concrete are reduced. Through addition of the thickening agent, thickness of the foamed concrete can be adjusted and upward-floating of the bubbles is reduced so that the bubble is distributed uniformly. The foamed concrete is low in water absorption, is uniform in volume weight, is stable in compressive strength and has a better thermal-insulation and temperature-preserving performance, a better mechanical performance and a better freeze-thaw-destroy resistant performance.

Owner:WUHAN UNIV OF TECH

Casein type aqueous ink and method for preparing same

The invention discloses a cheese water-type ink and its process for preparing. The method is as follows: polymerizing arbowax or polyester diol, dimethylol propionic acid and isophorone diisocyanate under accelerating effect of catalyst, stopping heating after 3-5 hours; adding triethylamine to neutralize after cooling, and adding water to prepare polymer solution with 20-40 % of solid content, adding drainable clay, stirring to obtain clay intercalation polyurethane, dissolving dry casein into the water in alkali condition, preparing to obtain aqueous solution of dry casein with 10-20 % of solid content; mixing intercalation polyurethane with aqueous solution of dry casein evenly to produce junction material of water-type ink, and adding pigments, alcohol, anti-fungus agent and water, grinding, adjusting viscosity to obtain water-type ink. The invention selects renewable natural resources as its main film forming matter, so it is environment-friendly and can save energy; the said water-type ink is of simple process and reasonable cost; and the quality of the obtained ink meets the requirement of the decorative laminate printing.

Owner:SUN YAT SEN UNIV

Stuffing modifier, dumpling and preparation methods thereof

InactiveCN107594323AKeep the clumping performancePreserve tendernessFood coatingGellan gumMonoglyceride

The invention relates to the technical field of food processing and specifically relates to a stuffing modifier, a dumpling and preparation methods thereof. The modifier is prepared from gellan gum, calcium hydrophosphate, xanthan gum, composite phosphate, monoglyceride and corn starch, wherein the gellan gum and the calcium hydrophsphate interact with each other to form gel; thus, under the situation that diced meat is utilized as a stuffing raw material, stuffing huddling performance can be still well kept, and granular sensation of meat stuffing is enhanced; the composite phosphate, the corn starch and the monoglyceride are added to effectively improve water binding capacity; thus, meat tenderness is kept, meat stuffing taste is prevented from being dry and skinny; meanwhile, product texture is improved, granular sensation is obvious when the meat stuffing is eaten, and the meat stuffing has elasticity; the xanthan gum is utilized as a thickener and can absorb moisture precipitatedfrom the meat stuffing, meat stuffing thickness is improved, and production operation is facilitated.

Owner:郑州研霖生物科技有限公司

Damping sound-insulating spraying mortar

The invention discloses a damping sound-insulating spraying mortar. The damping sound-insulating spraying mortar is a bagged damping sound-insulating dry-blend spraying mortar prepared through mixing of an inorganic cementitious material, a filling material, an organic cementitious material and an additive under stirring; and the motor is stirred on site and uniformly sprayed on a base layer by using a spray coater. The motor comprises, by weight, 25 to 35 parts of cement, 5 to 15 parts of fly ash, 25 to 50 parts of fine and light aggregate, 10 to 40 parts of rubber powder, 0.6 to 5 parts of redispersible powder, 0.1 to 0.3 part of methylcellulose ether, 0.02 to 0.1 part of short fiber and 0.01 to 0.1 part of a water reducer. The damping sound-insulating spraying mortar can improve the sound reduction index of a wall and a ceiling when sprayed on the wall and the ceiling, and can replace a leveling layer of a floor and improve the impact sound reduction index of the floor when sprayed on the floor; and the damping sound-insulating spraying mortar can totally cover a variety of special-shape structures to form an effective sound-insulating layer and can be constructed in a variety of complex environments with narrow space.

Owner:XIAMEN JIADA GREEN CONSTRUCION ENG CO LTD

Leak-proof leak-stopping cement mortar

InactiveCN101250047AImprove pressure bearing capacityThickenSolid waste managementFiberCarbon fibers

The invention relates to a leakage-blokage proof slurry product, which is composed of 100 portions of cement, 70 portions of water, 5-20 portions of floating bead, 5-10 portions of micro silicon, 3-10 portions of carbon fiber, 0.5-2 portions of calcium chloride or potassium chloride and 4-7 portions of sodium silicate. The leakage-blokage proof slurry product has better leakage-blockage resistance to seal leakage layer.

Owner:DAQING PETROLEUM ADMINISTRATION

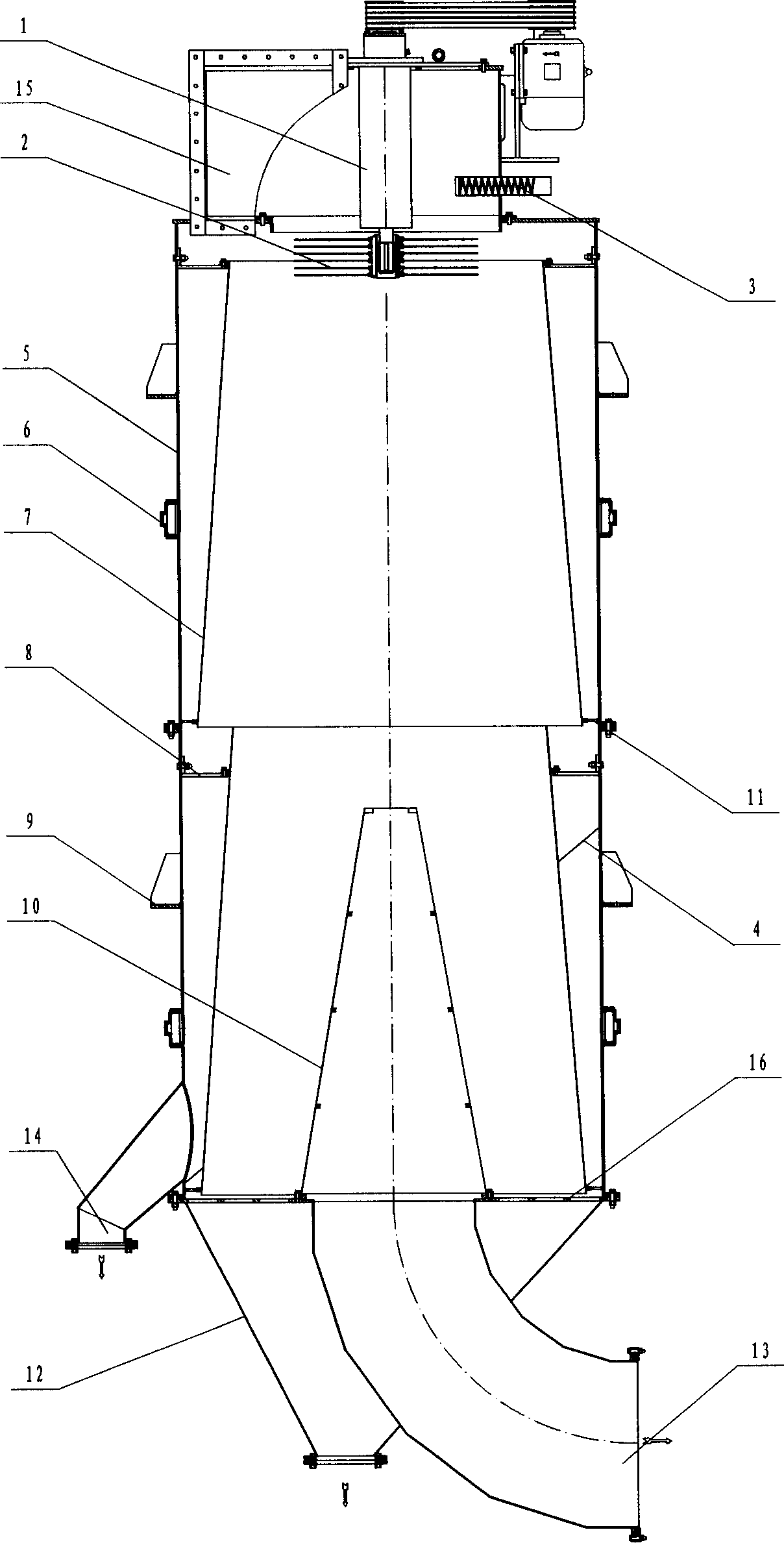

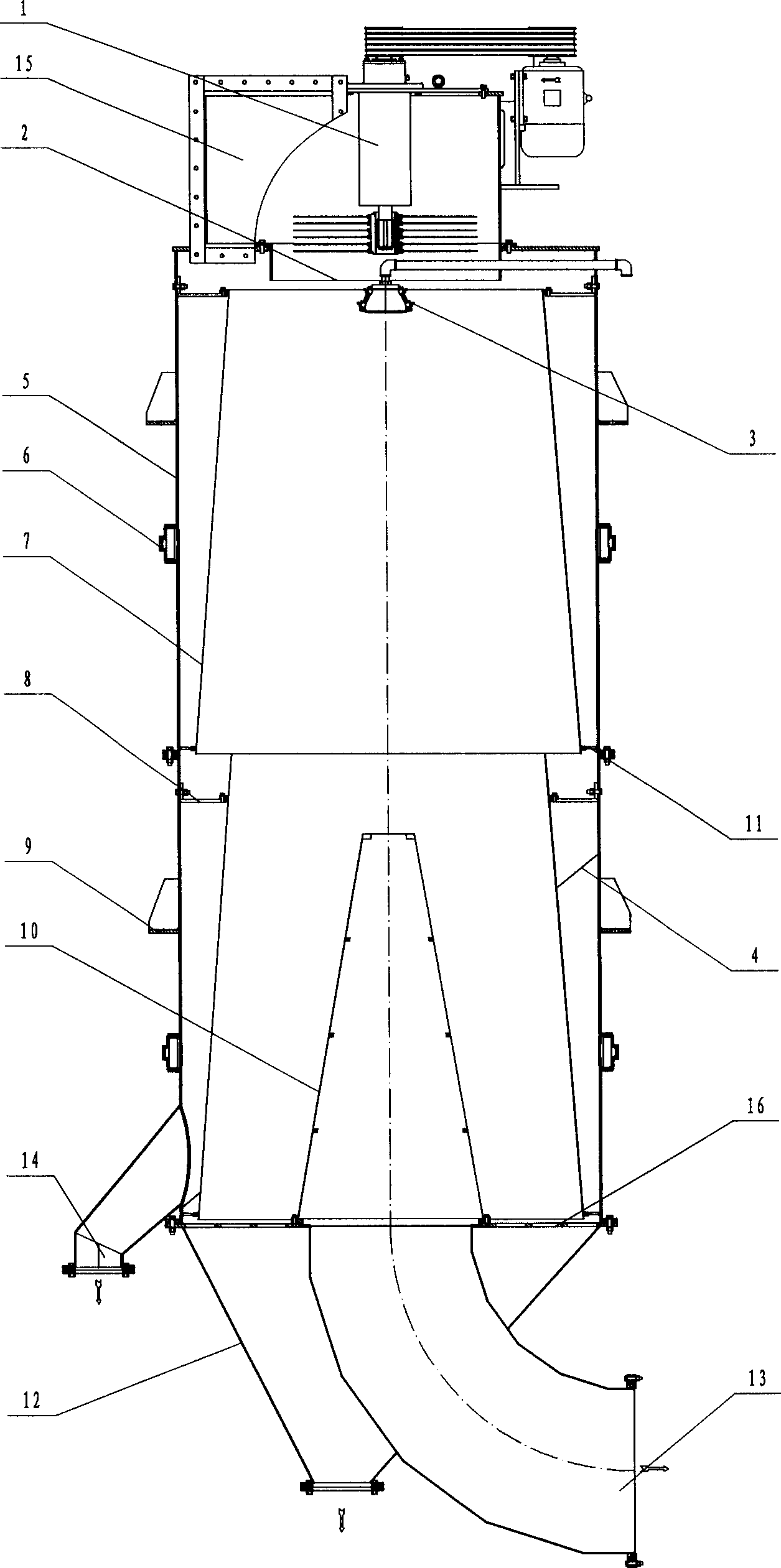

Drying separator

InactiveCN1419098ALarge three-dimensional space rangeIncrease profitDrying solid materials with heatDispersed particle separationThermal energyEngineering

The present invention relates to a drying separation equipment, containing tower body, driving device, start-rotating needle wheel, granule sorting device, separating needle wheel and air power separator. It is characterized by that it mainly utilizes the rotor of start-rotating needle wheel to disperse material and start rotational flow, and utilizes the rotational flow to enhance heat condution of material and gas flow, and can force the dried material to make regular centrifugal movement to clean tower wall and eliminate sticky wall phenomenon. The sorting device can be used for collecting the products with different grain sizes or cooling, and the separating needle wheel can raise separation effect. Said invention can implement air flow circularting drying and can raise utilization rate of heat energy.

Owner:高根树

Coated submicron feed-grade zinc oxide and preparation method thereof

ActiveCN102318750AReduce feeding costsReduce zinc excretionAnimal feeding stuffAccessory food factorsMagnesium stearateStearic acid

The invention provides coated submicron feed-grade zinc oxide and a preparation method thereof, and belongs to the field of feed additives. The invention aims at solving the problems in the prior art that zinc oxide can influence the biological potency of active components in feed, and coating wall materials can not degrade timely in intestinal environment; through shielding treatment for three times, a product is prepared by the following components by weight: 90-120 parts of submicron feed-grade zinc oxide, 28-35 parts of composite shielding agents; the composite shielding agent comprises the following components by weight: 80-90 parts of potato starch, 4-6 parts of ethyl cellulose, 3-4 parts of anhydrous alcohol, 0.5-0.8 parts of magnesium stearate. A feed-grade zinc oxide product and a corresponding preparation method thereof are provided, wherein the product combines appropriate control of the degeneration degree of the shielding agent, can deshield and release in animal digestive tract, gastric and intestinal environment, and is effectively used by microbe in posterior digestive tracts.

Owner:巨星农牧有限公司

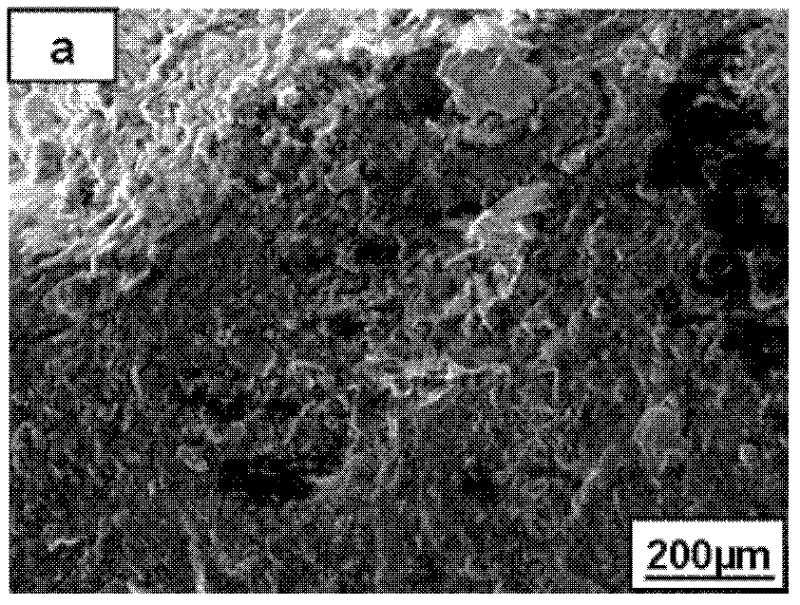

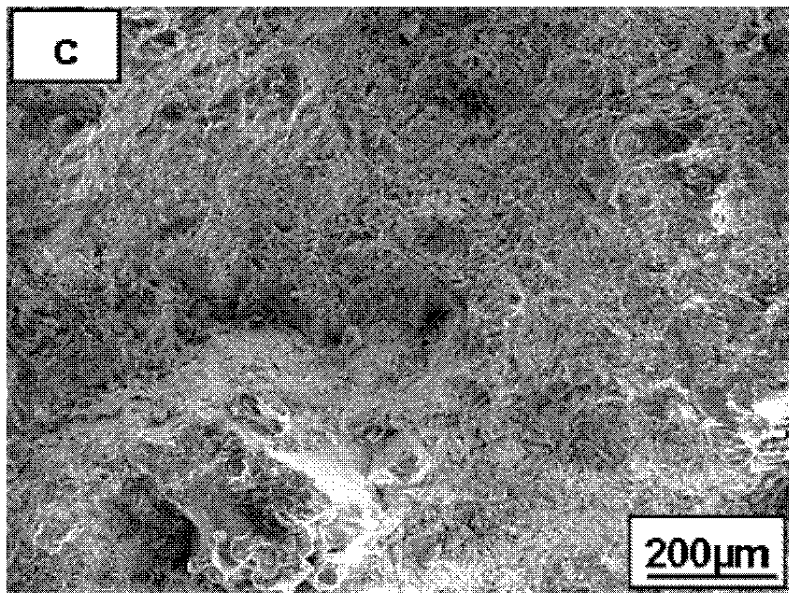

A kind of preparation method of silane coupling agent modified road petroleum asphalt

A preparation method of silane coupling agent modified road petroleum asphalt, adding 0.25% to 0.35% of asphalt quality silane coupling agent to 150°C hot-melt asphalt, then using high-speed shearing and stirring for 15 minutes, and placing it at 80°C Grow in an oven for 2 hours, or manually stir for 30 minutes and place in an oven at 80°C for 30 minutes, and so on. The total preparation time is 2 to 4 hours. The silane coupling agent modified road petroleum asphalt prepared by the invention can significantly improve the adhesion between granite and other acidic stones and the petroleum asphalt, and improve the adhesion level from 2 before modification to 5 after modification. The invention has the characteristics of simple preparation process and obvious improvement effect of road petroleum asphalt.

Owner:SHANDONG JIAOTONG UNIV

Interior wall plastering mortar and construction method thereof

InactiveCN101712545AHigh tensile strengthReduce stretchCovering/liningsSolid waste managementRiver sandFineness

The invention provides interior wall plastering mortar, which is prepared by mixing the following components in part by weight: 30 to 35 parts of ordinary Portland cement, 4 to 5 parts of hydrated lime, 5 to 10 parts of light aggregate, 50 to 60 parts of heavy aggregate, and 1.0 part of C-type composite auxiliary, wherein the light aggregate is an inorganic vitrified hollow cellular material of which the fineness is lower than 100 meshes; the heavy aggregate is ordinary river sand; and the C-type composite auxiliary is sold by Guangzhou Hecheng Trading Company. The construction method for the interior wall plastering mortar comprises the following steps: diluting the light energy-saving interior wall plastering mortar with water accounting for 30 to 50 percent of the weight of the mortar; and mechanically or manually stirring the diluted mortar until the mortar is mixed uniformly to achieve the viscosity suitable for mechanical spraying or manual construction. Therefore, the mortar can be sprayed mechanically or constructed manually. The interior wall plastering mortar has light weight and energy conservation, can prevent hollowness, cracking and falling off by being matched with a light wall body, can effectively reduce cracking of the mortar, ensures the quality of construction work, has the advantages of heat insulation and noise reduction, low cost of unit area, good grain composition, good peaceability, mechanical construction contribution and simple process.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

Glucose beverage and manufacture method thereof

The invention relates to a glucose drink, which comprises 250 to 350g of aerated water, citric acid and glucose, wherein the weight of the glucose is 50g, 75g or 100g. The aerated water and the citric acid contained in the drink can improve the taste both. After the oral glucose tolerance test, the tester does not feel nausea or other discomforts, so that the test is carried out smoothly. When the weight of the glucose is 50g, 75g or 100g, the requirements on the oral glucose tolerance test are met. The invention also provides a method for preparing the glucose drink.

Owner:廖瑛

Asphalt mixture anti-rutting additive and preparation and use method thereof

ActiveCN101805470AEnhanced recovery from deformationImprove toughnessBuilding insulationsPolypropylenePitch blende

The invention relates to an asphalt mixture anti-rutting additive and a preparation and use method thereof. The anti-rutting additive which is in common use at present has insufficient toughness and poor deformation recovery capability under the condition of heavy load, or has poor adaptability and small application range because the existing anti-rutting additive needs to take chemical reaction with the asphalt. The invention provides the asphalt mixture anti-rutting additive, which is prepared from the following ingredients in weight parts: 25 to 75 percent of polyethylene, 5 to 35 percent of polypropylene, 5 to 25 percent of PVC, 3 to 5 percent of rubber, 5 to 10 percent of asphalt, 1 to 5 percent of tougheners and 1 to 3 percent of UV ageing resistant agents. The ingredients are mixed and uniformly stirred according to the ingredient mixture ratio, and are put into a screw extruder to be heated into 110 to 180 DEG C, the materials are extruded into granules after being fused and prepared into uniform substances, and the asphalt mixture anti-rutting additive can be directly mixed with the asphalt mixture in a dry mode when in use. The additive of the invention has the advantages of low asphalt cost and stable structure, the wear resistance and pressure resistance performance is improved by 15 to 30 percent, the elasticity recover performance index of the asphalt is improved by 10 to 25 percent, and the time limitation of the road surface antifatigue performance is prolonged by 10 to 25 percent.

Owner:CCCCRUITONG ROAD & BRIDGE MAINTENANCE TECH +1

Production method of fried bean sauce with mushroom and beef

The invention provides a production method of fried bean sauce with mushroom and beef, wherein the main ingredients include beef stuffing or shredded beef, minced mushroom, flour paste and fermented soya paste, the beef stuffing or shredded beef are refrigerated and defreezed under atmospheric temperature, water-loss reducer and anti-oxidizing agent are charged into laminated pan to be boiled, at last soup stock and thickening agent are also charged.

Owner:杨秀敏

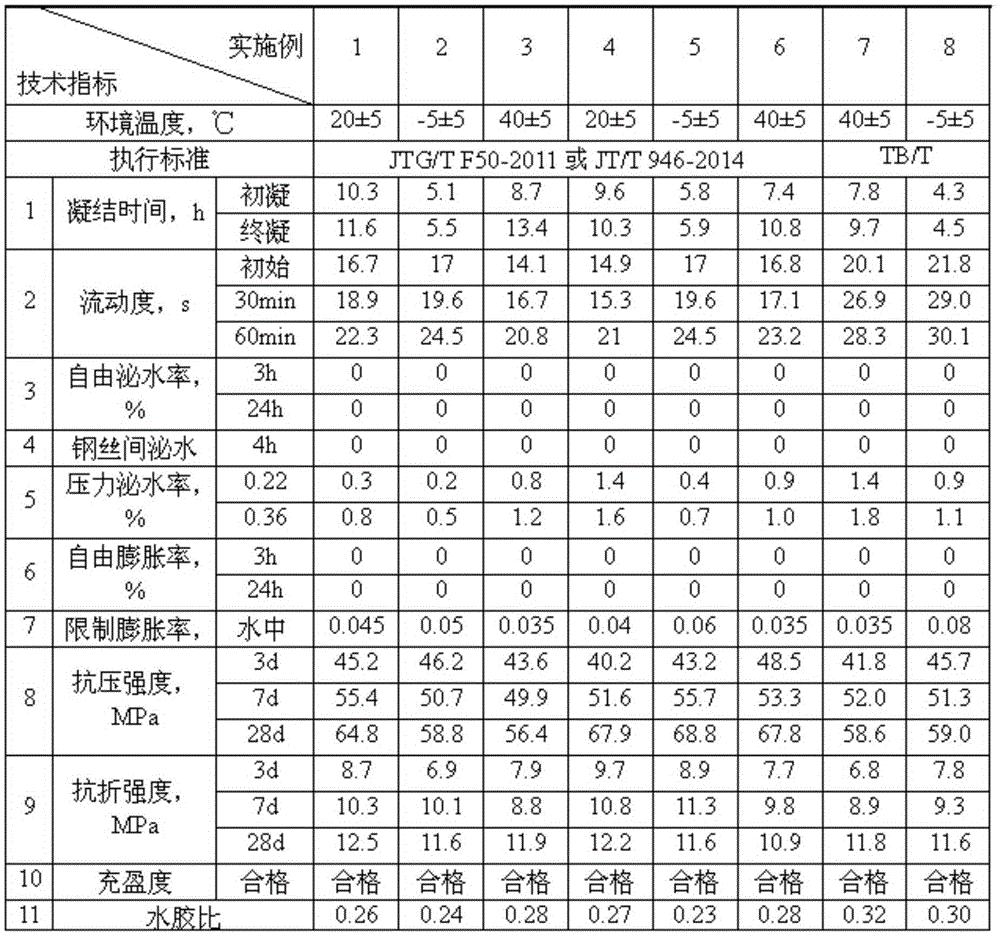

Pre-stressed duct grouting agent, and preparation and application methods thereof

The invention provides a pre-stressed duct grouting agent which has the characteristics of high fluidity, bleeding prevention and the like. The pre-stressed duct grouting agent comprises the following components: 2 to 10 percent of a water reducing agent, 0.1 to 10 percent of a viscosity modifying agent, 0 to 1 percent of a defoaming agent, and 35 to 78 percent of a coagulation time regulating agent; the coagulation time regulating agent comprises the following components: 28 to 52 percent of clinker, 42 to 68 percent of plaster, 4 to 30 percent of fillers, and 0 to 3 percent of a coagulation accelerator. The invention further provides a preparation method and an application method of the pre-stressed duct grouting agent. The invention has the advantages that the pre-stressed duct grouting agent contains the cement coagulation time regulating agent, so that the coagulation time of a cement-based composite material can be regulated based on external temperature changes to guarantee the normal use and normal strength growth of the cement-based composite material; meanwhile, the cement-based composite material achieves micro-expansion at the later stage due to the addition of the cement coagulation time regulating agent.

Owner:WUHAN BILLION TECH DEV CO LTD

Ecological dust reducing agent and preparing method thereof

InactiveCN106350014AIncrease surface viscosityReduce surface tensionOther chemical processesTransportation and packagingDegree CelsiusFilm-forming agent

An ecological dust reducing agent and preparation method thereof,components of which according to the mass percentage: 3-12% of hydrolyzing the animal protein ,0.15-0.8% of surfactant , 0.35-1% of film forming agent , 0.11-3.12% of auxiliary agent with the balance being water. The preparation method comprises the following steps: (1) adding the hydrolyzed animal protein, surfactant and film-forming agent into the water at 40-60 degrees Celsius to mix them proportionally; (2) adding the foam stabilizing agent into mixture solutions from the step 1; (3) the mixed solution obtained in the step (2) is slowly poured into a vessel, stirred and stirred with a mixer. And the pH is adjusted to 6- 8 with the PH regulator to obtain a dust-reducing agent. The invention proposes an ecological dedusting agent,which has functions of film formation, wetting and condensing. And it is with the hydrolyzed animal protein as the main body, which is non-corrosive. It has no toxic effect on the human body after being inhaled and no pollution to the environment. It has a high settling efficiency on the dust in the air and can be formed the continuous, complete and strong shell membrane to prevent the secondary dust.

Owner:辽宁点石技术开发有限公司

High-temperature lubricating grease for food processing and preparation method thereof

The invention relates to lubricating grease and a preparation method thereof, in particular to high-temperature lubricating grease for food processing and a preparation method thereof, and belongs to the technical field of chemistry. The high-temperature lubricating grease is prepared from base oil accounting for 70%-92% of the total weight of the lubricating grease, an inorganic thickening agent accounting for 3%-20% of the total weight of the lubricating grease, a tackifier accounting for 2%-6% of the total weight of the lubricating grease, an auxiliary dispersant accounting for 0.1%-1.5% of the total weight of the lubricating grease, an antioxidant accounting for 0.3%-1.0% of the total weight of the lubricating grease, a corrosion inhibitor accounting for 0.05%-1% of the total weight of the lubricating grease, a friction modifier accounting for 0.1%-0.5% of the total weight of the lubricating grease and a solid additive accounting for 2%-10% of the total weight of the lubricating grease. The high-temperature lubricating grease has the advantages of being capable of not being fused at high temperature, high in dropping point, few in high-temperature consistence change, good in colloid stability and the like and especially suitable for lubricating and sealing high-temperature food processing equipment.

Owner:JIANGSU LOPALTECH

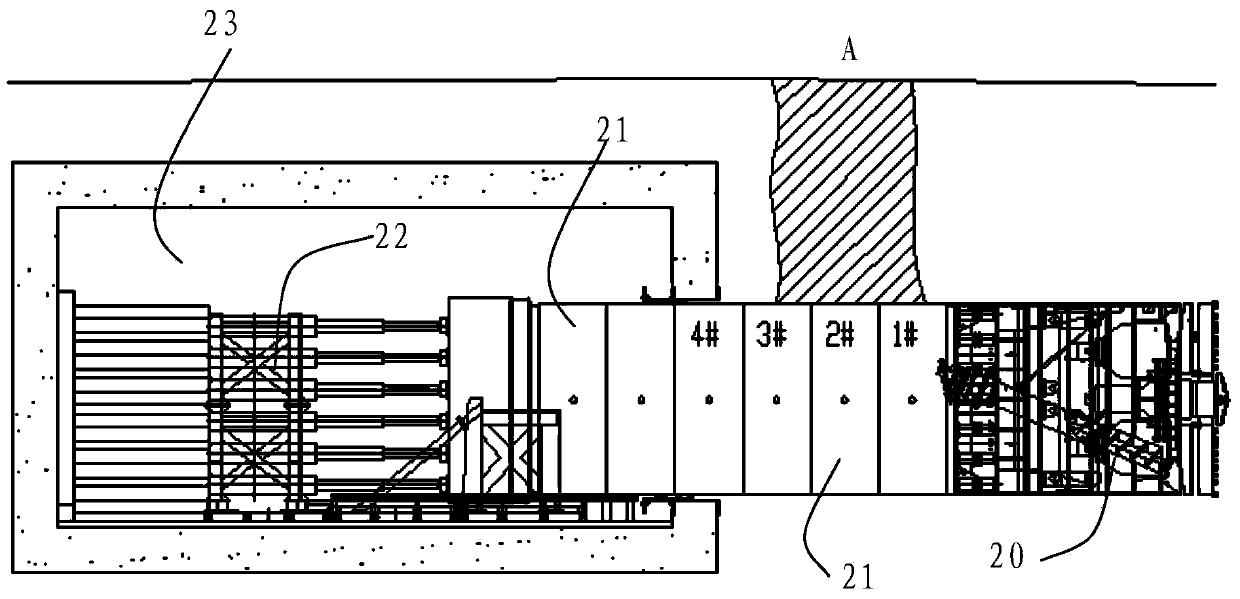

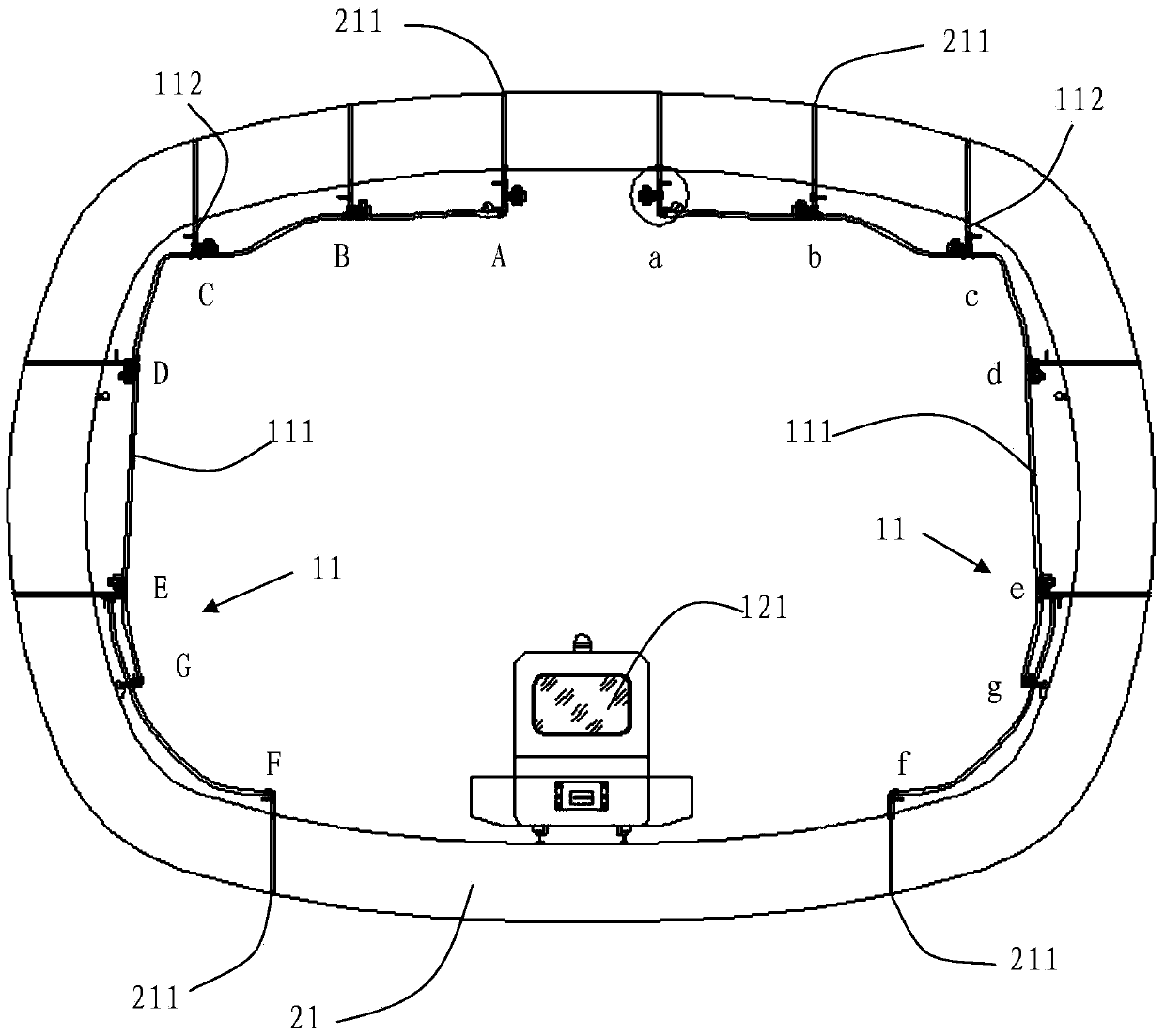

Method for controlling soil deformation in large rectangular pipe jacking

ActiveCN104265326AQuality improvementThickenUnderground chambersTunnel liningSoil horizonFriction reducing

The invention discloses a method for controlling soil deformation in large rectangular pipe jacking. The method comprises the following steps: friction reducing slurry is mixed, and comprises the components of water, bentonite and high-molecular polymers; a slurry injecting port is formed in a pipe piece of a rectangular pipe, and is connected with a slurry injecting pipeline; and in the promoting process of the pipe piece, the friction reducing slurry is injected between the outer surface of the pipe piece and soil through the slurry injecting pipeline to form a layer of mud sleeve on the outer surface of the pipe piece so as to isolate direct contact between the pipe piece and the soil. The soil deformation in the complex-soil layer and large-section rectangular pipe jacking process is controlled through comprehensive methods; firstly, the high-molecular polymers are added in bentonite slurry used for the traditional pipe jacking construction according to a certain proportion, so that the slurry filling viscosity and the pressure bearing capacity are largely improved, and the filter loss in complex soil layers is reduced; and then, the sedimentation is stabilized through soil compensation measures, and even the soil in a settled area is lifted, so that sedimentation parameters satisfy the construction requirements.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com