A kind of preparation method of silane coupling agent modified road petroleum asphalt

A technology of road petroleum asphalt and silane coupling agent, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problems of affecting the water stability of asphalt mixture, poor adhesion of acid stones, poor durability, etc., to achieve modification Effects of cohesiveness, increased consistency, and improved softening point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of silane coupling agent modified road petroleum asphalt, the raw materials are silane coupling agent and road petroleum asphalt; the steps are as follows:

[0025] The dosage of silane coupling agent is 0.25% of the asphalt mass, and it is added to the hot melt asphalt at 150 °C, mechanically stirred for 15 minutes with high-speed shearing equipment, the revolution is 10000 r / min, and then placed in an 80 °C oven for development 2 hours. Obtain modified road petroleum asphalt.

[0026] The obtained modified road petroleum asphalt was reheated to 150 ℃, and the adhesion test between the modified asphalt and granite stone was carried out. Test result: Adhesion grade reaches 4 + class.

Embodiment 2

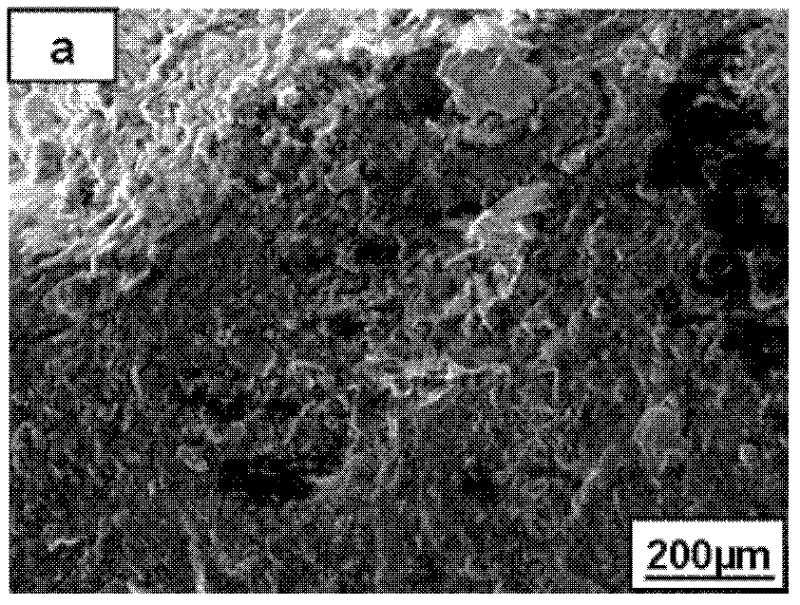

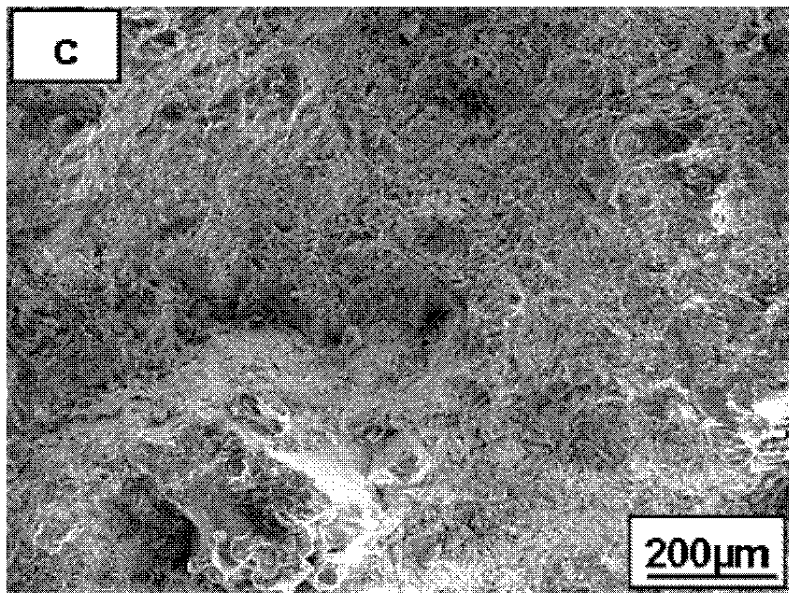

[0028] A preparation method of silane coupling agent modified road petroleum asphalt, the raw materials are silane coupling agent and road petroleum asphalt; the preparation method is the same as that in Example 1, the difference is that the dosage of silane coupling agent is asphalt 0.30% of the mass, the test result: the adhesion level reaches 5. Scanning electron microscope (SEM) pictures of silane coupling agent-modified asphalt and granite fines mortar, via figure 2 photo with figure 1 The scanning electron microscope (SEM) photos of unmodified common matrix asphalt and granite fine material mortar show that the granite matrix asphalt mortar is loose and scattered in structure, with many pores, and the silane coupling agent modified granite asphalt mortar is filamentous entanglement. Structure, dense, few holes. It shows that the adhesion interface between silane coupling agent modified asphalt and granite is improved, which is beneficial to improve the road properties...

Embodiment 3

[0031] A preparation method of silane coupling agent modified road petroleum asphalt, the raw materials are silane coupling agent and road petroleum asphalt; the preparation method is the same as that in Example 1, the difference is that the dosage of silane coupling agent is: 0.35% of asphalt mass, test result: Adhesion grade up to 5 - class.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com