Patents

Literature

10945 results about "Inorganic filler" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inorganic filler Market: Introduction. Inorganic fillers are defined as resin particles, designed to provide strength to the composite minimize polymerization, decrease thermal expansion, and reduce amount of swelling which is caused due to the water desorption.

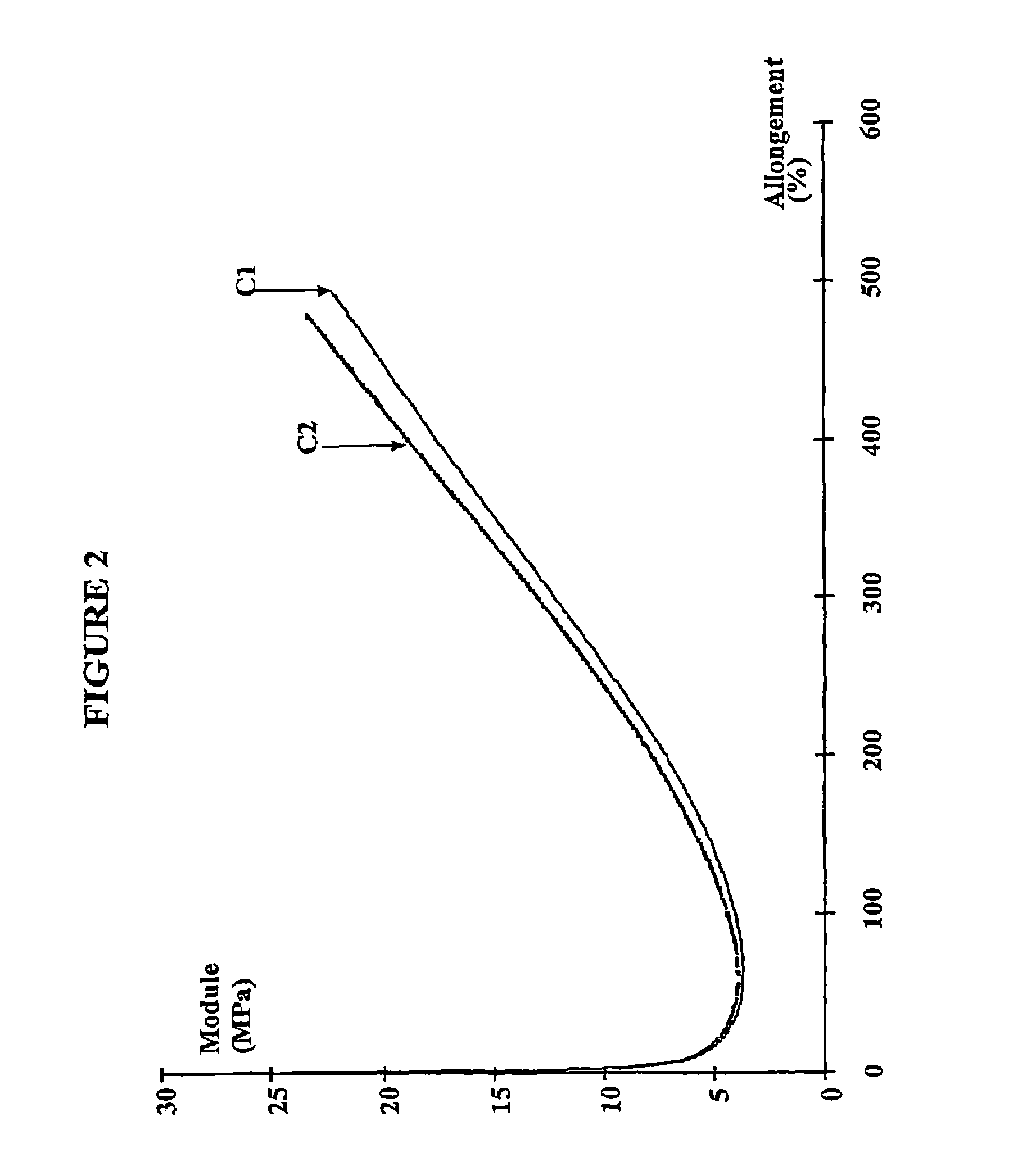

Process for obtaining a grafted elastomer having functional groups along the chain and a rubber composition

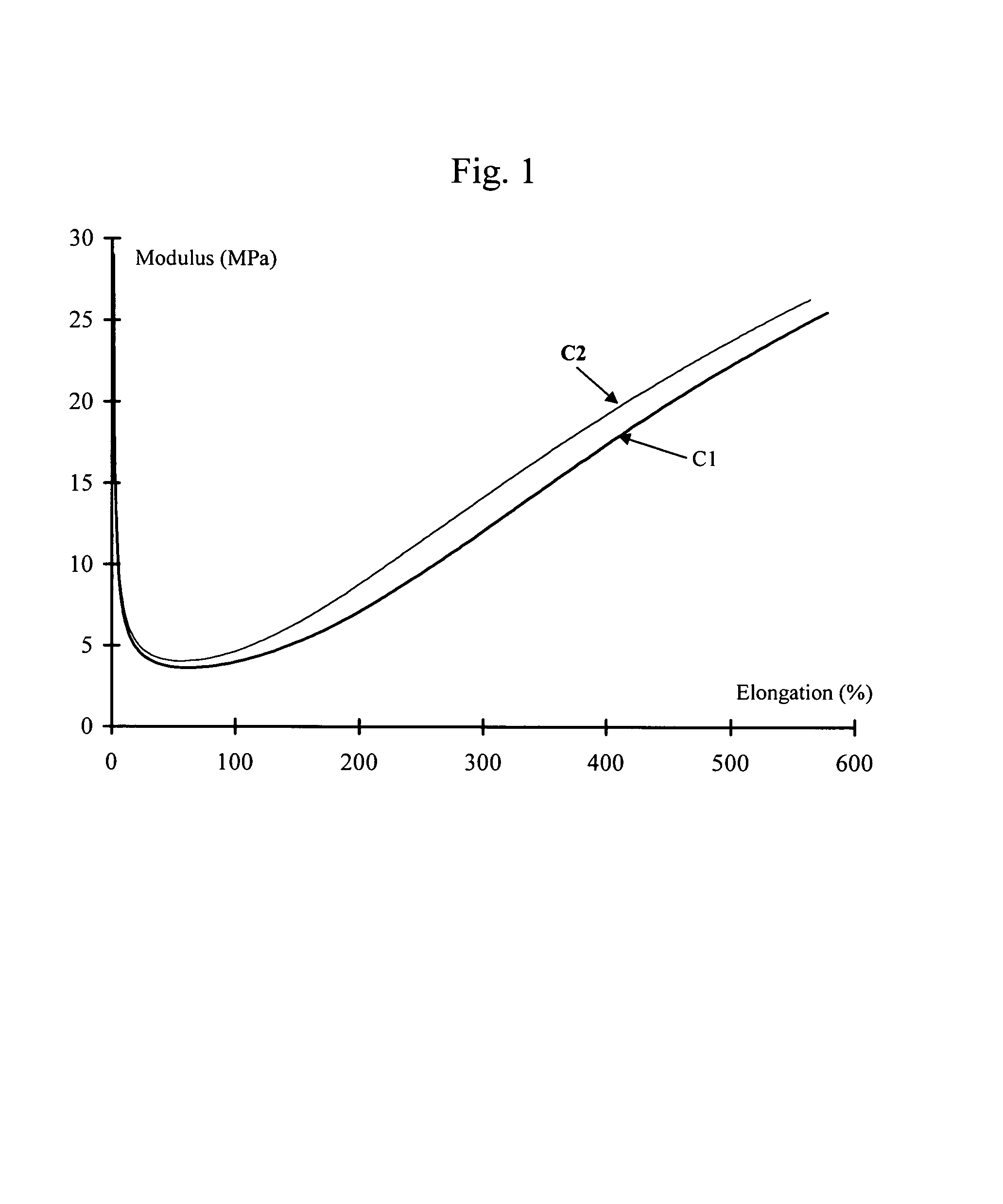

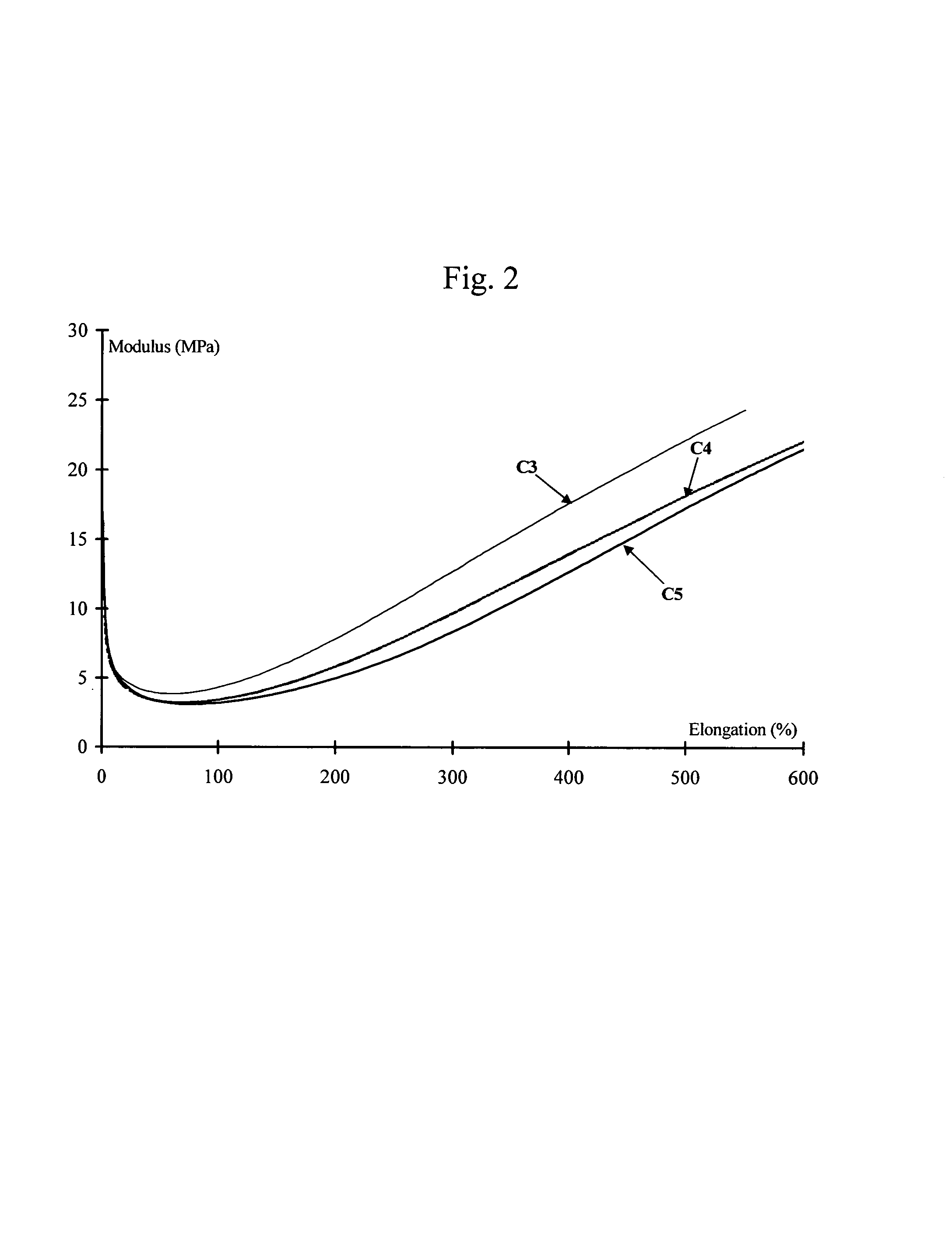

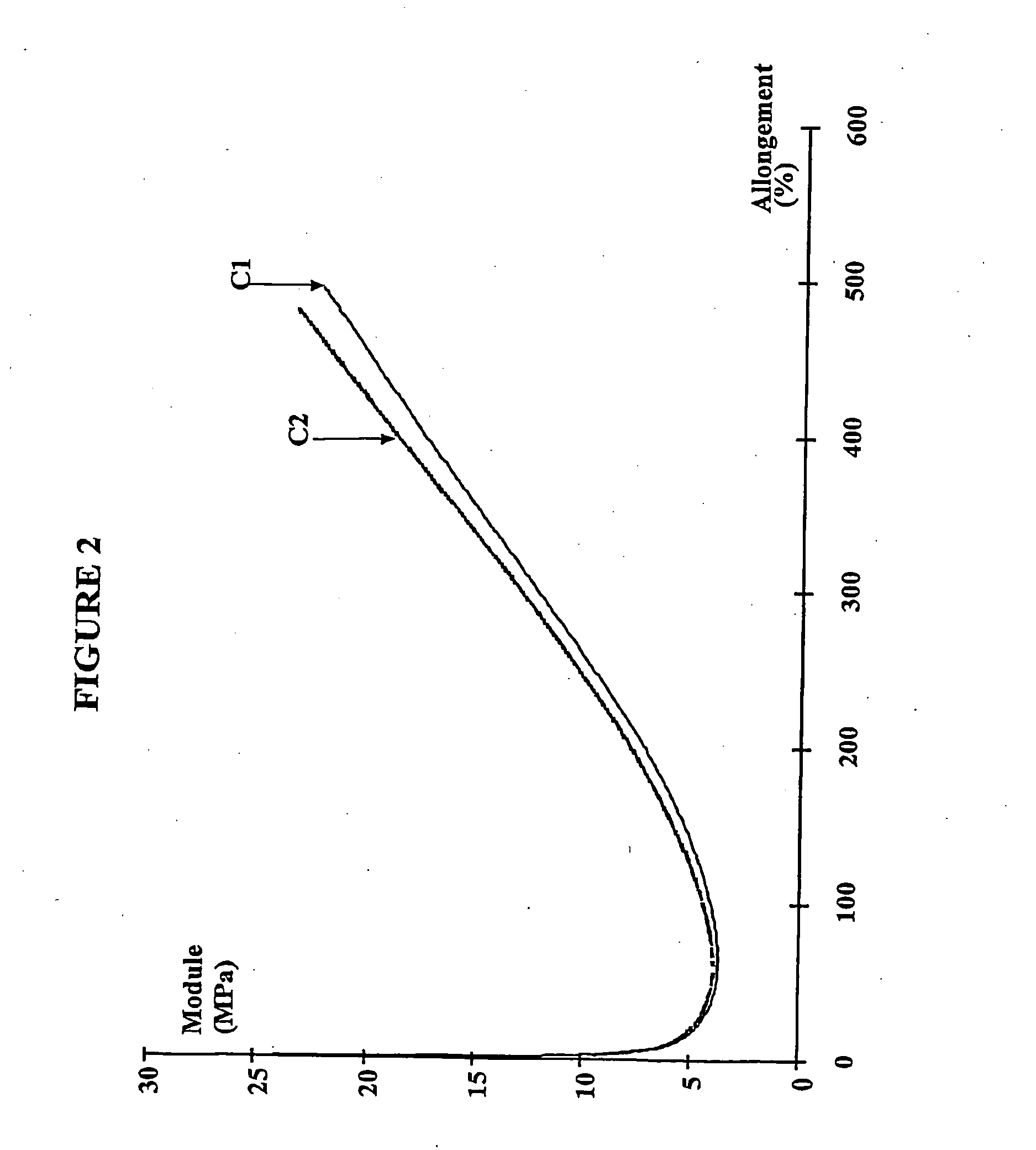

A process for obtaining a grafted diene elastomer having functional groups along the chain, a rubber composition containing this grafted elastomer and having in particular improved hysteresis properties in the cross-linked state, a preparation process for this composition, a tire tread made from this composition and a tire of reduced rolling resistance which incorporates this tread. A process for obtaining this grafted elastomer includes a radical grafting reaction carried out in solution or without a solvent by means of a reagent of the mercaptan type to graft functional groups on to the chain of a starting elastomer. The starting elastomer is treated with an antioxidant having at least one aromatic amine function before the grafting reaction, so that the grafted elastomer has a macrostructure which is practically identical to that of the starting elastomer. A rubber composition containing the grafted diene elastomer includes a reinforcing inorganic filler, and the grafted elastomer preferably has a molar ratio of units originating from conjugated dienes greater than 30%.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Thermoplastic starch compositions incorporating a particulate filler component

InactiveUS6231970B1Reduce molecular weightAvoid hydrolysisProtein adhesivesPaper coatingParticulatesCross-link

Thermoplastic starch compositions that include a particulate filler, e.g. an inorganic filler component, and optional fibrous component The compositions include a thermoplastic phase comprising a thermoplastic starch melt that contains, at a minimum, starch blended with an appropriate plasticizing agent under conditions in order for the starch to form a thermoplastic melt. The thermoplastic phase may also include one or more additional thermoplastic polymers and other optional reactants, liquids or cross-linking agents to improve the water-resistance, strength, and / or other mechanical properties of the thermoplastic melt, particularly upon solidification. The inorganic filler component may affect the mechanical properties but will mainly be added to reduce the cost of the thermoplastic starch compositions by displacing a significant portion of the more expensive starch or starch / polymer melt. Fibers may optionally be included in order to improve the mechanical properties of the thermoplastic starch compositions. The thermoplastic starch compositions may be shaped into a wide variety of useful articles, such as sheets, films, containers, and packaging materials. Because the thermoplastic starch compositions will typically include a thermoplastic phase that is biodegradable, and because the other components will either constitute a naturally occurring mineral and optionally a natural fiber, the overall composition will typically be more environmentally friendly compared to conventional thermoplastic materials.

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

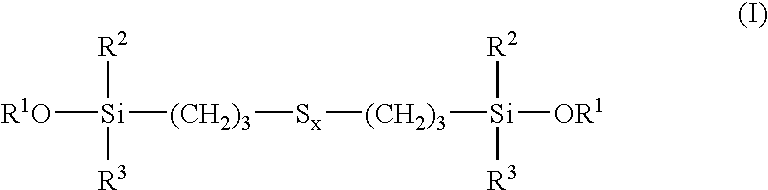

Tire and tread comprising a bis-alkoxysilane tetrasulfide as coupling agent

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

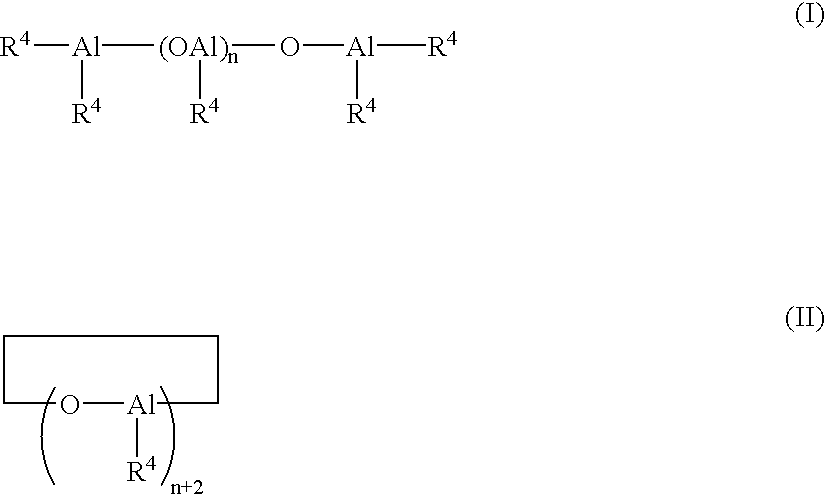

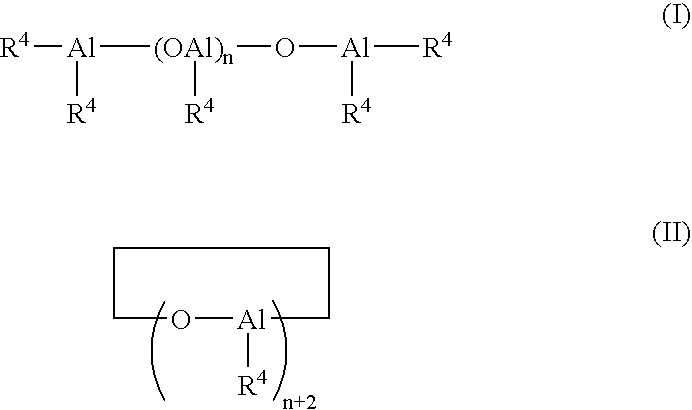

Modified polymers prepared with lanthanide-based catalysts

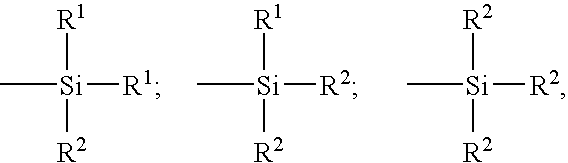

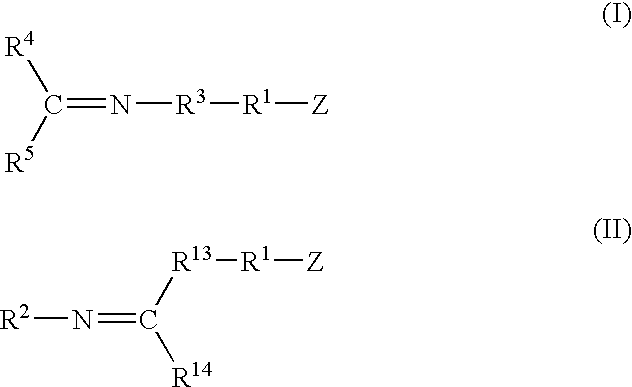

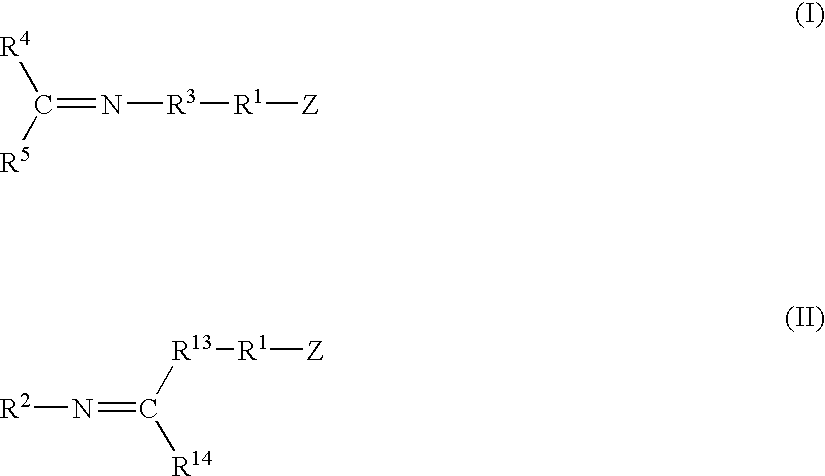

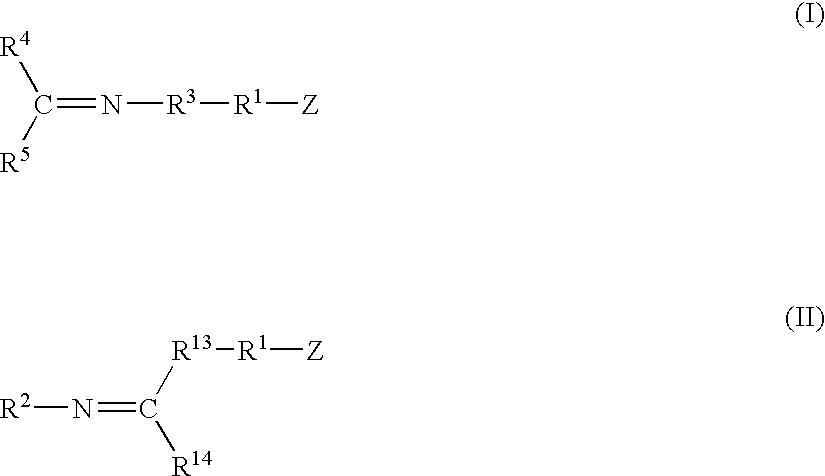

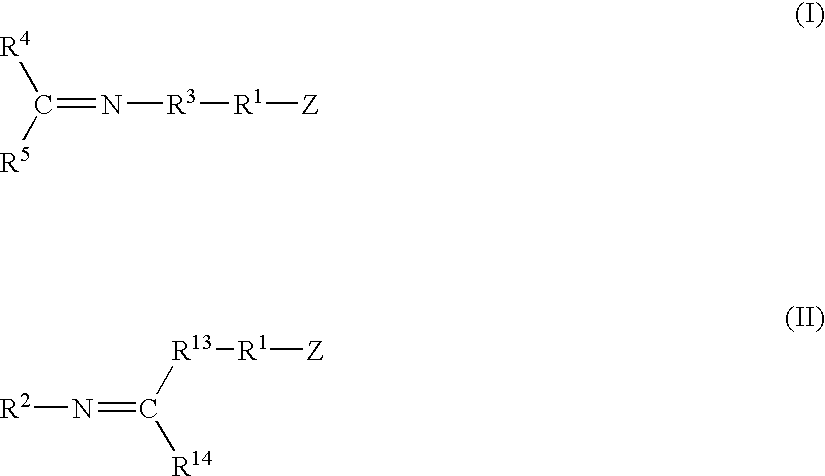

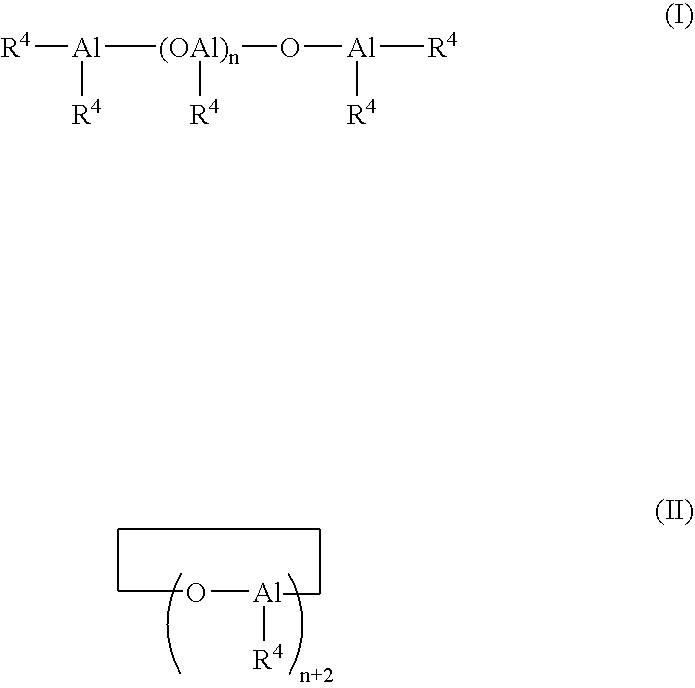

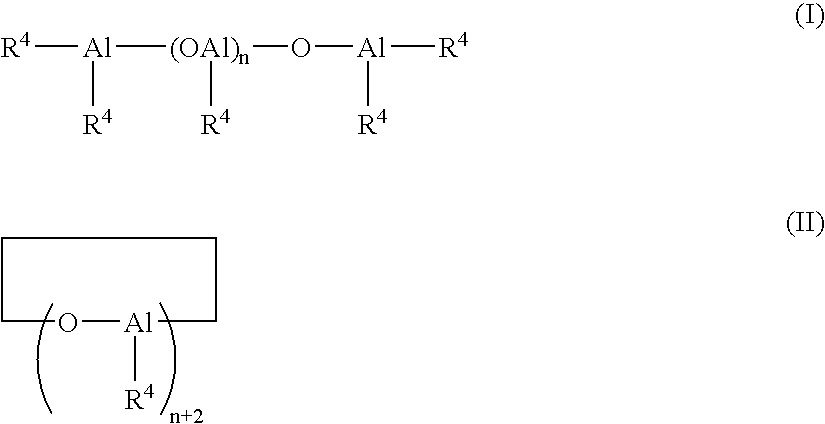

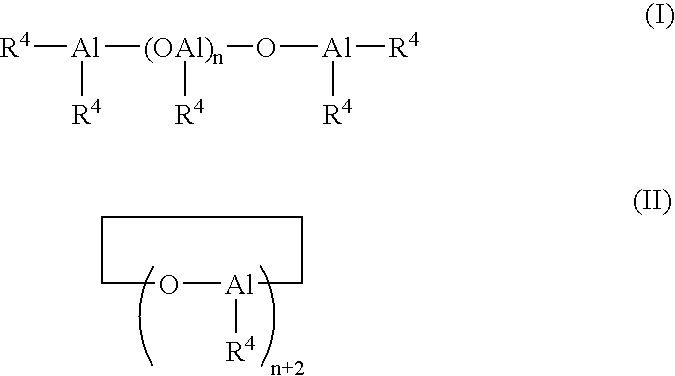

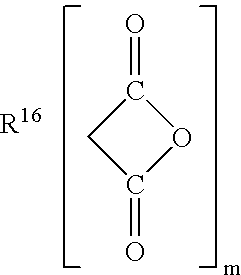

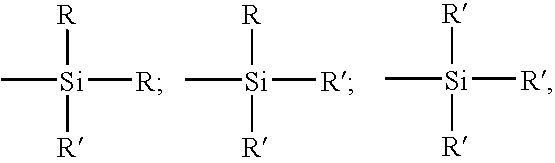

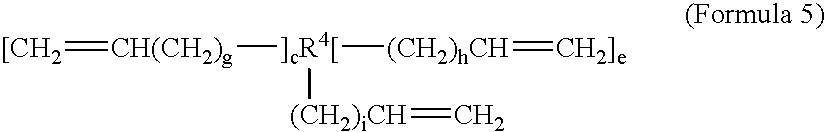

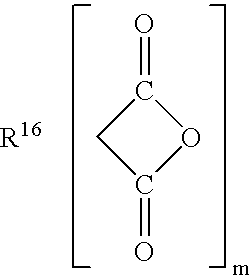

A method for preparing a functionalized polymer comprising the steps of preparing a pseudo-living polymer by polymerizing conjugated diene monomer with a lanthanide-based catalyst, where said pseudo-living polymer is characterized by having greater than about 85 percent of the polymer in the cis microstructure and less than about 3 percent of the polymer is in the 1,2- or 3,4-microstructure, and reacting the pseudo-living polymer with at least one functionalizing agent defined by the formula (I) or (II) where Z is a substituent that will react or interact with organic or inorganic fillers; R1 is a single bond or a divalent organic group; R2 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R13 or R14; R3 is a single bond, a divalent organic group, or a trivalent organic group that forms a cyclic organic group with R4 or R5; R13 is a single bond, a divalent organic group, or a trivalent organic group that forms a cyclic organic group with R2 or R14; R4 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R3 or R5; R14 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R2 or R13; and R5 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R3 or R4; with the proviso that each group attached to the imino carbon is attached via a carbon atom and R1, R2, R3, R4, R5, R13, R14 and Z are substituents that will not protonate a pseudo-living polymer.

Owner:BRIDGESTONE CORP

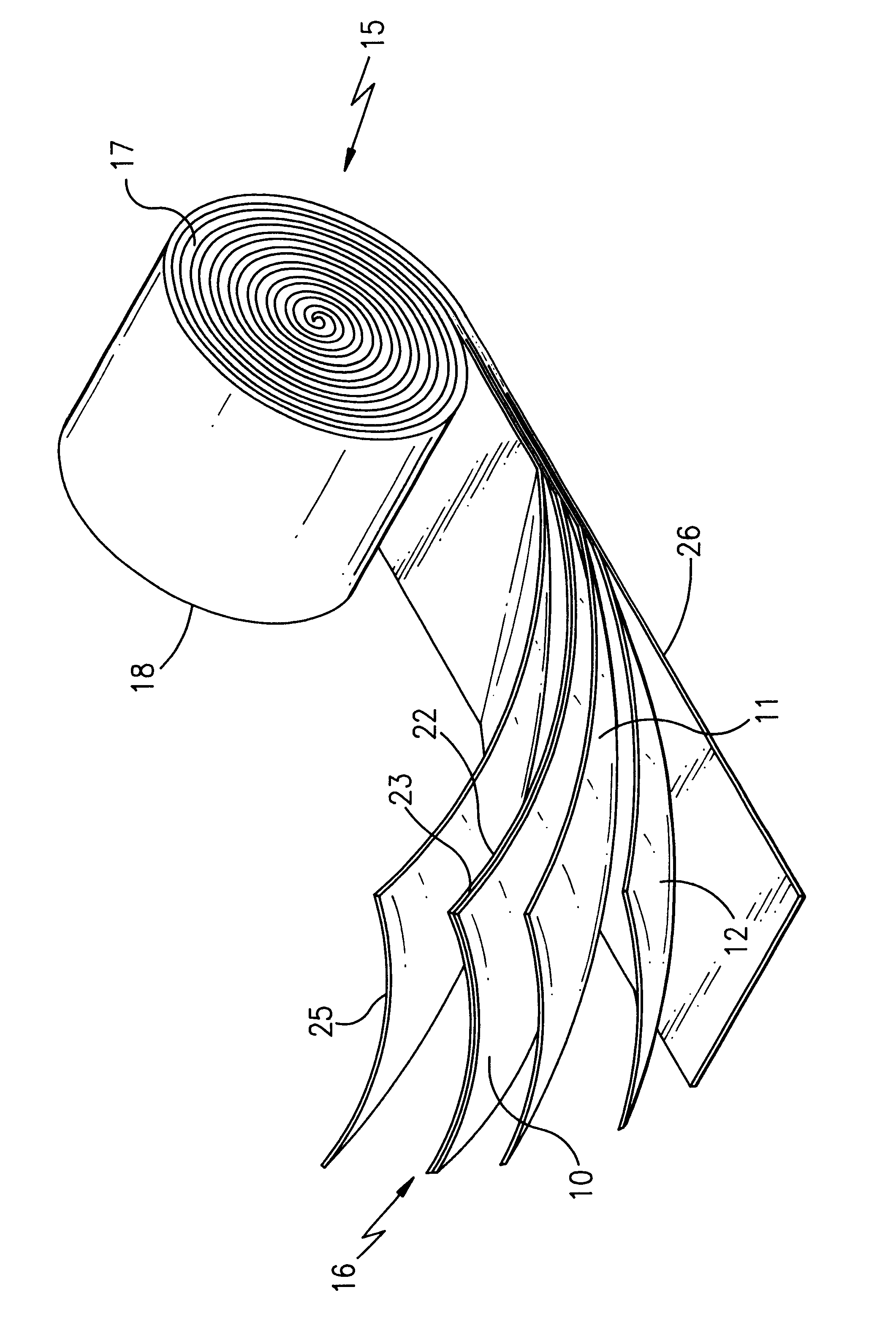

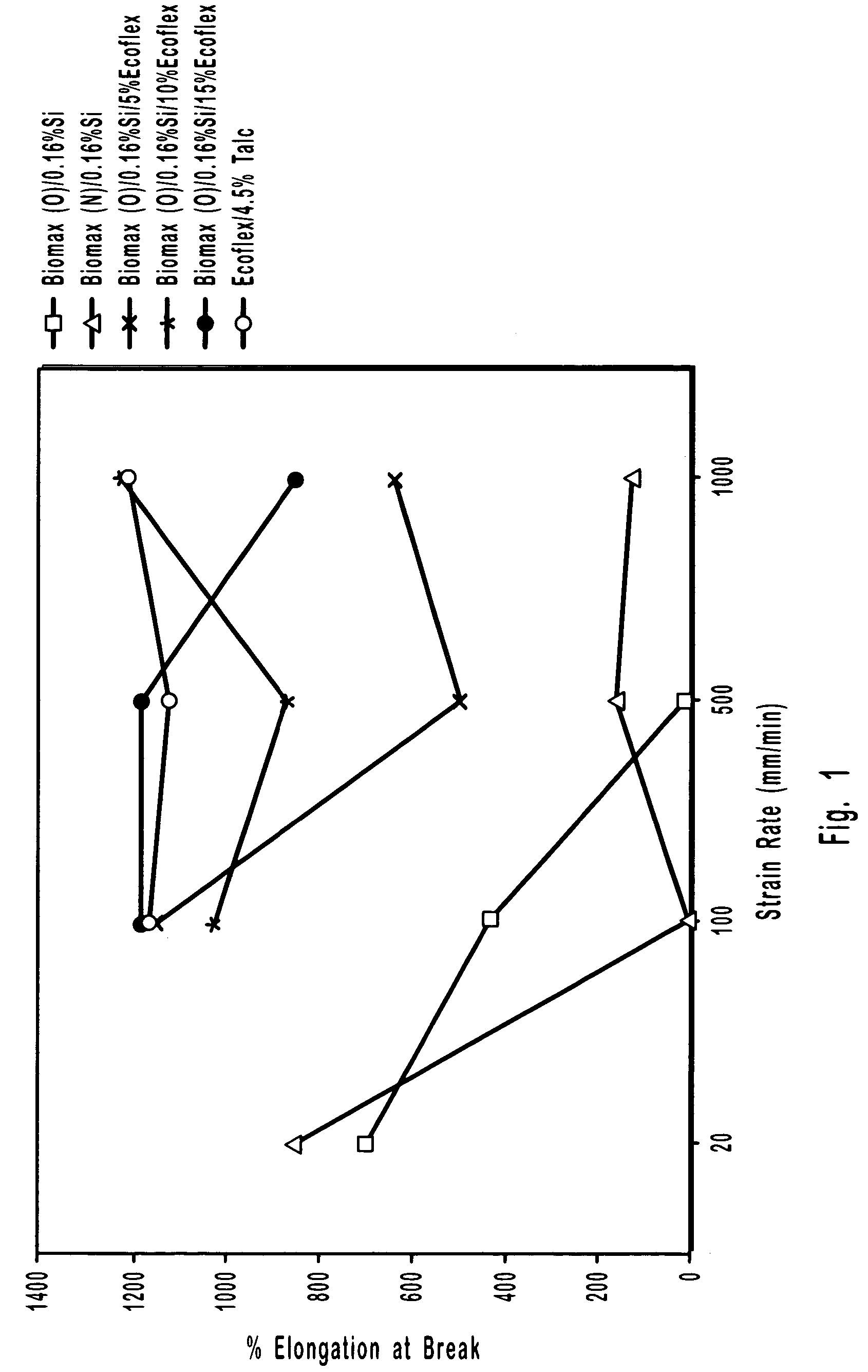

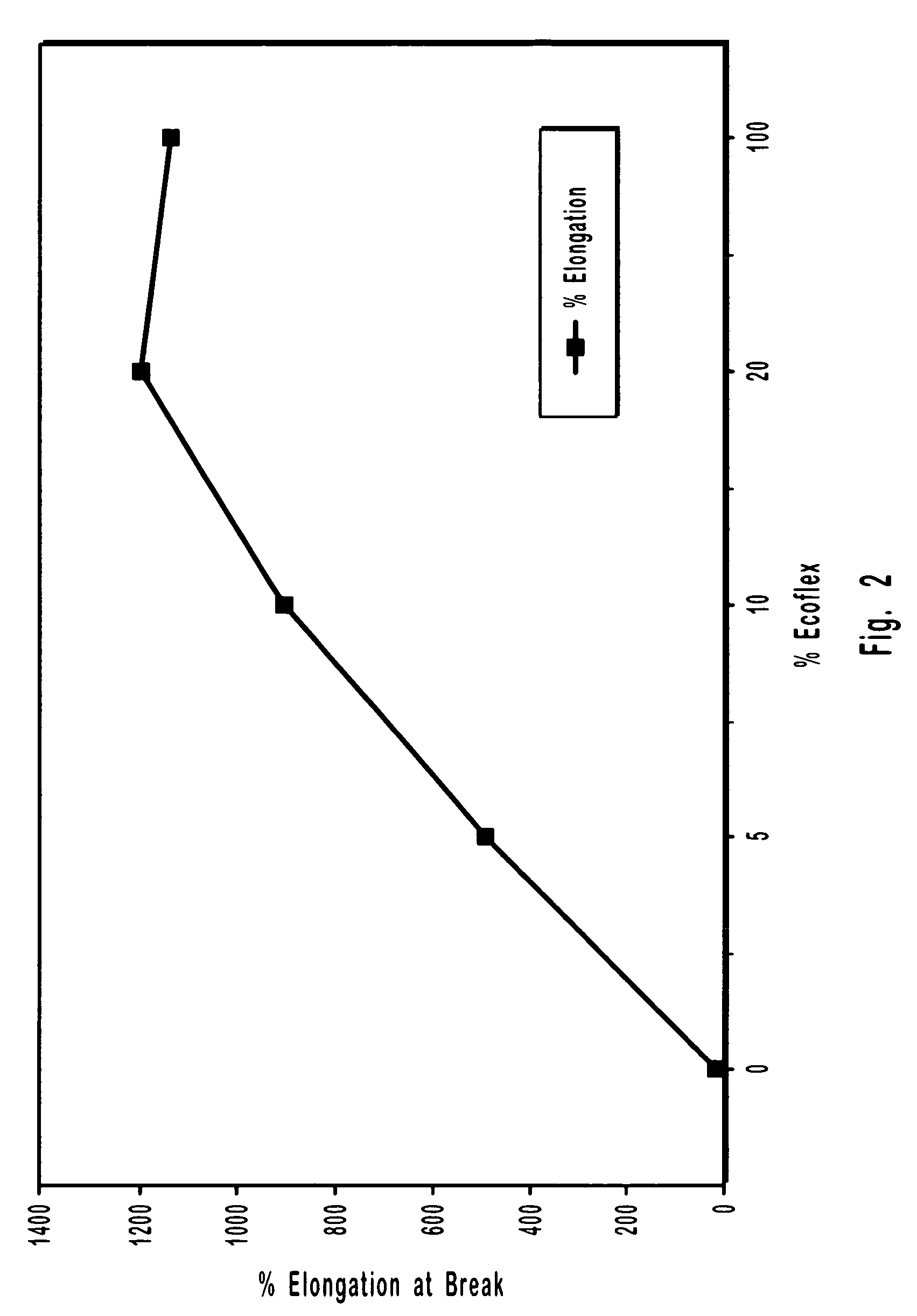

Biodegradable polymer films and sheets suitable for use as laminate coatings as well as wraps and other packaging materials

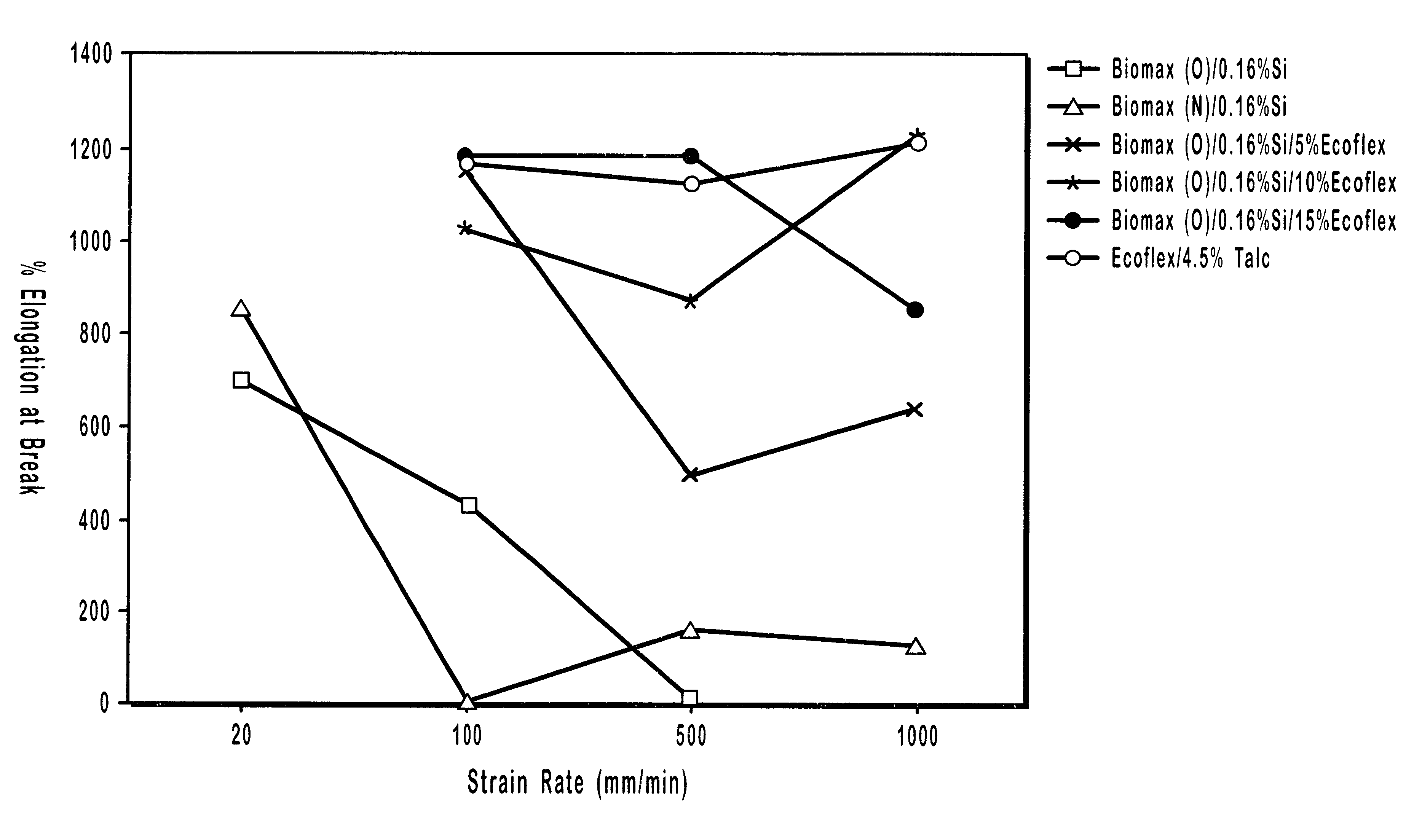

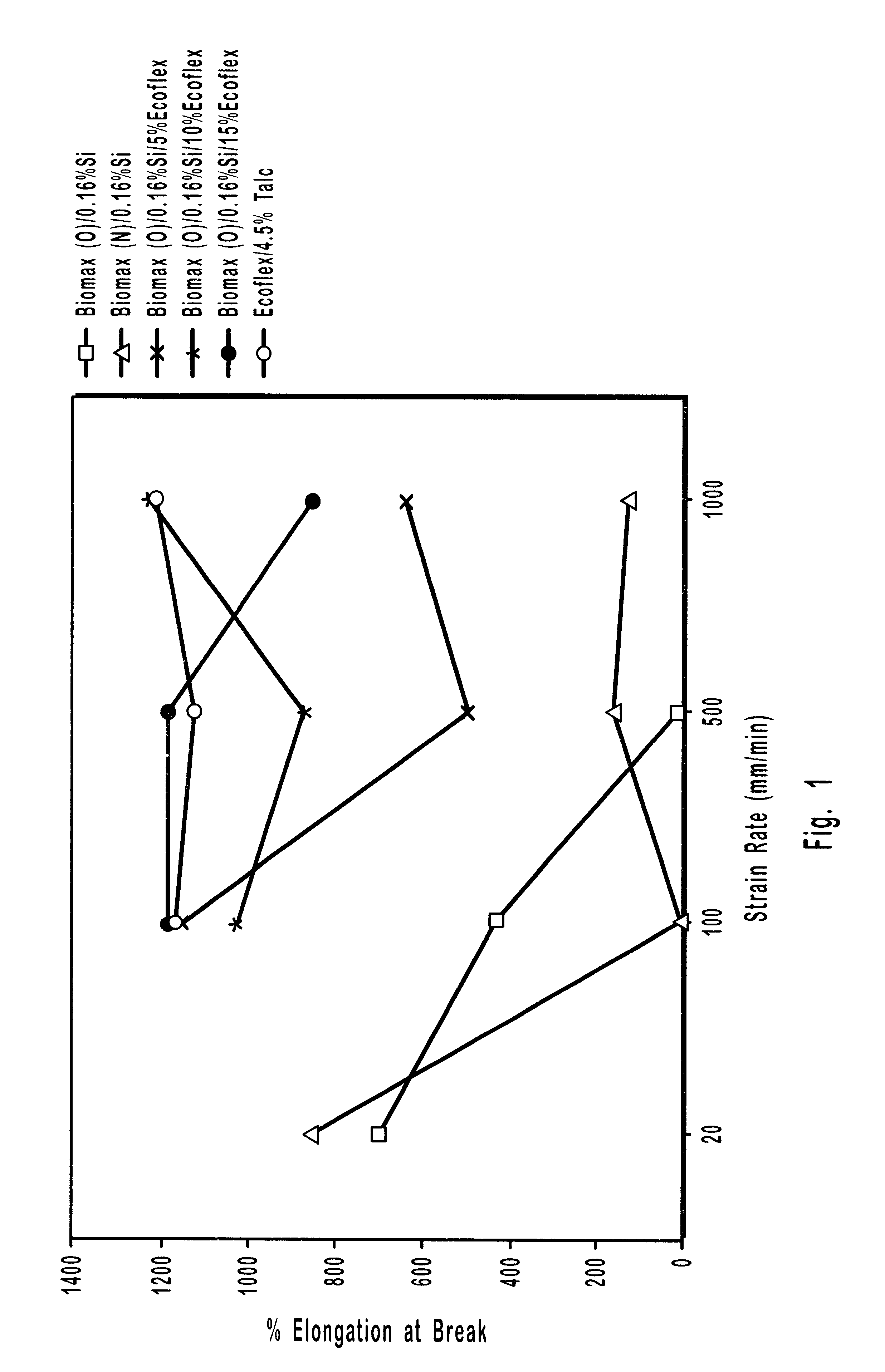

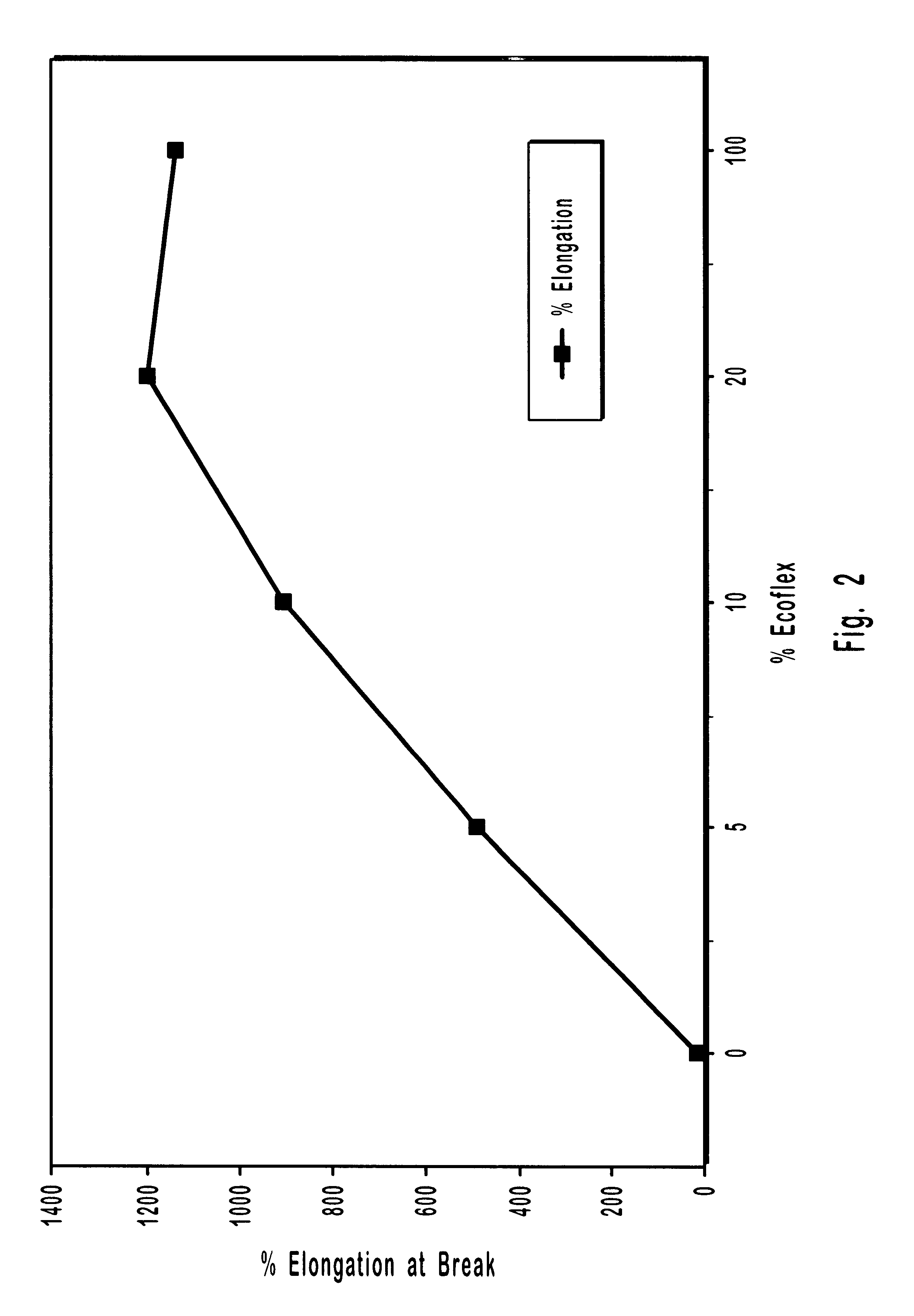

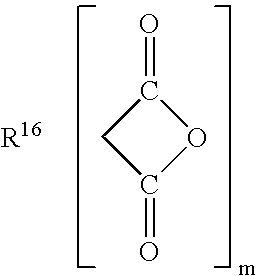

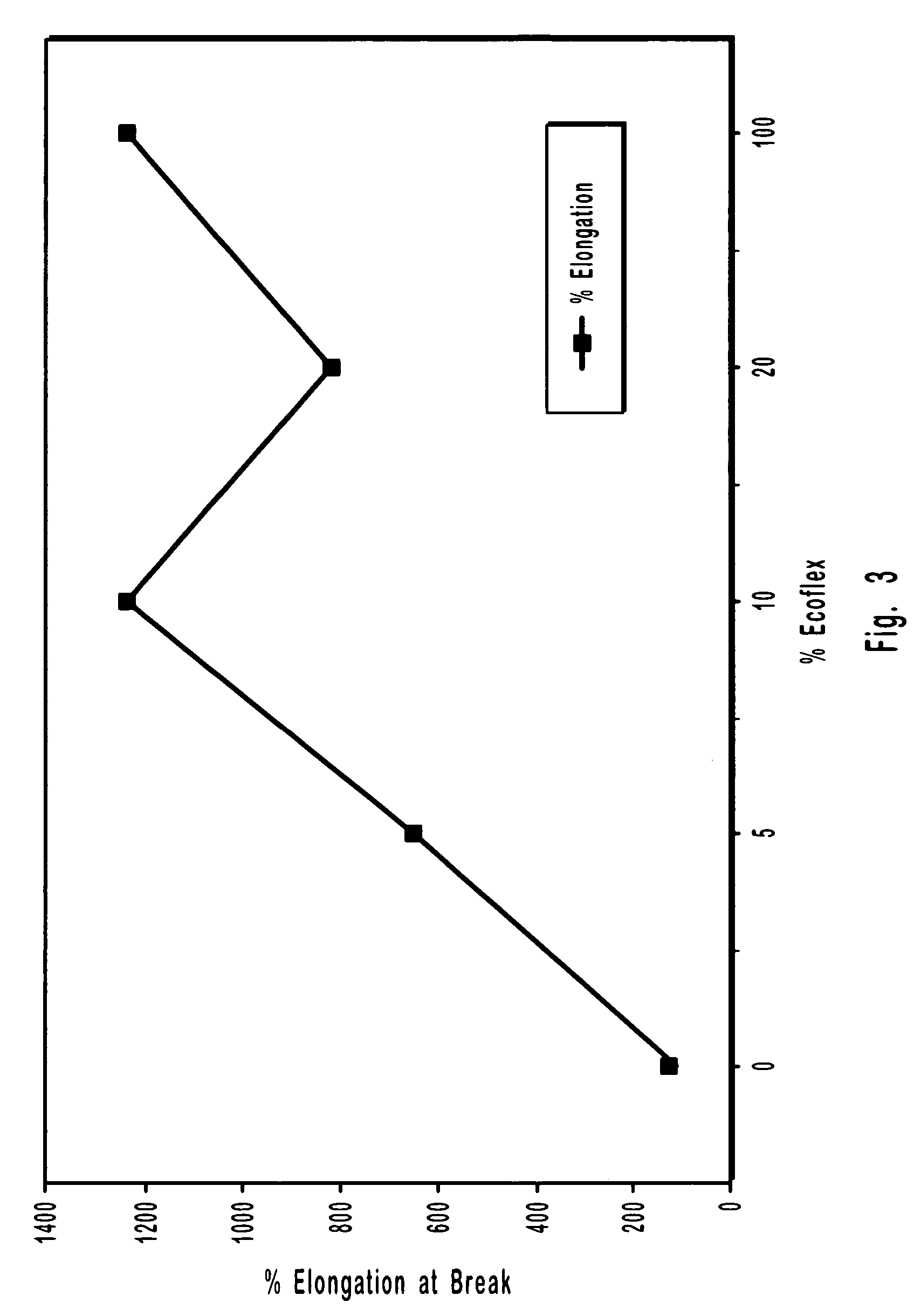

Biodegradable polymer blends suitable for laminate coatings, wraps and other packaging materials manufactured from at least one "hard" biopolymer and at least one "soft" biopolymer. "Hard" biopolymers tend to be more brittle and rigid and typically have a glass transition temperature greater than about 10° C. "Soft" biopolymers tend to be more flexible and pliable and typically have a glass transition temperature less than about 0° C. While hard and soft polymers each possess certain intrinsic benefits, certain blends of hard and soft polymers have been discovered which possess synergistic properties superior to those of either hard or soft polymers by themselves. Biodegradable polymers include polyesters, polyesteramides and thermoplastically processable starch. The polymer blends may optionally include an inorganic filler. Films and sheets made from the polymer blends may be textured so as to increase the bulk hand feel. Wraps will typically be manufactured so as to have good "dead-fold" properties so as to remain in a wrapped position and not spring back to an "unwrapped" and planar form. Laminate films will typically have good water vapor barrier properties as measured by the their Water Vapor Permeability Coefficient (WVPC).

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

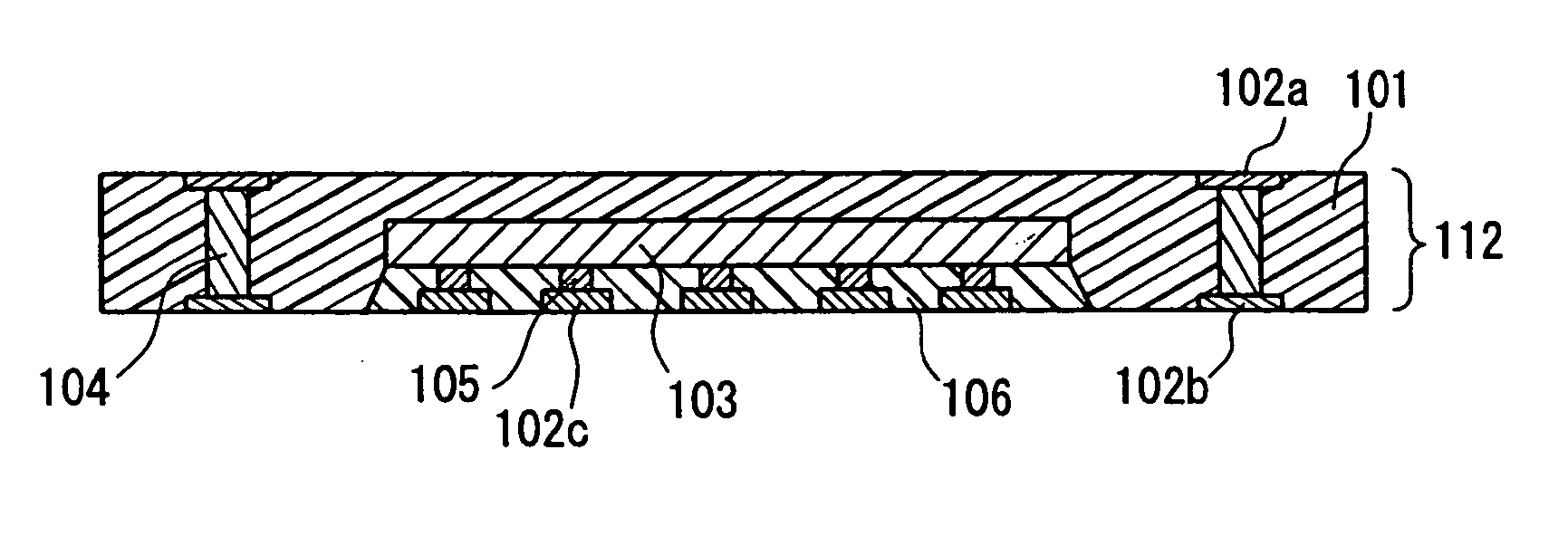

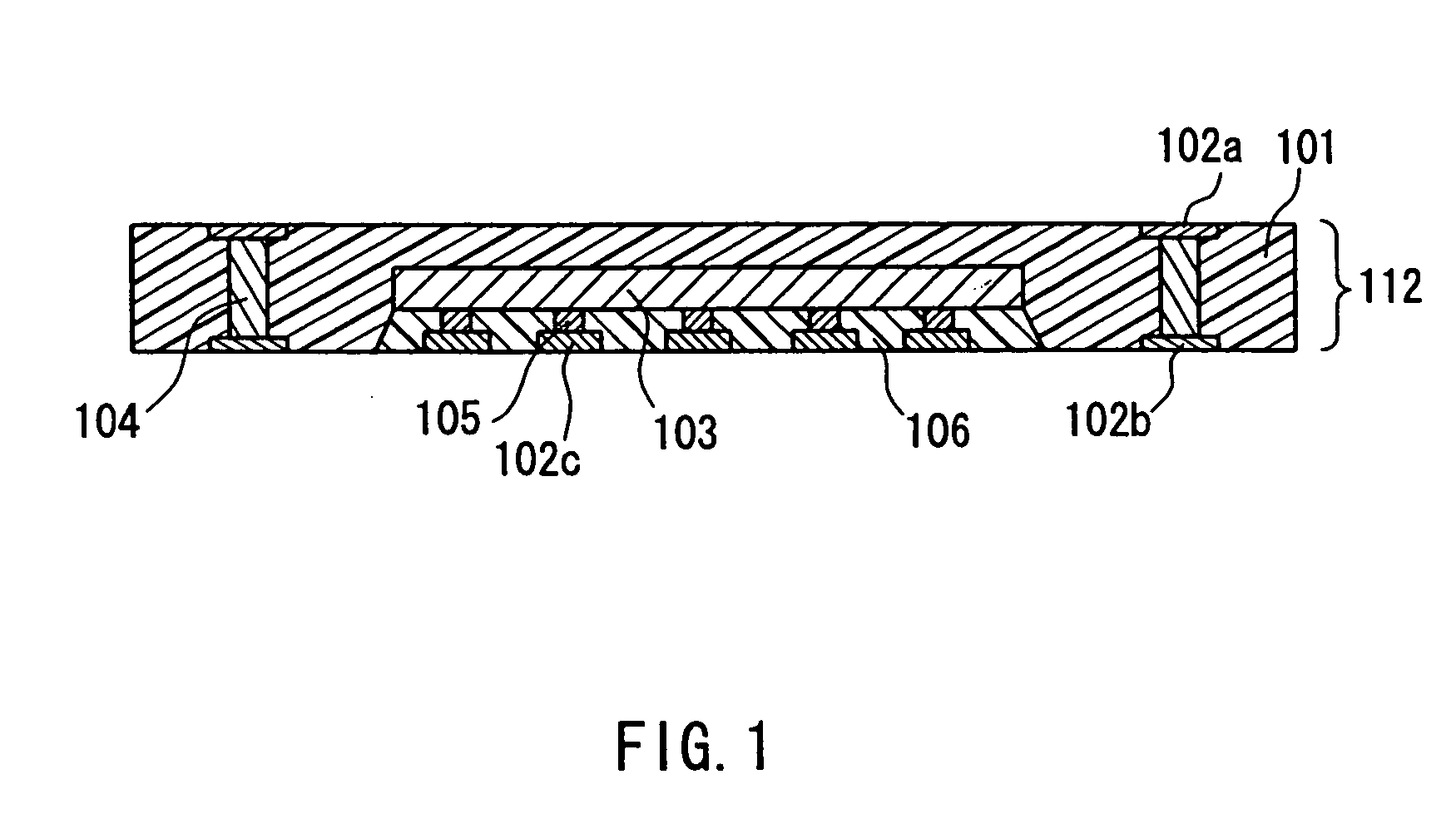

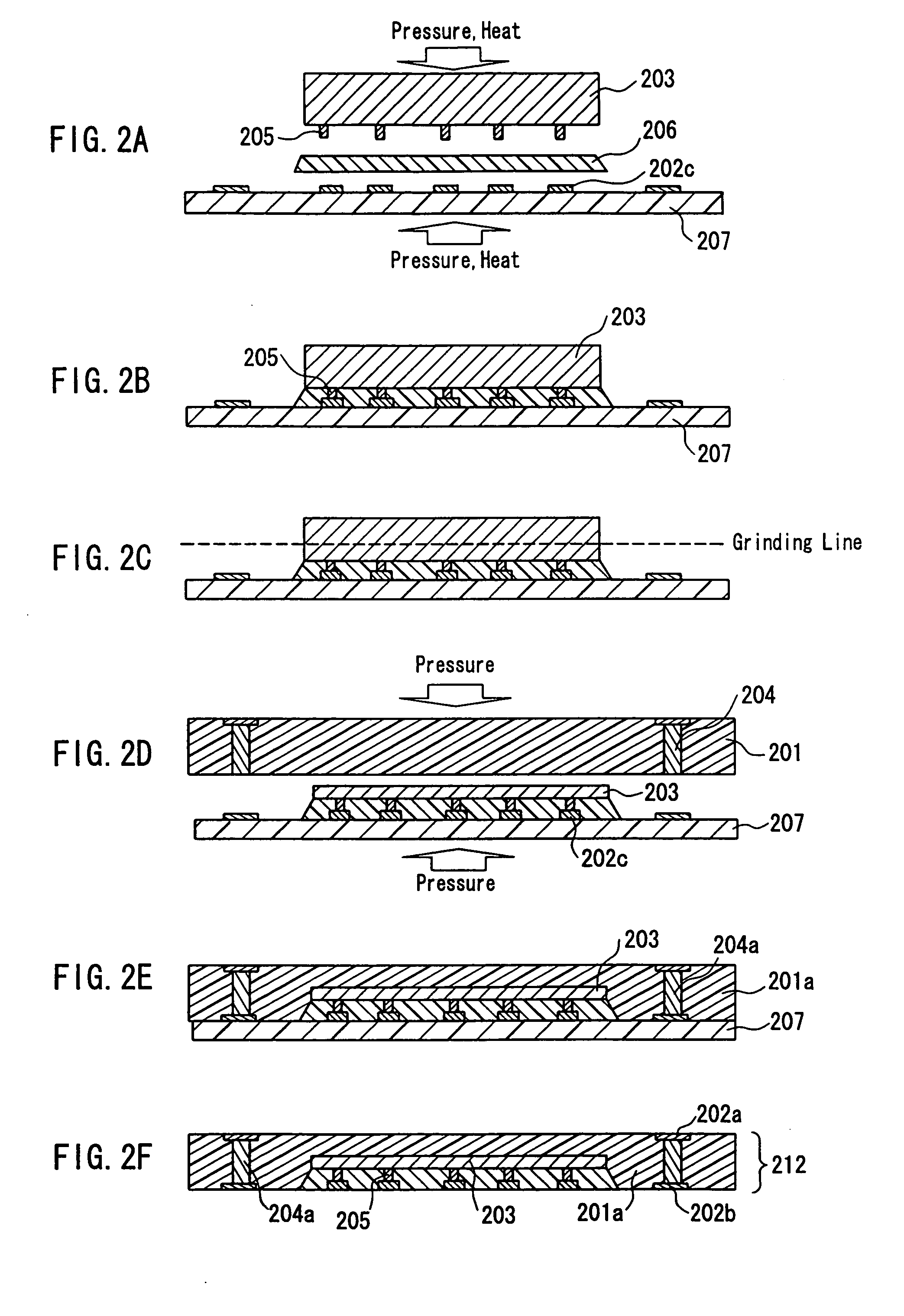

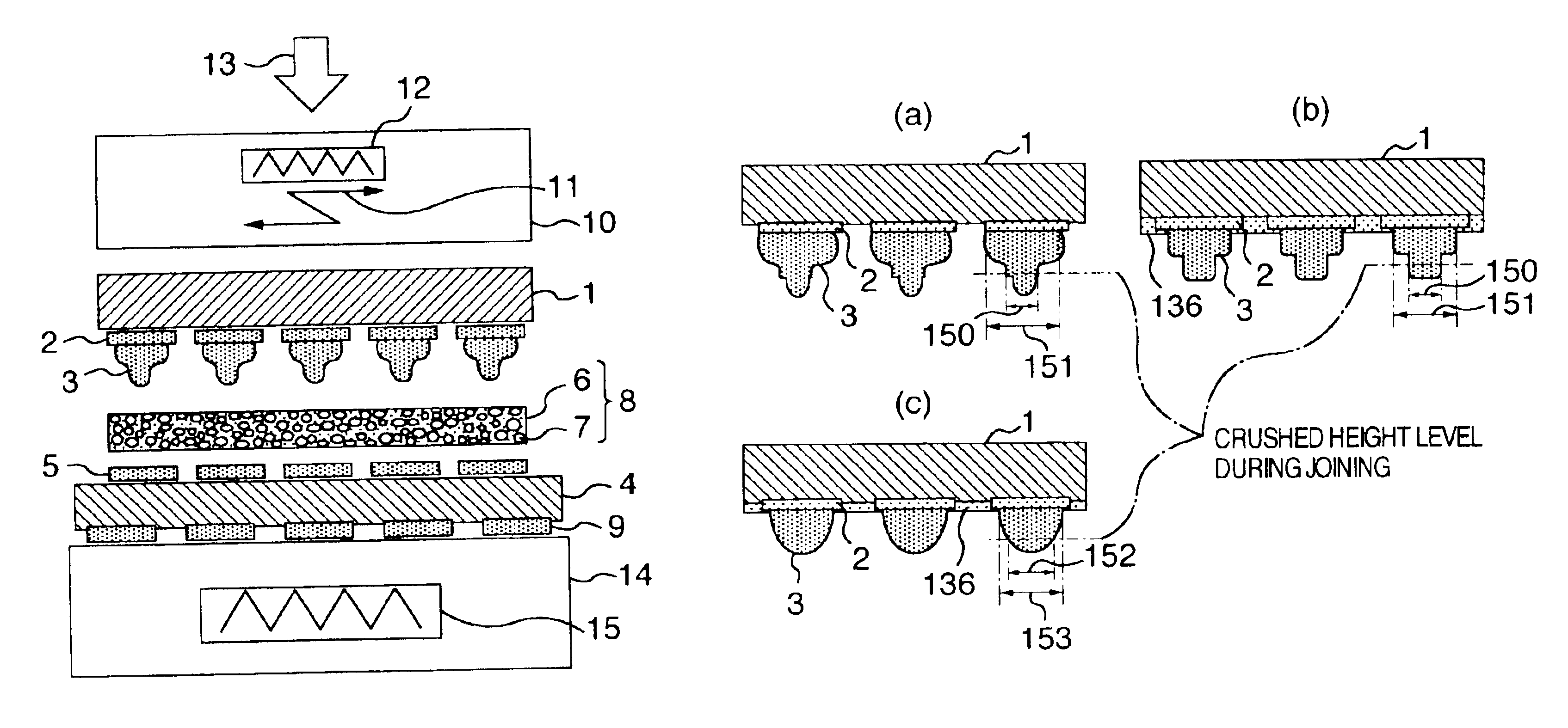

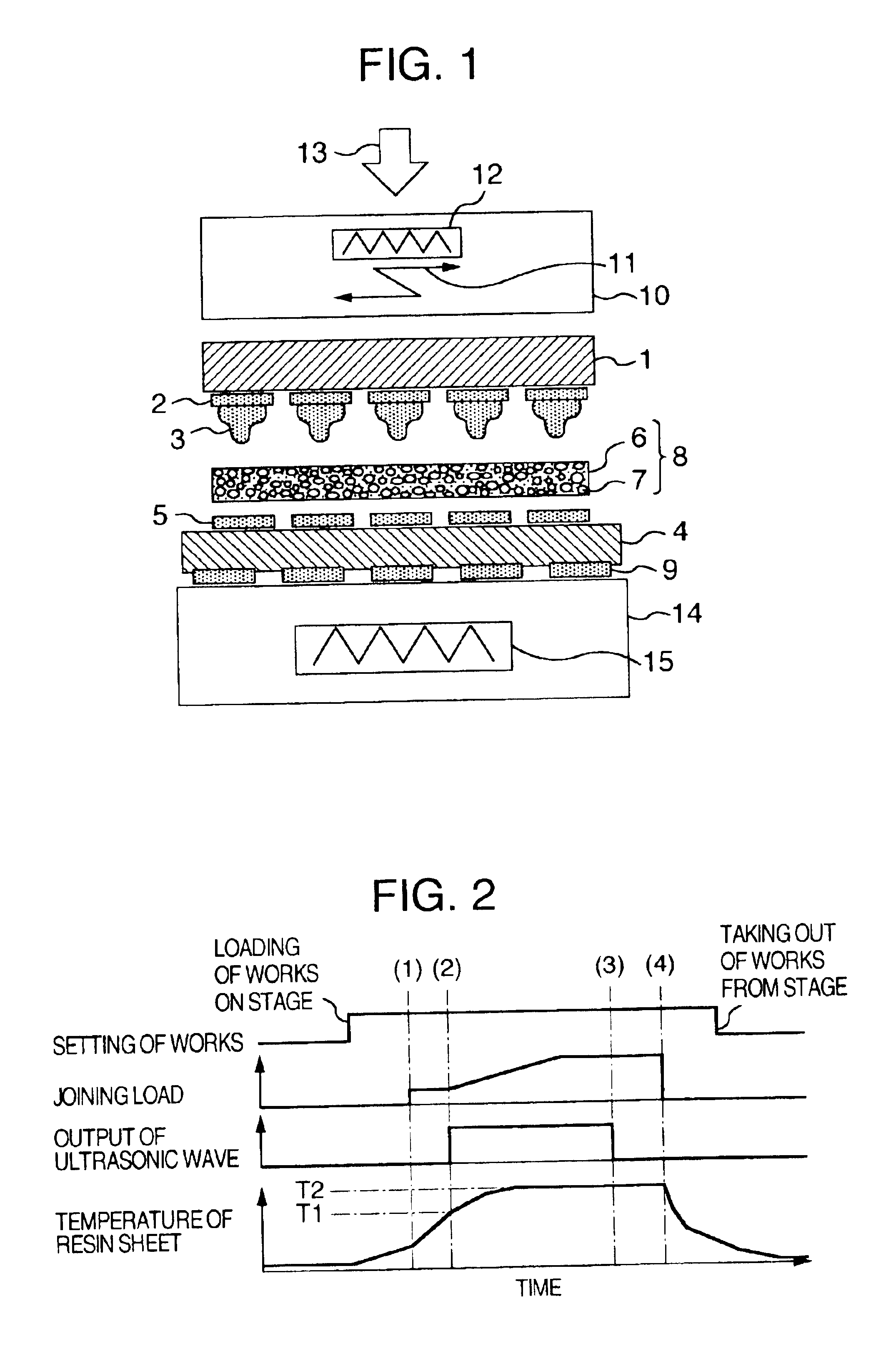

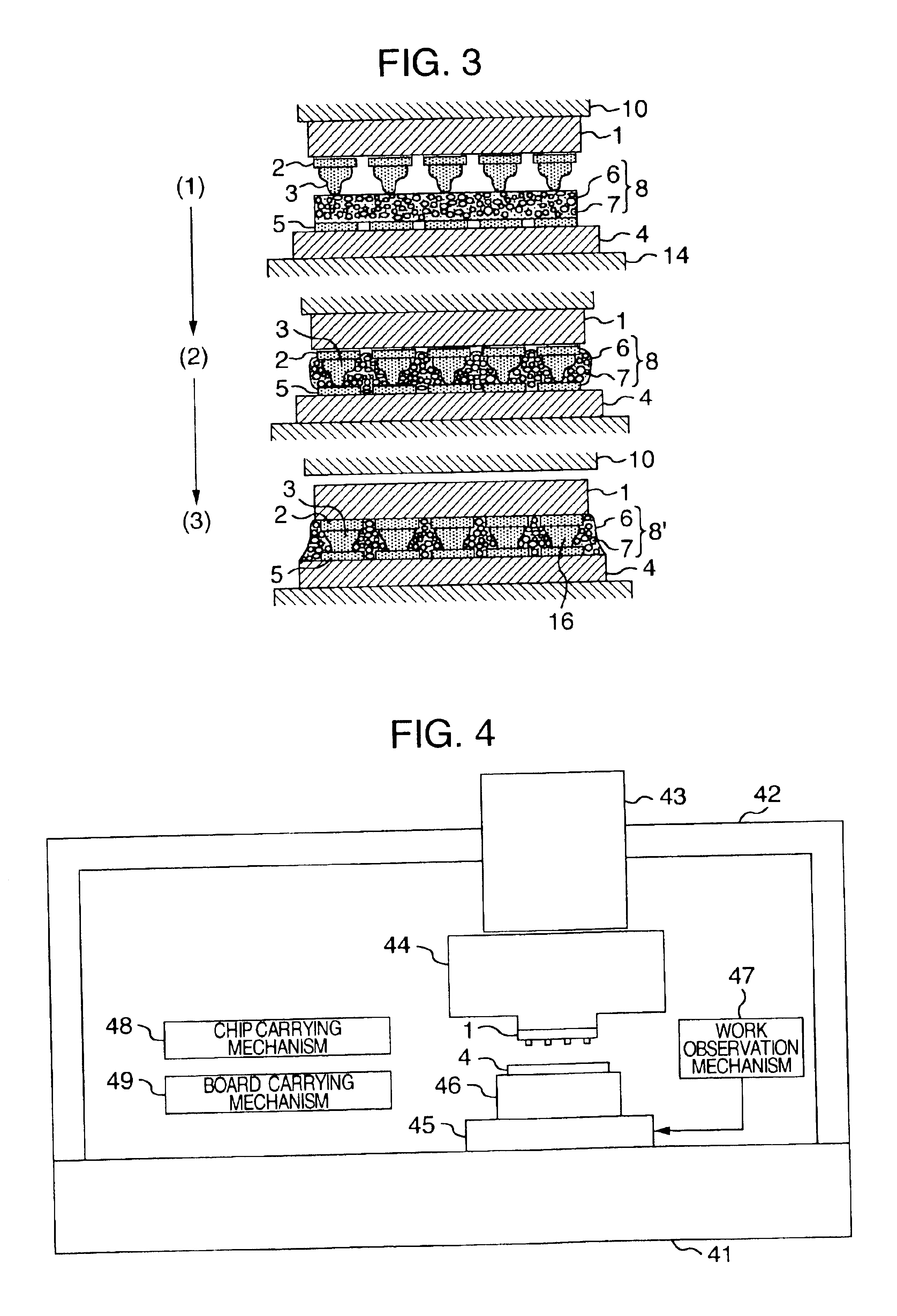

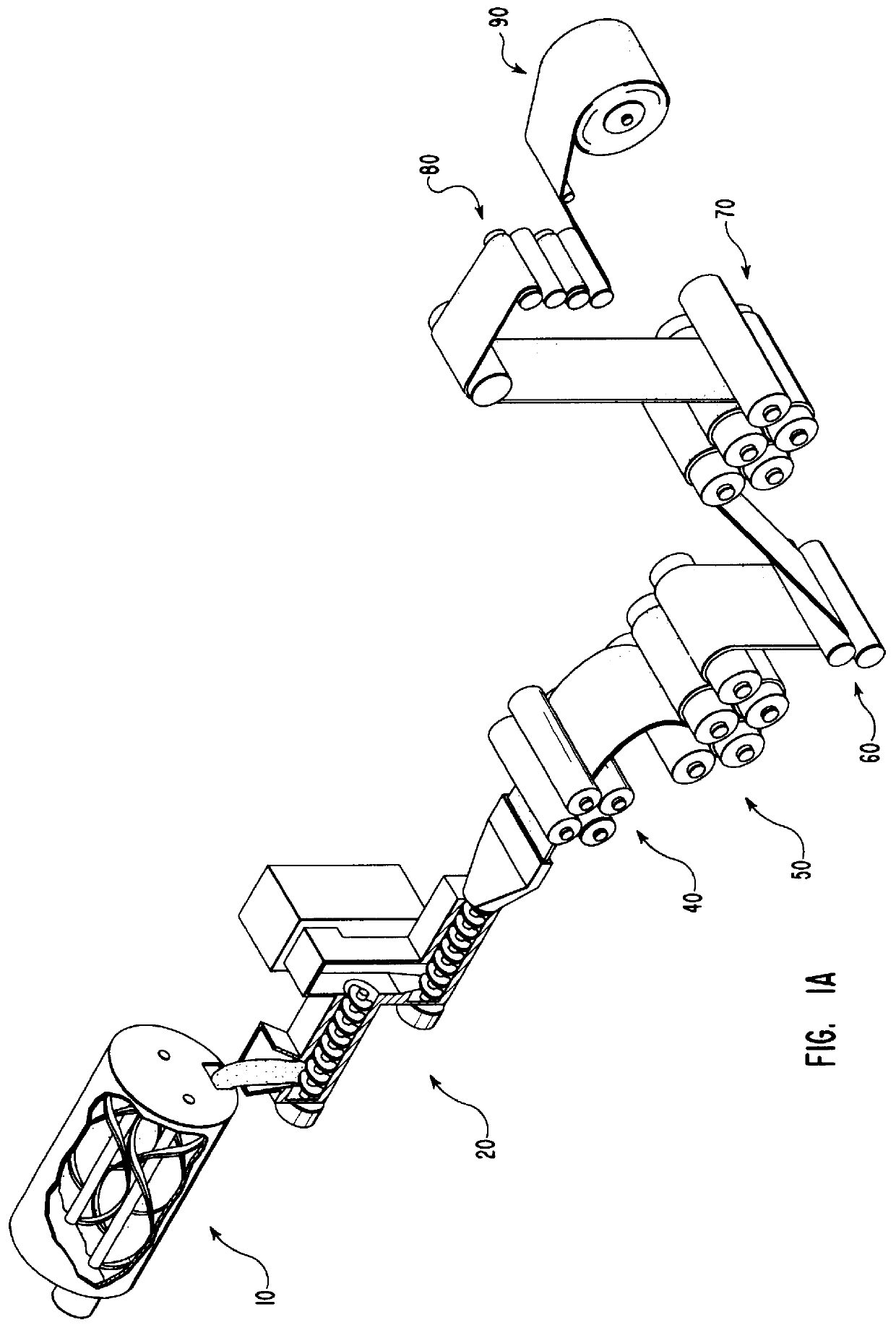

Circuit component built-in module with embedded semiconductor chip and method of manufacturing

InactiveUS20040145044A1Improve Noise PerformanceSemiconductor/solid-state device detailsSolid-state devicesHigh densityMiniaturization

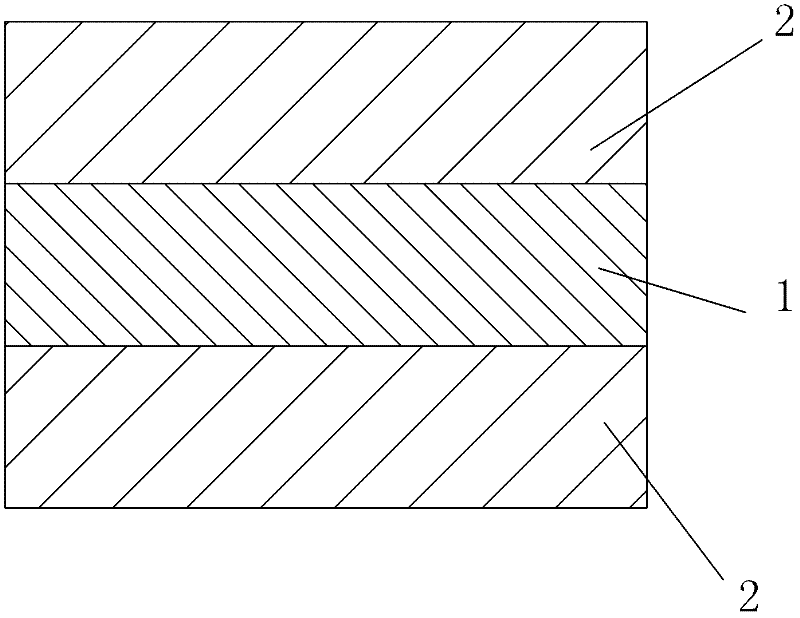

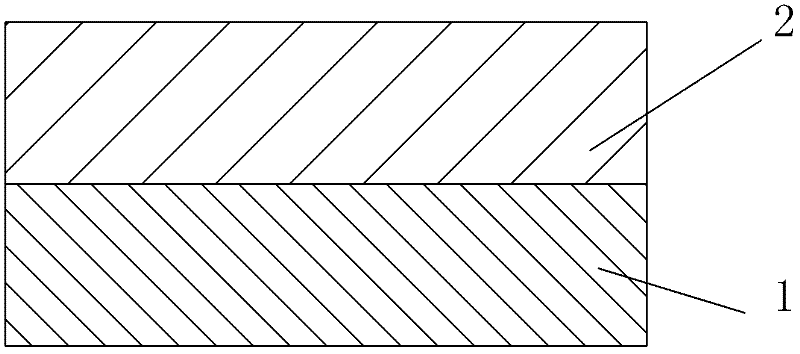

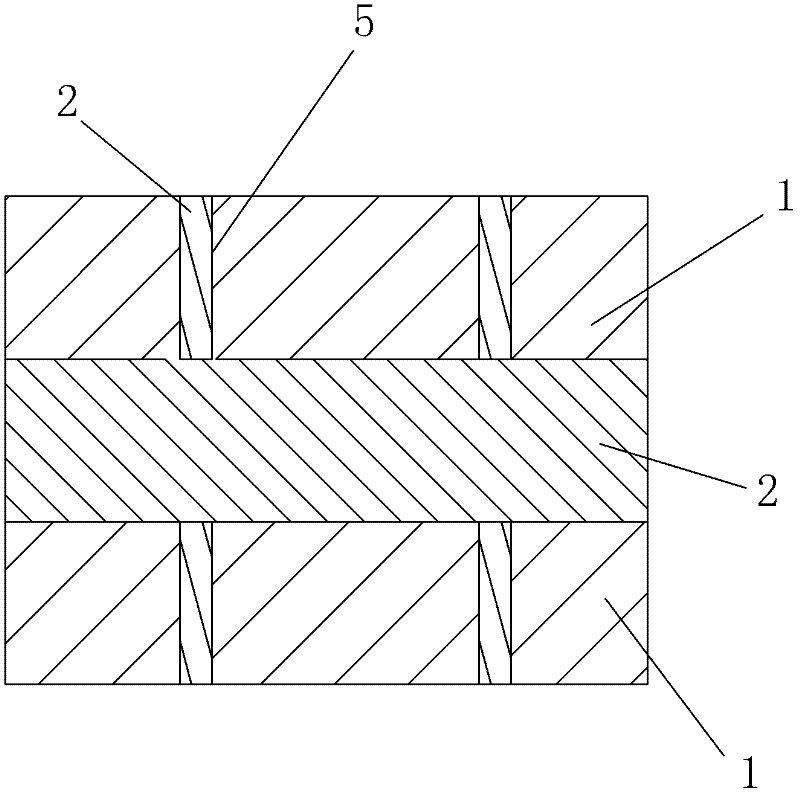

A circuit component built-in module includes: a first electrical insulating substrate made of a mixture containing an inorganic filler and a thermosetting resin; a plurality of wiring patterns formed at least on a principal surface of the first electrical insulating substrate; a semiconductor chip incorporated in the first electrical insulating substrate and connected electrically with the wiring patterns; and inner vias electrically connecting the plurality of wiring patterns with one another, the inner vias passing through the first electrical insulating substrate. In the circuit component built-in module, the semiconductor chip has a thickness of not less than 30 mum and not more than 100 mum, and has a non-wired surface ground, and the circuit component built-in module has a thickness in a range of not less than 80 mum and not more than 200 mum. With this configuration, the high-performance and compact-size circuit component built-in module in which circuit components are mounted at a high density is provided so as to be used suitably in various types of electronic information devices.

Owner:PANASONIC CORP

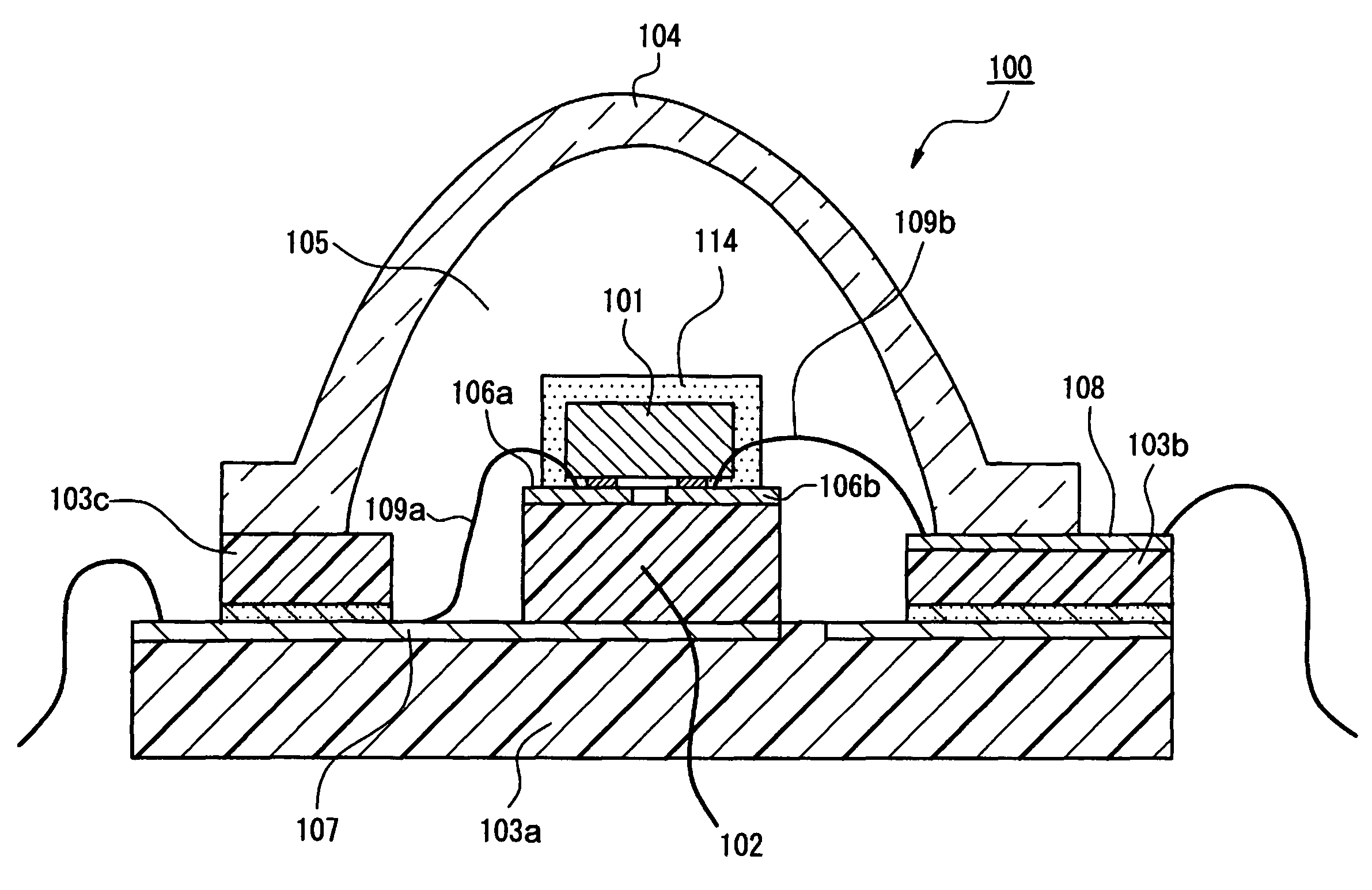

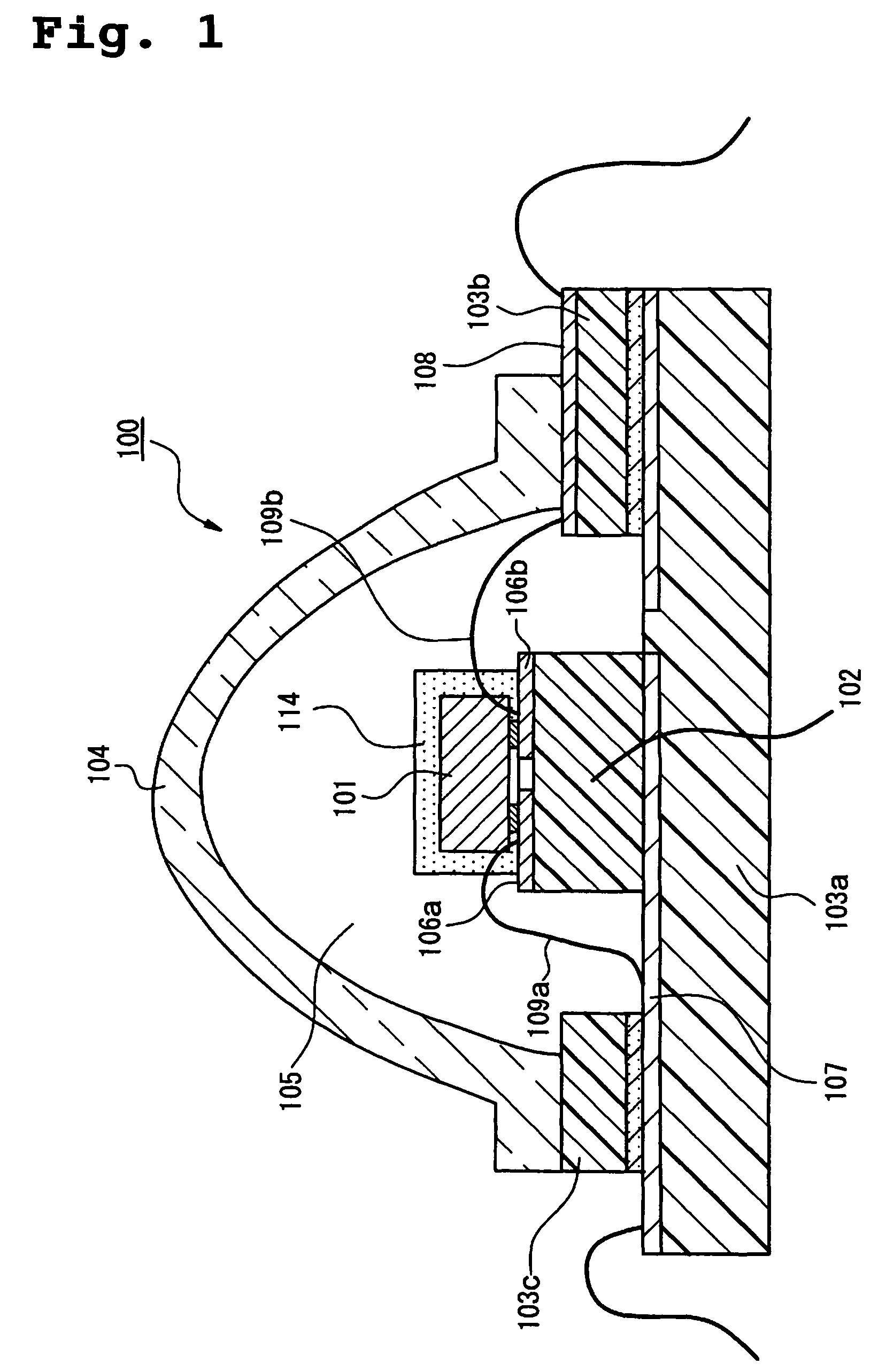

Light emitting device with silicone resin layer formed by screen printing

ActiveUS7745818B2Improve heat resistanceConvenient lightingDischarge tube luminescnet screensLamp detailsScreen printingPolystyrene

Owner:NICHIA CORP

Modified polymers prepared with lanthanide-based catalysts

A method for preparing a functionalized polymer comprising the steps of preparing a pseudo-living polymer by polymerizing conjugated diene monomer with a lanthanide-based catalyst, where said pseudo-living polymer is characterized by having greater than about 85 percent of the polymer in the cis microstructure and less than about 3 percent of the polymer is in the 1,2- or 3,4-microstructure, and reacting the pseudo-living polymer with at least one functionalizing agent defined by the formula (I) or (II) where Z is a substituent that will react or interact with organic or inorganic fillers; R1 is a single bond or a divalent organic group; R2 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R13 or R14; R3 is a single bond, a divalent organic group, or a trivalent organic group that forms a cyclic organic group with R4 or R5; R13 is a single bond, a divalent organic group, or a trivalent organic group that forms a cyclic organic group with R2 or R14; R4 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R3 or R5; R14 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R2 or R13; and R5 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R3 or R4; with the proviso that each group attached to the imino carbon is attached via a carbon atom and R1, R2 R3, R4, R5, R13, R14 and Z are substituents that will not protonate a pseudo-living polymer.

Owner:BRIDGESTONE CORP

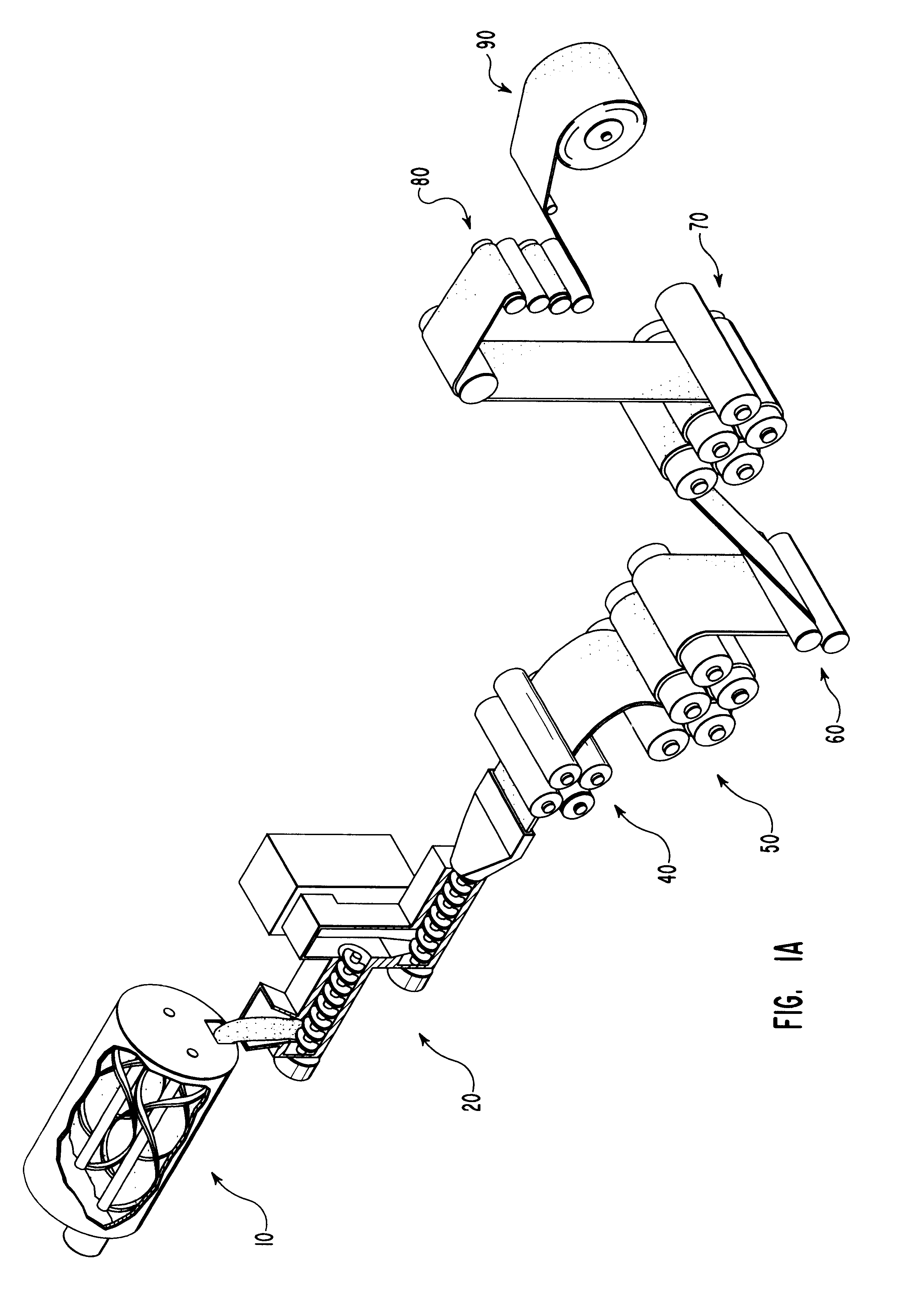

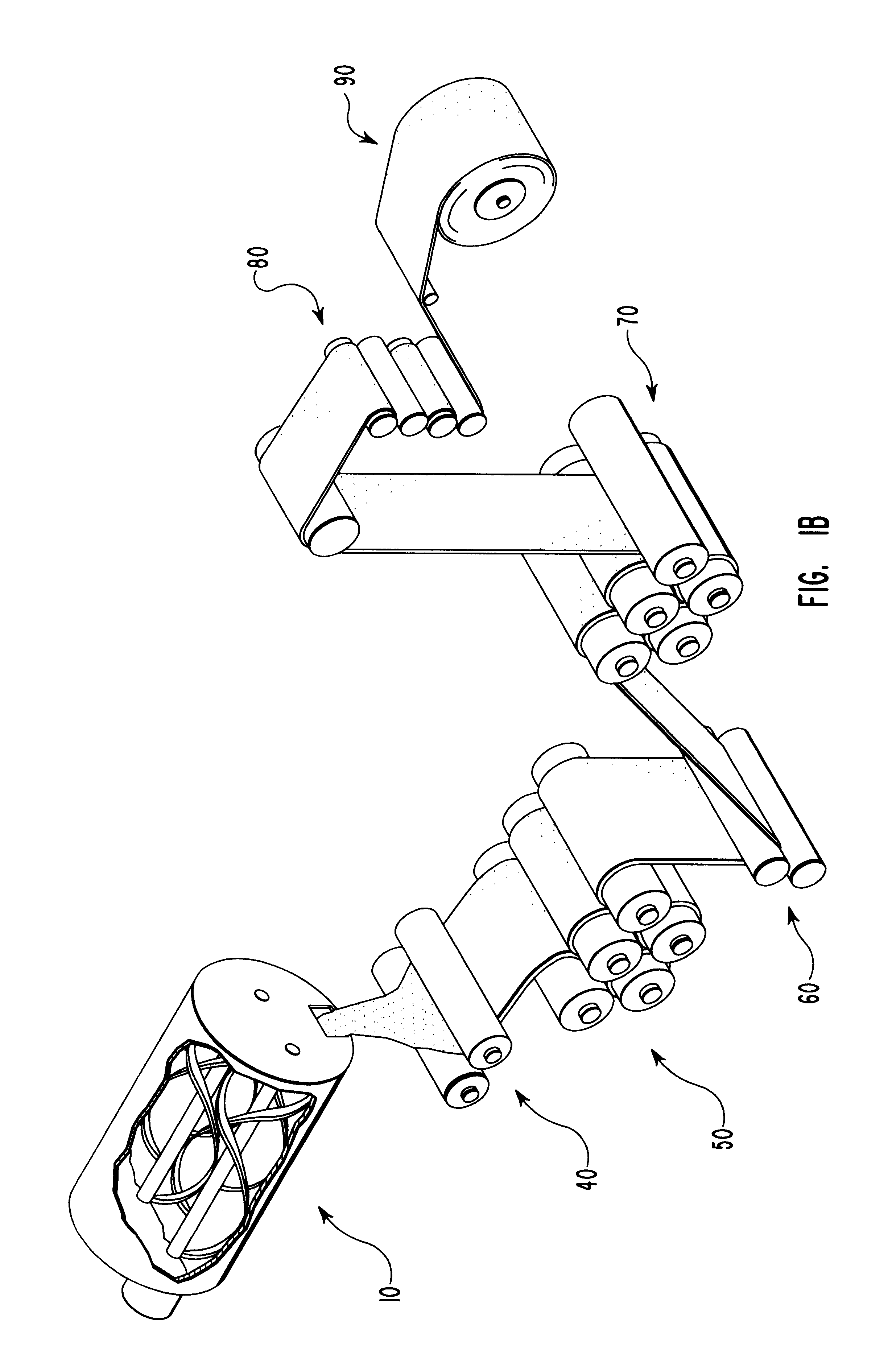

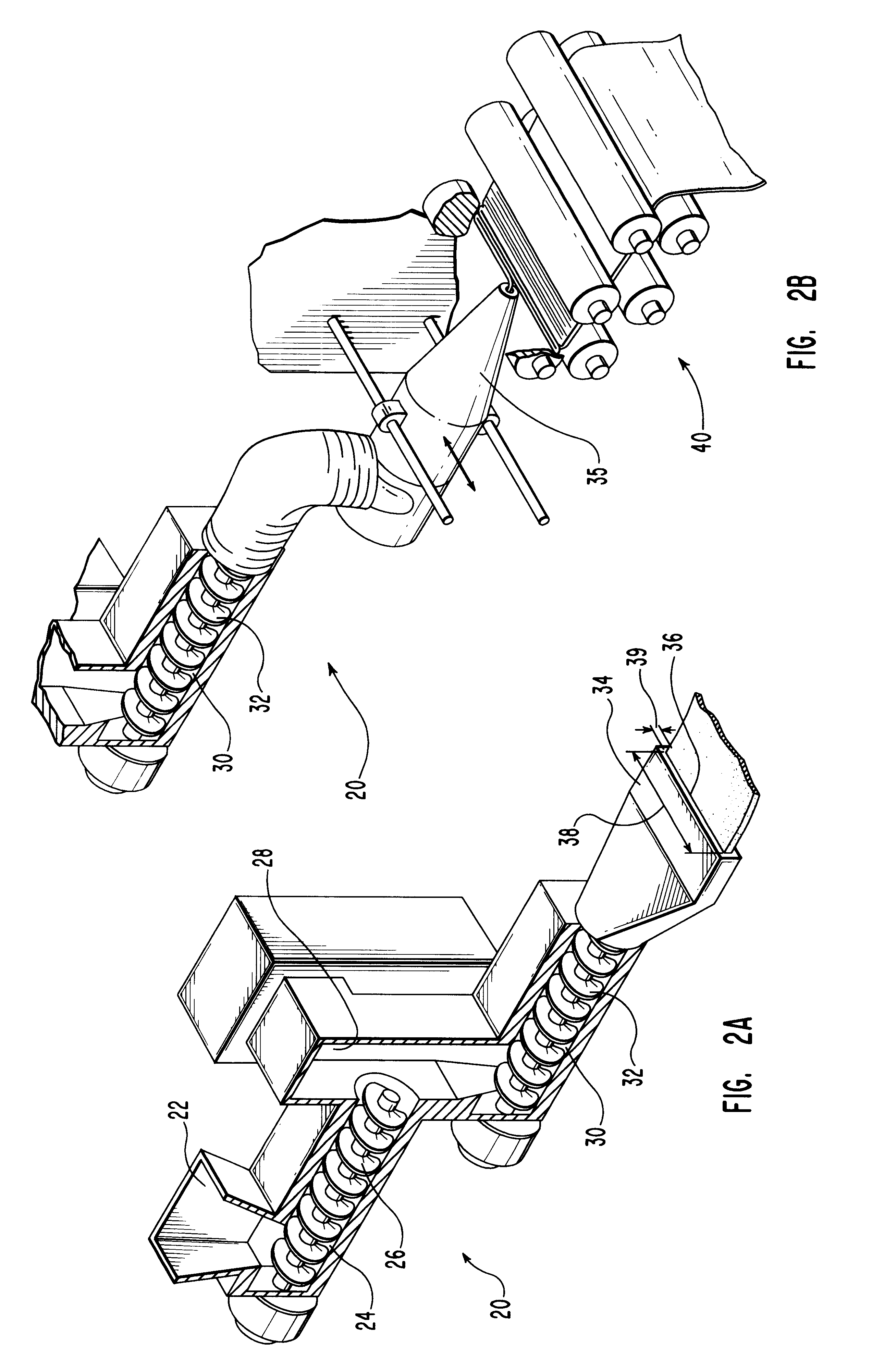

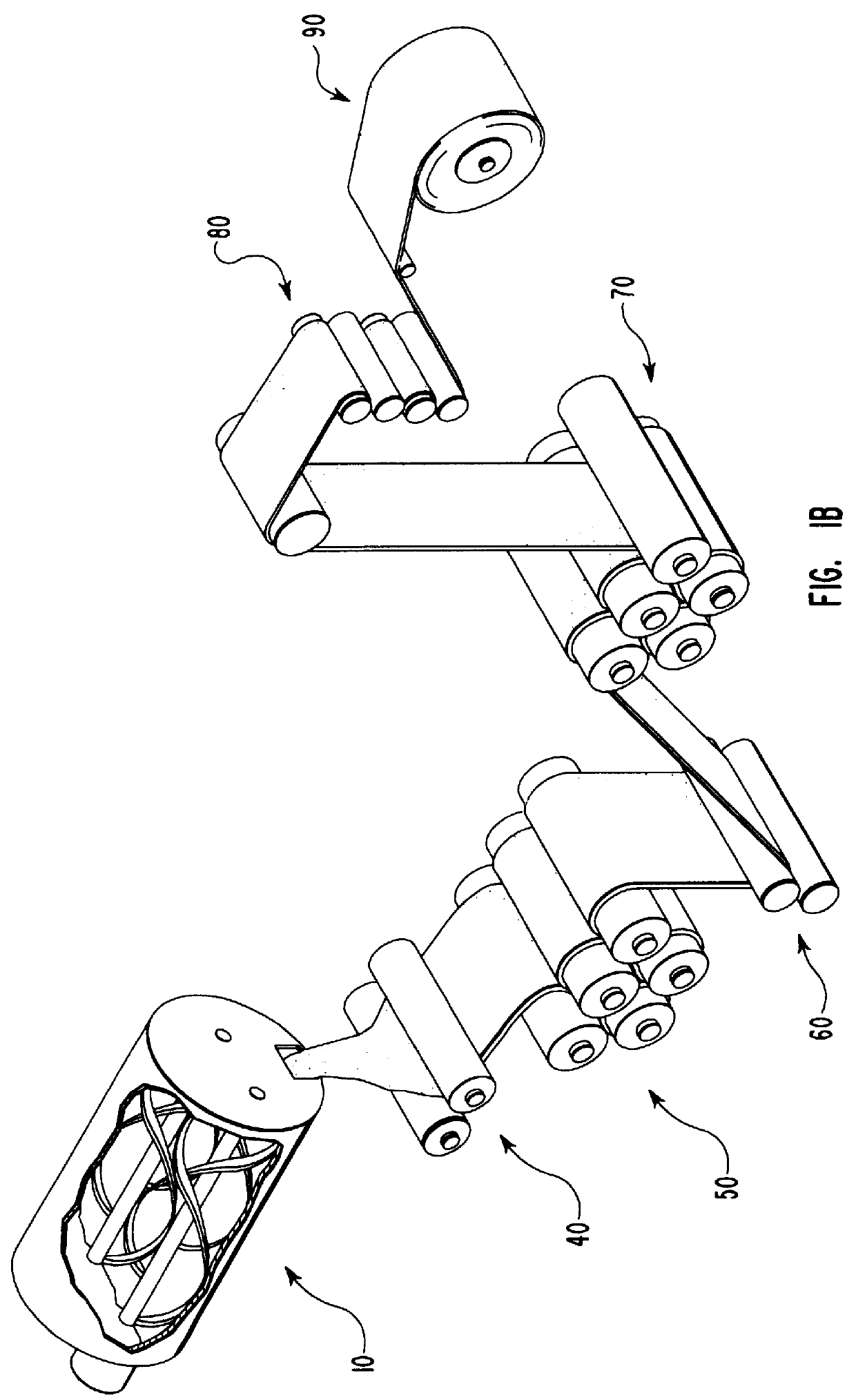

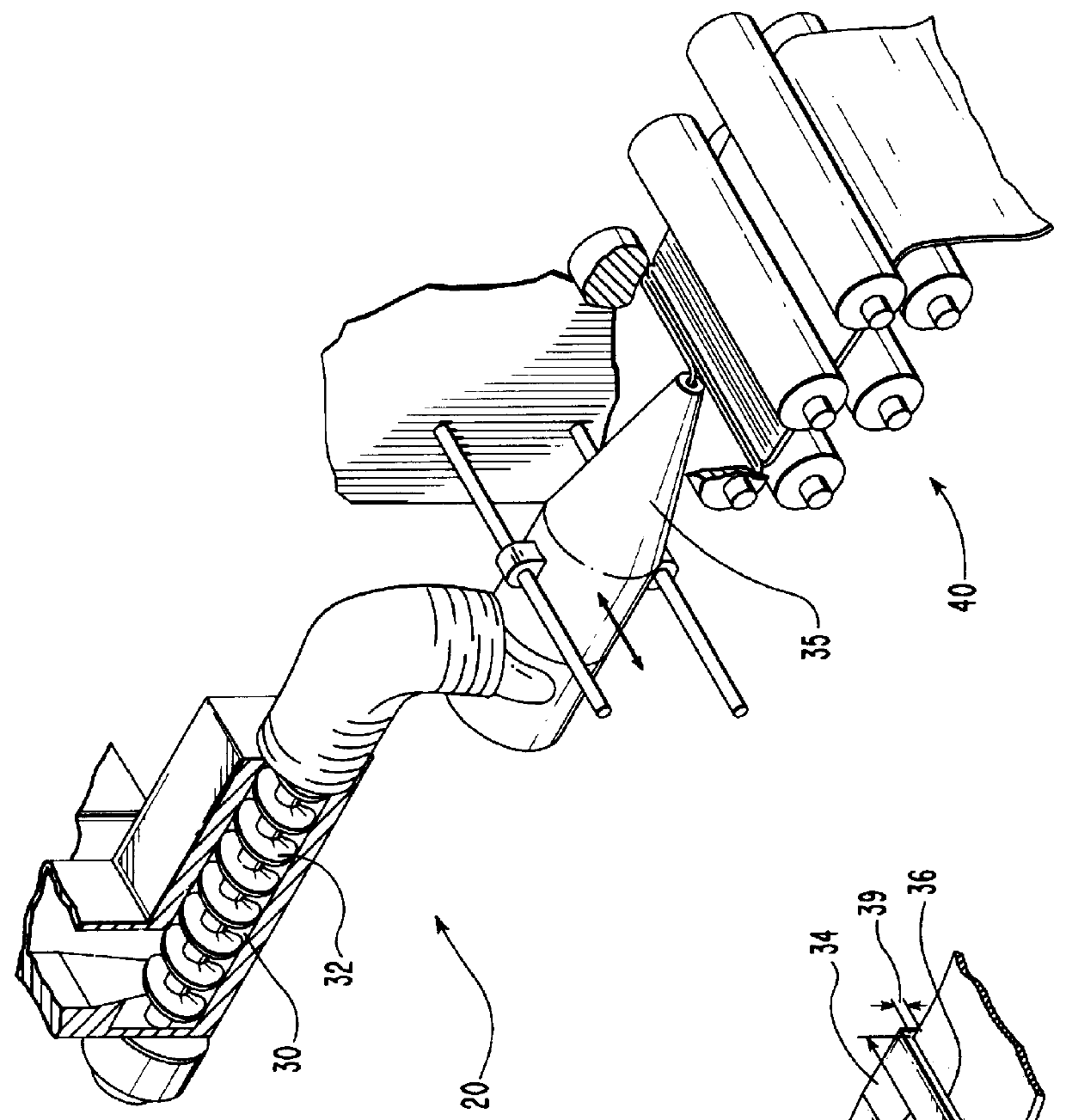

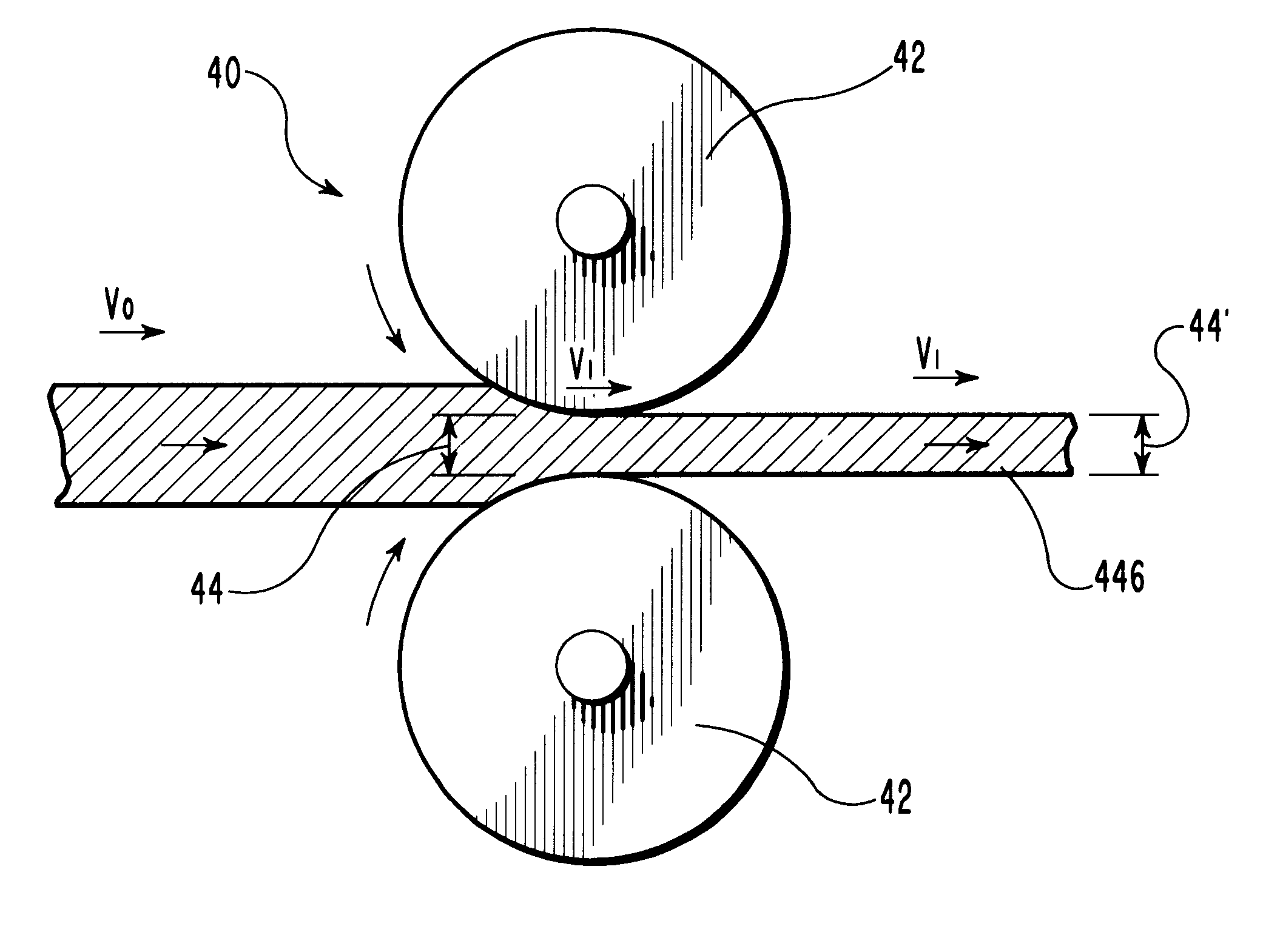

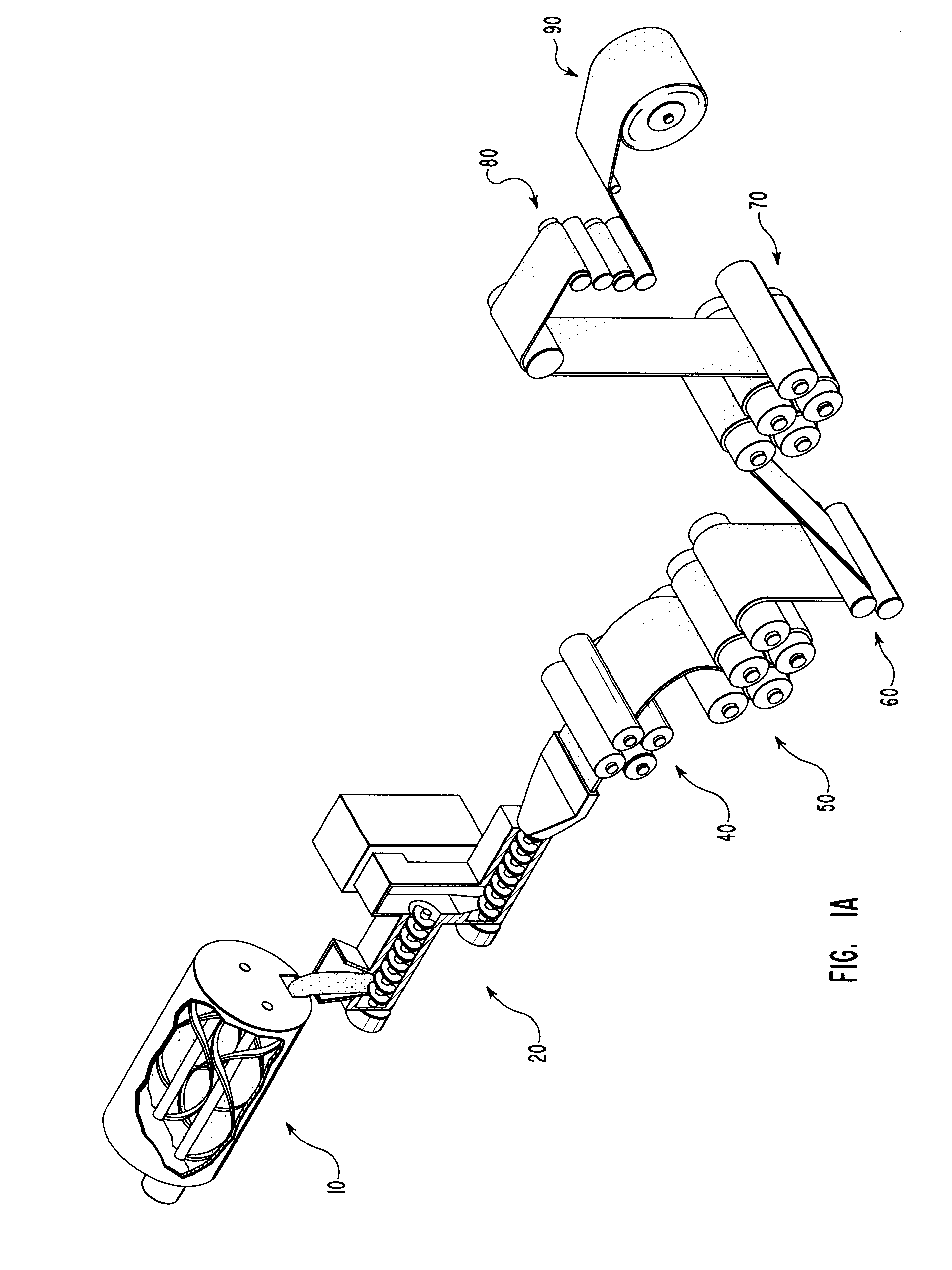

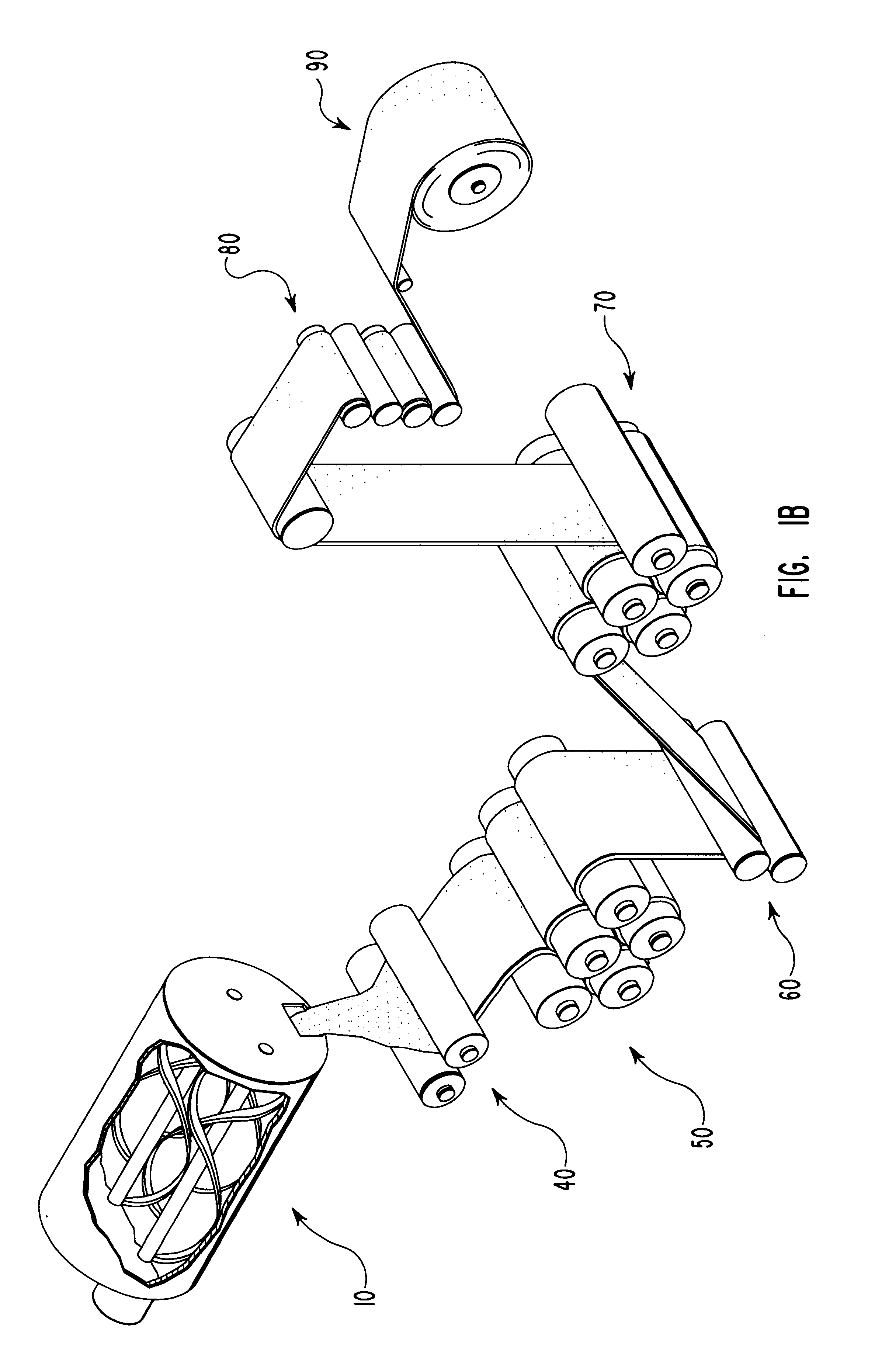

Compositions and methods for manufacturing starch-based compositions

Compositions and methods for manufacturing sheets having a starch-bound matrix reinforced with fibers and optionally including an inorganic mineral filler. Suitable mixtures for forming the sheets are prepared by mixing together water, unmodified and ungelatinized starch granules, an auxiliary water-dispersible organic polymer, fibers, and optionally an inorganic mineral filler in the correct proportions to form a sheet having desired properties. The mixtures are formed into sheets by passing them between one or more sets of heated rollers to form green sheets. The heated rollers cause the auxiliary polymer to form a skin on the outer surfaces of the sheet that prevents the starch granules from causing the sheet to adhere to the rollers upon gelation of the starch. The green sheets are passed between heated rollers to gelatinize the starch granules, and then to dry the sheet by removing a substantial portion of the water by evaporation. The starch and auxiliary polymer form the binding matrix of the sheets with the fibers and optional inorganic filler dispersed throughout the binding matrix. The starch-bound sheets can be cut, rolled, pressed, scored, perforated, folded, and glued to fashion articles from the sheets much like paper or paperboard. The sheets are particularly useful in the mass production of containers, such as food and beverage containers.

Owner:E KHASHOGGI INDS

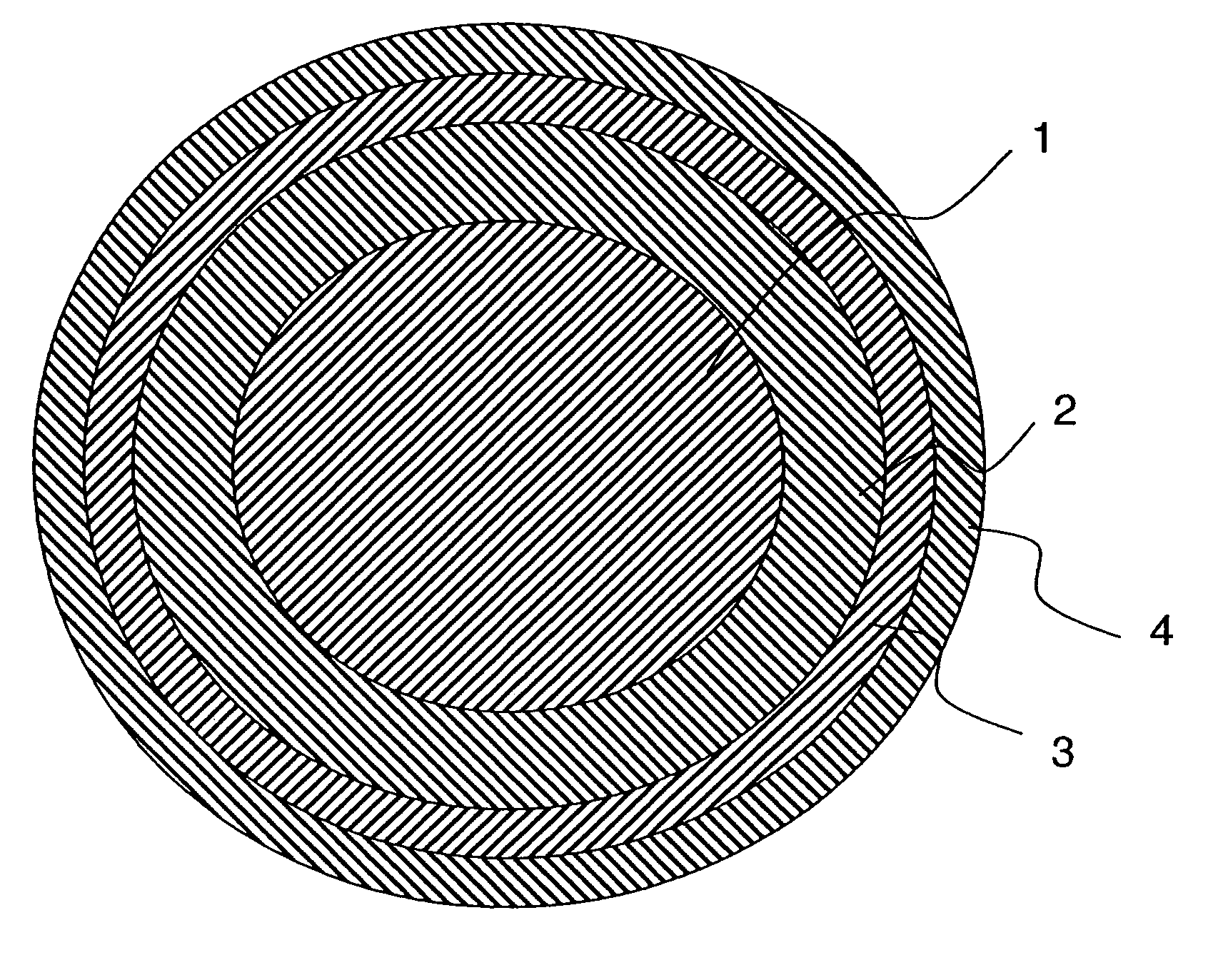

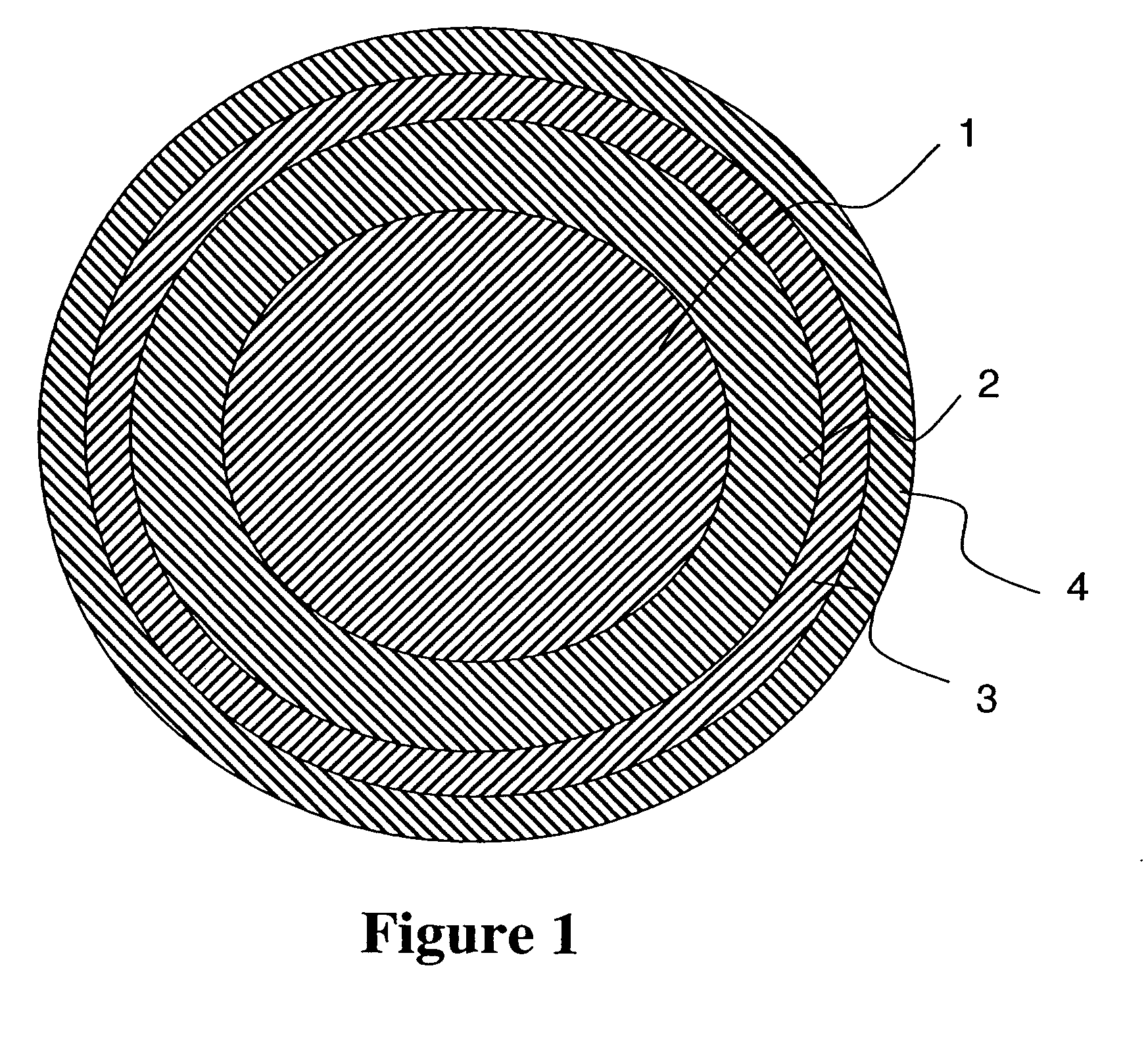

Golf ball

InactiveUS6921345B2Solid comfortable feelGood rebound characteristicsGolf ballsSolid ballsPolymer scienceAntioxidant

A golf ball includes a hot-molded product of a rubber composition comprising a base rubber composed of (a) 20-100 wt % of a polybutadiene having a high cis-1,4 content, a minimal 1,2 vinyl content, and a viscosity η of up to 600 mPa·s at 25° C. as a 5 wt % toluene solution, and satisfying a certain relationship between Mooney viscosity and polydispersity index Mw / Mn, in combination with (b) 0-80 wt % of another diene rubber, (c) an unsaturated carboxylic acid, (d) an organosulfur compound, (e) an inorganic filler, (f) an organic peroxide, and optionally, (g) an antioxidant. The hot-molded product has a difference in JIS-C hardness between the center and surface thereof of up to 15 units. The composition and hardness characteristics of the hot-molded product provide the golf ball with a solid comfortable feel upon impact and an excellent rebound.

Owner:BRIDGESTONE SPORTS

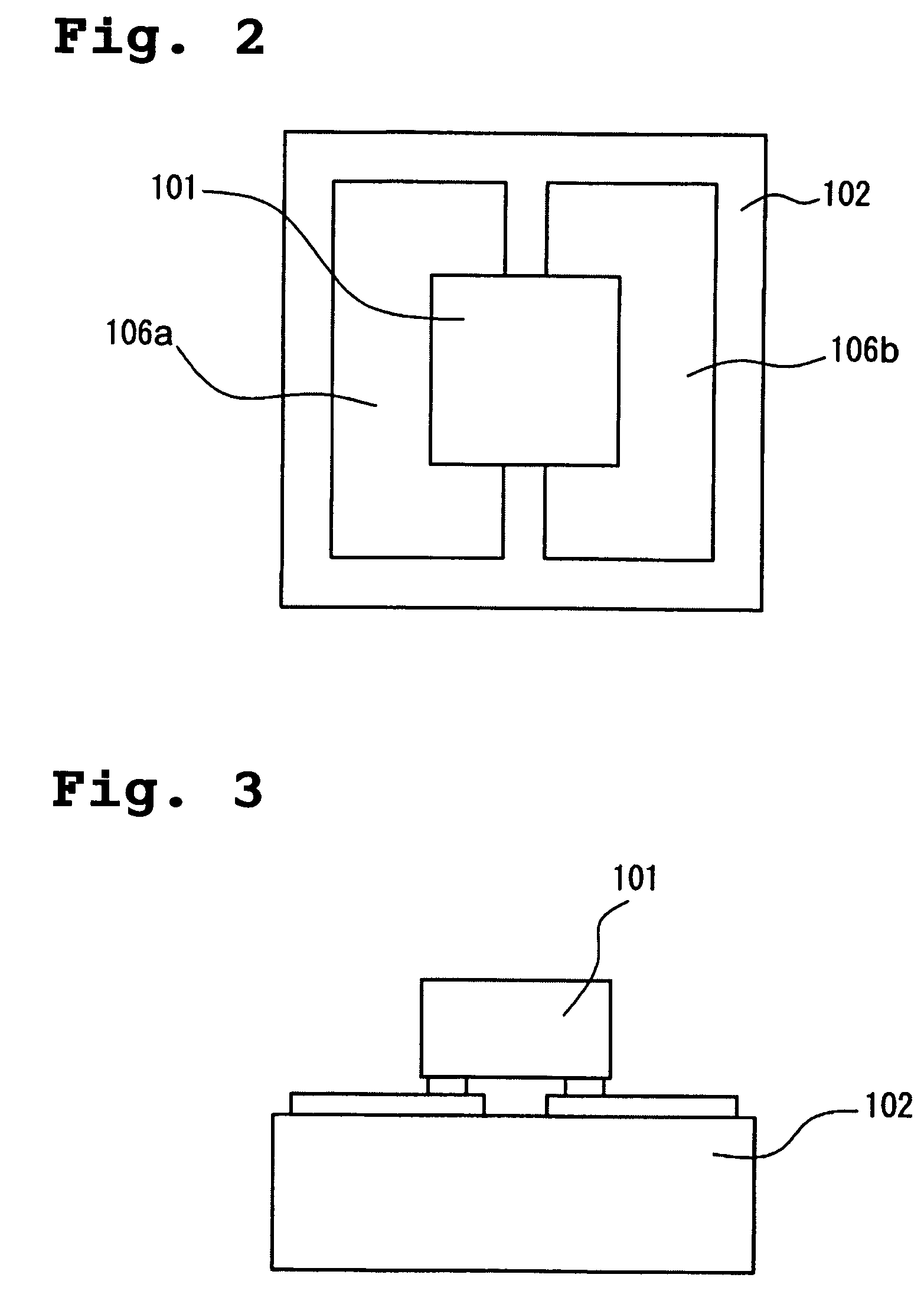

Flip chip assembly structure for semiconductor device and method of assembling therefor

InactiveUS6798072B2Improve productivityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesDevice materialMetallic materials

A semiconductor device includes a semiconductor chip and a printed circuit board. Metal electrodes of the semiconductor chip and the internal connection terminals of the printed circuit board are electrically connected through the metallic joining via precious metal bumps. A melting point of a metal material constituting each of the metallic joining parts is equal to or higher than 275 degrees, and a space defined between the chip and the board is filled with resin (under fill) containing 50 vol % or more inorganic fillers.

Owner:HITACHI LTD

Sheets having a starch-based binding matrix

Compositions and methods for manufacturing sheets having a starch-bound matrix, optionally reinforced with fibers and optionally including an inorganic mineral filler. Suitable mixtures for forming the sheets are prepared by mixing together water, unmodified and ungelatinized starch granules, a cellulosic ether, optionally fibers, and optionally an inorganic mineral filler in the correct proportions to form a sheet having desired properties. The mixtures are formed into sheets by passing them between one or more sets of heated rollers to form green sheets. The heated rollers cause the cellulosic ether to form a skin on the outer surfaces of the sheet that prevents the starch granules from causing the sheet to adhere to the rollers upon gelation of the starch. The green sheets are passed between heated rollers to gelatinize the starch granules, and then to dry the sheet by removing a substantial portion of the water by evaporation. The starch and cellulosic ether form the binding matrix of the sheets with the fibers and optional inorganic filler dispersed throughout the binding matrix. The starch-bound sheets can be cut, rolled, pressed, scored, perforated, folded, and glued to fashion articles from the sheets much like paper or paperboard. The sheets are particularly useful in the mass production of containers, such as food and beverage containers.

Owner:E KHASHOGGI INDS

Multi-piece solid golf ball

InactiveUS7086969B2Improve spin performanceIncrease total distance traveledGolf ballsSolid ballsPtru catalystSulphur compound

Owner:BRIDGESTONE SPORTS

Compositions and methods for manufacturing starch-based sheets

Compositions and methods for manufacturing sheets having a starch-bound matrix reinforced with fibers and optionally including an inorganic mineral filler. Suitable mixtures for forming the sheets are prepared by mixing together water, unmodified and ungelatinized starch granules, an auxiliary water-dispersible organic polymer, fibers, and optionally an inorganic mineral filler in the correct proportions to form a sheet having desired properties. The mixtures are formed into sheets by passing them between one or more sets of heated rollers to form green sheets. The heated rollers cause the auxiliary polymer to form a skin on the outer surfaces of the sheet that prevents the starch granules from causing the sheet to adhere to the rollers upon gelation of the starch. The green sheets are passed between heated rollers to gelatinize the starch granules, and then to dry the sheet by removing a substantial portion of the water by evaporation. The starch and auxiliary polymer form the binding matrix of the sheets with the fibers and optional inorganic filler dispersed throughout the binding matrix. The starch-bound sheets can be cut, rolled, pressed, scored, perforated, folded, and glued to fashion articles from the sheets much like paper or paperboard. The sheets are particularly useful in the mass production of containers, such as food and beverage containers.

Owner:E KHASHOGGI INDS

Water gel containing natural high molecule and its radiation preparing method

InactiveCN1944495AImprove water absorptionGood flexibilityOrganic active ingredientsAntipyreticCross-linkWound dressing

The present invention provides one kind of water gel containing natural high molecular material and its preparation process. The water gel has cross-linking degree of 70-95 % and water absorption of 500-80000 %, and contains natural high molecular material or its derivative selected from chitin, chitin derivative, chitosan, chitosan derivative, carrageenin, etc. The water gel may have synthetic high molecular material, inorganic filler, cross-linking sensitizer, medicine and other assistant added. It is prepared through radiation cross-linking, with the radiation dosage being 10-40 kGy. The water gel of the present invention has high water absorption, high flexibility, good medicine slow releasing performance, and may be used in wound dressing, etc.

Owner:厦门凝赋生物科技有限公司

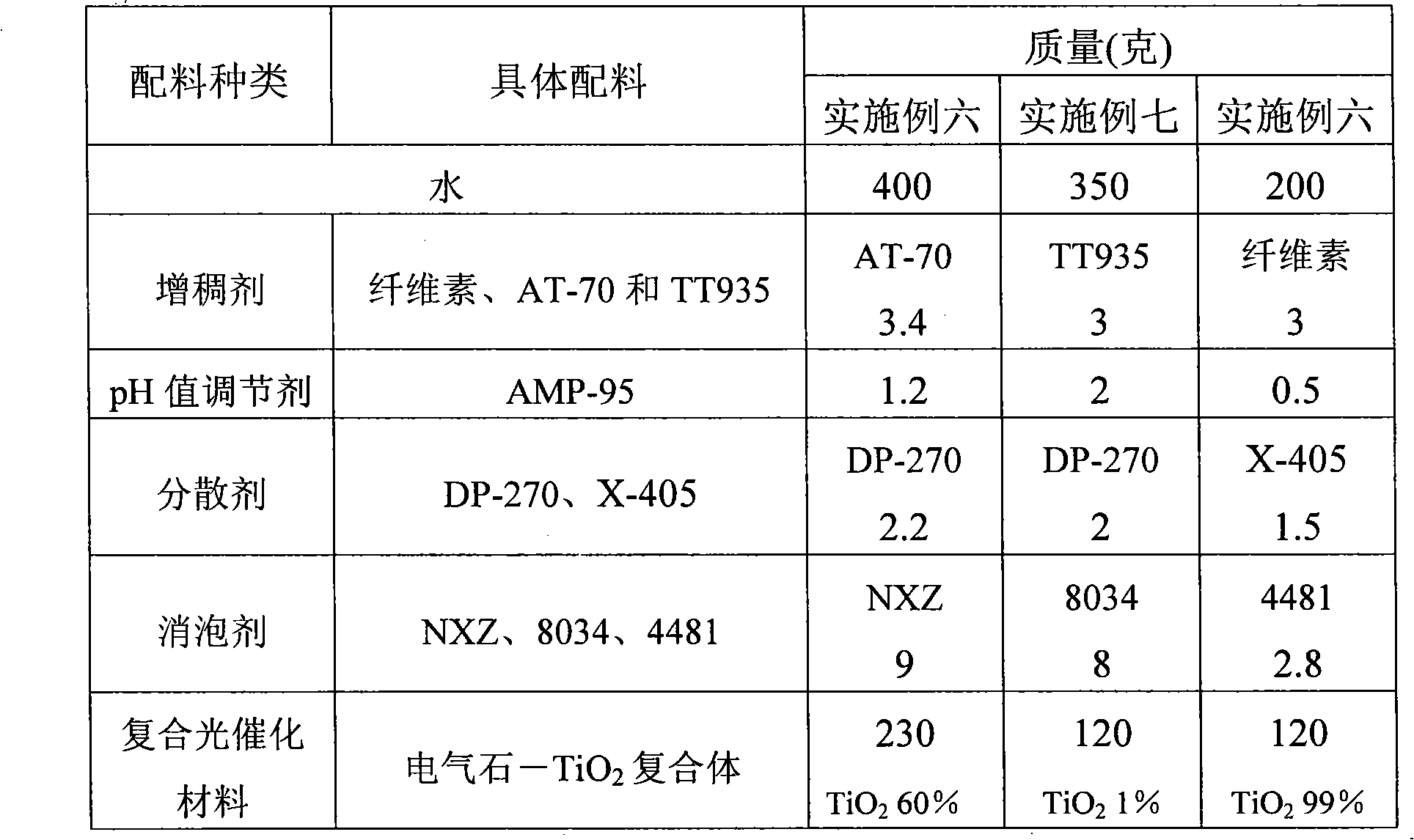

Thick coating material purifying air and preparing method thereof

ActiveCN101348628AGood purification effectImprove purification effectDispersed particle separationDeodrantsCompound aAir cleaning

The invention provides a thick coating material capable of purifying air and a preparation method thereof, belonging to the building material field. An internal wall coating decorative material comprises 5 to 40 weight portions of a porous absorbing material and 10 to 40 weight portions of a composite photocatalysis material in every 100 weight portion of the paint. In the preparation method, the coating material, is formed by compounding a mineral material with the nanometer photocatalysis material to obtain a high activity purifying material, matching the high activity purifying material with other nanometer materials and the porous absorbing material, and then adding an inorganic filling material, a skeletal material and other addition agents, can remove harmful gases such as formaldehyde and toluol in air and has the environmental protection function. The paint has good effect for removing formaldehyde, is effective continuously, has certain thickness when the coating layer is used, has simple construction, and beautiful and elegant patterns, is well-bedded, is strong in the three-dimension effect and has good decorative effect.

Owner:CHINA BUILDING MATERIALS ACAD

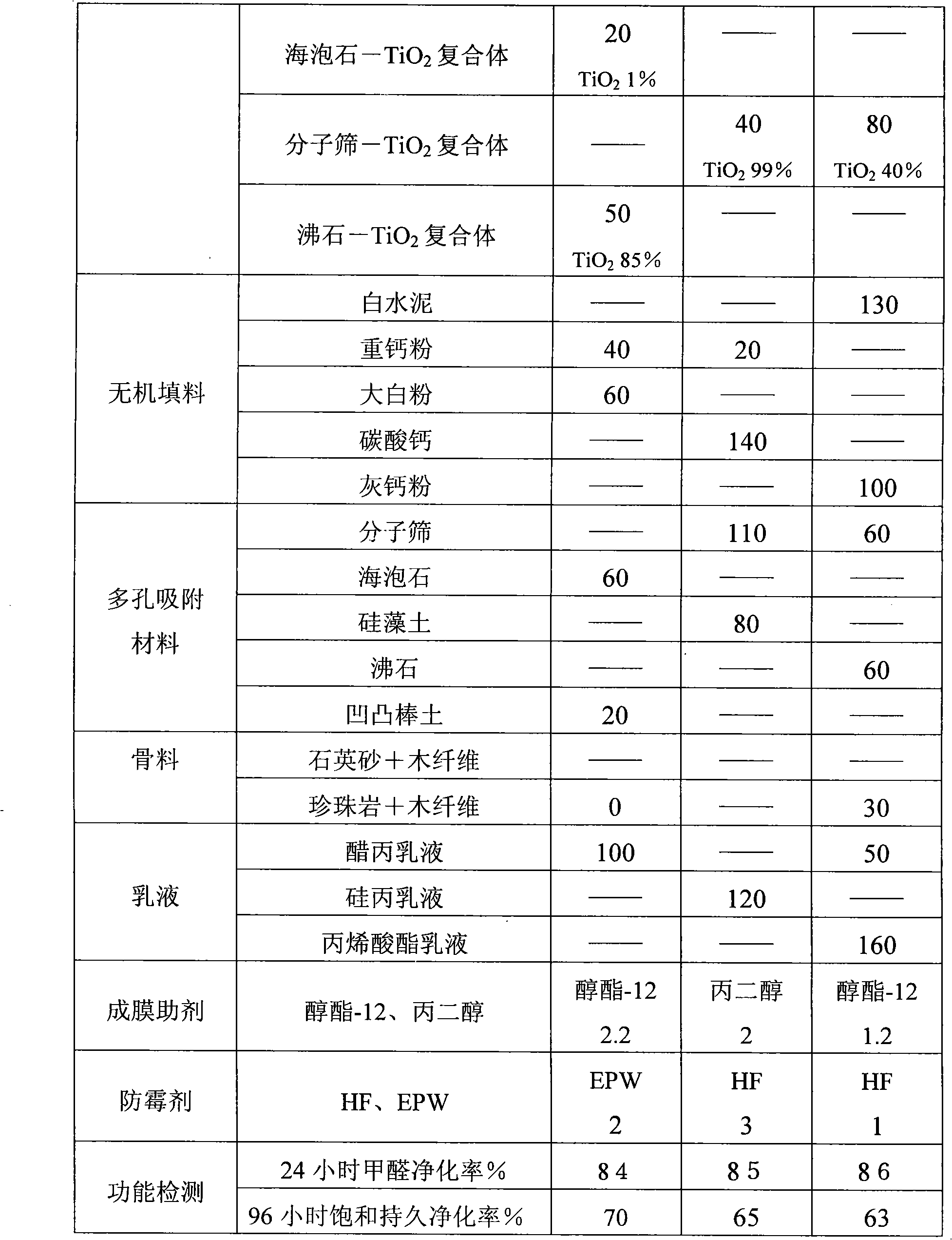

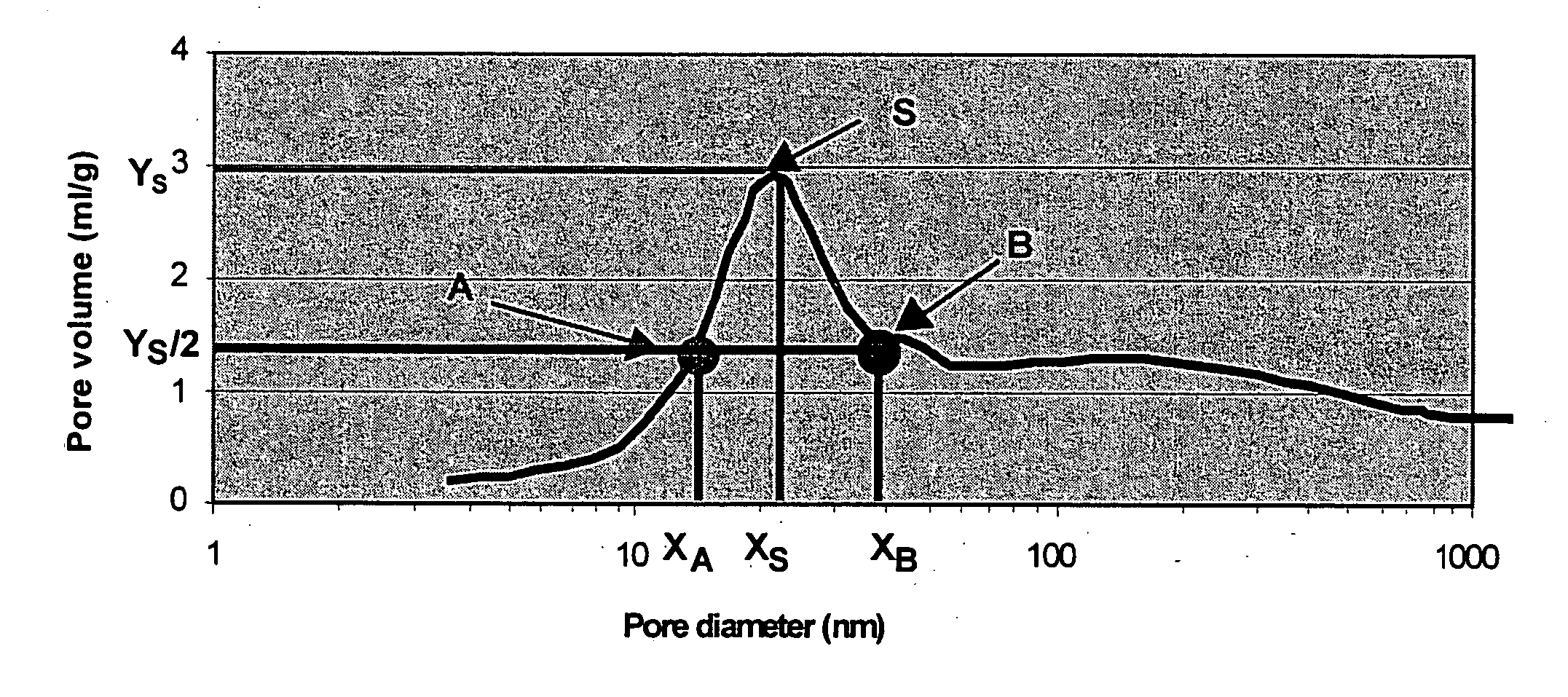

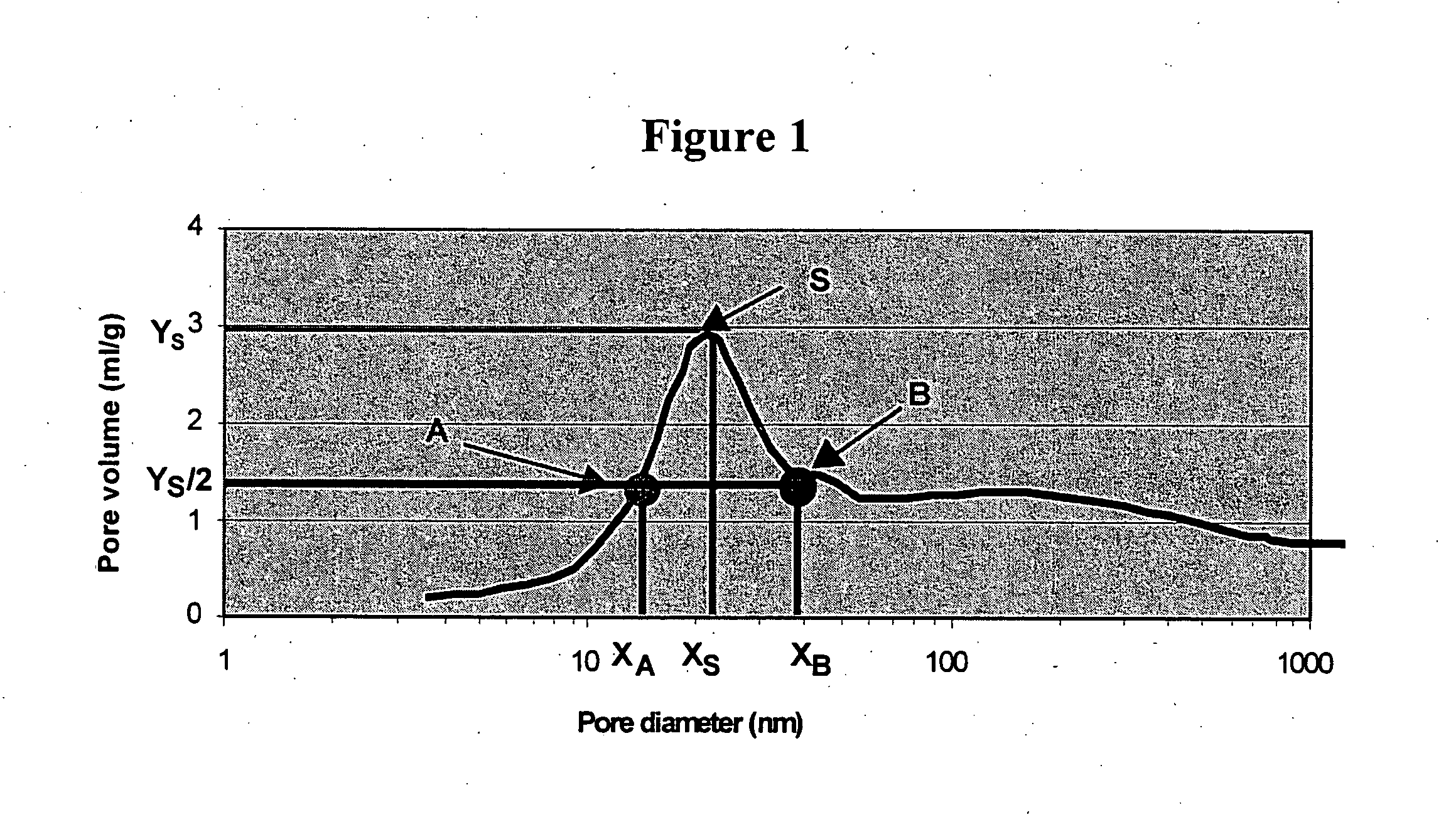

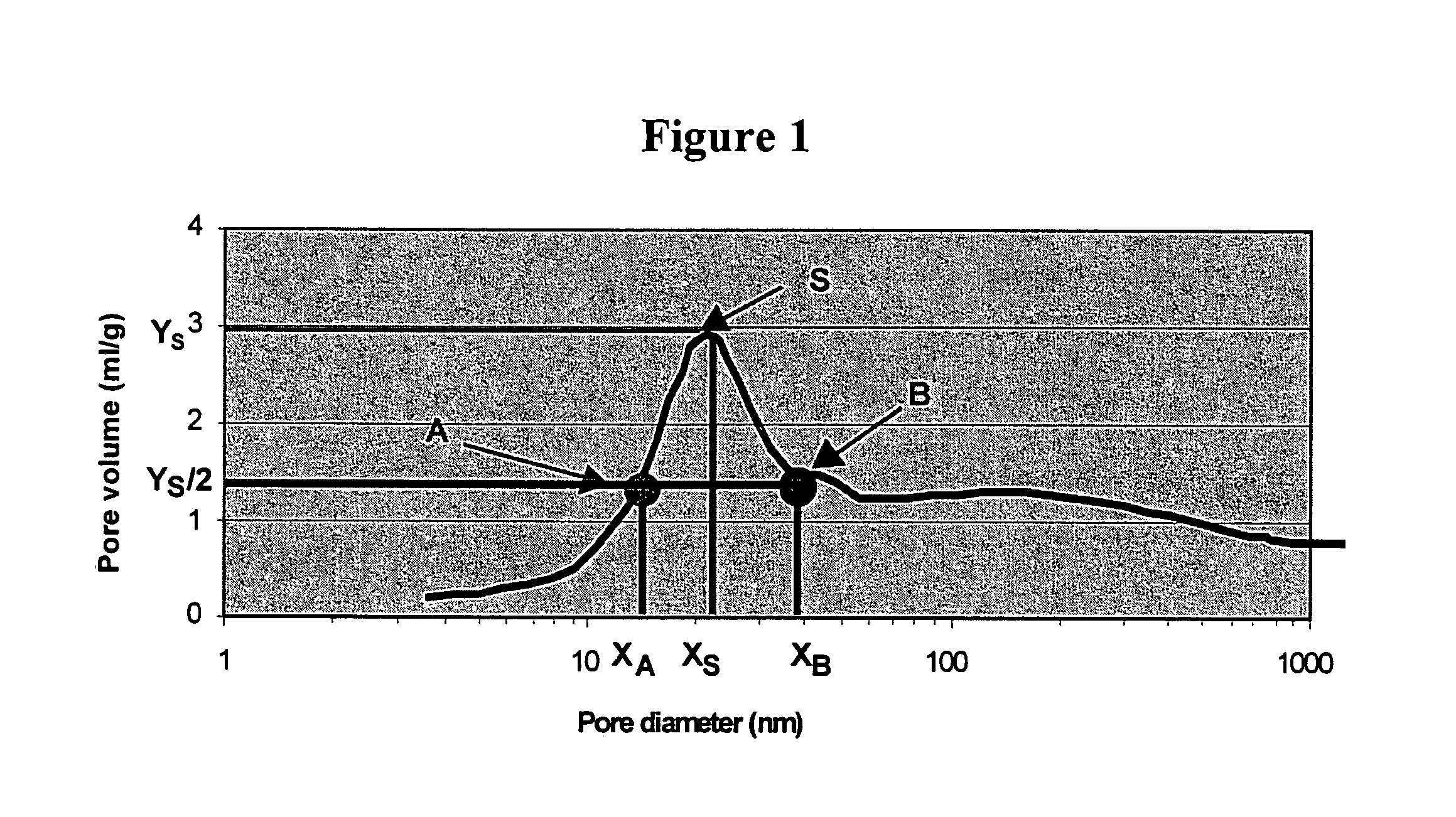

Diene rubber composition for tire comprising a specific silica as reinforcing filler

InactiveUS20050004297A1Less-difficult to processReduce hysteresisMaterial nanotechnologySpecial tyresElastomerPorosity

Diene rubber compositions are described containing a diene elastomer, a reinforcing inorganic filler, and a coupling agent wherein the inorganic filler includes a silica having the following characteristics: (a) a BET specific surface area between 45 and 400 m2 / g; (b) a CTAB specific surface area between 40 and 380 m2 / g; (c) an average particle size (by mass), dw, of 20 to 300 nm; and at least one of the following characteristics, preferably two and more preferably all three: (d) a particle size distribution such that dw≧ / CTAB)−30; (e) a porosity which meets the criterion L / FI≧−0.0025 CTAB+0.85; (f) an amount of silanols per unit of surface area, NSiOH / nm2; NSiOH / nm2≦−0.027 CTAB+10.5. These diene rubber compositions can be used for the manufacture of tires or of semi-finished products intended for tires.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Solid golf ball

InactiveUS20080194357A1Improve spin performanceIncrease distanceGolf ballsSolid ballsThermoplasticPolymer science

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, and an inorganic filler. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer is formed primarily of a thermoplastic or thermoset polyurethane material and has a thickness of 0.5 to 2.5 mm, a Shore D hardness at the surface of 50 to 70 and a flexural rigidity of 50 to 300 MPa. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

Golf ball

InactiveUS7226367B2Improve productivityIncrease elasticityGolf ballsSolid ballsPtru catalystEngineering

A golf ball comprises a solid core consisting of a center core and an outer core, wherein at least one of cores is made of a rubber composition comprising 100 parts by weight of a base rubber including. 60 to 100% by weight of a polybutadiene containing at least 60% by weight of cis-1,4-bond, having a Mooney viscosity (ML1+4 (100° C.)) of at least 52, and synthesized using a rare-earth catalyst, 10 to 60 parts by weight of an unsaturated carboxylic acid and / or a metal salt thereof, 5 to 80 parts by weight of an-inorganic filler, and an organic peroxide, and wherein the center core has a JIS-C hardness of 40 to 60 on its center and a JIS-C hardness of 55 to 75 on its surface and the difference therebetween is at least 10, the outer core is harder than the surface hardness of the center core, the cross-sectional hardness of 1 mm outside from the border between the center core and the outer core is from 65 to 85 on a JIS-C hardness, the surface of the outer core has a JIS-C hardness of 75 to 95.

Owner:BRIDGESTONE SPORTS

Weather-resistant and high thermal conductive coating, radiating solar rear panel and efficient solar cell panel

InactiveCN102516852AImprove thermal conductivityMeet service life requirementsPolyureas/polyurethane adhesivesPhotovoltaicsWeather resistanceConductive coating

The invention discloses a weather-resistant and high thermal conductive coating, a radiating solar rear panel and an efficient solar cell panel. The weather-resistant and high thermal conductive coating consists of 10 to 50 parts of weather-resistant resin, 5 to 30 parts of curing agent, 0.1 to 5 parts of organic filler, 30 to 80 parts of inorganic filler, and 30 to 100 parts of solvent. The radiating solar rear panel comprises a base layer, and the weather-resistant and high thermal conductive coating is arranged on at least one surface of the base layer or arranged between the base layers. The efficient solar cell panel comprises a solar front panel and the radiating solar rear panel, a solar cell circuit is arranged between the solar front panel and the radiating solar rear panel, and an encapsulation material is arranged on one side or two sides of the solar cell circuit. The weather-resistant and high thermal conductive coating can be directly coated on a base material and has high binding power and an excellent thermal conductive effect, and the weather resistance of the coating meets the requirement of a solar module for the service life of over 25 years.

Owner:ALLSTAE TECH ZHONGSHAN

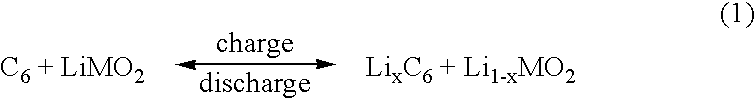

Lithium ion polymer electrolytes

InactiveUS6413676B1Prevent kinkingAvoid deformationElectrode manufacturing processesFinal product manufacturePorosityCross-link

A dimensionally stable, highly resilient, hybrid copolymer solid-solution electrolyte-retention film for use in a lithium ion battery in one preferred embodiment has a predominantly amorphous structure and mechanical strength despite contact with liquid solvent electrolyte. The film is a thinned (stretched), cast film of a homogeneous blend of two or more polymers, one of which is selected for its pronounced solvent retention properties. A very high surface area inorganic filler dispersed in the blend during formation thereof serves to increase the porosity of the film and thereby enhance electrolyte retention. The film is soaked in a solution of liquid polymer with liquid organic solvent electrolyte and lithium salt, for absorption thereof. Use of a cross-linked liquid polymer enhances trapping of molecules of the electrolyte into pores of the film. The electrolyte film is sandwiched between flexible active anode and cathode layers to form the lithium ion battery. Novel methods are provided for forming the electrodes, the polymer substrate, and other elements of the battery.

Owner:LITHIUM POWER TECH

Natural rubber master batch, production method thereof, and natural rubber composition

InactiveUS6841606B2Easy to processImprove propertiesPigmenting treatmentSpecial tyresPolymer scienceSlurry

The natural rubber master batch of the present invention is prepared by mixing a natural rubber latex having its amide linkages cleaved and an aqueous slurry having a filler dispersed in water. Alternatively, the natural rubber master batch is prepared by a method including a step for mixing a natural rubber latex and an aqueous slurry containing dispersed fillers having a specific particle size distribution and a limited range of 24M4DBP absorption. The natural rubber composition of the present invention is prepared by compounding natural rubber, which contains non-rubber components prepared by cleaving amide linkages of natural rubber latex, with silica and / or a particular inorganic filler.

Owner:BRIDGESTONE CORP

Biodegradable polymer blends for use in making films, sheets and other articles of manufacture

InactiveUS7214414B2Increase stiffnessIncrease flexibilitySynthetic resin layered productsEmulsion paintsPolyesterThermoplastic

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

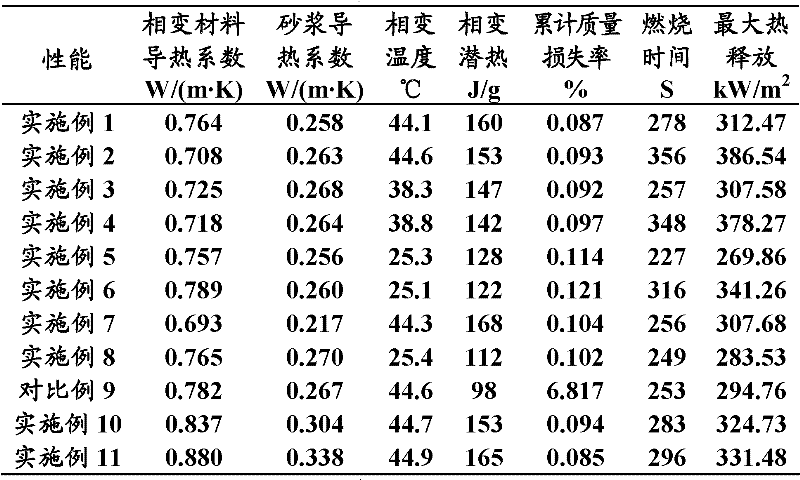

Phase-transition composite material, preparation method and application thereof

ActiveCN102408877APhase transition temperature is suitableLarge latent heat of phase changeClimate change adaptationHeat proofingParaffin waxThermal insulation

The invention relates to a phase-transition composite material which comprises: A) 30-65% of phase-transition materials which are low melting point paraffin with a melting point of 25-45 DEG C and / or dodecanol; B) 25-45% of carrier materials which are high density polyethylane and / or ethane-vinylacetate copolymer; C) 5-15% of inorganic fillers which are porous substances and are selected from one or two of expanded perlite and expandable graphite; D) 1-10% of heat-conduction reinforcing agents; and E) 1-10% of fire retardants. The composite material has an appropriate phase transition temperature which matches the building ambient temperature, has great phase transition latent heat, excellent heat-preservation and heat-insulation performance, is fireproof and flame-retardant, is easy to process, and has greatly reduced phase-transition material leakage. The invention also relates to a method for preparing the phase-transition composite material, which comprises the thermal insulation mortar of the phase-transition composite material and a method of heat preservation of a wall by using the mortar.

Owner:BEIJING UNIV OF CHEM TECH +1

Diene rubber composition for tire comprising a specific silica as reinforcing filler

InactiveUS7250463B2Less-difficult to processReduce hysteresisMaterial nanotechnologySpecial tyresPorosityElastomer

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

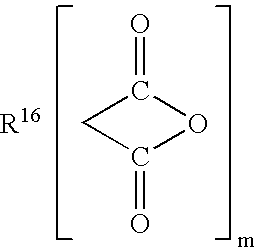

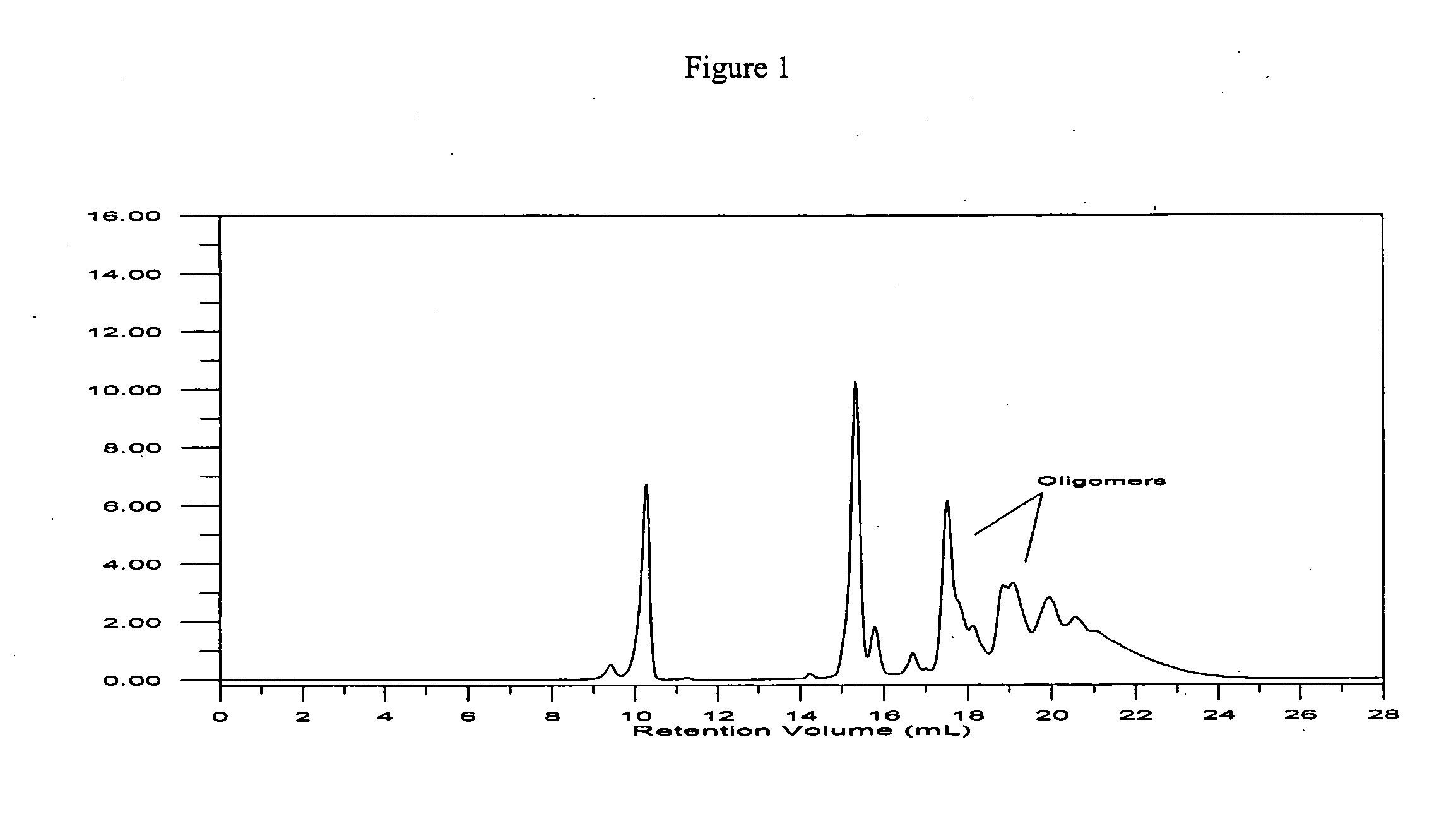

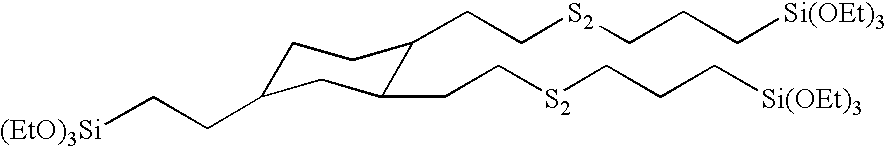

Silated core polysulfides, their preparation and use in filled elastomer compositions

ActiveUS20080161477A1Good dispersion of fillerImprove productivityGroup 4/14 element organic compoundsSpecial tyresElastomerSilanes

This invention relates to novel sulfur-containing silane coupling agents, and organic polymers containing carbon-carbon double bonds. These novel silanes can be carried on organic and inorganic fillers. The invention also relates to articles of manufacture, particularly tires, made from the elastomer compositions described herein.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Plant powder modified thermoplastic wood-plastic composite and preparation method and application

The invention discloses a plant powder modified thermoplastic wood-plastic composite and a preparation method and application thereof. The composite is composed of the following components by weight portion: 100 portions of thermoplastic resin, 1-400 portions of plant powder, 0.1-40 portions of dispersant, 0.5-60 portions of impact modifier, 0-100 portions of inorganic filler and 0-10 portions of antioxidant. Compared with wood, the plant powder modified thermoplastic wood-plastic composite prepared by the method has the advantages of durability, good dimensional stability, easy molding, small water absorption and corrosion resistance. Compared with plastics, the composite has the characteristics of low cost and high rigidity. The composite is suitable for a variety of injection molding parts, such as the shells of electrical equipment including TV, and the like.

Owner:KINGFA SCI & TECH CO LTD +1

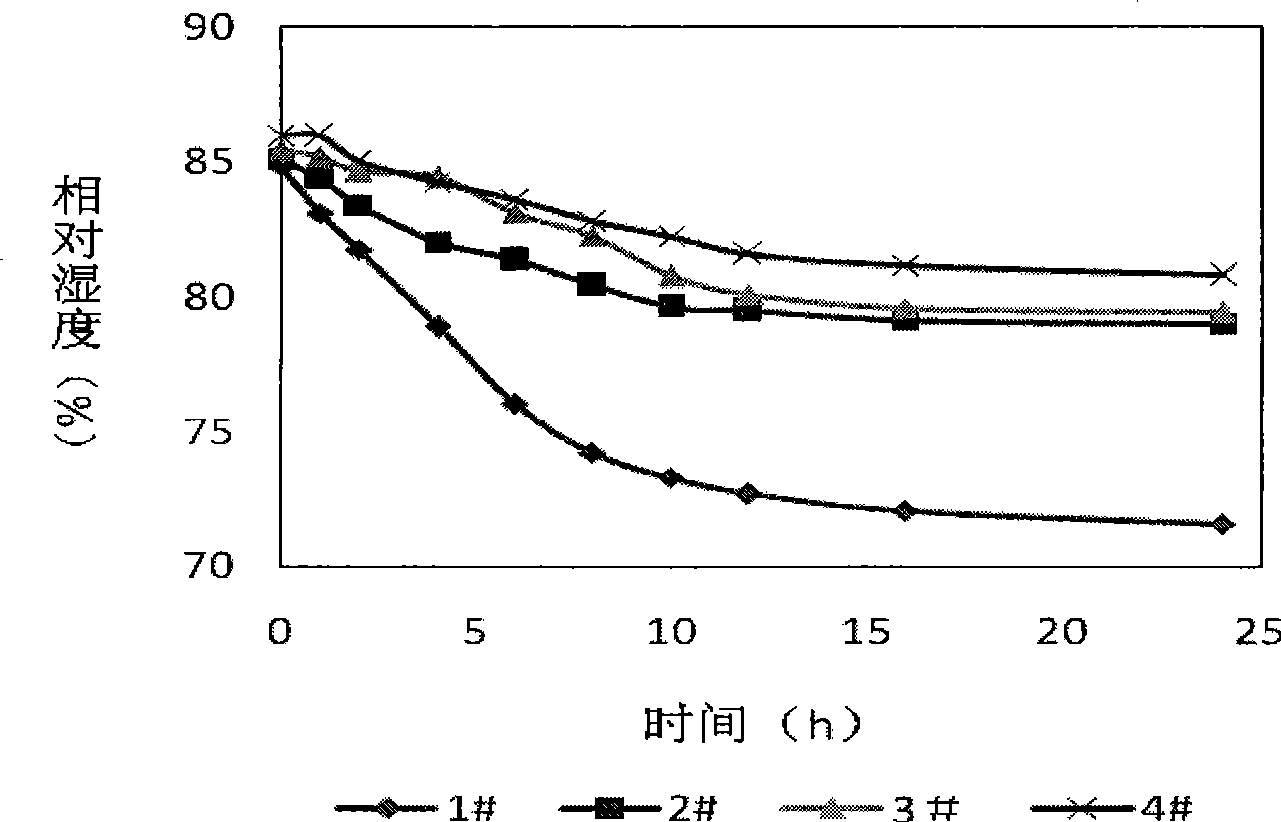

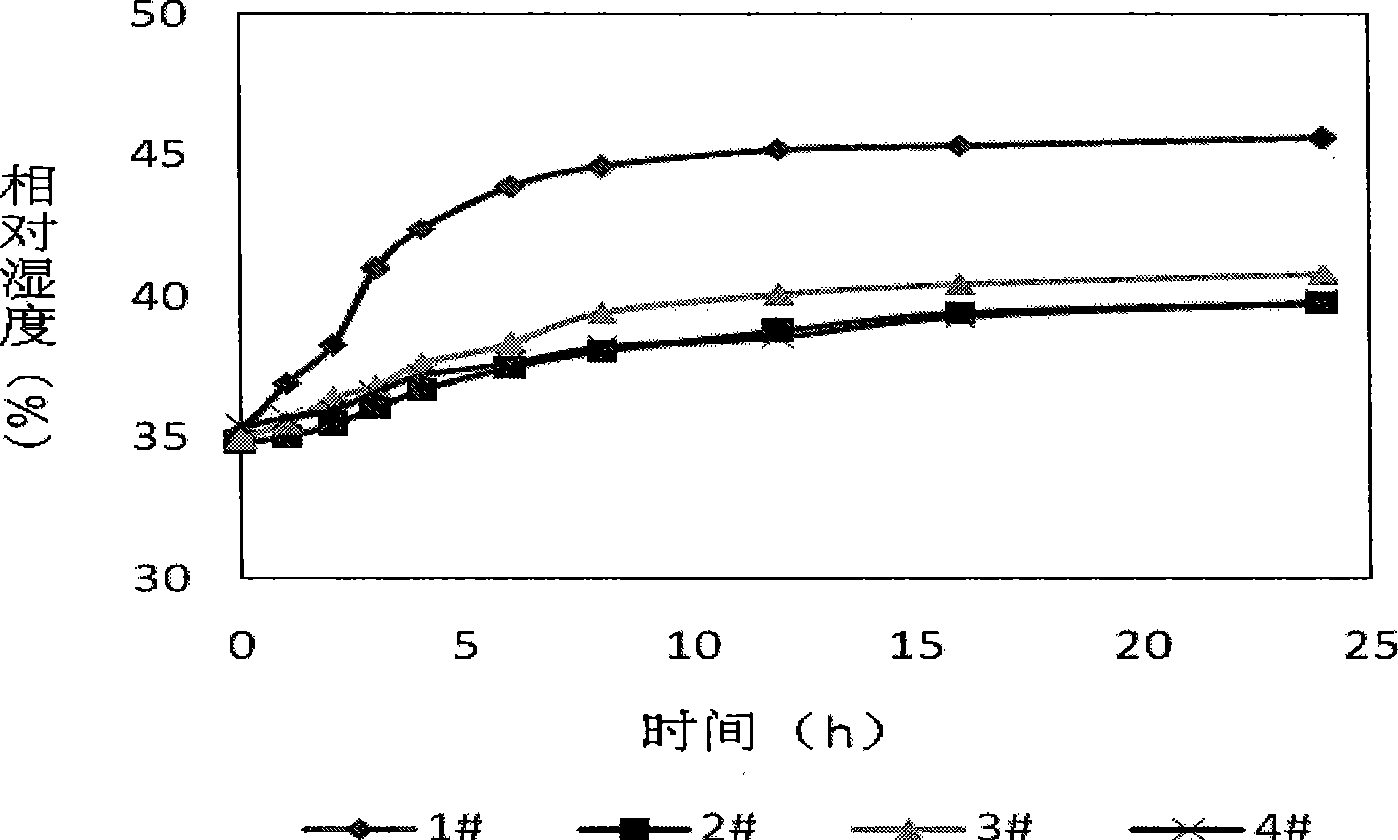

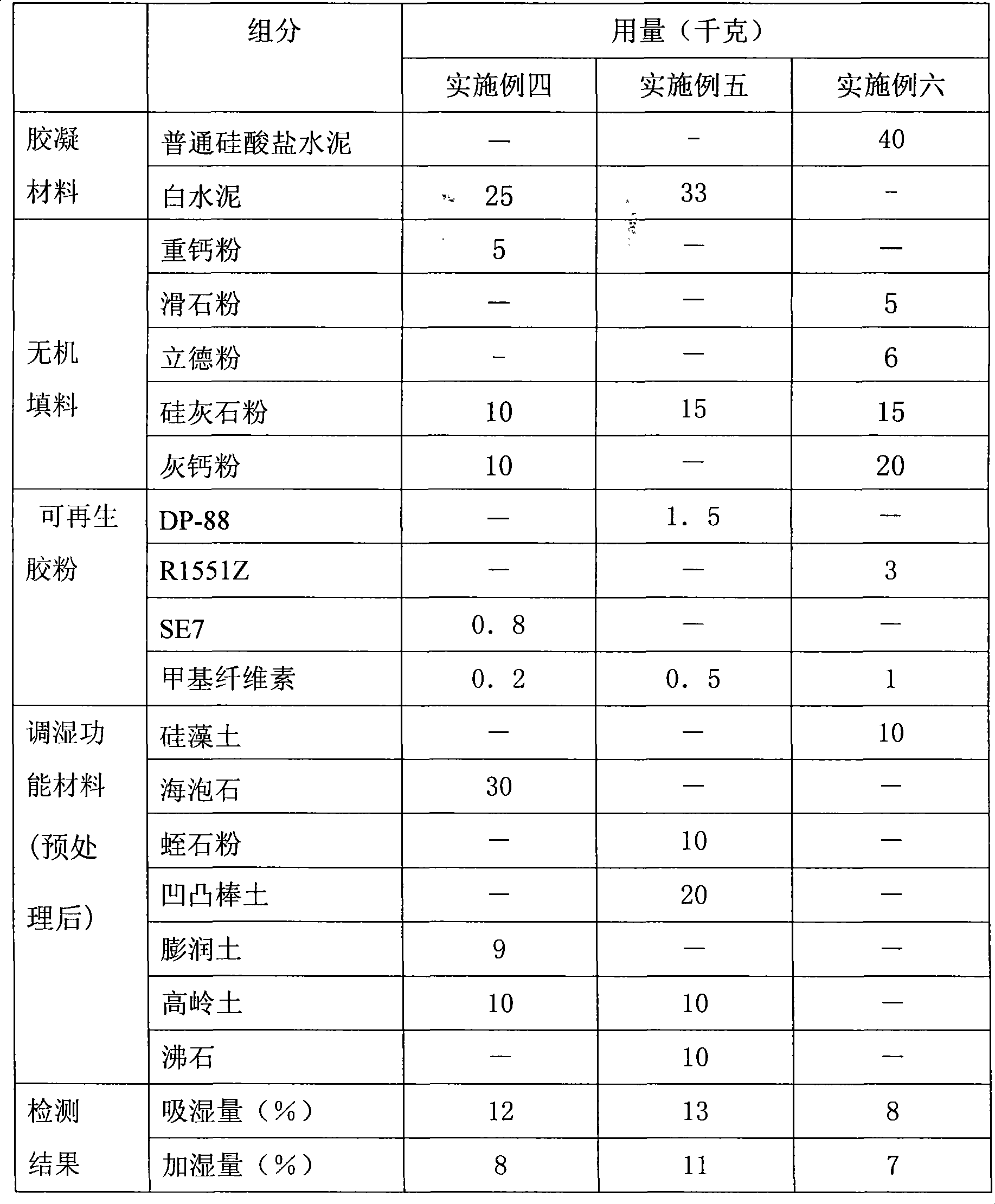

Inorganic putty powder with function of governing humidness

ActiveCN101368014AEffective regulation of relative humidityGood environmental protectionFilling pastesCement coatingsSodium BentoniteMetallurgy

The invention relates to interior wall putty powder with air humidity regulating function, which belongs to the field of building materials. The putty powder is composed of 10 to 50 weight portions of humidity regulating material, 15 to 50 weight portions of inorganic binding material, 15 to 50 weight portions of inorganic filler, and 1 to 5 weight portions of sub divisible rubber powder; the humidity regulating material comprises one type or more than one type of diatomite, sepiolite, attapulgite, vermiculite, zeolite powder, kaolin and bentonite. Because of the environment protection and humidity regulating functions, the multi-pore inorganic mineral material is taken as humidity regulating material and applied in the building interior wall putty powder. With water added in, the putty powder is mixed into lacquer putty and applied on the wall surface, which can effectively regulate the indoor air humidity, so that the indoor air humidity is controlled within the scope which is beneficial to the health of human body; meanwhile, the putty powder has no pollution, no VOC released and can be directly used for decoration.

Owner:CHINA BUILDING MATERIALS ACAD

Solid golf ball

InactiveUS20080312008A1Improve spin performanceIncrease distanceGolf ballsSolid ballsOrganosulphur compoundPolymer science

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, and an inorganic filler. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer is formed by injection molding a single resin blend composed primarily of (A) a thermoplastic polyurethane and (B) a polyisocyanate compound, which resin blend contains a polyisocyanate compound in at least some portion of which all the isocyanate groups on the molecule remain in an unreacted state, and has a thickness of 0.5 to 2.5 mm, a Shore D hardness at the surface of 50 to 70. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

Waterborne ultra-thin steel structure fire retardant coating and preparation method thereof

ActiveCN102838907AGood foaming effectThe pores are small and uniformFireproof paintsCarbonizationMaterials science

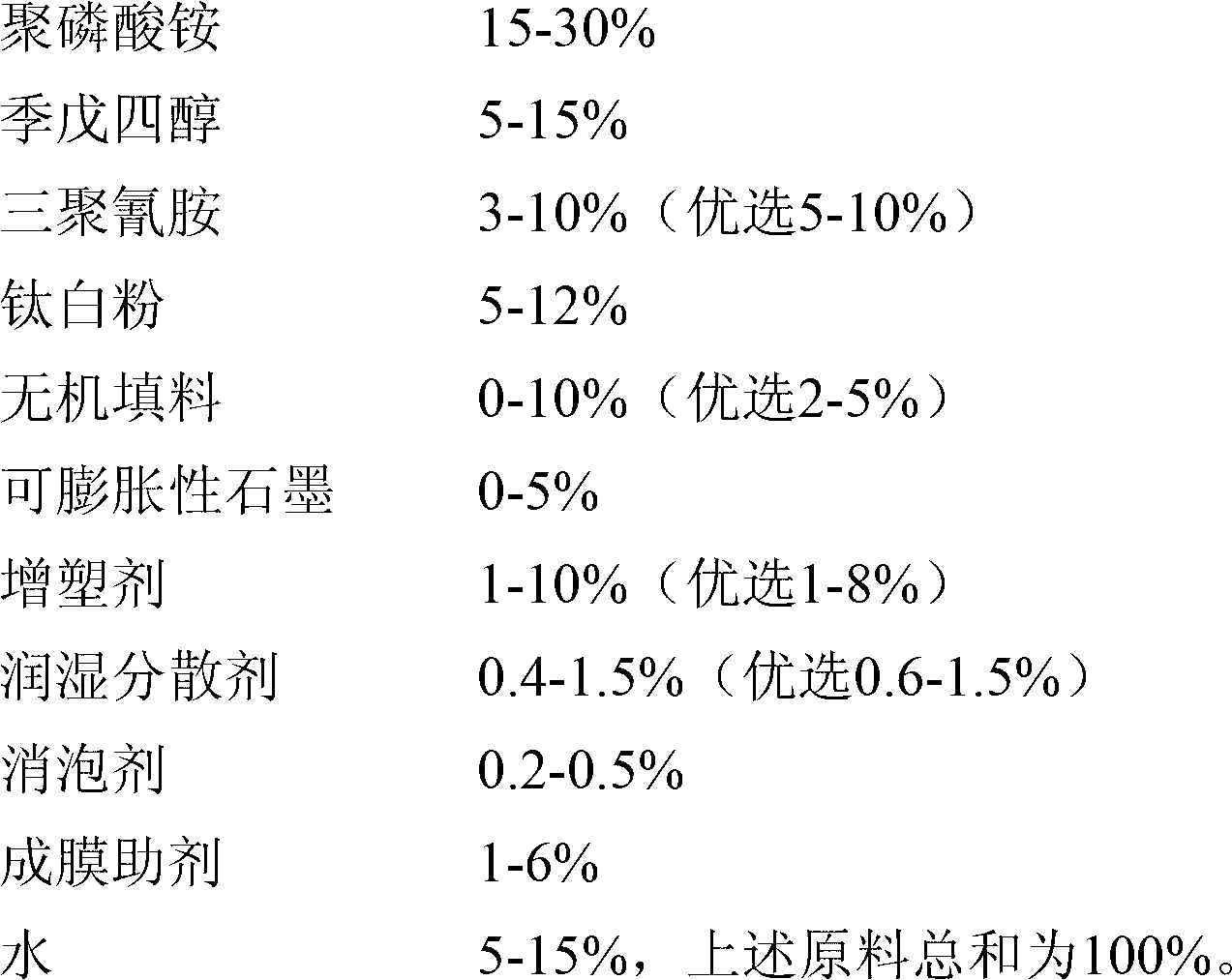

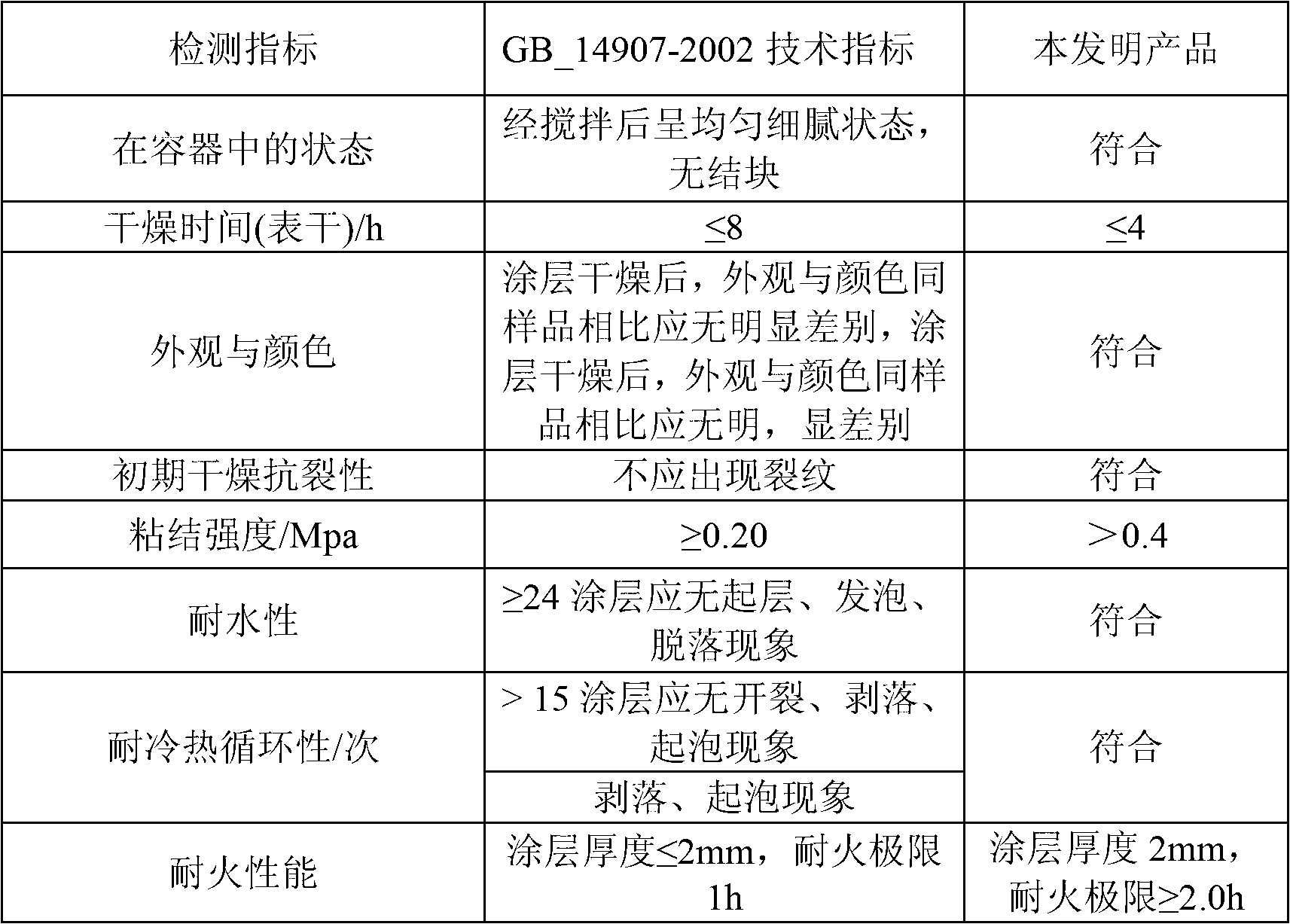

Provided is a waterborne ultra-thin steel structure fire retardant coating and a preparation method thereof. The raw material ratio of the coating includes 15-50% by weight of polymer latex, 15-30% by weight of ammonium polyphosphate, 5-15% by weight of pentaerythritol, 3-10% by weight of cyanurtriamide, 5-12% by weight of titanium dioxide, 2-13% inorganic filler, 0-5% by weight of expansiveness graphite, 1-10% by weight of plasticizer, 0.4-1.5% by weight of wetting dispersant, 0.2-0.5% by weight of defoamer, 1-6% by weight of coalescing agents and 5-15% by weight of water, and total raw material ratio is 100%. A high-speed dispersion method or a grinding dispersion method is adopted in preparation of the coating. A coating layer of the fire retardant coating can form a carbonization layer which is good in foaming effect, small and uniform in air holes and high in expansion times when in heating. The final fire retardant performance of the coating is far higher than technical requirements of a national standard. The waterborne ultra-thin steel structure fire retardant coating is a waterborne coating product, is non-poisonous and odorless and environment-friendly, and can be coated in a mode of brushing or spraying or roller coating.

Owner:SOUTH CHINA UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com