Patents

Literature

153results about How to "Good environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

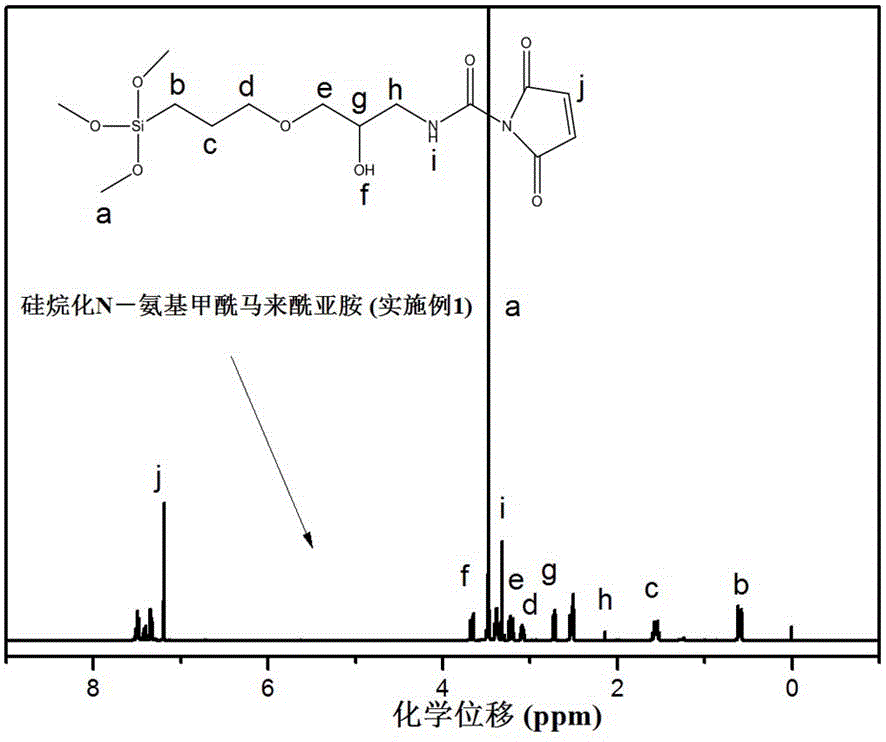

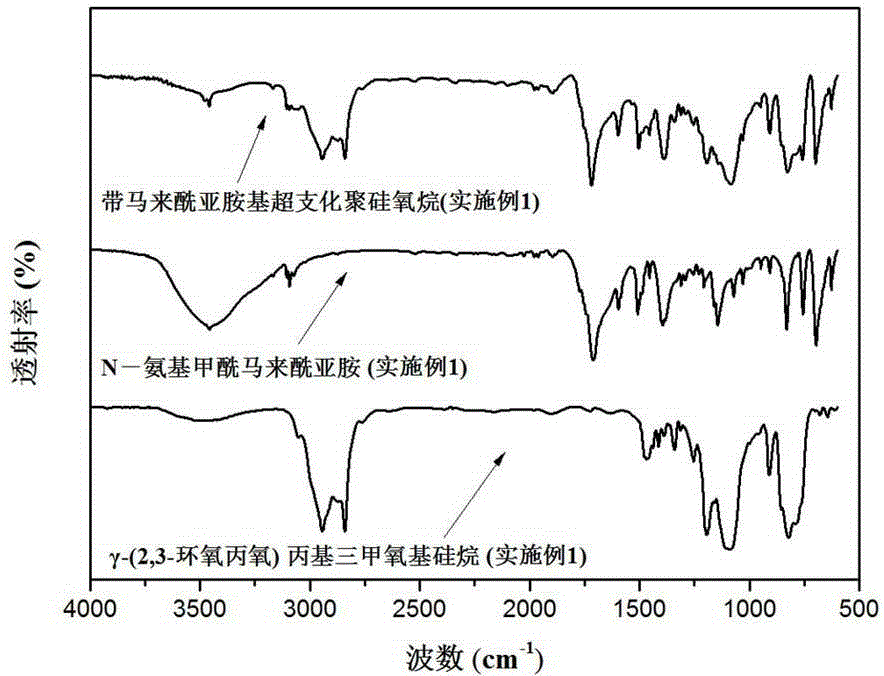

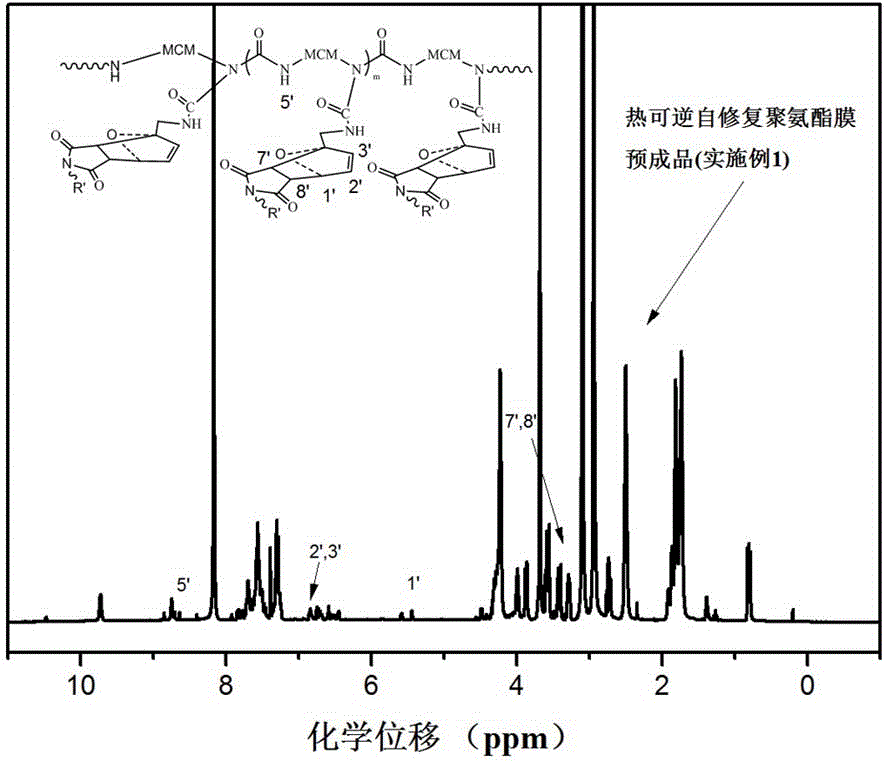

Thermal-reversible self-repair polyurethane membrane and preparation method therefor

The invention discloses a thermal-reversible self-repair polyurethane membrane and a preparation method therefor. Under protection of inert gases, 4,4-diphenylmethane diisocyanate, polycaprolactone glycol and N,N-dimethyl formamide are mixed uniformly, a reaction is carried out at a temperature of 50-60 DEG C, then the solution is cooled to a temperature of less than 5DEG C, 2-furan methylamine is added in the solution, the temperature is risen to 95-105 DEG C, the reaction is carried out for 10-11h, then hyperbranched polysiloxane with maleimide groups is added, the pre-finishing product prepared after the reaction is finished is poured into a die and dried, and a thermal-reversible self-repair polyurethane membrane is obtained. By utilization of the Diels-Alder (DA) reaction, thermal-reversible self-repair of a polyurethane membrane is achieved, the prepared polyurethane membrane has advantages of excellent thermal stability and high hardness, and raw materials have wide sources. The preparation method has characteristics of simple technology, strong practicality, wide applicability and the like.

Owner:SUZHOU UNIV

Method for polyolefin porous film mfg. method

InactiveCN1978037ANarrow pore size distributionHigh strengthSemi-permeable membranesSolventPolyolefin

The present invention relates to a preparation method of polyolefine microporous membrane. Said invention adopts thermal phase separation process to prepare said polyolefine microporous membrane, said process includes the following steps: mixing polyolefine compound and first solvent, melting them by using extruder, extruding melt, cooling and forming to obtain a colloidal material, making said colloidal material undergo the processes of supercritical extraction, thermal stretching and setting so as to obtain the invented product.

Owner:TIANJIN DG MEMBRANE

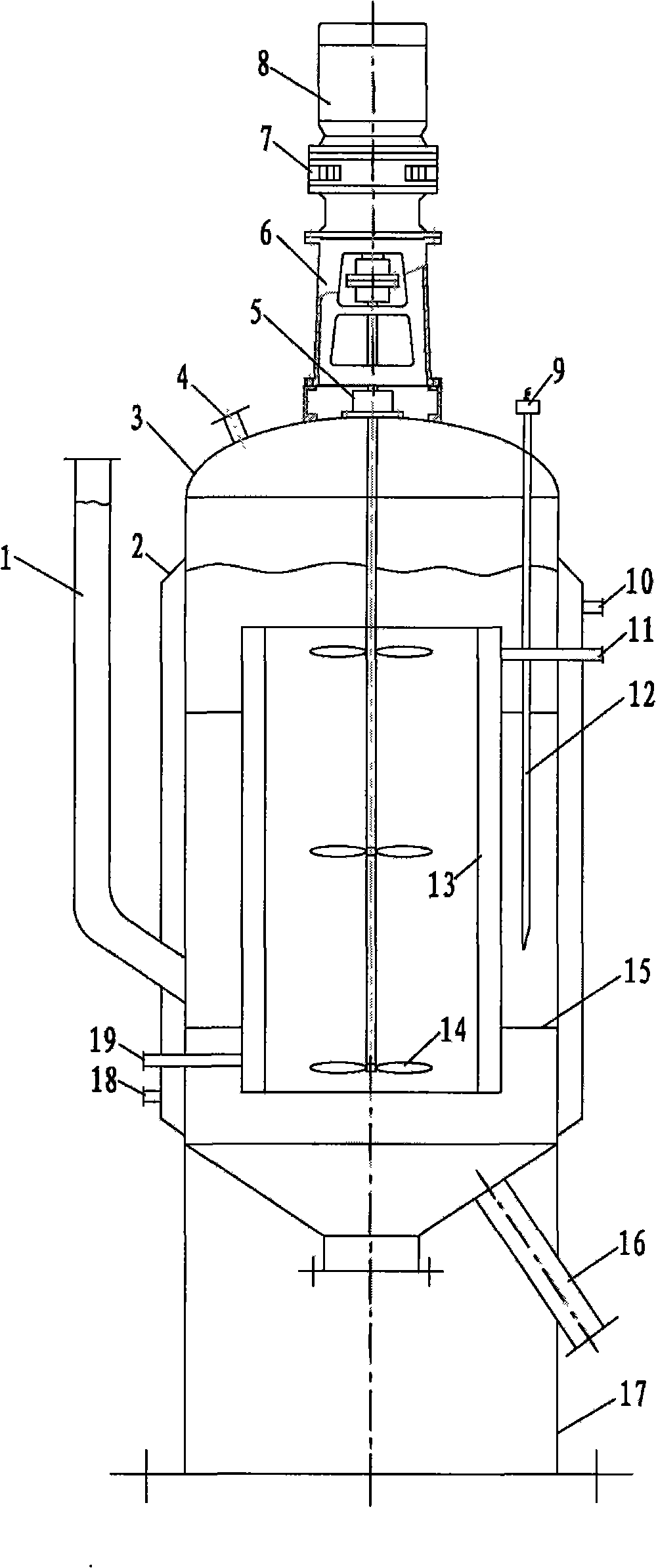

Reactor for producing acid phase with diphasic anaerobic digestion of urban biomass garbage

InactiveCN101402096AGood energy saving and environmental protection characteristicsLow consumption and efficient operationBiological substance pretreatmentsSolid waste disposalFermentationMaterials science

The invention discloses a two-phase anaerobic digestion acidogenic phase reactor for municipal biomass waste. The acidogenic phase reactor is provided with an enclosed vertical kettle formed with a thin corrosion resistant stainless steel inner barrel and a common carbon steel outer barrel. The kettle is welded with a dimple jacket outside, and is fixed with a hollow guiding barrel inside, and the insides of the dimple jacket and the hollow guiding barrel both have a heating medium so as to realize heating insulation operation under the combination control of a temperature sensing probe and a temperature controller. A multi-layer push type propeller blade with less flow resistance is used to perform mechanical stirring of the biomass waste entering the reactor, and meanwhile low consumption and high efficiency mixing of material and liquid can be realized with the forced current limit of the guiding barrel. The rotating inner stirring device and the resting kettle are mechanically sealed through a movable sealing element. The acidogenic phase reactor integrates the functions of stirring, mixture, reaction, fermentation, heating and insulation has good energy-saving and environmental-protection property, which can digest the high solid municipal biomass waste into small molecule organic acids that can be used by methanogens bacteria directly.

Owner:ZHEJIANG UNIV

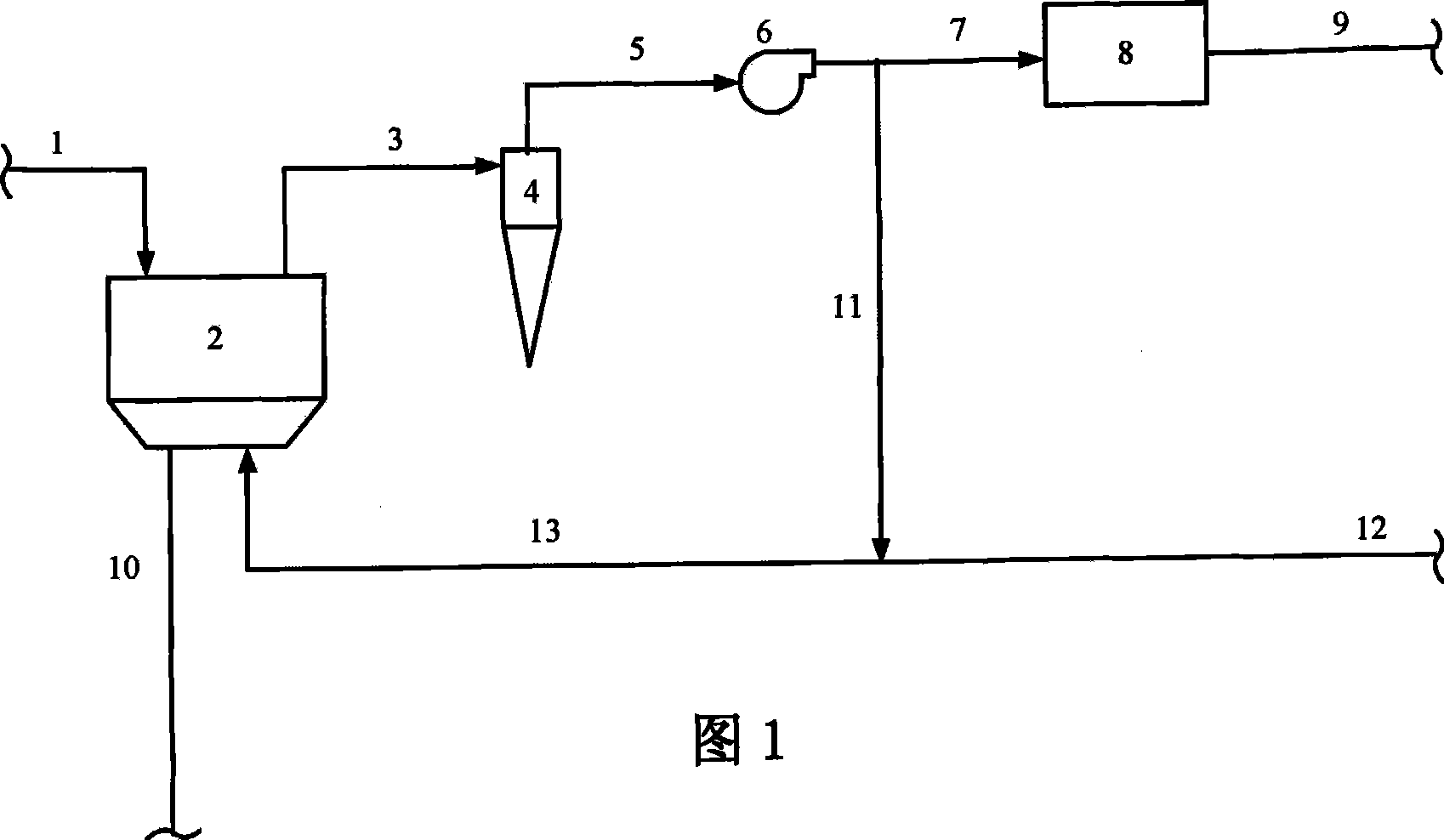

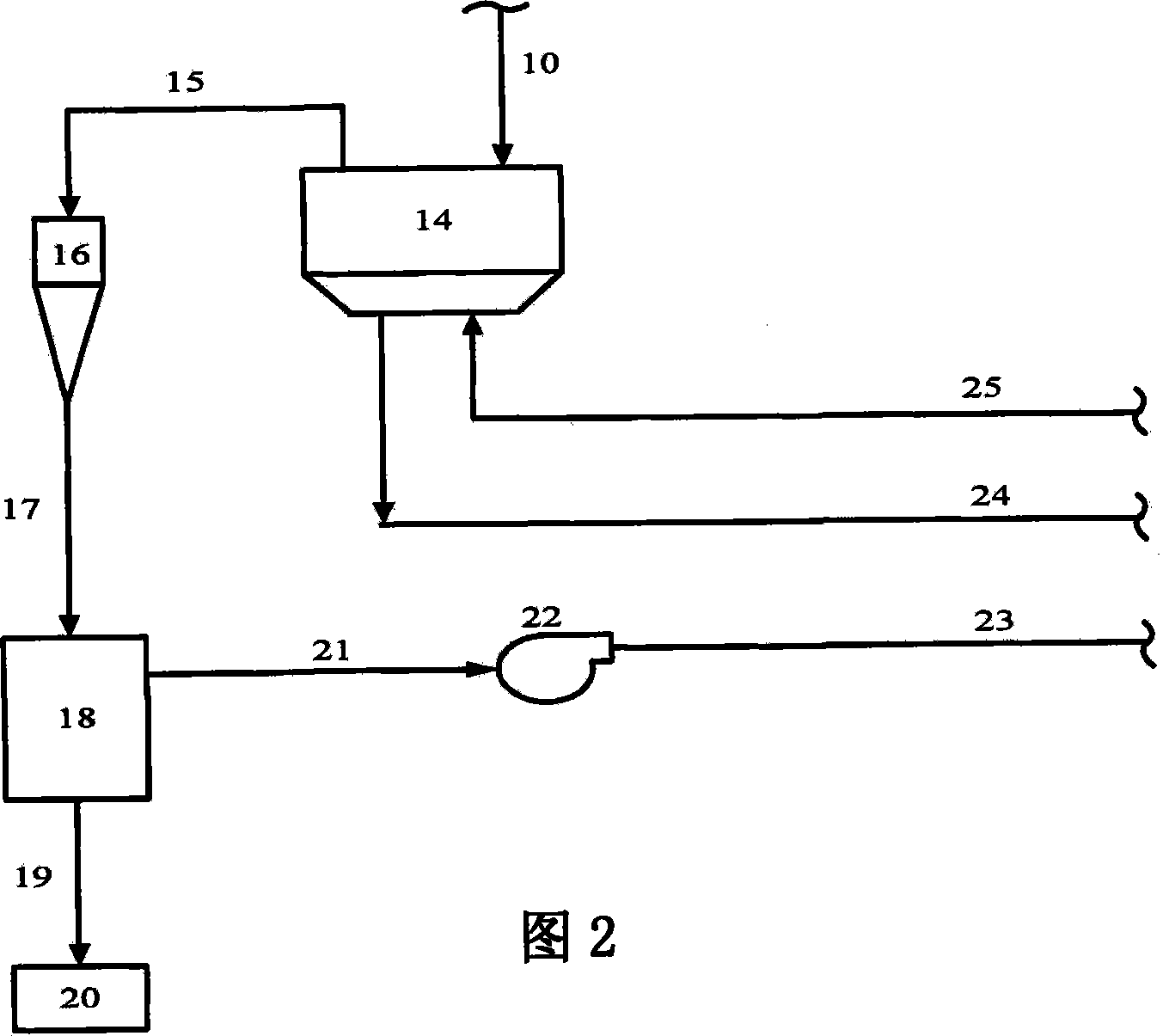

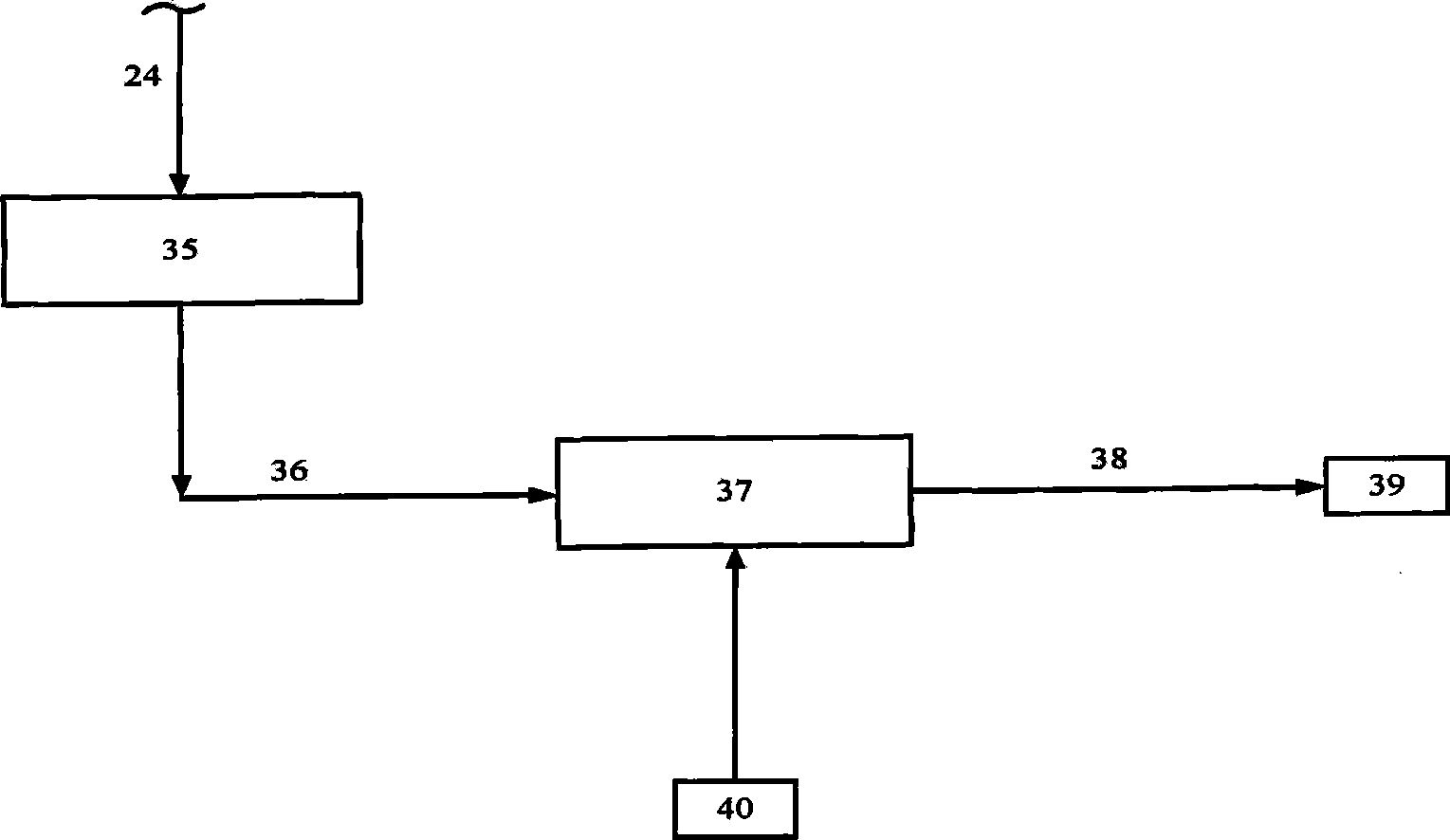

Process for processing coal with low degree of metamorphism

InactiveCN101429463AGood environmental protectionEmission reductionSolid fuelsEngineeringAtmospheric pollution

The invention provides a technique for processing coal with low metamorphism degree, which comprises the steps of crushing and sieving pretreatment. The technique is as follows: raw coal particles are sent into a drier, and subjected to anoxybiotic hot gas drying under normal pressure, wherein the drying condition is controlled to 10 to 50 cubic meters of hot gas required for each 1 kilogram of the coal, and the temperature of the raw coal particles is controlled to between 210 and 250 DEG C; the raw coal particles are sent into a pyrolysis apparatus, and high-temperature oxygen-poor hot gas is injected according to the flow ratio of 5 to 50 cubic meters per kilogram of coal, wherein the temperature of the oxygen-poor hot gas entering into a pyrolyzing furnace is controlled to between 400 and 950 DEG C, and the oxygen content is controlled to less than 6 percent of the volume; and the coal is fully mixed with the hot gas and heated to a temperature of between 530 and 580 DEG C. The technique has the advantages that the sulfur content is reduced compared with that in the raw coal, so that atmospheric pollution is reduced; solid products produced by the technique have high environment-friendly characteristic; the discharge amount of nitrogen oxide is obviously reduced; and atmospheric pollution is reduced.

Owner:HUNAN HUAYIN ENERGY TECH

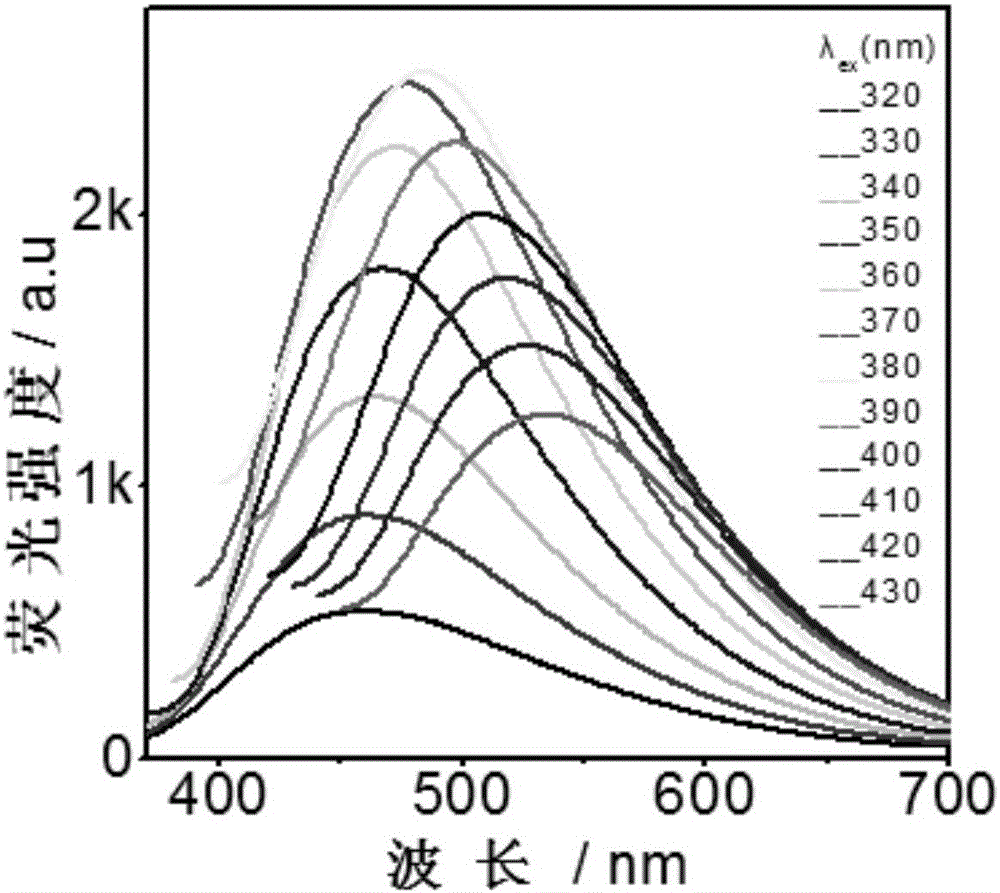

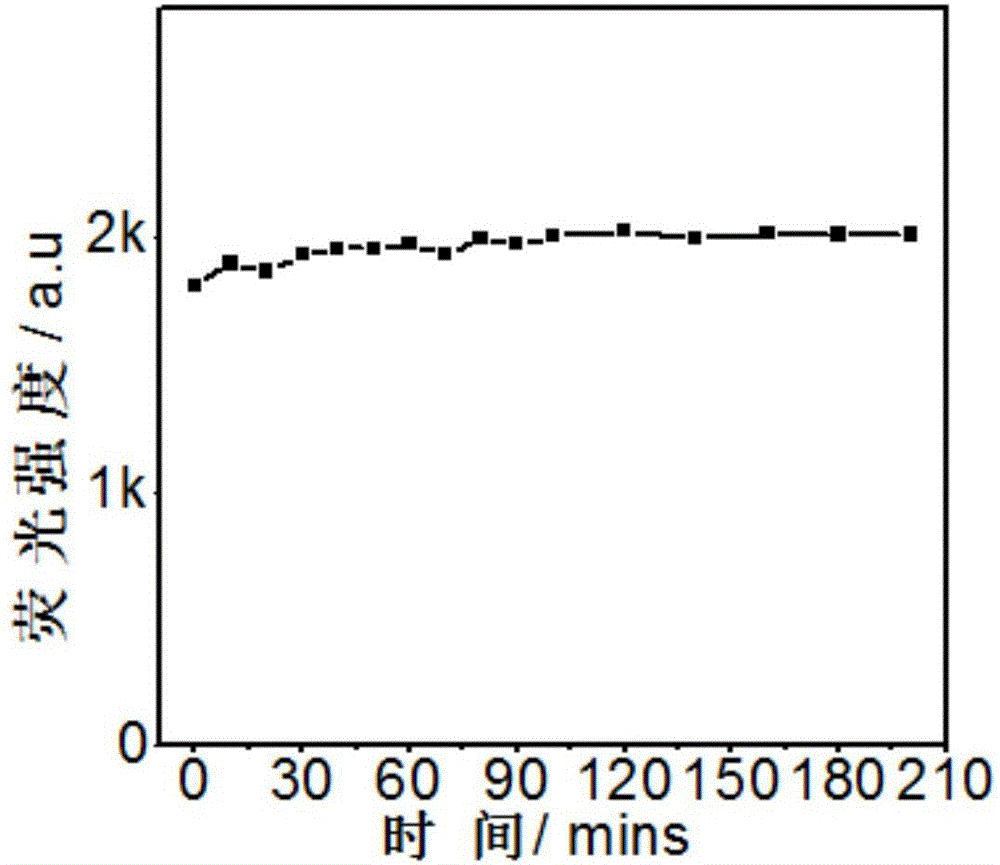

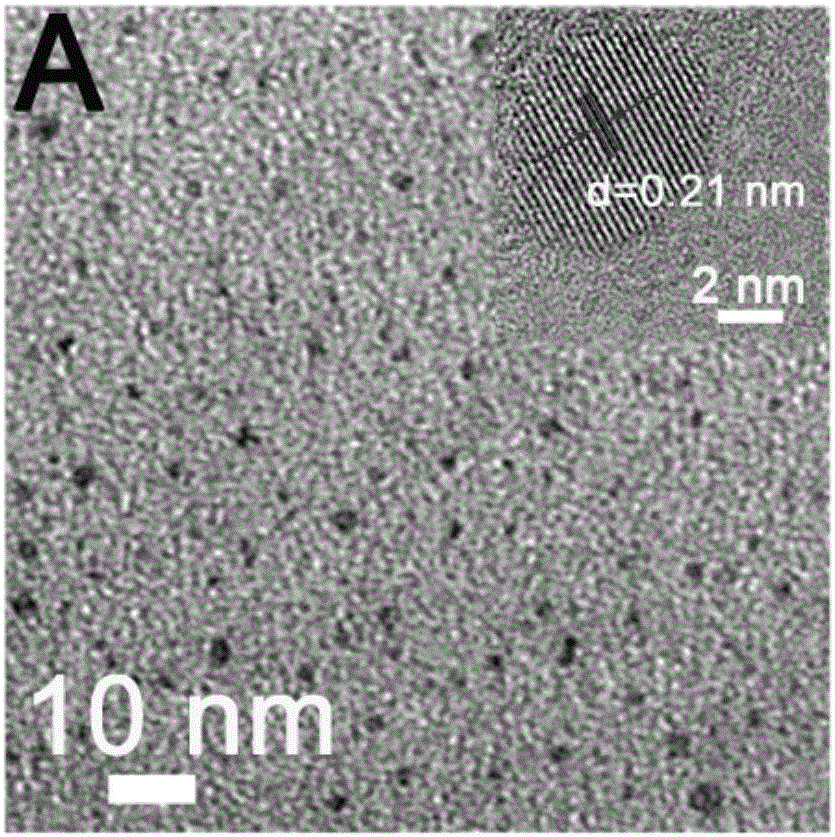

Hydrogen sulfide detection sensor, preparation method thereof, quantitative detection method of hydrogen sulfide, and qualitative detection method of hydrogen sulfide in cells

ActiveCN105928914AHigh quantum yieldGood environmental protectionFluorescence/phosphorescenceEthylenediamineFiltration

The invention discloses a hydrogen sulfide detection sensor, a preparation method thereof, a quantitative detection method of hydrogen sulfide, and a qualitative detection method of hydrogen sulfide in cells. The preparation method comprises the following steps: (1) preparing a water solution of copper complex by mixing disodium EDTA, soluble copper salts, and water; (2) subjecting the water solution of copper complex to hydrothermal reactions, filtration, centrifugation, and dialysis to obtain a water solution of copper doped carbon quantum dots in the dialysis bag; (3) mixing the water solution of copper doped carbon quantum dots with a buffer solution to obtain the hydrogen sulfide detection sensor. The hydrogen sulfide detection sensor can carry out quantitative determination on a hydrogen sulfide solution and qualitative detection on hydrogen sulfide in cells.

Owner:ANHUI NORMAL UNIV

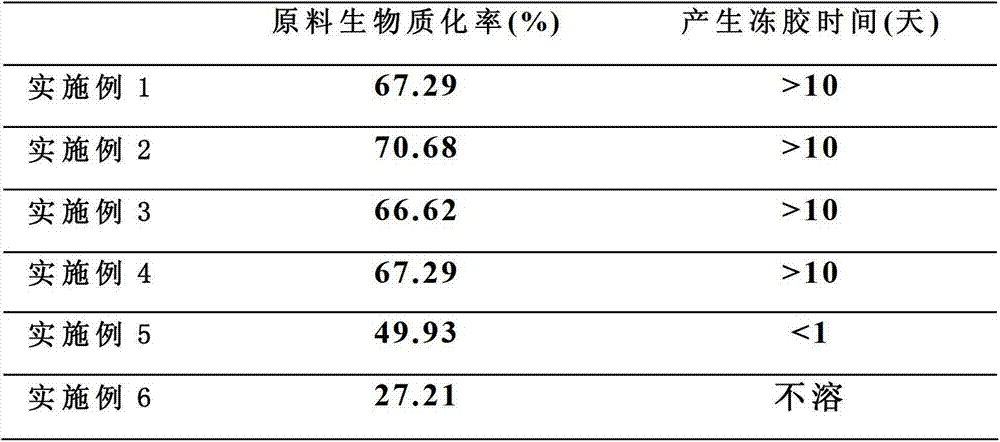

Alcohol-soluble copolyamide and preparation method thereof

The invention discloses alcohol-soluble copolyamide and a preparation method thereof. The alcohol-soluble copolyamide is characterized by being prepared by charging dicarboxylic acid, diamine, lactam and furan-2,5-dicarboxyic acid wchi are used as raw materials and carrying out fusion polycondensation to obtain the alcohol-soluble copolyamide, wherein the raw materials react in equivalent ratio of carboxyl to amino of 1:1. The novel alcohol-soluble copolyamide obtained by adopting the preparation method contains more than 60wt% of biomass-based raw material, has excellent alcohol solubility and can be applied to the fields of paints and binding agents.

Owner:苏州瀚海化学有限公司

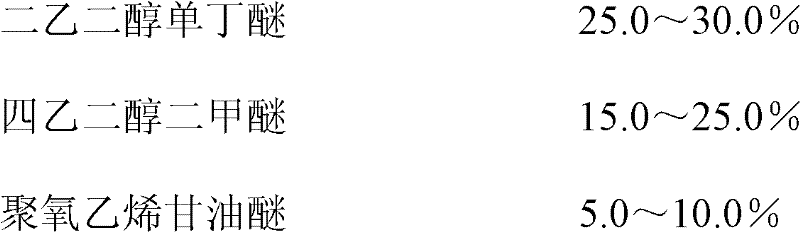

Lead-free solder paste for needle cylinder and preparation method

ActiveCN102528328ANot easy to oxidize and change colorReduce metal surface tensionWelding/cutting media/materialsSoldering mediaTetraethylene glycol dimethyl etherWax

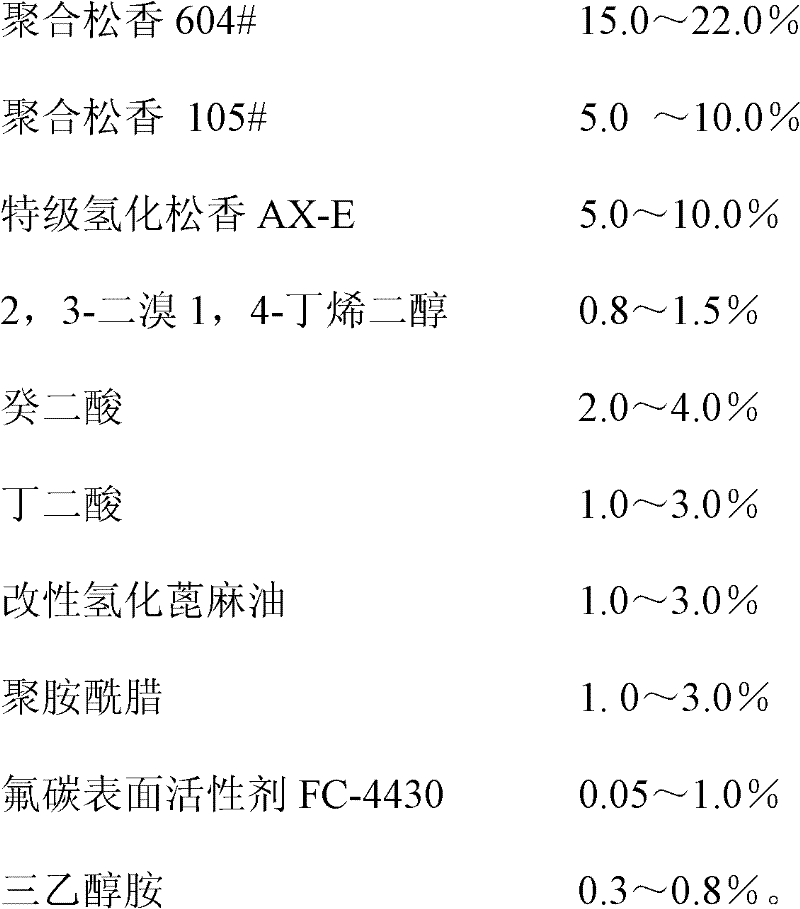

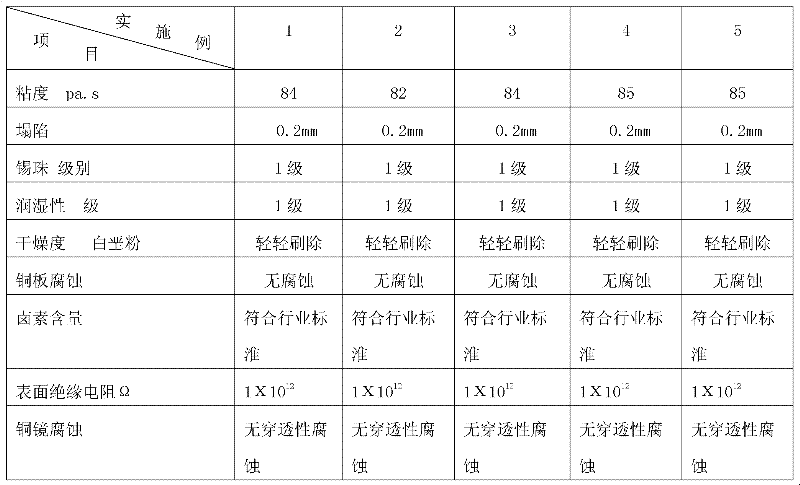

The invention relates to lead-free solder paste for a needle cylinder and a preparation method. The lead-free solder paste is characterized by comprising lead-free electronic grade tin alloy powder and flux, diethylene glycol monobutyl ether, tetraethylene glycol dimethyl ether and polyoxyethylene glycerin ether are sequentially added into a temperature control emulsifying machine and are heated and mixed, polymerized rosin 604#, polymerized rosin 105# and hydrogenated rosin are added into the temperature control emulsifying machine and are mixed to obtain primary mixed liquor, the primary mixed liquor is cooled, 2,3-dibromo 1,4-butylene glycol, sebacic acid and butanedioic acid are added into the primary mixed liquor and then are mixed to obtain secondary mixed liquor, the secondary mixed liquor is cooled, modified hydrogenated castor oil and polyamide wax are added into the secondary mixed liquor and then are mixed to obtain tertiary mixed liquor, the tertiary mixed liquor is cooled, fluorocarbon surfactant and triethanolamine are added into the tertiary mixed liquor and then are mixed and vacuumized until the temperature returns to room temperature, the tin alloy powder Sn42Bi58 is added into the prepared flux after standing for 24 hours at the temperature of 22-25 DEG C, and the tin alloy powder and the flux are mixed by a double-planet solder paste mixer to obtain the lead-free solder paste for the needle cylinder. The lead-free solder paste has the advantages of superior environmental friendliness, excellent dry resistance, fine thixotropy and fine uniformity.

Owner:惠州市斯泰尔科技有限公司

Biodiesel drilling fluid and preparation method thereof

The invention belongs to the field of oilfield chemistry, and particularly relates to a safe and easily-degradable drilling fluid based on biodiesel and a preparation method thereof. The biodesel drilling fluid comprises biodiesel, and 3-10 grams of organic soil, 1-15 grams of organic lignite and 3-10 grams of asphalt added into every 100 mL of biodiesel. According to the invention, biodiesel instead of crude oil and diesel is used for researching a biodiesel drilling fluid system, so that the requirements of excellent lubricating performance, strong rejection capability, high well wall stability and high temperature resistance on the conventional oil-based drilling fluid can be met; the drilling fluid has low sulfur content and low emission of sulfur dioxide and sulfides; and moreover, the drilling fluid does not contain aromatic alkane which causes pollution on the environment, so that damage to the environment is very low, biodegradation occurs very easily, and excellent environmental protection characteristic is achieved.

Owner:山东华阳油业有限公司 +1

Manioca biological fuel mixture

InactiveCN1594512AEmission reductionReduce in quantityBiofuelsLiquid carbonaceous fuelsAlcoholJatropha

Owner:四川长江科技有限公司 +1

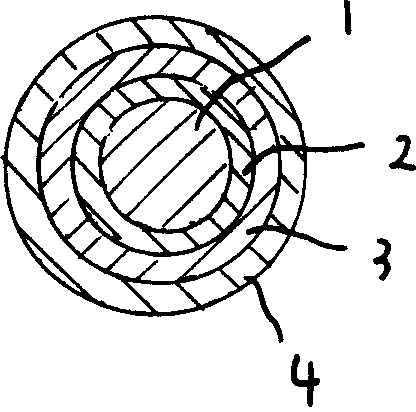

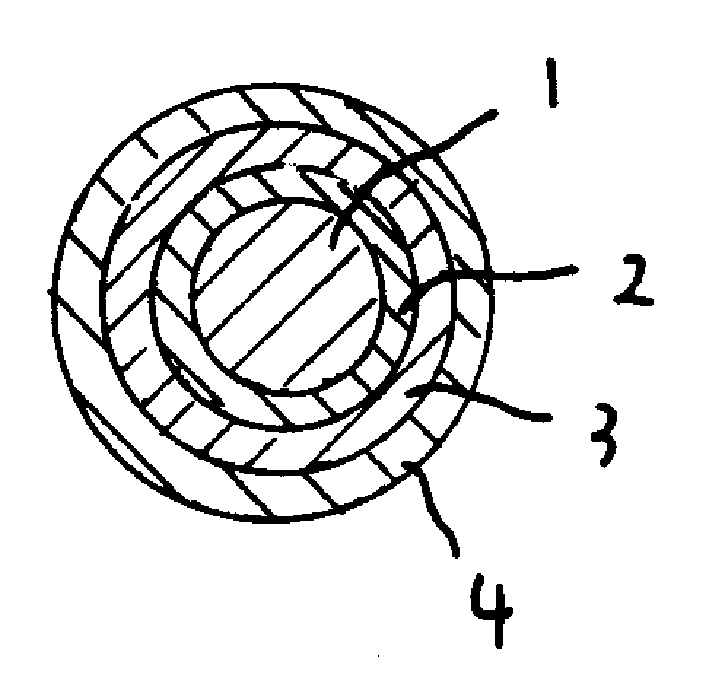

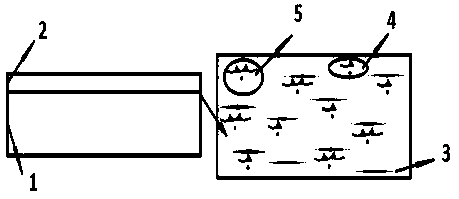

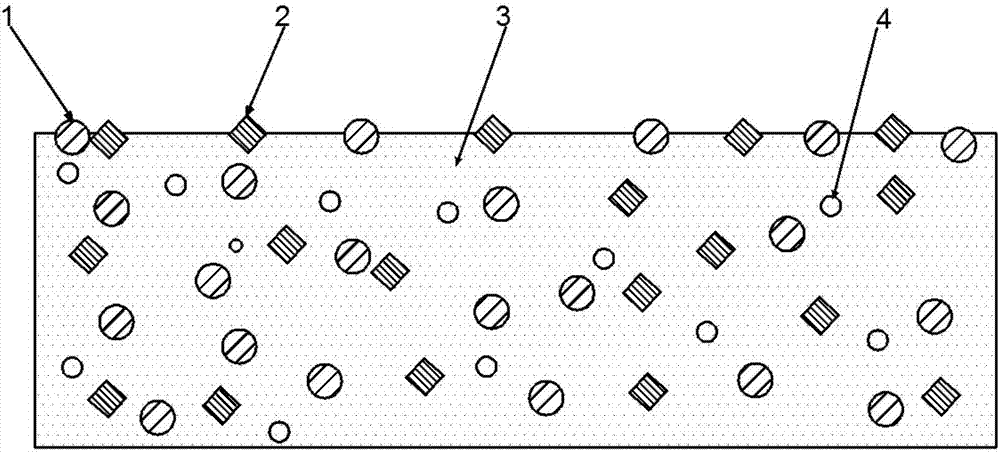

Silicon rubber heat resistant wire for heating coil

InactiveCN1490824AHigh strengthGood environmental protectionTransformers/inductances coils/windings/connectionsInsulated cablesLeading lineWear resistance

The present invention relates to a heat-resistant wire coated with silicone rubber which is used for the heating coil, the wire being mainly suitable to the coil winding and the leading line of microwave oven. It includes from the inner to outer portion a core 1 made of nickel plated copper wires, an insulating layer 2 made of silicone rubber, a weaving layer 3 made of Dacron and an outer heat-resistant coating 4. The weaving layer of the invention has high strength, good wear-resistance, long operating life and good firmness of color attachment.

Owner:马仕兴

Solder paste for signal processing substrate and preparation method thereof

ActiveCN105397343AModerate viscosityExtended shelf lifeWelding/cutting media/materialsSoldering mediaIndiumPolyethylene glycol

The invention discloses a solder paste for a signal processing substrate and a preparation method thereof. The method comprises the following steps: 1) mixing Sn-Zn alloy, copper, indium, chloroauric acid hydrated, polyvinylpyrrolidone, a reducing agent and water to enable contact reaction so as to obtain an activating metal composition; 2) heating and dissolve rosin, rosin amine, organic acid, imidazole and tris(2-carboxyethyl) isocyanurate to obtain mixed liquor I; 3) mixing the mixed liquor I, a thixotropic agent and a preservative, and then cooling to obtain mixed liquor II; 4) mixing the mixed liquor II and polyethylene glycol to obtain a soldering flux; 5) refrigerating the soldering flux, and then performing dispersion mixing for the soldering flux and the activating metal composition under a vacuum condition and in the presence of X-rays, so as to obtain the solder paste for the signal processing substrate. The solder paste prepared by the preparation method is outstanding in chemical stability, low in welding temperature, and outstanding in expansion rate.

Owner:芜湖雅葆轩电子科技股份有限公司

Preparation method of iron phosphate dihydrate

InactiveCN105895914AGood environmental protectionLow costCell electrodesSecondary cellsIonIron phosphate

The invention provides a preparation method of iron phosphate dihydrate. The method comprises the following steps: adding 115-126 parts by weight of phosphoric acid to 400 parts by weight of deionized water to prepare a phosphoric acid solution and keeping the temperature of the solution at 50-65 DEG C; adding 56 parts by weight of reduced iron powder in a stirring state, reacting for 1-3 hours, adding the obtained product to a ball mill for ball-milling to obtain a ball-milled material; putting the taken ball-milled material into a container, adding 56-68 parts of hydrogen peroxide, stirring the hydrogen peroxide evenly and then putting the hydrogen peroxide into a reaction kettle for treatment at 60-140 DEG C for 6-12 hours to obtain a reaction product; and stirring and dispersing the reaction product evenly and then carrying out spray drying at 150-180 DEG C to obtain the iron phosphate dihydrate. The iron phosphate dihydrate synthesized by the method has the characteristics of being high in purity, simple in preparation technology, low in cost and free of pollution in treatment, and can be used as a raw material of producing lithium iron phosphate.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

Pesticide containing biological diesel oil solvent and preparation process thereof

The invention relates to an agricultural chemical with biological diesel solvent, and relative preparation, wherein said chemical comprises original drug, solvent, emulsion, while said solvent is biological diesel or the mixture of biological diesel and normal chemical solvent. And its preparation comprises that; mixing the agricultural chemical, some biological diesel, or mixing the agricultural chemical, some biological diesel and some normal agricultural chemical solvent; adds some emulsion. The invention can reduce pollution, reduce cost and improve safety.

Owner:湖南万家丰科技有限公司

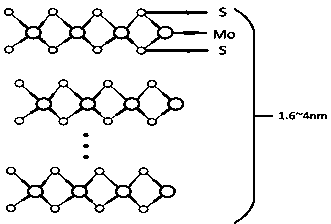

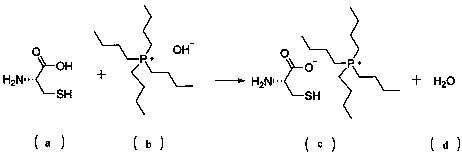

High-loading two-dimensional molybdenum disulfide-binary ionic liquid composite lubricating membrane and preparation method thereof

The invention discloses a high-loading two-dimensional molybdenum disulfide-binary ionic liquid composite lubricating membrane and a preparation method thereof. Two-dimensional molybdenum disulfide isuniformly dispersed in cysteine / cystine tetrabutyl phosphonium salt binary ionic liquid to form uniform and stable suspension, and the surface of a metal substrate is uniformly coated with the suspension. According to the preparation method, the two-dimensional molybdenum disulfide and the binary ionic liquid are combined, the two-dimensional molybdenum disulfide has a layered structure, the ionic liquid has a low shearing rate characteristic, the surface loading capacity of the composite lubricating membrane containing sulphur element formed by the synergistic reaction of the two-dimensionalmolybdenum disulfide and the ionic liquid can be improved, and the friction reducing and resisting performance and self lubricating performance of the surface are enhanced. Compared with a traditional ion lubricant and a molybdenum disulfide solid lubricant, the friction wearing coefficient and loading capacity of the metal substrate and the surface of the metal substrate can be improved.

Owner:XIANGTAN UNIV

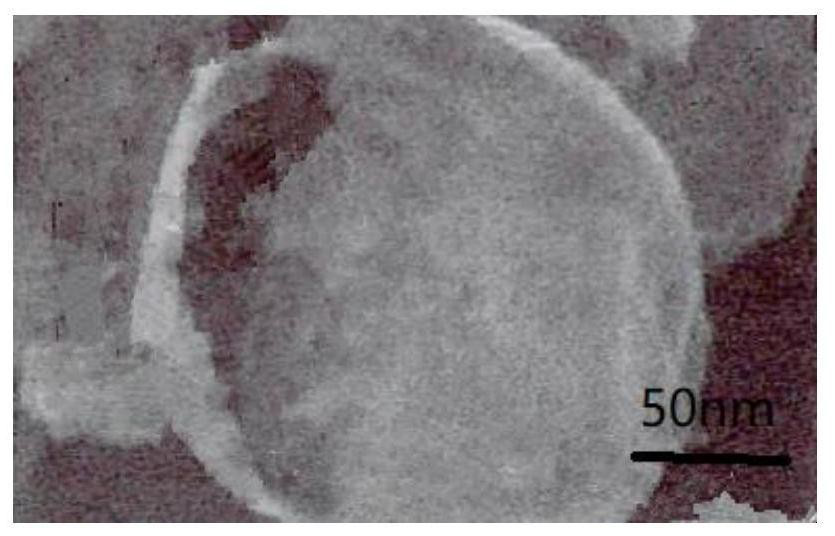

Process for preparing superparamagnetic starch

InactiveCN1970575AWide variety of sourcesGood environmental protectionSurgeryOrganic/organic-metallic materials magnetismFerrous saltsSuperparamagnetism

The invention discloses a making method of superparamagnetism starch, which comprises the following steps: allocating starch milk through starch and deionized water; adjusting pH value; adding soluble ferrous salt solution to adsorb once; filtering in the vacuum or separating centrifugally; removing water to obtain sediment; adding hydrogen peroxide solution to oxidize once; dehydrating; washing; obtaining starch product with water; repeating these steps to obtain magnified starch product with water; drying; obtaining the product.

Owner:SOUTH CHINA UNIV OF TECH

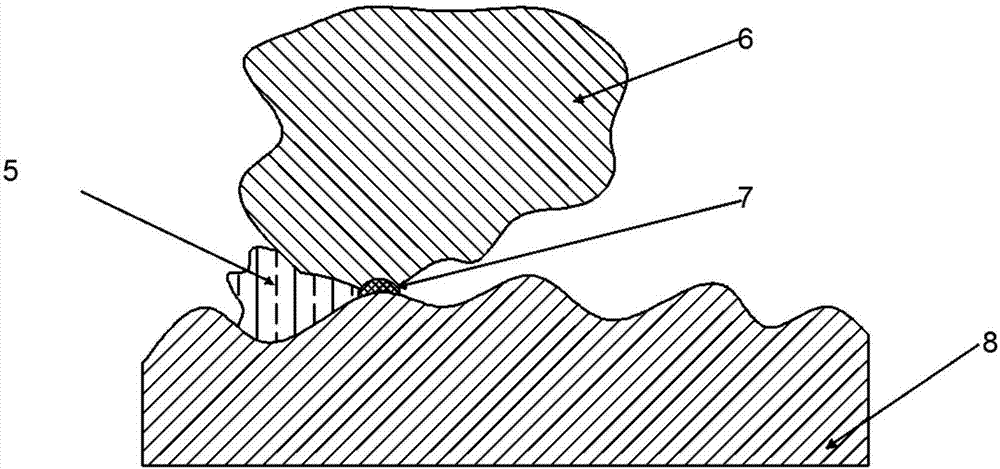

Sapphire wafer polishing method based on fixed abrasive tool containing neodymium compound and soft abrasive materials

InactiveCN107953148AThe reaction is easy to carry outLow processing roughnessGrinding devicesGrinding/polishing safety devicesHot pressingNeodymium

The invention discloses a sapphire wafer polishing method based on fixed abrasive tool containing neodymium compounds and soft abrasive materials. The method comprises the steps that 1), the fixed abrasive tool containing the neodymium compounds and the soft abrasive materials is prepared by comprising, 40%-60% of nano silicon dioxide, 20%-40% of a binding agent, 10%-15% of a curing agent, 5%-10%of a neodymium compound, and the balance deionized water; 2), the prepared raw materials undergo hot-press forming in a mould, heat curing is completed after demolding is carried out, and the upper end surface and the lower end surface of the formed abrasive tool are trimmed; 3), the abrasive tool is arranged on a polishing machine upper disc, a sapphire wafer to be machined is placed on a polishing machine lower disc capable of rotating and is fixed by a clamp, then a polishing machine is started, a water-based cooling liquid is injected between the upper disc and the lower disc, the neodymium compounds and the silicon dioxide abrasive particles on the abrasive tool scratch the sapphire surface and the solid-phase reaction is carried out, so that the sapphire wafer is polished. Accordingto the method, the removal rate of the sapphire wafer can be improved, the roughness can be reduced, the machining efficiency can be improved, and the production cost can be reduced.

Owner:ZHEJIANG UNIV OF TECH

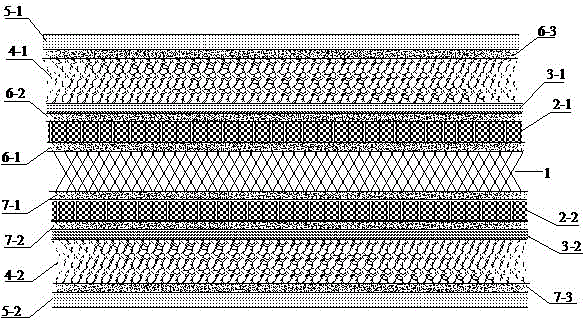

High anti-impact waterproof and dampproof composite board

ActiveCN104553094AImprove impact resistanceImprove wear resistanceSynthetic resin layered productsPaper/cardboard layered productsCardboardPolyester

The invention discloses a high anti-impact waterproof and dampproof composite board which is composited by multiple layers of materials. The high anti-impact waterproof and dampproof composite board comprises an upper structure, a lower structure and a honeycomb paperboard layer which is arranged between the upper structure and the lower structure, wherein the upper structure sequentially comprises an upper wear-resistant plastic film layer, an upper paperboard foaming layer, an upper waterproof film layer and an upper high anti-impact fiber layer from top to bottom; the lower structure sequentially comprises a lower wear-resistant plastic film layer, a lower paperboard foaming layer, a lower waterproof film layer and a lower high anti-impact fiber layer from bottom to top; the upper and lower paperboard foaming layers are panels by foaming paper fibers, polylactic acid, aliphatic polyester and a thermoplastic elastomer as main materials which are mixed. The composite board has excellent anti-impact and waterproof and dampproof properties, is simple in manufacturing process, easy to obtain raw materials and low in cost, can be widely applied in the field of high-grade packages, effectively reduces the thickness of the packaged products and improves the performance.

Owner:正业包装(中山)有限公司

Method for preparing biodiesel by catalytic cracking

The invention relates to a method for preparing biodiesel through catalytic cracking from vegetable oil under the action of a catalyst, which comprises the following operation steps: heating the vegetable oil and then performing flash vaporization on the vegetable oil when the temperature is between 130 and 170 DEG C to remove water vapor and light components; heating the vegetable oil after the flash vaporization to react with the catalyst at a temperature of between 360 and 450 DEG C, wherein the space velocity of the catalyst is between 0.5 and 1 ton / hour.ton catalyst; performing secondary catalytic reaction on the reaction products obtained in the step with the same catalyst with the space velocity of between 0.5 and 1 ton / hour.ton catalyst; and performing distillation separation on the prepared catalytic product with the feed temperature of between 350 and 380 DEG C to prepare biological gasoline, the biodiesel and residual oil respectively. The biodiesel prepared by the method has the advantages of excellent environmental protection property, better low temperature engine starting performance, and better lubrification.

Owner:王英国 +1

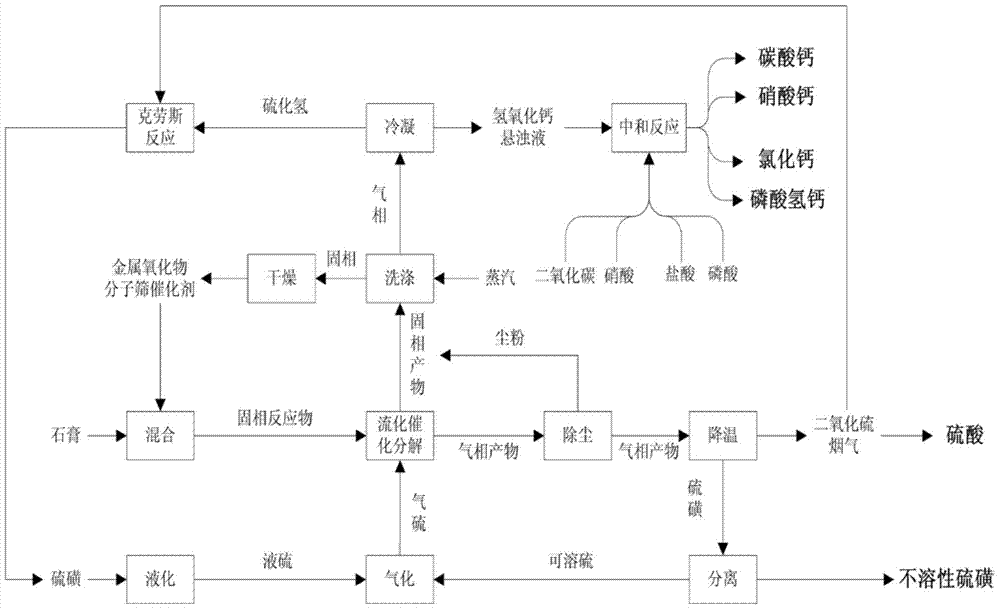

Method for fluidized catalytic decomposition of gypsum

InactiveCN104724678ALower reaction barrierReduce reaction energy consumptionCalcium/strontium/barium carbonatesCalcium/strontium/barium chloridesGas phaseCatalytic decomposition

The invention discloses a method for fluidized catalytic decomposition of gypsum. The method comprises the following steps: mixing gypsum with a metal oxide molecular sieve catalyst evenly, and adding to a fluidized reactor; feeding a sulphur gas from the bottom of the fluidized reactor, enabling the sulphur gas with a solid material, and reacting for decomposing the gypsum; washing a solid phase obtained by reaction with steam, wherein the washed solid phase is the metal oxide molecular sieve catalyst; drying and using in cycle; condensing the washed gas phase to obtain a Ca(OH)2 turbid liquid for preparation of a calcium salt; preparing sulphur employing individual uncondensed gas phase or SO2 in a gas-phase product obtained by decomposition reaction of the uncondensed gas phase and the gypsum according to claus reaction, and using the sulphur as a reducing agent in cycle; carrying out dust removal on the gas phase obtained by decomposition reaction of the gypsum, cooling and separating to obtain insoluble sulphur; and using the soluble sulphur as the reducing agent in cycle, and preparing the sulphur from the residual gas phase and H2S for cyclic use as the reducing agent or production of sulfuric acid. The gypsum decomposition is low in energy consumption and high in decomposition rate; the additional value of the product is high; and the process is environment-friendly and advanced.

Owner:SICHUAN UNIV

Resin composition and production method of plastic product of resin composition

The invention relates to a resin composition and a production method of a plastic product of the resin composition. The resin composition comprises the following components by weight percent: 50-99.999% of basic resin and 0.001-50% of carbonization accelerator, wherein the basic resin is selected from one or a mixture formed by more of acrylonitrile butadiene styrene (ABS), high impact polystyrene (HIPS), polycarbonate (PC), propene polymer (PP) or poly ethylene (PE); and the carbonization accelerator is selected from one or mixture formed by more of phosphorus or a phosphorus-containing compound, bromine or a bromine-containing compound, chlorine or a chlorine-containing compound, antimony or antimony-containing compound, boron or boron-containing compound. The resin composition is suitable for laser carving to form words or patterns, and the formed words or patterns have less possibility of falling off and are environment-friendly. The preparation method has the advantages of high work efficiency and low cost.

Owner:STARLIGHT PLASTIC MATERIAL SHENZHEN

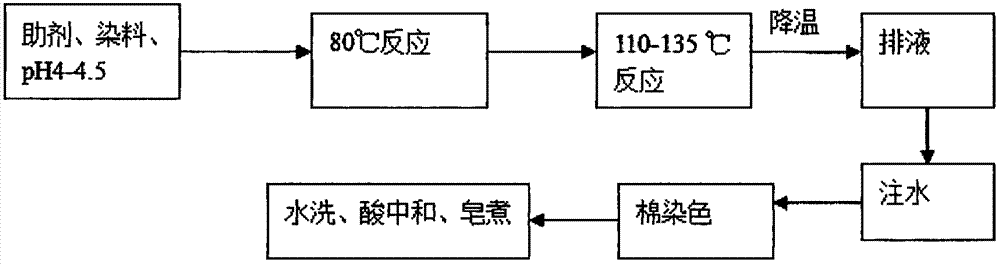

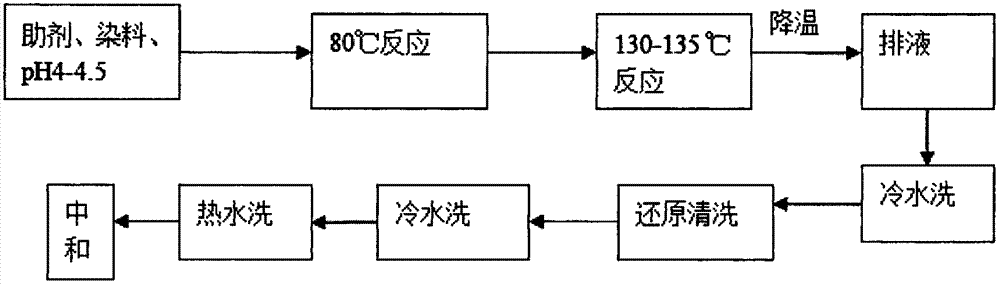

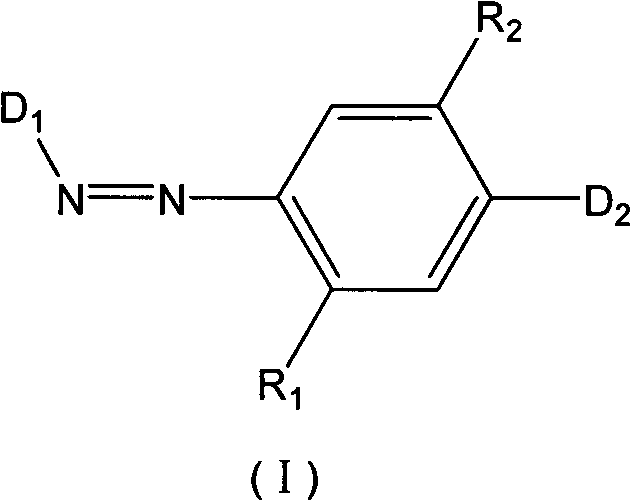

Disperse dye composition and applications thereof

ActiveCN102888129ASave energyIncrease productivityOrganic dyesDyeing processBenzoic acidDisperse dye

The invention relates to a disperse dye composition and an application method of the disperse dye composition. During dyeing polyester-cotton blended fabrics, the disperse dye composition can be adopted to remove traditional necessary technical step of reducing and cleaning after dyeing through the disperse dye, therefore, the energy is saved, the production efficiency is improved, and high color fastness can be ensured. The benzoic acid is added to the disperse dye composition to be served as a carrier, therefore, the disperse dye composition provided by the invention can be used for dyeing the polyester fiber at 110 to 120 DEG C without influencing the color fastness and degree of dyeing; meanwhile, the benzoic acid is served as a solid food additive; compared with a traditional carrier, the disperse dye composition can not harm a human body, and has high environmental-protection characteristics; and when the disperse dye composition is applied to pure terylene fabric, the residual dyeing temperature can be utilized for reducing and cleaning by adding sodium formaldehyde sulfoxylate composition without draining liquid, therefore, the resource consumption is reduced, and the production efficiency is improved.

Owner:SHANGHAI YILIAN CHEM TECH

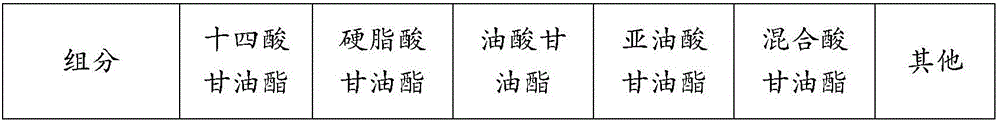

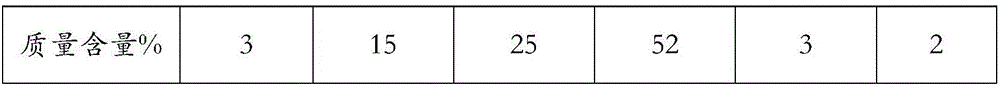

Flame-retardant degradable liquid insulating medium and application thereof

ActiveCN106590813AImprove heat resistanceImprove fire safetyLiquid organic insulatorsBase-materialsVegetable oilTransformer

The invention discloses a flame-retardant biodegradable liquid insulating medium. The flame-retardant biodegradable liquid insulating medium contains 90 mass% or more of glyceride, and the glyceride contains 10 mass% or less of C8-C14 fatty glyceride and 90 mass% or more of C1-C22 fatty glyceride. Raw materials of the insulating medium are mainly derived from vegetable oil, the biodegradation rate is up to 98% or above after 40 days, the flash point is higher than 300 DEG C, the breakdown voltage is higher than 60 kV, the pour point is lower than -20 DEG C, and the kinematic viscosity is less than 25 mm<2> / s. The provided liquid insulating medium has the advantages of being high in flash point, excellent in insulating property and environmentally friendly, can be widely applied in insulation of power equipment, such as the insulation and cooling of transformers, cables, switches and capacitors.

Owner:武汉泽电新材料有限公司

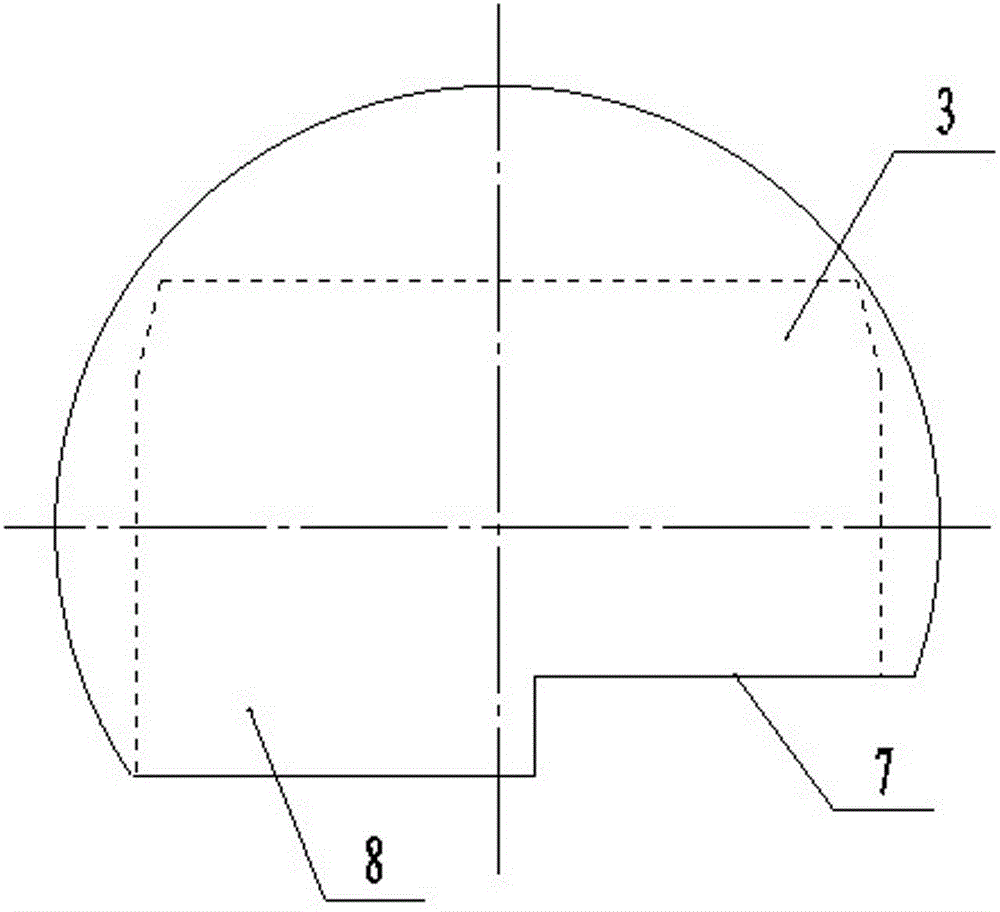

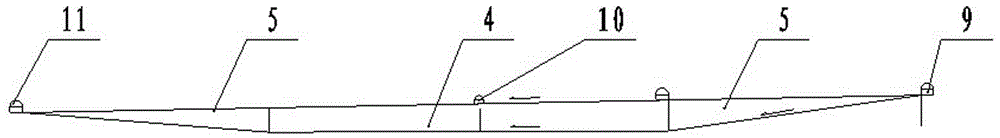

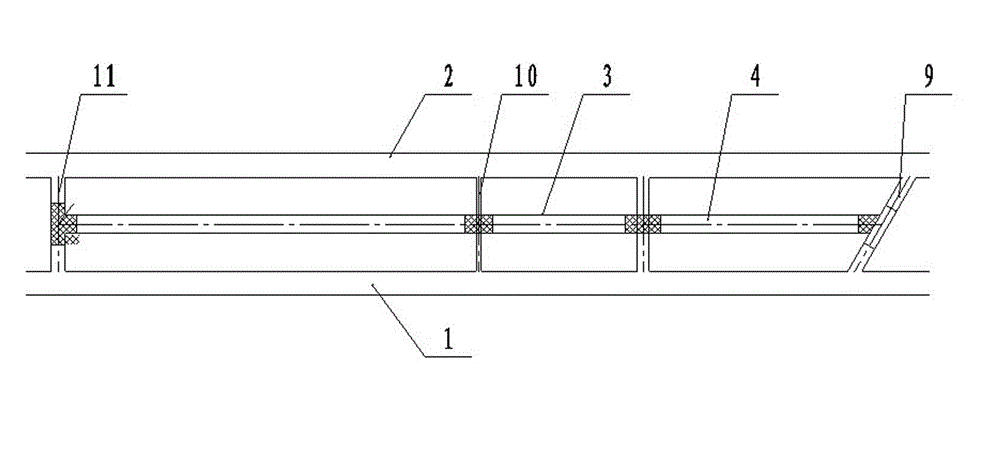

Tunnel construction structure for draining and desilting

InactiveCN102720511AEmbody superiorityGood environmental effectDrainageTunnelsArchitectural engineeringKarst

The invention belongs to the field of tunnel construction, and particularly relates to a tunnel construction structure for draining and desilting. The invention aims to solve the problems of long construction period, high investment and adverse impact on environmental friendliness of the conventional draining holes. The structure comprises draining and desilting chambers which are arranged between two main tunnel holes at intervals, lower than the designed elevation of a tunnel and longitudinally arranged along a central line of the tunnel, wherein the outlet of each draining and desilting chamber is provided with a draining and desilting basin communicated with a tunnel drainage system; both ends of the draining and desilting basin are provided with counter-slope type sand draining passages; and the inner wall of the draining and desilting chamber is annularly provided with multiple radial umbrella-like draining and decompression drill holes extending outward. The tunnel construction structure solves the problem that a tunnel structure and the drainage system are destroyed by karst mud and water gushing, and has the advantages of short construction period, small investment, rapid effectiveness, environmental friendliness and the like in the construction process, so that the structure can be widely popularized and used.

Owner:2ND ENG CO LTD OF CHINA RAILWAY 12TH BUREAU GRP +1

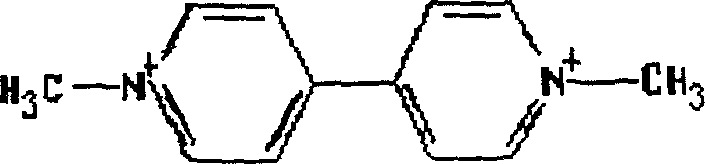

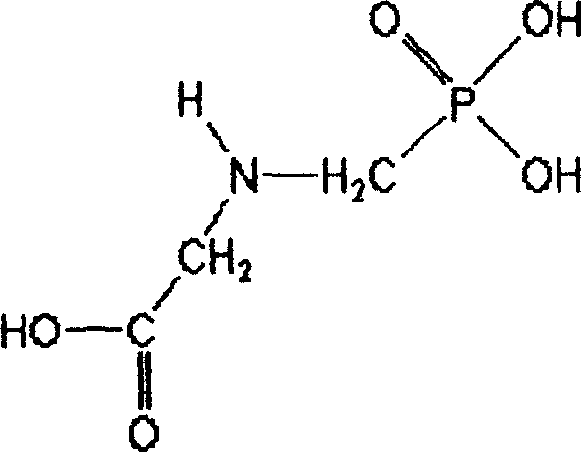

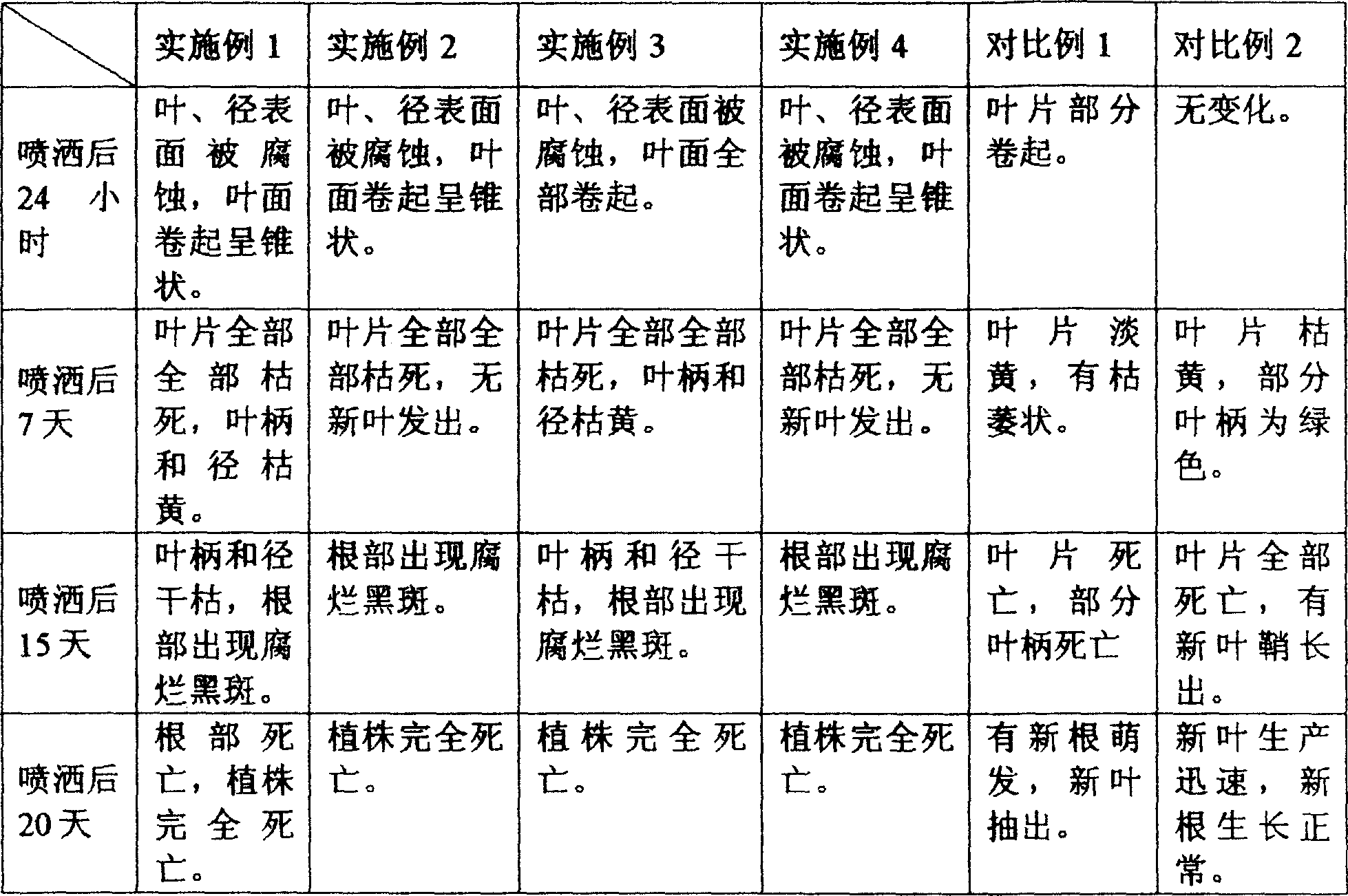

Environmental-protection quick thermo-osmosis dual-contact weedicide

InactiveCN1891047APrevent breeding spreadPlay a role in complex precipitationBiocideAnimal repellantsAluminium sulfateParaquat

The present invention relates to an environment-protecting type quick thermossmosis double-contact weedkiller. Said weedkiller is made up by using paraquat, glyphosate, hydrogen peroxide, aluminium sulfate, magnesium sulfate, sodium sulfate and osmotic agent JFC through a certain preparation process. Said invention also provides its preparation process.

Owner:叶允敏 +5

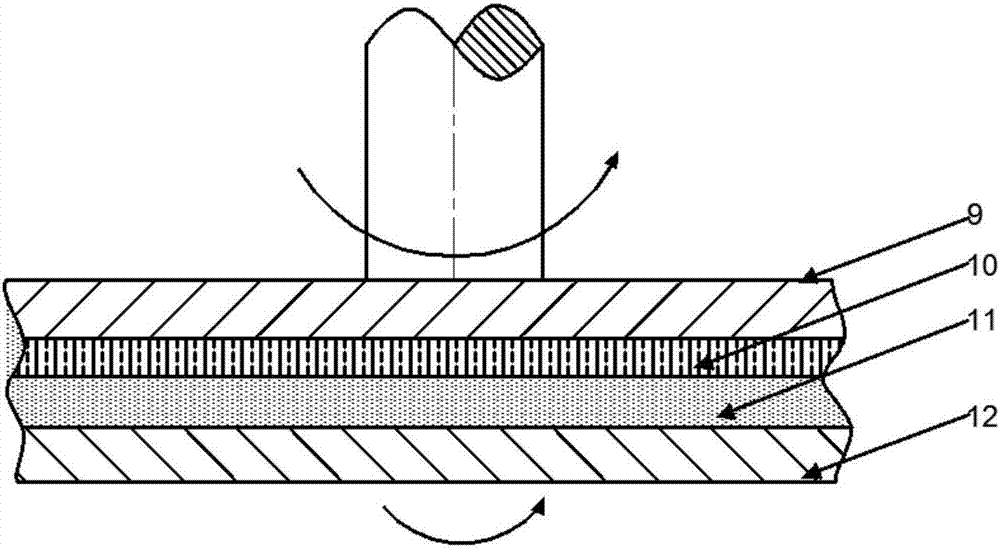

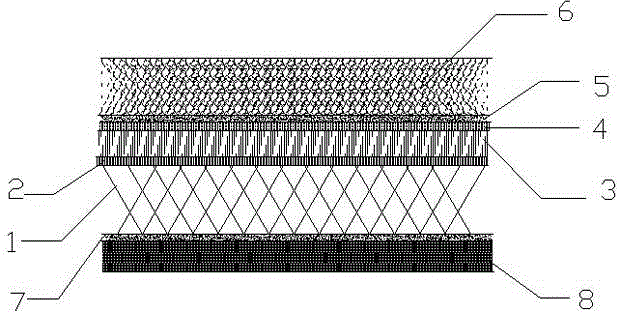

High buffer insulating composite paperboard

InactiveCN104553095AHigh impact resistanceImprove toughnessSynthetic resin layered productsCardboardElastomer composites

The invention discloses a high buffer insulating composite paperboard which comprises a honeycomb paperboard layer, wherein a barrier film I is attached to a honeycomb paperboard, a fiber fabric layer is arranged on the barrier film I, a barrier film II is arranged on the fiber fabric layer, the barrier film II is coated with an inorganic fiber coating I, and a polylactic acid-aliphatic polyester composite foaming board is arranged on the inorganic fibber coating I; an inorganic fiber coating II is arranged below the honeycomb paperboard, a polylactic acid-elastomer composite board is arranged below the inorganic fiber coating II, and the fiber fabric layer is filled with a nano composite suspension. The composite board disclosed by the invention has an excellent anti-impact buffering effect and a good insulating effect. Meanwhile, almost raw materials of the composite board are degradable materials, so that the composite paperboard has a good environment-friendly characteristic.

Owner:正业包装(中山)有限公司

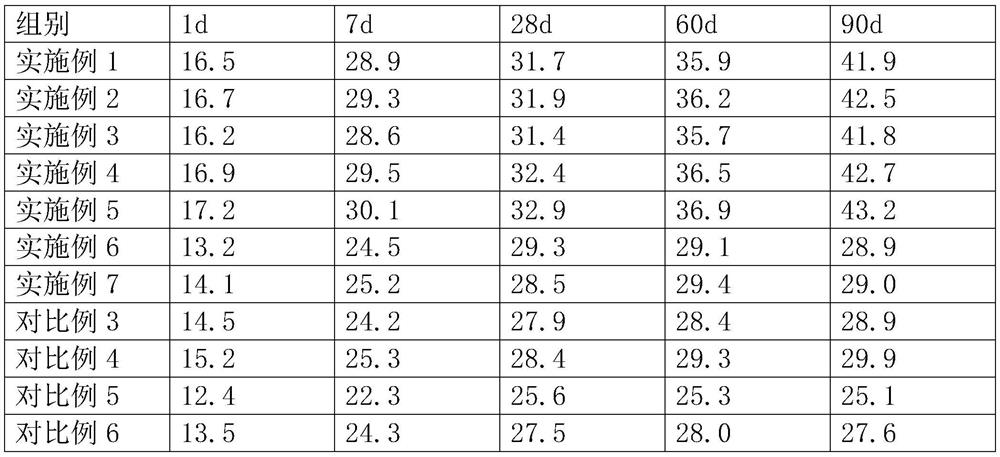

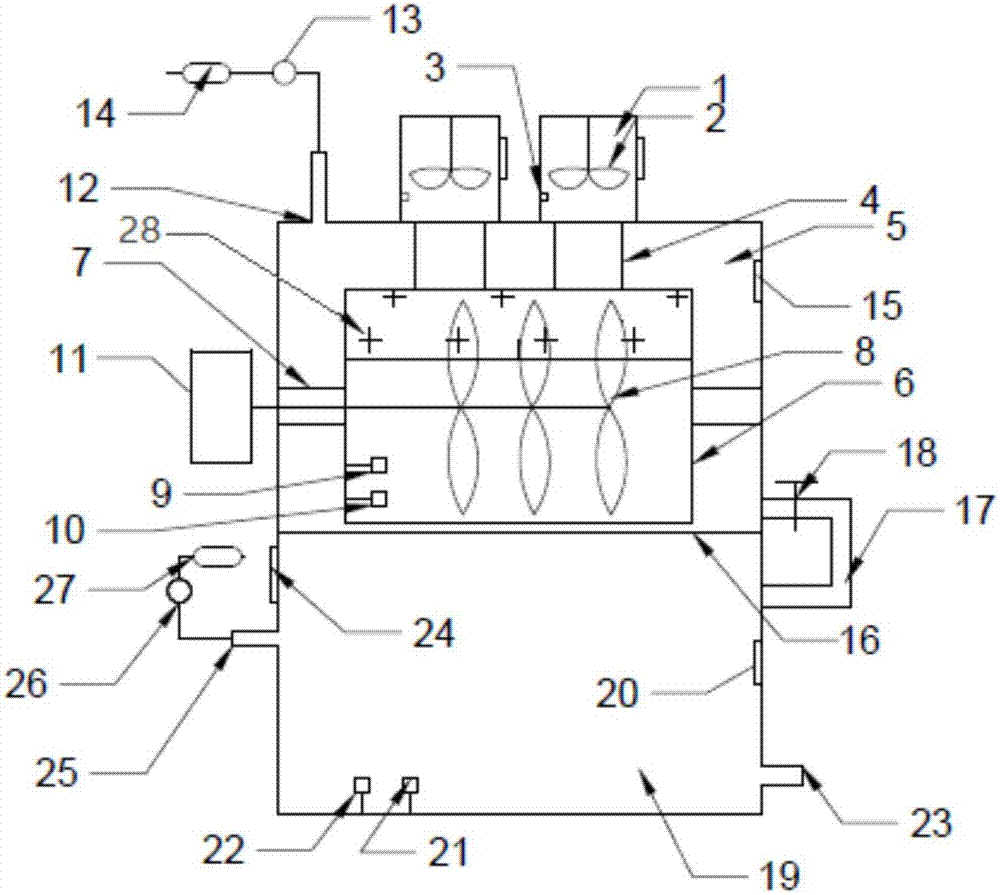

Modified aluminate cement and preparation method thereof

ActiveCN112209642AImprove corrosion resistanceImprove water resistanceSolid waste managementAluminateSilicic acid

Provided modified aluminate cement is prepared from the following raw materials: aluminate cement, titanium-silicon micro-nano capsules, magnesium oxide, a phosphate, fly ash, modified acrylic emulsion and an activating agent, wherein the titanium-silicon micro-nano capsule is prepared from orthosilicate and titanate under the conditions of a surfactant and alkalinity. The aluminate cement prepared by the invention is wide in raw material source and simple in preparation method, has good high-temperature resistance, wear resistance, sulfate corrosion resistance, adhesion, crack resistance, freezing resistance, seepage resistance, corrosion resistance and aging resistance, also has good effects of adsorbing and degrading formaldehyde and organic pollutants due to the TiO2 structure, plays agood role in environmental protection, ensures the safety as a structural part, and has a wide application prospect.

Owner:山东山铝环境新材料有限公司

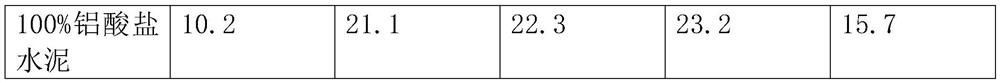

Reactor for producing acid phase from urban solid waste through two-phase anaerobic digestion

PendingCN106929410AReduce lossEfficient use ofBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlMethanogenesis

The invention belongs to the field of solid waste treatment devices and discloses a reactor for producing an acid phase from urban solid waste through two-phase anaerobic digestion. The reactor comprises a pretreatment device, a hydrolytic acidification region and a methanogenesis region which are distributed from top to bottom, wherein a crusher and a heating device are arranged in the pretreatment device, and a feeding channel is arranged in the pretreatment device and is connected with the hydrolytic acidification region; a rotatable semi-closed roller reactor and a heating device are arranged in the hydrolytic acidification region, and a multi-layer push type spiral stirrer is arranged in the roller reactor; the hydrolytic acidification region and the methanogenesis region are separated through a partition board and are communicated through a flow guide pipe; a heating device is arranged in the methanogenesis region. The reactor is of an integrated design, is integrated with functions of pretreatment, reaction fermentation, temperature control and air collection and is multifunctional equipment, the loss in a material transfer process can be reduced, and each space is effectively utilized.

Owner:SOUTH CHINA UNIV OF TECH

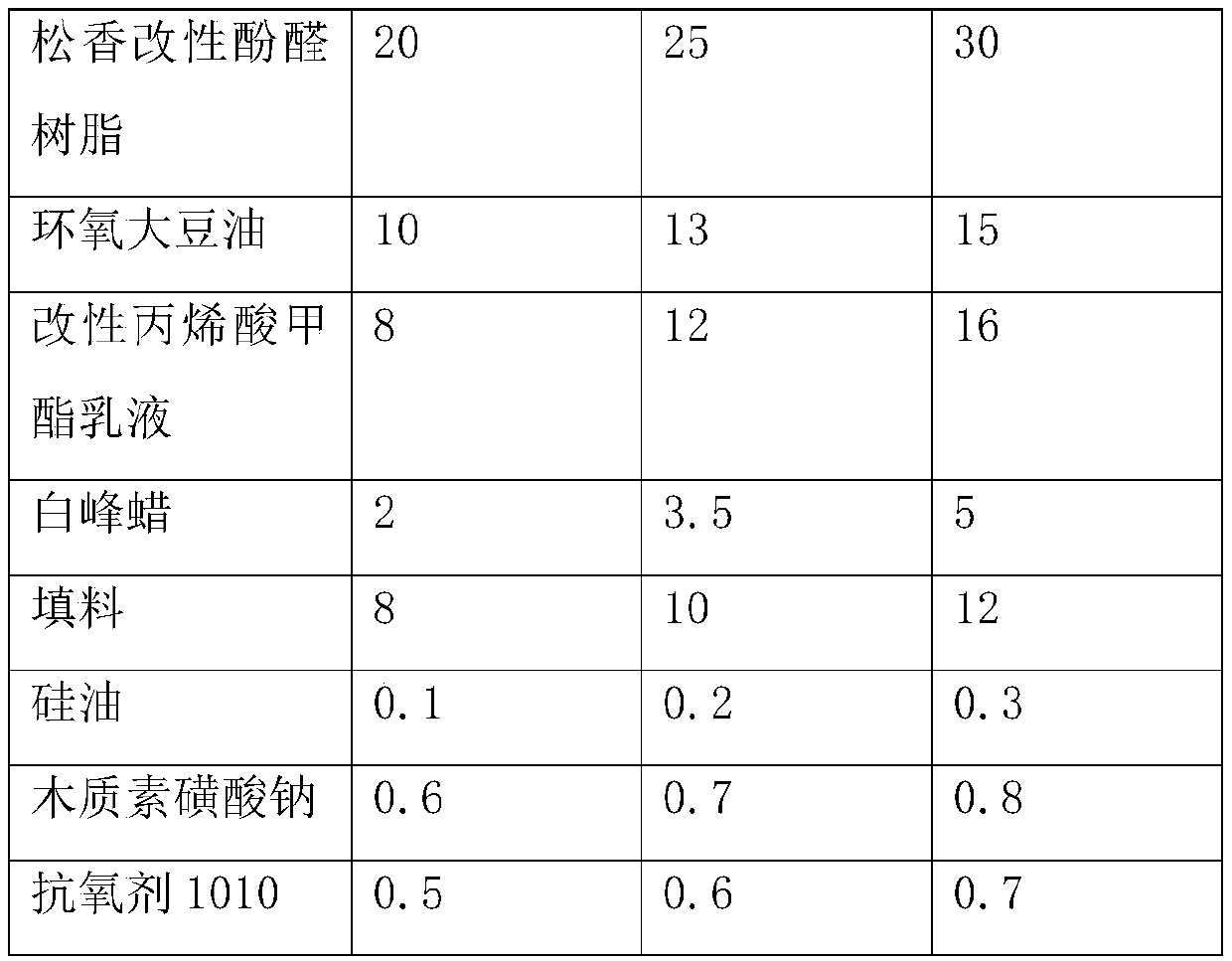

100% biodegradable garbage bag with traceable two-dimensional code identifier and production method

The invention discloses a 100% biodegradable garbage bag with a traceable two-dimensional code identifier and a production method. The 100% biodegradable garbage bag with the traceable two-dimensionalcode identifier comprises a bag body and the two-dimensional code identifier printed on the bag body, wherein the bag body comprises the following components in percentage by weight: 6-10% of polylactic acid, 60-91% of poly (butyleneadipate-co-terephthalate) and 3-30% of modified starch; and the two-dimensional code identifier is produced through soybean oil ink spraying and curing. The 100% biodegradable garbage bag with the two-dimensional code identifier has the advantages that pollution to the environment can be reduced, the 100% biodegradable garbage bag with the two-dimensional code identifier is safe and environmentally friendly, both the two-dimensional code identifier and the garbage bag body are 100% degradable, and a two-dimensional code is high in adhesion, not liable to fadeand high in traceability.

Owner:QINGDAO ZHOUSHI PLASTIC PACKAGE

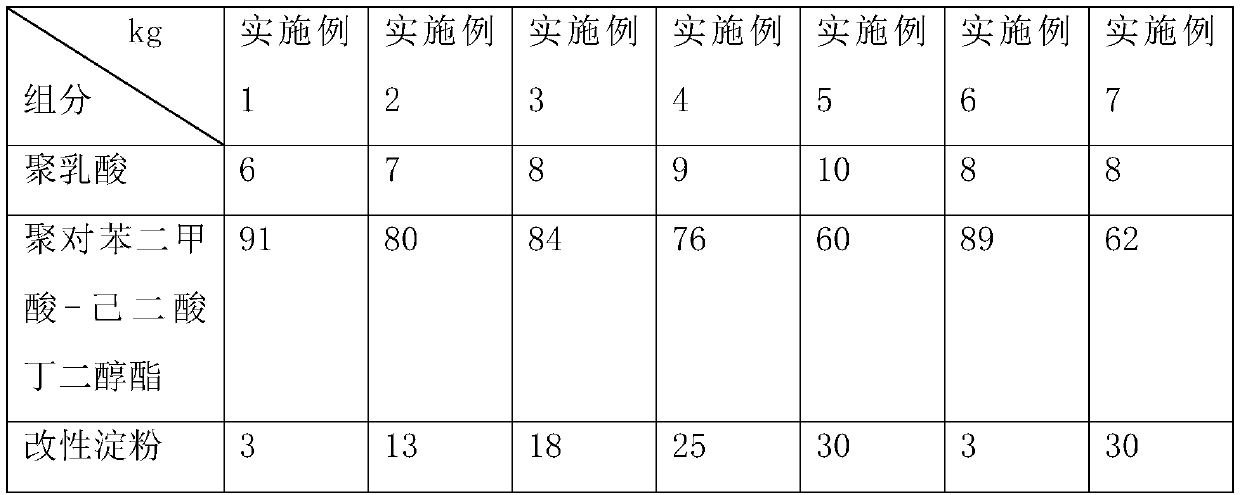

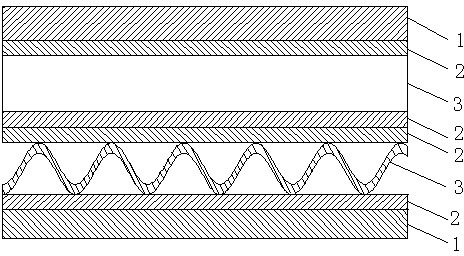

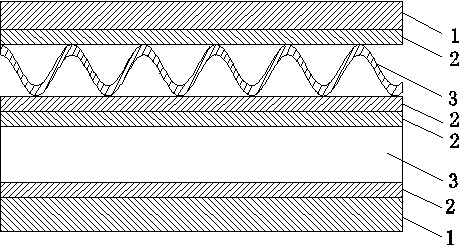

Environment-friendly corrugated paper decoration paperboard

The invention discloses an environment-friendly corrugated paper decoration paperboard, comprising surface layers, core layers and corrugated layers, wherein the corrugated layers are arranged between the surface layers, the core layers are arranged between the corrugated layers and the surface layers and between the corrugated layers, the corrugation directions of the corrugated layers are mutually perpendicular, and the surface layers, the core layers and the corrugated layers are bonded together through paste. Thus, the decoration paperboard provided by the invention can replace a plasterboard and be used as a separation layer for interior decoration; the paperboard has high hardness, is recyclable and shows good environmental protection performance; and the paperboard is also applicable to fields like repackaging and paper furniture and has a wide application scope.

Owner:苏州正隆纸业有限公司

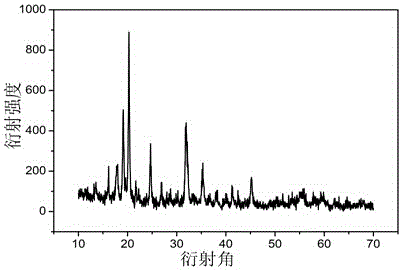

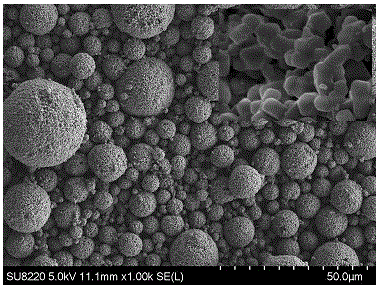

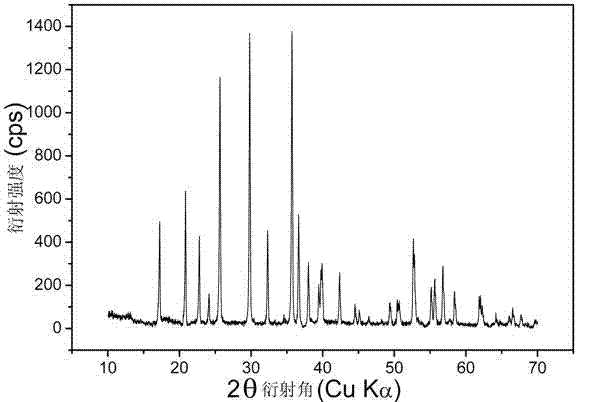

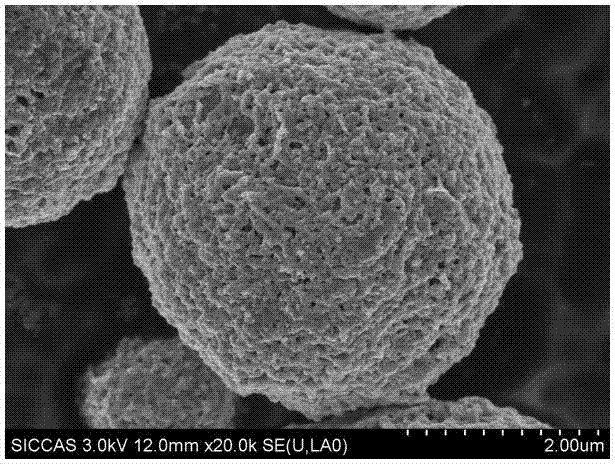

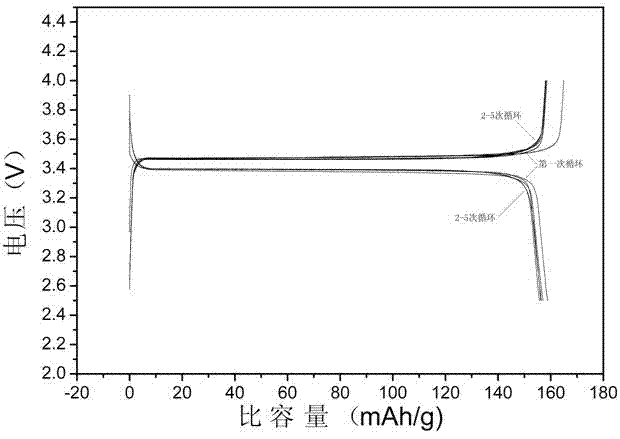

Synthesis method of lithium iron phosphate positive material for lithium ion battery

InactiveCN103208614AGood environmental protectionMaintain stability and consistencyCell electrodesPhosphorus compoundsLithium electrodeSpray dried

The invention discloses a synthesis method of a lithium iron phosphate positive material for a lithium ion battery. The synthesis method comprises the following steps: firstly, adding 105-126 parts of phosphoric acid into 400 parts of deionized water to prepare phosphoric acid solution, adding 50-62 parts of reduced iron powder while stirring to react for 2 hours, and adding the obtained resultant into a ball mill to perform ball milling; dissolving 38-46 parts of lithium hydroxide and 15 parts of cane sugar in 250 parts of deionized water to form solution, adding the solution into the ball-milled product, evenly stirring and mixing, spray-drying at 200 DEG C and carrying out vacuum calcinations on obtained spherical lithium iron phosphate powder at the temperature of 600-750 DEG C for 2-6 hours to obtain the positive material lithium iron phosphate for the lithium ion battery. The synthesis method has the characteristics of low production cost, environment friendliness and the like. The obtained positive material for the lithium ion battery, namely lithium iron phosphate, is of a spherical structure, and has even grain size, uniform shape, consistent electrochemical performance and good stability.

Owner:黄科竣 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com