Modified aluminate cement and preparation method thereof

An aluminate cement and modification technology, applied in the field of cement, can solve the problems of not completely preventing the transformation of hydration products, reducing the early strength of aluminate cement, and not preventing the strength of cement stone from shrinking, and improving the interface transition zone. Structure, improved dynamic impact strength and strain sensitivity, effect of shortened solidification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

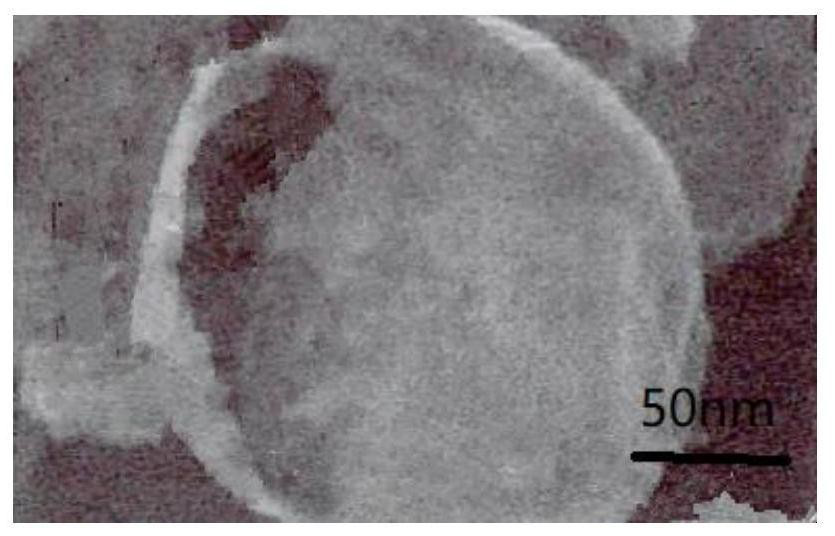

[0037] Preparation Example 1 Titanium Silicon Micro-nano Capsules

[0038] The preparation method is as follows: add 1 g of cetyltrimethylammonium bromide to 50 mL of ethanol / THF / water mixed solution, add 5 g of ammonia water as a catalyst, and add 2 g of ethyl orthosilicate and 1 g of tetratitanate Mixed solution of butyl ester (solvent is ethanol) 10mL, continue to stir for 1h, heat to 50°C to volatilize the solvent, heat the sample to 550°C at a rate of 1°C / min, and calcinate at this temperature for 2h to prepare titanium silicon microparticles. nanocapsules. figure 1 The SEM image of the titanium-silicon micro-nanocapsule prepared for this preparation example, it can be seen from the figure that the particle size of the titanium-silicon micro-nanocapsule is about 150-200nm

[0039] The content of ethanol in the ethanol / THF / water mixed solution is 10wt%, the content of THF is 15wt%, and the balance is deionized water.

preparation example 2

[0040] Preparation Example 2 Titanium Silicon Micro-nano Capsules

[0041] The preparation method is as follows: add 1 g of cetyltrimethylammonium bromide to 50 mL of ethanol / THF / water mixed solution, add 10 g of ammonia water as a catalyst, and add 5 g of ethyl orthosilicate and 5 g of tetratitanate Mixed solution of butyl ester (solvent is ethanol) 10mL, continue to stir for 3h, heat to 70°C to volatilize the solvent, heat the sample to 600°C at a rate of 3°C / min, and calcinate at this temperature for 5h to prepare titanium silicon microparticles. nanocapsules.

[0042] The content of ethanol in the ethanol / THF / water mixed solution is 25wt%, the content of THF is 20wt%, and the balance is deionized water.

preparation example 3

[0051] Preparation Example 3 Modified Acrylic Emulsion

[0052] Prepared by:

[0053] S1. Add 0.5g of emulsifier and 1g of buffer potassium carbonate to the reactor, add 50g of deionized water, heat the reactor in a water bath, and fully stir for 0.5h to fully emulsify the emulsifier solution; the emulsifier is lost from the non-ionic emulsifier It is compounded with sorbitan monooleate and anionic emulsifier sodium stearate, the mass ratio is 3:1;

[0054] S2. Mix 10 g of methyl methacrylate, 2 g of acrylamide, 10 g of butyl acrylate and 1 g of styrene as the reaction monomer, and stir thoroughly for 0.5 h to obtain a uniform mixed monomer;

[0055] S3. 0.2g initiator sodium persulfate is dissolved in 10g deionized water to prepare initiator solution;

[0056] S4. Add the mixed monomer and initiator solution to the reaction kettle dropwise through the peristaltic pump at 2mL / min, control the dropping within 2h, stir the reaction at 65°C, and then keep the temperature for 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| drying shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com