Patents

Literature

278 results about "Sulphate attack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulphate Attack is a chemical attack on the cement paste that binds the concrete together.

Preparation method of high-performance anti-corrosion repairing mortar

A preparation method of high-performance anti-corrosion repairing mortar including following components, by weight: 150-250 parts of cement, 280-725 parts of quartz sand, 50-200 parts of mineral powder, 50-150 parts of fly ash, 0-50 parts of silicon ash, 5-10 parts of barium nitrate, 0.1-1 part of an early strength agent, 1-4 parts of PP fibers, 0.5-20 parts of latex powder, 0.5-5 parts of cellulose ether, 0.5-2 parts of a water repellent agent, 0.001-0.1 parts of an air entraining agent, 0.1-2 parts of a water reducing agent, 0-1 part of a defoaming agent, and 100-250 parts of water. The invention, aiming to the characteristic of sulphate attack and the performance requirement of repairing mortar, discloses the repairing mortar which can repair the surface of damaged concrete with a protective film formed thereon to prevent the concrete form being corroded again. The repairing mortar is good in construction performance, can be used for coating the surface of the damaged concrete or filling damaged positions of the concrete. The repairing mortar is high in bonding strength and strength, is good in anti-permeability and flexibility, is simple in preparation process, is especially suitable for repairing the concrete subjected to sulphate attack, is great in market prospect and is good in practicability.

Owner:潍坊德霖建材科技有限公司

High-ductility cement-based composite material for repairing hydraulic concrete structure

The invention discloses a high-ductility cement-based composite material for repairing a hydraulic concrete structure. The cement-based composite material is prepared from the following components in parts by mass: 20 to 60 parts of cement, 0 to 80 parts of fly ash, 0 to 80 parts of pulverized slag powder, 5 to 10 parts of light-weight calcium powder, 1 to 5 parts of nanometer SiO2, 25 to 40 parts of a fine aggregate, 20 to 40 parts of water, 0.1 to 1 part of a water reducing agent and 0.5 to 2.5 parts of polyvinyl alcohol fibers. According to the high-ductility cement-based composite material for repairing the hydraulic concrete structure, the air content of a mixture is 7 to 10 percent; at the 28-day age, the uniaxial tensile strain is greater than or equal to 5.0 percent, the cube compressive strength is greater than or equal to 60MPa, the frost resistance is greater than or equal to F500, the sulfate corrosion resistance is greater than or equal to KS300, the chloride ion penetration resistance DRCM is less than or equal to 2.0*10<-12>m<2> / s, and the tensile bonding strength with base structure concrete is greater than or equal to 5.0MPa. Under the condition of not mixing any air-entraining agent, preservative or thickening agent, the high-ductility cement-based composite material for repairing the hydraulic concrete structure provided by the invention has high durability, enhanced capability in synergistically acting with an existing structure and a remarkable repairing and reinforcing effect.

Owner:NANJING HYDRAULIC RES INST

Self-compacted concrete of resisting erosion of sulfate and its preparing method

The invention relates to a sulfate corrosion-resistant self-compacted concrete and the preparing method, adopting fly ash, slag and siliceous dust and cement as concrete cementitous material and adding in water reducer and thickening agent to prepare a high-fluidity self-compacted concrete. And the components in the concrete which are corroded by sulfate are remarkably reduced so as to reduce possibility of corrosion to the concrete. And the concrete has high fluidity, slump above 25 cm, extensibility above 60 cm, and blocking ratio above 0.8; and the corrosion test of above 9 months with 10% sodium sulfate solution shows that compressive ratio is above 0.8 and the surface is complete. And the preparing method is simple, and has low cost and wide application.

Owner:TONGJI UNIV

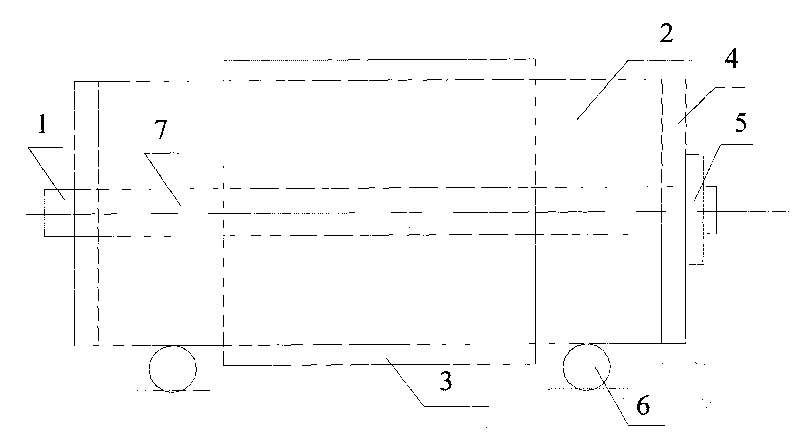

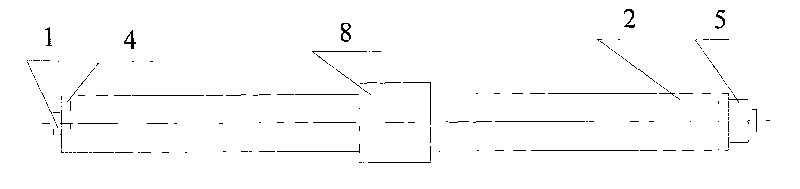

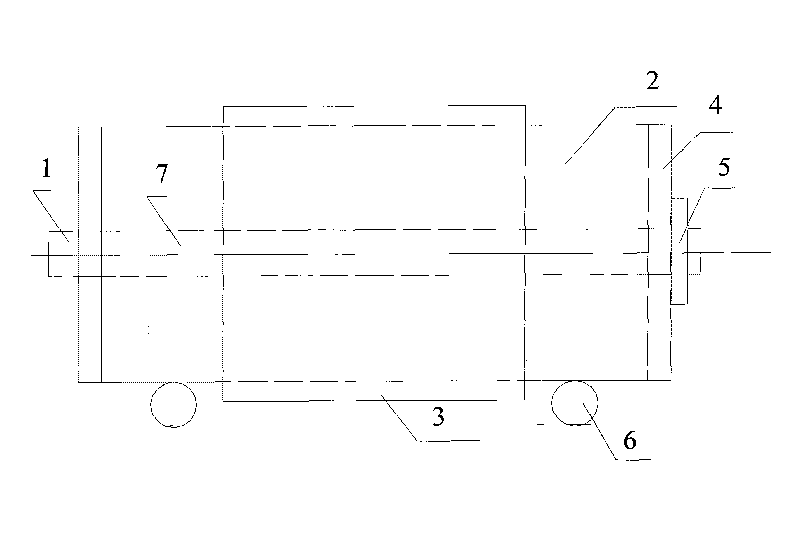

Method for testing concrete performance under pressure stress-chemical coupling effect and device thereof

InactiveCN101726439AConvenient performance testSmall footprintWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesCarbonizationEngineering

The invention discloses a method for testing concrete performance under pressure stress-chemical coupling effect and a device thereof. The method applies a pressure stress to a test piece through a prestressing mode, and provides specific chemical corrosion action through a matched sealing device so as to apply a pull force to concrete and apply common chemical action at the same time. The internal stress of the concrete is monitored through a pressure sensor, the pressure stress is kept constant through secondary tension prestressing force, and the sealing device is arranged on the middle part of the concrete test piece to provide the chemical action, so the corrosion action of the chemical medium on a loading device is avoided; and a sealed box can provide one or more chemical erosion environments of carbonization, sulfate erosion, alkali-aggregate reaction, chloride ion erosion and corrosion. The device has a string structure, and can conveniently apply the pressure stress-chemical coupling effects of different conditions to a plurality of concrete test pieces.

Owner:SOUTHEAST UNIV

High-early-strength magnesium phosphate concrete and preparation method thereof

InactiveCN101386518AQuickly restore functionalityFast setting and hardeningSolid waste managementMagnesium phosphateHazardous substance

The invention discloses a quick-hardening early strength magnesium phosphate concrete, which is mainly prepared from the following components in weight percentage: 12.7 to 30 percent of magnesia, 8.7 to 20 percent of phosphate, 1.2 to 15 percent of retarder, 10 to 25 percent of fine aggregate, 10 to 50 percent of water and the balance being water. The concrete material has the characteristics of quick coagulation and hardening, high early strength, good erosion resistance and the like, and can be widely applied to the quick repairing in projects or structures such as railways, airfields, bridges, harbors and docks and the quick solidification and closing of toxic and harmful substances, and can also be applied to the civil engineering and building construction under the sever conditions of sulfate erosion, marine corrosion, low temperature and the like. The invention has the advantages of simple preparation method, process and necessary equipment, low cost, no pungent ammonia gas generation in the construction and convenient popularization and application.

Owner:汪宏涛

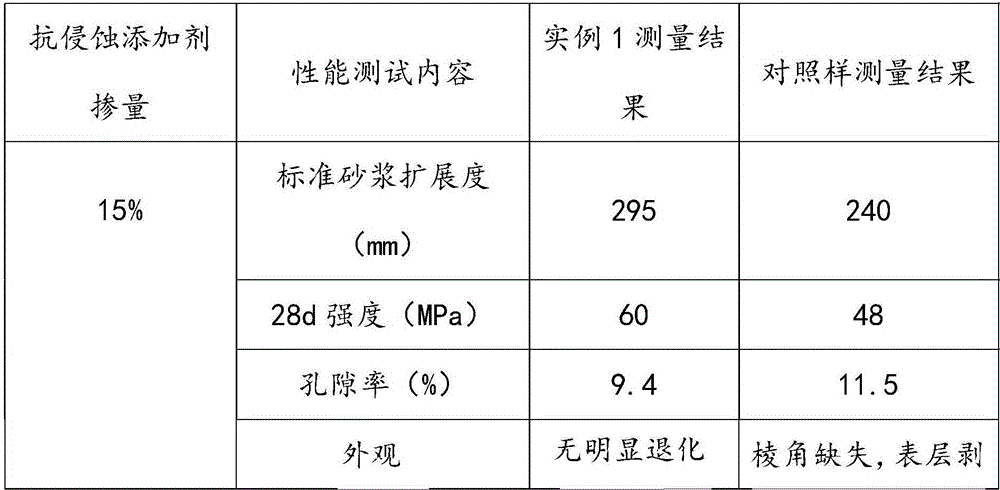

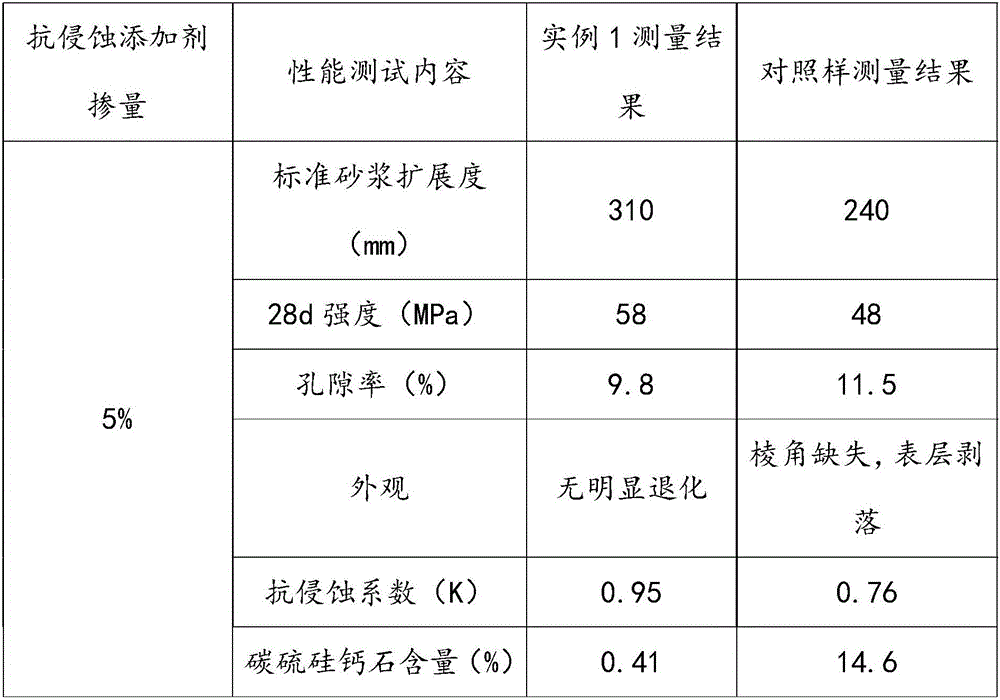

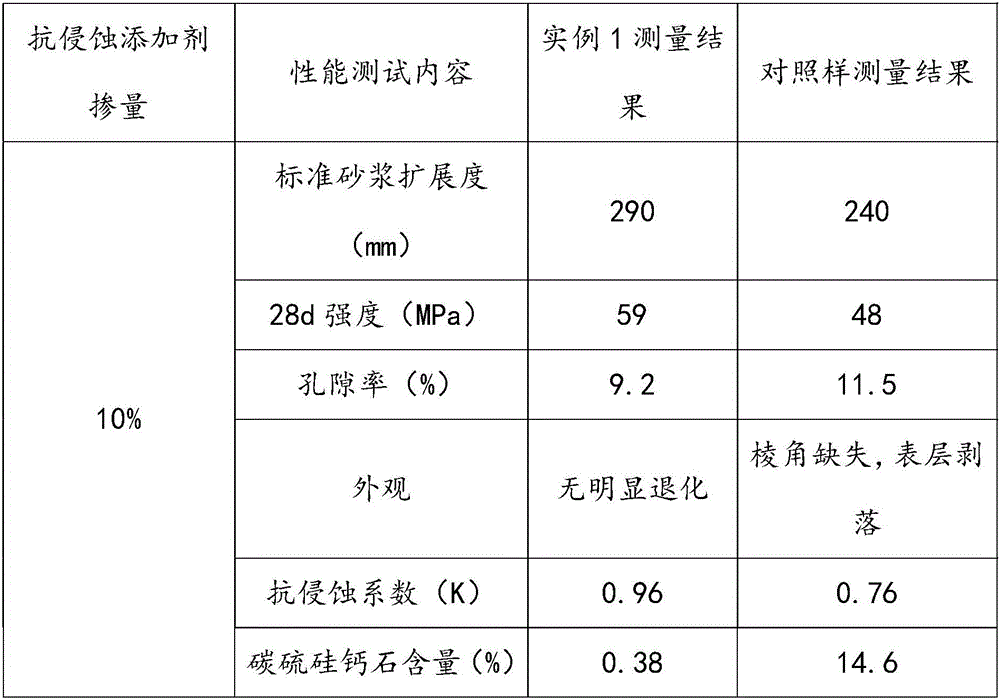

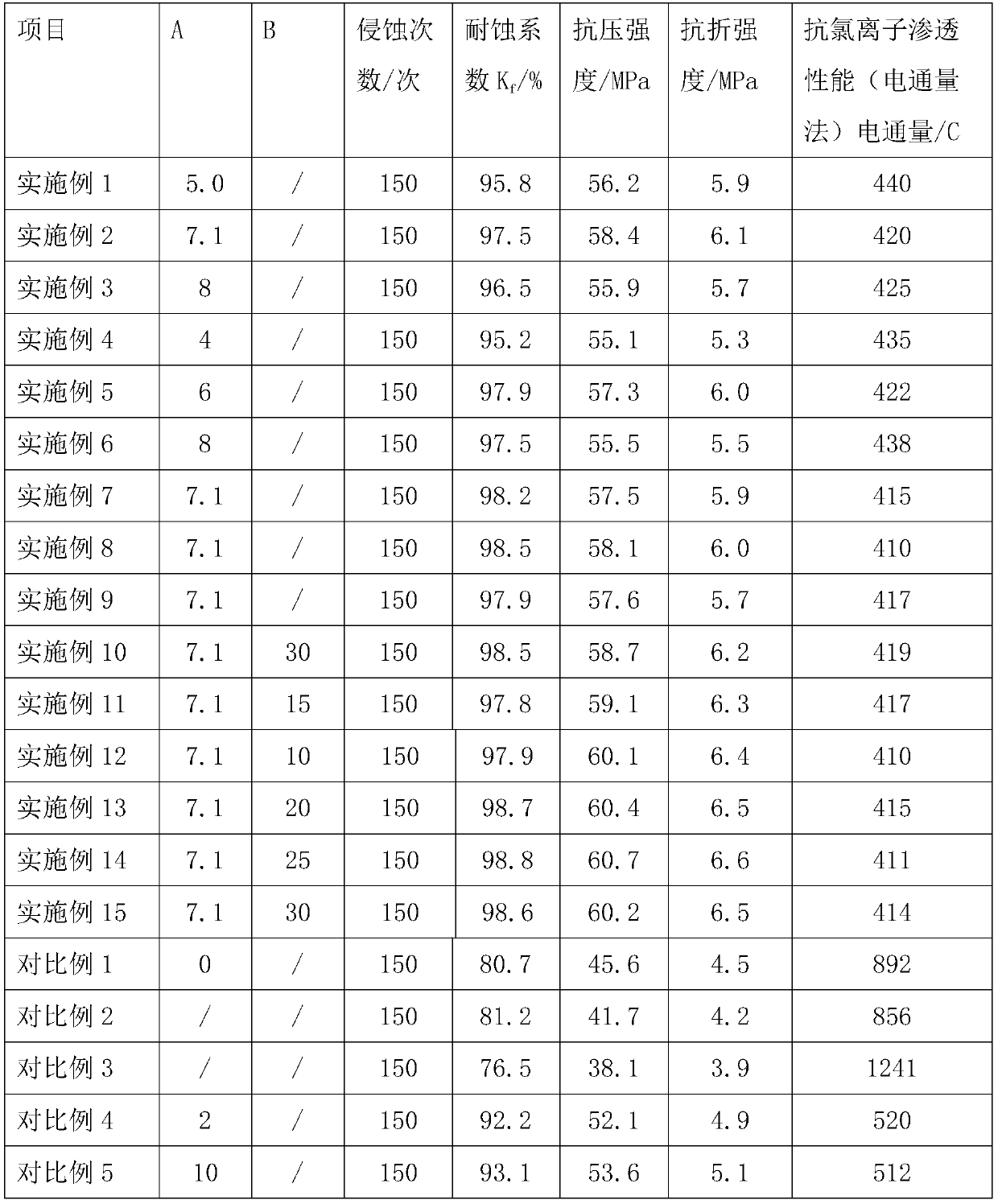

Concrete sulfate-corrosion-resistant additive and preparation method thereof

ActiveCN105084798AIncreased resistance to sulfate attackCompensation for strength lossSodium BentoniteSulfate

The invention relates to a concrete sulfate-corrosion-resistant additive and a preparation method thereof, and belongs to the technical field of civil engineering materials. The concrete sulfate-corrosion-resistant additive mainly comprises, by mass, 30-50% of barium-based modified bentonite, 20-40% of nanometer kaolin / metakaolin, 20-30% of water talcum powder and 10-15% of solid water glass. The preparation method includes the steps of evenly mixing barium-based modified bentonite, nanometer kaolin / metakaolin, water talcum powder and solid water glass in proportion, placing the mixture in a grinding machine to be ground till the specific surface area of the ground powder reaches 400 m<2> / kg or above, and conducting bagging and sealing. By means of the concrete sulfate-corrosion-resistant additive and the preparation method, the sulfate corrosion resistance of concrete can be improved, the compressive strength of concrete can be improved, the concrete hole structure and compactness are improved, and the durability of concrete is improved. The prepared additive has the advantages of being long in timeliness, free of toxin and environment pollution, simple in preparation process and low in cost.

Owner:海南胜凯建材有限公司

Method for solidifying heavy metal and soil polyalcohol composite cement special for the same

The invention discloses a soil polymer composite cement, which is prepared when the following weight percentages of materials react after being mixed: common Portland cement accounts for 40.0 to 77.0 percent; silicon powder accounts for 5.0-20.0 percent; pulverized fuel ash accounts for 10.0-30.0 percent; milled slag accounts for 0-10 percent, metakaolin accounts for 5.0-10.0 percent, alkali excitant accounts for 1.0-5.0 percent. After being fully mixed with water, the soil polymer composite cement prepared by the invention can harden into solid at room temperature. The soil polymer composite cement prepared by the invention has excellent sulfate corrosion resistance and chloridion corrosion resistance, has fine solidification effect on the added copper, lead, nickel, zinc, cadmium, and other heavy metals; the solidification rates are all more than 99.9 percent.

Owner:NANJING RUIDI HIGH TECH

Formula and preparation process of concrete sulfate resistance agent

The invention relates to a formula of a concrete sulfate resistance agent, which comprises the following ingredients by weight percentage: one or more of 30% to 50% ferric nitrate, ferrous nitrate and magnesium nitrate, 20% to 40% barium nitrate, 0.5% to 10% sodium silicate, 5% to 10% lithium hydroxide, 1% to 5% sodium benzoate and 30% to 60% coal ash or grounded mineral powder. A preparation process of the concrete sulfate resistance agent comprises the following steps of: mixing one or more of 30% to 50% ferric nitrate, ferrous nitrate and magnesium nitrate, 20% to 40% barium nitrate, 0.5% to 10% sodium silicate, 5% to 10% lithium hydroxide, 1% to 5% sodium benzoate and 30% to 60% coal ash or grounded mineral powder in a mixer or a mixing tank for 5 to 30 minutes, discharging the materials, sealing and preserving. The sulfate resistance coefficient of the concrete sulfate resistance agent can reach 95% to 98%, so that the impervious and the freeze proof levels of the concrete are greatly improved, and the service durability of the concrete is greatly enhanced.

Owner:WATER RESOURCES RES INST OF SHANDONG PROVINCE

Anti-erosion agent for concrete, preparation method and application thereof

InactiveCN101781100AImprove work performanceHigh activitySolid waste managementMicrosphereWater reducer

The invention relates to an anti-erosion agent for concrete, a preparation method and an application thereof. The anti-erosion agent comprises the following components in parts by weight: 100 parts of original-state superfine fly ash microsphere, 5-9 parts of water reducer, 30-80 parts of expanding agent, 0.075-0.3 part of air entraining agent, 25-75 parts of bulking agent and 0.37-1.25 parts of retarder. Compared with the prior art, the product of the invention utilizes the original-state superfine fly ash microspheres and has excellent performance, the production process is simple, the application is convenient, the applicability is universal, and the application effect is extremely standout. As for the concrete prepared by adopting the product of the invention, the anti-sulphate-erosion ability thereof can be improved by 5-8 times, the anti-chloridion-penetrating ability can be improved by more than 3 times, and the service life of the concrete structure can be prolonged by 3-4 times under the condition that the service environment of the concrete structure is not changed.

Owner:HUNAN CSCEC5B CONCRETE

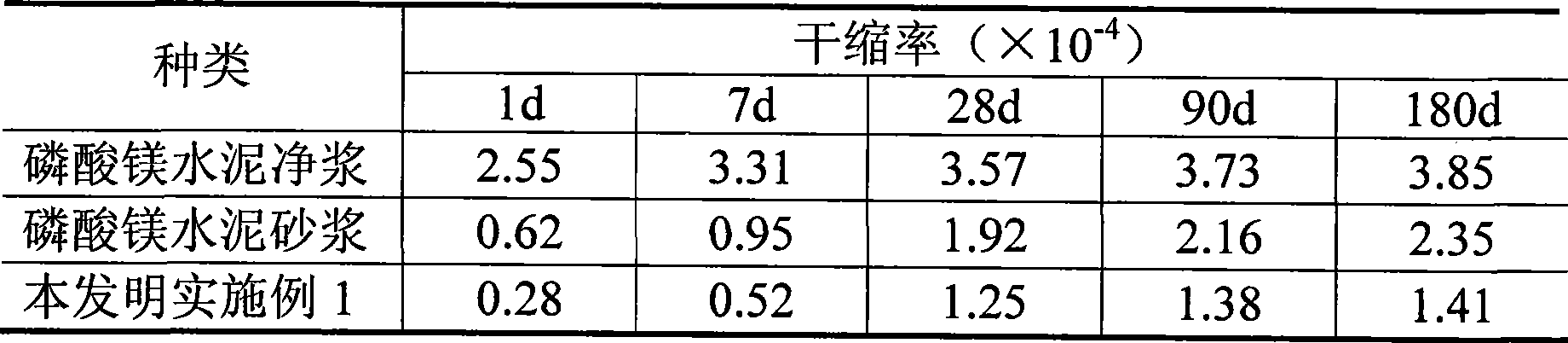

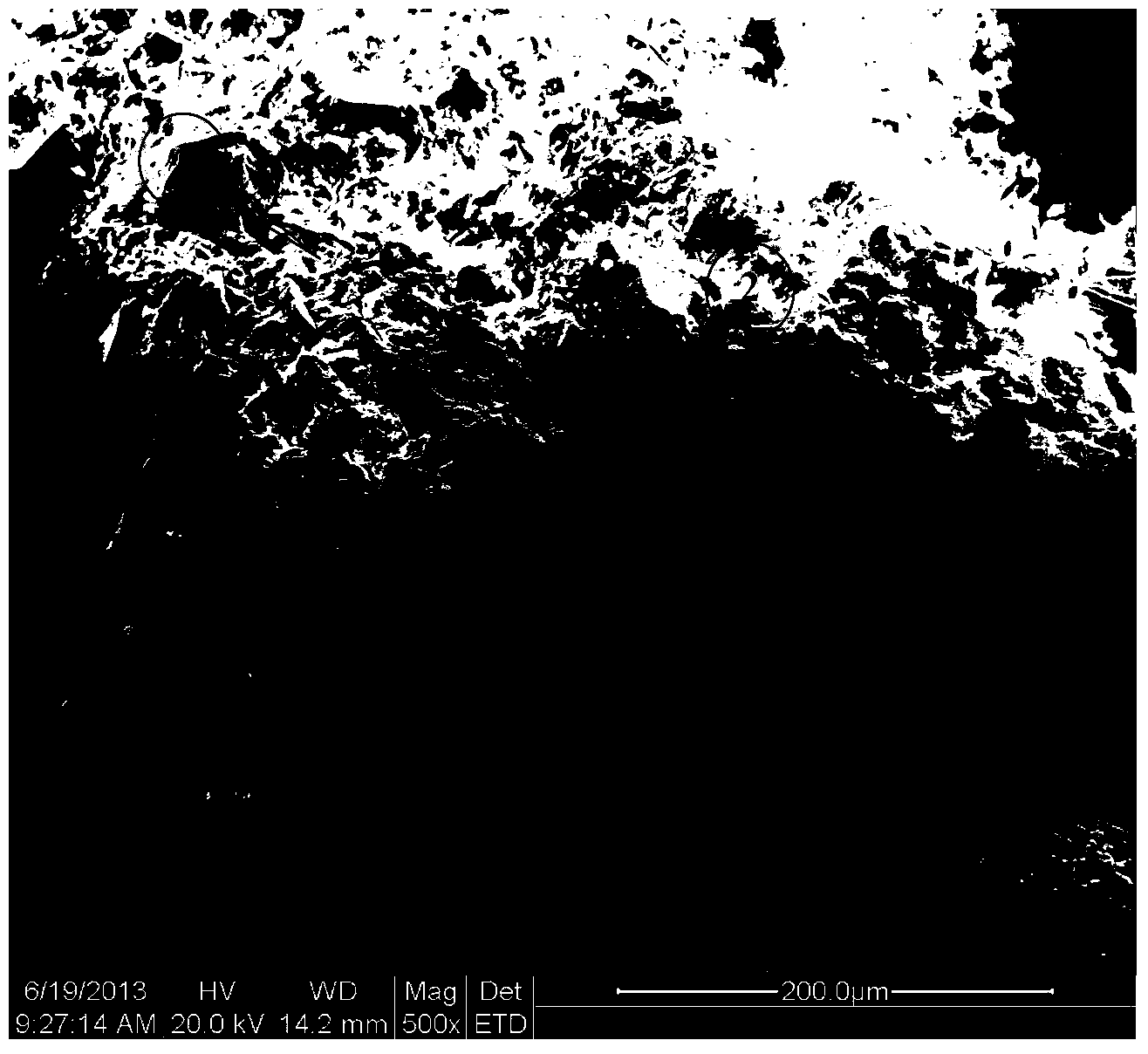

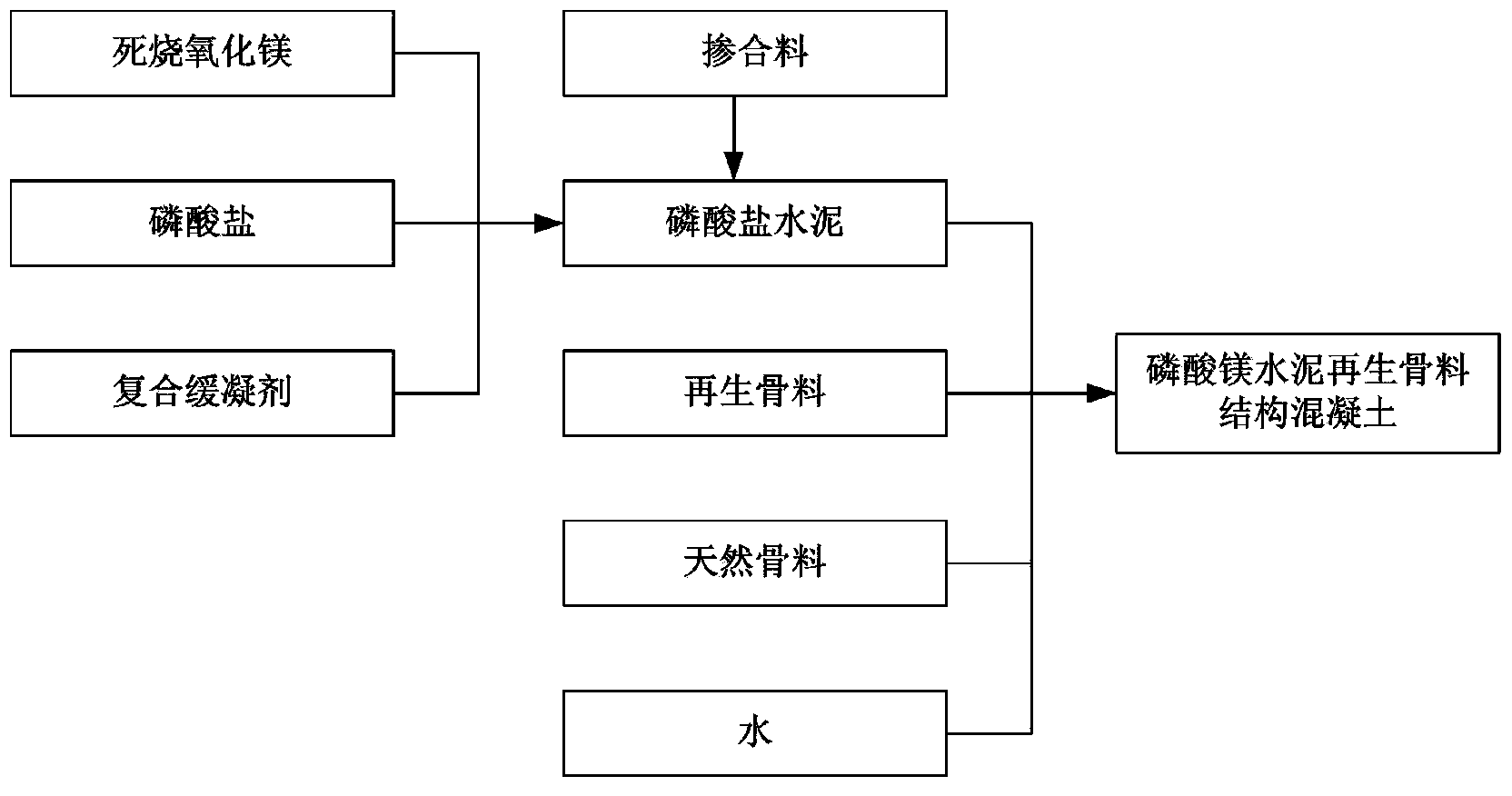

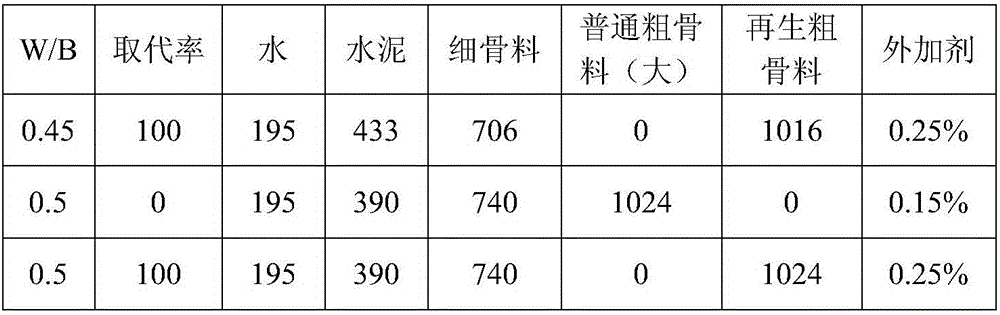

Magnesium phosphate cement recycled aggregate structure concrete and preparation method thereof

InactiveCN104072091AEarly hardening fastHigh strengthSolid waste managementAggregate (composite)Magnesium phosphate

The invention discloses magnesium phosphate cement recycled aggregate structure concrete and a preparation method thereof. The magnesium phosphate cement recycled aggregate structure concrete comprises the following components by weight percent: 12-30% of magnesium oxide, 8-20% of phosphate, 2-10% of composite retarder, 5-15% of admixture, 5-20% of recycled fine aggregate, 5-30% of recycled coarse aggregate, 0-10% of natural fine aggregate, 0-15% of natural coarse aggregate, and the balance being water. High early strength, small shrinkage rate, strong adhesive property and good corrosion resistance of the concrete are ensured by the magnesium phosphate cement; stable growth of the strength of the concrete is ensured by the admixture, and the durability and the volume stability are improved. The magnesium phosphate cement recycled aggregate structure concrete has the beneficial effects that the concrete material is applicable to the structure concrete and high-performance recycled aggregate concrete, can be applied to civil engineering in bad environments such as sulphate attack, marine corrosion, high-temperature environment and low-temperature environment, efficient utilization of the waste concrete is achieved, mining of natural gravel is reduced, the construction cost is reduced, and the targets of recycling wastes and protecting environment are achieved.

Owner:YANCHENG INST OF TECH

High efficiency sulfate attack resistant concrete additive and preparation method thereof

The invention discloses a high efficiency sulfate attack resistant concrete additive and a preparation method thereof. The technical scheme of the concrete additive comprises the following raw materials in parts by weight: 15-25 parts of barium salt, 5-10 parts of sorbitol, 15-30 parts of calcined diatomaceous earth, 0.5-1.0 part of a grinding aid, 30-50 parts of silica fume, 10-20 parts of ultrafine fly ash and 1.0-2.0 parts of a water reducer. The high efficiency sulfate attack resistant concrete additive can reduce the proper shrinkage cracks of concrete, improve the compactness, and greatly improve the multi-type attack resistant properties of the concrete effectively for a long time.

Owner:HUBEI UNIV OF TECH

Sulfate corrosion-resistance preservative for concrete

InactiveCN101913841AImproves resistance to sulfate attackImprove erosion abilitySolid waste managementSilicon oxideMaterials science

The invention provides a sulfate corrosion-resistance preservative for concrete, which is characterized by containing the following components of raw materials in percentage by weight: 15-80 percent of superfine mineral powder that is a by-product of smelting steel, contains calcium oxide, silicon oxide and alumina as the main components, and has the specific surface area of greater than or equalto 600m<2> / kg, 0-55 percent of cement clinker that contains anhydrous calcium sulphoaluminate and dicalcium silicate as the main components, and 0-30 percent of anhydrite. The compositions are simple, the process is simple and easy, and the antiseptic effect is obvious.

Owner:QINGDAO HUADING BUILDING MATERIAL

High-durability prestressed high-strength concrete pipe pile

InactiveCN101096114AImprove penetration resistanceGood resistance to chloride ion diffusionMixing operation control apparatusCeramic shaping apparatusHigh strength concretePre stressing

The invention discloses a high-durability pre-stressed high-strength concrete pipe pile. The invention is constituted by additive constituted by cementing material, water reduction agent of naphthalene sulfonated formaldehyde condensate and triterpenoid saponin non-ion surface active air-entraining agent, sand and stone, and water by centrifugal casting, steam curing and steam pressing. Addition amount of additive is 1.0-1.2 wt% of cementing material. The high-durability pre-stressed high-strength pipe pile is provided with good permeability resistance, sulfate-corrosion resistance and frost resistance in phase.

Owner:GUANGDONG SANHE PILE CO LTD

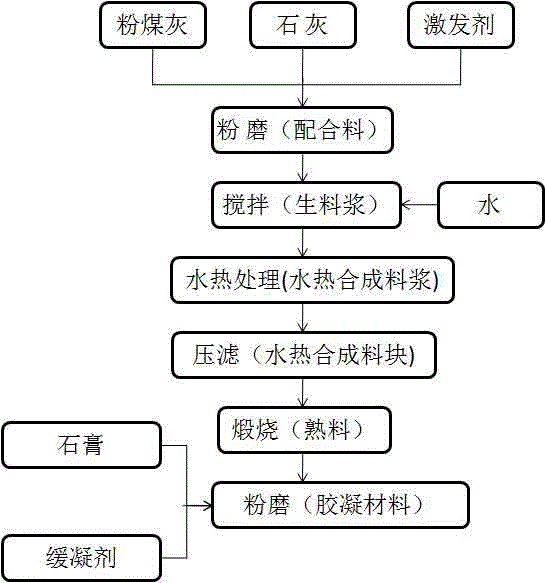

Cementing material prepared from fly ash and preparation method thereof

The invention discloses a cementing material prepared from fly ash and a preparation method thereof. The preparation method of the cementing material comprises the following steps: milling 62-78 parts by mass of fly ash, 22-38 parts by mass of lime and 0.5-2 parts by mass of excitant to obtain an admixture of which the 80 mu m screen residue is less than 5%, adding 150-250 parts by mass of water, stirring to obtain a uniform raw slurry, carrying out hydrothermal treatment on the raw slurry at 90-98 DEG C for 8-16 hours, dewatering in a filter press to obtain a hydrothermal synthesis block, calcining at 750-950 DEG C for 30-120 minutes, and cooling with air to obtain clinker; and milling 92-95 parts by mass of clinker, 5-8 parts by mass of gypsum and 0.2-1.5 parts by mass of retarder until the 80 mu m screen residue is less than 4%. The cementing material can utilize low-grade fly ash, and has the advantages of high utilization ratio of fly ash, low calcination temperature and low heat loss. The product has the characteristics of quick setting and hardening, high long-term strength and high sulfate attack resistance. The cementing material is especially suitable for tunnel, underwater, alkaline land and coastal area engineering.

Owner:HOHAI UNIV

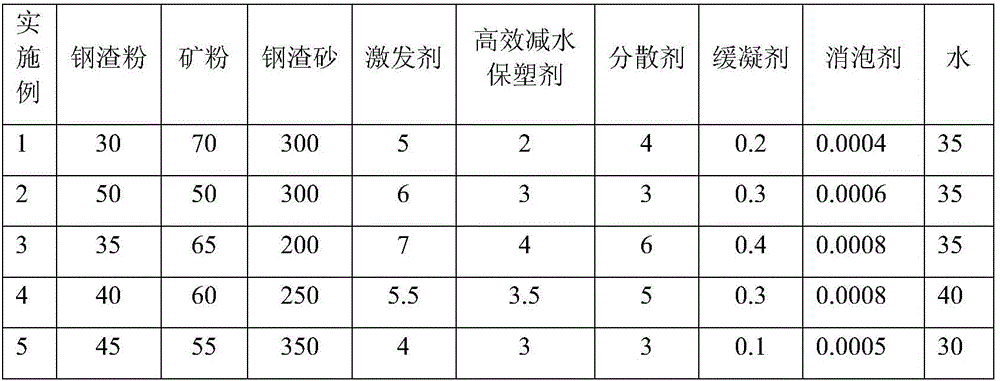

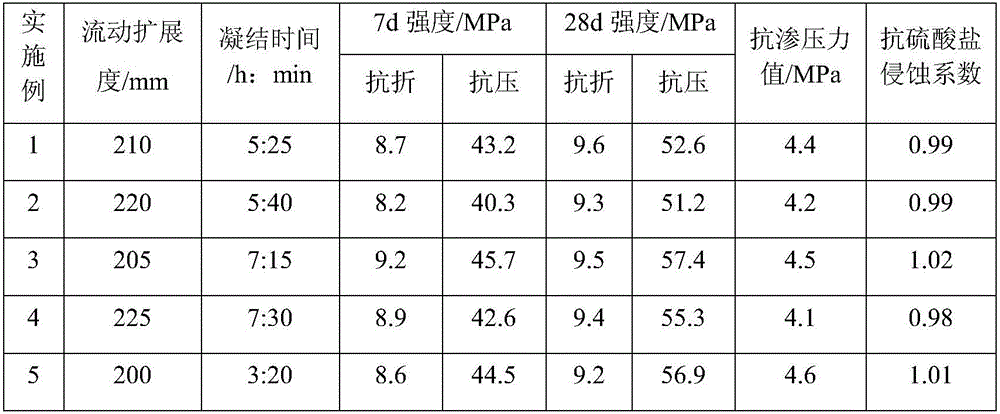

Non-cement green mortar by using steel slag as cementing material and fine aggregate and preparation method thereof

ActiveCN105859229AImprove overall utilizationImprove work performanceLeveling effectBreaking strength

The invention belongs to the field of building materials and particularly relates to a non-cement green mortar by using the steel slag as the cementing material and the fine aggregate and a preparation method thereof. The non-cement green mortar comprises the following components in weight part: 30-50 parts of steel slag powders, 50-70 parts of mineral powders, 200-350 parts of steel slag sands, 4-7 parts of activator, 1-4 parts of a water reducing agent, 3-6 parts of a dispersing agent, 0-0.4 parts of a retarder, 0.0002-0.001 part of a defoamer, and 30-40 parts of water. The non-cement green mortar is good in working performance, automatic in leveling effect, adjustable in setting time with the range of 0.5-8 hours, high in early-late strength, and excellent in impermeability and resistance to sulfate attack. The 7d breaking strength of the non-cement green mortar is larger than 8 MPa, and the compression strength thereof is larger than 40 MPa. The 28d breaking strength of the non-cement green mortar is larger than 9 MPa, and the compression strength thereof is larger than 50 MPa. Therefore, the non-cement green mortar can be widely applied to the engineering practice.

Owner:WUHAN UNIV OF TECH

Sulfate attack resistance method of concrete

InactiveCN102087180AIncreased corrosion resistanceImprove flexural strengthPreparing sample for investigationInvestigating abrasion/wear resistanceSulfateFlexural strength

The invention relates to an attack resistance method of concrete, in particular to a sulfate attack resistance method of concrete. The method is characterized by adopting mortar samples, curing 40cm*40cm*160cm prism samples in the water at the temperature of 50 DEG C for seven days and then carrying out an attack test; soaking the samples at the room temperature for 16 hours, soaking one group of the samples in the water at the temperature of 20 DEG C and soaking another two groups of samples in 0.3% of Na2SO4 solution and 3% of Na2SO4 solution respectively, drying the samples at the temperature of 75 DEG C for seven hours and cooling the samples for one hour, taking the above steps as a cycle, totally carrying out 28 cycles, then testing the flexural strength of the mortar, computing the relative flexural strength K of the mortar according to the following formula: K=flexural strength of the mortar after the mortar cycles in the sodium sulfate solution / flexural strength of the mortar after the mortar carries out the same cycling in the tap water; and finally relatively evaluating the attack resistance of the mortar by using K in the test result.

Owner:SHANGHAI SINO CARBIDE

All-solid-waste ecological cementing material

InactiveCN110041015AIncrease alkali concentrationFacilitate dissociationMetallurgical slagDefoaming Agents

The invention provides an all-solid-waste ecological cementing material and relates to the field of building materials. The all-solid-waste ecological cementing material is prepared from raw materialsin parts by mass as follows: 100 parts of solid waste, 1-5 parts of a chemical activator, 0.5-1 part of a water reducing agent and 0.5-1 part of a defoaming agent, wherein the solid waste is preparedfrom 50%-70% by mass of ferro-nickel residues, 10%-30% of slag, 5%-10% of fly ash, 0-10% of gypsum and 5%-10% of steel slag. According to the all-solid-waste ecological cementing material, the ferro-nickel residues, the slag and the steel slag are taken as raw materials, utilized as a clinker source of the cementing material and supplemented with industrial solid waste such as industrial byproducts gypsum and fly ash, and one low-hydration-heat ecological cementing material capable of partially replacing Portland cement is prepared by mechanical excitation and chemical excitation. Efficient recycling of the industrial metallurgical slag such as the ferro-nickel residues, the slag and the steel slag is realized, and usage amount of Portland cement clinker is effectively reduced. Compared with the Portland cement, the all-solid-waste ecological cementing material has the characteristics of low hydration heat and good sulfate corrosion resistance.

Owner:GUANGDONG TSINGDA TONGKE ENVIRONMENTAL PROTECTION TECH CO LTD

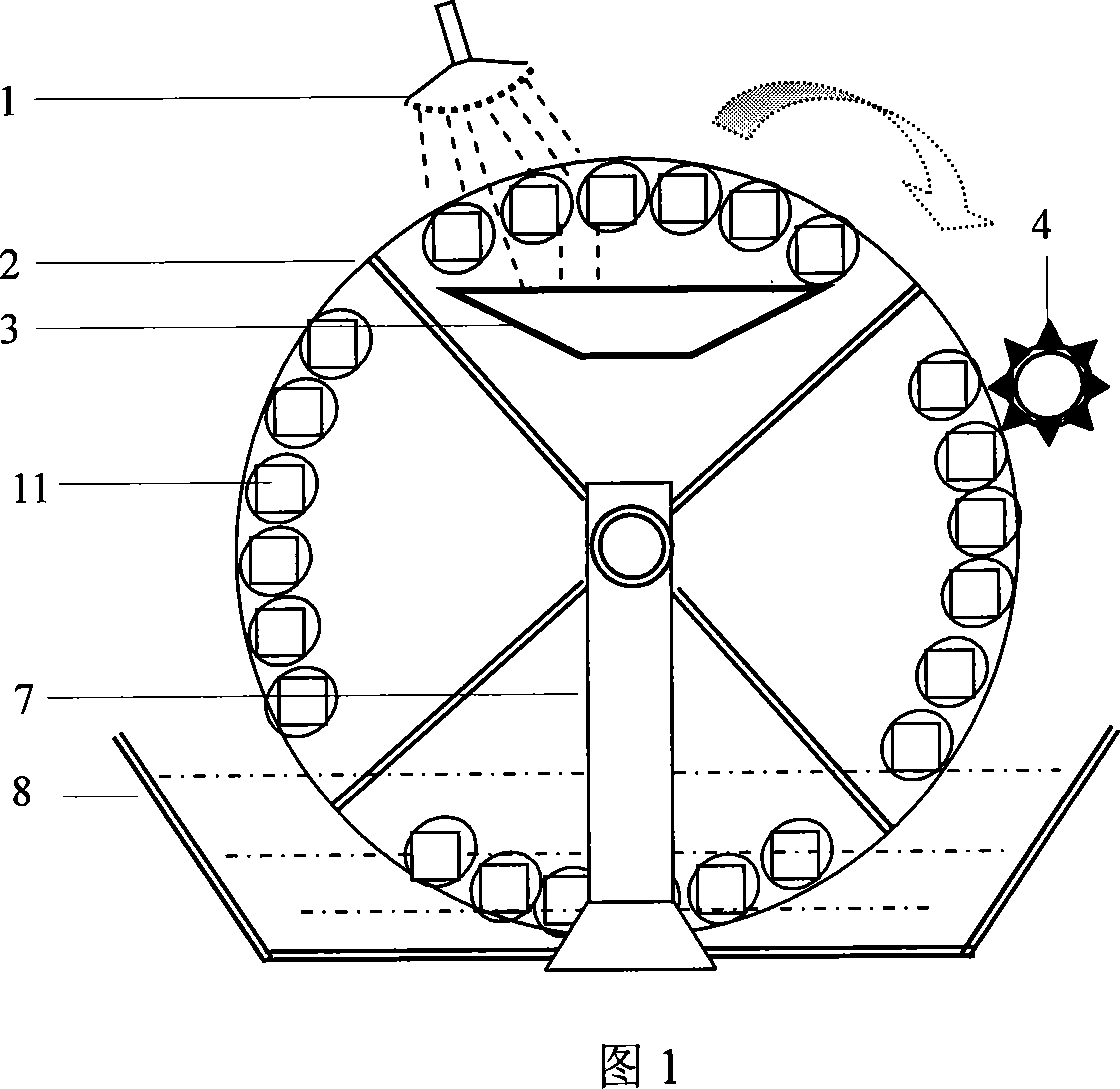

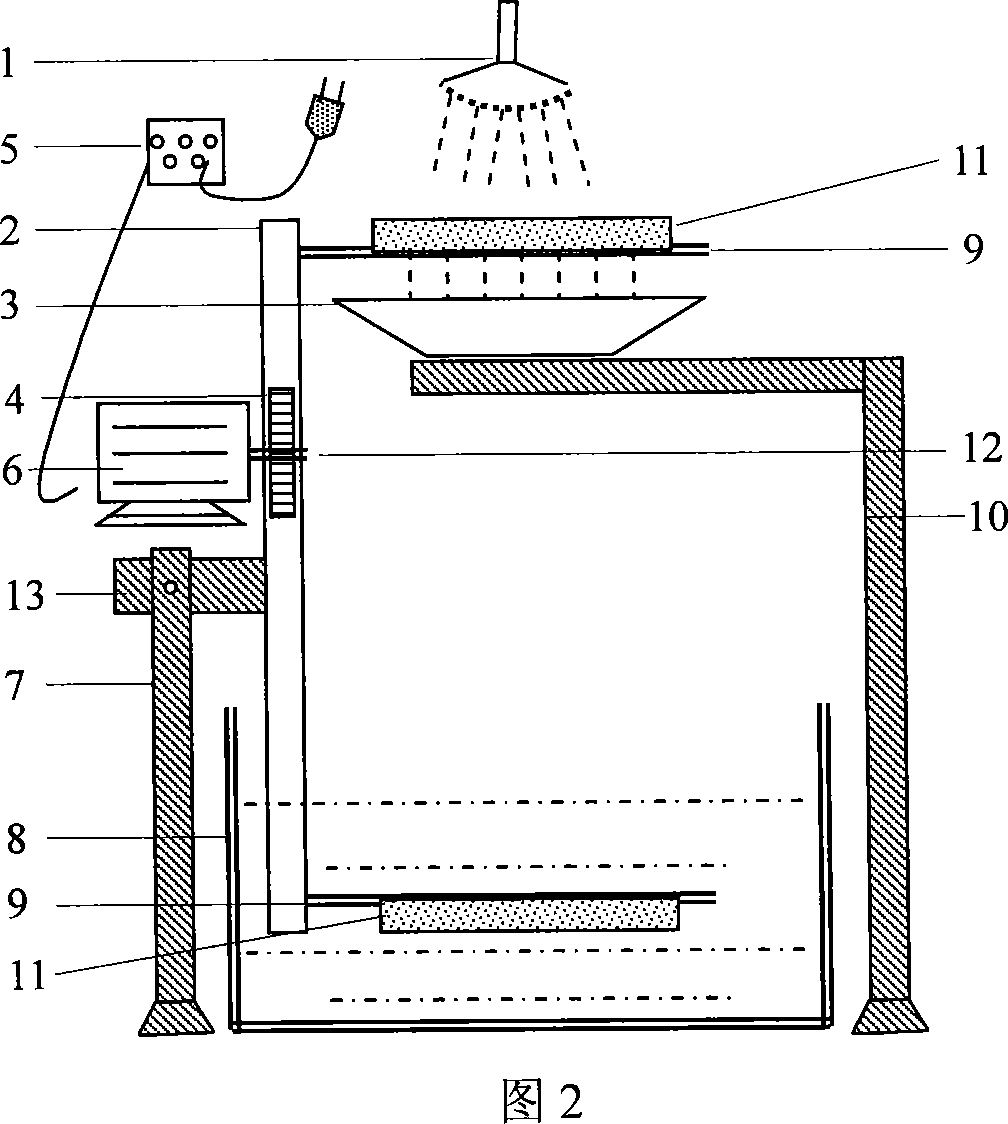

Equipment for simulating dry-wet circulation and fresh water to sea water circulation

InactiveCN101042329AImprove the efficiency of erosive studiesWeather/light/corrosion resistanceMaterial testing goodsElectric machineryFresh water

This invention relates to one dry and wet and fresh water and sea water recycle analogue device , which comprises shower spray head, water tank, tank rack, drive system, rotation rack and erosion liquid tank, wherein, the drive system gear is fixed onto motor axis connected to controller; the rotation rack is composed of round ring, round rack and specimen rack and the round ring is fixed on other side of round rack to make it vertical to earth level; the drive gear shape and round ring shape are meshed with one side set with erosion liquid tank and down part in the tank; specimen rack end is vertical to round ring outer one; the spray head is one round ring fixed down spray water tank rack.

Owner:TONGJI UNIV

Pit backfill material, preparation method thereof and application method thereof

The invention discloses a pit backfill material and an application method thereof. The pit backfill material comprises cement, calcined activated coal gangue, steel slag powder, lime hydrate powder, phosphogypsum, an expanding agent, glass quartz sand tailings, machine-made sand, a water reducer, and modified starch ether. The material can be constructed through pumping only by adding water with 35-90% of the total weight on a building site and stirring according to requirements. The pit backfill material which is prepared from a large amount of industrial solid wastes in the invention and allows workability, water retention, fluidity and self-compaction fallibility to be good, compressive strength to be high, bonding strength and sulphate erosion resistance to satisfy relevant requirements, and slight dilatability to be possessed has the advantages of simple production technology, convenient application, waste utilization, energy saving, consumption reduction, low carbon, and good market prospect.

Owner:GUANGDONG REDWALL NEW MATERIALS

Test method for XCT nondestructive detection of sulfate erosion damages of concrete material

InactiveCN105911077ANon-destructive testing for erosion damageIntegrity guaranteedMaterial analysis by transmitting radiationPorosityCoupling

The invention discloses a test method for XCT nondestructive detection of the sulfate erosion damages of a concrete material. The method comprises the following steps: measuring the X-ray attenuation in different directions to reconstruct an image, and quantitatively analyzing the initial state of a concrete test piece and the internal structure in the sulfate erosion process according to gray value change in order to obtain the defect (aperture and crack) information of the test piece, wherein the total porosity, the pore size distribution and other pore structure information can be obtained through the aperture analysis, and provides bases for researching the sulfate erosion damage accumulation rule of the concrete. The method can be combined with a loading device to realize real-time observation of the whole damage process of the microstructure of the concrete test piece under the load and sulfate coupling action.

Owner:SOUTHEAST UNIV

Fly ash cement and preparation method thereof

InactiveCN103803821AReduce pollutionAnti-alkali-aggregate reactionCement productionActive agentRed mud

The invention discloses fly ash cement comprising the following components in parts by weight: 30-40 parts of fly ashes, 53-65 parts of portland cement clinkers, 2-5 parts of dihydrate gypsum, 0.5-2 parts of excitants, 1-2 parts of active agents, 1.5-3 parts of early strength agents, 5-10 parts of lime, 6-12 parts of calcium-added slag and 15-25 parts of red mud. The fly ash cement disclosed by the invention can be used for also solving the problems of low early strength and long setting time, and the problem that later strength is still high besides that the fly ash cement has the excellent characteristics that the common flash ash cement is small in pollution, low in hydration heat, good in alkali-aggregate reaction resistance, sulfate corrosion resistance, dry shrinkage resistance, stability and the like, and especially, the excitants disclosed by the invention do not contain the substances such as sulfate, chloridion and the like, so that the latent instability of long-term durability of the cement and the concrete is effectively avoided, and meanwhile, the cost is greatly reduced due to adding of a lot of fly ashes and other slag. The obtained cement is extremely high in compressive strength, exceeds 40MPa after three days, and exceeds 70MPa after 28 days.

Owner:张家港市双林制墨涂装有限公司

Preparation method of high-activity red mud-based concrete admixture

The invention relates to a preparation method of a high-activity red mud-based concrete admixture, belonging to a preparation method of a composite activated mineral admixture. The preparation method comprises the steps of: by taking red mud as main raw materials and industrial waste slag of carbide slag, desulfurization gypsum and the like as auxiliary materials, performing heating power activation through the self combustion heat of unburned coal gangue to obtain the high-activity red mud-based concrete admixture, wherein in the process of blending concrete materials, 20% by weight of the red mud composite replaces PO52.5, or PO42.5, or PC32.5 portland cement, under the condition of keeping other blending materials, the cost of per cubic meter concrete blended can be saved greatly, the strength of the blended concrete in each age is equal to or higher than that of the compared concrete, and the newly blended concrete has the characteristics of being good in peaceability, small in slump loss, low in hydration heat, good in later strength transitivity, sulfate corrosion-resistant, strong in chemical corrosion resistance, and good in durability, having no adverse influence on the property of the concrete, and the like.

Owner:CHINA UNIV OF MINING & TECH

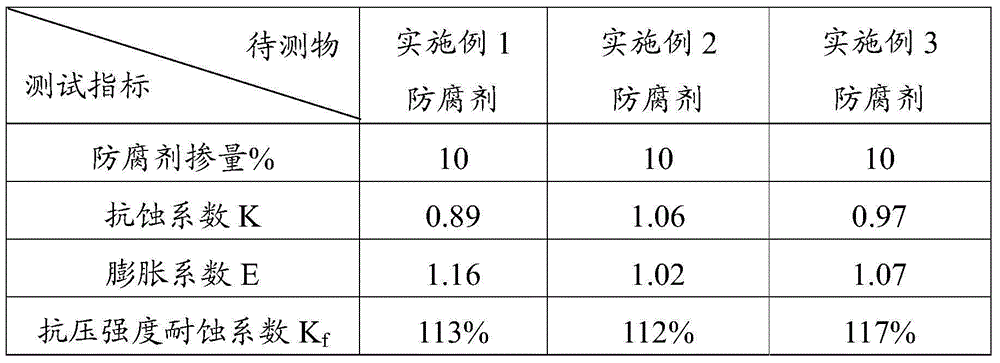

Sulfate-erosion-resistant preservative for underground concrete structure

ActiveCN105174808AMeet the requirements of anti-corrosion performanceExcellent resistance to sulfate attackPreservativeSulfate

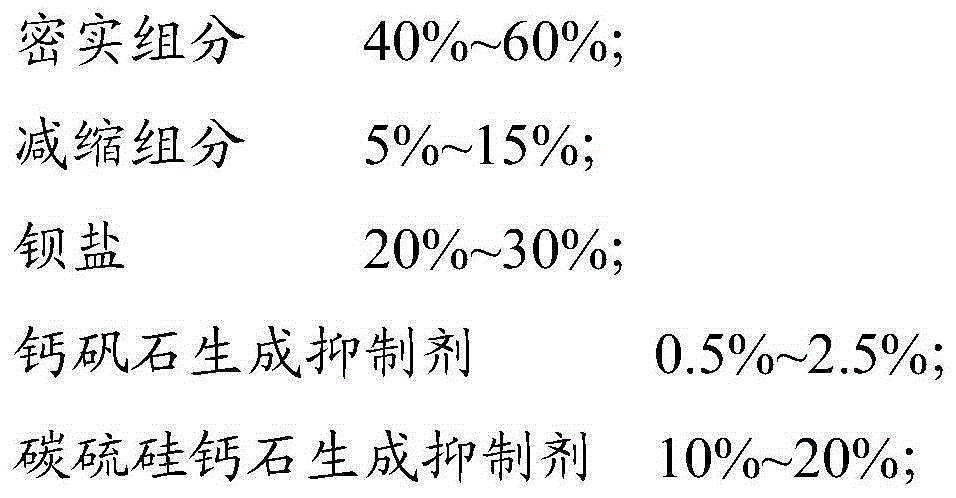

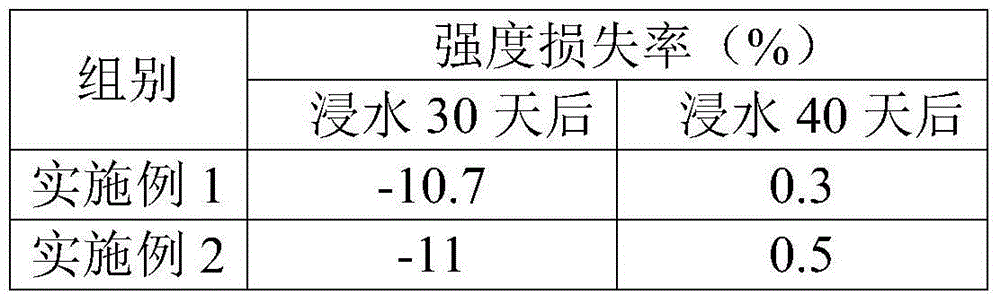

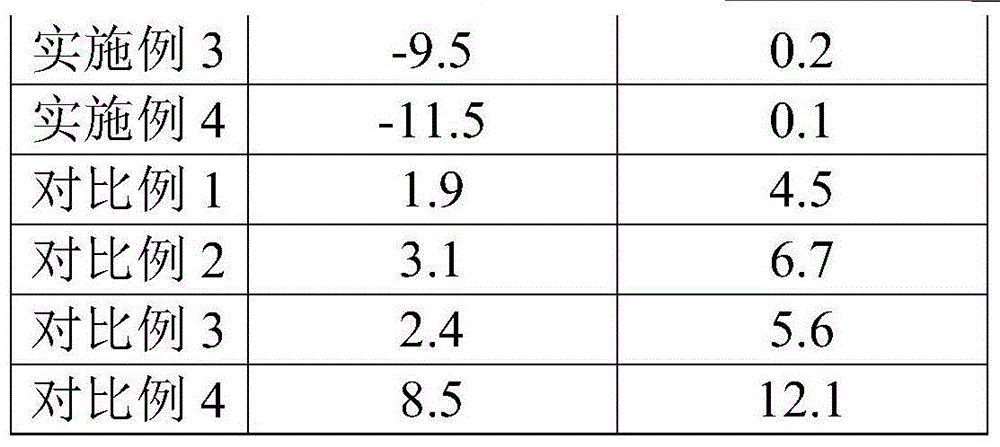

The invention provides a sulfate-erosion-resistant preservative for an underground concrete structure. The preservative is prepared from, by mass, 40-60% of compacting components, 5-15% of reduction components, 20-30% of barium salt, 0.5-2.5% of ettringite inhibitors and 10-20% of thaumasite inhibitors, wherein the compacting components are one or more of silica fume, metakaolin and fly ash, the reduction components are composed of polydimethylsiloxane and 2-methyl-2,4-pentanediol, and the mass ratio of polydimethylsiloxane to 2-methyl-2,4-pentanediol is 1:1-3. The preservative is resistant to erosion of ettringite and thaumasite and is also easy to manufacture and low in cost.

Owner:FUJIAN CONSTR ENG GRP BUILDING MATERIAL SCI & TECH DEV

Cement stabilized base material, preparation, application and preparation method of road base

The invention discloses a cement stabilized base material, a preparation, an application and a preparation method of a road base. The cement stabilized basic material comprises the following materials: 1%-3% of basic slag and 1%-3% of cement and base materials, wherein the basic materials comprises 0.5%-8% of desulfurization gypsum and 92%-99.5% of crushed stone in mass percentage of the basic materials. The preparation method of the cement stabilized base material comprises the step of uniformly mixing the components. According to the preparation method of the road base, the road base is prepared from the cement stabilized base material with the conventional preparation process and conditions. The cement stabilized base material has the advantages as follows: the material cost is reduced, the service life of a road structure is prolonged, the economic benefit is increased, the cement setting time is delayed, the strength, the airtightness, the water retention, the water resistance, the shrinkage crack resistance, the freeze-thaw resistance, the moisture damage resistance and sulfate corrosion resistance of the material are improved, novel application of the desulfurization gypsum is exploited, and the environment is protected effectively.

Owner:SHANGHAI HIGHWAY BRIDGE (GRP) CO LTD +1

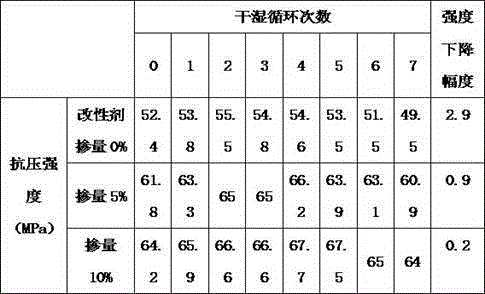

Cement concrete modifying agent resistant to sulfate erosion and preparation method thereof

The invention discloses a cement concrete modifying agent resistant to sulfate erosion and a preparation method thereof. The cement concrete modifying agent resistant to sulfate erosion is formed by mixing metakaolin, calcined hydrotalcite, fly ash and lime stone powder, wherein the admixture amount of the metakaolin is 50-70%, the admixture amount of the calcined hydrotalcite is 15-30%, the admixture amount of the fly ash is 10-20%, and the admixture amount of the lime stone powder is 0-10%. When metakaolin is doped in cement concrete, the metakaolin reacts with calcium hydroxide in cement hydrated products, a large amount of hydrated calcium silicate and hydrated calcium aluminate are generated, holes in the concrete is filled with the hydrated calcium silicate and the hydrated calcium aluminate, transfer of harmful sulfate ions in the concrete is delayed, and therefore the sulfate erosion resistance of the cement concrete is improved. According to the cement concrete modifying agent resistant to sulfate erosion, the sulfate erosion resistance and the compressive strength of the concrete can be remarkably improved at low admixture amount, and meanwhile the working performance of the concrete is not affected.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

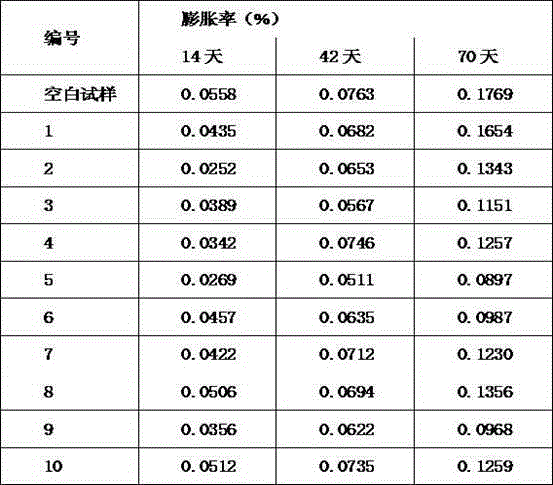

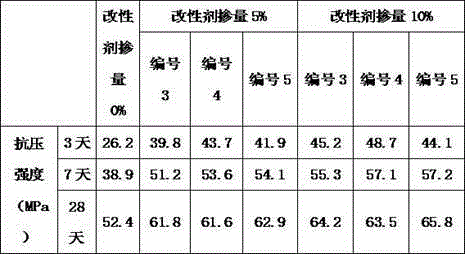

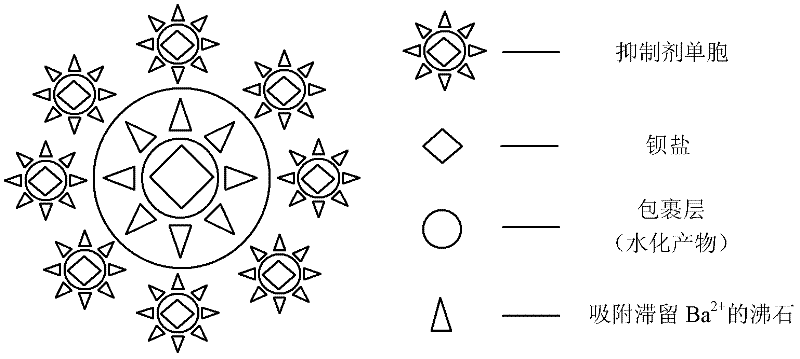

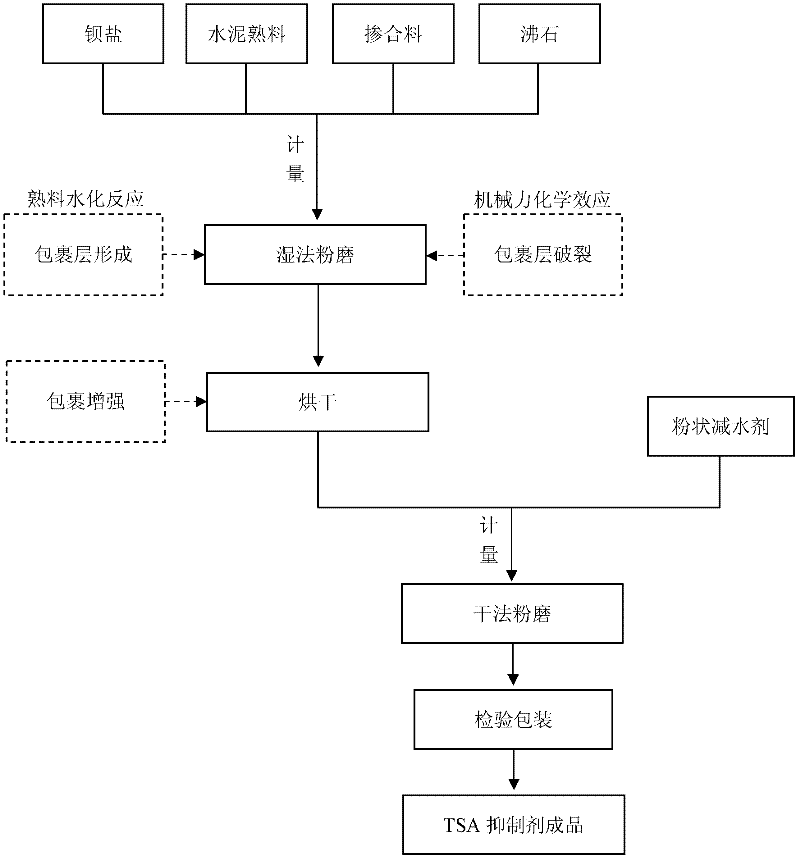

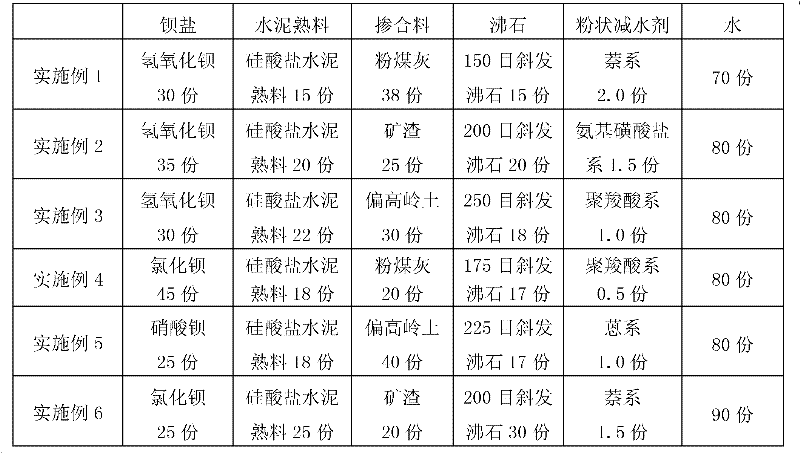

Thaumasite form sulfate attack (TSA) inhibitor, preparation method thereof and application thereof

The invention discloses a TSA inhibitor, a preparation method thereof and an application thereof. The TSA inhibitor comprises the following components, by weight, 25-45 parts of a barium salt, 15-25 parts of cement clinker, 20-40 parts of an admixture, 15-30 parts of zeolite, and 0.5-2.0 parts of a powdery water reducer. The TSA inhibitor has a multistage long-acting sustained-release characteristic to Ba<2+>, can durably improve the TSA destroy resistance of a cement-based material, and has a certain improvement effect on the workability, the strength, and the endurance of the cement-based material; and the preparation method of the invention has the advantages of simple technology of a used overlying packing technology, high efficiency, and strong adaptability. Experiments prove that the TSA inhibitor of the invention can substantially improve the TSA destroy resistance of the cement-based material, and can durably and effectively prevent the cement-based material from the TSA destroy.

Owner:CHINA BUILDING MATERIALS ACAD

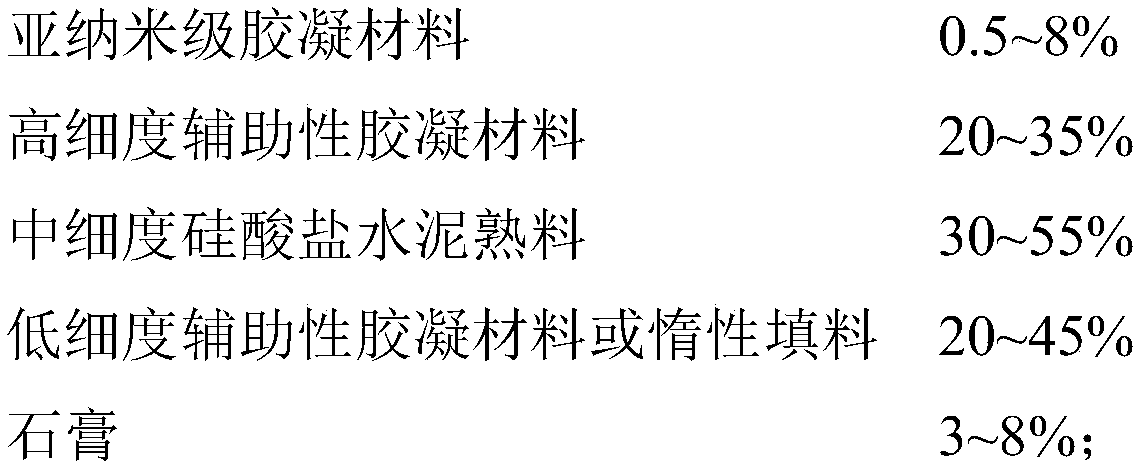

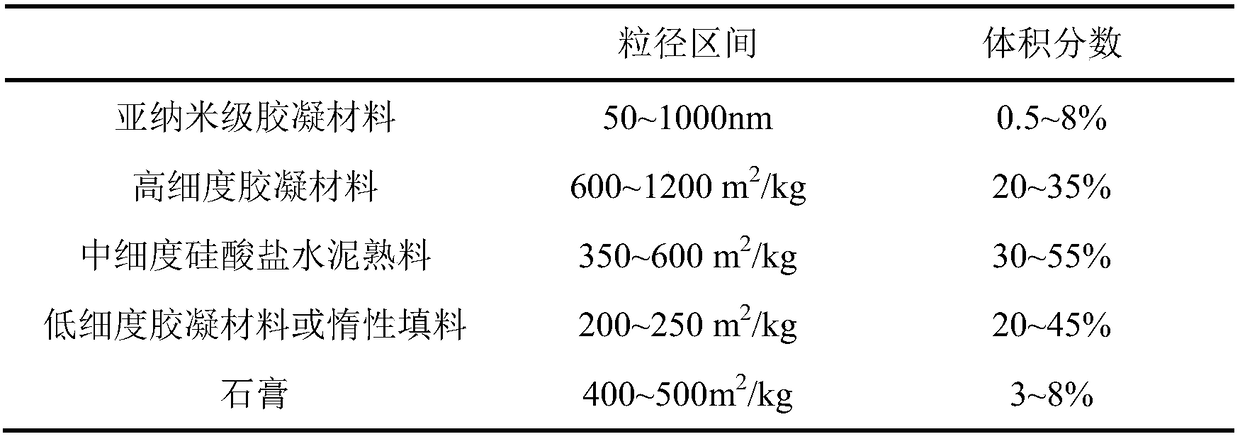

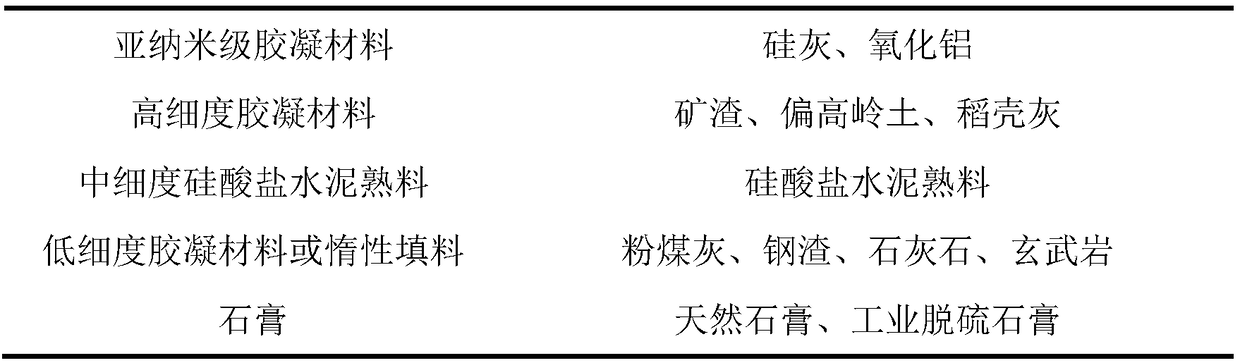

High-anticorrosion composite Portland cement and production method thereof

InactiveCN109020270AHigh strengthHigh resistance to sulfate attackCement productionSeawaterMaterials science

The invention belongs to the technical field of Portland cements, and discloses a high-anticorrosion composite Portland cement and a production method thereof. The high-anticorrosion composite Portland cement is mainly comprises, by volume, 0.5-8% of a sub-nanometer cementing material, 20-35% of a high-fineness auxiliary cementing materials, 30-55% of a medium-fineness Portland cement clinker, 20-45% of a low-fineness auxiliary cementing material or an inert filler and 3-8% of gypsum. The composite Portland cement has a good compressive strength and a high corrosion resistance, for example, the 28 d compressive strength is 45-65 MPa, the sulfate corrosion resisting coefficient is 1.1-1.3, the seawater erosion resisting coefficient is 1.2-1.4, and the chloride ion diffusion coefficient is 0.4 * 10<-12> to 0.8 * 10<-12> m<2> / s. The composite Portland cement is applied to fields with high requirements of the corrosion resistance.

Owner:SOUTH CHINA UNIV OF TECH

Sulfate-corrosion-resistant concrete and preparation method thereof

The invention discloses sulfate-corrosion-resistant concrete and a preparation method thereof, belonging to the technical field of concrete. The key points of the technical scheme are as follows, rawmaterials of the sulfate-corrosion-resistant concrete comprise, by weight, 240 to 360 parts of cement, 150-190 parts of water, 70-90 parts of fly ash, 80 to 120 parts of mineral powder, 660 to 760 parts of fine aggregate, 1200 to 1500 parts of coarse aggregate, 50-70 parts of epoxy resin, 10 to 20 parts of silica fume, 7 to 9 parts of additives, 1 to 4 parts of barium hydroxide, 0.2 to 0.5 part ofsodium citrate and 2 to 10 parts of steel fibers, wherein the additives comprise polycarboxylic acid, organic silicon oil and rosin soap in a weight ratio of (1.0 to 1.4) to 1.2 to (1.8 to 2.2). Thepreparation method of the sulfate-corrosion-resistant concrete comprises the following steps of stirring and mixing other components except water, adding water, and stirring for 10-20 minutes to obtain the sulfate-corrosion-resistant concrete. The sulfate-corrosion-resistant concrete disclosed by the invention has the effects of sulfate corrosion resistance and durability.

Owner:BEIJING TAIPINGYANG CEMENT PROD CO LTD

Three-slag mixed material with waste gypsum modified flyash

The three-slag mixed material with waste gypsum modified flyash consists of flyash with total AlO2 and Al2O3 content not less than 70 % in 5-30 wt%, slaked lime with active calcium oxide and magnesium oxide content at least 30 % in 5-15 wt%, crushed stone in 60-84 wt%, early strengthening agent in 0.5-1 wt%, waste gypsum with SO3 content at least 36 % in 0.5-7.5 wt% and water in 30 wt%. The three-slag mixed material, after being spread, can reach the strength requirement of road base in seven days, has no expansion, and has its antifreezing performance, wet-dry circulation resistance and sulfate corrosion resistance higher than common three-slag mixed material for road base.

Owner:SHANGHAI JINGAN NEW BUILDING MATERIAL SCI INST

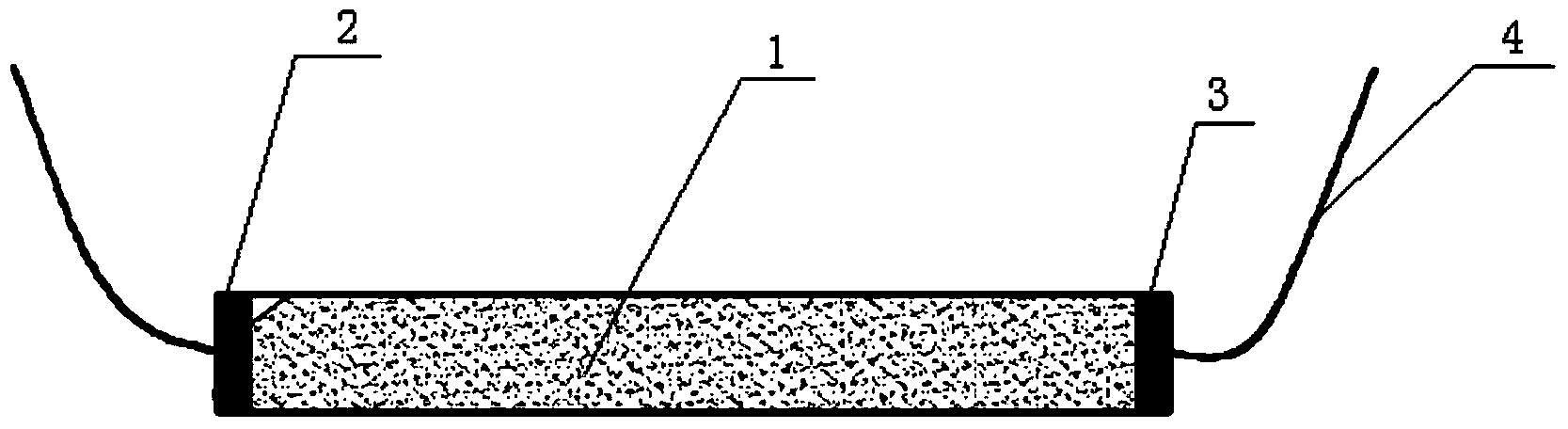

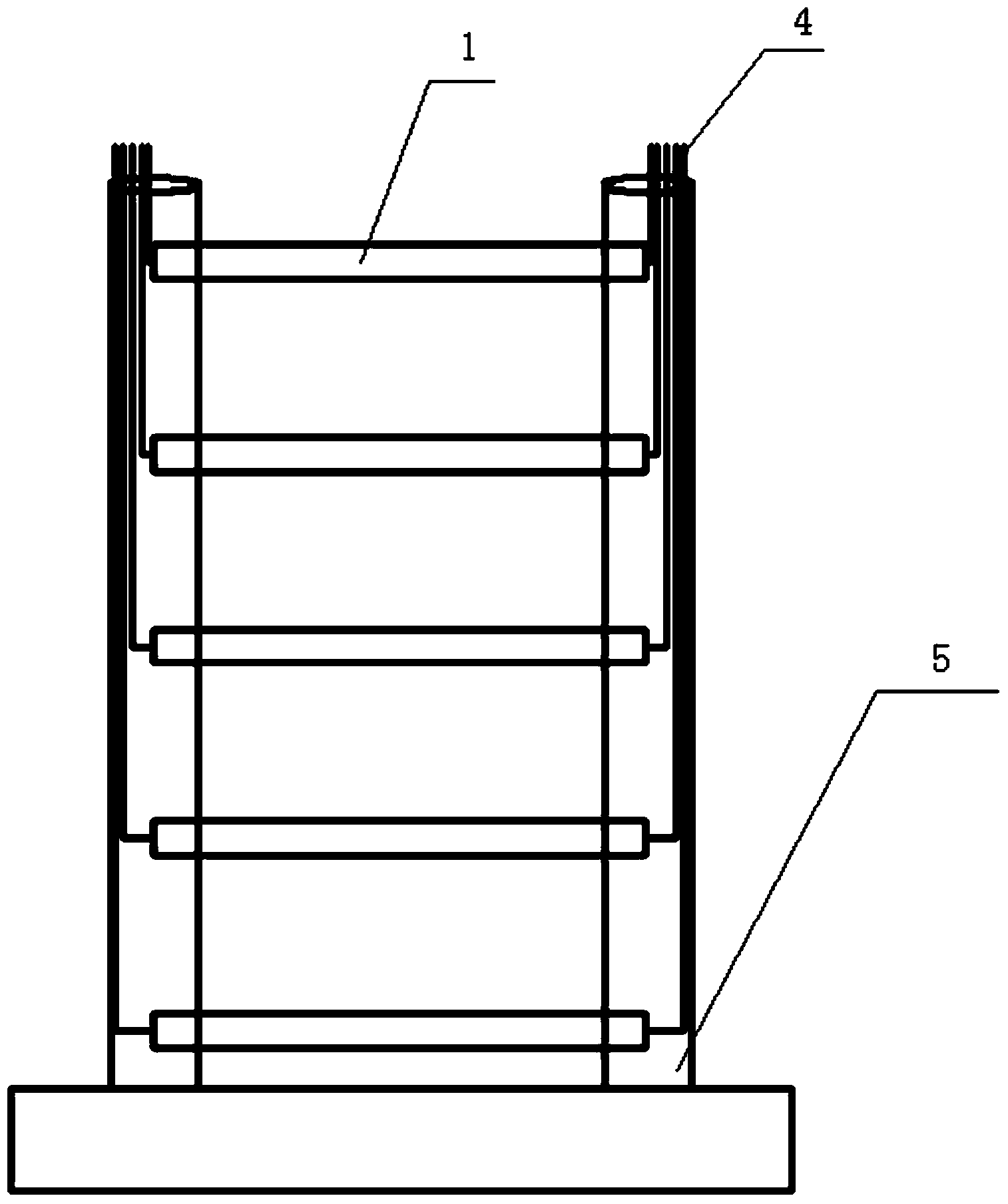

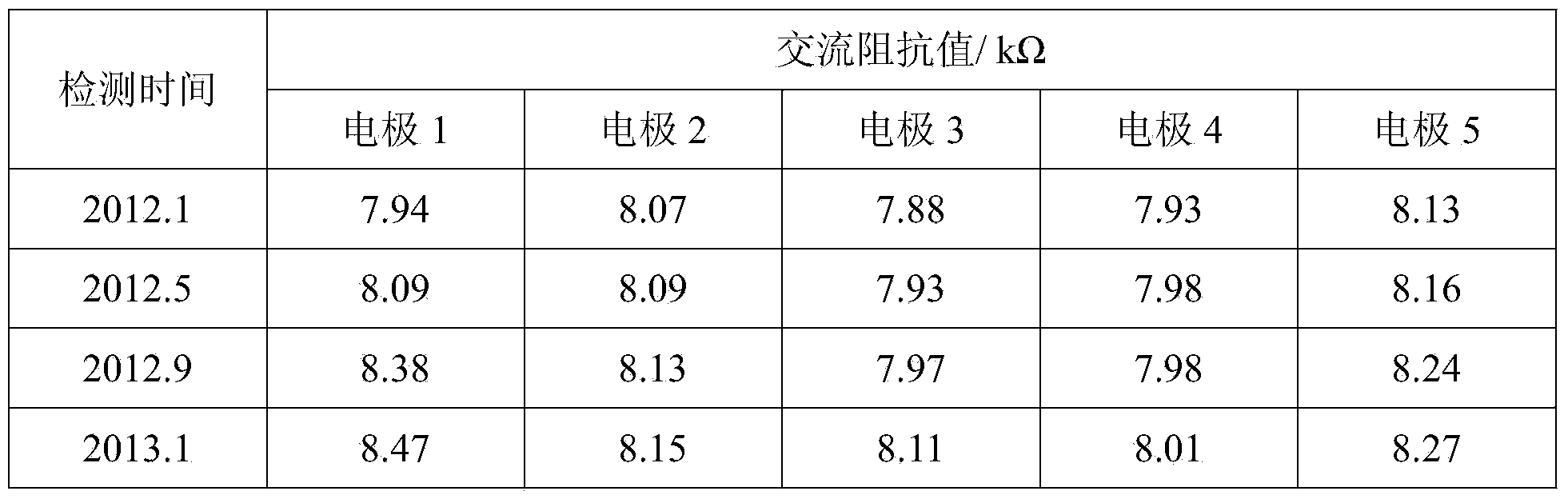

Cement-based mortar sensing electrode internally doped with nano-conductive material, as well as preparation method and application thereof

The invention provides a cement-based mortar sensing electrode internally doped with a nano-conductive material. The cement-based mortar sensing electrode comprises a cement base body, as well as graphene and nano-conductive carbon black which are dispersed in the cement base body. The invention further provides a preparation method of the electrode. The invention further provides a device for monitoring and sensing sulfate attack in concrete, which comprises the electrode. The electrode has the advantages of simple preparation process, low cost, stable performance, sensitivity in response and reliable detection data.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com