Thaumasite form sulfate attack (TSA) inhibitor, preparation method thereof and application thereof

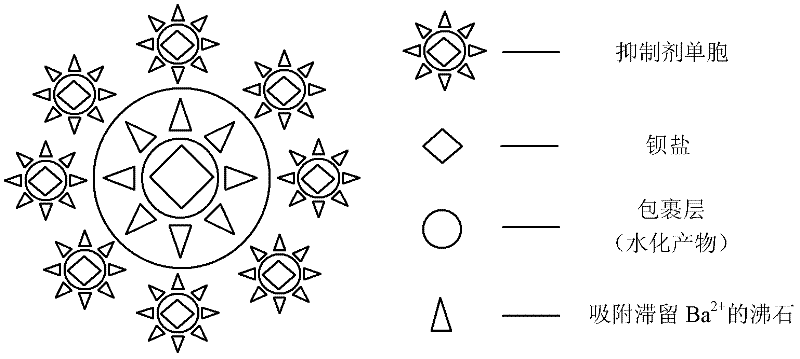

A tobermorite and inhibitor technology, applied in the field of TSA inhibitor and its preparation, and tobermorite-type sulfate corrosion inhibitor, can solve problems affecting the workability of cement-based materials, complex preparation process and numerous raw materials and other problems, to achieve the effect of improving the resistance to TSA damage, the process is simple, and the application prospect is broad.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

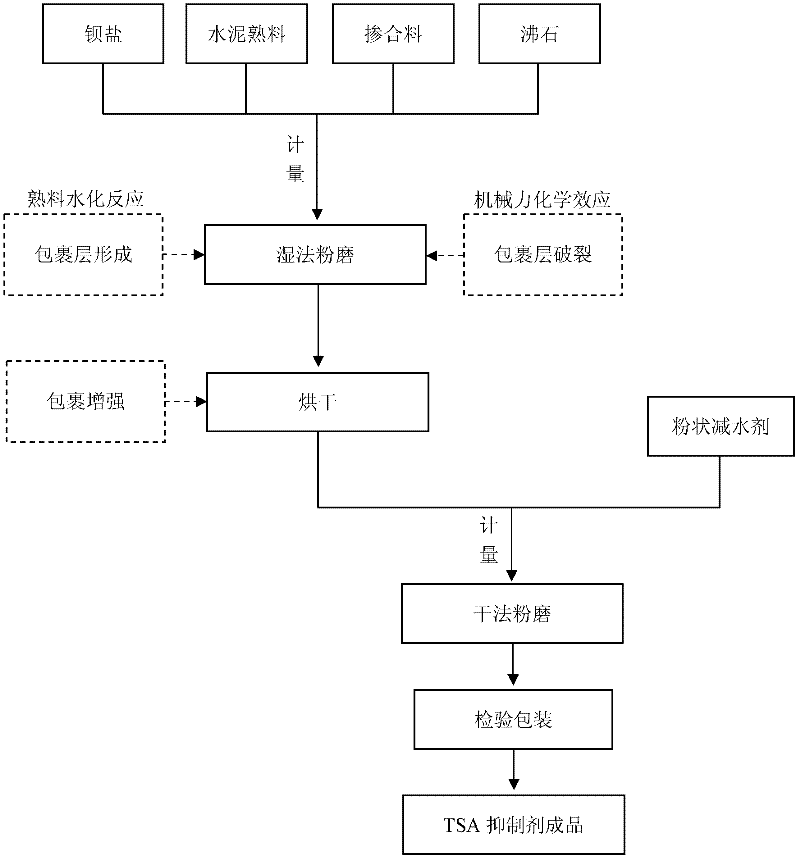

[0039] The present invention also provides a method for preparing the above-mentioned molarite-type sulfate corrosion inhibitor, the flow chart of the preparation method is as follows: figure 2 As shown, the following steps may be included:

[0040] 1) Weigh raw materials: 25-45 parts of barium salt, 15-25 parts of cement clinker, 20-40 parts of admixture, 15-30 parts of zeolite, 0.5-2.0 parts of powdered water reducer, 70-90 parts of water ;

[0041] 2) Wet grinding: Add barium salt, cement clinker, admixture, zeolite and water into the wet ball mill for mixing;

[0042] 3) drying: drying the wet mixed grinding slurry obtained in step 2) in an oven to constant weight;

[0043] 4) Dry grinding: add 98.0-99.5 parts of the wet mixed grinding slurry after drying in step 3) and 0.5-2.0 parts of powdered water reducer into the dry ball mill, and mix and grind until the Blaine specific surface area (350 ±10)m 2 / kg to obtain a molarite-type sulfate attack inhibitor.

[0044] I...

Embodiment 1-6

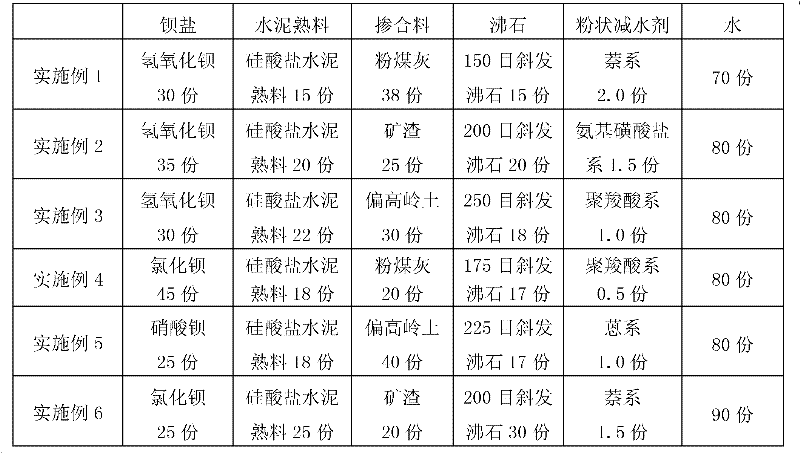

[0052] Embodiment 1-6, preparation of molarite type sulfate corrosion inhibitor

[0053] The preparation raw materials of the embodiment of the present invention 1-6 carbon sulfonotlite type sulfate corrosion inhibitor are as shown in table 1:

[0054] The raw materials for the preparation of table 1 embodiment 1-6 carbon sulfonotlite type sulfate erosion inhibitor

[0055]

[0056] Note: "Parts" refers to parts by weight, and the unit is kilogram or gram. The measurement basis can be set according to the actual scale, such as 1 part = 100 grams.

[0057] The preparation method of embodiment 1-6 molarite type sulfate erosion inhibitor comprises the following steps:

[0058] 1) Take the raw materials according to the formula shown in Table 1;

[0059] 2) Wet grinding: add barium salt, cement clinker, admixture, zeolite and water into a wet ball mill (model Φ1.2×2.4m) and mix and grind for (30±2) minutes;

[0060] 3) Drying: Dry the wet mixed grinding slurry obtained in st...

Embodiment 7

[0062] Embodiment 7, the detection of molarite type sulfate corrosion inhibitor

[0063] Detect the preventive TSA damage effect and action time of the carbon-sulfur wollastonite type sulfate erosion inhibitor of the present invention, the method is: to cement-limestone powder composite cementitious material (70 parts of cement+30 parts of limestone powder, water-cement ratio 0.40) Mix 2.0%~4.0% (mass percentage content) TSA inhibitor prepared by embodiment 1-6 respectively, take the cement-limestone powder composite cementitious material that mixes 1.5% (mass percentage content) barium hydroxide as Control, then placed at (5±2)°C, 5% MgSO 4 The solution was tested after 1 year respectively. The test items include the inspection of the appearance of the sample and the inspection of the MgSO 4 Determination of molarite content in solution (using XRD / Rietveld method). The results are shown in Table 2:

[0064] Table 2: Test results of cement-limestone powder composite cement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com