Patents

Literature

500 results about "Barium salt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

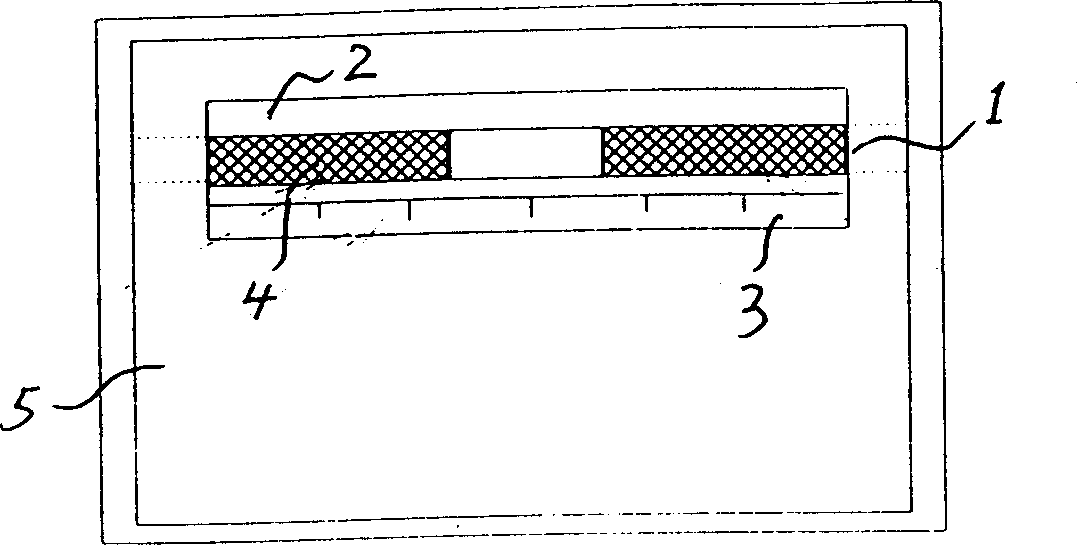

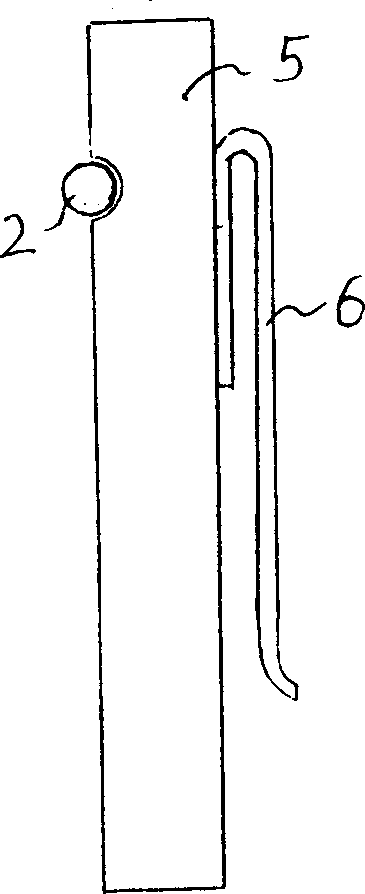

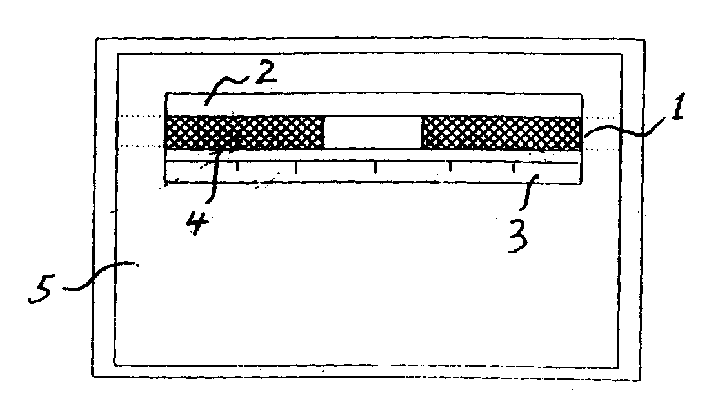

Absorbable implants and methods for their use in hemostasis and in the treatment of osseous defects

ActiveUS20050065214A1Stimulate bone healing processLower potentialBiocidePowder deliveryBarium saltTG - Triglyceride

Two (or more), -component, body-implantable, absorbable, biocompatible, putty, and non-putty hemostatic tamponades for use in surgery. Component 1 is a finely powdered bulking material, preferably less than 50 microns, e.g. the calcium, magnesium, aluminum, or barium salts of saturated or unsaturated carboxylic acids containing about 6 to 22 carbon atoms, hydroxyapatite, DBM, polyglycolide, polylactide, poldioxinones, polycaprolactones, absorbable glasses, gelatin, collagens, mono, and polysaccharides starches. Component 2, a dispersing vehicle, may be esters of C8-C18 monohydric alcohols with C2-C6 aliphatic monocarboxylic acids; C2-C18 monohydric alcohols with polycarboxylic acids; C8-C30 monohydric alcohols; tocopherol and esters thereof with C2-C10 aliphatic monocarboxylic acids or polycarboxylic acids; absorbable 10-14C hydrocarbons; free carboxylic acids such as oleic, capric, and lauric; dialkyl ethers and ketones; alkyl aryl ethers and ketones, polyhydroxy compounds and esters and ethers thereof; (ethylene oxide / propylene oxide copolymers), oils e.g. olive oil, castor oil and triglycerides.

Owner:ABYRX

Absorbable implants and methods for their use in hemostasis and in the treatment of osseous defects

ActiveUS20060013857A1Lower potentialMinimally inhibit osteogenesis and subsequent bone healingSurgical adhesivesSkeletal disorderBarium saltApatite

Two (or more), -component, body-implantable, absorbable, biocompatible, putty, and non-putty hemostatic tamponades for use in surgery. Component 1 is a finely powdered bulking material, preferably less than 50 microns, e.g. the calcium, magnesium, aluminum, or barium salts of saturated or unsaturated carboxylic acids containing about 6 to 22 carbon atoms, hydroxyapatite, DBM, polyglycolide, polylactide, poldioxinones, polycaprolactones, absorbable glasses, gelatin, collagens, mono, and polysaccharides starches. Component 2, a dispersing vehicle, may be esters unsubstituted and N-substituted pyrrolidones of C8-C18 monohydric alcohols with C2-C6 aliphatic monocarboxylic acids; C2-C18 monohydric alcohols with polycarboxylic acids; C8-C30 monohydric alcohols; tocopherol and esters thereof with C2-C10 aliphatic monocarboxylic acids or polycarboxylic acids; absorbable 10-14C hydrocarbons; free carboxylic acids such as oleic, capric, and lauric; dialkyl ethers and ketones; alkyl aryl ethers and ketones, polyhydroxy compounds and esters and ethers thereof; (ethylene oxide / propylene oxide copolymers), oils e.g. olive oil, castor oil and triglycerides.

Owner:ABYRX

Absorbable putty-like implants and methods for their use for mechanical hemostasis of bone and for the treatment of osseous defects

ActiveUS20060002976A1Lower potentialImproved bone healingPowder deliverySurgical adhesivesBarium saltTG - Triglyceride

Two (or more), component, body-implantable, absorbable, biocompatible, putty-like surgical mechanical hemostatic tamponades for use in surgery. Component 1, a carboxylic acid salt bulking material preferably less than 50 micron, preferably the calcium, magnesium, zinc, aluminum, lithium or barium salts of saturated or unsaturated carboxylic acids containing about 6 to 22 carbon atoms. Component 2, a dispersing vehicle, may be esters of C8-C18 monohydric alcohols with C2-C6 aliphatic monocarboxylic acids; C2-C18 monohydric alcohols with polycarboxylic acids; C8-C30 monohydric alcohols; tocopherol and esters thereof with C2-C10 aliphatic monocarboxylic acids or polycarboxylic acids; absorbable 10-14C hydrocarbons; free carboxylic acids such as oleic, linoleic, caprylic, capric, and lauric; dialkyl ethers; alkyl aryl ethers; dialkyl ketones and alkyl aryl ketones; polyhydroxy compounds and esters and ethers thereof; oils such as olive oil and castor oil and triglycerides.

Owner:ABYRX

Method for preparing chloroethylene by catalytic reforming

InactiveCN101817723ASolve the problem of high temperature energy consumptionSolve pollutionPhysical/chemical process catalystsHalogenated hydrocarbon preparationCatalytic reformingActivated carbon

The invention discloses a method for preparing chloroethylene by catalytic reforming, which relates to a method for preparing the chloroethylene. The method comprises: a step of preparing a catalyst by using active carbon as a carrier, in which a barium salt is used as a catalyst, the active carbon is used as the catalyst carrier, and the barium salt is dissolved in water, absorbed by the active carbon and dried to obtain the catalyst carried by the active carbon; and a step of synthesizing the chloroethylene, in which acetylene gas and dichloroethane vapour are mixed and introduced to a reactor containing the catalyst carried by the active carbon to react, the reaction effluent is cooled to room temperature, unreacted dichloroethane is condensed to be separated out, and the remaining gas is compressed and frozen to give liquid chloroethylene. In the invention, a mercury free catalyst is adopted, the mercury pollution of the chloroethylene production industry is eliminated, and the reaction is performed spontaneously with little energy consumption.

Owner:ZHONGKE YIGONG SHANGHAI CHEM TECH CO LTD

High-chloride-capacity liquid-phase dechlorinating agent as well as preparation method and application thereof

InactiveCN104437342ASmooth appearanceAvoid crackingOther chemical processesHydrocarbon oils refiningHas active ingredientAlkaline earth metal

The invention provides a high-chloride-capacity liquid-phase dechlorinating agent as well as a preparation method and an application thereof. The high-chlorine-capacity liquid-phase dechlorinating agent is suitable for removing inorganic chlorine from an oil product and is particularly suitable for removing hydrogen chloride from reformate. A carrier of the dechlorinating agent is a carbon molecular sieve, active ingredients of the dechlorinating agent comprise an alkali metal and an alkali earth metal oxide, and an auxiliary agent component is copper oxide, ferric oxide or zinc oxide. The preparation method of the solid dechlorinating agent provided by the invention comprises the following steps: dipping soluble copper salt, calcium salt, magnesium salt, barium salt and the like to a cylindrical carbon molecular sieve, drying, and performing stabilizing treatment to obtain the dechlorinating agent. The dechlorinating agent provided by the invention has the advantages of being relatively high in chloride capacity, low-price and easily available in raw material, having active ingredients uniformly distributed on the carrier, good in thermal stability, strong in water resistance, high in mechanical strength and the like, and the dechlorinating agent has desulfurization and denitrification effects at the same time.

Owner:TIANJIN POLYTECHNIC UNIV

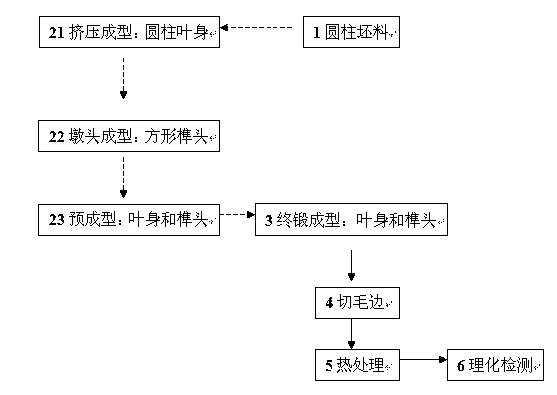

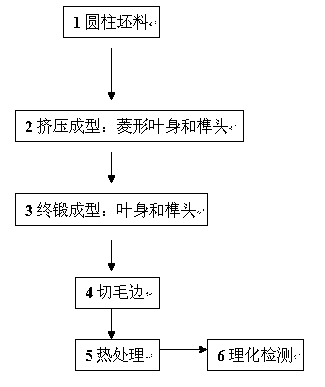

Manufacture method for ultra-fine grain and high-intensity alloy blade forged piece

ActiveCN103009018AShorten the design cycleReduce design processEngine componentsHeating/cooling devicesBarium saltMaterial consumption

The invention provides a manufacture method for an ultra-fine grain and high-intensity alloy blade forged piece. The manufacture method for the ultra-fine grain and high-intensity alloy blade forged piece comprises the following manufacture processes of extruding, finally forging, cutting burrs and carrying out thermal treatment and is characterized in that a barium salt furnace is adopted to heat before the extrusion process; an extrusion die is a ''rhombic blade body and rabbet'' split-type square frustum structure; and the throat part of the extrusion die is strengthened. According to the manufacture method for the ultra-fine grain and high-intensity alloy blade forged piece, which is disclosed by the invention, the die design period and the product technology flow are shortened, the material consumption is lowered, and the cost is saved. Meanwhile, the mean grain size of the prepared forged piece performance tissue is less than the tenth grade, and the performance achieves the level of a high-strength forged piece.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Long-acting emulsion-type antirust fluid

InactiveCN101608310AGood oil solubilityGood water solubilityDiethylene glycol monobutyl etherBarium salt

The invention relates to a long-acting emulsion-type antirust fluid used for metal rust prevention. Every 100 parts of the antirust fluid include the following components according to parts by weight: 3-15 oil soluble surfactant, 1-10 alcohol ether type couplant, 1-10 oily-type rust preventive and the balance base oil, wherein the oil soluble surfactant is any one of petroleum sodium sulfonate with molecular weight ranging from 300 to 800, sodium heavy alkylbenzene sulfonate and sodium sulfanilate, the alcohol ether type couplant is any one of ethyl alcohol, ethyl ether, butyl ether, diethylene glycol monobutyl ether, diethylene glycol propyl ether, butyl glycol ether and ethylene glycol propyl ether, the oily-type rust preventive is any one of barium petroleum sulfonate, dinonyl naphthalenesulfonic acid barium salt and barium soap of petroleum ester oxide, and the base oil is any one of cycloalkyl base oil and paraffin base oil. The long-acting emulsion-type antirust fluid has the advantages of meeting the demands of short-term rust prevention of metal and having lower using cost.

Owner:NANJING KERUN LUBRICANTS

Salts of benzimidazole compound and use thereof

InactiveUS20030181487A1Improve stabilityExcellent antiulcer actionAntibacterial agentsBiocideBarium saltMagnesium salt

Owner:TAKEDA PHARMA CO LTD

Method for producing polycrystal ingot

InactiveCN101696514AIncrease profitImprove efficiencyPolycrystalline material growthBy pulling from meltBarium saltShielding gas

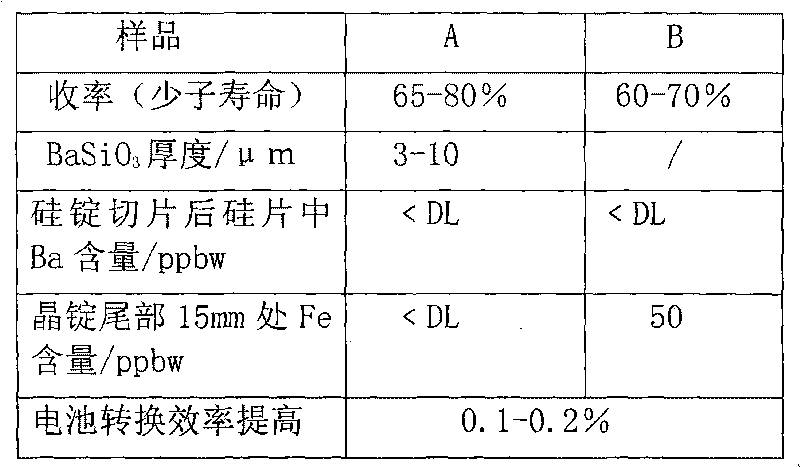

The invention relates to a method for producing a polycrystal ingot, which comprises the following steps: preparing a solution of barium hydroxide or a barium salt serving as a coating solution; preheating a quartz ceramics crucible; uniformly coating the coating solution of the solution of the barium hydroxide or the barium salt on the inner surface of the preheated quartz ceramics crucible; baking the quartz ceramics crucible; spraying silicon nitride on the inner surface of the quartz ceramics crucible after baking and rotating the quartz ceramics crucible; filling a silicon material into the quartz ceramics crucible; putting the quartz ceramics crucible into a polycrystal furnace; vacuumizing the polycrystal furnace and adding a protective gas to the polycrystal furnace; heating the silicon material to smelt the silicon material; gradually crystallizing the melted silicon material from the bottom to the top by directional solidification; at last performing high temperature annealing to form the polycrystal ingot used for making a battery through slicing; slicing a crystal ingot into silicon slices; making the silicon slices into battery plates by making herbs into wool, diffusing, etching edges, PECVD filming, screen painting and sintering; and testing and grading the battery plates. The coating in the crucible prevents impurities in the crucible from diffusing to the silicon material, and improves the lifetime of minority carrier close to the crucible, the utilization rate of the crystal ingot and the battery conversion efficiency.

Owner:TRINA SOLAR CO LTD

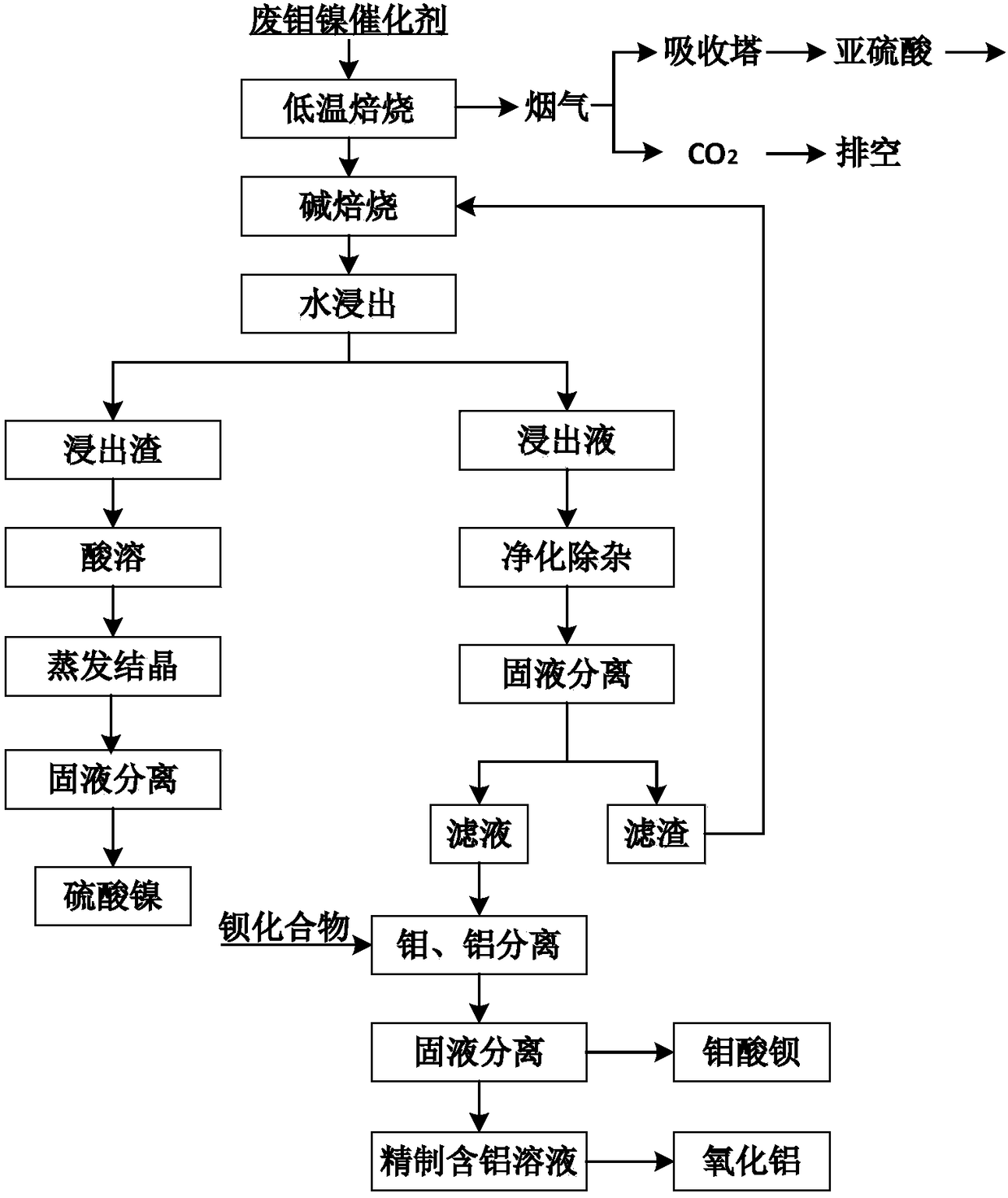

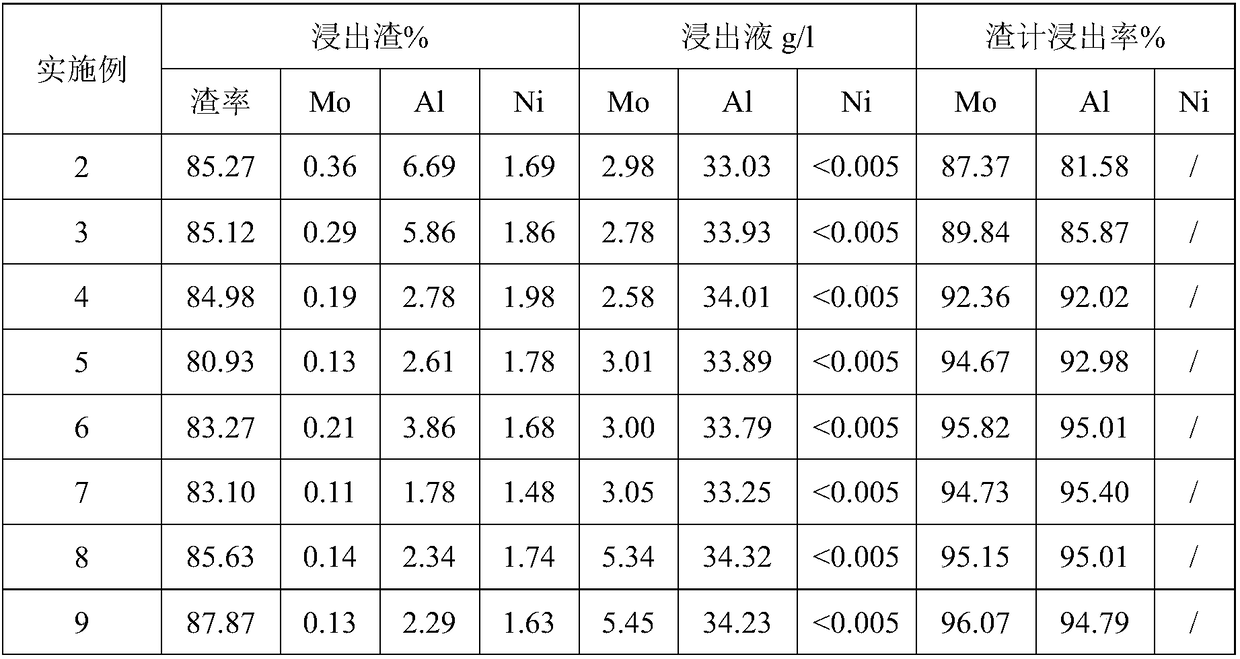

Method for recovering nickel and molybdenum from waste nickel-molybdenum catalyst

The invention discloses a method for recovering nickel and molybdenum from a waste nickel-molybdenum catalyst. The method comprises the concrete steps of firstly carrying out primary low-temperature roasting, then carrying out secondary high-temperature alkali roasting, and transforming molybdenum and aluminum components in the waste catalyst into water-soluble sodium molybdate and sodium metaaluminate; then carrying out water leaching and solid-liquid separation to obtain a nickel slag and an alkaline filter liquor containing molybdenum and aluminum; carrying out acid leaching, evaporative crystallization and solid-liquid separation on the nickel slag to obtain a nickel sulfate product; and adding a barium salt precipitant into the filter liquor to separate the aluminum and the molybdenum, obtaining a refined aluminum-containing solution, adopting a chemical precipitation method to obtain an aluminum hydroxide precipitate, and calcining to obtain an aluminum oxide product. According to the method for recovering the nickel and the molybdenum from the waste nickel-molybdenum catalyst provided by the invention, valuable metals in the catalyst is comprehensively recycled, three products such as nickel sulfate, barium molybdate and aluminum oxide are obtained, the valuable metal recovery rate is high, the product added value is high, and the method has a certain application value.

Owner:XUZHOU GUOMAO VALUABLE & RARE METAL COMPREHENSIVE UTILIZATION INST +1

Method for producing industrial ammonium dihydrogen phosphate

InactiveCN102701167AIncrease added valueReduce manufacturing costPhosphatesBarium saltPhosphoric acid

The invention discloses a method for producing industrial ammonium dihydrogen phosphate, which comprises the following steps: 1) adding a certain amount of phosphorite slurry into phosphoric acid by wet process, reacting and standing by for a period of time, and initially desulfurizing; 2) taking supernatant liquor, adding a certain amount of barium salt and sodium salt, thereby deeply desulfurizing and defluorinating; 3) introducing ammonia for neutralizing, and then filtering, thereby obtaining an ammonium acid phosphate solution containing few impurities; and 4) mixing the solution with phosphoric acid purified according to a solvent extraction method in proportion, adjusting neutralizing degree, concentrating and crystallizing, thereby obtaining the industrial ammonium dihydrogen phosphate. A chemical precipitation method is used for purifying the phosphoric acid by wet process produced by using medium / low-grade phosphorite; the purifying degree is not enough, so that the chemical precipitation method cannot be directly used for producing the industrial ammonium dihydrogen phosphate. Less solvent is added for purifying the phosphoric acid according to the solvent extraction method and then the concentrating and crystallizing are performed, thereby obtaining the ammonium dihydrogen phosphate which can reach II class standard in HG / T4133-2010. The production cost is lowered.

Owner:中化化肥有限公司重庆磷复肥工程技术研究中心

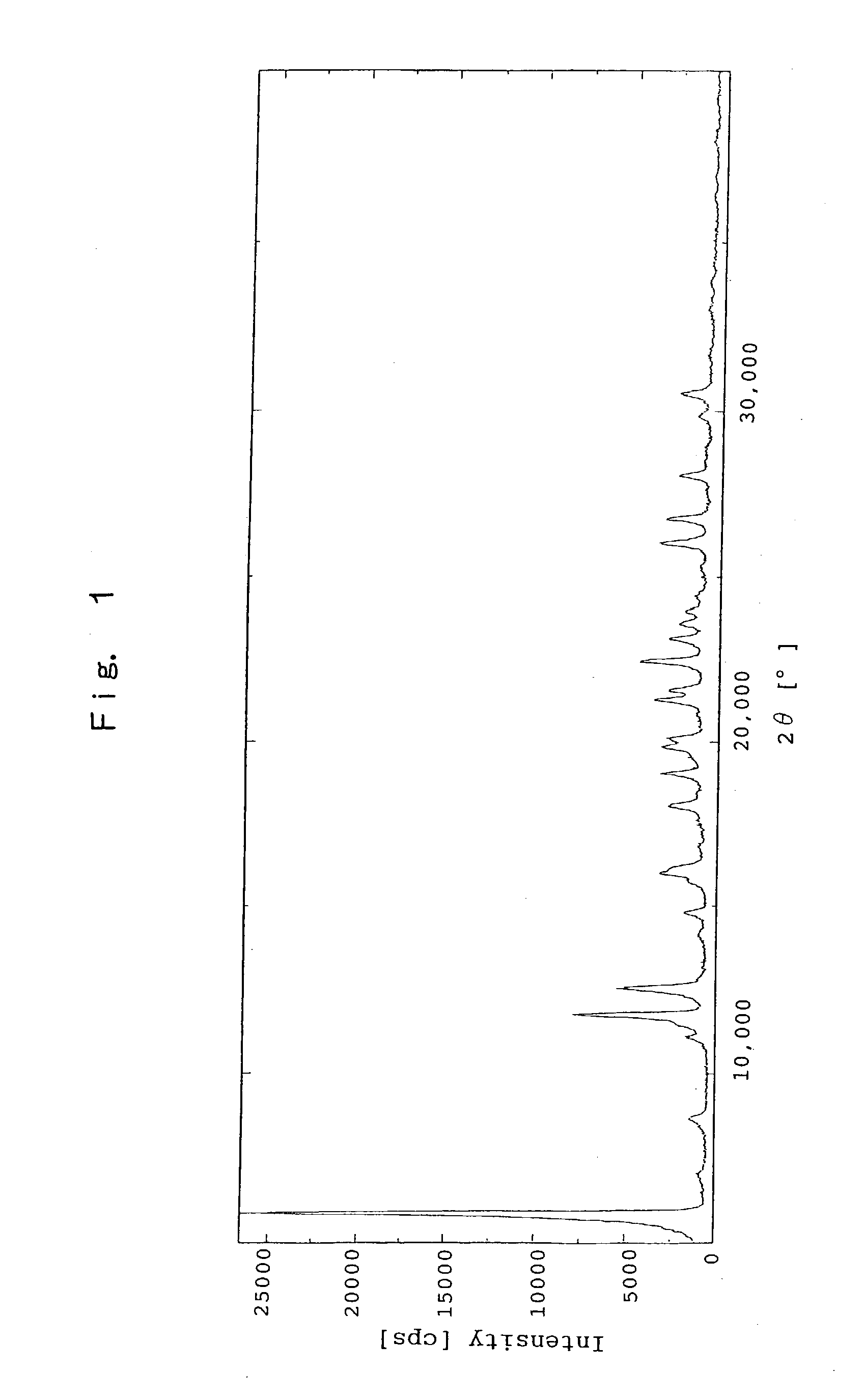

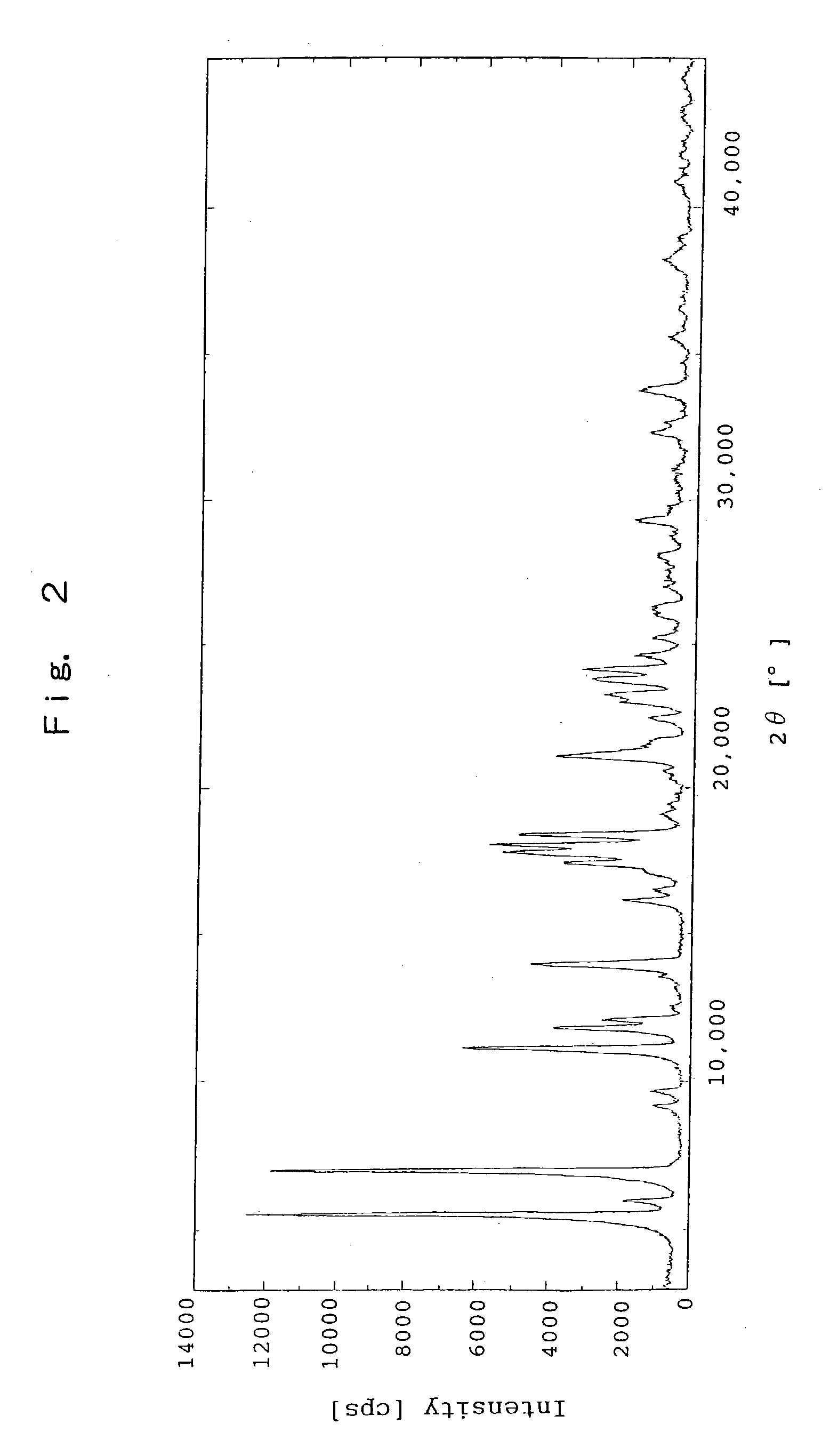

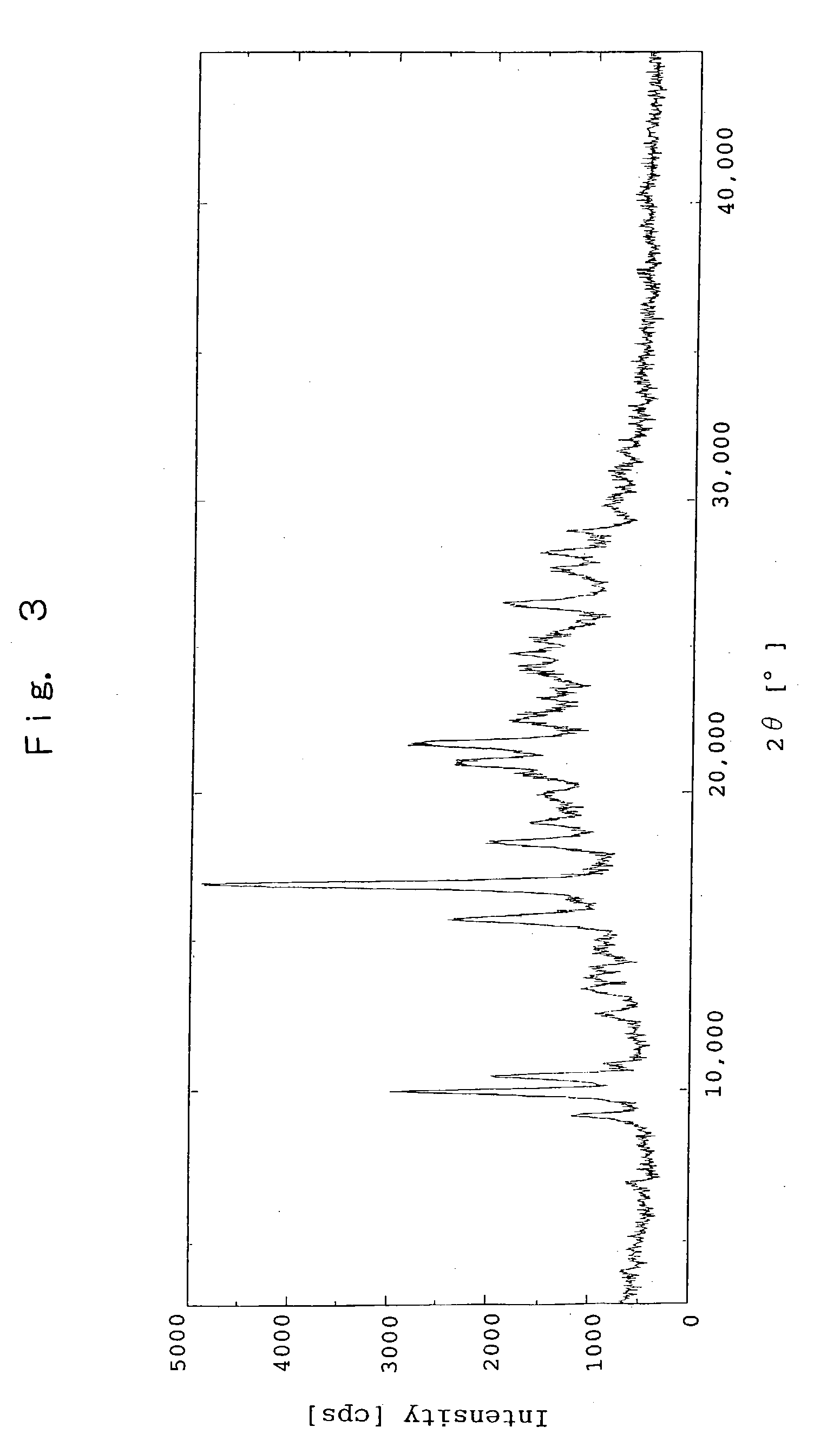

High purity metaphosphate and method for production thereof

A high purity metaphosphate, characterized in that it contains each coloring metal element in an amount of 5 ppm or less. Metaphosphates include an aluminum salt, a barium salt, a calcium salt, a magnesium salt and a strontium salt. Aluminum metaphosphate is suitably produced by a method comprising a first step of reacting an aluminum compound with phosphoric acid with heating to prepare a fluidized reaction mixture comprising aluminum biphosphate, a second step of spreading an aluminum metaphosphate powder in a vessel for firing, adding the fluidized reaction mixture comprising aluminum biphosphate from the first step on the powder and then firing them, and a third step of pulverizing the fired product from the second step.

Owner:NIPPON CHECMICAL IND CO LTD

Method for extracting vanadium and chromium from vanadium chromate mixed solution

InactiveCN106893877AReduce processing costsEasy to separateProcess efficiency improvementBarium saltSlag

The invention relates to a method for extracting vanadium and chromium from a vanadium chromate mixed solution. The method has the characteristics that the vanadium in the vanadium chromate mixed solution is separated and recycled through the crystallization precipitation method or the hydrolysis precipitation method or the calcium salt precipitation method at first, then the chromium in the enrichment solution is separated through the copper salt precipitation method or the barium salt precipitation method, an obtained chromium precipitation enrichment product is then transformed into chromium enrichment liquid, the chromium enrichment liquid is further processed into products of chromic acid and chromate, and production of vanadium-chromium reducing slag and ammonia-nitrogen wastewater in the separation and recycling process of the vanadium and the chromium in the solution is effectively avoided. The method for extracting the vanadium and the chromium from the vanadium chromate mixed solution has the advantages of being good in vanadium and chromium separation effect, short in technological process, high in metal recycling rate, easy and convenient to operate, low in production cost, environmentally friendly and the like and is suitable for industrial production and application.

Owner:CENT SOUTH UNIV

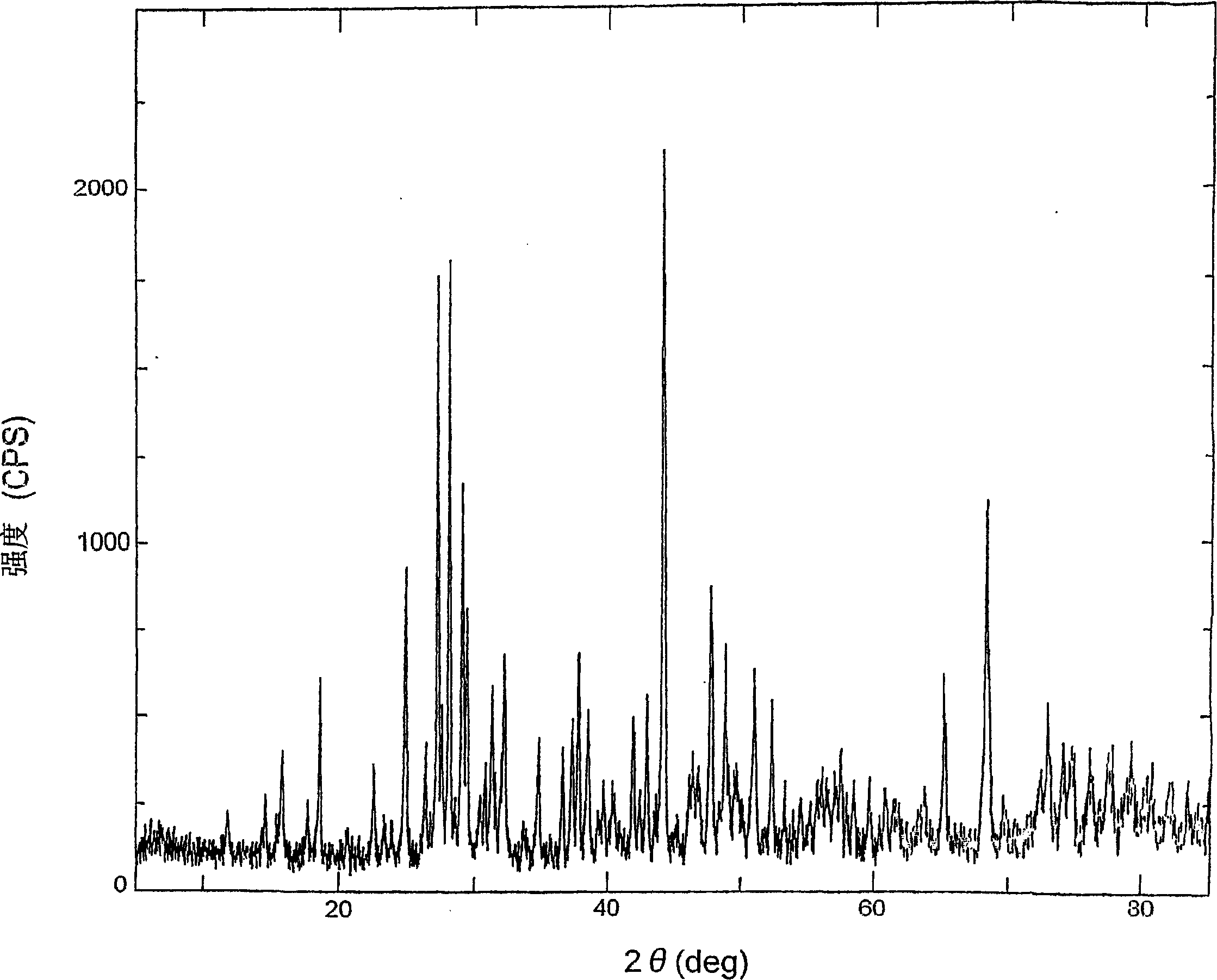

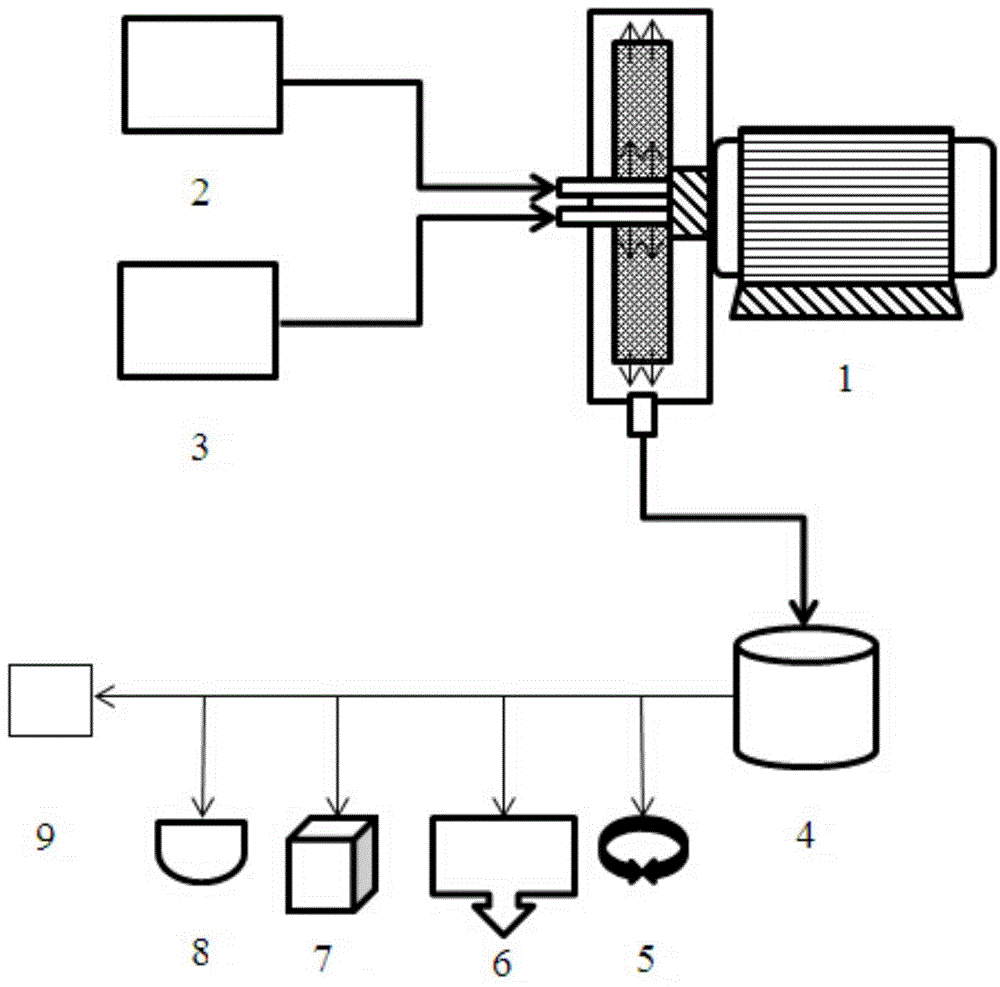

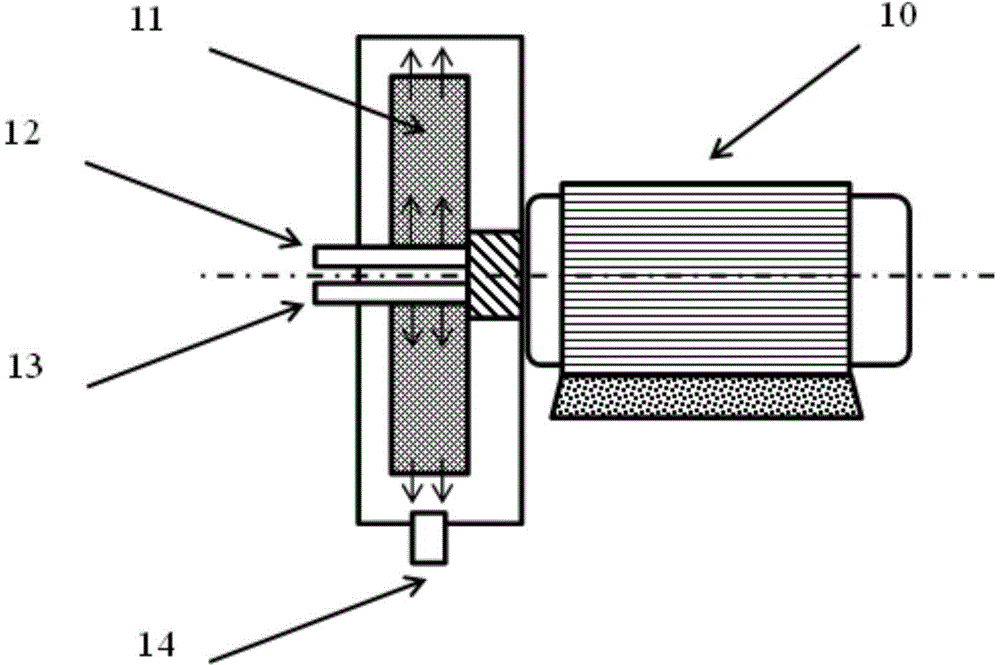

Method for preparing nanometer barium sulfate by using molecule mixing strengthening reactor

ActiveCN105329930ASmall particle sizeIncrease the nucleation rateMaterial nanotechnologyCalcium/strontium/barium sulfatesSulfateBarium salt

The invention discloses a method for preparing nanometer barium sulfate by using a molecule mixing strengthening reactor. A barium salt solution and dilute sulphuric acid or a sulphate solution are added into the molecule mixing strengthening reactor for reaction, after reaction, a barium sulfate suspending liquid is obtained; the molecule mixing strengthening reactor is a hypergravity rotating packed bed reactor or a tube-in-tube microchannel reactor; aftertreatment for the obtained barium sulfate suspending liquid is carried out, and nanometer barium sulfate powder is obtained. The hypergravity rotating packed bed reactor or the tube-in-tube microchannel reactor has the advantages of simultaneous control of reaction temperature, concentration of reaction solution, injection rate and injection speed ratio, and requirements of reaction product nanometer barium sulfate obtained finally, such as particle sizes (all smaller than 30nm) are smallest and distribution is narrowest, are met.

Owner:BEIJING UNIV OF CHEM TECH

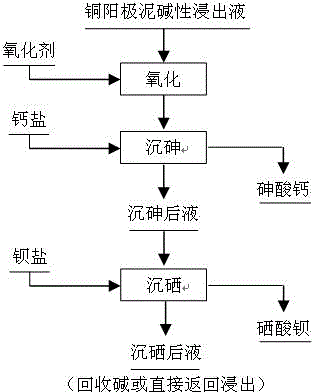

Method for separating arsenic and selenium from copper anode slime alkaline leach liquor

ActiveCN104911358ANo need to adjust pHRealize separation and enrichmentProcess efficiency improvementElemental selenium/telluriumPregnant leach solutionBarium salt

The invention discloses a method for separating arsenic and selenium from copper anode slime alkaline leach liquor. The method comprises the following steps: 1) oxidation, namely adding an oxidizing agent or introducing oxidizing gas into the copper anode slime alkaline leach liquor, so that oxidized copper anode slime alkaline leach liquor is obtained; 2) arsenic precipitation, namely adding a calcium salt into the oxidized copper anode slime alkaline leach liquor, stirring the obtained mixture so as to produce a precipitate, and carrying out filtration and separation on the precipitate so as to obtain a calcium arsenate precipitate and arsenic post-precipitation liquid; and 3) selenium precipitation, namely adding a barium salt into the arsenic post-precipitation liquid obtained in the step 2), stirring the obtained mixture so as to produce a precipitate, carrying out filtration and separation on the precipitate so as to obtain a barium selenate precipitate and selenium post-precipitation liquid, and carrying out evaporative crystallization on the selenium post-precipitation liquid so as to recycle alkali, or directly returning to a leaching process. The method disclosed by the invention is short in technological process, less in equipment and simple in operation, and can be used for realizing the separation and enrichment of arsenic and selenium, the precipitation rate of arsenic is higher than 96%, and the precipitation rate of selenium is higher than 99%; by virtue of carrying out evaporative crystallization on a solution for recycling or directly returning the solution to a leaching process, the recovery of alkali is realized.

Owner:CENT SOUTH UNIV

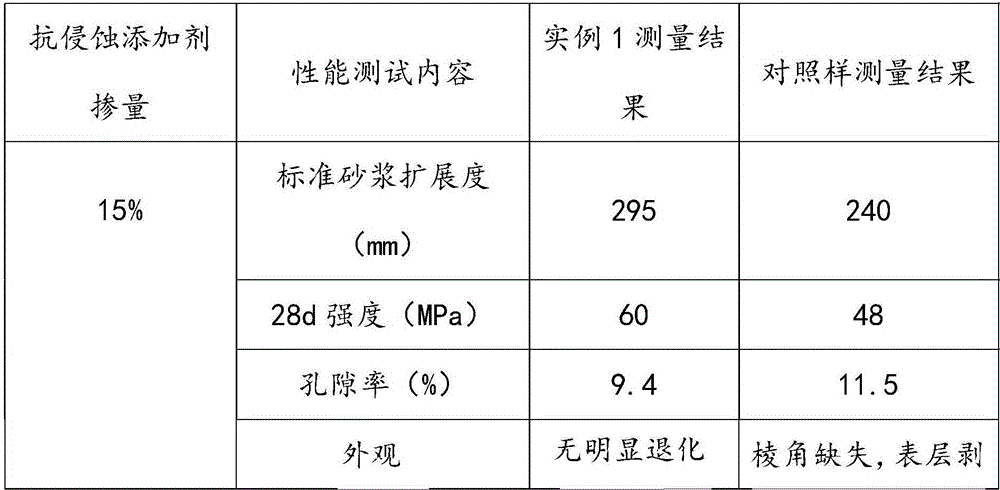

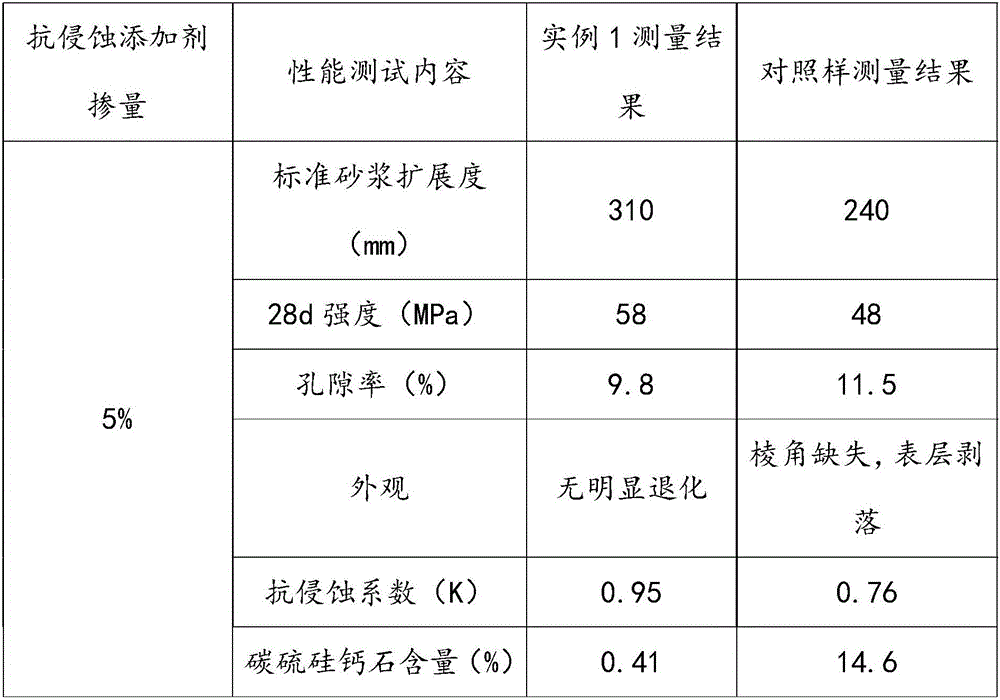

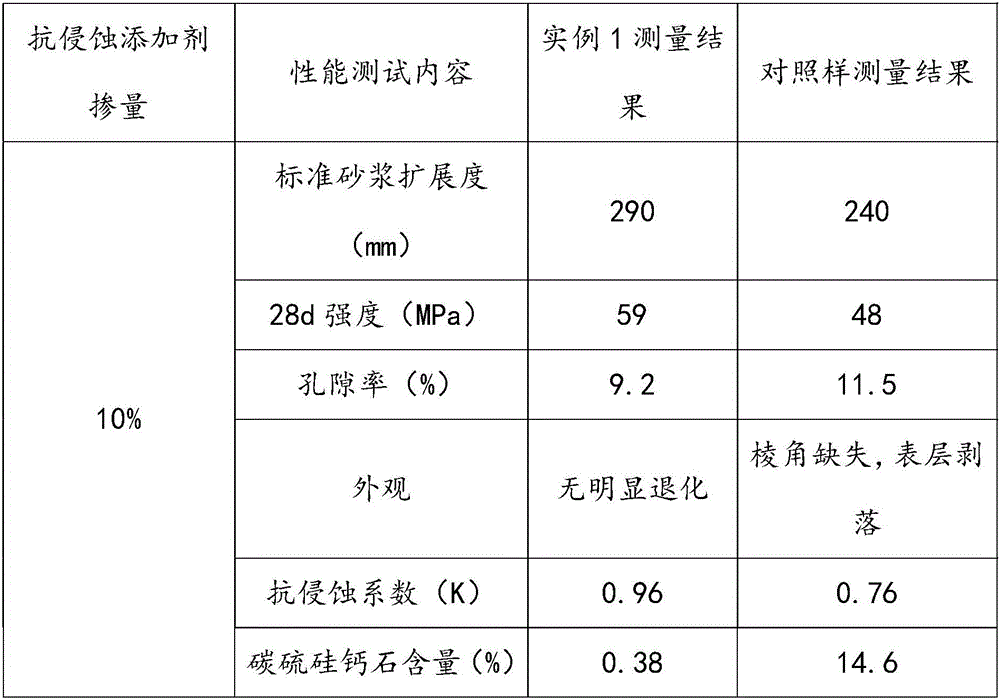

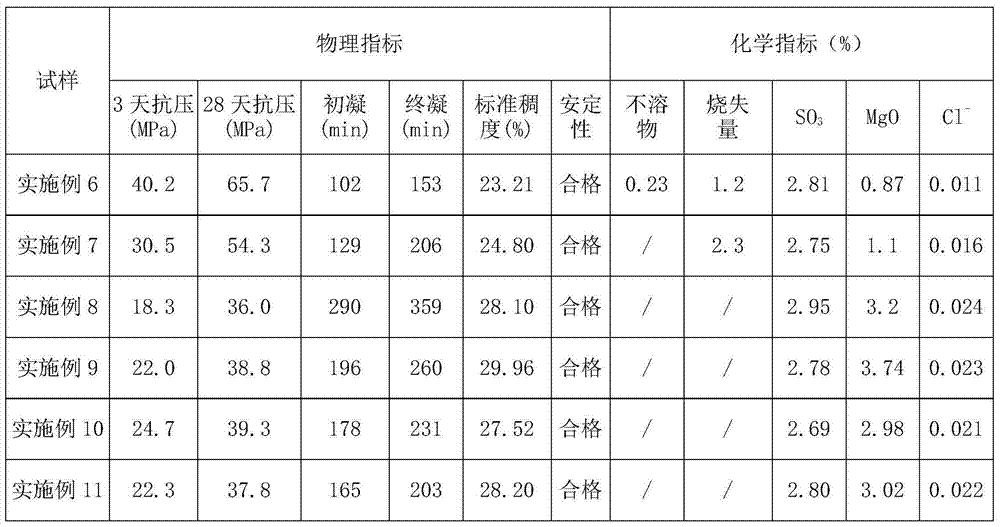

High efficiency sulfate attack resistant concrete additive and preparation method thereof

The invention discloses a high efficiency sulfate attack resistant concrete additive and a preparation method thereof. The technical scheme of the concrete additive comprises the following raw materials in parts by weight: 15-25 parts of barium salt, 5-10 parts of sorbitol, 15-30 parts of calcined diatomaceous earth, 0.5-1.0 part of a grinding aid, 30-50 parts of silica fume, 10-20 parts of ultrafine fly ash and 1.0-2.0 parts of a water reducer. The high efficiency sulfate attack resistant concrete additive can reduce the proper shrinkage cracks of concrete, improve the compactness, and greatly improve the multi-type attack resistant properties of the concrete effectively for a long time.

Owner:HUBEI UNIV OF TECH

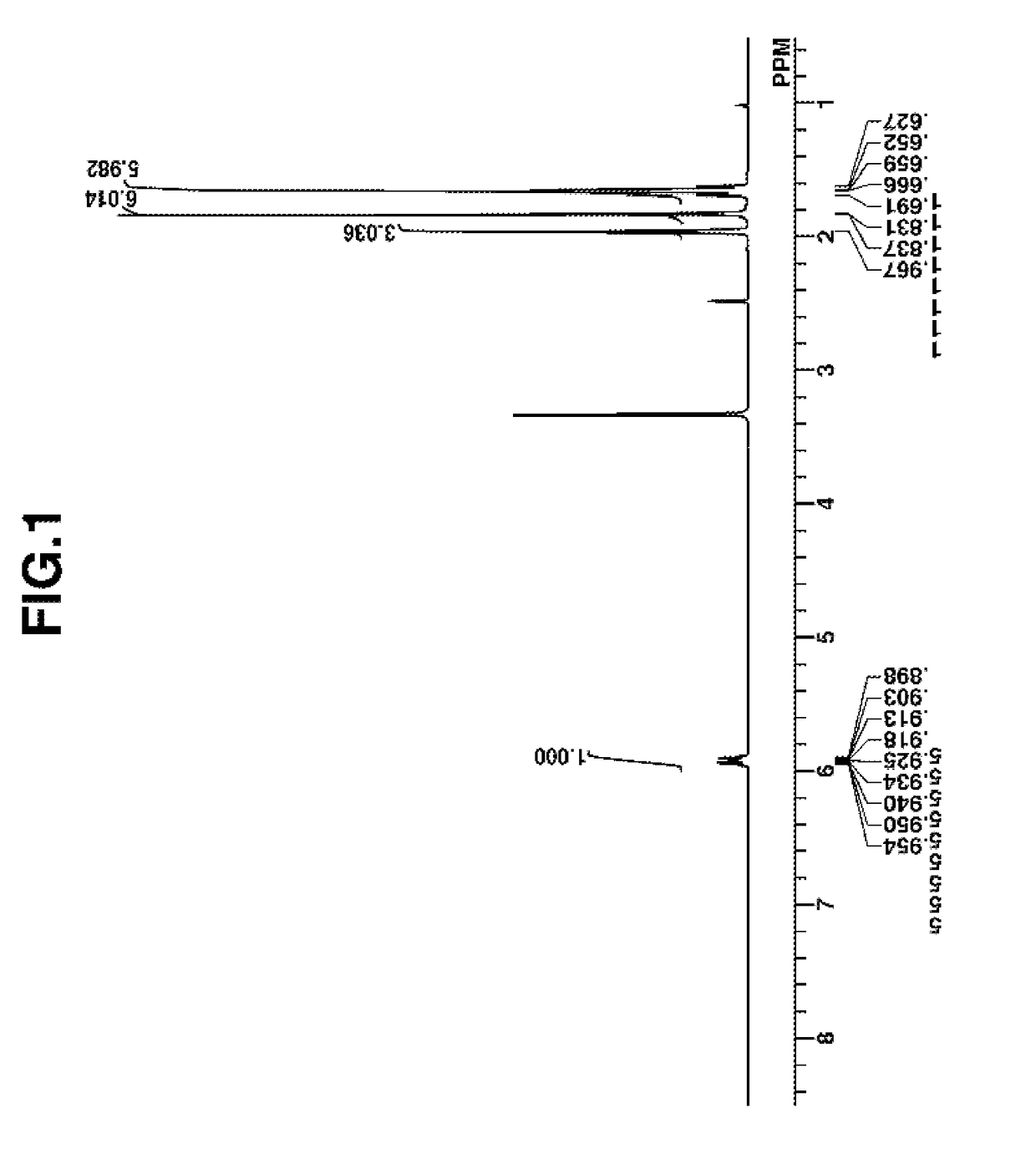

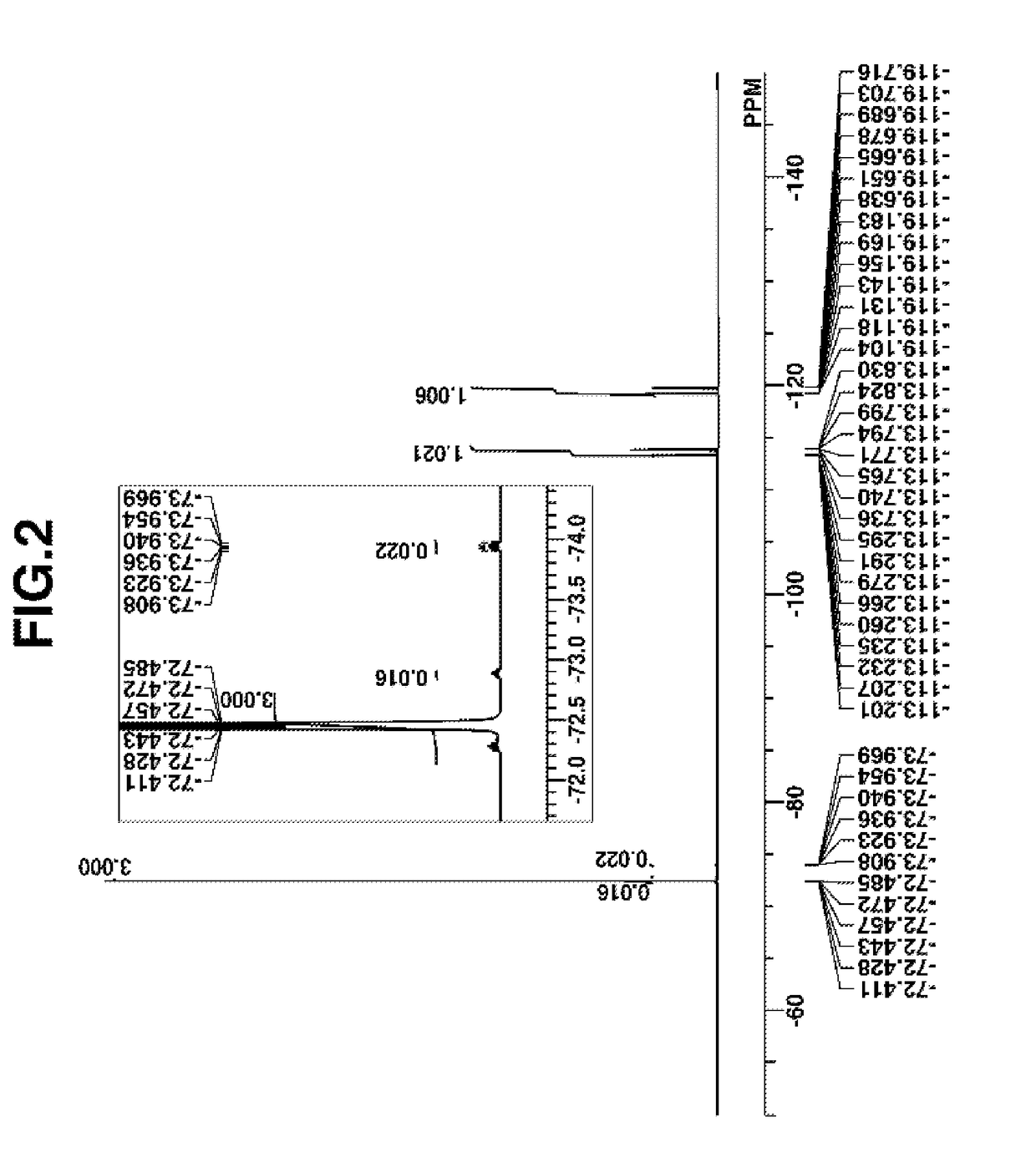

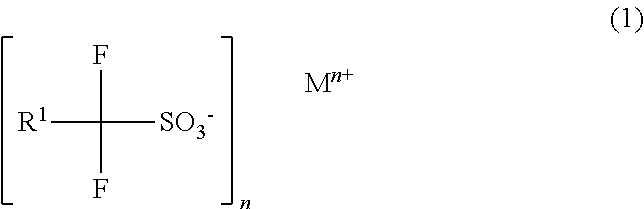

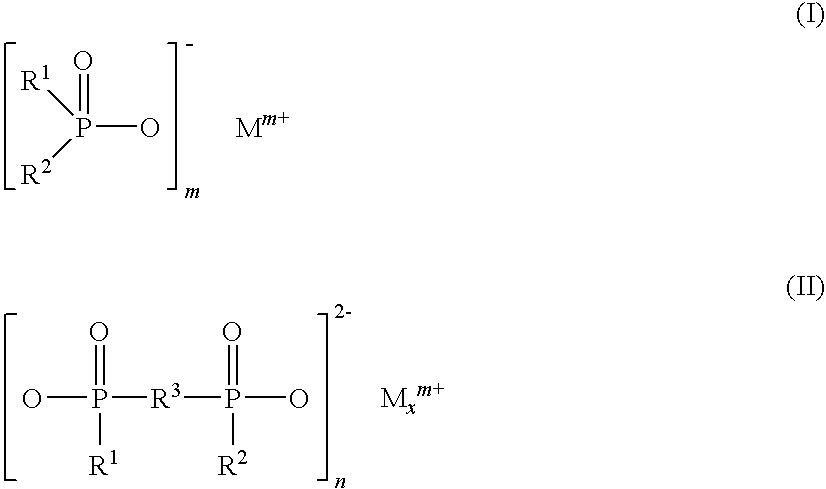

Resist composition, patterning process, and barium, cesium and cerium salts

ActiveUS20170115566A1Increase contrastSatisfactory pattern profileGroup 1/11 element organic compoundsOrganic compound preparationResistRubidium

A resist composition comprising a base resin comprising acid labile group-containing recurring units and preferably acid generator-containing recurring units, and a sodium, magnesium, potassium, calcium, rubidium, strontium, yttrium, cesium, barium or cerium salt of α-fluorinated sulfonic acid bonded to an alkyl, alkenyl, alkynyl or aryl group exhibits a high resolution and sensitivity and forms a pattern of satisfactory profile with minimal LWR after exposure and development.

Owner:SHIN ETSU CHEM IND CO LTD

Environment-friendly thixotropic antirust oil and preparation method thereof

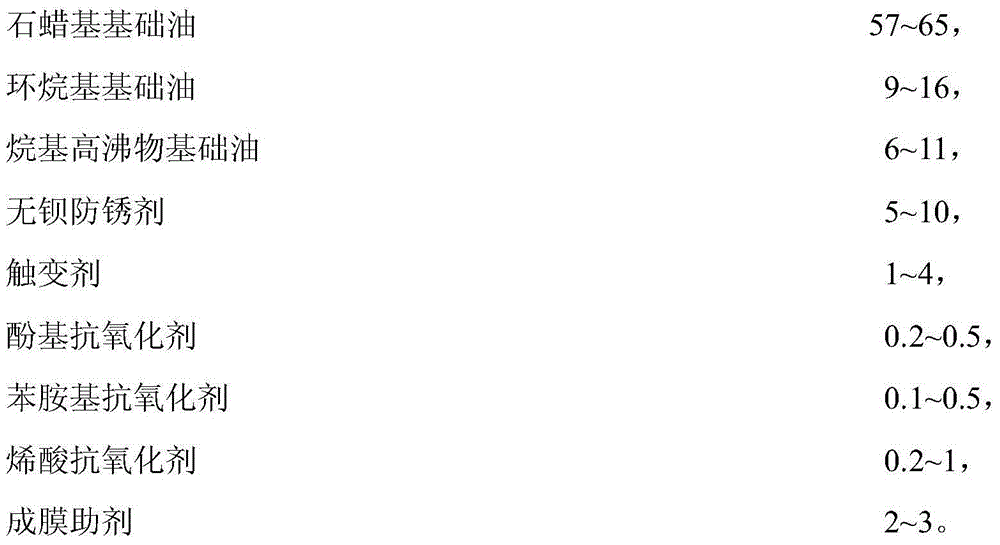

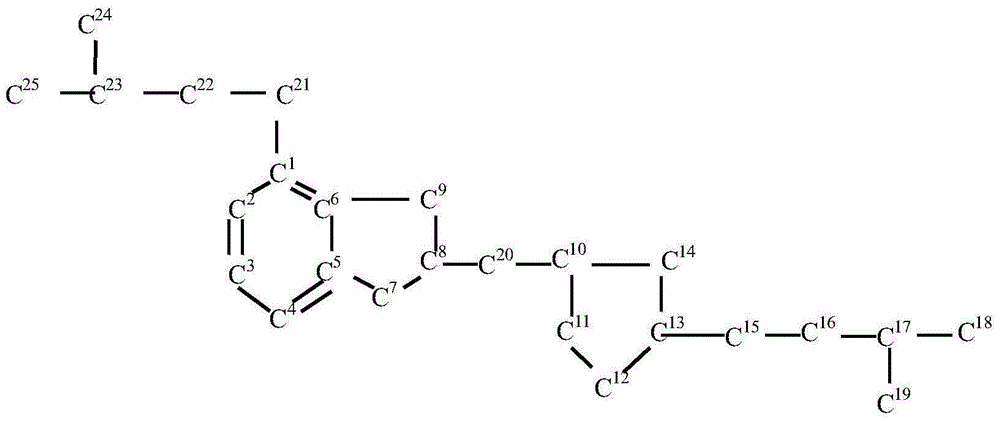

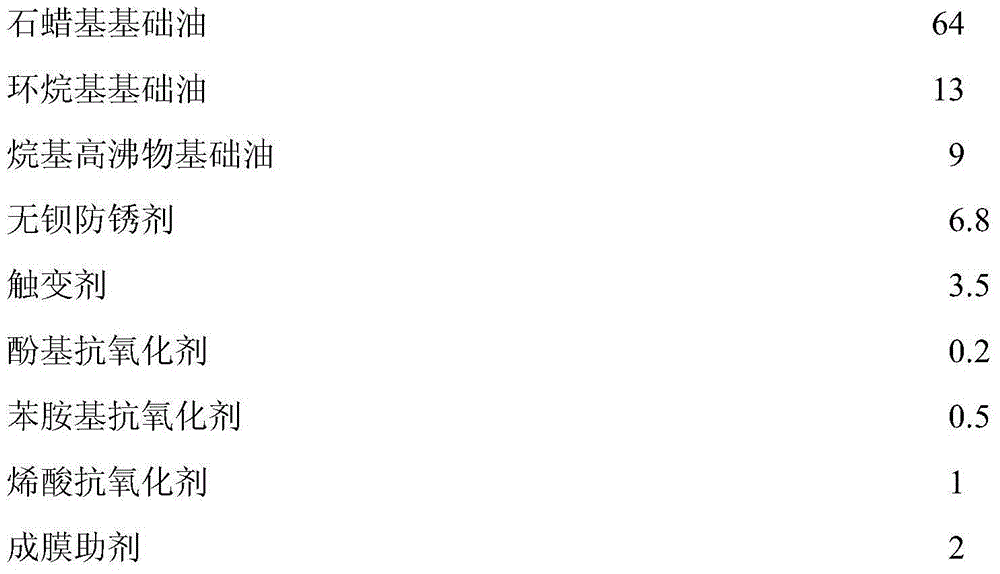

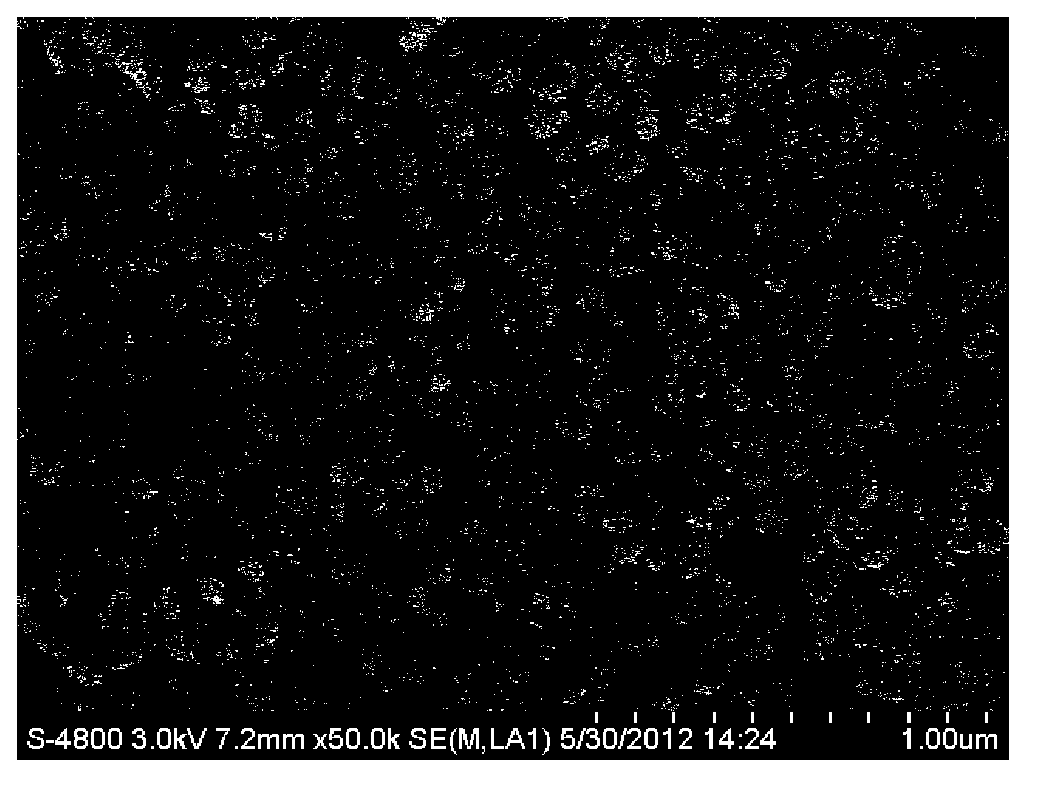

ActiveCN104312699AExcellent thixotropic recovery effectAchieve conversionLubricant compositionBarium saltCleansing Agents

The invention discloses environment-friendly thixotropic antirust oil which consists of the following raw materials in parts by weight: 57-65 parts of paraffin-based base oil, 9-16 parts of naphthenic base oil, 6-11 parts of alkyl high-boiling residue base oil, 5-10 parts of barium-free antirust agent, 1-4 parts of thixotropic agent, 0.2-0.5 part of a phenolic antioxidant, 0.1-0.5 part of an anilino antioxidant, 0.2-1 part of an olefine acid antioxidant and 2-3 parts of a coalescing agent. The invention also provides a method for preparing the environment-friendly thixotropic antirust oil. The environment-friendly thixotropic antirust oil does not contain harmful barium salt decomposed substances and is environment-friendly; the product can rapidly form a stable oil film on the elevation face of a workpiece and does not flow away and waste is reduced; the antirust oil has excellent high temperature resistance, heat and humidity resistance, excellent high-salinity salt mist erosion resistance and excellent antirust performance, has good voltage resistance and is conveniently used for electrostatic spraying; and moreover, the antirust oil has good cleaning performance, and the antirust oil film can be easily removed by using neutral or alkaline water-based cleaning agents.

Owner:上海中孚油品集团有限公司

Preparation method of submicron-grade barium sulfate

InactiveCN103073042AReduce pollutionFine control of particle sizeCalcium/strontium/barium sulfatesBarium saltBarium sulfate

The invention relates to a preparation method of submicron-grade barium sulfate, in particular to a method for preparing the submicron-grade barium sulfate by using nano barium sulfate as seed crystal. The preparation method comprises the following steps of: preparing soluble barium salt and soluble sulfate into a solution with the concentration of 0.01-2.0 mol / L; mixing two solutions and reacting to prepare the nano barium sulfate; and then, taking the nano barium sulfate as the seed crystal to prepare a submicron-grade barium sulfate product. The method disclosed by the invention has the advantages of no utilization of additives, moderate reaction conditions, uniform product appearance, controllable grain diameter and the like, has the advantages of small pollution, easiness for controlling and the like, and has a wide market prospect.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method capable of improving selenium content for preparing polysaccharide selenite

The invention discloses a method capable of improving selenium content for preparing polysaccharide selenite. The method comprises the steps of adding a selenium compound solution having the mass fraction of 60-80% by spraying to a polysaccharide or a polysaccharide complex under a stirring condition and reacting at a temperature in the range of 120-160 DEG C; after the reaction is completed, purifying and drying the reaction product to obtain polysaccharide selenite, wherein the selenium compound is seleninic acid or a selenite. The method is simple in process, easy in after-treatment, controllable in reaction conditions and good in repeatability; in the production process, the generation of toxic gases such as hydrogen selenide is avoided and the use of a strong acid and heavy metals such as a barium salt to catalyze the reaction and the use of toxic organic solvents such as pyridine and benzene are avoided, and therefore, the production process is green and environment-friendly; the polysaccharide selenite prepared by the method is low in toxicity and high in bioavailability, and the selenium content of the polysaccharide selenite is higher than 18% which is far higher than the selenium content of less than 2% of the present commercial organic selenium products.

Owner:浙江皇冠科技有限公司

Barium residue detoxifying method

The invention provides a barium residue detoxifying method which comprises the step of adding barium residue in the cement production process, wherein the barium residue is 0.2-0.8% of the cement raw material by mass percent. According to the barium residue detoxifying method provided by the invention, the aim of recycling the waste barium residues generated in the industrial production of barium salt is achieved; what is more, the barium residues are thoroughly detoxified to solve the pollution to the environment, particularly the pollution to the water quality; through the method, barium-containing cement is obtained; compared with the traditional Portland cement, due to the introduction of barium, the fracture resistance and the compressive strength of the cement are remarkably improved (both the early and later strengths of the calcium barium sulphoaluminate mineral are relatively high, and the Ba<2+> enters in the crystal lattice of C2S to enable the crystal to warp so as to improve the hydration activity of C2S), and strong absorption function is brought to the gamma-ray so as to bring a certain radiation protection performance.

Owner:陈世红

Method for preparing modified micro-barium sulfate

InactiveCN101792167AImprove performanceReduce adhesionCalcium/strontium/barium sulfatesInorganic saltsBarium salt

The invention relates to a method for preparing modified micro-barium sulfate, which comprises the following steps of: firstly, carrying out coprecipitation reaction on an aqueous solution which at least contains water-soluble barium salt and an aqueous solution which at least contains water-soluble sulfate at 0-99 DEG C to obtain a mixed sediment of a barium sulfate sediment and other inorganic salt sediments, wherein the inorganic salt sediments can act with a purifying agent to be converted into a water-soluble substance; then standing and curing the mixed sediment; and mixing / reacting the cured mixing sediment with a surface modifying agent to obtain the modified micro-barium sulfate. After cured, the mixed sediment is subjected to purifying processing according to the concrete requirement. The invention effectively overcomes the defect of difficult post processing of the traditional method for preparing the modified micro-barium sulfate, can realize industrialized production of nano barium sulfate and also has the advantages of flexible application, performance abundance of barium sulfate, time saving, labor saving and low cost.

Owner:张颖

Normal temperature barium salt modified phosphorizing liquid capable of avoiding water wash after phosphorized

InactiveCN101109081AQuality improvementImprove corrosion resistanceMetallic material coating processesEpoxyBarium nitrate

The invention relates to a phosphating washing-free phosphating solution modified with barium salt at ambient temperature. The phosphating solution comprises a phosphoric acid, a nitric acid, and Zn2+, Ca2+, Mn2+, Ni2 plus salt thereof, ammonium molybdate,ammonium tungstate, phytate, H2O2 and barium nitrate or barium hydroxide. The pH value ranges from 1.6 to 4.2. The invention can be phosphated under soak, rinse, brush or the combined way thereof at 3 DEG C.to 45 DEG C.. The phosphating solution is stable and capable of automatically precipating and removing the SO42- inside the phosphating solution and therefore eliminating the influence of SO42- on quality; the phosphorizating membrane is continues, uniform and compact, the membrane weight is between 0.5g is multiplied by m and 3.0g is multiplied by m minus 2 and the iron-red epoxy primer is sprayed and the adhesion thereof can be 1 grade.

Owner:余取民 +3

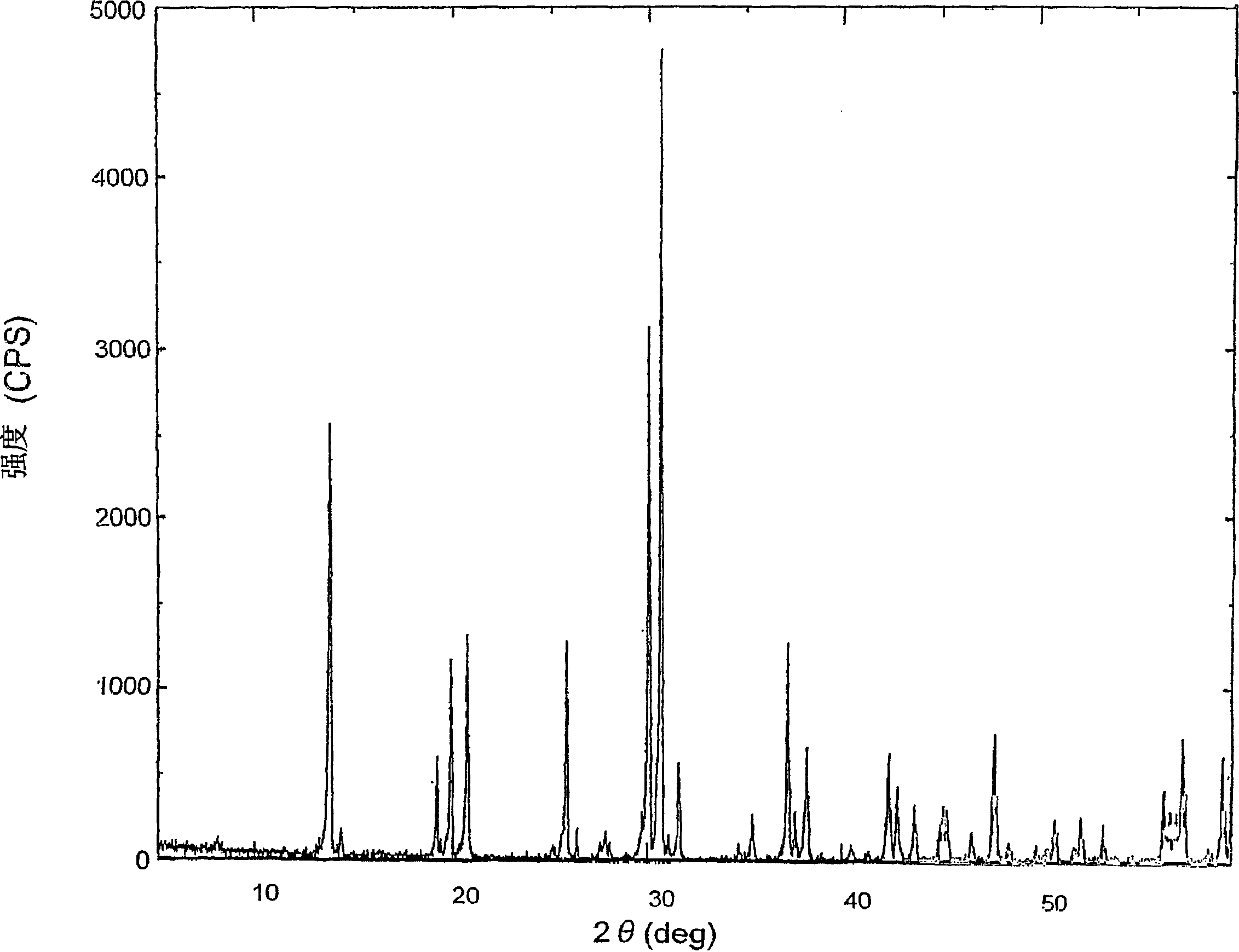

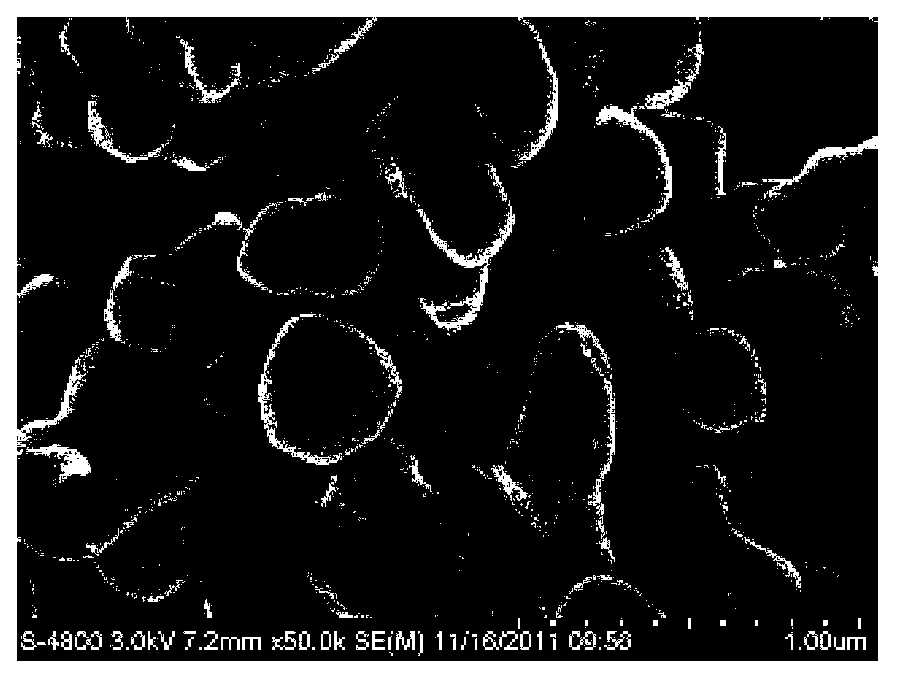

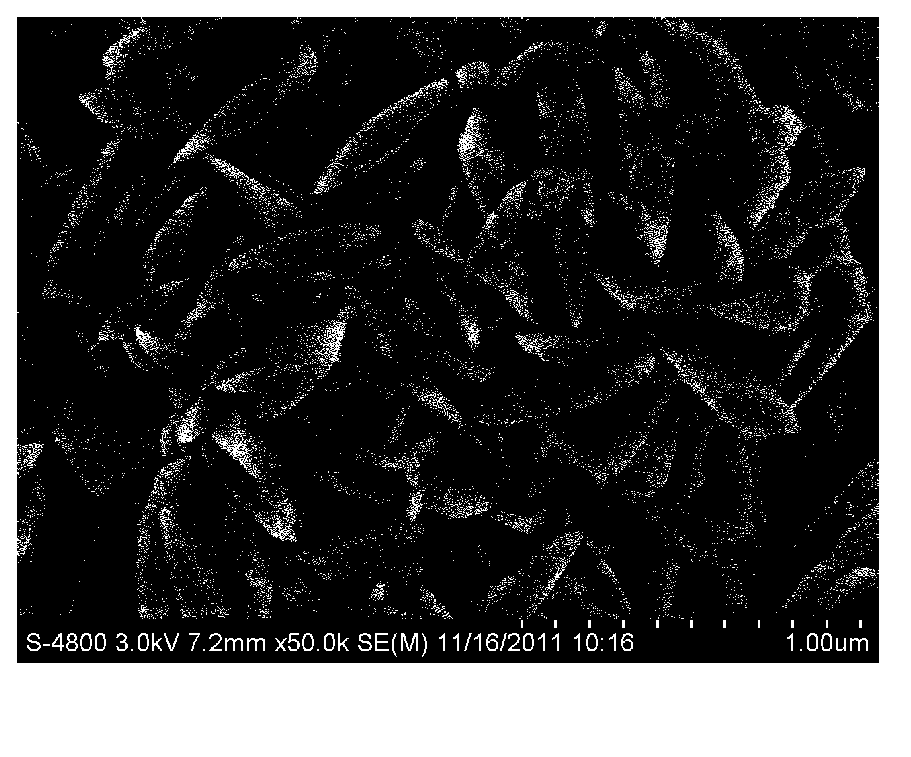

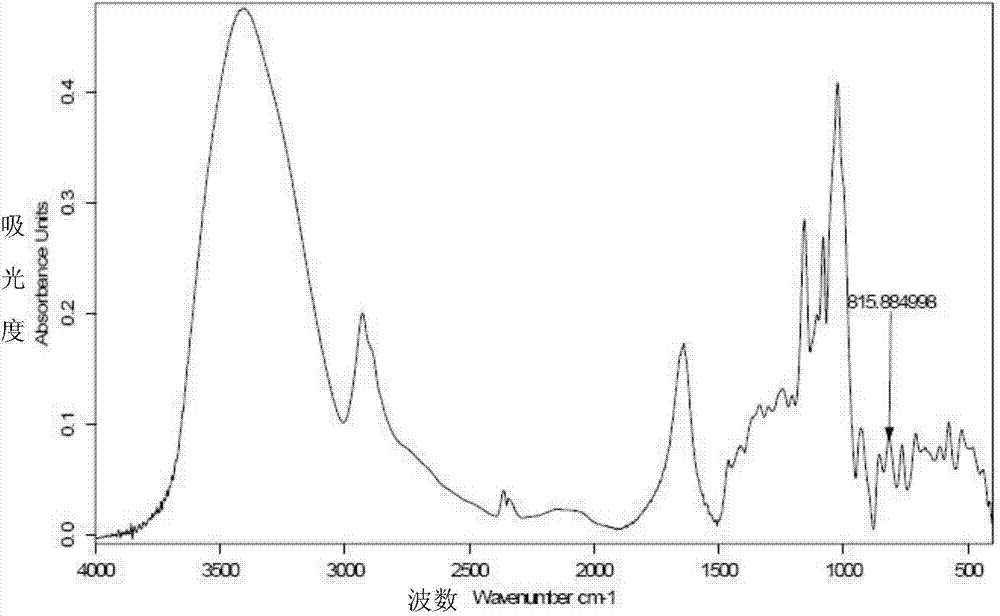

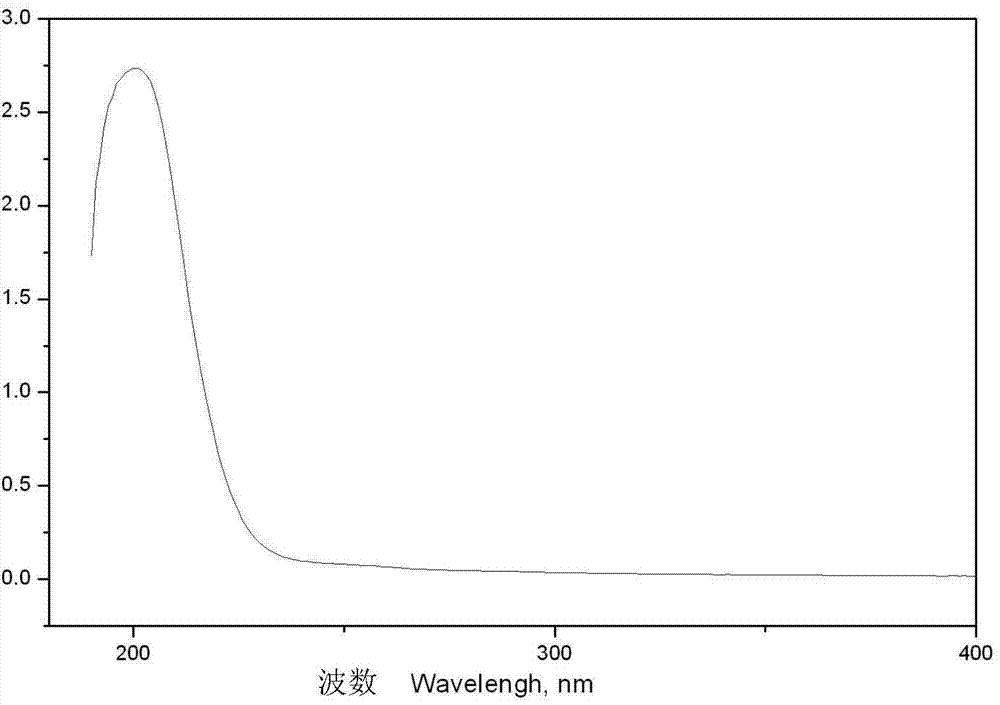

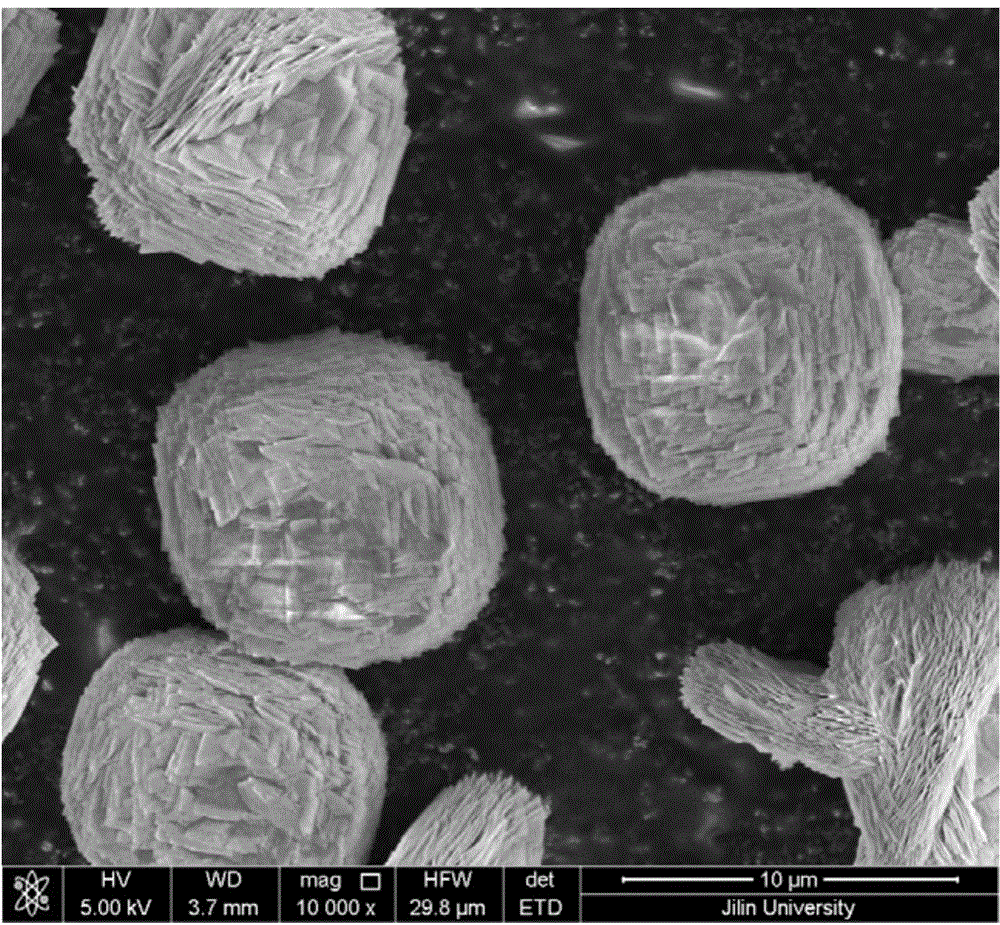

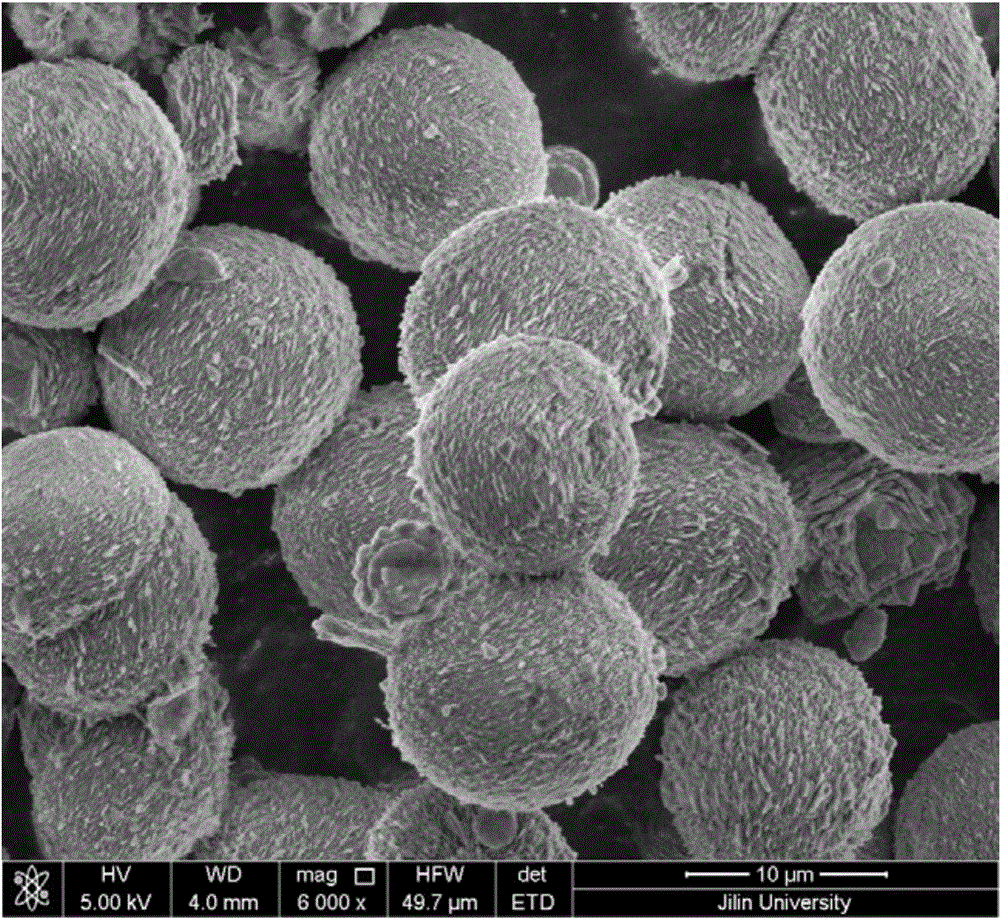

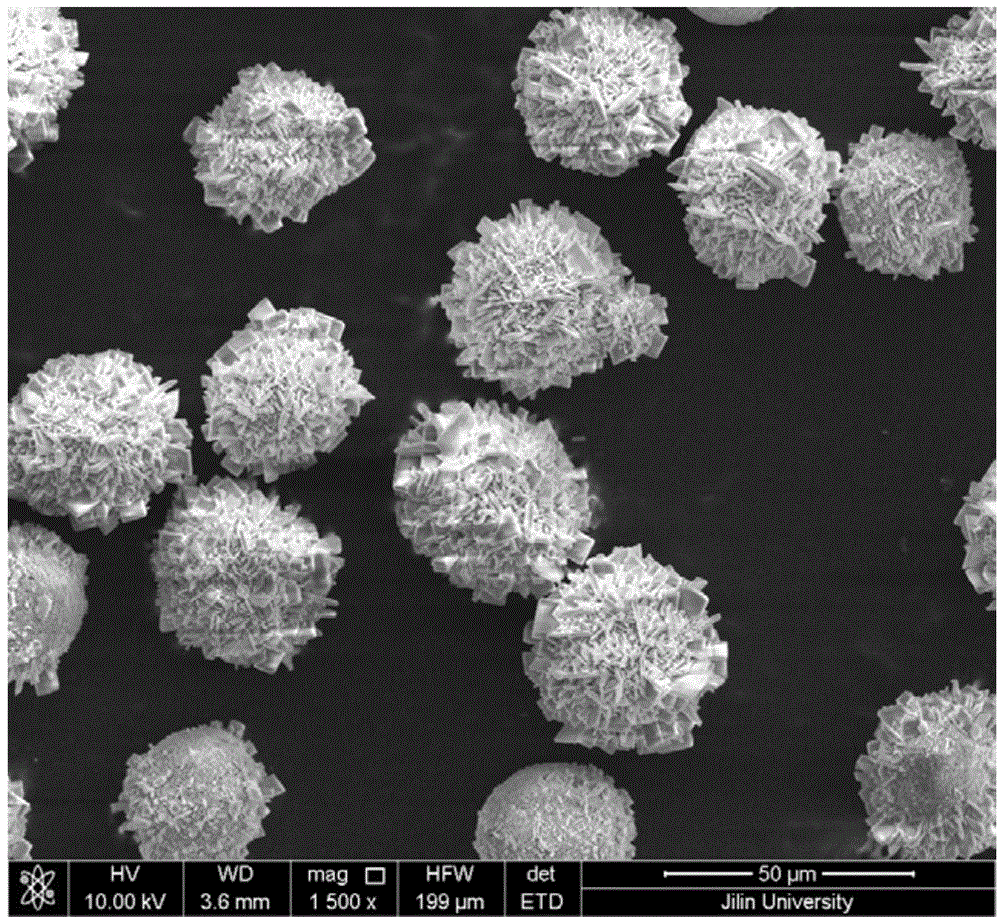

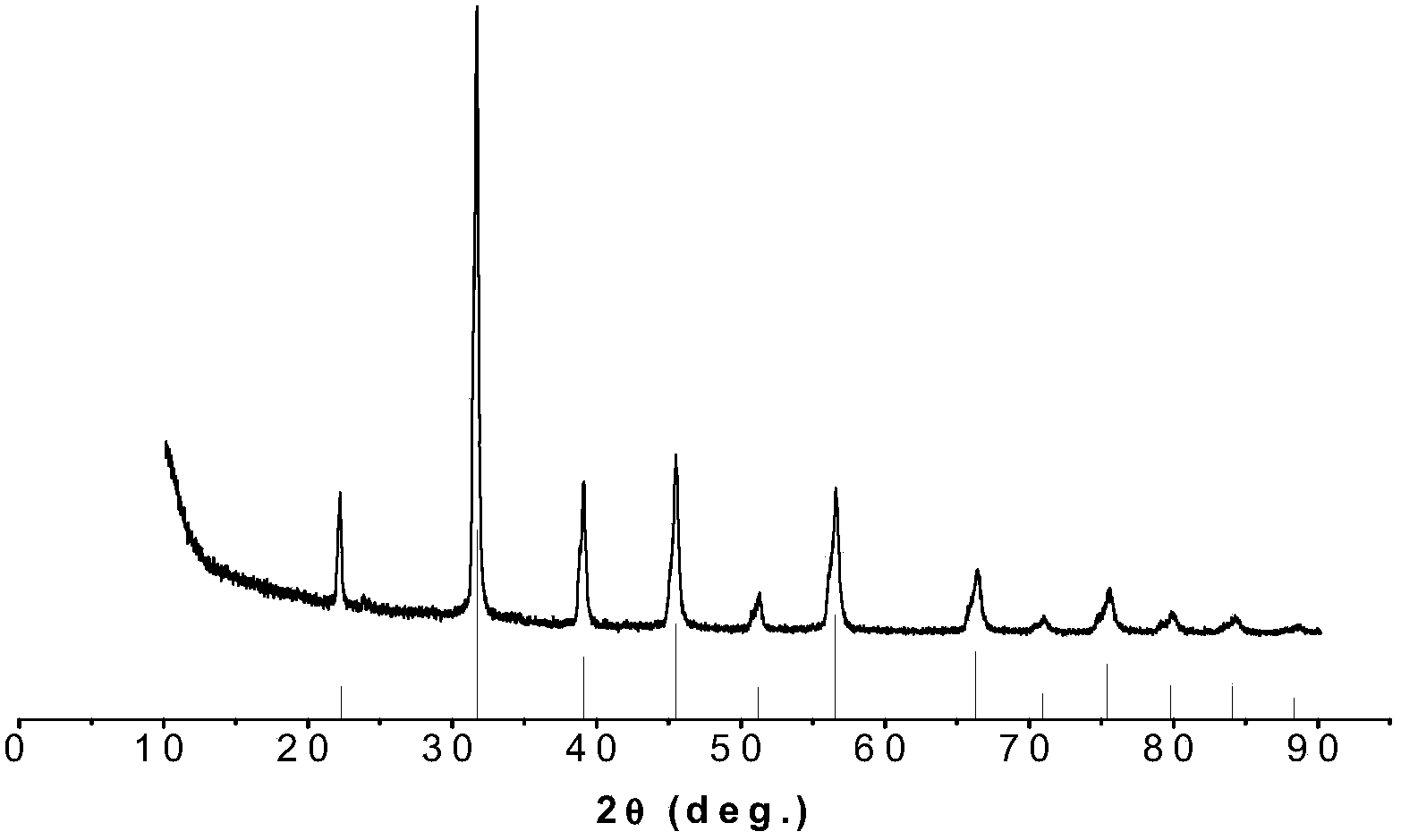

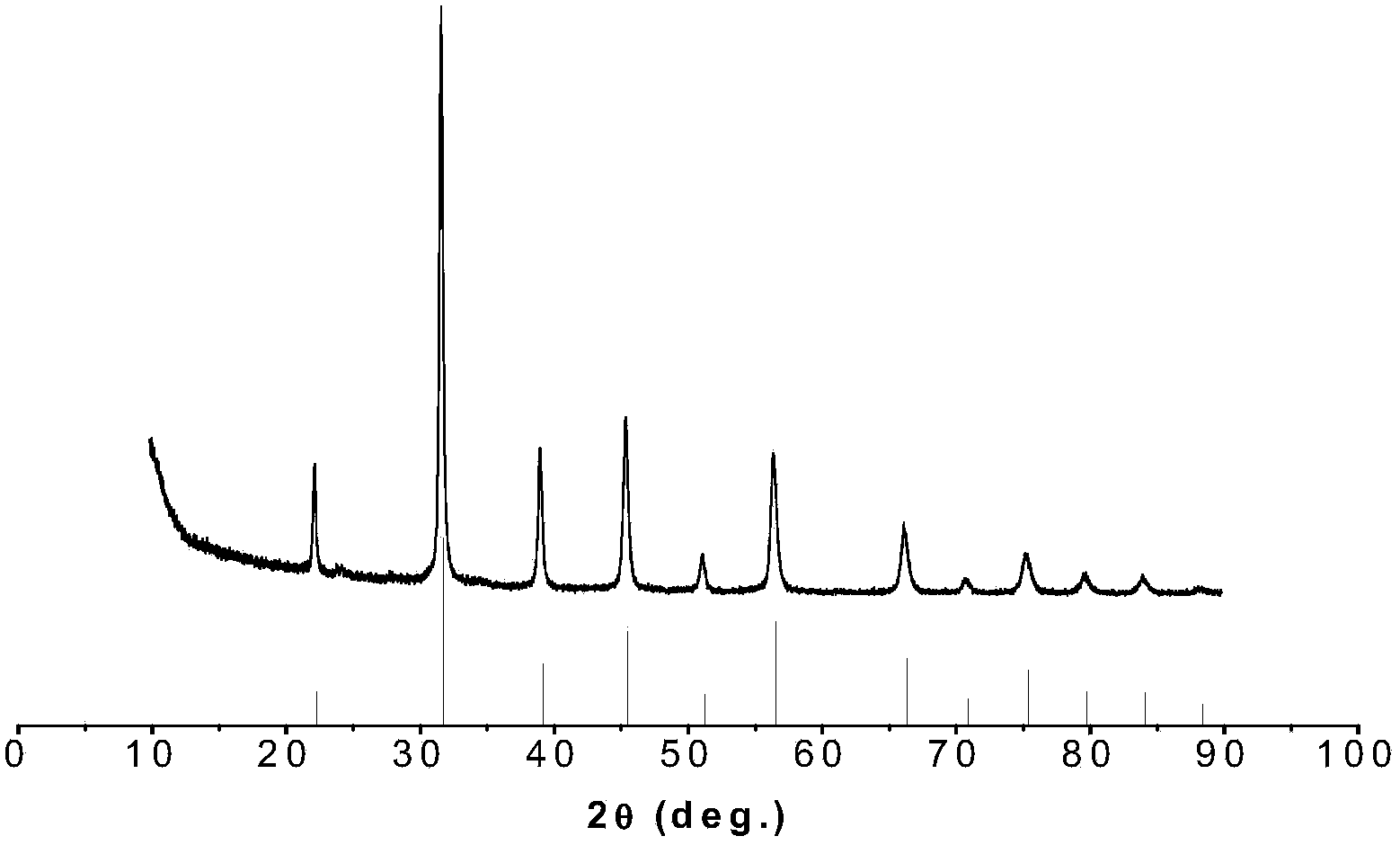

Method for preparing SrCuSi4O10 and BaCuSi4O10 blue pigments through hydrothermal technique

InactiveCN103601202AHigh purityMorphological rulesAlkaline-earth metal silicatesLuminescent compositionsDispersityLevel structure

The invention provides a method for preparing SrCuSi4O10 and BaCuSi4O10 blue pigments through a hydrothermal technique, and belongs to the technical field of hydrothermal chemistry. The method uses copper oxide powder or copper salt, barium salt or strontium salt, and silicate as raw materials, and NH4OH as a mineralizing agent and comprises the following hydrothermal reaction processes: mixing a reactant with distilled water according to a stoichiometric ratio of an objective product, adjusting the pH value of a solution to be greater than 10 and less than 14, putting in a high-pressure reactor so as to enable the filling degree to reach 40%-90%, sealing and reacting for 5-72 hours at the temperature of 230-300 DEG C; and cooling and filtering so as to obtain products. The invention provides a new reaction route and a green preparation method for SrCuSi4O10 and BaCuSi4O10 difficult to prepare. The products are multi-level structure microparticles, have high purity, regular morphology and good dispersity and are uniform in particle size. The preparation method is simple, efficient and high in yield; waste liquid generated in a hydrothermal reaction process can be recycled.

Owner:JILIN UNIV

Portable direct-reading type power-free hydrogen-sulfide gas detector and preparation of indicating matter

InactiveCN1438480ANo power requiredHigh sensitivityAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorDiffusionLead nitrate

The testing assembly comprises the glass tube, the indicating material in the glass tube and the diffusion control film on two ends of the glass tube. The indication scale for measuring value constitutes the indication window. The testing assembly and the scale are fixed on the carrier with badge shape. The indicating material comprises main agent, the inter surface modifying addition and ceramics powder in 80-120 mesh. One or several of lead acetate, lead nitrate and silver nitrate constitute the main agent. The intersurface modifying addition is soluble barium salt. The weight of the main agent is 1%-10% of the weight of the admixture. The invention provides the features of powerless, high sensitivity, good accuracy, low cost and convenience.

Owner:王宝辉 +1

Preparation method of nano flaky ferroelectric material for photocatalysis

InactiveCN103523824ASmall particle sizeHigh crystallinityMaterial nanotechnologyTitanium compoundsBarium strontium titanateBarium salt

The invention relates to a preparation method of a nano flaky ferroelectric material for photocatalysis. The preparation method comprises the steps of preparing barium salt, strontium salt and titanium salt to obtain premix according to a barium strontium titanate (BaxSr1-xTiO3) molecular formula, mixing barium salt and strontium salt according to proportions and dissolving in water, adding NaOH, dissolving titanium salt in absolute ethyl alcohol, uniformly mixing the raw materials, carrying out thermal reaction for 24 hours in a high-pressure kettle at 160-200 DEG C, cooling to room temperature in air, filtering, washing and drying the mixture to obtain nano flaky barium strontium titanate powder. Compared with the prior art, the preparation method has the advantages that the process is simple and few aggregation phenomena of prepared nano particles exist; in comparison with barium strontium titanate nano powder prepared by a conventional hydrothermal method, the preparation method, which adopts butyl titanate as a titanium source, has the characteristics of high purity of a prepared sample, good crystallinity of powder and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

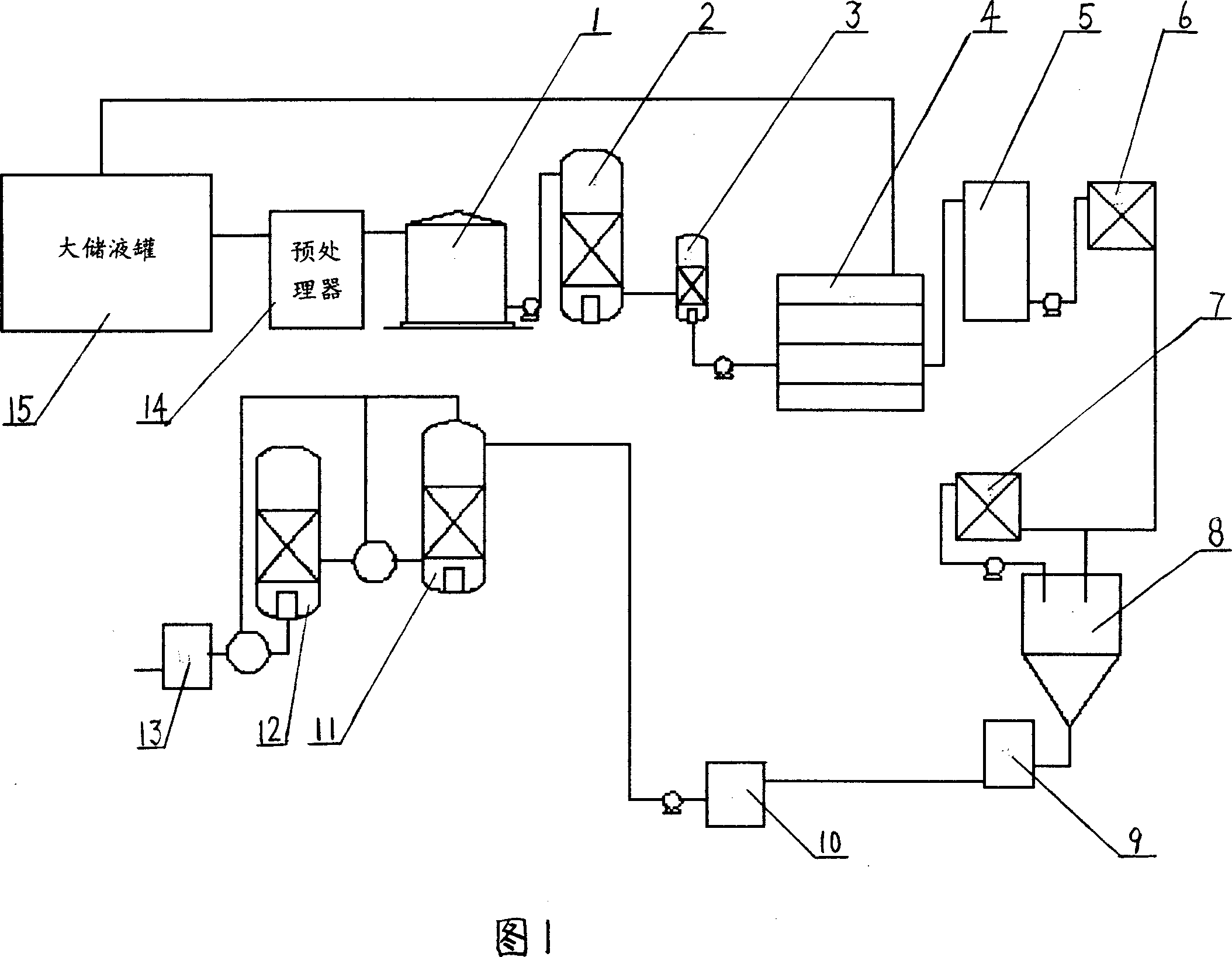

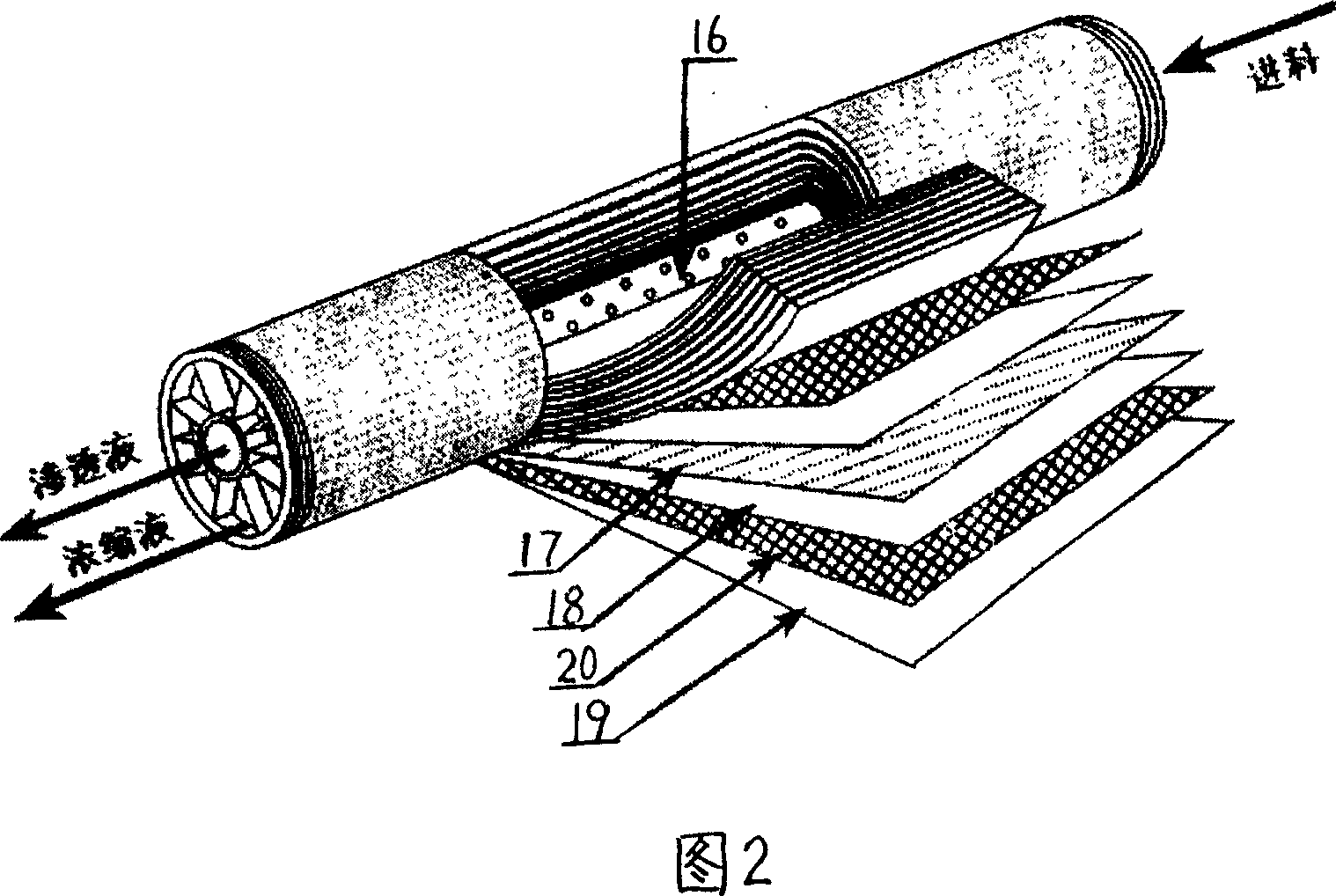

Method of eliminating magnesium sulfate from magnesium sulfate containing waste water solution

ActiveCN101016175ALow in magnesium sulfateIncrease concentrationWater contaminantsUltrafiltrationMagnesium saltBarium salt

The invention discloses a removing method of magnesium sulfate from waste water solution with magnesium sulfate, which comprises the following steps: predisposing waste water solution with magnesium sulfate; transmitting the solution into micro-filter film device to remove micro-particle impurity; transmitting the solution into nano-filter film; obtaining percolation liquid with low-content magnesium sulfate and condensate with high-content of magnesium sulfate; freezing the condensate; extracting the solid of magnesium sulphate heptahydrate or adding calcium salt or barium salt to obtain calcium sulfate or barium sulfate; reacting magnesium salt and calcium hydroxide to produce magnesium hydroxide and calcium salt; saving the disposing cost; protecting environment; recycling magnesium sulfate.

Owner:BEFAR GROUP CO LTD

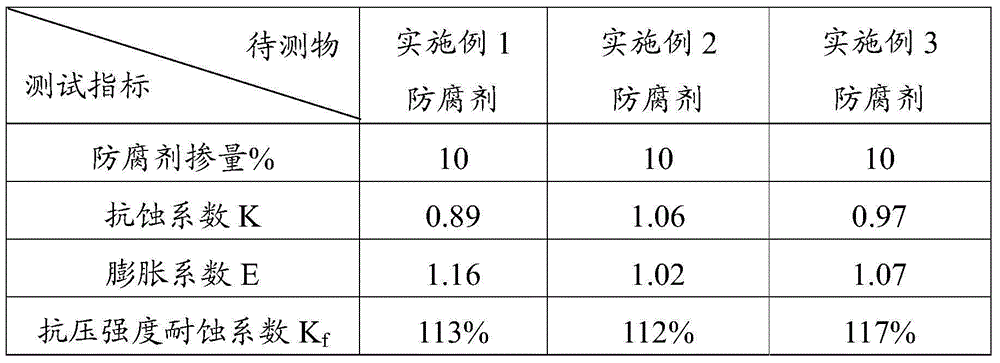

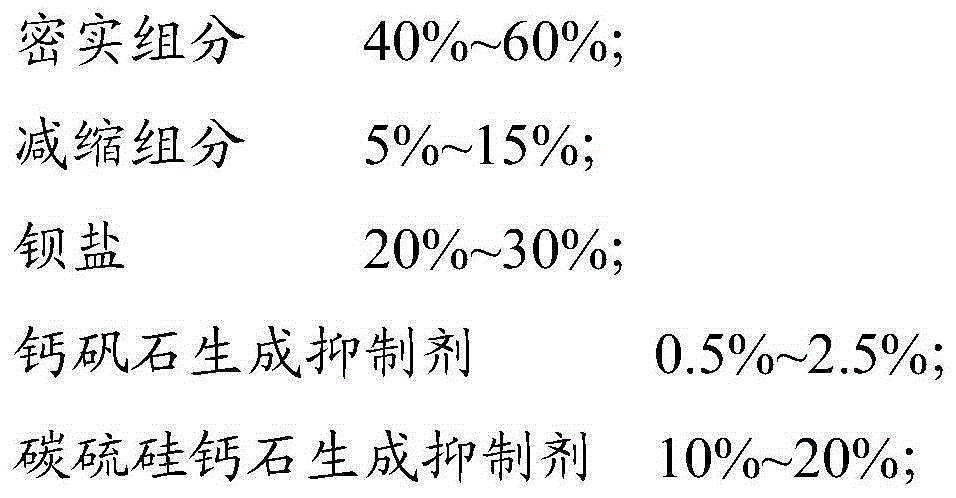

Sulfate-erosion-resistant preservative for underground concrete structure

ActiveCN105174808AMeet the requirements of anti-corrosion performanceExcellent resistance to sulfate attackPreservativeSulfate

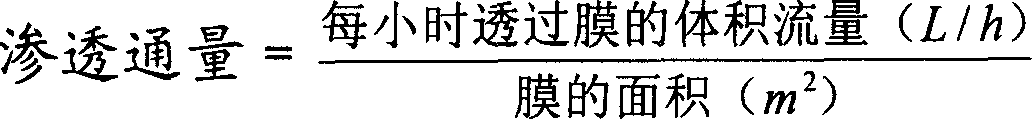

The invention provides a sulfate-erosion-resistant preservative for an underground concrete structure. The preservative is prepared from, by mass, 40-60% of compacting components, 5-15% of reduction components, 20-30% of barium salt, 0.5-2.5% of ettringite inhibitors and 10-20% of thaumasite inhibitors, wherein the compacting components are one or more of silica fume, metakaolin and fly ash, the reduction components are composed of polydimethylsiloxane and 2-methyl-2,4-pentanediol, and the mass ratio of polydimethylsiloxane to 2-methyl-2,4-pentanediol is 1:1-3. The preservative is resistant to erosion of ettringite and thaumasite and is also easy to manufacture and low in cost.

Owner:FUJIAN CONSTR ENG GRP BUILDING MATERIAL SCI & TECH DEV

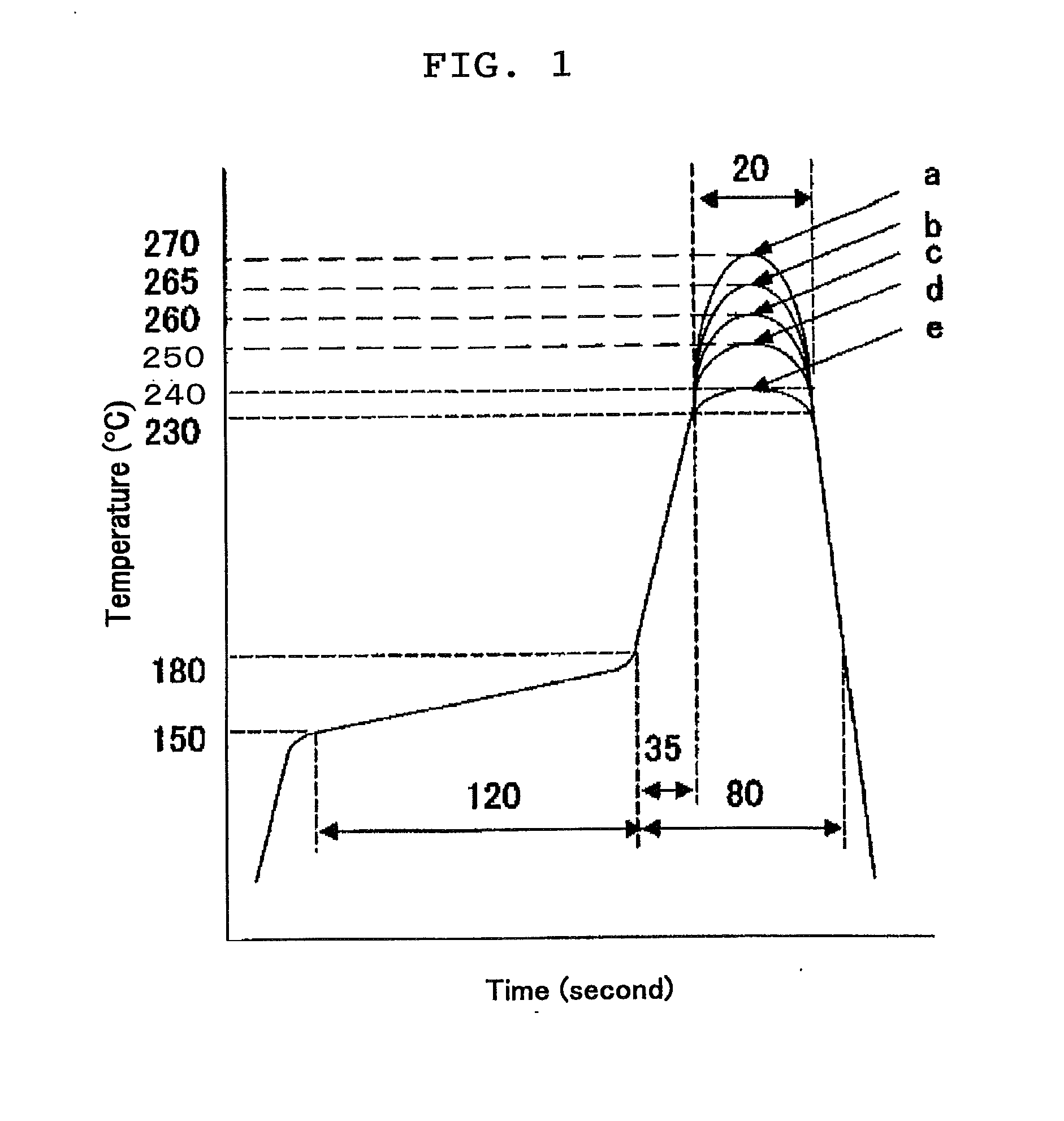

Flame-retardant polyamide composition

Disclosed is a flame-retardant polyamide composition which is excellent in mechanical properties such as toughness, and heat resistance, flame retardancy and flow ability during a reflow soldering process. In addition, this polyamide composition exhibits high thermal stability during molding. Specifically disclosed is a flame-retardant polyamide composition containing (A) 20-80% by weight of a specific polyamide resin, (B) 10-20% by weight of a metal phosphinate, (C) 0.05-1% by weight of a lithium salt, a calcium salt, a barium salt, a zinc salt or an aluminum salt of montanic acid, behenic acid or stearic acid. It is preferable that this flame-retardant polyamide composition contains no halogen flame retardant.

Owner:MITSUI CHEM INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com