Patents

Literature

48results about How to "Realize separation and enrichment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

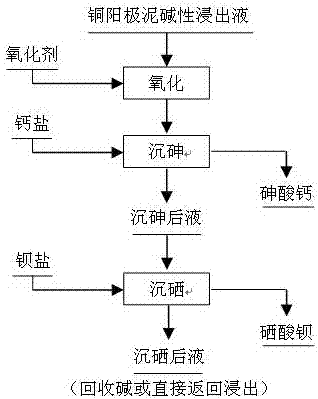

Method for separating arsenic and selenium from copper anode slime alkaline leach liquor

ActiveCN104911358ANo need to adjust pHRealize separation and enrichmentProcess efficiency improvementElemental selenium/telluriumPregnant leach solutionBarium salt

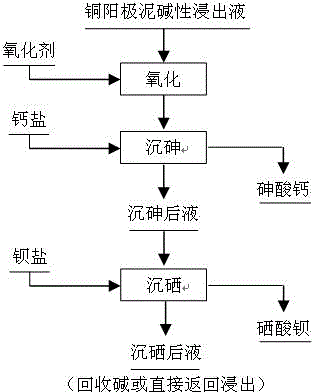

The invention discloses a method for separating arsenic and selenium from copper anode slime alkaline leach liquor. The method comprises the following steps: 1) oxidation, namely adding an oxidizing agent or introducing oxidizing gas into the copper anode slime alkaline leach liquor, so that oxidized copper anode slime alkaline leach liquor is obtained; 2) arsenic precipitation, namely adding a calcium salt into the oxidized copper anode slime alkaline leach liquor, stirring the obtained mixture so as to produce a precipitate, and carrying out filtration and separation on the precipitate so as to obtain a calcium arsenate precipitate and arsenic post-precipitation liquid; and 3) selenium precipitation, namely adding a barium salt into the arsenic post-precipitation liquid obtained in the step 2), stirring the obtained mixture so as to produce a precipitate, carrying out filtration and separation on the precipitate so as to obtain a barium selenate precipitate and selenium post-precipitation liquid, and carrying out evaporative crystallization on the selenium post-precipitation liquid so as to recycle alkali, or directly returning to a leaching process. The method disclosed by the invention is short in technological process, less in equipment and simple in operation, and can be used for realizing the separation and enrichment of arsenic and selenium, the precipitation rate of arsenic is higher than 96%, and the precipitation rate of selenium is higher than 99%; by virtue of carrying out evaporative crystallization on a solution for recycling or directly returning the solution to a leaching process, the recovery of alkali is realized.

Owner:CENT SOUTH UNIV

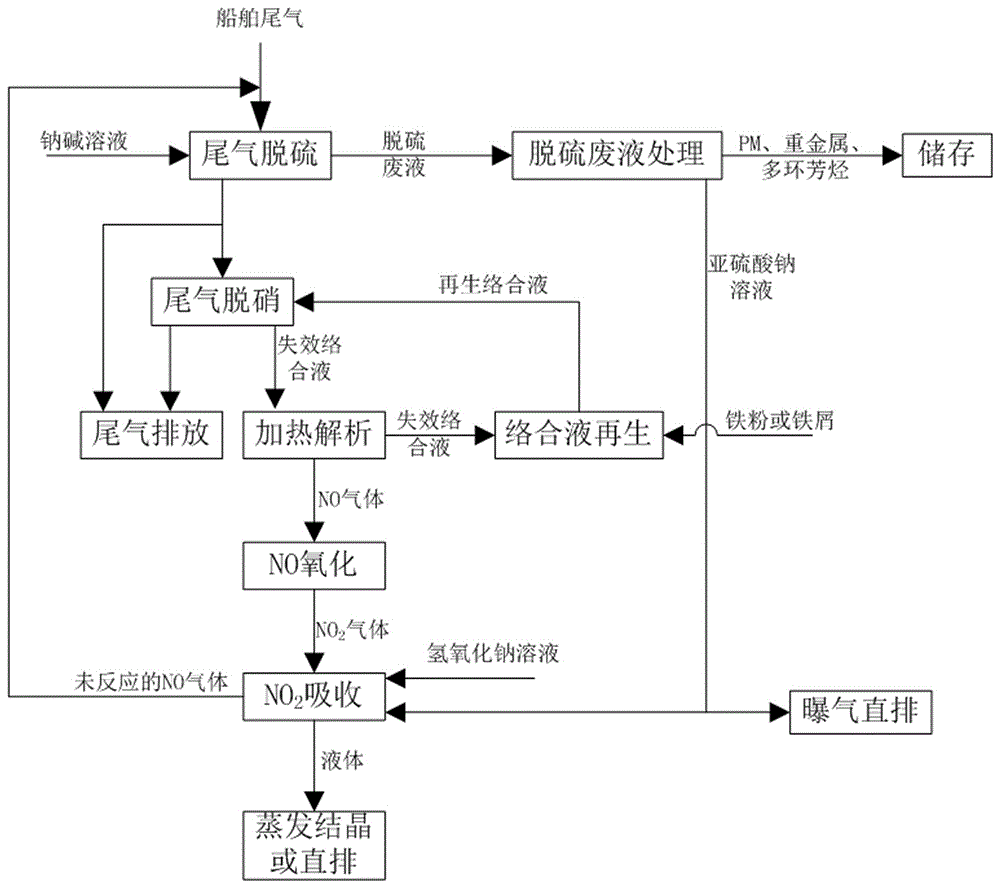

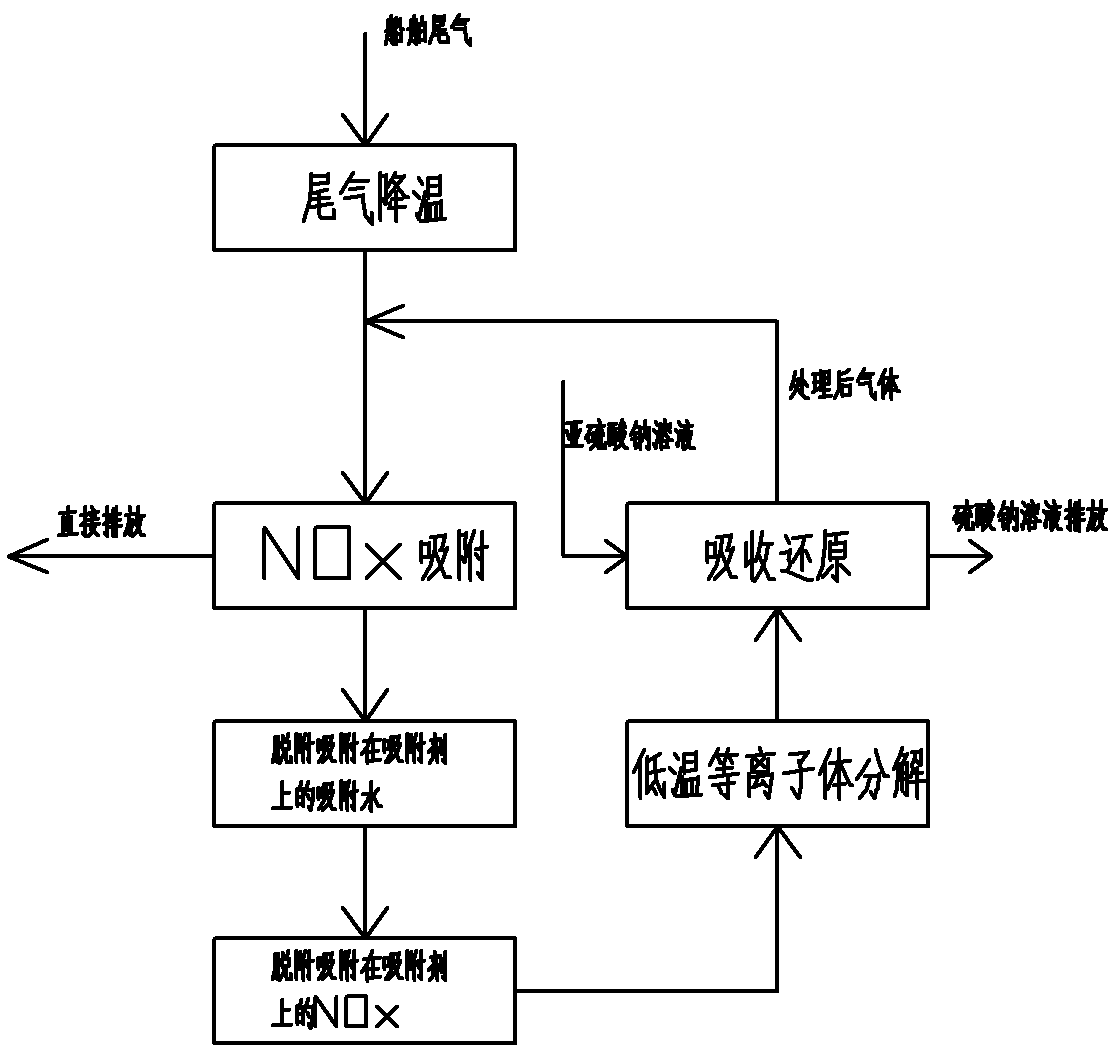

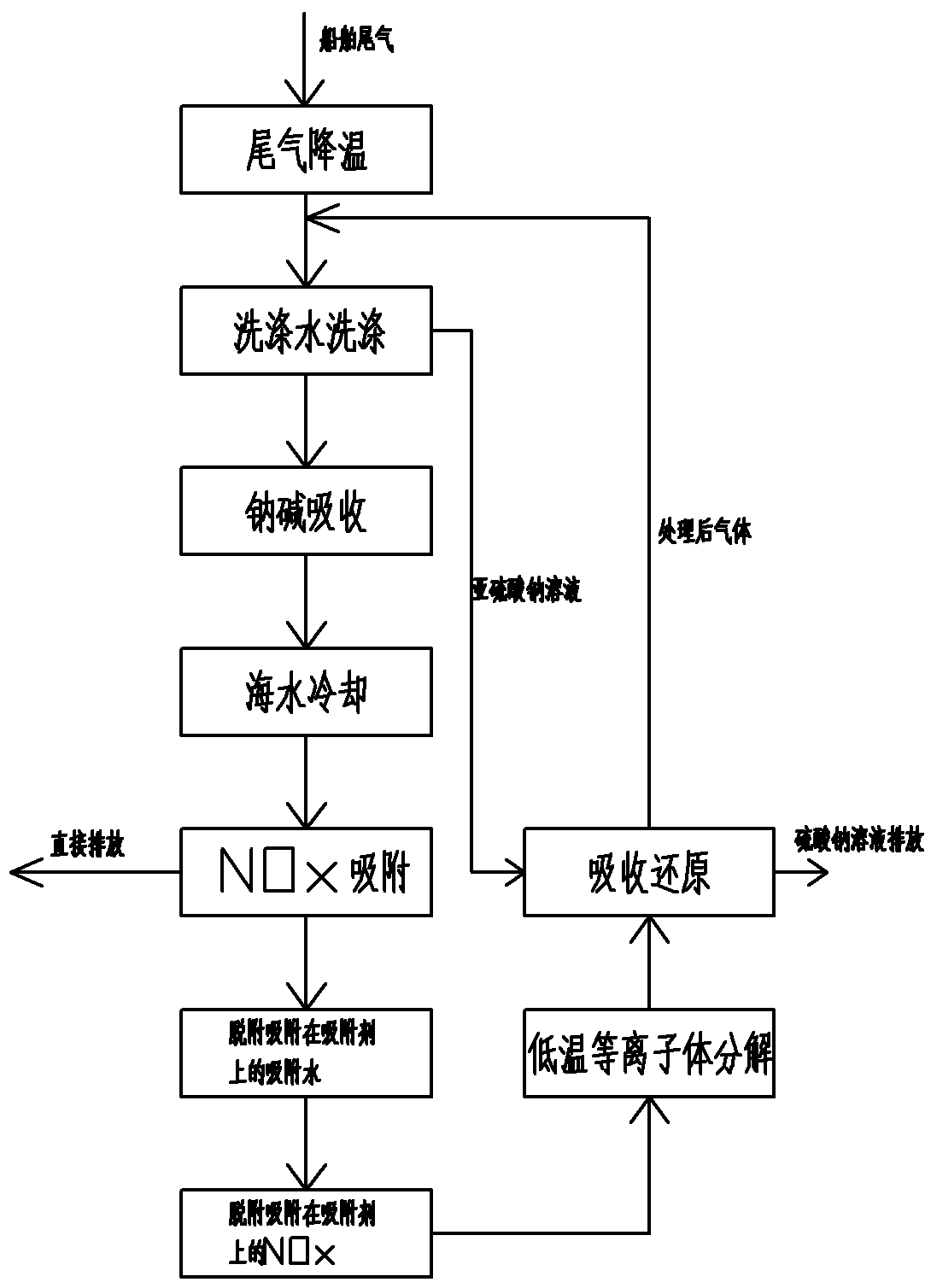

Ship tail gas denitration technology and system and desulfurization and denitrification integrated technology and system

ActiveCN105536486AEfficient use ofEfficient regenerationNitrous oxide captureGas treatmentSorbentDecomposition

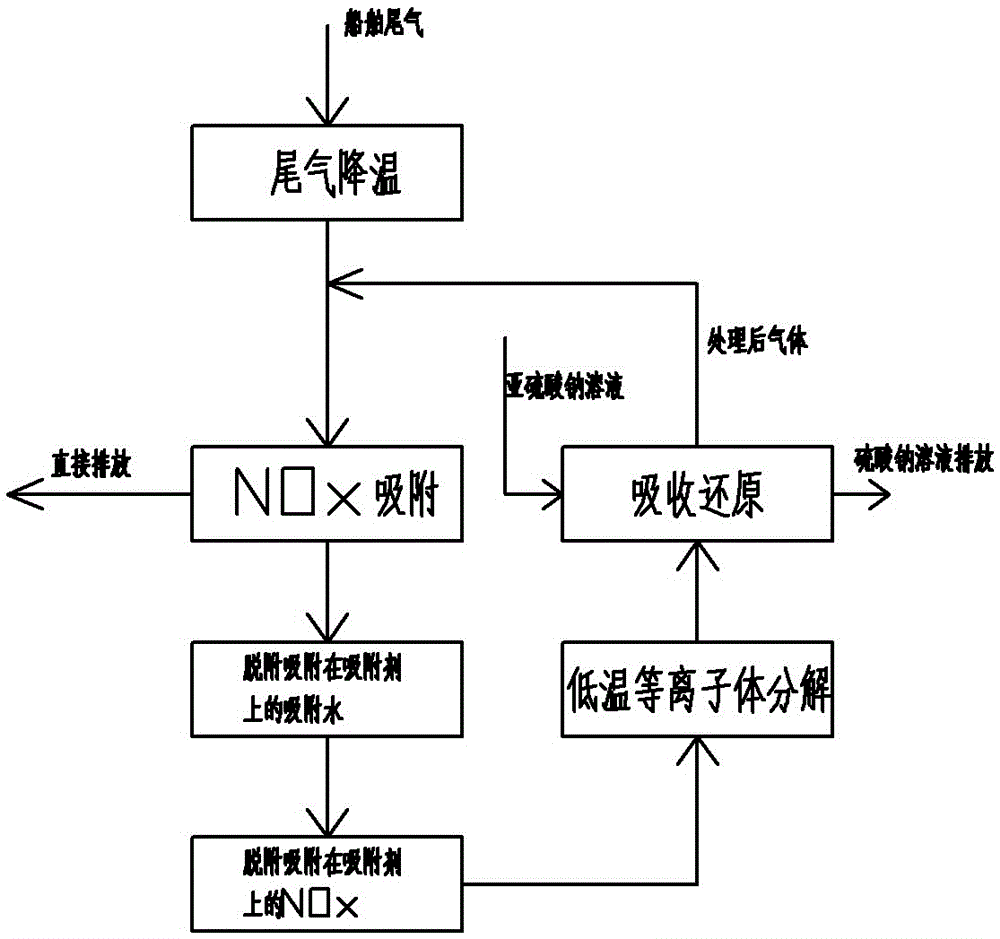

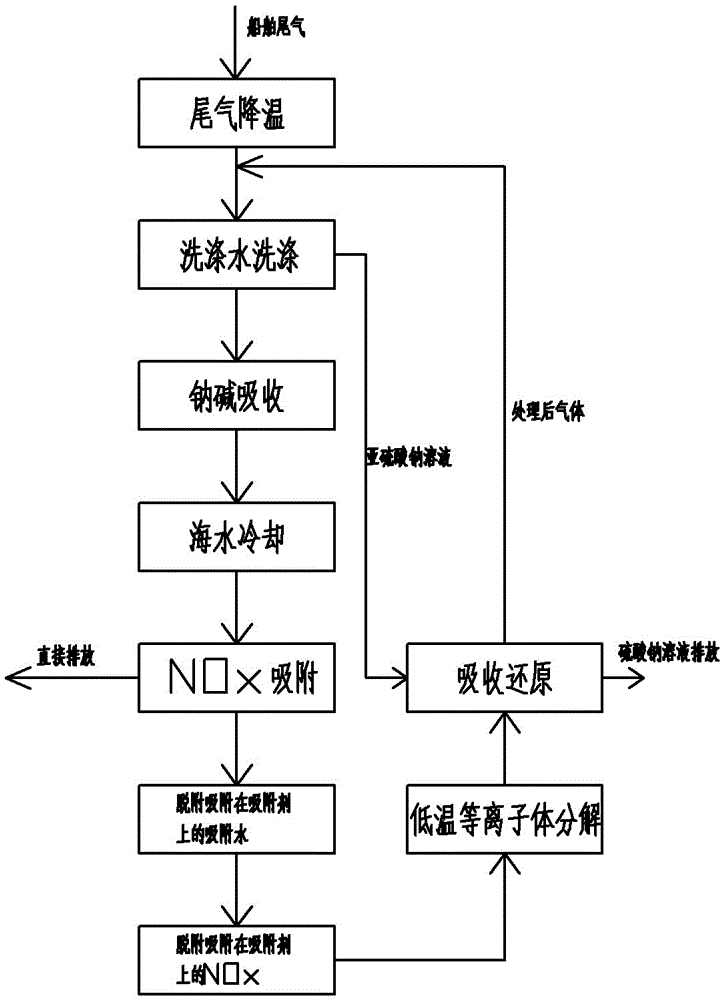

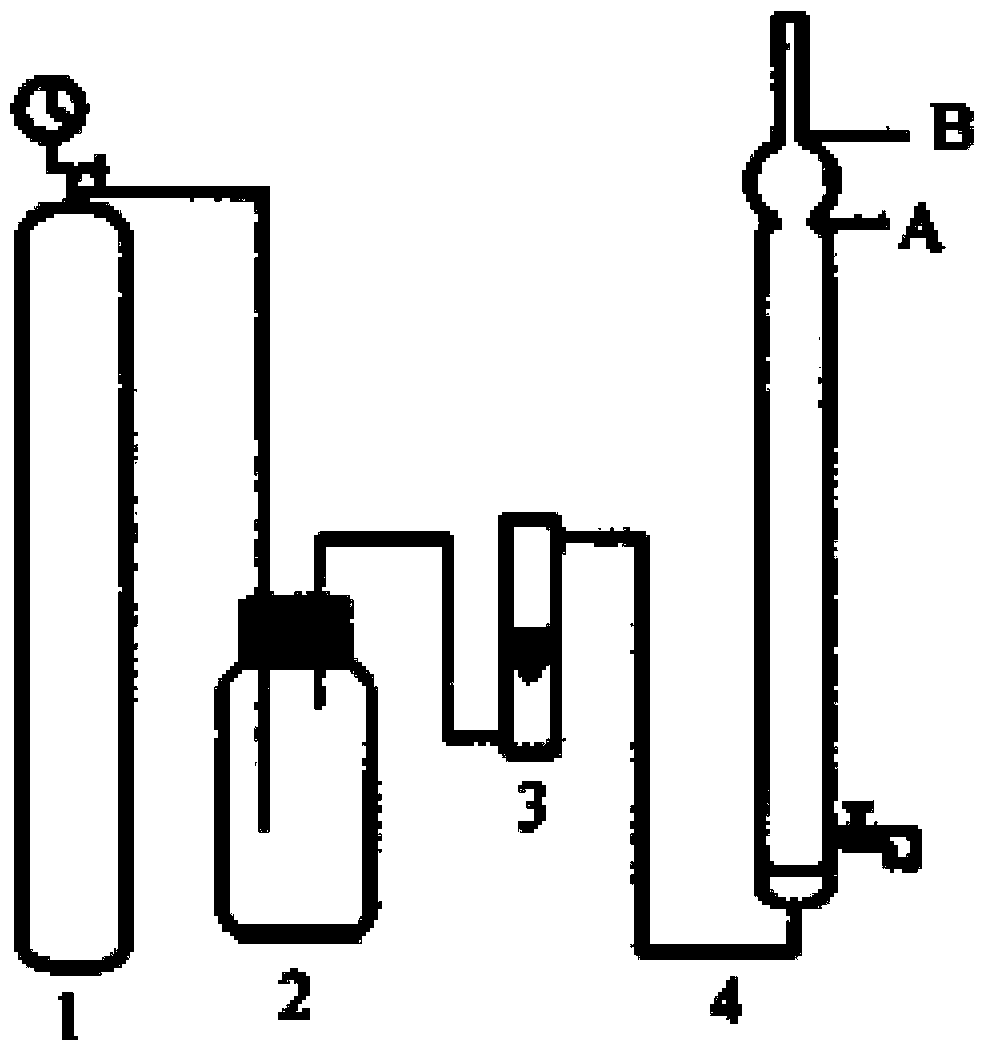

The invention belongs to the field of ship tail gas treatment, energy conservation and environment protection, and particularly relates to a ship tail gas denitration technology and system and a desulfurization and denitration integrated technology and system. When low sulfur oil is used for a ship, the ship tail gas denitration technology and system can achieve high denitration efficiency and reduce energy consumption; when high sulfur content is used for the ship, desulfurization and denitration are combined together, high desulfurization and denitration efficiency is achieved, meanwhile, the cost is greatly saved, and the tail gas exhaust standards are met. The ship tail gas denitration technology comprises the steps of 1, tail gas cooling, 2, NOX adsorption, 3, desorption of NOX adsorbed on an adsorbent, 4, low-temperature plasma decomposition and 5, absorption and reduction. The ship tail desulfurization and denitration integrated technology comprises the steps of 1, tail gas cooling, 2, washing performed through washing water, 3, soda absorption, 4, NOX adsorption, 5, desorption of adsorption water adsorbed on an adsorbent, 6, desorption of NOX adsorbed on an adsorbent, 7, low-temperature plasma decomposition and 8, absorption and reduction.

Owner:张拿慧

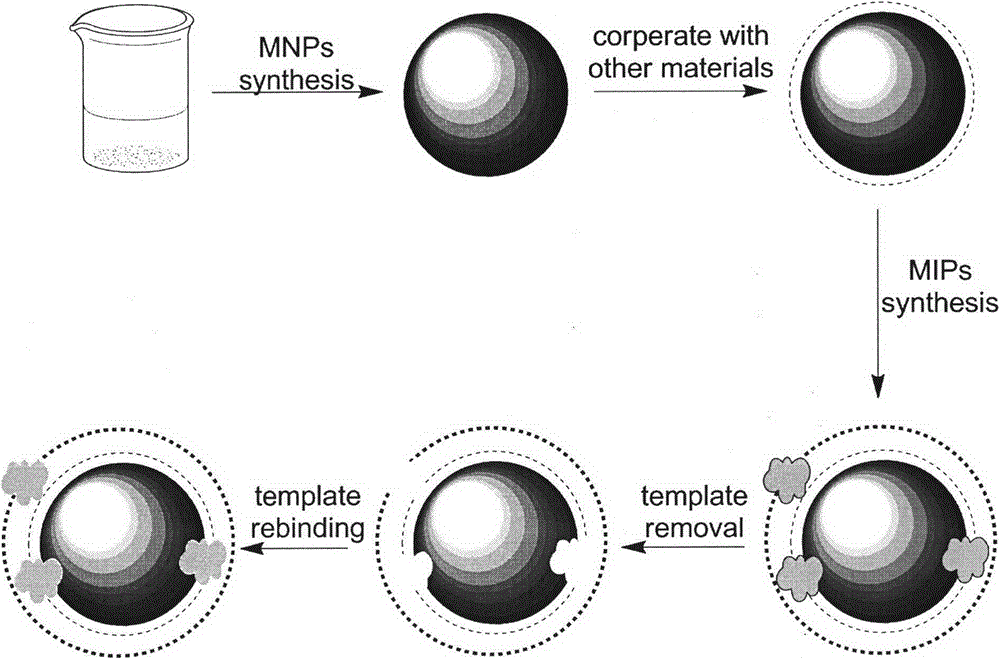

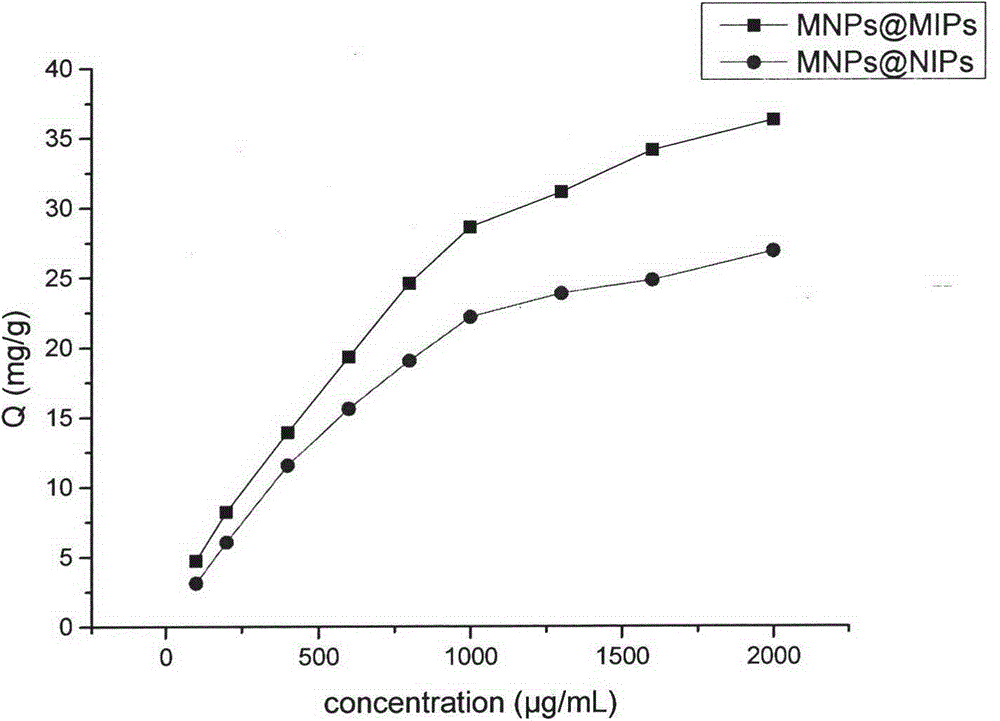

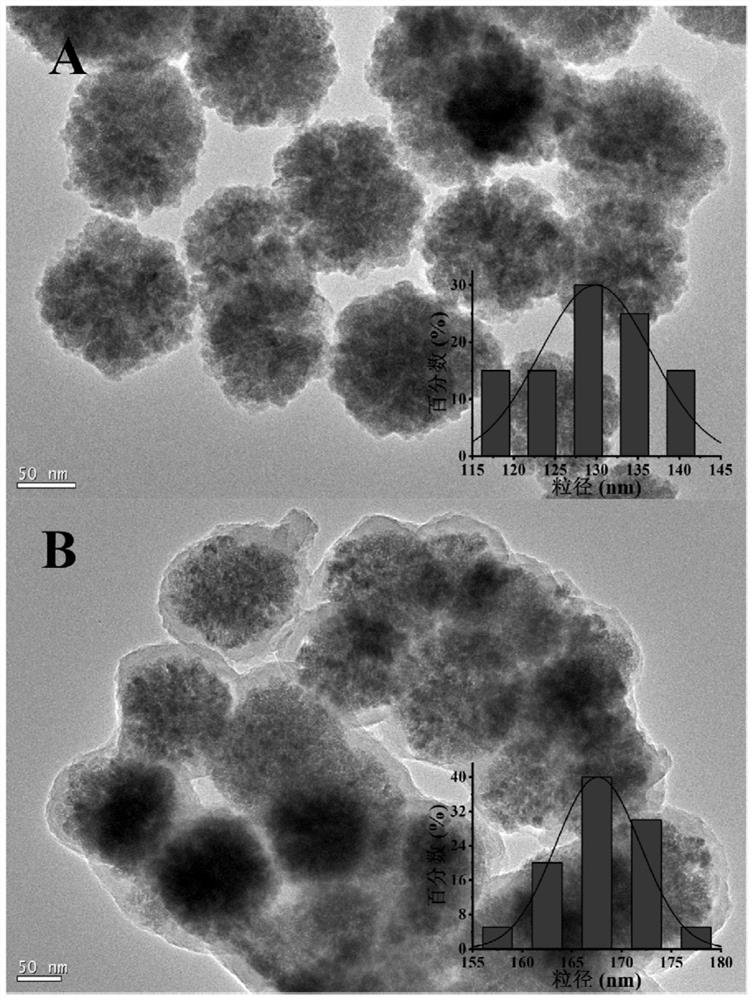

Preparation method of magnetic microspheres-based levofloxacin surface imprinted material

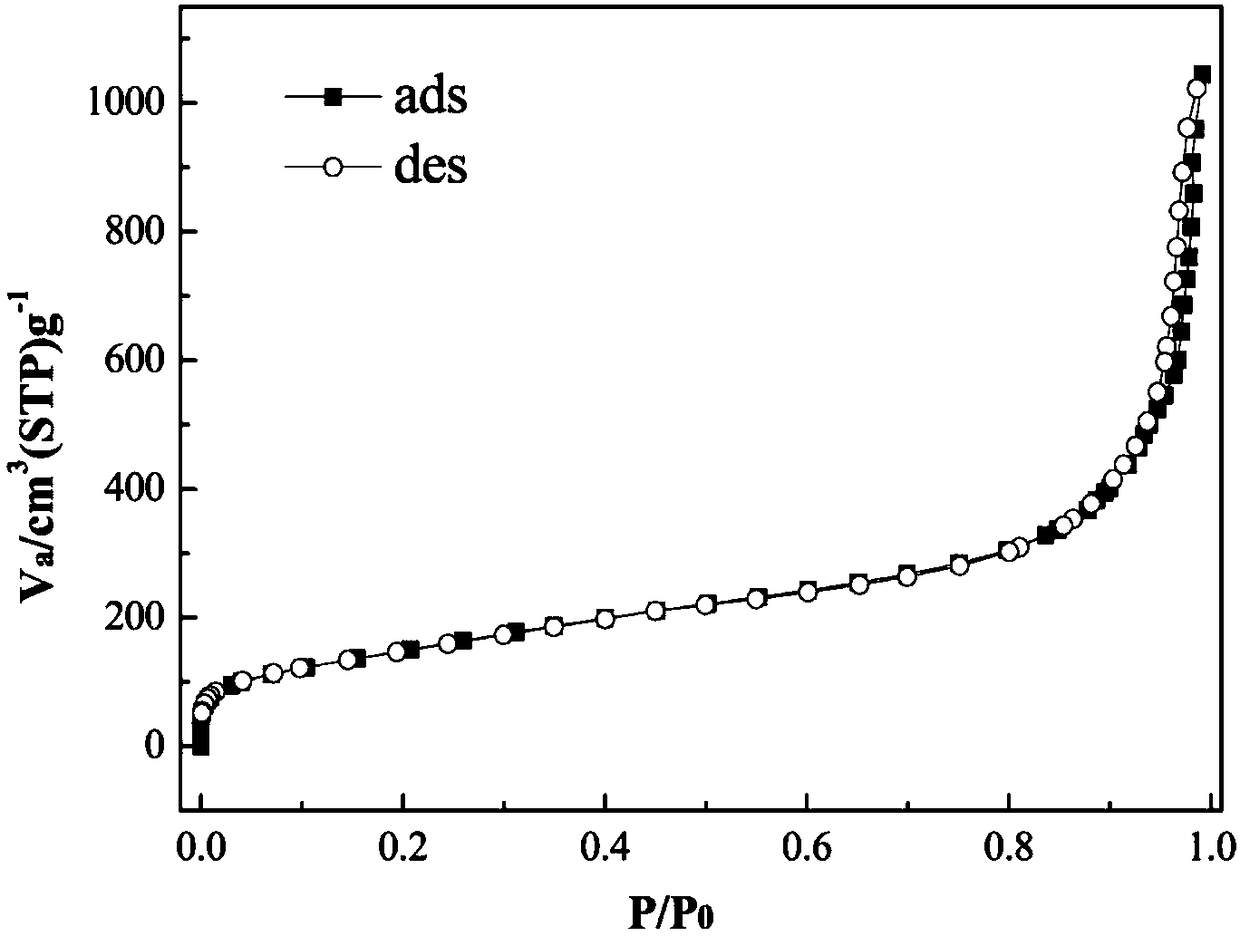

InactiveCN104788612AImprove adsorption capacityGood magnetic responseOther chemical processesAlkali metal oxides/hydroxidesSynthesis methodsMicrosphere

The invention relates to a preparation method of a magnetic microspheres-based levofloxacin surface imprinted material. The preparation process mainly comprises three steps: preparation of magnetic microspheres; coating of the magnetic microspheres with a molecularly imprinted material; and elution of template molecules. A synthetic method provided by the invention is simple. The prepared magnetic microspheres-based surface molecularly imprinted material has specific recognition function, high adsorption capacity and rapid adsorption ability of levofloxacin and has chiral resolution function of ofloxacin, has good magnetic response and high mechanical strength, can be used as an absorption filler or a coating material, also can be used in preparation of a molecular imprinting sensor and a chip, and is of great significance for researches on specific recognition, chiral resolution and highly sensitive detection of floxacin drugs.

Owner:CHINA PHARM UNIV

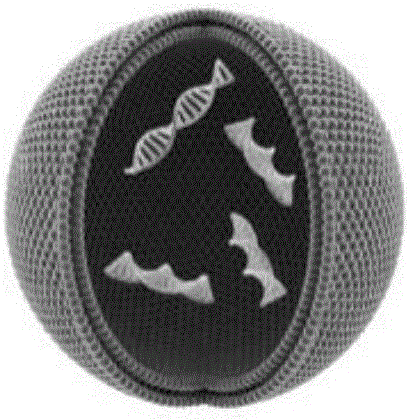

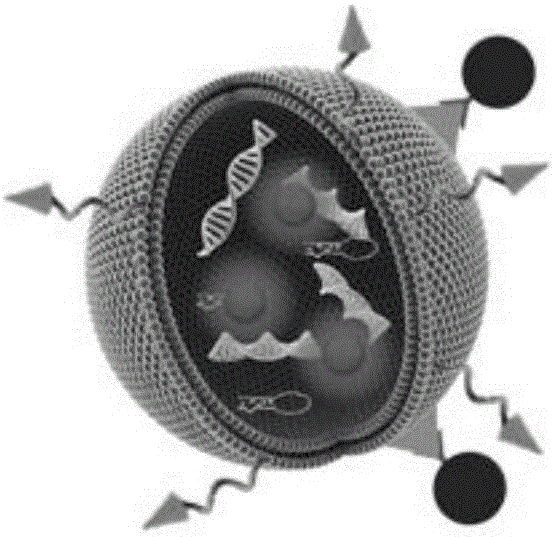

Tumor-targeted delivery carrier based on cell-derived micro-vacuoles, preparation method and application

ActiveCN106692984AGood biological stabilityHigh biosecurityEnergy modified materialsGenetic material ingredientsDspe pegCell culture supernatant

The invention discloses a tumor-targeted delivery carrier based on cell-derived micro-vacuoles, a preparation method and an application. The preparation method comprises the following steps of: (A) preparing a conditioned medium: supplementing fetal bovine serum, antibiotics, DSPE-PEG-Biotin and DSPE-PEG-Folate into a basal medium; (B) using the obtained conditioned medium in cell culture, and collecting cell culture supernatant for subsequent separation; (C) carrying out low-speed centrifugation on the obtained culture supernatant to remove cell debris and apoptotic bodies, then adding SA-IONPs, mixing uniformly, incubating, then separating by a magnet, using PBS for re-suspension, eluting for multiple times to obtain the cell-derived micro-vacuoles with membrane surfaces modified by folic acid and iron oxide nano-particles, and freezing for storage; and (D) loading chemotherapeutic drugs or therapeutic genes into the functionalized micro-vacuoles doubly-modified by an electroporation mode, and carrying out re-suspension after separation with the magnet. The tumor-targeted delivery carrier based on cell-derived micro-vacuoles, the preparation method and the application disclosed by the invention are applicable to specific targeting delivery of multiple chemotherapeutic drugs and therapeutic genes, and have the advantages of enhancing the anti-tumor effect, reducing the systemic toxicity and improving the clinical effect of the current therapeutic selection, so that a new hope is brought for clinical therapy of tumors.

Owner:珈泌生物科技(武汉)有限责任公司

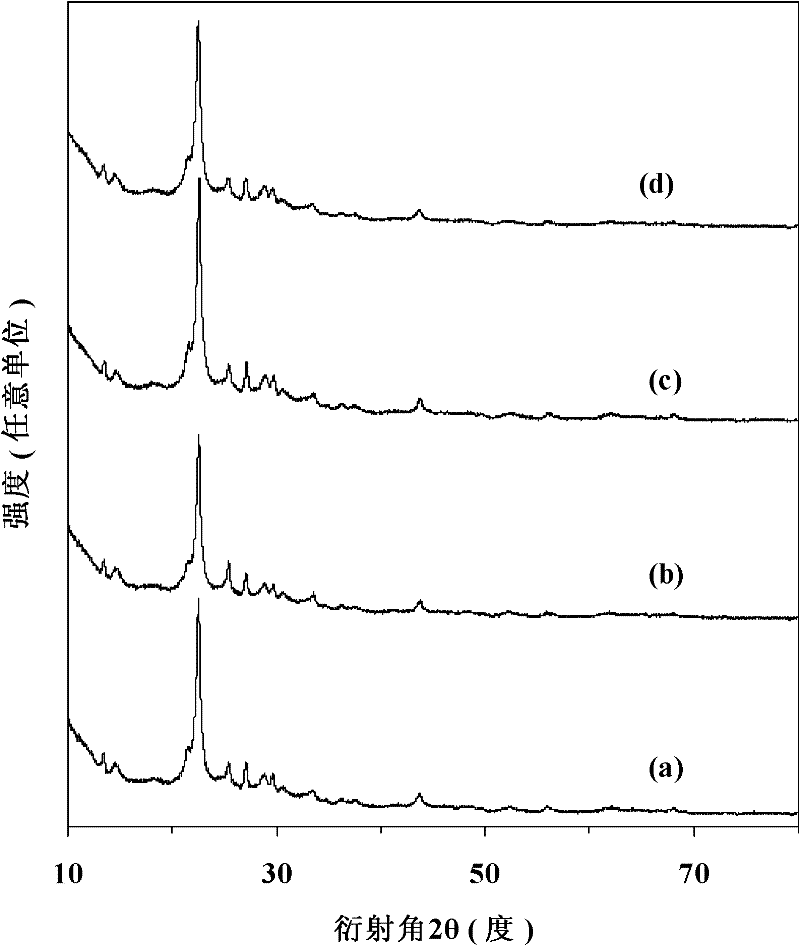

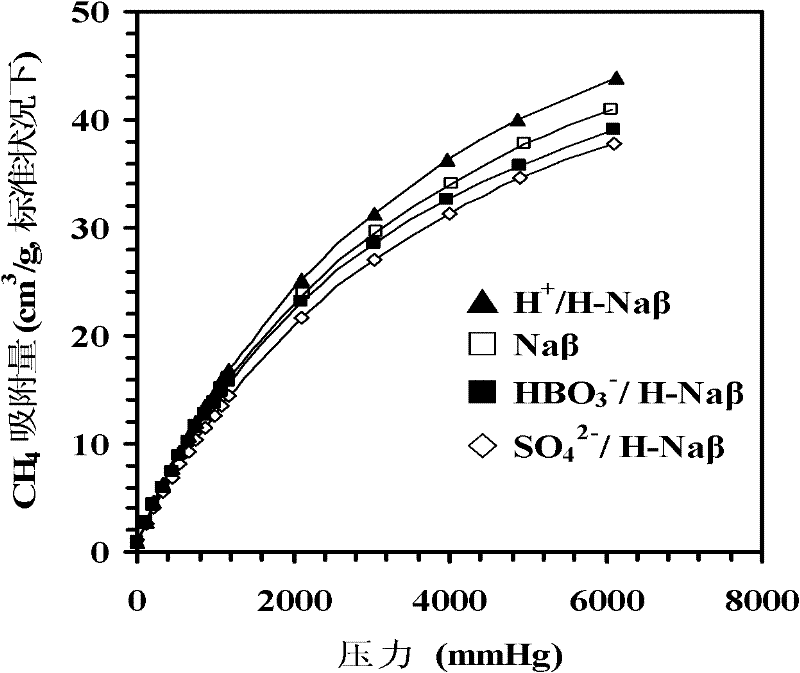

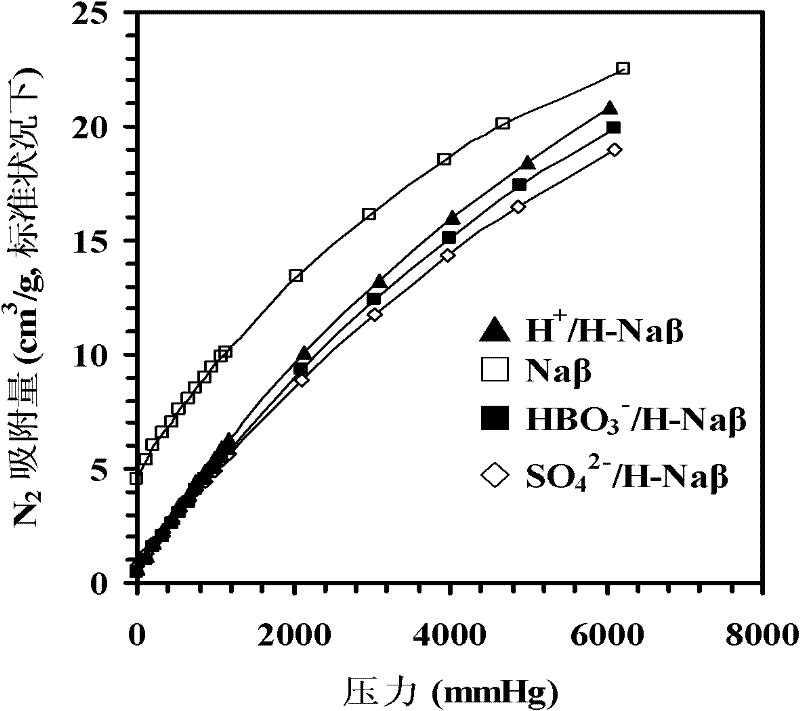

Molecular sieve modification method capable of increasing separation factor of CH4 and N2

InactiveCN102219235AImprove adsorption capacityHigh separation factorCrystalline aluminosilicate zeolitesSeparation factorMolecular sieve

The invention discloses a molecular sieve modification method capable of increasing a separation factor of CH4 and N2, belonging to the technical field of molecular sieve. The molecular sieve modification method comprises the following steps of: impregnating a Na-beta molecular sieve in H2SO4, H3BO3 and NH4NO3 aqueous solution with a certain concentration, filtering, drying and burning to obtain an acid-modified A / H-Na-beta molecular sieve. Compared with the Na-beta molecular sieve, the A / H-Na-beta molecular sieve provided by the invention has excellent adsorption selectivity to CH4 gas and prominent separation effect on CH4 and N2, wherein the NH4NO3-modified beta molecular sieve has the strongest adsorption capability to CH4 gas. The modified molecular sieve can simultaneously improve the adsorption capability to CH4 gas and reduce the adsorption capacity to N2, thus increasing the separation factor of CH4 and N2 and achieving the separation and enrichment of CH4 and N2.

Owner:BEIJING UNIV OF TECH

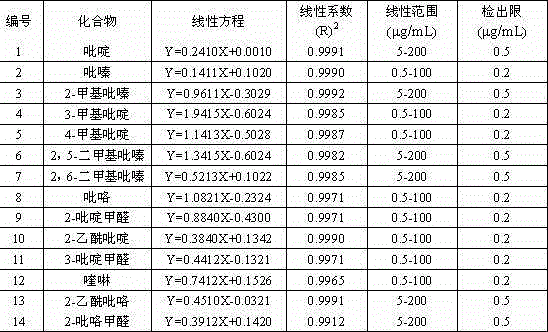

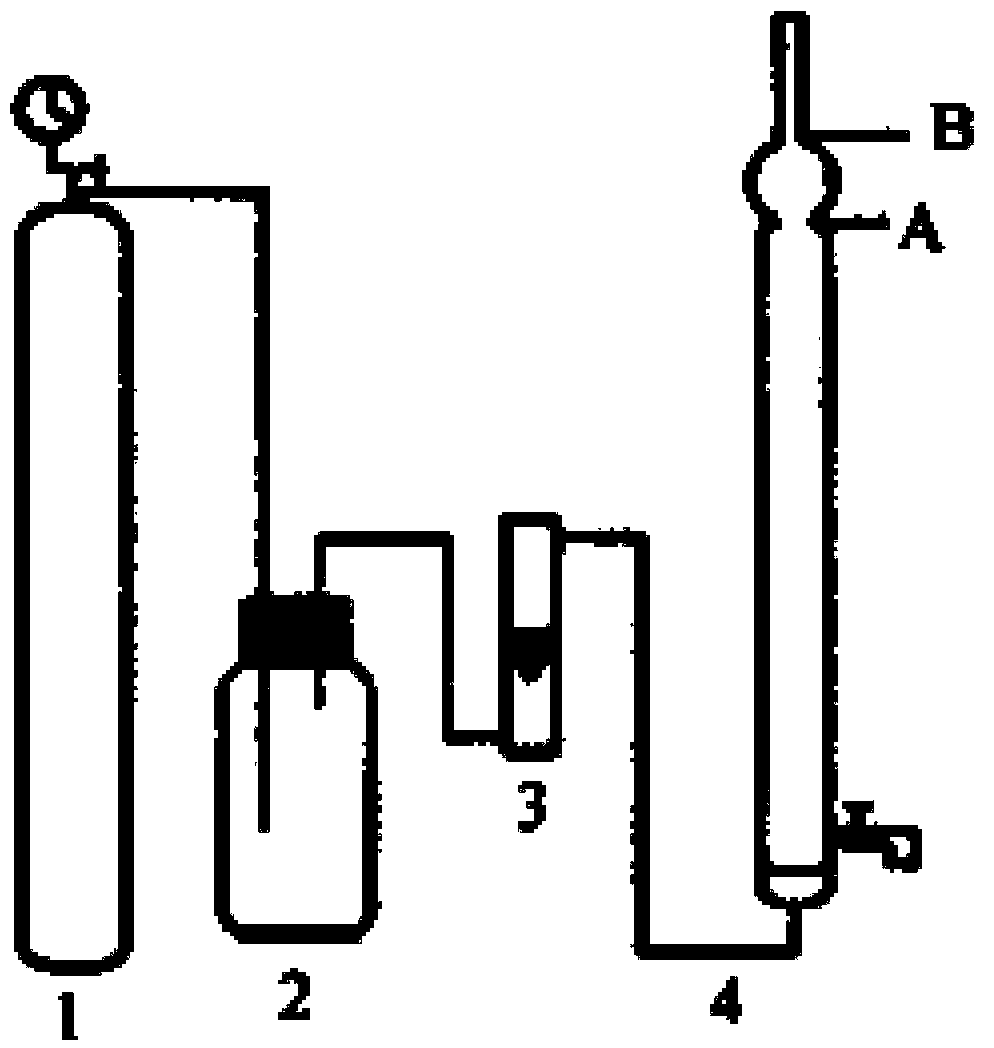

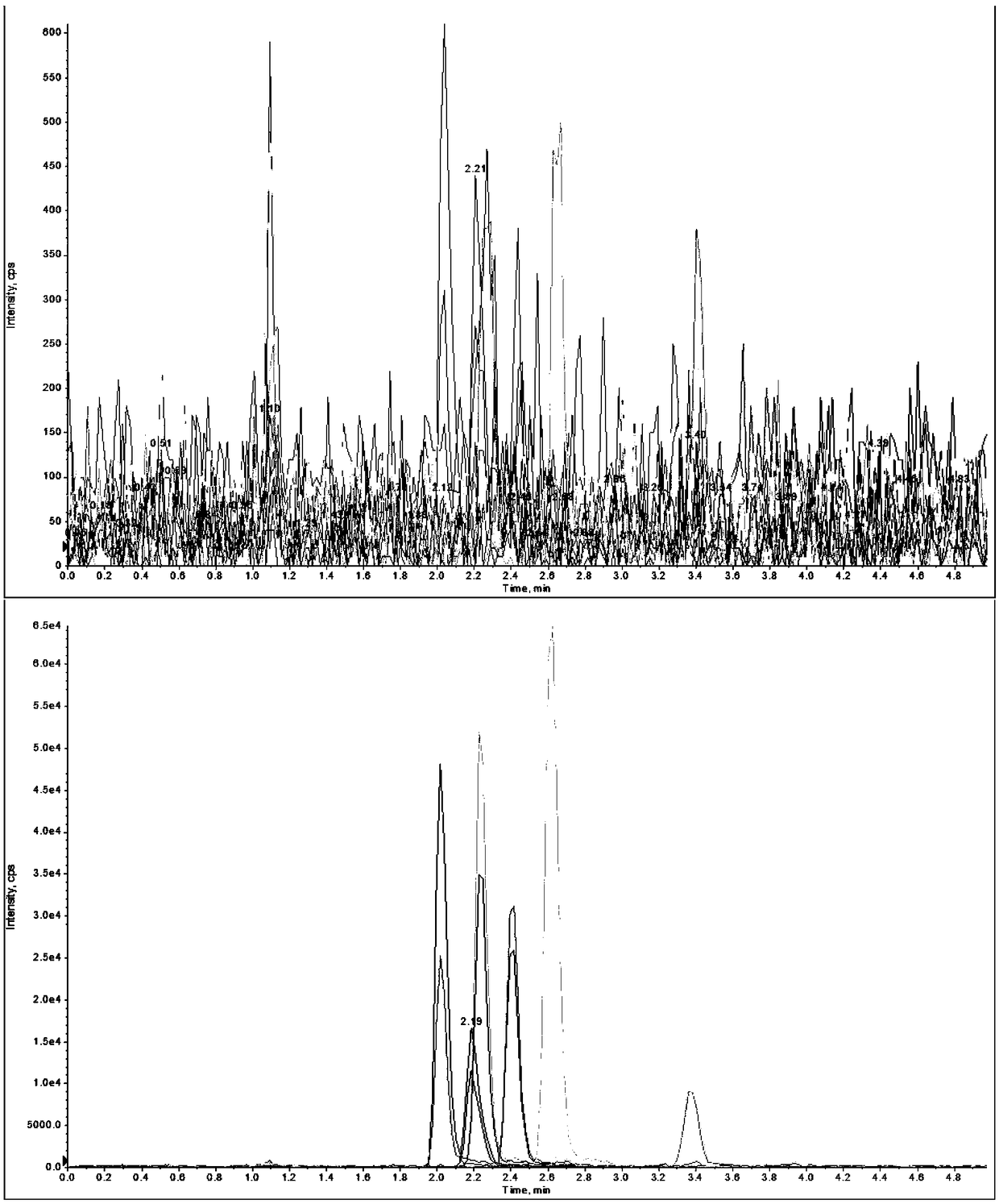

Method for analyzing and detecting alkaline aroma constituents in tobacco through ultrasound-assisted cloud-point extraction gas chromatography-mass spectrometry technology

InactiveCN105241994ARealize separation and enrichmentDoes not destroy the chemical structureComponent separationSolventActive agent

The invention discloses a method for analyzing and detecting alkaline aroma constituents in tobacco through an ultrasound-assisted cloud-point extraction gas chromatography-mass spectrometry technology. The method includes the steps that 1, a tobacco powder sample is accurately weighed, a sodium hydroxide solution and an internal standard solution are added, soaking and ultrasonic extraction are performed, centrifugation is performed to obtain supernate, a surfactant is added, the mixture is evenly stirred to form a 5%-15% solution, the 5%-15% solution is heated to a temperature higher than the cloud point temperature, and an aqueous phase is removed after standing layering or centrifugal layering; 2, reextraction solvent is added, ultrasonic extraction is performed, a reextraction solvent phase on the upper layer is taken, anhydrous sodium sulfate is added, the mixture is oscillated and then subjected to standing concentration, and the product is filtered through a filtration membrane to obtain a sample to be detected; 3, the sample is detected through a GC-MS, and graph spectrum data are processed to obtain an analysis and test result of the alkaline aroma constituents. The method has the advantages that the pretreatment process is simple, mild and fast, the alkaline aroma constituents in the tobacco can be accurately determined, and the method has great theoretical significance and application value for guiding a scientific formula of cigarettes and improving the aroma and taste quality of the cigarettes.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

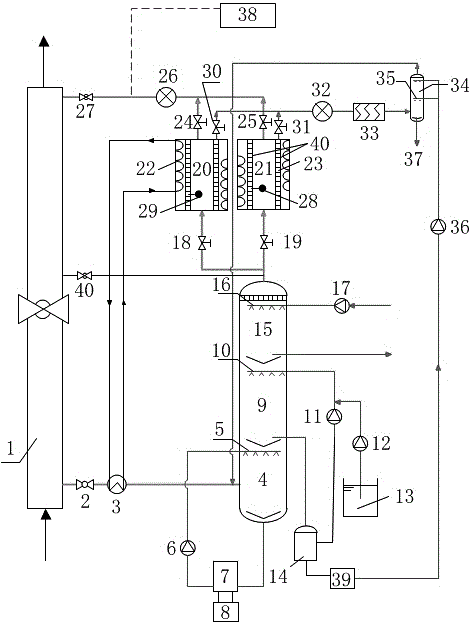

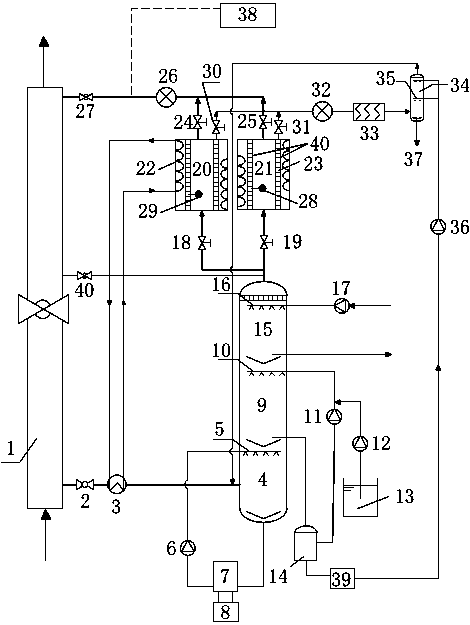

Marine exhaust gas after-treatment method

InactiveCN106237802ALow running costMild reaction conditionsGas treatmentDispersed particle separationChemistrySeawater

The invention discloses a marine exhaust gas after-treatment method. Exhaust gas generated by ships is introduced into a desulfurization and denitrification unified tower, absorbing desulfurization is conducted on the lower portion of the tower by means of sodium hydroxide solution, complexing denitrification can be achieved with complexing liquid on the upper portion of the tower, and exhaust gas up to standard after desulfurization and denitrification treatment is heated and then discharged out of a chimney; the complexing liquid after NO complexing is heated so that NO can be extracted; No extracted through heating is oxidized to be NO2 through catalytic oxidation or plasma oxidization, and then absorbed by sodium hydroxide solution or sodium sulfite solution. When ship usage meets the requirement for low-sulfur oil according to IMO convention, desulfurization is not needed, sodium alkali desulfurization section spraying liquid is changed to be seawater, and exhaust gas is cooled to prevent the temperature of a tower body from becoming too high. When ships sail in an area which does not need denitrification, a denitrification section complexing liquid sprinkling system is closed, and exhaust gas is heated and then directly discharged out of the chimney. In this way, separation and enrichment of NOX from exhaust gas is achieved, the concentration of NOx is improved, and the conversion rate of catalytic oxidation and plasma oxidization is increased.

Owner:SHANGHAI HENGYUAN MARINE EQUIP

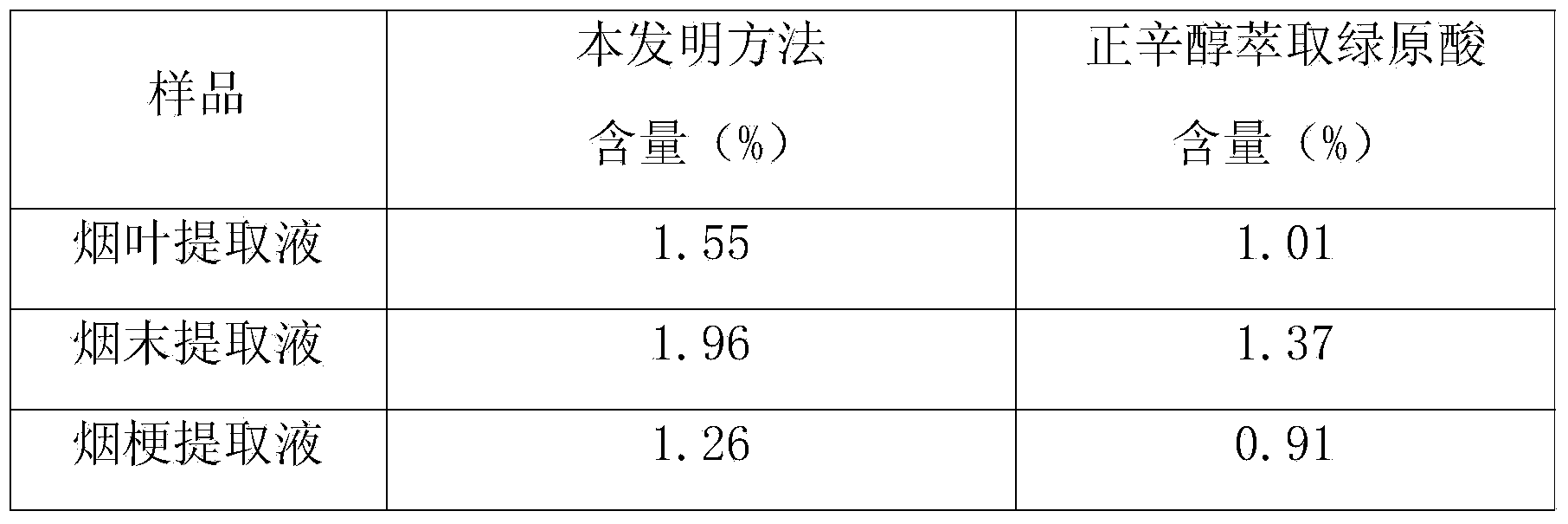

Method for separating and enriching chlorogenic acid in tobacco

ActiveCN103739491ARealize separation and enrichmentHigh extraction rateOrganic compound preparationCarboxylic acid esters preparationNicotiana tabacumChlorogenic acid

The invention relates to a method for separating and enriching chlorogenic acid in tobacco. According to the method, the chlorogenic acid in tobacco is separated and enriched by utilizing a solvent flotation technology, and a mixed organic solvent is added to serve as an extracting agent, so that the polarity of the extracting agent is changed, and the extraction rate of the chlorogenic acid is improved. The pH value of a tobacco extracting solution is regulated, so that the polarity of the extracting agent is matched with that of the chlorogenic acid, and the separation, enrichment and purification effect is good. The extraction can be performed at room temperature due to the adopted solvent flotation technology, and the operation conditions are mild. According to floatation of an air floatation solvent, an emulsification phenomenon generated due to shaking during common liquid-liquid extraction is avoided, the amount of the used organic solvent is small, and the method is large in enrichment factor, short in phase separation time, low in cost and feasible to operate.

Owner:CHINA TOBACCO GUANGXI IND

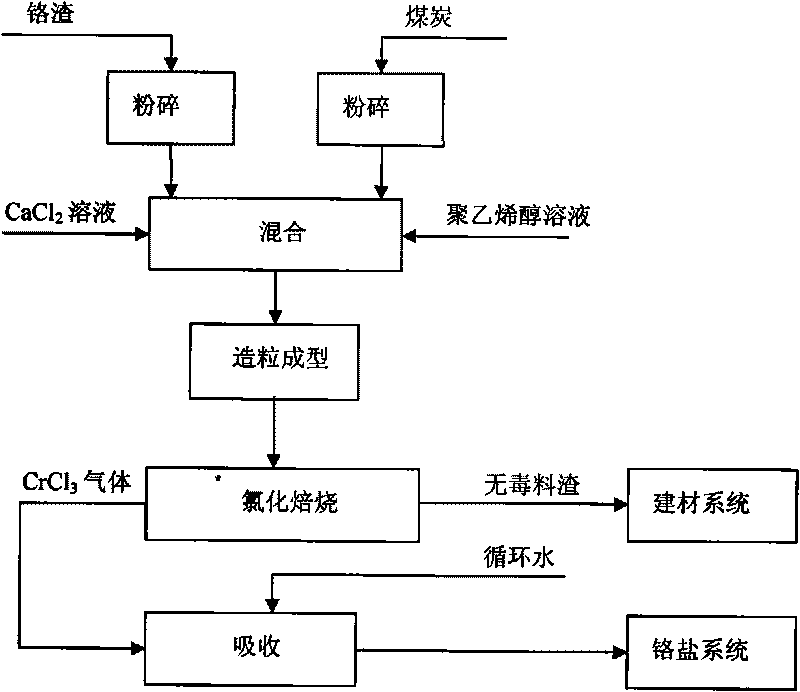

Method and process for recovering chromium from chromium residue by chlorination segregation method

InactiveCN101746828ASolve secondary pollutionSimple processSolid waste managementChromium halidesWater circulationIndustrial waste

The invention relates to a method for industrial waste residue resource disposal, in particular to a process for enriching and recovering chromium in the chromium residue by a chlorination segregation method. The concrete method comprises the following steps: the pulverized coal and chromium residue are respectively ground to 80 meshes, evenly mixed and then added with 10 percent of calcium chloride aqueous solution and 3 percent of polyvinyl alcohol aqueous solution to be sufficiently and evenly mixed, and then the mixed solution is molded by extrusion; then the mixed solution is transferred to a roasting furnace to be roasted for 80 minutes at the temperature of 980 DEG C, the gas discharged at the top of the roasting furnace is absorbed through water circulation to obtain chromium trichloride solution; the chromium trichloride solution can be used for producing chromium trichloride or other chromium salts; the overall content of chromium in the chromium residue discharged from the roasting furnace is lower than 5 ppm (the content of hexavalent chromium is lower than 1 ppm), and the chromium can be used as building material; the separation and the concentration of chromium are realized through the method, the chromium recovery ratio is up to 94 percent, the chromium residue is recycled, and the problem of secondary pollution existing in the chromium residue is solved. The method is simple in process, requires low equipment investment, is suitable for volume production and convenient for industrialization; and the method is an environment-friendly process which has better popularization and application prospect.

Owner:SOUTHWEAT UNIV OF SCI & TECH

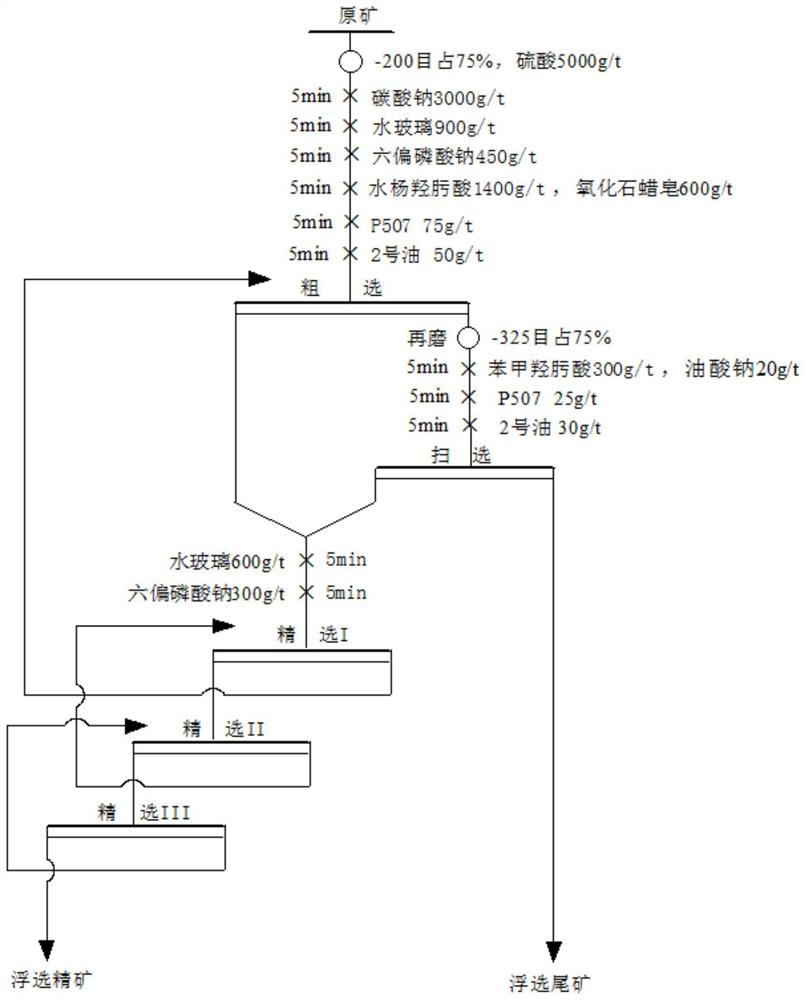

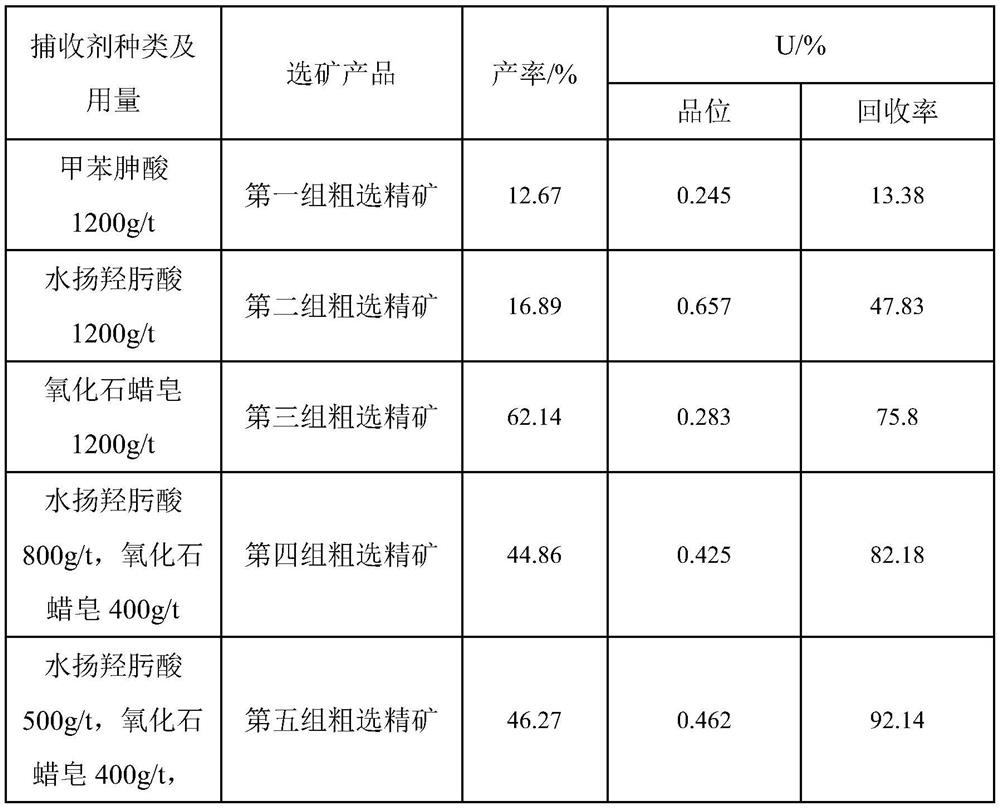

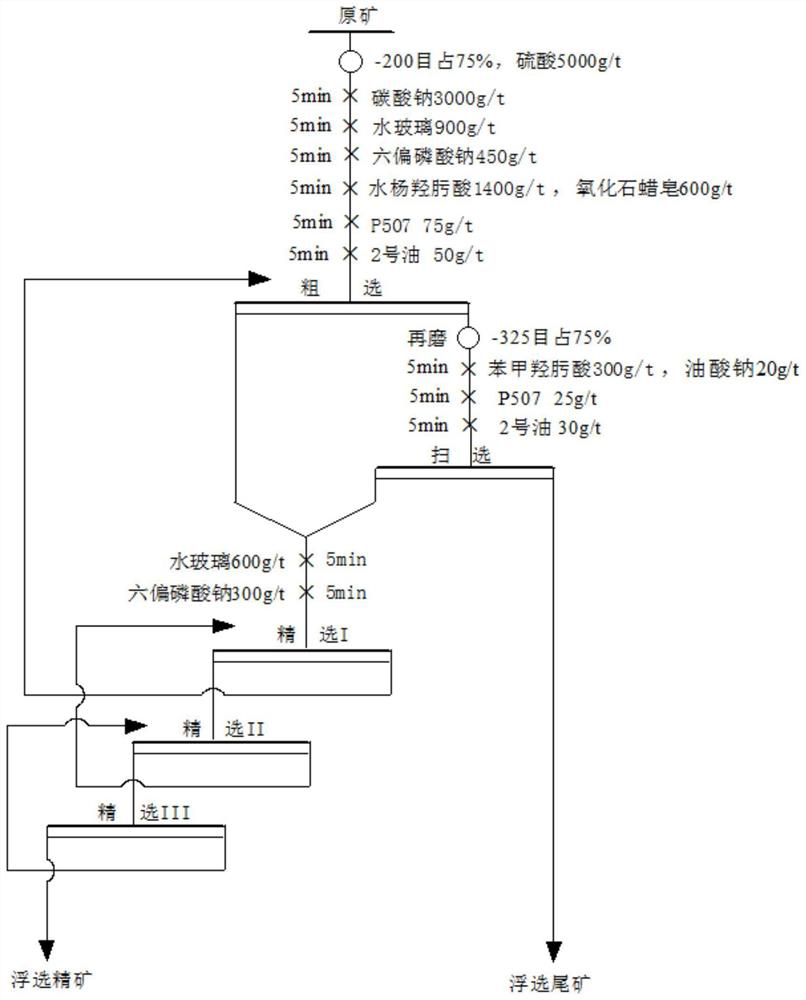

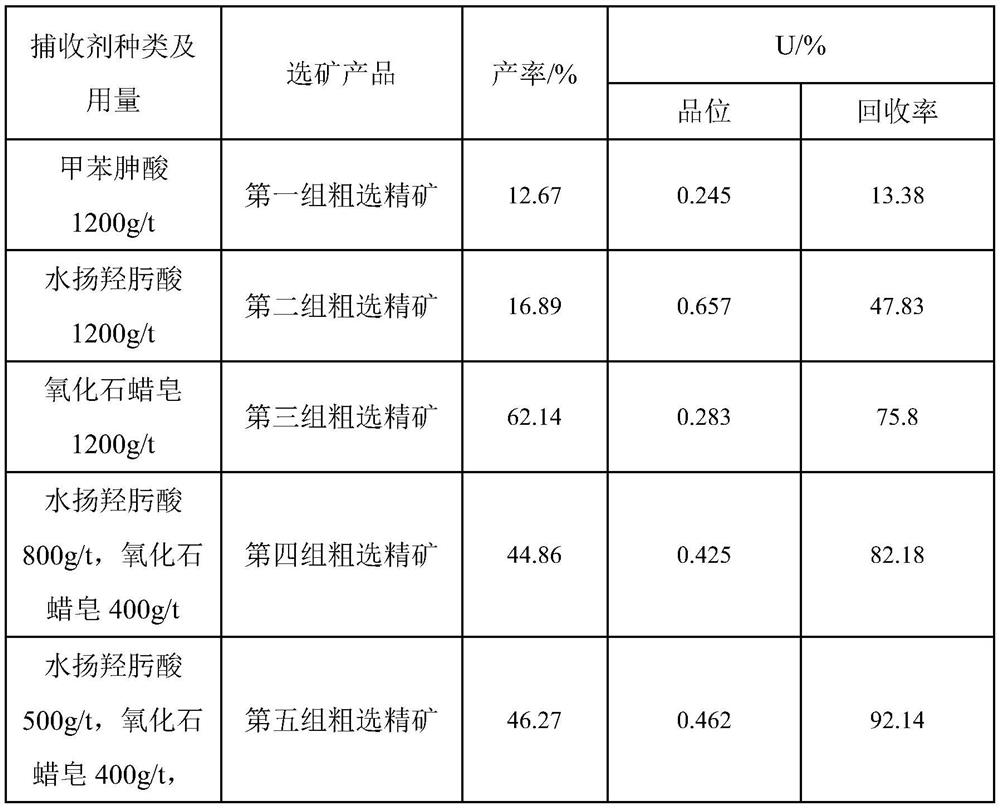

Method for flotation of uranium minerals from volcanic rock type uranium ores

ActiveCN112156894ARealize separation and enrichmentImprove flotation recoveryFlotationHydroxamic acidSodium phosphates

The invention discloses a method for flotation of uranium minerals from volcanic rock type uranium ores. The method comprises the following steps: crushing volcanic rock type uranium ores, adding an acid, performing ore grinding, and carrying out size mixing treatment to obtain ore pulp; and adjusting the ore pulp through sodium carbonate, and by taking sodium silicate and sodium hexametaphosphateas inhibitors, hydroxamic acid compounds and fatty acid compounds as collecting agents and P507 as an auxiliary collecting agent, performing froth flotation under the action of a foaming agent to obtain uranium concentrate. According to the method, sodium silicate and sodium hexametaphosphate are used as the inhibitors, and hydroxamic acid and fatty acid collecting agents and the P507 auxiliary collecting agent are used in cooperation, so that the yield of the flotation concentrate is greatly reduced, the content of carbonate minerals in the flotation concentrate is reduced, and reagent consumption and hydrometallurgy ore treatment capacity in the subsequent leaching process can be reduced; and meanwhile, separation and enrichment of uranium minerals are achieved, the flotation concentrate yield is 19.06%, the uranium grade is 1.073%, and the recovery rate is 86.63%.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

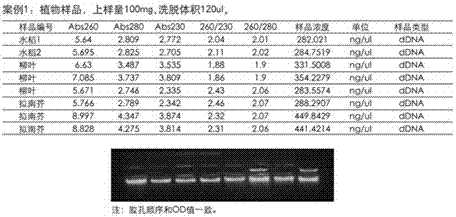

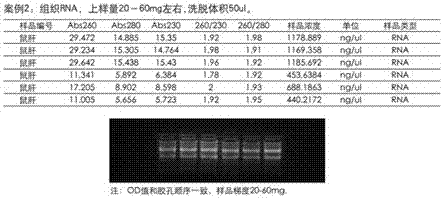

Method for direct extraction of nucleic acid without tissue grinding

InactiveCN107119039AQuick extractionImplement extractionMicrobiological testing/measurementDNA preparationCentrifugationTissue sample

The invention relates to the field of nucleic acid extraction, in particular to a method for direct extraction of nucleic acid without tissue grinding. In order to solve the defects of burdensome operation, long extraction cycle, no realization of automation, contact of toxic reagents and the like, and the technical problems that in the extraction process of a novel nucleic acid extraction instrument, animal tissue samples need grinding, cracking and centrifugation in advance and cannot achieve direct extraction on a machine, the invention provides a method for direct extraction of nucleic acid without tissue grinding. The method adopts a unique cracking reagent and employs a 96-channel nucleic acid extraction instrument for support to realize integration of instrument and consumables, and achieves full-automatic extraction of animal tissue nucleic acid. The reagent is optimized cracking liquid for different samples, and the instrument is nucleic acid extraction instrument, and the extraction conditions can be optimized according to different tissue samples. The method provided by the invention has the advantages of simple steps, full automatic operation, high purity of nucleic acid, short extraction cycle, and no contact with toxic reagent, etc.

Owner:BIOTEKE CORP (WUXI) CO LTD

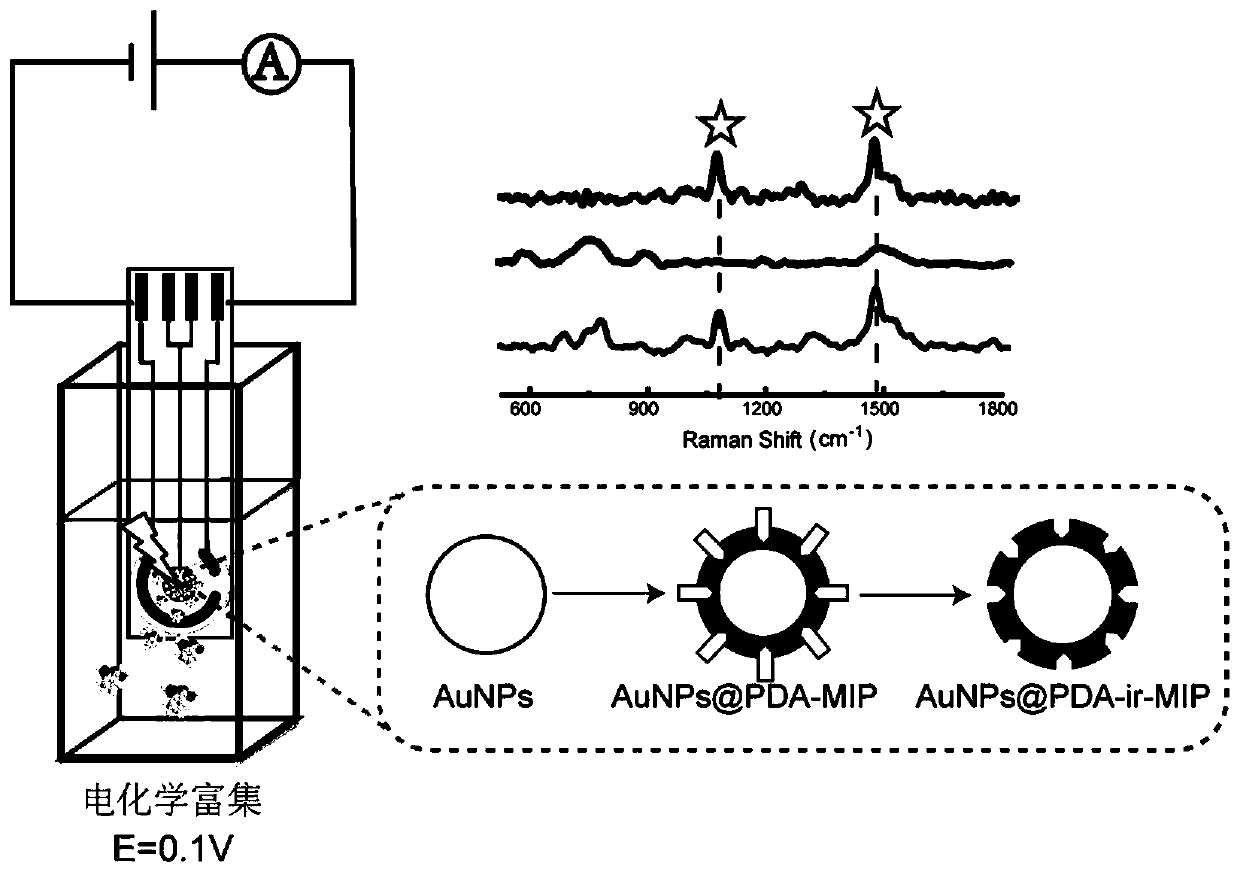

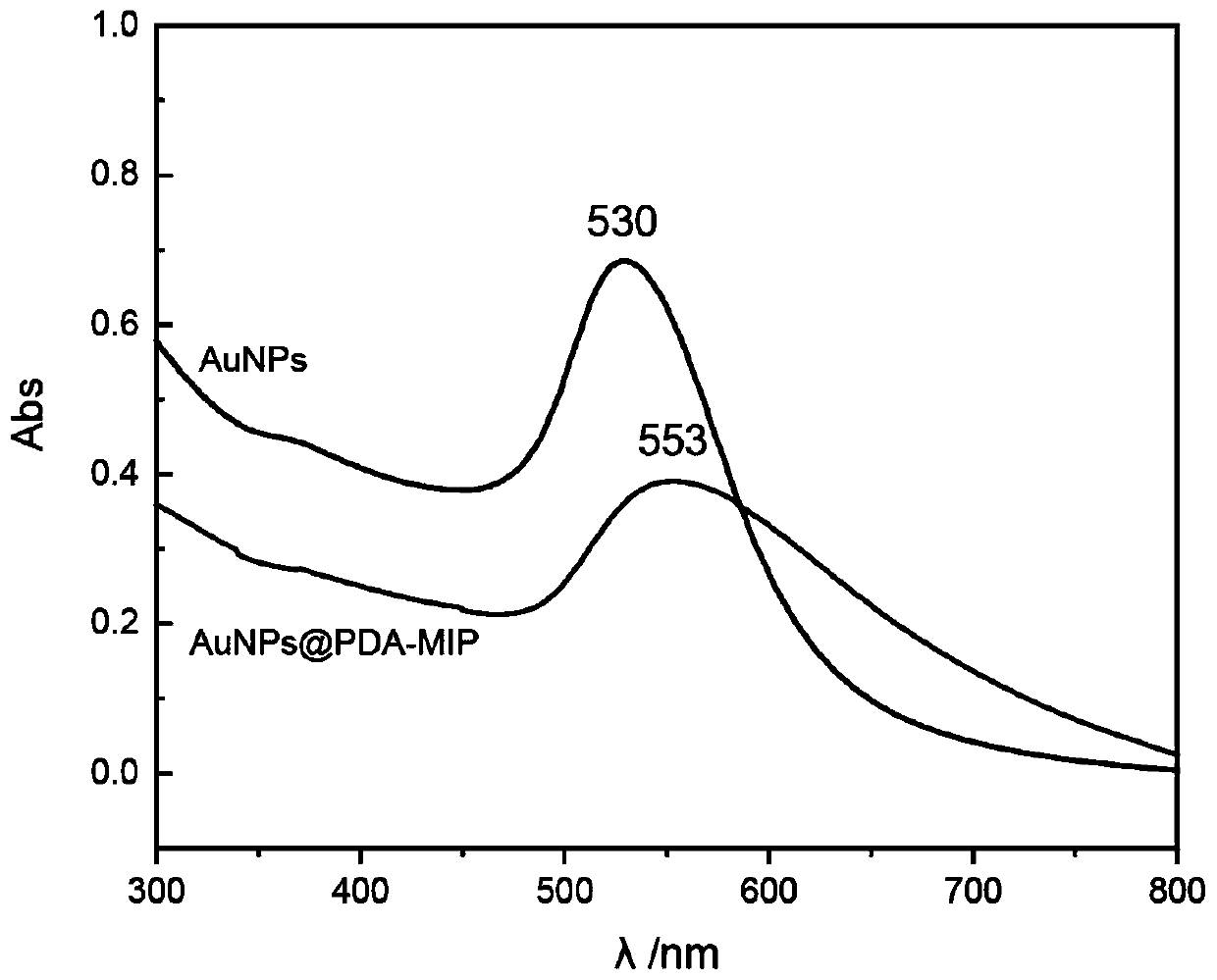

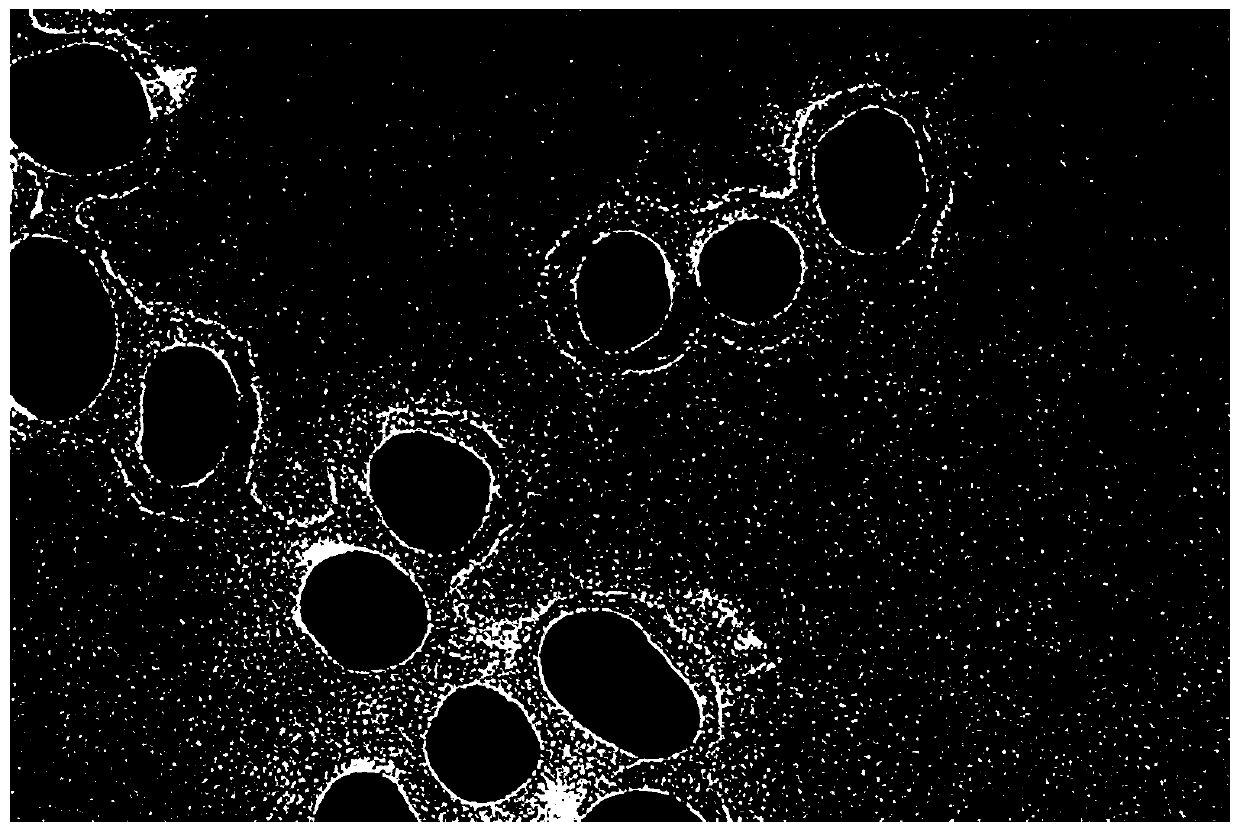

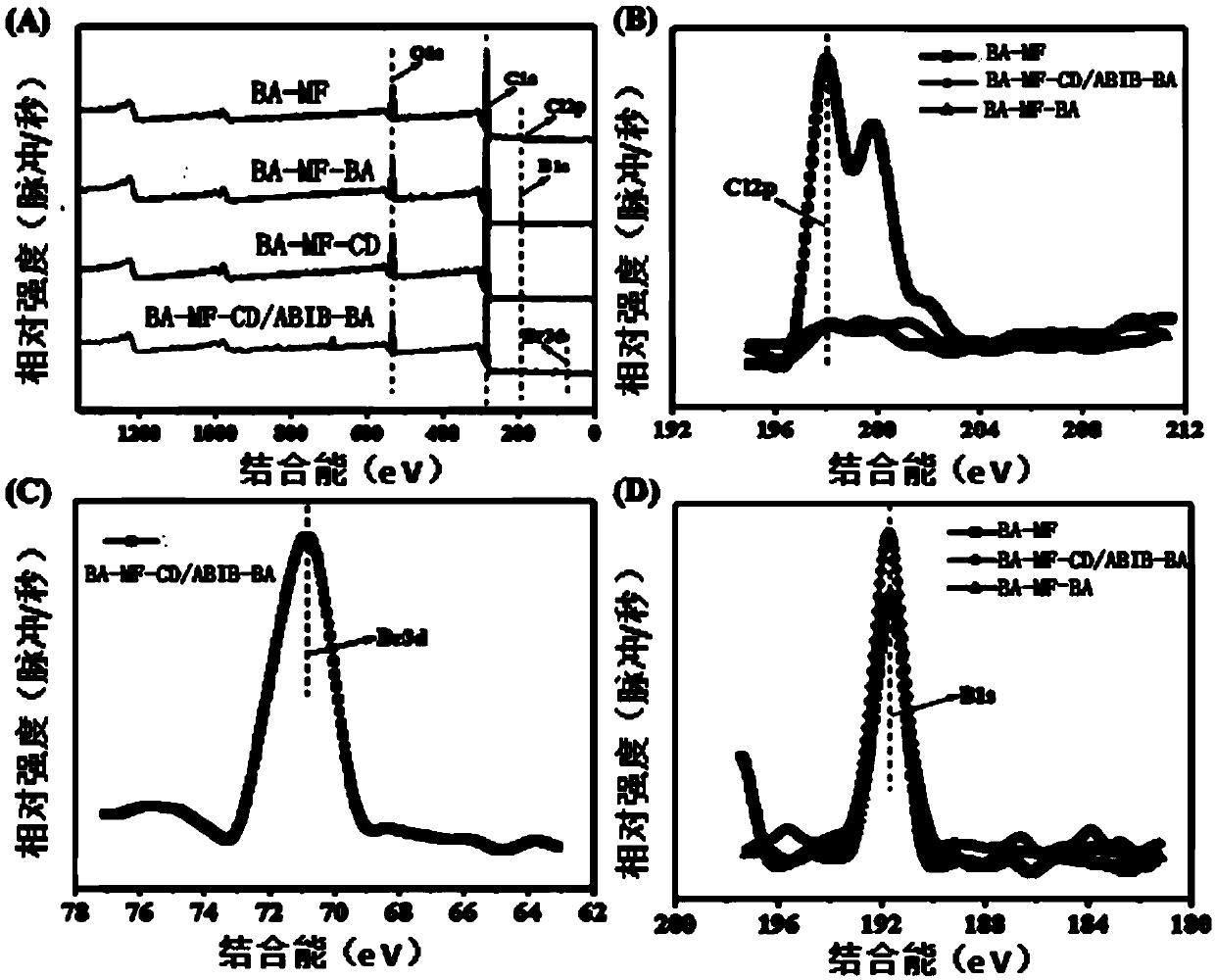

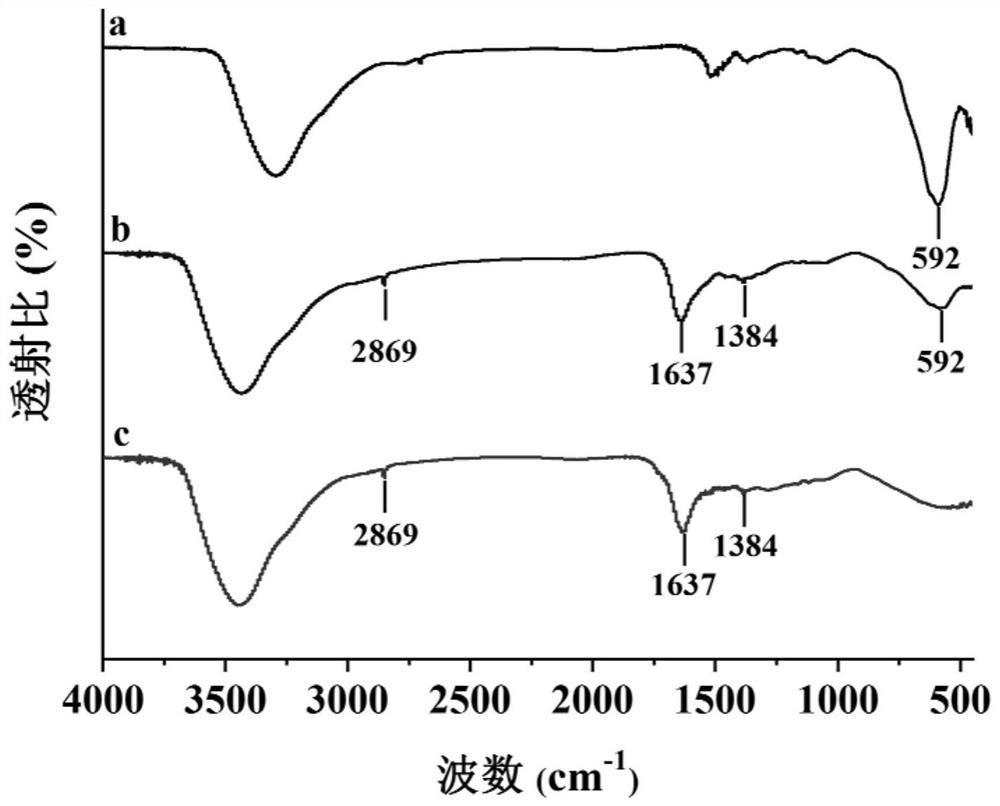

Surface molecular imprinting SERS (Surface Enhanced Raman Scattering) sensor based on core-shell structure polydopamine coated gold nanoparticles as well as preparation and application of surface molecular imprinting SERS sensor

ActiveCN110907425AIncrease contentGood biocompatibilityMaterial nanotechnologyGeneral water supply conservationFunctional monomerNanoparticle

The invention relates to a surface molecular imprinting SERS (Surface Enhanced Raman Scattering) sensor based on core-shell structure polydopamine coated gold nanoparticles as well as preparation andapplication of the surface molecular imprinting SERS sensor. A preparation method comprises the following steps: by taking dopamine as a functional monomer and a phthalate substance as a template molecule, carrying out self-polymerization on the surfaces of gold nanoparticles to obtain a molecularly imprinted polymer, eluting the molecularly imprinted polymer, and dropwise coating the surface of ascreen-printed electrode with the molecularly imprinted polymer to obtain the surface molecularly imprinted SERS sensor. Compared with the prior art, the invention is combined with a Raman spectrometer, by combining electrochemical enrichment and molecular imprinting technologies, high-selectivity and high-sensitivity detection of phthalate substances in a water body in a complex environment canbe realized at the same time, and the sensor has the advantages of simple preparation process, high detection speed, no need of sample pretreatment, environmental friendliness, low cost and the like,and shows a wide application prospect.

Owner:SHANGHAI INST OF TECH

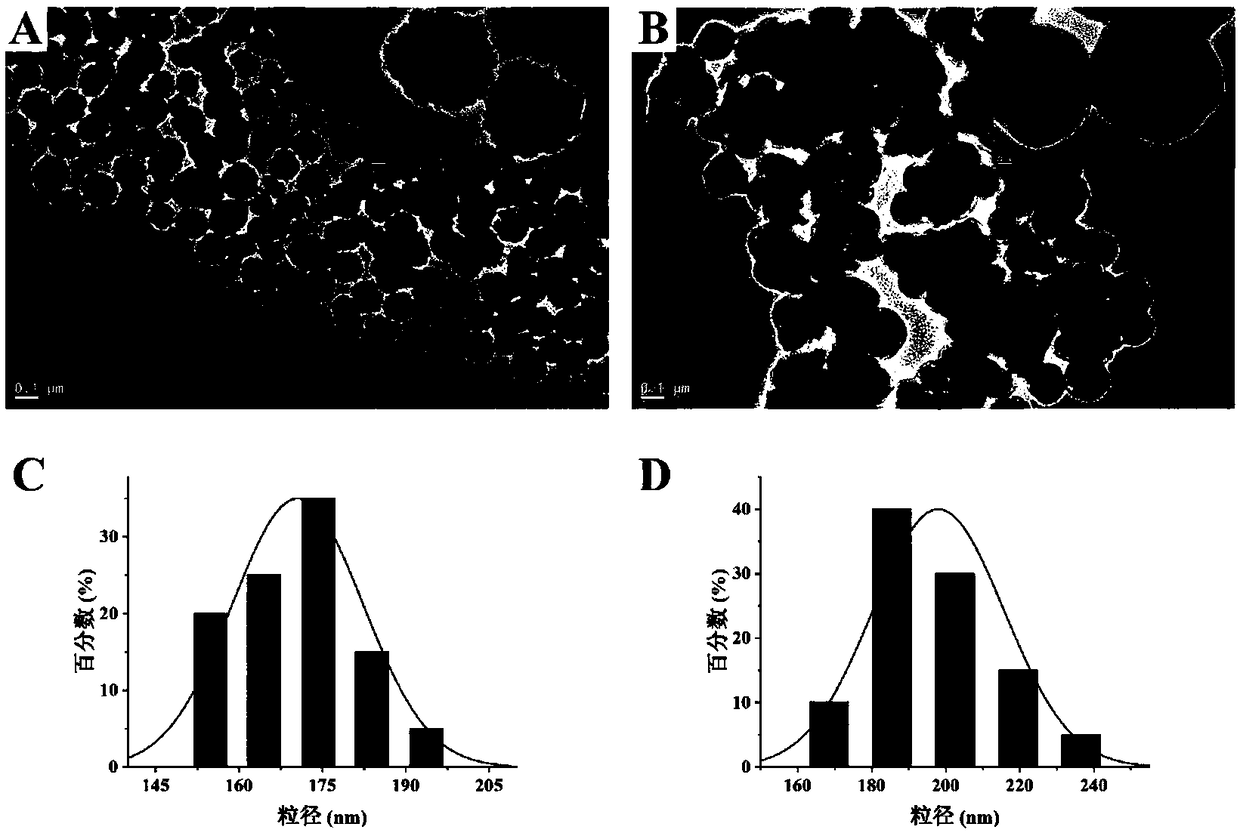

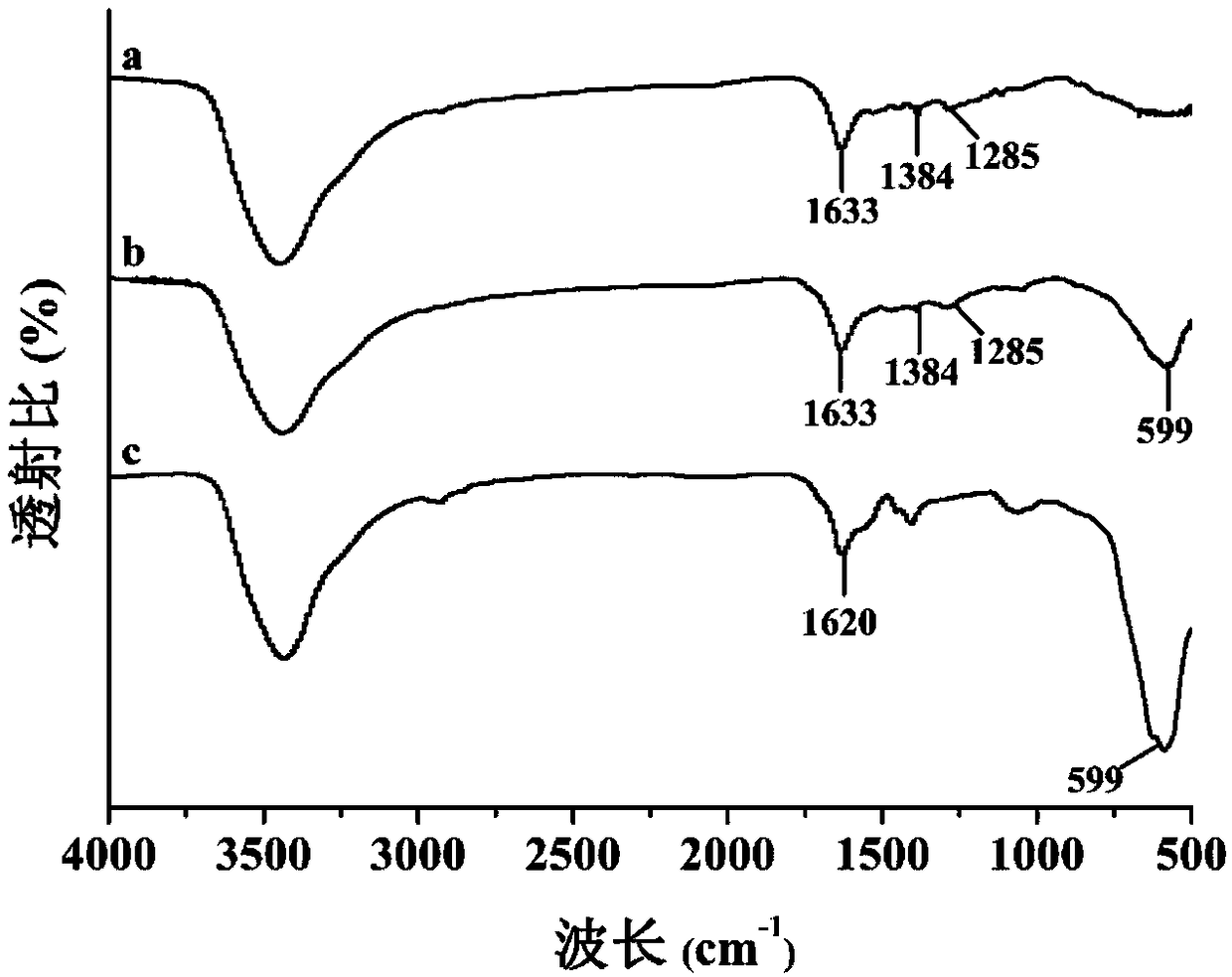

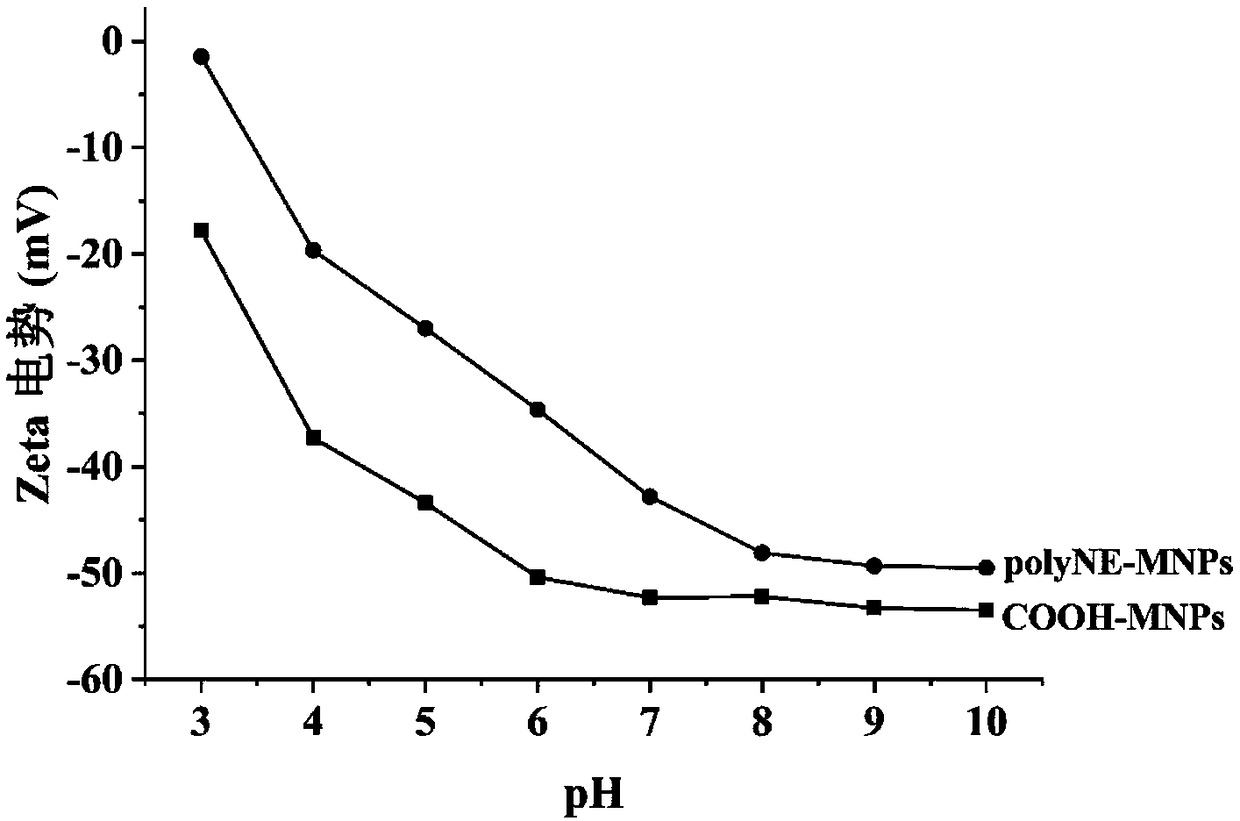

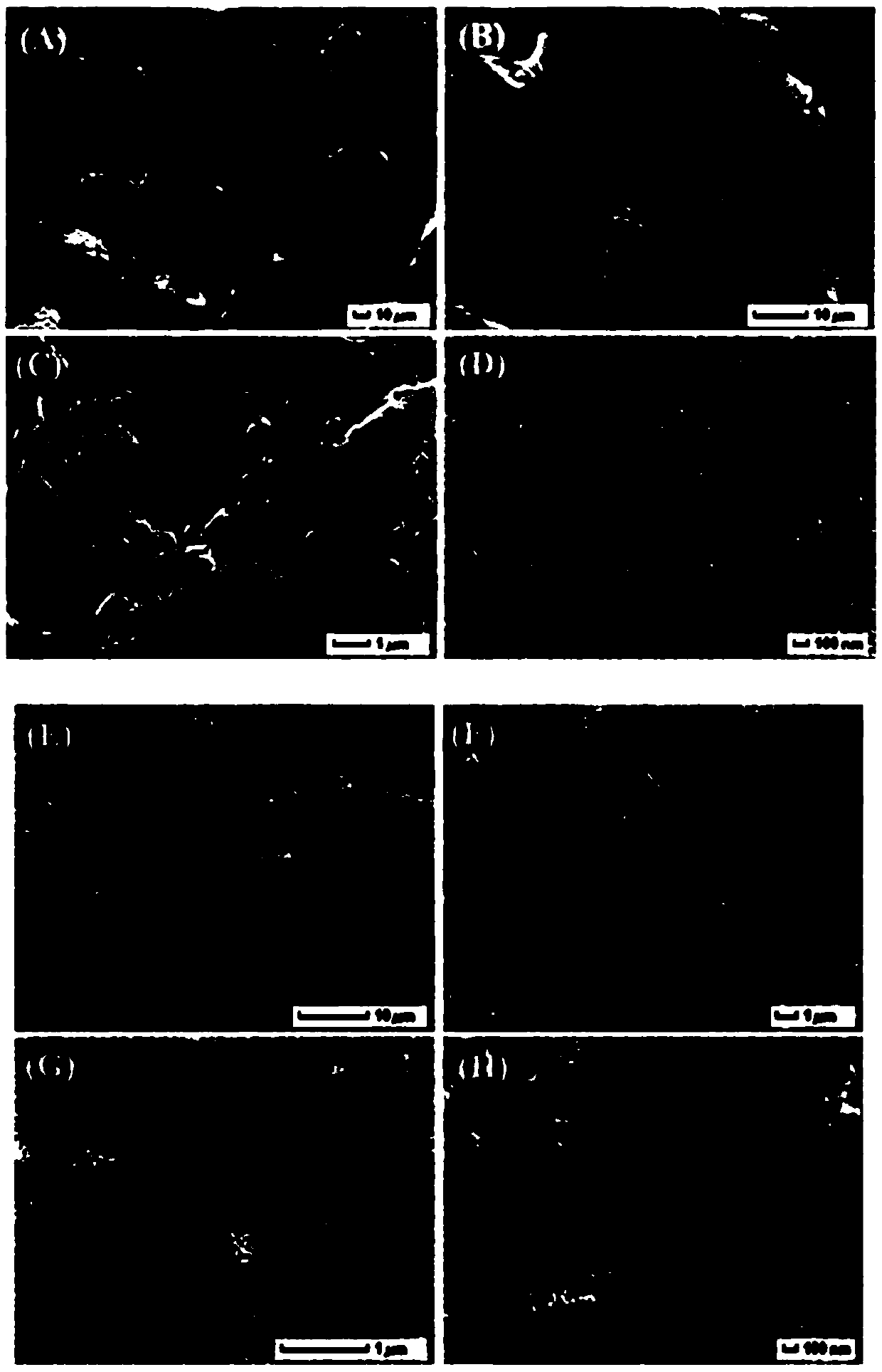

Polynorepinephrine modified magnetic particle and preparation method and application thereof

ActiveCN109012628AMild preparation conditionsSimple and fast operationOther chemical processesPreparing sample for investigationDiethylene glycolDiluted urine

The invention discloses a polynorepinephrine modified magnetic particle and a preparation method and application thereof, and the preparation method comprises the steps of: dissolving ferric chloridein a mixed solvent of diethylene glycol and ethylene glycol, adding anhydrous sodium acetate and sodium acrylate to mix well to obtain a mixture, pouring the resulting mixture into a Teflon high pressure reactor, heating to 180-200 DEG C, reacting for 10-20 h to obtain COOH-MNPs; adding the synthesized COOH-MNPs to a norepinephrine base solution, and performing heating, stirring and separating toobtain polyNE-MNPs. The polyNE-MNPs have mild preparation conditions, simple operation, good reproducibility and stability, and can well adsorb and elute beta-receptor antagonists, and can realize separation and enrichment of the beta-receptor antagonists in diluted urine samples.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Technology for preparing zinc sulfate from high-chloride zinc slag and coproducing ammonium chloride

ActiveCN107555469AIncreased washout rateLow costZinc sulatesProcess efficiency improvementSeparation technologySulfate

The invention discloses a technology for preparing zinc sulfate from high-chloride zinc slag and coproducing ammonium chloride. The technology comprises the following steps: (1) leaching chlorine fromthe high-chloride zinc slag through water washing-ammoniating two sections; (2) performing acid leaching on zinc in an ammonium leached residue by using oxidized sulfuric acid; (3) purifying chlorine-containing liquid; (4) preparing the ammonium chloride; (5) purifying zinc leached liquid. By a water washing-ammonium leaching and acid leaching step-by-step separation technology, the technical bottleneck problems during application of the conventional wet-process zinc smelting technology for recycling the zinc from the high-chloride zinc slag and discarding a chlorine resource are solved, so that the technology for recycling the zinc and chlorine from the high-chloride zinc slag is provided, and thus an environment-friendly technology for recycling the zinc and the chlorine at low cost, producing ammonium chloride and zinc sulfate products and ensuring zero discharge of three wastes is achieved; meanwhile, valuable metals lead, cadmium, copper and the like in the high-chloride zinc slag are enriched and recycled.

Owner:麻江县金泰工业废渣综合利用回收有限责任公司 +1

Phenyl bridge bond type fibrous porous silicon material and preparation method and application thereof

ActiveCN108568291AGood adsorption performanceSimple preparation stepsOther chemical processesComponent separationTandem mass spectrometryChemistry

The invention discloses a phenyl bridge bond type fibrous porous silicon material, and discloses a preparation method of the material and application of the material in the field of sulfonamide antibiotic analysis. The material is prepared by adopting a special microemulsion system, adopting a cationic surfactant as a structure directing agent, and adopting phenyl bridge bonded silane and an inorganic silicon source as a mixed silicon source precursor. The material prepared by the method is applied in enrichment of sulfonamide antibiotics in a sample in a solid phase extraction and enrichmentprocess, and the content of the sulfonamide antibiotics can be determined by liquid chromatography tandem mass spectrometry. The material has the advantages of a three-dimensional central radial fiberpleated porous structure, high specific surface area, high internal surface accessibility, and the like, and can effectively enrich and purify sulfonamide antibiotics in complex samples. The method has advantages of environmental friendliness, simple operation, high detection sensitivity, good reproducibility, and the like and has a huge application potential.

Owner:SHANDONG ANALYSIS & TEST CENT

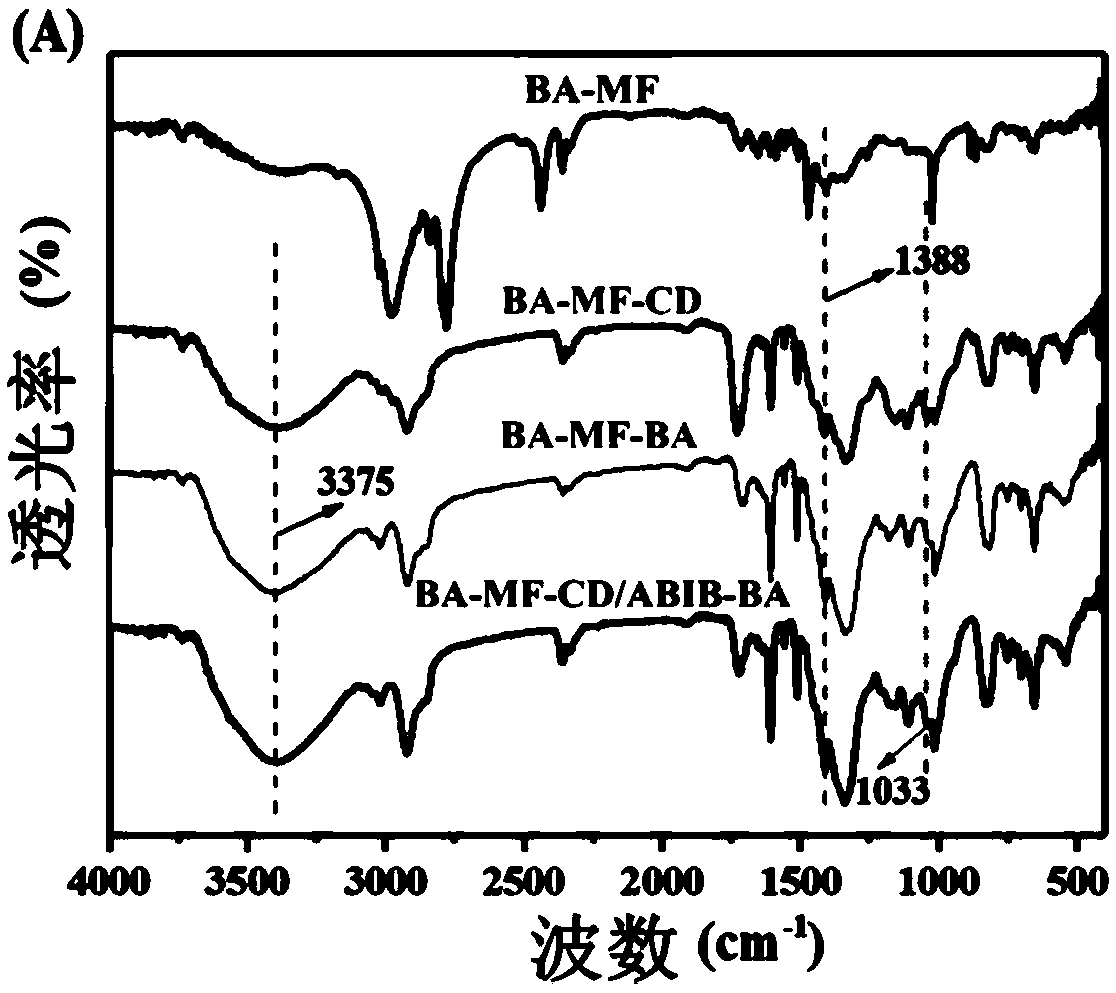

Method for preparing high-density boric acid site adsorbent based on supramolecular interface assembly strategy

ActiveCN109529791AImprove adsorption capacityHigh adsorption selectivityOther chemical processesMolecular identificationPolymer adsorbent

The invention belongs to the technical field of preparation of molecular identification selective separation materials, and relates to a method for preparing a high-density boric acid site polymer adsorbent based on a supramolecular interface assembly strategy. According to the invention, the high-density boric acid site polymer adsorbent is prepared by means of initiated atom transfer radical polymerization (ATRP) and a supramolecular action; and the prepared adsorbent is used for selective adsorption and separation of albumin in a neutral solution. The high-density boric acid site polymer adsorbent prepared by the invention has higher glycoprotein selective adsorption performance, larger adsorption capacity and good acid-base response performance, and has fast adsorption and desorption properties for glycoprotein albumin.

Owner:合肥九州龙腾科技成果转化有限公司

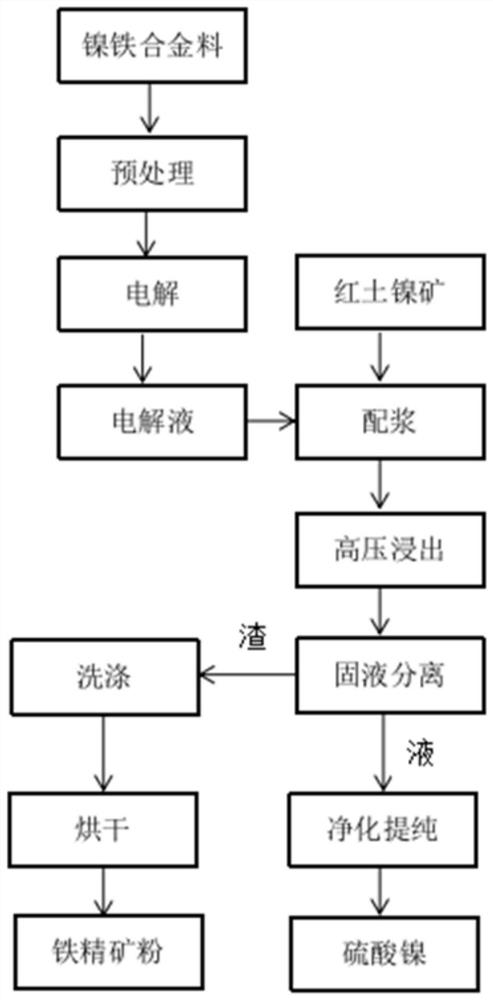

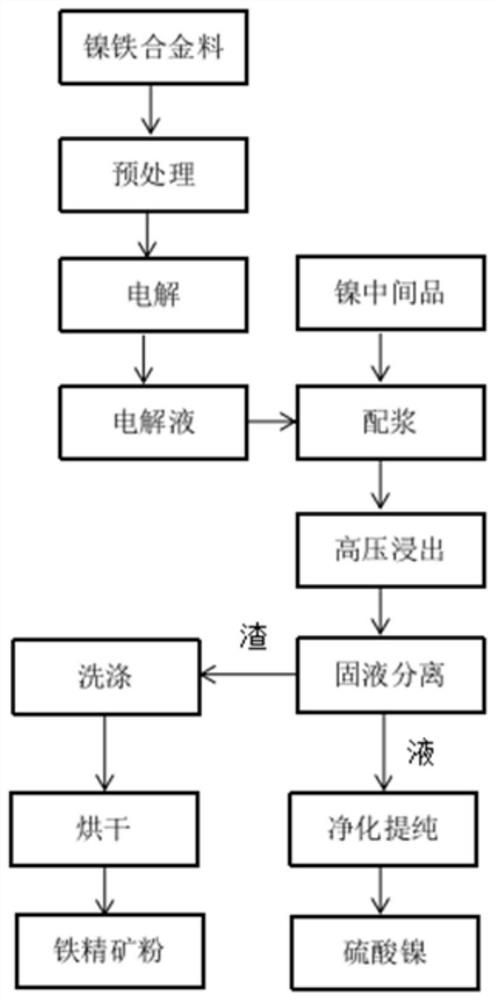

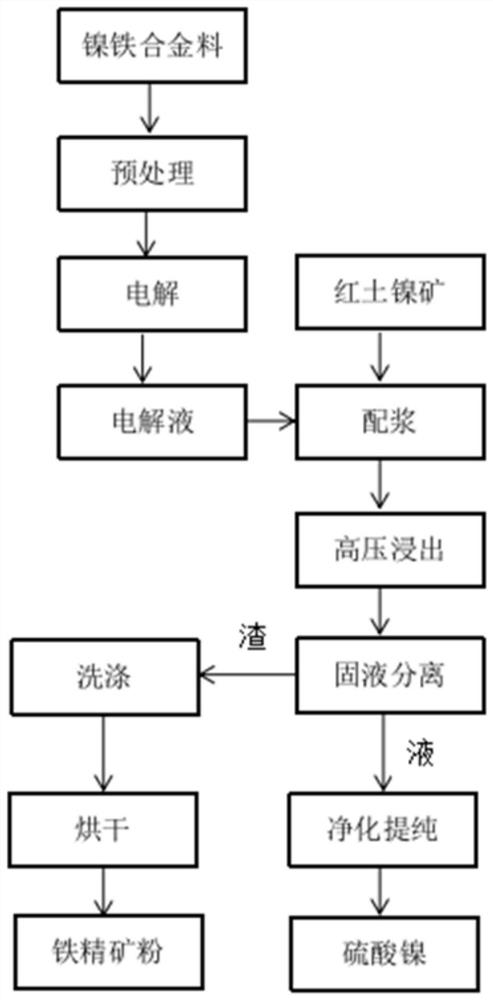

Combined treatment method for nickel-iron alloy material and nickel-containing raw material

PendingCN113957242AAlkali consumption decreasedReduce the cost of excipientsNickel sulfatesProcess efficiency improvementSlagCombined treatment method

The invention discloses a combined treatment method for a nickel-iron alloy material and a nickel-containing raw material. The method comprises the following steps of putting the nickel-iron alloy material into an anode basket of an electrolytic bath for electrochemical dissolution, dissolving nickel and iron in an electrolyte in an ion form after electron loss, mixing the electrolyte containing nickel and iron after electrolysis with the nickel-containing raw material to prepare pulp, transferring the mixed ore pulp into a high-pressure kettle, introducing oxygen to carry out pressurized reaction, carrying out solid-liquid separation on the slurry subjected to the pressurized reaction to obtain a nickel-rich solution and iron-rich slag, further purifying the nickel-containing solution to recover nickel, and recovering iron from the iron-rich slag. According to the method, the characteristic that the content of iron and residual acid in the nickel-iron alloy electrolyte is high is fully utilized, the nickel-containing raw material is leached through the residual acid in the electrolyte and the acid released by iron ion high-pressure hydrolysis precipitation, effective utilization of the acid is achieved, the two materials are treated at the same time, separation and enrichment of nickel and iron are achieved, and the effect that multiple purposes are achieved at one stroke is achieved.

Owner:JINGMEN GEM NEW MATERIAL

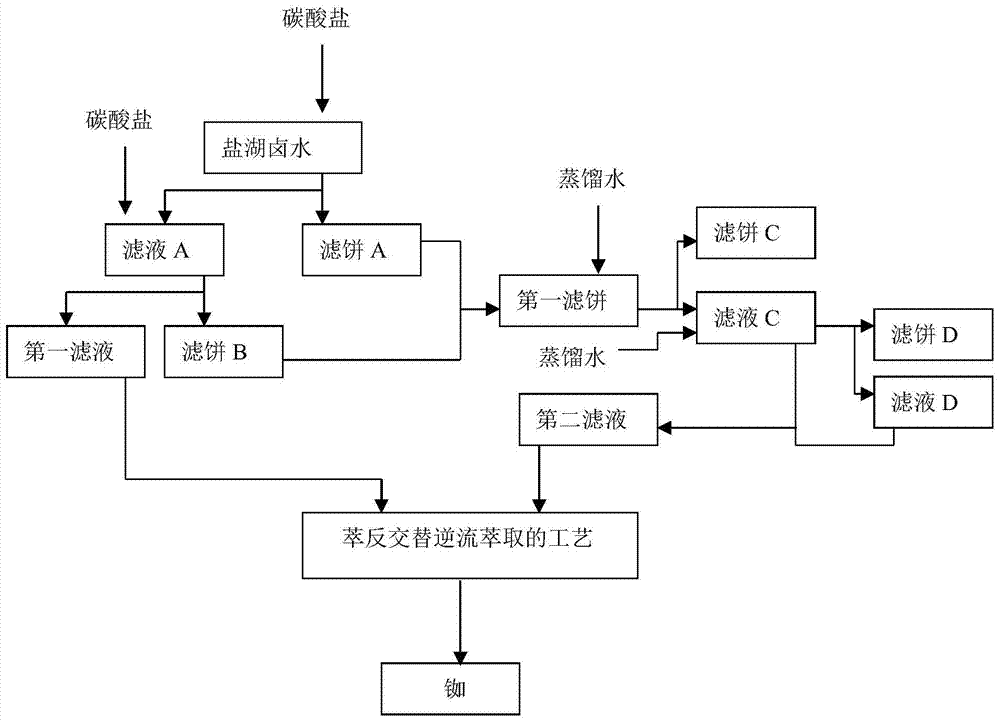

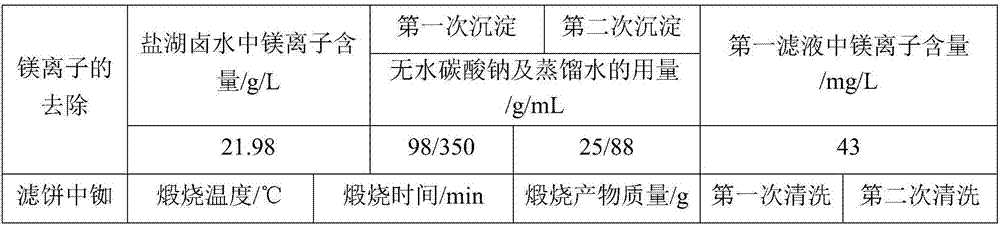

Method for Extracting Rubidium from Salt Lake Brine

ActiveCN104789800BImprove separation efficiencyRealize separation and enrichmentProcess efficiency improvementHigh concentrationRubidium

The invention provides a method for extracting rubidium from saline lake brine. The method comprises the following steps: (1) adding water-soluble carbonate precipitated magnesium ions into the saline lake brine, carrying out solid-liquid separation to obtain a first filtrate and a second filtrated cake, and enabling the content of magnesium ions in the first filtrate to be lower than 50mg / L; (2) extracting rubidium from the first filtrate by using 4-tert-butyl-2-(alpha-methylbenzyl) phenol as an extractant and using an extraction-backextraction alternate countercurrent extraction process in an environment that the amount-of-substance concentration of [OH-] is 0.8-1mol / L, wherein the concentration of 4-tert-butyl-2-(alpha-methylbenzyl) phenol in the extractant is 0.5-1mol / L. According to the method, rubidium is effectively obtained from brine with high concentration of potassium, and the efficiency of rubidium extraction is increased.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

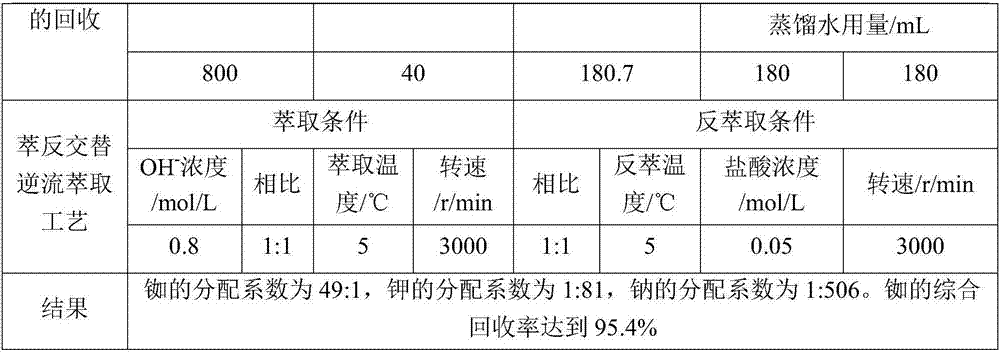

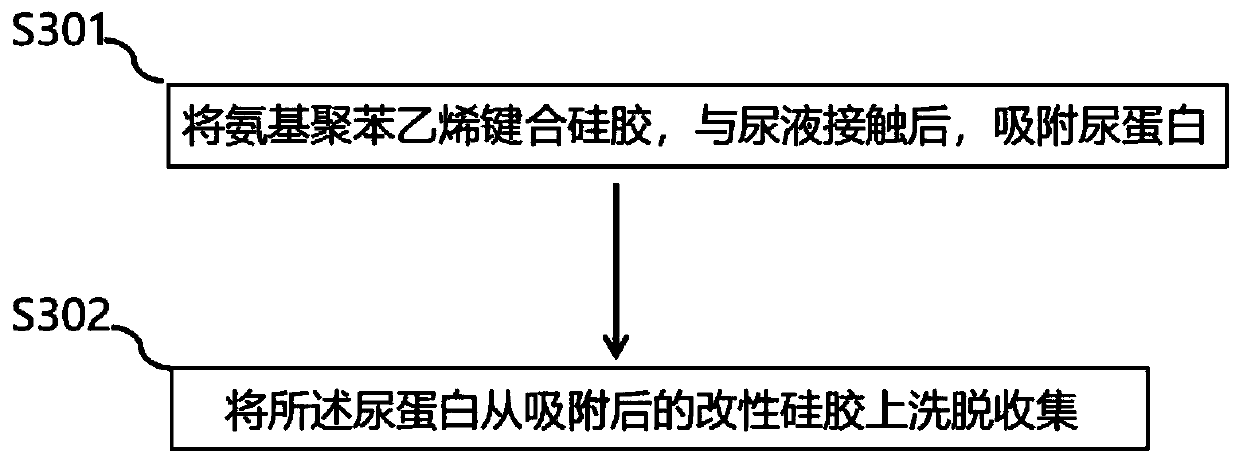

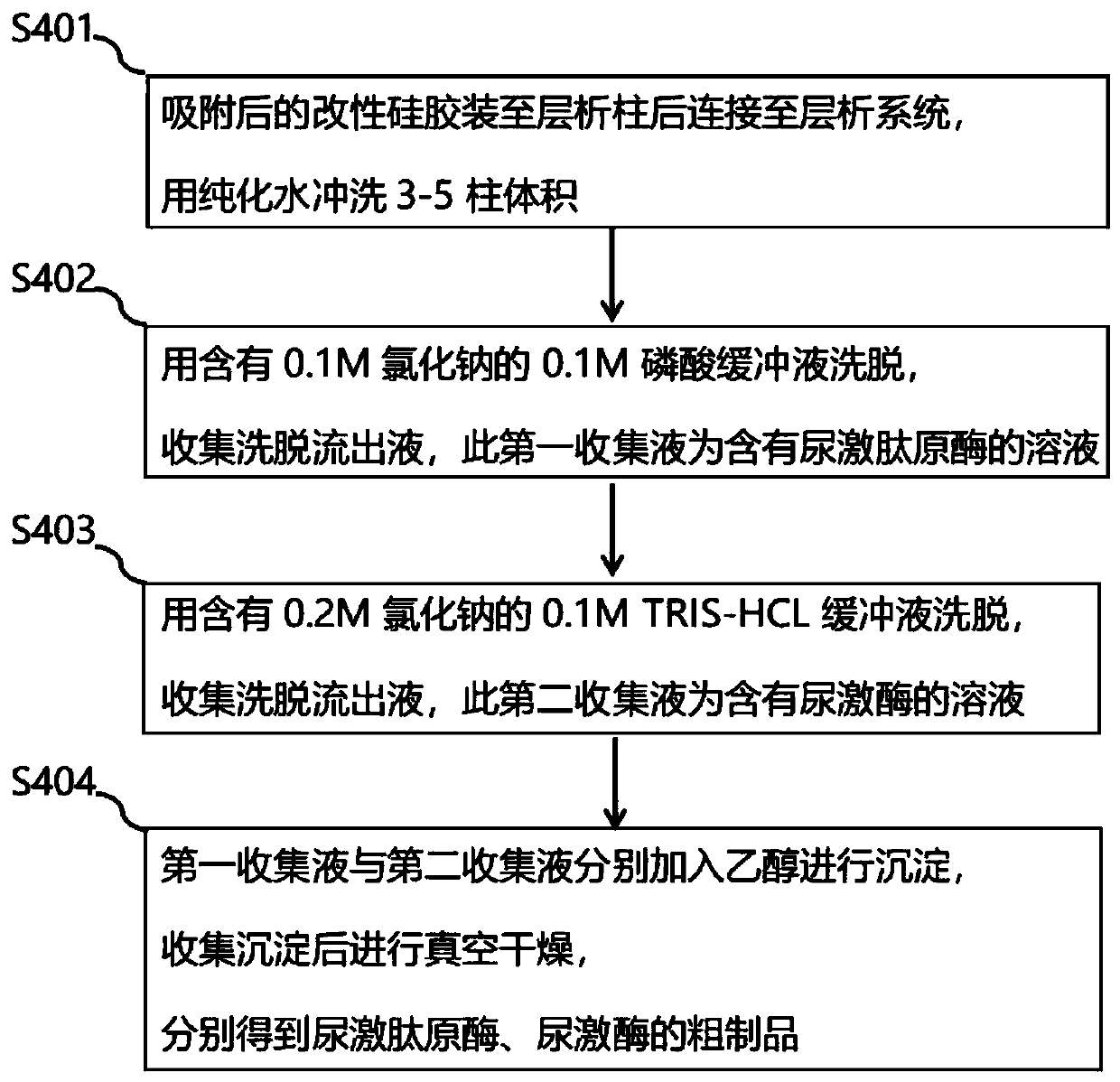

Preparation method and application of modified silica gel for extracting urine protein

ActiveCN111185141AIncrease profitImprove adsorption capacityOther chemical processesPeptidasesSilica gelIsoelectric point

The invention relates to a preparation method and application of modified silica gel for extracting urine protein. According to the invention, silica gel is modified into amino polystyrene bonded silica gel; urine proteins such as urokinase, human urokininogenase and the like in urine can be directly adsorbed by utilizing the modified silica gel, then the urine proteins are sequentially eluted byadopting different elution conditions according to the properties of different isoelectric points of the different urine proteins, and finally effective adsorption of the urine proteins and separationand enrichment of the different urine proteins can be realized; and the silica gel is high in utilization rate, good in adsorption separation effect, small in environmental pollution, convenient to use, low in cost and suitable for large-scale industrial production, and urine does not need to be collected and a urinal does not need to be transformed.

Owner:江西浩然生物制药有限公司

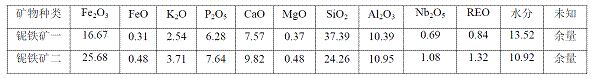

Comprehensive utilization method of columbite

ActiveCN112795793AAchieve separationRealize separation and enrichmentGas emission reductionSlagNiobium

The invention provides a comprehensive utilization method of columbite. The comprehensive utilization method of the columbiobite comprises the following steps of S1, carrying out reduction side-blown smelting on the columbiobite in a side-blown furnace to obtain molten iron, furnace slag and phosphorus-containing flue gas; and S2, carrying out deep reduction on the furnace slag in an electric furnace, and obtaining ferroniobium, slag rich in rare earth and electric furnace flue gas. According to the comprehensive utilization method of the columbite provided by the invention, firstly, the columbite is subjected to reduction side-blown smelting to achieve separation of phosphorus and iron, and the phosphorus content in the obtained molten iron and the furnace slag is low, so that the problem caused by the high phosphorus content in raw materials in the subsequent niobium and rare earth extraction process is solved; and reduction side-blown smelting and deep reduction are both low-cost smelting modes, so that the recovery cost of metal in the columbite is effectively controlled. Meanwhile, waste heat of the side-blown furnace can be recycled, the produced electric energy can be used for deep reduction in a subsequent electric furnace, and dependence on external electric energy resources is reduced. In the deep reduction stage, an iron-containing material is added to serve as an additional iron source to achieve deep reduction, and niobium molten iron is formed.

Owner:CHINA ENFI ENGINEERING CORPORATION

A kind of process of preparing zinc sulfate co-production ammonium chloride with high chloride zinc slag

ActiveCN107555469BIncreased washout rateLow costZinc sulatesProcess efficiency improvementSeparation technologyEthyl Chloride

Owner:麻江县金泰工业废渣综合利用回收有限责任公司 +1

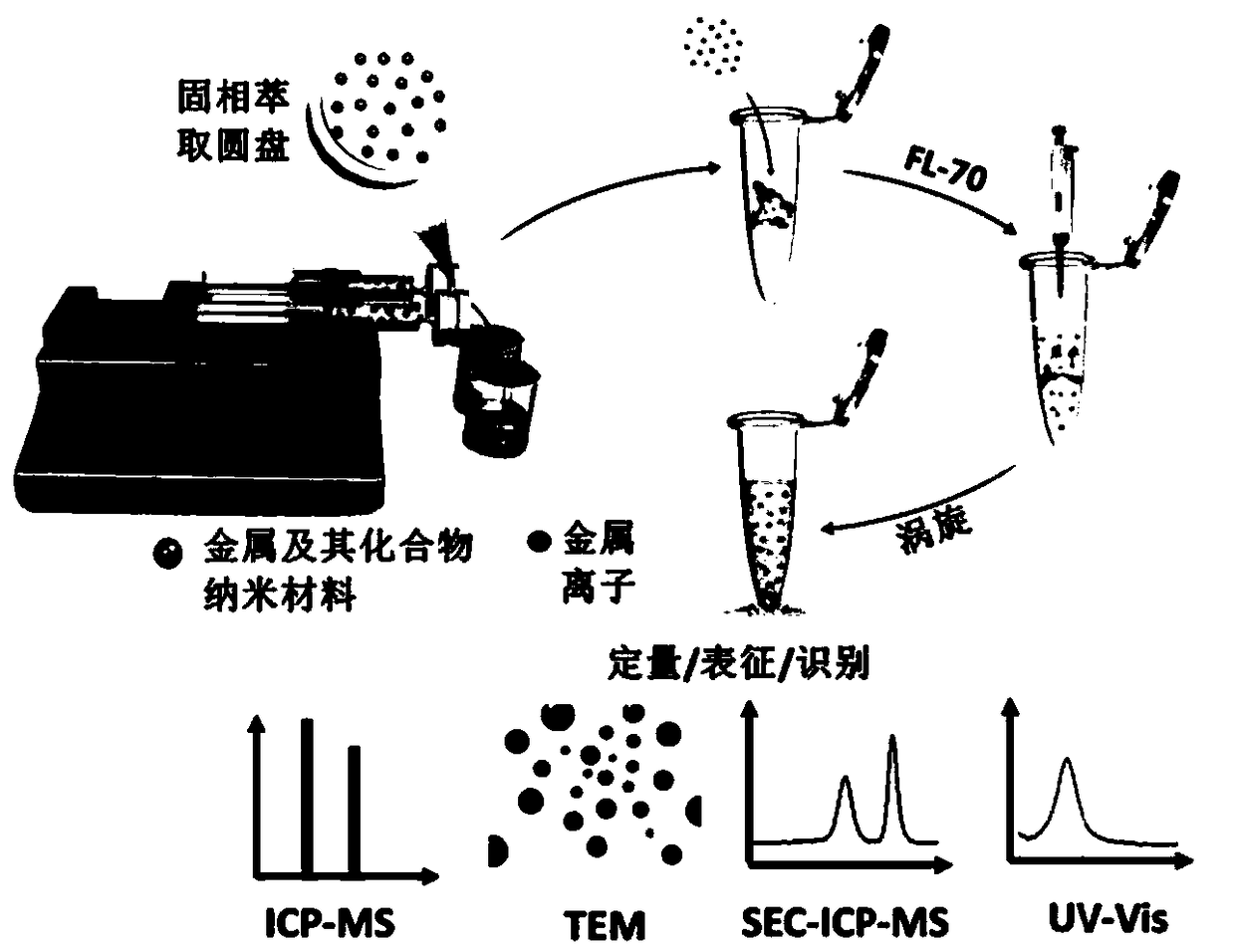

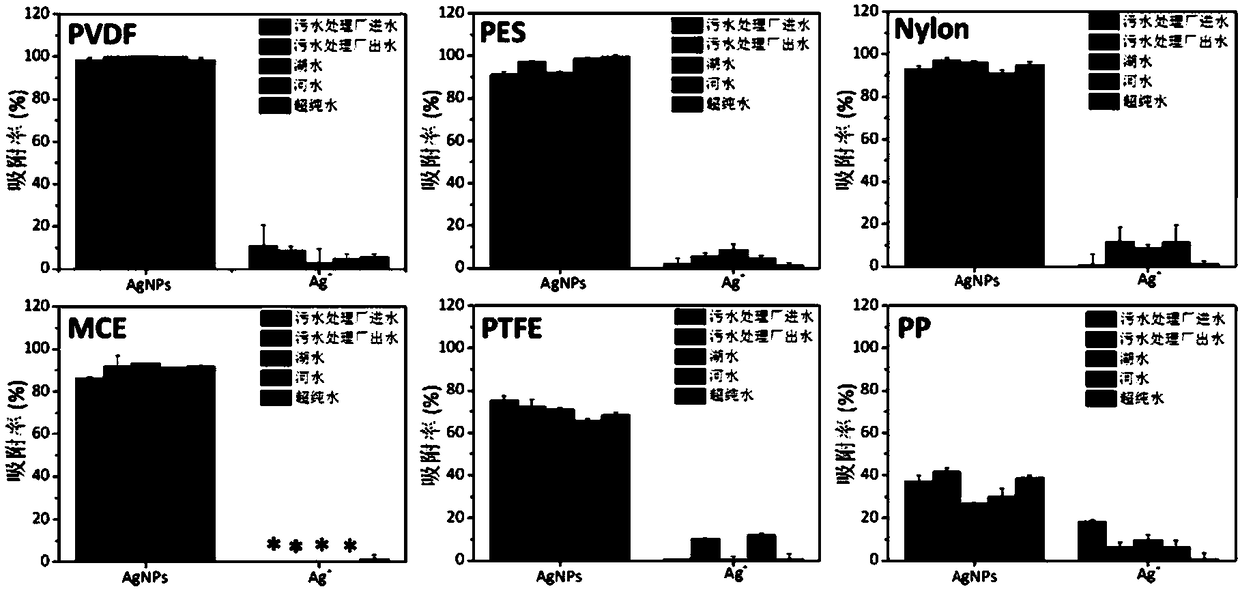

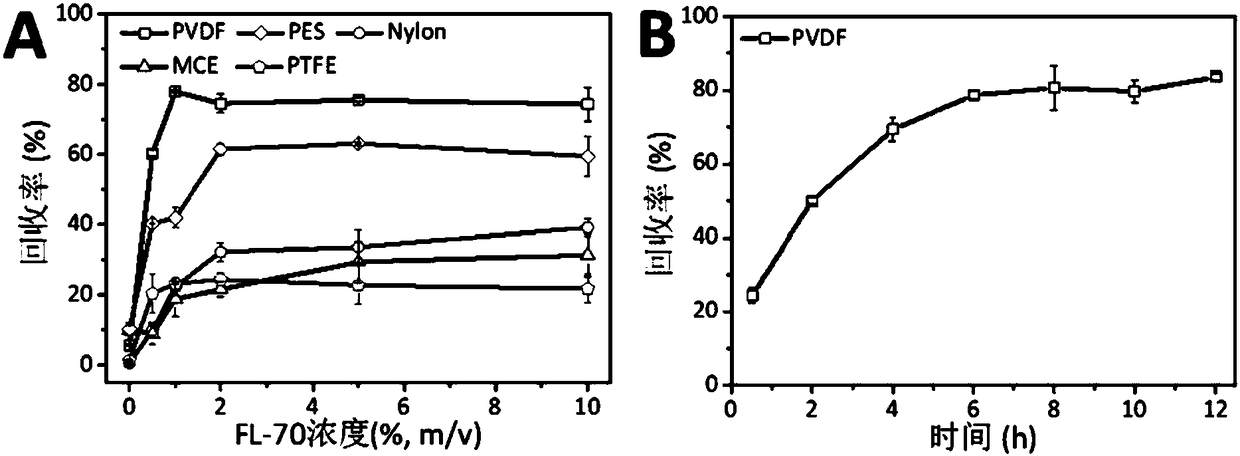

Method for separating and enriching trace metal and compound nanometer materials in water bodies

InactiveCN108333016ASimple and fast operationRealize semi-automationPreparing sample for investigationCircular discEnvironment water

The invention discloses a method for separating and enriching trace metal and compound nanometer materials in water bodies based on circular disc solid phase extraction. The method comprises the following steps of assembling a circular disc solid phase extraction device; controlling a sample to pass through a solid phase extraction circuit disc; using an elution agent for eluting the solid phase extraction circuit disc. By using the method, the 1000-time enrichment of the metal with the content as low as 0.2ng / L and the compound nanometer materials can be realized; the method can be used for mark determination of nanometer silver (AgNPa) in the four environment water bodies; the result is satisfactory. The method has the advantages that the operation steps are simple; through an injectionpump, the semi-automatic and speed-controllable extraction can be realized; the applicable sample size is large; the enrichment times are high. Meanwhile, in the extraction process, the appearance andthe particle diameter of the nanometer materials cannot be changed, so that after the nanometer material enrichment through circular disc solid phase extraction separation, the original appearance ofthe trace metal and the compound nanometer materials in the environment water bodies can be obtained.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

A method for separating arsenic and selenium from copper anode slime alkaline leaching solution

ActiveCN104911358BNo need to adjust pHRealize separation and enrichmentProcess efficiency improvementElemental selenium/telluriumFiltrationPost precipitation

The invention discloses a method for separating arsenic and selenium from copper anode slime alkaline leach liquor. The method comprises the following steps: 1) oxidation, namely adding an oxidizing agent or introducing oxidizing gas into the copper anode slime alkaline leach liquor, so that oxidized copper anode slime alkaline leach liquor is obtained; 2) arsenic precipitation, namely adding a calcium salt into the oxidized copper anode slime alkaline leach liquor, stirring the obtained mixture so as to produce a precipitate, and carrying out filtration and separation on the precipitate so as to obtain a calcium arsenate precipitate and arsenic post-precipitation liquid; and 3) selenium precipitation, namely adding a barium salt into the arsenic post-precipitation liquid obtained in the step 2), stirring the obtained mixture so as to produce a precipitate, carrying out filtration and separation on the precipitate so as to obtain a barium selenate precipitate and selenium post-precipitation liquid, and carrying out evaporative crystallization on the selenium post-precipitation liquid so as to recycle alkali, or directly returning to a leaching process. The method disclosed by the invention is short in technological process, less in equipment and simple in operation, and can be used for realizing the separation and enrichment of arsenic and selenium, the precipitation rate of arsenic is higher than 96%, and the precipitation rate of selenium is higher than 99%; by virtue of carrying out evaporative crystallization on a solution for recycling or directly returning the solution to a leaching process, the recovery of alkali is realized.

Owner:CENT SOUTH UNIV

A method for flotation of uranium minerals from volcanic rock type uranium ore

ActiveCN112156894BRealize separation and enrichmentImprove flotation recoveryFlotationHydroxamic acidSodium phosphates

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

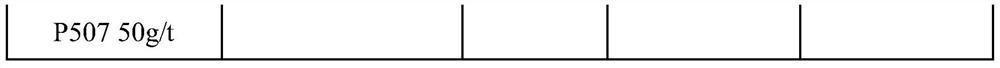

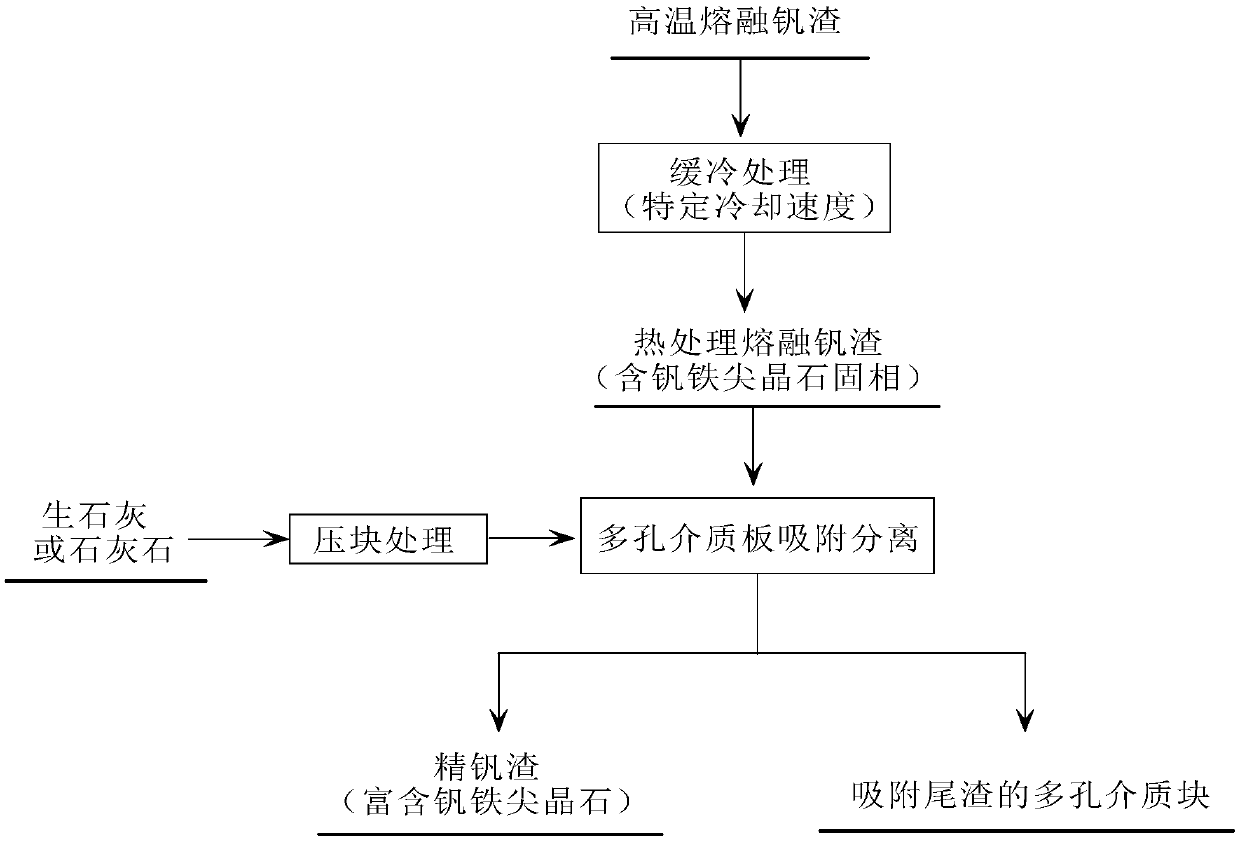

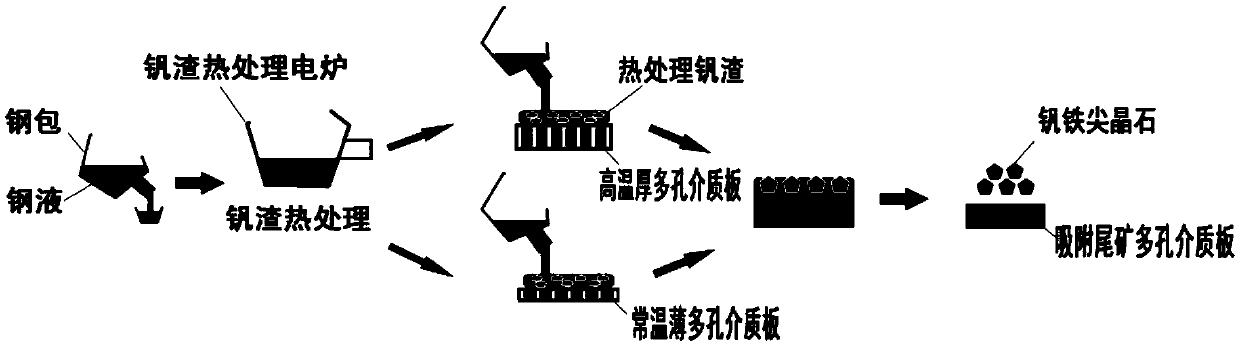

A method for porous media adsorption and separation of vanadium resources in vanadium slag

ActiveCN107354304BRealize separation and enrichmentReduce pollutionProcess efficiency improvementPorous mediumSpinel

The invention discloses a method for adsorbing and separating vanadium resources in vanadium slag by porous media, and belongs to the field of metallurgical slag solid-liquid two-phase separation. The method for adsorbing and separating the vanadium resources in the vanadium slag by the porous media comprises the following steps that 1, a porous medium plate is prepared; 2, the molten vanadium slag is cooled from the temperature of 1500-1550 DEG C to 1200-1250 DEG C at a cooling rate of less than 2 DEG C / min, and a heat-treated molten vanadium slag containing solid-phase vanadium-iron spinel is obtained; and 3, absorbing for the heat-treated molten vanadium slag is conducted by the porous medium plate to finish solid-liquid separation, and fine vanadium slag with the vanadium-iron spinel phase grade being 70-90% and tailings are obtained. According to the method for absorbing and separating the vanadium resources in the vanadium slag by the porous media, the fusion slag phase in the heat-treated vanadium slag is absorbed by capillary force of the porous medium plate, separation and enrichment of the vanadium-iron spinel solid-phase in the heat-treated vanadium slag are achieved, the vanadium-iron spinel fine vanadium slag separated through the porous media can be directly used as raw materials of hydrometallurgical vanadium extraction and pyrometallurgy of vanadium-iron, and the porous medium plate for absorbing the tailings can serve as raw materials of cement production.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

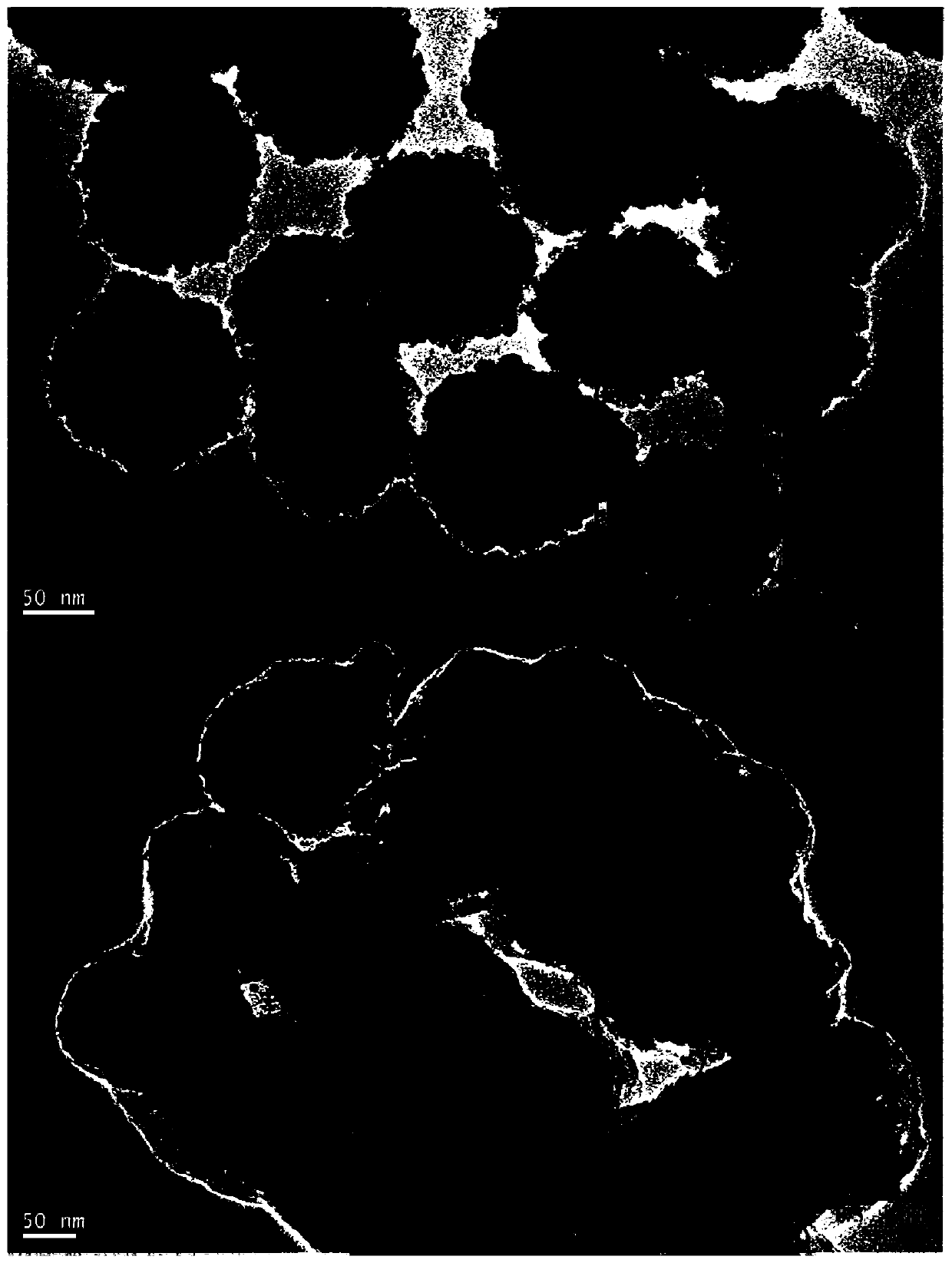

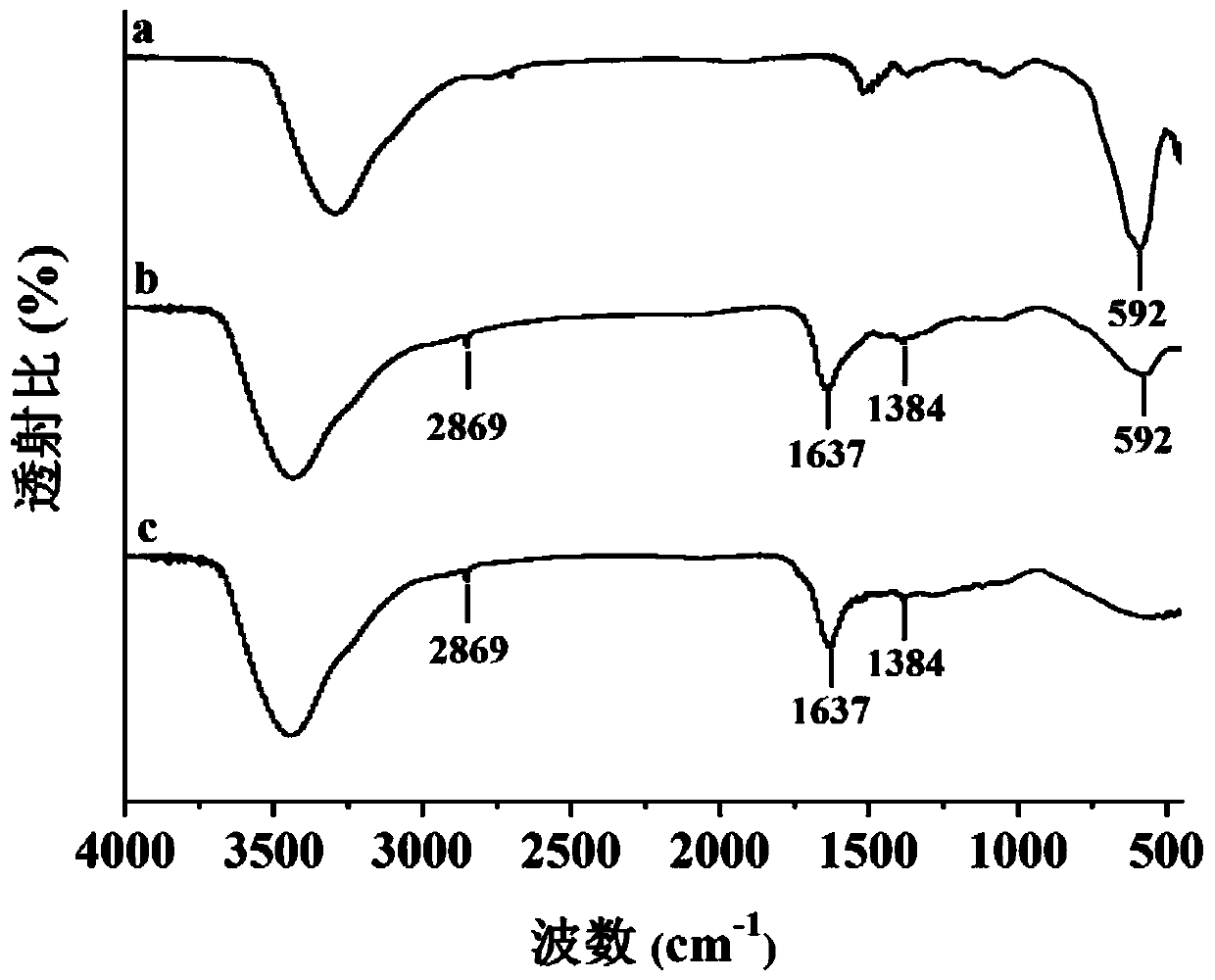

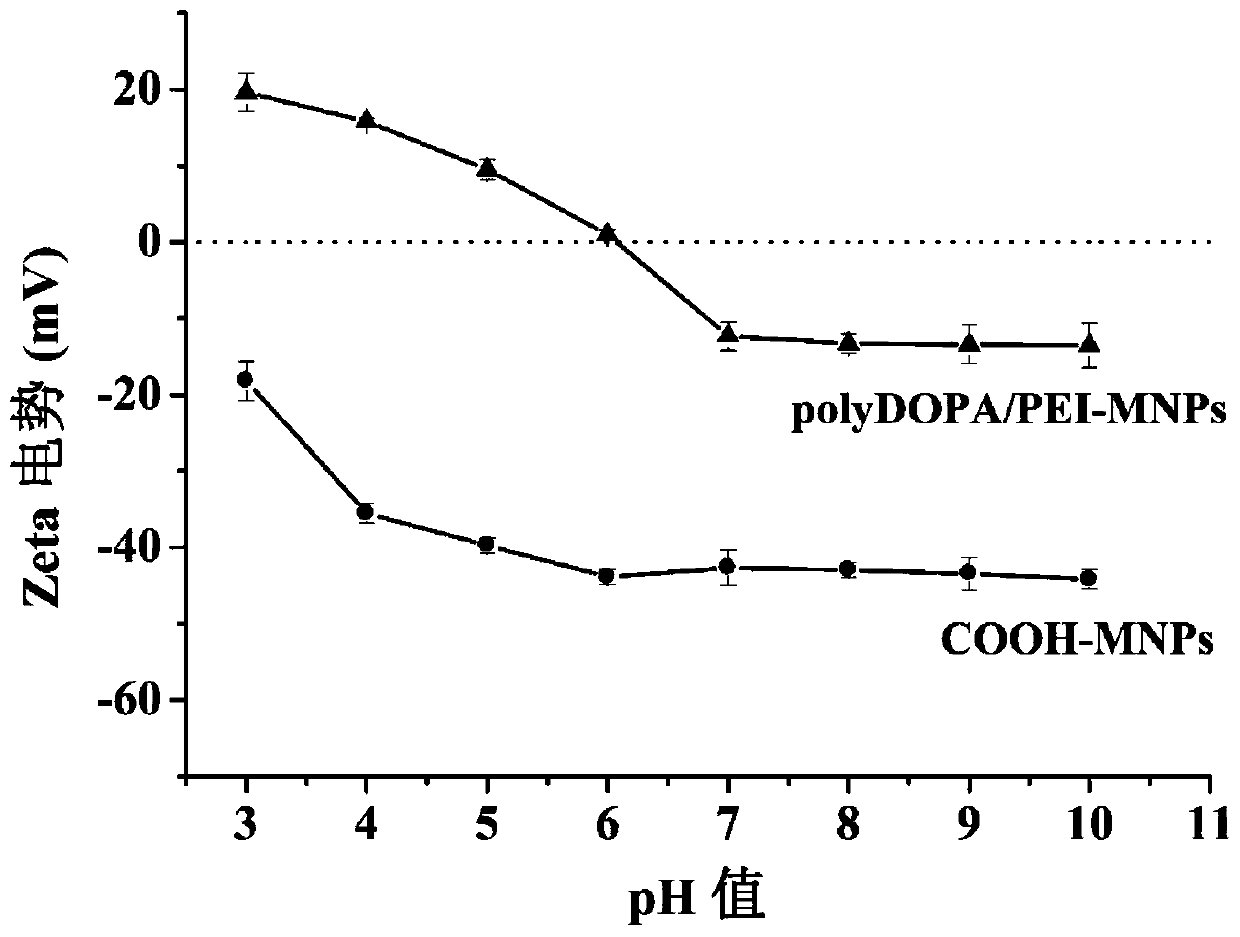

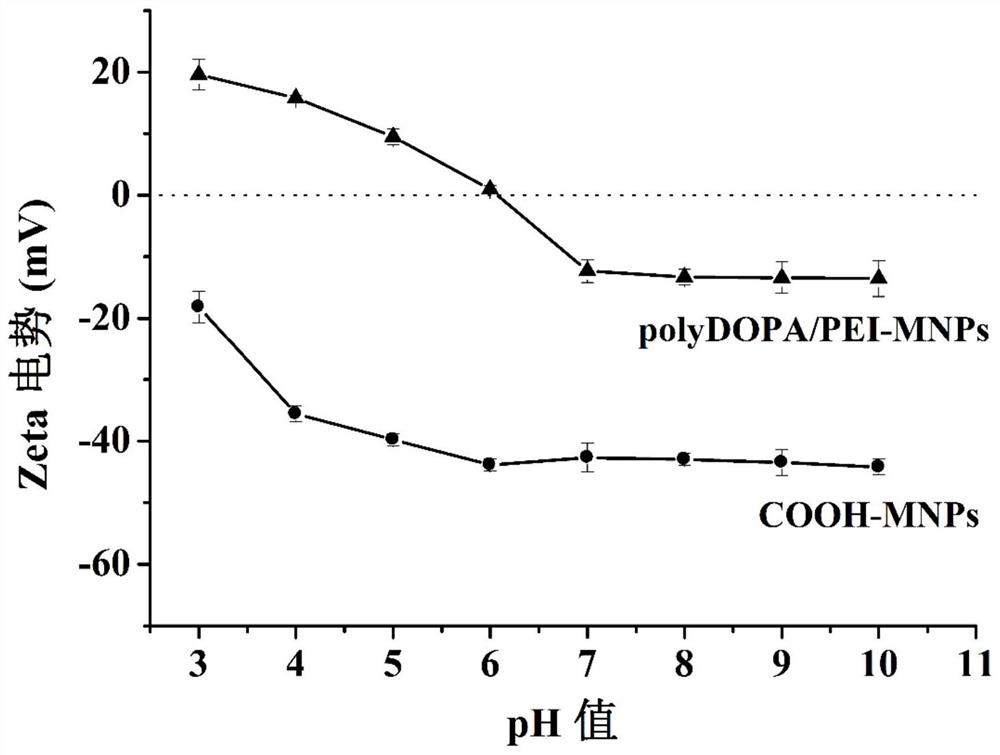

Polydopa/polyethyleneimine copolymer modified magnetic particles and preparation method and application thereof

ActiveCN109939653ASimple preparation processMild conditionsIon-exchange process apparatusOther chemical processesCatecholamineInducer

The invention discloses polydopa / polyethyleneimine copolymer modified magnetic particles and a preparation method and application thereof. The preparation method of the polydopa / polyethyleneimine copolymer modified magnetic particles includes the following steps that COOH-MNPs is added into an alkaline solution of dopa, then polyethyleneimine, CuSO4 and H2O2 are added to serve as inducers, the material is heated to 25-50 DEG C to be stirred for 0.5-2.0 h, and polyDOPA / PEI-MNPs is obtained after separation. The polyDOPA / PEI-MNPs has mild preparation conditions, the operation is easy and convenient, the reproducibility and the stability are good, and separation and enrichment of catecholamine in diluted body fluid (especially blood) can be achieved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Method for separating and enriching chlorogenic acid in tobacco

ActiveCN103739491BRealize separation and enrichmentHigh extraction rateOrganic compound preparationCarboxylic acid esters preparationBiotechnologyChlorogenic acid

The invention relates to a method for separating and enriching chlorogenic acid in tobacco. According to the method, the chlorogenic acid in tobacco is separated and enriched by utilizing a solvent flotation technology, and a mixed organic solvent is added to serve as an extracting agent, so that the polarity of the extracting agent is changed, and the extraction rate of the chlorogenic acid is improved. The pH value of a tobacco extracting solution is regulated, so that the polarity of the extracting agent is matched with that of the chlorogenic acid, and the separation, enrichment and purification effect is good. The extraction can be performed at room temperature due to the adopted solvent flotation technology, and the operation conditions are mild. According to floatation of an air floatation solvent, an emulsification phenomenon generated due to shaking during common liquid-liquid extraction is avoided, the amount of the used organic solvent is small, and the method is large in enrichment factor, short in phase separation time, low in cost and feasible to operate.

Owner:CHINA TOBACCO GUANGXI IND

Magnetic particle modified by polydopa/polyethyleneimine copolymer and its preparation method and application

ActiveCN109939653BMild preparation conditionsSimple and fast operationIon-exchange process apparatusOther chemical processesPolymer scienceCatecholamine

The invention discloses magnetic particles modified by polydopa / polyethyleneimine copolymer and its preparation and application. The preparation method comprises the following steps: adding COOH-MNPs to an alkaline solution of dopa, and then adding polyethylene imine, CuSO 4 and H 2 o 2 As an inducer, heat to 25-50°C and stir for 0.5-2.0 hours to separate and obtain polyDOPA / PEI‑MNPs. The polyDOPA / PEI-MNPs of the present invention has mild preparation conditions, simple and convenient operation, good reproducibility and stability, and can realize the separation and enrichment of catecholamines in diluted body fluids (especially blood).

Owner:SOUTH CHINA NORMAL UNIVERSITY

A Method for Separating Phospholipids in Edible Oil Based on Aminated Magnetic Hollow Composite Materials

ActiveCN111909789BRealize separation and enrichmentImprove extraction efficiencyFatty-oils/fats separationPhosphatide foodstuff compositionsOrganosolvDiethyl ether

The invention discloses a method for separating phospholipids in edible oil based on an aminated magnetic hollow composite material, comprising the steps of: diluting the edible oil with n-hexane, adding an aminated magnetic hollow composite material, so that the phospholipids are adsorbed in the material; The mixed solution of acetic acid-ether was used to wash away the impurities adsorbed on the material, the phospholipids were eluted with methanol, and dried under nitrogen. The invention provides a method for separating phospholipids in edible oil by using a self-made magnetic hollow composite material, which improves the adsorption capacity and separation efficiency. The operation is simple, the amount of organic solvent is less, the time consumption is short, and the purification effect is good. Magnetic technology combined with hollow materials exposes phospholipid binding sites on the surface, resulting in high adsorption efficiency and short time. The magnetic material is dispersed in the oil sample. Through the active adsorption of the target substance, the separation and enrichment of phospholipids can be realized in a short time, and then the material is quickly separated by an external magnetic field, thus simplifying the pretreatment operation and improving the extraction efficiency of phospholipids.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Ship tail gas denitrification process and system, desulfurization and denitrification integrated process and system

ActiveCN105536486BEfficient use ofEfficient regenerationNitrous oxide captureGas treatmentSorbentDesorption

The invention belongs to the field of ship tail gas treatment, energy conservation and environment protection, and particularly relates to a ship tail gas denitration technology and system and a desulfurization and denitration integrated technology and system. When low sulfur oil is used for a ship, the ship tail gas denitration technology and system can achieve high denitration efficiency and reduce energy consumption; when high sulfur content is used for the ship, desulfurization and denitration are combined together, high desulfurization and denitration efficiency is achieved, meanwhile, the cost is greatly saved, and the tail gas exhaust standards are met. The ship tail gas denitration technology comprises the steps of 1, tail gas cooling, 2, NOX adsorption, 3, desorption of NOX adsorbed on an adsorbent, 4, low-temperature plasma decomposition and 5, absorption and reduction. The ship tail desulfurization and denitration integrated technology comprises the steps of 1, tail gas cooling, 2, washing performed through washing water, 3, soda absorption, 4, NOX adsorption, 5, desorption of adsorption water adsorbed on an adsorbent, 6, desorption of NOX adsorbed on an adsorbent, 7, low-temperature plasma decomposition and 8, absorption and reduction.

Owner:张拿慧

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com