Patents

Literature

180results about How to "No need to adjust pH" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

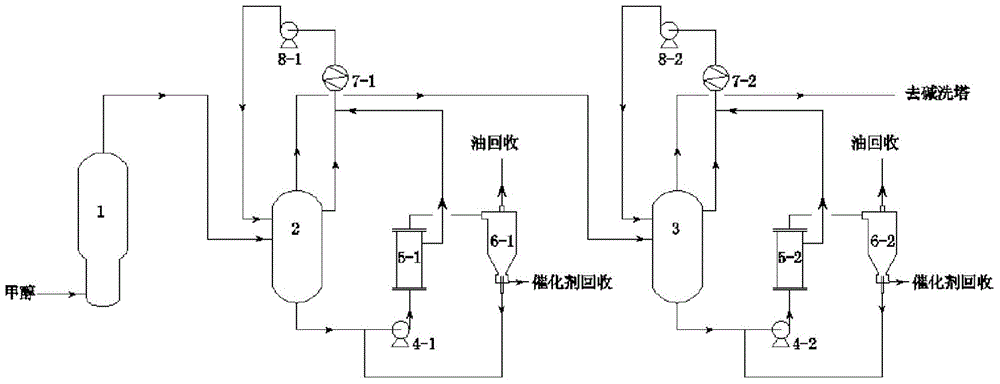

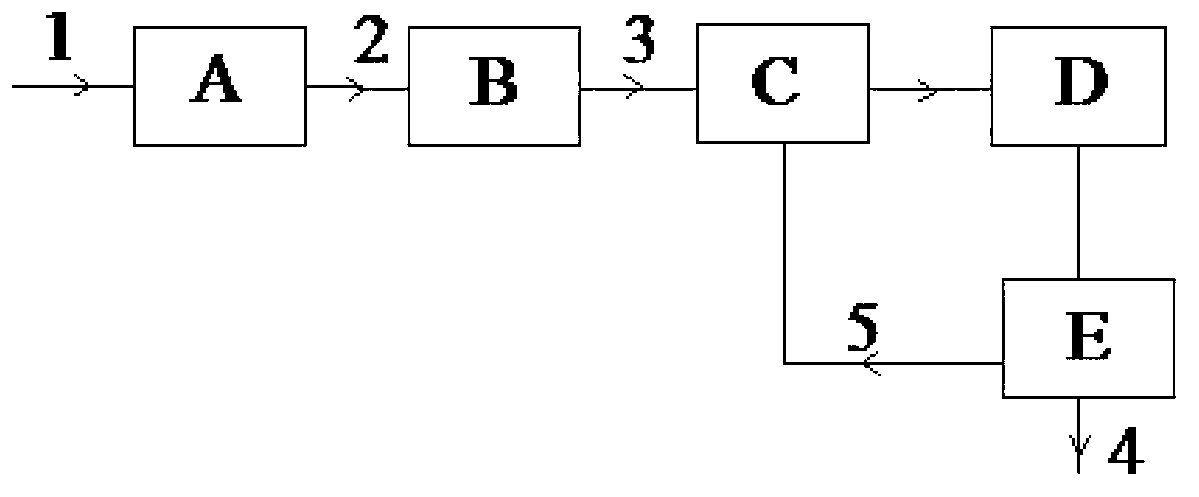

Solid and oil removal method and device for chilled water and washed water in MTO (methanol to olefin) process

ActiveCN103951098AEliminate enrichmentReduce the probability of forming large particlesHydrocarbon from oxygen organic compoundsMultistage water/sewage treatmentUF - UltrafiltrationChemistry

The invention relates to a solid and oil removal method and device for MTO (methanol to olefin) / MTP (methanol to propylene) chilled water and washed water. The method disclosed by the invention mainly comprises the following steps of carrying out ultrafiltration membrane separation on MTO / MTP chilled water, feeding an ultrafiltration membrane concentrated solution into a three-phase cyclone-separator separation system, and recovering a catalyst and oil; cooling ultrafiltration membrane permeated liquid, and feeding the obtained liquid back to a chilled water system to cyclically reuse; carrying out ultrafiltration membrane separation on MTO / MTP washed water, feeding an ultrafiltration membrane concentrated solution into the three-phase cyclone-separator separation system, and recovering a catalyst and oil; and cooling ultrafiltration membrane permeated liquid and feeding the obtained liquid back to a washed water system to cyclically reuse. The invention also provides a solid and oil removal device for MTO / MTP chilled water and washed water.

Owner:JIANGSU JIUWU HITECH

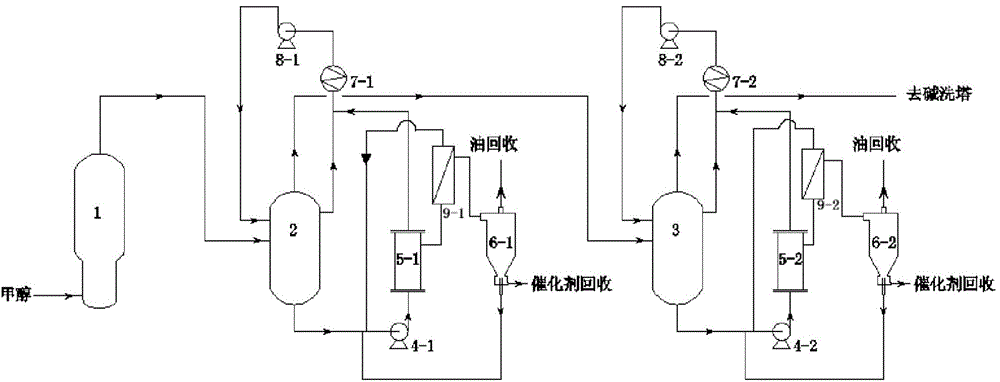

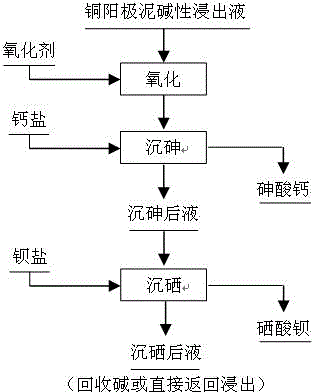

Method for separating arsenic and selenium from copper anode slime alkaline leach liquor

ActiveCN104911358ANo need to adjust pHRealize separation and enrichmentProcess efficiency improvementElemental selenium/telluriumPregnant leach solutionBarium salt

The invention discloses a method for separating arsenic and selenium from copper anode slime alkaline leach liquor. The method comprises the following steps: 1) oxidation, namely adding an oxidizing agent or introducing oxidizing gas into the copper anode slime alkaline leach liquor, so that oxidized copper anode slime alkaline leach liquor is obtained; 2) arsenic precipitation, namely adding a calcium salt into the oxidized copper anode slime alkaline leach liquor, stirring the obtained mixture so as to produce a precipitate, and carrying out filtration and separation on the precipitate so as to obtain a calcium arsenate precipitate and arsenic post-precipitation liquid; and 3) selenium precipitation, namely adding a barium salt into the arsenic post-precipitation liquid obtained in the step 2), stirring the obtained mixture so as to produce a precipitate, carrying out filtration and separation on the precipitate so as to obtain a barium selenate precipitate and selenium post-precipitation liquid, and carrying out evaporative crystallization on the selenium post-precipitation liquid so as to recycle alkali, or directly returning to a leaching process. The method disclosed by the invention is short in technological process, less in equipment and simple in operation, and can be used for realizing the separation and enrichment of arsenic and selenium, the precipitation rate of arsenic is higher than 96%, and the precipitation rate of selenium is higher than 99%; by virtue of carrying out evaporative crystallization on a solution for recycling or directly returning the solution to a leaching process, the recovery of alkali is realized.

Owner:CENT SOUTH UNIV

New technology for treating coking wastewater and wastewater from coal chemical industry

ActiveCN103288298AProcess parameters are easyAdjust process parametersMultistage water/sewage treatmentWater/sewage treatment by degassingChemistryCoal chemical industry

Owner:TIANJIN REDSUN WATER IND

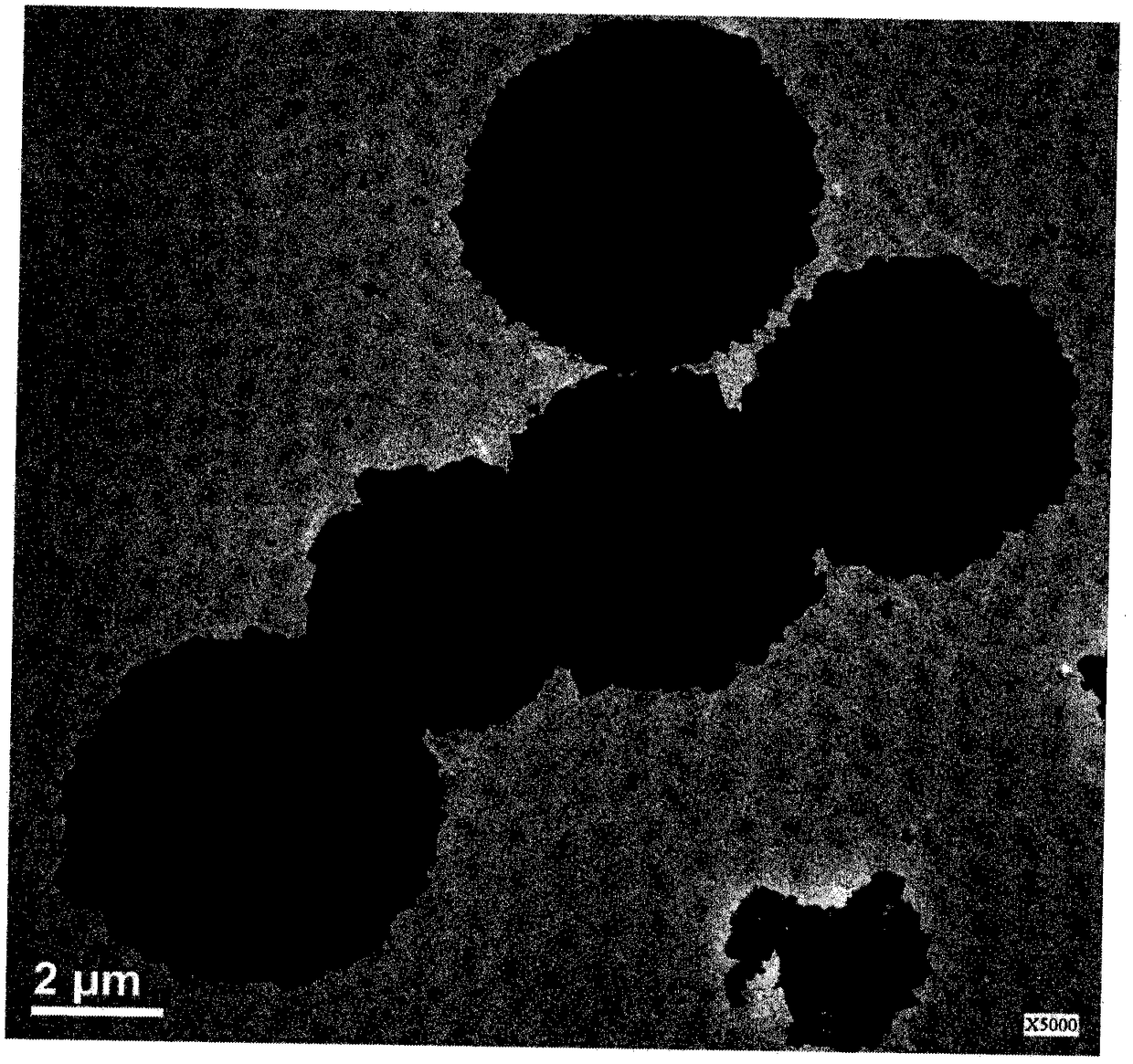

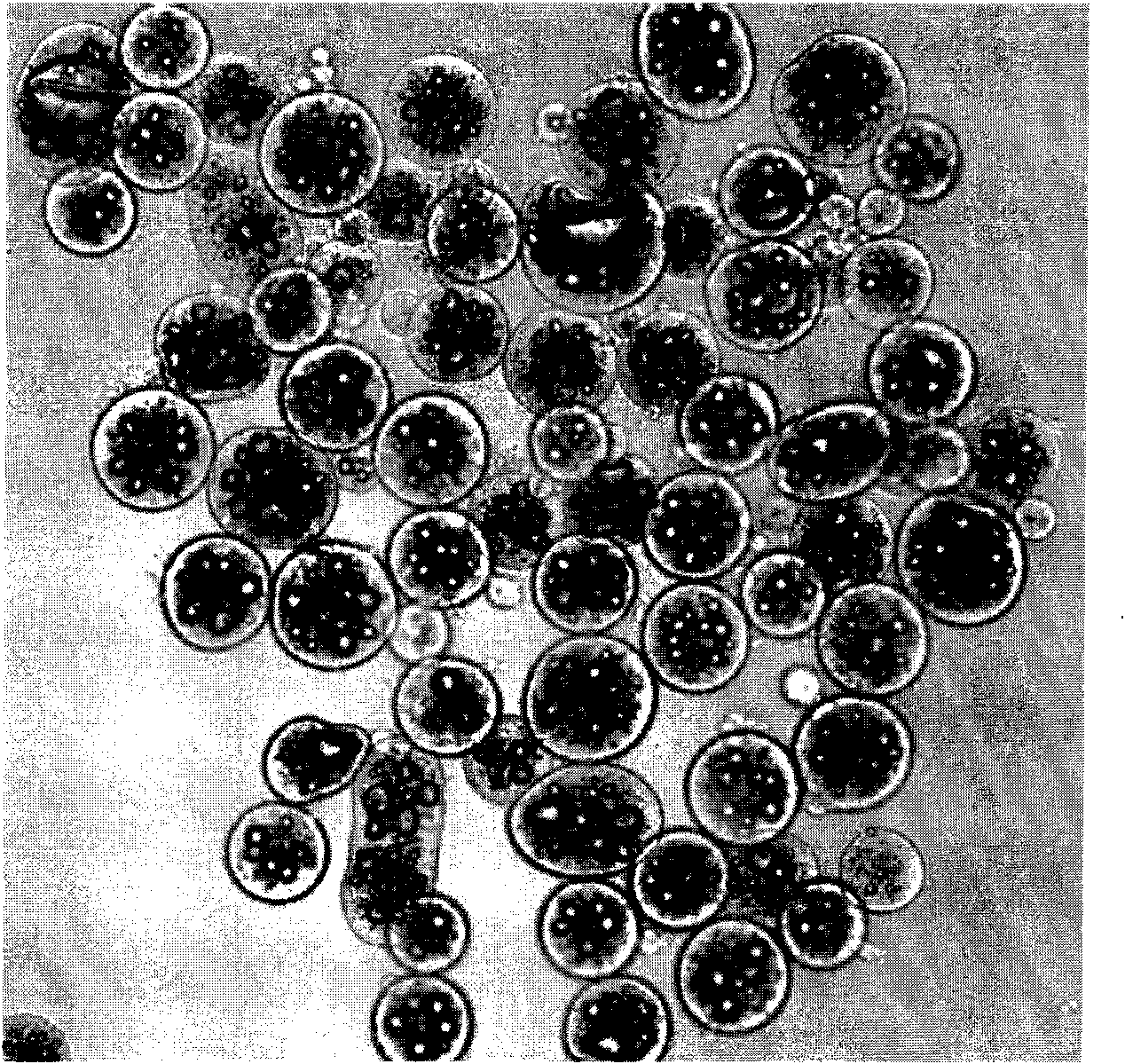

Hollow calcium carbonate microsphere and preparation method thereof

The invention discloses a hollow calcium carbonate microsphere and a preparation method thereof. The preparation method comprises the following steps: 1, preparing solutions of calcium chloride (CaCl2), sodium carbonate (Na2CO3), polyacrylic acid (PAA) and sodium dodecyl sulfate (SDS); 2, adding the prepared PAA in constant volume into the Na2CO3 solution and the CaCl2 solution; 3, adding the SDSsolution into a mixed solution containing the Na2CO3 and PAA only, and adding the solution into a mixed solution of CaCl2 and PAA; 4, filtering, washing and drying the reaction product, thereby obtaining the white powdered hollow calcium carbonate microsphere with excellent monodispersity. The obtained hollow calcium carbonate microsphere has a compound crystal form of calcite and vaterite, is uniform in particle size distribution, does not have an agglomeration phenomenon, and has the mean grain size of 5-8 microns and the specific surface area of 30-60m<2> / g. The preparation method is simplein process, low in cost, easy to control, green, environmentally friendly and capable of realizing industrialized production; the prepared hollow calcium carbonate microsphere has huge application value in the fields of drug sustained release and the like.

Owner:SHANGHAI HUAMING HI TECH GRP

Method for oxidizing CaSO3 in desulfurized fly ash in alkaline condition

The invention discloses a method for oxidizing CaSO3 in desulfurized fly ash in an alkaline condition. The method comprises the following steps of: (1) adding 2 to 10 times water by weight to the desulfurized fly ash, and uniformly stirring to obtain desulfurized fly ash slurry; (2) slowly adding H2O2 and / or persulfate solution with weight concentration being 10 to 30% of to the desulfurized fly ash slurry, wherein the molar mass ratio of H2O2 and / or persulfate to CaSO3 is 1- 2: 1; and (3) stirring and reacting mixtures of the desulfurized fly ash slurry, H2O2 and / or persulfate solution for 0.5 to 4 hours. According to the oxidization method, the pH of the solution does not need to be adjusted and metallic ions do not need to add, so that the reaction conditions are mild, and as a result, the oxidization cost is reduced, and the corrosion to the equipment is reduced; and the method has the characteristics of short reaction time, high efficiency, etc.

Owner:武汉钢铁有限公司 +1

Processing method of garbage leachate

InactiveCN102329023ALow toxicityReduce loadMultistage water/sewage treatmentWater/sewage treatment by oxidationLitterCalcium hypochlorite

The invention relates to a processing method of garbage leachate, which comprises the following steps: 1) adding sodium hypochlorite into garbage leachate to carry out preoxidation; 2) adding ferrous iron and hydroxide, stirring, and separating out the supernatant; and 3) adding ferrous iron and hydrogen peroxide into the supernatant, stirring, and regulating the pH value of the effluent water to reach the standard. Aiming at the garbage leachate after biochemical treatment, the invention is composed of sodium hypochlorite reinforced ferrous iron coagulation and Fenton technique. The sodium hypochlorite reinforced ferrous iron coagulation can remove nondegradable organic substances in the leachate, and generate active chlorine to effectively remove ammonia nitrogen. In the Fenton technique, ferrous iron and hydrogen peroxide in a certain proportion are added to generate hydroxy free radicals, thereby further oxidizing the organic substances and implementing partial mineralization, lowering the toxicity of the leachate and enhancing the biochemical quality of the leachate.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

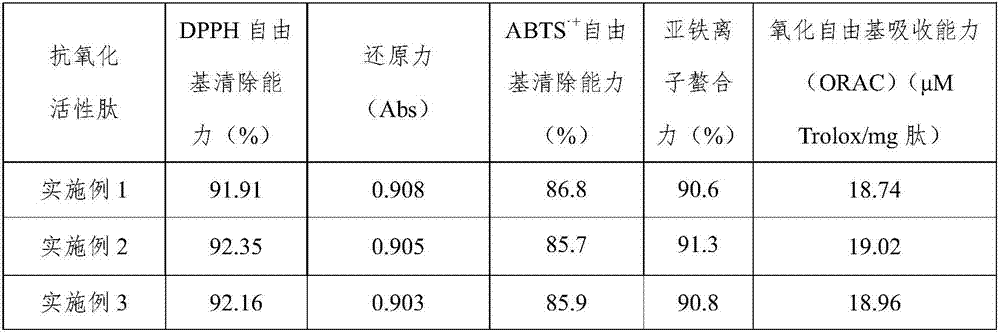

Fish-skin protein peptides with antioxidation function, and preparation method and application thereof

ActiveCN107164444ANo need to adjust pHImprove antioxidant functionCosmetic preparationsConnective tissue peptidesChromatographic separationAntioxidant protein

The invention provides fish-skin protein peptides with an antioxidation function. The amino acid sequences of the fish-skin protein peptides are respectively as shown in SEQ ID No. 1 and SEQ ID No. 2. Based on the characteristics of fish-skin proteins, fish-skin protein peptide powder is prepared from fish skin through ultrasonic pretreatment, high-temperature high-pressure pretreatment, step-by-step enzymatic hydrolysis via a plurality of proteases and separation technologies including membrane separation, gel separation and high-performance liquid chromatographic separation, and the fish-skin protein peptides as shown SEQ ID No. 1 and 2 account for 50% or more of the total weight of the fish-skin protein peptide powder; so a simple high-efficiency preparation method for the fish-skin protein peptides with the antioxidation function is established.

Owner:天津市宽达水产食品有限公司

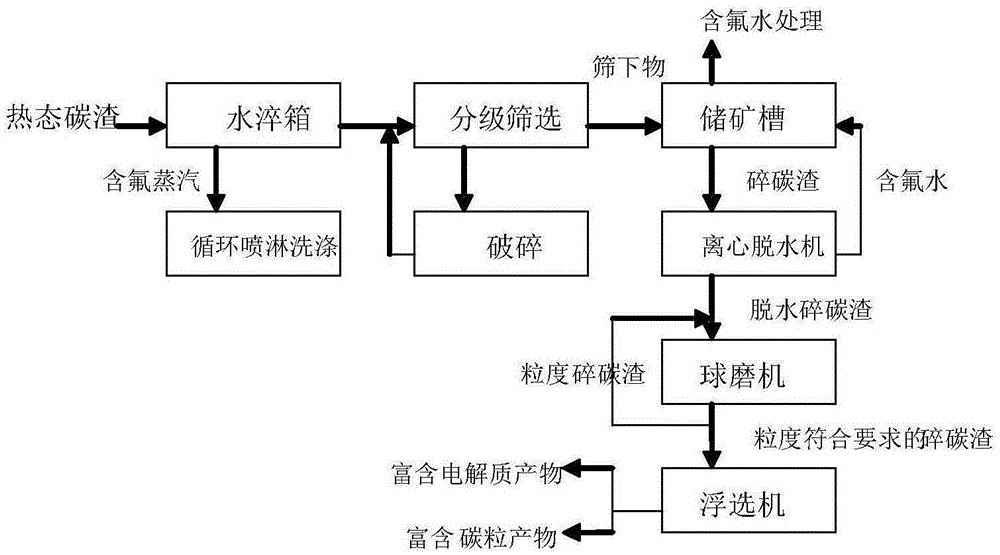

Water quenching and separating treatment method for anode carbon slime in aluminum electrolysis

ActiveCN105239097AReduce pollutionSimplified coarse crushingSolid waste disposalElectrolysisCarbon product

The invention discloses a water quenching and separating treatment method for anode carbon slime in aluminum electrolysis, and belongs to the technical field of aluminum electrolysis. The water quenching and separating treatment method comprises the steps of carrying out water quenching on the thermal-state carbon slime, classifying and sorting the water-quenched carbon slime, dehydrating the water-quenched carbon slime through a centrifugal dehydrator, carrying out wet grinding on the carbon slime and sorting the carbon slime through a flotation machine, finally carbon-rich products and electrolyte-rich products are obtained, the carbon-rich products can be used for producing carbon products, and the electrolyte-rich products can be purified and then used in the aluminum electrolysis process. According to the invention, the coarse crushing step and the fine crushing step can be simplified, and therefore the procedures are simplified, dust pollution in the crushing steps and the ore grinding step is greatly reduced, and the energy can be utilized more reasonably. The water quenching and separating treatment method can be effectively combined with the existing wet grinding technology, the existing flotation technology and the existing fluorine-containing water treatment technology.

Owner:北京森泉伟业科技有限公司

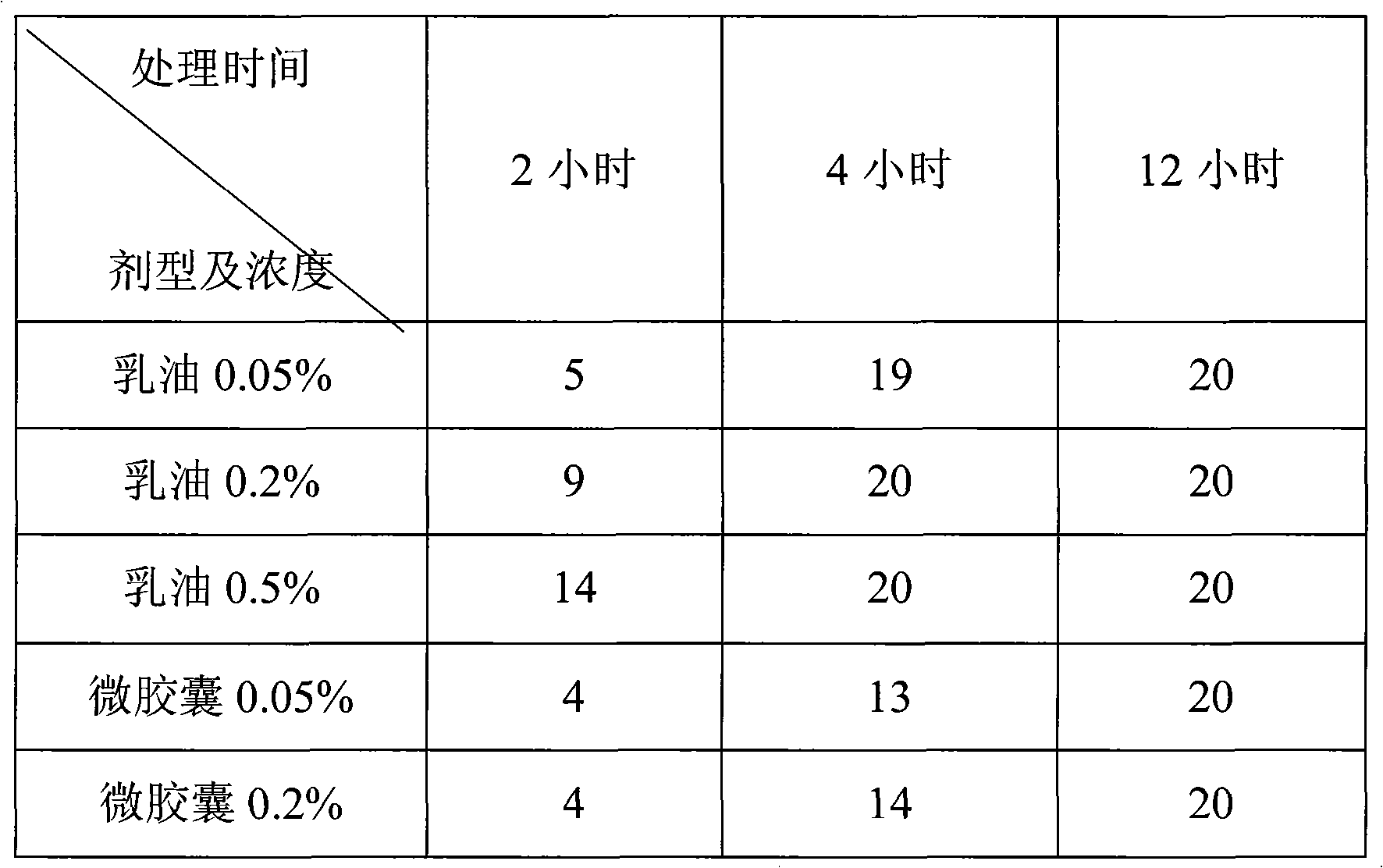

Pesticide microcapsule granule and preparation method thereof

ActiveCN101647431ANo pollution in the processWide variety of sourcesBiocideAnimal repellantsEmulsionPollution

The invention discloses a pesticide microcapsule granule and a preparation method thereof. The preparation method of the microcapsule granule comprises the following steps: (1) dissolving pesticide; (2) emulsifying the dissolved pesticide by gelatin solution to form emulsion; (3) adding a flocculating agent into the emulsion to form a microcapsule; (4) after the microcapsule is formed, adding white carbon black into the microcapsule; (5) condensing, solidifying and depositing the microcapsule; and (6) carrying out drying processing on the microcapsule to obtain the microcapsule granule. The preparation method of the pesticide microcapsule granule has simple operation and can reduce the cost and the pollution to the environment, and the prepared pesticide microcapsule granule has the effect of slow release and prolongs the service life of medicines.

Owner:SOUTH CHINA NORMAL UNIVERSITY

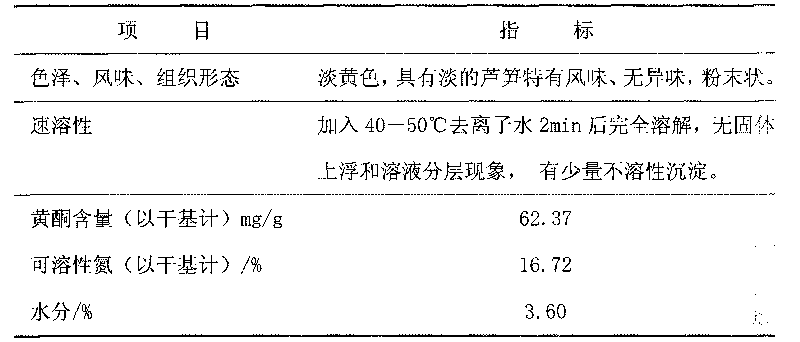

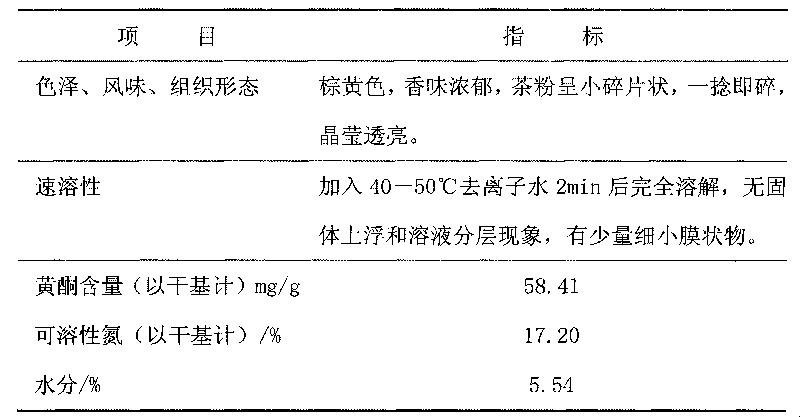

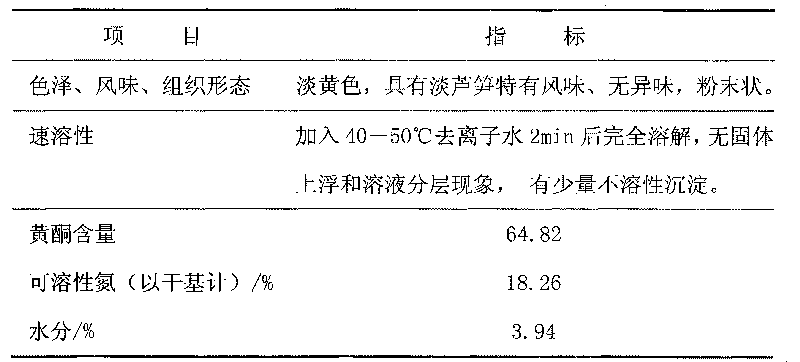

Preparation method of asparagus leaf instant tea

InactiveCN101715848AIncrease soluble nitrogen contentImprove immunityPre-extraction tea treatmentCelluloseInstant tea

The invention belongs to a preparation technology of an instant tea, relating to a preparation method of an asparagus leaf instant tea. As the prior art only picks vegetable asparagus, and loses the asparagus leaf, wherein the weight of the asparagus leaf is 70%-80% of the gross weight of plant, thereby wasting the resources; and the asparagus leaf is rotten, thereby polluting the environment. The preparation method of the asparagus leaf instant tea comprises the following four steps of: microwave inactivating enzyme of the asparagus leaf-composite formulating the leaf instant tea-hydrolyzing complex enzyme-concentrating and drying. The preparation technology has the advantages that the asparagus leaf instant tea has higher flavone content and soluble nitrogen content, and has physiological functions for enhancing human body immunity and anti-fatigue, and the like; is convenient in drinking, and can be drunken by adding water; is easy in storing and transporting; has a scientific and reasonable technology; has an energy-saving production technology, and is easy in controlling and operating; adopts an assistant extraction method with complex enzyme of cellulose and neutral protease to have mild hydrolysis condition and low ash content; and has wide raw materials source, abundant resource, low price, low cost and wide practicability.

Owner:SHANGHAI NORMAL UNIVERSITY

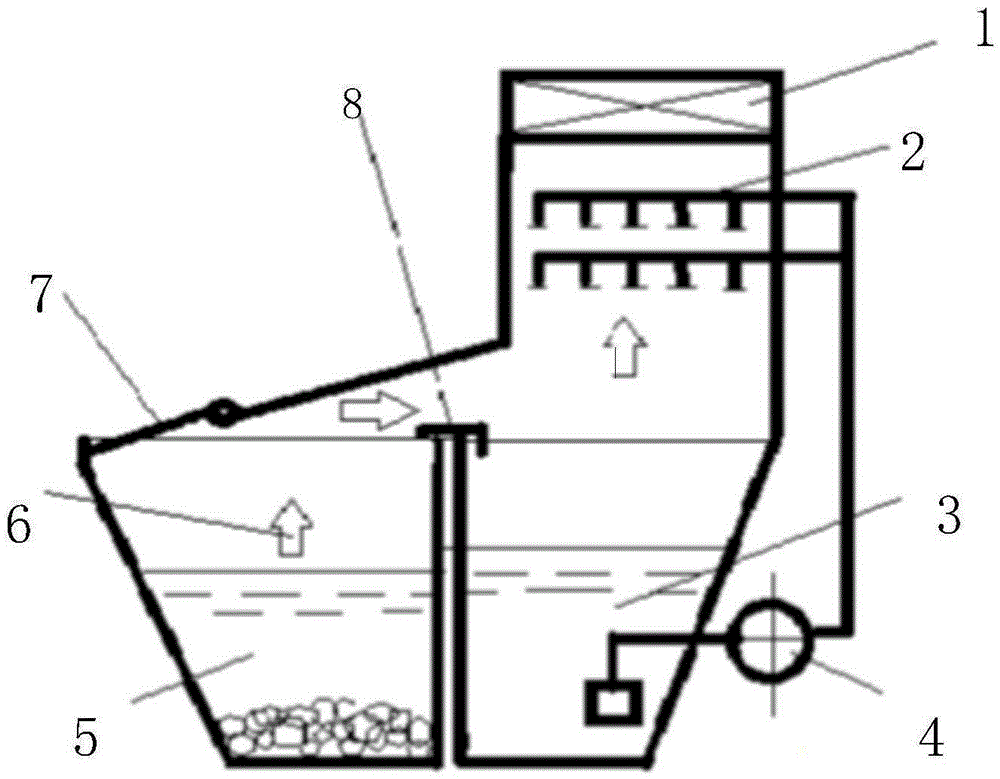

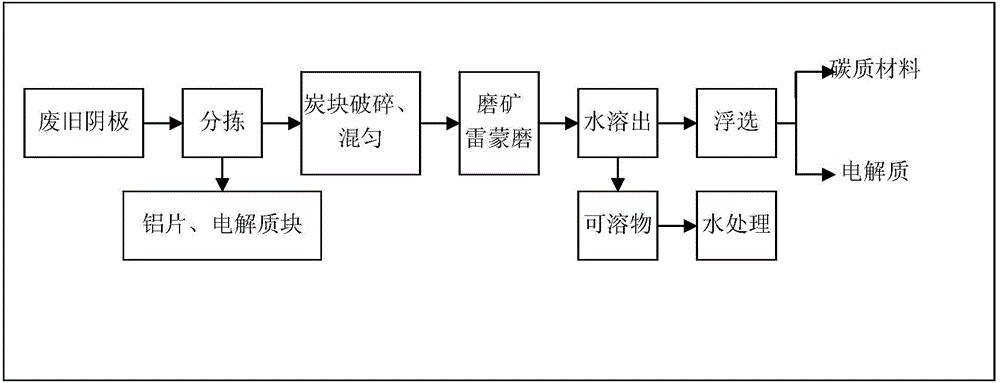

Method for sorting waste aluminum electrolytic cathodes

InactiveCN104438280AGuaranteed uniformityEasy to handleSolid waste disposalFlotationAluminium electrolysisMetallurgy

The invention relates to a method for sorting waste aluminum electrolytic cathodes. The method comprises the steps of carrying out crushing and blending treatment on sorted waste cathodes to obtain waste cathode fragments; grinding the waste cathode fragments to obtain crushed ores; soaking the crushed ores with water, and then carrying out solid-liquid separation to obtain dissolved ore bodies; and carrying out flotation treatment on the dissolved ore bodies to obtain carbon products and electrolyte products respectively. According to the method, a way of crushing, blending and then ore grinding is adopted for the waste cathodes, so that the uniformity of composition and the like of treated materials can be guaranteed, thus being beneficial to the improvement of a treatment effect; meanwhile, dissolution treatment is adopted for the ground waste cathode materials simultaneously, soluble parts are dissolved and separated to eliminate the impact of the soluble parts on subsequent flotation operation, and flotation can be carried out on the waste cathode materials directly after the dissolution treatment without adjusting the PH. The method for comprehensively recycling waste aluminum electrolytic cathodes, provided by the invention, is simple and feasible, low in production cost and good in production index.

Owner:北京森泉伟业科技有限公司

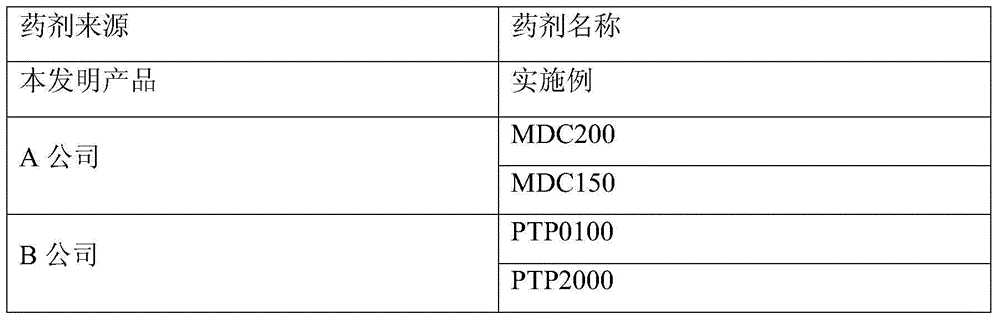

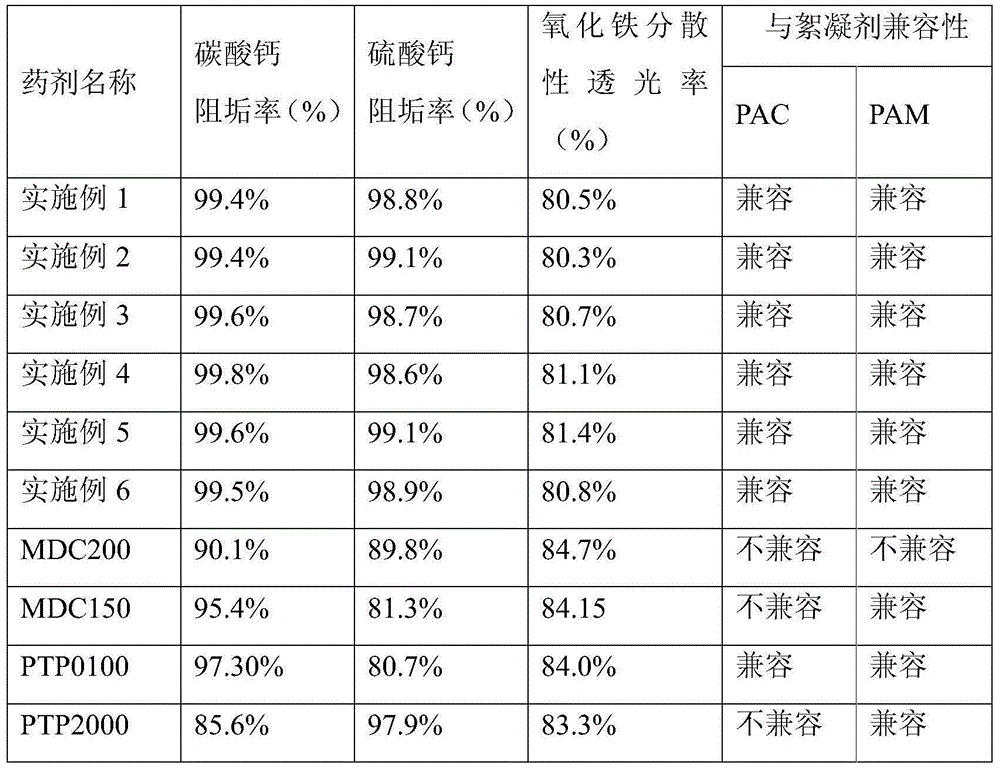

Reverse osmosis membrane scale inhibitor and application thereof

InactiveCN105126627AReduce or control aggregation and scalingCrystalline effectiveSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPhosphonium saltAluminium chlorohydrate

The invention provides a reverse osmosis membrane scale inhibitor. The reverse osmosis membrane scale inhibitor mainly comprises organic phosphonic acid, organic carboxylic polymers, sulfonic copolymers, a quaternary phosphonium salt, and methane dithiocyanate. The invention further provides an application of the reverse osmosis membrane scale inhibitor in scale inhibition of a reverse osmosis system. When used for reverse osmosis water treatment, the reverse osmosis membrane scale inhibitor provided by the invention can effectively eliminate membrane pollution caused by deposition of CaCO3, CaSO4, SiO2 and silicate; working efficiency of the reverse osmosis system is improved, service lives of the reverse osmosis membrane and reverse osmosis equipment are prolonged, and reverse osmosis cost is reduced; the reverse osmosis membrane scale inhibitor is compatible with various common flocculating agents such as polyaluminum chloride and cationic polyacrylamide; and a pH value is not required to regulate.

Owner:SHANDONG TIANQING TECH DEV

Method for repairing nano stick of zinc oxide in even diameter

InactiveCN1686820ALow costSimple processZinc oxides/hydroxidesLithium hydroxideZinc Acetate Dihydrate

The method for preparing zinc oxide nano rod with uniform diameter includes the following steps: (1) dissolving zinc acetate in absolute ethanol or absolute methanol, fully stirring them at zero deg.C to obtain suspended liquor whose concentration is 0.5-30%, dissolving lithium hydroxide in absolute ehtanol or absolute methanol at room temperature to obtain lithium hydroxide solution whose molar concentration is twice that of zinc acetate; (2). under the temperature of zero deg.C drop-by-drop adding isopyknic lithium hydroxide solution to stirring zinc acetate solution to obtain white colloidal mixed solution; (3) placing said colloidal solution into a hydrothermal reactor, sealing said reactor, heat-insulating for 5-24 hr, at 80-200 deg.C, and taking out reaction solution; and (4). centrifugally-separating reaction solution, fully washing separated material by using absolute ethanol, drying at room temp. so as to obtain the invented product.

Owner:ZHEJIANG UNIV

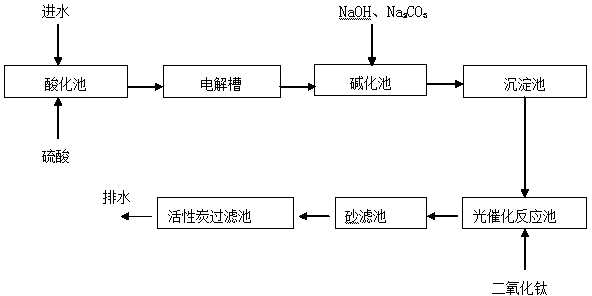

Advanced treatment method for coking wastewater

ActiveCN103922524AOvercome limitationsReduce CODMultistage water/sewage treatmentCyanide compoundWater use

The invention provides an advanced treatment method for coking wastewater. The steps of electrolysis, flocculation, advanced treatment, water draining and the like are used for treating the coking wastewater after being treated through a biological method. Waste water is heavy in color after being treated through a traditional biological treatment method, the COD concentration cannot meet the emission standard, and a small amount of phenols and cyanide are remained. The method effectively solves the boundedness of treating the coking wastewater through the biological method, the water quality of discharged water is stable, the water quality standard of reuse of recycled water is met, namely the water quality of urban wastewater reclamation and reuse and urban miscellaneous water (GB / T18920-2002), and the recycling of water resources is achieved.

Owner:SHANDONG SUNYON GRP

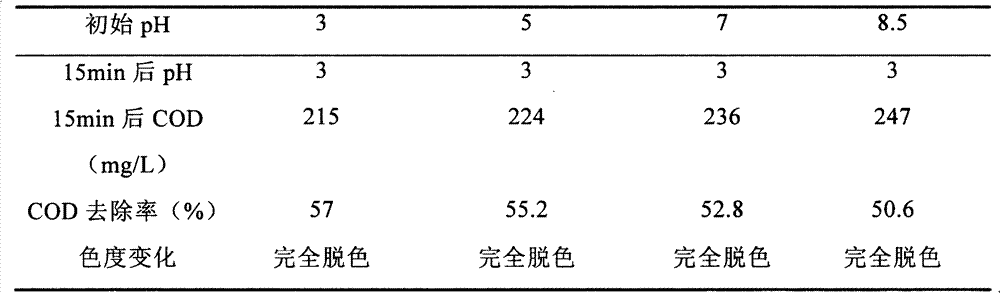

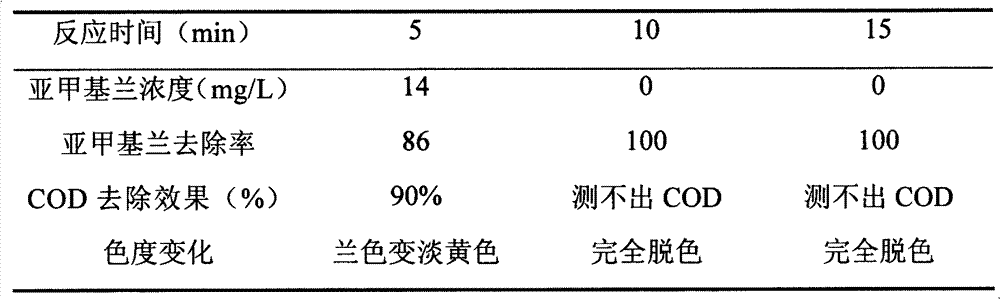

Method for preparing binary-oxide composite solid acid catalyst and method for treating degradation-resistant organic pollutants by catalyzing oxidization of H2O2

InactiveCN103357413AImprove catalytic performanceNo lossWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsSulfate radicalsMass ratio

The invention relates to a method for preparing a binary-oxide composite solid acid catalyst and a method for treating degradation-resistant organic pollutants by catalyzing oxidation of H2O2, belonging to the field of treatment and catalytic reaction of wastewater in environmental protection. The method for synthesizing the solid acid catalyst comprises the following steps: mixing SnCl4.5H2O with diatomaceous earth, adding Fe2(SO4)3 according to a certain mass ratio, and adjusting the pH value of the mixture by using strong aqueous ammonia to form sol; ageing, washing, settling centrifugally, drying, grinding and sieving the sol to obtain a precursor; and impregnating the precursor with sulfuric acids with different concentrations, filtering, drying and calcining to obtain the solid acid catalyst which takes a sulfate radical as an accelerator. The solid acid catalyst can form a heterogeneous Fenton system together with hydrogen peroxide to catalyze to generate a hydroxyl radical (.OH) for degrading pollutants and can be used for degrading the methylene-blue simulated wastewater, the methyl-orange simulated wastewater, the m-nitrobenzene simulated wastewater, the turquoise-blue real wastewater, the glyphosate real wastewater and the pharmaceutical-intermediate real wastewater quickly and effectively without adjusting the pH value of the wastewater and generating iron sludge, and thus fewer reagents are used. The solid acid catalyst has a strong sedimentation performance and can be recycled.

Owner:JIANGNAN UNIV

Pretreatment filming agent and pretreatment filming method for circulating cooling water system

A precoating agent for precoating a film on the inner surface of the equipment and pipeline in a circulating cooling water system is prepared from phosphoric acid (2-10 wt.%), zinc dihydrogen phosphate (1-10), organic phosphonic acid (5-18), hydrocinnamyl triazazole (0.5-2.0), and the copolymer containing carboxy. Its advantages are low cost and simplified operation.

Owner:中国石油化工股份有限公司北京燕山分公司研究院

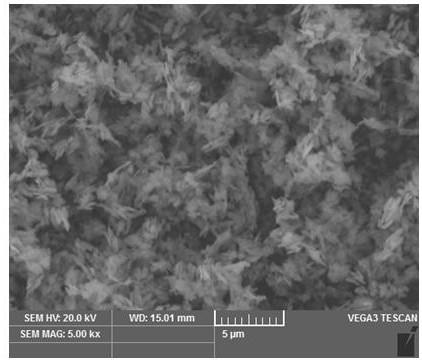

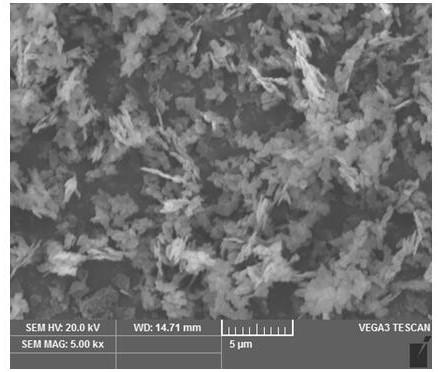

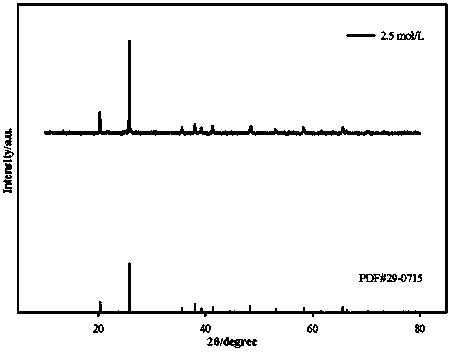

Preparation method for iron phosphate nanosheets

ActiveCN110294466AHigh purityAvoid interferenceMaterial nanotechnologyPhosphorus compoundsFiltrationPhosphate

The invention discloses a preparation method for iron phosphate nanosheets. The preparation method comprises the steps that iron black is slowly added to phosphoric acid with the concentration of 1.5-3.0 mol / L, stirring and heating are conducted for reacting, and after the reaction, the iron phosphate nanosheets are obtained through suction filtration, washing, drying, dewatering and other steps.The iron phosphate prepared by using the method has a nanosheet-shaped morphology, the thickness of the nanosheets is 70-80 nanometers, and the specific surface area is high. By optimizing the reaction conditions, in the reaction procsess, the pH value does not need to be adjusted, and no oxidizing agents are added; the interference with anionic and cationic impurities is effectively avoided, theiron phosphate obtained by using the method is free of impurity phases and high in purity. Besides, less water is used for washing iron phosphate precipitation, the iron phosphate synthesizing cost isreduced, and the pollution to the environment is reduced. The technology is simple, operation is convenient, industrial production is facilitated, and the preparation method is wide in application prospect.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

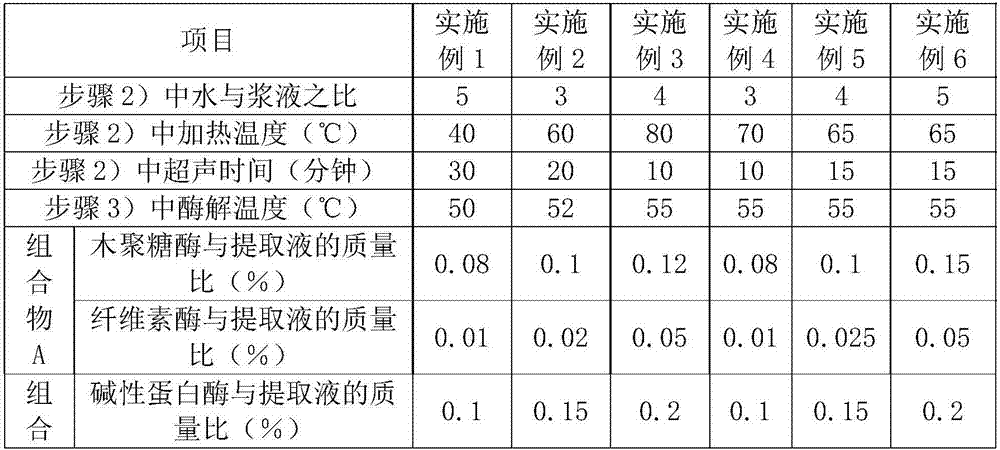

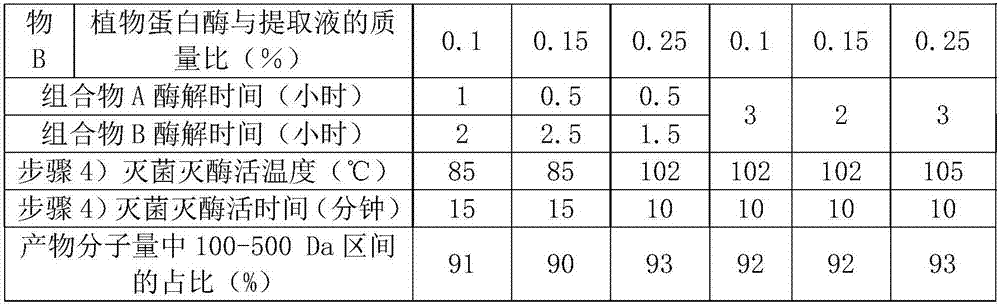

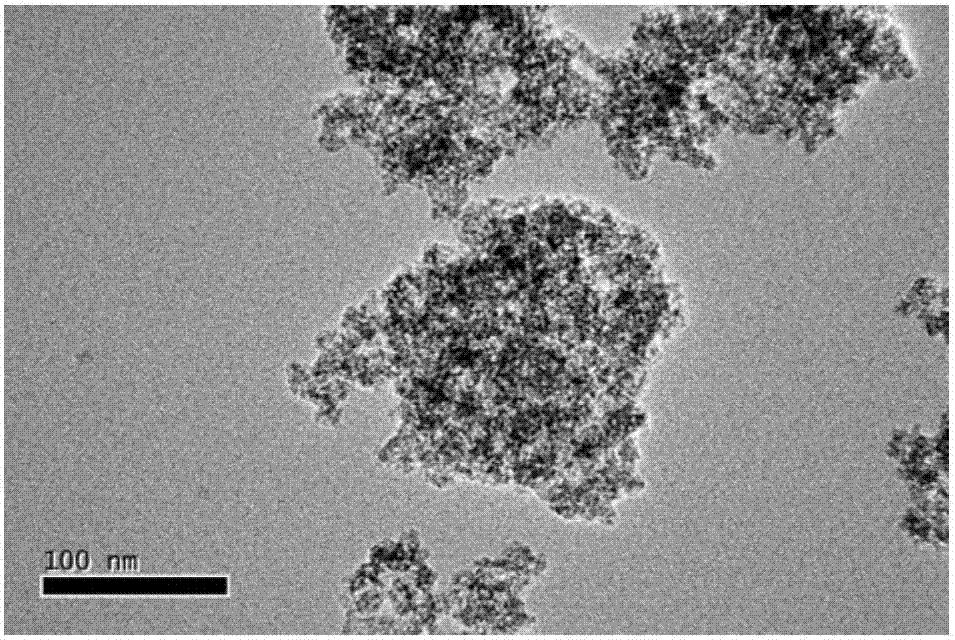

Dendrobium small molecule peptide and preparation method thereof

InactiveCN107446978AShorten the enzymatic digestion timeShorten the timePeptide preparation methodsFermentationAlkaline proteaseEnzyme digestion

The invention provides a preparation of dendrobium small molecule peptides and dendrobium small molecule peptides obtained therefrom. The preparation method comprises the following steps: 1) pretreatment; 2) extraction; 3) enzymolysis; 4) separation and purification; and 5) concentration and drying. The enzymolysis time is shortened to 2-3h by way of compound biological enzyme digestion on xylanase, cellulase, alkaline protease and plant protease. The pH value needs not to be adjusted during enzymolysis, so that the process time is shortened, and meanwhile, the desalting process is canceled, and the production efficiency of the dendrobium small molecule peptide is increased. The molecular weight of the dendrobium small molecule peptides obtained by the preparation method is primarily at 100-500Da, so that the dendrobium small molecule peptides are easily absorbed by a human body and can be applied to the field of food.

Owner:陈玫辛

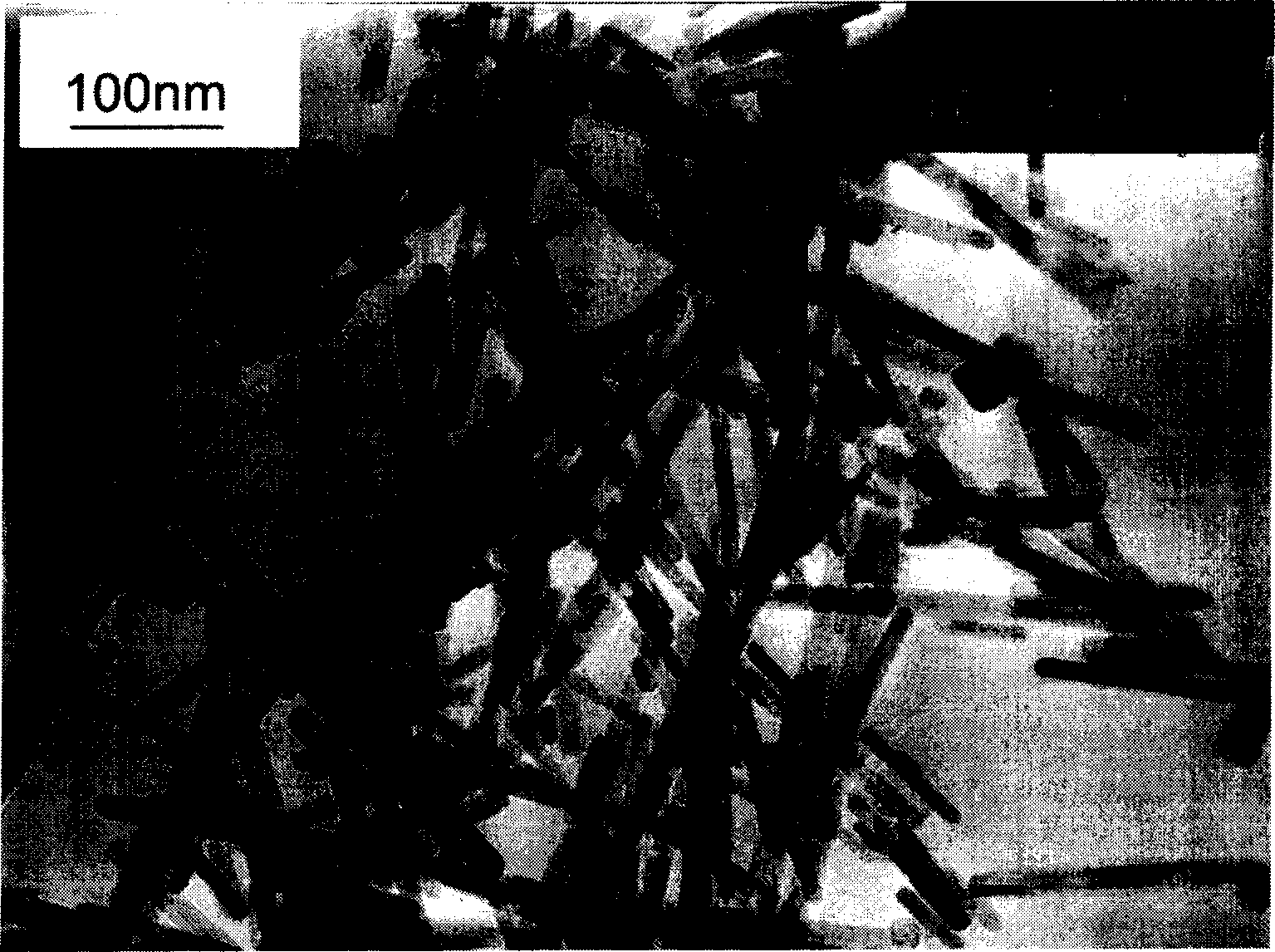

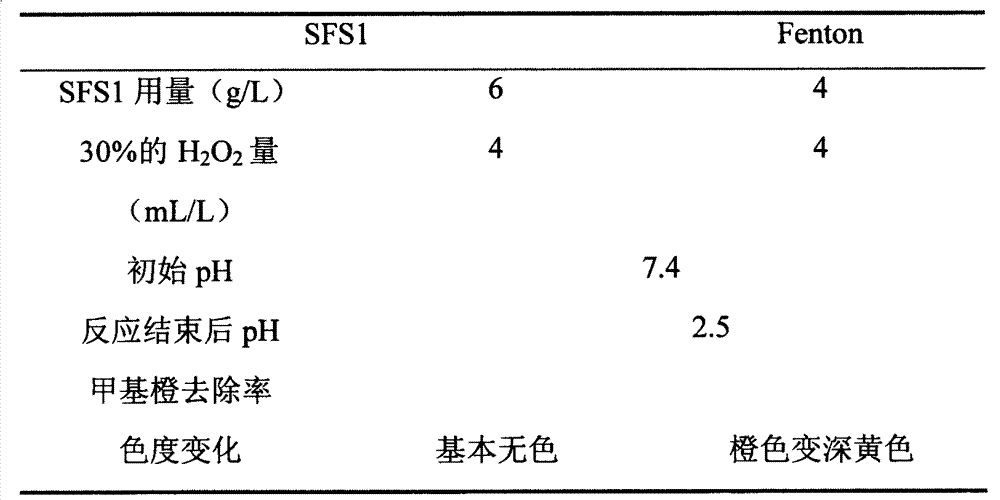

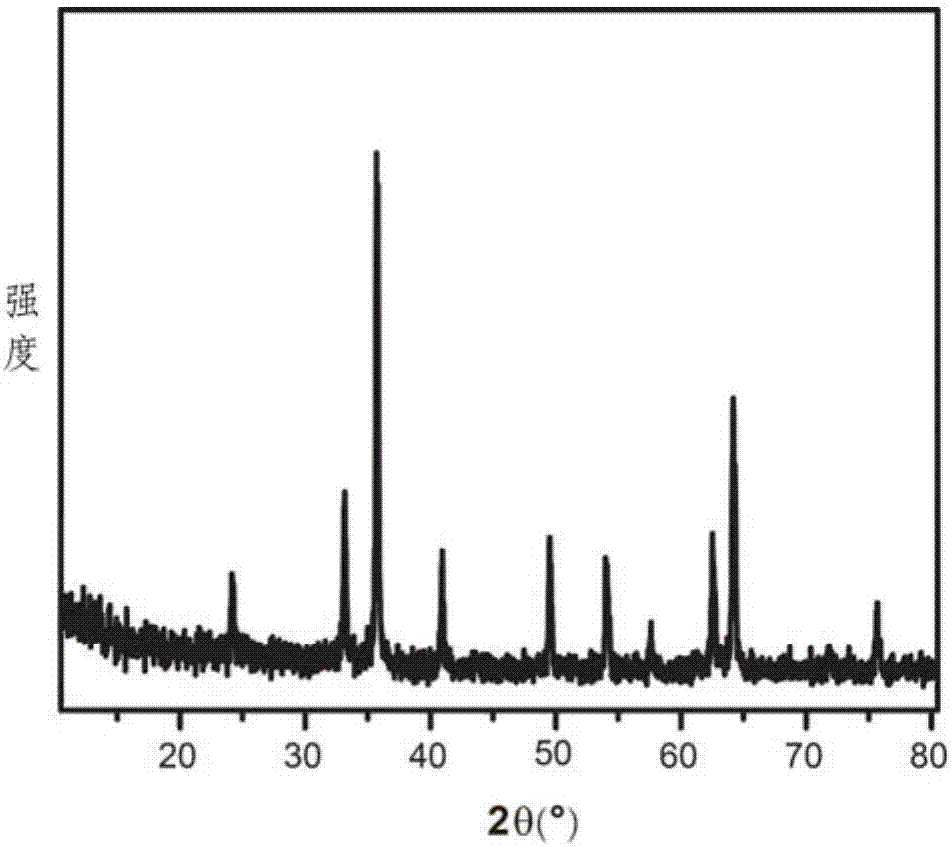

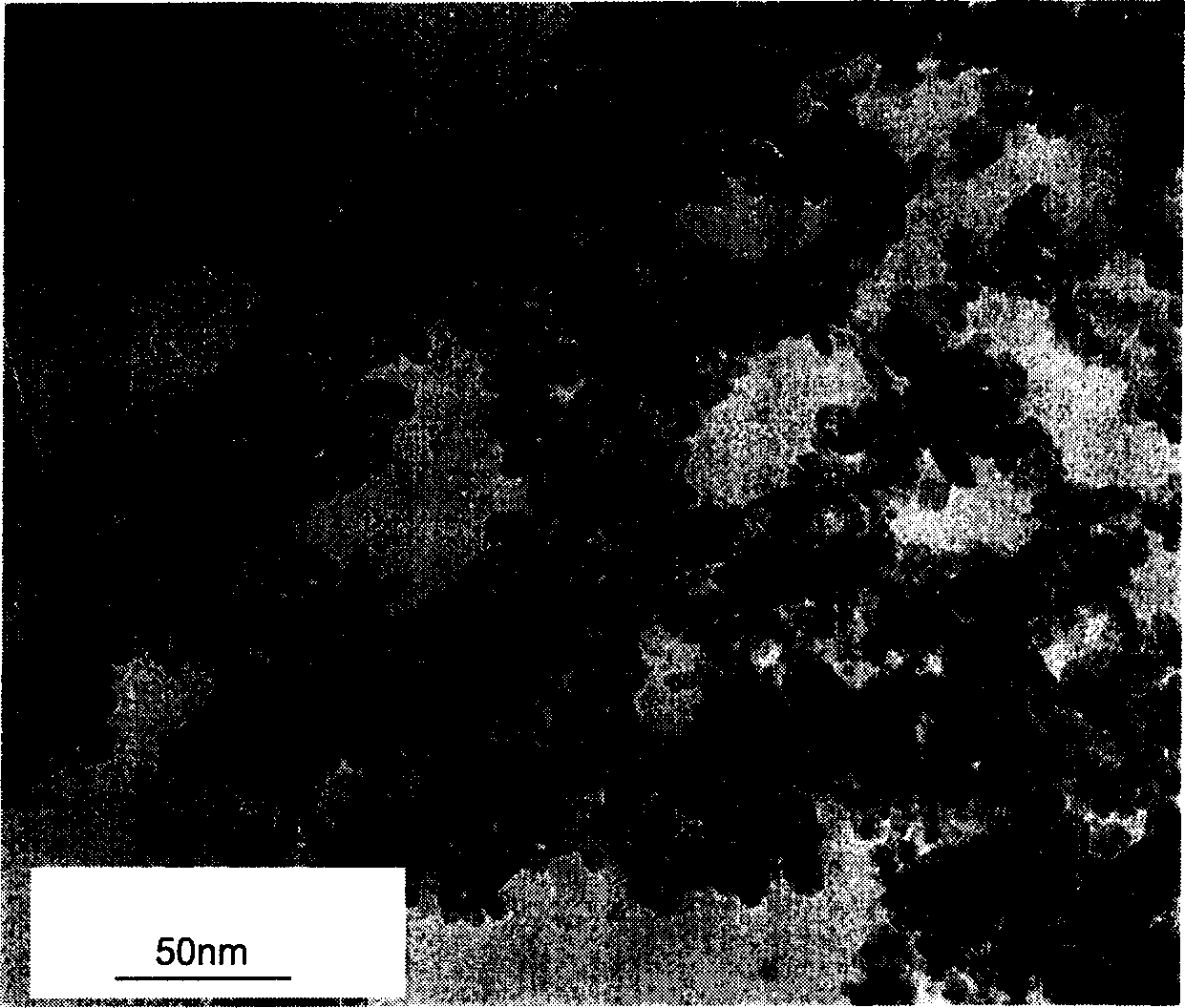

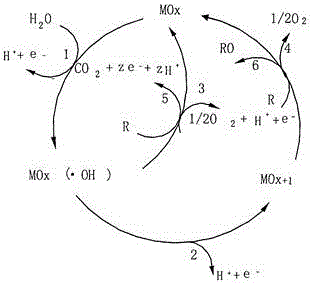

Catalyst for heterogeneous Fenton reaction

InactiveCN107497434AHigh catalytic activityNo need to adjust pHWater treatment compoundsWater contaminantsFenton reactionNitrobenzene

The invention discloses a catalyst for iron-based multi-phase Fenton reaction. The catalyst is prepared from ferric oxide and silicon oxide, wherein the silicon oxide coats the ferric oxide; the ferric oxide content is between 15 percent and 75 percent; the silicon oxide content is between 85 percent and 25 percent. The catalyst has good catalytic activity on catalytic degradation of organic contaminants (such as phenol, nitrobenzene and methylthionine chloride) through Fenton reaction. In addition, the cost is low, the recovery is easy; the repeated use and the good application prospects are realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for preparing nano granular of zinc oxide in monodisperse

The method for preparing mono-dispersed nano zinc oxide granules includes the following steps: (1). dissolving zinc acetate in absolute ethanol or absolute methanol, fully stirring them at zero deg.C to obtain suspended liquor whose concentration is 0.5-30%, dissolving lithium hydroxide in absolute ethanol or absolute methanol at room temperature to obtain lithium hydroxide solution whose molar concentration is twice that of zinc acetate; (2). under the temperature of zero deg.C drop-by-drop adding isopyknic lithium hydroxide solution to stirring zinc acetate solution to obtain white colloidal mixed solution; (3). placing the colloidal solution into a hydrothermal reactor, heat-insulating for 1-3 hr, at 80-200 deg.C, taking out the reaction solution; and (4). cetnrifugally-separating said reaction solution, fully washing said separated material by using absolute ethanol, drying at room temp. so as to obtain the invented product.

Owner:ZHEJIANG UNIV

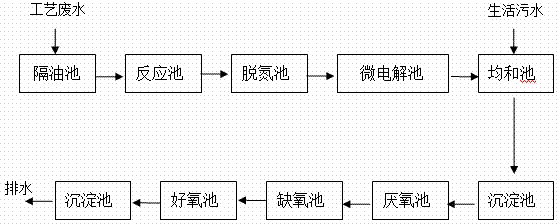

Coking wastewater treatment method

ActiveCN103936240AGuaranteed uptimeImprove biodegradabilityMultistage water/sewage treatmentVolatile phenolsChemical oxygen demand

The invention provides a coking wastewater treatment method. High-concentration coking wastewater with 7000-8000mg / L of COD (Chemical Oxygen Demand), 6000-6500mg / L of ammonia nitrogen, 800-900mg / L of volatile phenol and 100-200mg / L of cyanide is treated through the steps of: pretreatment; alkaline microelectrolysis; average value regulation; biological treatment; precipitation, drainage and the like. The method is high in efficiency for removing ammonia, phenol, cyanogen and suspended matters and stable in water quality of effluent.

Owner:SHANDONG SUNYON GRP

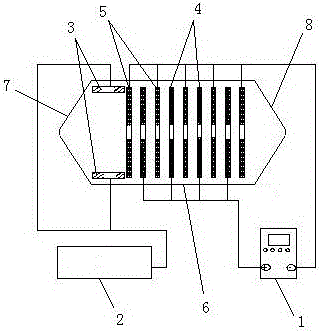

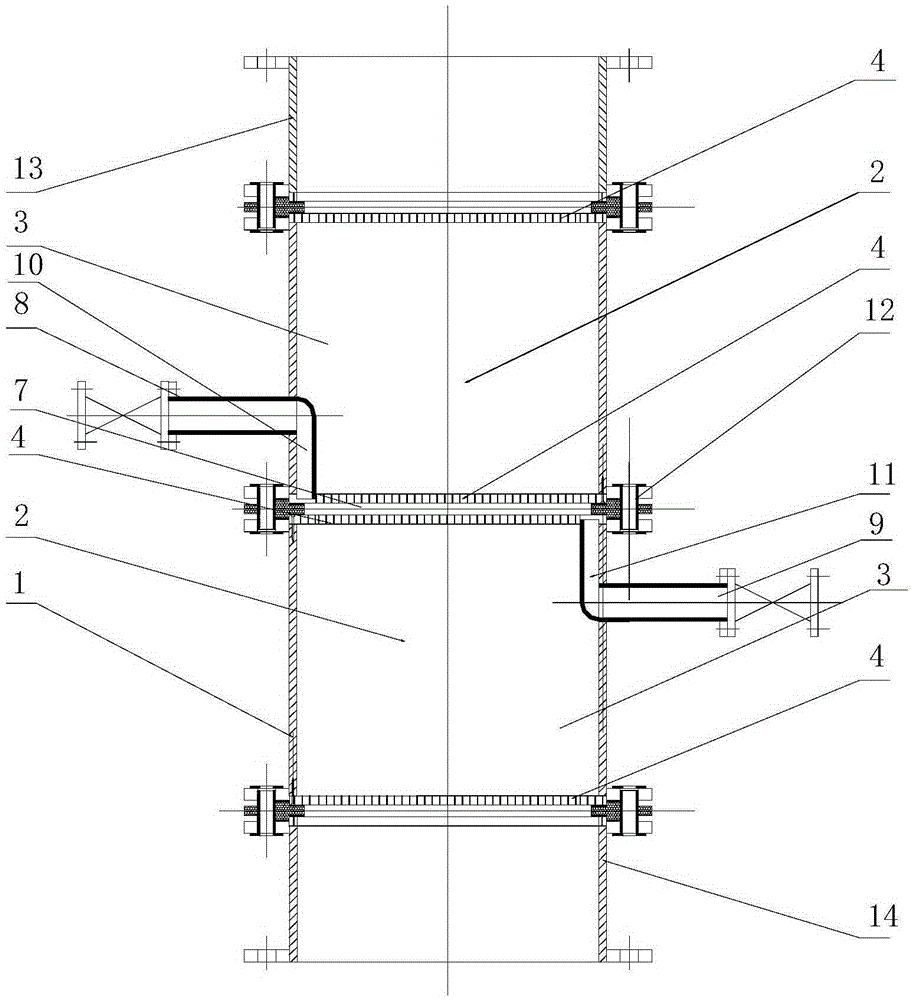

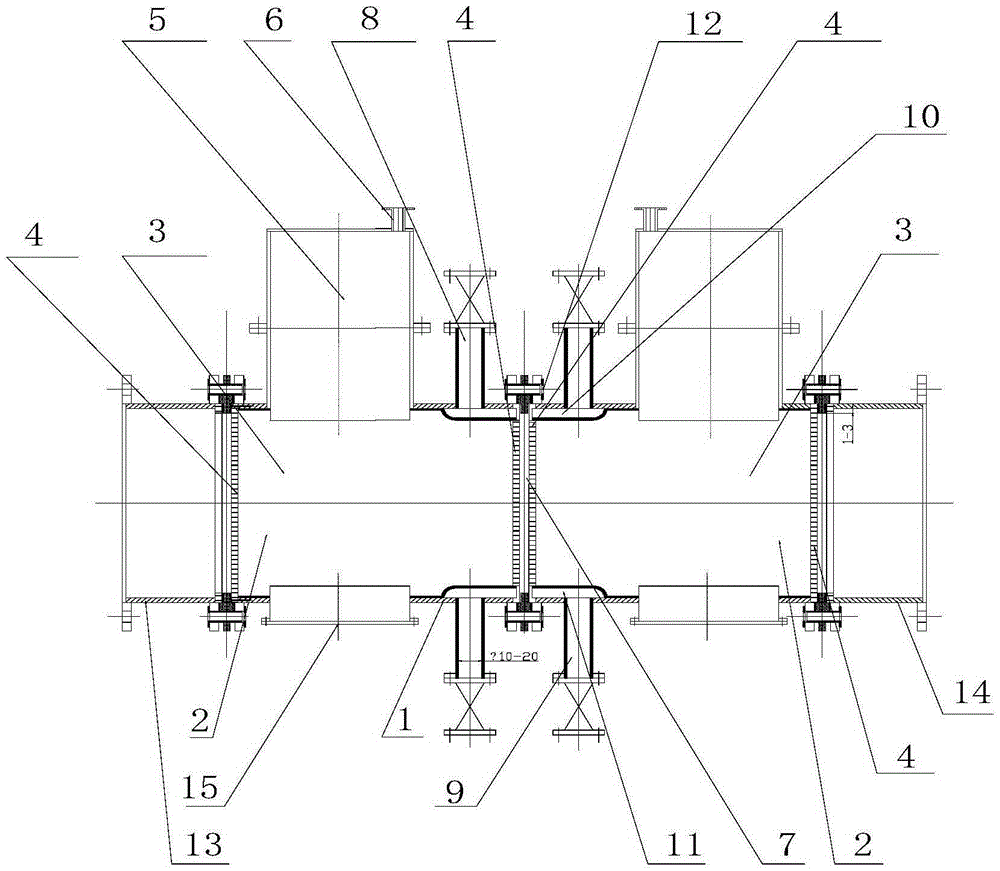

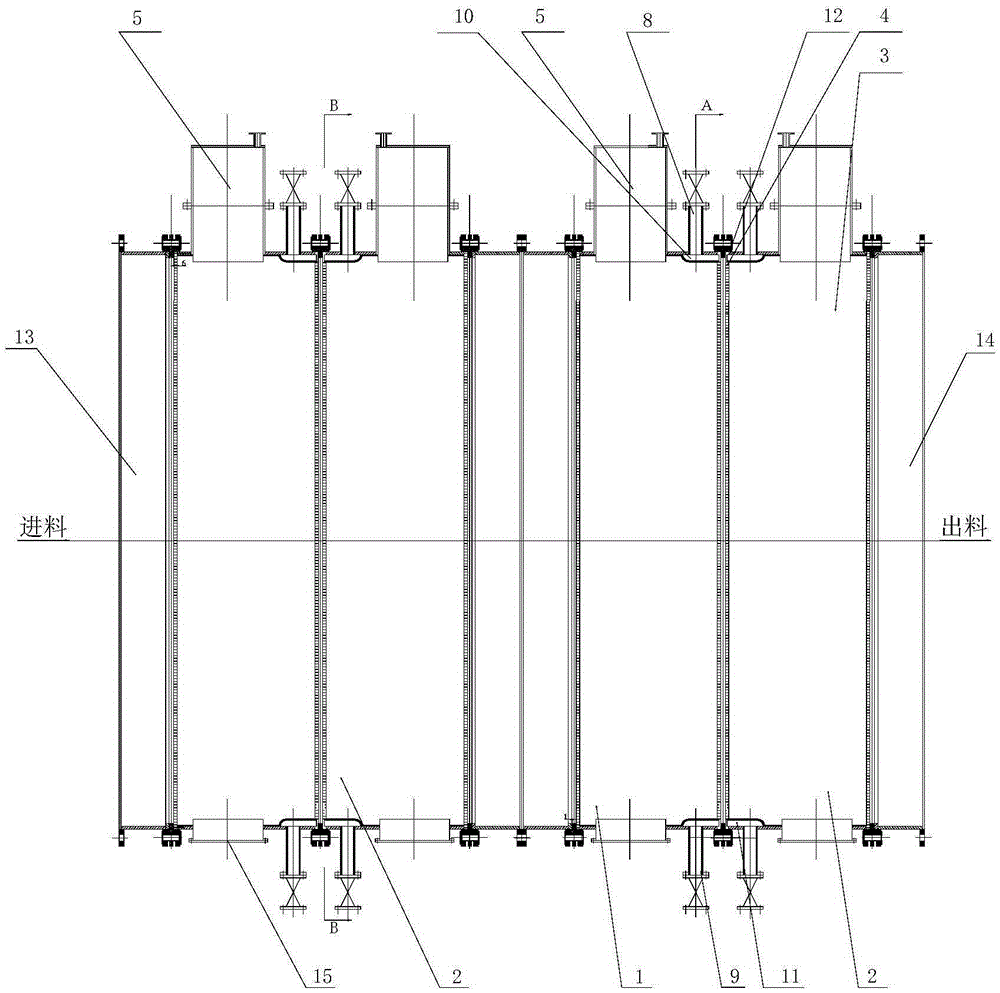

Electroacoustic multivariant catalytic oxidation device and method for treating wastewater by using same

PendingCN106629999AImprove oxidative degradation efficiencyNo need to adjust pHWater treatment parameter controlWater treatment compoundsElectricityUltrasound - action

The invention discloses an electroacoustic multivariant catalytic oxidation device and a method for treating wastewater by using the same. The electroacoustic multivariant catalytic oxidation device comprises a water inlet pipe, an integrated reactor and a water outlet pipe, wherein the integrated reactor adopts a cuboid structure; one end of the integrated reactor is connected with the water inlet pipe, and the other end of the integrated reactor is connected with the water outlet pipe; the integrated reactor is divided into an ultrasonic reaction zone and an electrocatalytic oxidation zone; the ultrasonic reaction zone is positioned at the upstream of the electrocatalytic oxidation zone. Compared with the prior art, the invention has the beneficial effects as follows: the electroacoustic multivariant catalytic oxidation device couples two advanced oxidation technologies; after electrification, wastewater flows in from the water inlet pipe of the electroacoustic multivariant catalytic oxidation device and first runs through the ultrasonic reaction zone, and pollutants in the wastewater are degraded under the action of ultrasonic; then, the wastewater enters the electrocatalytic oxidation zone and runs through each pole plate in a pushing-flow mode, organic matters in the wastewater are oxidized and degraded under the action of current, and treated effluent water is discharged from the water outlet pipe; chemicals are not required to be added; the electroacoustic multivariant catalytic oxidation device can efficiently treat various organic contaminant-containing industrial wastewater, and is easy and convenient to operate and stable in operation.

Owner:浙江科源环境科技有限公司

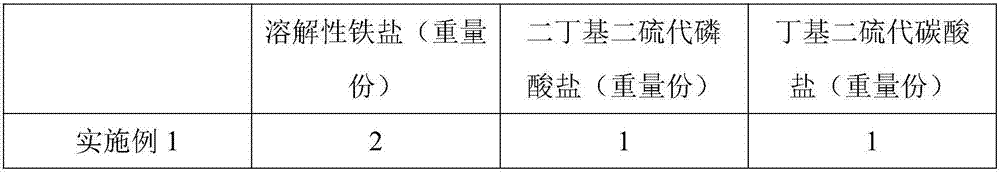

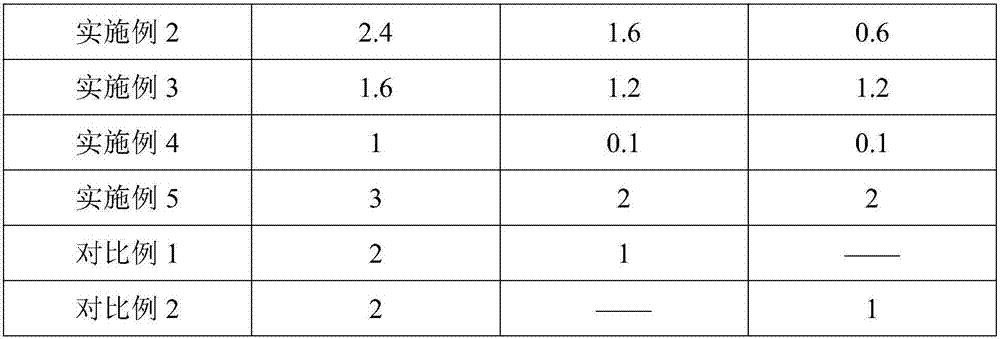

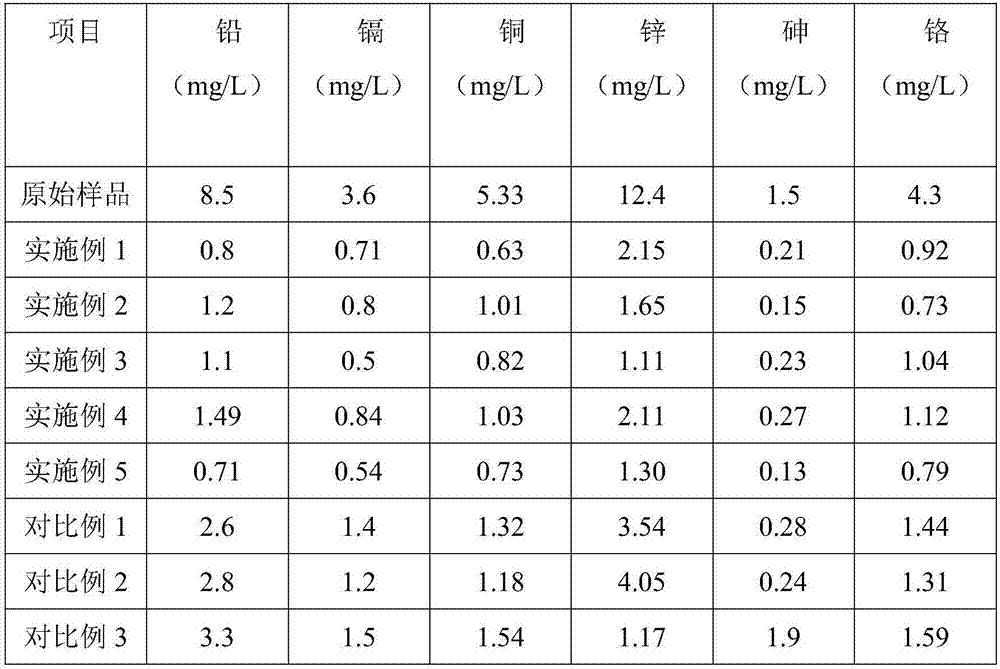

Preparation method and application of heavy metal contaminated soil/bottom mud stabilizer

ActiveCN107446587AImprove stabilityLimited ratioContaminated soil reclamationOrganic fertilisersDibutyl dithiophosphateSolubility

The invention relates to the technical fields of soil remediation and environmental protection, in particular to a heavy metal contaminated soil / bottom mud stabilizer. The heavy metal contaminated soil / bottom mud stabilizer is prepared from soluble ferric salt, dibutyl dithiophosphate and butyl dithiocarbonate in proportion. A heavy metal repair agent is low in cost, can effectively eliminate harm of heavy metal ions in soil, and has relatively good stabilizing effect on arsenic and other heavy metals in arsenic-containing composite heavy metal contaminated bottom mud under an acid condition, so that the defect that an existing product is poor in stabilizing effect on the arsenic-containing composite heavy metal contaminated bottom mud is overcome. The heavy metal contaminated soil / bottom mud stabilizer can be applied to stabilizing treatment of heavy metal contaminated muddy bottom of arsenic, lead, cadmium, copper, zinc and chromium. The heavy metal contaminated soil / bottom mud treated by the stabilizer can be used for roadbed building filler. The heavy metal contaminated soil / bottom mud stabilizer has the effects of protecting the environment, changing waste into things of value and increasing a waste utilization rate, and has a considerable economic value.

Owner:湖南新九方科技有限公司

Ammonia desulphurization and denitrification process for flue gas by synchronization of complexing absorption and electrolytic regeneration

ActiveCN105413422AEfficient regenerationEffective in removing ironGas treatmentDispersed particle separationAmmonium sulfateFlue gas

The invention discloses an ammonia desulphurization and denitrification process for flue gas by synchronization of complexing absorption and electrolytic regeneration and solves the problem of low absorption liquid regeneration efficiency in an existing synchronous ammonia desulphurization and denitrification process for the flue gas. The technical scheme includes that the flue gas is pressurized and then fed into a concentration tower to realize contact reaction with concentration liquid in the tower, the flue gas discharged from the concentration tower is fed into an absorption tower to realize contact reaction with cyclic absorption liquid in the absorption tower, the concentration liquid at the bottom of the concentration tower is subjected to deferrization through a first electrolytic reactor after reaction and then fed into an ammonium sulfate crystallization system, the absorption liquid at the bottom of the absorption tower is regenerated and then fed back to the upper portion of the absorption tower to serve as the cyclic absorption liquid, the concentration liquid enters an anode chamber of a reaction unit of the first electrolytic reactor to realize oxidation reaction and then enters a cathode chamber to realize a reduction reaction, and an electrolytic solution is discharged through a short outlet connection pipe of the reactor after reaction and fed into the ammonium sulfate crystallization system. The ammonia desulphurization and denitrification process for the flue gas by synchronization of complexing absorption and electrolytic regeneration has the advantages of simplicity, low investment cost and operation cost, high conversion efficiency and effectiveness in deferrization, desulphurization and denitrification.

Owner:武汉武钢绿色城市技术发展有限公司

Acicular hydroxyapatite micro-nanostructure coating on magnesium alloy surface and preparation method thereof

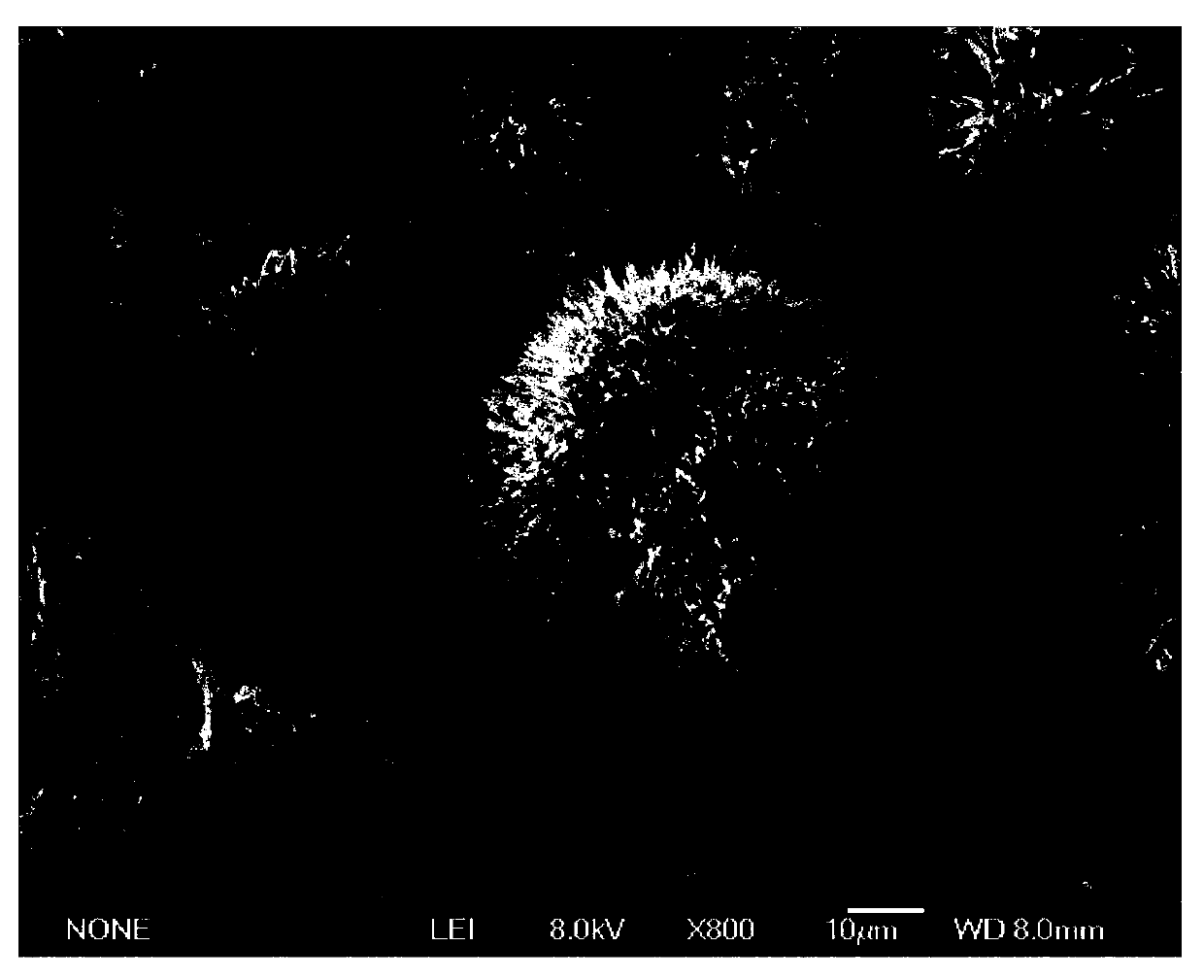

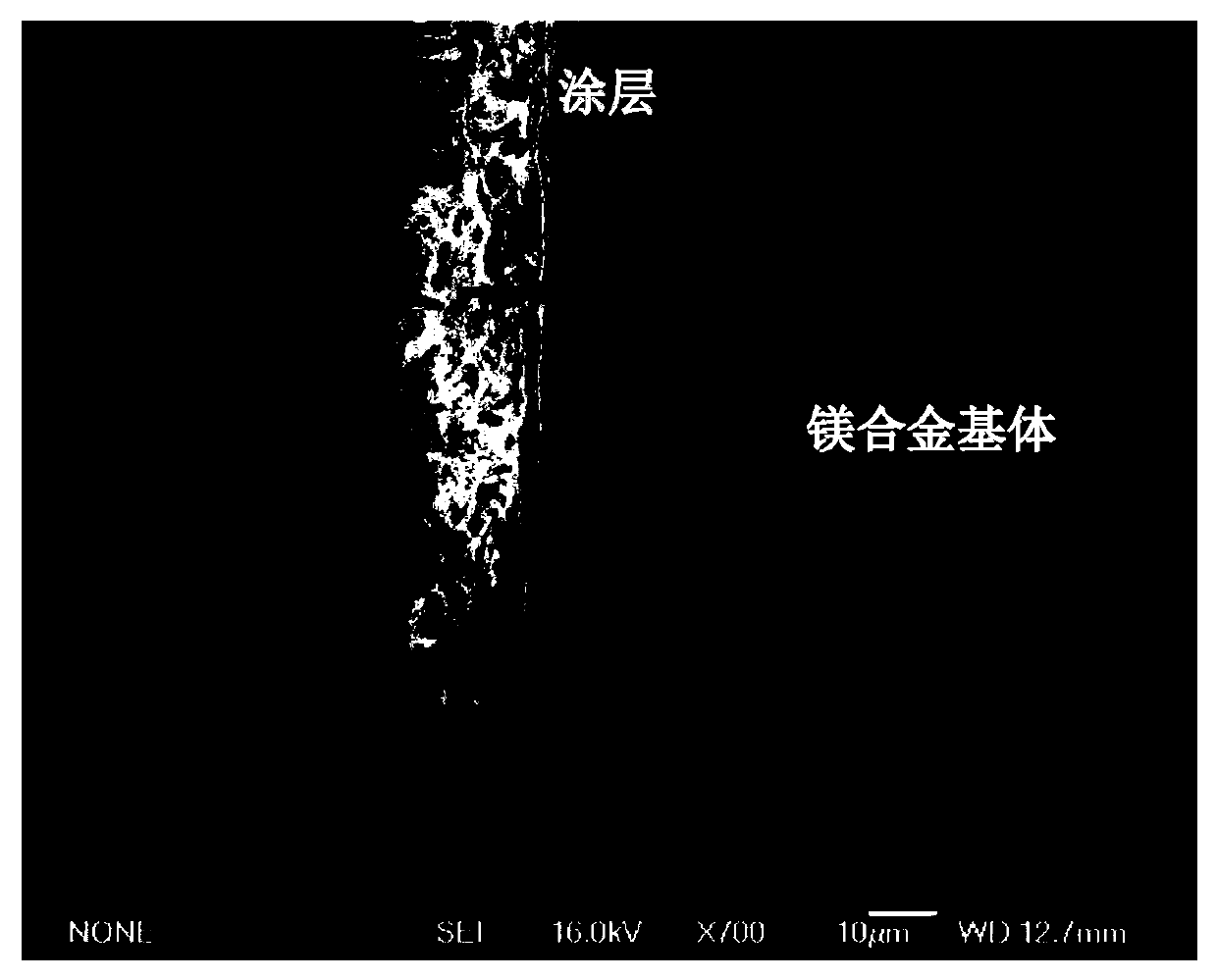

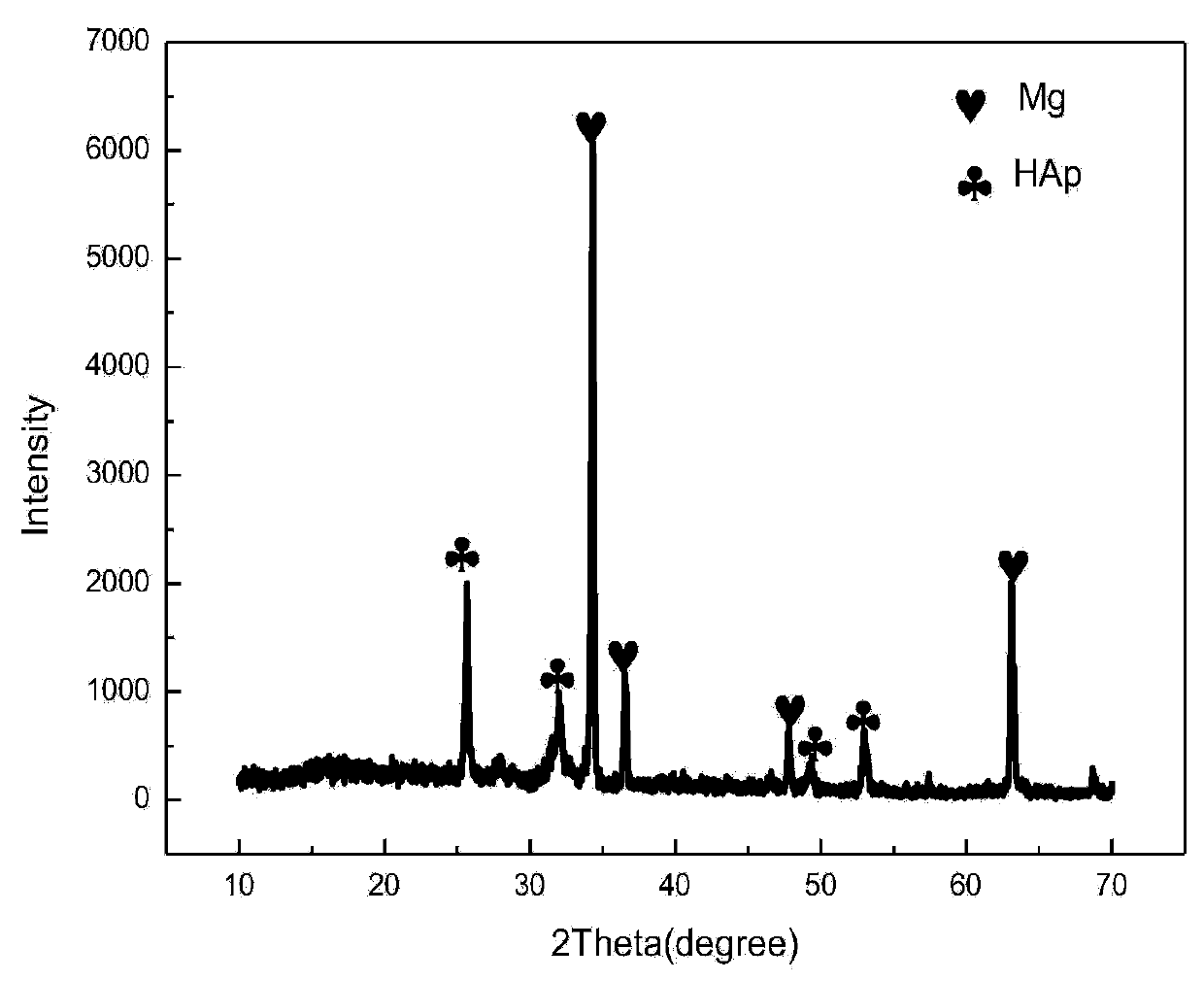

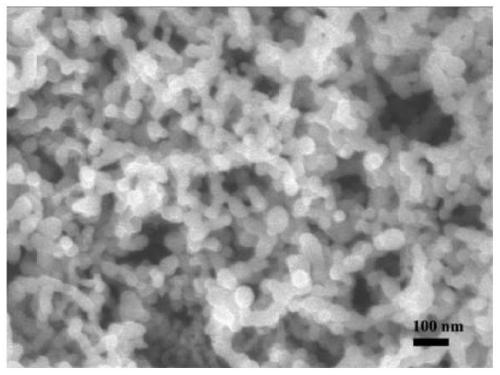

ActiveCN109758605AReduce adverse effectsUniform and dense structureCoatingsProsthesisMicro nanoElectrolytic agent

The invention belongs to the technical field of surface modification of degradable magnesium alloy implants, and particularly relates to an acicular hydroxyapatite micro-nanostructure coating on the magnesium alloy surface and a preparation method thereof. The preparation method comprises the following steps of immersing a pretreated magnesium alloy substrate in an electrolyte solution for electrochemical deposition, using a platinum electrode as a cathode and magnesium alloy as an anode, turning on a DC stabilized power supply, performing electrochemical deposition and then performing alkaliheat treatment to obtain the hydroxyapatite coating on the magnesium alloy surface. The electrolyte solution for the electrochemical deposition has simple formula, has no accelerator or oxidant, and does not need to adjust the pH value. The electrochemical deposition method with low temperature and low current density is easy to control and low in cost. The prepared hydroxyapatite coating is uniform and dense, has high purity and good corrosion resistance and has the acicular micro-nano structure, which is beneficial to adhesion and growth of the cells on the surface of the coating. The implantation success rate of the magnesium alloy implants can be improved.

Owner:QINGDAO UNIV OF SCI & TECH

High efficiency wet method for removal of hydrogen sulfide from iron-based ionic liquid

InactiveCN105561758ANo need to adjust pHAvoid churnDispersed particle separationHigh absorptionHeteropoly acid

Belonging to the technical field of gas purification, the invention relates to a high efficiency wet method for removal of hydrogen sulfide from iron-based ionic liquid. The desulfurization solution mainly contains iron-based ionic liquid and heteropoly acid ionic liquid, and is immiscible with water. The desulfurization method includes: using the iron-based ionic liquid to absorb and oxidize H2S into elemental sulfur, under the catalysis of the heteropoly acid ionic liquid, employing air to regenerate iron-based ionic liquid, and then subjecting the regenerated iron-based ionic liquid and heteropoly acid ionic liquid to cyclic removal of H2S. Because of the catalytic action of heteropoly acid ionic liquid, the low-temperature oxidation desulfurization rate of the iron-based ionic liquid is greatly improved. According to the invention, the desulfurization solution oxidizes hydrogen sulfide into elemental sulfur, is easy to regenerate, can be recycled, and the desulfurization method has the advantages of simple preparation process, high absorption efficiency, no side reaction, easy recovery of sulfur and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Deep scrap iron catalytic ozonation wastewater treatment method

InactiveCN104496077ALow priceLow costMultistage water/sewage treatmentMetal/metal-oxides/metal-hydroxide catalystsFiltration mechanismOrganic matter

The invention relates to a deep scrap iron catalytic ozonation wastewater treatment method. The deep scrap iron catalytic ozonation wastewater treatment method is characterized in that (1) a passivation layer is formed on surface of scrap iron through chemical modification, wherein main components of the passivation layer are Fe(II) and Fe(III) oxides, so that a heterocatalysis oxidation mechanism to O3 is formed; (2) a certain amount of ion-state Fe<2+> and Fe<3+> are formed by virtue of scrap iron not subjected to surface modification during oxidation of O3, so that an in-phase catalysis oxidation mechanism to O3 is formed; and (3) a certain amount of iron ions are also produced when the surface modified iron ions are used as a catalyst. The surface modified iron ions can be taken as a coagulate flocculating agent, and a coagulant aid is added to form a coagulating sedimentation or contact filtration mechanism, so that the iron ions are removed, and organic matters in the water can be further removed. During catalytic ozonation of the prepared catalyst, COD removal rate of secondary biochemical treated effluent of general industrial wastewater is 50-80%, and the new national discharge standard requirement can be completely met, so that application value is not influenced.

Owner:TONGJI UNIV

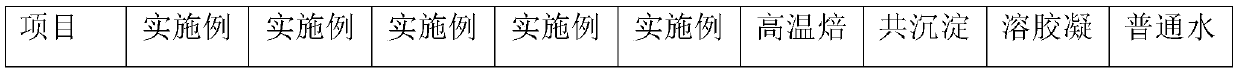

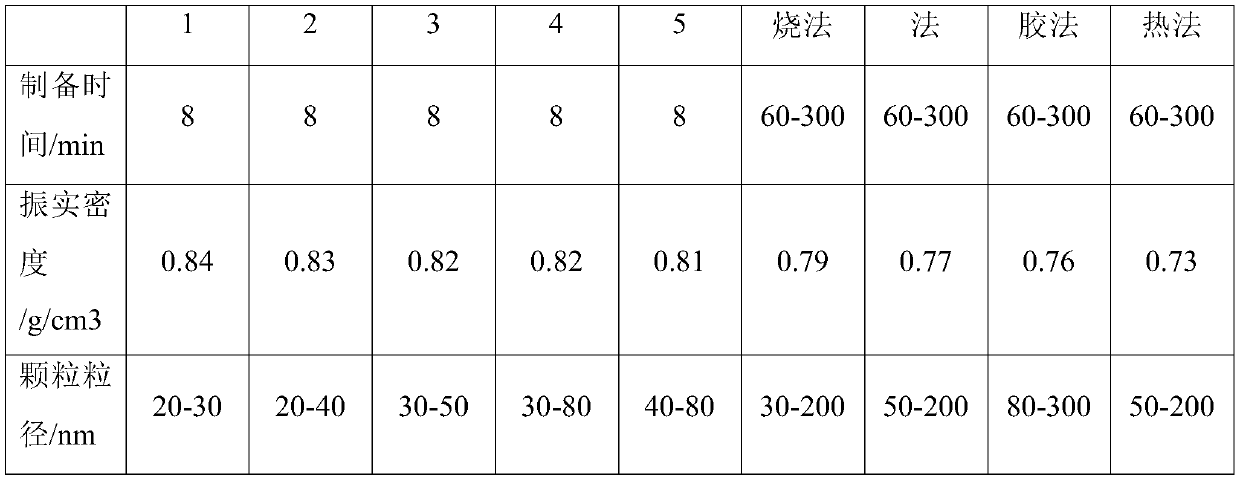

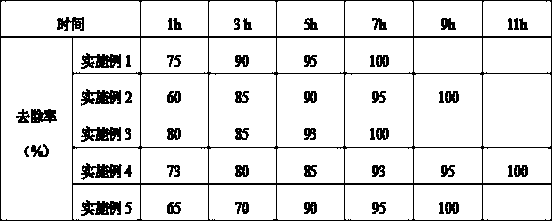

Nano lithium iron phosphate and preparation method thereof

ActiveCN111348637AFast heatingHeating evenlyMaterial nanotechnologyCell electrodesActive agentIron phosphate

The invention belongs to the field of material chemistry, and discloses a preparation method of nano iron phosphate, which comprises the following steps: (1) adding a ferric salt and a phosphate intowater to obtain a solution A; (2) adding a surfactant into the solution A to obtain a solution B; (3) stirring the solution B, carrying out ultrasonic treatment, and carrying out a microwave hydrothermal reaction in a microwave digestion instrument to obtain a solid C; and (4) drying and calcining the solid C to obtain the nano iron phosphate. A microwave hydrothermal method is adopted, the methodhas the advantages of being high in heating speed, uniform in heating, free of temperature gradient and the like, a conventional hydrothermal reaction needs 2-8 h, microwave hydrothermal reaction only needs 3-15 min, and the sample preparation time is greatly shortened. The iron phosphate prepared by the invention is nanoscale, has the particle size of 20-30nm, uniform particle size, no agglomeration phenomenon and high tap density, can be used as a precursor of battery-grade lithium iron phosphate, and has the advantages of simple preparation process, high production efficiency, high productpurity and good dispersion performance.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

Cleaning and prefilming agent and preparation method and application thereof

The invention discloses a cleaning and prefilming agent which is used for dissolving dirt on metal surfaces and forming inorganic films and organic films on the metal surfaces, and the inorganic filmsand the organic films intersect each other on the metal surfaces to form compact inorganic organic composite films. The ingredients of the cleaning and prefilming agent comprise organic carboxylic acid and salts thereof, sodium gluconate, inorganic zinc salt, organic acid polymers, a chelating agent, inorganic base and deionized water, and the weight percentage of all the ingredients in the cleaning and prefilming agent is 5-30% of organic carboxylic acid and salts thereof, 10-20% of sodium gluconate, 3-10% of inorganic zinc salt, 5-20% of organic acid polymers, 1-5% of the chelating agent, 10-30% of inorganic base and the balance deionized water. By means of the cleaning and prefilming agent, the purposes of protecting equipment and prolonging the equipment life are achieved, when the cleaning and prefilming agent is used for circulating cold water treatment, cleaning and prefilming can be finished at one time, adjustment of the system pH is not needed, and the cleaning and prefilming procedure is simplified.

Owner:XIAN JINGDA CHEM

Method for simultaneously removing hydrogen sulfide and ammonia gas by using iron-based ionic liquid

ActiveCN106310931AShort processSave equipment costsDispersed particle separationAir quality improvementHeteropoly acidIron based

The invention belongs to the technical field of gas purification, and relates to a method for simultaneously removing hydrogen sulfide and ammonia gas by using iron-based ionic liquid. The liquid for desulphurization and deamination mainly comprises iron-based ionic liquid and heteropoly acid ionic liquid, and the liquid for desulphurization and water are immiscible. The method for desulphurization and deamination employs the iron-based ionic liquid which contains a heteropoly acid ionic liquid catalyst to oxidize H2S into a elementary substance sulfur, and at the same time hydrogen at a second position in an iron-based ionic liquid imidazole ring and NH3 form an ammonium. The iron-based ionic liquid after desulphurization and deamination is treated with concentrated hydrochloric acid or concentrated phosphoric acid, and the iron-based ionic liquid can be regenerated and recycled after reaction with air. The method integrates and simplifies hydrogen sulfide and ammonia containing gas mixture purifying technology, and has the advantages of high absorption efficiency, easy regeneration without side reactions, easy recovery of products, and the like; and the method can be used for realizing combined desulphurization and deamination with low cost for a system with simultaneous existence of hydrogen sulfide and ammonia gas in coal coking, coal gasification, biogas, tail gas of ammonia synthesis, Claus tail gas, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com