Method for preparing nano granular of zinc oxide in monodisperse

A nano-zinc oxide, monodisperse technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of difficult synthesis of nano-ZnO materials, single and controllable preparation of refractory zinc oxide particle size, and achieve low raw material cost, easy operation, The effect of narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The inventive method prepares the example of monodisperse zinc oxide nanoparticle:

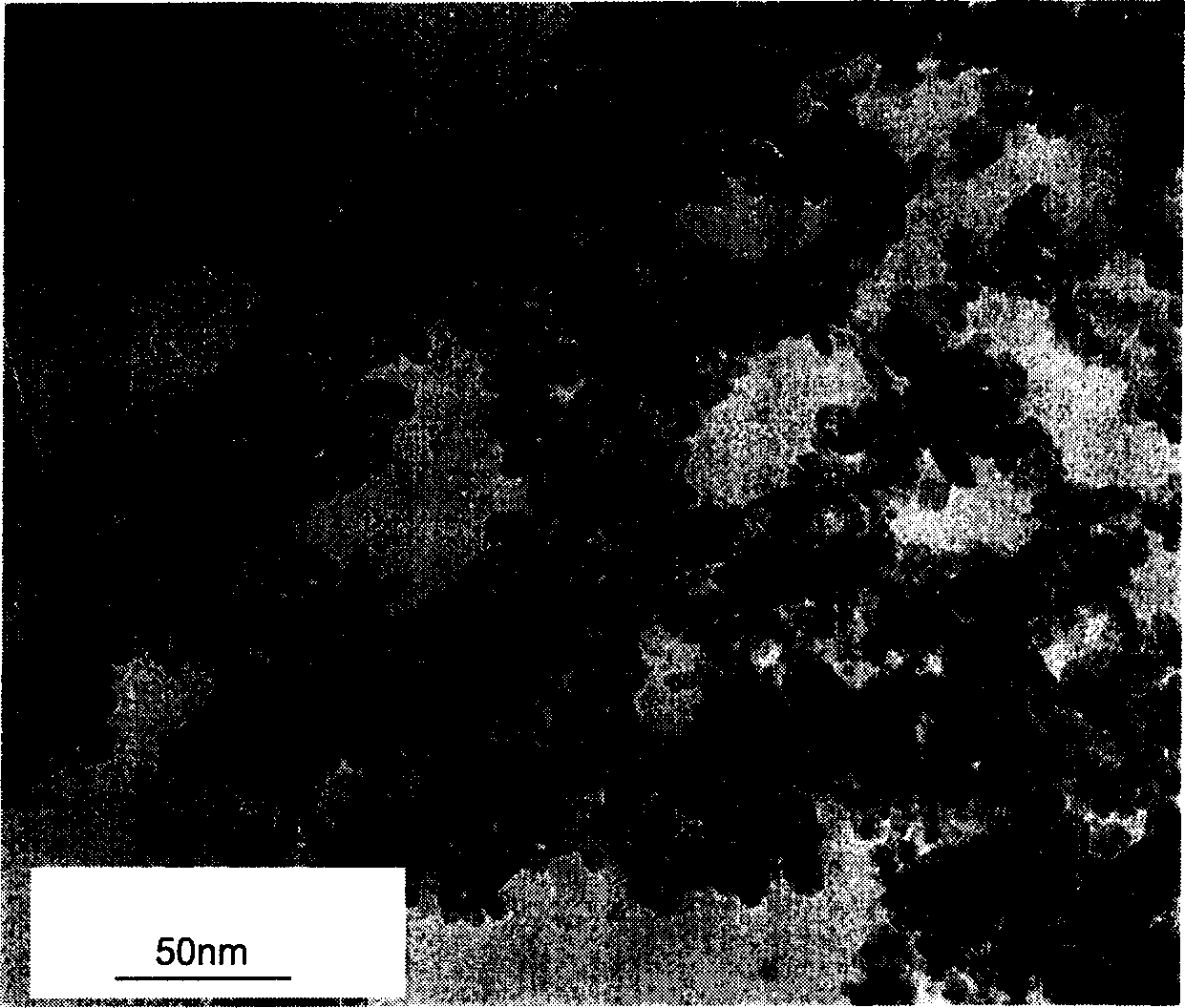

[0015] Dissolve zinc acetate in absolute ethanol, stir fully at 0°C to prepare a suspension with a concentration of 2%, and dissolve lithium hydroxide in absolute ethanol at room temperature to prepare a lithium hydroxide solution. The molar concentration Twice that of zinc acetate solution. An equal volume of lithium hydroxide solution was added dropwise to the stirred zinc acetate solution using a dropper, and the mixed solution was maintained at 0°C. Then the above mixed solution was sealed in a high-pressure reaction kettle, kept at 120°C for 2 hours, centrifuged to separate the reaction solution, fully washed with absolute ethanol, and dried to obtain zinc oxide nanoparticles with a single diameter distribution. The transmission electron microscope of the product see photos figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com