Patents

Literature

2468 results about "Lithium hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium hydroxide is an inorganic compound with the formula LiOH. It is a white hygroscopic crystalline material. It is soluble in water and slightly soluble in ethanol, and is available commercially in anhydrous form and as the monohydrate (LiOH·H₂O), both of which are strong bases. It is the weakest base among the alkali metal hydroxides.

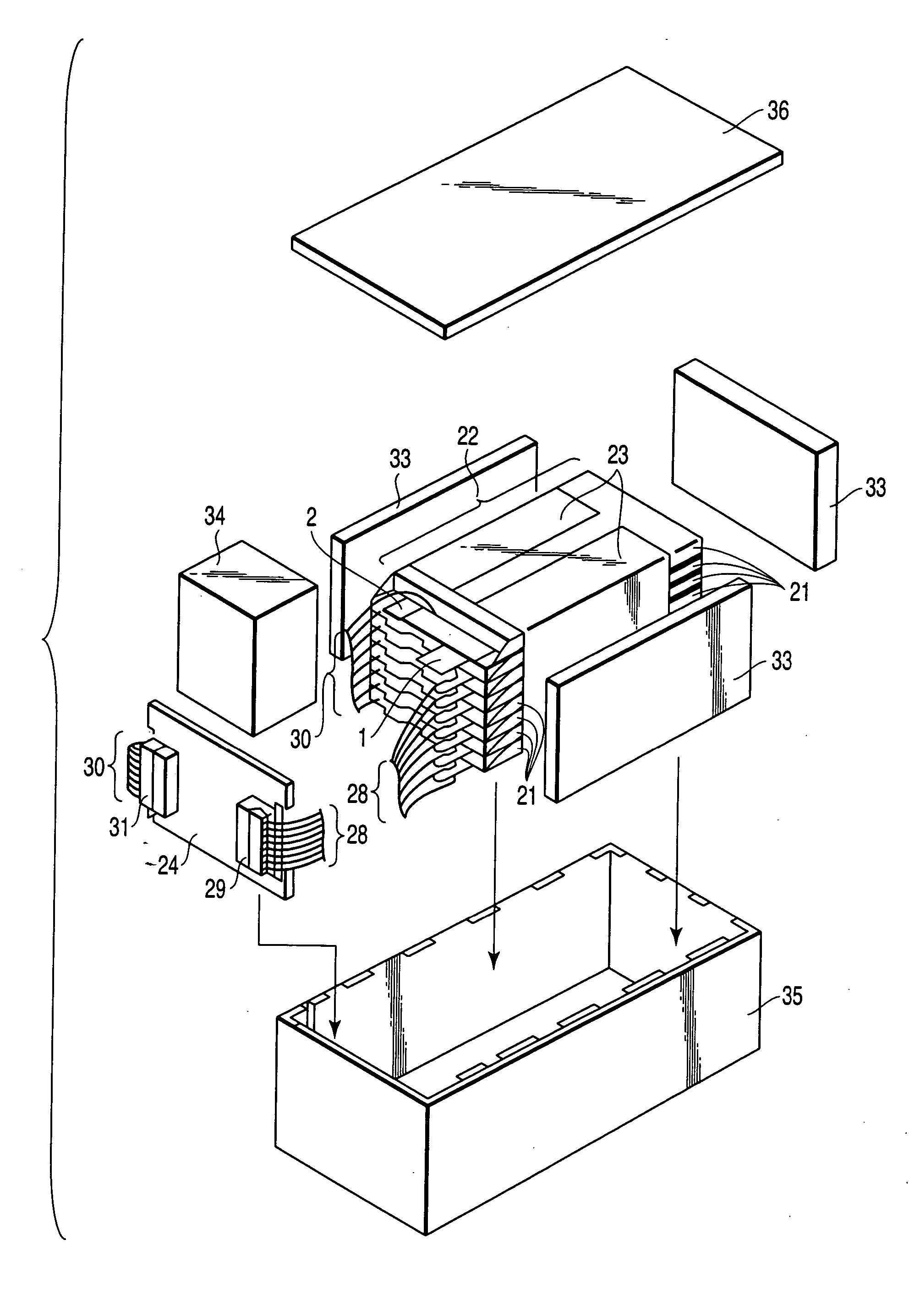

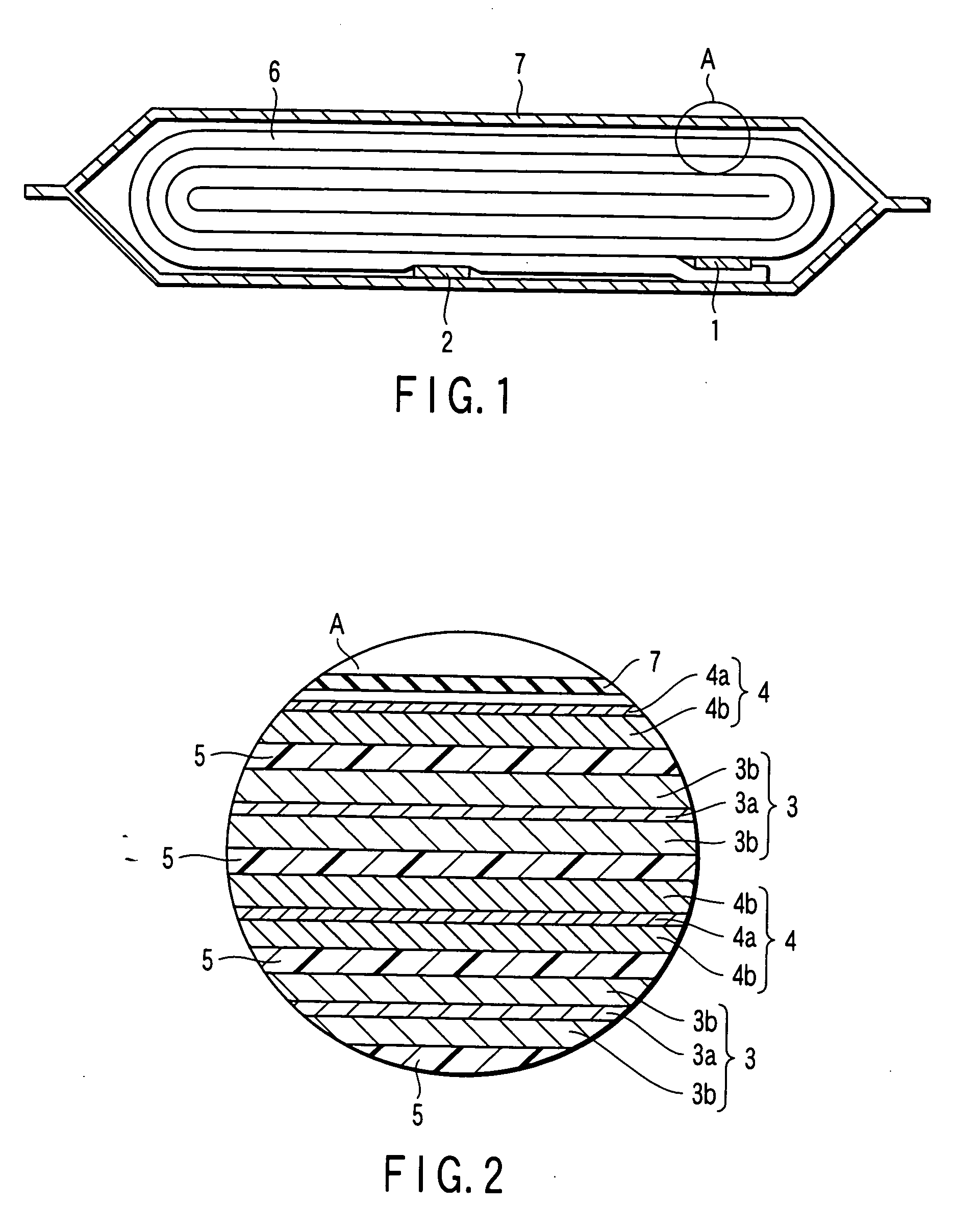

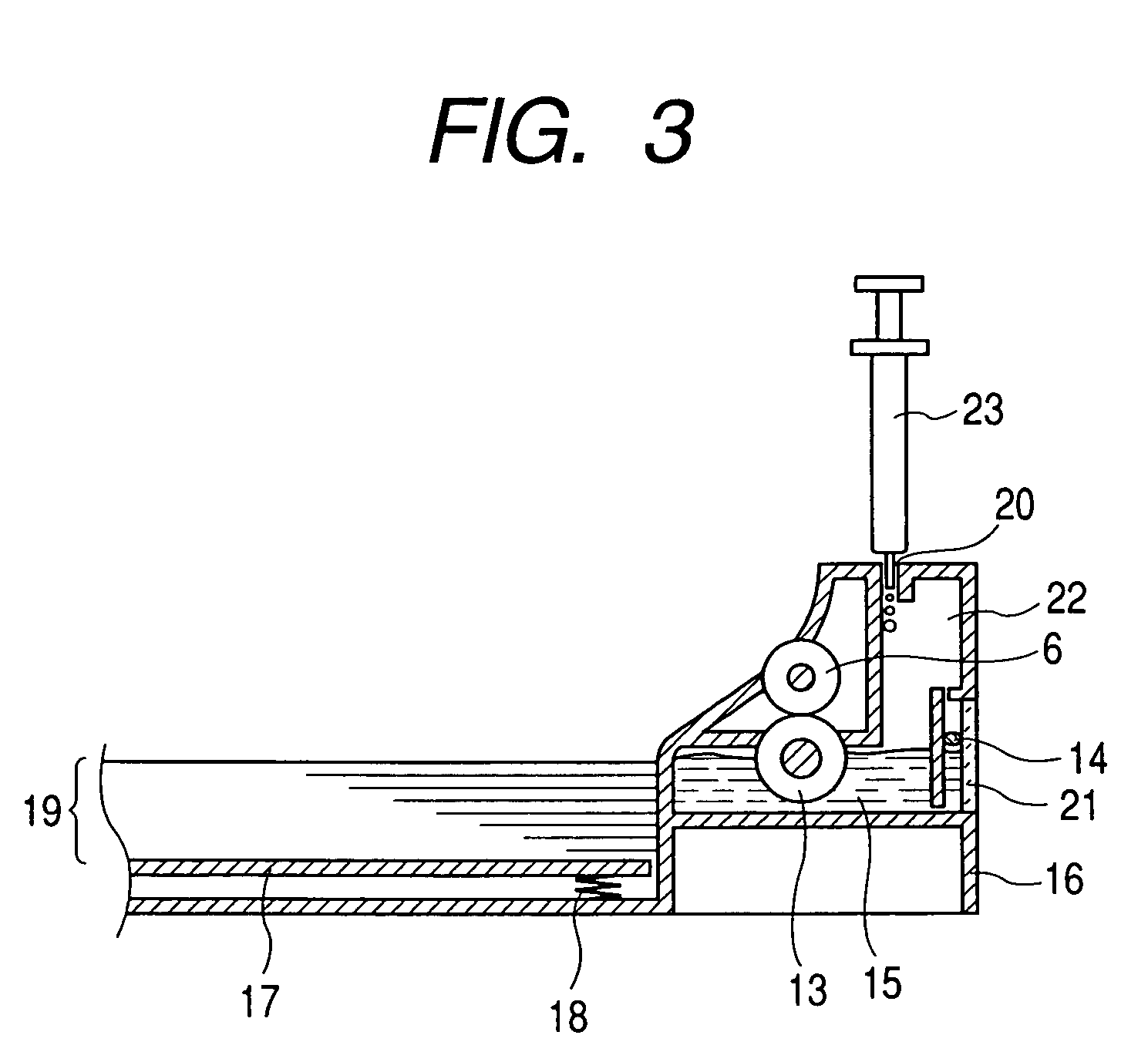

Nonaqueous electrolyte battery, battery pack and positive electrode active material

InactiveUS20060134520A1Improve storage characteristicsOrganic electrolyte cellsPositive electrodesLithium oxideLithium hydroxide

A nonaqueous electrolyte battery includes a case, a positive electrode housed in the case and including a positive electrode active material containing a lithium-nickel composite oxide and at least one of lithium hydroxide and lithium oxide, the sum of lithium hydroxide and lithium oxide falling within not less than 0.1% to not more than 0.5% by weight based on the total amount of the positive electrode active material, a negative electrode housed in the case and capable of lithium intercalation-deintercalation, and a separator sandwiched between the positive electrode and the negative electrode and impregnated with a nonaqueous electrolyte containing γ-butyrolactone.

Owner:KK TOSHIBA

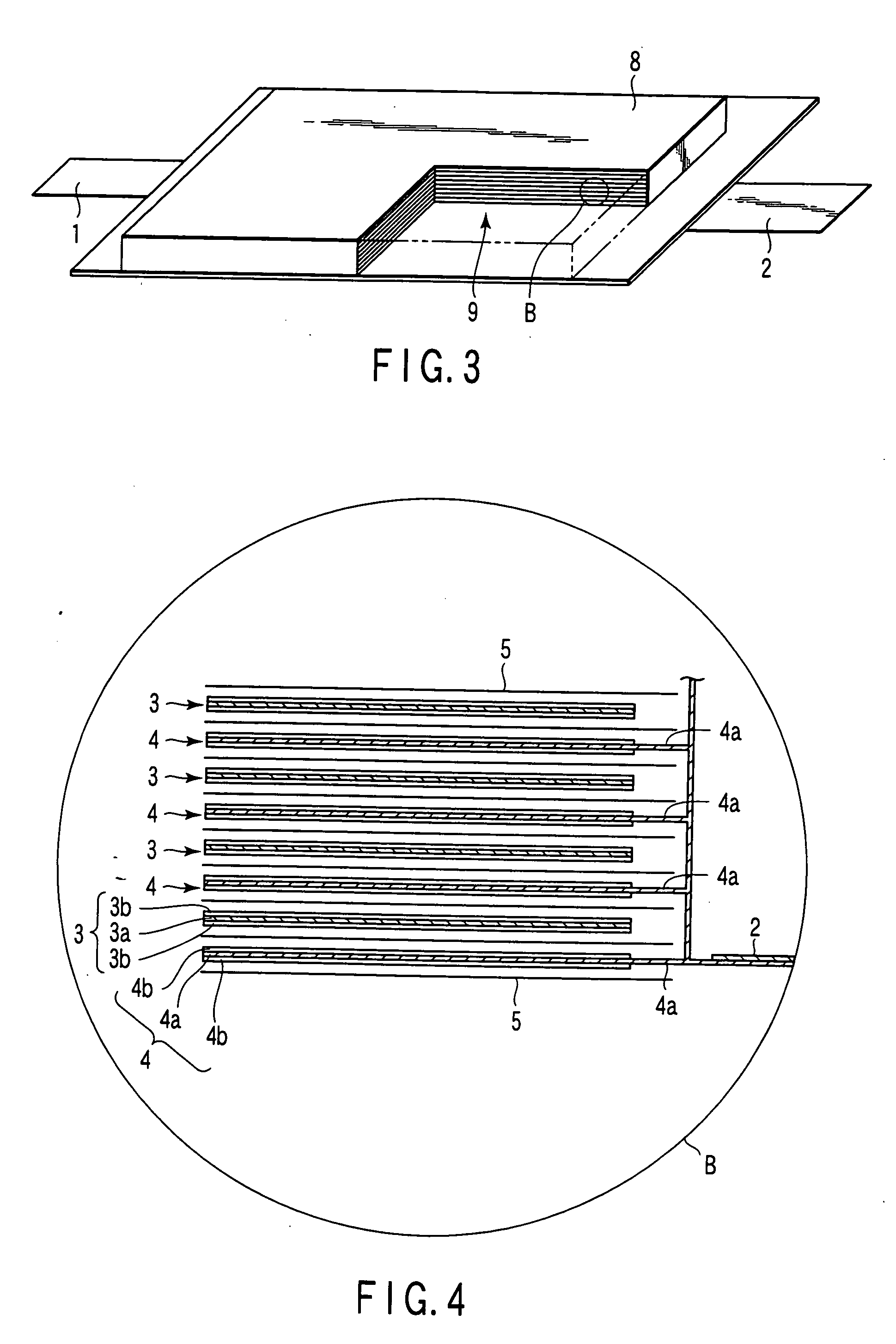

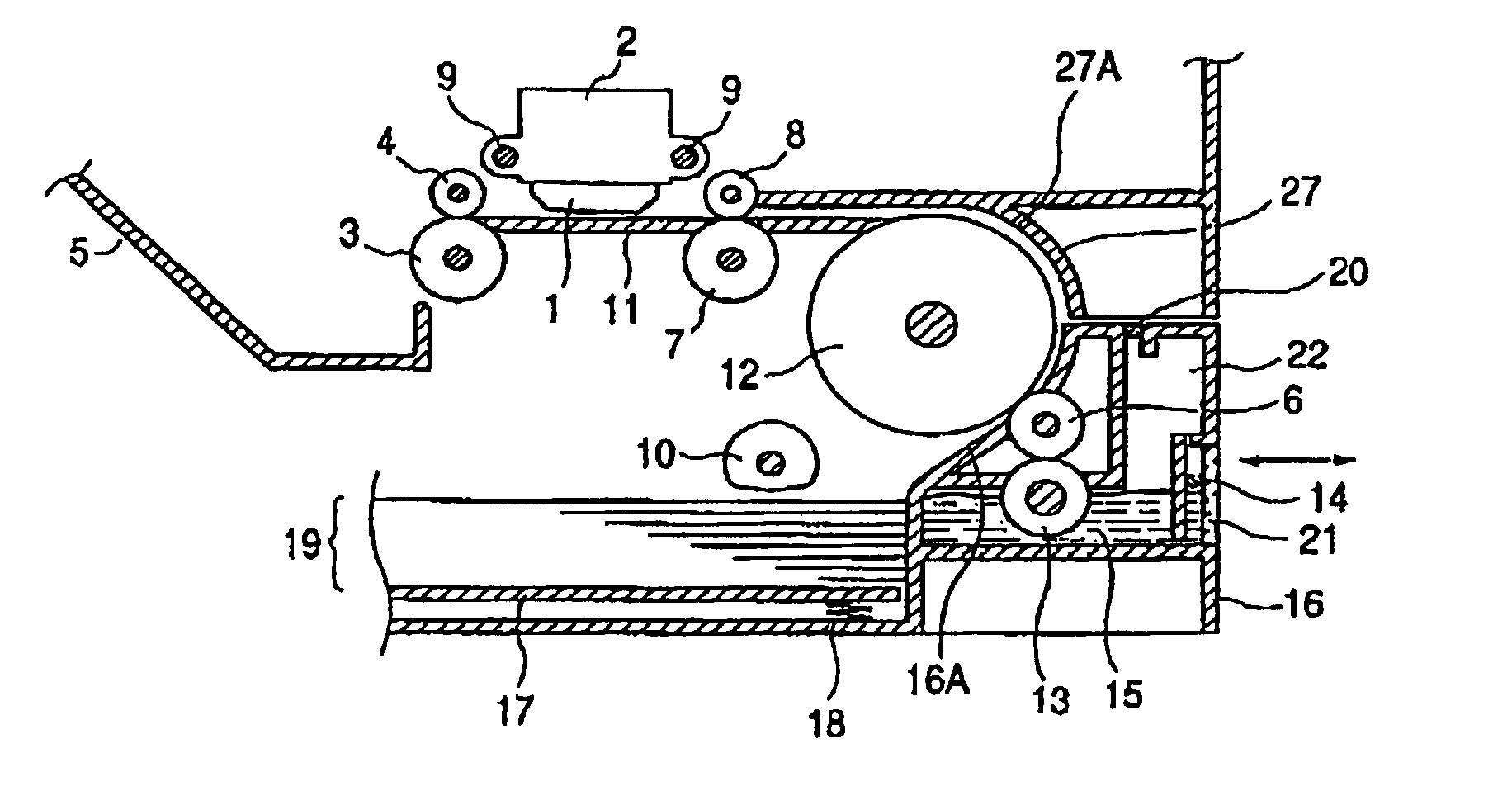

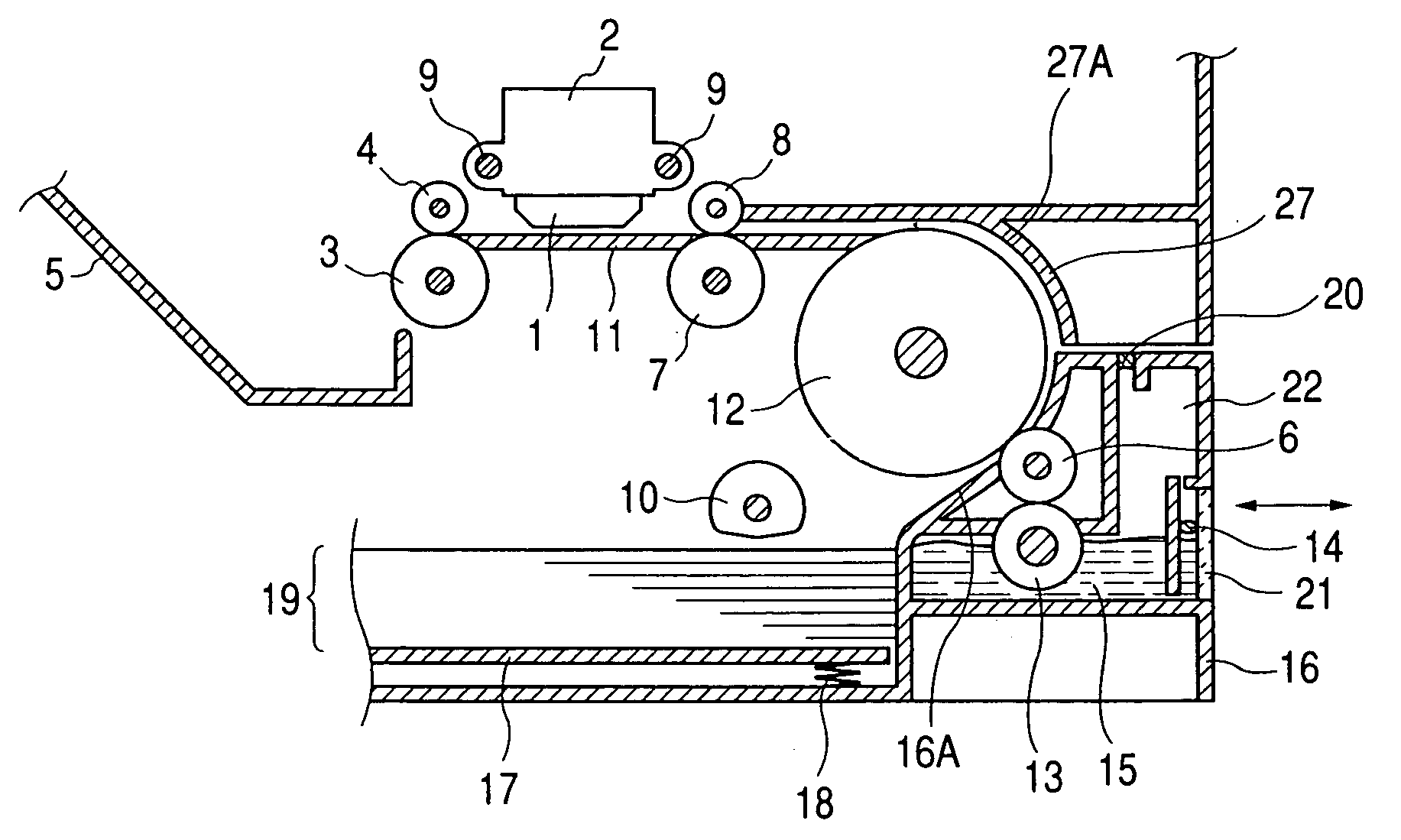

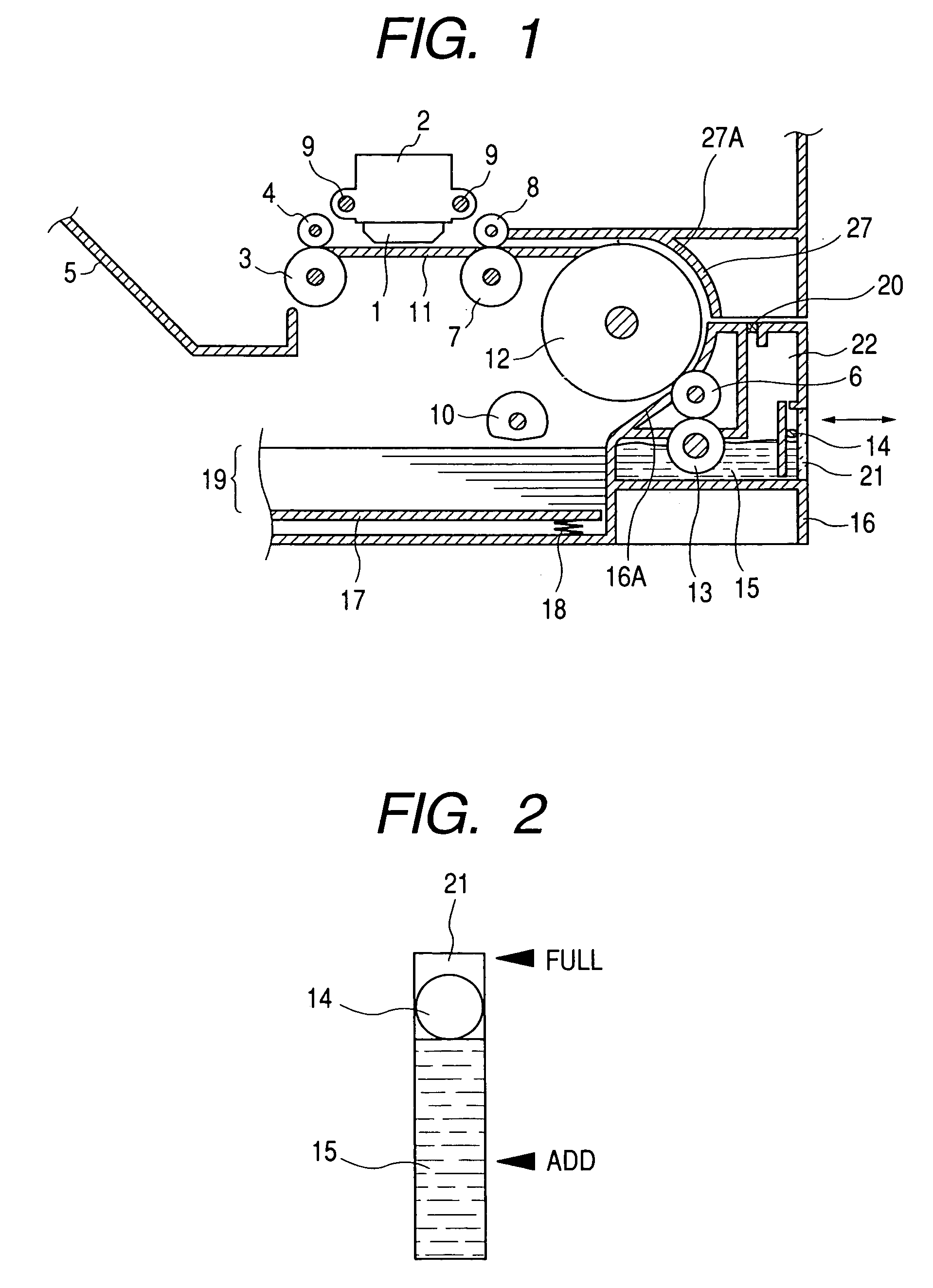

Reaction solution, set of reaction solution and ink, ink jet recording apparatus and image recording method

ActiveUS6932465B2Improve the level ofMeasurement apparatus componentsDuplicating/marking methodsOrganic solventLithium hydroxide

A reaction solution to be used for image recording with an ink containing a coloring material in a dissolved or dispersed state in order to achieve a high level of image density with stability, wherein the reaction solution contains a polyvalent metal ion and an organic solvent to destabilize the dissolved or dispersed state of the coloring material in the ink in contact with the ink, has a pH of 2 or higher, and has a buffering action for pH, wherein the buffering action means it can maintain pH variation within the range of 0.5 before and after the addition of 1.0 ml of a 0.1 N aqueous lithium hydroxide solution to 50 ml of the reaction solution.

Owner:CANNON KABUSHIKI KAOSJA

Processes for preparing highly pure lithium carbonate and other highly pure lithium containing compounds

ActiveUS20110200508A1Electrolysis componentsLithium organic compoundsLithium carbonateLithium hydroxide

Owner:TERRALITHIUM LLC

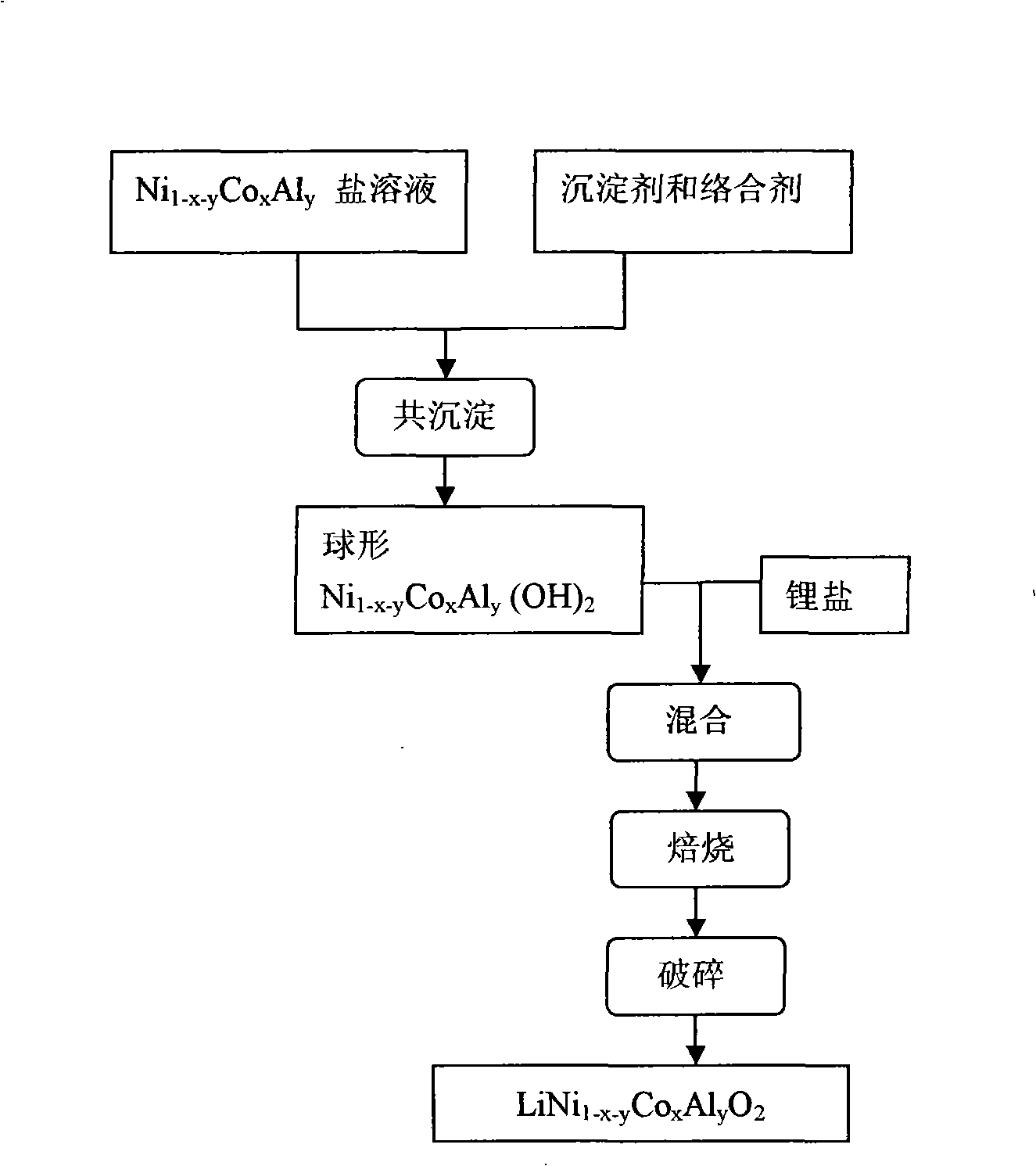

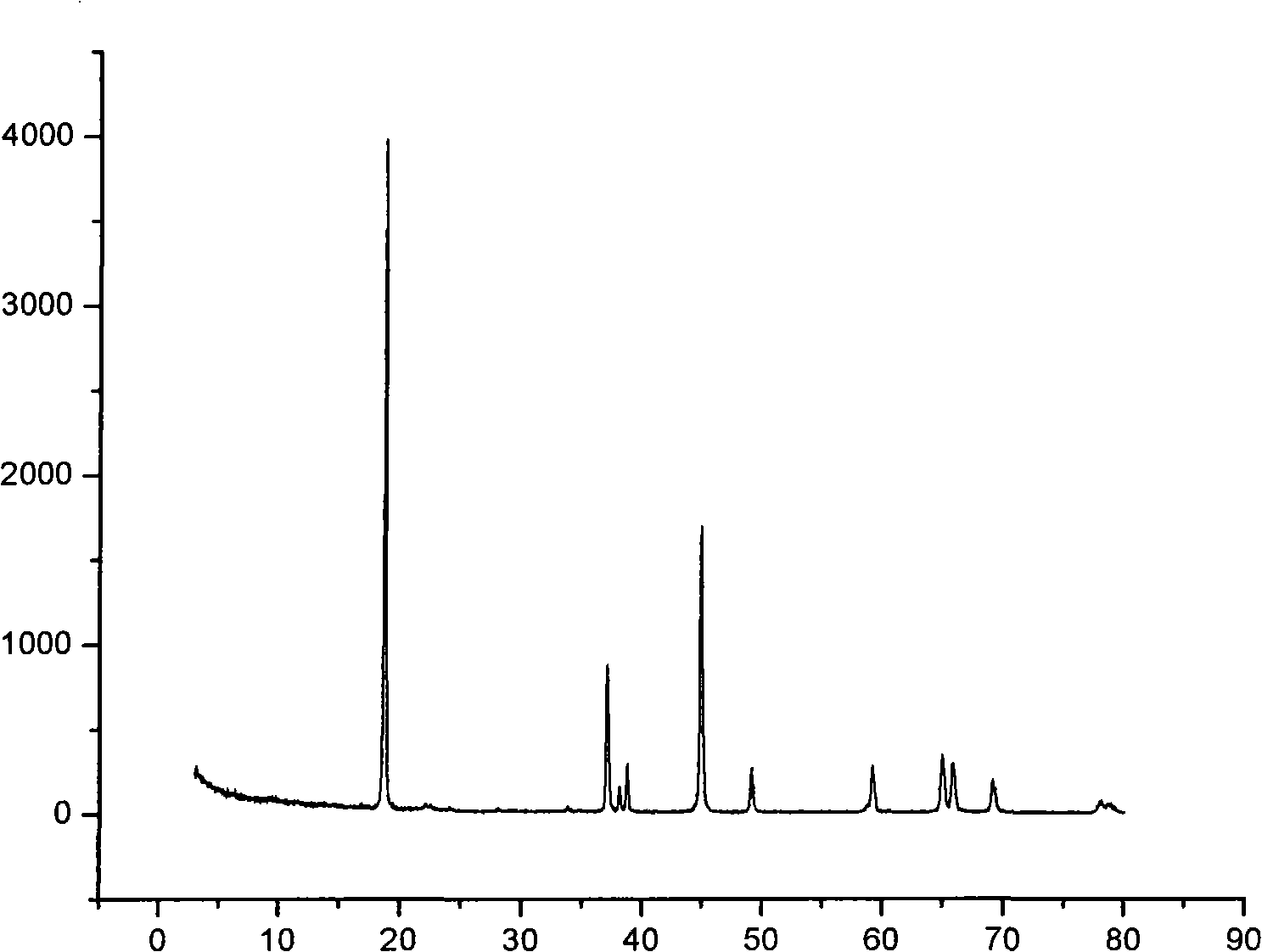

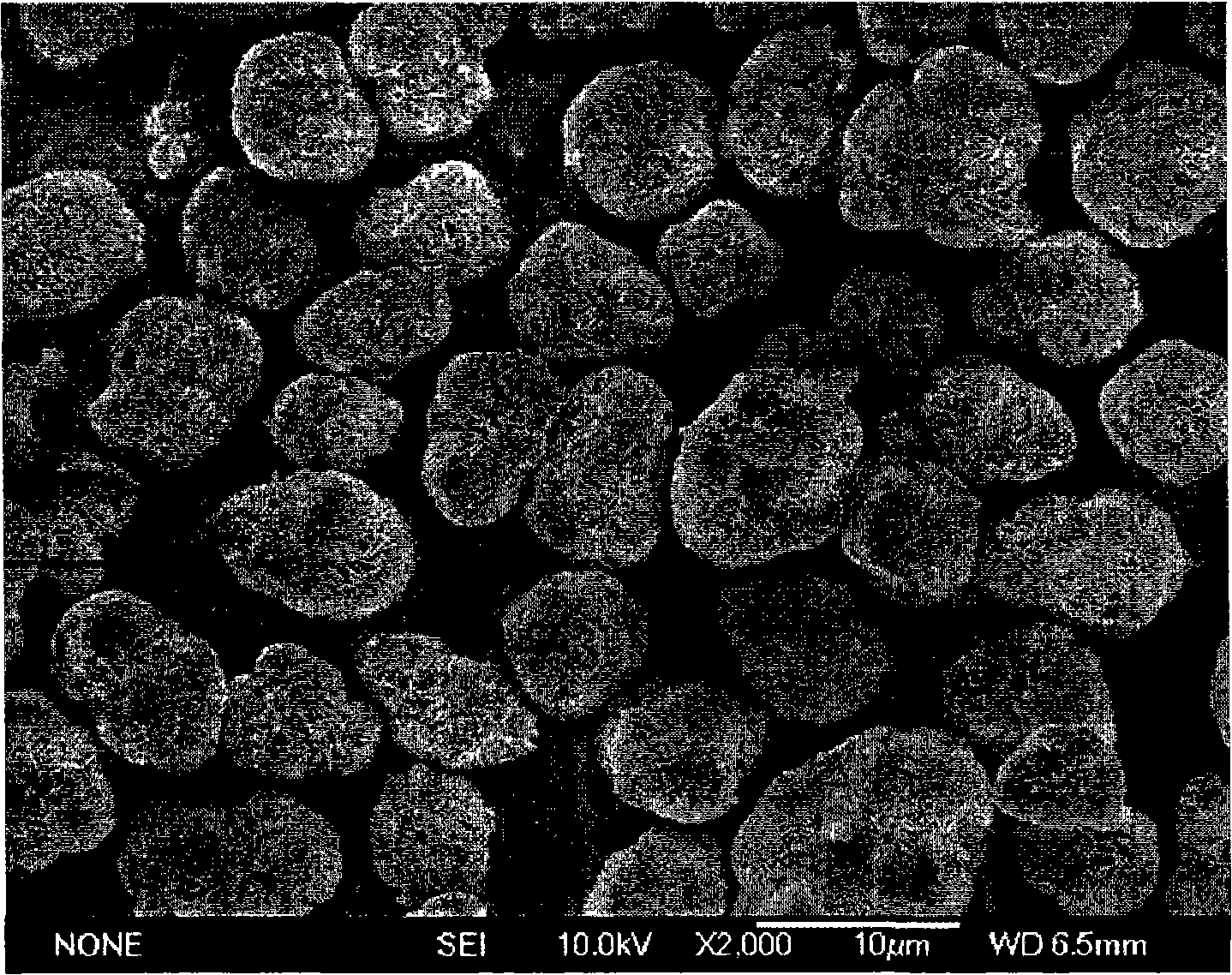

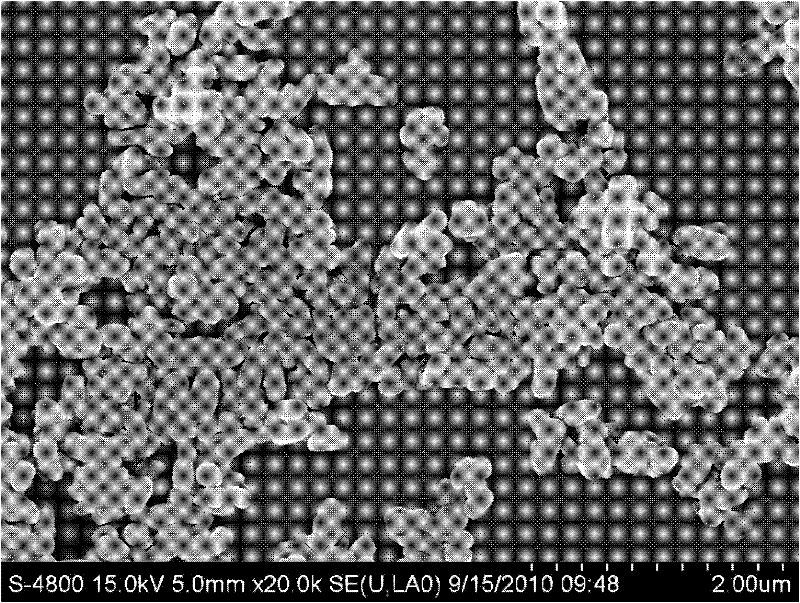

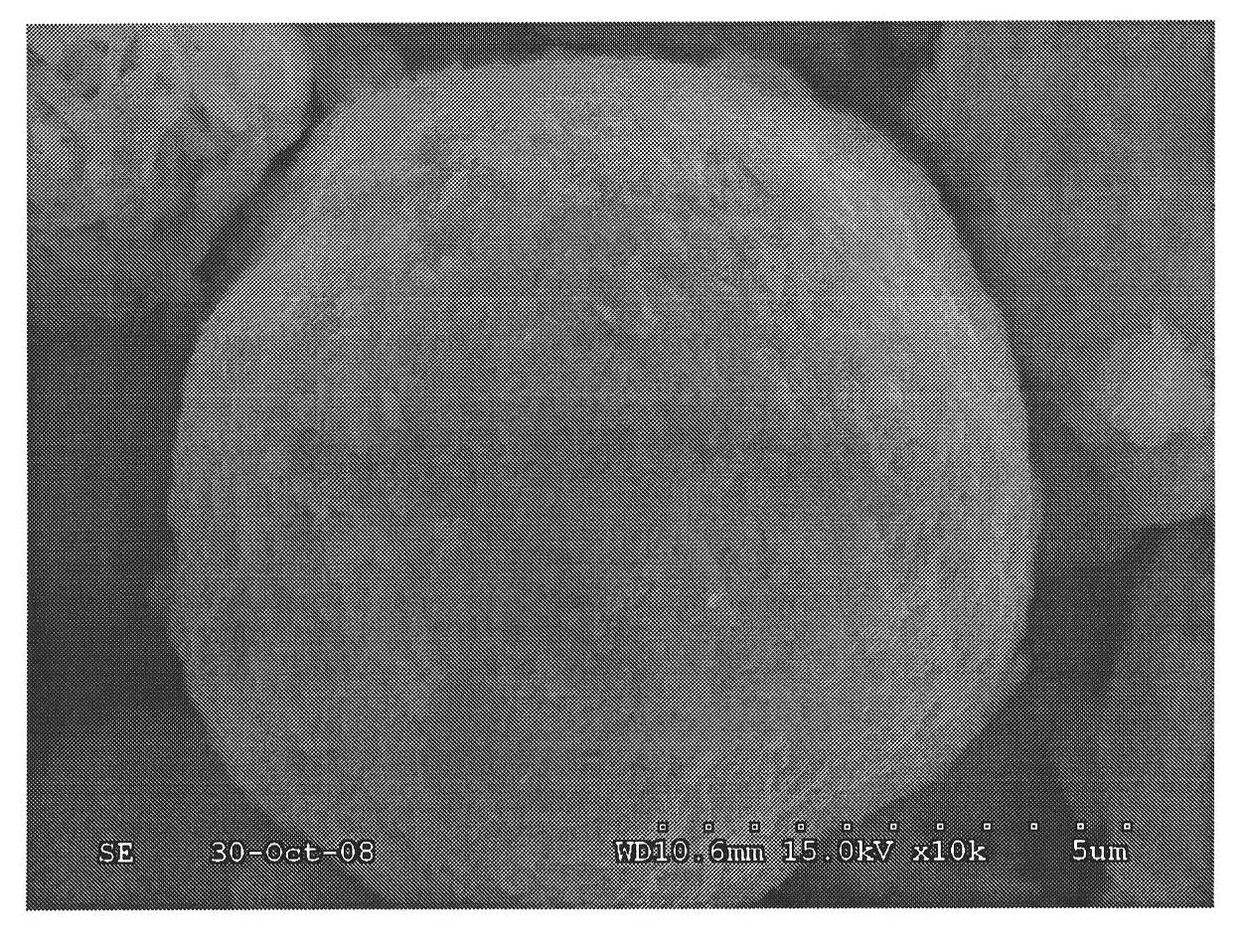

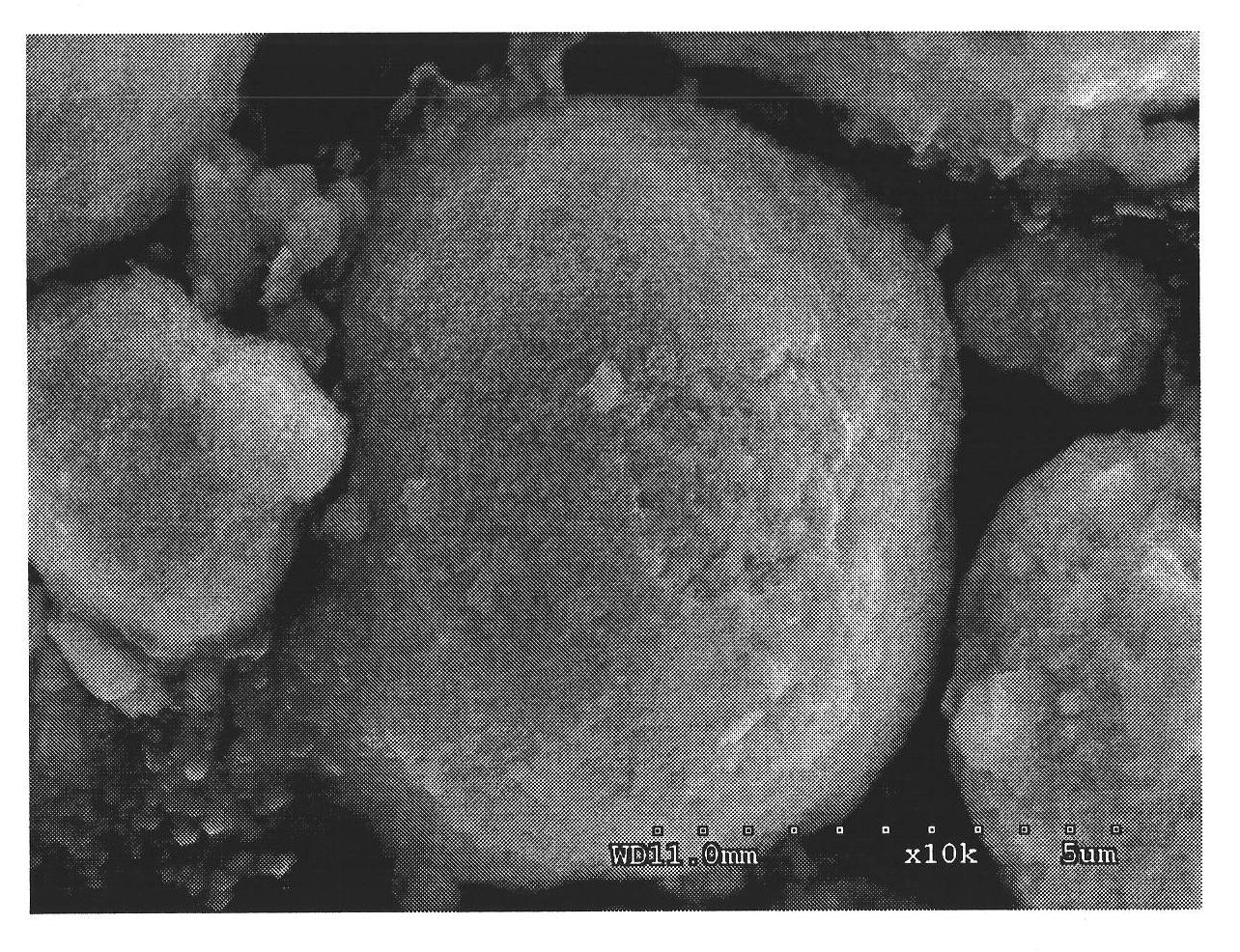

Spherical aluminum-doped nickel cobalt lithium for lithium ion battery and its making method

ActiveCN101262061AImprove liquidityImprove charge and discharge cycle stabilityElectrode manufacturing processesLithium compoundsDischarge efficiencyHigh rate

The invention discloses a preparation method of a spherical doped Al-Ni lithium cobalt oxide for lithium-ion battery. The preparation steps are that: first, sulfate, nitrate or chlorate of Al-Ni-Co react with strong alkali that is added with complex agent in liquid phase; the pH value, the temperature and the feeding speed of the reaction solution are controlled so as to produce a spherical precursor of Al-Ni-Co hydroxide; then the spherical precursor of Al-Ni-Co hydroxide is dried and evenly mixed with lithium hydroxide, lithium nitrate or lithium carbonate and dried; the obtained mixture is roasted into a spherical doped Al-Ni lithium cobalt oxide. The spherical doped Al-Ni lithium cobalt oxide has comparatively high tap density and remarkable cycle stability in the process of high-rate charge / discharge cycle, which improves over charge performance of Ni-Co substance and first obviously enhances charge / discharge efficiency; in addition, the preparation method of the spherical doped Al-Ni lithium cobalt oxide has the advantages of being simple, controllable and suitable for industrialized production with low energy consumption, high efficiency, short reaction time and low cost.

Owner:成都巴莫科技有限责任公司

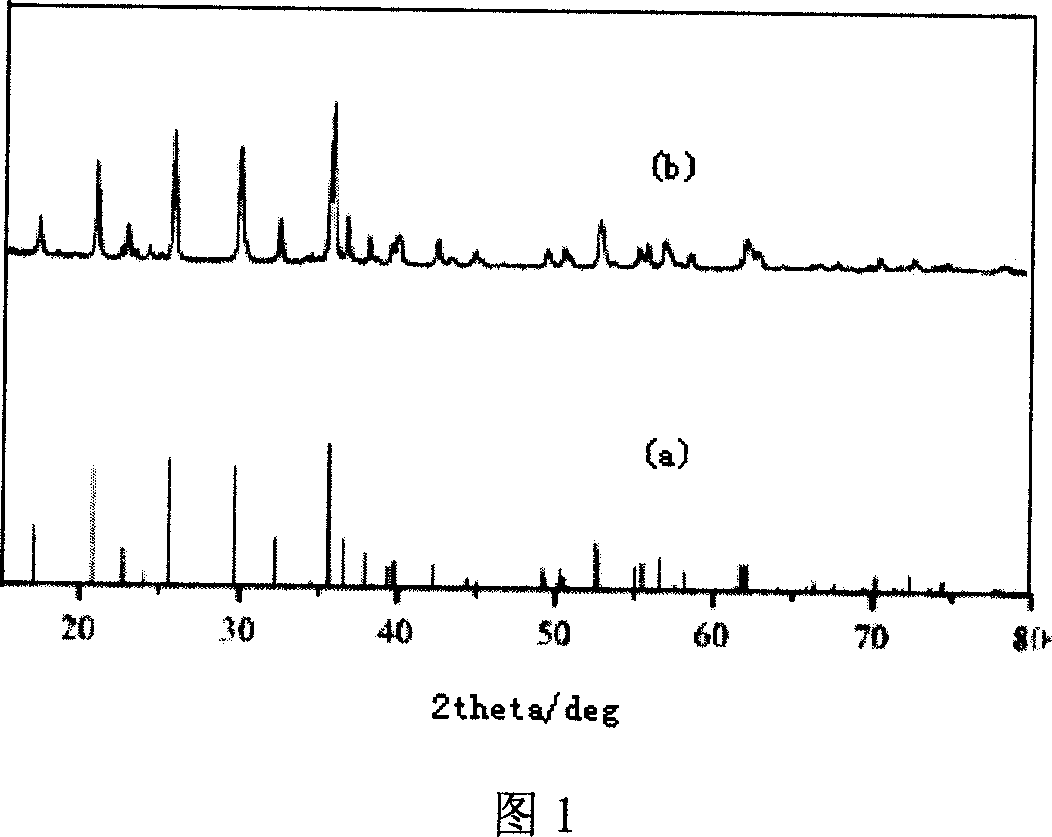

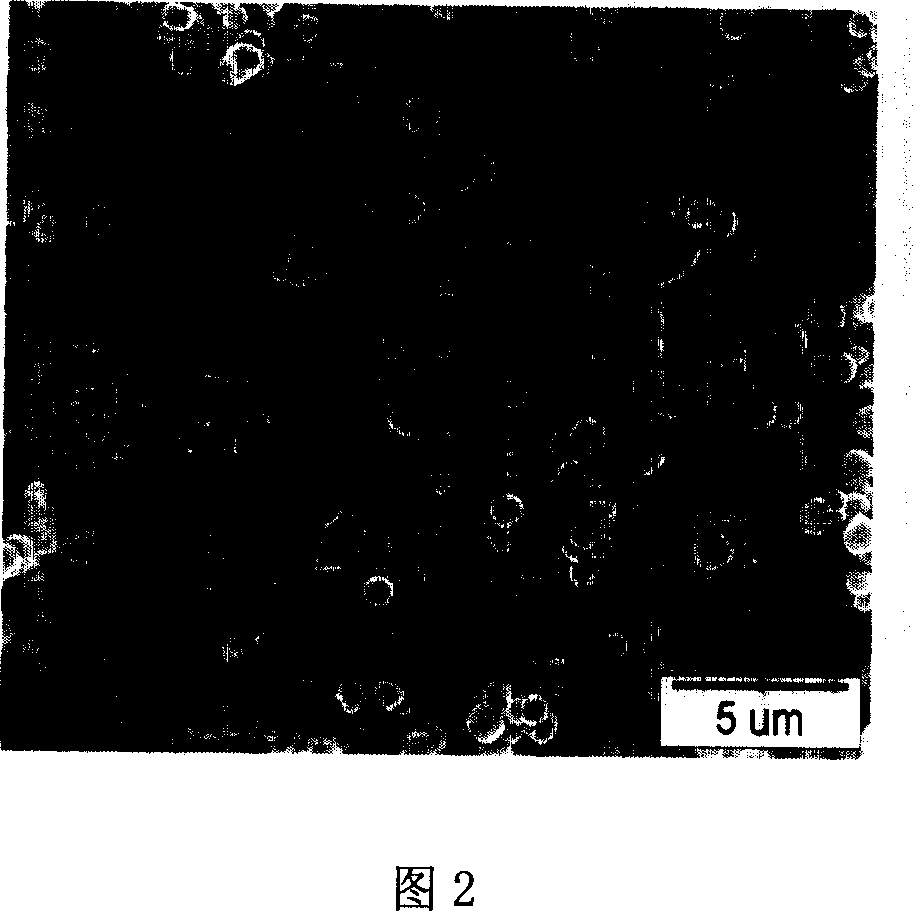

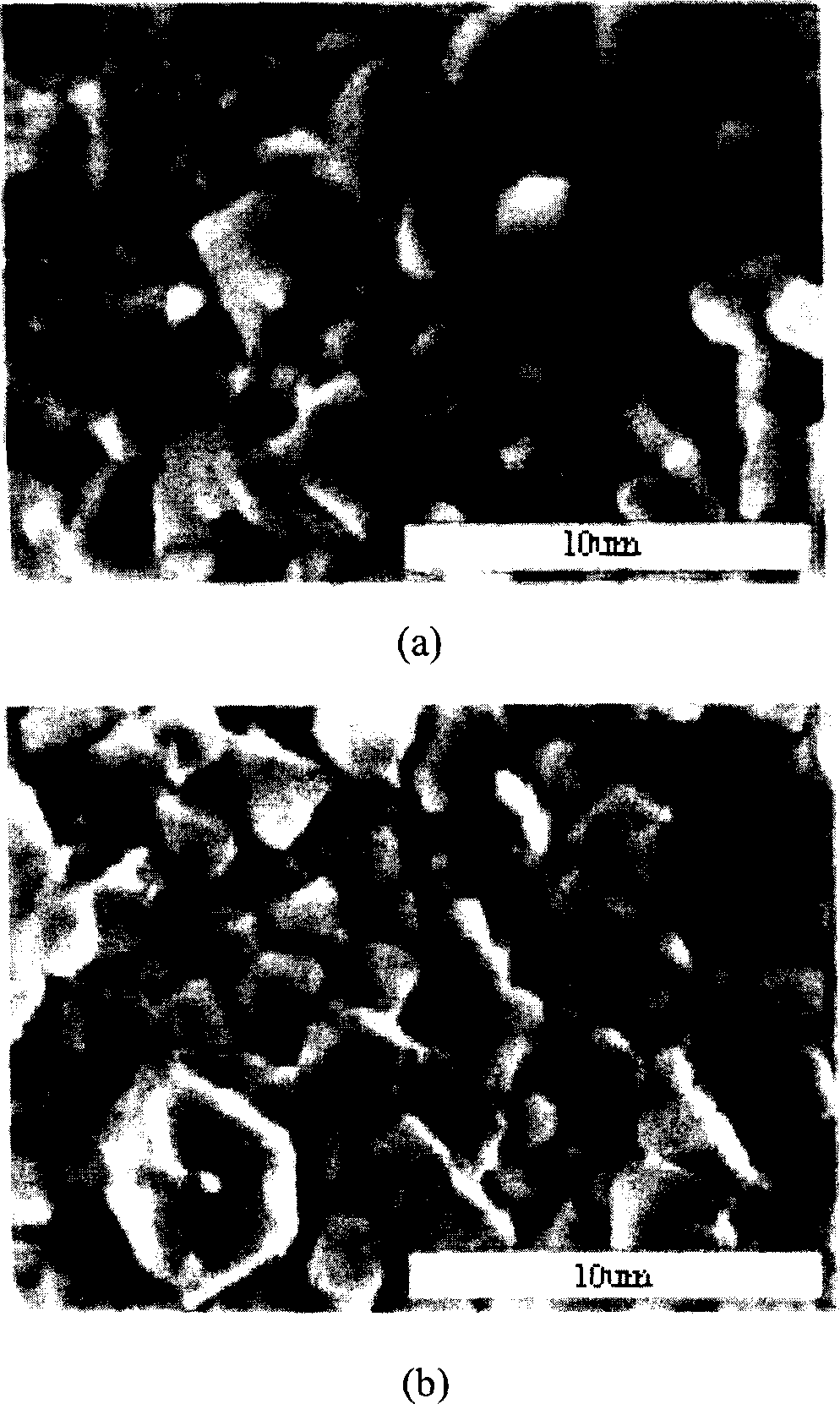

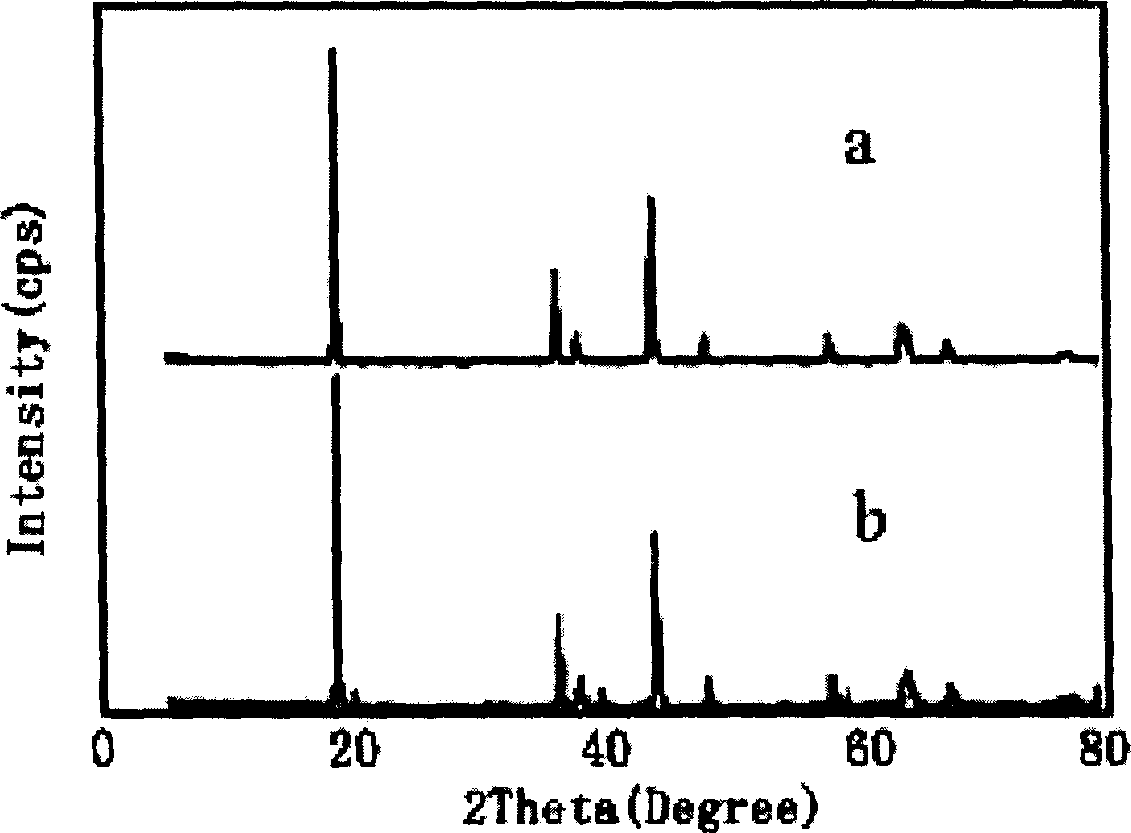

Method for preparing equal dispersion ferric phosphate lithium nano crystal by hydrothermal synthetis method

InactiveCN101047242AExcellent inert environmentElectrode manufacturing processesPhosphateFerrous salts

A method for preparing uniformly scattered nanocrystal of iron-lithium phosphate by hydrothermal synthesis includes using ferrous salt and phosphoric acid as well as lithium hydroxide as raw materials to obtain reaction pioneer matter under temperature of 40-100deg.c first, then reacting on obtained pioneer matter in high pressure reactor with temperature of 150-200deg.c under hydrothermal condition and processing obtained product by high temperature under protection of inert gas to finally obtain said uniformly scattered nanocrystal with average particle diameter of 0.2-0.5micron.

Owner:胜利油田华鑫石油材料有限公司

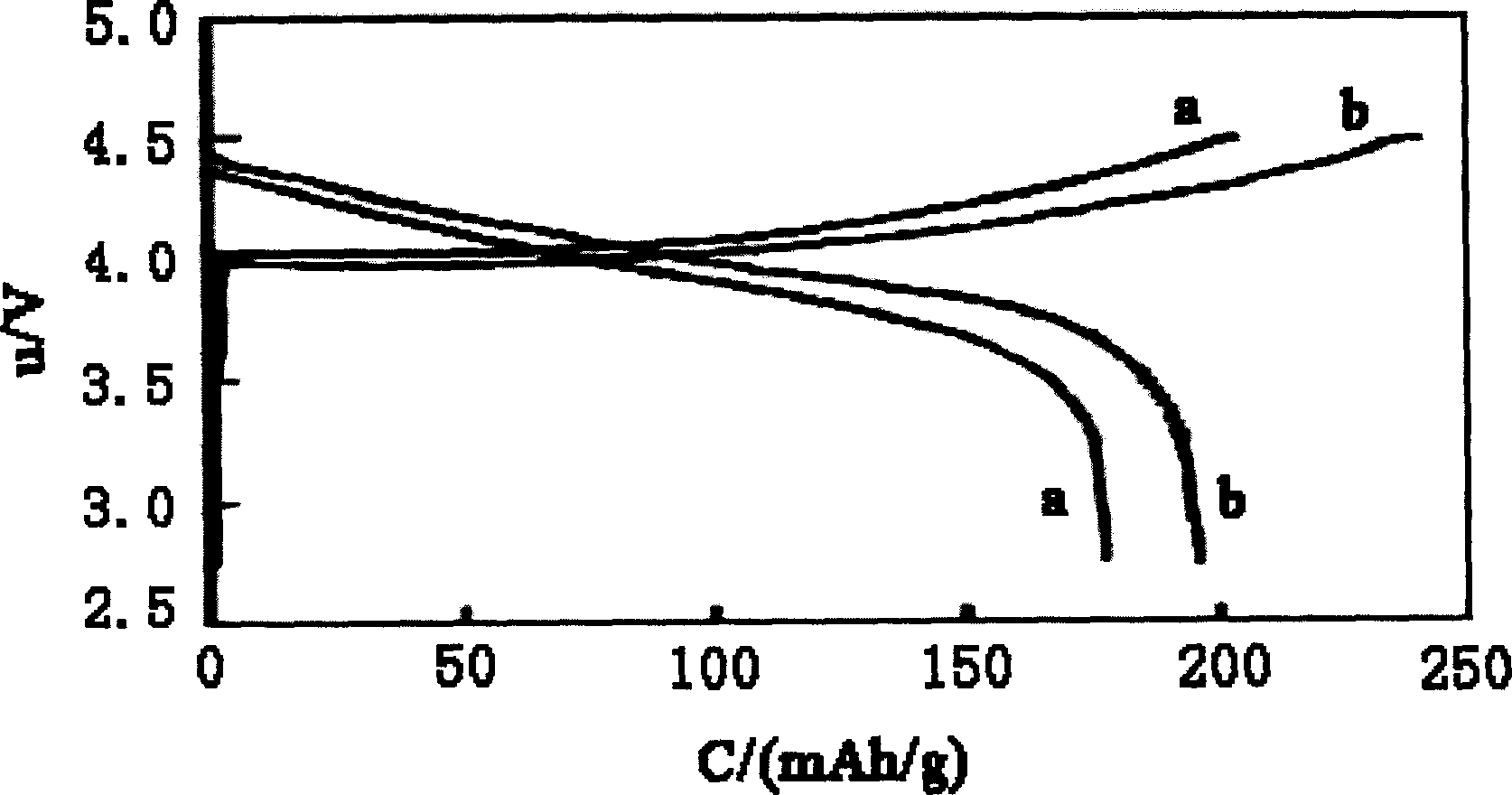

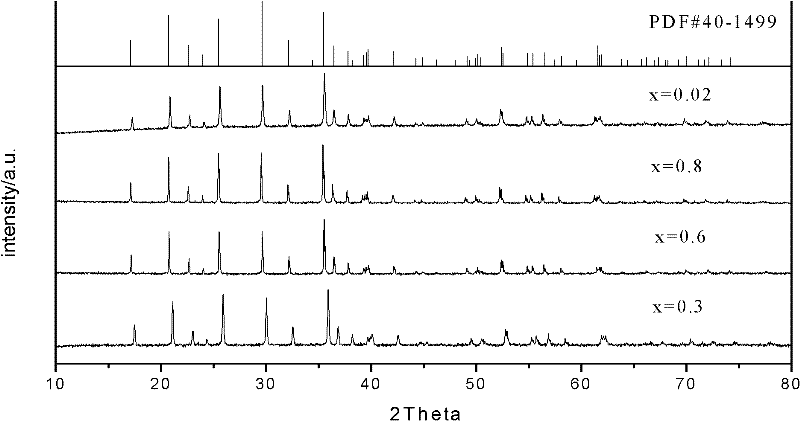

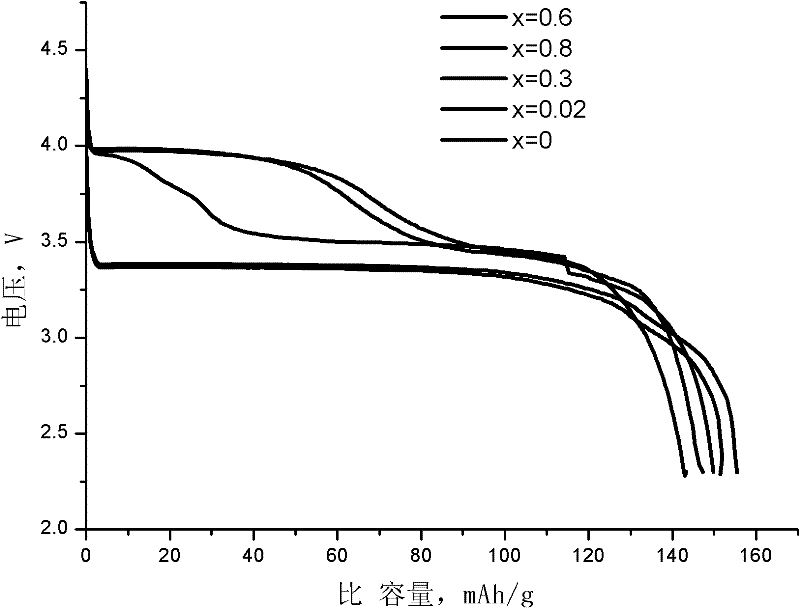

Method for preparing anode material lithium nickle cobalt manganic acid of lithium ion battery

InactiveCN101510603AConducive to neutralizing the balanceGood effectElectrode manufacturing processesNickel compoundsLithium hydroxideNew energy

The invention relates to a preparation method of Ni-Co lithium manganate which is a cathode material for a lithium ion battery, which pertains to the field of new energy material and preparative technique. The preparation method comprises the following steps: 1. a sulfate mixture solution of nickel, cobalt and manganese is prepared in accordance with a certain concentration; 2. the mixture solution, NH3 water and a sodium hydroxide solution are continuously injected into a reactor and stirred, and a spherical or quasi-spherical multiple hydroxide A of Ni, Co and Mn is obtained after the filtration, washing and drying are conducted over the mixture; 3. the dry multiple hydroxide A of Ni, Co and Mn is presintered to obtain a spherical multiple oxide B of Ni, Co and Mn; and 4. after being added with a right quantity of alcohol, the product B is evenly mixed with lithium hydroxide and the mixture is sintered, smashed and screened to obtain a spherical LizNixCoyMnxO2 cathode material C for the lithium ion battery. With the preparation method, the particle size and distribution of the product A and product B are easy to control and the spherical Ni-Co lithium manganate C with stable quality, high density, high capacity and high discharge plateau is obtained; therefore, the preparation method is applicable to stabilizing industrial production.

Owner:JILIN JIEN NICKEL IND

Reaction solution, set of reaction solution and ink, inkjet recording apparatus and image recording method

InactiveUS20050219341A1Improve the level ofMeasurement apparatus componentsDuplicating/marking methodsOrganic solventLithium hydroxide

A reaction solution to be used for image recording with an ink containing a coloring material in a dissolved or dispersed state in order to achieve a high level of image density with stability, wherein the reaction solution contains a polyvalent metal ion and an organic solvent to destabilize the dissolved or dispersed state of the coloring material in the ink in contact with the ink, has a pH of 2 or higher, and has a buffering action for pH, wherein the buffering action means it can maintain pH variation within the range of 0.5 before and after the addition of 1.0 ml of a 0.1 N aqueous lithium hydroxide solution to 50 ml of the reaction solution.

Owner:CANON KK

Preferred materials for pigmented ink jet ink

InactiveUS6866379B2Measurement apparatus componentsDuplicating/marking methodsAddition polymerLithium hydroxide

An ink jet ink composition including from 40.0 to 99.0% by weight of water; from 0.1 to 20.0% by weight of a pigment dispersed with an oleoyl methyl taurine salt dispersant from 0 to 70.0% by weight of a water miscible co-solvent; and from 0.1 to 20.0% by weight of a water-reducible addition polymer; wherein the weight average molecular weight of the polymer is from 2,000 to 100,000; the acid number is from 50 to 400; and the acid group on the polymer is neutralized by an alkaline metal hydroxide such as lithium hydroxide, sodium hydroxide potassium hydroxide, or a mixture thereof; and wherein all weight percentages are based on the total weight of the ink composition. An ink jet printing method is also disclosed.

Owner:EASTMAN KODAK CO

Manganese-included multi-element metal oxide, lithium ion secondary battery anode material and its preparing method

ActiveCN1770513AImprove cycle performanceUniform particle sizeCell electrodesSecondary cellsNickel saltLithium hydroxide

This invention relates to one multi-element metal oxidation and discloses The process method, which comprises the following steps: a, in nitrogen or inertance gas depositing the mixture of cobalt salt, nickel salt and maganism salt to generate Ni-Co-Mn compound hydrogen oxidation to process front drive after drying and grinding; b, adding lithium hydrate into the front drive grinding and processing mixture to remove absorbed water and structure water; c, processing products under degrees of 650 to 850 degrees; d, using high polymer as assistant agent to process surface covering on product; e, processing the product to remove solvent to process multi-metal oxidation.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

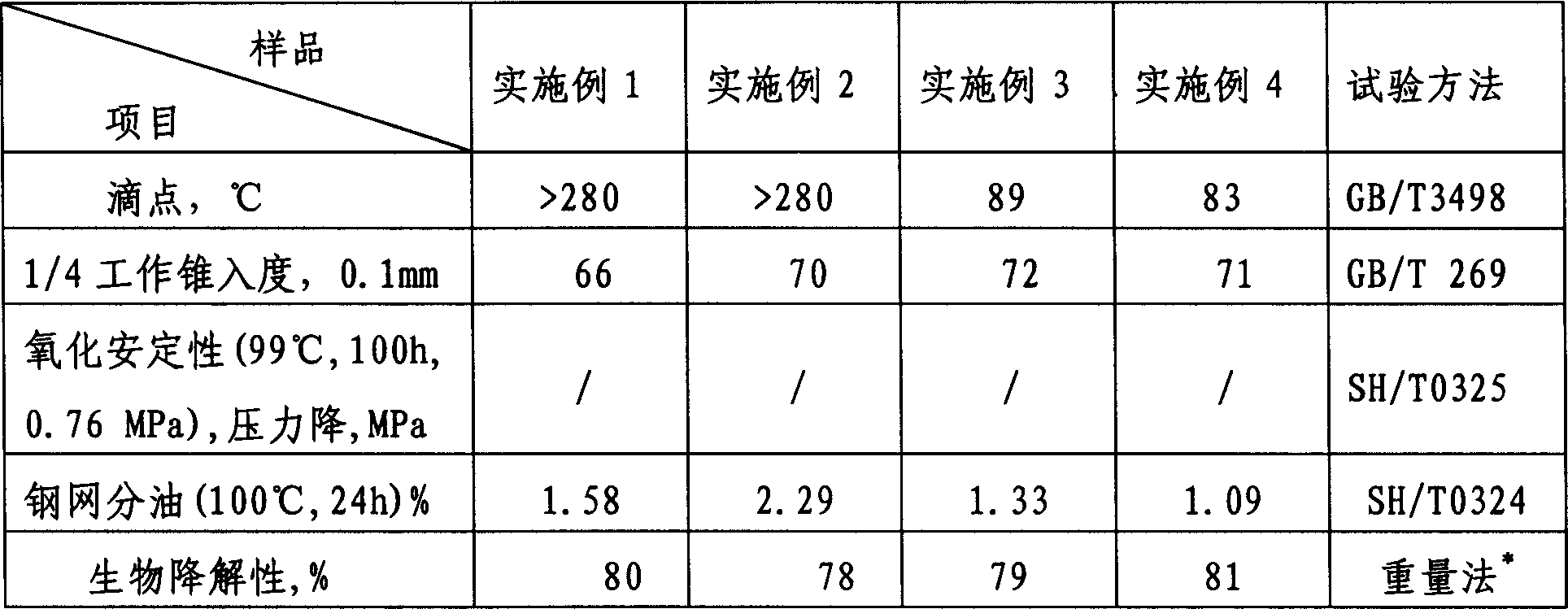

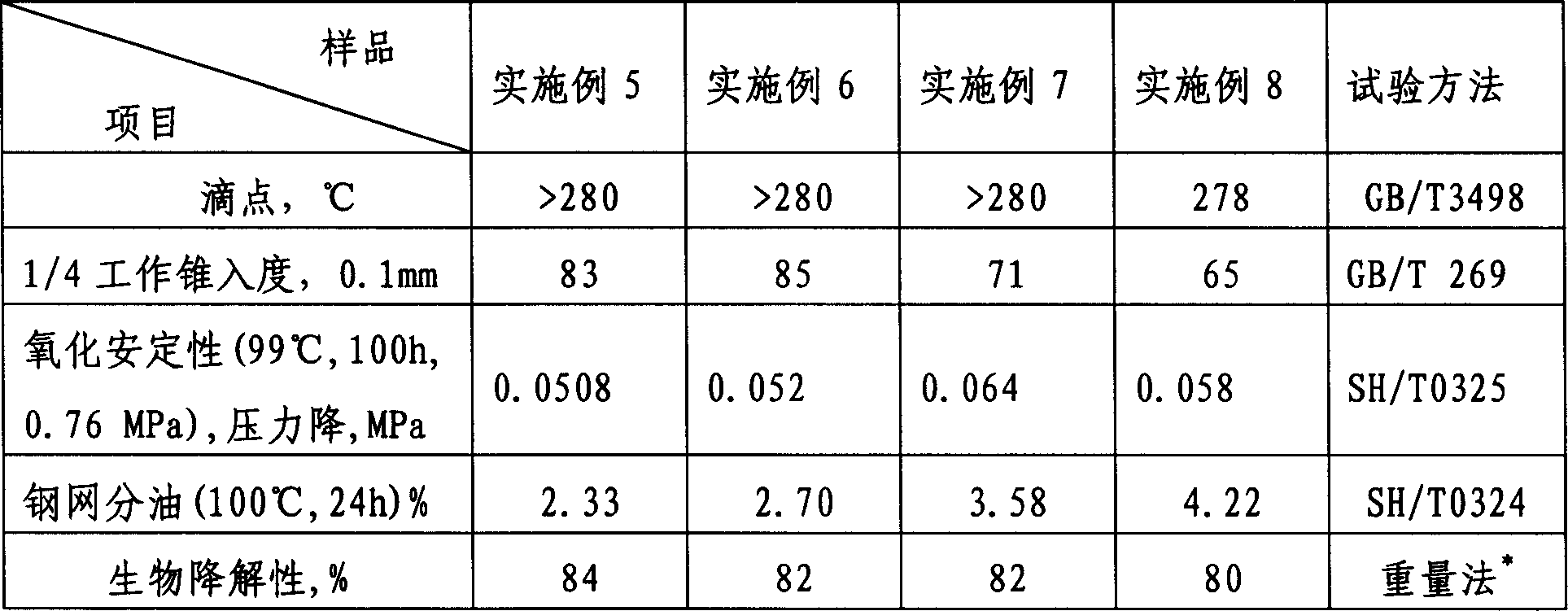

Biodegradable lubricating grease

InactiveCN1504552AExcellent conventional physical and chemical propertiesWill not polluteLubricant compositionLithium oxideVegetable oil

A biodegradable lubricating grease comprises (overall composition weight as benchmark) (1) 70-94% vegetable oil whose kinetic viscosity is 100-250 square mm per second, (2) 6-30% thickening agent, wherein the thickening agent is alta-mud, or single saponin or composite saponin produced through the reaction of C1-C20 organic acid with calcium hydroxide, calcium oxide, lithium hydroxide or lithium oxide, (3) 0-2% amine antioxidant or phenol and amine mixed anti-oxidant. The lubricating grease possesses both fine normal physical chemical properties and good bio-ecological characteristics.

Owner:CHINA PETROLEUM & CHEM CORP +1

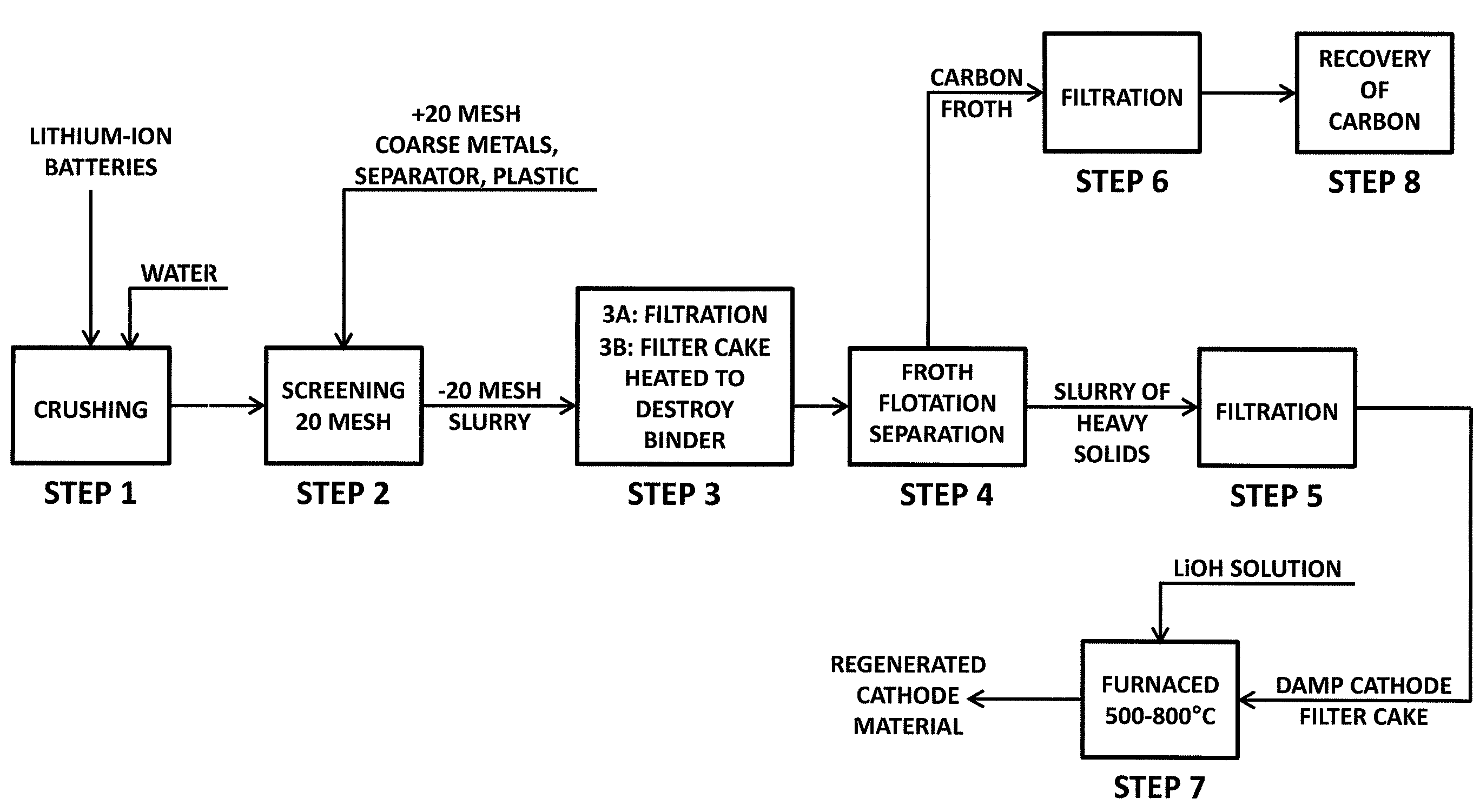

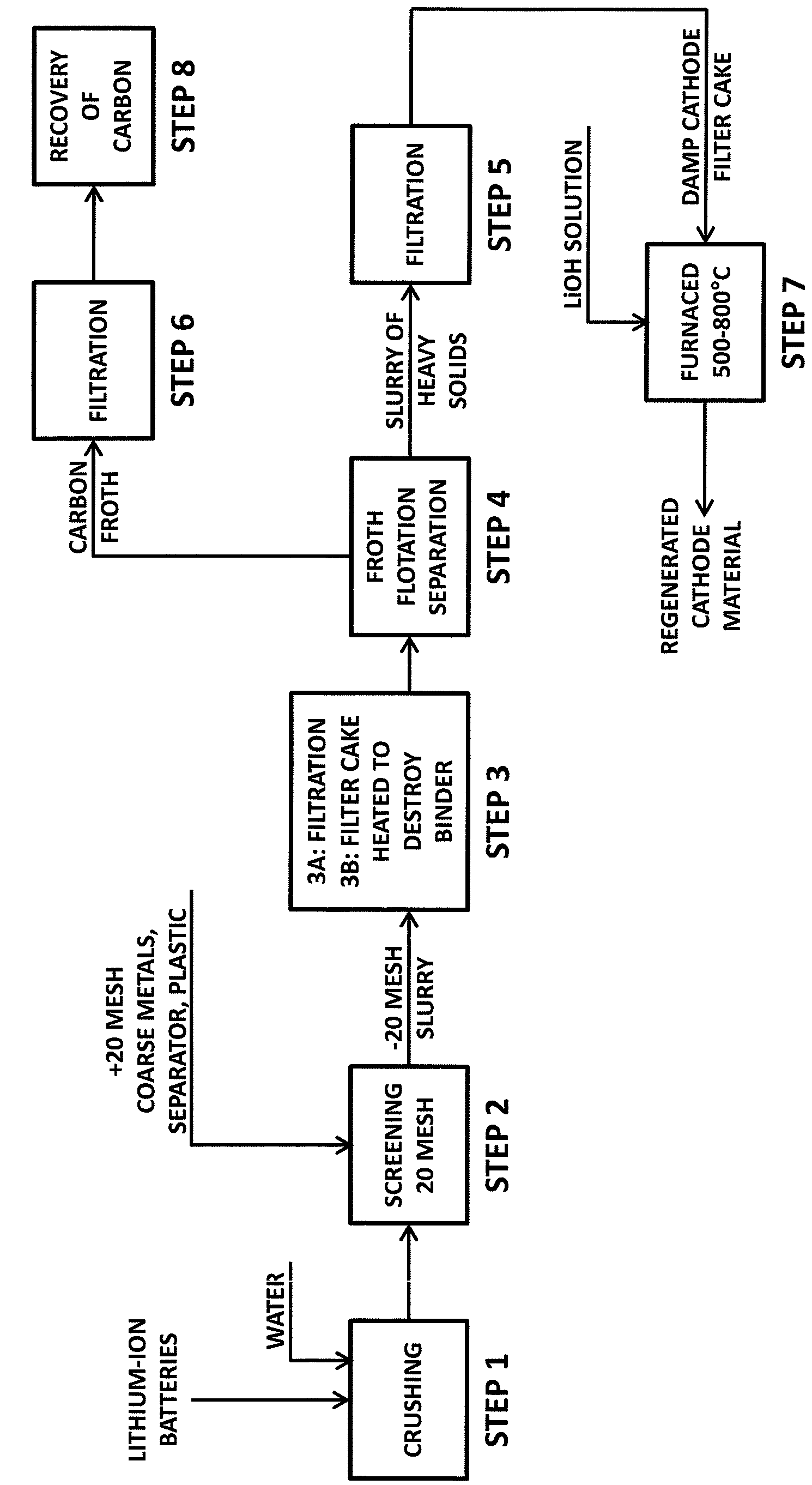

Recovery of lithium ion batteries

ActiveUS8616475B1Small particle sizeCell electrodesElectrolyte/reactants regenerationLithium hydroxideLithium metal

Owner:RETRIEV TECH

Hydrothermal synthesis method for lithium ferromanganese phosphate anode material of lithium ion battery

InactiveCN102249208AHigh degree of crystallinitySingle phaseCell electrodesNanotechnologyPhosphateLithium hydroxide

The invention relates to a hydrothermal synthesis method for lithium ferromanganese phosphate anode material of a lithium ion battery, belonging to the technical field of lithium ion batteries. The method has the following processing steps of: step 1, preparing LiMnxFe1-xPO4 through a hydrothermal synthesis reaction: mixing an aqueous lithium hydroxide solution, an aqueous ferrous sulfate solution and phosphoric acid under a stirring condition, after sealing, heating to 150 DEG C to 180 DEG C within 0.5 to 2 h, reacting for 0.5-4 h under the pressure of 0.48-1.0 Mpa, cooling to less than 80 DEG C, and filtering; step 2, mixing with organic matters and drying: mixing a wet filter cake with a soluble carbon source organic matter, and carrying out spray drying or expansion drying; and step 3, carrying out carbon-coated processing: roasting LiMnxFe1-xPO4 carbon source compound powder at a temperature between 600 DEG C and 750 DEG C for 4-6 h under an insert gas condition, and cooling to less than 150 DEG C to obtain a carbon-coated lithium ferromanganese phosphate anode material of the lithium ion battery. The hydrothermal synthesis method disclosed by the invention has the advantages of simple and controllable technology, convenience for operation, low cost, high crystallization degree of products, uniform dispersion, high specific capacity, high conservation rate of the cycling capacity, and the like.

Owner:朱鸥鹭

Lithium hydrate and carbamide composition solvent for dissolving cellulous fiber and its use

InactiveCN1546556AHigh strengthWide range of usesMonocomponent cellulose artificial filamentSpinning solutions preparationAcid waterLithium hydroxide

The invention relates to a dissolvent for cellulose dissolution through freezing-unfreezing method or direct dissolution method, and process for preparing the regenerated cellulose fibers and films by utilizing the dissolvent, wherein the dissolvent is the water solution of lithium hydroxide and urea whose compositions are 3.0-7.0wt% of lithium hydroxide, 4.0-30.0.0wt% of urea, the rest is water. The water solution of lithium hydroxide and urea can directly dissolve cellulose through freezing-unfreezing method or by pre-cooling the dissolvent in advance to -10 deg. C - -4 deg. C. It can be used to obtain high dissolvability transparent concentrated cellulose solution. By using the concentrated cellulose solution and through 3-5wt% diluted acid water solution coagulation, regeneration, regenerated cellulose films and fibers can be prepared.

Owner:WUHAN UNIV

Bearing lubricating grease and preparation method thereof

ActiveCN102977978AHigh dropping point temperatureNot collapseLubricant compositionLithium hydroxideAntioxidant

The invention relates to bearing lubricating grease comprising the following components of: (a) a compound thickening agent formed by lithium 12-hydroxystearate soap, lithium binary acid soap and lithium borate, (b) an additive, and (c) base oil, wherein the compound thickening agent is formed by soapnifying 12-hydroxystearic acid, binary acid and boric acid with lithium hydroxide; and the additive amount of the boric acid is 1-5 parts by weight while the weight of the base oil is 100 parts by weight, wherein the additive is one or combination of at least two of an antioxidant, an antirusting agent, an anti-wear reagent at extreme pressure and a metal passivator. The dropping point temperature of the bearing lubricating grease provided by the invention is more than or equal to 300 DEG C, and the bearing lubricating grease provided by the invention does not collapse or fade and has the characteristics of long service life, silence and high temperature resistance.

Owner:安徽意博润滑科技有限公司

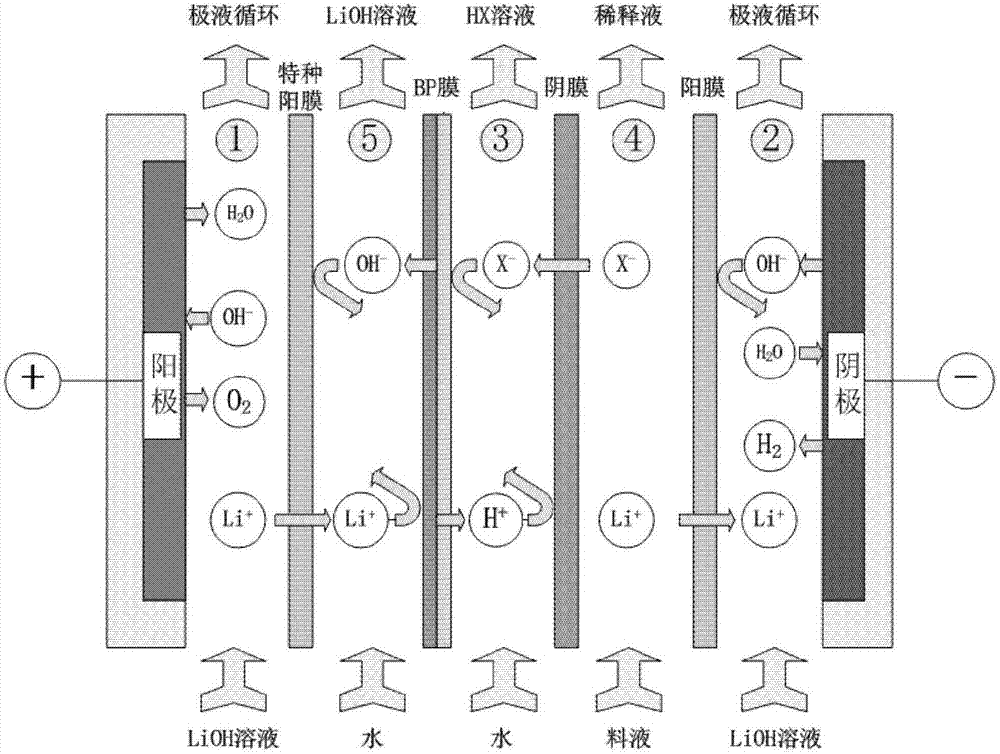

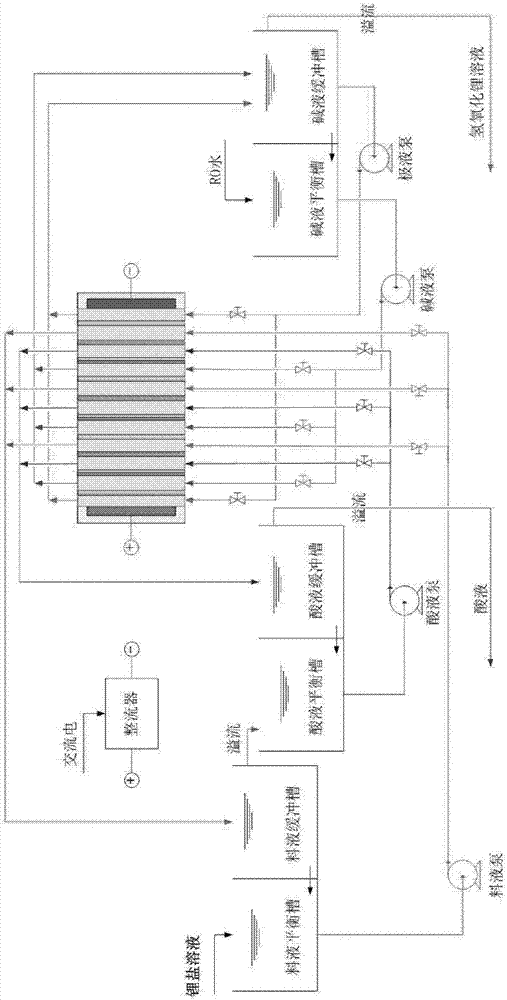

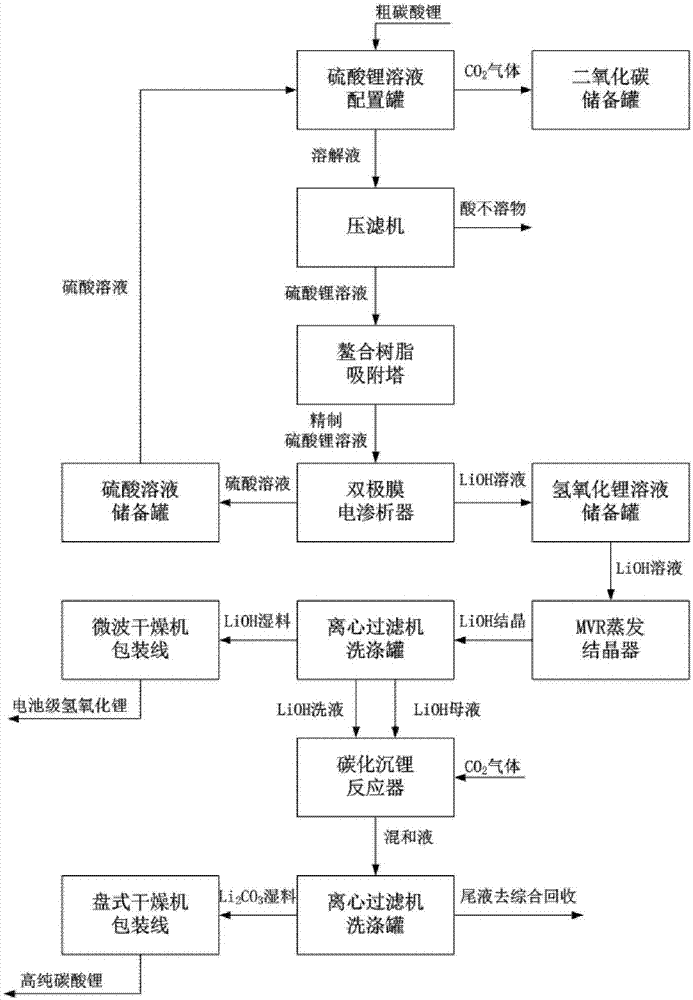

Method for preparing lithium hydroxide and lithium carbonate by utilizing soluble lithium-salt solution

ActiveCN107298450AAvoid cumbersomeAvoid pollutionLithium oxides/hydroxidesLithium carbonates/bicarbonatesCalcium hydroxideHigh concentration

The invention discloses a method for preparing lithium hydroxide and lithium carbonate by utilizing a soluble lithium-salt solution. The method comprises the following steps: the soluble lithium-salt solution is used as a raw material to produce the battery-level lithium hydroxide, and a lithium hydroxide solution is utilized to produce the high-purity lithium carbonate. The method is characterized in that various soluble lithium-salt solutions (the lithium solutions are expressed as LiX in the description) can be utilized, and a bipolar membrane electrodialyzer is applied to treat the soluble lithium-salt solutions, so that a higher-concentration LiOH solution and a corresponding HX acidic solution are obtained; the HX acidic solution returns to a previous-stage process for preparing the lithium salt solution; and the LiOH solution is subjected to evaporation concentration and crystallization to obtain the battery-level lithium hydroxide solid, and the produced lithium hydroxide solution can be further reacted with a carbon dioxide gas through a gas-liquid reactor, so that the high-purity lithium carbonate is obtained. The method can realize continuous stable production with low energy consumption, free pollution and large scale, and realize low-cost and high-efficiency manufacture of the battery-level lithium hydroxide and the high-purity lithium carbonate.

Owner:JIANGSU LITHITECH CO LTD

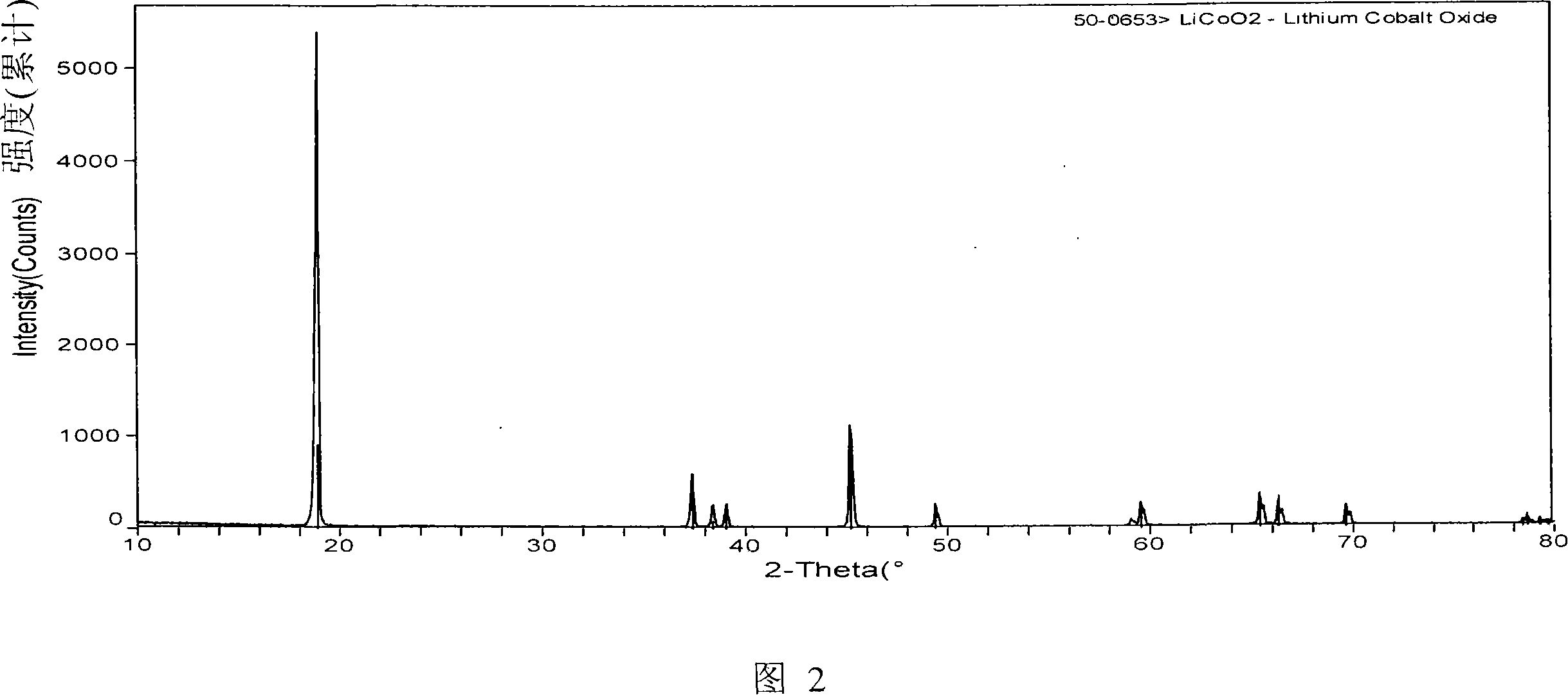

Anode material zirconium and phosphor adulterated lithium cobaltate of lithium ion secondary battery and its making method

ActiveCN101150190AImprove cycle performanceImprove securityCell electrodesCobalt compoundsLithium hydroxidePhosphate

This invention relates to LiCoO2 doped with Zr and P, positive material of Li ionic secondary cells and its preparation method characterizing that the chemical formula is: LiZrxCo(1-x-y)PyO2, in which, it is a laminated structure, and x=0.001-0.003, y=0.02-06, the preparation steps are as folow: 1, mixing Co3O4, CoCO3 or CoC2O4 with Li2CO3 or LiOH in the atomic ratio of Li and Co(0.9801.05) :1.00, 2, baking it for 6-24h under 600-1000deg.C, 3, crushing LiCoO2 to particles of 6-15mum, 4, mixing the LiCoO2 and water 1-3times weight into pulp, 5, adding ZrNO3 and phosphate at the same time, 6, spraying and drying it, 7, baking it for 4-12h under 600-1000deg.C, 8, crushing the doped LiCoO2 to particles of 6-15mum.

Owner:TIANJIN B&M SCI & TECH

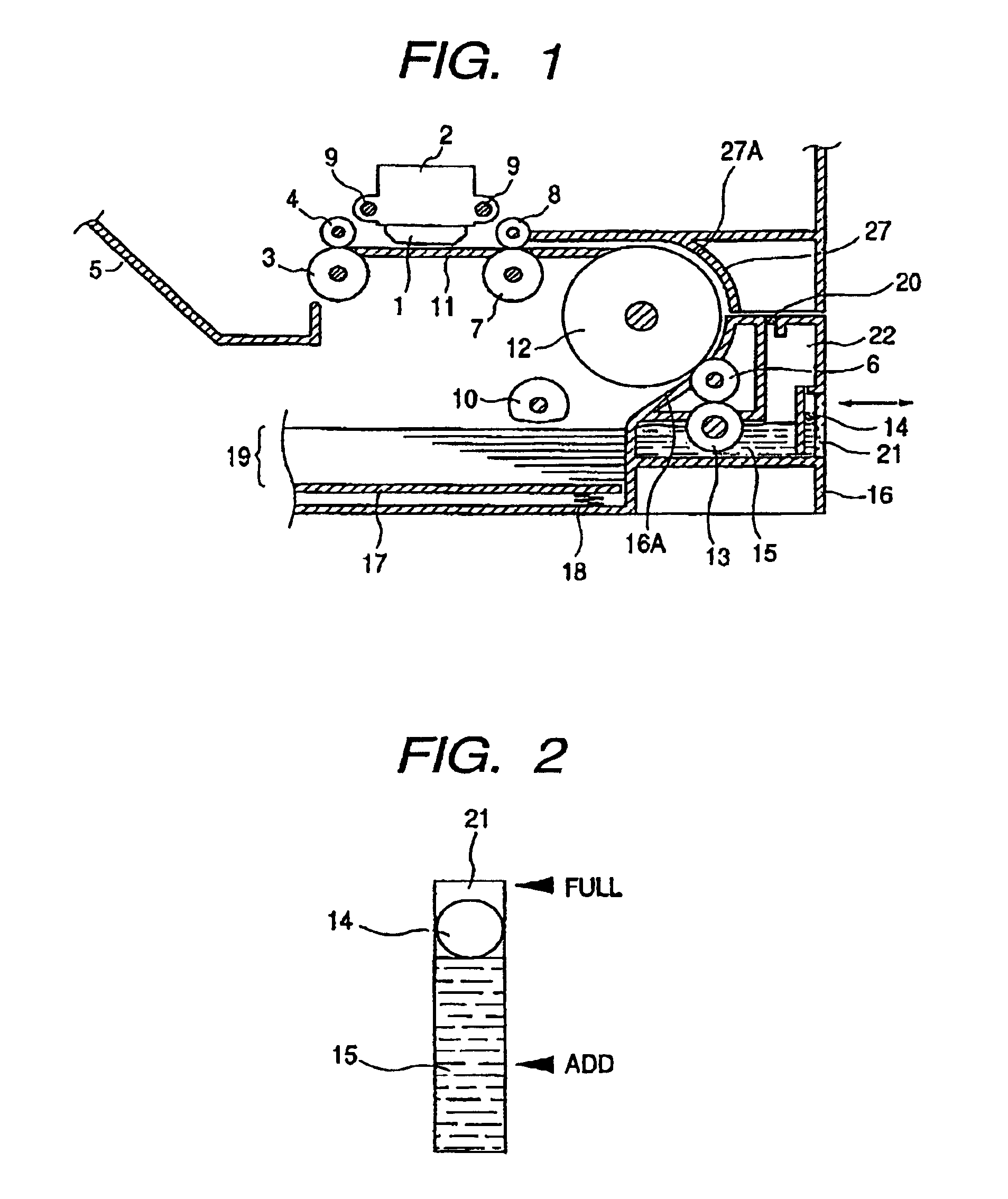

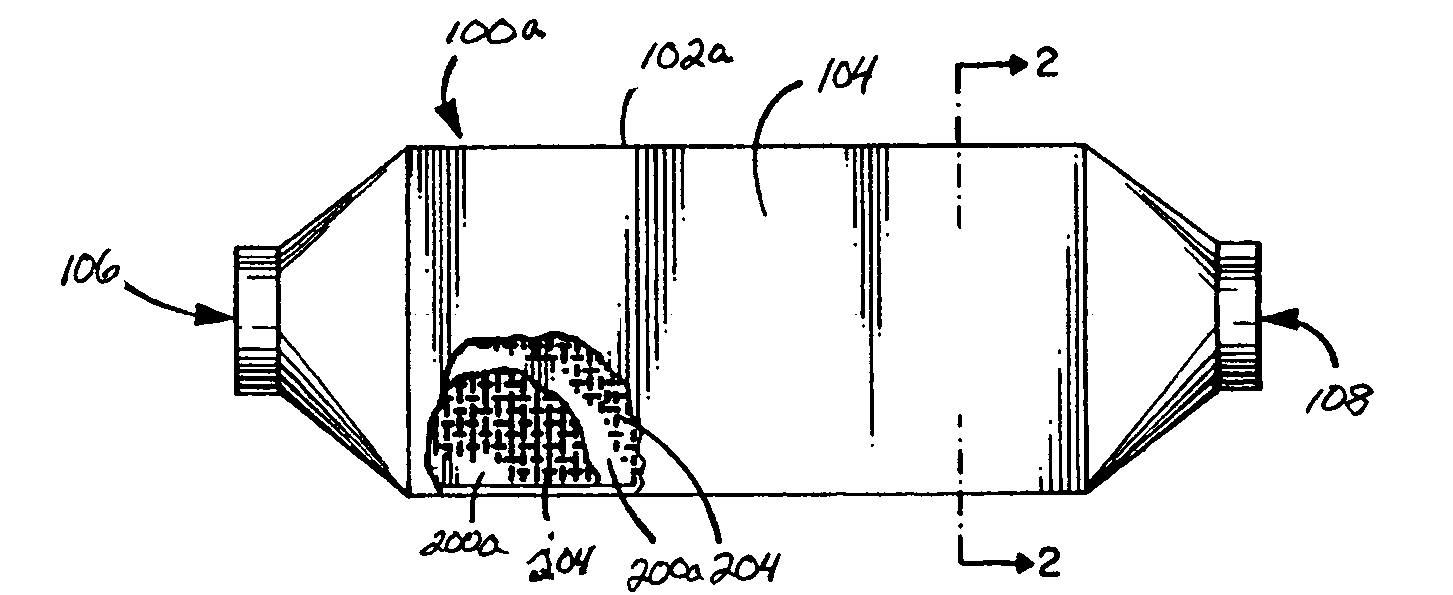

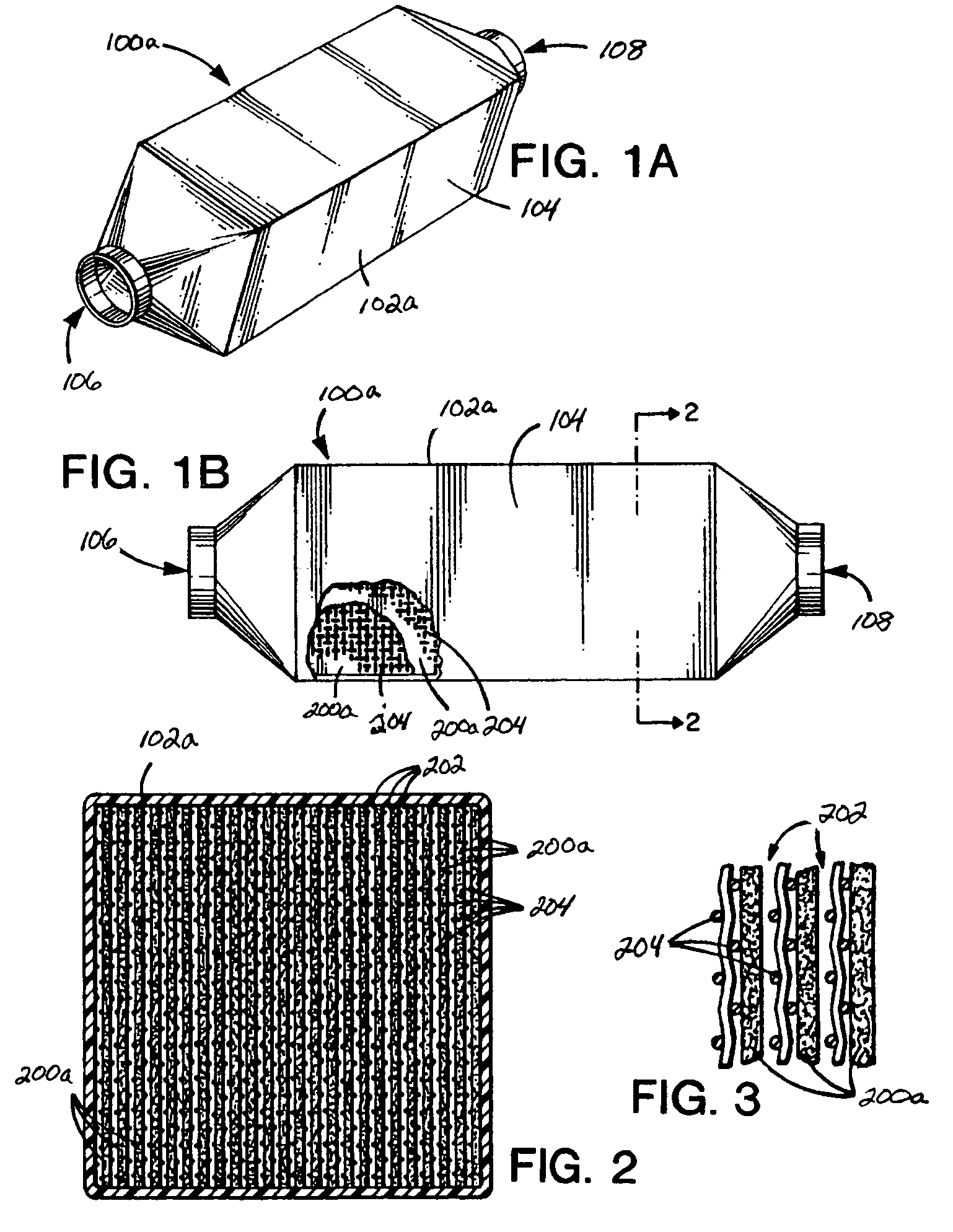

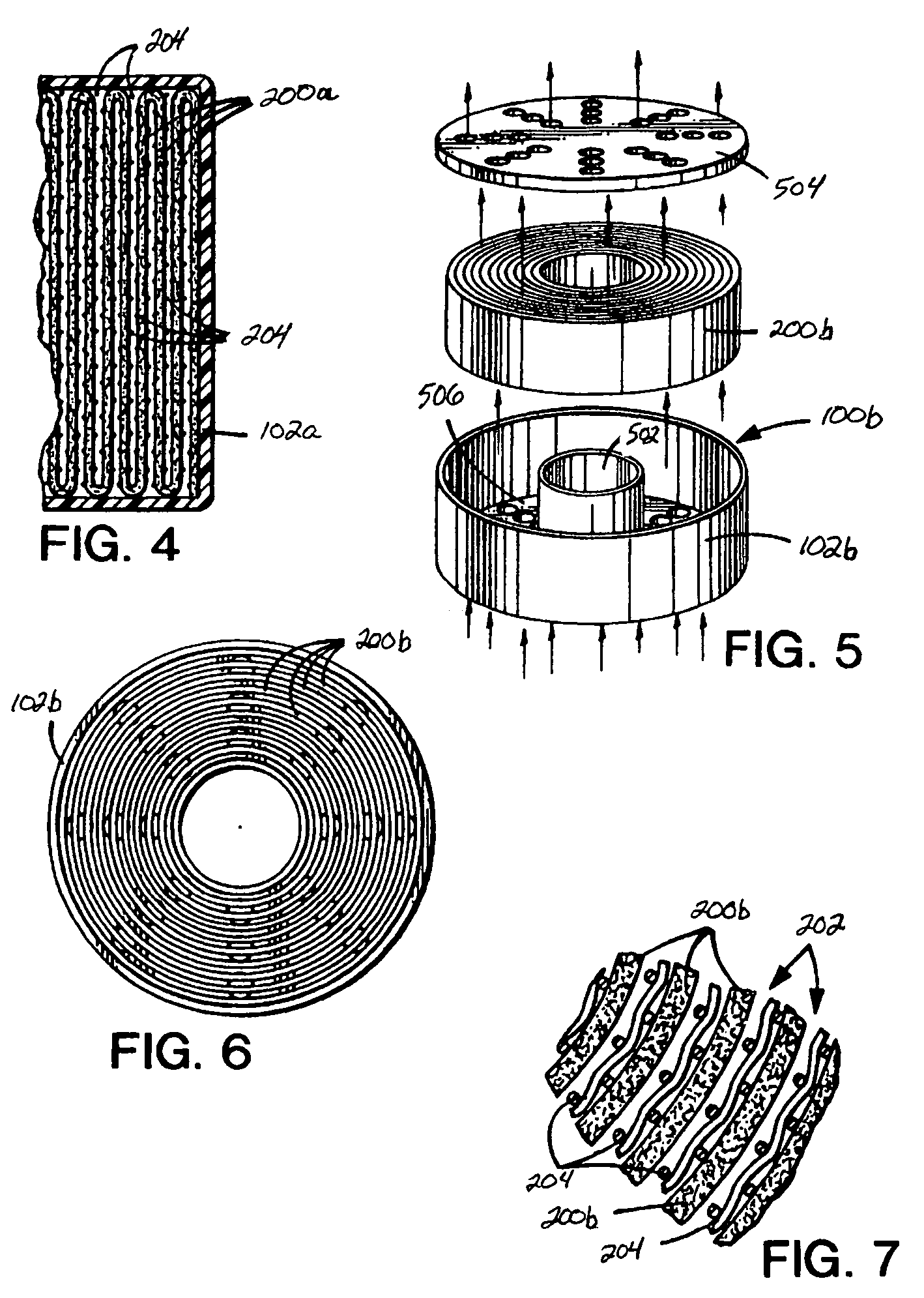

Method of manufacturing and using enhanced carbon dioxide adsorbent

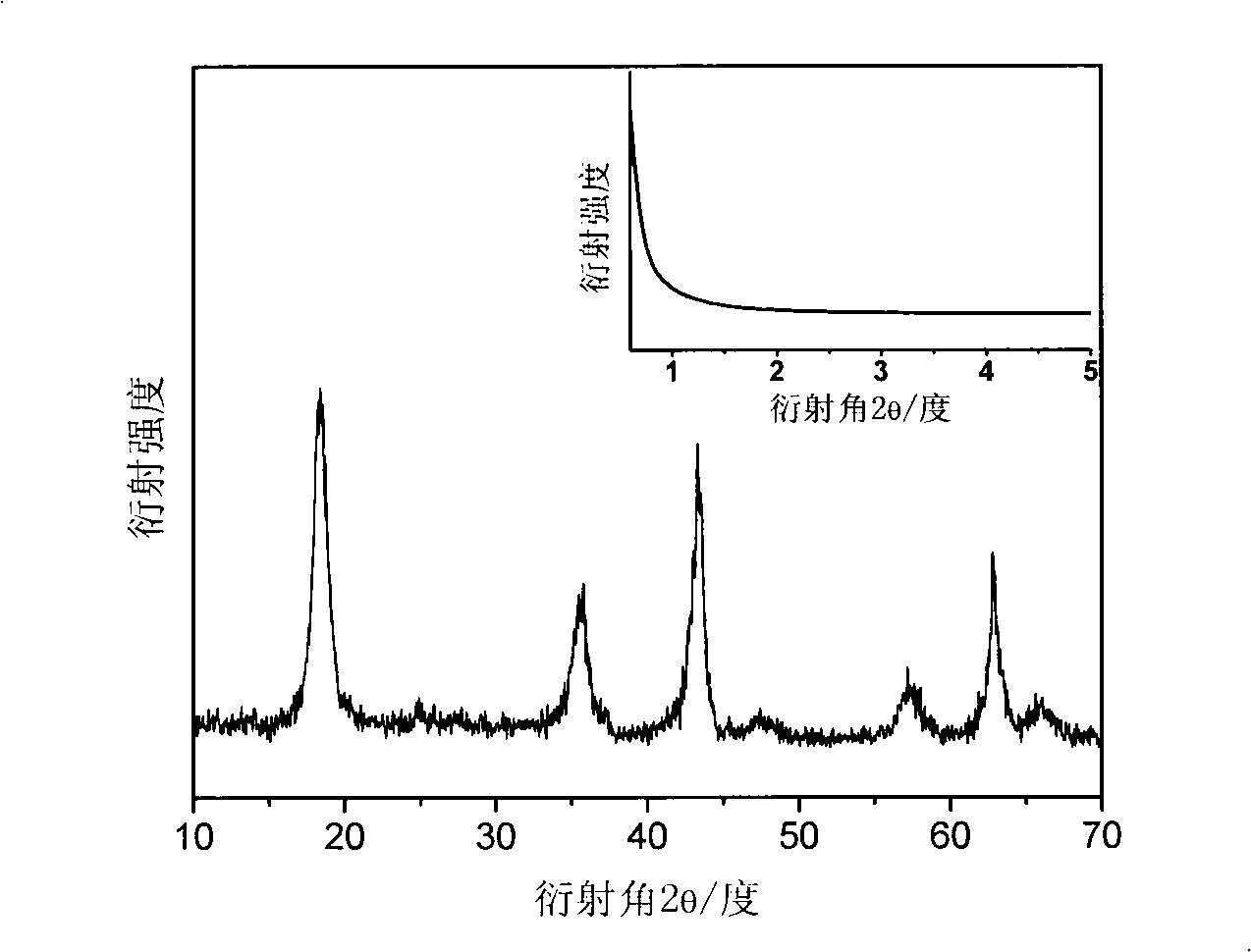

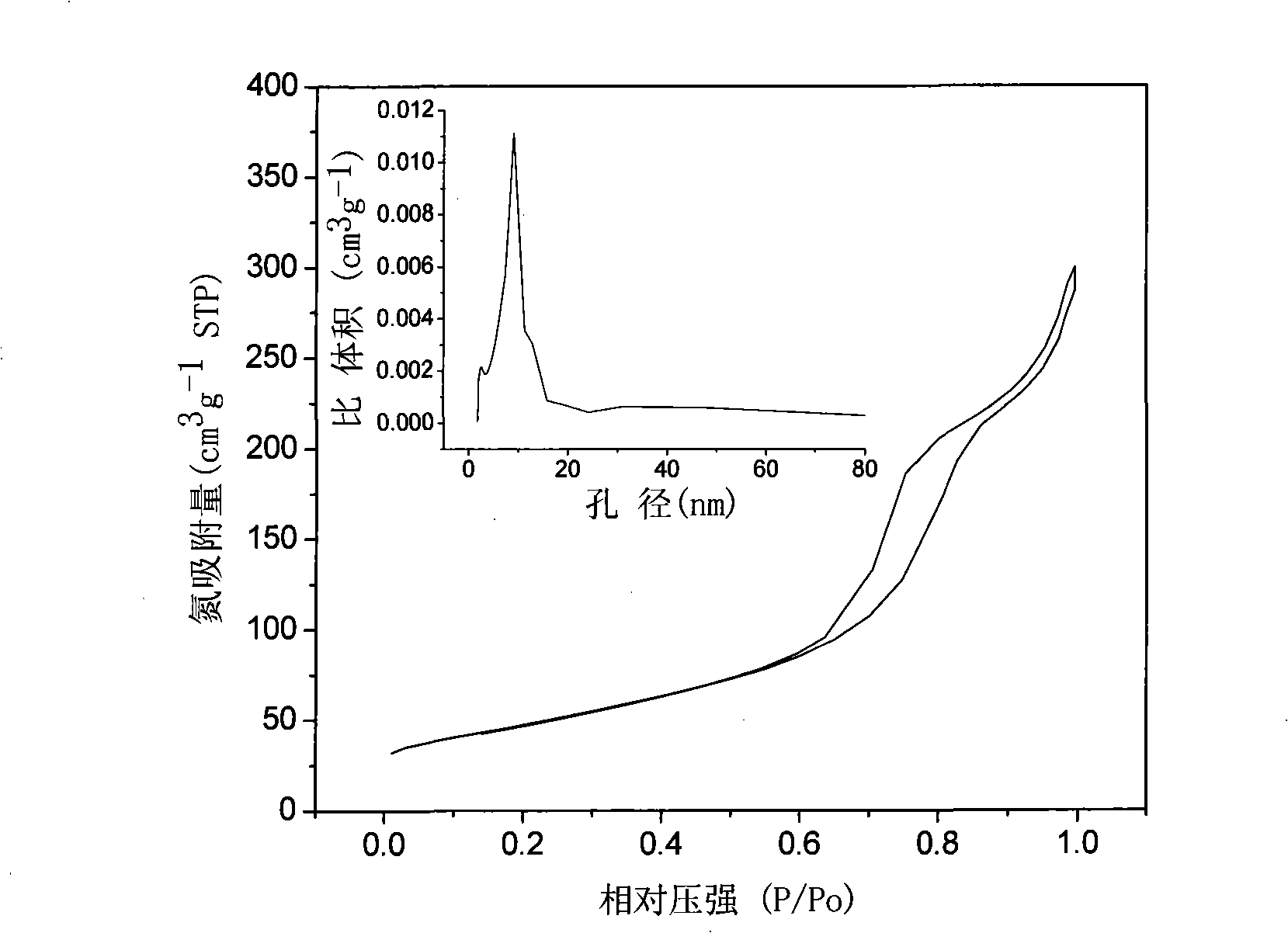

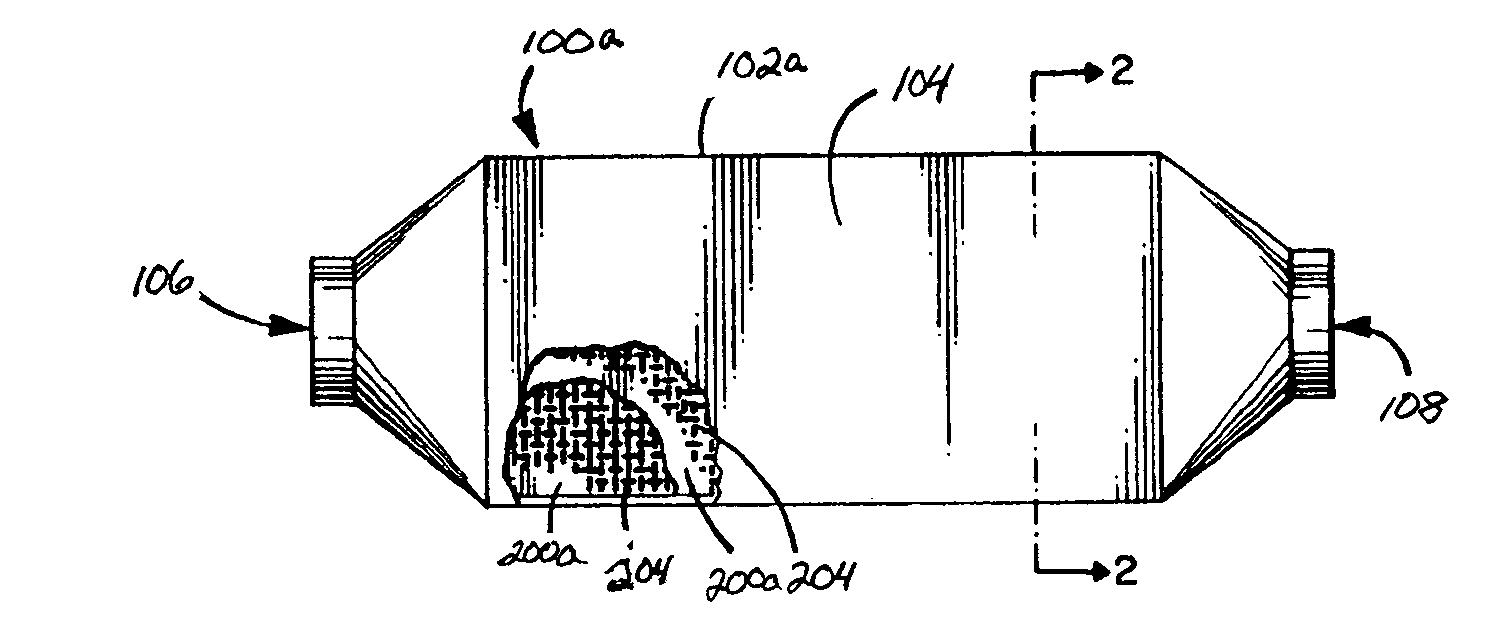

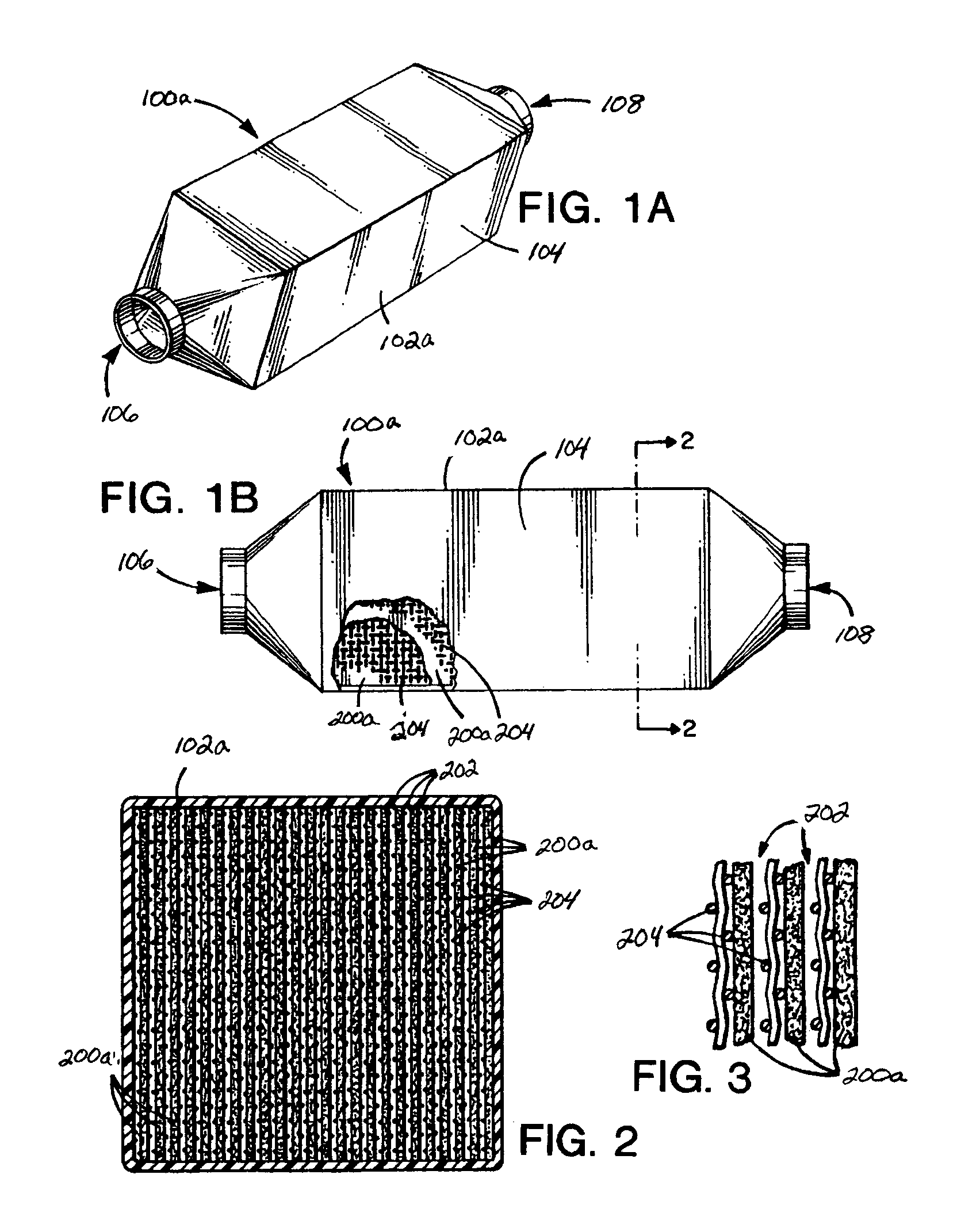

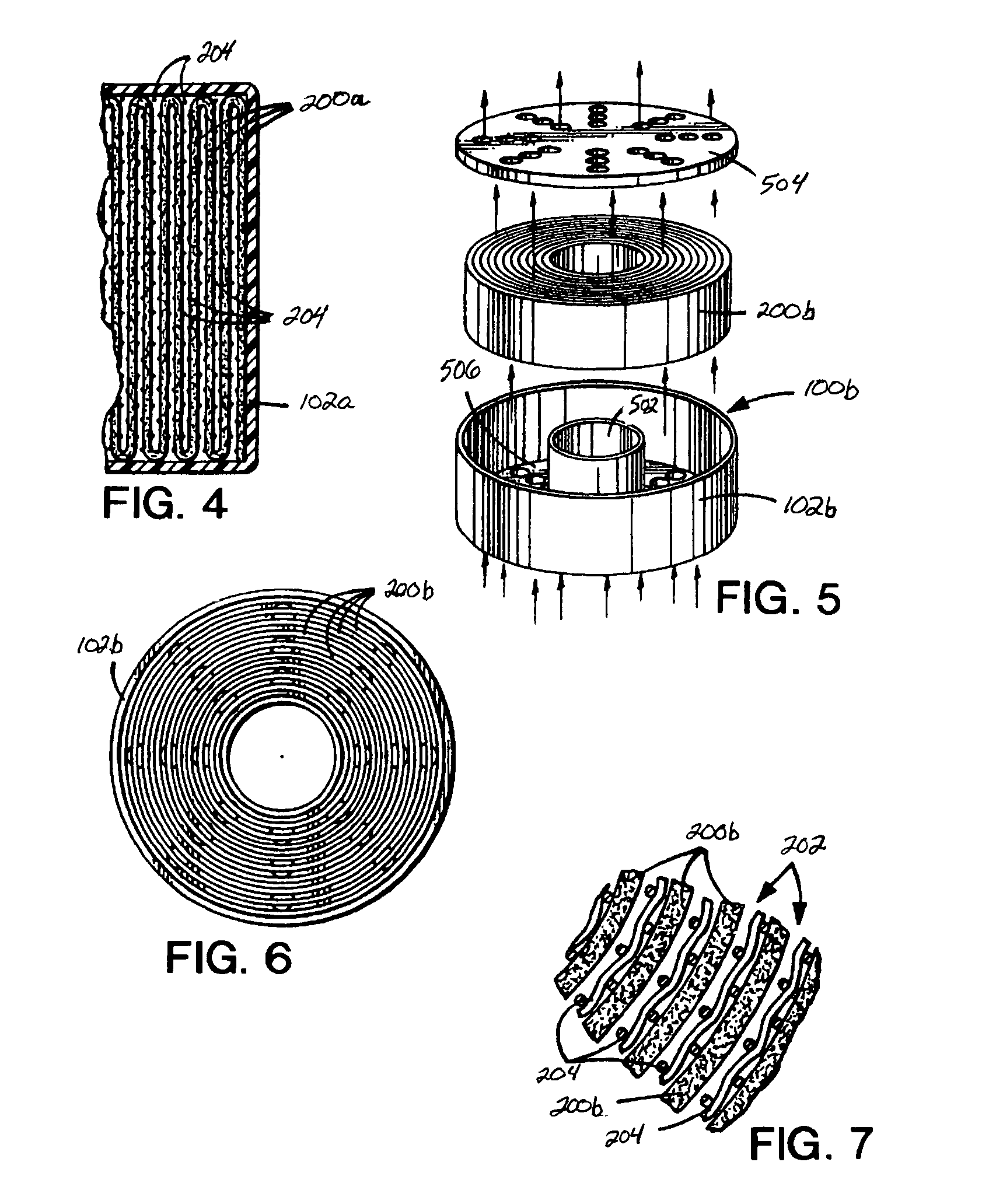

A method of processing carbon dioxide adsorbent for use in a CO2 removal system. The method includes combining a polymer, lithium hydroxide (LiOH), and lubricant that dissolves the polymer to form a first LiOH adsorbent. A structure may be formed using the first LiOH adsorbent. The lubricant may be extracted from the structured LiOH adsorbent using a solvent to form a second LiOH adsorbent. The solvent may be removed from the second LiOH adsorbent to form a third LiOH adsorbent. The third LiOH adsorbent may be hydrated to form a fourth LiOH adsorbent having a water content above an anhydrous level.

Owner:MICROPORE

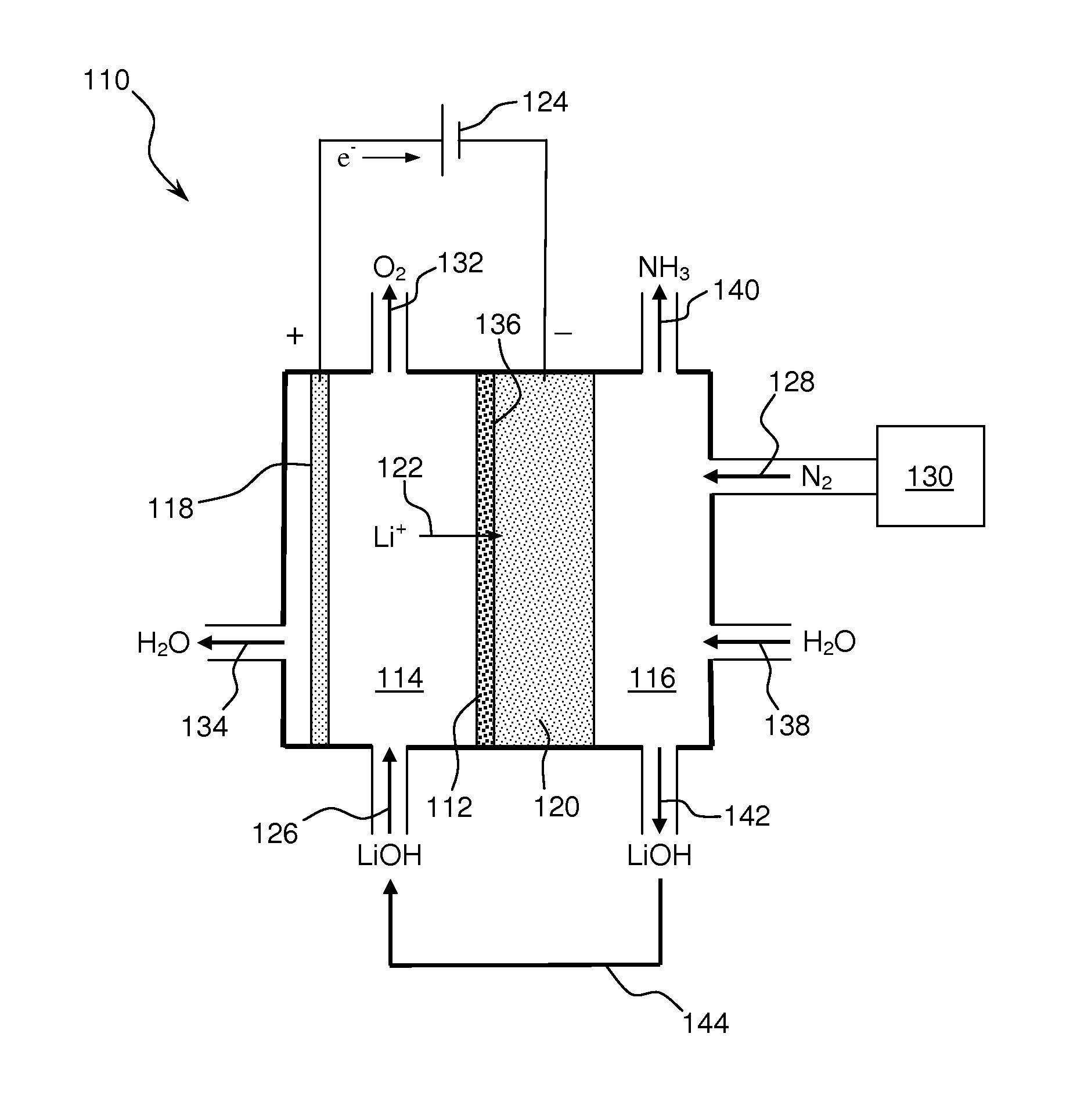

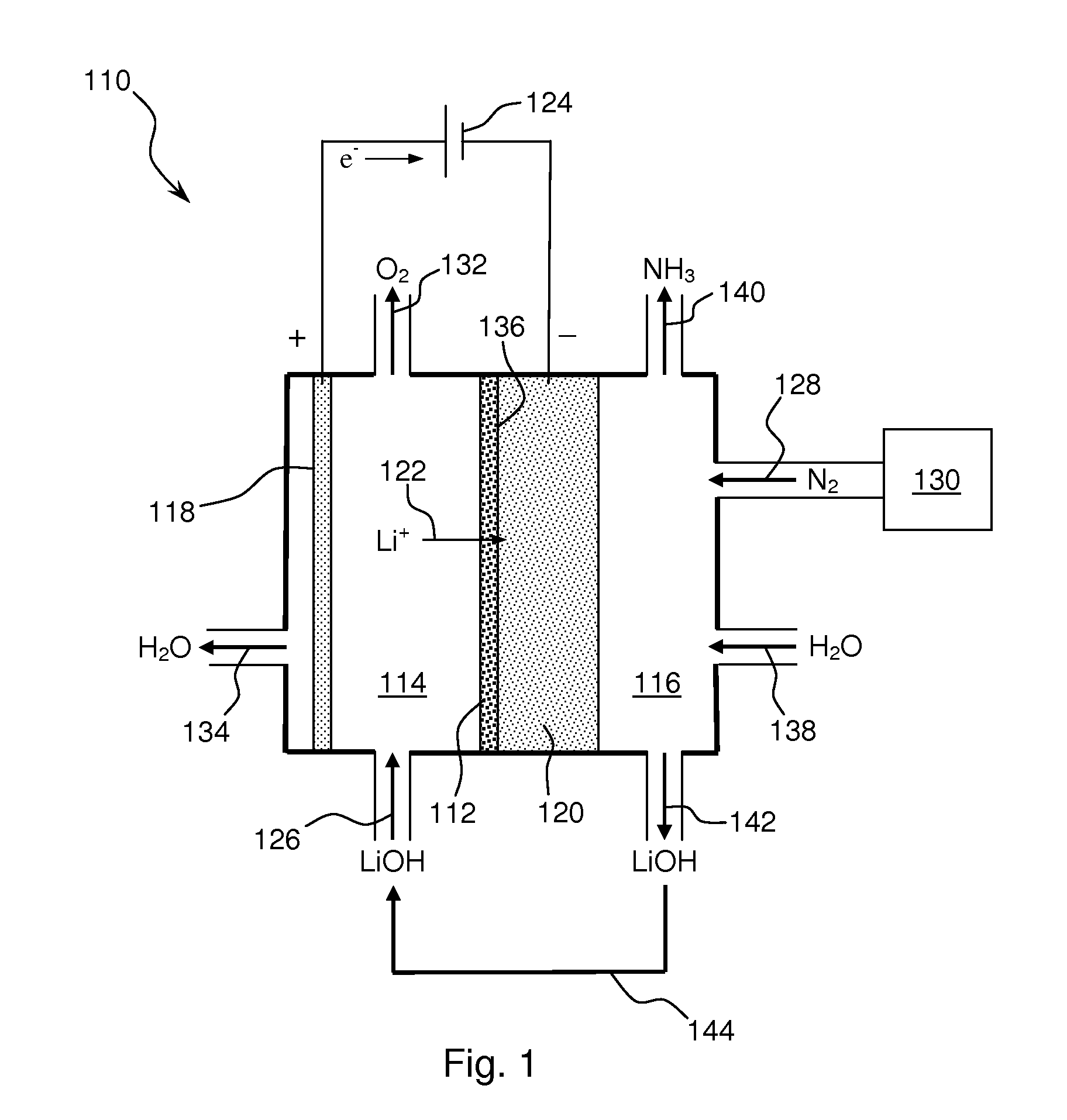

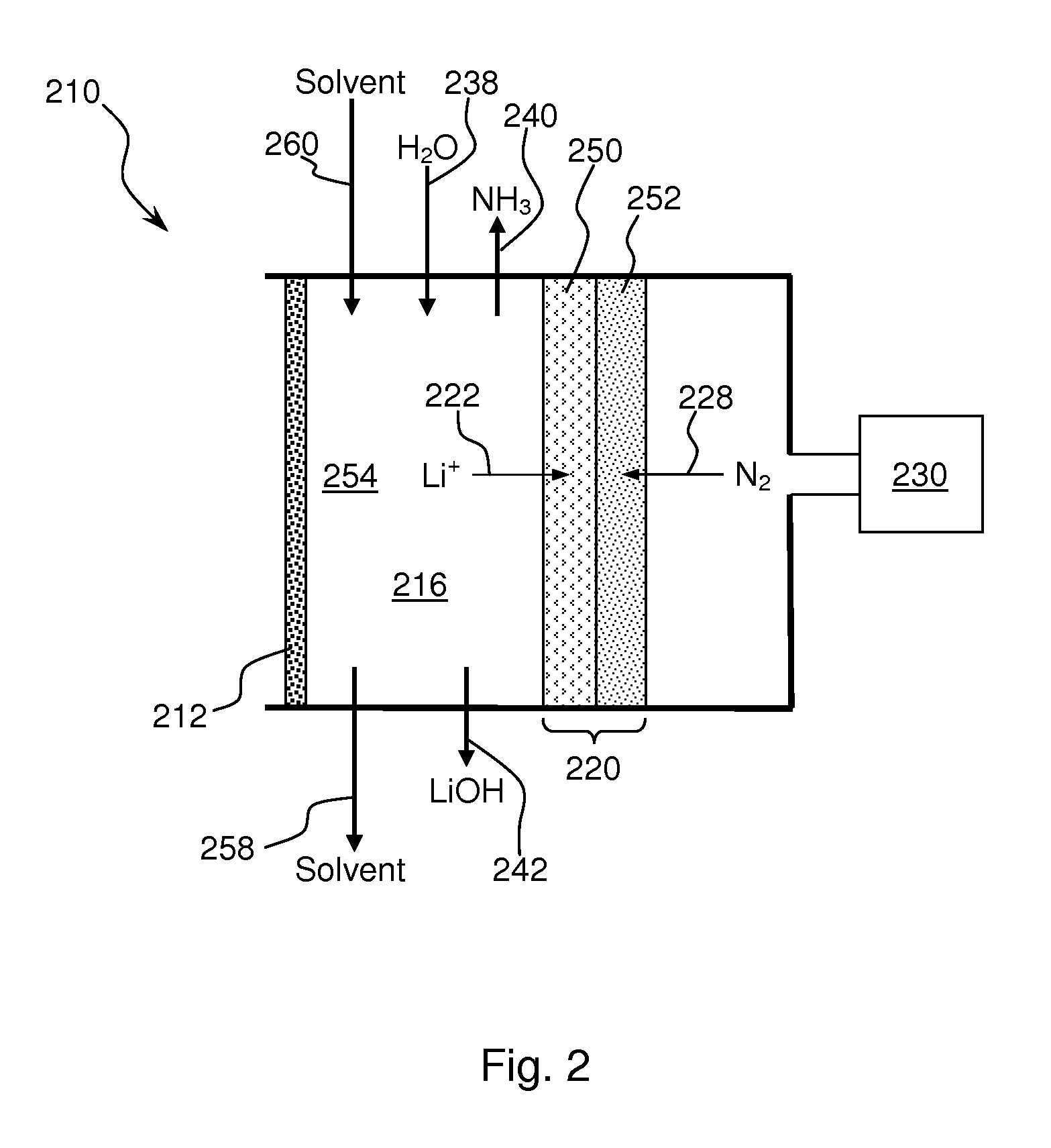

Ammonia synthesis using lithium ion conductive membrane

Ammonia is synthesized using electrochemical and non-electrochemical reactions. The electrochemical reactions occur in an electrolytic cell having a lithium ion conductive membrane that divides the electrochemical cell into an anolyte compartment and a catholyte compartment. The catholyte compartment includes a porous cathode closely associated with the lithium ion conductive membrane. The overall electrochemical reaction is: 6LiOH+N2→Li3N (s)+3H2O+3 / 2O2. The nitrogen may be produced by a nitrogen generator. The non-electrochemical reaction involves reacting lithium nitride with water and / or steam as follows: Li3N (s)+3H2O→3LiOH+NH3 (g). The ammonia is vented and collected. The lithium hydroxide is preferably recycled and introduced into the anolyte compartment. The electrolytic cell is shut down prior to reacting the lithium nitride with water. The cathode is preferably dried prior to start up of the electrolytic cell and electrolyzing Li+ and N2 at the cathode.

Owner:ENLIGHTEN INNOVATIONS INC

Method for preparing positive electrode material of lithium ion accumulator

InactiveCN1595680AReduce manufacturing costImprove securityElectrode manufacturing processesSecondary cellsLithium hydroxideLithium carbonate

The invention relates to a manufacture method for positive material of lithium ion accumulator , whose component concentration is: at least one element between LiNi0.5-xM0.5-XM2xO2 (M=Co,Ti,Al) (0<=X<0.5). The manufacture method includes the following steps: dry or wet mix of sentiment hydroxide or carbonate compounds of at least one element between Ni,Mn,Co,Ti and Al or its oxide and lithium hydroxide or carbonate lithium (dry for the material of wet mixture); accumulate the mixture whose width is 2mm~60mm; make particle under the pressure of 4MPa~40MPa; high temperature solid state reaction happens under the temperature of 700~1050deg.C; shatter it after cooling, the diameter of particle is 0.5~25mu m. The manufacture method can make the density of products reach 2.0g / cm3~2.8g / cm3, increase positive filler level of lithium ion and lithium polymer accumulator and its capacity.

Owner:吴孟涛

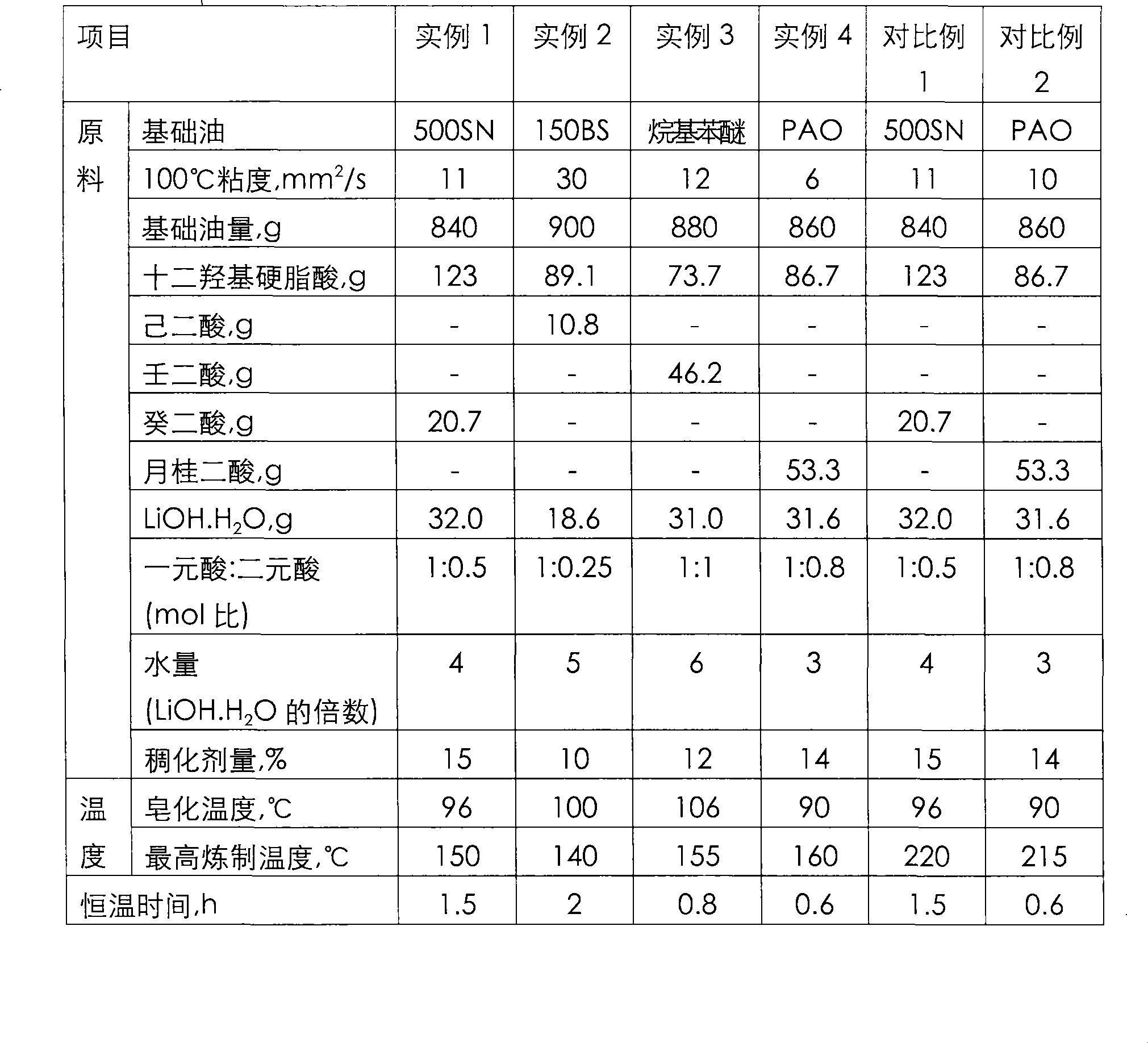

Process for preparing composite lithium base grease

ActiveCN101481637AReduce oxidationImprove Oxidation StabilityThickenersBase-materialsOrganic acidLithium hydroxide

The invention provides a method for preparing complex lithium grease, comprising: part of base oil is mixed with C12-C24 monobasic organic acid and at least one C4-C18 binary organic acid; the mixture is heated up to 80-120 DEG C and then added with lithium hydroxide aqueous solution for saponification reaction, and then moisture is removed; the temperature is risen to 130-180 DEG C for refining at the constant temperature, the rest base oil is added into the mixture to reduce the temperature, and the mixture is ground. The invention adopts lower refining temperature to prepare the complex lithium grease with high dropping point, so as to not only save the power resource, but also have the equivalent performances compared with the grease prepared by the prior art. Meanwhile, the method reduces the oxidation of lubricating oil when in the preparation process and improves the oxidation stability of the grease.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing spherical gradient lithium-rich anode material

The invention discloses a method for synthesizing a spherical gradient lithium-rich anode material, which comprises the following steps of: adding deionized water into MnSO4 and [Ni0.4Co0.2Mn0.4](OH)2 in a molar ratio of x:1-x to form suspension, and dripping 0.025 to 0.1mol / L NaCO3 solution into the suspension in a 60 DEG C water bath to form a compact manganese carbonate precipitate layer; filtering, washing, and drying at the temperature of between 80 and 120 DEG C; and uniformly mixing precursor particles and lithium hydroxide in a molar ratio of 1:1.15-1.45, performing heat treatment in air at the temperature of between 400 and 500 DEG C for 3 to 5 hours, raising the temperature for 22 to 32 hours, and sintering at the temperature of between 750 and 900 DEG C for 12 to 15 hours. The material synthesized by the method has certain Mn concentration gradient, improves the tap density of lithium-rich materials, has high cyclical stability and specific capacity, and keeps high rate performance.

Owner:BEIJING UNIV OF TECH

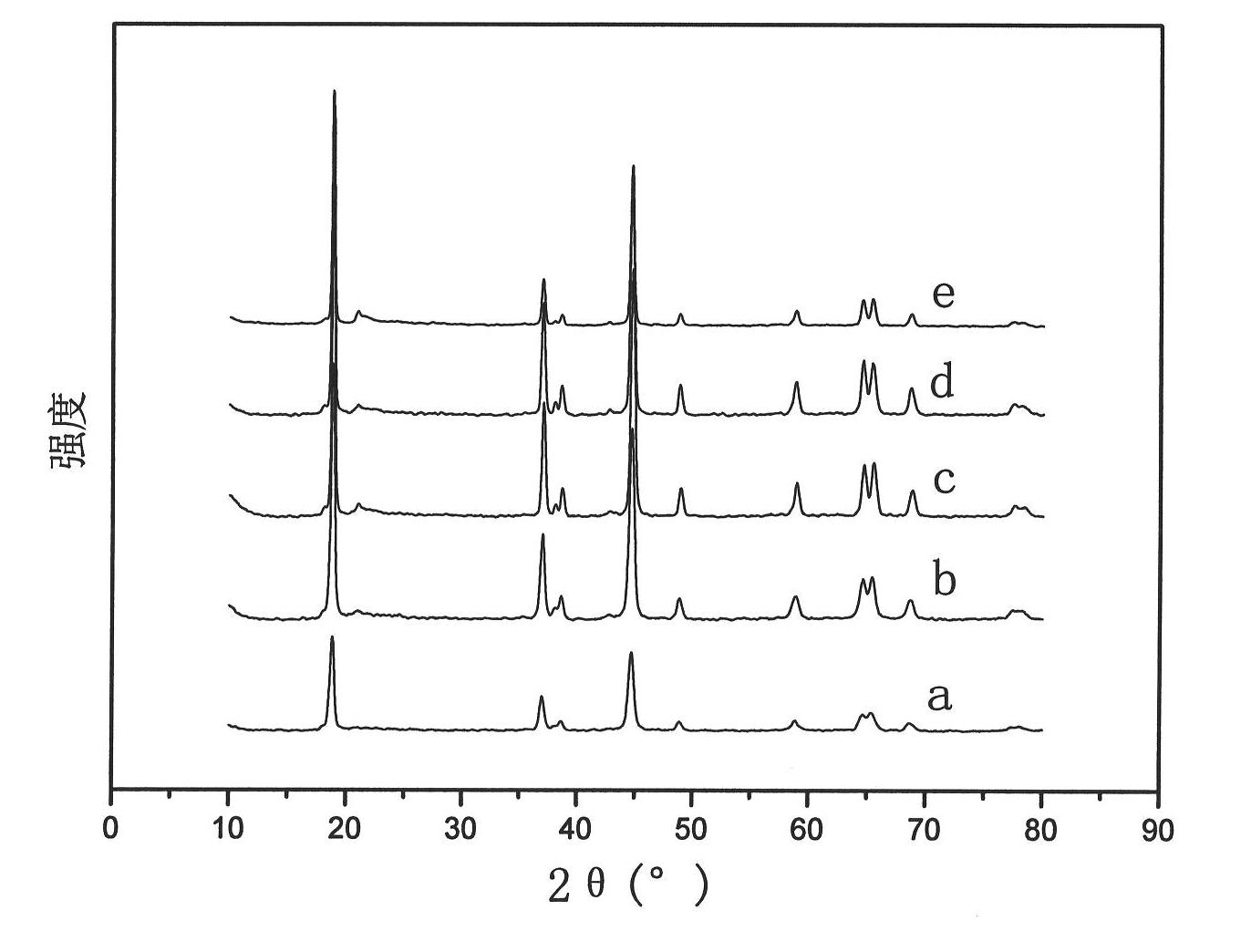

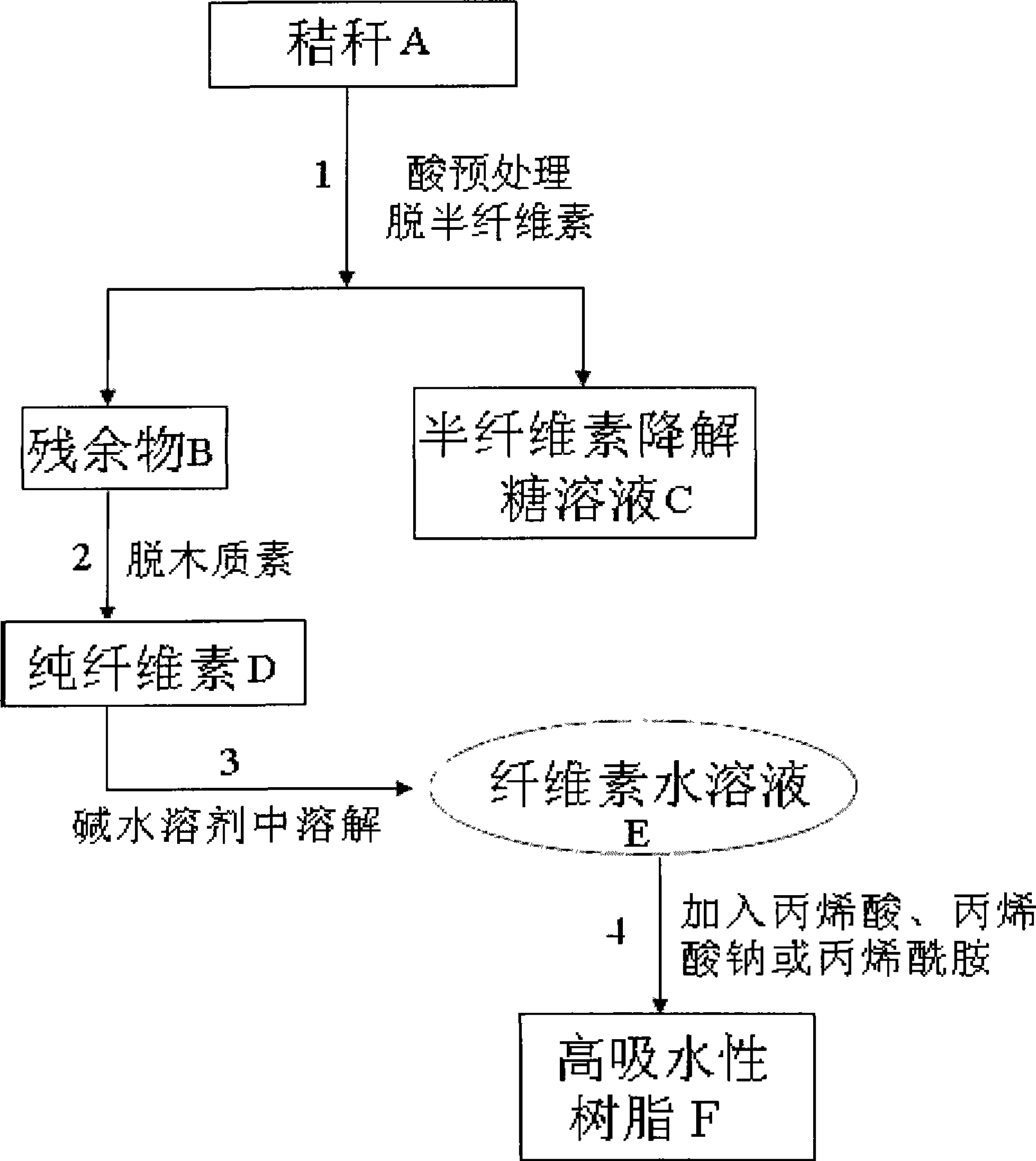

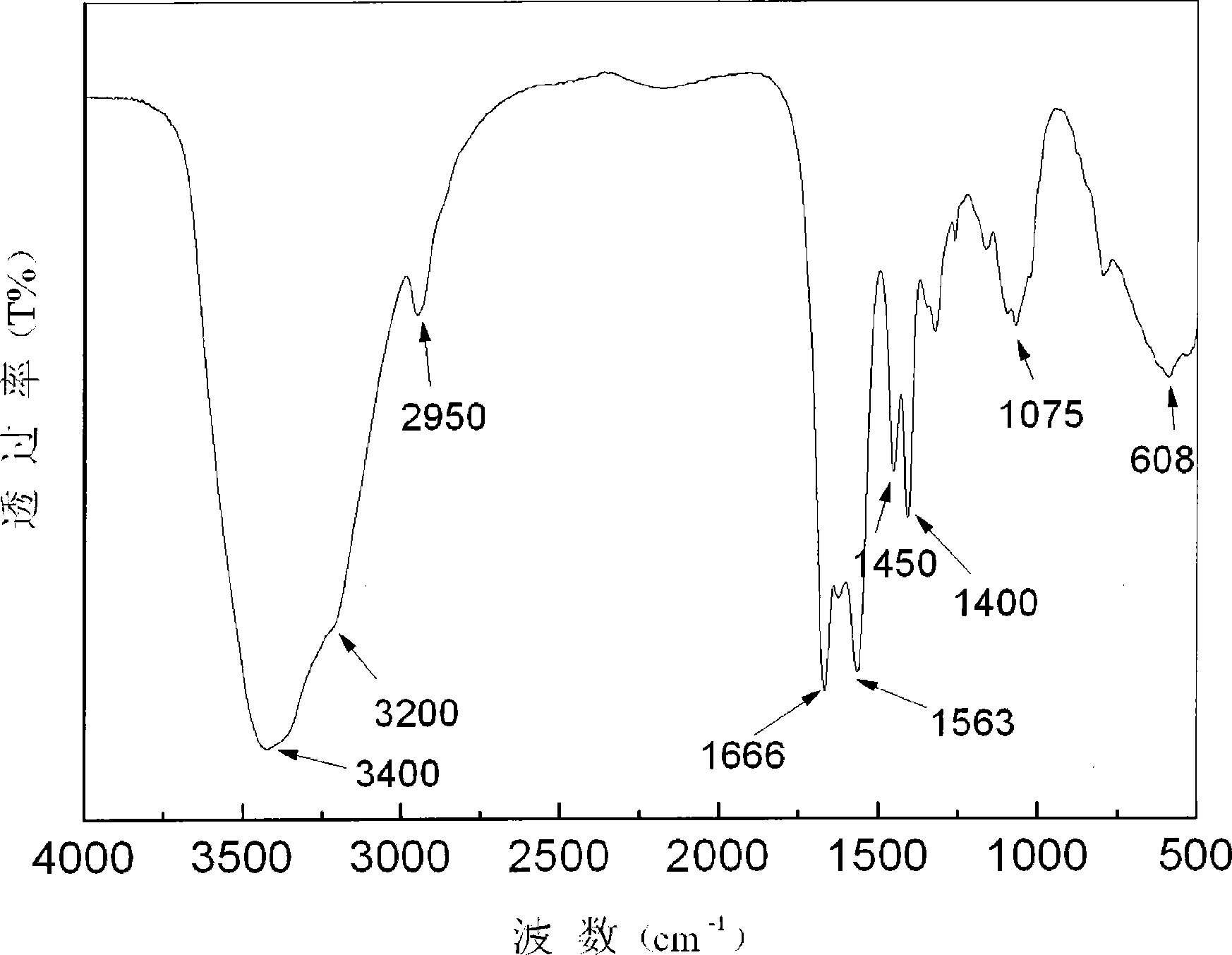

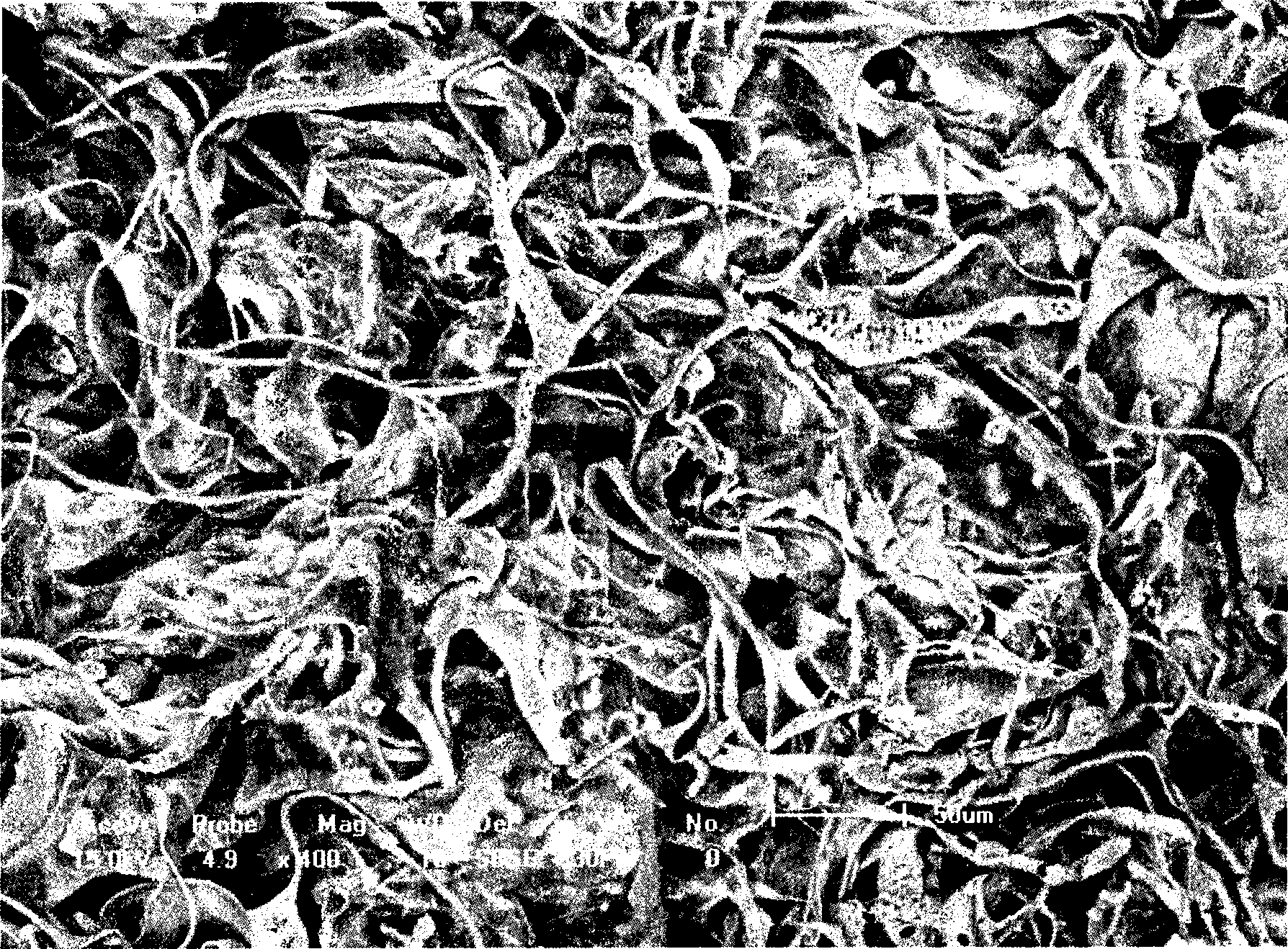

Method for preparing high-hydroscopicity resin in homogeneous aqueous medium by using straw as raw material

InactiveCN101519476AAvoid the disadvantages of microscopic heterogeneous phase separationHas biodegradable propertiesPaper material treatmentCelluloseDouble phase

The invention relates to a method for preparing high-hydroscopicity resin in uniform-phase aqueous medium by using straw as a raw material. The method comprises the following steps: adopting a double-phase saline aqueous solution system of inorganic acid and polyethylene glycol to sequentially process the straw to obtain cellulose; then, adding the cellulose to a pre-prepared sodium hydroxide-urea aqueous solution or a lithium hydroxide-urea aqueous solution; putting the solution in a refrigerator to be cooled, taking out the solution for mechanically stirring to obtain a uniform cellulose solution; afterwards, adding propenyl monomer to the obtained cellulose aqueous solution and carrying out homogeneous glycerol polymerization to obtain the high-hydroscopicity resin. The hydroscopicity resin has the advantages of low cost, high hydroscopicity and potential biodegradable characteristic and has wide application space in the fields, such as agriculture, forestry, sanitary health products, building materials, perfume emission, and the like.

Owner:UNIV OF SCI & TECH OF CHINA

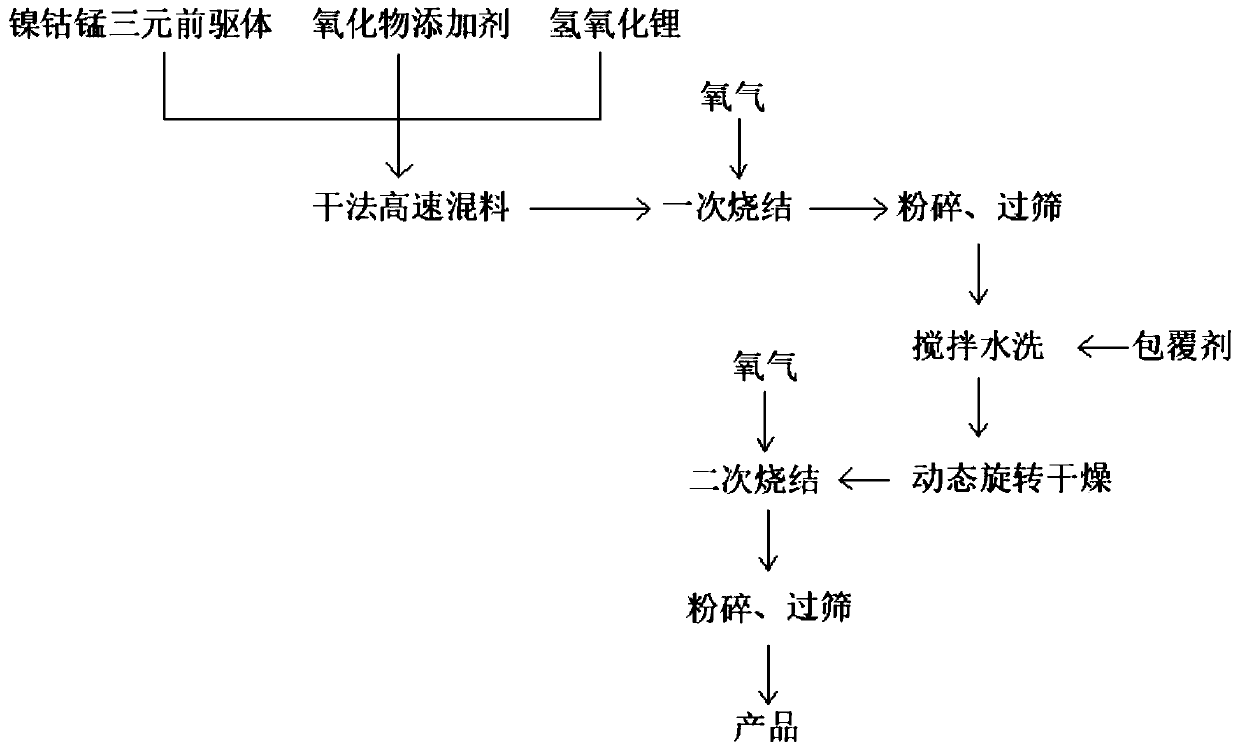

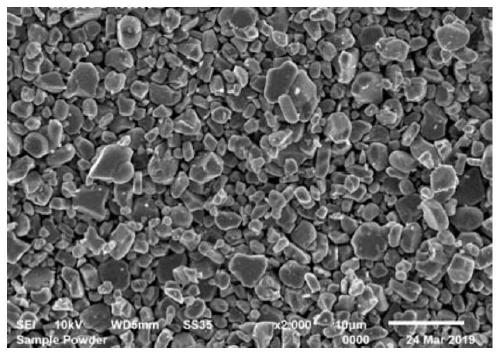

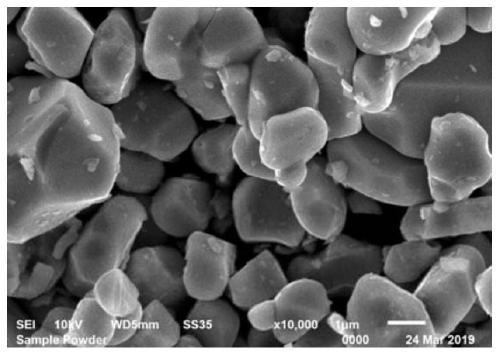

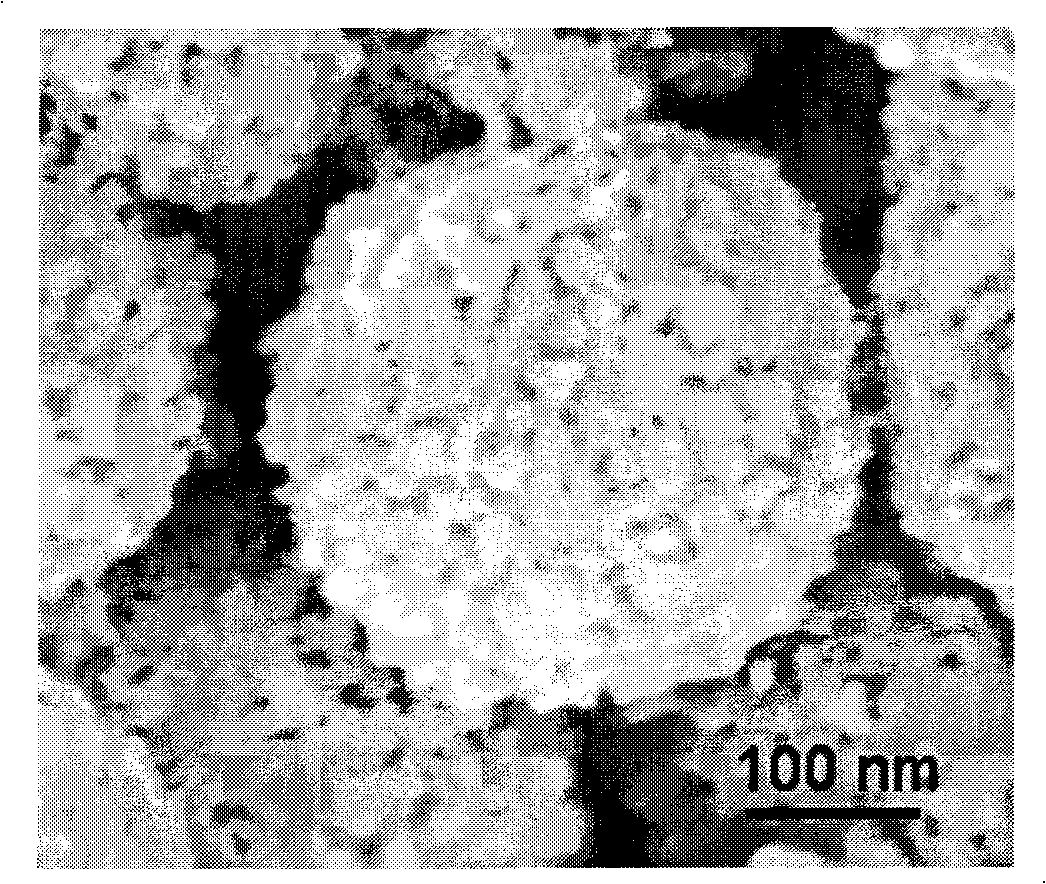

High-nickel single-crystal ternary cathode material with low surface residual alkali content and preparation method thereof

InactiveCN110436531AIn-situ encapsulationUniform coating in situCell electrodesSecondary cellsLithium hydroxideSingle crystal

The invention discloses a high-nickel single-crystal ternary cathode material with low surface residual alkali content and a preparation method thereof. The preparation method comprises the followingsteps: weighing lithium hydroxide, an oxide additive and a nickel-cobalt-manganese ternary precursor, and carrying out uniform mixing through a dry high-speed mixing process so as to prepare a mixed material; subjecting the mixed material to first sintering so as to obtain a first sintered material; crushing the first sintered material, and carrying out sieving so as to obtain a first crushed material; weighing the first crushed material, a coating agent and deionized water, and carrying out water washing under stirring so as to prepare a slurry, wherein the coating agent comprises an elementX which is one or more selected from the group consisting of B, Al, Ba, Zr, Mg, Ca, Ti, Si, V, Sc, Nb, Ta and Z; drying the slurry under a vacuum condition through a dynamic rotary drying process so as to obtain a dry material; subjecting the dry material to secondary sintering so as to obtain a secondary sintered material; and crushing the secondary sintered material, and carrying out sieving soas to obtain a product. The high-nickel single-crystal ternary cathode material and the preparation method thereof provided by the invention has the following advantages: alkali reduction by water washing and in-situ coating by a wet process can be synchronously completed; the process is simple; high compaction density is realized; and the content of residual alkali is low.

Owner:ZHEJIANG MEIDU HITRANS LITHIUM BATTERY TECHNOLOGY CO LTD

Method for preparing lithium titanate cathode material of lithium ion battery

InactiveCN101409341AExcellent high rate charge and discharge performanceElectrode manufacturing processesHigh rateLithium hydroxide

The invention discloses a preparation method of a lithium titanate cathode material for a lithium ion battery. Titanium dioxide colloid is taken as an initial raw material; the titanium dioxide colloid and lithium hydroxide are added to a mixture of water and ethanol while stirring, then the obtained solution is transferred to a hydrothermal reaction kettle for hydrothermal ion exchange reaction at 150-200 DEG C for 10-18h, the reacted solution is naturally cooled to room temperature, then filtered to obtain white precipitate; the obtained precipitate is placed in a muffle furnace with the temperature of 350-600 DEG C for 1-3h heat treatment to obtain the lithium titanate cathode material used in the lithium ion battery. The lithium titanate cathode material which is used in the lithium ion battery and synthesized by the method has stable discharge specific capacity of 125mAh / g at the rate of 20C (3.5A / g), and has good high-rate charge and discharge performance.

Owner:SHANGHAI JIAO TONG UNIV +1

Enhanced carbon dioxide adsorbent

A CO2 removal system including a member having a first opening and a second opening to enable air flow containing carbon dioxide (CO2) to pass from the first opening to the second opening and lithium hydroxide (LiOH) supported by the member and having an initial water content above an anhydrous level. In one embodiment, LiOH adsorbent density is a maximum of approximately 1.0 g / cm3.

Owner:MICROPORE

Novel method for producing lithium carbonate and lithium hydroxide

InactiveCN102115101ASimple production processLow costLithium oxides/hydroxidesLithium carbonates/bicarbonatesLithium sulphateCalcium hydroxide

The invention relates to a novel method for producing lithium carbonate and lithium hydroxide, which belongs to the technical field of production of lithium salts. The method comprises the following steps of: baking spodumene concentrate; preparing a lithium sulfate solution; preparing lithium carbonate mother liquor; and preparing lithium hydroxide, wherein the lithium hydroxide can also be obtained by adding barium hydroxide into the lithium carbonate mother liquor. The method has the advantages that: lime is added into a lithium carbonate sinker mother liquor to produce the lithium hydroxide by causticizing and transforming, and the production of lithium carbonate is combined with the production of the lithium hydroxide, so that a process flow is simplified, investment and production costs are lowered, a production process is more flexible to regulate and control, and the quality of a lithium carbonate product is more stable. By adopting the method, the mother liquor of lithium carbonate is easier to treat, impurities in the lithium hydroxide mother liquor are easy to treat, and the product quality is not influenced.

Owner:屈俊鸿

Method for preparing lithium ion battery anode material nickle cobalt lithium manganate

ActiveCN101355159AWell mixedImprove performanceCell electrodesManganates/permanganatesLithium hydroxideManganate

The invention relates to a method for preparing a LiCoxNiyMnzO2 anode material for a lithium ion battery. The method comprises the following steps that soluble salts of nickel, cobalt and manganese undergo coprecipitation to prepare composite carbonate of nickel, manganese and cobalt; then, the carbonate is reacted with lithium hydroxide; moreover, when the carbonate is converted into hydroxide, lithium is deposited on the surface of the prior particles containing nickel, cobalt and manganese in the form of lithium carbonate. In this way, even mixing of lithium and elements such as nickel, cobalt and manganese is realized to obtain a top-quality precursor for preparing the LiCoxNiyMnzO2 material; moreover, the precursor can be made into a LiCoxNiyMnzO2 product with excellent properties after twice sintering. The method has the advantages of simple and easily controlled technological process, low production cost of prepared product and stable and controllable product performance, and can be used in industrial production.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for preparing chitosan fibers

InactiveCN102199810AOvercoming instabilityEnsure no hydrolysisWet spinning methodsFibre chemical featuresFiberGlycoside

The invention discloses a method for preparing chitosan fibers, which comprises the following steps: mixing 2.0 to 6.0 weight percent of chitosan, 4.0 to 6.0 weight percent of lithium hydroxide, 0.5 to 4.0 weight percent of urea, 0.1 to 3.0 weight percent of glycerol and the balance of water, and swelling to prepare chitosan spinning solution; and spinning by a wet-process spinning method, coagulating and precipitating in a coagulating bath to form protofilaments, washing, drawing, and drying to obtain the chitosan fibers. In the invention, the spinning solution is prepared by dissolving chitosan in an alkaline solvent, the chitosan macromolecular chains exist in a high-swelling state, the arrangement of the chitosan macromolecular chains is more compact, the high instability of the chitosan in acidic solution is overcome, the hydrolysis of the chitosan macromolecular chains and the breakage of the glucosidic bonds are avoided, the oriented arrangement of the macromolecular chains is promoted, and the mechanical properties of the chitosan fibers are improved.

Owner:ZHEJIANG UNIV

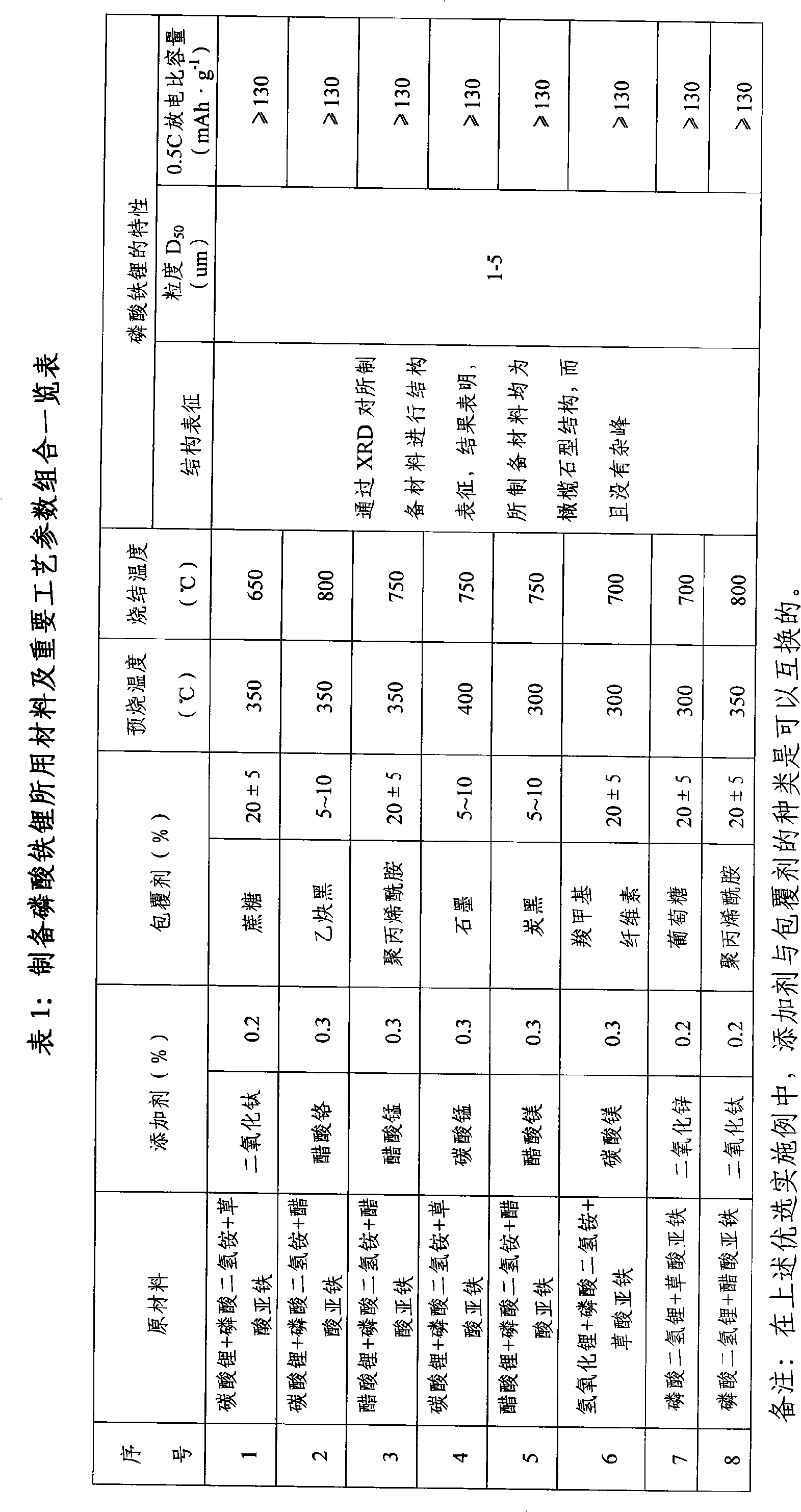

Preparation of lithium iron phosphate positive electrode material for lithium ion power cell

InactiveCN101339995ANo danger of flammabilityImprove securityElectrode manufacturing processesPhosphorus compoundsWater wetPhosphate

The invention discloses a preparation method of a lithium iron phosphate anode material used in a lithium-ion power battery. The preparation method takes ammonium dihydrogen phosphate and lithium carbonate or lithium hydroxide or lithium acetate and ferrous oxalate or ferrous acetate or takes the lithium dihydrogen phosphate and the ferrous oxalate or ferrous acetate as raw materials, the raw materials are prepared according to the ratio of Li, P and Fe of 1:1:1 or the ratio of LiH2PO4 to Fe of 1:1, and is added with micro amount of nano-metallic oxide or metal salt. After the process of mixing by a water wet method, spraying, drying, rolling and prilling, the mixture is pre-sintered for 10 minus or plus 2 hours at the constant temperature of 300-400 DEG C and is clad with carbon for prilling after being cooled; and then after the process of mixing by the water wet method, spraying, drying, rolling and prilling, the mixture is sintered for 10 minus or plus 2 hours at the temperature of 650-800 DEG C and then is cooled to obtain the lithium iron phosphate which is made after being crashed by gas stream and being compacted. The preparation method has the prominent advantages of safe preparation process, simple operation procedure, easy realization of industrialization and stable material performance of the product.

Owner:中国兵器工业第二一三研究所

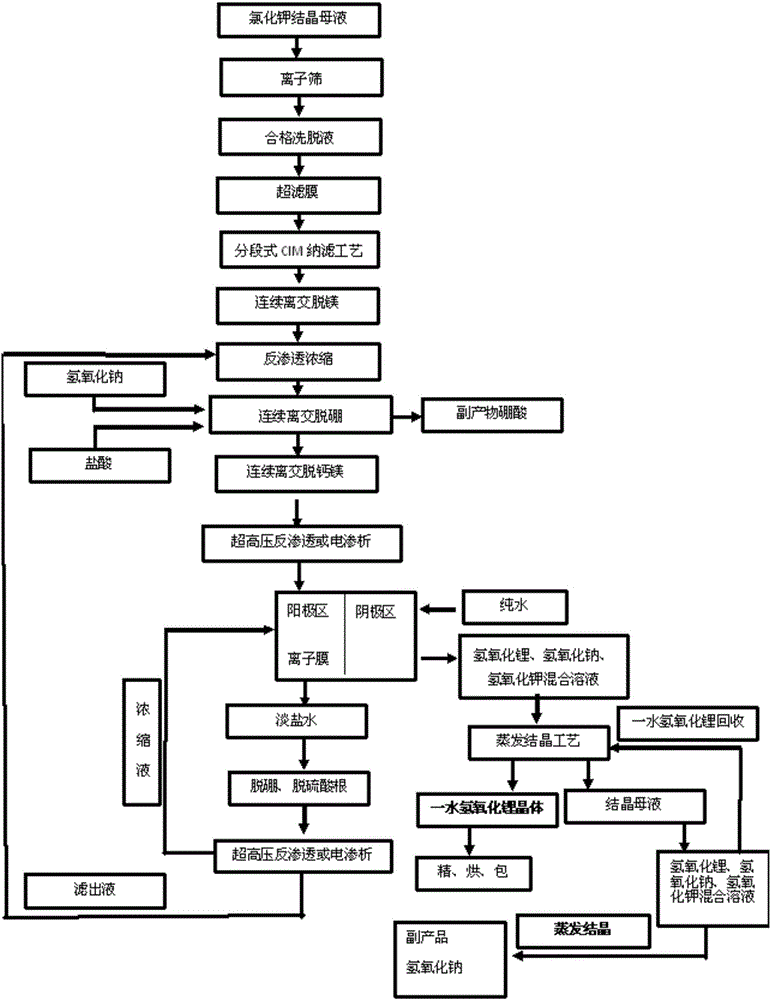

Production method of high-purity lithium hydroxide

ActiveCN106011917AHigh yieldReduce consumptionCellsBoron-oxygen compoundsLithium hydroxideUltrafiltration

The present invention relates to a production method of high-purity lithium hydroxide. A crystallization mother liquor waste water is obtained after production of potassium chloride by using a salt lake bittern as the raw material, a magnesium-lithium ratio of the crystallization mother liquor waste water is 200-500:1, an eligible eluant is obtained through ion sieve adsorption and elution of the crystallization mother liquor waste water, and after treatment of the eluant through the ultrafiltration membrane technology, the sectional type nanofiltration technology, the external regeneration continuous hybridization technology and the reverse osmosis technology, a reverse osmosis concentrated solution is obtained. In the reverse osmosis concentrated solution, the content of magnesium ions is <=300 ppm, the content of lithium ions is 4-6 g / L, the content of sodium ions is 3-5 g / L, the content of calcium ions is <=5 ppm, the content of sulfate ions is 1-30 ppm and the content of boron is <=400 ppm. According to the production method provided by the present invention, the reverse osmosis concentrated solution is used as the raw material, the process comprises ultrahigh pressure reverse osmosis continuous hybridization for boron-removing, continuous hybridization for sulfate radical removing, ion-exchange membrane electrolysis, and crystallizing evaporation, and by using the hybridization boron-removing technology, the ion-exchange membrane electrolysis technology and the crystallizing evaporation technology, the high-purity lithium hydroxide is obtained, with the byproducts being the boric acid and sodium hydroxide. The process is continuous, controllable, high in extraction rate, low in production cost and easy to industrialize.

Owner:启迪清源(上海)新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com