Hydrothermal synthesis method for lithium ferromanganese phosphate anode material of lithium ion battery

A technology of lithium manganese iron phosphate and lithium-ion batteries, which is applied in the direction of battery electrodes, phosphorus compounds, chemical instruments and methods, etc., can solve the problems of not having high capacity and specific energy, and achieve the purpose of increasing specific capacity and specific energy, reducing The effect of cost and great application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Reactor: The effective volume is 1000L, heated by heat conduction oil jacket.

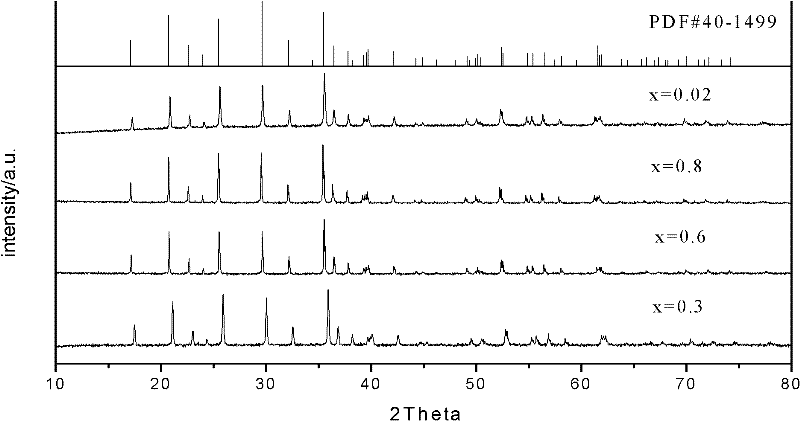

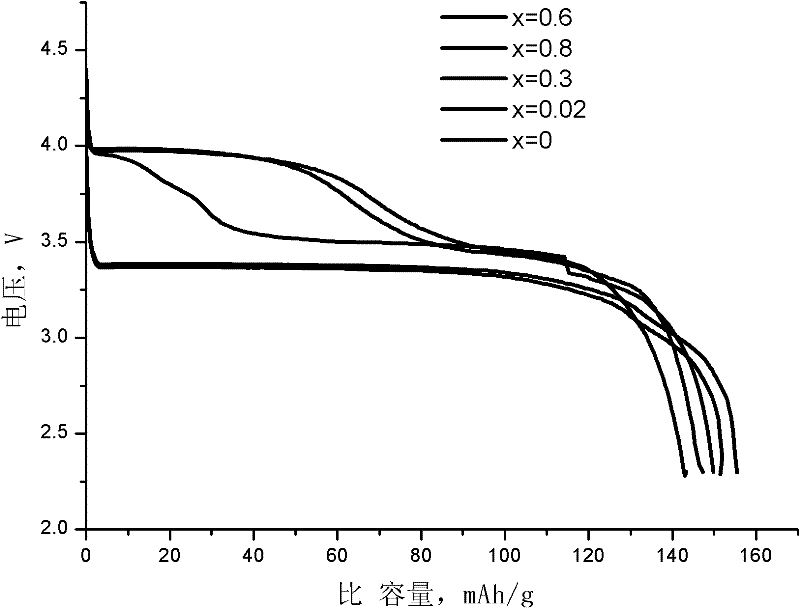

[0039] The first step, hydrothermal synthesis reaction to prepare the basic material LiMn 0.6 Fe 0.4 PO 4 (Li:M:P=3.00:1.00:1.03, x=0.6)

[0040] Weigh 44.5kg or 0.16kmol of FeSO4 ·7H 2 O and 40.56kg or 0.24kmol of MnSO 4 ·H 2 O is dissolved in water and diluted to 400L. After standing for 2 hours, filter with a precision filter to remove a small amount of insoluble matter; weigh 47.5kg of 85% phosphoric acid, which is 0.412kmol of phosphoric acid, and 44.2kg of 1.05kmol of LiOH. h 2 O is dissolved in water and diluted to 400L. Filter with a precision filter for later use.

[0041] Vacuum first, then pass nitrogen gas to purge the reactor to remove the air in it, add water seal to the air outlet to seal the autoclave, open the feeding valve, at room temperature, first add phosphoric acid, then add ferrous sulfate and manganese sulfate mixture. Stirring was started at a speed of 200...

Embodiment 2

[0066] The first step, hydrothermal synthesis reaction to prepare the basic material LiMn 0.8 Fe 0.2 PO 4

[0067] Weigh 2.22kg or 0.008kmol of FeSO 4 ·7H 2 O and 5.41kg or 0.032kmol of MnSO 4 ·H 2 O was dissolved in water and diluted to 400L. After standing for 10 hours, filtered to remove a small amount of insoluble matter; weighed 5.3kg of 85% phosphoric acid (0.046kmol of phosphoric acid), and 5.37kg of 0.128kmol of LiOH·H 2 O is dissolved in water and diluted to 400L. Filter and set aside.

[0068] Vacuum first, then pass nitrogen gas to purge the reactor to remove the air in it, add water seal to the air outlet to seal the autoclave, at room temperature, first add phosphoric acid, then add lithium hydroxide solution. Stirring was started at a speed of 300 rpm, and the mixed solution of ferrous sulfate and manganese sulfate was added into the reaction kettle, and the feeding time was 2 minutes. Then seal the autoclave, set the temperature of the heat transfer oil...

Embodiment 3

[0082] The first step, hydrothermal synthesis reaction to prepare the basic material LiMn 0.3 Fe 0.7 PO 4

[0083] Weigh 40.1kg or 0.144kmol of FeSO 4 ·7H 2 O and 56.76kg or 0.336kmol of MnSO 4 ·H 2 O was dissolved in water and diluted to 400L. After standing for 12 hours, filtered to remove a small amount of insoluble matter; weighed 58.1kg of 85% phosphoric acid (0.504kmol of phosphoric acid), and 62.4kg of 1.49kmol of LiOH·H 2 O is dissolved in water and diluted to 400L. Filter and set aside.

[0084] Vacuum first, then pass nitrogen gas to purge the reactor to remove the air in it, add water seal to the air outlet to seal the autoclave, at room temperature, first add the mixed solution of ferrous sulfate and manganese sulfate into the reactor from the feeding port , then add phosphoric acid, start stirring, the rotating speed is 300rpm, then add lithium hydroxide solution, and the feeding time is 5 minutes. Then seal the autoclave, set the temperature of the heat tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com