Patents

Literature

3502 results about "Hydrothermal synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrothermal synthesis includes the various techniques of crystallizing substances from high-temperature aqueous solutions at high vapor pressures; also termed "hydrothermal method". The term "hydrothermal" is of geologic origin. Geochemists and mineralogists have studied hydrothermal phase equilibria since the beginning of the twentieth century. George W. Morey at the Carnegie Institution and later, Percy W. Bridgman at Harvard University did much of the work to lay the foundations necessary to containment of reactive media in the temperature and pressure range where most of the hydrothermal work is conducted.

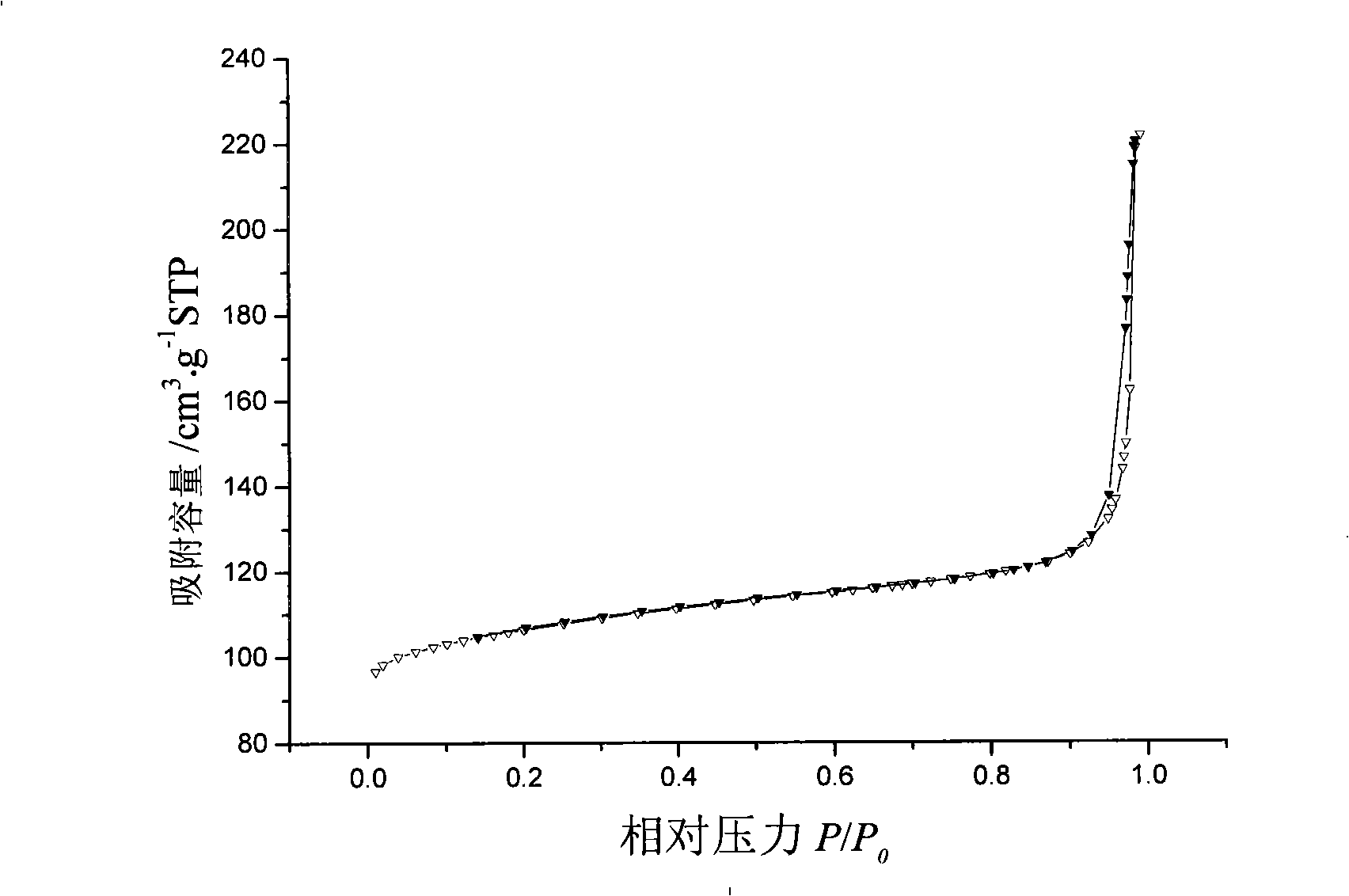

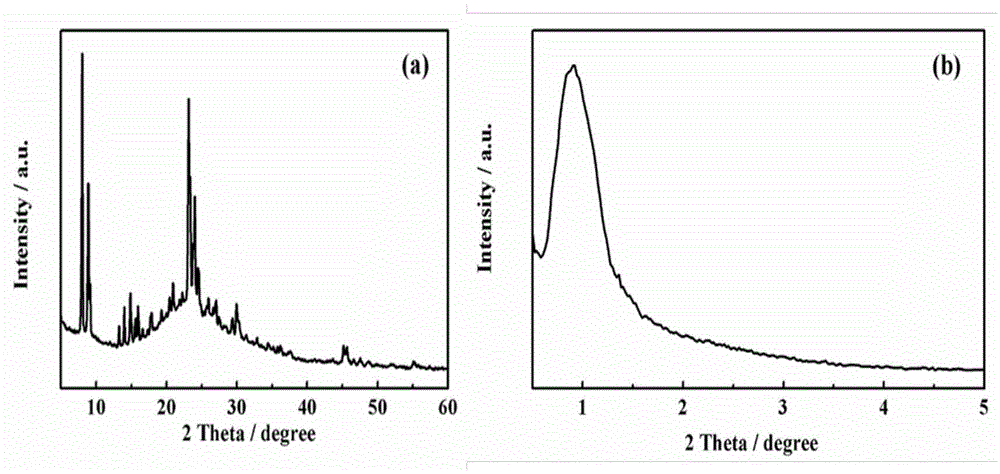

Preparation method of mesonic pore molecular sieve carrier material

The present invention belongs to the field of inorganic nanometer material technology, in particular, it relates to a method for preparing mesoporous molecular sieve carrier material by using diblockmacromolecular polymer. It is characterized by that under the acid condition it uses polyoxyethylene-polyoxybutylene diblock macromolecular surfactant as template agent and makes hydrothermal synthesis at 100 deg.C to prepare mesoporous silicon oxide material with two-dimensional hexagonal structure with high degree of order and large specific surface area and laminate silicon oxide material withhigh degree of order. These new material can be used as catalyst, catalyst carrier, adsorption film, organic-inorganic composite material, sensor and chromatographic packing, etc.

Owner:FUDAN UNIV

Method for quick-speed preparing aerogel by hydro-thermal synthesis at low cost

InactiveCN101456569AReduce surface tensionIntegrity guaranteedSilicaAlkali metal silicatesReaction temperatureHydrothermal synthesis

The invention discloses a method for preparing aerogel materials by combining hydrothermal synthesis technology and sol-gel technology. The prepared aerogel comprises one or more of alumina aerogel, silica aerogel, zirconia aerogel and titania aerogel. The method comprises the following steps: mixing a reactant and a structure-directing agent according to certain proportion, and adding a pH value control agent to adjust the pH value; sealing hydrothermal reaction equipment, heating the mixture to be between 50 and 280 DEG C, making the mixture stand for 0 to 72 hours, raising the temperature to be between 60 and 300 DEG C, and continuously reacting for 0.1 to 72 hours; and cooling gel, taking out the gel, drying the gel and obtaining the aerogel. Compared with the prior art, the method has low reaction temperature and pressure, small equipment investment and simple and controllable technology, reduces potential safety hazards, greatly improves the preparation speed of the aerogel, saves the production cost, and is favorable to realize commercial mass production.

Owner:纳诺科技有限公司 +1

Manganese-based composite oxide catalyst for catalytically decomposing ozone, and preparation method of manganese-based composite oxide catalyst

ActiveCN102600861AAchieve decentralizationAchieve catalytic effectDispersed particle separationPerfluorocarbons/hydrofluorocarbons captureAir treatmentHydrothermal synthesis

The invention relates to a manganese-based composite oxide catalyst for catalytically decomposing ozone, and a preparation method of the catalyst. The catalyst comprises manganese oxide and at least one transition metal oxide. The preparation method is a homogeneous precipitation method or a hydrothermal synthesis method. The manganese-based composite oxide catalyst adopts innocuous and non-poisonous materials, prepares a manganese-based composite oxide catalyst with high catalytic activity, good wet resistance and high catalytic deposition content by the simple and easy method, so that the catalyst is suitable for catalytically decomposing ozone produced in water or air treatment and modern industry and home appliance.

Owner:上海棕晟企业管理合伙企业(有限合伙)

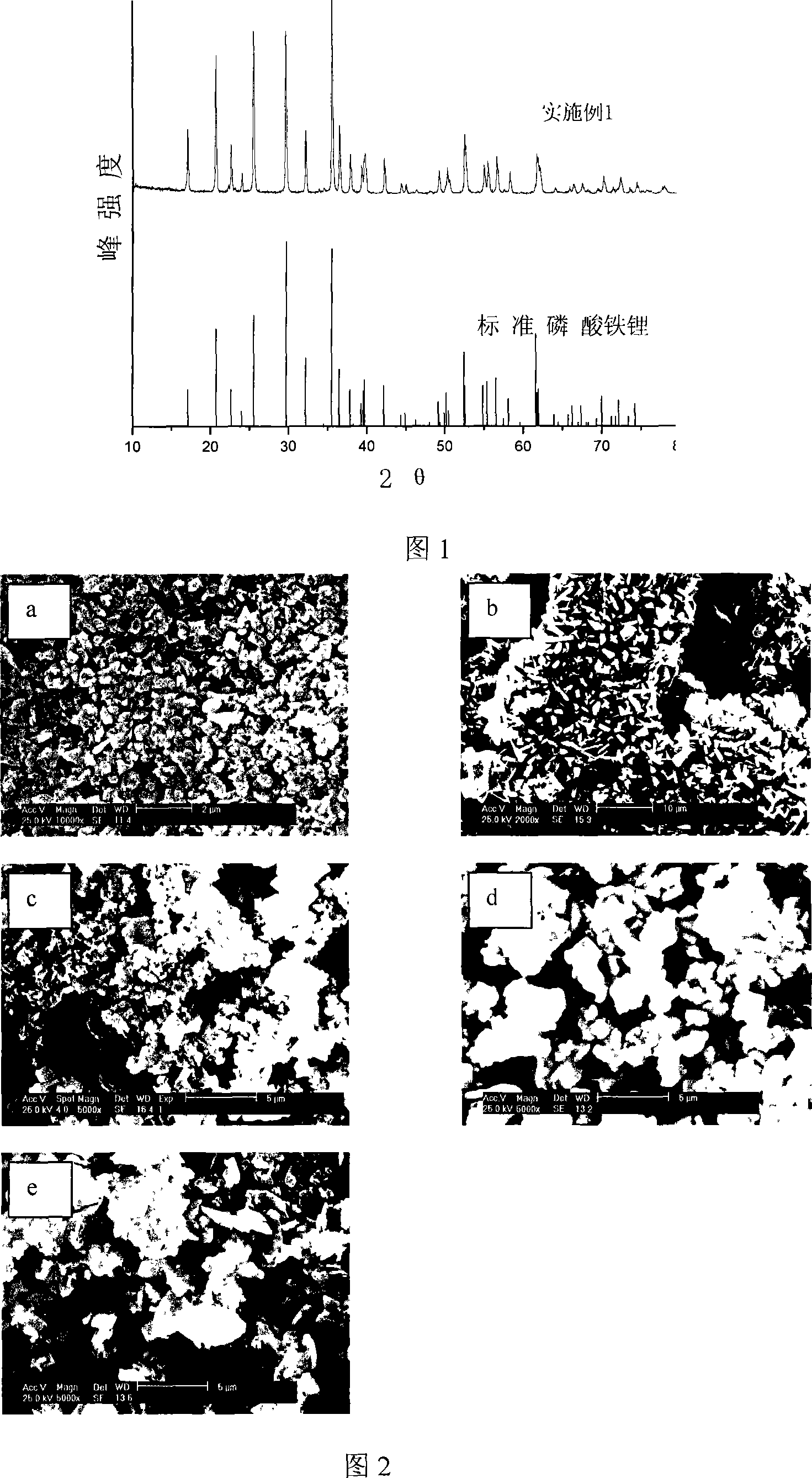

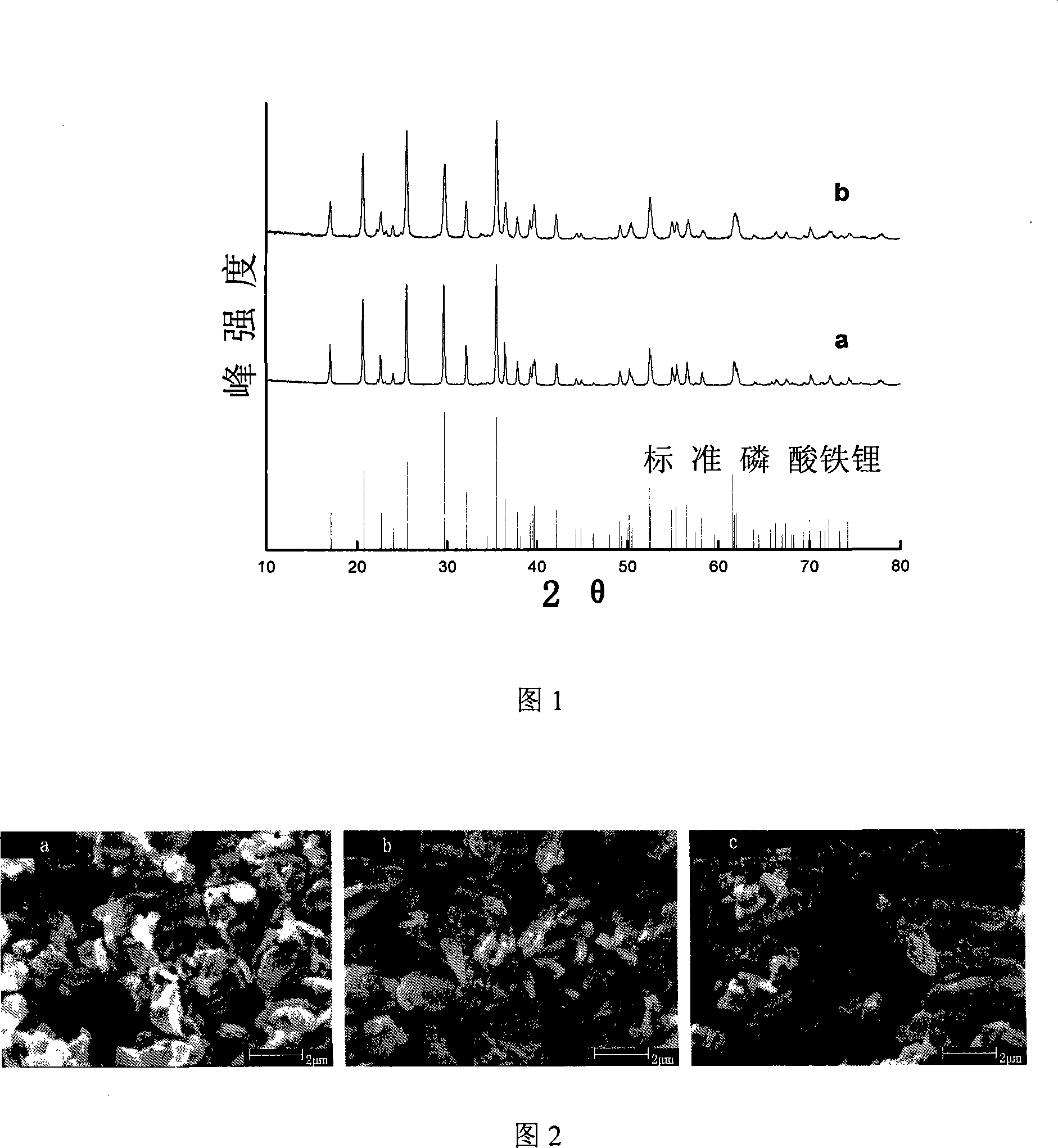

Hydrothermal synthesis method for lithium ion-cell anode material of ferric phosphate lithium

InactiveCN101117216AImprove electrochemical performanceShorten the diffusion pathCell electrodesPhosphorus compoundsExhaust valveDead volume

The invention discloses a hydrothermal synthesis method of lithium-ion battery anode material of lithium iron phosphate, relating two kinds of metal phosphate. The steps are as follows: lithium source and phosphorus source are dissolved in water or mixed with water, and added into the reaction autoclave, the quaternary cationic surfactants and the alkylphenols polyoxyethylene ethers nonionic surfactant is also added into the reaction autoclave, the air in the dead volume of the autoclave inside is purged by the inert gas, the autoclave is sealed and heated to 40-50 DEG C with stirring, a feed valve and an exhaust valve are opened, pure ferrous salting liquid is added into the autoclave, and then the autoclave is sealed for the reaction of the material at 140 to 180 DEG C for 30 to 480 minutes; the mixture ratio of the invention is set as follows: the molar ratio of Li, Fe and P is 3.0-3.15:1:1.0-1.15, and then the resultant is filtered, washed, dried and carbon-coated, thus the lithium iron phosphate is obtained. The lithium iron phosphate which is produced by the invention has the advantages that: the electrochemical performance is excellent, the particle size distribution of which the D50 is between 1.5 um to 2 um is even, the phase purity is above 99 percent and the electronic conductivity of the material is improved.

Owner:HEBEI LITAO BATTERY MATERIAL

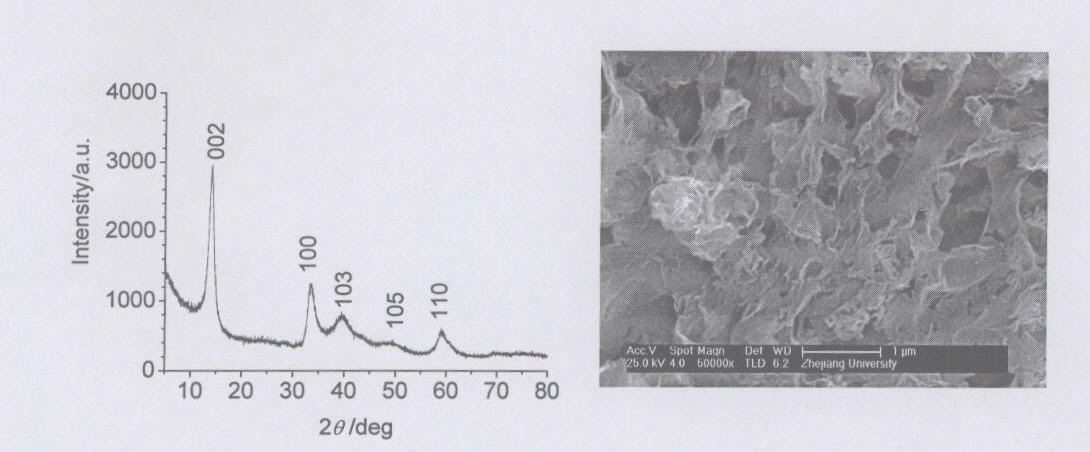

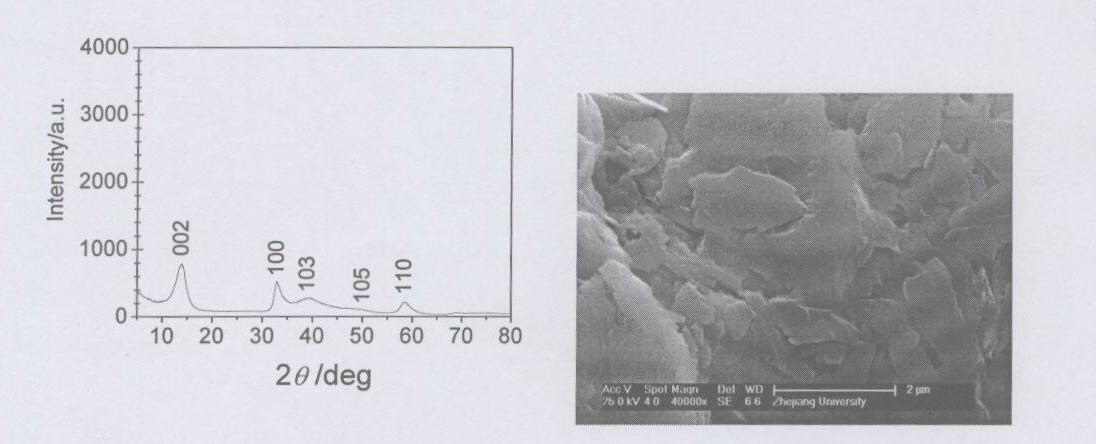

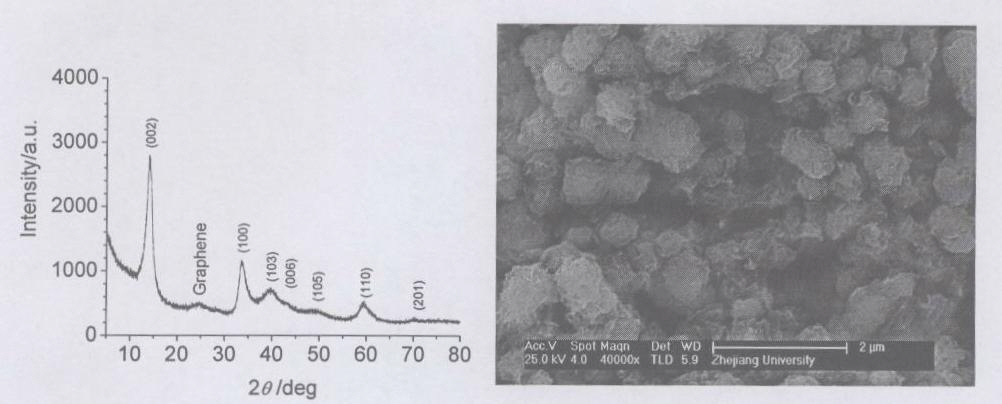

Graphene nano sheet/MoS2 composite nano material and synthesis method thereof

InactiveCN102142551AMild reaction conditionsSimple processMaterial nanotechnologyCell electrodesSynthesis methodsThiourea

The invention discloses a graphene nano sheet / MoS2 composite nano material and a synthesis method thereof. The method comprises the following steps of: preparing a graphite oxide nano sheet from graphite by using a chemical oxidation method, then dissolving molybdate into deionized water to form a solution of 0.02 to 0.07M, and adding thioacetamide or thiourea serving as a sulfur source and a reducer, wherein the mass ratio of the thioacetamide or the thiourea to the molybdate is 5:1-12:1; and adding the graphite oxide nano sheet into the solution, performing ultrasonic treatment for 1 to 2 hours so that the graphite oxide nano sheet is fully dispersed in a hydrothermal reaction solution, transferring the mixture into a hydrothermal reaction kettle, sealing, reacting for 20 to 36 hours at the temperature of between 220 and 260 DEG C, and obtaining the graphene nano sheet / molybdenum disulfide composite nano material by one-step hydrothermal synthesis, wherein the mass ratio of the graphene nano sheet to the molybdenum disulfide in the composite material is 1:2-4:1. The method has the characteristics of mild reaction condition and simple process. The synthesized graphene nano sheet / molybdenum disulfide composite nano material serving as an electrochemical lithium storage and electrochemical magnesium storage electrode material has wide application.

Owner:ZHEJIANG UNIV

Hydro-thermal synthetic preparation method for lithium ion battery anode material lithium iron phosphate

InactiveCN101121509AImprove electrochemical performanceHigh purityCell electrodesPhosphorus compoundsPhosphateInlet valve

The present invention relates to a hydrothermal synthesis preparation method of a lithium iron phosphate of an anode material used by a lithium ion battery, concerning a phosphate containing two metals. The step is that a lithium source and a phosphor source are solubilized into the water or mixed with the water and then put into a high pressure kettle. After the air in the kettle is blown out by an inert gas, the high pressure kettle is sealed and heated to a temperature between 40 DEG C and 50 DEG C from a room temperature after being stirred. An inlet valve and a vent valve are opened and then a prepared divalent ferric salt liquor is added in. The high pressure kettle is sealed and the reaction time lasts from 200 minutes to 480minutes at the temperature between 140 DEG C and 170 DEG C. At the time, the inner pressure corresponding to the system is from 0.36 MPa to 0.85 MPa. The mixture rate of the added substance is Li: Fe: P and the mol ratio is 3.0-3.15: 1: 1.0-1.15. When the reaction starts, the reactant concentration is from mol / L 0.2 to 1.0mol / L, computed according to the concentration of the ferrous ion and then the resultant is filtrated, cleaned, dried and coated with the carbon. Finally the lithium iron phosphate product can be obtained. The present invention has the advantages of simple technology, good batch stability, good electrochemical performance and even distribution. The purity quotient can be more than 99 percent and the grain diameter D50 is between1.5Mu m and 2Mum.

Owner:HEBEI UNIV OF TECH

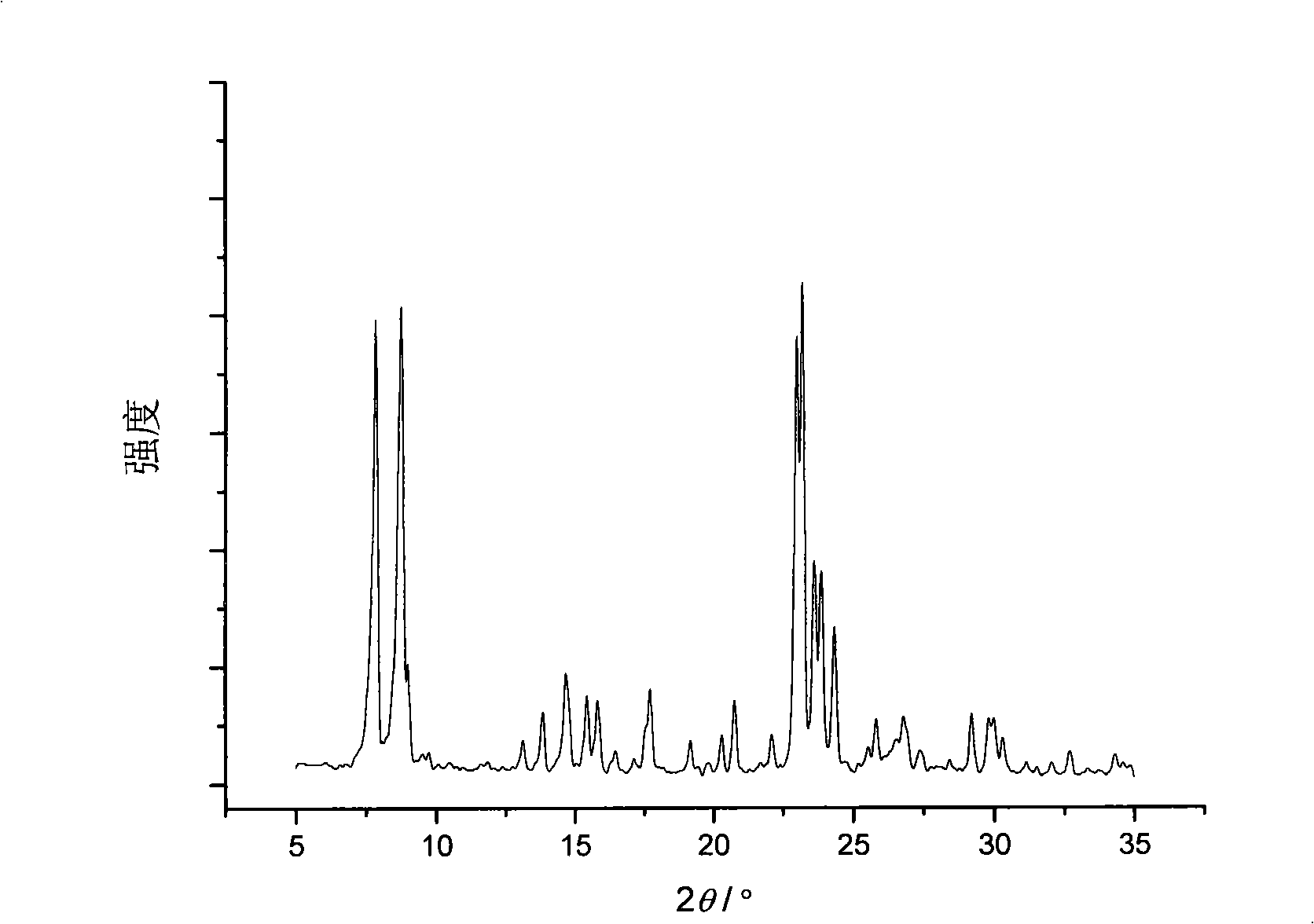

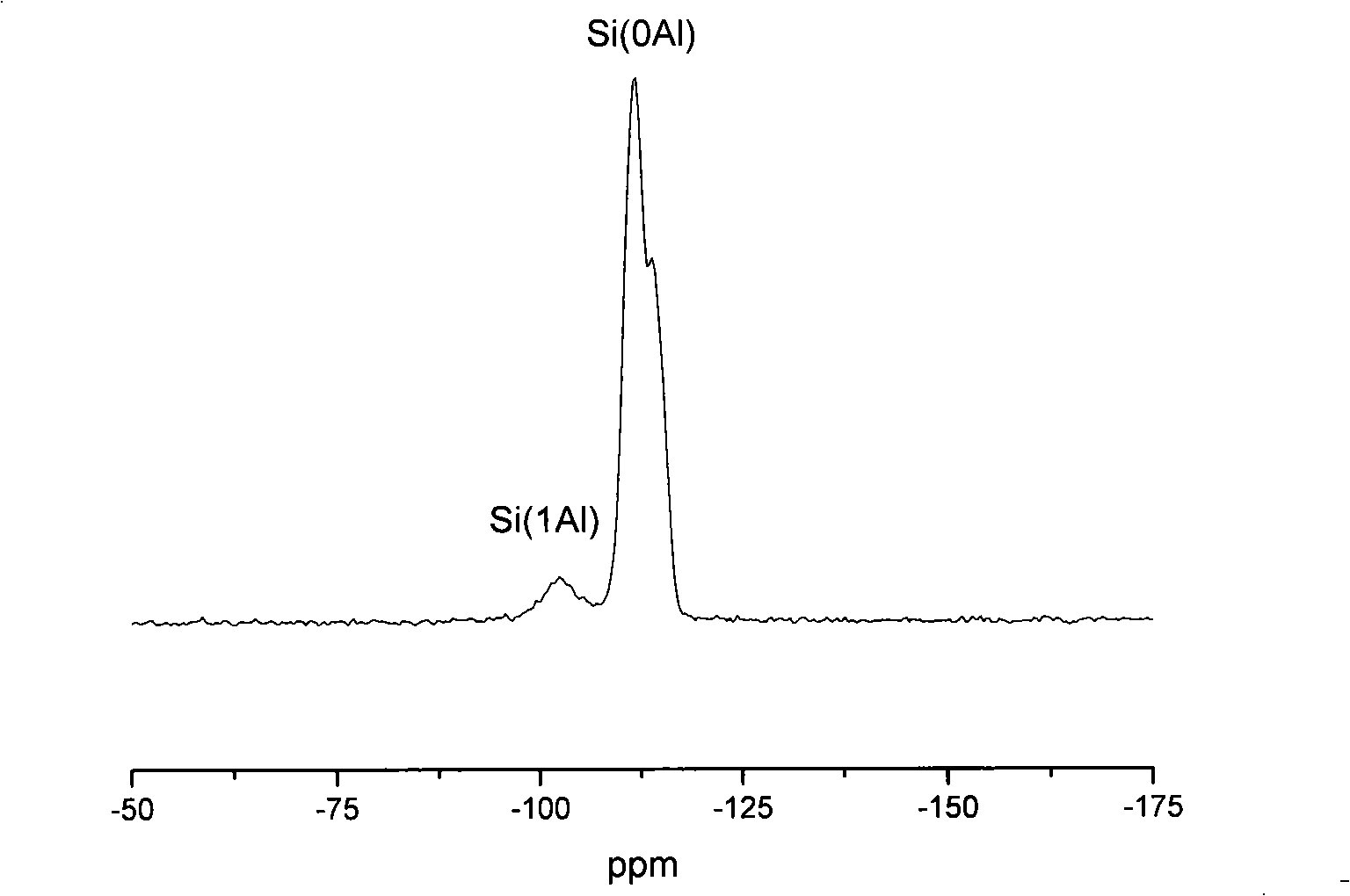

High silicon-aluminum ratio ZSM-5 zeolite catalyst, preparation method and application thereof

InactiveCN101269340ASkeleton silicon aluminum ratio is highHigh reactivityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsHydrothermal synthesisSilicon

The invention belongs to the catalyst technical field, in particular to a ZSM-5 zeolite catalyst characterized by high ratio of silica and alumina as well as a preparation method and the application thereof. The catalyst, taking a pure silicon compound with activity as a silicon source, is made by a hydrothermal synthesis method by adding trace aluminum. The ratio of silica and alumina in the zeolite catalyst is over 1,000, sub-micron crystal particles with open channels have large surface area and good molecular diffusivity. The catalyst in the reaction of MTP has excellent catalytic activity, high selectivity of propylene, and high ratio of propylene and ethylene. The catalyst has simple regeneration method and good restoration of performance after regeneration.

Owner:FUDAN UNIV

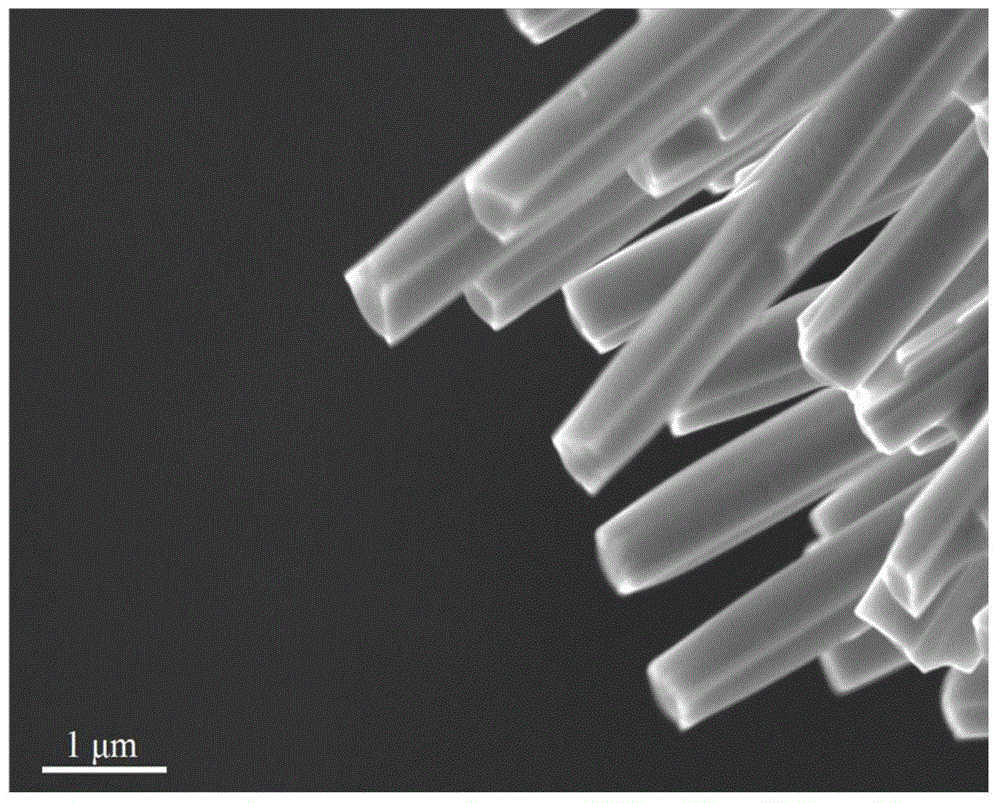

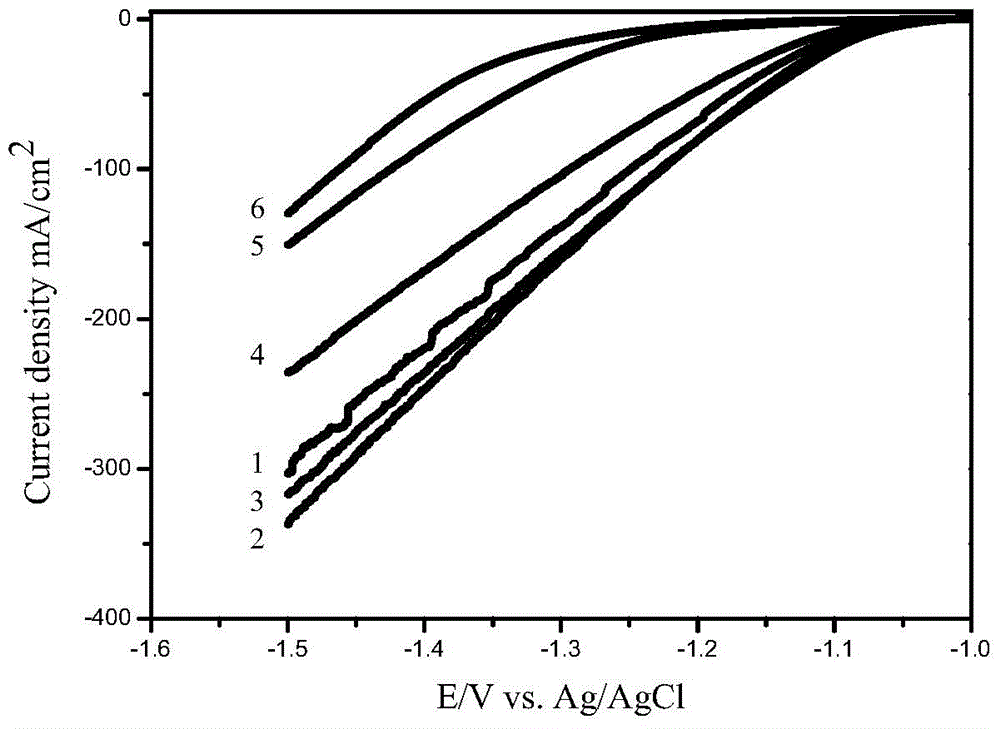

Method for preparing high-performance molybdenum-based hydrogen evolution electrode by phosphatizing molybdate precursor

The invention provides a method for preparing a high-performance molybdenum-based hydrogen evolution electrode by phosphatizing a molybdate precursor and belongs to the fields of water electrolysis and electric catalytic hydrogen evolution in the chlor-alkali industry. The method comprises the steps of pre-processing foamed nickel, growing the molybdate precursor in situ on the surface of a pre-processed foamed nickel base with the hydrothermal synthesis method, and finally placing the prepared precursor and a phosphorus source into a rube furnace together for phosphating of the molybdate precursor so that the high-performance molybdenum-based hydrogen evolution electrode can be prepared. The method is novel, the technology adopted is simple, production cost is low, the requirement for equipment is low, and the method is suitable for industrial production. Furthermore, the electrode is large in specific area, can be combined with the base firmly, has excellent hydrogen evolution activity and stability, and can be widely applied to the fields of water electrolysis and hydrogen evolution in the chlor-alkali industry.

Owner:CHONGQING UNIV

Preparation method of one-step hydrothermal synthesis of carbon/molybdenum disulfide composite microsphere

InactiveCN1994896AUniform particle sizeSimple methodVanadium oxidesMolybdenum sulfidesSucroseMicrosphere

The invention discloses a making method of carbon / molybdenum disulfide composite microball through water heat method, which comprises the following steps: dissolving molybdate in the deionized water to form 0.02-0.1m solution; adding thioacetamide or sulfourea as sulfur source with molar rate of thioacetamide or sulfourea and molybdate at 31-51; stirring evenly; adding glucose or sucrose as carbon source with the molar rate of glucose or sucrose and molybdate at 51-251; stirring completely; transmitting solution into water heat reacting autoclave to react under 200-240 deg. c for 20-24h; cooling naturally; separating; washing; drying to obtain the product.

Owner:ZHEJIANG UNIV

Controllable synthetic method of graphitized carbon spheres with hollow structure

InactiveCN103193223AHas a microporous structureWith mesoporous carbon support structureMaterial nanotechnologyCarbon compoundsHydrothermal synthesisOrganic chemistry

The invention provides a controllable synthetic method of graphitized carbon spheres with a hollow structure. The controllable synthetic method comprises the following steps of: (1) dissolving a carbon source, soluble metal salts and a catalyst in deionized water according to proportioning, stirring till completely dissolving, transferring to a hydrothermal reaction kettle for hydro-thermal synthesis, and washing, filtering and drying precipitates to obtain primary products; (2) reducing the primary products at a high temperature in a high-temperature reaction furnace under the production of gas; and (3) placing the products obtained through reduction in an acid solution for soaking, and washing, filtering and drying to obtain the graphitizing carbon spheres with the hollow structure. The graphitizing carbon spheres with the hollow structure have the advantages that the morphology is uniform, the carbon shells are of microcellular structures, the interiors of the carbon spheres are of mesoporous support structures, the graphitization degree is good, and the like. The graphitizing carbon spheres can be used in numerous fields of high-efficiency catalytic conversion, energy source storage and transition, medicine release control, matter adsorption and separation and the like. An invented formwork-free hydrothermal synthesis technology is simple and controlled and can be used for large-scale production.

Owner:CHINA UNIV OF MINING & TECH

Method for preparing equal dispersion ferric phosphate lithium nano crystal by hydrothermal synthetis method

InactiveCN101047242AExcellent inert environmentElectrode manufacturing processesPhosphateFerrous salts

A method for preparing uniformly scattered nanocrystal of iron-lithium phosphate by hydrothermal synthesis includes using ferrous salt and phosphoric acid as well as lithium hydroxide as raw materials to obtain reaction pioneer matter under temperature of 40-100deg.c first, then reacting on obtained pioneer matter in high pressure reactor with temperature of 150-200deg.c under hydrothermal condition and processing obtained product by high temperature under protection of inert gas to finally obtain said uniformly scattered nanocrystal with average particle diameter of 0.2-0.5micron.

Owner:胜利油田华鑫石油材料有限公司

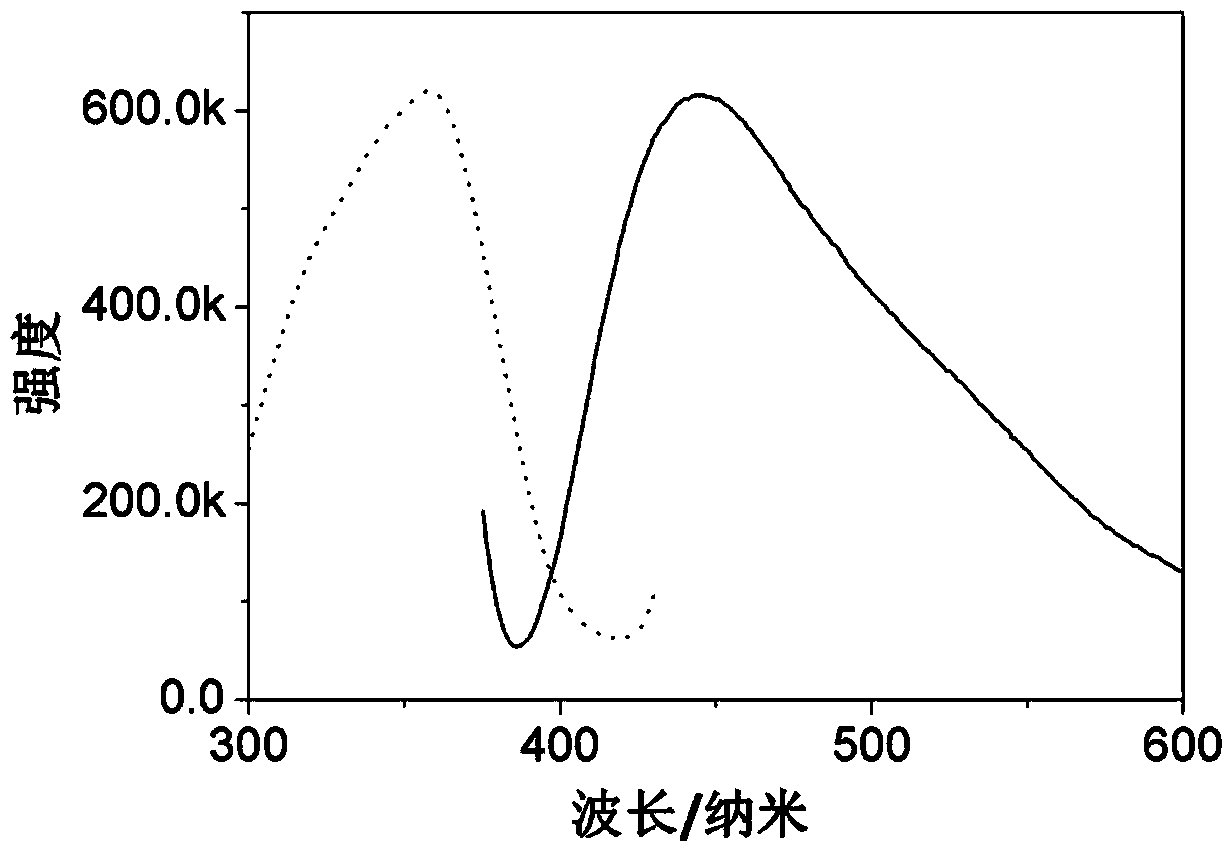

Preparation method of carbon quantum dots with adjustable fluorescence colors

InactiveCN103663412AHigh yieldImprove quantum efficiencyNano-carbonFluorescence/phosphorescenceUltraviolet lightsTumor cells

The present invention relates to a preparation method of carbon quantum dots with adjustable fluorescence colors, and belongs to the technical field of nanometer materials. According to method, citric acid or a citrate is adopted as a carbon source, a nitrogen-containing compound is adopted as a nitridation agent, hydrogen peroxide is adopted as an oxidant, a hydrothermal synthesis method is adopted to obtain an aqueous solution of carbon quantum dots emitting blue or green fluorescence under ultraviolet light excitation, reaction conditions are easily controlled, and the method is suitable for scale production. The prepared carbon quantum dots have advantages of adjustable fluorescence color, high yield, high quantum efficiency, good result reproducibility and the like, wherein the product can be directly used for tumor cell labeling and live cell imaging labeling. According to the present invention, only the one reactant is required, the raw materials are easily-available and non-toxic, the production process does not require special protection, the reaction condition is easily controlled, and the obtained carbon quantum dots have advantages of high yield, high quantum efficiency, good result reproducibility and the like; and the method has characteristics of high yield, simple preparation process, low cost, easy scale production and the like.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

Controllable synthesis method of N-doped graphitized carbon ball with hollow structures

InactiveCN103183341AWith mesoporous carbon support structureLow priceMaterial nanotechnologyCarbon compoundsSynthesis methodsHydrothermal synthesis

The invention discloses a controllable synthesizing method of an N-doped graphitized carbon ball with hollow structures. The method comprises the following steps: (1) dissolving silicon source, soluble metal salt and a catalyst to the solvent according to the molar ratio, transferring the solvent to the thermal water kettle to conduct hydro-thermal synthesis after being stirred until being thoroughly dissolved, and cleaning, filtering and drying the sediment to obtain a primary commodity; (2) reducing the primary commodity at high temperature under the protection of gas in a high-temperature reaction furnace; and (3) soaking the product obtained by high-temperature reducing in acidic solution, and obtaining the graphitized carbon ball nitrogen doping with the hollow structure after cleaning, filtering and drying. The graphitized carbon ball with the hollow structures provided by the invention has the advantages that the carbon sphere has a uniform appearance, the carbon shell has millipore structures, a mesoporous carbon support structure is formed inside the carbon sphere and a better graphitize degree is provided, and can be used in the field of high-efficient catalyzing and transforming, energy storage and transforming, medicine releasing, substance adsorptive separation and the like. The non-template hydrothermal synthesis technique provided by the invention is simple and controllable, and can be used in large scale production.

Owner:CHINA UNIV OF MINING & TECH +1

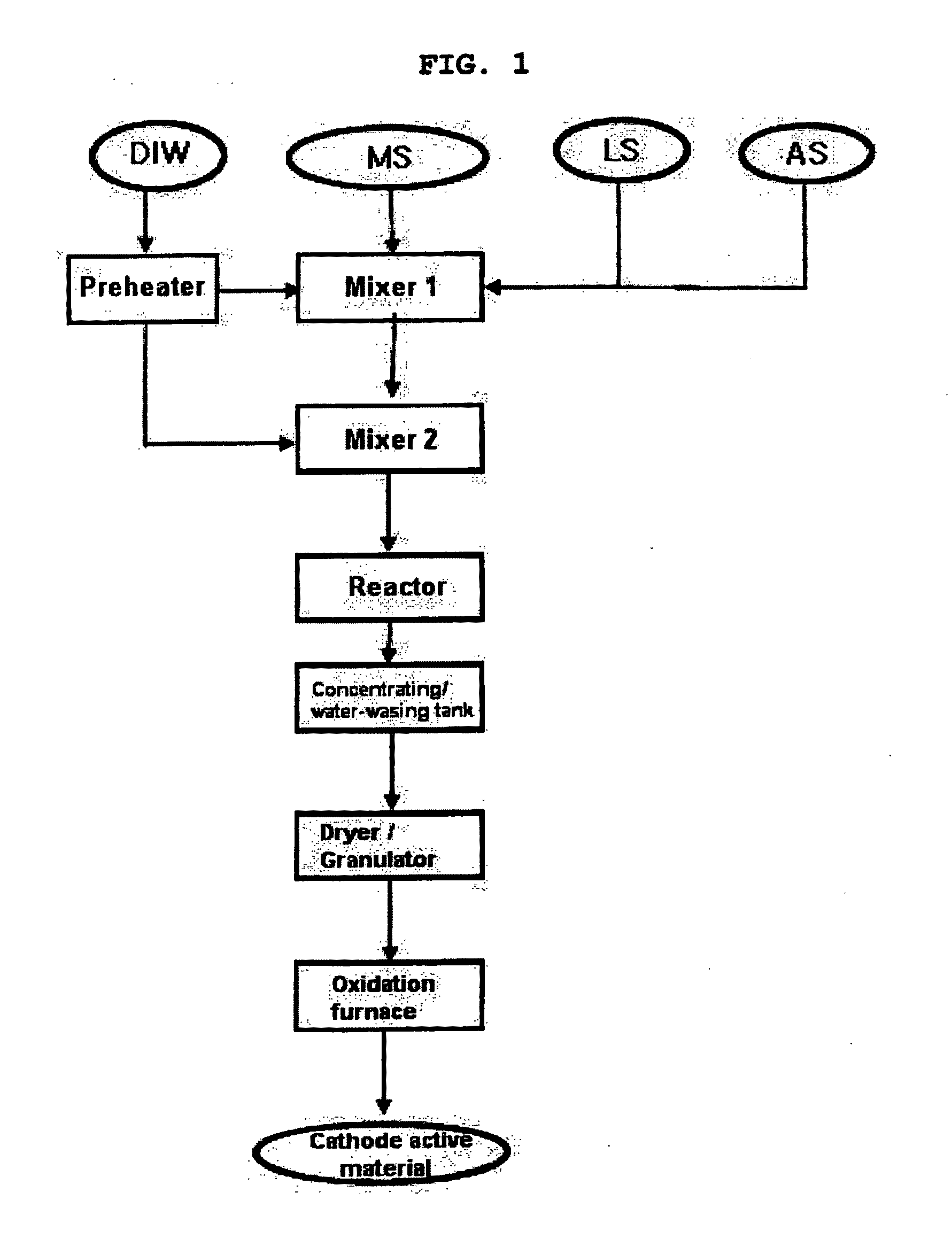

Preparation Method of Lithium-Metal Composite Oxides

ActiveUS20100227221A1High Capacity FeaturesImproved cycle life characteristicsLithium compoundsActive material electrodesLithium metalElectrochemistry

Disclosed is a method for preparing a lithium-metal composite oxide, the method comprising the steps of: (a) mixing an aqueous solution of one or more transition metal-containing precursor compounds with an alkalifying agent and a lithium precursor compound to precipitate hydroxides of the transition metals; (b) mixing the mixture of step (a) with water under supercritical or subcritical conditions to synthesize a lithium-metal composite oxide, and drying the lithium-metal composite oxide; and (c) subjecting the dried lithium-metal composite oxide either to calcination or to granulation and then calcination. Also disclosed are an electrode comprising the lithium-metal composite oxide, and an electrochemical device comprising the electrode. In the disclosed invention, a lithium-metal composite oxide synthesized based on the prior supercritical hydrothermal synthesis method is subjected either to calcination or to granulation and then calcination. Thus, unlike the prior dry calcination method or wet precipitation method, a uniform solid solution can be formed and the ordering of metals in the composite oxide can be improved. Accordingly, the lithium-metal composite oxide can show crystal stability and excellent electrochemical properties.

Owner:HANWHA CHEMICAL CORPORATION +1

Titanium dioxide/graphene nanocomposite material and preparation method and application thereof

InactiveCN102569761AShape is easy to controlControllable surface structureCell electrodesGraphene nanocompositesHigh energy

The invention relates to a titanium dioxide / graphene nanocomposite material, a preparation method of the nanocomposite material and application of the nanocomposite material in the field of energy source and cleaning environment. The graphene accounts for 1-25wt% and the balance is titanium dioxide. Morphology of the titanium dioxide is a mesoporous structure or a structure with a dominant high energy surface, and titanium dioxide is scattered uniformly on the surface of graphene. According to the invention, by adopting a titanium source and graphene as initial materials, and water or organic solvents as reaction solvents, the nanocomposite material with titanium dioxide with the mesoporous structure or a titanium dioxide nano sheet with the dominant high energy surface compounded with graphene can be obtained through hydrothermal synthesis or a hydrolysis reaction. The invention can be carried out in an aqueous solution system and the crystallinity of the product is high. The composite material can be applied to a cathode material of a power ion battery, has a higher charge-discharge capacity, is excellent in high current charge and discharge, stable in circulating performance, has very good photocatalytic performance and can be used to light degradation of organic pollutants and water photolysis for preparing hydrogen.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

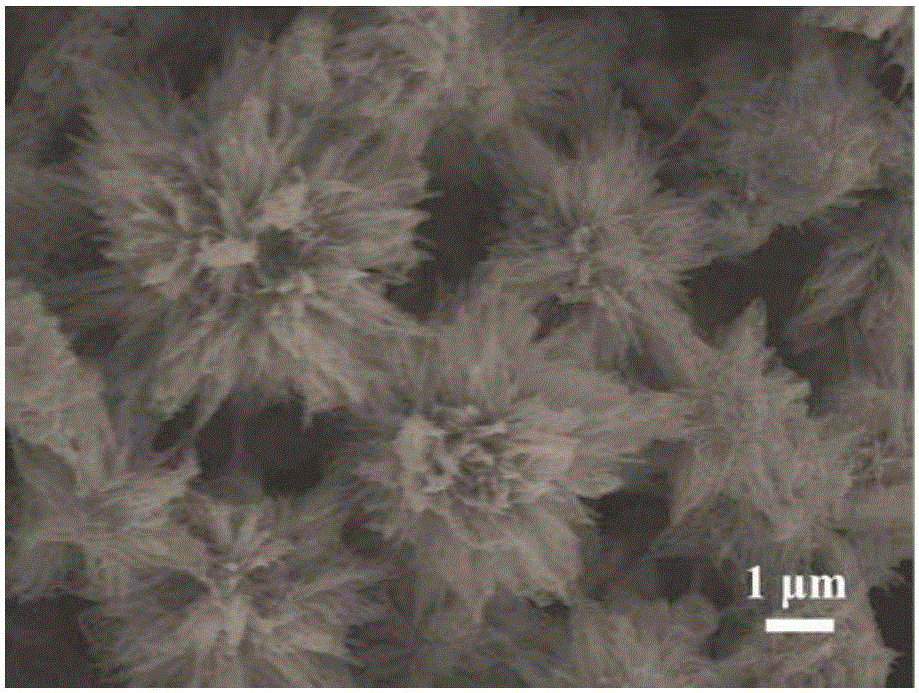

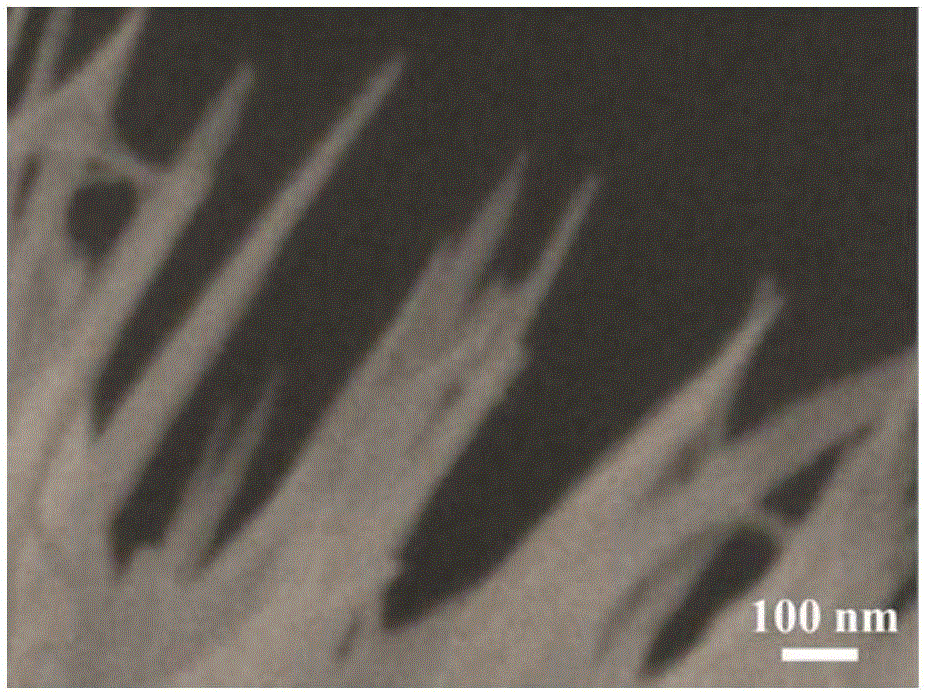

Hydrothermal synthesis method of molybdenum disulfide nano flowers

InactiveCN103613137AAvoid direct exposureGuaranteed purityNanotechnologyMolybdenum sulfidesAir exposureSulfur

The invention discloses a hydrothermal synthesis method of molybdenum disulfide nano flowers. The hydrothermal synthesis method mainly comprises the following steps: adding an inorganic molybdenum source, an organic sulfur source and a proper amount of reducing agent into deionized water, uniformly mixing the ingredients, transferring the mixture into a high pressure reaction kettle, and then heating the mixture at a high temperature for 24 hours; washing and centrifugally separating the obtained solution for multiple times, and finally drying the solution to obtain black solid powder, namely, the molybdenum disulfide nano flowers. The hydrothermal synthesis method disclosed by the invention has the beneficial effects that the whole reaction and drying process is carried out in a sealed environment to avoid direct air exposure so as to ensure the product purity; since the reducing agent adopted by the hydrothermal synthesis method disclosed by the invention can be both used as the sulfur source and as a catalyst, no impurity is generated, and thus, the product purity is further improved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

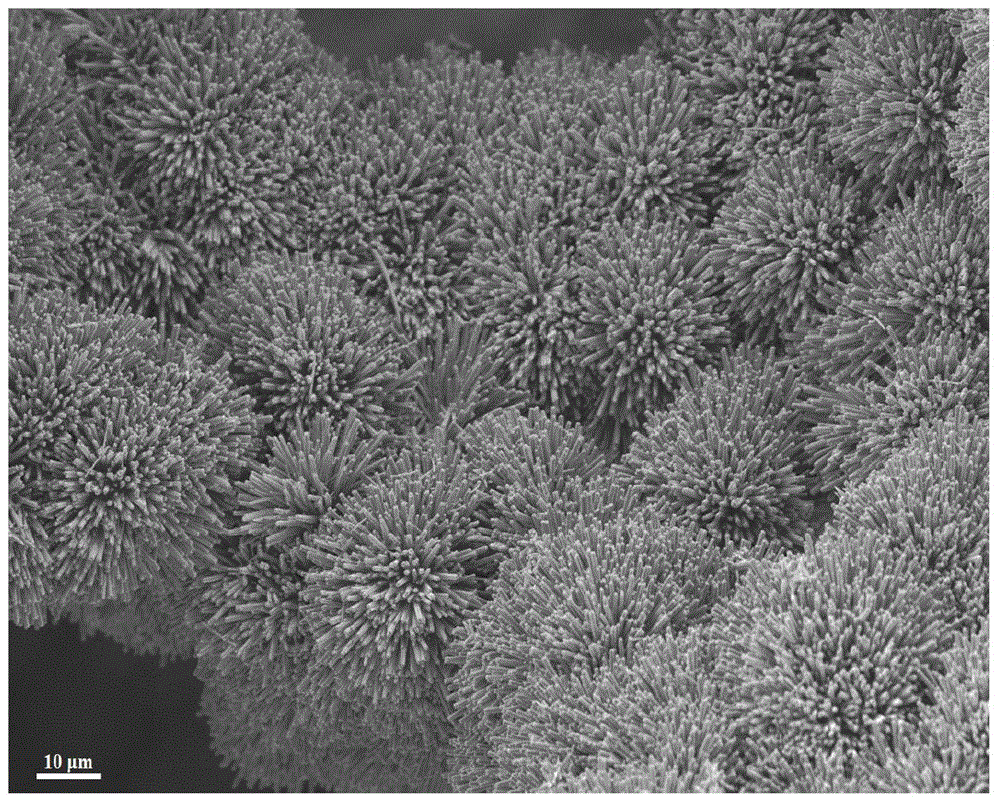

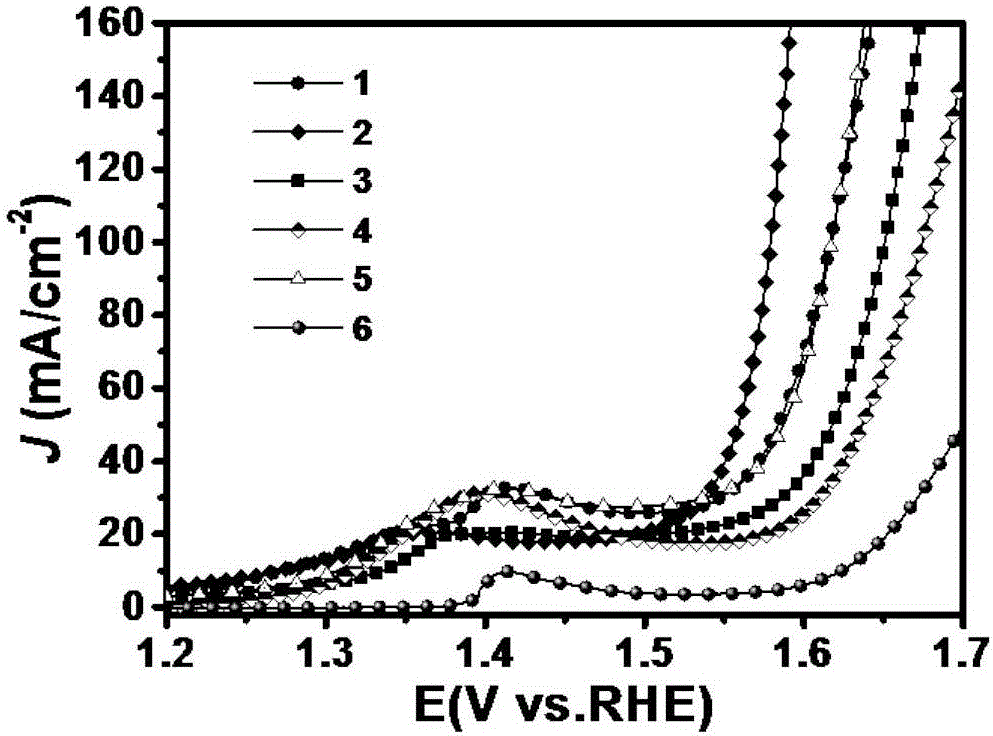

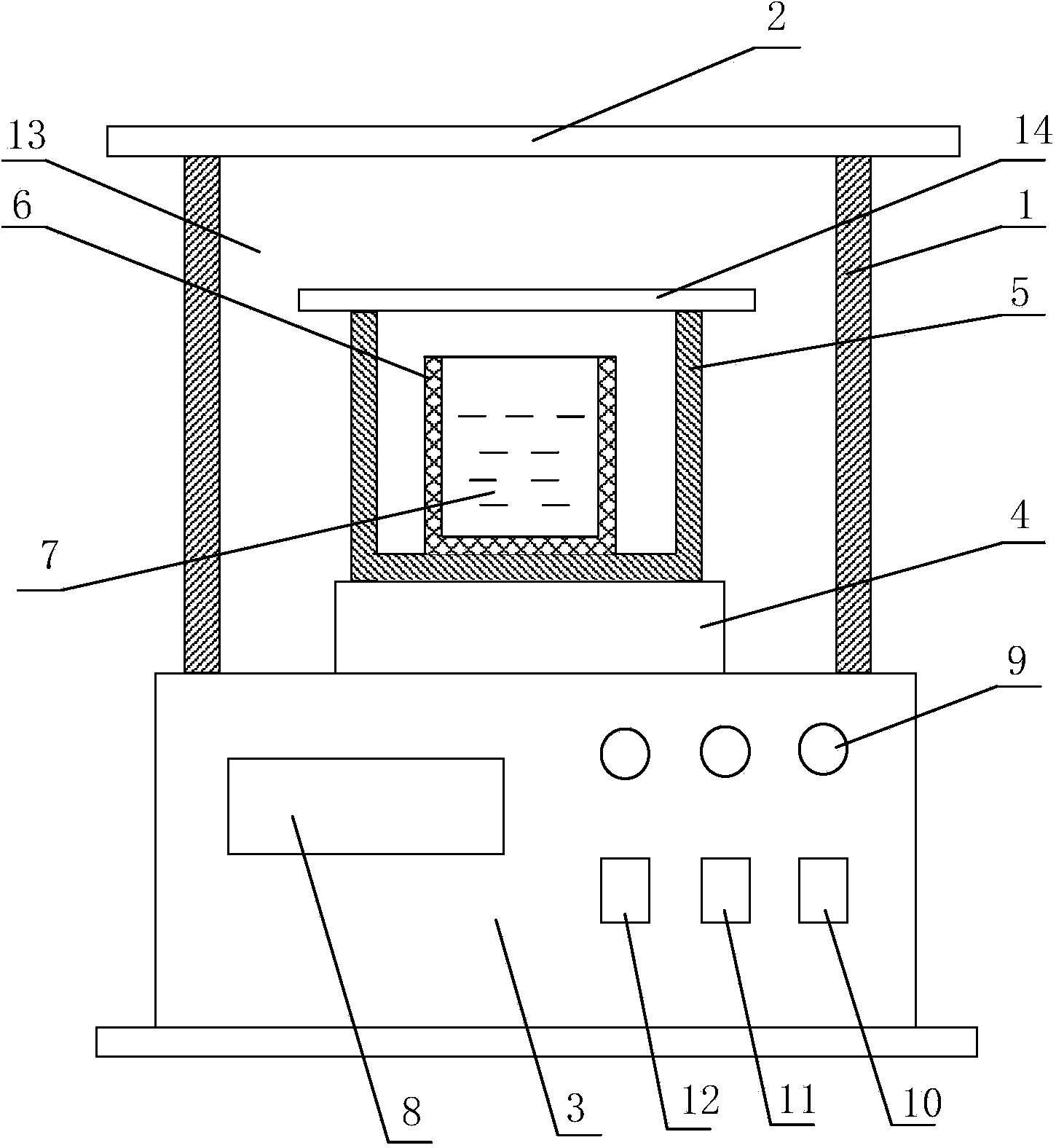

Method of partial vulcanization to improve oxygen evolution electrode performance of metal hydroxide

InactiveCN106011911AIncrease intrinsic activityImprove bindingPhysical/chemical process catalystsElectrodesVulcanizationHydrothermal synthesis

The invention provides a method of partial vulcanization to improve oxygen evolution electrode performance of metal hydroxide and belongs to the field of oxygen evolution catalyzation of electrolysis of water. The method comprises the following steps: firstly, pretreatment is carried out on nickel foam, then, special nano floriform metal hydroxide is formed on the surface of the nickel base after the pretreatment in an in-situ growth manner through the hydrothermal synthesis method, and finally, the prepared metal hydroxide and a sulphur source have hydrothermal reaction to prepare a hydroxyl metal sulfide oxygen evolution electrode. According to the invention, the method is novel, the demanded technology is simple, the production cost is low, requirements to equipment are lower, and industrial production is suitable; in addition, the prepared electrode has excellent oxygen evolution activity and stability, is large in specific surface area, firmly combines with a base, and can be applied to the field of oxygen evolution through industrial electrolysis of water.

Owner:CHONGQING UNIV

Synthetic method of visible light catalyst Bi2MoO6

InactiveCN101254463AEvenly dispersedSmall particle sizeMetal/metal-oxides/metal-hydroxide catalystsMolybdateSynthesis methods

A synthetic method of a novel visible light photocatalyst Bi2MoO6 (bismuth molybdate) is provided. The method includes the following steps: weighing Bi(NO3)3*5H2O and (NH4)6Mo7O24*4H2O solids at the theoretical ratio by mass of 14:1, dispersing the weighed solids into an appropriate amount of deionized water, stirring to obtain white curdy precipitates, placing the precipitates in a magnetic stirrer and stirring at normal temperature for 30 minutes, subjecting to ultrasonic treatment with a ultrasonic generator for 30 minutes to allow intensively mixing, allowing reactions of the treated white precipitates at 150-200 DEG C under sealed conditions, filtering the reaction product to collect flavescent precipitates, washing, drying, and grinding to obtain Bi2MoO6 (bismuth molybdate) photocatalyst. The photocatalyst has good photodegradation effect on target pollutants; and when the temperature of hydrothermal synthesis is 160 DEG C, the removal rate of target pollutant 4BS after photodegradation for 90 minutes reaches 99.5%. The inventive synthetic method has the advantages of simple process and low requirement for equipment, and is suitable for the synthesis of highly-active visible light photocatalyst Bi2MoO6 (bismuth molybdate).

Owner:NANJING UNIV

Method for preparing water-soluble fluorescent carbon dots

The invention relates to a method for preparing water-soluble fluorescent carbon dots. The method comprises the following steps: by adopting a citric acid as a carbon source, urea as a passivator and a dopant and deionized water as solvents aiming at the conditions that the fluorescent carbon dots are high in accuracy and difficult to synthesize, preparing a carbon dot water solution by adopting a hydrothermal synthesis method; and preparing the carbon dots by the following processes of preparing the solution, air-tight reaction, filtering, dialyzing, freezing and drying, and grinding. The technology is advanced in process, rapid and efficient, accurate and specific in data, and good in product shape; the product is green powder particles; and the diameters of the particles are smaller than or equal to 5.5nm; the product is high in purity which can be up to 99%, and good in water-solubility which can be up to 99.5%. The method is an ideal method for preparing the fluorescent carbon dots. The product can be applied to the fields such as ion detection, bioimaging, photoelectric devices and composite materials.

Owner:TAIYUAN UNIV OF TECH

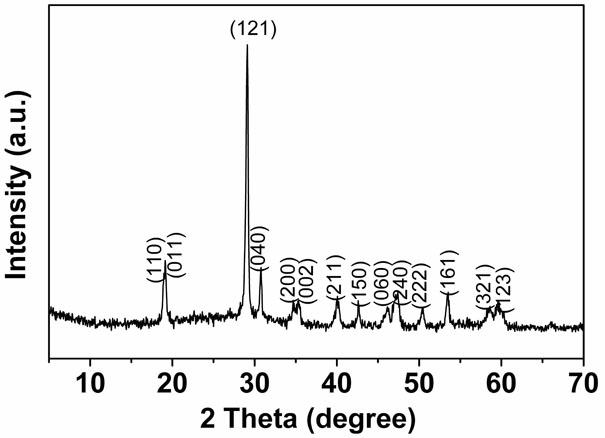

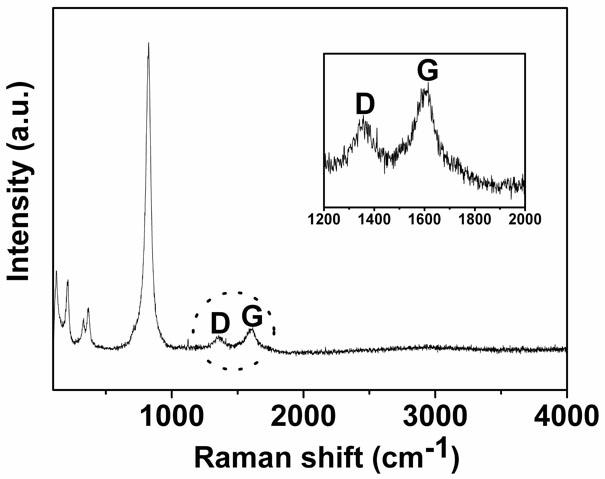

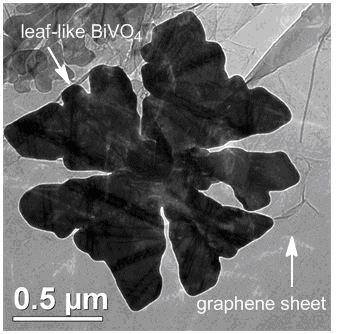

Visible light responsive pucherite-graphene composite photocatalyst and preparation method thereof

ActiveCN102125832AImprove adsorption capacityIncrease surface areaMetal/metal-oxides/metal-hydroxide catalystsAmmonium metavanadateUltrasonic dispersion

The invention discloses a visible light responsive pucherite-graphene composite photocatalyst and a preparation method thereof. The composite photocatalyst is prepared by compositing pucherite and graphene according to the mass ratio of (1:2)-(1:5). The preparation method comprises the following steps of: putting graphite oxide into a mixed solution of water and ethanol for ultrasonic dispersion,respectively adding bismuth nitrate and ammonium metavanadate into ethanol for stirring, and finally mixing the three systems and regulating the pH to be greater than 7; then, transferring the mixed system into a hydrothermal kettle for reacting; and after the reaction is finished, centrifugally separating, washing and drying the product to obtain a leaf-shaped pucherite-graphene composite photocatalyst. In the invention, by using graphene as a template, the leaf-shaped pucherite-graphene composite photocatalyst is prepared by a hydrothermal synthesis method. The pucherite-graphene composite photocatalyst prepared by the method disclosed by the invention has better application prospect and economic benefit in the aspect of sewage treatment.

Owner:NANJING UNIV OF SCI & TECH

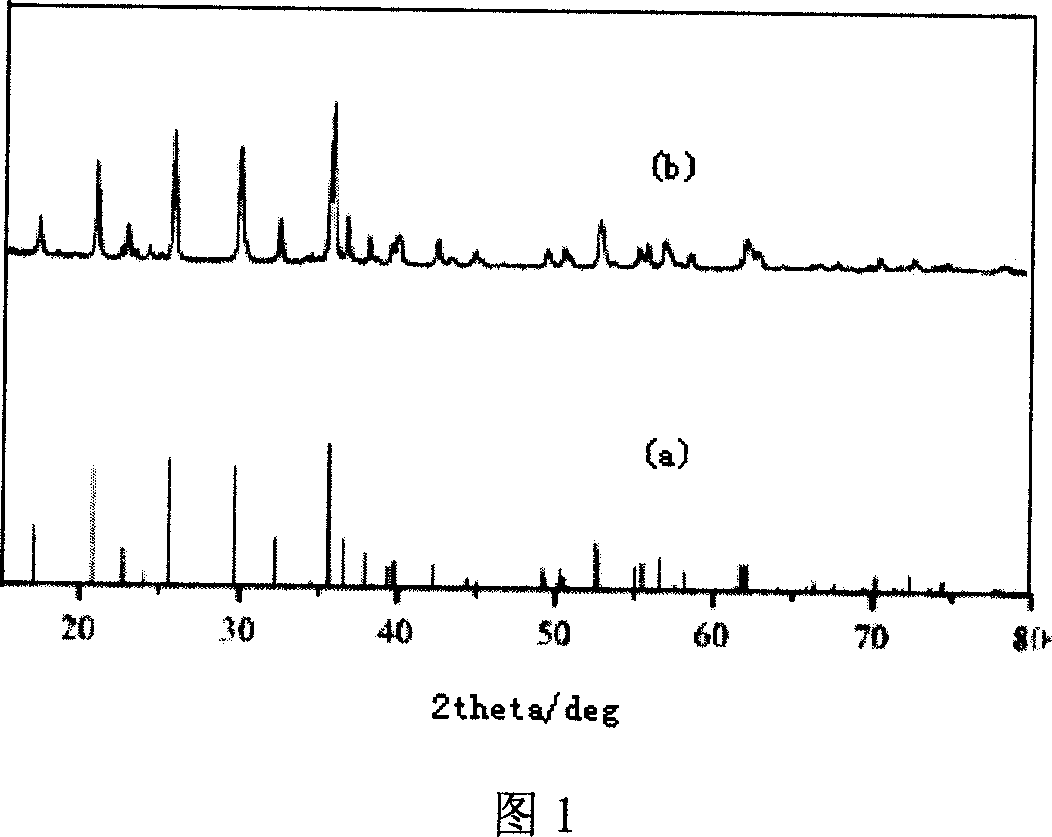

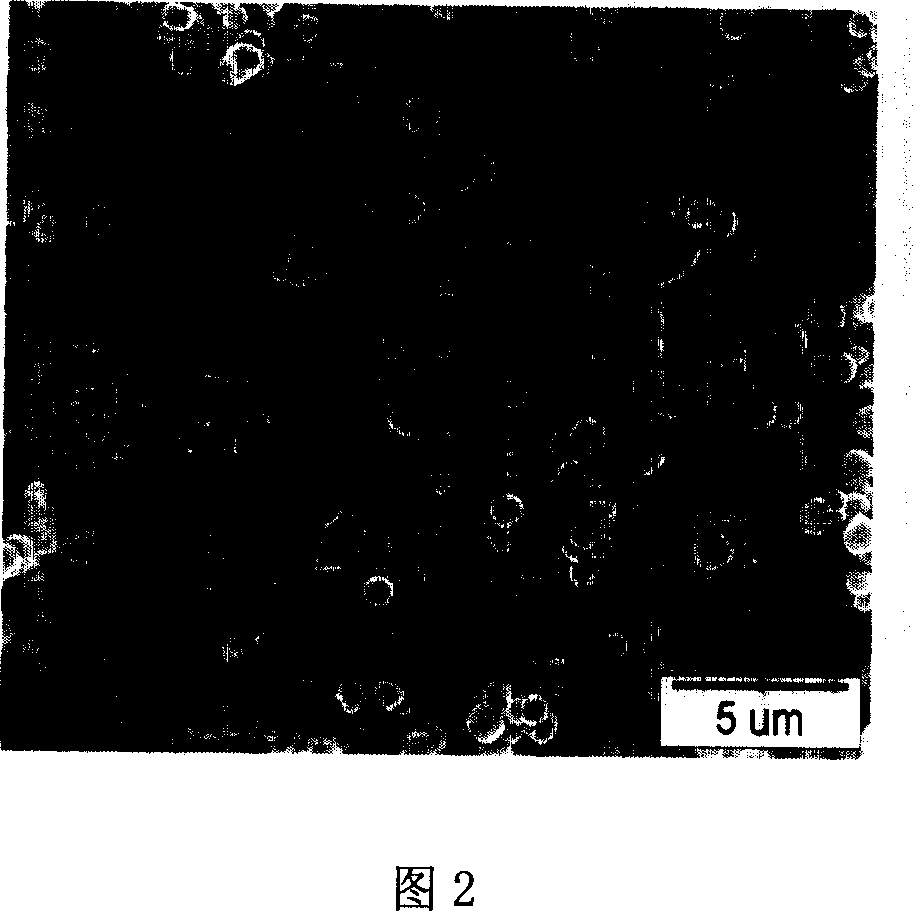

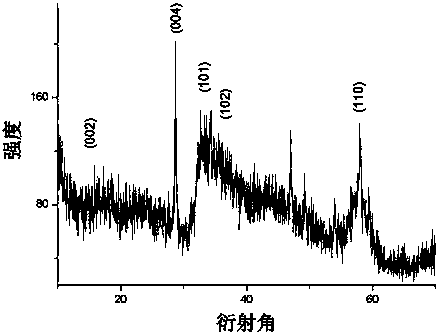

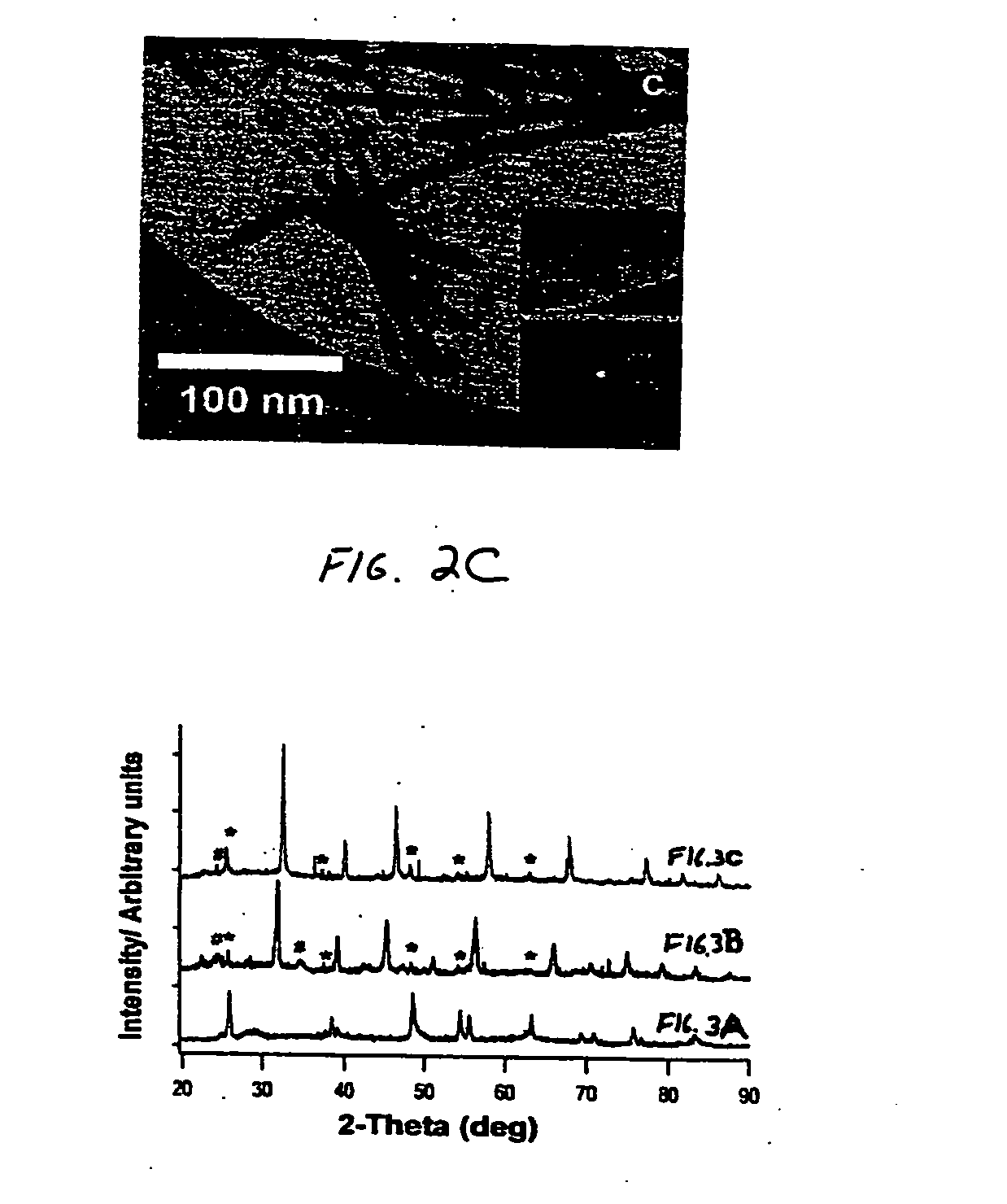

Hydrothermal synthesis of perovskite nanotubes

ActiveUS20050036939A1Reduce the amount requiredThe instrumentation is simpleDigital storageGermanium dioxideStrontium titanateBarium titanate

A low-temperature hydrothermal reaction is provided to generate crystalline perovskite nanotubes such as barium titanate (BaTiO3) and strontium titanate (SrTiO3) that have an outer diameter from about 1 nm to about 500 nm and a length from about 10 nm to about 10 micron. The low-temperature hydrothermal reaction includes the use of a metal oxide nanotube structural template, i.e., precursor. These titanate nanotubes have been characterized by means of X-ray diffraction and transmission electron microscopy, coupled with energy dispersive X-ray analysis and selected area electron diffraction (SAED).

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

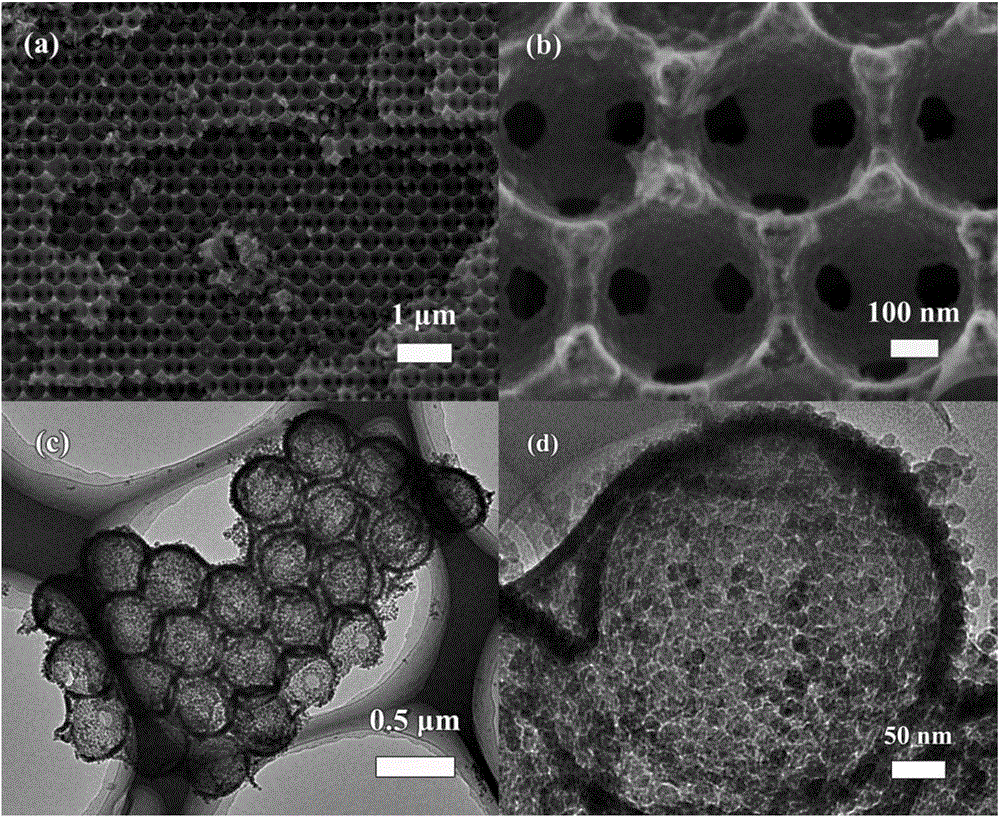

Method for synthesizing ordered macroporous-mesoporous-microporous hierarchical-pore molecular sieve by using hard template

ActiveCN104058423AImprove flow and diffusion performanceUniform and adjustable mesopore diameterCrystalline aluminosilicate zeolitesMolecular sieveHydrothermal synthesis

The invention discloses a method for synthesizing an ordered macroporous-mesoporous-microporous hierarchical-pore molecular sieve TS-1 by using a hard template. The method comprises the following steps: with a three-dimensional ordered macroporous-mesoporous hierarchical carbon material as a hard template, performing limited-range growth of TS-1 nanocrystals in a three-dimensional ordered cage type mesoporous canal of the hard template by adjusting and controlling hydrothermal synthesis conditions according to a hydrothermal synthesis method of the TS-1 nanocrystals, and removing the hard template to obtain the ordered macroporous-mesoporous-microporous hierarchical-pore molecular sieve TS-1. The method disclosed by the invention is simple and feasible, synthetic conditions are easy to control, and the cycle is short; the molecular sieve TS-1 prepared by adopting the method has a novel ordered macroporous-mesoporous-microporous hierarchical pore structure, mesopores are uniform and controllable in diameter, and the method has an important promotion effect on expansion of application of the molecular sieve TS-1 in the field of catalysis.

Owner:WUHAN UNIV OF TECH

Hydrothermal synthesis method for lithium ferromanganese phosphate anode material of lithium ion battery

InactiveCN102249208AHigh degree of crystallinitySingle phaseCell electrodesNanotechnologyPhosphateLithium hydroxide

The invention relates to a hydrothermal synthesis method for lithium ferromanganese phosphate anode material of a lithium ion battery, belonging to the technical field of lithium ion batteries. The method has the following processing steps of: step 1, preparing LiMnxFe1-xPO4 through a hydrothermal synthesis reaction: mixing an aqueous lithium hydroxide solution, an aqueous ferrous sulfate solution and phosphoric acid under a stirring condition, after sealing, heating to 150 DEG C to 180 DEG C within 0.5 to 2 h, reacting for 0.5-4 h under the pressure of 0.48-1.0 Mpa, cooling to less than 80 DEG C, and filtering; step 2, mixing with organic matters and drying: mixing a wet filter cake with a soluble carbon source organic matter, and carrying out spray drying or expansion drying; and step 3, carrying out carbon-coated processing: roasting LiMnxFe1-xPO4 carbon source compound powder at a temperature between 600 DEG C and 750 DEG C for 4-6 h under an insert gas condition, and cooling to less than 150 DEG C to obtain a carbon-coated lithium ferromanganese phosphate anode material of the lithium ion battery. The hydrothermal synthesis method disclosed by the invention has the advantages of simple and controllable technology, convenience for operation, low cost, high crystallization degree of products, uniform dispersion, high specific capacity, high conservation rate of the cycling capacity, and the like.

Owner:朱鸥鹭

Synthesis method of magnetic metal organic framework composite material and application of material

InactiveCN103894161AGood magnetic responseImprove hydrophilicityOther chemical processesPreparing sample for investigationN dimethylformamideSynthesis methods

The invention discloses a synthesis method of a metal organic framework composite material which has a sandwich structure, comprises magnetic microsphere ferroferric oxide surface coating polydopamine and takes zirconium ion as central metal ion and application of the material. The synthesis method comprises the following steps: firstly synthesizing ferroferric oxide magnetic microspheres by using a hydrothermal synthesis method; dispersing the magnetic microspheres in an aqueous solution of polydopamine hydrochloride to coat the surfaces of the magnetic microspheres with polydopamine layers; dispersing the magnetic microspheres coated with the polydopamine in an N,N-dimethylformamide mixed solution of zirconium chloride and terephthalic acid to prepare the magnetic metal organic framework composite material with a sandwich structure. The synthesis method is simple and quick; the magnetic metal organic framework composite material obtained by synthesizing is high in specific surface area, good in biocompatibility and applicable to selective enrichment of phosphorylated peptide and MALDI-TOFMS detection in biological samples.

Owner:FUDAN UNIV

Photocatalyst for preparing hydrogen and sulphur by decomposing hydrogen sulfide and preparation method thereof

InactiveCN101927173AIncrease profitReduce chance of recombinationPhysical/chemical process catalystsDispersed particle separationIndiumHYDROSOL

The invention discloses a photocatalyst for preparing hydrogen and sulphur by decomposing hydrogen sulfide and a preparation method thereof, relating to a photocatalyst and a preparation method thereof. The invention solves the problem that the existing photocatalyst ZnIn2S4-CdIn2S4 the atomic ratio of which is that Zn:Cd=7:3 has low photocatalysis activity. The photocatalyst of the invention is ZnIn2S4-CdIn2S4 doped by transition metal ions. The preparation method comprises: adding sol prepared from transition metal salt, bivalent cadmium salt, bivalent zinc salt, trivalent indium salt and thioacetamide into an autoclave; and carrying out hydrothermal synthesis and vacuum drying to obtain the photocatalyst for preparing the hydrogen and the sulphur by decomposing the hydrogen sulphide. The invention has high catalytic activity; the speed for producing the hydrogen by carrying out photocatalysis on the hydrogen sulphide is 1100-3500 mu mol / h.g which is 1.8-6 times of that obtained by utilizing the ZnIn2S4-CdIn2S4. The photocatalyst of the invention can be used for processing tail gas containing hydrogen sulphide.

Owner:HARBIN 6 RING PETROCHEM TECHN DEVCORP

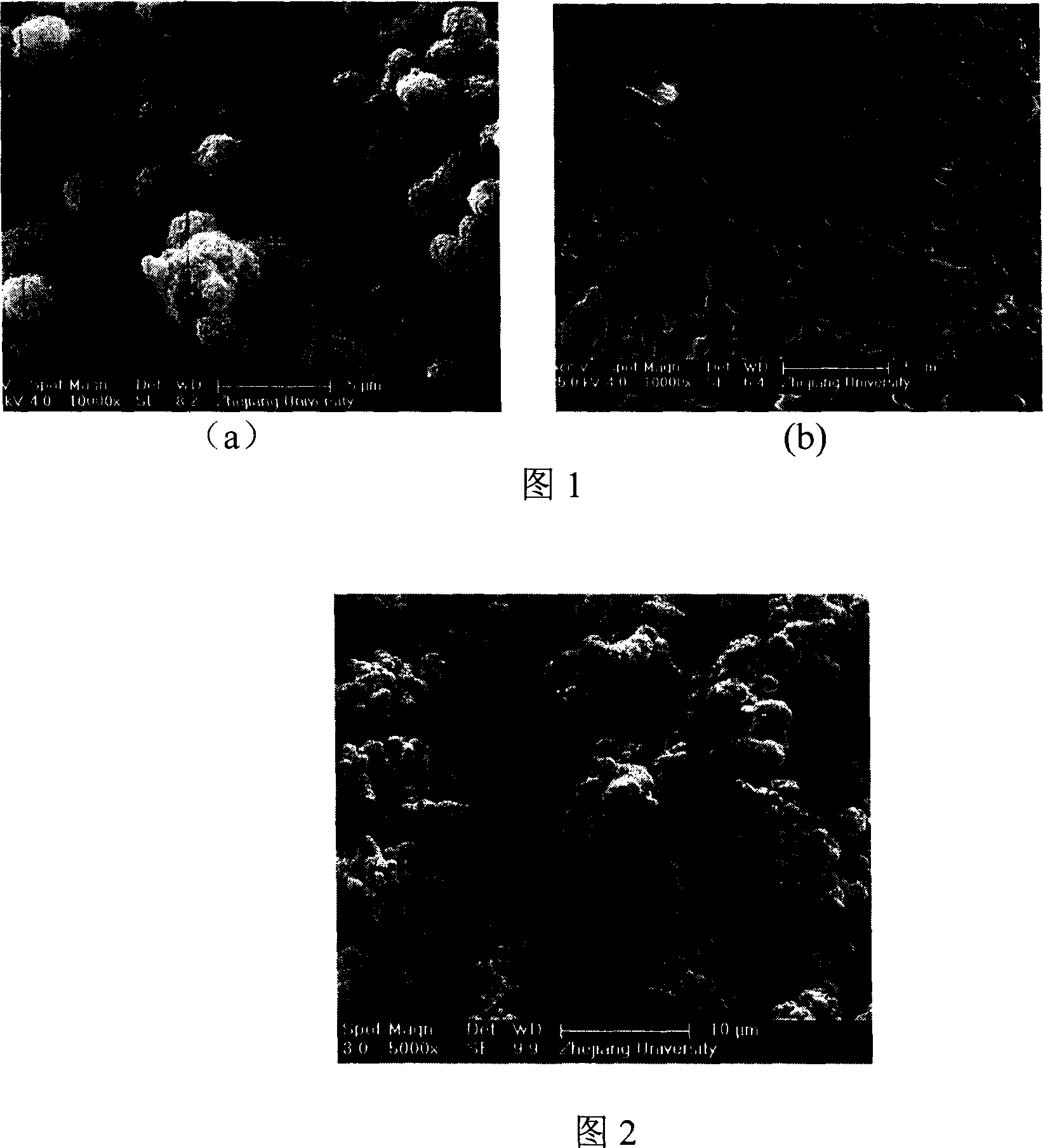

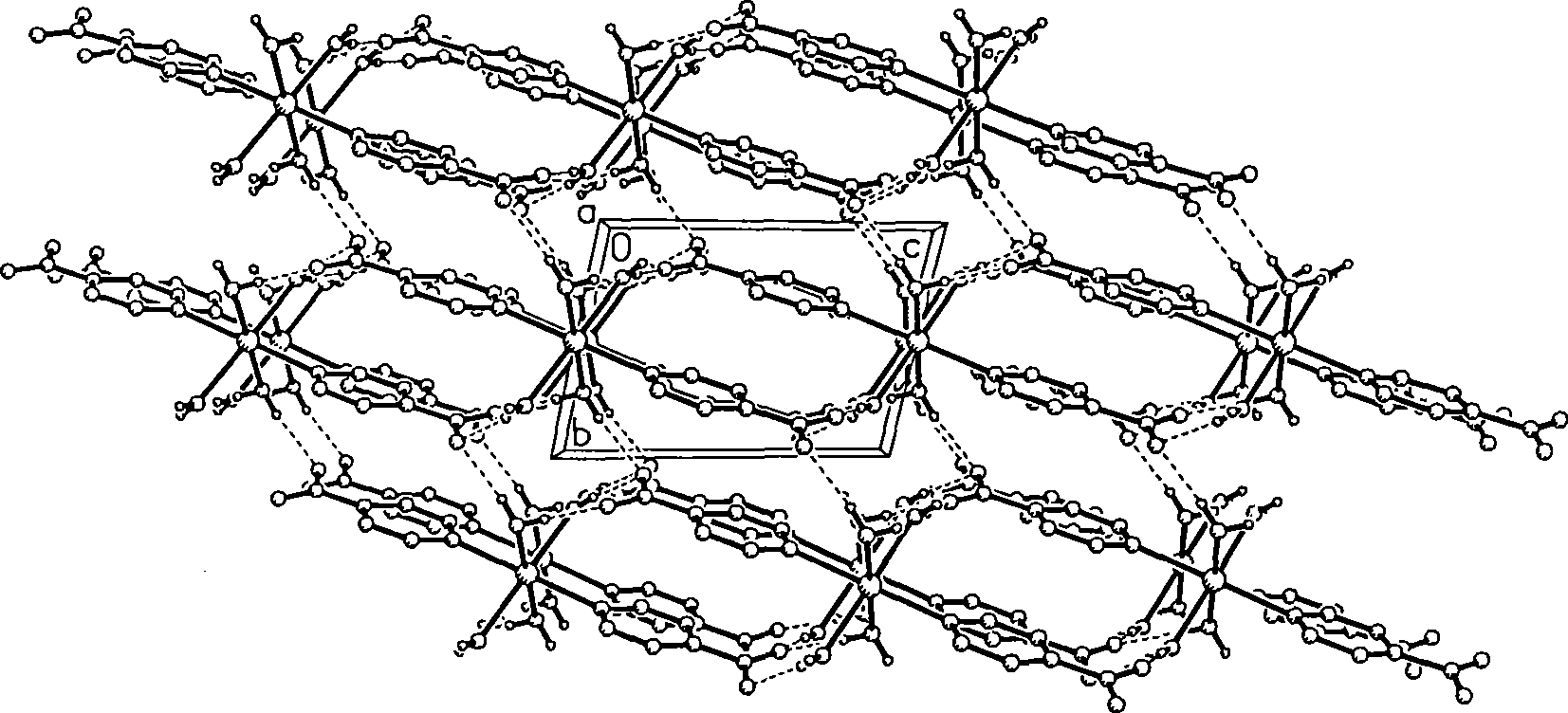

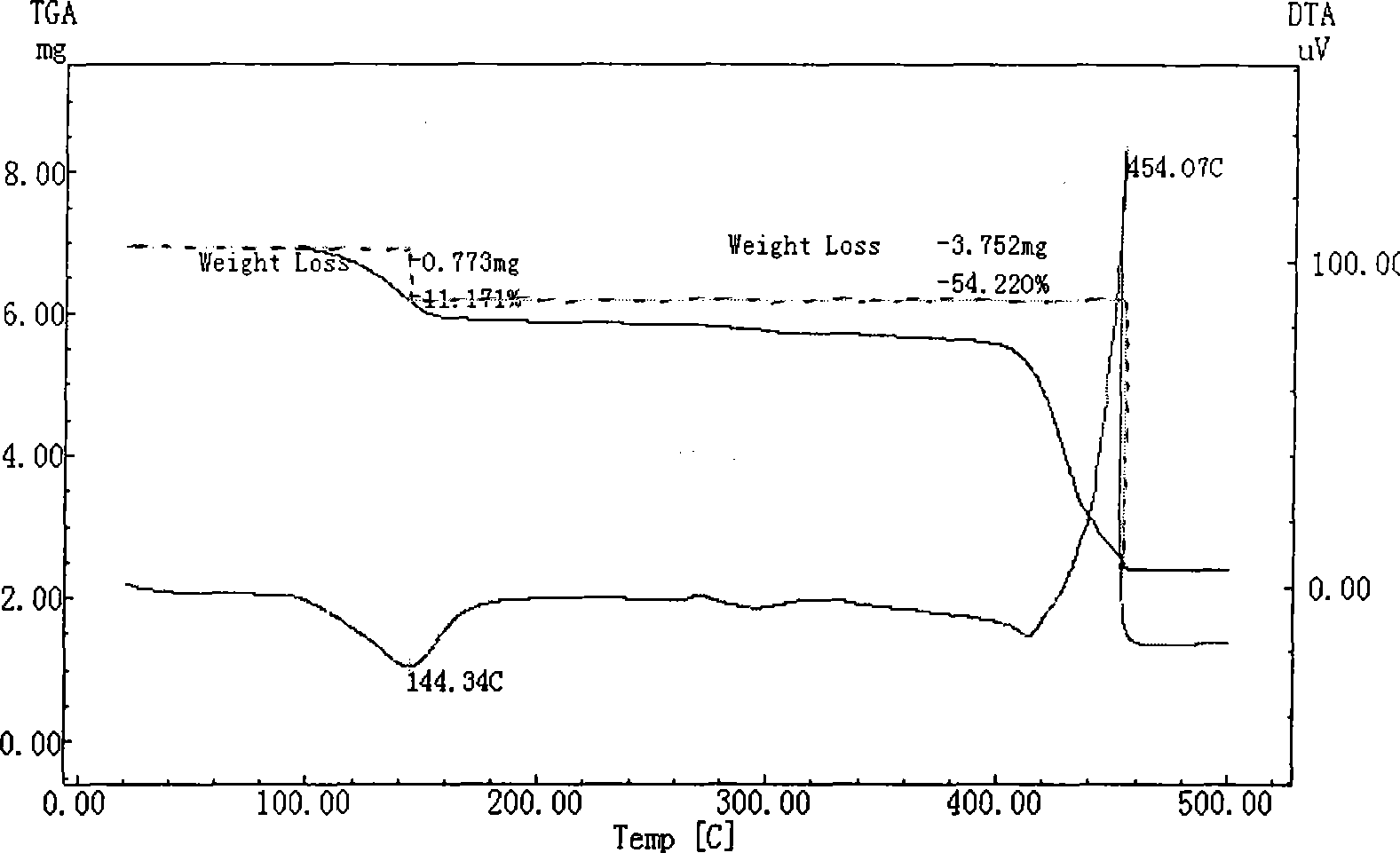

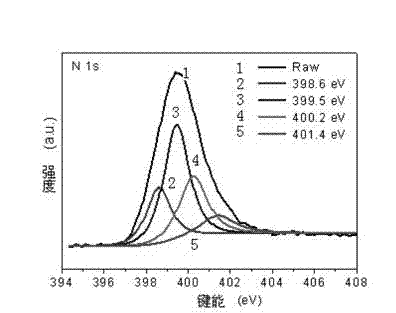

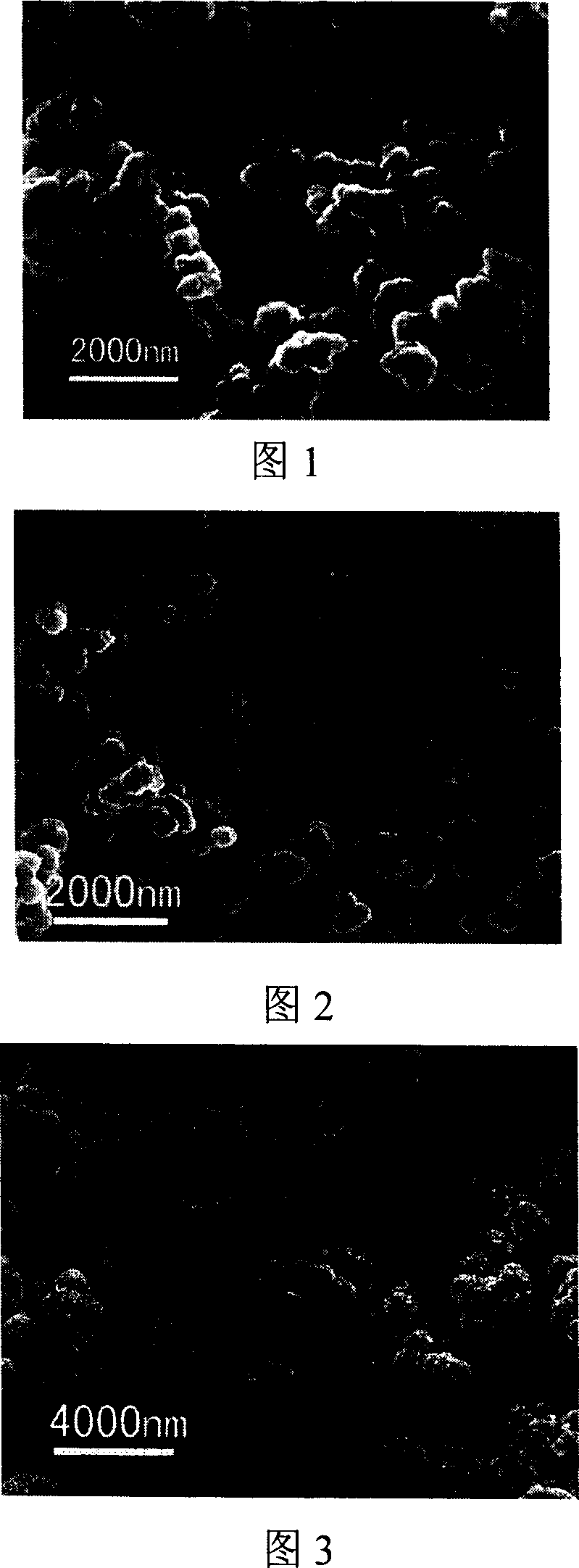

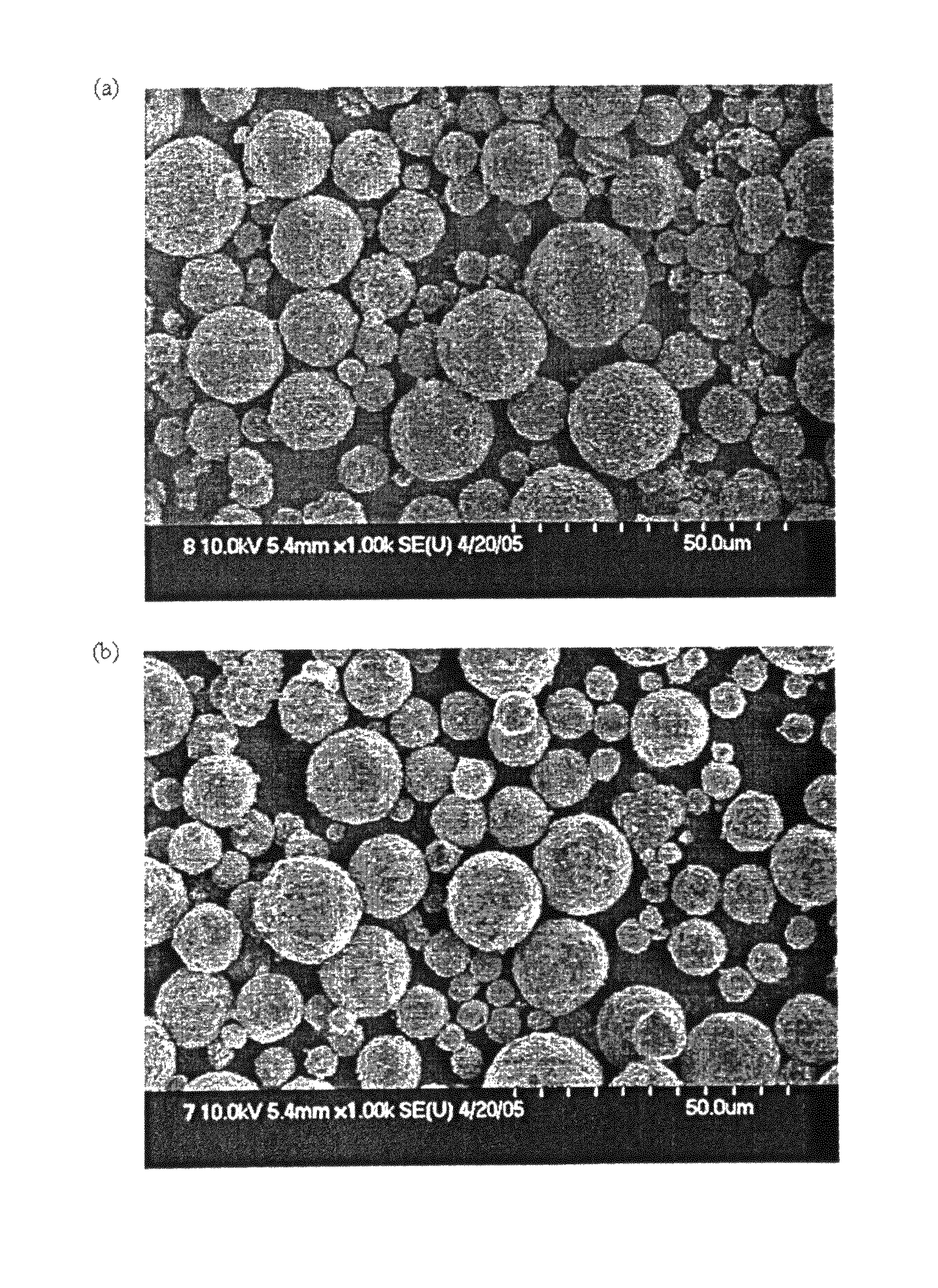

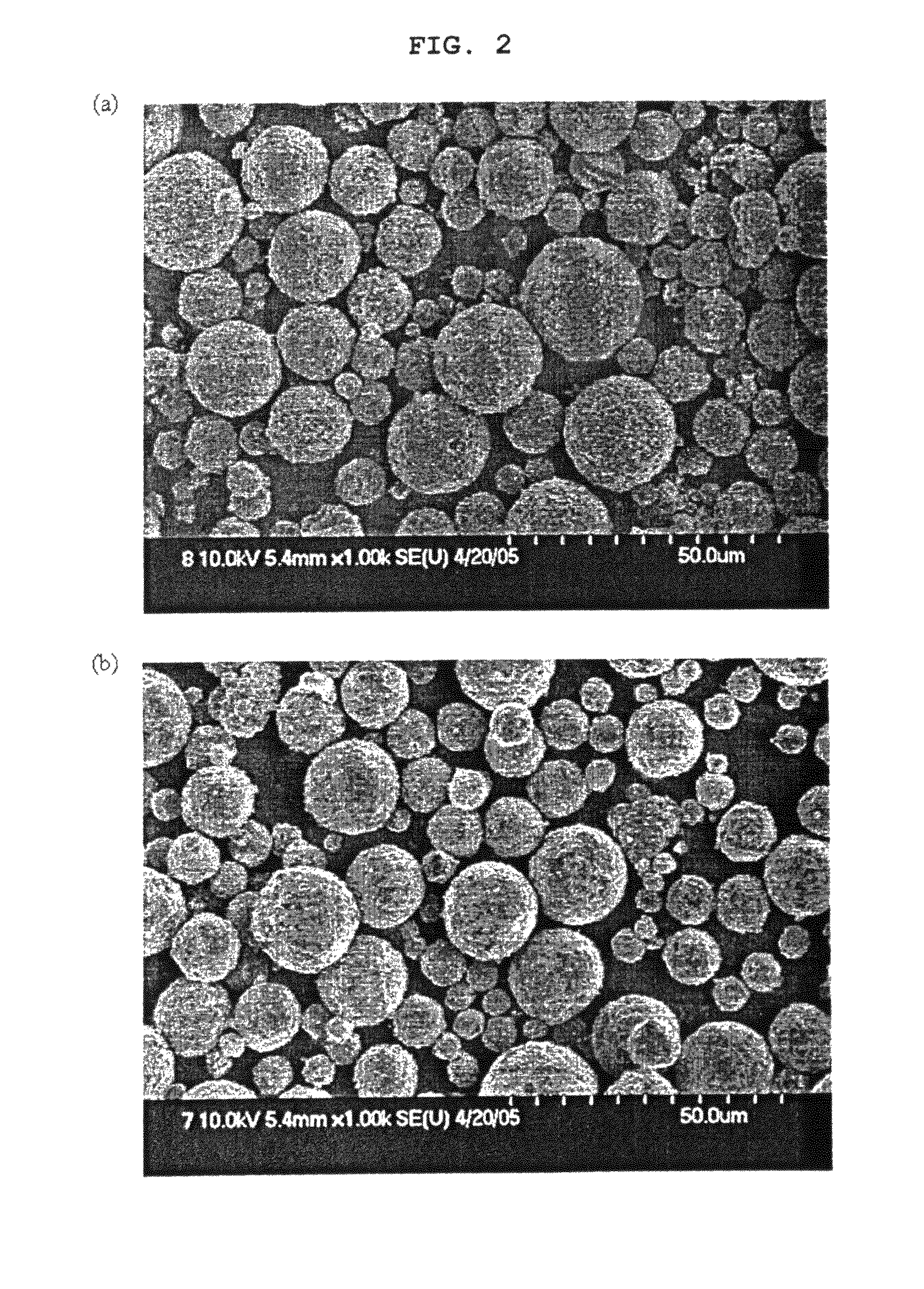

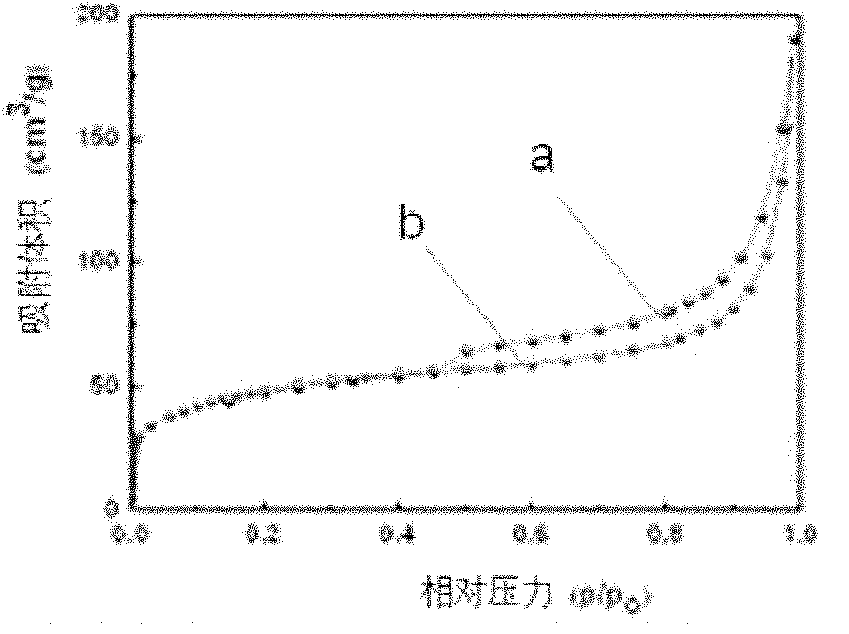

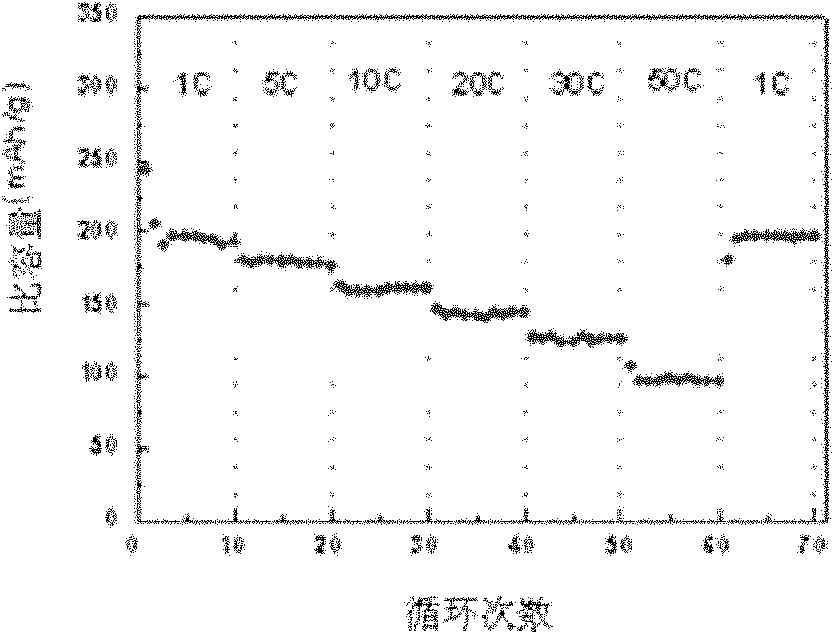

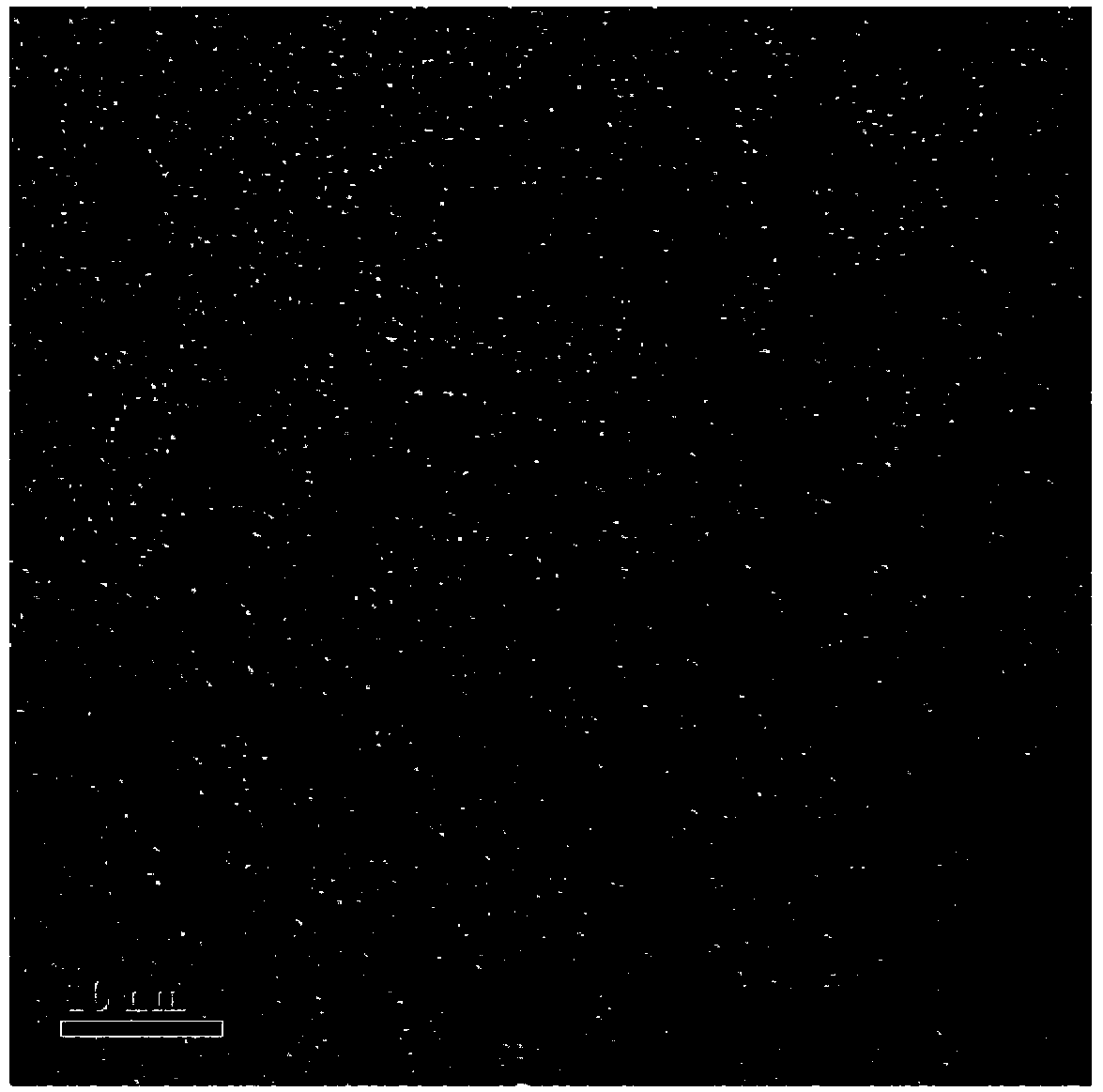

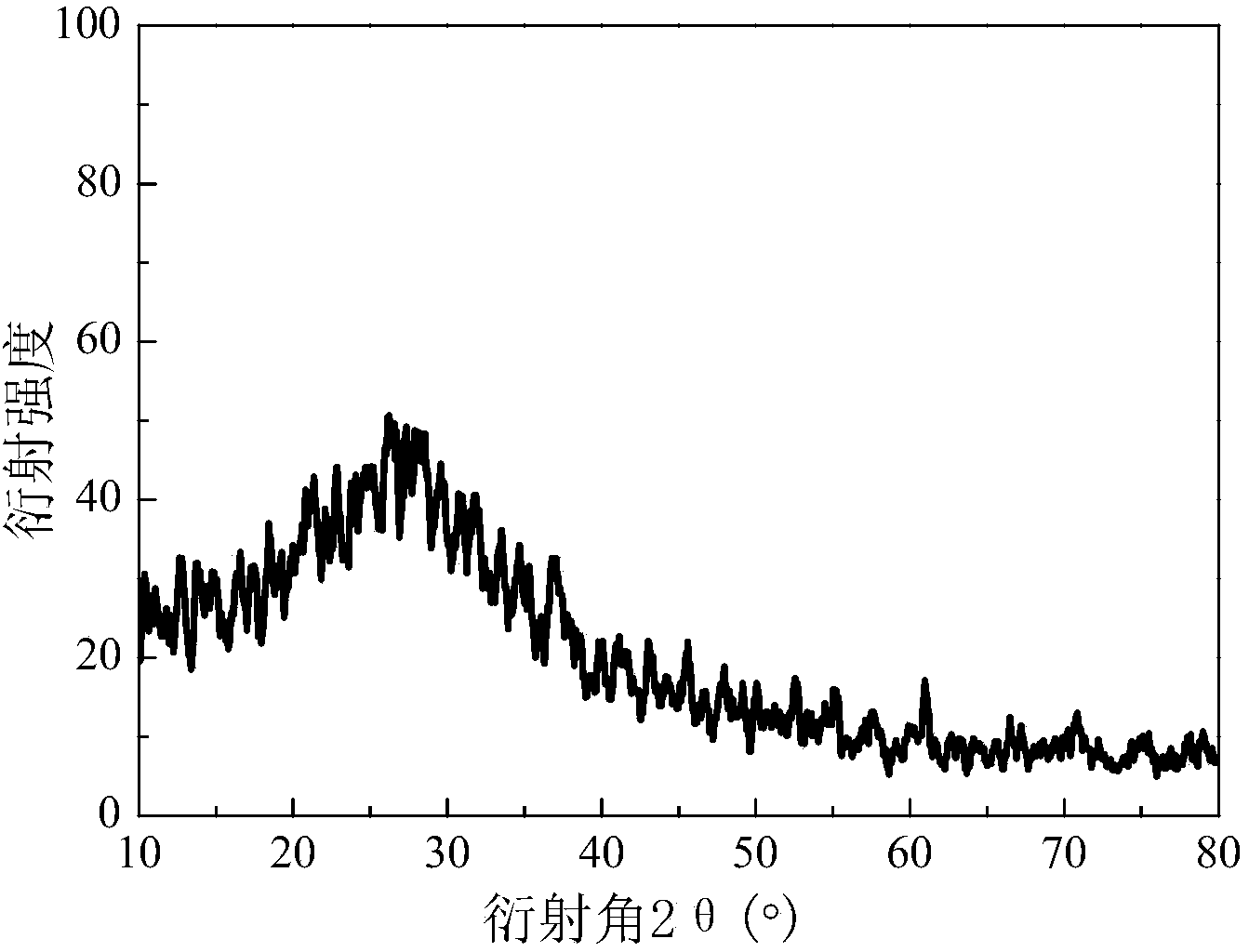

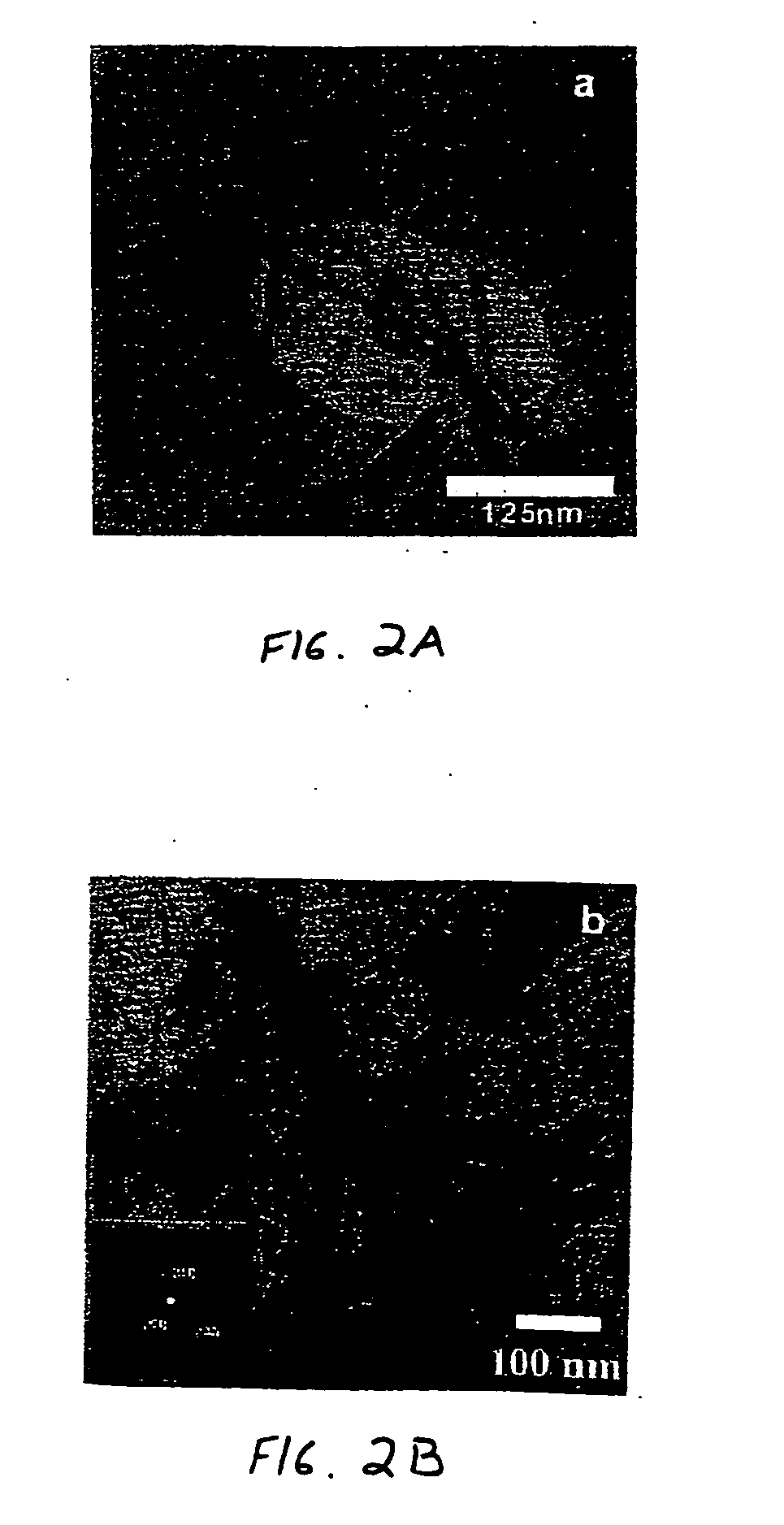

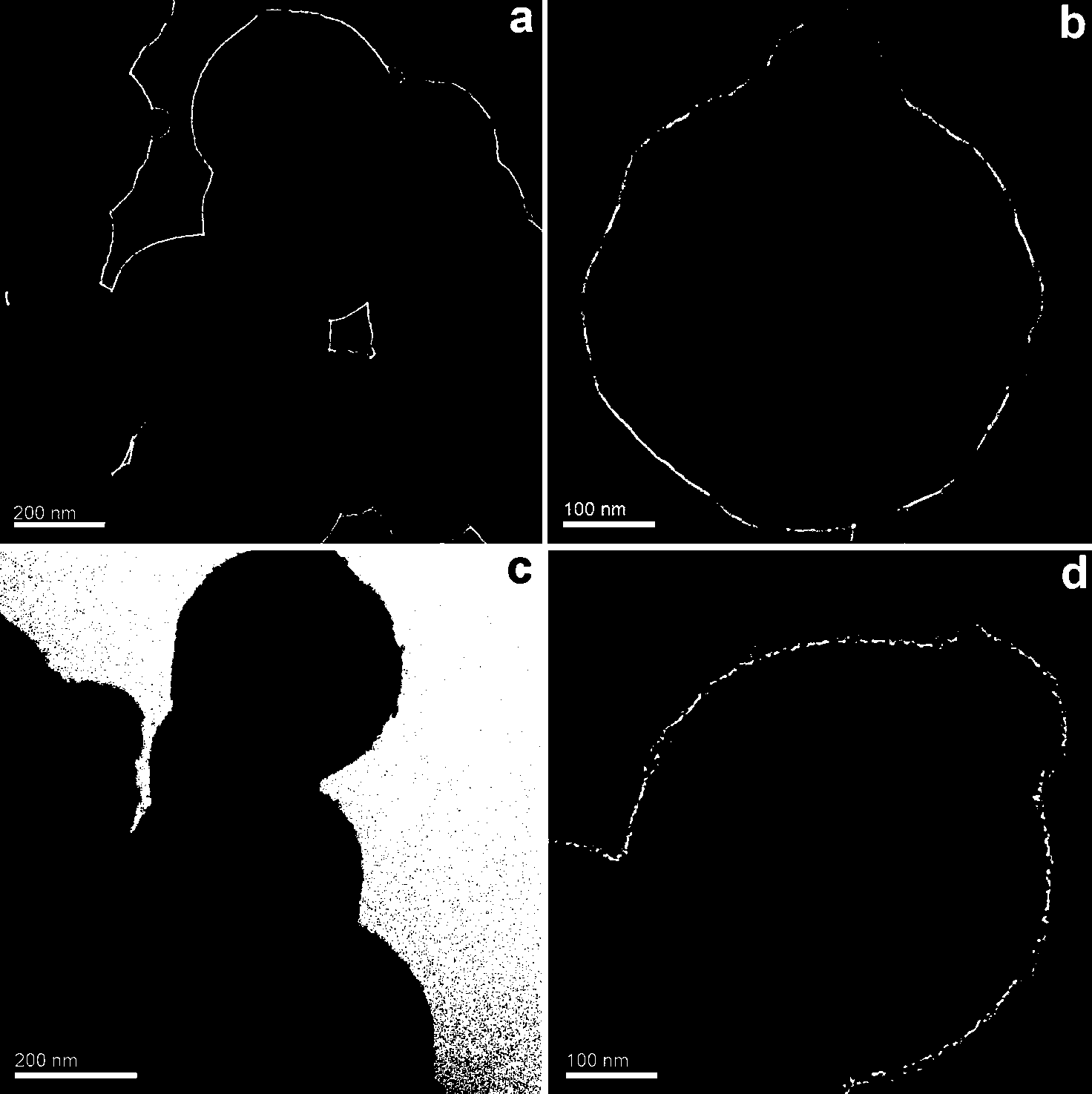

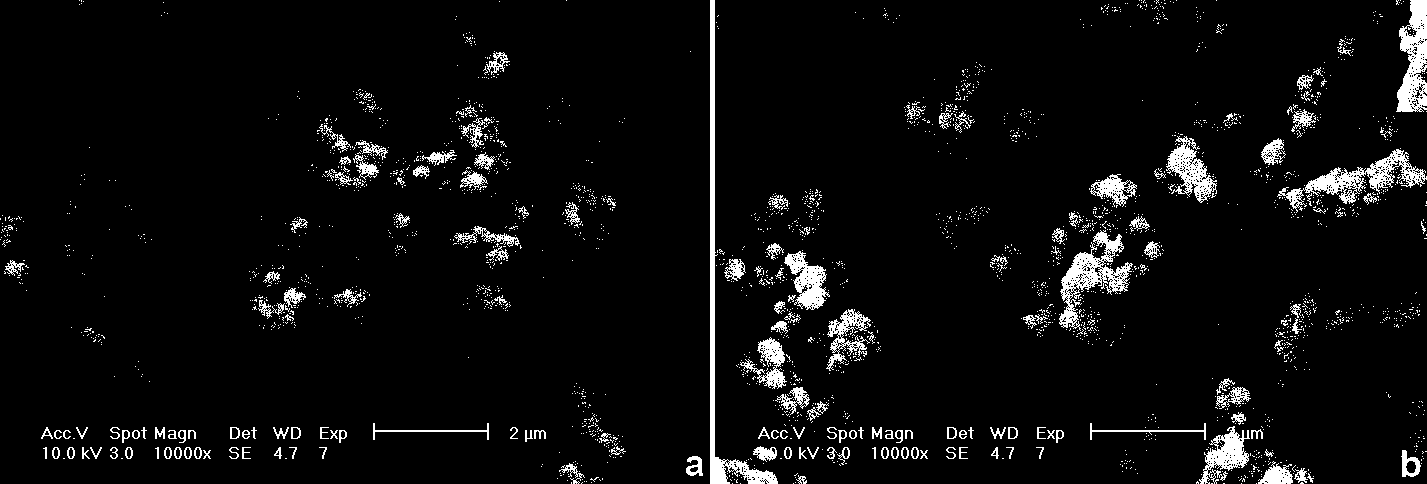

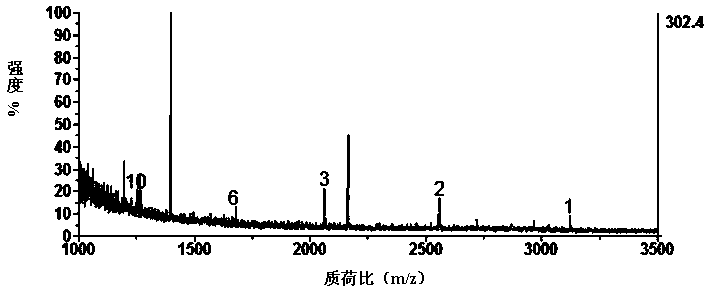

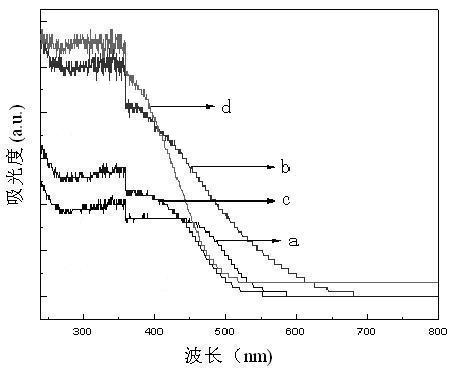

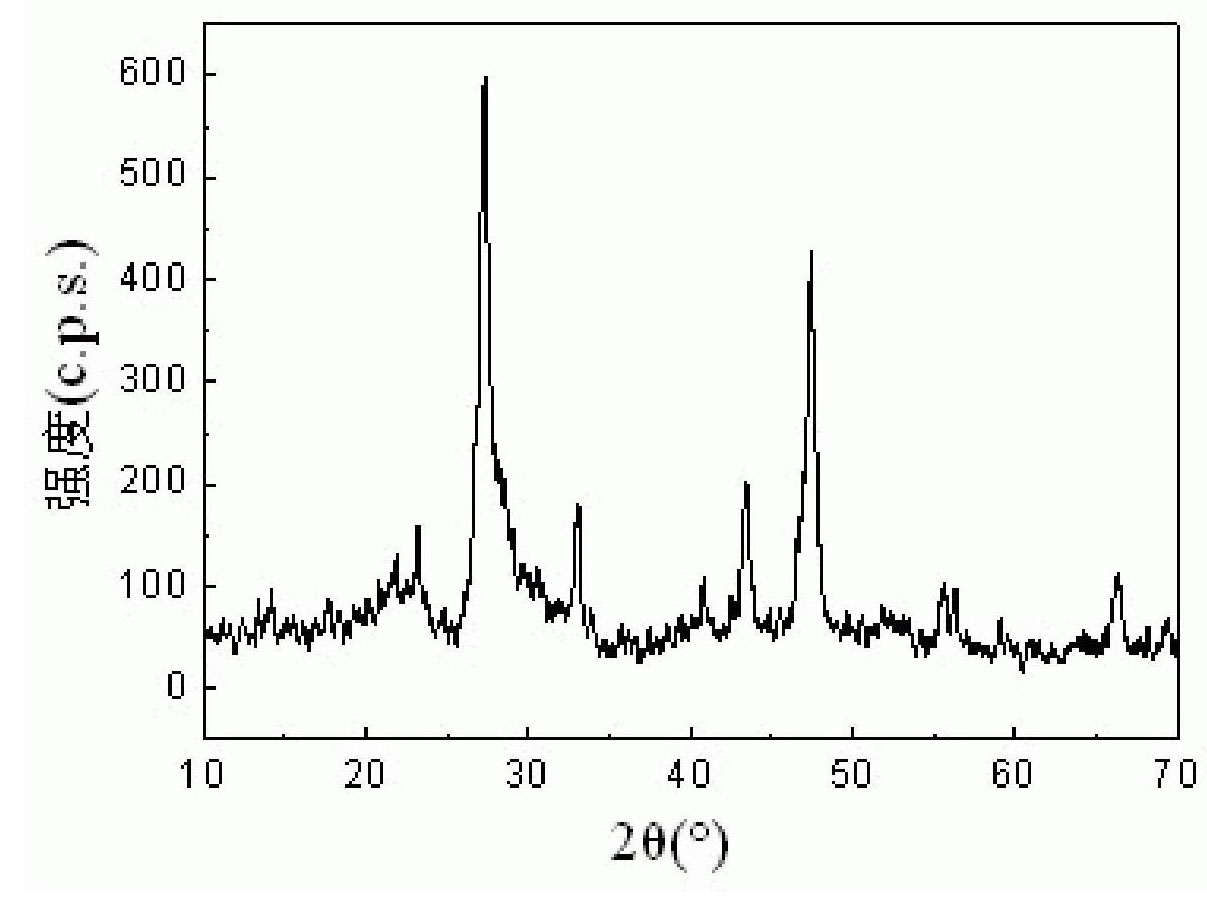

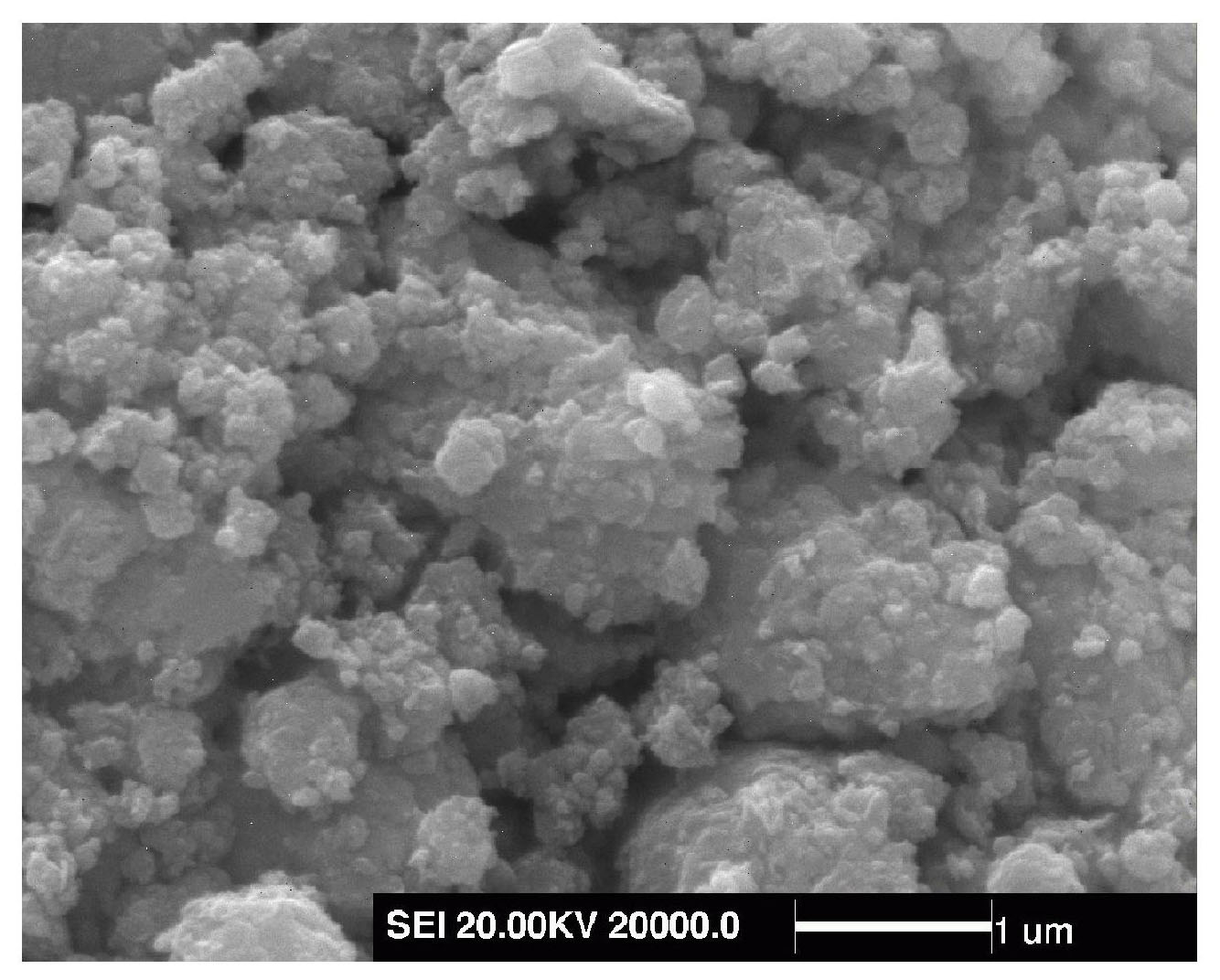

Synthetic method for magnetic metal organic framework composite material coated by [Cu3(btc)2] on surfaces of ferroferric oxide microspheres and application of composite material

InactiveCN103143331AGood magnetic responseReduce adsorptionOther chemical processesComponent separationMicrosphereMetal-organic framework

The invention relates to a synthetic method for a magnetic metal organic framework composite material coated by [Cu2(btc)2] on surfaces of ferroferric oxide microspheres and application of the composite material. The method comprises the following steps of: firstly synthesizing ferroferric oxide microspheres by a hydrothermal synthesis method; dispersing magnetic spheres in an ethanol liquid of mercaptoacetic acid, wherein hydroxyls are formed on the surface of the spheres; dispersing mercaptoacetic acid modified magnetic spheres to an ethanol liquid of copper acetate, reacting for 15 minutes at 70 DEG C, and then dispersing the product in an ethanol liquid of trimesic acid and reacting for 30 minutes at 70 DEG C; and performing alternate reaction of magnetic spheres with copper acetate and the ethanol liquid of trimesic acid to finally, obtain the magnetic metal organic framework composite material with a core-shell structure. The material has a metal organic framework shell layer and can be coordinated with peptide fragments with amino groups and carboxylic group so as to enrich low concentration peptide. Meanwhile, the enriching and separating process is fast, simple and convenient due to high paramagnetism of ferroferric oxide. The synthetic method is simple and low in cost, and can be used for enrichment and separation of low abundance peptide fragments less than 1nM and MALDI-TOFMS (Matrix-Assisted Laser Desorption Ionization-Time Of Flight Mass Spectrometer) detection.

Owner:FUDAN UNIV

Preparation method for ion liquid assisted hydrothermal synthesis of MoS2 microsphere

InactiveCN1994895AImprove performanceMild reaction conditionsMolybdenum sulfidesTetrafluoroborateMolybdate

The invention discloses a making method of MoS2 microball synthesized by ionic liquid auxiliary water, which comprises the following steps: dissolving molybdate in the deionized water to form 0.05-0.1m solution; adding thioacetamide or sulfourea as sulfur source with molar rate of thioacetamide or sulfourea and molybdate at 31-51; stirring evenly; adding 1-butyl-3-methyl imidazole tetrafluoride borate as ionic liquid with the bulk rate of ionic liquid and synthetic solution at 1300-1 50; stirring completely; transmitting solution into water heat reacting autoclave to react under 200-240 deg. c for 20-24h; cooling naturally; separating; washing; drying to obtain the product.

Owner:ZHEJIANG UNIV

Method for low-temperature atmosphere-pressure hydrothermal synthesis of stephanoporate metal-organic framework

InactiveCN101429209AFully contactedQuality improvementCadmium organic compoundsZinc organic compoundsMetal-organic frameworkChemistry

The invention discloses a method for hydrothermally synthesizing a porous metal-organic framework under low temperature and normal pressure, which comprises the following steps: 1) bivalent transition metal salt is put into proper amount of distilled water to be dissolved; 2) a multidentate organic ligand is put into proper amount of distilled water, and ammonia (30 percent, W / W) is added into the solution until the organic ligand is dissolved; 3) solutions obtained in step 1) and step 2) are mixed, and diluted by the distilled water; 4) the solution obtained in step 3) reacts for 4 to 24h at a temperature of between 80 and 100 DEG C, and is naturally cooled to room temperature at an environmental temperature to obtain an MOF crystal product; and 5) the MOF crystal product obtained in step 4) is filtered, MOF crystals are colleted and washed by the distilled water and absolute ethyl alcohol respectively, and the product is obtained after the natural drying. By performing a hydrothermal reaction in an ammonia solution, the method has mild conditions needed by the synthesis, less energy consumption and time consumption, and does not need a voltage resistant reactor. Therefore, the method is simpler and has lower cost; and a porous crystal material obtained by the synthesis has potential application value in the fields of gas separation, gas storage and heterogeneous catalysis.

Owner:CHONGQING UNIV

Nitrogen-doped graphene hydrogel, preparation method and applications thereof

InactiveCN102849731AEffective adjustment of capacitiveEffectively adjust the internal structureElectrolytic capacitorsGrapheneCapacitanceNitrogen doped graphene

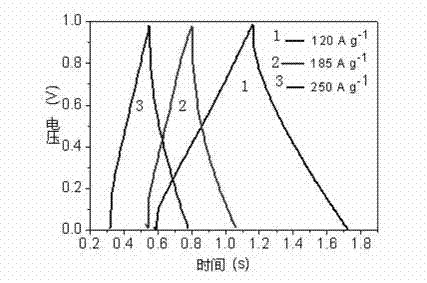

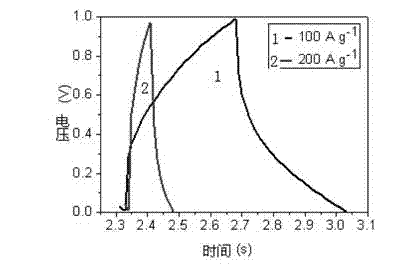

The present invention provides a preparation method for a nitrogen-doped graphene hydrogel. The preparation method comprises the following steps: (1) adding an oxidized graphite to water according to a certain ratio, and carrying out ultrasonic dispersion to obtain an oxidized graphene aqueous solution; (2) adding an organic amine to the oxidized graphene aqueous solution obtained from the step (1) in a dropwise manner, and stirring for a certain time to form an oxidized graphene and organic amine compounded intermediate product; and (3) carrying out a hydrothermal synthesis reaction on the intermediate product obtained from the step (2) to obtain the nitrogen-doped graphene hydrogel. The method of the present invention is a new and easy method for synthesis and regulation of the three dimensional structure of the graphene, and has characteristics of simple operation, easy control, low cost, no pollution and easy industrialization. With application of the graphene hydrogel of the present invention as a super-capacitor electrode material, results show that good specific capacitance and high power density are provided under the very high charge and discharge current circumstance.

Owner:UNIV OF SCI & TECH OF CHINA

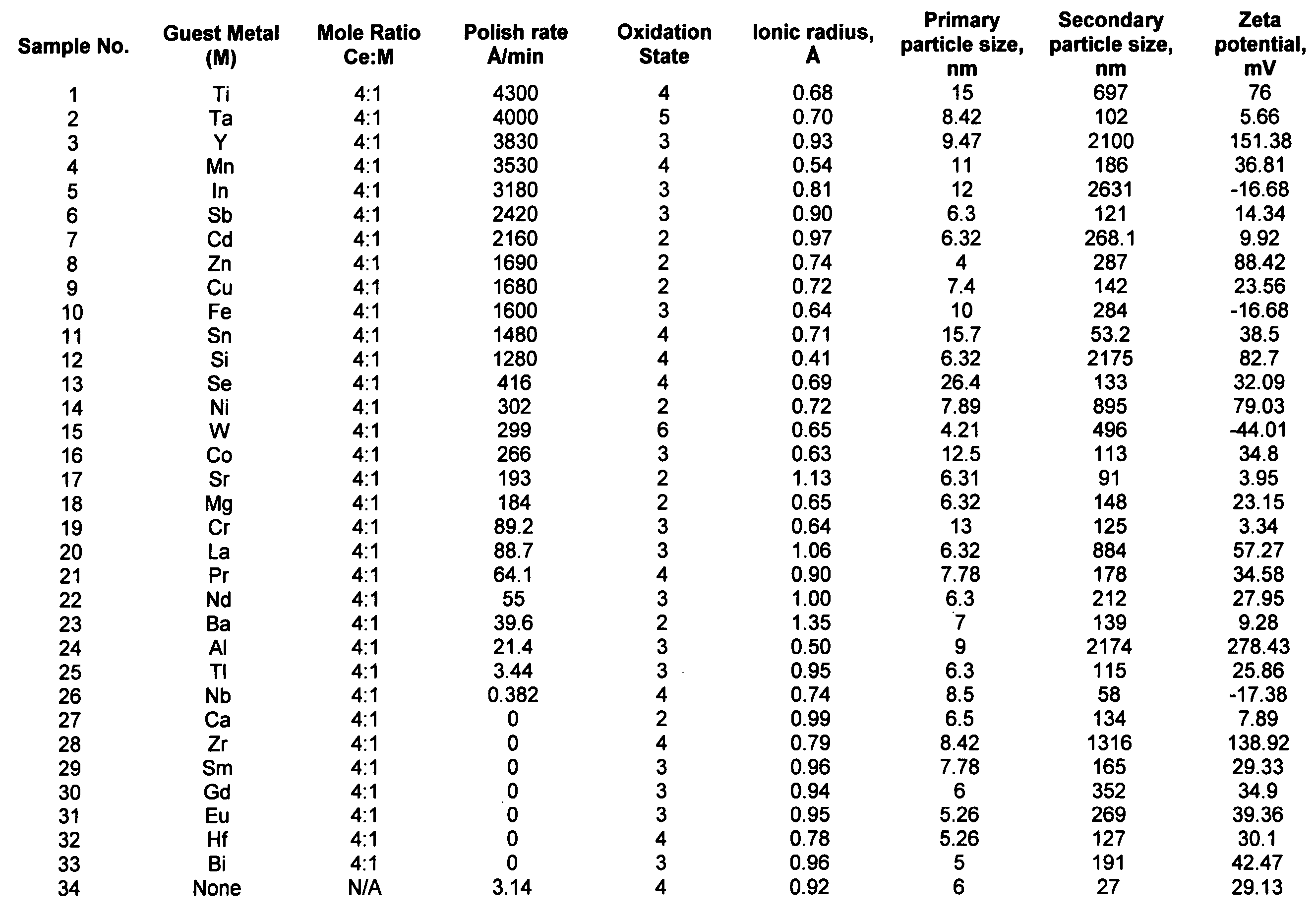

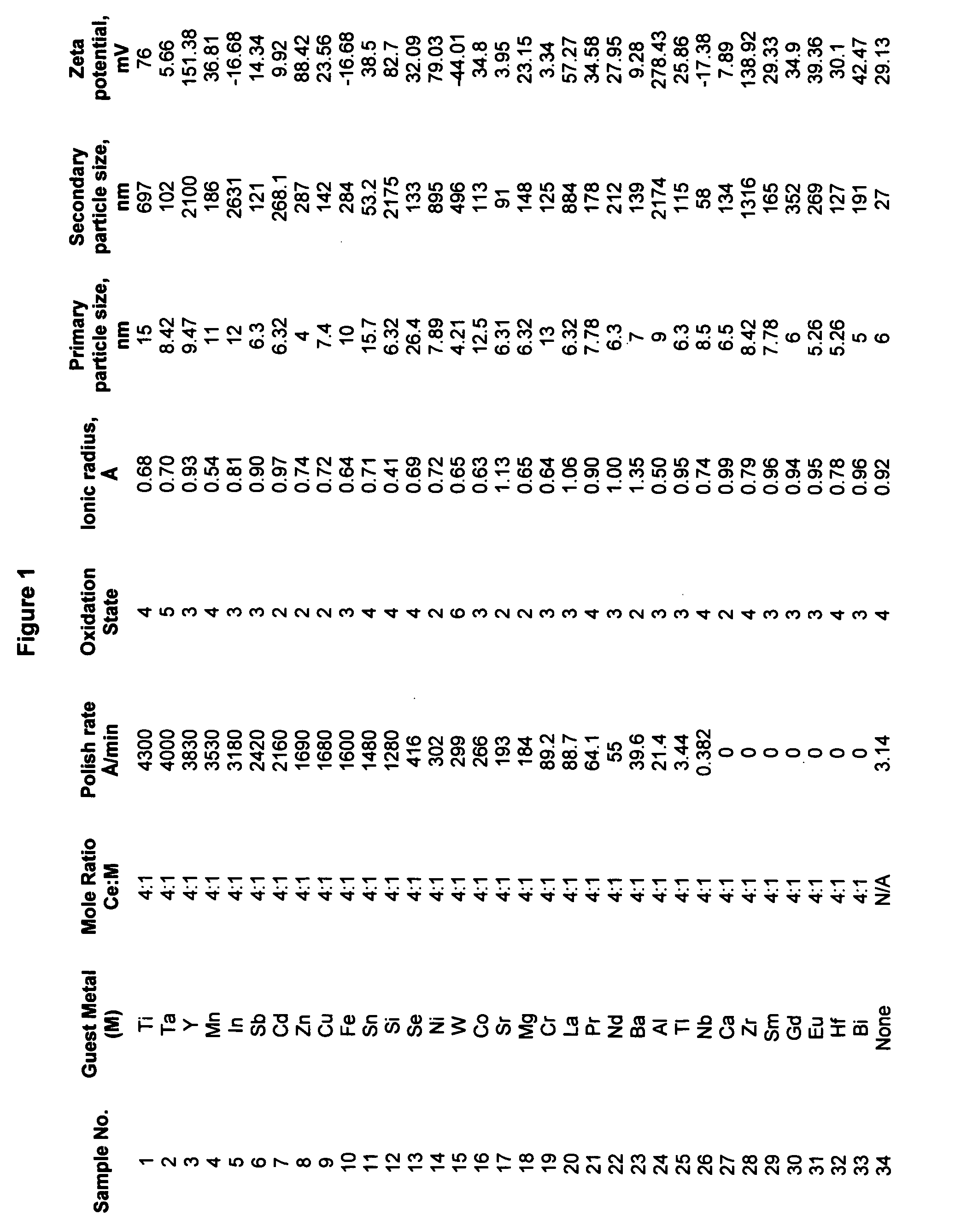

Synthesis of chemically reactive ceria composite nanoparticles and CMP applications thereof

InactiveUS20050003744A1Eliminate concernsReduce environmental impactPigmenting treatmentMaterial nanotechnologyChemical reactionCerium

The present invention provides a method of synthesizing nanosized abrasive particles and methods of using the same in chemical mechanical polishing slurry applications. The nanosized abrasive particles according to the invention are produced by hydrothermal synthesis. The crystallites of the particles include cerium atoms and atoms of metals other than cerium. In a preferred embodiment of the invention, the crystallites exhibit a cubic crystal lattice structure. The differences in electric potential between the cerium atoms and the atoms of metals other than cerium facilitate the polishing of films without the need for chemical oxidizers.

Owner:FERRO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthetic method for magnetic metal organic framework composite material coated by [Cu3(btc)2] on surfaces of ferroferric oxide microspheres and application of composite material Synthetic method for magnetic metal organic framework composite material coated by [Cu3(btc)2] on surfaces of ferroferric oxide microspheres and application of composite material](https://images-eureka.patsnap.com/patent_img/02083782-a159-4611-b11f-ac69b2a26ec4/130312135516.PNG)

![Synthetic method for magnetic metal organic framework composite material coated by [Cu3(btc)2] on surfaces of ferroferric oxide microspheres and application of composite material Synthetic method for magnetic metal organic framework composite material coated by [Cu3(btc)2] on surfaces of ferroferric oxide microspheres and application of composite material](https://images-eureka.patsnap.com/patent_img/02083782-a159-4611-b11f-ac69b2a26ec4/130312135520.PNG)

![Synthetic method for magnetic metal organic framework composite material coated by [Cu3(btc)2] on surfaces of ferroferric oxide microspheres and application of composite material Synthetic method for magnetic metal organic framework composite material coated by [Cu3(btc)2] on surfaces of ferroferric oxide microspheres and application of composite material](https://images-eureka.patsnap.com/patent_img/02083782-a159-4611-b11f-ac69b2a26ec4/130312135523.PNG)