Patents

Literature

9424results about How to "High reactivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for improving catalyst reacting activity in the propylene producing through propane dehydrogenation

InactiveCN101138734AHigh reactivityHigh mechanical strengthMolecular sieve catalystsHydrocarbonsRare earthDehydrogenation

A method to promote the activity of a catalyst for dehydrogenation of propane to propylene is as follows: (1) an inorganic oxide bonding agent, a promoter and an acid solvent are added into a heat-resistant oxide; then after the oxide bonding agent, the promoter, the acid solvent and the oxide are kneaded evenly, the oxide is molded by rolling or band-extruding; (2) the catalyst carrier prepared is dried for 2 to 10 hours under the temperature of 60 centigrade degrees, and calcined under the temperature of 400 to 800 degrees; (3) the calcined carrier is immersed in a rare earth metal water solution under the temperature of 60 to 100 centigrade degrees for 2 to 10 hours; (4) the catalyst carrier modified by the rare earth is immersed in a water solution comprising platinum metal elementsand the fourteenth metal elements under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours, and then the carrier is filtered, washed with distilled water, dried under the temperature of 60 to 180 centigrade degrees for 2 to 10 hours, and calcined under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours; (5) the catalyst prepared is activated in the air under the temperature of 400 to 600 centigrade degrees for 3 to 10 hours, and reduced in a hydrogen flow under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours; the reduced catalyst is used for catalytic reaction for dehydrogenation of propane to propylene.

Owner:SOUTHEAST UNIV

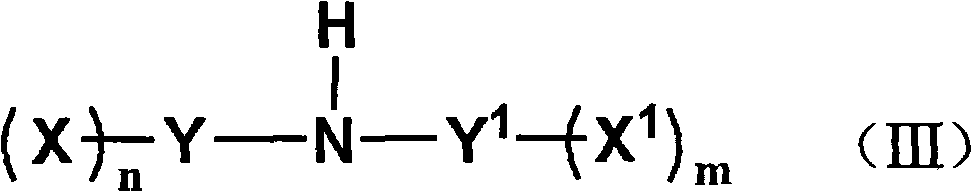

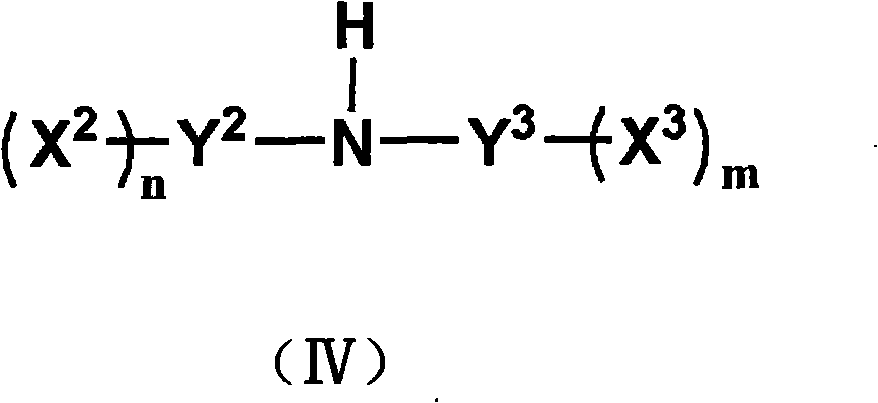

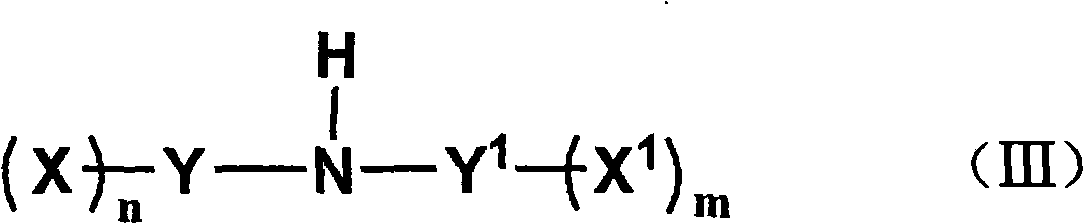

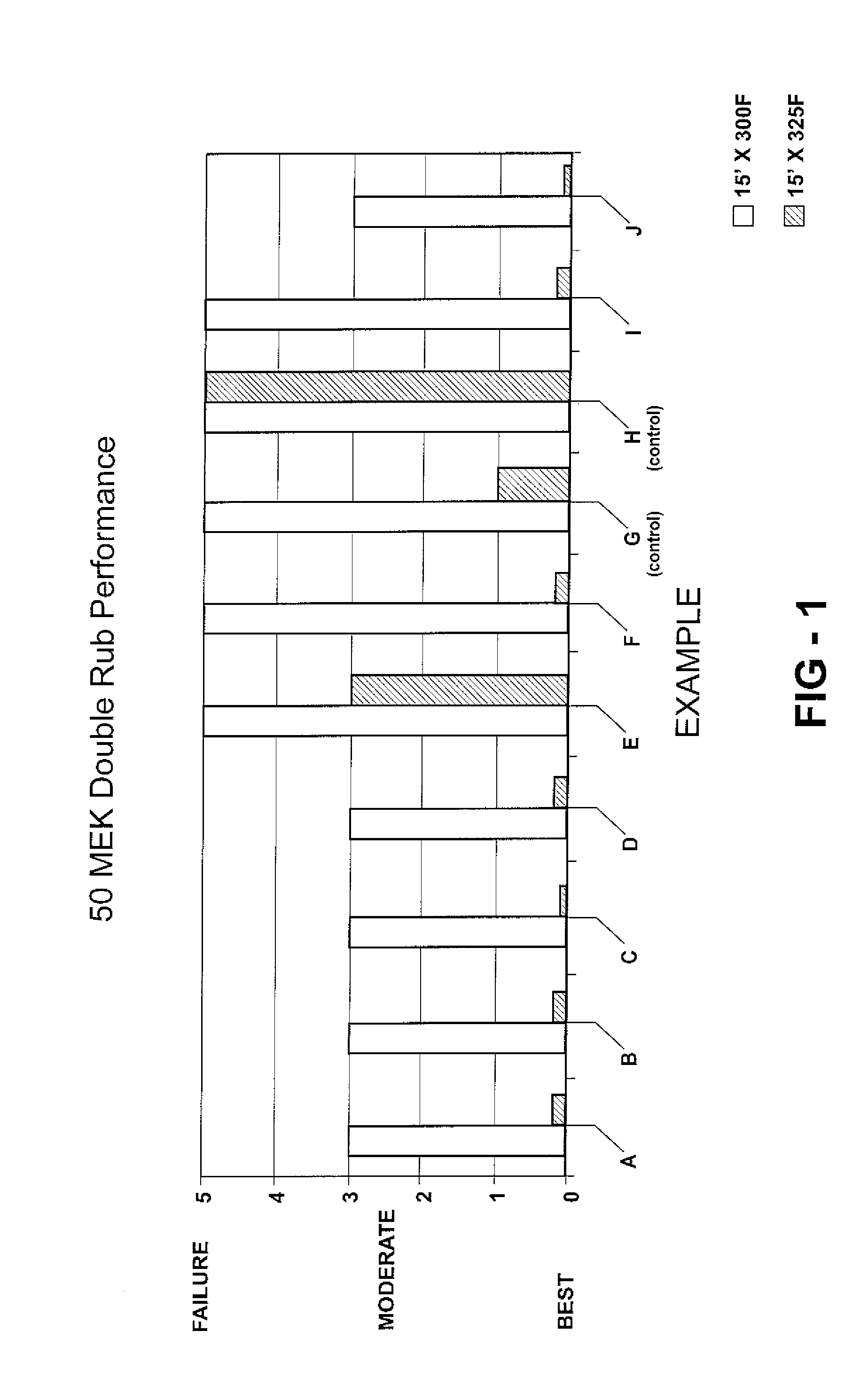

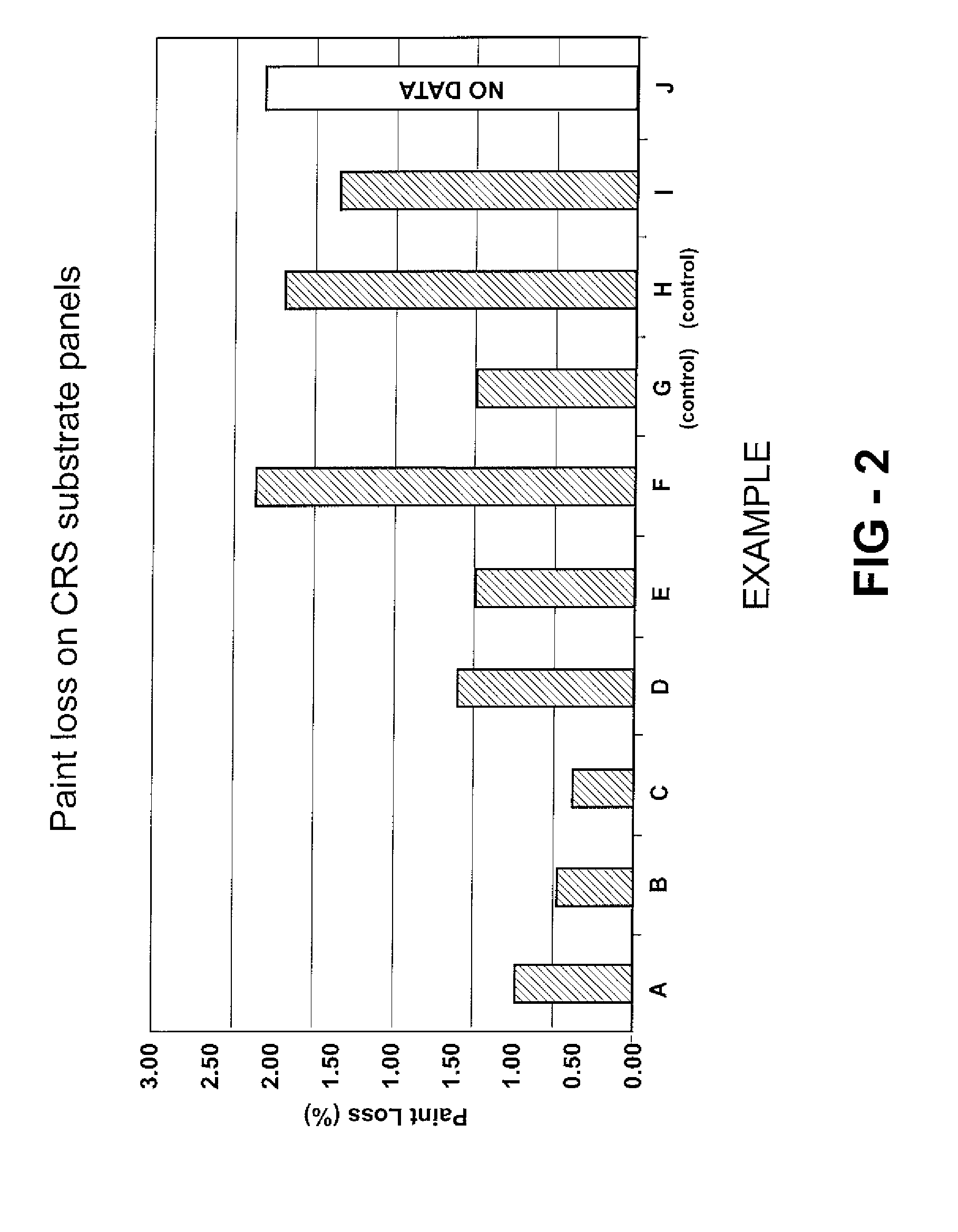

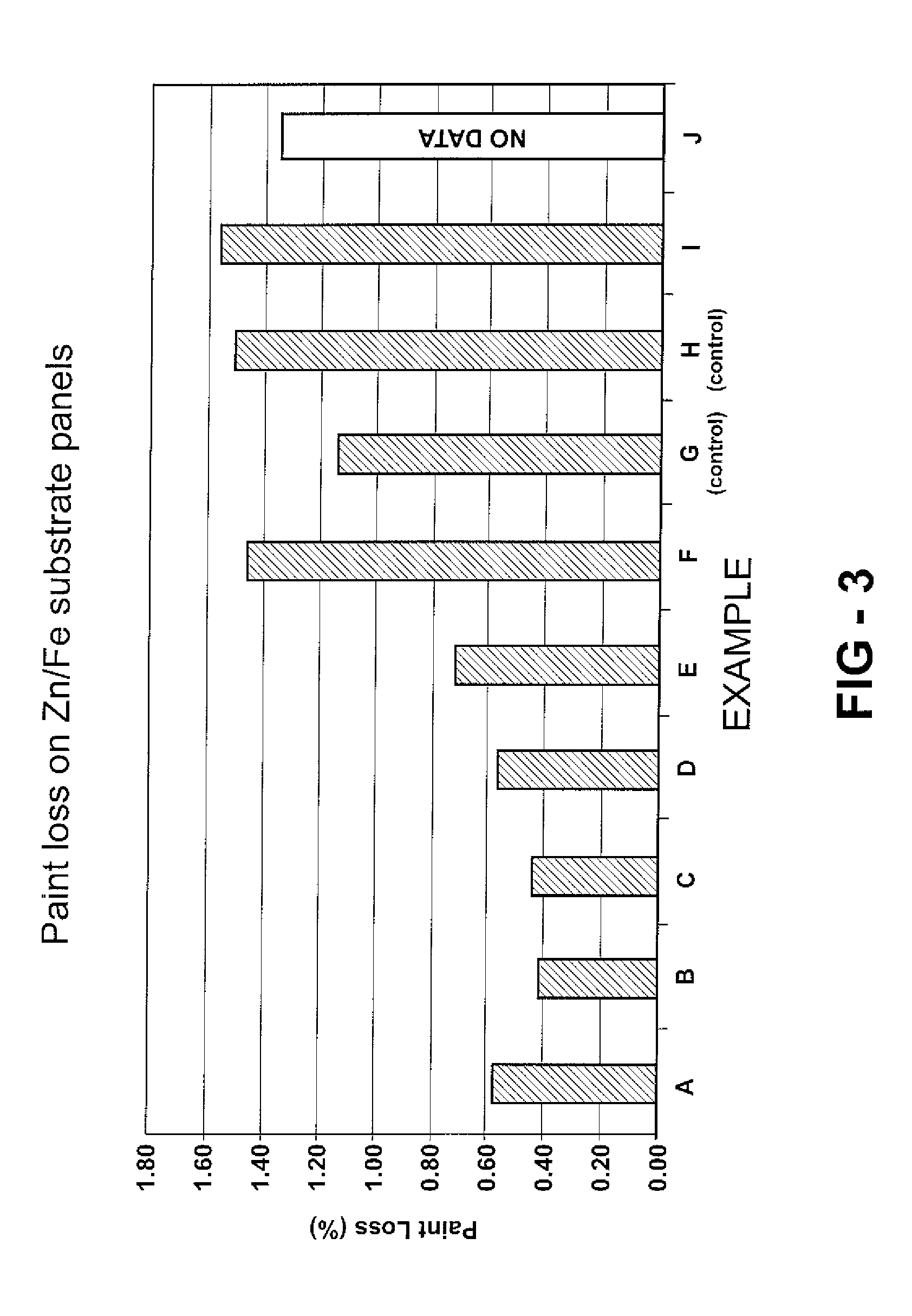

Method of preparing an aliphatic polyurea spray elastomer system

This invention concerns a method for the preparation of polyurea elastomers, comprising: (a) reacting an amine chain extender with dialkyl maleate to form an aspartic ester, wherein the chain extender has a molar amount of amine groups that is less than the moles of dialkyl maleate; (b) blending the aspartic ester with one or more polyoxyalkyleneamines to prepare a resin blend; (c) contacting the resin blend with an isocyanate under conditions effective to form a polyurea elastomer. This invention also concerns a a polyurea elastomer, comprising the reaction product of (a) a resin blend containing one or more polyoxyalkyleneamine and an aspartic ester and (b) an isocyanate, wherein the aspartic ester in the resin blend comprises a reaction product of an amine chain extender and a dialkyl maleate, wherein the mole ratio of amine functionality in the amine chain extender to dialkyl maleate or fumarate is greater than 1:1.

Owner:JPMORGAN CHASE BANK N A AS COLLATERAL AGENT +1

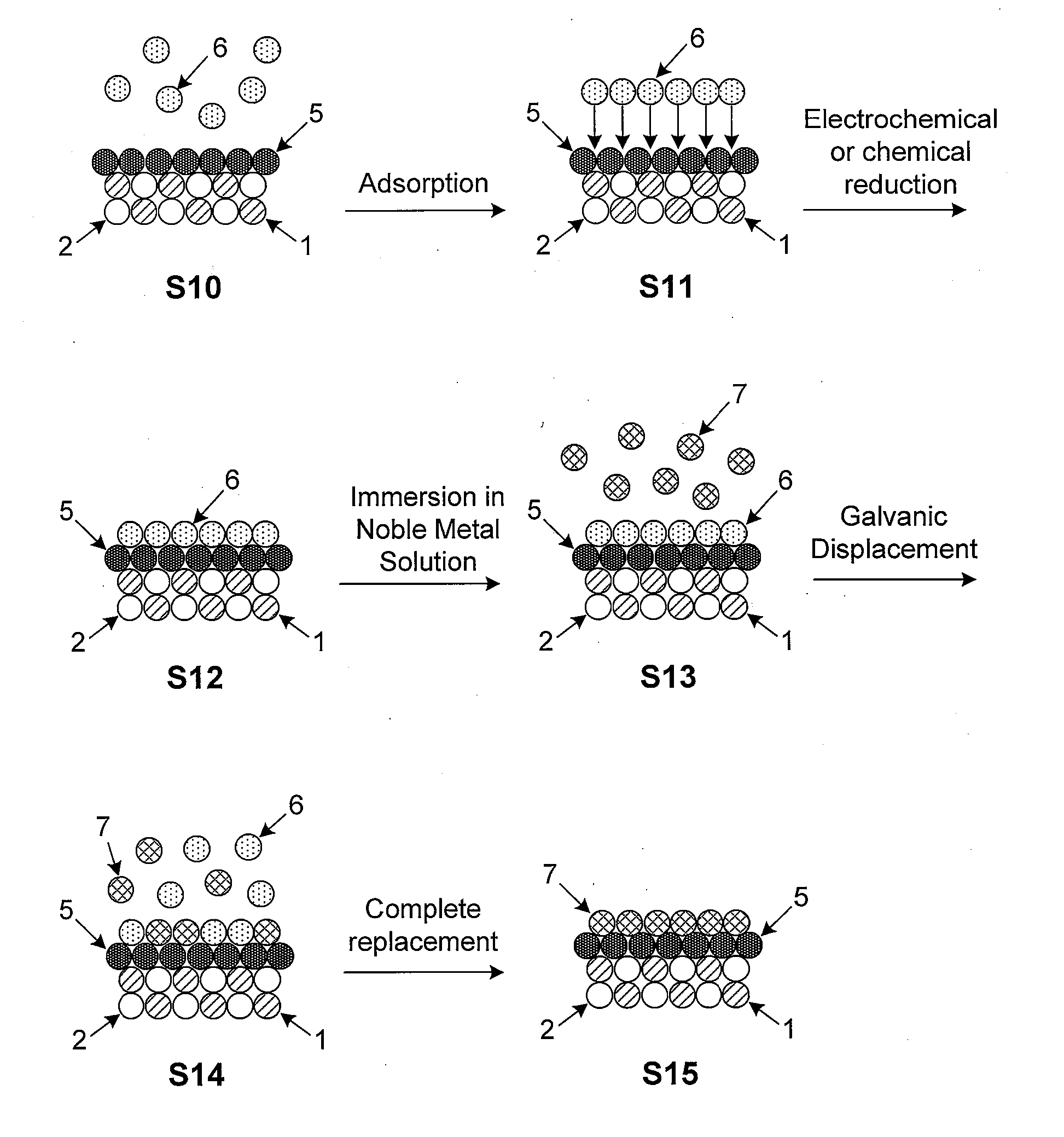

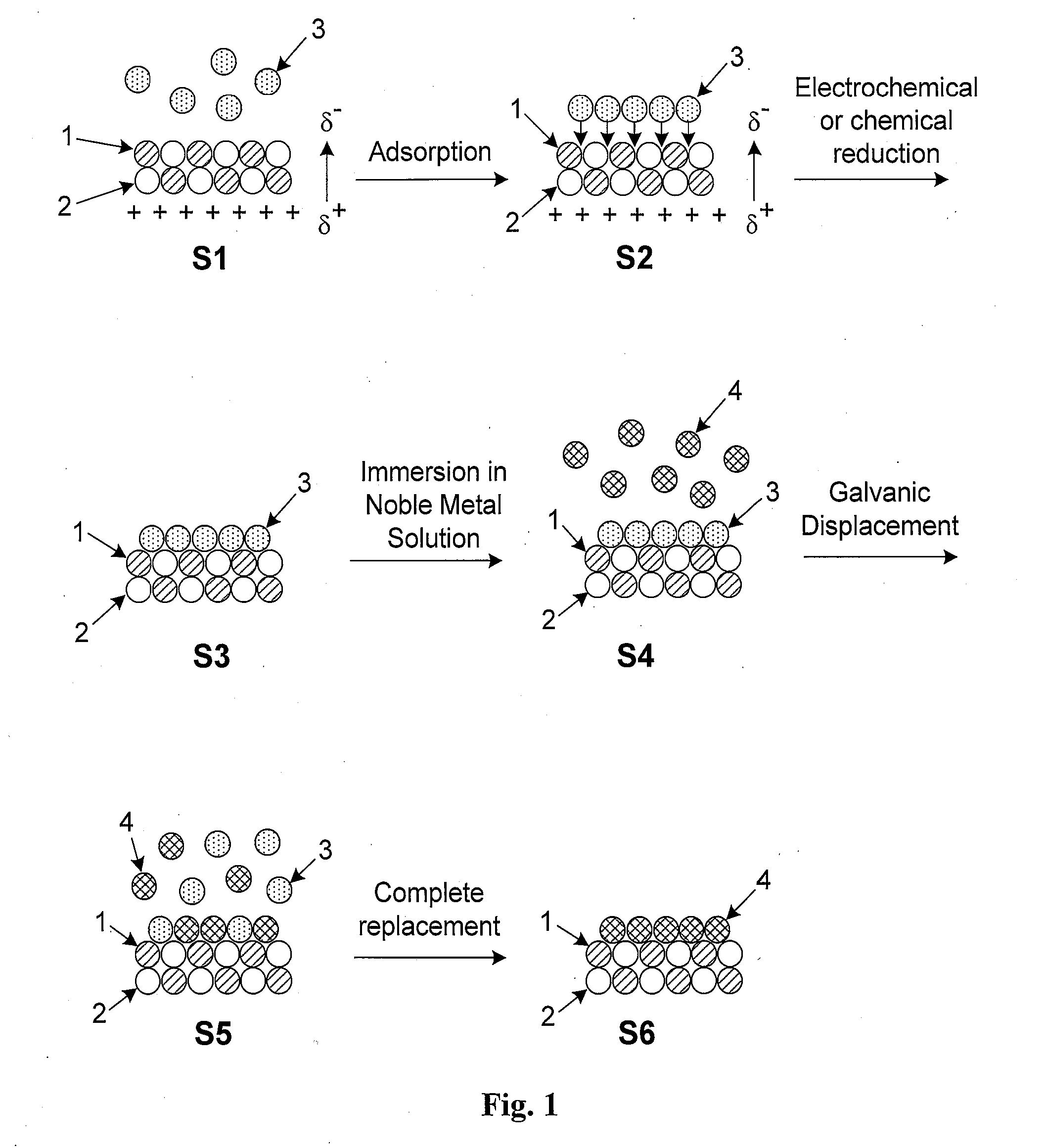

Platinum-Based Electrocatalysts Synthesized by Depositing Contiguous Adlayers on Carbon Nanostructures

InactiveUS20100177462A1High catalytic activityImprove stabilityMaterial nanotechnologyCarbon compoundsNanostructurePt element

High-surface-area carbon nanostructures coated with a smooth and conformal submonolayer-to-multilayer thin metal films and their method of manufacture are described. The preferred manufacturing process involves the initial oxidation of the carbon nanostructures followed by immersion in a solution with the desired pH to create negative surface dipoles. The nanostructures are subsequently immersed in an alkaline solution containing non-noble metal ions which adsorb at surface reaction sites. The metal ions are then reduced via chemical or electrical means and the nanostructures are exposed to a solution containing a salt of one or more noble metals which replace adsorbed non-noble surface metal atoms by galvanic displacement. Subsequent film growth may be performed via the initial quasi-underpotential deposition of a non-noble metal followed by immersion in a solution comprising a more noble metal. The resulting coated nanostructures may be used, for example, as high-performance electrodes in supercapacitors, batteries, or other electric storage devices.

Owner:BROOKHAVEN SCI ASSOCS

Method for preparing fluorine-containing sulphonyl (phosphoryl) imine and alkali metal salt thereof

ActiveCN101654229AHigh reactivityHigh yieldAmidosulfonic acidOrganic-compounds/hydrides/coordination-complexes catalystsChemistryAlkali metal

The invention provides a method for preparing fluorine-containing sulphonyl (phosphoryl) imine and fluorine-containing sulphonyl (phosphoryl) imine alkali metal salt. The method comprises the following steps: taking one or two or more than two of Lewis acid, perfluoro-alkyl sulfuryl fluoride and perfluoro-alkyl acyl fluoride as a catalyst, catalyzing anhydrous hydrogen fluoride to react with chlorine-containing sulphonyl (phosphoryl) imine in a high-pressure kettle and then obtaining the fluorine-containing sulphonyl (phosphoryl) imine by depressurization distilling; taking Lewis base as a catalyst, catalyzing the anhydrous hydrogen fluoride to react with the chlorine-containing sulphonyl (phosphoryl) imine, then acting with different alkali metal carbonate and obtaining the correspondingfluorine-containing sulphonyl (phosphoryl) imine alkali metal salt. Compared with the prior art, the method has the characteristics of simple operation steps, mild reaction conditions, low cost, easyseparation and purification of the product, high purity and yield and the like and is suitable for industrialized mass production.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Polydopamine-based biofunction modification method

InactiveCN102000658AImprove deformation resistanceImprove stabilityPretreated surfacesCoatingsAir atmosphereMetallic materials

The invention discloses a polydopamine-based biofunction modification method. The method comprises the following steps of: soaking clean inorganic / metal materials in dopamine alkaline aqueous solution with a pH value of 7.2 to 10, introducing oxygen to fully oxidize the clean inorganic / metal materials to obtain a monolayer polydopamine modification layer, drying, placing the material in the air atmosphere at 50 to 200 DEG C, performing thermal oxidation to obtain a multi-layer firmly-combined high-reactivity polydopamine layer, and soaking the treated material into the amino-containing and sulfydryl-containing biofunctional molecular solution to obtain a firmly combined biofunction simulate modification layer on the surface of the materials. The polydopamine modification layer obtained bythe method has excellent anti-deformation performance, stability and reactivity, can directly react with amino or the sulfydryl in the biomolecule to immobilize the bioactive molecule on the surface by covalent bonds; moreover, the process is simple, the condition is mild, and the method is easy to implement.

Owner:CO WITH LTD LIABILITY OF MEDICAL SCI +1

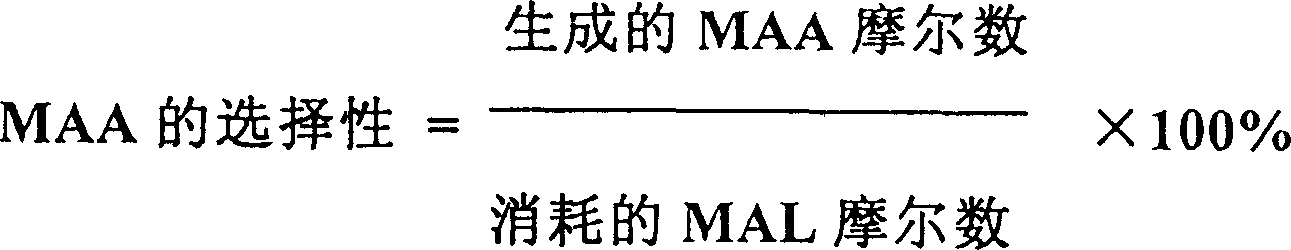

Catalyst for selectively oxidizing methyl acrylic aldehyde to synthesize methyl propenoic acid and its use

ActiveCN1647854AHigh reactivityHigh selectivityPhysical/chemical process catalystsOrganic compound preparationHeteropoly acidGas phase

The present invention provides catalyst for selectively oxidizing methyl acrolein to synthesize methylpropenoic acid and its usage in catalyzing gas phase oxidation of methyl acrolein to synthesize methylpropenoic acid. The catalyst is one heteropoly acid salt containing Mo, P, K, Sb, Cu, As, etc., and has high catalytic activity and stability, long service life, methyl acrolein converting rate higher than 85 % and methylpropenoic acid selectivity over 87 % in the presence of molecular oxygen and diluting gas.

Owner:SHANGHAI HUAYI NEW MATERIAL

Silicon dioxide aerogel material and preparation method thereof

The invention relates to a silicon dioxide aerogel material and a preparation method thereof. The method comprises the following steps: by using water glass as silicon source, adding an acid-containing organic solvent free of chlorine ions and fluorine ions to generate a precipitate of sodium ions, potassium ions and other metal salt ions, filtering to remove the precipitate to obtain high-purity silica sol, carrying out a sol-gel process, aging, acidifying, modifying, and drying to obtain the silicon dioxide aerogel material. The acidification before modification enhances the surface reaction activity of the silicon gel, thereby obviously enhancing the modification effect and efficiency. The method has the advantages of low cost and simple and efficient technique, is beneficial to mass high-efficiency production, is free of chlorine ions and fluorine ions in the whole technical process, and enhances the equipment operation safety and reliability; and the product can be used for heat preservation and thermal insulation of nuclear power and liquefied natural gas equipment and pipelines with higher requirement for corrosion resistance, and can also be used for thermal insulation in the field of aerospace, petrochemical engineering, track transportation, ships, automobiles, construction and the like.

Owner:浙江圣润纳米科技有限公司

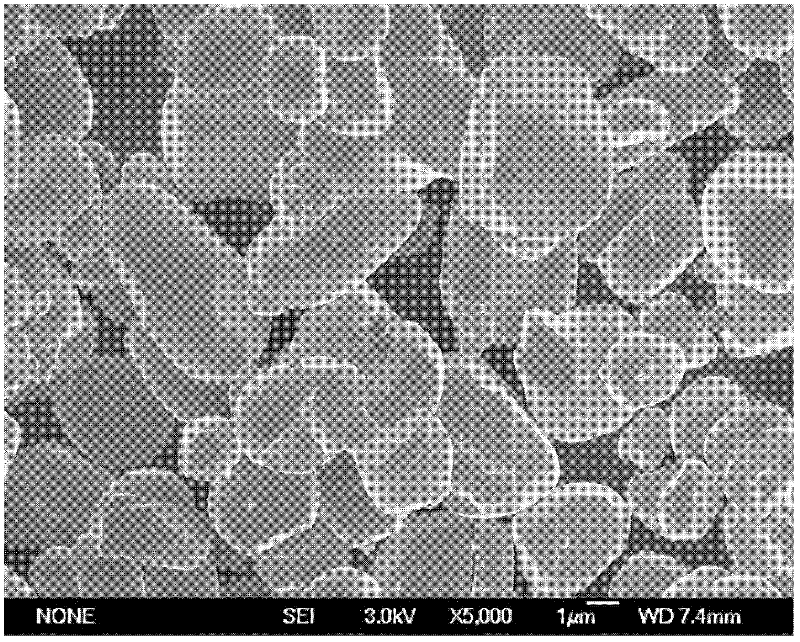

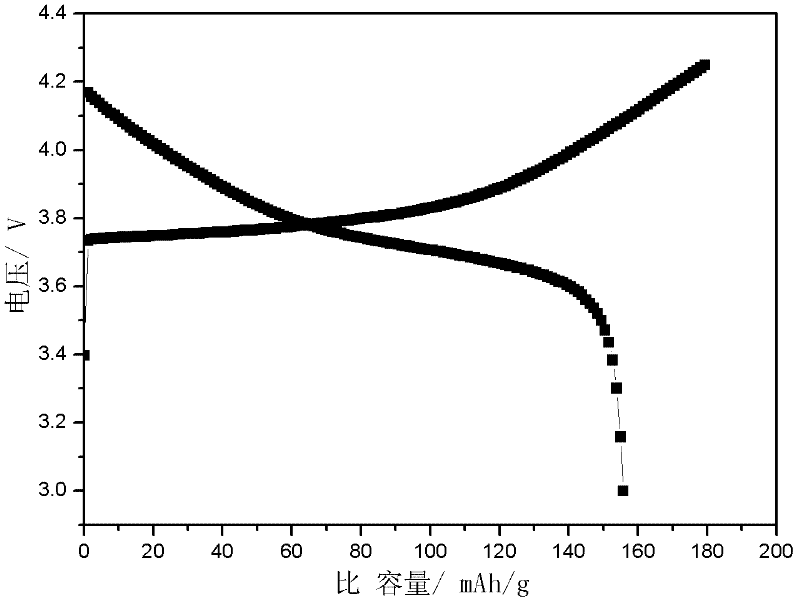

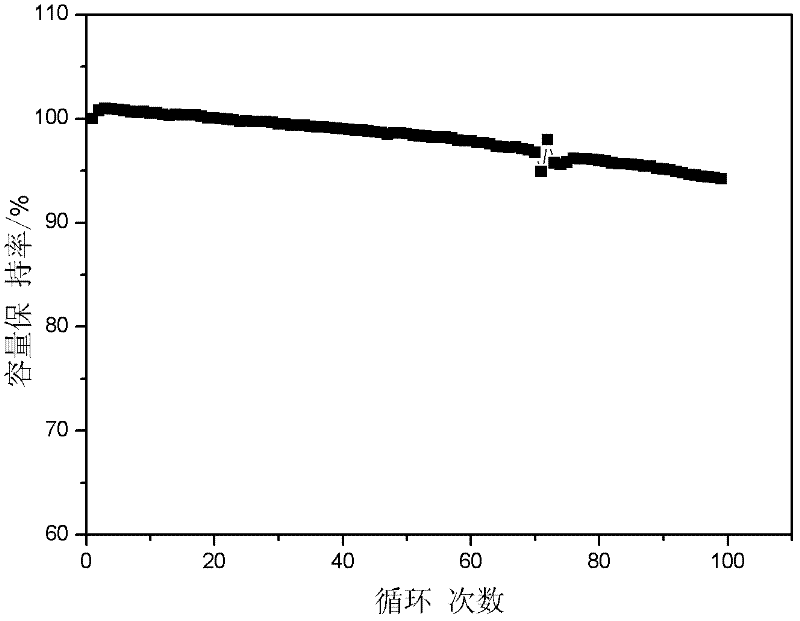

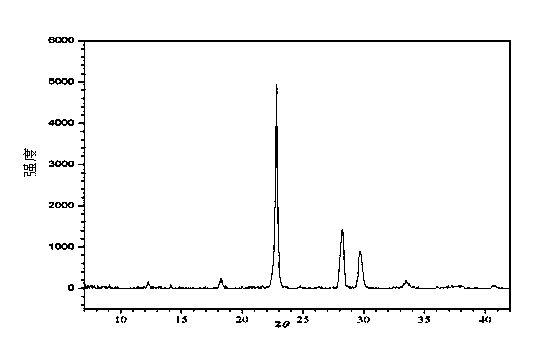

Preparation method of lithium ion battery ternary cathode material

The invention discloses a preparation method of a lithium ion battery ternary cathode material. According to the preparation method, full grinding is performed through a colloid mill to improve the reactivity of a precursor and a lithium salt and the uniformity of a mixed material; and a carbon chain organic additive is added in the process of grinding to improve the viscosity of a sizing material, inhibit raw material segregation in the process of drying, quickly balance the temperature of each part of a system in the process of high-temperature reaction and inhibit agglomeration among particles, so that a uniform-appearance and regular mono-crystal ternary cathode material is obtained. Meanwhile, the ternary cathode material is doped and subjected to surface coating modification, so that the structure of the material is stabilized, the side reaction between the material and electrolyte is inhibited, and the high-temperature cycle performance of the material is improved.

Owner:PULEAD TAIAN TECH IND

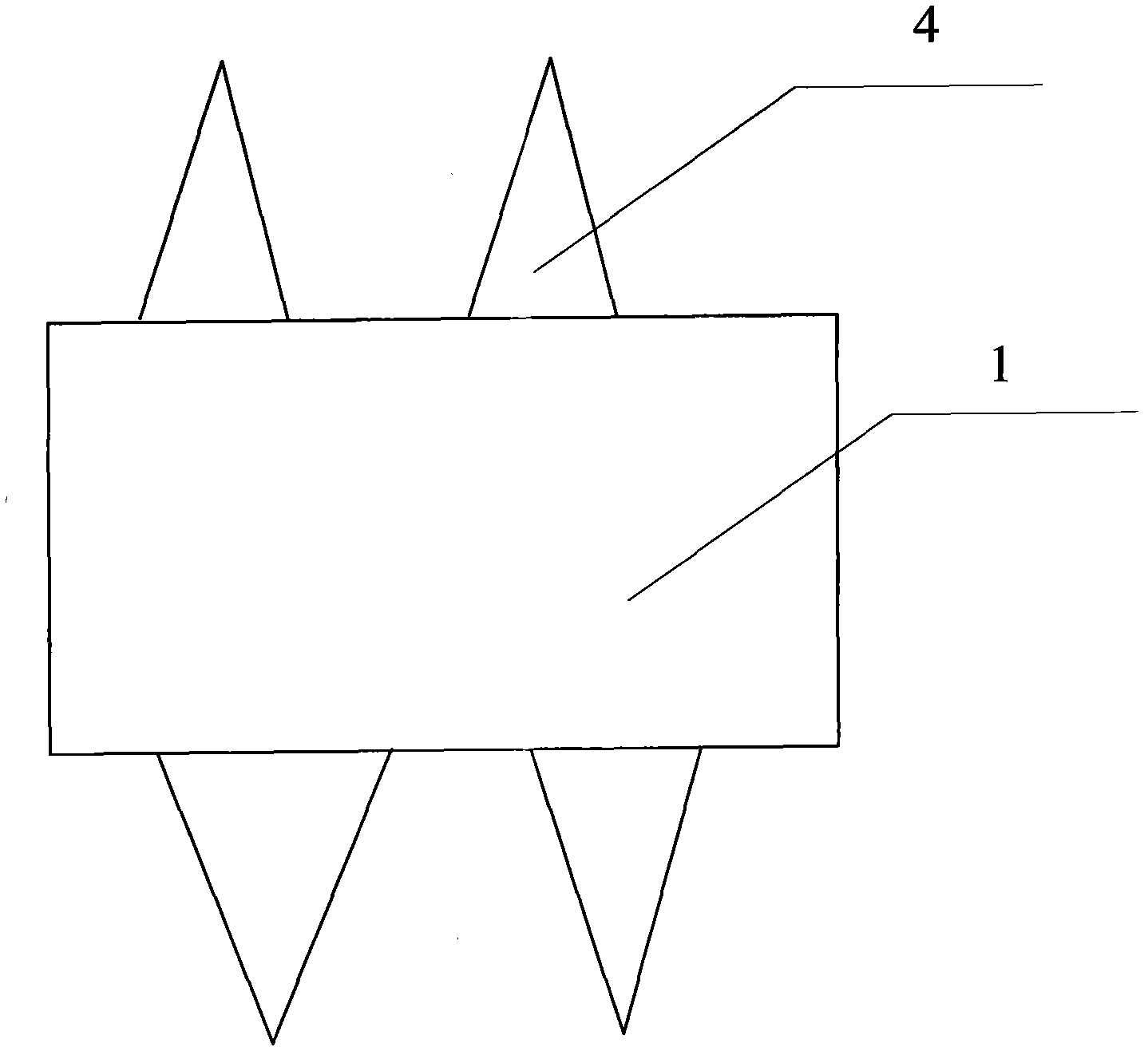

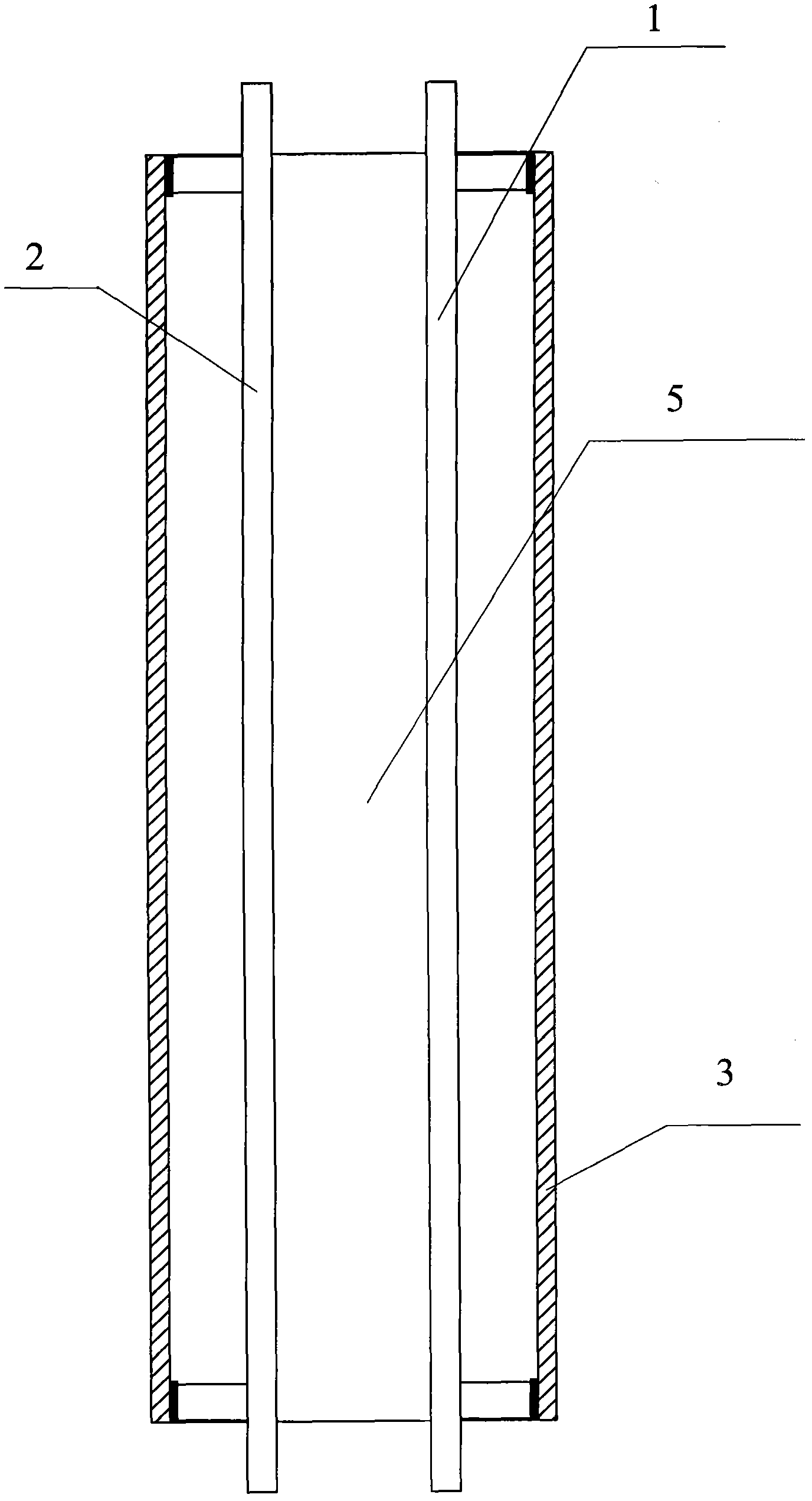

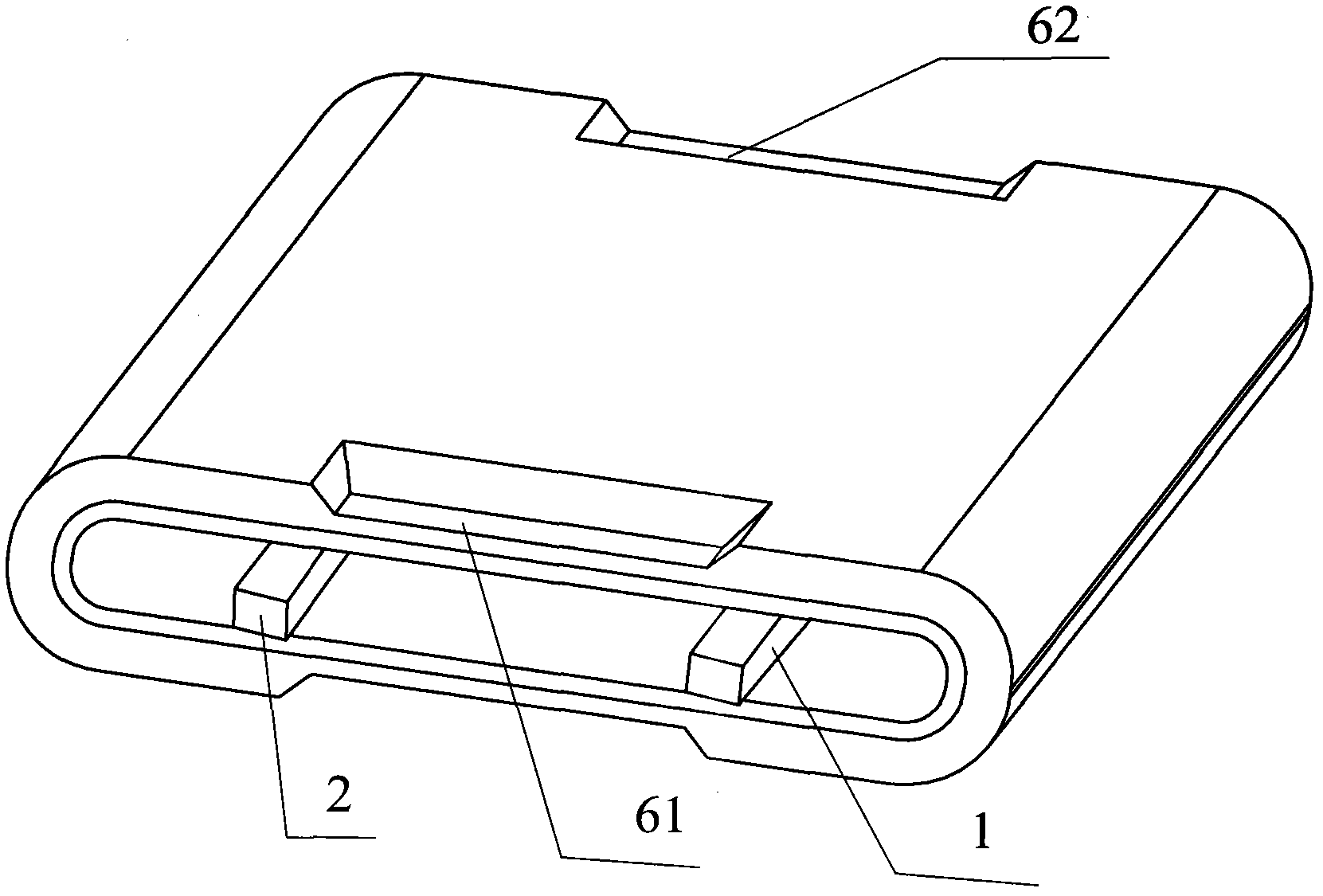

Battery

InactiveCN102569866AStable temperatureConsistent temperatureFinal product manufactureCell temperature controlHeat conductingReaction temperature

The invention provides a battery, comprising a cover plate, a shell, a battery cell and electrolyte. The battery cell and the electrolyte are sealed in the shell of the battery, and the cover plate is hermetically connected with the shell. The battery cell comprises a positive polar plate, a negative polar plate and a diaphragm arranged between the positive polar plate and the negative polar plate. A positive polar lug is arranged on the positive polar plate, and a negative polar lug is arranged on the negative polar plate. The battery cell is further internally provided with a positive polar current and heat conducting member and a negative polar current and heat conducting member, and the positive polar current and heat conducting member and the negative polar current and heat conducting member are mutually insulated. The positive polar current and heat conducting member and the positive polar lug are conducted; the negative polar current and heat conducting member and the negative polar lug are conducted; the positive polar current and heat conducting member and / or the negative polar current and heat conducting member penetrate(s) through the cover plate to leading out current. According to the invention, the internal heat of the battery cell can be reduced rapidly, substances on the polar plates can be prevented from further thermal reaction, and thus, the safety performance of the battery is increased. Meanwhile, the stability of the internal temperature of the battery cell is guaranteed, the cyclic performance and the like of the battery are improved. In addition, the temperature at all parts in the battery cell can be ensured to be consistent so as to eliminate temperature differences and make the reaction temperature of all parts of the polar plates consistent. Meanwhile, the current and heat conducting members can play roles of backbone and support to support the battery cell, and is beneficial to not only assembly but also winding of the battery cell.

Owner:BYD CO LTD

Method for polymerization of an alpha -olefin

InactiveUS6066702AHigh reactivityEasy to operateOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElectron donorAlpha-olefin

A method for polymerization or copolymerization of alpha -olefin, characterized in that the polymerization is performed using a solid complex titanium catalyst comprising magnesium, a halogen-containing titanium compound, and internal electron donors; organometallic compounds of metals belonging to Groups I and III on the periodic table of elements; and, as external electron donors, a mixture of three or more kinds of organic silicon compounds, from which homopolyolefins having MFR less than 5, MFR in the range from 5 to 20, and MFR greater than 20 are polymerized under the same polymerization conditions. By use of the present invention it is possible to produce an olefin polymer with high stereoregularity, broad molecular weight distribution, and good fluidity, at high rates of yield.

Owner:HANWHA TOTAL PETROCHEMICAL CO LTD

Isomerization dewaxing catalyst and preparing method thereof

InactiveCN1488733AHigh reactivityHigh selectivityMolecular sieve catalystsPetroleum wax recoveryMolecular sieveIsomerization

The present invention discloses an isodewaxing catalyst for producing base oil of lubricating oil and its preparation method. Said catalyst contains a new-type phosphorus silicon aluminium molecular sieve with AEL structure and active metal component, and the surface acidity of said molecular sieve is strong, and its mesopore distribution is more. Said catalyst is used for isodewaxing reaction of lubricating oil fraction, and has the characteristics of low reaction temp. high base oil yield, low product pour point and high viscosity index.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing the reactive tinting compound and the tinted contact lens

A method for preparing the tinted contact lens with the covalently bonded novel reactive tinting compound is disclosed. The reactive tinting compound with mono vinyl functionality is prepared by reacting the reactive dye with a hydrophilic monomer containing both pendent hydroxyl and vinyl groups under an alkaline condition. The water soluble reactive dyes containing either difluoro-chloropyrimidine or β-sulphatoethylsulphone reactive groups are used for synthesis of the reactive tinting dye. The lens forming materials are photo-polymerized in the presence of the reactive tinting compound to prepare a tinted contact lens. The reactive tinting compound is copolymerized with the lens forming monomers in a single photo-polymerization step that requires no subsequently alkaline soaking or developing step as used in the prior art. In addition, the covalently bonded dye is stable and durable in the lens and does not fade or leach out after multiple high-pressure thermal sterilizations.

Owner:SMART PERFORMER

A method of catalyzing a reaction to form a urethane coating and a complex for use in the method

ActiveUS20070244270A1Improved physical propertyMaximum compatibilityPolyurea/polyurethane coatingsPolymerCarbamate

A urethane coating is formed by a reaction of a hydroxy-functional resin and a blocked isocyanate crosslinker. A method of catalyzing this reaction includes forming a polymeric ligand from the resin and / or the crosslinker. The method also includes incorporating a metal catalyst with the polymeric ligand to complex the metal catalyst with the polymeric ligand The method further includes reacting resin and the crosslinker to form the urethane coating

Owner:BASF CORP

Sulfenylation process of pyrozole compound with trifluoromethanesulfonyl radical

InactiveCN1374298AEasy to manufactureHigh reactivityOrganic chemistryAcyl groupCombinatorial chemistry

The present invention relates to one sulfenylation process of pyrazole compound with CF3SO2K or the mixed salt of CF3SO2K and CF3SO2Na. CF3SO2K or the mixed salt of CF3SO2K and CF3SO2Na are made to react first with reagent A and then with pyrazole compound to obtain pyrazole compound with trifluoromethanesulfonyl radical, where the reagent A is selected from phosgene, TCF, POCl3, PC1 and SOC12. The present invention finds one new sulfenylation reagent, and is easy to prepare, high in reaction, activity, easy to use and high in yield.

Owner:JIANGSU PESTICIDE RES INST

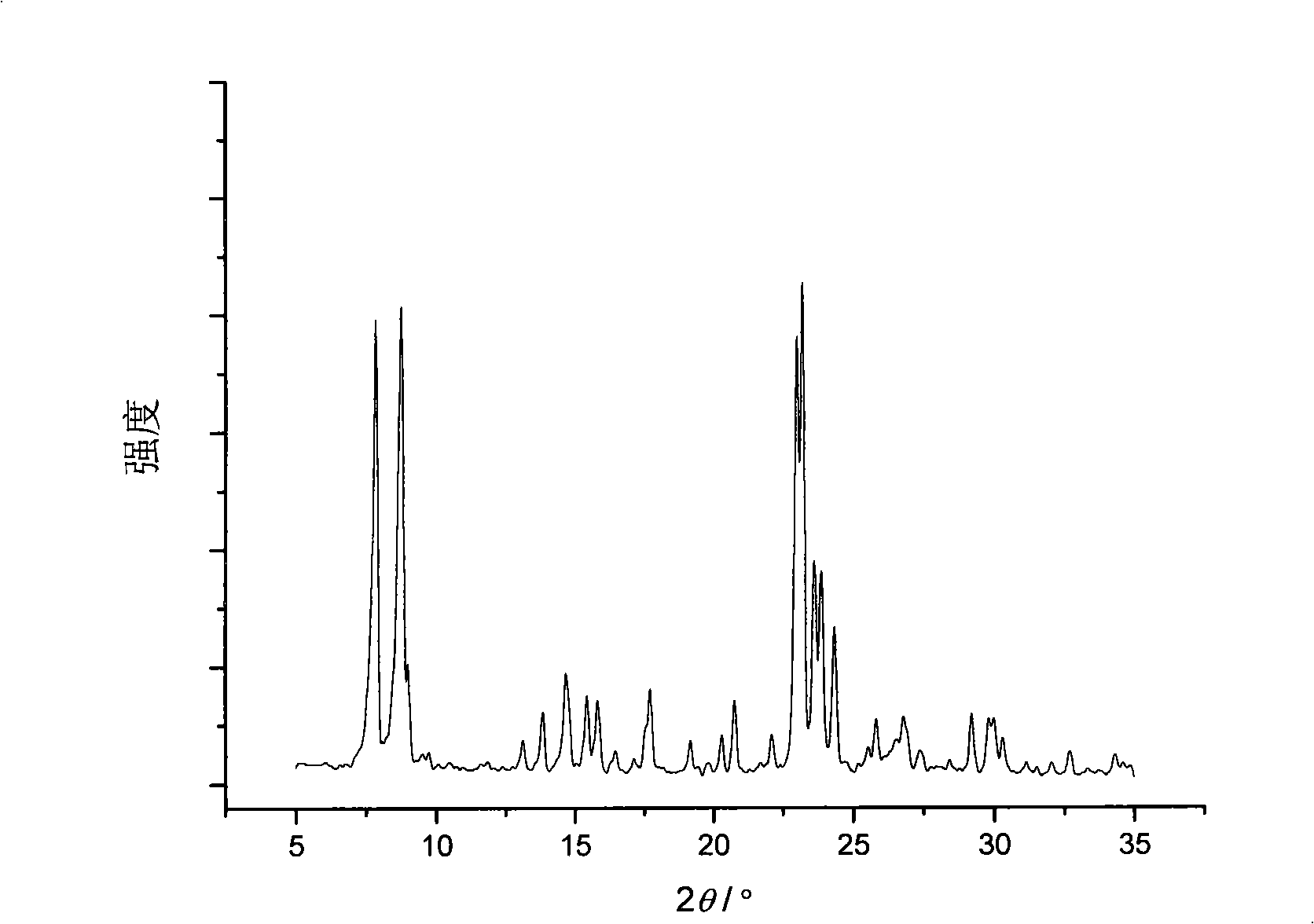

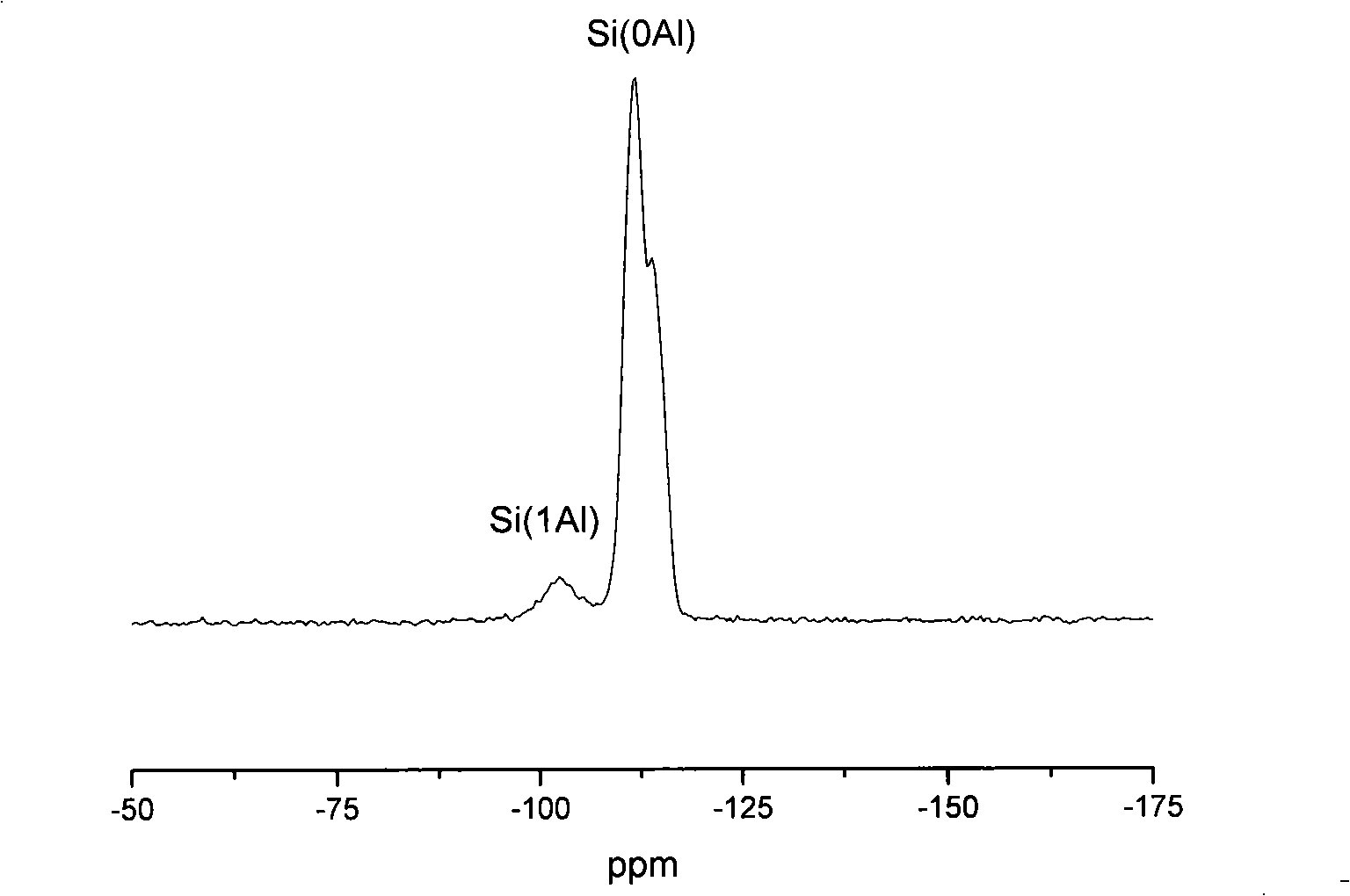

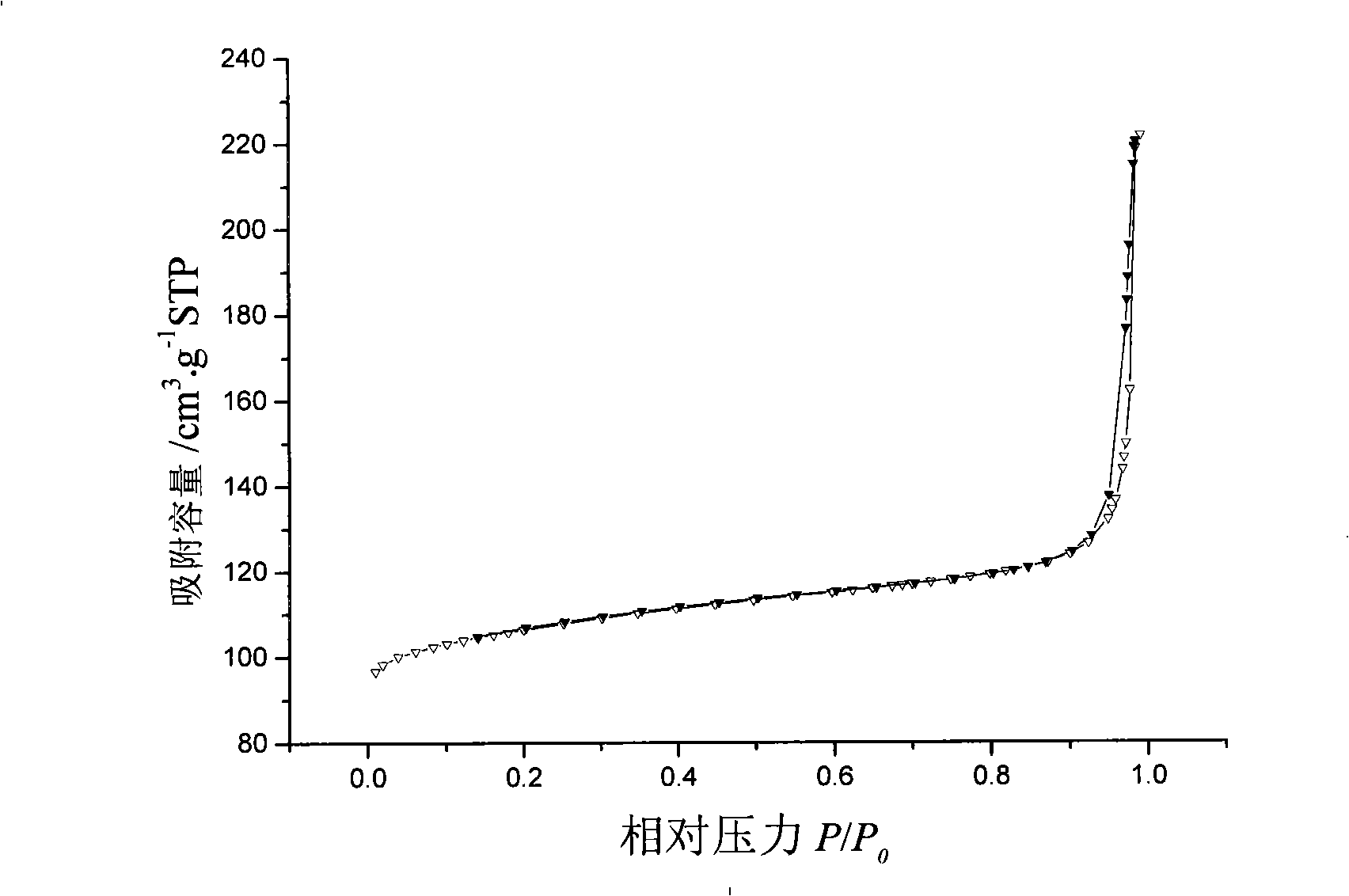

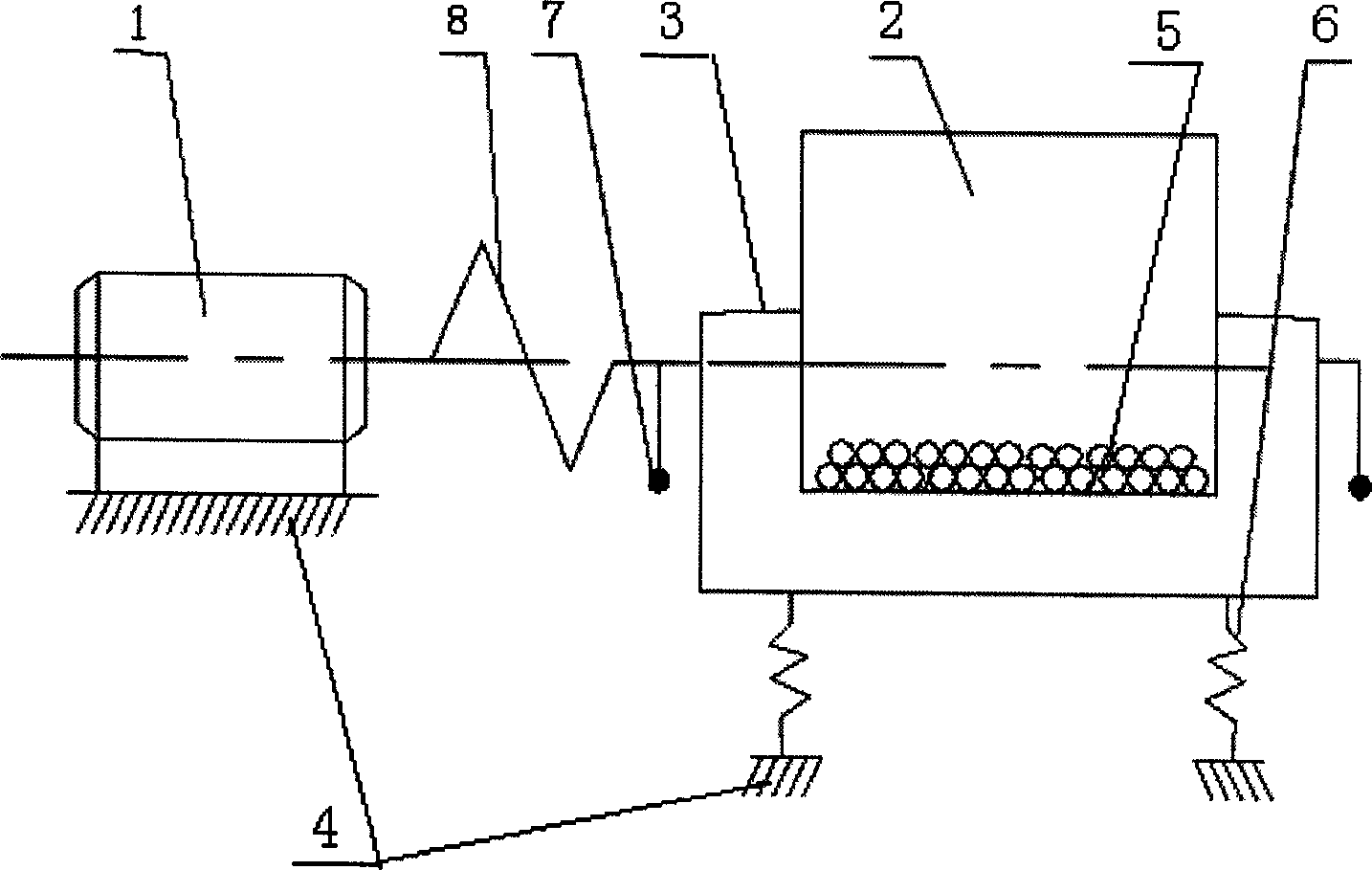

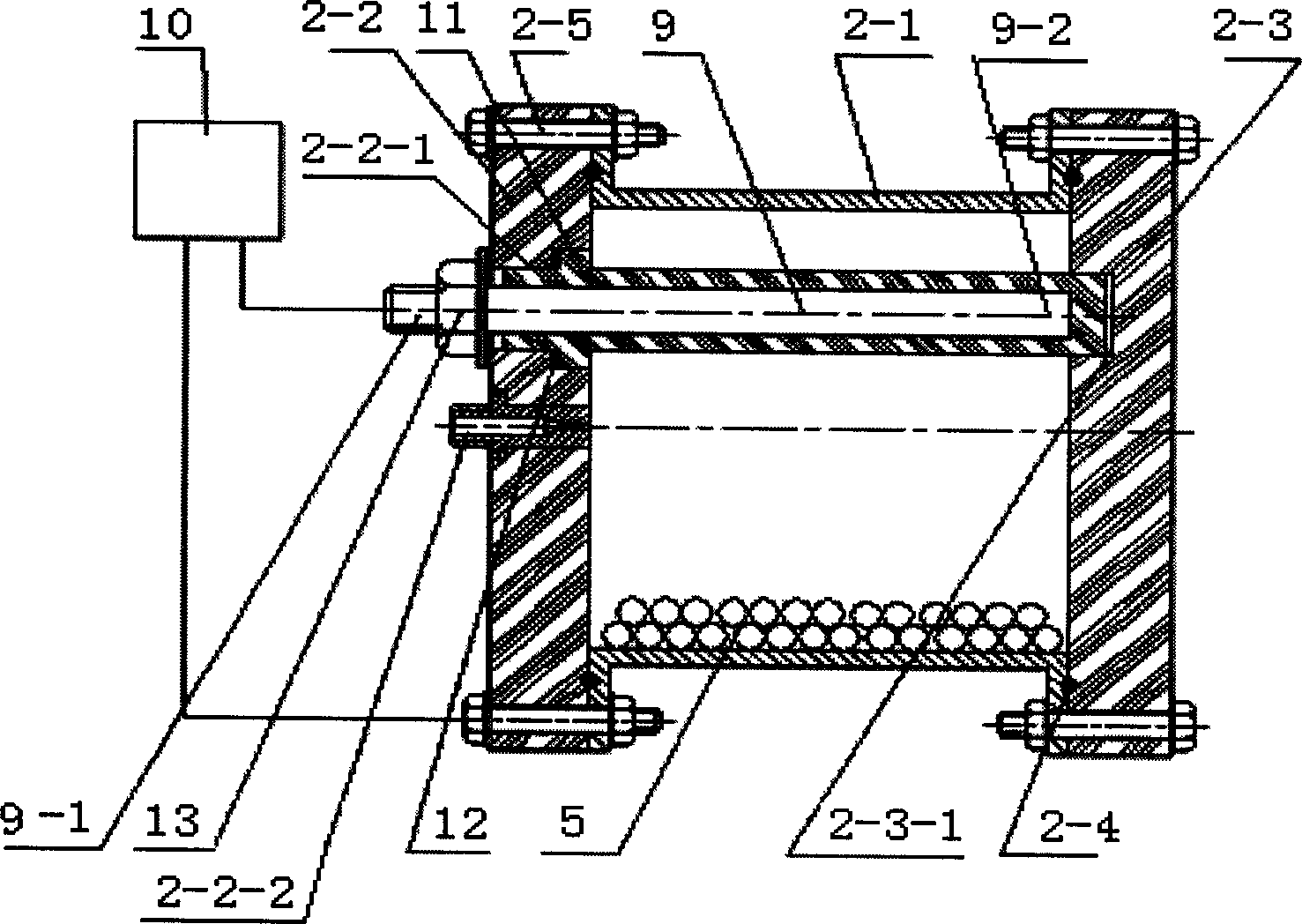

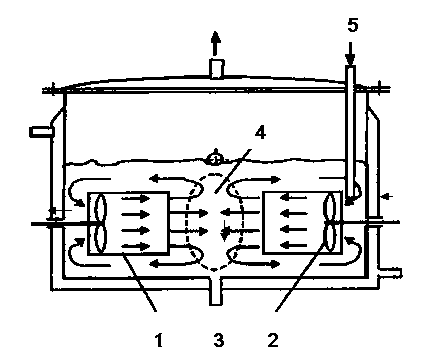

High silicon-aluminum ratio ZSM-5 zeolite catalyst, preparation method and application thereof

InactiveCN101269340ASkeleton silicon aluminum ratio is highHigh reactivityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsHydrothermal synthesisSilicon

The invention belongs to the catalyst technical field, in particular to a ZSM-5 zeolite catalyst characterized by high ratio of silica and alumina as well as a preparation method and the application thereof. The catalyst, taking a pure silicon compound with activity as a silicon source, is made by a hydrothermal synthesis method by adding trace aluminum. The ratio of silica and alumina in the zeolite catalyst is over 1,000, sub-micron crystal particles with open channels have large surface area and good molecular diffusivity. The catalyst in the reaction of MTP has excellent catalytic activity, high selectivity of propylene, and high ratio of propylene and ethylene. The catalyst has simple regeneration method and good restoration of performance after regeneration.

Owner:FUDAN UNIV

High energy ball mill method with plasma aid

A plasma aided high-energy ball grinding method includes such steps as installing the front cover plate and rod electrode of ball grinder, respectively connecting the ball grinder and rod electrode to the poles of plasma power supply, loading the powder to be ground in the ball grinder, pumping negative pressure, filling discharging gas medium, turning on the plasma power supply, regulating discharge parameters for corona discharge or glow discharge, and turning on the motor to drive the vibration exciting block for ball grinding.

Owner:SOUTH CHINA UNIV OF TECH

Coated optical fibers

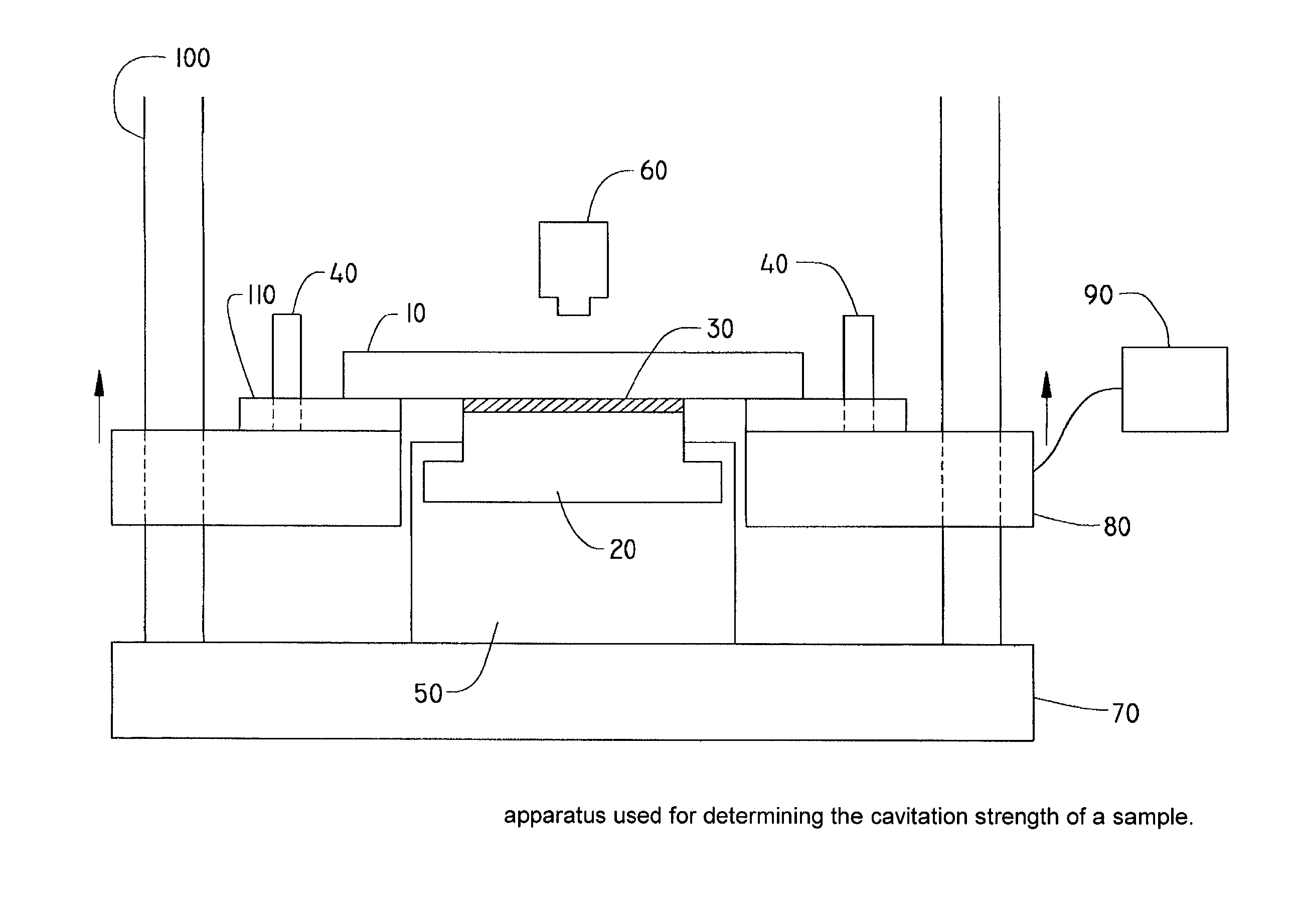

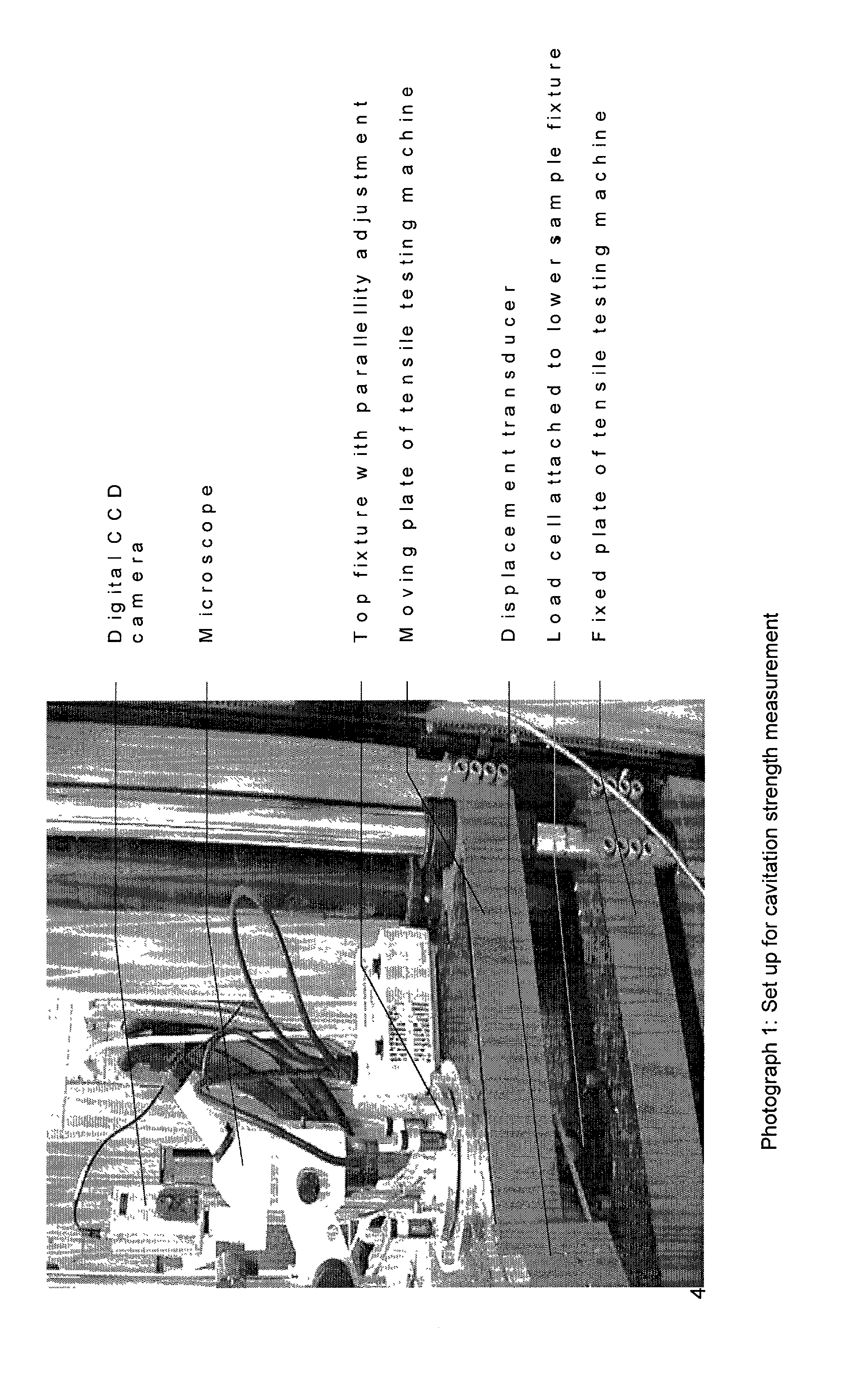

InactiveUS20020146225A1Sufficient high cavitation strengthLow modulusGlass optical fibreSynthetic resin layered productsHigh resistanceCavitation

The invention relates to coated optical fibers comprising soft primary coatings and to such primary coatings for protecting glass optical fibers having a sufficient high resistance against cavitation. In particular, the primary coatings have a cavitation strength at which a tenth cavitation appears (sigma10cav) of at least about 1.0 MPa as measured at a deformation rate of 0.20% min-1 and of at least about 1.4 times their storage modulus at 23° C. The coating preferably shows strain hardening in a relative Mooney plot, preferably has a strain energy release rate Go of about 20 J / m2 or more, and preferably has a low volumetric thermal expansion coefficient. The invention furthermore provides a method and apparatus for measuring the cavitation strength of a primary coating.

Owner:DSM IP ASSETS BV

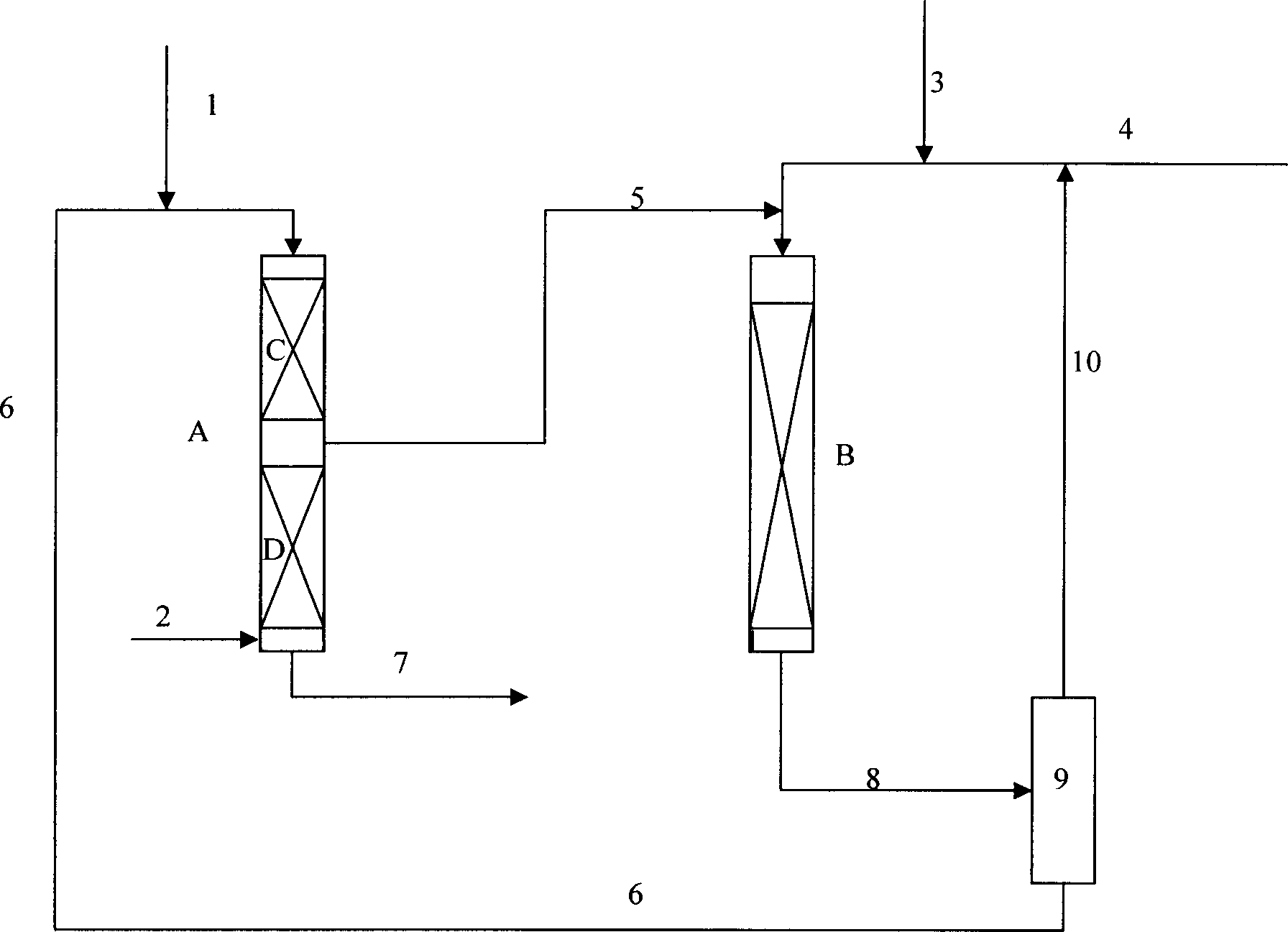

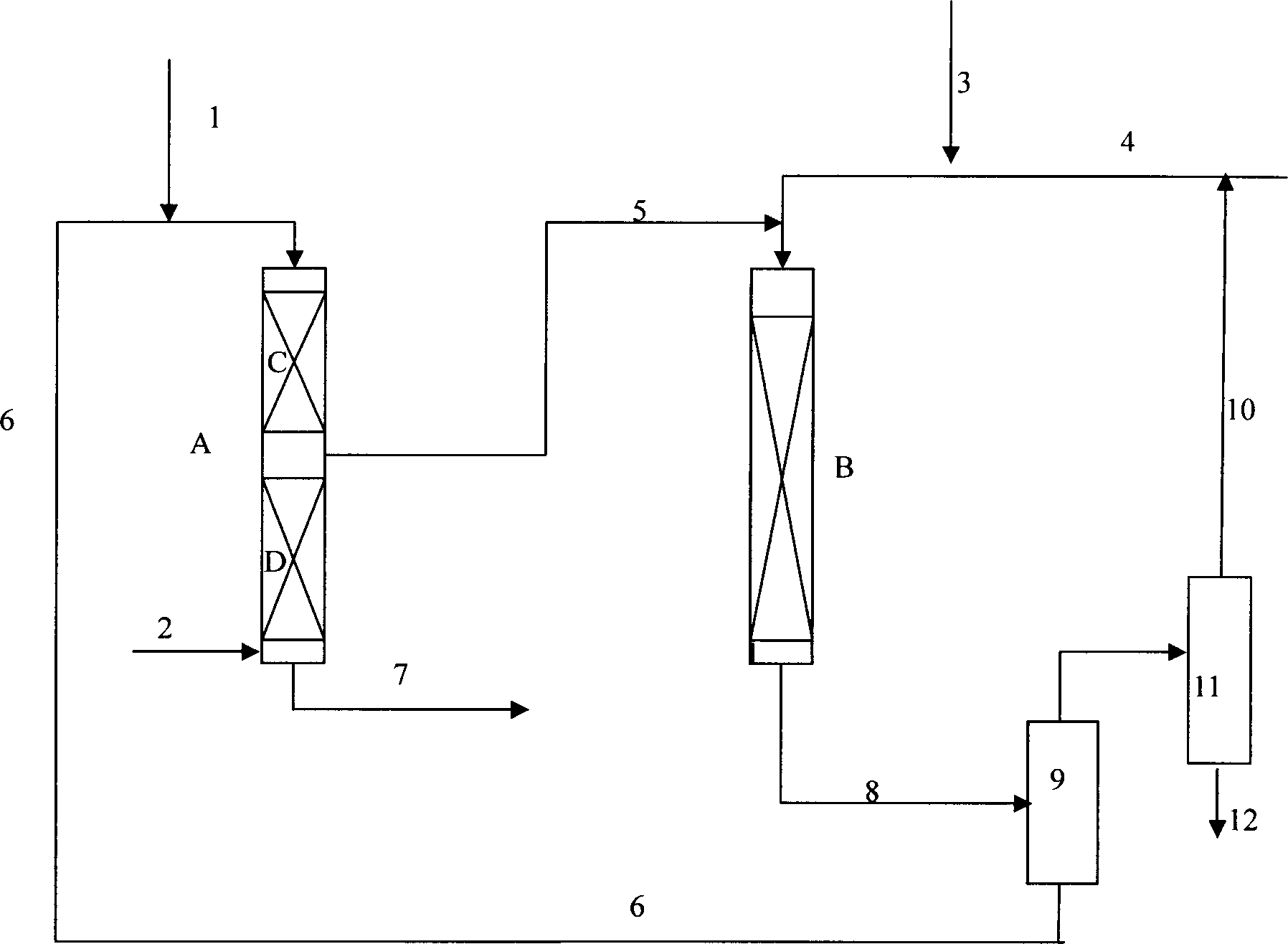

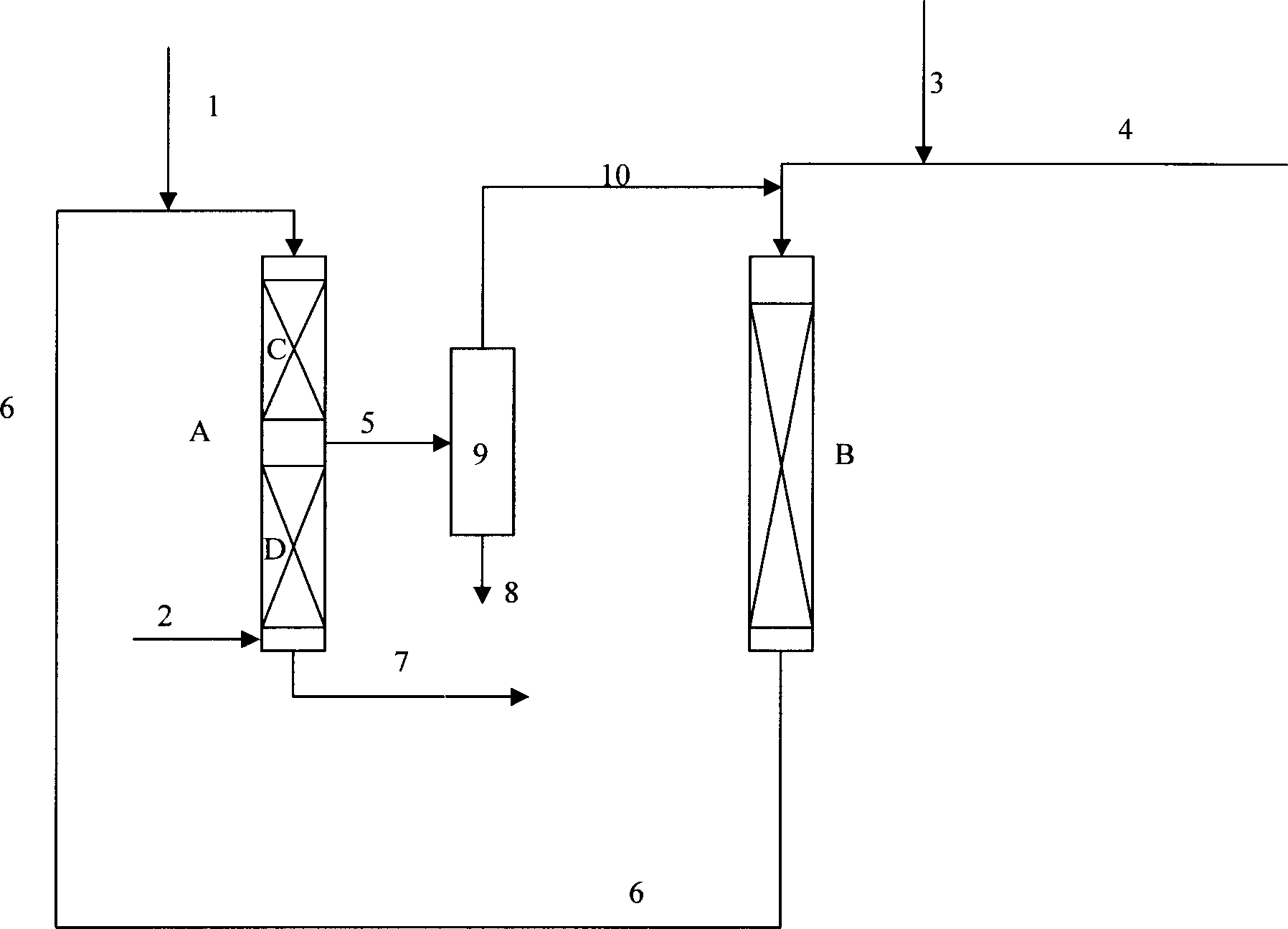

Deep desulphurizing and dearomating process for diesel oil

InactiveCN1552812AReduce loadIncrease flexibilityRefining to eliminate hetero atomsHydrodesulfurizationHydrogenation reaction

The invention relates to deep desulfurization and dearomatization of diesel fuel. A conventional co-current hydrofining reactor is connected with deep hydrodesulfurization and dearomatization reactors. Raw oil gets through the conventional hydrofining reactor firstly, reacted liquid phase material is mixed with fresh hydrogen to feed into the tops of deep hydrodesulfurization and dearomatization reactors, taking gas-liquid co-current hydrogenation, and then, reacted material is separated in gas-liquid separating zone. Gas phase is discharged and fed into the conventional hydrofining reactor, and liquid phase flows down to contact with fresh hydrogen inlet from the bottom of the reactor, finally, refined product is discharged from the bottom of the reactor. The invention process eliminates hepatic gas etc. impurity influence to arena saturation reaction in deep hydrodesulfurization and dearomatization reacting system of process now available, utilizes fully fresh hydrogen resource in the system, improves system reacting activity, usability of different raw oil, controllability and stability of counter- current hydrogenation reaction, and has better flexibility.

Owner:CHINA PETROLEUM & CHEM CORP +1

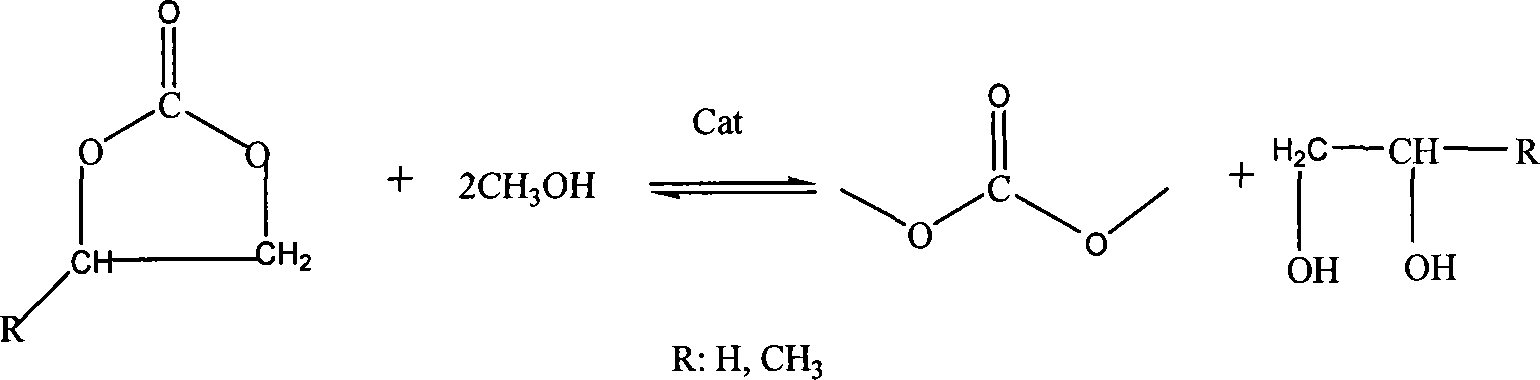

Load type solid body base catalyst of synthesizing dimethyl carbonate and method of preparing the same

InactiveCN101249452AEasy to makeEasy to preparePhysical/chemical process catalystsPreparation from organic carbonatesMethyl carbonatePotassium fluoride

The invention relates to a carrier type solid base catalyst for synthesizing dimethyl carbonate, which belongs to the technical field of catalytic material. The catalyst's formula is KF / M<2+>-N<3+>-(O), wherein M<2+>-N<3+>-(O) represents the composite metal oxide, M<2+> can be divalent metal ion (Mg<2+> or Ca<2+> ) and N<3+> can be trivalent metal ion (Fe<3+> and / or Al<3+>). The catalyst is prepared from potassium fluoride and composite metal oxide at a certain weight ratio by immersing the potassium fluoride into the composite metal oxide, wherein the composite metal oxide is prepared from hydrotalcite precursor and in nucleation / crystallization isolation method by calcining at a certain temperature. The catalyst has the advantages of nanoscaled particle size, high specific surface area and high activity, selectivity in catalytic reaction and simple preparation, and can be reused as it can be centrifugally separated after reacting.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of super-retarding type polycarboxylate superplasticizer

The invention discloses a preparation method of a super-retarding type polycarboxylate superplasticizer. The super-retarding type polycarboxylate superplasticizer comprises a copolymer and water serving as a solvent, wherein the copolymer comprises an unsaturated polyether macromonomer, an unsaturated carboxylic acid / anhydride mini-monomer, an unsaturated sulfonic acid mini-monomer and an unsaturated phosphonic acid mini-monomer; the pH is 6-7. According to the preparation method, a phosphonate structure capable of retarding is introduced into a water reducer molecular structure; the prepared super-retarding type polycarboxylate superplasticizer can be directly applied to the concrete which needs a relatively long setting time, and thus the process of compounding a retarder can be saved, the production efficiency can be improved, the obtained product is uniform and stable, and abnormal concrete setting time can be avoided.

Owner:KZJ NEW MATERIALS GROUP CO LTD

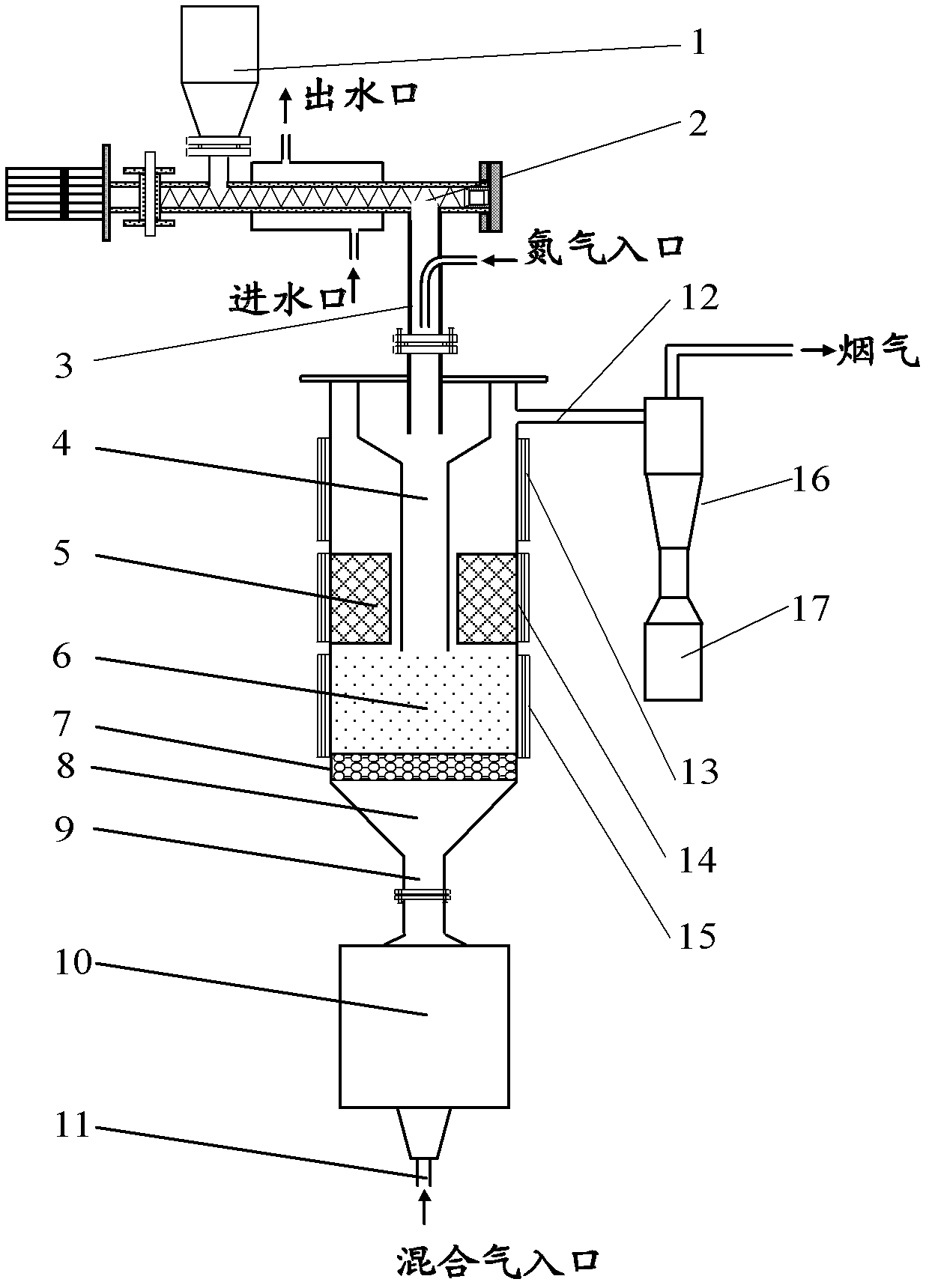

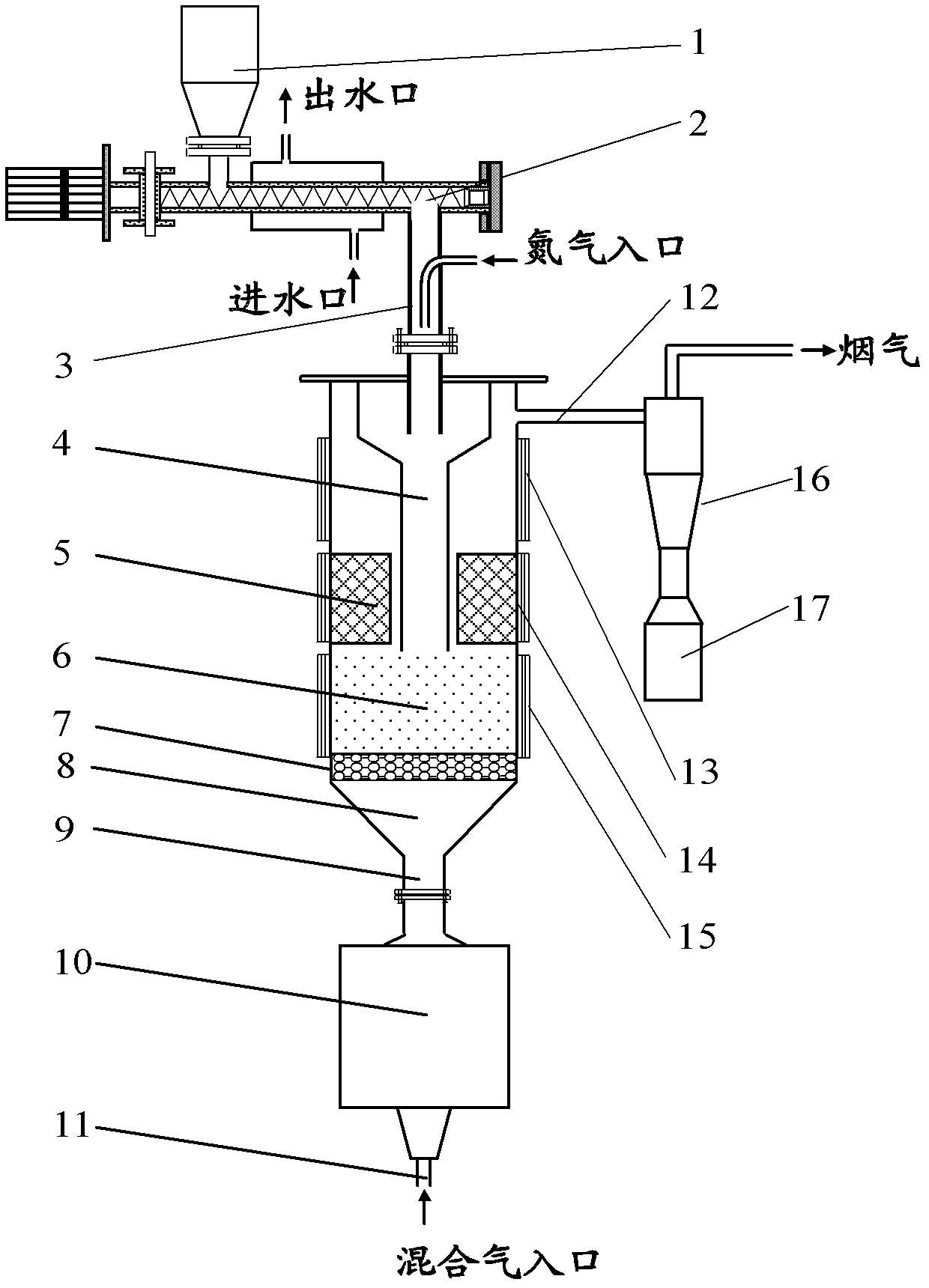

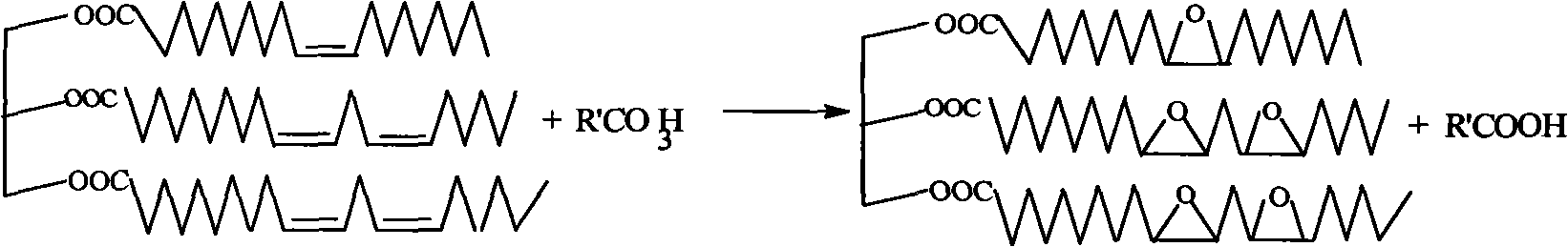

Method for preparing synthetic gas by three-phase type biomass pyrolysis-gasification-catalytic reforming

ActiveCN102424359AImprove conversion utilizationHigh yieldHydrogenWaste based fuelCatalytic reformingChemical industry

The invention belongs to the technical field of energy chemical industry. The process for preparing synthetic gas by biomass pyrolysis and gasification is divided into three steps of biomass low-temperature pyrolysis, coke or semi-coke high-temperature gasification and crude synthetic gas / tar catalytic reforming. The three reaction steps are successively and continuously carried out in three relatively independent spaces of an upper pyrolysis hearth, a lower gasification hearth and a catalyst bed inside the same gasification reaction device so as to finally obtain the high-quality synthetic gas. The method provided by the invention has high carbon conversion rate, produces no secondary pollution and is simple to realize. In addition, required biomass is rich in reserves and can be regenerated, thus realizing integrated sustainable utilization of resource, energy and environment.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL +1

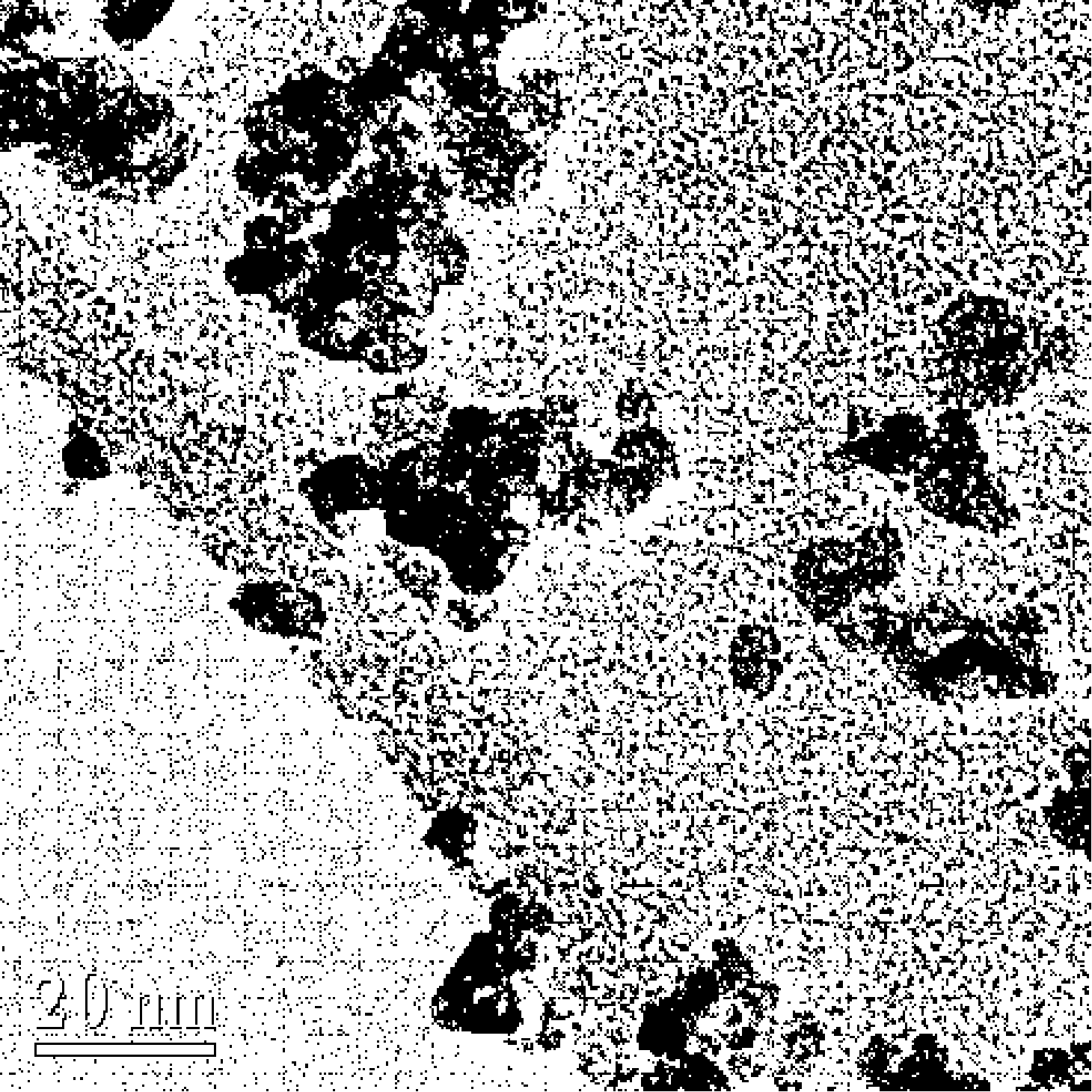

Catalyst for hydrogen production from methane vapor reforming and preparing method thereof

InactiveCN101224427AEasy to prepareHigh reactivityHydrogenMetal/metal-oxides/metal-hydroxide catalystsChemistryComposite oxide

The invention discloses a methane reforming catalyst for the production of hydrogen and a preparation method thereof, which more particularly relates to a Ni methane vapor reforming catalyst for the production of hydrogen which takes a nanometer cerium zirconium composite oxide as the carrier and the corresponding preparation method, and belongs to the methane reforming catalyst field. The catalyst comprises 5-30 wt% of active Ni, 0-10 wt% of noble metal catalytic promoter, 0-10 wt% of rare earth and / or the catalytic promoter of alkaline earth oxide, 50-95 wt% of nanometer cerium zirconium composite oxide carrier with the particle diameter of 5-20 nm. The invention is characterized by simple preparation method, high reactivity, strong anti carbon performance, good stability, low cost, etc.; when the invention is applied to the methane vapor reforming catalyst for producing hydrogen, the requirements of industrialization on catalyst reactivity and usage life can be satisfied. The invention can be largely applied in fuel cell-hydrogen area.

Owner:HANERGY TECH

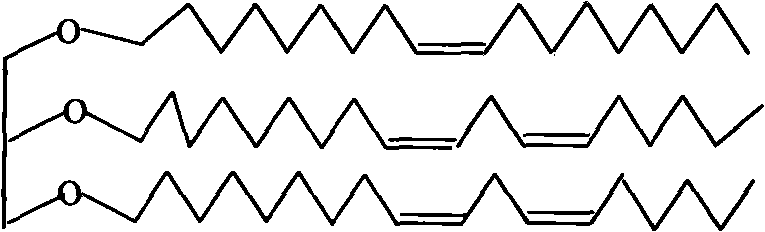

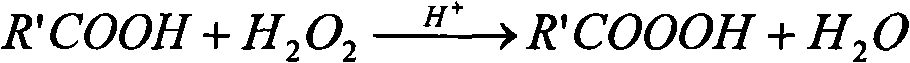

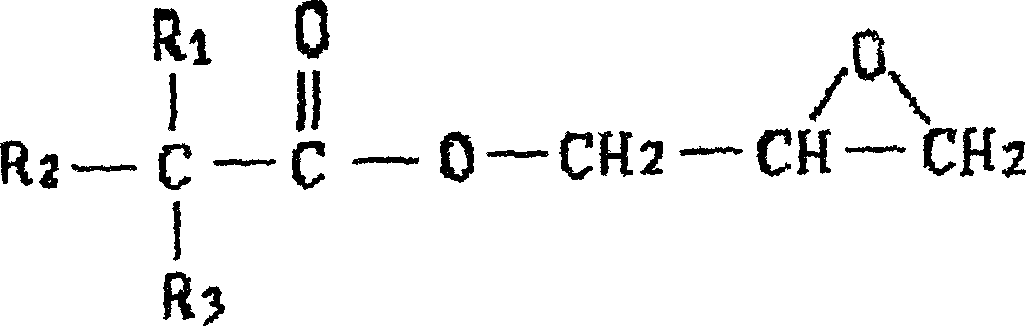

Method for preparing hard polyurethane foam plastics with soybean oil

ActiveCN101314632AImprove water resistanceImprove heat resistancePolyesterFatty acid glycerol esters

The invention provides a method for preparing hard polyurethane foam plastics from soybean oil. The method comprises the steps as follows: (1) carrying out epoxidation including the sub-steps of subjecting soybean oil and epoxidizing agent to reaction to obtain epoxidized soybean oil; (2) carrying out ring-opening reaction including the sub-steps of subjecting epoxidized soybean oil and nucleophilic reagent of reactive hydrogen to the ring-opening reaction of epoxy chemical bond in the presence of a catalyst to obtain mixed hydroxyl fatty acid glyceride; (3) carrying out alcoholysis and esterification including the sub-steps of adding alcohol, heating for alcoholysis to obtain mixed hydroxyl fatty acid monoester, i.e. soybean oil based polyol, and esterifying with organic acid and acid anhydride to generate polyester polyol; and (4) sequentially adding 80-150 weight parts of isocyanate, 0.3-4 weight parts of triethanolamine and 0.5-4 weight parts of foam stabilizer to 100 weight parts of soybean oil based polyol, intensively stirring, adding 0.5-3 weight parts of distilled water, and uniformly foaming while stirring at the high speed.

Owner:NANTONG HAIERMA TECH CO LTD

Vanadium-phosphorus-oxygen catalyst, and preparation method thereof

ActiveCN103769181AHigh reactivityEvenly distributedOrganic chemistryPhysical/chemical process catalystsPtru catalystPhysical chemistry

The invention discloses a vanadium-phosphorus-oxygen catalyst, and a preparation method thereof. According to the preparation method, a nano vanadium phosphorus oxide is taken as a precursor, is subjected to activating and then moulding, or is subjected to moulding and then activating so as to obtain the vanadium-phosphorus-oxygen catalyst; grain size of the nano vanadium phosphorus oxide is less than 100nm, and by volume, particles with a grain size of 30 to 50nm accounts for 7 to 14%, particles with a grain size of 50 to 70nm accounts for 54 to 79%, and particles with a grain size more than 70nm accounts for 7 to 39%. According to the vanadium-phosphorus-oxygen catalyst prepared by taking the nano vanadium phosphorus oxide as a precursor, octahedral structure of (VO)2P2O7 is neater, catalyst structure is stable, and catalytic activity and catalyst stability are higher. When the vanadium-phosphorus-oxygen catalyst is used for catalytic preparation of maleic anhydride via oxidation of n-butane, n-butane conversion rate reaches 87 to 95mol%, and maleic anhydride selectivity reaches 72 to 84mol%.

Owner:CHINA PETROLEUM & CHEM CORP +1

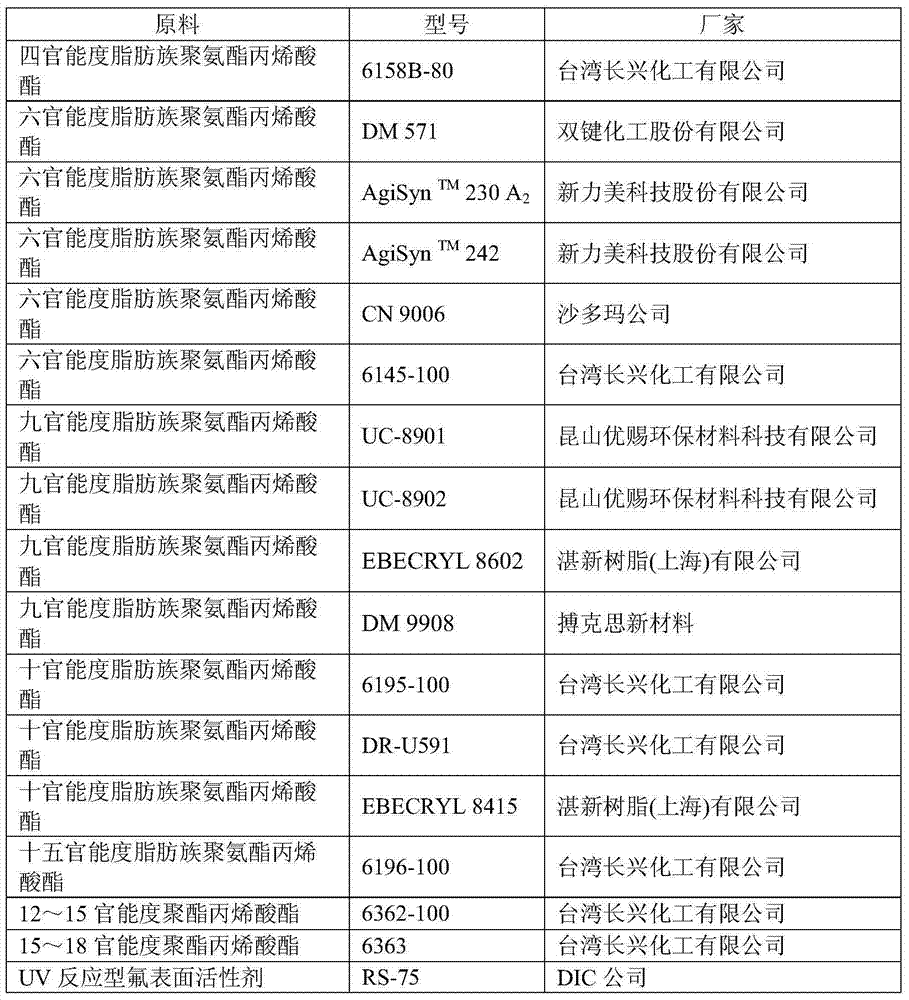

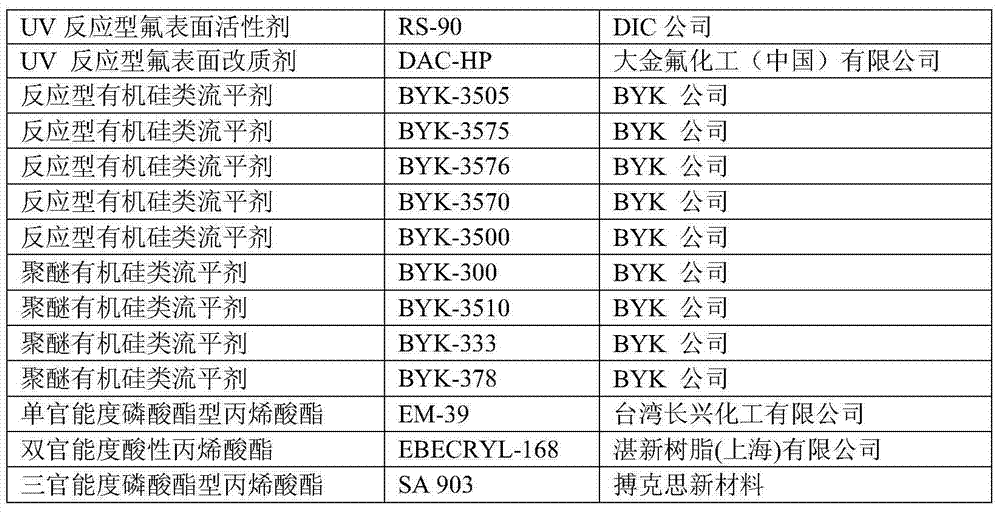

UV curing coating, wear-resistant and antifouling coating layer and mobile phone protection film containing wear-resistant and antifouling coating layer

ActiveCN104845521AHigh reactivityIncrease crosslink densityAntifouling/underwater paintsPaints with biocidesWear resistantPolysilazane

The invention provides an UV curing coating, a wear-resistant and antifouling coating layer and a mobile phone protection film containing the wear-resistant and antifouling coating layer. The coating comprises, in parts by weight, 10-95 parts of a first prepolymer, 5-60 parts of a second prepolymer, 0.05-8 parts of a polysilazane-based polymer, 0.05-8 parts of a fluorine-containing aid, 1-15 parts of a photoinitiator and 100-300 parts of a solvent, wherein the first prepolymer is a urethane acrylate prepolymer with a functionality degree of 4-8; the second prepolymer is an acrylate prepolymer with a functionality degree of 9-18. The wear resistance of the coating layer formed after curing the UV curing coating can be improved by the first prepolymer and the second prepolymer with high functionality degrees, improvement for the wear resistance of the coating layer and prolonging for the service life of the coating layer are benefited due to the adding of the polysilazane-based polymer and a polar compound, and the good antifouling performance of the coating layer can be ensured, and the reduction of the antifouling performance of the coating layer can be suppressed due to the fluorine-containing aid. The coating layer has both good antifouling performance and wear resistance.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Edible collagen food packaging film and preparation method thereof

InactiveCN102093722AEasy to degradeEnvironmental protection is goodFlexible coversWrappersSide effectPlasticizer

The invention provides an edible collagen food packaging film and a preparation method thereof. The preparation method comprises the following steps: firstly, stirring a 5-30wt% collagen solution and a 0.1-3wt% modifier solution at the temperature of 30-60 DEG C to react for 30-60 minutes, thus obtaining a compound solution; then adding a plasticizer and an auxiliary additive into the compound solution, then continuing to stir for 20-40 minutes at the temperature of 30-60 DEG C so as to obtain a mixed solution; and pouring the mixed solution in a die, molding, drying for 5-15 hours at the temperature of 40-80 DEG C, so as to obtain the edible collagen food packaging film. The edible collagen food packaging film has the advantages of better mechanical property, better heat stability, better moisture barrier property, safety, effectiveness and no side effect; wastes can be degraded and do not cause environment pollution; and the edible collagen food packaging film can be widely applied to the fields of various food packaging and medicament packaging, and has a good market application prospect.

Owner:SICHUAN UNIV

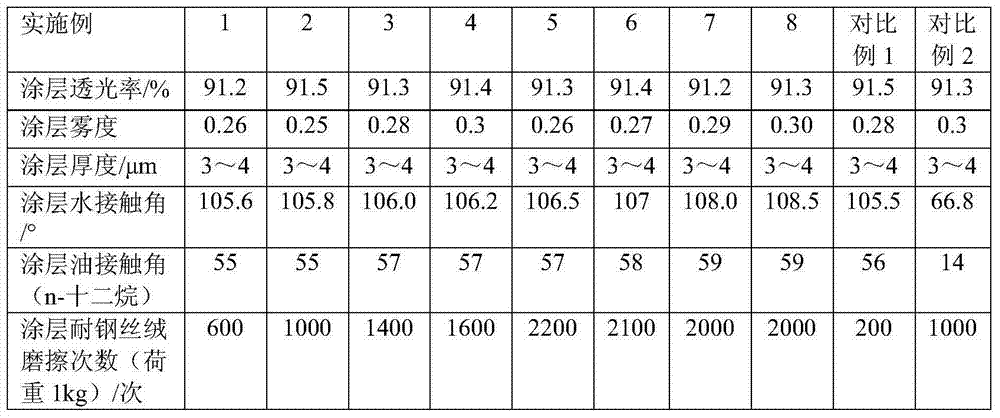

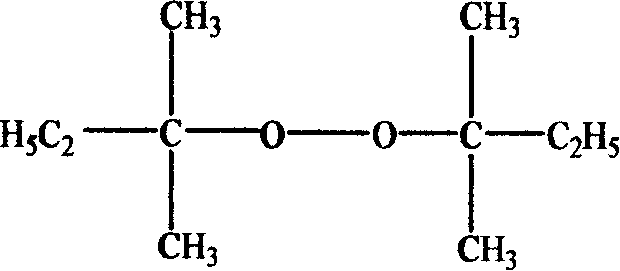

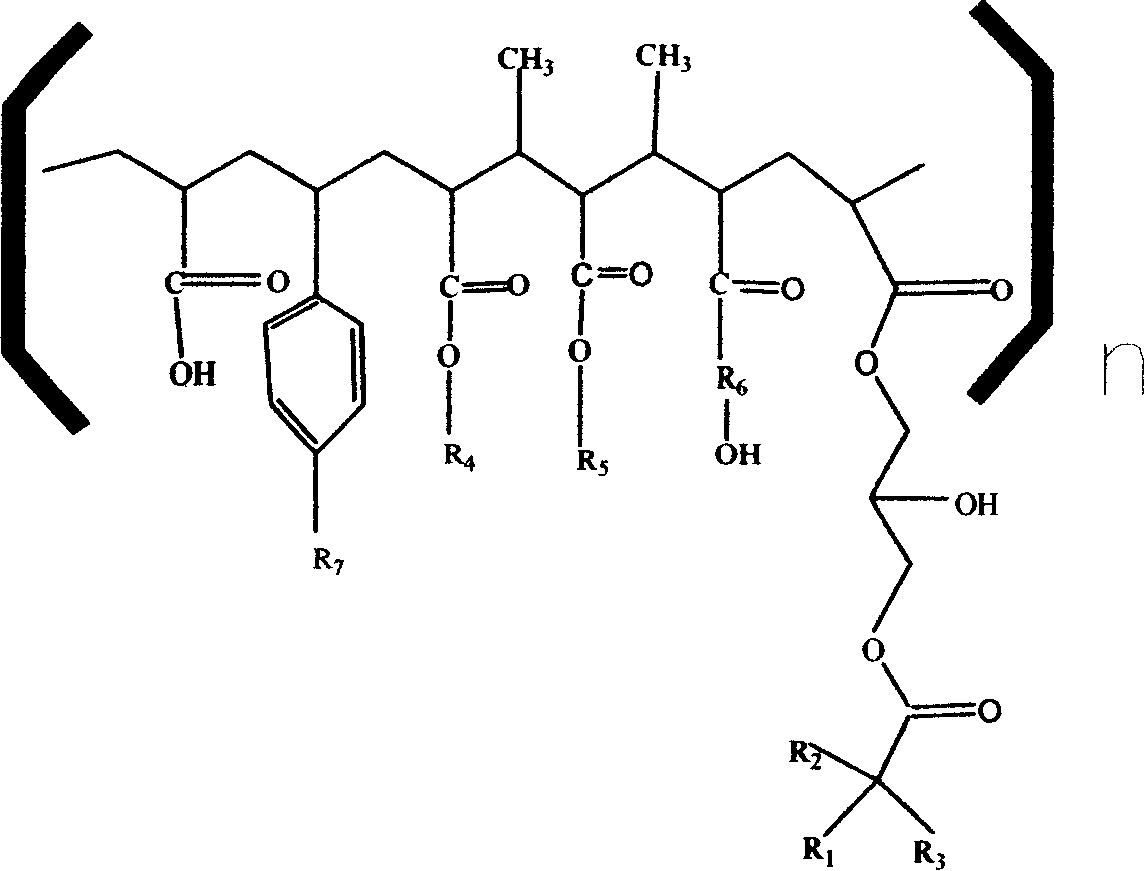

Environmentally-friendly type solvent-free impregnating resin and preparation method thereof

InactiveCN102225986AConservation TrendsPromote safe productionApplying solid insulationCoils manufactureLow voltageTransformer

The invention discloses an environmentally-friendly type solvent-free impregnating resin and a preparation method thereof. The impregnating resin comprises: 100 parts by weight of one or more high heat-resistant unsaturated polyester resins, 0 to 100 parts by weight of one or more modified epoxy resins, 50 to 200 parts by weight of one or more novel reactive diluents, 0.1 to 1 parts by weight of one or more polymerization inhibitors, 1.5 to 3.8 parts by weight of one or more initiators and 0 to 2 parts by weight of one or more auxiliary agents. Under the same work conditions, a baking time of the solvent-free impregnating resin is less than about one third of a baking time of the existing conventional solvent-free type impregnating resin utilized for middle and low voltage motors and transformers, and an energy consumption of the solvent-free impregnating resin is lower than about 25% of an energy consumption of the existing conventional solvent-free type impregnating resin middle and low voltage motors and transformers.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

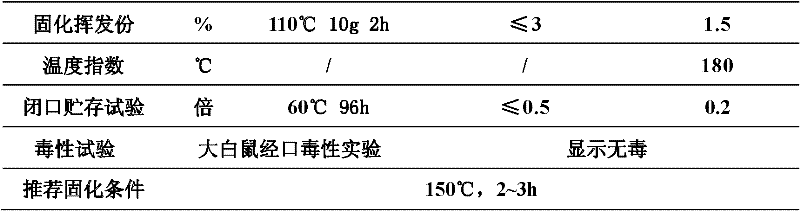

Prepn process of 3-hydroxy propionate and propylene glycol

InactiveCN101020635AHigh activityImprove stabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAccelerantCobalt catalyst

The present invention is process of preparing 3-hydroxy propionate and 1, 3-propylene glycol with epoxide as material. The present invention prepares 3-hydroxy propionate with epoxide, CO and alcohol under the action of cobalt catalyst and co-catalyst, and prepares 1, 3-propylene glycol under the action of 3-hydroxy propionate hydrogenating catalyst. The present invention has the advantages of simple reaction apparatus, simple operation, mild reaction condition, high catalyst activity, no environmental pollution, low production cost, etc.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

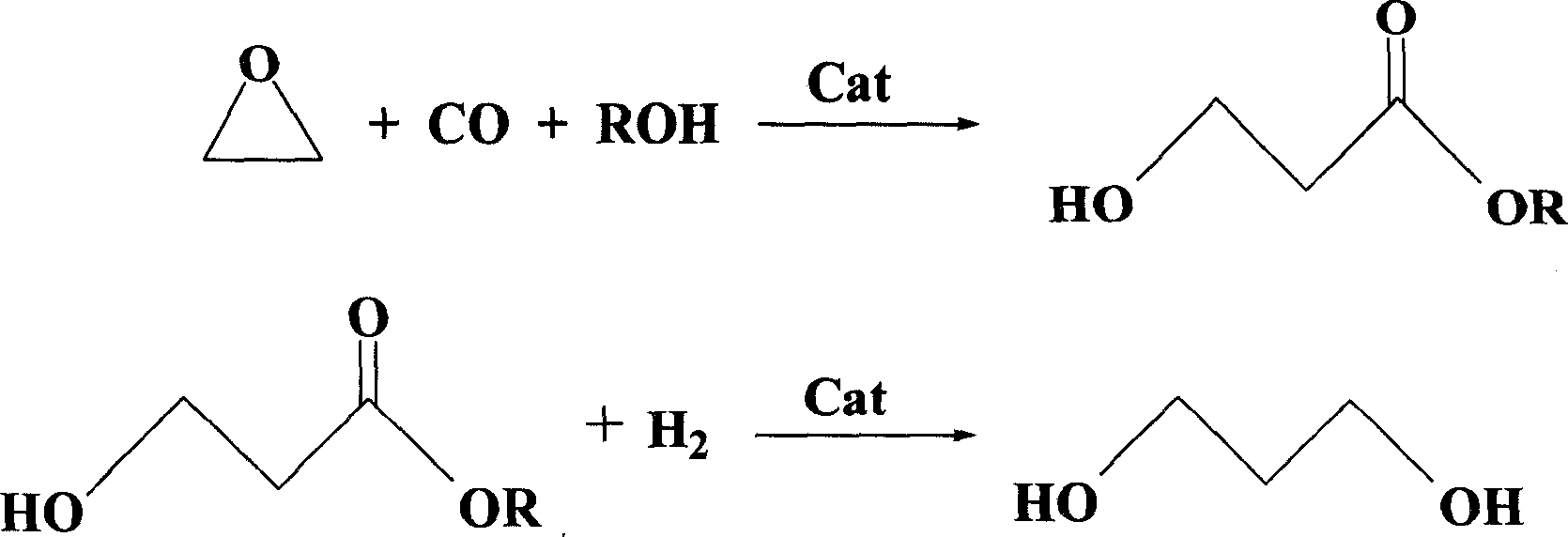

Water acrylic resin and preparing method thereof

The utility model relates to a water-based acrylic resin paintand the manufacturing method. The basic ray materials comprise acrylic monomer, styrene monomer, initiator, cosolvent, and active solvent. The utility model is characterized in that the acrylic monomer comprises acrylic derivative with hydroxyl; the cosolvent is ether alcohol solvent; the active solvent is butyl carbonate ethylene derivative active solvent; the initiator is peroxide initiator; and the neutralizer is Amine neutralizer. The resin is manufactured through two-step process. In the first step, water-based acrylic resin prepolymer is manufactured and is then manufactured into resin latex through inner emulsification on the second step. The product is of long storage time and is of no added emulsifier. Under the room temperature, the product can cross-link with water-based isocyanate curing agent to form membrane. The utility model is of excellent membrane, good water resistance, anti-scrubbing property, chemical resistance and sullying resistance.

Owner:上海市涂料研究所有限公司

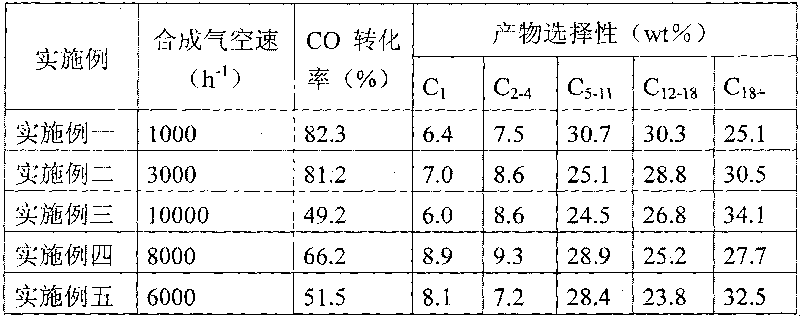

Cobalt-based compounded catalyst and preparing method and application thereof

InactiveCN101698152AHigh reactivityHigh activityLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsParaffin waxSlurry

The invention provides a cobalt-based compounded catalyst and preparing method and application thereof, comprising a carrier component and a metal component; the carrier uses spherical powder Al2O3; the metal component comprises a first metal component Co; a second metal component is one of Ce, La and Zr; a third metal component is one of Pt, Ru, Rh and Re; the weight percentage of each metal component in the finished catalyst is as follows: the first metal component is 10-35%; the second metal component is 0.5-10%; the third metal component is 0.05-3%; and the rest is aluminum oxide carrier. The invention is cobalt-based compounded catalyst with the diesel oil and paraffin as the main products; and the catalyst is applied for slurry bubble column reactor or continuous-stirring reactor with simple preparing method, less selectivity in methane, high reacting activity and good selectivity in C5+.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com