Environmentally-friendly type solvent-free impregnating resin and preparation method thereof

An impregnating resin and solvent-free technology, which is applied in the field of environmentally friendly solvent-free impregnating resin and its preparation, can solve the problems of low volatile matter, low viscosity, environmental pollution, etc., and achieve the effect of shortening baking time and no volatile loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Weigh 200g of glycidyl methacrylate into a three-necked flask, heat up to 80°C, add dropwise a mixed solution of 100g of acrylic acid, 0.3g of hydroquinone, and 2.8g of benzylamine, and heat up to 115°C after about 1 hour of dropping , After reacting for 5 hours, vacuumize to remove unreacted acrylic acid and other small molecular substances, and cool to room temperature to obtain a low-viscosity modified epoxy resin (A).

[0040] Take by weighing 100g isophthalic unsaturated polyester resin, 58.68g low-viscosity modified epoxy resin (A), 78.51g 1,6-hexanediol diacrylate, 0.1g hydroquinone, 2.37g dihydrogen peroxide Cumene, 1.54g zinc isooctanoate, stirred evenly to obtain environment-friendly, low-volatility solvent-free impregnating resin.

Embodiment 2

[0042] Weigh 200g of bisphenol A type epoxy resin E-51 purified by molecular distillation technology in a three-necked flask, heat up to 80°C, add dropwise a mixed solution of 47g of acrylic acid, 0.24g of hydroquinone, and 2.5g of benzylamine. After about 0.5h of dropwise addition, heat up to 130°C, and when the acid value is less than 3mg-KOH / g, vacuumize to remove unreacted acrylic acid and other small molecular substances, and cool to room temperature to obtain a modified epoxy resin ( B).

[0043] Take by weighing 100g unsaturated polyesterimide resin, 25g modified epoxy resin (B), 71.43g 1,6-hexanediol diacrylate hexanediol diacrylate, 13.5g ethylene glycol dimethacrylate , 25g cyclohexyl methacrylate, 0.15g hydroquinone, 2.3g benzoyl peroxide, 0.2g aluminum acetylacetonate, 0.75g zinc naphthenate, stir evenly to obtain environmentally friendly, low-volatile solvent-free polyester sub Amine impregnated resin.

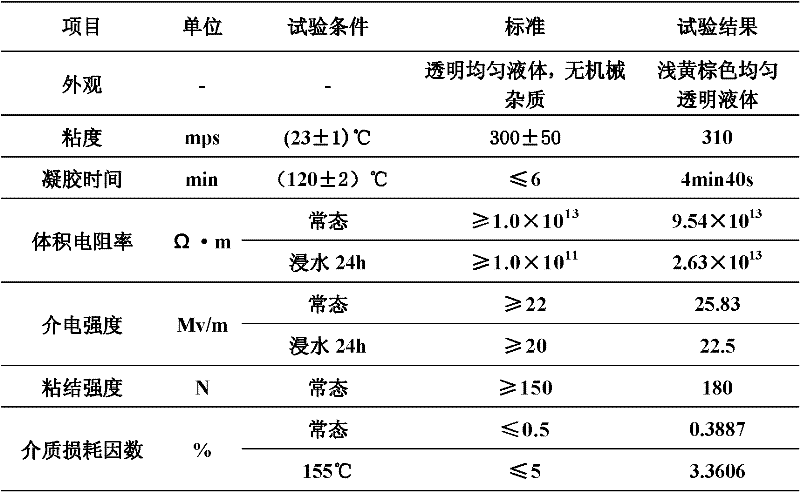

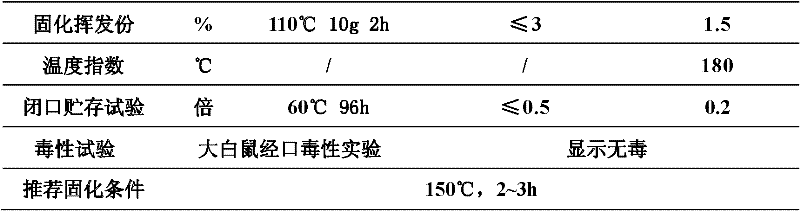

[0044] The prepared environment-friendly, low-volatility, ...

Embodiment 3

[0049] Take the unsaturated polyester resin modified by 100g N-phenylmaleimide, the modified epoxy resin (B) synthesized by 10g embodiment 2, 70.58g dicyclopentadiene acrylate, 20.32g methacrylic acid Phenyl ester, 10.79g diethylene glycol dimethacrylate, 10g glycerol dimethacrylate, 0.2g p-benzoquinone, 2.3g benzoyl peroxide, 0.2g zinc isooctanoate, stir evenly to prepare high-resistant Environmentally friendly solvent-free impregnation resin with thermal properties and low volatility.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com