Four-phase double-percolation electromagnetic shielding material and preparation method thereof

A technology of electromagnetic shielding materials and composite materials, applied in the field of electronic packaging materials, can solve the problems of unsafe and reliable large-scale application, failure of plastic packaging parts, difficulty in meeting composite performance requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

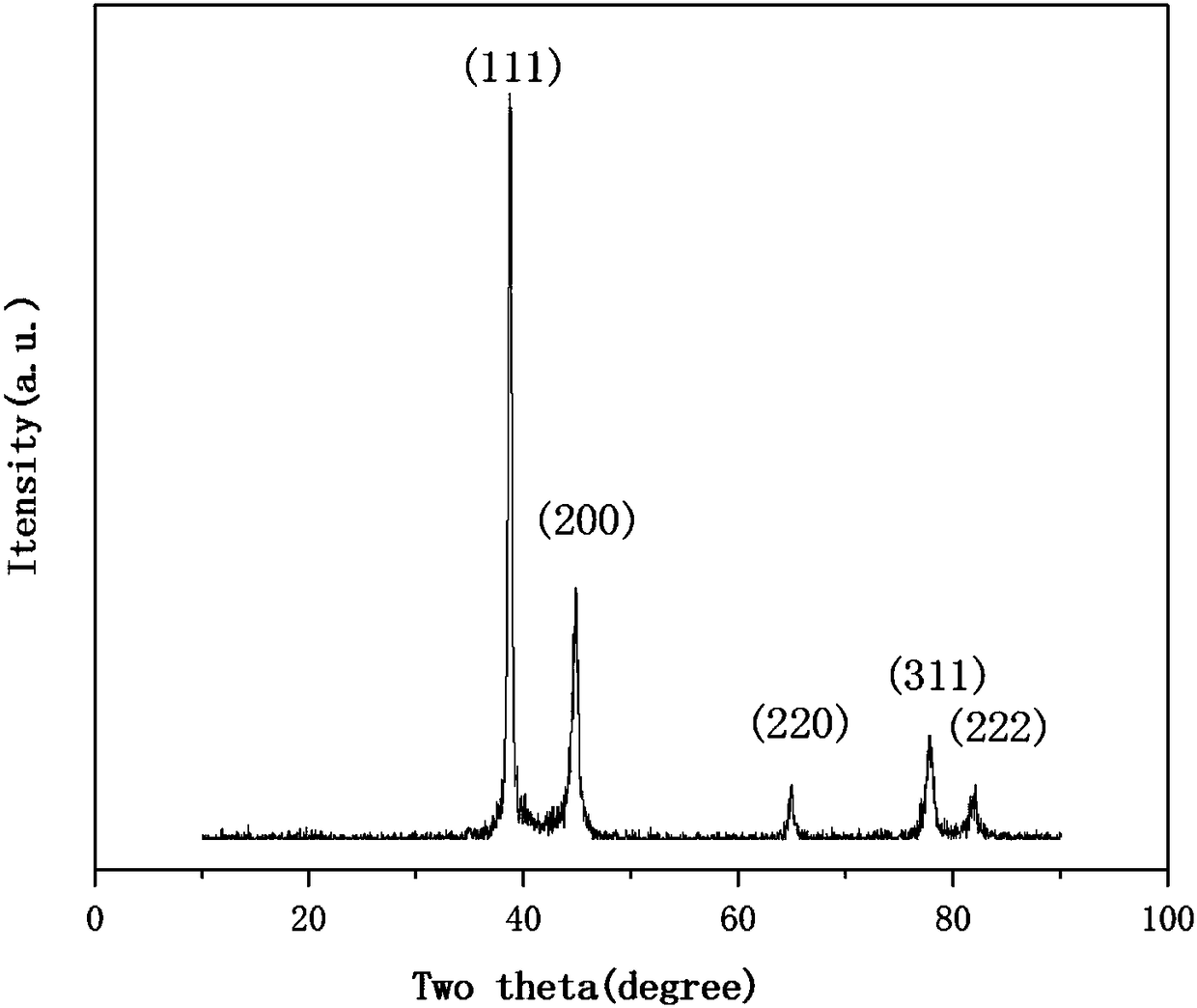

[0073] Preparation of silver-coated carbon fiber (APCF)

[0074] First, remove the weak interface layer such as slurry coated on the CF surface and adsorbed impurities: put CF in a muffle furnace and bake at 300°C for 12 minutes to remove surface organic impurities, ultrasonically clean for 30 minutes, and dry under reduced pressure for 10 minutes.

[0075] Then, put CF into NaOH solution and ultrasonically disperse for 1 h to roughen the surface of CF. Filter, rinse with water to remove residual NAOH solution, then in SnCl 2 Soak in a mixed solution with HCl for 1 h at room temperature to sensitize the surface of CF. Sn formed in solution 2 (OH) 3 Cl is adsorbed on the surface of CF, filtered with suction and washed with water.

[0076] Finally, using the mixed solution PdCl 2 、H 3 A mixed solution of BO and HCl is used to activate it, and a redox reaction occurs. After sensitization and activation treatment, Pd 2+ By Sn 2+ It is reduced to metal Pd atoms, adsorbed...

Embodiment 2

[0086] Preparation of APCF

[0087] Stepless silver plating on the surface of CF: first remove the weak interface layer such as slurry coated on the surface of CF and adsorbed impurities, put CF in a muffle furnace and bake at 320°C for 10 minutes to remove surface organic impurities, ultrasonic 20 minutes to remove attachments, wash, Vacuum dry. Then carry out CF surface treatment, put CF in NaOH solution and ultrasonically disperse for 1.5h to roughen the CF surface; then in SnCl 2 and HCl in a mixed solution at room temperature for 1 h to sensitize the surface of CF, and the Sn generated in the solution 2 (OH) 3 Cl is adsorbed on the surface of CF, filtered and washed with suction. Finally, using the mixed solution PdCl 2 , H 3 A mixed solution of BO and HCl is used to activate it, and a redox reaction occurs. After sensitization and activation treatment, Pd 2+ By Sn 2+ It is reduced to metal Pd atoms, adsorbed on the surface of CF, and becomes the catalytic activ...

Embodiment 3

[0091] CF / ABS preparation

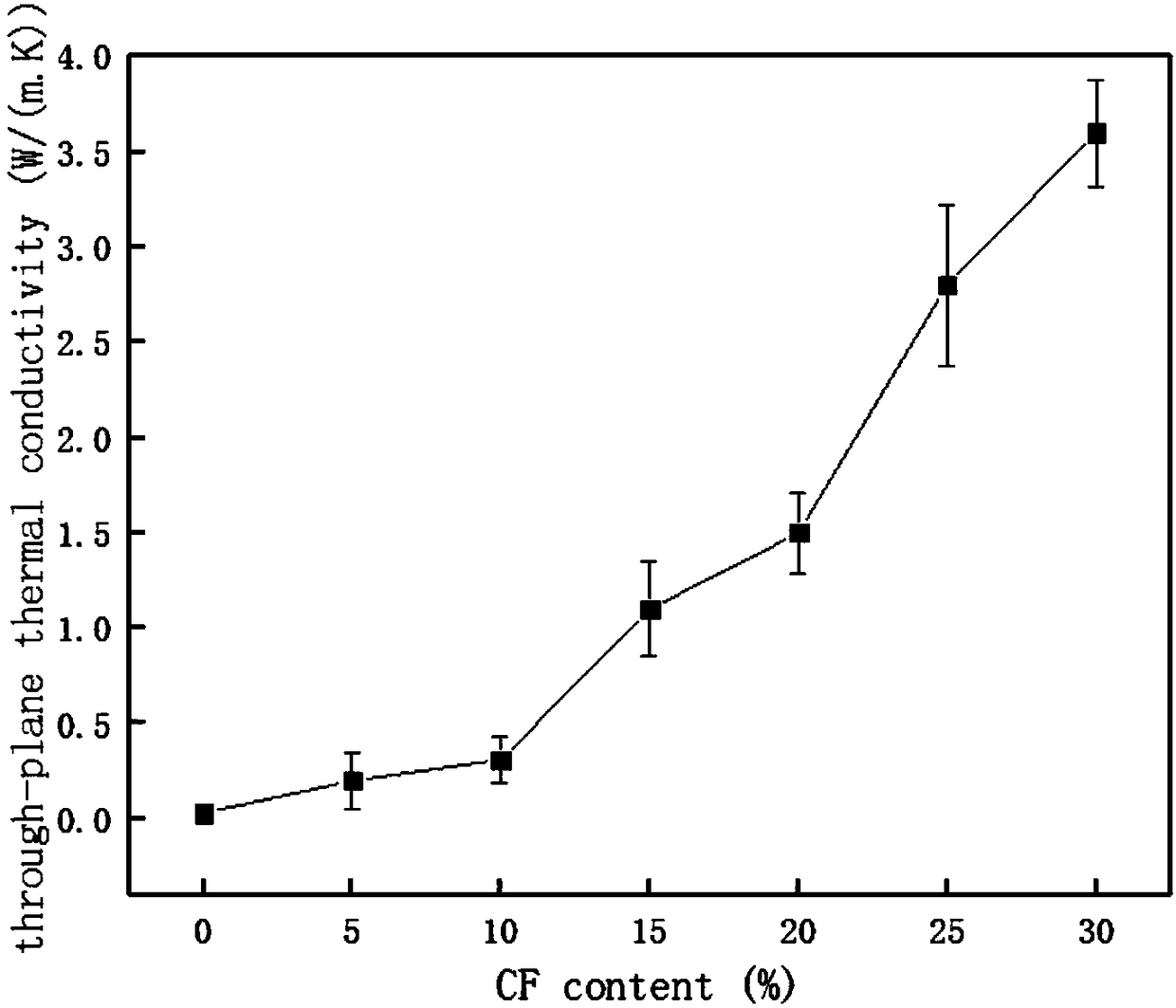

[0092] Using the melt blending method, taking ABS as the matrix and CF as the filler, adding 0.5% polyethylene paraffin, 2% SMA, and 0.5% antioxidant 1010, the CF reinforced ABS composite material was prepared, and the microstructure of the composite material, CF The effect of the filling amount on the thermal conductivity and mechanical properties of composites. Add CF to the ABS matrix material and melt blend to make CF / ABS composite material. The added amount of CF is 5%, 10%, 15%, 20%, 25%, 30% (relative to the weight ratio of the matrix ABS raw material).

[0093] It was found that CF was more uniformly dispersed in ABS, but the distribution direction was disordered, and there was no obvious agglomeration. The thermal conductivity of the composite material is figure 2 It can be seen that when the CF loading is less than 30wt%, the thermal conductivity of the composite increases significantly with the increase of the CF filling, but no per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com