Patents

Literature

165 results about "Percolation threshold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The percolation threshold is a mathematical concept in percolation theory that describes the formation of long-range connectivity in random systems. Below the threshold a giant connected component does not exist; while above it, there exists a giant component of the order of system size. In engineering and coffee making, percolation represents the flow of fluids through porous media, but in the mathematics and physics worlds it generally refers to simplified lattice models of random systems or networks (graphs), and the nature of the connectivity in them. The percolation threshold is the critical value of the occupation probability p, or more generally a critical surface for a group of parameters p₁, p₂, ..., such that infinite connectivity (percolation) first occurs.

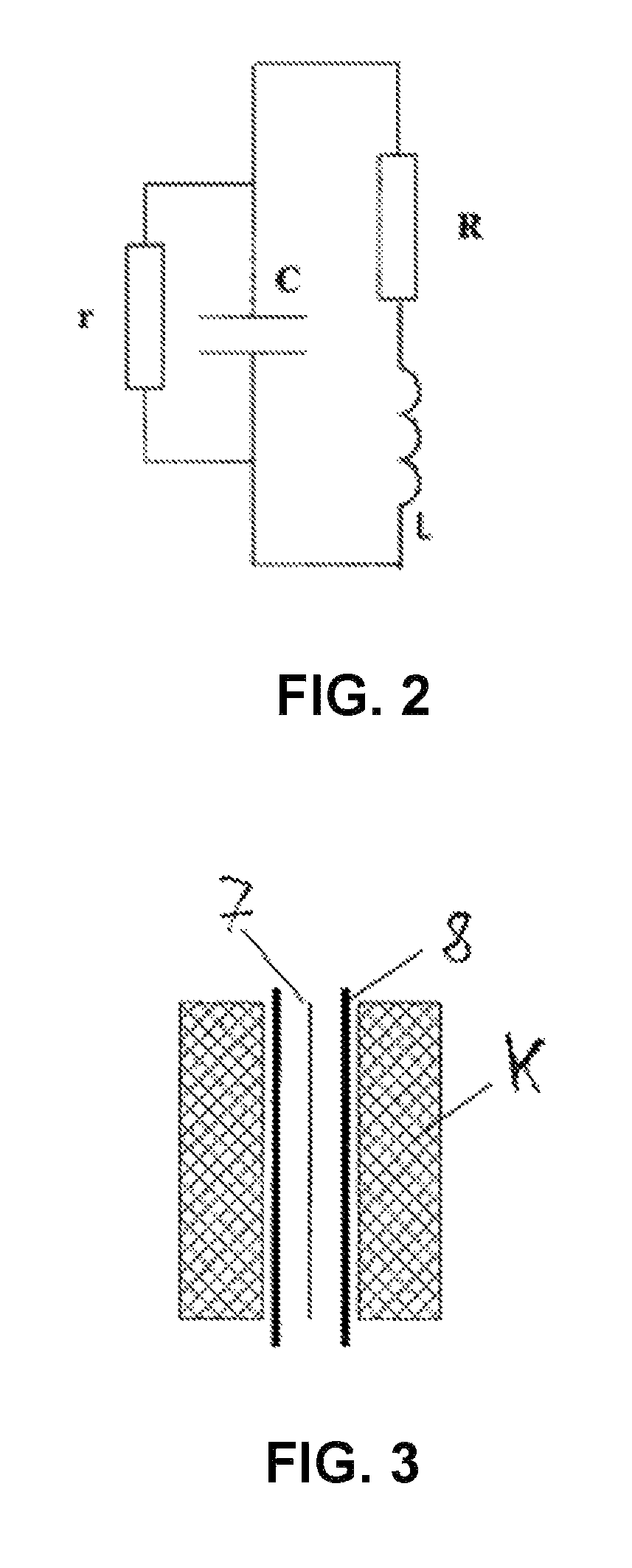

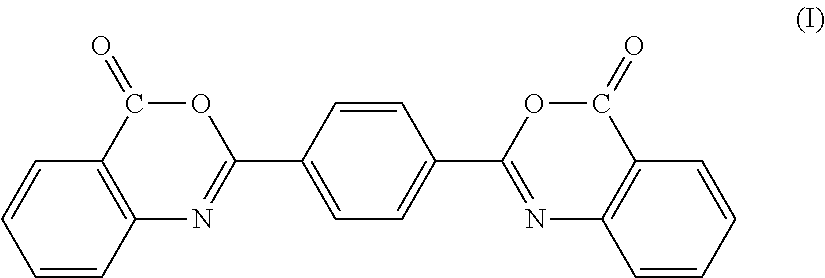

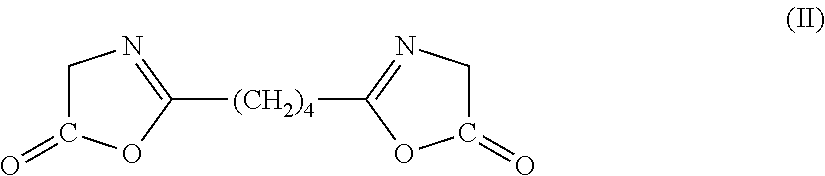

Electro-optic display and adhesive composition for use therein

InactiveUS6657772B2Non-macromolecular adhesive additivesStatic indicating devicesDisplay deviceElectric resistivity

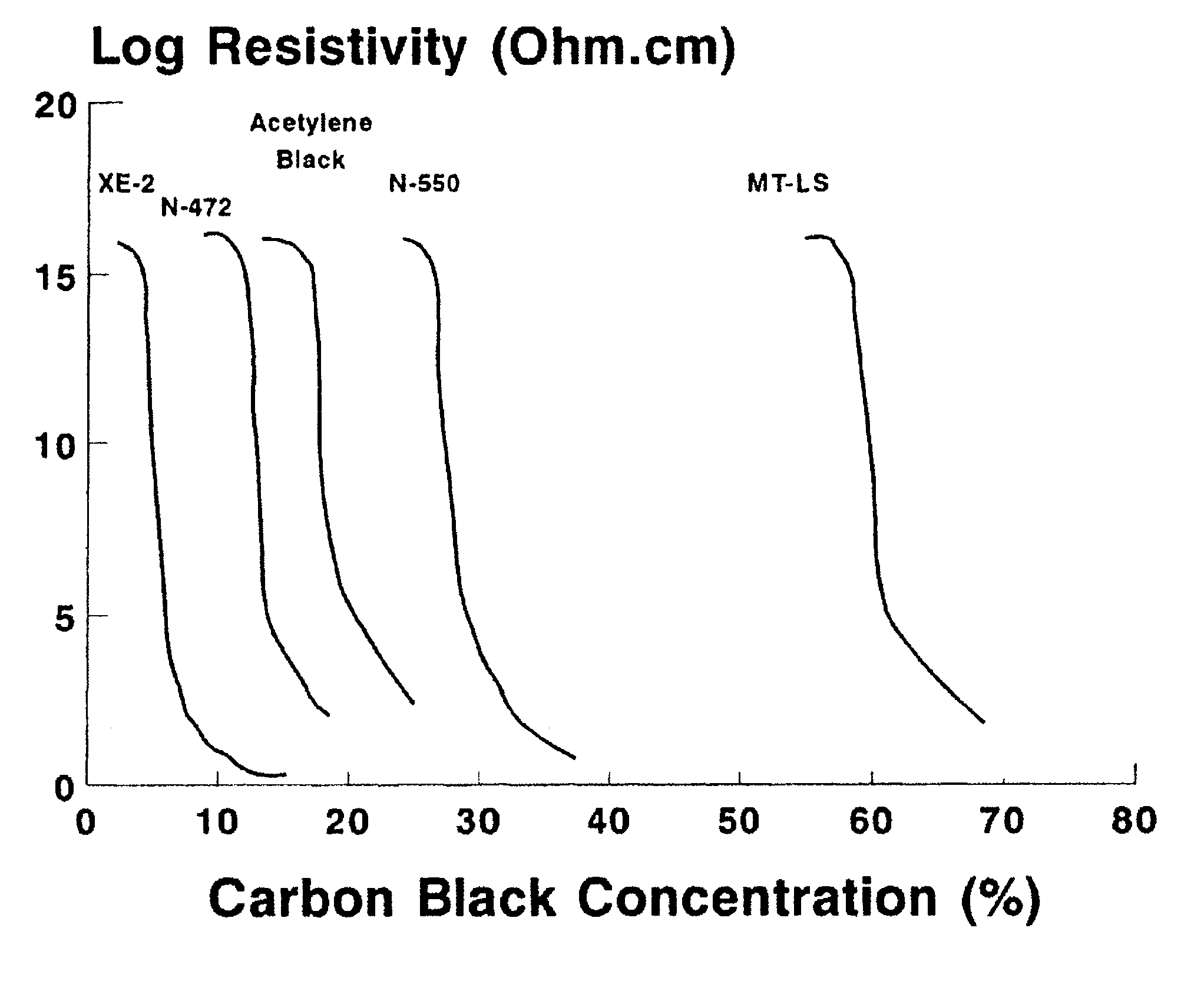

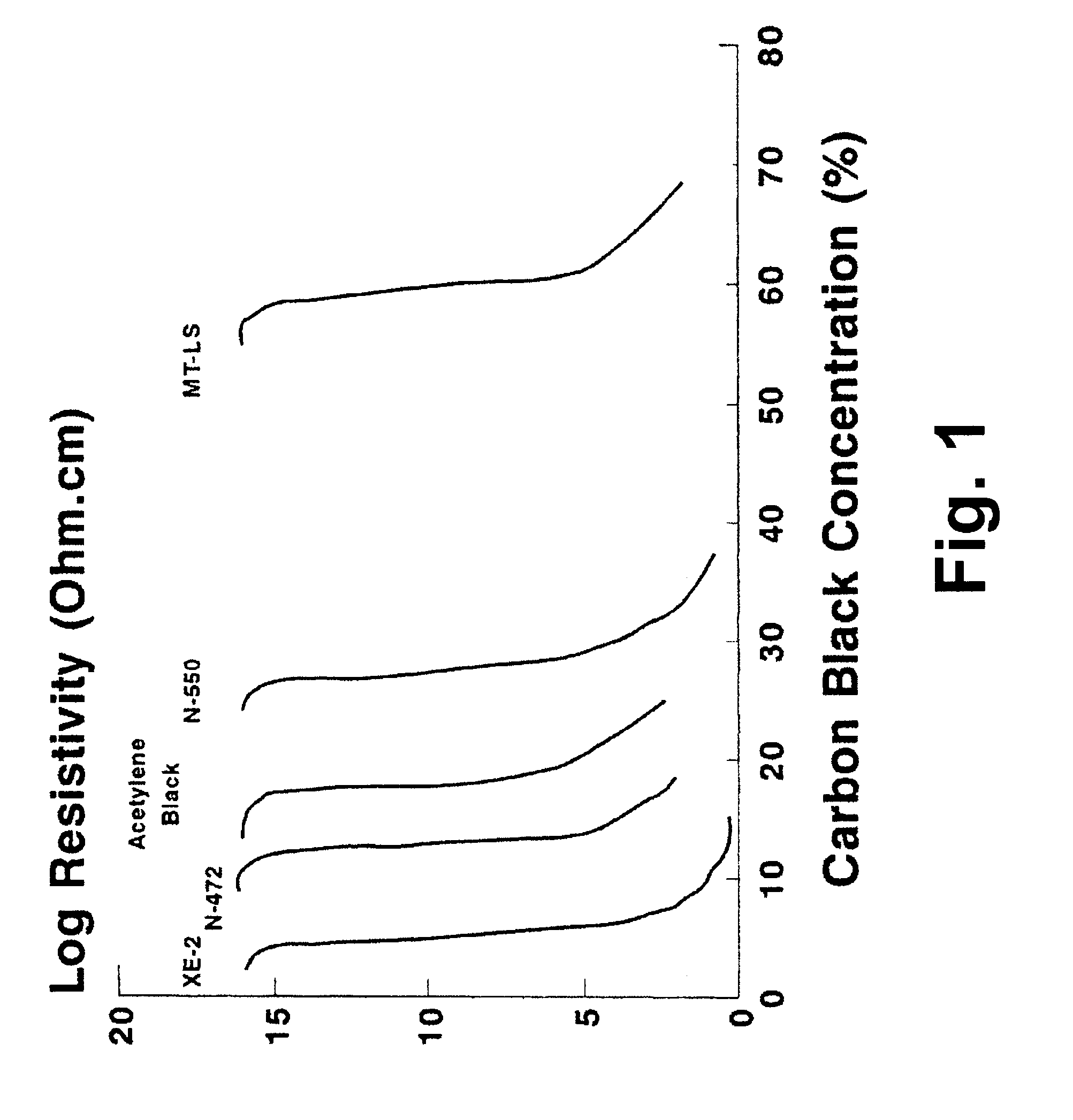

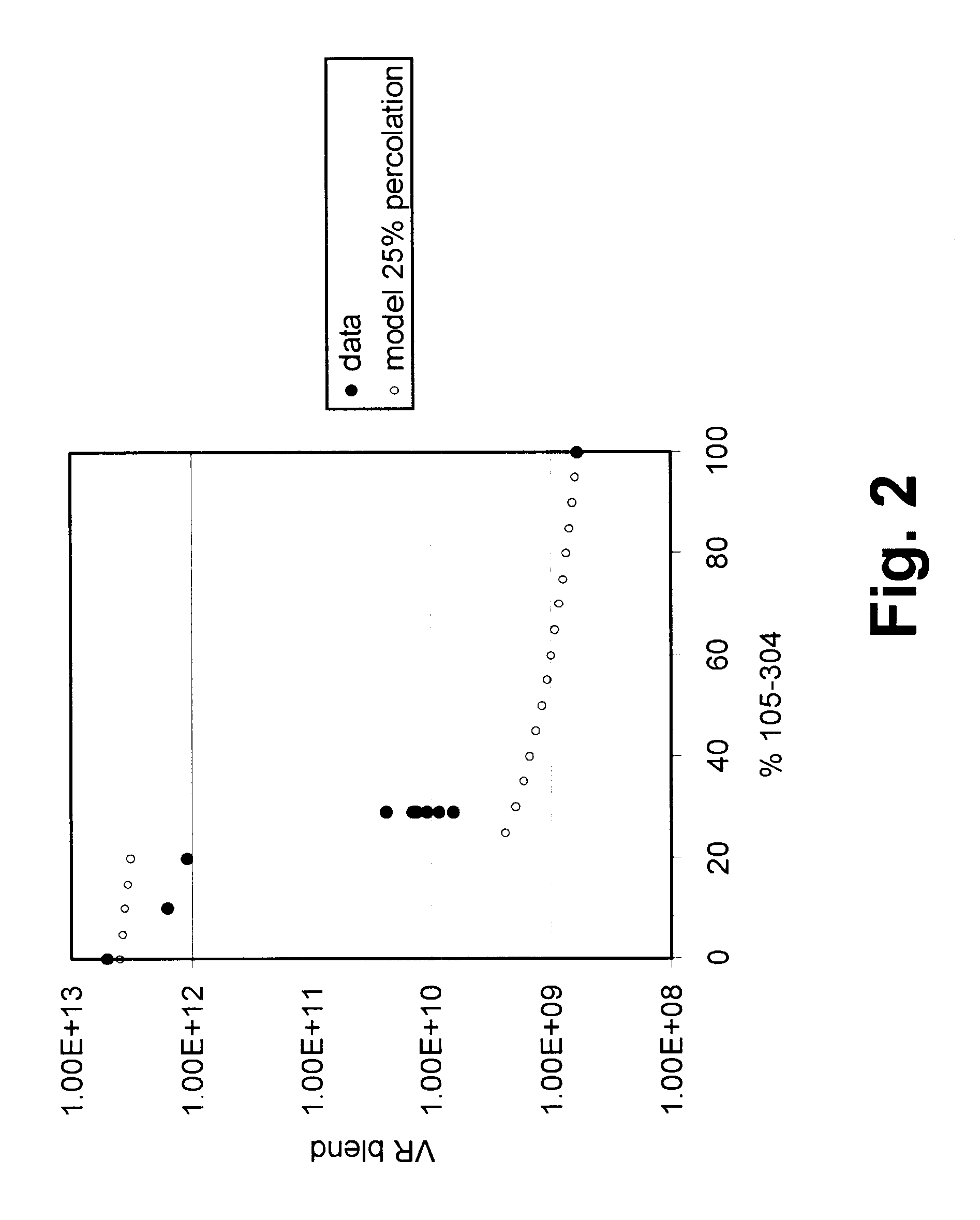

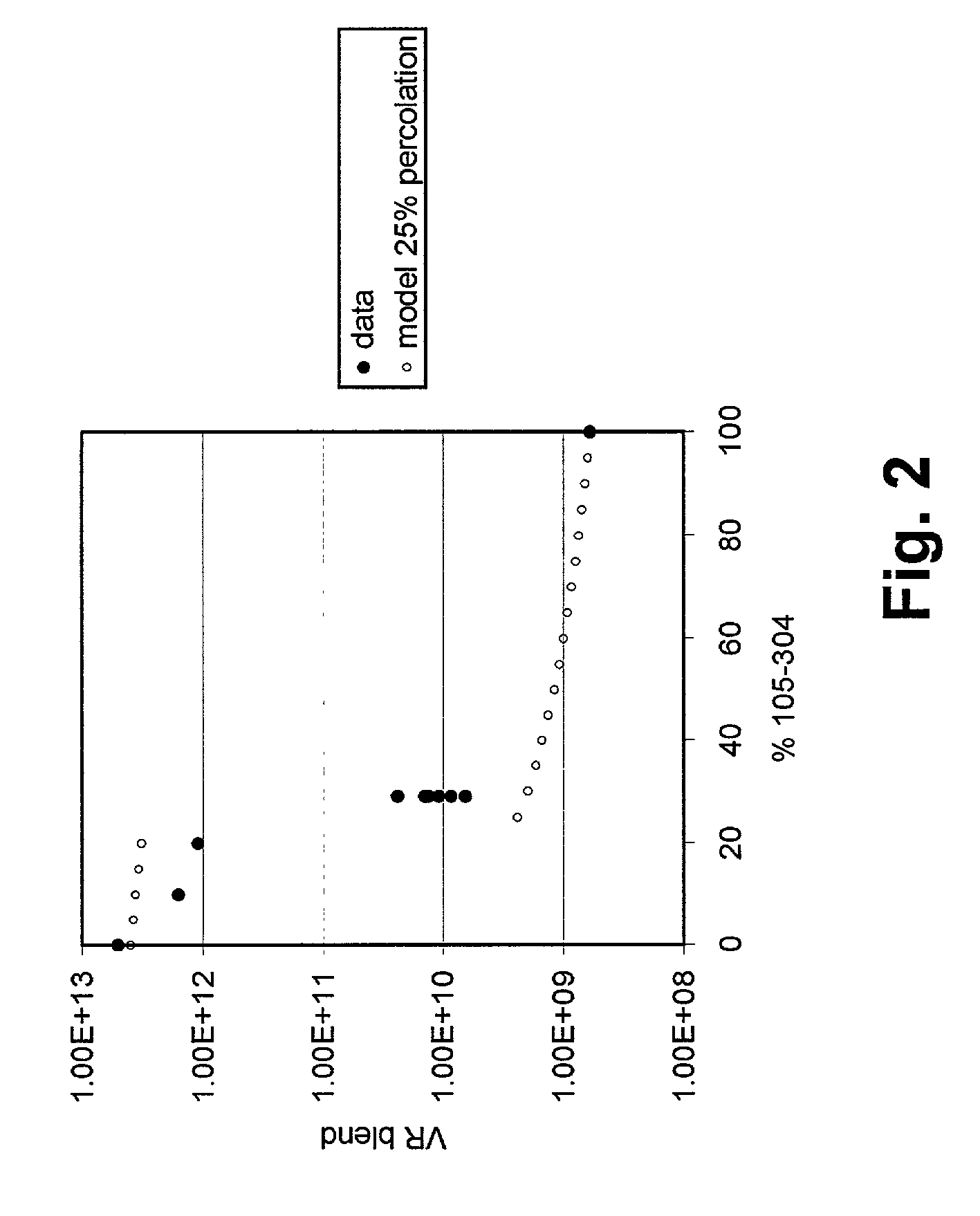

An electro-optic display comprises first and second substrates, and an adhesive layer and a layer of electro-optic material disposed between the first and second substrates. The adhesive layer has a volume resistivity in the range of about 10<9 >to about 10<11 >ohm cm and comprises a mixture of an adhesive material having a volume resistivity of at least about 5x10<11 >ohm cm and a filler having a volume resistivity not less than about 10<7 >ohm cm, the filler being present in the mixture in a proportion above its percolation threshold in the adhesive material.

Owner:E INK CORPORATION

Nanocomposites and methods thereto

ActiveUS7479516B2Good dispersionImprove conductivityMaterial nanotechnologyGraphiteMechanical propertyPercolation threshold

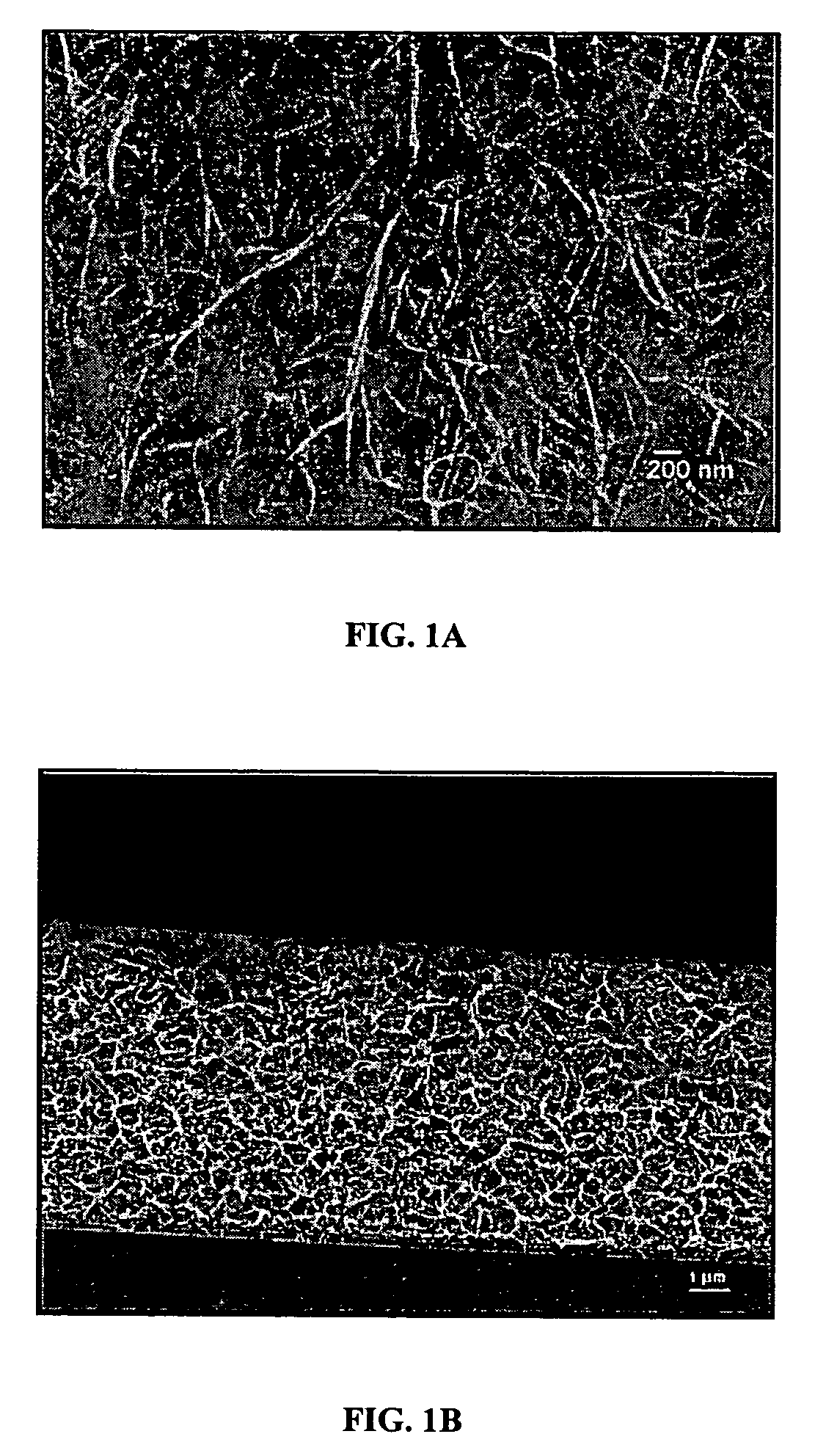

Electrical, thermal and mechanical applications are provided for nanocomposite materials having low percolation thresholds for electrical conductivity, low percolation thresholds for thermal conductivity, or improved mechanical properties.

Owner:EVERMORE APPLIED MATERIALS CORP

Electro-optic display and adhesive composition for use therein

InactiveUS20030011867A1Non-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDisplay deviceAdhesive materials

An electro-optic display comprises first and second substrates, and an adhesive layer and a layer of electro-optic material disposed between the first and second substrates. The adhesive layer has a volume resistivity in the range of about 109 to about 1011 ohm cm and comprises a mixture of an adhesive material having a volume resistivity of at least about 5x1011 ohm cm and a filler having a volume resistivity not less than about 107 ohm cm, the filler being present in the mixture in a proportion above its percolation threshold in the adhesive material.

Owner:E INK CORPORATION

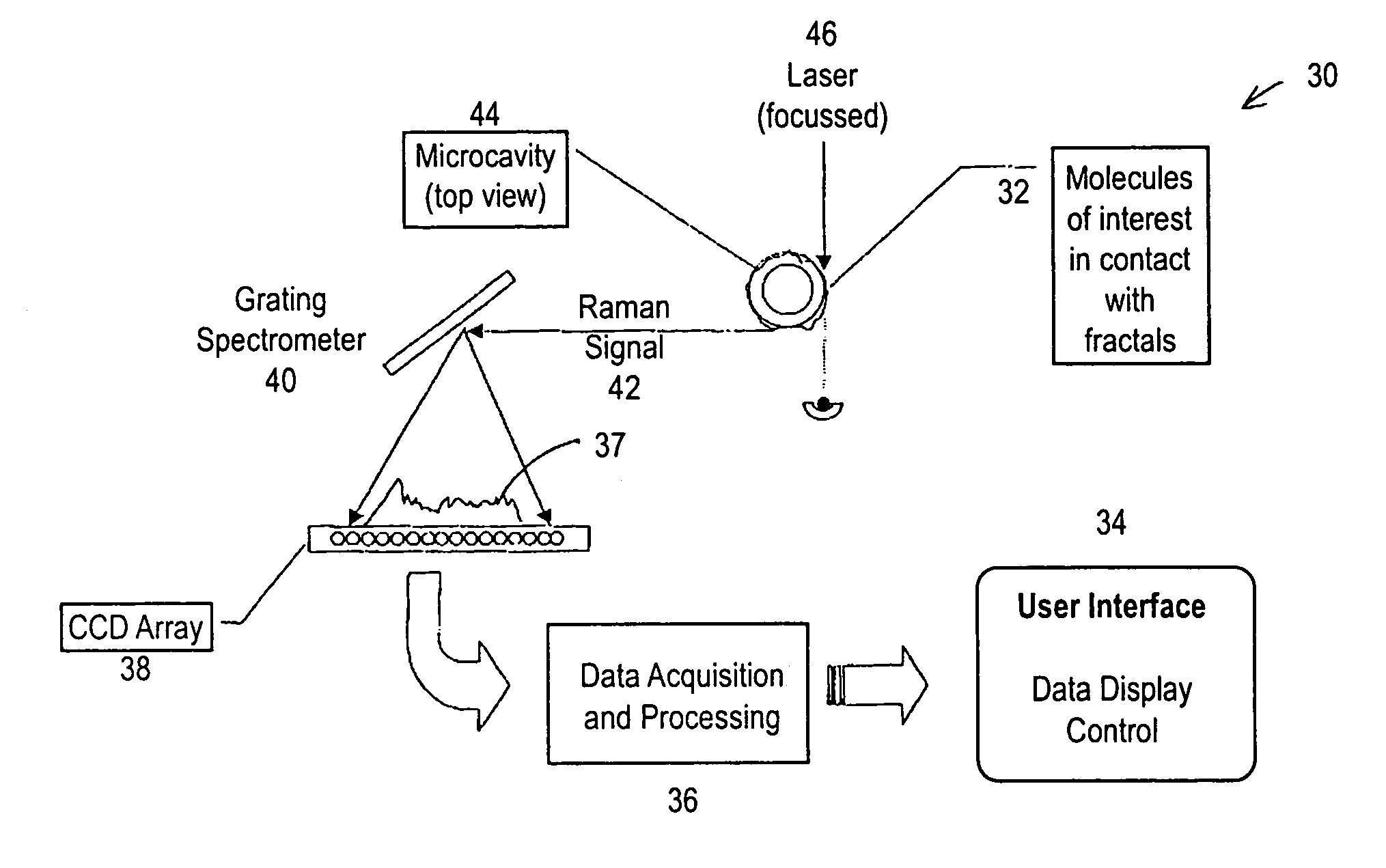

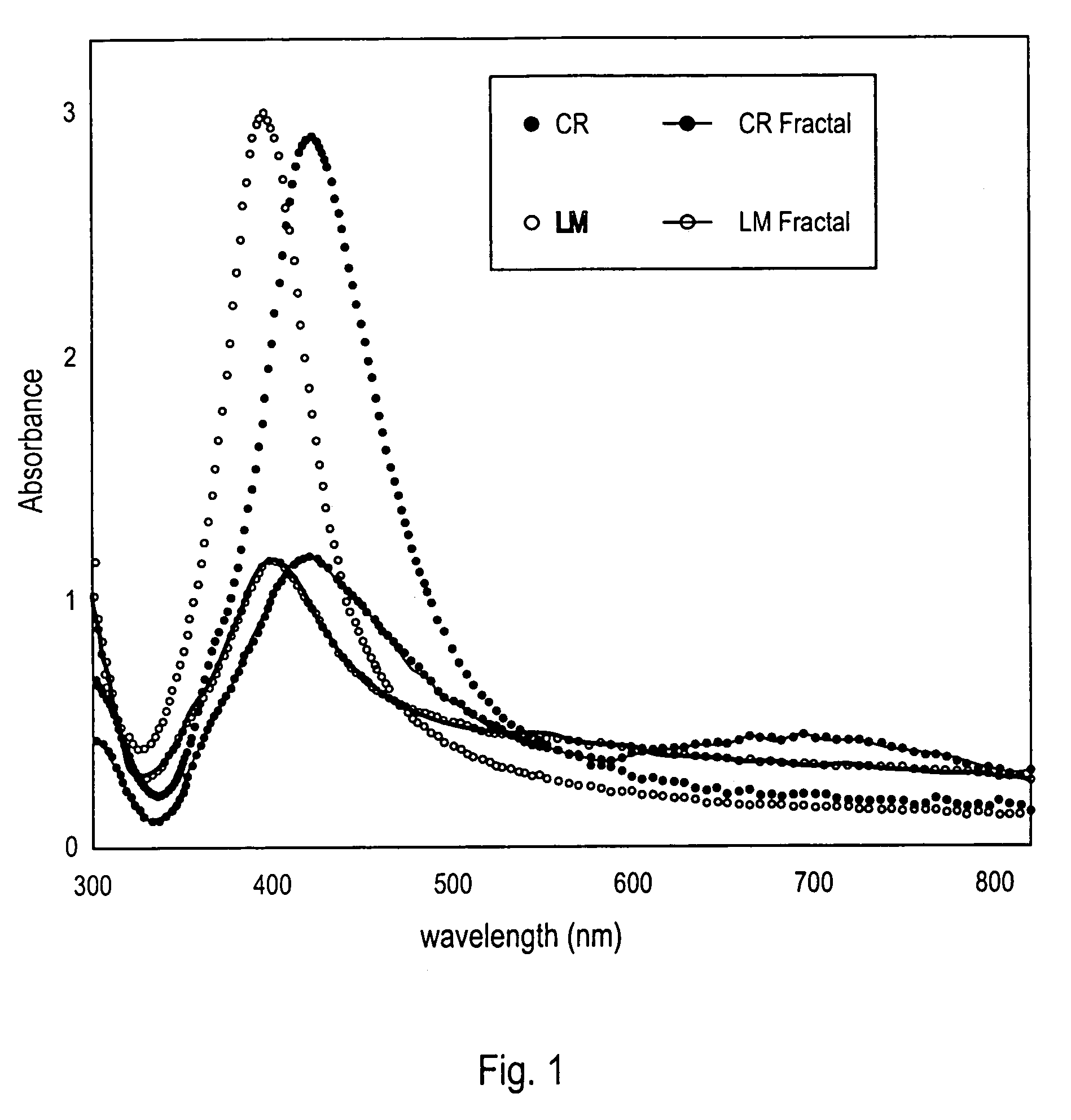

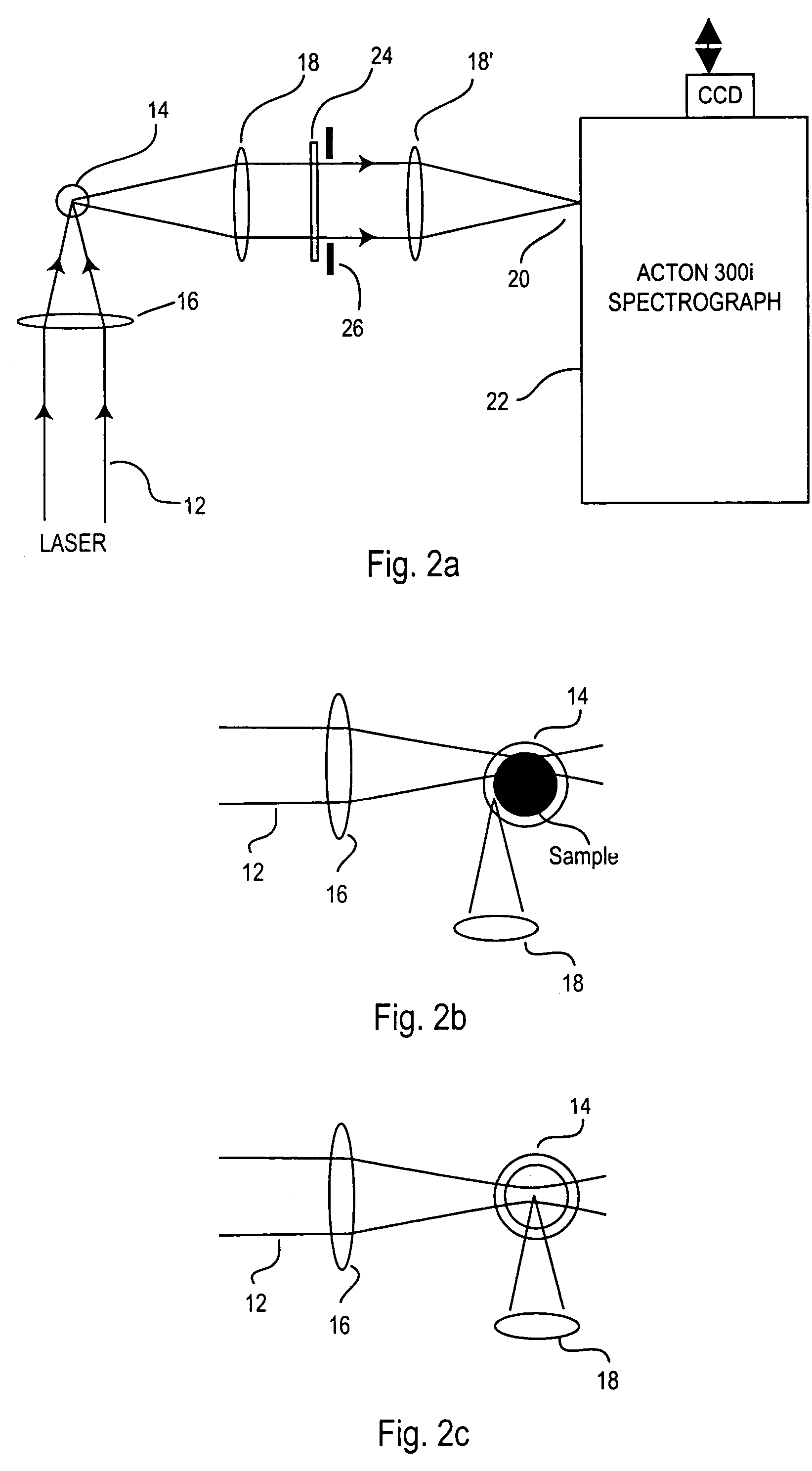

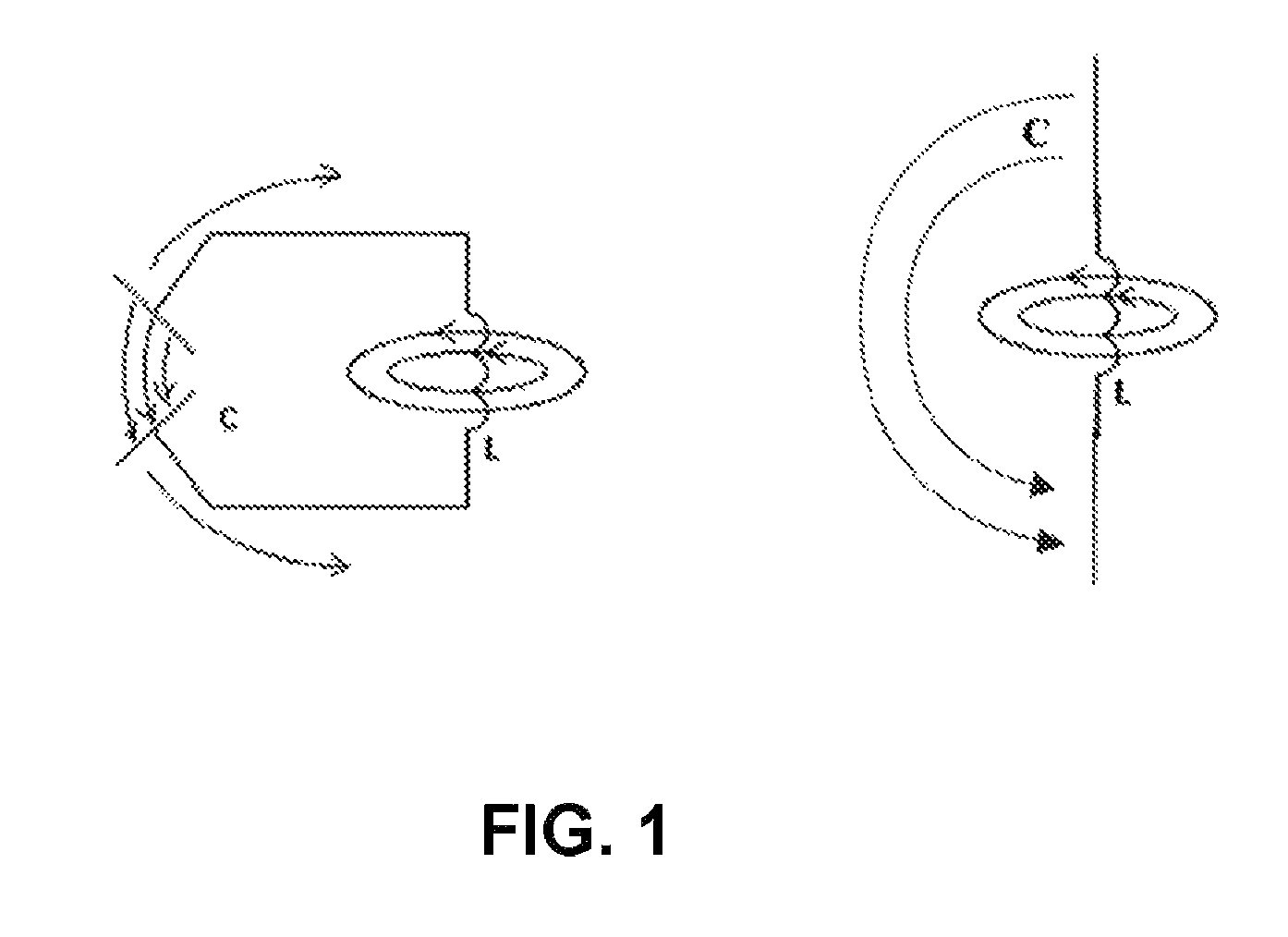

Optical devices and methods employing nanoparticles, microcavities, and semicontinuous metal films

InactiveUS7123359B2Enhanced optical emissionEnhanced optical emission and lasingRadiation pyrometryLaser using scattering effectsNanoparticleMetal particle

An optical sensing enhancing material (and corresponding method of making) comprising: a medium, the medium comprising a plurality of aggregated nanoparticles comprising fractals; and a microcavity, wherein the medium is located in a vicinity of the microcavity. Also an optical sensor and sensing method comprising: providing a doped medium, the medium comprising a plurality of aggregated nanoparticles comprising fractals, with the material; locating the doped medium in the vicinity of a microcavity; exciting the doped medium with a light source; and detecting light reflected from the doped medium. Also an optical sensing enhancing material comprising a medium, the medium comprising a semicontinuous metal film of randomly distributed metal particles and their clusters at approximately their percolation threshold. The medium preferably additionally comprises a microcavity / microresonator. Also devices and methods employing such material.

Owner:ARROWHEAD CENT

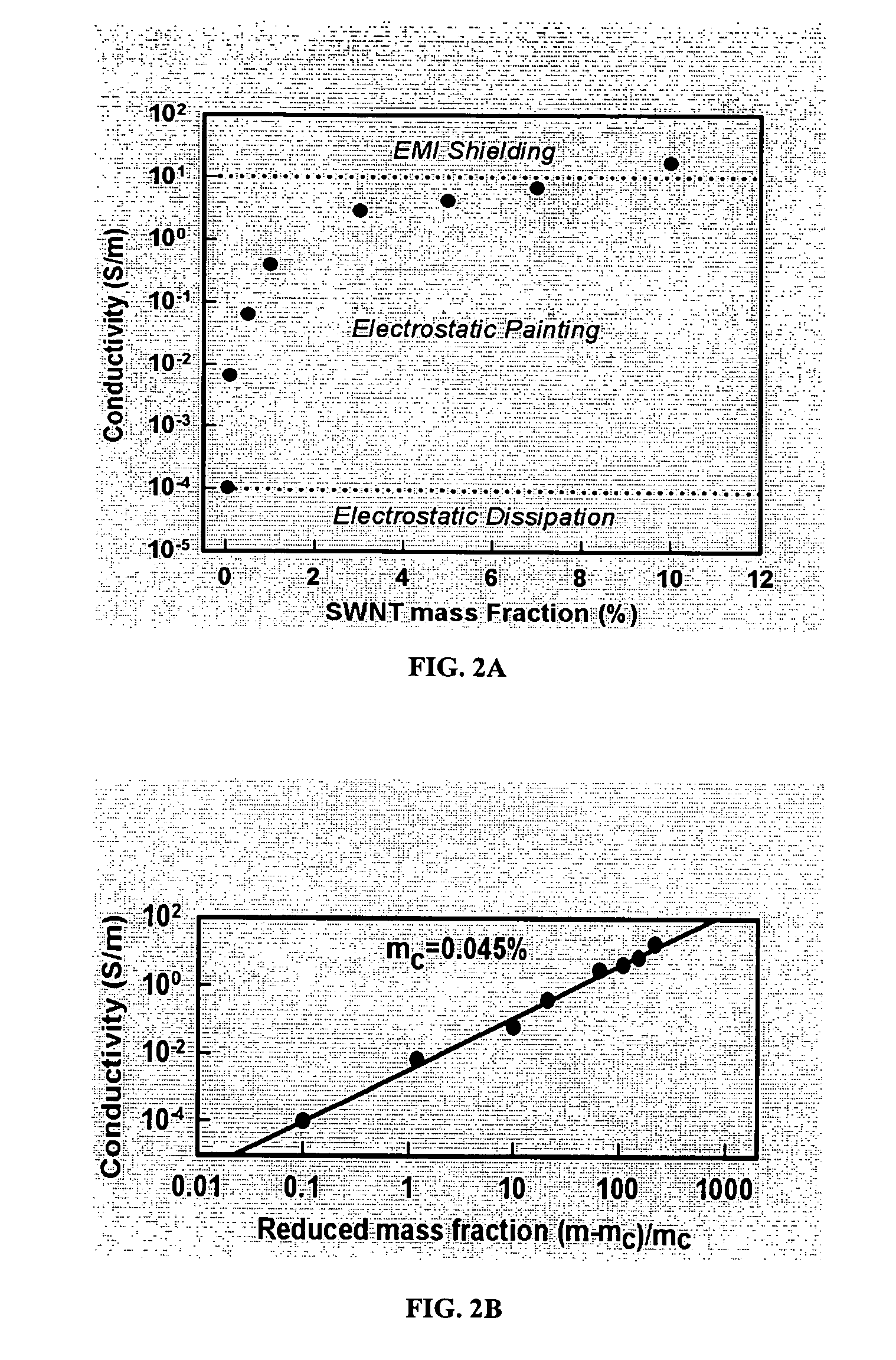

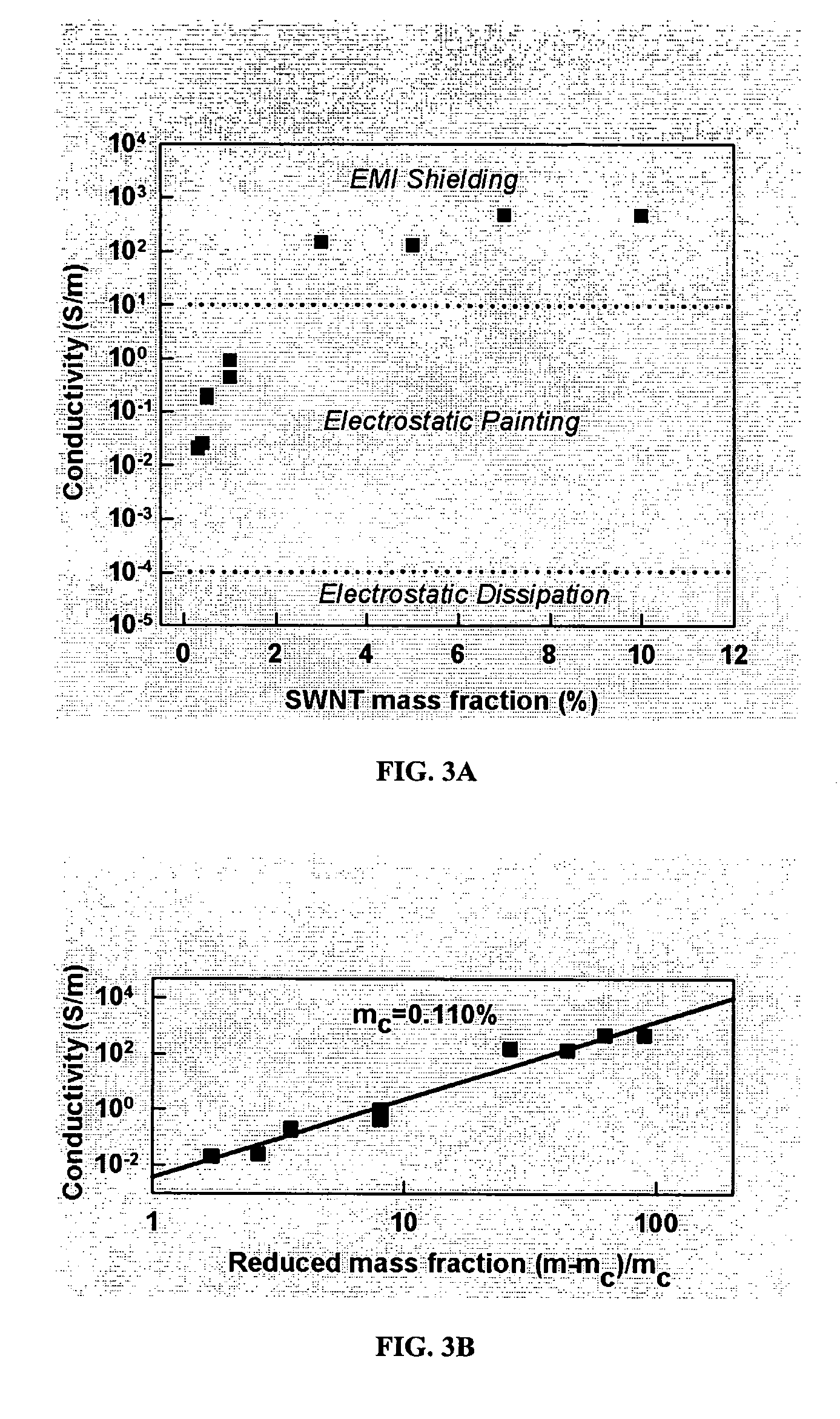

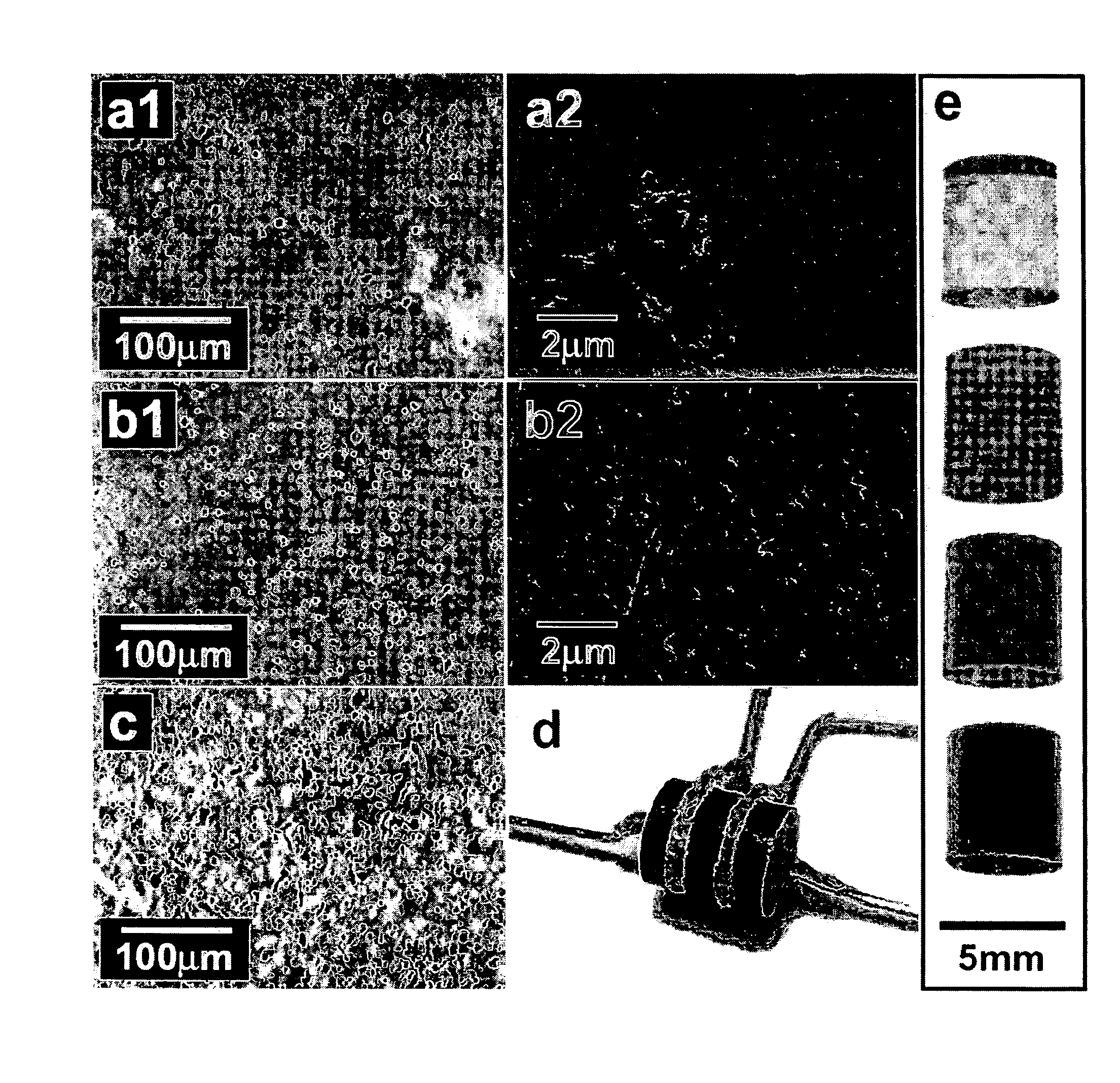

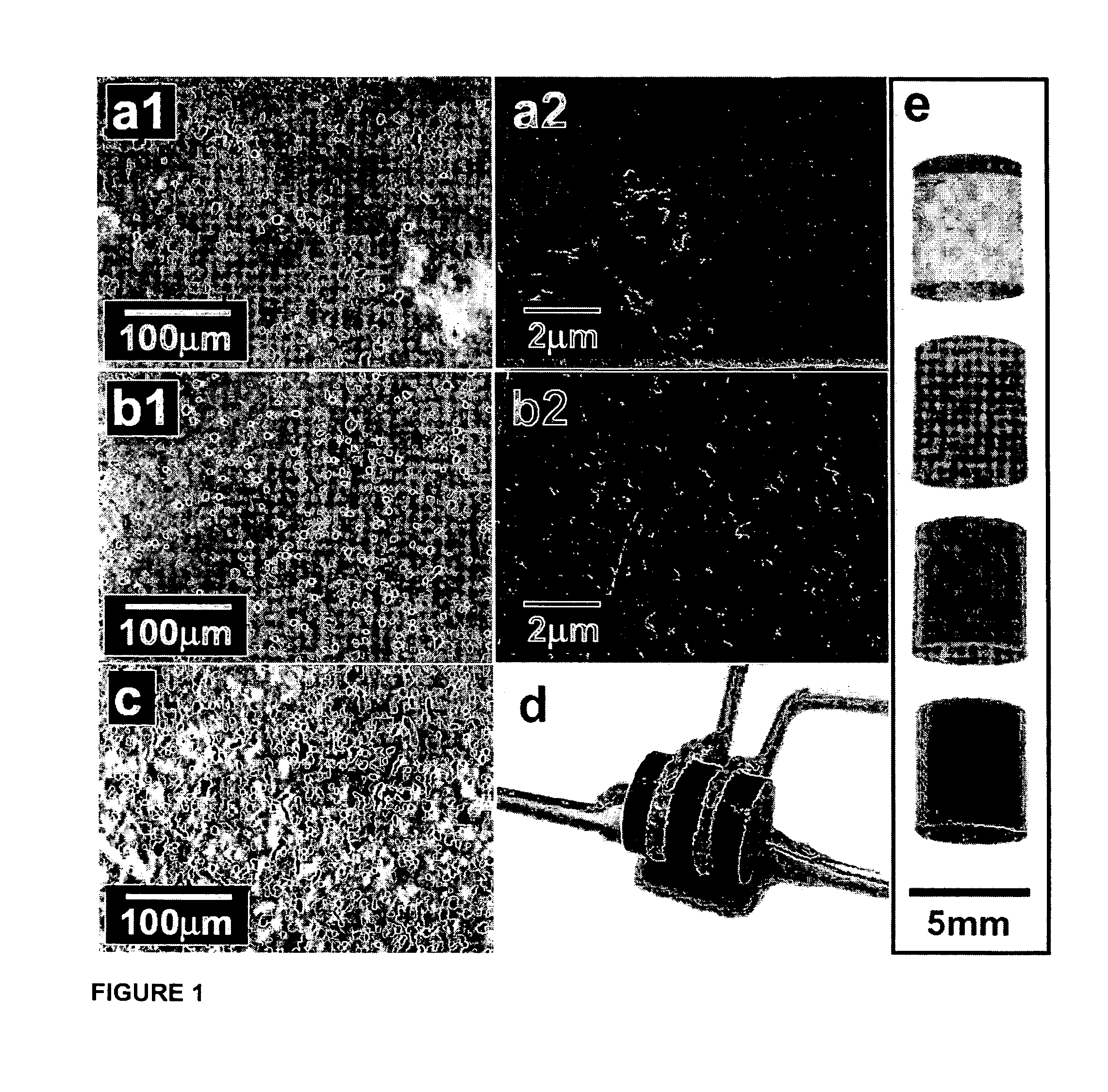

Single wall nanotube composites

Methods for preparing composite materials containing carbon nanotubes and a matrix material are provided. Nanotube composite materials and electrical devices made using nanotube composite materials are also provided. Composite materials composed of nanotubes near the percolation threshold provide electrical conductivities greater than about 10−9 S / cm.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

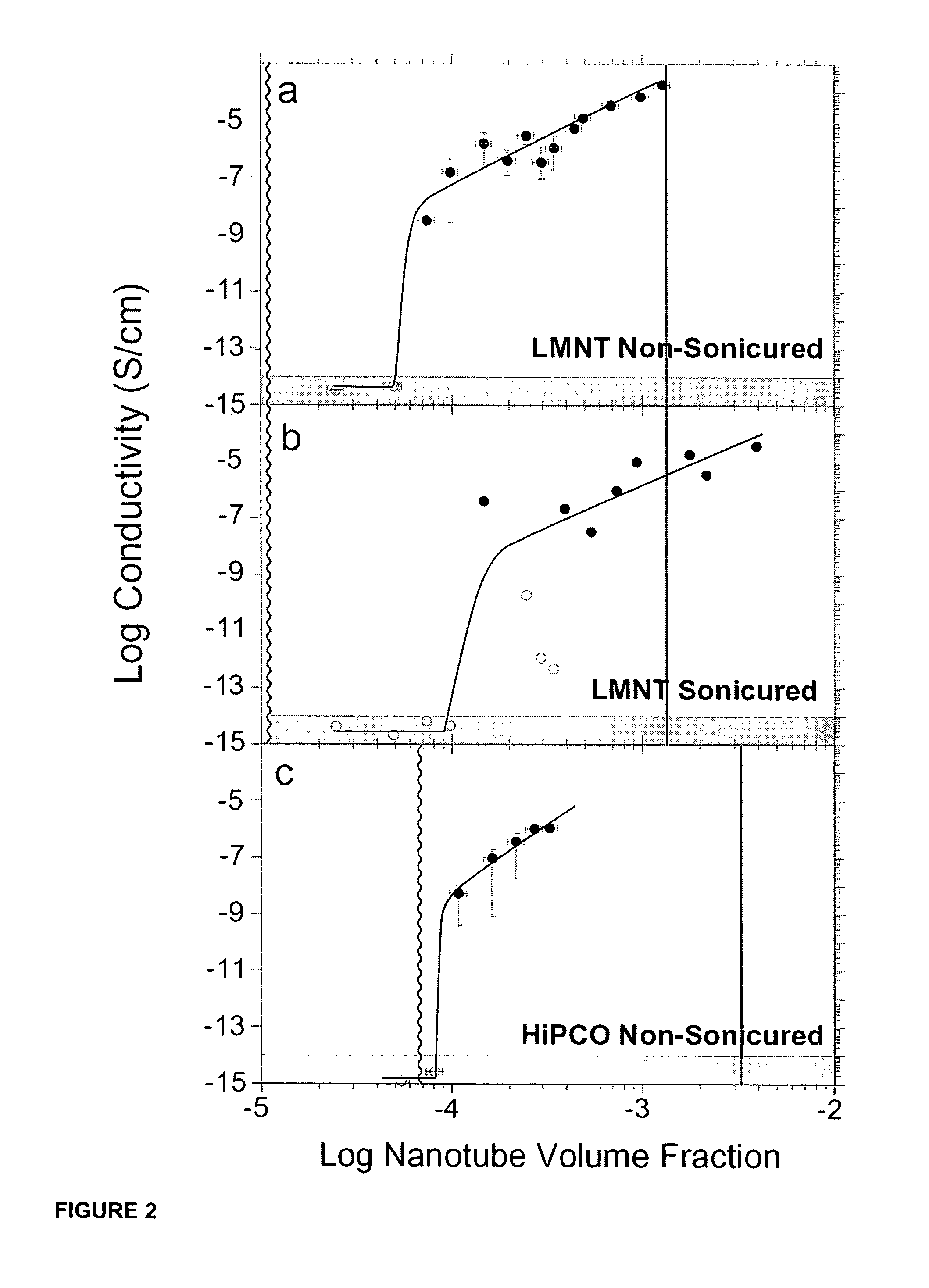

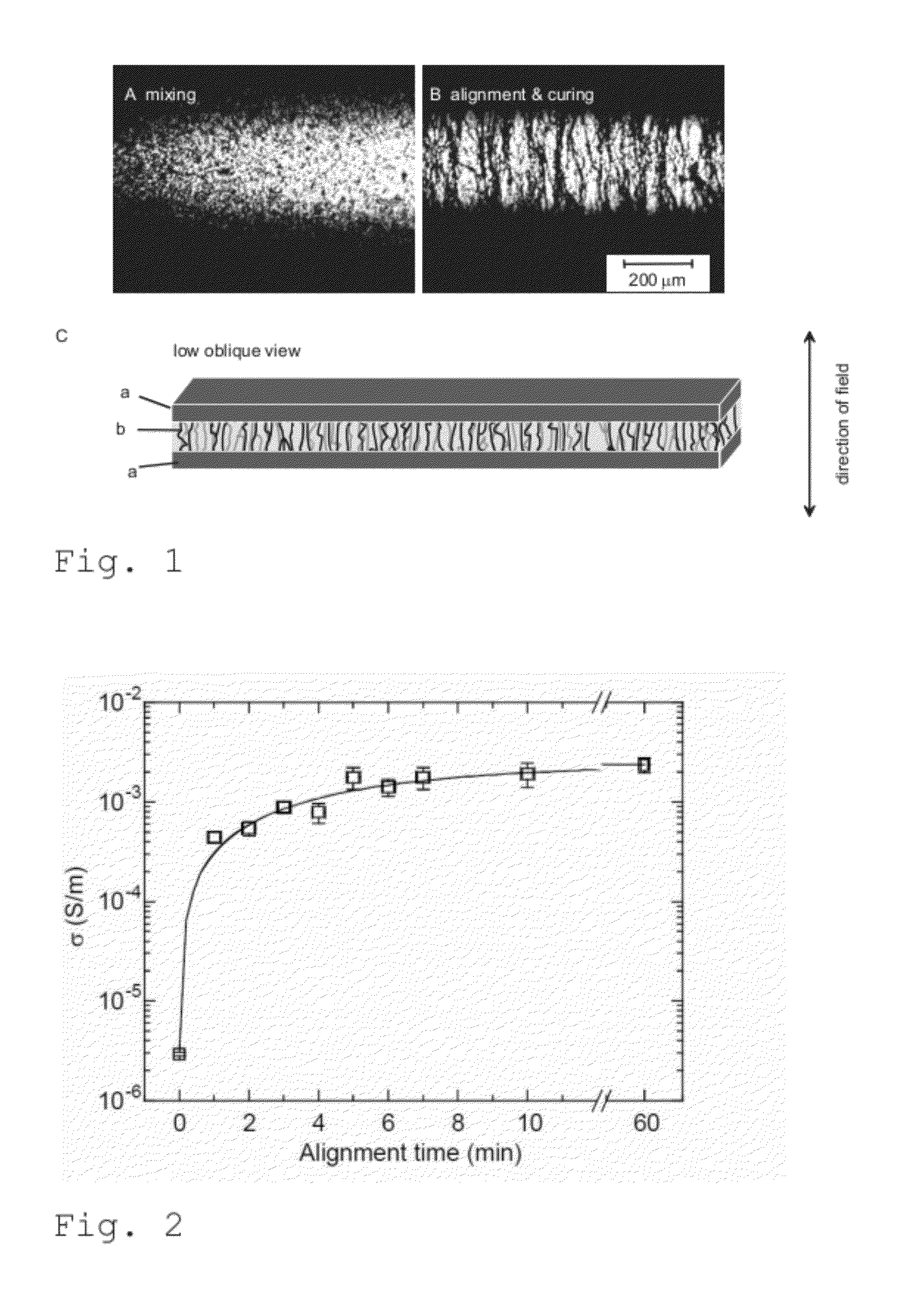

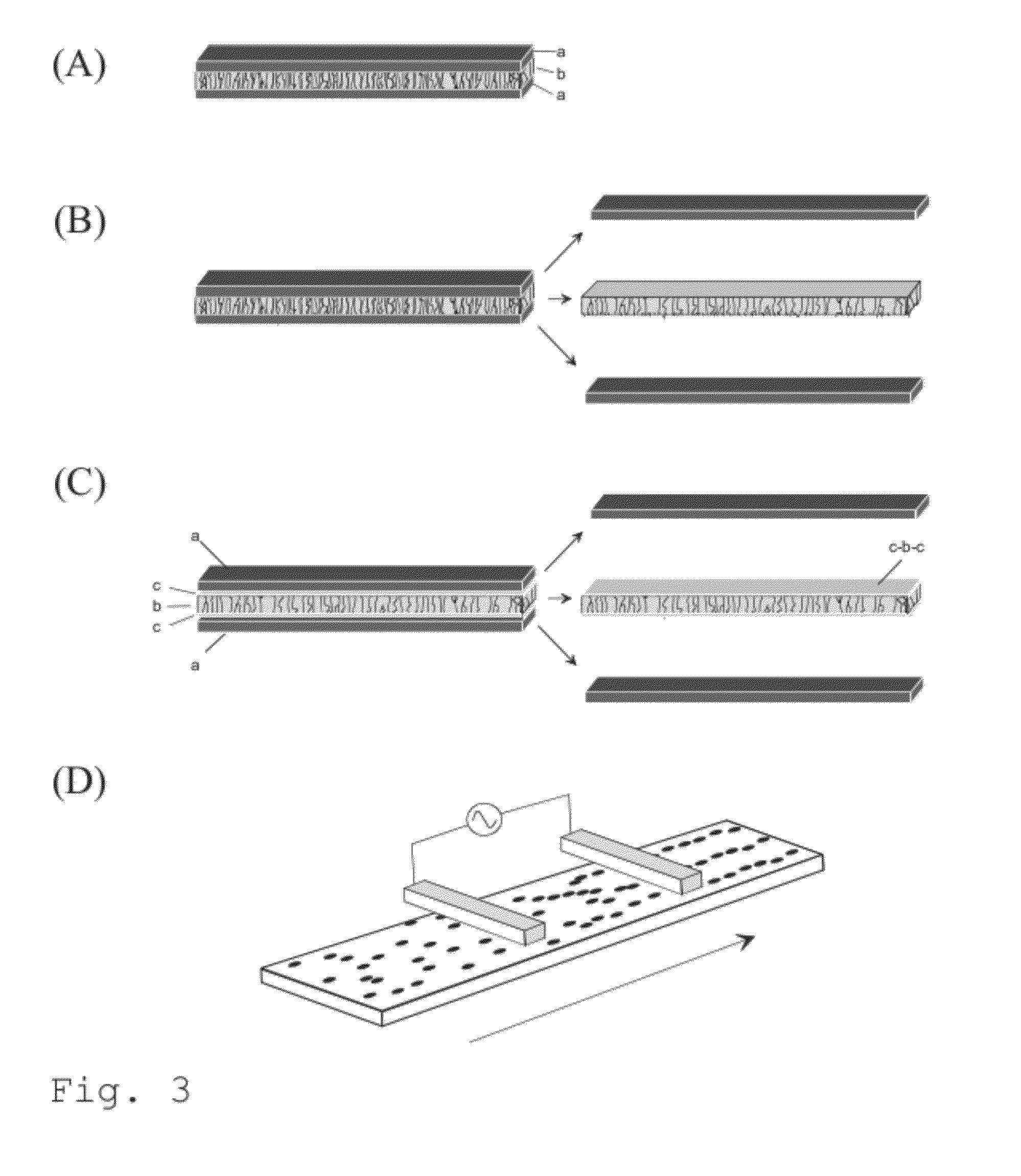

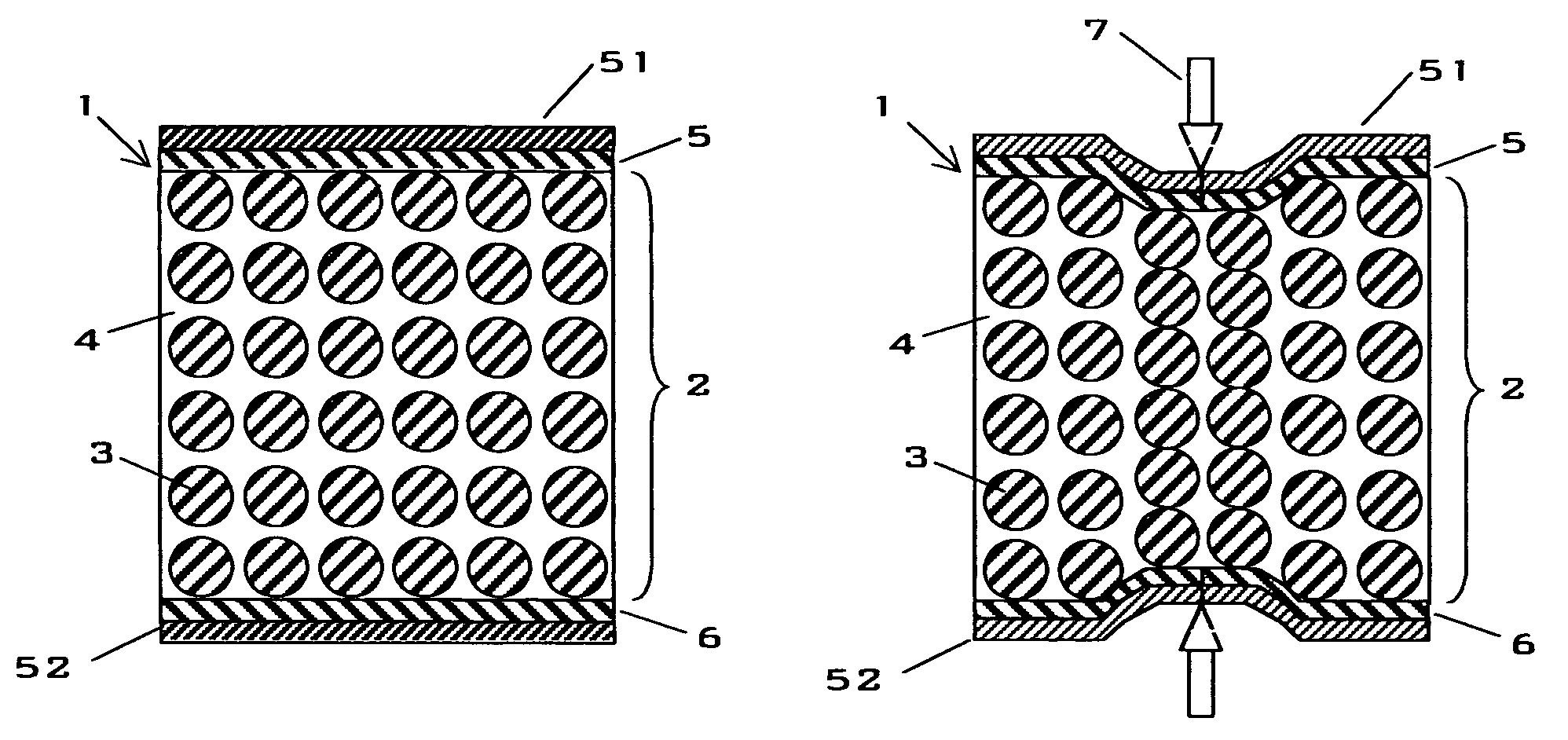

Anisotropic conductive polymer material

ActiveUS20120145315A1Fast curing timeHigh bonding strengthMaterial nanotechnologyNon-macromolecular adhesive additivesConductive polymerPercolation threshold

A method for forming a body comprising a mixture of a matrix and conductive particles, whereby the conductive particles are formed into aligned conductive pathways in an alignment step by applying an electric field between alignment electrodes and thereafter stabilizing the mixture wherein the conductive particles have a low aspect ratio; and a polymeric composition and method for producing such composition which is curable by UV light to an anisotropic electrically conductive polymer layer, comprising i) providing a non-conductive matrix of a flowable polymer composition having inherent photocurability, ii) adding to matrix conductive particles having low aspect ratio in an amount to allow the concentration of the conductive particles to be maintained at a level lower than the percolation threshold, and iii) placing the formed composition in a receptacle where exposure to UV light is prevented, and a method for establishing an anisotropic electrically conductive, optionally thermally conductive

Owner:CONDALIGN AS

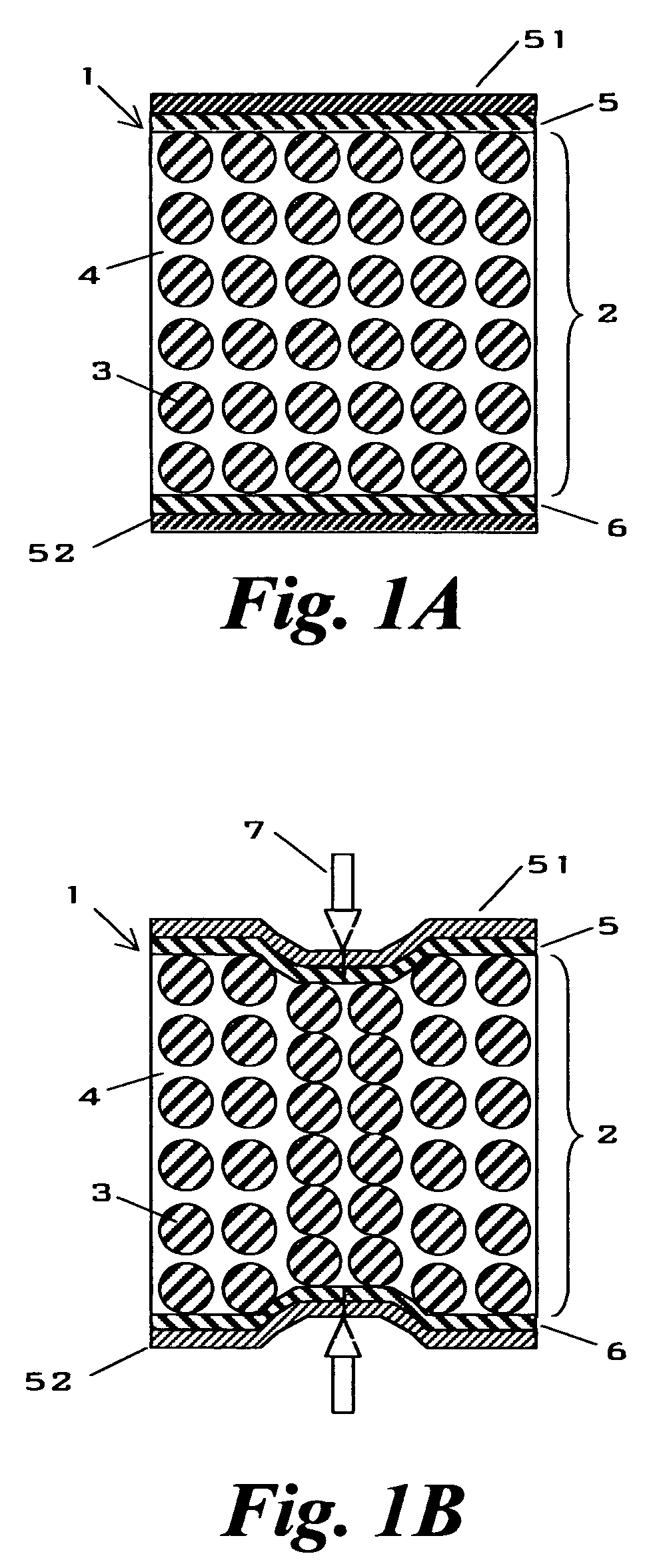

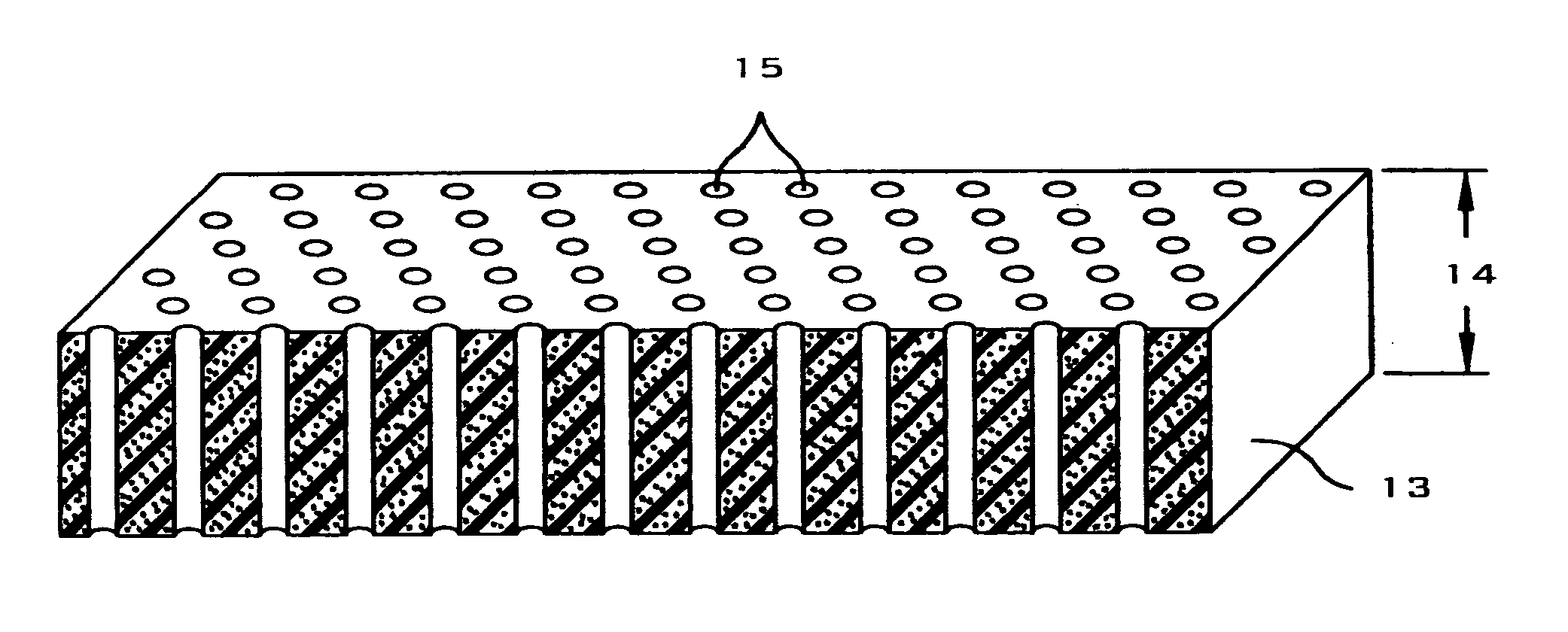

High-sensitivity pressure conduction sensor for localized pressures and stresses

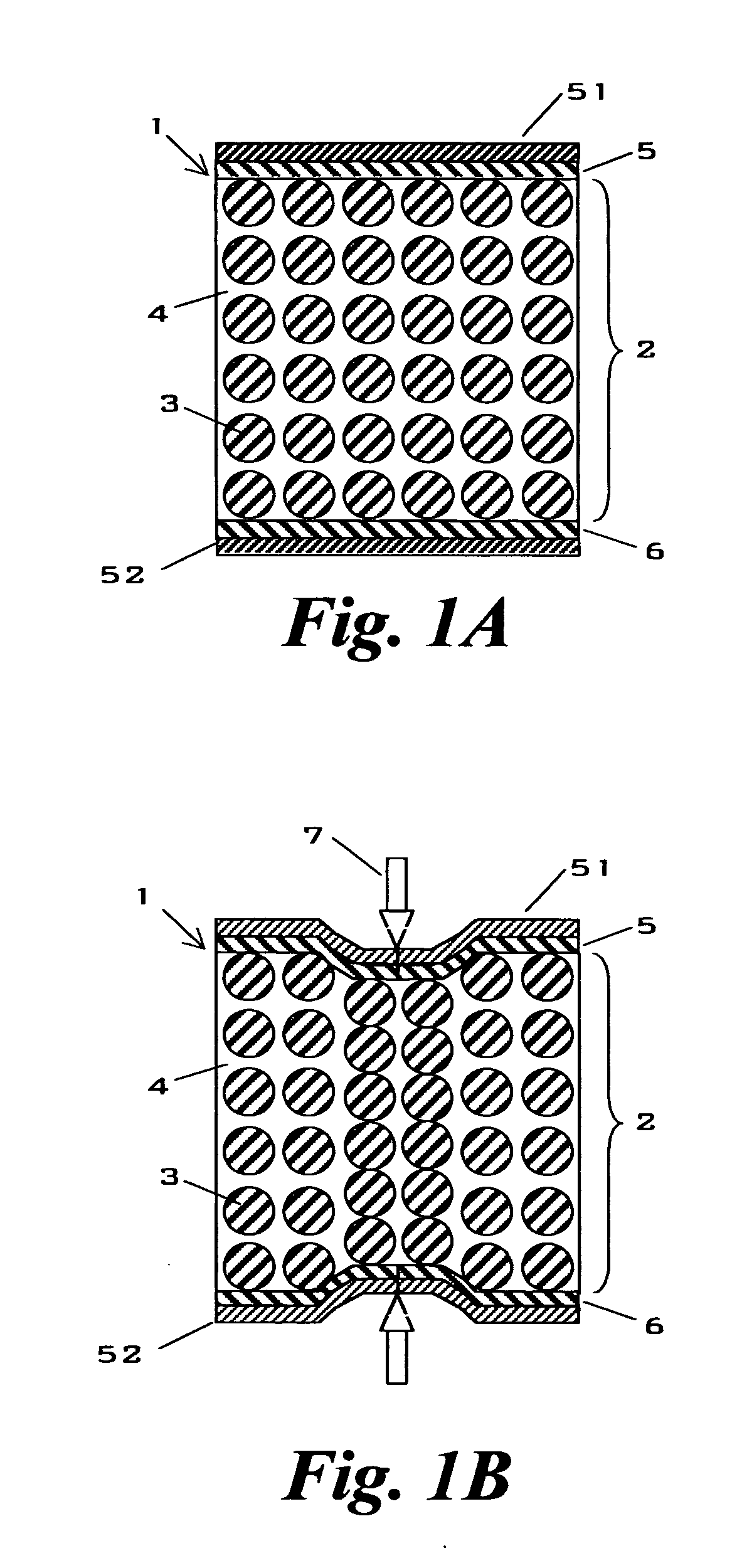

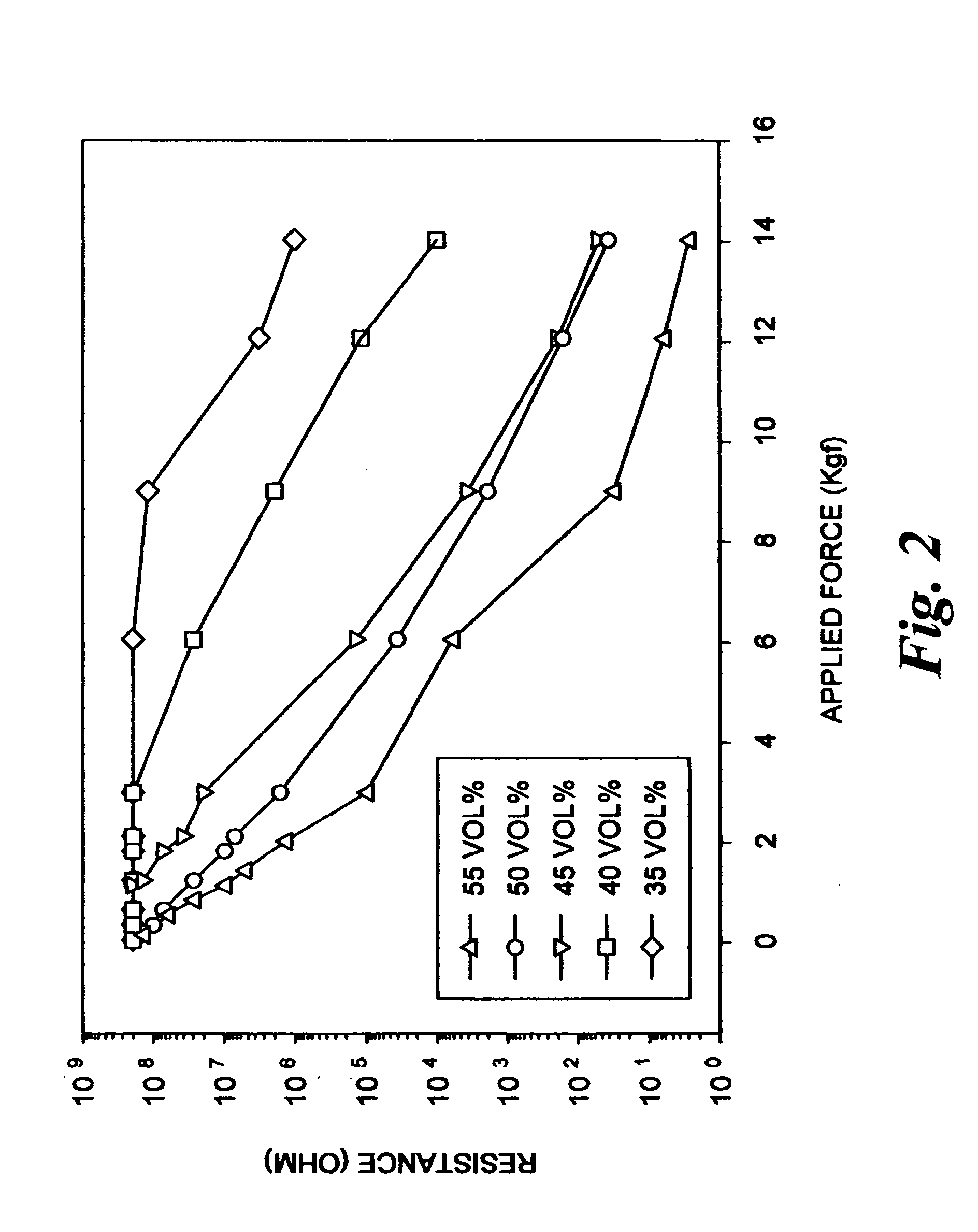

ActiveUS7080562B2Minimizes signal-processing requirementAvoid harmful effectsForce measurementMaterial strength using tensile/compressive forcesElectricityControl system

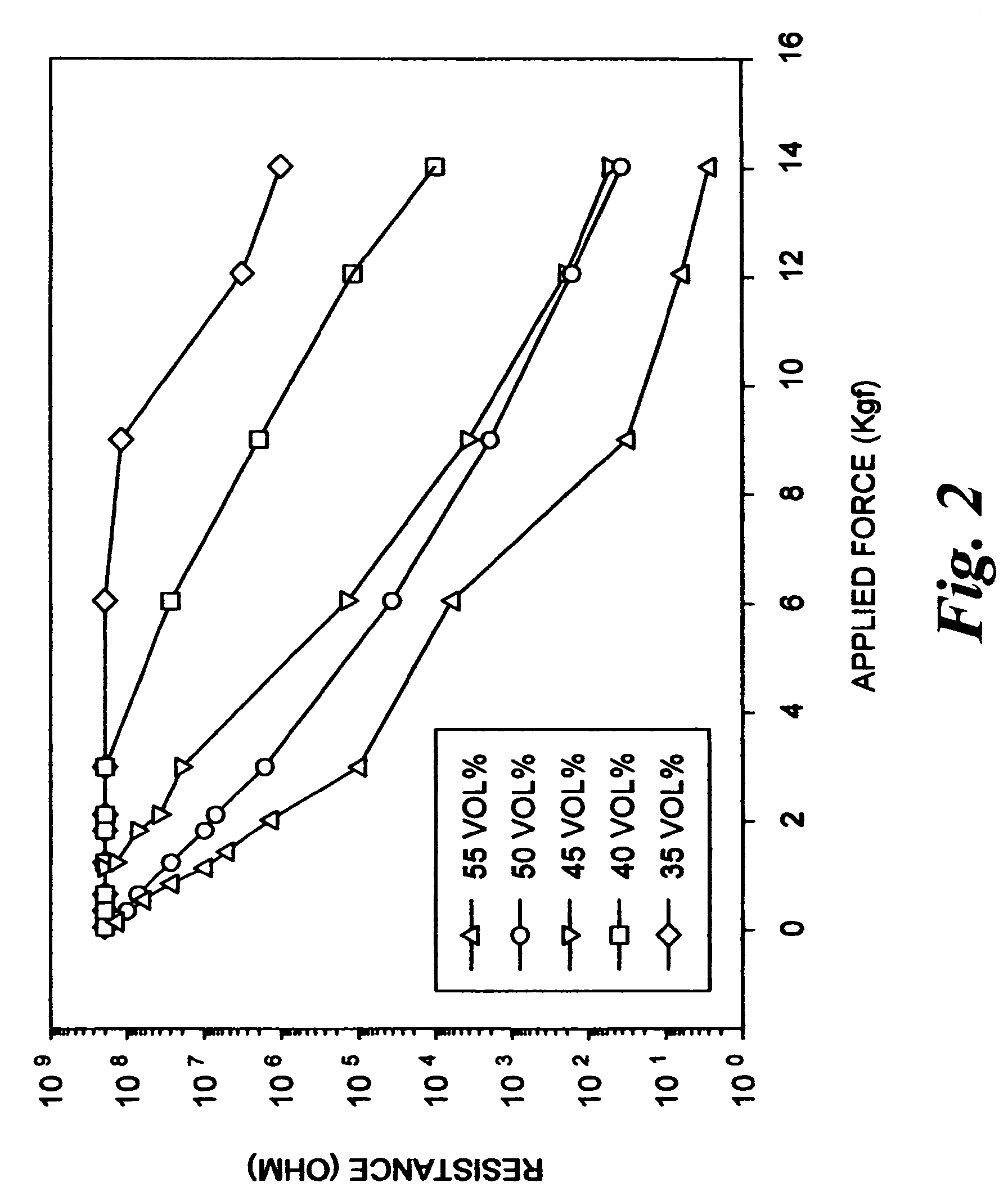

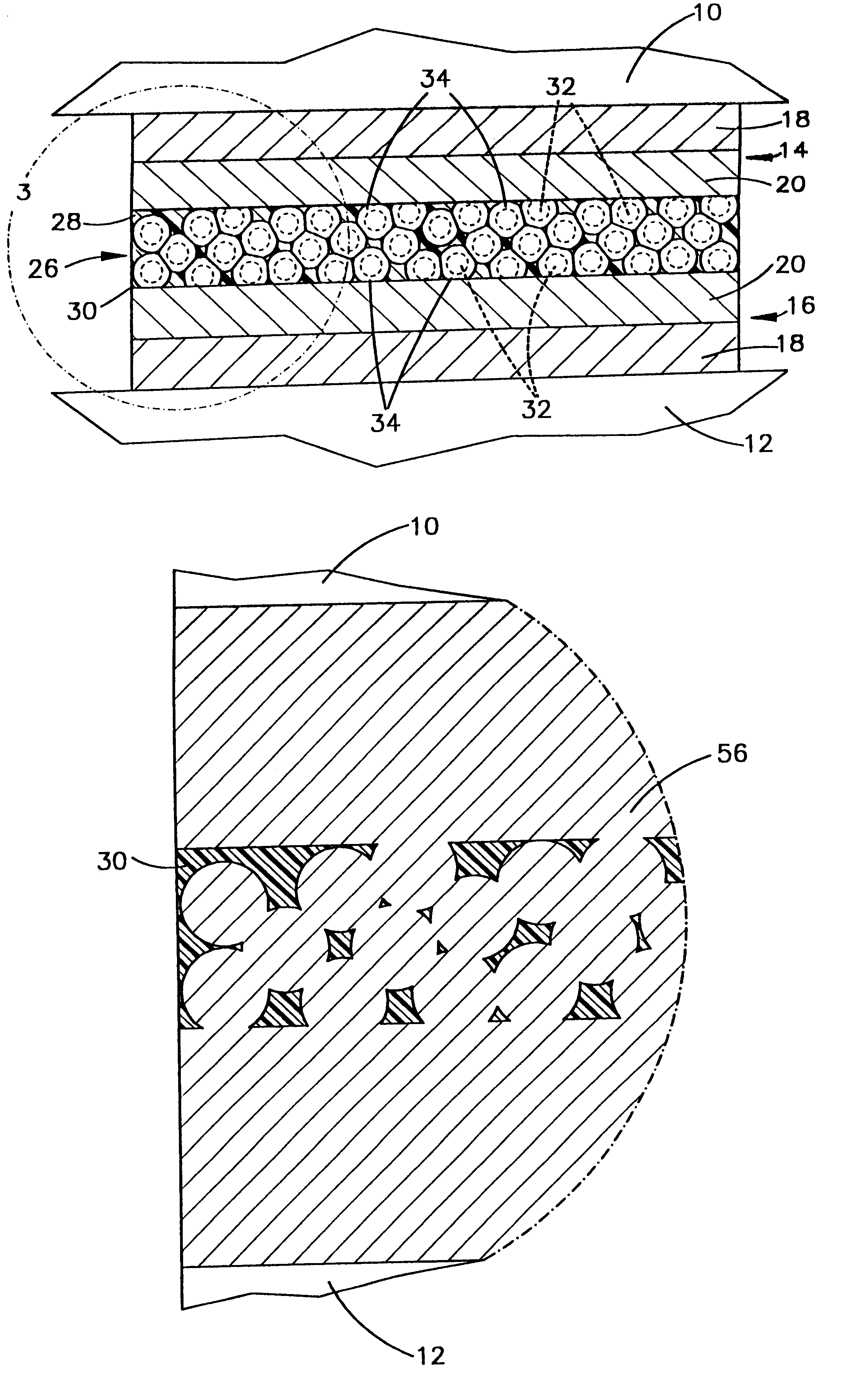

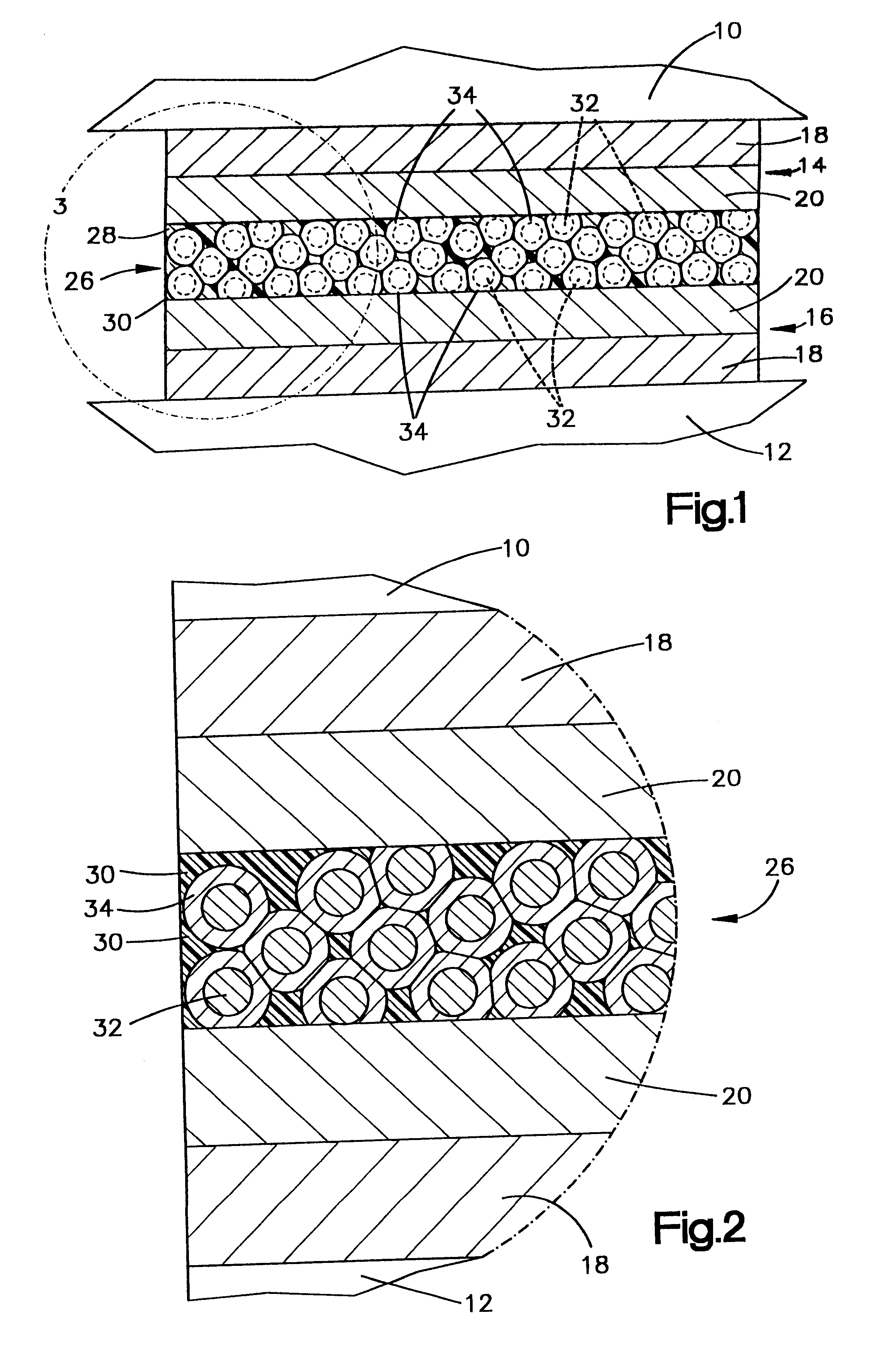

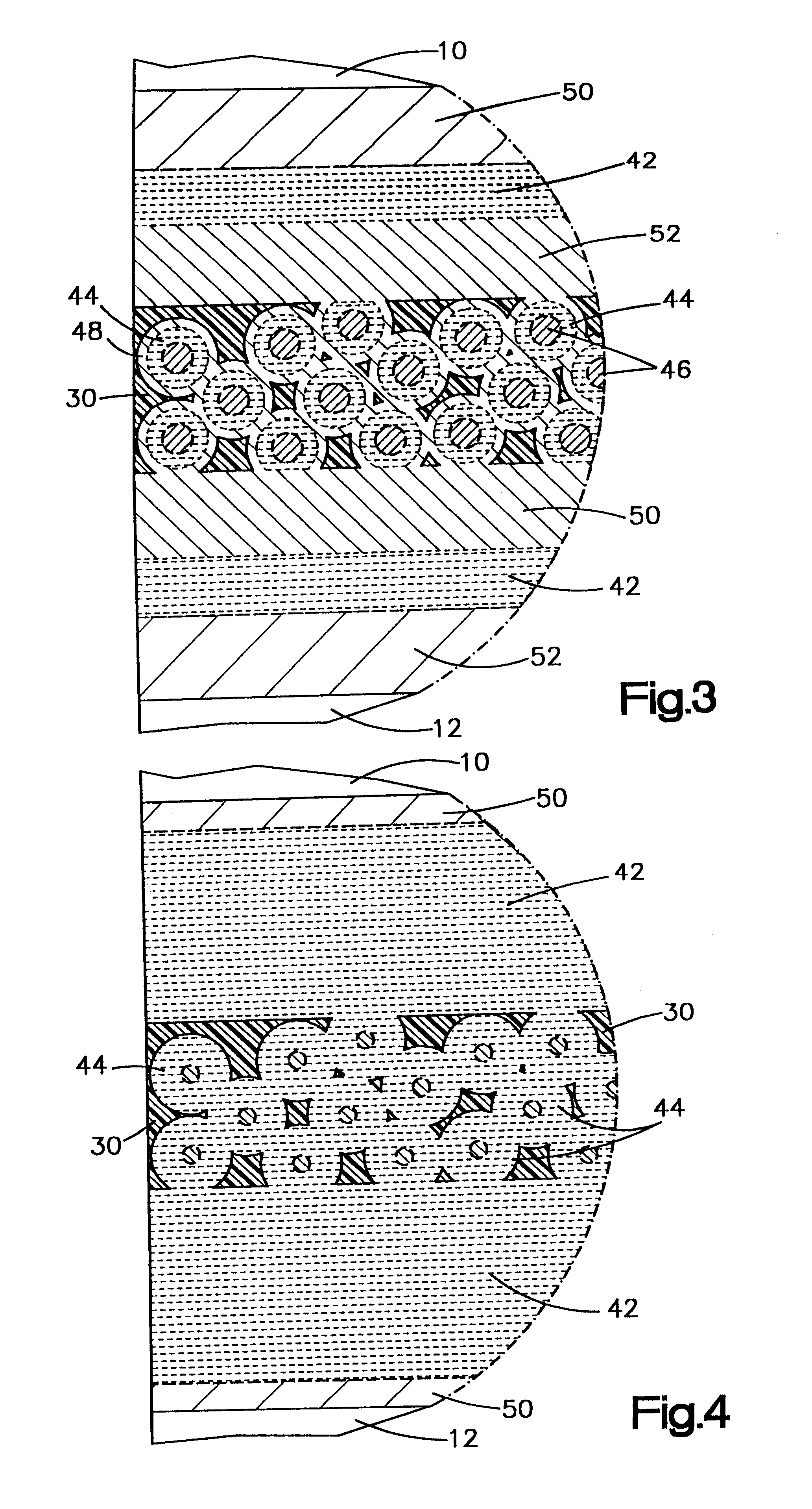

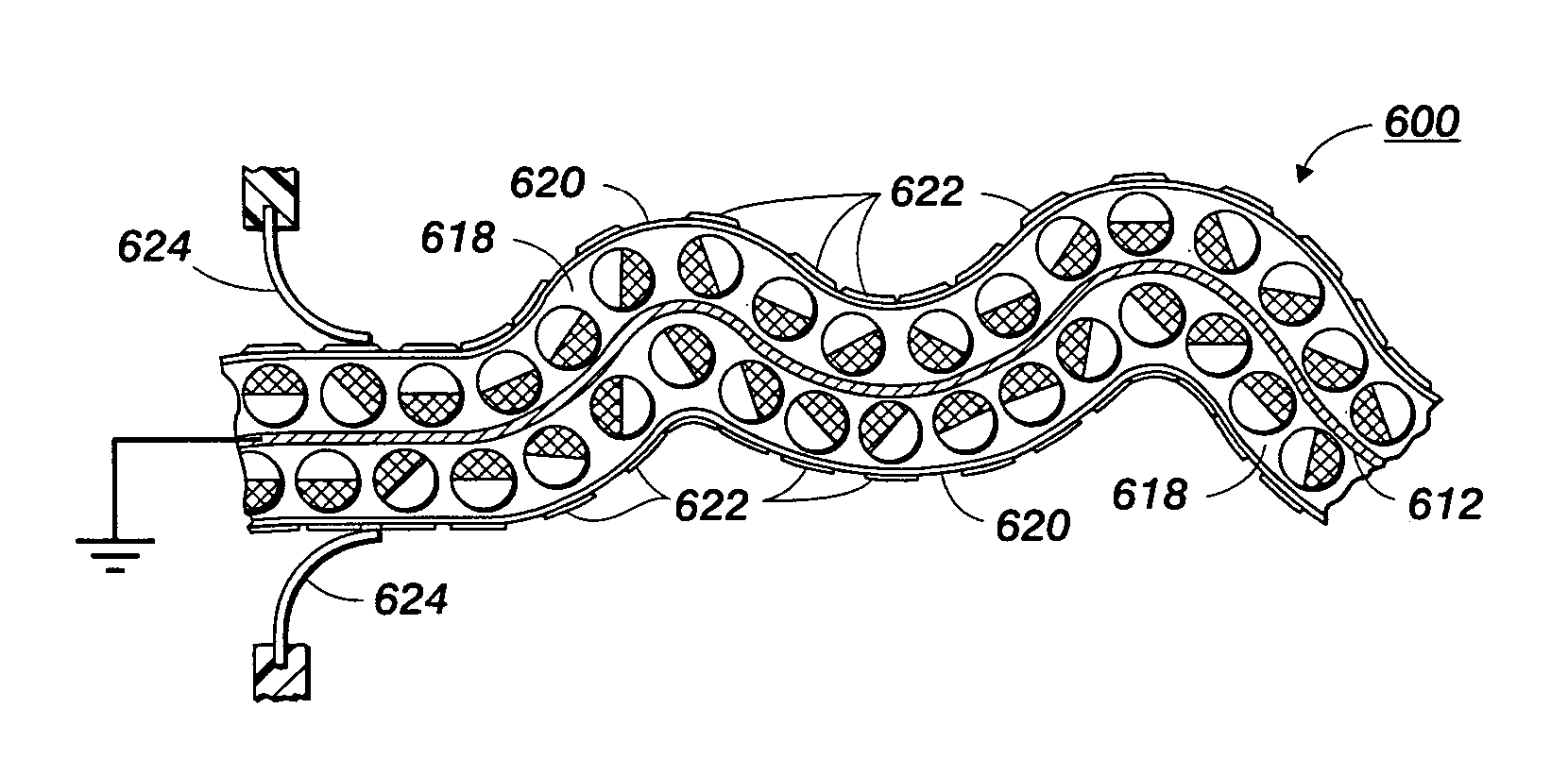

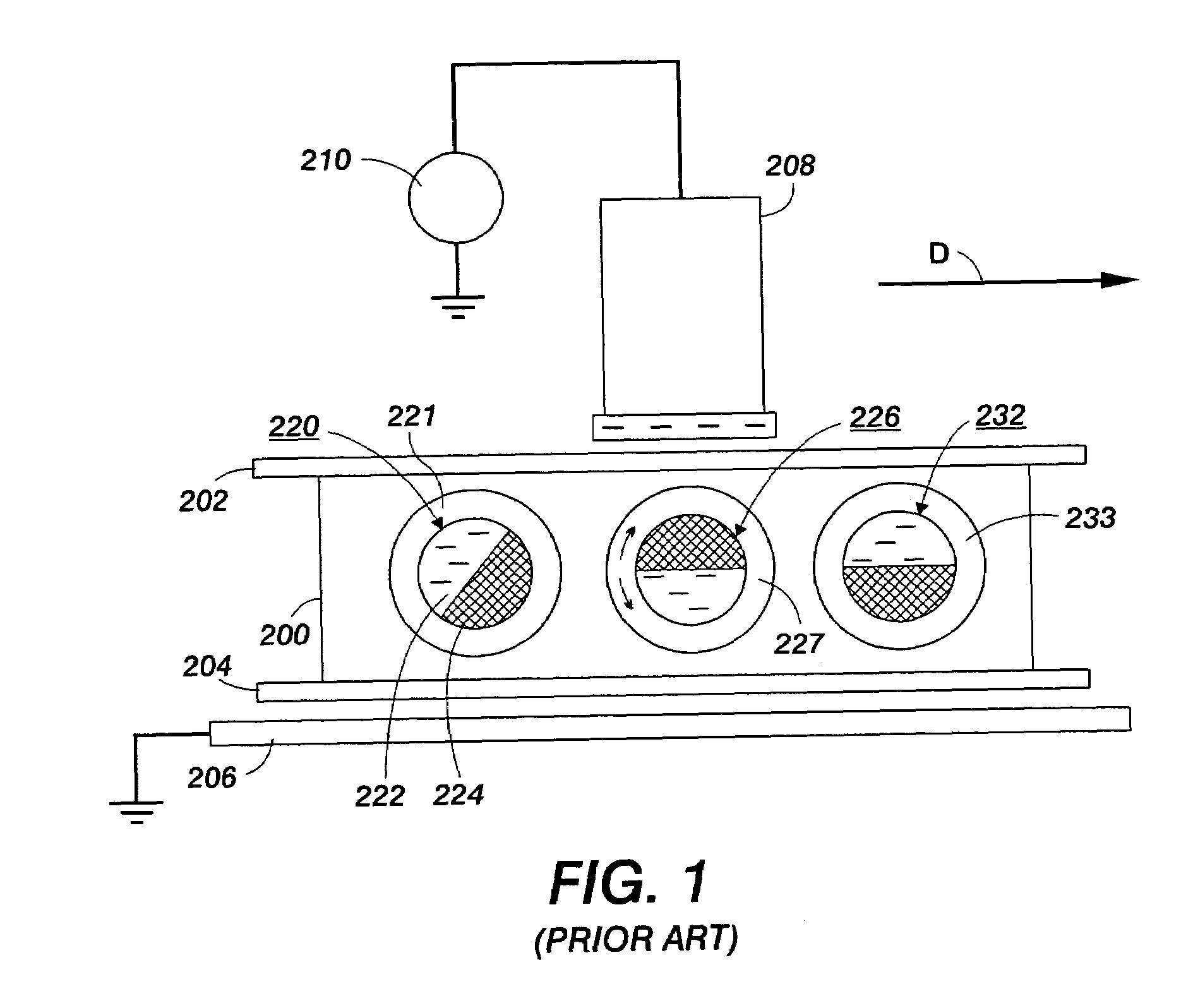

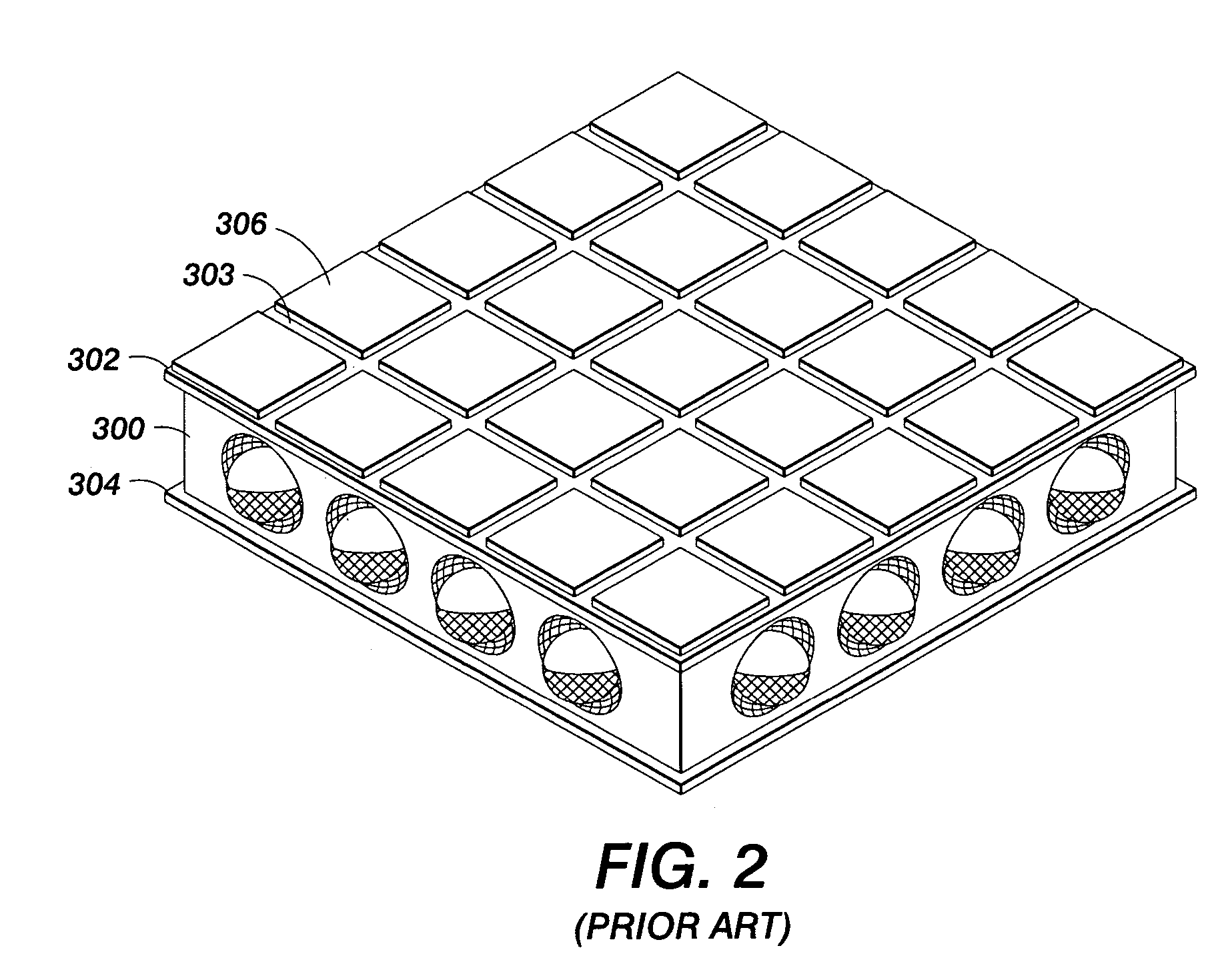

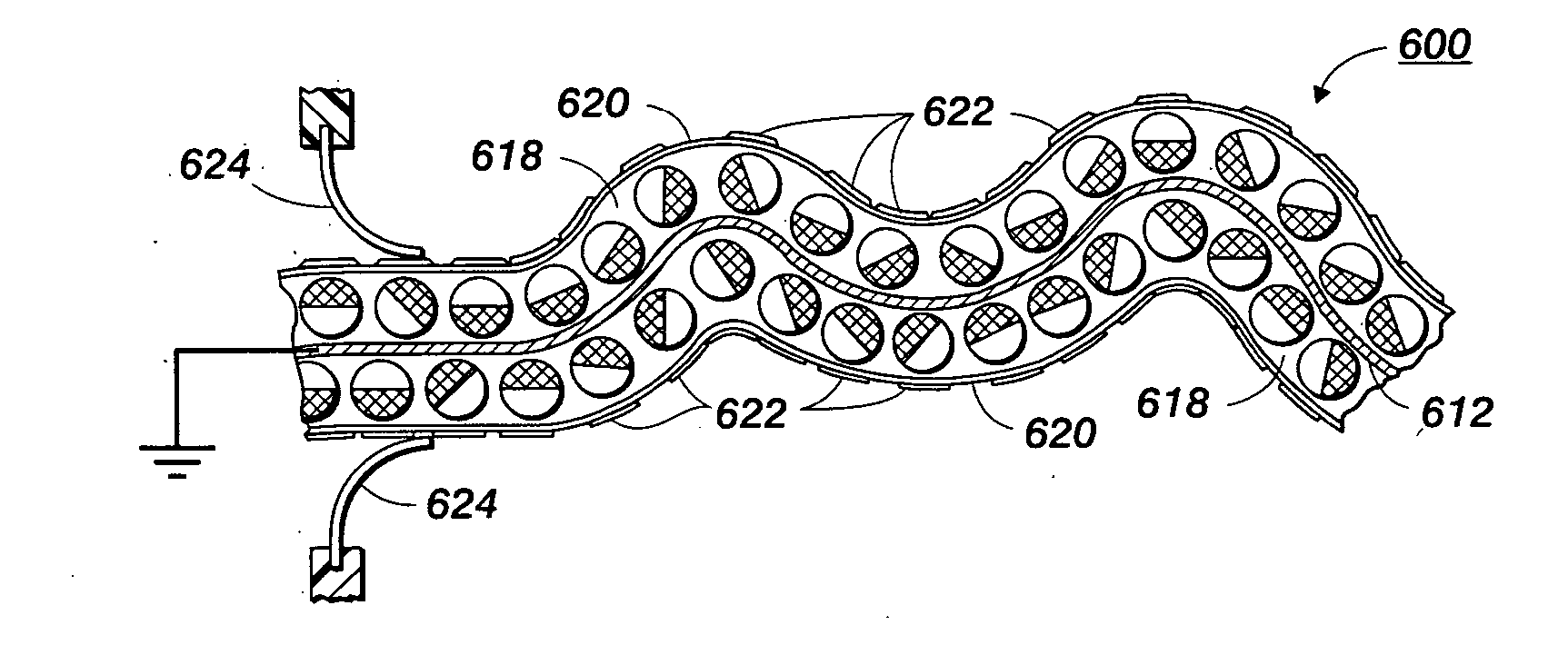

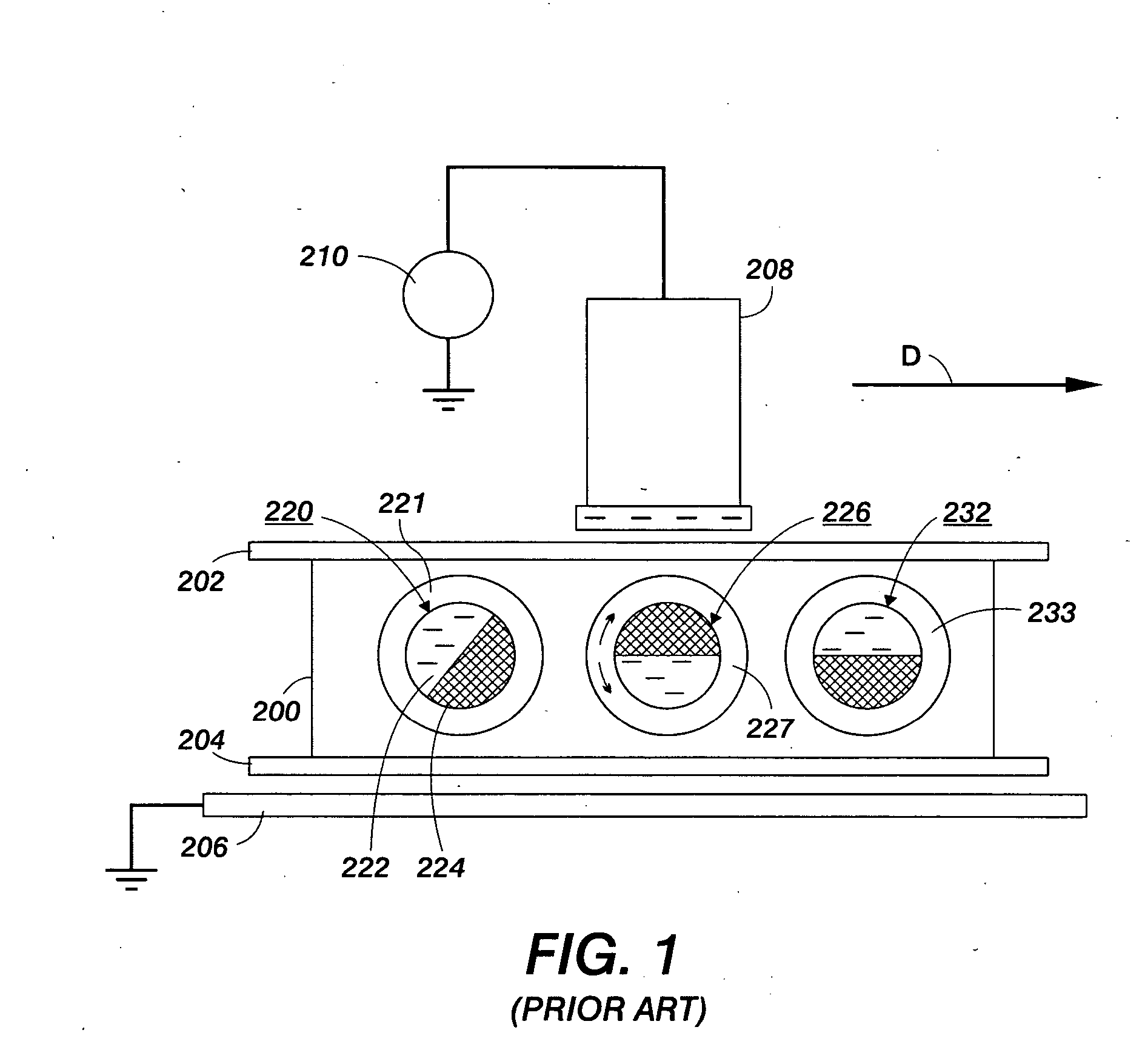

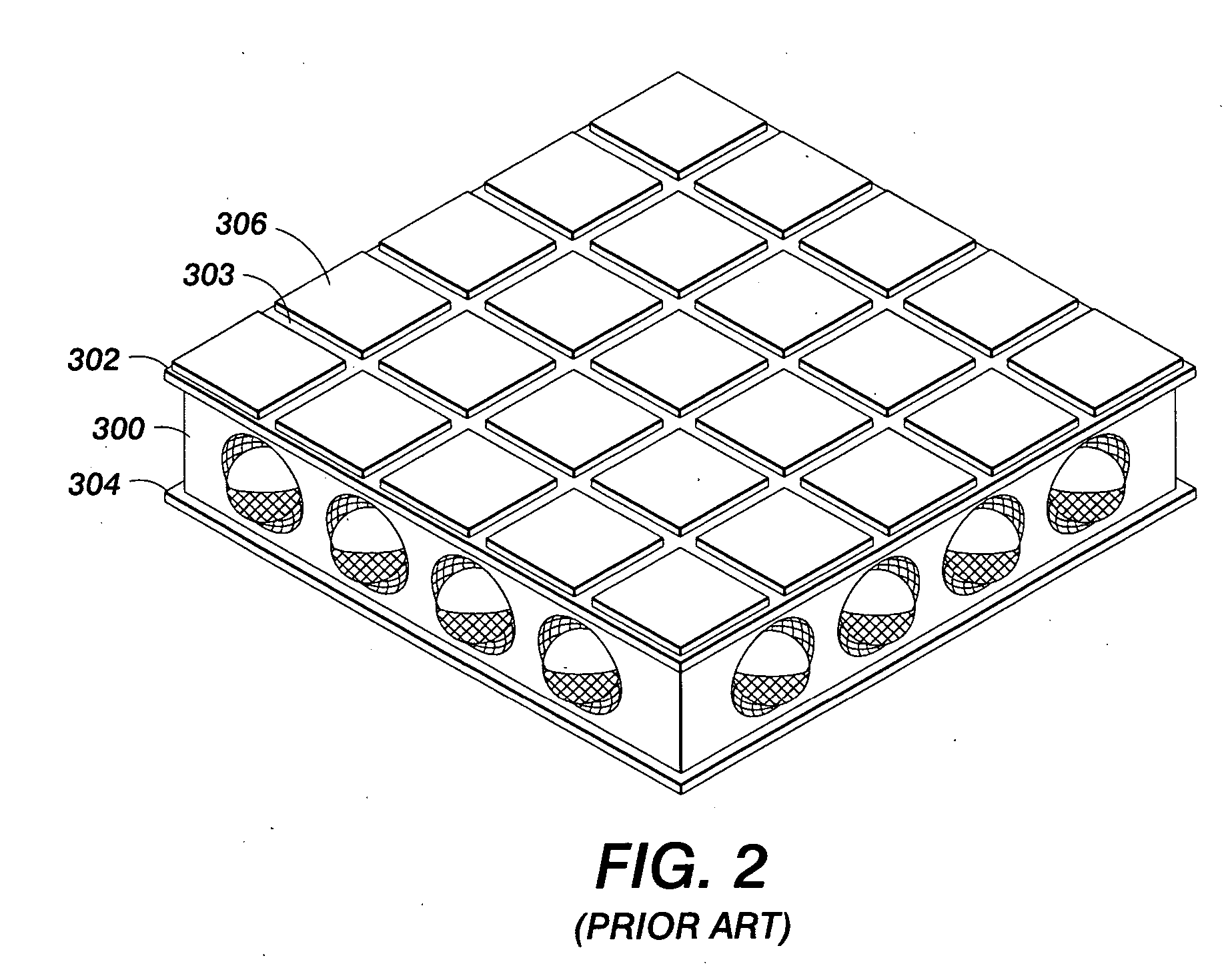

A high-sensitivity pressure conduction sensor is presented. The present invention includes a pair of locally resilient conductive layers and a locally resilient pressure conduction composite disposed between and contacting both conductive layers. Alternate embodiments include at least three locally resilient conductive layers and at least two locally resilient pressure conduction composites, each having a critical percolation threshold. Each composite is disposed between and contacting two conductive layers in a multi-layer fashion. Other embodiments include a locally resilient pressure conduction composite, a flexible substrate completely surrounding the composite so as to seal it therein, and a pair of electrical leads contacting the composite and terminating outside of the flexible substrate. Pressure conduction composites are composed of a plurality of conductive particles electrically isolated within a non-conductive matrix. Conductive particles are loaded so as to have a volume fraction approaching the critical percolation threshold of the material system and exhibit a conductance that greatly increases with pressure. Sensors may be arranged to form one or more arrays including planar and conformal configurations. The present invention has immediate application in keyboards, intrusion systems, control systems, submarines, ships, sonobuoys, doors, and switches.

Owner:QORTEK

Polymer with transient liquid phase bondable particles

A technique of forming a metallurgical bond between pads on two surfaces is provided. A metal coating placed on each surface includes a first metal base layer and a second metal surface layer. The first and second metals include a low melting point constituent. A first ratio of the two metals forms a liquid phase with a second ratio of the two metals forming a solid phase. The volume of the base layer metal exceeds the volume necessary to form the solid phase between the base metal and the surface metal. Conductive metal particles are provided having a core metal and a coating metal dispersed in an uncured polymer material, at a volume fraction above the percolation threshold. The core metal and the coating metal together include a low melting point constituent. At a first ratio the components form a liquid phase and at a second ratio the two components form a solid phase. The polymer containing particles is placed between the two metal surfaces with the particles interfacing with each other and the surface layer of metal. The structure is heated to a temperature higher than the low melting liquid constituent to form a liquid phase which extends to include the surface of the pads and the surface of the particles, and thereafter form a solid phase by diffusion of the core material into the surface material and the base metal into the coating material.

Owner:GLOBALFOUNDRIES INC +1

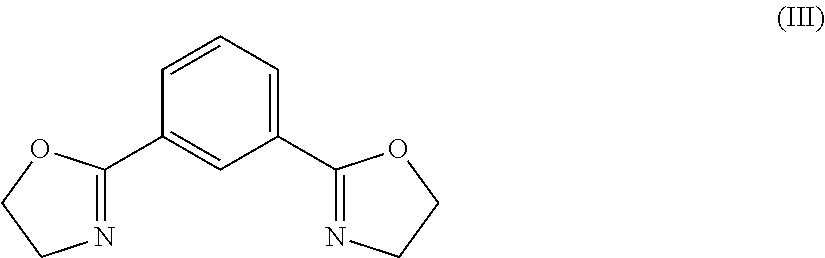

Bisymmetrical electric paper and a system therefor

Owner:PALO ALTO RES CENTE

Dynamic polymer elastomer with hybrid crosslinked network and application of dynamic polymer elastomer

The invention discloses a dynamic polymer elastomer with a hybrid cross-linked network. The elastomer comprises the hybrid crosslinked network, and the hybrid crosslinked network contains covalent crosslinking and supermolecular hydrogen bond crosslinking, wherein the covalent crosslinking achieves a percolation threshold or more of a covalent cross-linked gel, and the hydrogen bond crosslinking is realized through hydrogen bond groups brought by polymer chain side groups and / or side chains. According to the invention, hydrogen bonds are dynamically reversible, thus the dynamic polymer elastomer has good performance such as toughness, energy dissipation performance, and self repairability. The dynamic polymer elastomer with the hybrid cross-linked network is widely applied to aspects suchas body protection in sports and daily life and work, military police body protection, explosion protection, airborne and air-drop protection, automotive collision avoidance, and electronic material impact resistant protection.

Owner:厦门逍扬运动科技有限公司

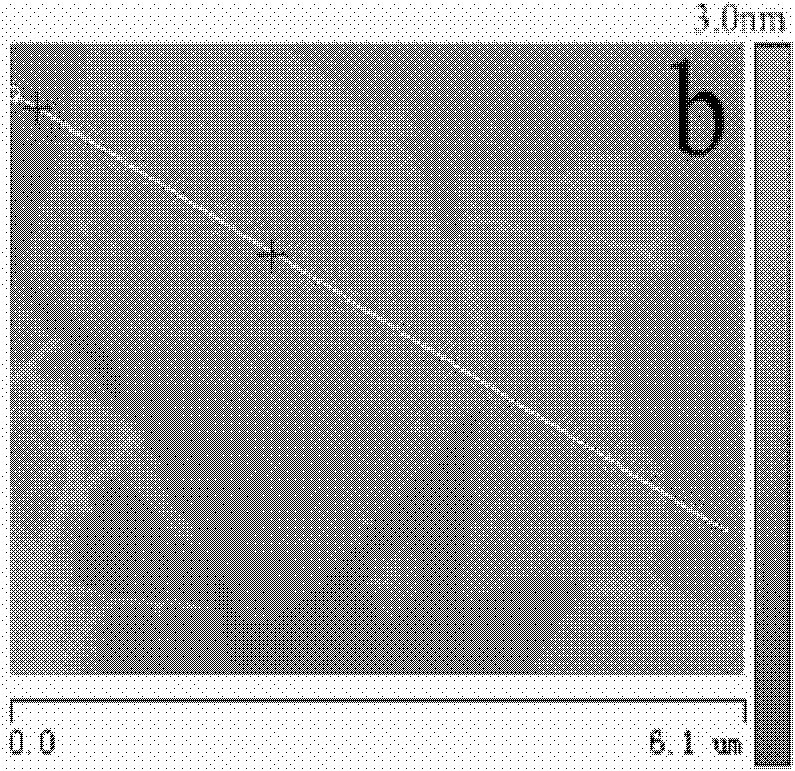

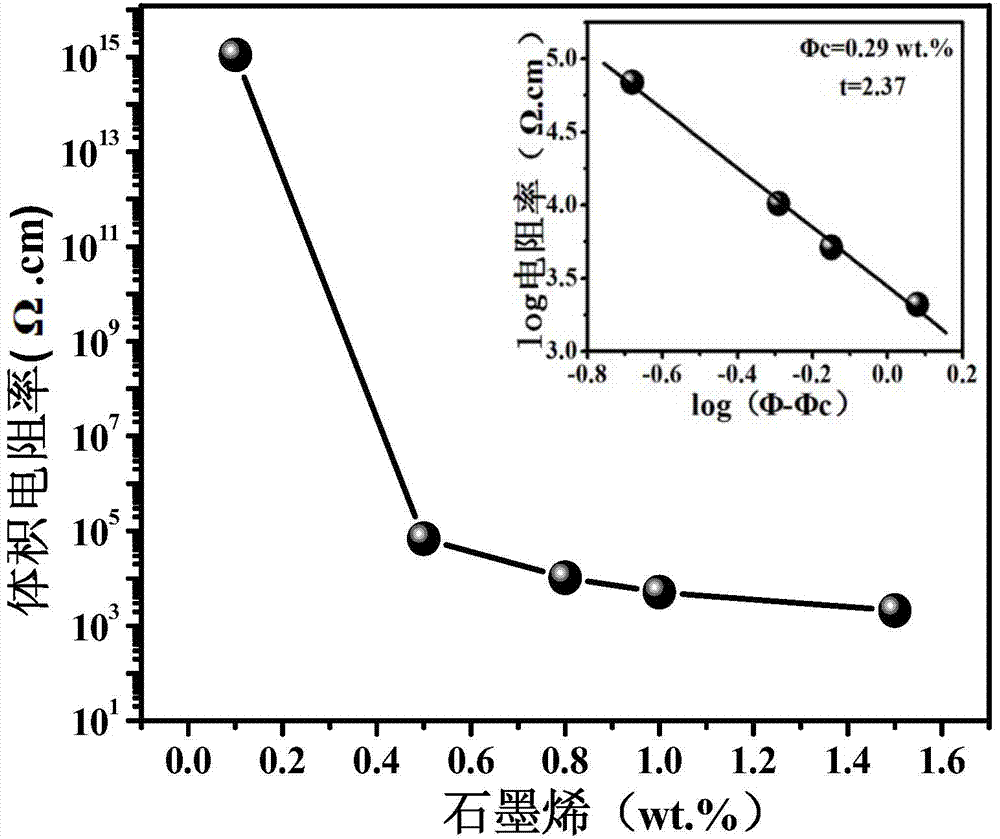

Method for preparing polyethylene/graphene conductive composite material

InactiveCN102585335AGood dispersionReduce reunionNon-conductive material with dispersed conductive materialPolymeric surfaceConductive polymer

The invention relates to a method for preparing a polyethylene / graphene conductive composite material, and belongs to the technical field of preparation of composite conductive polymer materials. The method comprises the following steps of: putting graphite oxide into a solvent consisting of water and ethanol, performing ultrasonic dispersion, adding polyethylene powder, and performing mechanicalstirring; evaporating the solvent, and drying in vacuum to remove the residual solvent so as to obtain core-shell structured composite particles in which the polyethylene powder is coated with a layer of graphene oxide; and adding the core-shell structured composite particles into a hydrazine hydrate solution, heating and stirring, and reducing the graphene oxide on polymer into graphene so as toobtain the powdered polyethylene / graphene conductive composite material. By the method, the graphene oxide can be effectively and uniformly coated on the surface of the polymer; the graphene does notfall into the solution in the reduction process, and the agglomeration of a final product, namely the graphene is effectively reduced; and a platy composite material prepared by hot pressing has a low percolation threshold value and high electric conductivity.

Owner:JILIN UNIV

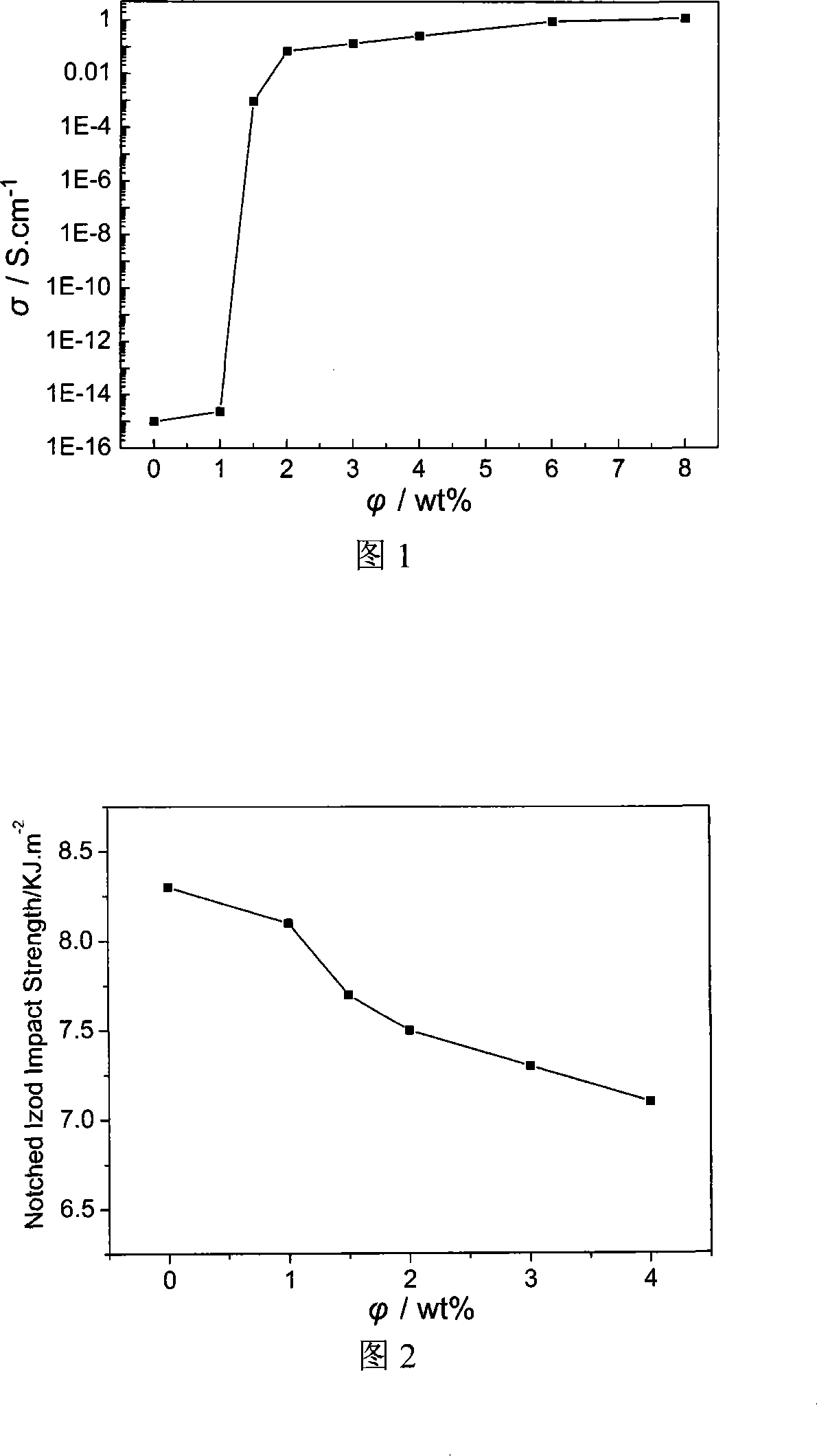

Polyamide/graphite nano conductive composite material and its prepairng method

The present invention relates to a kind of nanometer conductive composite polyamide / graphite material and its preparation process. The nanometer conductive composite material consists of polyamide as main base 100 weight portions, auxiliary base 5-60 weight portions, and graphite 2-40 weight portions. It has relatively low percolation threshold, 3-4 %, and relatively high conductivity. Owing to the filled conductive material in relative small amount, the nanometer conductive composite material has excellent mechanical performance and processability similar to that of nylon and high electrostatic resistance, so that it is wide application foreground in electrostatic resisting material, electromagnetic shielding material, microwave absorbing material, etc.

Owner:YANGZHOU UNIV

Carbon nanotube/polylactic acid conductive composite material and preparation method

ActiveCN102952383AAdd lessReduce the conductive percolation valueCarbon nanotubePercolation threshold

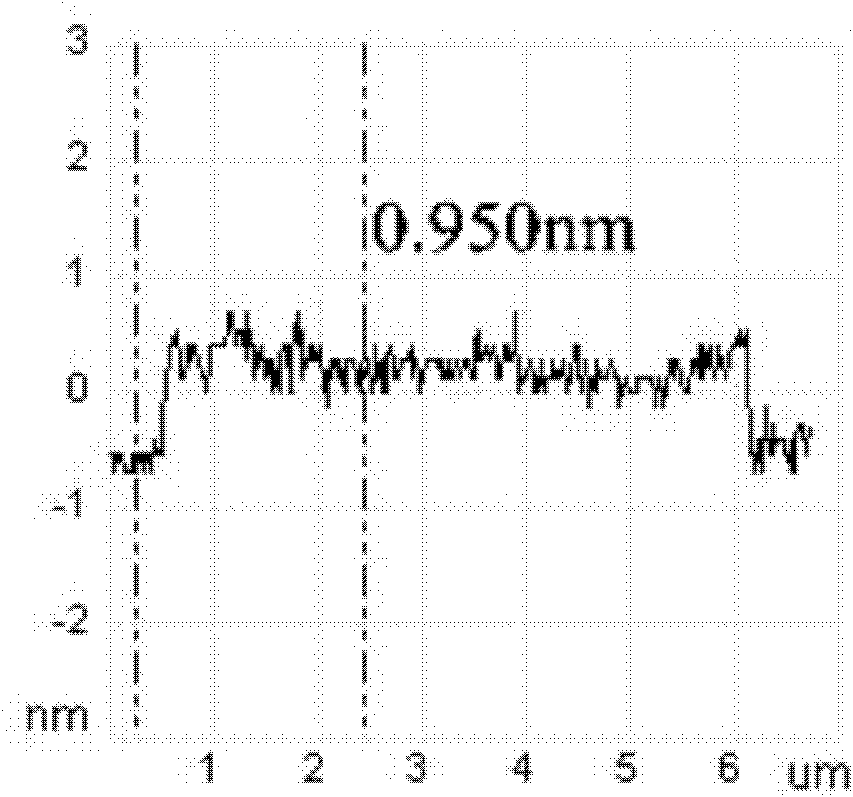

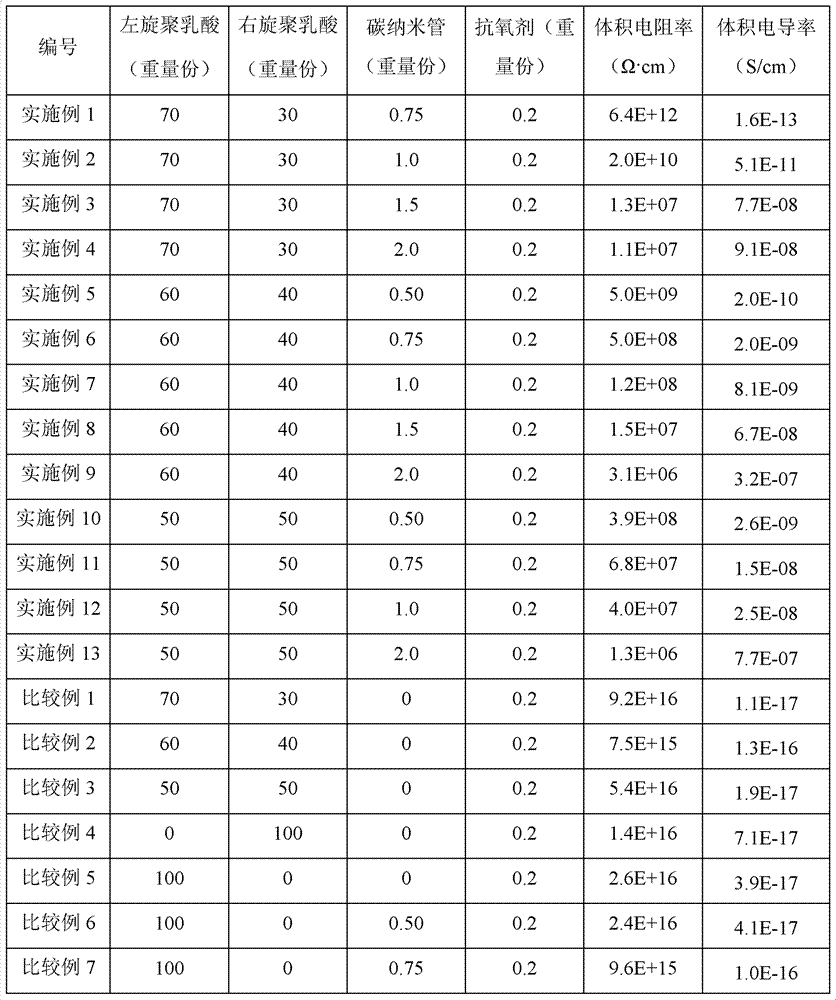

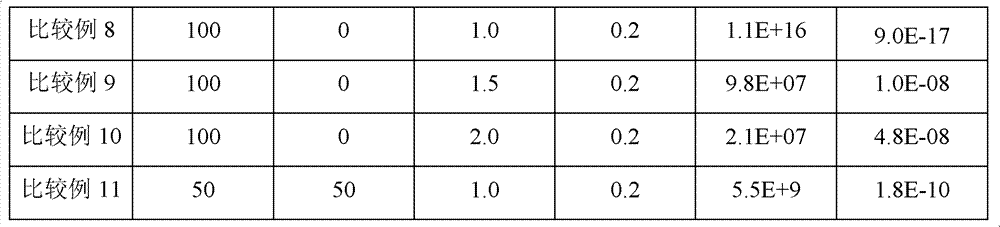

The invention discloses a carbon nanotube / polylactic acid conductive composite material and a preparation method; the conductive composite material comprises the following blended components: levorotatory polylactic acid resin, and dextrorotatory polylactic acid resin, carbon nanotube and an anti-oxidant; the using amount of the carbon nanotube is 0.2-3 parts by weight; the weight ratio of the levorotatory polylactic acid resin and the dextrorotatory polylactic acid resin is (80-50):(20-50). The method comprises the following steps: performing melt blending of the levorotatory polylactic acid resin, the carbon nanotube, and the anti-oxidant according to the using amounts to prepare a master batch, then performing melt blending with the dextrorotatory polylactic acid resin to prepare the carbon nanotube / polylactic acid conductive composite material. The conductive composite material of the invention is added with a few CNTs, and thus the material is provided with good conductivity; the conductive percolation threshold is significantly reduced to 0.5 wt%; the operation process is simple, and is suitable for continuous mass production.

Owner:CHINA PETROLEUM & CHEM CORP +1

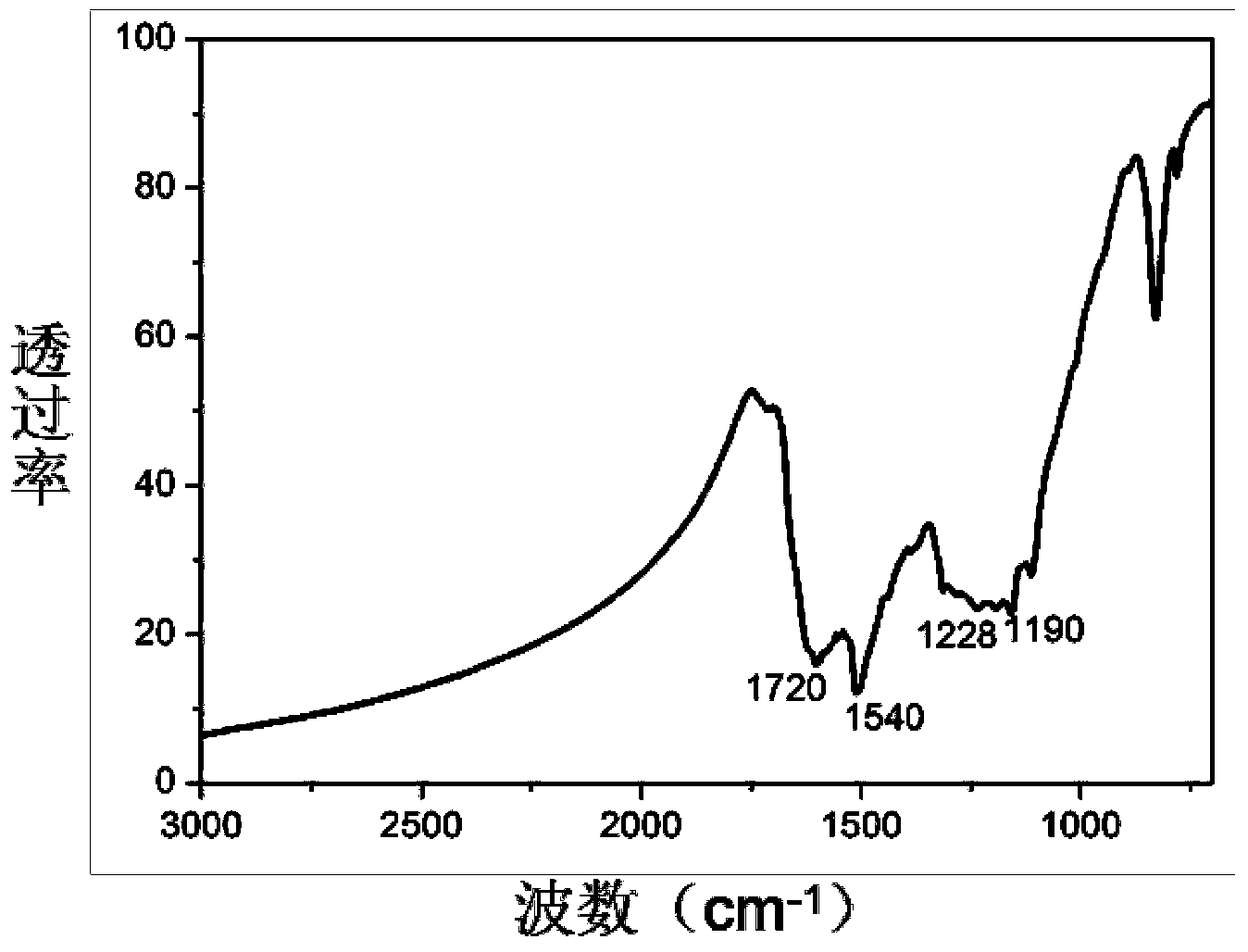

Conductive polyester/graphite oxide composite material and preparation method thereof

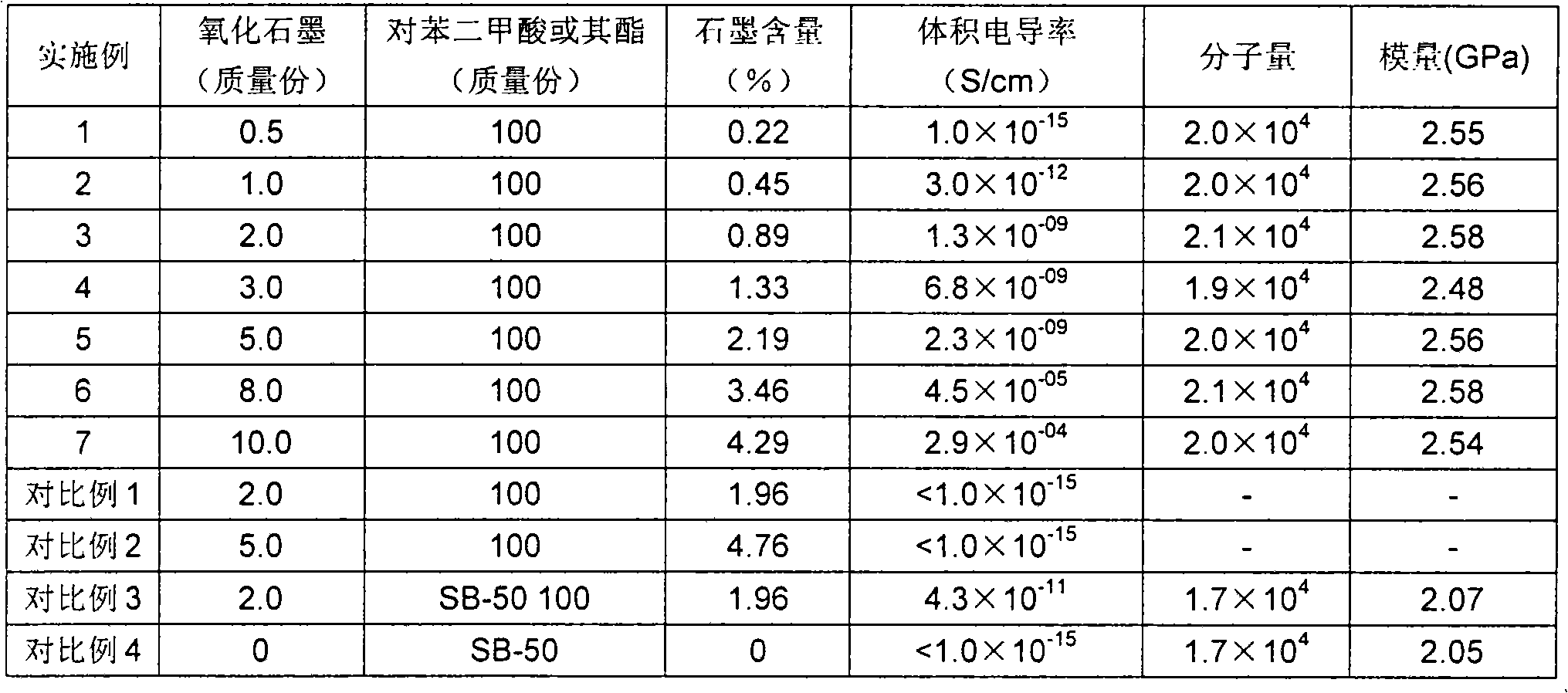

InactiveCN101875718AImprove conductivityReduce the amount of fillerConductive polymerElectromagnetic shielding

The invention discloses a conductive polyester / graphite oxide composite material and a preparation method thereof. The composite material is prepared from the following raw materials in part by mass: 0.25 to 10 parts of graphite oxide, 100 parts of terephthalic acid or ester thereof, 60 to 200 parts of alkaline glycol, 0.01 to 3 parts of catalyst, 0.01 to 0.5 part of stabilizing agent and 0 to 100 parts of dispersant. The polyester / graphite oxide composite material of the invention is prepared by polymerizing a polyester substrate and a nano-graphite packing in situ, has the percolation threshold of 0.5 to 1.0 weight percent, can achieve the electric conductivity of 10 to 5 S / cm when graphite content is 3.5 weight percent, and compared with a conventional natural graphite conductive composite material and an expanded graphite conductive composite material, can achieve the high properties of low packing amount and high electric conductivity without adding an auxiliary substrate, and can be widely applied in the fields of conductive materials, antistatic materials, electromagnetic shielding materials, microwave absorption and the like.

Owner:TORAY IND INC

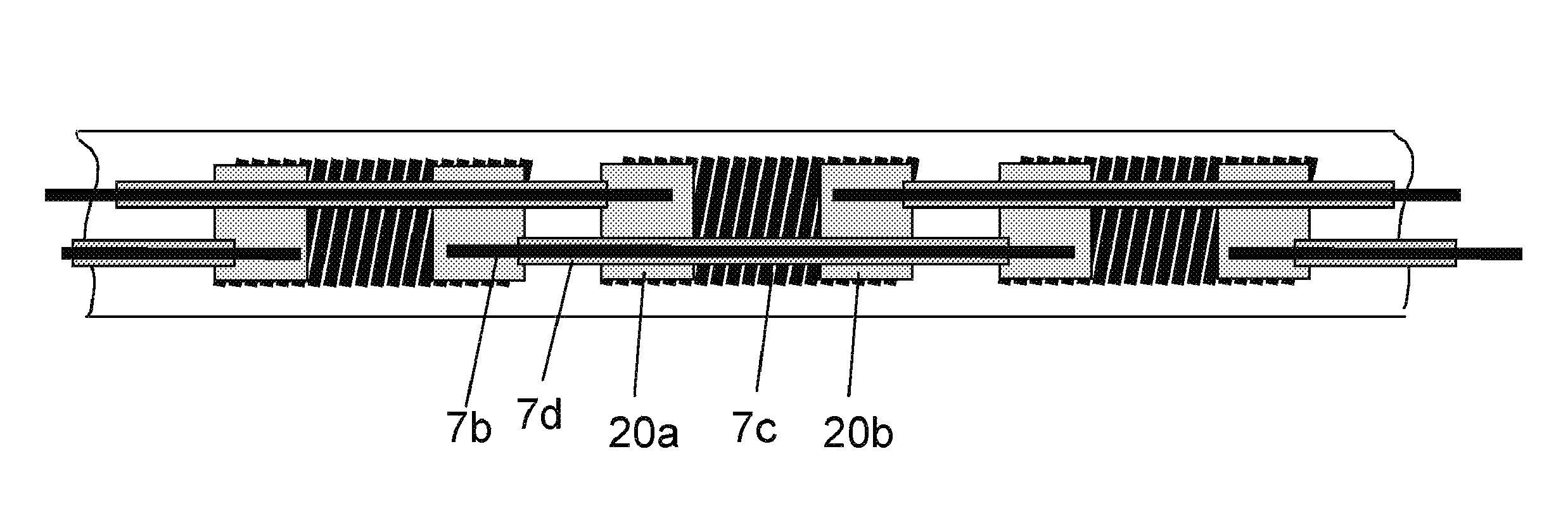

Electrode catheter for interventional use

InactiveUS8386057B2Simple and materialDeterioration of propertyTransvascular endocardial electrodesExternal electrodesCardiac pacemaker electrodeCardiac pacemaker

Owner:BIOTRONIK SE & CO KG

High conductive polyamide/graphite nano conductive composite material and preparation method thereof

InactiveCN101081926AAdvanced technologySimple processNon-conductive material with dispersed conductive materialPolyamideElectromagnetic shielding

The present invention discloses nanometer conducting polyamide / graphite composite material and its preparation process. The nanometer conducting polyamide / graphite composite material is prepared through the following steps: soaking 30-200 mesh natural scale graphite powder in mixed liquid of concentrated sulfuric acid and concentrated nitric acid in the weight ratio of 4 to 1 for 24 hr, water washing, drying and heating at 900-1100 deg.c in a muffle furnace to obtain expandable graphite of expansion ratio over 200; dissolving polyamide resin in 90-99 weight portions in some solvent, adding the expandable graphite in 1-10 weight portions, ultrasonically dispersing for 2 hr, adding precipitant while stirring, suction filtering the precipitate and drying to obtain the composite material. The composite material with relatively low percolation threshold and high conductivity may be applied as antistatic material, electromagnetic shielding material, etc.

Owner:扬州利贞复合材料有限公司

Composite medium film material based on polyvinylidene fluoride and graphene, and preparation method thereof

InactiveCN102729562AStay flexibleEasy to processSynthetic resin layered productsComposite mediaPolyvinylidene difluoride

The invention which discloses a composite medium film material based on polyvinylidene fluoride and graphene, and a preparation method thereof belongs to the technical field of electric functional materials. The composite medium film is obtained through compounding polyvinylidene fluoride and graphene, wherein the graphene mass percent content is 0.5-3% of the mass of the composite medium film. The preparation method comprises the following steps: preparing an organic solution (a system A) of polyvinylidene fluoride powder; adding graphene powder to the system A to obtain a system B; spraying the system B on the surface of a substrate through adopting an ultrasonic atomization technology; and drying the system B sprayed on the surface of the substrate to obtain the composite medium film material based on the polyvinylidene fluoride and the graphene. According to the invention, the graphene which approaches and does not exceed a percolation threshold is added to a polyvinylidene fluoride film to obtain the composite medium film material with the dielectric constant 100% higher than that of the pure polyvinylidene fluoride film material, and the original flexibility and the easy processability are maintained; and the preparation method has the advantages of simplicity, easy control and low cost.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

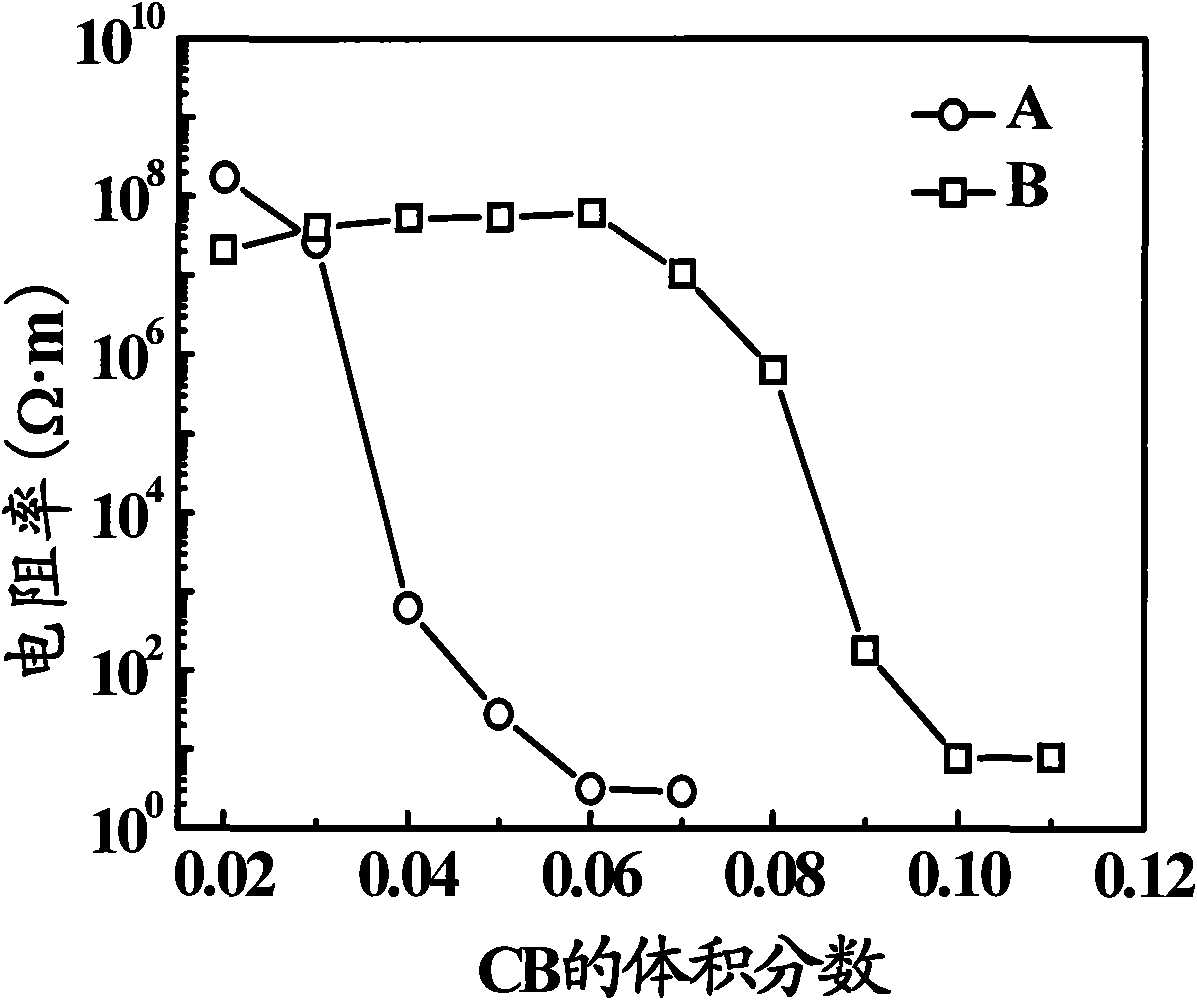

Polymer based temperature-sensitive resistance material with negative temperature coefficient (NTC) effect and preparation method thereof

ActiveCN104497394AImprove electrical performanceLow percolation valueElectrical resistance and conductanceManufacturing technology

The invention belongs to the technical field of manufacturing of conductive polymer composites, and in particular relates to a preparation method of a conductive polymer composite with negative temperature coefficient (NTC) characteristics. The invention discloses a polymer based temperature-sensitive resistance material with a NTC effect, and the polymer based temperature-sensitive resistance material comprises the following raw materials in parts by weight: 88.5-96.9 parts of a polymer 1 and a polymer 2, 0.1-1.5 parts of a conductive filler and 3-10 parts of a compatilizer; moreover, the conductive filler is selectively distributed in the polymer 2; the MFI of the polymer 1 is less than or equal to 7g / 10 minutes, and the MFI of the polymer 2 is more than or equal to 12g / 10 minutes; the thermal expansion coefficient of the polymer 2 is greater than that of the polymer 1, and the conductive filler is a two-dimensional conductive filler; and the mass ratio of the polymer 1 to the polymer 2 is (3:7)-(7:3). The resistance material prepared by the method disclosed by the invention is low in percolation threshold, the NTC characteristic repeatability of the obtained resistance material is good, and the resistance material is convenient to use for a long time.

Owner:ZHENGZHOU UNIV

Conductive polymer composite and preparation method thereof

ActiveCN103113732ALower Conductive Percolation ThresholdEasy to prepareNon-conductive material with dispersed conductive materialConductive polymer compositePolyethylene terephthalate glycol

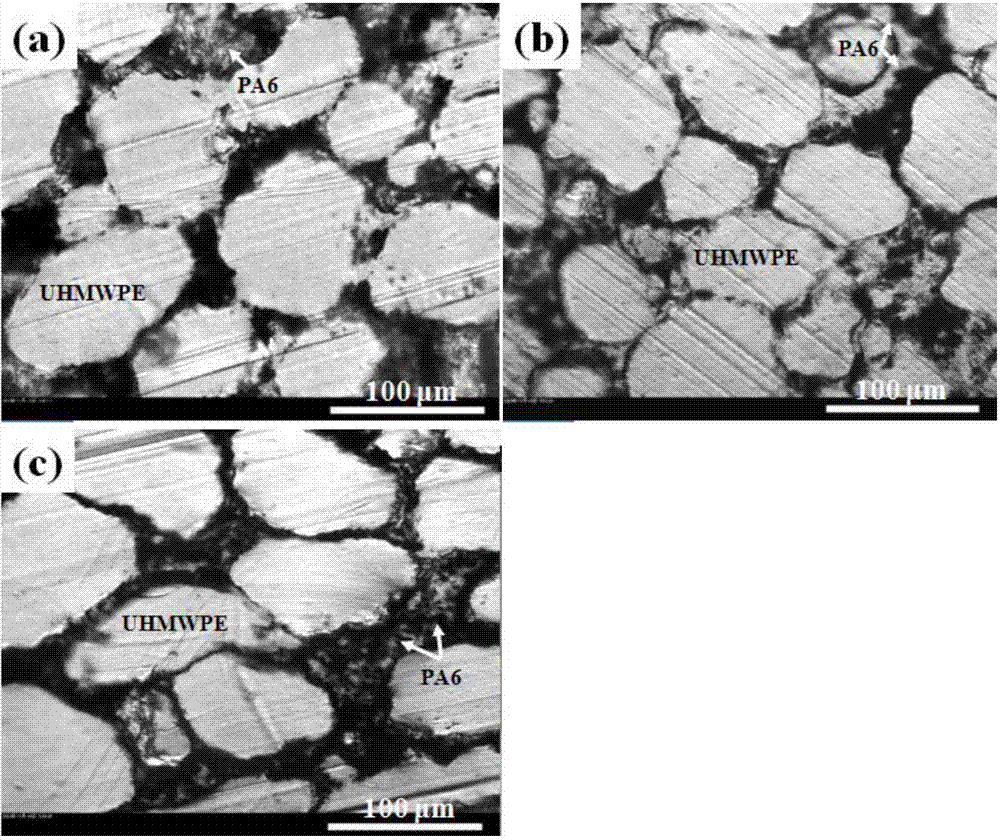

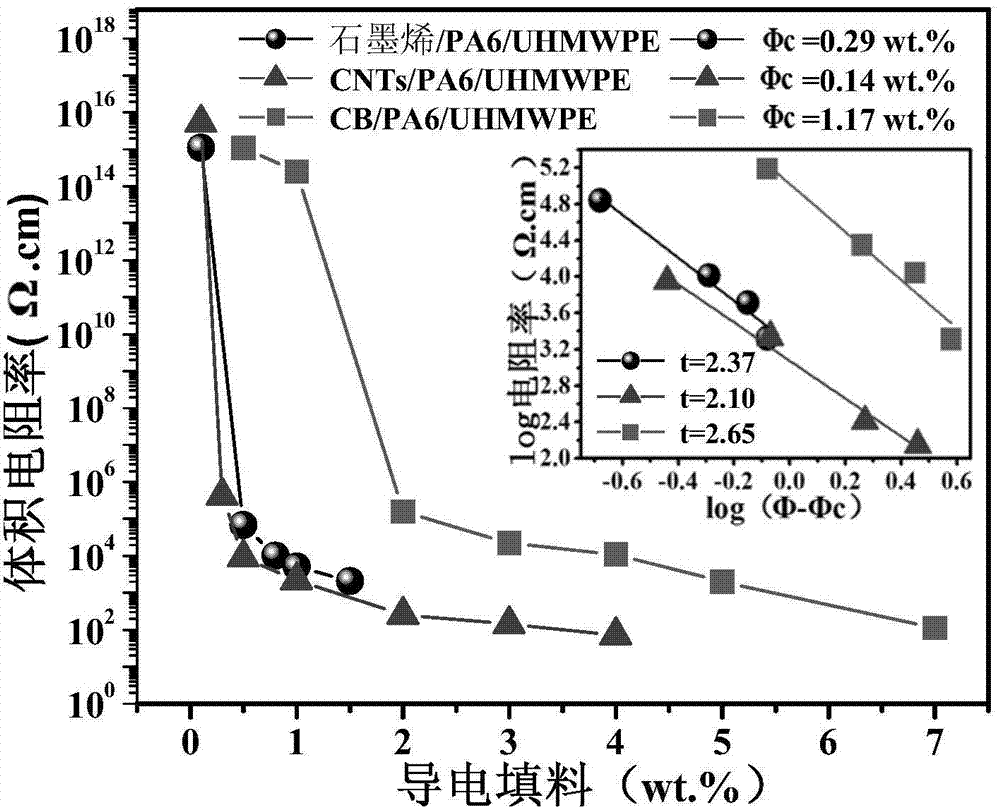

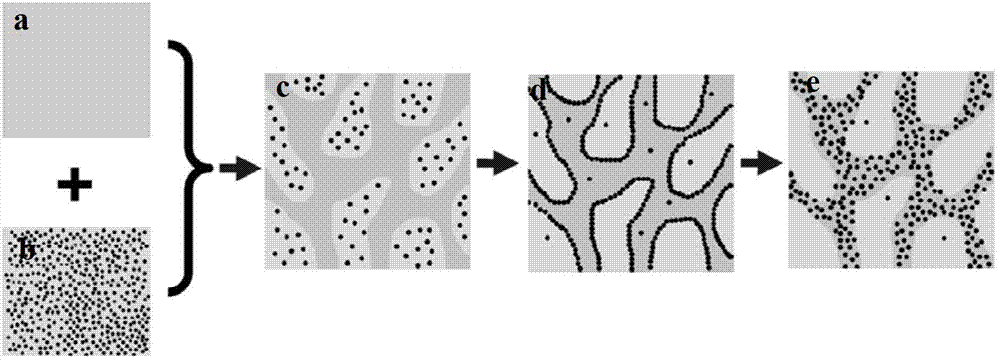

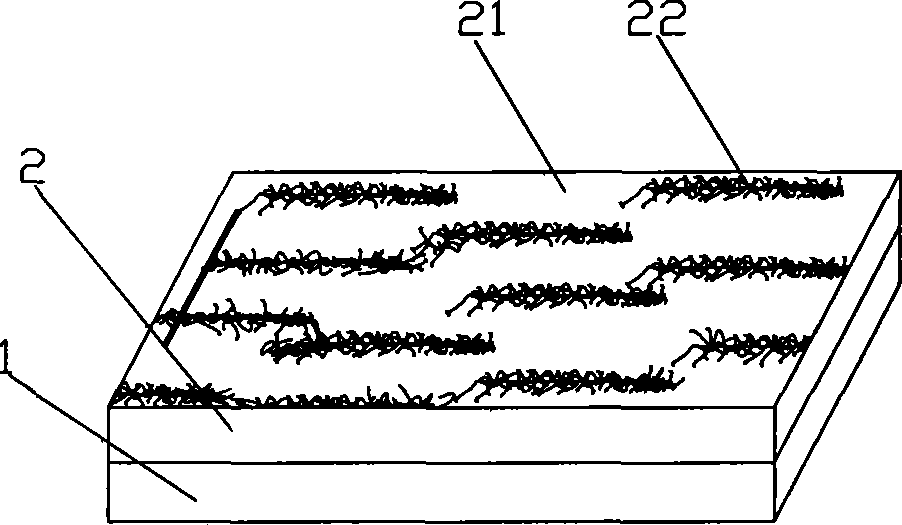

The invention provides a conductive polymer composite and a preparation method thereof. The conductive polymer composite comprises 100 parts by weight of matrix and 0.01-1.5 parts by weight of conductive nanofiller, wherein the matrix is an incompatible polymer blend system with dual-continuous structure, and the length-diameter ratio of the conductive nanofiller is greater than or equal to 100. Compared with a conductive fibering polymer composite prepared from carbon black, polyethylene and polyethylene terephthalate in the prior art, the conductive polymer composite has the advantages that firstly, the length-diameter ratio of the conductive nanofiller adopted in the conductive polymer composite is larger, so that the insulated polymer can conduct electricity by few addition of the conductive nanofiller, thus the conductive percolation threshold of the conductive polymer composite is reduced; secondly, the matrix of the dual-continuous structure and the conductive polymer nanofiller are distributed on a two-phase interface of the incompatible polymer blend system with the dual-continuous structure, so that the conductive percolation threshold of the conductive polymer composite is reduced; and finally, the preparation method provided by the invention is simple, safe and environment-friendly.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

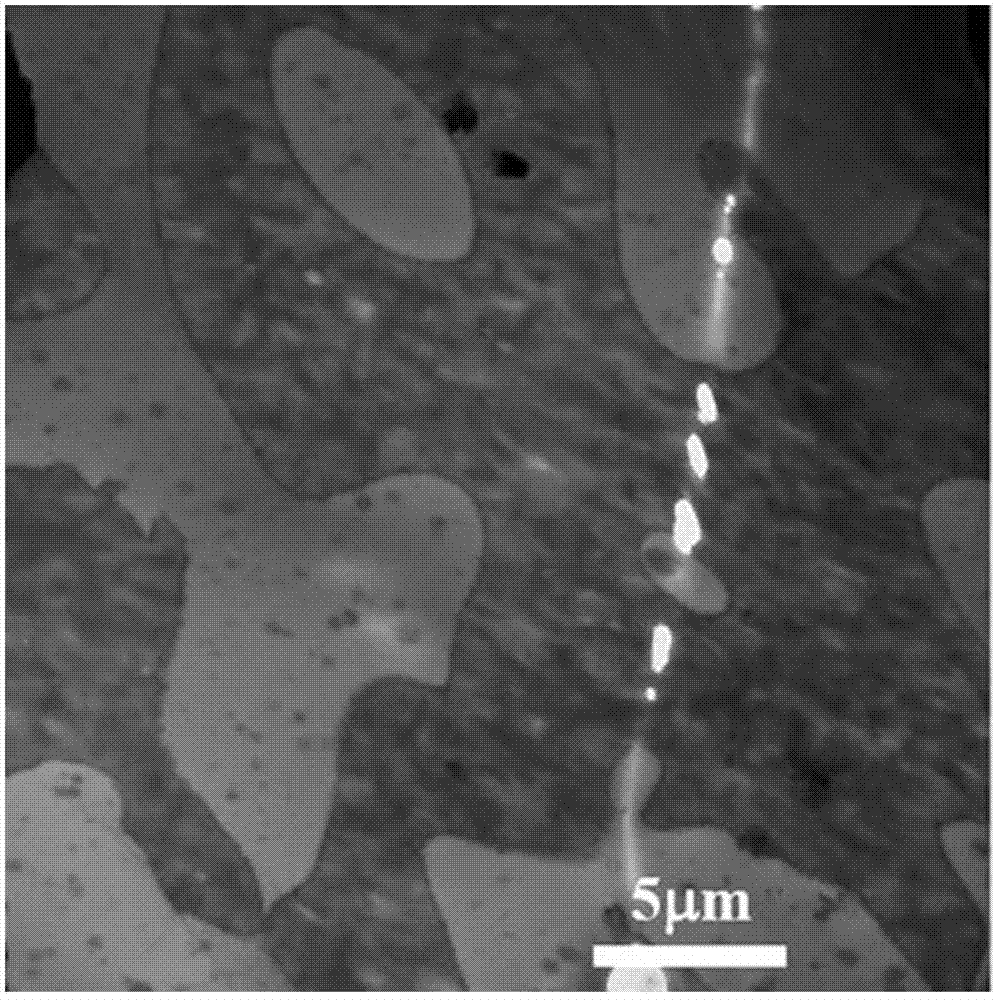

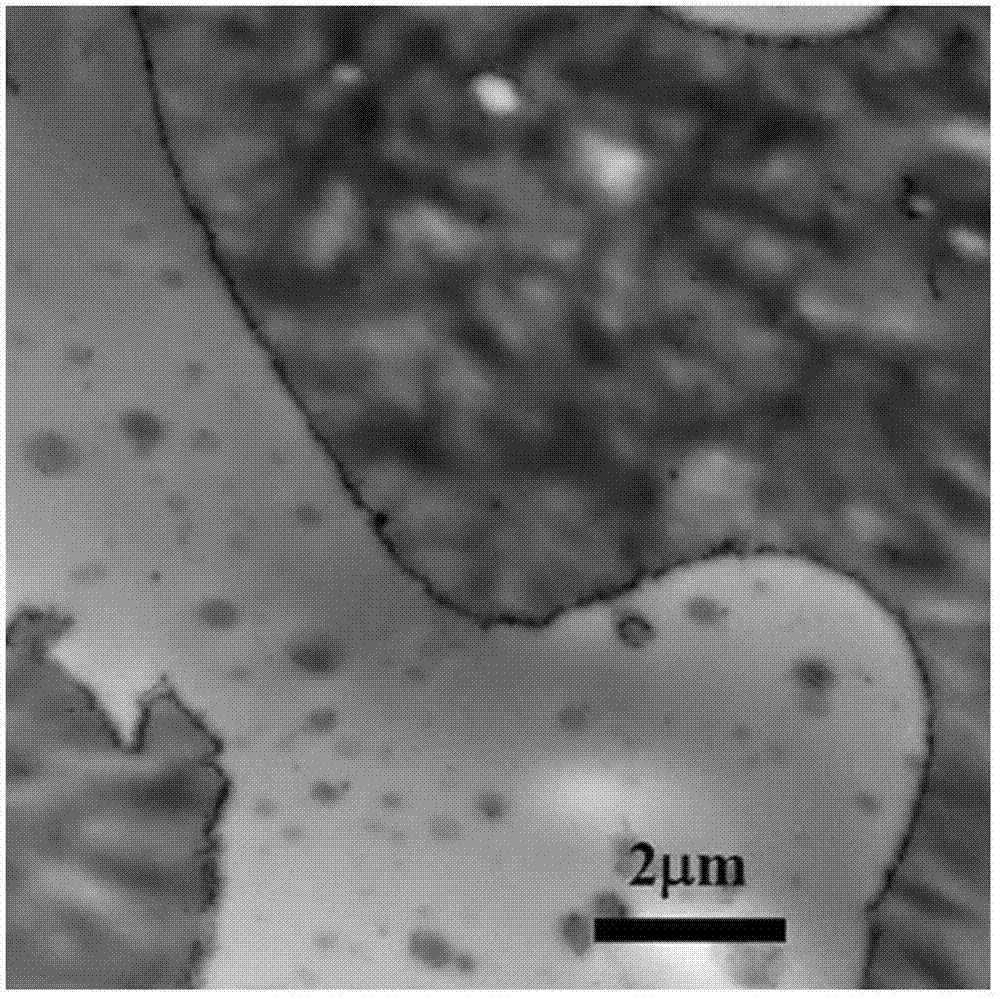

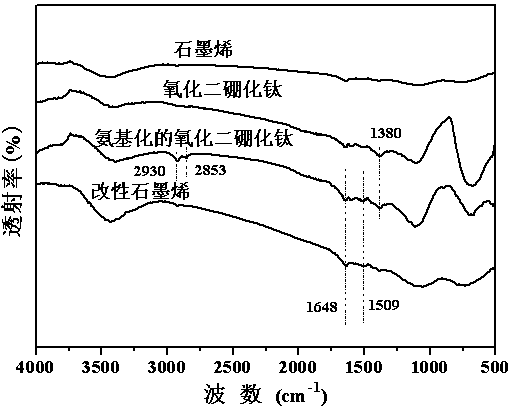

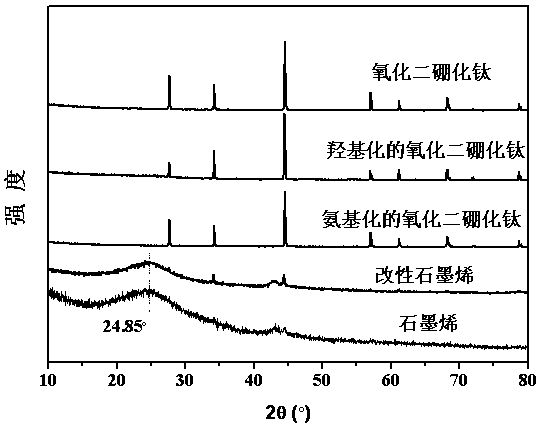

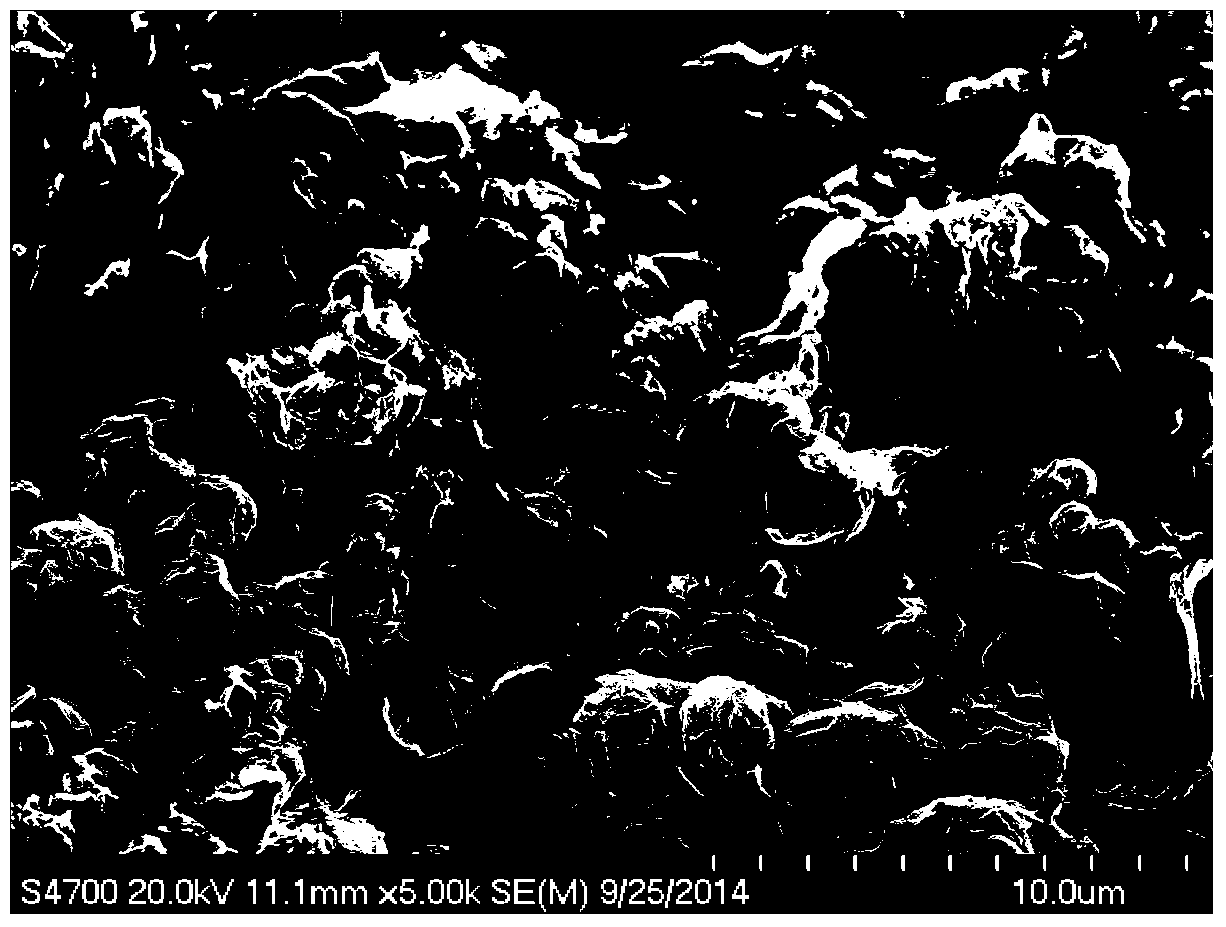

Modified graphene/thermosetting resin composite material and preparation method thereof

The invention relates to a modified graphene / thermosetting resin composite material and a preparation method thereof. The method comprises the steps of dispersing graphite oxide into N, N-dimethylformamide, adding titanium diboride oxide subjected to amination, filtering, washing and drying reactants to obtain modified graphene; curing modified graphene and molten heat-curable resin to obtain the modified graphene / thermosetting resin composite material. The composite material has the advantages of high dielectric constant, low dielectric loss and low percolation threshold value; moreover, the control of the dielectric properties of the composite material can be realized by regulating the changes of the content of graphene surface-coated titanium diboride. The preparation method of the composite material, provided by the invention, has the characteristics of simple process, low cost, wide applicability and the like.

Owner:SUZHOU UNIV

Polymeric Strain Sensor

InactiveUS20080191177A1Easy to manufactureEasy to useConductive materialForce measurementPolymer scienceNanoparticle

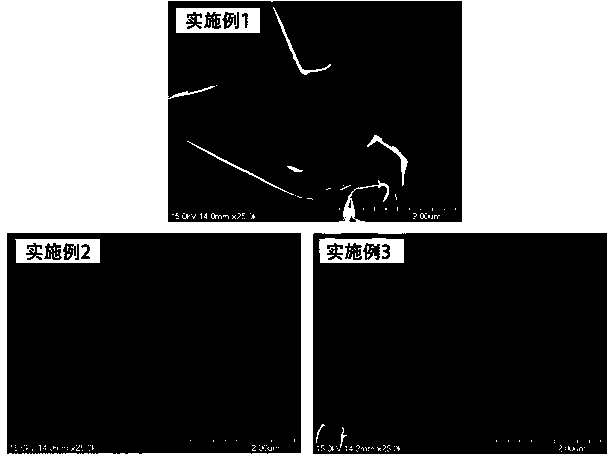

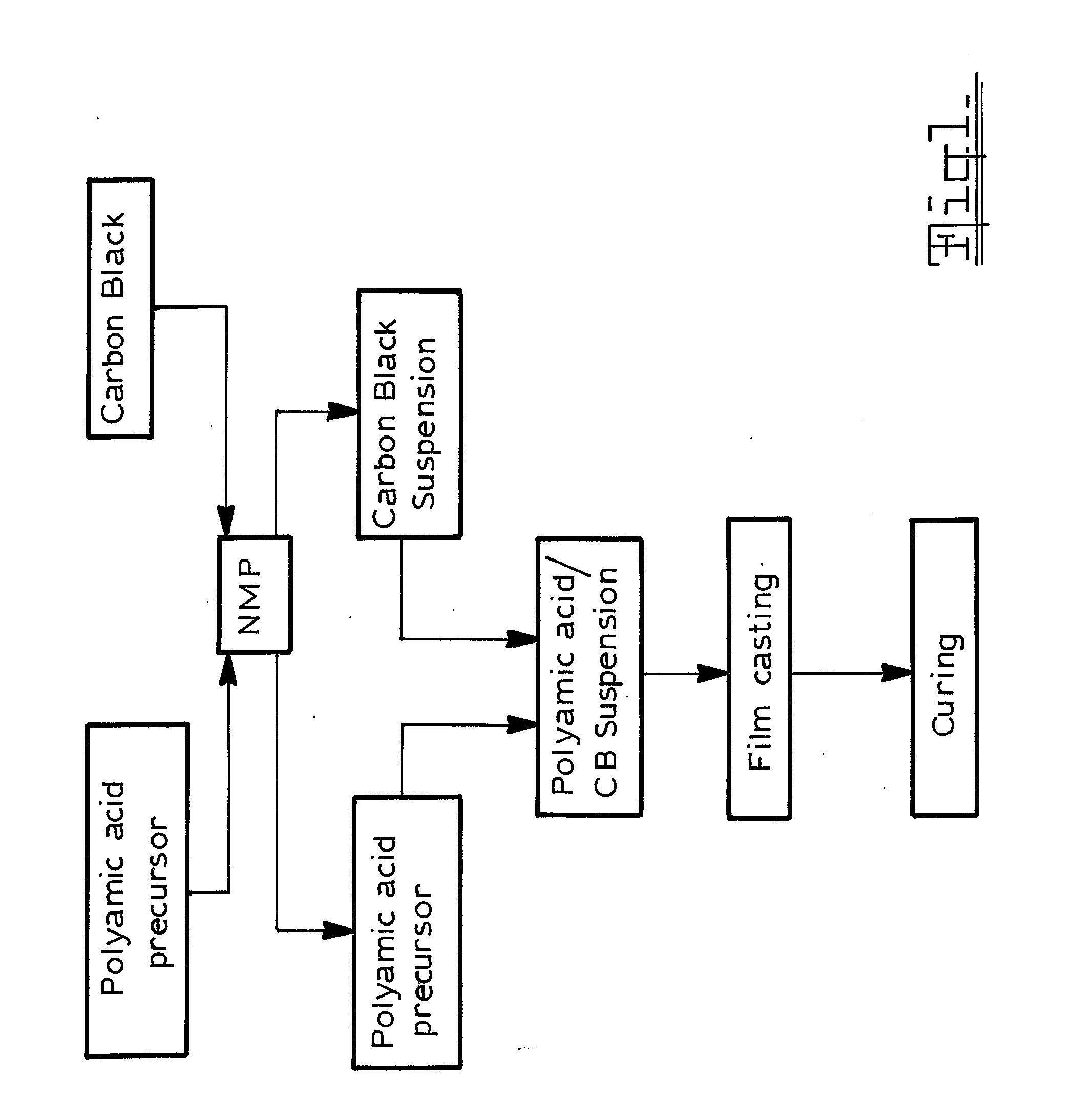

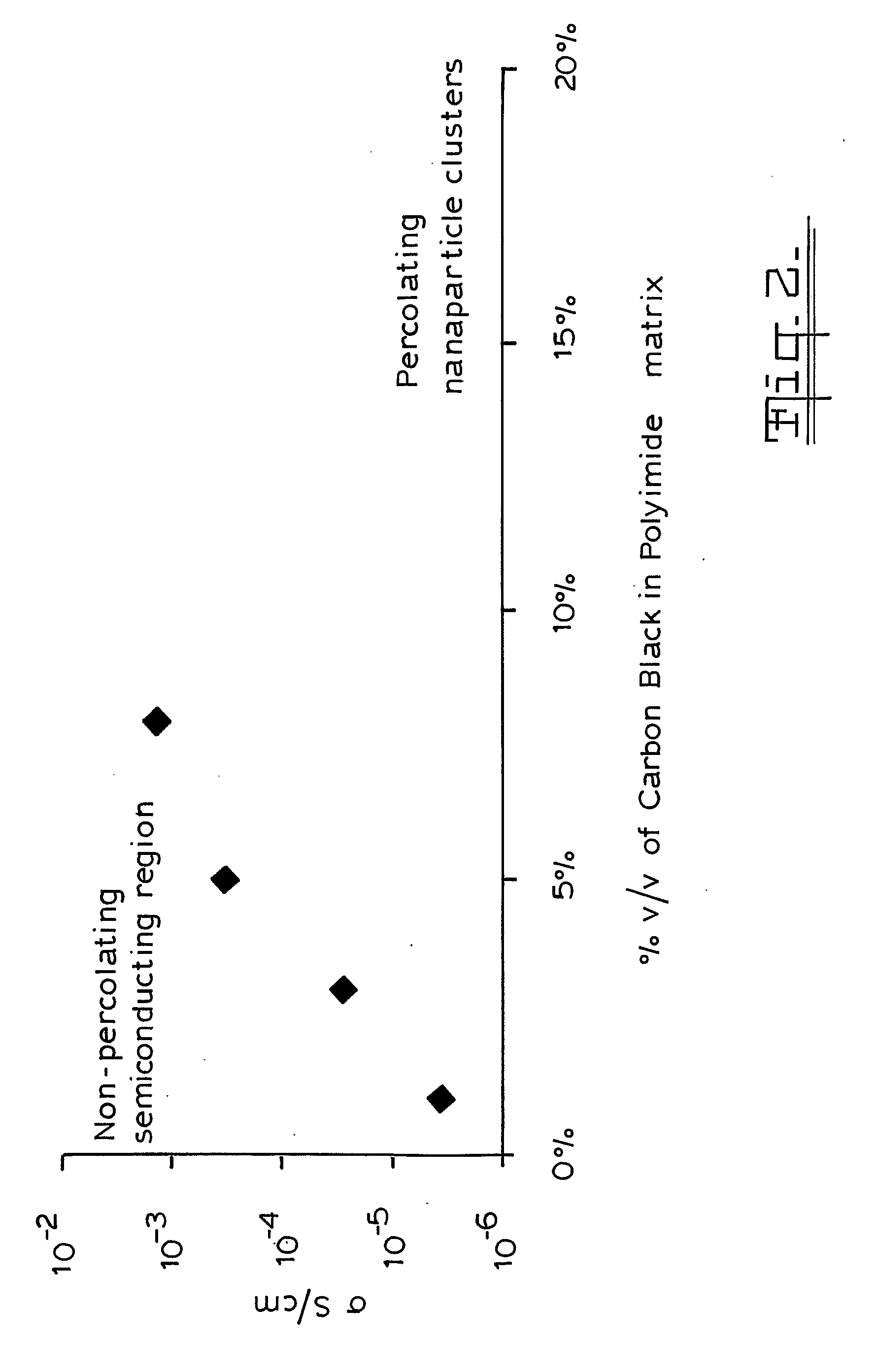

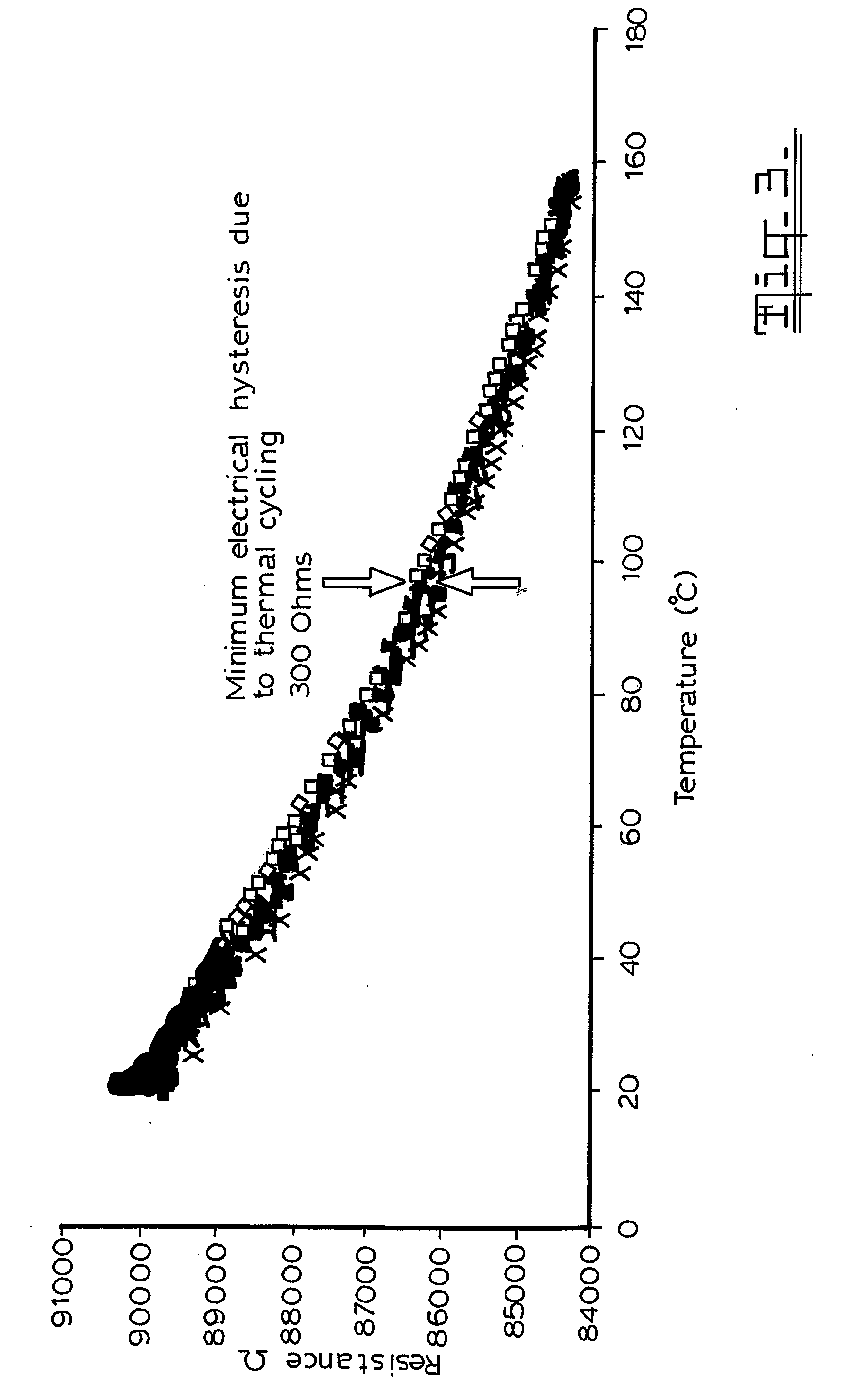

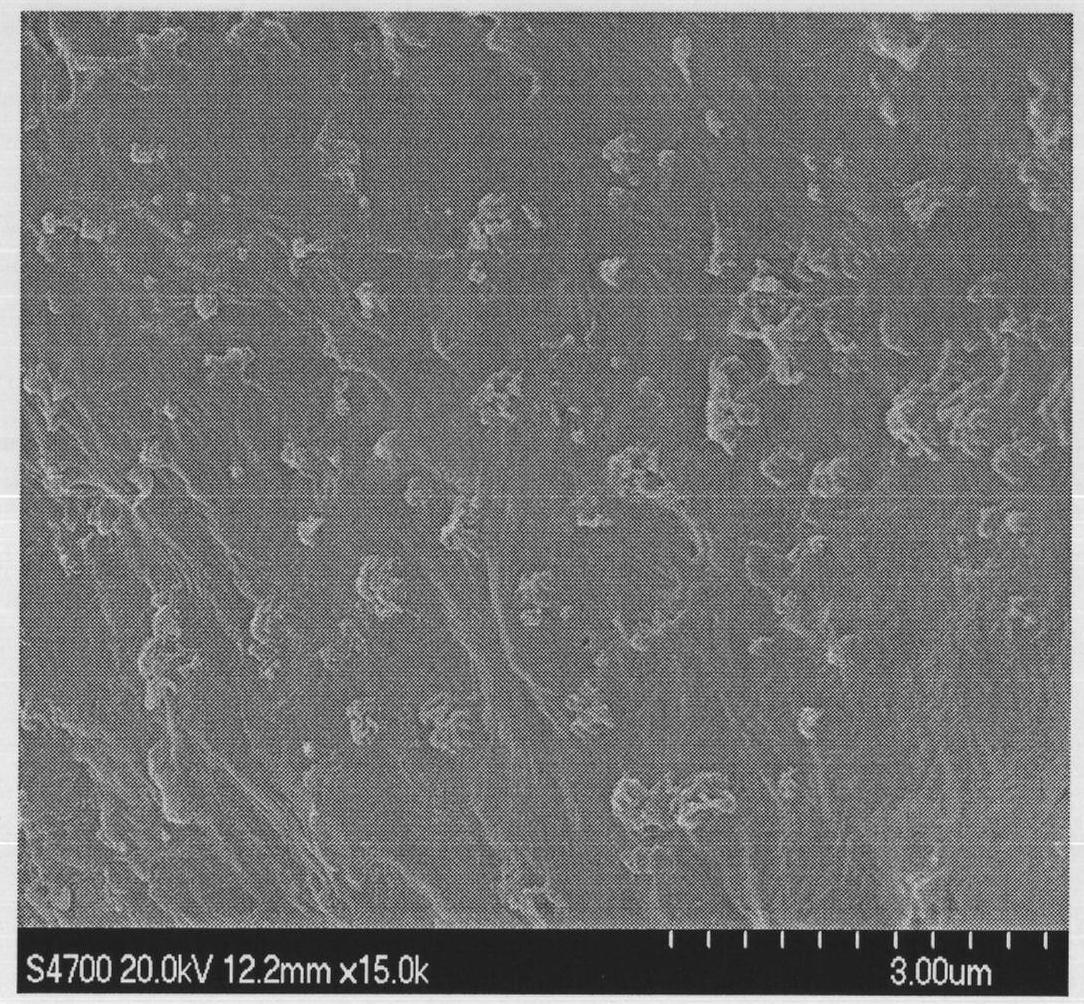

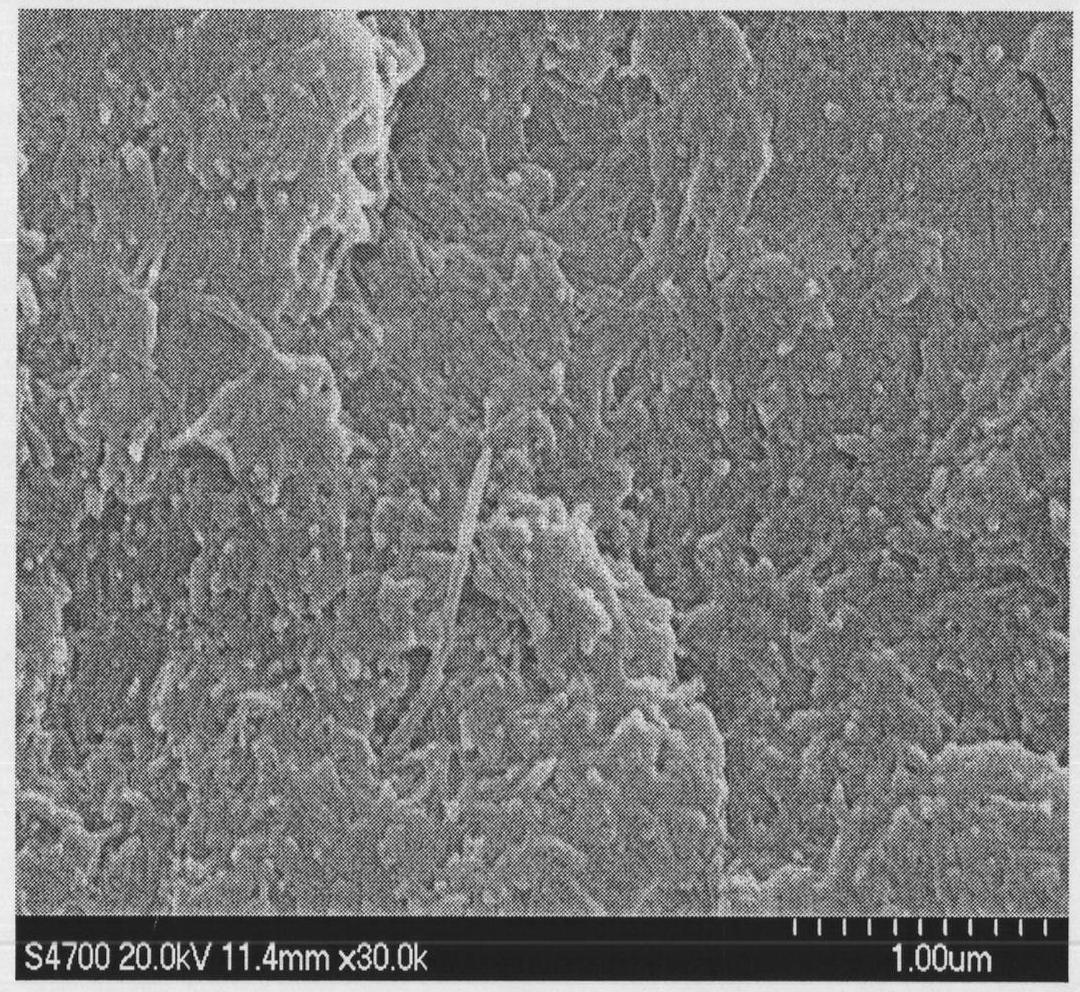

A strain sensor consisting of a non conducting polymer incorporating conductive nanoparticles below the percolation threshold and preferably less than 10% v / v of the polymer. The polymer is a polyimide and the conducting nanoparticle is carbon black having an average particle size of 30-40 nm and an aggregate size of 100-200 nm. The sensor can sense strain in extension, compression and torsion.

Owner:ROYAL MELBOURNE INST OF TECH

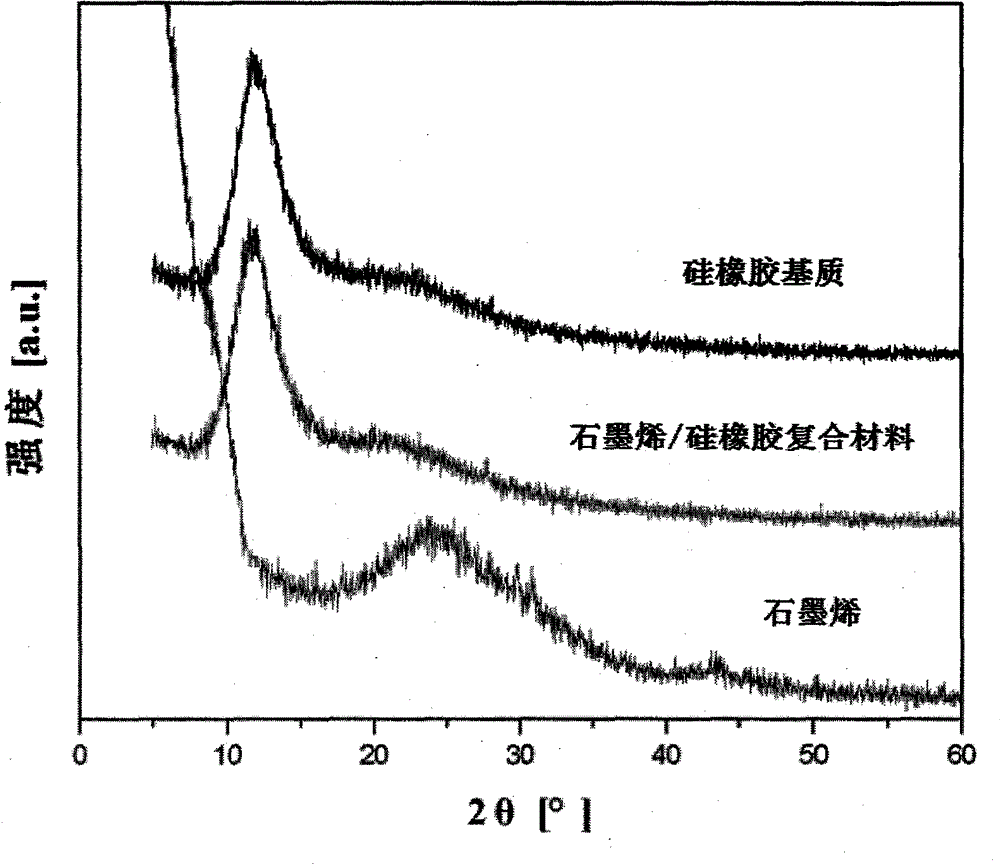

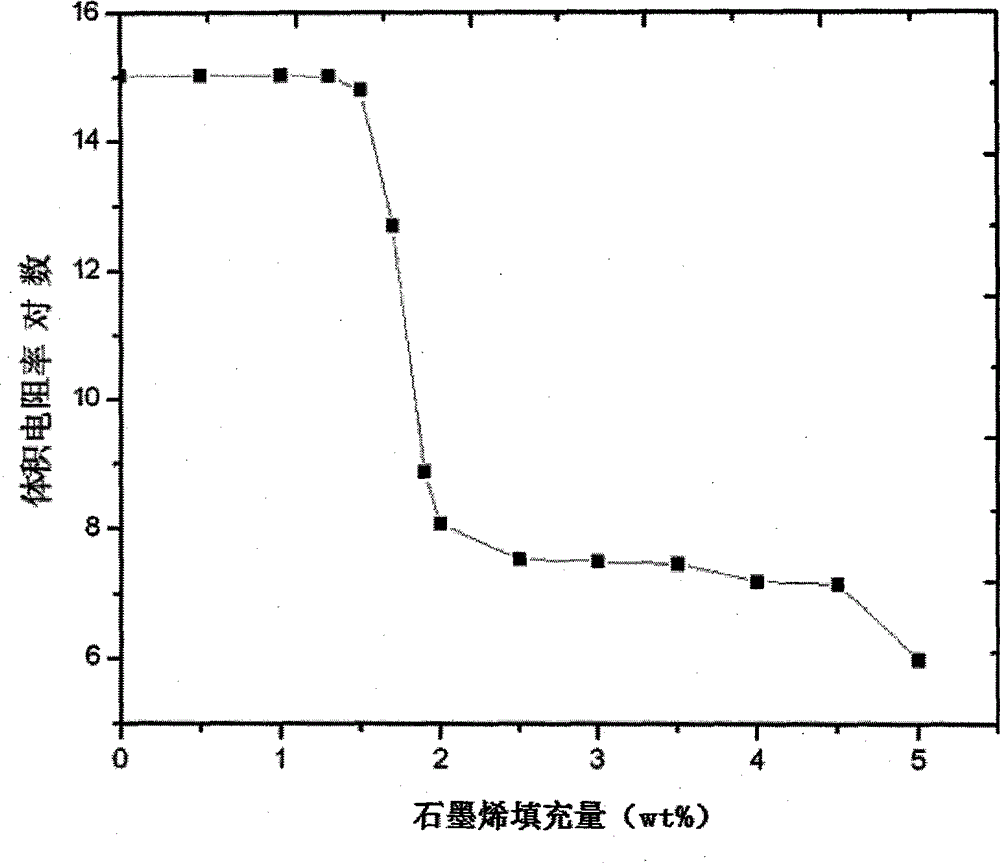

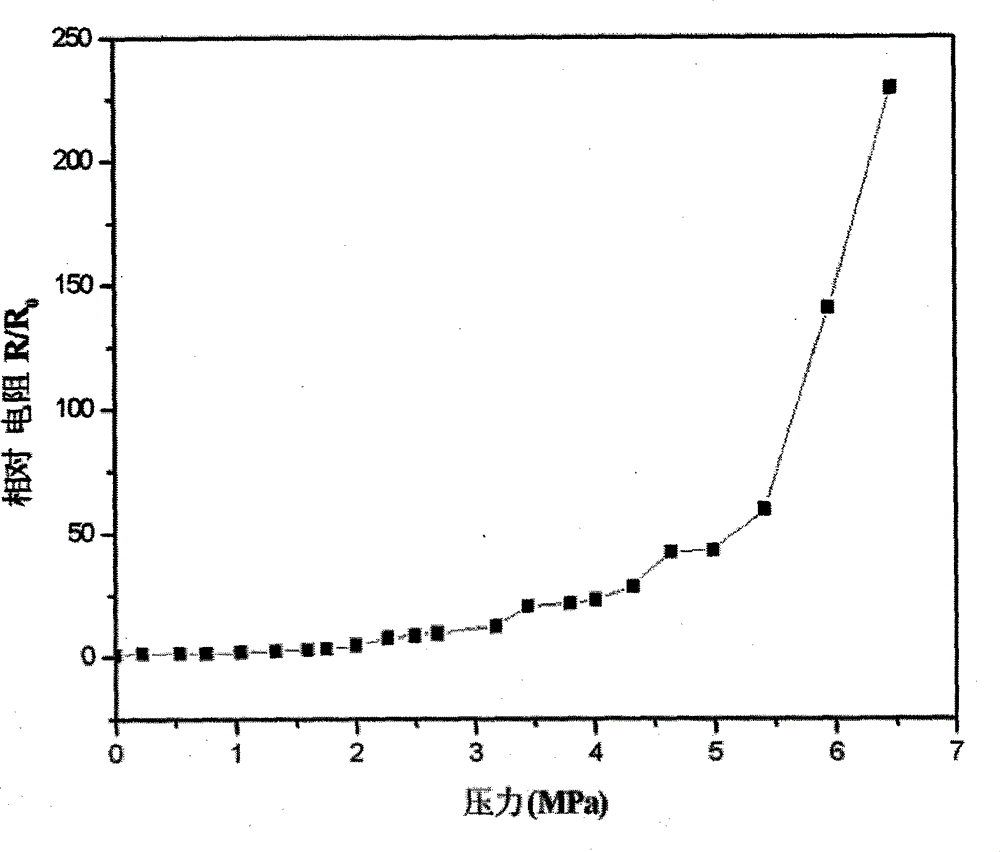

Preparation method of graphene/silicon rubber pressure-sensitive conductive composite

The invention relates to a preparation method of a graphene / silicon rubber pressure-sensitive conductive composite and belongs to the technical field of composite preparation. The preparation method comprises the following steps: dispersing the graphene used as a packing into a silicon rubber matrix by using an ultrasonic-assisted solution mixing method, and furthermore, preparing the graphene / silicon rubber pressure-sensitive conductive composite by using a high-temperature sulphidization method. The graphene has a high diameter-thickness ratio, and a conductive network can be formed in silicon rubber by using a relatively small quantity of graphene through the ultrasonic-assisted solution mixing and high-temperature sulphidization methods, so that the percolation threshold of the graphene / silicon rubber composite is relatively low; in addition, the system is sensitive to pressure so as to achieve a remarkable positive piezoresistive effect. The composite provided by the invention is widely applied to the fields of antistatic rubber, electromagnetic shielding products and pressure sensors.

Owner:TAISHAN MEDICAL UNIV

High-sensitivity pressure conduction sensor for localized pressures and stresses

ActiveUS20050081640A1Accurate measurementInexpensive and scalable in and formForce measurementMaterial strength using tensile/compressive forcesElectricityControl system

A high-sensitivity pressure conduction sensor is presented. The present invention includes a pair of locally resilient conductive layers and a locally resilient pressure conduction composite disposed between and contacting both conductive layers. Alternate embodiments include at least three locally resilient conductive layers and at least two locally resilient pressure conduction composites, each having a critical percolation threshold. Each composite is disposed between and contacting two conductive layers in a multi-layer fashion. Other embodiments include a locally resilient pressure conduction composite, a flexible substrate completely surrounding the composite so as to seal it therein, and a pair of electrical leads contacting the composite and terminating outside of the flexible substrate. Pressure conduction composites are composed of a plurality of conductive particles electrically isolated within a non-conductive matrix. Conductive particles are loaded so as to have a volume fraction approaching the critical percolation threshold of the material system and exhibit a conductance that greatly increases with pressure. Sensors may be arranged to form one or more arrays including planar and conformal configurations. The present invention has immediate application in keyboards, intrusion systems, control systems, submarines, ships, sonobuoys, doors, and switches.

Owner:QORTEK

Conductive and antistatic nylon

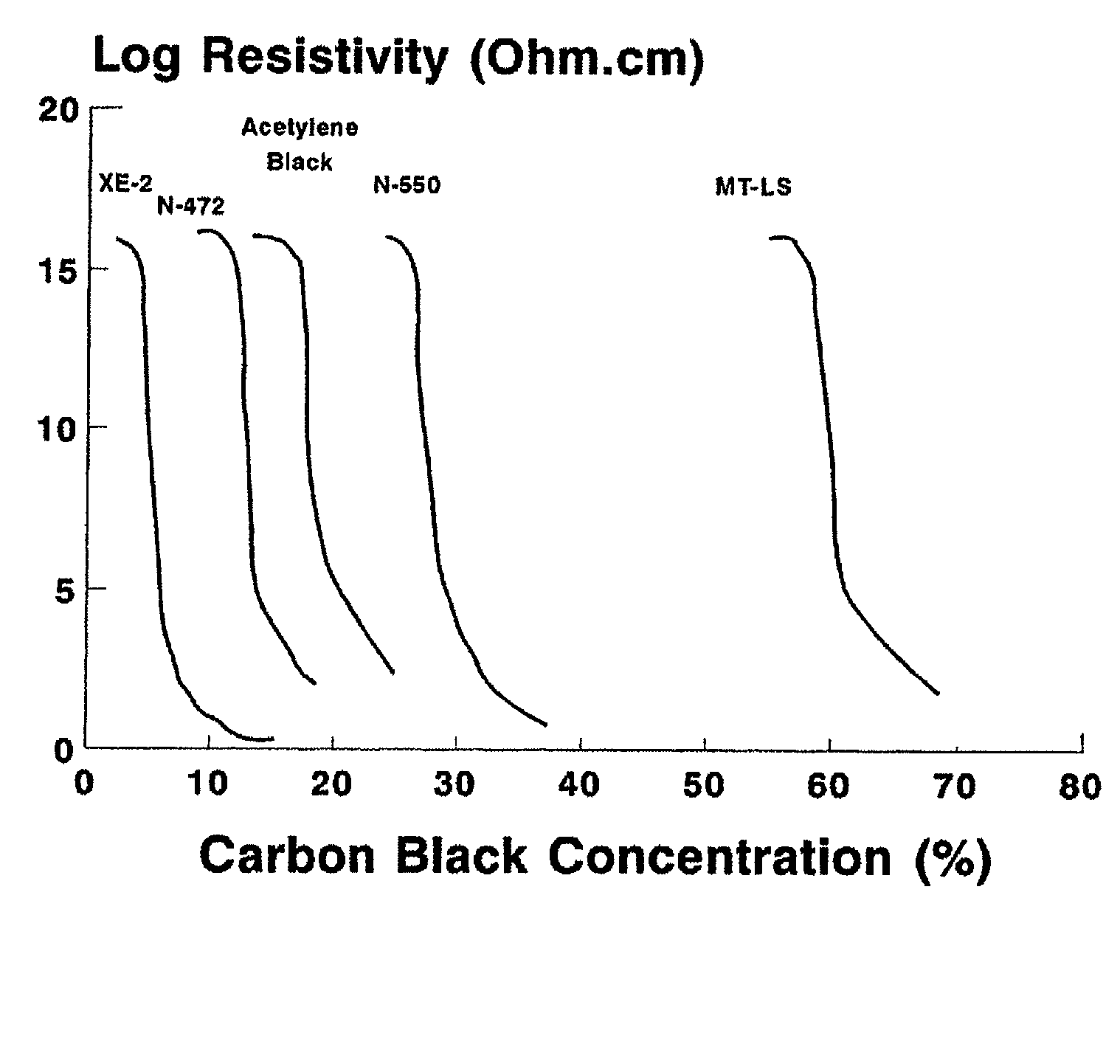

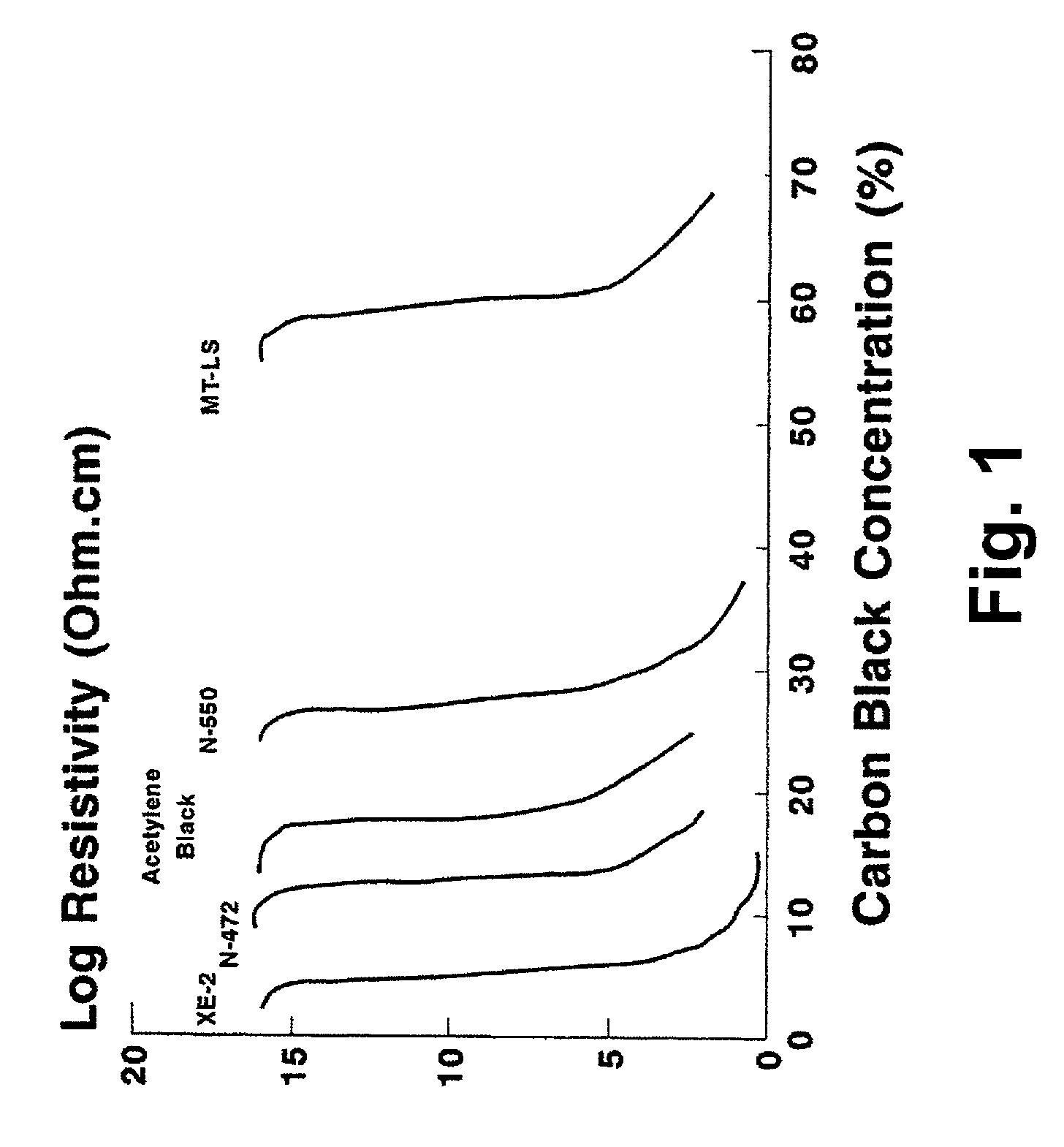

The invention discloses a conductive and antistatic nylon which adopts polyamide resin as basic material and adds nano inorganic filling material, conductive carbon black, a lubricating agent, a surface processing agent and an antioxidant and the like; the part by weight ratio of all the components is as follows: 60 parts to 98 parts of polyamide resin, 1 part to 15 parts of nano inorganic filling material, 5 parts to 30 parts of conductive carbon black, 0.1 part to 1.0 part of lubricating agent, 0.1 part to 1.0 part of surface processing agent and 0.1 part to 0.5 part of antioxidant; the invention adds the conductive carbon black in the polyamide resin to improve the conductive effect of the material, reduces the using amount of the carbon black under the premise of guaranteeing the same conductivity and antistatic electricity and effectively improves the cost performance of the material, effectively improves the dispersion of the carbon black, and reduces the 'percolation threshold' of plastic; and the nano material is added into the nylon and has the effect of a nucleating agent, which has obvious strengthening and toughening effects to matrix resin and improves the comprehensive performance of the product.

Owner:GUANGDONG HIGH & NEW ENG PLASTICS

Polyamide composition containing electrically conductive carbon

ActiveUS20130240799A1Maintain good propertiesImprove mechanical propertiesNon-metal conductorsConductive materialEnd-groupCarbon nanotube

A polyamide composition which provides moldings having a significantly reduced percolation threshold and an improved electrical conductivity is provided. The composition contains a) at least 40 parts by weight of a polyamide; b) from 0.15 to 25 parts by weight of an electrically conductive carbon; c) from 0.3 to 8 parts by weight of an oligofunctional compound; and, optionally, d) conventional auxiliaries and additives, wherein the electrically conductive carbon comprises at least one of carbon nanotubes and graphene, the oligofunctional compound comprises at least one functional group reactive with reactive groups on a surface of the electrically conductive carbon and at least one functional group reactive with an end group of the polyamide, and the sum of the parts by weight of the components a) to d) is 100.

Owner:EVONIK OPERATIONS GMBH

Bisymmetrical electric paper and a system therefor

The presently described embodiments provide electric paper, in one form, that is bisymmetrical, both sides of the paper have the same thicknesses of mylar layers and the same thicknesses and patterns of ITO islands. In another form, a disordered layer of conductive particles, non-conductive particles and display elements has the same percolation threshold throughout, and thus is bisymmetrical. In either form, in a system for printing all asymmetries in the printing process are transferred to the printhead, just like in conventional ink printers and paper. As a result, both sides of the electric paper are equally capable of being printed on, just like conventional paper, and the electric paper has the same flexural properties when flexed in a concave or convex manner, just like conventional paper. This construction has the additional practical advantage that there is no longer any need to ensure the electric paper is oriented “right side up” before printing on it. These improvements all make electric paper more paper-like in feel and use.

Owner:PALO ALTO RES CENTE

Polymer matrix composite material with high PTC strength and stability and preparation method thereof

The invention discloses a polymer matrix composite material with high PTC strength and stability and a preparation method thereof, and the composite material comprises UHMWPE and PVDF, CB and MWNT conductive filling materials which are treated by surface treatment by a titanate coupling agent, and an antioxidant 1010; the preparation method comprises the following steps: performing surface treatment of the CB and MWNT conductive filling materials by the titanate coupling agent, performing vacuum drying of PVDF and UHMWPE with a volume ratio of 1:1, adding PVDF into a torque rheometer, heating and melting for 2 min, adding another matrix of UHMWPE and the antioxidant 1010, wherein the amount of the antioxidant 1010 is 1% of the total mass of the matrix; mixing the mixture of the two matrixes for 10 min, adding the filling materials, mixing at 250 DEG C for 15 min; after melt blending, performing hot pressing with a constant temperature of 250 DEG C and a constant pressure of 18 MPa for 10 min to obtain the sample. The composite material of the invention has good conductivity and low room-temperature conductivity, and has a conductivity of up to 10-1 near a percolation threshold; the conductivity of the composite material can be changed by adjusting the contents of the filling materials in the composite material; the composite material has high PTC strength, good repetition stability, and reduced NTC effect.

Owner:BEIJING UNIV OF CHEM TECH

Conductive composite material, preparation and use thereof

ActiveCN101488373ALower percolation thresholdImprove mechanical propertiesNon-conductive material with dispersed conductive materialState of artFiber

The invention discloses a conductive composite material and a manufacturing method and an application thereof, comprising a second polymer and the conductive composite which is combined with the second polymer and is provided with continuous phase, the conductive composite is composed of a first polymer and conductive filler which is contained in the first polymer and forms a conductive network, fusion temperature of the second polymer is higher than the fusion temperature of the first polymer, the invention adopts the manufacturing methods of stretching and heat treatment, so that the conductive composite material has relatively low percolation threshold after processing and forming, in addition, in the process of the processing, the conductive composite material can still maintain most of the mechanical properties after the heat treatment at relatively high temperature, thus ensuring that the whole material has fine conductivity and mechanical properties and can be applied to anti-static products, electromagnetic shielding products or circuits. The invention features easy operation of the manufacturing method, good universality and relatively easy recovery of the conductive composite material, in addition, the invention eliminates the problem in the prior art that the recovery of the composite material is difficult as the high strength fiber is added to the composite material to increase strength of the composite material.

Owner:JIANGSU ZJA NEW MATERIAL

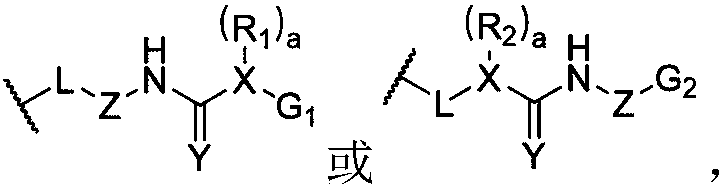

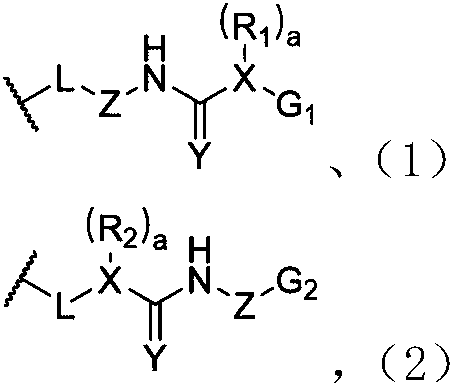

Graphene-containing composite material as well as preparation method and application thereof

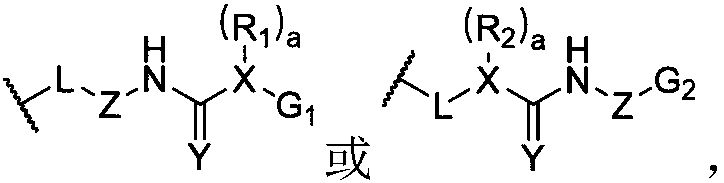

ActiveCN104371279ALower surface energyImprove bindingCarbon compoundsHybrid capacitor electrodesConductive polymerComposite function

The invention discloses a graphene-containing composite material as well as a preparation method and application thereof. The graphene-containing composite material comprises a composite functional material with a double-conductive channel and a polymer matrix, wherein the composite functional material with the double-conductive channel is sulfonated graphene surface grafted conductive polymer poly-3,4-(ethylenedioxythiophene), and the structure formula is as shown in formula I in the specification. The composite functional material with the double-conductive channel and the graphene-containing composite material can be used for preparing a piezoresistance response material, or an antistatic or electromagnetic shielding material and the like and have excellent piezoresistance response, piezoresistance repeatability and electromagnetic shielding effect. The graphene-containing composite material is simple and easy to operate, can be prepared in large scale and has excellent piezoresistance performance and sensitive piezoresistance response, the percolation threshold is 0.5Wt%, original performance of the polymer can be maintained, and an unstable conductive network system can be formed to be beneficial to improving the sensitivity of piezoresistance response.

Owner:SHANGHAI UNIV OF ENG SCI

Method for preparing graphene/polystyrene conductive composite material

The invention aims to propose a preparation method of a graphene / polystyrene conductive composite material. A kind of preparation method of graphene / polystyrene conductive composite material, adopt following steps: Step 1: the preparation of graphene oxide (GO) powder; Step 2: dispersion polymerization prepares cationic polystyrene (PS+) microsphere; Step 3 : Preparation of GNS / PS composites. The invention can inhibit the self-aggregation and induction of GNs and the selective distribution of graphene on the surface of polymer particles, forming a perfect three-dimensional graphene network skeleton; the relatively ordered three-dimensional structure of GNs constitutes a free electron conduction path, and GNs / The PS composite material exhibited extremely low conductive percolation value and high conductivity; the addition of graphene improved the thermal stability of PS, and the decomposition temperature of PS increased by 13.5 °C. This facile method provides a new idea for the construction of ordered inorganic filler microstructures in high-viscosity polymer systems, which is conducive to further expanding the application field of graphene-based conductive composites.

Owner:SHAANXI SHENGMAI PETROLEUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com