Patents

Literature

3180 results about "Electro conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrical conductivity. Electrical conductivity is the ability of a material to carry the flow of an electric current (a flow of electrons). Imagine that you attach the two ends of a battery to a bar of iron and a galvanometer.

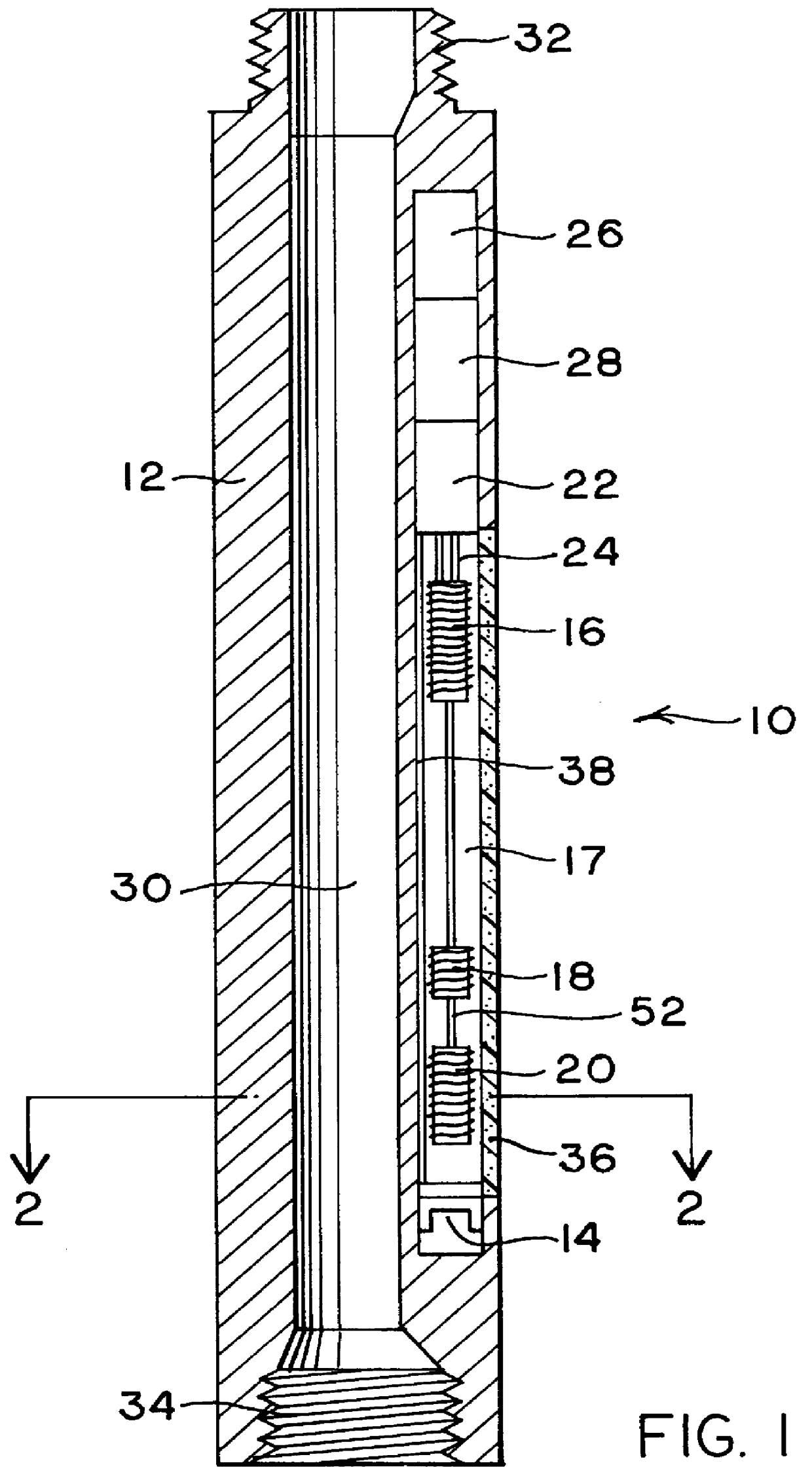

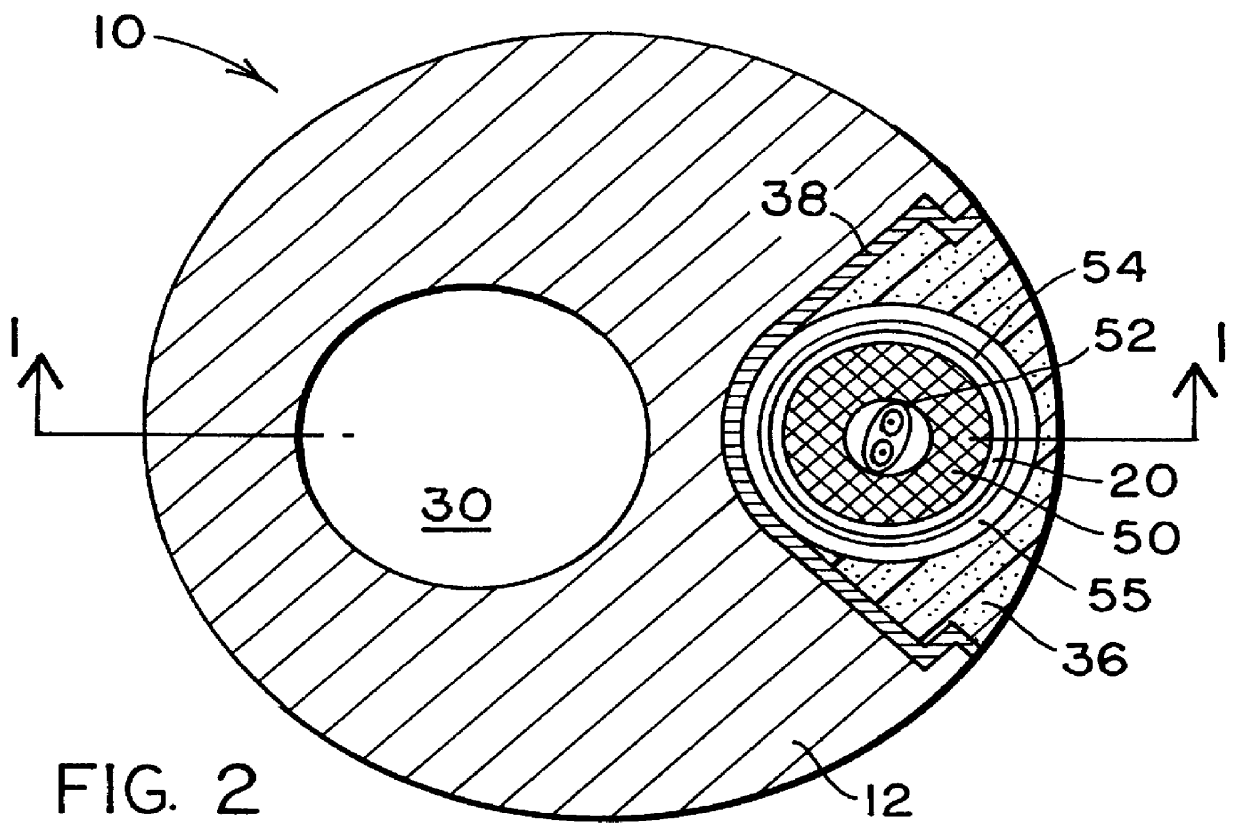

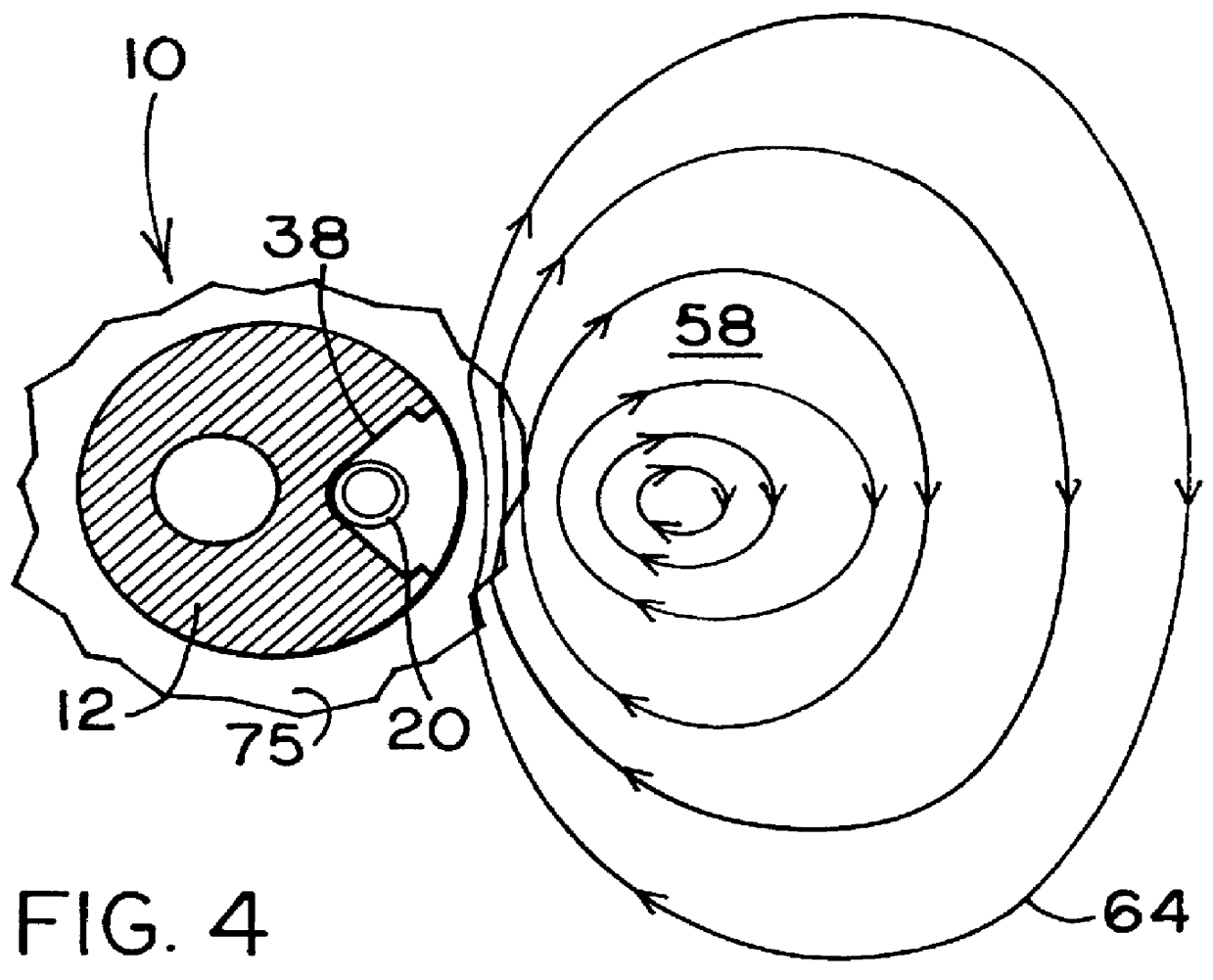

Method and apparatus for directional measurement of subsurface electrical properties

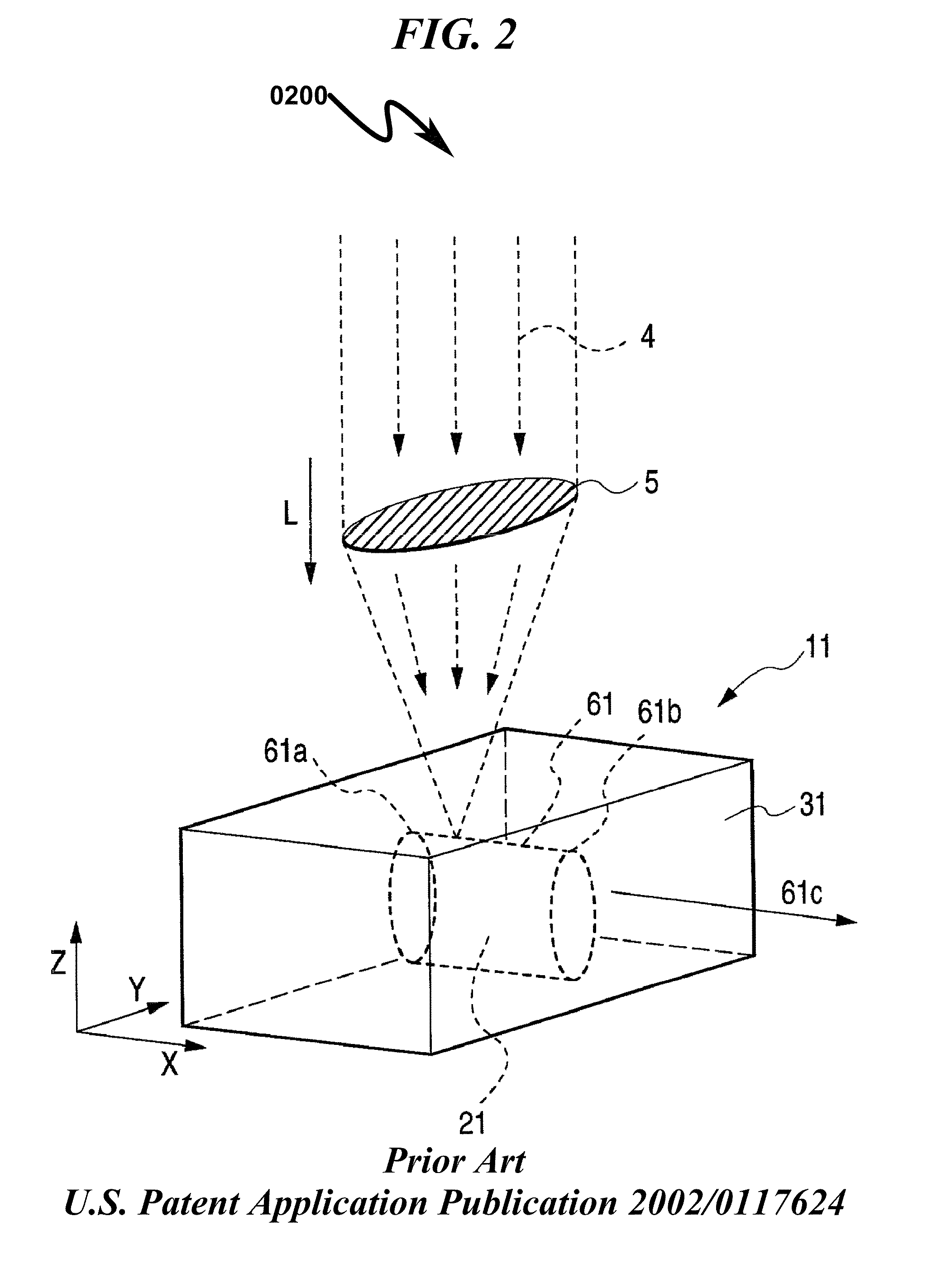

InactiveUS6100696AElectric/magnetic detection for well-loggingAcoustic wave reradiationPhysicsInduction logging

A directional induction logging tool is provided for measurement while drilling. This tool is preferably placed in a side pocket of a drill collar, and it comprises transmitter and receiver coils and an electromagnetic reflector. The reflector, which may be a layer of highly conductive material placed between the coils and the body of the drill collar, serves to focus the electromagnetic fields generated and sensed by the tool in the direction away from the reflector, thus providing a directional response to formation conductivity with a relatively high depth of investigation. In preferred embodiments of the invention, magnetically permeable cores are placed within the coils to concentrate the magnetic fields that pass through them. Circuitry is described for balancing the mutual inductive coupling of the coils by injecting a direct current signal through one or more of the coils, which alters the magnetic permeability of the core material. The magnitude of the direct current required to achieve a balanced condition may be derived from the quadrature phase component of the return signal. Circuitry is also provided for generating a transmitted signal and for processing the return signals, including digital-to-analog conversion circuitry for providing digital data for transmission to the surface. This tool may be employed to provide real-time directional conductivity information that may be used to detect and follow bed boundaries in geosteering operations.

Owner:SINCLAIR PAUL L

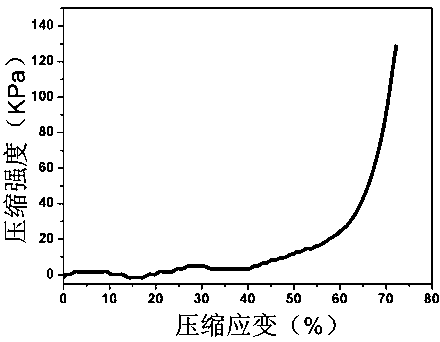

Nitrogen mixed grapheme hydrogel or aerogel and preparation method thereof

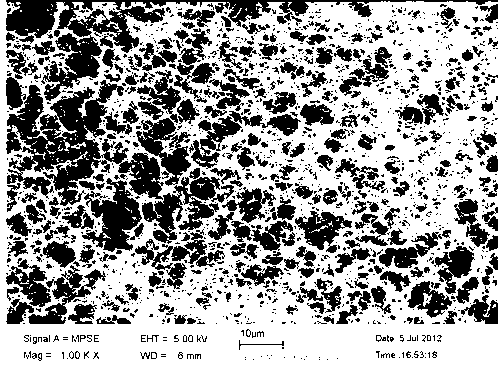

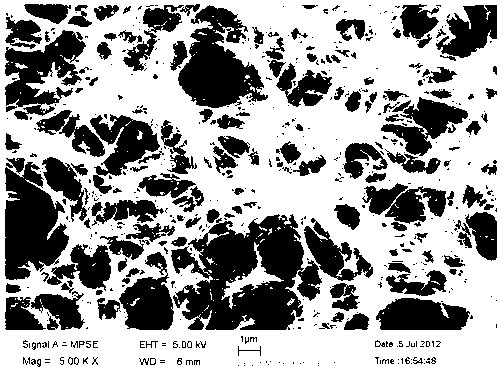

InactiveCN102874796AImprove adsorption capacityGood processing effectGrapheneApparent densityNitrogen

The invention provides nitrogen mixed grapheme hydrogel of which the water content is 90 to 99.5 percent, the electric conductivity is 10-3-100 S / m, and the molar ratio of N and C is 1 to 25 percent. The invention further provides nitrogen mixed aerogel of which the molar ratio of N and C is 2 to 20 percent, the molar ratio of C and O is 15 to 5, nitrogen atoms existing in the form of amidogen nitrogen accounts for 40 to 70 percent, pyridine type nitrogen accounts for 10 to 40 percent, graphite type nitrogen accounts for 10 to 30 percent, the specific area is 300 to 1500 m<2> / g, the apertures which are micropore account for 10 to 20 percent, the apertures which are mesoporous 20 to 50 percent, the apertures which are macropore 30 to 70 percent, the apparent density is 0.01 to 0.2 g / cm<3>, the pore volume is 5 to 20 cm<3> / g, and the electric conductivity is 1 to 1000 S / m. The nitrogen mixed grapheme hydrogel or aerogel and preparation method thereof provided by the invention has the characteristics that the operation is simple, the equipment requirement is low, the production efficiency is high, the scale-up of the technology is easy, the nitrogen mixed content is controllable and the compounding with other functional substances is simple.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

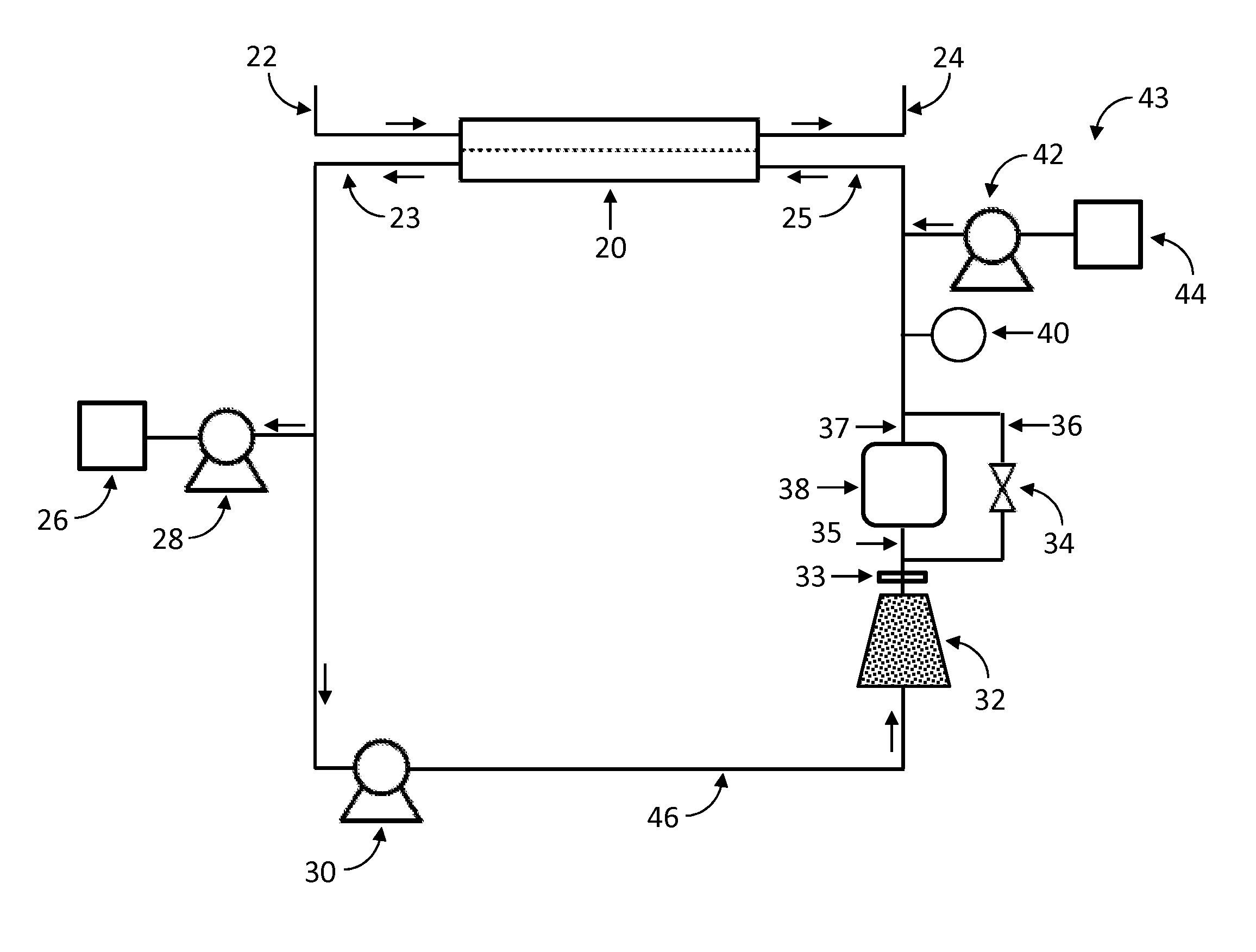

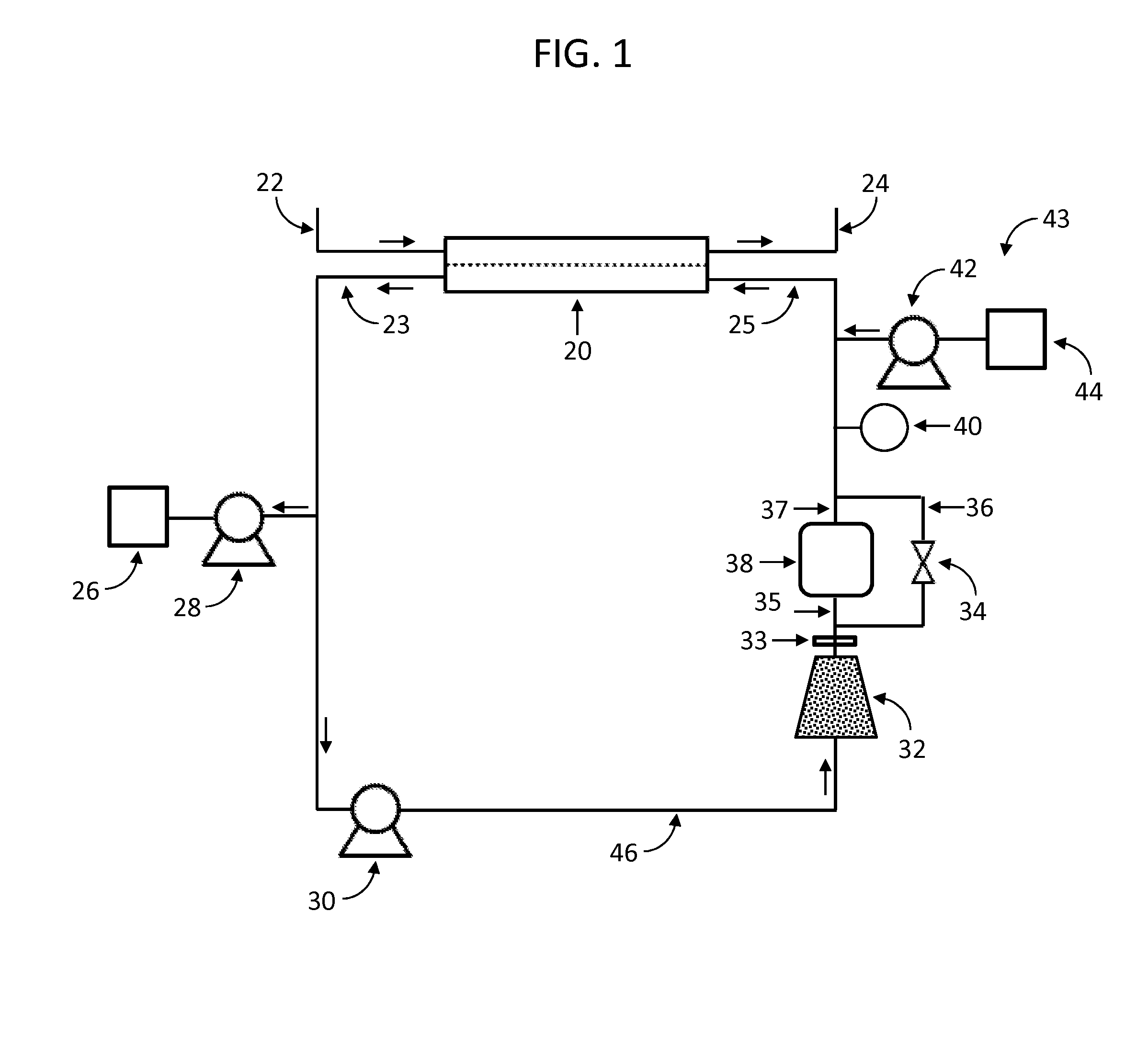

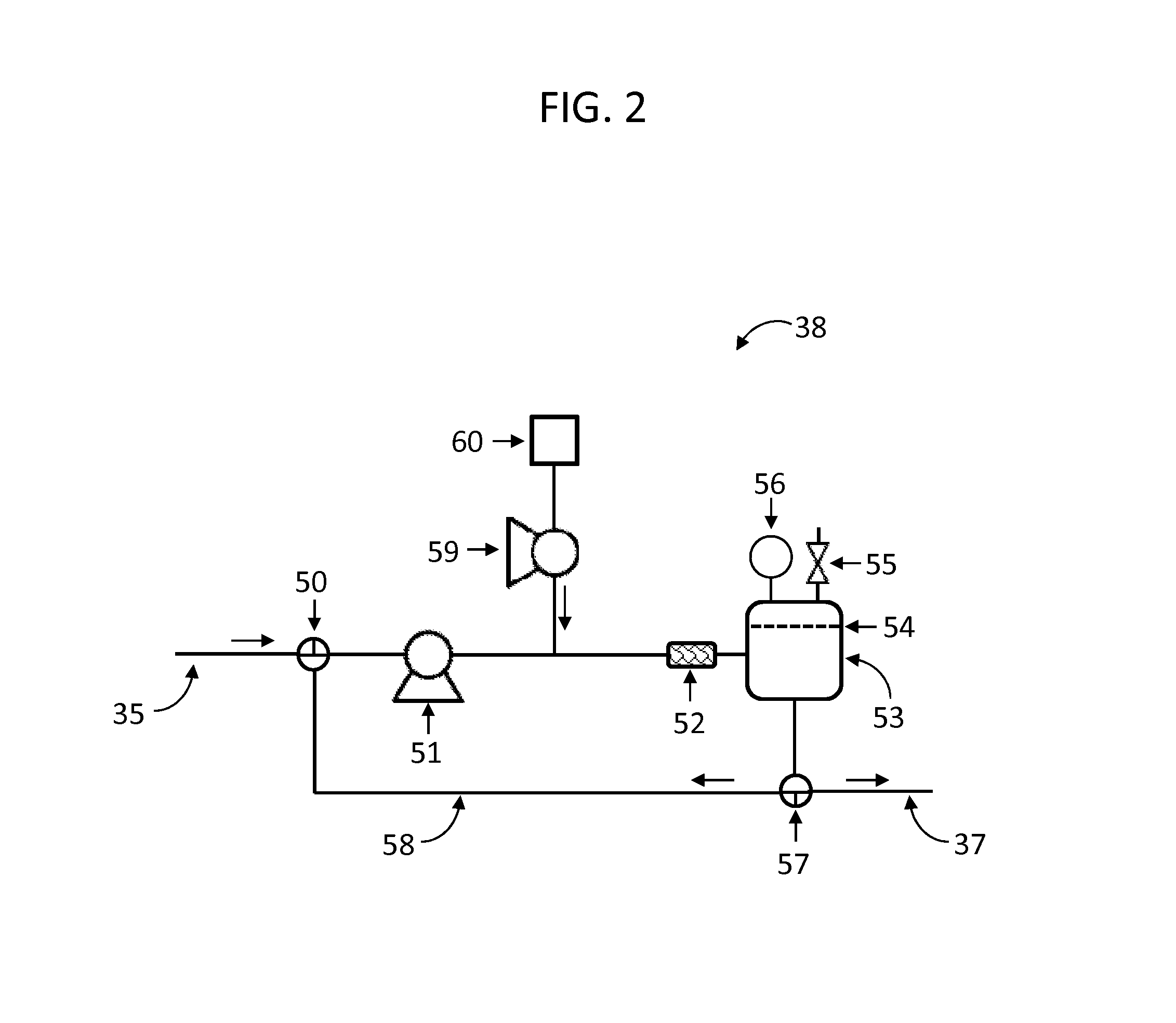

pH BUFFER MEASUREMENT SYSTEM FOR HEMODIALYSIS SYSTEMS

ActiveUS20140220699A1Well mixedSemi-permeable membranesAnalysis using chemical indicatorsThermodynamicsHemodialysis care

A pH-buffer measurement system that has at least one source for modifying the pH of a fluid entering the system, the source selected from an acid source and a base source. The acid source adds an acid equivalent to provide an acid reacted fluid and the base source adds a base equivalent to provide a base reacted fluid. The source is in fluid communication with a flow path and a component for determining a fluid characteristic of the acid reacted fluid or the base reacted fluid. The fluid characteristic that is measured is any one of a gas phase pressure, an electrical conductivity, or thermal conductivity.

Owner:MOZARC MEDICAL US LLC

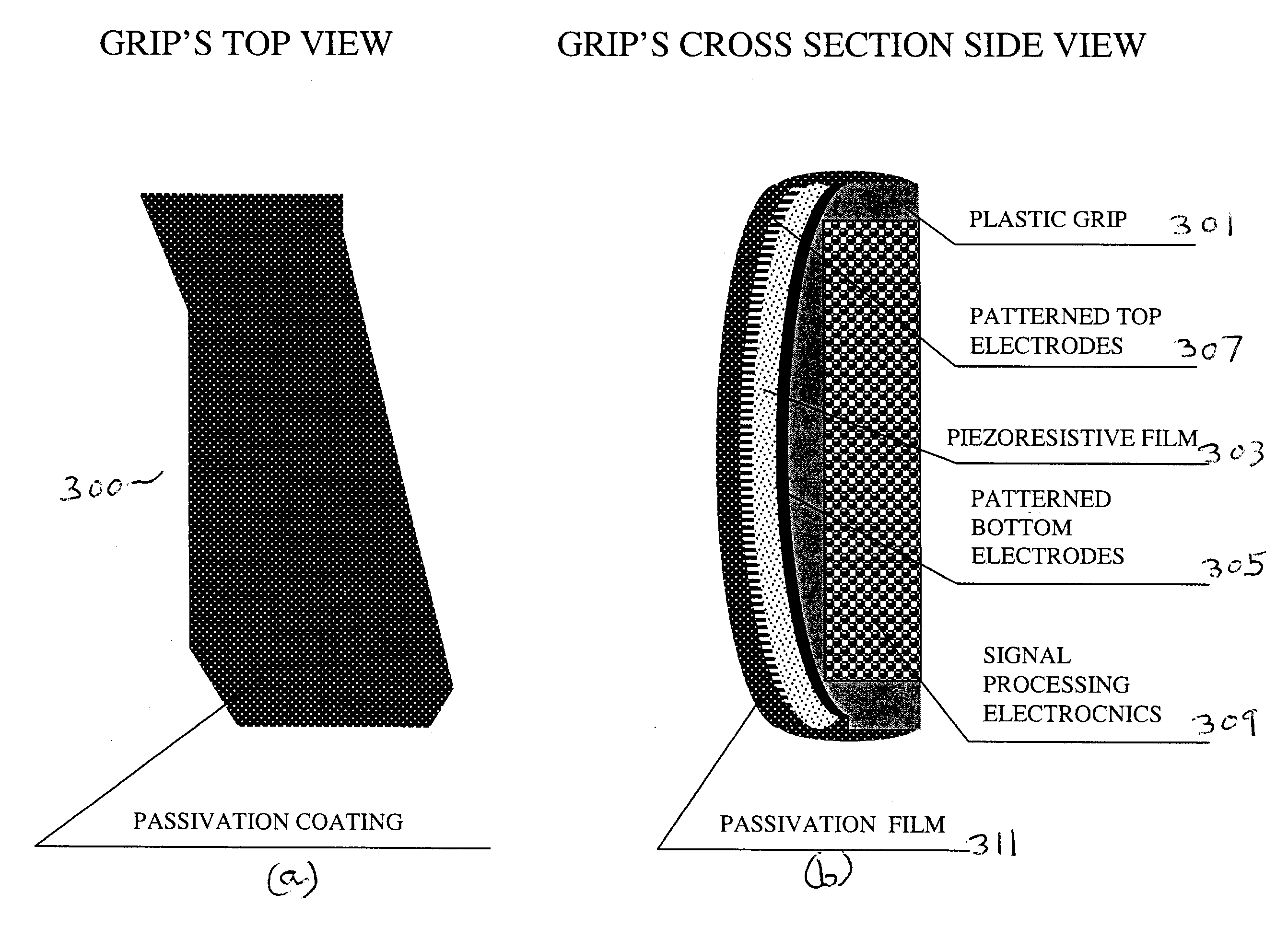

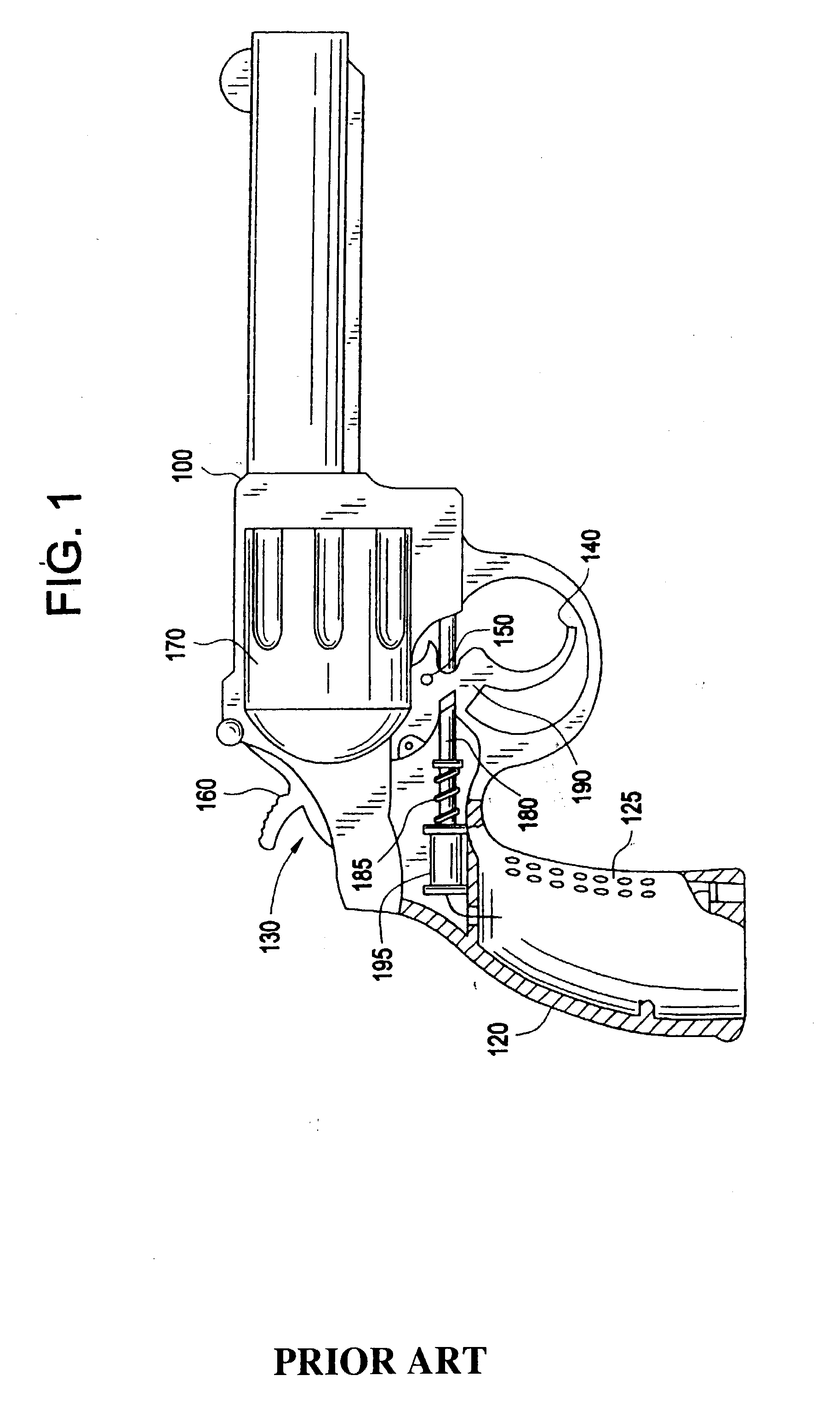

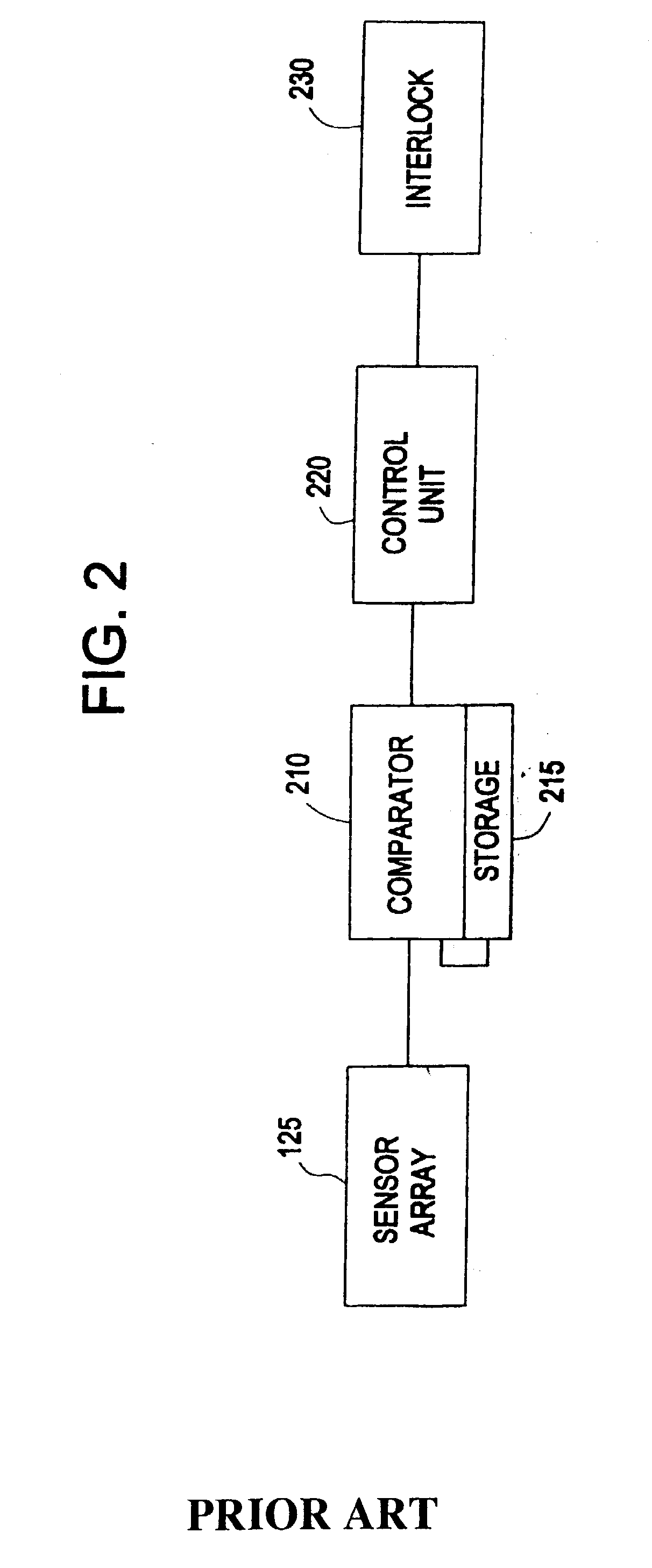

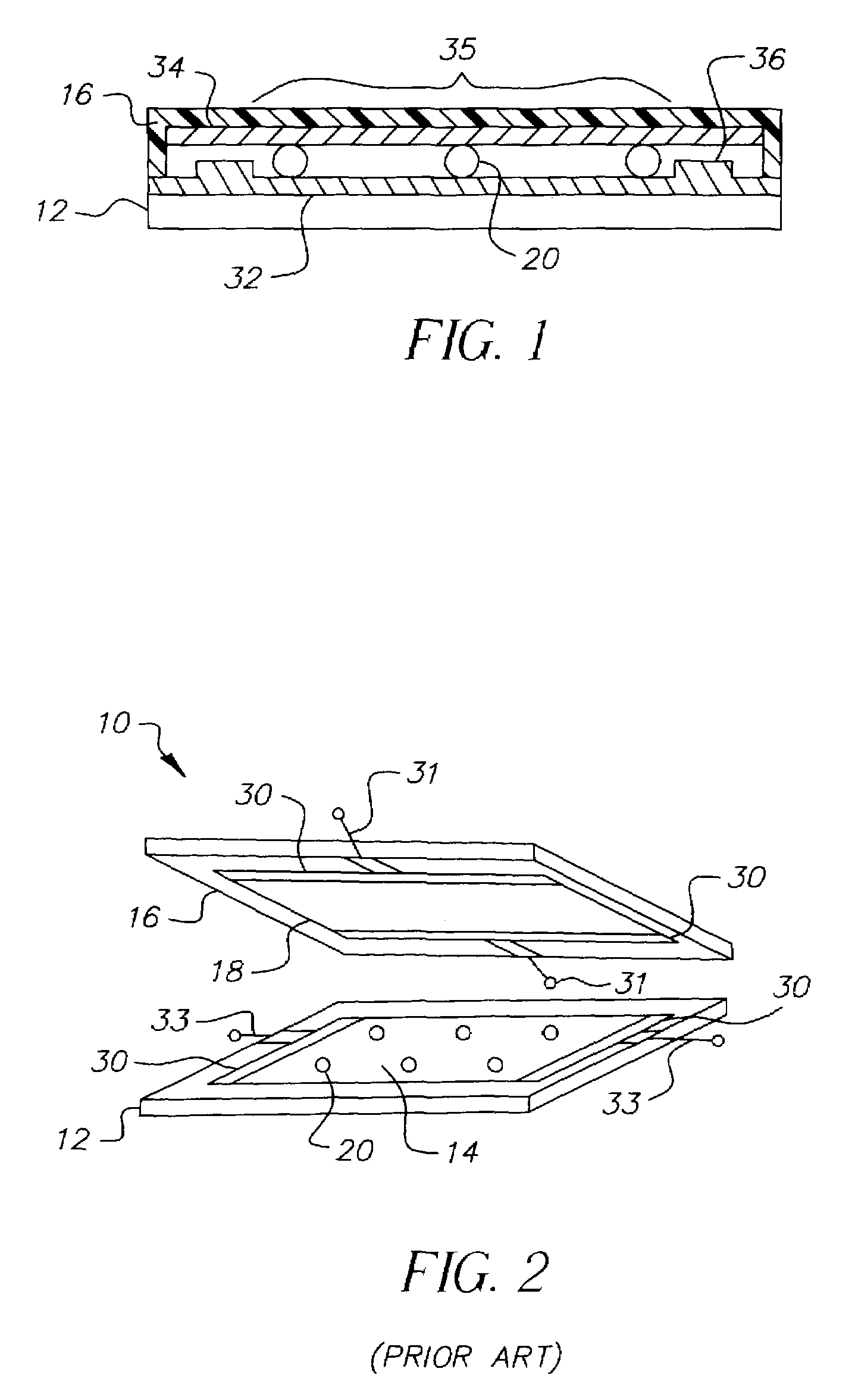

Sensor array for unauthorized user prevention device

InactiveUS20040031180A1Safety arrangementCharacter and pattern recognitionSensor arrayComputer module

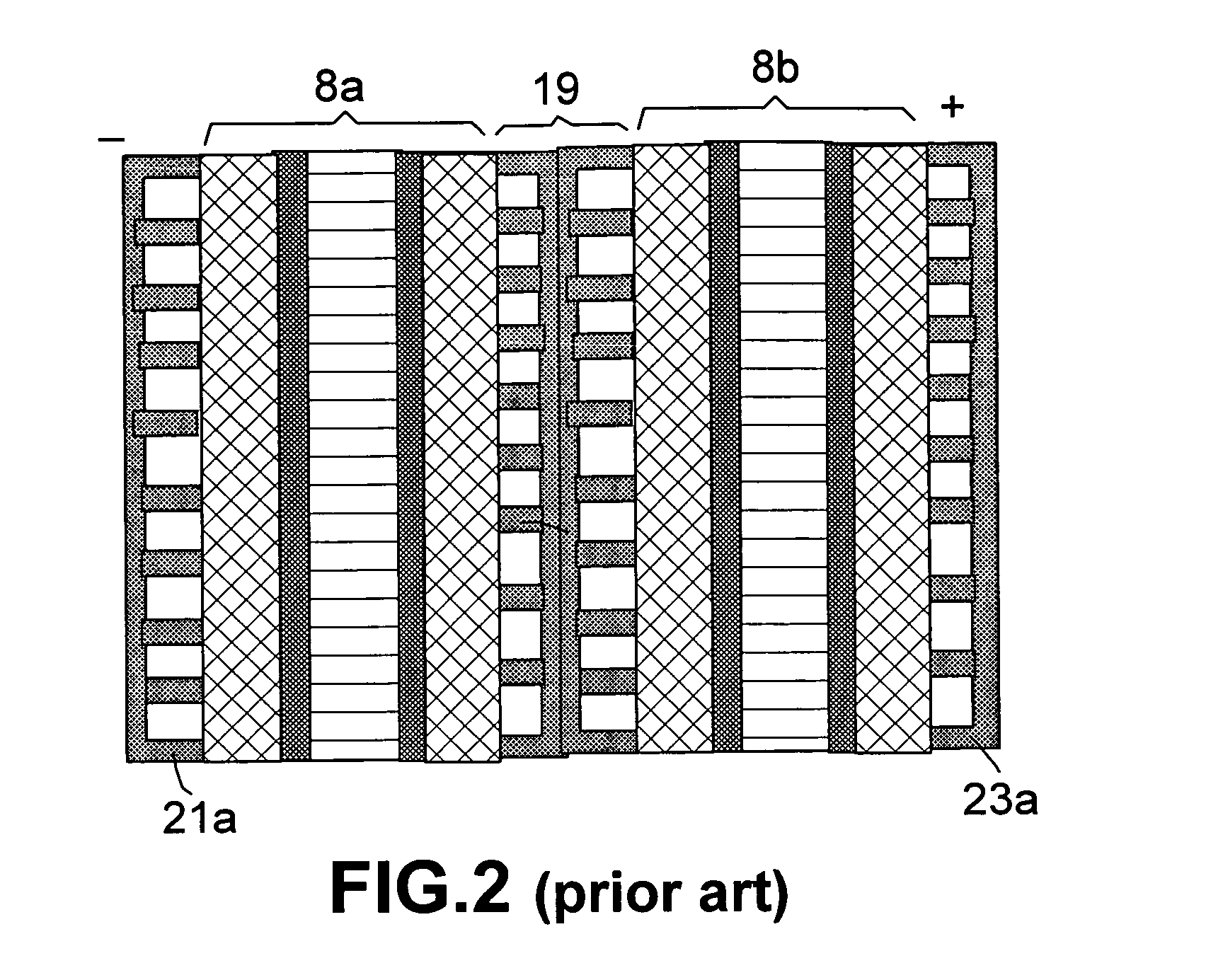

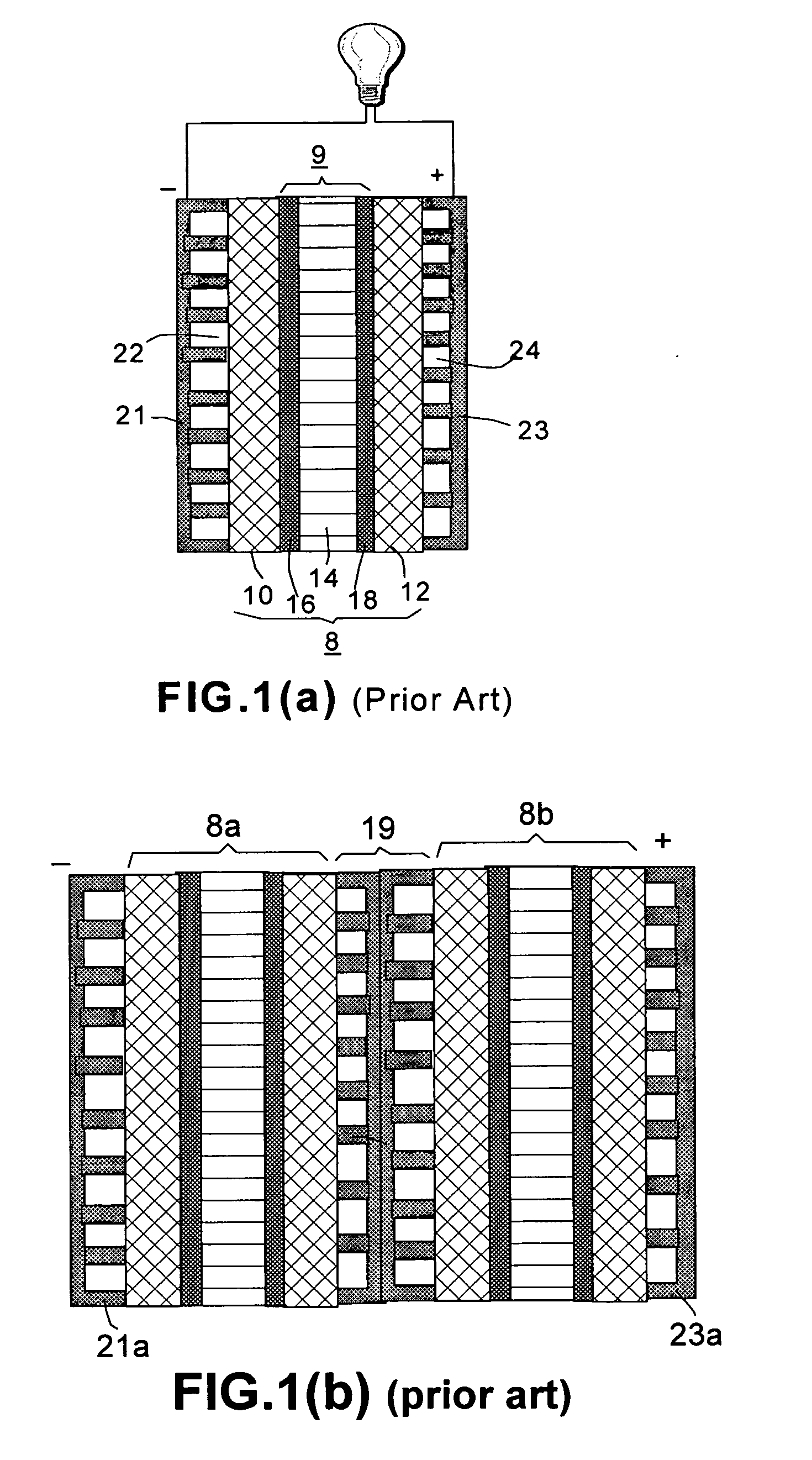

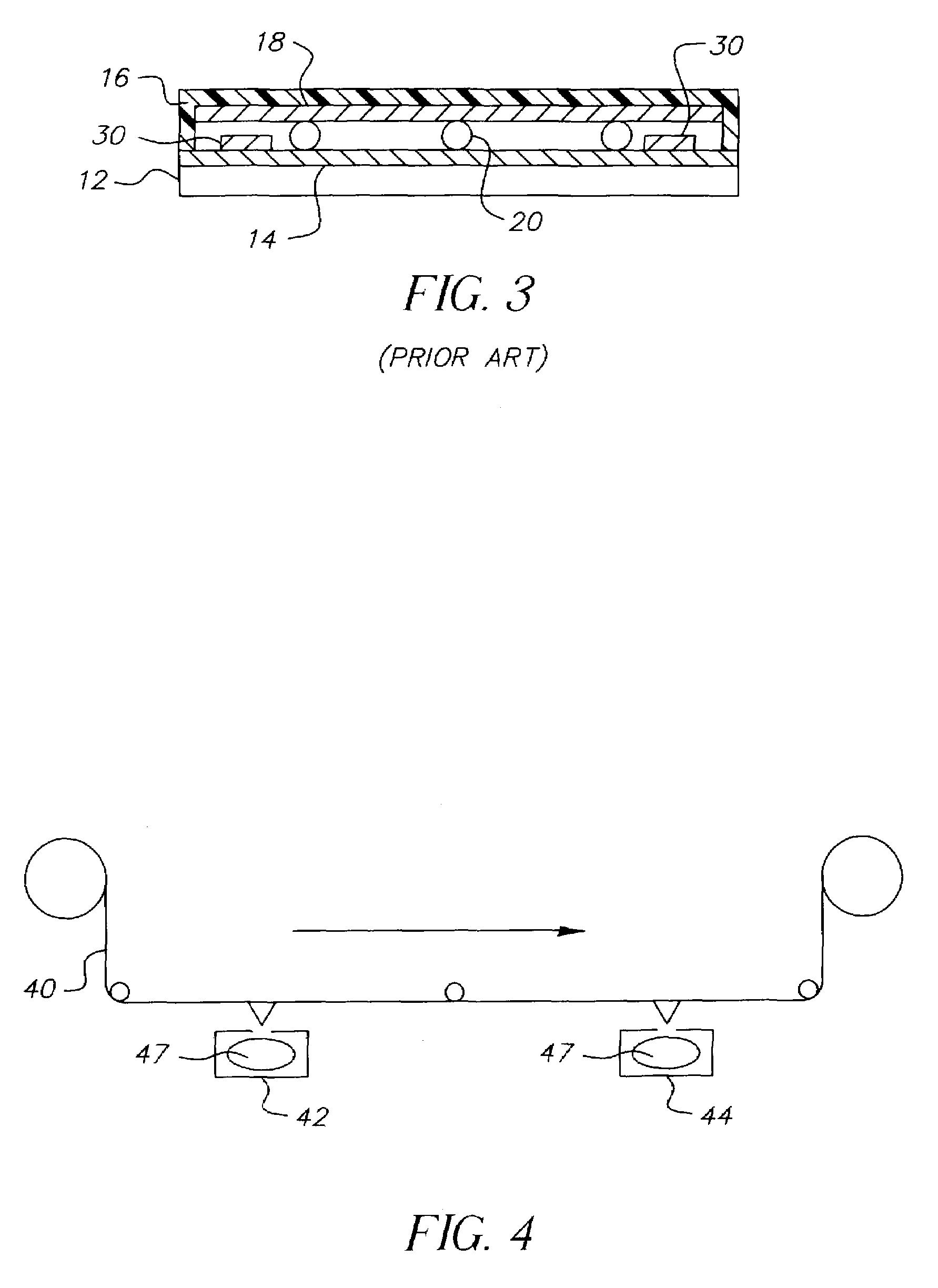

Improvements in the sensor array are disclosed for an array used in a module for preventing unauthorized use of a firearm or other device. The module to which the invention is applicable of the type including a plurality of pressure sensors for sensing a user's handgrip on the device; comparator means for comparing a pressure signature profile compiled from an output from said pressure sensors with at least one pressure signature profile in storage; and means for preventing operation of the device when the compared profiles do not match. The improved sensor array comprises a first set of spaced electrically conductive lines formed on the gripping surface; a thin layer of (preferably) piezoresistive material overlying the first set of conductive lines; and a second set of spaced electrically conductive lines formed over the piezoresistive layer. The lines of the second set are orthogonal to the lines of the first set, to establish a grid-like pattern of conductive lines sandwiching the piezoresistive layer. The projected intersections between the lines of the first and second sets (i.e., the grid crossing points) thereby define with the intervening portion of the piezoresistive layer, an array of sensors which are responsive to pressure applied against the gripping surface by a user of the device. Such pressure changes the electrical conductivity in the path including the intersecting lines and intervening piezoresistive material. Signal outputs from the electrical paths including the array of sensors serve to define the pressure signal profile.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

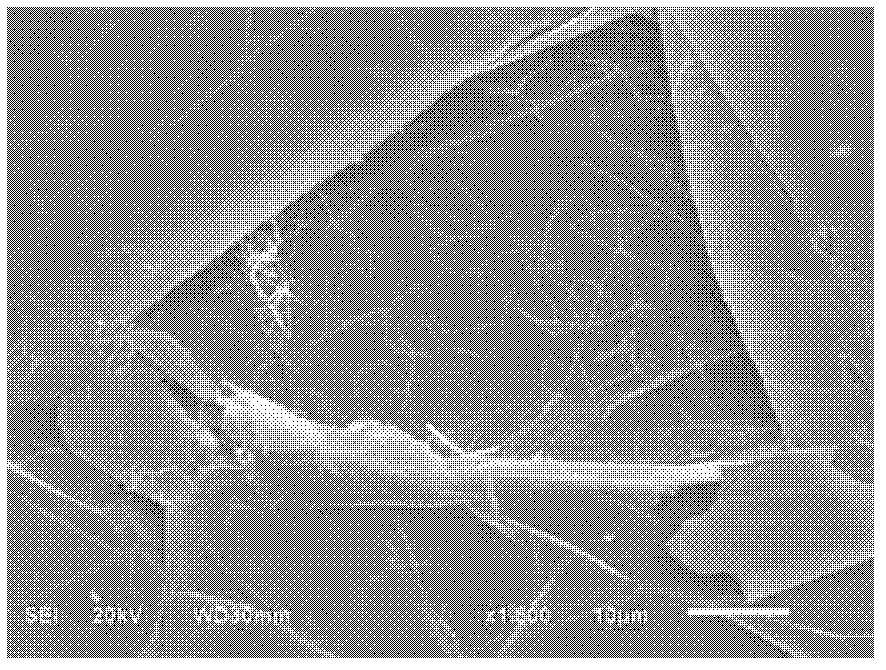

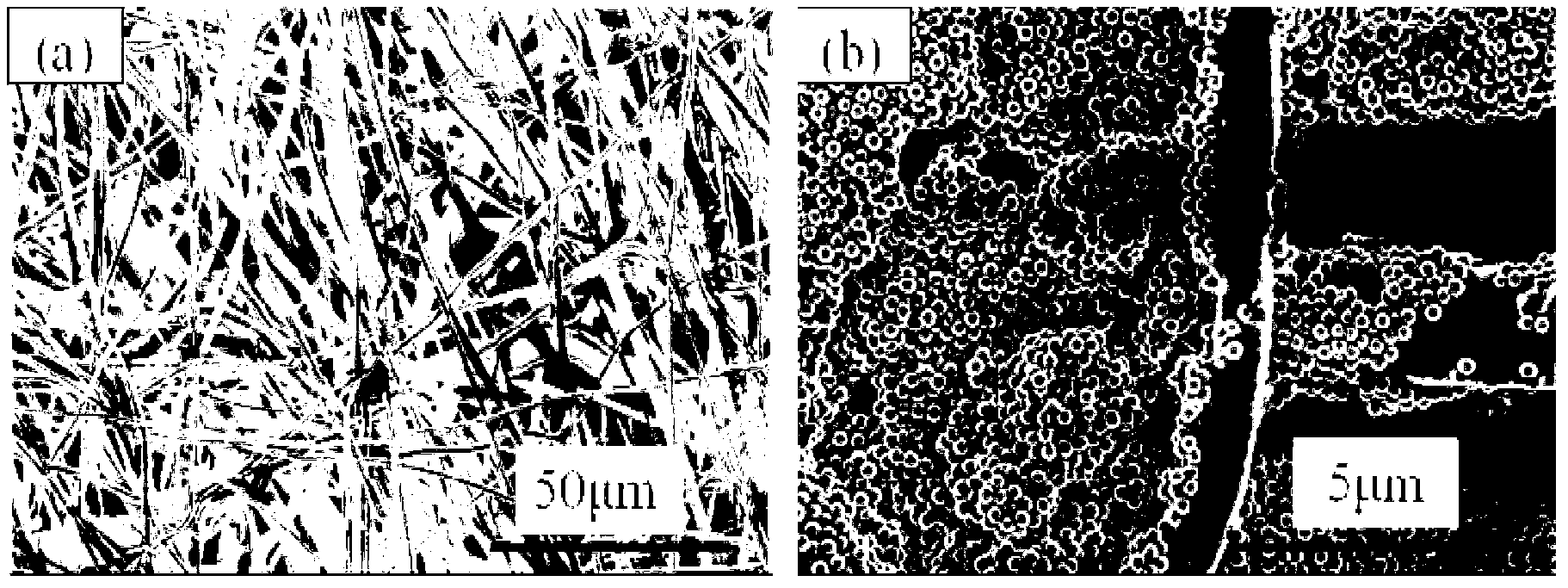

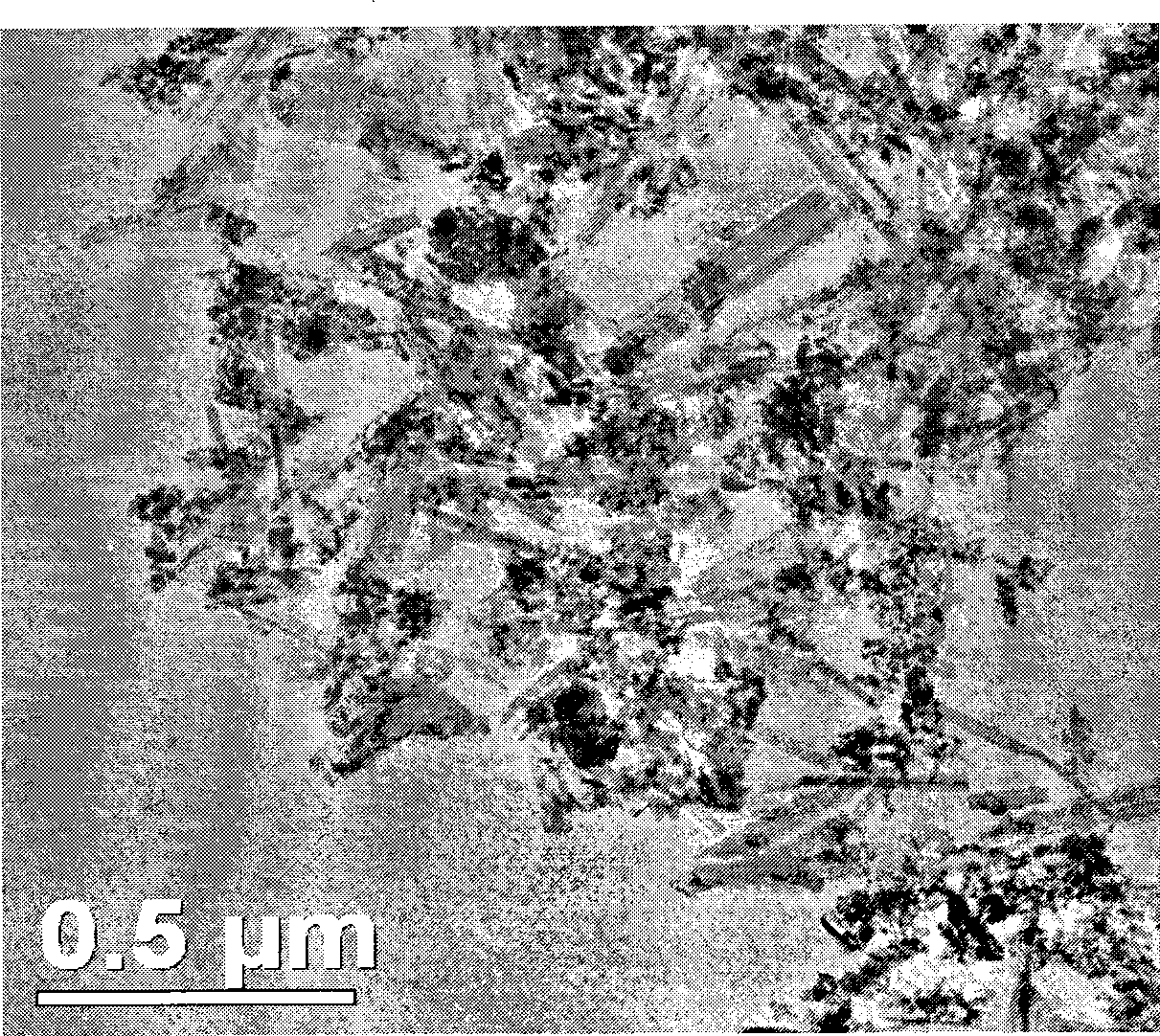

Flexible conductive thin film compositing two-dimensional graphene and one-dimensional nanowire and preparation method thereof

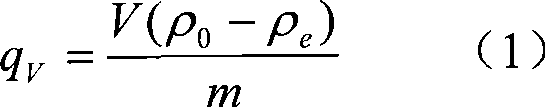

ActiveCN103219066AHigh strengthImprove flexibilityConductive layers on insulating-supportsCarbon-silicon compound conductorsComposite filmNanowire

The invention relates to a flexible conductive thin film compositing a two-dimensional graphene and a one-dimensional nanowire and a preparation method of the flexible conductive thin film. The preparation method includes the following steps: dispersing the graphene, the nanowire and dispersion auxiliary in solvent, obtaining graphene / nanowire solvent which is well dispersed after the solvent is processed through ultrasound concussion, and obtaining a graphene / nanowire composite thin film after the graphene / nanowire solvent is processed through vacuum filtration and drying. The thickness of the composite thin film is 10 nanometers to 1000 micrometers, the composite thin film has good strength and flexibility, square resistance is between 0.001 ohm per square and 3000 ohms per square, and electrical conductivity is between 0.01 siemens per centimeter to 5000 siemens per centimeter. The graphene / nanowire composite thin film which is obtained with the adoption of the preparation method has good strength, flexibility, and electrical conductivity, and is controllable in thickness, cuttable in shape, simple in preparing process, easy to operate, low in manufacturing cost, and suitable for solar batteries, energy storage, heat dissipation, catalysis, sensing, and conductive composite material fields.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

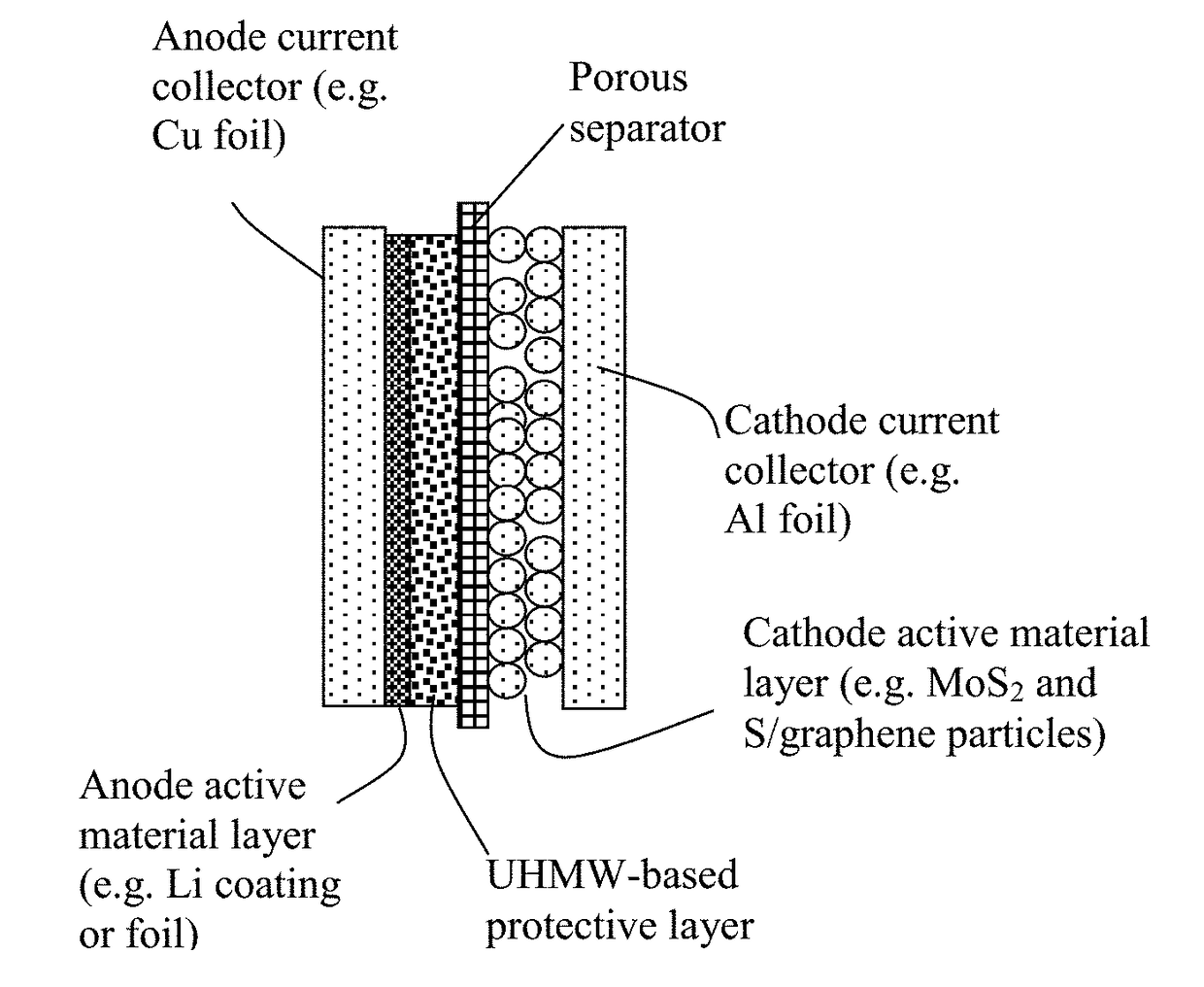

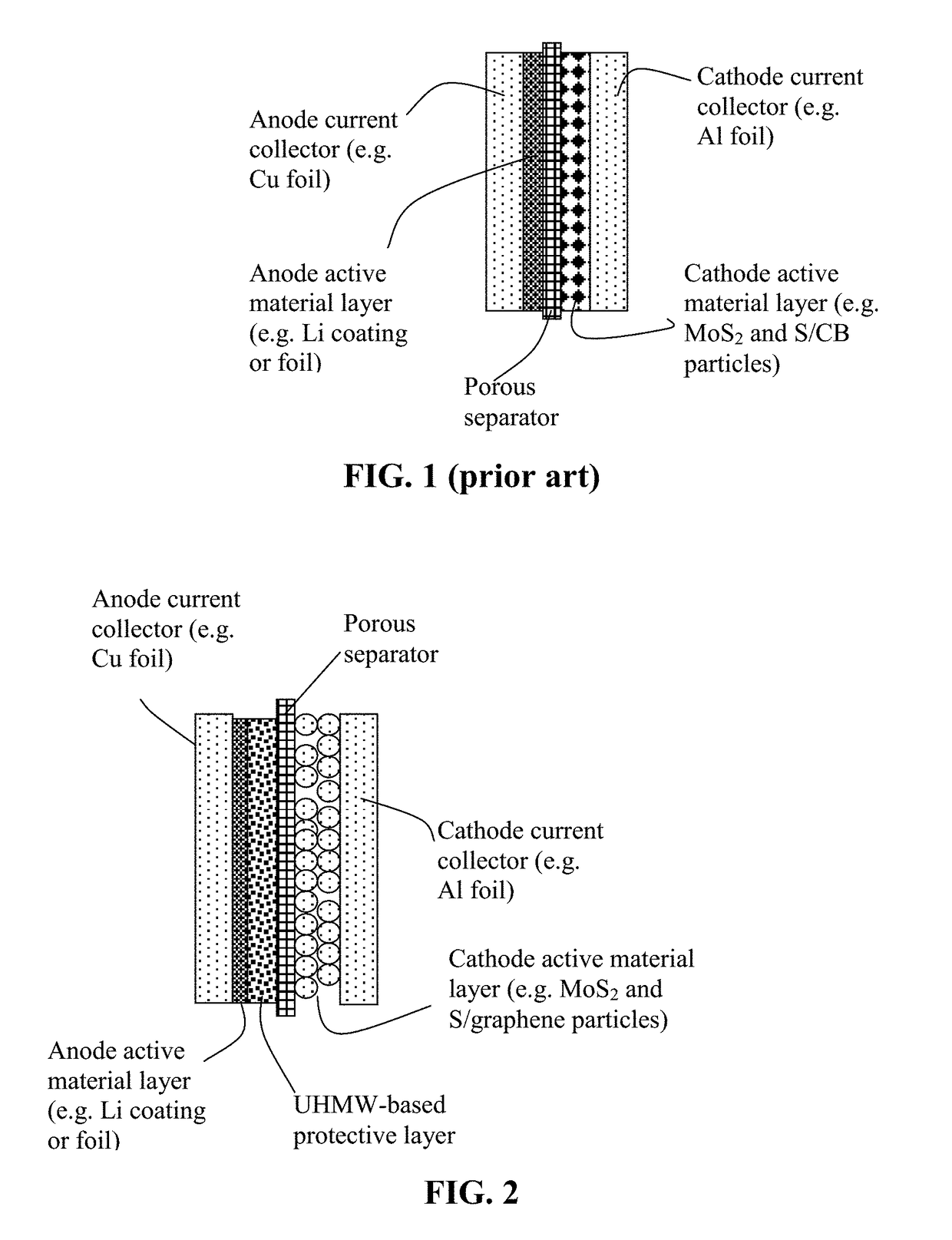

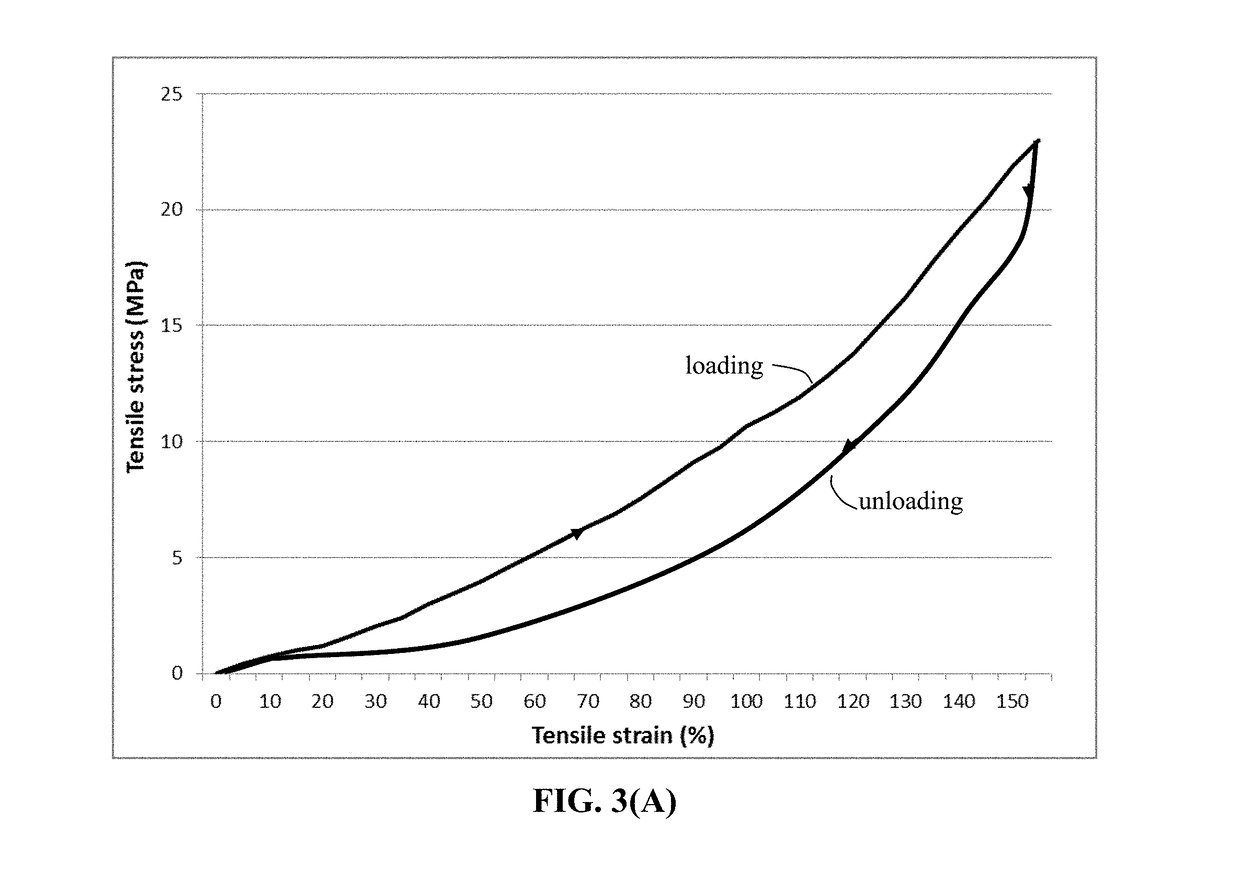

Lithium Metal Secondary Battery Containing an Anode-Protecting Polymer Layer and Manufacturing Method

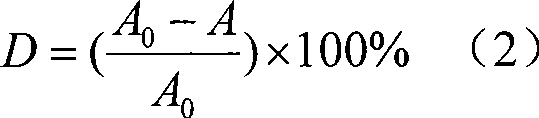

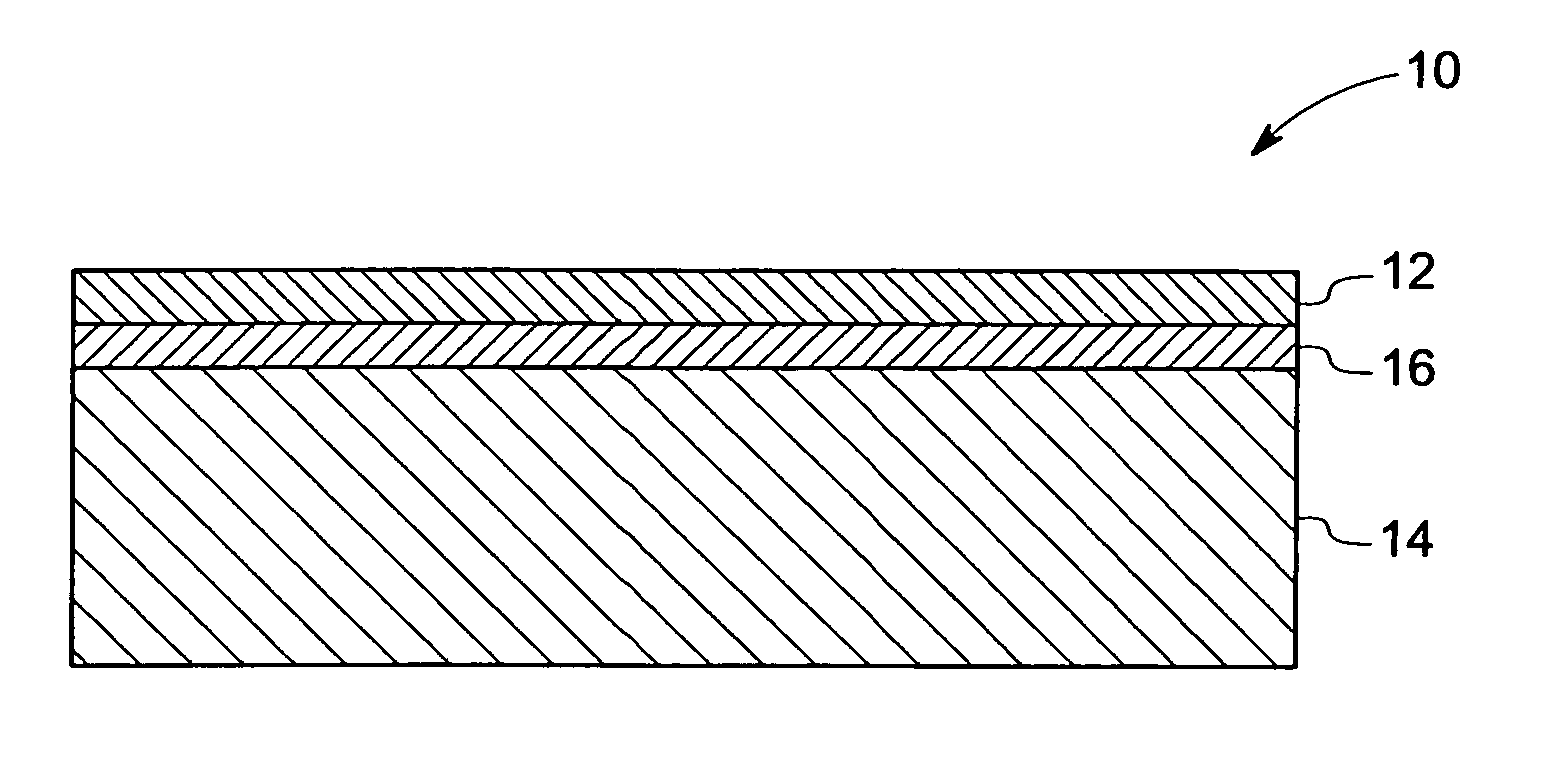

ActiveUS20180294476A1Improve lithium ion conductivityReduce thicknessSolid electrolytesFuel and secondary cellsTensile strainLithium metal

Provided is lithium secondary battery comprising a cathode, an anode, and an electrolyte or separator-electrolyte assembly disposed between the cathode and the anode, wherein the anode comprises: (a) a foil or coating of lithium or lithium alloy as an anode active material; and (b) a thin layer of a high-elasticity polymer having a recoverable tensile strain no less than 5%, a lithium ion conductivity no less than 10−6 S / cm at room temperature, and a thickness from 1 nm to 10 μm, wherein the high-elasticity polymer contains an ultrahigh molecular weight polymer having a molecular weight from 0.5×106 to 9×106 g / mole and is disposed between the lithium or lithium alloy and the electrolyte or separator-electrolyte assembly.

Owner:GLOBAL GRAPHENE GRP INC

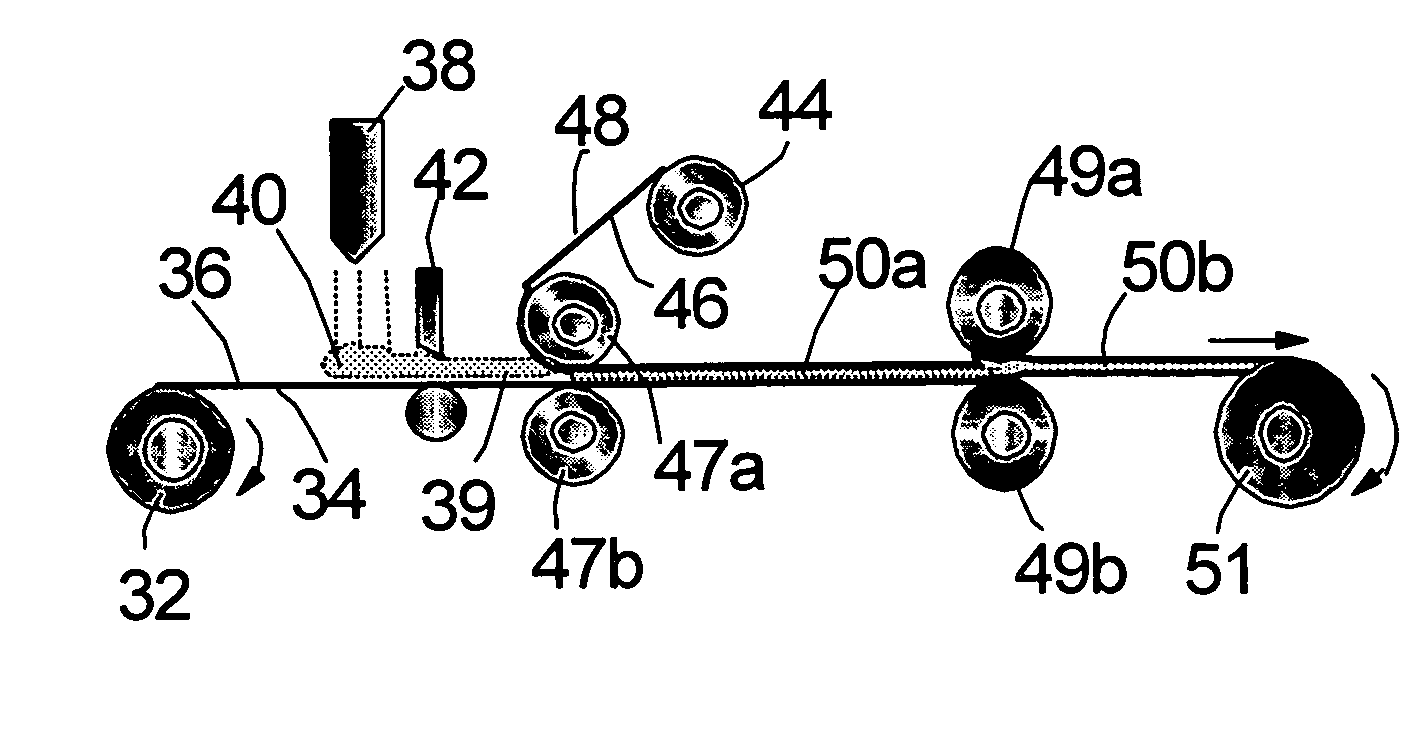

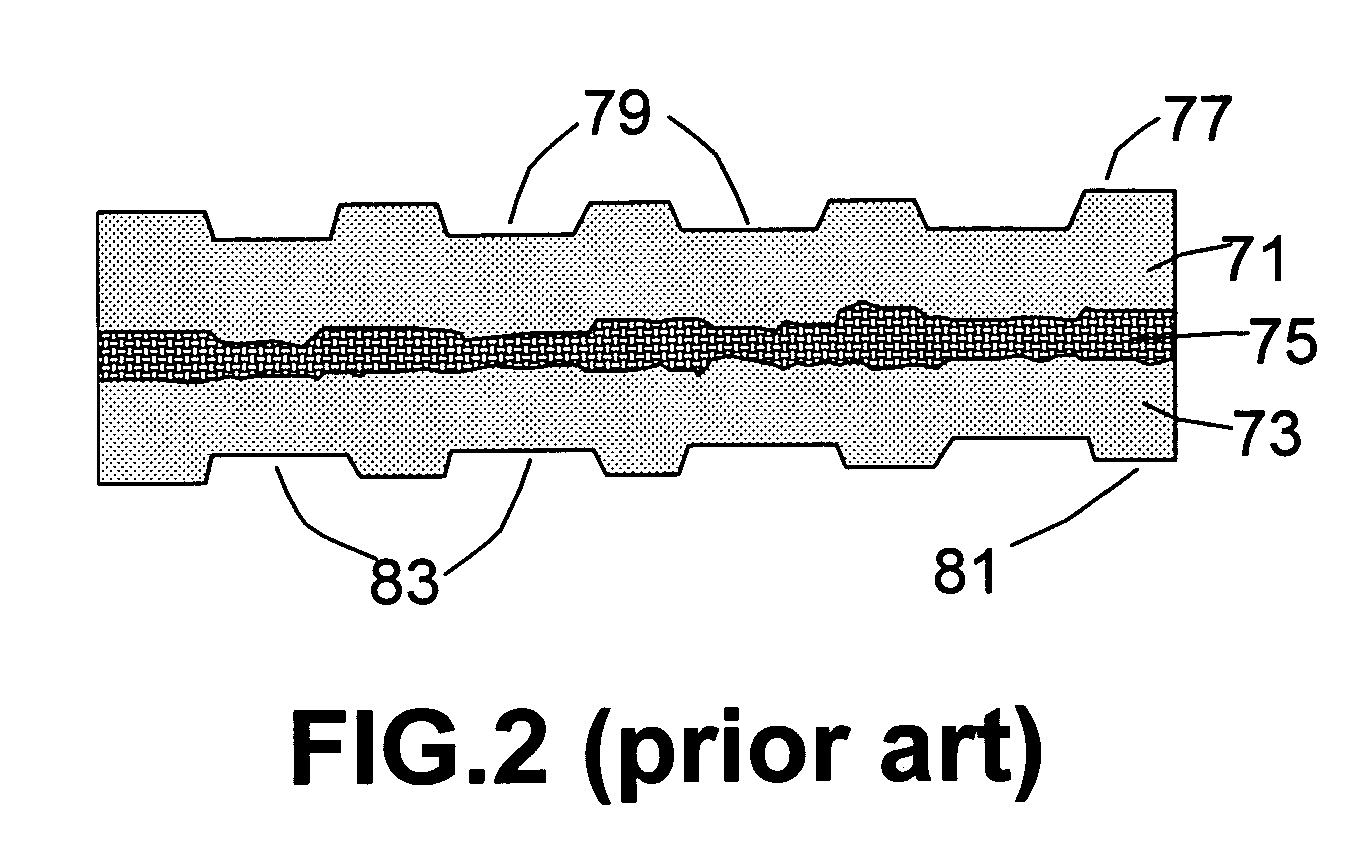

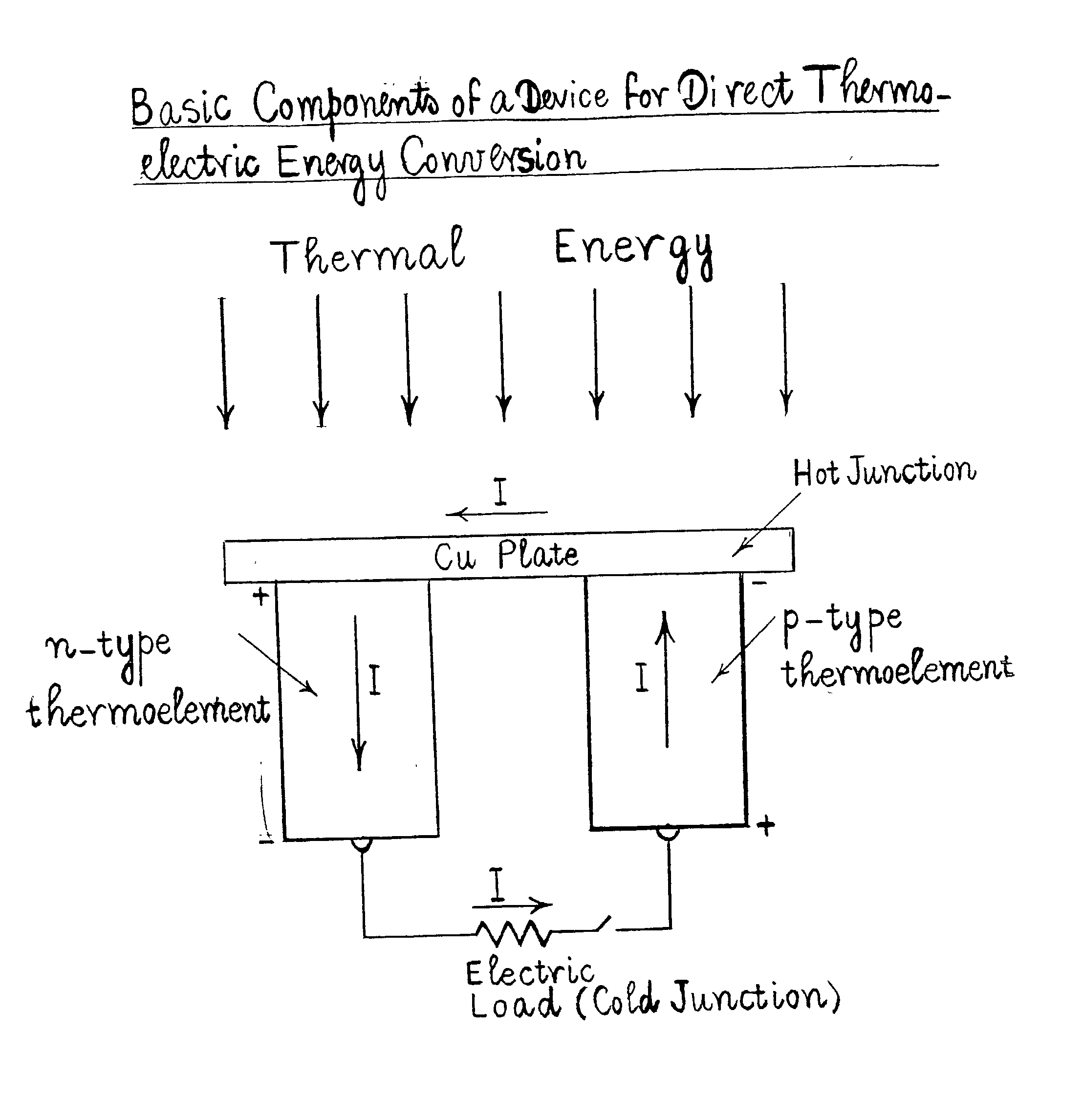

Method for producing highly conductive sheet molding compound, fuel cell flow field plate, and bipolar plate

ActiveUS20070125493A1Improves Structural IntegrityAdhesive processesMechanical working/deformationFuel cellsSheet moulding compound

This invention provides a method of producing a highly electrically conductive sheet molding compound (SMC) composition and a fuel cell flow field plate or bipolar plate made from such a composition. The plate exhibits a conductivity typically greater than 100 S / cm and more typically greater than 200 S / cm. In one preferred embodiment, the method comprises: (a) providing a continuous sheet of a substrate material (bottom sheet) and a continuous sheet of flexible graphite (top sheet) from respective rollers; (b) feeding a resin mixture (comprising a thermoset resin and a conductive filler) to a space between the top sheet and the bottom sheet in such a way that the resin mixture forms a uniform core layer sandwiched between the two sheets to obtain a laminated structure; (c) compressing the laminated structure to obtain a SMC composition having two opposite outer surfaces; and (e) impressing a fluid flow channel to either or both of the outer surfaces (e.g., via embossing or matched-die molding) and curing the thermoset resin to obtain the plate.

Owner:NANOTEK INSTR GRP LLC

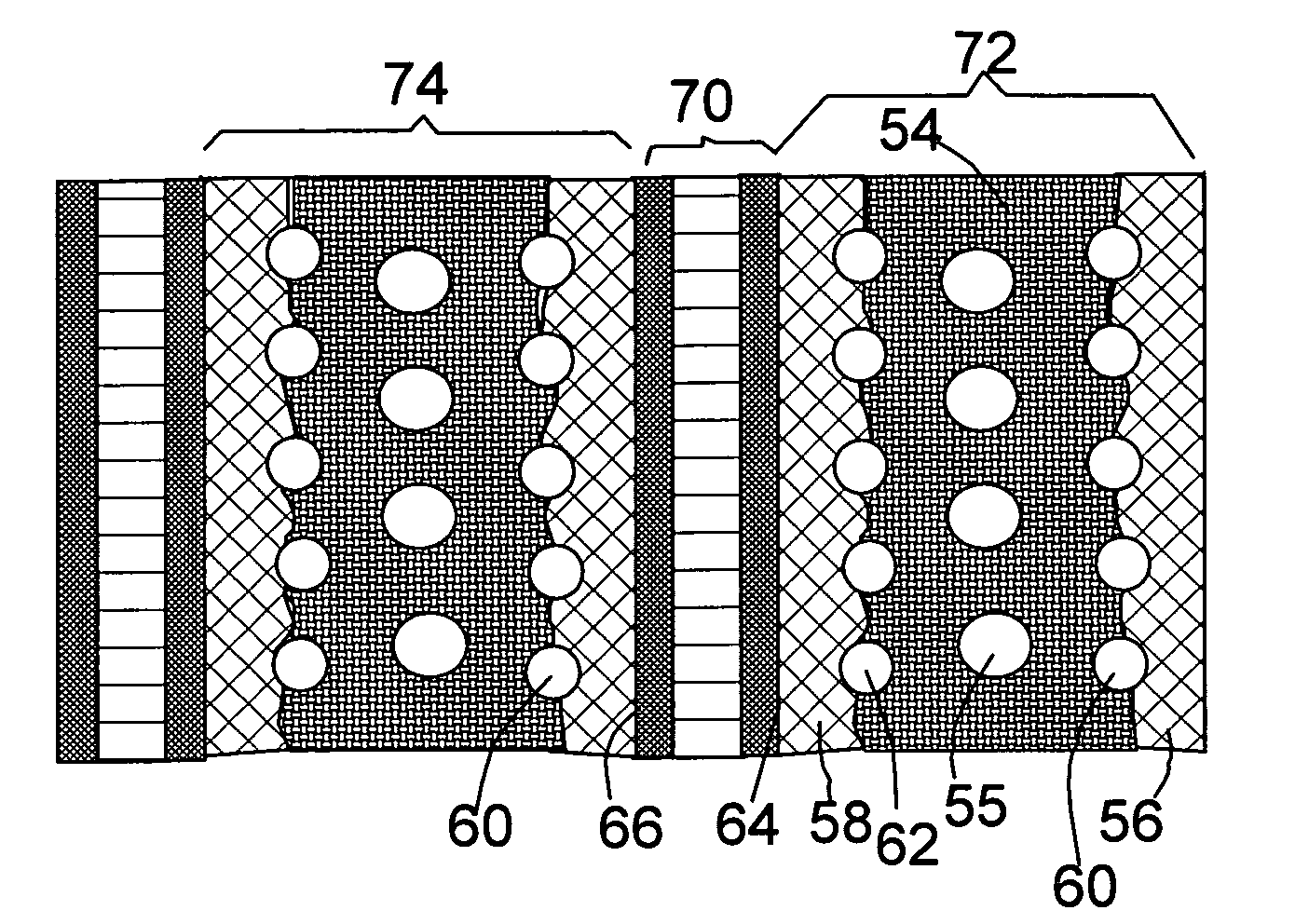

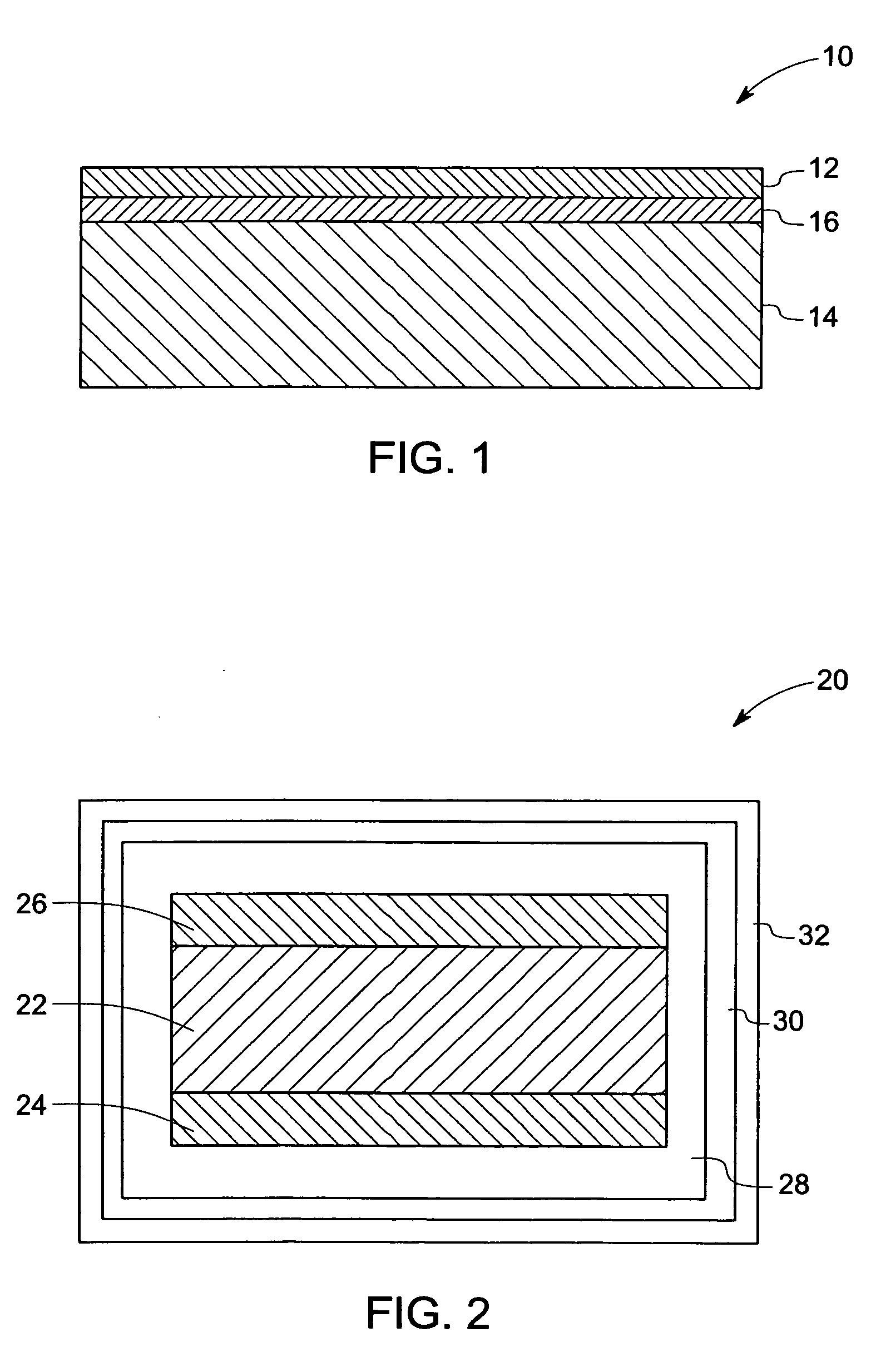

Carbon cladded composite flow field plate, bipolar plate and fuel cell

The present invention provides a carbon-cladded composite composition for use as a fuel cell flow field plate or bipolar plate. In one preferred embodiment, the composition comprises a core composite layer sandwiched between two clad layers, wherein (a) the clad layer comprises a conductive carbon or graphite material (e.g., carbon nano-tubes, nano-scaled graphene plates, graphitic nano-fibers, and fine graphite particles); (b) the core composite layer comprises a matrix resin and a conductive filler present in a sufficient quantity to render the composite layer electrically conductive with an electrical conductivity no less than 1 S / cm (preferably no less than 100 S / cm); and (c) the composition has a planar outer surface on each clad side having formed therein a fluid flow channel.

Owner:EVERPOWER SHENG TIE (XIAMEN) GRAPHENE TECH CO LTD +1

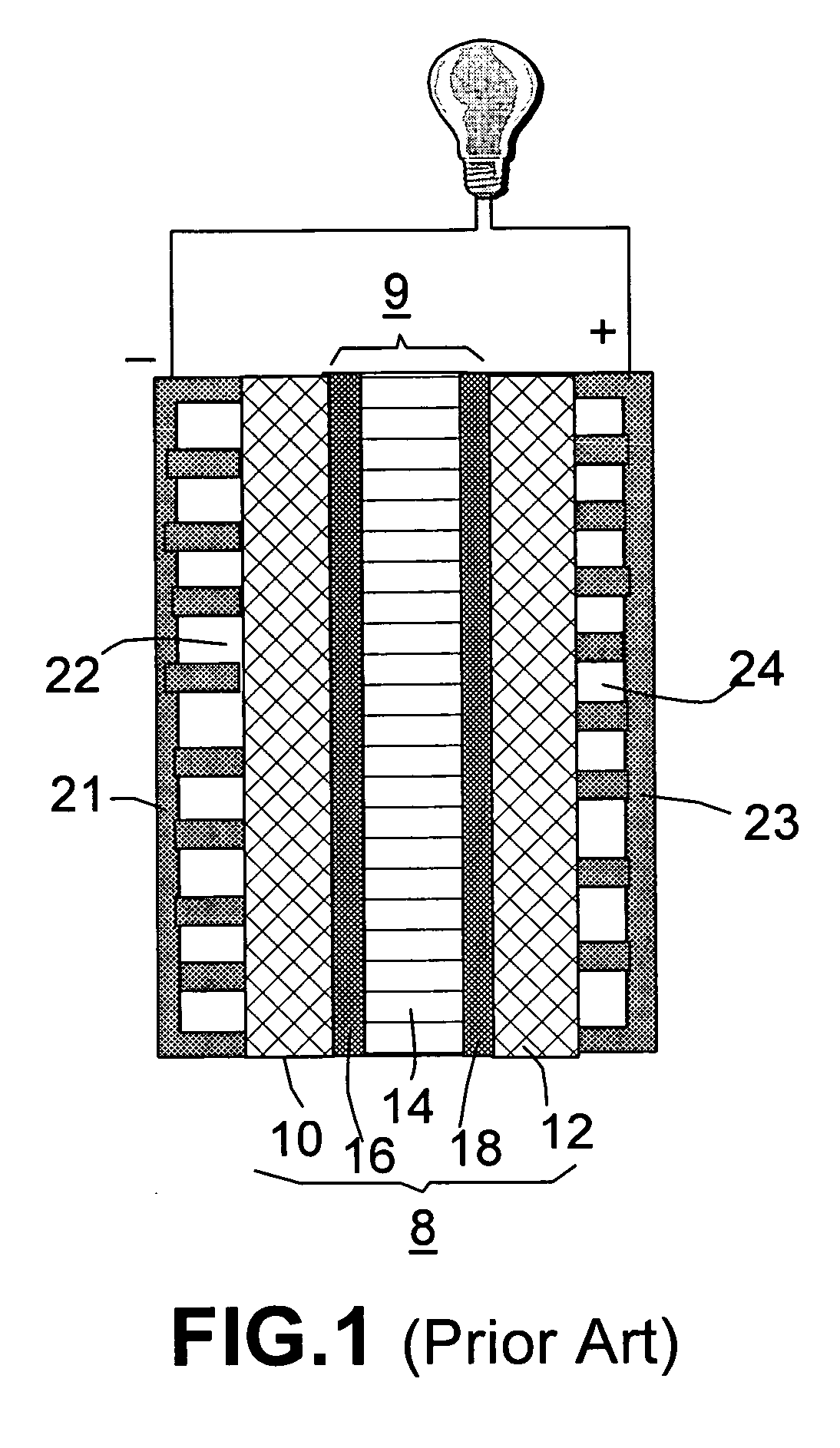

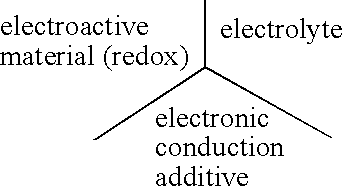

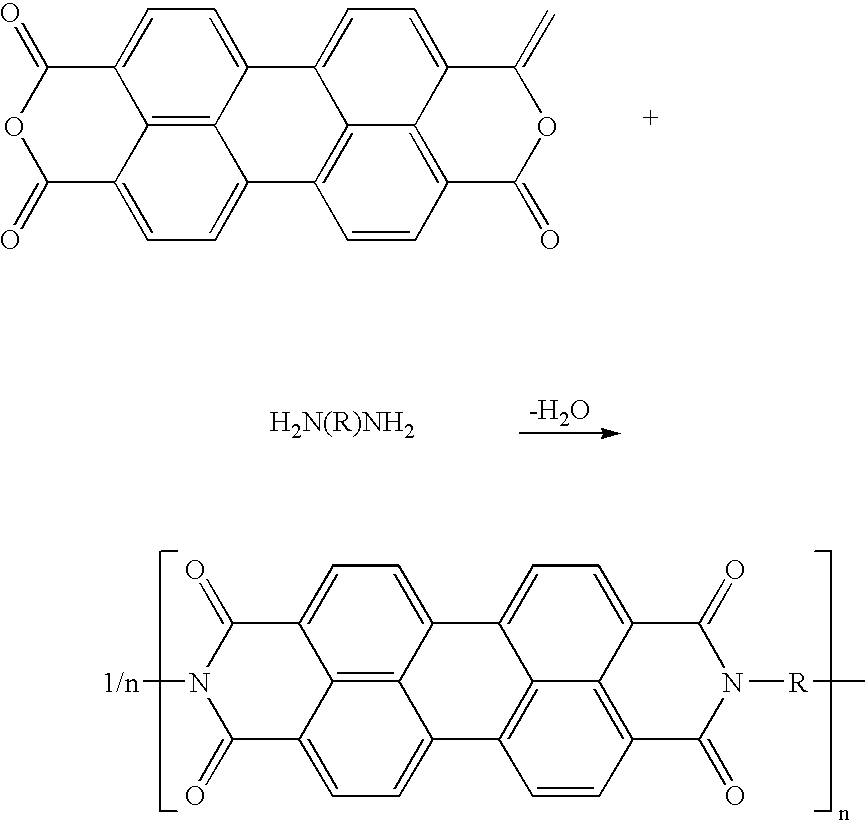

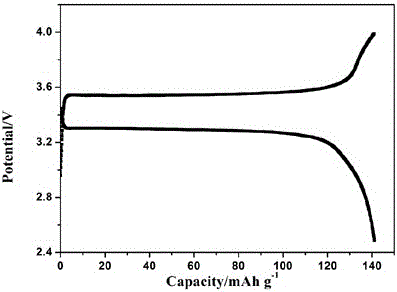

Electrode materials with high surface conductivity

InactiveUS20040140458A1Simple structureHigh crystallinityElectrode manufacturing processesDouble layer capacitorsSurface conductivityIon exchange

The present invention concerns electrode materials capable of redox reactions by electrons and alkaline ions exchange with an electrolyte. The applications are in the field of primary (batteries) or secondary electrochemical generators, super capacitors and light modulating system of the super capacitor type.

Owner:CENT NAT DE LA RECHERCHE SCI +2

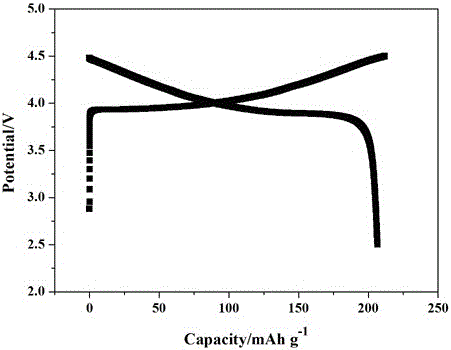

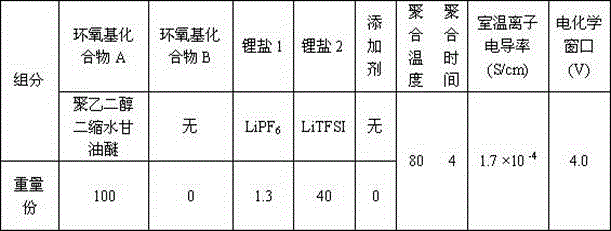

Preparation method of all-solid polymer electrolyte through in-situ ring opening polymerization of epoxy compound, and application of the all-solid polymer electrolyte in all-solid lithium battery

ActiveCN105914405AIncrease contactImprove interface compatibilityFinal product manufactureLi-accumulatorsEpoxySolid state electrolyte

The invention discloses a preparation method of an all-solid polymer electrolyte through in-situ ring opening polymerization of an epoxy compound, and an application of the all-solid polymer electrolyte in an all-solid battery. The preparation method is characterized in that a liquid-state epoxy compound, a lithium salt, a battery additive and the like are employed as precursors and are injected into between a positive pole sheet and a negative pole sheet of the battery, and under a heating condition, in-situ polymerization solidification is carried out to form the all-solid polymer electrolyte, and furthermore, the all-solid battery is produced. The ionic conductivity at room temperature of the all-solid polymer electrolyte can reach from 1*10<-5> S / cm to 9*10<-3> S / cm and electric potential window is 3.5-5 V. The all-solid polymer electrolyte is prepared through the in-situ copolymerization method, so that the all-solid polymer electrolyte has excellent contact with electrodes, thereby greatly improving interface compatibility of the solid-state battery, reducing interface wetting and modification steps of the solid-state battery, reducing production cost of the solid-state battery and improving performances of the solid-state battery. The invention also discloses an all-solid polymer lithium battery assembled from the all-solid polymer electrolyte.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

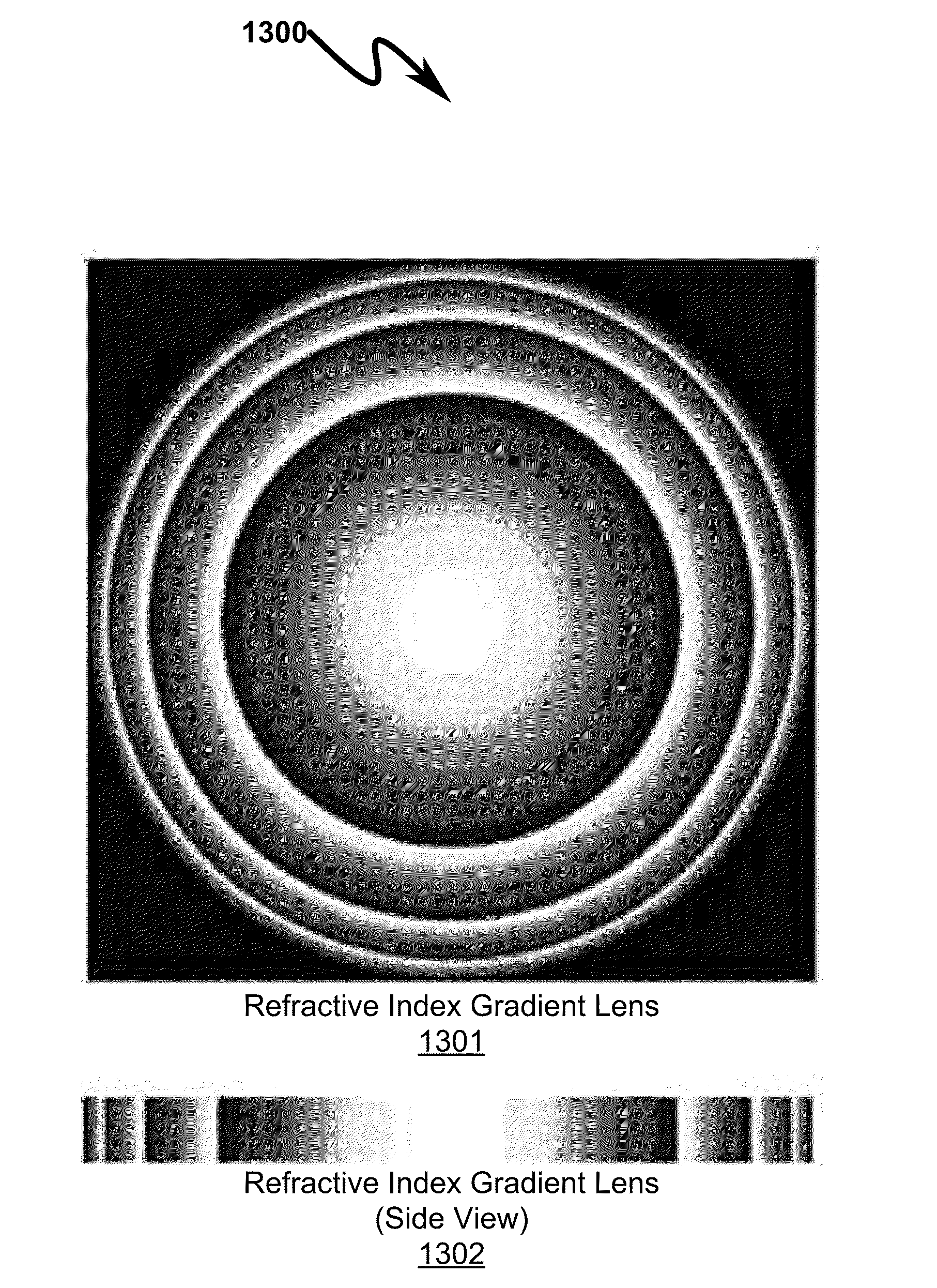

Hydrophilicity Alteration System and Method

ActiveUS20140135920A1Increase optical powerCorrection errorLaser surgeryOptical articlesOptical propertyRefractive index

A system / method allowing hydrophilicity alteration of a polymeric material (PM) is disclosed. The PM hydrophilicity alteration changes the PM characteristics by decreasing the PM refractive index, increasing the PM electrical conductivity, and increasing the PM weight. The system / method incorporates a laser radiation source that generates tightly focused laser pulses within a three-dimensional portion of the PM to affect these changes in PM properties. The system / method may be applied to the formation of customized intraocular lenses comprising material (PLM) wherein the lens created using the system / method is surgically positioned within the eye of the patient. The implanted lens refractive index may then be optionally altered in situ with laser pulses to change the optical properties of the implanted lens and thus achieve optimal corrected patient vision. This system / method permits numerous in situ modifications of an implanted lens as the patient's vision changes with age.

Owner:PERFECT IP

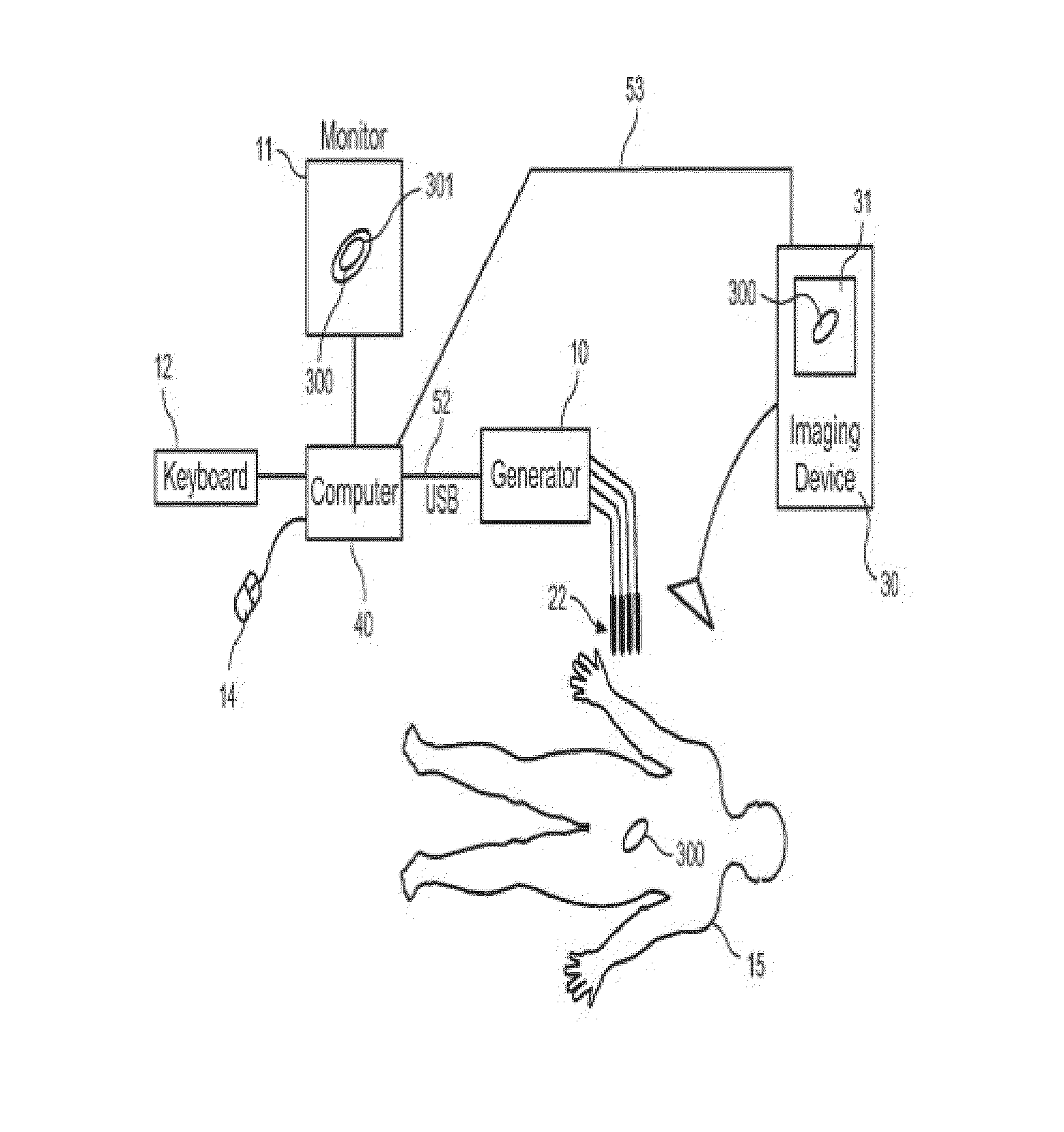

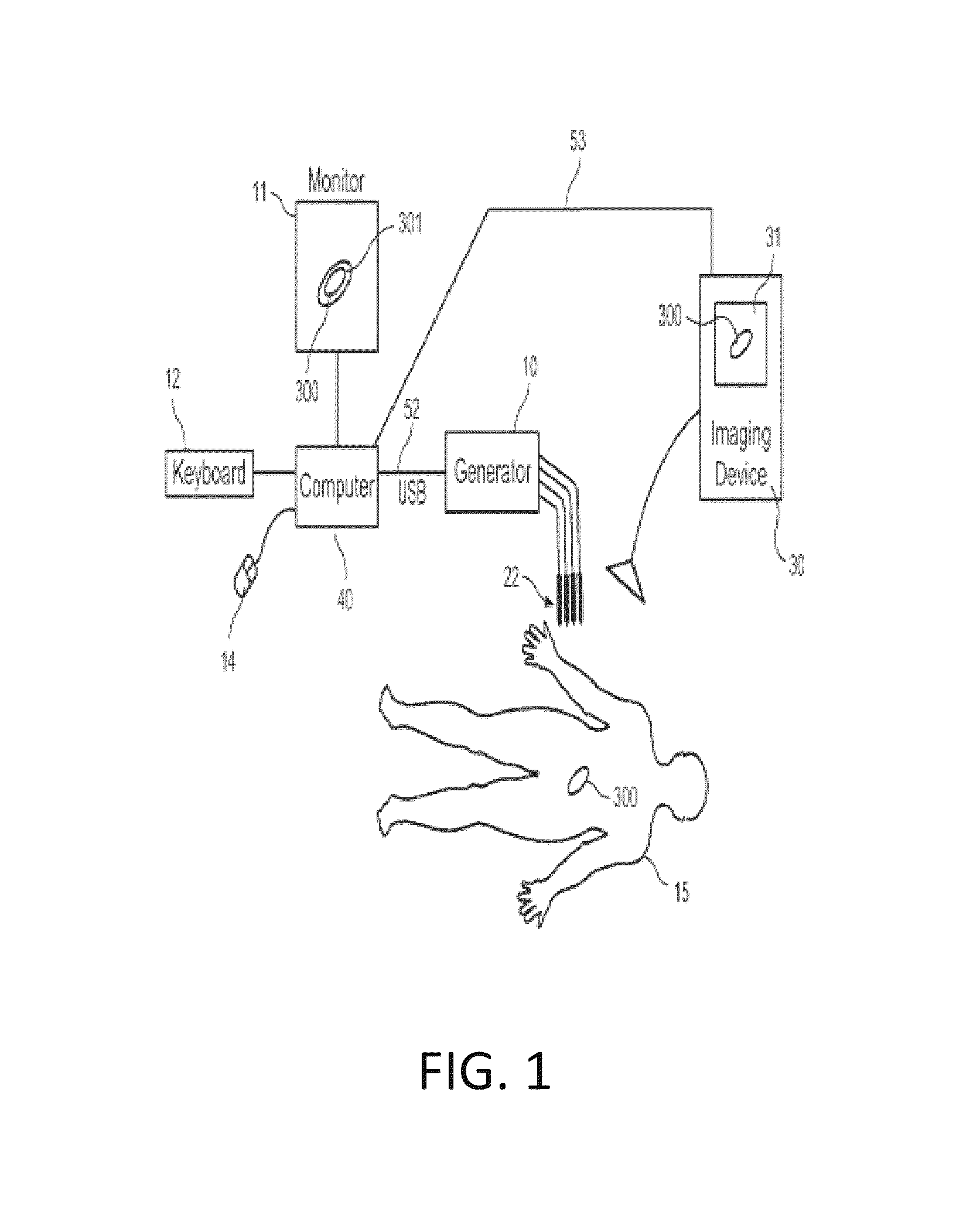

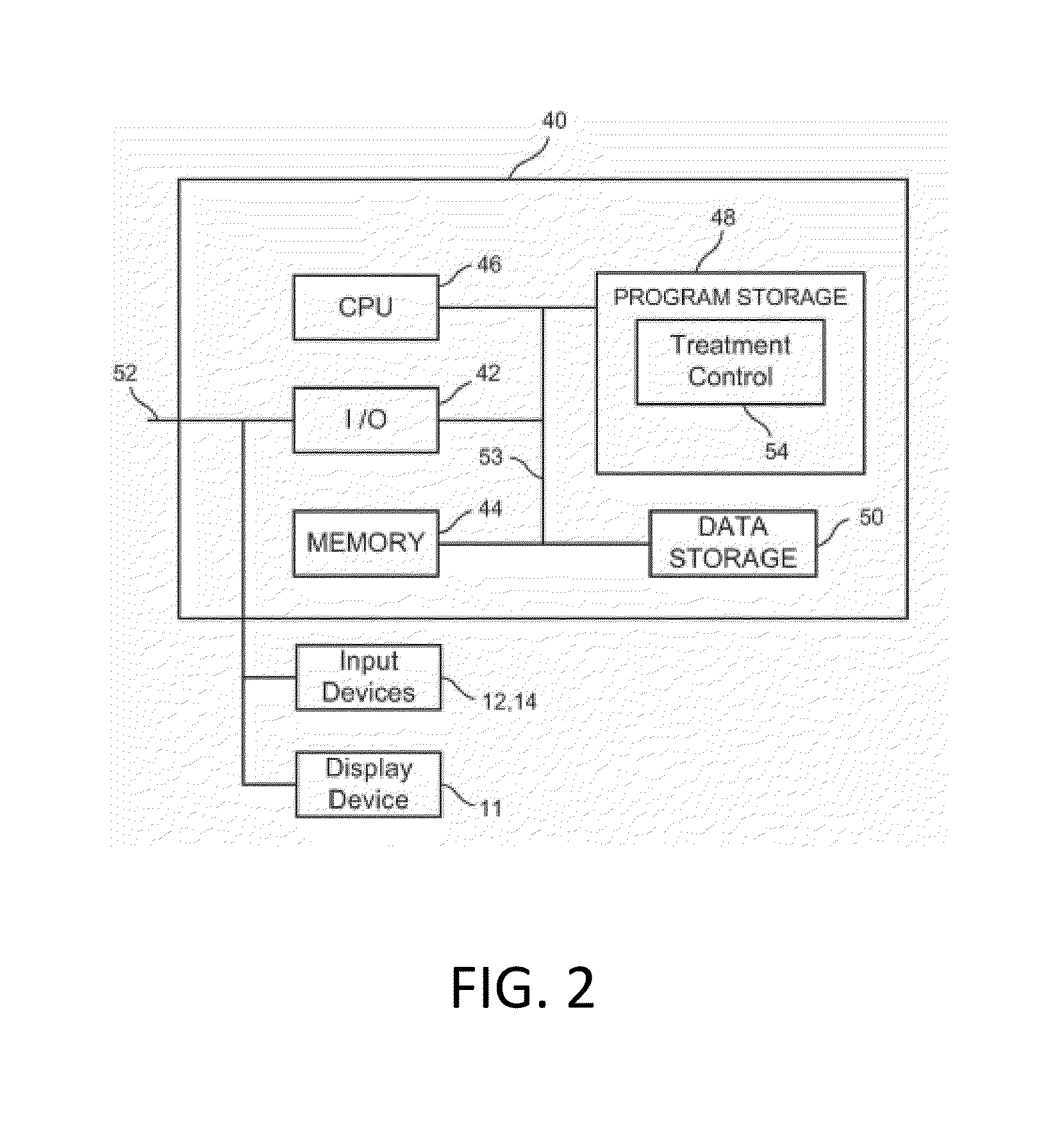

System and method for estimating a treatment volume for administering electrical-energy based therapies

ActiveUS9283051B2Accurate predictionDetermine the extent of electroporationSurgical needlesComputer-aided planning/modellingMedicineComputer module

The invention provides for a system for estimating a 3-dimensional treatment volume for a device that applies treatment energy through a plurality of electrodes defining a treatment area, the system comprising a memory, a display device, a processor coupled to the memory and the display device, and a treatment planning module stored in the memory and executable by the processor. In one embodiment, the treatment planning module is adapted to generate an estimated first 3-dimensional treatment volume for display in the display device based on the ratio of a maximum conductivity of the treatment area to a baseline conductivity of the treatment area. The invention also provides for a method for estimating 3-dimensional treatment volume, the steps of which are executable through the processor. In embodiments, the system and method are based on a numerical model which may be implemented in computer readable code which is executable through a processor.

Owner:VIRGINIA TECH INTPROP INC

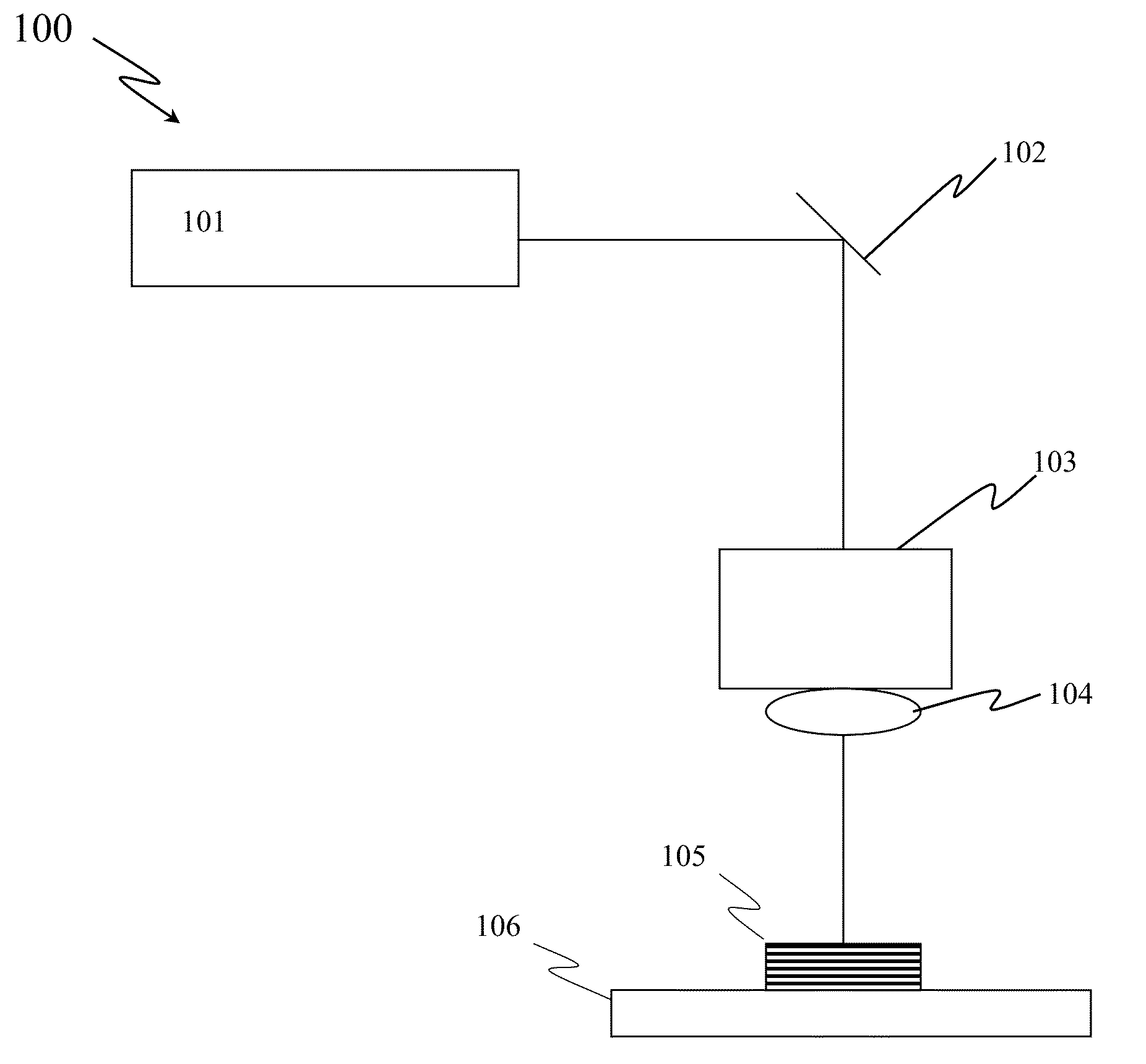

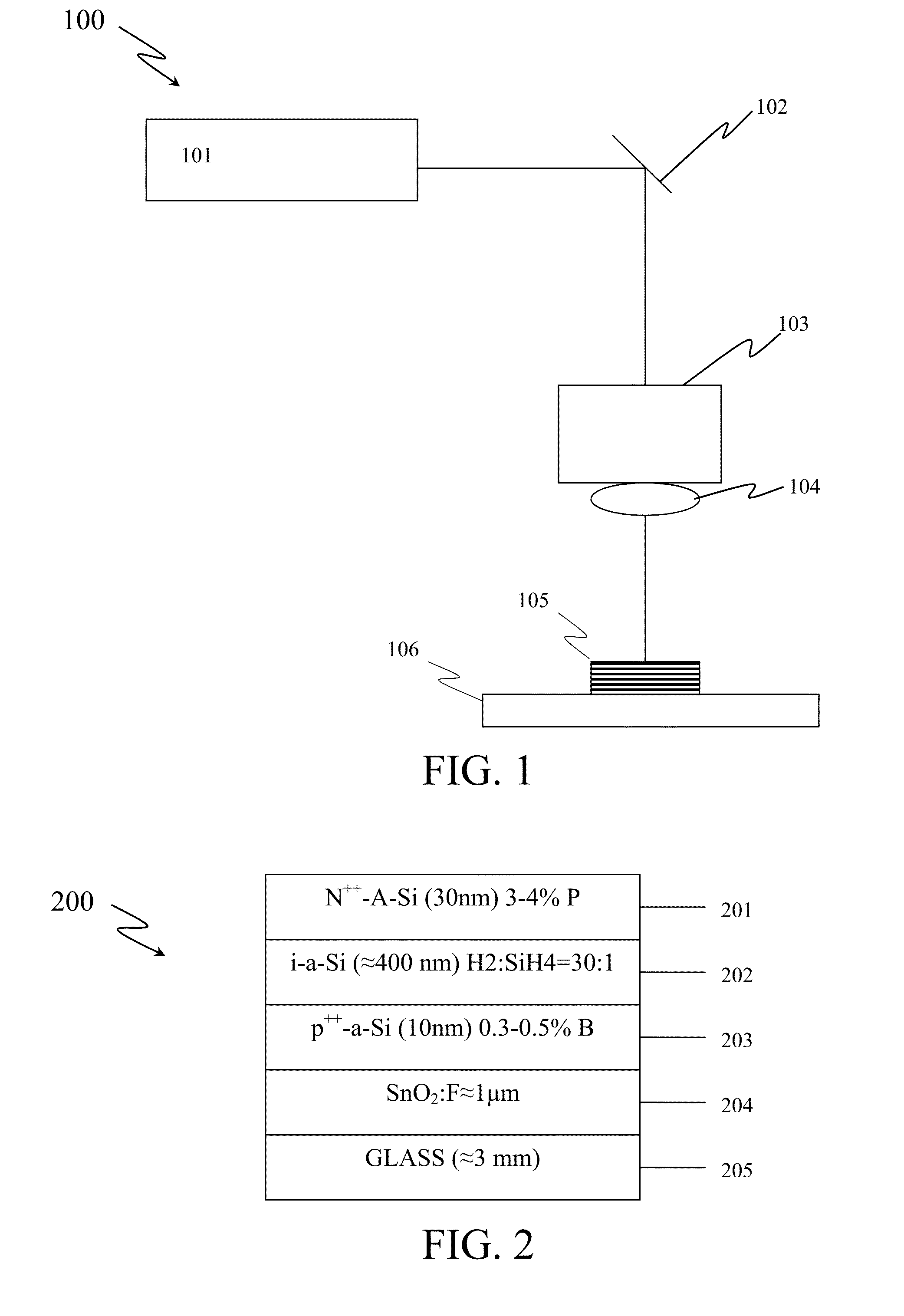

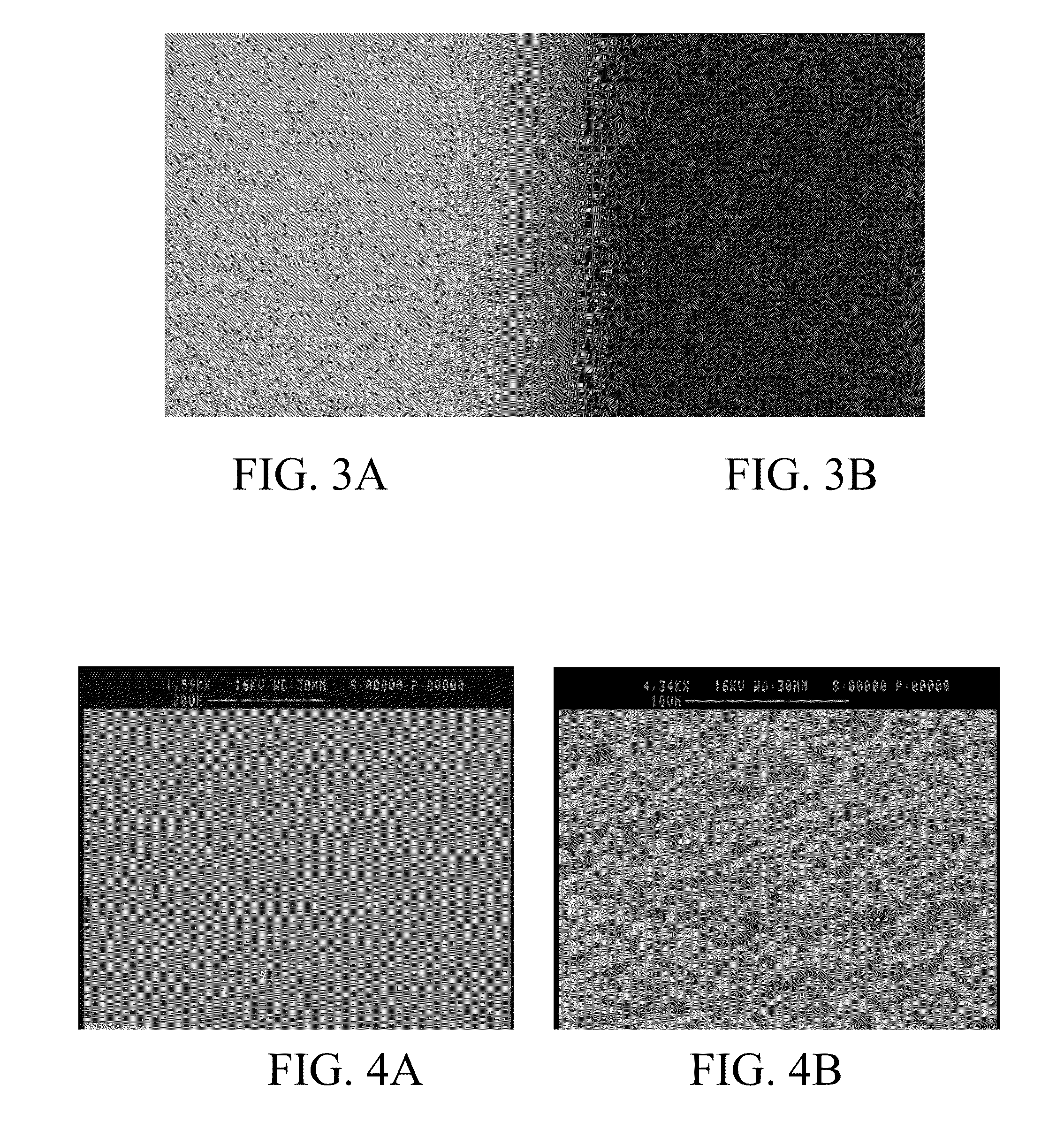

Systems and methods of laser texturing of material surfaces and their applications

ActiveUS20130020297A1Enhance light absorptionImprove conductivityNanotechLaser beam welding apparatusAlloyElectron

The surface of a material is textured and by exposing the surface to pulses from an ultrafast laser. The laser treatment causes pillars to form on the treated surface. These pillars provide for greater light absorption. Texturing and crystallization can be carried out as a single step process. The crystallization of the material provides for higher electric conductivity and changes in optical and electronic properties of the material. The method may be performed in vacuum or a gaseous environment. The gaseous environment may aid in texturing and / or modifying physical and chemical properties of the surfaces. This method may be used on various material surfaces, such as semiconductors, metals and their alloys, ceramics, polymers, glasses, composites, as well as crystalline, nanocrystalline, polycrystalline, microcrystalline, and amorphous phases.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

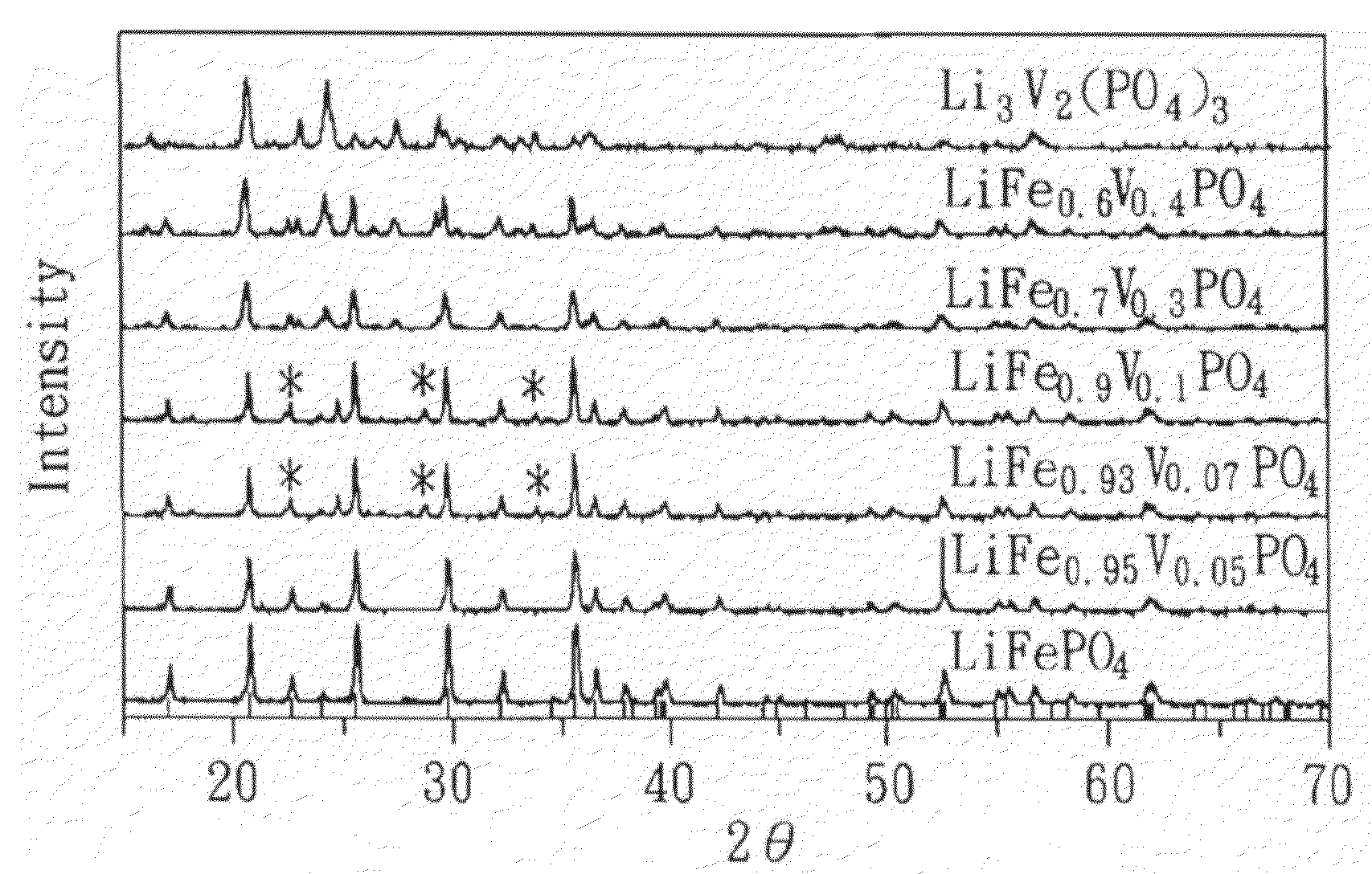

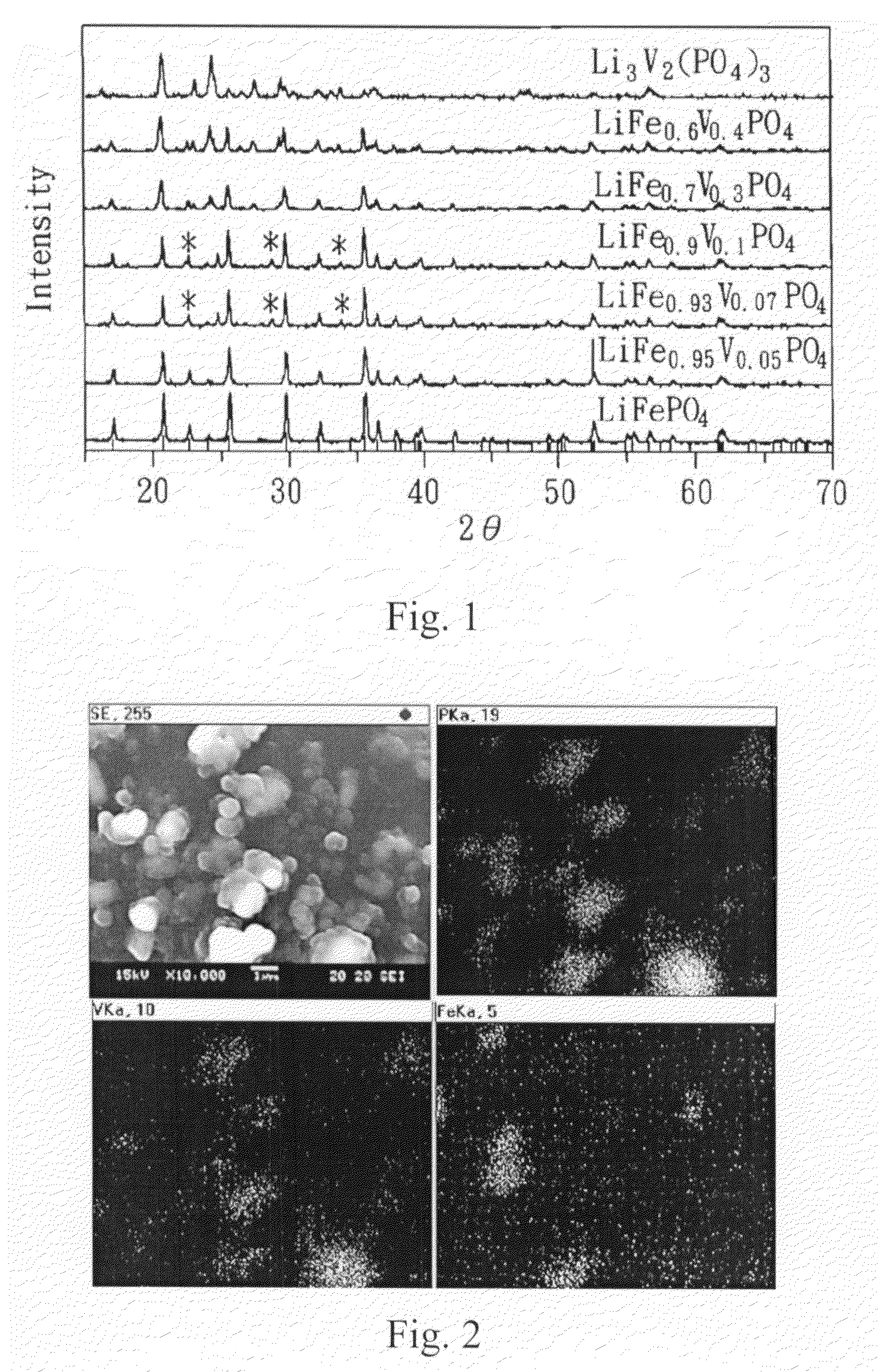

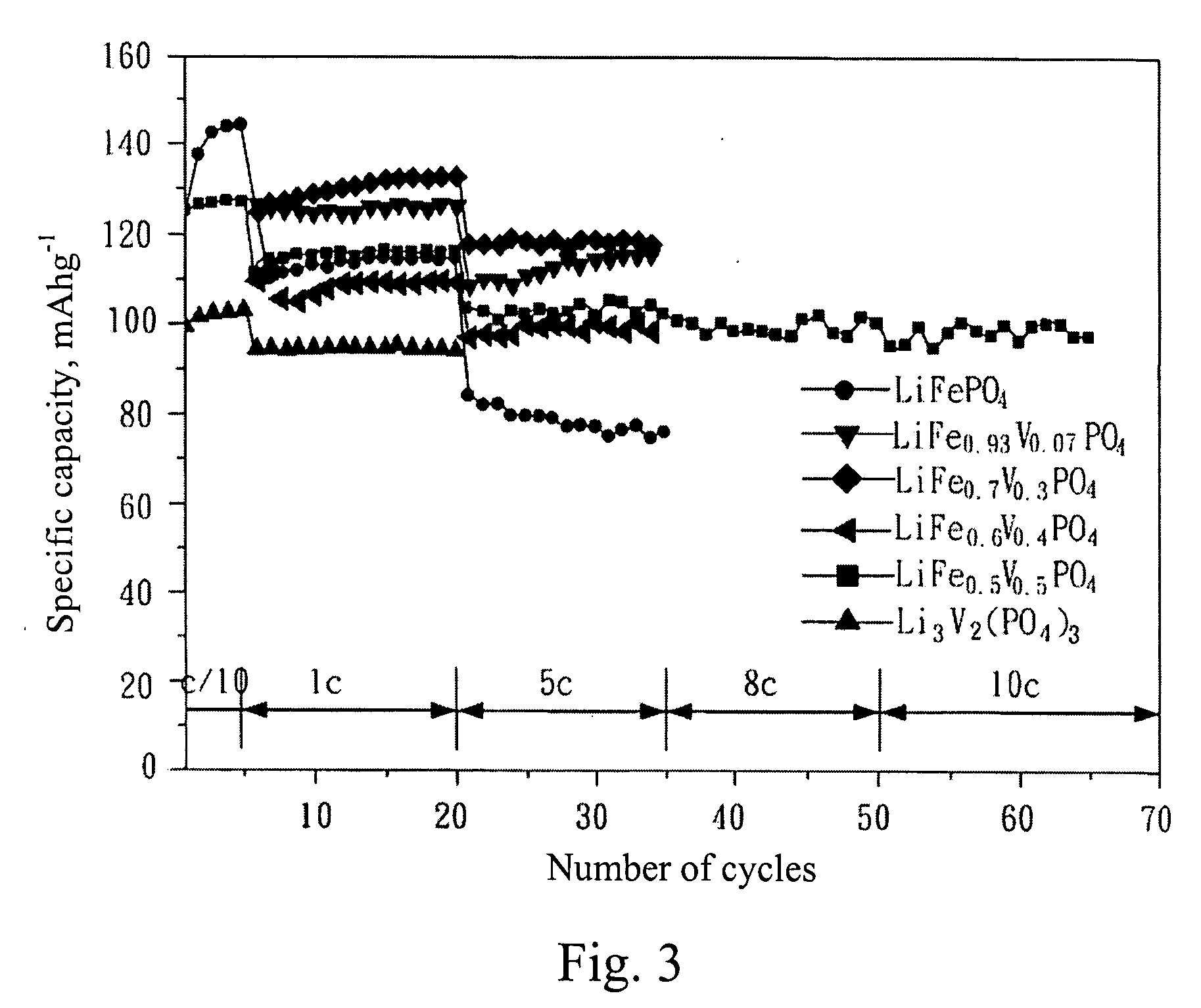

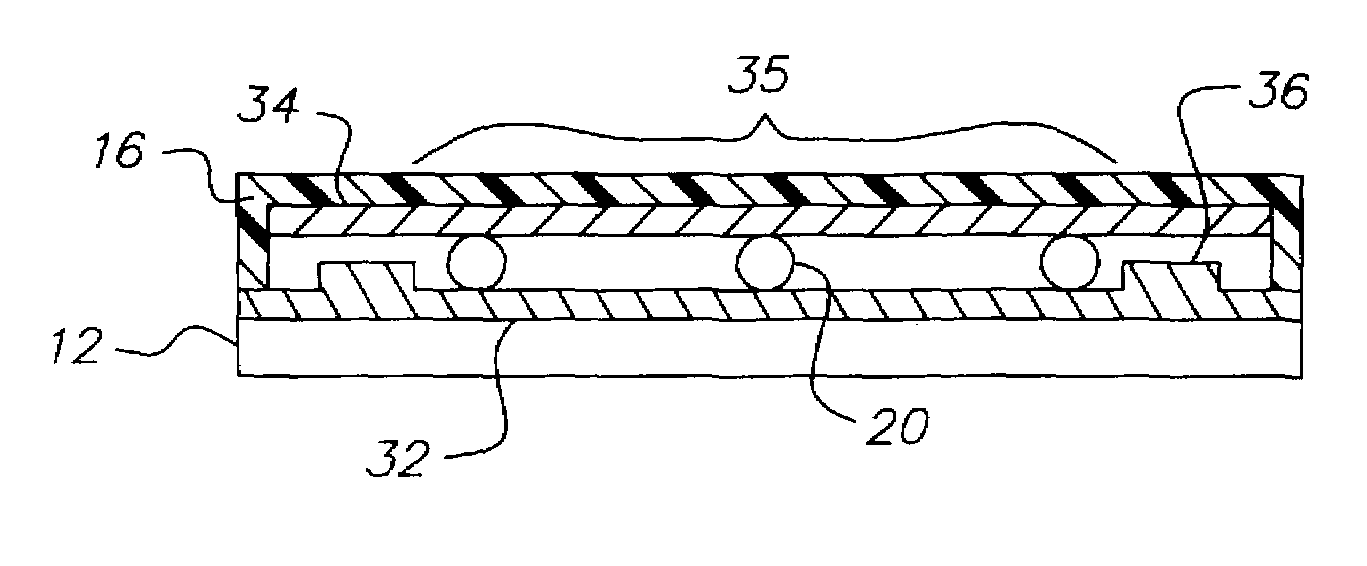

Preparation and application of LiFePO4/Li3V2 (PO4)3 composite cathode materials for lithium ion batteries

InactiveUS20080008938A1Improve conductivityCathode material of highElectrode manufacturing processesDuplicating/marking methodsComposite cathodeIron powder

A method of preparing LiFePO4 / Li3V2(PO4)3 composite cathode materials and their applications as cathode materials for lithium ion batteries are disclosed. The preparation method includes the following steps: (A) providing a mixture of iron powder, lithium salt, vanadium salt, and a phosphate salt whereafter these compounds are dissolved into a mixed acid solution; (B) drying the solution in order to obtain precursor powders; and (C) heating the precursor powders at a temperature ranging between 400 and 1000° C. to form LiFe1-y′Vy′PO4 / Li3V2-y″Fey″(PO4)3 composite powders. Alternatively, prepare the composite cathode by preparing olivine LiFe1-y′Vy′PO4 and monoclinic Li3V2-y′Fey″(PO4)3 powders as in previous procedures followed by mixing adequately. The low cost of iron powder thus facilitates to prepared composite cathode materials exhibiting higher electrical conductivity and superior cycling performance at high C rates than those of olivine LiFe1-y′Vy′PO4 and monoclinic Li3V2-y″Fey″(PO4)3. The invention will help the development of the lithium ion batteries and related industries.

Owner:TATUNG COMPANY

Resistive touch screen with variable resistivity layer

InactiveUS7064748B2Easy to manufactureLow costTransmission systemsCathode-ray tube indicatorsElectrical connectionResistive touchscreen

A resistive touch screen includes a transparent substrate defining a touch area; a first layer of conductive material formed on the transparent substrate and extending over the touch area; an electrical connection to the first layer of conductive material; a transparent flexible cover sheet; a second layer of conductive material formed on the transparent flexible cover sheet, the cover sheet being mounted in a spaced apart relationship from the substrate, whereby a touch in the touch area results in an a electrical contact between the first and second layers of conductive material at the point of touch; an electrical connection to the second layer of conductive material; and at least one of the first or second layers of conductive material having a variable conductivity.

Owner:EASTMAN KODAK CO

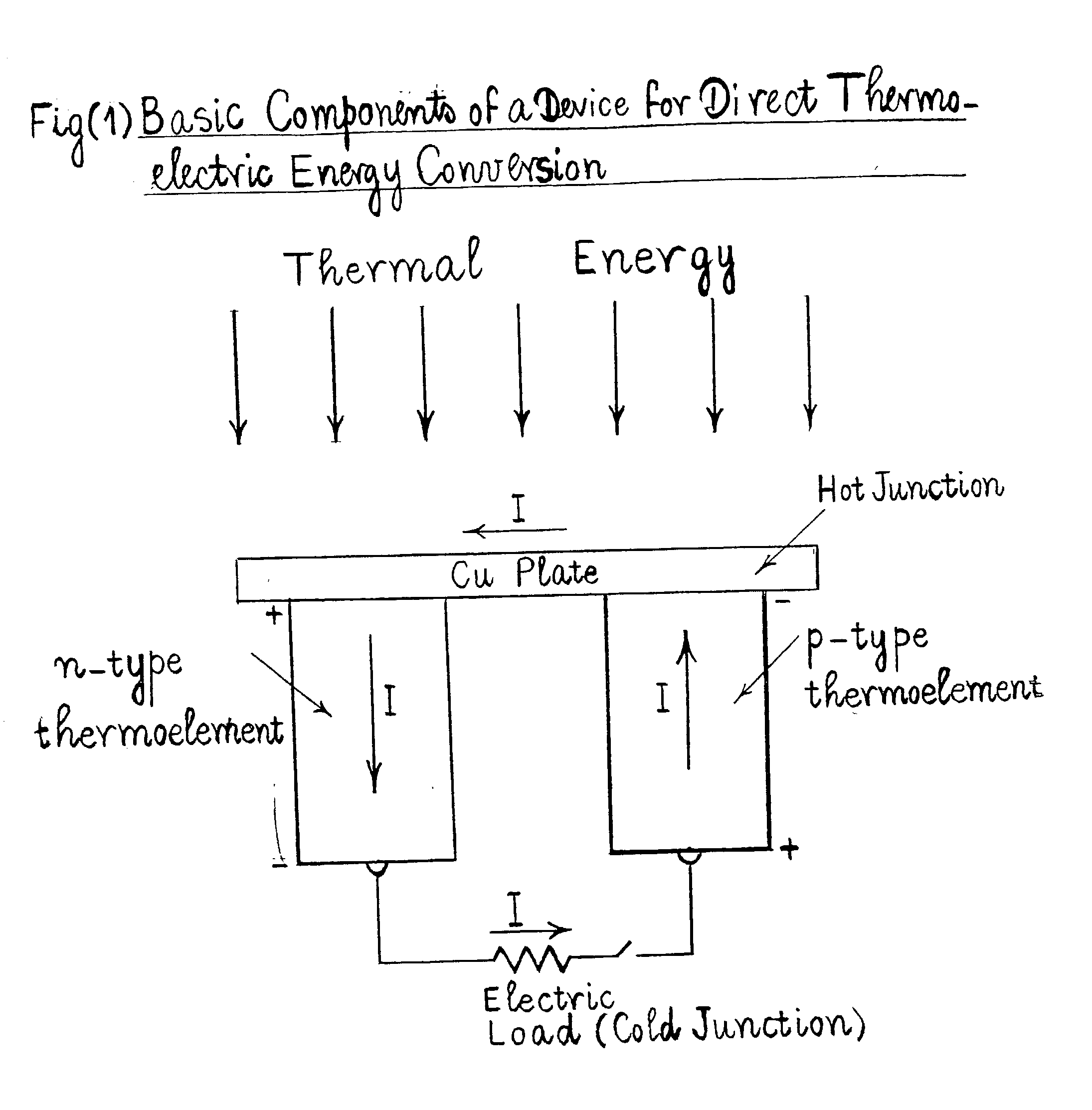

Method for producing a device for direct thermoelectric energy conversion

InactiveUS20030110892A1Polycrystalline material growthThermoelectric device manufacture/treatmentJunction temperatureEngineering

In devices used for the direct conversion of heat into electricity, or vice versa, known in the art as thermoelectric power generators, thermoelectric refrigerators and thermoelectric heat pumps, the efficiency of energy conversion and / or coefficient of performance have been considerably lower than those of conventional reciprocating or rotary, heat engines and / or vapor-compression systems, employing certain refrigerants. The energy conversion efficiency of power generating devices, for example, aside from the hot and cold junction temperatures, also depends on a parameter known in the art as the thermoelectric figure of merit Z=S2sigma / k, where S is the thermoelectric power, sigma is the electrical conductivity and k is the thermal conductivity, of the material that constitutes the p-type, and / or n-type, thermoelements, or branches, of the said devices. In order to achieve a considerable increase in the energy conversion efficiency, a thermoelectric figure of merit of the order of 10-2 K-1, or more, is needed. It is reasonably expected that such an order of magnitude, for the figure of merit, can be realized with a composition of matter, comprising magnesium, silicon, lead and barium, and optionally comprising one, or more, additional doping materials.

Owner:NICOLOAU MICHAEL C

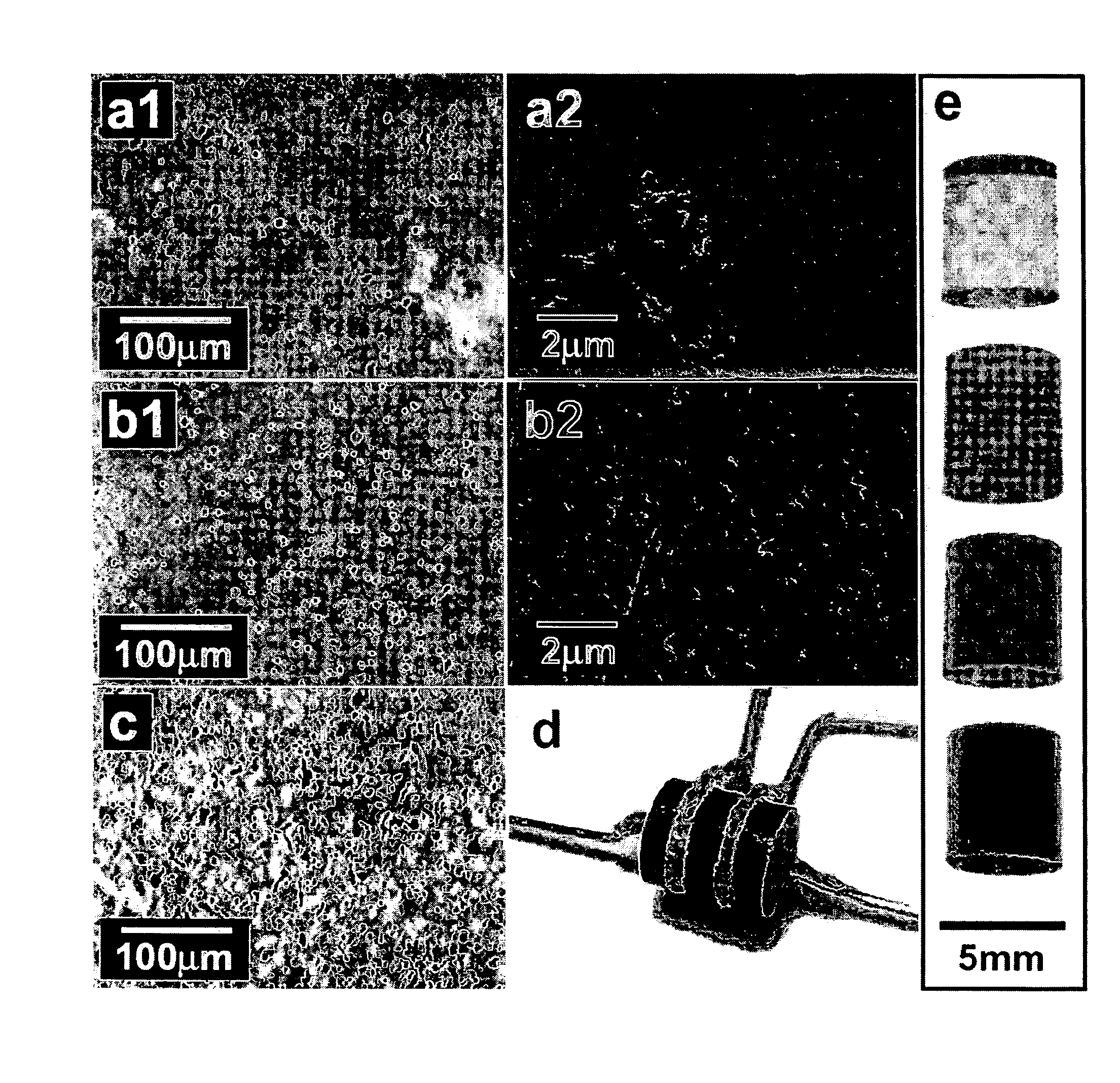

High-performance flexible composite nonwoven fabric membrane for lithium ion battery, as well as preparation method and application of membrane

InactiveCN103296240AGood flexibilityGood high current discharge performanceCell component detailsAdhesiveCharge discharge

The invention discloses a high-performance flexible composite nonwoven fabric membrane for a lithium ion battery, as well as a preparation method and an application of the membrane, which belongs to the technical field of a lithium-ion battery membrane material. The prepared composite nonwoven fabric membrane is formed by coating functional serous fluid with thermally curable or optically curable functional groups onto a substrate membrane containing an active functional group, thermally curing or optically curing the substrate membrane, removing a pore-forming agent, and hot pressing and drying the substrate. The prepared composite nonwoven fabric membrane is good in flexibility. The composite nonwoven fabric membrane has good ion electric conductivity and hot shrinkage resistance, can bear the large-current discharge, and also can improve the safety performance of the battery. Since no fluorine-containing adhesive is used in a preparation process, nano particles or nano optical fibers are connected with the substrate membrane through a chemical key, the nano particles or the nano fibers are bonded together through the chemical key and free from dropping off in the charging-discharging cycle, the stability of the coating is enhanced, and the cycling performance of the battery can be improved. The prepared flexible composite nonwoven fabric membrane is used as a membrane assembly of the lithium ion battery.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

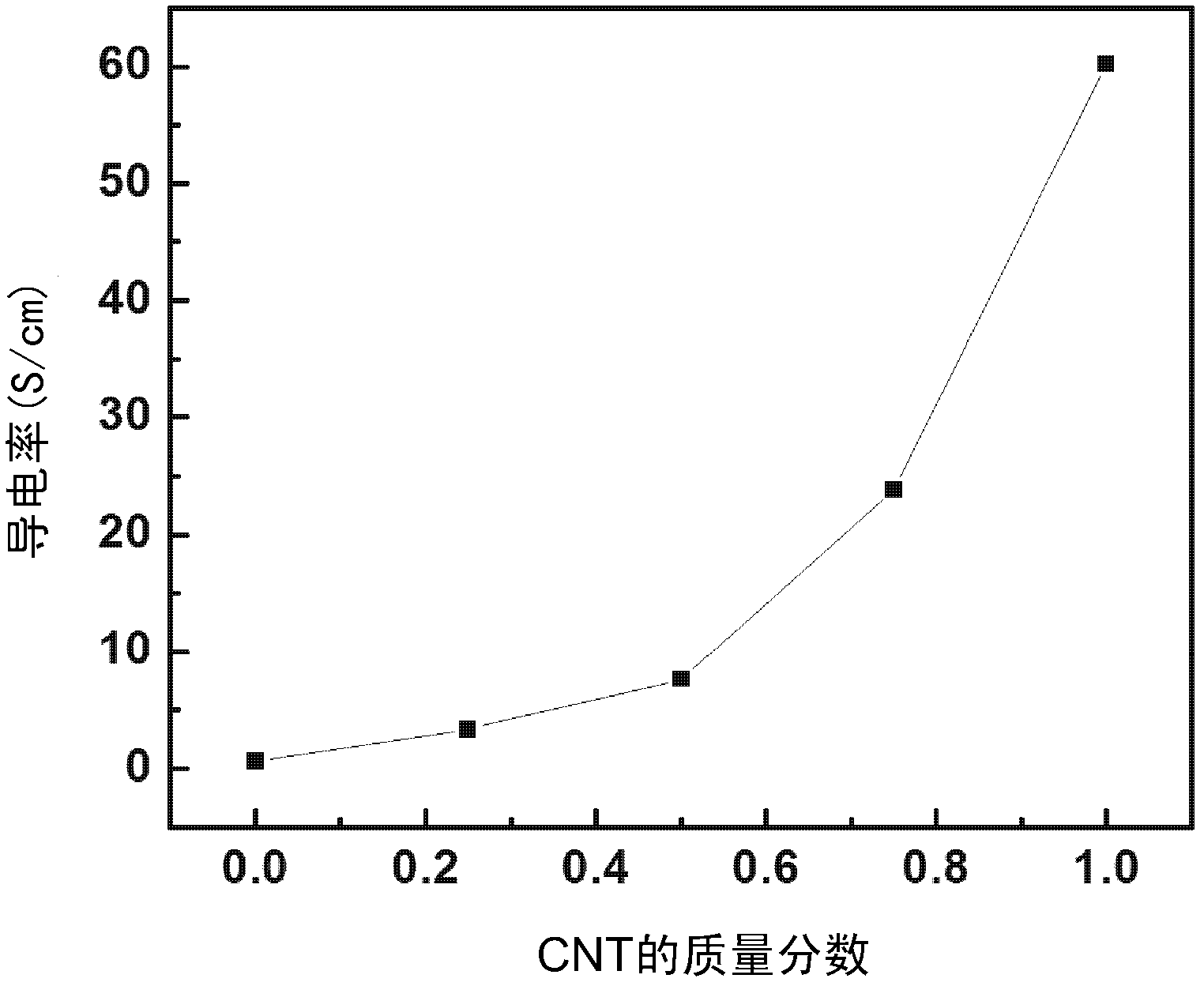

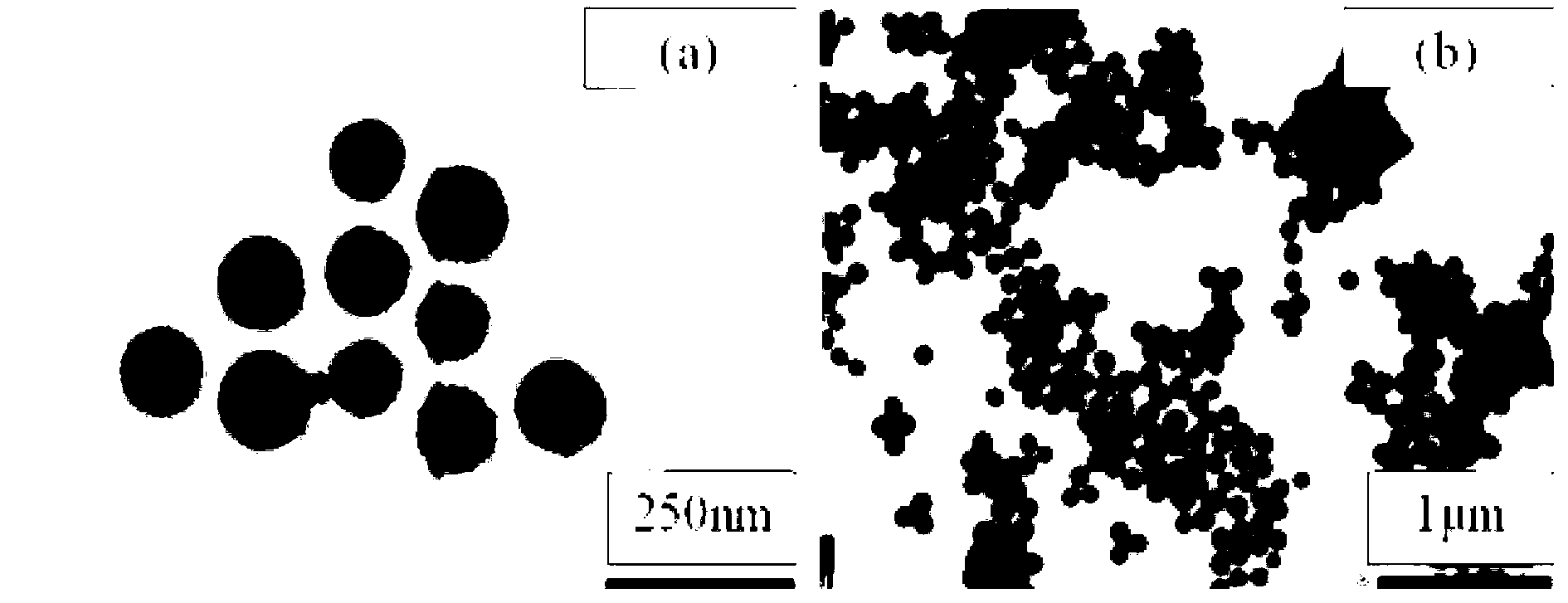

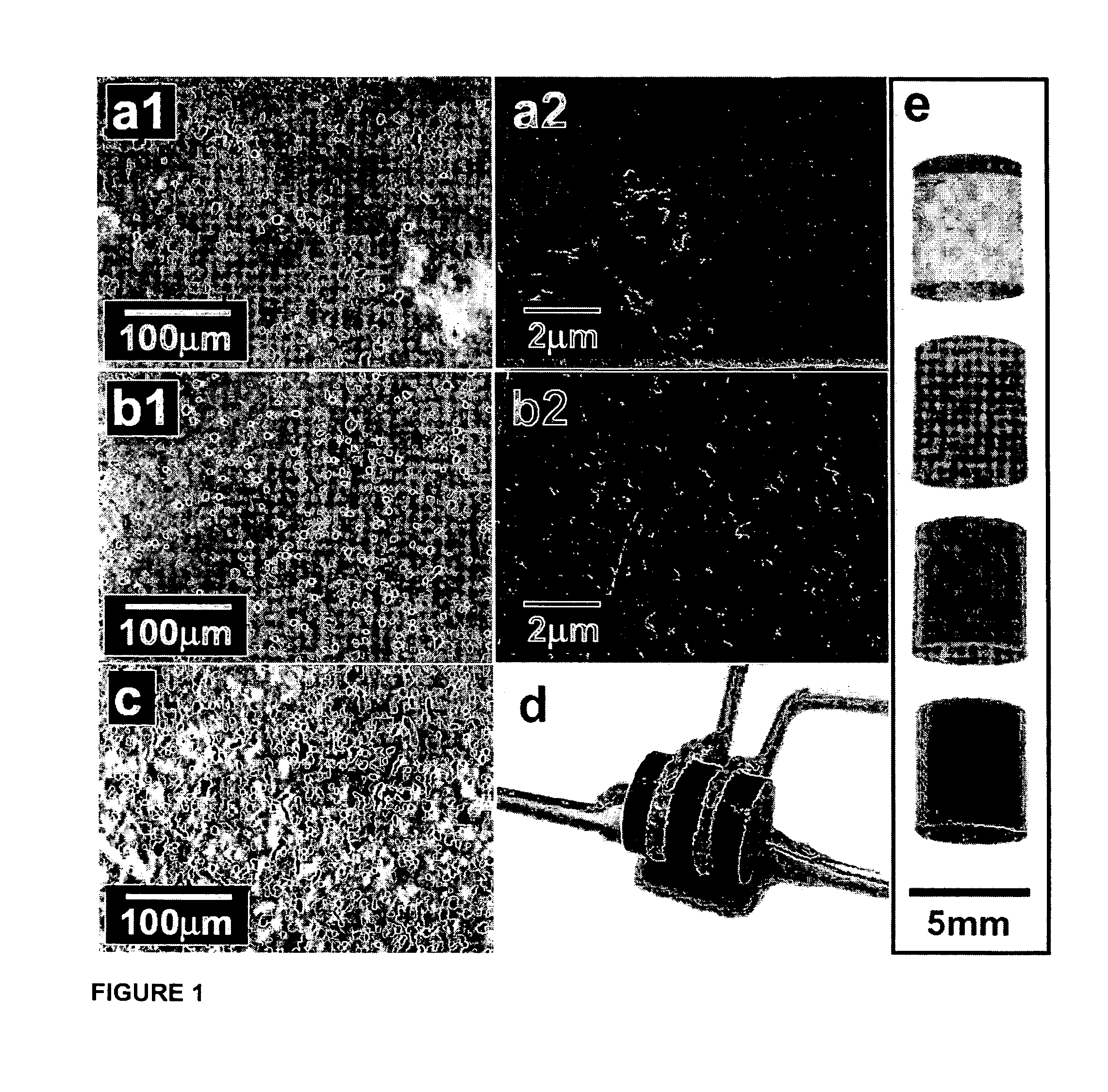

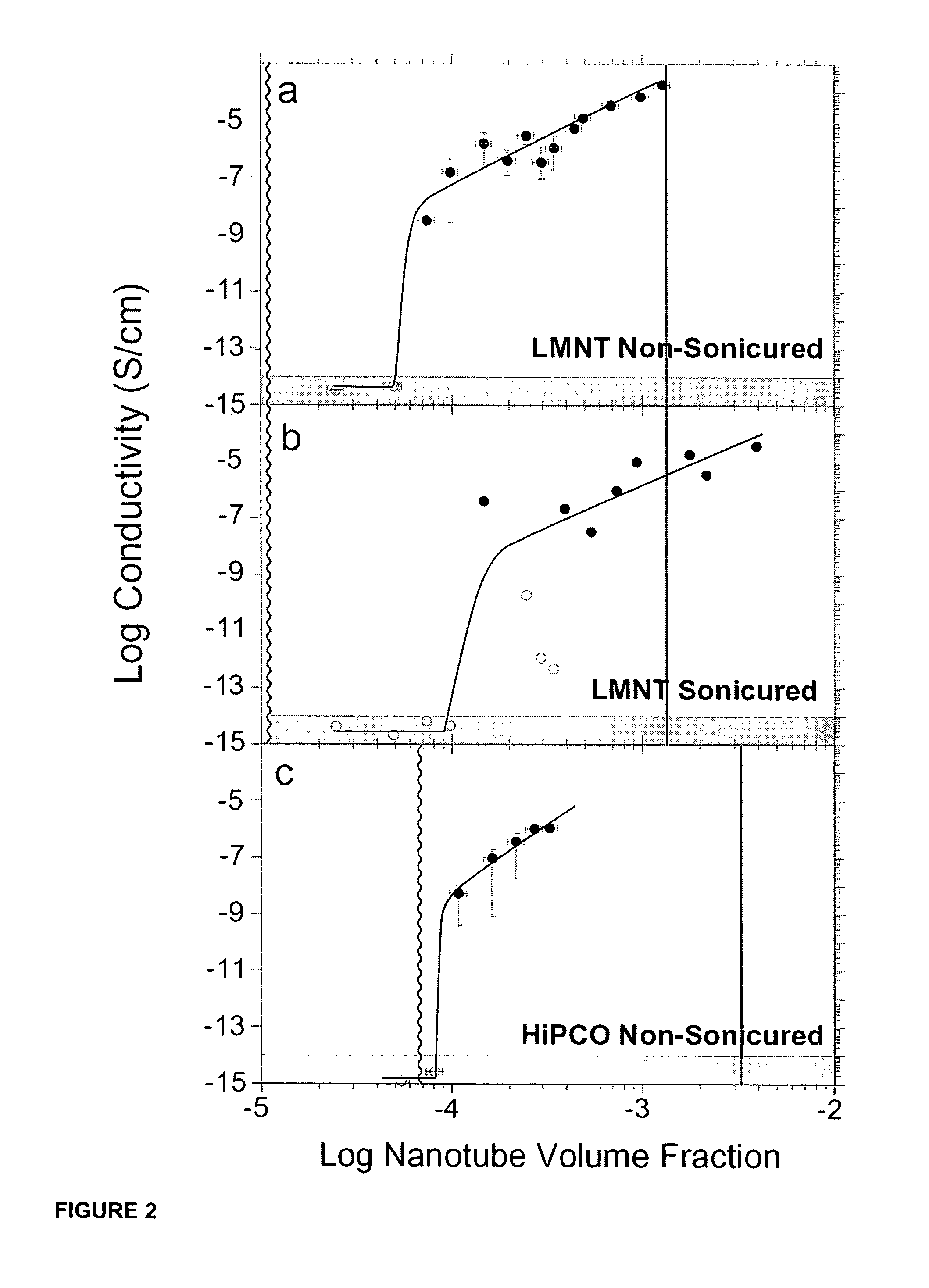

Single wall nanotube composites

Methods for preparing composite materials containing carbon nanotubes and a matrix material are provided. Nanotube composite materials and electrical devices made using nanotube composite materials are also provided. Composite materials composed of nanotubes near the percolation threshold provide electrical conductivities greater than about 10−9 S / cm.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

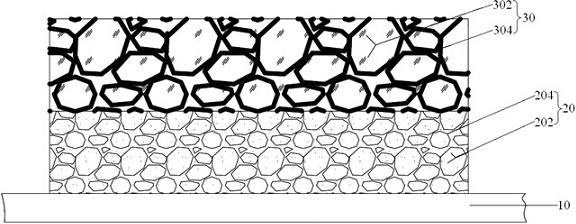

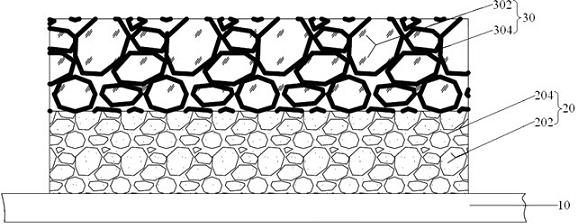

Thick electrode with good electrochemical performance and its preparation method

ActiveCN102324493AImproved magnification performanceSolve the problem of concentration polarizationNon-aqueous electrolyte accumulator electrodesElectrolytic agentEngineering

The invention discloses a thick electrode with a good electrochemical performance. The electrode comprises a current collector and an electrode membrane containing active substances and conductive substances. With a thickness greater than 300 micrometers, the electrode membrane includes an internal membrane layer close to the current collector and an external membrane layer far from the current collector. The conductivity of the electrode membrane decreases from the internal membrane layer to the external membrane layer, while the porosity of the electrode membrane increases from the internal membrane layer to the external membrane layer. The internal membrane layer has great conductivity which can make electrons at the current collector entering or separating from the internal membrane layer rapidly. With great porosity, the external membrane layer can adsorb a lot of electrolyte, thus solving the problem of poor electrolyte wettability of thick electrodes. In addition, the invention also discloses a preparation method of a thick electrode with a good electrochemical performance.

Owner:DONGGUAN AMPEREX TECH +1

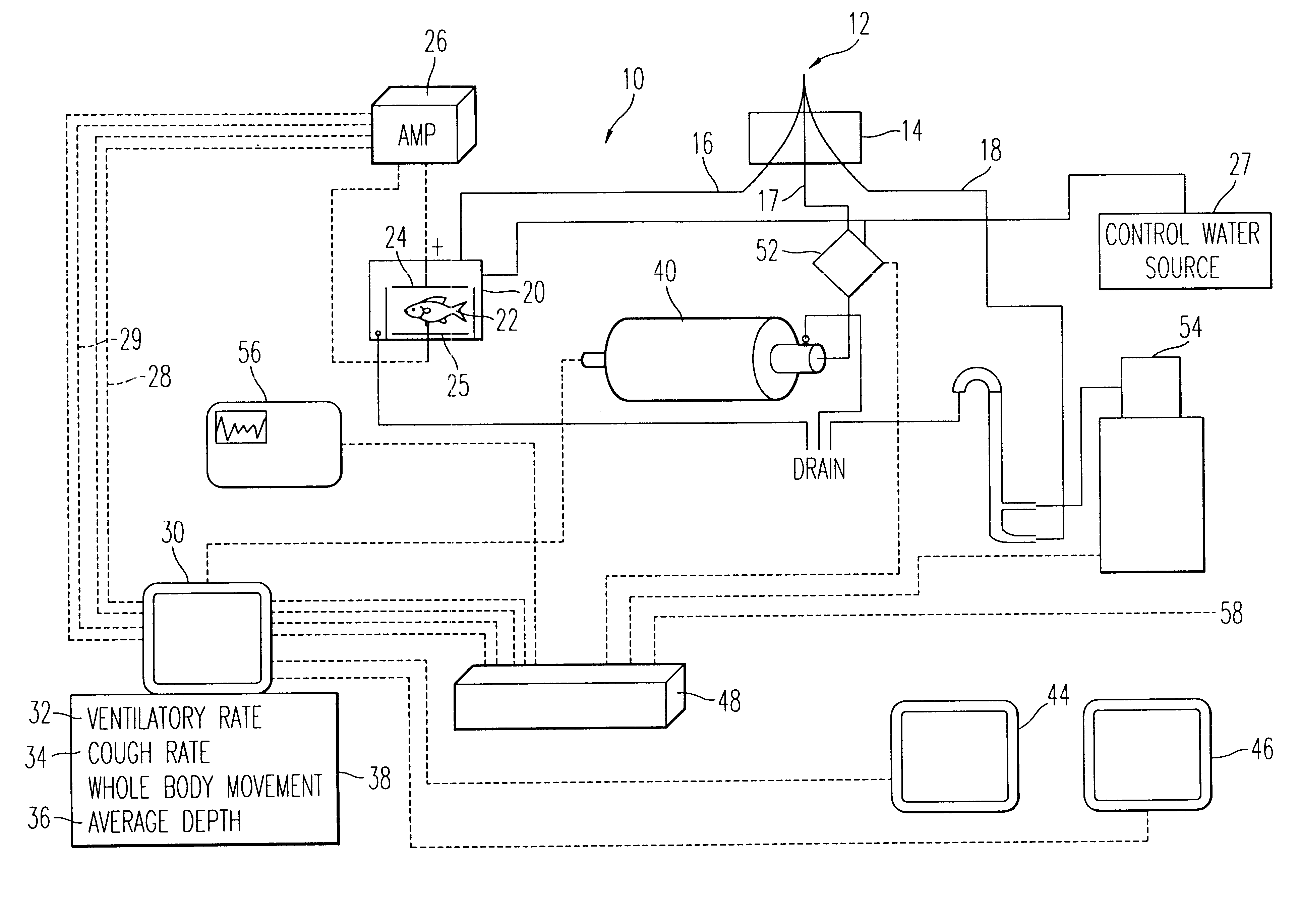

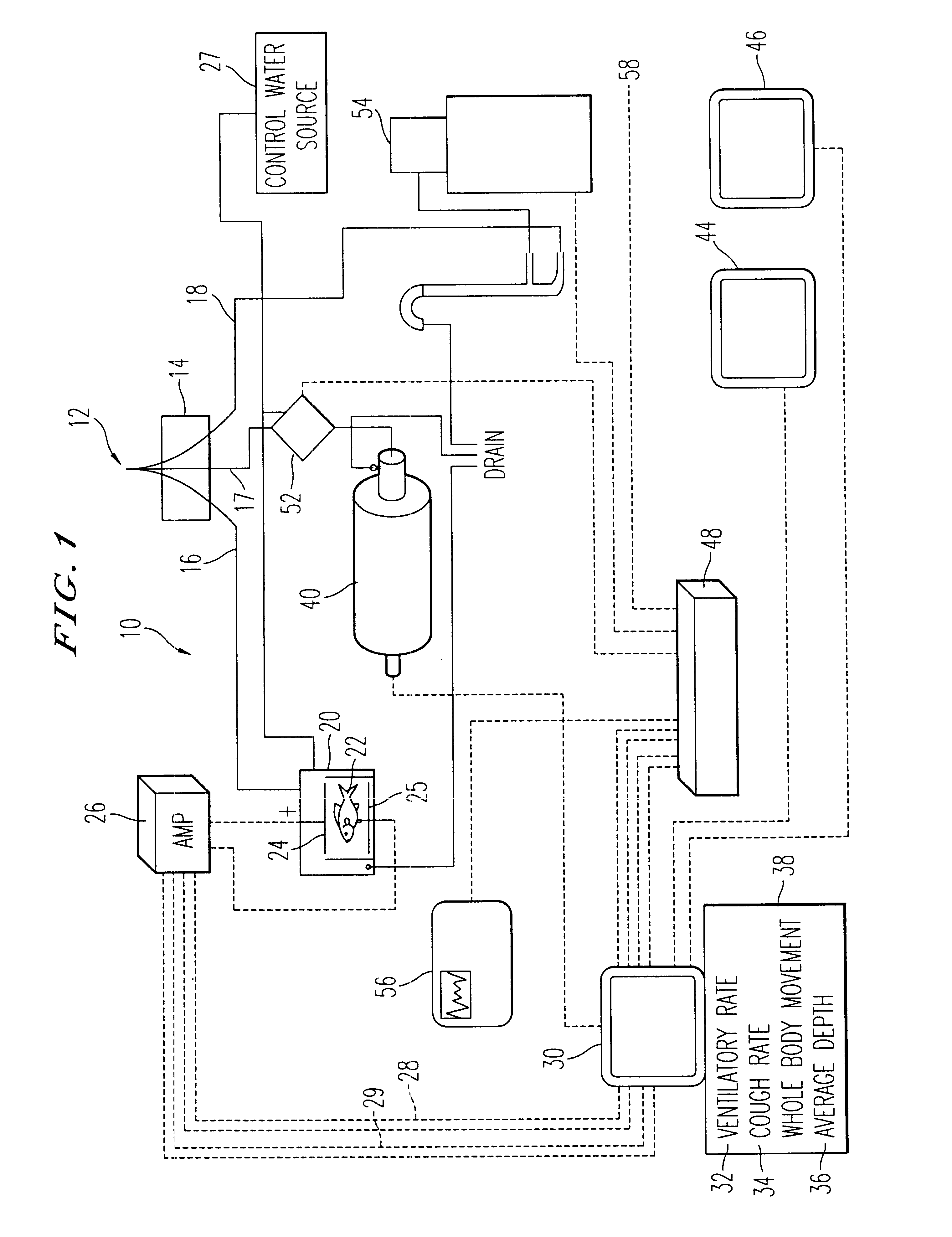

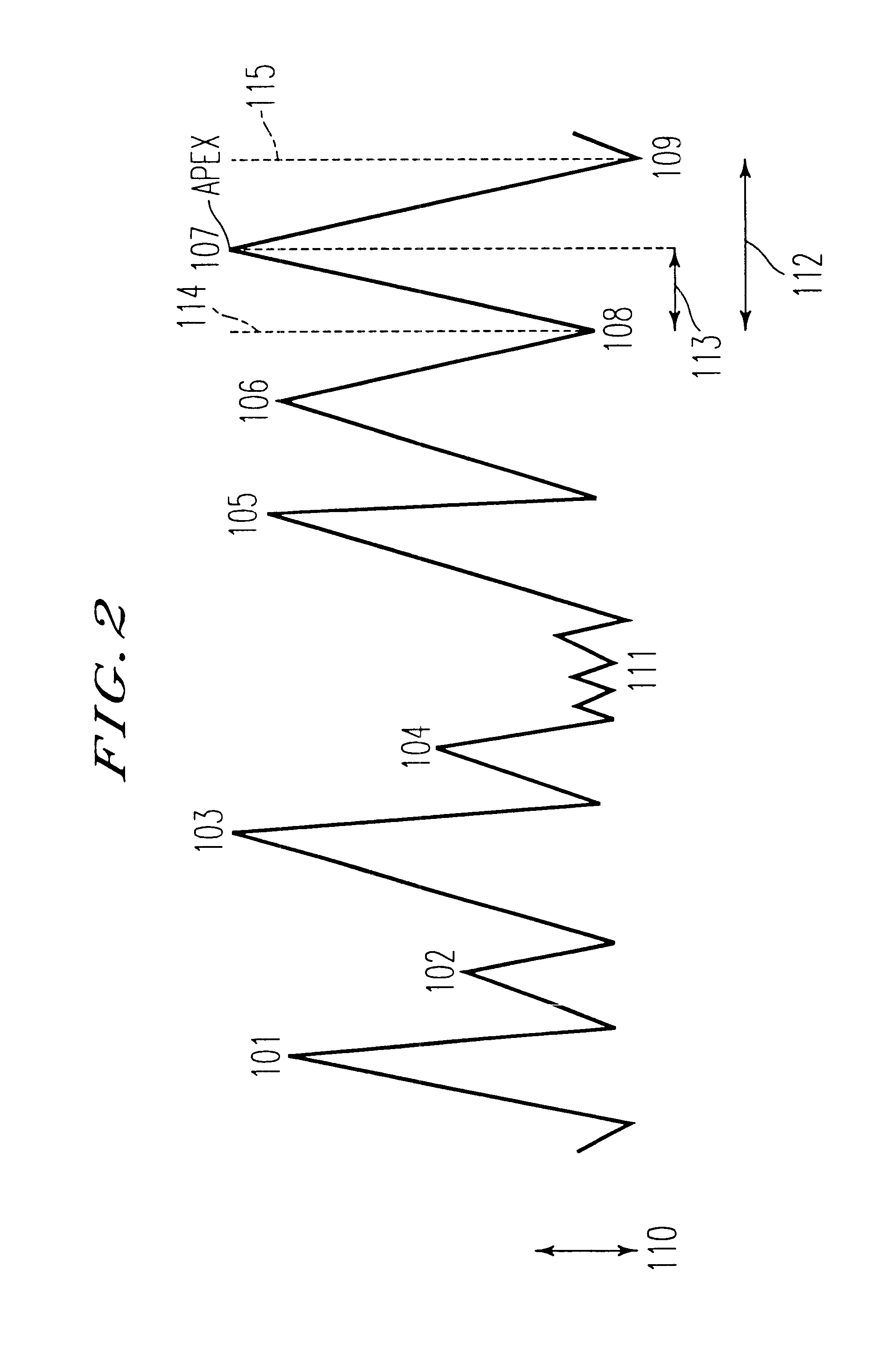

Apparatus and method for automated biomonitoring of water quality

InactiveUS6393899B1Improved waveform processing of data signalLow spuriousPisciculture and aquariaTesting waterWater qualityEngineering

An automated biomonitoring system for monitoring water quality includes an exposure chamber for housing an aquatic organism having ventilatory behavior and body movement sensitive to water quality. Electrodes capture electrical signals produced by the organism during its ventilatory behavior and body movement, and a controller responsive to signals from the electrodes determines one or more ventilatory parameters based on the signals. The ventilatory parameters are compared with corresponding thresholds to determine when the water to which the organism is exposed has caused physiological stress to the organism. The signals captured by the electrodes may be corrected for variations in water conductivity so that the signals processed by the controlled are not influenced by conductivity.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Method for preparing concavo-convex rod soil/zinc oxide nanometer composite material

The invention discloses a method for preparing concavo-convex rod soil / zinc oxide nanometer composite materials, which comprises the following steps: purifying and dispersing the concavo-convex rod soil in water to prepare concavo-convex rod soil dispersion liquid; then adjusting the temperature of the concavo-convex rod soil dispersion liquid to 30 to 100 DEG C; agitating the concavo-convex rod soil dispersion liquid dispersion liquid and while adding zinc salt aqueous solution with the concentration of 0.3 to 3 mol.L<-1> and carbonate aqueous solution with the concentration of 0.3 to 2 mol.L<-1> to the concavo-convex rod soil dispersion liquid dispersion liquid; and keeping the pH value of mixed liquid within the range of 6.0 to 8.0. The prepared mixed serous fluid comprising the prepared nanometer concavo-convex rod soil and basic zinc carbonate is filtered; and a filter cake is washed by deionized water; when the electrical conductivity of filtrate is less than 300 MuS.cm<-1>, the washing is finished; and the filter bake obtained is dried at the temperature of below 100 DEG C, then baked for 1 to 10 hours at the temperature of 300 to 600 DEG C, and finally crushed. The invention is simple and has the advantages of low energy consumption and high safety; the load of the adsorbing material prepared is uniform and has good dispersibility, strong adsorbability and remarkable photo-catalyzed degradation property.

Owner:JIANGSU POLYTECHNIC UNIVERSITY +1

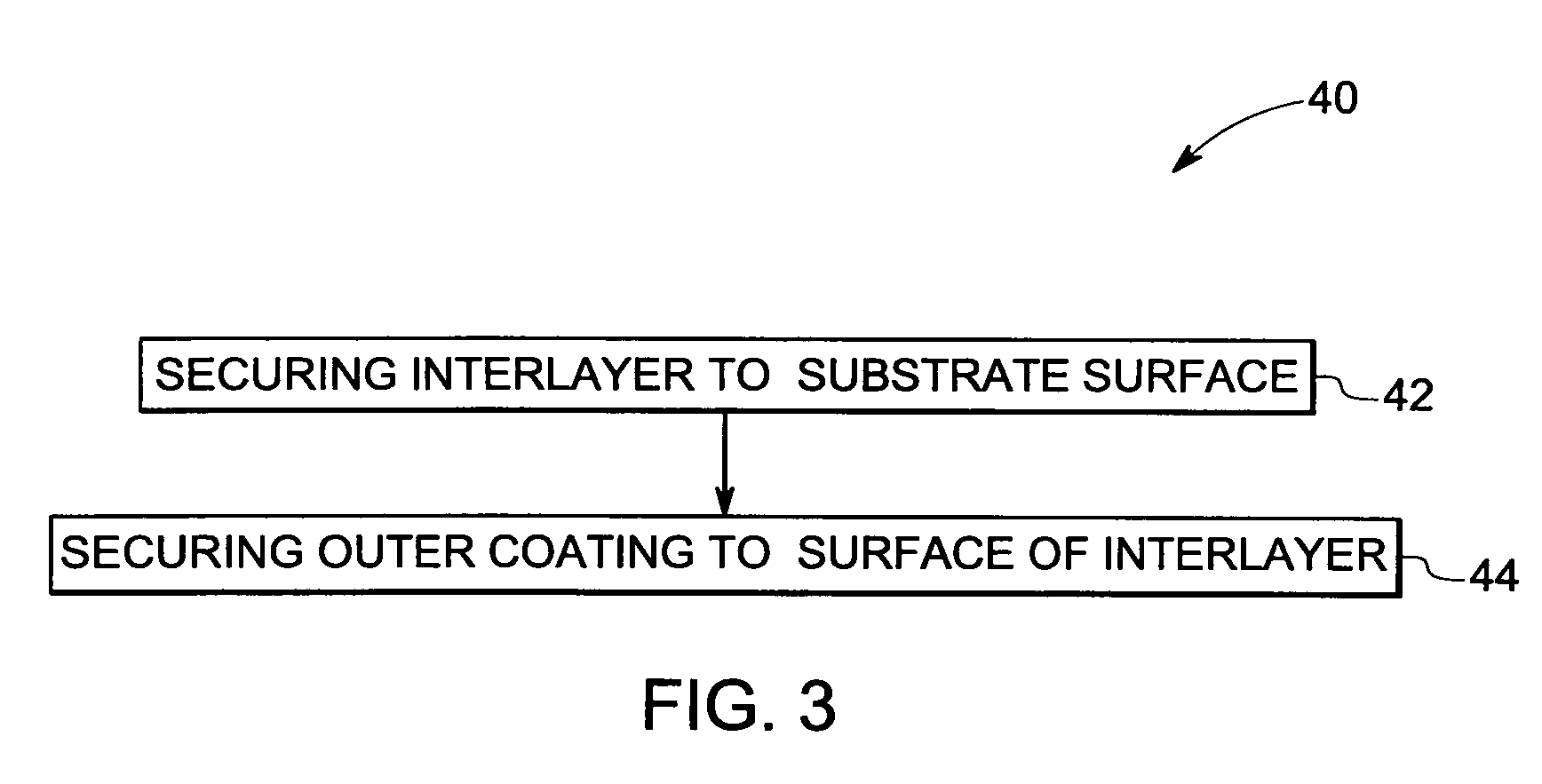

Coating structure and method

InactiveUS20060051602A1Extend article lifeGood thermal expansionLiquid surface applicatorsVacuum evaporation coatingRare earthThermal expansion

A coating structure including an outer coating comprising aluminum; and an interlayer disposed between a substrate and the outer coating is provided. The interlayer may include a rare earth metal, a transition metal, or a noble metal. The interlayer may have one or more property of being less responsive to halogen etching relative to the outer coating; having a coefficient of thermal expansion that is greater than the coefficient of thermal expansion of the substrate and less than the coefficient of thermal expansion of the outer coating or vice versa; having a color different from the color of the outer coating; having a electrical conductivity different from the electrical conductivity of the outer coating. A method of making is article is provided. The method may include securing an interlayer to a substrate surface, and securing an outer coating to a surface of the interlayer opposite the substrate.

Owner:GENERAL ELECTRIC CO

High-strength and high-conductivity dispersion-strengthened alloy and preparation method thereof

InactiveCN101956094AImprove conductivityImprove interface structureElectro conductivityHigh conductivity

The invention relates to a high-strength and high-conductivity dispersion-strengthened alloy, which comprises a copper base, a ceramic dispersion-strengthening phase and a doping element, wherein the ceramic dispersion-strengthening phase may be one or several of ZrO2, Y2O3, MgO, Al2O3 and TiB2 which accounts for 0.1 to 2 mass percent of the copper alloy; and the doping element may be one or several of Ni, Y, Ag, Ti, Zr and Hf which accounts for 0.1 to 1 percent of the copper alloy. In the invention, the problems of ceramic particle agglomeration caused by low bonding performance of the copper and ceramic interface, the roughening of the ceramic particles in sintering and material conductivity reduction caused by the scattering of electrons at the copper and ceramic interface are solved, and the dispersion-strengthened alloy with higher hardness and higher conductivity is obtained. The invention also relates to a preparation method of the high-strength and high-conductivity dispersion-strengthened alloy.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

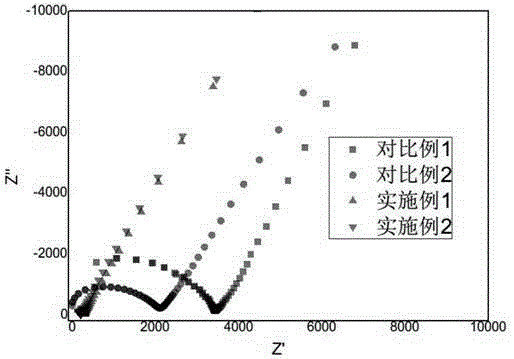

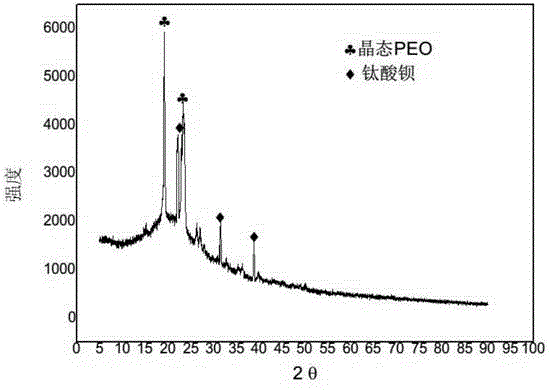

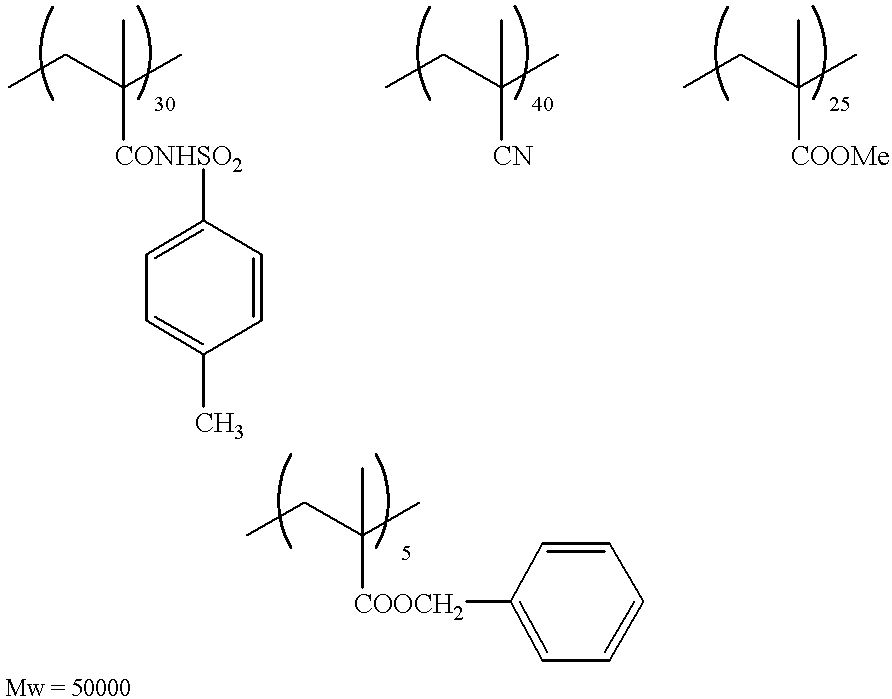

All-solid polymer electrolyte, and preparation method and application of all-solid polymer electrolyte

InactiveCN104538670AImprove conductivityHigh mechanical strengthSolid electrolytesFinal product manufacturePolyethylene oxideBarium titanate

The invention discloses an all-solid polymer electrolyte, and a preparation method and an application of the all-solid polymer electrolyte, and belongs to the field of lithium ion batteries. The all-solid polymer electrolyte comprises polyethylene oxide, lithium salt, inorganic nano particles and ion liquid, wherein a mass ratio of the lithium salt to polyethylene oxide is 0.1-0.5; the mass sum of the inorganic nano particles and the ion liquid is 10-30% of the mass of the all-solid polymer electrolyte; the lithium salt comprises one or several of bistrifluoromethane sulfonimide lithium salt, lithium tetrafluoroborate, lithium perchlorate, lithium hexafluorophosphate, lithium hexafluoroarsenate, lithium trifluoromethanesulfonate and lithium bis borate; and the inorganic nano particles comprise one or several of nano aluminum oxide, nano silicon oxide, nano zirconium oxide and nano barium titanate. The all-solid polymer electrolyte has better mechanical strength and higher ion conductivity. The method is simple in technology and low in cost; and raw materials are easy to obtain.

Owner:HUAZHONG UNIV OF SCI & TECH RES INST SHENZHEN

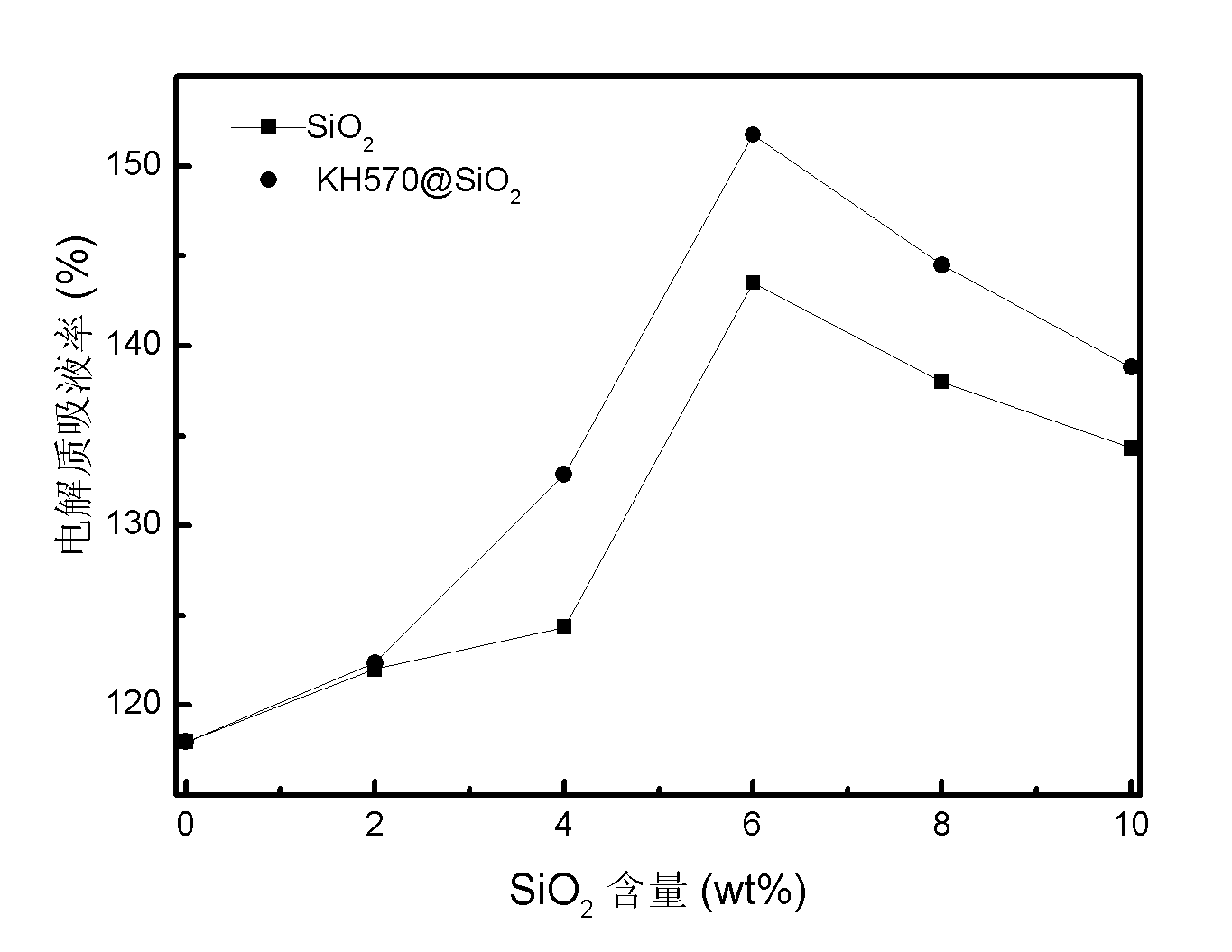

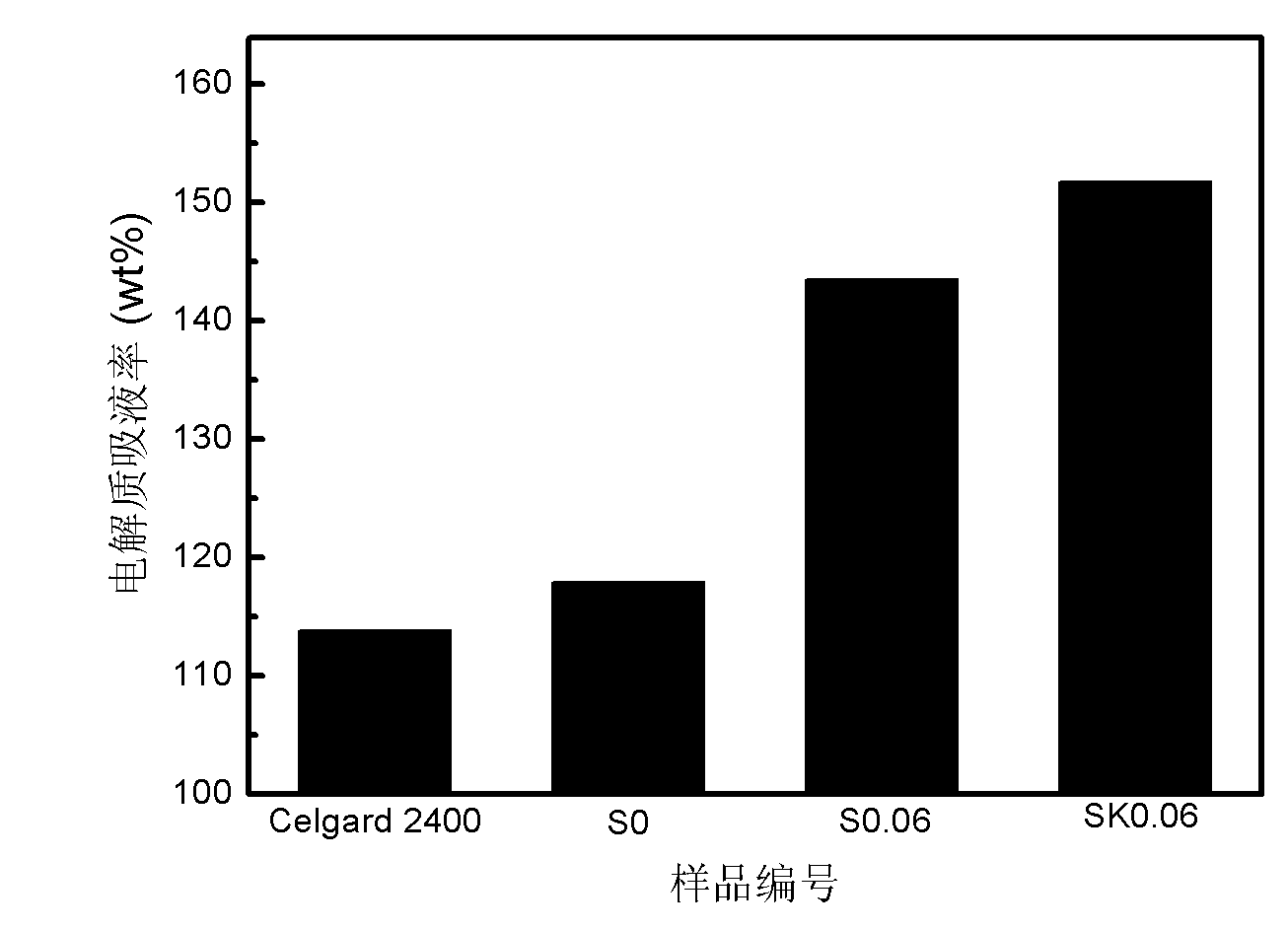

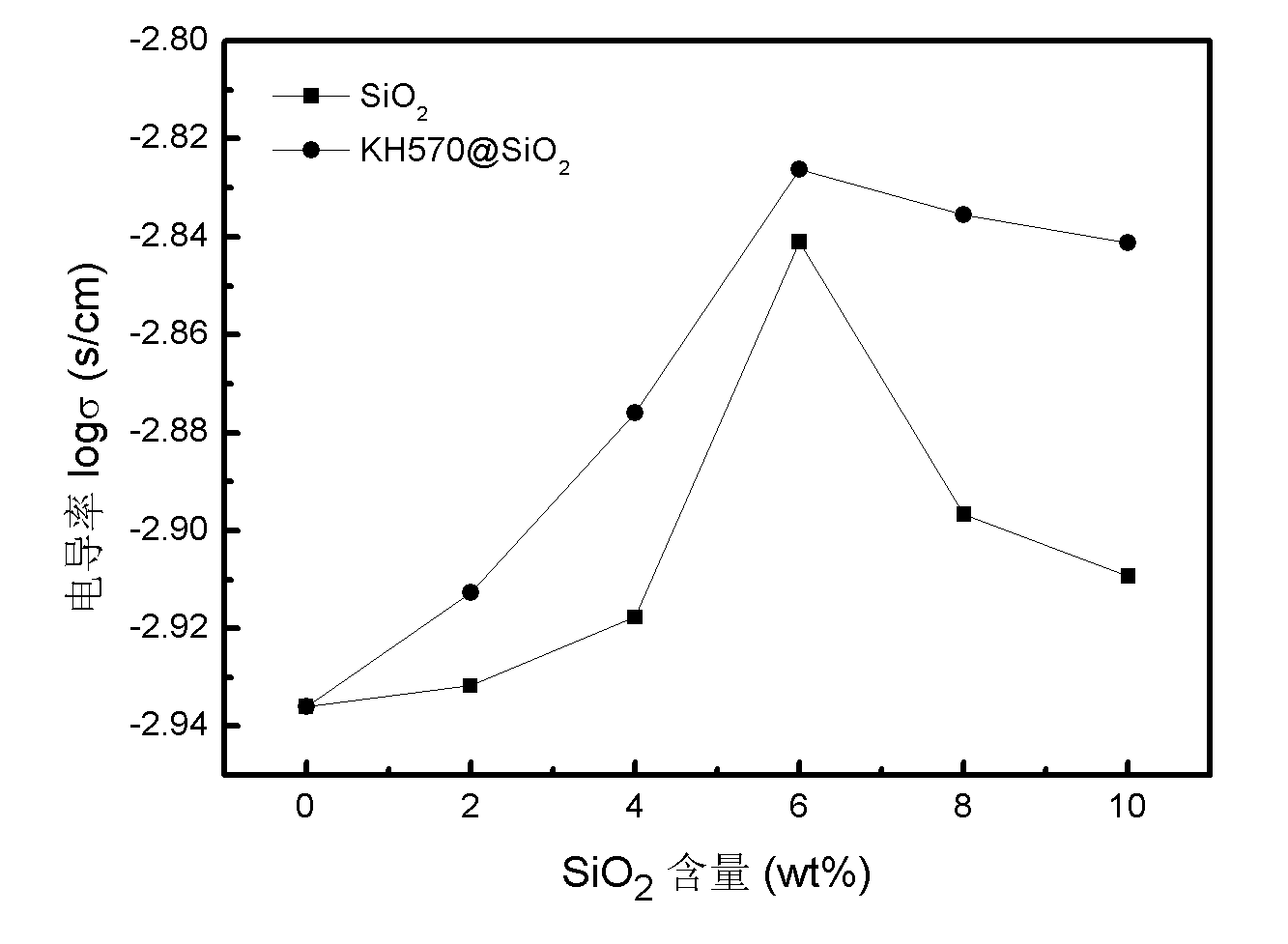

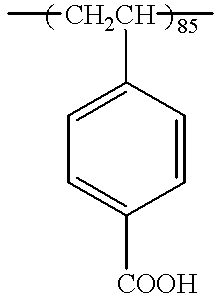

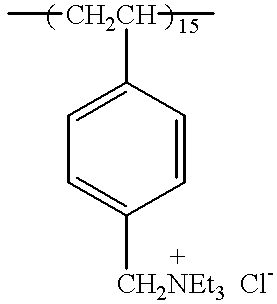

Inorganic/organic composite porous lithium battery diaphragm and preparation method thereof

ActiveCN102529247AHigh liquid absorptionImprove ionic conductivitySynthetic resin layered productsCell component detailsSilica nanoparticlesHexafluoropropylene

The invention belongs to the field of lithium batteries, and relates to an inorganic / organic composite porous lithium battery diaphragm and a preparation method thereof. The inorganic / organic composite porous lithium battery diaphragm comprises a base material layer and an inorganic / organic composite porous diaphragm layer arranged on the surface of the base material layer, wherein the base material layer adopts polypropylene non-woven fabrics; the inorganic / organic composite porous diaphragm layer adopts a polyvinylidene fluoride- hexafluoropropylene multipolymer containing inorganic nano grains and hydrophilizing agents; and the inorganic nano grains are silicon dioxide nano grains or coupling agent improved silicon dioxide nano grains. The inorganic / organic composite porous lithium battery diaphragm provided by the invention has the advantages that the production cost of the lithium battery diaphragm is lowered while high ion-conductivity, excellent electrochemical performance, high mechanical strength and low thermal shrinking percentage are ensured.

Owner:SUZHOU UNIV

Automatic developing apparatus and method of replenishing replenisher for developer for said apparatuses

InactiveUS6364544B1Reduce conductivityPrevent fluctuationsPhotosensitive material processingLiquid processing circulationDiluentEngineering

In order to compensate the reduction of a developing activity during working and / or stopped period, a replenisher and / or a diluent is added to the developer according to predetermined replenishing conditions, and also in order to compensate the reduction of the developing activity caused by processing photosensitive materials, the replenisher and / or the diluent is added to the developer. Then, in cases where the electric conductivity of the thus replenished developer exceeds a predetermined target value, the diluent is replenished to the developer tank until the electric conductivity of the developer falls below the target value.

Owner:FUJIFILM HLDG CORP +1

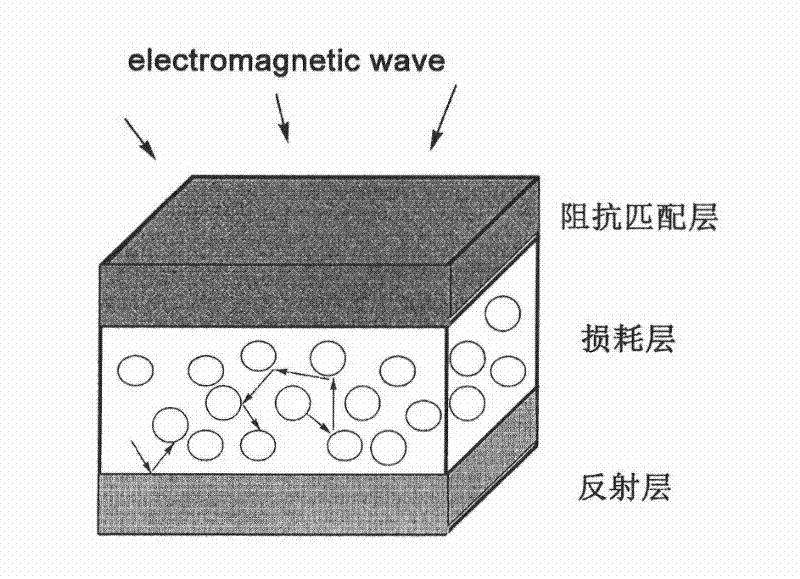

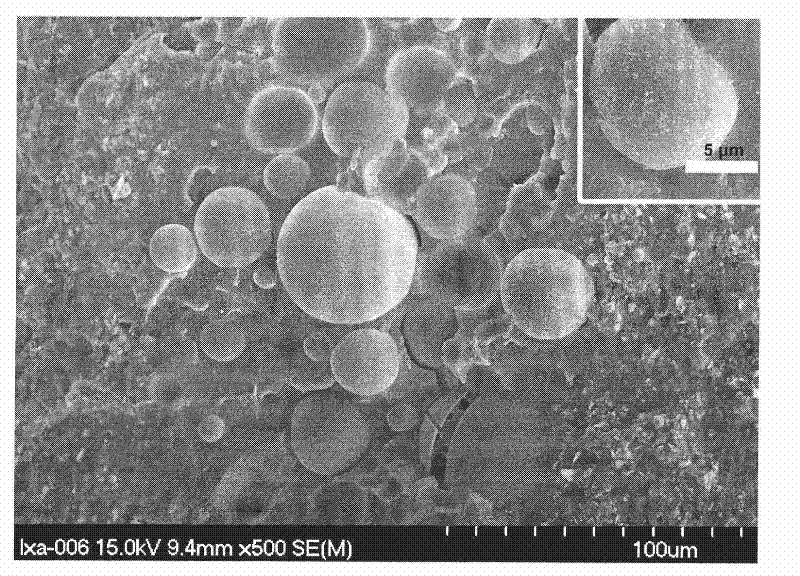

Three-layer composite wave-absorbing film and preparation method thereof

The invention discloses a three-layer composite wave-absorbing film and a preparation method thereof. The three-layer composite wave-absorbing film consists of an impedance matching layer, an absorption layer and a reflection layer, wherein the impedance matching layer consists of a dielectric material and an organic carrier; the absorption layer consists of magnetic particles and the organic carrier; the reflection layer consists of a carbon material with better electro-conductivity and the organic carrier; the thickness of the impedance matching layer is 0.1 to 0.3 millimetre (mm); the thickness of the absorption layer is 0.2 to 0.4 mm; and the thickness of the reflection layer is 0.1 to 0.3 mm. The preparation method of the three-layer composite wave-absorbing film comprises the following steps of: firstly, processing organic particles; secondly, uniformly dispersing the organic particles in an organic phase in a certain mode, and spreading to form a film; and finally, after a solvent of a first layer is completely volatilized, spreading a second layer and a third layer to form the three-layer composite wave-absorbing film. The three-layer composite wave-absorbing film has the advantages of high efficiency, light weight and low thickness, can be applied to electromagnetic shielding materials, and has a wide application prospect in ultra-thin radar wave-absorbing materials.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS +1

Lithium ion conductive solid electrolyte and method for producing the same

InactiveUS8431287B2Easy to getLow moisture permeabilityNon-metal conductorsActive material electrodesLithiumPorosity

In a solid electrolyte obtained by sintering a powder, high ionic conductivity and remarkably low moisture permeation applicable to a lithium ion secondary battery or a lithium primary battery are realized. A method for producing a solid electrolyte including the steps of preparing a green sheet containing a lithium ion conductive inorganic material powder; and firing the green sheet, wherein in the step of firing the green sheet, at least one surface of the green sheet is covered by a setter having a porosity of not more than 10% by volume, is disclosed.

Owner:OHARA

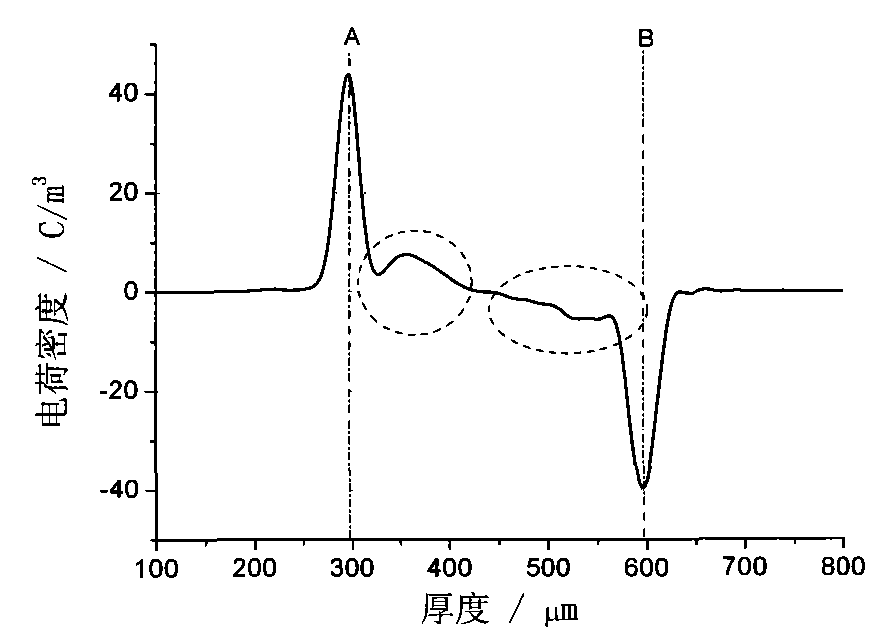

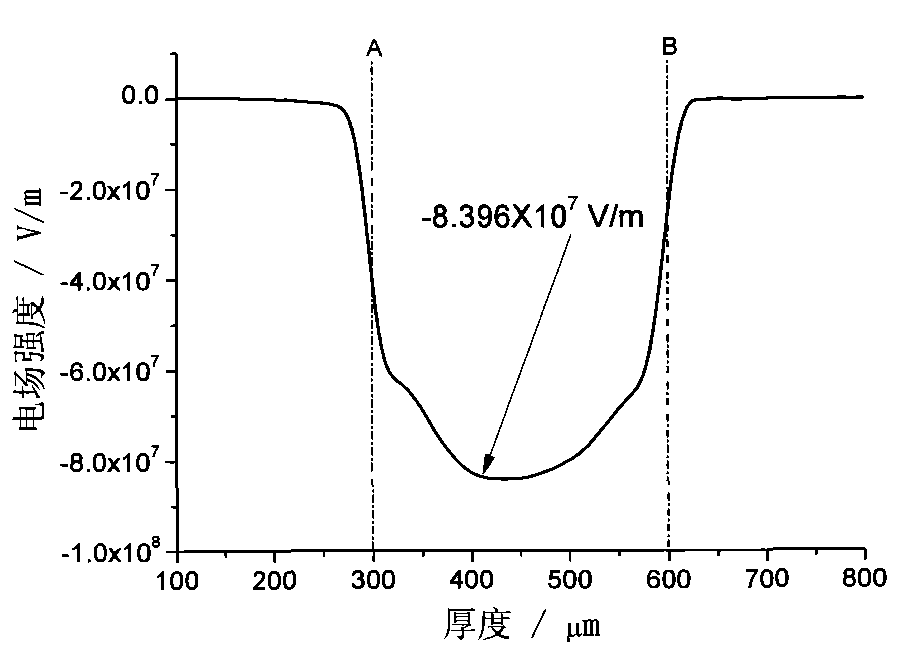

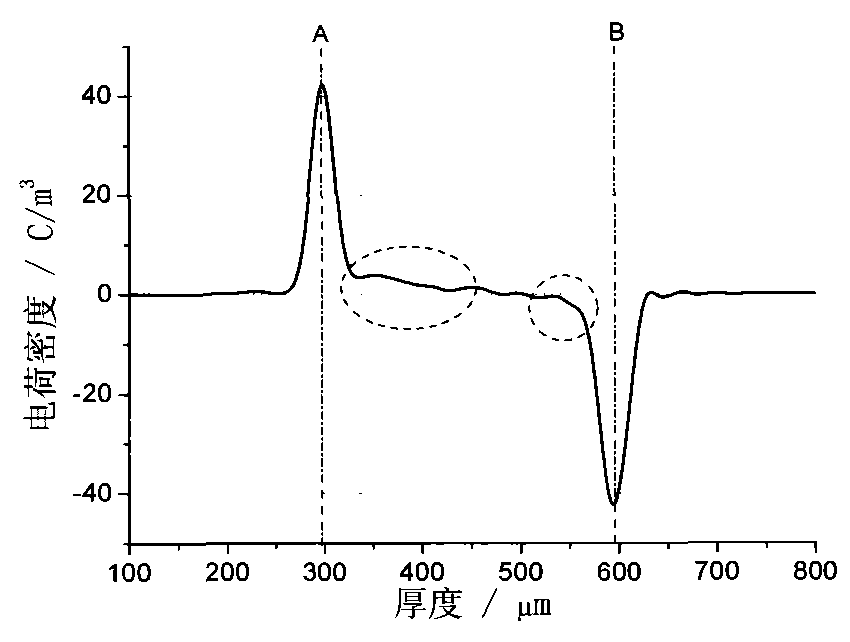

Cable semi-conductive shielding material and preparation method thereof

InactiveCN101585943AAvoid accumulationReduces the effect of increased conductivityPower cables with screens/conductive layersLinear low-density polyethyleneCross linker

The invention provides a cable semi-conductive shielding material which belongs to the field of electric cable fabrication technique and a preparation method thereof, and the components of the material and the content thereof are as follows: ethylene-vinyl acetate copolymer or linear low density polyethylene 100 proportion by weight, black carbon 10-50 proportion by weight, anti-oxidant 0.1-5 proportion by weight as well as cross linker 0.1-5 proportion by weight. The method provided by the invention can effectively inhibit accumulation of space charges in insulation material, and improves electric field threshold value of injected space charge, which reduces insulation material electric conductivity increased effect induced by space charge-limited current (SCLC), and the electric field distortion rate in XLPE is only 14-19% under -60kV / mm extra electric field for 60 minutes.

Owner:SHANGHAI JIAO TONG UNIV

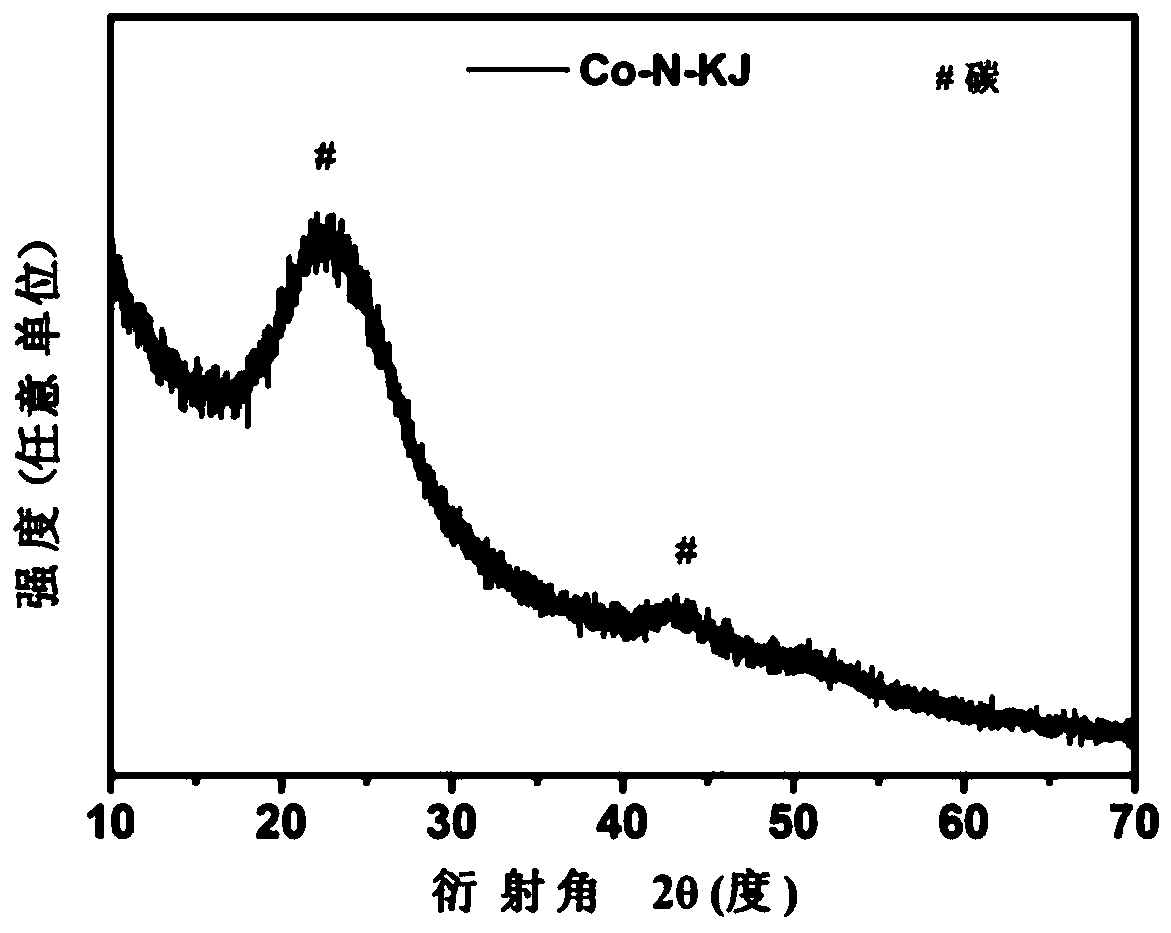

Non-noble metal catalyst used for catalytic oxygen reduction and preparation method thereof

ActiveCN108963276AImprove conductivityCapable of single-atom dispersionFuel and secondary cellsCell electrodesOxygenCalcination

The invention relates to a non-noble metal catalyst used for catalytic oxygen reduction and a preparation method thereof. The catalyst has the general formula of Me-N-C. By means of adsorption capability and range-limited calcination of the active carbon, non-noble metal atoms, Me and N which are dispersed to the atomic scale, are adsorbed and limited in the pores in the active carbon C, so that on the basis of high-electro-conductivity of the active carbon, a high-effective oxygen reduction catalyst having single-atom-dispersing capability can be obtained. The non-noble metal catalyst is lowin metal content, can be prepared at low cost and has very large specific surface area, wherein the Me and N are distributed in interior of pores in the active carbon, in a mono-atom dipsersed manner,instead of on the surface of the active carbon, so that excellent mass transfer capability and conductivity are achieved. The catalyst has excellent oxygen reduction catalytic activity, can be applied to preparation of MEA membrane electrodes and cathode catalytic reaction process of large-scale Zn-air batteries, Al-air batteries and fuel cell stacks. The invention provides the high-effective andstable catalyst for the MEA membrane electrode.

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com