Patents

Literature

32results about How to "Solve the problem of concentration polarization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thick electrode with good electrochemical performance and its preparation method

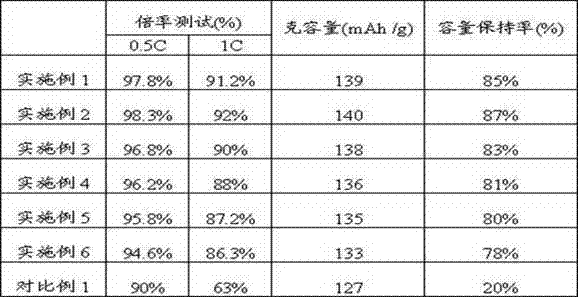

ActiveCN102324493AImproved magnification performanceSolve the problem of concentration polarizationNon-aqueous electrolyte accumulator electrodesElectrolytic agentEngineering

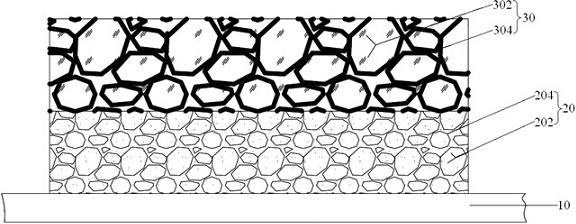

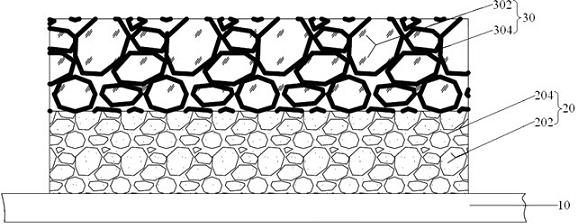

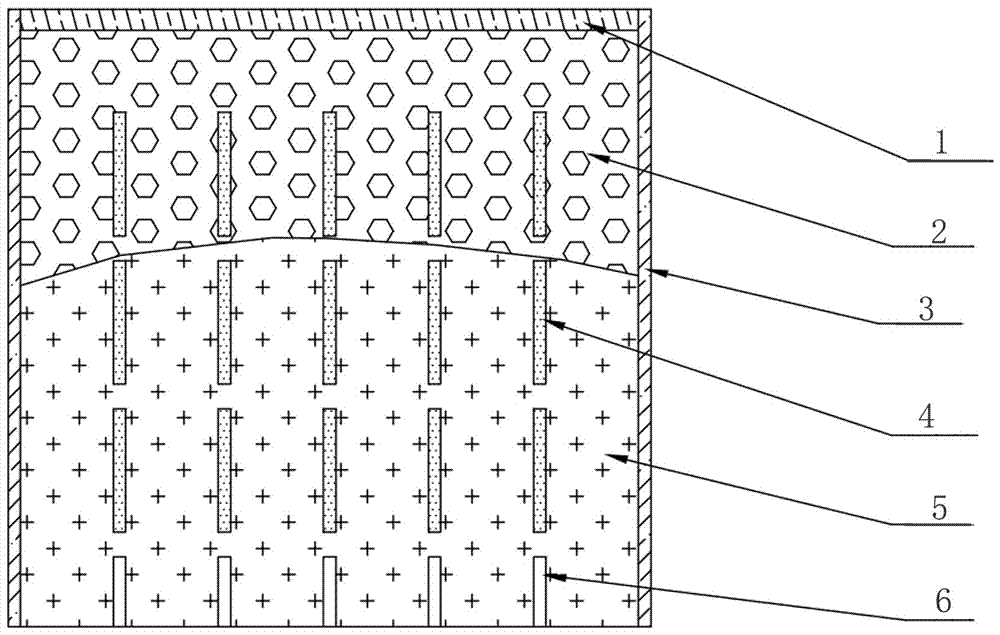

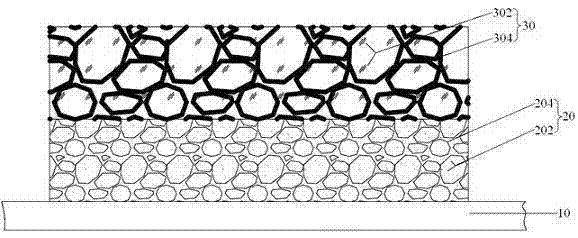

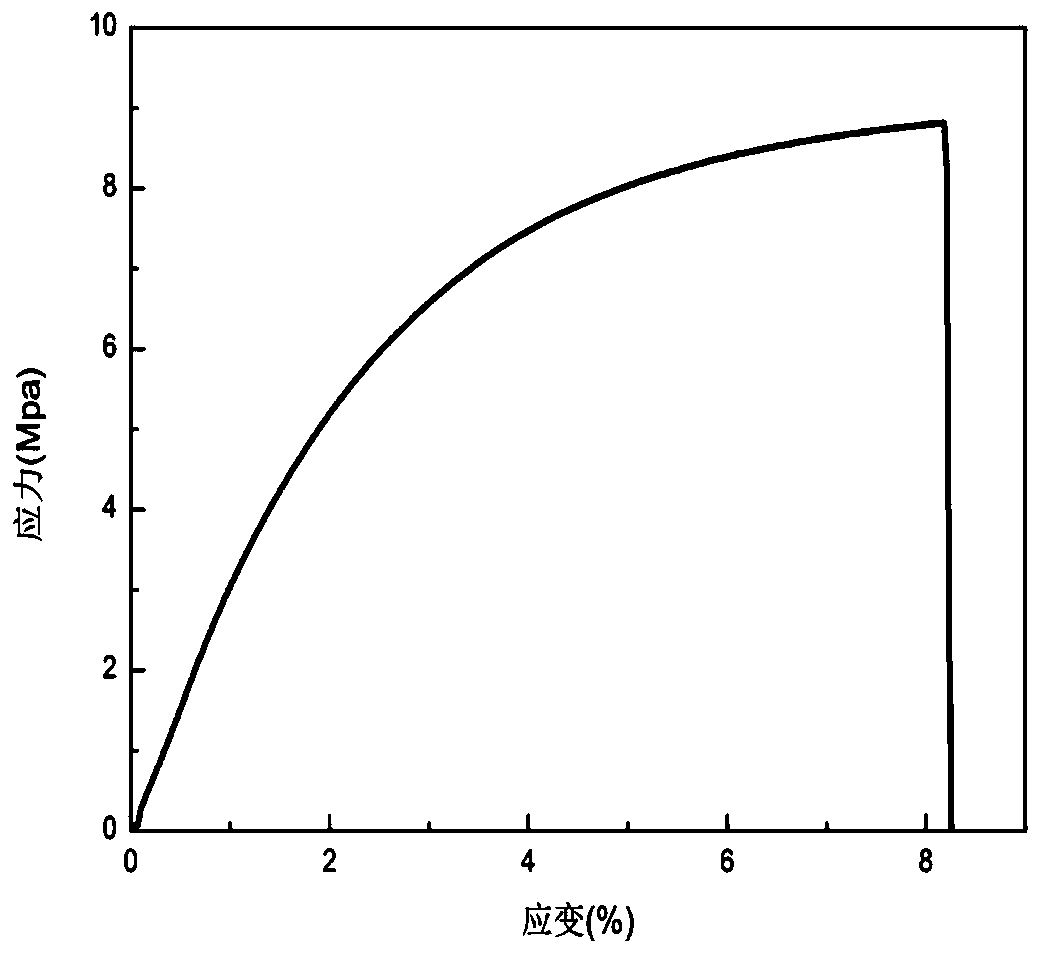

The invention discloses a thick electrode with a good electrochemical performance. The electrode comprises a current collector and an electrode membrane containing active substances and conductive substances. With a thickness greater than 300 micrometers, the electrode membrane includes an internal membrane layer close to the current collector and an external membrane layer far from the current collector. The conductivity of the electrode membrane decreases from the internal membrane layer to the external membrane layer, while the porosity of the electrode membrane increases from the internal membrane layer to the external membrane layer. The internal membrane layer has great conductivity which can make electrons at the current collector entering or separating from the internal membrane layer rapidly. With great porosity, the external membrane layer can adsorb a lot of electrolyte, thus solving the problem of poor electrolyte wettability of thick electrodes. In addition, the invention also discloses a preparation method of a thick electrode with a good electrochemical performance.

Owner:DONGGUAN AMPEREX TECH +1

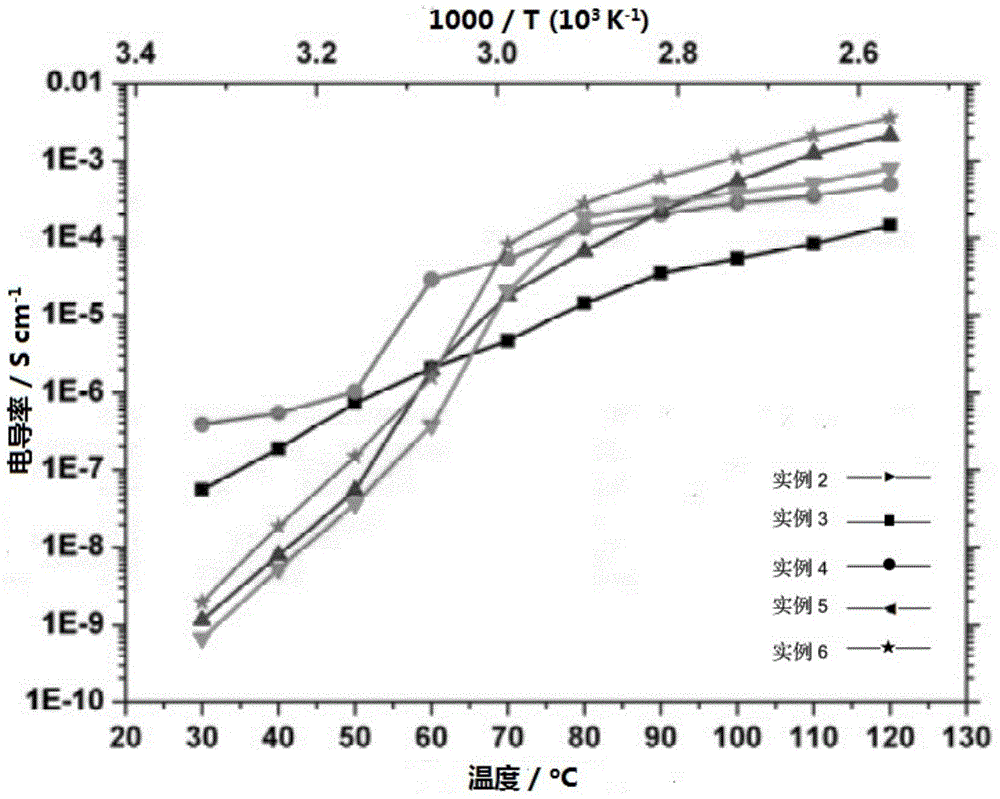

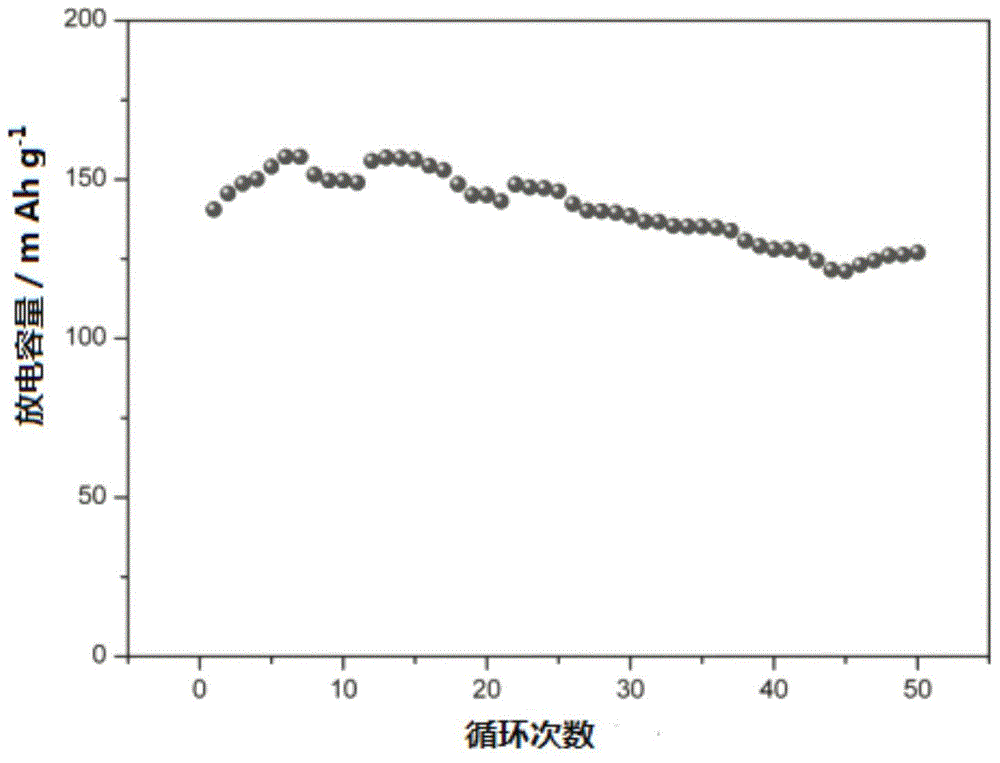

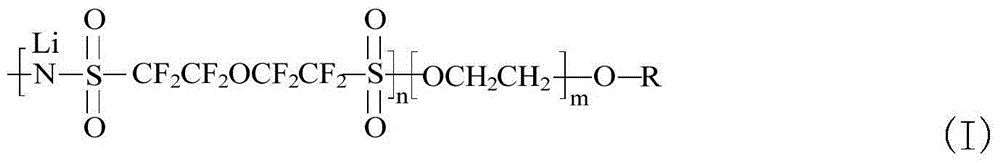

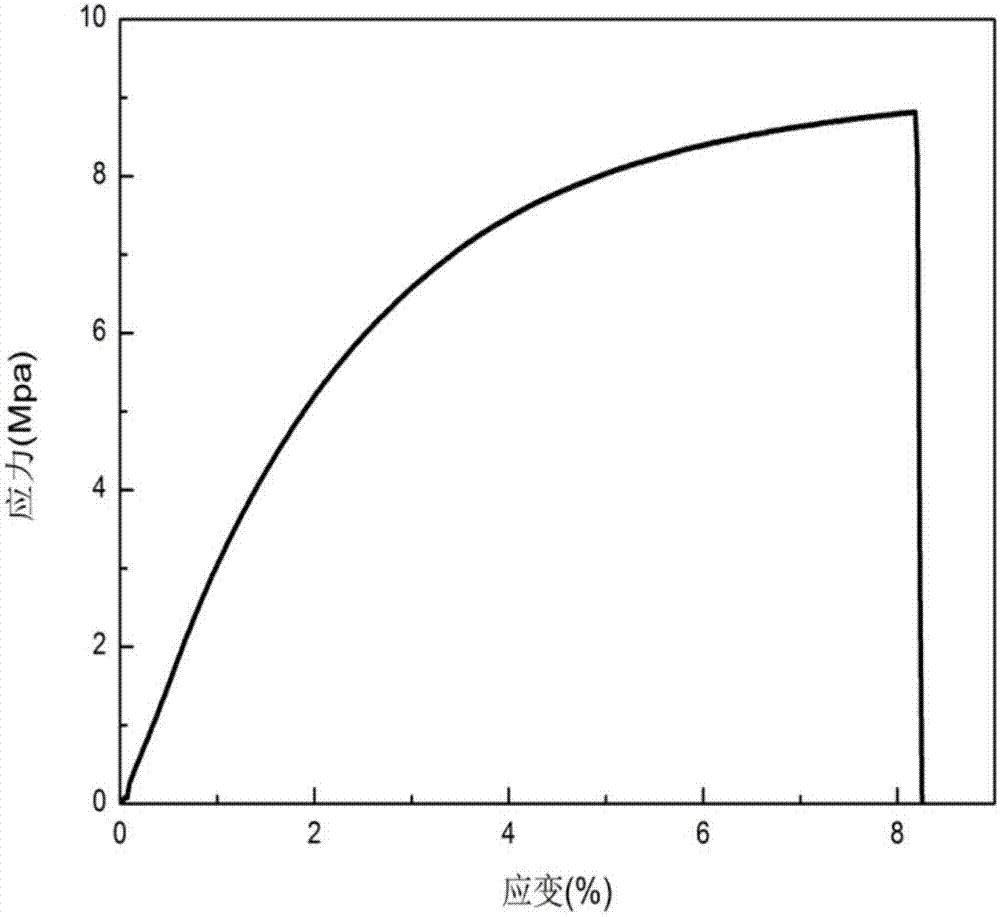

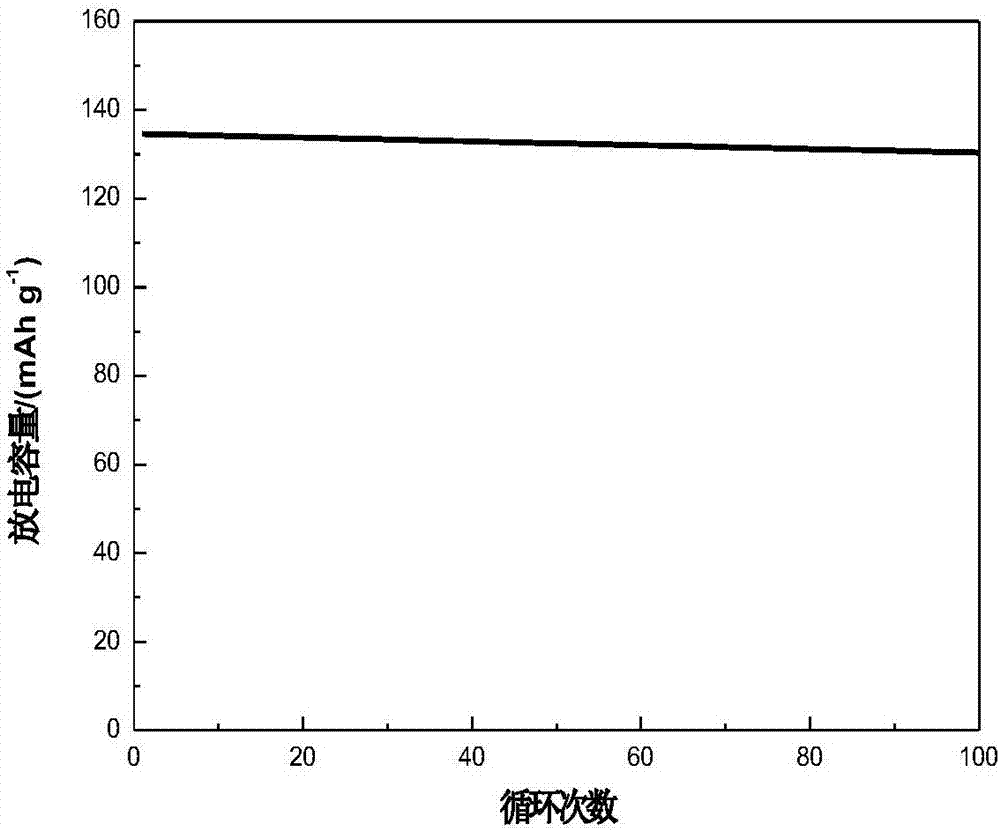

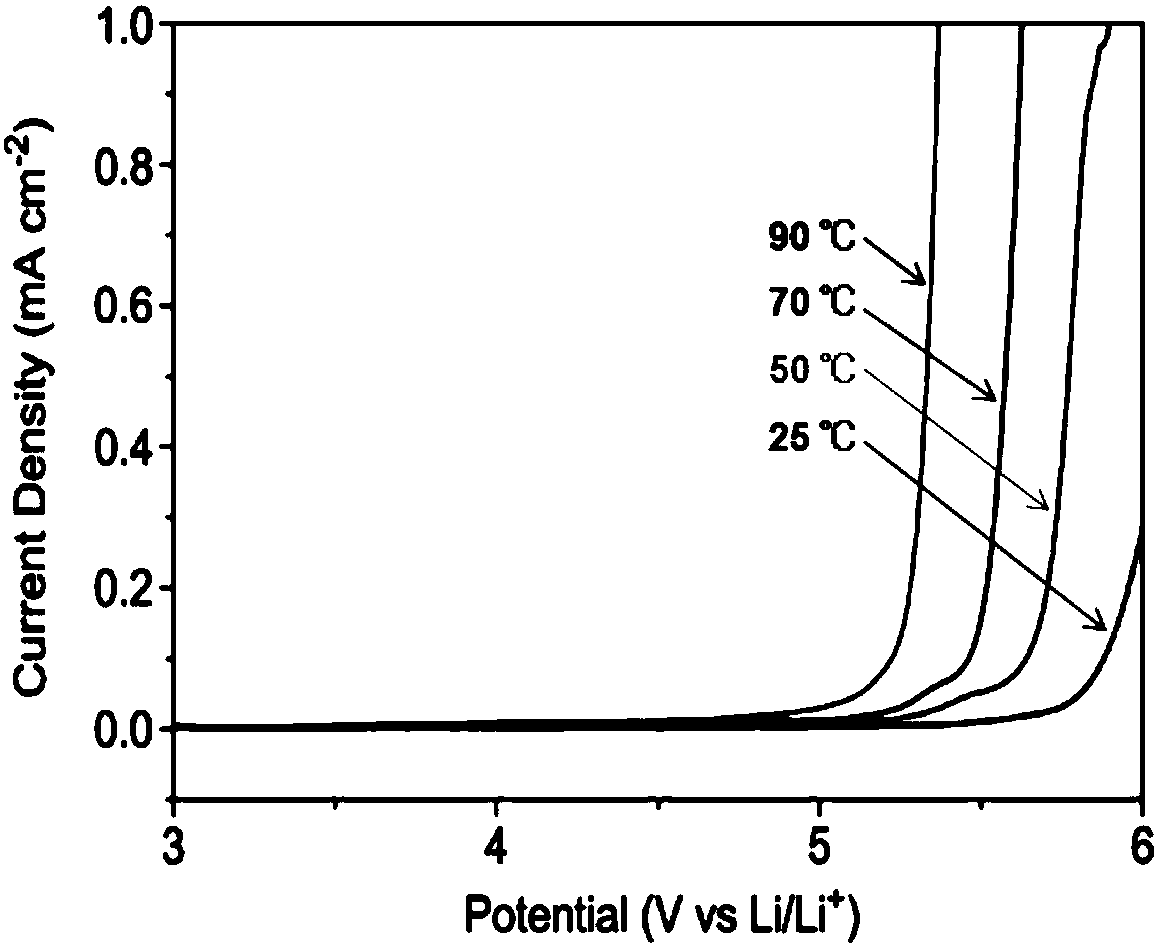

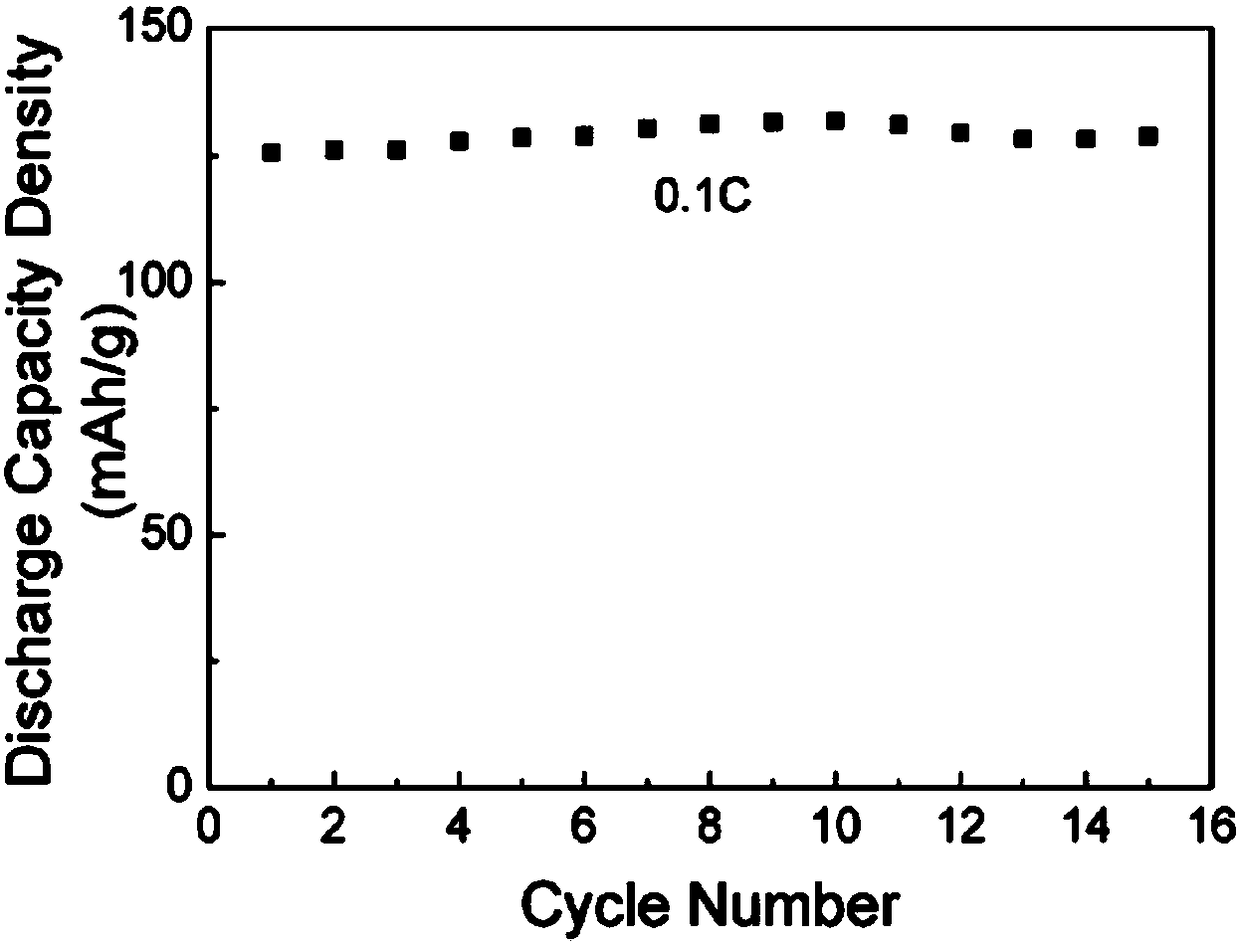

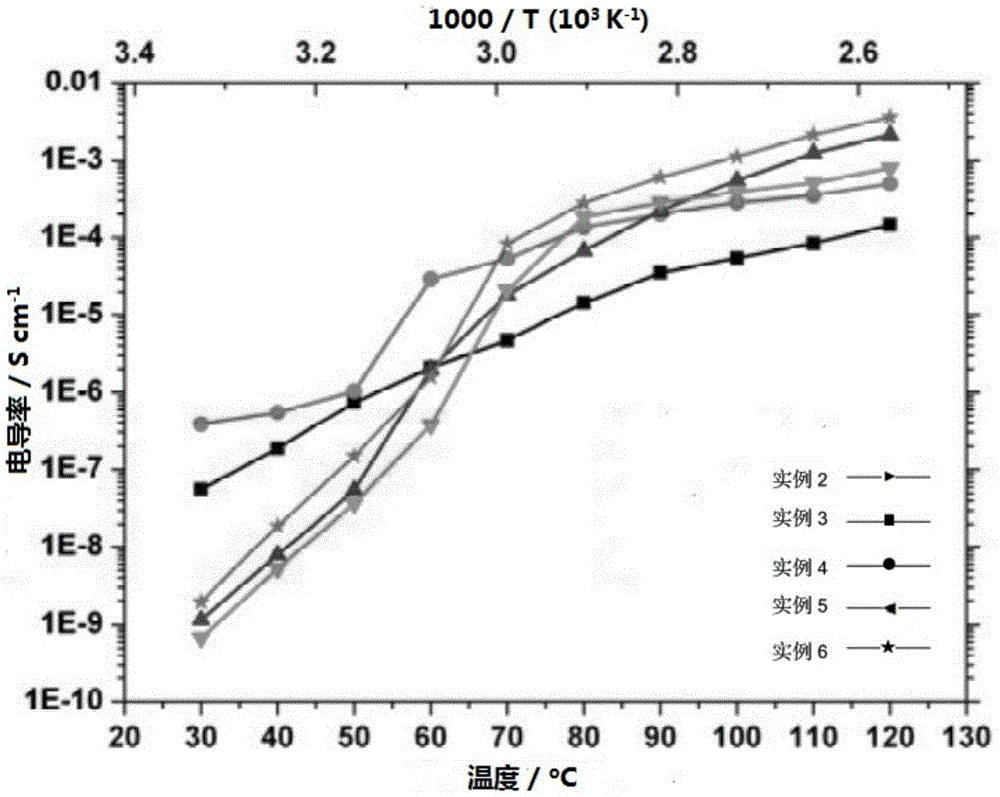

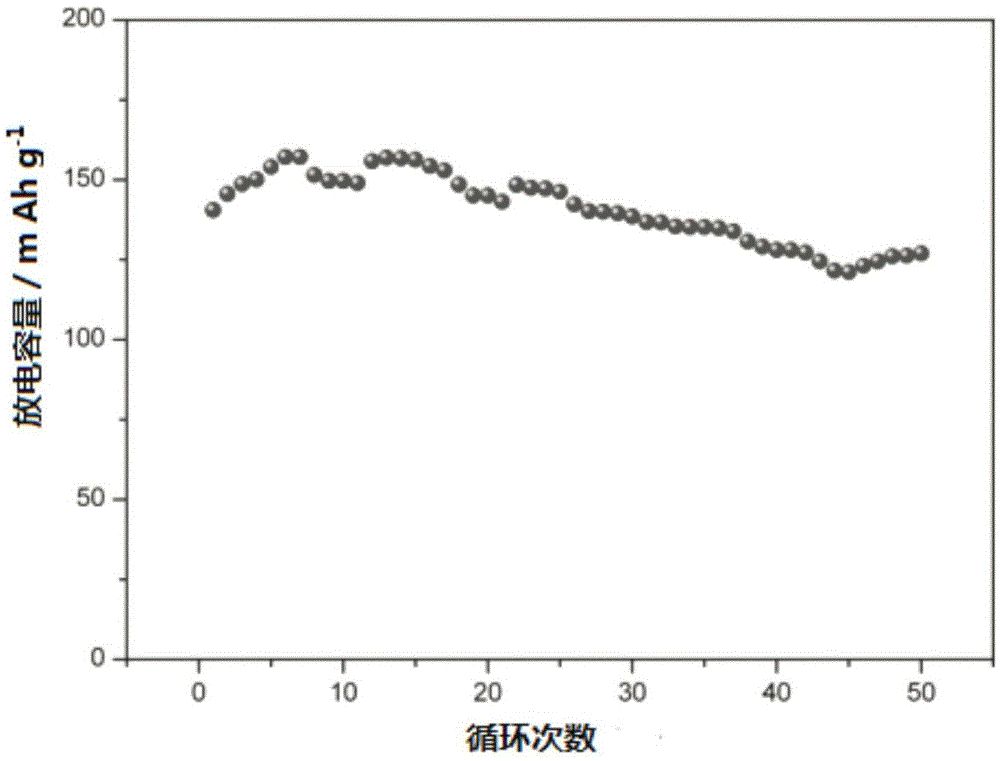

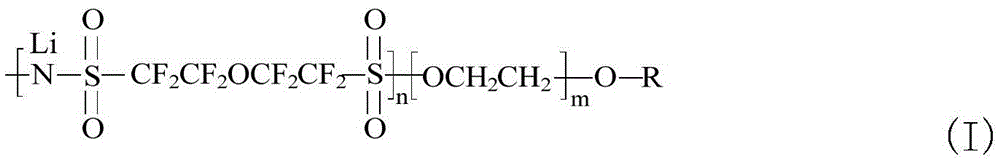

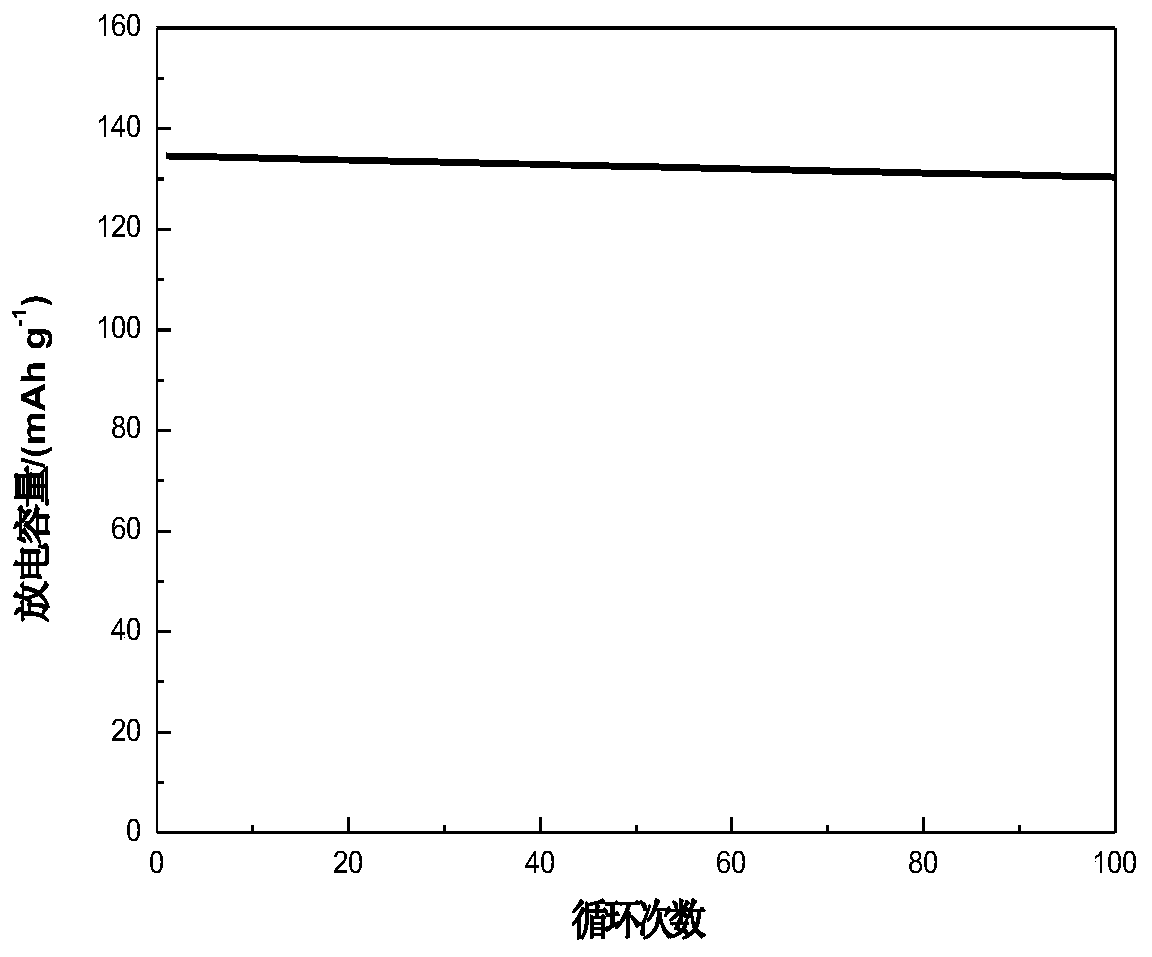

Novel solid-state electrolyte membrane material capable of being used as lithium ion battery as well as preparation method and application thereof

ActiveCN104466241ASolve the problem of concentration polarizationIncrease the number of transfersSecondary cellsOrganic electrolytesSolid state electrolytePolyethylene oxide

The invention discloses a novel solid-state electrolyte membrane material capable of being used as a lithium ion battery as well as a preparation method and application thereof. The material is a segmented copolymer containing a polyfluorosulfimide based lithium salt and a polyethylene oxide structure and the molecular structure is shown in the formula (I). The method comprises the following steps: mixing a fluorine-containing monomer and polyethylene oxide and dissolving into dry acetonitrile; adding an acid-binding agent and reacting at 0-100 DEG C for 1-10 days to obtain a polymer in a form of metal ion salt; dissolving the polymer in the metal ion salt form into an organic solvent; and adding LizX to carry out a lithium ion exchange reaction to obtain a polymer in a lithium salt form. The material can be used as a battery solid electrolyte material to be applied to preparation of the lithium ion battery. The material is used as solid electrolyte and has a better application prospect in terms of inhibiting the growth of lithium dendrites in the lithium ion battery, improving the transference number of lithium ions and ensuring high conductivity at room temperature and stable battery circulation.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Composite anode of aluminum electrolytic cell

ActiveCN107881531AExpand the added areaUniform and rapid dispersionElectrical conductorFluid electrolytes

The invention relates to the technical field of aluminum electrolysis, in particular to a composite anode of an aluminum electrolytic cell. In order to overcome the defect of the mode that raw materials are added into a liquid electrolyte in the electrolytic cell separately, according to the adopted technical scheme, filler is added to an aluminum frame with a built-in conductor, and the filler comprises the raw materials; the raw materials are aluminum oxides used for preparing metal aluminum or aluminum oxides and corresponding alloy element oxides or alloy element fluorides for preparing aluminum alloy; and the raw materials are directly added into the composite anode, the raw material adding modes and the raw material adding areas are increased, thus, the raw materials continuously andslowly enter and disperse in the large-area electrolyte area simultaneously, even under the low electrolysis temperature condition, the raw materials added in the liquid electrolyte can be rapidly and completely dissolved, less precipitation is generated at the furnace bottom, the low electrolysis temperature is adopted for operation, heat losses of the electrolytic cell can be reduced, the current efficiency is improved, the yield is increased, carbon consumption is reduced, energy consumption is reduced, and emission of fluorine-containing gas is reduced.

Owner:党建平

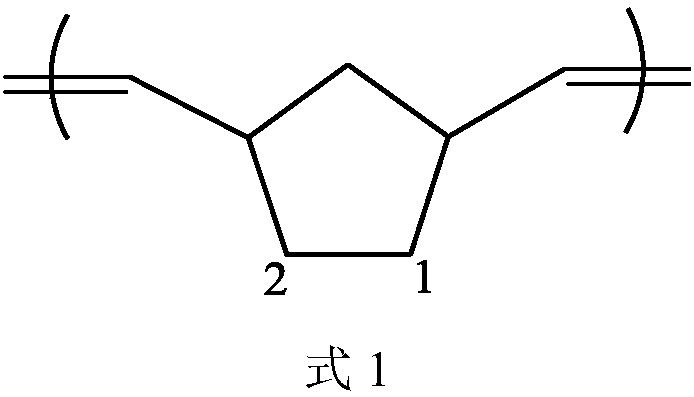

Single-ion polymer electrolyte, preparation method thereof, single-ion polymer electrolyte membrane and lithium ion battery

ActiveCN107141450AFlame retardantImprove performanceSolid electrolytesSecondary cellsLithium electrodeLithium

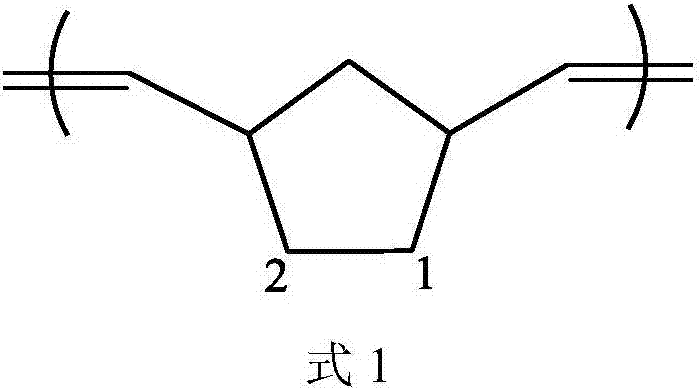

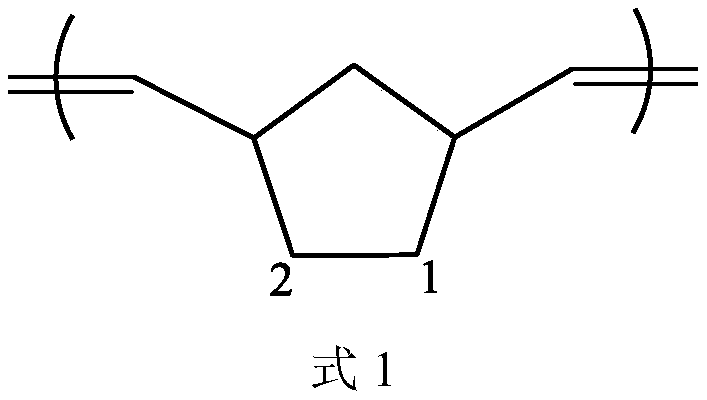

The invention belongs to the technical field of lithium ion batteries and particularly relates to a single-ion polymer electrolyte, a preparation method thereof, a single-ion polymer electrolyte membrane and a lithium ion battery. The single-ion polymer electrolyte comprises polymer chains formed by structure units represented by formula 1 (shown in the description), wherein membrane supporting groups are linked between the two polymer chains, and two ends of the membrane supporting groups are respectively connected to sites 1 or 2 of the structure units; lithium ion providing groups are connected to the sites 1 or 2 of the structure units; the lithium ion providing groups and the membrane supporting groups are respectively connected to the site 1 or 2 of each independent structure unit; and the molar ratio of the lithium ion providing groups to the membrane supporting groups is 1 to (1-2). The single-ion polymer electrolyte has the advantages of high room temperature conductivity, mechanical strength and flame retardance and the like and further has very considerable application prospects in the field of the lithium ion batteries.

Owner:DO FLUORIDE CHEM CO LTD

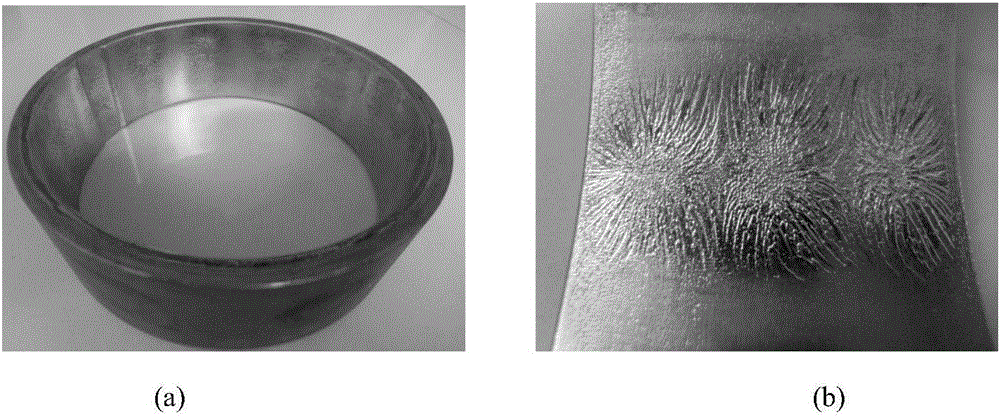

Device and method of industrially carrying out magnetized copper electrolysis

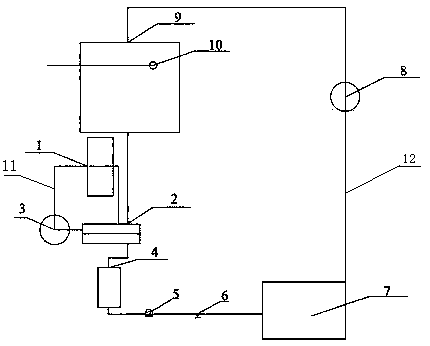

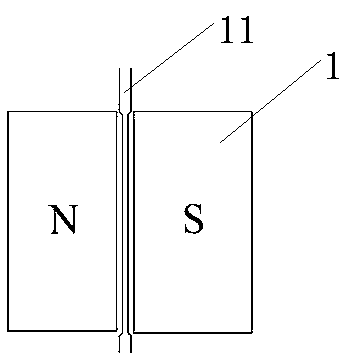

ActiveCN110219018AAddress reactivitySolve quality problemsPhotography auxillary processesElectrolysis componentsMagnetic tension forceElectrolysis

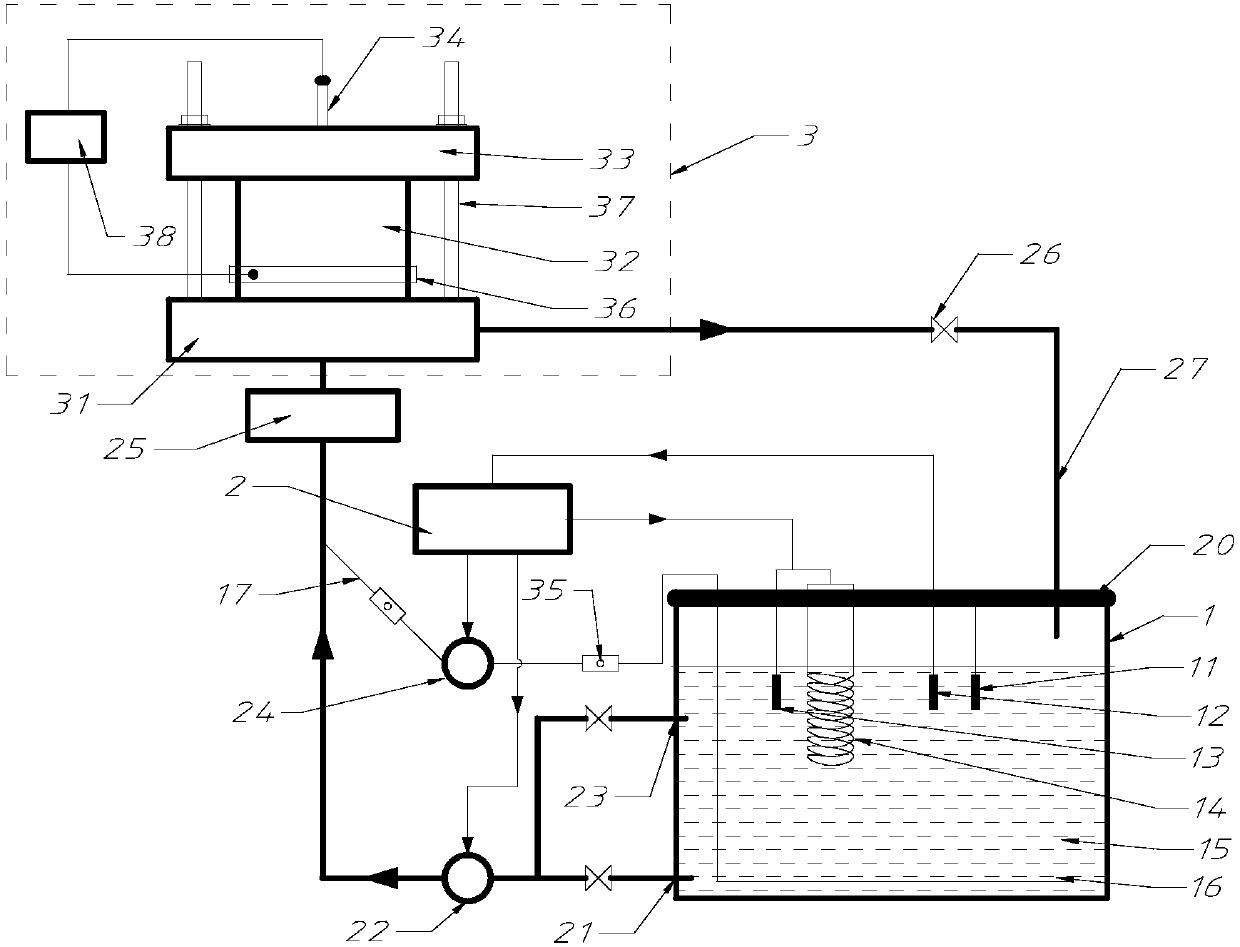

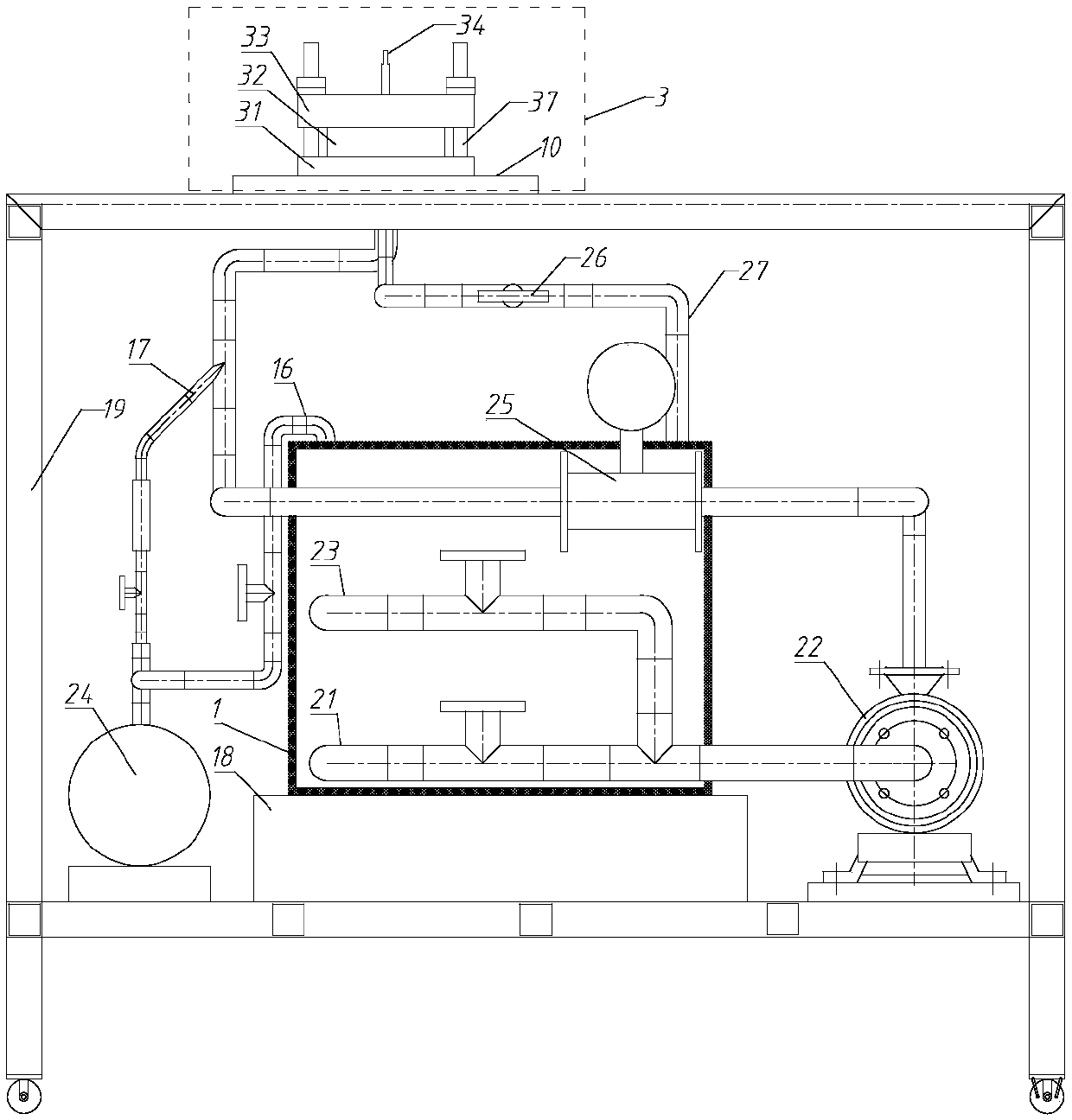

The invention belongs to the technical field of copper electrolysis smelting, and particularly relates to a device and method of industrially carrying out magnetized copper electrolysis. The device comprises a permanent magnet device, a transition tank, an electrolytic tank, a low tank, an elevated tank and a steam heating device. According to the device and method, the large-scale and high-efficiency utilization of the copper magnetic electrolysis technology is achieved by the bypass cycle of a magnetic treatment device, and the magnetic treatment efficiency can be improved in the mode that an electrolyte passes through the permanent magnet device at the high speed. The loren magnetic force borne by the electrolyte in the process that the electrolyte passes through the magnetic field canbe enhanced, the electrolyte is greatly activated, the impurity flocculating setting is reinforced, the clarity of the electrolyte is improved, cathode copper crystal grains are refined, the number ofbubbles in the electrolyte is reduced, and the problem that due to the facts that the air bubbles in the electrolyte are prone to having a reaction on the surface of an anode to generate an oxide film, and anodic passivation happens, the cathode copper quality is affected is solved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

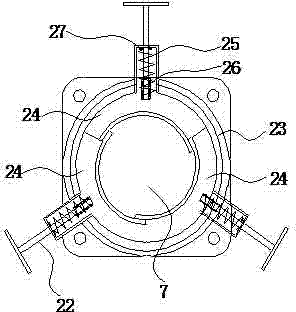

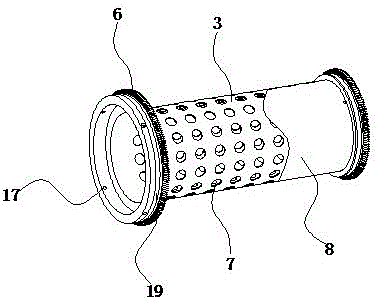

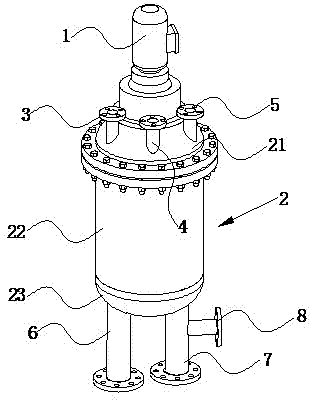

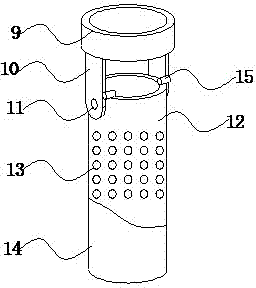

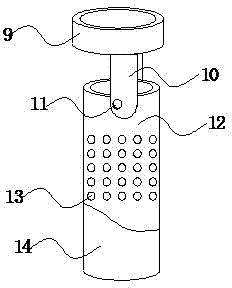

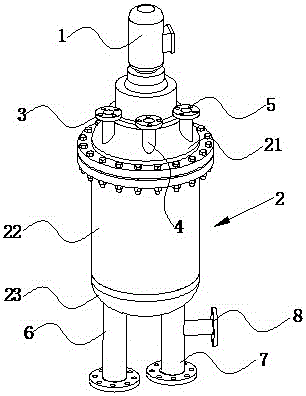

Improved rotating membrane sewage filtration device

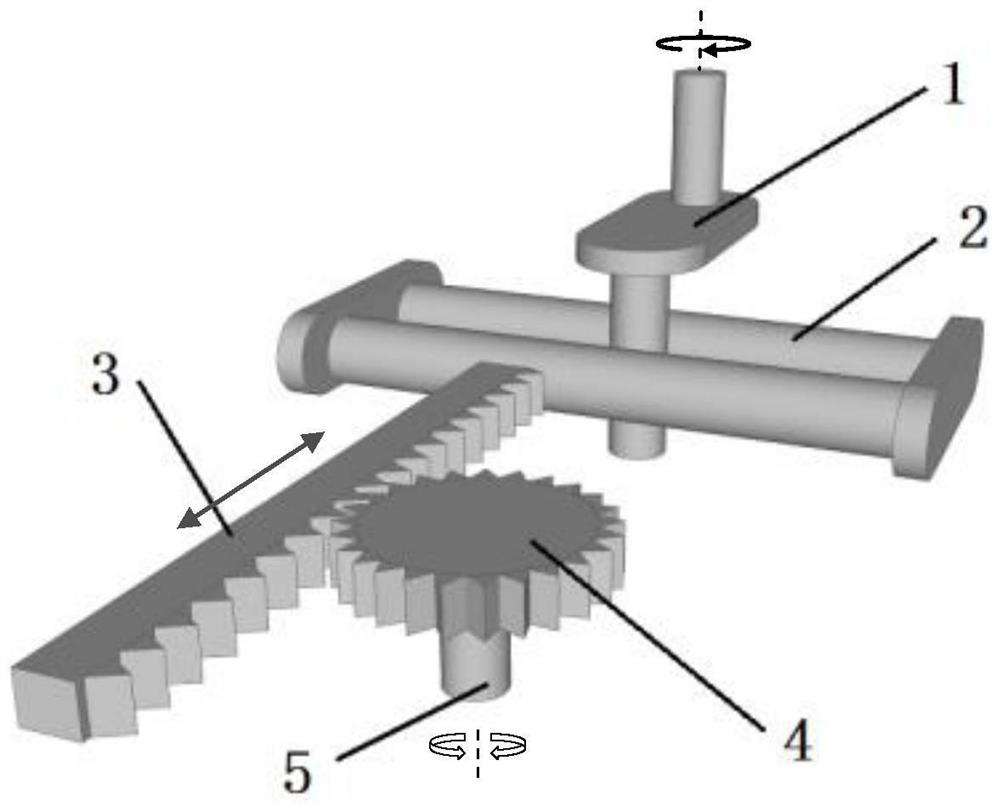

ActiveCN104772042ASolving Concentration PolarizationSolving Membrane FoulingSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisSlagConcentration polarization

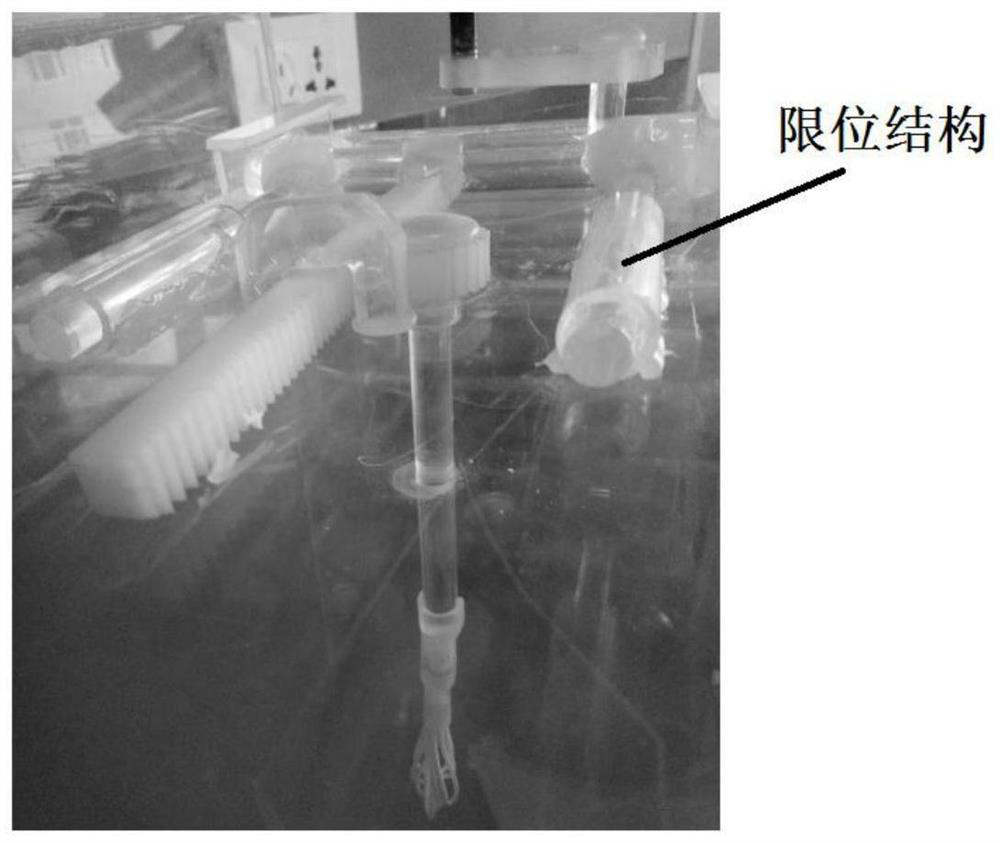

The invention discloses an improved rotating membrane sewage filtration device, which comprises a rack, a filter box, a first rotating shaft, a motor and a filter cartridge. A plurality of filter holes are formed on the circumferential wall of the filter cartridge, the outer circumferential wall of the filter cartridge is fixedly sleeved with a membrane member, the left side wall of the filter cartridge is connected to a liquid inlet tank, the bottom side wall of the filter box is provided with a liquid outlet, the right end side wall of the filter cartridge is provided with a slag outlet, a second rotating shaft in transmission connection with the first rotating shaft is mounted on the filter box, the second rotating shaft is equipped with a gear able to rotate synchronously therewith, and engaging teeth engaged with the gear are formed on the right side of the filter cartridge. The right end of the slag outlet is connected to a convergent cylinder, a rubber sleeve is inserted in the convergent cylinder, the right end of the rubber sleeve is connected to a plurality of petals, and each petal is equipped with an adjustment unit. The improved rotating membrane sewage filtration device provided by the invention well solves the concentration polarization and membrane pollution problems of the membrane surface, significantly increases the membrane permeation flux, and greatly improves the membrane separation performance.

Owner:惠州市同方水务有限公司

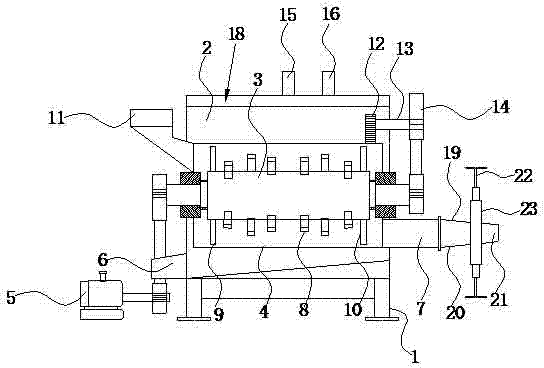

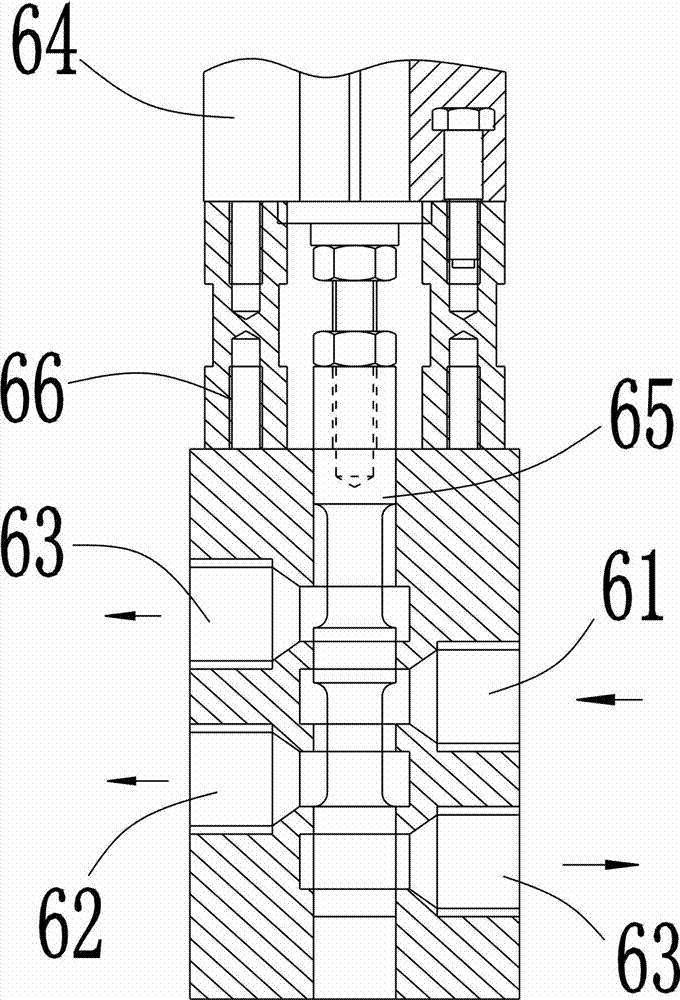

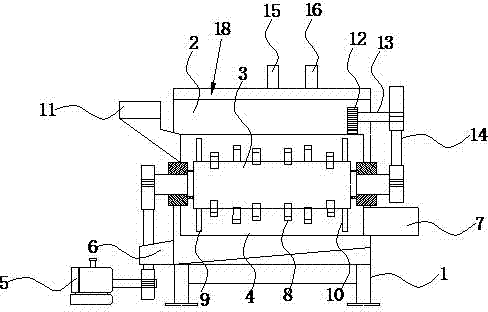

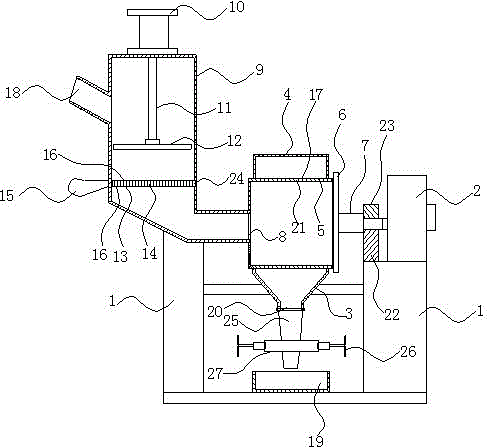

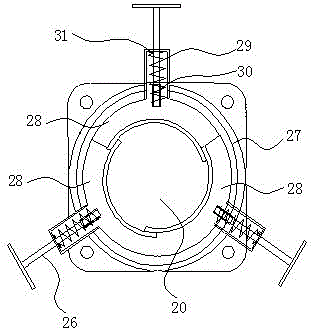

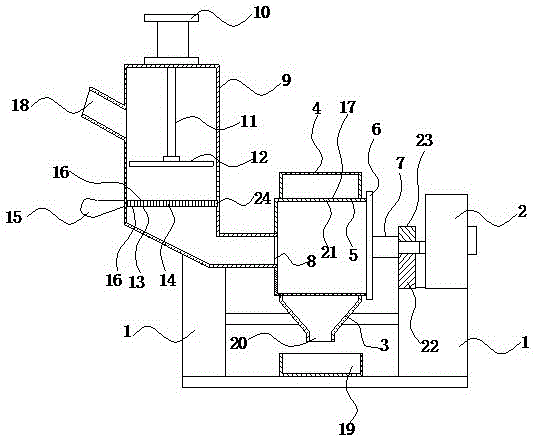

Perfusion type electronickelling and silicon carbide device for air cylinder

The invention discloses a perfusion type electronickelling and silicon carbide device for an air cylinder. The perfusion type electronickelling and silicon carbide device for the air cylinder comprises an electroplating base, an electroplating solution groove, a cathode conducting rod and an anode conducting rod. The air cylinder to be electroplated is placed inversely on the electroplating base which is internally provided with a groove. One end of the anode conducting rod is arranged in the groove, while the other end of the anode conducting rod extends into a chamber of the air cylinder to be electroplated. The cathode conducting rod is arranged above the electroplating base and can move up and down. The electroplating base is provided with a liquid inlet which is communicated with the electroplating solution groove through a flow divider. The flow divider comprises an electroplating solution inlet, an electroplating solution outlet and at least a return opening. The electroplating solution outlet is communicated with a liquid outlet. The electroplating solution inlet and the return opening are communicated with the electroplating solution groove. The perfusion type electronickelling and silicon carbide device for the air cylinder further comprises a drive device which drives the electroplating solution to flow upward along the inner wall of the air cylinder and flow from the top of the air cylinder back to the electroplating solution groove. According to the device, the electroplating solution is less polluted, the life cycle of the electroplating solution is long, the electroplating solutions in grooves are not needed to be prepared, and the regenerating time and cost of the electroplating solution are reduced.

Owner:ZHENGJIANG FENGLONG ELECTRIC CO LTD

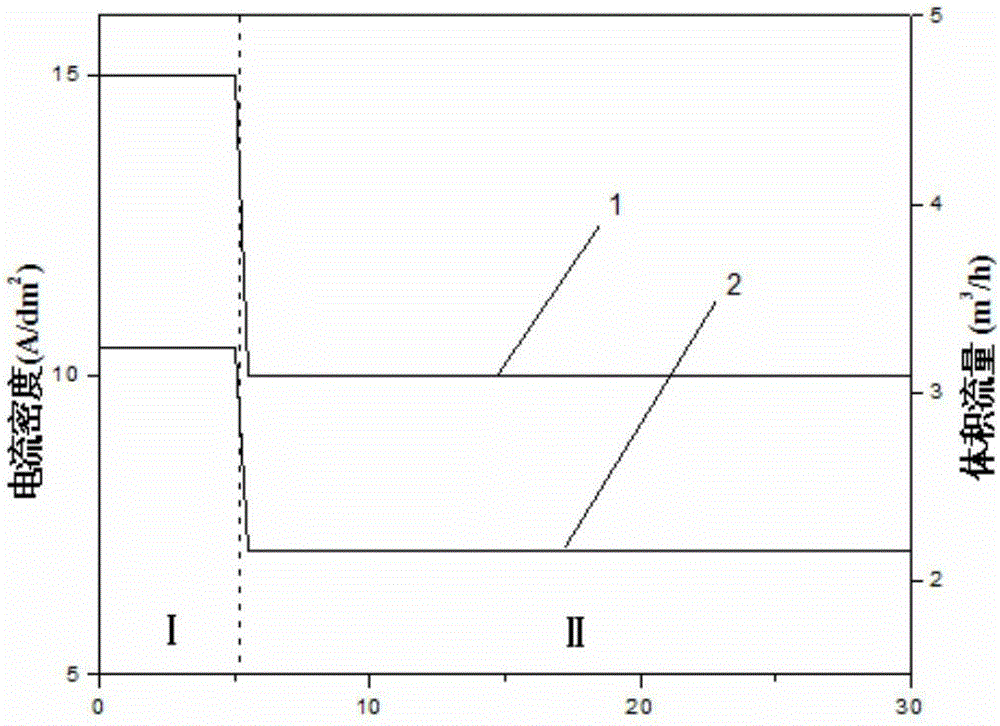

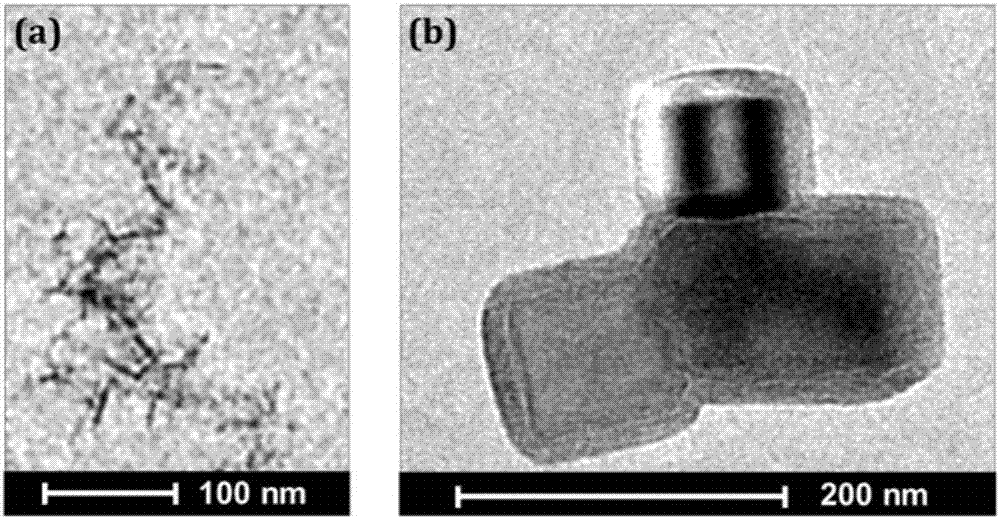

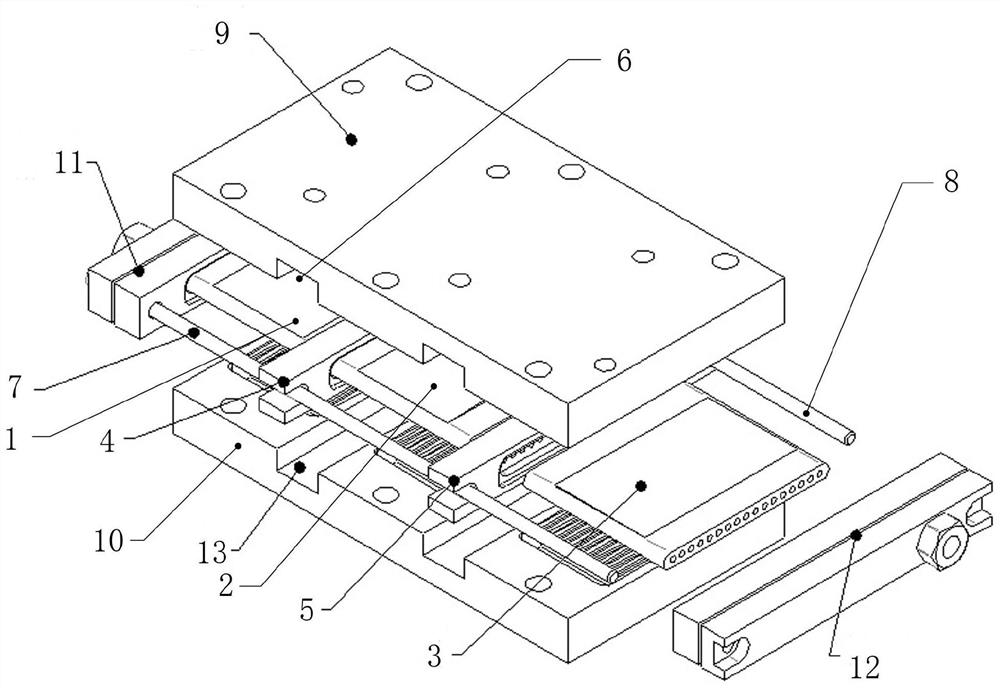

Method for preparing Ni-SiC composite coating on inner surface of hollow workpiece

ActiveCN106567118AHigh SiC contentFully suspendedElectrolytic coatingsConcentration polarizationCorrosion

The invention provides a method for preparing a Ni-SiC composite coating on the inner surface of a hollow workpiece. By means of a cyclic electroplating solution code position technology, an electroplating solution only makes contact with the inner surface of the hollow workpiece, and only the composite coating is deposited on the inner surface of the hollow workpiece without affecting the status of the outer surface of the hollow workpiece. The SiC content of the composite coating prepared in the composite electroplating solution with the SiC concentration being 20 g / L reaches up to 18.8%vol, and the utilization rate of SiC is effectively increased. The deposition rate of the Ni-SiC composite coating reaches up to 83 microns per 30min. Compared with a pure nickel coating, the Ni-SiC composite coating is low in surface roughness, uniform and compact and has the characteristics of high hardness, high abrasion resistance and high corrosion resistance. Through the method, the problem of concentration polarization of a composite electroplating solution in an immersion type electroplating system is effectively solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

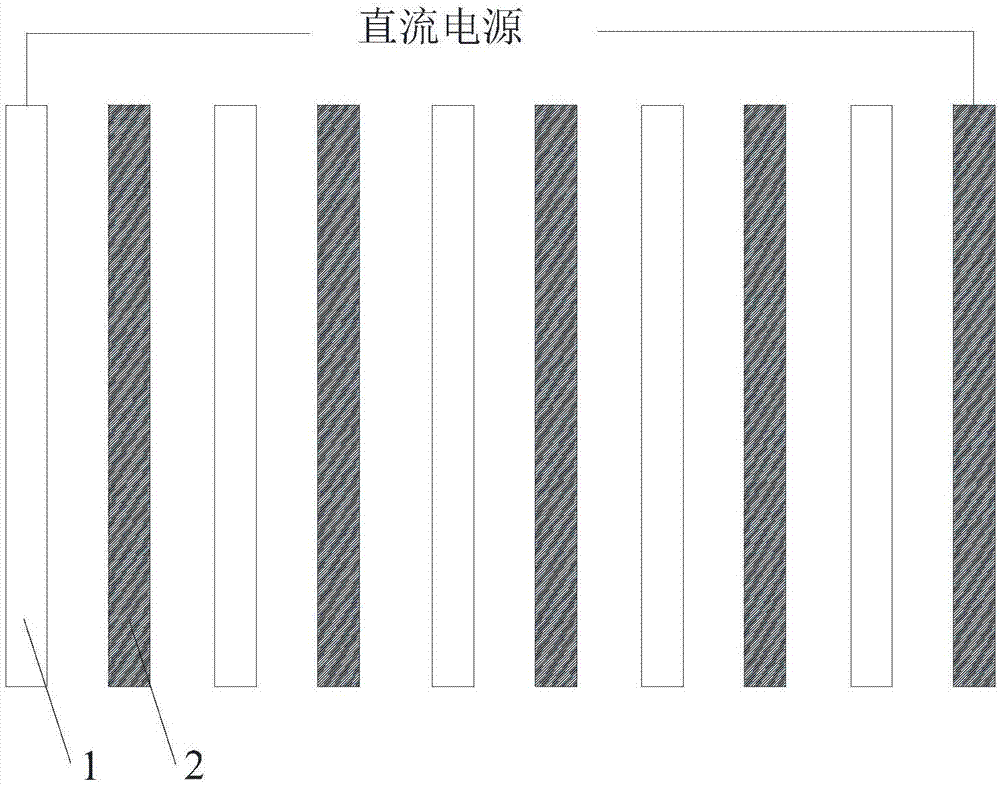

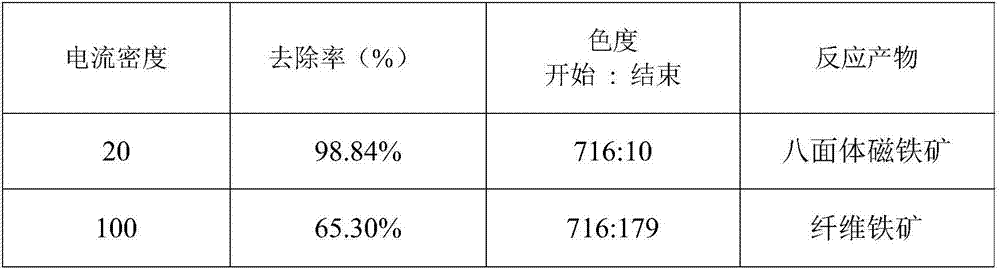

Method for treatment of electroplating chromium-containing wastewater by periodic polarity reversal

InactiveCN107244719AUniform corrosionReduce spacingWaste water treatment from metallurgical processWater/sewage treatmentElectrolysisConcentration polarization

The invention relates to a method for treatment of electroplating chromium-containing wastewater by periodic polarity reversal. The method adopts the steps of: adjusting the pH of electroplating chromium-containing wastewater to 5-7 and the conductivity to 500-2000micros / cm, then inserting pole plates, introducing direct current, carrying out electrocoagulation reaction and periodically reversing the pole plate polarity to electrolyze wastewater, then letting the mixed solution enter a sedimentation tank, recycling the supernatant, and using the precipitated floc as the raw material for preparation of alloy. Compared with the prior art, periodic polarity reversal adopted by the invention can make anode dissolved metal ions better diffuse into water, improves the mass transfer efficiency, alleviates concentration polarization, and can overcome the problems of low current efficiency, electrical energy waste, low treatment efficiency and the like caused by passivation, in addition by a mixed anode method, iron and aluminum metals can be dissolved at anode simultaneously, the floc undergoes coprecipitation, the flocculation effect is better, the effluent water is clear and transparent, has a chromium content of less than 0.01mg / L, and is recyclable.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

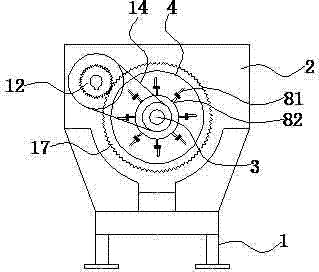

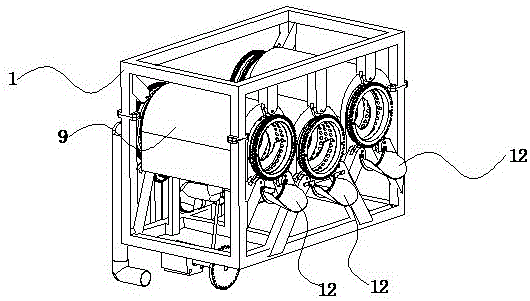

Rotary membrane sewage filtration device

ActiveCN104773790ASolve the problem of concentration polarizationSolve the problem of membrane foulingWater/sewage treatment bu osmosis/dialysisConcentration polarizationFiltration

The invention discloses a rotary membrane sewage filtration device, which comprises a frame, a filter box, a first rotating shaft, a motor, and a filter cartridge. The filter box is installed on the frame, the first rotating shaft is rotatably installed in the filter box, the motor is used for driving the first rotating shaft to work, the filter cartridge is rotatably sheathed on the first rotating shaft, a plurality of filter holes are formed on the circumferential wall of the filter cartridge, a membrane member is fixedly sleeved on the external circumferential wall of the filter cartridge, the left end side wall of the filter cartridge is connected to a liquid inlet box, the bottom side wall of the filter box is provided with a liquid outlet, the right end side wall of the filter cartridge is provided with a slag hole, a second rotating shaft in transmission connection with the first rotating shaft is mounted on the filter box and is equipped with a gear able to rotate synchronously with it, and meshing teeth engaged with the gear is formed on the right side of the filter cartridge. The rotary membrane sewage filtration device provided by the invention well solves the membrane surface concentration polarization and membrane pollution problems, significantly increases the membrane permeation flux, and greatly improves the separation performance of the membrane.

Owner:南大环保科技服务南通有限公司

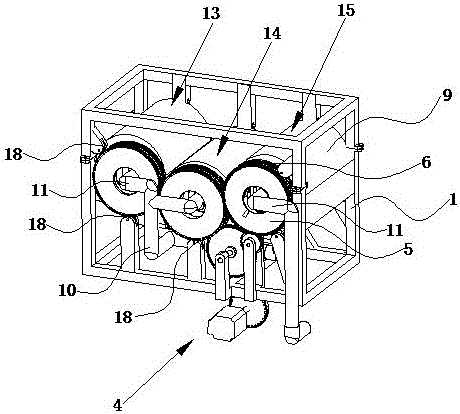

Two-stage rotating purification device

InactiveCN104787915ASolve the problem of concentration polarizationSolve the problem of membrane foulingMultistage water/sewage treatmentConcentration polarizationFixed frame

The invention discloses a two-stage rotating purification device. The two-stage rotating purification device comprises a fixing frame, a casing, a rotating drum, a filtering drum and a first motor, wherein multiple first filtering holes are formed in the circumferential wall of the rotating drum, a first membrane piece is mounted on the outer circumferential wall of the rotating drum in a sleeve manner, a liquid outlet is formed in the bottom of the casing, an end cover is detachably connected with the right end of the rotating drum, a first rotating shaft is fixedly connected onto the end cover and connected with an output shaft of the first motor, a mounting hole is formed in the left end side wall of the rotating drum, the filtering drum is communicated with the rotating drum via the mounting hole, the side wall of the filtering drum is connected with a liquid inlet pipe, a filtering plate is inserted and mounted in the filtering drum, multiple second filtering holes are formed in the filtering plate, second membrane pieces are fixedly mounted on the upper surface and the lower surface of the filtering plate, and a positioning groove where the head end of the filtering plate is inserted and mounted is formed in the inner side wall of the filtering drum. With the adoption of the two-stage rotating purification device, problems of concentration polarization of membrane surfaces and membrane pollution can be well solved, and the purification effect of the device is significantly improved.

Owner:谢洁萍

Adjustable double-stage-rotation purifying device

ActiveCN104787848ASolve the problem of concentration polarizationSolve the problem of membrane foulingSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisConcentration polarizationFixed frame

The invention discloses an adjustable double-stage-rotation purifying device. The device comprises a fixed frame, an adjusting device, a casing, a rotating drum, a filtering drum and a first motor, wherein multiple first filtering holes are formed in the circumferential wall of the rotating drum, the outer circumferential wall of the rotating drum is sleeved with a first membrane piece, a liquid outlet is formed in the bottom of the casing, an end cover is detachably connected with the right end of the rotating drum, a first rotating shaft is fixedly connected onto the end cover and connected with an output shaft of the first motor, a mounting hole is formed in the left end side wall of the rotating drum, the filtering drum is communicated with the rotating drum through the mounting hole, the side wall of the filtering drum is connected with a liquid inlet pipe, a filtering plate is inserted in the filtering drum, multiple second filtering holes are formed in the filtering plate, and second membrane pieces are fixedly mounted on upper and lower surfaces of the filtering plate. The device can better solve the problems of concentration polarization of membrane surfaces and membrane pollution, the purifying effect of the device can be significantly improved, and the flow of the liquid flowing out of the liquid outlet can be adjusted according to actual operation conditions.

Owner:山西惠净泉环保科技有限公司

Improved type filter device

InactiveCN105854614ATo achieve the purpose of filteringImprove permeabilityMembranesSemi-permeable membranesConcentration polarizationBiochemical engineering

The invention discloses an improved type filter device which comprises a fixed frame, a driving component and a filter component installed on the fixed frame. The filter component comprises a spiral stirring part and a filter cartridge. One end of the spiral stirring part is provided with a first gear portion, one end of the filter cartridge is provided with a second gear portion, and the first gear portion and the second gear portion are coaxially arranged and are both driven by the driving component. The two ends of the filter cartridge are open. The spiral stirring part is inserted into the filter cartridge. The filter cartridge is provided with multiple filter holes and sleeved with a filter film and a sleeving shell. The bottom of the sleeving shell is connected with a water outlet pipe. The filter component further comprises a liquid inlet pipe and a bearing pipe, wherein the liquid inlet pipe is inserted to the open end, close to the second gear portion, of the filter cartridge, and the bearing pipe is used for bearing solid particles at the open end, away from the second gear portion, of the filter cartridge. The problems of film face concentration polarization and film pollution can be solved, and the film permeation flux and filter effect are significantly improved.

Owner:江先庆

Single ion polymer electrolyte, single ion polymer electrolyte composite film and preparation method thereof, and lithium ion battery

ActiveCN108341933AFlame retardantImprove ionic conductivitySecondary cellsElectrolyte immobilisation/gelificationStructural unitLithium electrode

The invention relates to a single ion polymer electrolyte, a single ion polymer electrolyte composite film and a preparation method thereof and a lithium ion battery, and belongs to the technical field of lithium ion batteries. The single ion polymer electrolyte comprises a polymer chain composed of structural units, 1# or 2# position of the structural unit of the polymer chain is connected with alithium ion providing group and a lithium ion conductive group, and the molar ratio of lithium ion providing group to lithium ion conductive group is 1: (0.5 to 2). The uniform distribution of a lithium source of the single ion polymer electrolyte composite film ensures the integral electrical conductivity of the single ion polymer electrolyte composite film. The oxirane group and the lithium phosphate group of the single ion polymer electrolyte composite film provide the electrolyte with good electrical conductivity, flame retardancy and high mechanical properties. The single ion polymer electrolyte composite film has potential application value in the lithium ion batteries.

Owner:DO FLUORIDE CHEM CO LTD

Thick electrode with good electrochemical performance and preparation method thereof

ActiveCN102324493BImproved magnification performanceSolve the problem of concentration polarizationNon-aqueous electrolyte accumulator electrodesElectrolytic agentConductive materials

The invention discloses a thick electrode with good electrochemical performance, which includes a current collector and an electrode membrane distributed on the current collector containing active materials and conductive materials. The electrode membrane includes an inner layer membrane close to the current collector and a The outer diaphragm of the current collector, the thickness of the electrode diaphragm is greater than 300 μm, the conductivity of the electrode diaphragm decreases from the inner diaphragm to the outer diaphragm, and the pores of the electrode diaphragm from the inner diaphragm to the outer diaphragm rate increase. The electrical conductivity of the inner membrane is relatively high, so that the electrons at the current collector can quickly enter or exit the inner membrane. The outer diaphragm has a large porosity, which can absorb more electrolyte, which solves the problem of poor electrolyte wettability caused by thick electrodes. In addition, the invention also discloses a method for preparing a thick electrode with good electrochemical performance.

Owner:DONGGUAN AMPEREX TECH +1

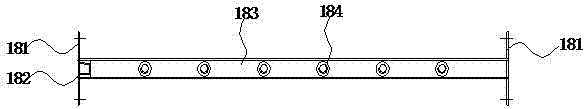

Torsional vibration type hollow fiber membrane filtering device

ActiveCN113069928ATorsional vibration achievedAvoid energy consumptionSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisConcentration polarizationMembrane fouling

The invention discloses a torsional vibration type hollow fiber membrane filtering device, belonging to the technical field of water treatment. The torsional vibration type hollow fiber membrane filtering device overcomes the problems of a concentration polarization phenomenon and membrane pollution in the process of filtering raw water by using a hollow fiber membrane module in the prior art, and the problems of adverse influence on the filtering effect and many limitations of an existing membrane pollution control method. The invention provides a torsional vibration assembly which is connected with a hollow fiber membrane assembly for use, so torsional vibration of a hollow fiber membrane is realized, the problem of energy consumption caused by axial up-and-down vibration of the hollow fiber membrane in the prior art is avoided, the problem of requirement on the space of a reactor by horizontal vibration of the hollow fiber membrane in the prior art is solved, and the problems of concentration polarization and membrane pollution in a raw water filtering process are effectively solved.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

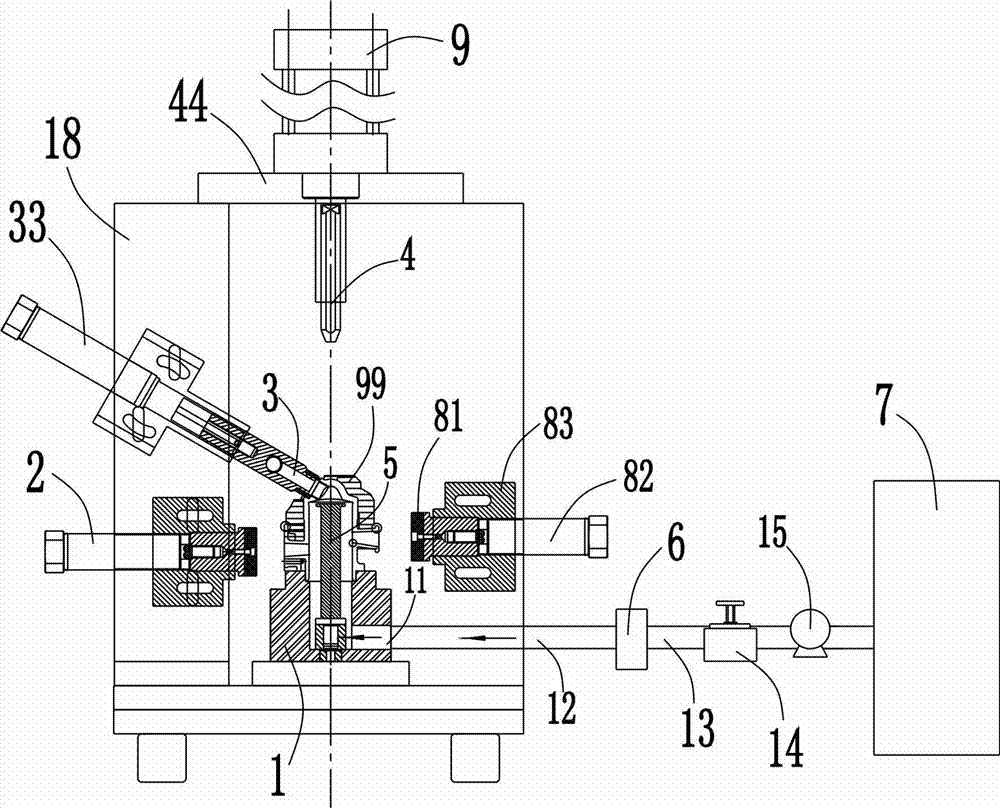

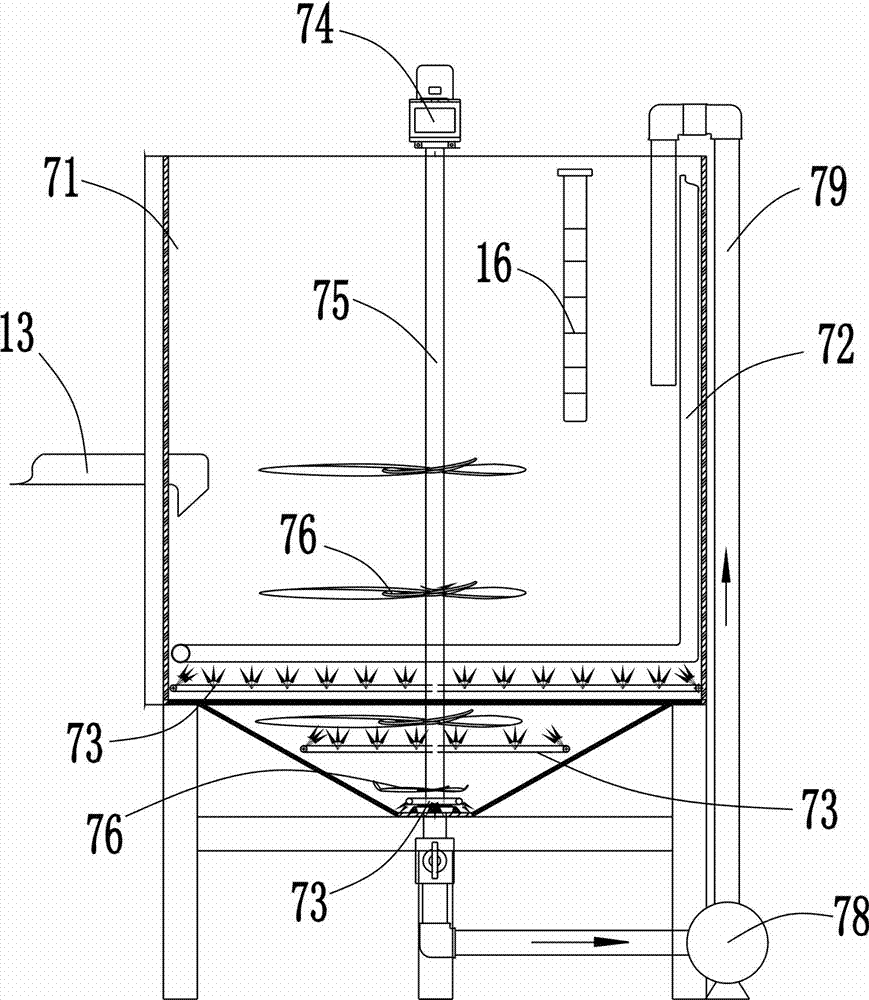

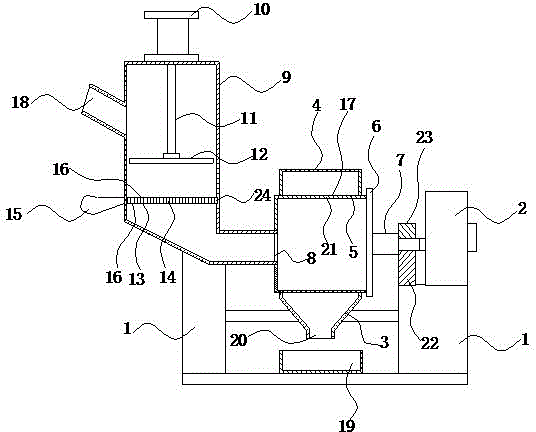

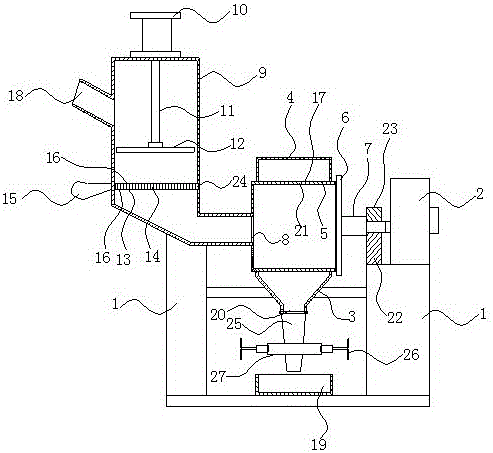

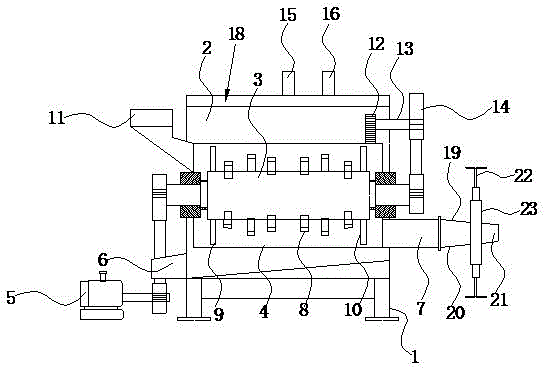

A device for preparing ni-sic composite coating on the inner surface of a hollow workpiece

ActiveCN106283166BSpeed up the flowImprove liquidityElectrolysis componentsElectrolytic coatingsLiquid storage tankEngineering

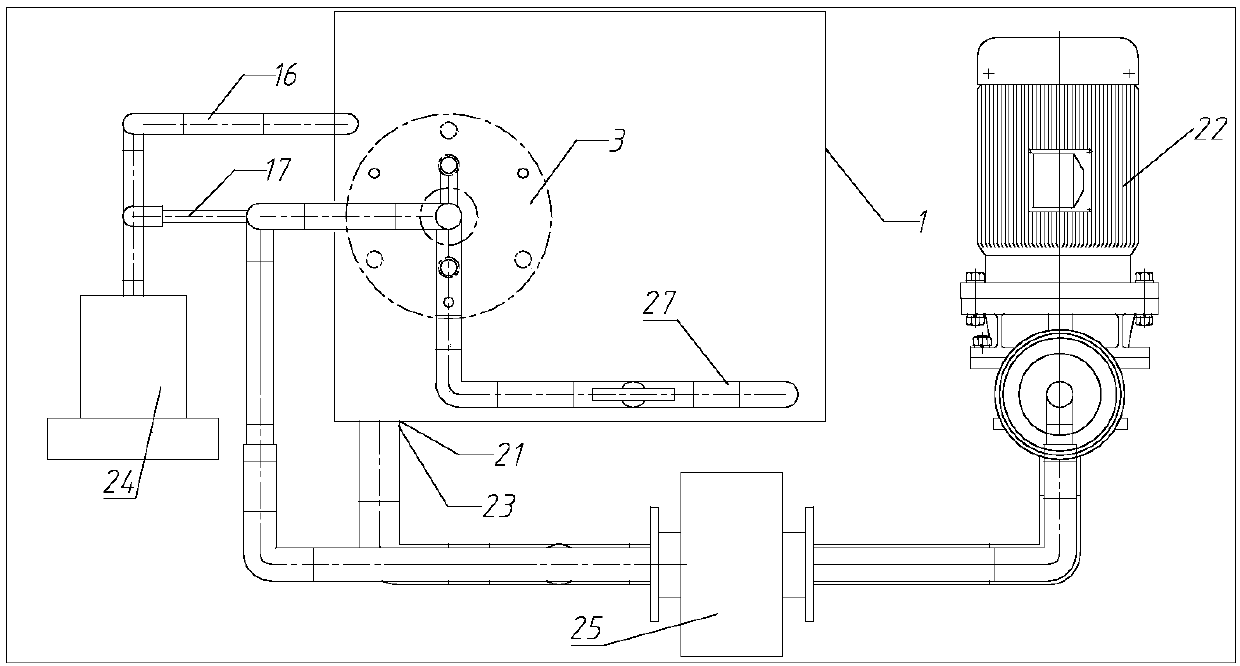

The invention discloses a device for preparing a Ni-SiC composite coating on the inner surface of a hollow workpiece. A lower water outlet pipe and an upper water outlet pipe which are parallel and are arranged in an up-and-down manner are arranged in a liquid storage tank. After electroplating liquid flowing out of the upper water outlet pipe and electroplating liquid flowing out of the lower water outlet pipe are converged, the mixed electroplating liquid flows towards a sealed electroplating table under the drive force of an electroplating liquid circulation pump, and an electromagnetic flow meter is adjusted to control the volume flow rate of the electroplating liquid flowing towards the sealed electroplating table. After composite electroplating is completed in the sealed electroplating table, the electroplating liquid flows back into the liquid storage tank through a loop. One end of an air discharging pipe is connected with an outlet of a compressed air pump, and the other end of the air discharging pipe is connected in the liquid storage tank. The device is a the sealed and continuous-circulation electroplating device developed based on a traditional non-closed immersion type electroplating device and has the beneficial effects of being reasonable in structure, reliable in operation and convenient to use and operate, and the Ni-SiC composite coating with the good quality can be obtained on the inner surface of the hollow workpiece.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

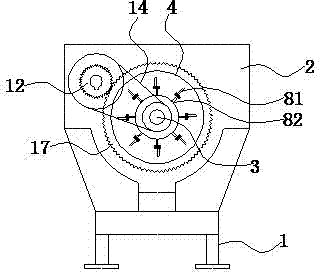

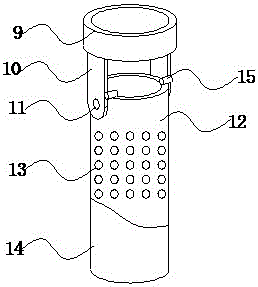

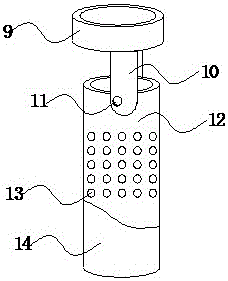

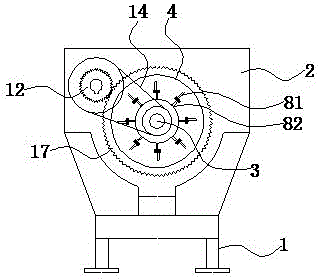

Eccentric rotating film filtering device

ActiveCN104492271AIncrease centrifugal forceHigh permeation fluxSemi-permeable membranesConcentration polarizationEngineering

The invention discloses an eccentric rotating film filtering device which comprises a fixed shell, a rotating sleeve, a motor and a filter cartridge, wherein the rotating sleeve is rotationally arranged on the top of the fixed shell; the motor is used for driving the rotating sleeve to operate; the filter cartridge is positioned in a cavity of the fixed shell; the upper end of the filter cartridge is open, and the filter cartridge is of a hollow structure; multiple filtering holes are formed in the peripheral side wall of the filter cartridge; a film piece of which the outline is matched with the outline of the filter cartridge is fixedly arranged on the peripheral wall of the filter cartridge in a sleeving manner; a liquid inlet facing the opening of the filter cartridge is formed in the top of the fixed shell; a liquid outlet pipe is arranged at the bottom of the fixed shell; two sides of the bottom of the rotating sleeve downwards extend to form two connecting rods; the filter cartridge is hinged to the two connecting rods; and the mass center of the filter cartridge deviates from the center line of the rotating sleeve. According to the device disclosed by the invention, the phenomena of concentration polarization of the film surface and the film pollution can be well avoided, the permeation flux of the film is obviously improved, and the film separation performance is greatly improved.

Owner:GUANGDONG YEANOVO ENVIRONMENTAL PROTECTION CO LTD

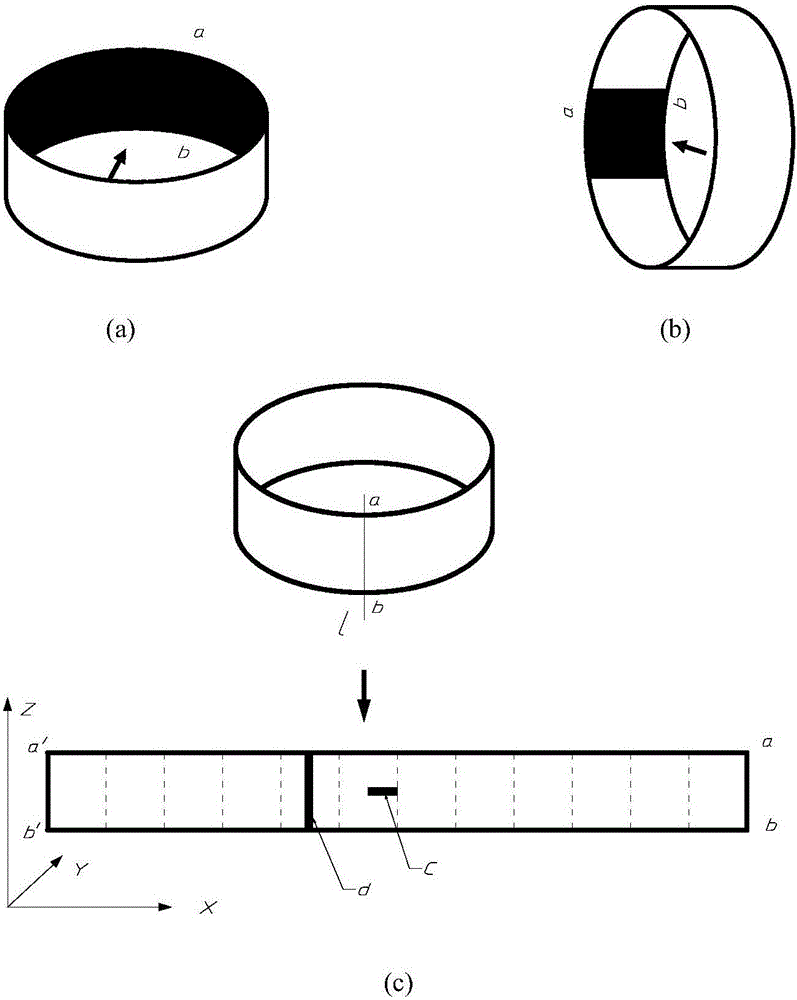

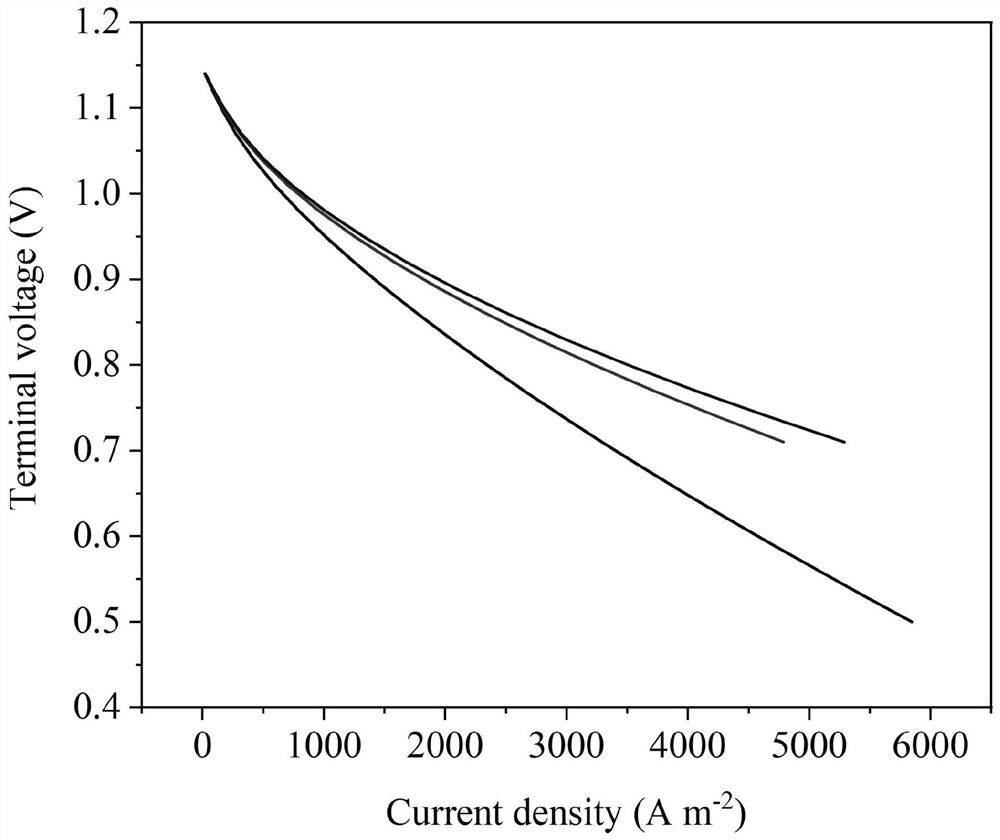

Symmetrical double-cathode structure battery and preparation method and discharging method thereof

PendingCN114361552AAchieve consistencySolve the problem of concentration polarizationFuel cells groupingSegmented cellBattery cell

The invention discloses a symmetrical double-cathode structure battery and a preparation method and a discharge method thereof, and the symmetrical double-cathode structure battery comprises a battery upper cathode plate, a battery lower cathode plate, a battery left anode plate, a battery right anode plate, a first current lead-out rod, a first battery connecting piece, a first segmented battery and a second segmented battery, the battery upper cathode plate is buckled on the battery lower cathode plate, and a battery left anode plate, a first sectional battery, a first battery connecting piece, a second sectional battery and a battery right anode plate are clamped between the battery upper cathode plate and the battery lower cathode plate; a first current lead-out rod penetrates through one ends of the battery left anode plate, the first battery connecting piece and the battery right anode plate, a first upper groove is formed in the battery upper cathode plate to avoid the first battery connecting piece, and a first lower groove is formed in the battery lower cathode plate to avoid the first battery connecting piece. According to the symmetrical double-cathode structure battery provided by the invention, the problem of concentration polarization caused by current collecting area difference in cathode and anode discharge reaction can be solved.

Owner:浙江氢邦科技有限公司

A new type of solid electrolyte membrane material that can be used as lithium ion battery and its preparation method and application

ActiveCN104466241BSolve the problem of concentration polarizationIncrease the number of transfersSecondary cellsOrganic electrolytesSolid state electrolytePolyethylene oxide

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

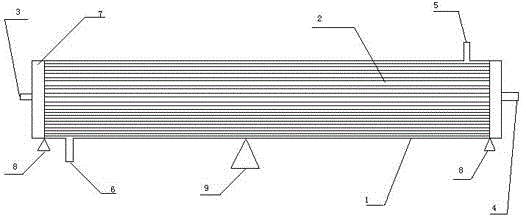

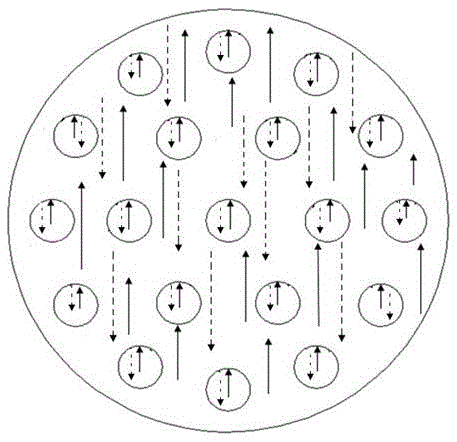

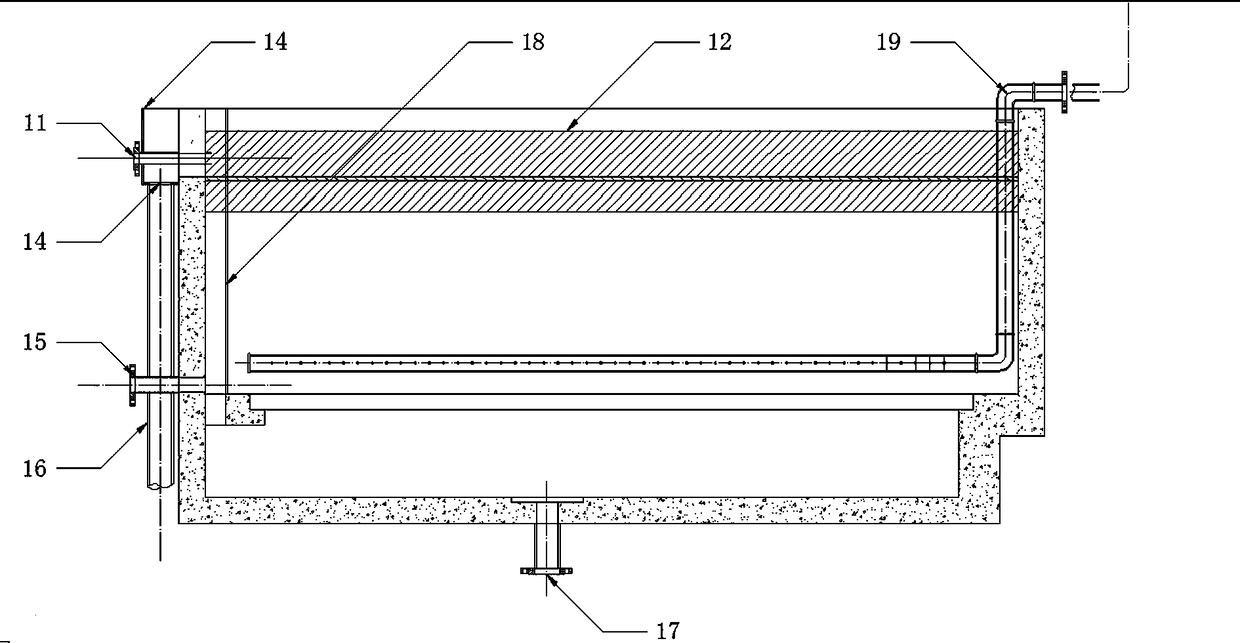

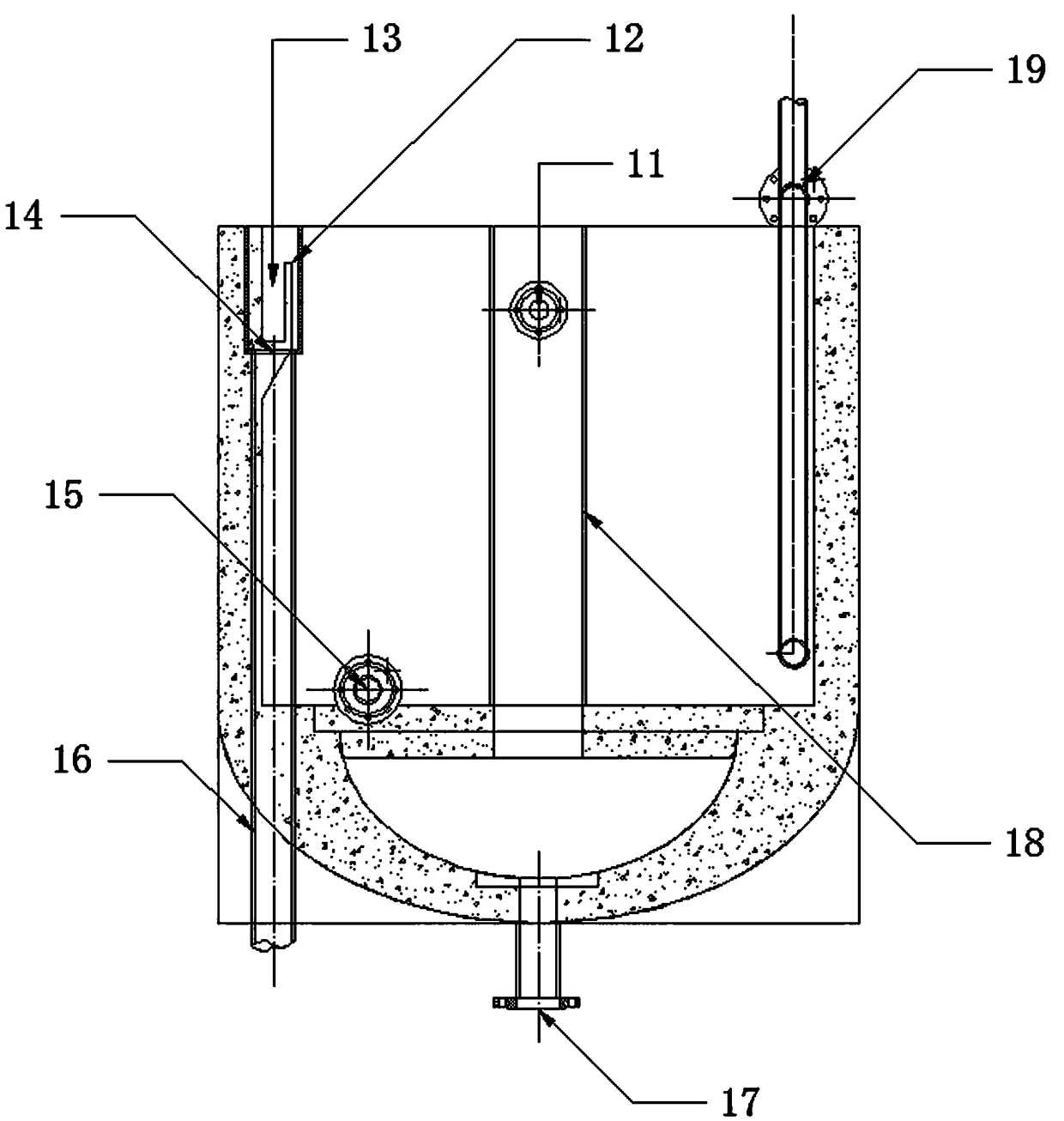

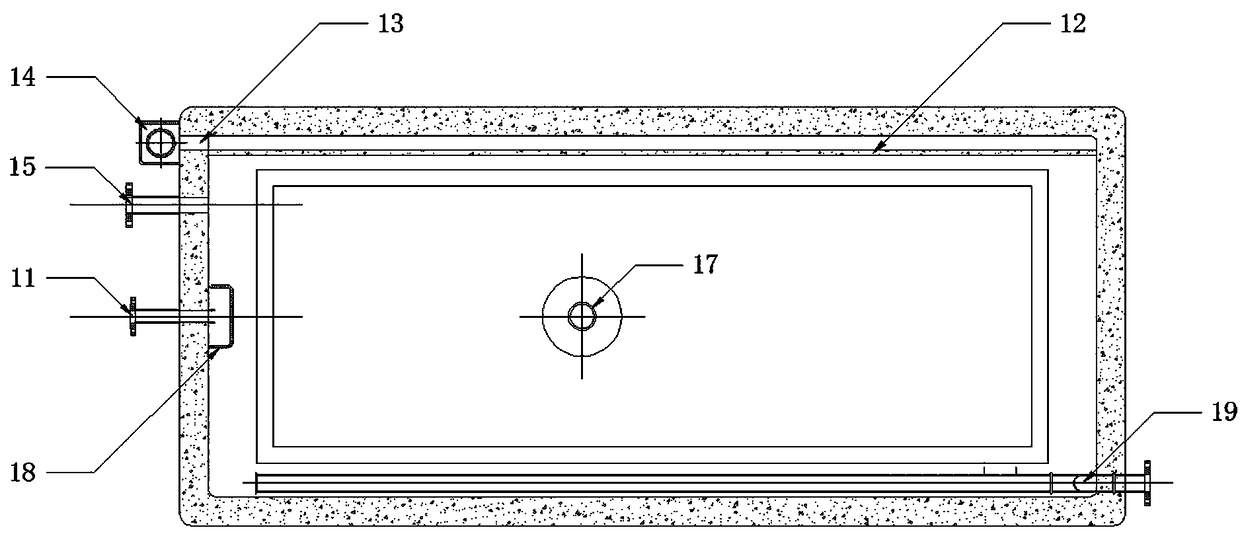

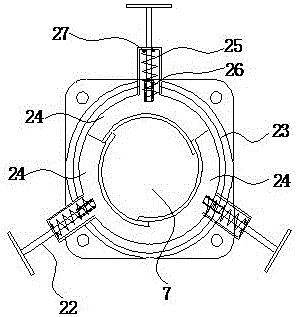

Medical dialyzer

InactiveCN106730087ASolve the problem of concentration polarizationRelieve painDialysis systemsMedical devicesFiberEngineering

The invention relates to a medical dialyzer. The medical dialyzer comprises a casing, flow distributing devices, hollow fiber pipes and a vibration device, wherein the casing is cylindrical; the flow distributing devices are arranged at two ends of the casing; the hollow fiber pipes are arranged between the flow distributing devices and are in airtight connection with the flow distributing devices; the two flow distributing devices are connected with a blood inlet and a blood outlet respectively; a dialysate inlet is formed in the upper part of the casing, a dialysate outlet is formed in the bottom of the casing, and the vibration device is arranged in the middle of the bottom of the casing.

Owner:杨宴敏

A kind of single ion polymer electrolyte and preparation method thereof, single ion polymer electrolyte membrane, lithium ion battery

ActiveCN107141450BFlame retardantImprove performanceSolid electrolytesSecondary cellsPolymer scienceElectrical battery

The invention belongs to the technical field of lithium ion batteries and particularly relates to a single-ion polymer electrolyte, a preparation method thereof, a single-ion polymer electrolyte membrane and a lithium ion battery. The single-ion polymer electrolyte comprises polymer chains formed by structure units represented by formula 1 (shown in the description), wherein membrane supporting groups are linked between the two polymer chains, and two ends of the membrane supporting groups are respectively connected to sites 1 or 2 of the structure units; lithium ion providing groups are connected to the sites 1 or 2 of the structure units; the lithium ion providing groups and the membrane supporting groups are respectively connected to the site 1 or 2 of each independent structure unit; and the molar ratio of the lithium ion providing groups to the membrane supporting groups is 1 to (1-2). The single-ion polymer electrolyte has the advantages of high room temperature conductivity, mechanical strength and flame retardance and the like and further has very considerable application prospects in the field of the lithium ion batteries.

Owner:DO FLUORIDE CHEM CO LTD

A turbulent flow electrolyzer and a turbulent flow electrolysis production system composed of turbulent flow electrolyzers

ActiveCN105671597BIncrease cleaning speedGuaranteed uptimeElectrolysis componentsPhotography auxillary processesEngineeringCell bodies

Owner:中锰(湖北)科技发展有限公司

An eccentric rotating membrane filter device

ActiveCN104492271BIncrease centrifugal forceHigh permeation fluxSemi-permeable membranesConcentration polarizationEngineering

The invention discloses an eccentric rotating film filtering device which comprises a fixed shell, a rotating sleeve, a motor and a filter cartridge, wherein the rotating sleeve is rotationally arranged on the top of the fixed shell; the motor is used for driving the rotating sleeve to operate; the filter cartridge is positioned in a cavity of the fixed shell; the upper end of the filter cartridge is open, and the filter cartridge is of a hollow structure; multiple filtering holes are formed in the peripheral side wall of the filter cartridge; a film piece of which the outline is matched with the outline of the filter cartridge is fixedly arranged on the peripheral wall of the filter cartridge in a sleeving manner; a liquid inlet facing the opening of the filter cartridge is formed in the top of the fixed shell; a liquid outlet pipe is arranged at the bottom of the fixed shell; two sides of the bottom of the rotating sleeve downwards extend to form two connecting rods; the filter cartridge is hinged to the two connecting rods; and the mass center of the filter cartridge deviates from the center line of the rotating sleeve. According to the device disclosed by the invention, the phenomena of concentration polarization of the film surface and the film pollution can be well avoided, the permeation flux of the film is obviously improved, and the film separation performance is greatly improved.

Owner:GUANGDONG YEANOVO ENVIRONMENTAL PROTECTION CO LTD

An adjustable two-stage rotary purification device

ActiveCN104787848BSolve the problem of concentration polarizationSolve the problem of membrane foulingSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFixed frameMembrane surface

Owner:山西惠净泉环保科技有限公司

An improved two-stage rotary purification device

ActiveCN104787916BAvoid cloggingHigh permeation fluxMultistage water/sewage treatmentConcentration polarizationMembrane surface

Owner:柳州紫荆技术转移中心有限公司

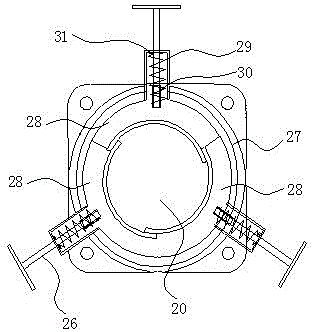

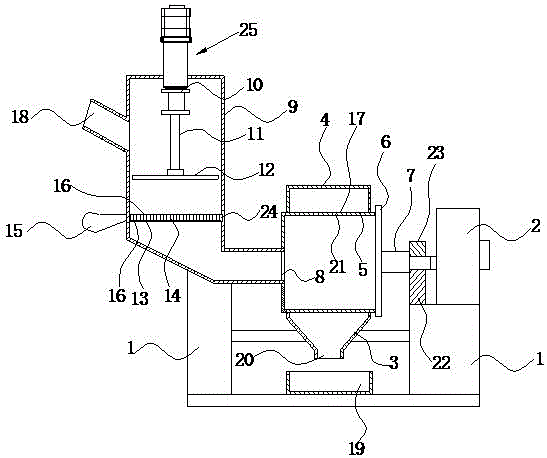

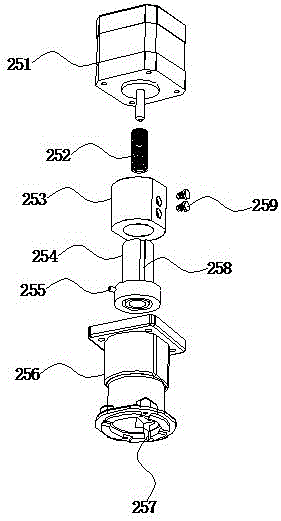

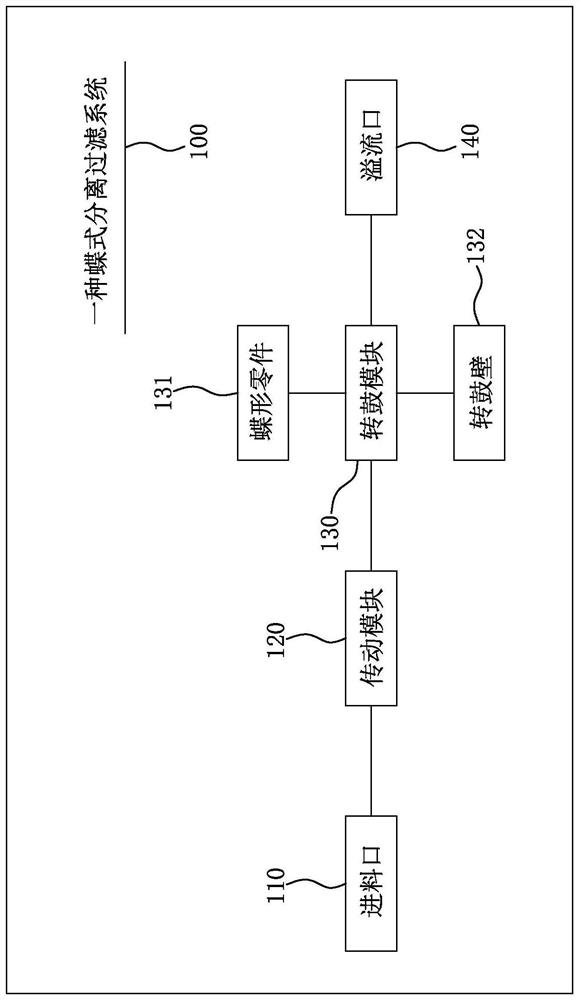

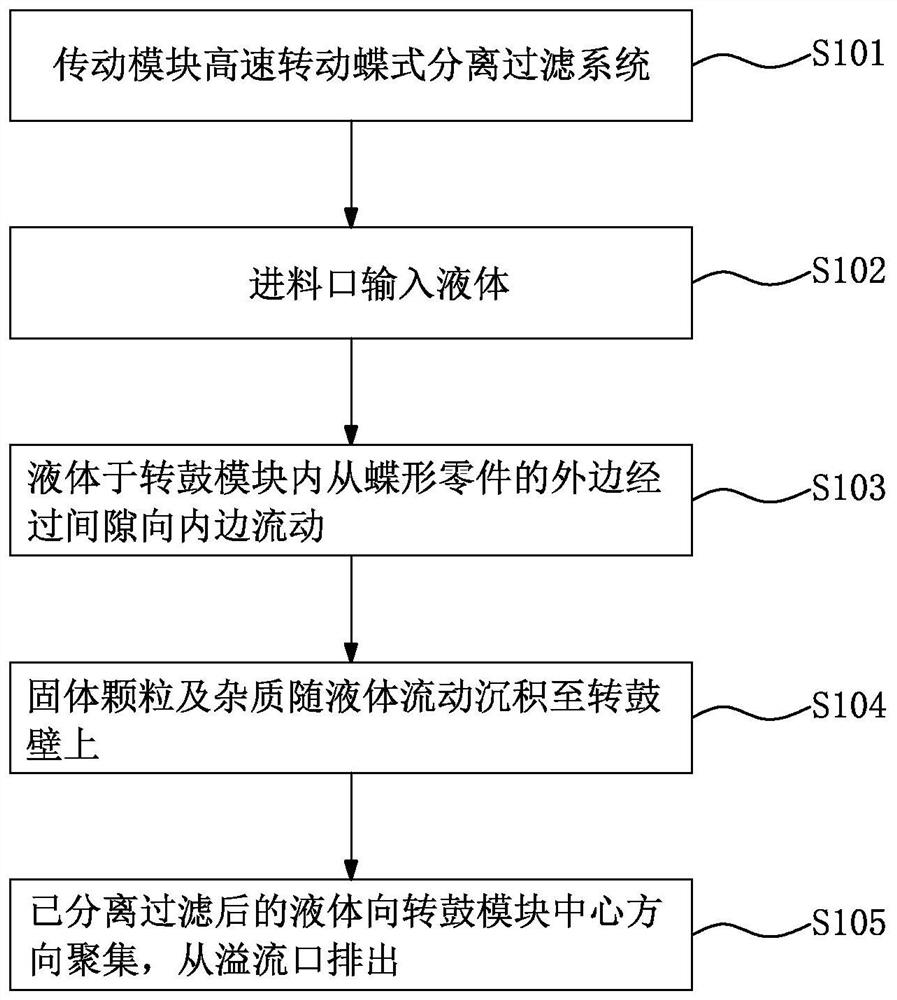

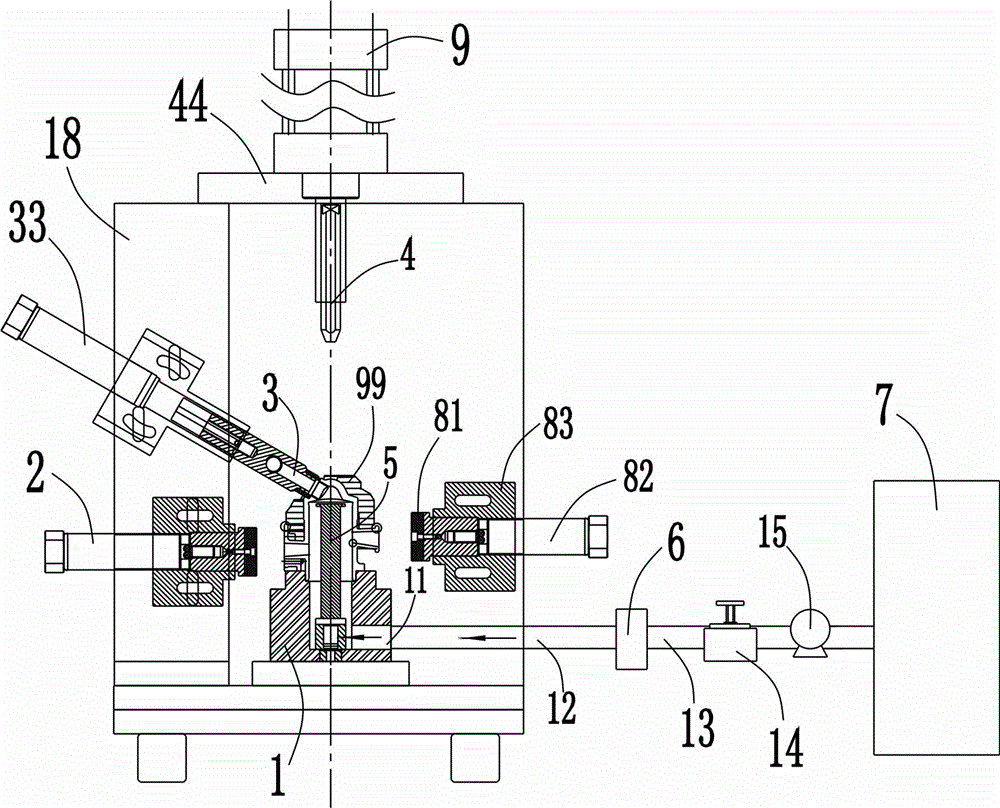

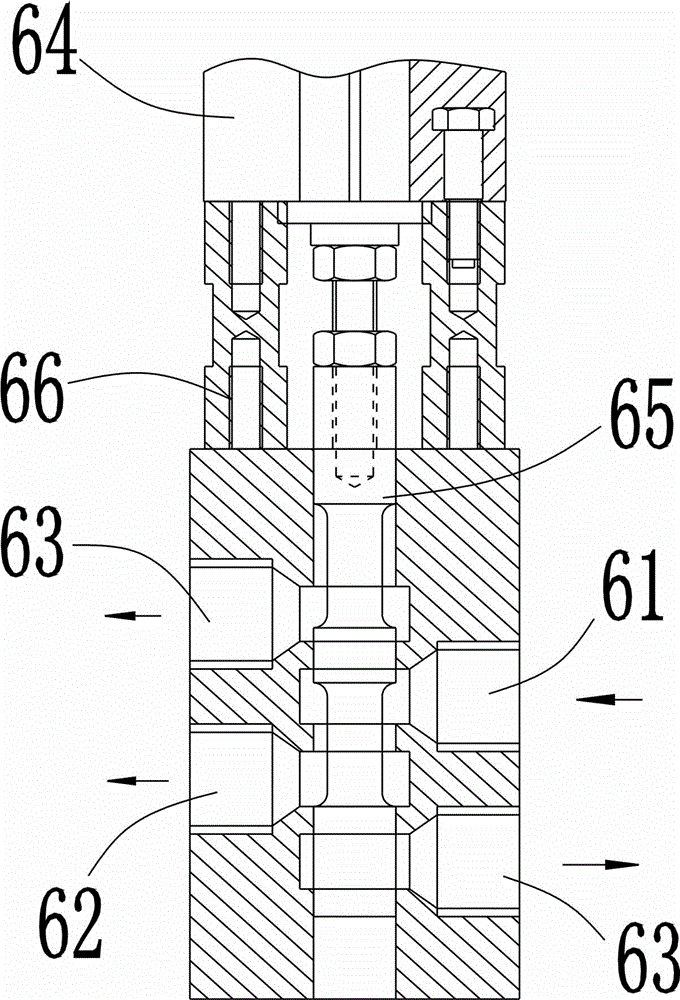

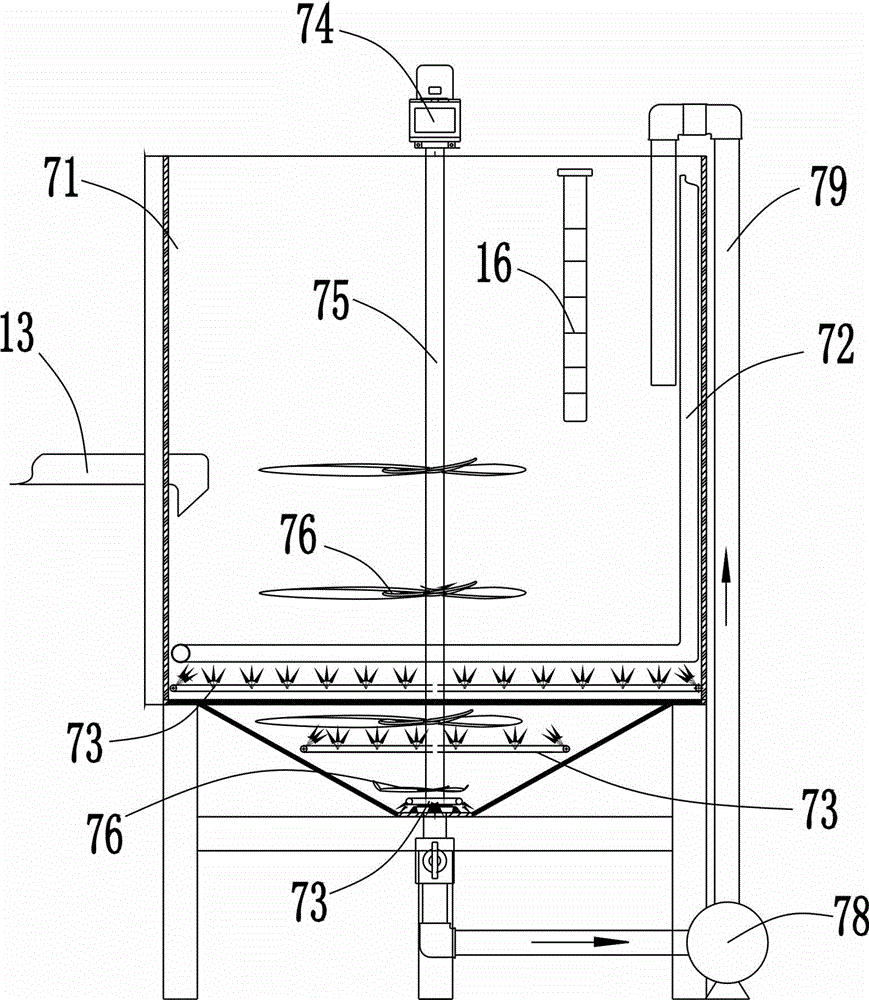

Butterfly type separating and filtering system and method

PendingCN112958290AIncrease productivityReduce cleaning and maintenance costsRotary centrifugesConcentration polarizationFiltration

The invention relates to a butterfly type separating and filtering system and method. The system comprises a feeding hole which is used for inputting liquid, a transmission module connected with the feeding hole and used for rotating the butterfly type separating and filtering system, a rotary drum module and an overflow hole. The rotary drum module is connected with the transmission module and is provided with butterfly-shaped parts and a rotary drum wall, the butterfly-shaped parts are mutually nested, a certain gap is formed between the butterfly-shaped parts, and the rotary drum module is used for separating and filtering liquid; and the overflow hole is connected with the rotary drum module and used for discharging the separated and filtered liquid, by means of the butterfly type separating and filtering system and method, the problem of concentration polarization is solved, the cleaning and maintenance cost of a membrane is reduced, the service life of the membrane is prolonged, and the production efficiency of liquid separation and filtration is greatly improved.

Owner:KUNSHAN HANDING PRECISION METAL CO LTD

Perfusion type electronickelling and silicon carbide device for air cylinder

The invention discloses a perfusion type electronickelling and silicon carbide device for an air cylinder. The perfusion type electronickelling and silicon carbide device for the air cylinder comprises an electroplating base, an electroplating solution groove, a cathode conducting rod and an anode conducting rod. The air cylinder to be electroplated is placed inversely on the electroplating base which is internally provided with a groove. One end of the anode conducting rod is arranged in the groove, while the other end of the anode conducting rod extends into a chamber of the air cylinder to be electroplated. The cathode conducting rod is arranged above the electroplating base and can move up and down. The electroplating base is provided with a liquid inlet which is communicated with the electroplating solution groove through a flow divider. The flow divider comprises an electroplating solution inlet, an electroplating solution outlet and at least a return opening. The electroplating solution outlet is communicated with a liquid outlet. The electroplating solution inlet and the return opening are communicated with the electroplating solution groove. The perfusion type electronickelling and silicon carbide device for the air cylinder further comprises a drive device which drives the electroplating solution to flow upward along the inner wall of the air cylinder and flow from the top of the air cylinder back to the electroplating solution groove. According to the device, the electroplating solution is less polluted, the life cycle of the electroplating solution is long, the electroplating solutions in grooves are not needed to be prepared, and the regenerating time and cost of the electroplating solution are reduced.

Owner:ZHENGJIANG FENGLONG ELECTRIC CO LTD

A two-stage rotary purification device

InactiveCN104787915BSolve the problem of concentration polarizationSolve the problem of membrane foulingMultistage water/sewage treatmentConcentration polarizationMembrane surface

The invention discloses a two-stage rotating purification device. The two-stage rotating purification device comprises a fixing frame, a casing, a rotating drum, a filtering drum and a first motor, wherein multiple first filtering holes are formed in the circumferential wall of the rotating drum, a first membrane piece is mounted on the outer circumferential wall of the rotating drum in a sleeve manner, a liquid outlet is formed in the bottom of the casing, an end cover is detachably connected with the right end of the rotating drum, a first rotating shaft is fixedly connected onto the end cover and connected with an output shaft of the first motor, a mounting hole is formed in the left end side wall of the rotating drum, the filtering drum is communicated with the rotating drum via the mounting hole, the side wall of the filtering drum is connected with a liquid inlet pipe, a filtering plate is inserted and mounted in the filtering drum, multiple second filtering holes are formed in the filtering plate, second membrane pieces are fixedly mounted on the upper surface and the lower surface of the filtering plate, and a positioning groove where the head end of the filtering plate is inserted and mounted is formed in the inner side wall of the filtering drum. With the adoption of the two-stage rotating purification device, problems of concentration polarization of membrane surfaces and membrane pollution can be well solved, and the purification effect of the device is significantly improved.

Owner:谢洁萍

An Improved Rotating Membrane Sewage Filtration Device

ActiveCN104772042BQuick inhalationHigh permeation fluxSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisConcentration polarizationSlag

The invention discloses an improved rotating membrane sewage filtration device, which comprises a rack, a filter box, a first rotating shaft, a motor and a filter cartridge. A plurality of filter holes are formed on the circumferential wall of the filter cartridge, the outer circumferential wall of the filter cartridge is fixedly sleeved with a membrane member, the left side wall of the filter cartridge is connected to a liquid inlet tank, the bottom side wall of the filter box is provided with a liquid outlet, the right end side wall of the filter cartridge is provided with a slag outlet, a second rotating shaft in transmission connection with the first rotating shaft is mounted on the filter box, the second rotating shaft is equipped with a gear able to rotate synchronously therewith, and engaging teeth engaged with the gear are formed on the right side of the filter cartridge. The right end of the slag outlet is connected to a convergent cylinder, a rubber sleeve is inserted in the convergent cylinder, the right end of the rubber sleeve is connected to a plurality of petals, and each petal is equipped with an adjustment unit. The improved rotating membrane sewage filtration device provided by the invention well solves the concentration polarization and membrane pollution problems of the membrane surface, significantly increases the membrane permeation flux, and greatly improves the membrane separation performance.

Owner:惠州市同方水务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com