Thick electrode with good electrochemical performance and preparation method thereof

An electrochemical and electrode technology, which is applied in the field of thick electrodes and its preparation, can solve the problems of reducing the electrochemical performance of the outer layer of the pole piece, unable to retain the electrolyte, etc., to solve the problem of concentration polarization, good electrochemical performance, and improve Effect of Magnification Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

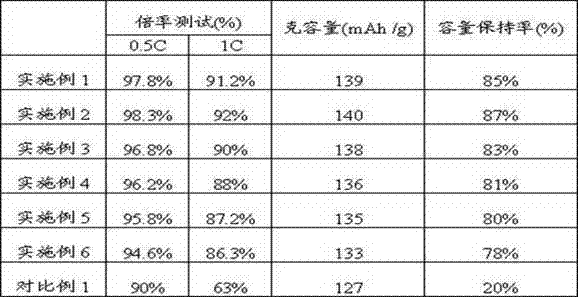

Embodiment 1

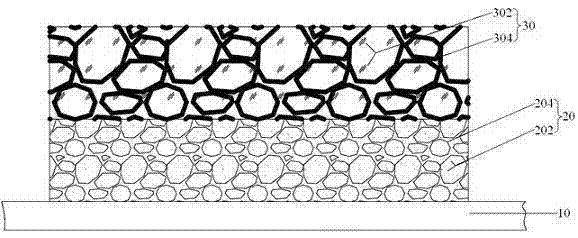

[0046] The production of the positive electrode sheet: the positive electrode active material lithium cobaltate (LiCoO 2 ), the conductive agent carbon black, the binder polyvinylidene fluoride (PVDF) and the solvent N-methylpyrrolidone (NMP) are uniformly mixed in a weight ratio of 92:3:5:80 to obtain the inner layer slurry to be coated ;The inner layer slurry is evenly coated on the aluminum foil current collector with a thickness of 14 microns, and then dried at 110°C, and the inner layer diaphragm with a coating thickness of about 150 microns is obtained after the first cold pressing treatment.

[0047] The positive electrode active material lithium cobaltate (LiCoO) coated with 0.6% aluminum oxide 2 ), carbon nanotubes, polyvinylidene fluoride (PVDF) and solvent N-methylpyrrolidone (NMP) in a weight ratio of 94:1.5:4.5:80 to uniformly mix the outer layer slurry to coat the baked The dried inner membrane is then dried at 110° C., and the outer membrane with a coating thic...

Embodiment 2

[0051] The production of the positive electrode sheet: the positive electrode active material lithium cobaltate (LiCoO 2 ), the conductive agent carbon black, the binder polyvinylidene fluoride (PVDF) and the solvent N-methylpyrrolidone (NMP) are uniformly mixed in a weight ratio of 92:3:5:80 to obtain the inner layer slurry to be coated ; The inner layer slurry is evenly coated on the aluminum foil current collector with a thickness of 14 microns, the thickness of the coating is about 150 microns, and then dried at 110° C. to obtain the inner membrane.

[0052] The positive electrode active material lithium cobaltate (LiCoO) coated with 0.6% aluminum oxide 2 ), carbon nanotubes, benzoic acid, polyvinylidene fluoride (PVDF) and solvent N-methylpyrrolidone (NMP) in a weight ratio of 92: 1.5: 1.5: 5: 80 to uniformly mix the outer layer slurry Coating on the baked inner membrane, the thickness of the coating is about 150 microns, and then drying at 110°C to obtain the outer memb...

Embodiment 3

[0056] The production of the positive electrode sheet: the positive electrode active material lithium cobalt oxide (LiCoO 2 ), the conductive agent carbon black, the binder polyvinylidene fluoride (PVDF) and the solvent N-methylpyrrolidone (NMP) are uniformly mixed in a weight ratio of 90:3:7:80 to obtain the inner layer slurry to be coated ; The inner layer slurry is evenly coated on an aluminum foil current collector with a thickness of 14 microns, the coating thickness is about 250 microns, and then dried at 110° C. to obtain an inner membrane.

[0057] The positive electrode active material lithium cobaltate (LiCoO) coated with 0.6% aluminum oxide 2 ), carbon nanotubes, benzoic acid, polyvinylidene fluoride (PVDF) and solvent N-methylpyrrolidone (NMP) in a weight ratio of 90:1.5:1.5:7:80 to uniformly mix the outer layer slurry Coating on the dried inner membrane, the thickness of the coating is about 300 microns, and then drying at 110°C to obtain the outer membrane, thus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com