Hard carbon negative electrode material of lithium ion battery, preparation method and application of hard carbon negative electrode material

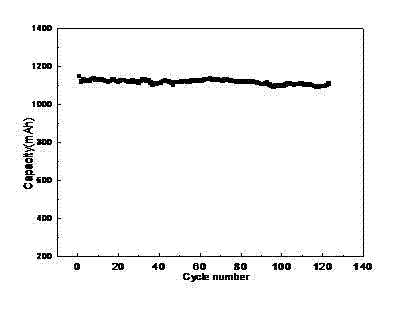

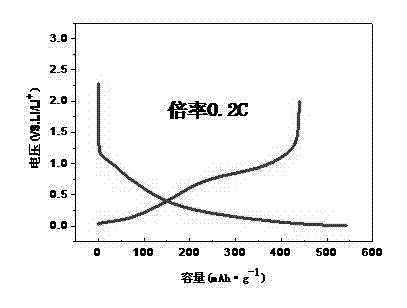

A lithium-ion battery and anode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of insignificant increase in specific capacity, poor compatibility of graphite, cumbersome preparation methods, etc., and achieve excellent cycle performance, compatibility Good performance, the effect of improving the first Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

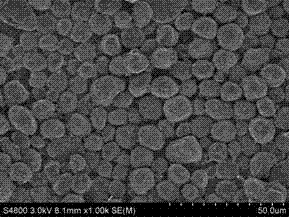

[0037] Example 1 Preparation of hard carbon anode materials for lithium-ion batteries

[0038] The preparation of lithium ion battery hard carbon negative electrode material comprises the following steps:

[0039] 1) Weigh 20g of phenolic resin, add it into 100ml of absolute ethanol, dissolve it fully, and obtain the ethanol solution of phenolic resin;

[0040] 2) Add 2g of nano-silicon liquid and 2g of phosphoric acid into the phenolic resin solution prepared in step 1), and stir mechanically to make it evenly mixed to obtain a mixed solution;

[0041] 3) Filter the mixed solution prepared in step 2), take the filtrate, place it in a drying oven, and keep it at 95°C for 4 hours for drying to obtain a reactant precursor;

[0042] 4) Take out the precursor of the reactant, put it into a tube furnace, and under the protection of nitrogen, raise the temperature to 350°C at a heating rate of 2° / min, keep it warm for 2 hours, perform preheating treatment, and then ...

Embodiment 2

[0044] Example 2 Preparation of hard carbon anode materials for lithium-ion batteries

[0045] The preparation of lithium ion battery hard carbon negative electrode material comprises the following steps:

[0046] 1) Weigh 50g of phenolic resin, 5g of nano-silicon liquid and 10g of phosphorus pentoxide, put the three into a ball mill jar, and ball mill for 3 hours at a speed of 280r / min to make them evenly mixed to obtain a precursor mixture;

[0047] 2) Put the precursor mixture into a tube furnace, under the protection of nitrogen, raise the temperature to 350°C at a heating rate of 2° / min, keep it warm for 2 hours, perform preheating treatment, and then raise the temperature to 350°C at a heating rate of 2° / min 950°C, carbonization for 3 hours, and naturally cooled to room temperature;

[0048] 3) The carbonized material is taken out and ground to obtain a hard carbon negative electrode material for lithium-ion batteries.

Embodiment 3

[0049] Example 3 Preparation of hard carbon anode materials for lithium-ion batteries

[0050] The preparation of lithium ion battery hard carbon negative electrode material comprises the following steps:

[0051] 1) Weigh 30g of epoxy resin, add it to 100ml of absolute ethanol, fully dissolve, and obtain an ethanol solution of epoxy resin;

[0052] 2) Add 2.5g of silicone resin and 3g of ammonium phosphate to the epoxy resin solution prepared in step 1), and stir mechanically to make it evenly mixed to obtain a mixed solution;

[0053] 3) Filter the mixed solution, take the filtrate, place it in a drying oven, and keep it at 100°C for 4 hours for drying to obtain a dry reactant precursor;

[0054] 4) Take out the dry reactant precursor, put it into a tube furnace, and under the protection of nitrogen, raise the temperature to 350°C at a heating rate of 2° / min, keep it warm for 2 hours, and perform preheating treatment, and then heat it at a heating rate of 2°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com