Patents

Literature

127 results about "Defense industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pneumatic artificial muscles

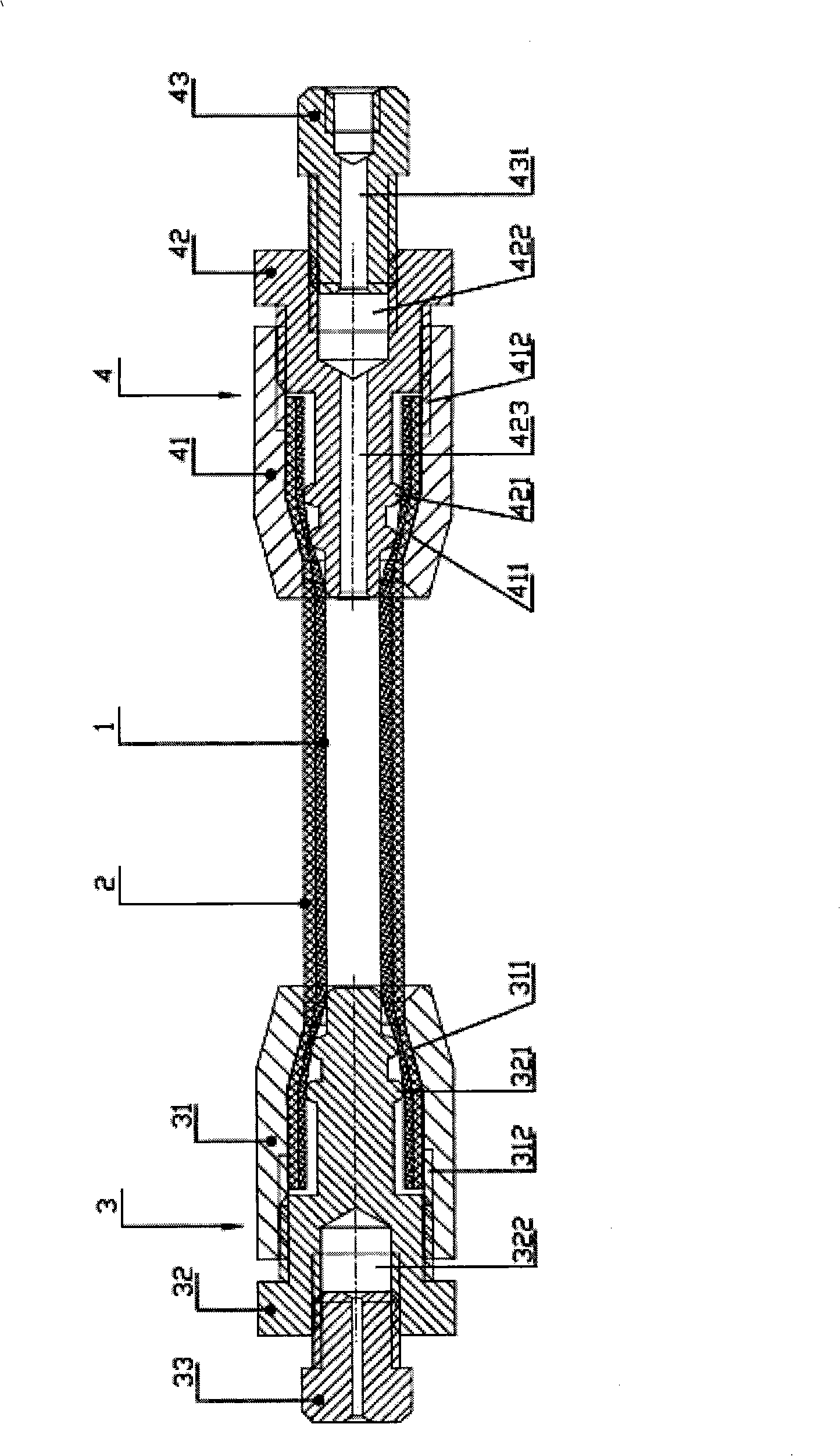

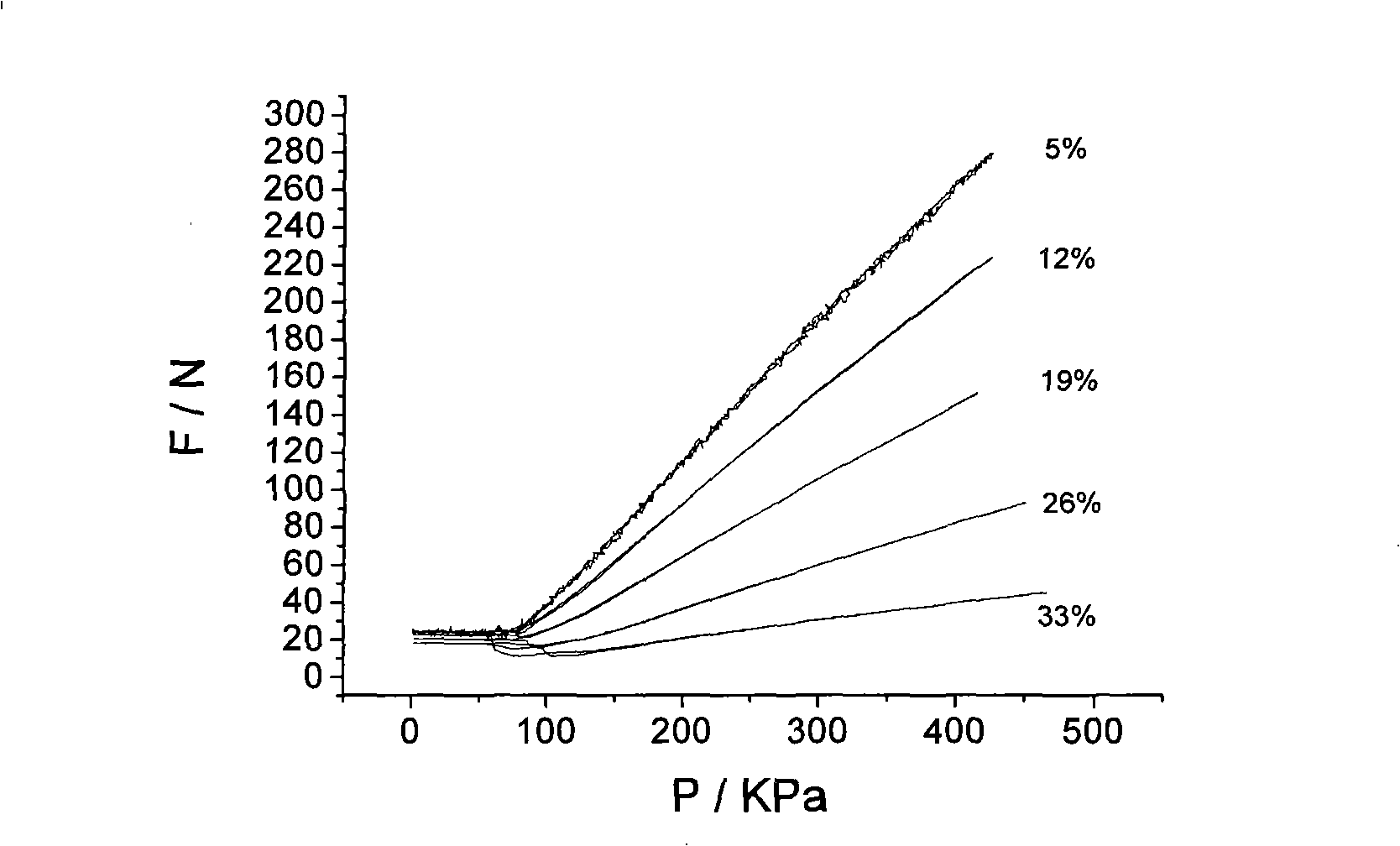

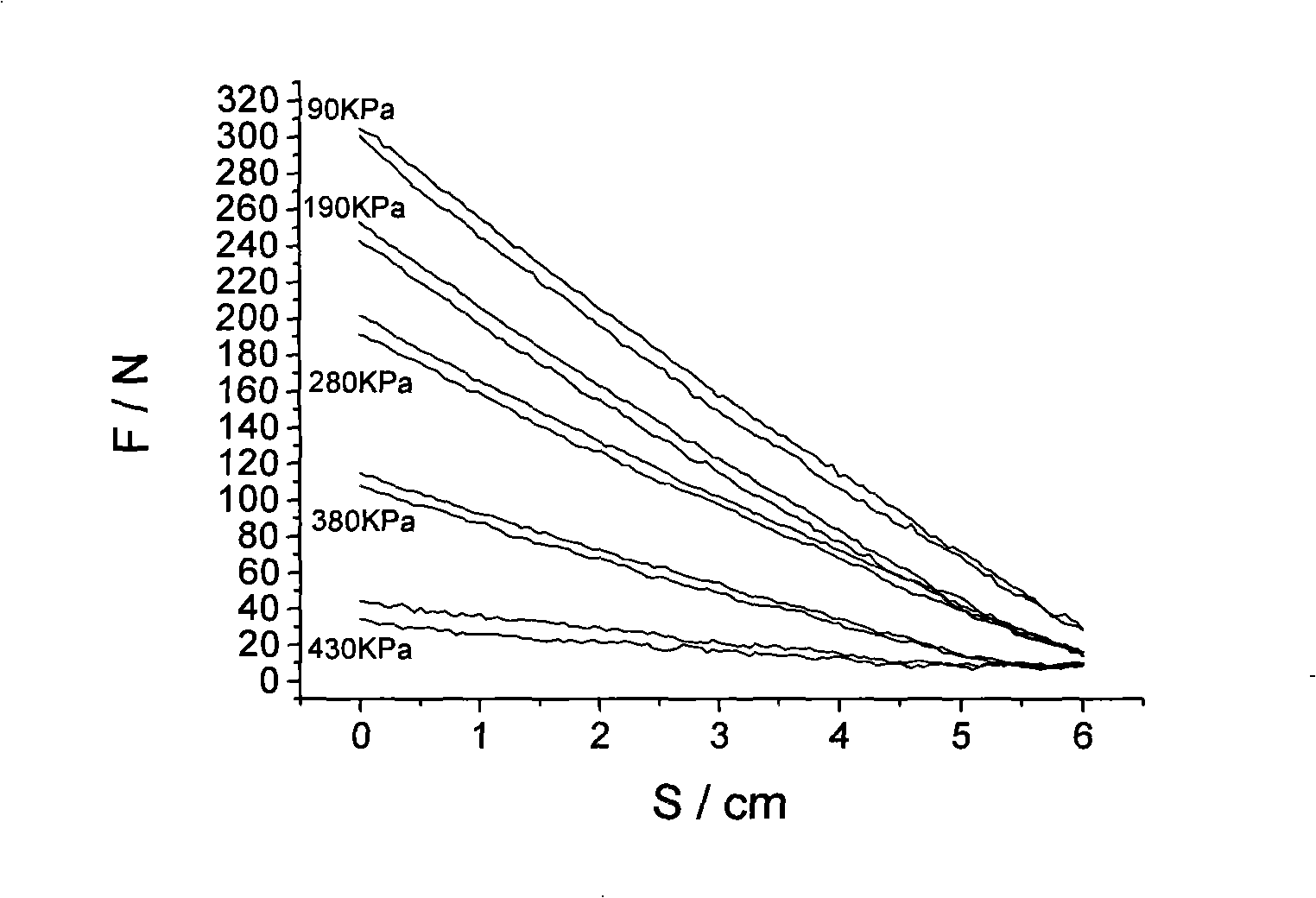

InactiveCN101306535ASelf-bufferingSelf-dampingProgramme-controlled manipulatorGripping headsEngineeringPneumatic artificial muscles

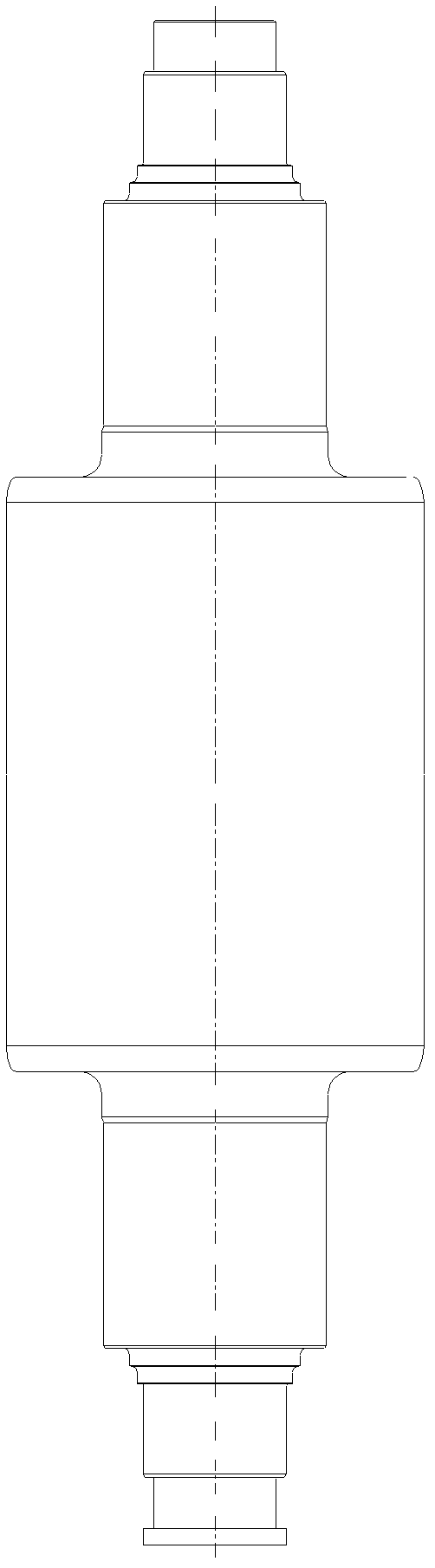

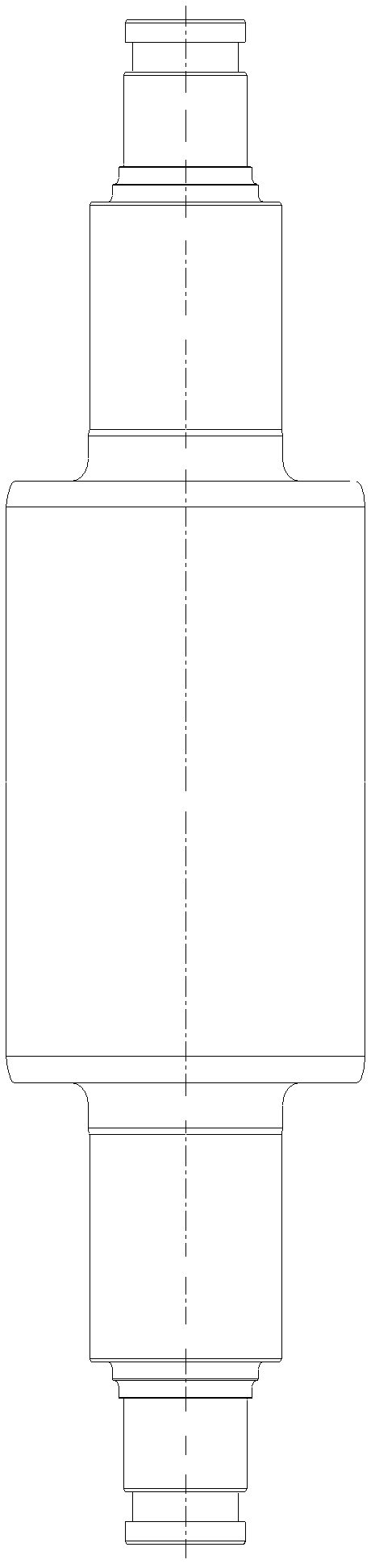

The invention belongs to the pneumatic technology field, and relates to pneumatic artificial muscle. The artificial muscle consists of an outer mesh grid, an inner expansion tube, a sealing component and a sealing component with air vents. The outer mesh grid is aligned with the inner expansion tube at two ends and sleeved on the inner expansion tube, with the original length thereof a little longer than that of the inner expansion tube; and one end of the outer mesh grid is inserted into the sealing component, and the other end thereof is inserted into the sealing component with air vents. The inner expansion tube of the pneumatic artificial muscle is inflated with air with a certain pressure, so that the inner expansion deforms to cause the outer mesh grid to expand in the radial direction, so as to enable the pneumatic artificial muscle to expand in the radial direction, contract in the axial direction and output certain tensile force. The pneumatic artificial muscle has the characteristics of compact structure, simple manufacture, low price, high flexibility, high ratio of output force to dead weight, effective energy conservation, automatic buffer, pollution resistance, etc., and can be widely applied to the fields of robots, auxiliary medical apparatus and instruments, aviation, defense industry, etc.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

High-pure magnesium preparation method and apparatus

Owner:GUIYANG AL-MG DESIGN & RES INST

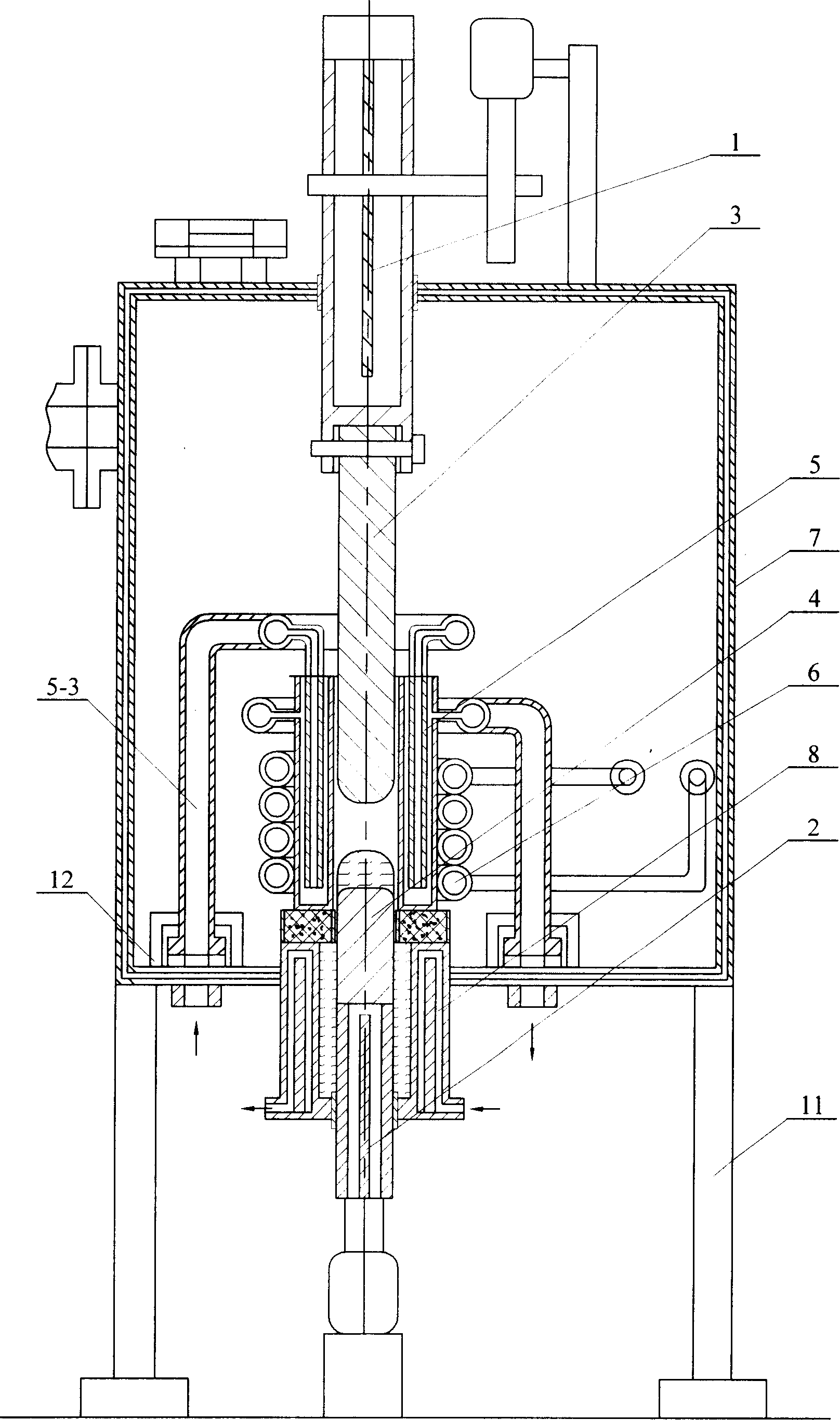

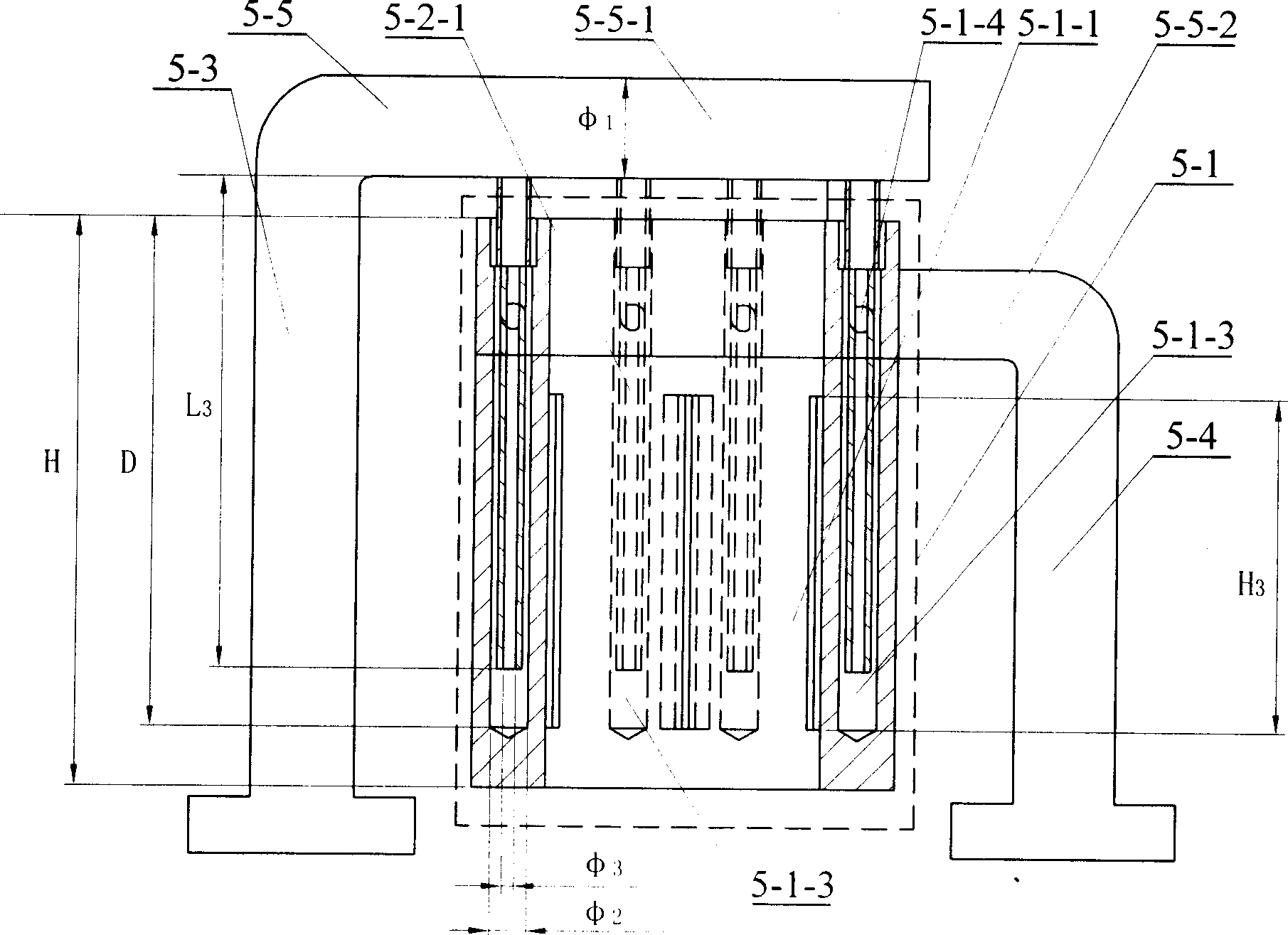

Magnetic suspension type ultra-low-frequency vibration sensor

ActiveCN102901556ARealize measurementLow measurement lower limit frequencySubsonic/sonic/ultrasonic wave measurementUsing electrical meansLower limitVibration measurement

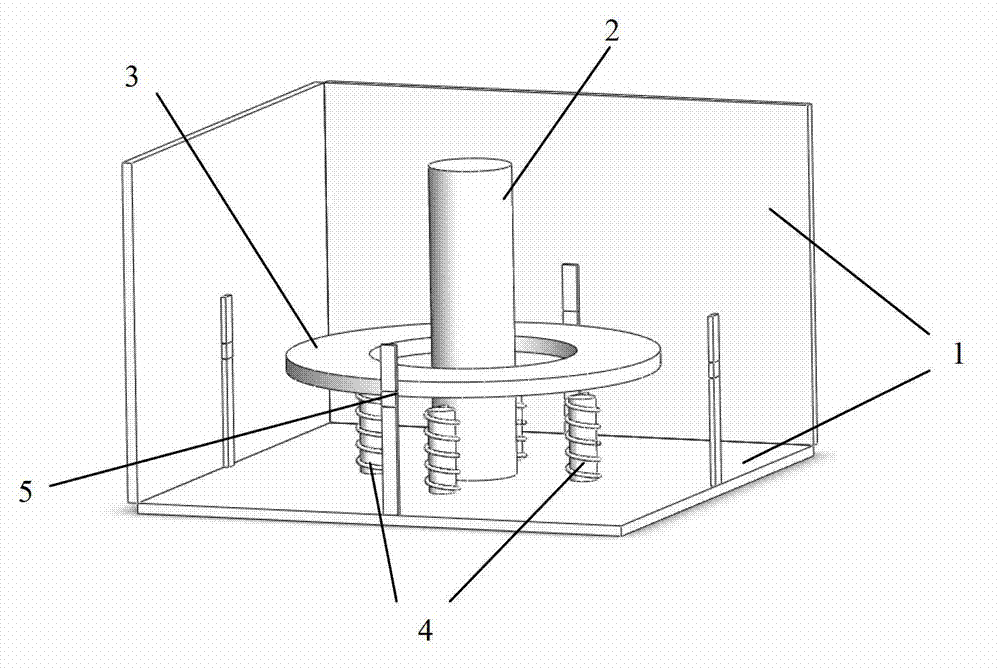

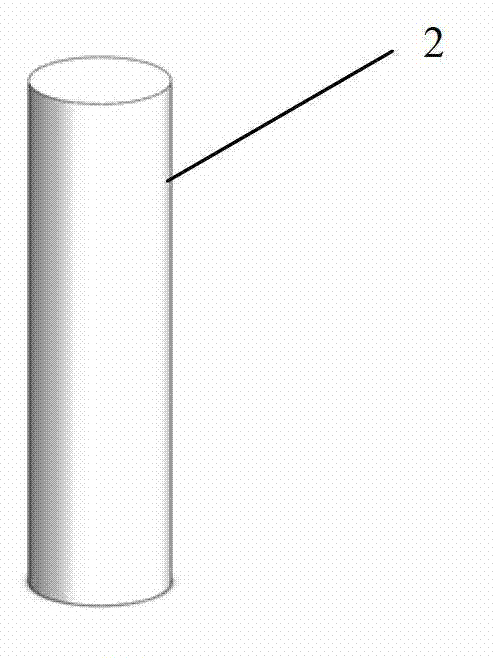

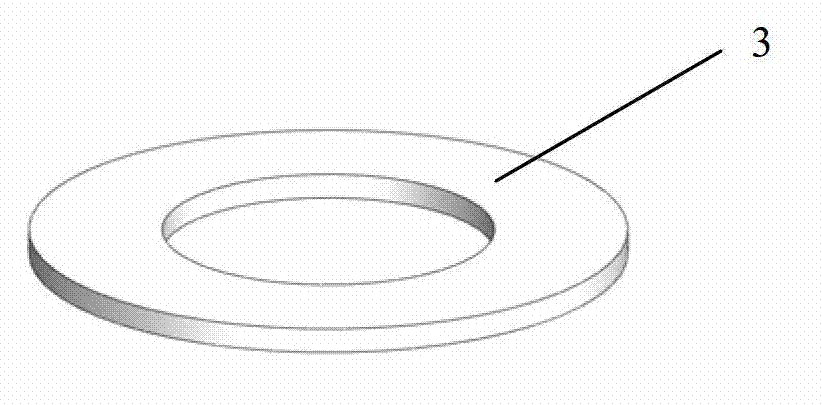

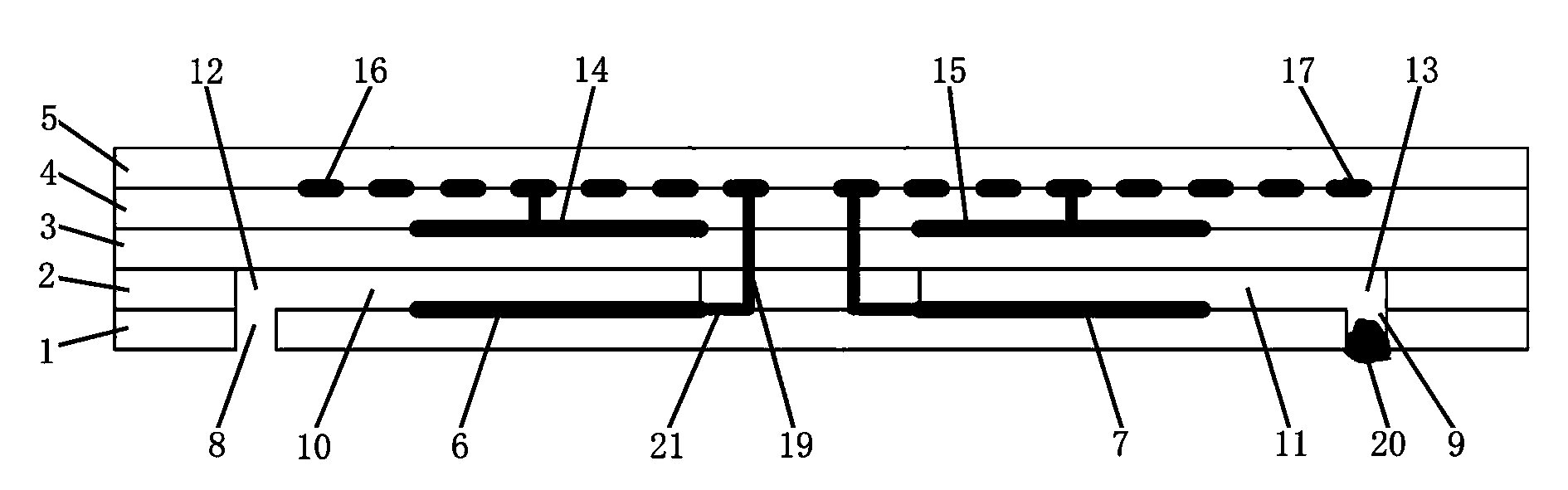

The invention provides a magnetic suspension type ultra-low-frequency vibration sensor. The magnetic suspension type ultra-low-frequency vibration sensor comprises a housing, a cylindrical permanent magnet, an annular permanent magnet, electromagnetic coils and a photoelectric displacement detector. The conventional spring structure is replaced with a mixed structure of permanent magnetic and electromagnetic, and equivalent support stiffness and equivalent damp of a suspension system are reduced, so that mechanical inherent frequency of the system is effectively reduced, lower limit of ultra-low-frequency band measurement is greatly extended, and the size and the weight of the sensor are reduced. Multiple pairs of symmetric electromagnetic coils are mounted at the bottom of the sensor so as to support a mass block in a suspension way, and the photoelectric displacement detector is adopted to detect displacements in all directions to measure multi-directional torsional vibration parameters so as to further expand application range of the magnetic suspension type ultra-low-frequency vibration sensor. The magnetic suspension type ultra-low-frequency vibration sensor can satisfactorily meet requirements of the fields of national defense industry, aerospace, engineering measurement and the like on ultra-low-frequency vibration measurement, and effectively extends lower limit of ultra-low-frequency vibration measurement.

Owner:BEIHANG UNIV

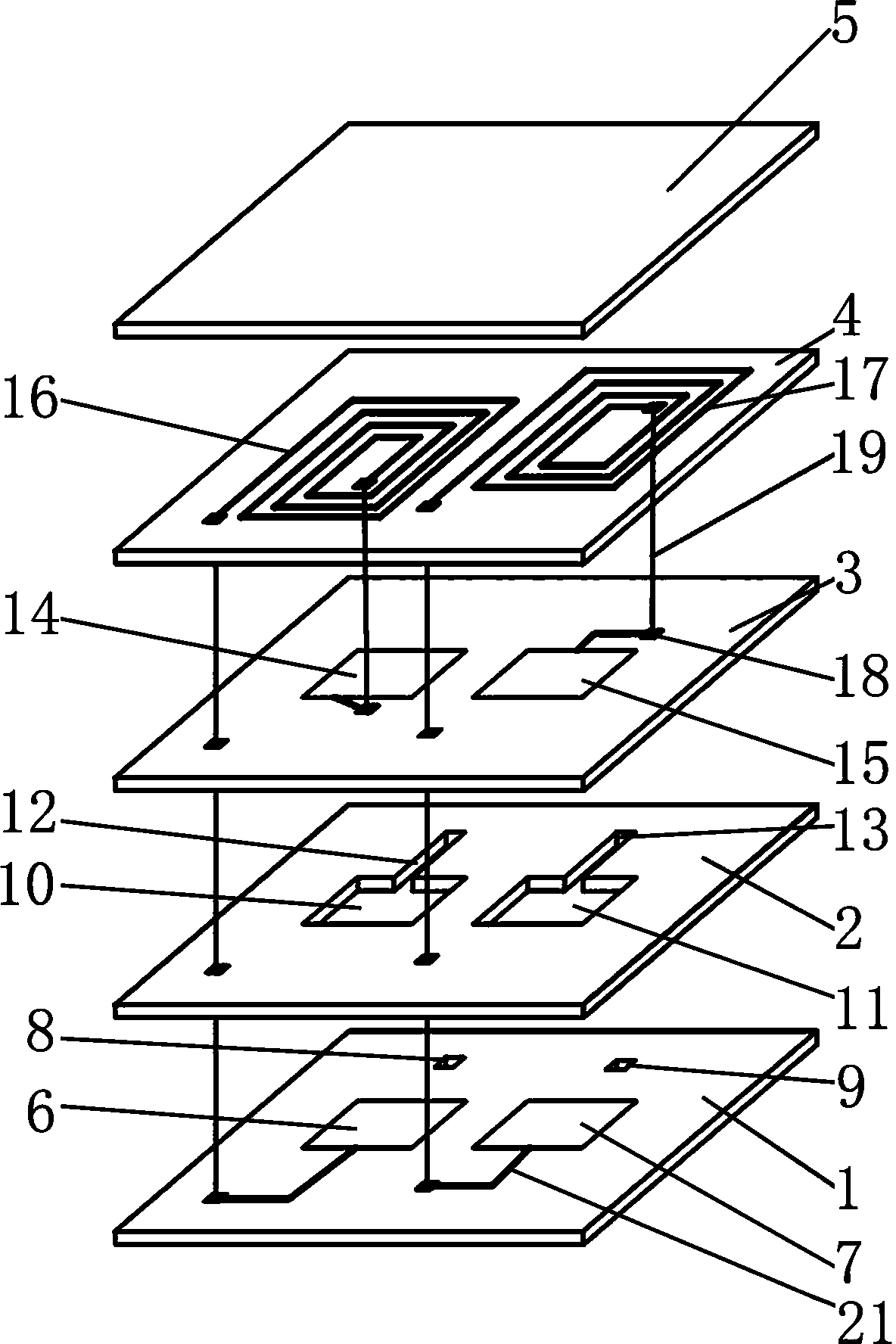

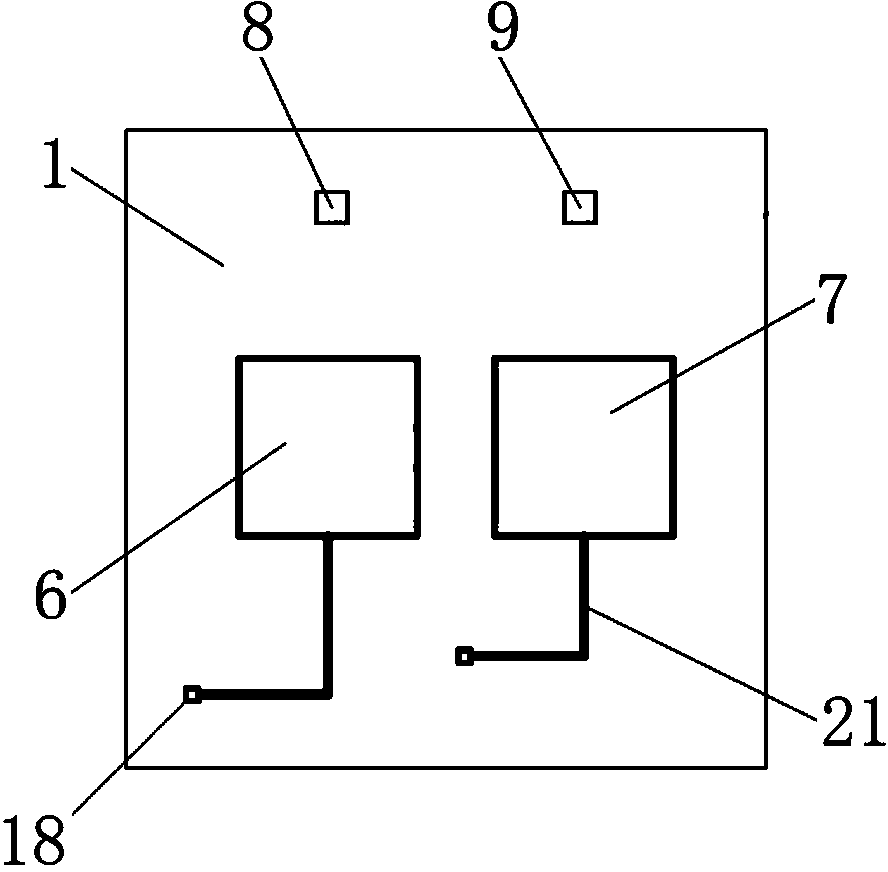

Wireless passive high-temperature pressure sensor with temperature compensation and temperature compensation algorithm thereof

ActiveCN103698060ASolve the problem that pressure measurement cannot be performed in an environment where the temperature changes constantlyLow costForce measurementFluid pressure measurement using capacitance variationAstronauticsInductance

The invention relates to a wireless passive high-temperature pressure sensor, in particular to a wireless passive high-temperature pressure sensor with temperature compensation and a temperature compensation algorithm thereof. The invention solves the problem that the conventional wireless passive high-temperature pressure sensor cannot measure pressure under the environment in which temperature constantly changes. The wireless passive high-temperature pressure sensor with temperature compensation comprises a first green ceramic plate, a second green ceramic plate, a third green ceramic plate, a fourth green ceramic plate and a fifth green ceramic plate; a lower polar plate of a first flat capacitor is arranged on the left part of the top surface of the first green ceramic plate; a lower polar plate of a second flat capacitor is arranged on the right part of the top surface of the first green ceramic plate; a first induction coil and the first flat capacitor are jointly formed into a temperature-compensating sensitive LC loop; a second induction coil and the second flat capacitor are jointly formed into a main sensitive LC loop. The invention is applicable to pressure measurement under high-temperature environments in the fields of automation, astronautics, aeronautics and national defense industry.

Owner:ZHONGBEI UNIV

Directional freeze method for TiAl-based alloy plate

The continual casting directional solidification method for TiAl-base alloy plate comprises, putting TiAl alloy material bar 3 and dummy ingot 4 with rectangular intersection into the electromagnetic induction range of coil 6, galvanizing to coil 6 with single-phase alternating current with power of 75~100kW from electrical power for 20~25min; the alloy bar 3 and ingot 4 move downward with velocity of 0.01-0.05mm / min and get into the bottom crystallizer 8. This invention overcomes the limit to rectangular intersection blank and fits to press for high performance material in economy, science and national defense industry.

Owner:HARBIN INST OF TECH

Method of preventing corrosion degradation using ni or ni-alloy plating

ActiveUS20090252883A1Prevent degradationPretreated surfacesLiquid/solution decomposition chemical coatingMachine partsPetrochemical

Disclosed herein is a method of preventing corrosion degradation in a defective region including an expansion transition region and / or an expansion region of a heat transfer tube of a steam generator in a nuclear power plant by using nickel (Ni) plating or nickel (Ni) alloy plating. The method can prevent various types of corrosion damage, such as pitting corrosion, abrasion, stress corrosion cracking, lead-induced stress corrosion cracking and the like, occurring during the operation of the steam generator, and particularly, pitting corrosion or primary and secondary stress corrosion cracking, so that the life span of the steam generator is increased, maintenance costs are reduced, and the operation rate of a nuclear power plant is increased, with the result that the unit cost of the production of electric power can be decreased, thereby improving economic efficiency. Further, the method can be usefully used to prevent the corrosion damage of parts and equipment of nuclear, hydroelectric or thermoelectric power plants or of petrochemical plants, and that of industrial and machine parts and equipment, and parts and equipment in a defense industry.

Owner:KOREA ATOMIC ENERGY RES INST +1

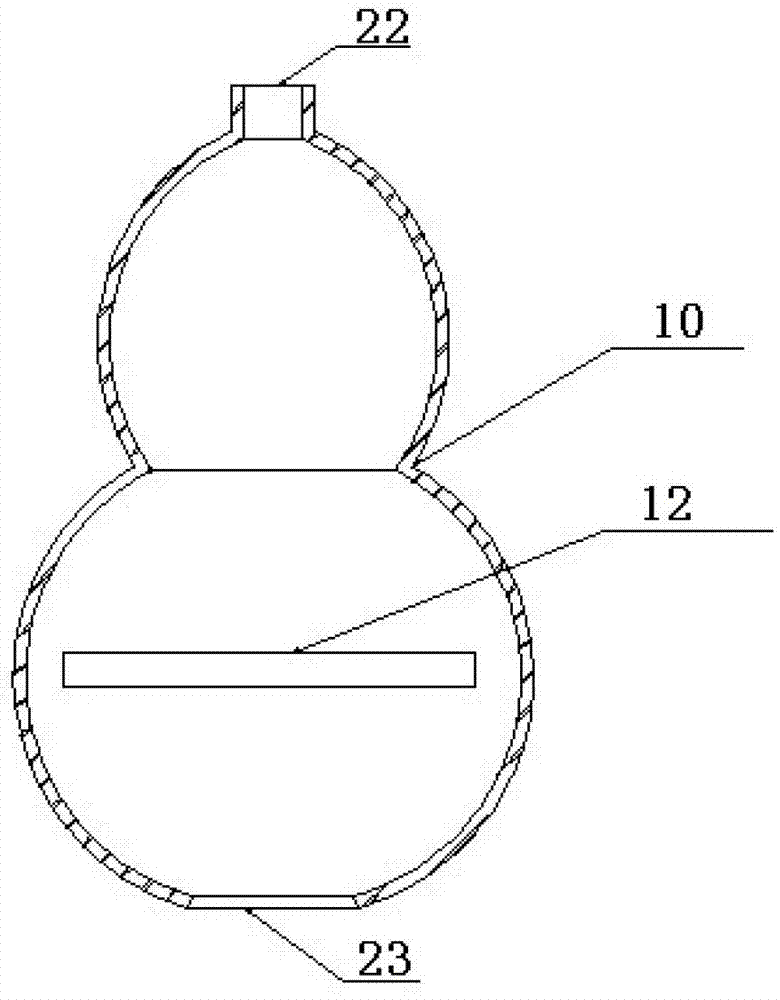

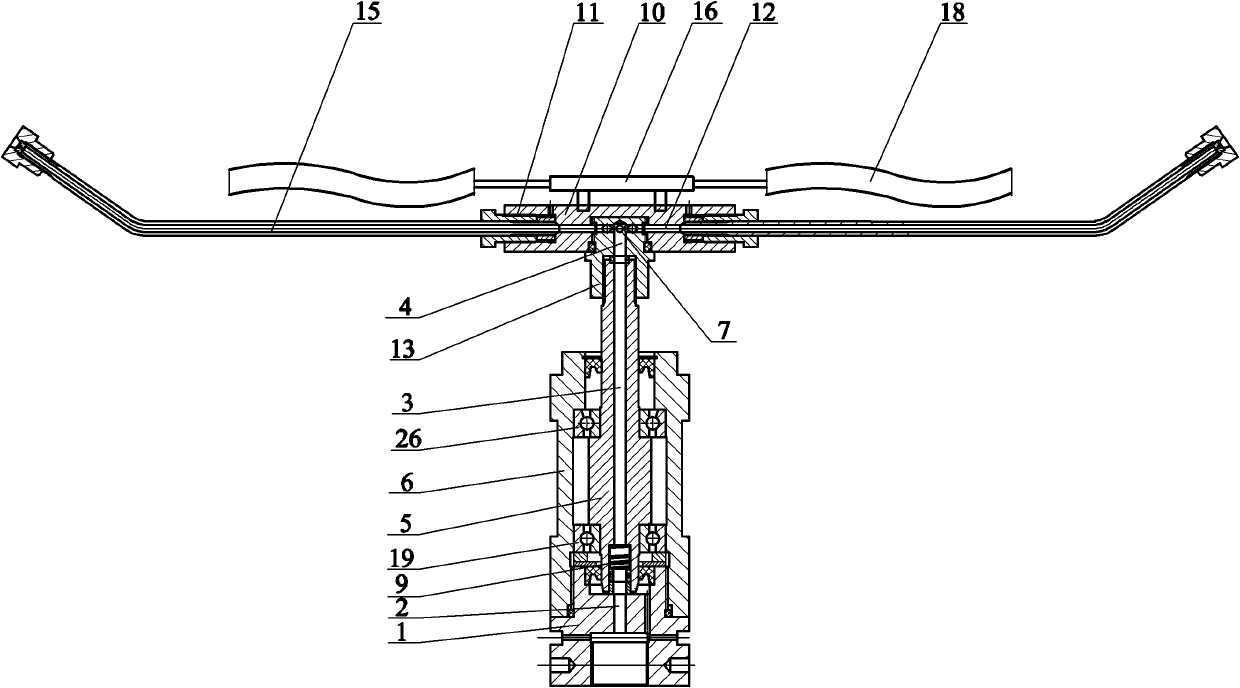

Portable saddle-shaped cutting machine

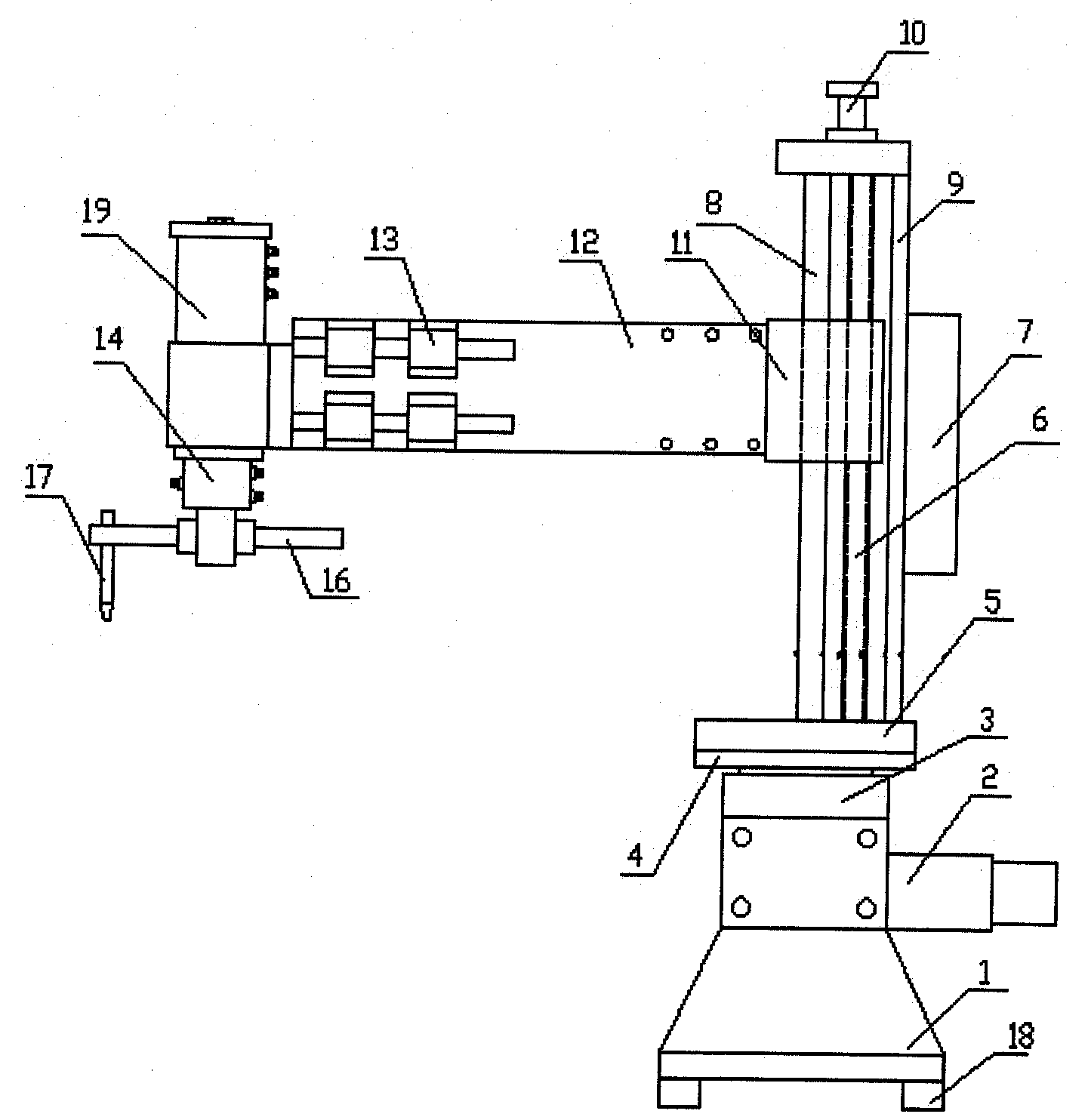

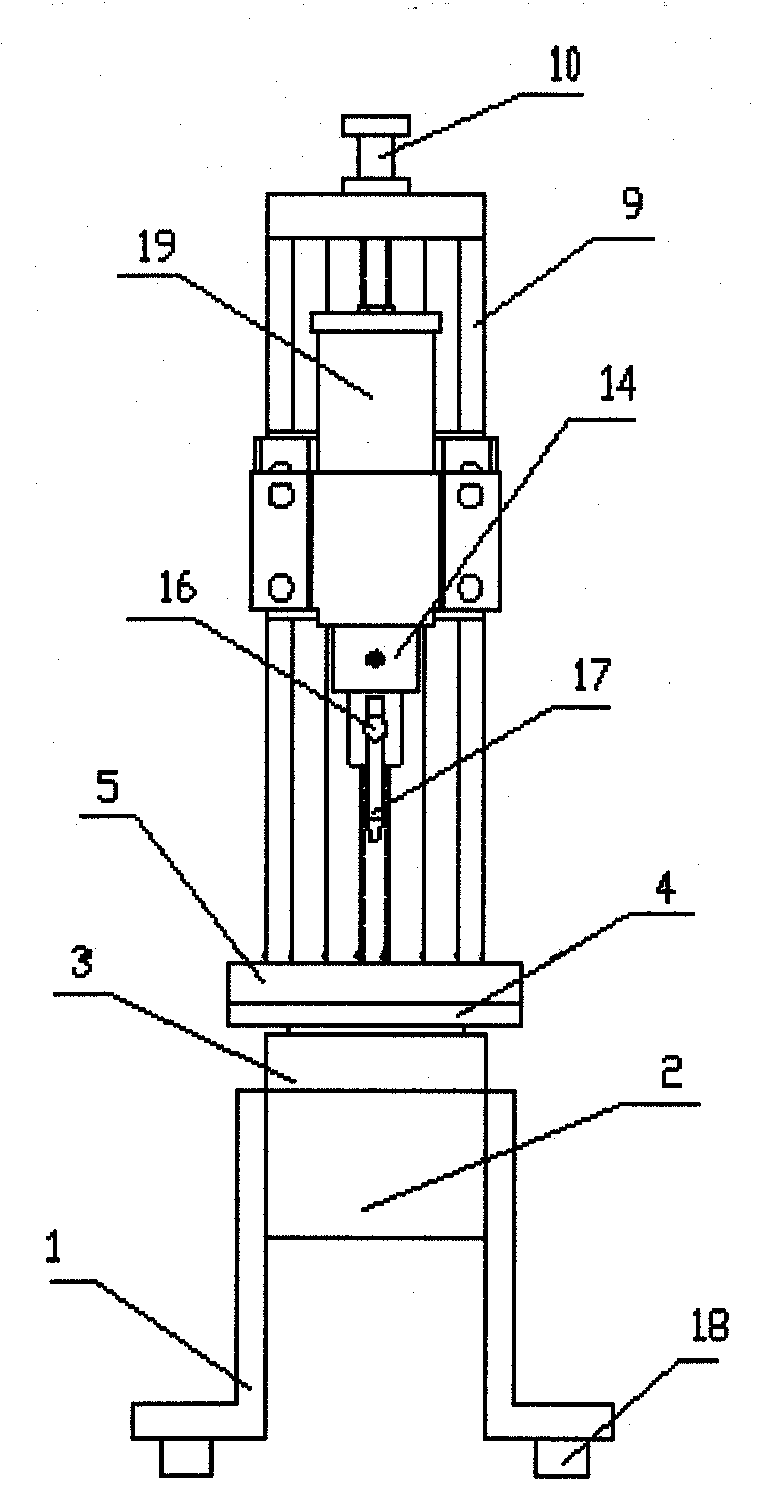

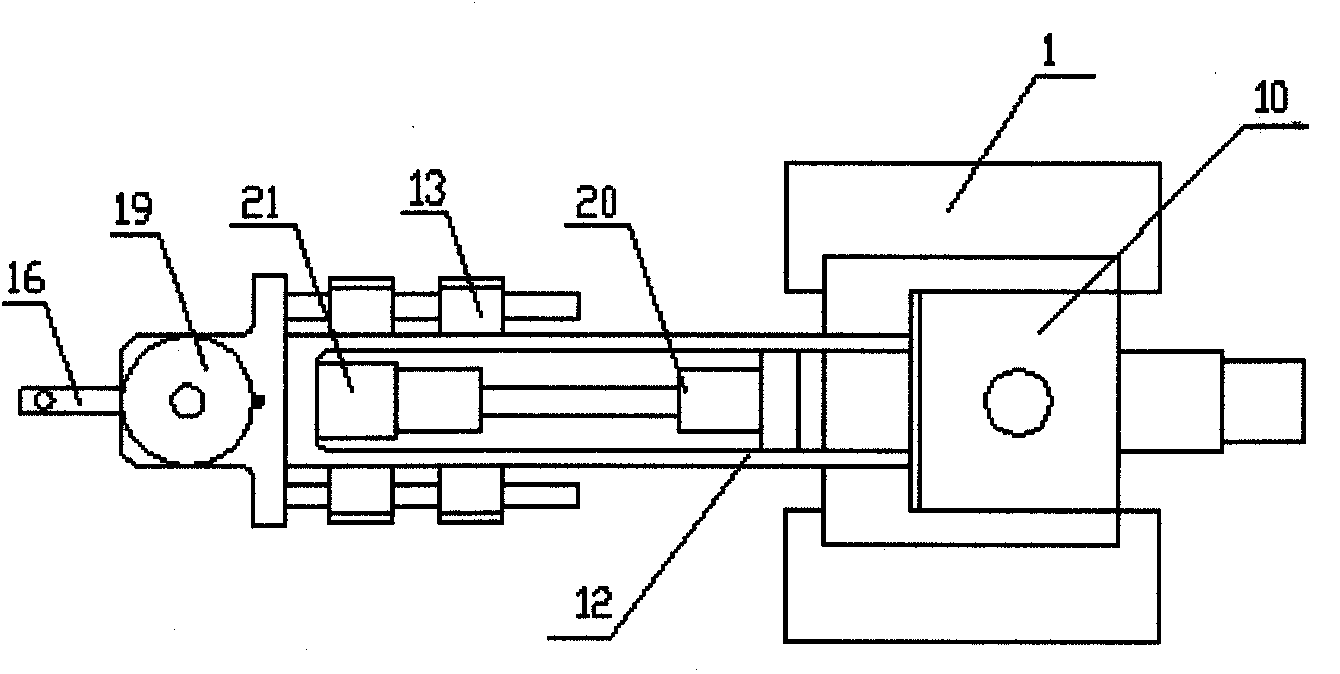

InactiveCN104028874AWide range of cutting objectsImprove cutting accuracyGas flame welding apparatusChemical industryEngineering

The invention belongs to a cutting machine for cutting circles on arc faces and particularly relates to a portable saddle-shaped cutting machine. The portable saddle-shaped cutting machine comprises a fixed base, a great circle cutting mechanism and a small circle cutting mechanism; the great circle mechanism comprises a great circle cutting spindle arranged on the upper portion of the fixed base, and a lifting sliding table is arranged on the great circle cutting spindle and connected with a lifting arm; the small circle cutting mechanism is arranged at the end, away from the lifting sliding table, of the lifting arm and comprises a telescoping mechanism connected with the lifting arm, and a cutting mouth assembly is arranged at the bottom of a rotary air distribution assembly which is arranged at the end, away from the lifting arm, of the telescoping mechanism. The portable saddle-shaped cutting machine is a perforating machine widely applicable to national defense industry, shipbuilding and ocean engineering, pressure vessels for chemical industry, nuclear power plant equipment and utility boiler industry, and is capable of not only perforating on cylindrical shells and oval shells but also cutting projection round holes on other types of complex spatial curved surfaces and cutting variable-angle double grooves.

Owner:ANHUI SUDONG PETROCHEM POWER EQUIP MFG GRP

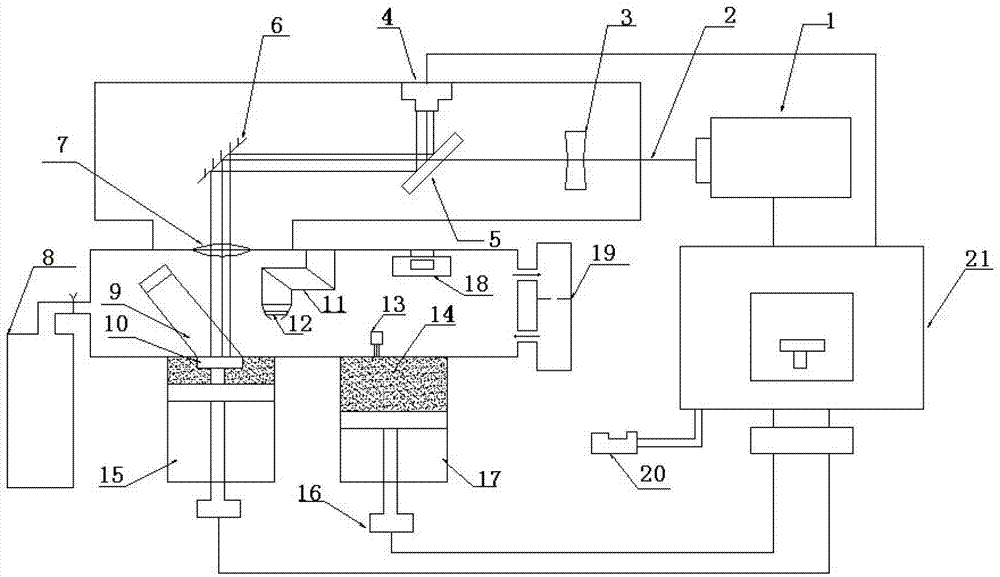

Method and equipment for manufacturing metal part with embedded FRID (Radio Frequency Identification) label with SLM (Selective Laser Melting)

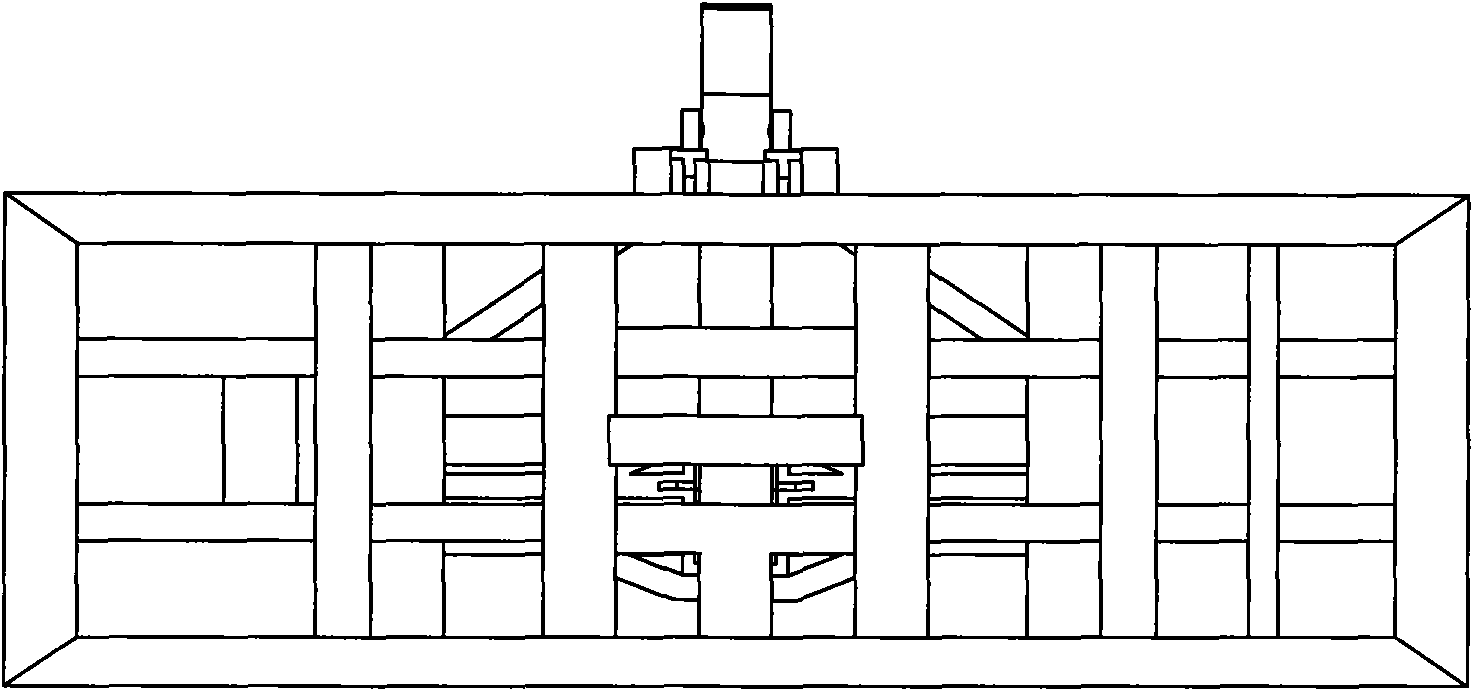

ActiveCN103400165AImprove production efficiencyOvercoming distractionsCo-operative working arrangementsIncreasing energy efficiencySelective laser meltingLength wave

The invention discloses a method and equipment for manufacturing a metal part with an embedded FRID (Radio Frequency Identification) label with SLM (Selective Laser Melting), which belongs to the field of laser melting and solves the problem that the current selective laser melting is mutually independent with the FRID. The equipment is technically characterized by comprising a beam focusing system, a near wavelength coaxial visual positioning system, a gas protection system, a real-time monitor, a label embedding system and the like. The FRID label being embedded in the metal part has a high requirement on the manufacturing method, and the traditional processing method cannot realize one-step formation. The method adopts the combination of the SLM and the FRID to overcome the limitation that the traditional process cannot realize the one-step formation. The method and the equipment reasonably control the distance between the label and metal to eliminate a heat effect, and a metal-resisting film is pasted on the label to solve the problem. The method and the equipment overcome manufacturing difficulties, successfully manufacture the metal part with the embedded FRID label, are mainly applied to the defense industry and can also be applied to industries such as workpiece tracking and positioning in a special environment.

Owner:SOUTH CHINA UNIV OF TECH

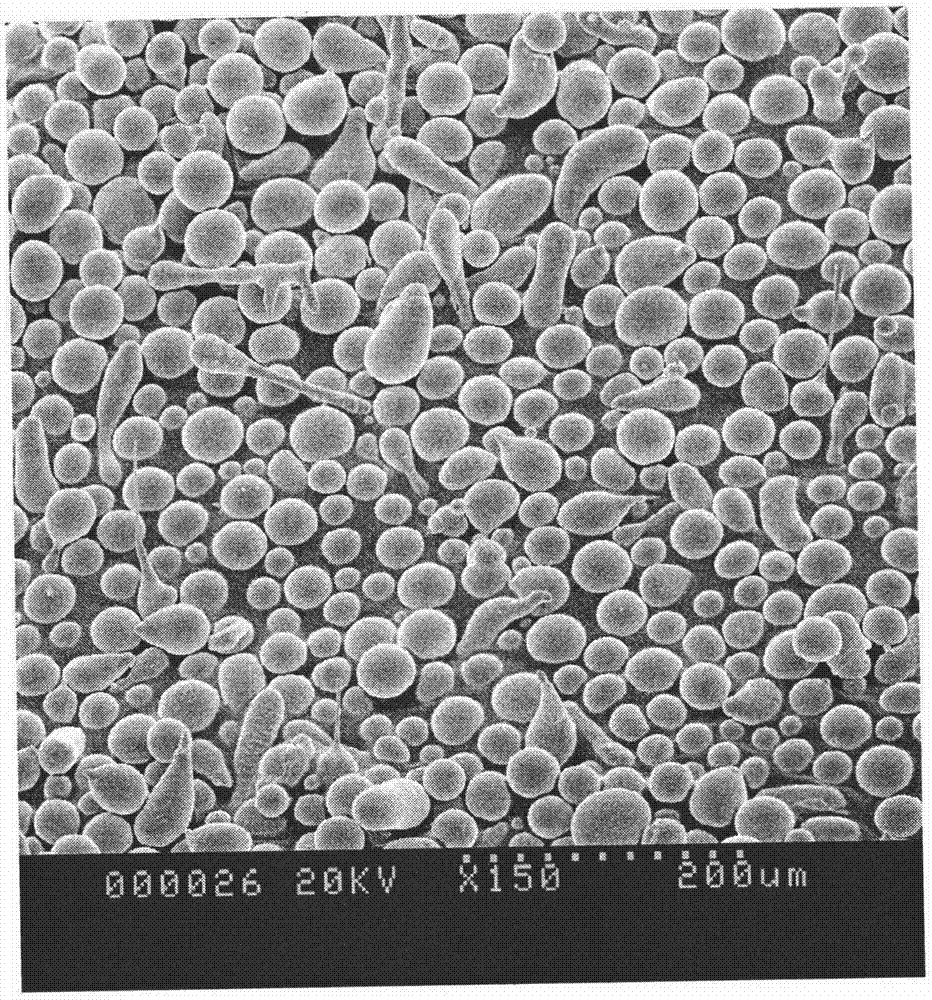

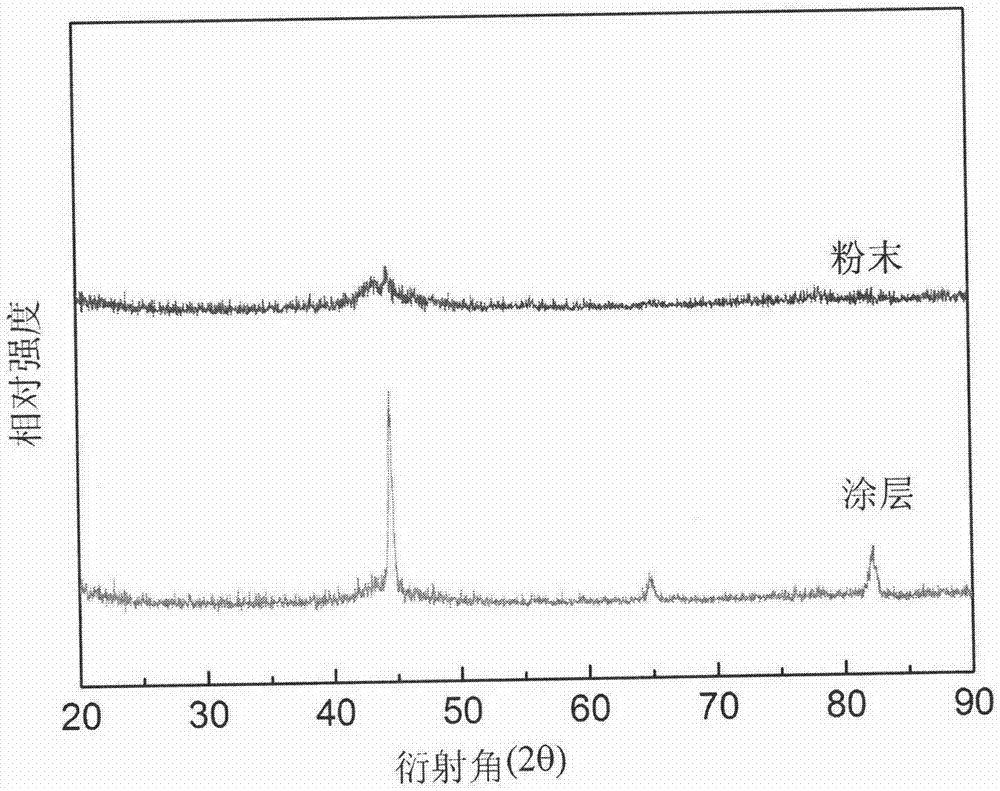

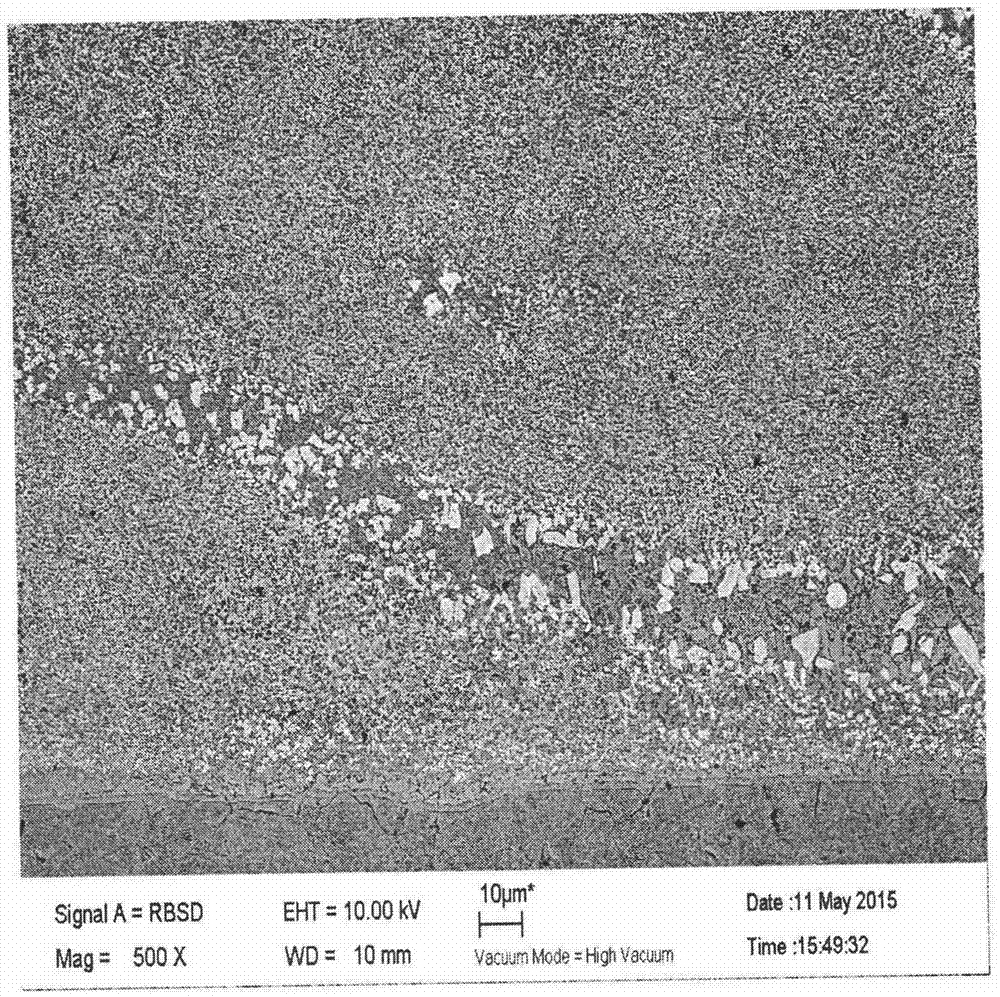

Method for preparing anticorrosion wear-resisting iron-based amorphous coating through laser cladding technology

InactiveCN106868496AUniform tissueNo crackMetallic material coating processesChemical compositionCoupling

The invention relates to a method for preparing an anticorrosion wear-resisting iron-based amorphous coating through a laser cladding technology. Chemical components of Fe-based amorphous alloy powder comprise, by mass percent, 17.3% to 19.4% of Cr, 1.8% to 2.2% of Mn, 12.9% to 15.8% of Mo, 5.0% to 6.2% of W, 2.8% to 4.1% of B, 0.7% to 1.1% of C, 1.0% to 1.5% of Si and the balance Fe, wherein the total mass is 100%. The industrial pure raw materials and the tight coupling gas atomization technology are adopted for preparing the iron-based amorphous alloy with the components into powder stock, and the single-pass diode laser cladding technology is used for preparing the amorphous alloy coating. The preparing technology of the iron-based amorphous coating approaches to the actual industrial level, the technology condition is controllable, the cost is low, the beneficial effects of being compact in structure, uniform in structure, free of crack and hole defects, high in hardness, anti-corrosion, resistant to wear and the like are achieved, and the great utilization potentiality is achieved in the national defense industry.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method of doping type fluorescent micron-nano fibers

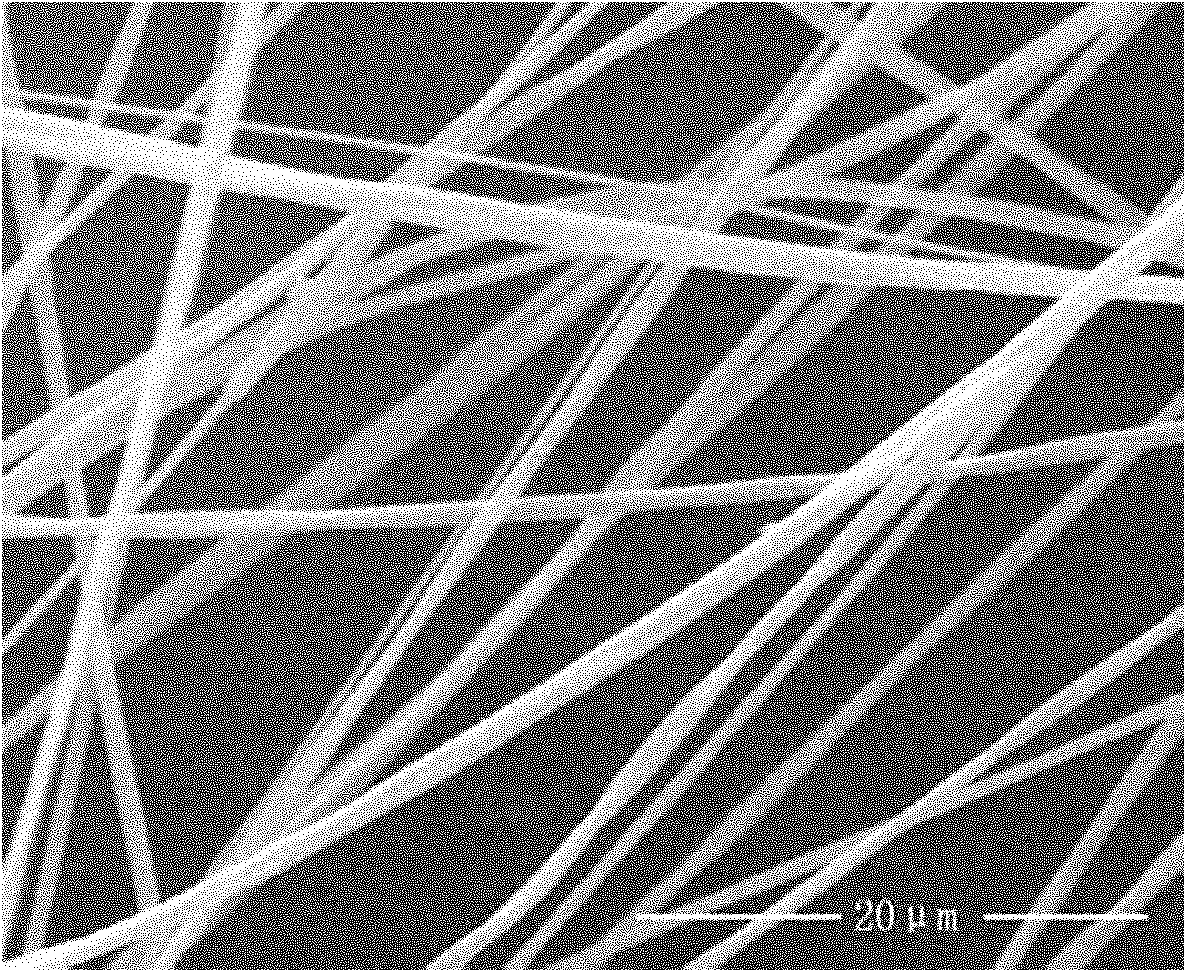

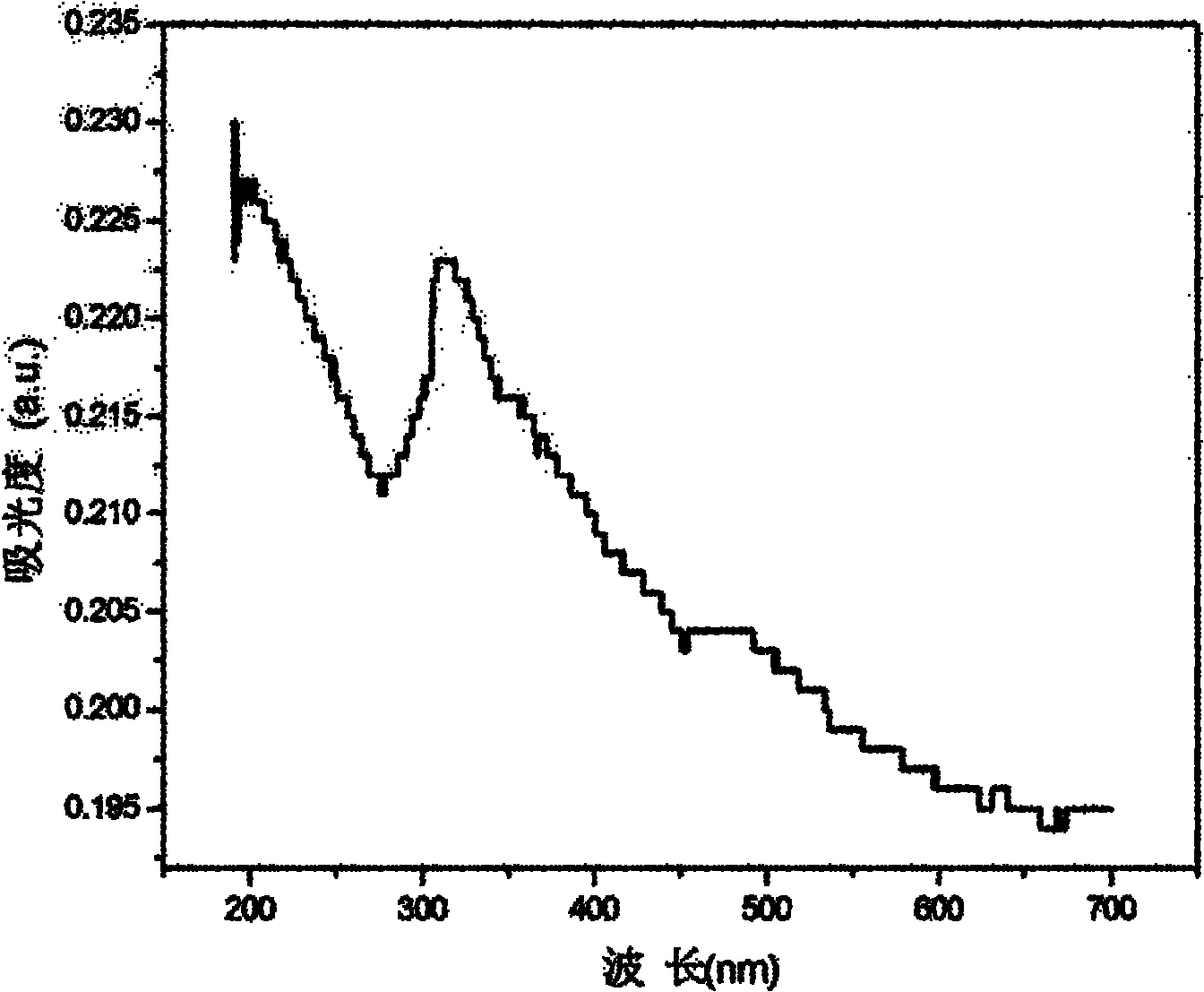

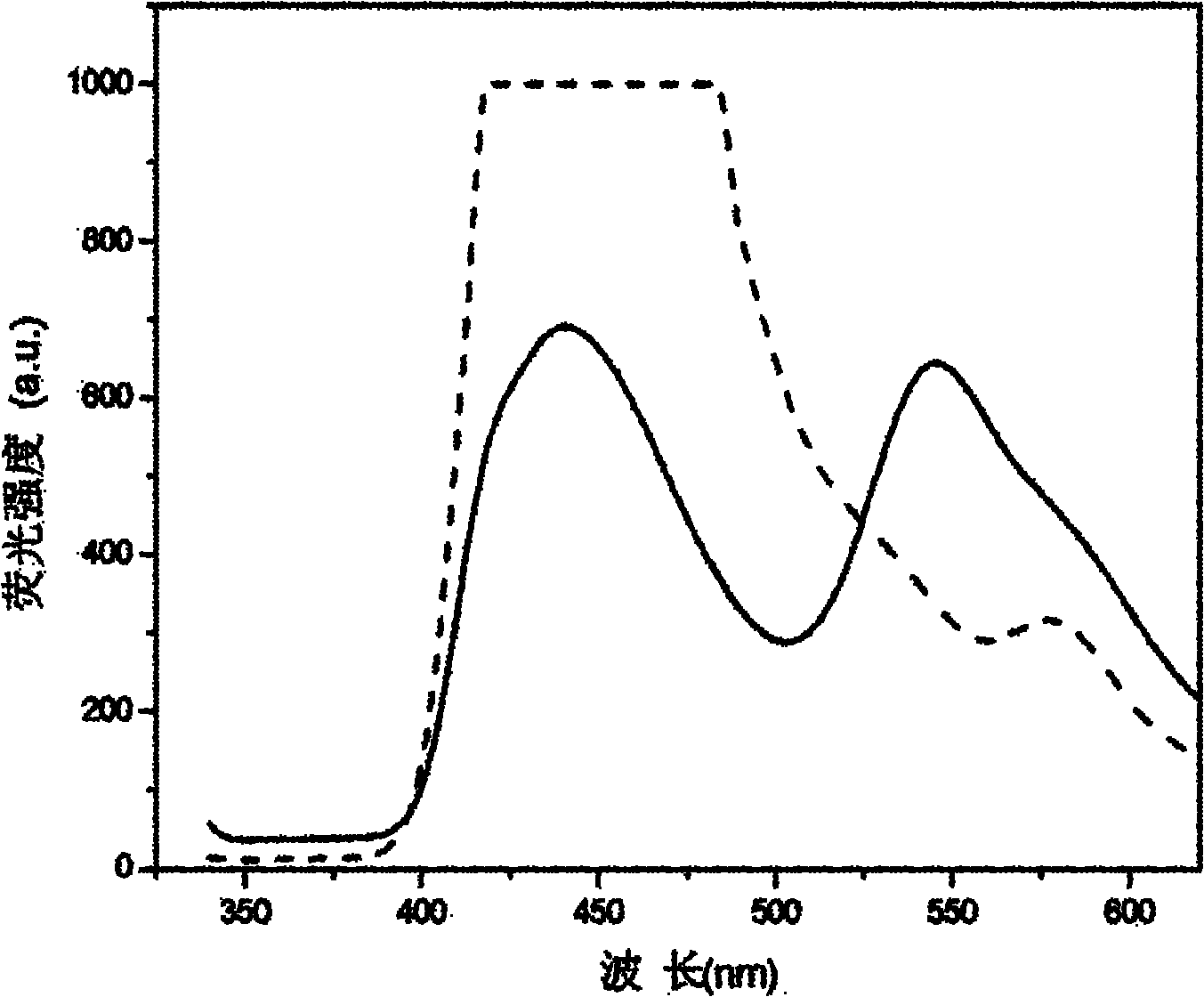

InactiveCN101962818AUniform diameterSmooth diameterFilament/thread formingMonocomponent polyolefin artificial filamentFiberAviation

The invention relates to a preparation method of doping type fluorescent micron-nano fibers, relating to a preparation method of fluorescent fibers and solving the problems of complex method realizing fluorescent light with different colors through the traditional organic fluorescent fibers of a monogenic dye, poor spectrum stability and short service life of physically blended organic fluorescent fibers and large diameters of the traditional organic fluorescent fibers. The preparation method of the doping type fluorescent micron-nano fibers comprises the following steps of: dissolving dialdehyde triphenylamine and poly [2-methoxyl-5(2'-ethylhexoxy) para-phenylacetylene] into a polymer solution according to different mass ratios; and then carrying out electrostatic spinning to obtain the doping type fluorescent micron-nano fibers. The doping type fluorescent micron-nano fibers have good fluorescence spectrum stability, long service life reaching two years and diameters of 10 nanometers-3 micrometers, and can be used in the life and highly technical fields of textile clothing, aviation, navigation, national defense industry, building decoration, transportation, night operation, daily life, amusement, leisure, optical-fiber communication, laser waveguide, and the like.

Owner:HEILONGJIANG UNIV

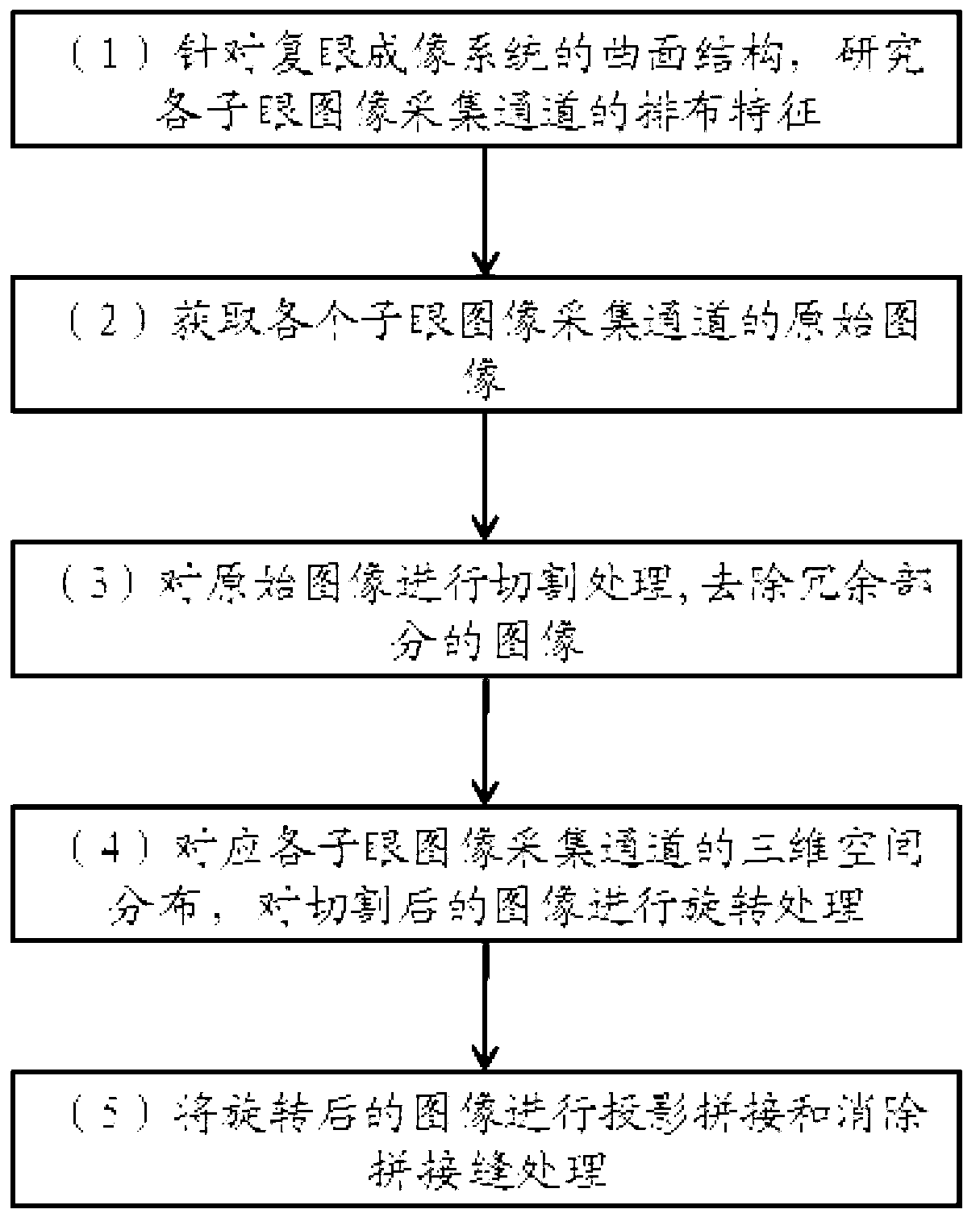

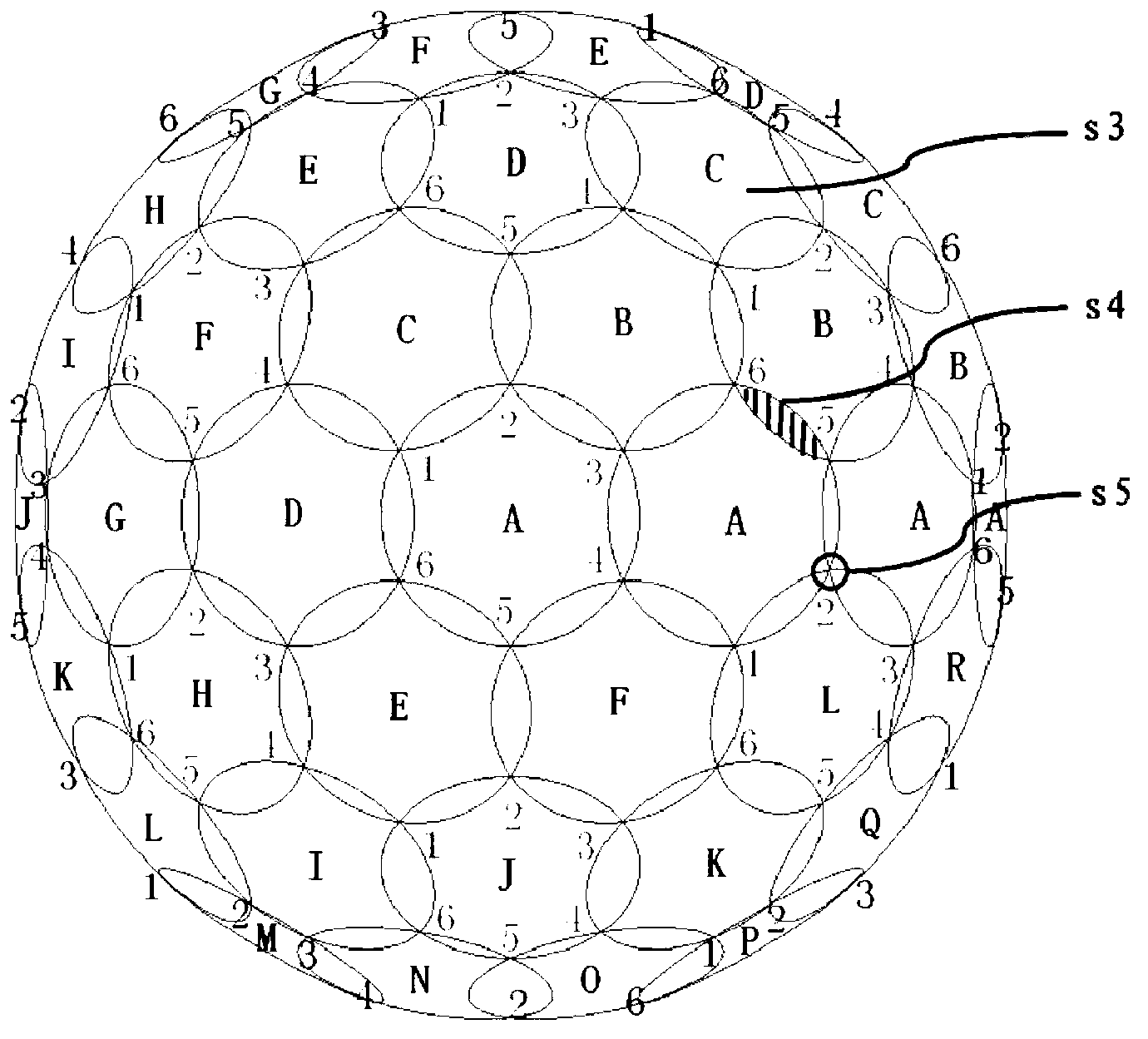

Multichannel image processing method for curved compound eye imaging system

InactiveCN103325088AEfficient use ofImprove clarityImage analysisGeometric image transformationMulti dimensionalVisual perception

The invention discloses a multichannel image processing method for a curved compound eye imaging system and relates to the application fields of biologic clinical experiments, industrial machine vision, aerial surveillance in defense industries and the like. The image processing method aims at a distribution structure of curved surfaces of the curved compound eye imaging system and imaging features of multi-dimensional optical channels, the corresponding multichannel image processing method is provided by analyzing and researching the relation between a two-dimensional image collected by each sub-eye image collection channel and a curved three-dimensional space structure of the compound eye imaging system; the large-visual-field dead-zone-free detection of the curved compound eye imaging system is realized by utilizing techniques such as slicing, rotating and developing of the image; the image processed and obtained by utilizing the multichannel image processing method is high in definition and strong in visuality and meets practical requirements, and the application of the curved compound eye imaging system is further promoted by a research result.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Process adopting barite-fluorite paragenic ore for preparing barite powder

A process adopting barite-fluorite paragenic ore for preparing barite powder comprises the steps of (1), after crushing, screening and classifying the raw barite-fluorite paragenic ore, carrying out classification and gravity concentration; (2), dehydrating and drying the concentrate subjected to classification and gravity concentration in the step (1) so as to obtain barite rough concentrate; (3), separately carrying out photoelectric separation on the barite rough concentrate with the size fraction of 1-3 mm and 3-6 mm obtained in the step (2) so as to obtain barite concentrate with the whiteness classified; (4), grinding the barite rough concentrate with the size fraction smaller than 1 mm obtained in the step (2), the barite concentrate with the whiteness smaller than 88% obtained in the step (3) and the barite concentrate with the whiteness greater than or equal to 88% obtained in the step (3) so as to obtain the barite powder. The process has the advantages that the procedures are simple, the investment is small, the energy consumption is low, and gravity concentration waste water can be reused after being clarified so that environmental friendliness can be achieved. The yield of the barite concentrate with the whiteness greater than or equal to 88% is high, and the barite concentrate can be used in the high-end fields such as coatings, oil paint, rubber and the national defense industry after being ground to form powder.

Owner:湖南楚天钡业有限公司

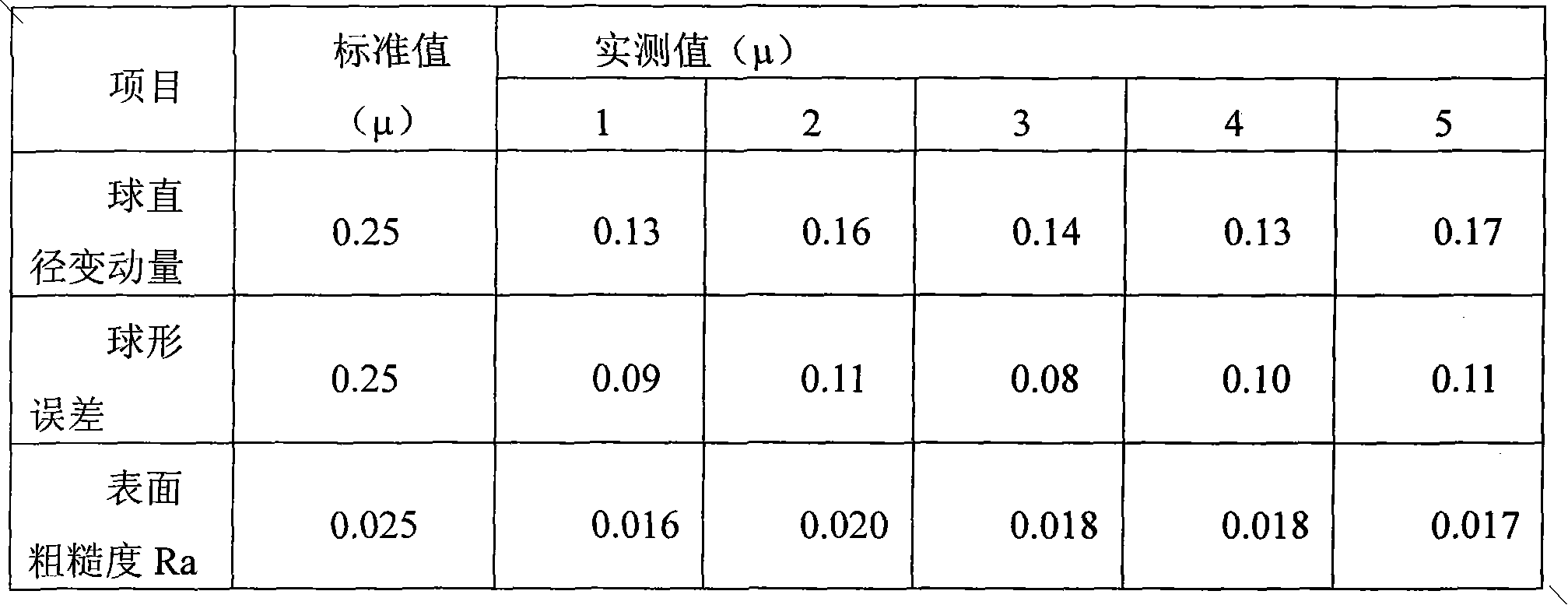

Manufacturing process of 0.68 mm nonmagnetic alloy balls

The invention relates to a manufacturing process of 0.68 mm nonmagnetic alloy balls, which comprises the following successive steps: (1) inspecting a raw material; (2) cutting the material; (3) finishing the balls; (4) thermally treating; (5) cleaning and drying; (6) roughly grinding; (7) processing by using a rough millstone; (8) primarily grinding; (9) sorting; (10) fine grinding for the first time; (11) fine grinding for the second time; (12) inspecting for the first time; (13) cleaning; (14) visually sorting the balls; (15) inspecting for the second time; and (16) oiling and packaging in plastic bottles. The invention has the advantages that (1) the traditional equipment are fully utilized to process the extremely small product made of special materials and used for special purposes, and the product has stable quality level and fully meets the requirements of national defense industry; (2) the processing mode of the millstone with a small groove angle, small groove spacing, great groove depth and middle opening is adopted so as to ensure the stability and the consistency of the processing process of the extremely small steel balls, and unqualified products are prevented.

Owner:温州市中特钢球有限公司

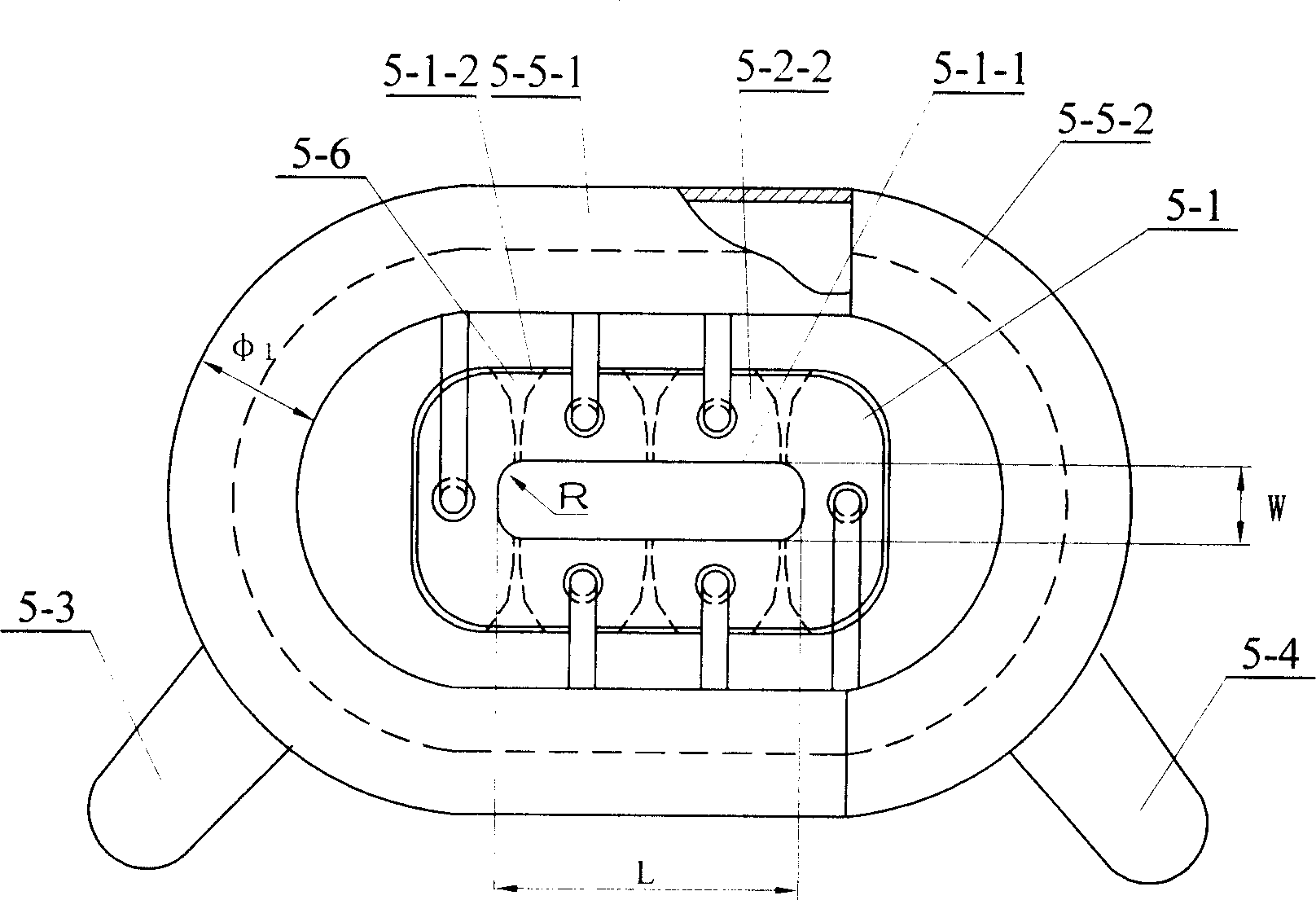

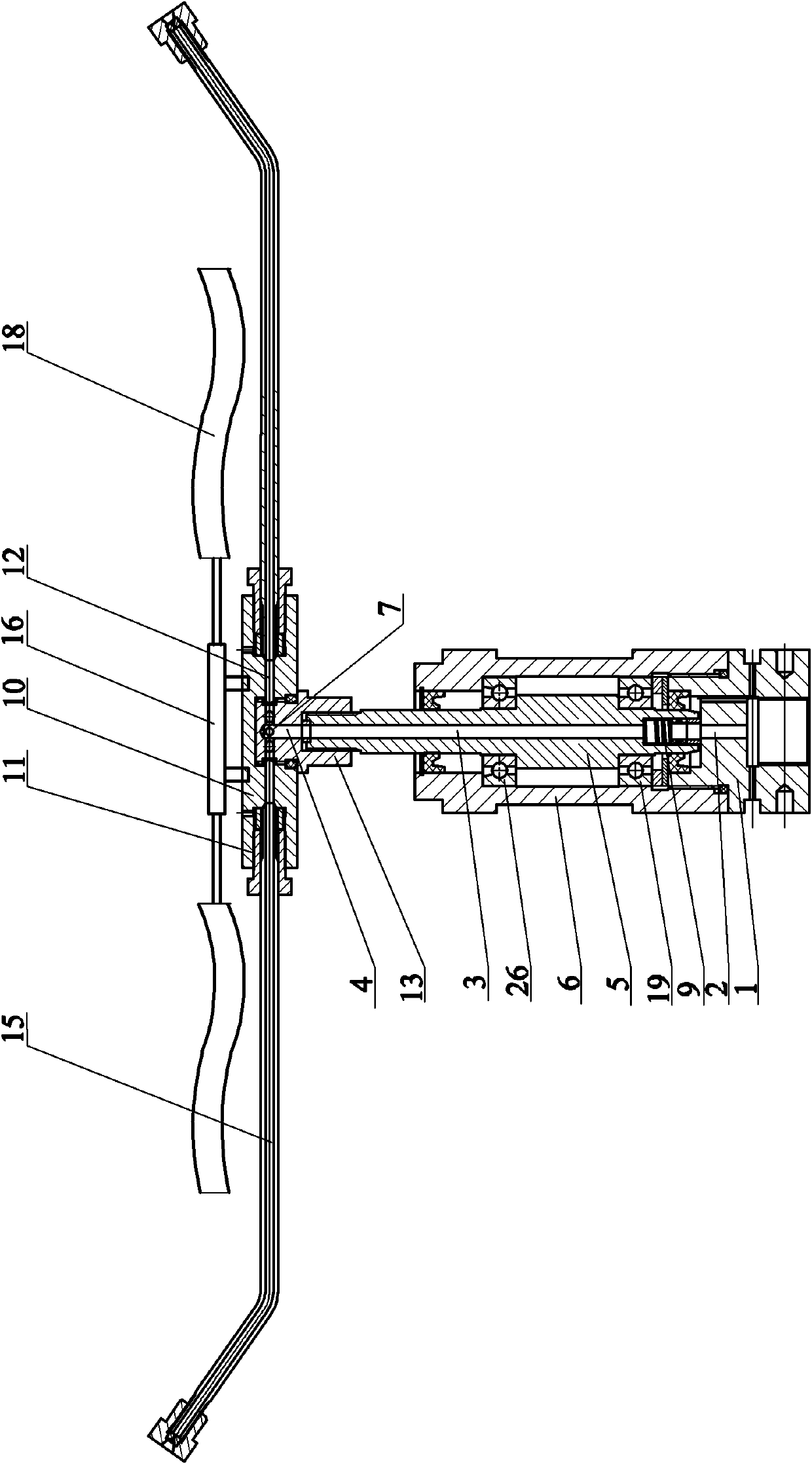

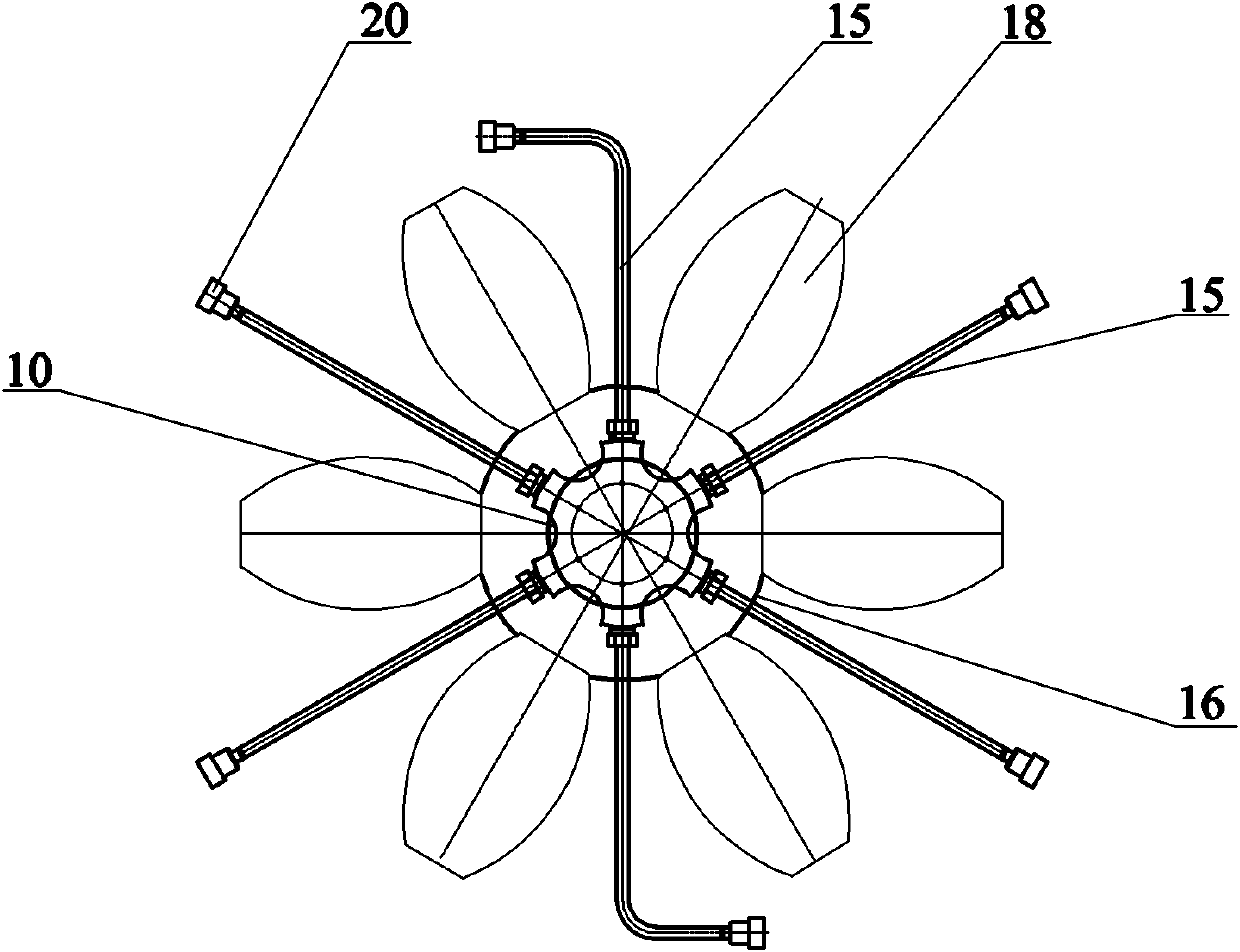

Vortex high pressure water jet water mist generating device

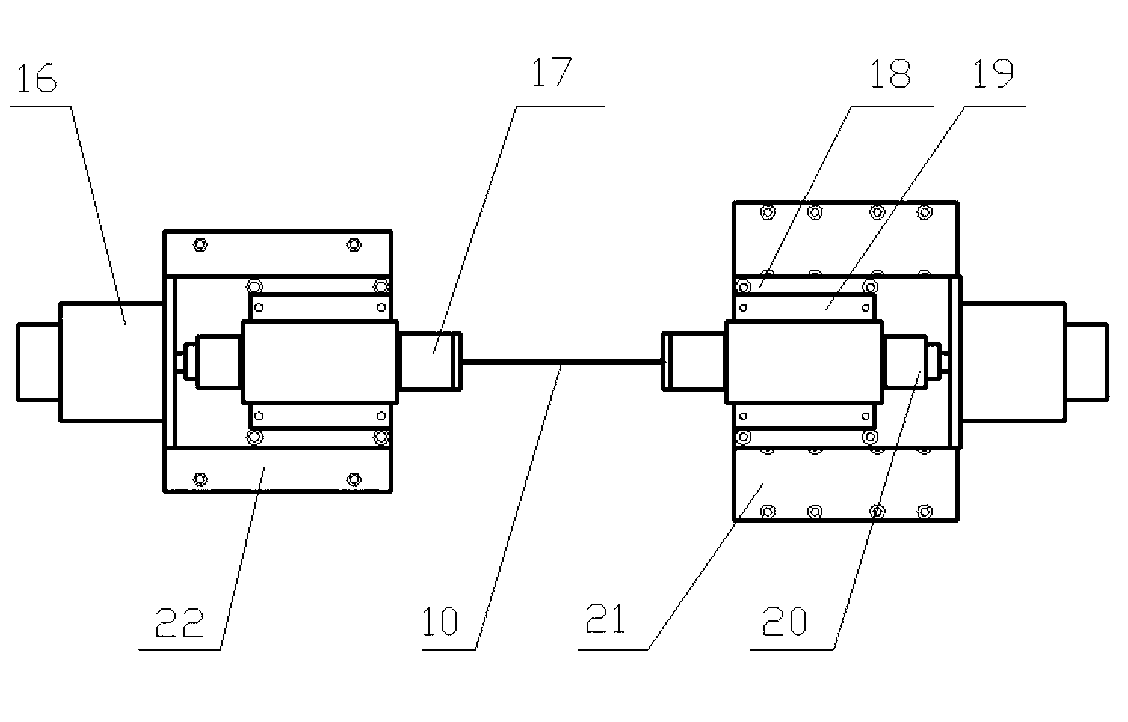

InactiveCN101905199AFix stability issuesSolve the problem of the influence of windMovable spraying apparatusSpray nozzlesRotational axisFire control

The invention relates to a vortex high-pressure water jet water mist generating device which is widely applied to the industrial fields such as target stealth shielding, fire control extinguishment, dust removal, temperature reduction and the like as well as military and national defense industry. The vortex high-pressure water jet water mist generating device comprises a rotating body, a rotating shaft and a bearing seat, wherein the rotating body is internally provided with a liquid inlet hole; the rotating shaft is internally provided with a rotating shaft inner hole along the axial direction; the bearing seat is fixed on the rotating body; the rotating shaft is internally provided with an elastic sealing mechanism; the top of the rotating shaft is fixedly provided with a shunt body which is internally provided with a shunt main hole along the axial direction and a shunt branch hole along the radial direction; the shunt branch hole is communicated with the shunt main hole; the shunt body is fixedly connected with a spray head mounting body which is internally provided with a mounting hole and a mounting body branch hole along the radial direction; the mounting hole is internally and fixedly connected with a connecting pipe; and the end part of the connecting pipe is fixedly provided with a fogging nozzle mechanism. The vortex high-pressure water jet water mist generating device successfully solves the problems of stability, persistence and the influence of wind when high-pressure water jet water mist is generated, and is flexible and reliable in control.

Owner:西安捷通水射流技术应用有限公司

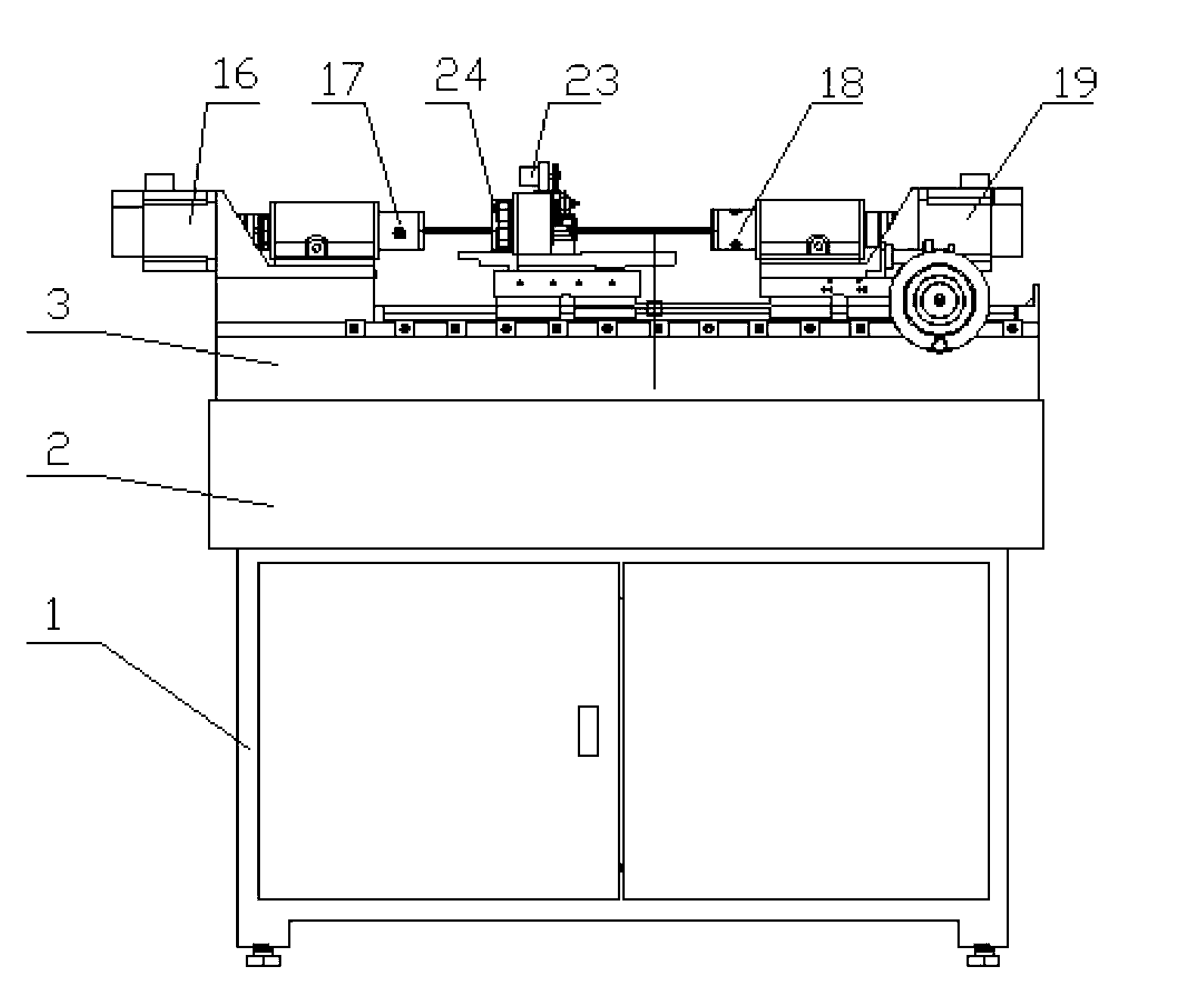

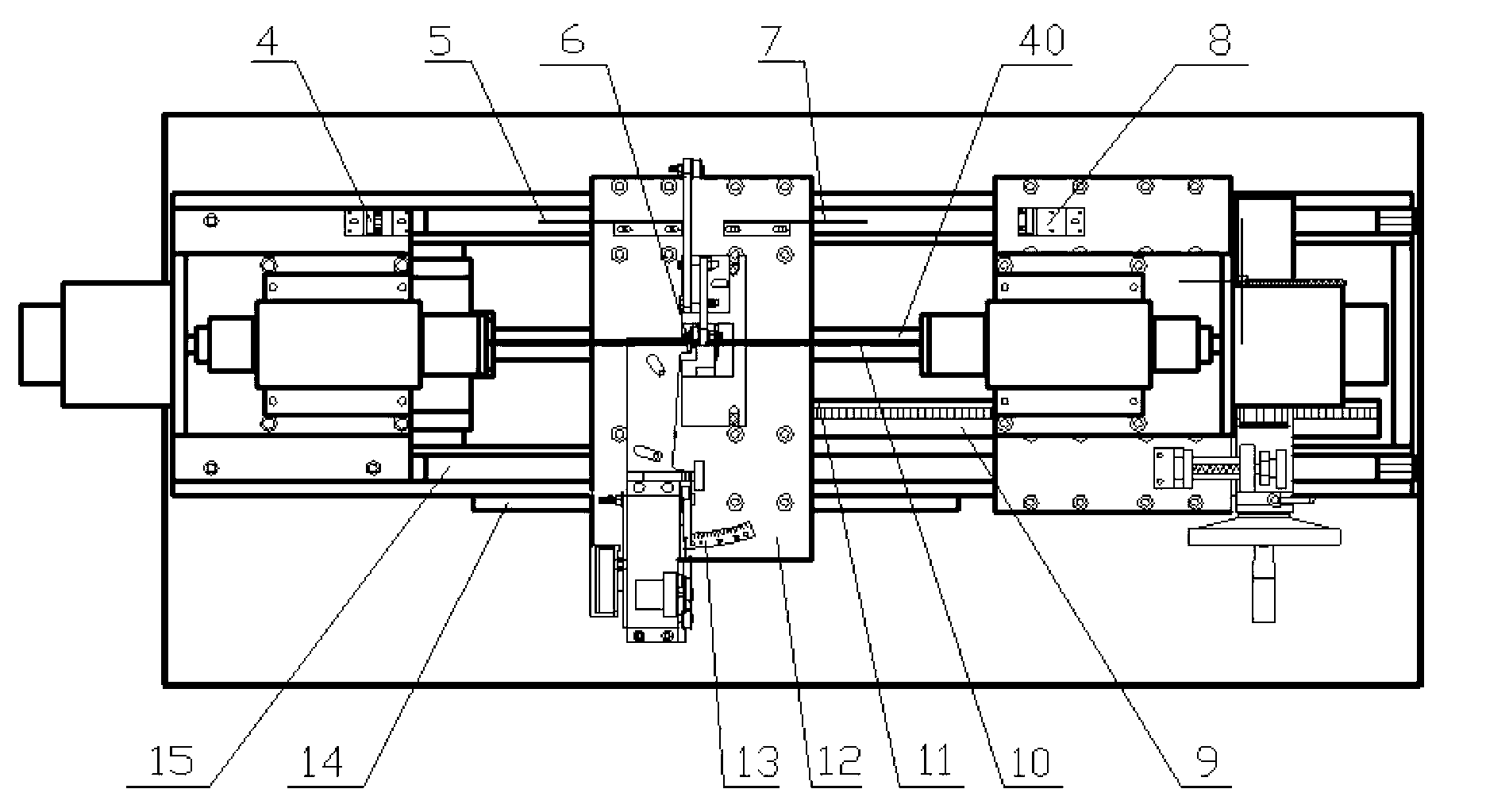

High-precision spiral wire winding machine

InactiveCN103317063AEasy to transformDeformation reachesMetal-working feeding devicesPositioning devicesWinding machineClosed loop feedback

The invention discloses a high-precision spiral wire winding machine. By coordinated movement of a wire winding mechanism, a wire guiding mechanism, a wire discharging mechanism with a torque motor and a magnetic powder brake in combined action, a working table driving mechanism, a locking mechanism with a mandrel tension adjusting device, a position detection system used for accurately controlling working table movement and detecting and monitoring the closed loop feedback position and an electrical control system, a wire or a strip spiral wire is wound at a high precision, the spiral wire types comprise equal screw pitch, gradual change screw pitch, jumping screw pitch and mixed screw pitch of the wire or a strip and edgewise winding of the strip, and the screw pitch error is smaller than 2 mu m. The high-precision spiral wire winding machine is further provided with a heating device for the wire or the strip, the wire or the strip which is hard is deformed easily by heating before wound on a mandrel, and the goal of winding is achieved. The spiral wire winding machine is low in cost and meets the multi-mode high-precision spiral wire production requirements of communication enterprises and national defense industries.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Process for manufacturing large high-chromium medium-carbon alloy forging back-up rolls

The invention relates to a process for manufacturing large high-chromium medium-carbon alloy forging back-up rolls. The process includes the steps: firstly, forging a blank after smelting alloy steel and annealing the forged blank; secondly, performing rough turning, semi-fine turning and fine turning; and thirdly, polishing the forged blank to obtain a finished product. The large back-up rolls are manufactured by means of advanced full-automatic numerical control differential-temperature integral quenching heat treatment process, the hardening depth of each large back-up roll reaches and exceeds 100 millimeters, hardness uniformity of roll bodies is within two Shore hardness units, and the weight of a single roll exceeds that of each large back-up roll of 25 tons. The practical service lift of the rolls is greatly prolonged, roll consumption is reduced, production cost is saved, and high-precision wide strips with even and smooth rolled plate surfaces can be used for automobile manufacture, space shuttle and national defense industry.

Owner:CHANGZHOU ECCO ROLLER

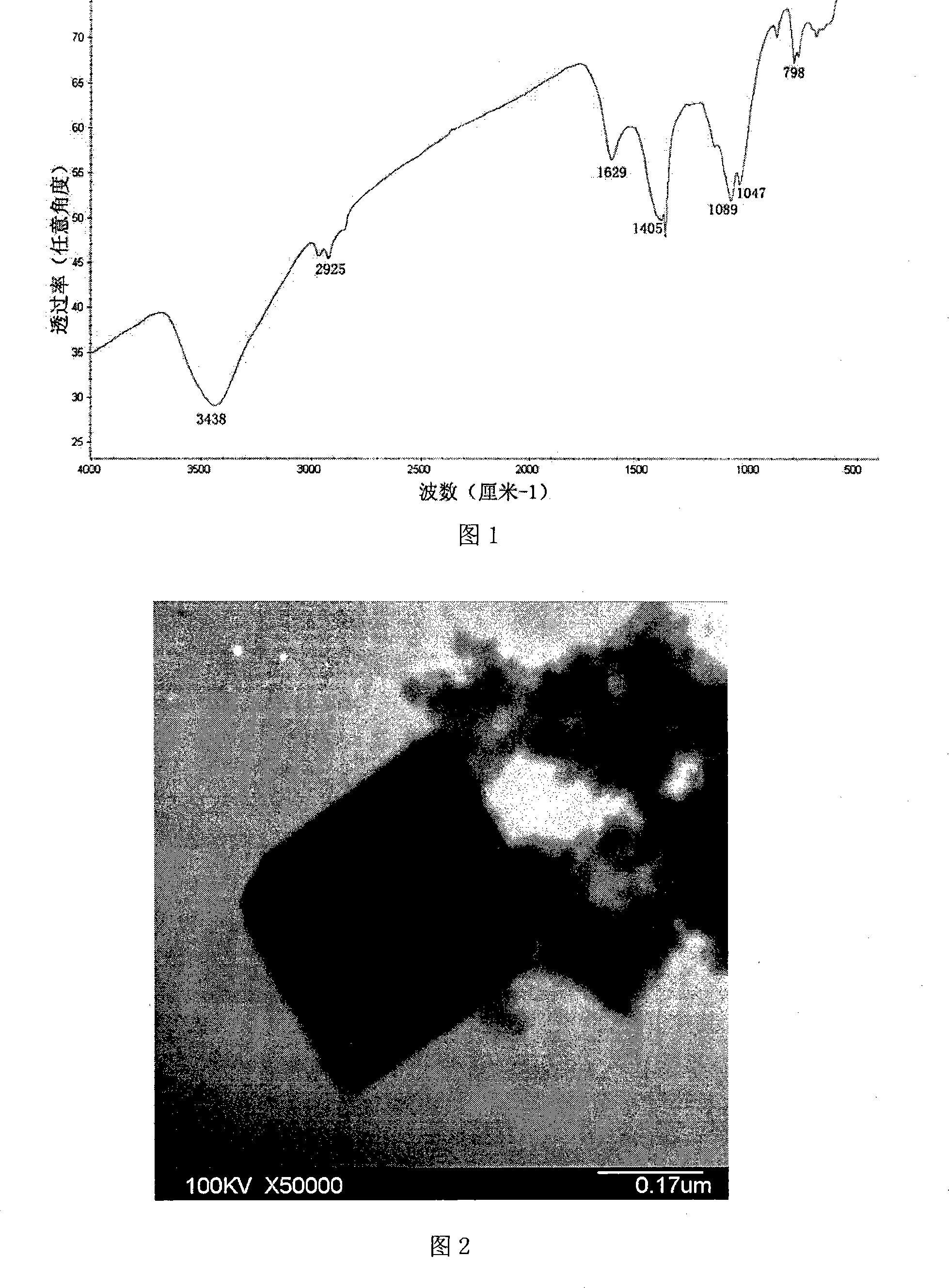

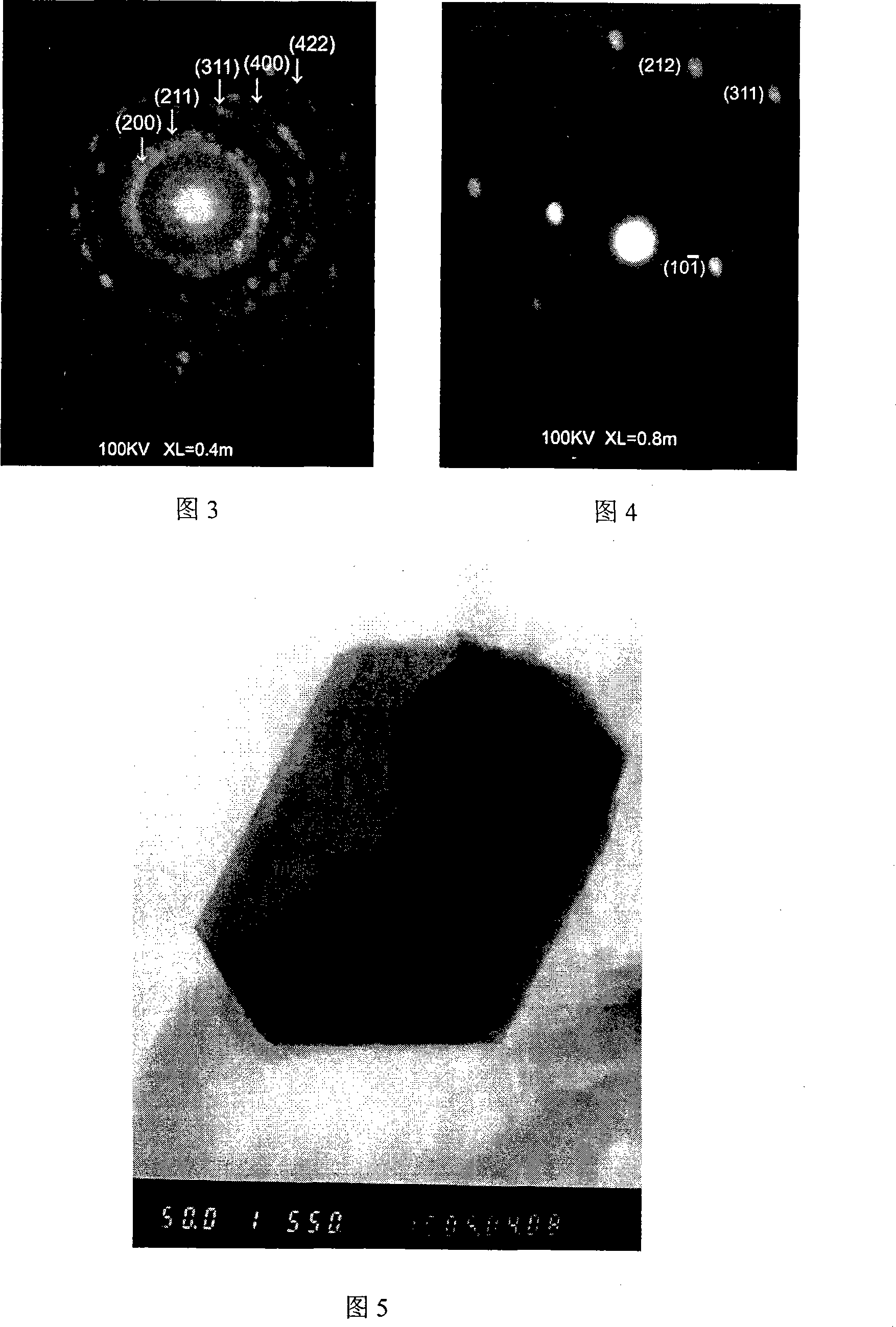

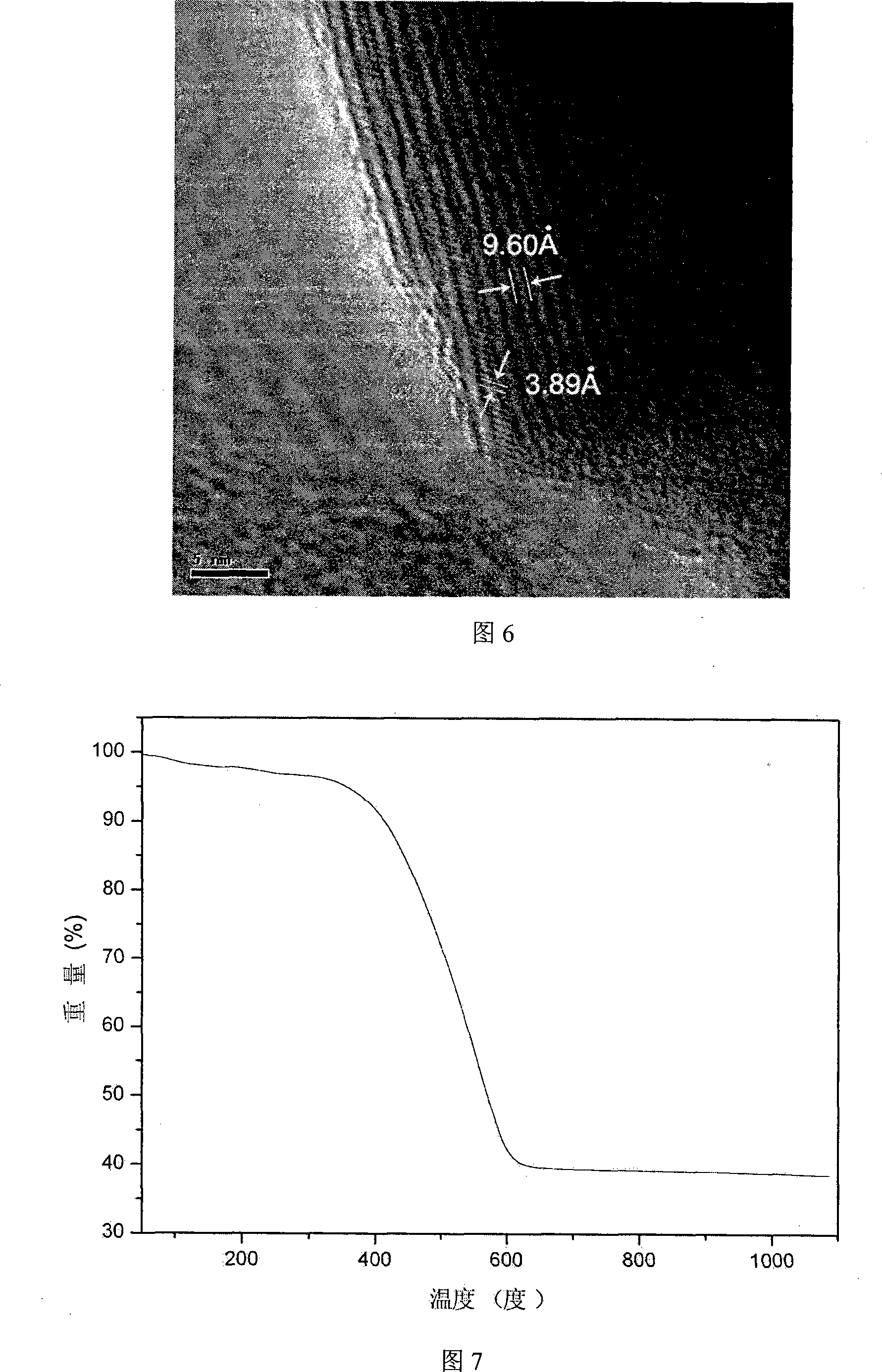

Controllable hydrothermal constant pressure synthesizing method for producing BCN material

InactiveCN101219780ARich varietyControllable granularityNitrogen and non-metal compoundsBoron nitridePetroleum

The invention relates to a controllable hydrothermal synthetic method of constant pressure for preparing boron carbon nitride material, belonging to a chemical technical field of new material. The method comprises the following processes of treatment of deionized water, preparation of boron source liquid, carbon source liquid and nitride source liquid, and loading a kettle; before an autoclave is heated up, pressure of 20 to 2,000 MPa is added; then the temperature is adjusted and the autoclave is heated up to 240 to 1,000 DEG C at a speed of 0.01 to 60 DEG C / minute, and the reaction is lasted for 6 to 480 hours. When the method is used for synthesizing boron carbon nitride material, the temperature and pressure of the system can be separately modulated, and the reaction speed and direction of the synthesized boron carbon nitride material can be controlled. Diamond, cube boron nitride and carbon nitride crystal can be obtained from the hydrothermal environment of constant pressure. The material has wide application prospect in fields of fine machinery processing, defense industry, drilling and exploitation of petroleum, photoelectronic elements of high temperature, large power and short wavelength.

Owner:SHANDONG UNIV

Method for preparing high toughness epoxy resin matrix by using heat fusion method

The present invention relates to a method for preparing a high toughness epoxy resin matrix by using a heat fusion method. In the prior art, a viscosity of the high toughness thermosetting epoxy resin system prepared by the traditional method is excessively increased so as to cause substantially-increased difficulty of the subsequent processing process. Based on the problem in the prior art, after a main body epoxy resin is mixed, a curing agent is added under a suitable condition, a small particle size thermoplastic powder material is mixed to the main body epoxy resin at a suitable temperature, and grinding is adopted to uniformly mix the resin so as to complete uniformity. Compared to the traditional toughening method, the method of the present invention has the following characteristics that: the minimum viscosity of the resin matrix can be substantially reduced, placement of the corresponding prepreg can be improved, and manufacturability of the prepreg can be improved. With the present invention, manufacturability and placement of the heat fusion method high toughness epoxy resin prepreg are improved, and the prepreg can be applicable for high toughness epoxy resin matrix composite material structures applied in aerospace, high toughness epoxy resin matrix composite material structures applied in warships, weapons and other defense industries, and various civil high toughness composite materials.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Alumina particle dispersion strengthened copper composite material and preparation method thereof

The invention relates to the technical field of electronic materials, and particularly discloses an alumina particle dispersion strengthened copper composite material and a preparation method thereof. The alumina particle dispersion strengthened copper composite material comprises the following chemical components in percentage by weight: 0.05-1.5 percent of alpha-Al2O3, 0.38-0.94 percent of gamma-Al2O3 and the balance of copper. The preparation method of the alumina particle dispersion strengthened copper composite material provided by the invention has the advantages of short internal oxidation time, low cost and high efficiency. The prepared alumina particle dispersion strengthened copper composite material has high strength, high conductivity, high anti-softening temperature and high high-temperature strength, can meet the requirements of microelectronic industry and electronic information industry on high-conductivity, high-strength and high-temperature-resistant copper alloy andis widely applied to mechanical industry, defense industry and electronic information industry.

Owner:HENAN UNIV OF SCI & TECH

Novel corrosion resistant, wear resistant and high temperature resistant alloy material and production process thereof

InactiveCN101942617AImprove mechanical propertiesHigh hardnessChemical industrySilicon-controlled rectifier

The invention relates to a novel corrosion resistant, wear resistant and high temperature resistant alloy material and a production process thereof. The alloy comprises the following components in mass percent: 1.6-2.0% of C, 0.8-1.2% of Si, 8.0-11.0% of Mn, 24-27% of Cr, 2.0-3.0% of Mo, 5.0-7.5% of Ni, less than or equal to 1.0% of Nb, less than or equal to 1.0% of Ti, less than or equal to 0.20% of B, less than or equal to 0.10% of Re, less than or equal to 0.030% of S and less than or equal to 0.030% of P. The invention comprises the following production steps: firstly, proportioning according to the requirements of finished products for chemical components of raw materials; then, smelting in a medium-frequency induction furnace of a silicon controlled rectifier; and finally, carrying out casting and heat treatment. By using the micro-alloying technology, the invention greatly improves the mechanical property of the material, ensures the higher corrosion resistance, improves the hardness, the wear resistance, the high temperature strength and the high temperature resistance, and can be widely applied to the fields of petroleum, chemical industry, metallurgy, electric power, coal, defense industry and the like. Compared with a common stainless steel acid resistant pump, the service life of a pump product produced by the invention is prolonged by more than one time, and the cost of the pump product is lowered by 1 / 3, thereby really realizing the purposes of excellent quality and reasonable price.

Owner:沈绍敖 +1

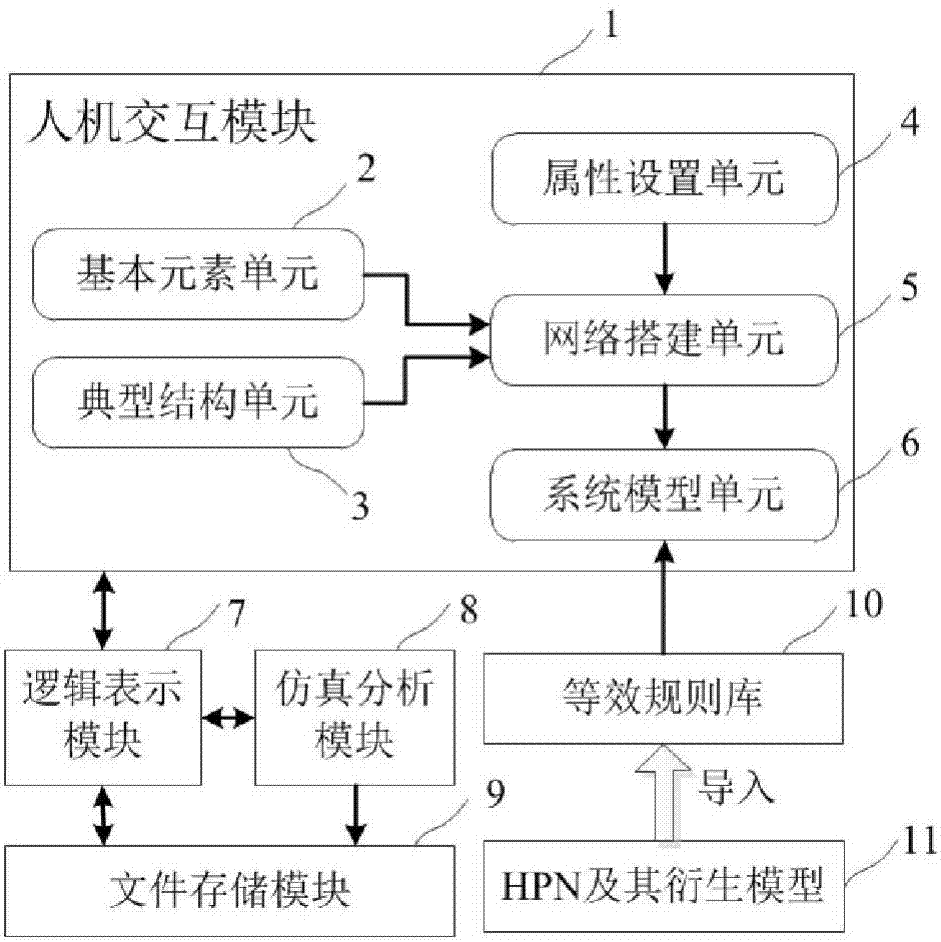

Hybrid-system modeling and simulation platform and method based on HSTPN model

ActiveCN107229789AImprove scalabilityReduce Model ComplexityDesign optimisation/simulationResourcesDecision takingPetri net

The invention discloses a hybrid-system modeling and simulation platform and method based on a HSTPN model. The hybrid-system modeling and simulation platform comprises a human-computer interaction module, a logic expression module, a simulation analysis module, a file storage module and an equivalent rule library. The platform can carry out modeling and simulation on a hybrid system with five hybrid characteristics of dispersing, continuation, delaying, random and decision at the same time, the hybrid characteristics are only defined in a five-type library, the modeling complexity can be reduced, the transitional moment theory is guaranteed, and the modeling expandability is improved; a hybrid state of the HSTPN model is jointly described through a library identification and the continuous state; the platform provides the equivalent function of the HSTPN model by establishing equivalent rules of a hybrid Petri net and a derivative model of the hybrid Petri net. The hybrid-system modeling and simulation platform and method can be applied to modeling and simulation of hybrid systems such as an information physical fusion system, a flexible manufacturing system, a logistic system and defense industry.

Owner:NORTHEASTERN UNIV

Luminous fiber, luminous yarn and method for preparing luminous yarn

InactiveCN103361753AStable light storageImprove luminous performanceFilament forming substance formingArtificial filament heat treatmentFiberAviation

The invention discloses a luminous fiber. The luminous fiber comprises a fiber main body and photoluminescence materials, wherein the fiber main body is used for preparing a chemical fiber and consists of high-molecular compound materials; the photoluminescence materials are uniformly distributed in the fiber main body. The photoluminescence materials such as rare earth mineral substances with a luminance performance are added into spun threads, and are uniformly scattered in the fiber, so that the threads are stable in light storage and light emitting effects, non-toxic, innocuous, non-radiative, harmless to a human body, stable in luminance performance, and long in service life, has the environment-friendly effect, and can be permanently used in an endless loop. A luminous fiber material can be used for spinning, and are suitable for other purposes; people can regard the luminous fiber material as a carrier to manufacture a product by using sunlight which can be used as a clean and pollution-free energy source in accordance with environment protection and sustainable development, and the manufactured product is widely applied to the fields of aviation, navigation, national defense industry, building decoration, transportation, night operation, daily life, leisure and entertainment, and the like.

Owner:PUTIAN HUAFENG IND & TRADE CO LTD

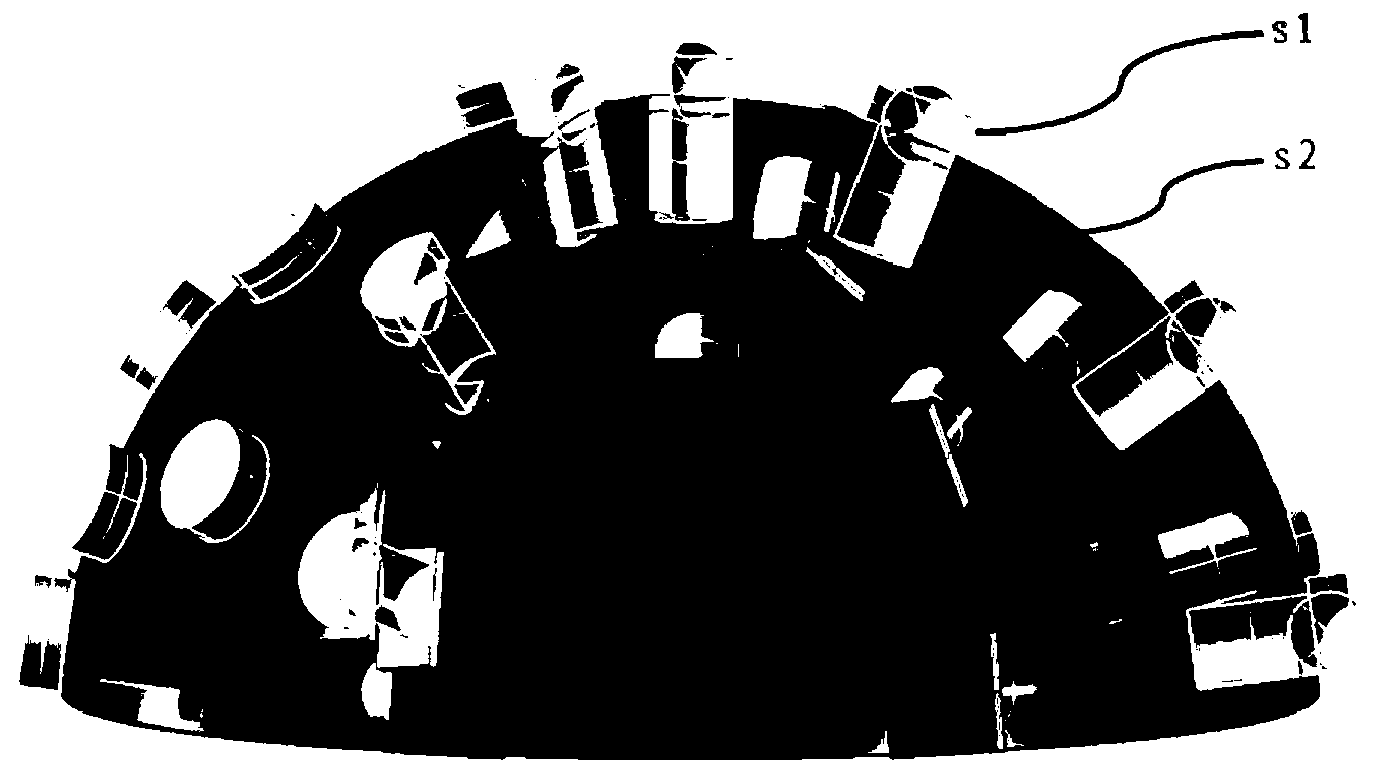

Fixed hemisphere camera

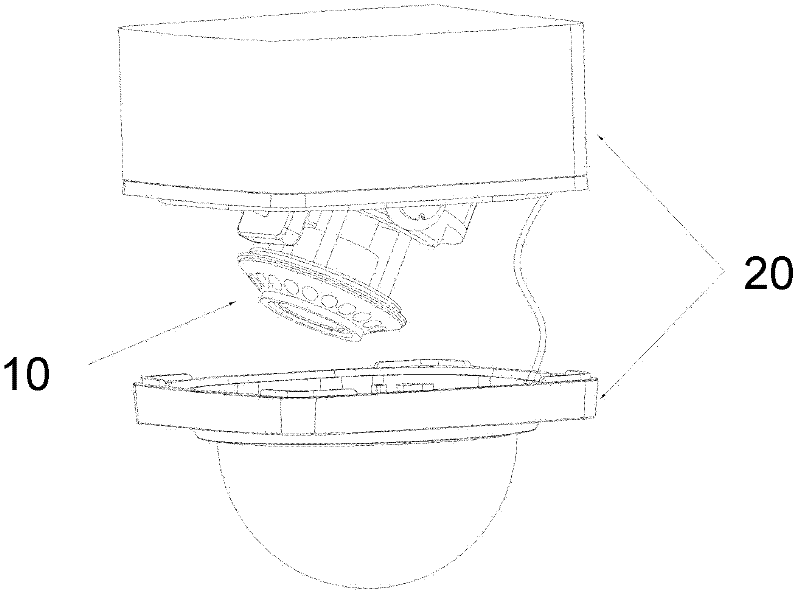

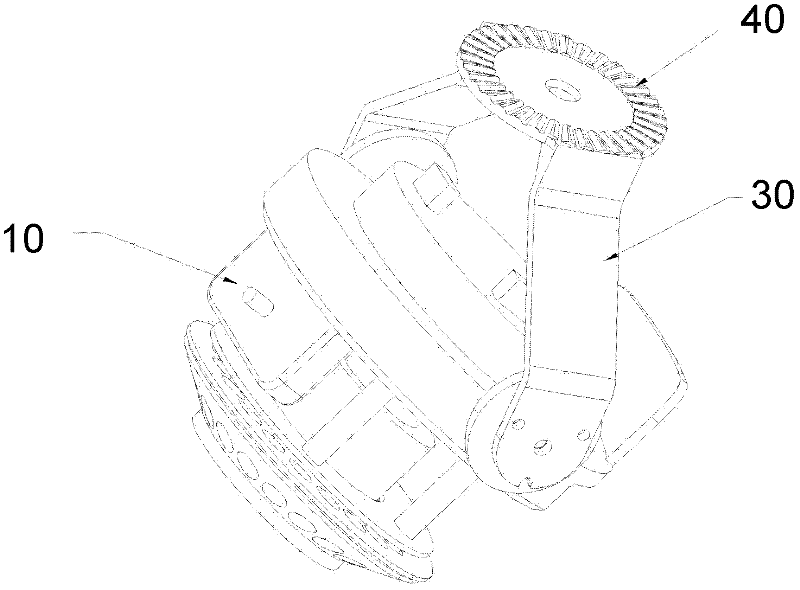

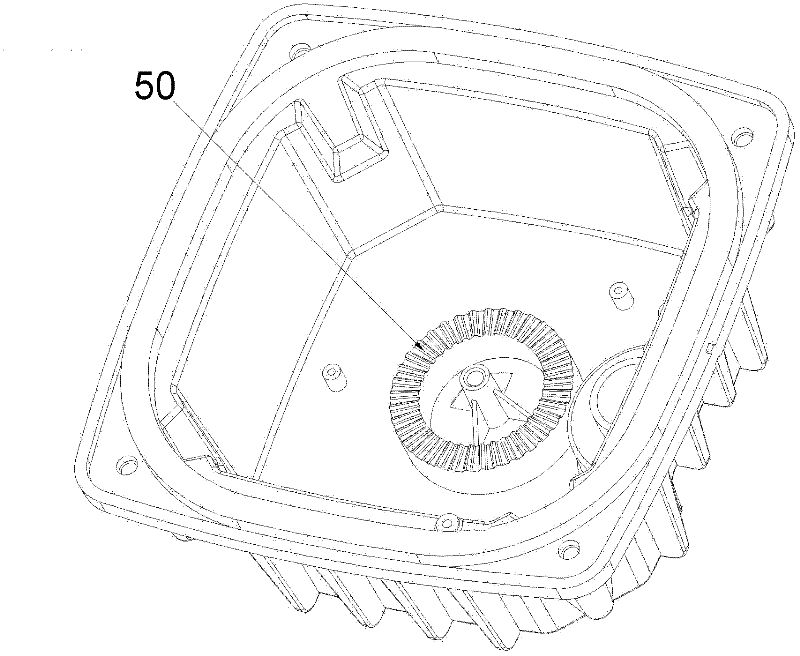

InactiveCN102333187AReduce labor intensityImprove work efficiencyTelevision system detailsColor television detailsEngineeringMechanical engineering

The invention relates to a camera device in a security defense industry, in particular to a fixed hemisphere camera, which comprises an outer cover, a machine core arranged in the outer cover, a bracket for supporting the machine core, and a power supply system providing a power source for the machine core. The camera is characterized in that the top surface of the outer side of the bracket is provided with a first tooth-shaped pattern, the top surface of the inner side of the outer cover is provided with a second tooth-shaped pattern meshed with the first tooth-shaped pattern in a coaxial way, and the bracket is fixed in the outer cover through an elastic locking device, so that the bracket can be rotated without the need of adjusting the tightness of screws so as to make the machine core rotate freely in the horizontal direction along with the bracket, the work efficiency is greatly improved, and the labor intensity of operators is reduced.

Owner:SHENZHEN SANBOT INNOVATION INTELLIGENT CO LTD

Preparation method of modified phenolic resin

The invention discloses a preparation method of a modified phenolic resin. Firstly a phenolic compound is reacted with an aldehyde to generate a phenolic product, then polyimide is added to react with the phenolic product to obtain the modified phenolic resin; and wherein the molar ratio of the phenolic compound to the aldehyde is (1.2-1.7):1.0, and the polyimide accounts for 0.5-1 time by mass of the total amount of the phenolic compound and the aldehyde. Compared with the prior art, the prepared modified phenolic resin is substantially improved in heat resistance and toughness, and thus is adapted to the needs of high and new technology fields such as automobile, electron, aviation, spaceflight, national defense industry and the like.

Owner:南京市荣达树脂有限公司

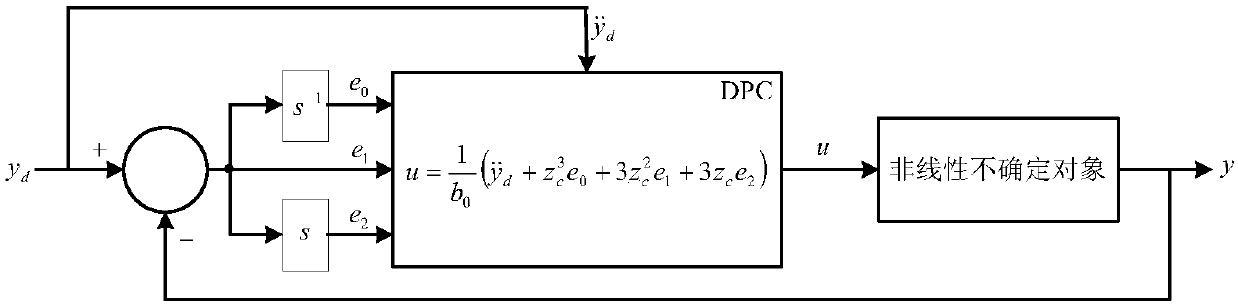

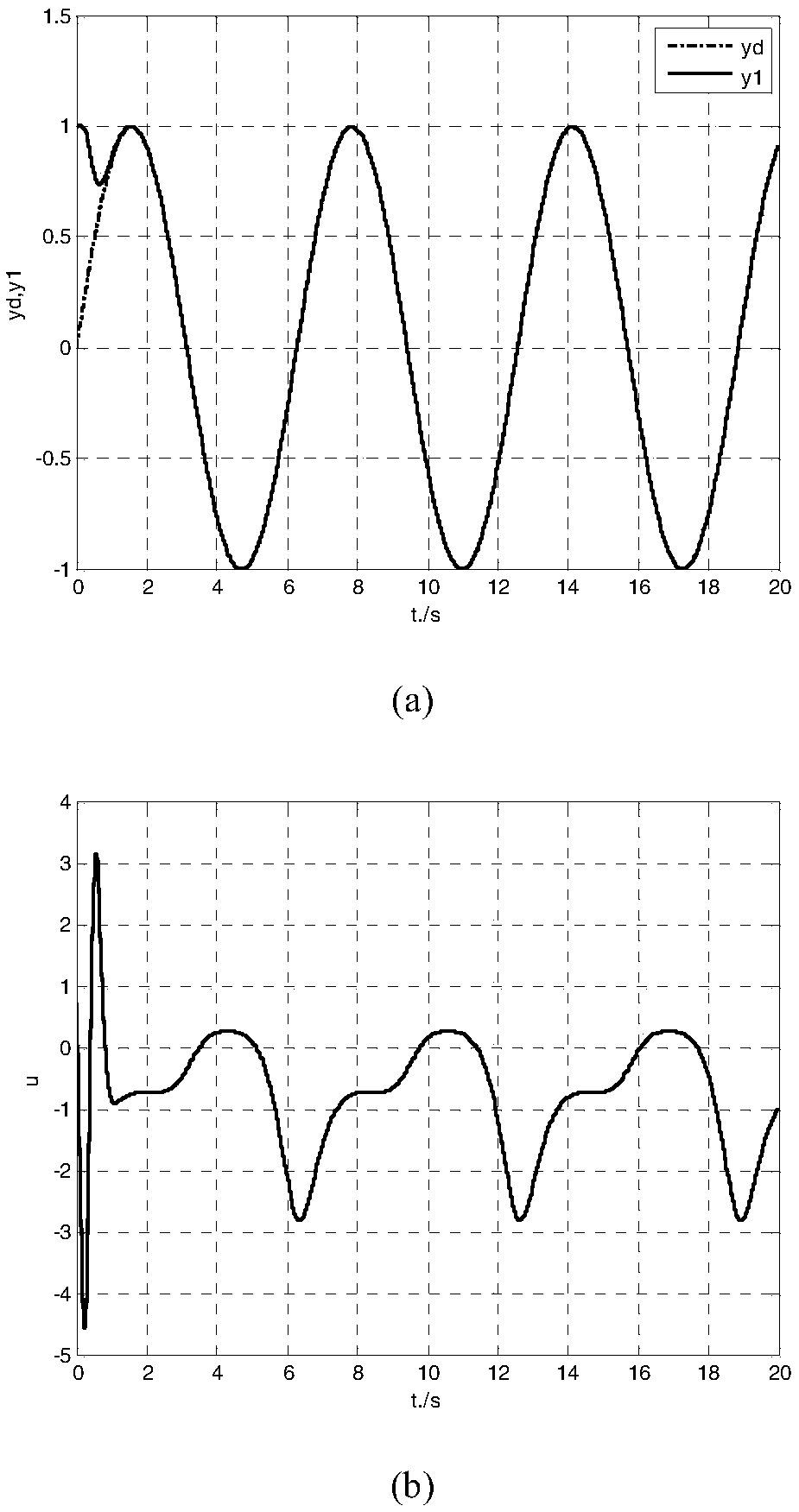

Disturbance perception control method

An advanced signal processing technology is integrated into a PID framework to improve performance, such as a self-correcting PID, a fuzzy PID, a nerve cell PID, a parameter self-learning PID, an expert PID and the like. Various improved PIDs can effectively solve the online stabilization problem of a controller gain parameter and improve a nonlinear control ability, but, the improved PIDs do nothave a high anti-disturbance capability. The ''disturbance perception control (DPC) method'' of the invention can be used to effectively solve the contradiction between rapidity and overshoot, and hascharacteristics that control precision is high, robust stability is good, an anti-disturbance capability is high, and the gain parameter is completely determined by an integration step and so on. Especially when an external environment changes drastically, the gain parameter of the DPC does not need to be re-stabilized, the control strategy of a classical control theory and a modern control theory is completely overturned. The method has a wide application value in the fields of electric power, machinery, a chemical industry, a light industry and a national defense industry.

Owner:曾喆昭 +1

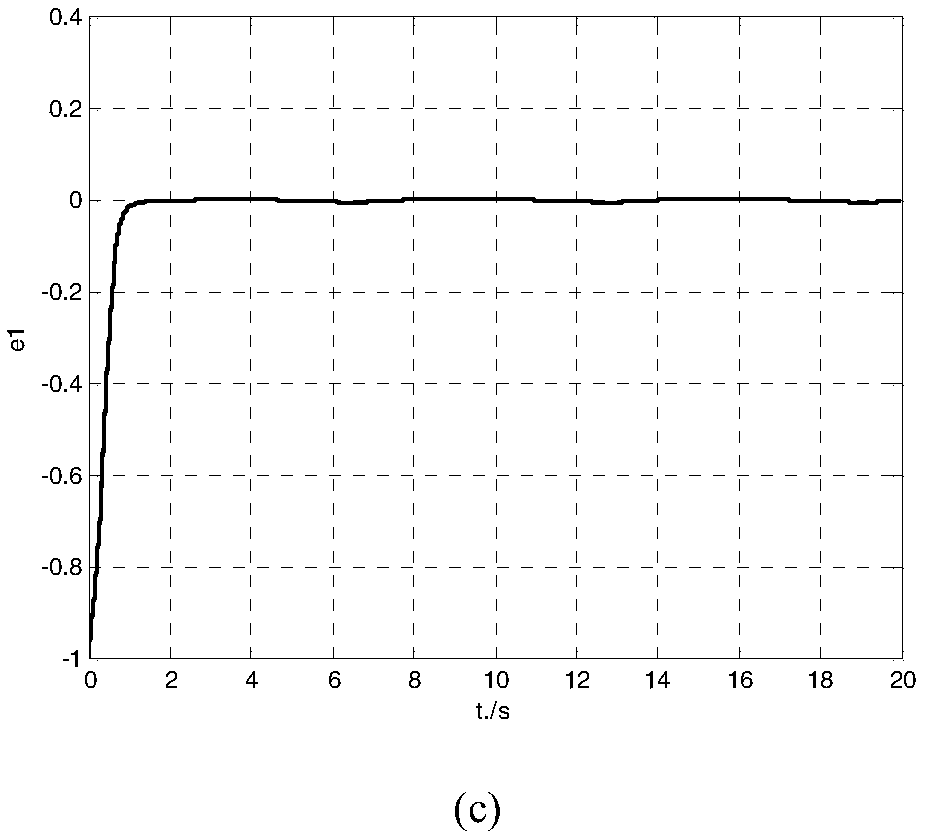

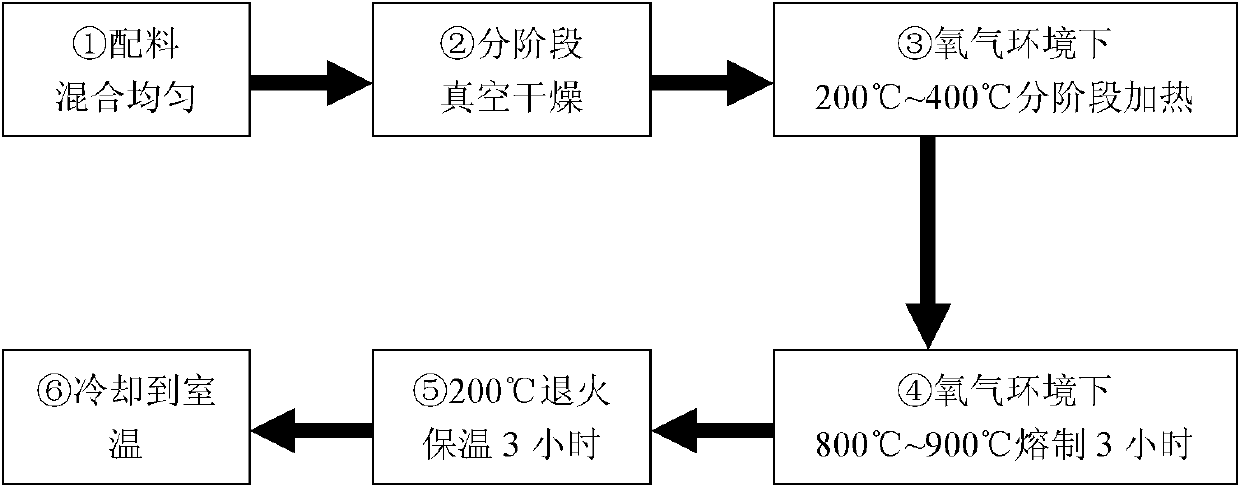

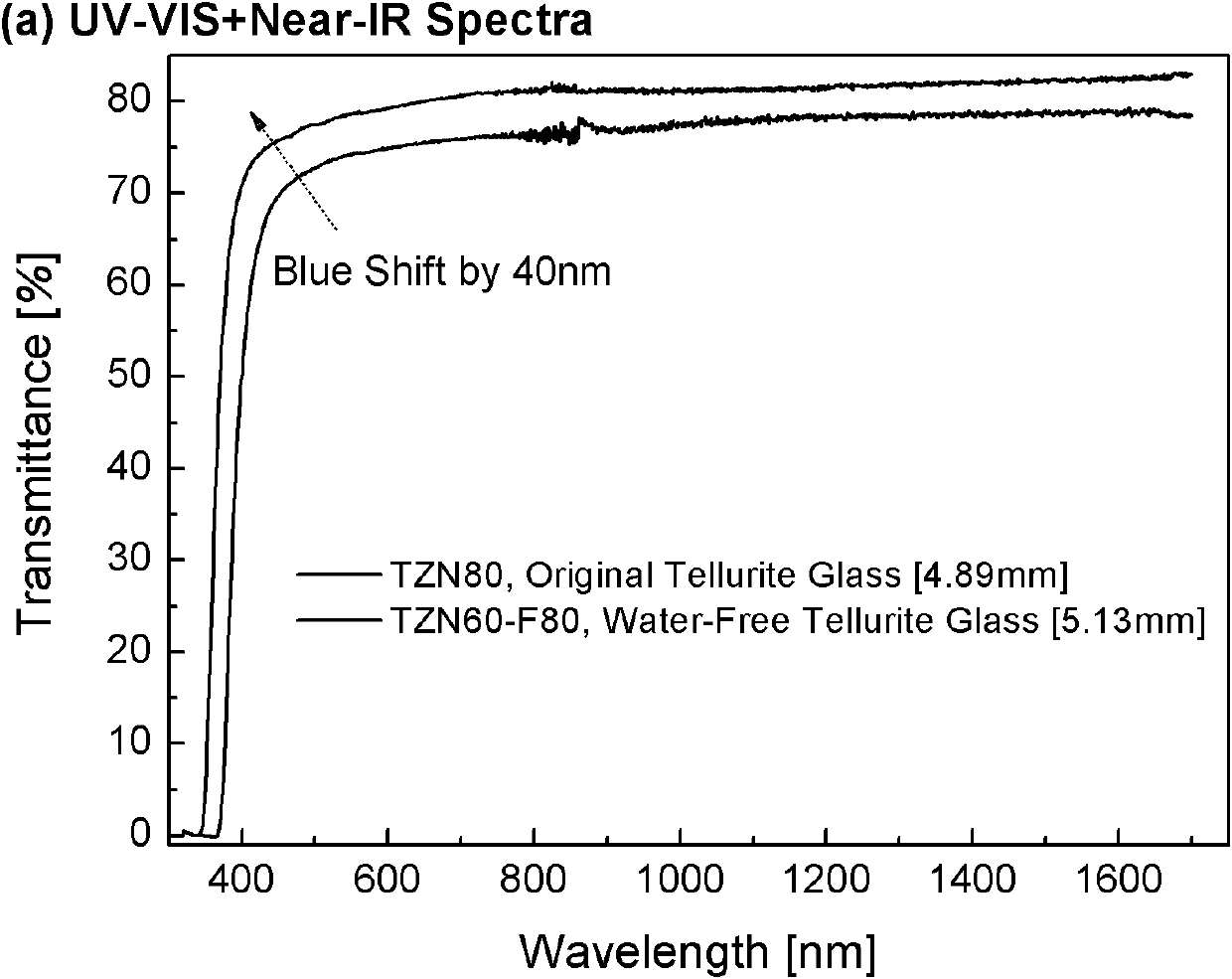

Mid-infrared anhydrous tellurate glass and preparation method thereof

The invention relates to mid-infrared anhydrous tellurate glass and a preparation method of the tellurate glass. The mid-infrared anhydrous tellurate glass is prepared by the components of: 55-80mol% of TeO2 and 20-45mol% of ZnF2. The mid-infrared anhydrous tellurate glass provided by the invention is anhydrous, capable of satisfying requirements of mid-infrared window glass and signal transmission in an atmospheric window range of 0.3-5 micrometers and expected to be widely applied to national defense industry and economic construction.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

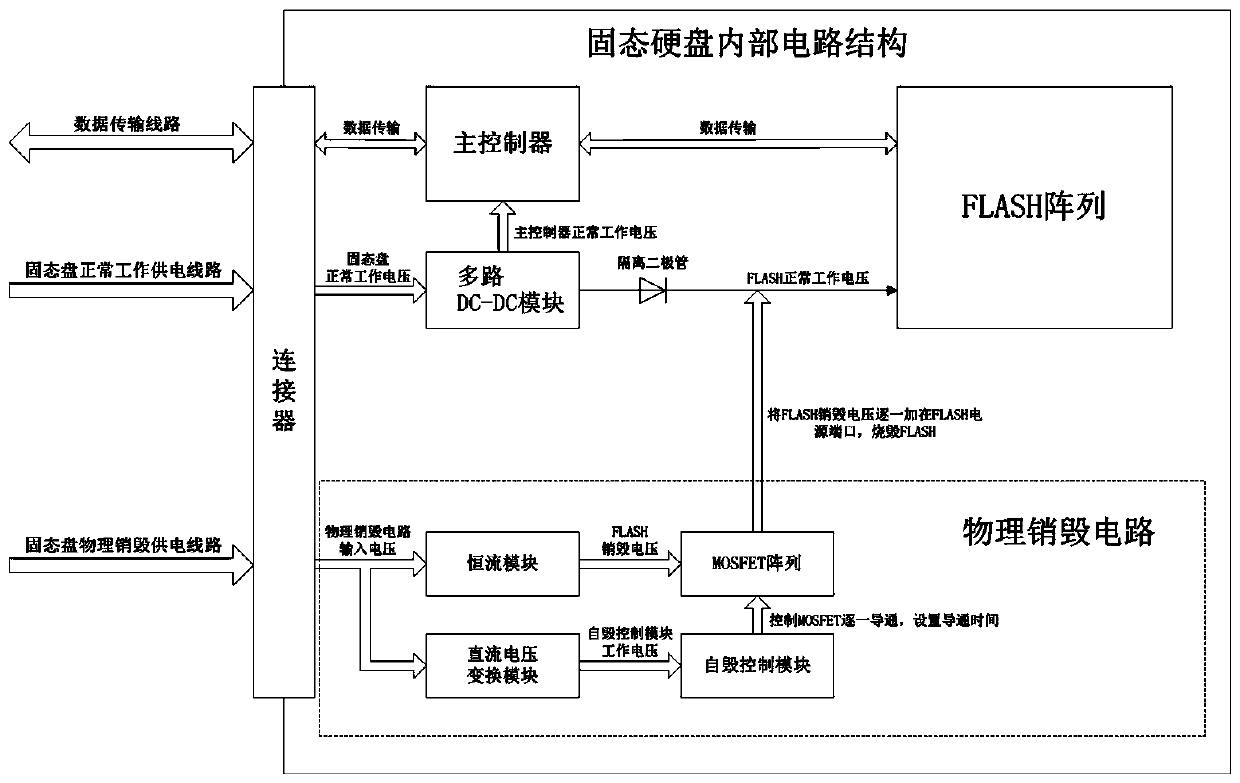

A high-reliability universal solid state disk rapid physical destruction circuit and method

PendingCN109670348APrevent high pressure backflowStable voltageInternal/peripheral component protectionConfidentialityComputer module

The invention discloses a high-reliability universal solid state disk rapid physical destruction circuit and method, and belongs to the technical field of electronics. The circuit comprises a DC module and a FLASH array, and is characterized by further comprising an input power limiting module, a direct-current voltage conversion module, a self-destruction control module and a switch tube, whereinthe input power limiting module and the direct current voltage conversion module are arranged in parallel; the direct current voltage conversion module, the self-destruction control module and the switch tube are electrically connected in sequence; and the switch tube is electrically connected with the FLASH array. The circuit design is simple, the number of peripheral elements is small, the sizeis small, the destruction time is controllable, and the destruction rate is high; the circuit and the method can solve the problems that a self-destruction circuit in the prior art is too large in size, the self-destruction time is long, the input power is large, the self-destruction is incomplete, a self-destruction circuit is too complex, and the reliability is low, and become a universal physical destruction circuit and method suitable for solid state disks of various environmental conditions and various mainstream standard sizes, and meet the confidentiality requirement of the national defense industry, the finance industry and other industries for data safety.

Owner:XIAN KEYWAY TECH

Ferrous metal surface fireproof flame resistance paint and production method thereof

The invention relates a ferrous metal surface fireproof flame resistance paint and a production method thereof; the paint comprises the following raw materials according to the parts by weight: 25-35 parts of phenolic resin, 20-25 parts of aluminum naphthenate, 5-8 parts of additive, 9-10 parts of each metal of aluminum, tungsten, molybdenum, manganese, gypsum and talcum powder and 0.01-0.05 part of pigment, wherein, the additive comprises glacial acetic acid, phosphorus trichloride and pure water. The production method of the paint comprises the following steps: 1) grinding metal powders to 350-400 meshes of ultrafine powders, then adding additive, aluminum naphthenate and pigment in a the charging basket of a agitator to stir and react to obtain fireproof flame resistance base material; 2) adding the base material in a reaction kettle, gradually dripping phenolic resin while stirring the materials, after fully stirring and discharging the obtained paste; 3) transferring the paste into a three-roll ball mill and finally obtaining the finished paint after performing ball milling 2-3 times. The product can not burn at 800-1200 DEG C, which can not cause fire accident and can eliminate potential safety hazard and environmental pollution. The paint can be widely used as the coating inside and outside buildings, ships, trains, cars, tanks, armored cars and mechanical equipments in civil use, industry, aviation, national defense industry and other fields, and the paint can retard flame and fire.

Owner:邵阳市创捷化工有限公司

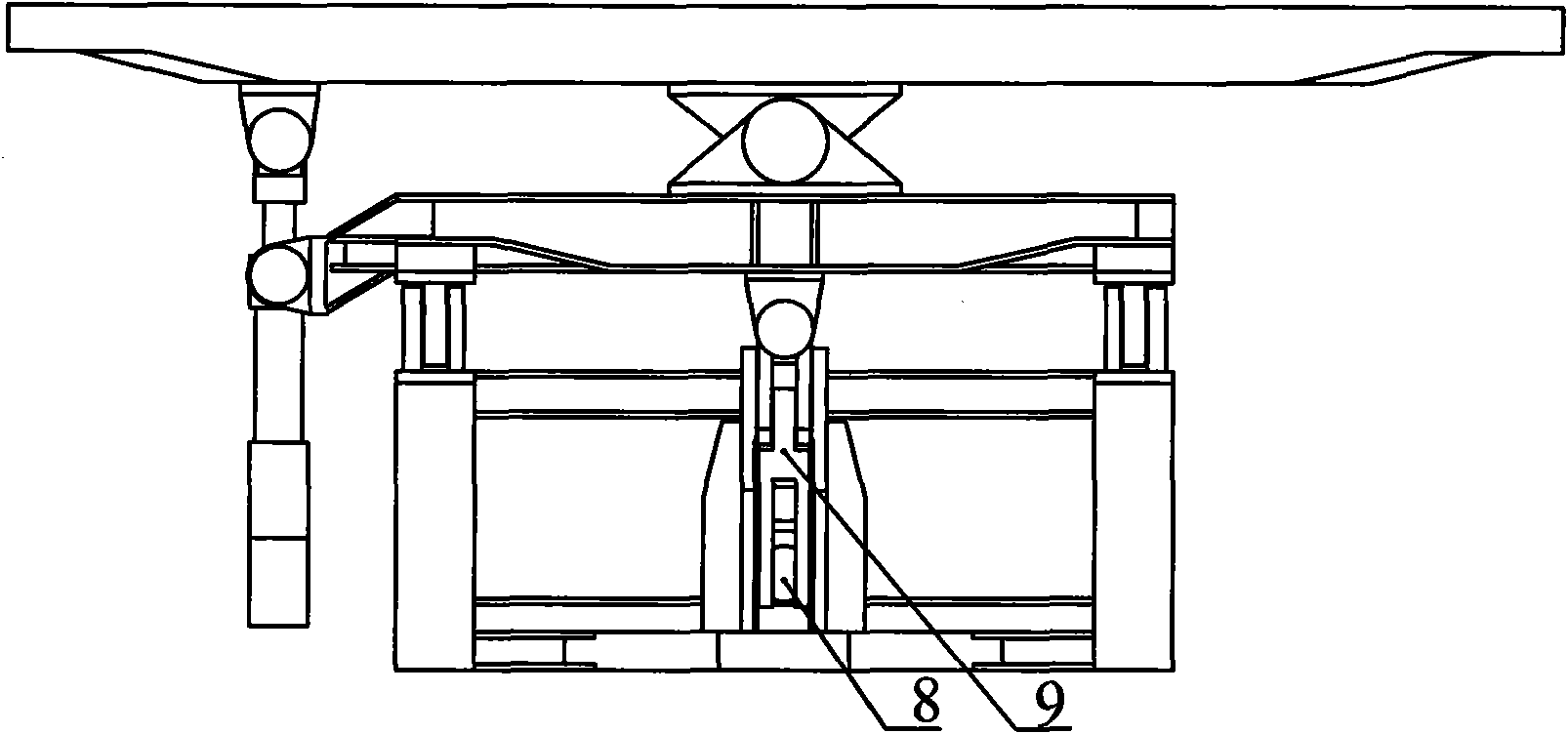

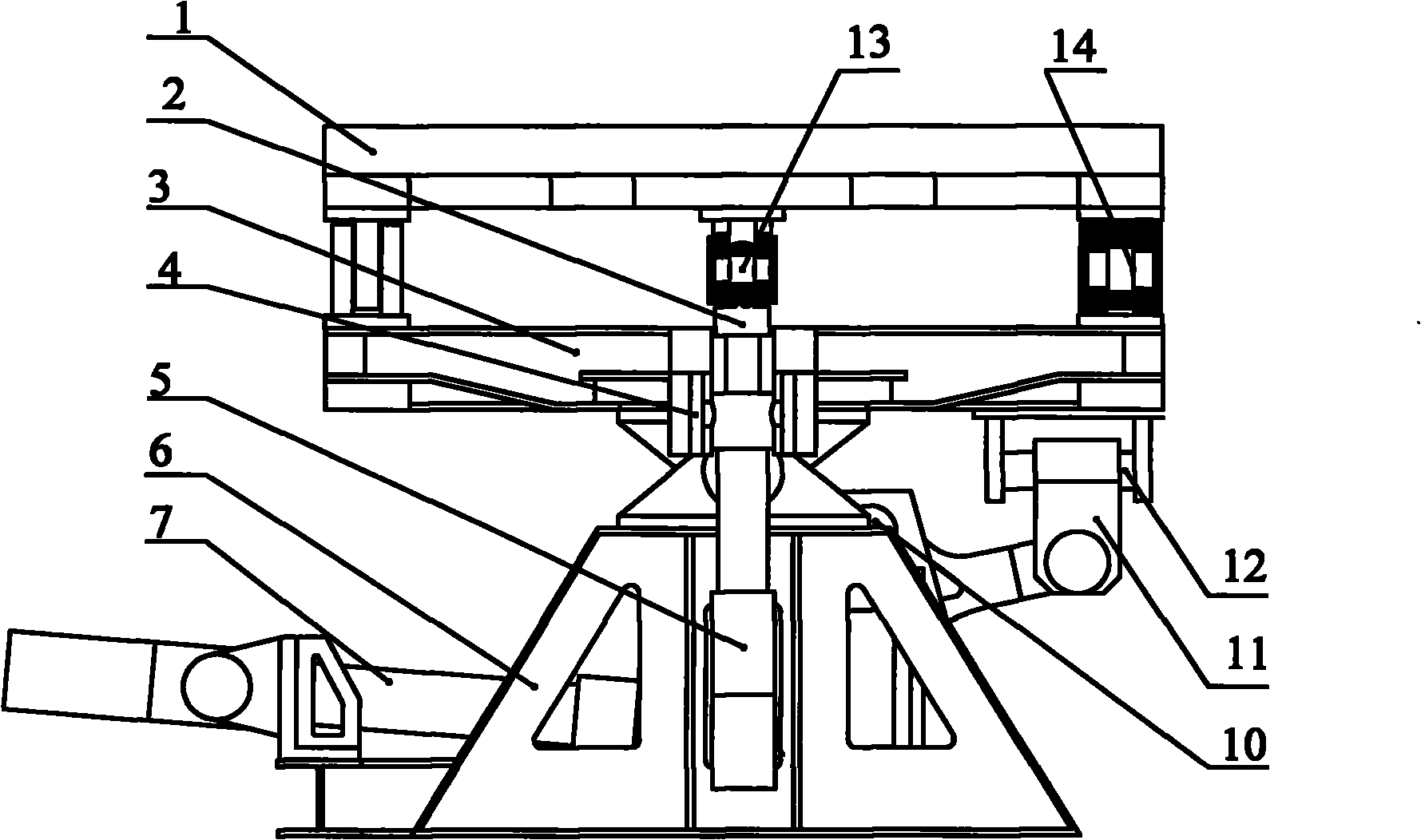

High-precision two-degrees-of-freedom stable platform

ActiveCN101858820AHigh precisionMovement precisionVessel partsVibration testingAviationDegrees of freedom

The invention discloses a high-precision two-degrees-of-freedom stable platform, which mainly comprises an upper layer of platform, a middle layer of platform, a lower layer of platform, a crank, a crankshaft, a crankshaft connecting piece, a middle layer of macro-axle and the like. The high-precision two-degrees-of-freedom can realize the motion of the two-degrees-of-freedom of rotating around an X-axis and rotating around a Y-axis, and can realize any of two-degrees-of-freedom composite motions at the same time. The test platform has the advantages of favorable stability, high precision, compact structure and low integral height, and is a simulated analogue device which aims attt the motion process under different sea conditions and other dynamic conditions, therefore, the invention is suitable for product tests in the national defense industry such as aviation, aerospace, weapons, ships, electronics and the like.

Owner:水木星光国际创新科技(北京)有限公司

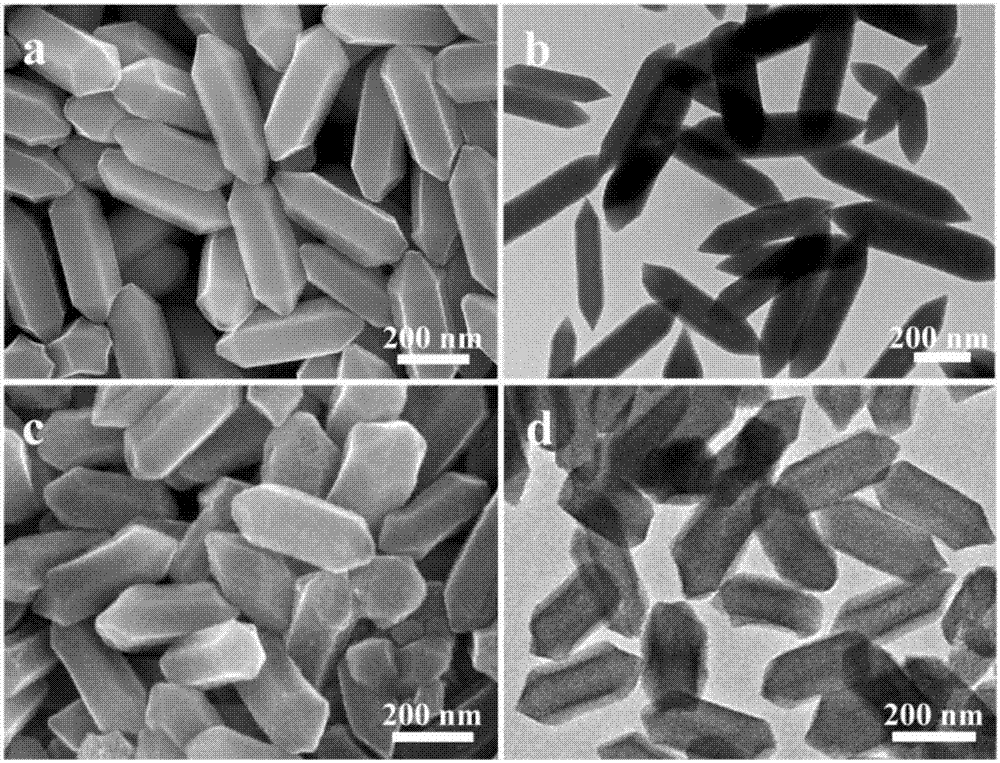

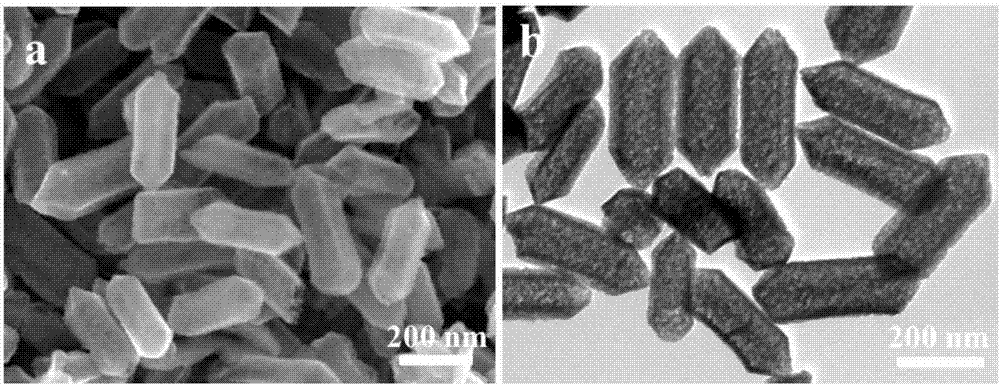

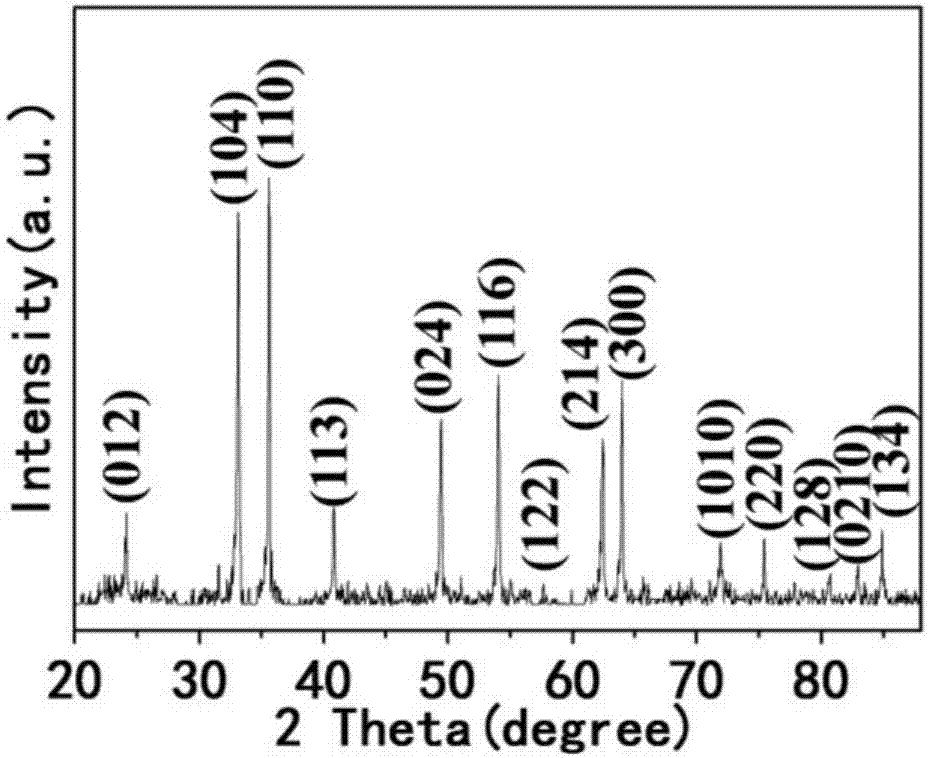

Preparation and application method for hollow porous nano alpha-Fe2O3 hexagonal prism material

ActiveCN107381499AQuality improvementImproved magnification performanceMaterial nanotechnologyCell electrodesEtchingMetal-organic framework

The invention discloses a preparation and application method for a nano-hollow-porous alpha-Fe2O3 hexagonal prism material, and belongs to the field of energy materials. The method includes the steps of firstly, preparing a nano Fe-MIL-88A metal-organic-framework material (MOFs) hexagonal prism material; secondly, processing by using sodium hydroxide, and through the process of self-etching, obtaining a nano material of a hollow MOFs @ Fe (OH) 3 structure; finally, conducting heat treatment in the air to obtain a hollow porous nano Fe2O3 hexagonal prism anode material. The method has the advantages of being simple in method and equipment, controllable in process parameter, high in repeatability, abundant in raw material needed by preparation, low in cost and convenient in large-scale. The prepared hollow porous nano Fe2O3 hexagonal prism anode material has high specific capacity and good cyclic stability, is an ideal anode material for a lithium ion battery, and can be widely used in the fields of portable electronic equipment, electric vehicles, aerospace technologies, national defense industry and the like.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com