Patents

Literature

156 results about "Astronautics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Astronautics (or cosmonautics) is the theory and practice of travel beyond Earth's atmosphere. The term astronautics (originally astronautique in French) was coined in the 1920s by J.-H. Rosny, president of the Goncourt academy, in analogy with aeronautics. Because there is a degree of technical overlap between the two fields, the term aerospace is often used to describe both at once. In 1930, Robert Esnault-Pelterie published the first book on the new research field.

Aerogel heat insulation composite material and its preparing method

The heat insulating composite aerogel material consists of silica aerogel, titania as infrared opacifier and reinforcing fiber in the weight ratio of 1 to 0.1-0.7 to 0.7-3. Its preparation process includes compounding sol with silanolate, surface modifier, titanolate, alcohol solvent, acid catalyst and alkaline catalyst in certain proportion; soaking fiber felt or prefabricated fiber part in the sol; and supercritical fluid drying. The material of the present invention has high blocking effect on solid heat transfer, air heat transfer and infrared radiation heat transfer, excellent hydrophobicity, simple preparation process, low cost, mechanical strength over 2 MPa, and wide application range, and may be used in strict heat protection condition in aeronautics, astronautics, military and civil uses.

Owner:NAT UNIV OF DEFENSE TECH

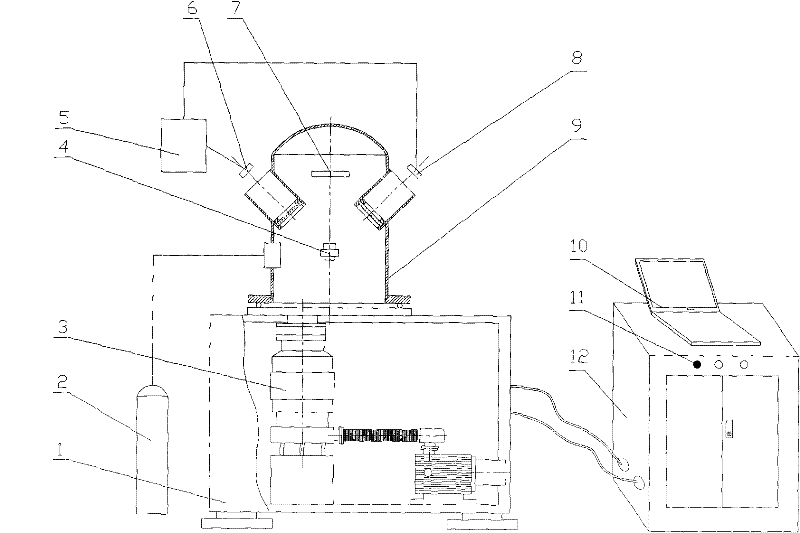

Stereo vision measuring apparatus based on binocular omnidirectional visual sense sensor

Disclosed is a stereo vision measuring device based on a binocular omni-directional vision sensor. Each ODVS composing the binocular omni-directional vision sensor adopts the design of mean angle resolution. The parameters of two image collection cameras are in complete accord and in possession of a pretty good symmetry, and can quickly realize the point-to-point matching. The device adopts a unified spherical coordinate in the process of data collection, processing, description and representation of space objects in terms of centering on human in visual space, and adopts the elements of distance sense, direction sense and color sense to express features of each characteristic point, thereby simplifying the complication of calculus, omitting the calibration of the cameras, facilitating the feature extraction and realizing the stereo image matching easily, finally realizing the purpose of high-effective, real-time, and accurate stereo vision measurement. The device can be applied in a plurality of fields of industrial detection, object identification, robot automatic guidance, astronautics, aeronautics, military affairs, etc.

Owner:汤一平

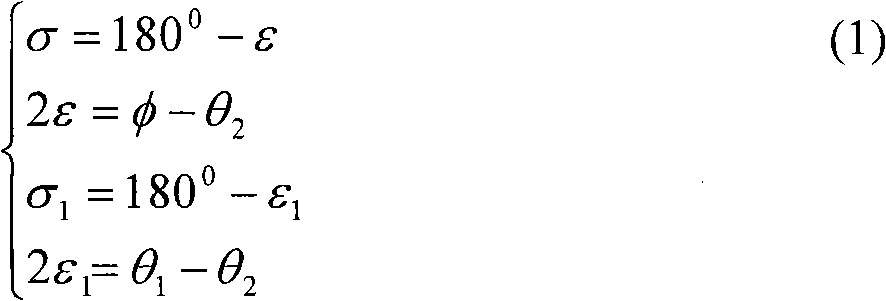

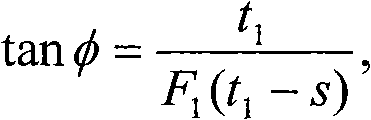

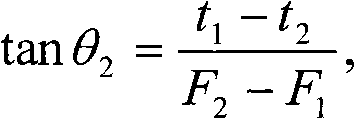

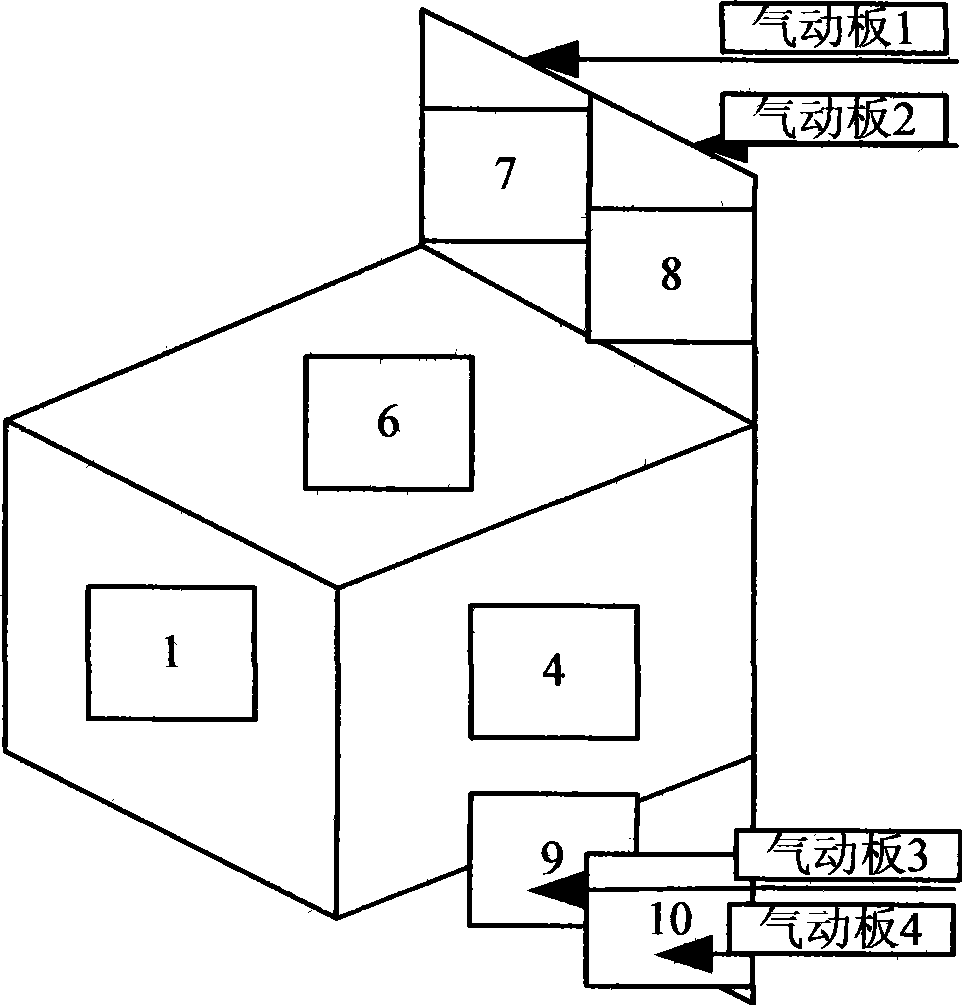

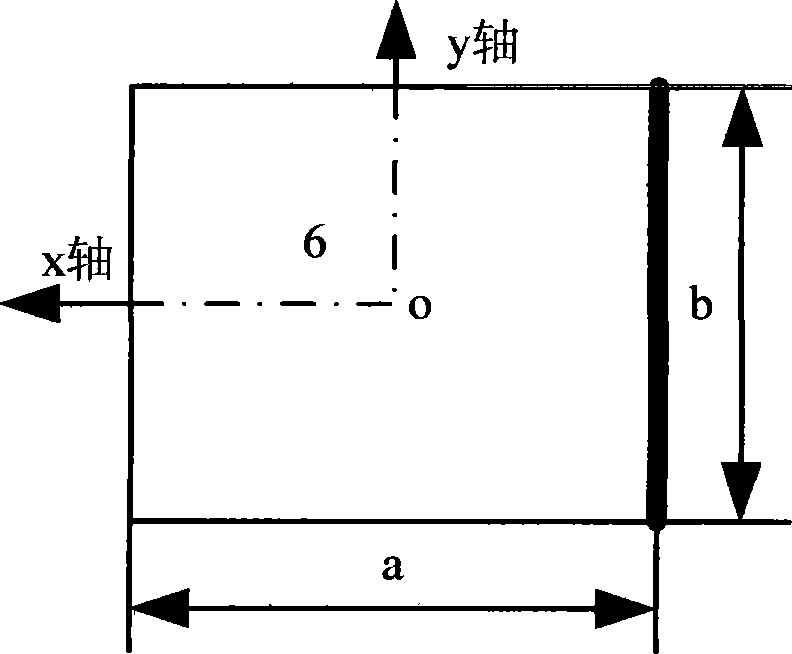

Tiny satellite formation flying control method based on atmospheric drag and control device

InactiveCN101381004ANo pollution in the processReduce power consumptionCosmonautic vehiclesCosmonautic vehicle trackingAstronauticsPower consumption

The invention provides a control method and a control device used for micro-satellite cluster flying based on atmosphere resistance, and relates to the technical field of micro-aircraft and astronautics measuring and controlling. The signal output terminal of a GPS receiver is connected with the signal input terminal of a track determining device; the signal output terminals of a solar battery array and a three-axis magnetometer are connected with the input terminal of an attitude fusion filter; the output terminal of the three-axis magnetometer is connected with the input terminal of a pure magnetic measuring attitude fusion filter; the signal output terminal of the attitude fusion filter is connected with the second input terminal of a satellite line; the first output terminal of the satellite chain is connected with the input terminal of a cluster formation control law; the second output terminal of the satellite chain is connected with the input terminal of the satellite attitude control law; the formation and attitude of the satellite cluster flying are controlled by controlling a pneumatic plate. The method and the device achieve the objects of long service life of the aircraft, low power dissipation, low cost and no pollution on the basis of atmosphere resistance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

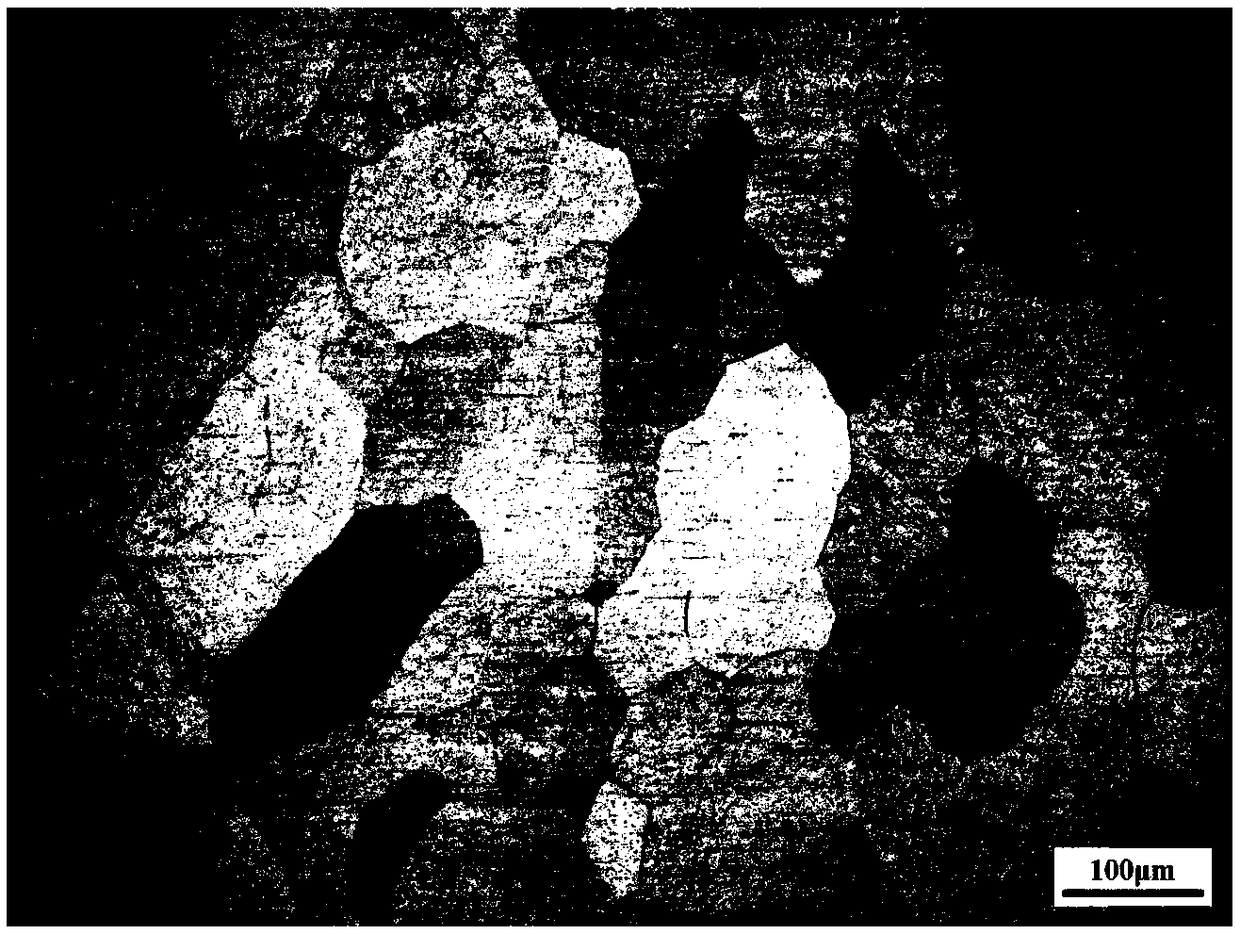

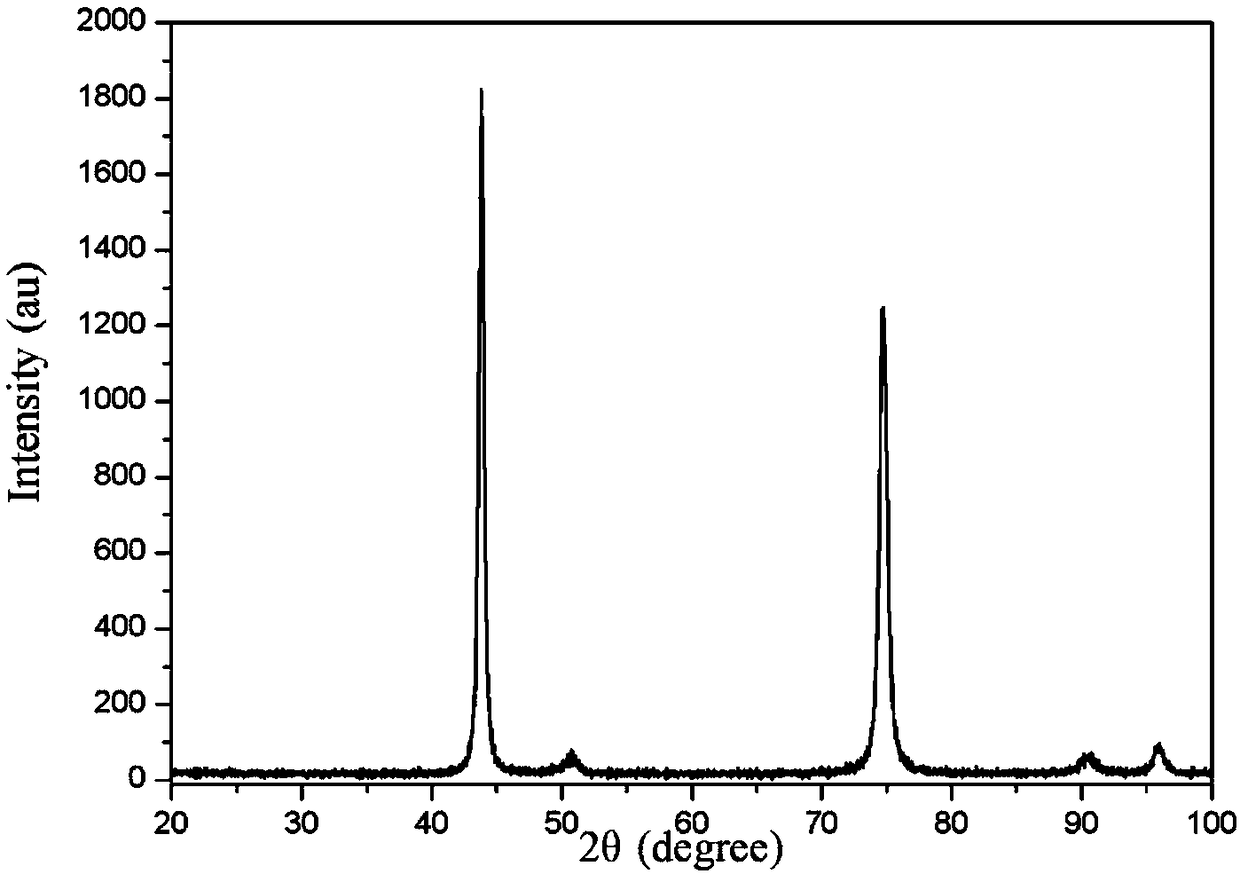

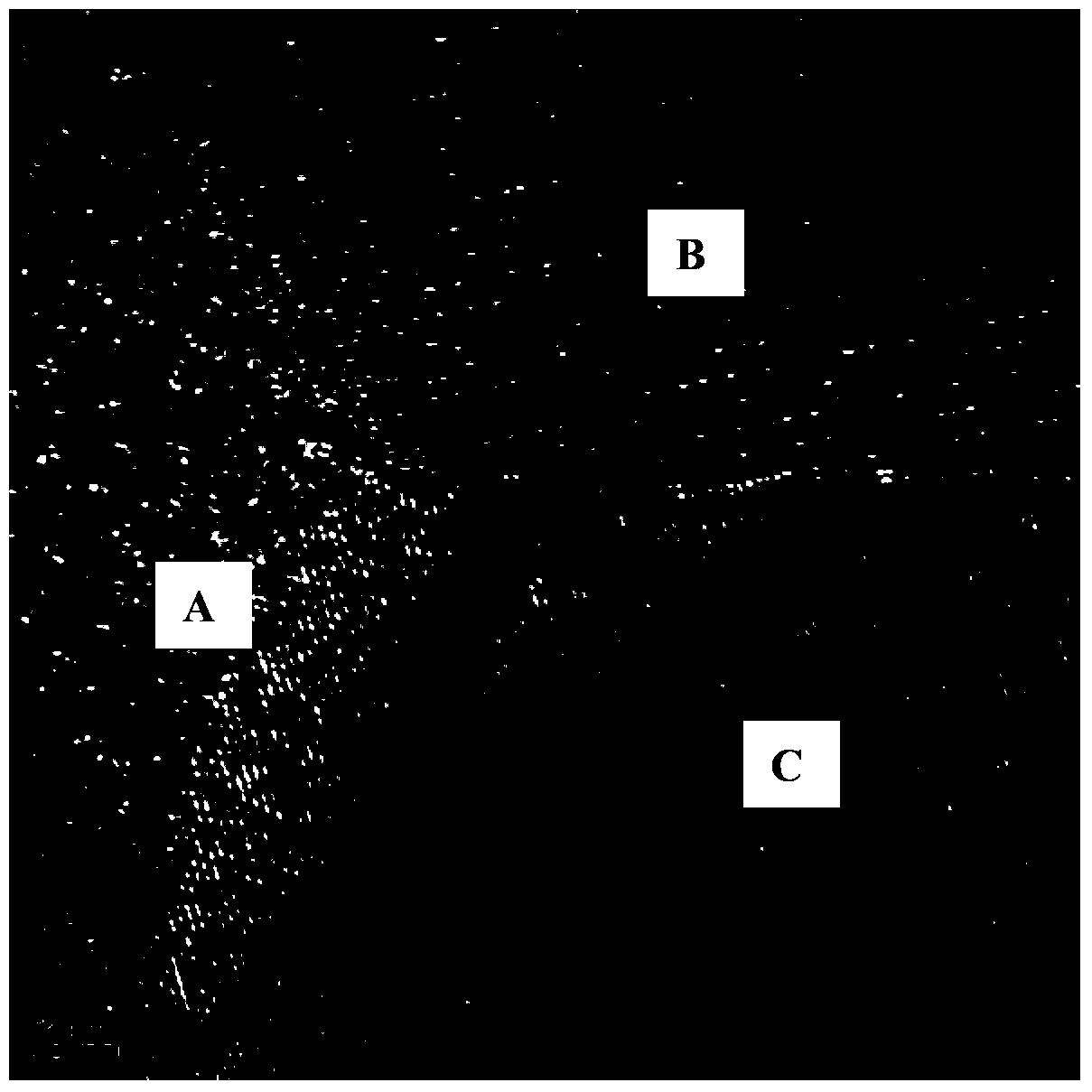

Preparation method of ultra-fine grain high-entropy alloy

The invention belongs to the technical field of metal materials and machining and relates to a preparation method of an ultra-fine grain high-entropy alloy. Firstly, smelting is conducted, an FeCoCrNiMn series high-entropy alloy is compounded to be an intermediate alloy composed of pure metal with the purity being higher than 99.5% or alloy elements, a vacuum furnace is adopted for smelting, and the furnace casting temperature is 1550-1600 DEG C; then after cast ingots are subjected to homogenization heat treatment at the temperature of 1000-1350 DEG C, strong deformation asynchronous and synchronous mixed cold rolling treatment is conducted, continuous rolling is conducted through single-pass large percent reduction, the total rolling quantity is no smaller than 85%, and alloy structure nanocrystallization is achieved; and the rolled alloy is subjected to annealing treatment under the temperature of 450-800 DEG C, and the high-entropy alloy of an ultra-fine grain structure is obtained. Compared with the prior art, the preparation method is simple in technique, easy to achieve on a plate rolling production line, high in production efficiency and low in cost; and the size of the prepared ultra-fine grain high-entropy alloy is large, the comprehensive mechanical performance is excellent, and the preparation method can be applied to the fields of engineering machinery, aeronauticsand astronautics, military industry, electronics, instruments and the like.

Owner:SHANGHAI JIAO TONG UNIV

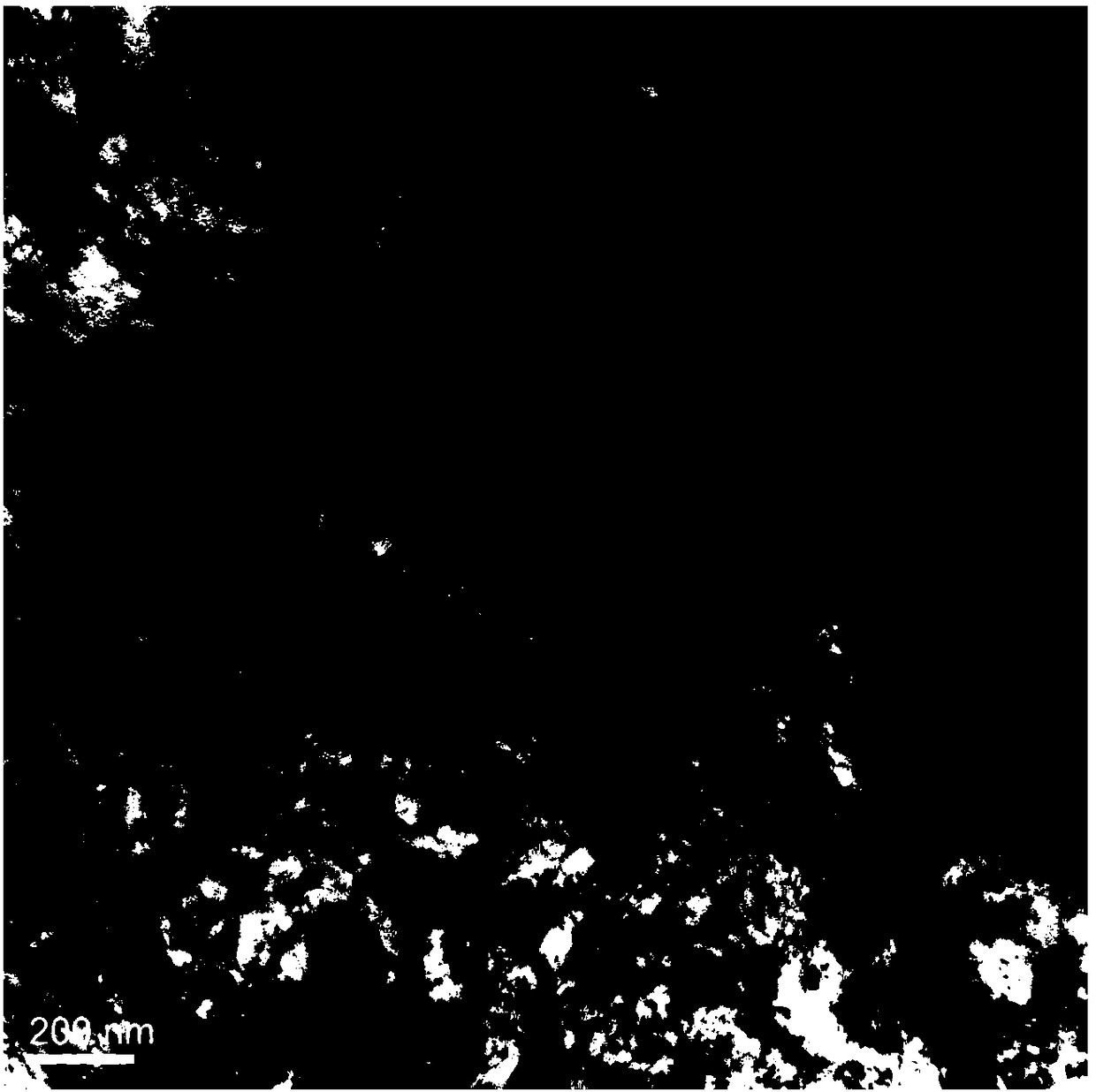

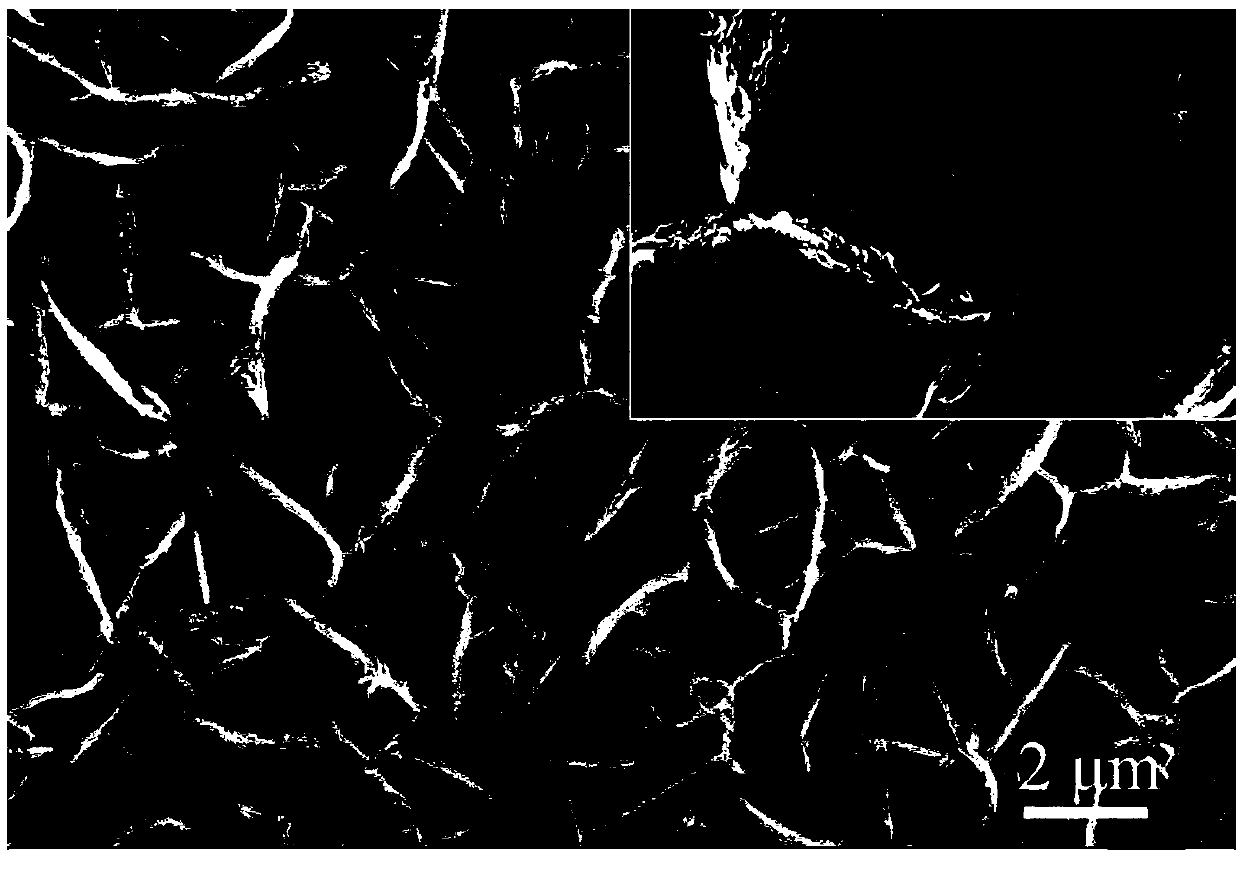

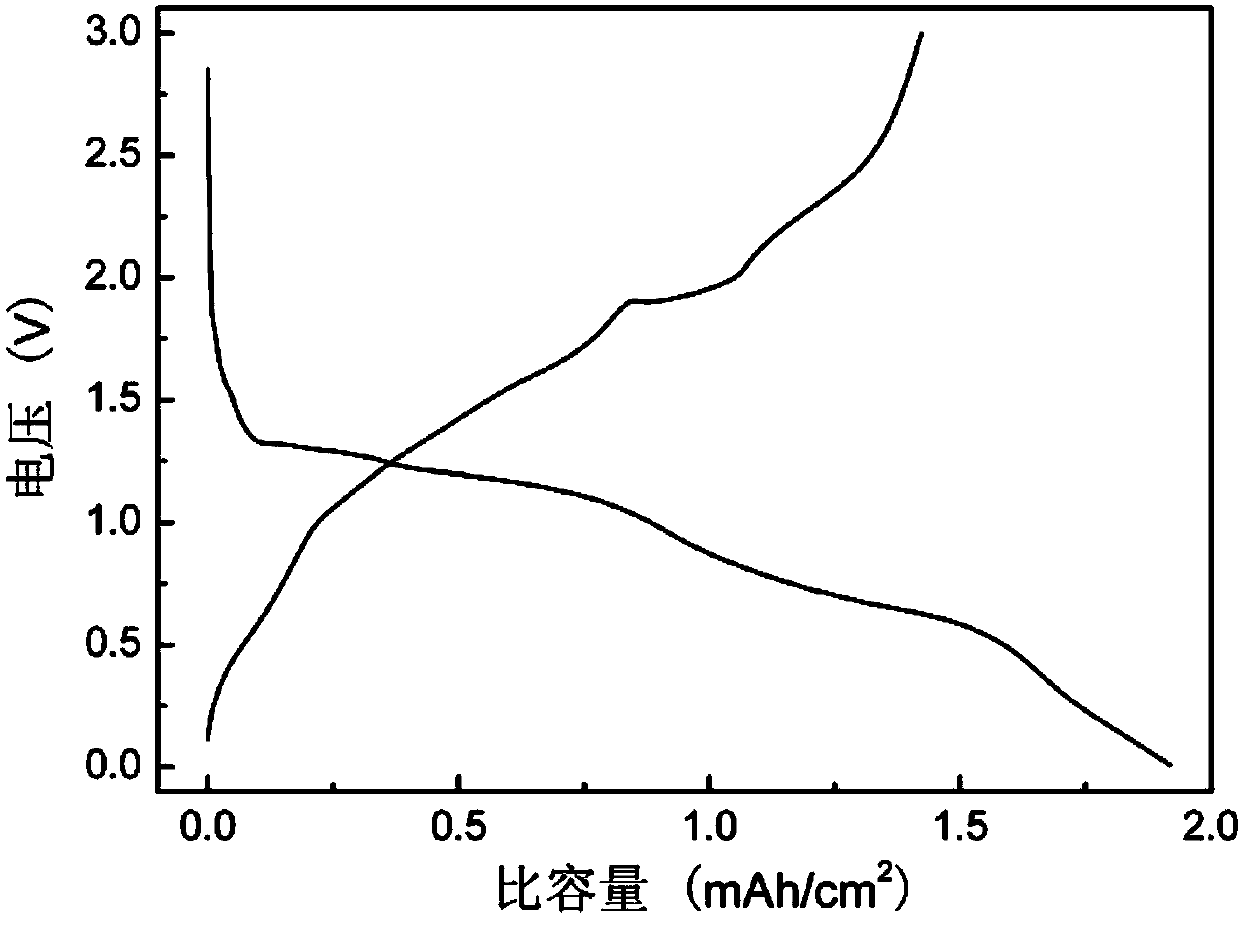

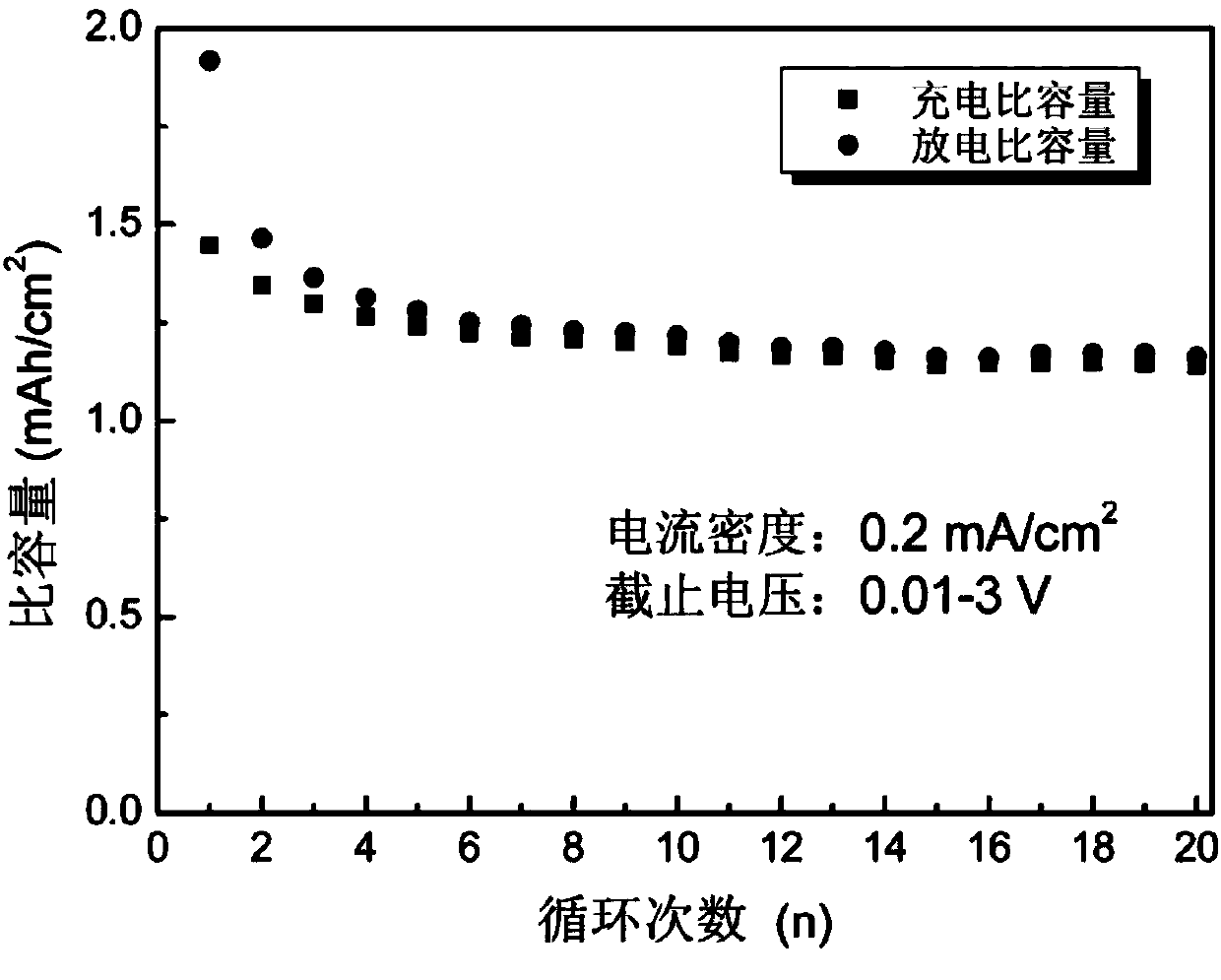

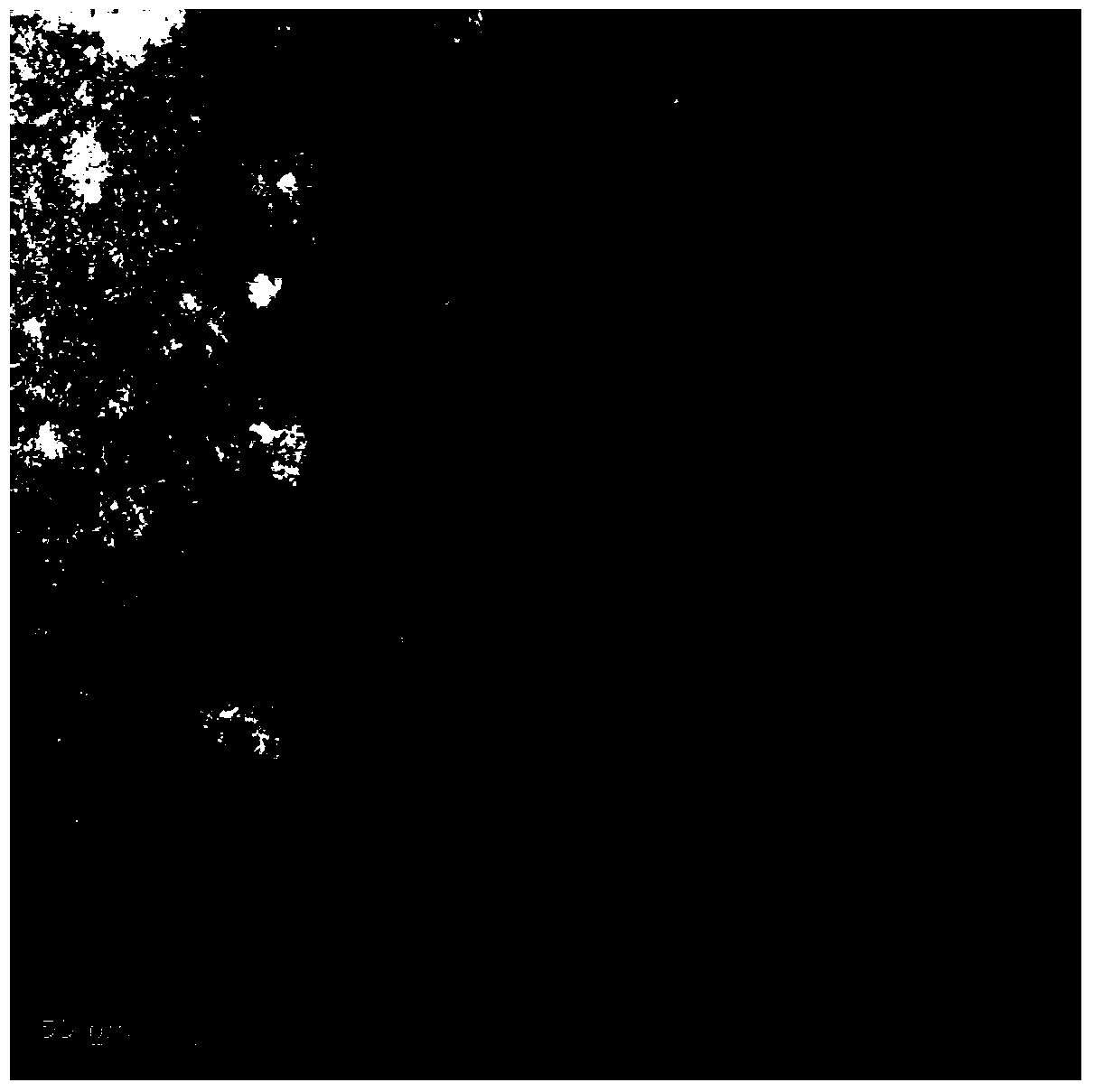

Preparation method of nano Ni3S2 material with lamellar structure

InactiveCN104201380AImprove electrochemical performanceSmall particle sizeMaterial nanotechnologyCell electrodesPolymer adhesiveAstronautics

The invention discloses a preparation method of a nano Ni3S2 material and belongs to the field of novel energy resources and electrochemistry. The preparation method of the nano Ni3S2 material is characterized by synthesizing the nano Ni3S2 material by taking a Ni net with a three-dimensional porous structure by virtue of a solvothermal method. A nano Ni3S2 active substance formed during the solvothermal process is directly loaded on an upper matrix of the Ni net, so that the active substance Ni3S2 is in relatively firm contact with a Ni net of a current collector; gaps of the porous Ni net can effectively buffer the volume change of the Ni3S2 in the processes of removing and embedding lithium, so that the cycle stability of the composite material can be improved; meanwhile, by virtue of a three-dimensional conductive network of the Ni net, the electronic conductivity of the composite material can be improved, so that the rate performance of the material is improved. The preparation method of the nano Ni3S2 material is simple, green, free from pollution, low in cost and suitable for industrial production. The Ni3S2 material prepared by adopting the method is small in particle size and uniform in particle distribution; according to an electrode prepared from the material, a polymer adhesive and a conductive agent do not need to be added in the electrode; the electrode has the high electrochemical performance and can be widely used in the fields of various portable electronic devices, electric automobiles, aeronautics and astronautics, and the like.

Owner:UNIV OF SCI & TECH BEIJING

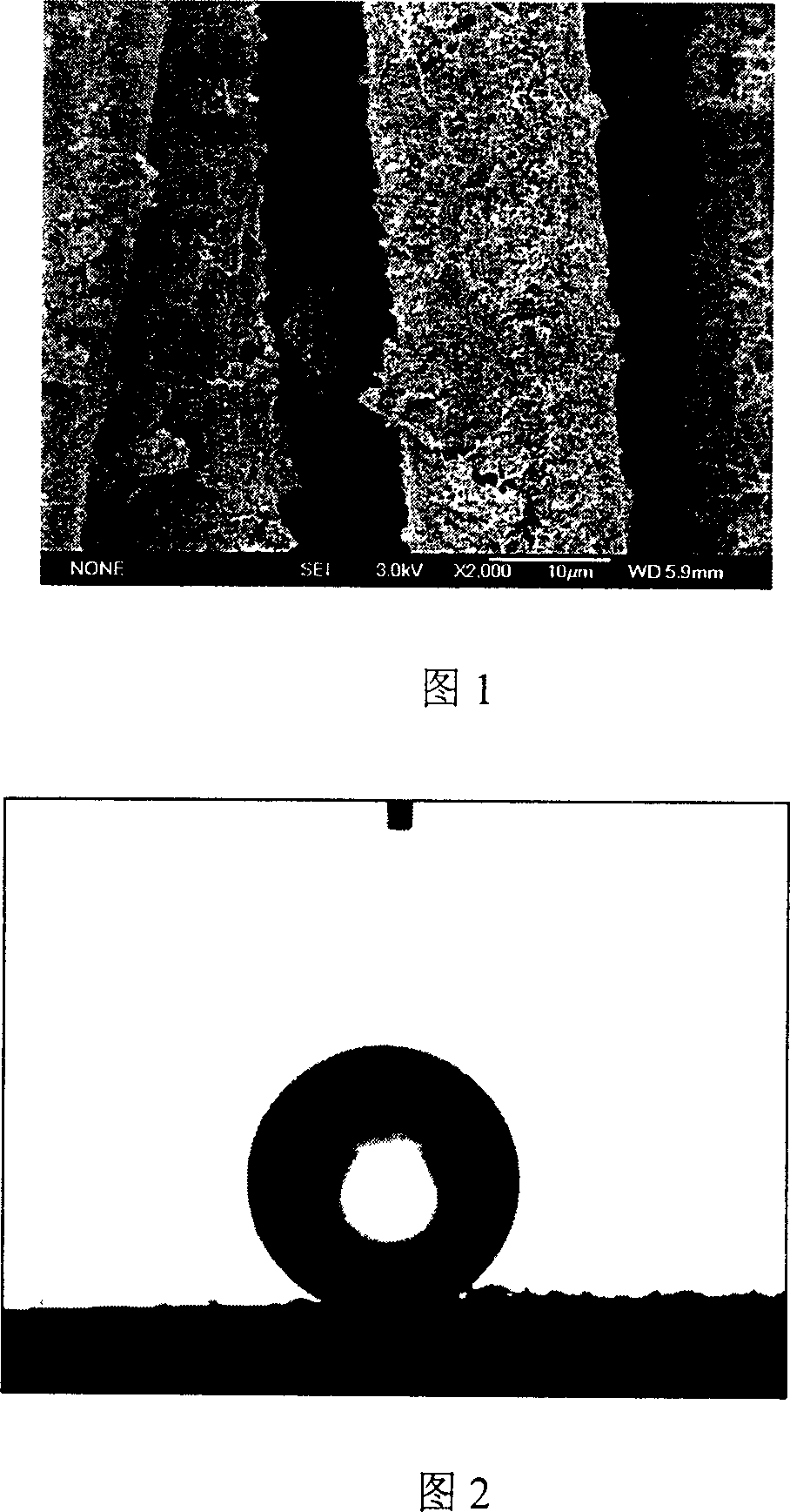

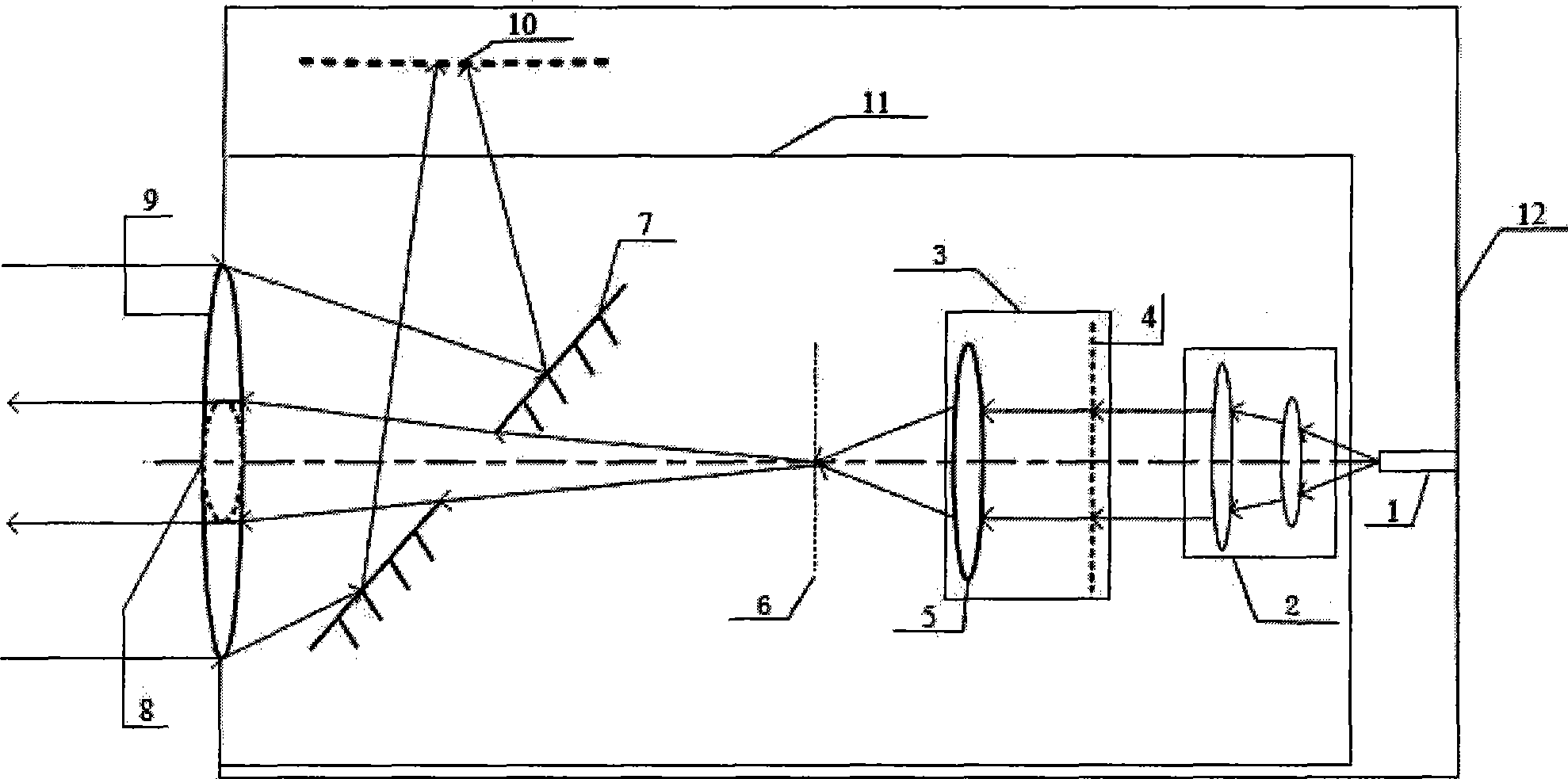

Super-hydrophobic conductive fiber, fabric and preparing method and use

This invention relates to an ultra sparse water conductive fiber. The superficial gable is the fiber of electric conduction polymer which is composed by 20-1000 nanometers thick, diameter of 400-900 nanometer electric conduction high polymer. This fiber is for using electric conduction polymer chemical oxidation position polymerization method in fiber surface gable electric conduction polymer level. This invention also relates to a ultra sparse water electric conduction fabric, it for in the superficial gable a fabris composed of 20-1000 nanometers thick, by the diameter was the electric conduction polymer level fabric which 400-900 nanometer electric conduction high polymer particle. This fabric for use electric conduction polymer chemical oxidation home position polymerization method in fabric surface gable electric conduction polymer level. This invention's fiber or the fabric surface resistance for 200 omega / cm2-300M omega / cm2, the angel contact with water is bigger than 160degree, the roll position is smaller than 14degree. It displays highly clean ability, has the electromagnetic screen, the anti-static electricity, the stealth, the waterproofing, the dustproof function, specially for war industry, astronautics aviation, factory and mining enterprise, health and so on.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Non-scanning 3D imaging laser radar optical system based on APD array

InactiveCN101430377ASimple structureEasy to processElectromagnetic wave reradiationRadar systems3d image

A non-scanning 3D imaging laser radar optical system based on an APD array is arranged in a shell of a laser radar system. The non-scanning 3D imaging laser radar optical system is composed of a laser, a Galilean telescope, an optical splitter, an emitting optical unit consisting of an emitting-receiving spectroscope and an emitting lens with the focal length of f1 and a receiving optical unit consisting of a receiving lens with the focal length of f2 and the emitting-receiving spectroscope; the inner wall of the tail part of the shell of the laser radar system is provided with the laser, the Galilean telescope is arranged in front of the laser, the optical splitter is arranged in front of the Galilean telescope, the emitting-receiving spectroscope is arranged in front of the optical splitter, is a plane mirror with a hole provided at the center thereof, is positioned between a light spot and the receiving lens with the focal length of f1 and placed at 45 degrees to an optical axis, a port on the shell of the laser radar system is provided with the receiving lens with the focal length of f2, the emitting lens is positioned in the hole at the center of the receiving lens, and the emitting-receiving spectroscope reflects beams at 90 degrees to a detector at a focal plane position of the receiving lens. The optical system has simple structure and high accuracy, and can be applicable to the fields of plotting, navigation and astronautics.

Owner:BEIHANG UNIV

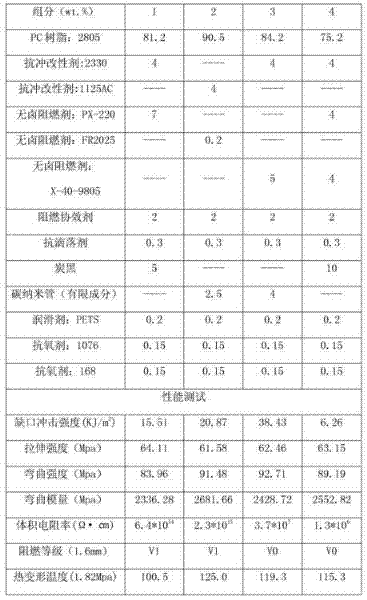

Halogen-free inflaming-retarding conductive PC resin composition, and preparation method thereof

InactiveCN102250460AGood physical propertiesImprove flame retardant performanceNon-conductive material with dispersed conductive materialConductive materialsAstronautics

The invention relates to a halogen-free inflaming-retarding conductive PC resin composition, and a preparation method thereof. The composition is prepared from raw materials of, by weight: 40 to 95% of PC resin, 1 to 10% of an impact modifier, 2 to 15% pf a halogen-free inflaming retardant, 1 to 10% of an inflaming retardant synergist, 0.1 to 1.5% of an anti-dripping agent, 1 to 15% of a conductive material, 0.1 to 2% of a lubricant, and 0.1 to 1% of an anti-oxidant. PC resin is dried in an air dry oven at a temperature of 120 DEG C for 2 to 4 hours; raw materials weighed according to the weight ratio are mixed in a low-speed mixer for 3 to 5 minutes; the mixed raw material is added to a hopper of a twin screw extruder, and is fused, extruded, and granulated. According to the invention, excellent physical properties of PC resin are maintained, and the composite has good inflaming-retarding performance and conductivity. The halogen-free inflaming-retarding conductive PC resin composition can be widely applied in industries of automobiles, astronautics and aerospace, and electronics and electrics.

Owner:MILESTONE CORP

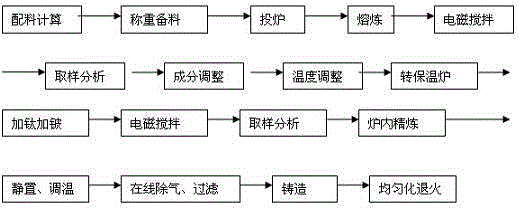

Super-large-sized high-magnesium-content aluminum-alloy slab ingot and preparation method thereof

The invention provides a super-large-sized high-magnesium-content aluminum-alloy slab ingot of which the maximum thickness reaches 1,000mm, the maximum width reaches 2,670mm and the maximum length reaches 8,000mm, and a preparation method thereof. The slab ingot is prepared from the following ingredients in percentage by mass: lower than 0.35% of Si, lower than 0.35% of Fe, lower than 0.15% of Cu, 0.20-1.0% of Mn, 4.0-6.5% of Mg, lower than 0.25% of Cr, lower than 0.25% of Zn, lower than 0.15% of Ti, lower than 0.005% of B, Al and the like. According to the method provided by the invention, the casting stress of the slab ingot is eliminated, the microscopic structure of alloy is uniform, the crystal grain is fine, the cast ingot is flawless, and the mechanical properties of the cast ingot are good. After the large-sized slab ingot is subjected to homogenizing treatment, the slab ingot is divided into thick plates or ingot bars with the thickness of 10-1,000mm through machining, is applied to rolling, mold manufacturing and other machined parts and is extensively applied to the fields of tools / dies, traffic, transportation, aeronautics / astronautics, shipbuilding, vehicles and the like.

Owner:广西南南铝加工有限公司

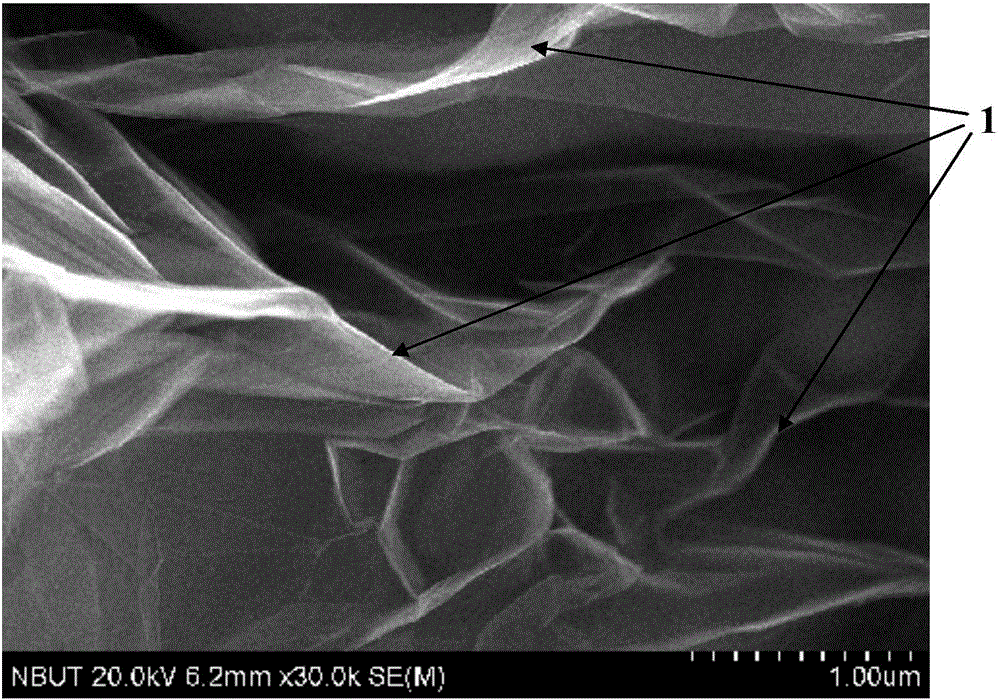

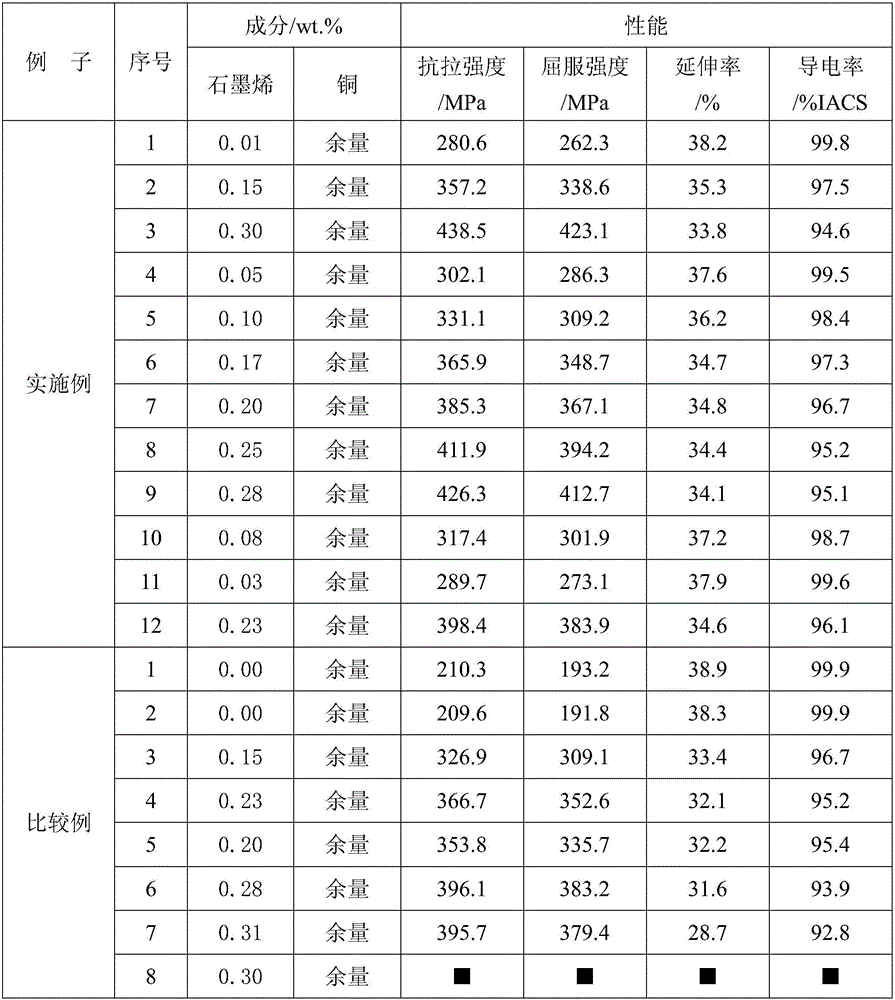

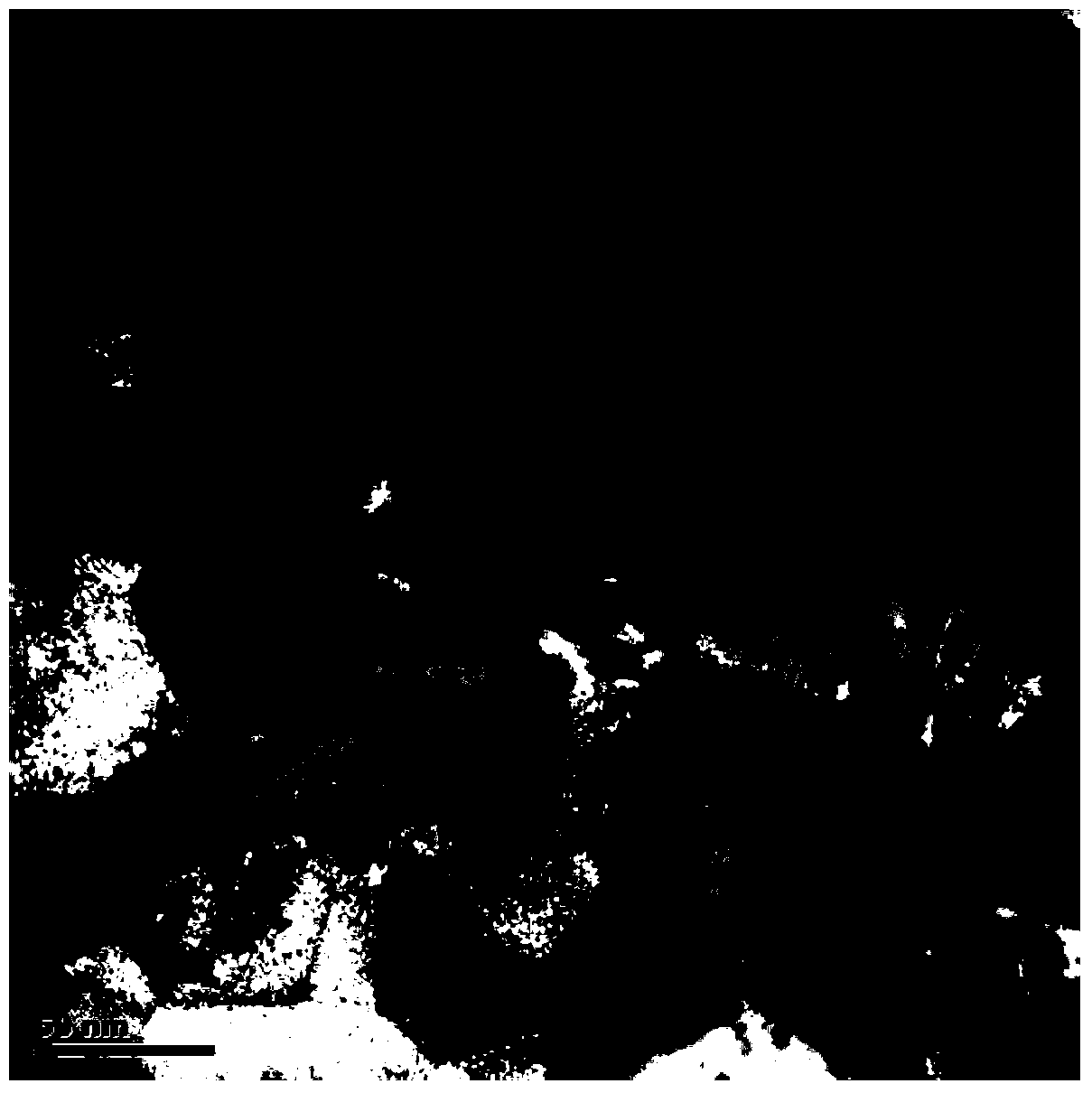

Copper-graphene composite material and preparation method thereof

ActiveCN105714139APrevent oxidationControllable distribution densityLead frameUltimate tensile strength

The invention relates to a copper-graphene composite material and a preparation method thereof. The copper-graphene composite material comprises graphene and copper, and is characterized in that the graphene is evenly distributed in a copper matrix in a sheet structure; distribution density of the graphene is 100 sheets per square centimeter to 3000 sheets per square centimeter; and preferably, the content of the graphene is 0.01 wt% to 0.30 wt%, and the balance is Cu. The copper-graphene composite material disclosed by the invention is prepared by adding the graphene into the copper; the copper matrix can be served as an electrical conduction main body to enable electrical conductivity of the composite material to be close to pure copper, and the graphene is served as a reinforcement phase, so that tensile strength performance and yield strength performance are both increased; therefore the copper-graphene composite material can be widely applied to the fields of consumer electronics, electrics, aeronautics and astronautics, high-speed rails, lead frames, electronic connector preparation; and the preparation method provided by the invention is suitable for industrial and scale production.

Owner:NINGBO POWERWAY ALLOY MATERIAL

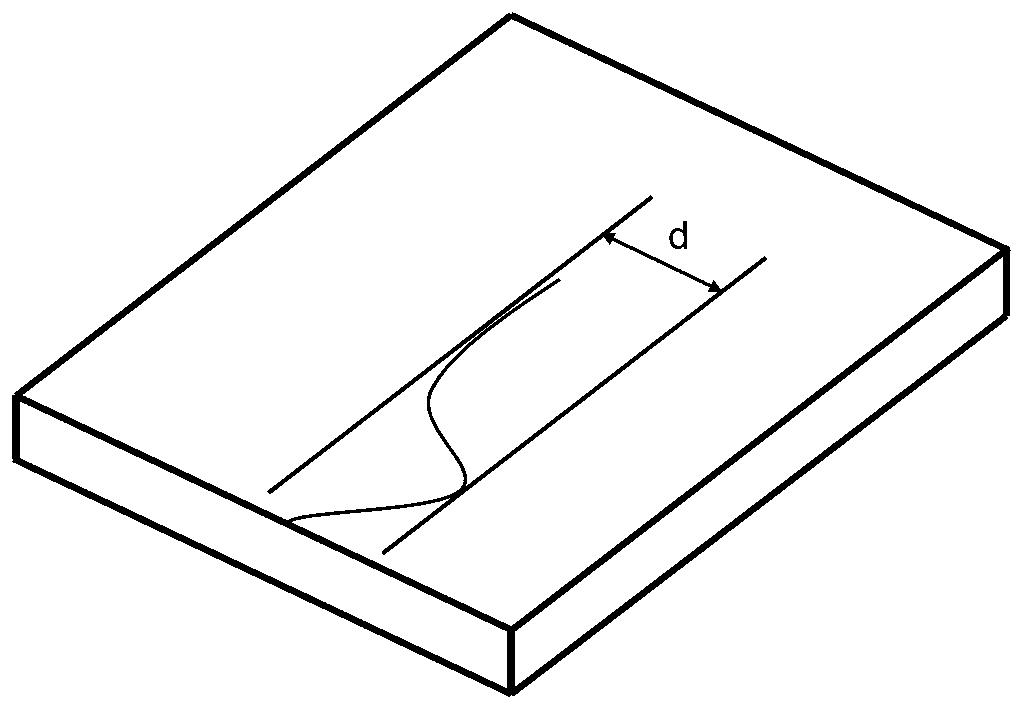

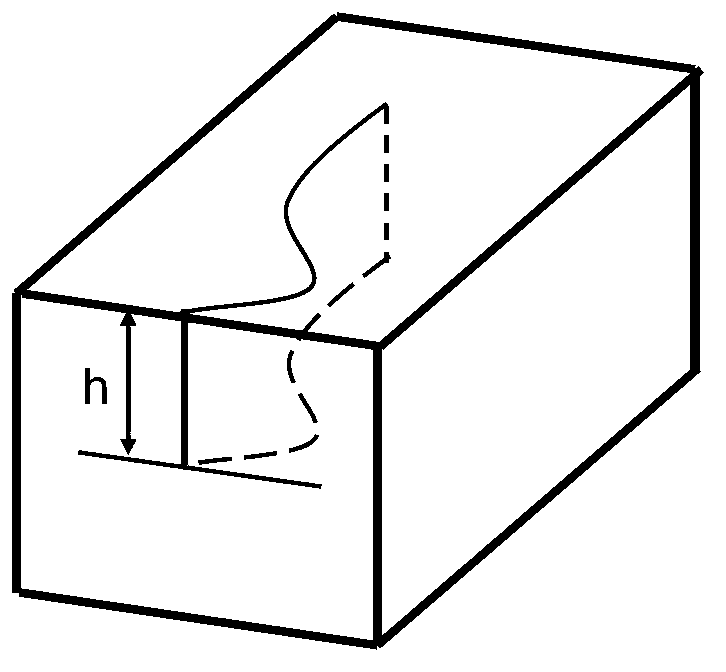

Stirring-friction-based crack repair method

InactiveCN103212778AReduce distortionReduce stressNon-electric welding apparatusUltimate tensile strengthAstronautics

The invention relates to a stirring-friction-based crack repair method which mainly is used for solving the problems in the prior art that the repair cost is high, the repair quality is poor and cracks appear repeatedly. The method is applied to the repair of surface cracks and through cracks of plate-shell metal structures, so as to enable cracked workpieces to meet reuse requirements. The method comprises the following specific steps of designing and manufacturing a friction repair tool according to the position and size of a crack, a material to be repaired, structural characteristics and the like; and realizing the friction between a shaft shoulder and the surface of the material to be repaired through the rotation of the repair tool so as to enable metal of a repair area to reach a thermoplastic state under the action of frictional heat, and realizing the flowing transfer and dynamic recrystallization of thermoplastic metal around the crack by using the rotating and upsetting action of the shaft shoulder of the repair tool, thereby realizing the filling repair of the crack. The method has the advantages that the method is simple, the damage to base metal is little, the quick, equal-strength and in-situ repair of engineering cracks can be realized, and the repair process is economical and environment-friendly. The method can be applied to the crack repair in fields, such as aeronautics and astronautics, shipbuilding, automobiles and rail transportation and has broad application prospects.

Owner:SHENYANG AEROSPACE UNIVERSITY

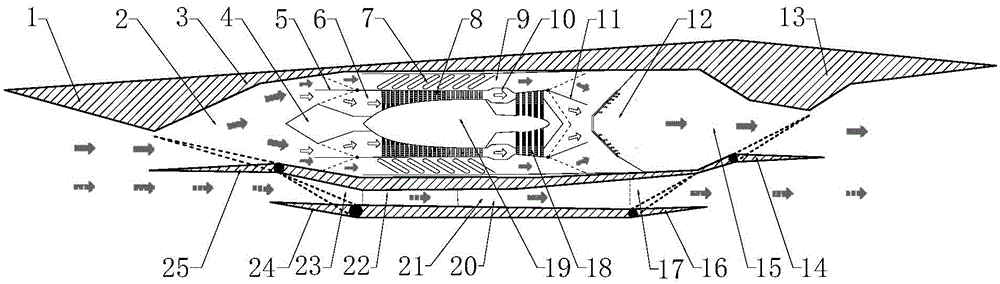

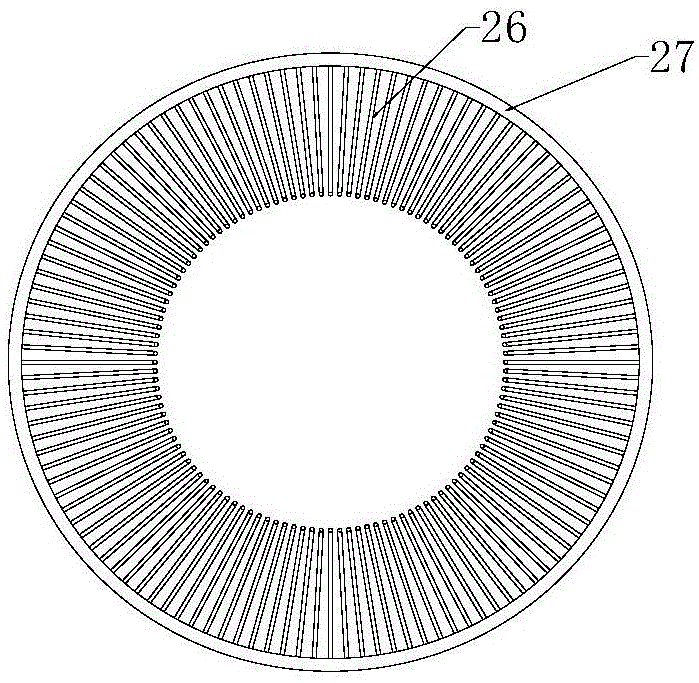

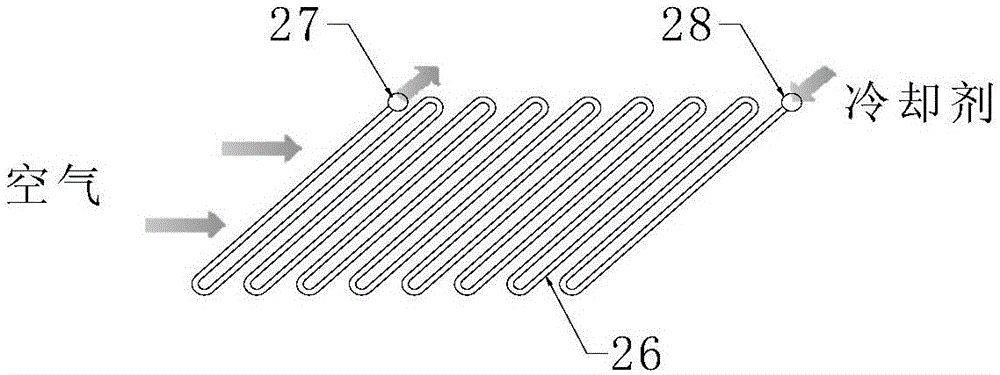

Pre-cooling air-breathing type variable cycle engine

InactiveCN105156227ALower airflow temperatureReduce the temperatureTurbine/propulsion engine coolingGas turbine plantsRamjetCombustion chamber

The invention discloses a pre-cooling air-breathing type variable cycle engine and relates to the reusable pre-cooling air-breathing type variable cycle engine applied to aeronautics and astronautics devices. The engine mainly consists of a pre-cooler, a turbine engine, a super combustion chamber and a super combustion ramjet engine, wherein the pre-cooler and the super combustion chamber form a subsonic combustion ramjet engine; a turbine subsonic combustion ramjet engine is connected with the super combustion ramjet engine in parallel; working states of the turbine subsonic combustion ramjet engine and the super combustion ramjet engine are selected by adjusting a switching adjusting device, so that the working modal of the whole engine is controlled. The pre-cooler can reduce an inlet gas flow temperature of a super combustion chamber, can increase the efficiency of the super combustion chamber, can expand the working range of a subsonic combustion punching modal, and can make up insufficient thrust force when turbine subsonic combustion ramjet engine is transferred to the super consumption ramjet engine, so that the pre-cooling air-breathing type variable cycle engine has the advantage that the transfer class of a combined engine is stably transferred.

Owner:TSINGHUA UNIV

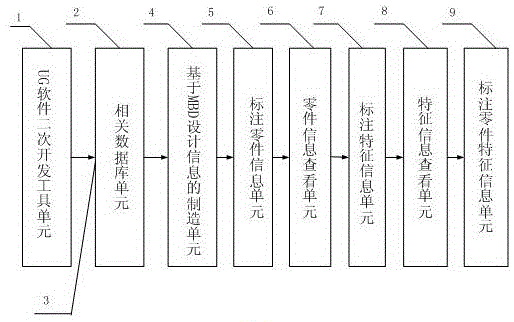

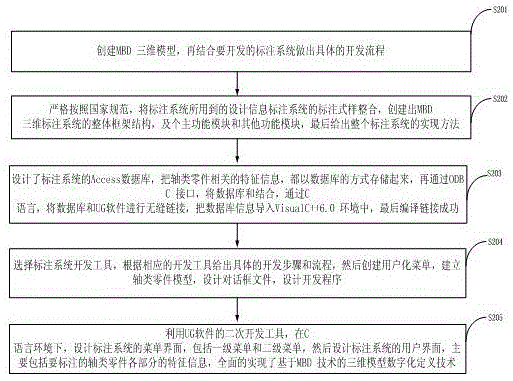

MBD based three-dimensional model design information tagging system and method

InactiveCN105005653AReduce the probability of participation errorsReduce digital system requirementsSpecial data processing applicationsDesign informationManufacturing cell

The invention discloses an MBD based three-dimensional model design information tagging system and method. The system comprises a related database unit, a MBD design information based manufacturing unit, an ODBC interface, a UG software secondary development tool unit, a marking part information unit, a part information viewing unit and a marking feature information unit. The method comprises steps of: firstly, creating an overall framework of an MBD three-dimensional marking system, a main function module and other function modules; designing an Access database of the marking system, and performing seamless connection between the database and the UG software through the ODBC interface; introducing database information into Visual C ++ 6.0 environment; creating a customized menu, establishing a shaft parts model, designing a dialog file and designing a development program; and designing a user interface of the marking system by using a secondary development tool of the UG software. According to the system and method provided by the invention, the accuracy and comprehensiveness of the data can be ensured, and the system and method can be more applicable to related development technologies of technology modernization in the aeronautics and astronautics fields.

Owner:XIAN TECH UNIV

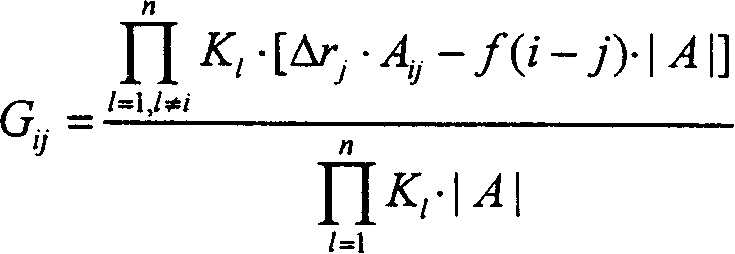

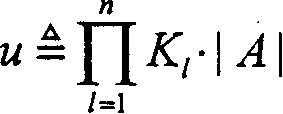

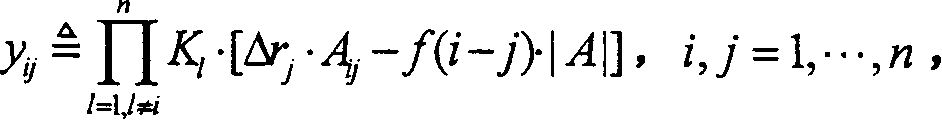

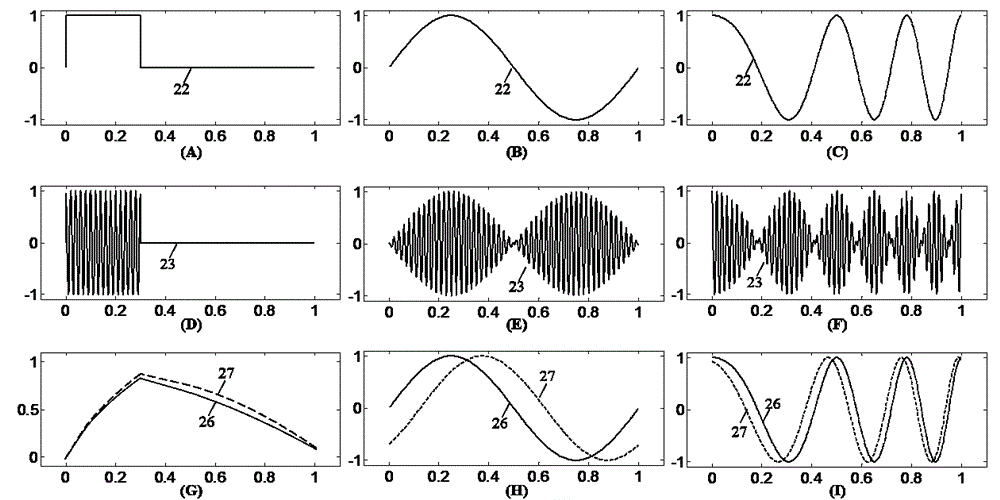

Multi-varible system structural colsed-loop distinguishing method based on step response test

InactiveCN1487268ARealize real-time online identificationSmall running impactAdaptive controlSpecial purpose recording/indication apparatusAviationTransfer function matrix

The present invention belongs to the field of multi-variable system application technology. Via one set of simple and practical step response test, the distinction in powerfully coupled multi-variable system is amalyzed into the distinction in several single-in single-out systems so as to obtain precise transfer function model of the multi-variable system. Specially, the process includes four steps of initialization, step response test, synthesis of multi-variable process and parameter distinction in synthesized subprocess. The present invention can realize the real-time on-line distinction of the multi-variable system, and has less impact of step test signal required for system distinction on the normal operation of the control system and no special requirement of distinction algorithm in signal amplitude. The method of the present invention is suitable for industrial process control, robot, aeronautics, astronautics and other multi-variable systems.

Owner:SHANGHAI JIAO TONG UNIV

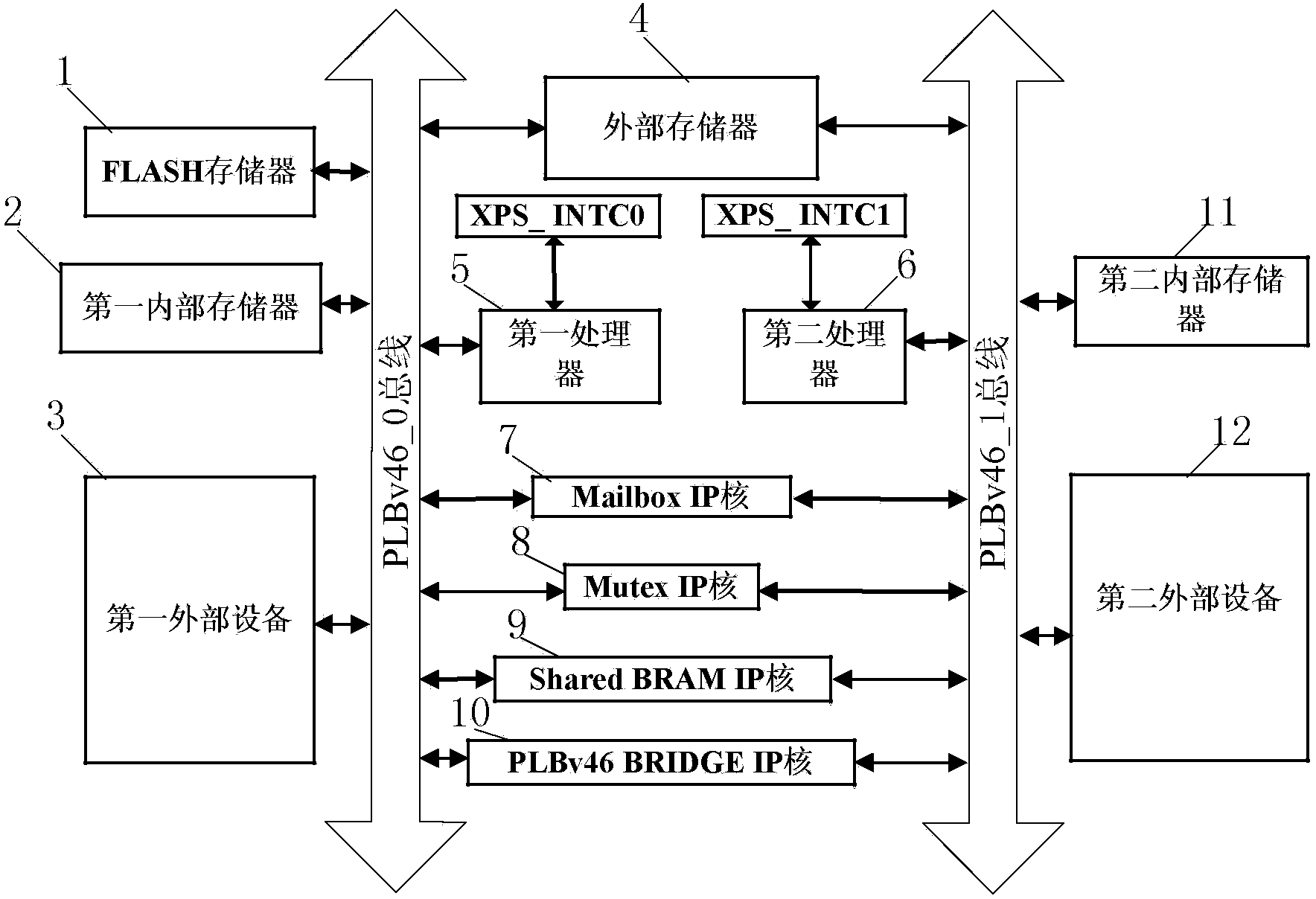

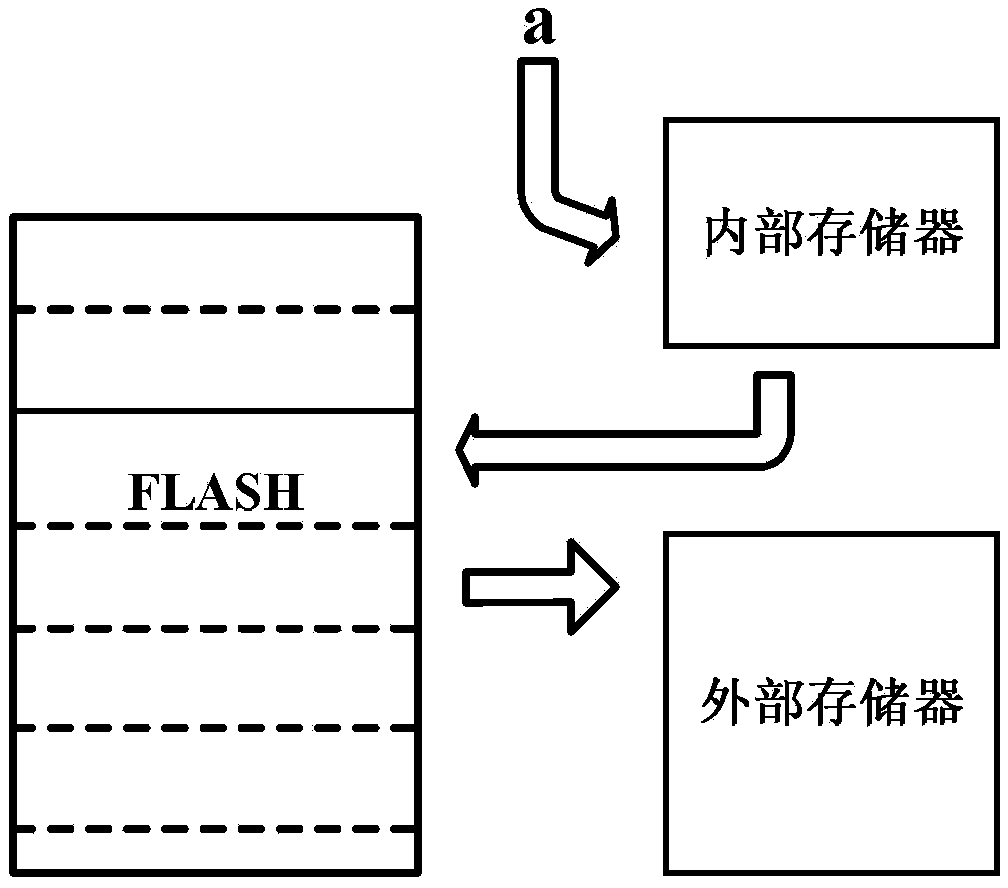

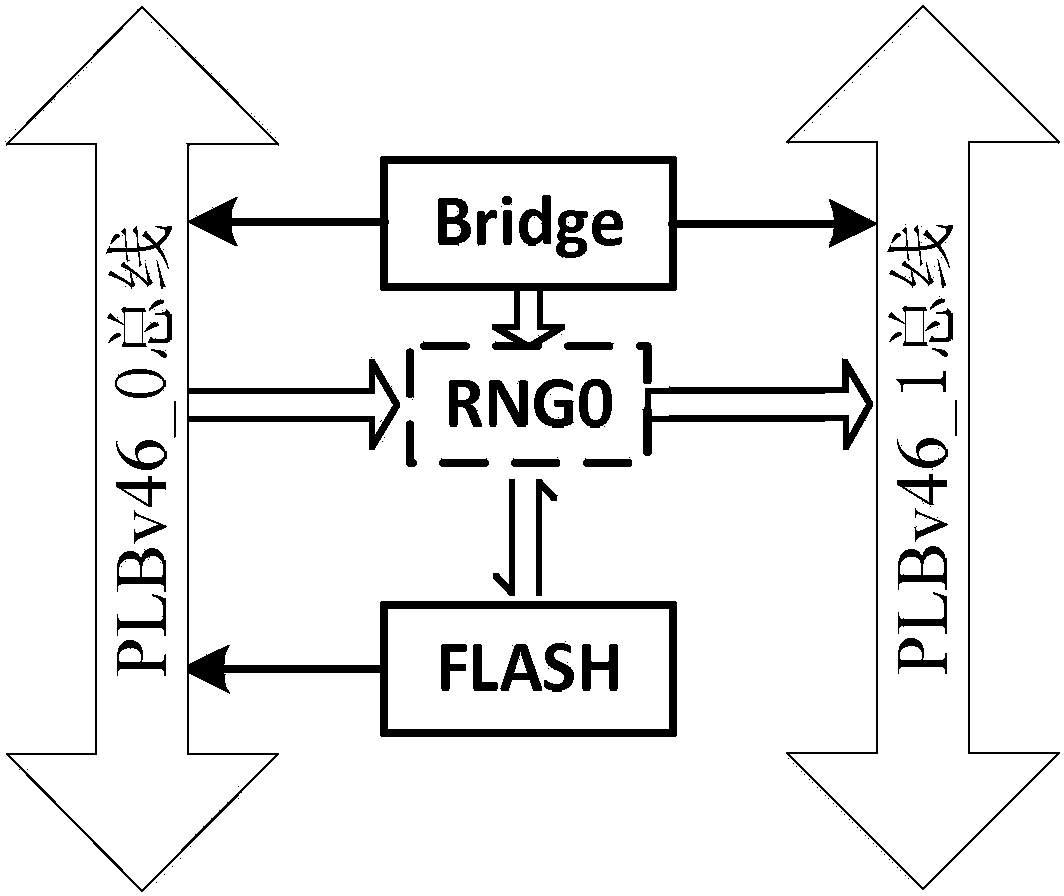

Autonomous configuration method for FPGA (field programmable gate array)-based embedded dual-core system

InactiveCN103744713AImplement storageRealize the loadProgram loading/initiatingHardware structureDual core

The invention discloses an autonomous configuration method for an FPGA (field programmable gate array)-based embedded dual-core system, belongs to the field of embedded systems, and aims to solve the problem of incapability of a conventional FPGA-based embedded dual-core system in the autonomous storage and loading of a configuration file. The method comprises the following steps of enabling two PLBs (processor local buses) to share a FLASH memory by using a PLBv46BRIDGE IP core, designing a hardware structure of the dual-core system in Xilinx Platform Studio, generating a bit stream file, programming the bit stream file in the FLASH memory in Xilinx Software Development Kit, moving an executable file in the FLASH memory into an external memory for execution by using a bootstrapper after the system is powered on or reset, and stopping running the system until a stopping marker bit is discovered. The method can be used for aeronautics and astronautics, consumer electronics, communication, instruments and apparatuses, military equipment and industrial control.

Owner:HARBIN INST OF TECH

Method for preparing high-strength and high-conductivity copper-based alloy coating by means of laser-induction hybrid cladding

InactiveCN102912342AOvercoming the problem of easy oxidation at high temperatureHigh thermal conductivityMetallic material coating processesEconomic benefitsAlloy coating

The invention discloses a method for preparing a high-strength and high-conductivity copper-based alloy coating by means of laser-induction hybrid cladding, which is characterized by comprising the following steps of: firstly, performing chemical nickel-plating treatment on a special copper-based alloy powder to form a nickel-coated copper-based alloy powder with a core-shell structure; secondly, performing oil removal, rust removal, surface activation and chemical nickel-plating treatment on the surface of a matrix; and finally, preparing the high-conductivity copper-based alloy coating on the surface of the matrix by means of laser-induction hybrid cladding. The method disclosed by the invention has the advantages of being high in machining efficiency, low in cost, good in technical and economic benefits, and has a wide application prospect in the surface reinforcement and repair of fields of aeronautics, astronautics, automobile, metallurgy, electricity and the like, in which aluminium and aluminium alloy, magnesium and magnesium alloy, and copper and copper alloy are widely used.

Owner:NANCHANG HANGKONG UNIVERSITY

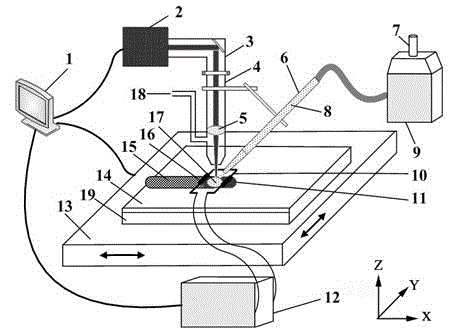

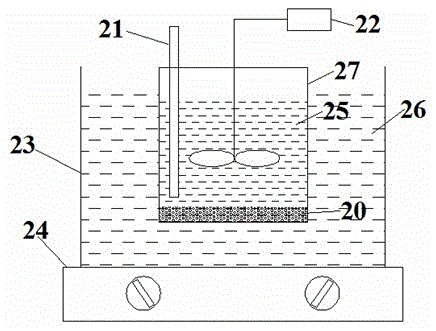

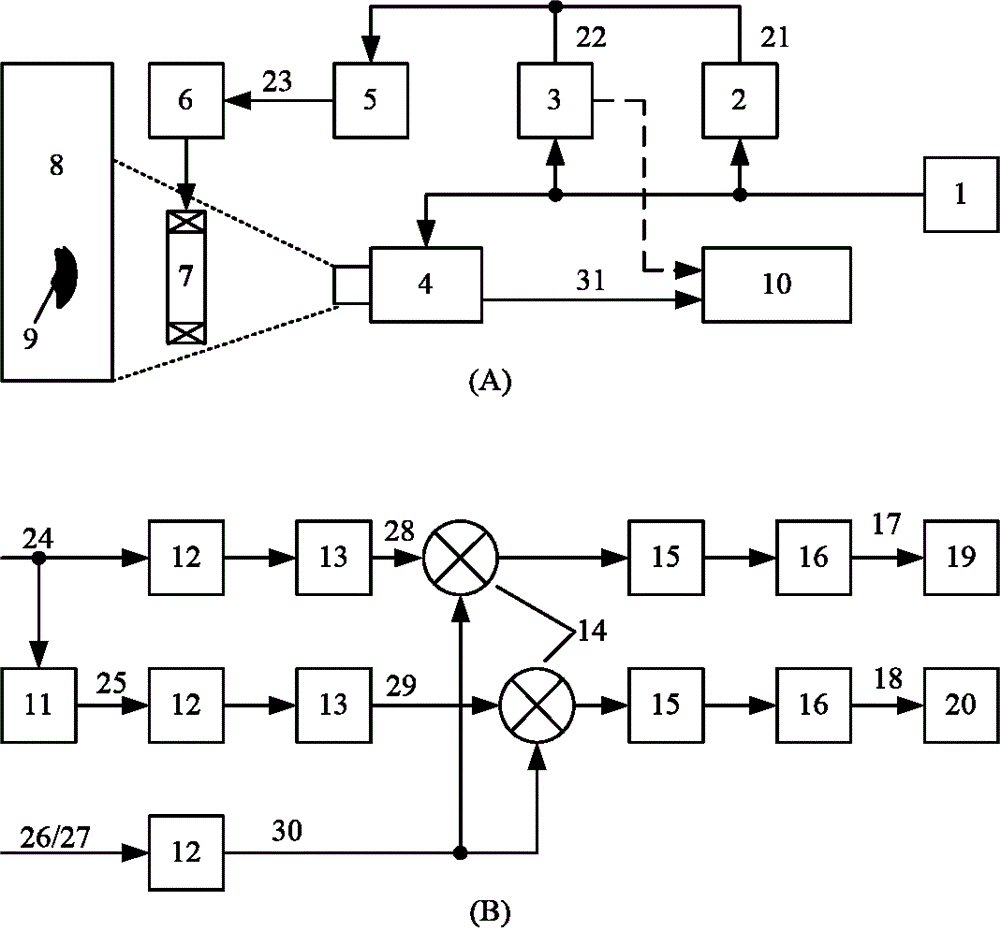

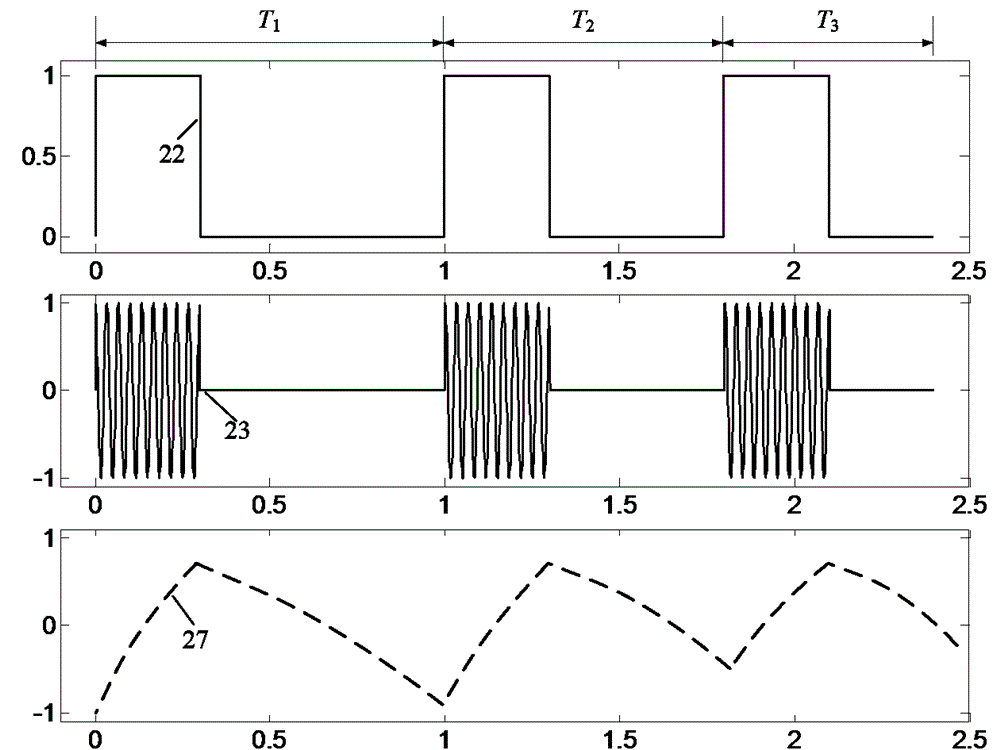

Cross-correlation eddy current thermal imaging defect detection and tomography method and cross-correlation eddy current thermal imaging defect detection system

ActiveCN104535615AEasy to detectEnhanced tomographyMaterial flaws investigationNuclear powerStructural health monitoring

The invention discloses a cross-correlation eddy current thermal imaging defect detection and tomography method and a cross-correlation eddy current thermal imaging defect detection system. The system can work in the pulse mode, phase-lock mode, frequency modulating mode, phase modulating mode and other modes to generate different modulation signals, a high-frequency AC signal is modulated to generate different excitation signals so as to realize induction heating of a detected object, and at the same time, the time-dependent temperature information on the surface of the detected object is recorded to serve as detection data. A specific signal is adopted or is generated to serve as a reference signal, and the detection data and the reference signal are subjected to cross-correlation algorithm to realize pulse compression so as to obtain matching information such as phase coincidence, orthogonality, amplitude value and phase position of the detection data and the reference signal at different moments. Characteristic values are extracted from the matching information, the detection signal-to-noise ratio is enhanced, the internal defect detection capability is improved, change of surface emissivity is inhibited, and tomography of the detected object is realized. The method and the system can be applied to equipment nondestructive detection, material representation evaluation, product quality control and structural health monitoring in the fields of aeronautics and astronautics, new materials, petrochemical engineering, nuclear power, railways, automobiles, special equipment, machinery, metallurgy, civil construction and the like.

Owner:WUXI DOUBLE HORSE DRILLING TOOLS

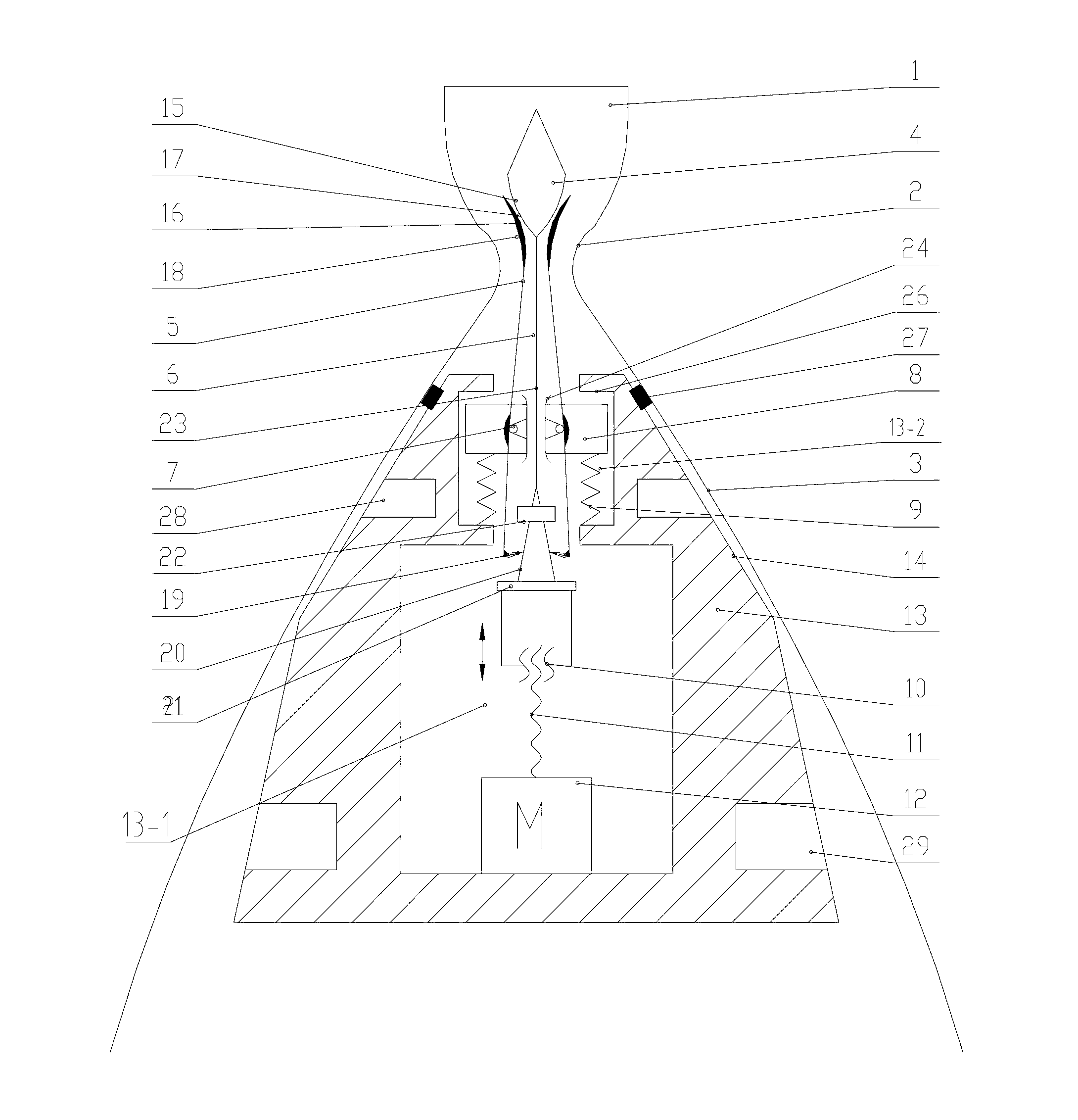

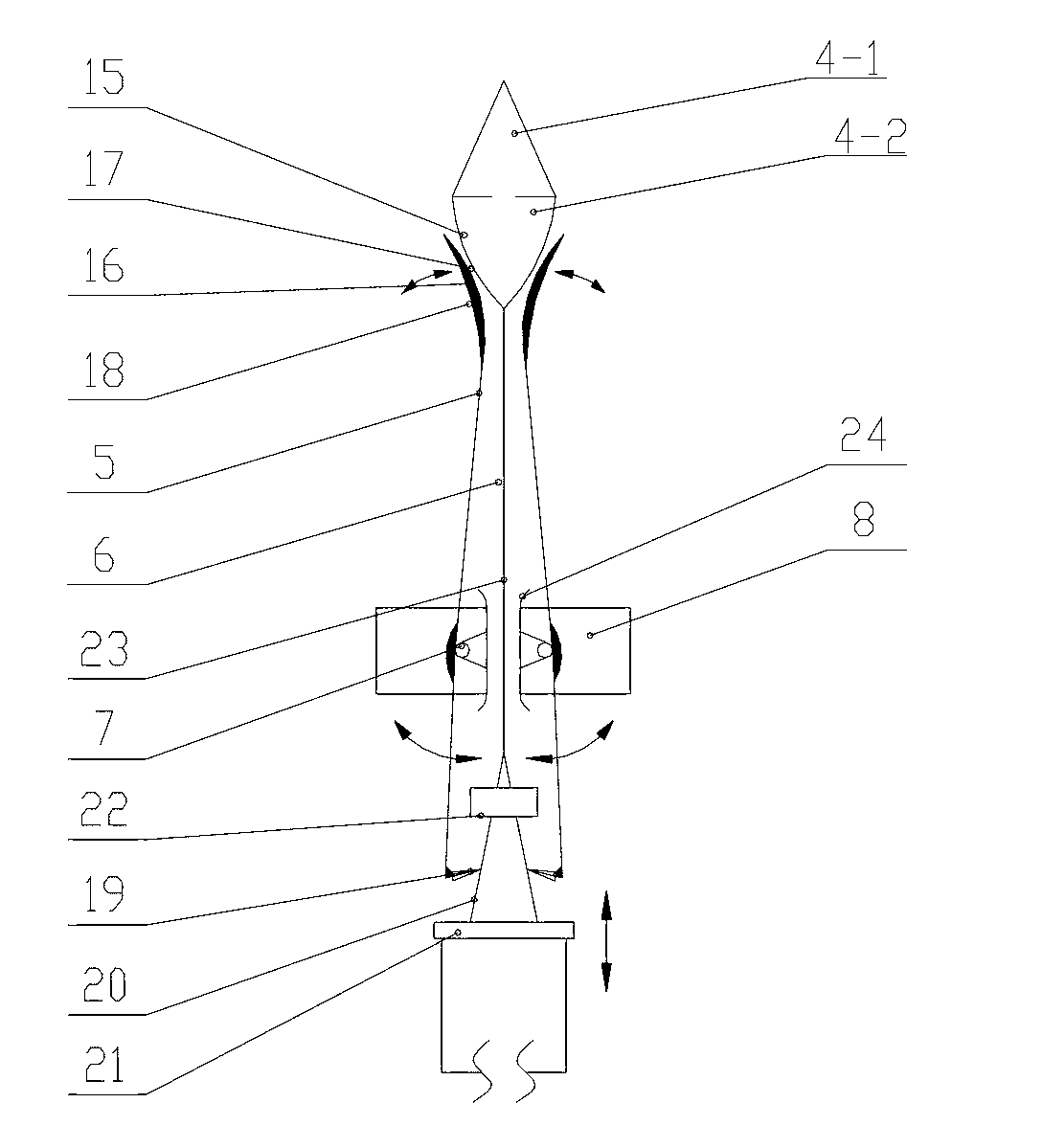

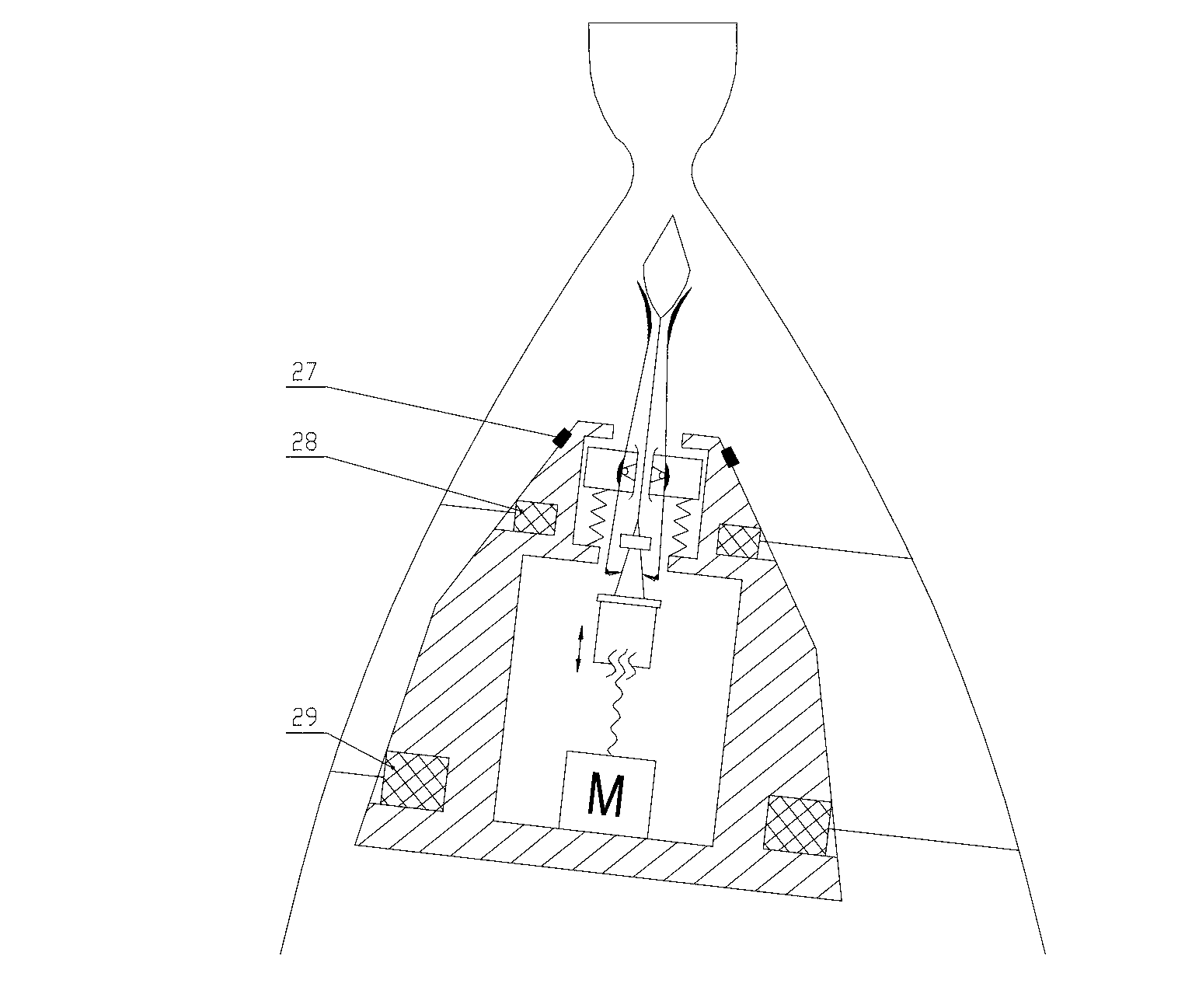

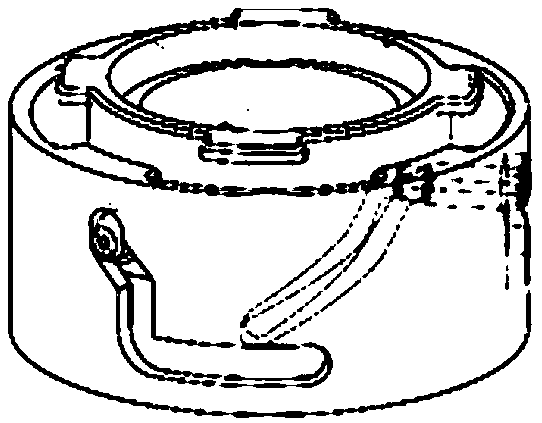

Non-cooperative target docking mechanism with peripheral swing-rod-type expansion joint

InactiveCN102849228ASmall form factorCompact structureCosmonautic component separationGeostationary orbitMovement control

The invention relates to a non-cooperative target docking mechanism with a peripheral swing-rod-type expansion joint, which aims to solve the problems of the complex structure, large size, heavy weight, and limitation on the application in the missions of 'GEO (geostationary orbit) protection' and 'in-orbit maintenance' of the present non-cooperative target docking mechanism. The mechanism realizes the rotation around a rotary shaft via the contact and the interaction of a swing rod, a slide surface and a conical inclined surface to finish the expansion and folding functions of a swing rod and realize docking and docking unlocking. An expansion mechanism is used for docking a throat structure of the inner surface of a spray tube, and after the swing rod is expanded, the docking rigidity is ensured by virtue of the compression surfaces of a locking slider and a shell, thereby realizing a docking function. The mechanism performs stepping by virtue of the expansion of the swing rod caused by a return spring and the locking movement of the locking slider, so that the control on the locking movement is simple. The mechanism disclosed by the invention is used for the field of aeronautics and astronautics.

Owner:黄刚

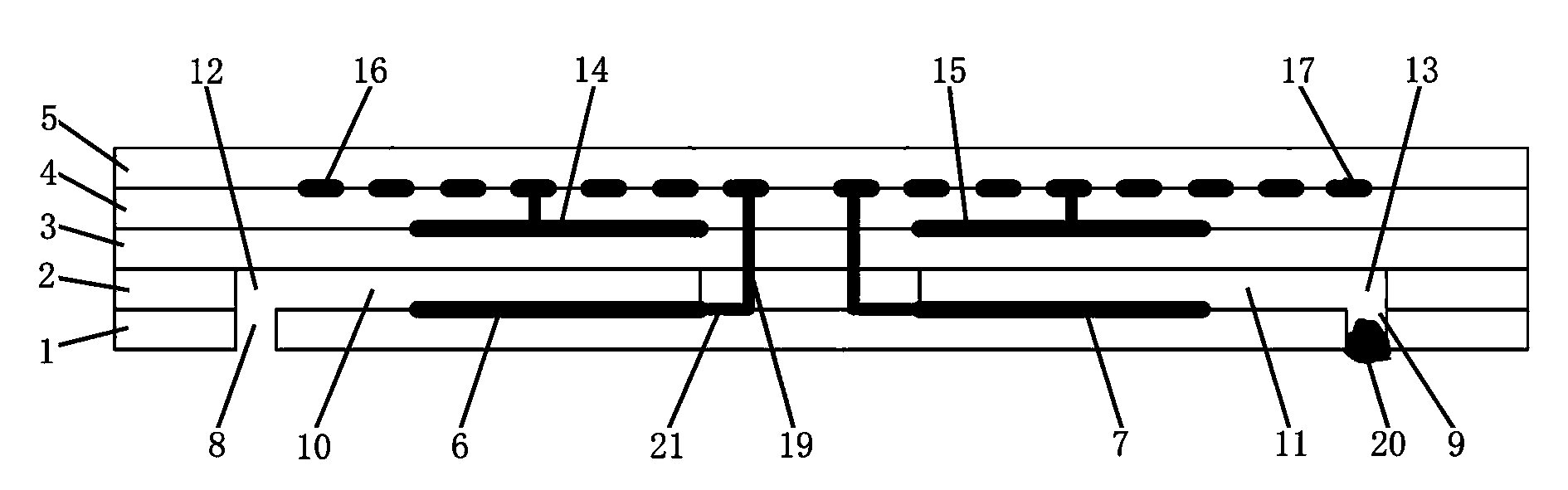

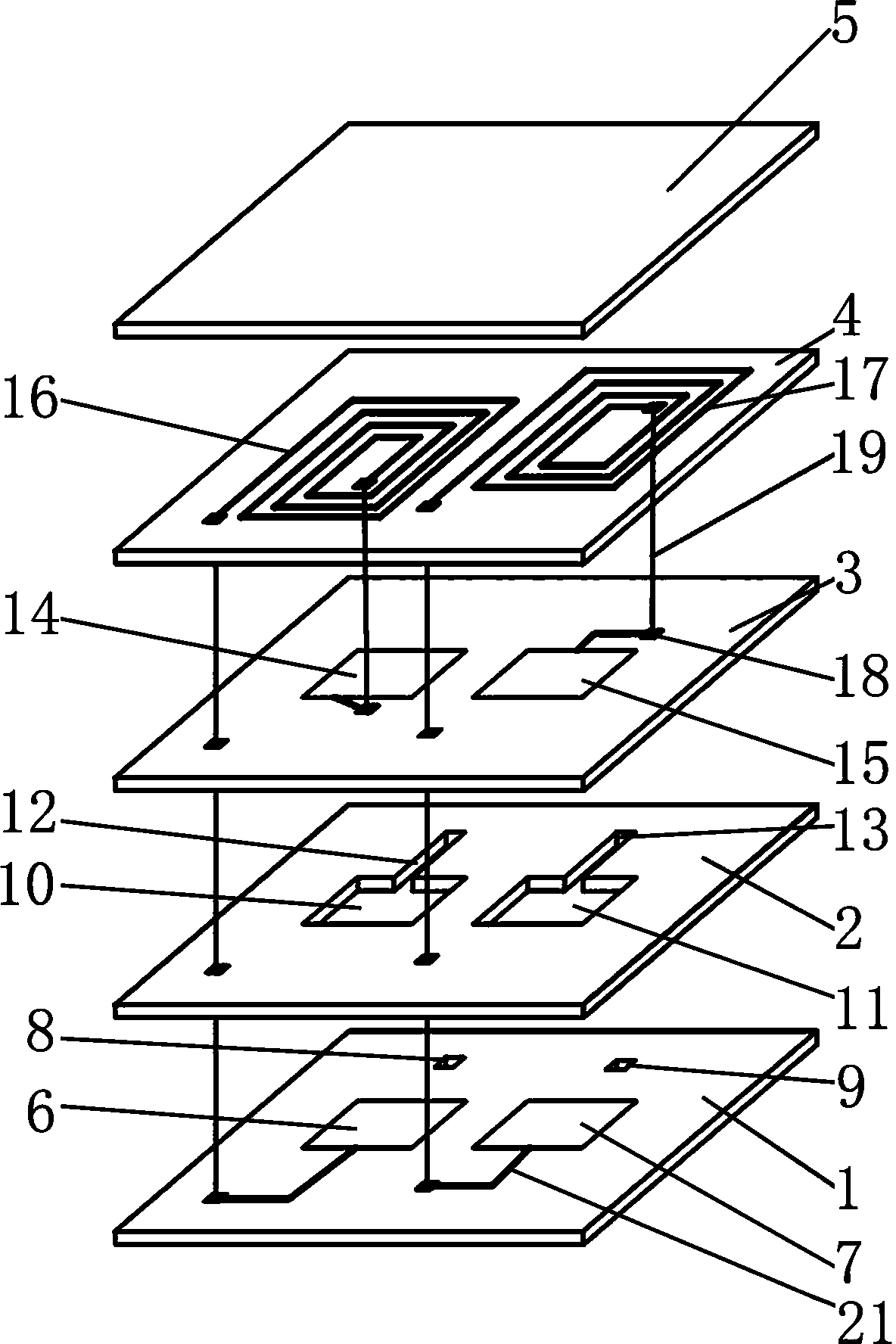

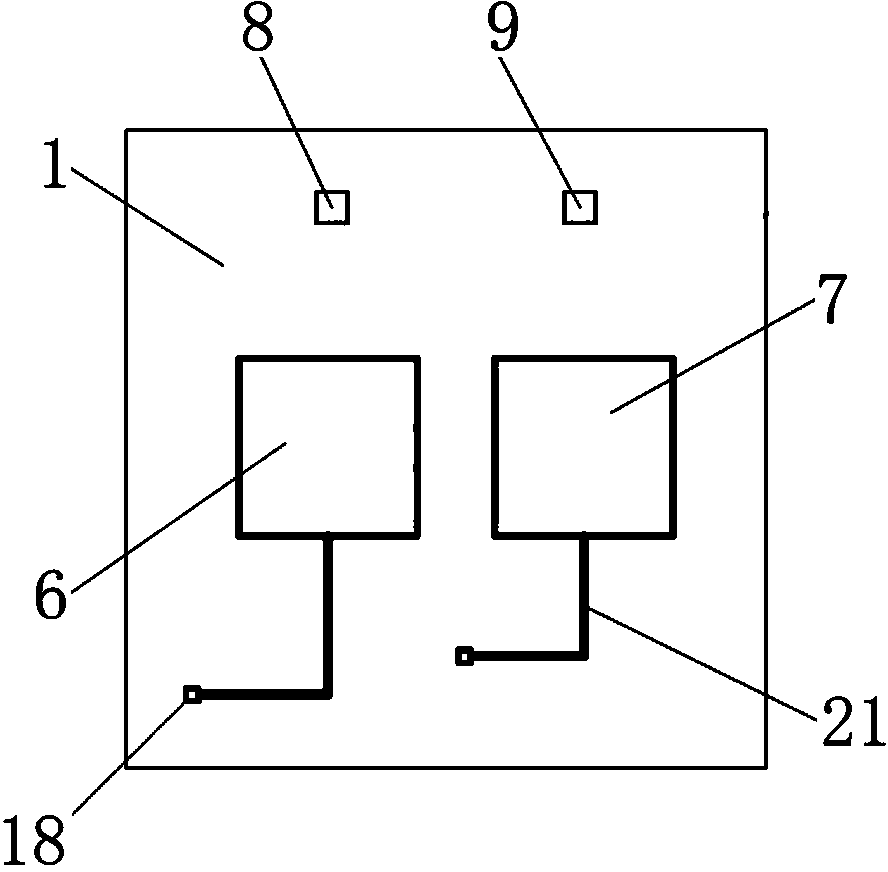

Wireless passive high-temperature pressure sensor with temperature compensation and temperature compensation algorithm thereof

ActiveCN103698060ASolve the problem that pressure measurement cannot be performed in an environment where the temperature changes constantlyLow costForce measurementFluid pressure measurement using capacitance variationAstronauticsInductance

The invention relates to a wireless passive high-temperature pressure sensor, in particular to a wireless passive high-temperature pressure sensor with temperature compensation and a temperature compensation algorithm thereof. The invention solves the problem that the conventional wireless passive high-temperature pressure sensor cannot measure pressure under the environment in which temperature constantly changes. The wireless passive high-temperature pressure sensor with temperature compensation comprises a first green ceramic plate, a second green ceramic plate, a third green ceramic plate, a fourth green ceramic plate and a fifth green ceramic plate; a lower polar plate of a first flat capacitor is arranged on the left part of the top surface of the first green ceramic plate; a lower polar plate of a second flat capacitor is arranged on the right part of the top surface of the first green ceramic plate; a first induction coil and the first flat capacitor are jointly formed into a temperature-compensating sensitive LC loop; a second induction coil and the second flat capacitor are jointly formed into a main sensitive LC loop. The invention is applicable to pressure measurement under high-temperature environments in the fields of automation, astronautics, aeronautics and national defense industry.

Owner:ZHONGBEI UNIV

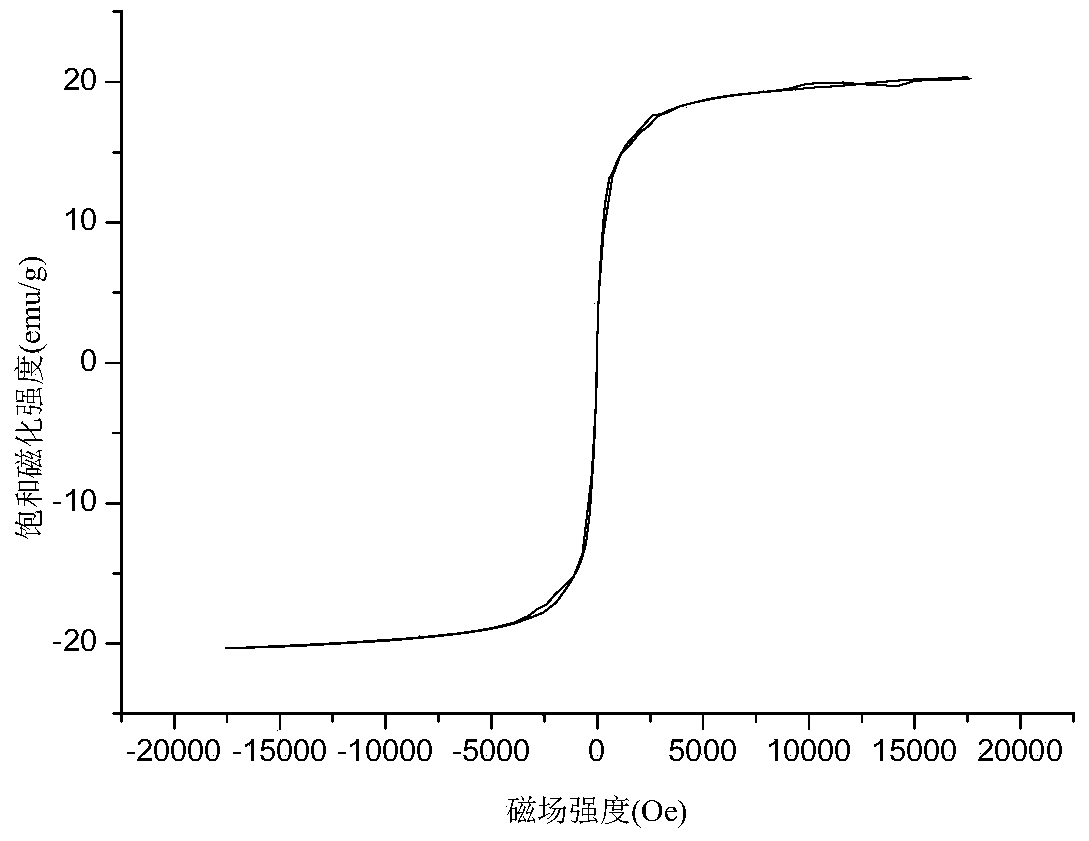

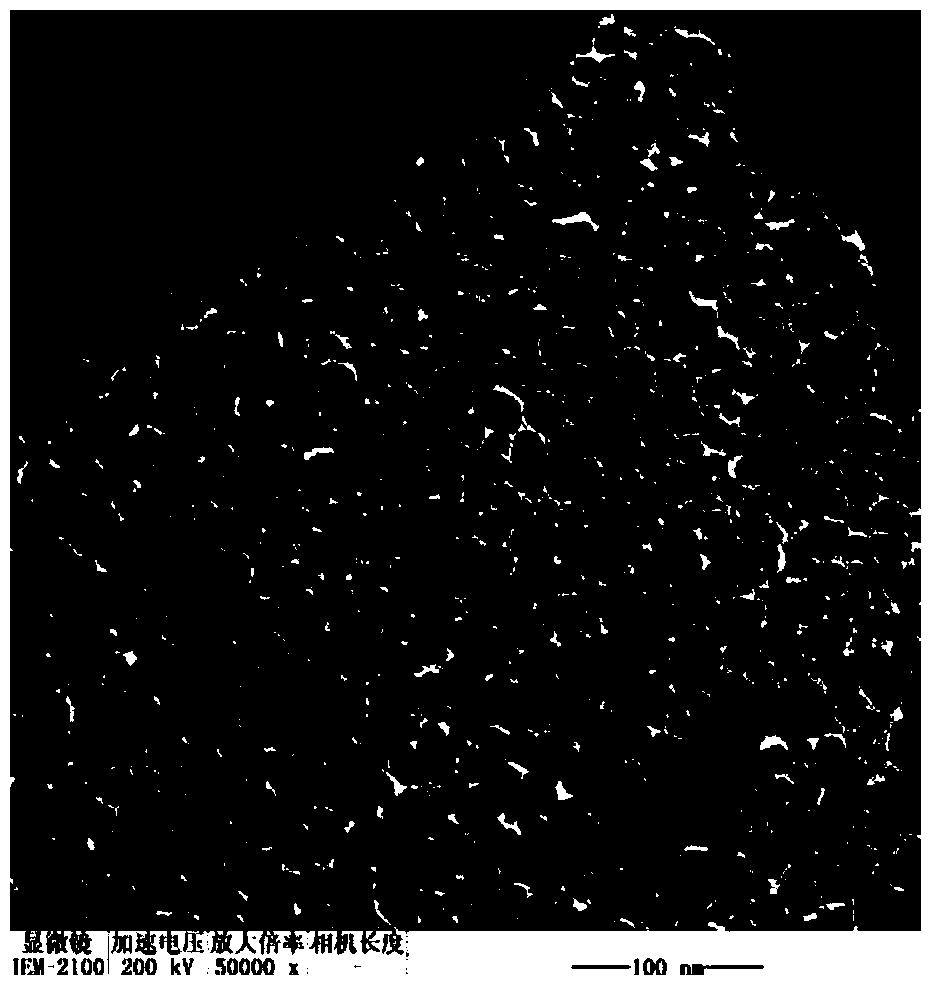

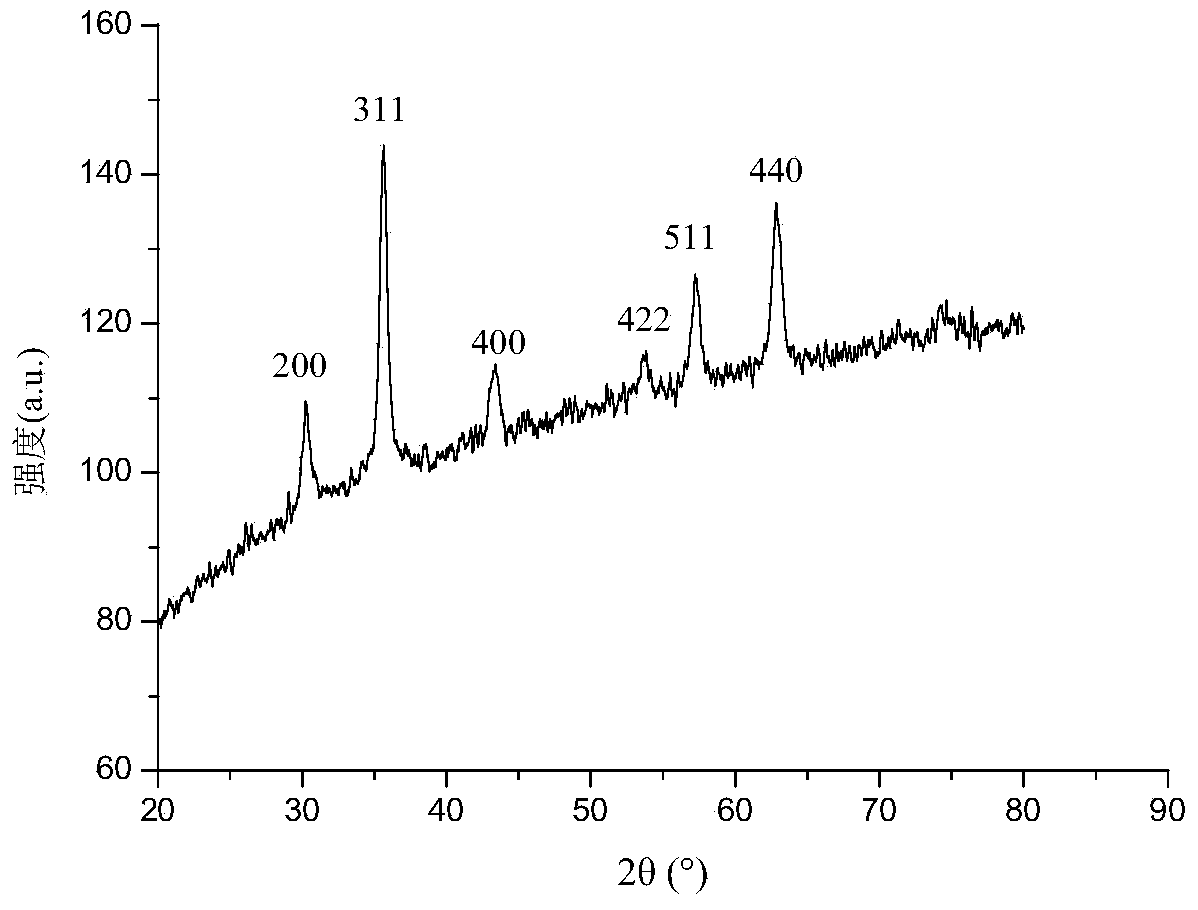

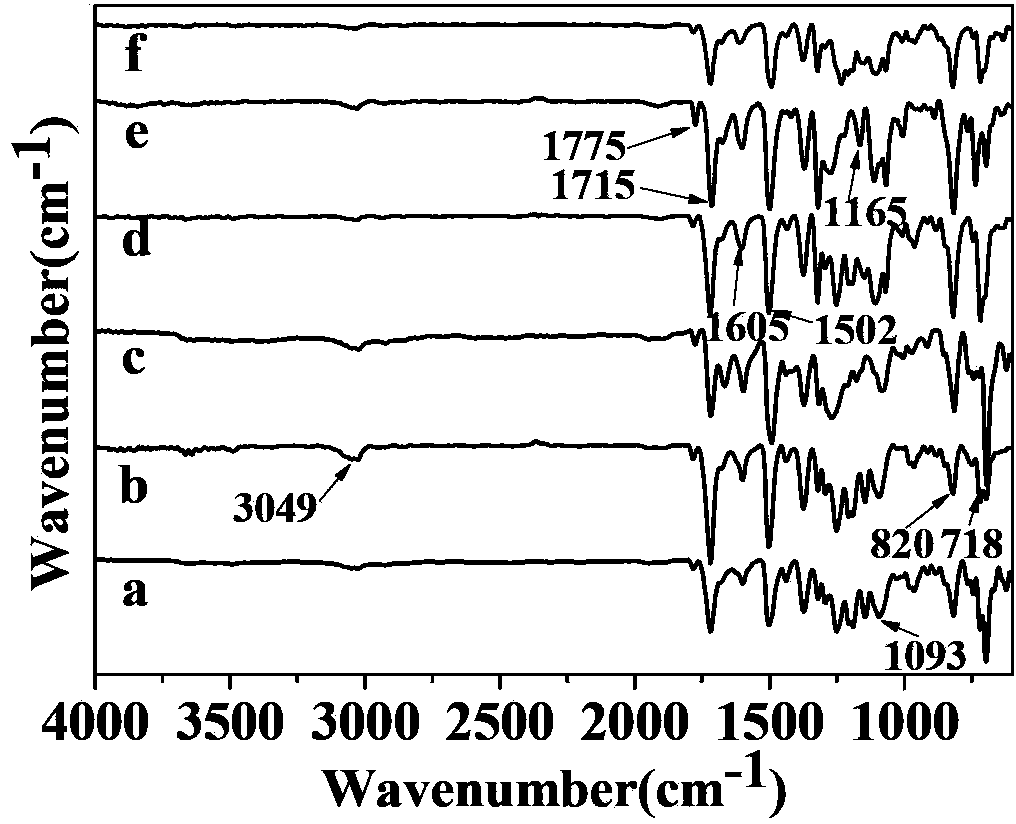

Preparation method for perfluor polyether oil-based magnetic liquid

InactiveCN103680798AExtended application environmentEasy to useMagnetic liquidsOrganic/organic-metallic materials magnetismHigh energyMagnetization

The invention discloses a preparation method for a perfluor polyether oil-based magnetic liquid. The magnetic liquid is formed by bare Fe[3]O[4] magnetic nano-particles, a perfluor polyether carboxylic acid surface active agent and a perfluor polyether oil-based carrier liquid in a prepared mode. The bare Fe[3]O[4] nano-particles with the average particle diameter of 10 nanometers are firstly prepared by the adoption of a chemical coprecipitation method; the perfluor polyether carboxylic acid surface active agent is then adopted for modifying the bare Fe[3]O[4] nano-particles; finally, the modified Fe[3]O[4] magnetic nano-particles and the perfluor polyether oil-based carrier liquid are blended through a high-energy ball milling or ultrasonic shaking method to form the uniform and stable perfluor polyether oil-based magnetic liquid, and the saturation magnetization of the perfluor polyether oil-based magnetic liquid is 14-600 Gs. The magnetic liquid has the excellent special performance of resisting to chemical corrosion, high temperature, low temperature resistance and radiation and never burning, can work stably for a long time at the temperature of 40 DEG C below zero-200 DEG C at the pH value of 1-14, and is particularly suitable for space stations, aeronautics and astronautics and other military industry fields.

Owner:BEIJING JIAOTONG UNIV

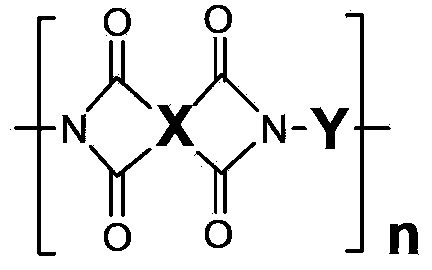

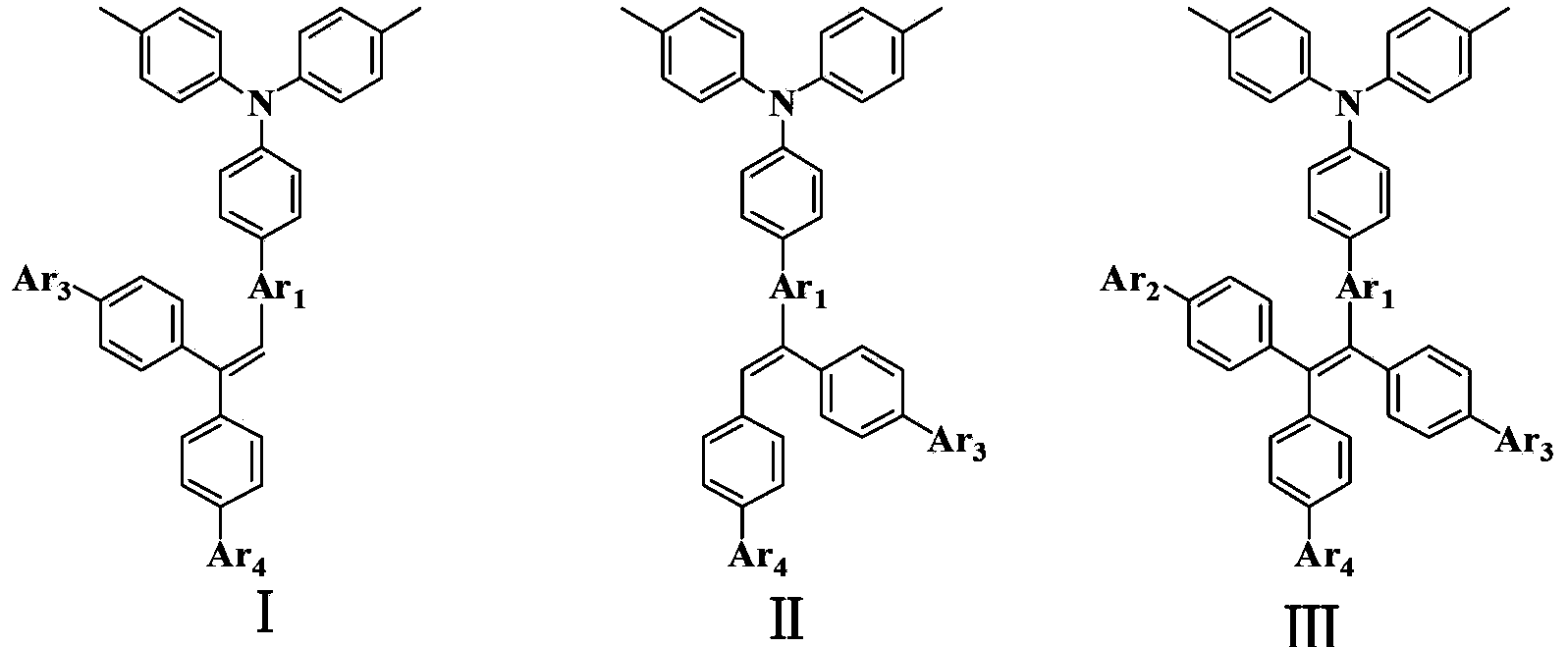

Polyimide with low dielectric properties, and preparation method and application thereof

The invention discloses polyimide with low dielectric properties, and a preparation method and an application thereof. The polyimide provided by the invention is prepared through an imidization method by using the raw materials of aromatic diamine comprising triphenylamine and with large side group comprising triphenylethylene / tetraphenylethylene, and various tetra-dianhydrides. The polyimide provided by the invention has ultra-low dielectric constant, relatively low dielectric loss, excellent solubility, relatively high glass transition temperature, relatively high thermal stability, excellent mechanical performances, excellent photo-luminescent performance, and the like. The synthesis method of the polyimide is simple and diverse, and is suitable for industrial productions. The polyimide provided by the invention can be used for preparing low dielectric materials, and can be widely applied in high-tech industry fields such as electronics, microelectronics, information, luminescent materials, aeronautics and astronautics, and specially very large scale integrated circuits.

Owner:SUN YAT SEN UNIV

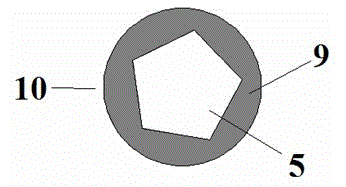

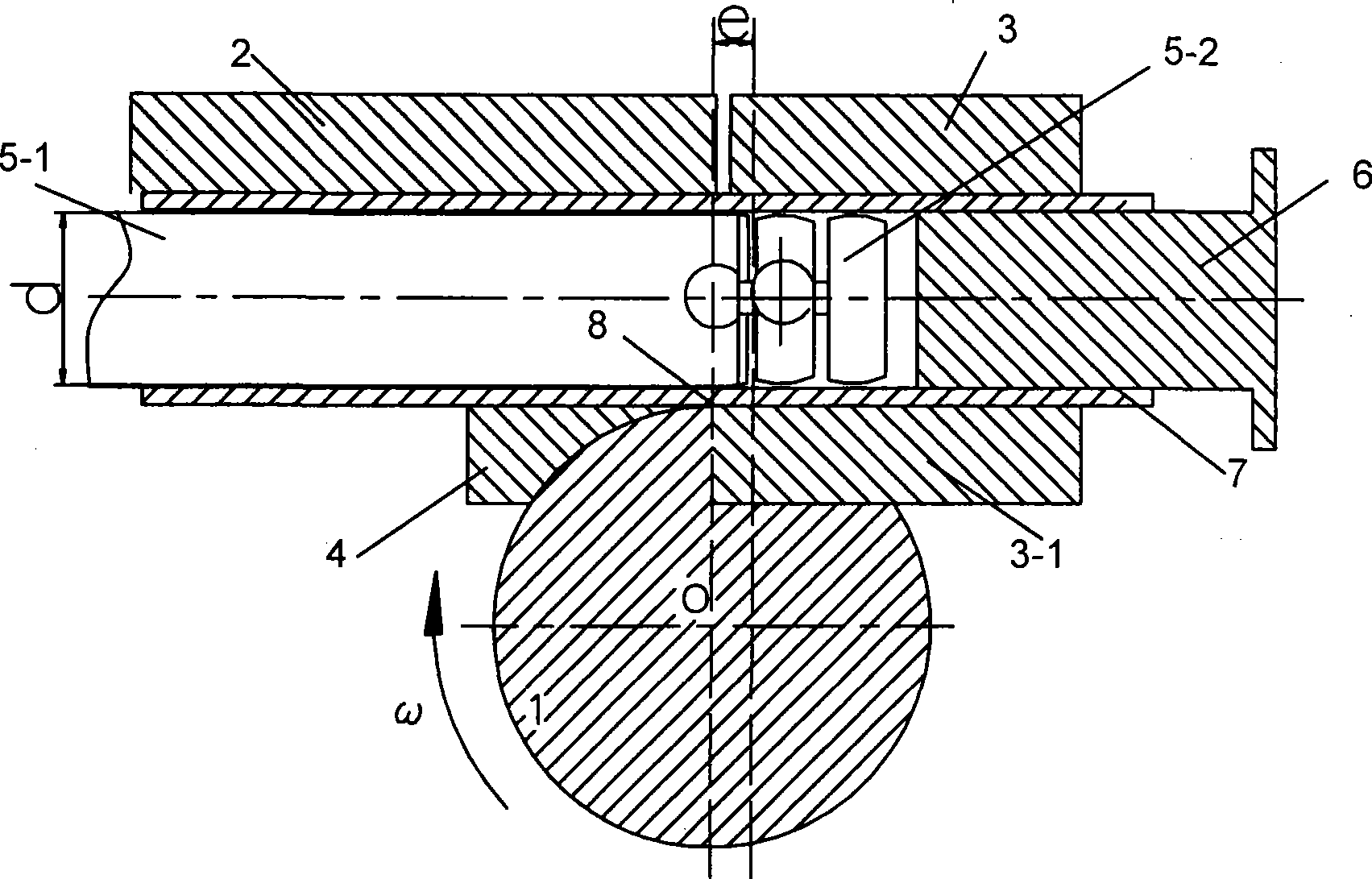

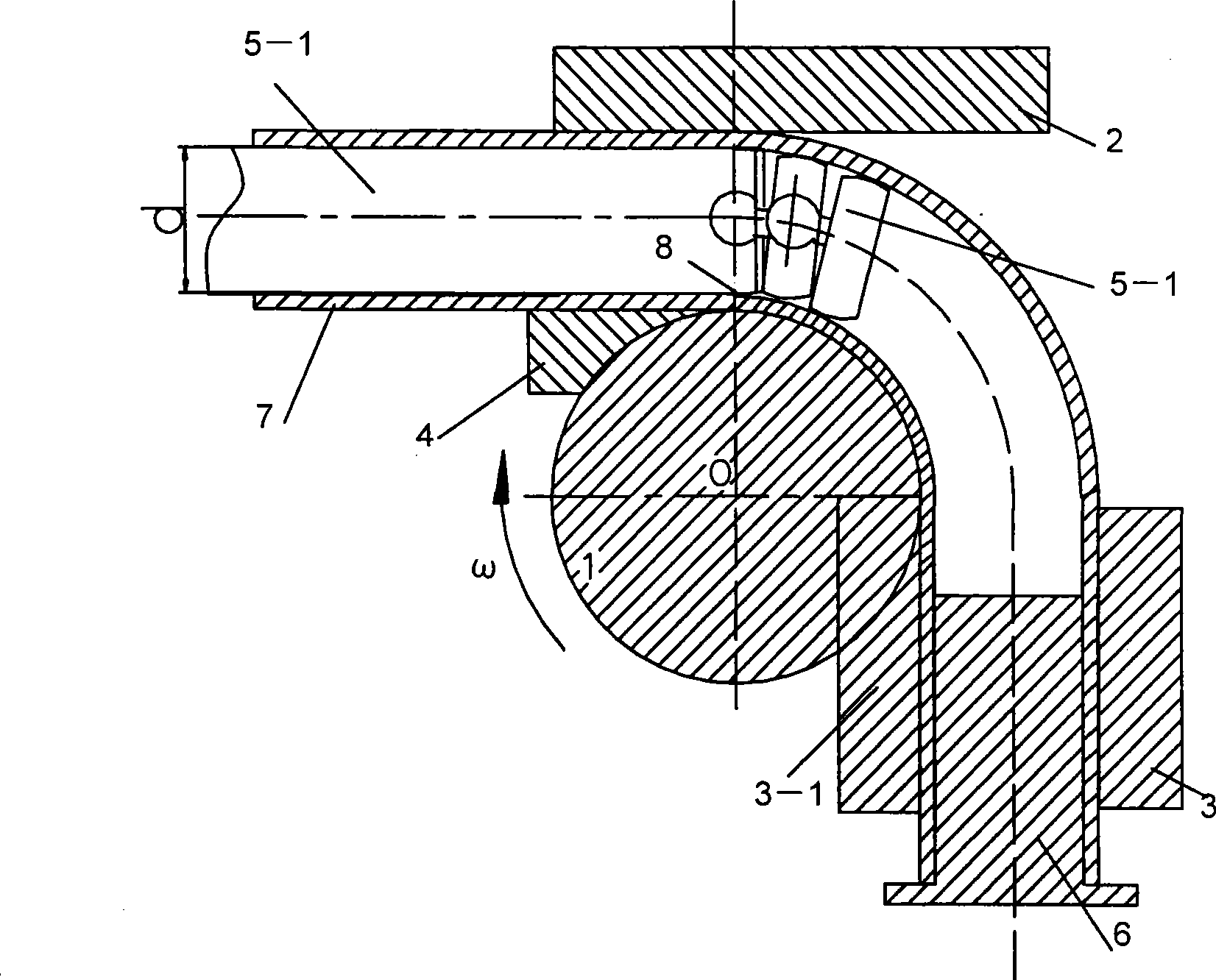

Adjustment method of thin-wall numerical-controlled bend-pipe forming die

InactiveCN101422792AScientific adjustment methodReliable and practical mold adjustment methodShaping toolsNumerical controlEngineering

The invention discloses a numerically controlled method for adjusting the forming die of a bent pipe with thin wall. The forming die of the bent pipe comprises a bending die (1) fixed and coupled with a machine tool, a lock block (2), a fixture block (3), a mandrel (5) and a crease resistant block (4) with six degrees of freedom. The method for adjusting the forming die gradually adjusts and installs the die according to the destructiveness of each defect of the bent pipe and the effect of forming parameters on each quality parameter so as to acquire the qualified bent pipe which does not crease and has thinned wall and section distortion satisfying the requirements. The method can ensure the smooth process of the bending forming experiment of pipes with thin wall, and is used for guiding the forming of the bend of the pipe with thin wall and small bending radius in practical engineering, so as to reduce the die adjusting times, lower the production cost and satisfy the requirements of high-tech industries such as aeronautics and astronautics and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

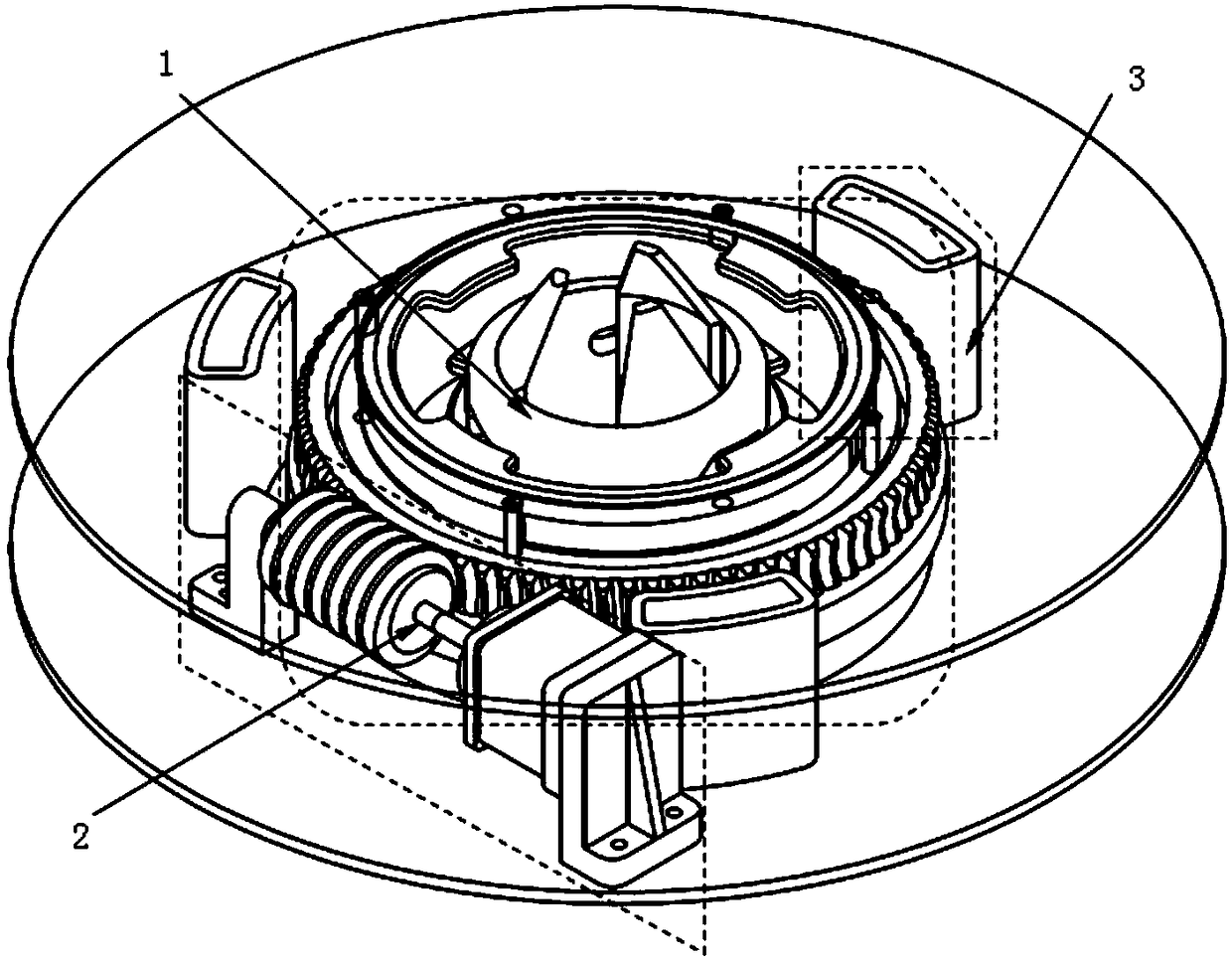

Different-body isomorphic connection and separation device and system

ActiveCN108609205AImprove acceleration performanceEnable connectivityCosmonautic component separationReconfigurabilityCoupling

The invention relates to the technical field of aeronautics and astronautics, and discloses a different-body isomorphic connection and separation device and system. The different-body isomorphic connection and separation device comprises a driving assembly, a connection and separation executing assembly and a supporting assembly, wherein the driving assembly and the connection and separation executing assembly are arranged through the supporting assembly in a supported mode; and the connection and separation executing assembly comprises a sliding pin, a fixed guide ring, a coupling ring, a driving ring, a bolt driving ring and a bolt ring, wherein the fixed guide ring, the coupling ring, the driving ring, the bolt driving ring and the bolt ring are sequentially arranged from inside to outside in a sleeved mode. The different-body isomorphic connection and separation device and system have universality, the child-mother docking of tiny modular satellites can be realized, the child-childdocking and mother-child docking can be further realized, and the docking reconfigurability and expandability among the multiple tiny modular satellites are increased.

Owner:BEIHANG UNIV +1

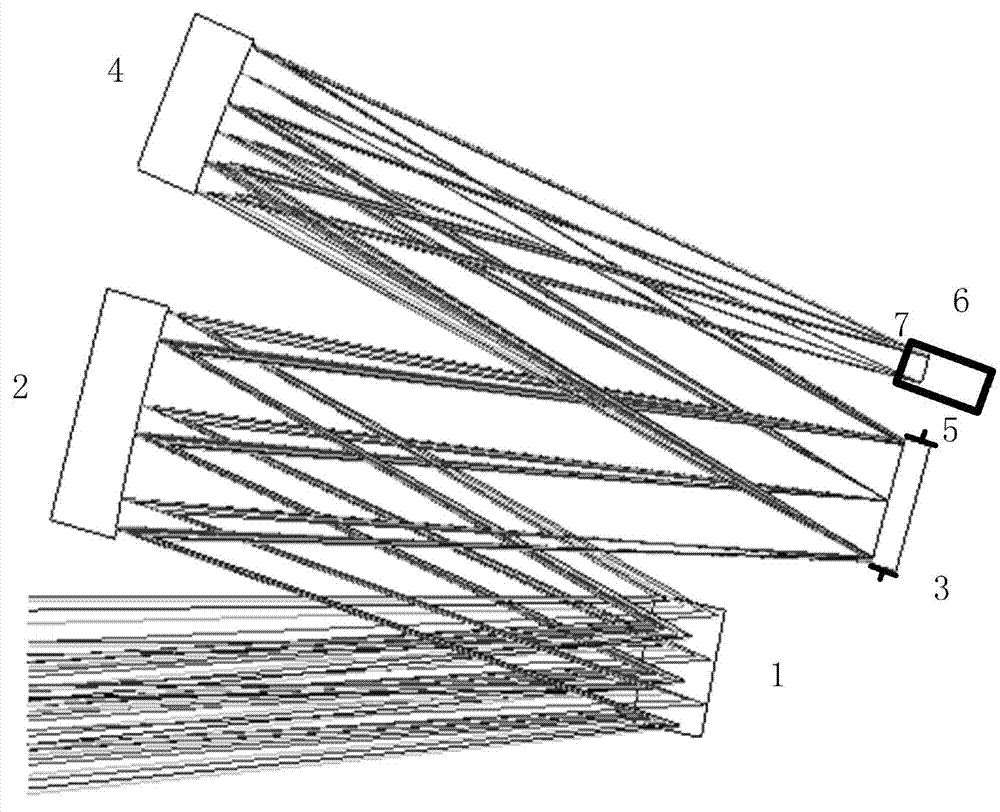

Free-form surface imaging optical system

InactiveCN103592749AReasonable spacing designReduced band driftRadiation pyrometrySpectrometry/spectrophotometry/monochromatorsFree formOptoelectronics

The invention discloses a free-form surface imaging optical system. The free-form surface imaging optical system comprises a first reflector, a second reflector, a third reflector, a fourth reflector, an aperture diaphragm and a detector. A target is irradiated on the second reflector after being reflected by the first reflector, is irradiated on the third reflector after being reflected by the second reflector, is irradiated on the fourth reflector after being reflected by the third reflector, and finally is irradiated on the image plane of the detector after being reflected by the fourth reflector. The aperture diaphragm coincides with the third reflector in position. The first reflector is a long-strip-shaped spherical reflector of which the focal power is negative. The second reflector is a free-form surface reflector of which the focal power is positive. The third reflector is a free-form surface reflector of which the focal power is negative. The fourth reflector is a free-form surface reflector of which the focal power is positive. A camera with the free-form surface imaging optical system adopted is huge in view field and small in distortion, and can achieve multi-spectrum imaging. The free-form surface imaging optical system can be applied to the field of aeronautics and astronautics photo-electronic imaging.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

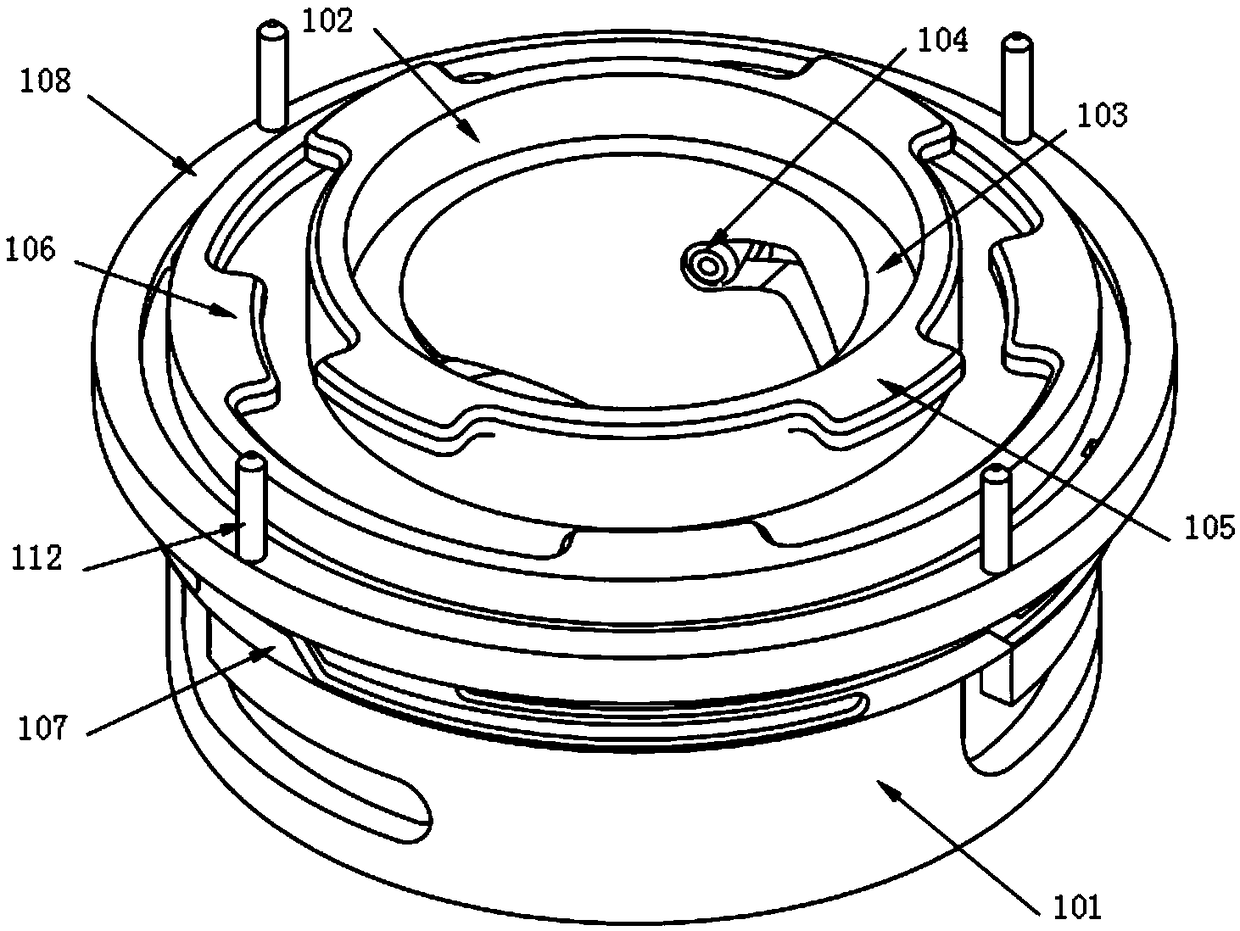

Multi-degree-of-freedom bionic piezoelectric drive device

ActiveCN102291039AImprove rigidityImprove dynamic characteristicsPiezoelectric/electrostriction/magnetostriction machinesTorsion testMicroelectromechanical systems

The invention relates to a multi-degree-of-freedom bionic piezoelectric driver, which belongs to the field of precision machining. The multi-degree-of-freedom bionic piezoelectric driver comprises a case, a stator and a rotor, and is based on a stepping operation mode, the stator does not have embedded elements, and by utilizing the combined action of the forward thrust of piezoelectric stacks and the backward resilient force of flexible hinges, the multi-degree-of-freedom bionic piezoelectric driver realizes the forward and backward motion and axial linear motion of the rotor of the driver. In addition, in terms of the tests of micro-characteristics of materials, the driver can simultaneously carry out the nano-level elongation and torsion tests of fine materials. Based on inchworm type piezoelectric drive, the multi-degree-of-freedom bionic piezoelectric driver has high-precision positioning and repetitive positioning capability, and can be applied in the fields of ultraprecision machining machine tools, the testing of nano mechanical properties of material test specimens, microelectromechanical systems, precision optics, aeronautics and astronautics, robots and the like. The driving precision of ordinary drivers can be greatly increased, and the multi-degree-of-freedom bionic piezoelectric driver has the advantages of high displacement control precision, quick response, high driving force, low driving power, wide operating frequency, low cost, little investment, quick return, high benefit and the like.

Owner:吉林大学重庆研究院

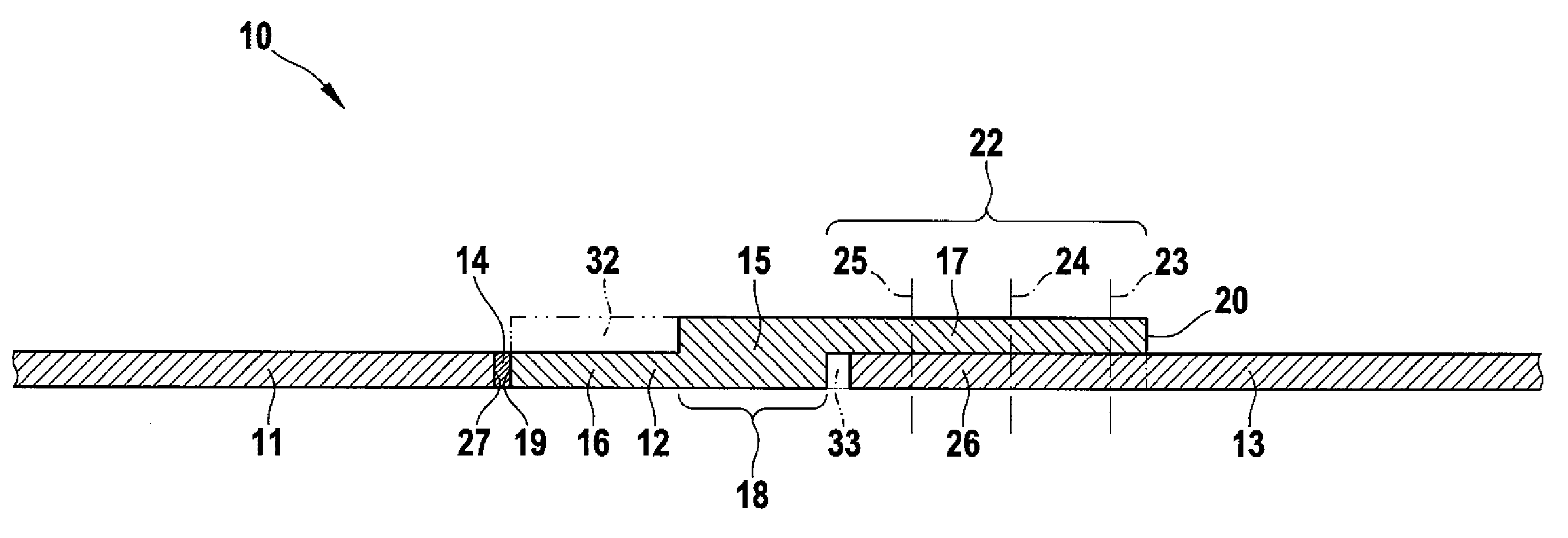

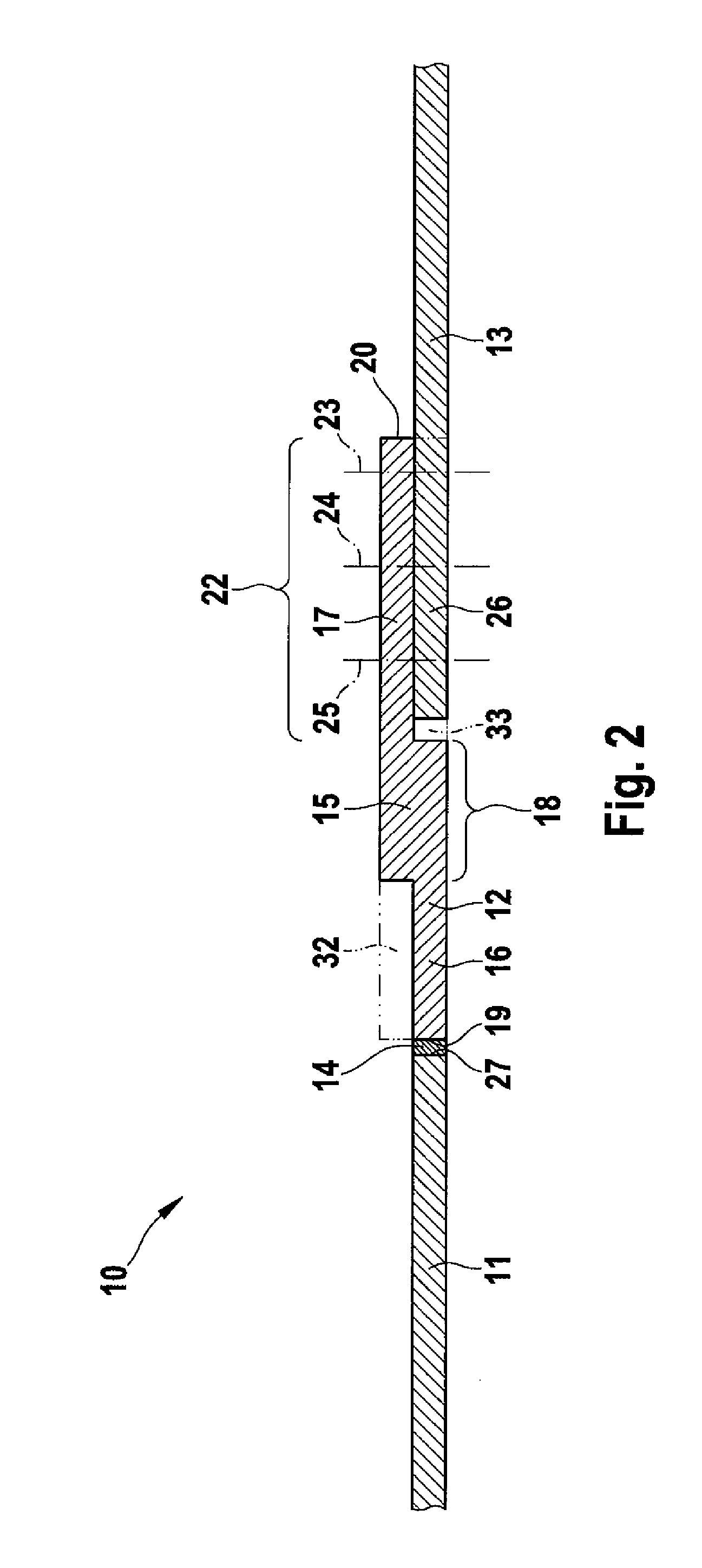

Method for producing a composite skin in the field of aeronautics and astronautics

ActiveUS9314875B2Reduce weightEasy to produceFuselage framesEfficient propulsion technologiesComposite skinEngineering

A composite skin for the aeronautics and astronautics industries, and also a method for producing a composite skin of this type is provided. The method comprises the following method steps: removing excess material from a butt plate to form a butt strap at one end thereof, subsequently connecting the other end of the butt plate to a skin plate with a substance-to-substance bond, and then fastening a further skin plate to the butt strap to form the composite skin. The idea behind the invention involves replacing a rivet connection with a substance-to-substance bond. This provides the advantage that the weight of the composite skin and the production costs for the composite skin are reduced.

Owner:AIRBUS OPERATIONS GMBH

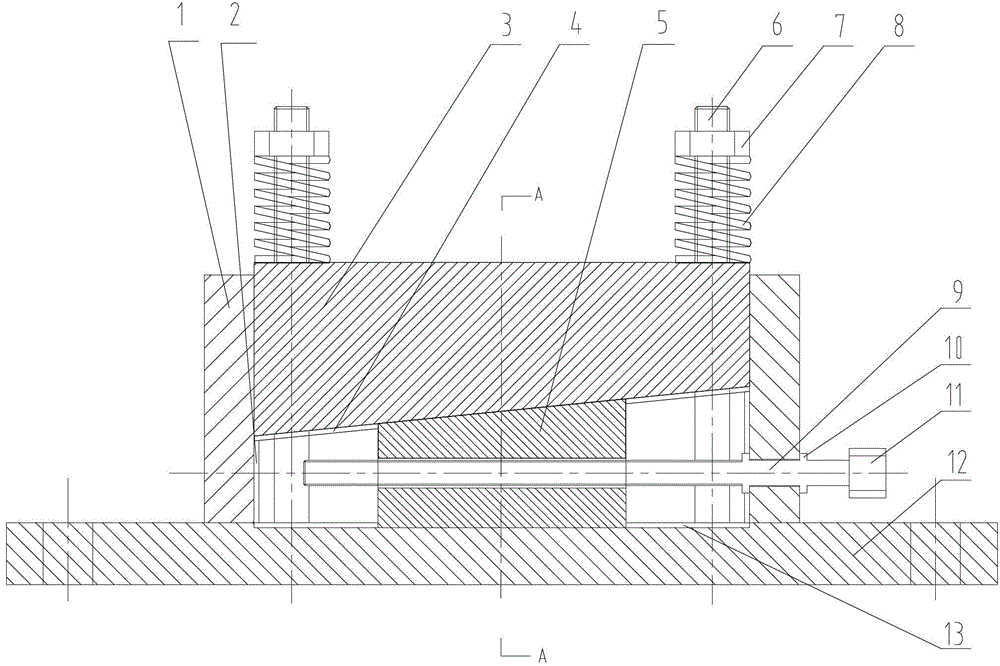

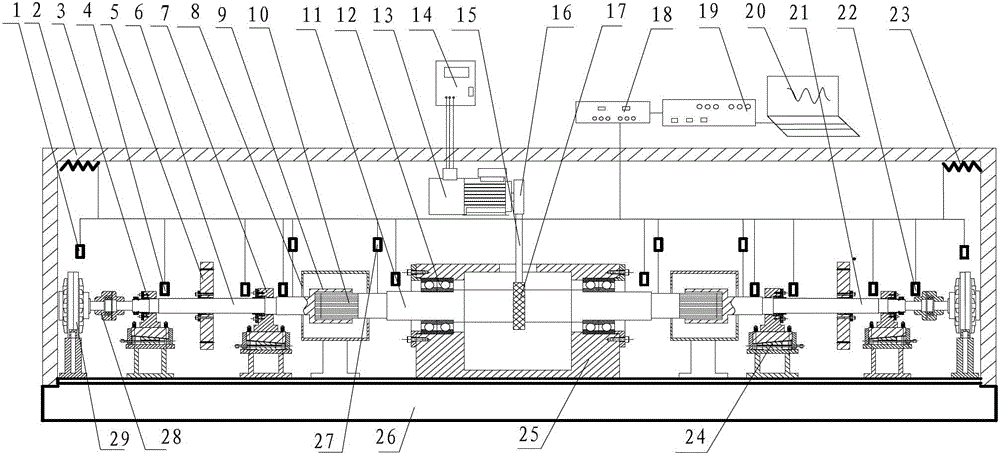

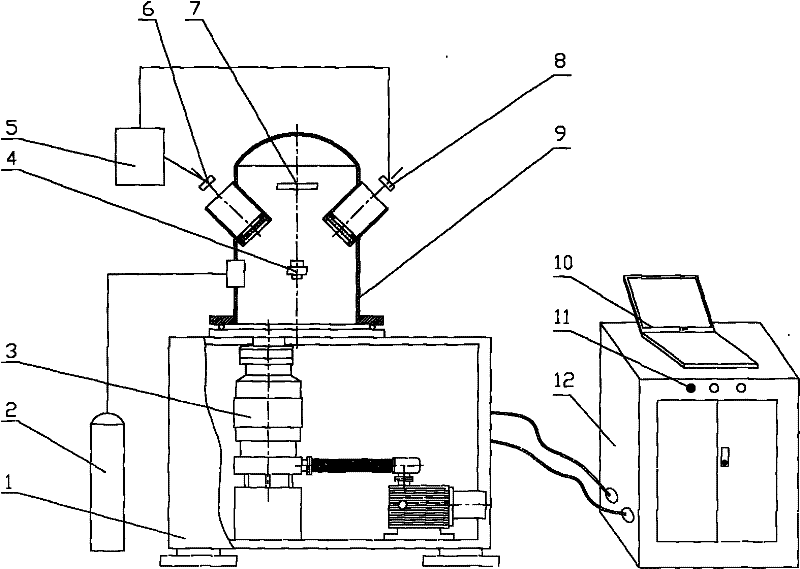

Misaligned spline vibration wear contrast experimental device

ActiveCN103335838AComparableMany experimental functionsMachine gearing/transmission testingBall bearingDrive wheel

The invention relates to a misaligned spline vibration wear experimental device and belongs to the aeronautics and astronautics vibration field. The misaligned spline vibration wear experimental device is characterized in that the misaligned spline vibration wear experimental device is composed of temperature sensors, constant-temperature covers, ball bearings, vibration displacement sensors, wheel discs, a rotor 1, bearing seats, grease collecting covers, spline jackets, splines, a rotor 2, double-row bearings, a motor, a frequency converter, a synchronizing belt, a synchronizing wheel, a driven wheel, a preamplifier, a signal acquisition device, an industrial personal computer, a rotor 3, a rotation speed sensor, electric heating wires, bearing elevation adjusting devices, an integrated bearing seat, a basic platform, infrared thermometers, flexible couplings and magnetic powder brakes. The misaligned spline vibration wear experimental device of the invention has a spline comprehensive condition contrast test function, a spline lubricating oil temperature and temperature rise research function, a spline / bearing misalignment research function, a spline engaging torque loading function and a comprehensive data online monitoring function. The misaligned spline vibration wear experimental device is advantageous in multiple experiment functions, strong comparability, excellent repeatability, stable operation, convenience in assembly and disassembly.

Owner:DALIAN UNIV OF TECH

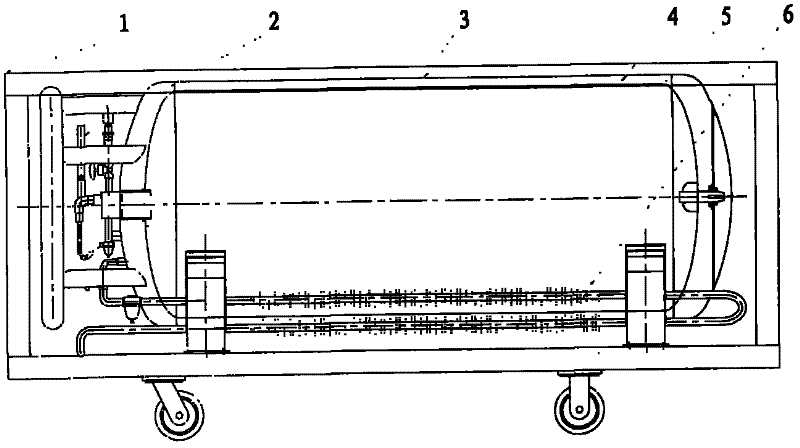

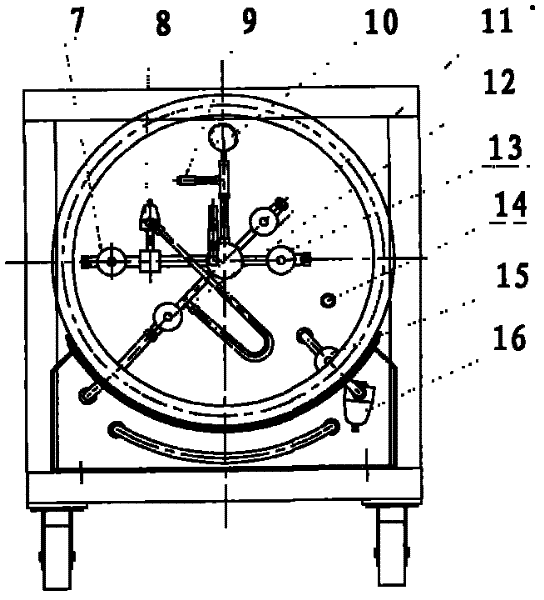

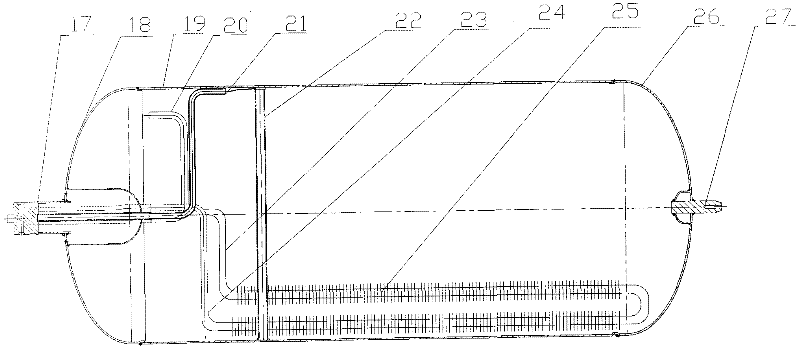

A low-temperature gas supply device

InactiveCN102261558AImprove methodReduce energy consumptionContainer filling methodsPressure vesselsProcess engineeringGas supply

The invention relates to a gas supplying apparatus, and discloses a low temperature gas supplying apparatus. The low temperature gas supplying apparatus comprises a supporting carriage, a valve and pipe system, a housing, a heat insulation interlayer, an inner liner, a vaporizer, a front supporting component, a rear supporting component, and a cooling shield. The housing is fixed on the supporting carriage. The inner liner is connected to the housing through the front supporting component and the rear supporting component. The valve and pipe system is arranged on the front part of the housing. The vacuum insulation interlayer is formed between the inner liner and the housing. The cooling shield is arranged in the lower part of the inner liner. With the apparatus provided by the present invention, low temperature liquid can be stored, and low temperature gas can be supplied. The apparatus has advantages of simplified structure, complete functions, and convenient and flexible low temperature gas supplying capacity. The apparatus is safe, environment protecting, energy saving, and is readily available. The apparatus is suitable for scientific institutions, and is suitable for scientific research fields of aeronautics and astronautics.

Owner:青岛瑞丰气体容器设备有限公司

Amorphous composite materials, and preparation method and applications thereof

The invention belongs to the field of metal amorphous composite materials, and discloses amorphous composite materials, and a preparation method and applications thereof. The amorphous composite materials comprise nickel, zirconium, titanium, niobium, aluminum and copper with a nickel-based amorphous phase as a matrix phase and beta-Ti and (Cu,Ni) Ti2 as reinforcing phases, and comprise the specific components according to the atomic percentage: 30-59 at.% of Ni, 10-24 at.% of Zr, 10-35 at.% of Ti, 7-10 at.% of Nb, 3-7 at.% of Al, 1-3 at.% of Cu, and the balance being inevitable trace impurities. The amorphous composite materials are prepared by rapidly sintering a nickel-based amorphous powder and a titanium-based amorphous powder. With control of the addition amount of the nickel-based amorphous powder, the amorphous composite materials with different amorphous phase content can be obtained. The amorphous composite materials are nearly fully dense, and can be applied in the fields of aeronautics and astronautics, military industry and the like.

Owner:SOUTH CHINA UNIV OF TECH

Calibration method of quartz crystal microbalance

ActiveCN101750140AHigh sensitivityImprove accuracyWeighing apparatus testing/calibrationQuartz crystal microbalanceTest procedures

The invention relates to a calibration method of a quartz crystal microbalance, belonging to the technical field of aeronautics and astronautics. The method comprises depositing heavy metal gold at the surface of the quartz crystal microbalance by using a magnetron sputtering device; injecting an inert gas in a vacuum system; observing and recording the vacuum degree of a vacuum chamber; monitoring and storing the frequency value and the temperature value of the quartz crystal microbalance; monitoring and storing the S polarized light current and P polarized light current of ellipsometry system, and finally closing the testing system, closing the gas charging system of inert gas, and closing the vacuum system. The method improves the sensibility of precision measurement of the quartz crystal microbalance; the test procedure is stable and reliable, and has good replicability; an ellipsometry film thickness measuring apparatus is used for providing direct film thickness measuring method for the quartz crystal microbalance; and the method has high measuring accuracy, stable test procedure and good replicability.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com