Patents

Literature

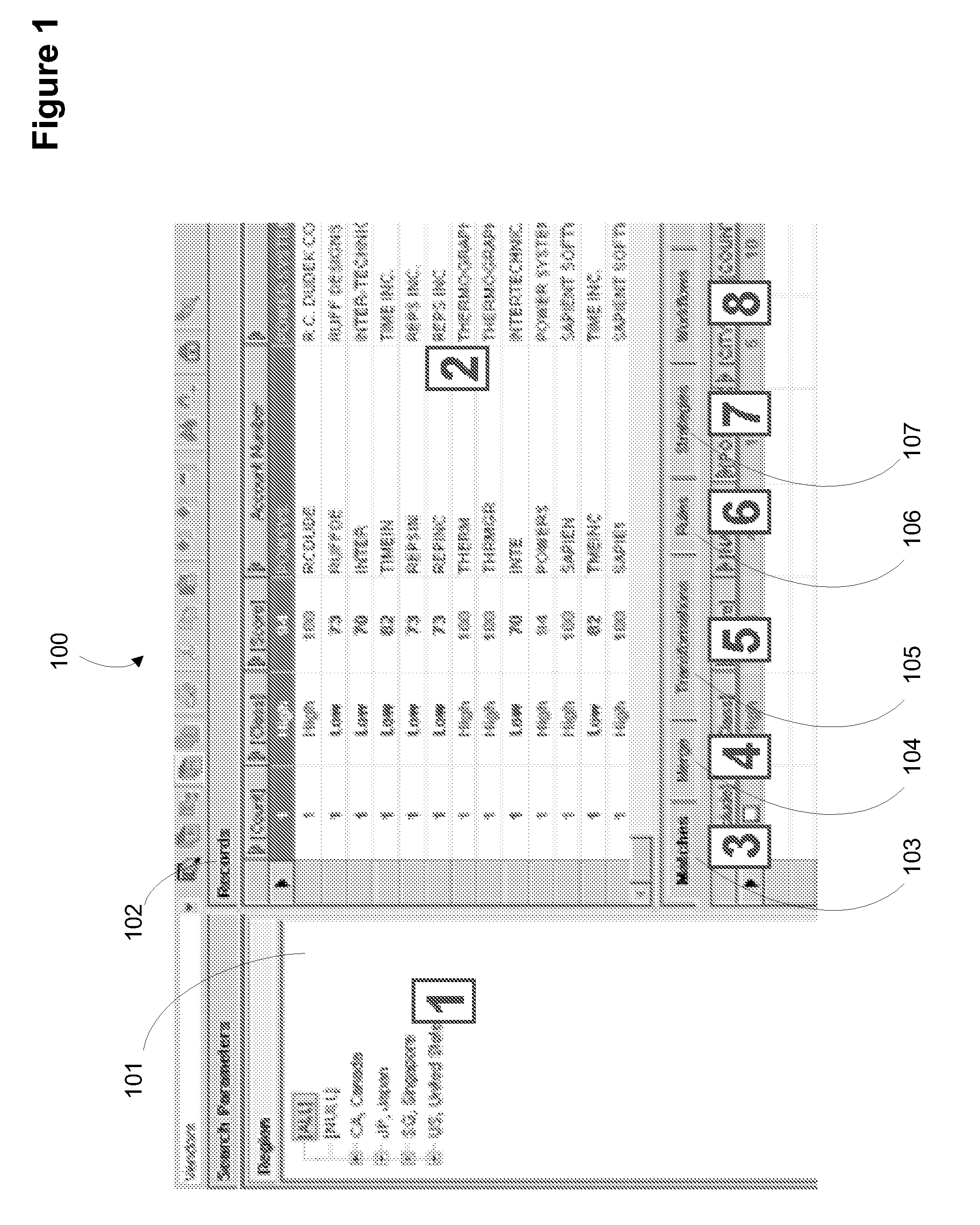

849results about How to "Quick match" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

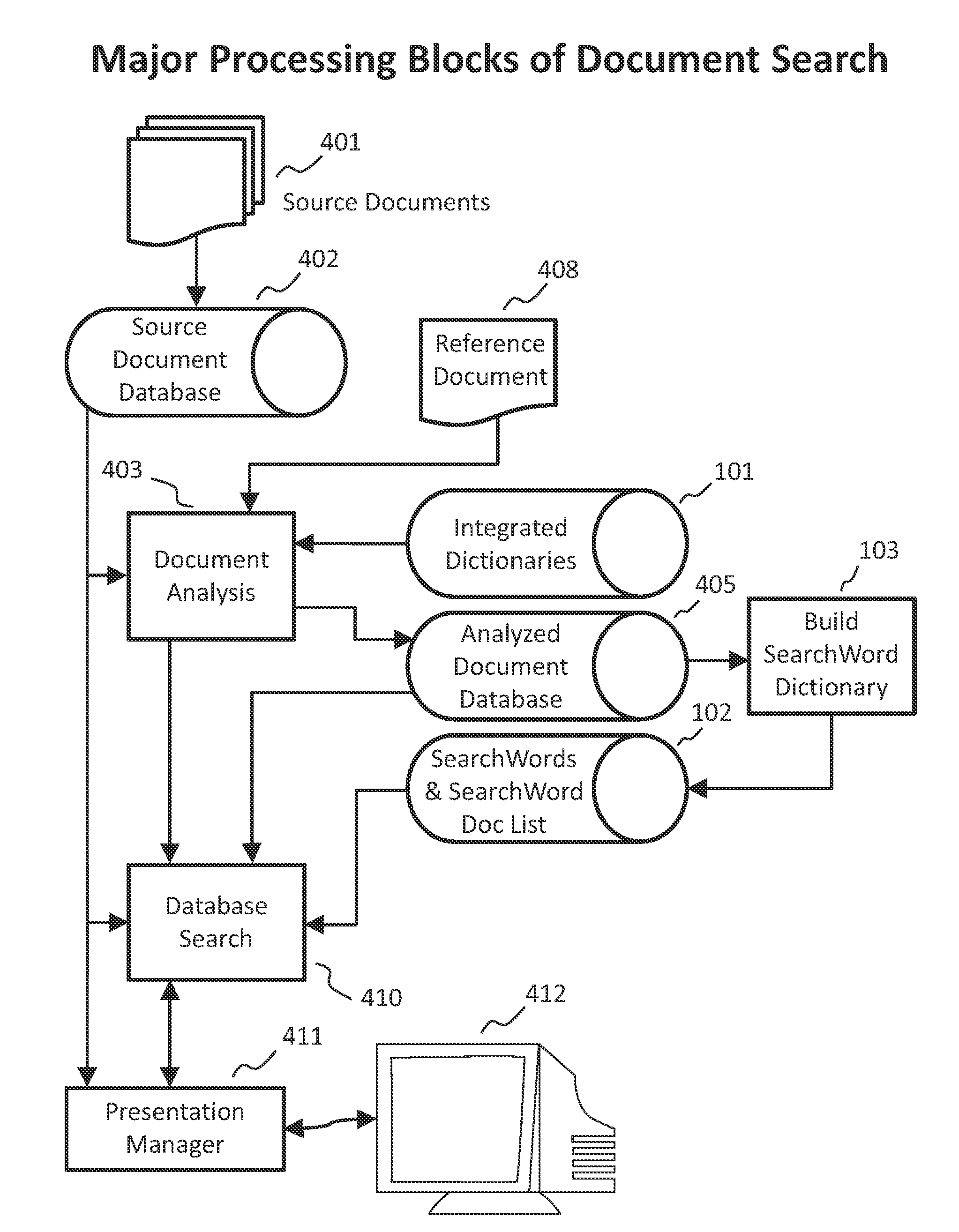

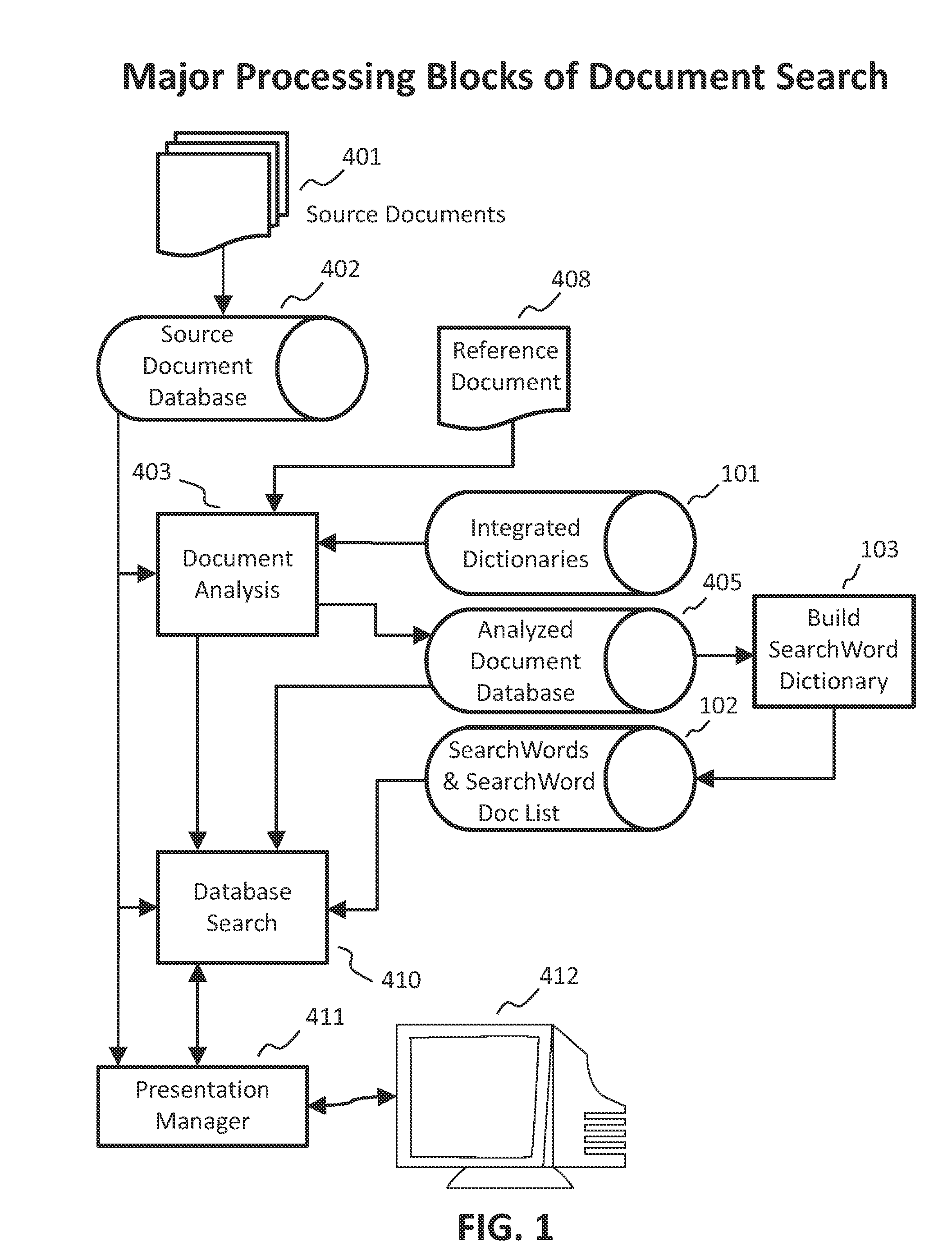

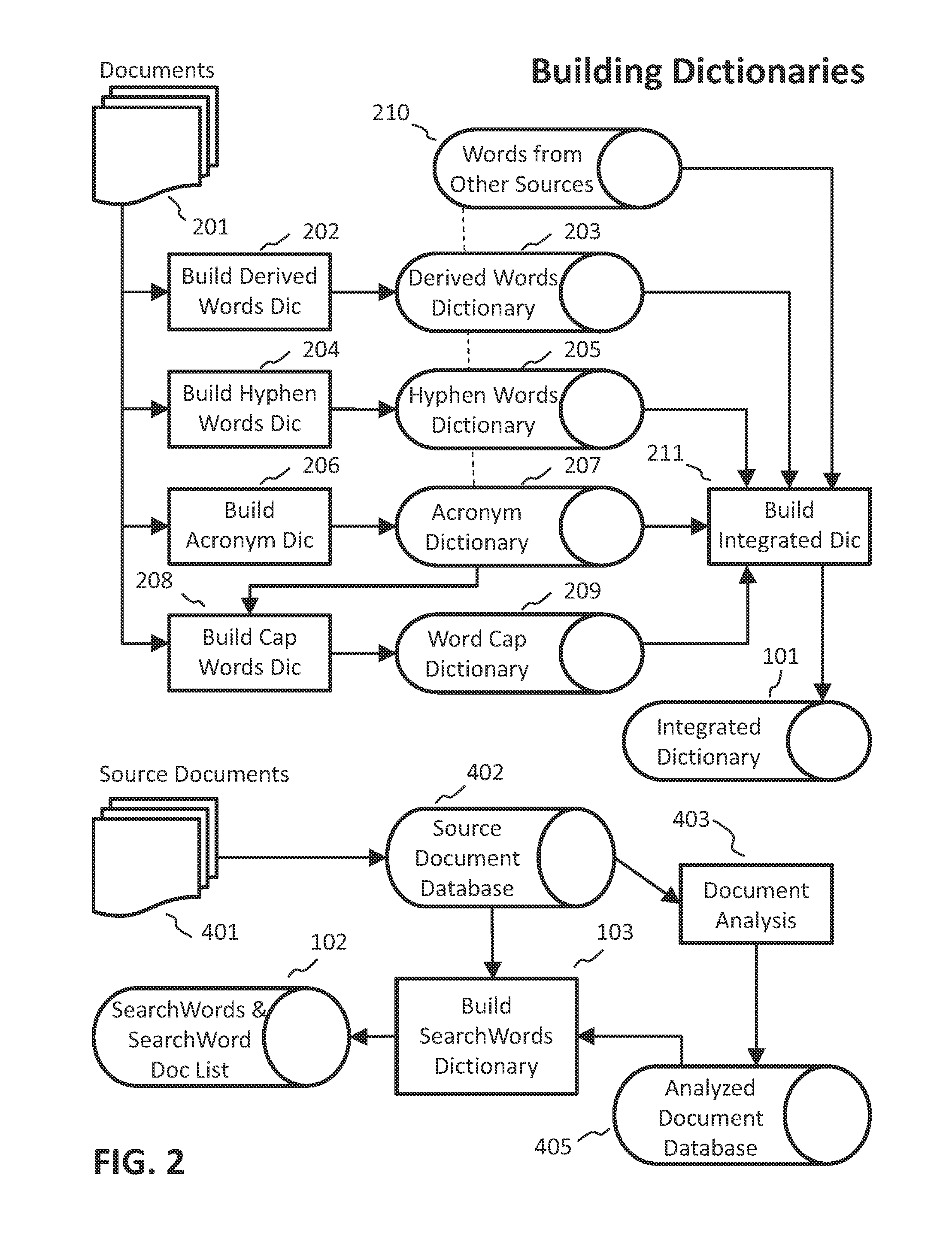

Method and system for document classification or search using discrete words

ActiveUS20120117082A1Quick matchImprove versatilityDigital data information retrievalDigital data processing detailsDocument preparationDocumentation

A method of operating a computerized document search system where information is matched against a database containing documents in response to user queries includes receiving a query identifying a source document that has information content related to the documents within the database. Important words within the source document are detected automatically, where at least one of the important words has been processed using at least two dictionary functions consisting of Derived Words, Acronym, Word Capitalization, and Hyphenation. An importance value is generated for important words in a processed document using a WordRatio and at least one of a selected set of values. A score is generated for a processed document based partly on the importance value of at least one important word in that document. A document list is created for identifying documents that are related to a source document.

Owner:NEXTGEN DATACOM

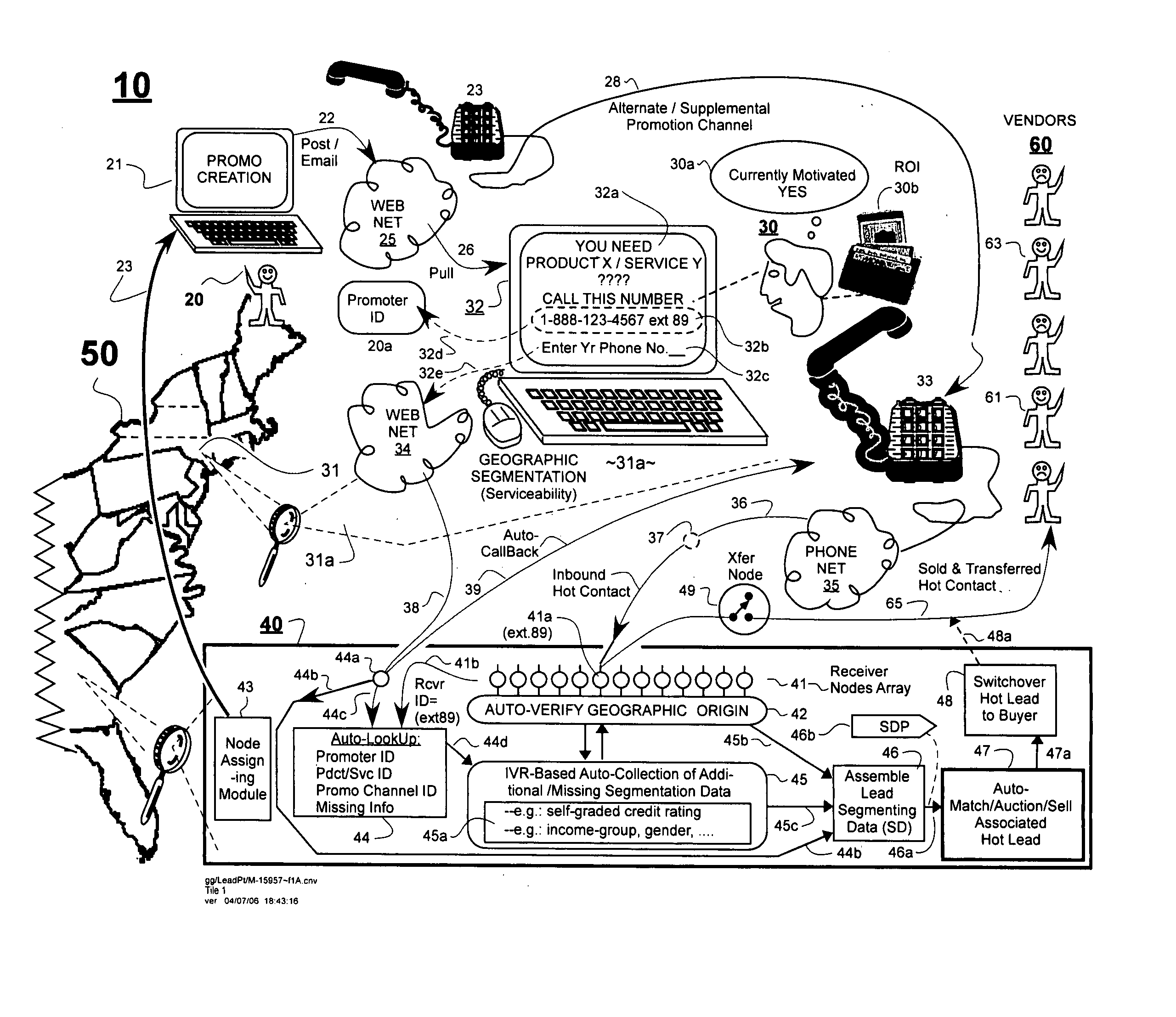

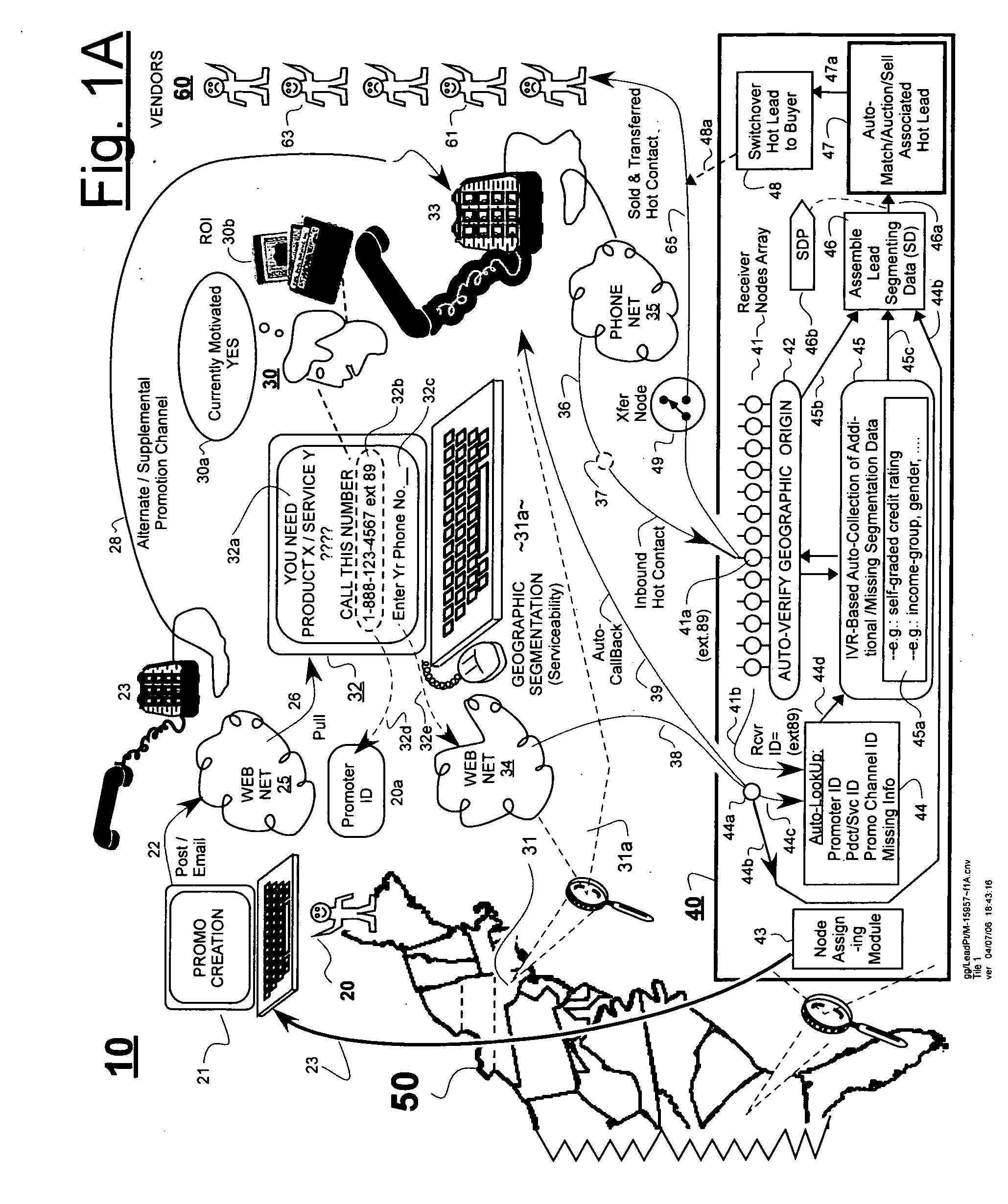

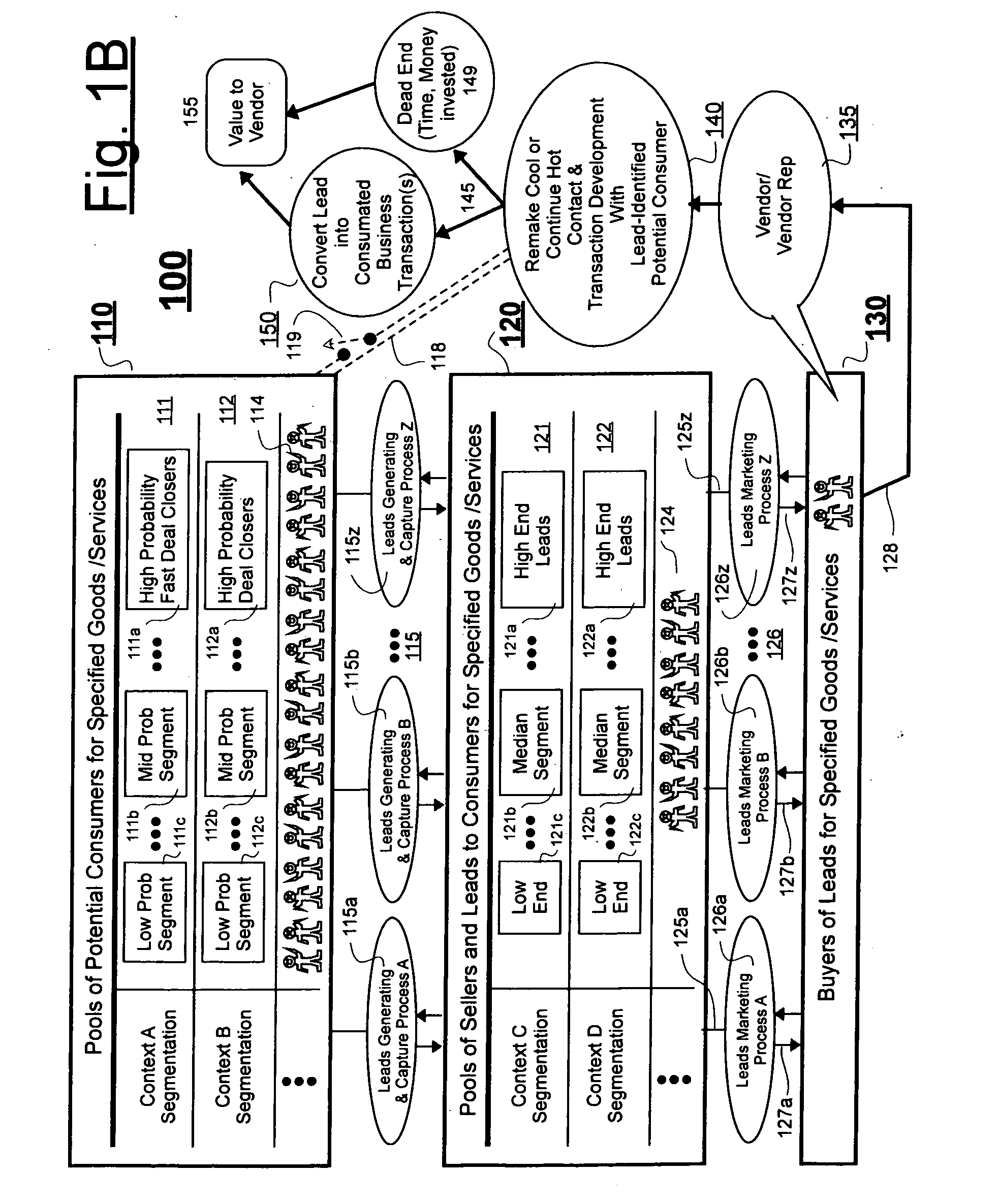

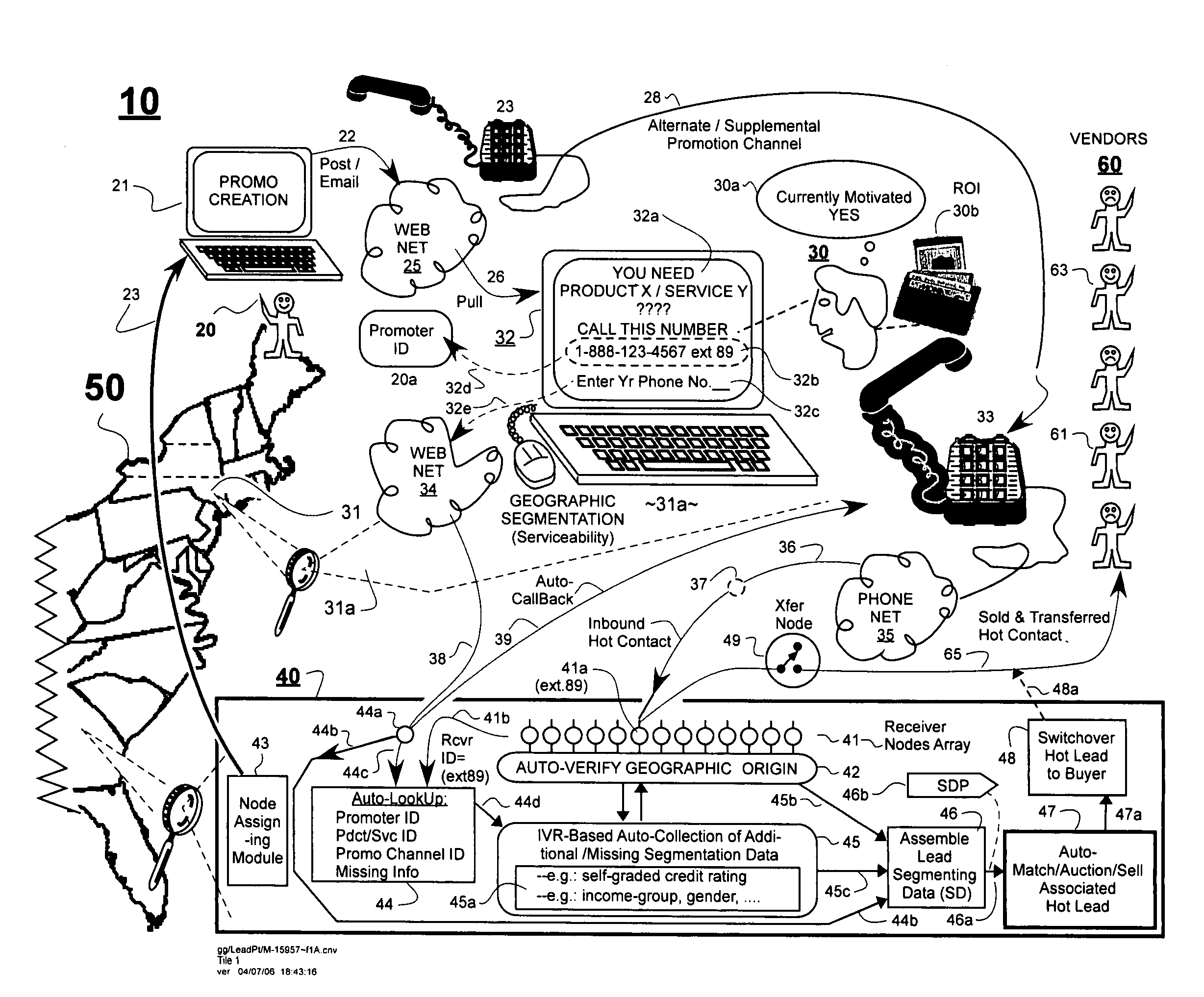

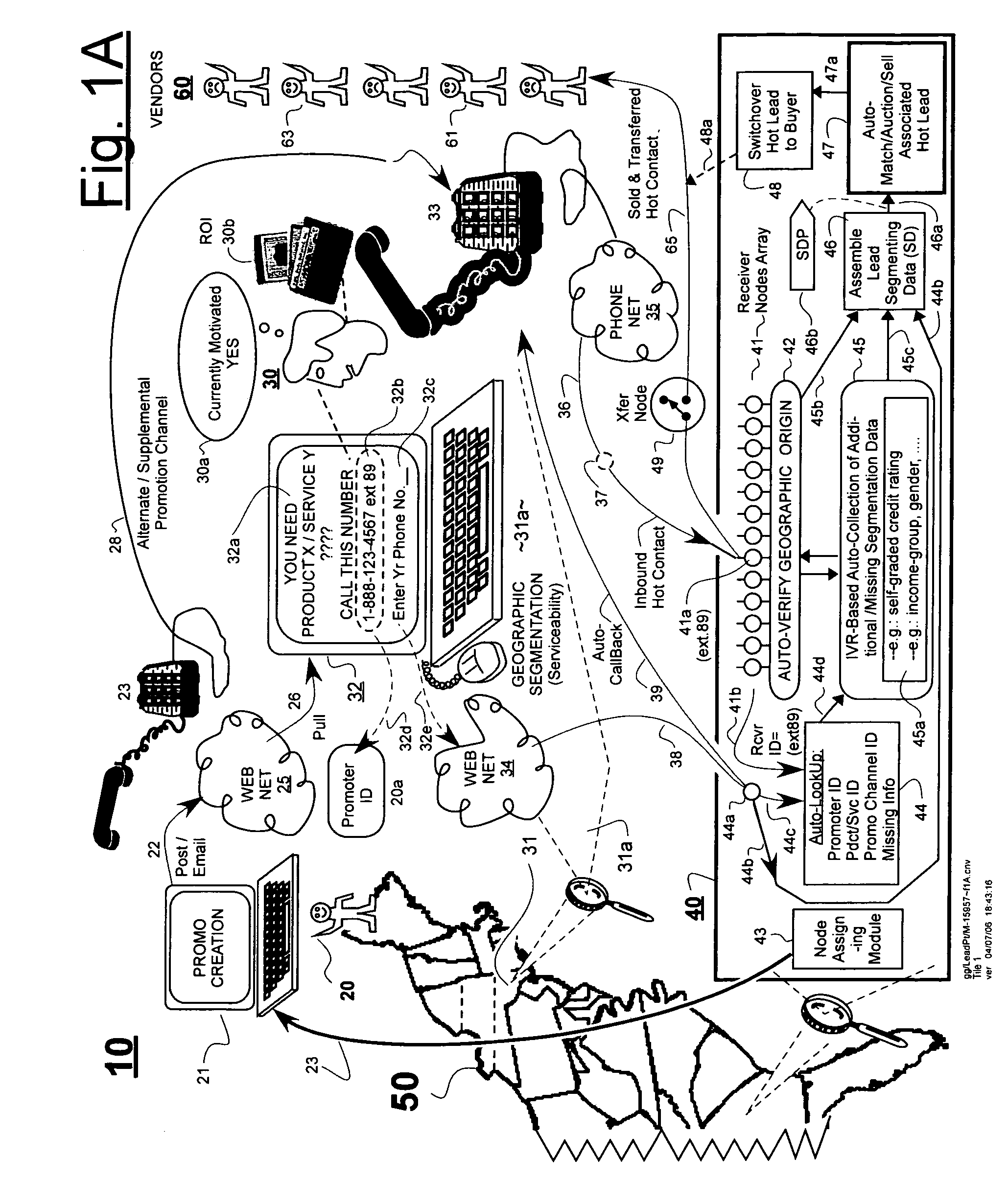

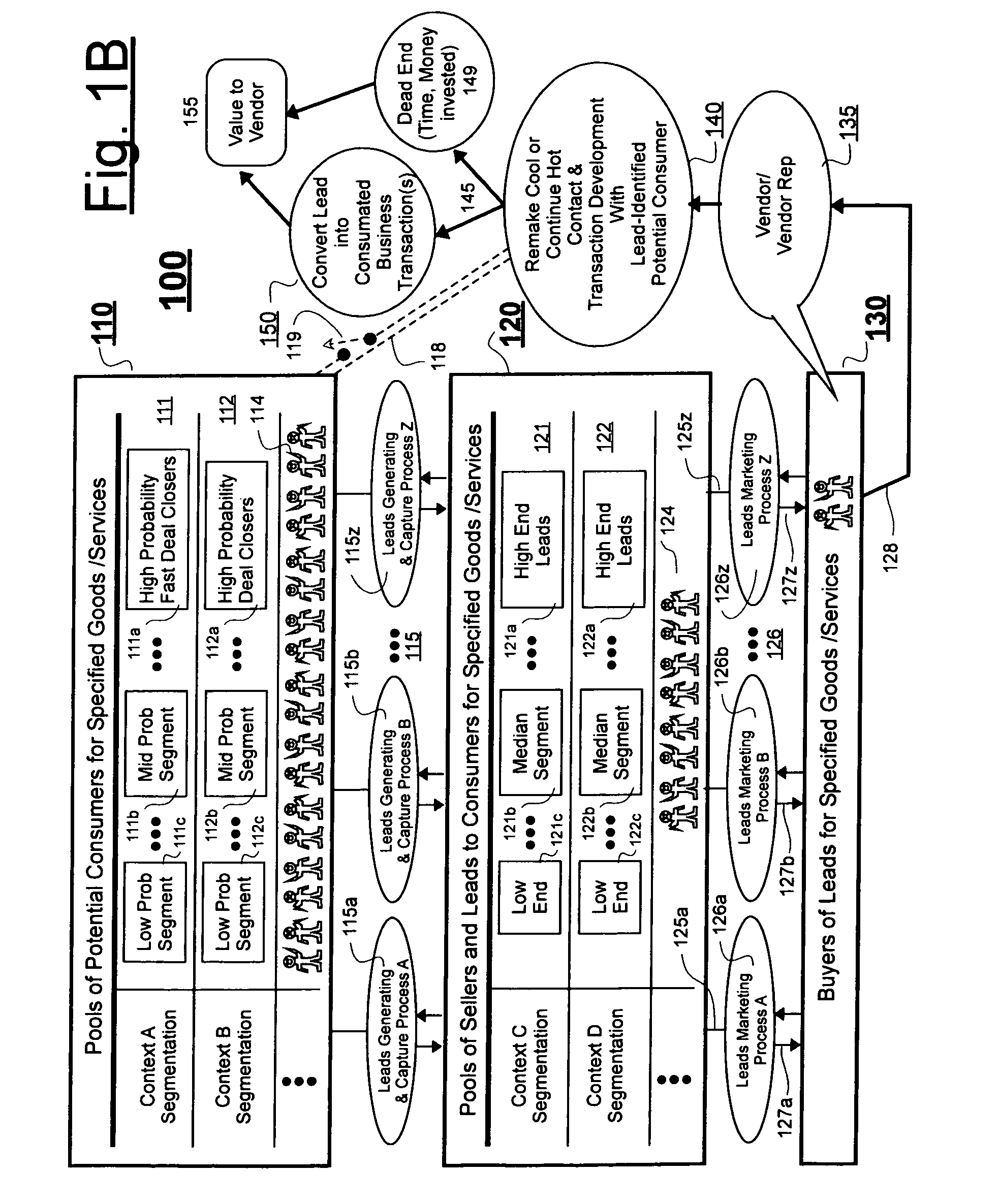

Automated attachment of segmentation data to hot contact leads for facilitating matching of leads to interested lead buyers

ActiveUS20060265259A1Reduce probabilityWaste timeFinanceSpecial data processing applicationsLive voiceWeb site

In an automated leads-and-bids matching system, bid profiles are defined to describe desires of lead buyers. Received leads are matched to active ones of the bid profiles whose specifications the leads substantially match. Lead segmentation data is captured on-the-fly for example by inducing potential consumers to navigate their way through tree-organized web sites that categorize the consumers according to their geographic location, income / revenue range, class of products desired and / or other attributes. Live voice or other telecommunication connections to the pre-classified consumers are coupled to corresponding, pre-classified telecommunication nodes of a call processing system. The call processing system deduces the segmentation data of the consumers from the identities of the pre-classified nodes through which their connections pass. The deduced segmentation data is passed to an automated matching system or auctioning subsystem that finds the highest bids for each given lead. A quality rating database rates the quality of leads provided by different sellers. A price discounting engine discounts the amount paid to sellers who are hot-rated as sources of inferior leads.

Owner:LEADPOINT

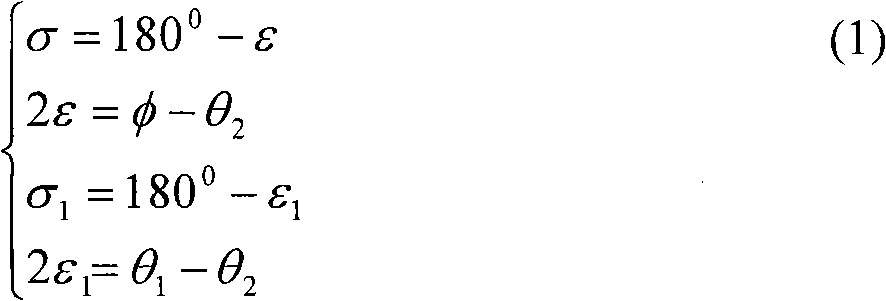

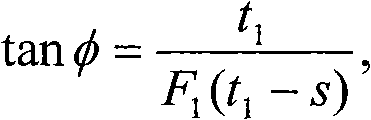

Stereo vision measuring apparatus based on binocular omnidirectional visual sense sensor

Disclosed is a stereo vision measuring device based on a binocular omni-directional vision sensor. Each ODVS composing the binocular omni-directional vision sensor adopts the design of mean angle resolution. The parameters of two image collection cameras are in complete accord and in possession of a pretty good symmetry, and can quickly realize the point-to-point matching. The device adopts a unified spherical coordinate in the process of data collection, processing, description and representation of space objects in terms of centering on human in visual space, and adopts the elements of distance sense, direction sense and color sense to express features of each characteristic point, thereby simplifying the complication of calculus, omitting the calibration of the cameras, facilitating the feature extraction and realizing the stereo image matching easily, finally realizing the purpose of high-effective, real-time, and accurate stereo vision measurement. The device can be applied in a plurality of fields of industrial detection, object identification, robot automatic guidance, astronautics, aeronautics, military affairs, etc.

Owner:汤一平

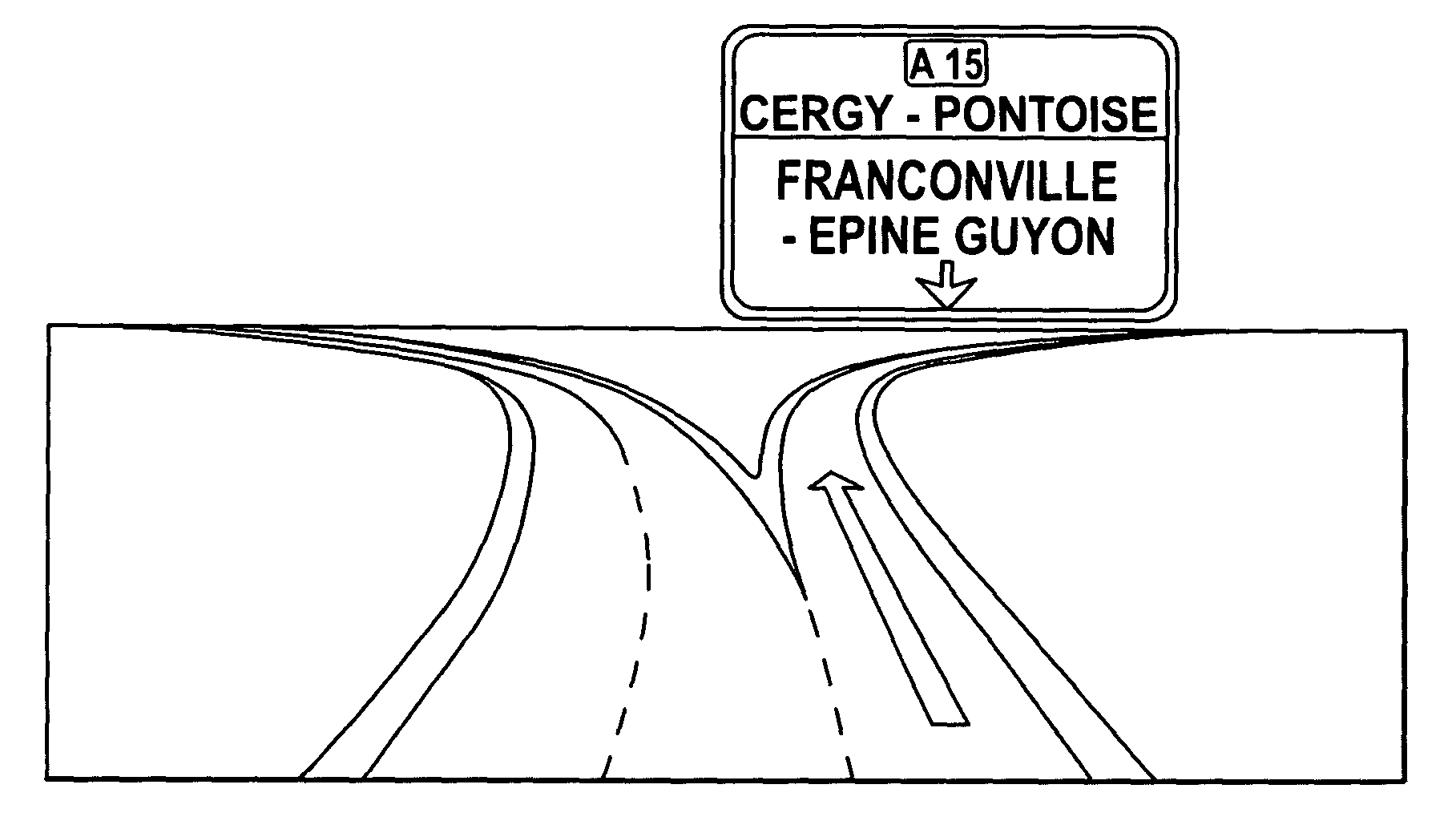

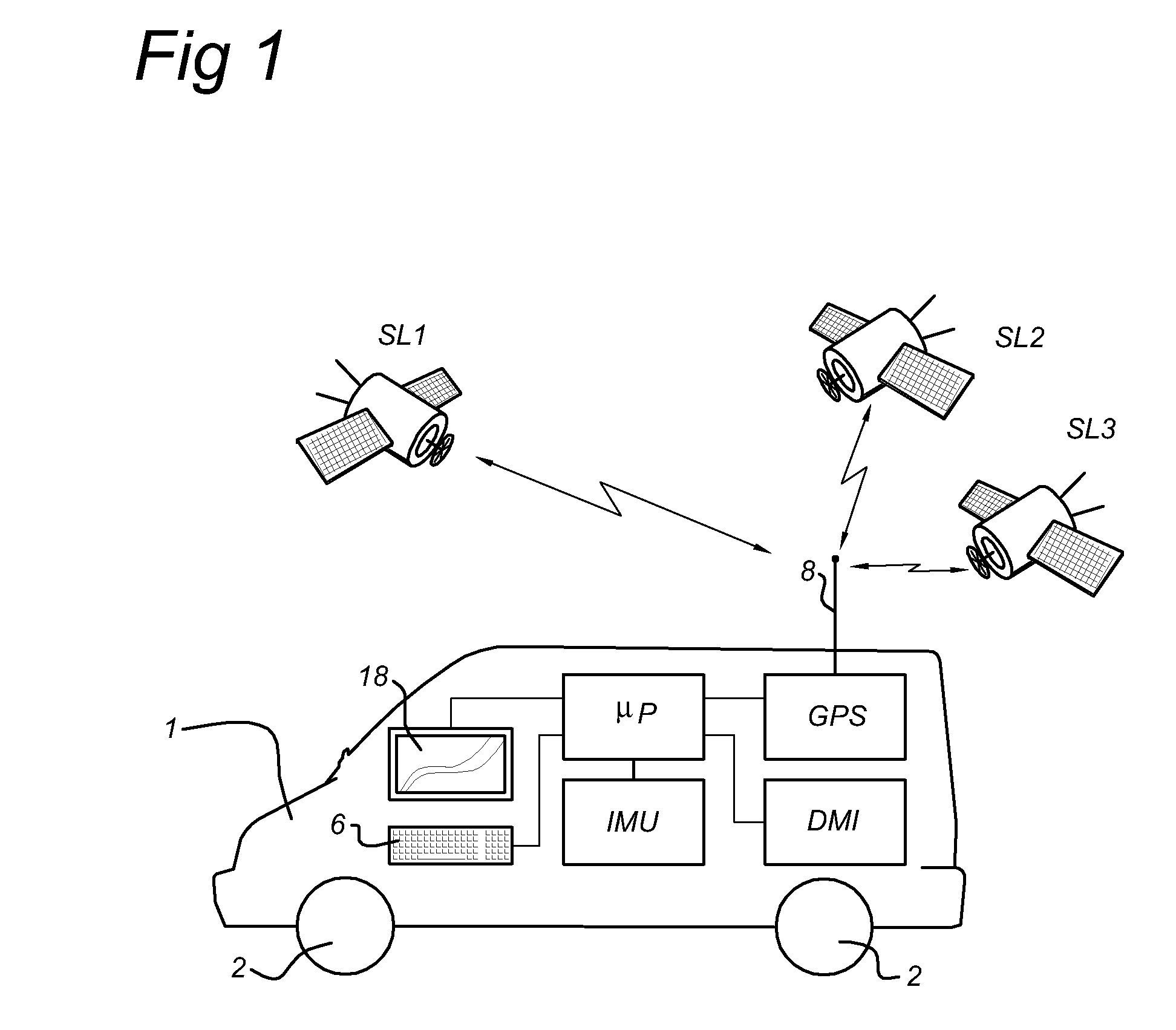

Apparatus for and method of junction view display

ActiveUS8612151B2Quick understandingQuick matchInstruments for road network navigationRoad vehicles traffic controlRoute planning softwareDisplay device

A navigation method and navigation system are disclosed. In at least one embodiment, the method has the following actions: a.) receiving position data from a position determining device; b.) when approaching a junction with the navigation system, displaying the junction view on a display, the junction view showing data as to a real-life view of the junction inclusive of an image of each signpost present on the junction as visible to a user of the navigation system; c.) receiving route information from route planning software indicating a route to be followed by the user; and d.) highlighting on the display a signpost related to a road segment to be followed by the user relative to all other signposts as shown on the display.

Owner:TOMTOM NAVIGATION BV

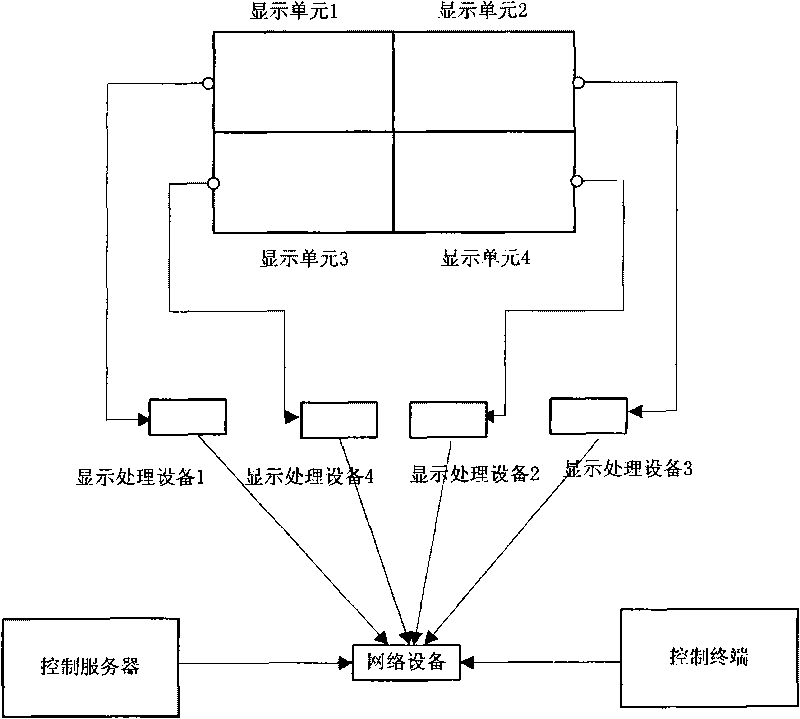

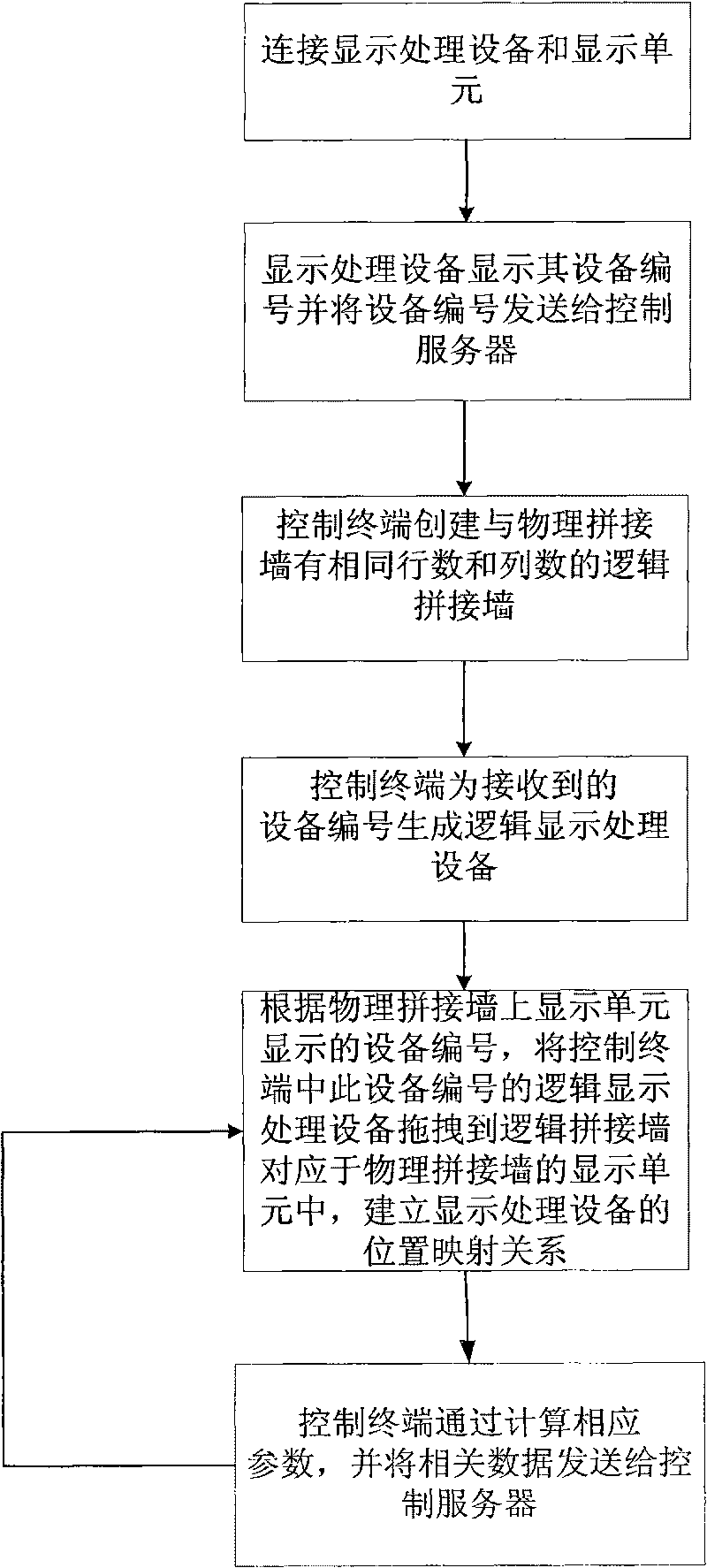

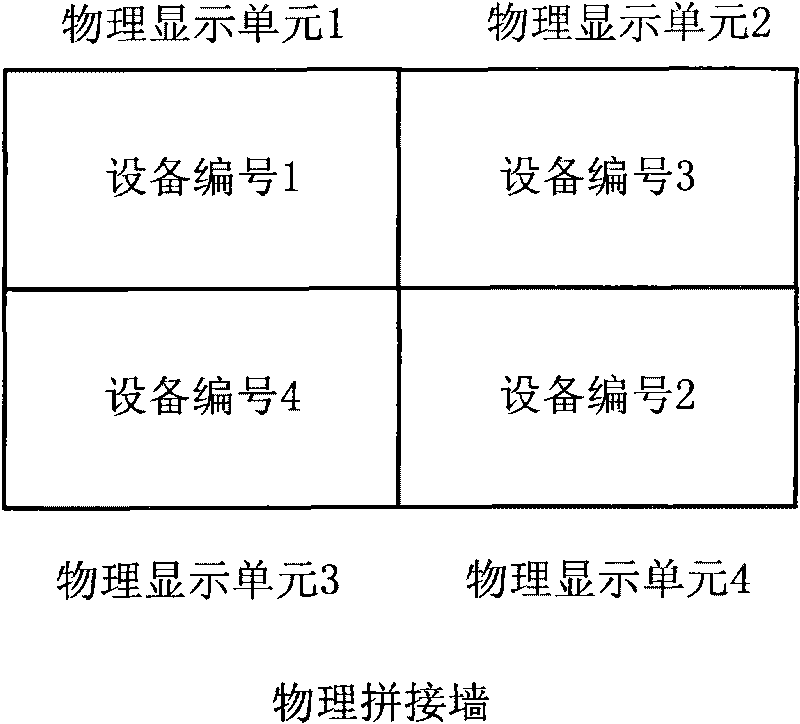

Spliced wall body allocation system and position mapping method for establishing display units

InactiveCN101763842AQuick matchReduce workloadCathode-ray tube indicatorsDigital output to display deviceComputer terminalWorkload

The invention discloses a spliced wall body allocation system, comprising a plurality of display processing equipment, a plurality of display units, a control server and a control terminal; wherein, the control server and the control terminal are connected with a plurality of the display processing equipment networks, and the display processing equipment are connected with the display units. The invention also discloses a position mapping method for establishing display units by the system. In the method, the display processing equipment and the display units are connected in arbitrary consequences; the characteristic numbers of the display processing equipment are self-displayed; logical spliced walls corresponding to physical spliced walls and corresponding logical display processing equipment are established by the control terminal; the logical display processing equipment in the control terminal are dragged into the display units corresponding to the logical spliced walls according to the characteristic numbers on the physical spliced walls to establish position display relationships of the display processing equipment. The invention has the advantages of speediness, less workload and low cost.

Owner:GUANGDONG VTRON TECH CO LTD

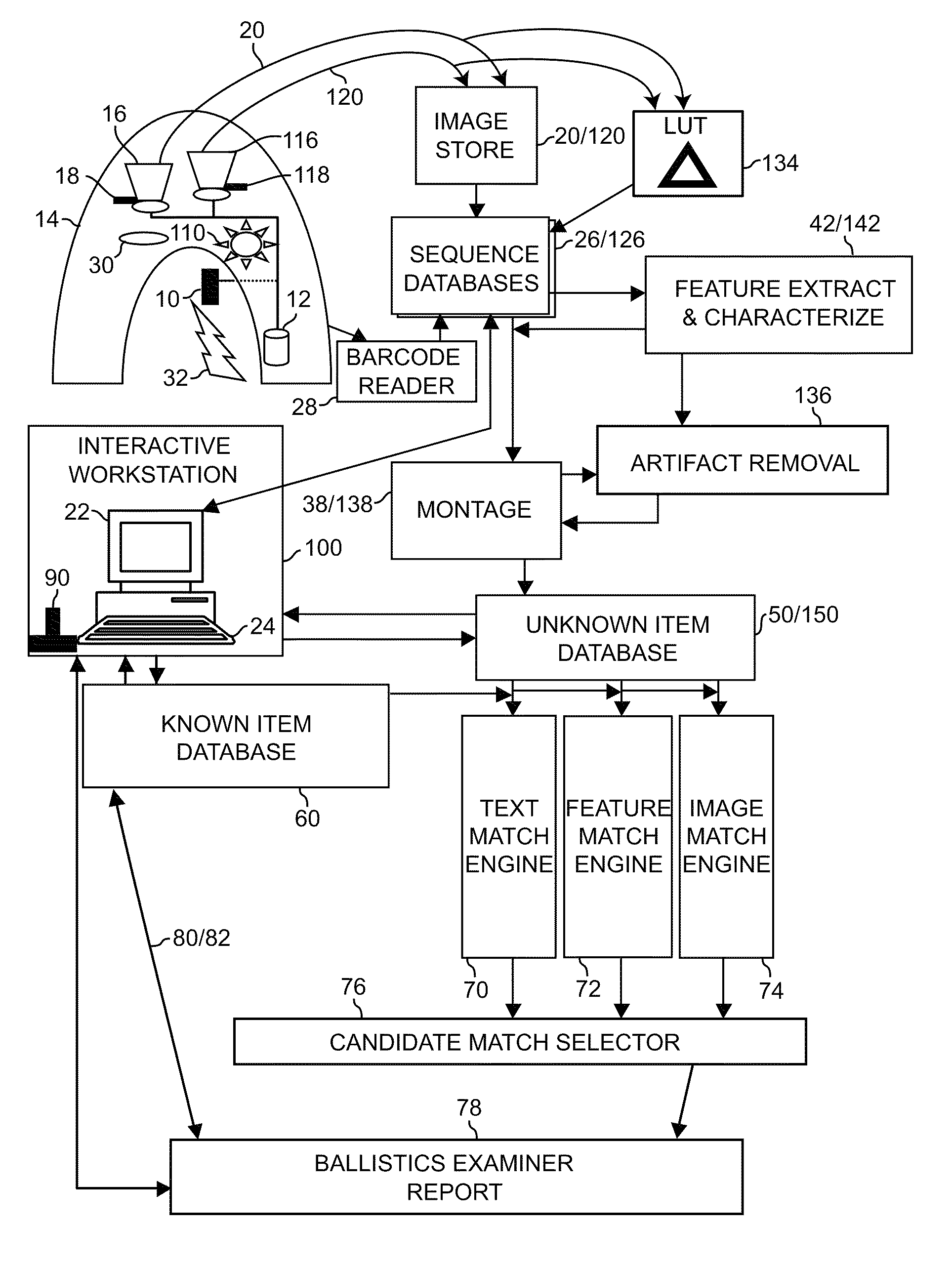

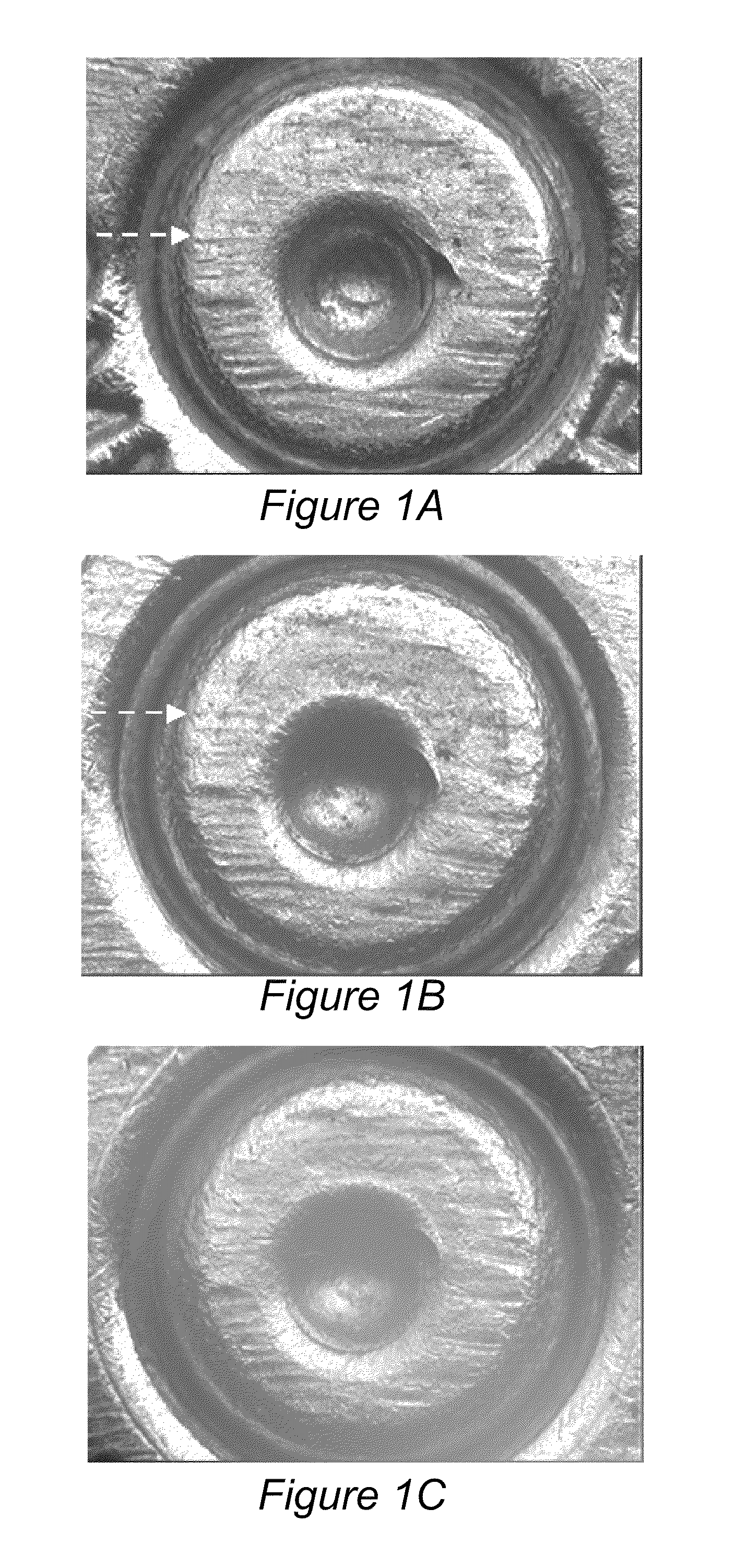

Method and apparatus for alignment, comparison and identification of characteristic tool marks, including ballistic signatures

InactiveUS7822263B1Quick matchAmmunition testingThree-dimensional object recognitionEngineeringMinutiae

Systematic use of infrared imaging characterizes marks made on items and identifies the particular marking tool with better accuracy than use of visual imaging. Infrared imaging performed in total darkness eliminates shadows, glint, and other lighting variations and artifacts associated with visible imaging. Although normally used to obtain temperature measurements, details in IR imagery result from emissivity variations as well as thermal variations. Disturbing an item's surface texture creates an emissivity difference producing local changes in the infrared image. Identification is most accurate when IR images of unknown marks are compared to IR images of marks made by known tools. However, infrared analysis offers improvements even when only visual reference images are available. Comparing simultaneous infrared and visual images of an unknown item, such as bullet or shell casing, can detect illumination-induced artifacts in the visual image prior to searching the visual database, thereby reducing potential erroneous matches. Computer numerically controlled positioning of the toolmark relative to imaging sensors which use fixed focus optics with shallow depth of focus, varying focus distance and orientation systematically to construct a sequence of images, maximizes reliability of resulting images and their comparisons.

Owner:PROKOSKI FRANCINE J

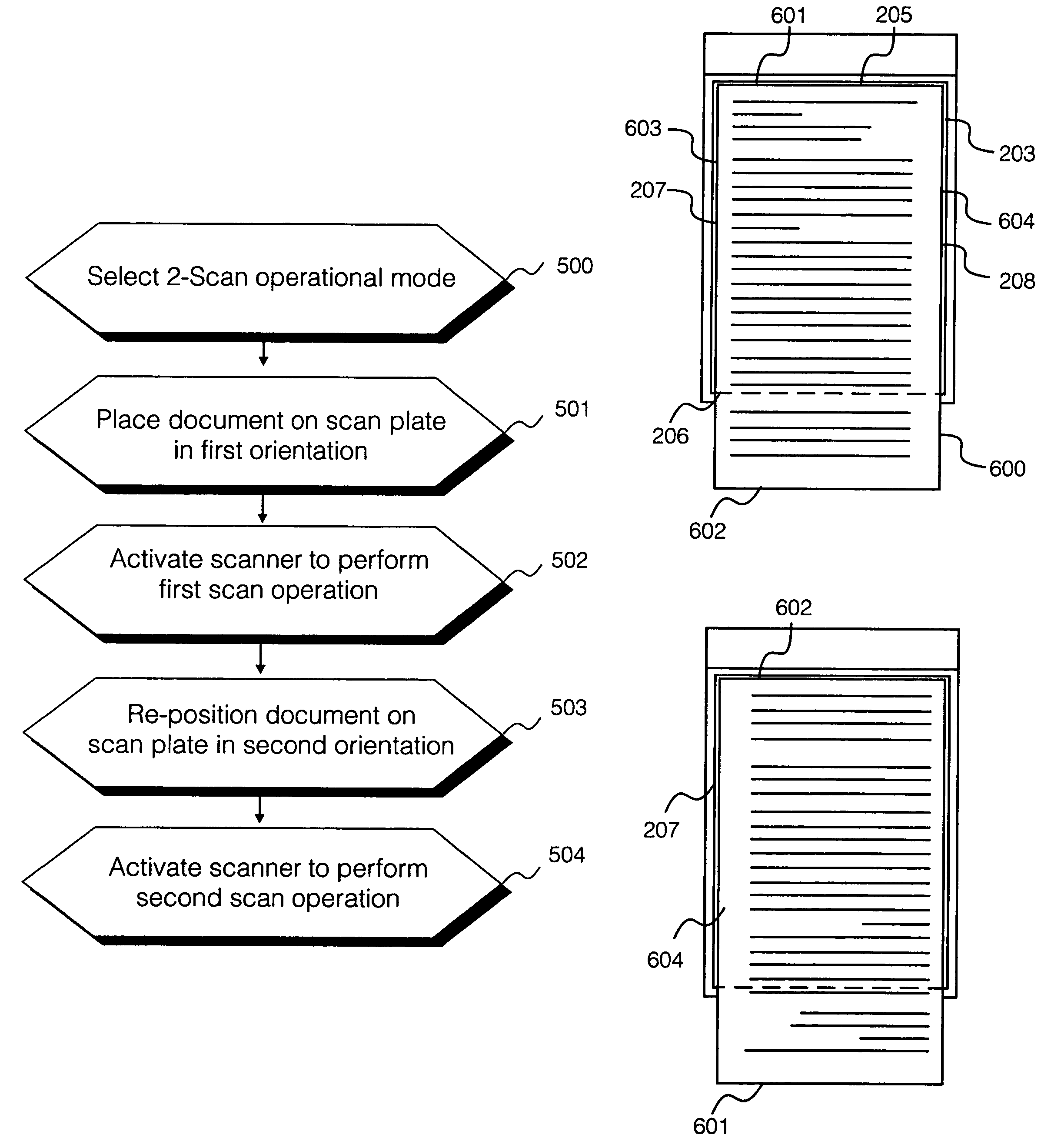

Method and apparatus for scanning oversized documents

InactiveUS6975434B1Expanded size rangeQuick matchCharacter and pattern recognitionPictoral communicationPersonal computerTwo step

An image capture apparatus comprises a computer device, for example a personal computer, and a scanning device, for example a flat bed scanning device, configured to operate a two-scan image capture process followed by data processing for combining first and second images obtained in said two-step image capture process, and a three-step image capture process followed by data processing for combining first, second and third images obtained in said three-step image capture process for obtaining a combined full image of a document. Algorithms are disclosed for stitching first and second images together to obtain a combined image data. In both the two-step and three-step image capture operation and subsequent data processing, a document having a size larger than an image capture area of said image capture device can be combined to produce a combined image data representing the whole of the document in a fully automated manner without the need for user intervention in matching images.

Owner:HEWLETT PACKARD DEV CO LP

Intelligent control method of cabinet system

ActiveCN104217502AEasy to operateAchieve matchingApparatus for meter-controlled dispensingControl signalComputer terminal

The invention discloses an intelligent control method of a cabinet system. The cabinet system comprises a cabinet, an electronic coded lock, a control module, a communication module and a user intelligent terminal, wherein the control module, the communication module and the user intelligent terminal are sequentially connected; the control module is used for controlling the electronic coded lock. The cabinet system is characterized in that the communication module is connected to a server; the server is connected to the user intelligent terminal and stores the state information of the cabinet and using account information of client software of the user intelligent terminal. The intelligent control method comprises the steps of controlling storage operation and taking operation. Due to the fact that a user terminal scans the only code to be communicated with the remote server, the server sends a control signal to control the electronic coded lock to be unlocked to open the cabinet, and intelligent opening and closing operation is realized, the problems of operation complexity and long waiting time caused by manual input are solved, a client software account is very quickly and effectively matched with a specific cabinet in the server by the way, and the cabinet is also conveniently and quickly operated.

Owner:浙江标谱软件科技有限公司

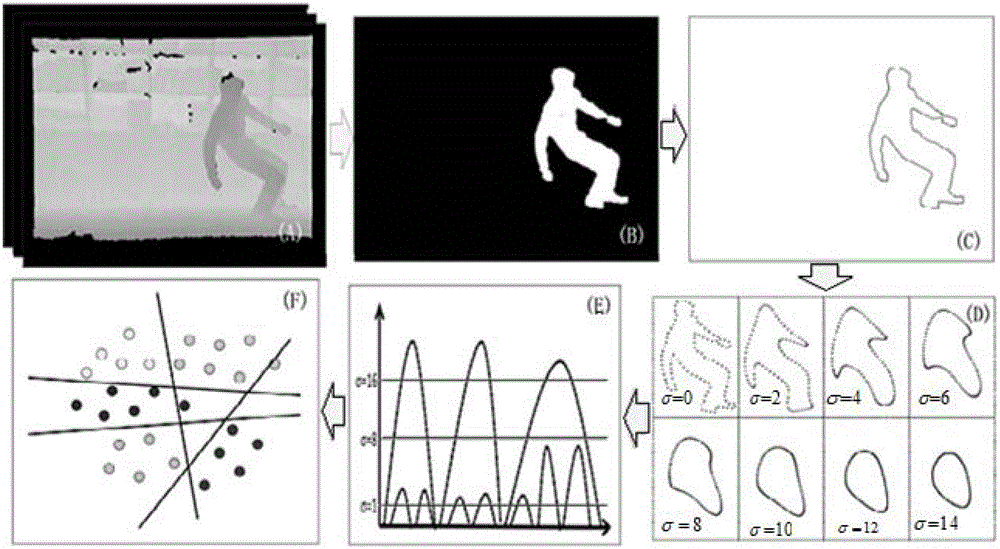

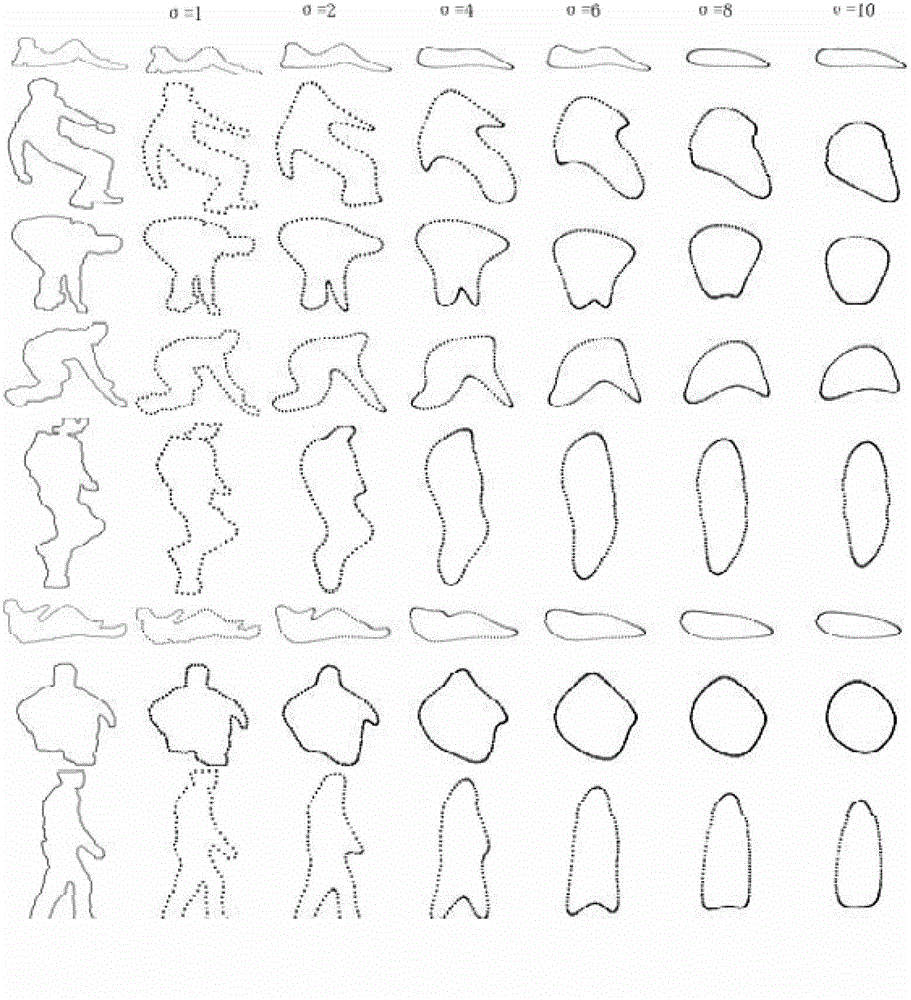

Human falling detection method based on machine vision

InactiveCN102722721AQuick matchImprove detection accuracyImage analysisCharacter and pattern recognitionLearning machineMachine vision

The invention provides a human falling detection method based on machine vision. Under the conditions that all detected objects are people in indoor environment and the activities of all people can be captured by a depth camera, the method comprises the following steps of: (1) acquiring an image by using the depth camera; (2) subtracting a background from the image which is acquired, and extracting a foreground from the image; (3) acquiring a foreground contour by using a binary image contour extraction algorithm; (4) performing convolution computation on the foreground contour and Gaussian functions in different scales, mapping a contour image to a curvature scale space (CSS) to form a CSS image, extracting peak points of the CSS image, and thus obtaining a video word bag based on curvature scale characteristics by the peak points in different scales; and (5) training an extreme learning machine classifier by using the video word bag which is obtained. By adoption of the method, under the condition of few training samples, an accurate falling detection result can be obtained within a short training time.

Owner:SHANDONG UNIV

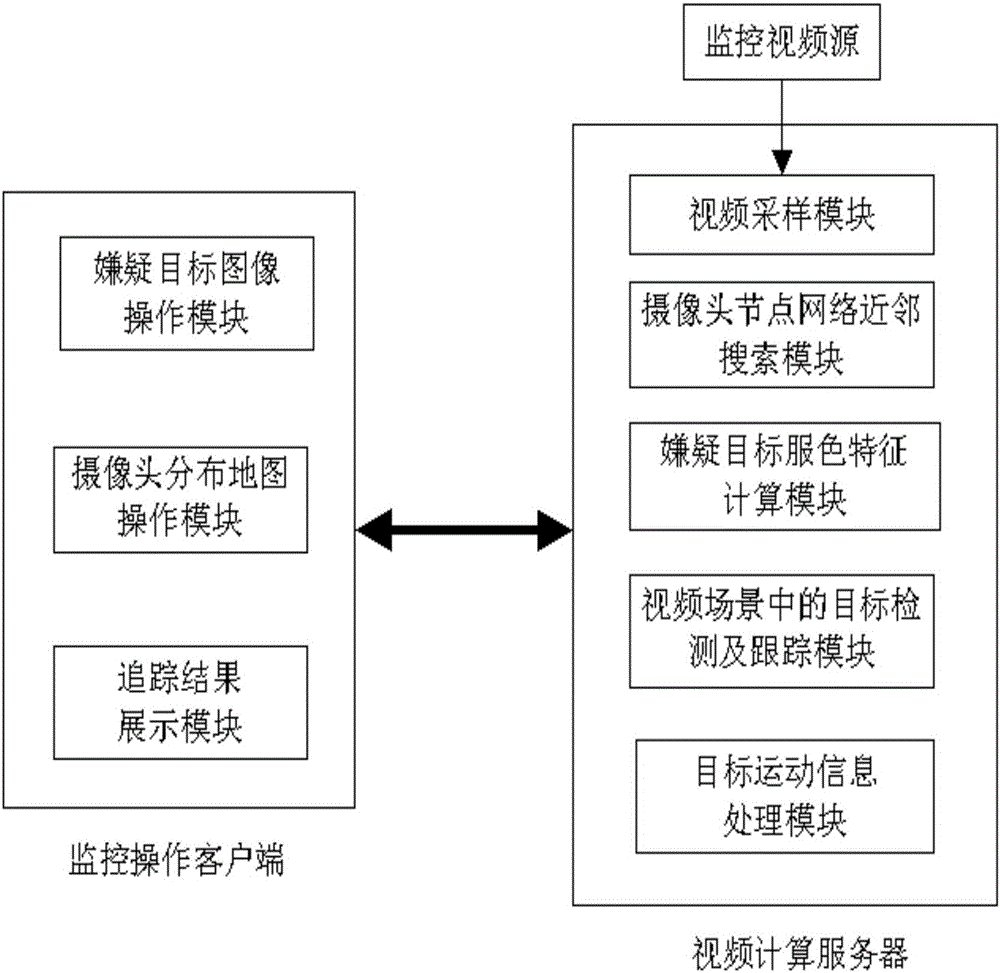

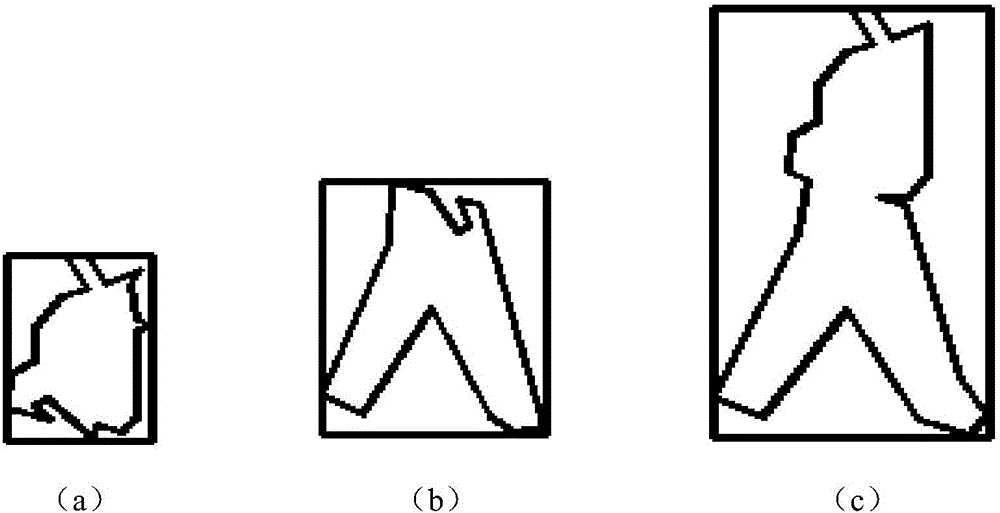

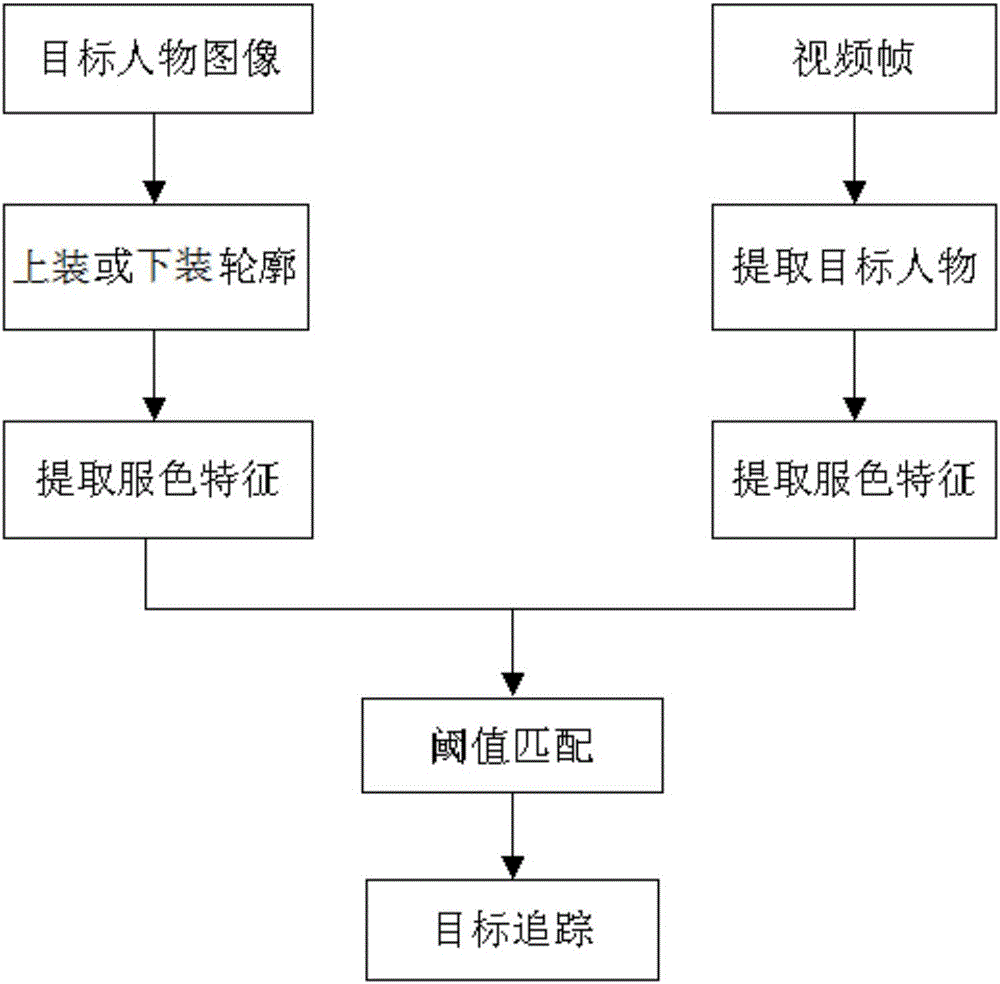

Object tracking system and object tracking method in camera-distributed map

ActiveCN106096577AEasing the hard work of staring at screen searchesLighten the hard workCharacter and pattern recognitionFeature extractionSafety monitoring

The invention discloses an objective tracking system and an objective tracking method in a camera-distributed map. The object tracking system comprises a monitoring operation client and a video calculating server. The monitoring operation client inputs an image of a suspected object and sets a to-be-searched range through the camera-distributed map. The video calculating server performs processing on a video and an image which are obtained through sampling. The object tracking method comprises the steps of extracting color characteristic of the image of the suspected target, detecting and tracking the target in a video scene, recording motion information of the target, and then transmitting a corresponding calculating result to the monitoring operation client; on the map in which camera nodes are marked by the monitoring operation client, acquiring the path track of the suspected object on the map according to the camera nodes where the suspected object appears, and simultaneously collecting information such as advancing speed and state of the target, thereby facilitating analysis by safety monitoring personnel. The objective tracking system and the objective tracking method have advantages of greatly reducing work difficulty in observing a screen for searching, making personnel concentrate on effective video segments, and realizing relatively high application value at a scientific police improvement aspect.

Owner:徐州汉泽信息科技有限公司

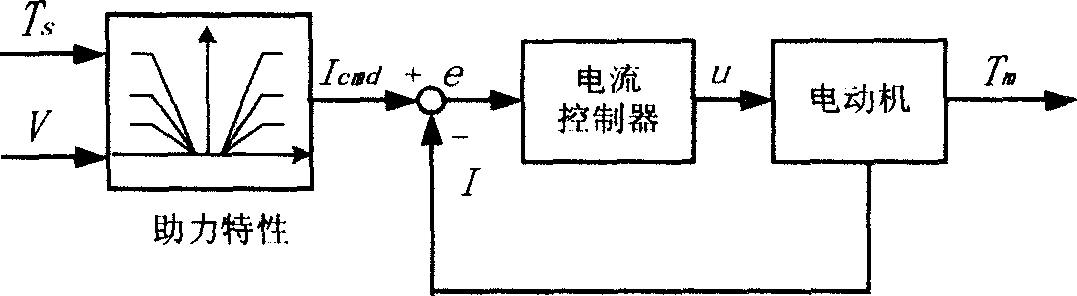

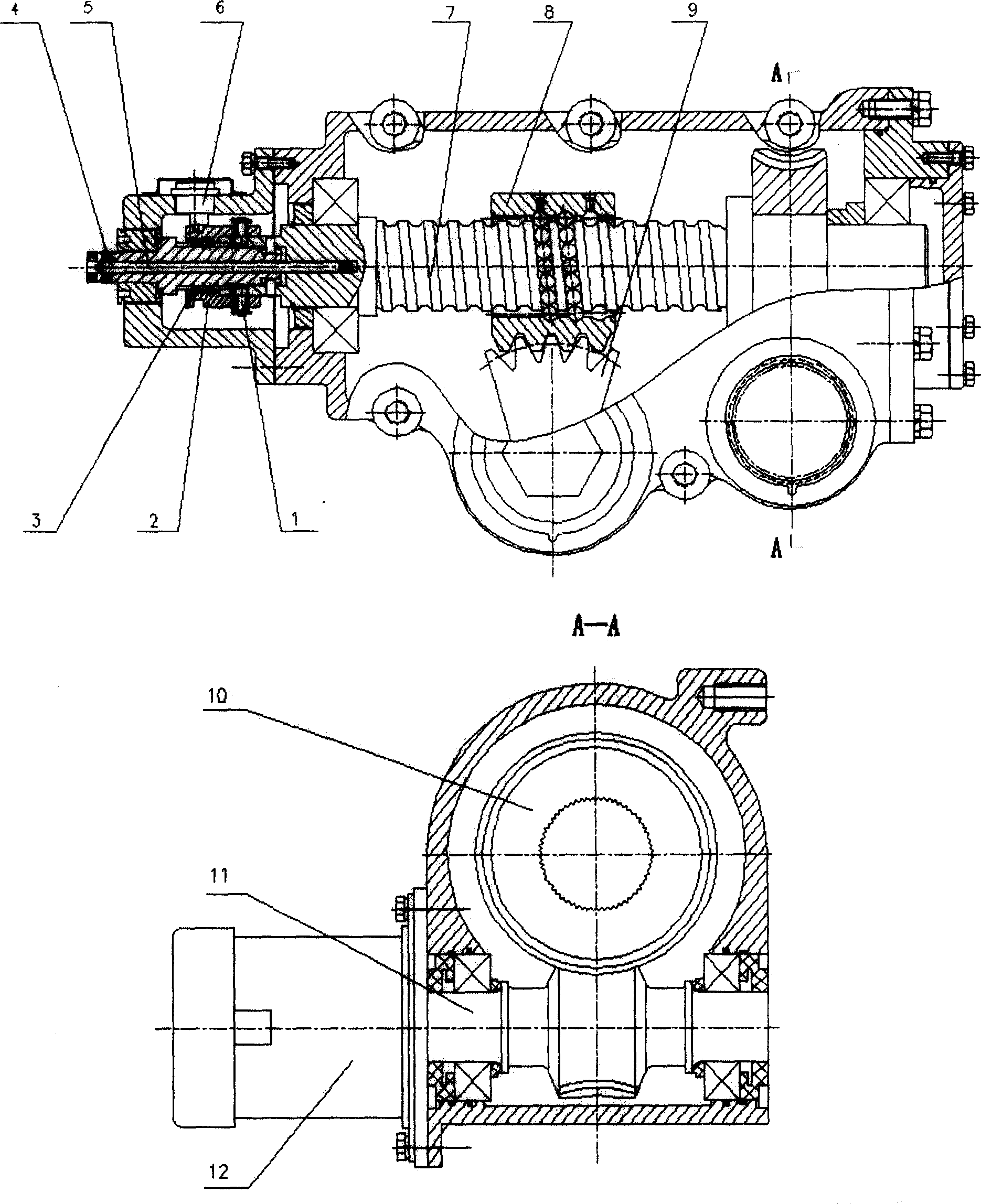

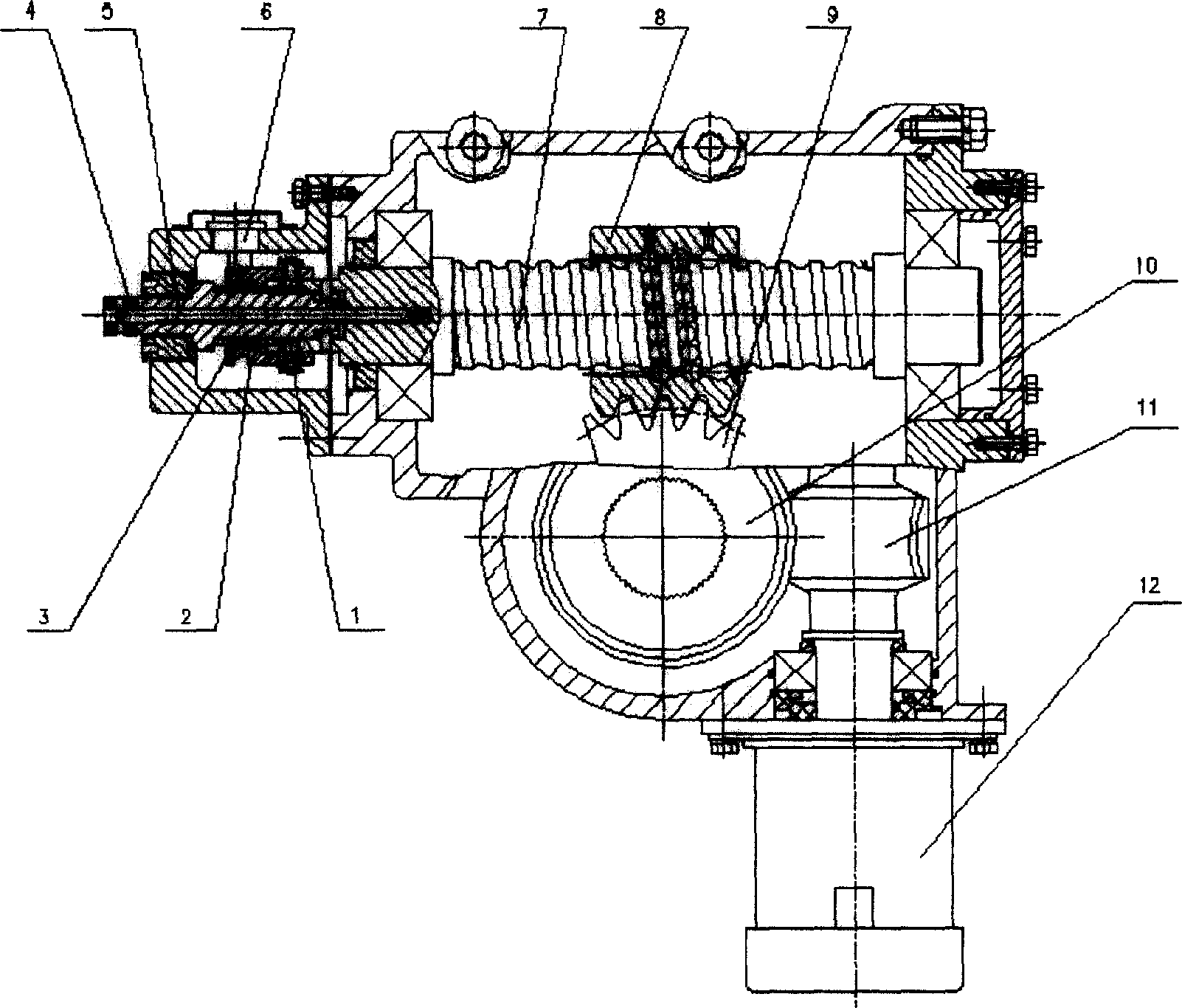

Circular ball type electric booster steering device

ActiveCN1647984AReduce disturbanceReduce pollutionMechanical steering gearsElectrical steeringElectric power steeringElectronic controller

The circular ball type electric booster steering device has, except screw, nut, gear sector, steel ball and other mechanical parts, torque sensor, boosting motor, decelerating mechanism, electronic controller unit, etc. The electronic controller unit determines the target current of the motor based on the steering disc torque and the vehicle speed to complete the feedback tracking control of the motor current. The decelerating mechanism has input connected to the motor and output connected to the screw or gear sector shaft in the circular ball steering unit. The present invention has saving in energy, provides proper power force fitting different running conditions, and has less parts, light weight, compact structure and high automation.

Owner:BEIJING AUTONICS TECH

Automated attachment of segmentation data to hot contact leads for facilitating matching of leads to interested lead buyers

ActiveUS8571951B2Exact matchReduce probabilityFinanceSpecial data processing applicationsLive voiceWeb site

In an automated leads-and-bids matching system, bid profiles are defined to describe desires of lead buyers. Received leads are matched to active ones of the bid profiles whose specifications the leads substantially match. Lead segmentation data is captured on-the-fly for example by inducing potential consumers to navigate their way through tree-organized web sites that categorize the consumers according to their geographic location, income / revenue range, class of products desired and / or other attributes. Live voice or other telecommunication connections to the pre-classified consumers are coupled to corresponding, pre-classified telecommunication nodes of a call processing system. The call processing system deduces the segmentation data of the consumers from the identities of the pre-classified nodes through which their connections pass. The deduced segmentation data is passed to an automated matching system or auctioning subsystem that finds the highest bids for each given lead.

Owner:LEADPOINT

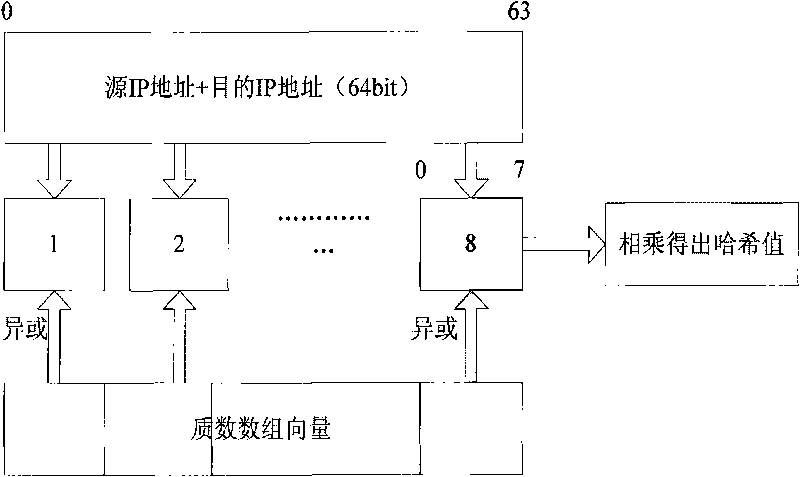

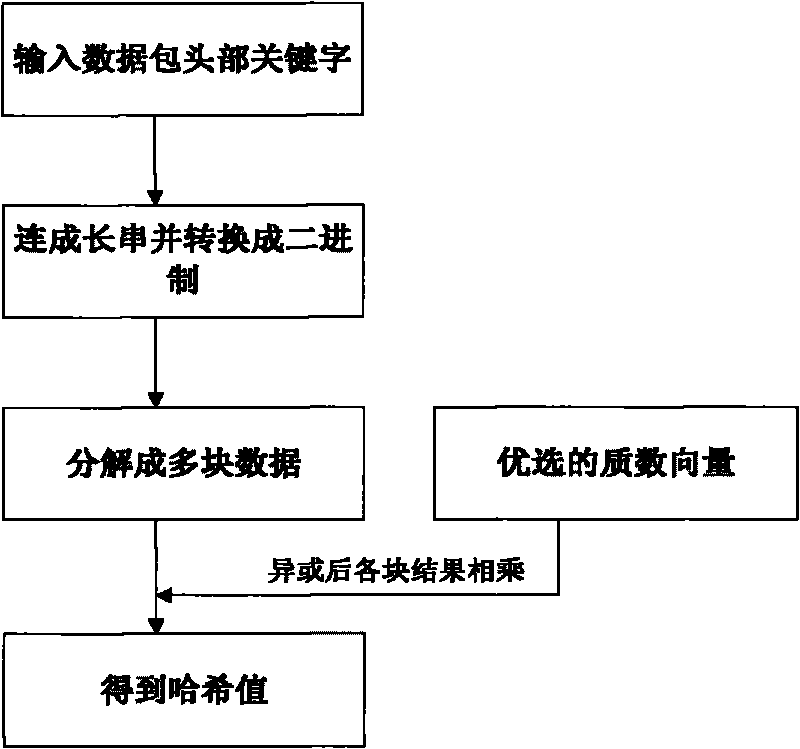

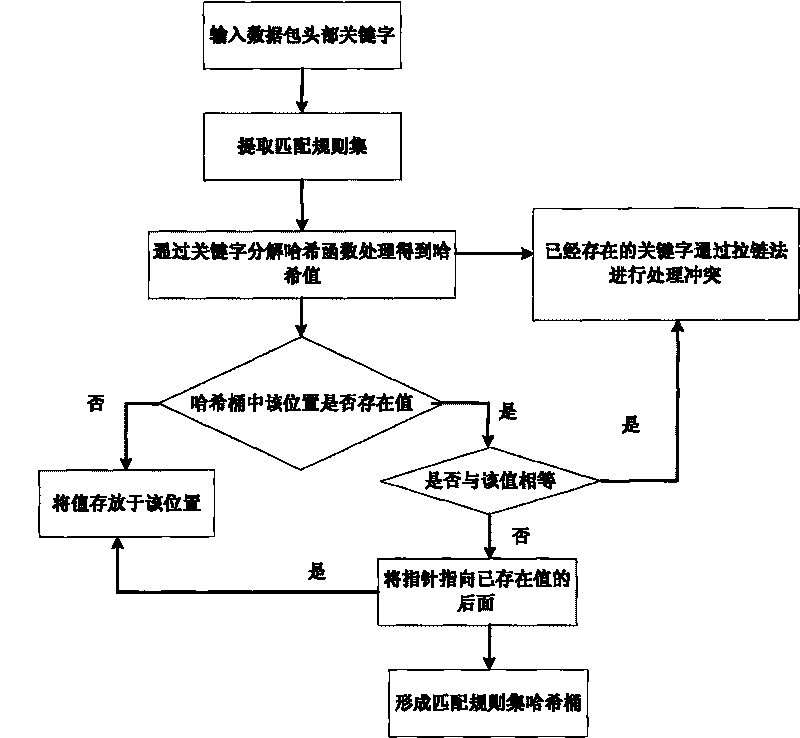

Fast flow classification method based on keyword decomposition hash algorithm

InactiveCN101753445AAccelerateReduce conflict rateData switching networksCollision rateTraffic volume

A fast flow classification method based on keyword decomposition hash algorithm relates to network flow measurement technology. The data blocks of multiple keywords of the packet head are connected into an integral binary string, and then the binary string is divided into a series of data blocks, the binary strings of the series of data blocks and prime numbers are performed with exclusion OR to obtain hash key values, the hash key values are processed by the hash function to obtain the matching rule set which is stored in a hush bucket, each matching rule set is simplified to a hash matched value stored in a matched linked list; the hash matched value is used as the index value of the linked list under query, the captured packets from the network receive keyword decomposition and hash value computation, and also perform quick flow matching with the rule sets in the hash bucket. The invention supports multiple keywords, is applicable to various classification modes, has high speed, low collision rate and is applicable to high speed network flow measurement.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

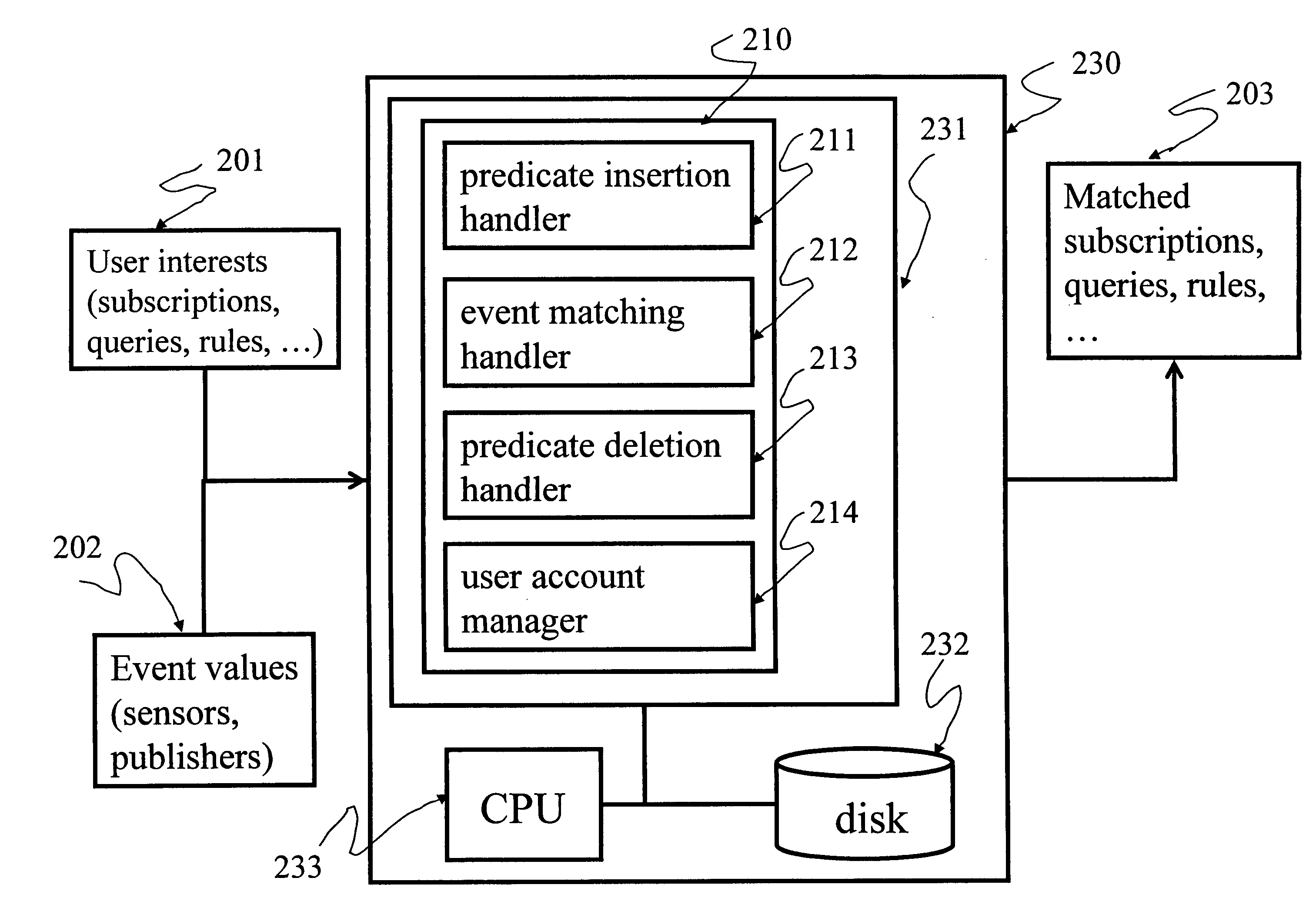

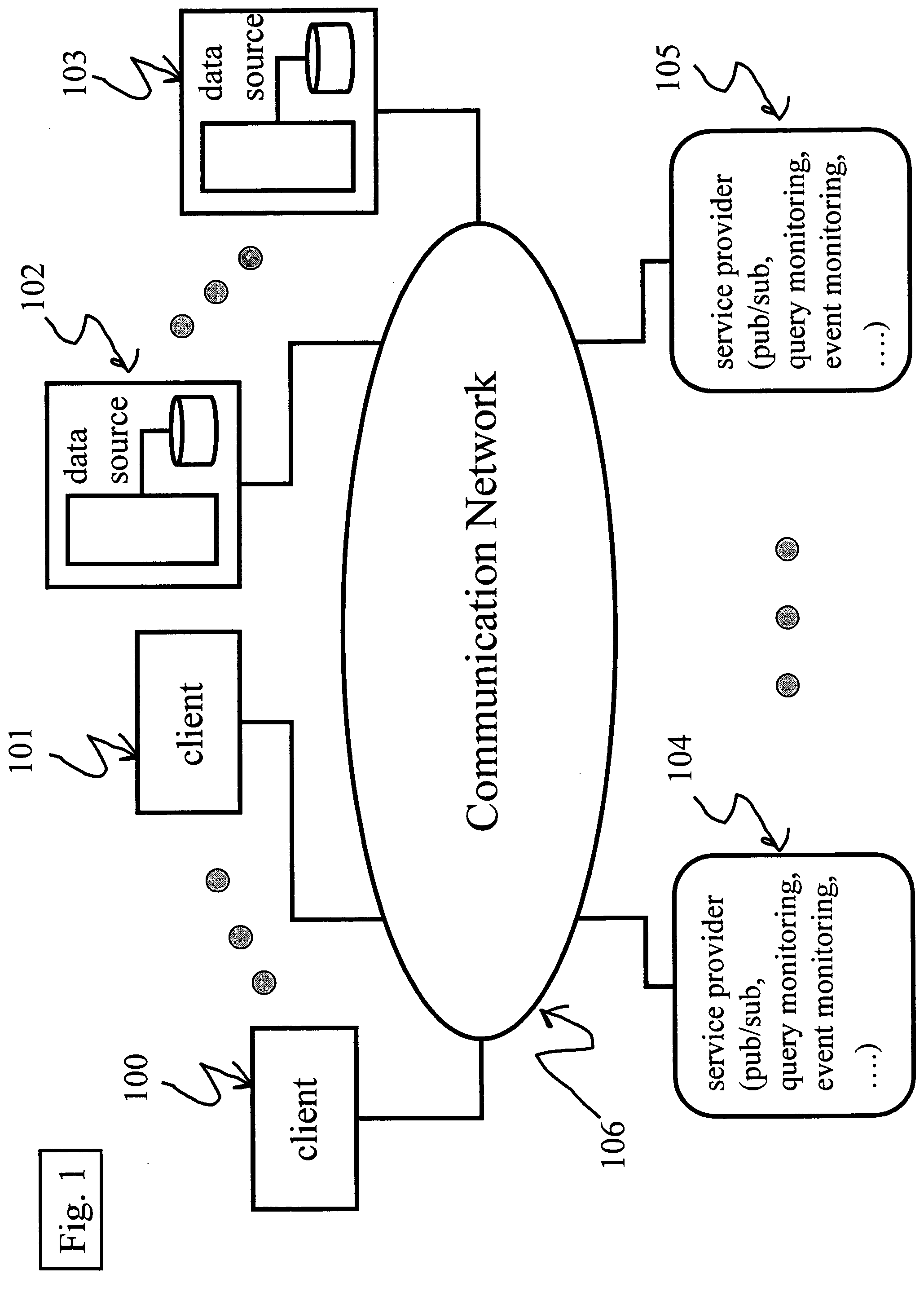

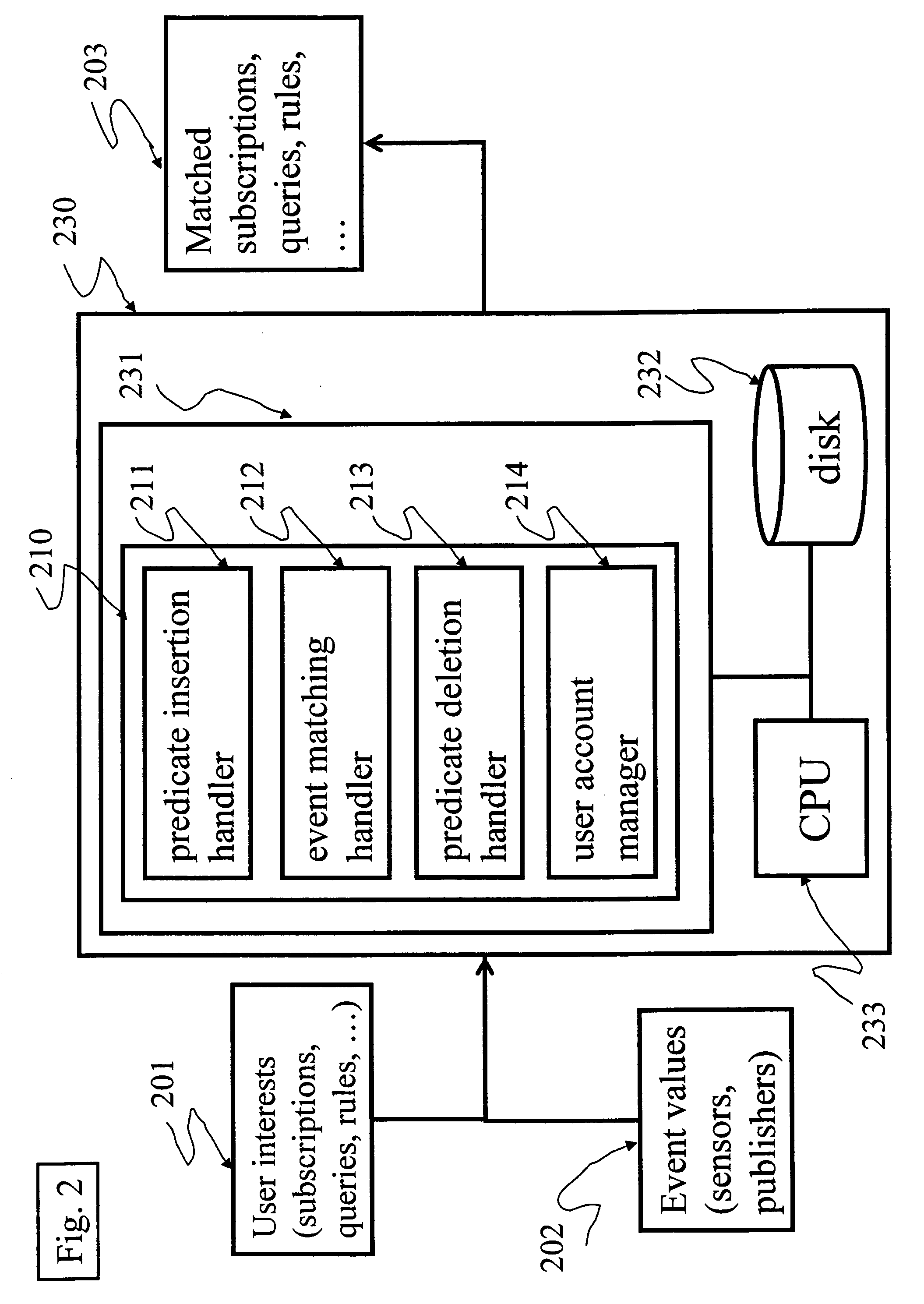

System and method for indexing queries, rules and subscriptions

ActiveUS20050071322A1Quick matchEfficient continual query/rule monitoringData processing applicationsDigital data information retrievalTheoretical computer scienceBiological activation

This invention introduces a new concept called virtual construct intervals (VCI), where each predicate interval is decomposed into one or more of these construct intervals. These VCIs strictly cover the predicate interval. Namely, every attribute value covered by the predicate interval is also covered by at least one of the decomposed VCIs, and vice versa. Each construct interval has a unique ID or interval coordinate and a set of endpoints. A construct interval is considered activated when a predicate interval using it in its decomposition is added to the system. The predicate ID is then inserted into the ID lists associated with the decomposed VCIs. To facilitate fast search, a bitmap vector is used to indicate the activation of VCIs that cover an event value. The challenge is to find an appropriate set of construct intervals to make predicate decomposition simple and, more importantly, to build efficient bitmap indexes. Because each construct interval covers only a small range of attribute values, the invention also uses bitmap clipping to cut unnecessary bitmap storage. To facilitate bitmap clipping, the invention introduce the covering segment concept. Bit positions outside a covering segment are pruned.

Owner:IBM CORP

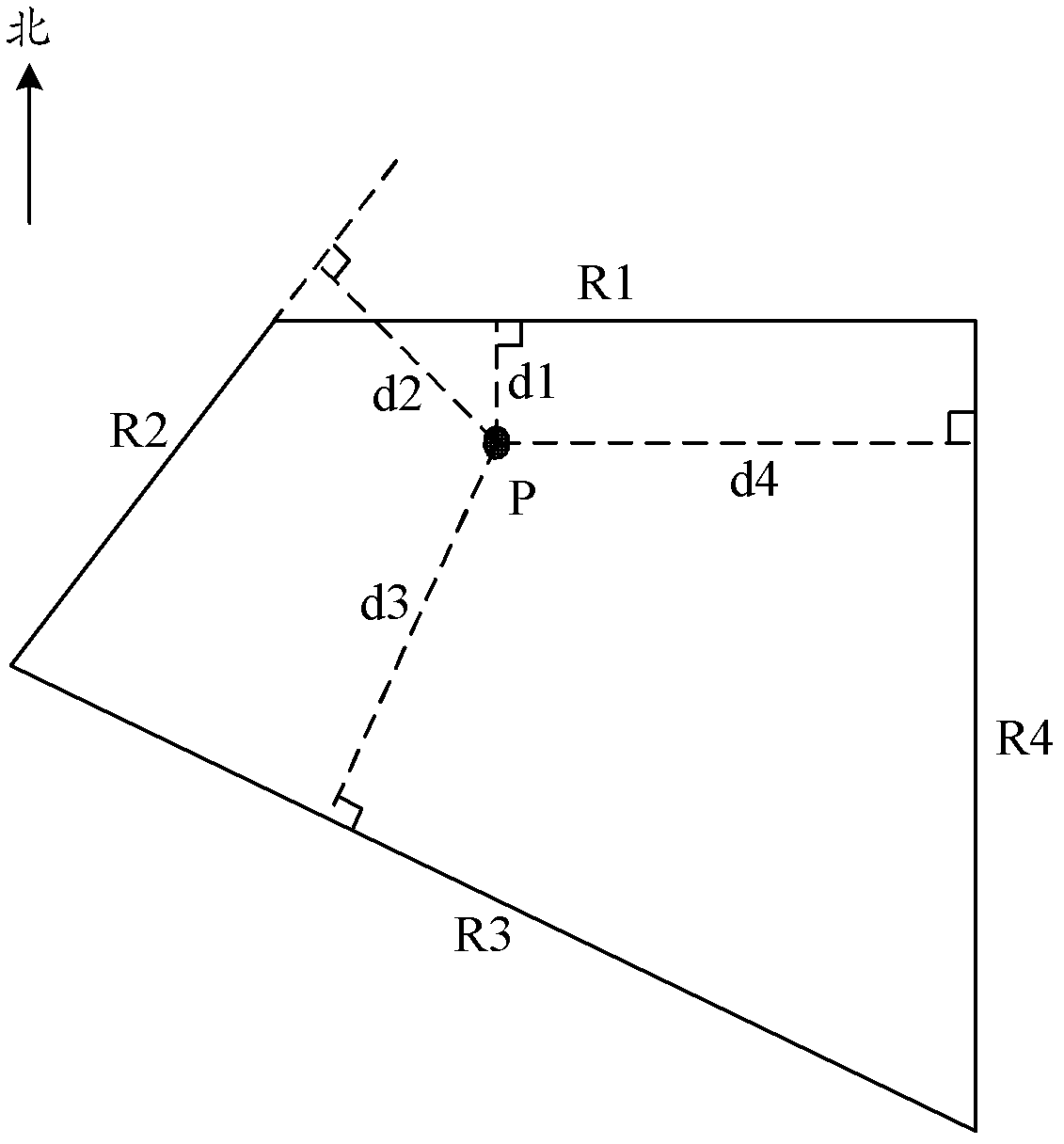

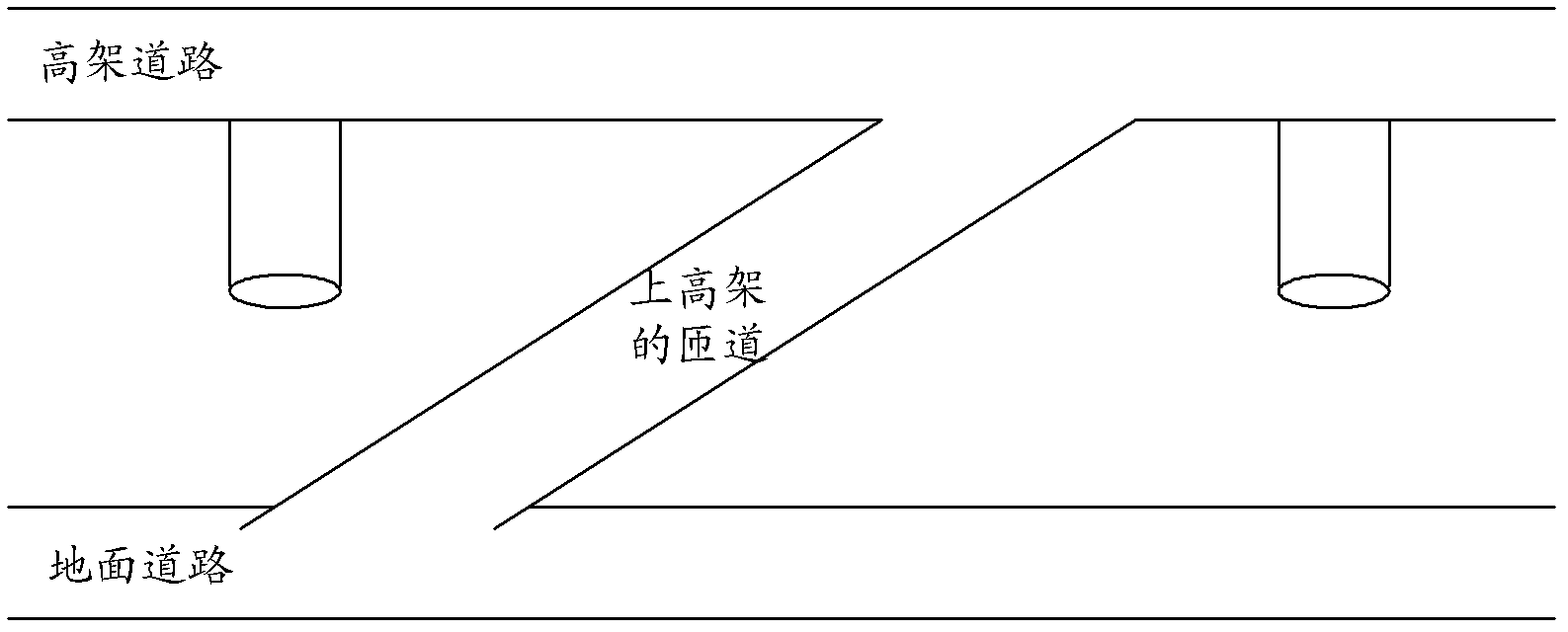

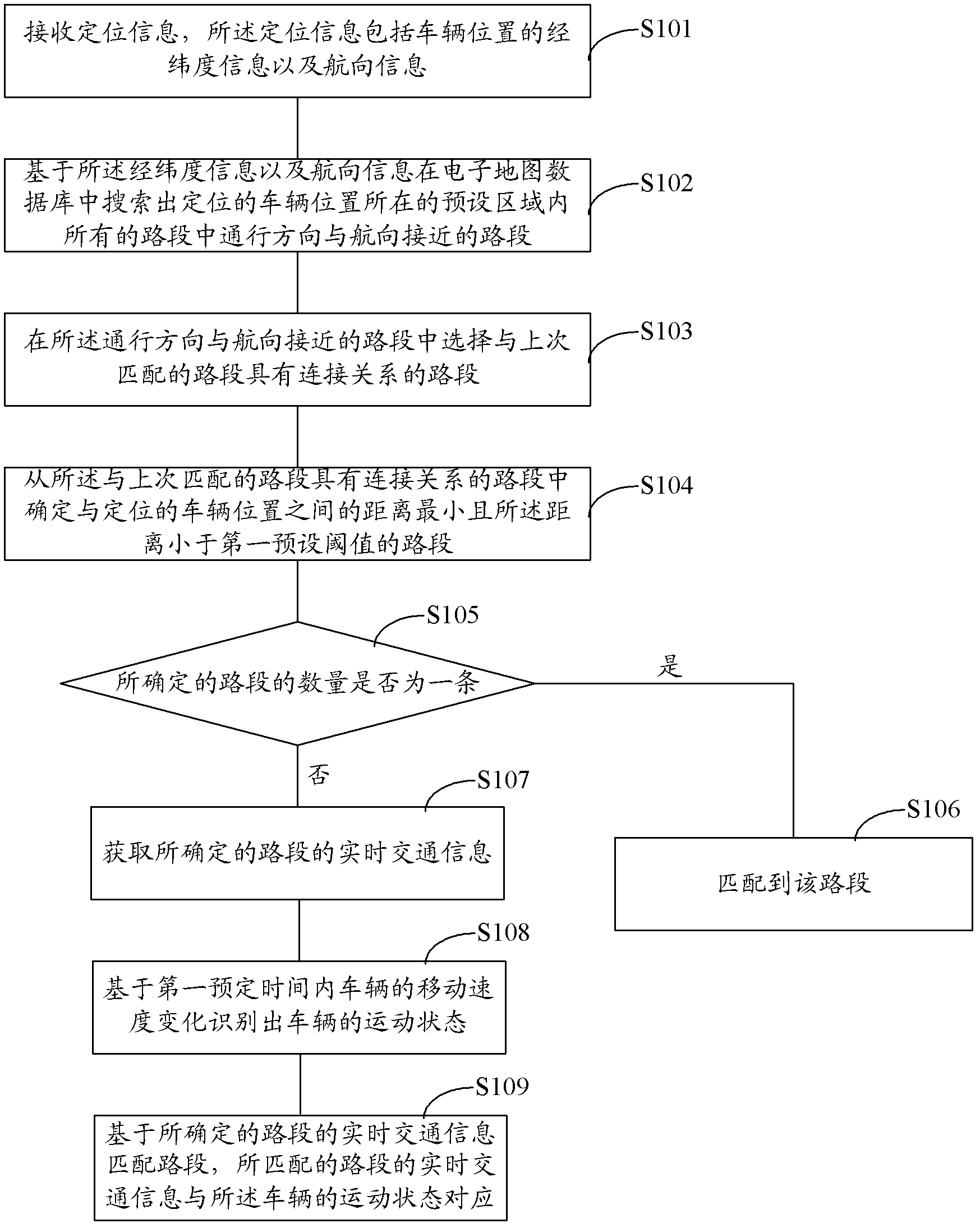

Navigation system and road matching method and device

ActiveCN103033832AQuick matchExact matchInstruments for road network navigationSatellite radio beaconingLongitudeEngineering

Provided are a navigation system and a road matching method and device. The road matching method comprises receiving positioning information which comprises longitude and latitude of a vehicle position and the driving direction; on the basis the longitude, the latitude and the driving direction, in an electronic map database, searching road sections with the passing directions close to the driving direction in all road sections within a preset area where the positioned vehicle position is located; selecting road sections having connected relations with road sections matched for the last time in the road sections close to the driving direction; determining road sections which have the smallest distance away from the positioned vehicle position and enable the smallest distance to be smaller than a preset threshold in the road sections with the connected relations; if the number of the determined road sections is one, matching to the road section, or else recognizing a motion state of a vehicle on the basis of movement speed changes of the vehicle in first preset time, matching the road sections on the basis of real-time traffic information of the determined road sections, and enabling the real-time traffic information of the matched road sections to correspond to the motion state of the vehicle. According to the technical scheme, the correct road sections can be matched rapidly and accurately.

Owner:SHANGHAI PATEO ELECTRONIC EQUIPMENT MANUFACTURING CO LTD

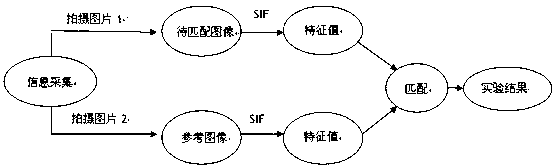

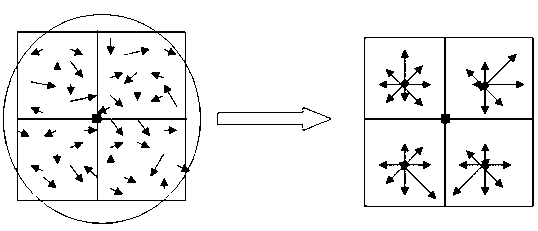

License number matching algorithm based on digital image processing

InactiveCN103065135AImprove stabilityImprove robustnessCharacter and pattern recognitionDigital signal processingLicense number

The invention relates to a license number matching algorithm based on digital image processing. The license number matching algorithm based on the digital image processing comprises the following steps of: twice shooting a same license through shooting equipment to obtain two images, and carrying out scale space extreme value detection, accurate characteristic point position positioning, characteristic point principal direction determination and characteristic vector generation on the two images to obtain image characteristics; and then matching the characteristic vectors of the two images. The license number matching algorithm based on the digital image processing, which is disclosed by the invention, can still complete the matching and keep good stability and robustness under the conditions of scaling, rotation, brightness variation, affine transformation and noise influence through a particular experiment verification algorithm and is suitable for carrying out fast and accurate matching in a great number of characteristic databases.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Air supply system experiment device for proton exchange membrane fuel cell for automobile

InactiveCN104993161AQuick matchQuick verificationFuel cell auxillariesSolid electrolyte fuel cellsCombined useIntercooler

The invention relates to an air supply system experiment device for a proton exchange membrane fuel cell for an automobile. The device comprises a filter, a compressor, an intercooler, a heater, a humidifier, a gas and water separator, a fuel cell pile and a control computer. The filter is sequentially connected with the compressor, the intercooler, the humidifier and an air inlet of the fuel cell pile through a pipeline and is connected back to an inlet of the compressor by means of an air outlet of the fuel cell pile sequentially through the humidifier and the gas and water separator, the heater and the intercooler are arranged in parallel, a plurality of electromagnetic valves and induction units are further arranged on the pipeline, and the electromagnetic valves and the induction units are both connected with the computer through a circuit. Compared with the prior art, the device is simple and compact in structure, the electromagnetic valves are combined for use and controlled in a combined mode, various fuel cell pile cooling loop structures are configured, and the purposes of fast matching part parameters of a system and fast verifying a control algorithm are achieved.

Owner:TONGJI UNIV

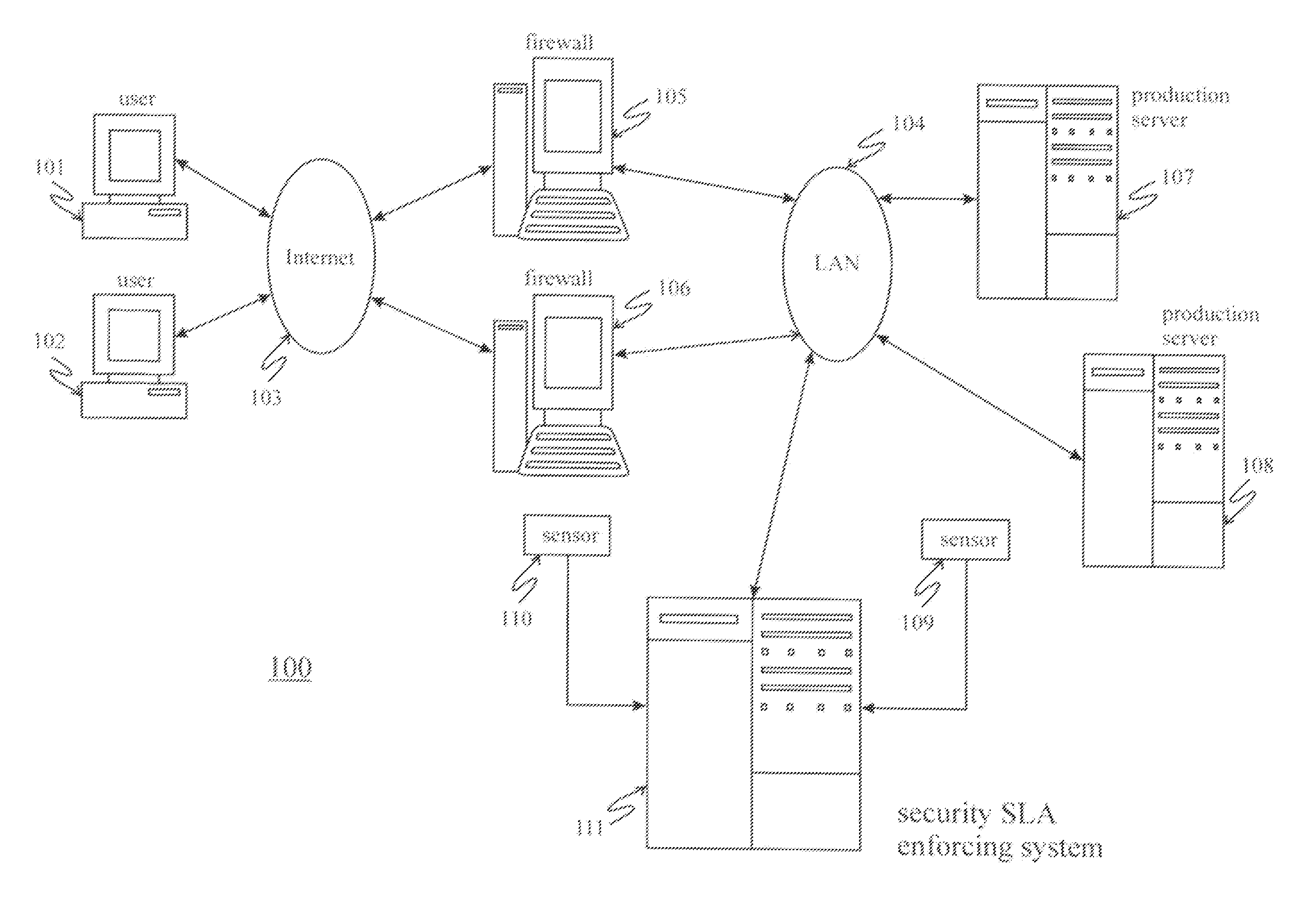

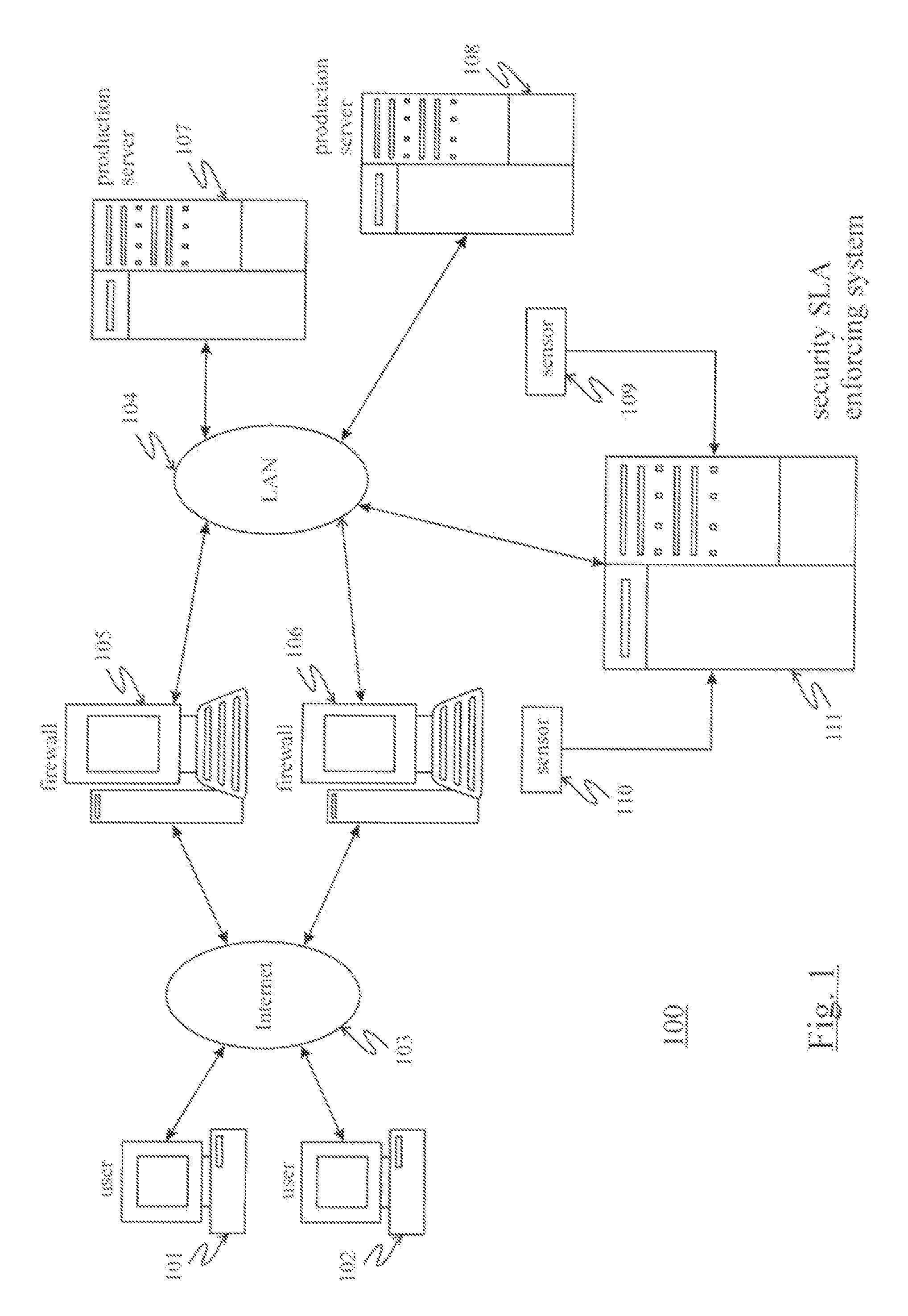

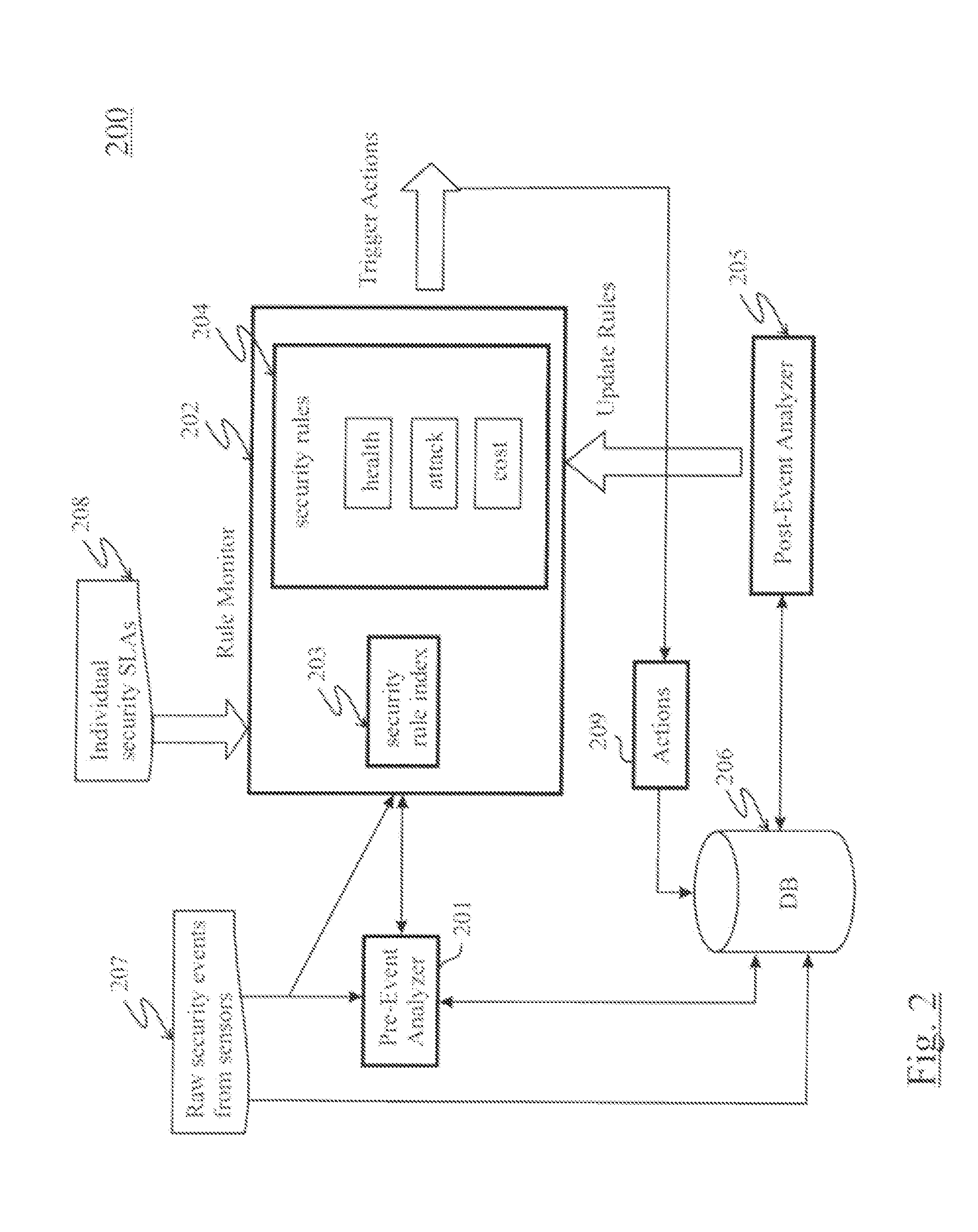

System and method for enforcing security service level agreements

ActiveUS7278156B2Valid matchQuick matchMemory loss protectionError detection/correctionService-level agreementMonitoring system

Systems and methods for providing e-business services based on security SLAs (service level agreements) in a hosted computing environment. More specifically, the systems and methods enable efficient enforcement of individualized security SLAs, wherein individualized SLA agreements are specified, mapped into security rules and continually monitored against system events via an efficient rule index to determine security violations and trigger proper actions.

Owner:SERVICENOW INC

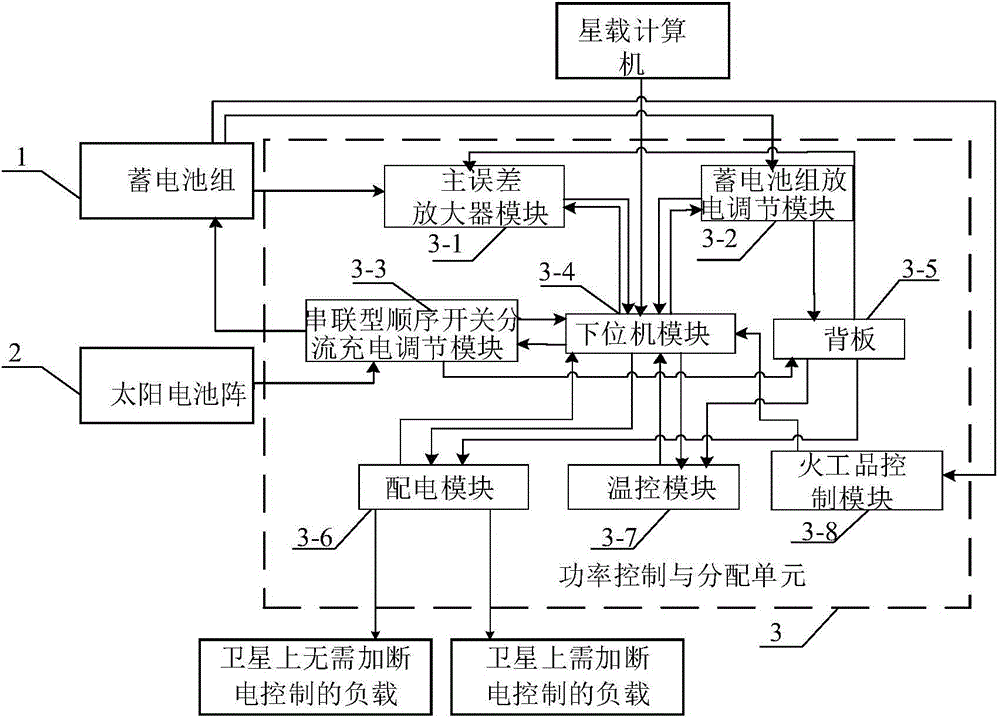

Quickly-integrated satellite power system

ActiveCN103956822AImprove compatibilityQuick matchBatteries circuit arrangementsElectric powerElectricityLight energy

The invention belongs to the field of power sources, and relates to a satellite power system, in particular to a quickly-integrated satellite power system which solves the problem that an existing satellite power system is poor in system compatibility. The system comprises a storage battery pack, a solar battery array and a power control and distributing unit. The storage battery pack is used for supplying power for load of a whole satellite and the power control and distributing unit, the solar batter array is used for converting received light energy to electric energy to charge the storage battery pack, the solar battery array is connected with the power control and distributing unit through an electric connector, the solar battery array comprises n solar batteries which are connected in series or in parallel through wires, and n is an integer which is larger than or equal to 2. The quickly-integrated satellite power system is suitable for charging satellites.

Owner:HARBIN INST OF TECH

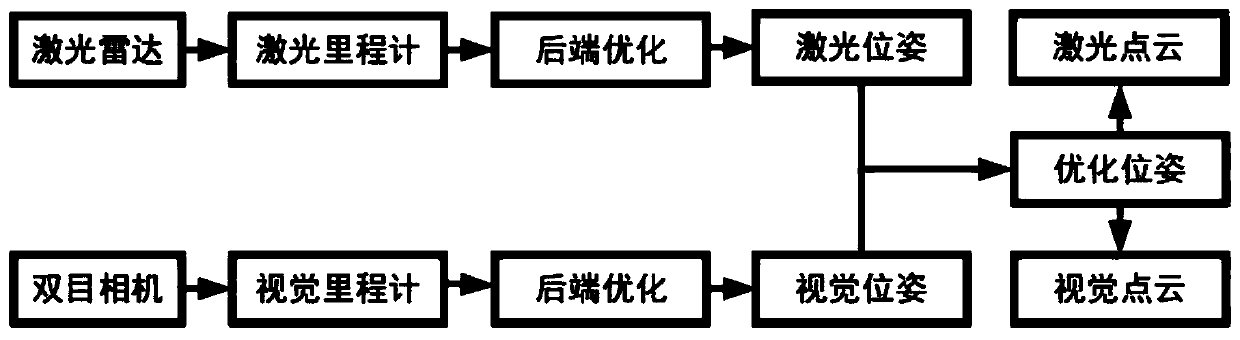

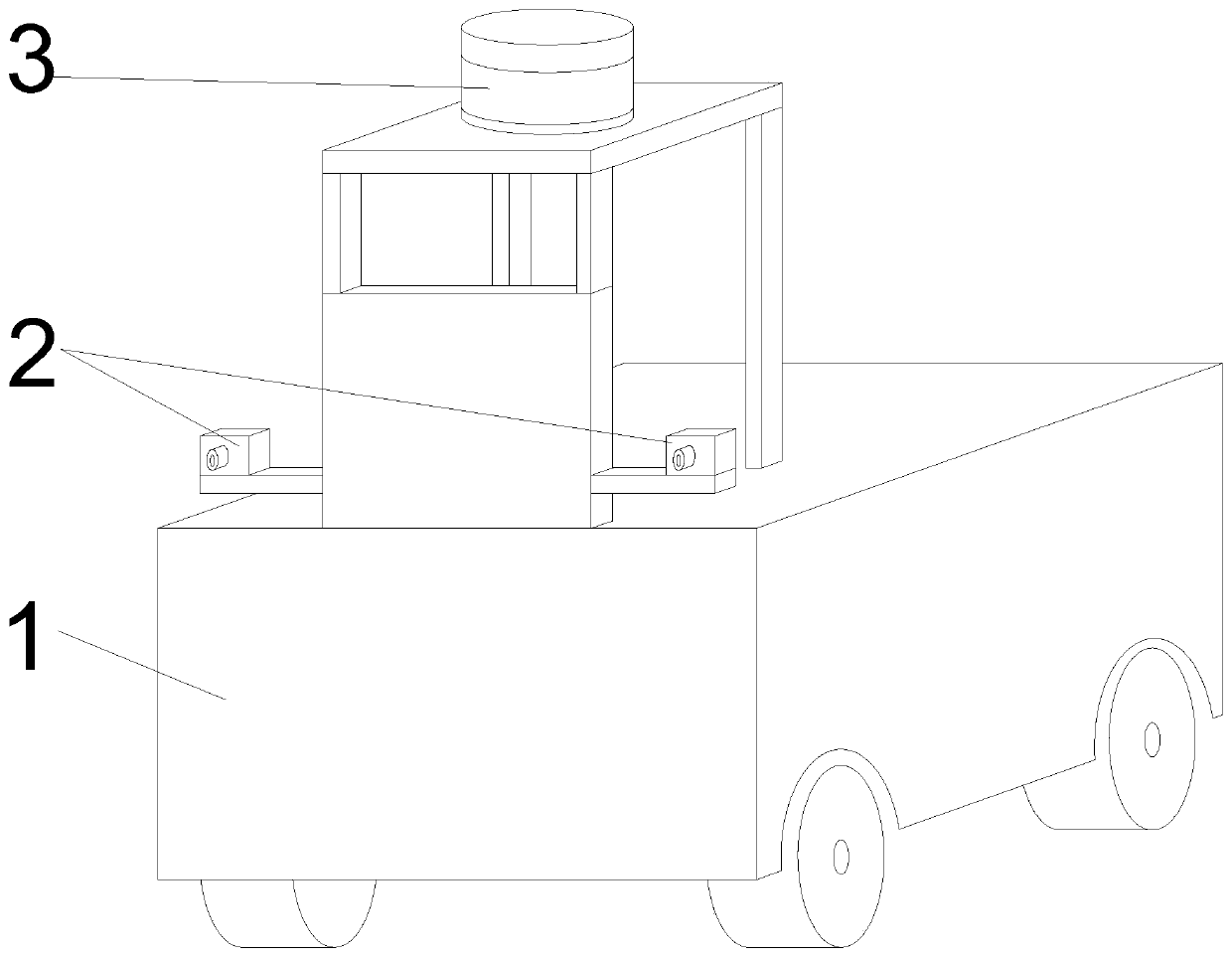

Positioning and navigation method and device based on lidar and binocular camera

The invention relates to a positioning and navigation method based on a lidar and a binocular camera, comprising the steps of acquiring a camera image through a binocular stereo camera and processingthe image information from the binocular stereo camera to acquire a pose; acquiring a radar image through a lidar and processing the image information from the lidar to acquire a pose; optimizing andfusing the two poses to obtain a dense point cloud model and a sparse point cloud model with respect to the environment for navigation and precise positioning respectively. A positioning and navigation device based on the lidar and the binocular camera includes an image module, a lidar module, a pose optimization module, a binocular stereo camera, and a lidar. The device uses the pose optimizationmodule for optimizing and fusing the pose from the binocular stereo camera and the pose from the lidar, combines the binocular stereo camera with the multi-line lidar to achieve high-precision pose estimation and a high-precision dense point cloud map, and can be used directly for navigation and positioning of unmanned vehicles.

Owner:SICHUAN UNIV

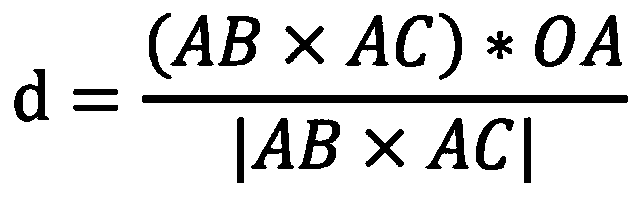

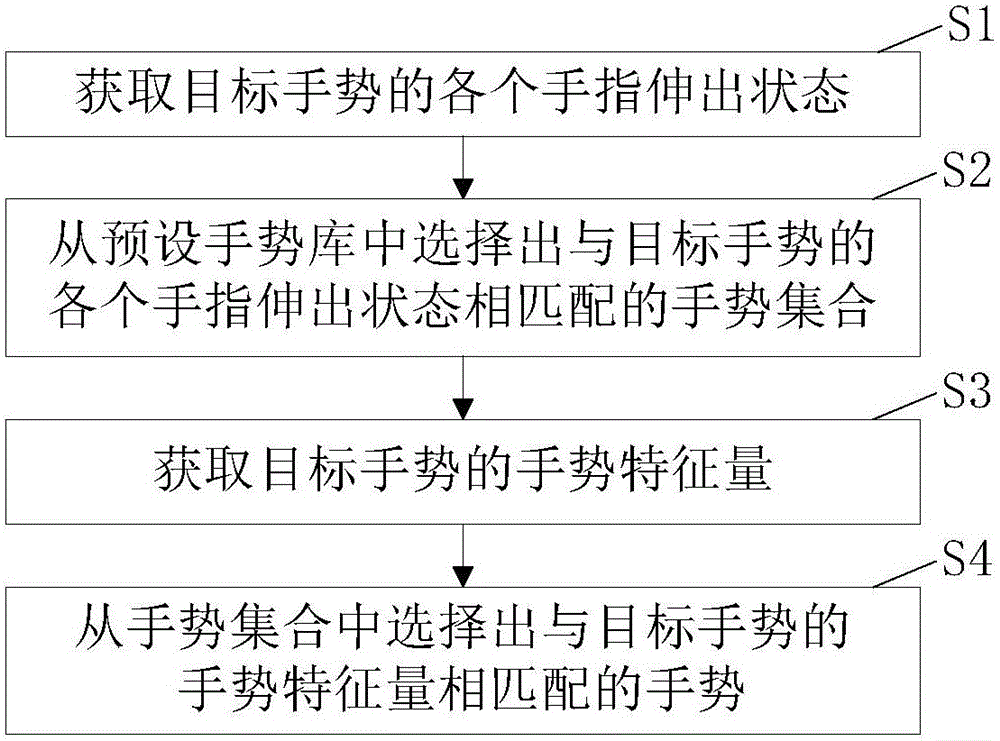

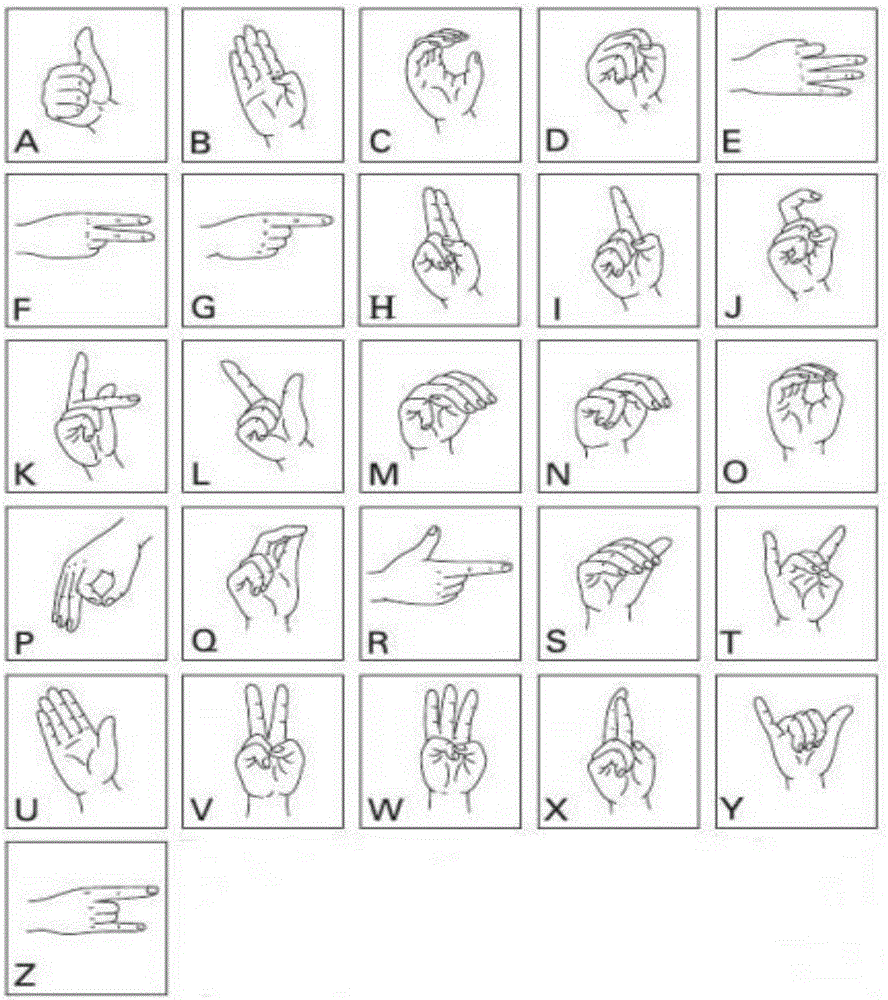

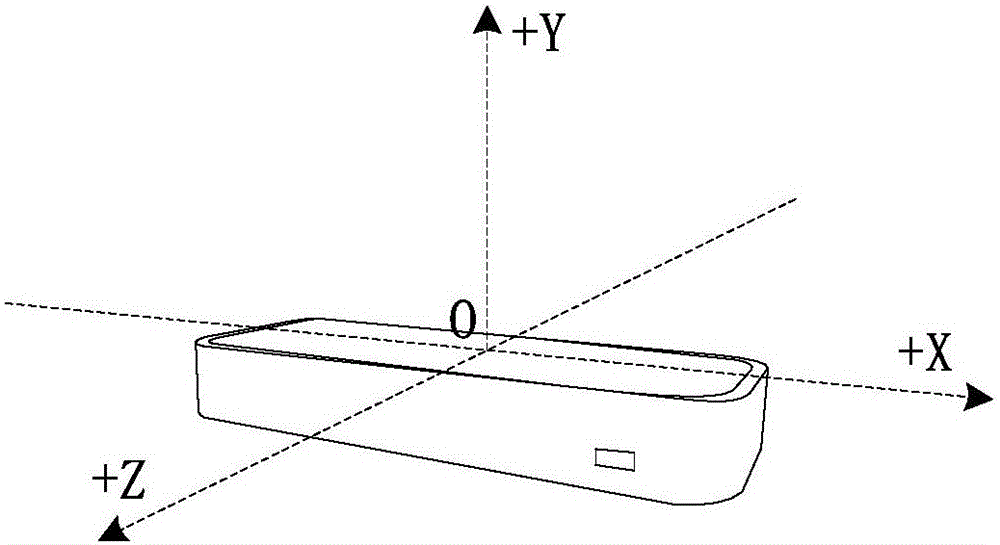

Hand gesture identifying method, apparatus and hand gesture learning system

ActiveCN105868715AAccurate identificationEliminate communication barriersCharacter and pattern recognitionHuman–computer interactionHuman language

The invention provides a hand gesture identifying method, an apparatus and a hand gesture learning system, which are configured such that: acquiring an extending state of each finger of an object hand gesture; selecting a hand gesture set which matches the extending state of each finger of the object hand gesture from a preset hand gesture database; acquiring a hand gesture feature amount of the object hand gesture; selecting a hand gesture which matches the hand gesture feature amount of the object hand gesture from the hand gesture set. The hand gesture identifying method, the apparatus and the hand gesture learning system can accurately identify static sign language, identify abundant meaning expressed by the hand gesture, and eliminate communication barriers between sign language and natural language.

Owner:SUZHOU KEDA TECH +1

Universal method for correlating single items of different e-commerce websites

InactiveCN105005917AQuick matchAvoid manual settingsSpecial data processing applicationsMarketingPaired DataE-commerce

The invention belongs to the technical field of e-commerce, and provides a universal method for correlating single items of different e-commerce websites. The method comprises the steps as follows: step 1, extracting commodity identification; step 2, obtaining the key value pair data of the commodity identification from commodity single item pages of different websites; step 3, describing and classifying the commodity identification obtained in the step 1; dividing the description information of each item ID obtained in the step 1 into a page headline and an attribute list; step 4, matching each commodity identification with the commodity identification in other websites, and selecting the item ID similar to the commodity identification in the other websites. The method of the invention improves the matching degree of the commodities in different websites, and enables the matching to be faster, thereby greatly increasing number of the users with purchasing intensions and improving commercial value.

Owner:上海晶赞企业管理咨询有限公司

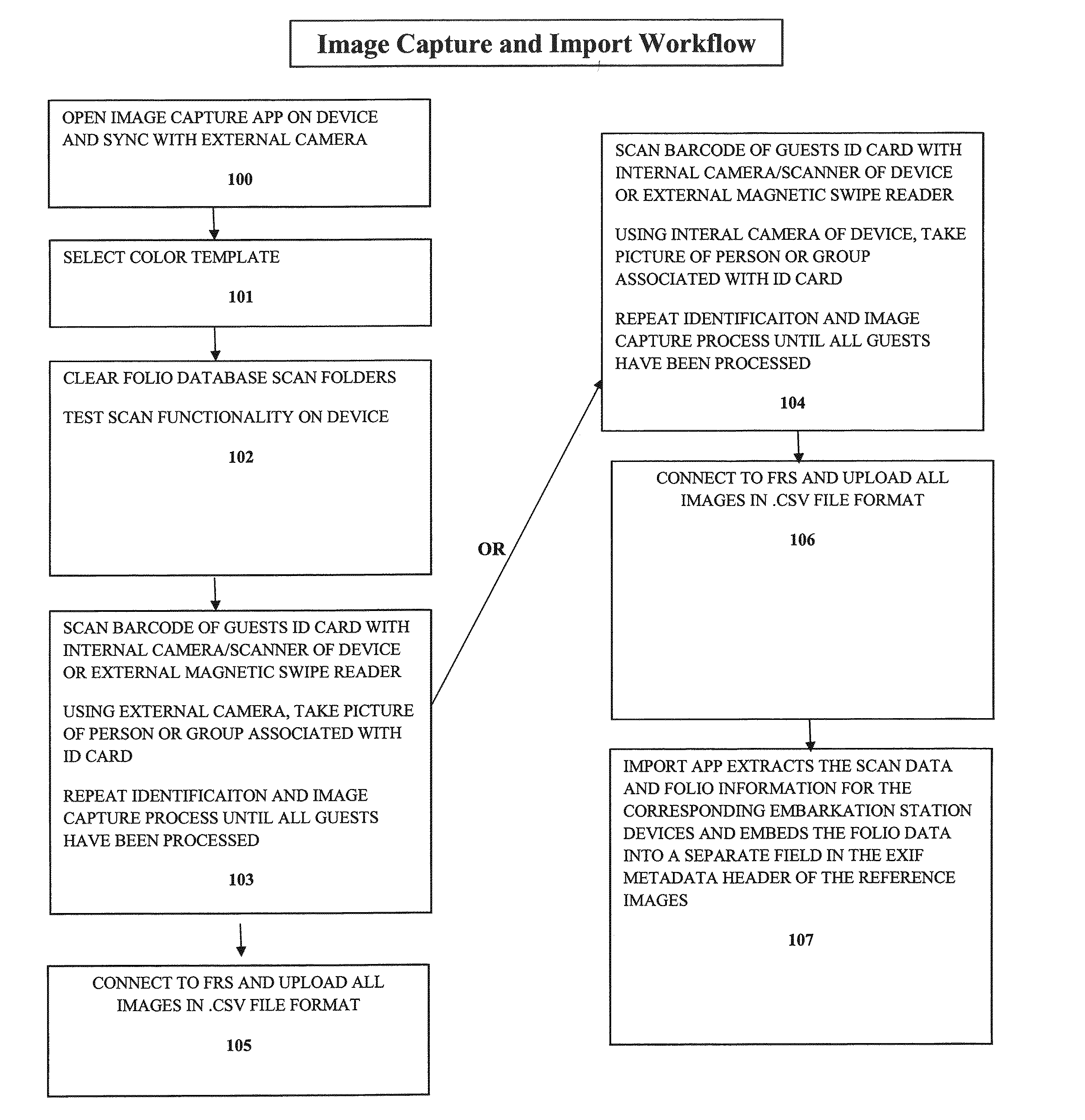

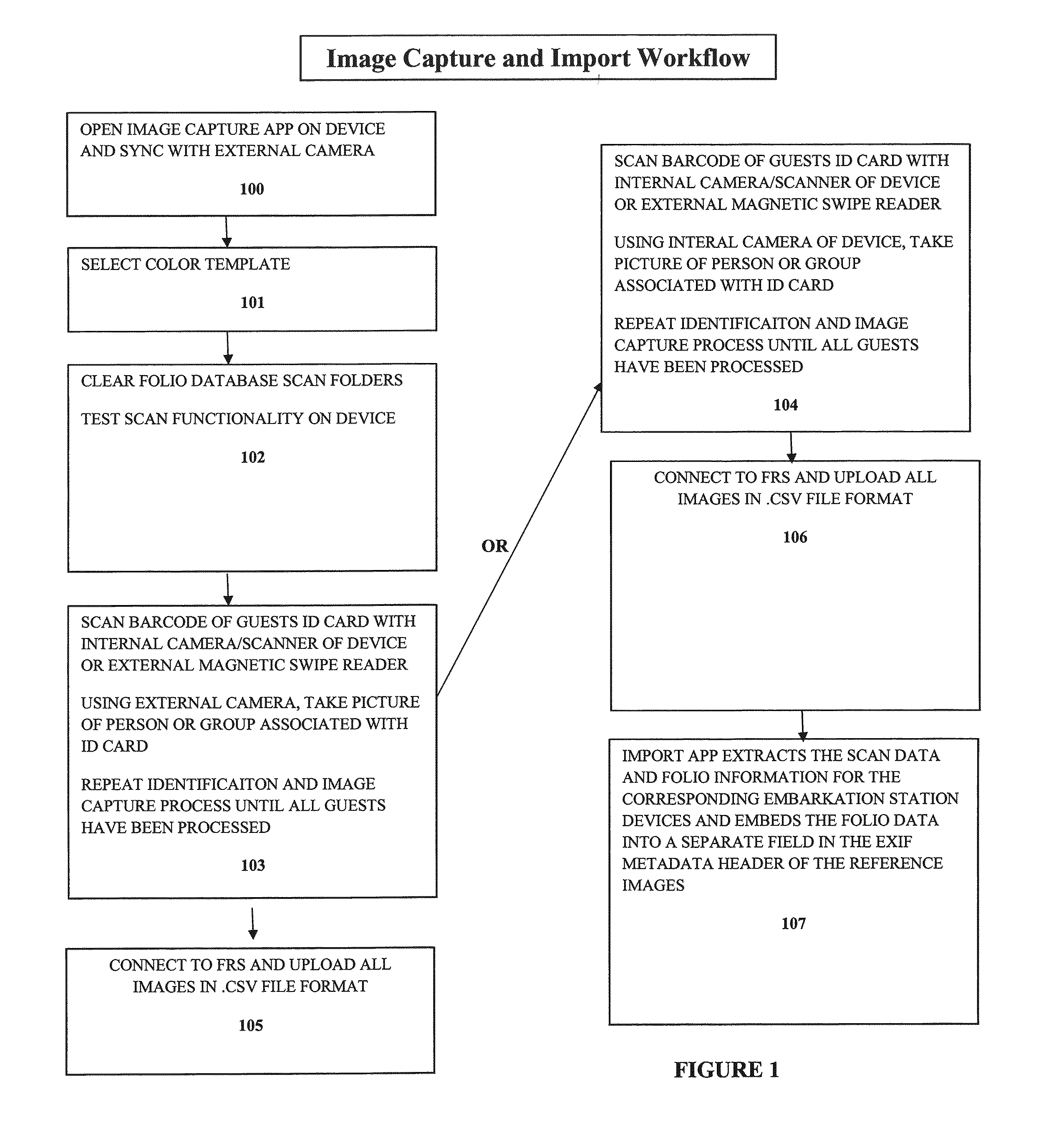

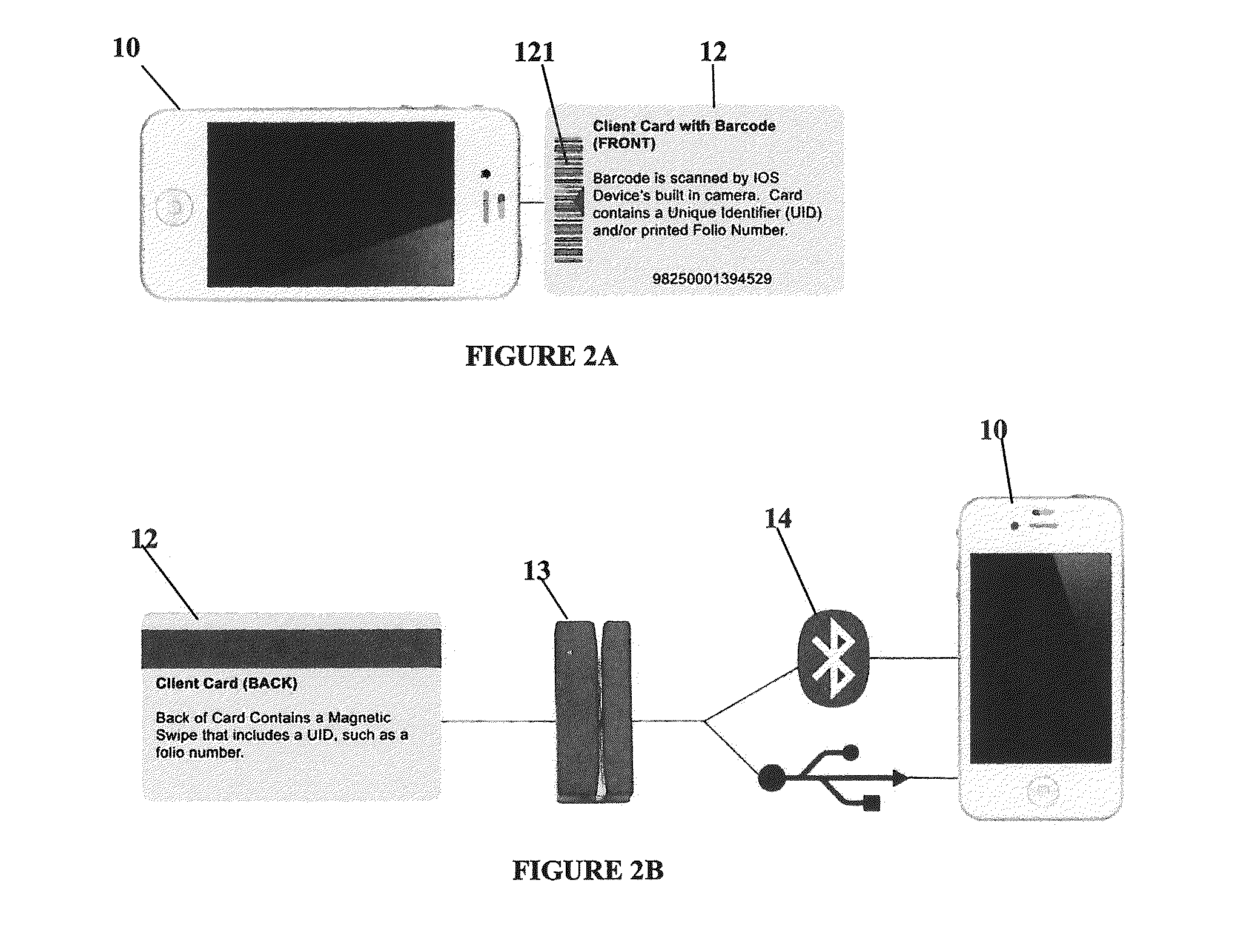

Interactive photography system and method employing facial recognition

InactiveUS20140105466A1Fast and accurate selectionQuick matchCharacter and pattern recognitionSpecial data processing applicationsUnique identifierReference image

A system and method for providing social photography services at locations such as Cruise Ship and Theme Parks with the purpose of giving a customer a unique identifier, associating the unique identifier with a reference imagine of the customer, and matching reference images to images shot at the locale using facial recognition techniques. A photograph gallery application is also provided, allowing customers and employees to access the facially recognized images for viewing, purchasing, and printing. This system and method employs computer based technology and facial recognition to provide fast and accurate photography production, processing, selection, printing, and sale.

Owner:OCEAN IMAUK

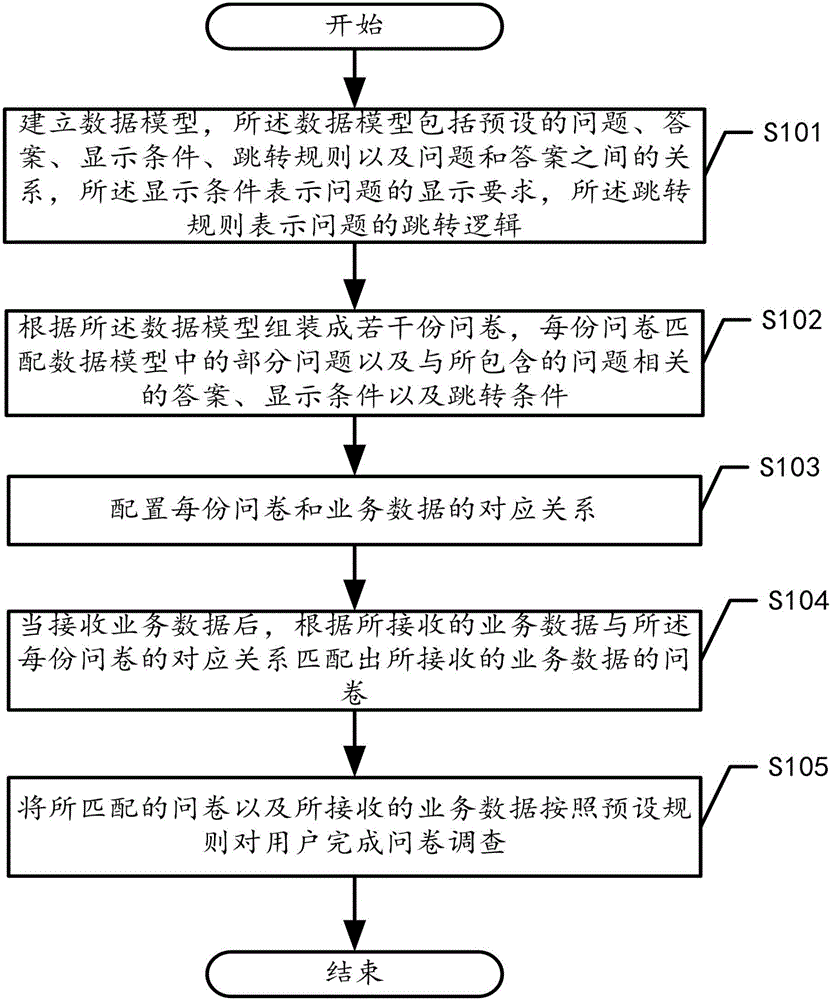

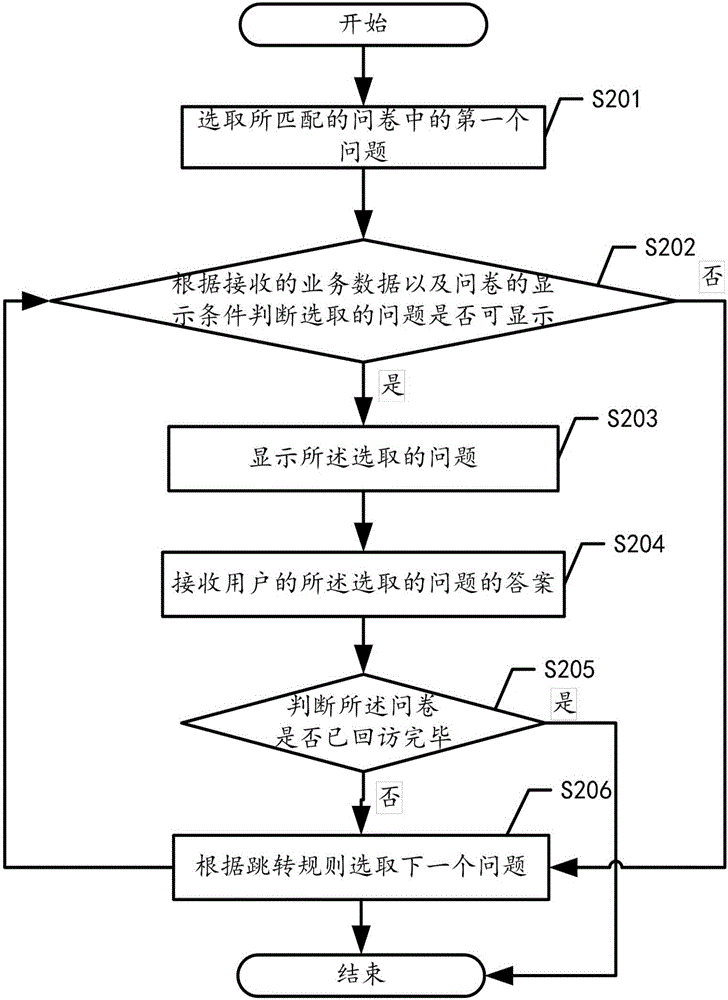

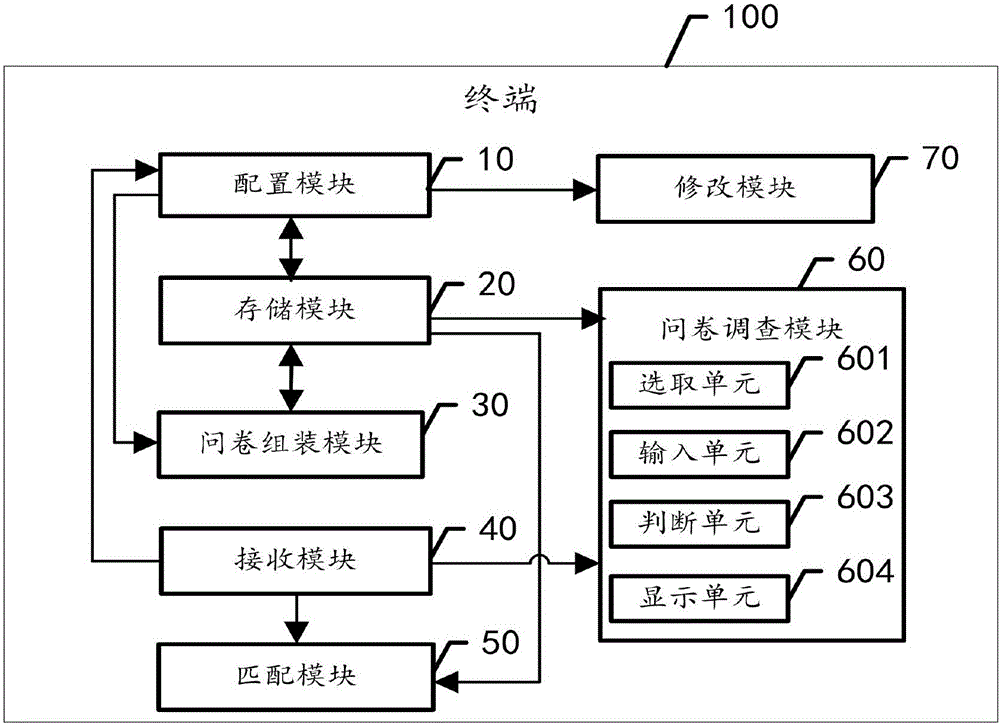

Method for generating questionnaire and terminal

InactiveCN105824918AQuick matchSave human effortSpecial data processing applicationsBusiness dataData model

The embodiment of the invention discloses a method for generating a questionnaire and a terminal. The method comprises the following steps of establishing a data model, wherein the data model includes preset questions, answers, display conditions and skip rules, the display conditions represent display requirements of the questions, and the skip rules represent the skip logic of the questions; assembling to form a plurality of questionnaires according to the data model, wherein each questionnaire includes a plurality of questions, and the answers, the display conditions and the skip rules which are relevant to the included questions; configuring a corresponding relation between each questionnaire and business data; after the reception of the business data, forming the questionnaire of the received business data in a matching manner according to the corresponding relation between the received business data and each questionnaire. In the embodiment of the invention, through the method for generating the questionnaire, after the reception of the business data, the questionnaire can be formed automatically in the matching manner to be used for the staff to pay a return visit, the labor is saved, and the efficiency is improved. The embodiment of the invention also provides a terminal.

Owner:PING AN TECH (SHENZHEN) CO LTD

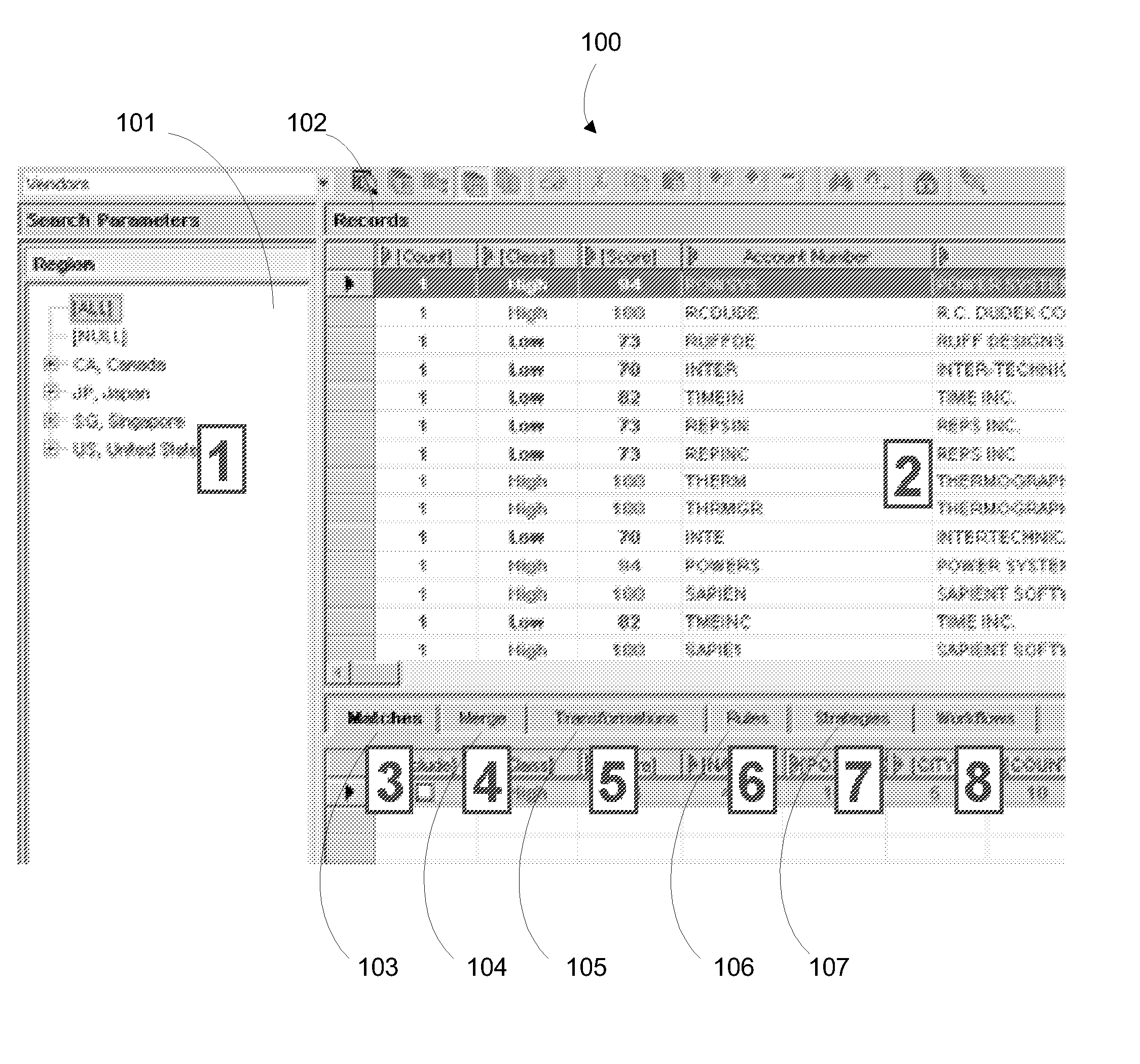

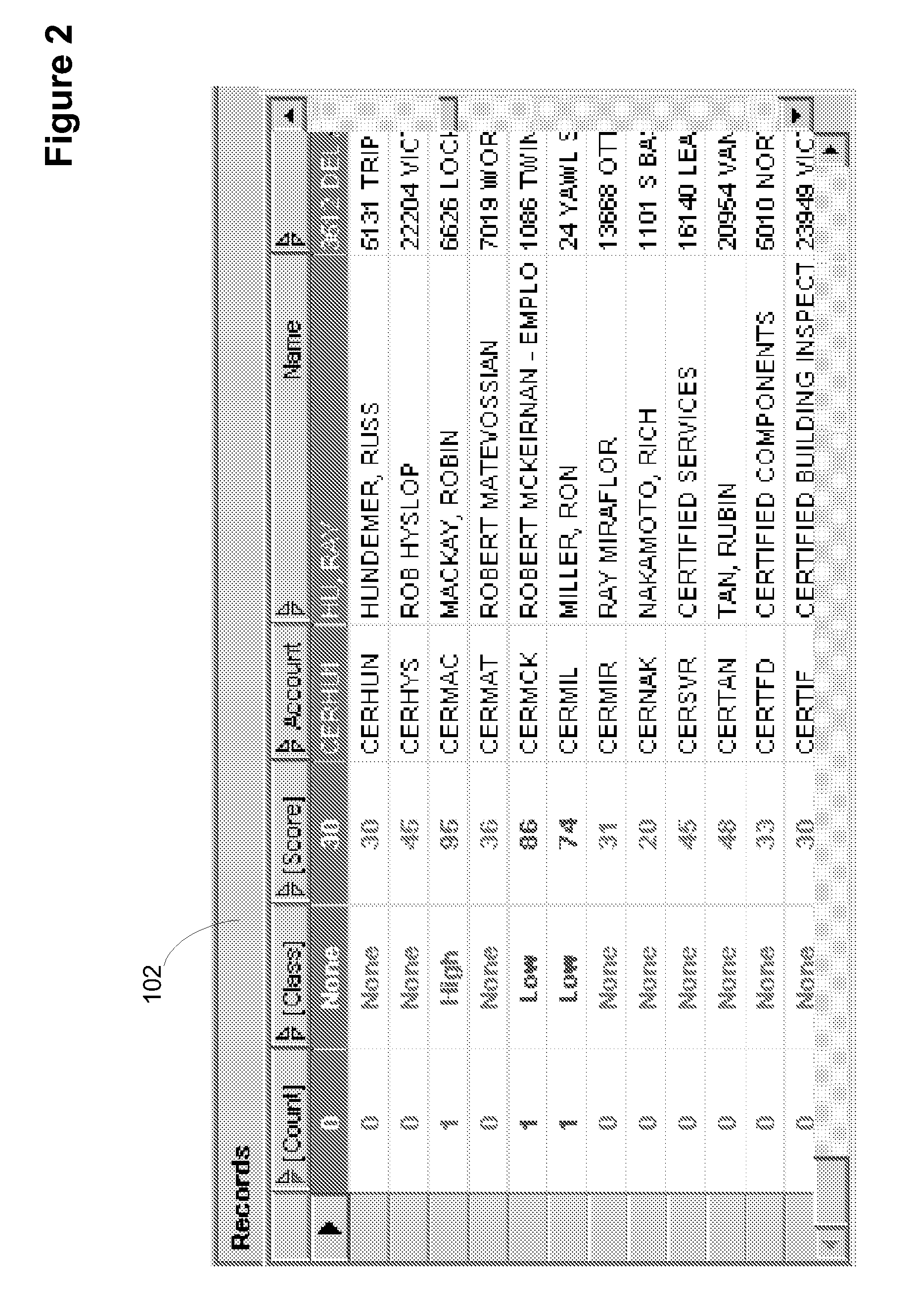

Method and apparatus for matching non-normalized data values

ActiveUS20080077573A1Good choiceAmount of timeData processing applicationsDigital data information retrievalExact matchUser input

Enables locating and merging potential data record matches. Enables locating duplicates through the definition of matching strategies. Each strategy may include transformations, matching rules and scoring thresholds to implement fuzzy matches that match closely related data records that are not exact matches. Performing a search allows for narrowing down the records to a desired set on which to apply a given matching strategy. Merging is performed on the potential duplicates thus located to consolidate data and remove duplicates. By narrowing down the records to a closely related set via a search, merging is simplified to work on a small number of closely related records, thus simplifying the process. The total matching score obtained via execution of match strategies may be utilized to determine which potential record(s) to merge for example. May utilize past user input to provide intelligent inputs for rules, tokens, weights, fields, parameters or any other past user input.

Owner:SAP AG

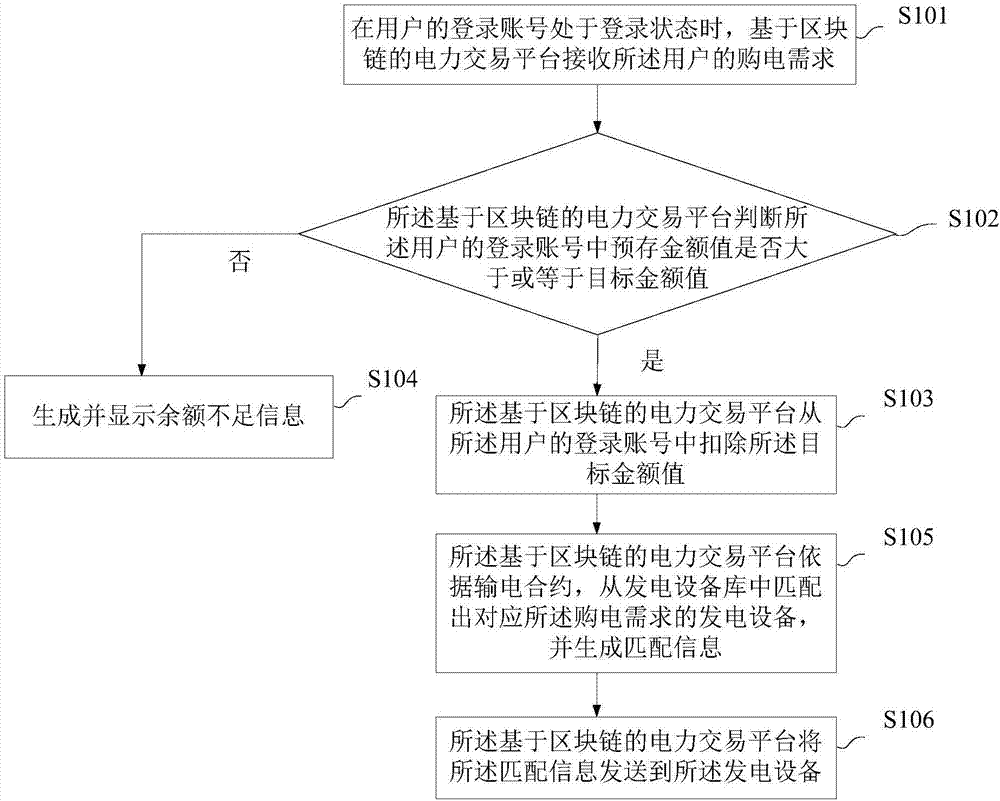

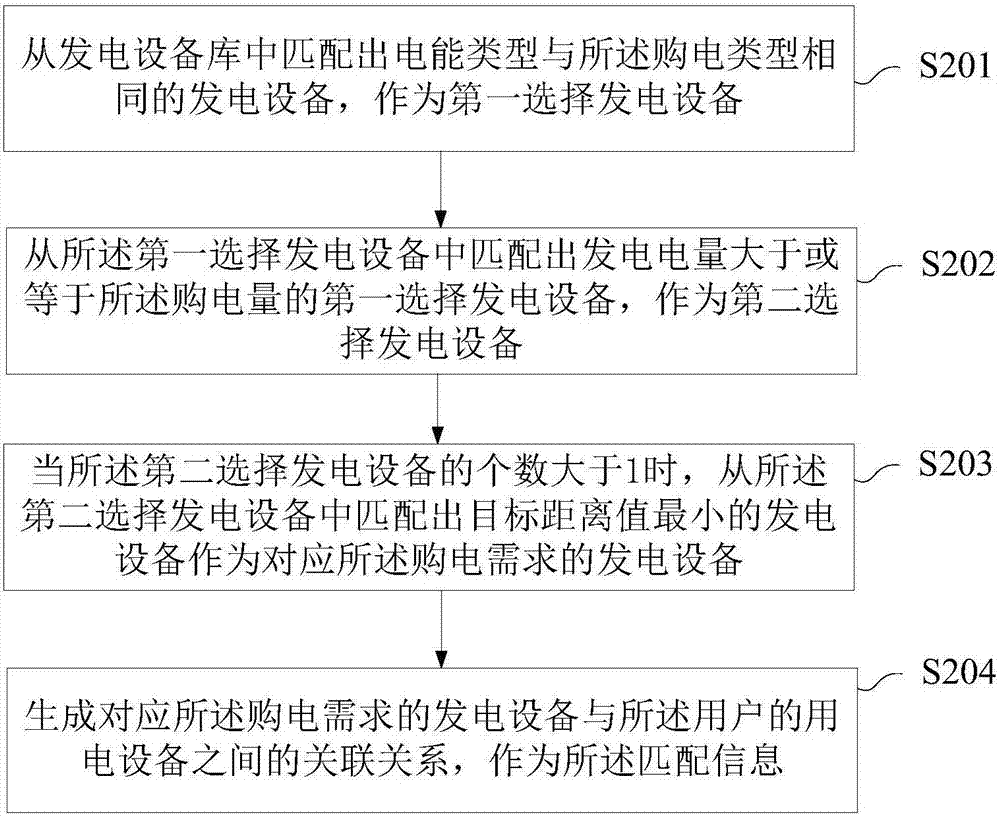

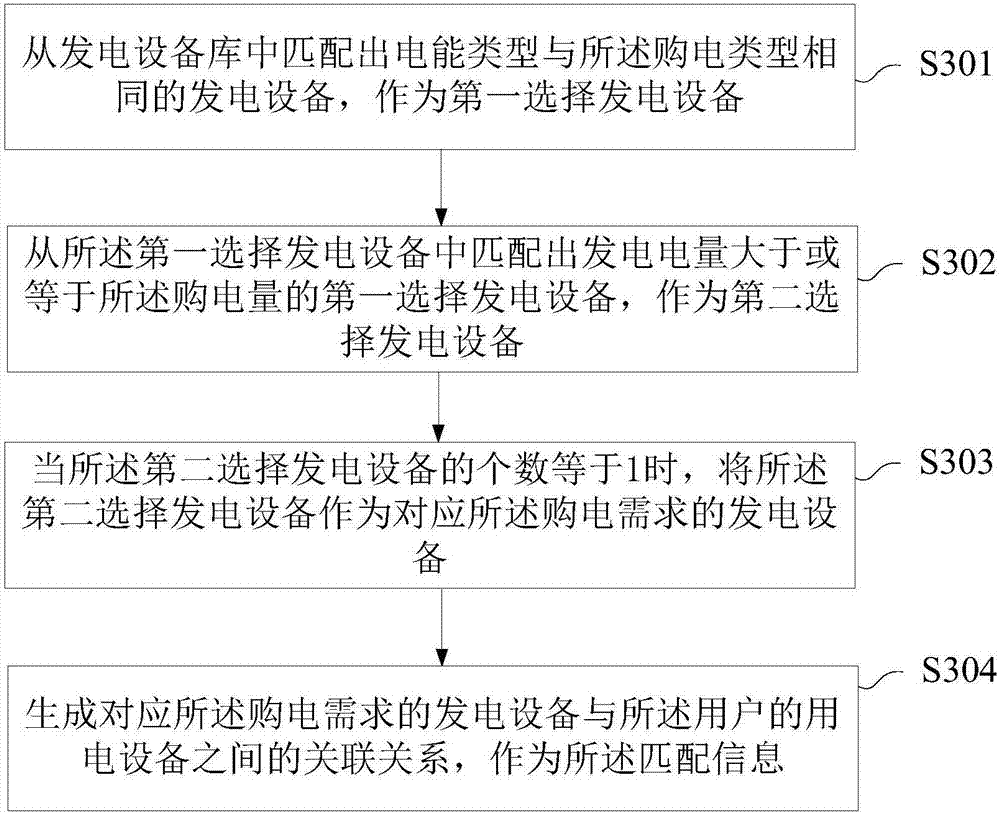

Power transaction method and apparatus, and micro-grid system

ActiveCN107240002AEasy to handleImprove processing efficiencyBuying/selling/leasing transactionsDigital currencyElectricity

The invention provides a power transaction method and apparatus, and a micro-grid system. The power transaction method includes the steps: after a power purchasing demand from a user is received, a power transaction platform based on block chains automatically determines whether the digital currency pre-stored sum value in a log-in account of the user is enough for paying the target sum value required by the power purchasing demand to complete operation of deducting the sum value so as to realize automation of payment and settlement of transaction fund, thus avoiding consuming manpower and time of the user who has to arrive at a specified power sale place for power transaction payment, and avoiding the workload for a worker for recharging power quantity so as to accelerate the power transaction processing process on the basis of reducing the middle links for power transaction; and then an intelligent power transmission contract is used to perform matching, thus being able to quickly and automatically match generating equipment of the corresponding power purchasing demand from a generating equipment warehouse, being able to generate the matching information, and improving the processing efficiency of power transaction.

Owner:BEIJING HUITONG JINCAI INFORMATION TECH +2

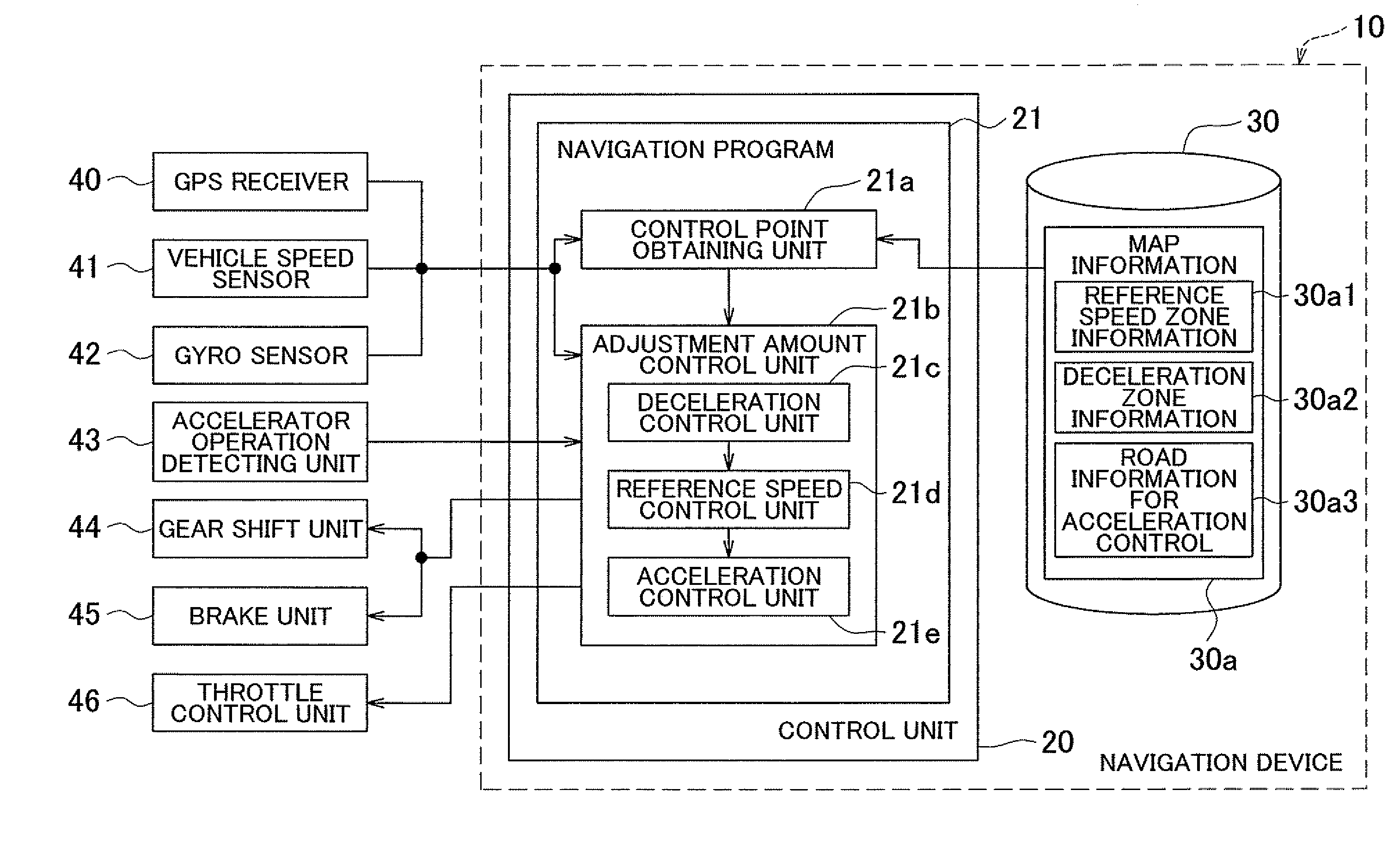

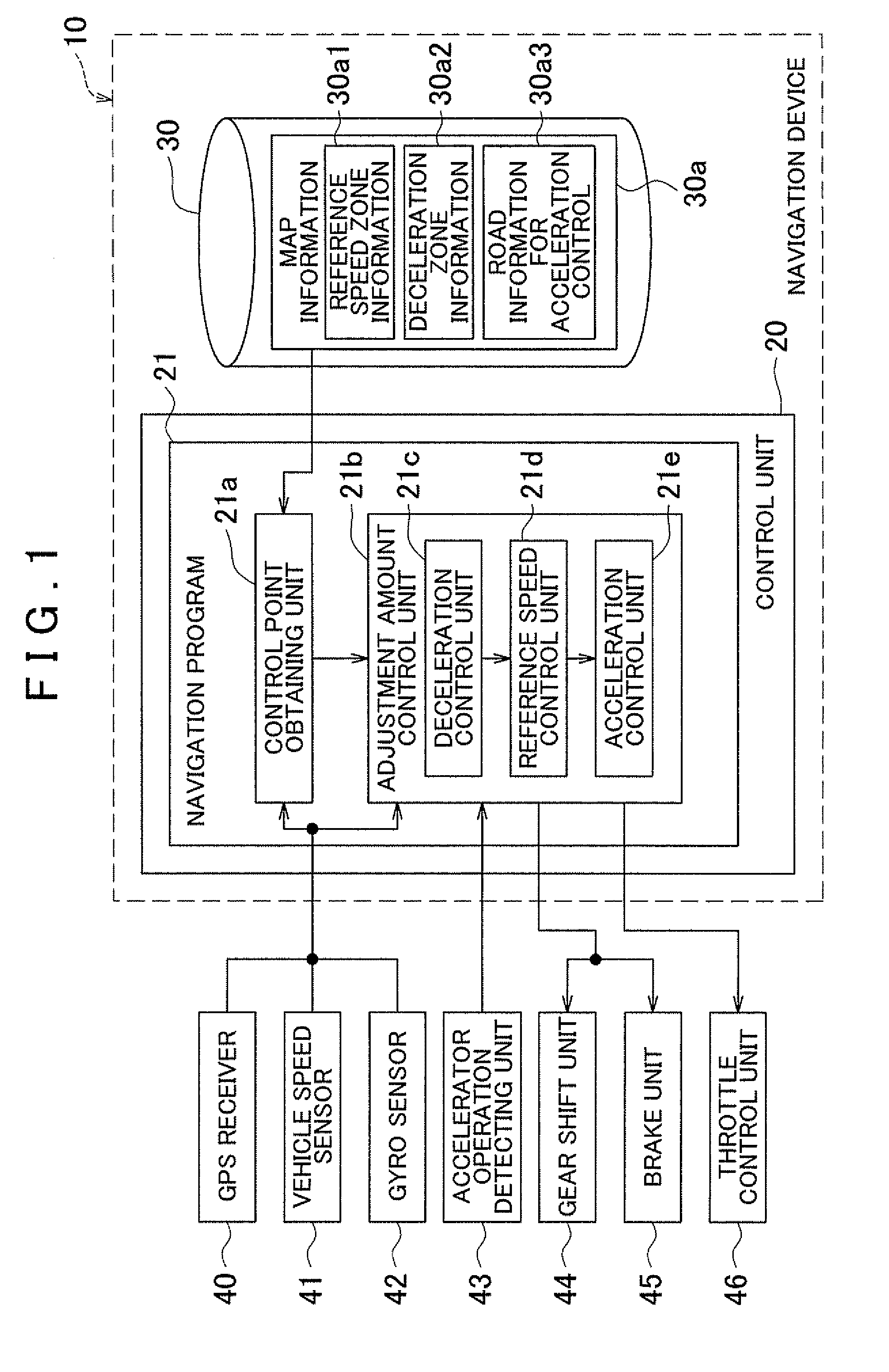

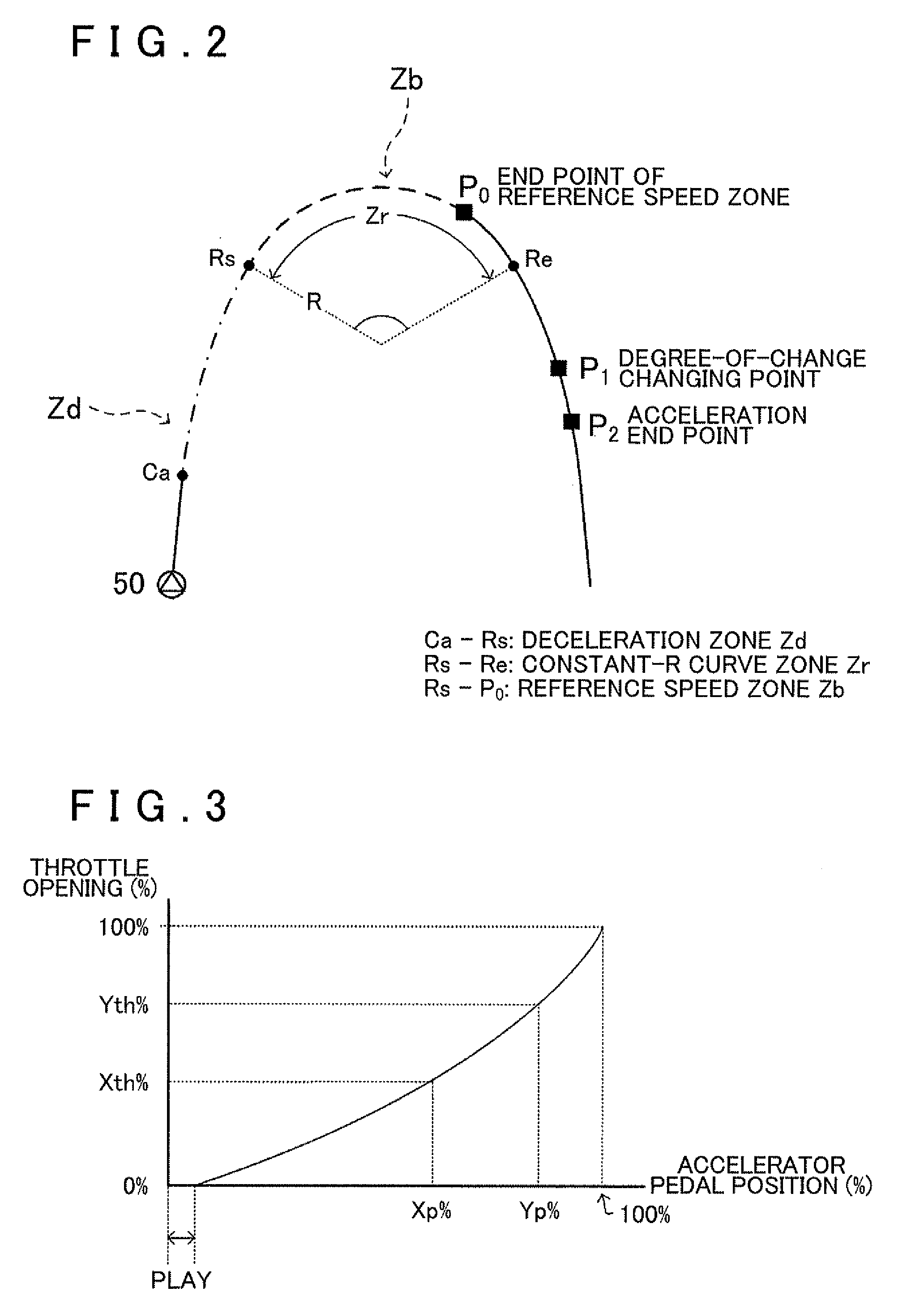

Driving support device, driving support method, and driving support program

InactiveUS20090265072A1Reduce incongruityReduced sensationInstruments for road network navigationHand manipulated computer devicesEngineering

Owner:AISIN AW CO LTD

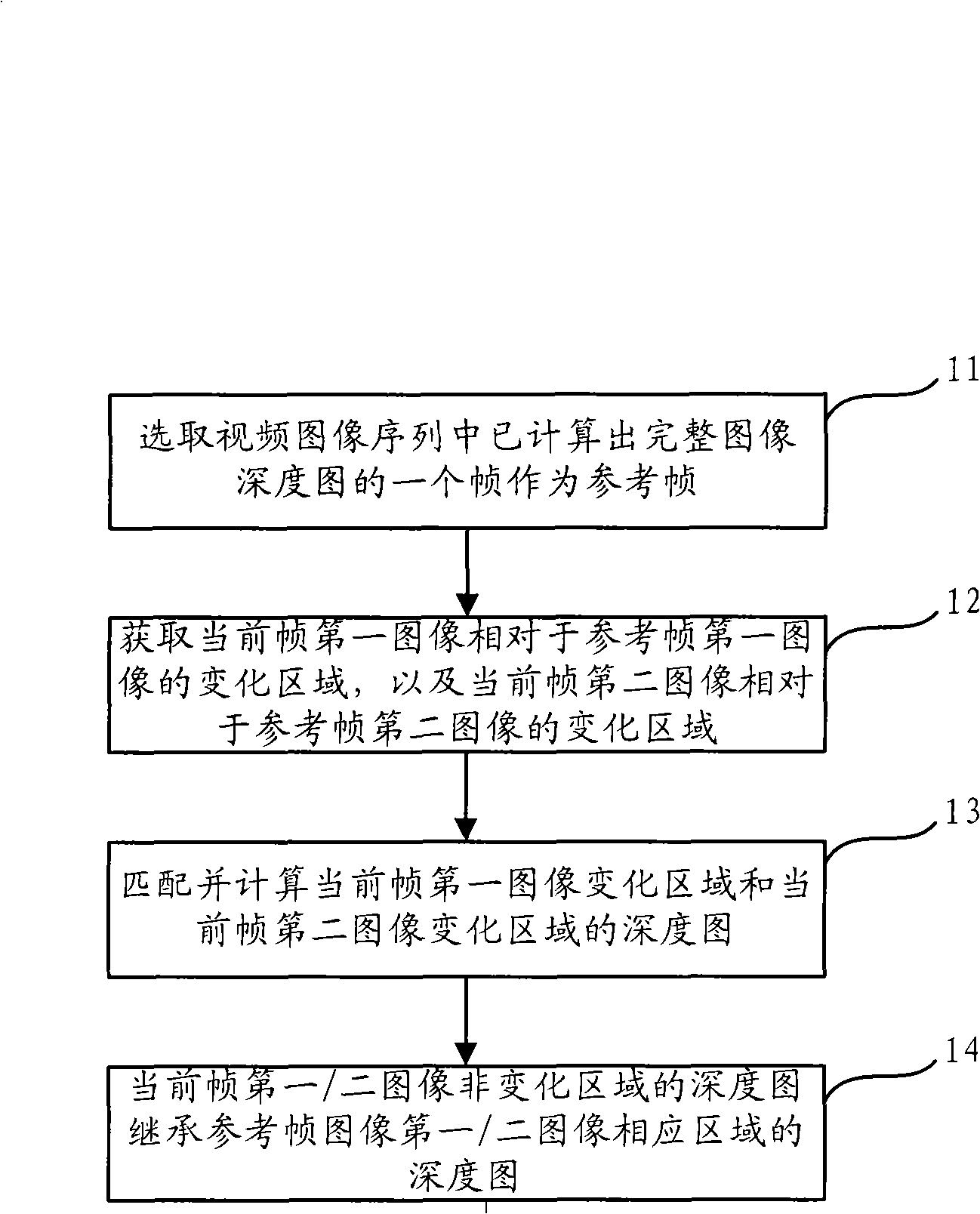

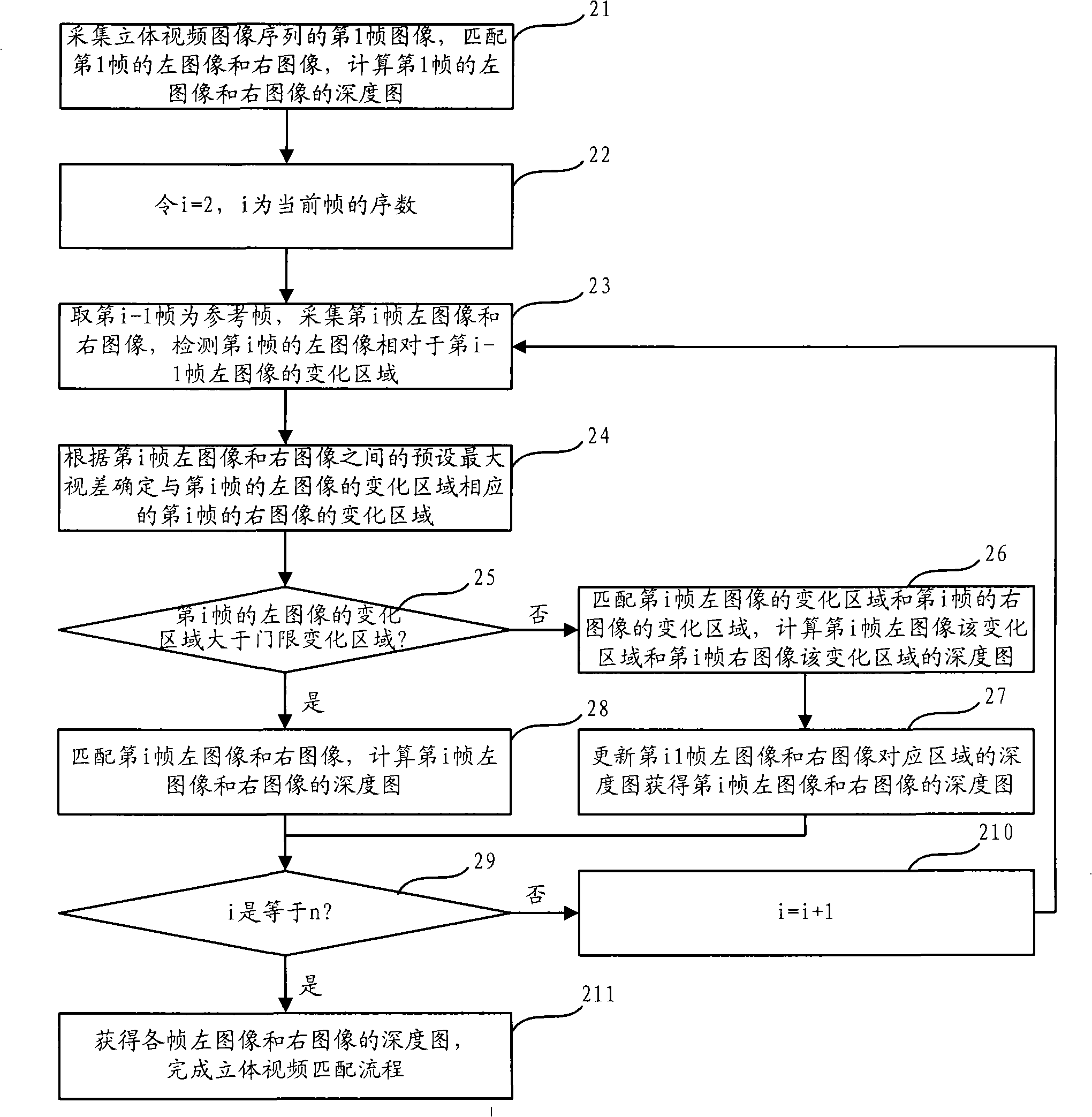

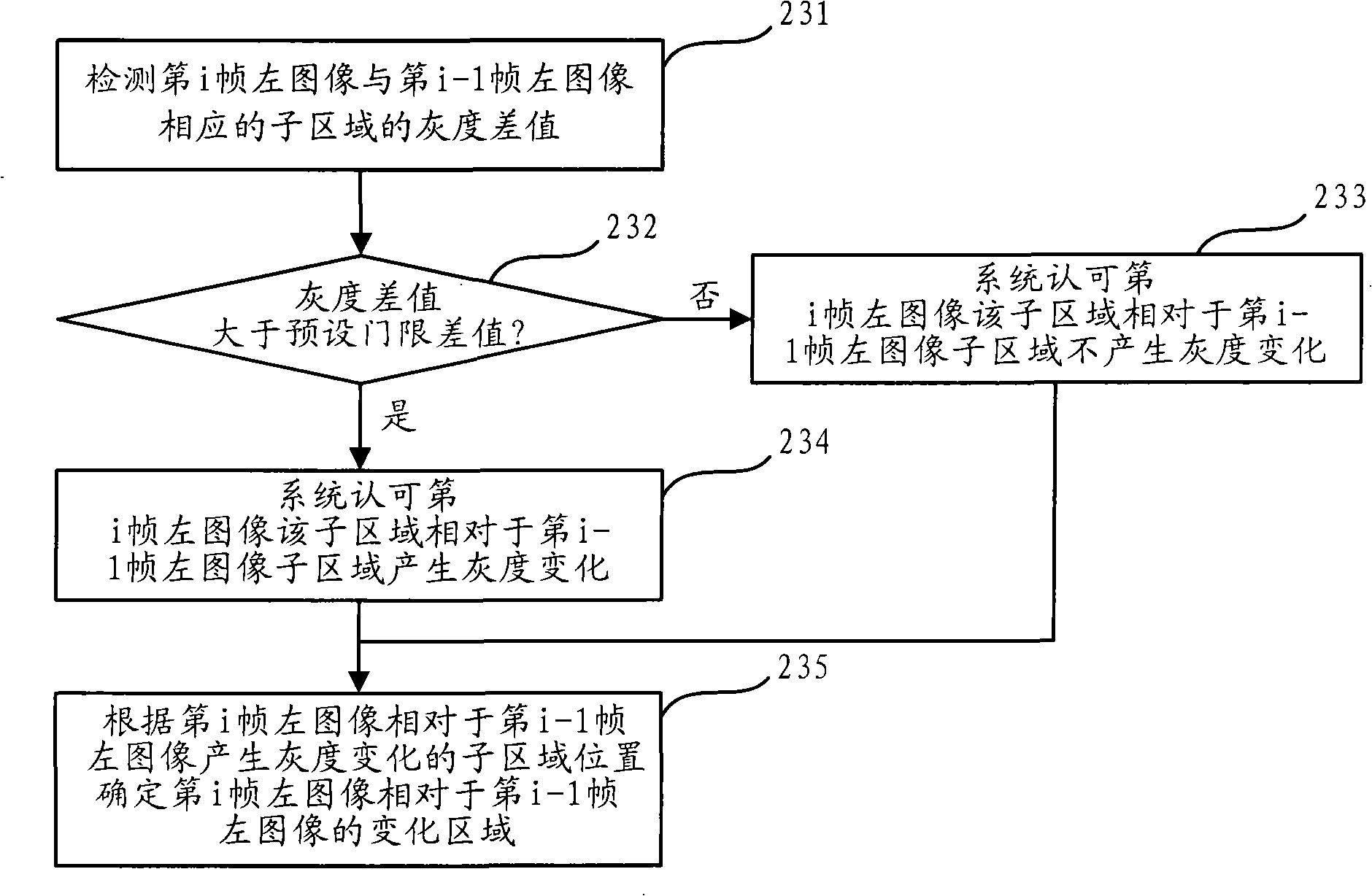

Video matching method, device and system

InactiveCN101516040AQuick matchImprove matching speedImage analysisSteroscopic systemsImage matchingVideo image

The invention relates to a video matching method, which comprises the following steps: selecting one frame calculated with an integral image depth map in a video image sequence as a reference frame; acquiring a varying area of a first image of a current frame relative to a first image of the reference frame, and a varying area of a second image of the current frame relative to a second image of the reference frame; and matching and calculating depth maps of the varying area of the first image and the varying area of the second image of the current frame. The invention also relates to a video matching device and a system. The invention utilizes video images, particularly correlation among video image sequences to select the frame matched with the integral image and calculated with the depth map as the reference frame, and newly performs corresponding image matching and depth map calculation only for the varying area of the current frame by detecting the varying area of the image of the current frame relative to the image of the reference frame, therefore, the invention shortens the matching time of the image of the current frame remarkably so as to improve the matching speed of the video and achieve the quick matching of the video.

Owner:HUAWEI DEVICE CO LTD

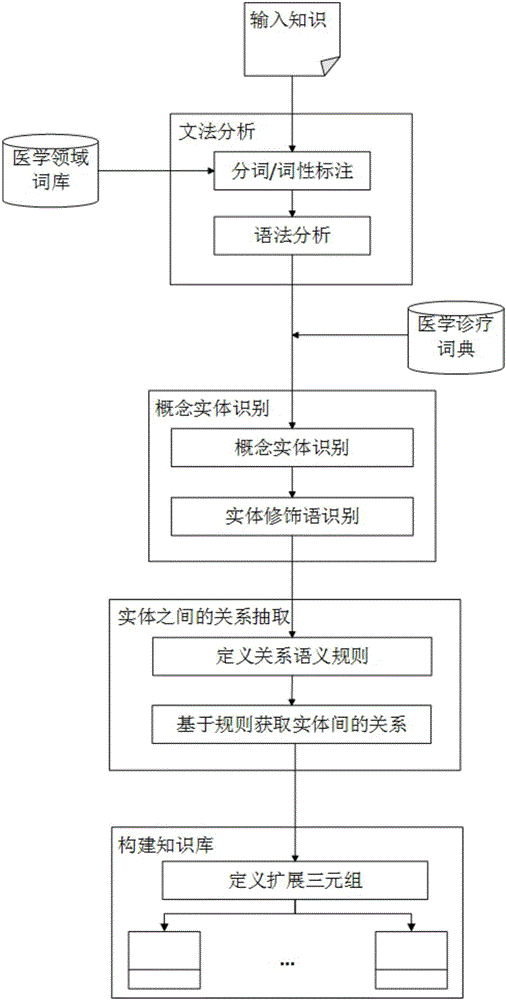

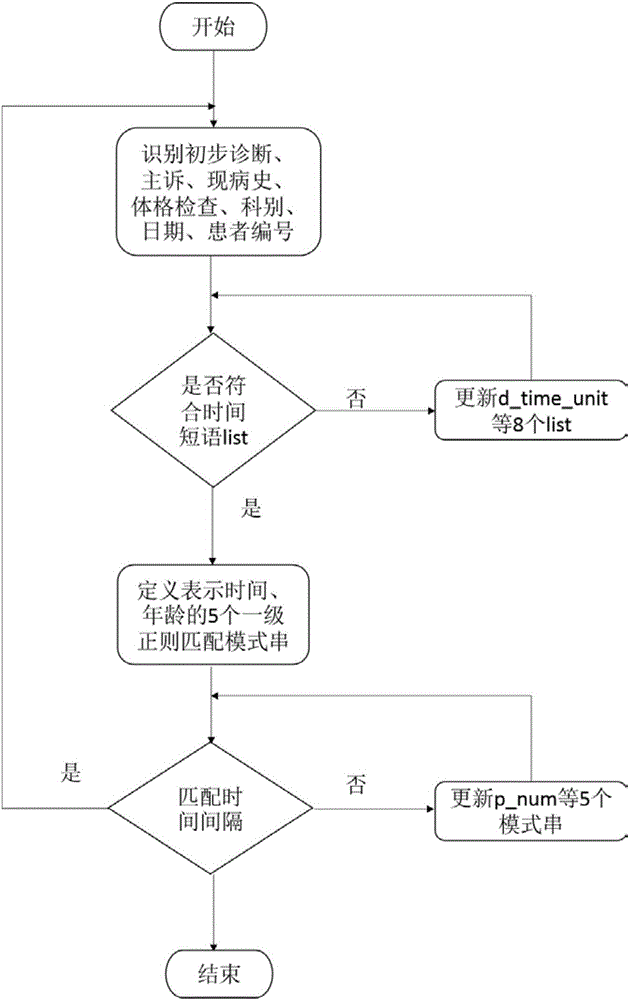

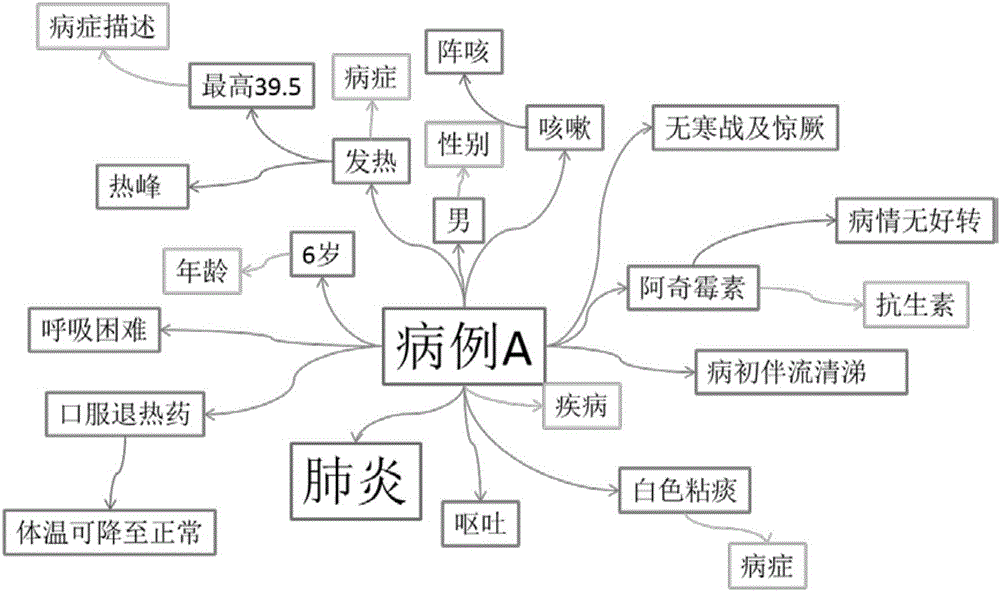

Knowledge base construction method and system for intelligent clinical assistant decision making supporting system

InactiveCN106295187AComputing efficiencyEasy to update and maintainMedical automated diagnosisSpecial data processing applicationsDecision making support systemsSupporting system

The invention provides a knowledge base construction method and system for an intelligent clinical assistant decision making supporting system, and relates to the field of knowledge base construction. The method comprises the steps that input information is acquired, word segmenting processing, part-of-speech tagging and grammatical analysis are conducted on the input information, a relational dependence tree is acquired, and concepts, entities and entity modifiers in the relational dependence tree are extracted; the relation among all the entities in the relational dependence tree is acquired through relational semantic rules according to the concepts, the entities and the entity modifiers; an extending ternary group is set, the relation among all the entities in the relational dependence tree is stored through the extending ternary group, and then knowledge base construction is completed. The method and the system can be applied to the condition of more clinical examples and characteristics and can be flexibly expanded for case description information.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

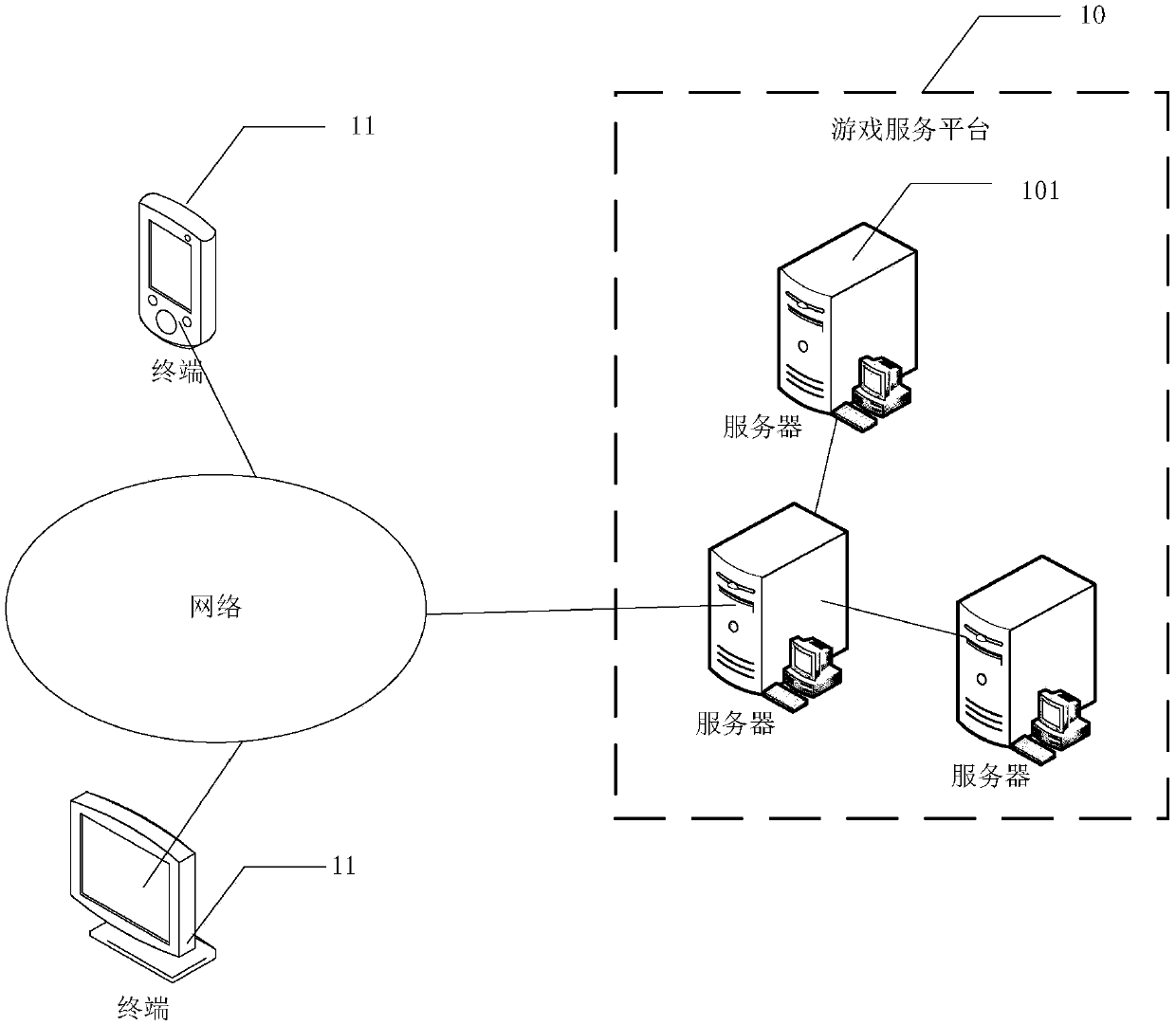

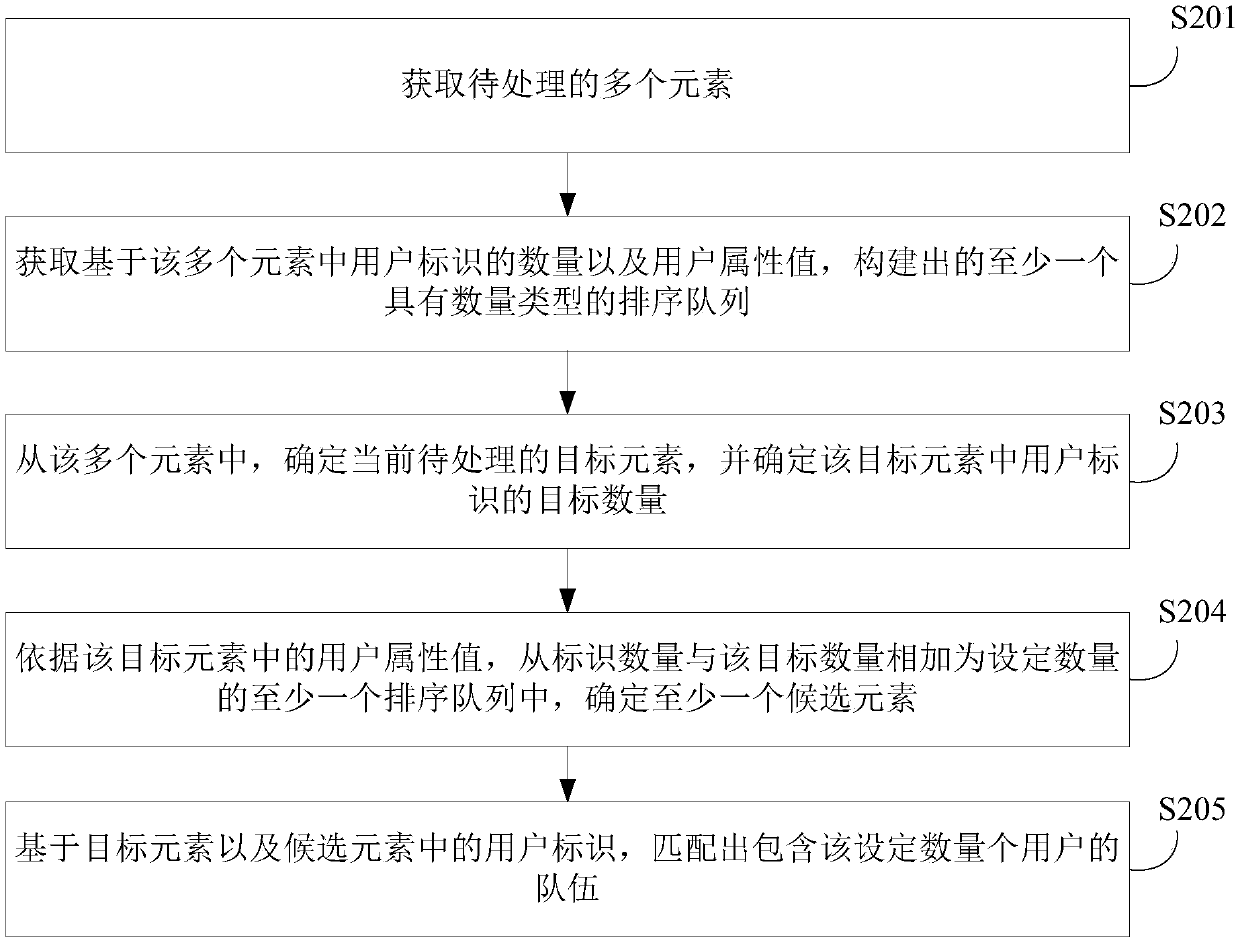

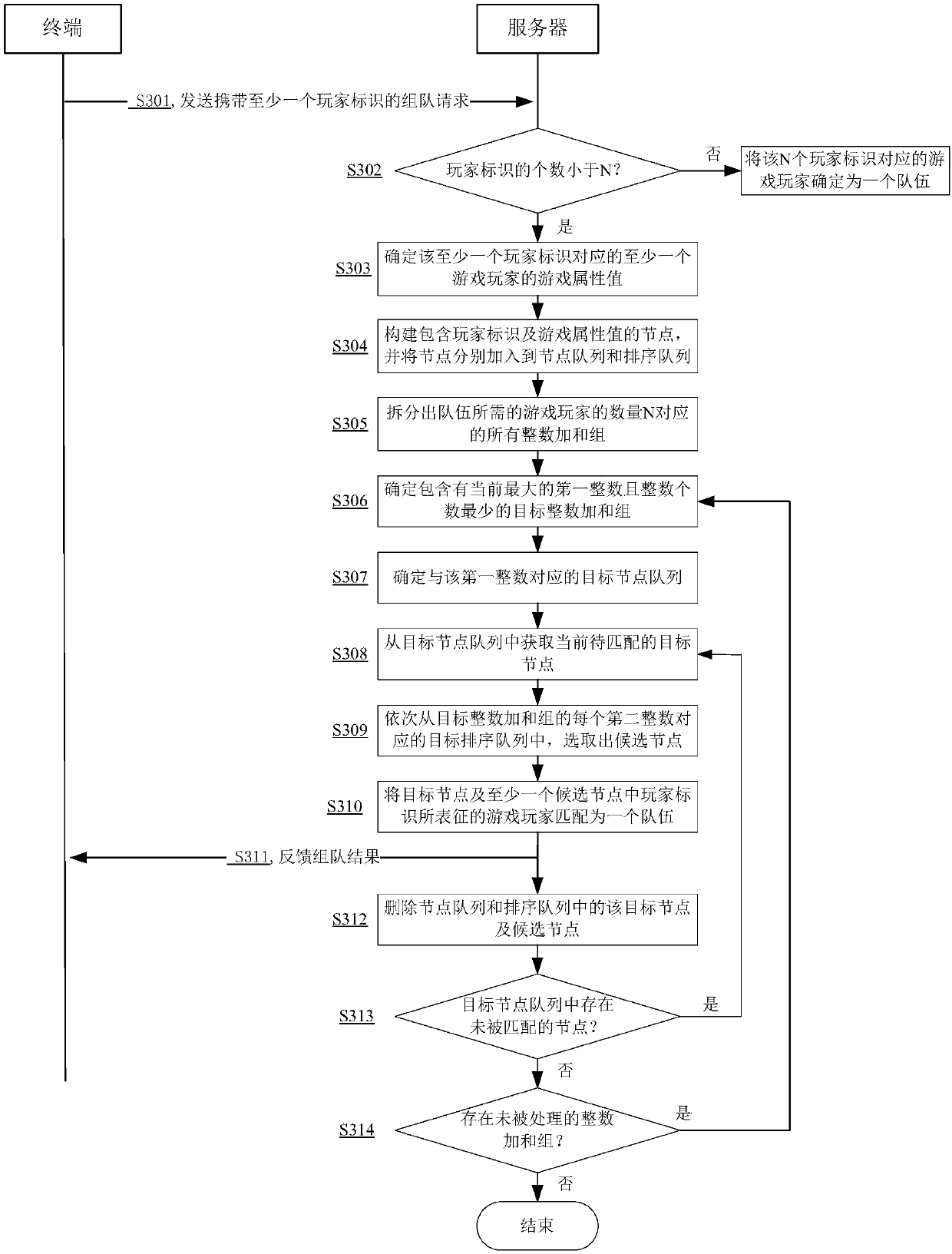

User matching method and device, server and storage medium

ActiveCN107837532AReduce matching workloadImprove matching efficiencyVideo gamesMatching methodsData mining

The invention provides a user matching method and device, a server and a storage medium. The method includes: acquiring multiple to-be-processed elements, wherein the user identification and user attribute value of at least one user are recorded in the elements; acquiring at least one sorting queue which comprises at least one element sorted according to the preset sequence of the user attribute values, wherein the number of user identification in the elements of the sorting queues is identical with the number of identification corresponding to the sorting queues; determining a current to-be-processed target element from the multiple elements, and determining the target number of the user identification in the target element; determining at least one candidate element from at least one sorting queue with identification number adding the target number being a set number according to the user attribute value of the target element; matching queues containing the set number of users according to the user identification of the target element and the candidate element. By the method, the matching efficiency of user queue matching can be increased.

Owner:TENCENT TECH SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com