Patents

Literature

87 results about "Case description" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A case is a particular instance of something. In a business context, a case is a collection of information about a particular instance of something, such as a person, company, incident or problem.

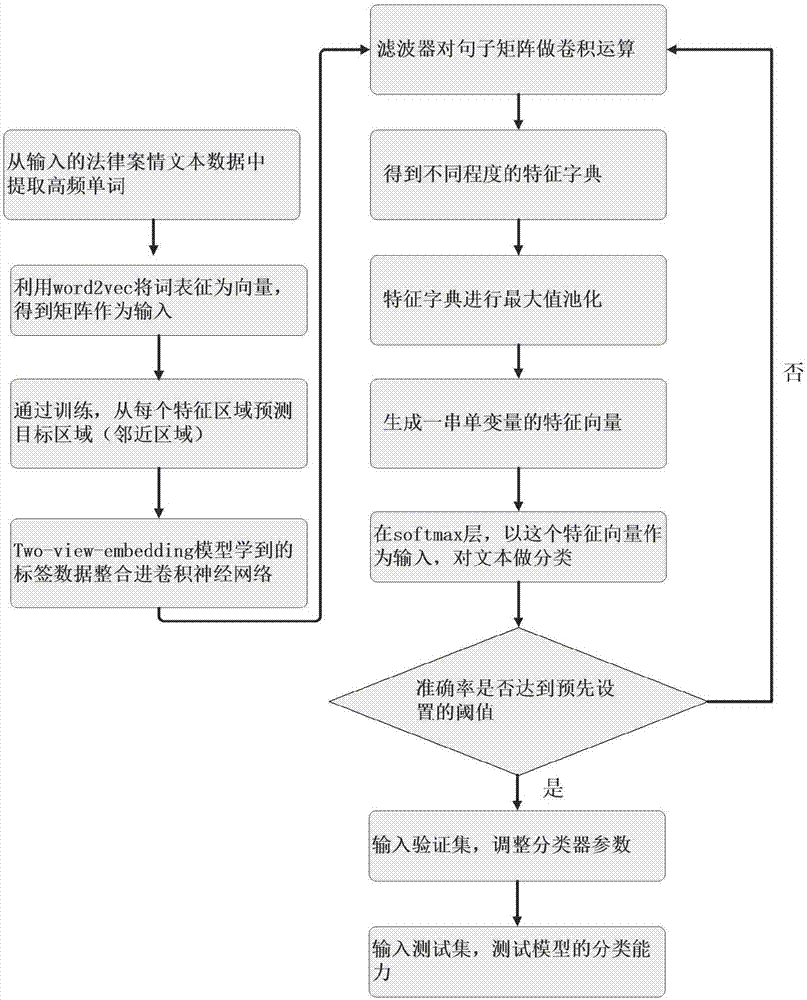

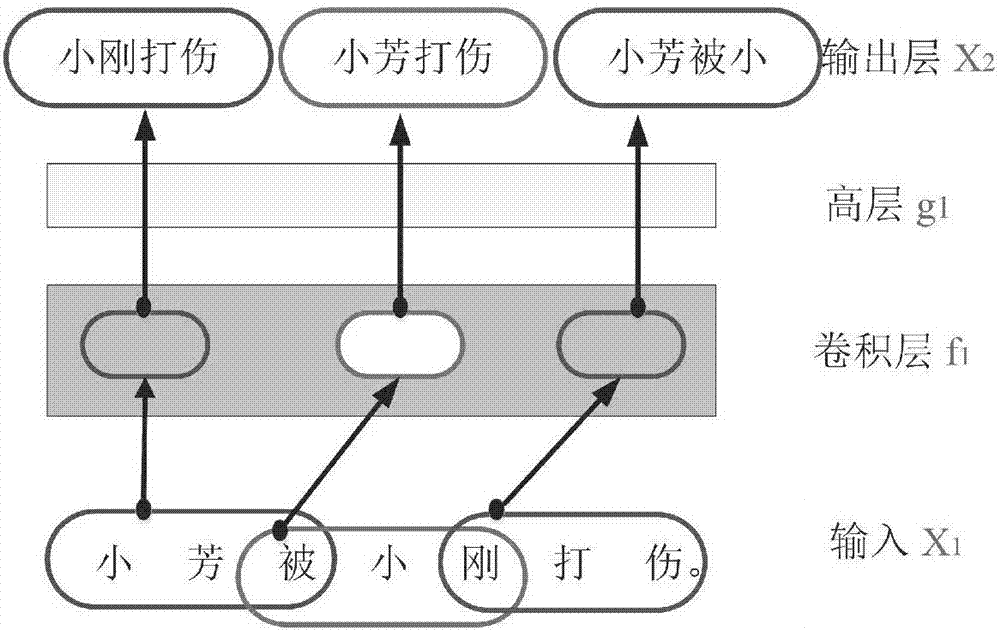

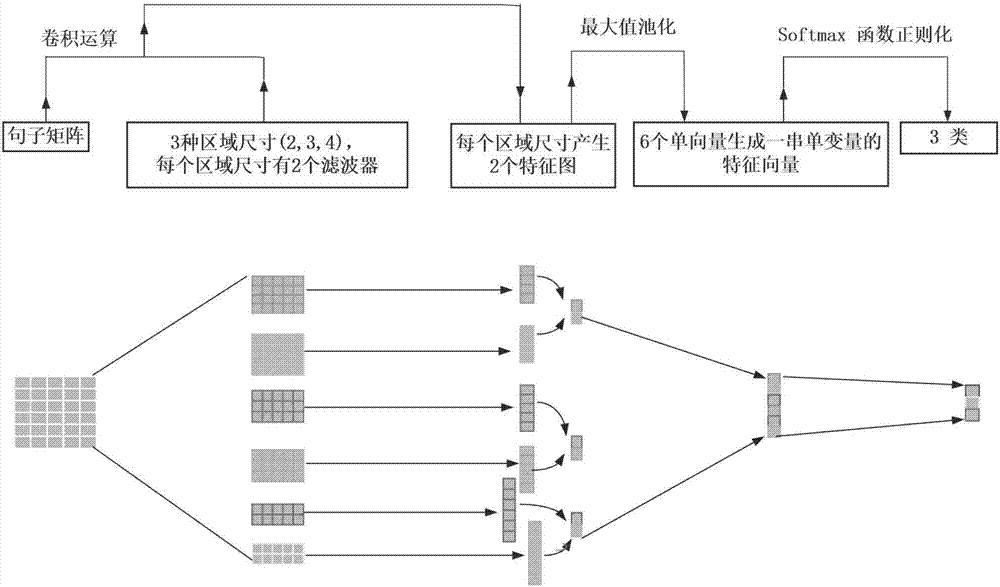

Method for classifying legal texts by adopting semi-supervised convolutional neural network (SSC)

InactiveCN108009284AAbility to understand literal meaningHave logical reasoningNatural language data processingNeural architecturesNatural language understandingMulti-label classification

The invention relates to a method for classifying legal texts by adopting a semi-supervised convolutional neural network (SSC) and belongs to the field of neural networks. According to the method, natural languages are processed by utilizing the SSC to achieve the main objective of a system; and through the processing on the legal case description, the problems that what rights and interests of parties does the legal case description violate or which laws and regulations does the parties violate are preliminarily solved, probably more than one rights and interests of the parties is violated orthe parties violate a plurality of laws and regulations at the same time and multi-label classification is realized. Through the legal service platform, case handlers are helped to efficiently handlevarious legal cases and the various legal cases are subjected to semantic analysis to achieve classification to ensure that not only the ability to understand literal meanings but also the ability tologically reason and understand deep meanings are provided in the aspect of the natural language understanding function.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

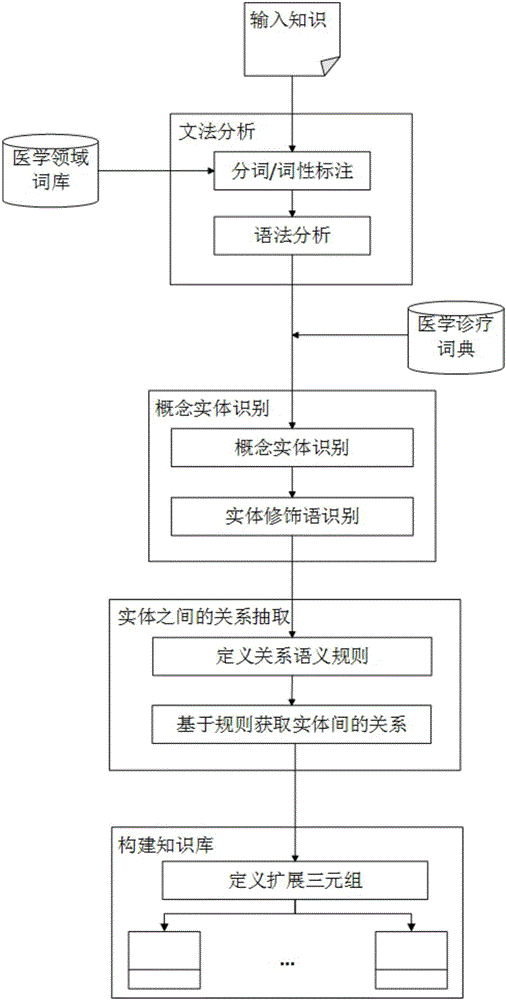

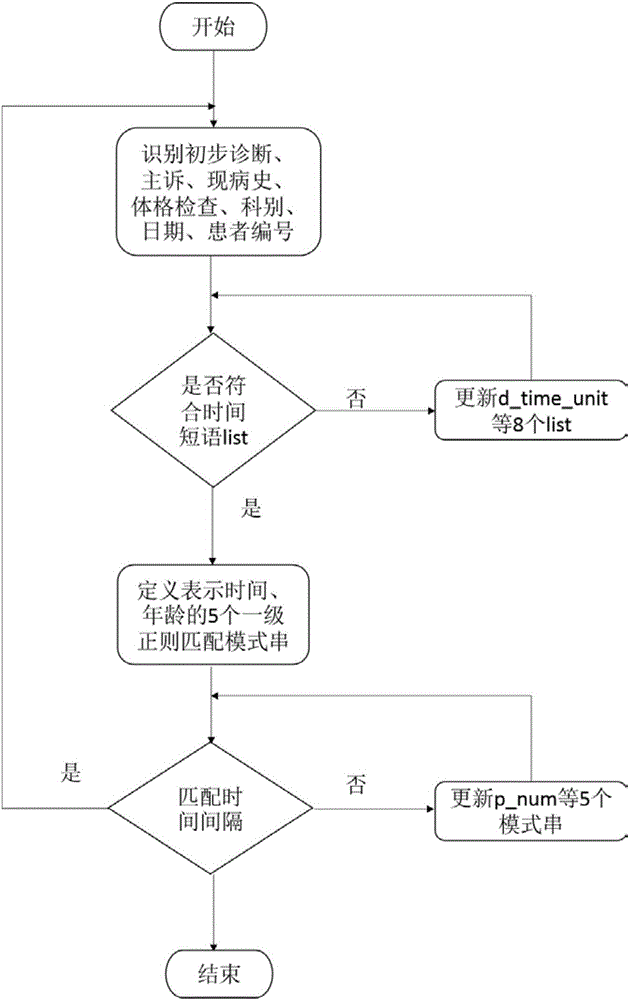

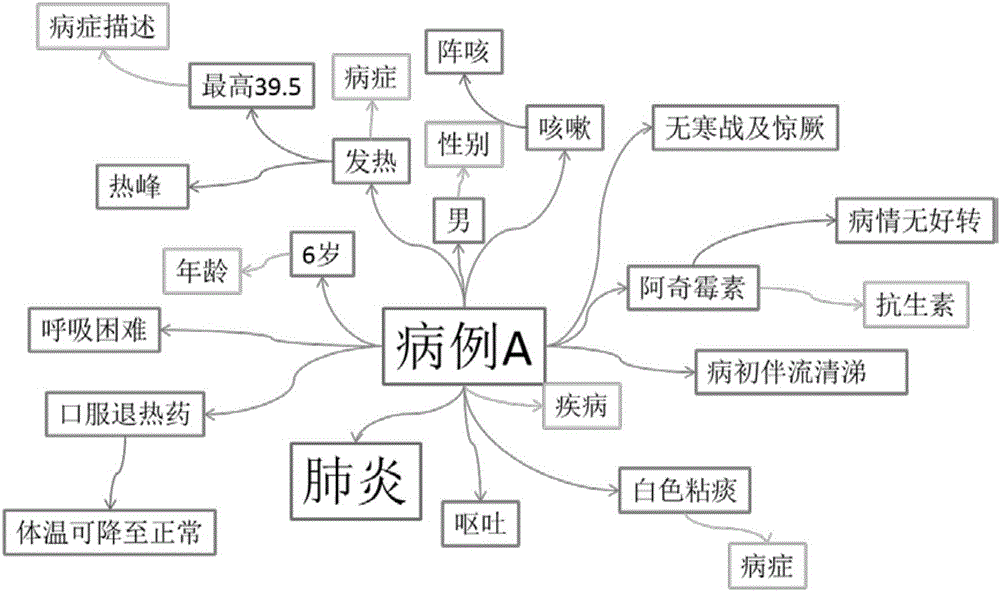

Knowledge base construction method and system for intelligent clinical assistant decision making supporting system

InactiveCN106295187AComputing efficiencyEasy to update and maintainMedical automated diagnosisSpecial data processing applicationsDecision making support systemsSupporting system

The invention provides a knowledge base construction method and system for an intelligent clinical assistant decision making supporting system, and relates to the field of knowledge base construction. The method comprises the steps that input information is acquired, word segmenting processing, part-of-speech tagging and grammatical analysis are conducted on the input information, a relational dependence tree is acquired, and concepts, entities and entity modifiers in the relational dependence tree are extracted; the relation among all the entities in the relational dependence tree is acquired through relational semantic rules according to the concepts, the entities and the entity modifiers; an extending ternary group is set, the relation among all the entities in the relational dependence tree is stored through the extending ternary group, and then knowledge base construction is completed. The method and the system can be applied to the condition of more clinical examples and characteristics and can be flexibly expanded for case description information.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

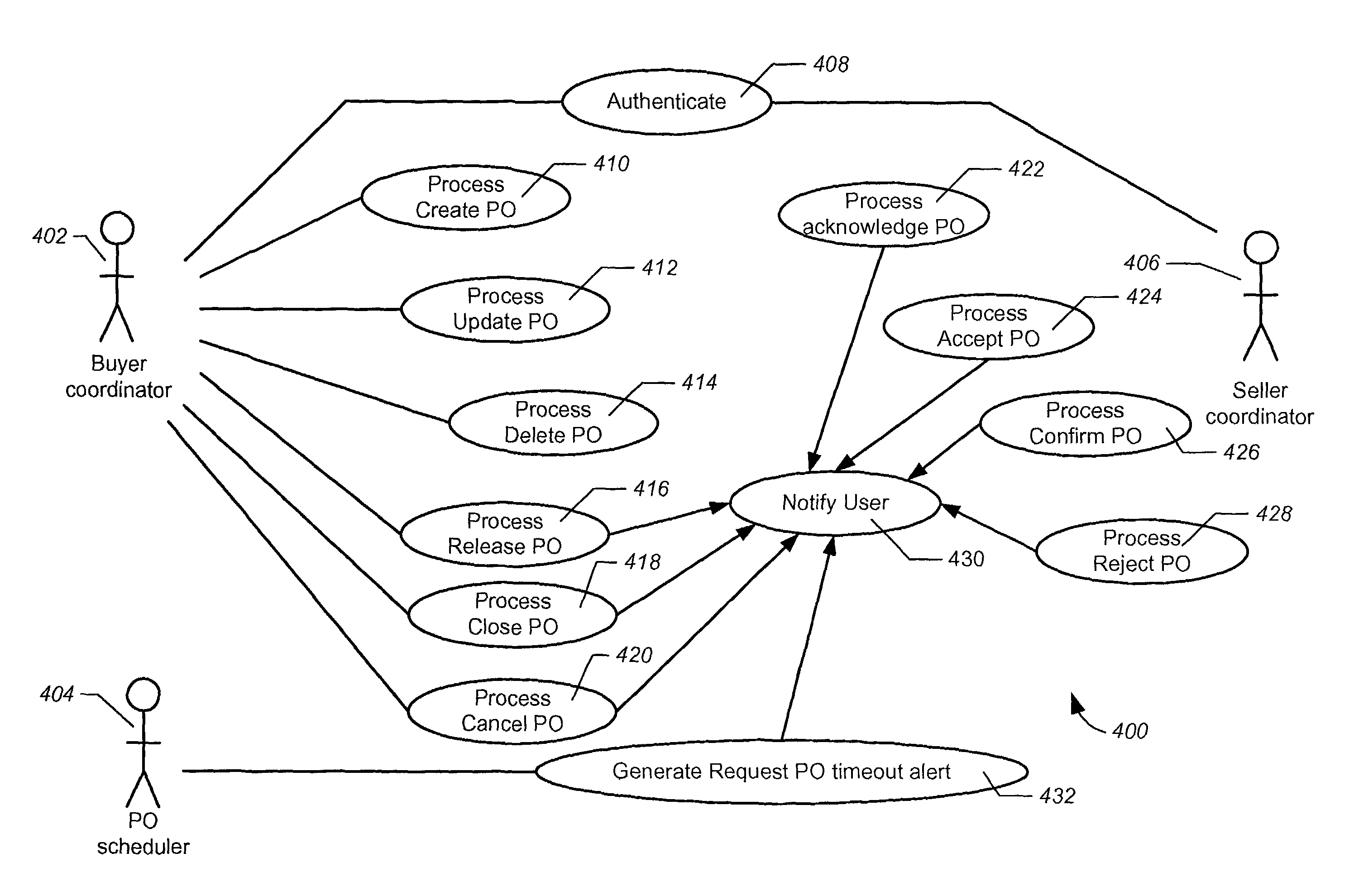

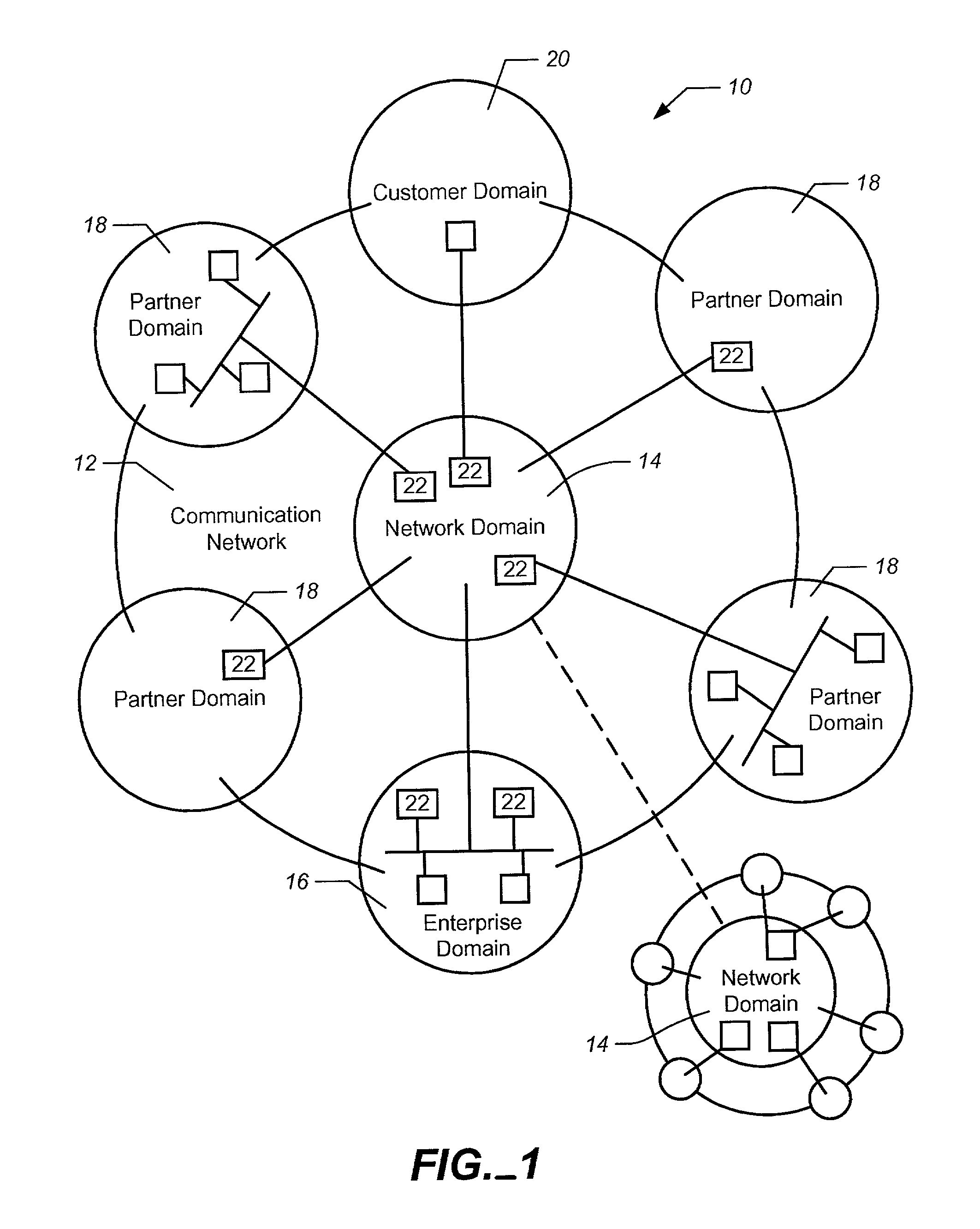

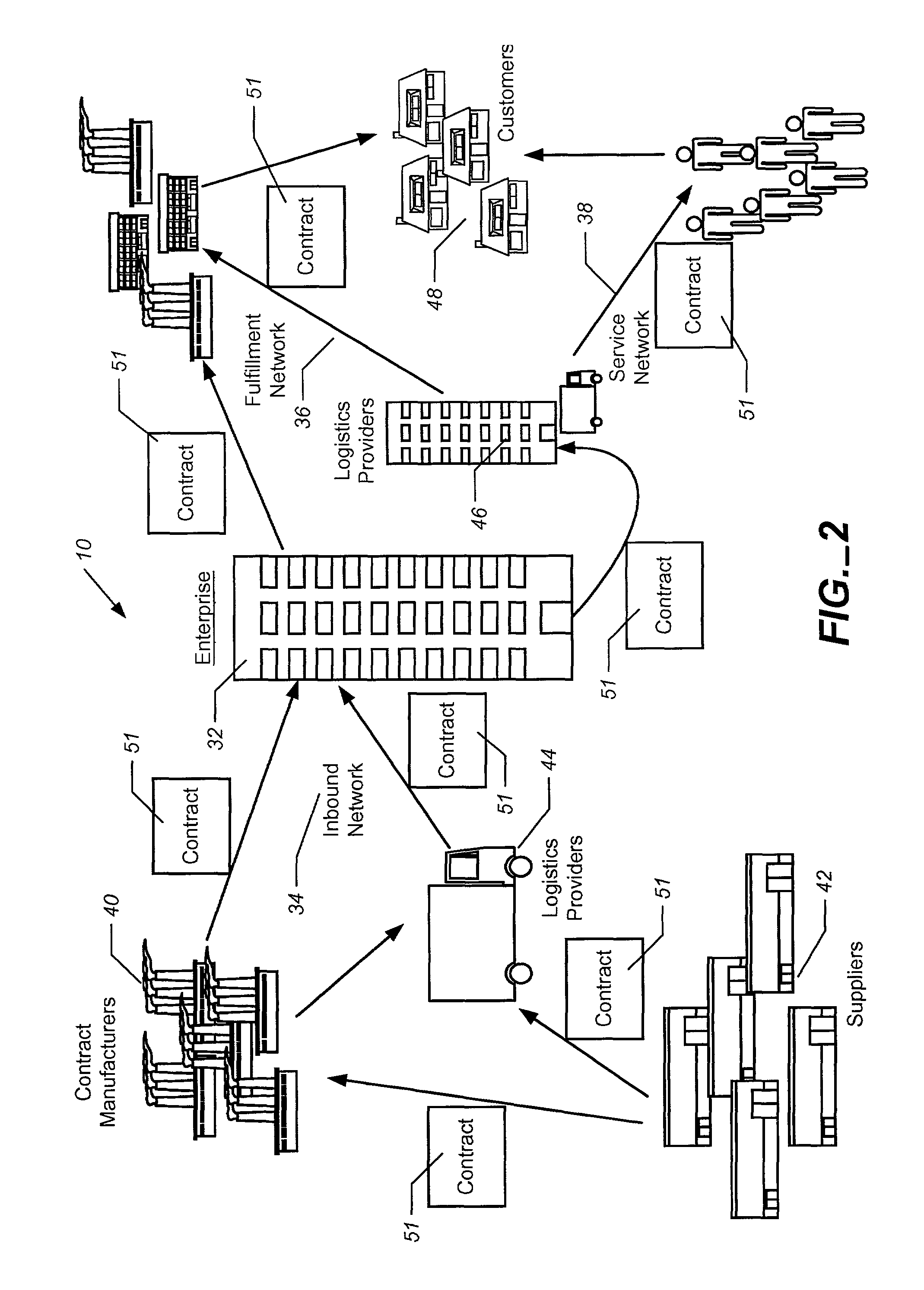

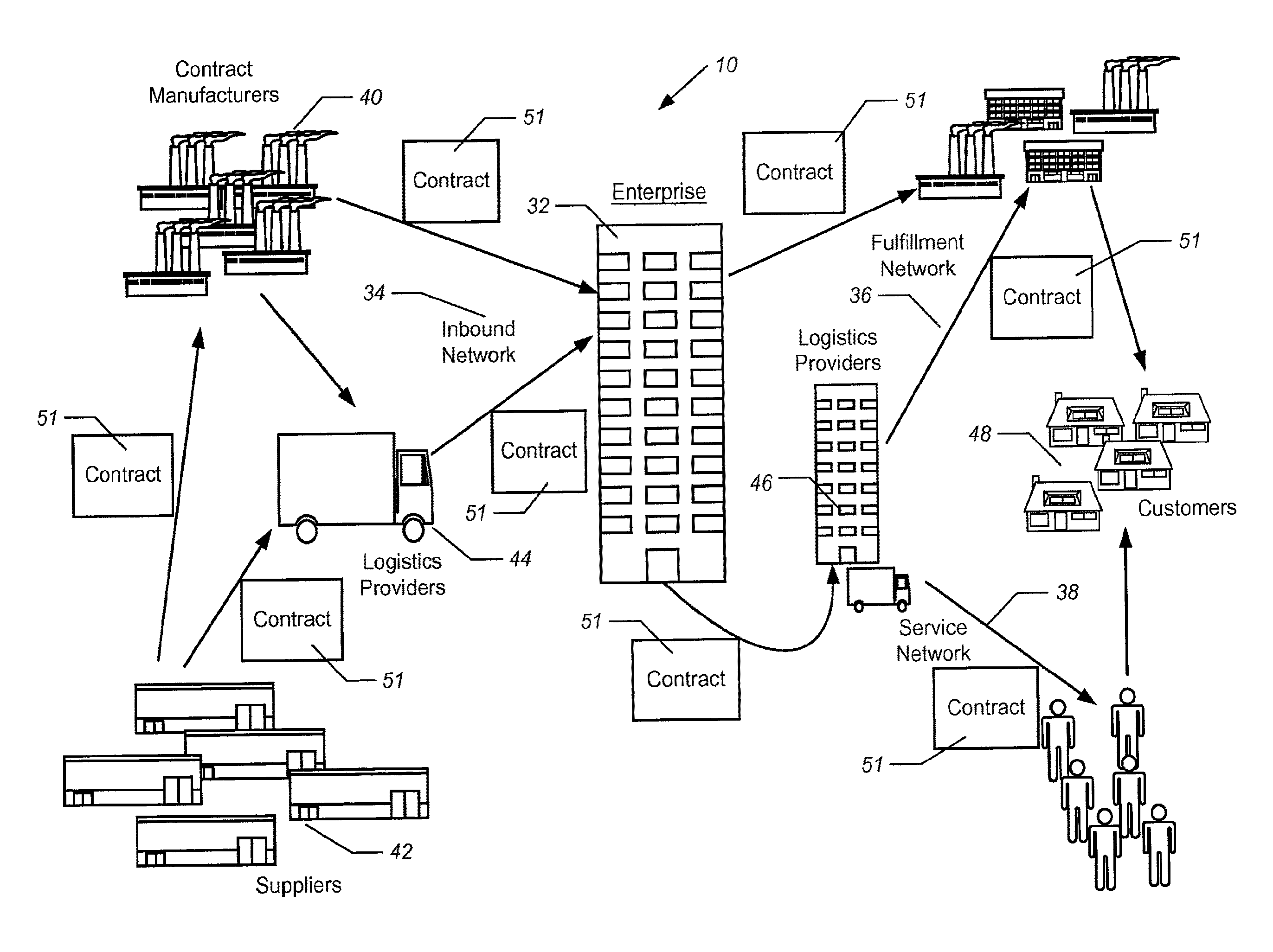

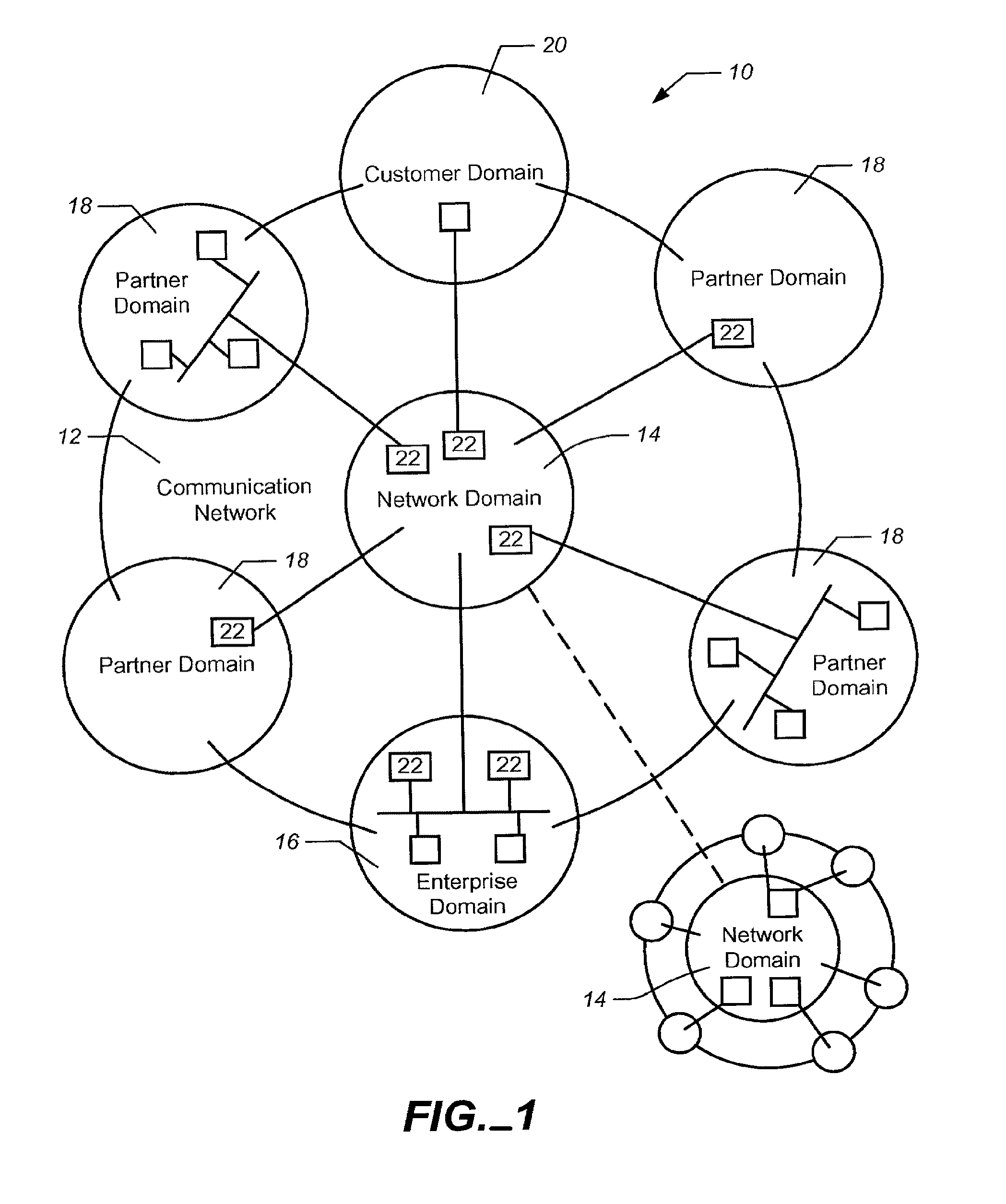

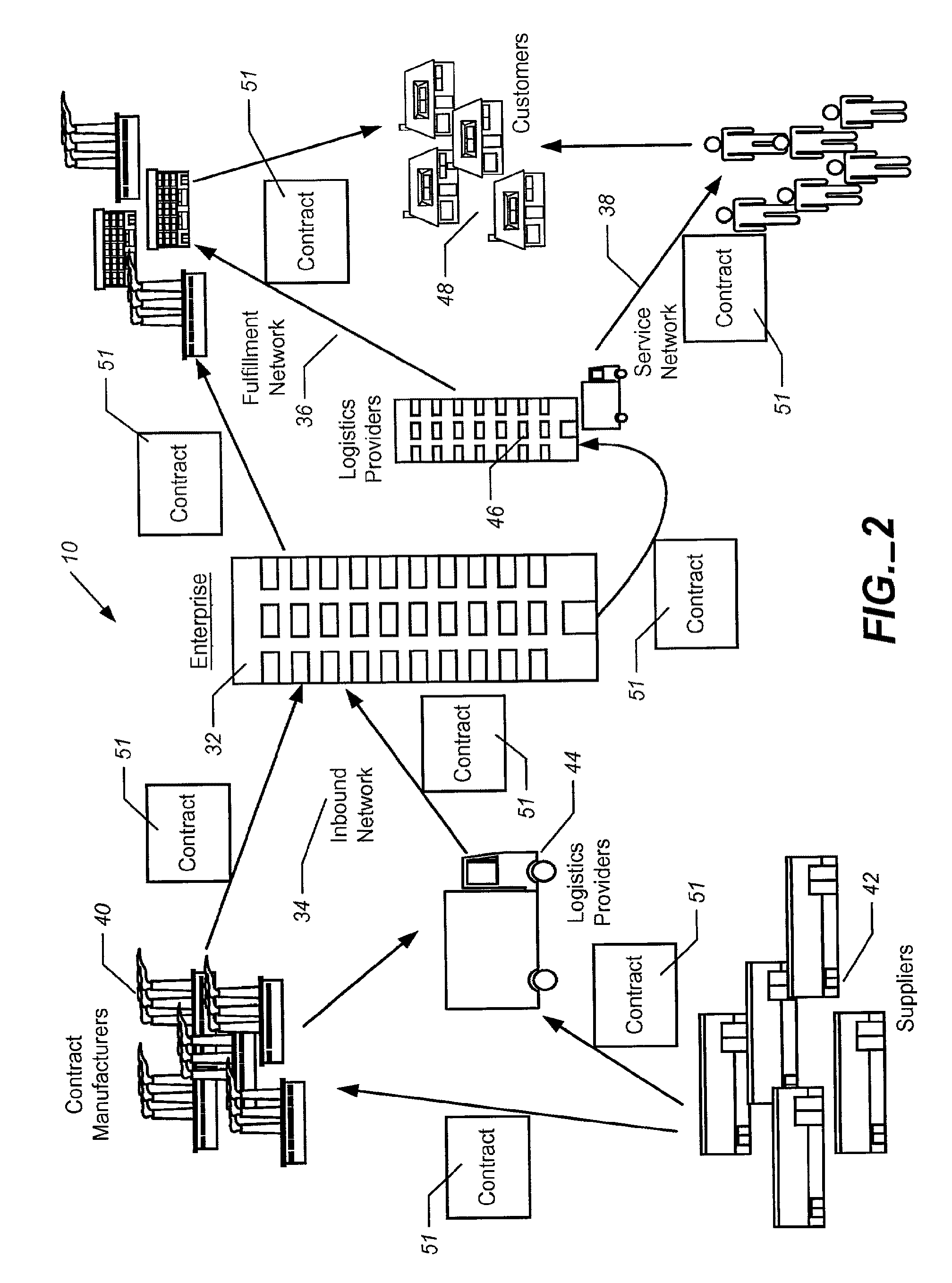

Policy based automation for a supply chain

A method is provided for implementing a computer network system for managing a supply chain, wherein the computer network system comprising a plurality of application server computers. The method includes: identifying a business context for the supply chain; identifying a set of business policy rules for the business context, the set of business policy rules governing the relationship between two or more entities involved in the supply chain; creating at least one use-case description from the set of business policy rules; creating a plurality of executable code modules corresponding to the use-case description; specifying a plurality of name / value pair for modeling the set of business policy rules; provisioning the plurality of application server computers of the computer network system with the executable code modules; and provisioning a central directory database with the plurality of name / value pairs; whereby the computer network system, in response to one or more events in business transactions between at least two entities involved in the supply chain, is operable to dynamically deliver at least one name / value pair from the central directory database and to execute at least one code module.

Owner:PARAMETRIC TECH CORP

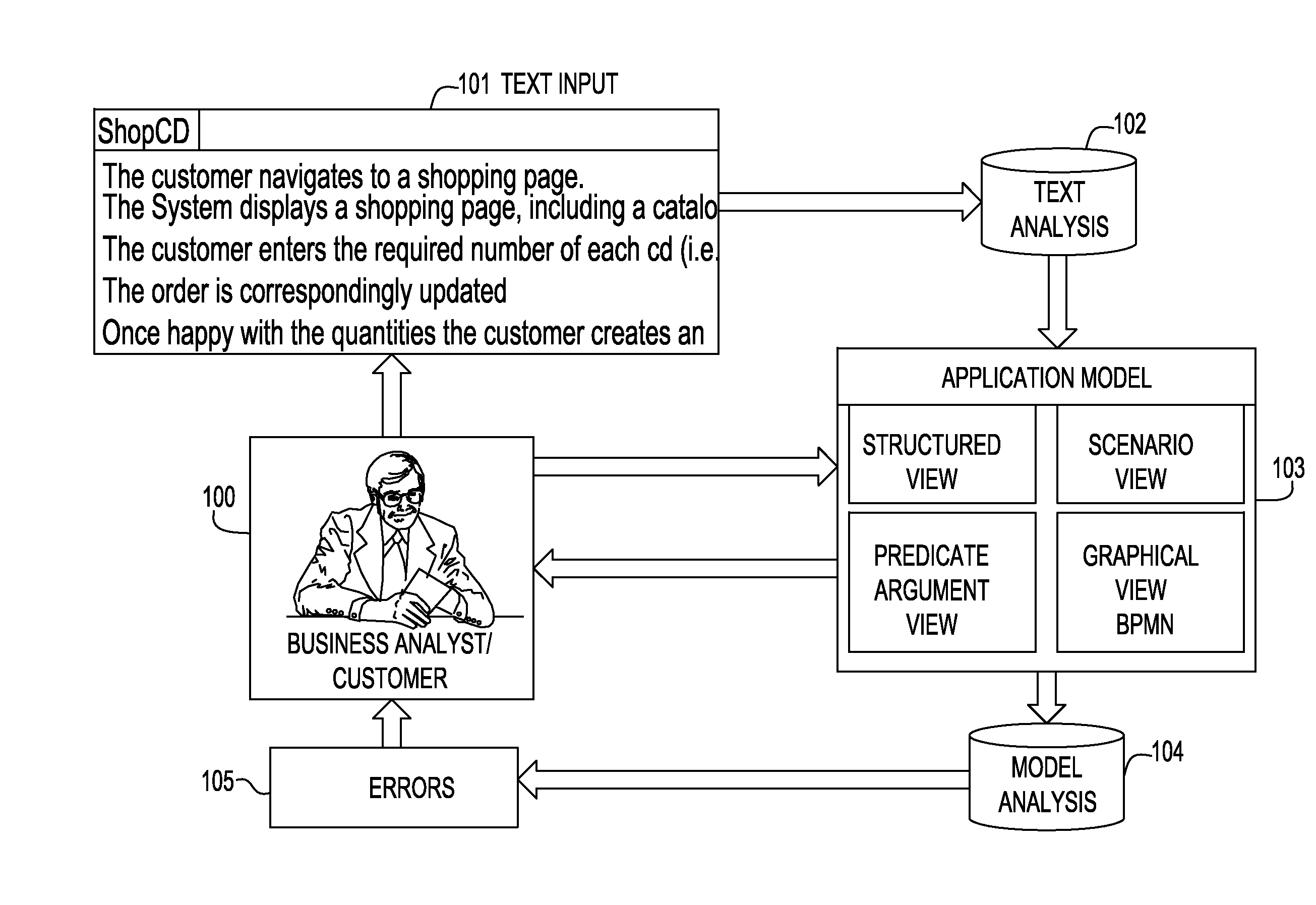

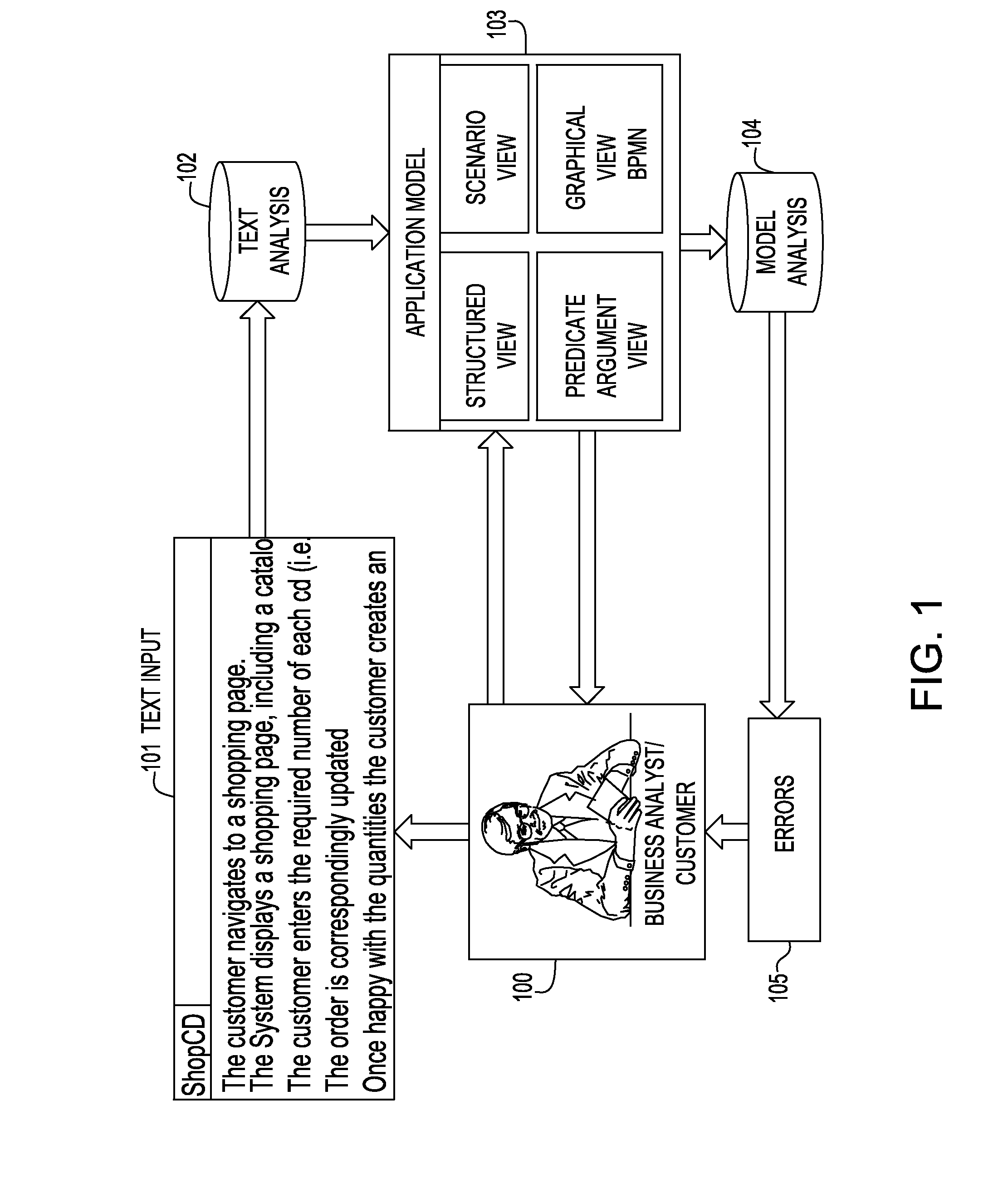

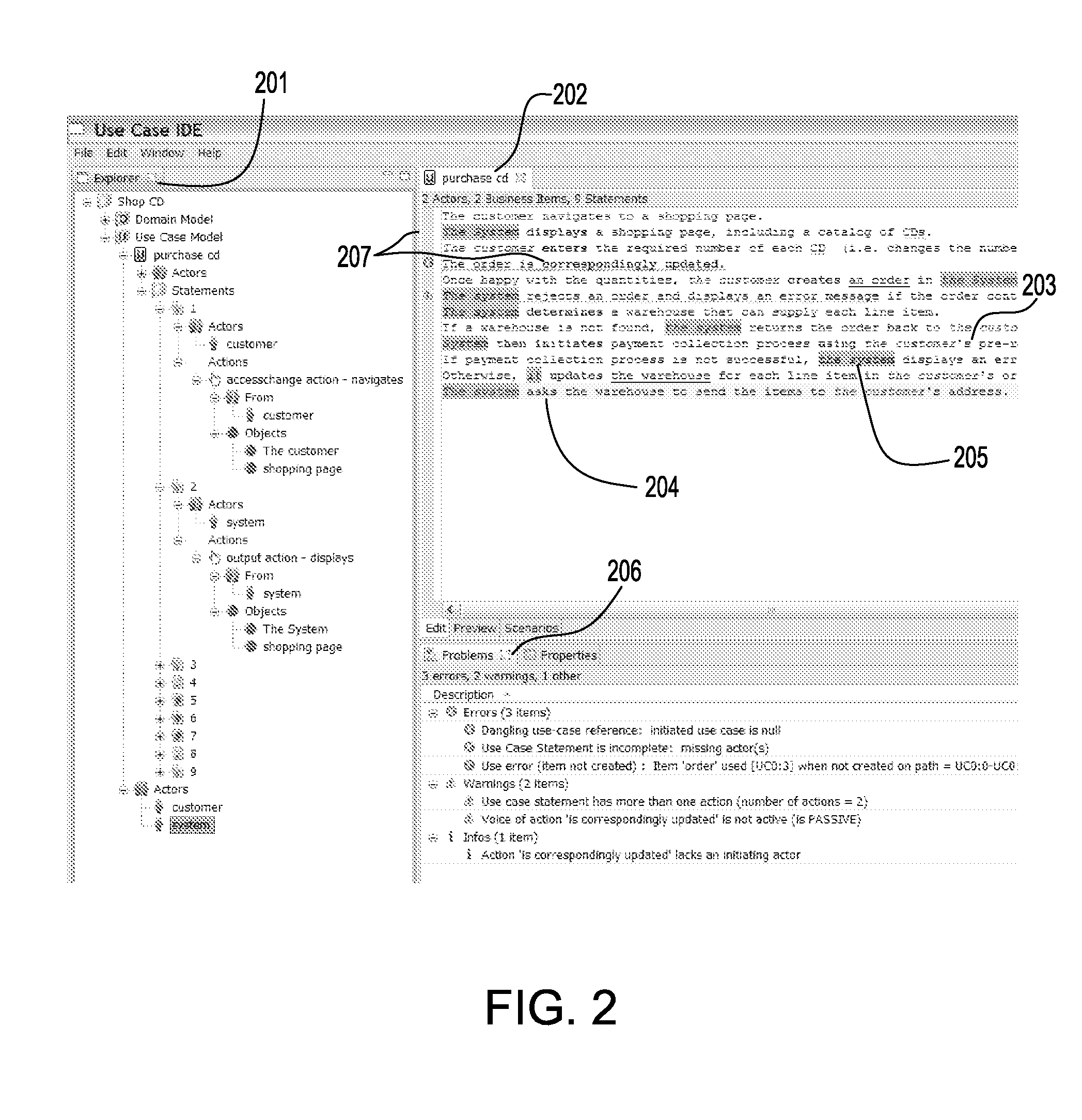

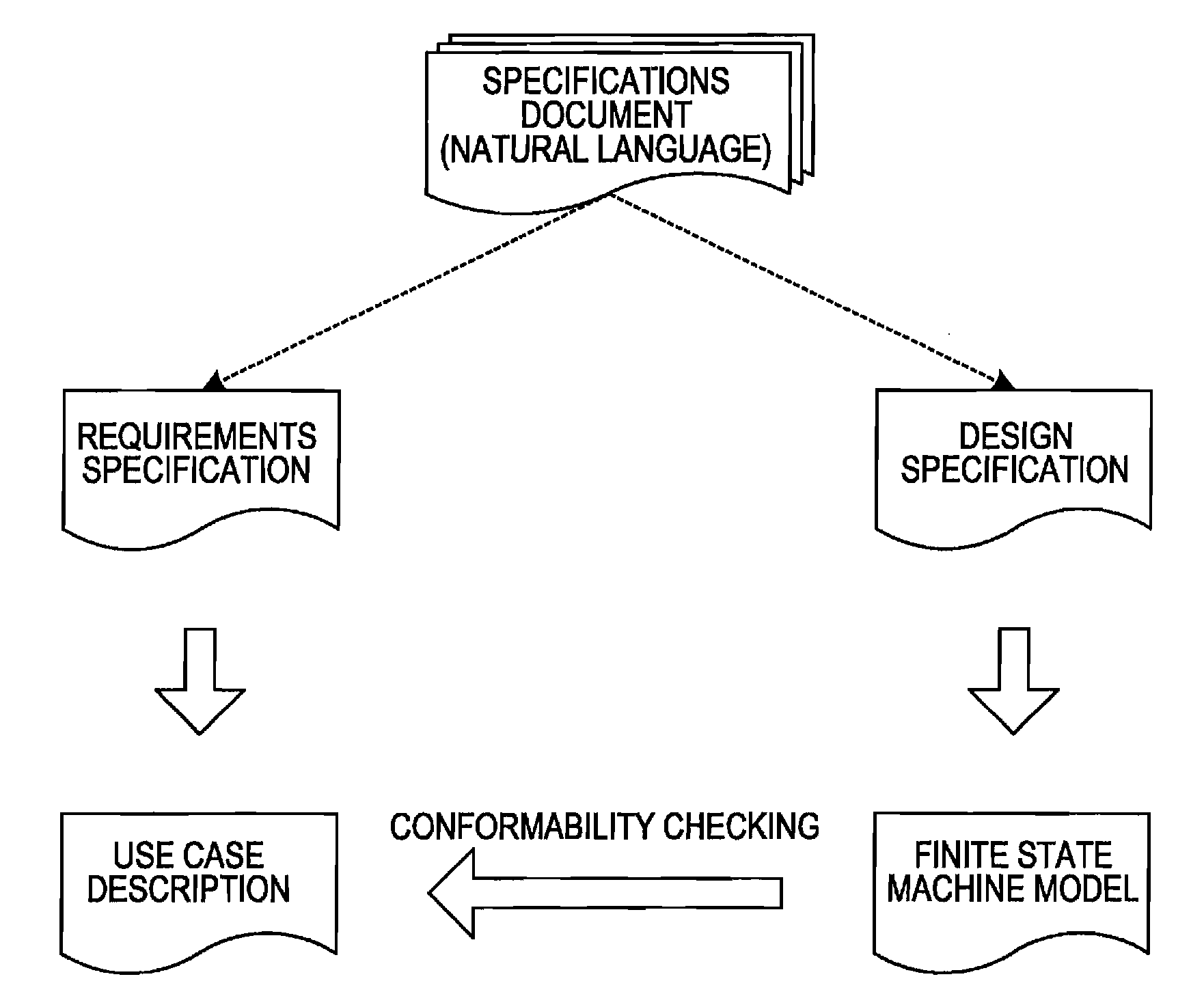

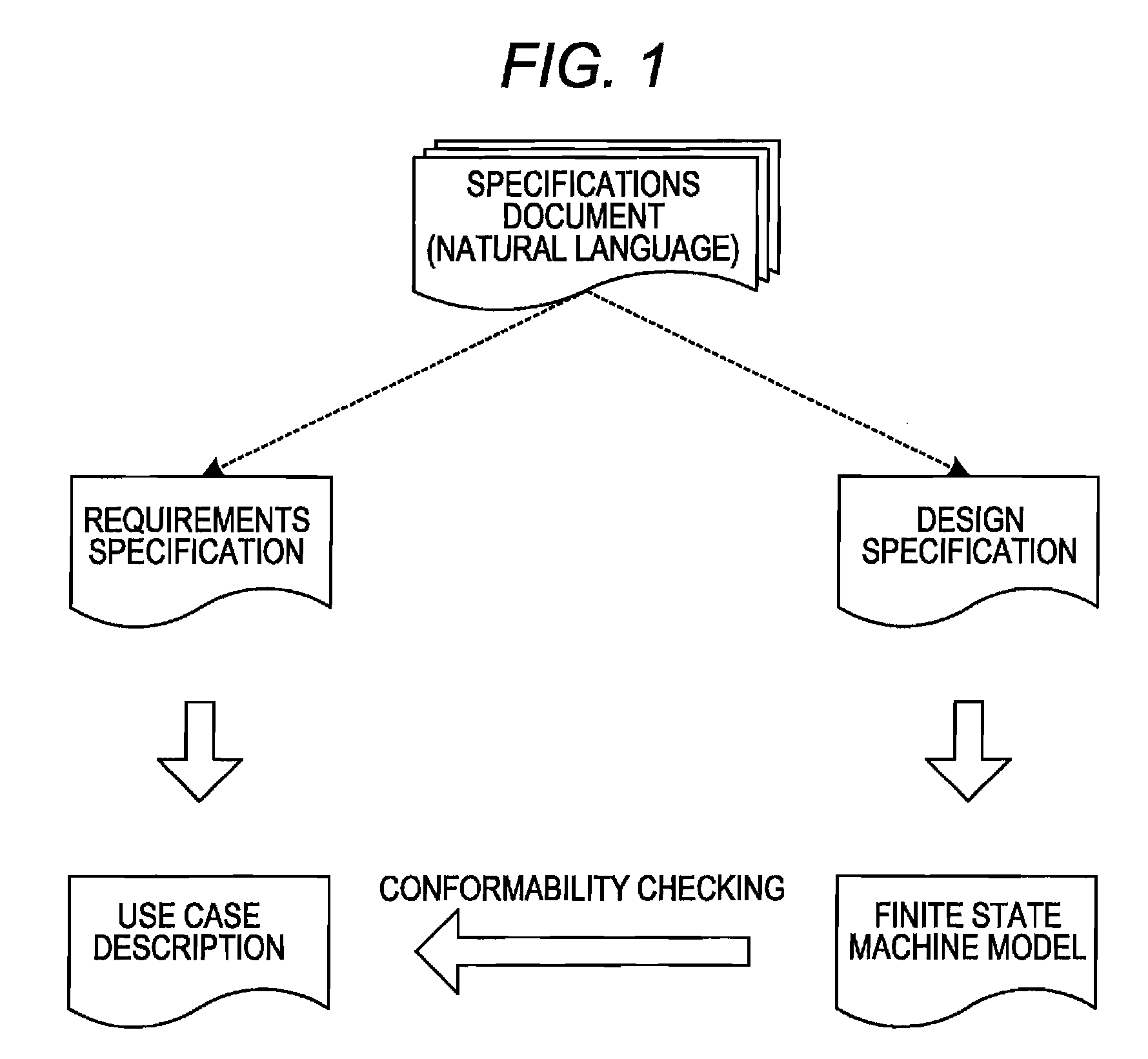

Mining a use case model by analyzing its description in plain language and analyzing textural use case models to identify modeling errors

InactiveUS20100325491A1Reverse engineeringNatural language data processingSoftware engineeringApplication software

A system and method for identifying modeling errors in textual use case description analyze an input text describing a use case and create an application model representing the use case, the application model containing information obtained from analyzing the input text describing the use case. The application model may be automatically analyzed using automatic process and one or more errors in the use case and / or reports about the use case may be generated. In one aspect, processing components may be integrated into a user development environment to allow developing use cases and improving them incrementally and / or iteratively as information is identified about the use cases.

Owner:IBM CORP

Policy Based Automation for a Supply Chain

A method for managing a supply chain includes: identifying a business context for the supply chain; identifying a set of business policy rules for the business context governing the relationship between entities involved in the supply chain; creating use-case description from the set of business policy rules; creating a plurality of executable code modules corresponding to the use-case description; specifying a plurality of name / value pair for modeling the set of business policy rules; provisioning the plurality of application server computers of the computer network system with the executable code modules; and provisioning a central directory database with the plurality of name / value pairs; whereby the computer network system, in response to events in business transactions between at least two entities involved in the supply chain, is operable to dynamically deliver at least one name / value pair from the central directory database and to execute at least one code module.

Owner:PARAMETRIC TECH CORP

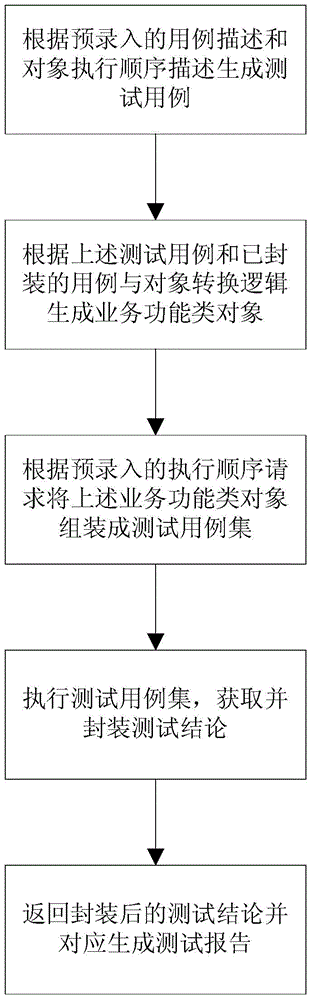

Automatic function test method and system applied to BS (browser/server) framework

ActiveCN103984628AEasy to testImprove test efficiencySoftware testing/debuggingProgramming languageTest efficiency

An automatic function test method applied to a BS (browser / server) framework comprises a test case generation step: generating a test case according to a prerecorded case description and an object execution sequence description; a service function class object generation step: generating service function class objects according to the test case, the packaged case and an object conversion logic; a test case assembling step: assembling the service function class objects to a test case set according to the prerecorded execution sequence; a test result generation step: executing the test case set and obtaining and packaging a test conclusion; a test result output step: returning the packaged test conclusion and correspondingly generating a test report. By applying the automatic function test method applied to the BS framework, the test efficiency is effectively improved, and the technological threshold of a function tester is lowered. The invention also relates to an automatic function test system applied to the BS framework.

Owner:中国南方航空股份有限公司 +1

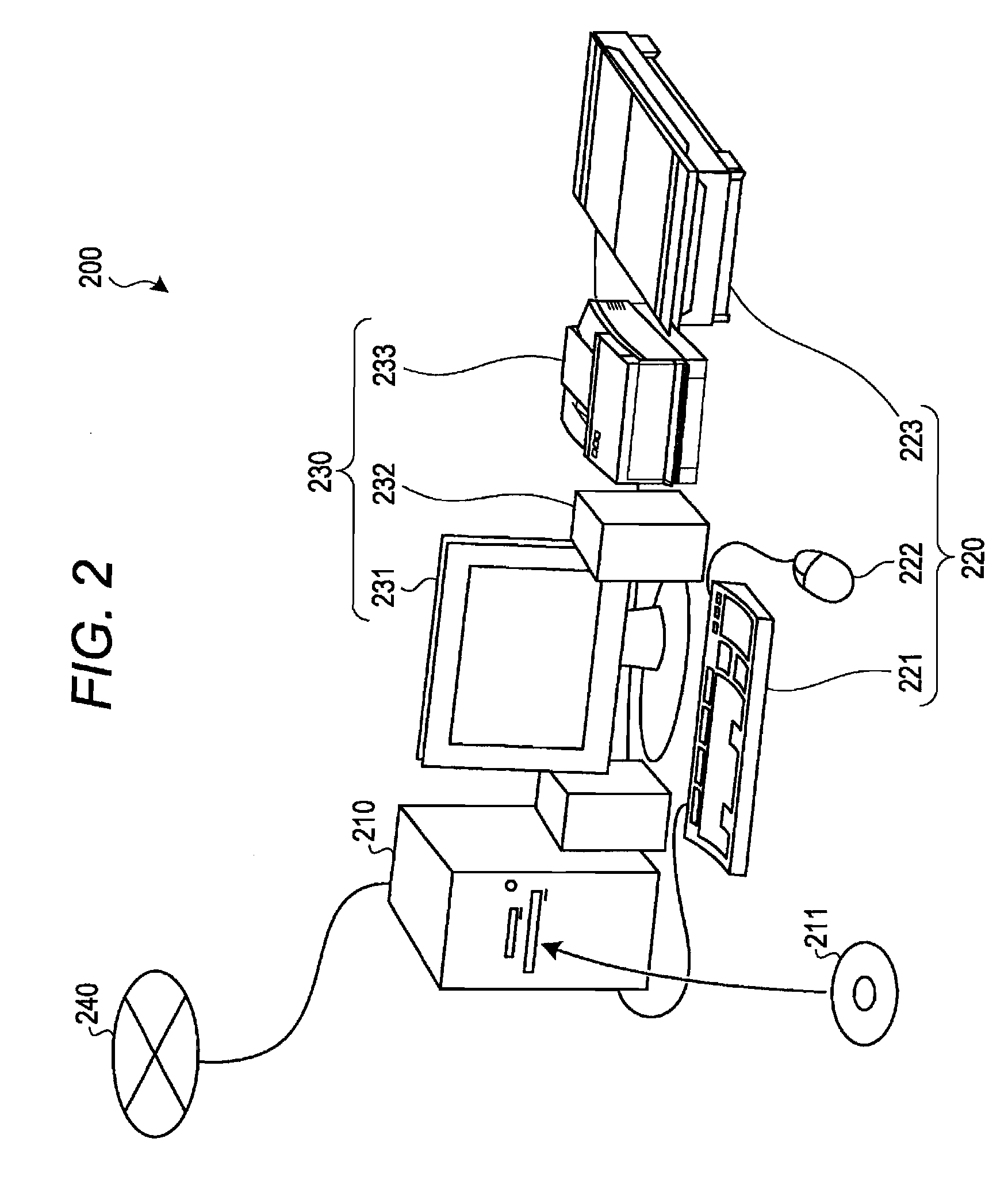

Specification verification program, computer-readable storage medium storing specification verification program, specification verification apparatus, and specification verification method

InactiveUS20080312890A1Requirement analysisSoftware simulation/interpretation/emulationFinite-state machineTheoretical computer science

Conditions necessary to be satisfied for execution of each use case from a use case description indicative of a requirements specification of the design object are acquired. Then a state satisfying the conditions, from among a set of states represented in a finite state machine model indicative of a design specification of the design object are detected. A presence or absence of an undetected state in the set of states in accordance with the detection is determined and output.

Owner:FUJITSU LTD

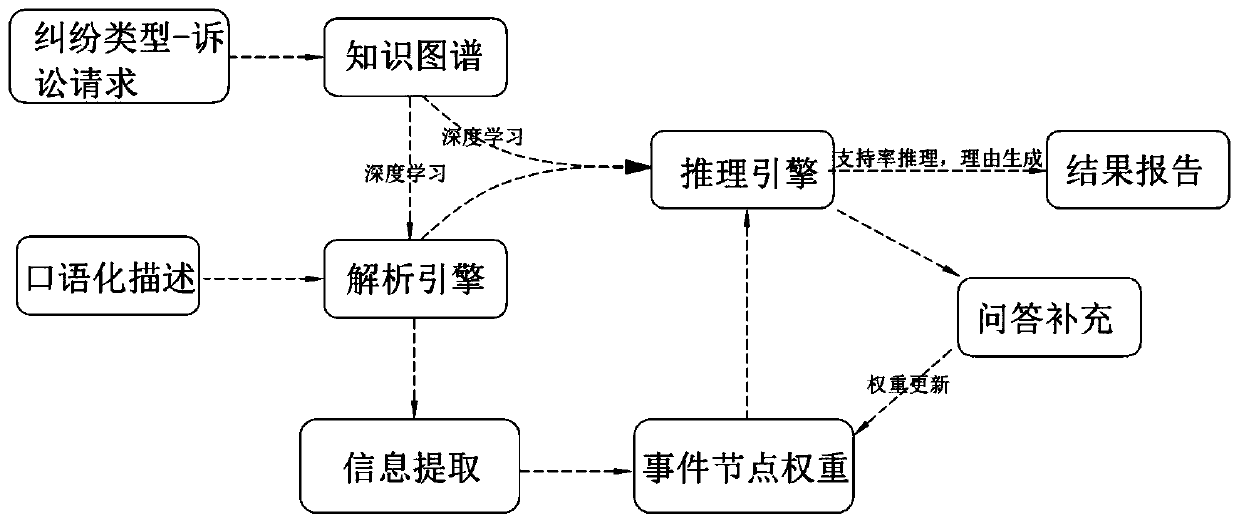

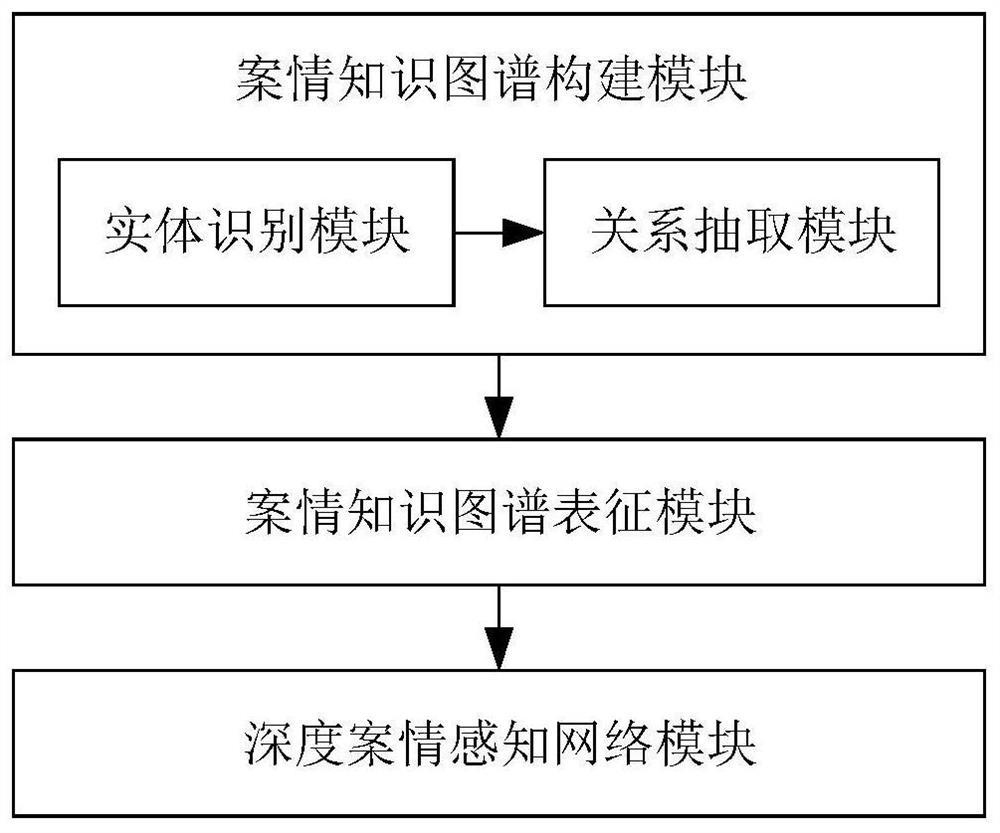

Law case deep reasoning method

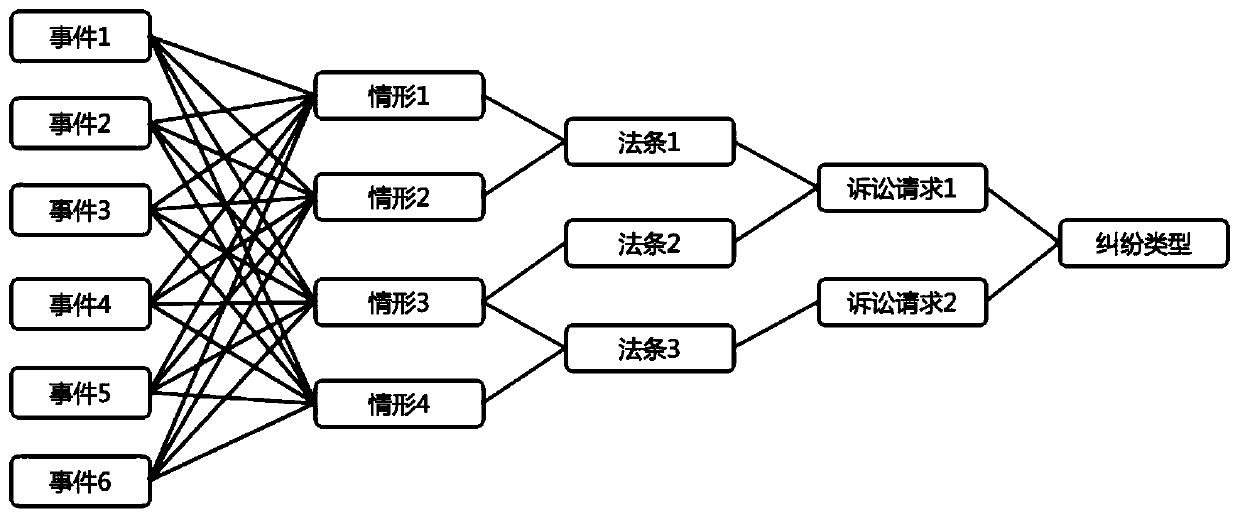

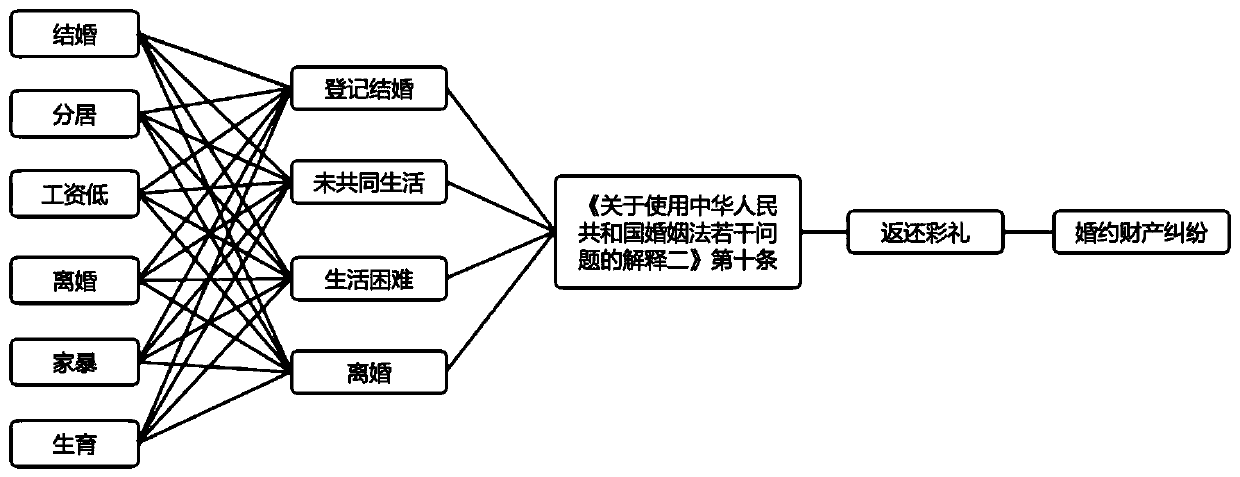

ActiveCN110232447AAvoid disadvantagesIntegrity guaranteedData processing applicationsInference methodsSpoken languageAlgorithm

The invention relates to a law case deep reasoning method which comprises the following steps: S1, receiving a dispute type, a lawsuit request and a spoken language case description selected by a user; s2, constructing a knowledge graph according to the dispute type and the litigation request; s3, on the basis of the knowledge graph, processing the colloquial case description to obtain an analysisresult; and S4, performing support rate reasoning of the litigation request based on the knowledge graph according to the analysis result, and outputting a reasoning result. According to the method,the support rate of the litigation request is predicted in a deep reasoning mode, a corresponding support reason is given, the support reason can be displayed to a user in a visual reasoning process mode, and compared with a current result report, the method is more intelligent and more visual.

Owner:杭州实在智能科技有限公司

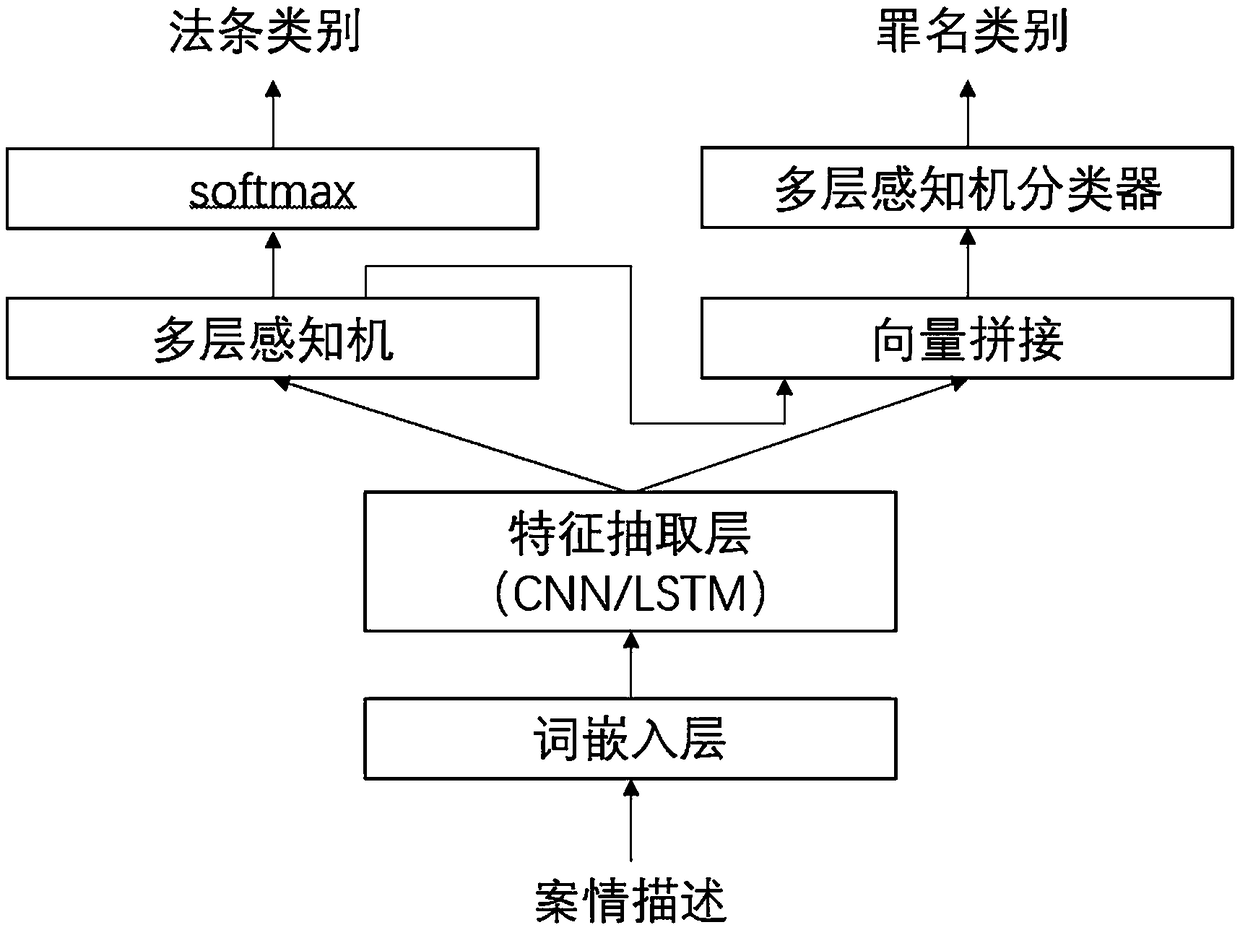

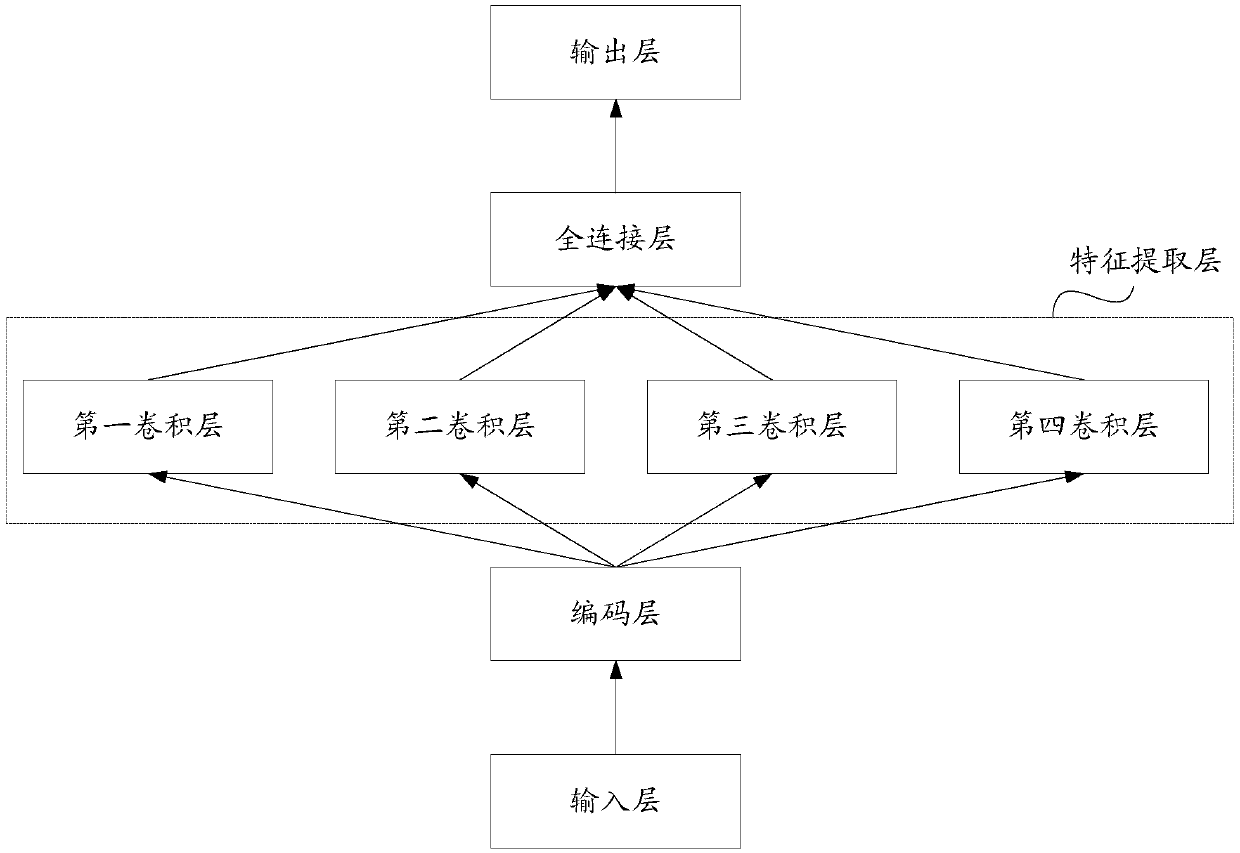

A neural network-based joint forecasting method of criminal charges and articles

The method comprises the following steps: (1) constructing a training data set: climbing a standard criminal ruling to obtain a case description and corresponding charges and relevant laws as trainingdata; (2) obtaining a training data set from the training data set; The offence or offences to which the description of the case corresponds and the relevant articles are one or more, each of which is mapped to a unique integer as its encoding; 2, establishing a neural network joint prediction model by adopting a multi-layer perception mechanism and train that neural network through a training data set; Step 3, predicting the accusations of criminal cases through the trained neural network joint prediction model. The invention can improve the accuracy rate of the prediction model in two aspects of the law prediction and the accusation prediction, thereby providing a reliable reference for the judicial trial, and improving the judicial automation and intelligence degree.

Owner:HANGZHOU SHIPING INFORMATION & TECH

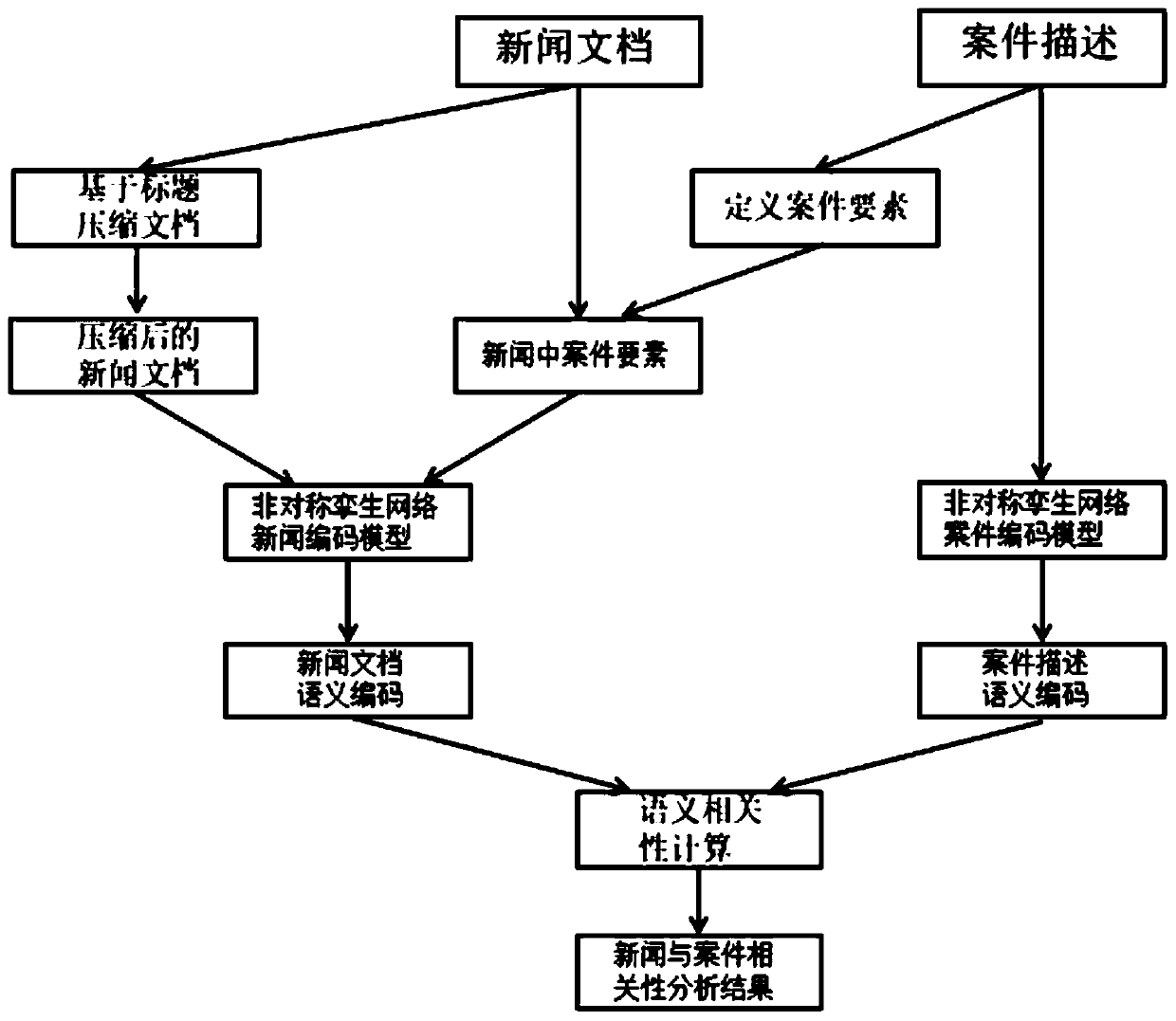

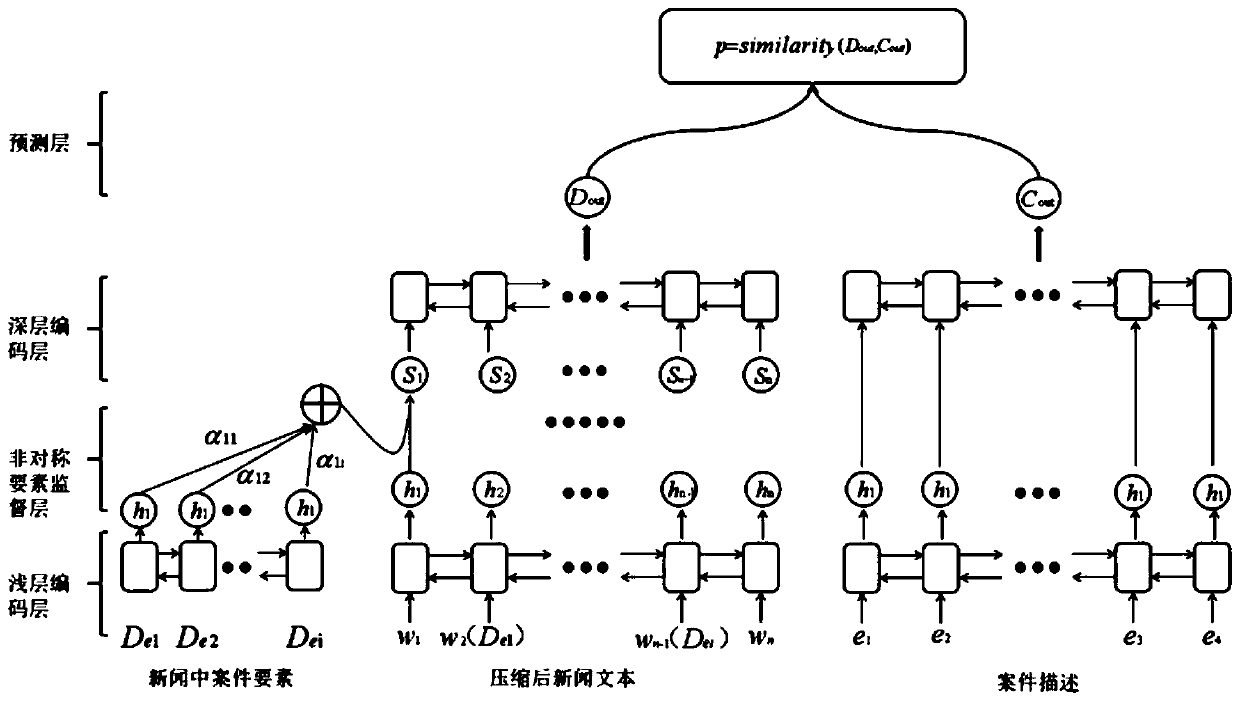

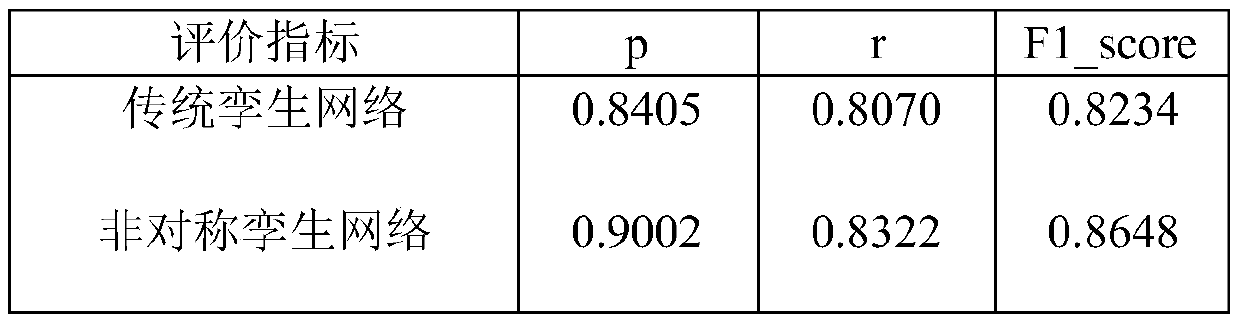

News and case similarity calculation method based on asymmetric twin network

ActiveCN110717332ASolve the problem of redundant contentEasy to learnSemantic analysisText processingDocument similarityTheoretical computer science

The invention relates to a news and case similarity calculation method based on an asymmetric twin network, and belongs to the technical field of natural language processing. The method comprises thefollowing steps: firstly, selecting a sentence representation document most relevant to a news title by calculating the similarity between sentences and titles in a text so as to remove redundant sentences in the news text; describing and modeling a document and a case by using an asymmetric twin network, fusing the case element serving as supervision information into the asymmetric twin network to encode a news document and case description in consideration of key semantic information of the case contained in the case element, and finally judging the correlation between news and the case by calculating document similarity. According to the method, similarity calculation is carried out on the news text and the case description based on the asymmetric twin network, semantic coding modelingcan be carried out on the unbalanced news text and case description, and the accuracy of similarity calculation can be improved.

Owner:KUNMING UNIV OF SCI & TECH

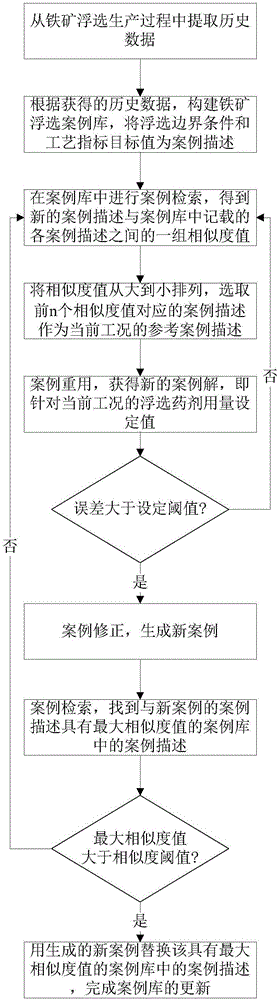

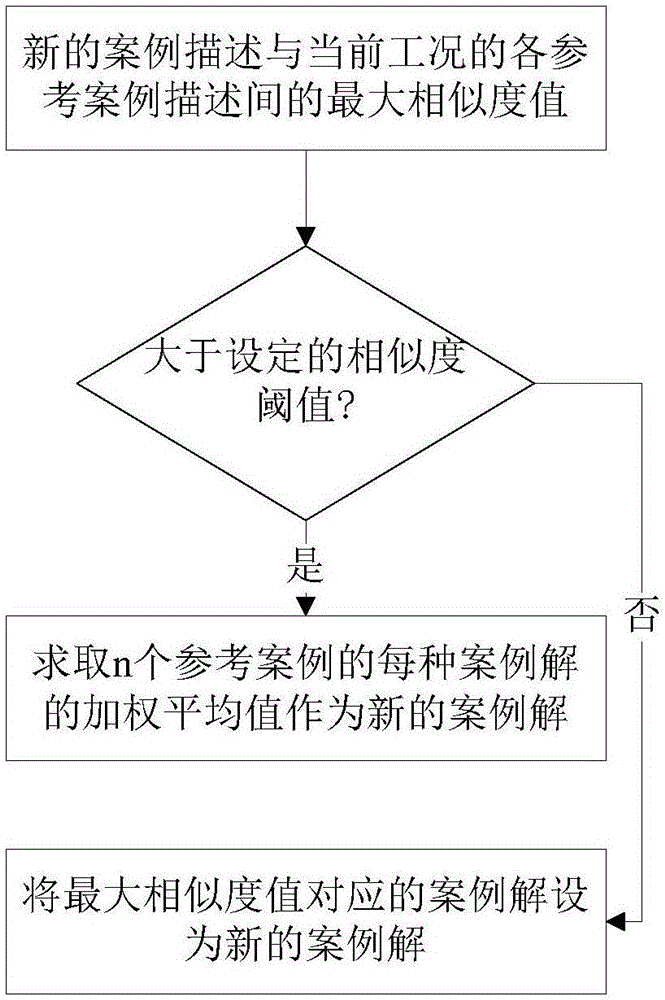

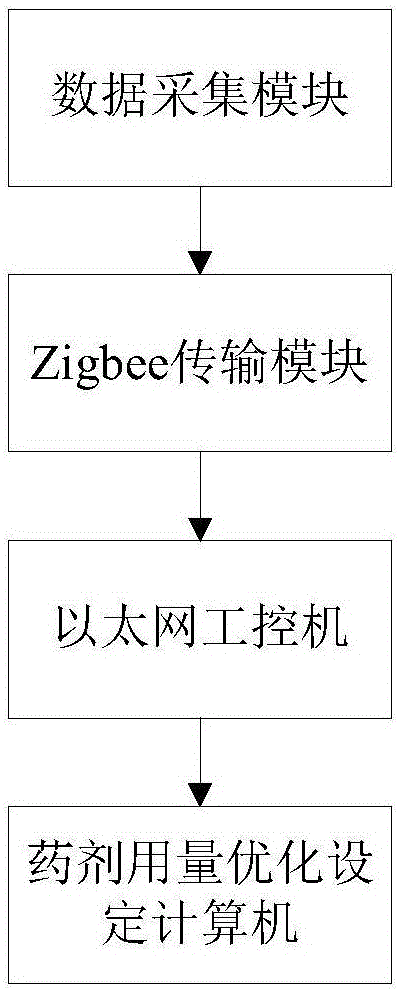

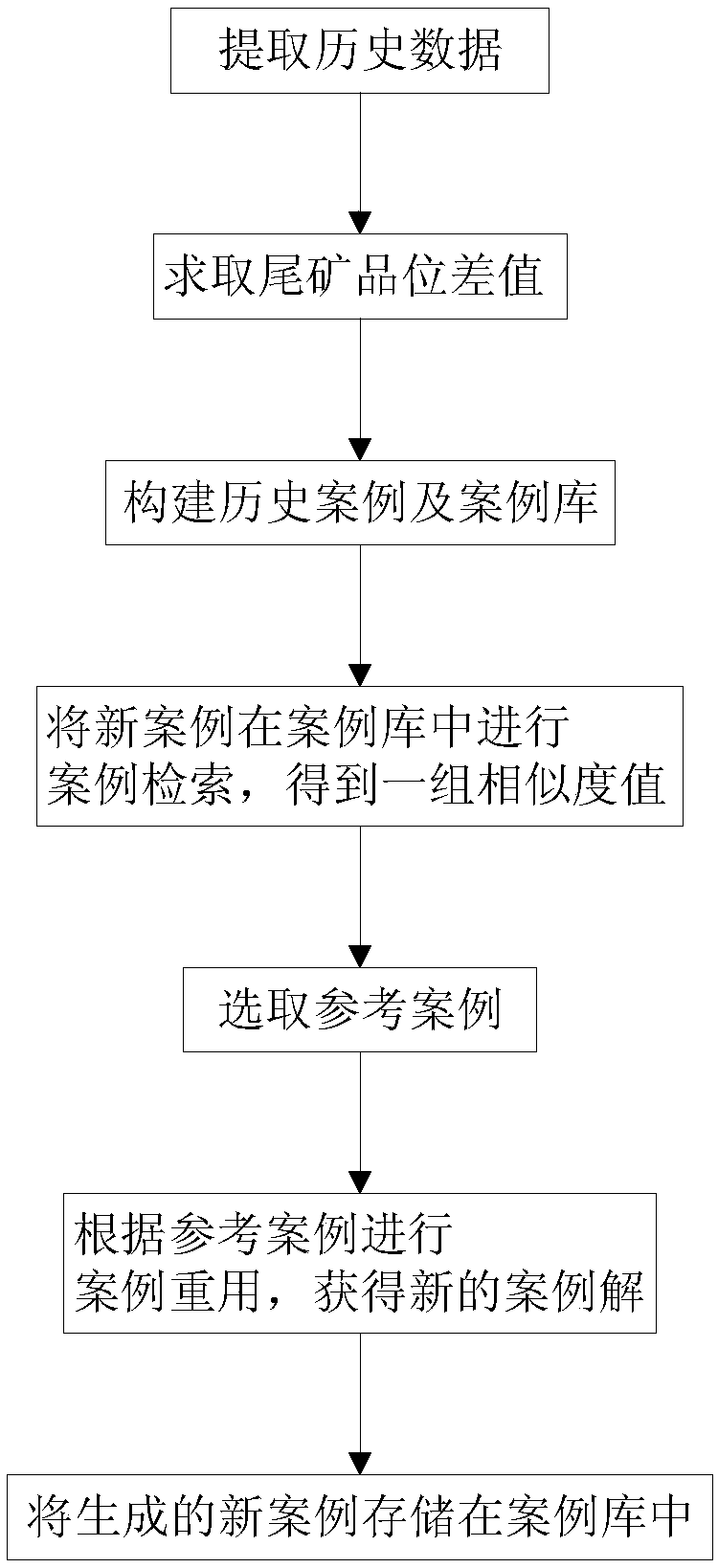

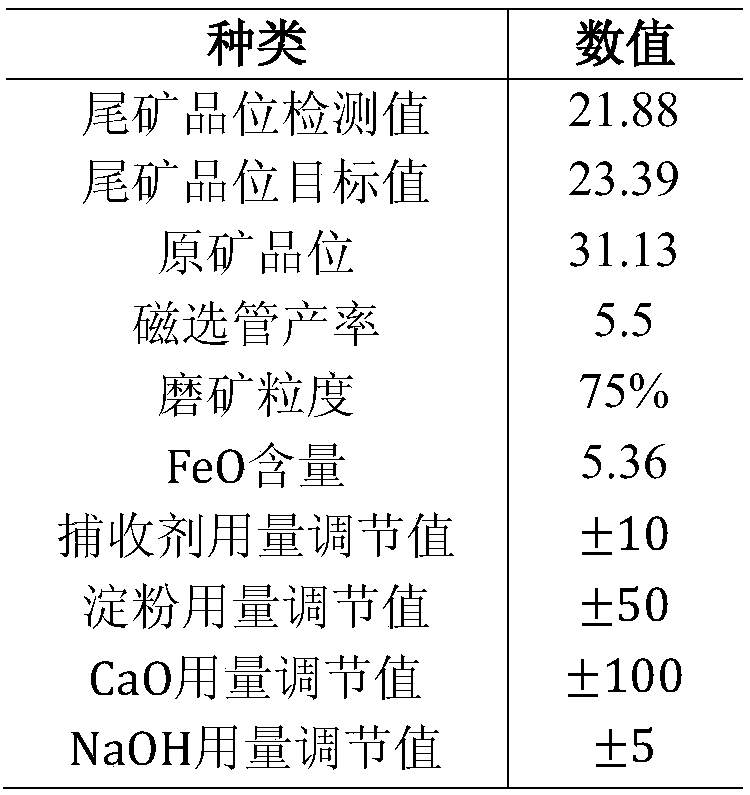

Case reasoning-based iron ore floatation reagent dosage optimization setting method and system

The invention provides a case reasoning-based iron ore floatation reagent dosage optimization setting method and a case reasoning-based iron ore floatation reagent dosage optimization setting system. The method comprises the following steps: extracting historical data from the production process of iron ore floatation; establishing an iron ore floatation case library, wherein a floatation boundary condition and a process index target value serve as case description, and a floatation reagent dose serves as case solution; performing case retrieval in the case library to obtain a group of similarity values; arranging the similarity values from large to small and selecting the case description corresponding to the previous n similarity values to serve as reference case description of the current working condition; reusing the case to obtain a new case solution; when error is more than a set threshold value, correcting the case and generating a new case; finding the case description with the maximal similarity value with the case description of the new case through case retrieval to finish case library updating. By the method and the system, a reagent dosage setting value suitable for various working conditions is given out by virtue of measurable production data related to the iron ore floatation reagent dosage, so that the safety, the reliability and the economic performance of the iron ore floatation production can be improved.

Owner:ANSTEEL GRP MINING CO LTD

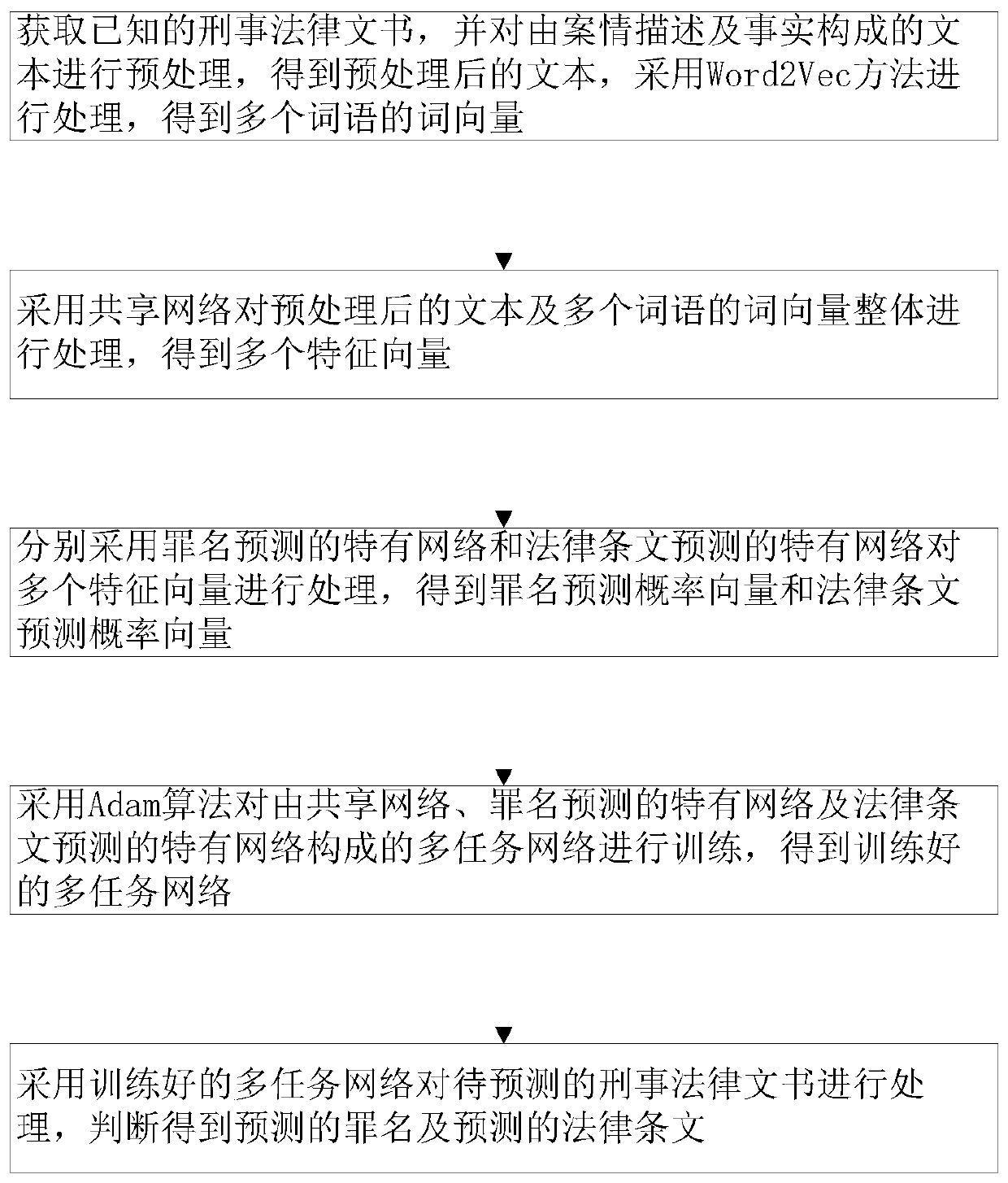

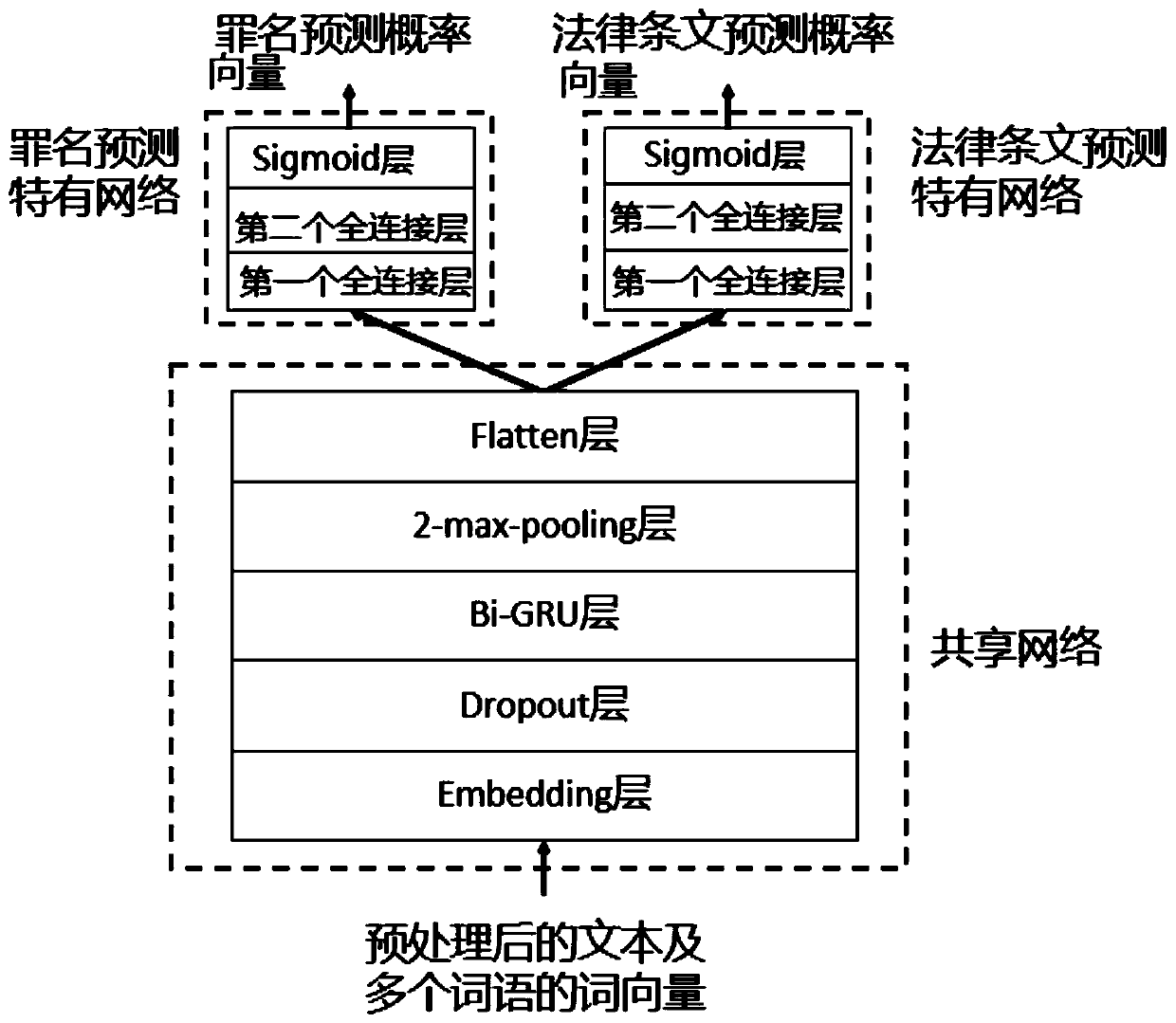

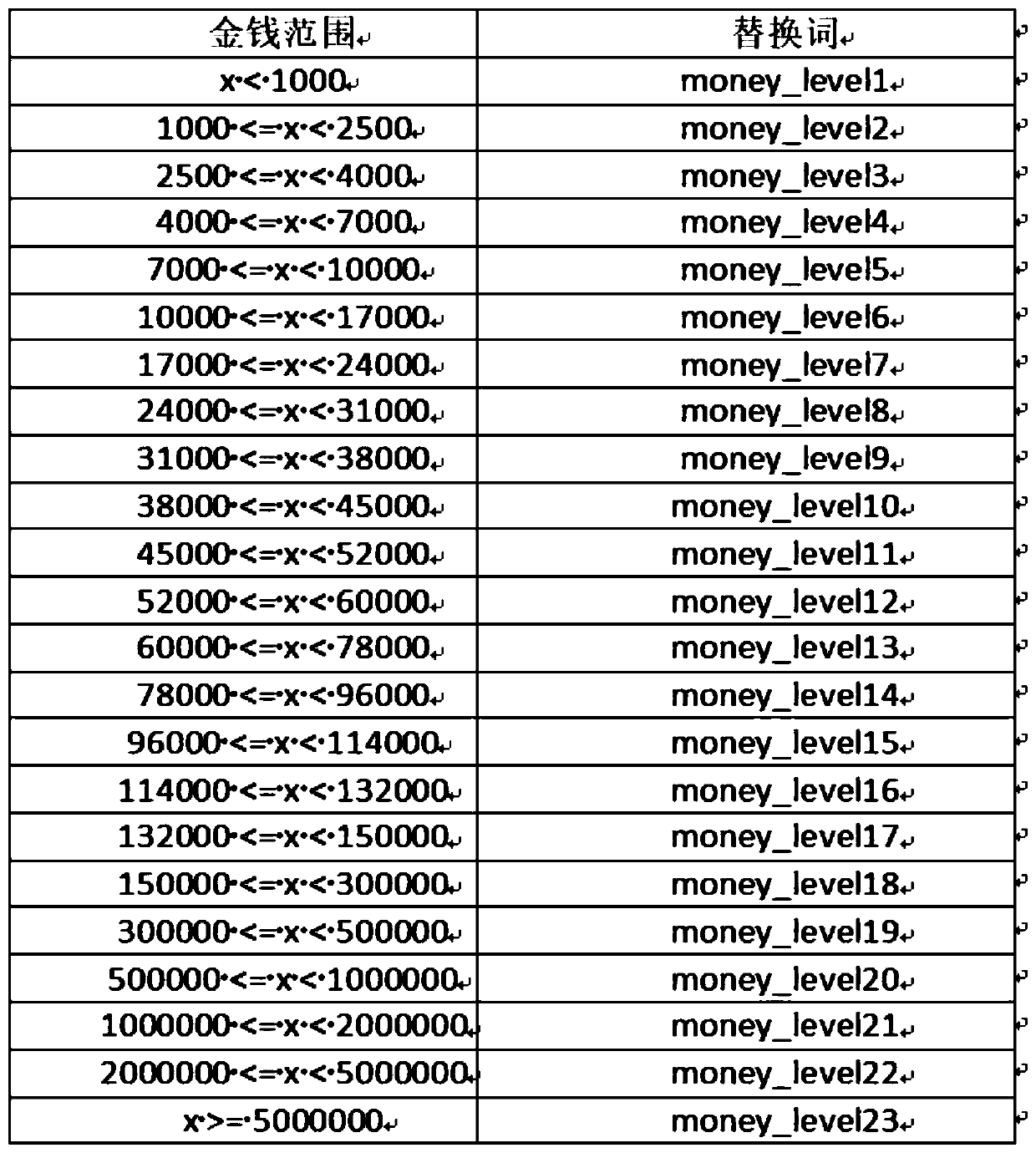

Multi-task network construction and multi-scale charge legal provision joint prediction method

ActiveCN110188192AQuick updateImprove accuracySemantic analysisForecastingTask networkCoverage ratio

The invention provides a multi-task network construction method, which comprises the following steps: processing a text consisting of case description and facts in a known criminal legal document to obtain a preprocessed text and word vectors of a plurality of words; processing and training the preprocessed text and word vectors of a plurality of words by adopting a multi-task network formed by aspecial network of a shared network, charge prediction and legal provision prediction, and finally obtaining a trained multi-task network. The invention also provides a multi-scale charge legal provision joint prediction method, which comprises the following steps: processing a text consisting of case description and facts in the charge legal document to be predicted to obtain a preprocessed textand word vectors of a plurality of words, processing by adopting the trained multi-task network, and judging to obtain a predicted charge and a predicted legal provision. According to the method, thetwo tasks are combined to extract the features together, the prediction accuracy can be effectively improved, and meanwhile, the coverage rate and diversity of prediction on categories are improved.

Owner:XIDIAN UNIV

A case intelligent pushing method and system based on case semantic analysis

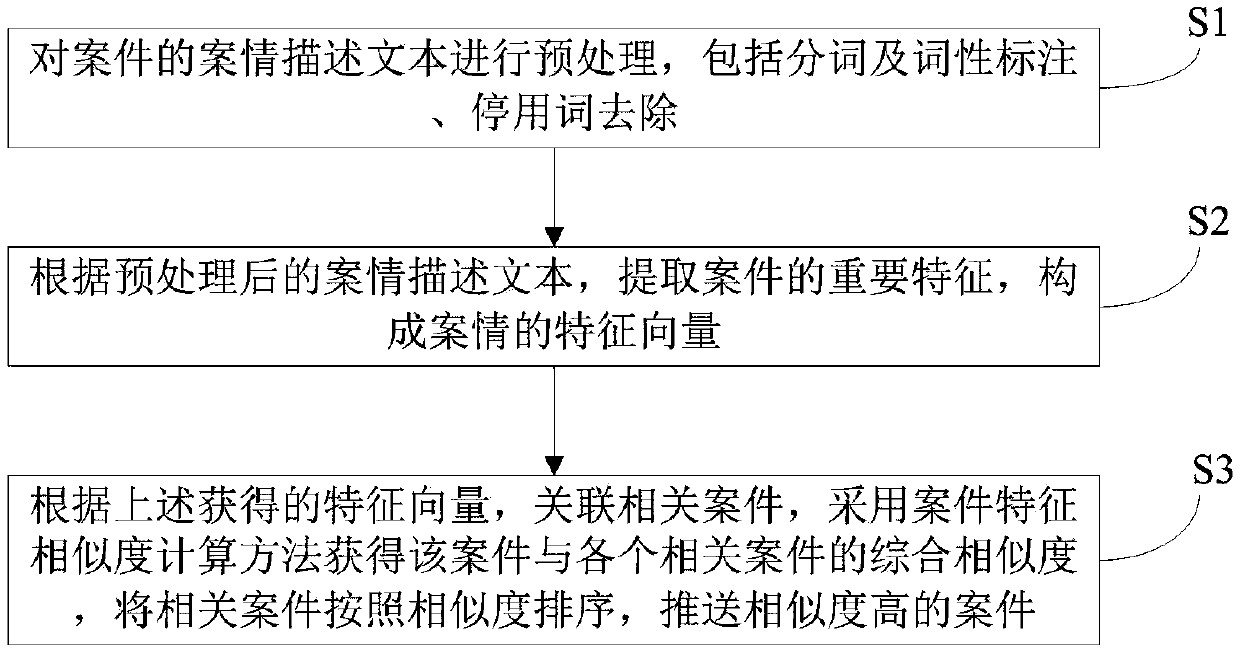

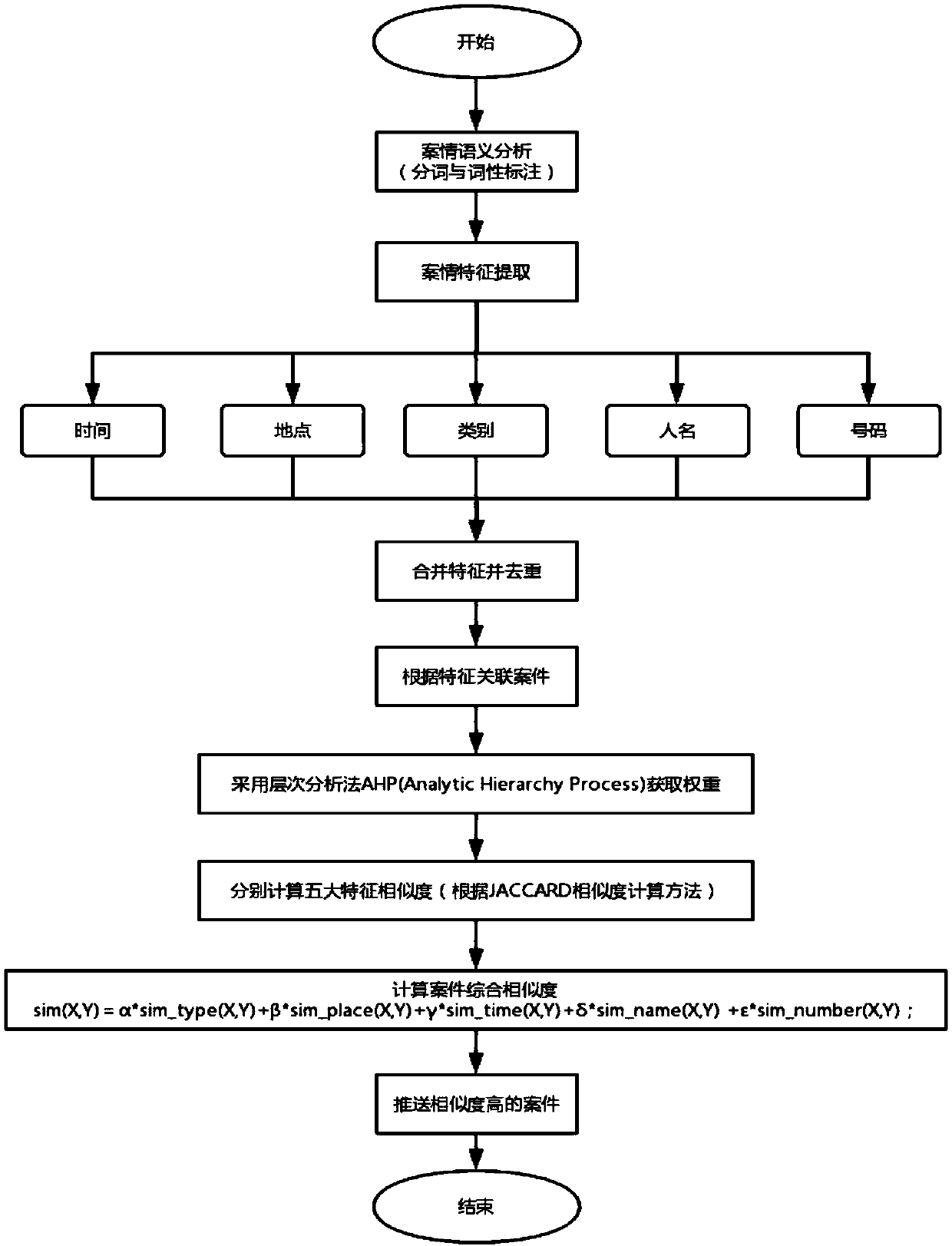

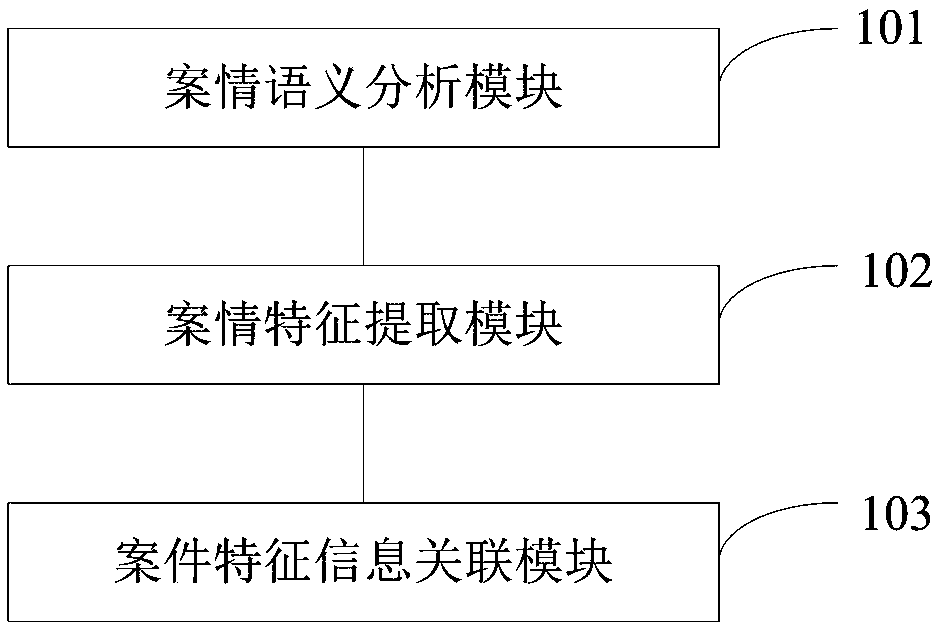

PendingCN109684628ARapid Analytical ProcessingAccurate analysis and processingData processing applicationsSemantic analysisFeature vectorCase analysis

The invention provides a case intelligent pushing method and system based on case semantic analysis, and the method comprises the following steps: S1, carrying out the preprocessing of a case description text of a case, which comprises word segmentation, part-of-speech tagging, and stop word removal; S2, extracting important features of the case according to the preprocessed case description textto form a feature vector of the case; And S3, associating related cases according to the feature vectors, obtaining the comprehensive similarity between the case and each related case by adopting a case feature similarity calculation method, sorting the related cases according to the similarity, and pushing the cases with high similarity. Through the method and the system provided by the invention, the workload of case analysis and manual processing can be reduced, the working cost and the time cost of police officers are greatly reduced, and the case solving efficiency is improved.

Owner:武汉众智数字技术有限公司

Legal document analysis method based on case factors

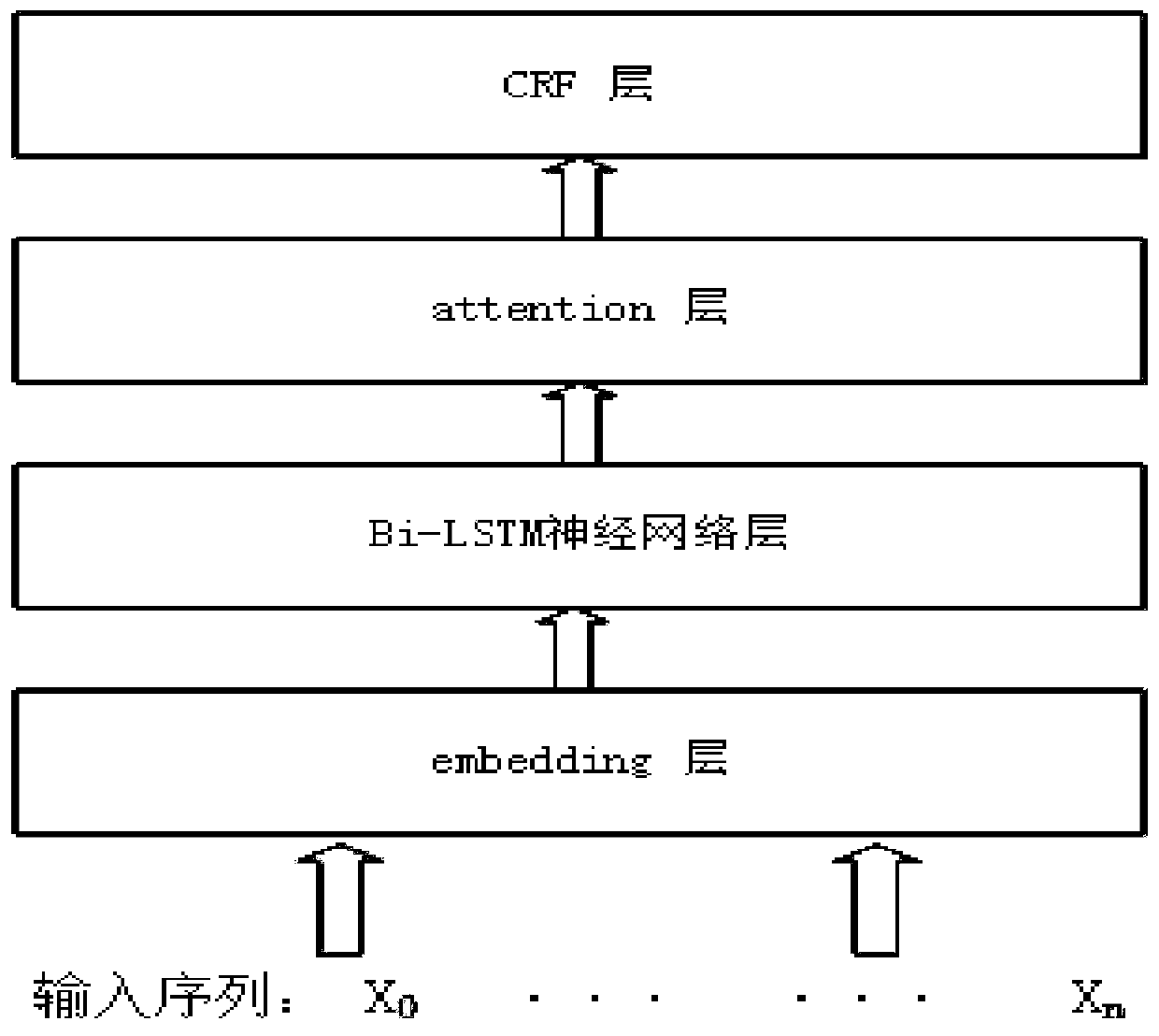

InactiveCN110147553AEasy to identifyAvoid manual selection of featuresNatural language data processingNeural architecturesStructural representationDocument analysis

The invention discloses a legal document analysis method based on a case element, which comprises the following steps of: 1, extracting case description information from a legal document by utilizinga machine learning algorithm, and labeling case description according to the priority of case element labeling; 2, carrying out data preprocessing: identifying the case elements marked in the step 1;and 3, carrying out case element identification based on the deep neural network: taking the labeled document data as the original input of the labeling model to realize end-to-end case element identification. By carrying out flattening associated case element labeling on legal documents, processing labeled document data into a classical BIO sequence labeling format by taking sentences as units, and identifying case elements in documents by adopting a related sequence labeling model, case element recognition is beneficial to structural representation of legal documents, supports fusion analysis of legal documents and other application researches, and brings great convenience to information retrieval, automatic review and other practice applications of the legal documents.

Owner:GUIZHOU UNIV +2

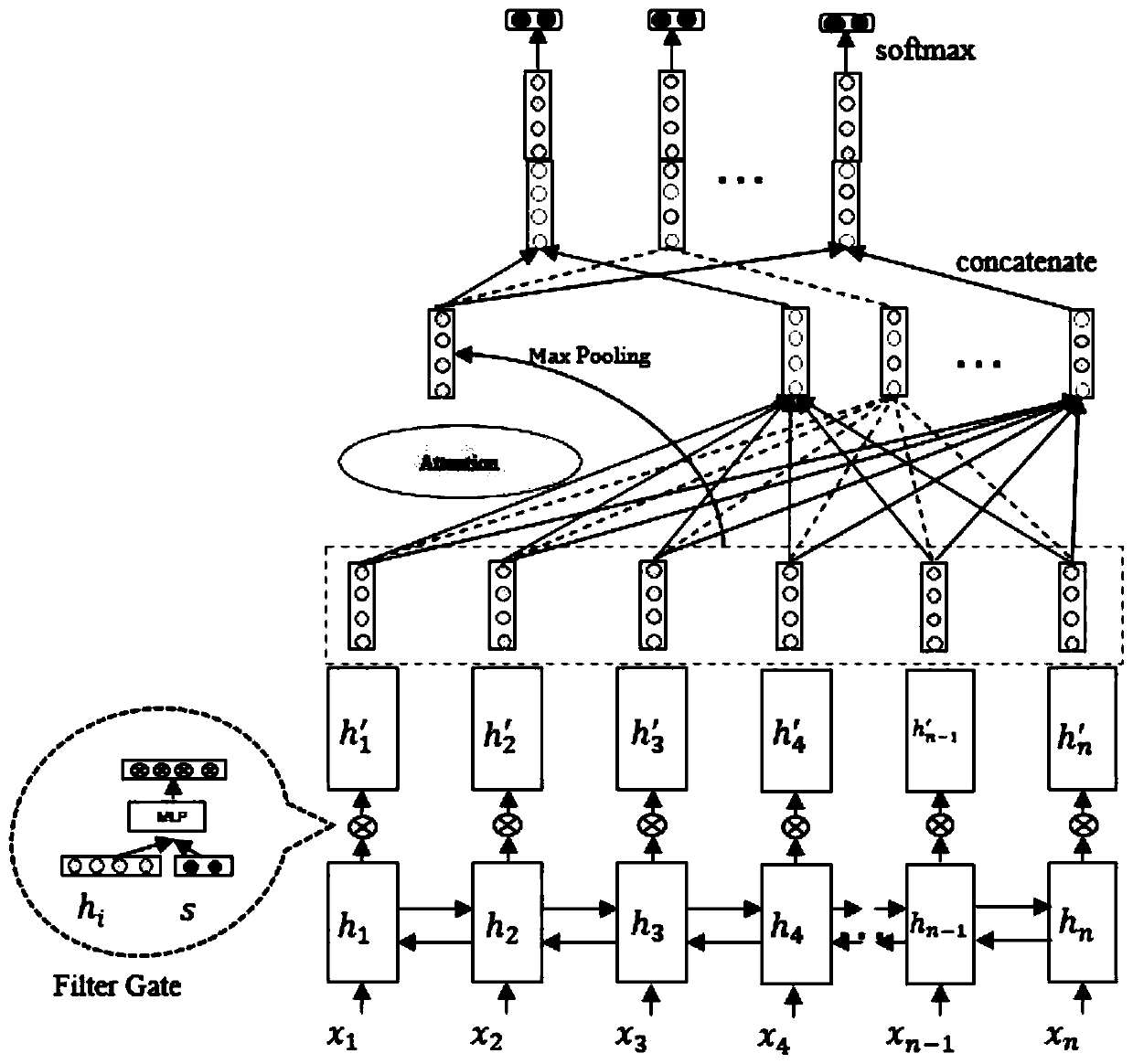

User legal provision prediction method based on a filtering door mechanism

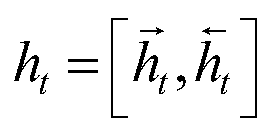

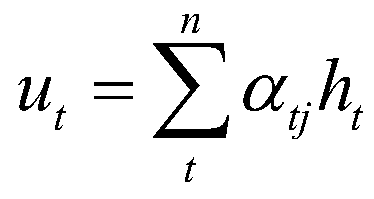

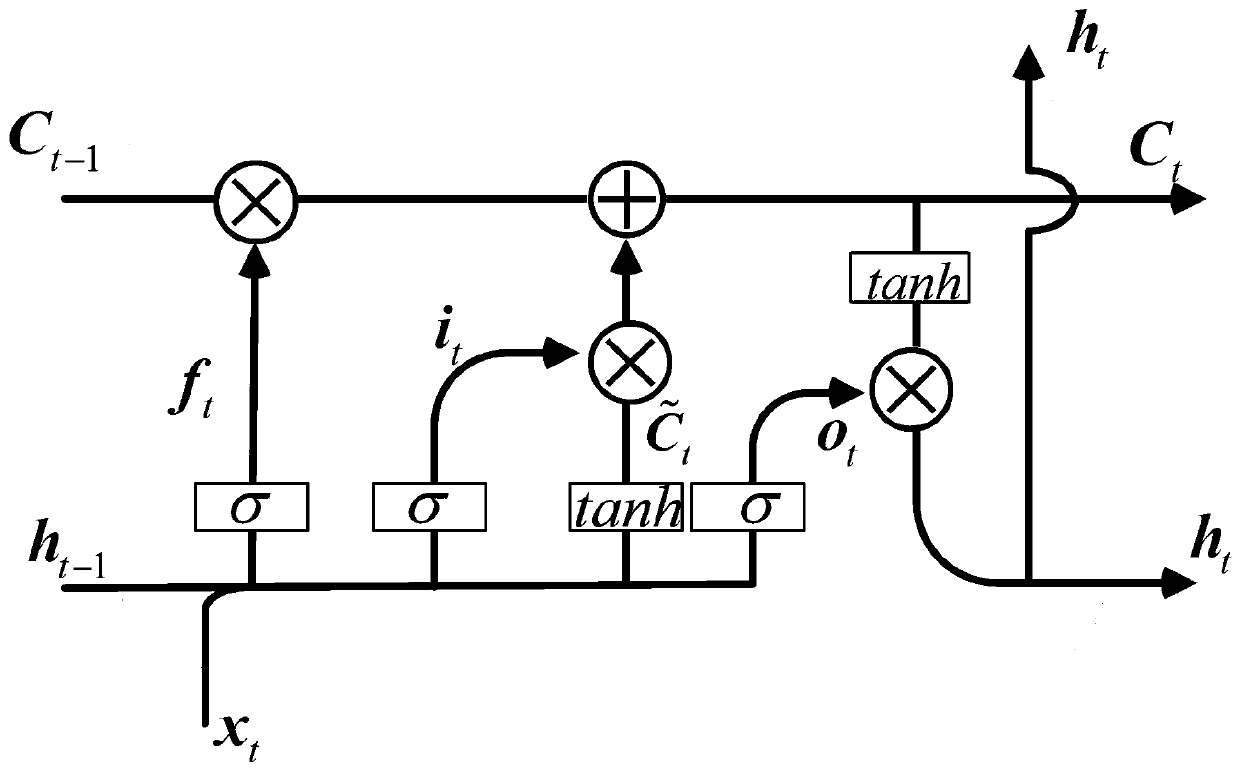

ActiveCN109829055AFully excavatedEfficient extractionForecastingPhysical realisationText categorizationPrediction system

The invention discloses a user legal provision prediction method based on a filtering door mechanism. The user legal provision prediction method based on the filter door mechanism comprises the stepsthat a bidirectional LSTM network is adopted to encode case description, and a coded vector passes through a filter door structure to obtain high-level representation of the case description; Selecting an appropriate text feature for each criminal name by utilizing an attention mechanism, and splicing the vector passing through the maximum pooling layer and the attention representation of each criminal name to obtain a final vector for prediction; And judging whether each criminal name starts from the case description or not by utilizing a binary classification model. The method has the advantages that in a traditional method in a user legal provision prediction system, manual features are usually matched with classic text classifiers, so that the accuracy of final legal provision prediction highly depends on the quality of the manual features, the universality of cross-business prediction is not achieved, and meanwhile the law of similar cases cannot be well predicted through the traditional method.

Owner:SUZHOU UNIV

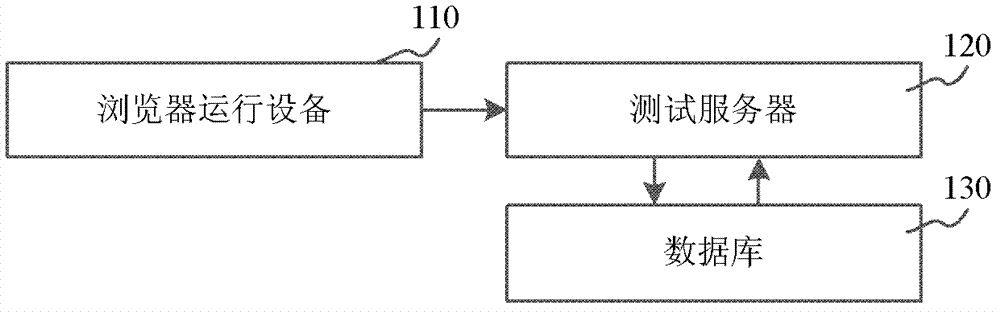

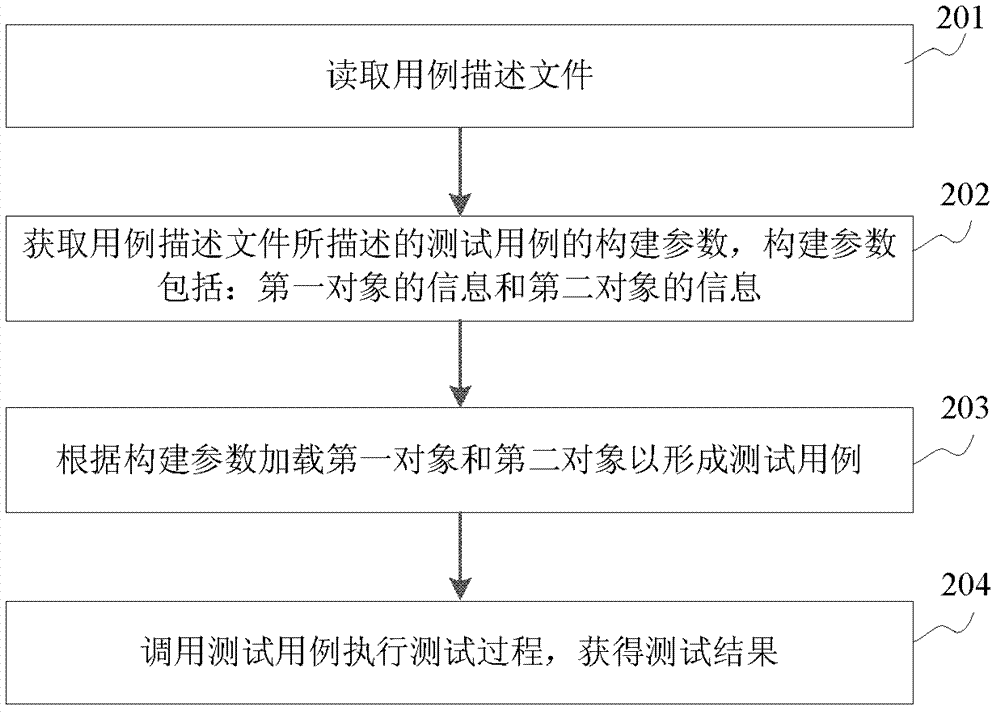

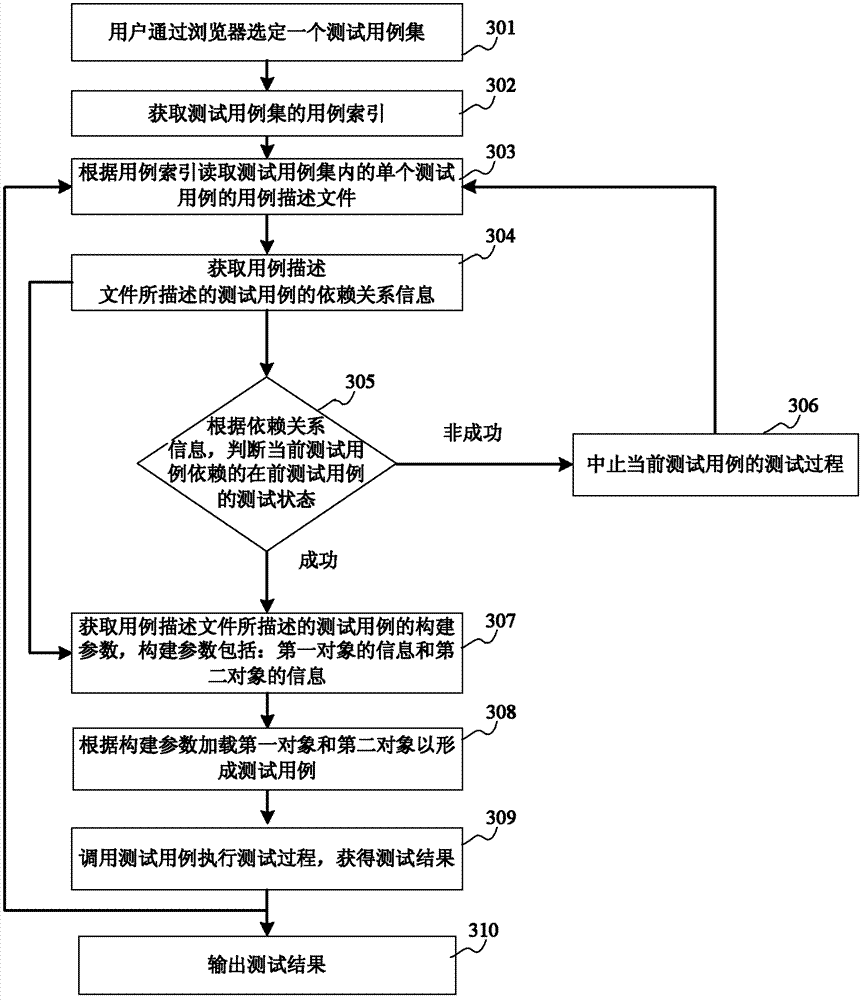

Testing method and device

ActiveCN103246601AImprove reusabilityEasy constructionSoftware testing/debuggingDocumentationComputer testing

The invention discloses testing method and device and belongs to the field of computer testing. The testing method includes: reading a case description file; acquiring building parameters which belong to a test case described by the case description file and which include information of a first object and information of a second object; loading the first object and the second object according to the building parameters to form the test case; and calling the test case to execute a test process and acquiring test results. According to the method, the first type of object and the second type of object are separated, so that importance of HTML (hypertext markup language) documents and JS (javascript) files is improved. By the aid of the case description file, the new test case can be built conveniently and dependency between the test cases is overcome.

Owner:TENCENT TECH (SHENZHEN) CO LTD

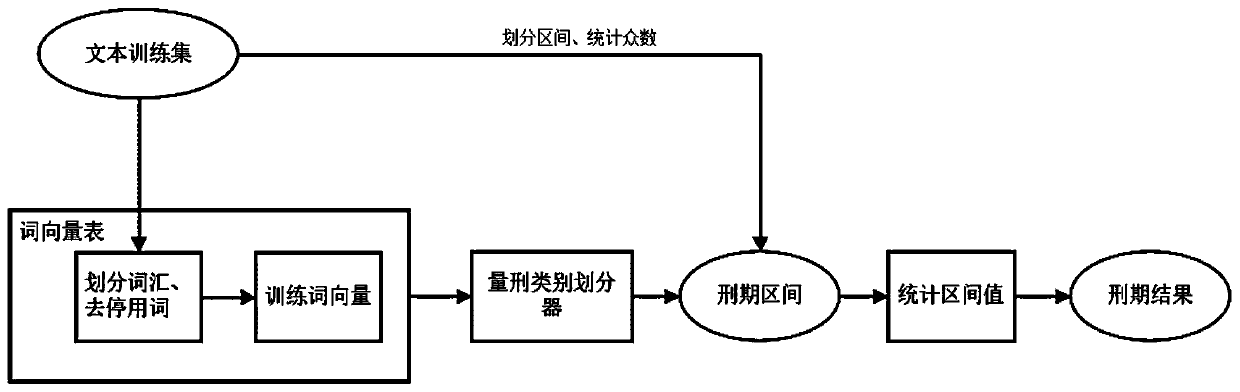

Multiple neural network combination-based punishment calculation method

ActiveCN109740728ASolve the problem of poor sentencing calculation effectOvercome resourcesNeural architecturesNeural learning methodsData setComputational model

The invention discloses a multiple neural network combination-based penalty calculation method, which comprises the following steps of: S1, constructing a training data set, obtaining a document training set from a judgment document network, segmenting case description and judgment criminal periods, training word vectors for each case description text, counting criminal period intervals, and classifying and training a penalty category classifier; and step S2, after the case description text of the criminal period to be calculated inquired word vectors, inputting the word vectors into the penalty category divider obtained in the step S1 for classification, predicting a penalty interval, and using a representative value counted in the interval as a criminal period result. The method overcomes the defects that a traditional feature analysis method is too complex; according to the method for calculating the prisons in the case description text prisons, the defects that a large number of human resources are consumed and expert system quality is not high are overcome, a specific prisons calculation model can be effectively fitted under the reliable document data size, the problem that the case description text prisons calculation effect is poor is solved, and the prediction performance can be obviously improved when the method is applied to prisons calculation.

Owner:HANGZHOU SHIPING INFORMATION & TECH

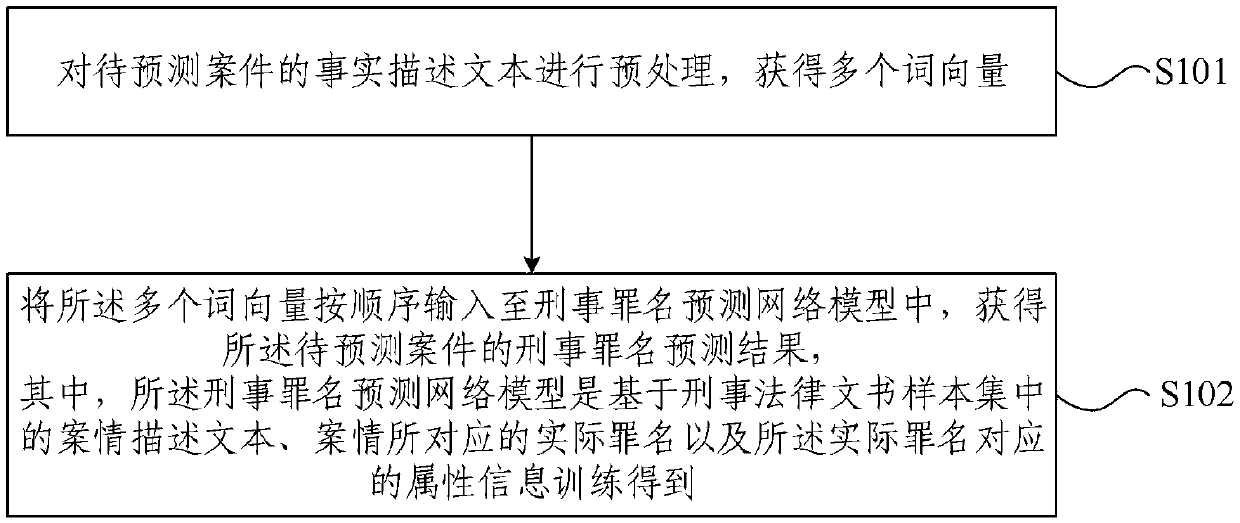

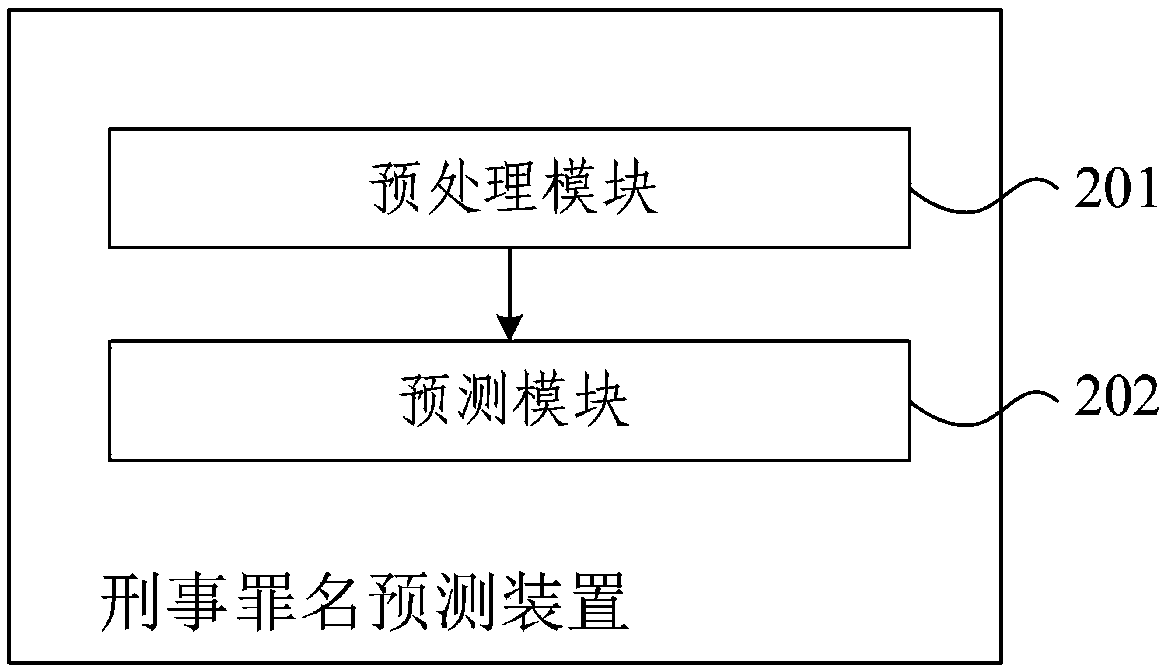

Criminal name prediction method and device

ActiveCN110858269AAccurate predictionForecastingNatural language data processingEngineeringNetwork model

The embodiment of the invention provides a criminal name prediction method and device. The method comprises the following steps: carrying out the preprocessing of a fact description text of a to-be-predicted case, and obtaining a plurality of word vectors; inputting the plurality of word vectors into a criminal name prediction network model in sequence to obtain a criminal name prediction result of the to-be-predicted case; the criminal name prediction network model is obtained by training based on a case description text in a criminal legal document sample set, an actual criminal name corresponding to the case and attribute information corresponding to the actual criminal name. According to the embodiment of the invention, the attribute information of the criminal names is added into themodel training process, so that the trained criminal name prediction model can effectively predict the criminal names with fewer samples, the criminal names which are easy to confuse can be better distinguished by utilizing the attribute information of the criminal names, and the accuracy of automatic criminal name prediction is improved.

Owner:TSINGHUA UNIV

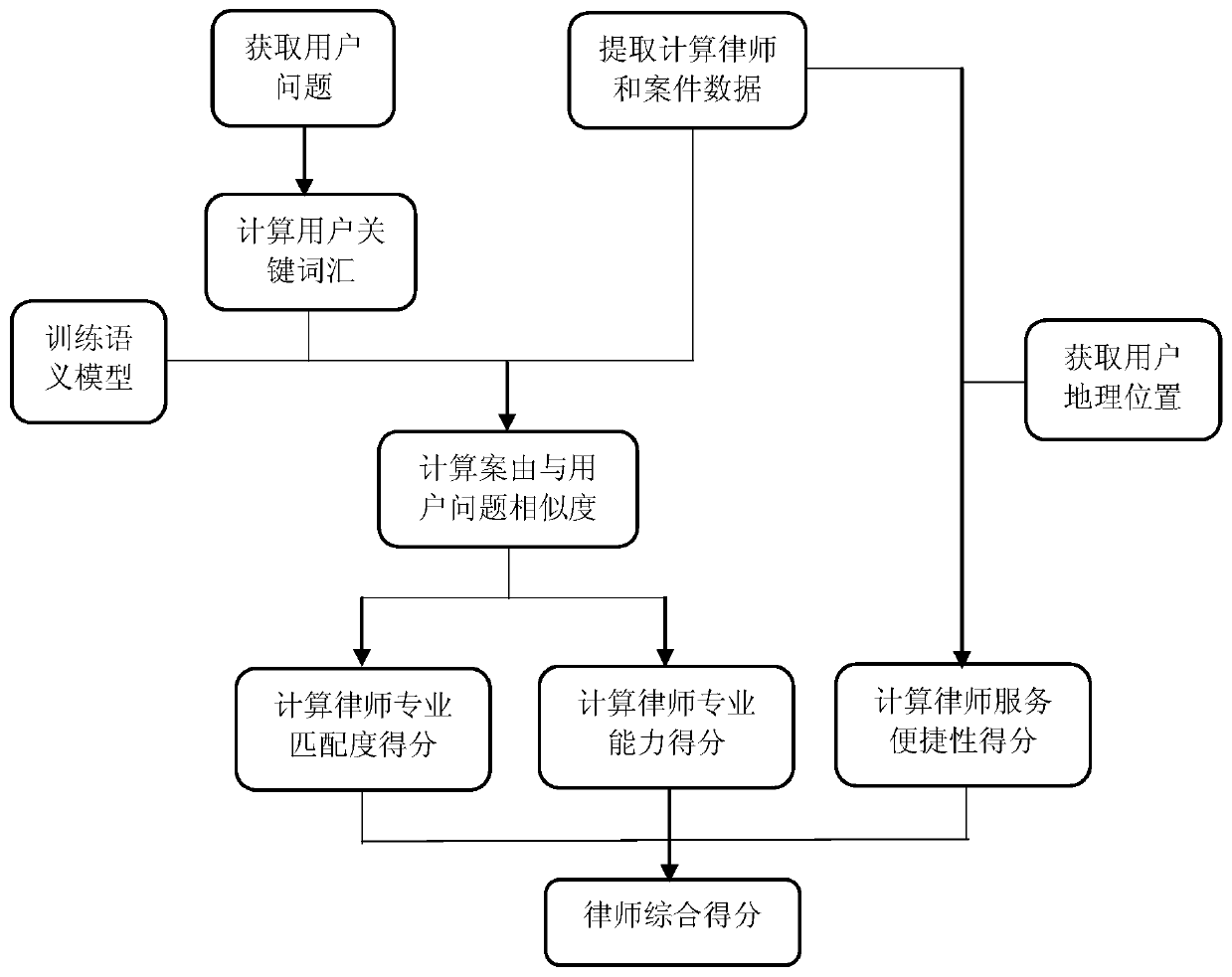

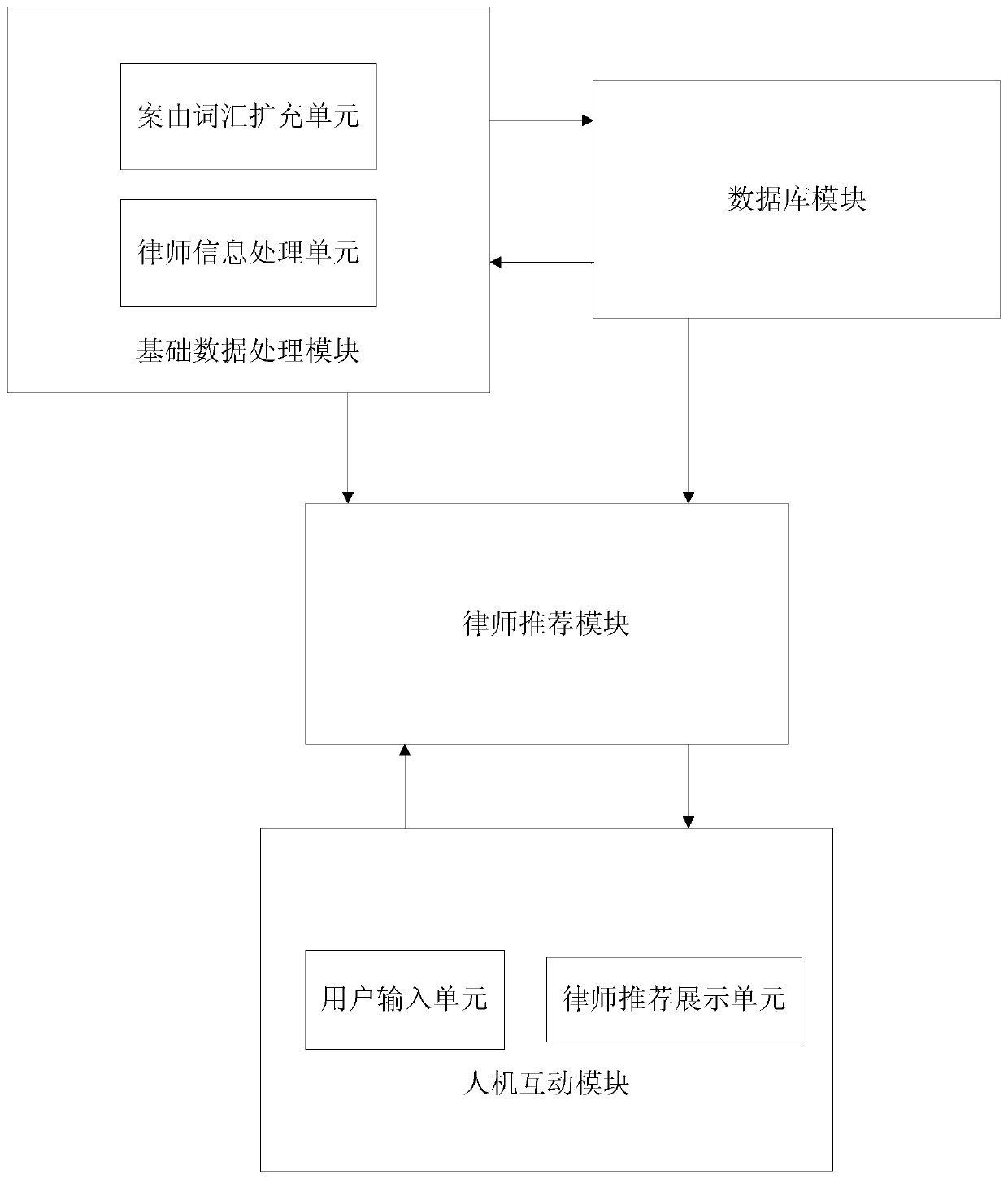

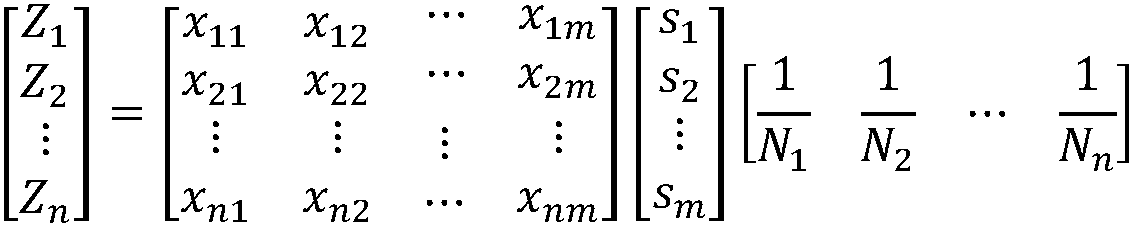

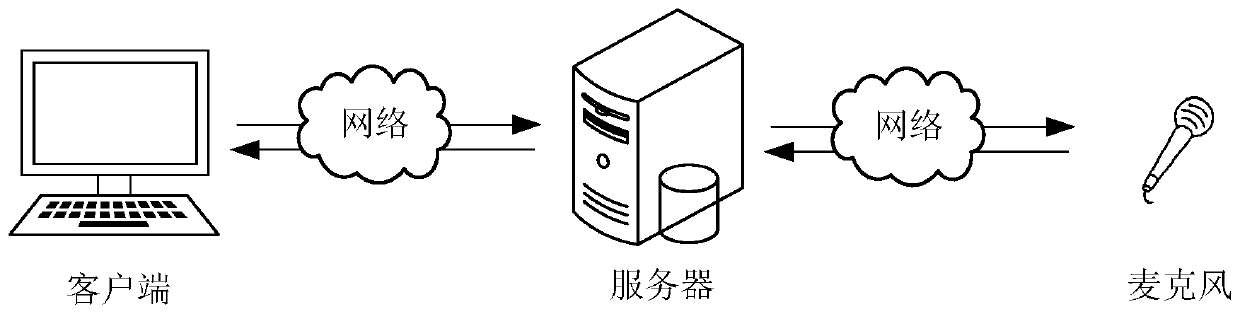

Lawyer accurate recommendation method and system

ActiveCN110347814AReduce instances of missegmentationThe result is accurateData processing applicationsDigital data information retrievalUser inputData mining

A lawyer accurate recommendation method comprises the steps: firstly obtaining case description input by a user, then obtaining key vocabularies through a word segmentation means, and obtaining the similarity between a case cause and a user question by calculating the similarity between the case cause and expansion vocabularies of the case cause and each key vocabulary; obtaining professional matching degree scores of the lawyers according to case information handled by the lawyers in the database; obtaining four evaluation items including lawyer on-duty years, case handling duration, lawyer winning rates and expert scores through calculation, giving corresponding weights to the evaluation items, and obtaining professional ability scores of lawyers; according to the location of the user, obtaining two evaluation items, namely the distance between lawyers and the user and the number of cases which are being accepted by the lawyers, and endowing corresponding weights to obtain a serviceconvenience score of the lawyers; and finally, synthesizing the three dimensions to obtain a comprehensive evaluation score of the lawyer, and recommending the lawyer to the user. The invention further discloses a lawyer accurate recommendation system. The lawyer accurate recommendation method and system are high in accuracy and good in service convenience.

Owner:ENJOYOR COMPANY LIMITED

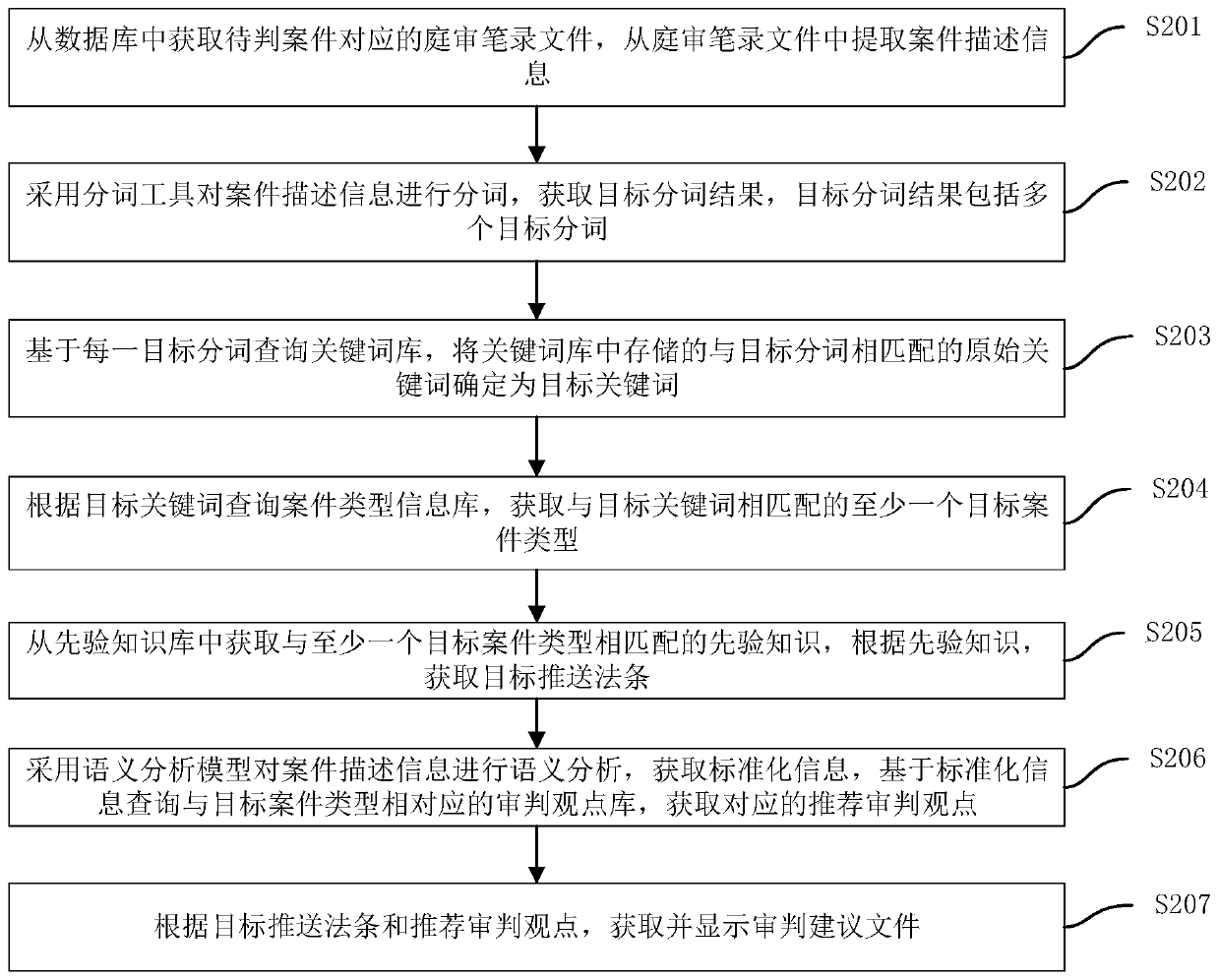

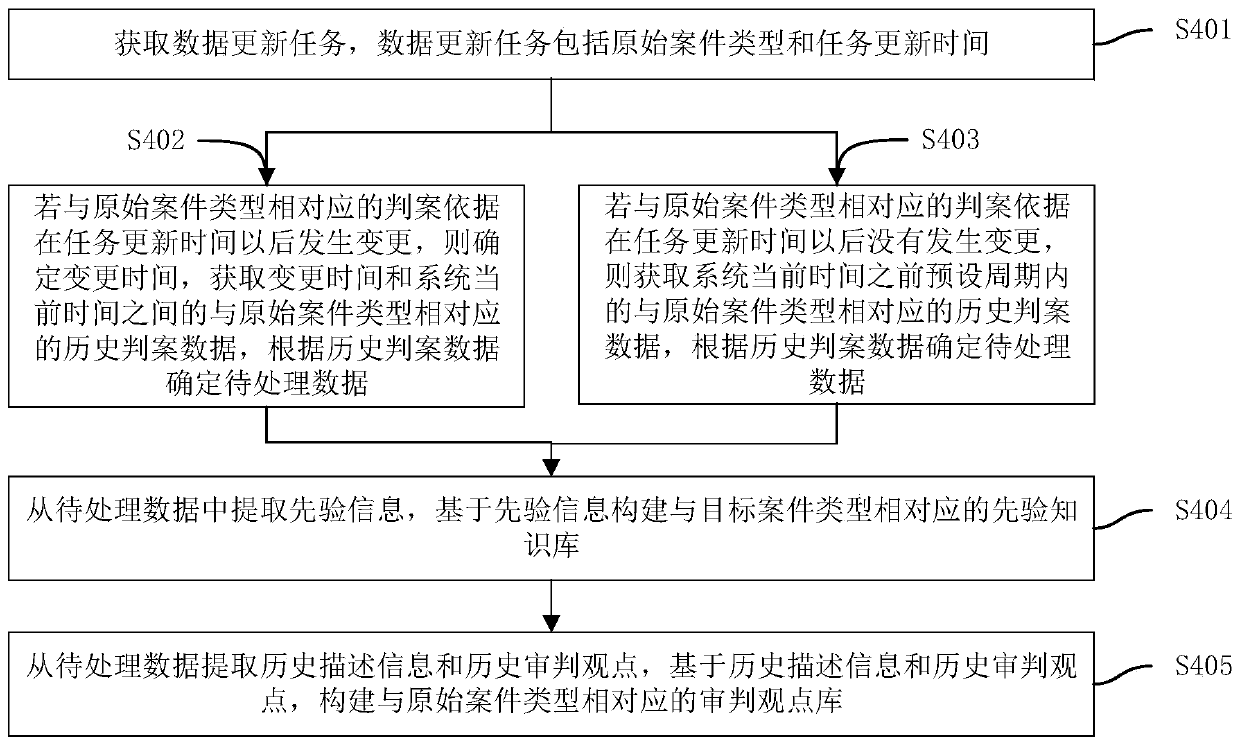

Intelligent auxiliary judgment method and device, computer equipment and storage medium

ActiveCN110675288AEasy accessImprove acquisition efficiencyData processing applicationsEnergy efficient computingInformation repositoryEngineering

The invention discloses an intelligent auxiliary judgment method and device, computer equipment and a storage medium. The method comprises the steps of obtaining a court trial record file corresponding to a to-be-judged case, and extracting case description information from the court trial record file; performing word segmentation on the case description information by adopting a word segmentationtool to obtain a target word segmentation result; querying a keyword library based on each target segmented word, and determining the keyword library as a target keyword; querying a case type information base according to the target keyword, and obtaining at least one matched target case type; obtaining priori knowledge matched with the at least one target case type from a priori knowledge base,and processing the priori knowledge by adopting an intelligent legal provision pushing model to obtain a target pushing legal provision; performing semantic analysis on the case description information by adopting a semantic analysis model to obtain corresponding recommended judgment viewpoints; and obtaining and displaying a trial suggestion file according to the target push legal provision and the recommendation trial viewpoint, so as to reduce the workload of a judge in a trial process, thereby reducing the workload.

Owner:PING AN TECH (SHENZHEN) CO LTD

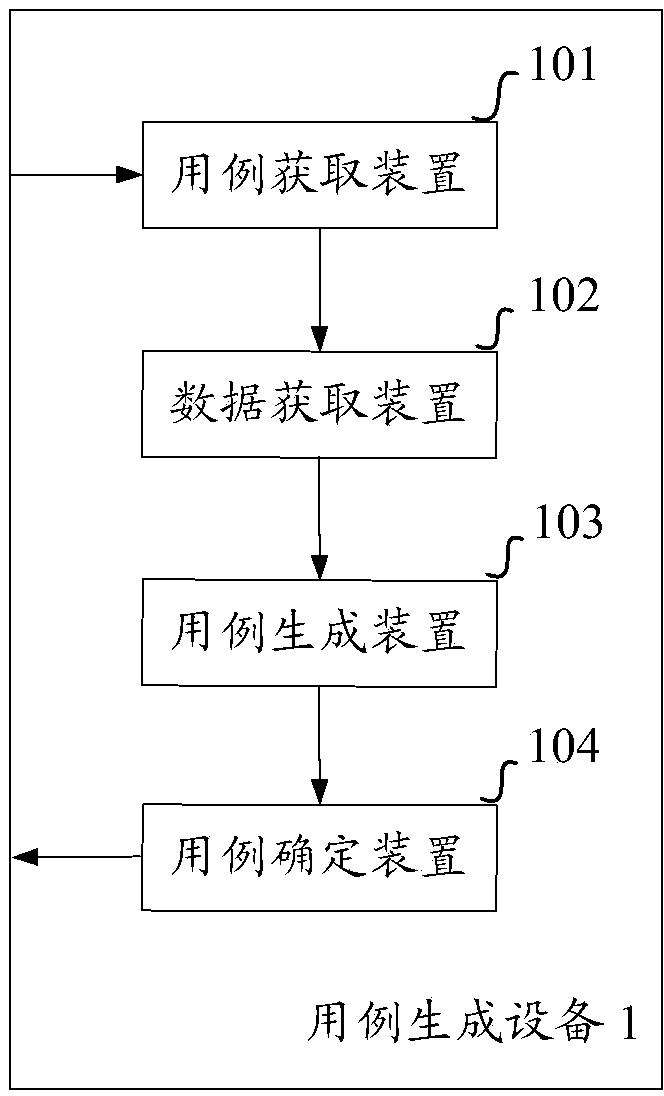

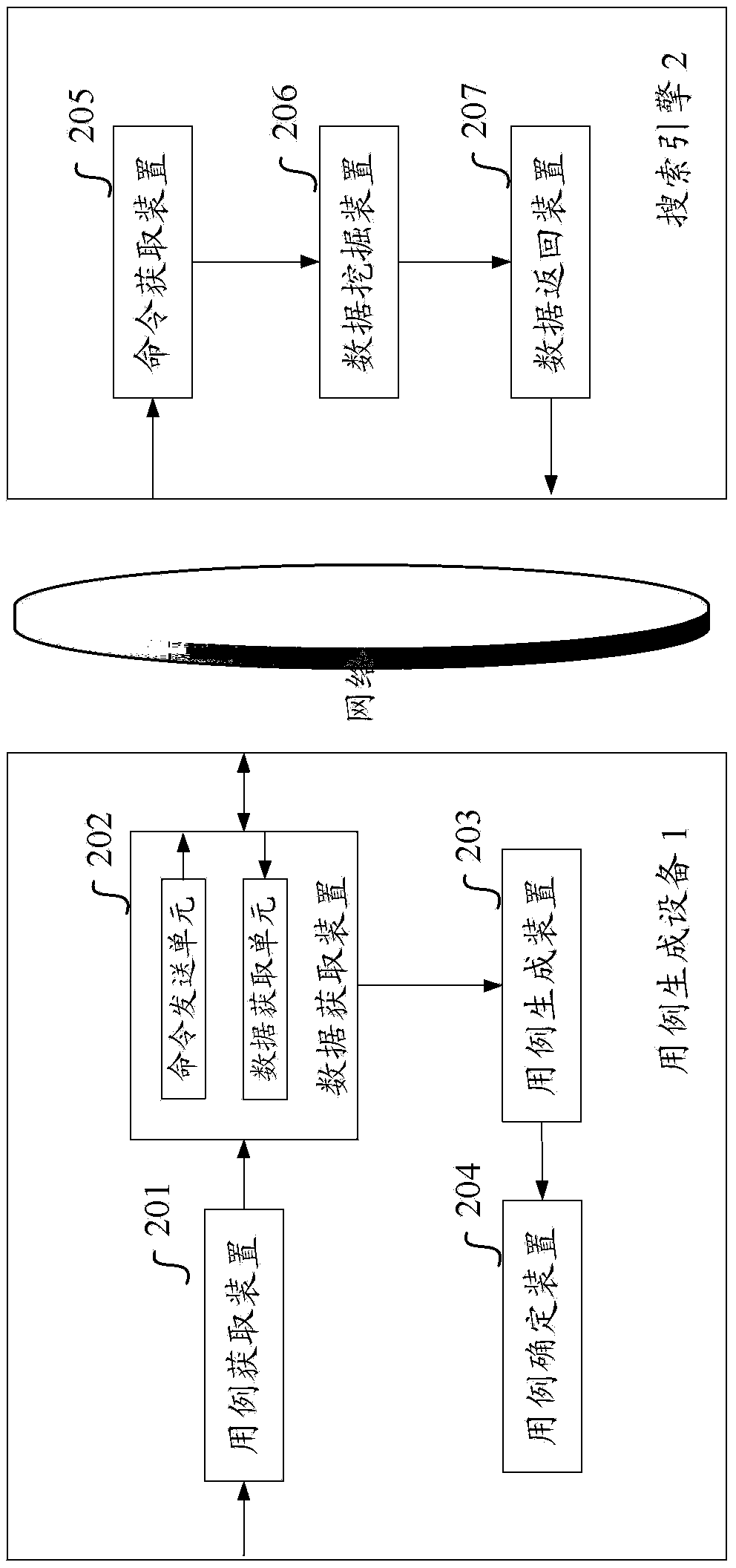

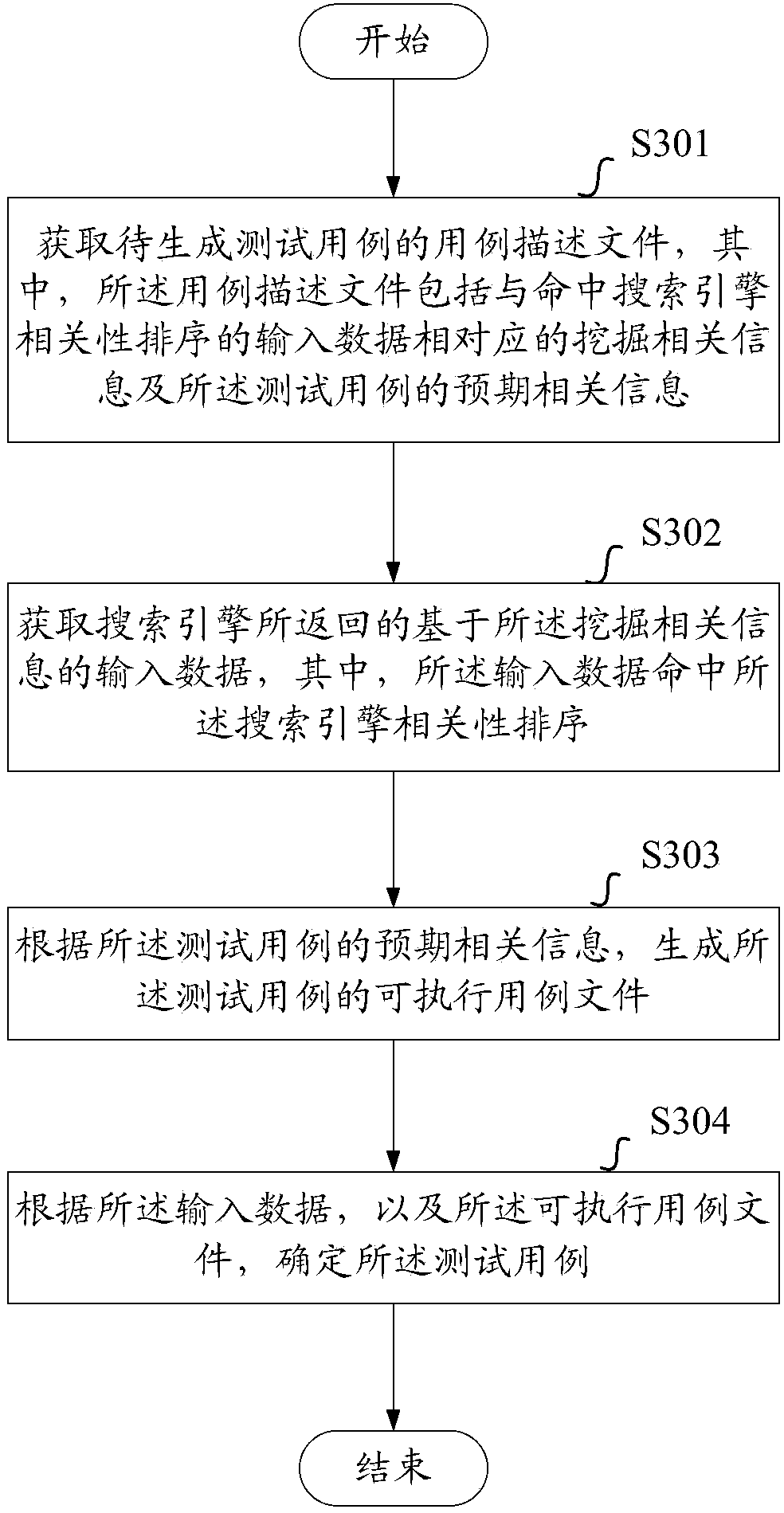

Method and device for generating search engine relevance ranking test case

ActiveCN103902449AReduce maintenance costsIncrease the number ofSoftware testing/debuggingSpecial data processing applicationsData feedRelevant information

The invention aims to provide a method and device for generating a search engine relevance ranking test case. The method includes the steps of obtaining a case description file of the test case to be generated; obtaining input data fed back by a search engine, wherein the input data are based on excavation relevant information in the case description file, and the input data hit search engine relevance ranking; generating an executable case file of the test case according to expectation relevant information of the test case; determining the test case according to the input data and the executable case file. Compared with the prior art, the method and device for automatically generating the search engine relevance ranking test case have the advantages that based on key path coverage, internal codes of the search engine module are transformed, the case input data are automatically excavated, the case expected content is automatically generated, the complex and mass test requirements are met, the test case generation number and generation efficiency are largely improved, and the case maintenance cost is lowered.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

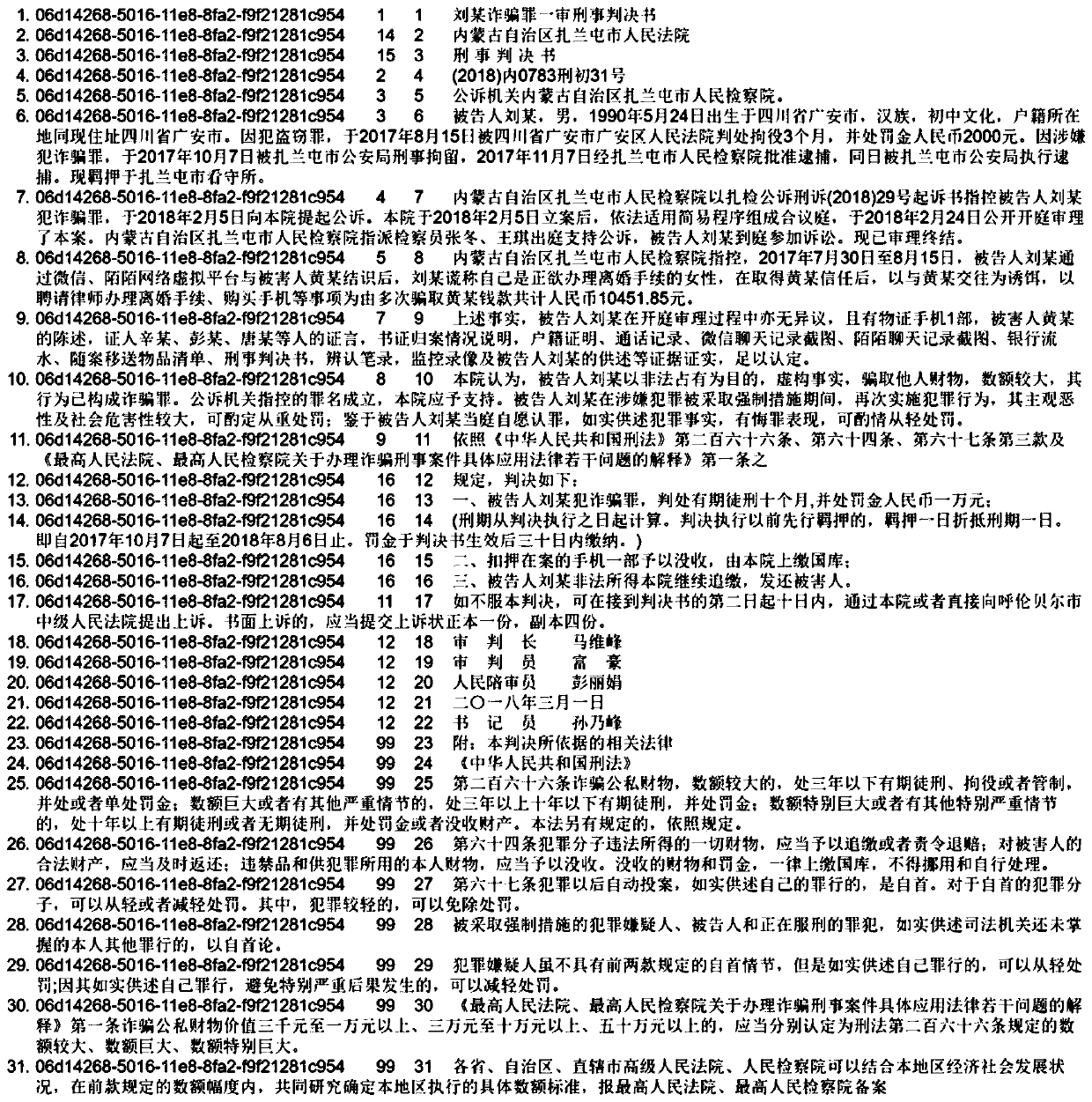

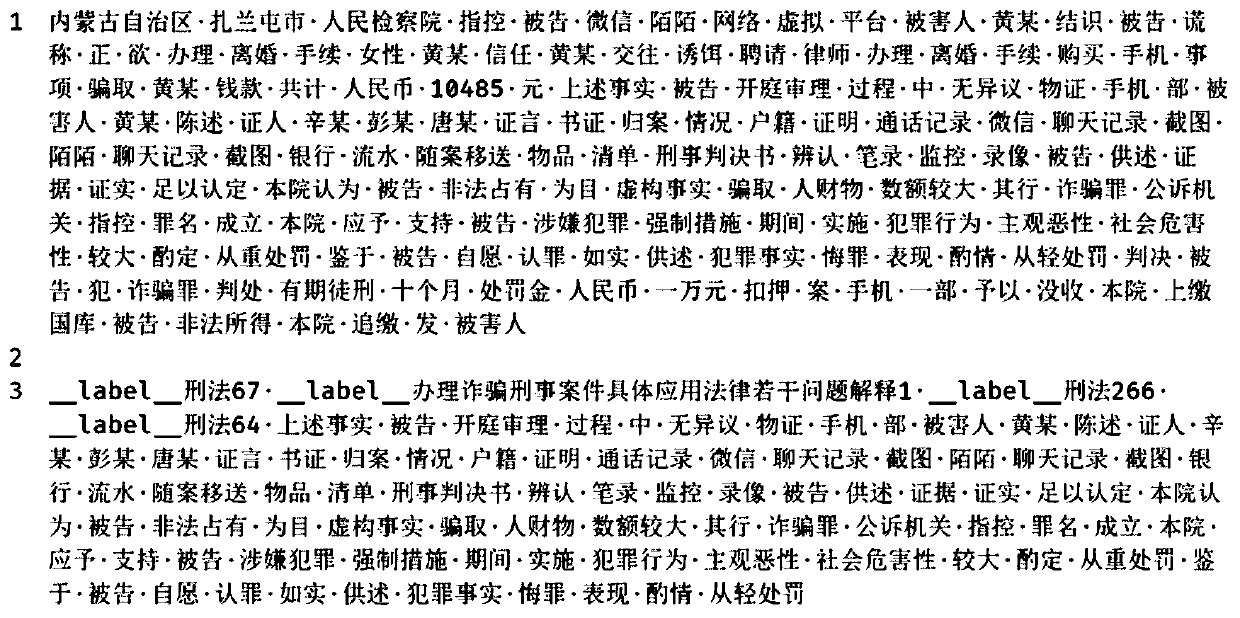

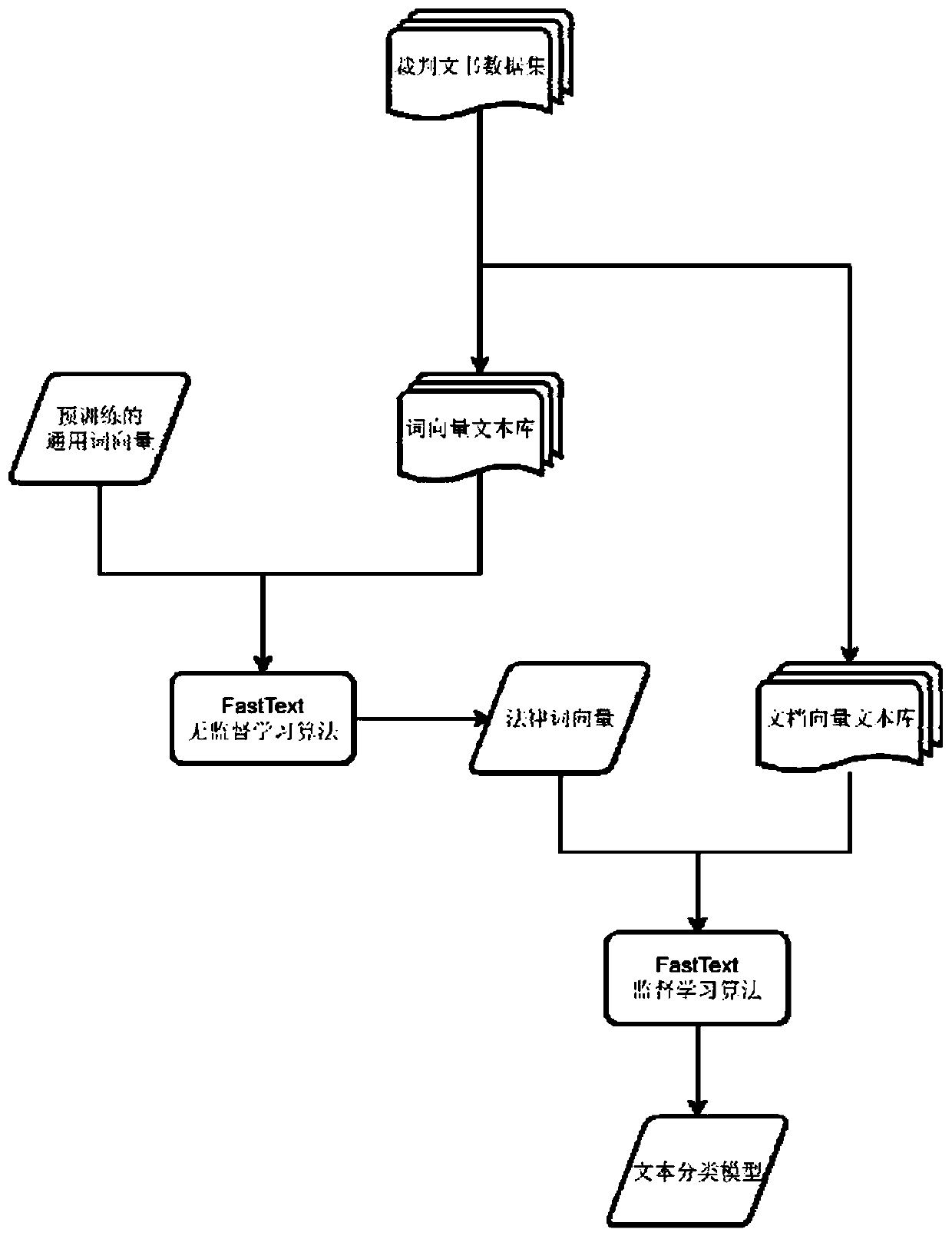

Intelligent law article recommendation auxiliary system based on FastText algorithm

PendingCN111177382AEase of useData processing applicationsSpecial data processing applicationsData setAlgorithm

The invention discloses an intelligent law article recommendation auxiliary system based on a FastText algorithm. The intelligent law article recommendation auxiliary system comprises a judgment document data set, a word vector text library, law word vectors, a document vector text library and a text classification model, wherein the judgment document data set is used for storing judgment documents; the word vector text library is used for storing text segment categories, and the document vector text library is used for storing text segment categories; each text segment category is the contentin the judgment document; the law word vector is obtained by taking a pre-trained general word vector as an initial vector and training the word vector text library by using a FastText unsupervised learning algorithm; and the text classification model is obtained by taking a trained law word vector as an initial vector and performing text classification on a document vector text library by usingthe FastText supervised learning algorithm. Applicable laws are comprehensively and accurately recommended for case description, a new thought is developed for providing judicial assistance work for artificial intelligence, and text classification models are established for various types of crimes such as cheating crimes, robbery, economic crimes or marriage dispute cases.

Owner:SICHUAN UNIV

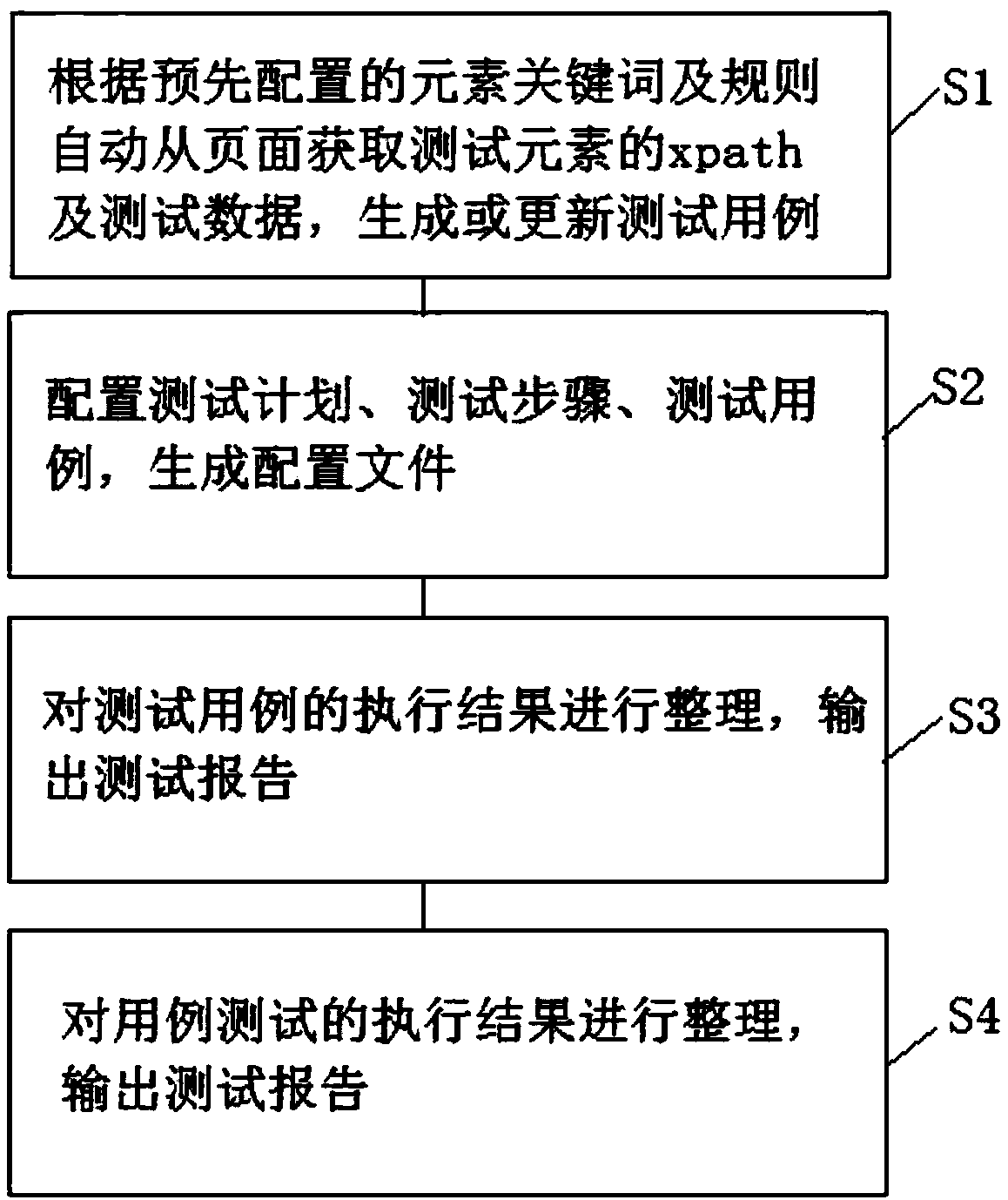

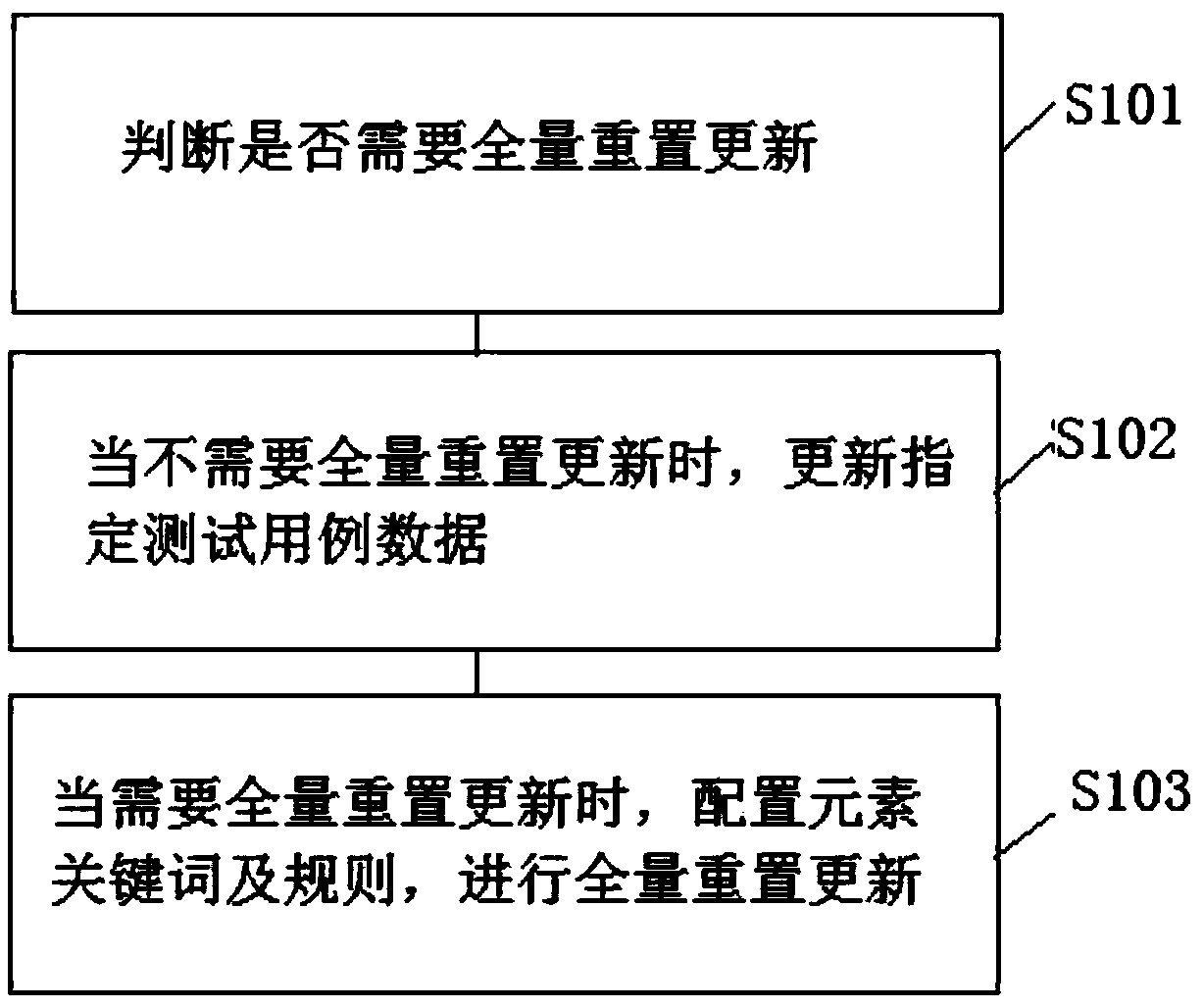

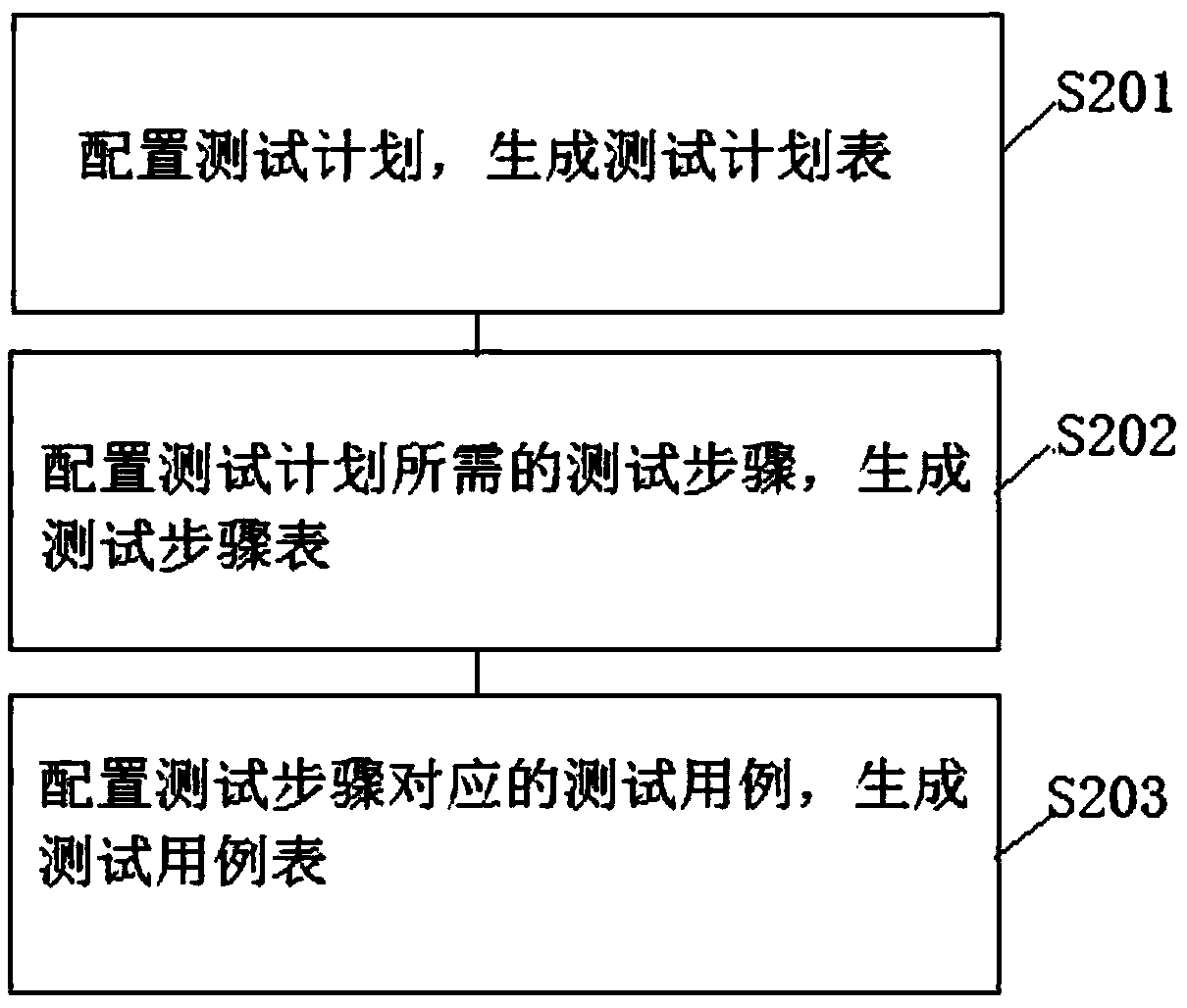

Encoding-free Selenium automated test method and system

InactiveCN107783902AFast automated testingEfficient automated testingSoftware testing/debuggingComputer hardwareComputer science

The invention discloses an encoding-free Selenium automated test method and system. The method comprises the following steps: A, automatically acquiring xpath and test data of a test element from a page according to pre-configured element keywords and rules, and generating or updating a test case; B, configuring a test plan, test steps and the test case and generating a configuration file; C, reading configuration information of the test case, and judging whether the verification content is correct or not; D, sorting out execution results of the test case and outputting a test report, whereinthe test case comprises a case number, element Xpath, a case description, an execution action, verification content and a verification result. According to the scheme, test personnel can quickly and efficiently perform automatic testing, and the coverage rate and the execution efficiency of automated testing are greatly increased.

Owner:中电万维信息技术有限责任公司

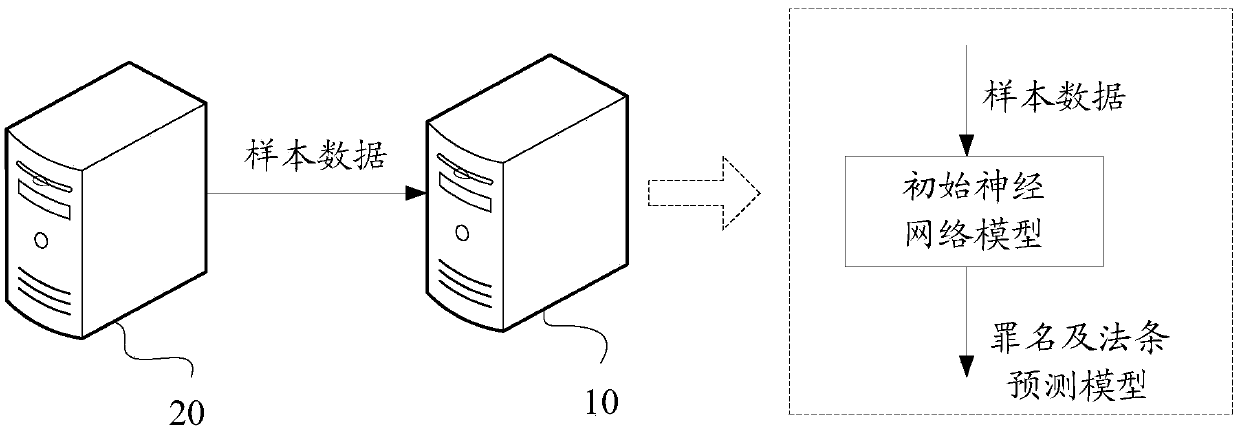

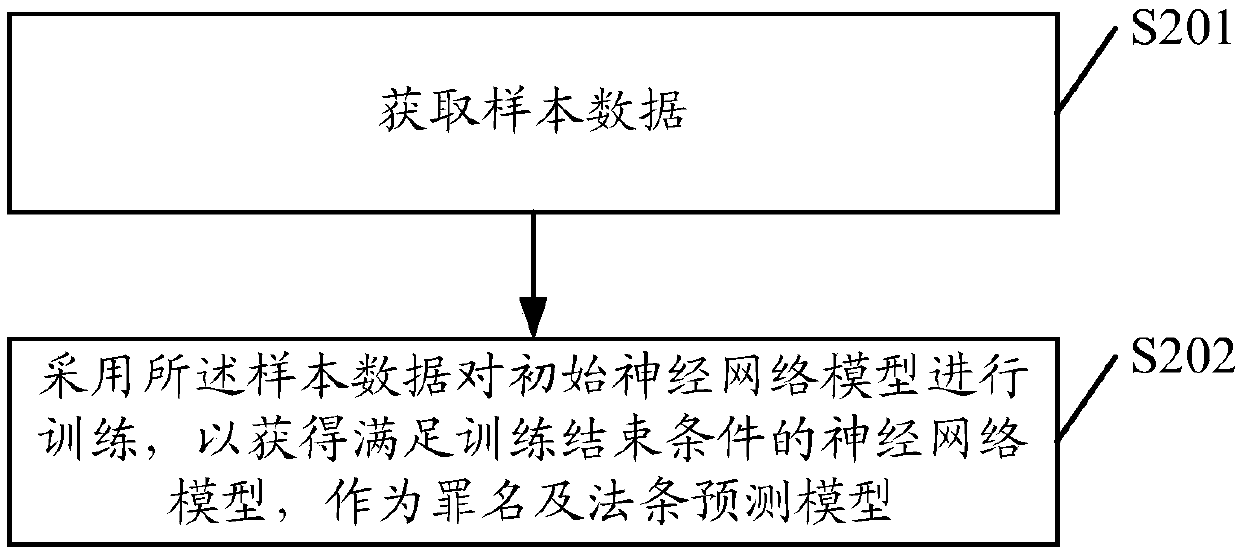

Training method of criminal name and law article prediction model and criminal name and law article prediction method

PendingCN110968689AImprove classification accuracyForecastingText database clustering/classificationData packEngineering

The invention discloses a training method of a crime name and law article prediction model. The method comprises the steps of obtaining sample data; wherein the sample data comprises case description,a crime name label corresponding to the case description and a corresponding legal provision label; and training an initial neural network model by adopting the sample data to obtain a neural networkmodel meeting a training end condition as a crime name and law article prediction model. The crime name label and the legal provision label corresponding to the same case description are highly related; when the sample data is used for training, the incidence relation between the criminal name and the legal provision can be learned, so that the criminal name and legal provision prediction model obtained by training through the method has relatively high classification accuracy when executing a criminal name classification task and a legal provision classification task. The invention further discloses a crime name and law article prediction method, a training device, a prediction device, a processor and a storage medium.

Owner:BEIJING GRIDSUM TECH CO LTD

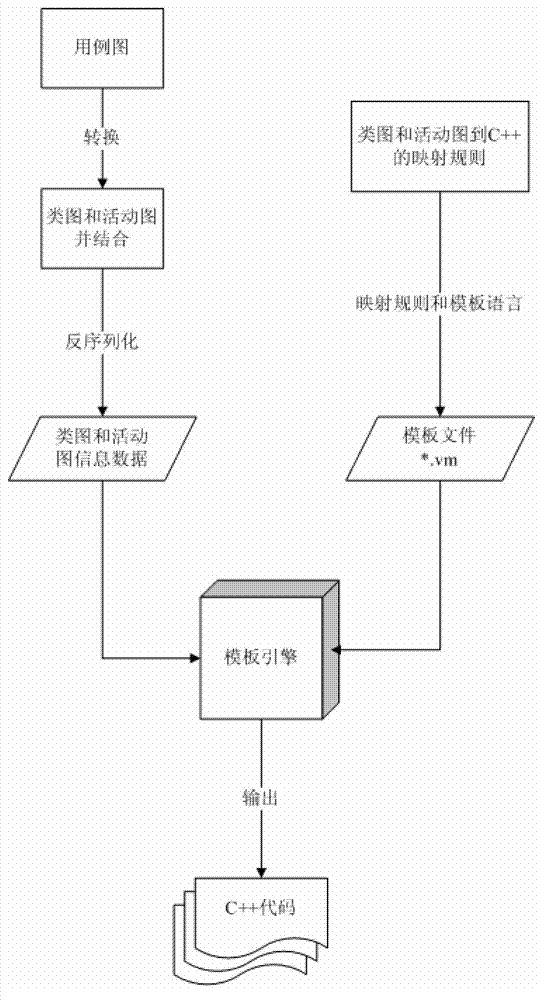

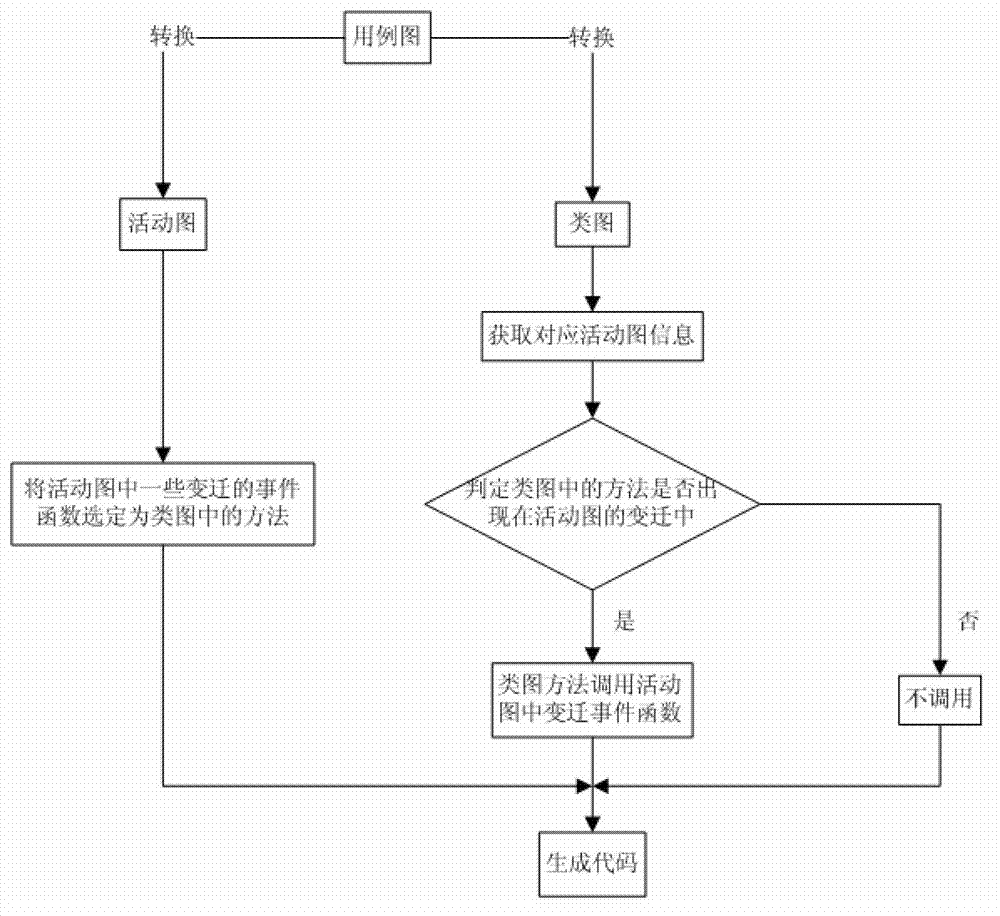

Method for generating C++code based on combination of class diagram and activity diagram

InactiveCN103176830AEasy accessImprove operational efficiencyProgram controlMemory systemsControl flowActivity diagram

The invention discloses a method for generating a C++code based on combination of a class diagram and an activity diagram. The generation method comprises the following steps of: converting a use case diagram into the class diagram and the activity diagram, wherein each use case is taken as the basis, and generating the class diagram and the activity diagram according to the information in the use case diagram, i.e. the use case description, the precondition, the post condition, the control flow and the like; building a mapping rule of the class diagram and the activity diagram to the C++code, wherein in order to improve the practical applicability and the effectiveness of the code, the class diagram and the activity diagram need to be combined with each other to generate the code; and after a template-based technology is taken as a frame, enabling input information of a template engine to be selected from the class diagram and the activity diagram based on a model technology, and generating the code by a template code generating technology based on the class diagram and the activity diagram.

Owner:XIDIAN UNIV

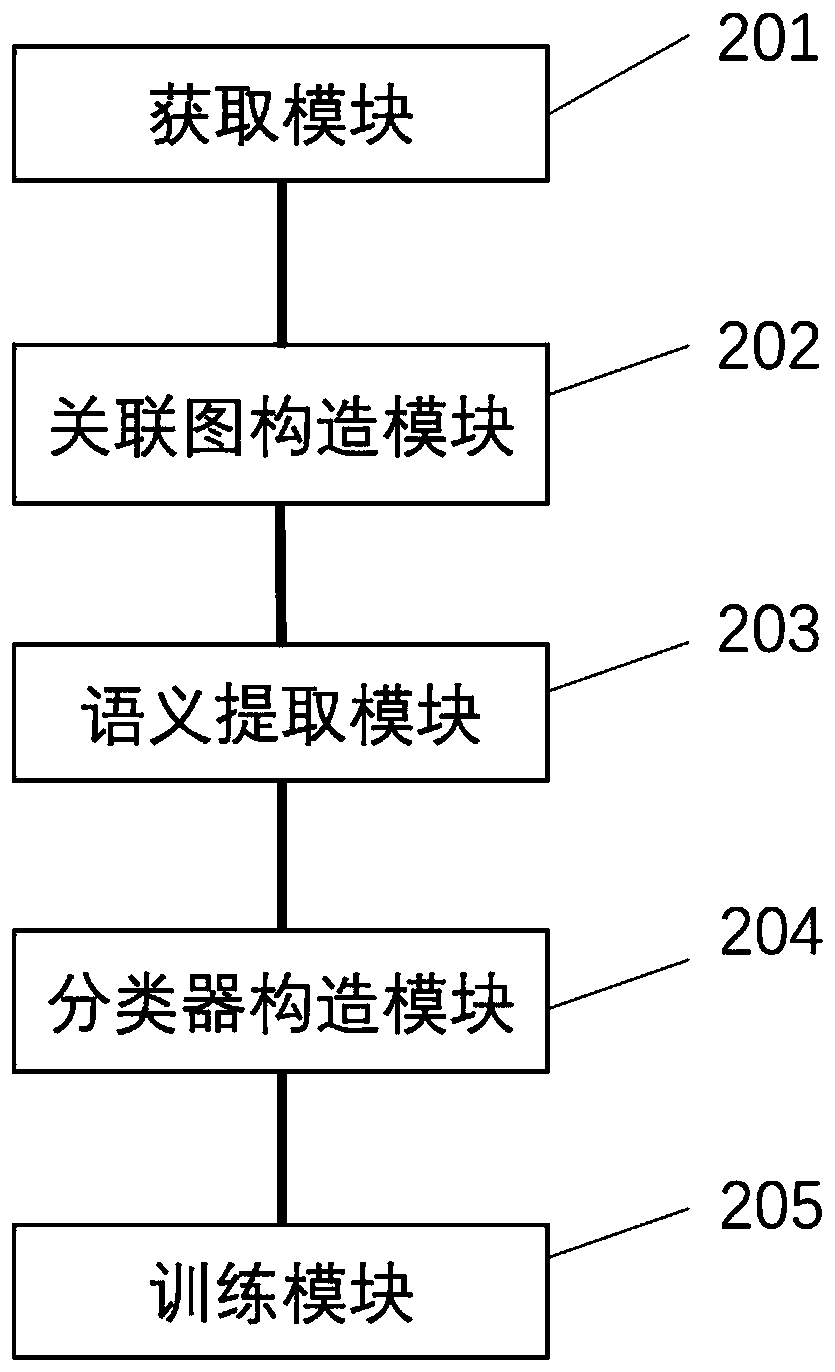

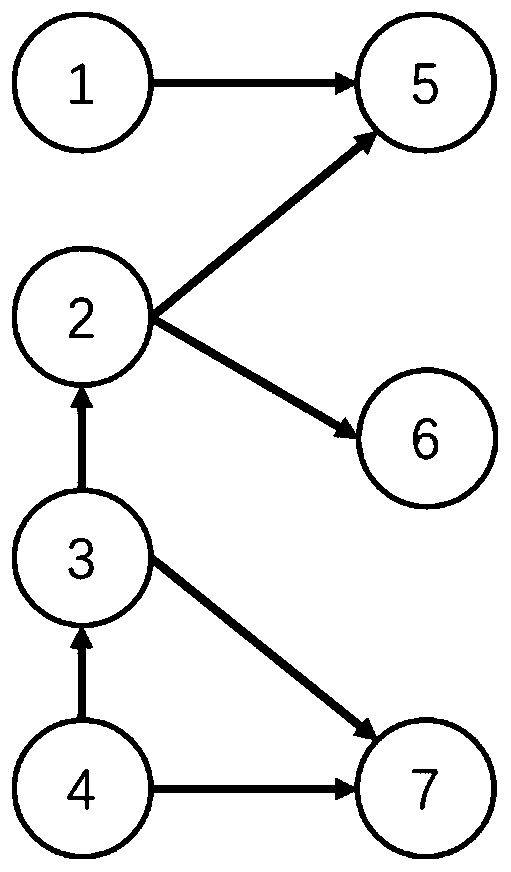

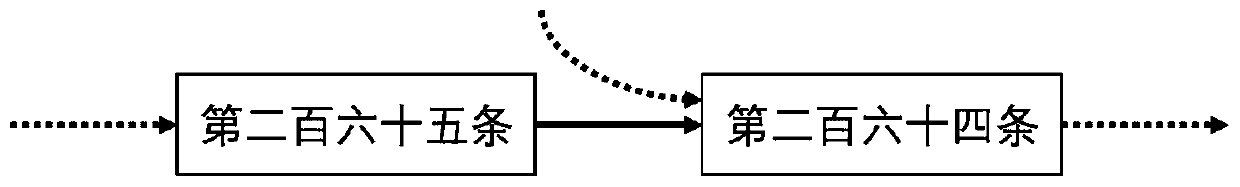

A legal provision recommendation prediction system and method based on an association graph

ActiveCN109919368AImprove recommendation accuracyOvercoming the inability to consider the citation relationship of legal articlesForecastingSpecial data processing applicationsPrediction systemData mining

The invention provides a legal provision recommendation system and method based on an association graph. The system includes: an acquisition module for obtaining a description of the case, laws and the reference relationships between the laws; an association diagram construction model for constructing an association diagram by using the reference relationship between the rules; a semantic extraction module for constructing the learning model and extracting the main semantic information including the text of the case description; a classifier construction module which is configured to constructa classifier corresponding to each node in the association diagram to predict the likelihood that the corresponding node tag of the node is true and the next flow direction of the node; a training module which trains the mesh model composed of classifiers by using an optimization algorithm of deep learning. The system is applied to the recommendation task of the law, and can use the reference relationship between the rules to carry out multi-label prediction, and improve the accuracy of the recommendation work of the law.

Owner:XI AN JIAOTONG UNIV

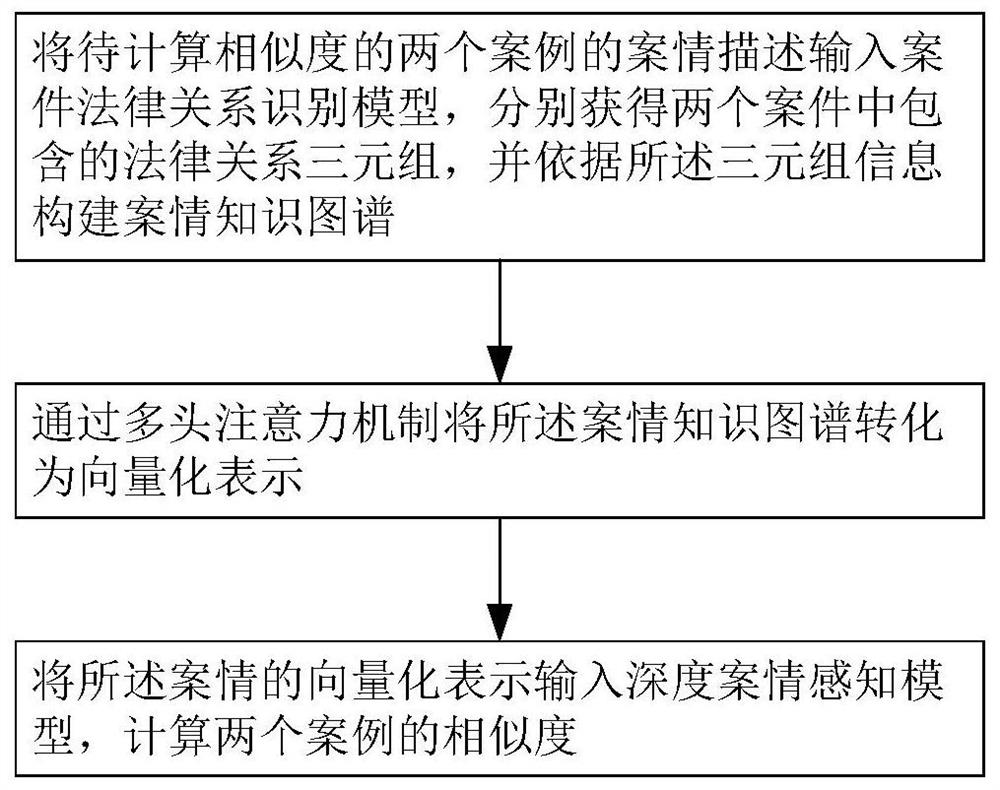

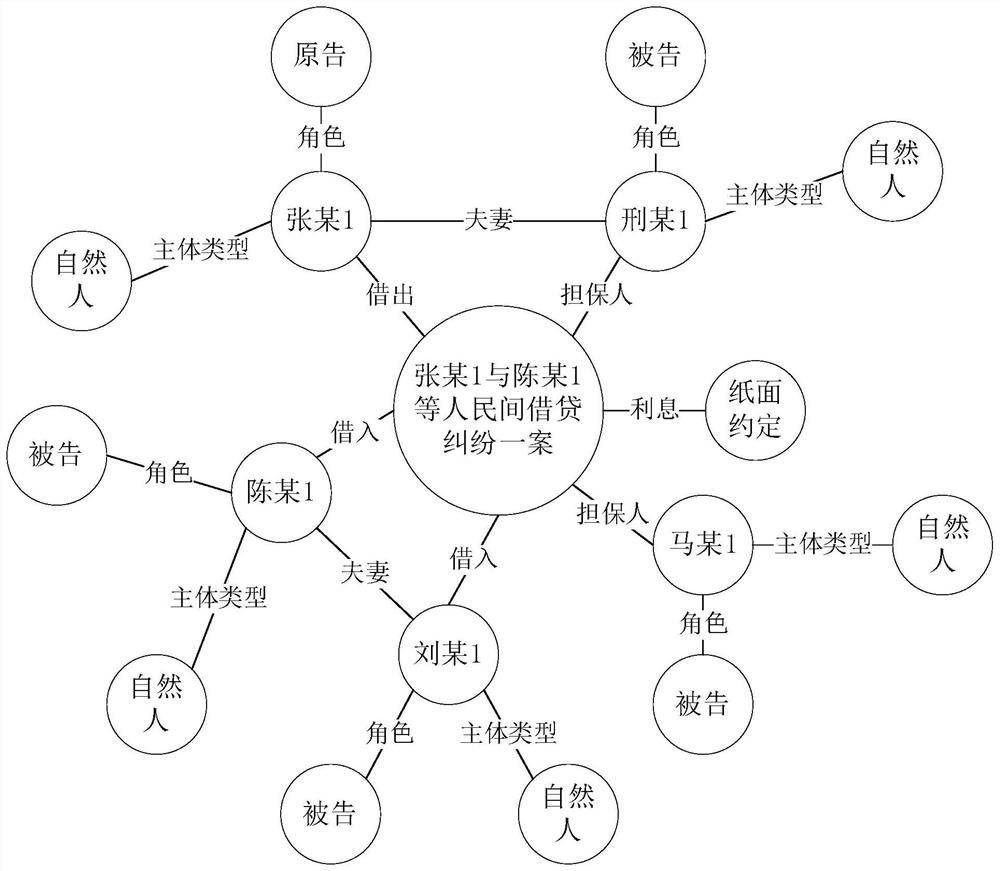

Legal case similarity calculation method and system based on multi-head attention

ActiveCN111858940AImprove accuracyData processing applicationsNatural language data processingAlgorithmTheoretical computer science

The invention discloses a legal case similarity calculation method based on multi-head attention. The method comprises the steps: (1) inputting the case descriptions of two cases with similarity to becalculated into a case legal relation recognition model, and extracting triples formed by legal relations in the two cases respectively, wherein the triples comprise a head entity, a relation and a tail entity, and constructing a case knowledge graph according to the triples; (2) converting the case knowledge graph into vectorized representation through a multi-head attention mechanism; (3) inputting the vectorized representation of the case into a deep case perception model to obtain the similarity of the two cases. According to the technical scheme of the invention, the method can improve the accuracy of class case retrieval, class case recommendation and other application scenes in law by calculating the similarity.

Owner:XIANGTAN UNIV

Automatic control method of iron ore flotation reagent dosage based on tailings grade

InactiveCN109569887ARealize online closed-loop controlImprove securityFlotationAutomatic controlReference case

The invention provides an automatic control method of an iron ore flotation reagent dosage based on tailings grade. The automatic control method includes extracting historical data from production process of iron ore flotation; solving difference value of tailings grade; setting the difference value of tailings grade and ore properties as case description and setting a flotation reagent regulatedvalue as case solution; retrieving case in a case library to acquire a group of similar values; arranging the similar values from large to small, selecting the historical cases, corresponding to frontbeta similar values, from the case library as reference cases for the current new case; reusing the case to obtain new case solution, saving the new cases in the case library, thereby completing updating of the case library. Online closed-ring control of the iron ore flotation reagent dosage can be realized according to fluctuation of the tailings grade, and accordingly safety, reliability and economic efficiency of iron ore flotation production can be improved.

Owner:ANSTEEL GRP MINING CO LTD

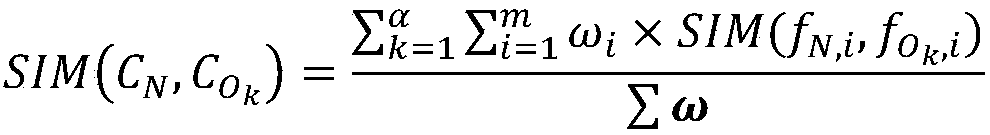

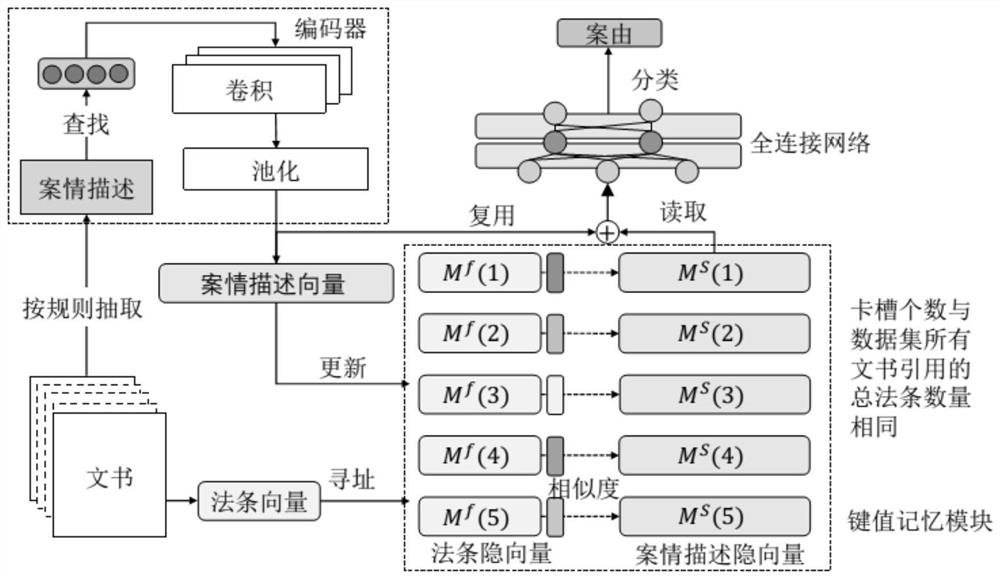

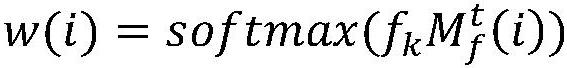

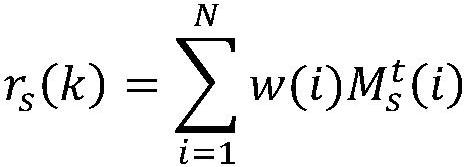

Case cause classification method based on key value memory network and medium

ActiveCN111651594AImprove classification accuracyData processing applicationsNatural language data processingData setClassification methods

The invention provides a case cause classification method based on a key value memory network and a medium. The case cause classification method comprises: 1) data preprocessing: extracting case description text information and legal provision information quoted by a document from a judicial document; 2) model construction: establishing a case cause classification model based on a key value memorynetwork, wherein the case cause classification model comprises modeling of citation laws, modeling of case casecase description texts and modeling of a key value memory enhancement neural network; 3)model training: optimizing the established cause classification model through training data to obtain optimal parameters; and 4) model prediction: inputting a case casecase description text of the test data set, and predicting the cause category corresponding to the case by the model. The key value memory enhanced neural network is used for case cause classification, case key information can be effectively extracted by means of reference information of legal provisions, the classification accuracy of case causes with a small number of samples is improved, and then the overall accuracy of casecause classification is improved.

Owner:SHANGHAI JIAO TONG UNIV

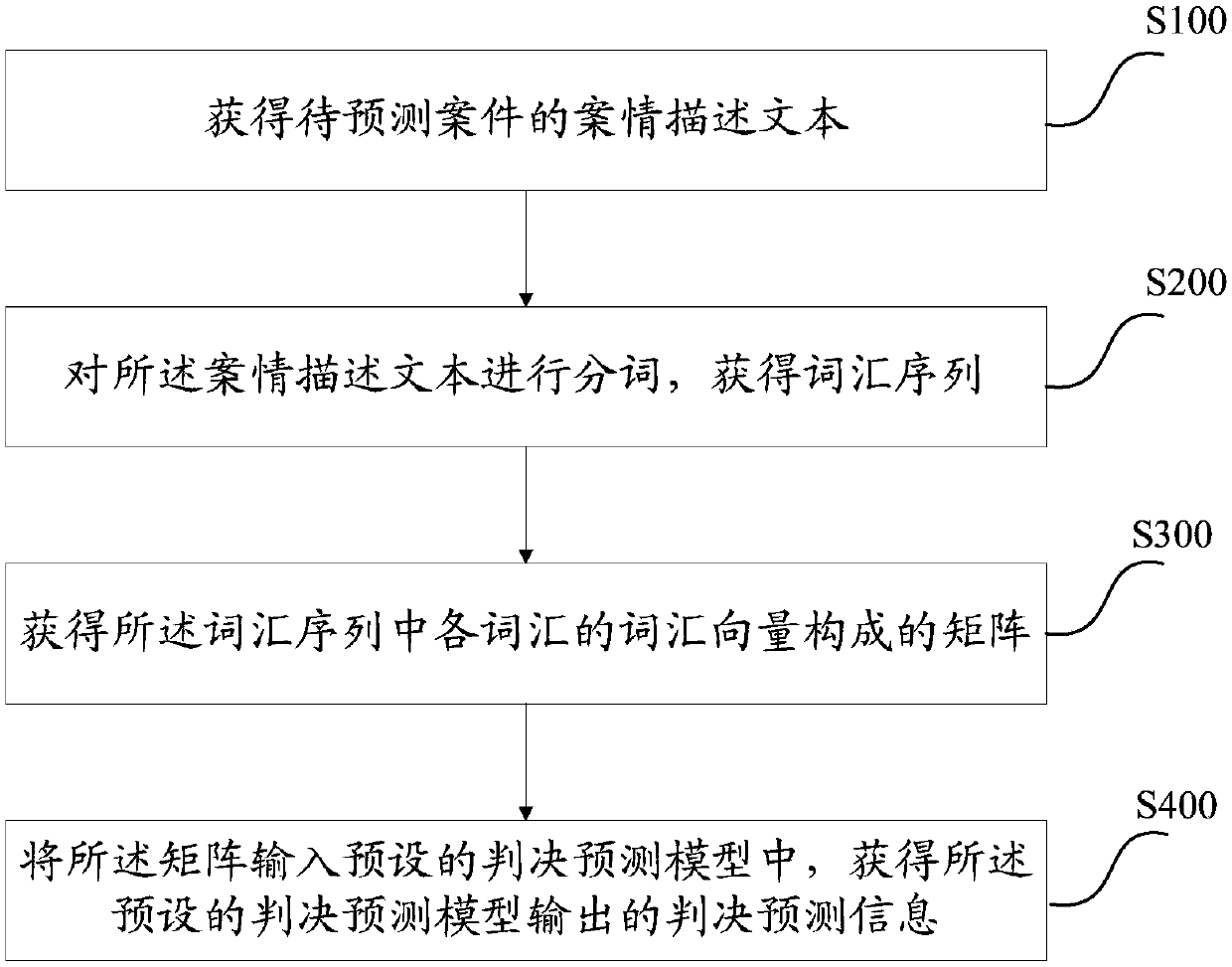

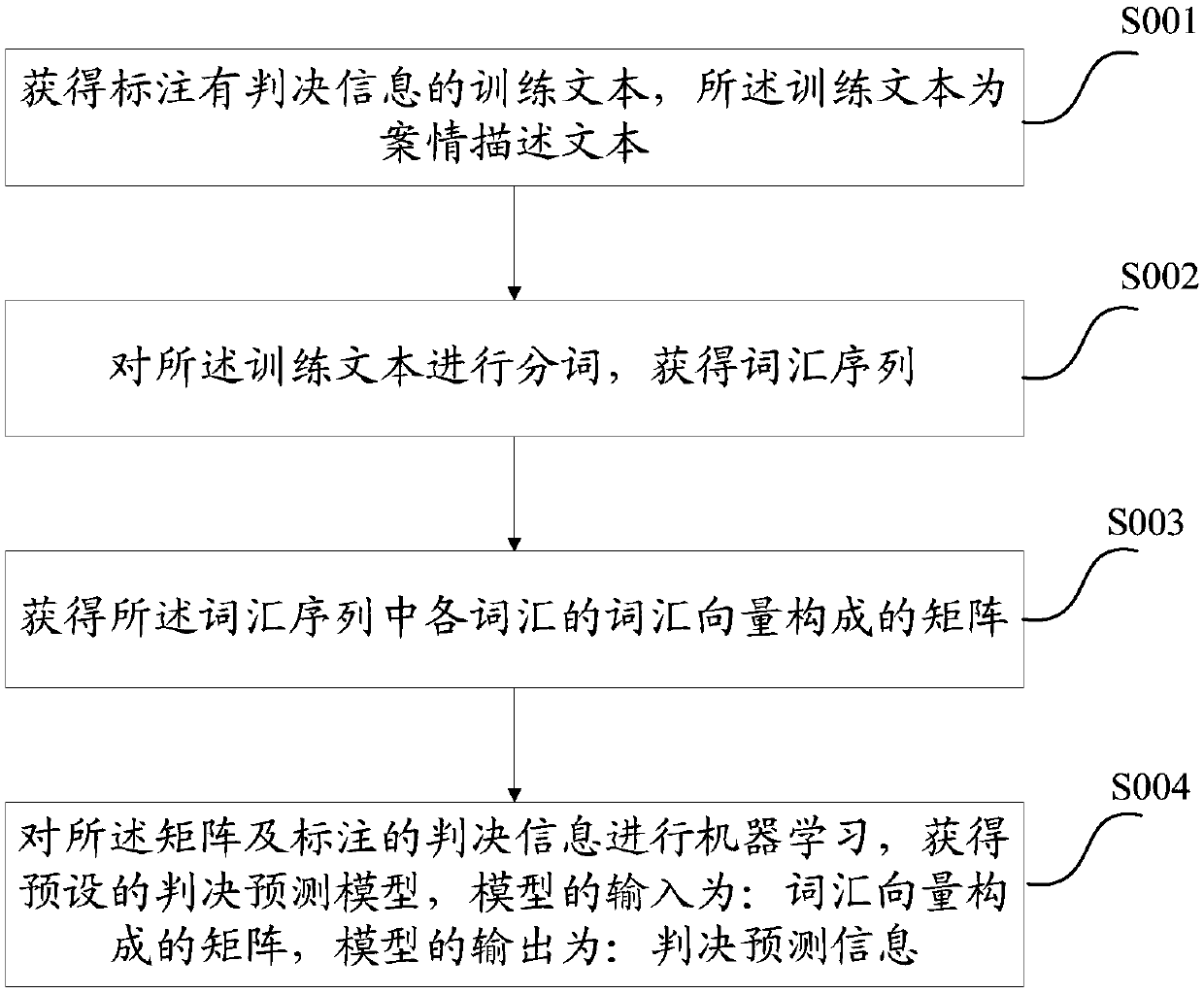

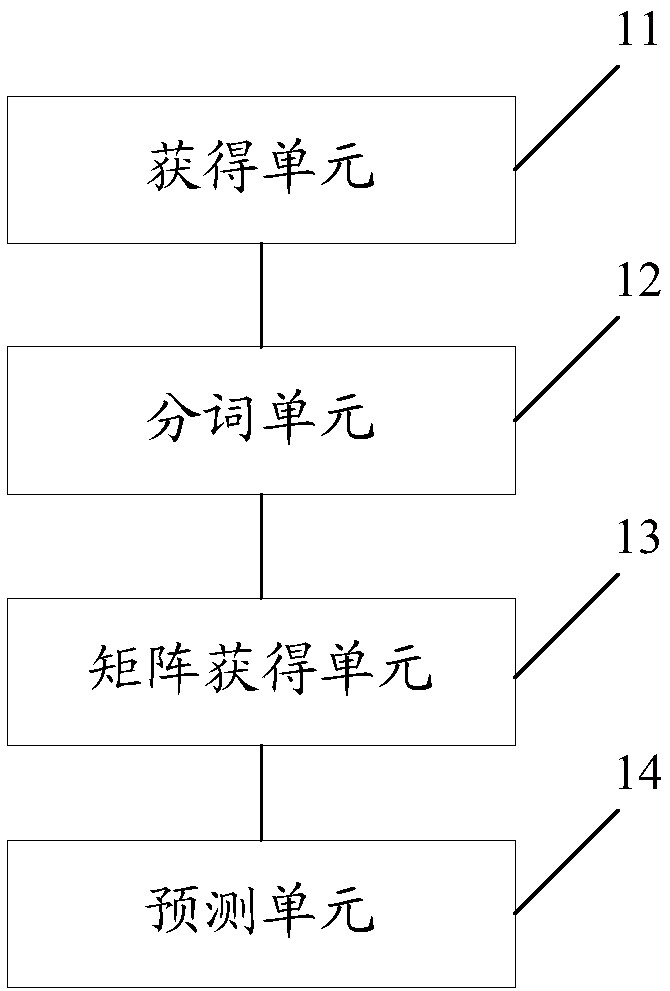

Decision prediction method, method and device for obtaining the decision prediction model

ActiveCN110969276AAccurate predictionForecastingNatural language data processingPredictive methodsEngineering

The invention discloses a decision prediction method, a method and device for obtaining the decision prediction model. The decision prediction method comprises the steps of obtaining a case description text of a to-be-predicted case; performing word segmentation on the case description text to obtain a vocabulary sequence; obtaining a matrix formed by vocabulary vectors of all vocabularies in thevocabulary sequence; and inputting the matrix into a preset judgment prediction model to obtain judgment prediction information output by the preset judgment prediction model, thereby realizing accurate and intelligent prediction of judgment, facilitating improvement of the efficiency of criminal case judge, improving the justice and fairness of case judgment, and facilitating popularization of legal knowledge in the masses.

Owner:BEIJING GRIDSUM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com