Case reasoning-based iron ore floatation reagent dosage optimization setting method and system

A flotation reagent and optimized setting technology, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems of waste of resources, excessive reagents, and high maintenance costs, reducing the probability of errors, reducing maintenance costs, Reduce the effect of data loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

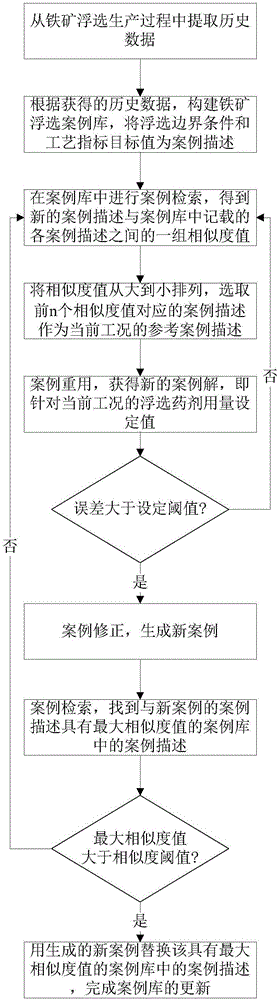

[0029] A case-based reasoning method for optimal setting of reagent dosage in iron ore flotation, such as figure 1 shown, including the following steps:

[0030] Step 1: Extract historical data from the iron ore flotation production process, including the dosage of flotation agents, flotation boundary conditions and process index target values, as shown in Table 1:

[0031] Table 1 historical data

[0032]

[0033] Combined with historical data, production site research and theoretical analysis of the flotation process, the above-mentioned flotation boundary conditions and process index target value data have a direct impact on the amount of flotation reagents, and they account for a large proportion. It affects the matching of different types of reagents in flotation reagents; flotation time and flotation temperature affect the ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com