Patents

Literature

263 results about "Volatiles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In planetary science, volatiles are the group of chemical elements and chemical compounds with low boiling points that are associated with a planet's or moon's crust or atmosphere. Examples include nitrogen, water, carbon dioxide, ammonia, hydrogen, methane and sulfur dioxide. In astrogeology, these compounds, in their solid state, often comprise large proportions of the crusts of moons and dwarf planets.

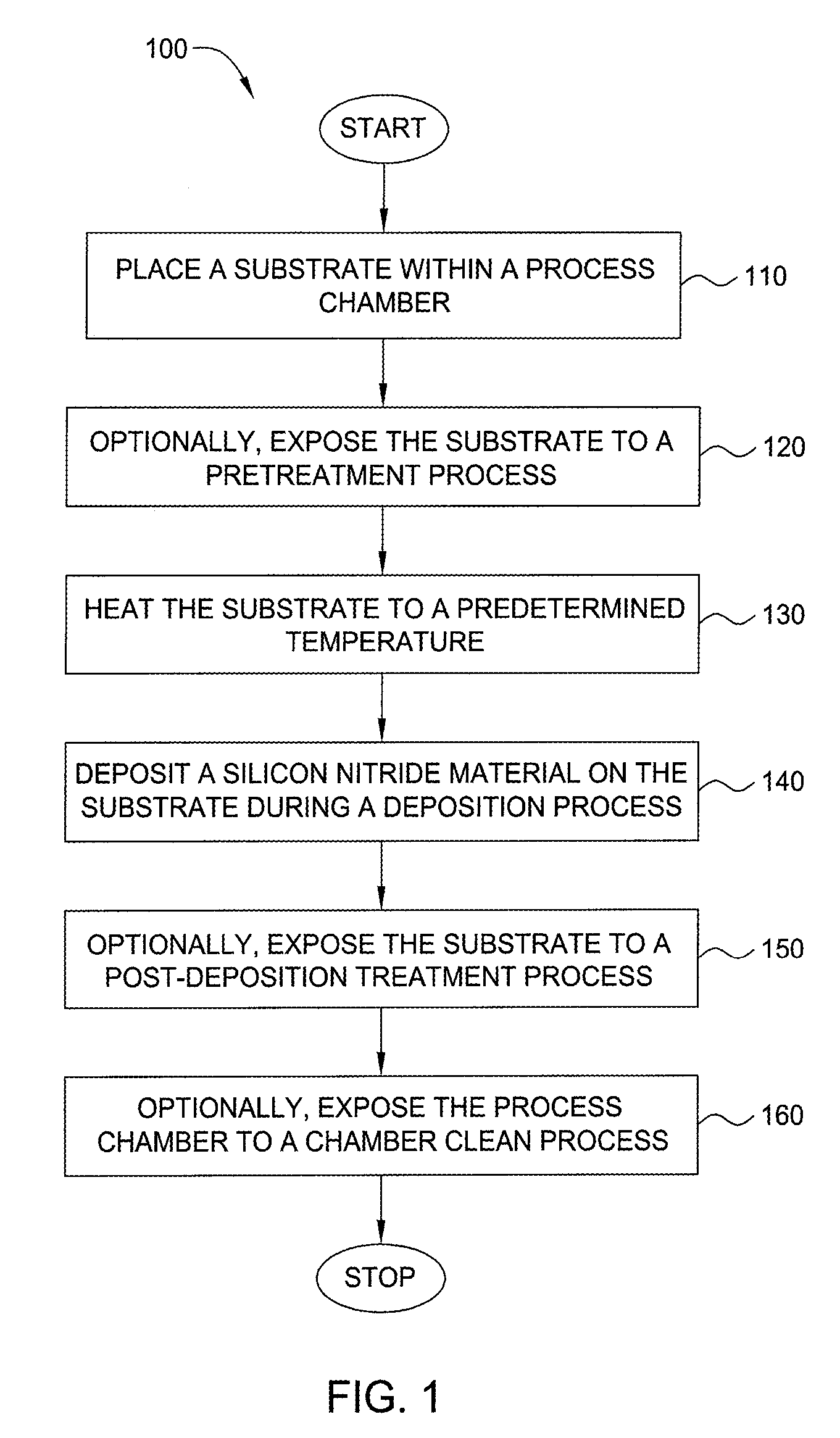

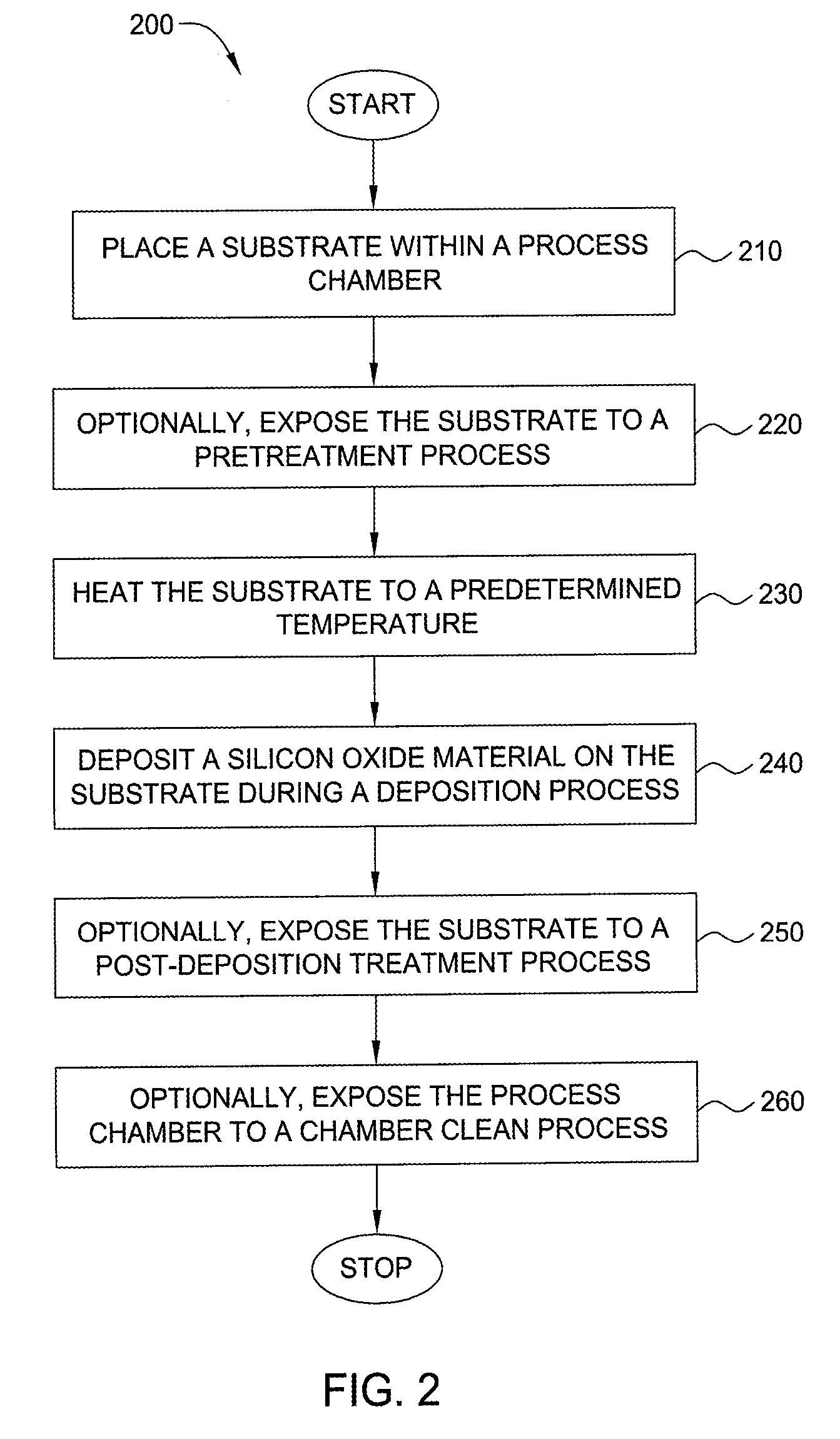

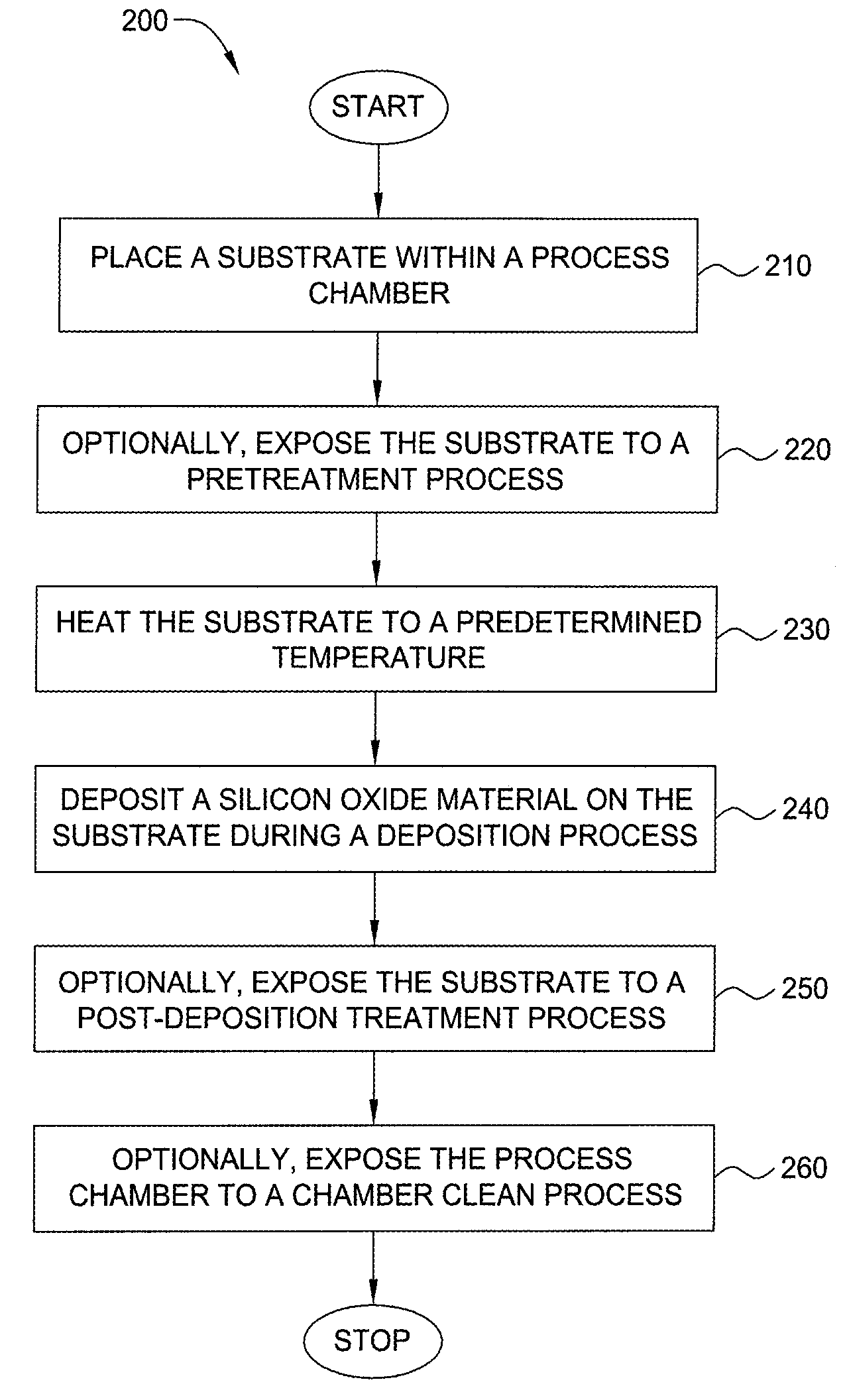

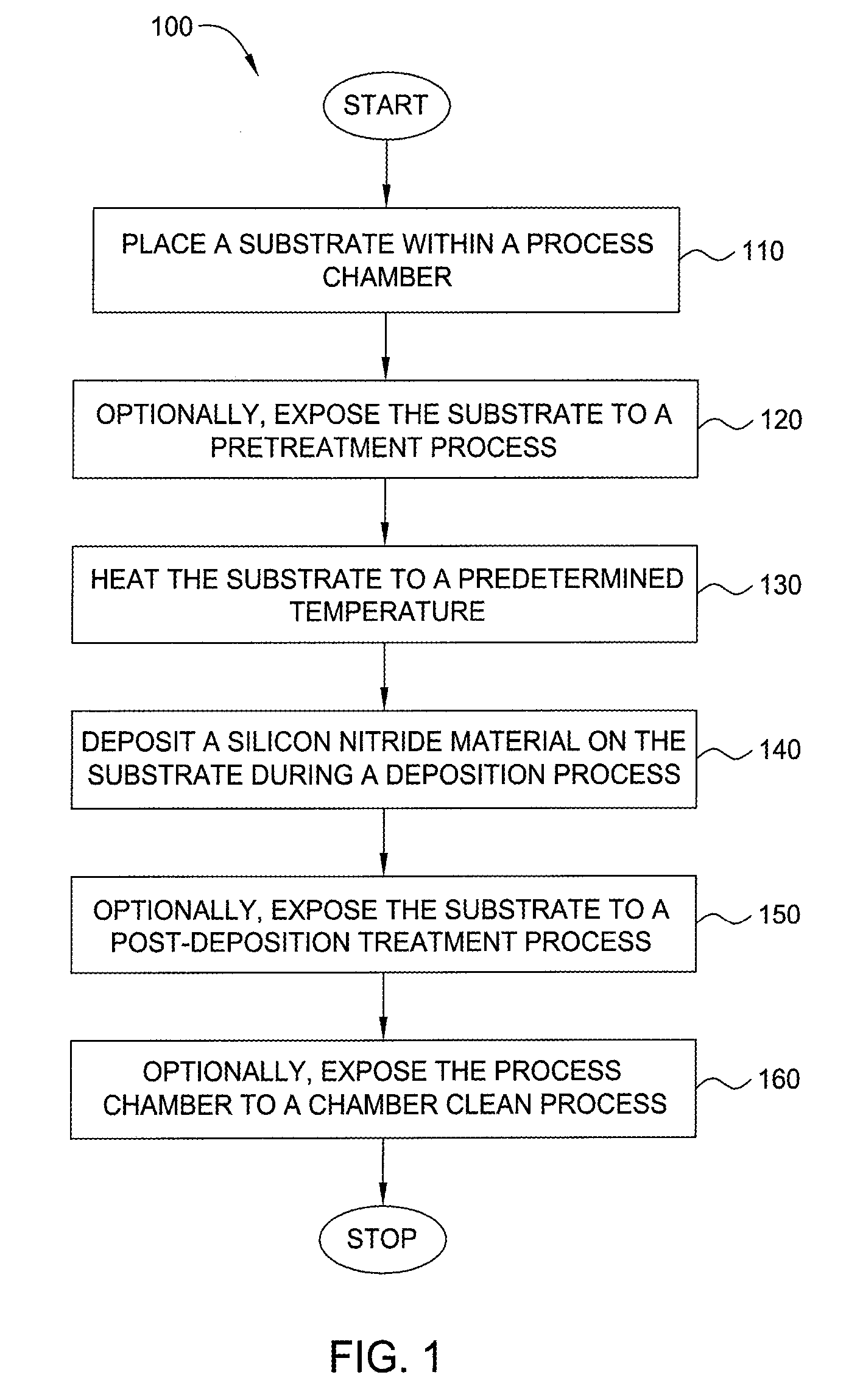

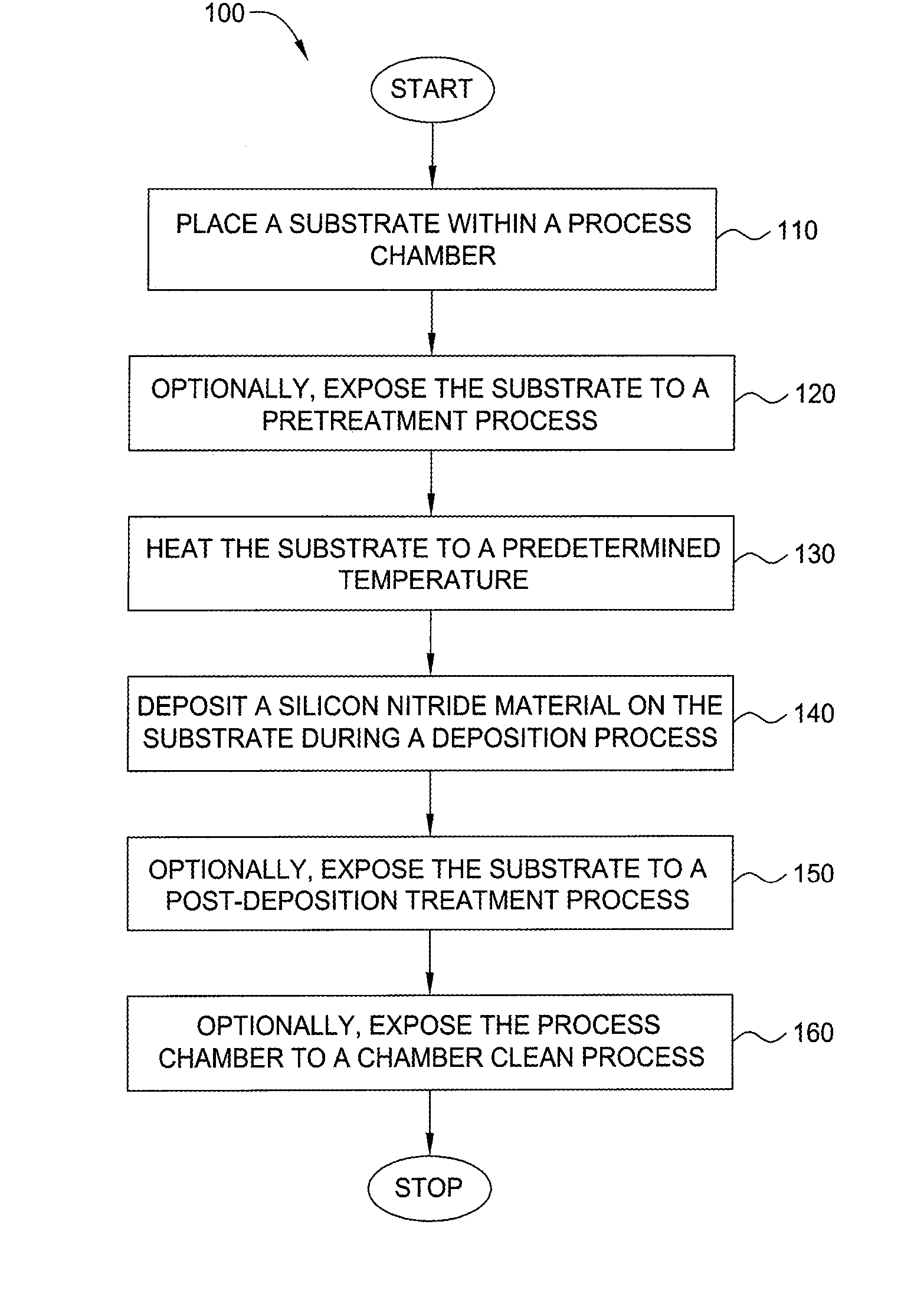

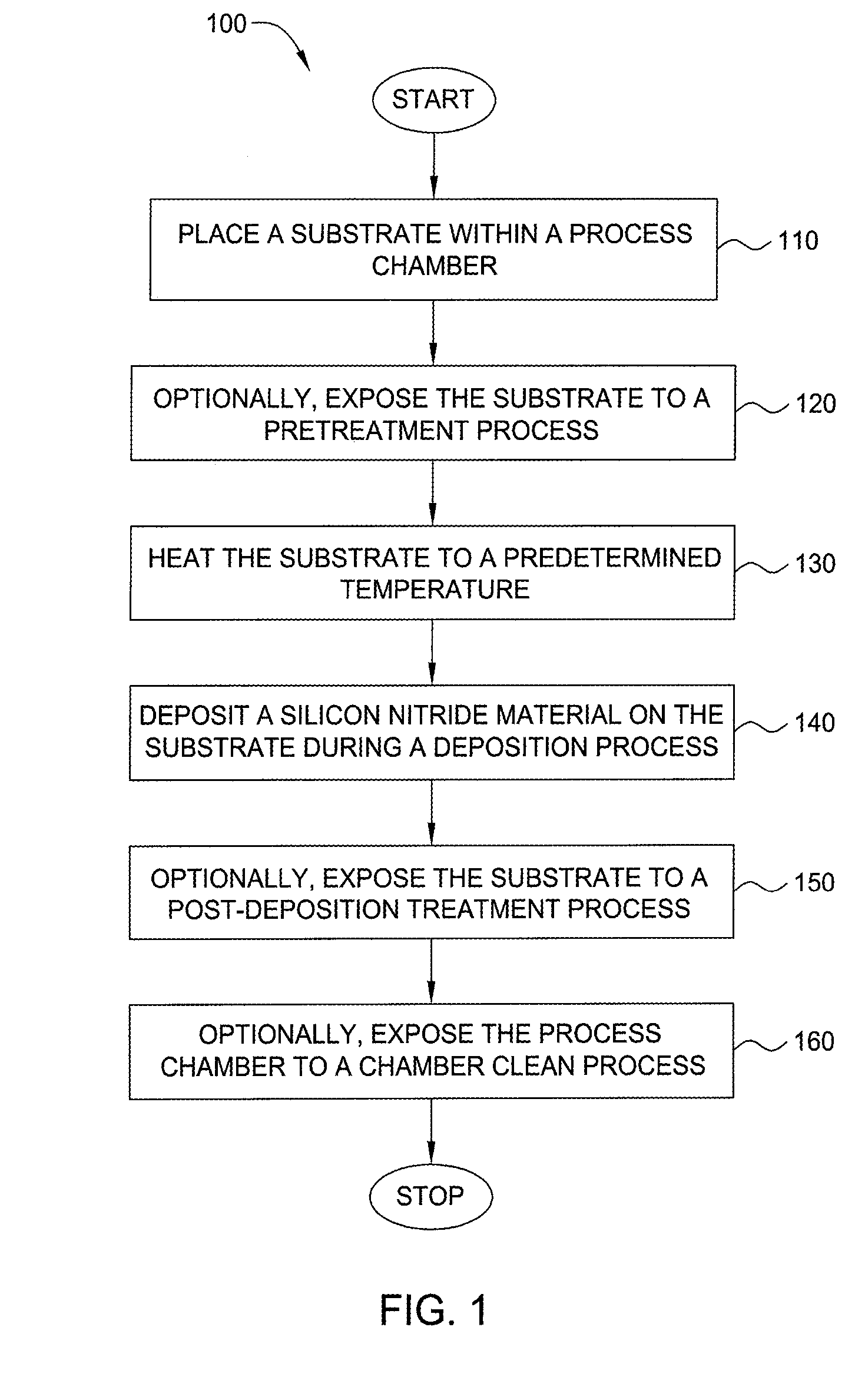

Method for forming silicon-containing materials during a photoexcitation deposition process

InactiveUS20060286774A1Enhance chamber cleaning processHigh surface energyPolycrystalline material growthSemiconductor/solid-state device manufacturingVolatilesSilicon oxide

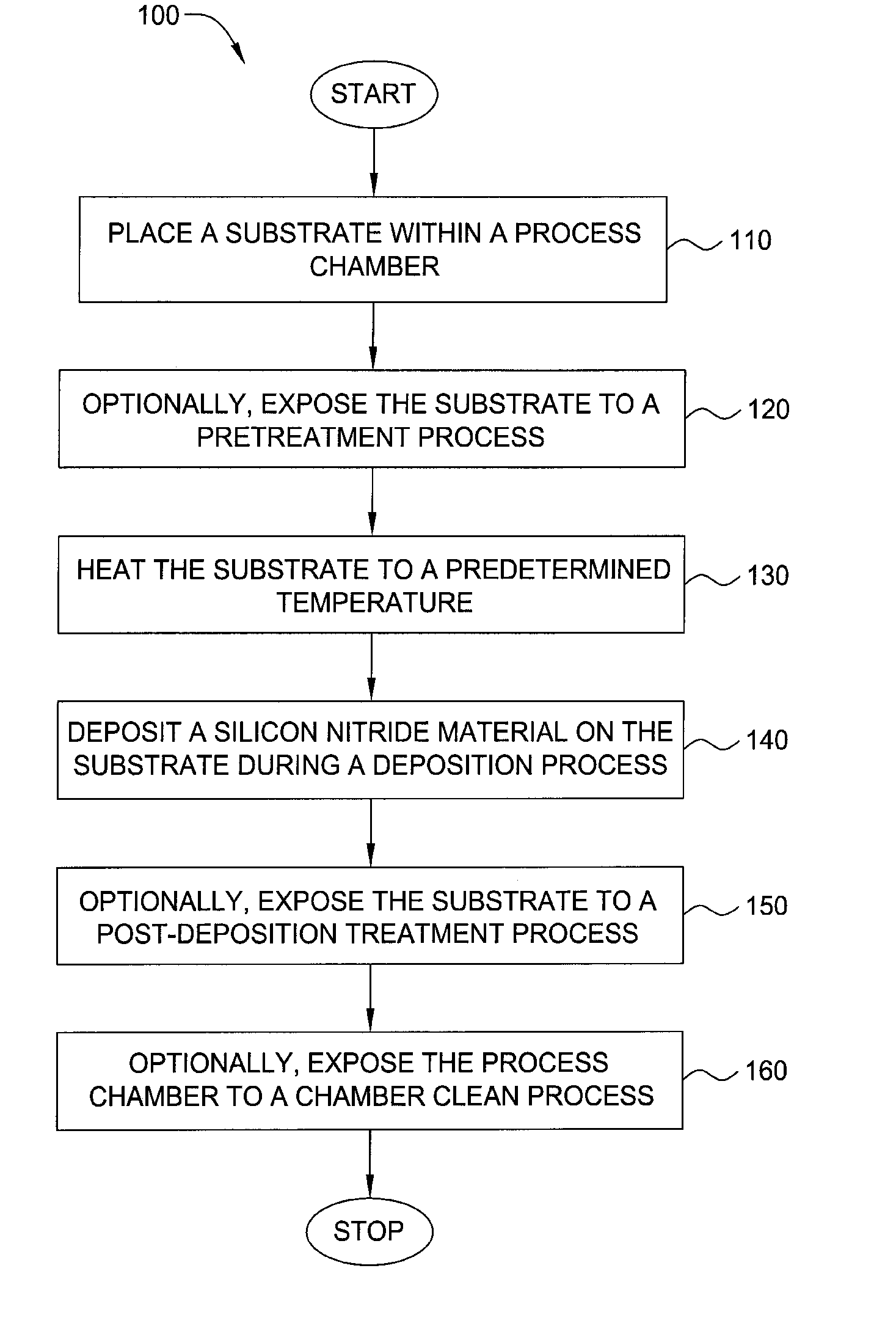

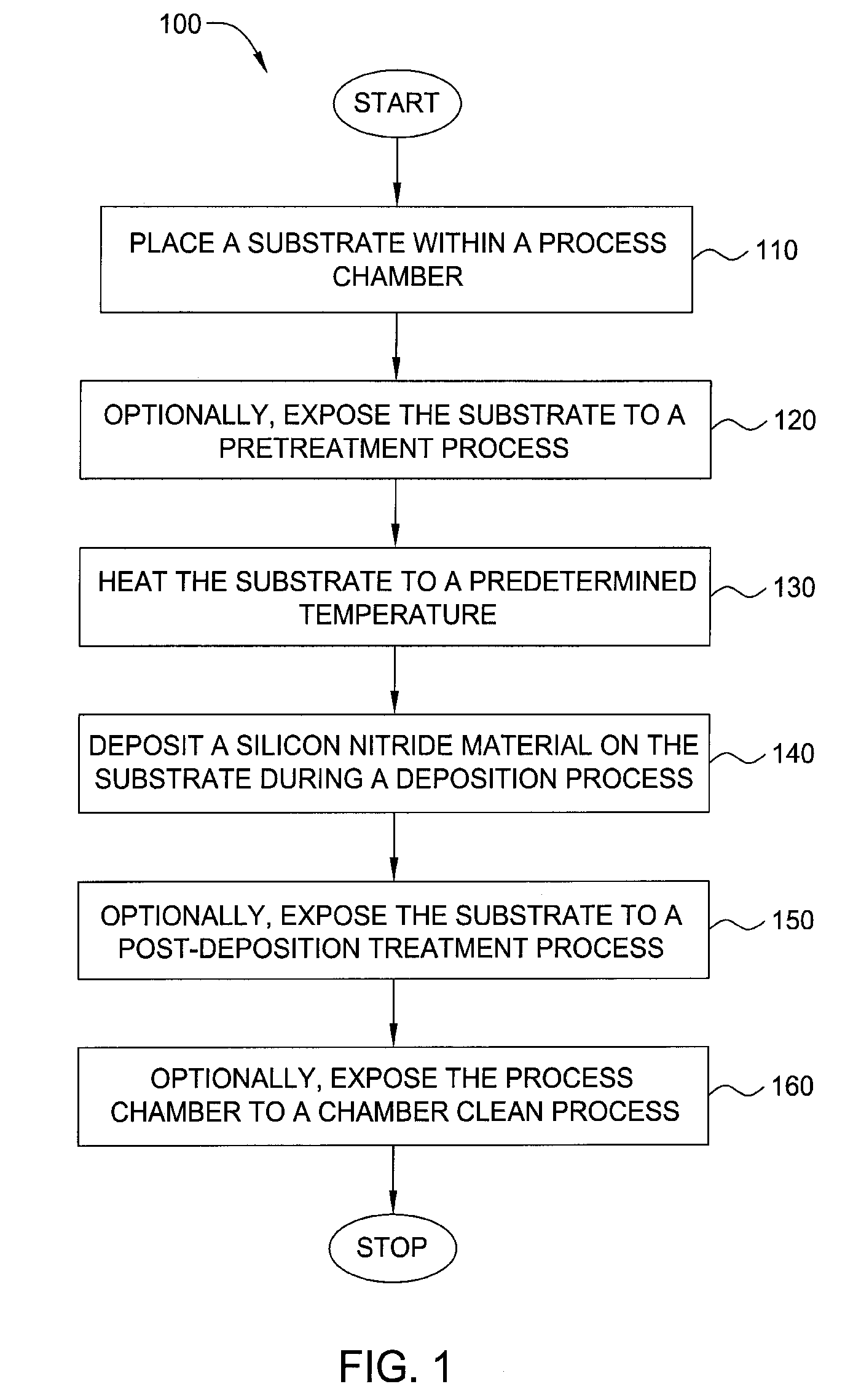

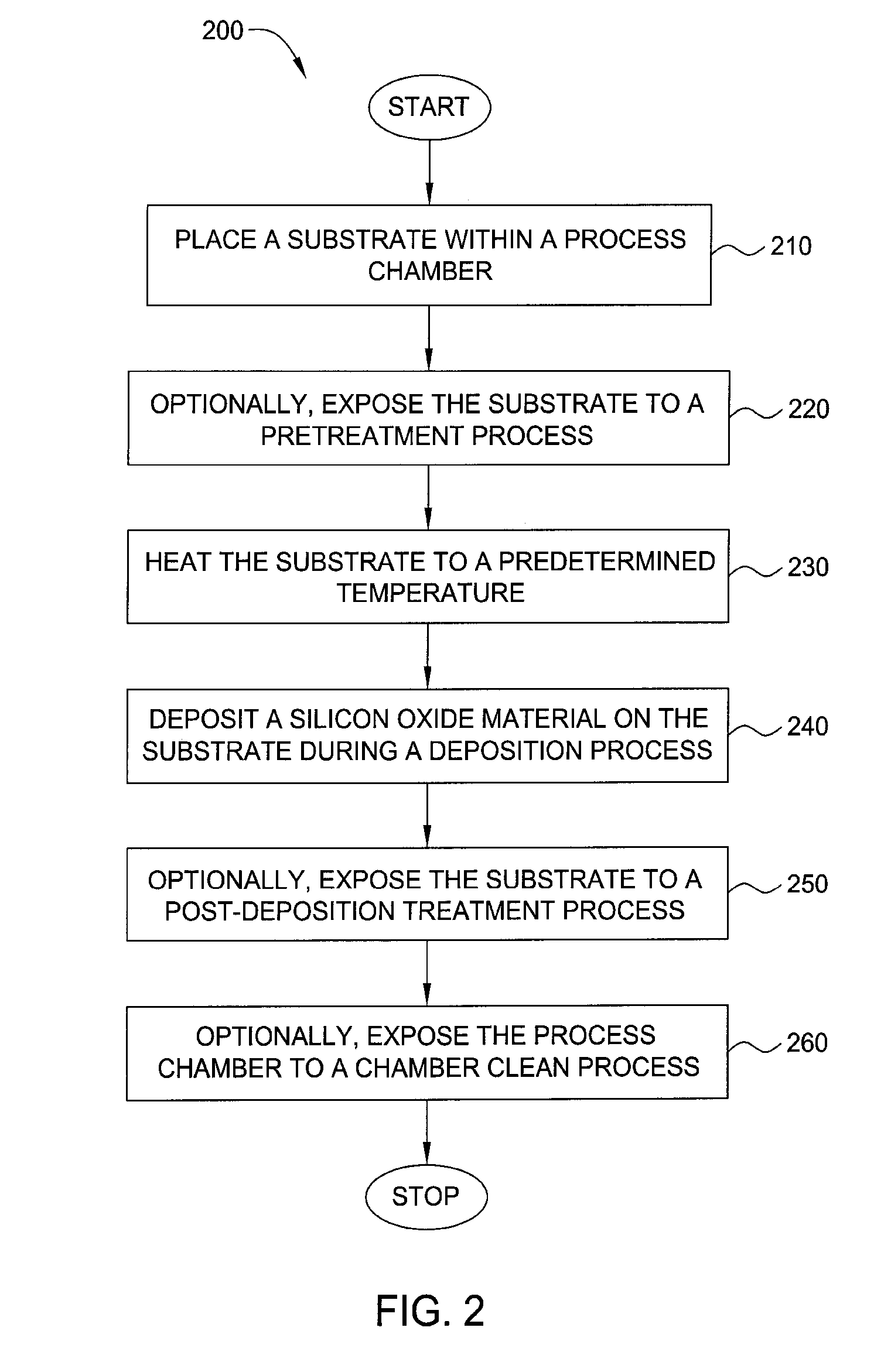

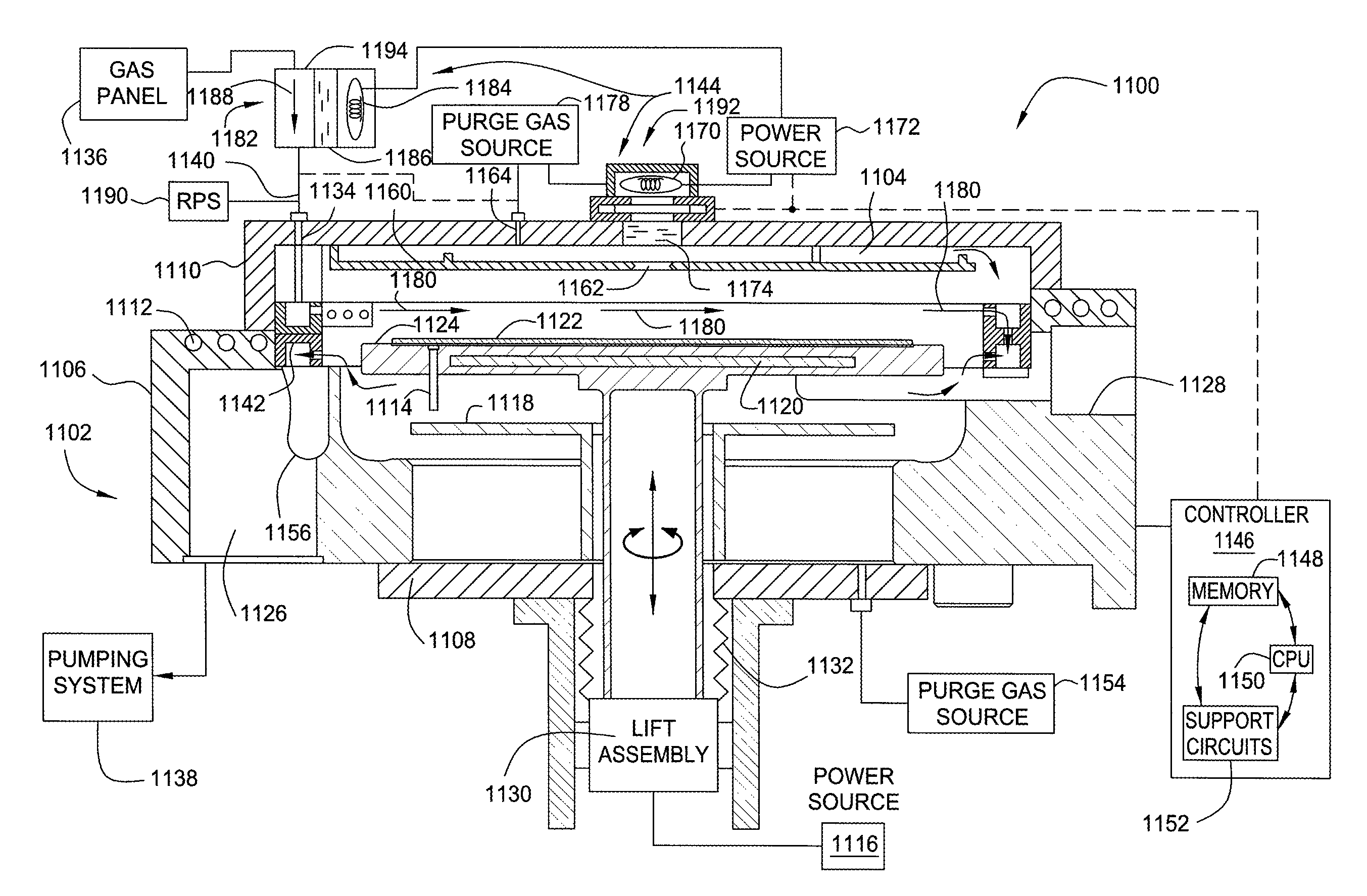

Embodiments of the invention generally provide a method for depositing films or layers using a UV source during a photoexcitation process. The films are deposited on a substrate and usually contain a material, such as silicon (e.g., epitaxy, crystalline, microcrystalline, polysilicon, or amorphous), silicon oxide, silicon nitride, silicon oxynitride, or other silicon-containing materials. The photoexcitation process may expose the substrate and / or gases to an energy beam or flux prior to, during, or subsequent a deposition process. Therefore, the photoexcitation process may be used to pre-treat or post-treat the substrate or material, to deposit the silicon-containing material, and to enhance chamber cleaning processes. Attributes of the method that are enhanced by the UV photoexcitation process include removing native oxides prior to deposition, removing volatiles from deposited films, increasing surface energy of the deposited films, increasing the excitation energy of precursors, reducing deposition time, and reducing deposition temperature.

Owner:APPLIED MATERIALS INC

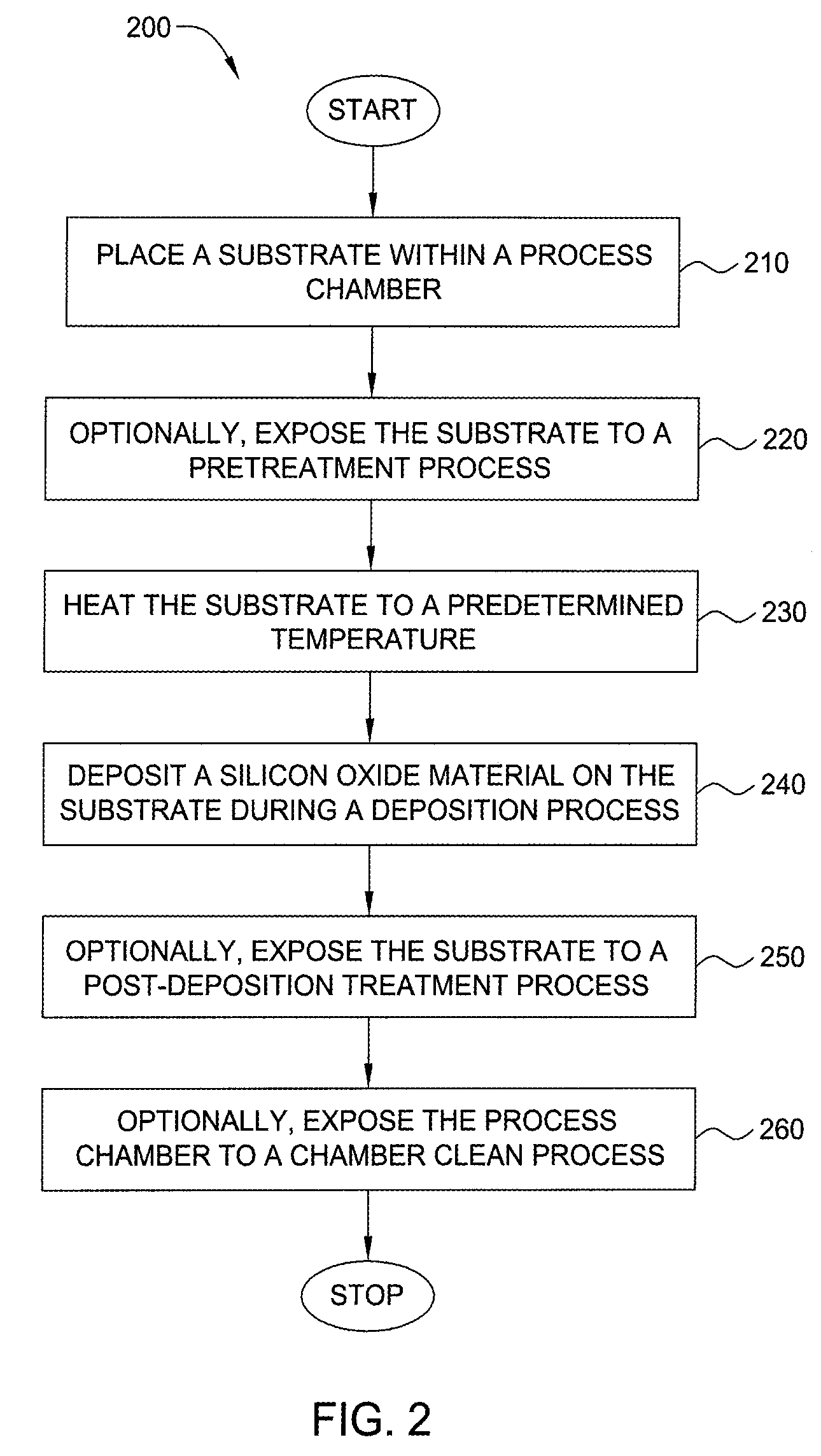

Method for forming silicon-containing materials during a photoexcitation deposition process

InactiveUS7651955B2Easy to cleanHigh surface energyPolycrystalline material growthSemiconductor/solid-state device manufacturingAutoxidationDeposition temperature

Embodiments of the invention generally provide a method for depositing films or layers using a UV source during a photoexcitation process. The films are deposited on a substrate and usually contain a material, such as silicon (e.g., epitaxy, crystalline, microcrystalline, polysilicon, or amorphous), silicon oxide, silicon nitride, silicon oxynitride, or other silicon-containing materials. The photoexcitation process may expose the substrate and / or gases to an energy beam or flux prior to, during, or subsequent a deposition process. Therefore, the photoexcitation process may be used to pre-treat or post-treat the substrate or material, to deposit the silicon-containing material, and to enhance chamber cleaning processes. Attributes of the method that are enhanced by the UV photoexcitation process include removing native oxides prior to deposition, removing volatiles from deposited films, increasing surface energy of the deposited films, increasing the excitation energy of precursors, reducing deposition time, and reducing deposition temperature.

Owner:APPLIED MATERIALS INC

Method for forming silicon-containing materials during a photoexcitation deposition process

InactiveUS7648927B2Easy to cleanHigh surface energyPolycrystalline material growthSemiconductor/solid-state device manufacturingAutoxidationDeposition temperature

Embodiments of the invention generally provide a method for depositing films or layers using a UV source during a photoexcitation process. The films are deposited on a substrate and usually contain a material, such as silicon (e.g., epitaxy, crystalline, microcrystalline, polysilicon, or amorphous), silicon oxide, silicon nitride, silicon oxynitride, or other silicon-containing materials. The photoexcitation process may expose the substrate and / or gases to an energy beam or flux prior to, during, or subsequent a deposition process. Therefore, the photoexcitation process may be used to pre-treat or post-treat the substrate or material, to deposit the silicon-containing material, and to enhance chamber cleaning processes. Attributes of the method that are enhanced by the UV photoexcitation process include removing native oxides prior to deposition, removing volatiles from deposited films, increasing surface energy of the deposited films, increasing the excitation energy of precursors, reducing deposition time, and reducing deposition temperature.

Owner:APPLIED MATERIALS INC

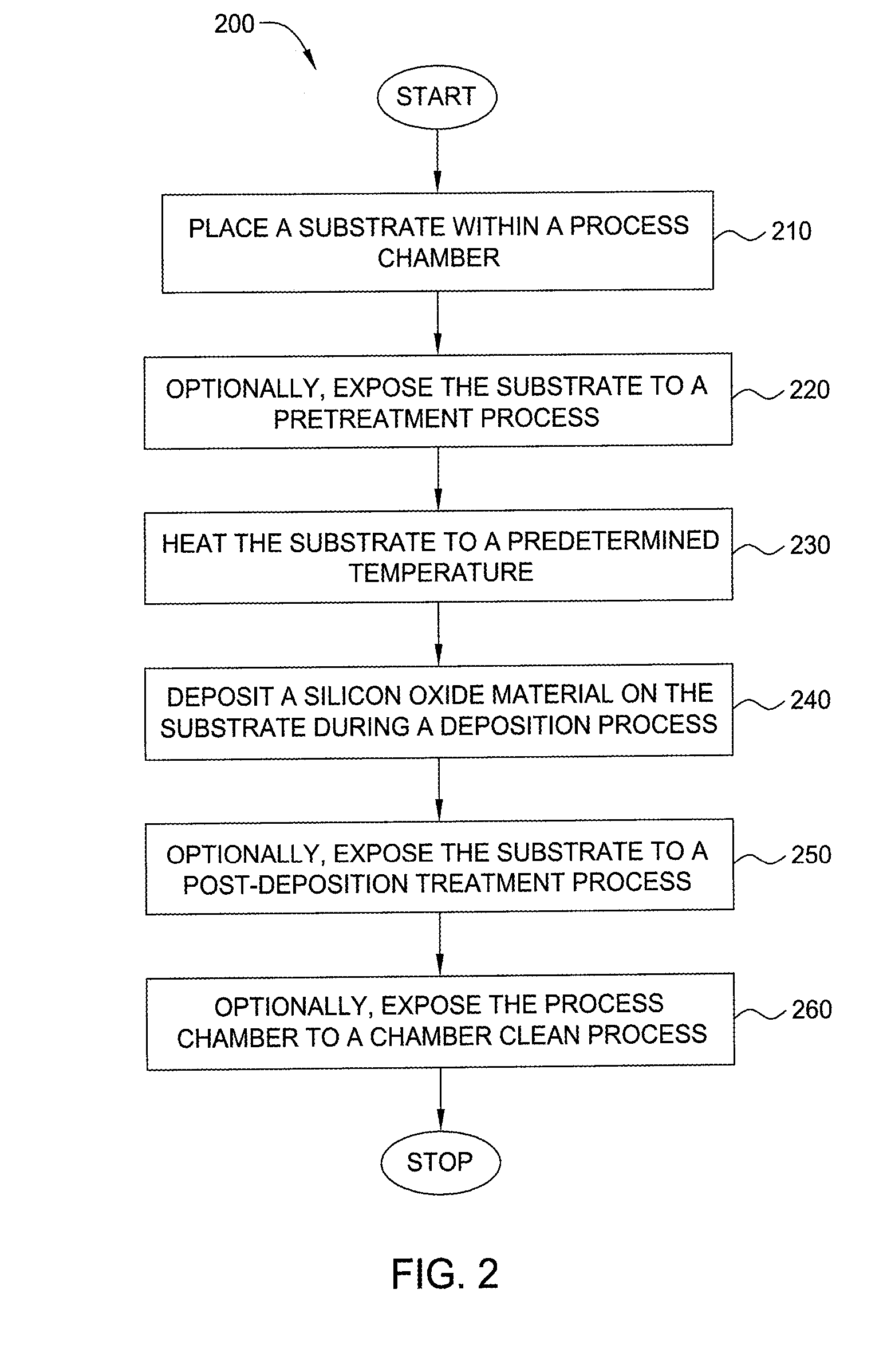

Method for forming silicon-containing materials during a photoexcitation deposition process

InactiveUS20060286776A1Enhance chamber cleaning processHigh surface energyPolycrystalline material growthSemiconductor/solid-state device manufacturingVolatilesSilicon oxide

Embodiments of the invention generally provide a method for depositing films or layers using a UV source during a photoexcitation process. The films are deposited on a substrate and usually contain a material, such as silicon (e.g., epitaxy, crystalline, microcrystalline, polysilicon, or amorphous), silicon oxide, silicon nitride, silicon oxynitride, or other silicon-containing materials. The photoexcitation process may expose the substrate and / or gases to an energy beam or flux prior to, during, or subsequent a deposition process. Therefore, the photoexcitation process may be used to pre-treat or post-treat the substrate or material, to deposit the silicon-containing material, and to enhance chamber cleaning processes. Attributes of the method that are enhanced by the UV photoexcitation process include removing native oxides prior to deposition, removing volatiles from deposited films, increasing surface energy of the deposited films, increasing the excitation energy of precursors, reducing deposition time, and reducing deposition temperature.

Owner:APPLIED MATERIALS INC

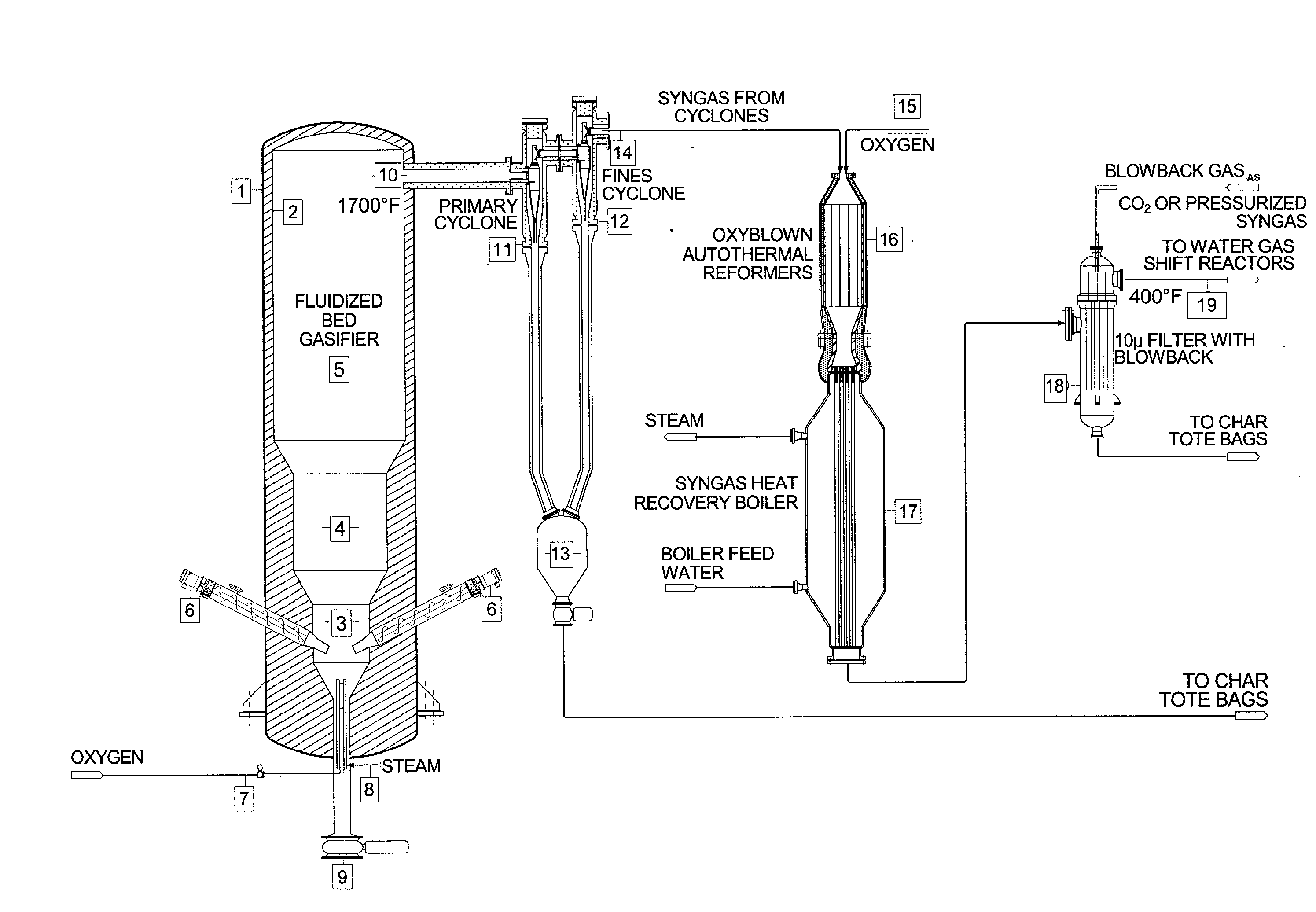

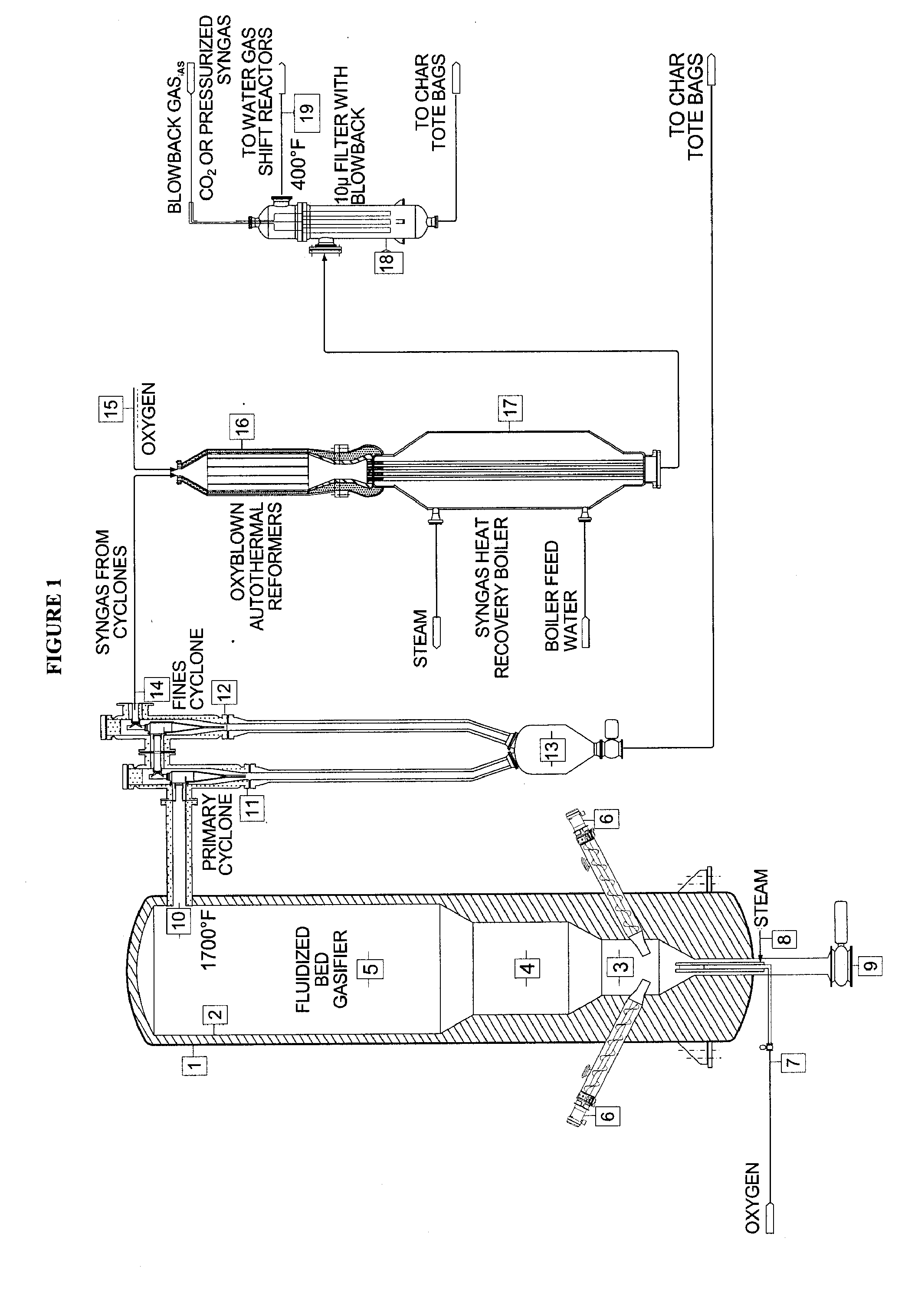

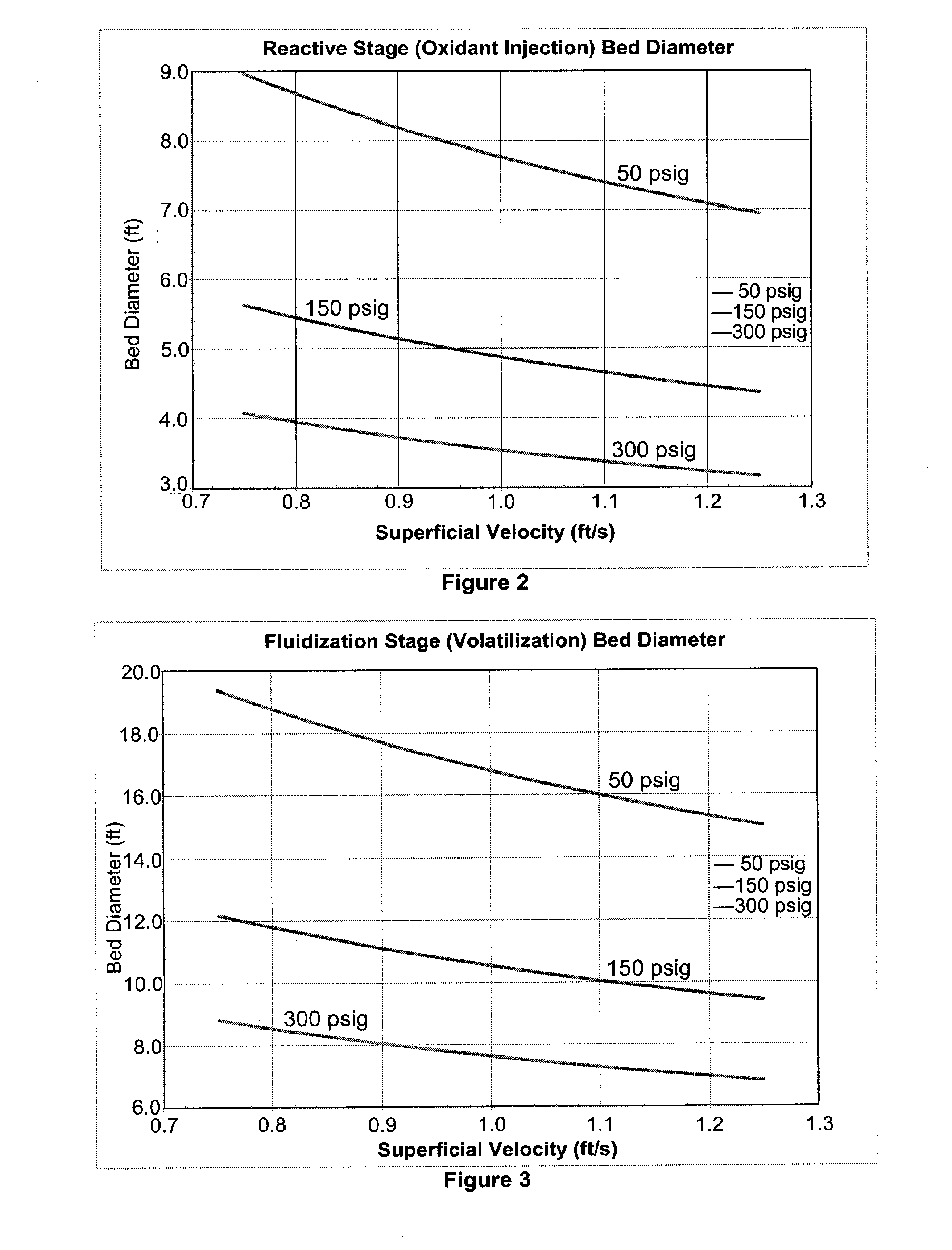

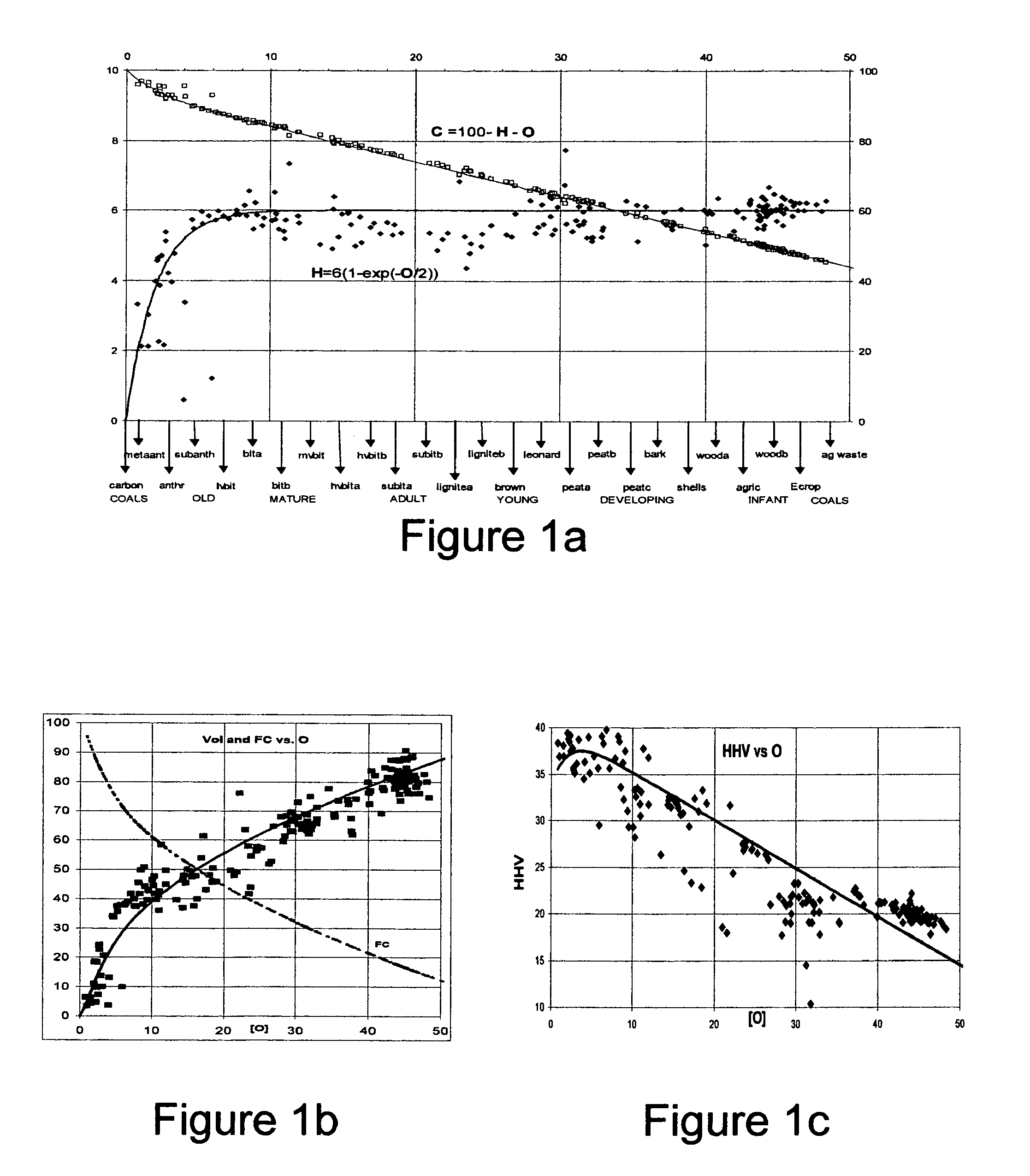

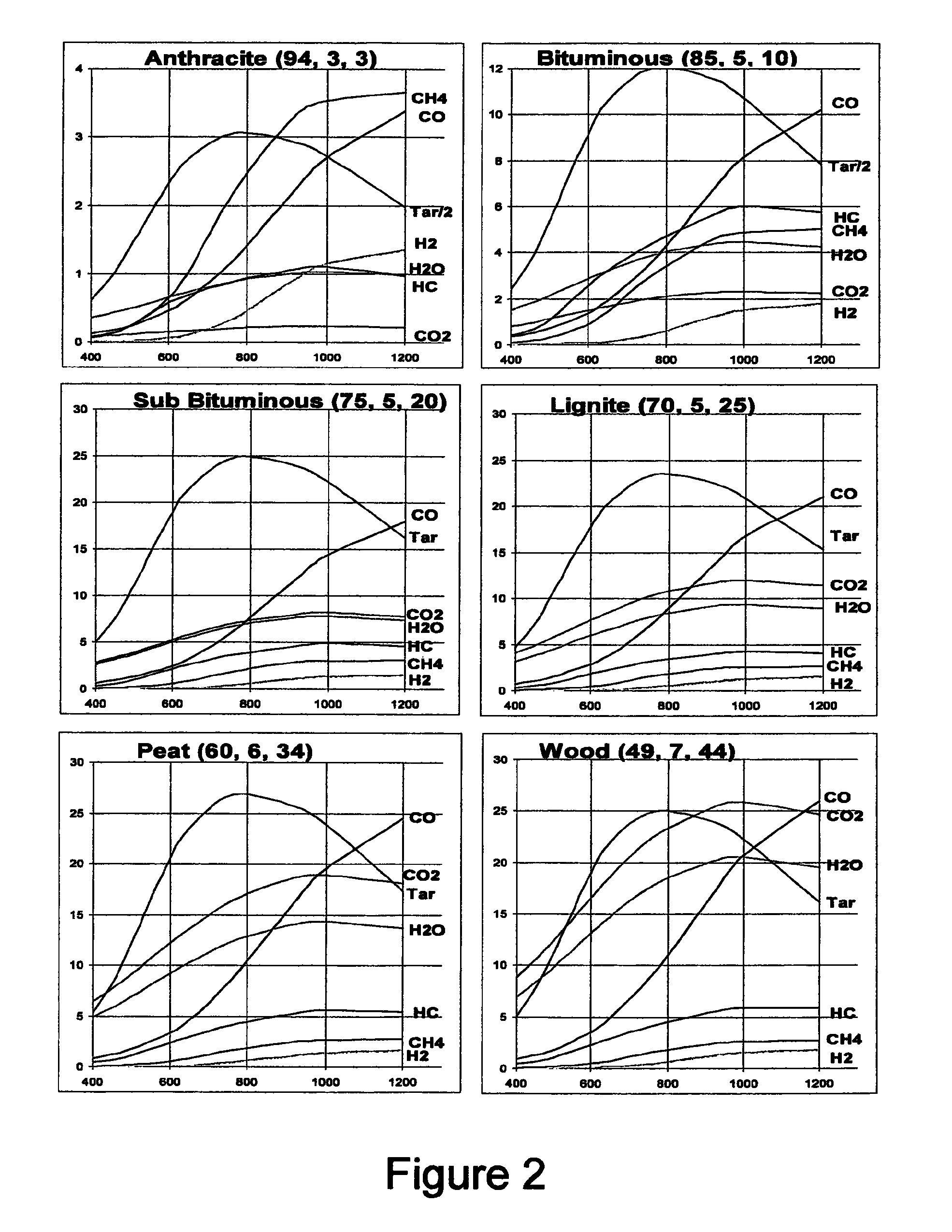

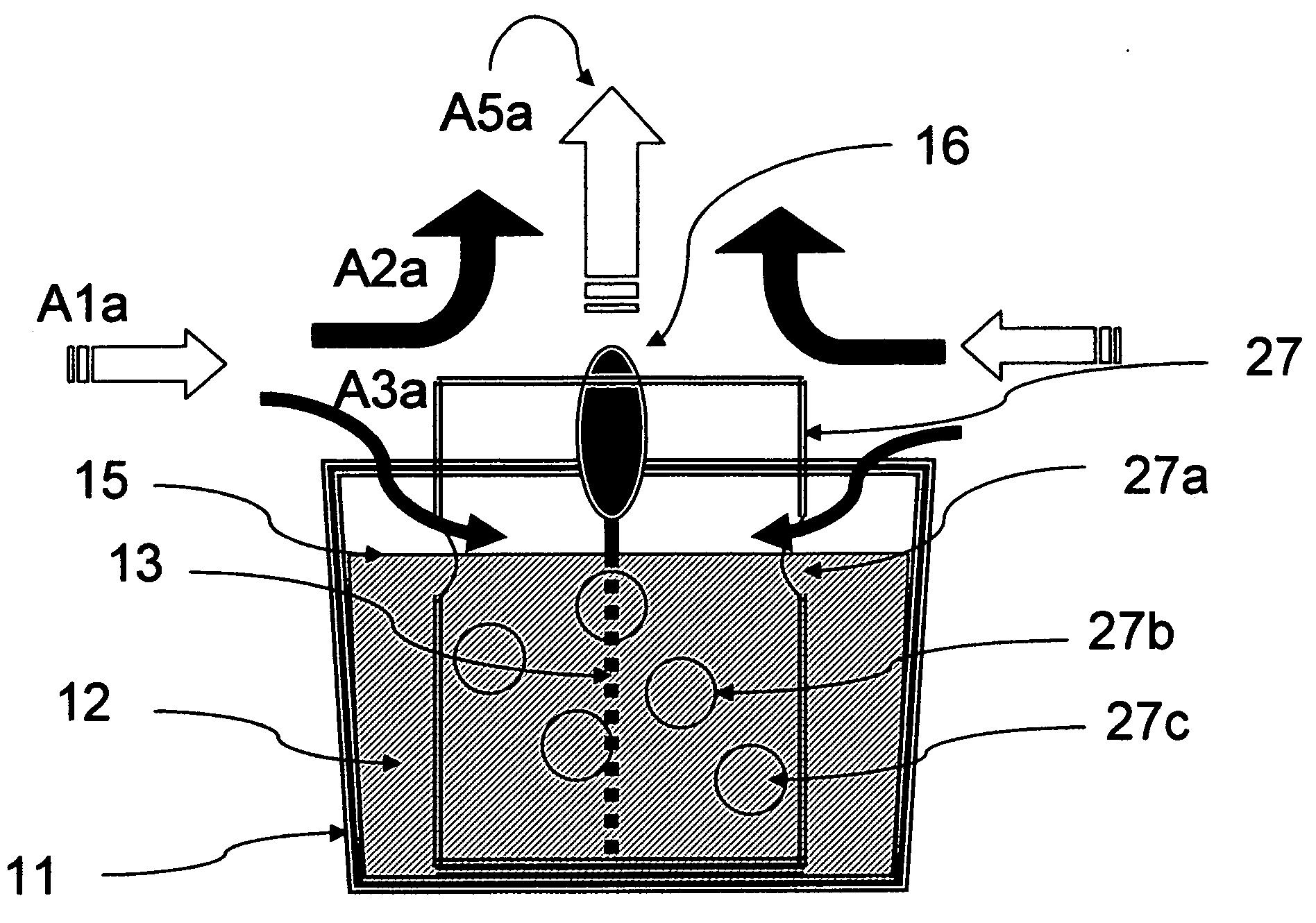

Method for converting biomass into synthesis gas using a pressurized multi-stage progressively expanding fluidized bed gasifier followed by an oxyblown autothermal reformer to reduce methane and tars

InactiveUS20100040510A1Lower Level RequirementsGasifier mechanical detailsCombustible gas catalytic treatmentSyngasFluidized bed gasifier

The invention provides systems and methods for converting biomass into syngas using a pressurized multi-stage progressively expanding fluidized bed gasifier to eliminate or reduce the formation of methane, volatiles such as BTX, and tars. The gasifier may include a reactive stage that may receive a biomass feed through a feed line and oxygen through an oxygen feed line. The gasifier may also include a fluidized bed section that may be configured to receive the reaction products from the first stage, mix them and perform fluidized bed activity. A gasifier may also have a disengagement section that may be configured to separate fluidized media and particulate matter from syngas product. A gasification system may also include oxyblown catalytic autothermal reactor and a cryogenic air separation unit.

Owner:SYNT

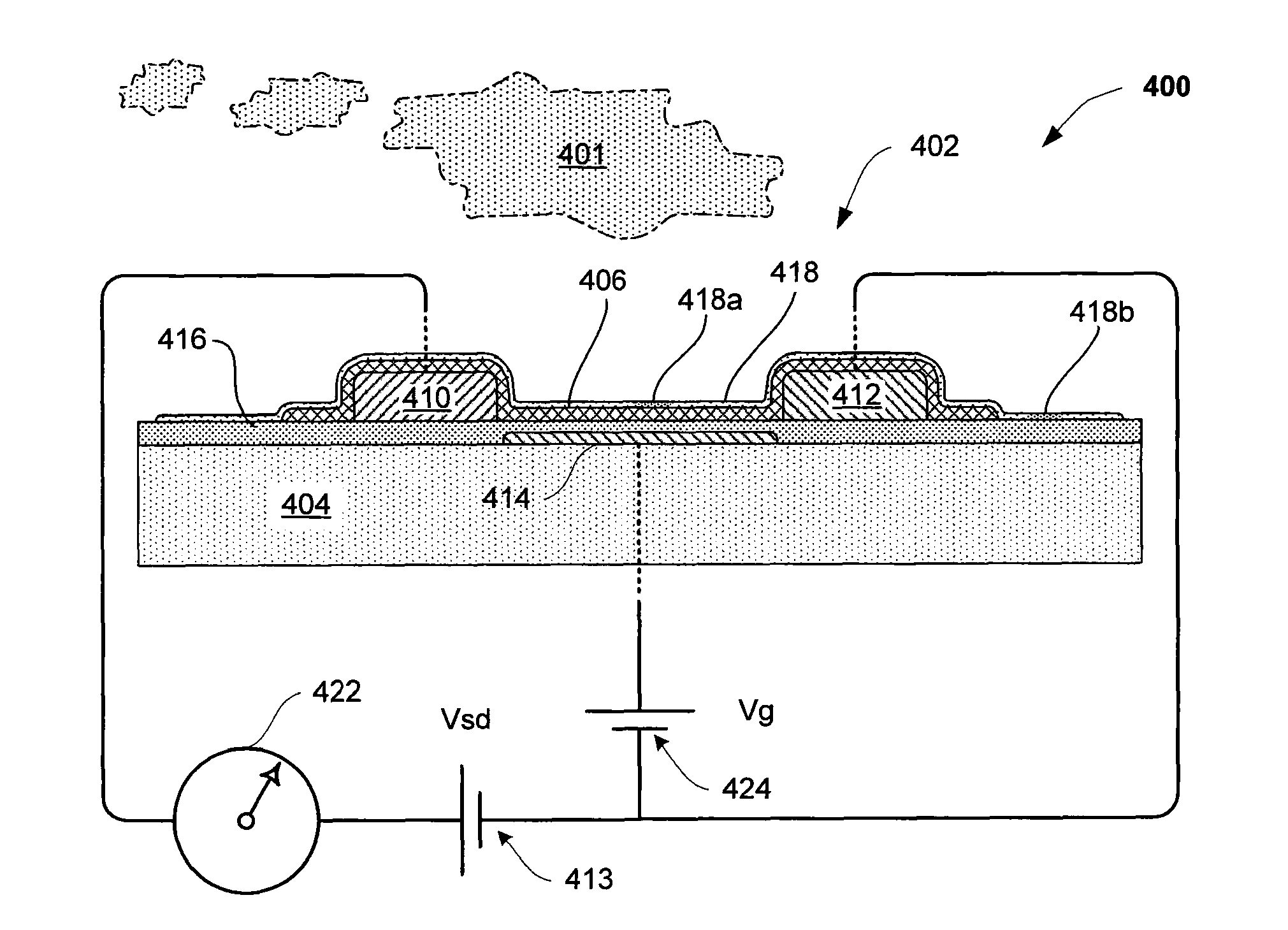

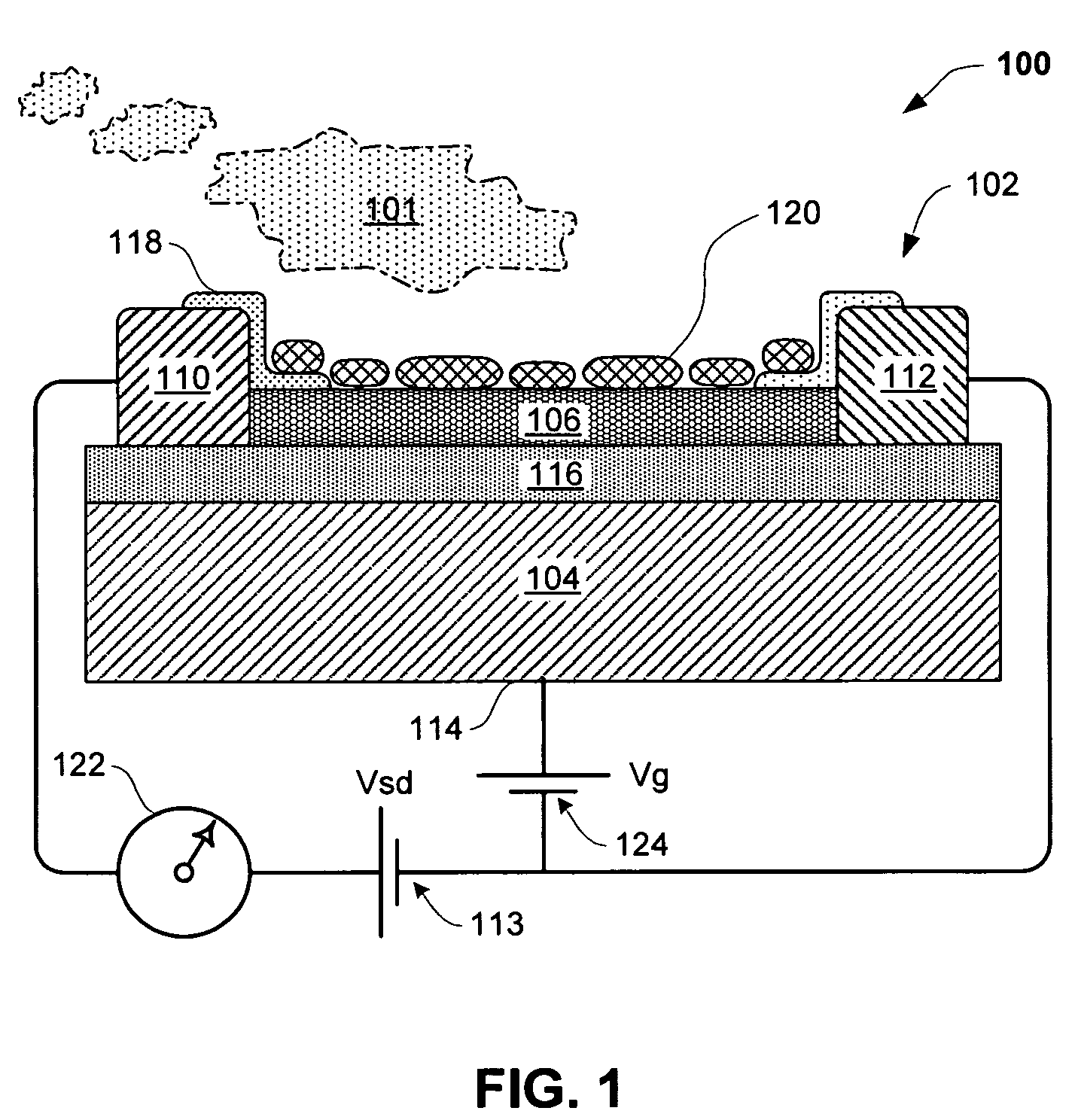

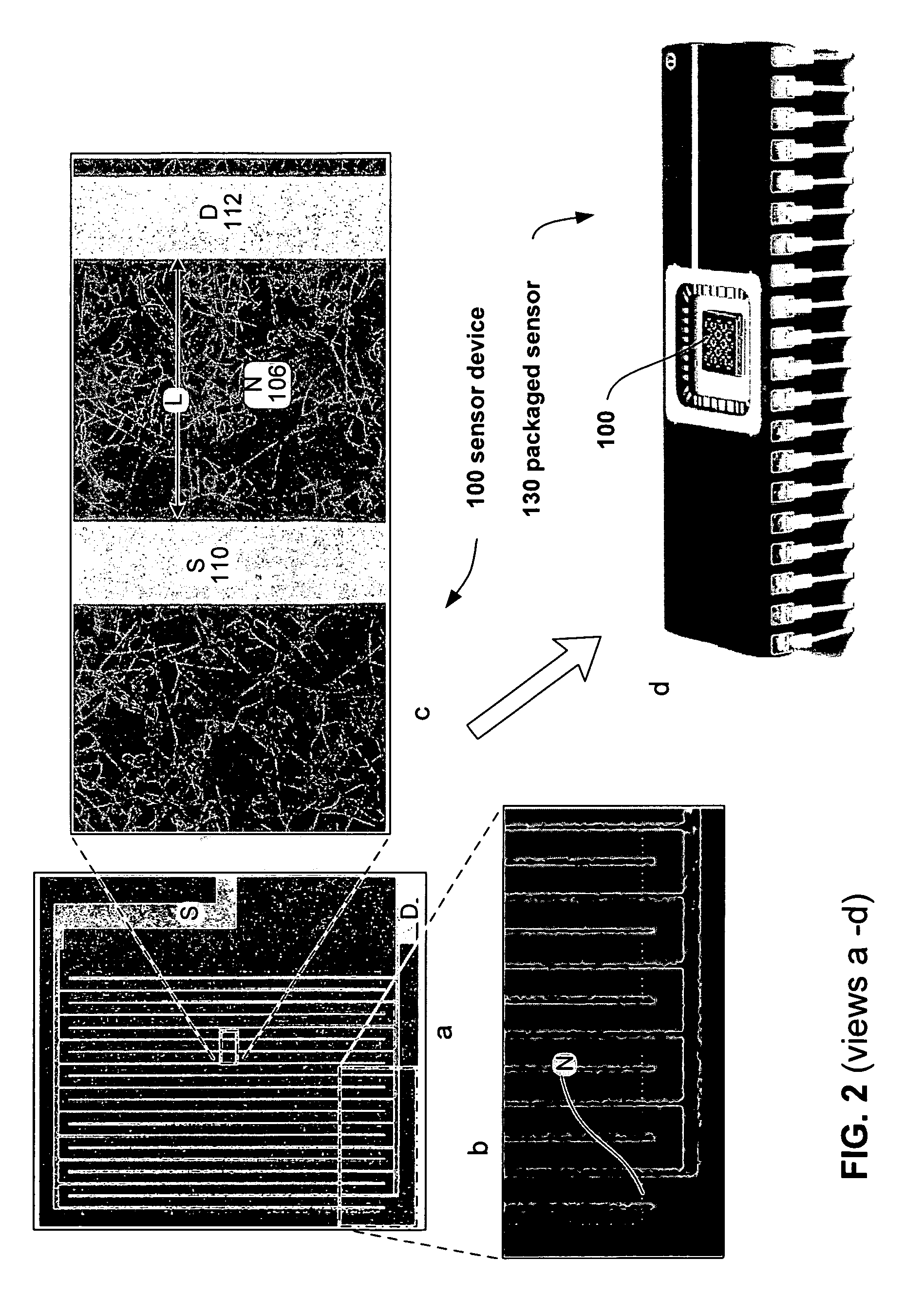

Sensor having a thin-film inhibition layer, nitric oxide converter and monitor

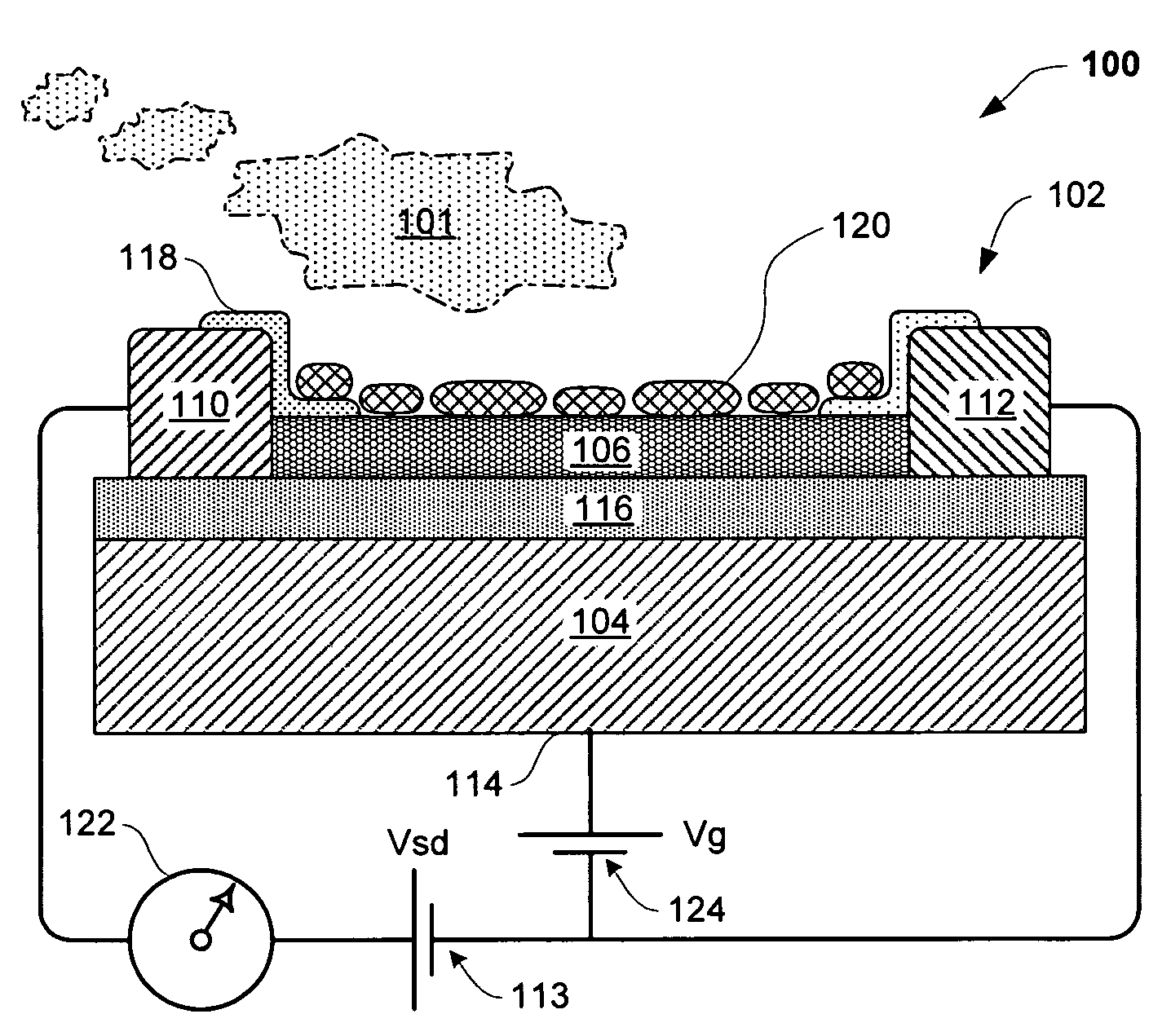

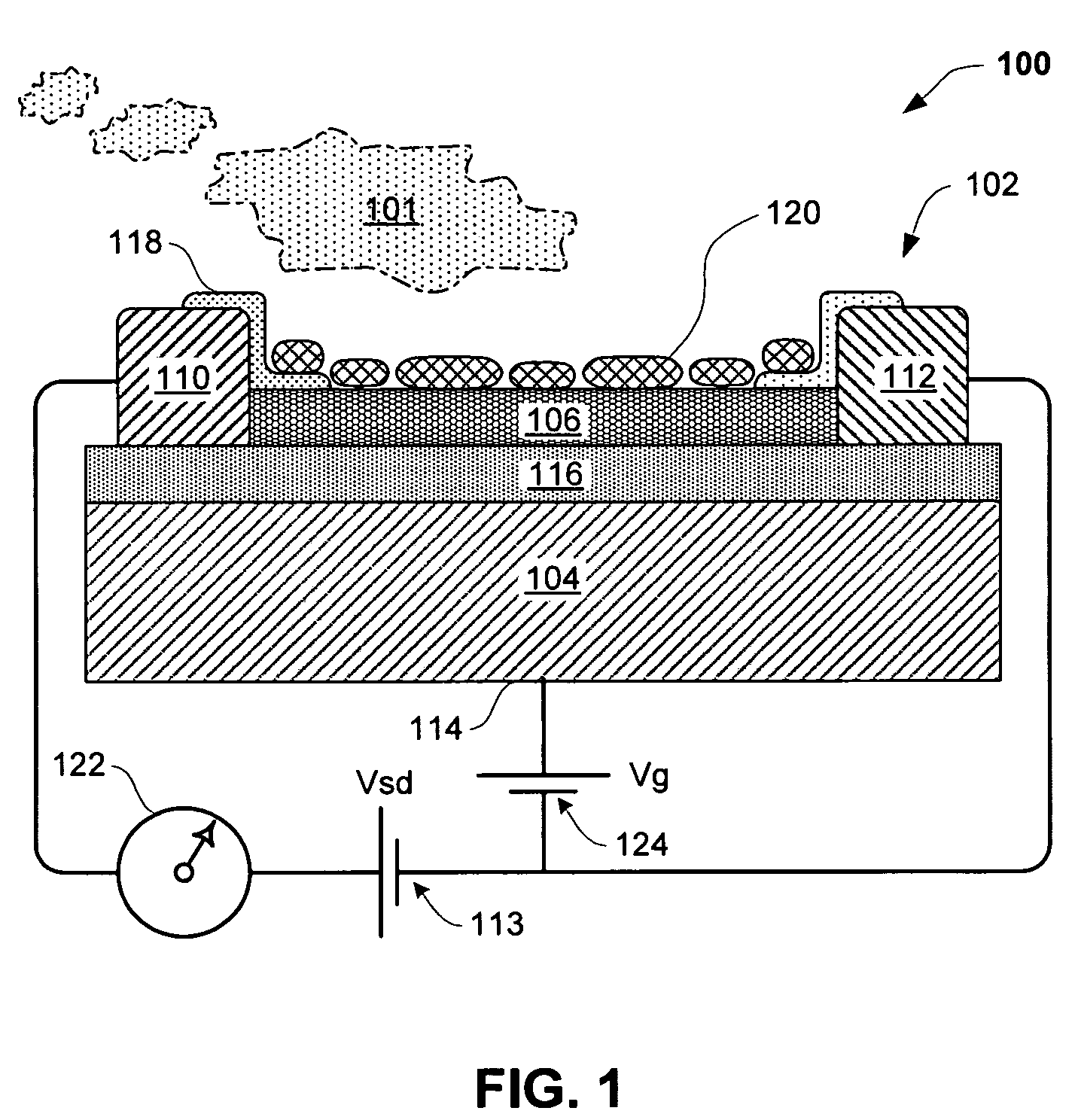

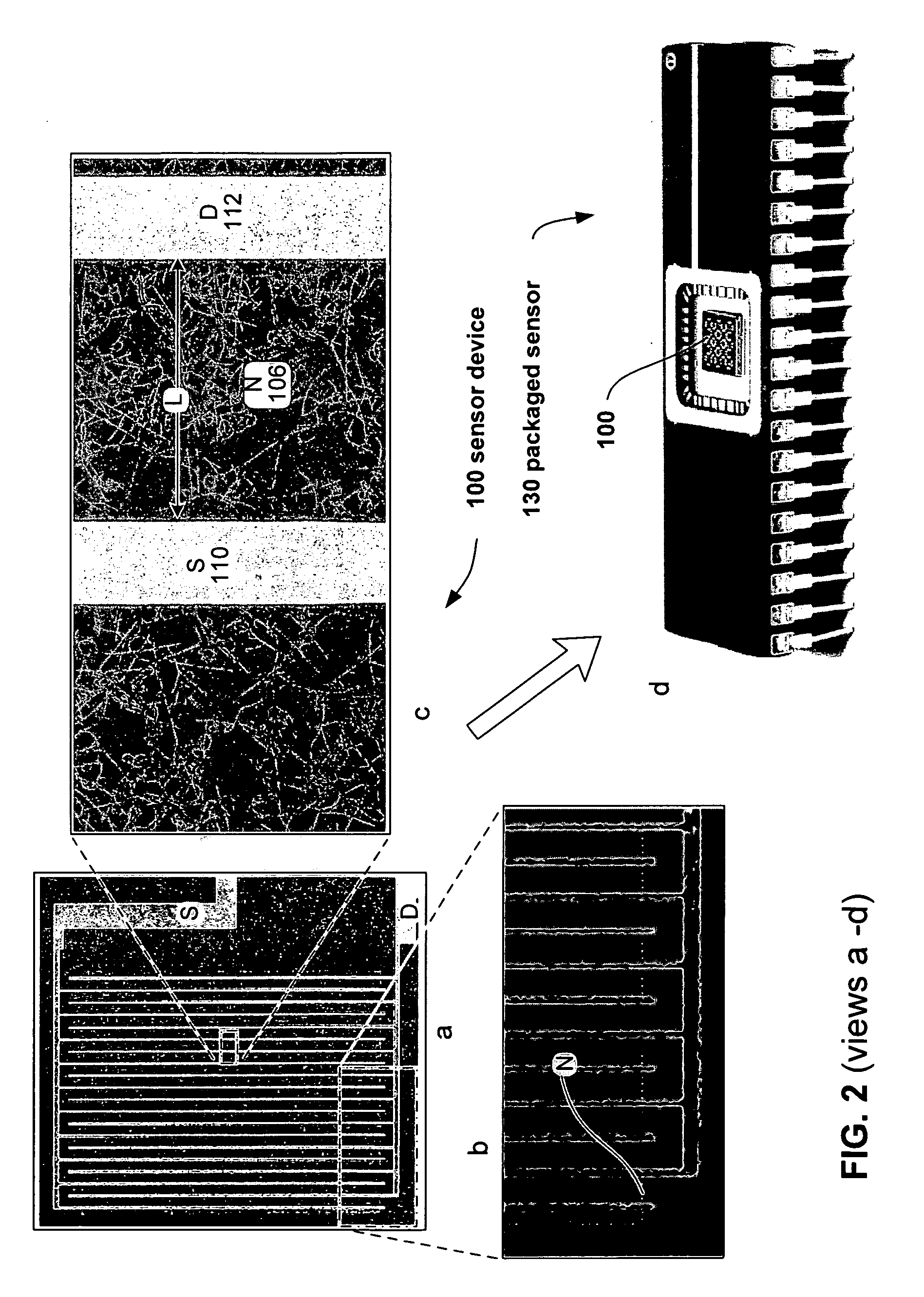

ActiveUS20080221806A1High sensitivityLarge dynamic rangeMaterial nanotechnologyTemperatue controlDiseaseVolatiles

Sensors and detection systems suitable for measuring analytes, such as biomolecule, organic and inorganic species, including environmentally and medically relevant volatiles and gases, such as NO, NO2, CO2, NH3, H2, CO and the like, are provided. Certain embodiments of nanostructured sensor systems are configured for measurement of medically important gases in breath. Applications include the measurement of endogenous nitric oxide (NO) in breath, such as for the monitoring or diagnosis of asthma and other pulmonary conditions.

Owner:NANOMIX

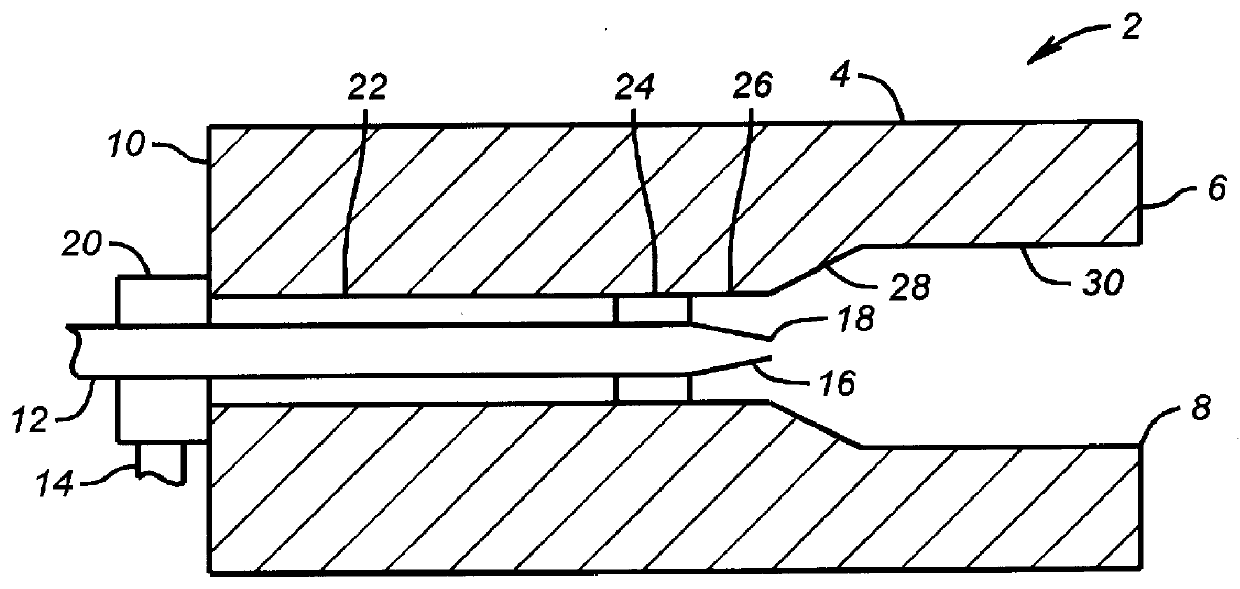

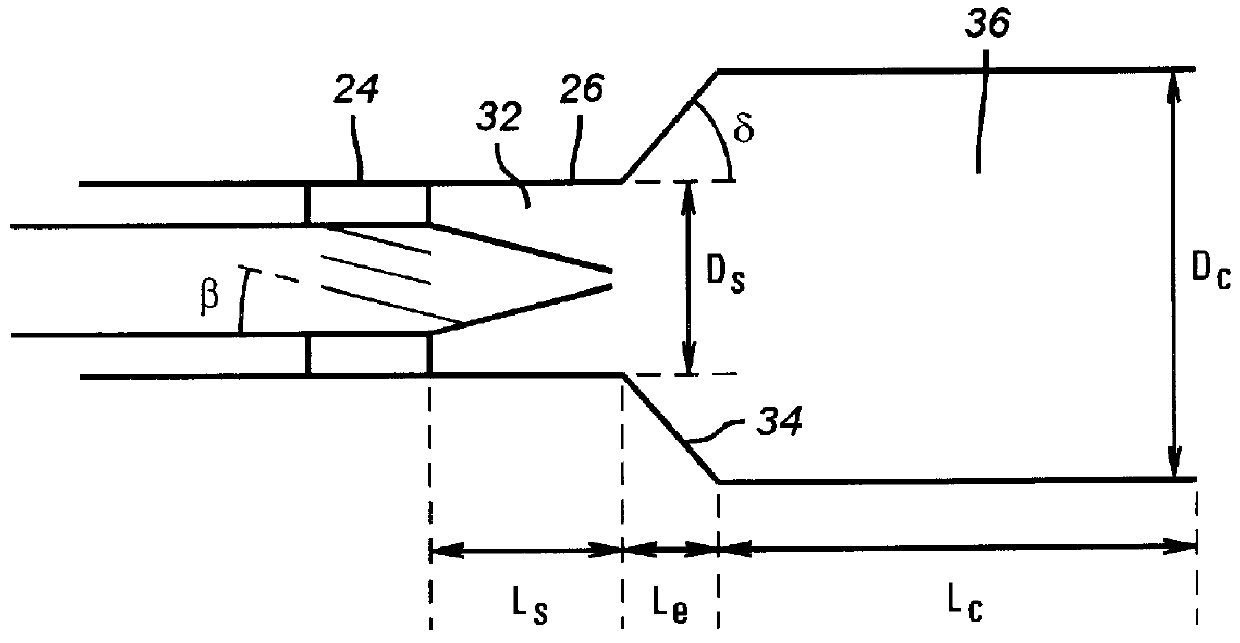

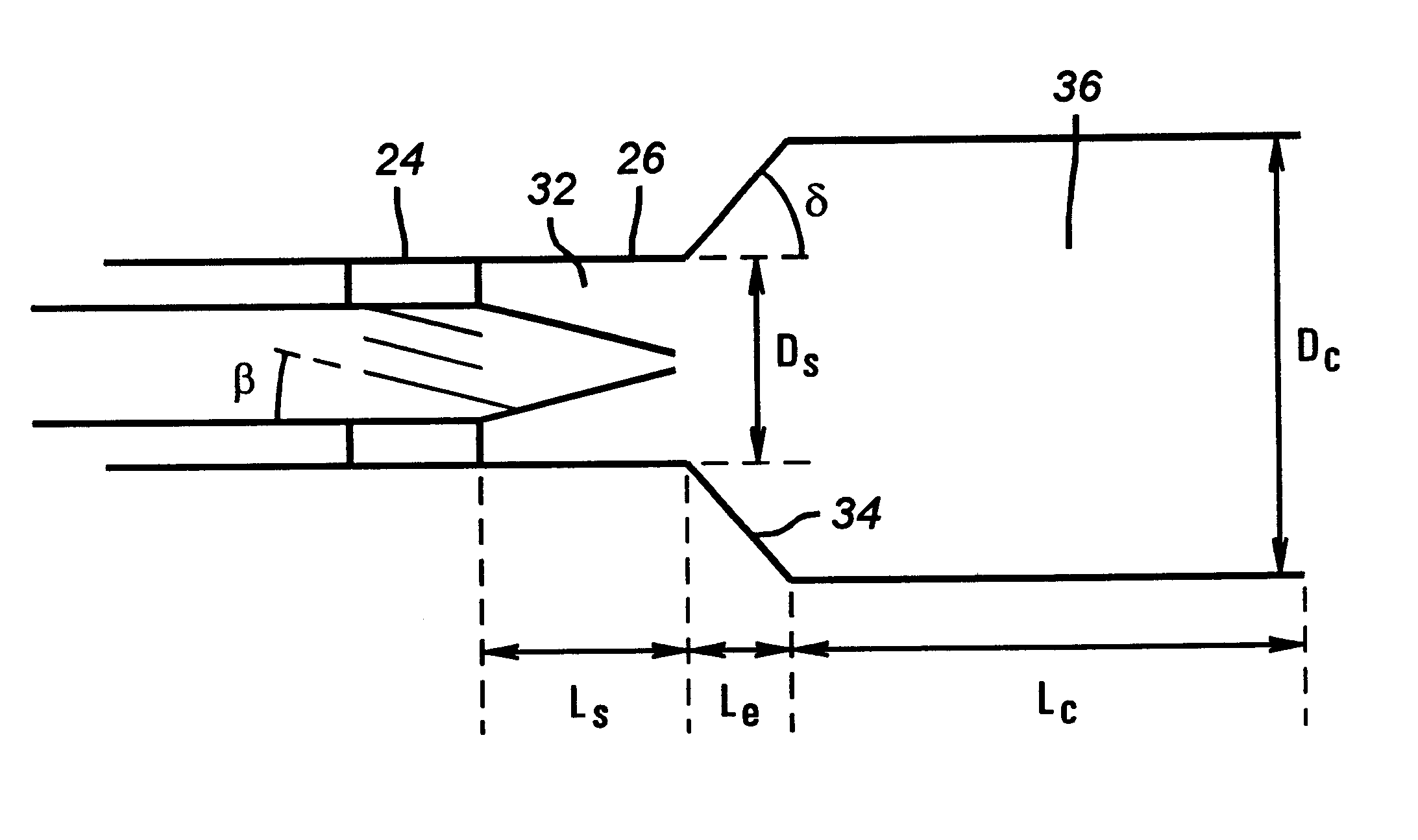

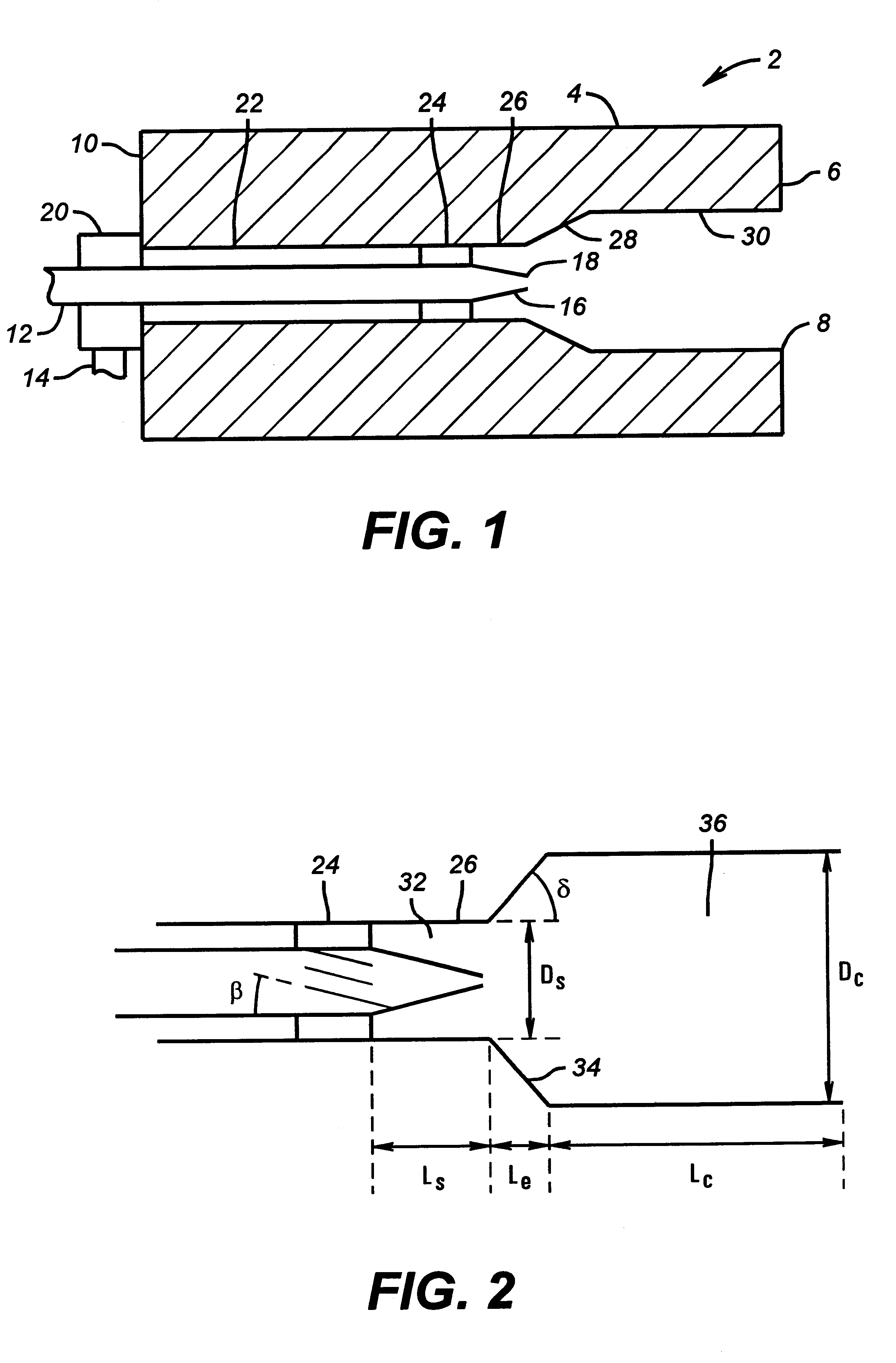

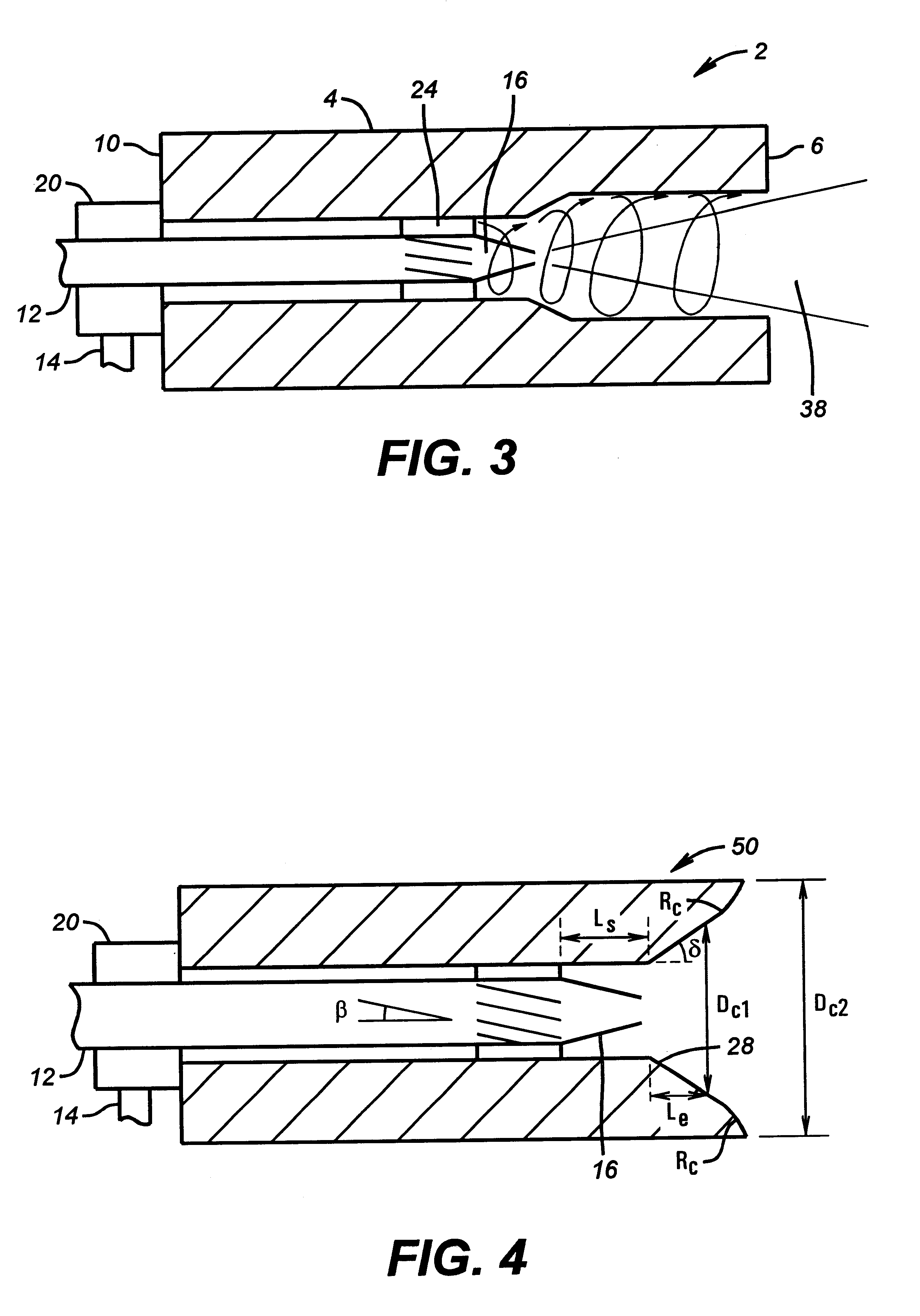

Self-cooled oxygen-fuel burner for use in high-temperature and high-particulate furnaces

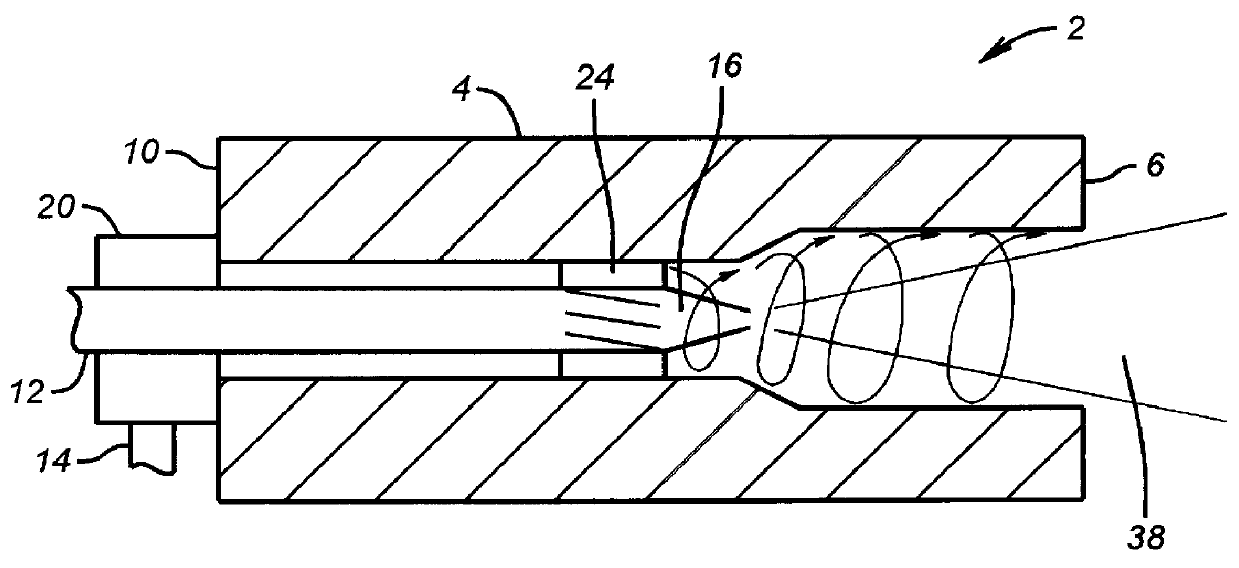

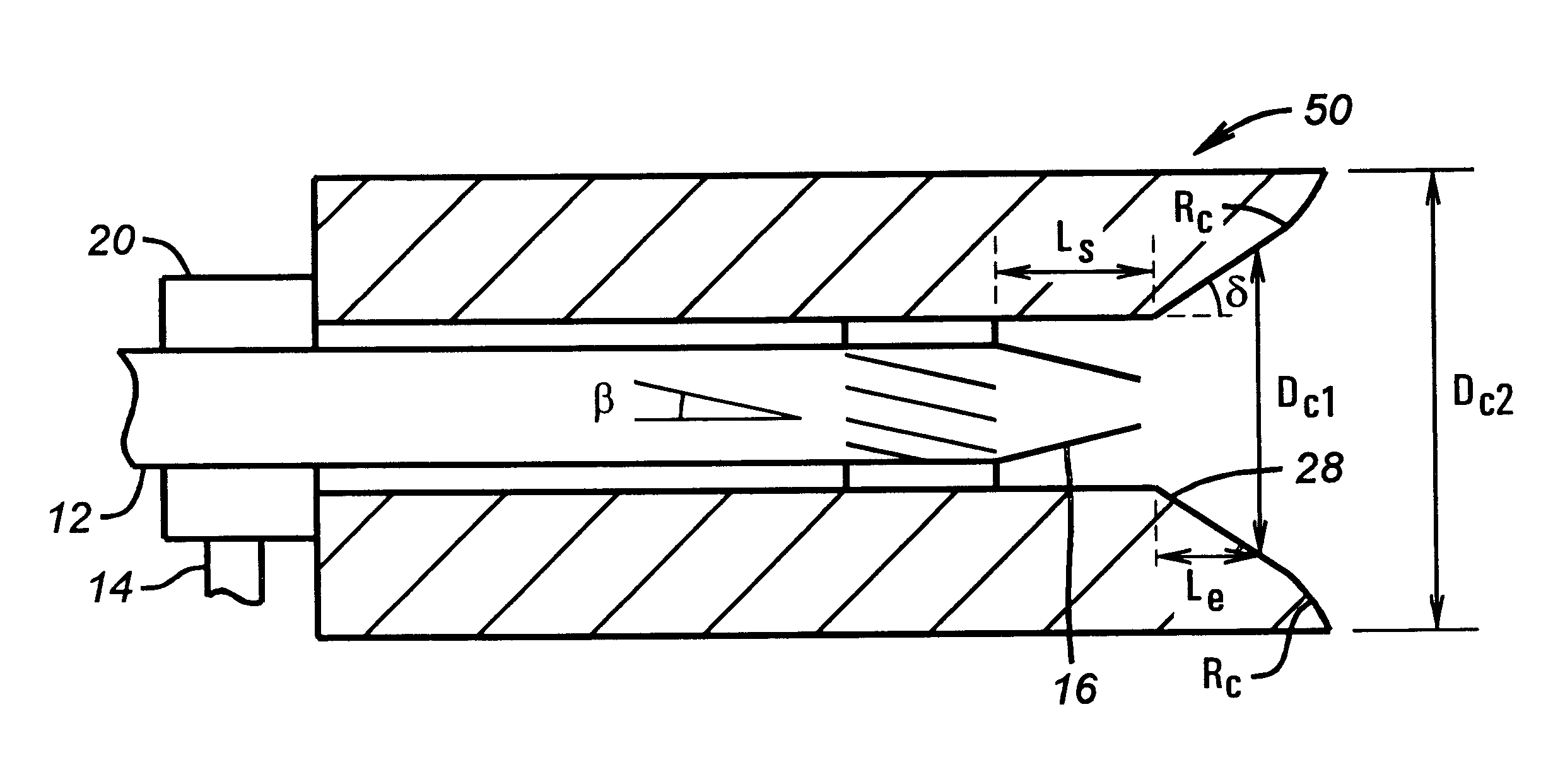

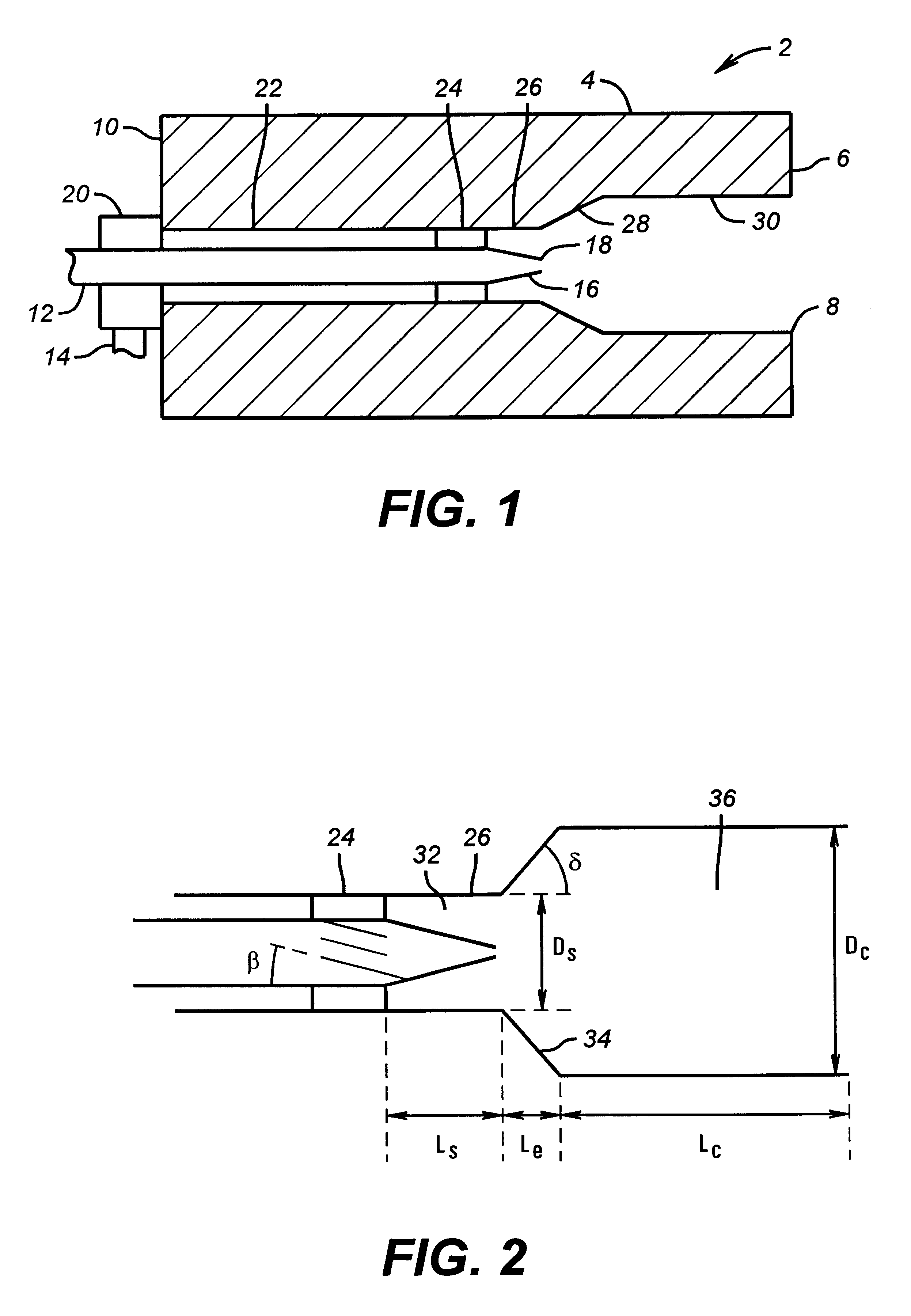

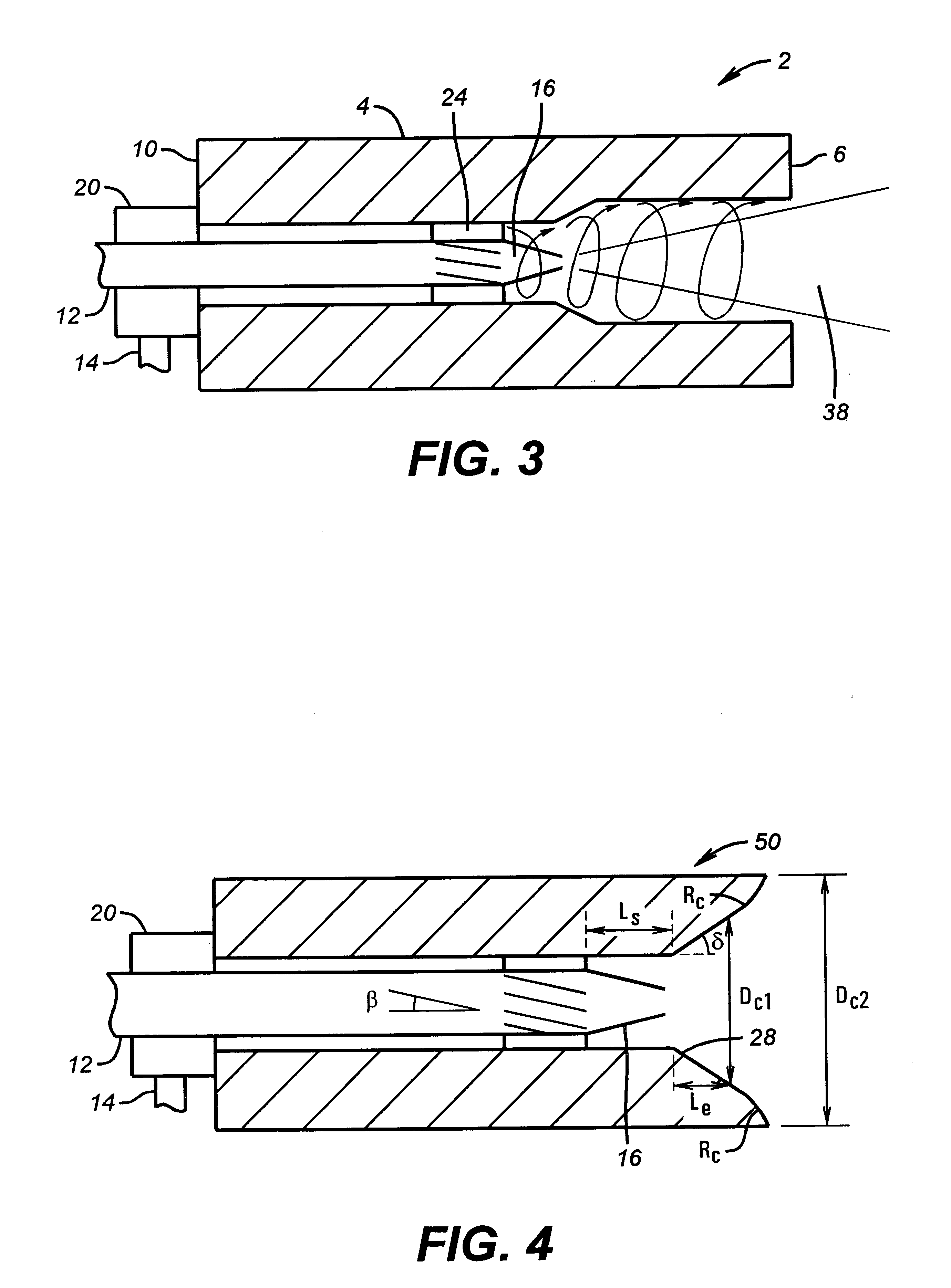

InactiveUS6123542AAvoiding particulate inspiration.TheControl expansionGlass furnace apparatusGlass melting apparatusParticulatesCombustor

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200 DEG F. to 3000 DEG F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:LAIR LIQUIDE SA POUR L ETUD ET LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

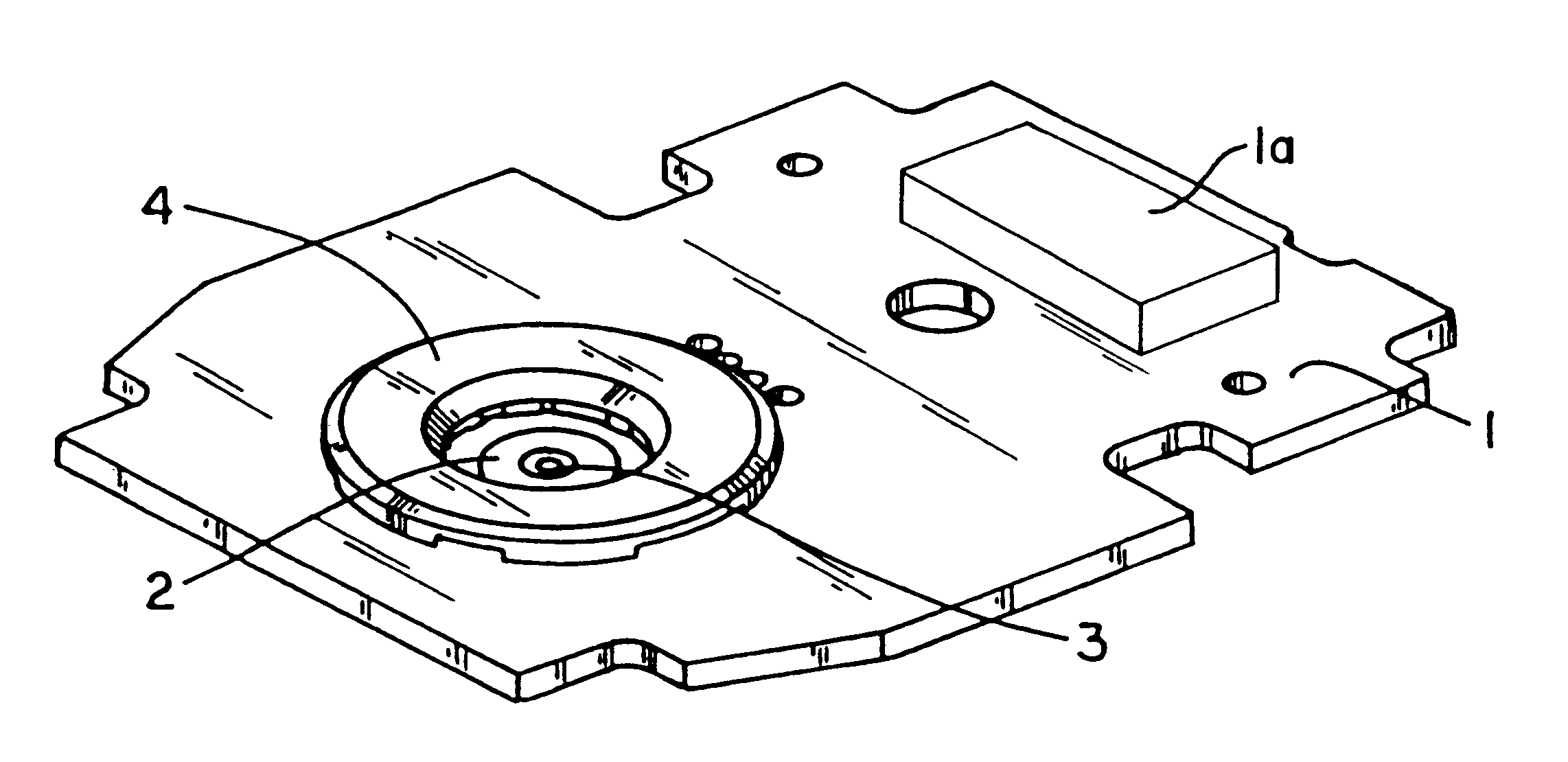

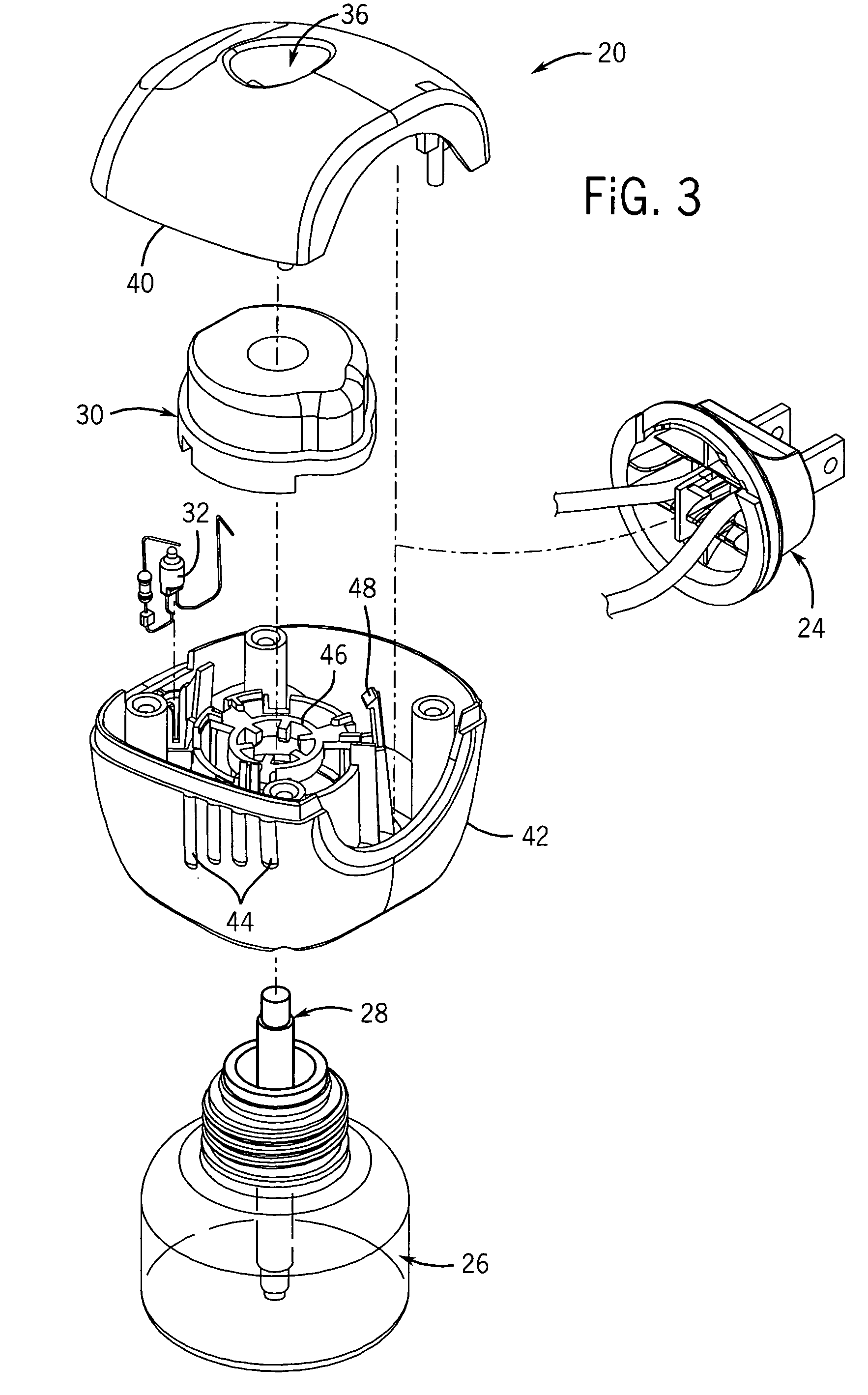

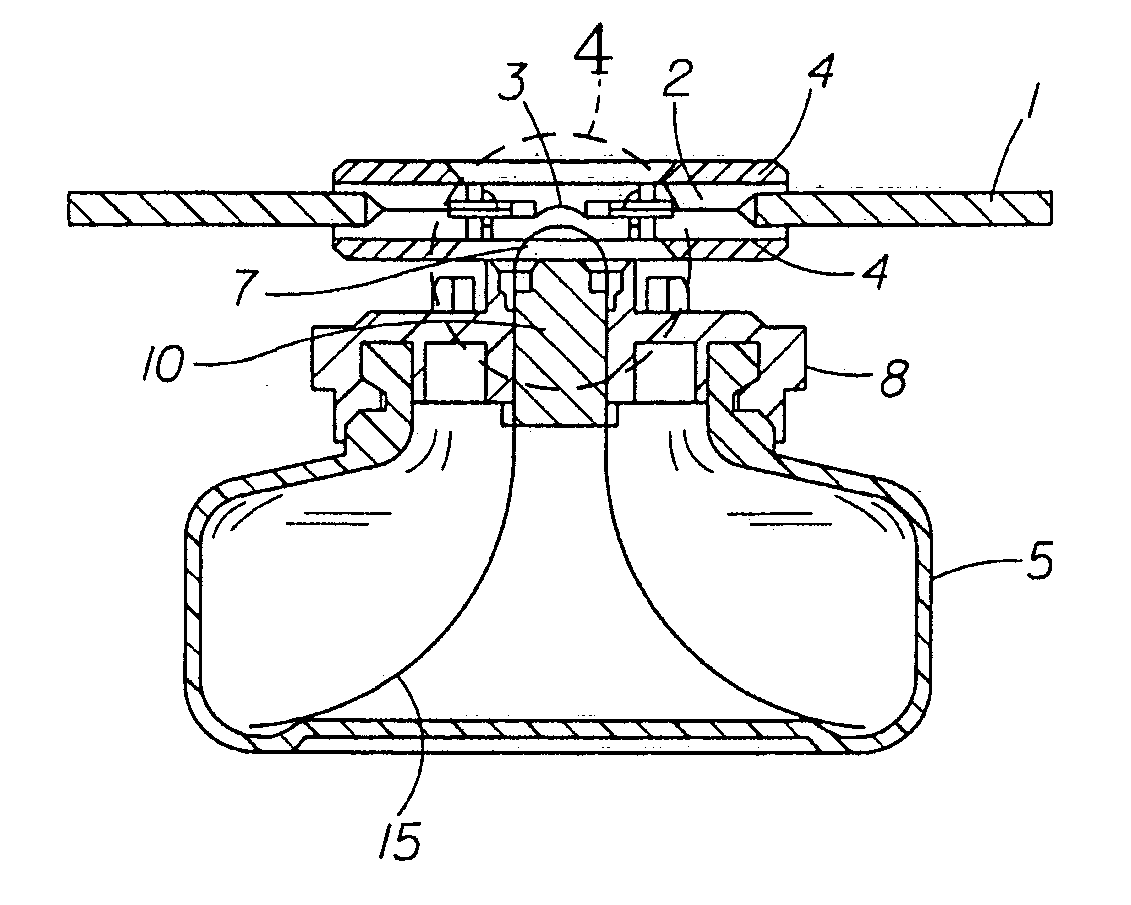

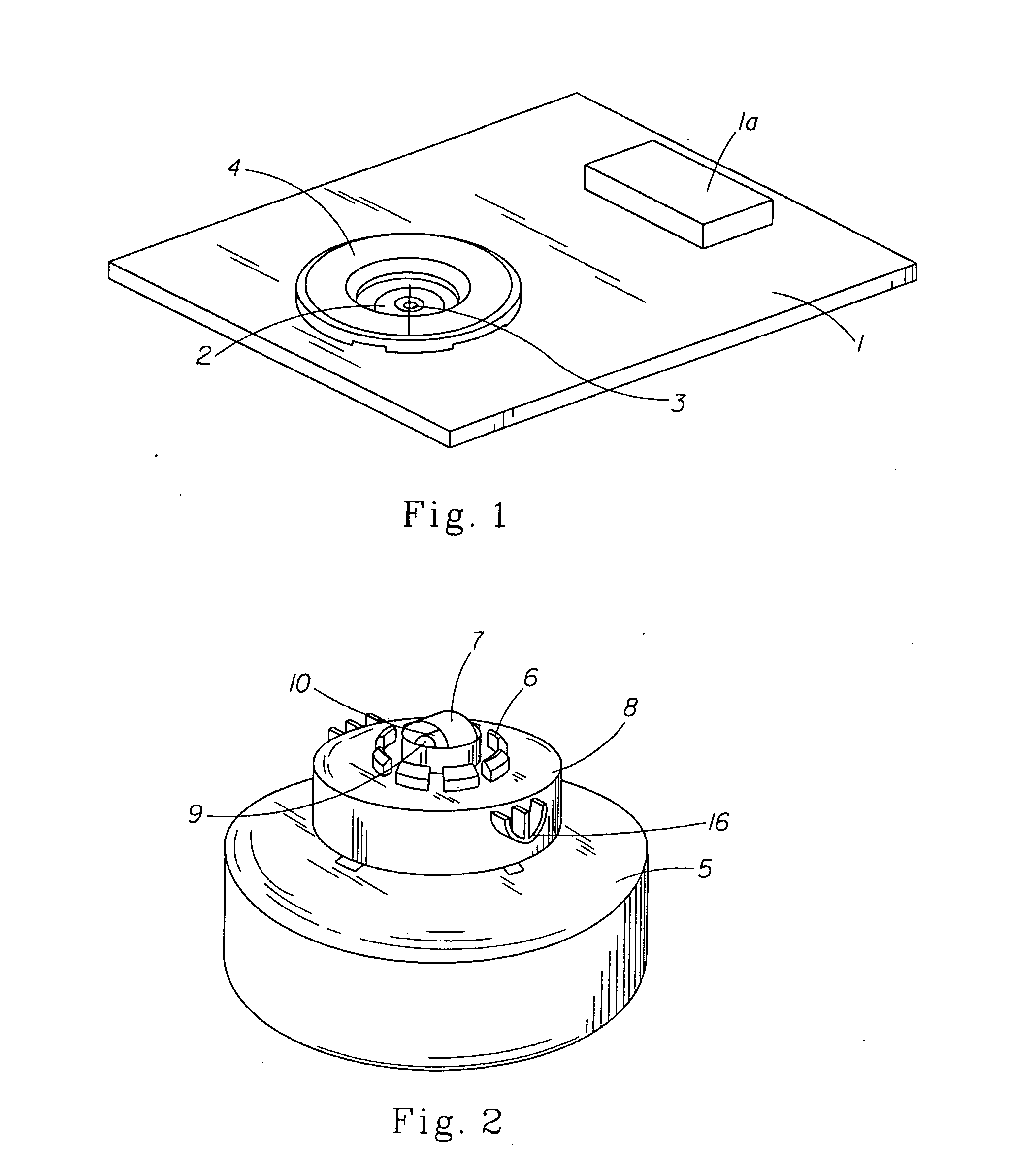

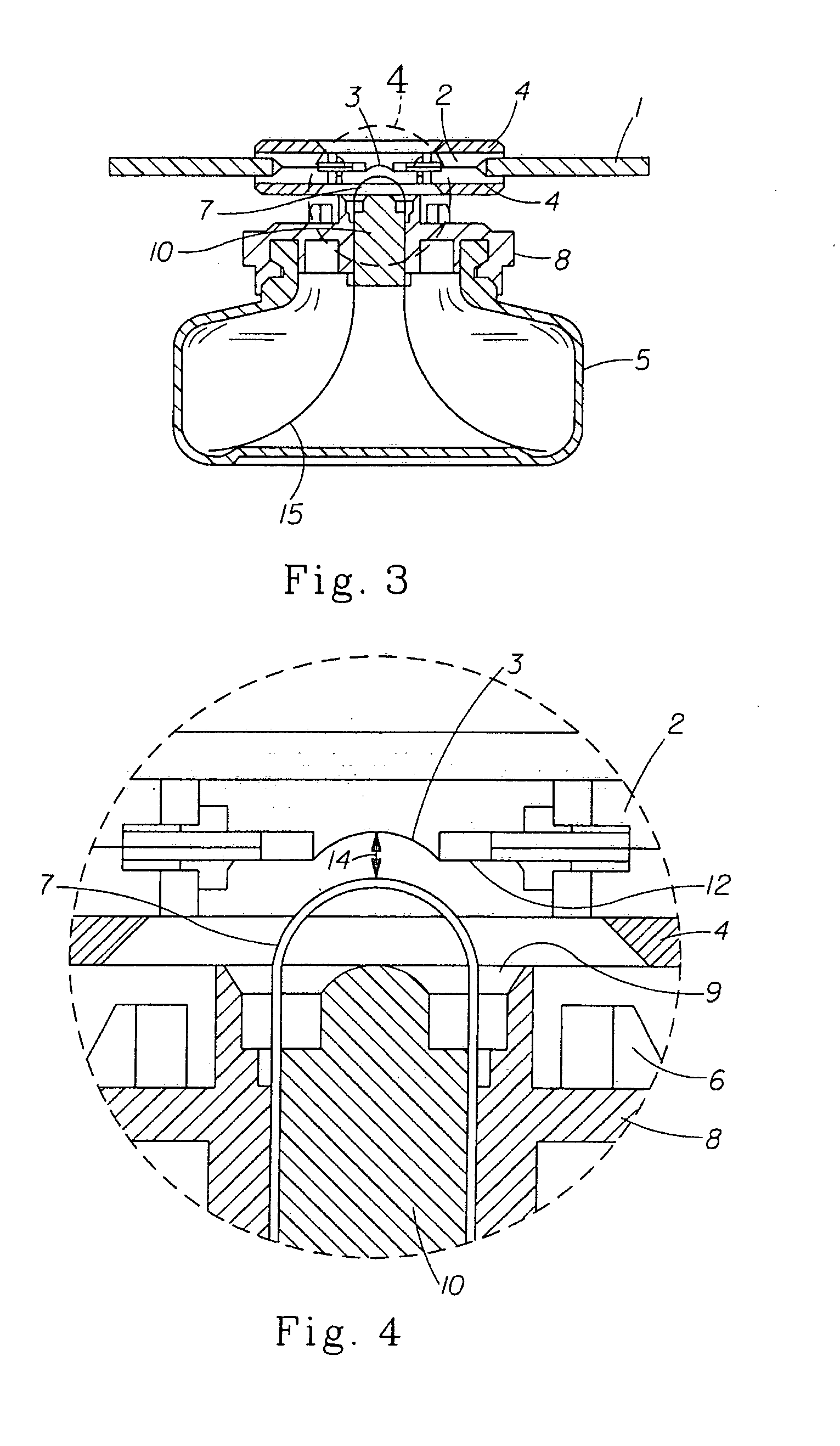

Delivery system for dispensing volatiles

InactiveUS6378780B1Easy to carryMaintain consistencyMovable spraying apparatusSpray nozzlesVena contracta diameterVolatiles

Disclosed herein is a piezoelectric liquid delivery system or atomizer for production of droplets of liquid or liquid suspensions by a battery operated dispenser utilizing an orifice plate in communication with a piezoelectric element. By control of the viscosity and surface tension of the liquid to be dispersed, an improved method of dispensing such liquid is achieved.

Owner:SC JOHNSON & SON INC

Self-cooled oxygen-fuel burner for use in high-temperature and high-particulate furnaces

InactiveUS6210151B1Avoiding particulate inspiration.TheControl expansionIndirect carbon-dioxide mitigationGaseous fuel burnerParticulatesVolatiles

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200° F. to 3000° F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:AIR LIQUIDE AMERICA INC +1

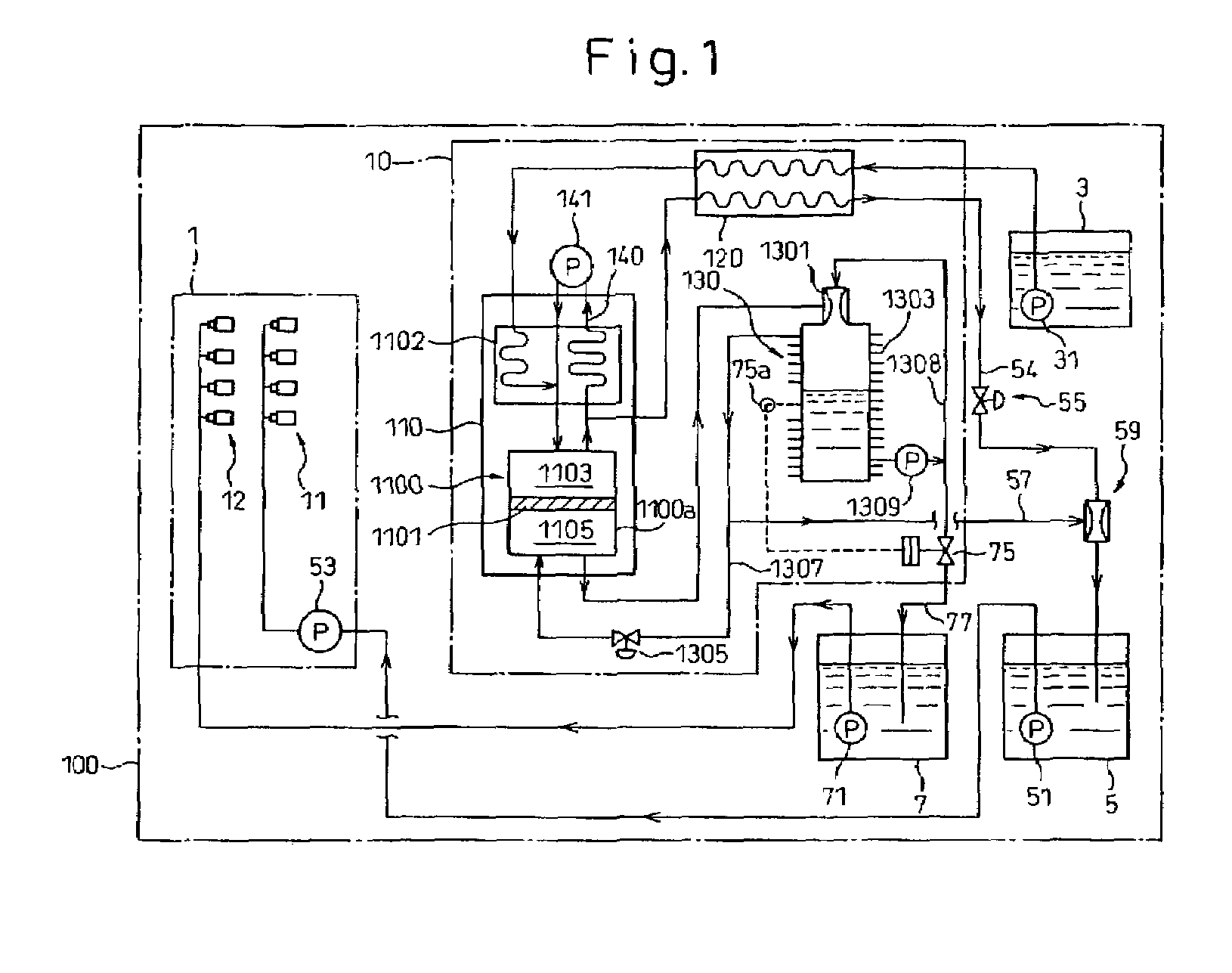

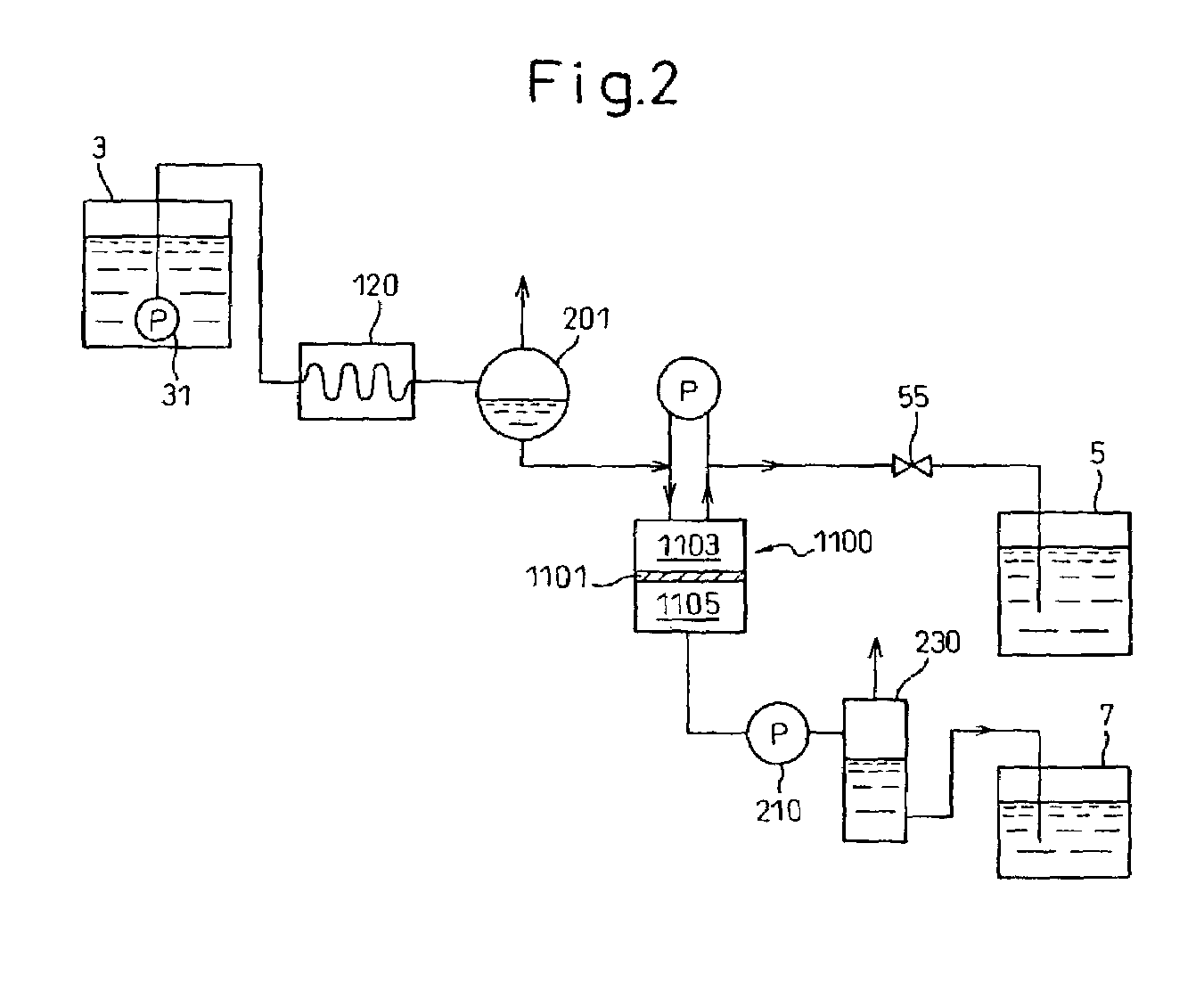

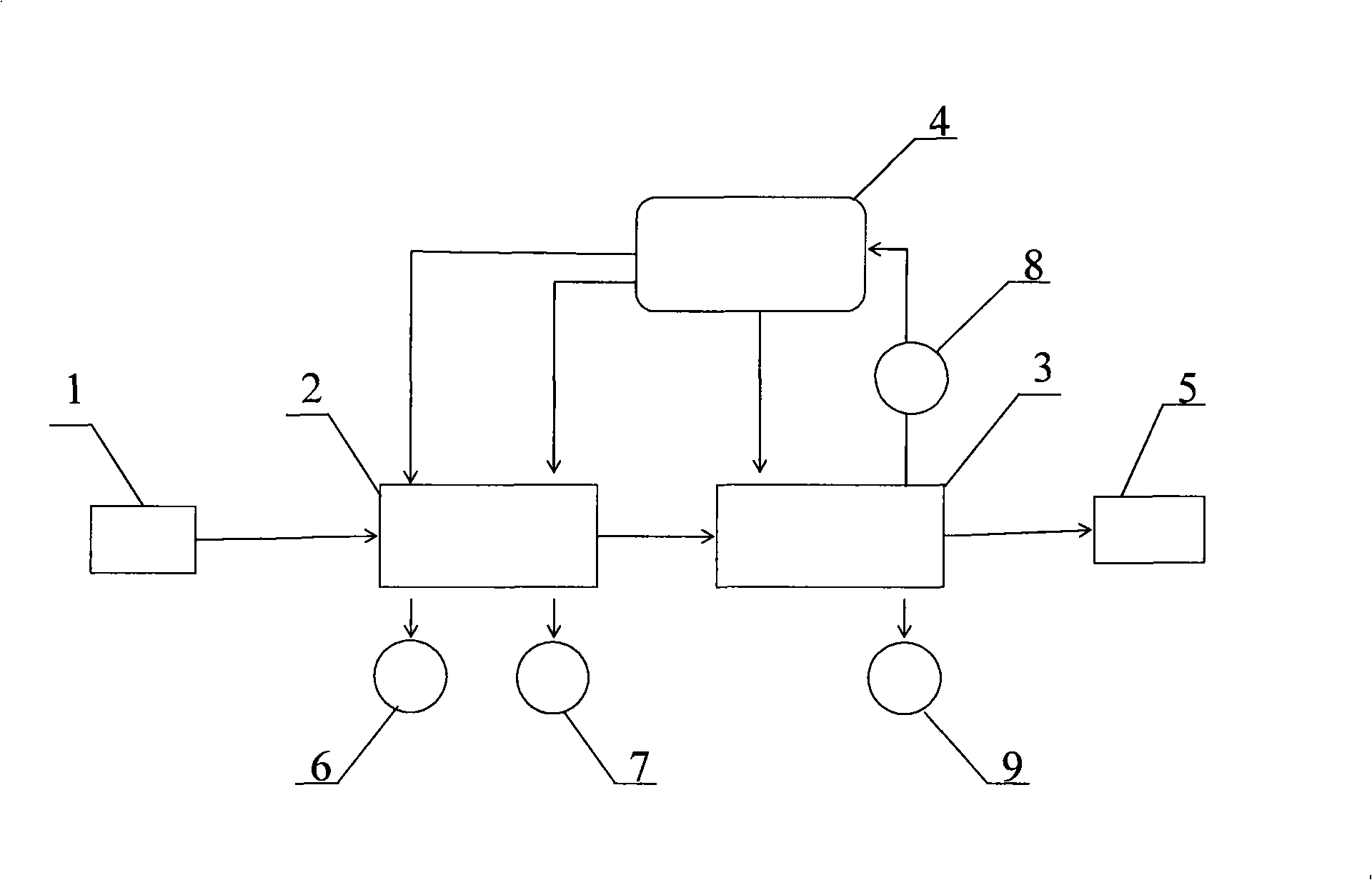

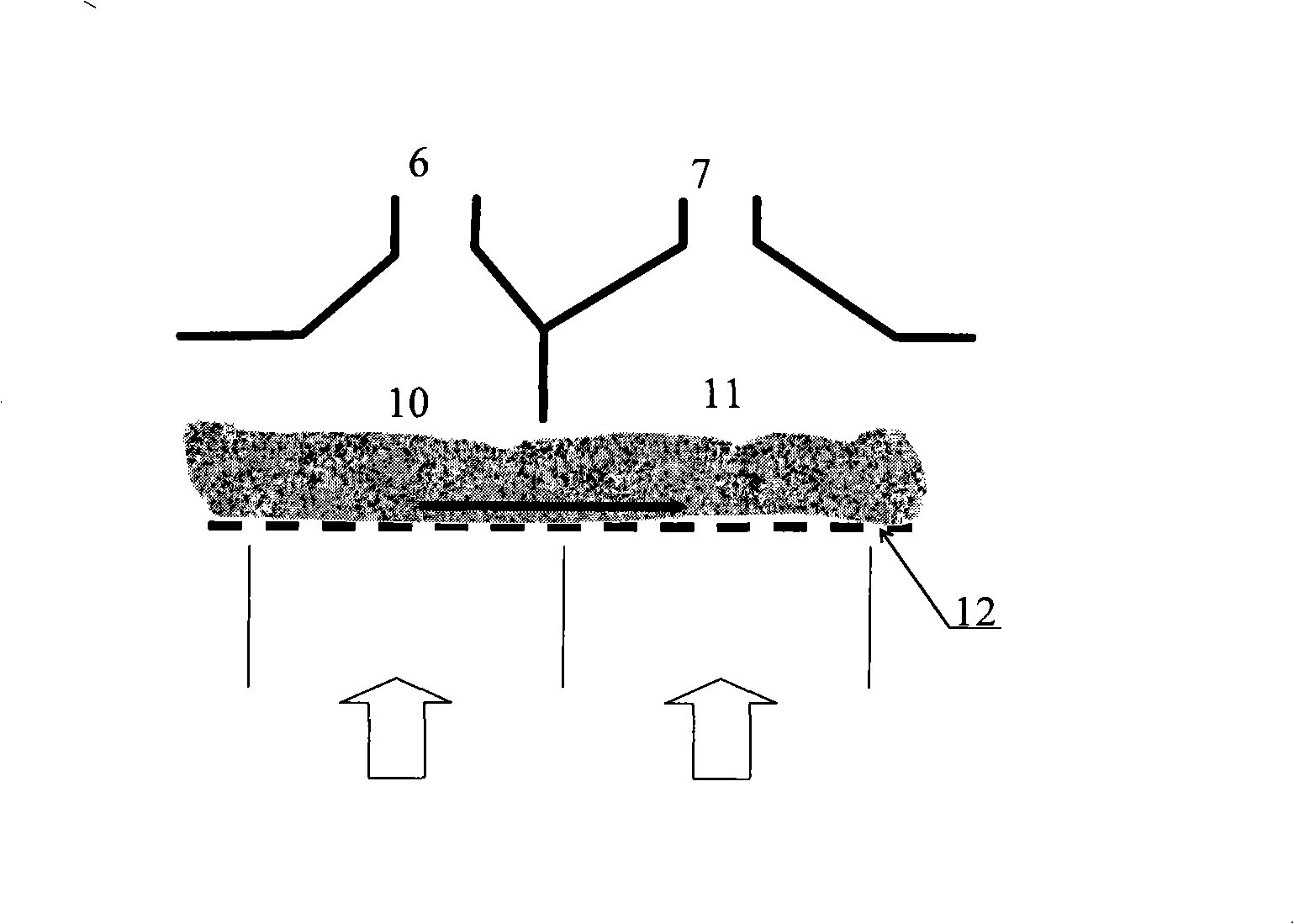

Onboard fuel separation apparatus for an automobile

InactiveUS6972093B2Increase volumeBoost octaneInternal combustion piston enginesUsing liquid separation agentVolatilesEngineering

An onboard fuel separation apparatus separates a material fuel (gasoline) into a high-octane fuel having a higher octane value than the material fuel and a low-octane fuel having a lower octane value than the material fuel using a separation membrane which selectively allows high-octane value components (such as aromatic components) permeate through the membrane. The apparatus increases the ratio of the amount of the high-octane value components permeating through the membrane to the amount of the high-octane value components contained in the material fuel by, (A) Controlling the temperature of the material fuel supplied to the membrane (B) Increasing partial pressure of the low-octane value components on the high-octane fuel side of the membrane and removing volatiles from the permeate, and (C) Bypassing volatiles in the material feed around the membrane.

Owner:EXXON RES & ENG CO +1

Self-cooled oxygen-fuel for use in high-temperature and high-particulate furnaces

InactiveUS6276924B1Avoiding particulate inspiration.TheControl expansionGlass furnace apparatusGlass melting apparatusParticulatesCombustor

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200° F. to 3000° F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:AIR LIQUIDE AMERICA INC +1

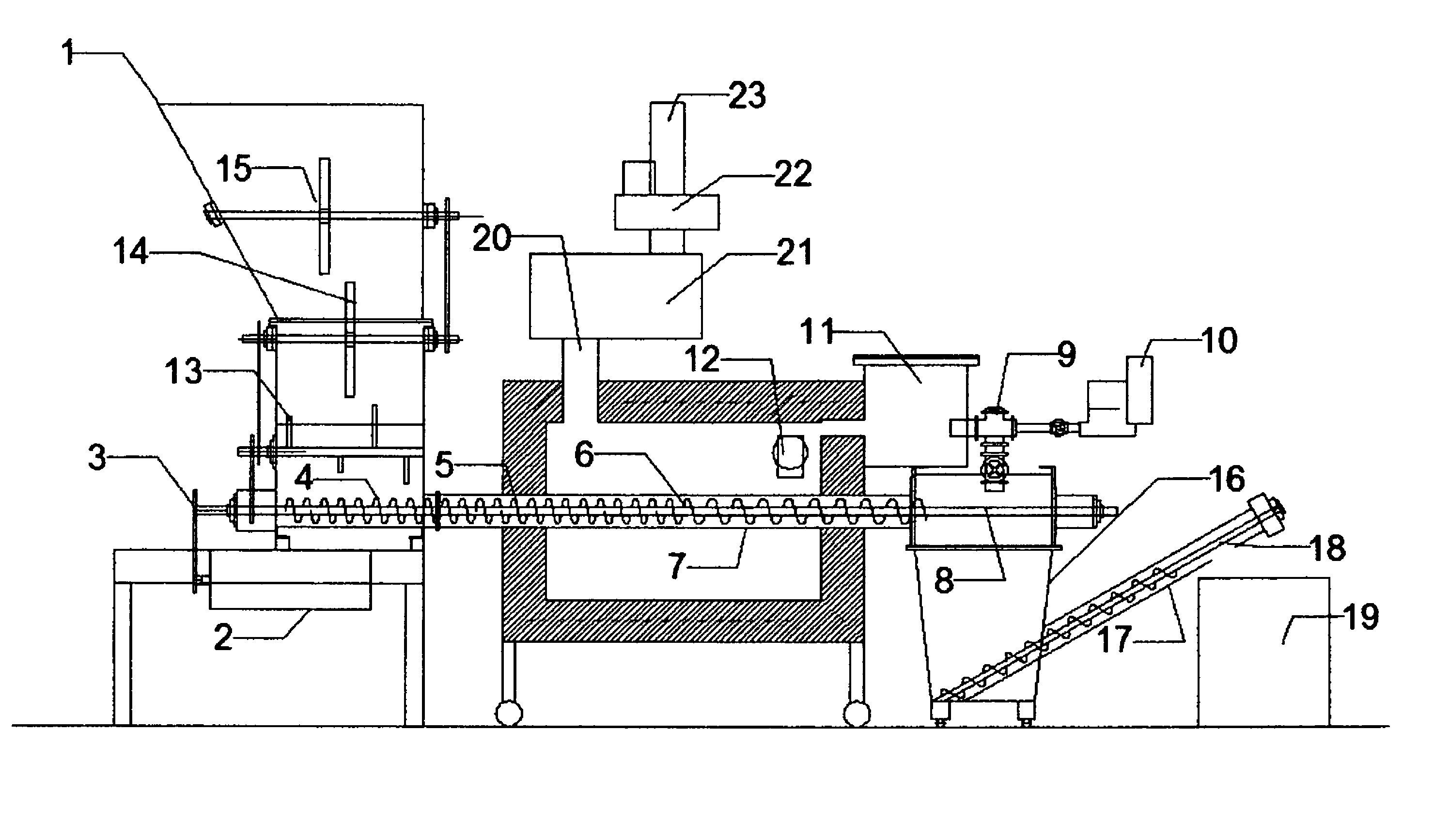

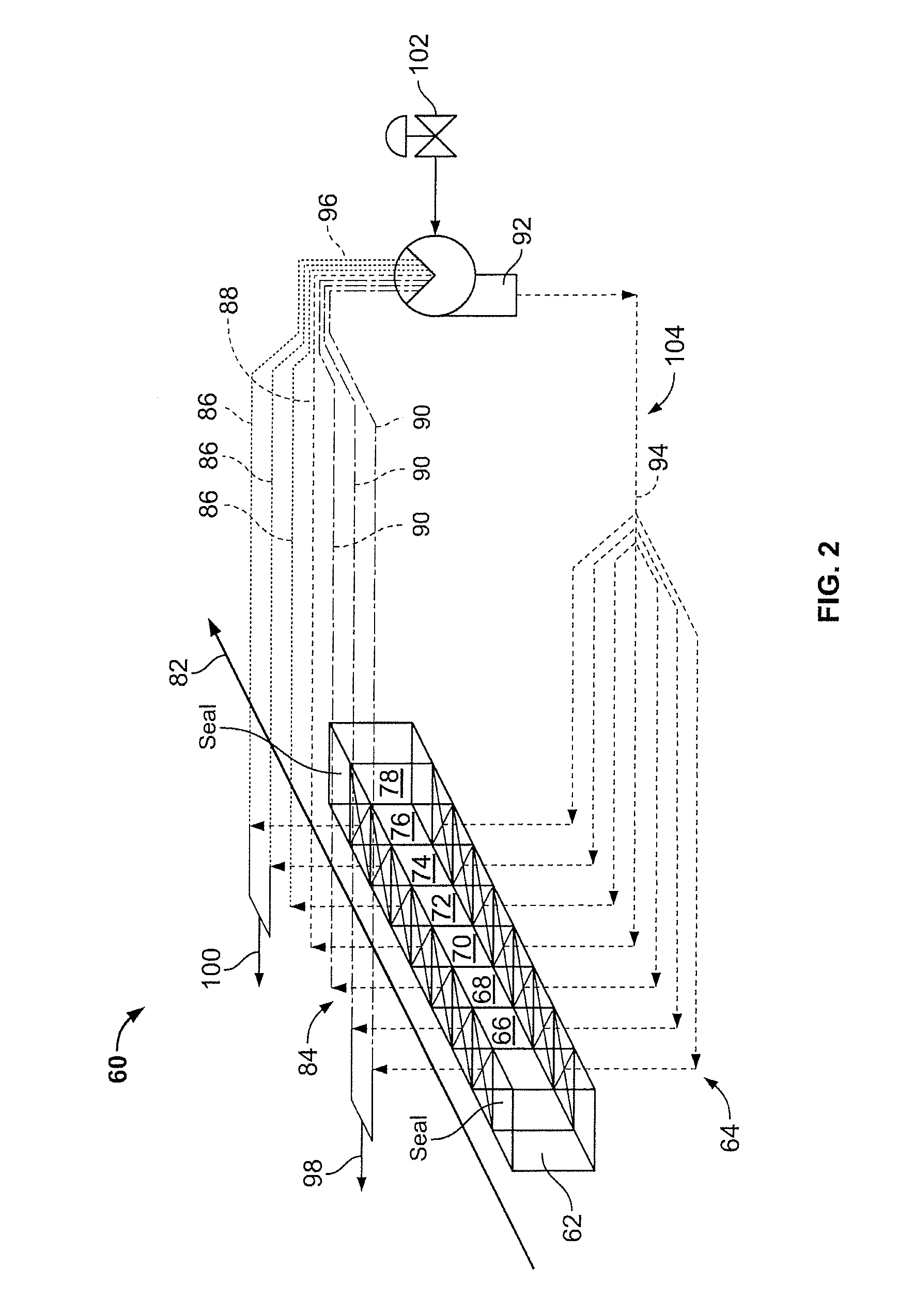

Process and device for the pyrolysis of feedstock

InactiveUS7947155B1Thermal non-catalytic crackingCombustible gas coke oven heatingVolatilesEngineering

This invention involves pyrolysis of feedstock by introducing carbonaceous feedstock, into a hopper and moving it into a reactor tube enclosed in an oven, generating heat within the oven that is in part transferred to the feedstock, heating it to sufficient temperature to pyrolyze the feedstock into useful volatiles and char. A Venturi system produces a negative pressure directing volatiles into a pyro-gas oven producing heat necessary for pyrolysis and generating useful excess heat. The extruded pyrolysis char has uses including charcoal fuel, soil amendments, and activated charcoal while liquids can be produced for processing into fuels. Excess heat may be used to heat water, steam, and air, may be used in air heating and cooling systems, perform mechanical work with a Stirling engine or generate electricity on the order of 100 kW and higher. The system may be operated in a carbon neutral or even carbon negative manner, allowing sequestration of atmospheric carbon dioxide.

Owner:GREEN LIQUID & GAS TECH

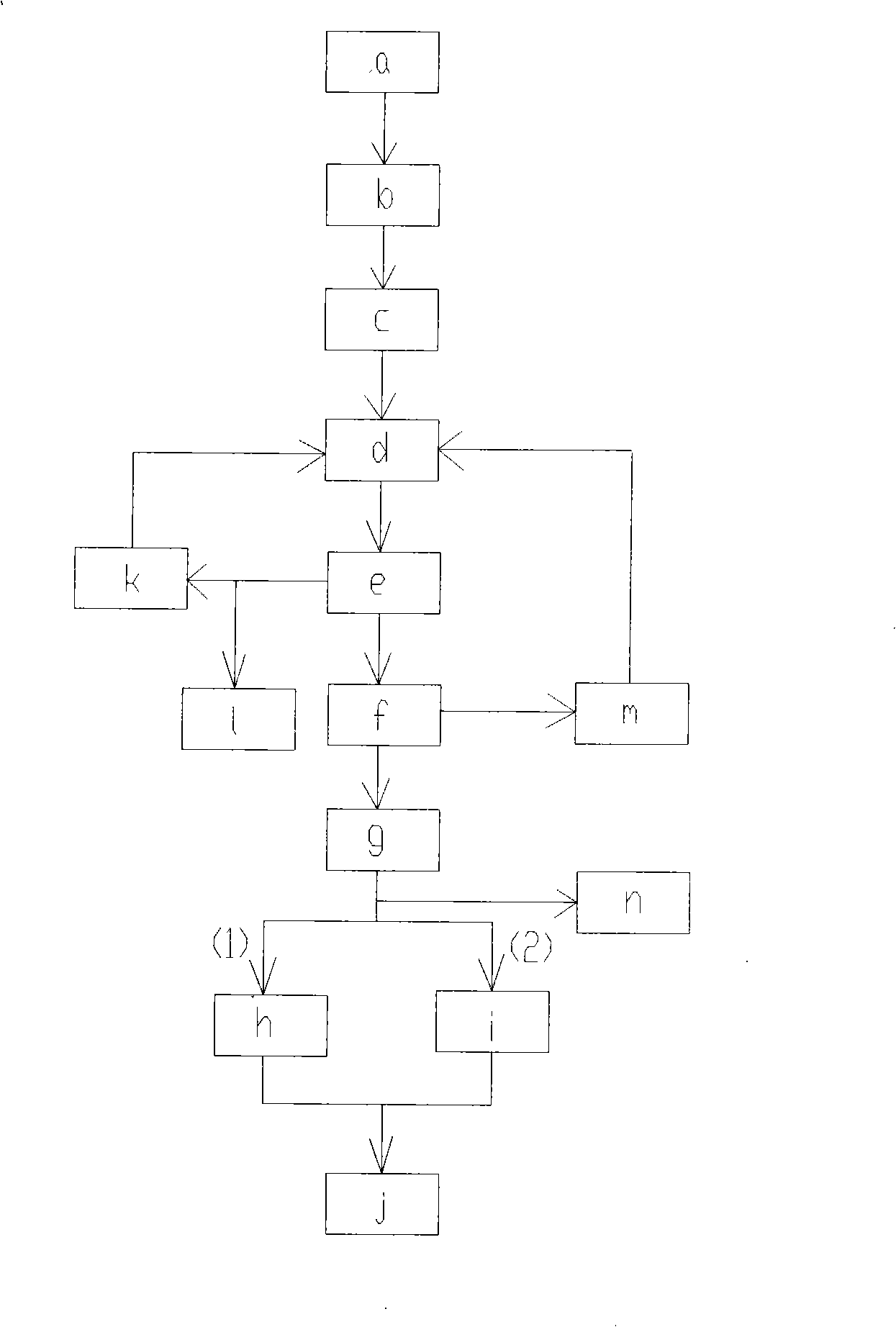

Method of converting pyrolyzable organic materials to biocarbon

InactiveUS20100300866A1Simple methodWidespread benefit to the efficiency of the method and the biocarbon qualityCombustible gas coke oven heatingCarbon compoundsVolatilesCarbonization

A method of forming a pyrolysed biocarbon from a pyrolyzable organic material is delineated. The method involves the conversion of pyrolyzable organic materials to biocarbon for subsequent use. A carbonization circuit is employed with individual feedstock segments being advanced through the circuit. The method facilitates user manipulation of rate of advancement of the feedstock through the circuit, selective collation of volatiles from pyrolyzing feedstock, selective exposure of predetermined feedstock segments to collated volatiles as well as thermal recovery and redistribution as desired by the user. This results in the capacity for a customizable biocarbon product, the latter being an auxiliary feature of the methodology.

Owner:ALTERNA ENERGY

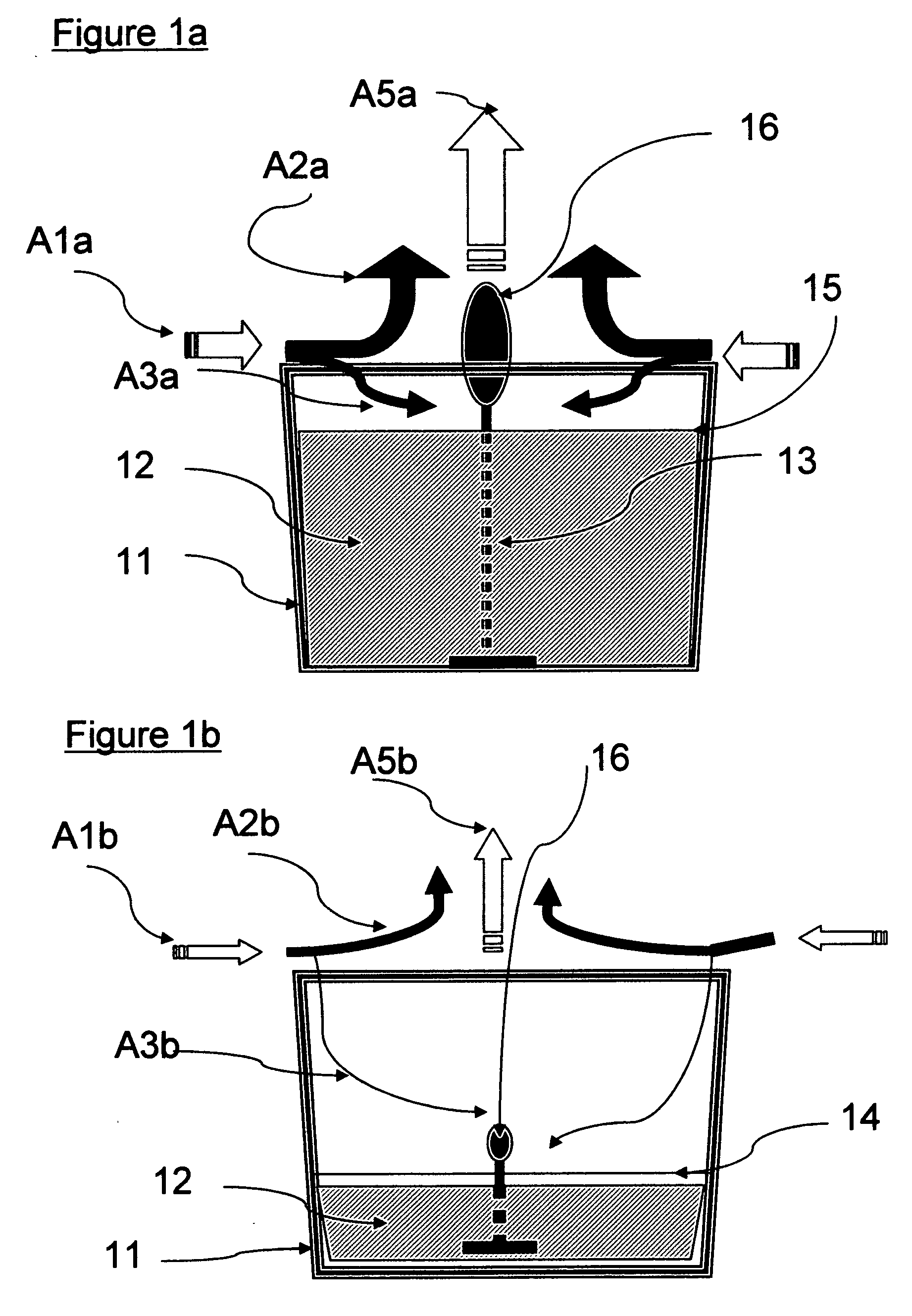

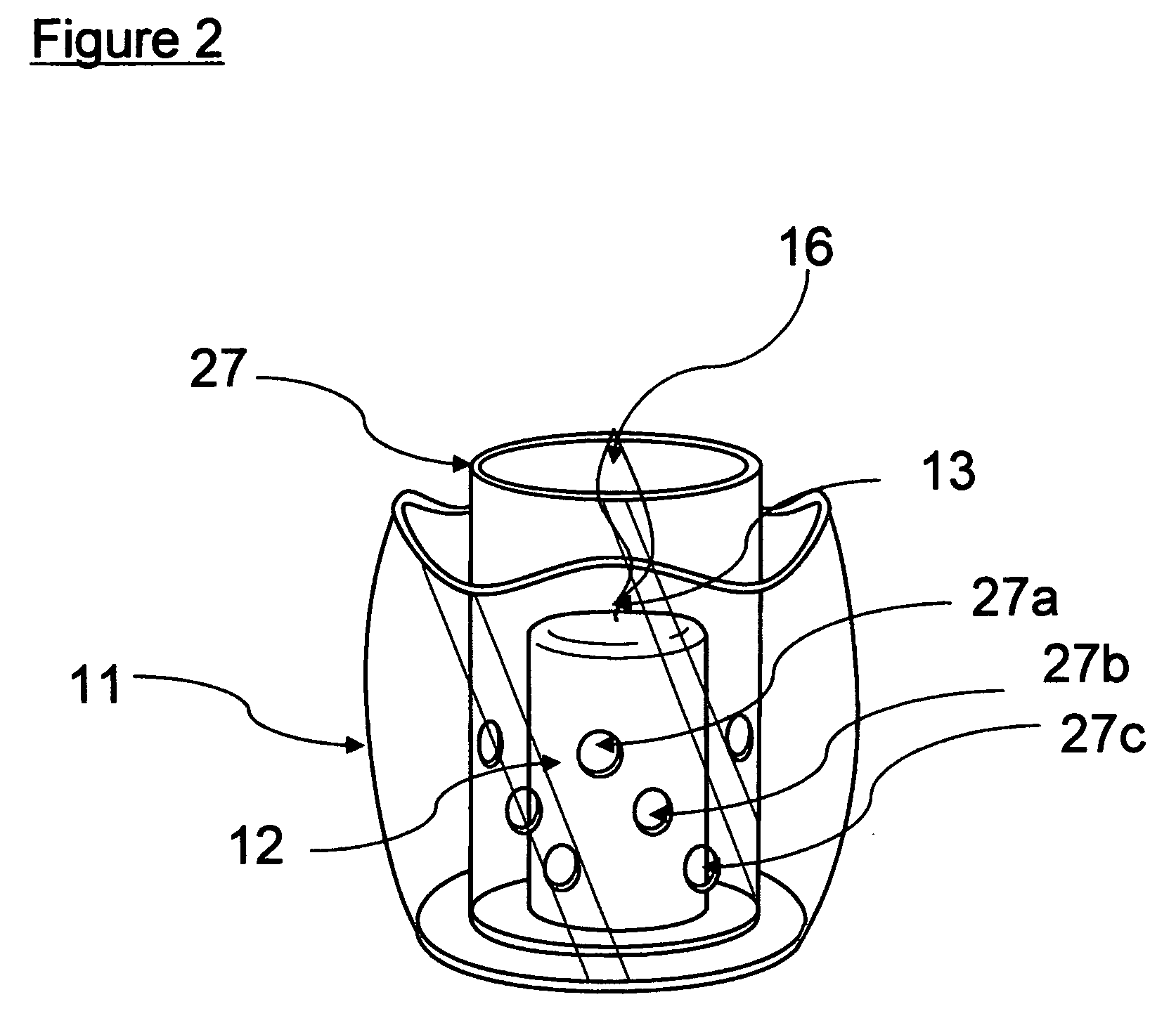

Candle system for enhancing burning and improving volatiles performance and a manufacturing method for the same

A system and a method for enhancing burning candle and improving volatiles performance with a tube having holes and / or cuts or a candle container having at least one inner-tube having holes and / or cuts, continuously supplying the fresh air through the holes and / or cuts, and supplying the fresh air to the foot of the burning wick, and for manufacturing the same.

Owner:NAKATSU TETSUO

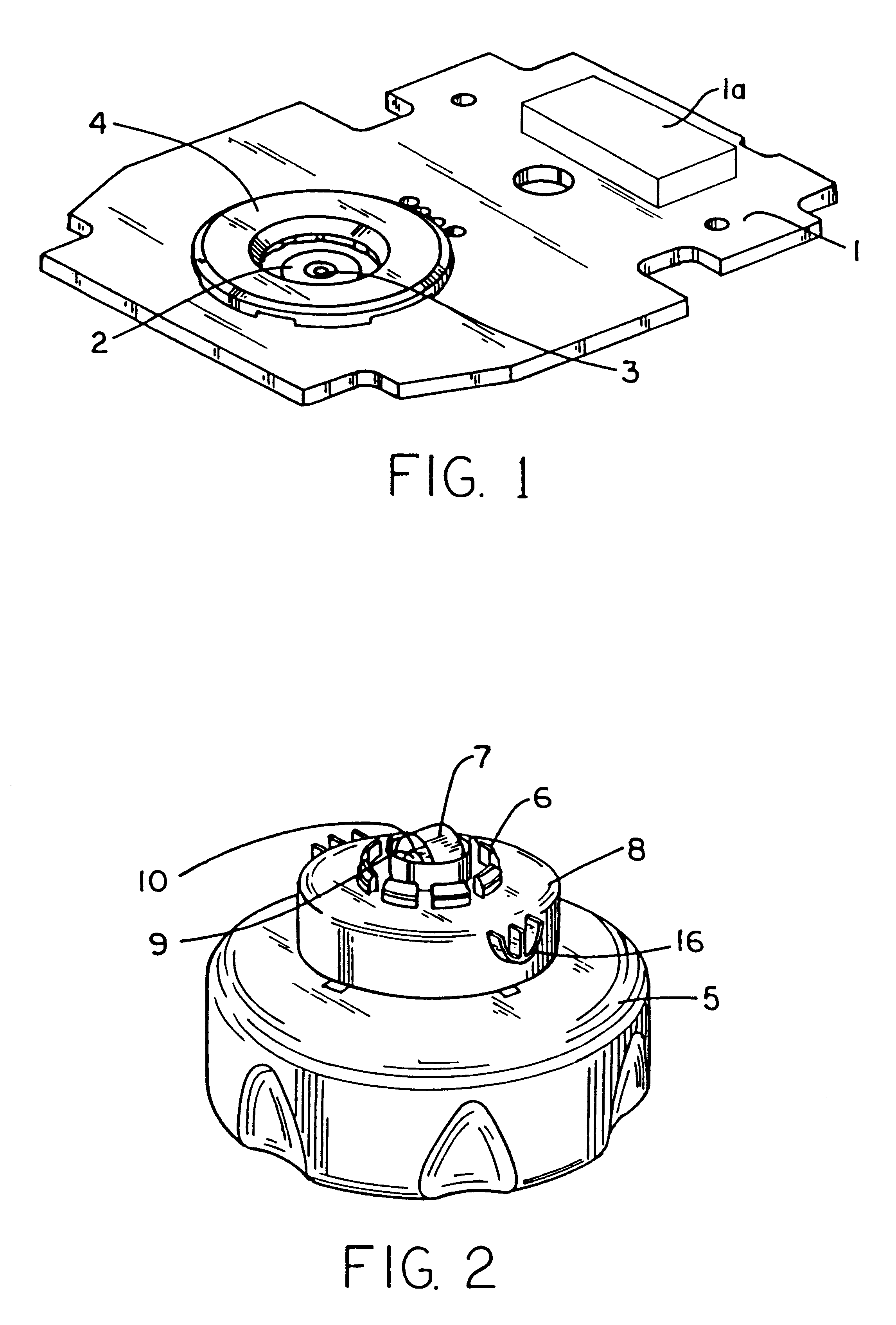

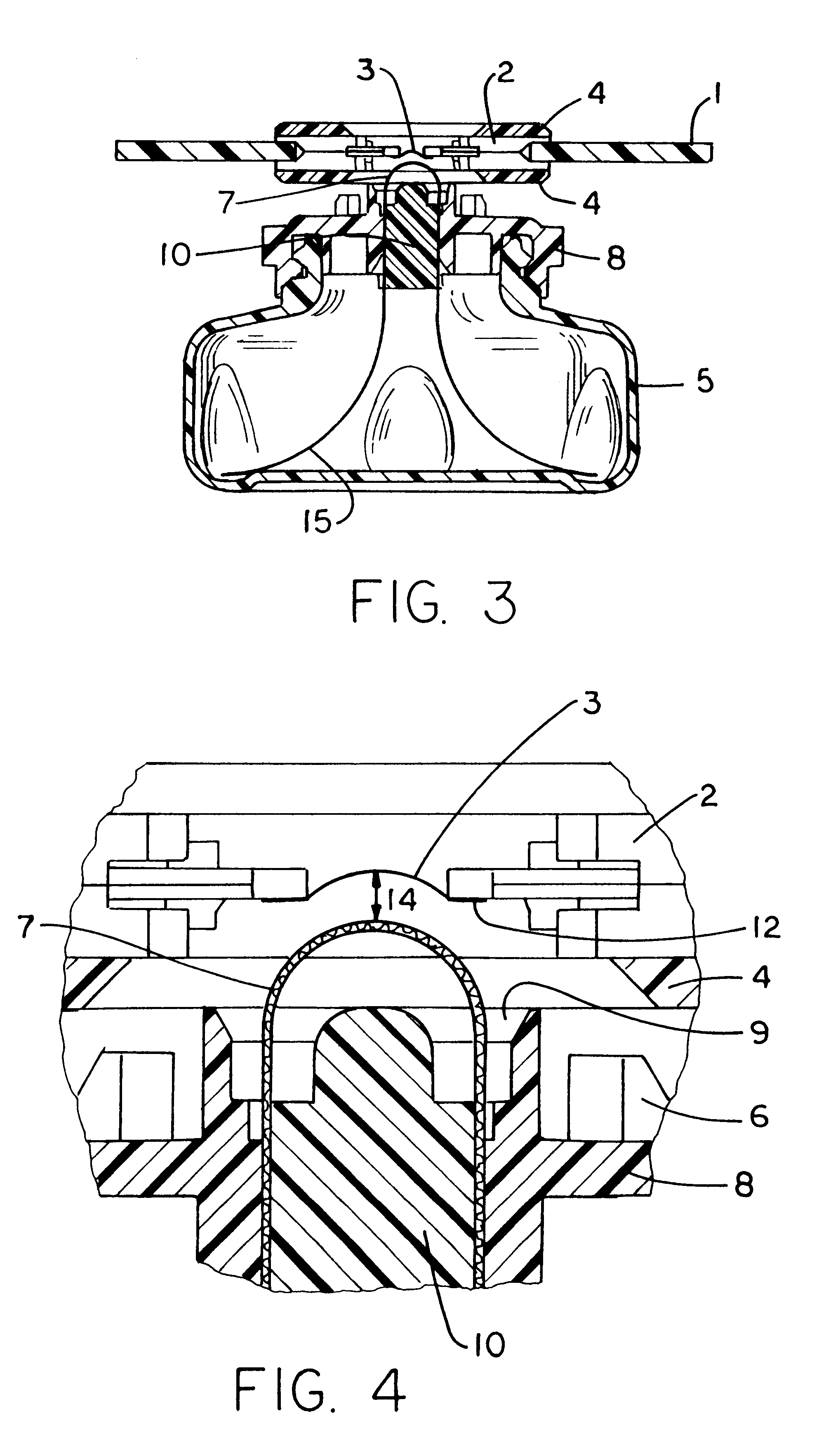

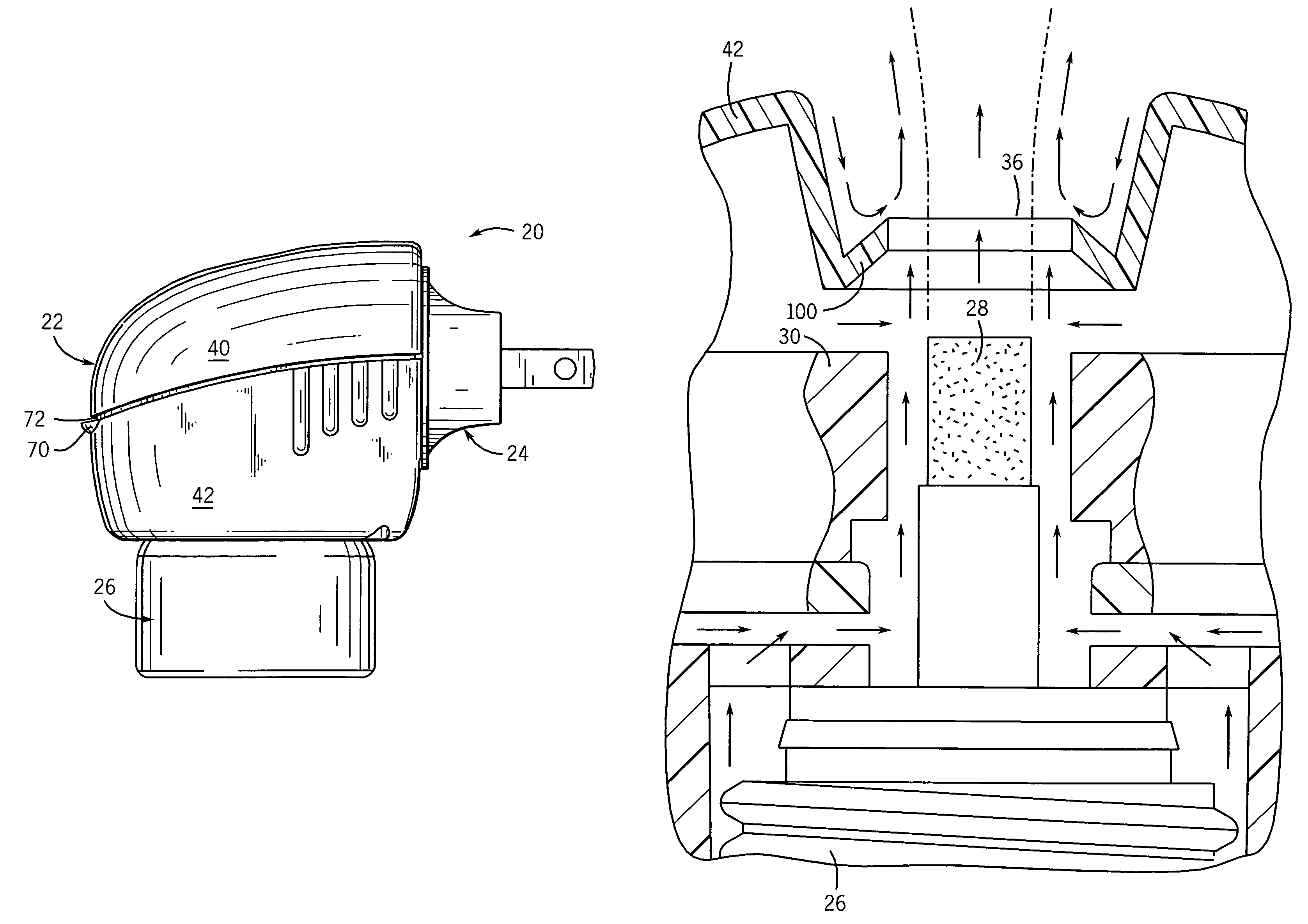

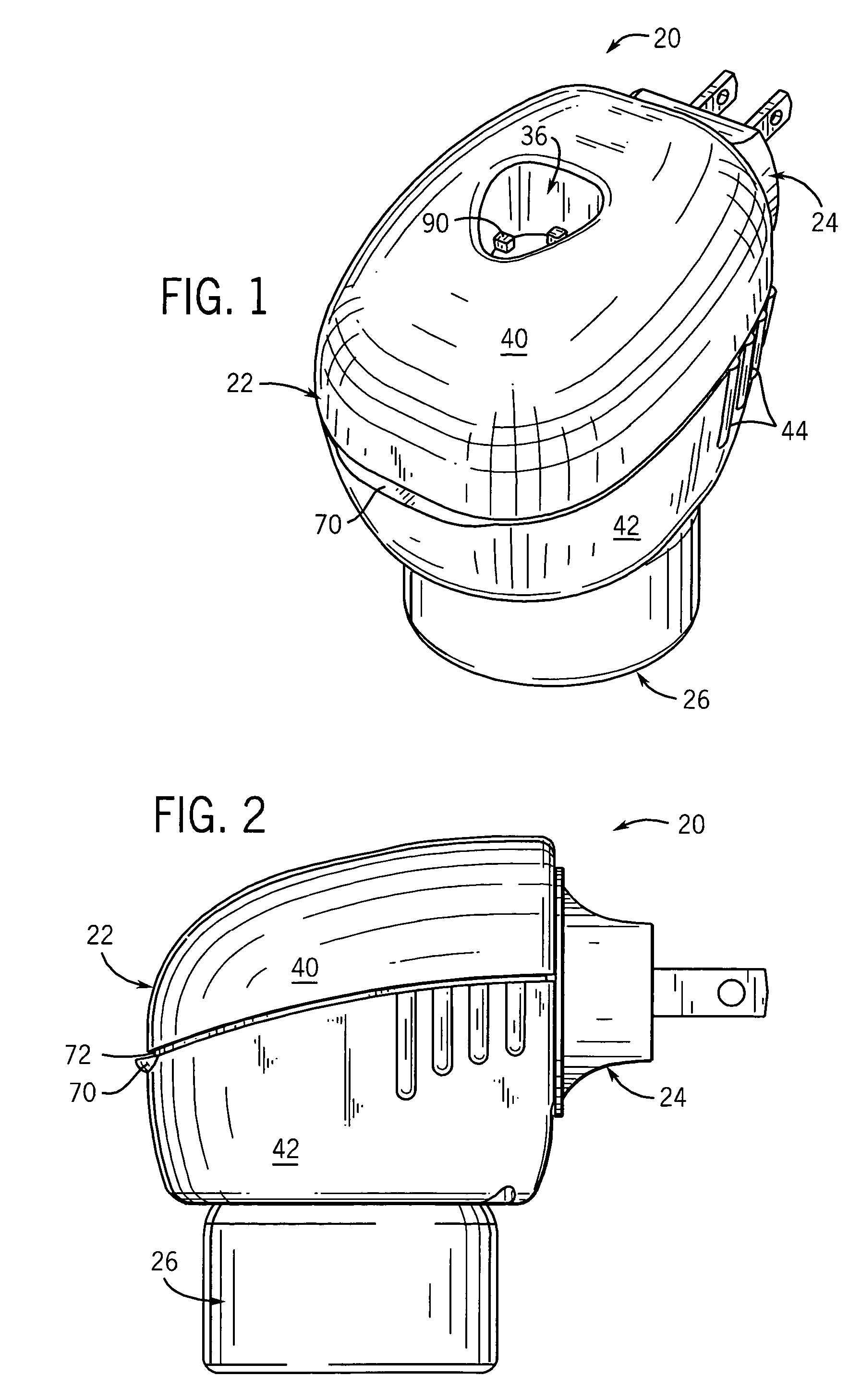

Electric liquid volatile dispenser

A plug-in type dispenser of liquid volatiles, such as insecticides, fragrants, and the like, of the type having a heater for evaporating the liquid volatiles from a wick, provides improved volatile dispersion characteristics and in-use indication. Air flow through the dispenser and around the wick is increased, and the outlet is sized and configured to avoid condensation on the inside and outside of the housing as well as to increase the vertical component of the expelled air stream. An internal lamp transmits light to be reflected off of an exterior in-use indicator surface of the housing to provide visual indication that the dispenser is active.

Owner:SC JOHNSON & SON INC

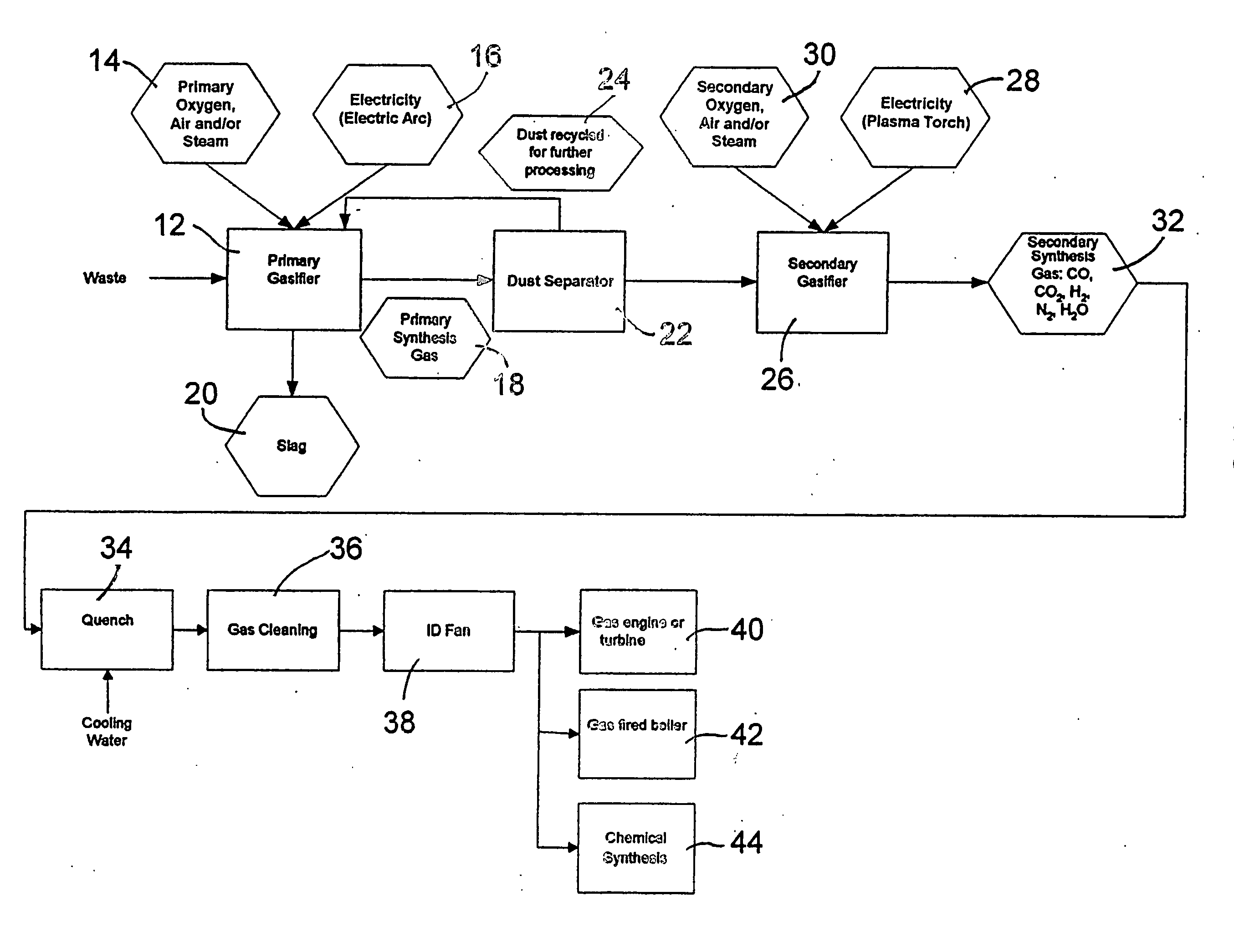

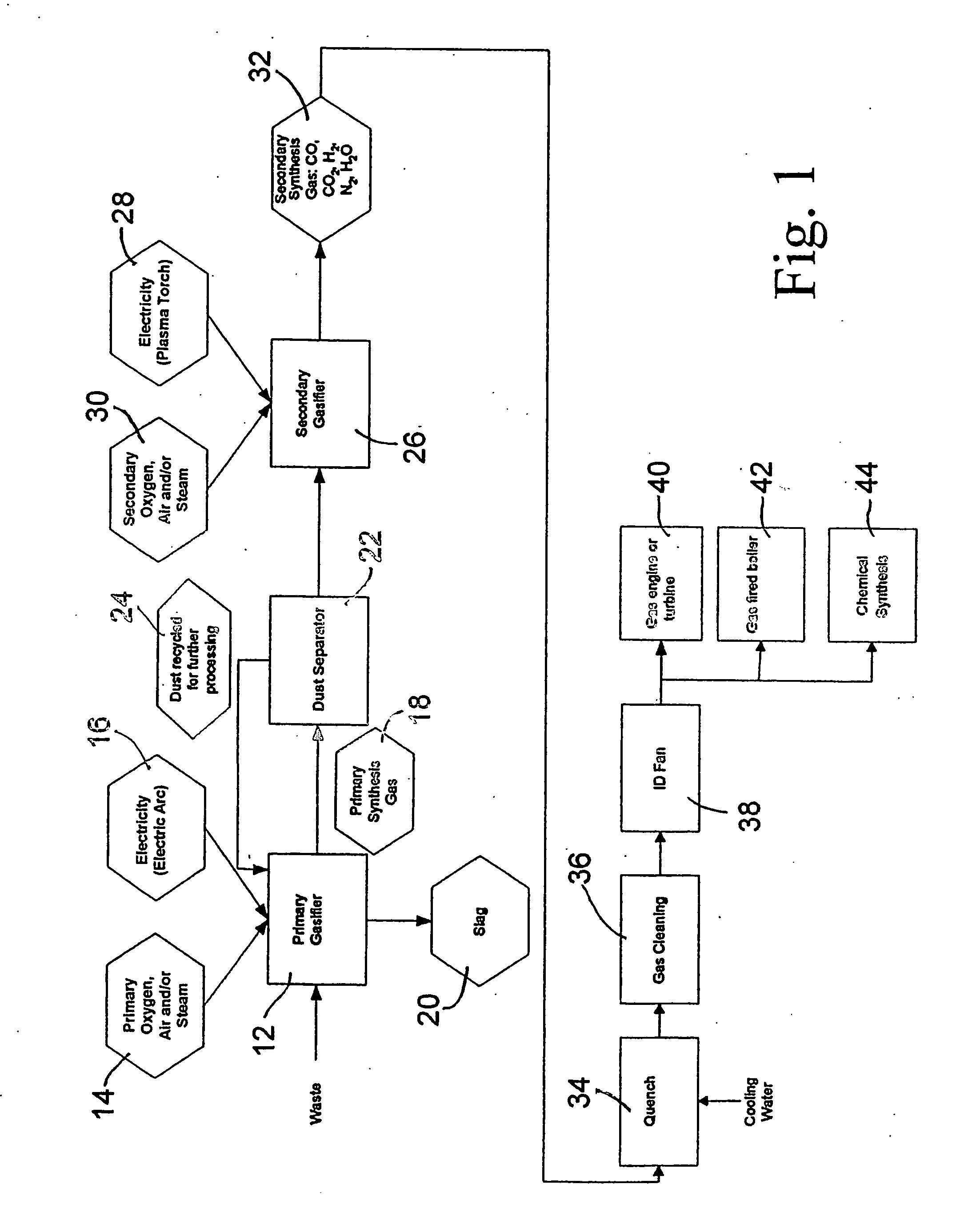

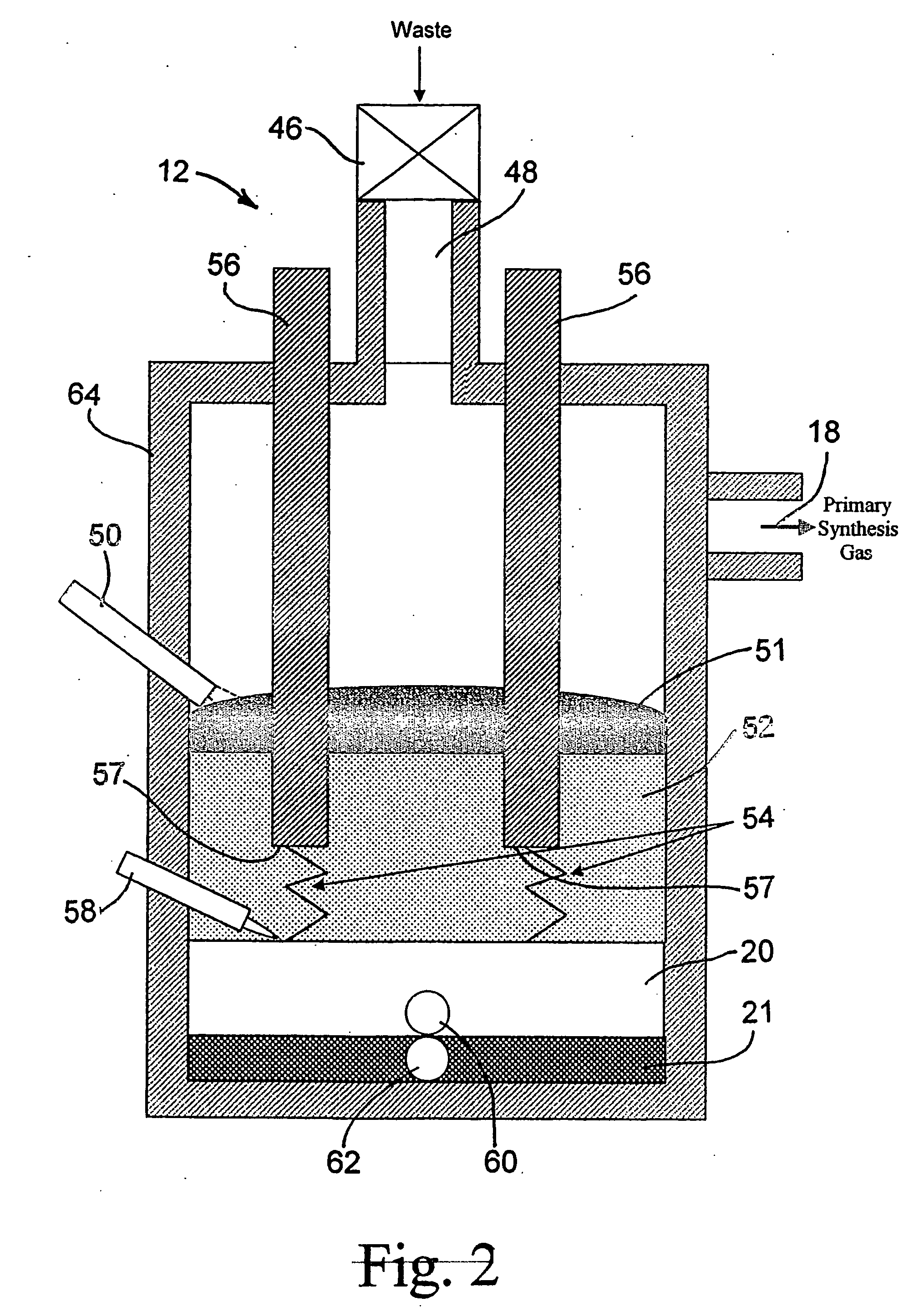

Two-Stage Plasma Process For Converting Waste Into Fuel Gas And Apparatus Therefor

InactiveUS20070272131A1Limited amountImprove energy efficiencyGasifier electrodesGasification processes detailsPlasma jetCyclone

A two-step gasification process and apparatus for the conversion of solid or liquid organic waste into clean fuel, suitable for use in a gas engine or a gas burner, is described. The waste is fed initially into a primary gasifier, which is a graphite arc furnace. Within the primary gasifier, the organic components of the waste are mixed with a predetermined amount of air, oxygen or steam, and converted into volatiles and soot. The volatiles consist mainly of carbon monoxide and hydrogen, and may include a variety of other hydrocarbons and some fly ash. The gas exiting the primary gasifier first passes through a hot cyclone, where some of the soot and most of the fly ash is collected and returned to the primary gasifier. The remaining soot along with the volatile organic compounds is further treated in a secondary gasifier where the soot and the volatile compounds mix with a high temperature plasma jet and a metered amount of air, oxygen or steam, and are converted into a synthesis gas consisting primarily of carbon monoxide and hydrogen. The synthesis gas is then quenched and cleaned to form a clean fuel gas suitable for use in a gas engine or a gas burner. This offers higher thermal efficiency than conventional technology and produces a cleaner fuel than other known alternatives.

Owner:PHOENIX HAUTE TECH

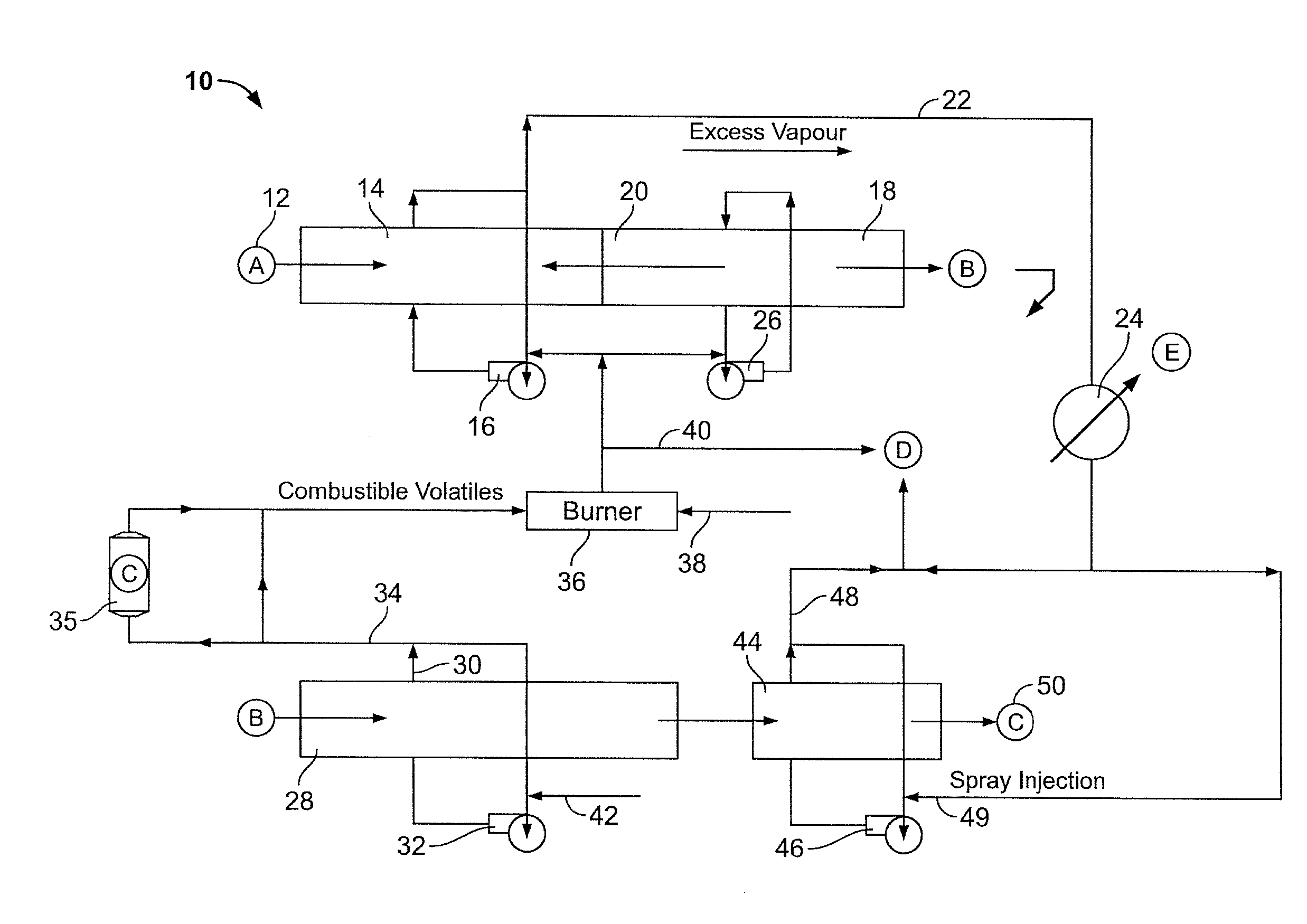

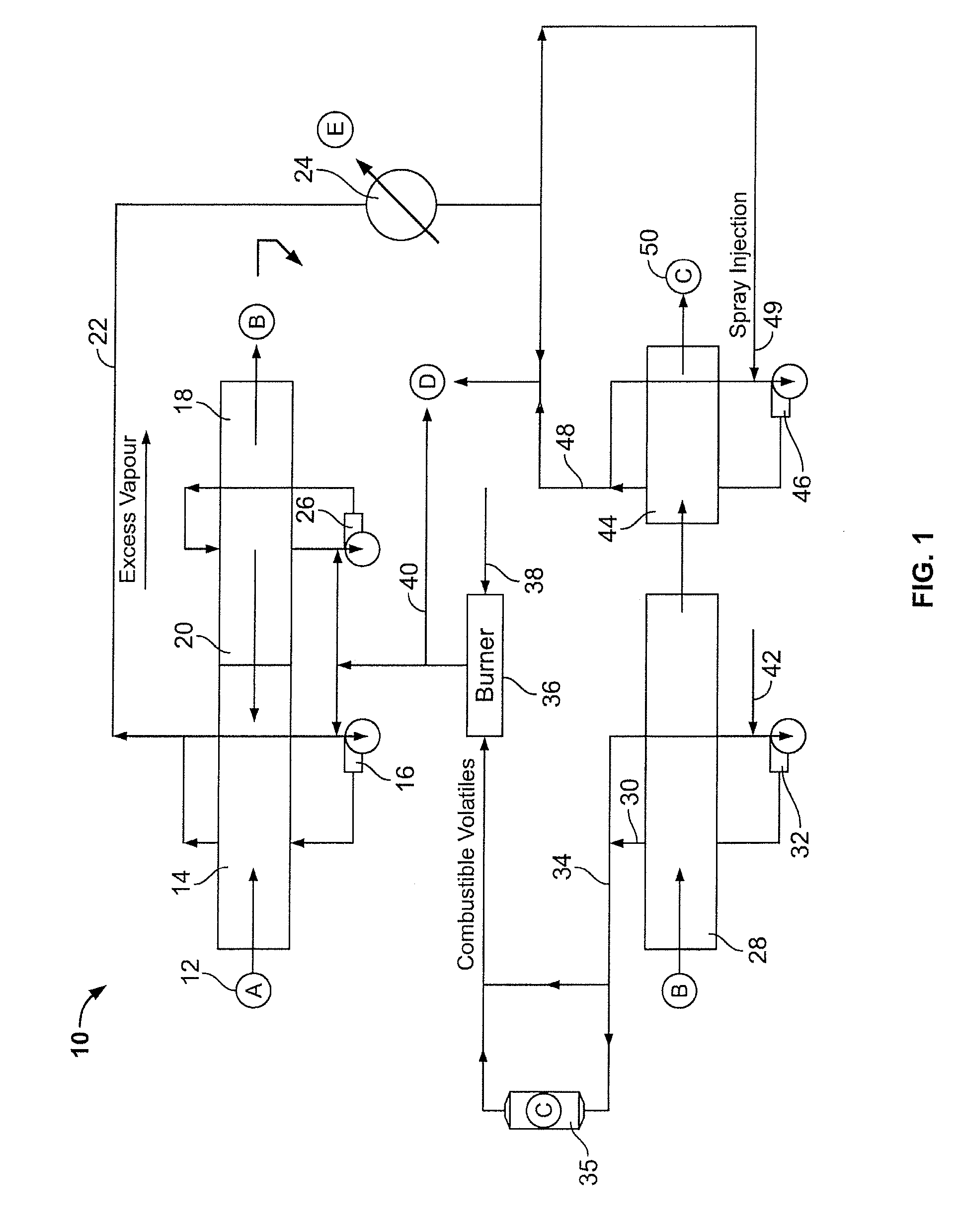

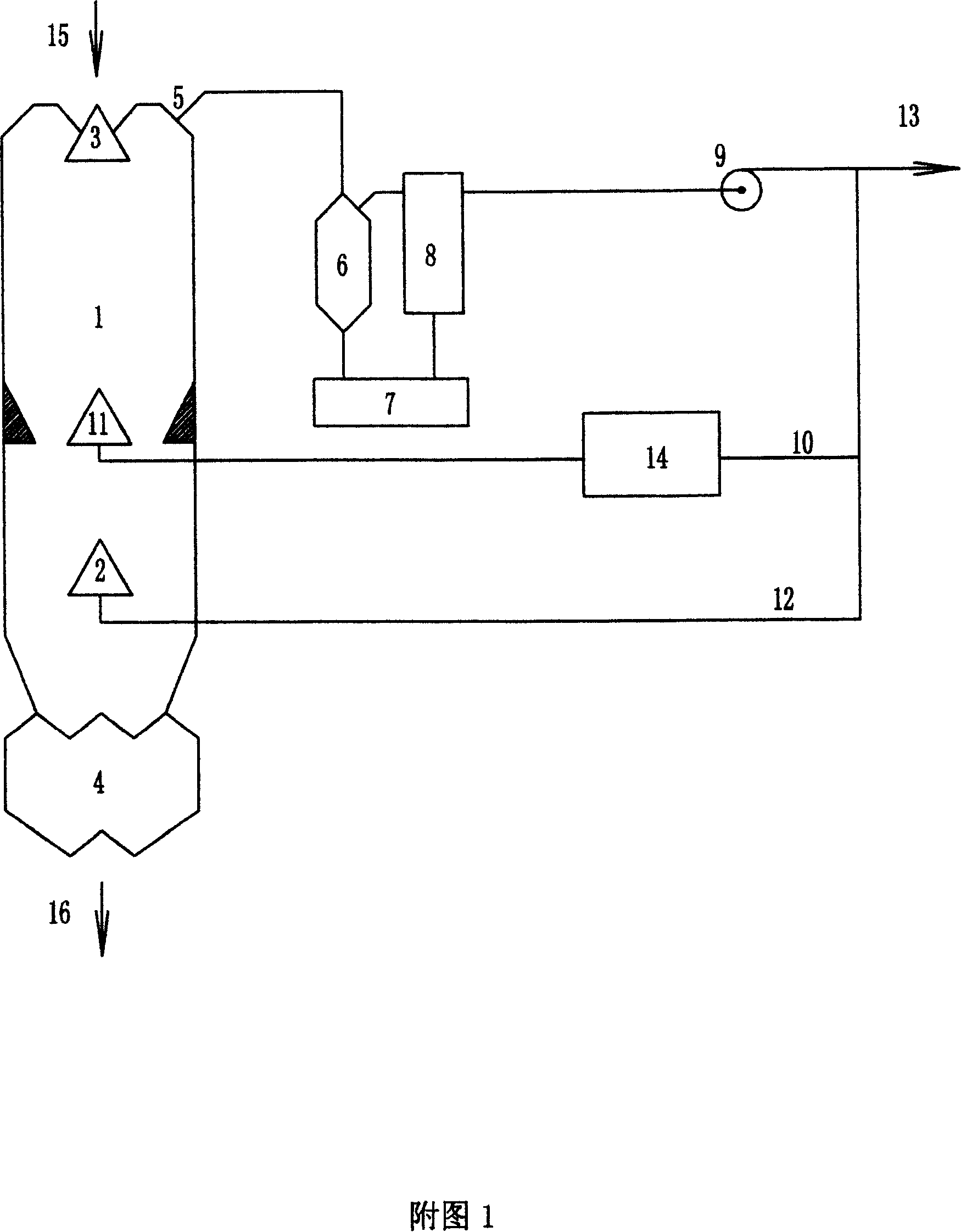

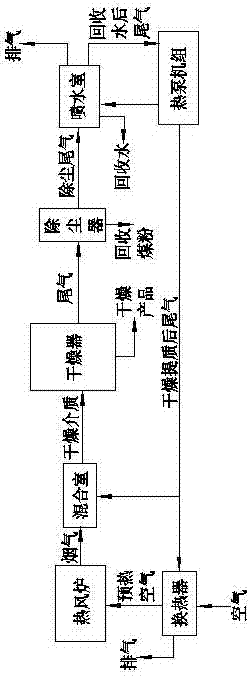

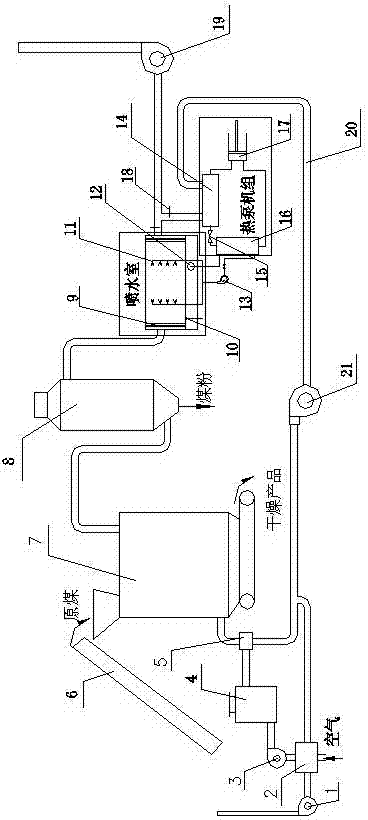

Brown coal drying quality-increasing device and technique

InactiveCN101260307AAvoid burnsGuaranteed classificationDrying solid materials with heatCoke ovensBrown coalLiquid product

A drying and upgrading device for lignite and a technological method thereof, relating to the lignite efficient utilization field. The invention comprises a chamber dryer for the lignite, a fluidized-bed pyrolysis device, a combustion device for the pyrolysed gas, and other adjuvant devices. The dried lignite is fed into the pyrolysis device, volatiles and liquid products are extracted, the volatiles are sent into the combustion device to be burnt to generate fume and steam, the fume and a part of the steam are sent into the drying device to serve as the drying media. The rest steam is sent into the pyrolysis device to provide the heat source for the pyrolysis. A chain conveying method and a method of chamber drying / discharge of the fume and the steam are adopted for the drying device. Two different steams with different temperatures are generated in the combustion device and used for drying and pyrolysis of the lignite respectively. Compared with the prior technology, the device and the method provided by the invention have the advantages of safe and reliable operation, reasonable design, steady running in the large-scale application, and capability of improving the comprehensive utilization rate of the lignite.

Owner:TSINGHUA UNIV

Data storage medium and method for the preparation thereof

ActiveUS20040063031A1Improve melt processingImprove moldingRadiation applicationsLayered productsHeat deflection temperatureVolatiles

A data storage medium includes a substrate, a reflective metal layer, and a haze-prevention layer between the substrate and the reflective metal layer. The substrate includes an amorphous thermoplastic resin having a heat distortion temperature of at least about 140° C., a density less than 1.7 grams per milliliter, and an organic volatiles content less than 1,000 parts per million measured according to ASTM D4526. The haze-prevention layer includes a material having a volume resistivity of at least 1x10<-4 >ohm-centimeters and a tensile modulus of at least about 3x10<5 >pounds per square inch. The data storage medium resists hazing of the reflective layer at elevated temperatures.

Owner:SHPP GLOBAL TECH BV

Conversion of crude tall oil to renewable feedstock for diesel range fuel compositions

ActiveUS20110049012A1Efficient removalEfficient separationFatty oils/acids recovery from wasteFatty acid hydrogenationVolatilesBoiling point

There is disclosed a method for conversion of crude tall oil into high-quality diesel fuels comprising the steps of: (a) removal of non-oil contaminants present in the crude tall oil and recovering valuable organic compounds present in the crude tall oil, thereby forming a refined tall oil stream; (b) removal of the volatile fraction of the refined tall oil stream from step a), thereby forming a volatiles free oil stream comprising organic components with boiling points, at atmospheric pressure, of 170 degrees C. or higher; (c) separation in a vacuum distillation column of the volatiles free oil stream of step b) into two process streams or phases wherein a first process stream or phase is substantially comprising components with boiling points, at atmospheric pressure, in the range of 170-400 degrees C. and a second process stream or phase is substantially comprising components with boiling points, at atmospheric pressure, over 400 degrees C.; (d) lowering the oxygen content in the stream comprised of components with boiling points in the range 200-400 degrees C. from step c) by decarboxylation and / or decarbonylation.

Owner:SUNPINE

Carbonization process of high-volatilize content coal

InactiveCN101113340AGuaranteed not to oxidizeGuaranteed to burnDirect heating destructive distillationHeat carrierVolatiles

The invention relates to a carbonization process of high volatile coal, a direct heating process that heats and distills high volatile coal by using high temperature cycle gas in a shaft furnace as a carrier. Lump coal that moves up and down in the shaft furnace is heated by rising hot gas and the discharged volatiles form char; the char is cooled by cold gas that is introduced by the furnace bottom from the lower part of a furnace and then discharged outside the furnace; the rising gas is introduced outside finally by the furnace top, washed, purified and cooled; one part is taken as a cycle cooling medium, one part is taken as a cycle heat carrier after being per-heated and the rest is taken as a gas external supply and the calorific value is equal to that of a coke oven gas.

Owner:万天骥

Delivery system for dispensing volatiles

InactiveUS20080099572A1Easy to carryMaintain consistencyMovable spraying apparatusSpray nozzlesVena contracta diameterVolatiles

A liquid formulation with uniform consistency over extended periods of time, said method comprising the steps of: providing a liquid formulation in a container, said liquid formulation having a viscosity greater than five centipoise; driving, by means of a power source, a piezoelectric actuator which is coupled to an orifice plate so that the piezoelectric actuator vibrates said plate to produce and disperse fine droplets of said liquid formulation, said plate being formed with orifices having diameters in the range of 1-25 microns; said piezoelectric actuator operating in a bending mode; and during vibration of said plate, delivering said liquid formulation from said container to said plate by capillary action.

Owner:THE PROCTER & GAMBLE COMPANY

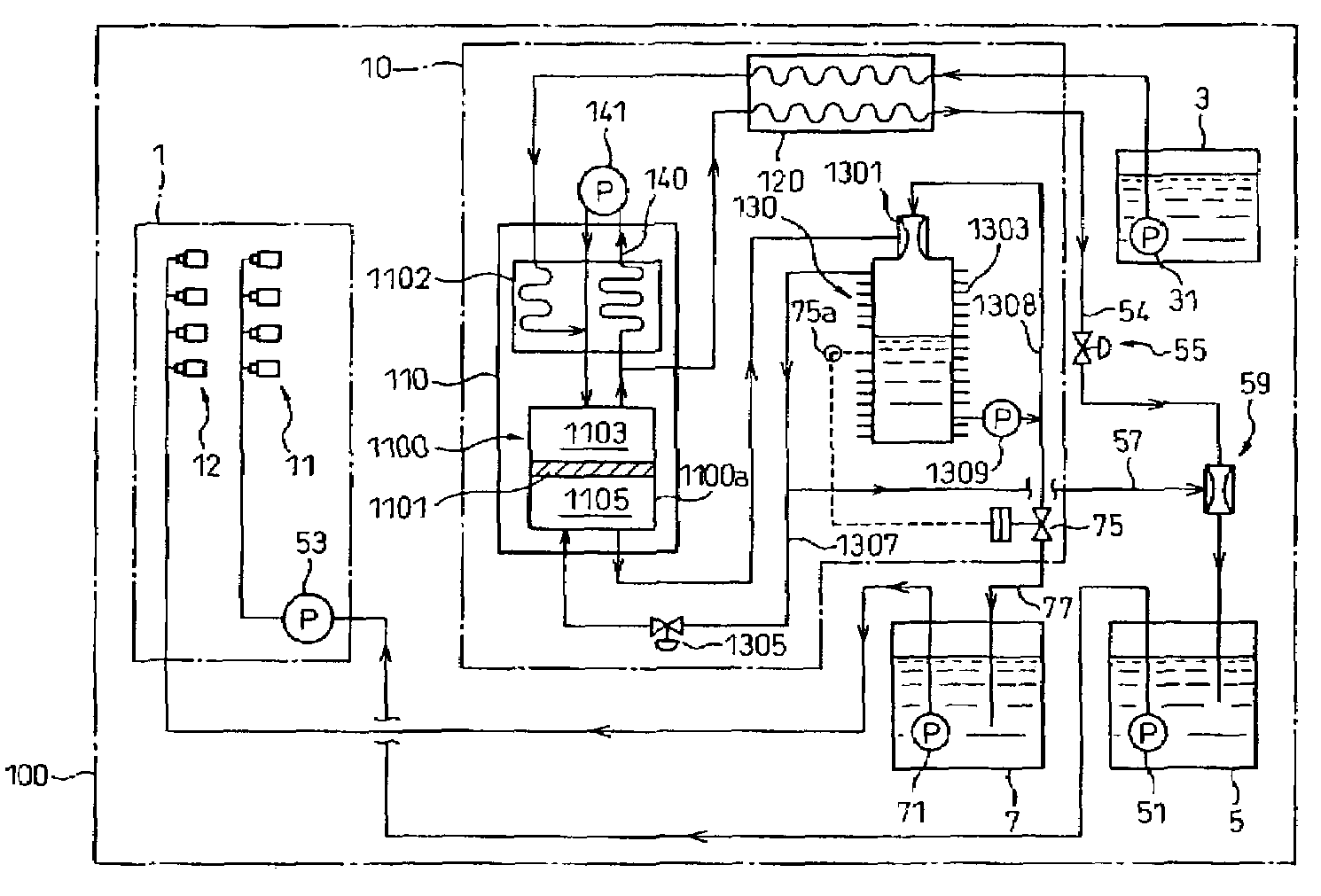

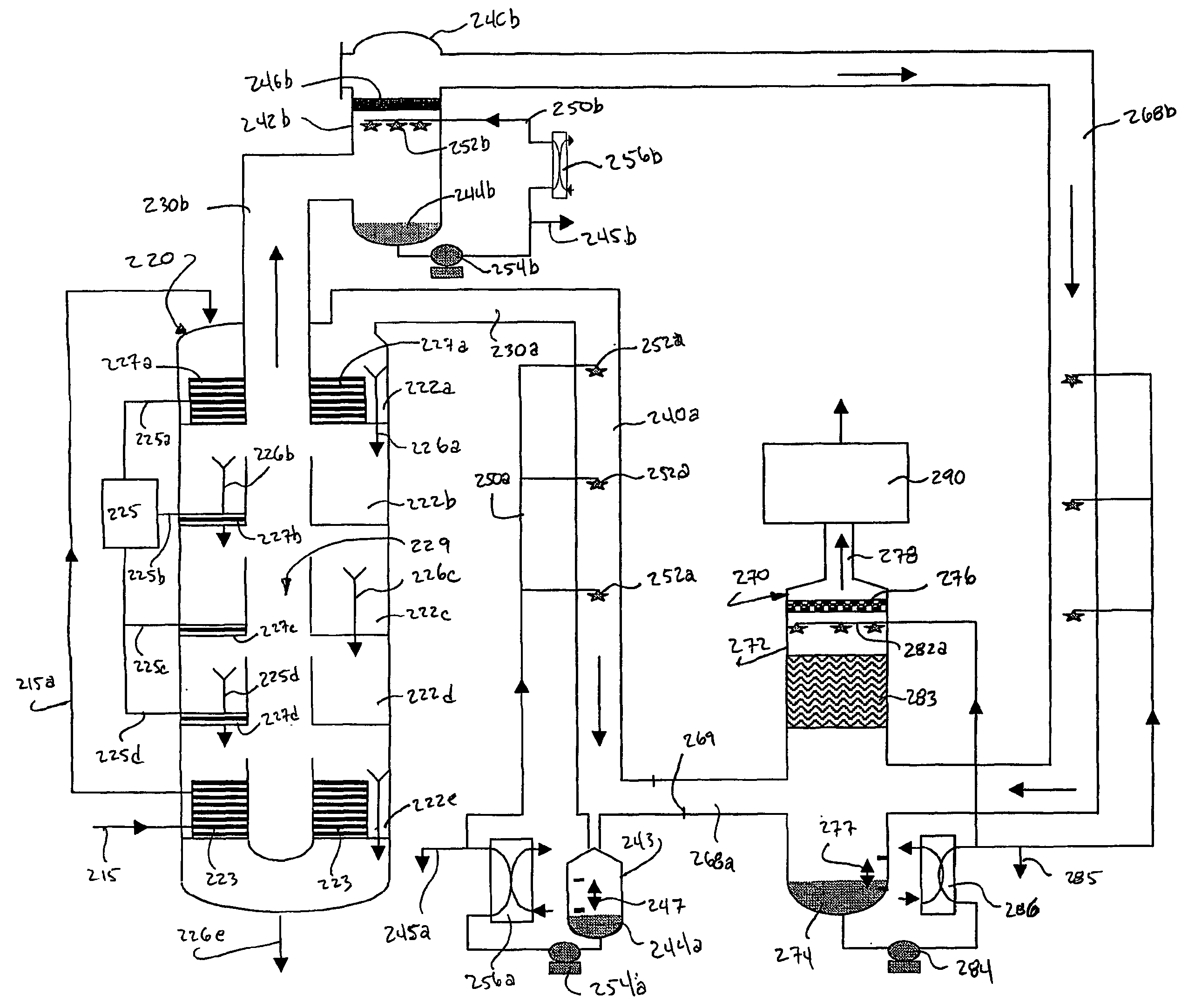

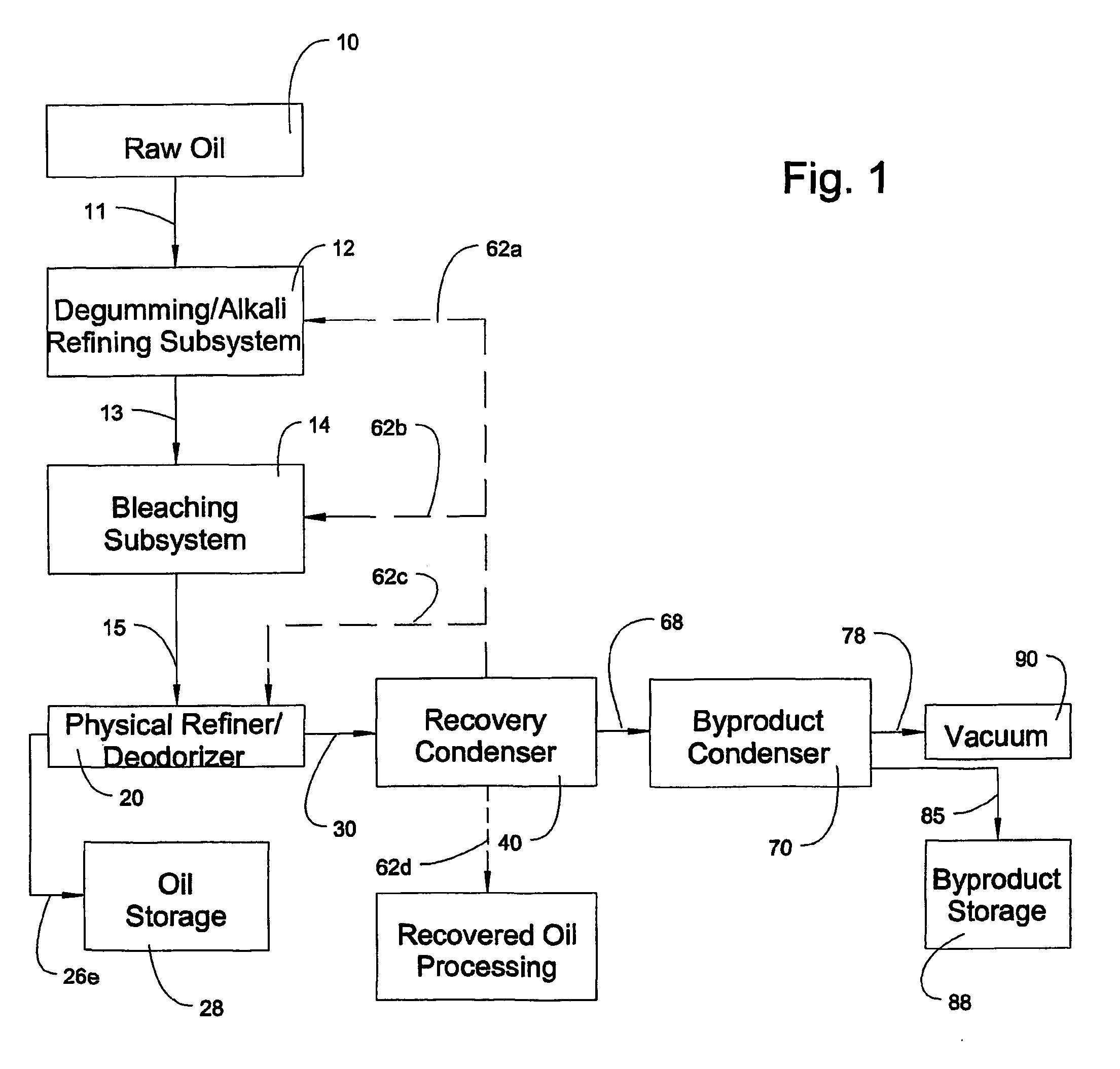

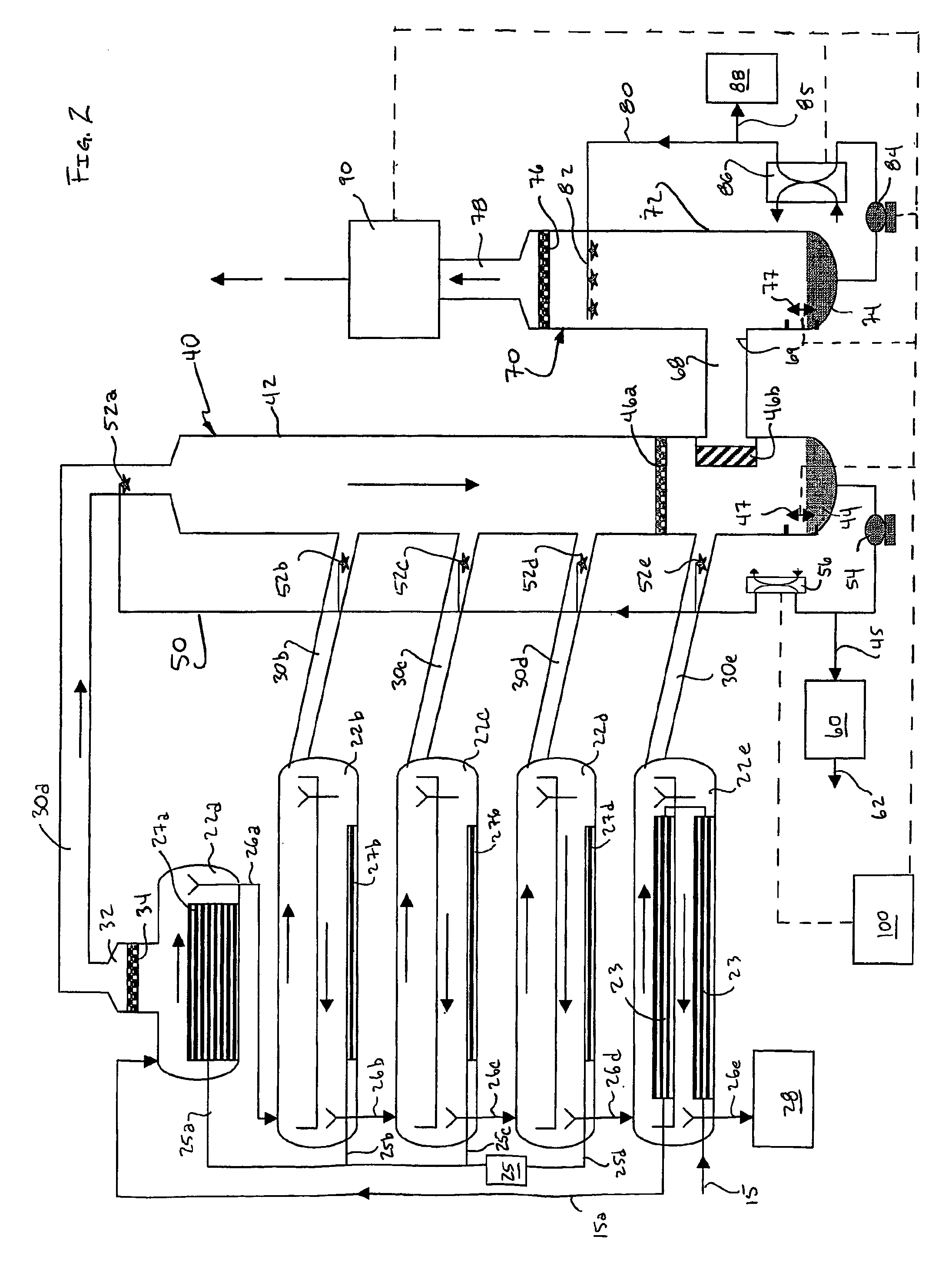

Method and apparatus for processing vegetable oils

InactiveUS7597783B2Fatty oils/acids recovery from wasteOrganic compound preparationVegetable oilVolatiles

Methods for processing oils and apparatus for carrying out such methods are disclosed herein. One embodiment provides a method for processing a partially processed oil, wherein the oil includes glycerides and a volatilizable impurity fraction. The partially processed oil may be processed by driving off a first volatiles stream having a portion of the glycerides and at least a portion of the volatilizable impurity fraction, leaving a deodorized oil. The first volatiles stream may be introduced into a first condensing chamber and a glyceride-rich, impurity-poor fraction may be condensed from the first volatiles stream, leaving a glyceride-poor, impurity-rich second volatiles stream. The second volatiles stream may be passed into a second condensing chamber and a glyceride-poor, impurity-rich second condensate may be condensed from the second volatiles stream.

Owner:CARGILL INC

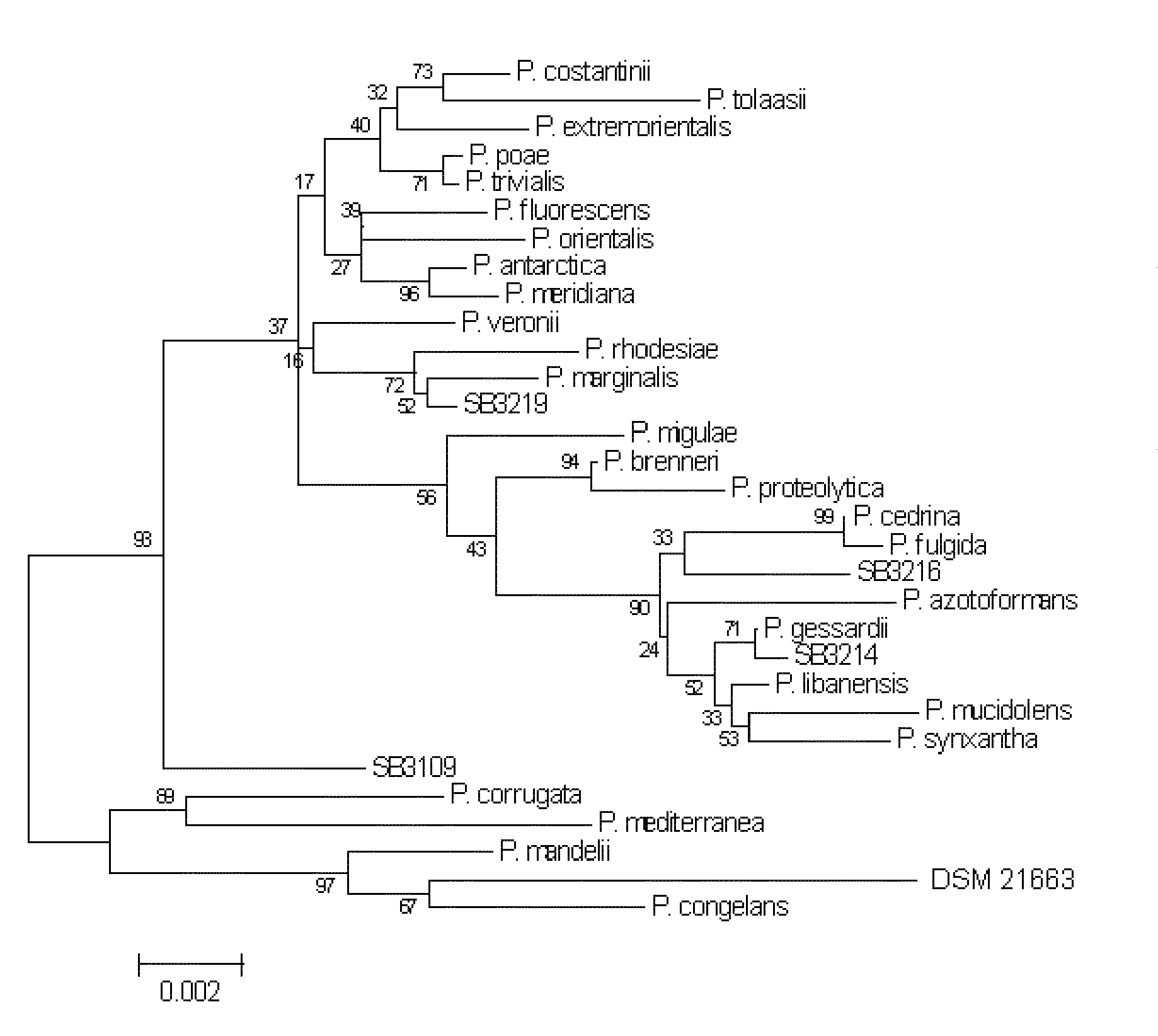

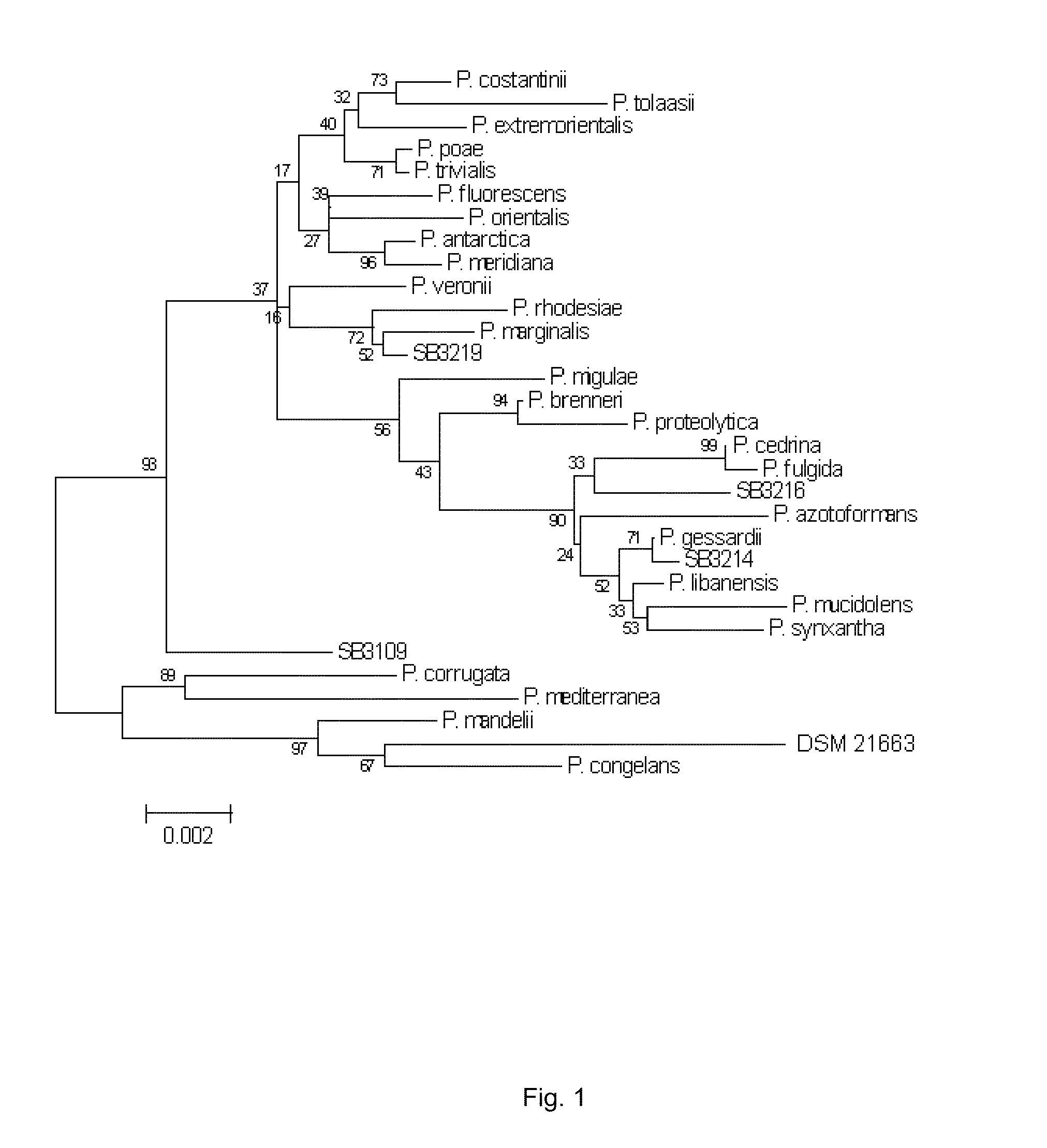

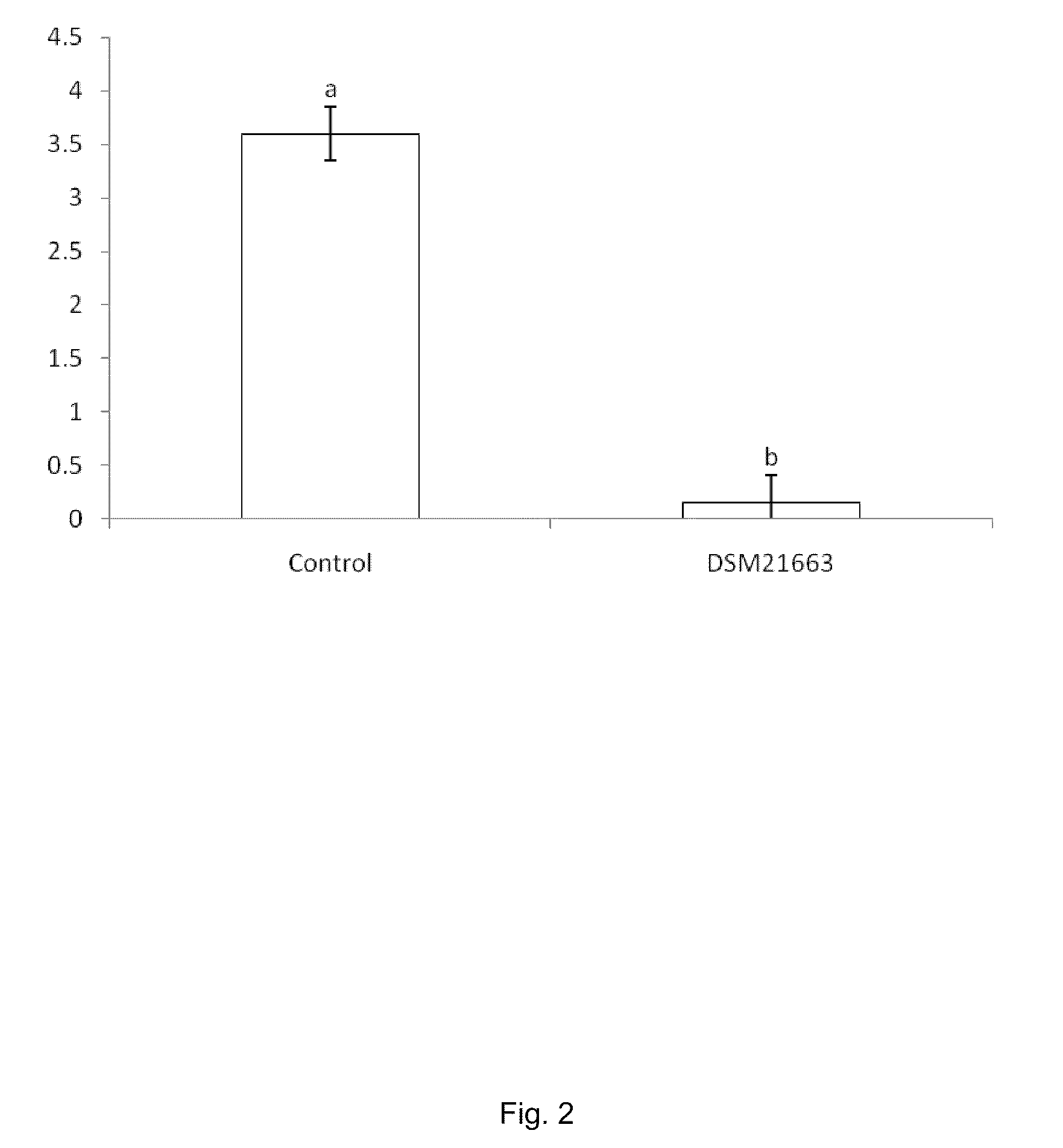

Pseudomonas Bacterium

According to the present invention a new isolate of a Pseudomonas spp, DSM 21663, has been shown to possess unique properties. This Pseudomonas is a plant growth-promoting rhizobacterium (PGPR). Among its modes of action involved in plant growth-promotion are anti-biotic production (2,4-diacetylphloroglucinol, (DAPG); pyrrolnitrin, PRN and others), indole-3-acetic acid (IAA) production and phosphate solubilization, and production of unique volatiles. The strain is fluorescent, oxidase-positive, and has the ability to suppress soil-borne root and foliar pathogens of both fungal and bacterial origin.

Owner:NOVOZYMES AS

Sensor having a thin-film inhibition layer

ActiveUS7948041B2Small sizeReduce power consumptionMaterial nanotechnologyTemperatue controlAnalyteVolatiles

Owner:NANOMIX INC

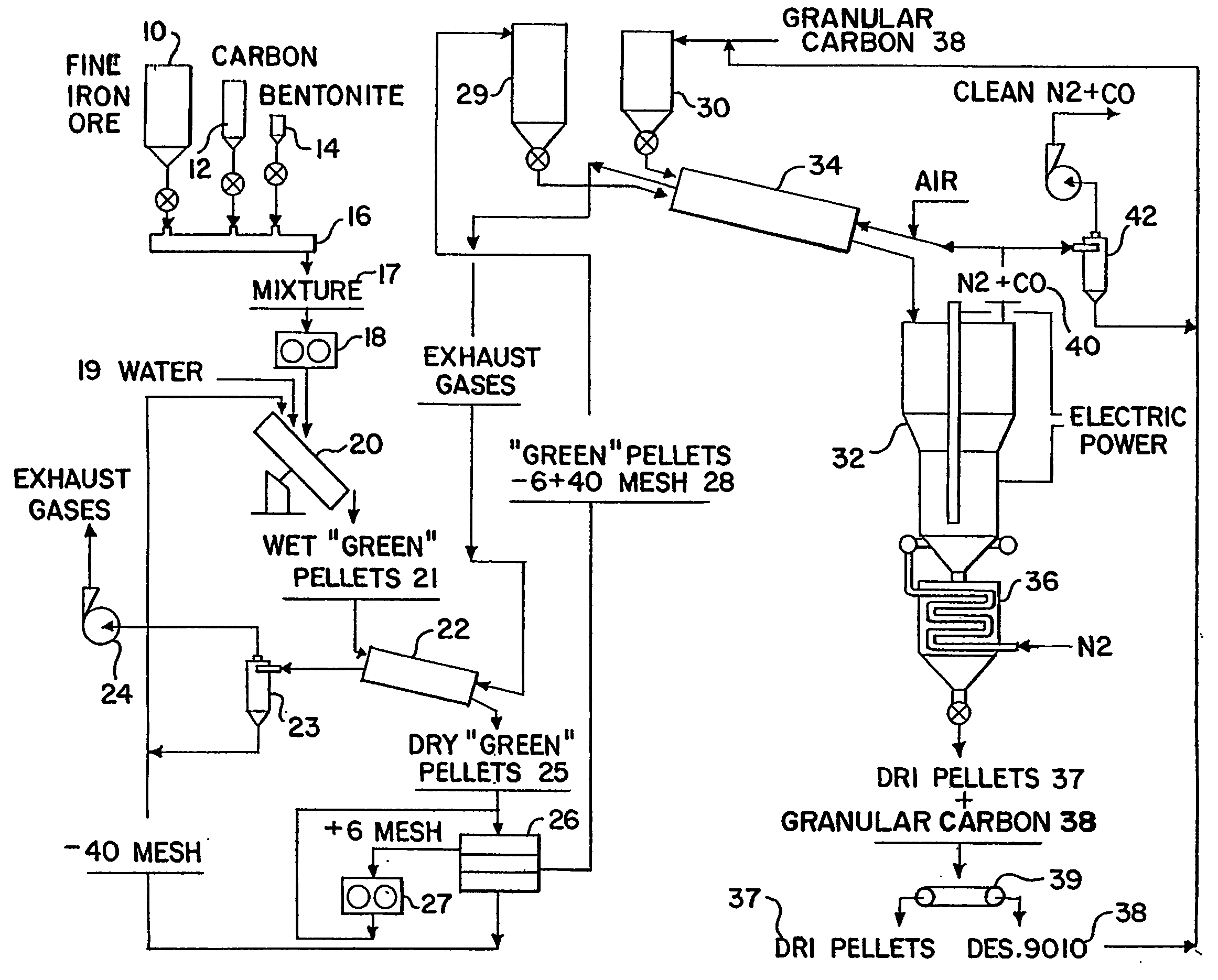

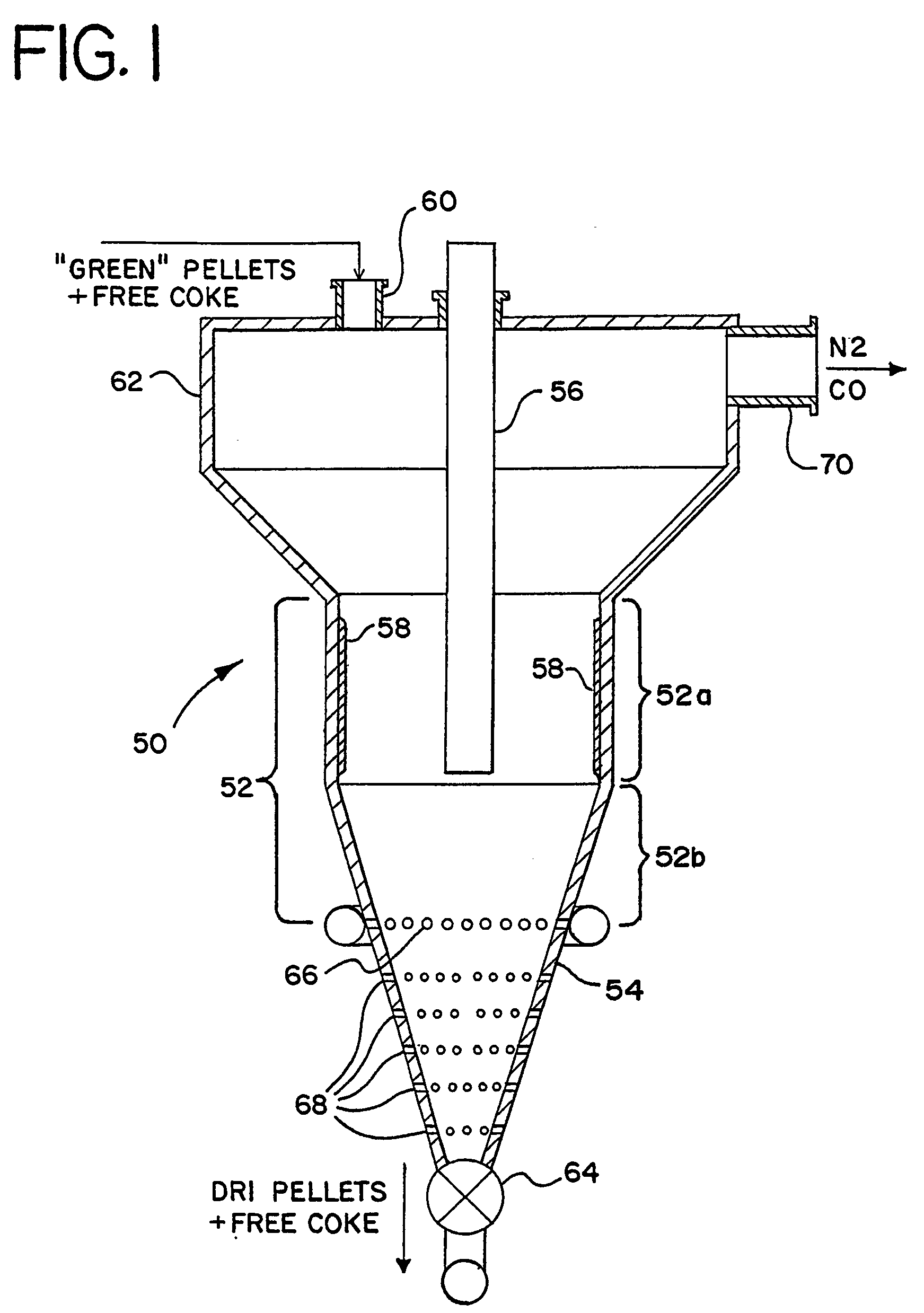

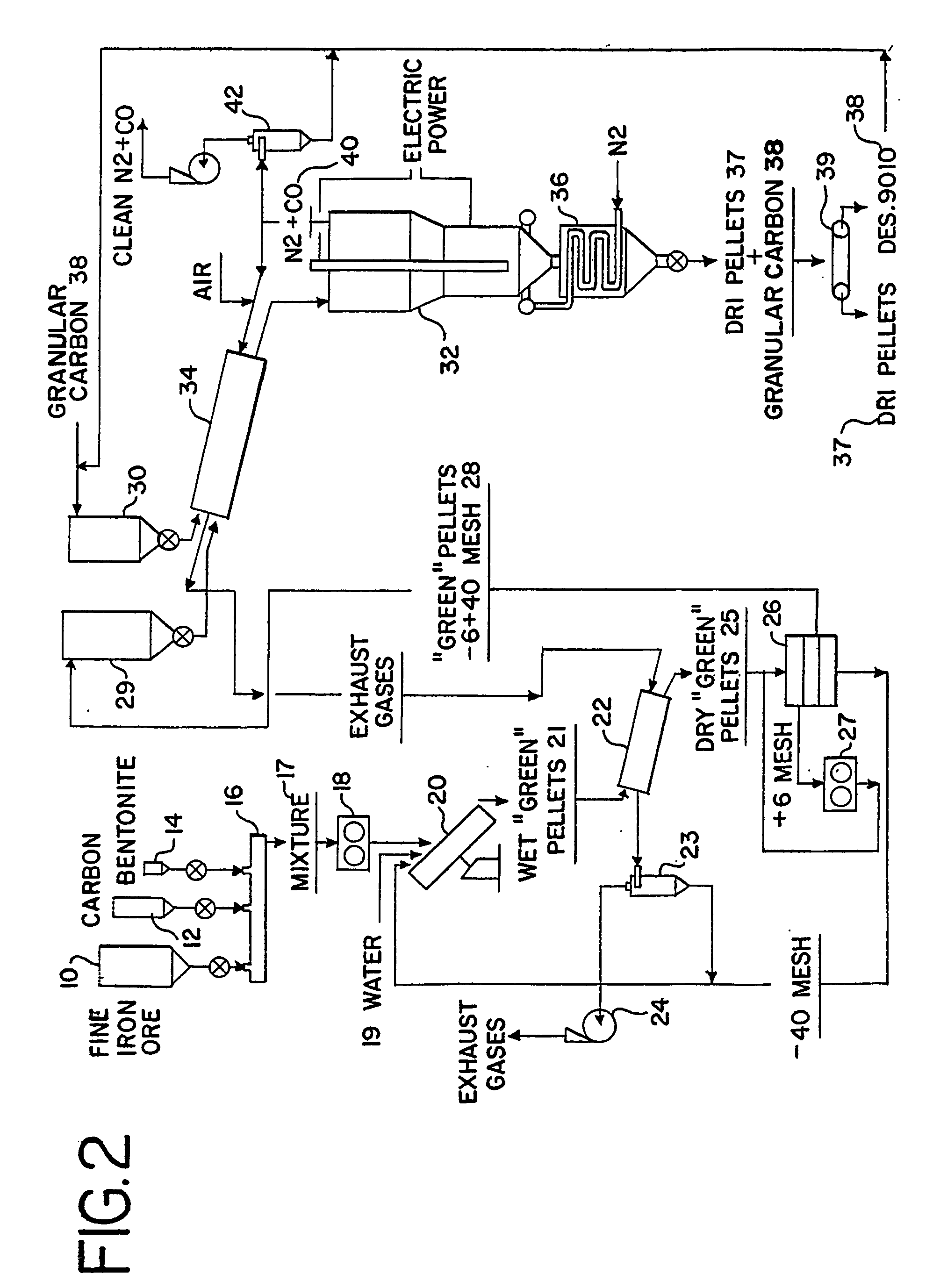

Process and apparatus for the direct reduction of iron oxides in an electrothermal fluidized bed and resultant product

InactiveUS20050092130A1Avoid particle agglomerationInhibits the formation of depositsMaintainance of heating chambersCharge manipulationVolatilesFluidized bed

A method and an apparatus (50) for producing direct reduced iron (37) from dry pellets (25) composed of iron oxide and carbonaceous material. A mixture of pellets (25) and free coke particles (38) with weight relation from 3:1 to 5:1 is fed into the top of an electrothermal fluidized bed (32) that is fluidized by nitrogen. By exposing pellets (25) in the electrothermal fluidized bed (32) to temperatures of between approximately 850-1,100° C. for an average period of between approximately 15-60 minutes, the volatiles are removed and the pellets (25) metallized. Reduced pellets (37) mixed with free coke (38) are discharged from the bottom of fluidized bed (32) and cooled. The reduced iron pellets (37) are physically separated from any free coke (38) and the free coke (38) is recycled back into the fluidized bed (32).

Owner:GOLBERGER WILLIAM M +1

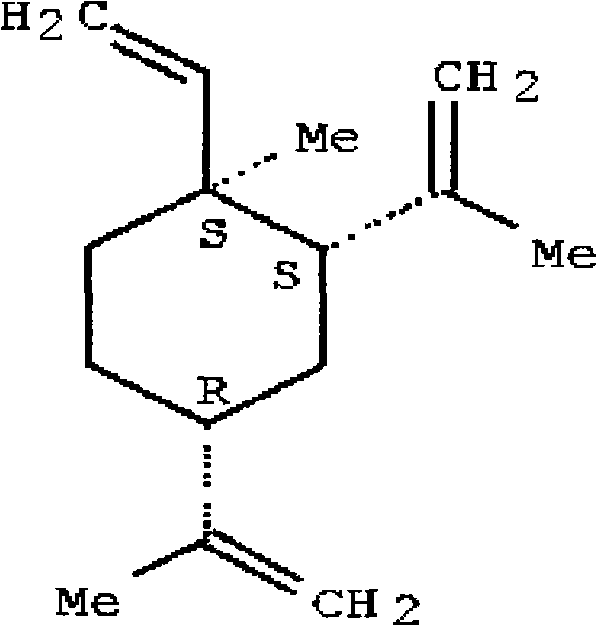

Beta-elemi alkene bulk medicament and method of preparing its preparations

InactiveCN101402543AHydrocarbon active ingredientsDistillation purification/separationVolatilesSelf emulsifying

The invention provides a method for preparing high-purity beta elemene from natural plants containing the beta elemene such as curcuma zedoary (earthnuts or tubers of the curcuma zedoary), cedronella (fresh leaves of the cedronella), yellowtop (roots, stems, leaves, flowers and seeds of the yellowtop) and so on, which can improve the production efficiency from starting materials to the high-purity beta elemene and reduce production cost. Compared with the prior art, the method is mainly different in that the roots, stems, leaves, flowers and seeds of the natural plants are taken as raw materials; oleum volatile of specific parts of the natural plants is obtained by methods for extracting different oleum volatiles, and is distilled by molecular distillation method to remove compositions with high boiling points and non-volatile compositions; impurity compositions are removed by the ethanol extraction method and silver nitrate complex extraction method; and finally the beta elemene with the content between 95.0 and 99.9 percent is obtained through reduced pressure distillation or rectification. The bulk pharmaceutical chemicals not only can be prepared into oral dosing preparation such as emulsion oral liquid, self-emulsifying / self-microemulsifying capsules, soft capsules and so on, but also can be prepared into non-alimentary dosing preparation such as emulsion injection, liquid drugs injection, transdermal absorbent, lung sprays, suppository and so on. The method has the advantages of novel design, concise operating steps, mild operating conditions and improvement of the production efficiency of the beta elemene.

Owner:沈阳万爱普利德医药科技有限公司

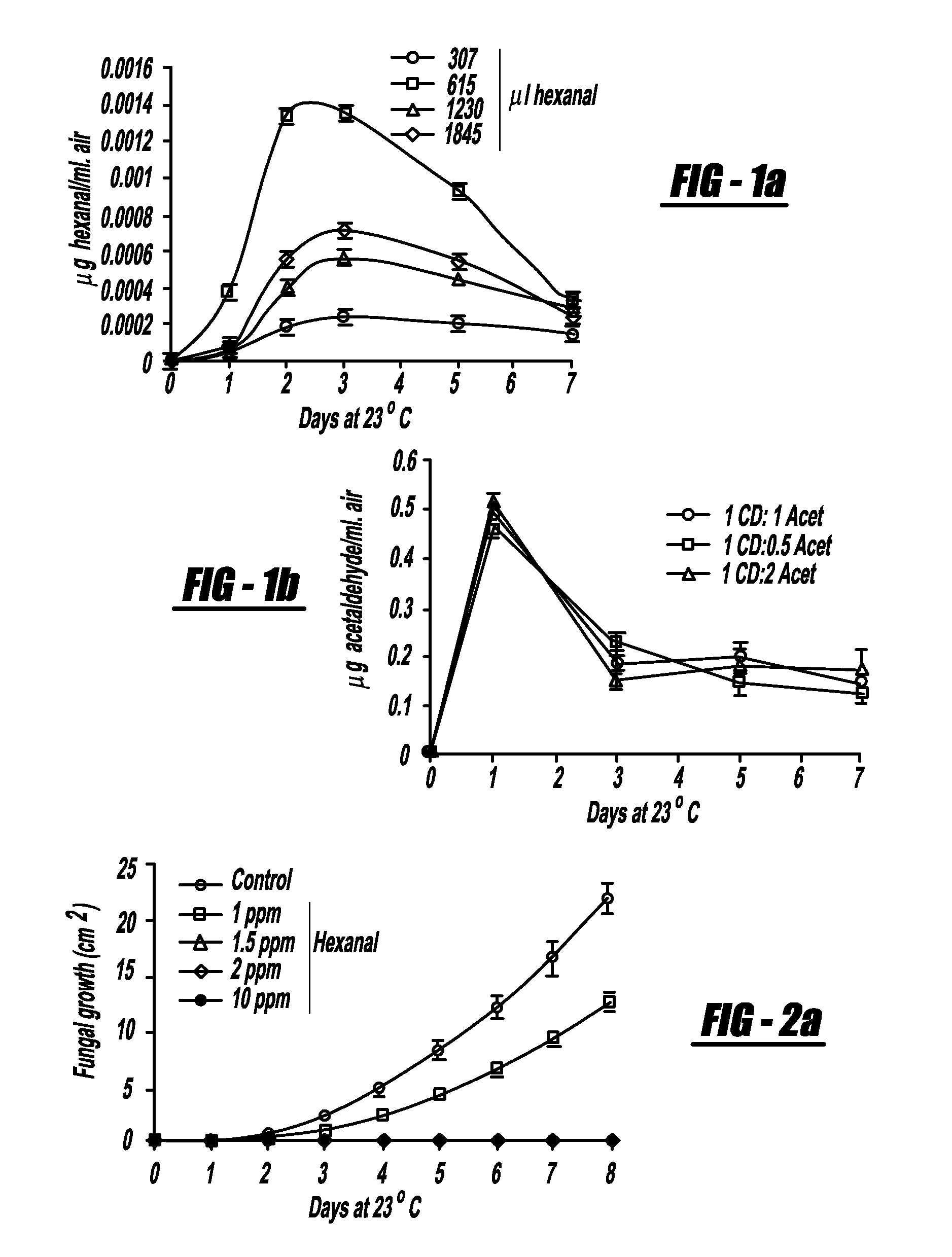

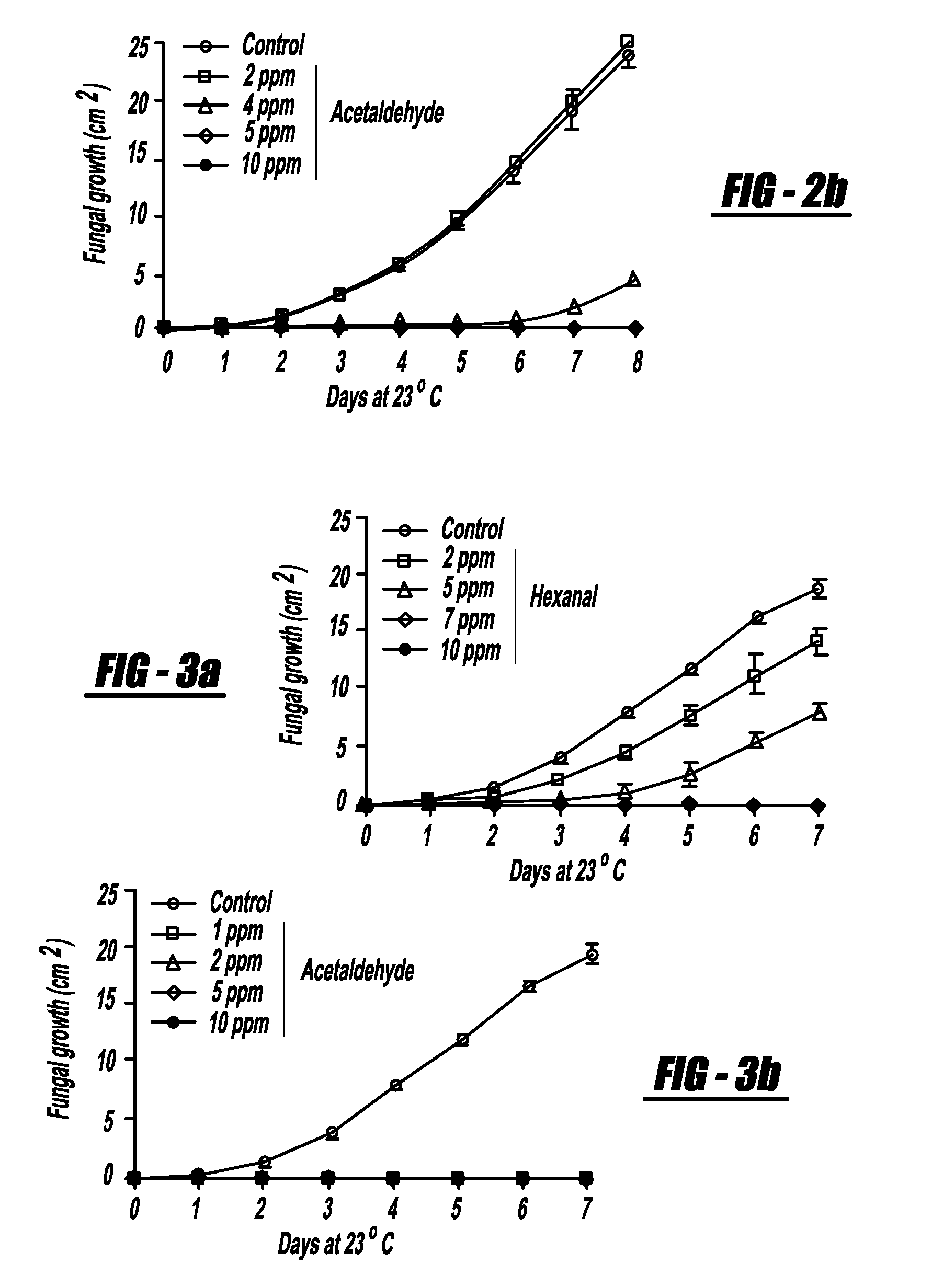

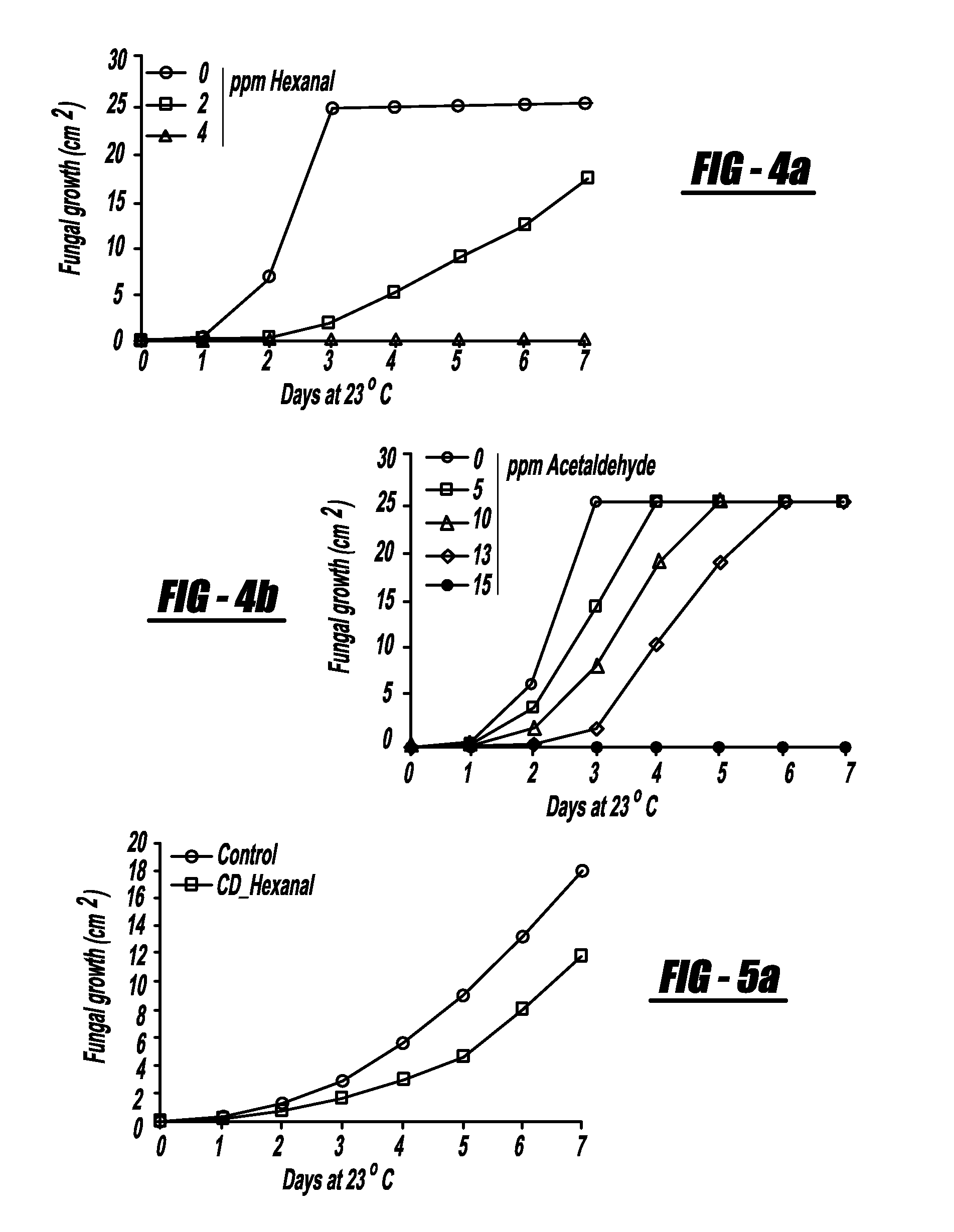

Micro-encapsulation of volatile compounds into cyclodextrins: a new technology to reduce post harvest losses

InactiveUS20070207981A1Reduce economic lossProduced in advanceBiocideFruit and vegetables preservationVolatilesAnti fungal

Systems are provided for preventing post harvest fungal diseases of food systems, such as but not limited to fresh produce, such as but not limited to berries (e.g., blueberries). For example, various anti-fungal compounds can incorporated or encapsulated into cyclodextrins, such as but not limited to α, β and / or γ cyclodextrins. The encapsulated anti-fungal materials can be used alone (e.g., brought into proximity to the produce) or incorporated into film and / or packaging materials that are used in the packing and / or storing of produce. By way of a non-limiting example, the anti-fungal compounds can include volatile compounds such as but not limited to acetaldehyde, hexanal and 2E-hexenal. The cyclodextrins provide controlled release of the volatiles over a period of at least several days such that they prevent or inhibit fungal growth, including but not limited to several species of the Colletotrichum, Altermaria, Botrytis, Penicillium and / or Aspergillus genera.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Lignite drying water recycling and drying tail gas recycling system

InactiveCN103575068AImprove recycling efficiencyPromote circulationDrying solid materials with heatDispersed particle filtrationWater useVolatiles

The invention relates to a lignite drying water recycling and drying tail gas recycling system which comprises a hot blast heater, a drier, a dry type deduster, a heat pump machine set, a mixing chamber and a water spraying chamber, wherein the mixing chamber is used for mixing fume of the hot blast heater and a recycled tail gas heated by the heat pump machine set into low-temperature hot fume to be used as a drying medium of the drier; the dried tail gas and the cold water sprayed out from a nozzle of the water spraying chamber are sufficiently mixed and subjected to heat-humidity exchange in the water spraying chamber; part of steam in the dried tail gas is condensed into water to be recycled; at the same time, visible heat and latent heat of vaporization are released; the cold water used in the water spraying chamber is supplied by the heat pump machine set; the water recycled in the water spraying chamber flows out through an overflowing tube and is collected. The fume discharged from the water spraying chamber is heated by an air cooling condenser of the heat pump machine set, is subsequently fed into the mixing chamber, is mixed with the fume generated from the hot blast furnace, and is subsequently used as the drying medium of the drier. The system is at a low temperature and is dry, and the oxygen content of the drying medium is low, so that volatiles in coal are prevented from being lost, and precious water resource is recycled.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

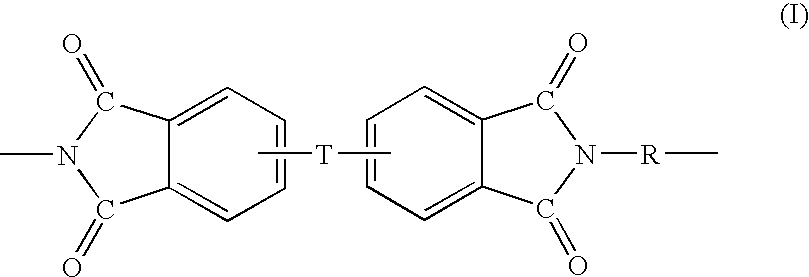

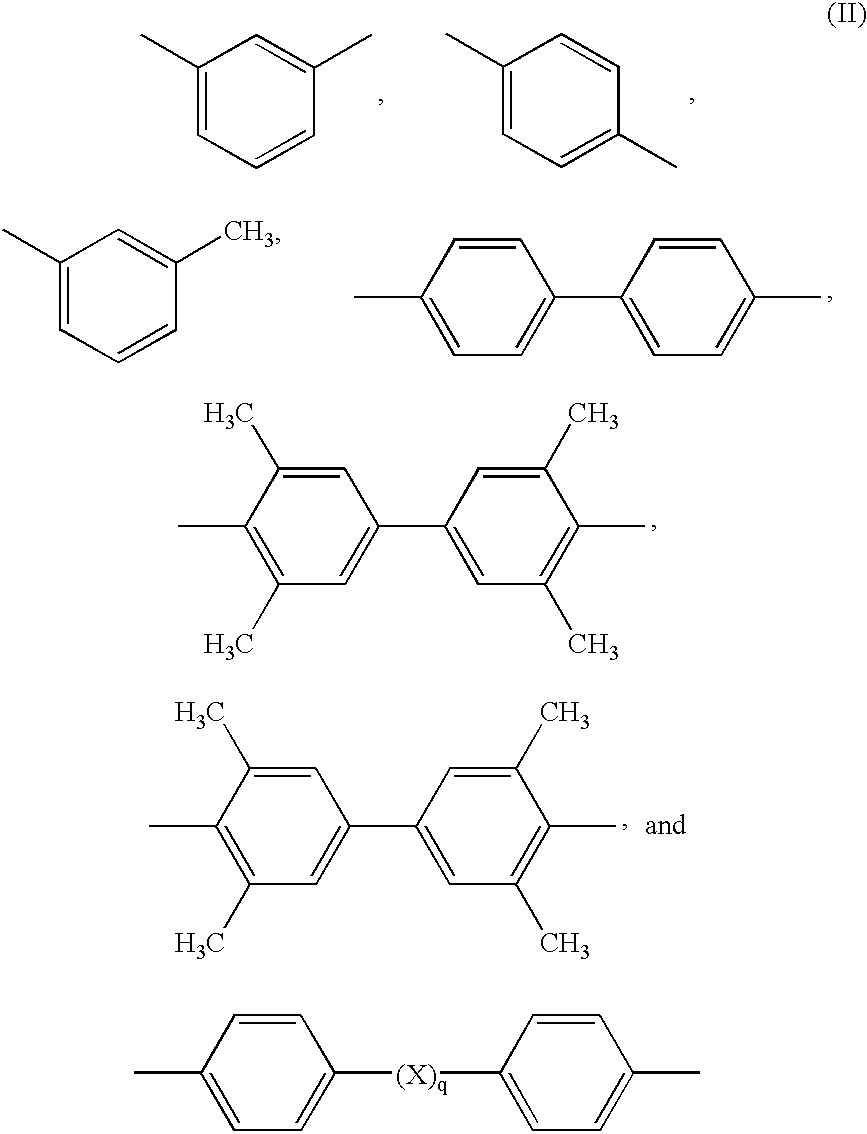

Process for producing metha crylic polymer

InactiveCN1303397AHigh transparencyGood moldabilityChemical/physical/physico-chemical stationary reactorsProduction rateVolatiles

A process for producing a methacrylic polymer comprising: a step in which bulk polymerization is conducted in one complete mixing type reactor at a temperature of 110 to 160 DEG C using a chain transfer agent in a specific concentration and a free-radical initiator having a specific half-life so as to result in a polymer content of 35 to 65% by weight; a step in which the reaction mixture is continuously discharged from the reactor and sent through a plug flow type reactor while pressurizing the mixture at or above a given value throughout the reactor; a step in which the reaction mixture is passed through a plug flow type reactor having a specific inner-wall temperature while polymerizing the mixture using a free-radical initiator having a specific half-life so as to result in a polymer content at the outlet of 50 to 85% by weight; and a subsequent step in which volatiles are continuously removed from the reaction mixture. By the process, a methacrylic polymer having excellent moldability can be efficiently produced.

Owner:MITSUBISHI CHEM CORP

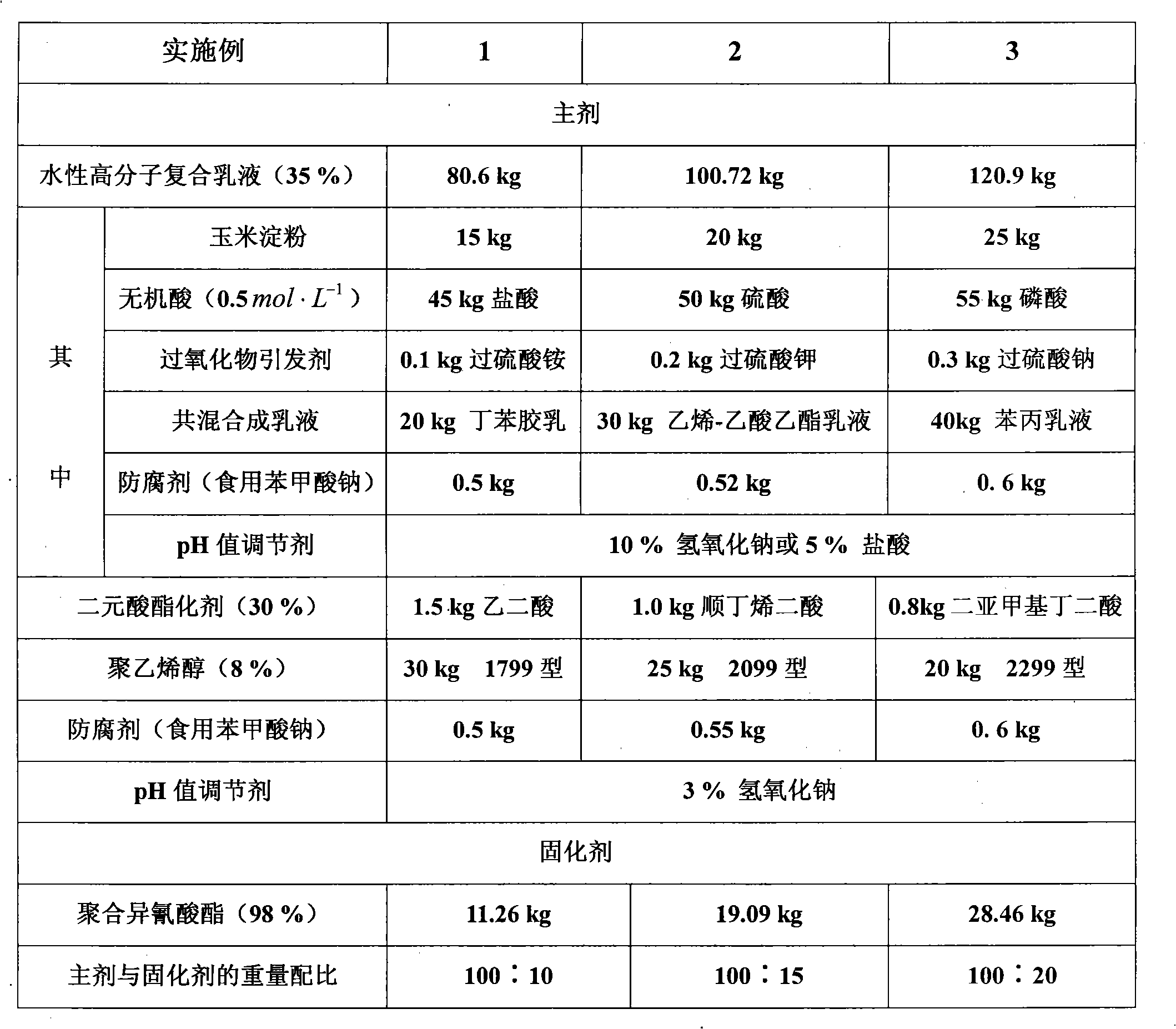

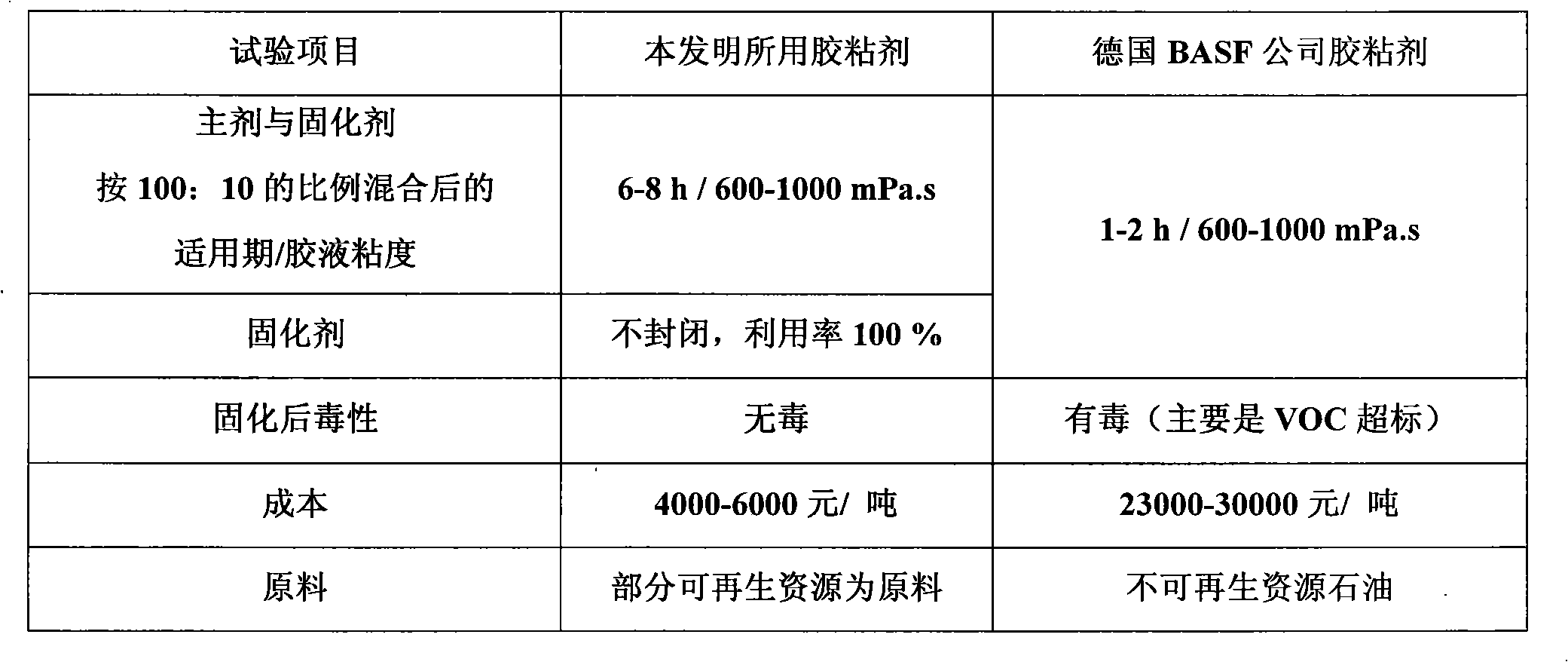

Aqueous macromolecule-isocyanic ester stalk artificial board and preparation thereof

ActiveCN101314235ARealize green productionGood workmanshipPolyureas/polyurethane adhesivesFlat articlesWater basedVolatiles

The invention relates to a water-based macromolecule-isocyanate straw hard board and a preparation method thereof. Straws of rice, wheat, corn or other crops, a water-based macromolecule-isocyanate adhesive and a straw interface performance modifying agent are used as raw materials, and the straws are treated by section cutting, kneading and modification, adhesive application and heat pressing to produce the water-based macromolecule-isocyanate straw hard board. A mixture ratio of the absolute dry straws to the water-based macromolecule-isocyanate adhesive to the straw interface performance modifying agent by weight is 100 to 10-16 to 0.05-0.15. The straw hard board uses the water-based macromolecule-isocyanate adhesive to replace a pure isocyanate adhesive, radically improves the problems of toxic organic volatiles, poor prepressing performance, adhesion on boards, etc., remarkably reduces cost and really realizes green production, and the raw materials after the treatment of kneading and modification have good prepressing and molding performances and high one-off qualified rate. The water-based macromolecule-isocyanate straw hard board has the characteristics of unique design, long active period, excellent aging, water and heat resisting performances, simple operation, easy availability of equipment, no environmental pollution, easy implementation, etc., and produces huge entironmental, social and economical benefits after the water-based macromolecule-isocyanate straw hard board is popularized.

Owner:BEIHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com