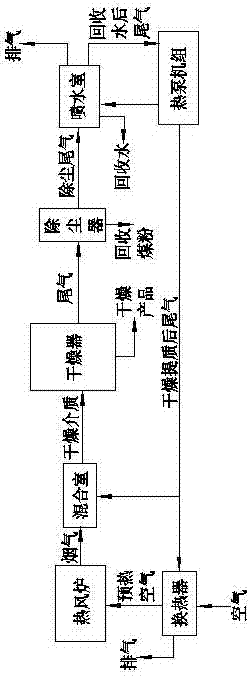

Lignite drying water recycling and drying tail gas recycling system

A technology for drying tail gas and water, which is applied in the directions of drying solid materials, heating to dry solid materials, and drying. It can solve the problems of unavoidable volatiles such as CO, high investment, and low water recovery efficiency, so as to improve energy efficiency. Utilization efficiency and recycling level of resources, high system safety, and high recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

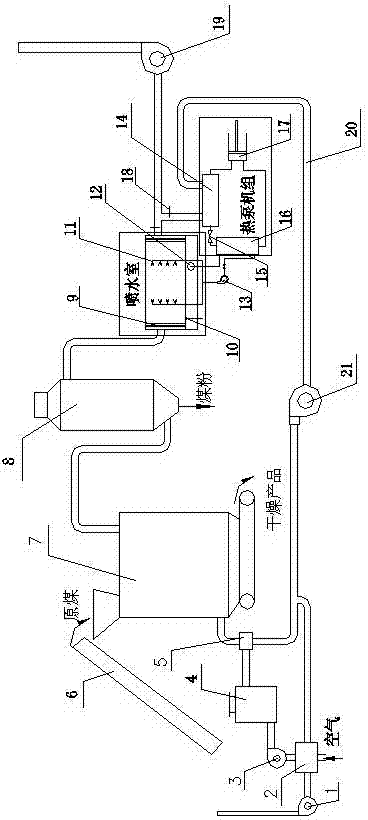

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the purpose is only to better understand the content of the present invention. Therefore, the examples given do not limit the protection scope of the present invention.

[0026] In this embodiment, the raw coal is dried at 100 t / h, and the total moisture content of the raw coal is dehydrated from 35% to 15% as an example for illustration. The annual average temperature of the place where the embodiment is located is 5°C.

[0027] Referring to the accompanying drawings, the air is preheated by the air preheater 2 and enters the hot blast stove 4 through the blower 3. In the hot blast stove 4, the air and coal undergo a combustion reaction to generate high-temperature hot flue gas at 900-1200°C. The dry tail gas after upgrading by the heat pump unit is fully mixed in the mixing chamber 5 into low-temperature hot flue gas at 200-350°C, and sent to the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com