Patents

Literature

1975 results about "Water recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water Recovery, LLC is an award-winning Centralized Wastewater Treatment plant specializing in non-hazardous waste-water treatment and used oil recycling. Services: WRI offers a full spectrum of integrated services to manage your wastewater from generation through treatment, while reducing your handling costs and remaining fully compliant.

Process to produce aromatics from crude oil

ActiveUS20150321975A1Low impurity contentHigh API gravityThermal non-catalytic crackingTreatment with plural serial stages onlyVapor–liquid separatorWater flow

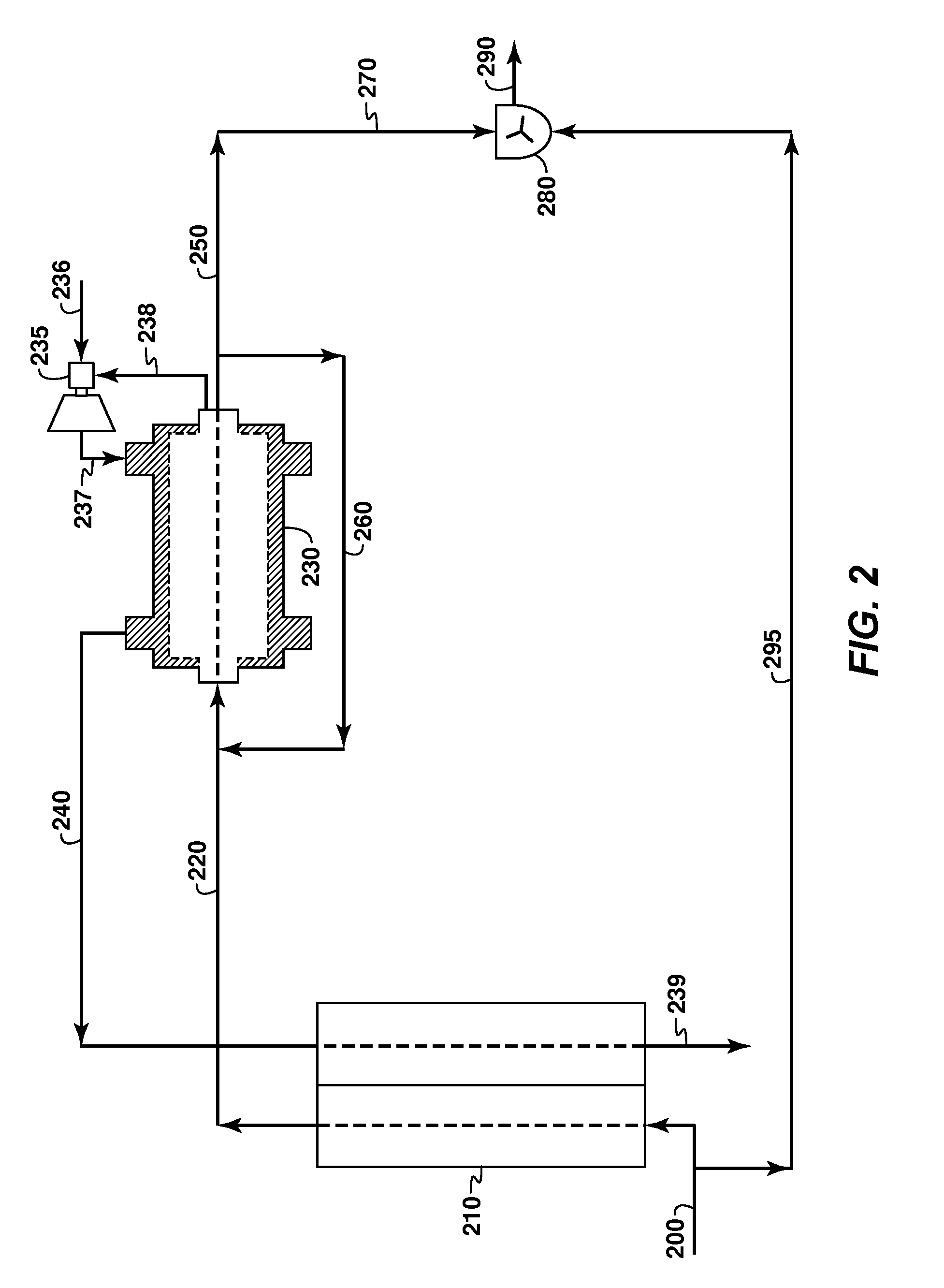

A process for producing aromatics from a hydrocarbon source in the presence of supercritical water comprising the steps of mixing a pressurized, pre-heated water stream with a pressurized, pre-heated petroleum feedstock, the pressurized, pre-heated water stream at a pressure above the critical pressure of water and a temperature above the critical temperature of water, feeding the combined stream to a supercritical water reactor to create a modified stream, cooling and depressurizing the modified stream, separating the depressurized stream in a vapor-liquid separator, condensing the vapor stream, separating the condensed stream into a water recovery stream and a light product recovery stream, extracting the aromatics from the light product recovery stream, depressurizing the liquid stream, separating the depressurized liquid stream in a heavy separator into an upgraded product stream, and recycling part of the upgraded product stream to the pressurized, pre-heated petroleum feedstock as a product recycle.

Owner:SAUDI ARABIAN OIL CO

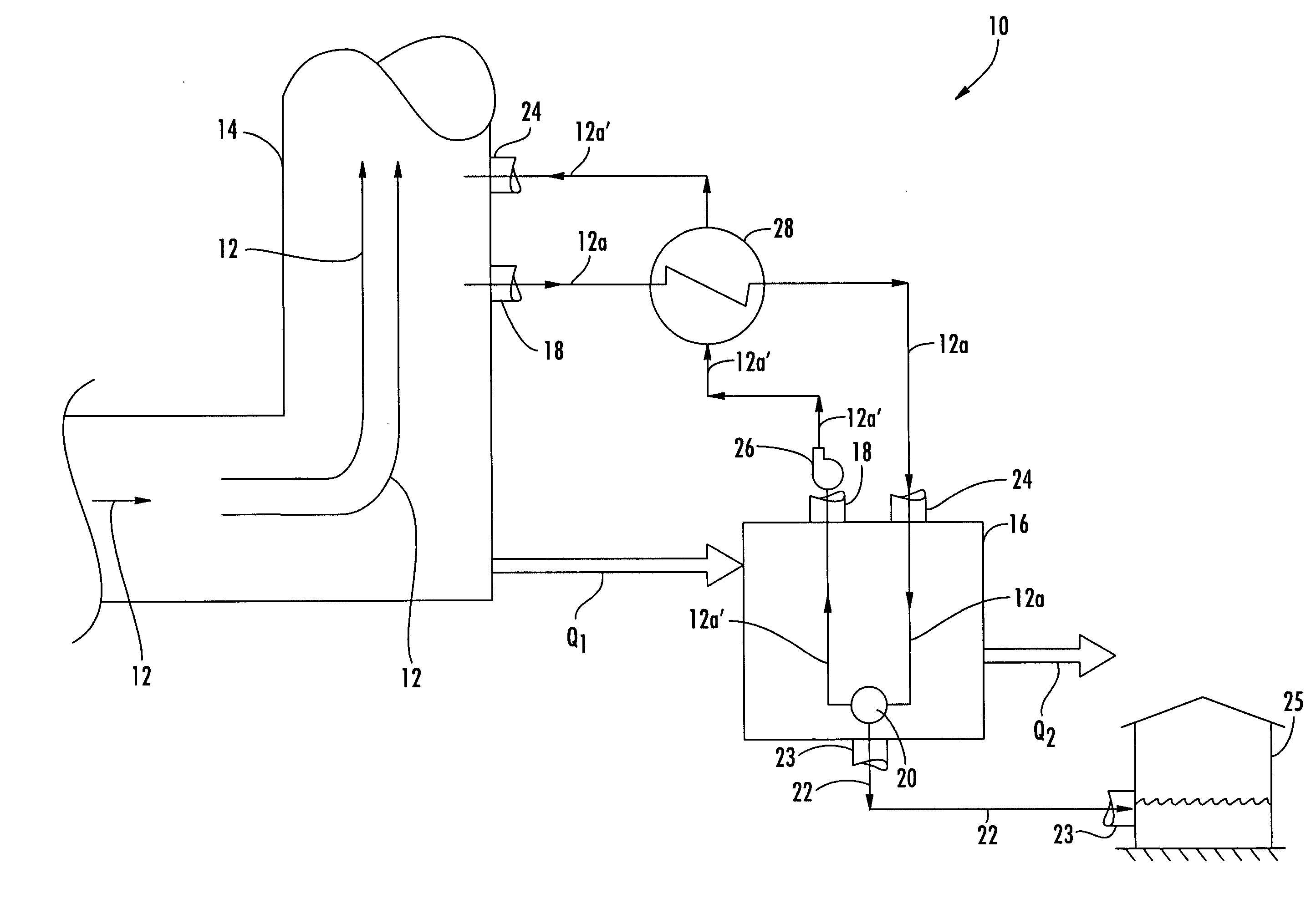

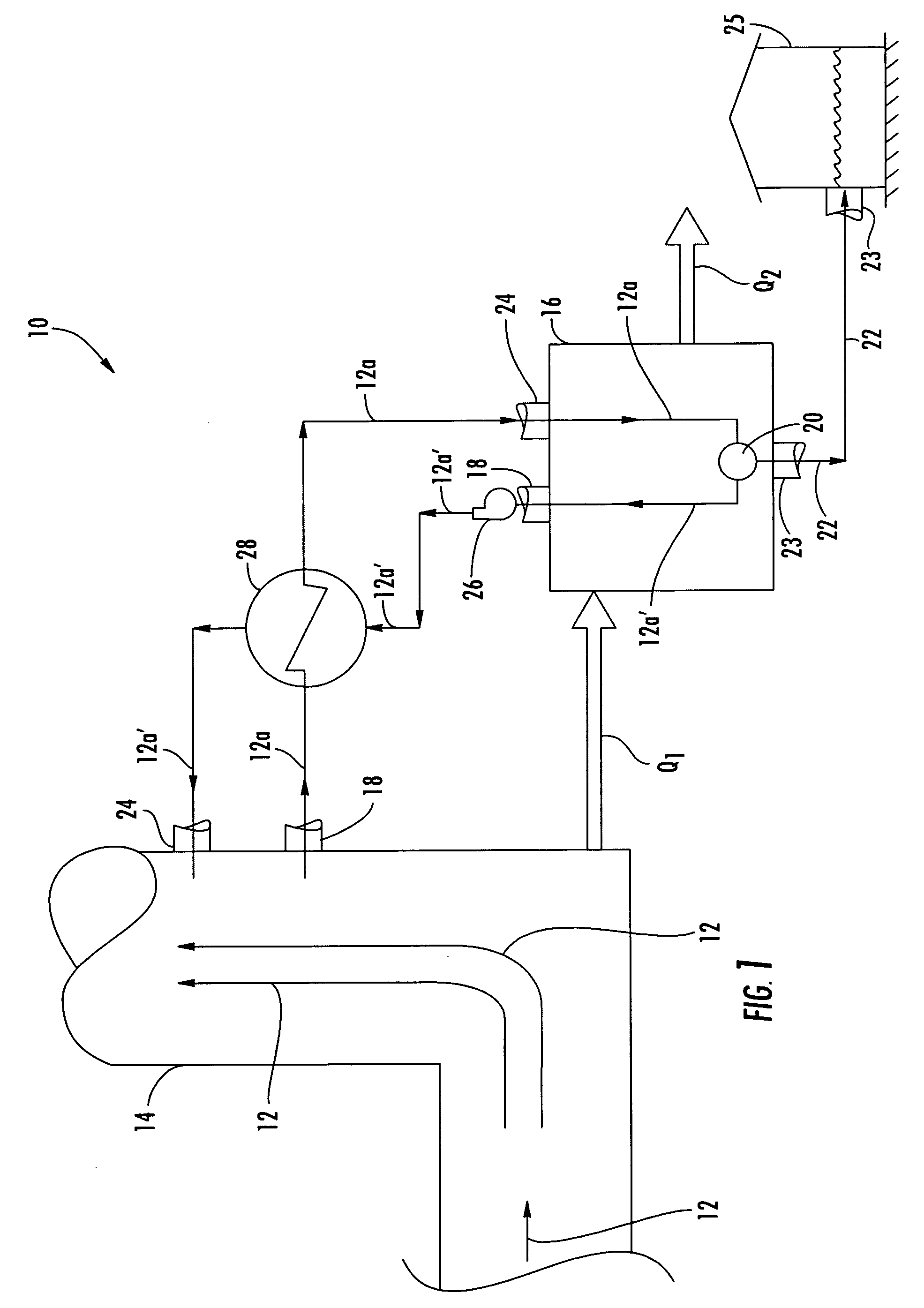

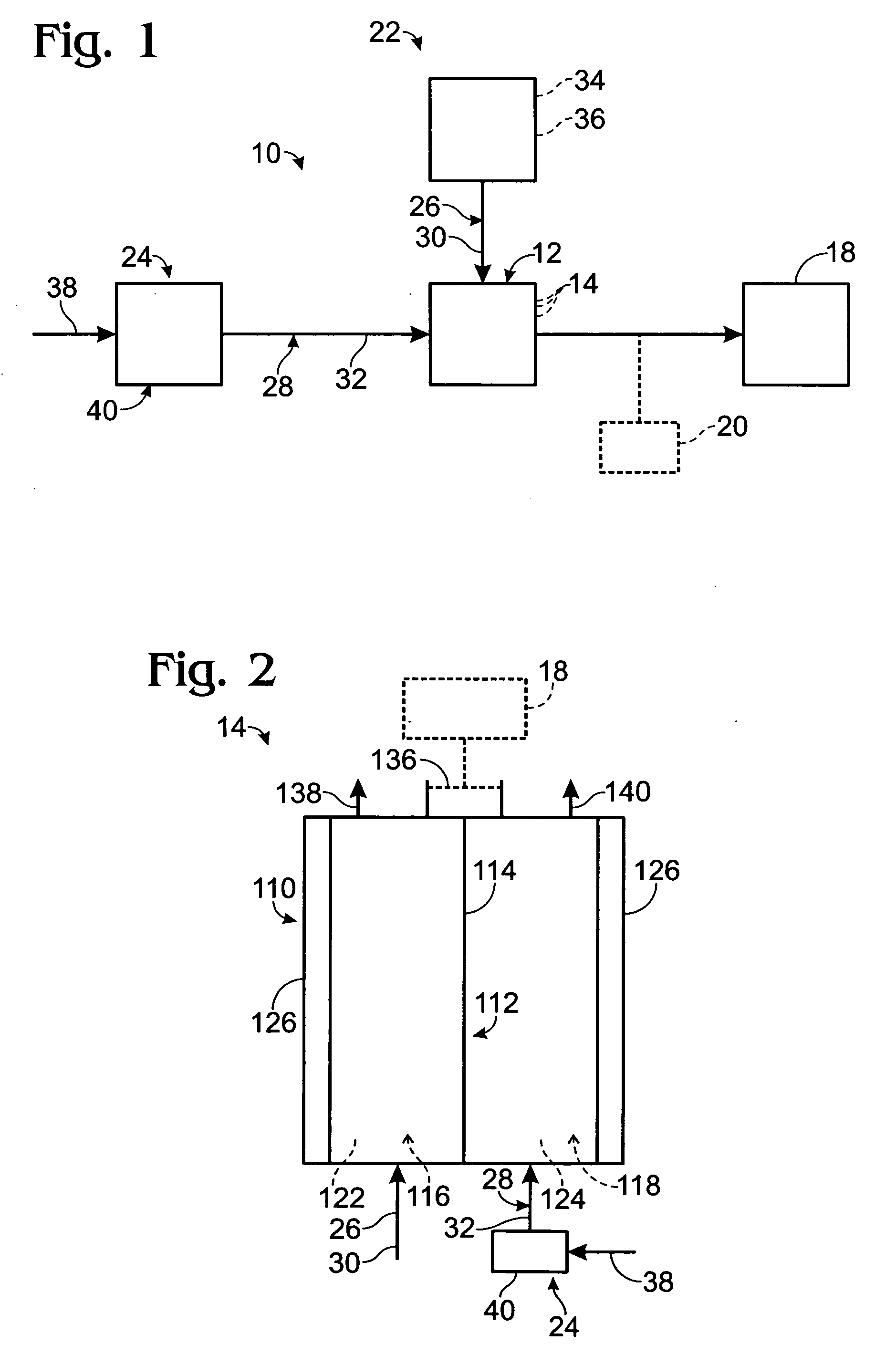

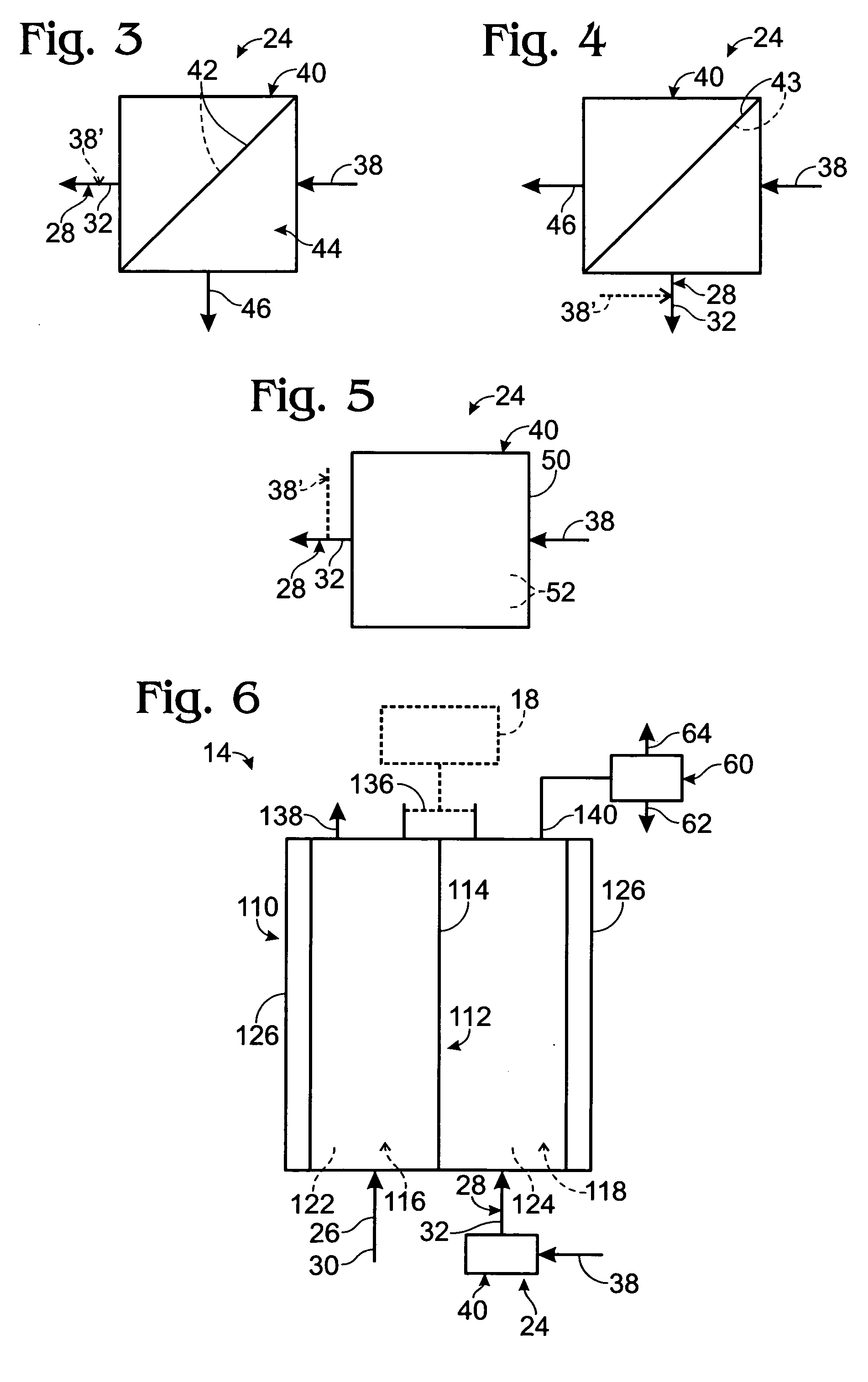

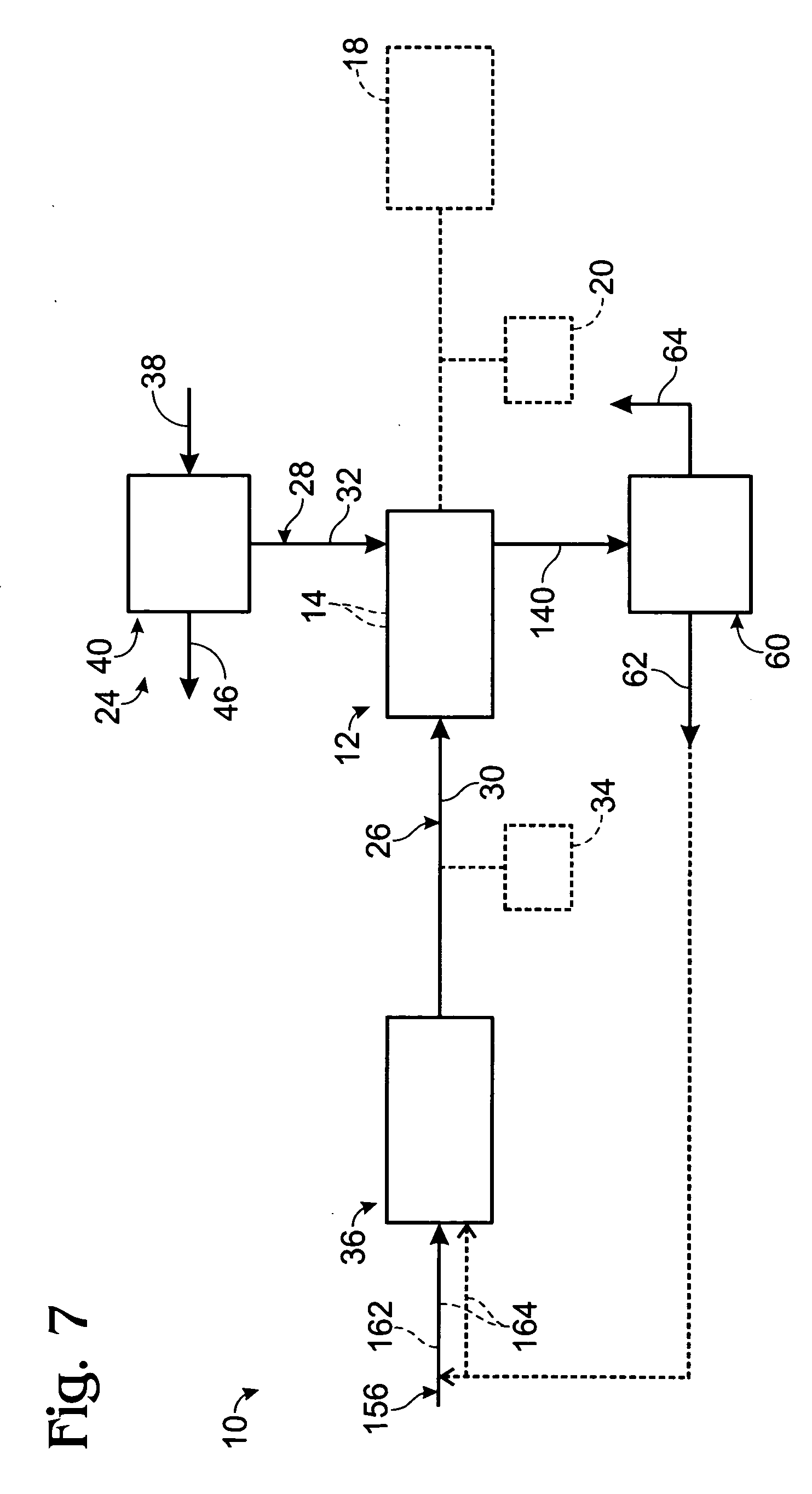

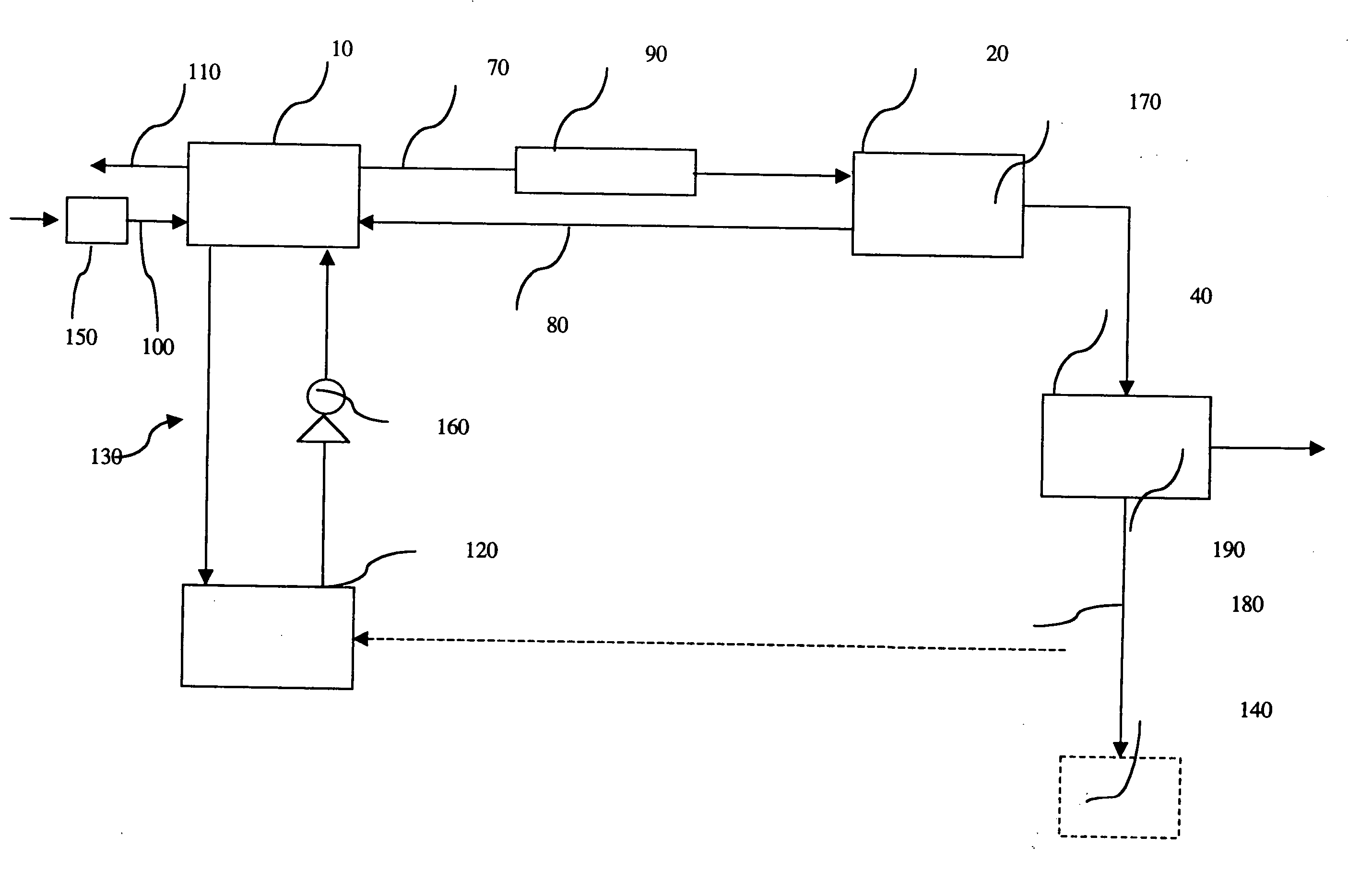

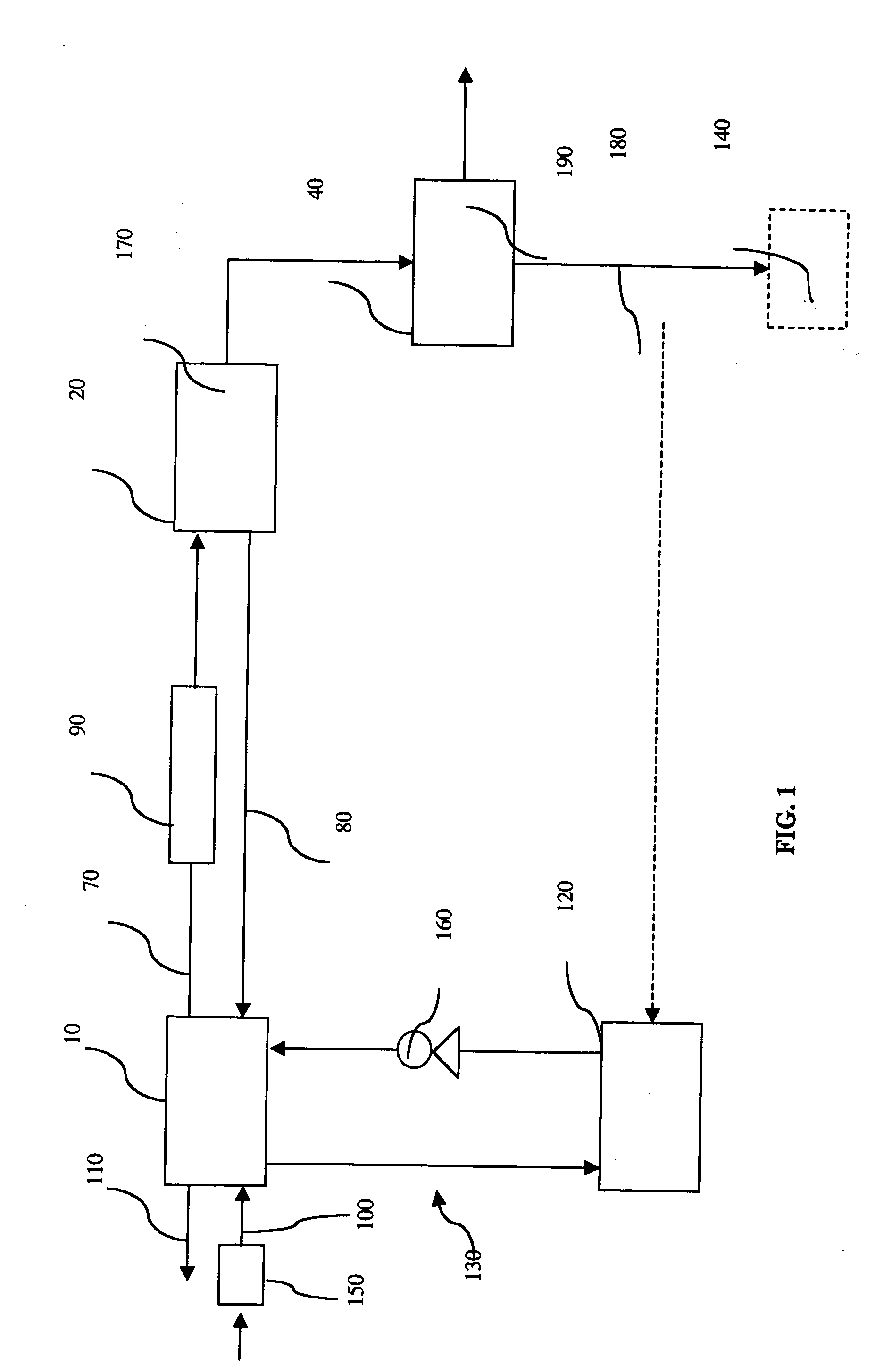

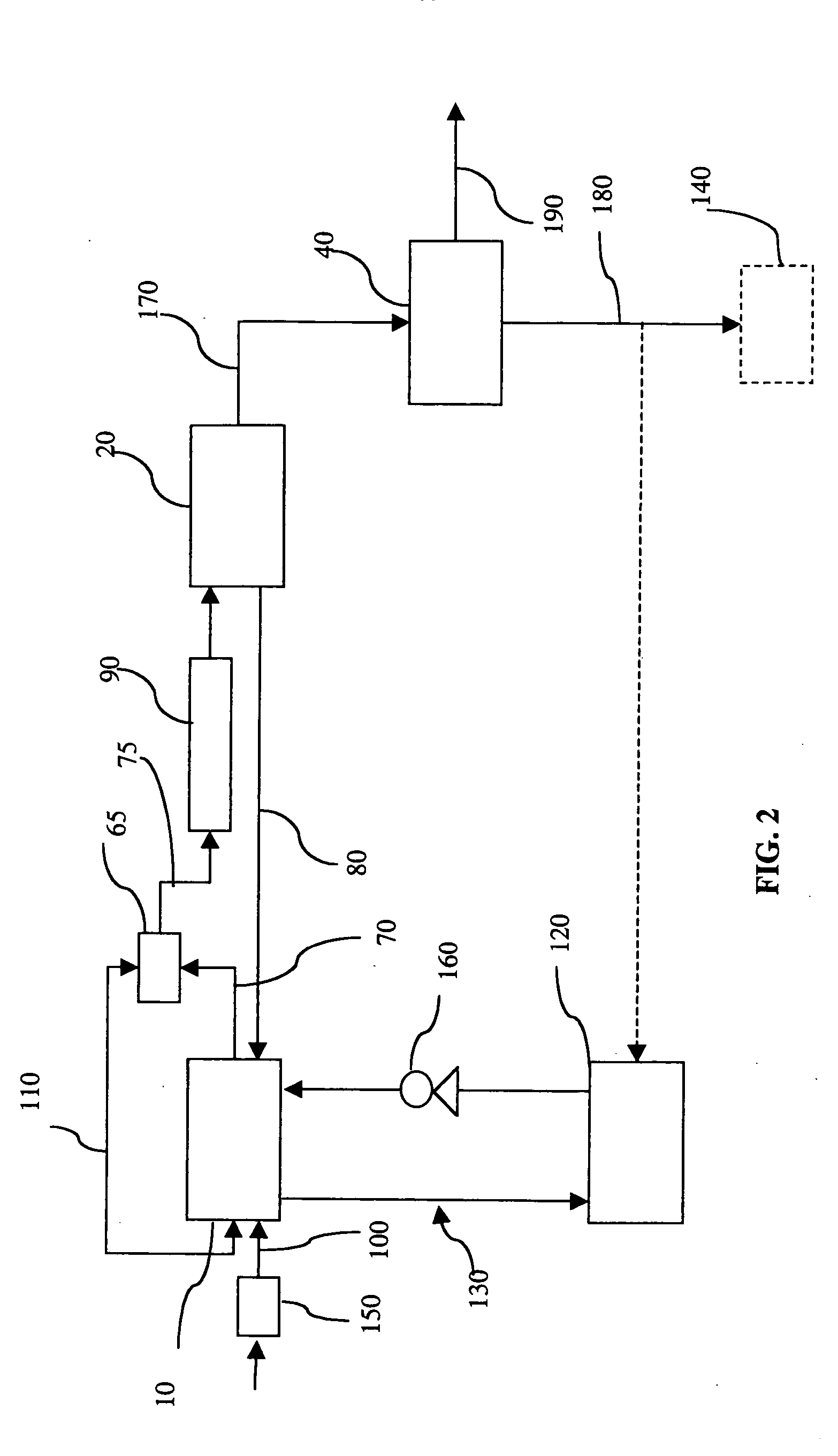

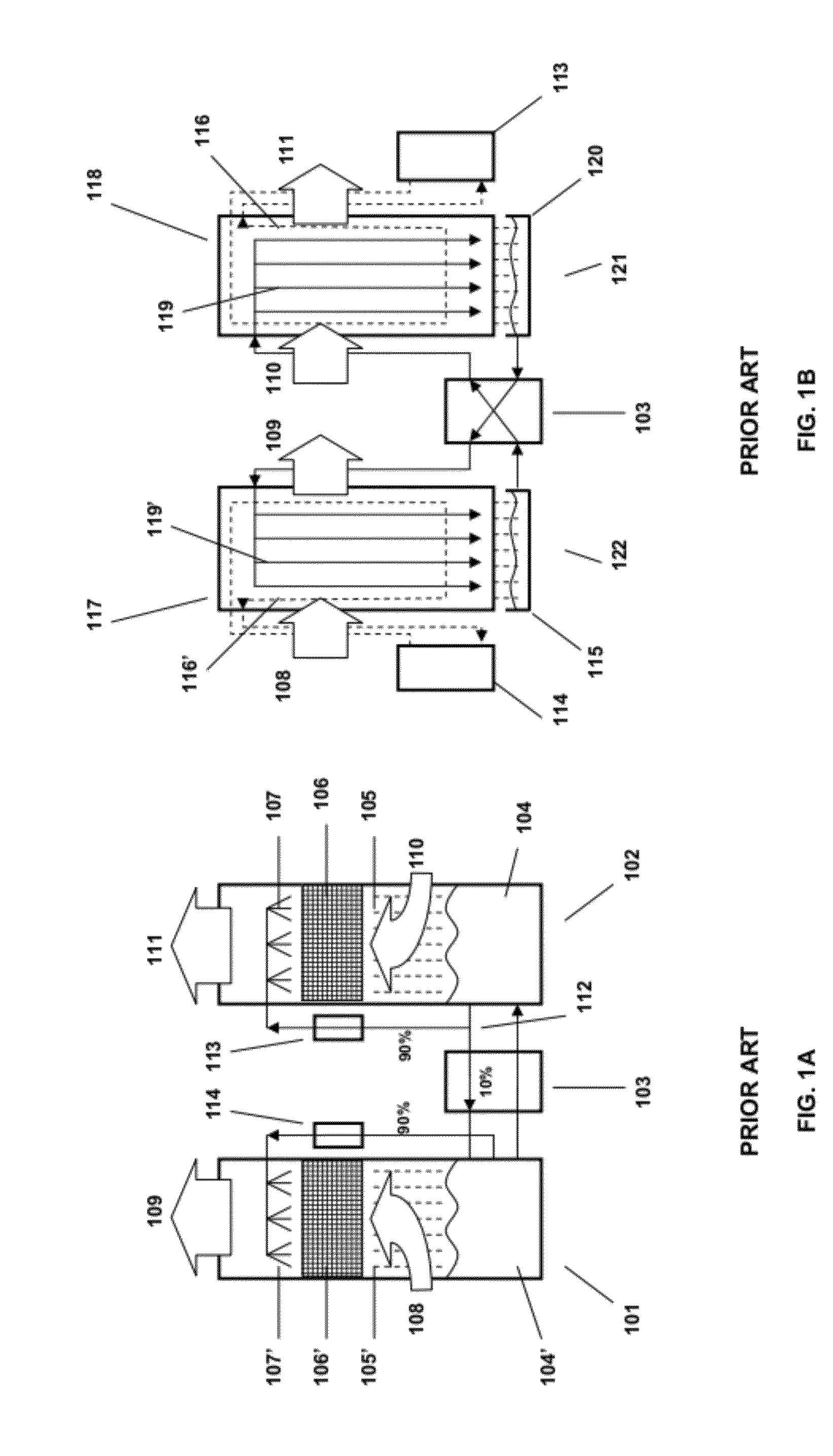

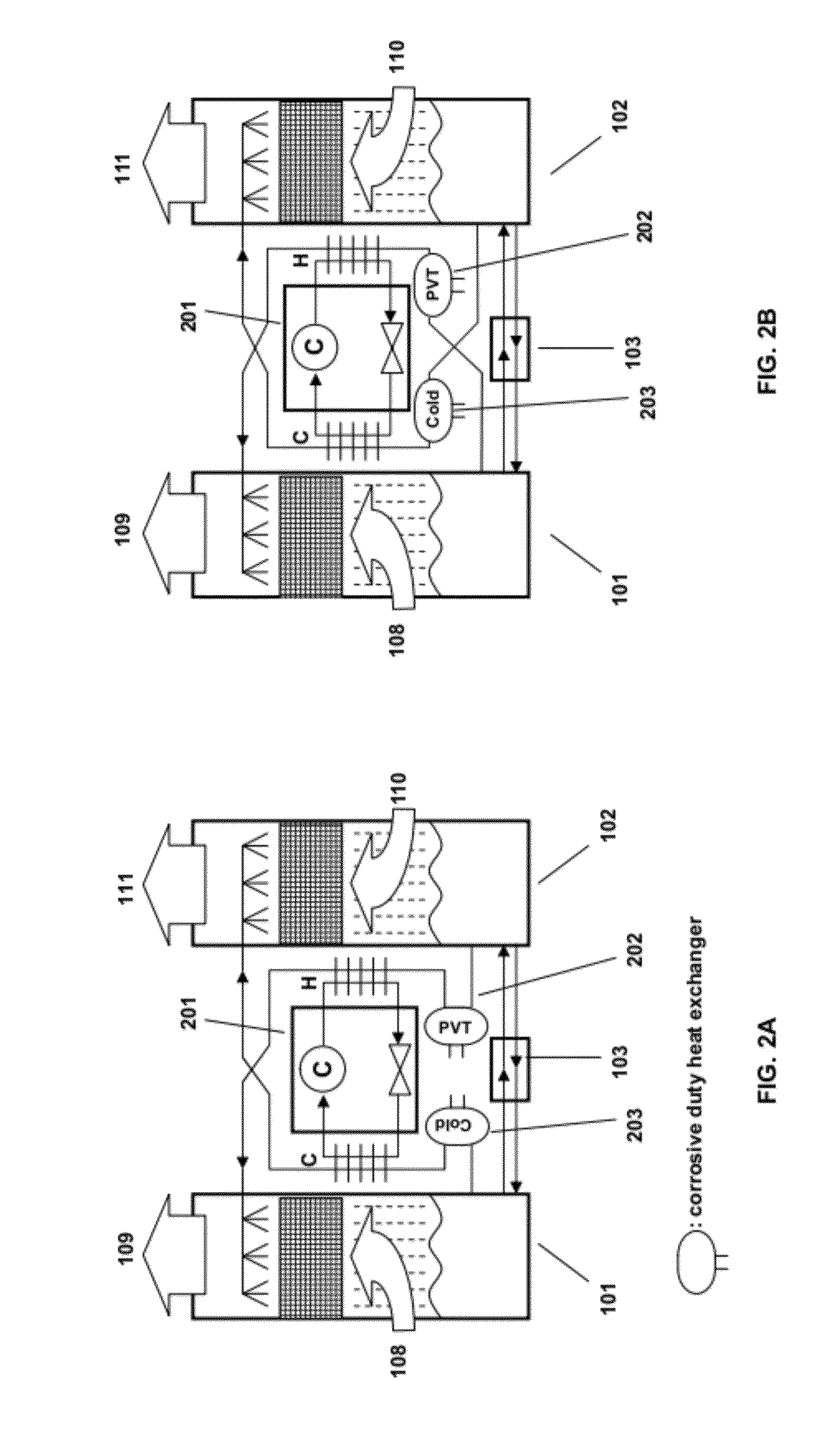

Turbine exhaust water recovery system

ActiveUS7194869B2Reduce the temperaturePromote sportsUsing liquid separation agentGas turbine plantsWater sourceLiquid water

The exhaust gas of a turbine engine can include water vapor. Aspects of the invention relate to various systems for recovering water from the exhaust gas of a gas turbine engine. In one system, a portion of the exhaust gas can be routed to an absorption chiller. In another system, a portion of the exhaust gas can be routed to a direct contact heat exchanger. In a third system, a portion of the exhaust gas can be routed to a fin-fan cooler. In each of these systems, the portion of gas can be cooled below its dew point temperature to release a portion of its humidity as liquid water. Aspects of the invention can be used with the turbine exhaust of simple and combined cycle power plants. A water recovery system according to aspects of the invention can minimize or eliminate a power plant's dependence on local water sources.

Owner:AMEC FOSTER WHEELER IND POWER CO INC

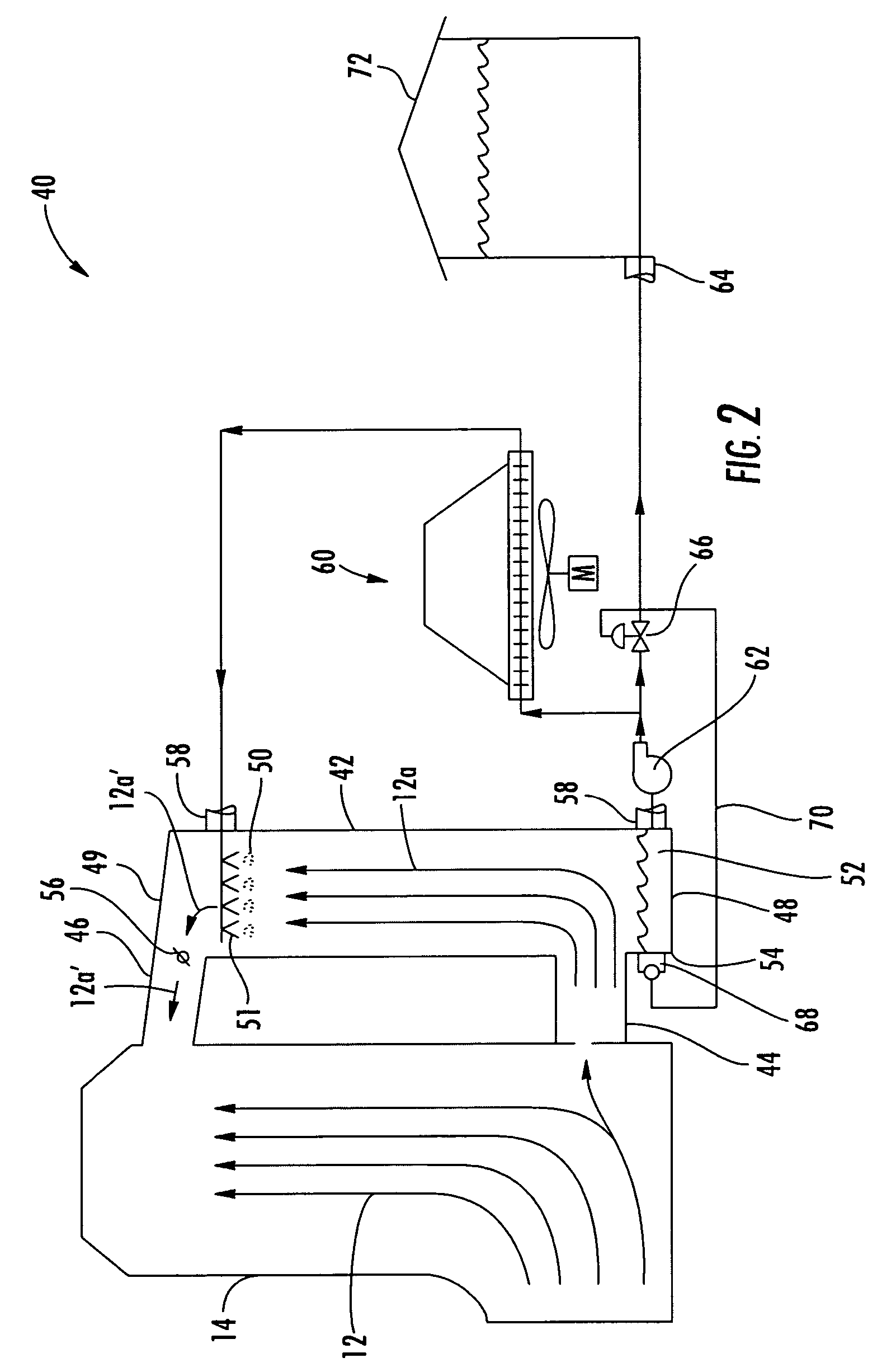

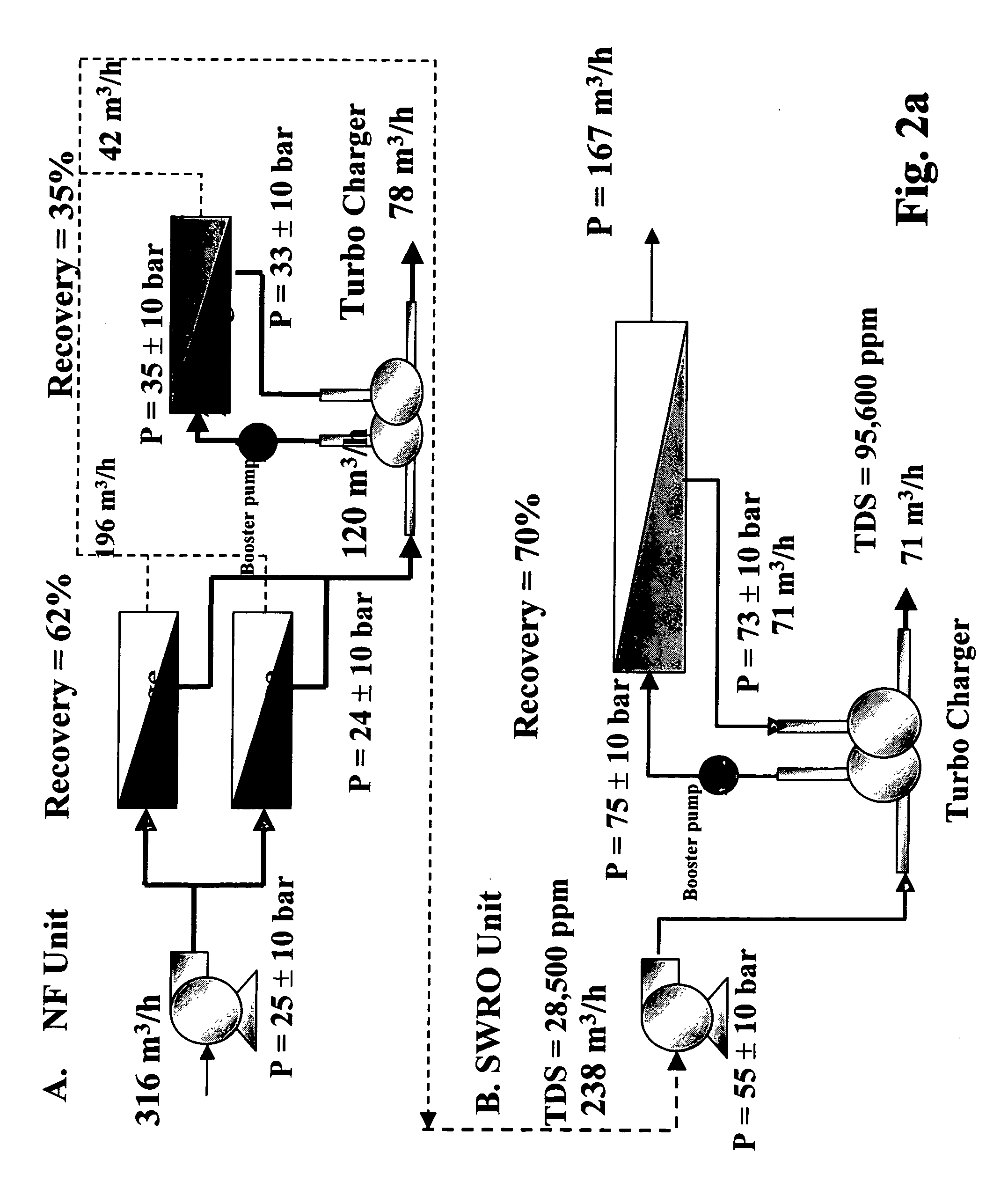

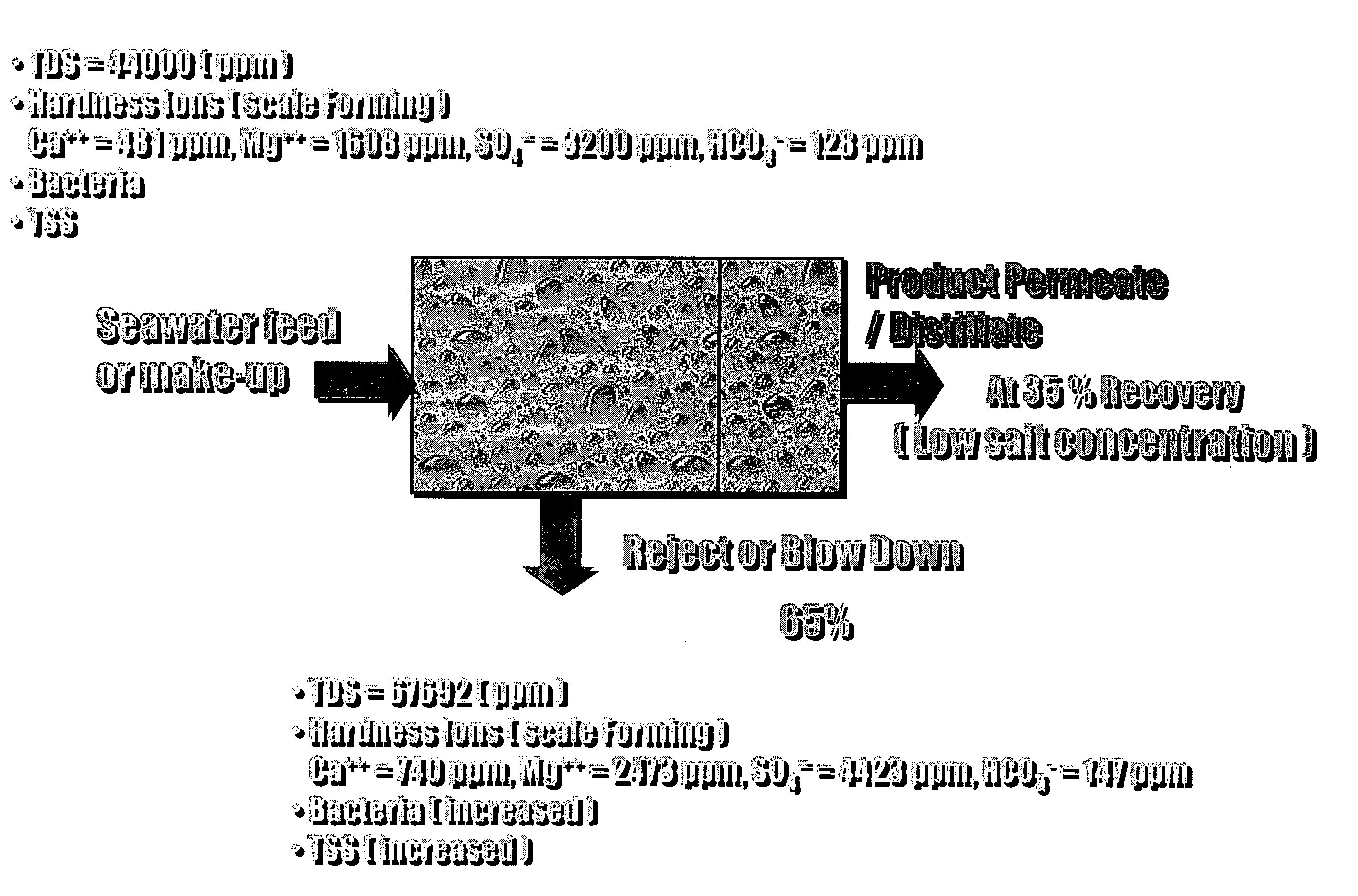

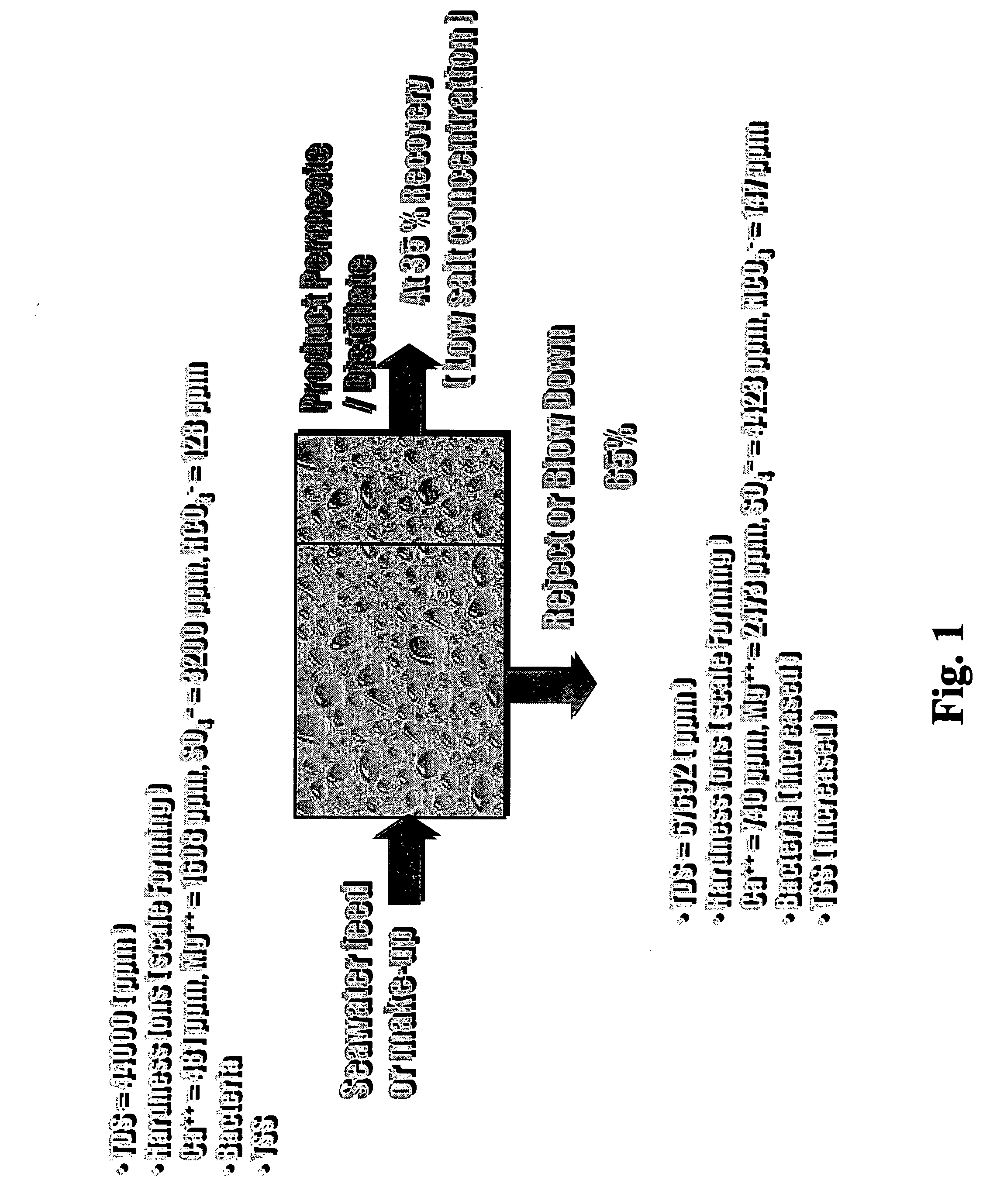

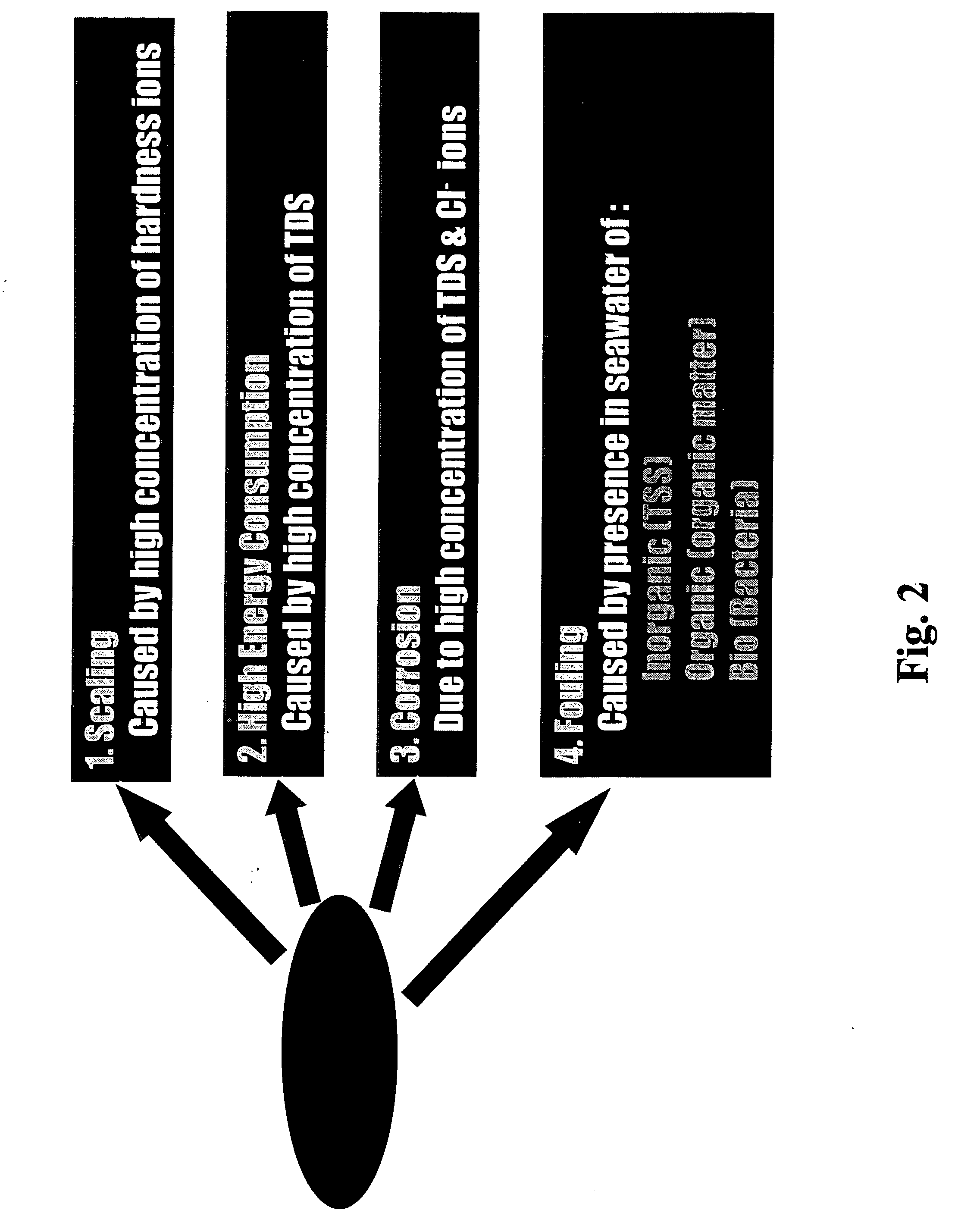

Fully integrated NF-thermal seawater desalination process and equipment

InactiveUS20060157410A1High yieldEffectively and efficiently dealGeneral water supply conservationReverse osmosisDistillationEngineering

An optimal thermal seawater desalination process is disclosed, which combines two or more substantially different water pretreatment processes in a unique manner and in a special configuration, hereto unknown to prior desalination arts, to produce a high yield of high quality fresh water, including potable water. In this process a two stage NF membrane pretreatment unit (NF2) with an energy recovery turbo charger (TC) device in between the stages or equipped with an energy recovery pressure exchanger (PX) is synergistically combined with at least one thermal desalination unit to form a dual hybrid of NF2-Thermal (FIG. 4 ), or alternatively the two stage NF2 unit is synergistically combined with a two stage SWRO unit (SWRO2) with an energy recovery TC in between the stages or combined with one stage SWRO (SWRO1) equipped with an energy recovery TC or PX system and the reject from the SWRO2 or SWRO1 unit is made make-up to a thermal unit to form a tri-hybrid of NF2-SWRO2 reject-Thermal (FIG. 5 ). In both the cases of di- or trihybrids the thermal unit is equivalent to a multistage flash distillation (MSFD) or multieffect distillation (MED) or vapor compression distillation (VCD) or thermal reheat (RH) evaporator. Typically a process of this invention using the two stage NF2 initial pretreatment step will perform a semi-desalination step by reducing feed TDS by about 35 to 50%, but most important, especially to the thermal seawater desalination process, it removes the water recovery limiting, scale forming hardness ions of Ca++ and Mg++ by better than 80% and their covalent anions of sulfate to better than 95% and bicarbonate to about 65%. The removal of scale forming hardness ions, especially SO4=, and bicarbonates allowed for the operation of thermal unit in the above hybrids at top brine temperature (TBT) much greater than its present TBT limit by the singular conventional process of 120° C. for MSFD and operation of MED or VCD or RH unit at TBT much higher than their present TBT limit of 65-70° C., with many advantages gained by this process over prior art sweater desalination processes. The process of this invention exceeds all prior thermal seawater desalination arts in efficiency, including water yield, product water recovery ratio and unit water cost as well as in energy consumption per unit product which is equivalent or less than other efficient prior art seawater thermal desalination processes. By this process, an NF product recovery ratio of 75 and 80% or better is achieved from the high salinity Gulf sea (TDS≈45,000 ppm) and about an equal product recovery ratio is also obtained from the SWRO or thermal unit when it is operated on NF product for a total water recovery ratio in excess of 52% for seawater

Owner:SALINE WATER CONVERSION CORP SWCC

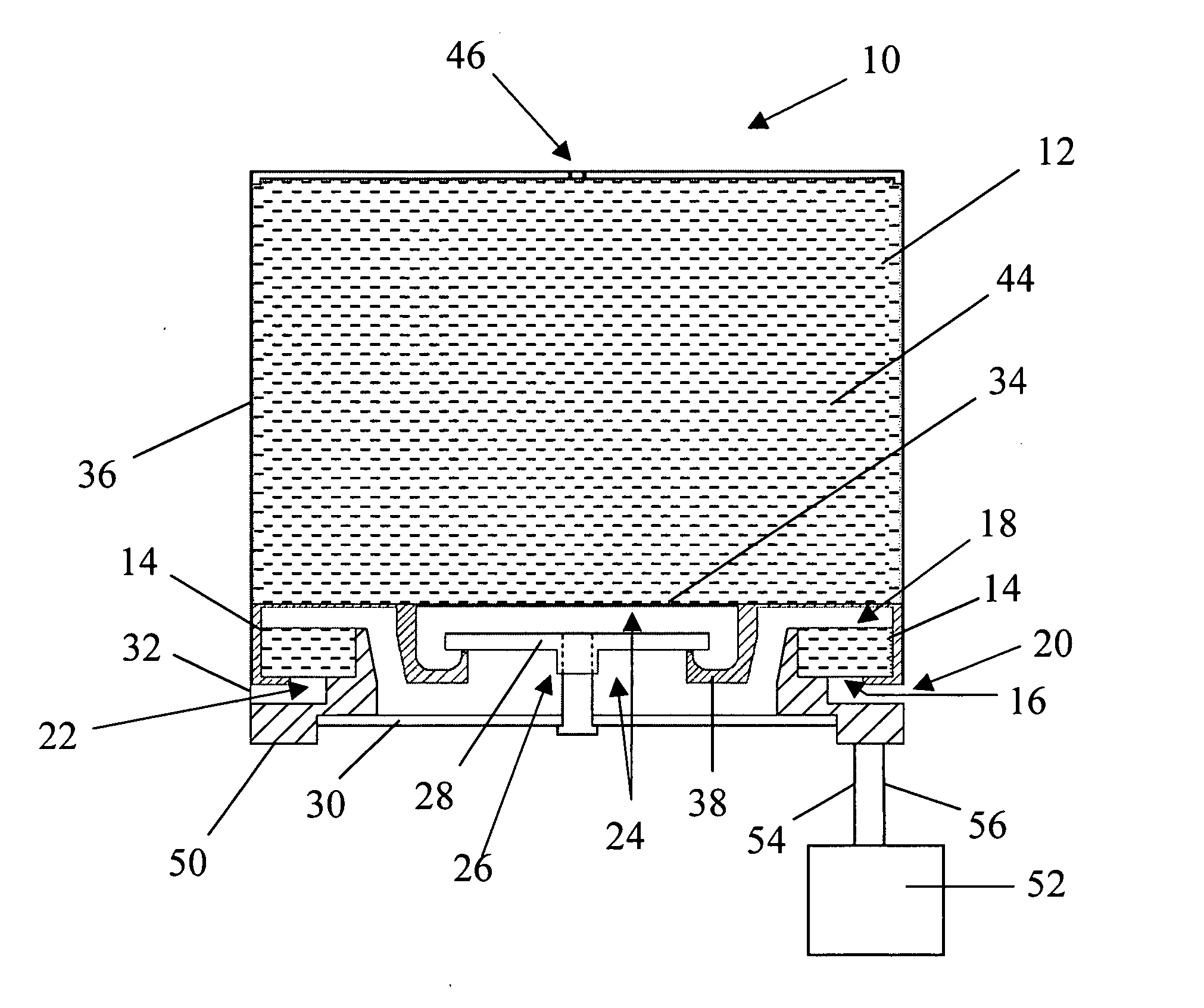

Water reclamation in a micropower generator

A waterless power generator, particularly a waterless electrical power generator and a passively controlled process for producing electricity with a fuel cell using stoichiometric amounts of a solid hydrogen fuel and byproduct water vapor produced by the fuel cell to generate hydrogen gas. A fuel cell reaction of hydrogen and oxygen produces electrical energy as well as by-product water which diffuses back into the power generator as water vapor to react with the hydrogen fuel, producing more hydrogen gas. This generated hydrogen gas is then used as a fuel which allows the fuel cell to generate additional electrical power and additional water. The process runs without any attached water source or water supply other than the water which is produced by the fuel cells themselves.

Owner:HONEYWELL INT INC

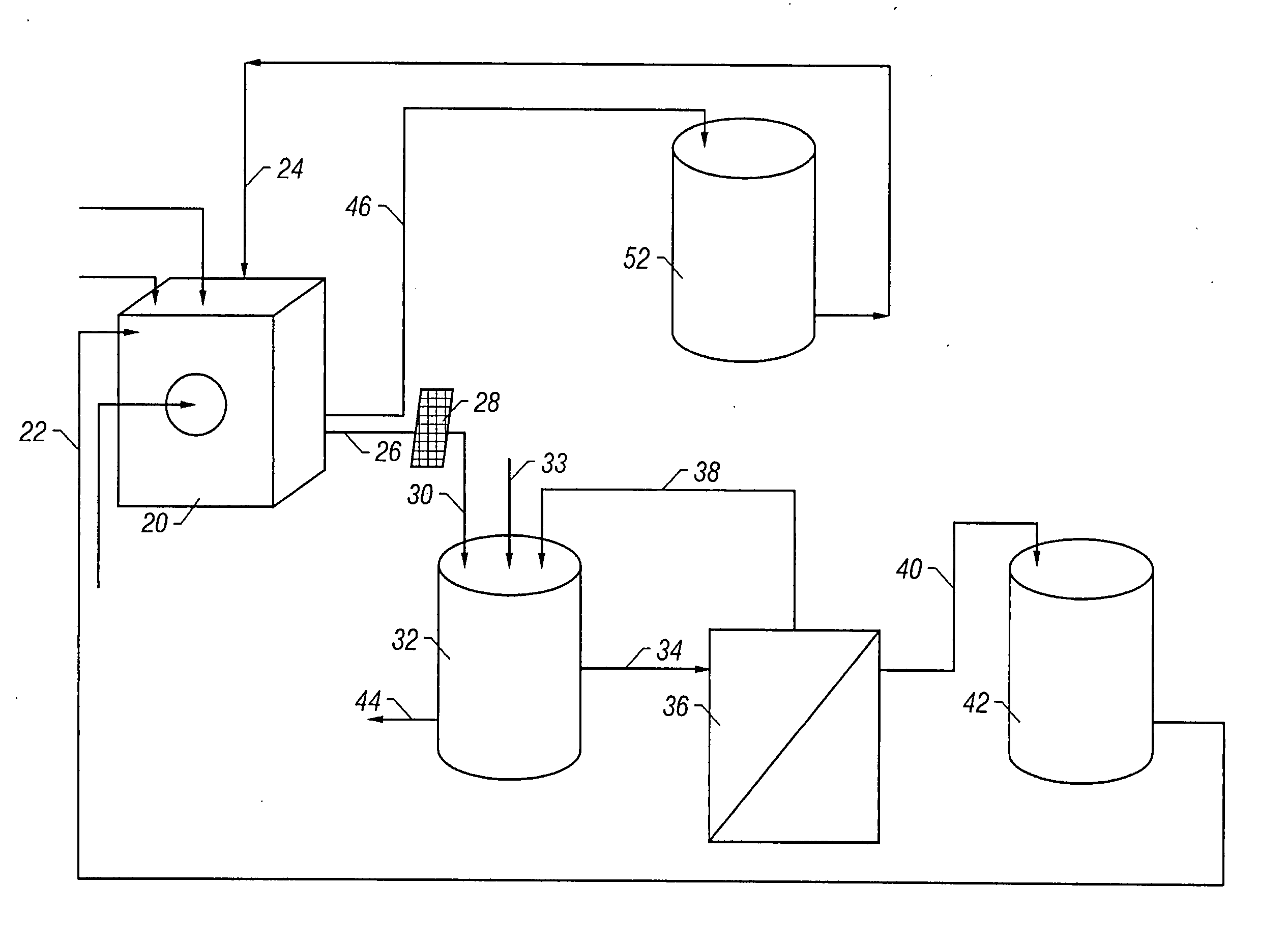

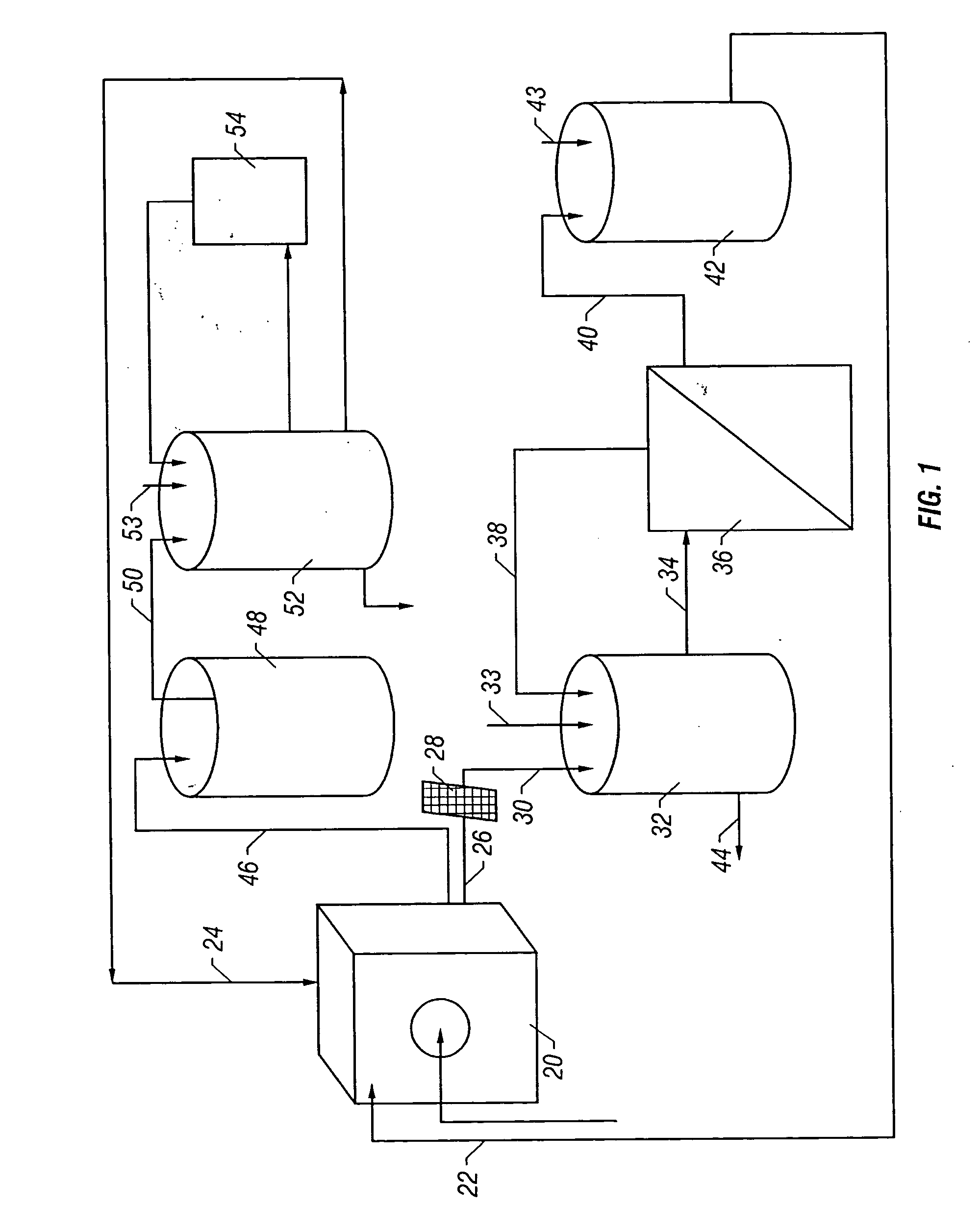

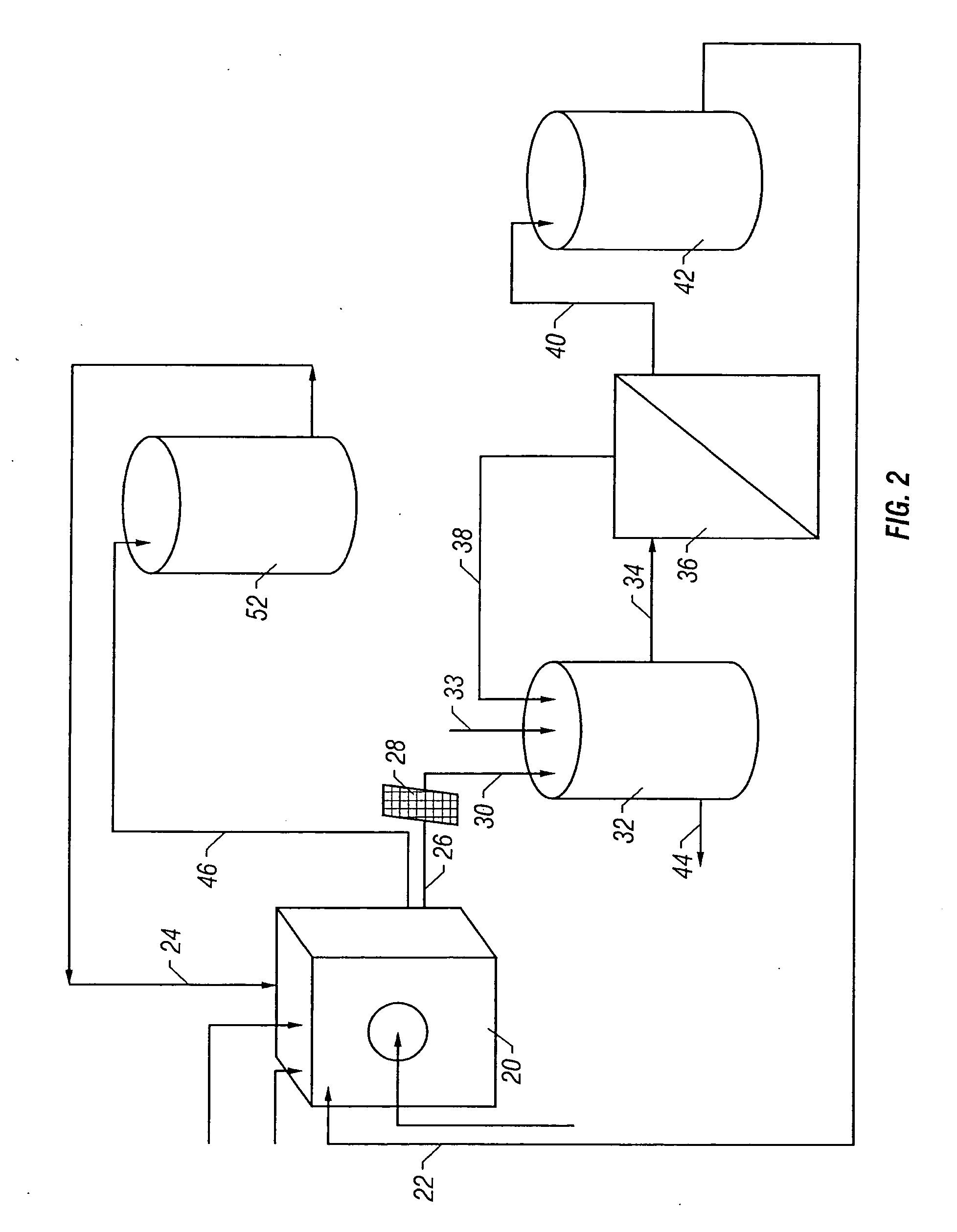

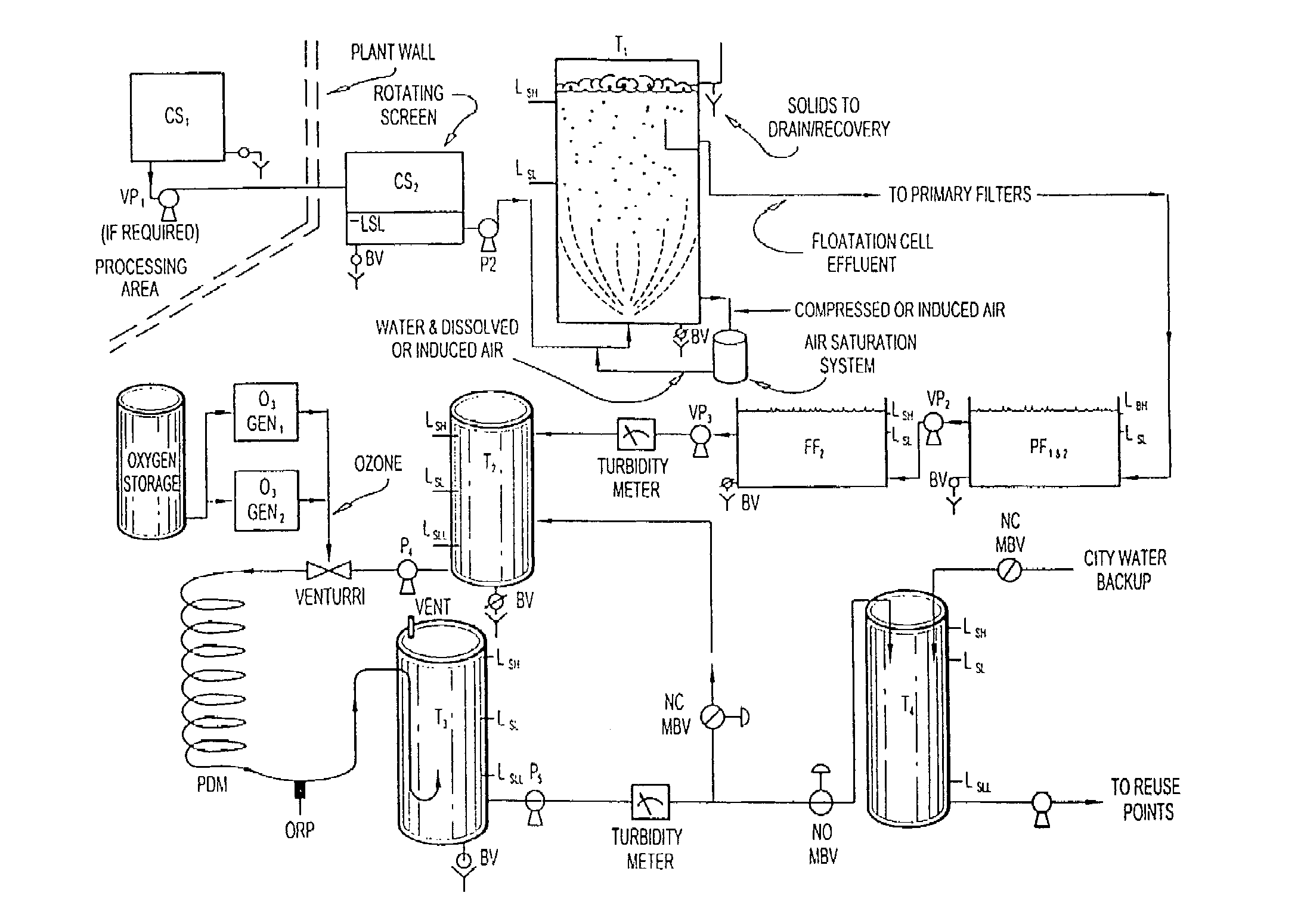

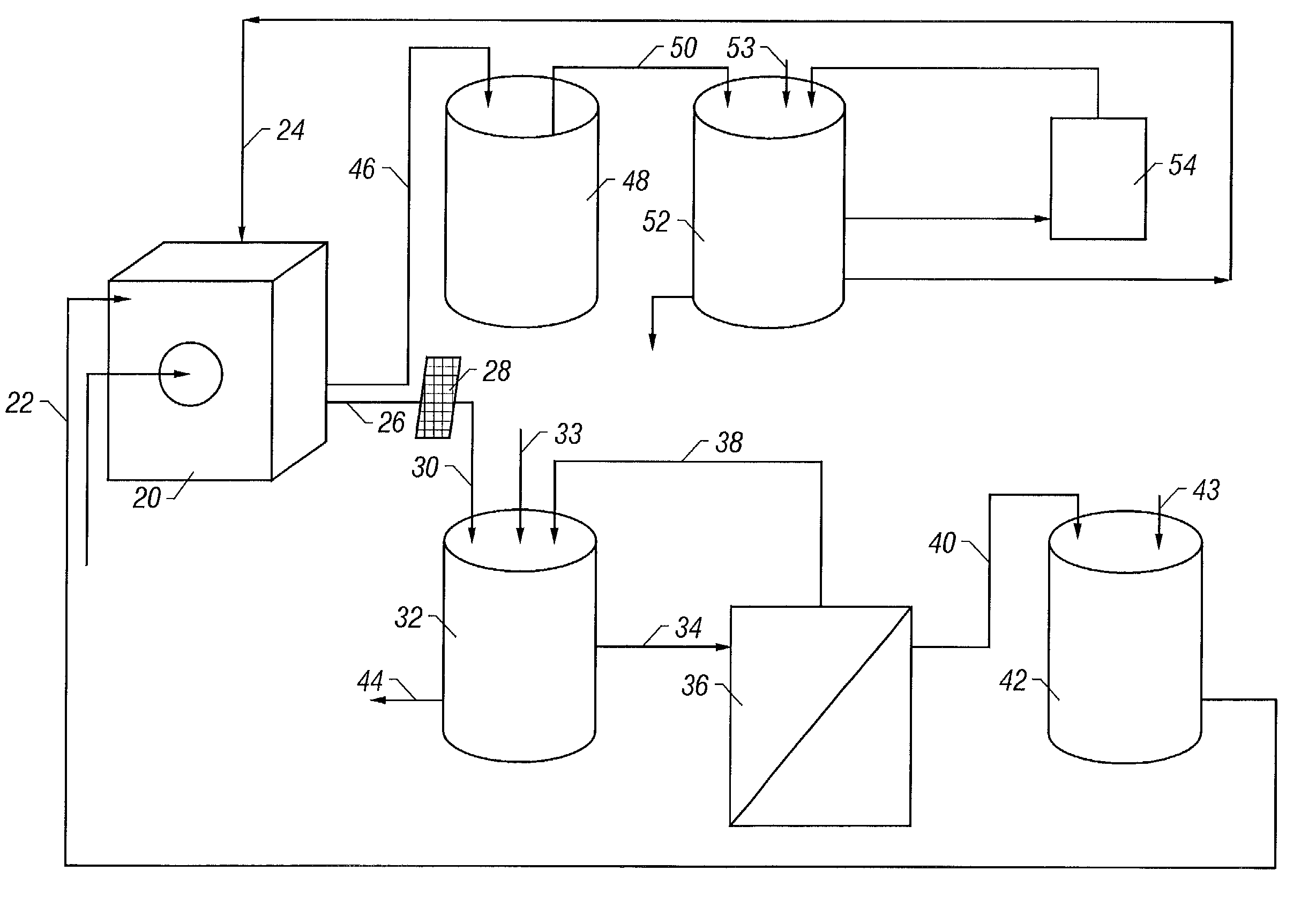

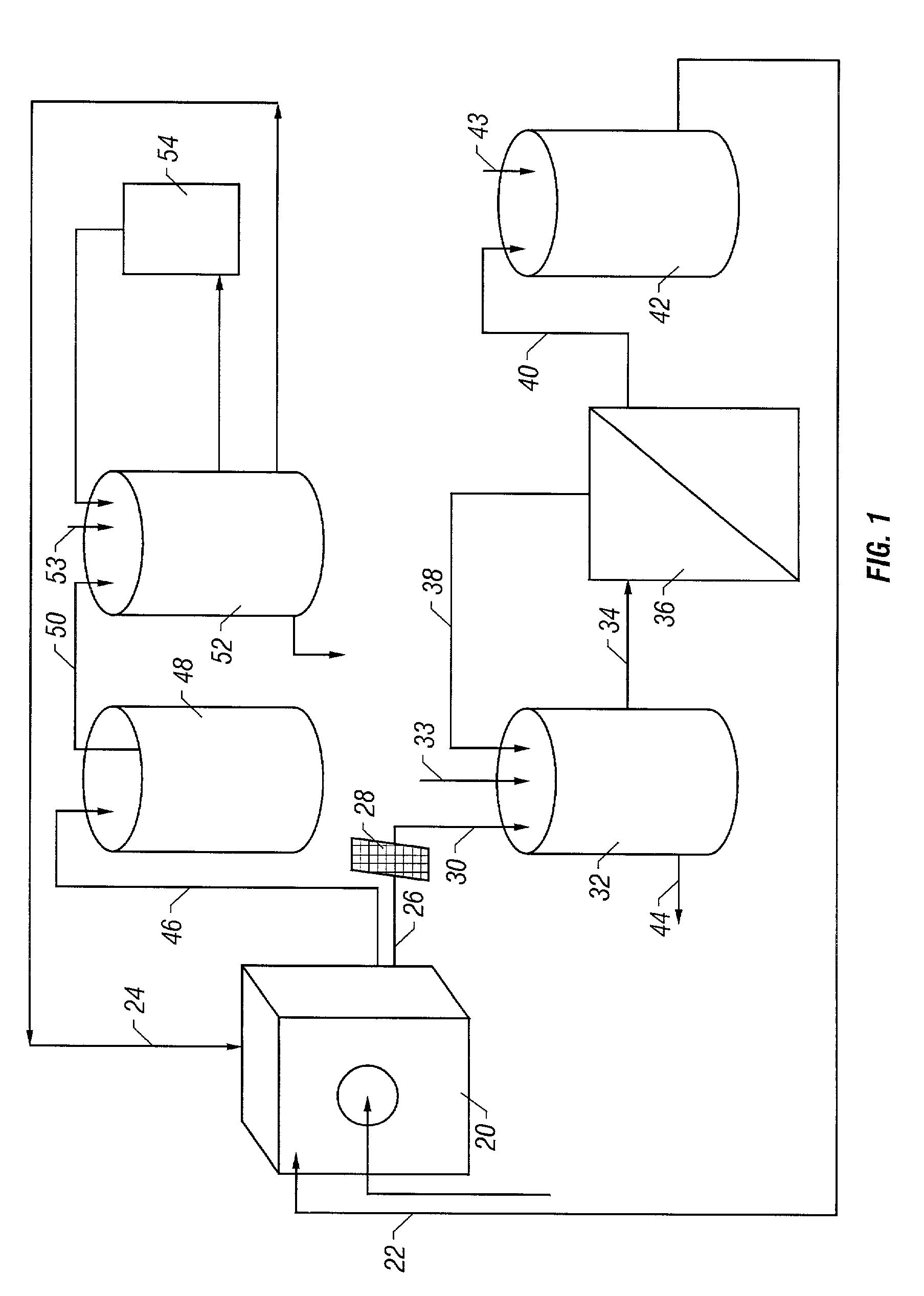

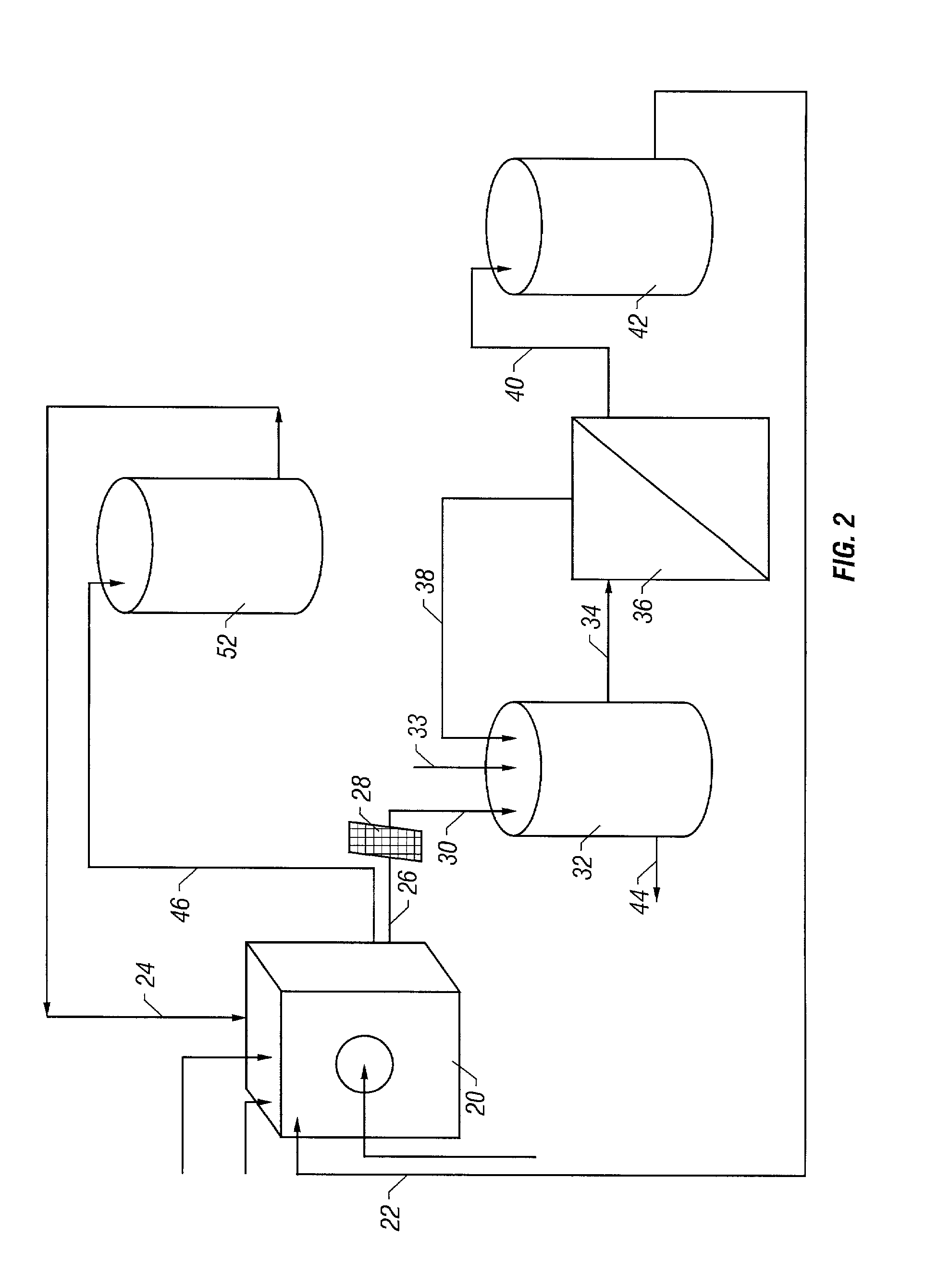

Method for economically viable and environmentally friendly central processing of home laundry

InactiveUS20060123563A1Reduce productionPromote recoveryTableware washing/rinsing machine detailsOther washing machinesEnvironmental effectWash water

An economically viable process and system for centrally processing multiple loads of laundry with minimum environmental impact. A system and method of laundering whereby successive loads of laundry may be washed while continuously providing effective soil removal comprising at least partially recycled wash water from at least one previous wash cycle. The system and the method of using the same comprises filtering wash water with at least one filter to form wash retentate and wash permeate. The use of wash permeate in successive washes provides for reuse of chemicals and water recovery. A similar arrangement may be used with regard to the rinse water. Advantageously, one embodiment of the invention provides for the use of rinse retentate as make up water in the wash loop which increases water recovery and chemical recovery. Ultimately, the invention can reduce the production of gray water and recover chemicals used in the laundering process.

Owner:RANEY KIRK HERBERT +5

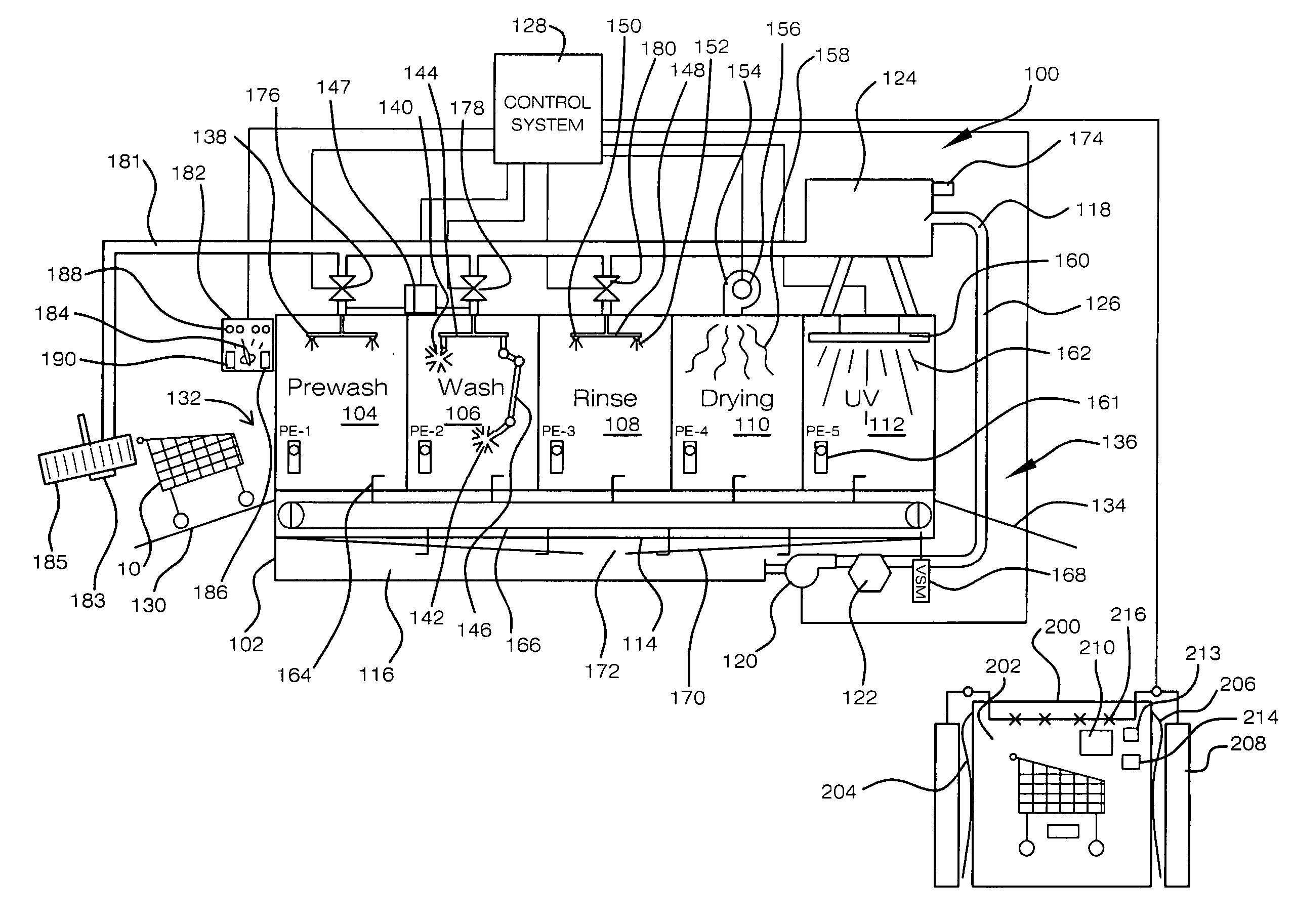

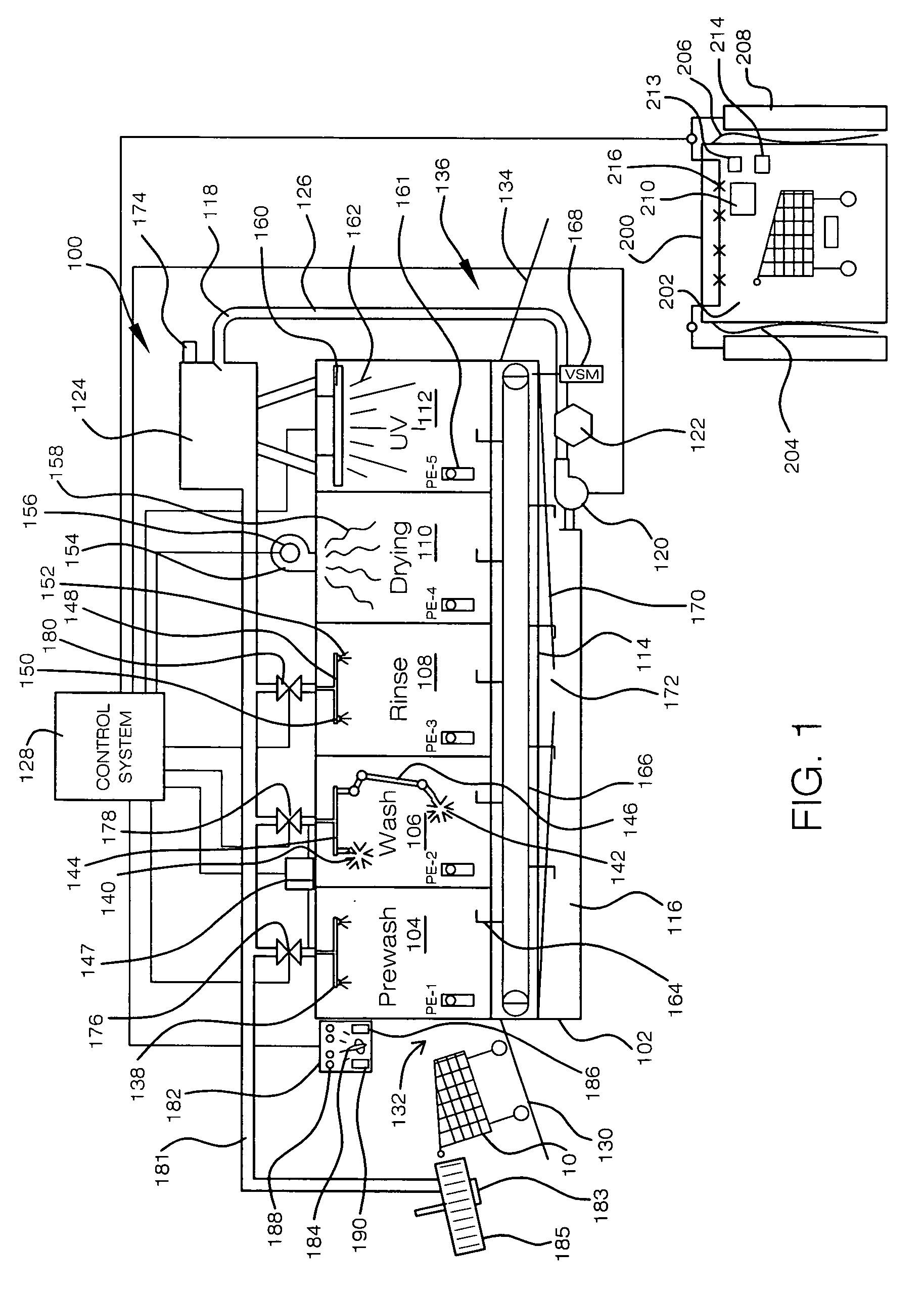

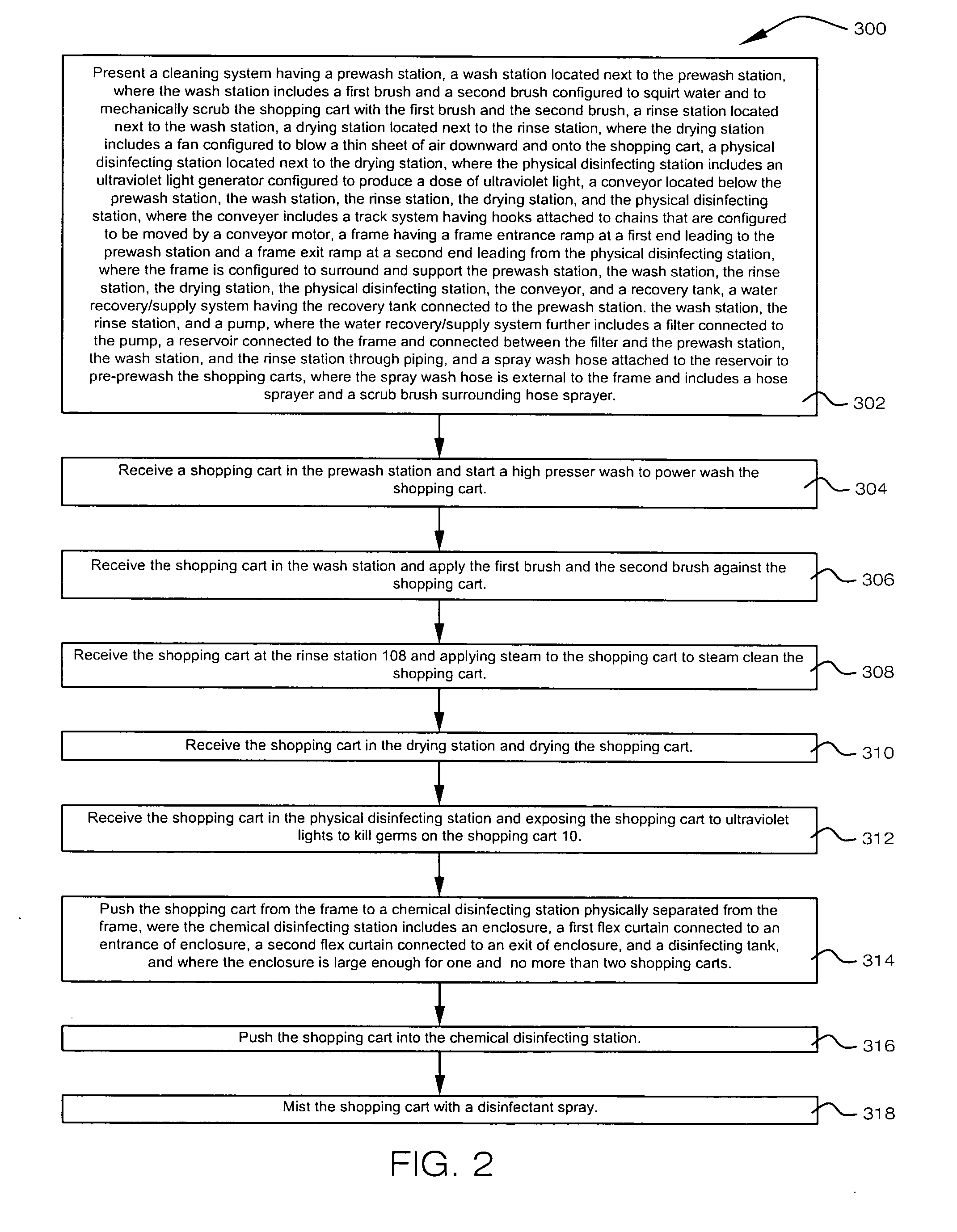

Cleaning system for shopping carts

This patent discloses a cleaning system for shopping carts. The cleaning system may include a prewash station, a wash station, a rinse station, a drying station, a physical disinfecting station, a conveyor, and a recovery tank. The wash station may include brushes. The drying station may include a fan configured to blow a thin sheet of air downward and onto the shopping cart. The physical disinfecting station may include an ultraviolet light generator. The conveyor may include a track system having hooks attached to chains that are configured to be moved by a conveyor motor. A frame may surround and support the stations. The cleaning system additionally may include a water recovery / supply system and an external spray wash hose attached to a reservoir to pre-prewash the shopping carts.

Owner:KITER MICHAEL A

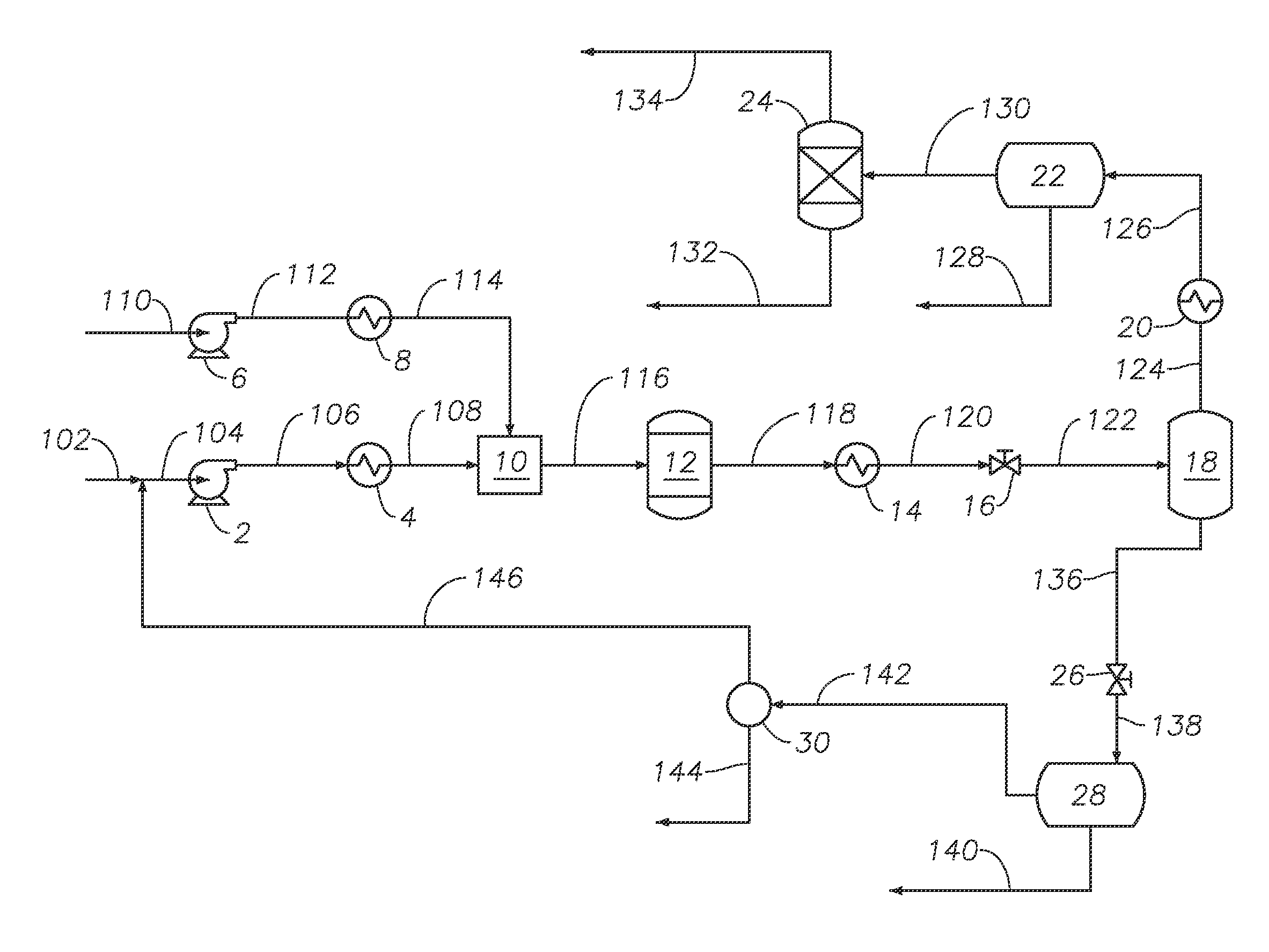

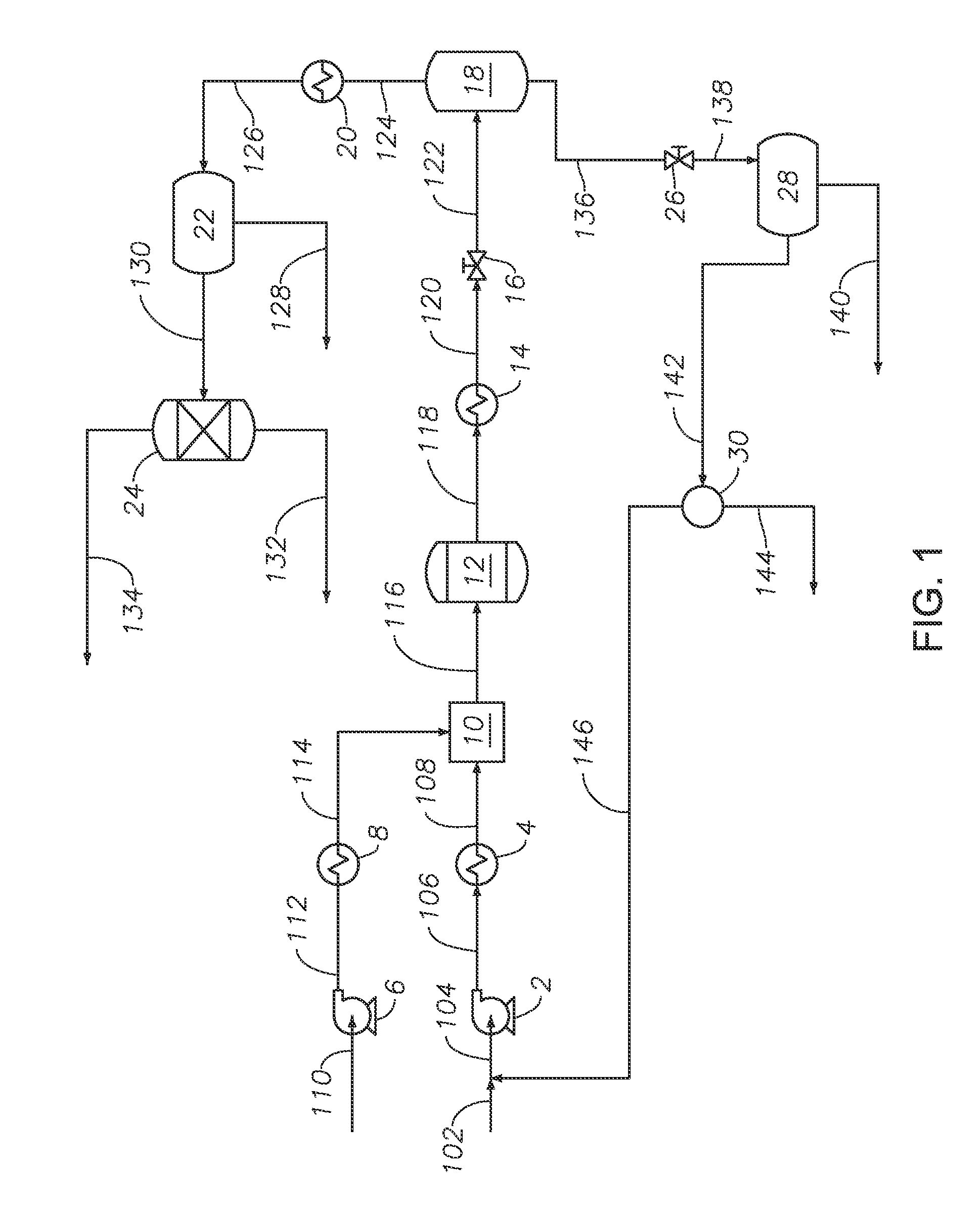

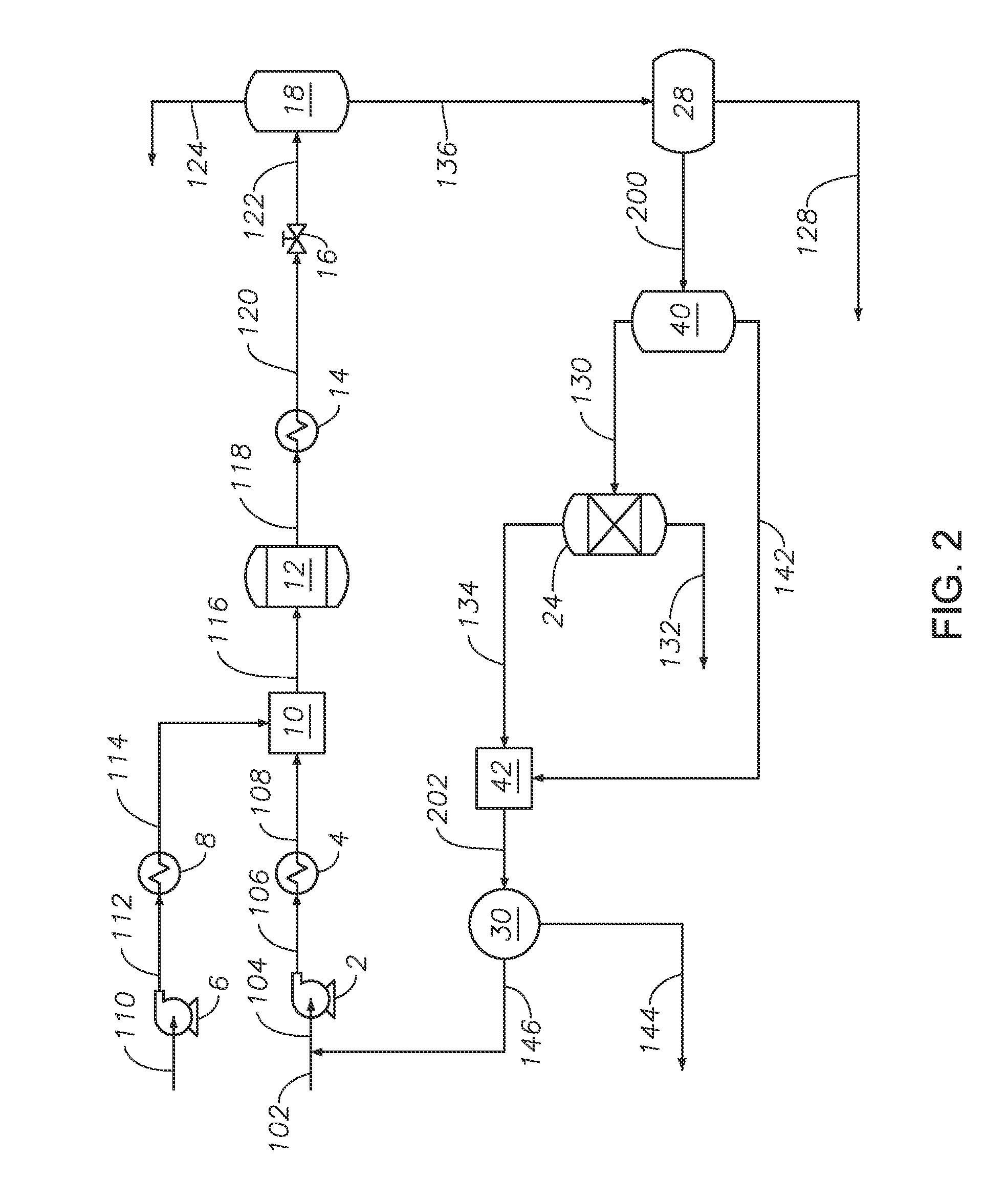

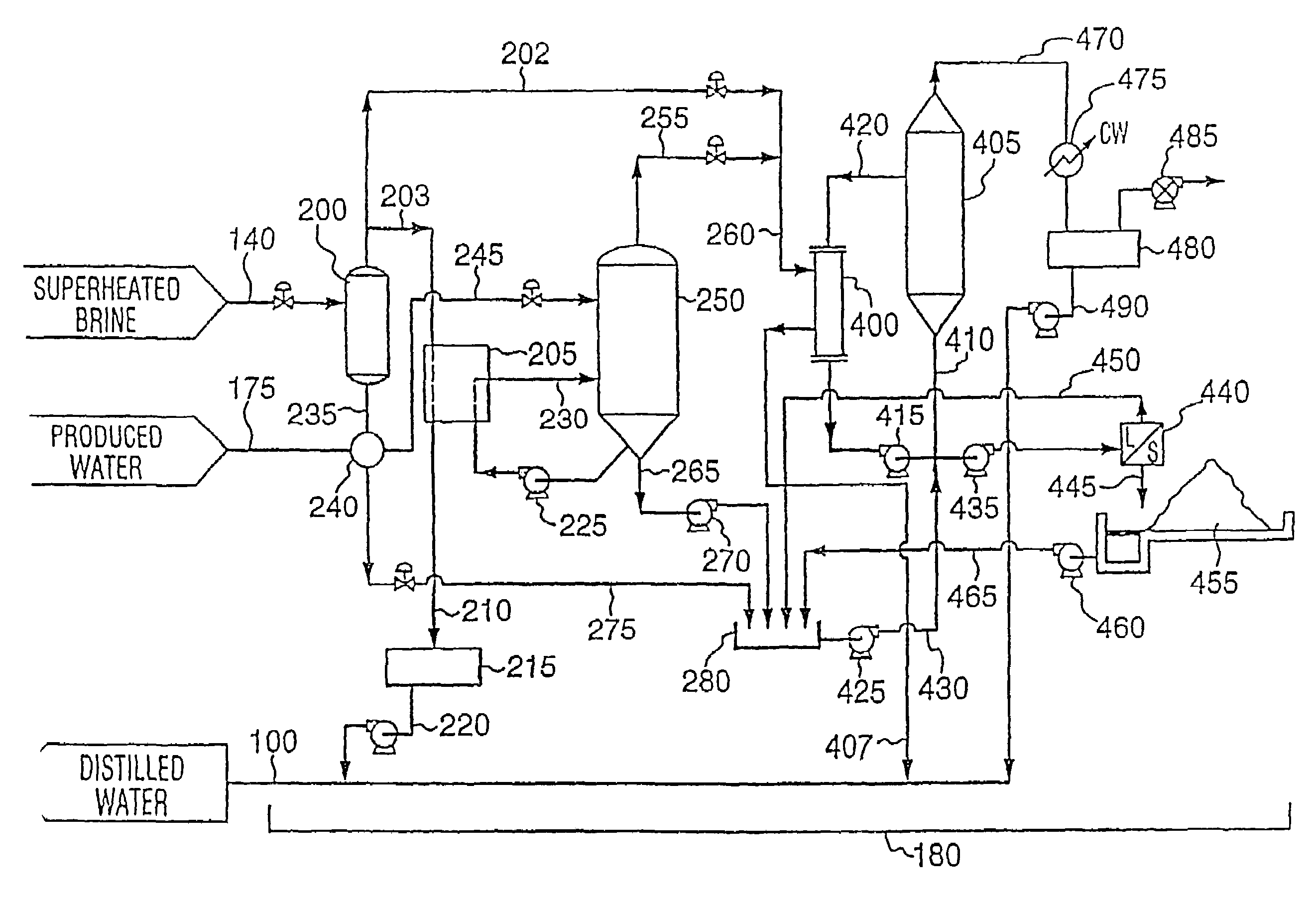

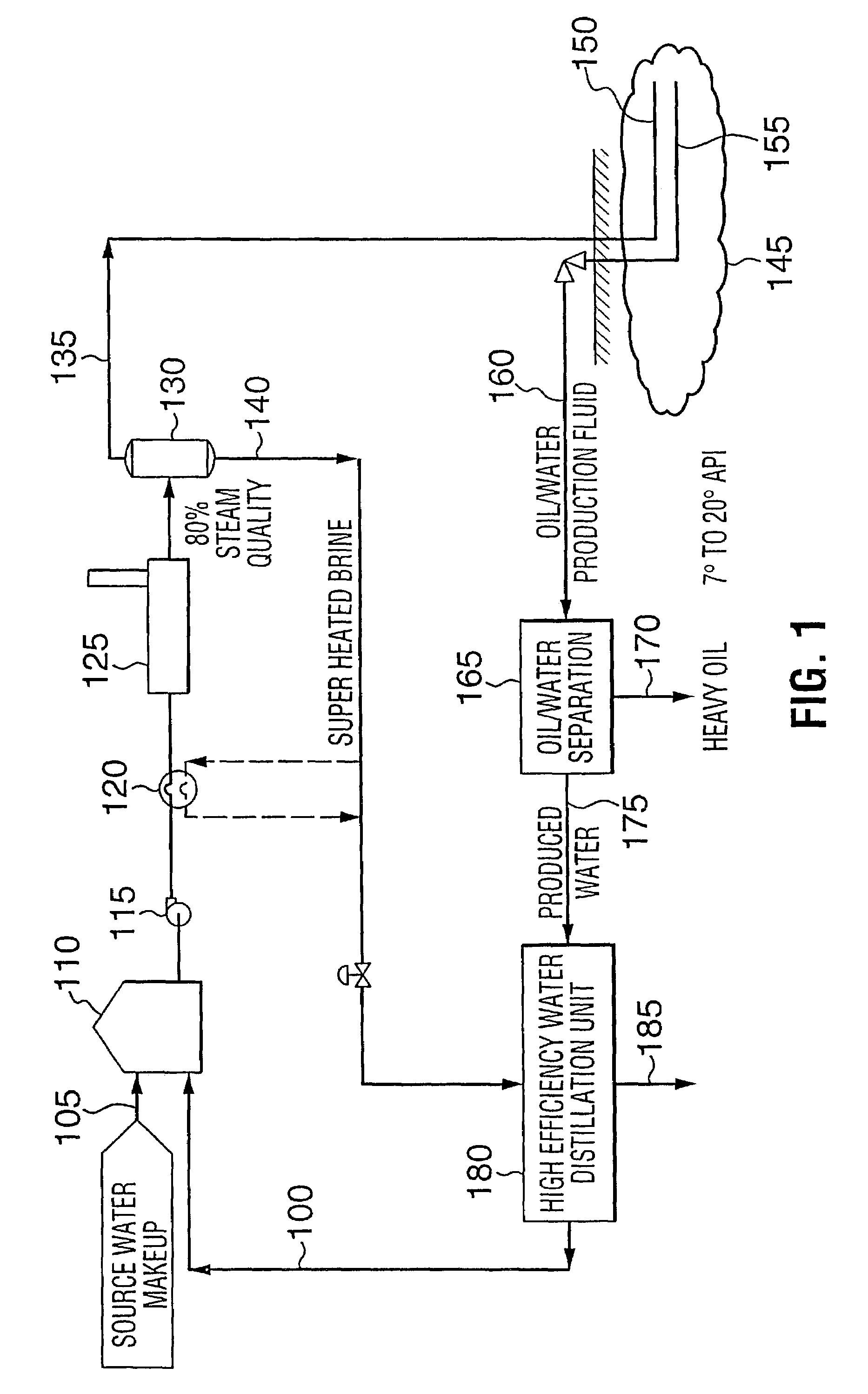

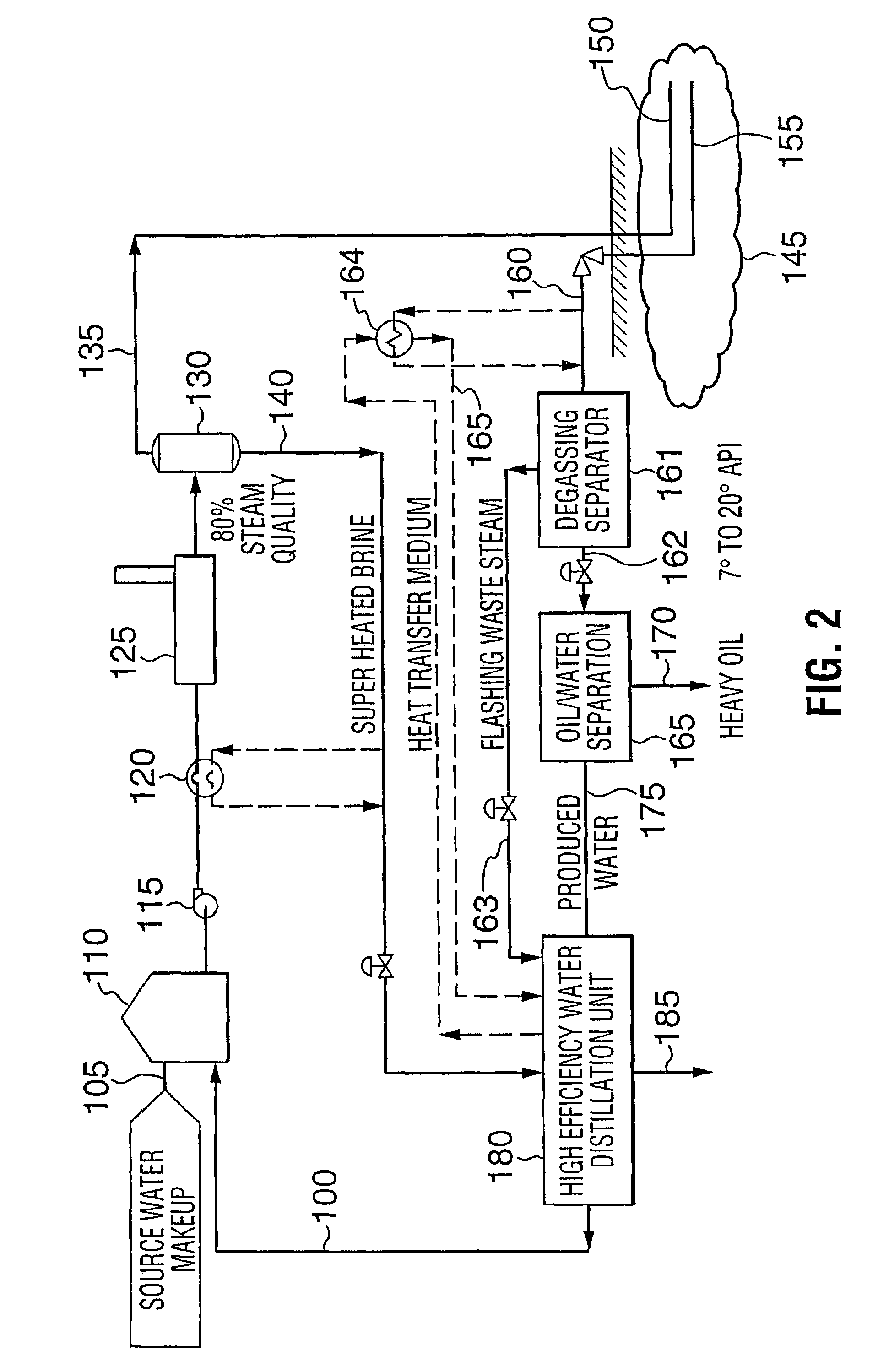

Water treatment process for thermal heavy oil recovery

There is disclosed a method and apparatus for treating produced water from a heavy oil thermal recovery unit to achieve water recovery and recycle levels of greater than 80% and as high as 100% to achieve zero discharge criteria. The method includes the initial steps of capturing the waste heat energy from the high pressure steam separator located downstream of the steam generators. Further, transferring the heat energy into a heated separator and reboiler exchanger to distill oil reservoir produced water and recover distilled water and a concentrated brine or solid product. The heated separator concentrated stream is circulated through the reboiler exchanger to maintain from 1% to about 50% mass vapour in the stream returning to the heated separator and prevent fouling and scaling. The apparatus includes a low pressure waste energy separator, heated separator and vapour compressor in combination with a forced circulation circuit to generate the distilled water.

Owner:FOUNTAIN QUAIL WATER MANAGEMENT LLC +1

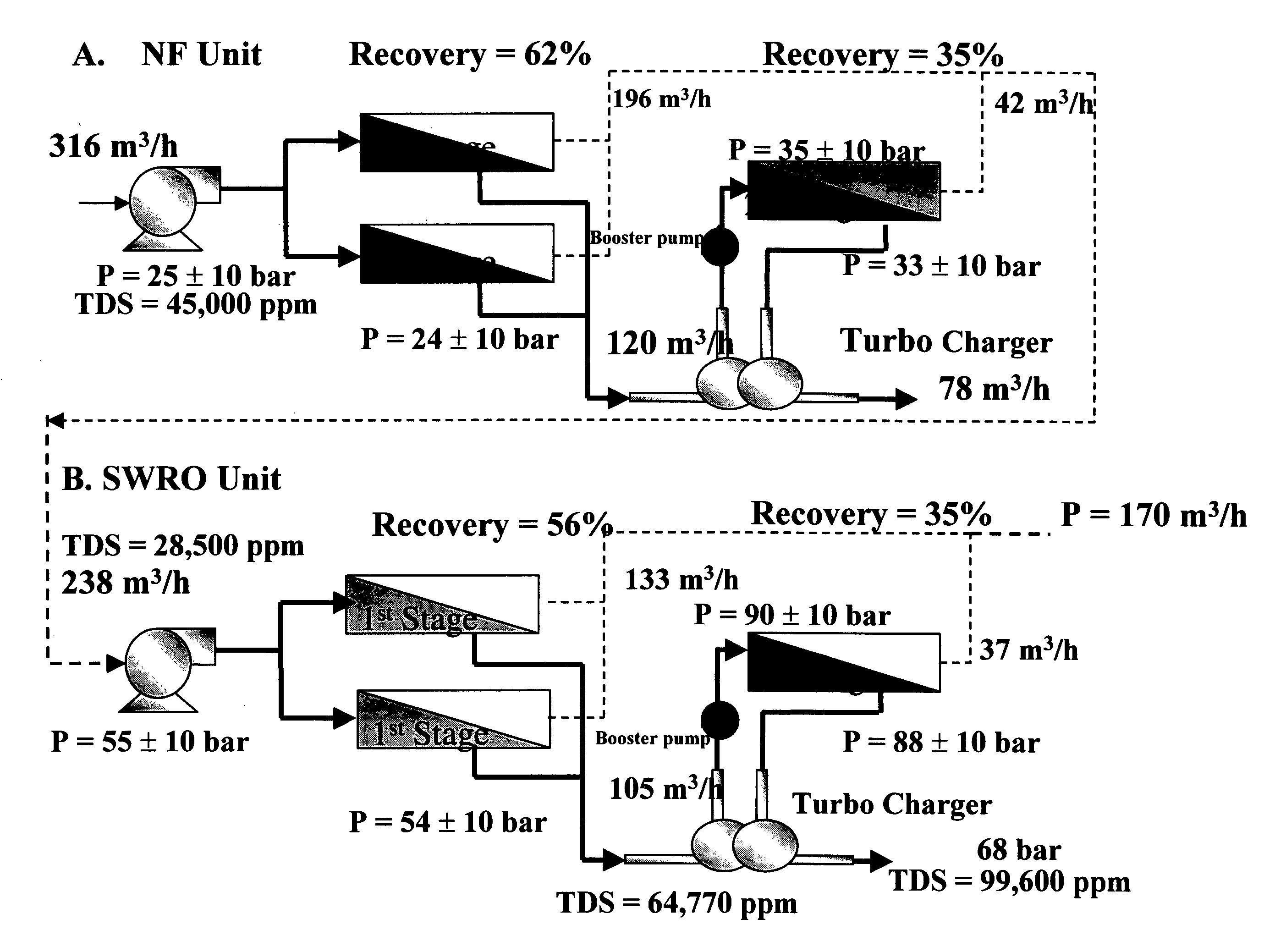

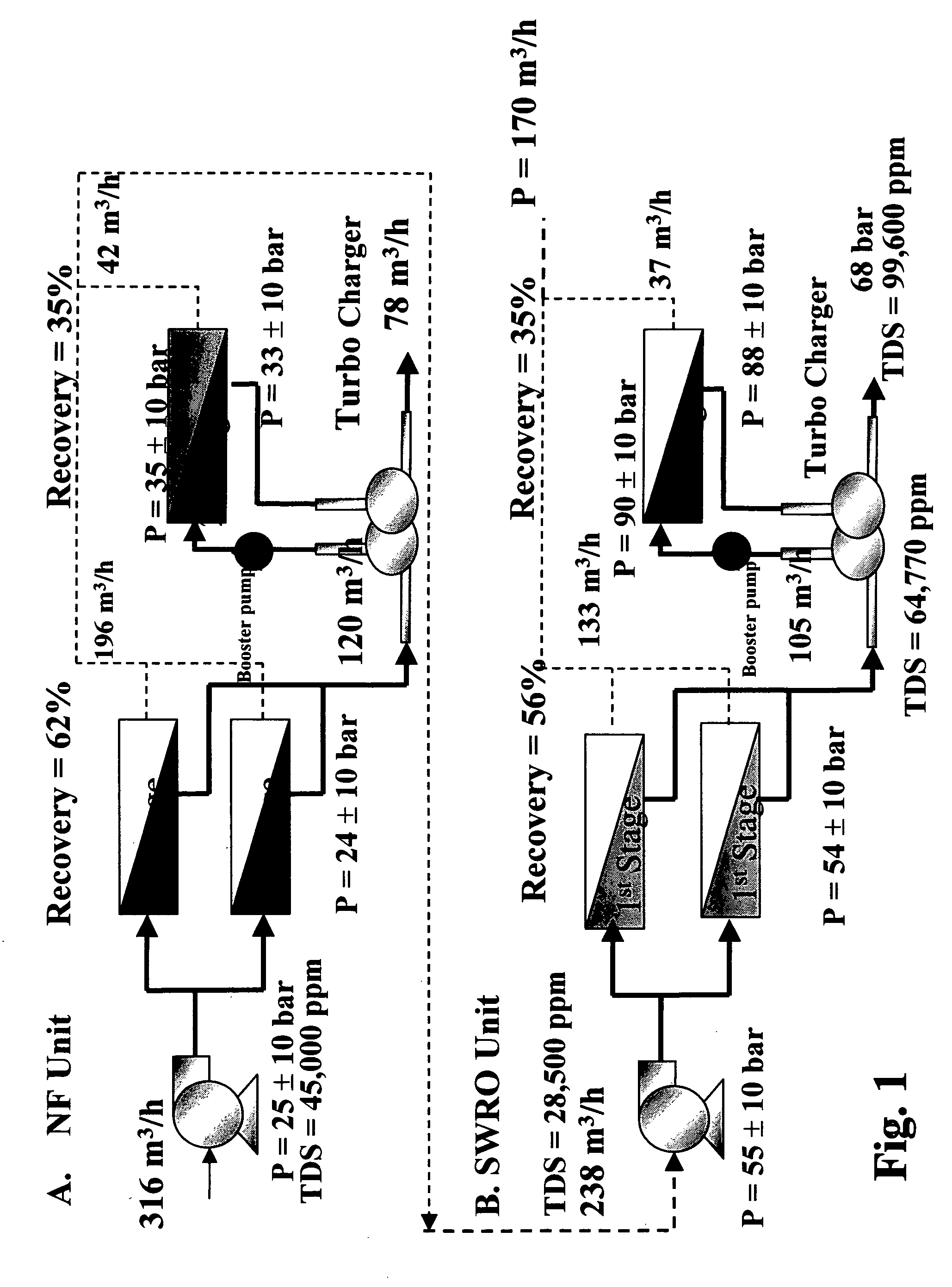

Optimal high recovery, energy efficient dual fully integrated nanofiltration seawater reverse osmosis desalination process and equipment

InactiveUS20060157409A1Reduce yieldHigh water recoveryMembranesSeawater treatmentTurbochargerWater production

An optimal two stage NF2 membrane pretreatment unit is synergistically combined with a following two stage SWRO2 desalination unit, where each of the two stage NF2 and SWRO2 has an energy recovery device (ERD) turbocharger (TC) in between the stages to form a dual hybrid of NF2-SWRO2 (FIG. 1 ); alternatively the two stage NF2 unit is synergistically combined with one stage ERD equipped SWRO, unit operated at up to 85 bar (FIG. 2 a, b); or the two stage NF2 unit combined with one stage ERD equipped SWRO1 unit, with part of its reject recycled constituting part of the feed to the NF units (FIG. 3 a,b). The process of this invention raises significantly the product water recovery ratio, producing SWRO hybrids that exceed all prior arts in efficiency, including water yield, product recovery ratio, dramatically reduces both the energy consumption and water production unit cost.

Owner:SALINE WATER CONVERSION CORP SWCC

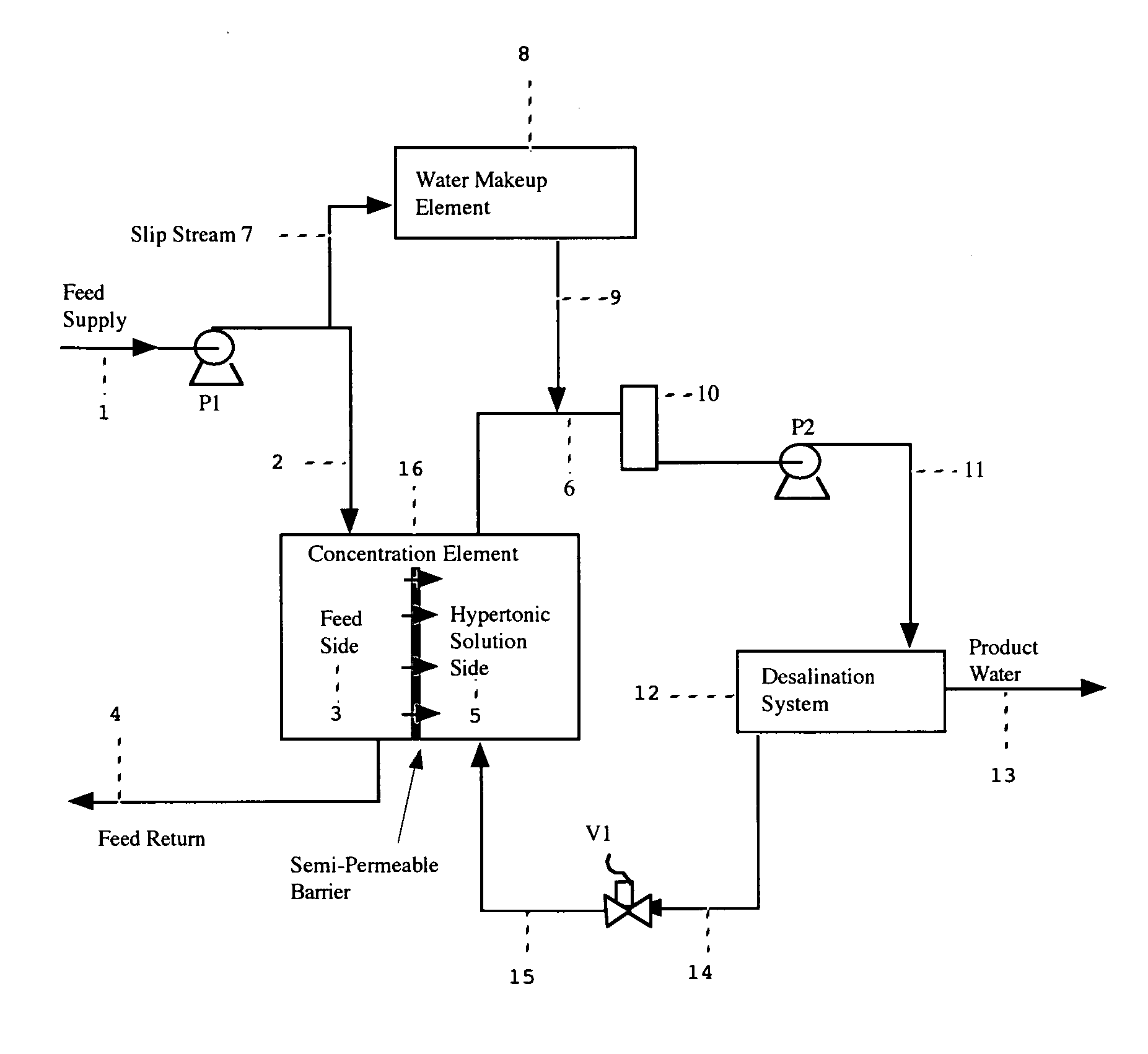

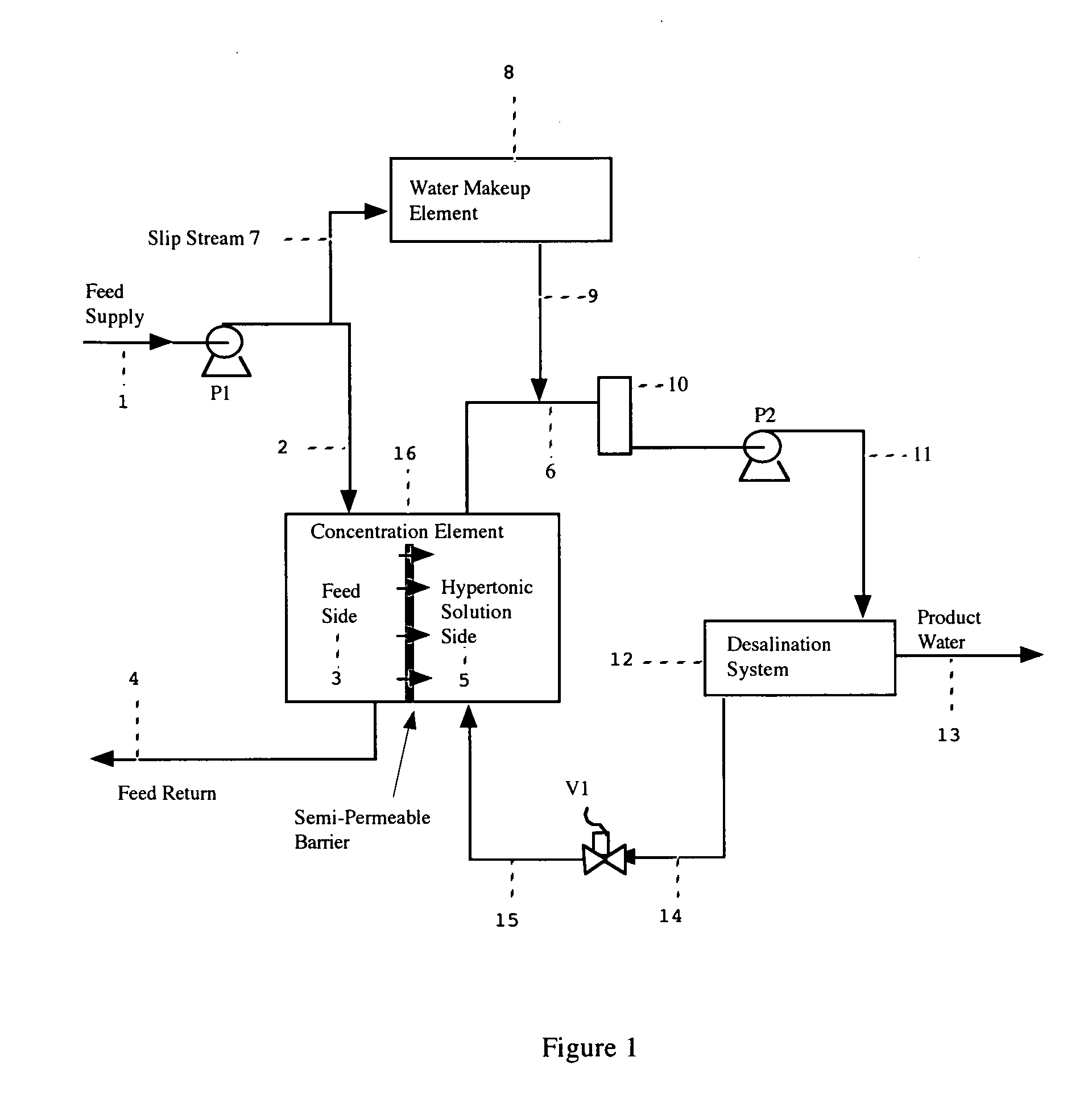

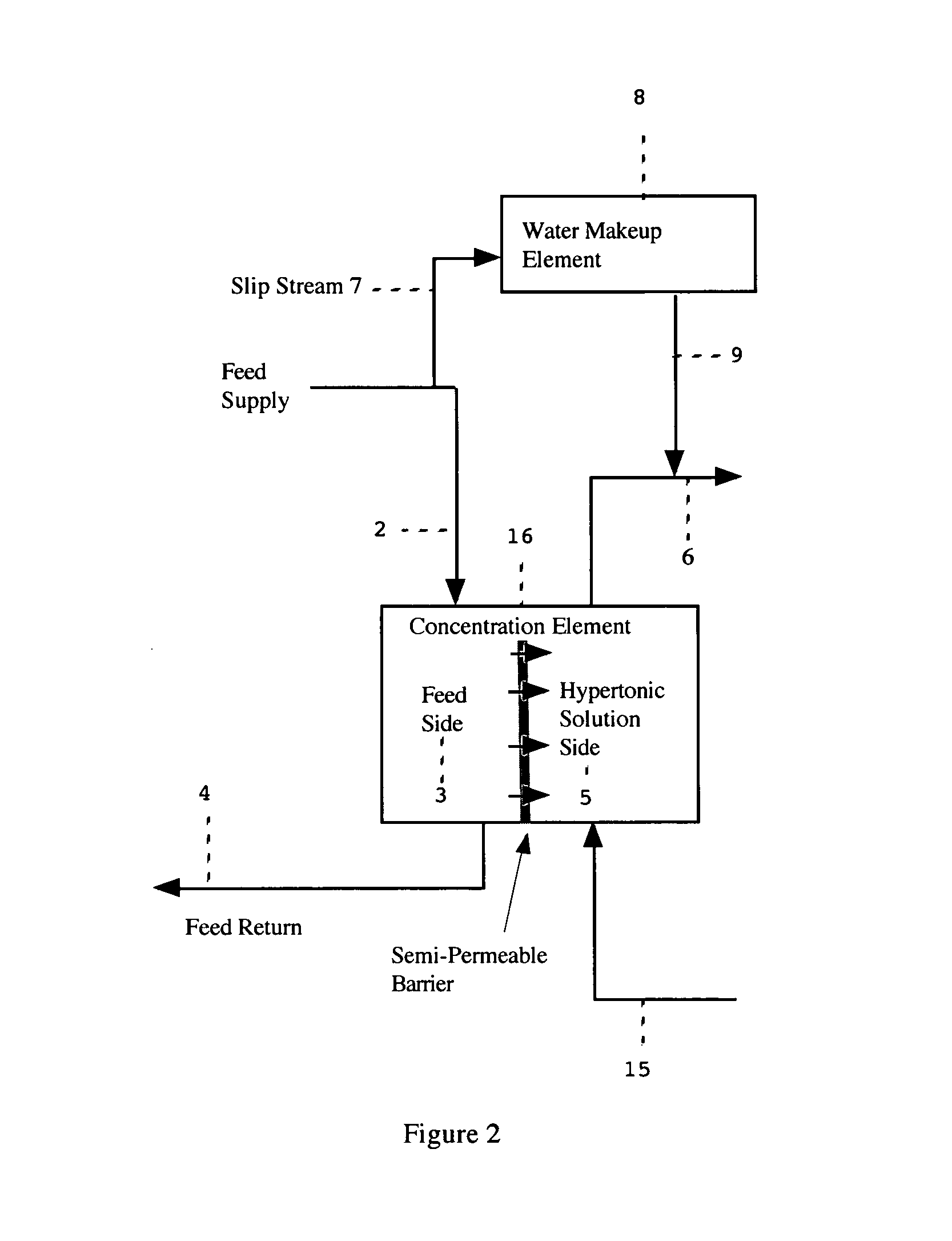

Low water recovery rate desalination system and method

A low water recovery rate desalination system and method. This system and method enables the purification of water in a more environmentally sustainable manner than conventional systems. The environmental benefit of this invention is derived from its ability to desalinate water and produce a brine byproduct that is less concentrated than that of conventional desalination systems. The system is composed of three elements. They are a water makeup element, a concentration element and a desalination system. The water makeup element and the concentration element can integrated with a conventional desalination technology to form a complete desalination system.

Owner:FLYNN MICHAEL

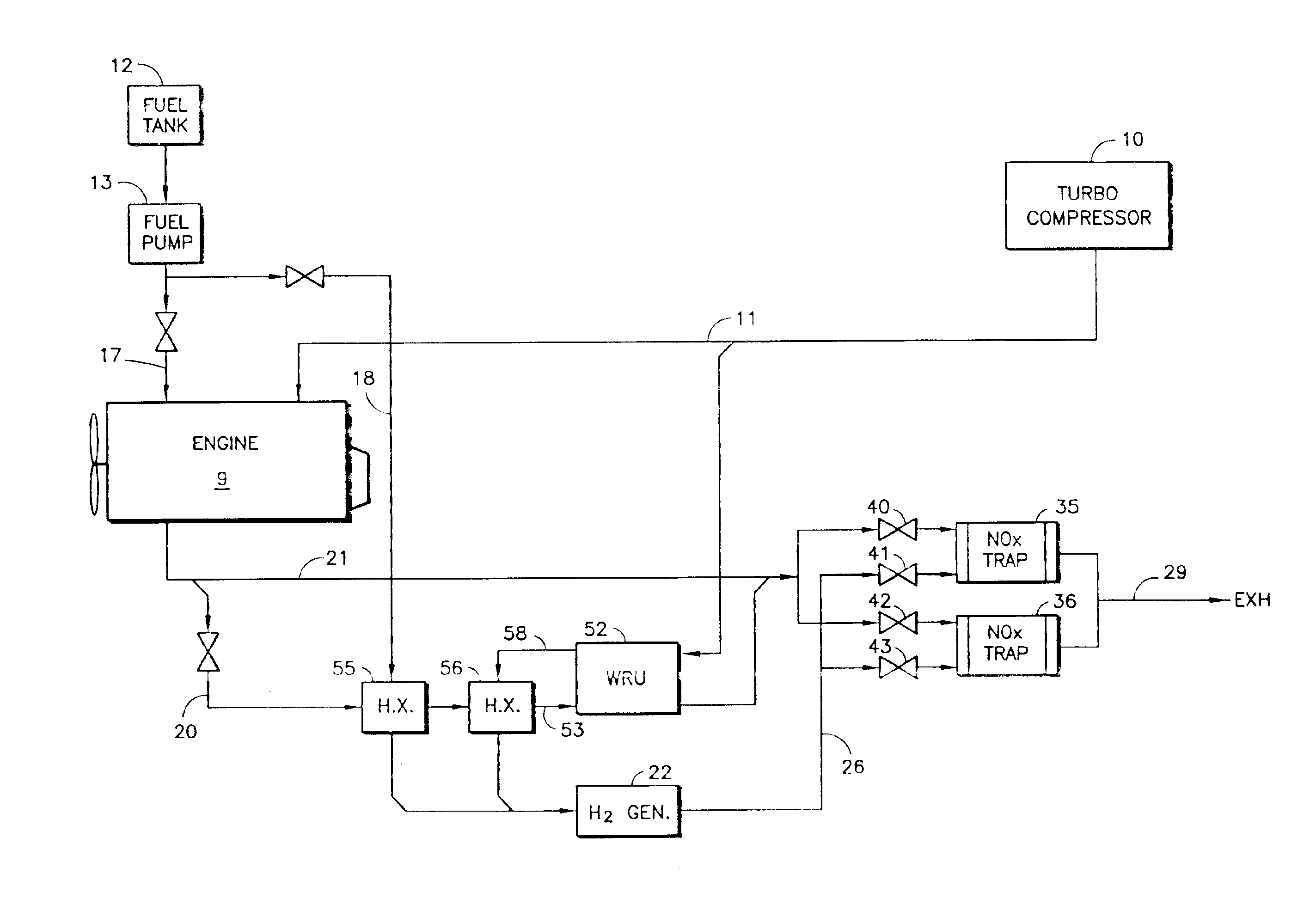

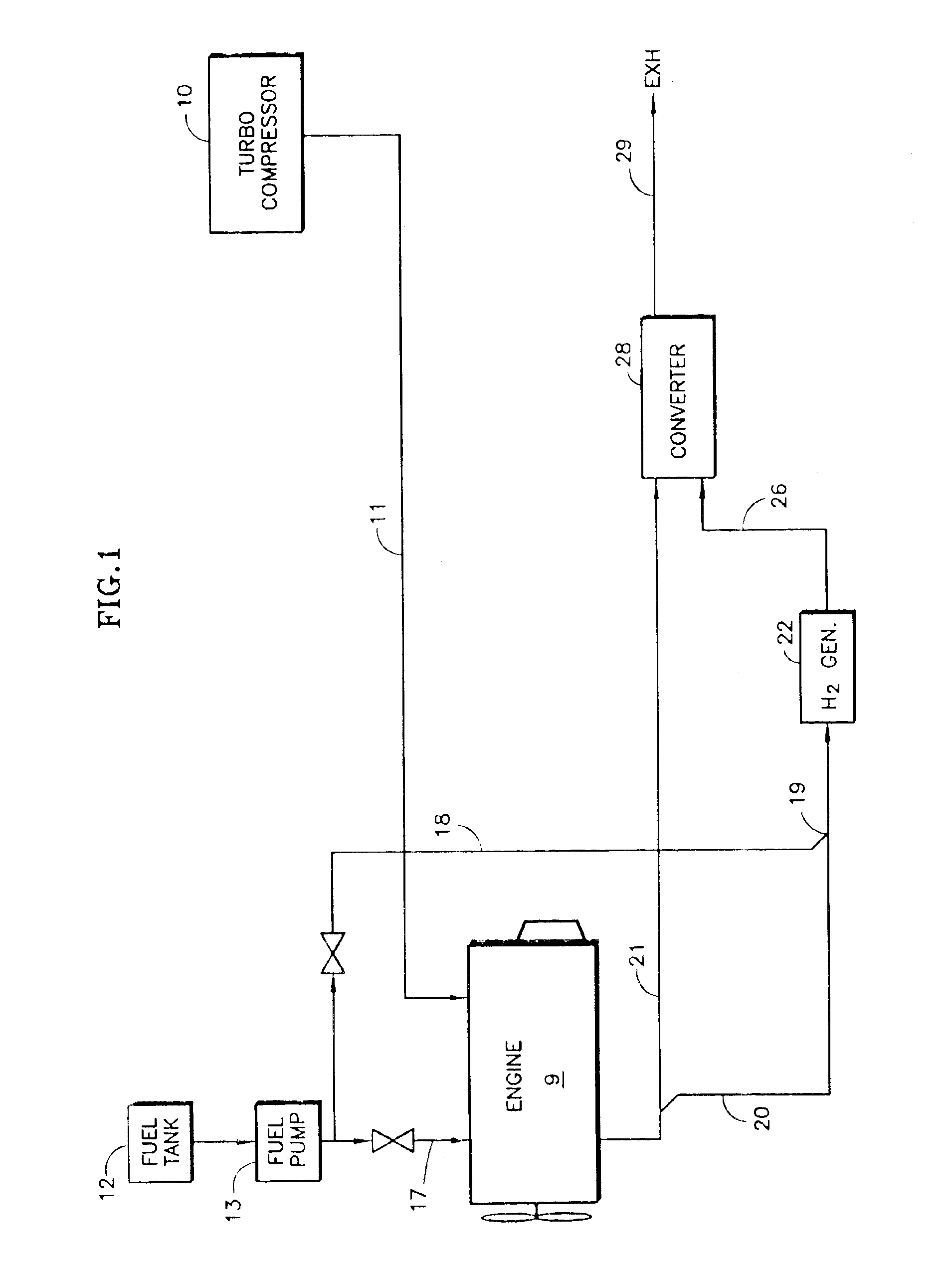

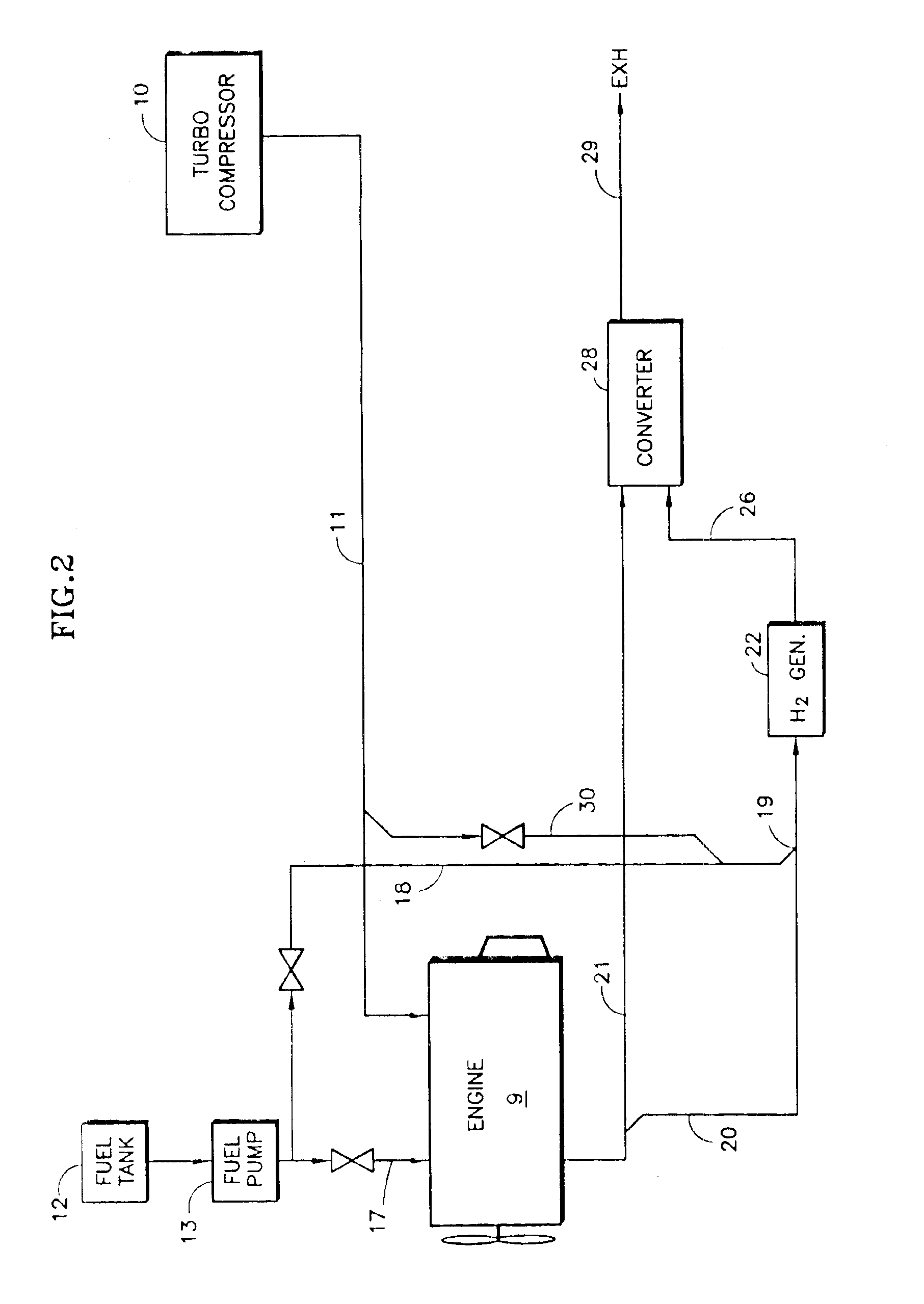

Reducing oxides of nitrogen using hydrogen generated from engine fuel and exhaust

InactiveUS6895746B2Reduce additionalInternal combustion piston enginesExhaust apparatusMethaneAir bubble

Either (a) the exhaust (20) of an engine (9) and / or (b) inlet air (11) is sent to a hydrogen generator (22) along with diesel fuel (18) to produce hydrogen and carbon monoxide (26) for either (c) mixing with the mainstream of exhaust fed to a catalytic converter (28) or (d) regenerating a pair of NOx adsorption traps (35, 36), thereby reducing oxides of nitrogen (NOx) to provide system exhaust (29) which may have less than 0.20 grams / bhp / hr of NOx and 0.14 grams / bhp / hr of non-methane hydrocarbons. A water recovery unit (52, 63) may extract water from either the exhaust or the effluent of the NOx traps to humidify inlet air (11) for mixture with fuel. Inlet air (11) may be humidified in an air bubbling humidifier (72) that receives water from a condenser (76) that uses inlet air to cool NOx trap effluent.

Owner:SHELL OIL CO

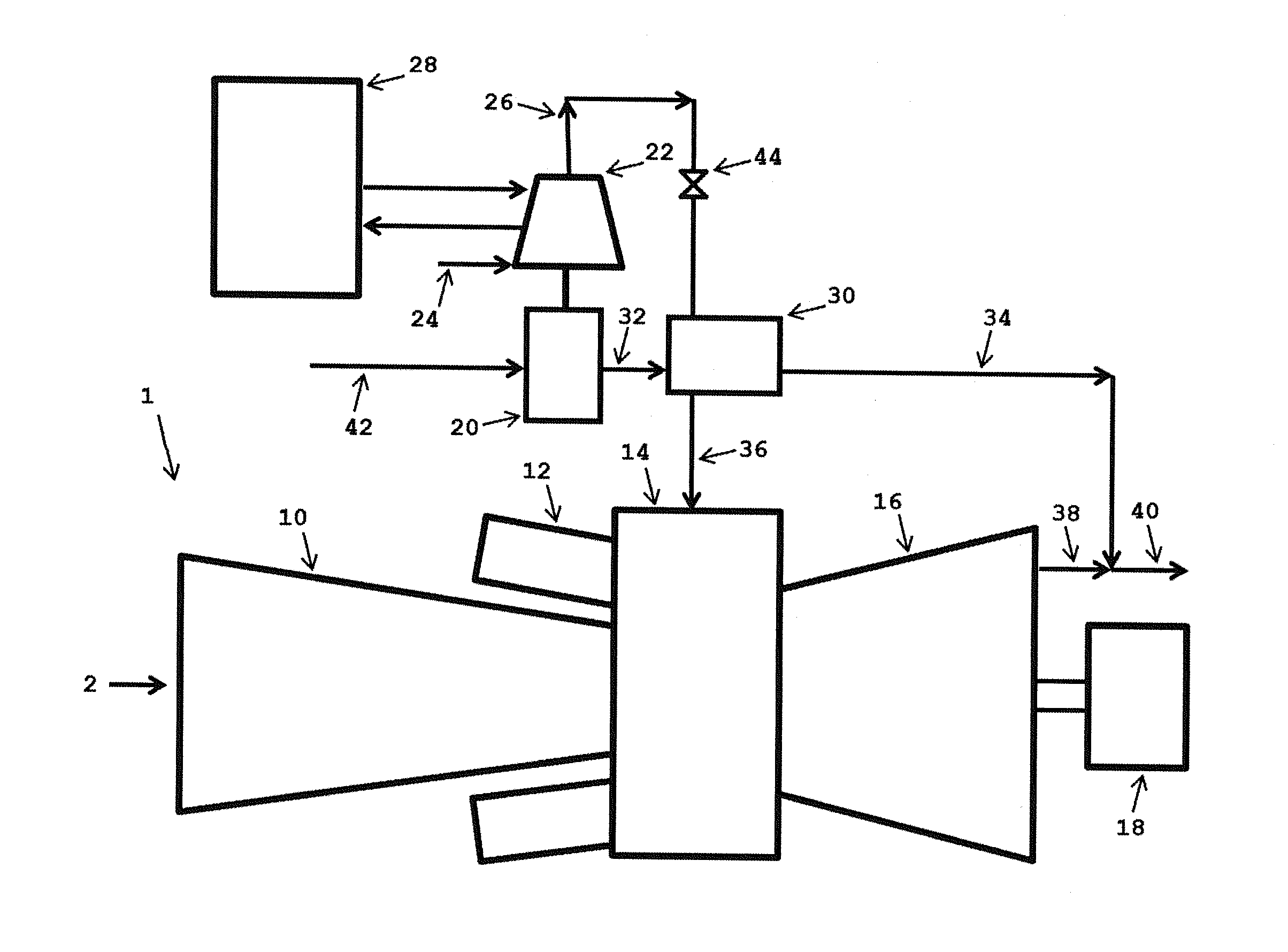

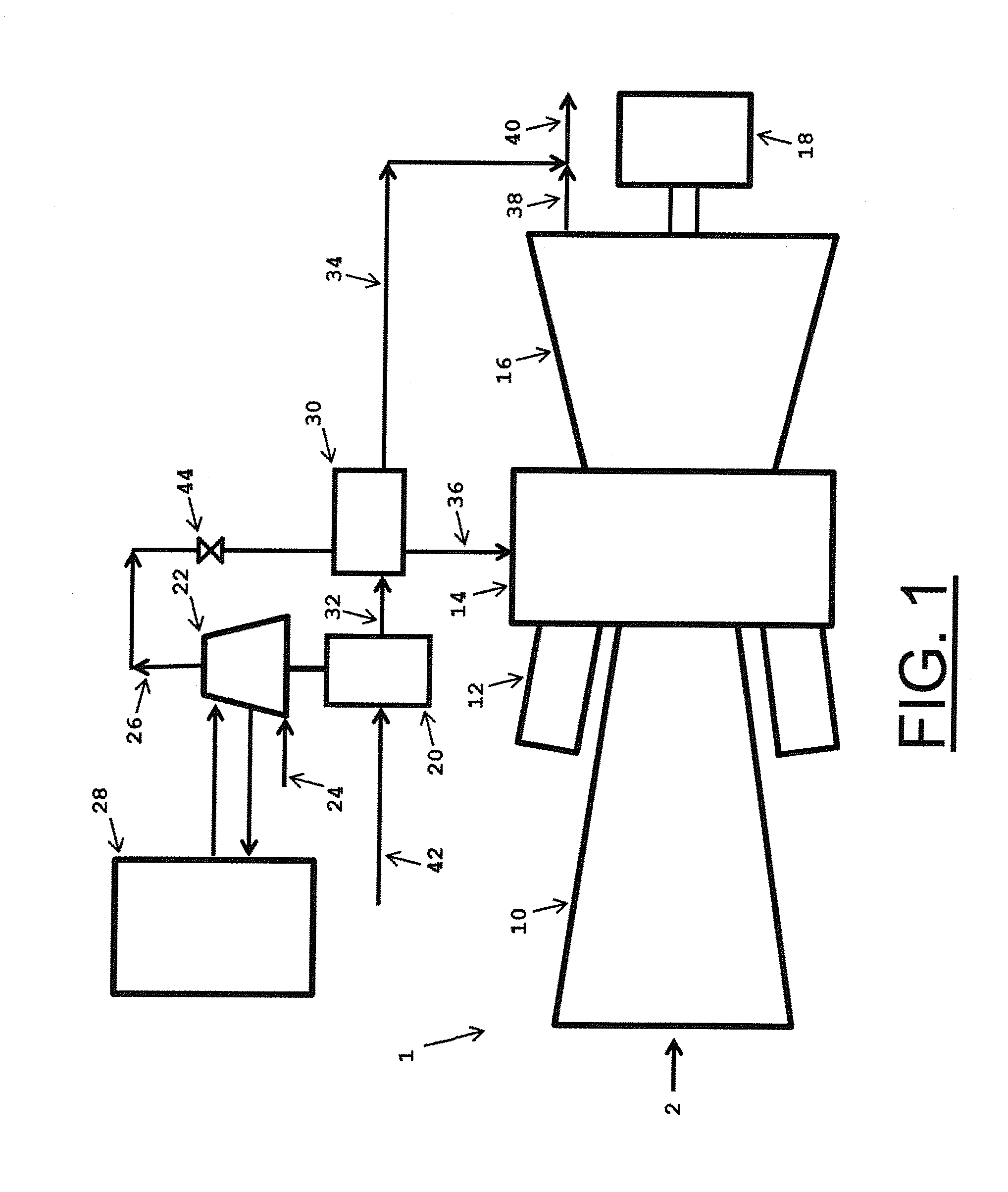

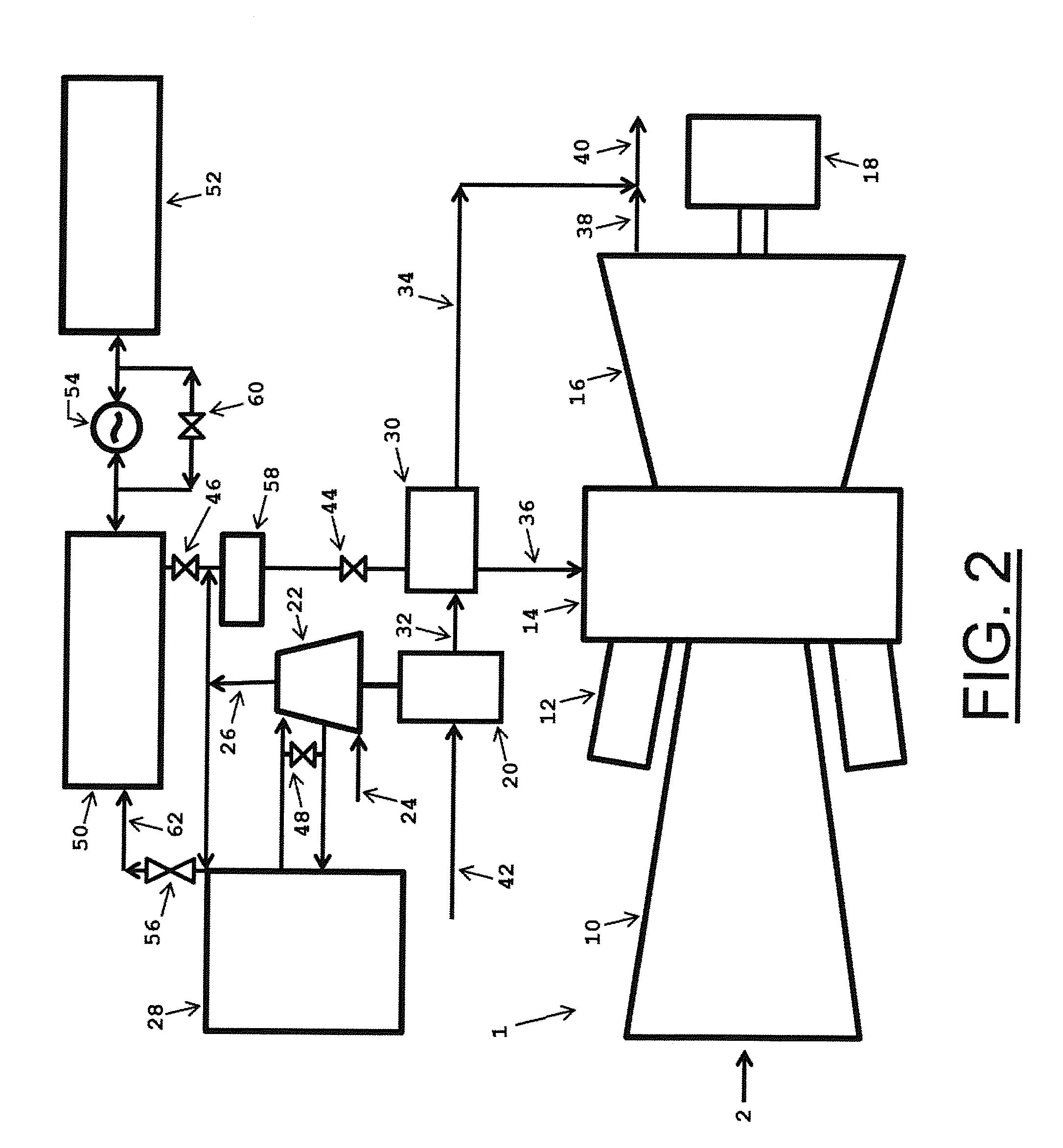

Gas turbine efficiency and regulation speed improvements using supplementary air system continuous and storage systems and methods of using the same

ActiveUS20140366547A1Improve efficiencyEliminating heating loadEngine fuctionsCombustion enginesPower stationExhaust fumes

The present invention discloses a novel apparatus and methods for augmenting the power of a gas turbine engine, improving gas turbine engine operation, and reducing the response time necessary to meet changing demands of a power plant. Improvements in power augmentation and engine operation include additional heated compressed air injection, steam injection, water recovery, exhaust tempering, fuel heating, and stored heated air injection.

Owner:POWERPHASE

Oxidant-enriched fuel cell system

Fuel cell systems that include at least one fuel cell stack adapted to receive a fuel stream containing hydrogen gas or other proton source, and an oxidant stream containing oxygen gas. The systems include an oxidant supply system adapted to deliver an enriched, or concentrated, oxidant stream to the fuel cell stack. In some embodiments, the oxidant supply system is adapted to receive an air stream and produce an oxygen-enriched stream therefrom. In some embodiments, the fuel cell system includes a water-recovery system adapted to recover water produced in the fuel cell stack, such as may be recovered from the cathode exhaust stream from the fuel cell stack. In some embodiments, the recovered water is utilized as at least a portion of a feed stream for the fuel cell system, such as for a reformer or electrolyzer that produces hydrogen used as fuel for the fuel cell stack.

Owner:IDATECH LLC

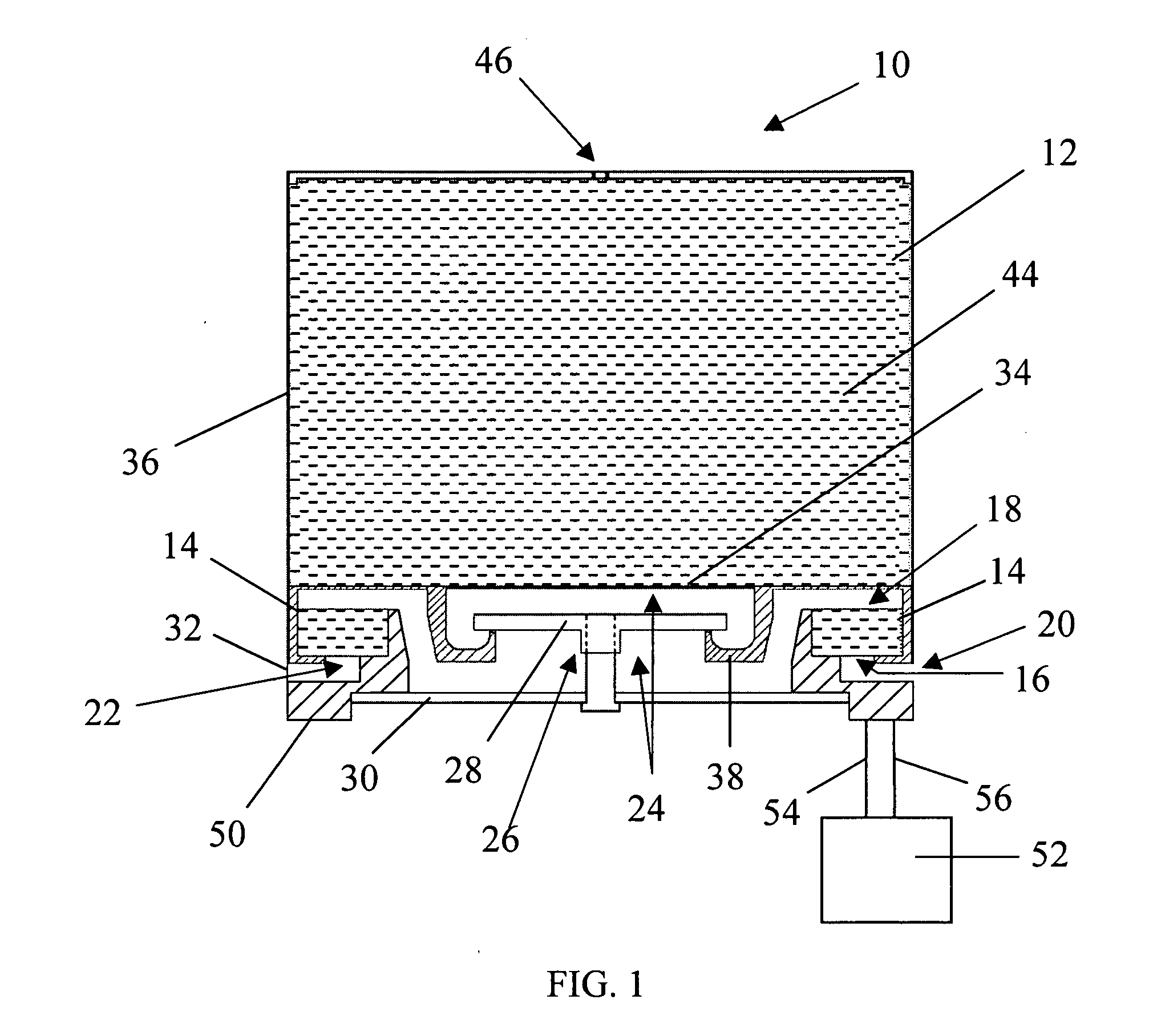

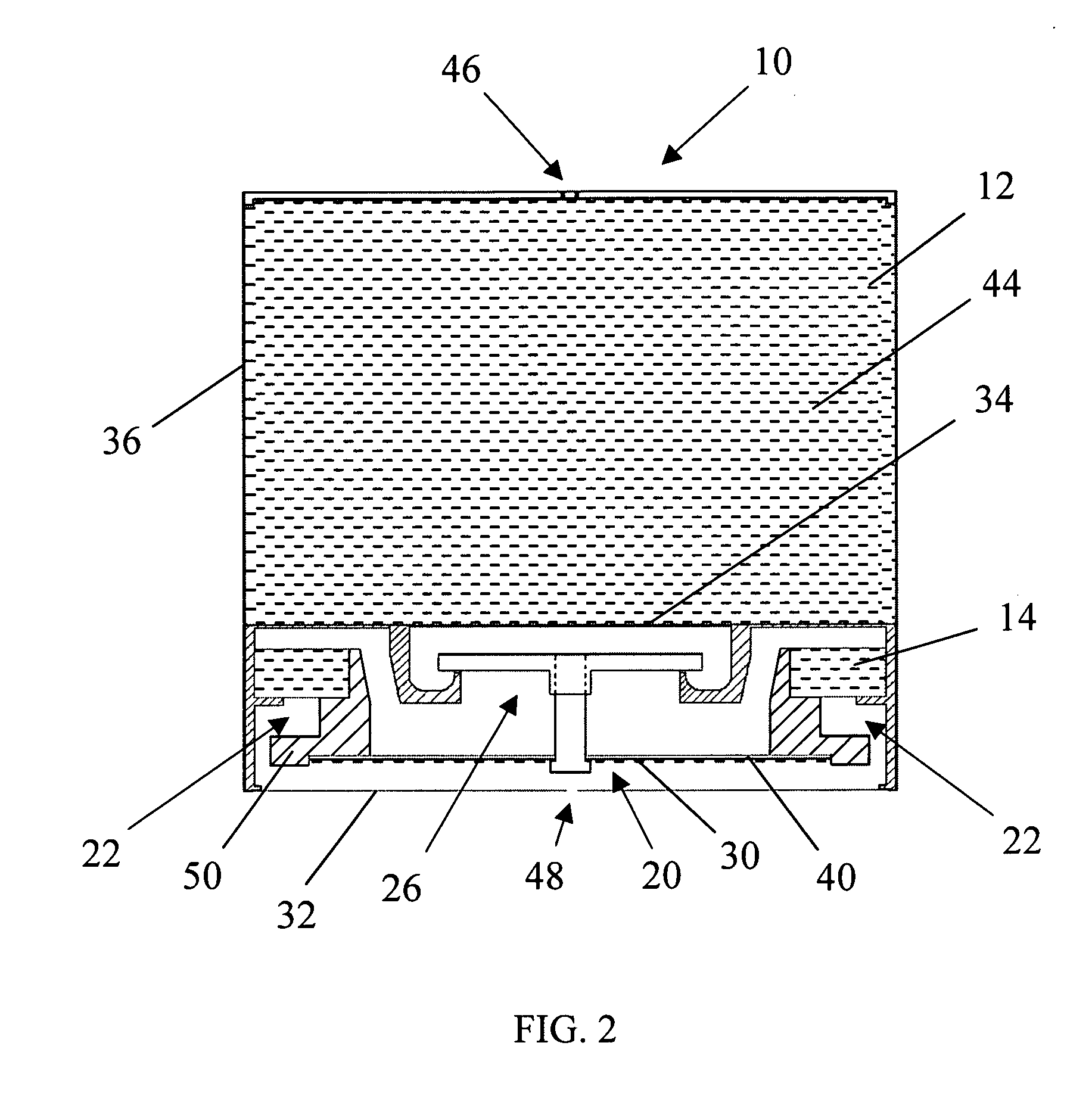

Hydrogen production and water recovery system for a fuel cell

InactiveUS20050074657A1Reduce in quantityImprove system efficiencyRegenerative fuel cellsFuel cell auxillariesFuel cellsElectrolysis

A hydrogen production and water recovery system for a fuel cell utilizes hydrogen storage in a metal hydride or the like. An exhaust stream from the fuel cell is passed through the storage media, simultaneously to cool the exhaust stream to promote condensation of water vapor and to heat the media to promote generation of hydrogen. The recovered water can be stored, returned to a coolant loop, and at a later time electrolyzed to generate hydrogen.

Owner:HYDROGENICS CORP

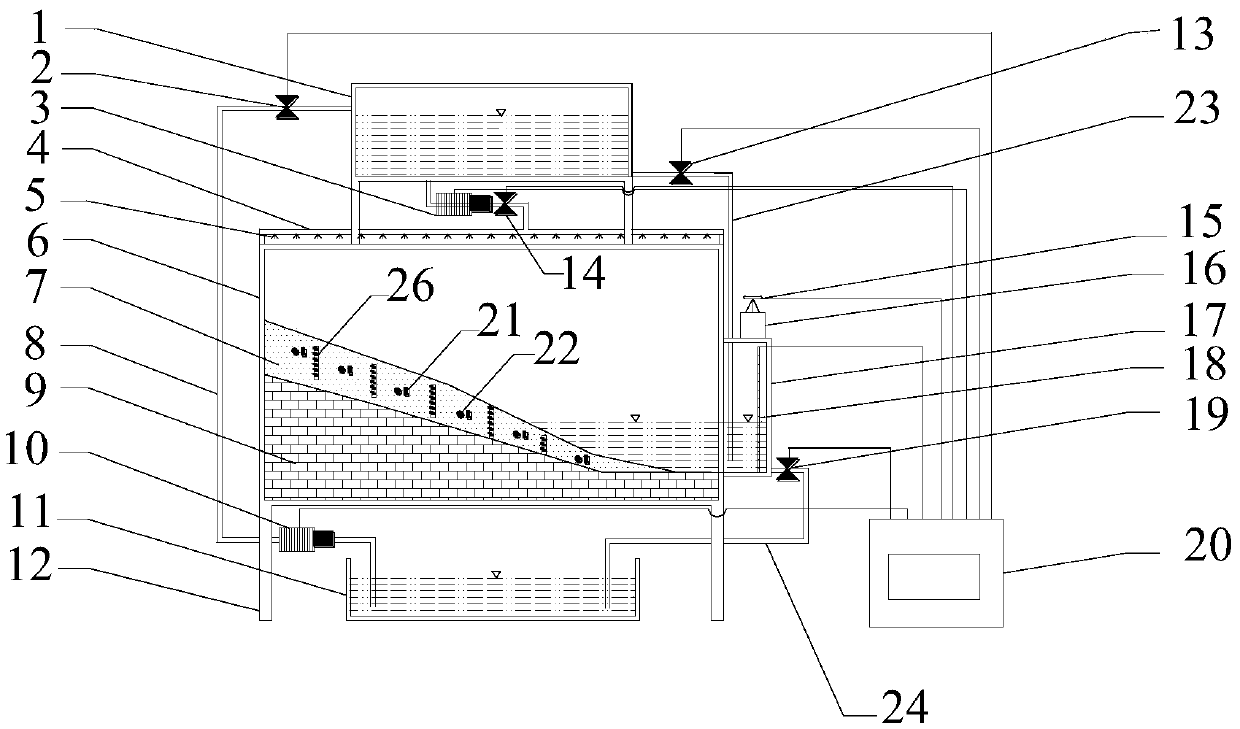

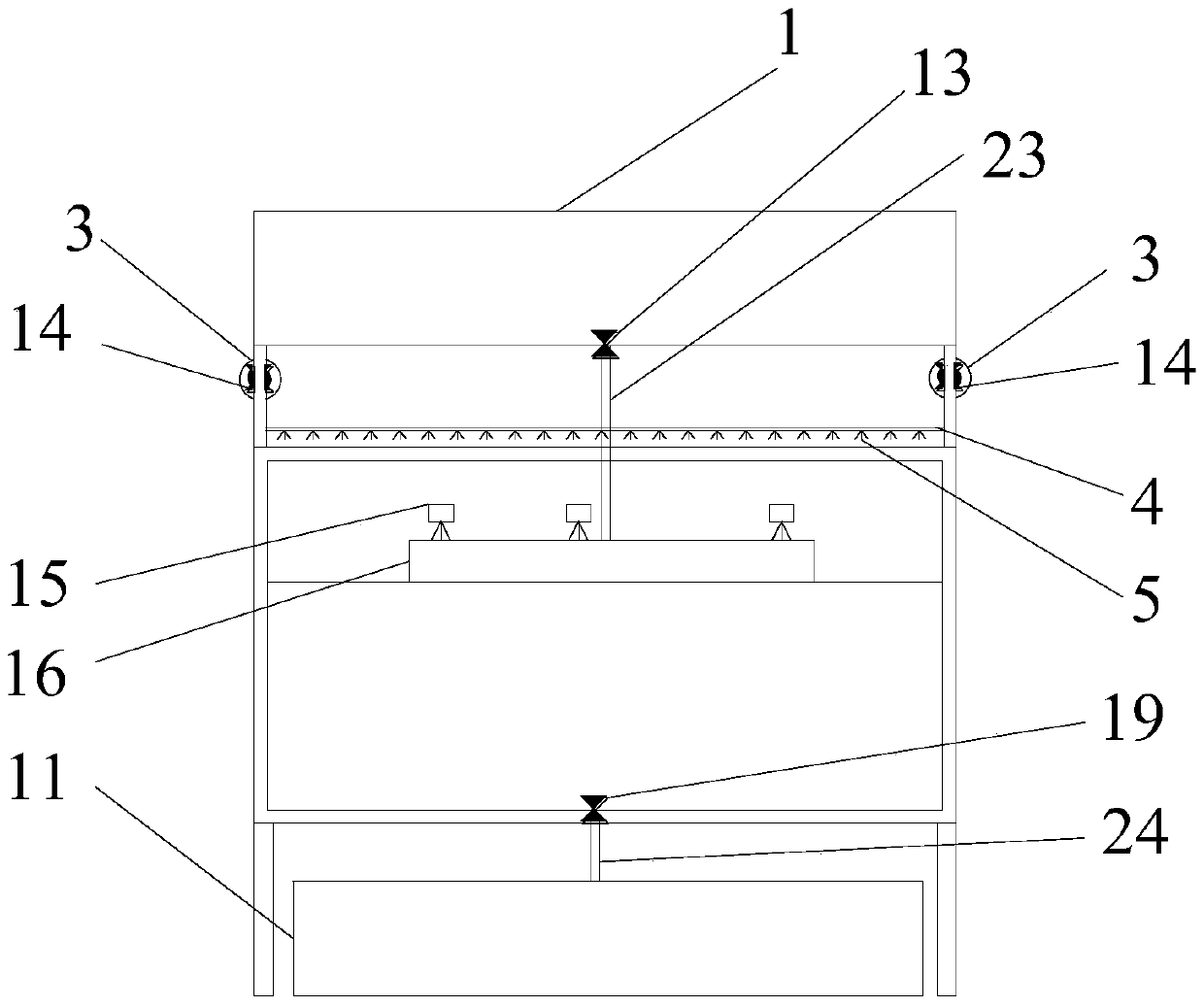

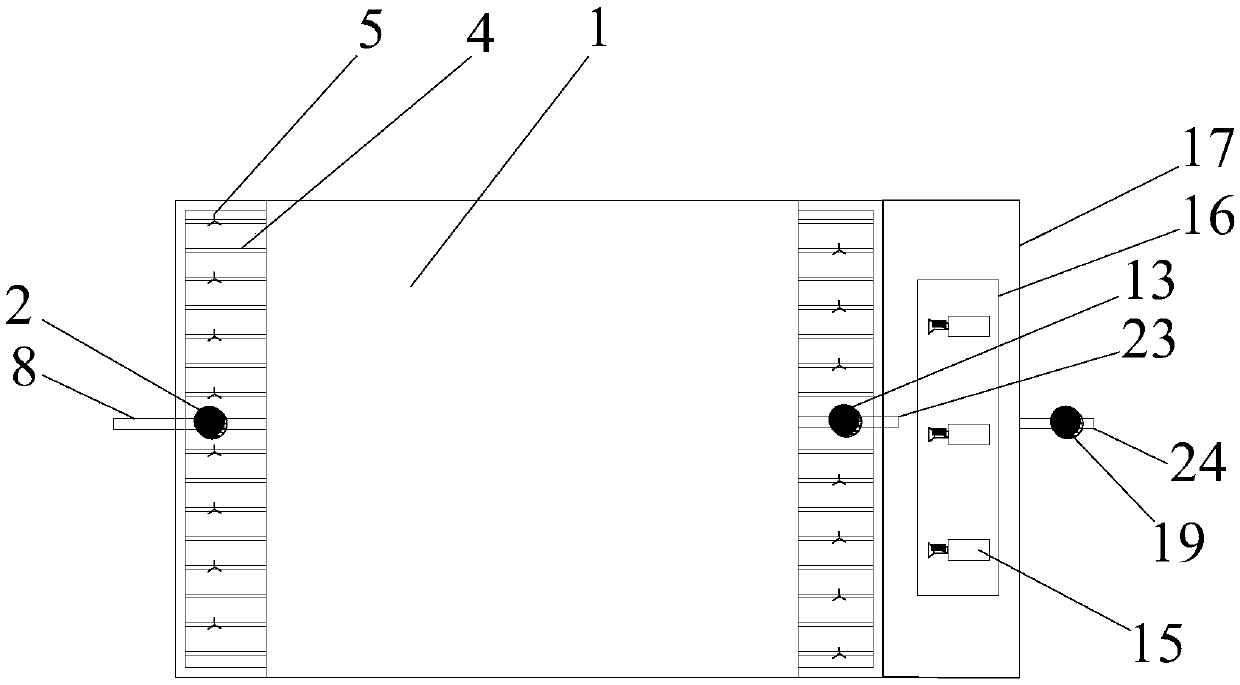

Device and method for landslide model test

InactiveCN105510556ALow costShorten the timeRadiation pyrometryEarth material testingExternal dataLandslide

The invention discloses a device for a landslide model test. The device comprises a landslide model, a model box, a rainfall system, a water supply system, a water recovery system, a reservoir water level rising and falling system, a landslide model external data acquisition device and a landslide model internal data acquisition device, wherein the rainfall system, the water supply system, the reservoir water level rising and falling system, the landslide model external data acquisition device and the landslide model internal data acquisition device are connected with an integrated control platform; the rainfall system is arranged above the model box; the water supply system is arranged above the rainfall system; the water recovery system is arranged under the model box; the water recovery system is connected with the water supply system through a water supply pipe; the reservoir water level rising and falling system is arranged on the lateral side of the model box and is communicated with the model box through a water supply and drainage hole with a filter net. The invention also provides a method for the landslide model test. The device can be used for simulating and realizing the water level change and rainfall intensity within a short period of time; the device can be comprehensively automatically controlled; the precision of the device for the landslide model test can be increased; the method is simple and can be used for increasing the efficiency of the landslide model test.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

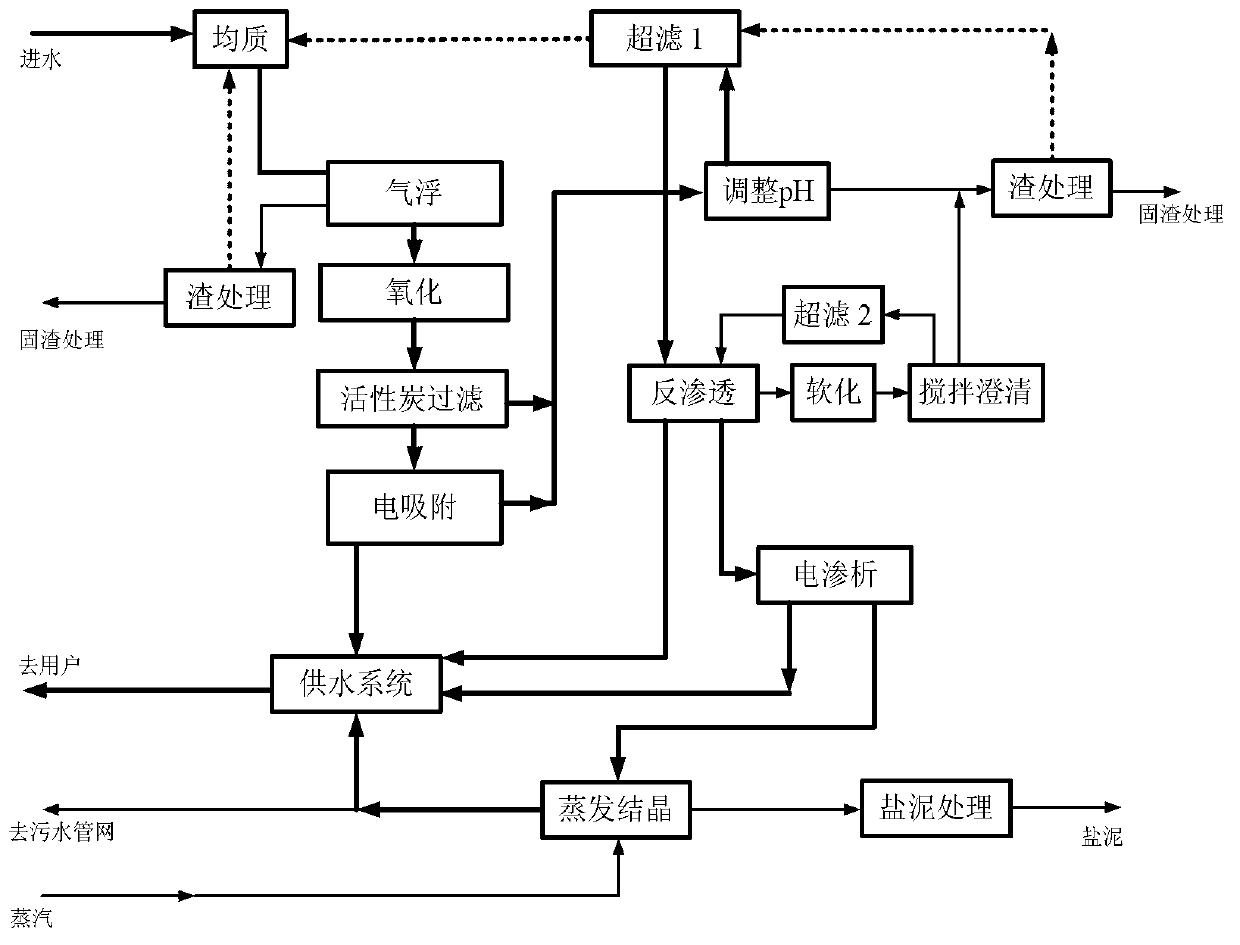

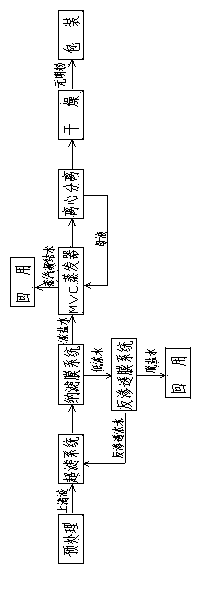

Near zero emission process of salt-containing waste water

ActiveCN103342432AHigh recovery rateReduce processing costsDispersed particle separationWater/sewage treatment bu osmosis/dialysisChemical oxygen demandUltrafiltration

The invention relates to a near zero emission process of salt-containing waste water. The process specifically comprises the following steps of: 1) pretreatment, namely, removing part of COD (Chemical Oxygen Demand), suspended solids, hardness and the like from raw water; 2) electric absorption, namely, removing inorganic salt in pretreated partial water, wherein concentrated water generated in the process and part of oxidized waste water which is not subjected to electric adsorption treatment enter into a membrane filtering system together; 3) treatment in a membrane treatment system, wherein the membrane treatment system mainly comprises ultrafiltration, reverse osmosis and electroosmosis processes; and 4) evaporative crystallization and salty mud treatment process, namely, evaporating and crystallizing concentrated salty water generated by electroosmosis, wherein fresh water generated in the process enters into a water supply system while solids generated in the process enter into the salty mud treatment system. The comprehensive water recovery rate of the near zero emission process can reach 99.5%, so that resource and harmful treatment of the salt-containing waste water is realized.

Owner:NANJING UNIV OF TECH +1

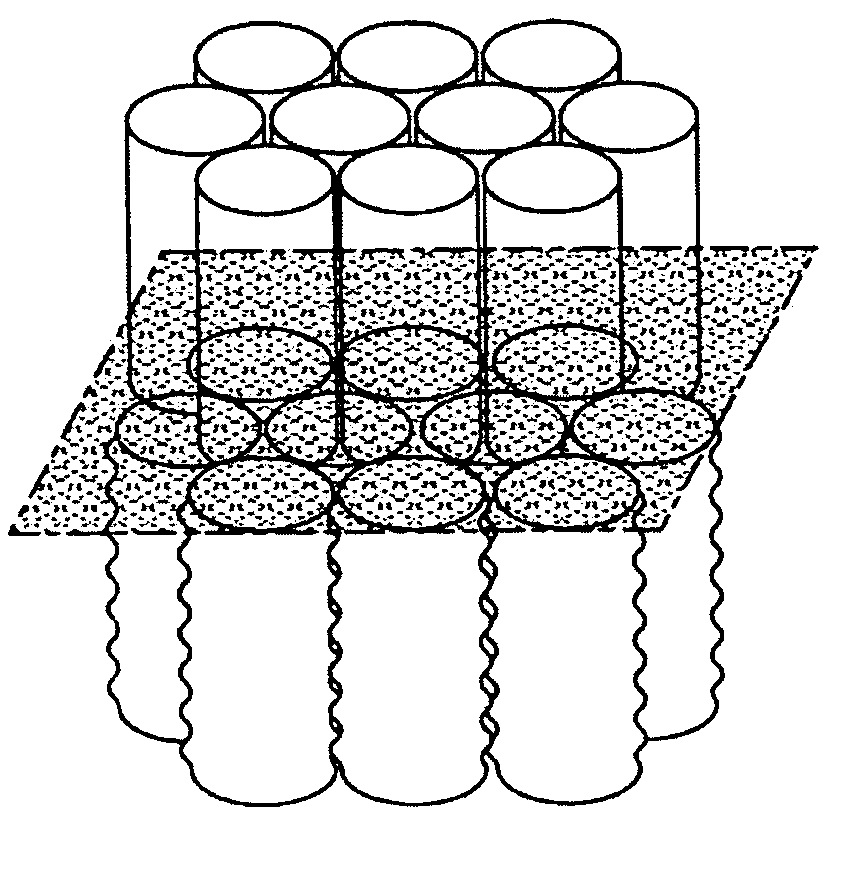

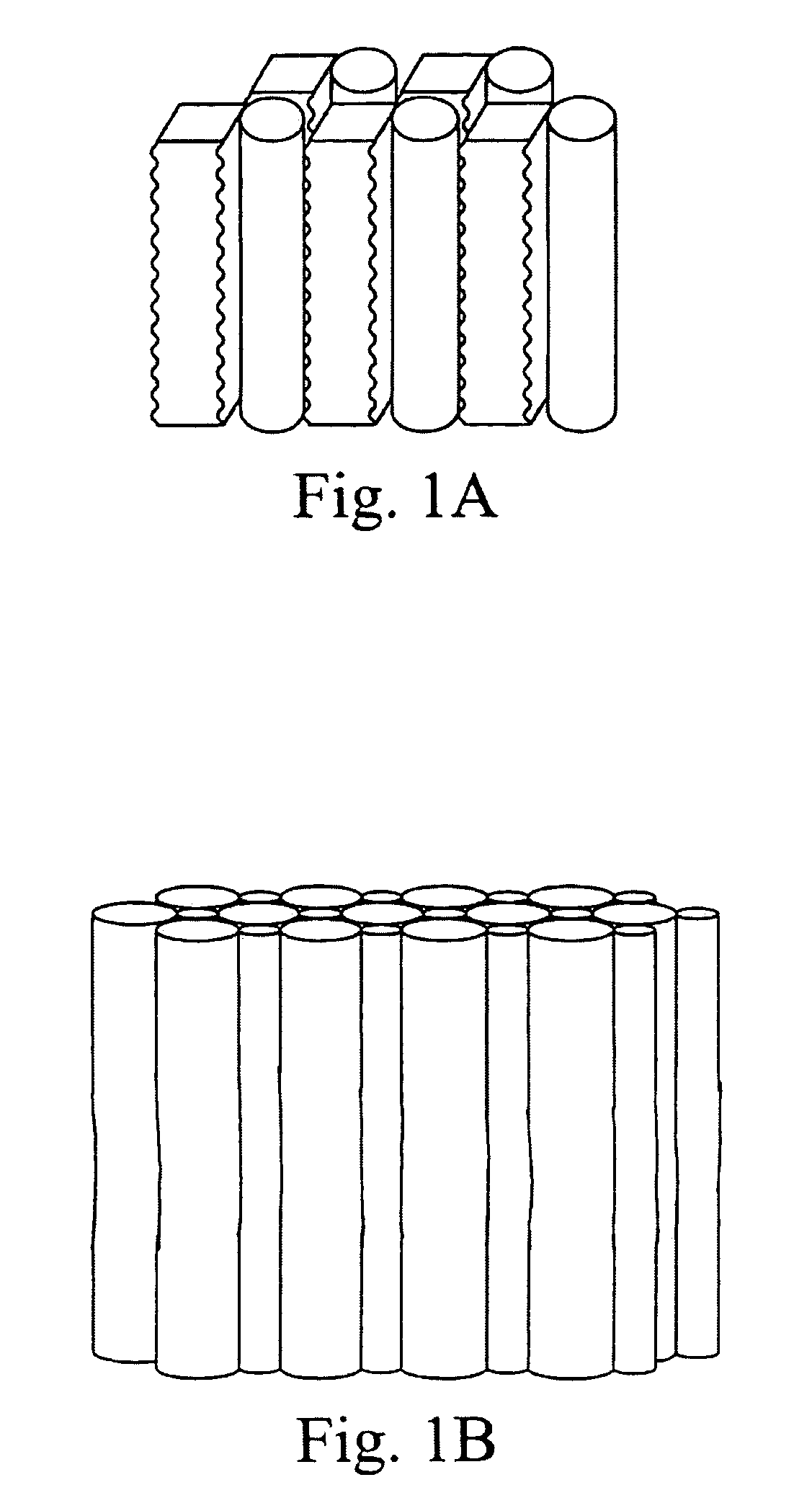

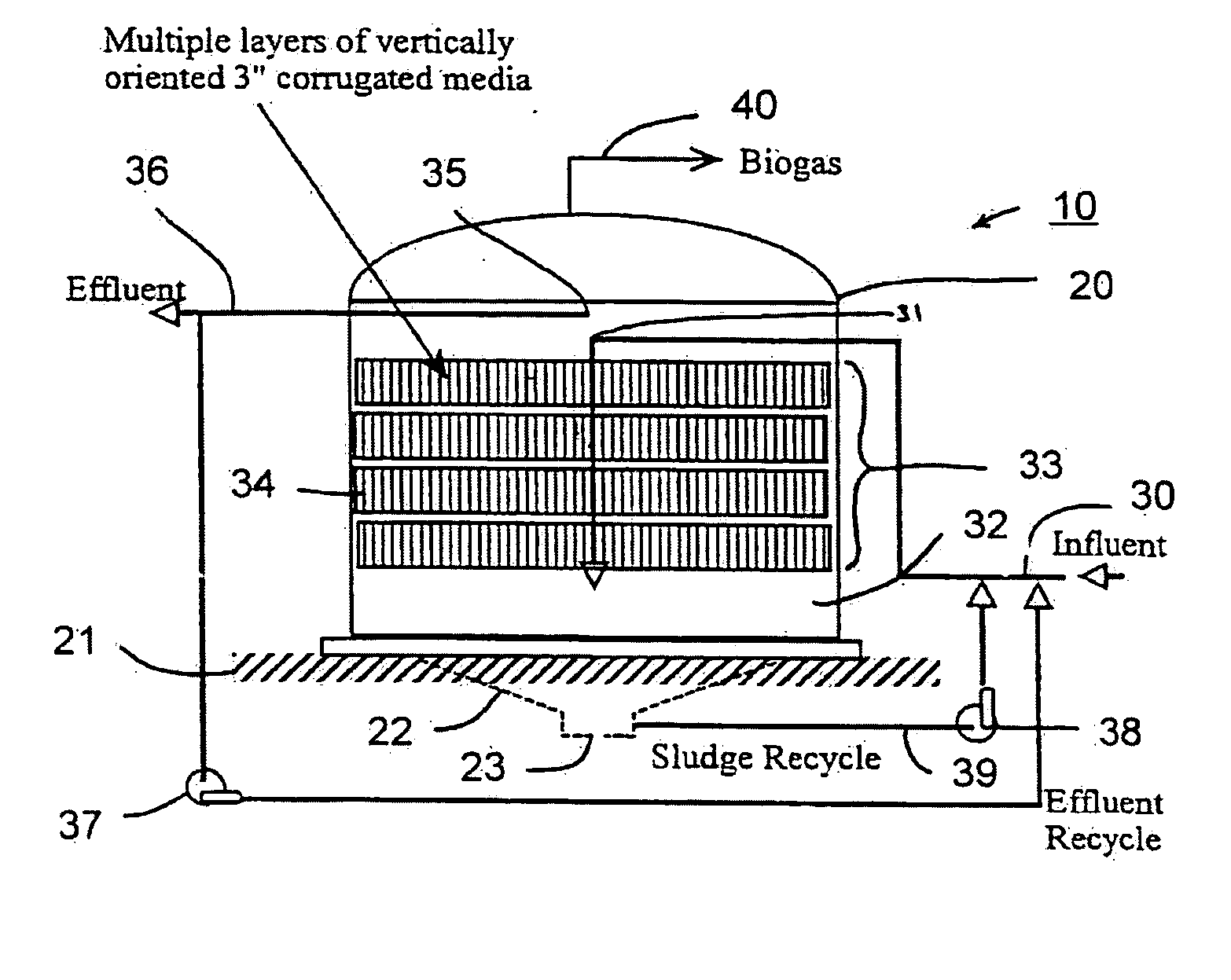

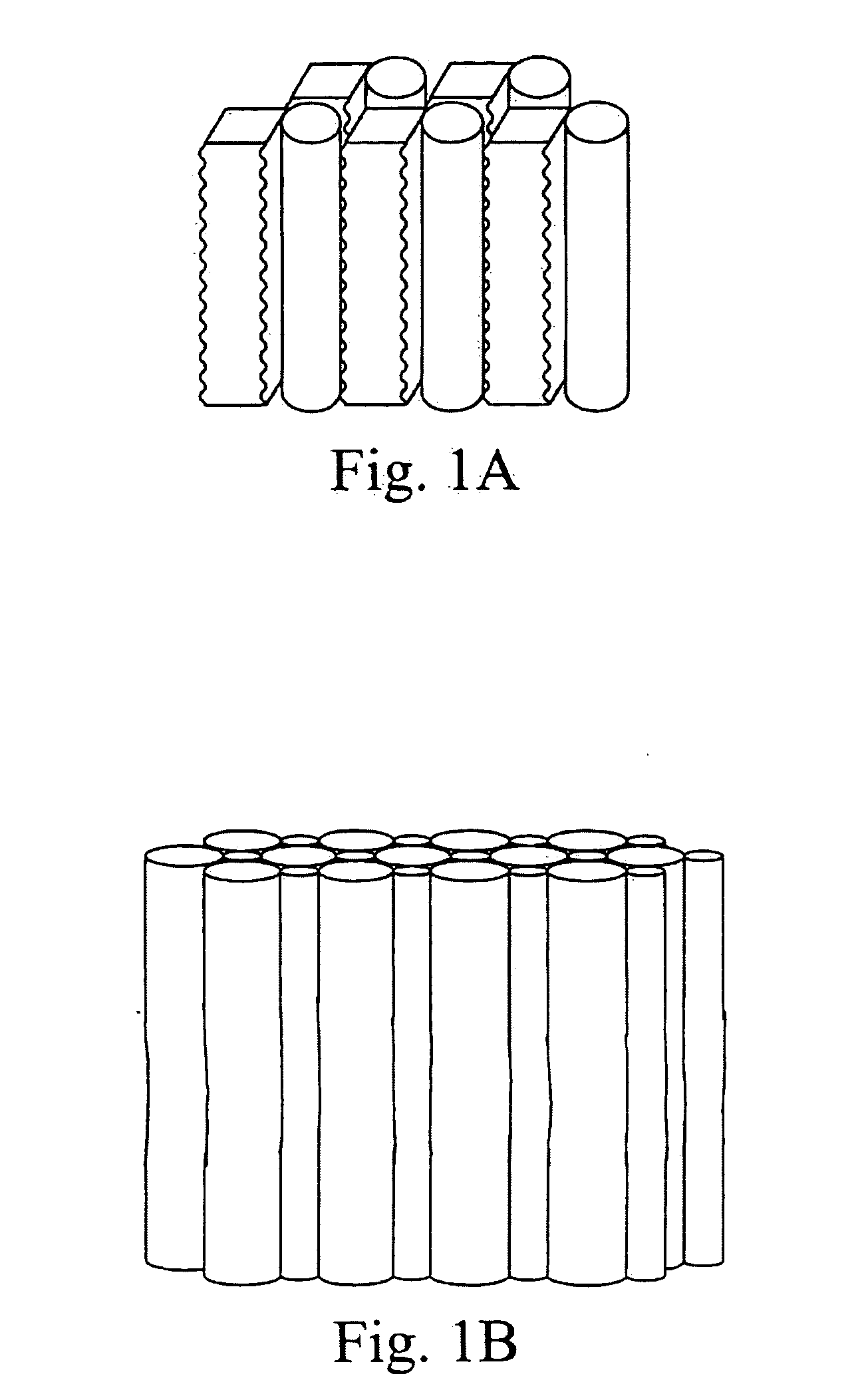

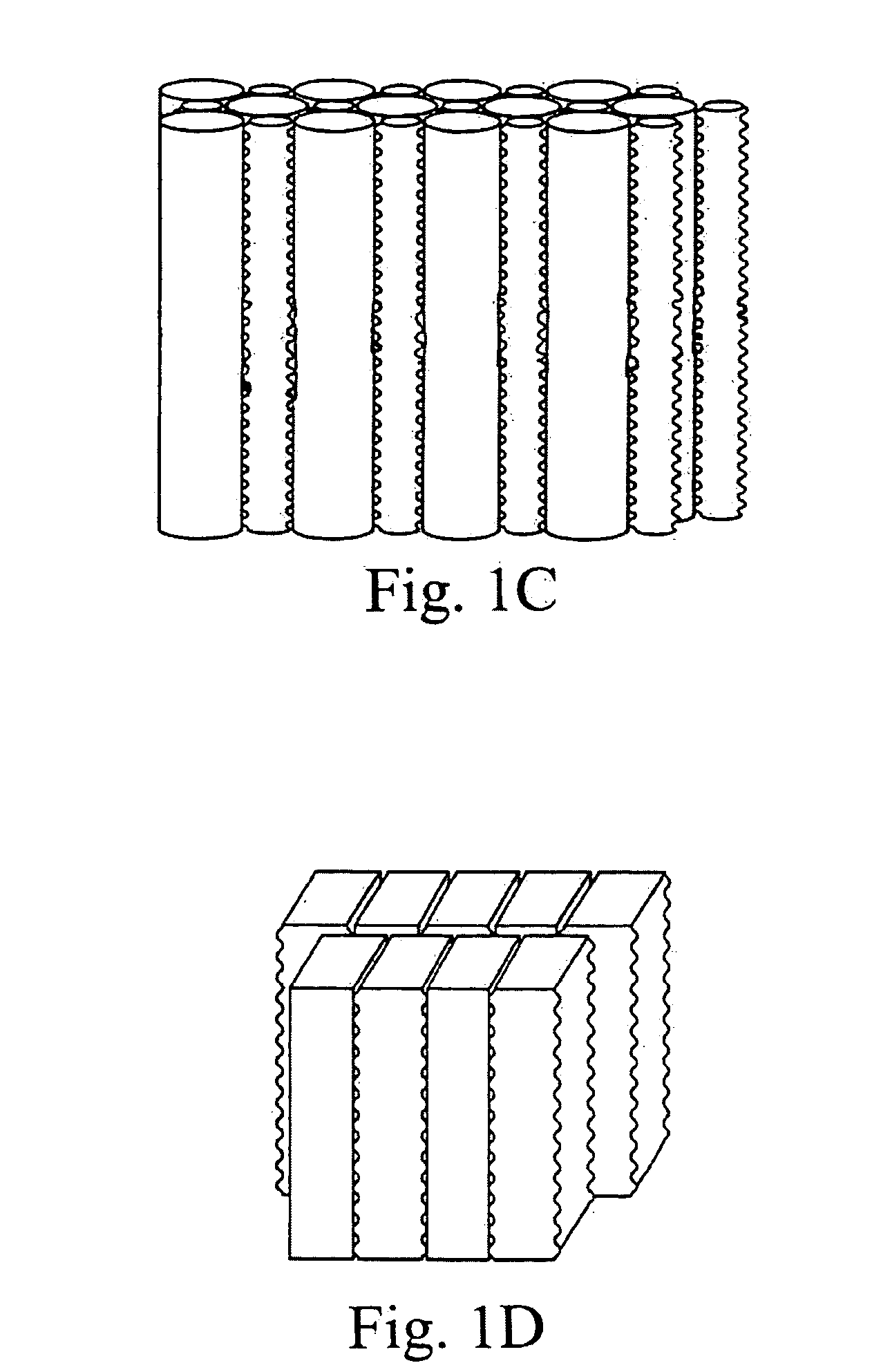

Fixed-film anaerobic digestion of flushed waste

InactiveUS7297274B2Reduce odorMinimizing offensive odorsWaste water treatment from animal husbandryGas production bioreactorsFecesLivestock manure

An apparatus for the fixed-film anaerobic digestion of flushed livestock manure includes an enclosed digester tank (fixed or flexible roof), internal media for biofilm development, a biogas collection and flare system, various pumps, and hydraulic control systems. The preferred media has substantially vertically-oriented, uninterrupted channels to promote enhanced bacterial attachment and biofilm development. The immobilization of microbial biomass within the reactor as a biofilm allows effective treatment of the wastewater at ambient and higher temperatures, as well as reasonable hydraulic retention times. The composition and concentration of bacterial groups in the biofilm developed on the media in the fixed-film digester result in a significantly enhanced anaerobic degradation process. This novel fixed-film digester design expands the potential application of anaerobic digestion to dilute livestock waste with significant levels of suspended solids. This holistic manure treatment system not only stabilizes the wastewater but also produces energy (biogas), controls odors, reduces pathogens, minimizes environmental impact from waste emissions, and maximizes fertilizer and water recovery for reuse.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

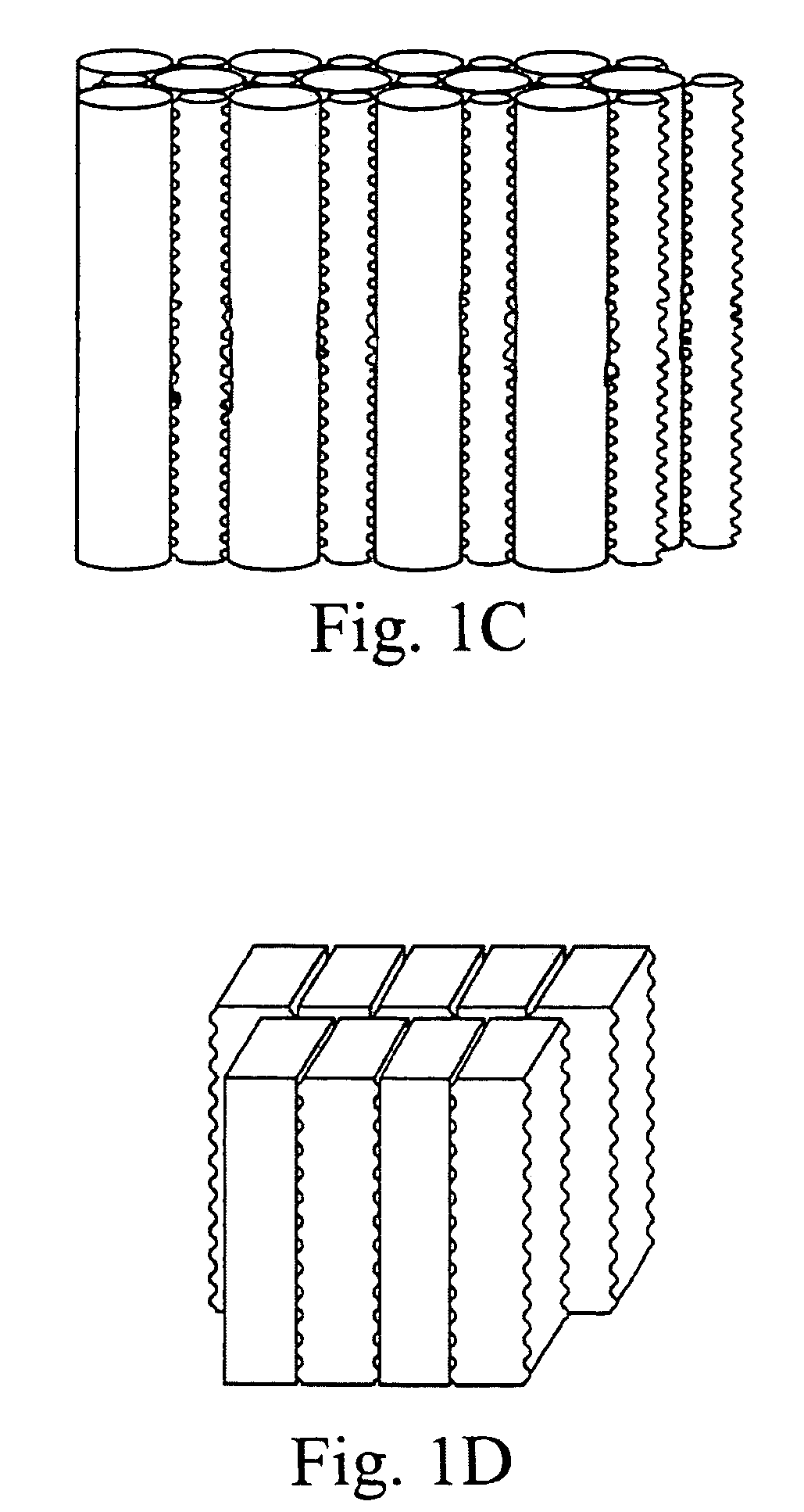

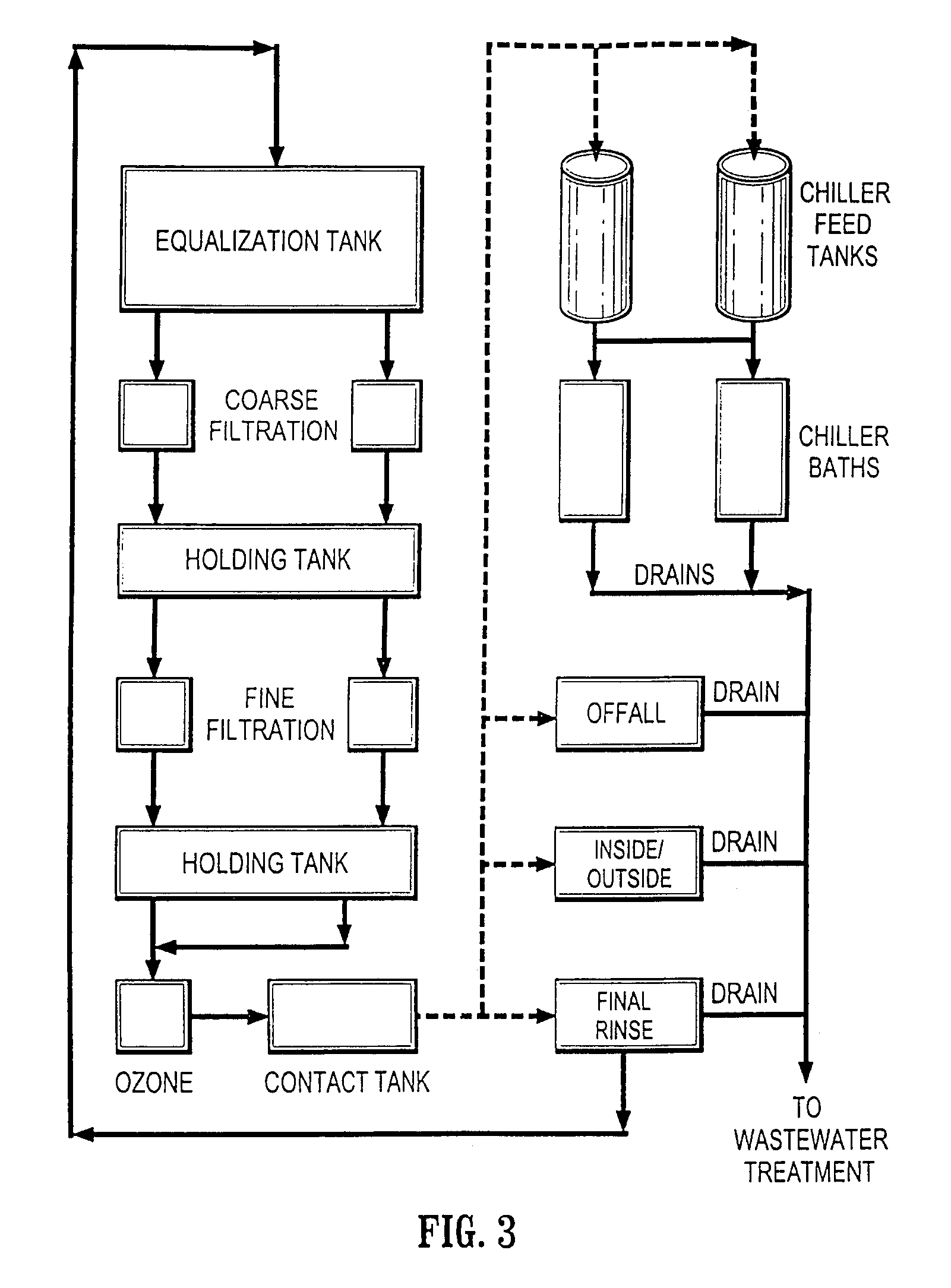

Poultry processing water recovery and re-use process

InactiveUS7077967B2Shorten the counting processImprove food safetyLoose filtering material filtersWater/sewage treatment by neutralisationWater useOil and grease

The inventions of the present disclosure are directed to processes designed to recover water used in certain aspects of the processing of poultry, treat the recovered water to remove solids, fats, oils and greases, animal proteins and pathogenic organisms and to reuse the treated water for poultry processing operations. The processes described herein reduce bacteria and microorganisms associated with the poultry and reuse water. The present disclosure can be employed with an approach that includes unexpected positive results of reacting ozone and chlorine with water being treated for reuse to generate hypochlorous acid and / or other effective biocides. Ozone reacts with fats, oils, and greases, dissolved in the reuse water, to produce specific surface-active agents and surfactants which reduce the surface tension of the water which it is dissolved. The combination of these surface-active agents and surfactants and the biocides cause an extraordinary release and destruction of bacteria from the poultry carcass as well as the reuse water.

Owner:ZENTOX CORP

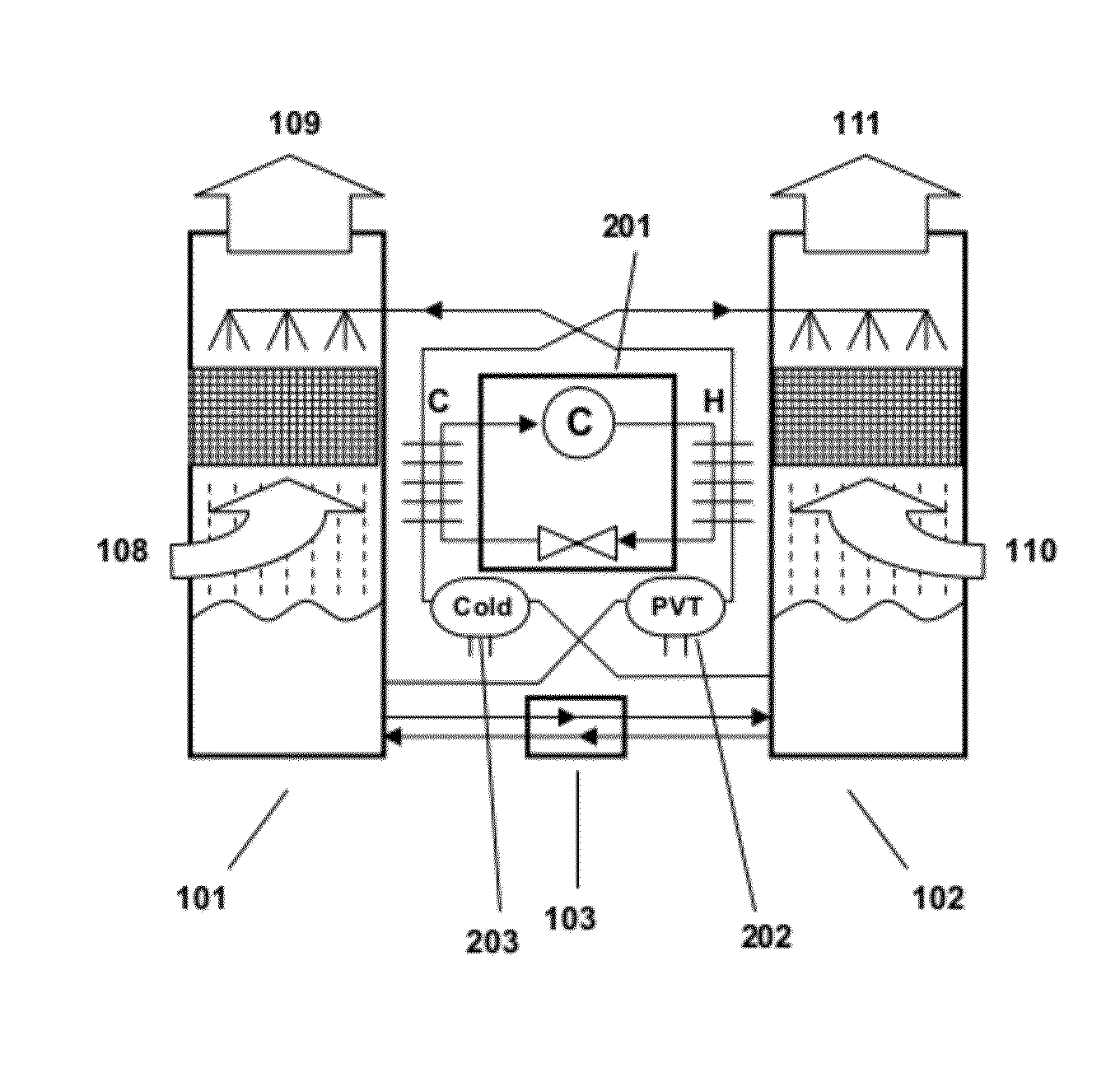

Water recovery methods and systems

Methods and systems are provided for air conditioning, capturing combustion contaminants, desalination, and other processes using liquid desiccants.

Owner:COPELAND LP

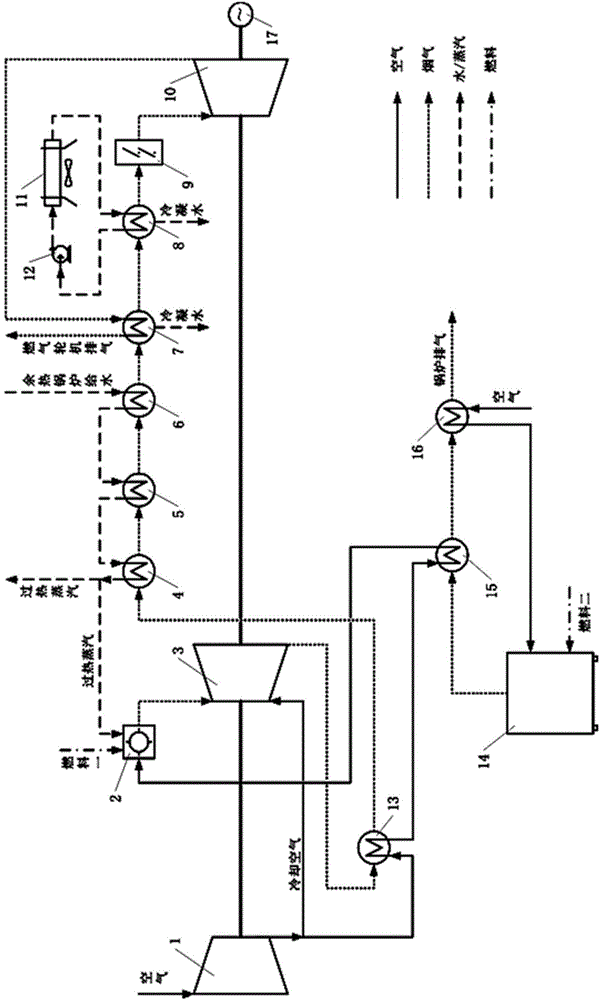

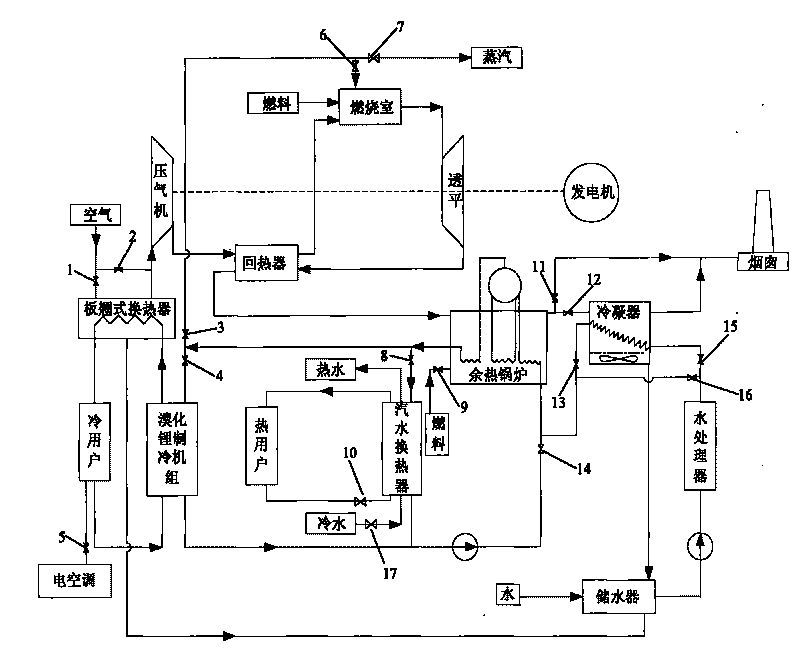

Dual-fuel steam injection direct-inverse gas turbine combined cycle

ActiveCN104533621ACombined Cycle Efficiency ImprovementEmission reductionTurbine/propulsion engine coolingGas turbine plantsSystem integrationBrayton cycle

The invention relates to a clean fuel and biomass fuel dual-fuel steam injection direct-inverse gas turbine combined cycle. A backheating type steam injection-inverse gas turbine combined cycle form is adopted for a gas turbine, and clean fuel is adopted for the gas turbine; flue gas produced when biomass fuel burns in a boiler indirectly heats the air entering a combustion chamber of the gas turbine first and then preheats the air entering the boiler, wherein the steam cyclically produced by the gas turbine can be used for supplying heat to the outside. According to the dual-fuel steam injection direct-inverse gas turbine combined cycle, the gradient utilization principle of energy is utilized, an external combustion method and the advanced steam injection direct-inverse Brayton cycle are organically combined through system integration, the energy utilization efficiency of the biomass fuel can be substantially improved, the proportion of the biomass fuel to the clean fuel is adjustable, and self-balance of water consumption and water recovery for steam injection can be achieved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

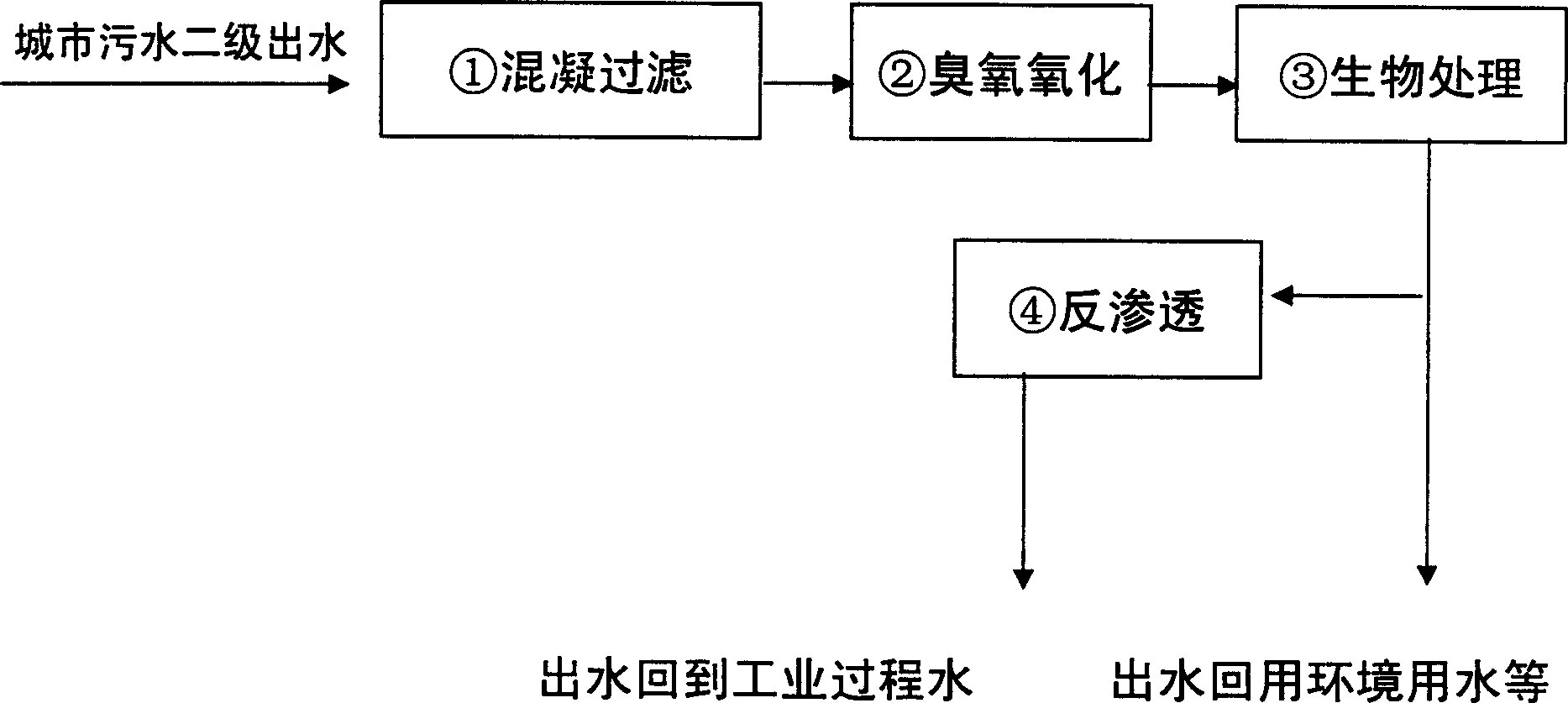

Method for processing urban sewage deeply

ActiveCN1796314AChange sizeChange structureTreatment using aerobic processesWater/sewage treatment bu osmosis/dialysisFiltrationReverse osmosis

This invention is related to a process of disposing urban sewage, which comprise the steps of coagulate filtration, ozone oxidation, biological oxidation to dispose urban sewage, so that the residual undegradable organic substances, bacteria and virus in the second-class urban sewage can be removed and the water can be recycled. According to different usages of the recycled water, the process also comprises reverse osmosis or nanoscale filtration treatment to further remove the residual organic and inorganic substances in the water. The process is a combination of coagulate filtration, ozone oxidation, biological oxidation and reverse osmosis, designed to resolve such problems as urban sewage disposal and water recovery. The process can obtain high-quality recycled water with a low cost, showing high cost performance, which is important to resolving urban water depletion, raising the utilization rate of water resources, reducing environmental pollution and promoting sustainable development of the society.

Owner:北京国中科创环境科技有限责任公司

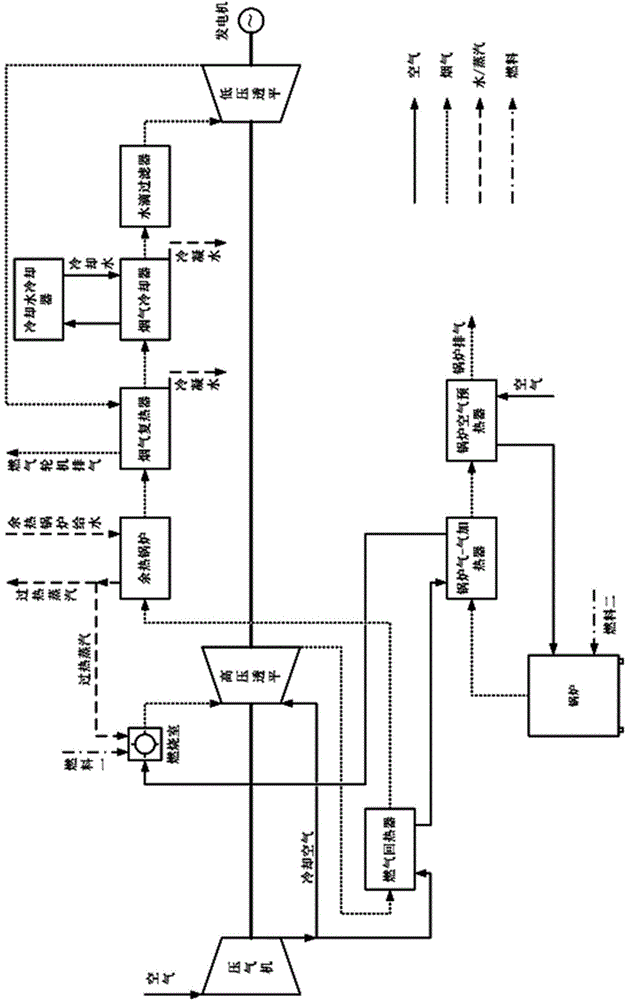

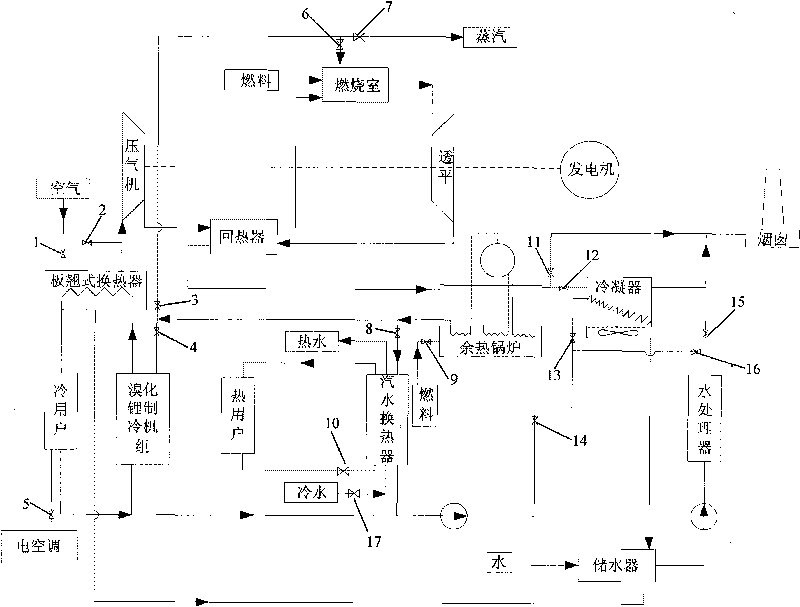

Heat and cool power cogeneration system of integrated multi-functional efficient mini-type gas turbine

InactiveCN101761392AIncrease power generationImprove power generation efficiencyClimate change adaptationGas turbine plantsElectricityCogeneration

The invention proposes a heat and cool power cogeneration system of an integrated multi-functional efficient mini-type gas turbine, which belongs to the novel heat and cool power cogeneration system device. To solve the frequent mismatching of cold and heat load and low efficiency operation of the conventional cogeneration system, measures such as steam reinjection, inlet gas cooling, gas fume and condensate water recovery are introduced on the basis of the heat and cool power cogeneration system of the mini-type gas turbine; in addition, the number of steam outlets and hot-water outlets is increased, thus forming the heat and cool power cogeneration system of the integrated multi-functional efficient mini-type gas turbine. The system is provided with various operation modes suitable for different occasions, can effectively solve the problem of mismatching of cold and heat load of the cogeneration system, so that the system can keep working in highly efficient mode.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Fixed-film anaerobic digestion of flushed waste

InactiveUS20050167359A1Reduce odorEase of inspectionGas production bioreactorsWaste water treatment from animal husbandryLivestock manureFeces

An apparatus for the fixed-film anaerobic digestion of flushed livestock manure includes an enclosed digester tank (fixed or flexible roof), internal media for biofilm development, a biogas collection and flare system, various pumps, and hydraulic control systems. The preferred media has substantially vertically-oriented, uninterrupted channels to promote enhanced bacterial attachment and biofilm development. The immobilization of microbial biomass within the reactor as a biofilm allows effective treatment of the wastewater at ambient and higher temperatures, as well as reasonable hydraulic retention times. The composition and concentration of bacterial groups in the biofilm developed on the media in the fixed-film digester result in a significantly enhanced anaerobic degradation process. This novel fixed-film digester design expands the potential application of anaerobic digestion to dilute livestock waste with significant levels of suspended solids. This holistic manure treatment system not only stabilizes the wastewater but also produces energy (biogas), controls odors, reduces pathogens, minimizes environmental impact from waste emissions, and maximizes fertilizer and water recovery for reuse.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

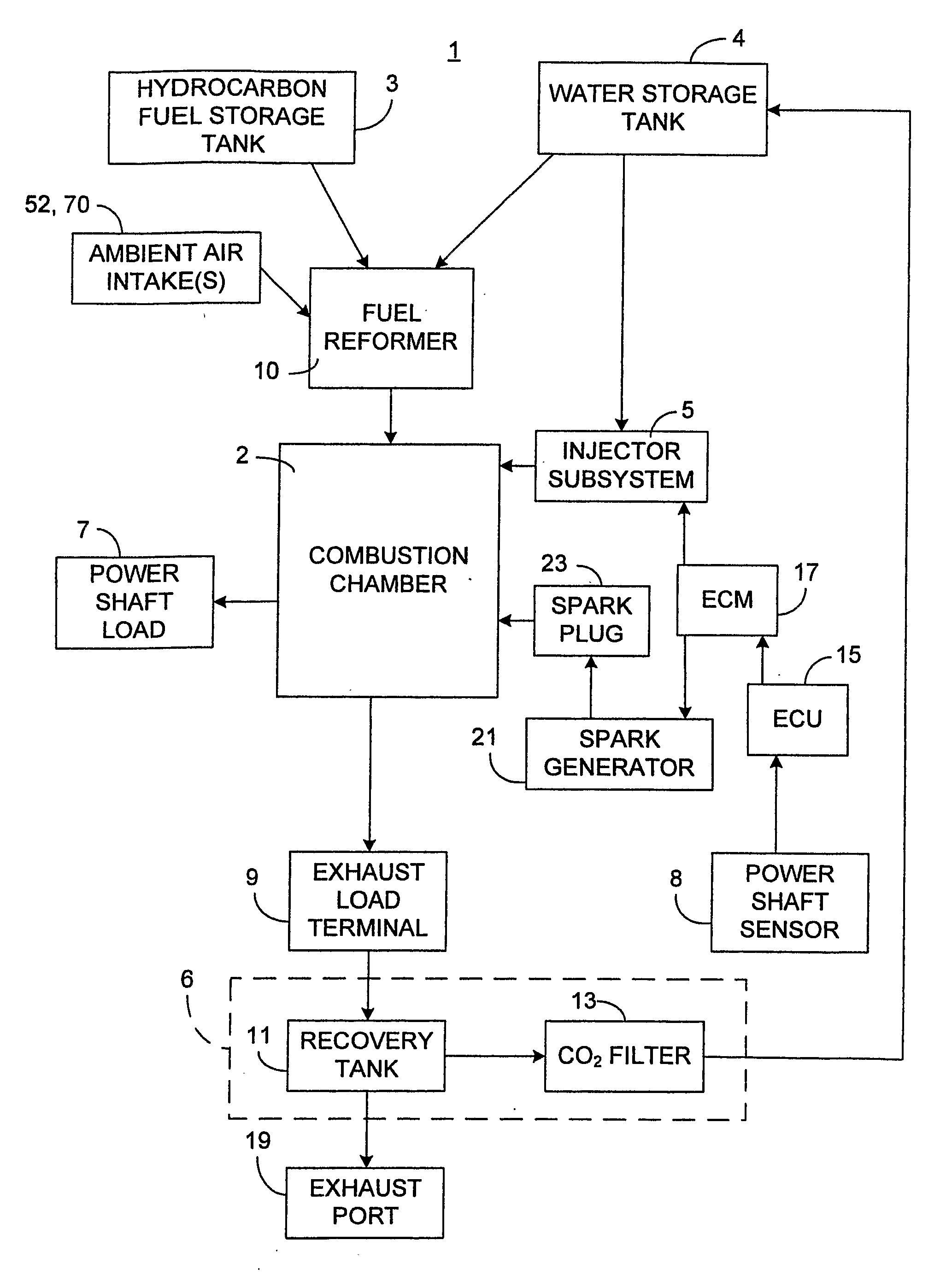

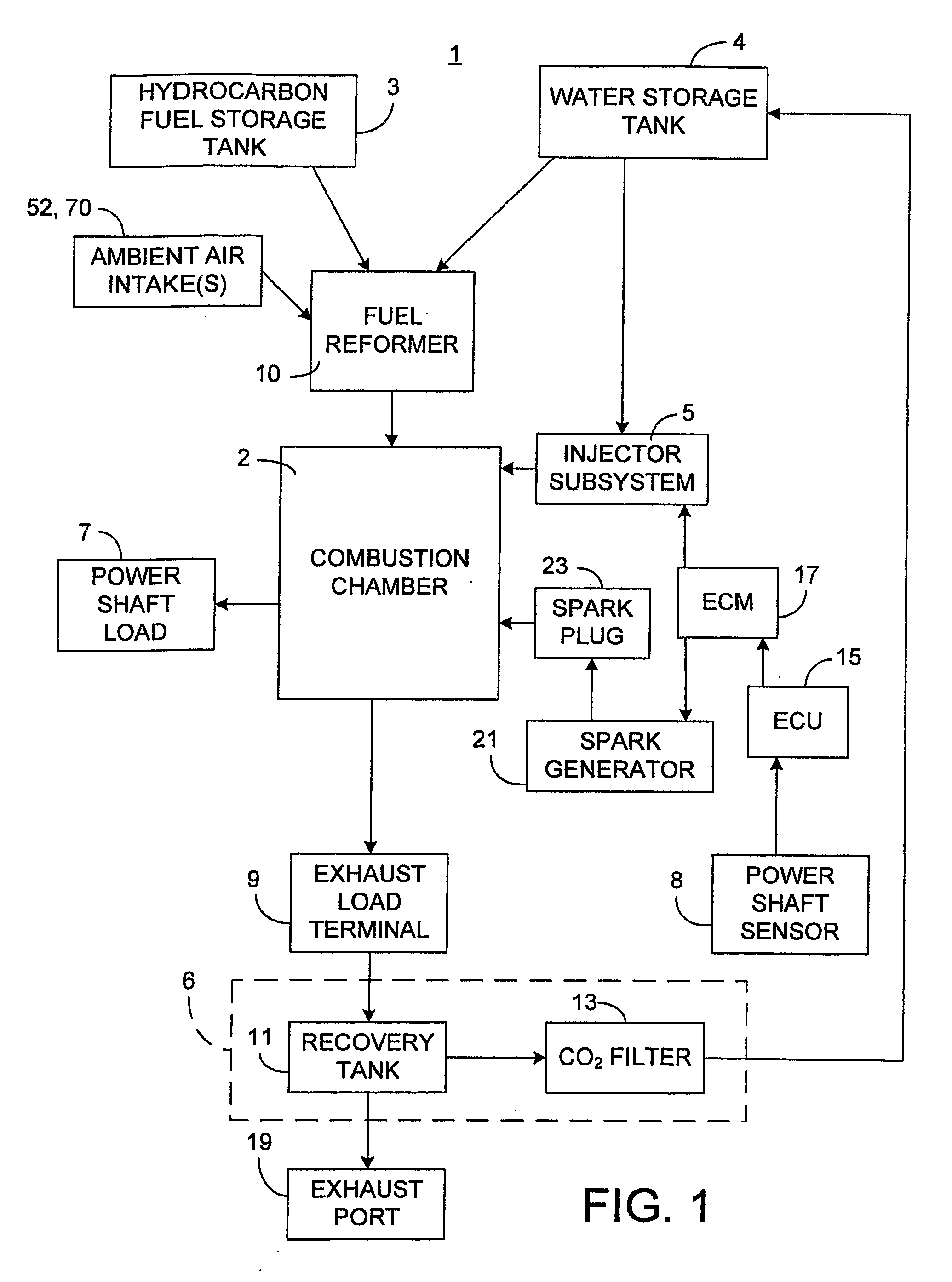

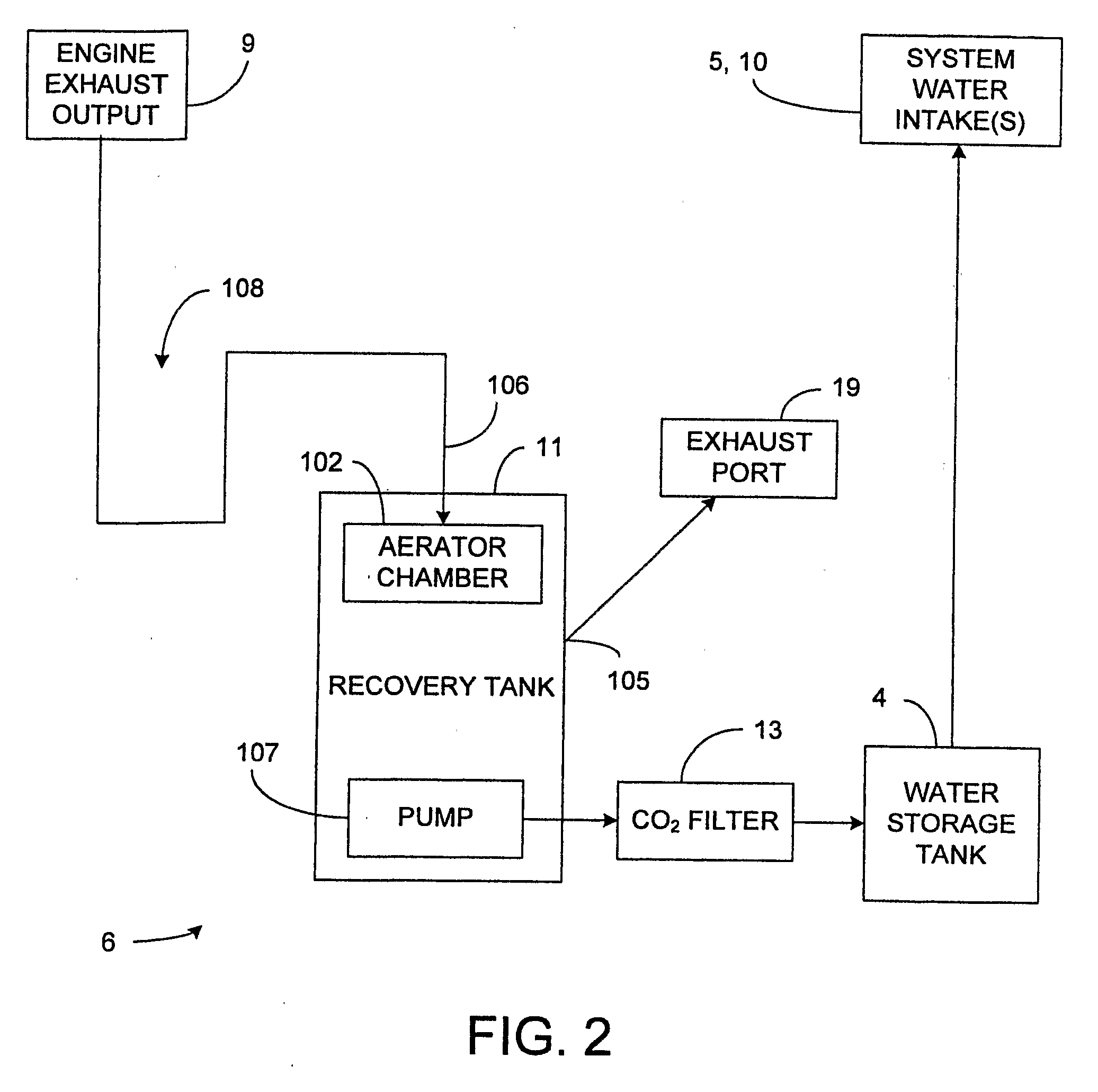

Fuel Supply System for a Vehicle Including a Vaporization Device for Converting Fuel and Water into Hydrogen

InactiveUS20090194042A1Internal combustion piston enginesNon-fuel substance addition to fuelCombustion chamberHydrogen

A fuel supply system (1) is disclosed for use with an internal combustion engine or a fuel cell system (408). The fuel supply system may include a water supply (4) for supplying water; a fuel supply (3) for supplying fuel; a fuel reformer (10) including an air inlet (52,70) converts the water, air, and fuel into hydrogen and byproducts, and supplies the hydrogen to combustion chambers (2) of an internal combustion engine; and an injector subsystem (5) coupled to the water supply injects water into the combustion chambers following ignition of the hydrogen in the combustion chambers. The fuel supply system may include a water recovery subsystem (6) coupled to an exhaust output (9) of the internal combustion engine, the internal combustion engine producing an exhaust including water vapor and CO2, the water recovery subsystem comprising a filter (13) for removing CO2, from the water vapor.

Owner:TYMA

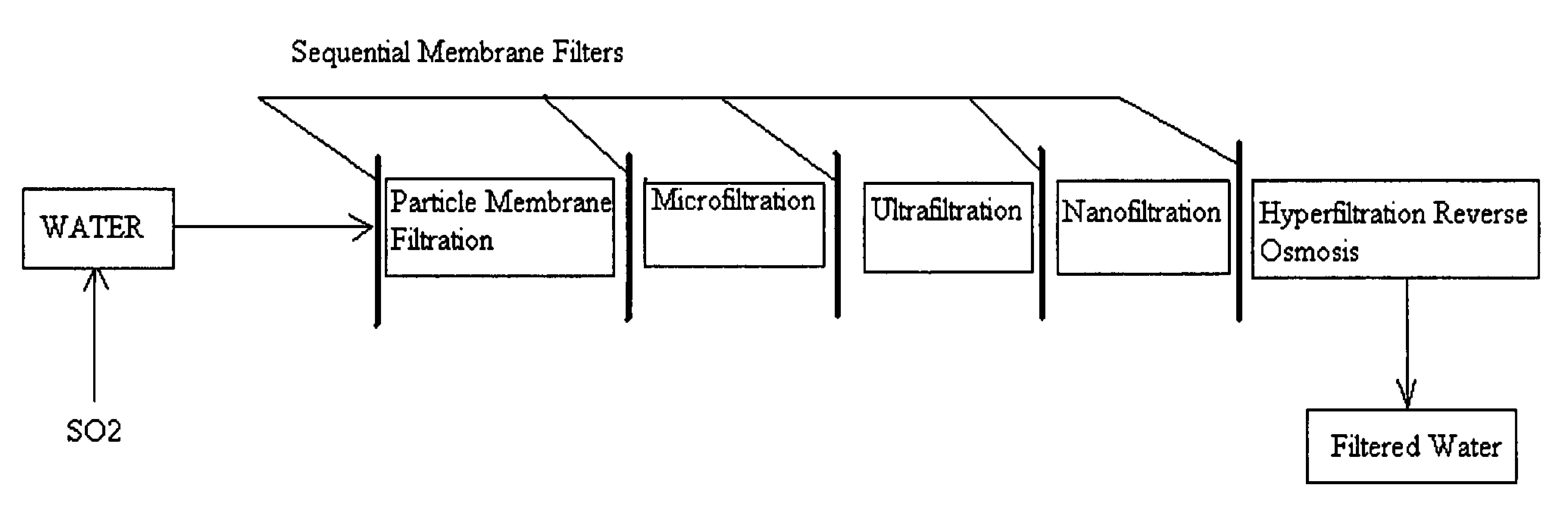

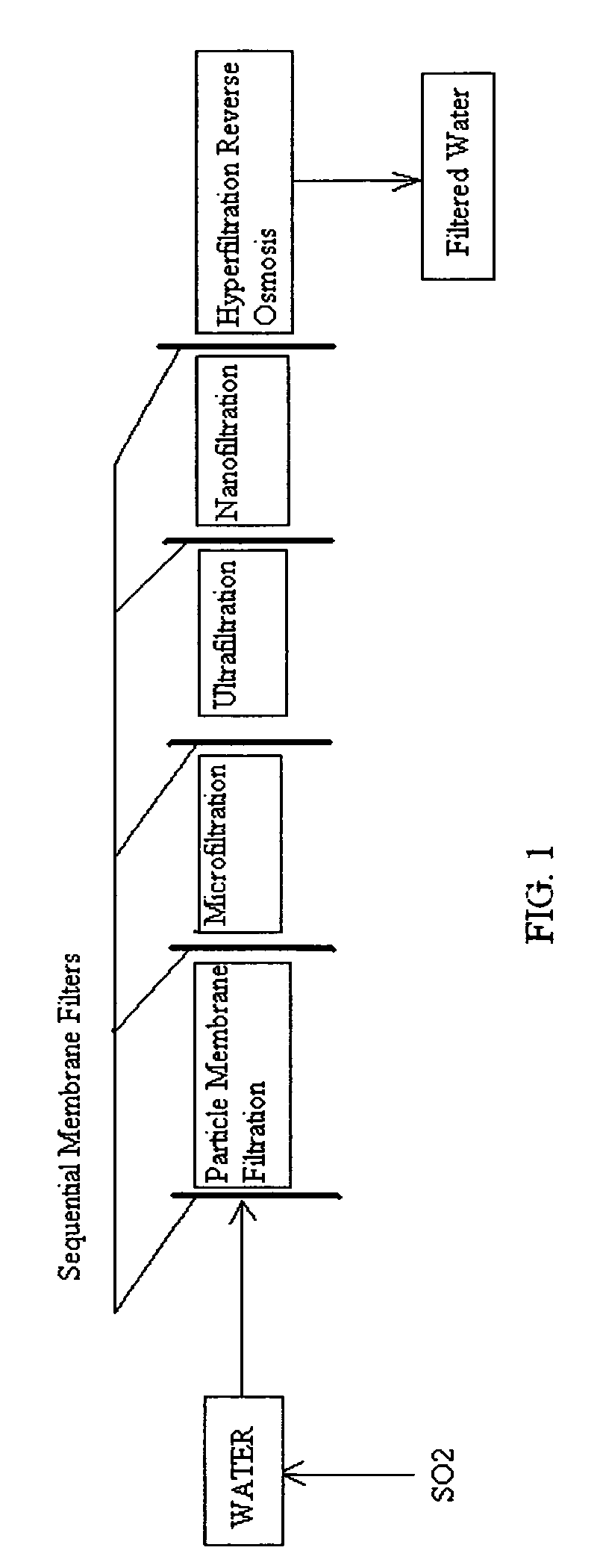

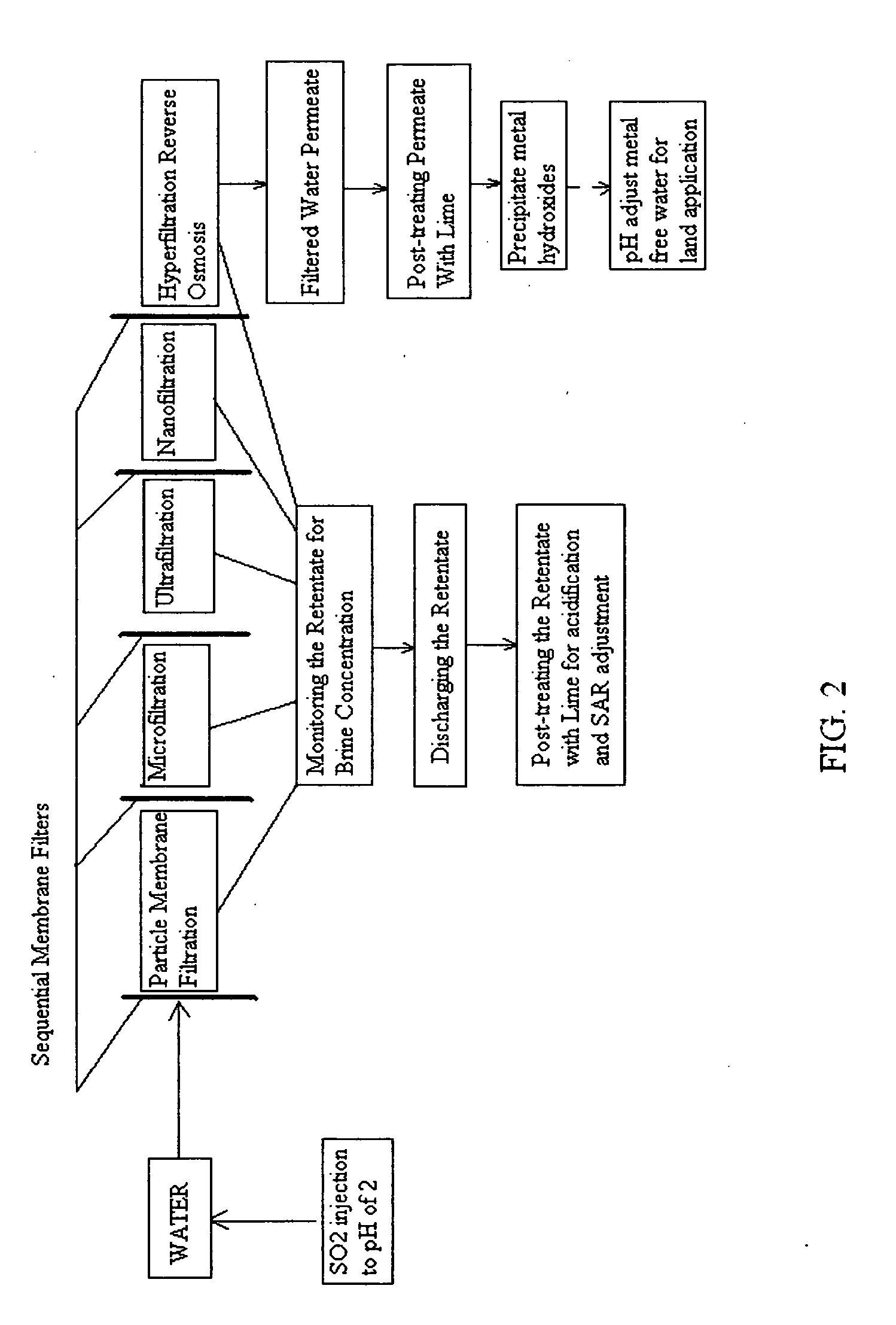

Pre-treatment reverse osmosis water recovery method for brine retentate metals removal

ActiveUS20100193436A1Minimize adhesionPrevent bacterial growthMembranesOther chemical processesRecovery methodPretreatment method

A pre-treatment method for cleaning and maintaining reverse osmosis membrane filters by injecting sulfurous acid into waters with suspended solids in a liquid fraction to be filtered to form sulfurous acid (H2SO3) to acid leach heavy metals into the liquid fraction, reduce alkalinity and mineral scaling, add sufficient SO2 as a biocide to attack bacteria and other micro organisms to prevent membrane fouling, reduce iron to prevent iron deposit build-up, scavenge and remove dissolved oxygen prior to filtration to prevent membrane oxidation, and then sequentially filtering the acidified water through membrane filters to create a metal free permeate and a brine retentate, which can be pH adjusted to remove the heavy metals as metal hydroxide precipitates.

Owner:EARTH RENAISSANCE TECH

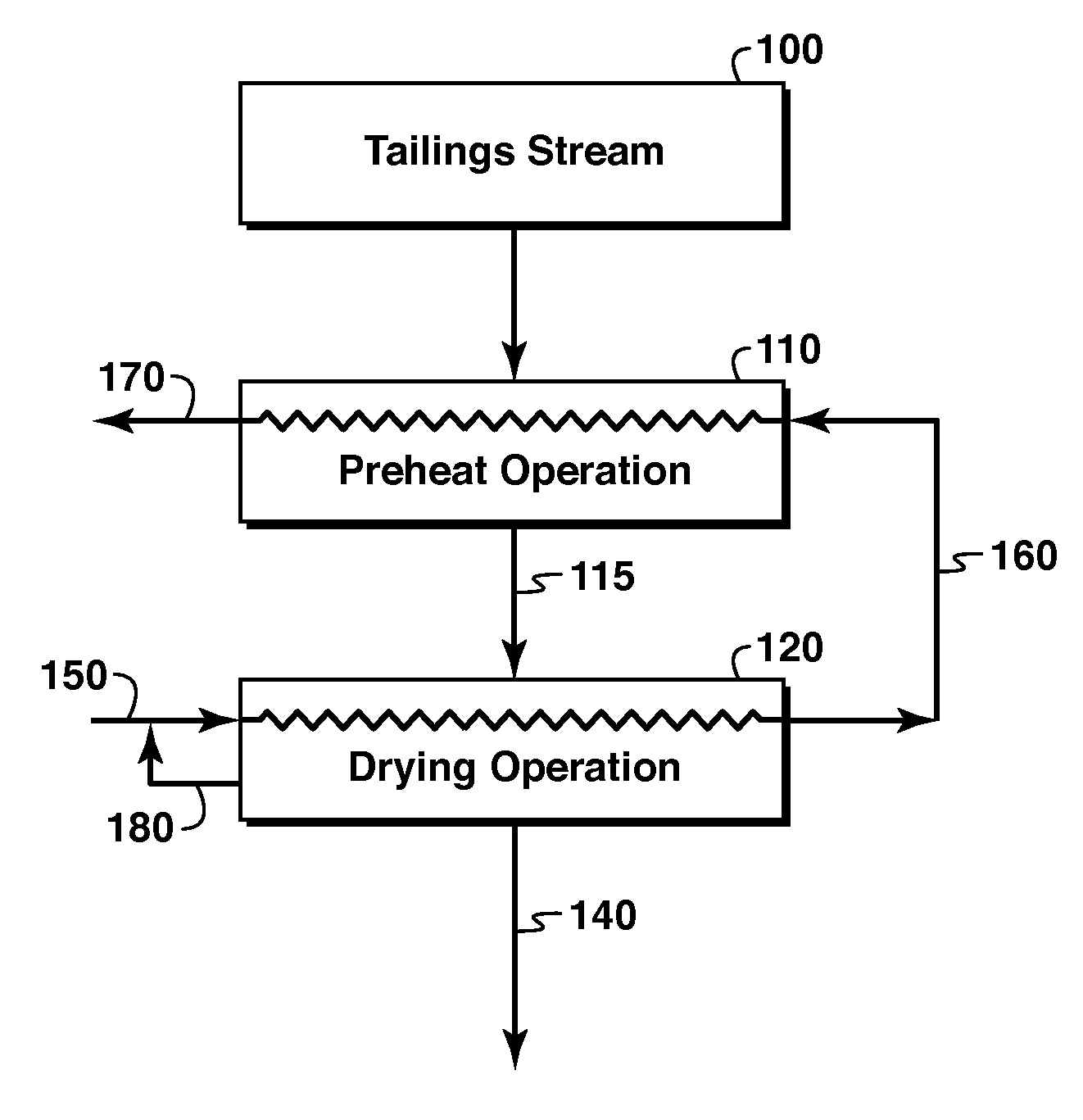

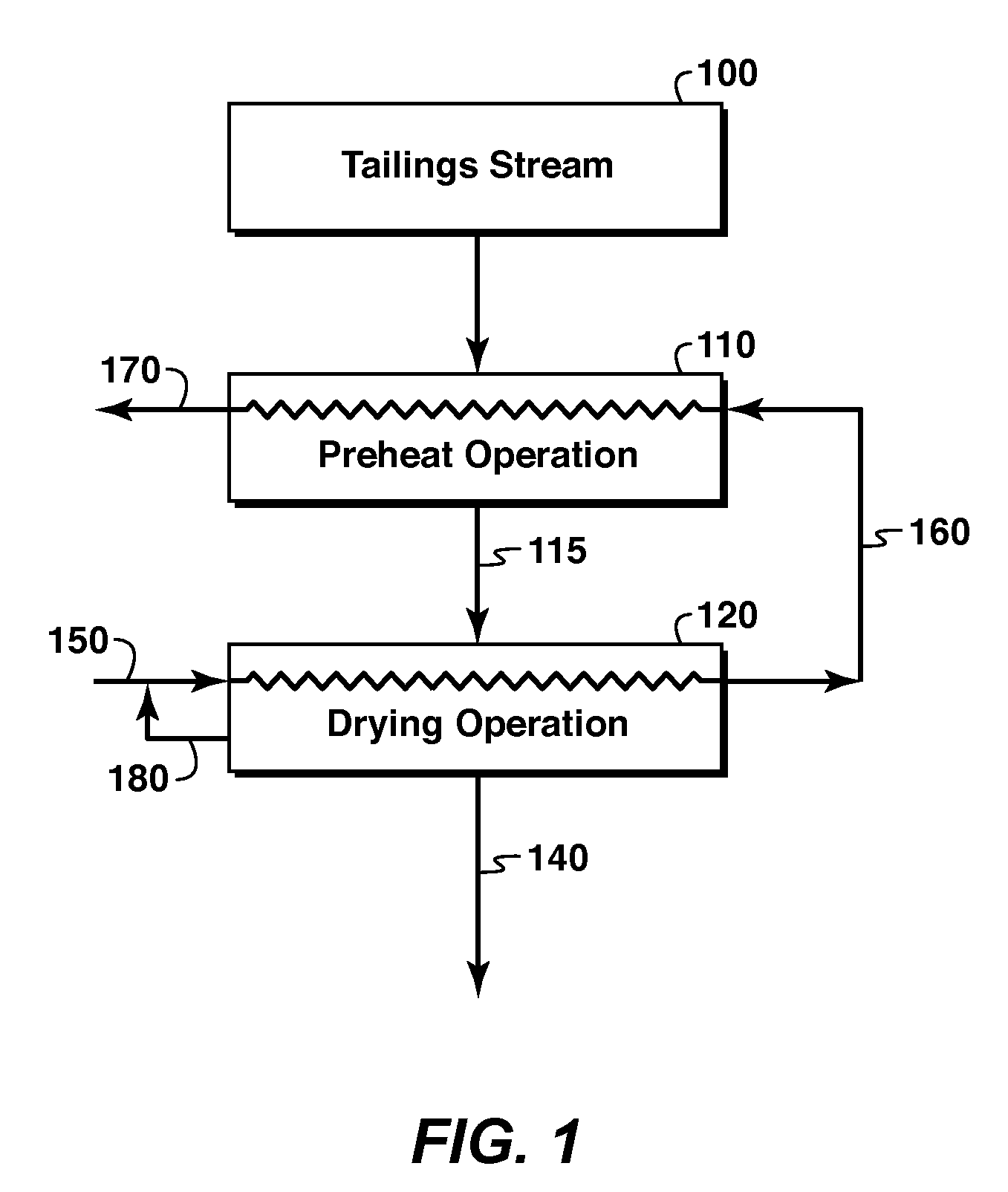

Heat and Water Recovery From Oil Sands Waste Streams

InactiveUS20110061610A1Lower energy requirementsReduce heatSand dryingLiquid hydrocarbon mixture productionWaste streamProcess engineering

Methods and systems for recovering heat and water from waste streams produced during oil sands extraction to form dry, stackable tailings. A tailings stream is preheated in a heat exchanger, thereby reducing the energy required to dry the tailings. The preheated tailings are then dried, thereby reducing the tailings to dry stackable tailings or thickened tailings suitable for mine backfill. Heat and high-quality water are recovered from the drying operation and re-used in the preheat operation, or in other steps of oil sands extraction or treatment processes, thereby reducing the overall heat and water requirements.

Owner:EXXONMOBIL UPSTREAM RES CO

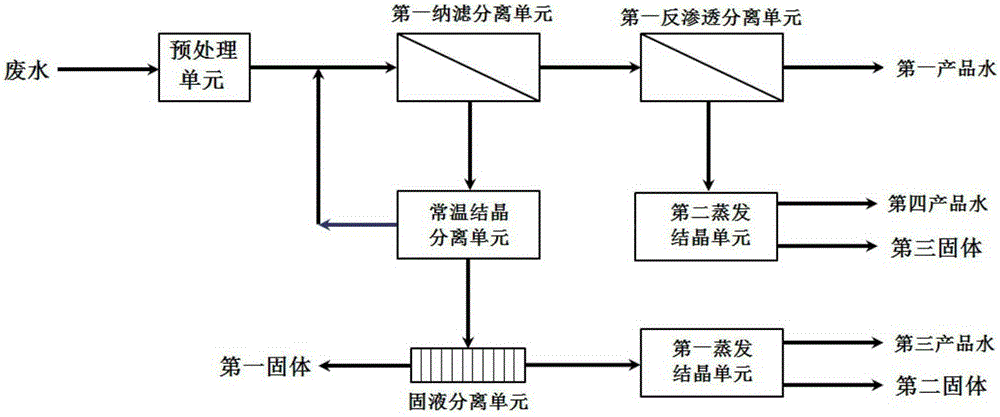

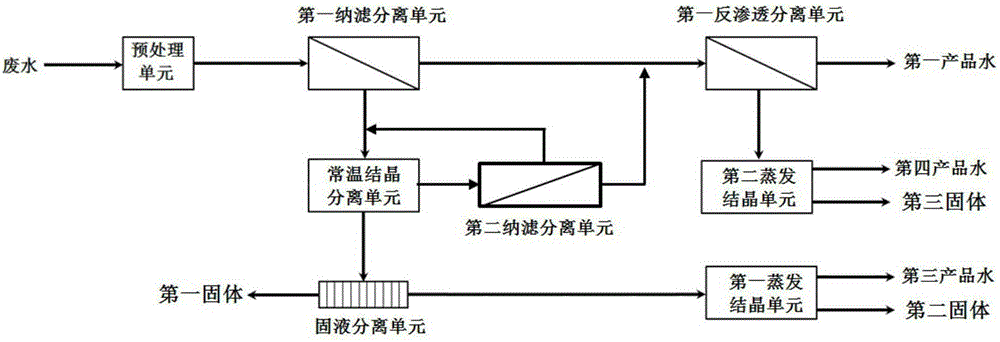

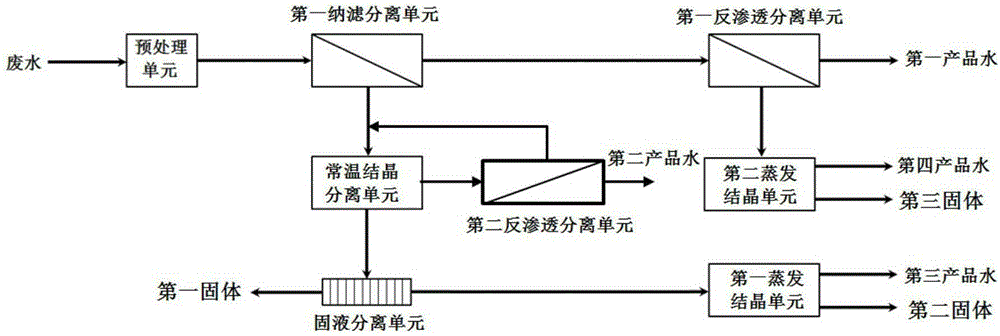

Processing method of salt containing water and salt containing processing system

ActiveCN105174512ASimple processLow investment costMultistage water/sewage treatmentSaline waterFiltration

The invention discloses a salt containing water processing method and system. The processing comprises the following steps: subjecting salt containing water to nano filtration and separation to obtain nano filtration producing water and nano filtration concentrated water; subjecting nano filtration producing water to reverse osmosis separation to obtain product water and reverse osmosis concentrated water; and subjecting nano filtration concentrated water to normal temperature crystallization and separation. The provided salt containing water processing method and system has the advantages that the technology procedure is concise, the investment, operation, and maintenance costs can be reduced prominently, and the operation procedure is simplified. The provided method and system are used to process salt containing water, and can obtain a water recovery rate of 90% or more; only about 10% of concentrated water is separated through evaporation and crystallization, and thus the working amount of the evaporation and crystallization step is greatly reduced. In the other aspect, during the processing process, the ions in the salt containing water can be separated according to the valence state, and thus comprehensive utilization of recyclable resources in salt containing water can be achieved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

System and method for economically viable and environmentally friendly central processing of home laundry

InactiveUS7000437B2Reduce productionPromote recoveryTableware washing/rinsing machine detailsOther washing machinesWash waterChemical recovery

An economically viable process and system for centrally processing multiple loads of laundry with minimum environmental impact. A system and method of laundering whereby successive loads of laundry may be washed while continuously providing effective soil removal comprising at least partially recycled wash water from at least one previous wash cycle. The system and the method of using the same comprises filtering wash water with at least one filter to form wash retentate and wash permeate. The use of wash permeate in successive washes provides for reuse of chemicals and water recovery. A similar arrangement may be used with regard to the rinse water. Advantageously, one embodiment of the invention provides for the use of rinse retentate as make up water in the wash loop which increases water recovery and chemical recovery. Ultimately, the invention can reduce the production of gray water and recover chemicals used in the laundering process.

Owner:SHELL OIL CO

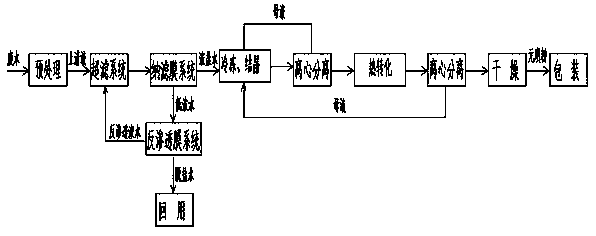

White carbon black production wastewater treatment technology

ActiveCN103539281AAchieve enrichmentReduce energy consumptionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentWater sourceFiltration

The invention belongs to the technical field of chemical wastewater treatment, and in particular relates to a white carbon black production wastewater treatment technology. The technology comprises the steps of pretreating white carbon black production wastewater so that the water quality of the treated wastewater can reach the water quality requirement of a membrane treatment system; carrying out membrane filtration so that enriching sodium sulfate in the wastewater is enriched at one side of a membrane until the content of sodium sulfate is not less than 10% and the produced water at the other side reaches a recycle water index and is recycled to a production system for reuse; carrying out freezing crystallization on the thick water to separate out mirabilite, separating out the crystallization mother liquor so as to obtain the mirabilite and returning the crystallization mother liquor back to a membrane concentration system, and thermally dehydrating the mirabilite so as to obtain anhydrous sodium sulphate which is not less than 98% and used for selling; or evaporating and crystallizing the thick water with the sodium sulfate being not less than 10% through directly utilizing an evaporator so as to separate out the anhydrous sodium sulphate. The water source recycling and chemical raw material recovery are realized through low energy consumption. Through cooperatively using two technologies, the energy consumption for treating each tonnage of wastewater can be greatly reduced, and the water recovery rate of a whole treatment system is not less than 92%; the sodium sulfate content of an anhydrous sodium sulphate product is not less than 98%.

Owner:JINNENG SCI & TECH

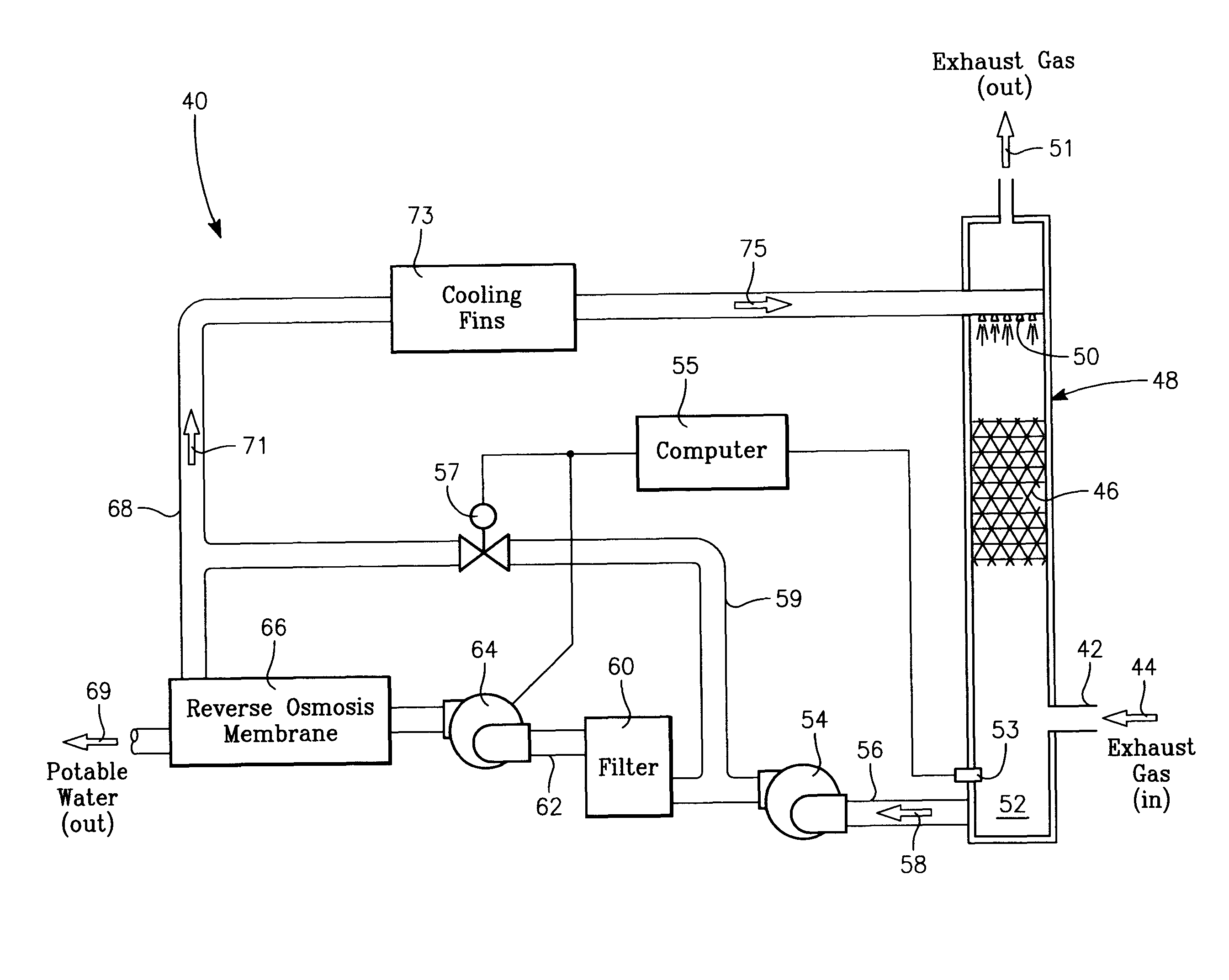

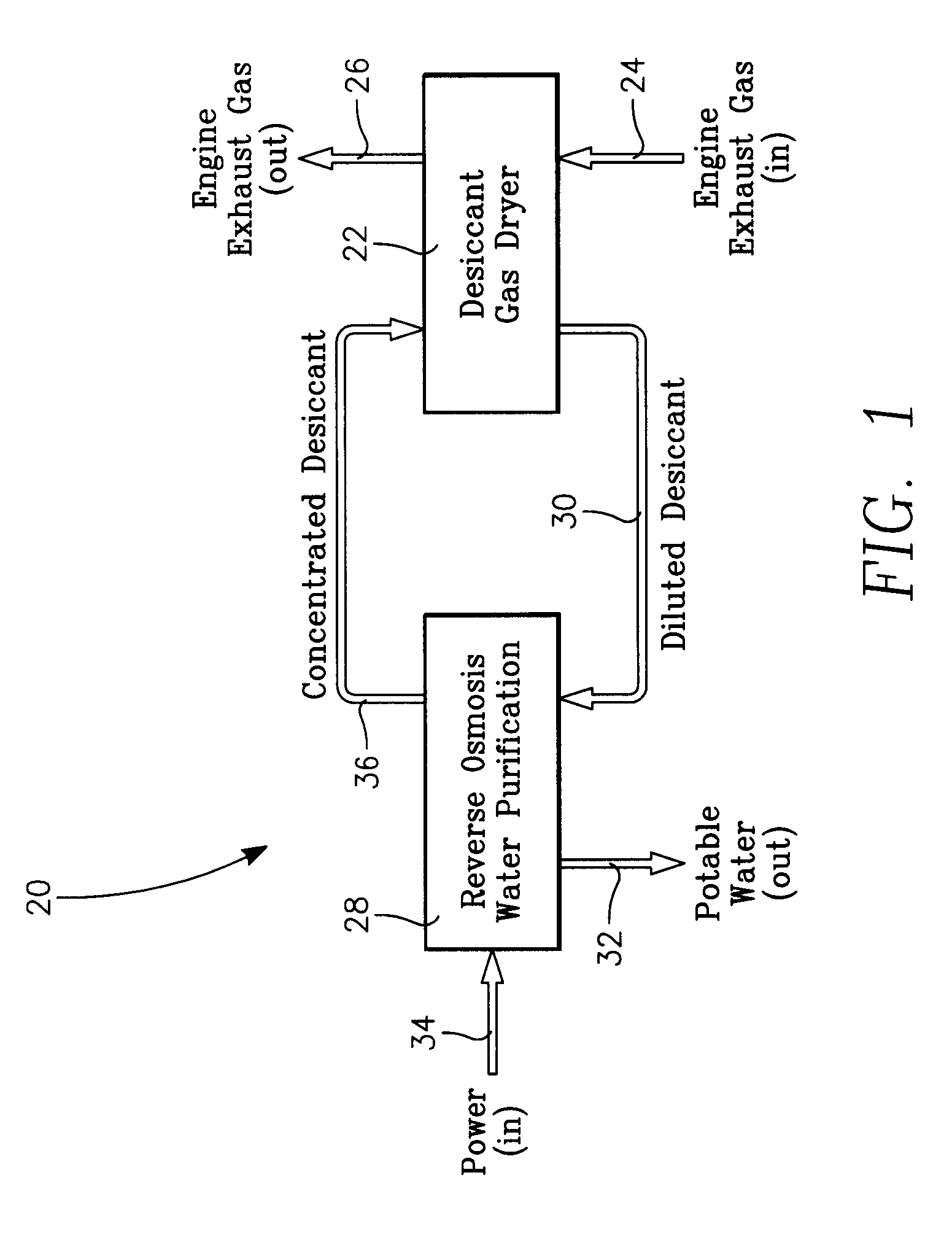

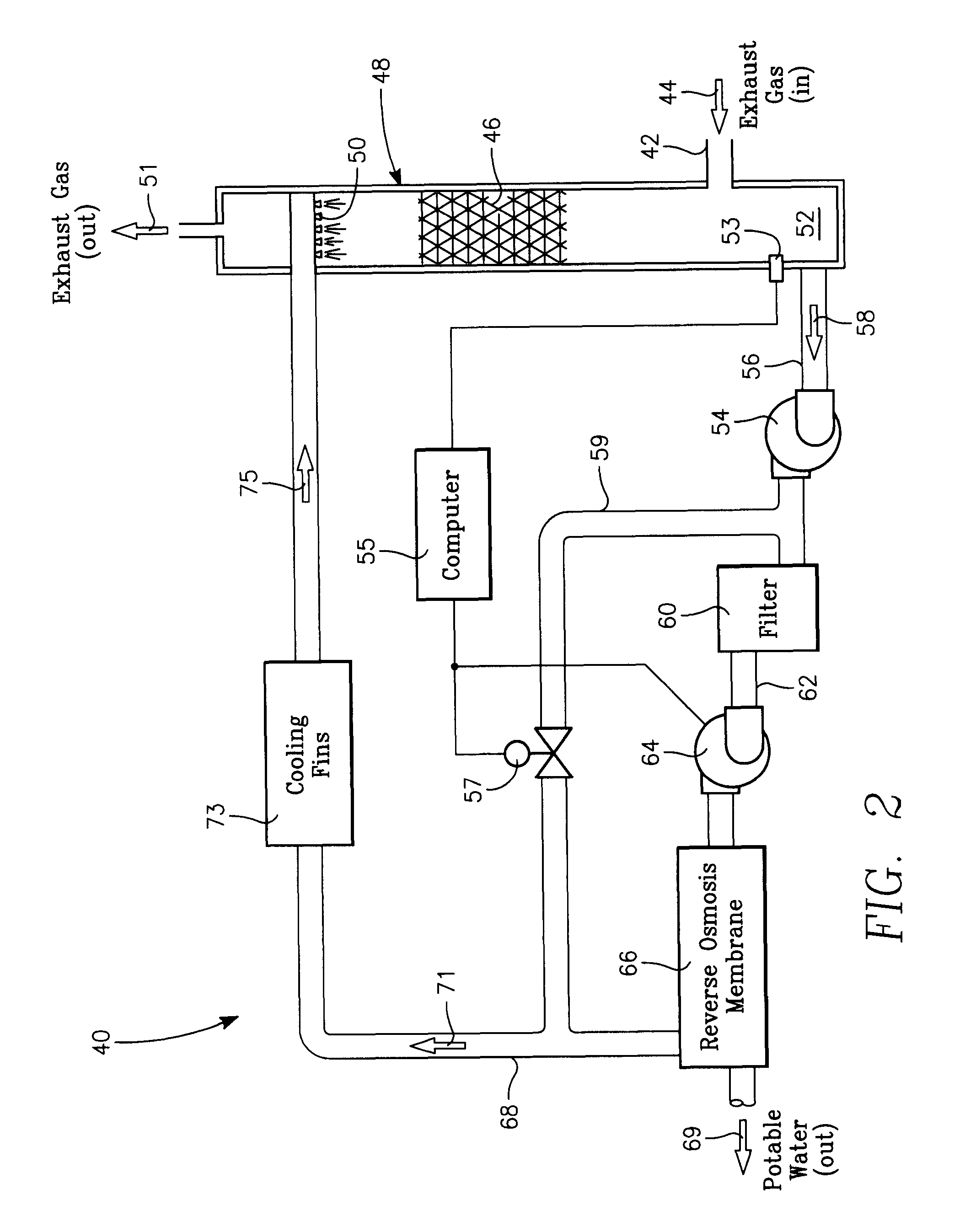

Method for recovering potable water from the exhaust of an internal combustion engine

InactiveUS8021542B2Simple designEfficient methodLiquid separation auxillary apparatusLiquid degasificationLithium chlorideDesiccant

A water recovery method and apparatus which uses a desiccant, such as lithium chloride, to recover water vapor from the engine exhaust of a vehicle. The apparatus uses liquid-contactor to transfer water vapor from the vehicle exhaust to the liquid desiccant. The desiccant is then transferred to a reverse osmosis system which separates the liquid desiccant into potable water and a concentrated desiccant.

Owner:USA REPRESENTED BY THE SEC OF THE NAVY

Hybrid magnetohydrodynamo (MHD) field sanitation generator for treating wastewater, sewages & sludge and recovering potable water

InactiveUS20050029174A1Sludge treatment by thermal conditioningWater/sewage treatment by irradiationSludgeFiltration

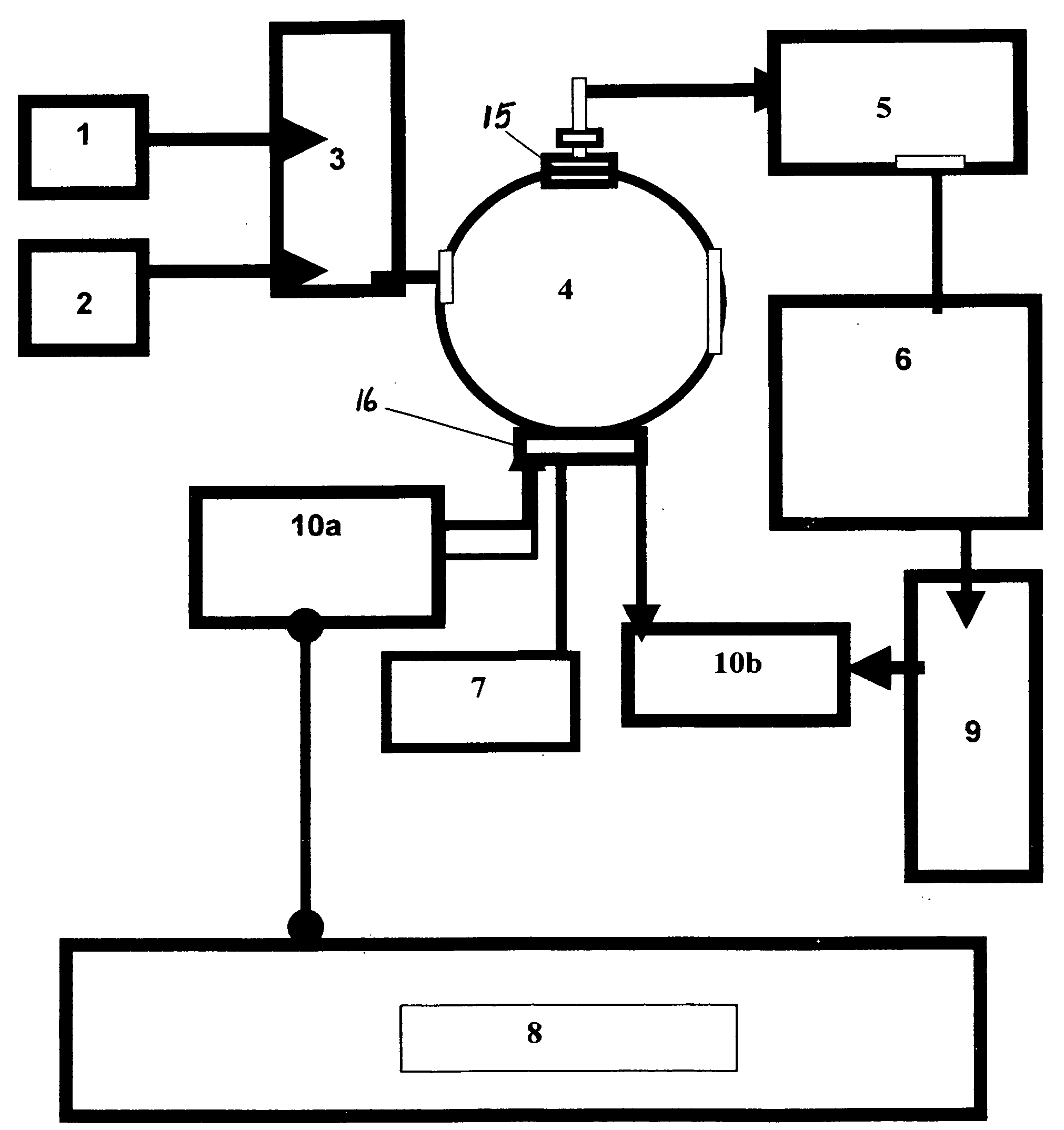

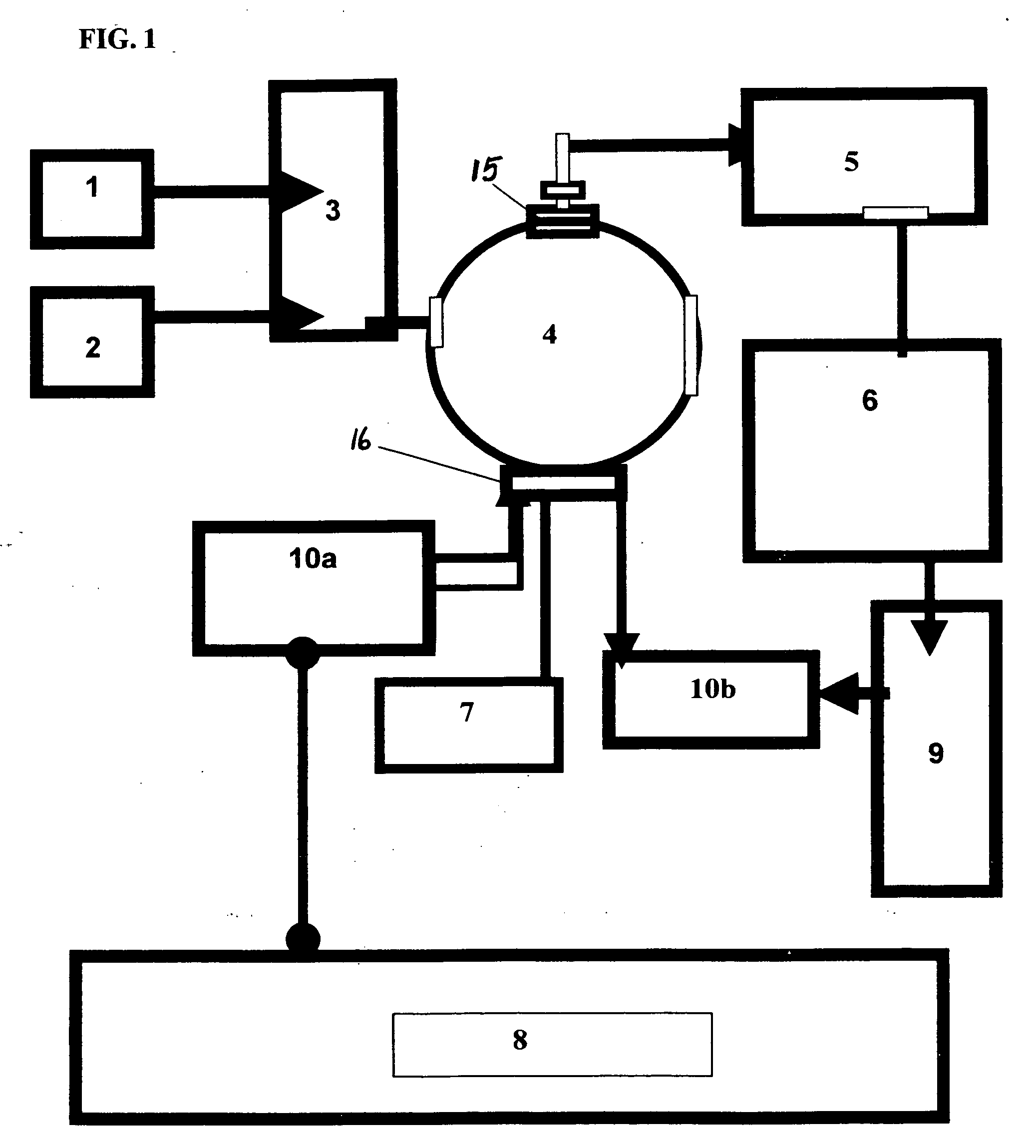

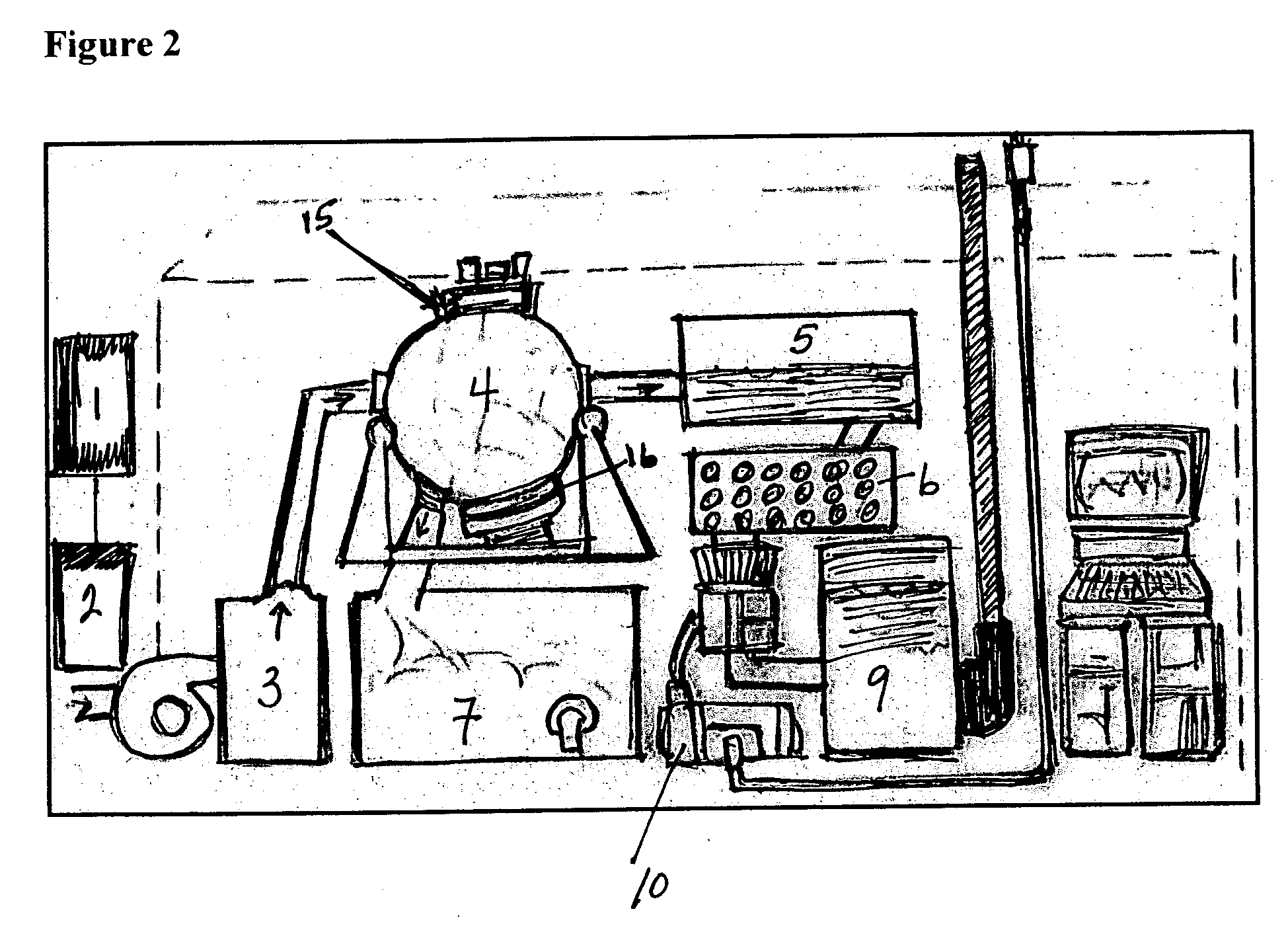

The Hybrid MHD-FSU (Field Sanitation Unit) innovation is a self-contained sewage treatment plant that fully converts sewage / wastewater into (1) solid organic material, (2) potable, pathogen-free drinking water, and (3) generates electricity. At a high level, the system consists of four main components: (1) Mixer, (2) MHD Reactor, (3) Filter, and (4) Turbine. The innovation presents a stand-alone compact configuration of typical wastewater treatment components (equalization & mixing, process treatment, filtration) that are combined with the customized MHD reactor to perform the waste treatment / water recovery processing. The Hybrid magnetohydrodynamo (MHD) Field Sanitation Unit has the ability (1) to recover an organic material (2) to recover a pathogen free, clean potable drinking water, and (3) to generate electricity using wastewater as the conductive medium. The invention also relates a core heating microwave source coupled to an outer rigid mantle boundary that compose an MHD electrode pair. The invention assemblies are generally configured of three components: (a) magnetron, waveguide & a launch assembly; (b) the perovskite ceramic components; and (c) the conductive wastewater sludge fluid but more specifically the MHD assemblies are described herein in detail. FIG. 1 illustrates a general process flow of the invention. The main components of the invention are composed of the following: (1) the clean water supply feed, (2) the influent raw wastewater (3) the mixer, (4) the MHD reactor chamber, (5) the storage tank for clean water, (6) the filtration system producing potable water, (7) the storage bin for solids & organic material (8) hydro-turbine (9) the potable drinking water storage, (10b) the battery storage system with power conditioning subsystem.

Owner:SPIRALCAT OF MARYLAND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com