Patents

Literature

51results about How to "High water recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

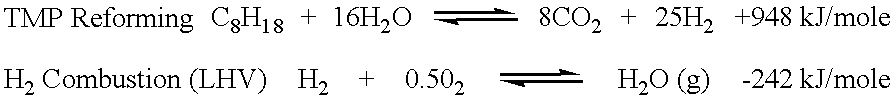

Method and system for supplying hydrogen for use in fuel cells

InactiveUS6348278B1Reduce hydrogen concentrationImprove concentrationElectricity cogenerationRegenerative fuel cellsHydrogenCombustor

The present invention provides a method and system for efficiently producing hydrogen that can be supplied to a fuel cell. The method and system of the present invention produces hydrogen in a reforming reactor using a hydrocarbon stream and water vapor stream as reactants. The hydrogen produced is purified in a hydrogen separating membrane to form a retentate stream and purified hydrogen stream. The purified hydrogen can then be fed to a fuel cell where electrical energy is produced and a fuel cell exhaust stream containing water vapor and oxygen depleted air is emitted. In one embodiment of the present invention, a means and method is provided for recycling a portion of the retentate stream to the reforming reactor for increased hydrogen yields. In another embodiment, a combustor is provided for combusting a second portion of the retentate stream to provide heat to the reforming reaction or other reactants. In a preferred embodiment, the combustion is carried out in the presence of at least a portion of the oxygen depleted air stream from the fuel cell. Thus, the system and method of the present invention advantageously uses products generated from the system to enhance the overall efficiency of the system.

Owner:MOBIL OIL CORP

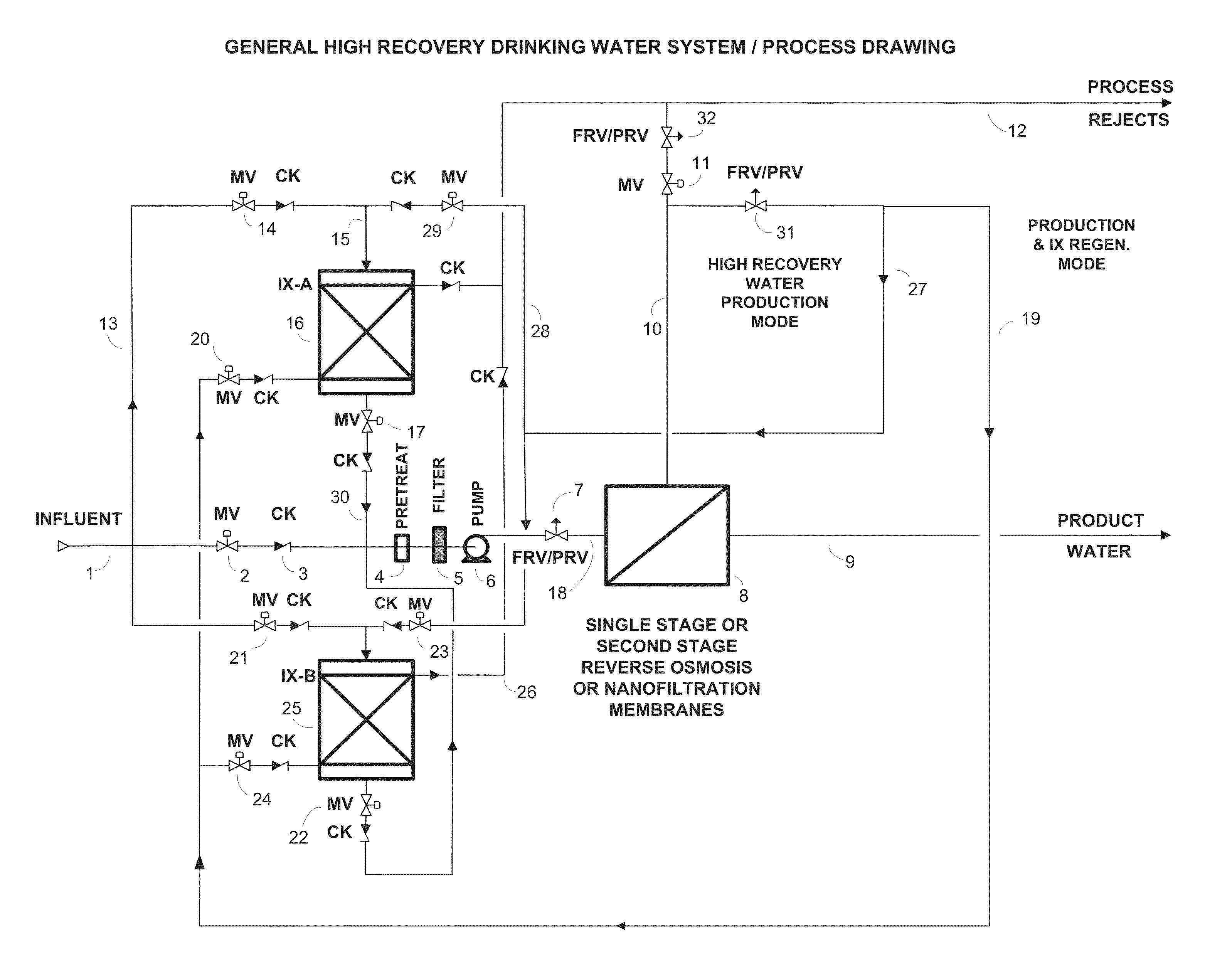

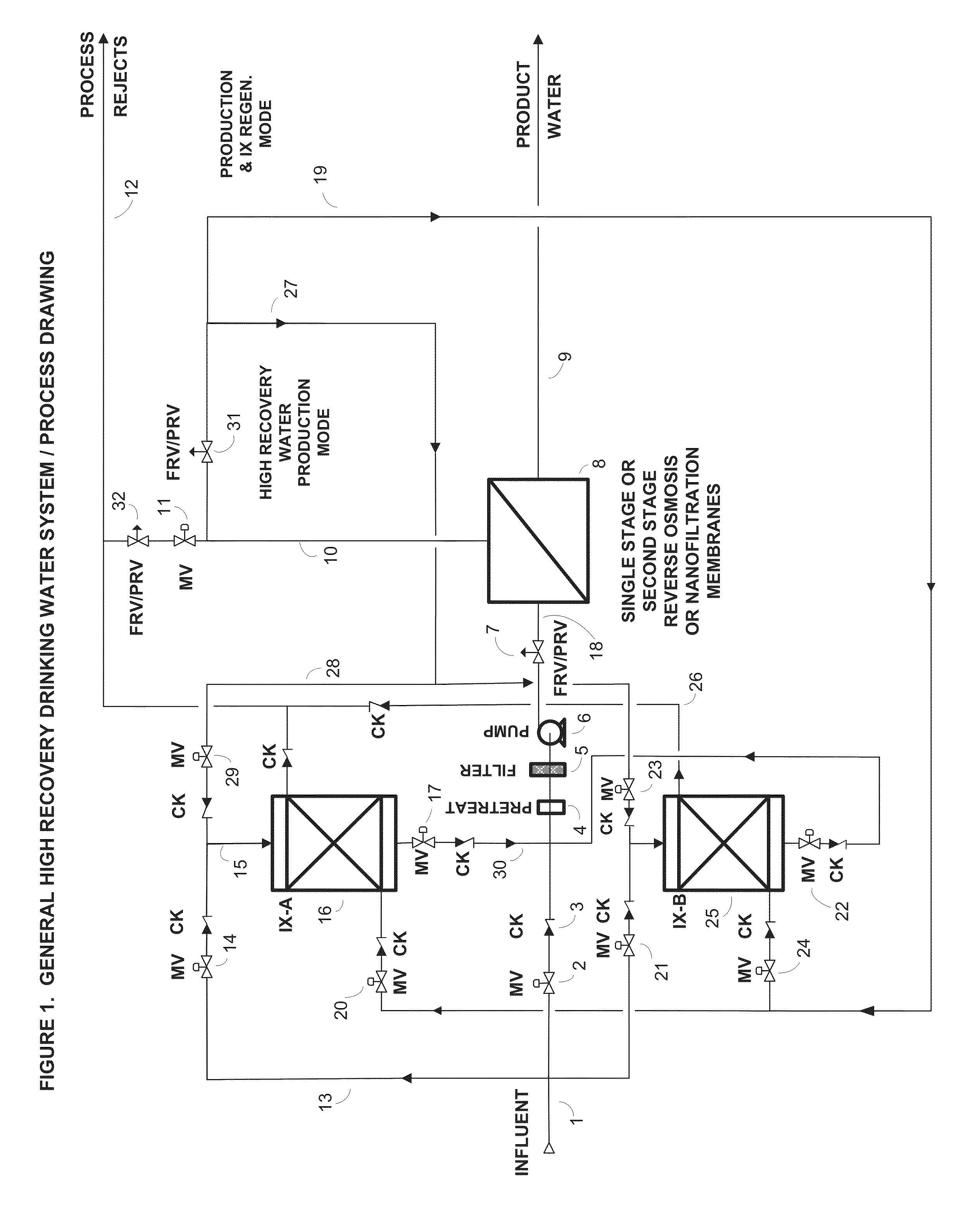

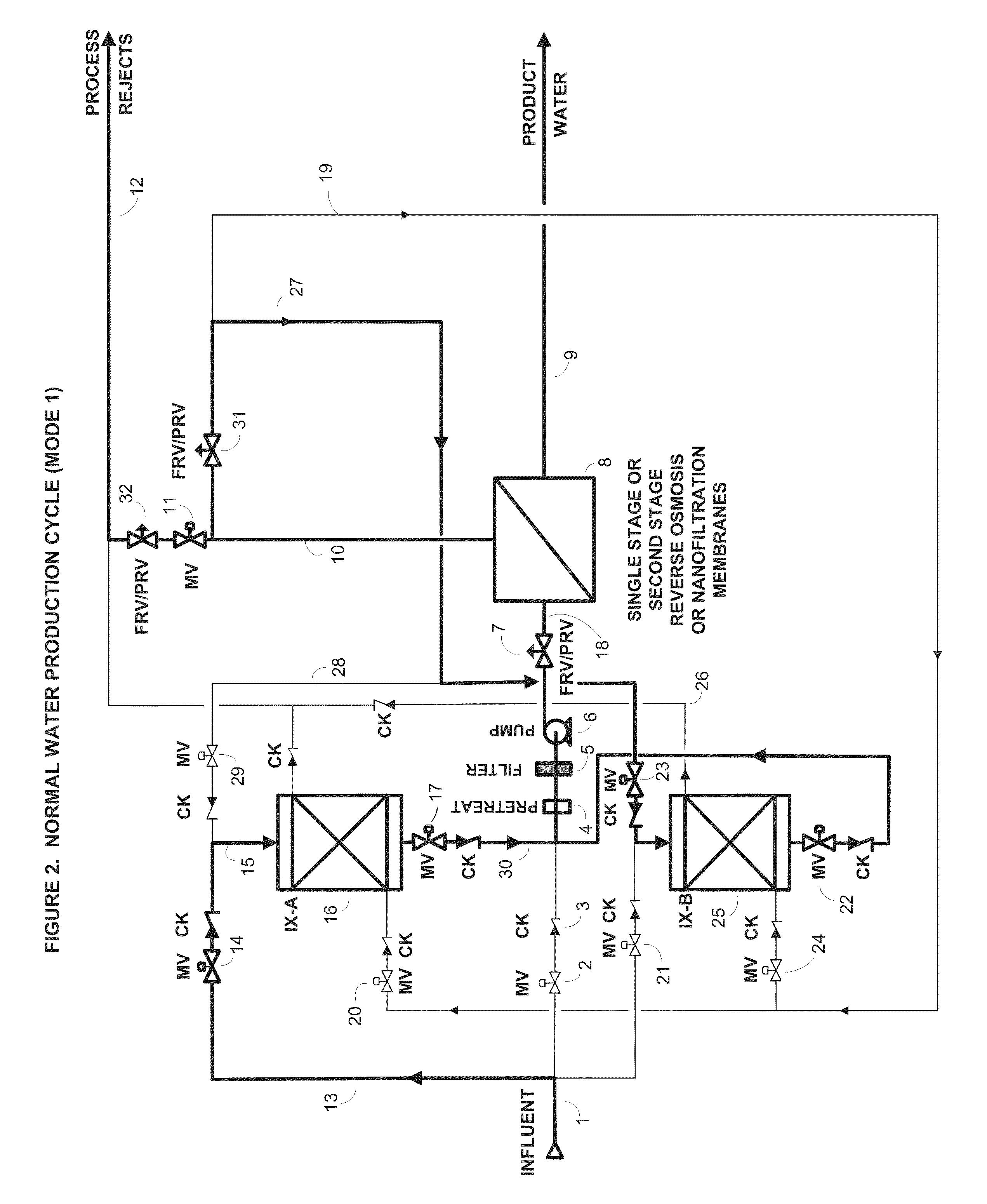

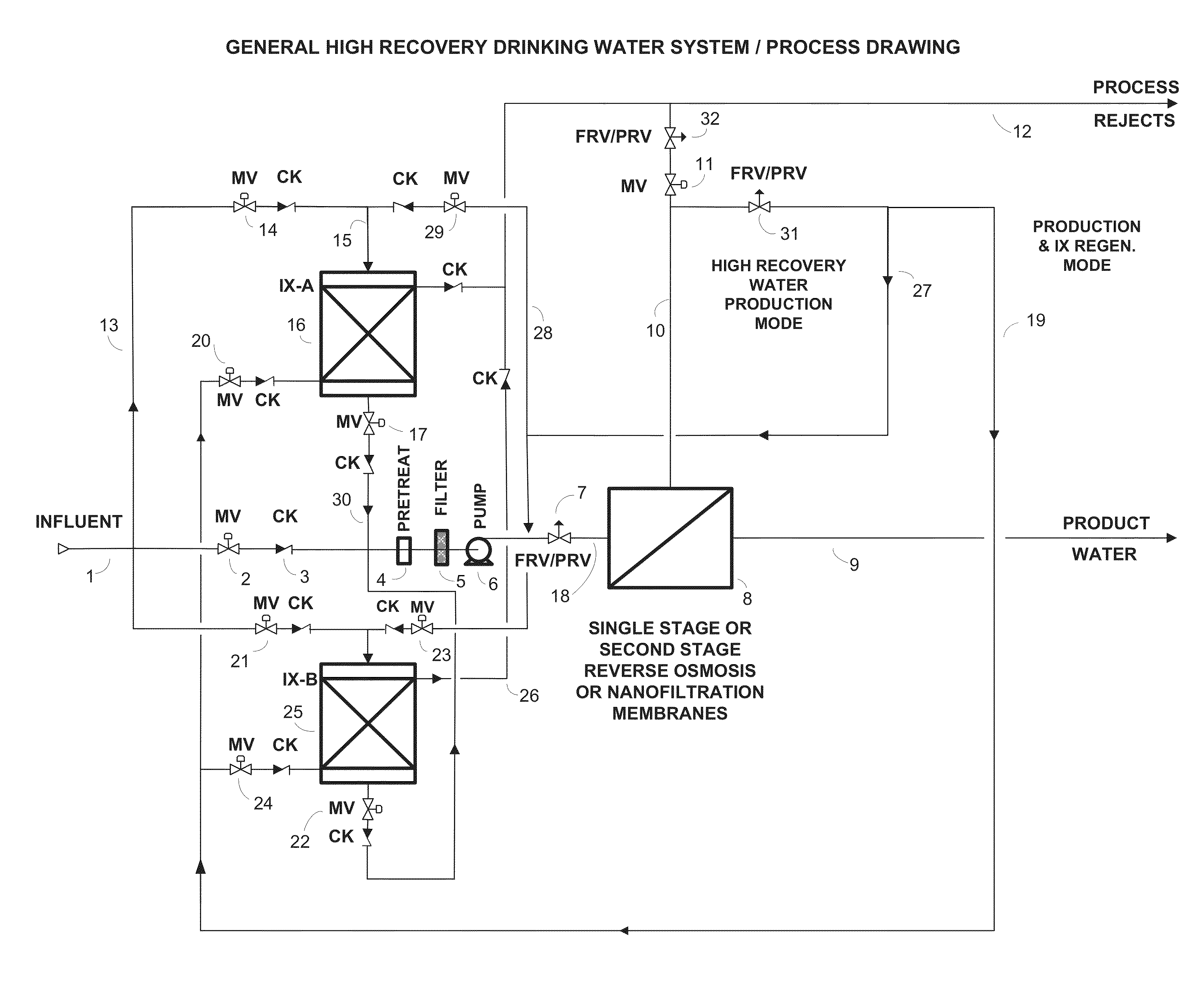

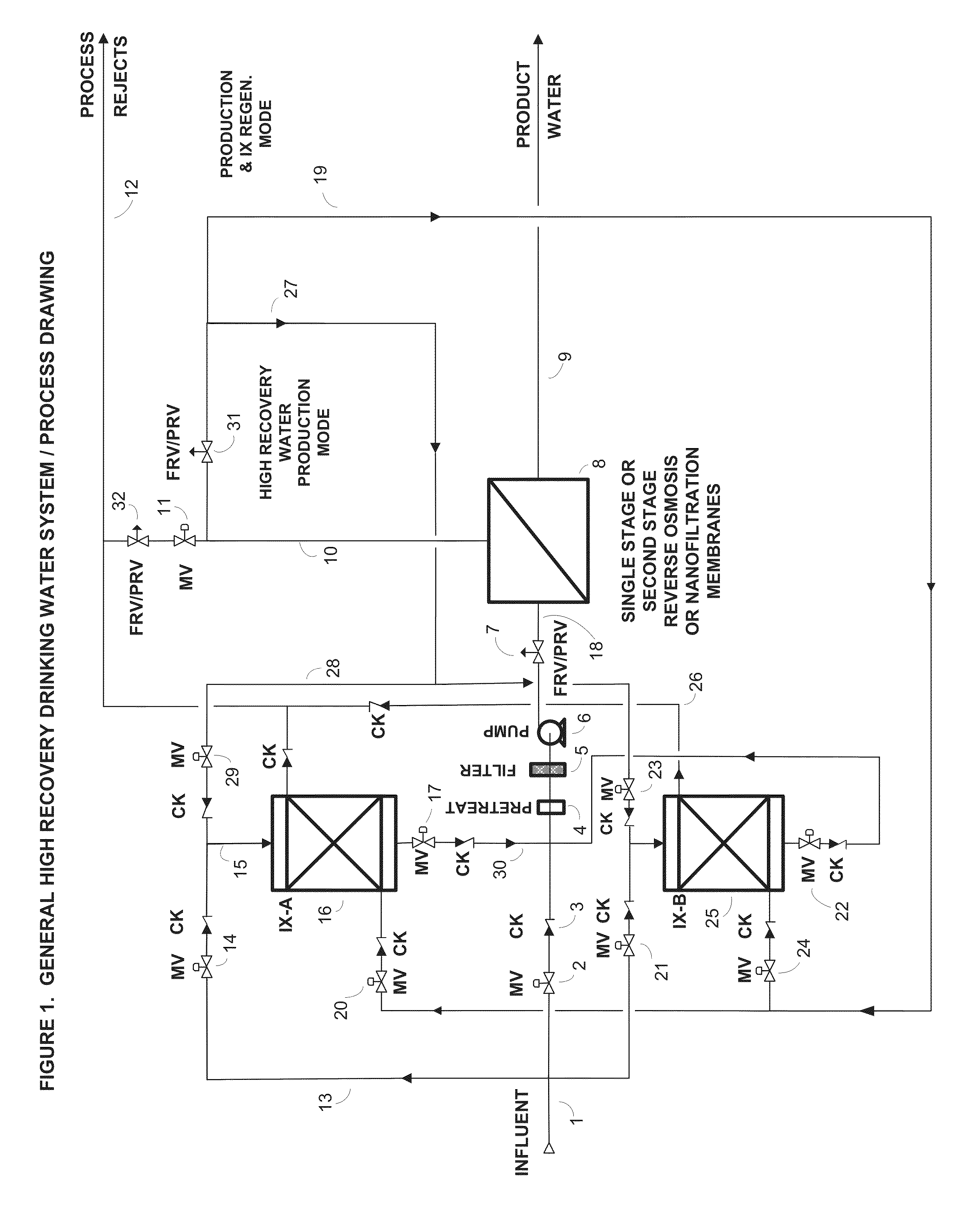

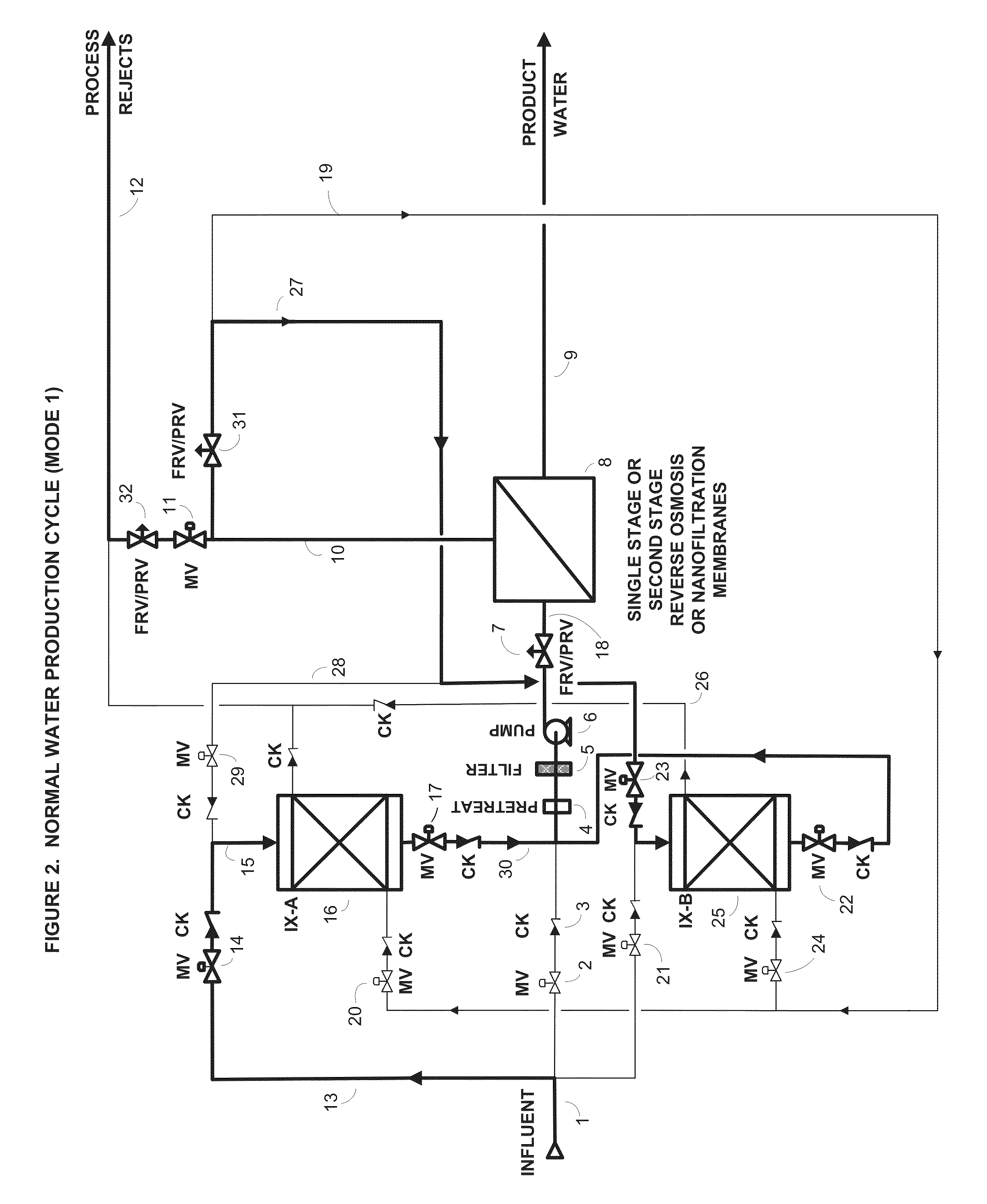

High Recovery Drinking Water Process

ActiveUS20130043190A1High water recoveryEliminate needIon-exchanger regenerationOrganic anion exchangersWater softeningIndustrial effluent

Disclosed is a process that uses reverse osmosis (RO) or nanofiltration (NF) membranes and ion exchange (IX) water softening resins to maximize the production of drinking water, purified industrial service water or recycled purified municipal or industrial effluents. The membrane and ion exchange units are configured in a manner that enables operation of the system at high permeate recoveries in the range 90% to 99%, thus producing purified drinking water with a minimum volume of wastewater to drains and a very low membrane cleaning or membrane replacement frequency. The process mitigates membrane fouling and scale formation and minimizes the use of water treatment chemicals including acidic and alkali solutions and sodium chloride salt that is normally required to regenerate the IX resin.

Owner:AL SAMADI RIAD A

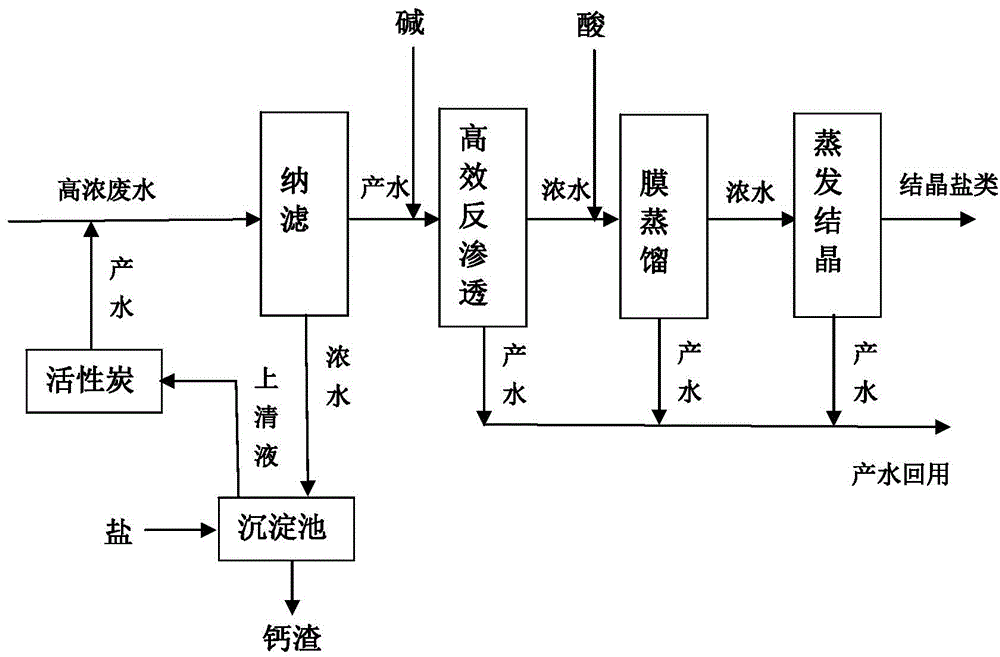

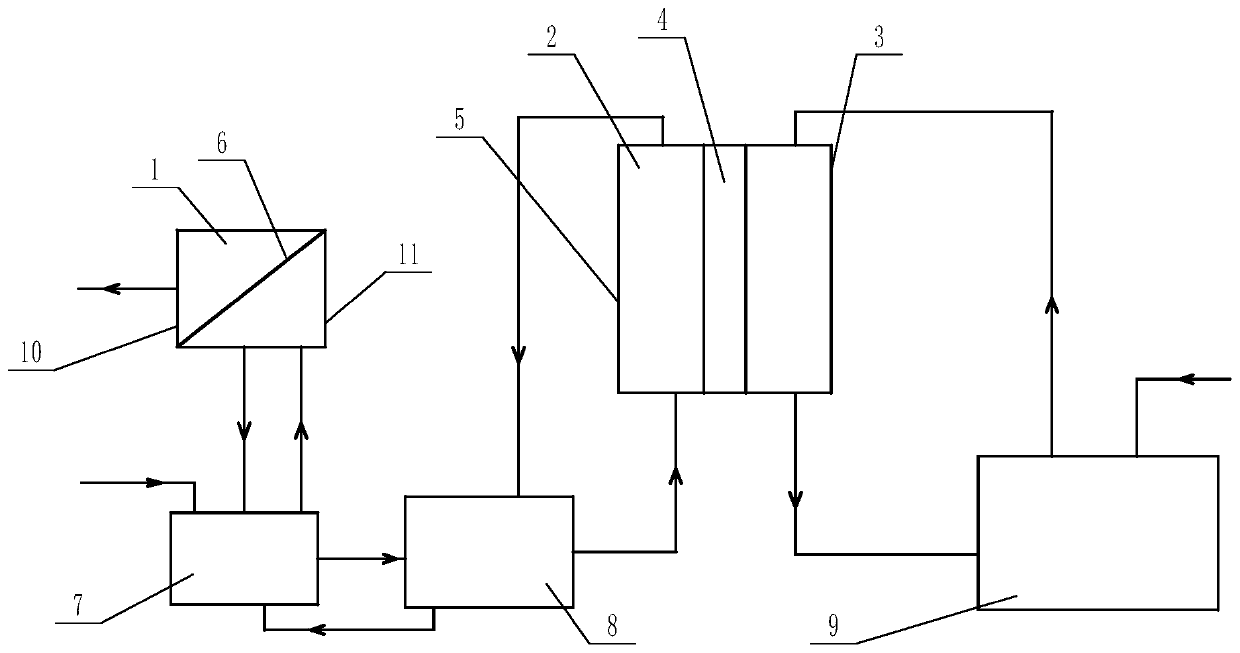

High-concentration wastewater zero-discharging method

ActiveCN105198143ARealize in-depth treatment and even zero discharge problemsEfficient reverse osmosis treatmentEnergy based wastewater treatmentMultistage water/sewage treatmentHigh concentrationReverse osmosis

The invention relates to the field of industrial wastewater treatment, in particular to a high-concentration wastewater zero-discharging method. Accoridng to the method, a 'nanofiltration + efficient reverse osmosis + membrane distillation + evaporative crystallization' method is adopted to treat high-concentration wastewater. Firstly, nanofiltration is adopted to remove hardness, multivalent ions and parts of organic matter in the high-concentration wastewater so as to obtain nanofiltration producing water and nanofiltration concentrated water, then an efficient reverse osmosis technology is adopted to conduct deep concentration treatment on the nanofiltration producing water, deep concentration treatment is conducted on the obtained efficient reverse osmosis concentrated water through membrane distillation to obtain membrane-distillation concentrated water, further evaporative crystallization treatment is performed to enable salt solids in the membrane-distillation concentrated water to crystallize out, and centralized drying disposal is performed, wherein salt is added into the nanofiltration concentrated water to perform precipitation treatment so as to obtain calcium residues, supernate obtained after precipitation is subjected to activated carbon adsorption and then is mixed with the high-concentration wastewater, and the mixed liquid is fed into a nanofiltration unit for circular treatment. By means of the high-concentration wastewater zero-discharging method, water resources are recycled to the most degree while the problem of high-concentration wastewater discharging is solved, and zero discharging of high-concentration wastewater is basically achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

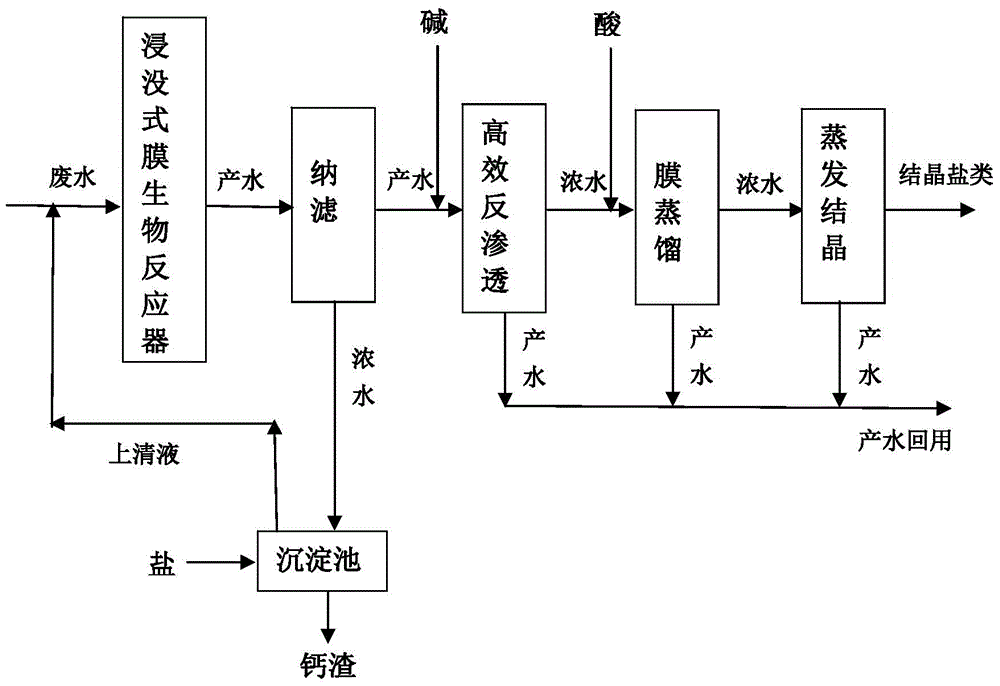

High-salinity high-organic-matter contentwastewater zero discharge method

InactiveCN105461157ASolve the problem of advanced treatment and even zero dischargeEfficient reverse osmosis treatmentWater contaminantsEnergy based wastewater treatmentFiltrationEvaporation

The invention relates to the field of industrial wastewater treatment, and specifically relates to a high-salinity high-organic-matter content wastewater zero discharge method. According to the invention, the high-salinity high-organic-matter content wastewater is treated with submerged membrane bioreactor treatment, nano-filtration, high-efficiency reverse osmosis, membrane distillation, and evaporation crystallization. Most of the suspended solids and organic matters in the wastewater are removed with the submerged membrane bioreactor; hardness matters such as multivalent ions, and part of the remaining organic matters in the wastewater are removed through nano-filtration, such that nano-filtration produced water and nano-filtration concentrated water are obtained; the nano-filtration produced water is subjected to a deep concentration treatment with the high-efficiency reverse osmosis technology, such that high-efficiency reverse osmosis produced water and high-efficiency reverse osmosis concentrated water are obtained; the high-efficiency reverse osmosis concentrated water is subjected to a membrane distillation deep concentration treatment, such that membrane distillation produced water and membrane distillation concentrated water are obtained; and the membrane distillation concentrated water is subjected to the evaporation crystallization treatment, such that salt solids in the concentrated water are crystallized. Through the above process flow, water resource is recovered to a maximal extent while a wastewater discharge problem is solved , and high-salinity high-organic-matter wastewater zero discharge is substantially realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

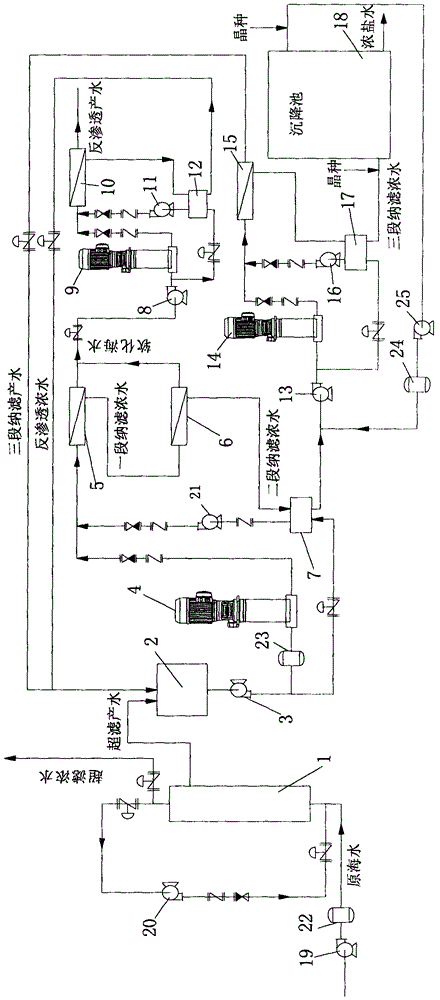

Full-membrane method seawater desalting integration system adopting ultrafiltration-nanofiltration-reverse osmosis, and full-membrane method seawater desalting integration process adopting ultrafiltration-nanofiltration-reverse osmosis

InactiveCN104817134AReduced fouling tendencyReduce energy consumptionGeneral water supply conservationSeawater treatmentMembrane methodThree stage

The invention relates to a full-membrane method seawater desalting integration system adopting ultrafiltration-nanofiltration-reverse osmosis, and a full-membrane method seawater desalting integration process adopting ultrafiltration-nanofiltration-reverse osmosis, wherein the nanofiltration seawater softening recovery rate can be increased, and the membrane surface scaling tendency can be reduced. According to the present invention, the nanofiltration system is a three-stage nanofiltration system, wherein the first-stage nanofiltration membrane assembly and the second-stage nanofiltration membrane assembly are adopted as the pretreatment of the reverse osmosis, and the third-stage nanofiltration membrane assembly further treats the concentrated water obtained through the first-stage nanofiltration and the second-stage nanofiltration, such that the seawater recovery rate is increased, and the scaling tendency on the nanofiltration membrane surface of the first-stage nanofiltration membrane assembly and the second-stage nanofiltration membrane assembly is reduced so as to reduce the seawater desalting cost and reduce the scaling tendency of the third-stage nanofiltration membrane assembly during the high salinity concentrated water treatment.

Owner:OCEAN UNIV OF CHINA

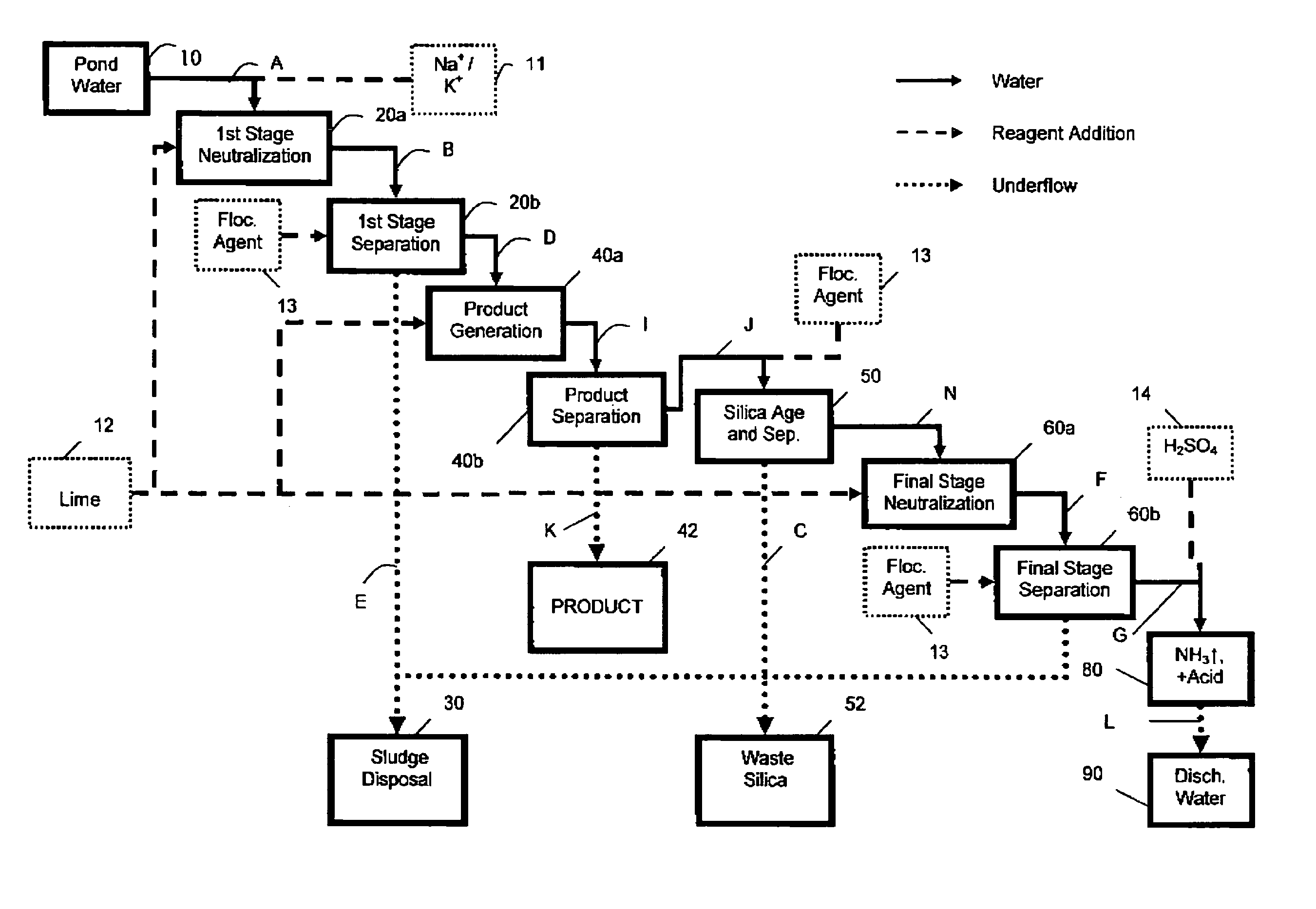

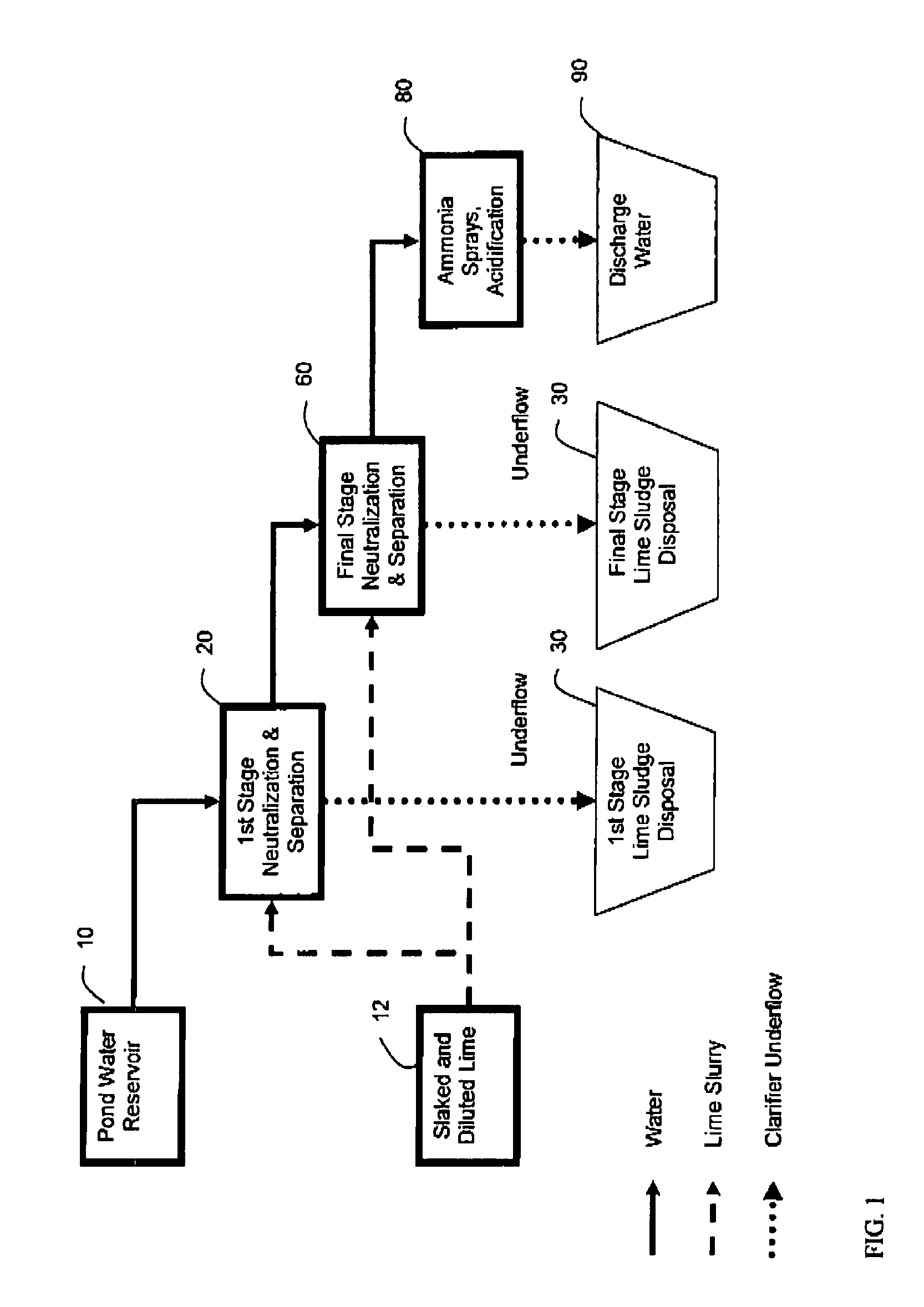

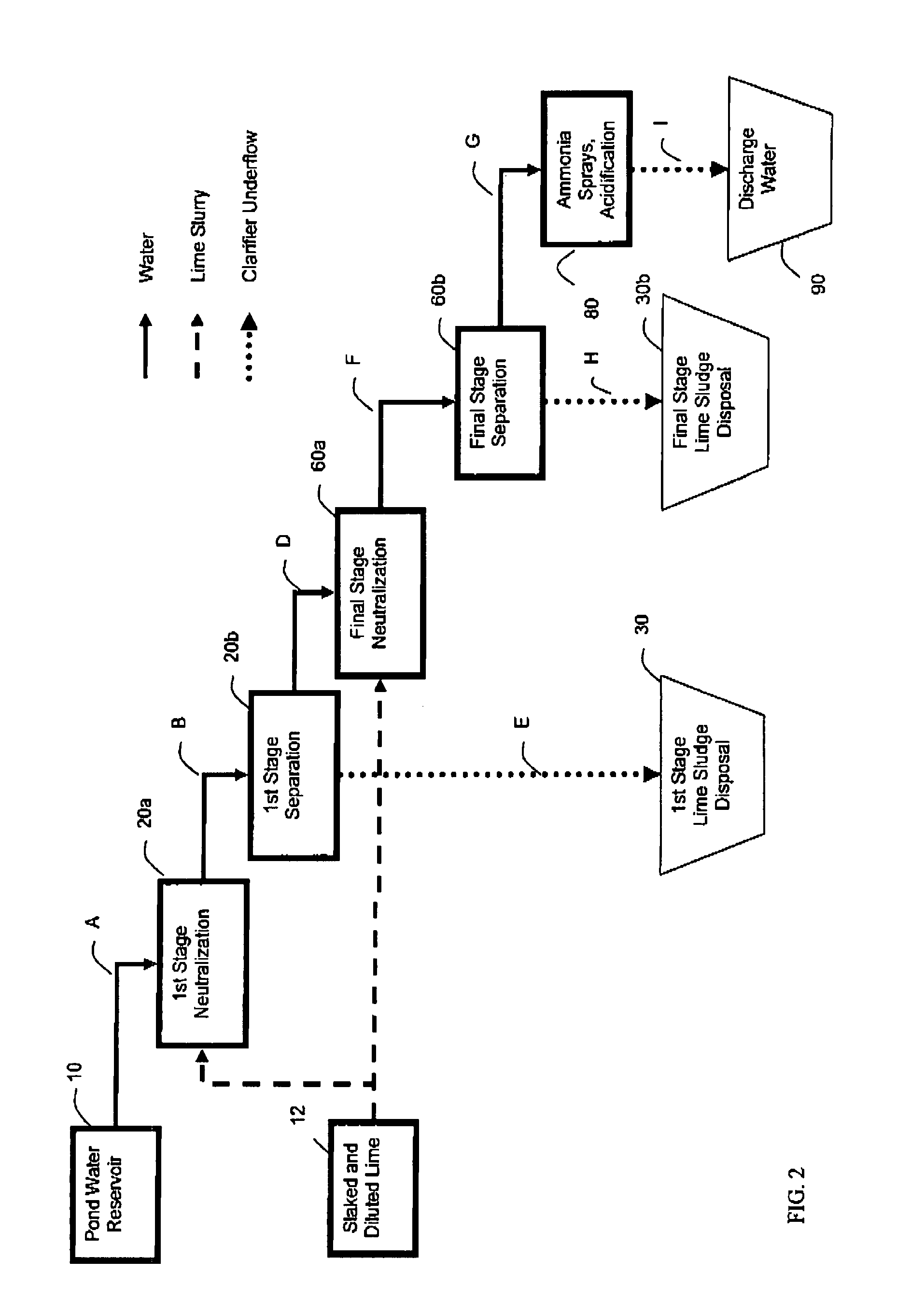

Process for treating pond water

ActiveUS7560031B1Promote recoveryLow fluoride valueWater contaminantsPhosphorus oxyacidsSludgePhosphate product

A process for the treatment of phosphoric acid plant pond water facilitating the recovery of phosphorus values from the input pond water. In certain aspects the process recycles solids from a later stage neutralization and separation into the clarified liquid stream from an initial clarification and neutralization stage. A sufficient amount of solids are added to the clarified liquid stream to effect the pH-dependent precipitation of a phosphate product. In alternative aspects an intermediate pH-dependent precipitation of a phosphate product is achieved through the addition of a neutralizing agent. The phosphate product is further characterized by a low concentration of fluoride. In addition the phosphate product can be further processed to a high purity technical grade phosphoric acid. In certain aspects the process employs flocculating agents to enhance the formation of precipitates. In further aspects, methodologies taught herein facilitate the reduction of silica in the process streams. Processes according to the present invention are further characterized by an enhanced recovery of treated water, reduced sludge impoundment and reduced lime consumption when compared to conventional double liming processes.

Owner:VEOLIA WATER NORTH AMERICA OPERATING SERVICES

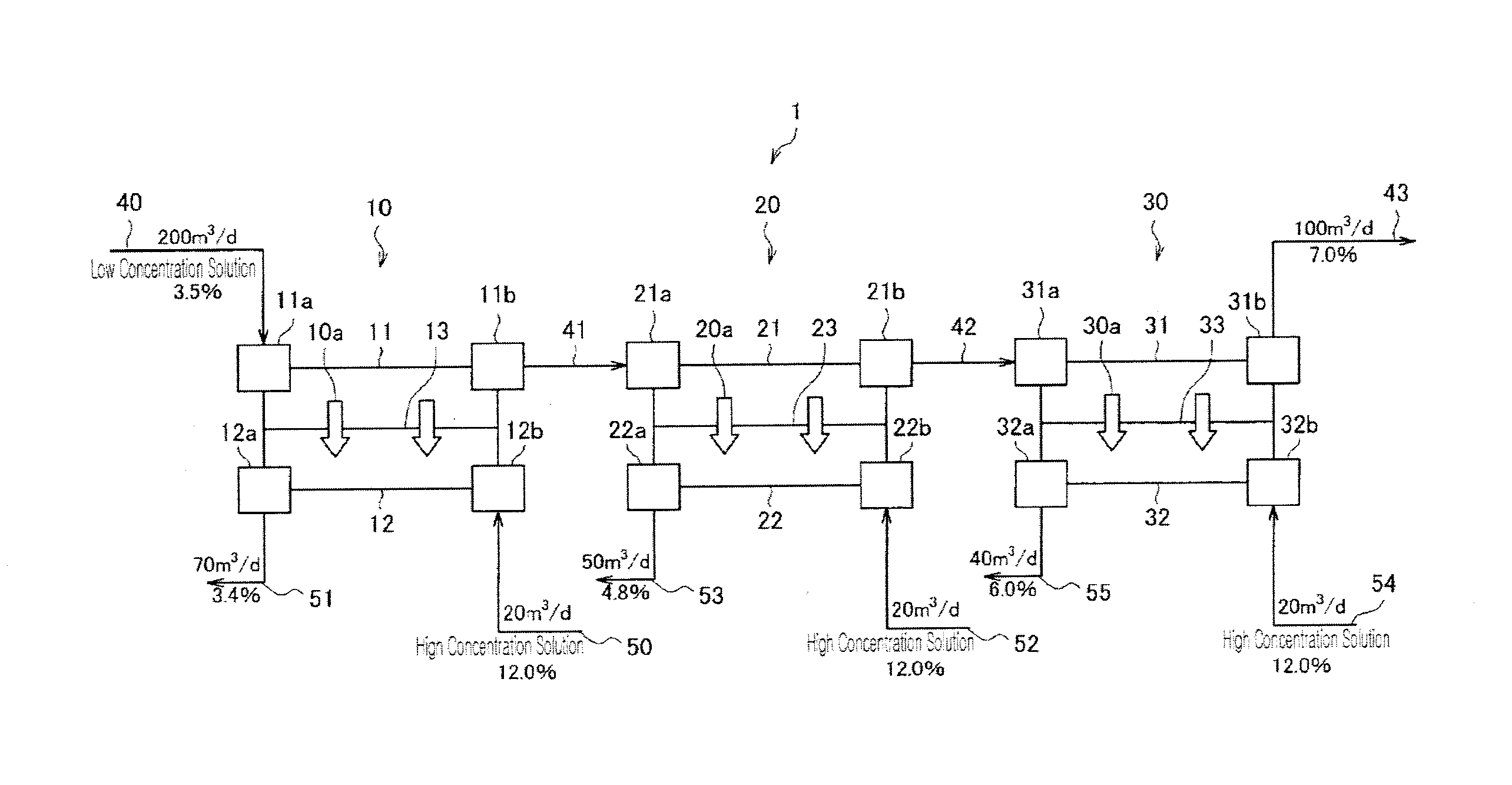

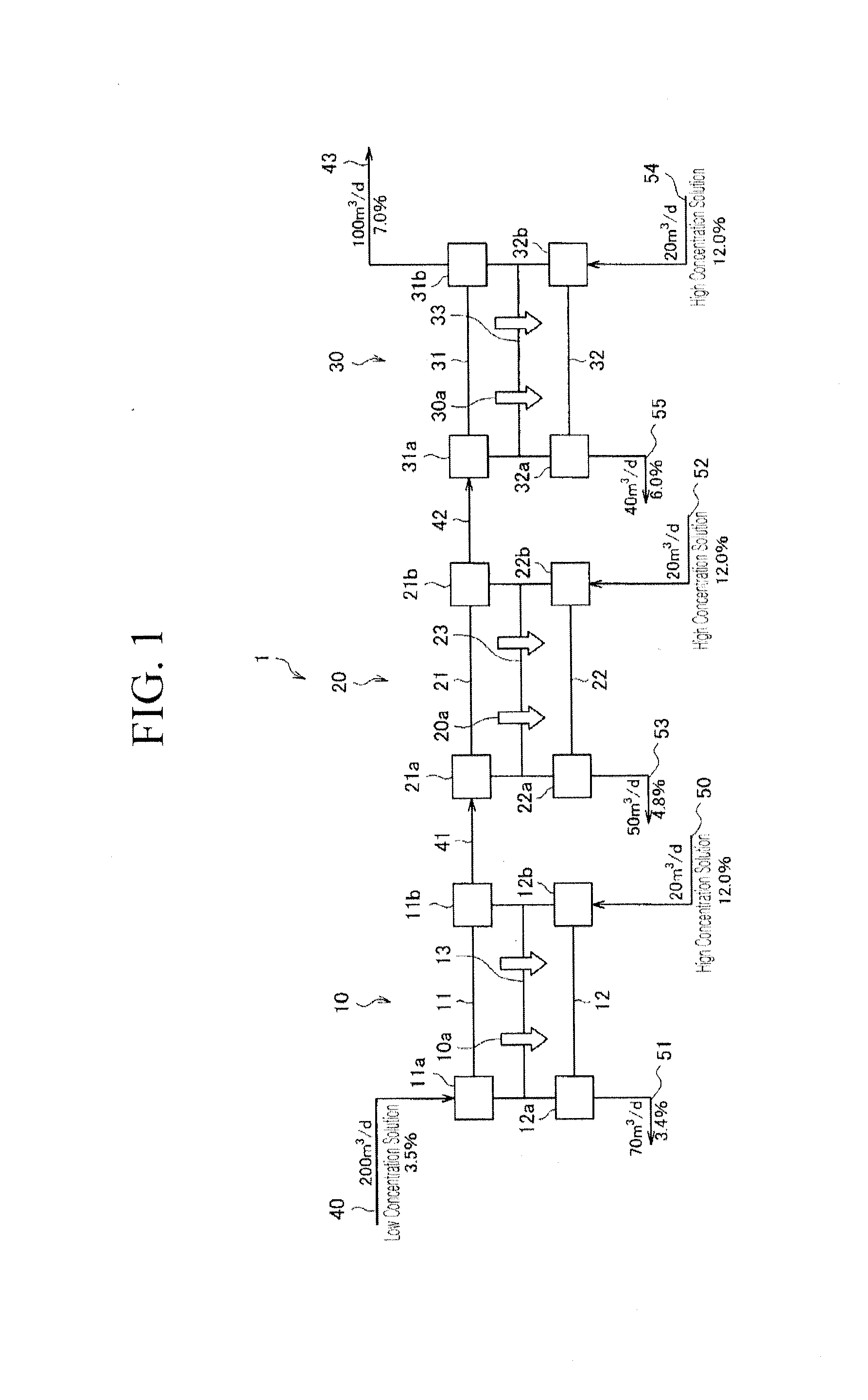

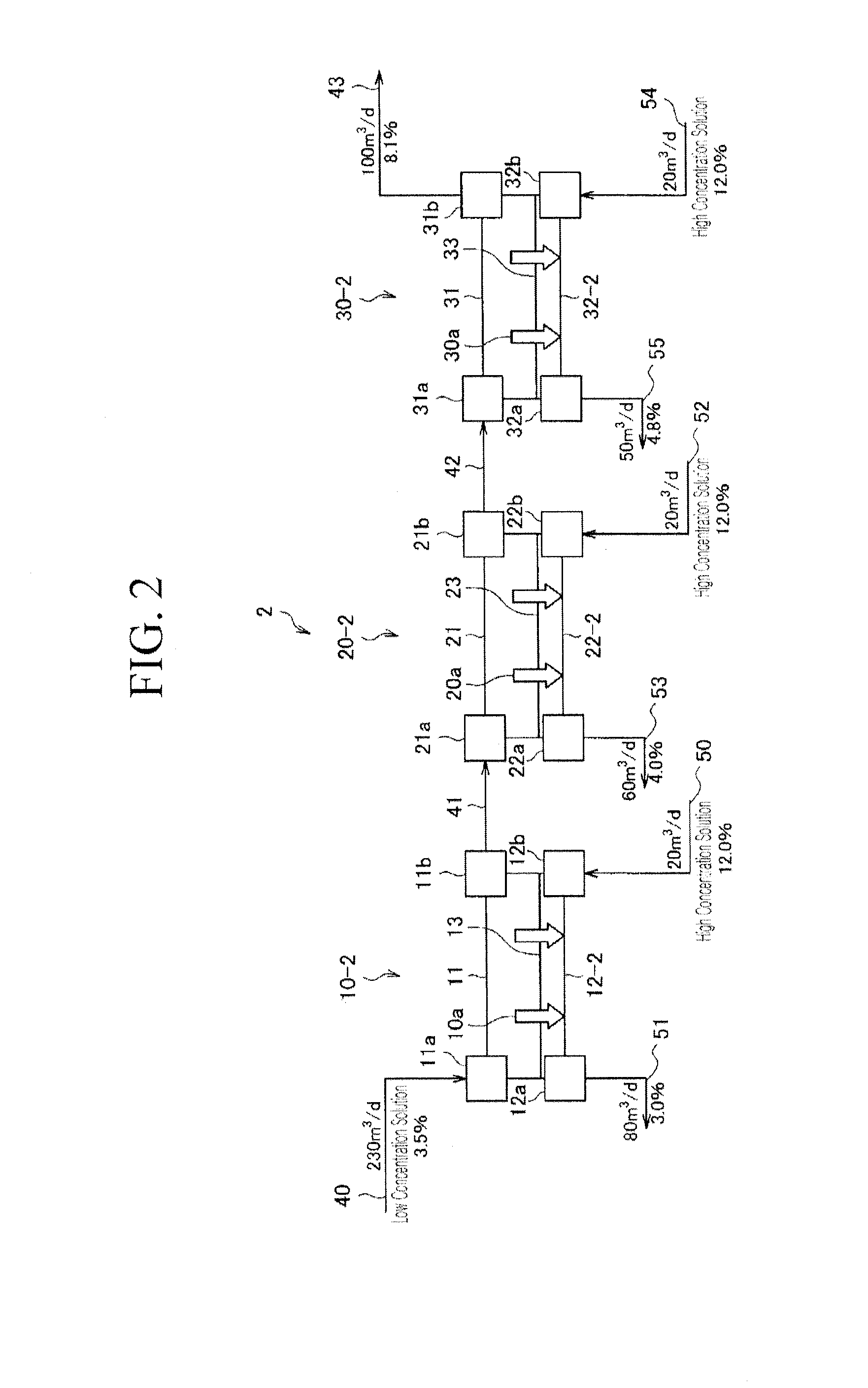

Water recovery method

InactiveUS20140138313A1Improve the level ofHigh water recoveryMembranesSolvent extractionWater recoveryHigh concentration

A water recovery method for improving water recovery efficiency may include inflowing a low concentration solution including water into an in-series flow path. The in-series flow path may include a plurality of flow paths for a low concentration solution coupled in series. The method may additionally include inflowing a high concentration solution having the same concentration into a plurality of flow paths for a high concentration solution. Each of the plurality of flow paths for the high concentration solution may be connected to each of plurality of flow paths for the low concentration solution via a respective semipermeable membrane being interposed therebetween.

Owner:SAMSUNG ELECTRONICS CO LTD

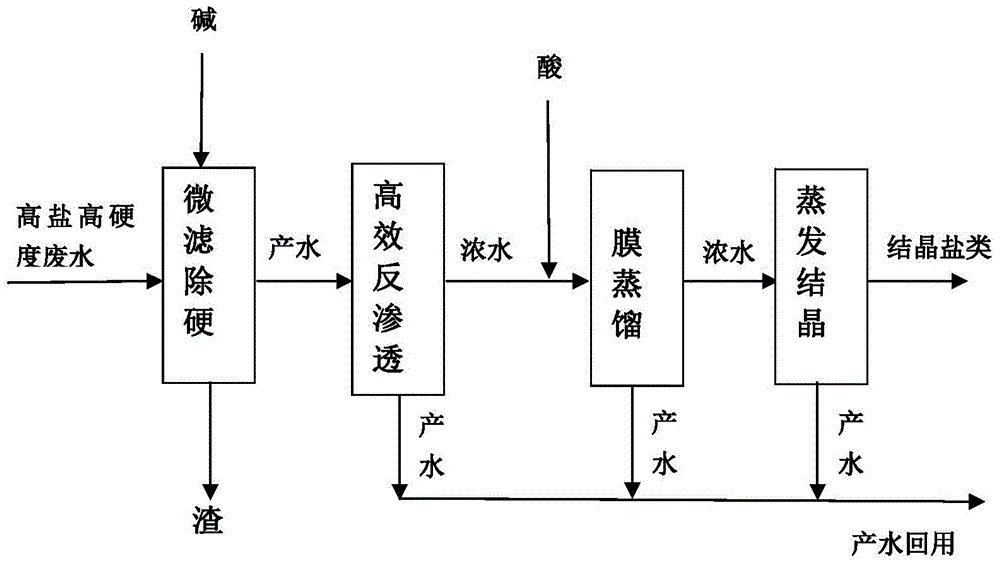

High-salinity high-hardness wastewater zero-discharging method

ActiveCN105198144AAchieving zero emissionsGuarantee continuous and stable operationMultistage water/sewage treatmentReverse osmosisWater resources

The invention relates to the field of industrial wastewater treatment, in particular to a high-salinity high-hardness wastewater zero-discharging method. According to the method, a 'microfiltration and hardness removal + efficient reverse osmosis + membrane distillation + evaporative crystallization' method is adopted to treat high-salinity high-hardness wastewater. Firstly, a microfiltration and hardness removal technology is adopted to remove hardness of the high-salinity high-hardness wastewater, then an efficient reverse osmosis technology is adopted to further concentrate the wastewater without hardness so as to obtain efficient reverse osmosis producing water and efficient reverse osmosis concentrated water, deep concentration is conducted on the efficient reverse osmosis concentrated water through membrane distillation to obtain membrane-distillation producing water and membrane-distillation concentrated water, evaporative crystallization treatment is further conducted on the membrane-distillation concentrated water to enable salt solids in the concentrated water to crystallize out, and centralized drying disposal is performed. The efficient reverse osmosis producing water, the membrane-distillation producing water and evaporative-crystallization producing water produced in the treating process can be reused for a production process, water resources are recycled to the most degree while the problem of wastewater discharging is solved, and zero discharging of high-salinity high-hardness wastewater is basically achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

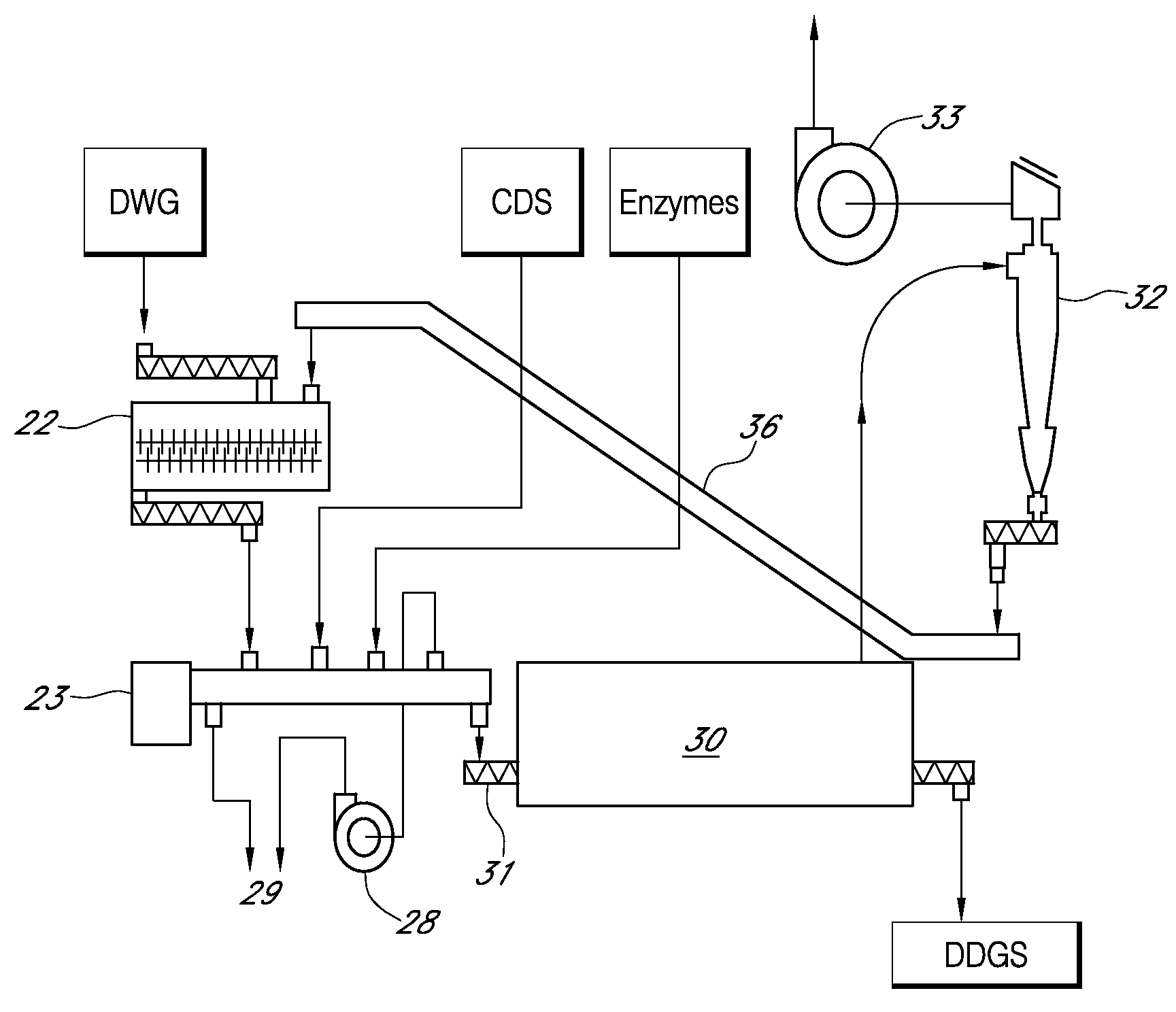

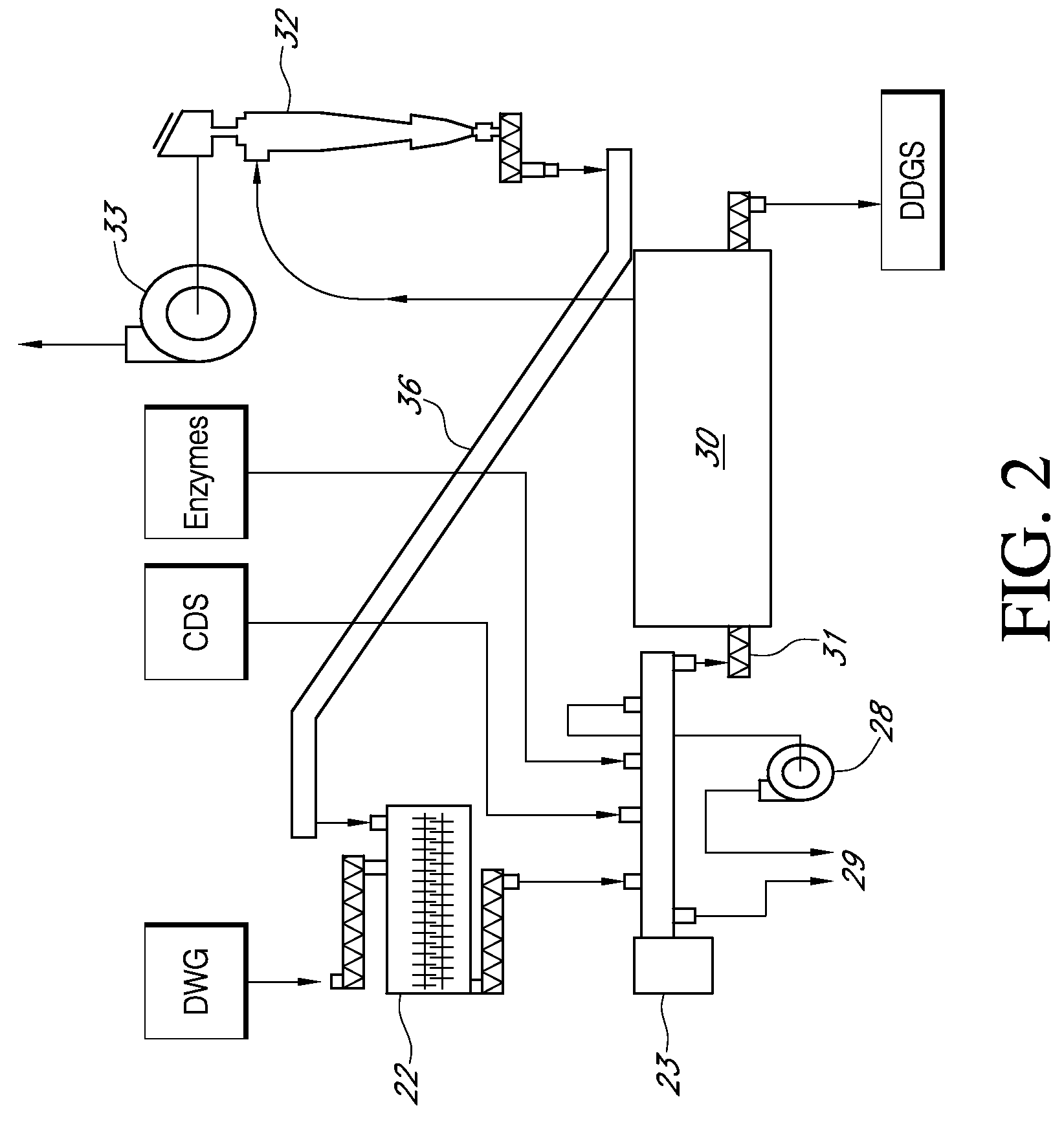

Method of producing dried distillers grain agglomerated particles

ActiveUS7695747B2Reduce Particle GenerationHigh water recoveryDough treatmentBiofuelsSufficient timeMoisture

A method of producing Dried Distiller's Grain with Solubles (DDGS) agglomerated particles is disclosed. The method comprises the steps of separating a first product stream out of the whole stillage that is primarily solid material from a second product stream that is primarily liquid, agglomerating the first product stream using a mechanical compression machine such as an extruder, and exposing the agglomerated particles to microwave radiation of a sufficient energy for a sufficient time so that the resulting moisture of the agglomerated particles is between 3% and 40% by weight. The second product stream may be condensed and blended with the first product stream prior to, or concurrently with, the step in which the agglomerated particles are formed. Additionally, other additives, such as enzymes, may be added to the first product stream to enhance the final product's desirability as a nutritional source.

Owner:MEIER RUSSELL

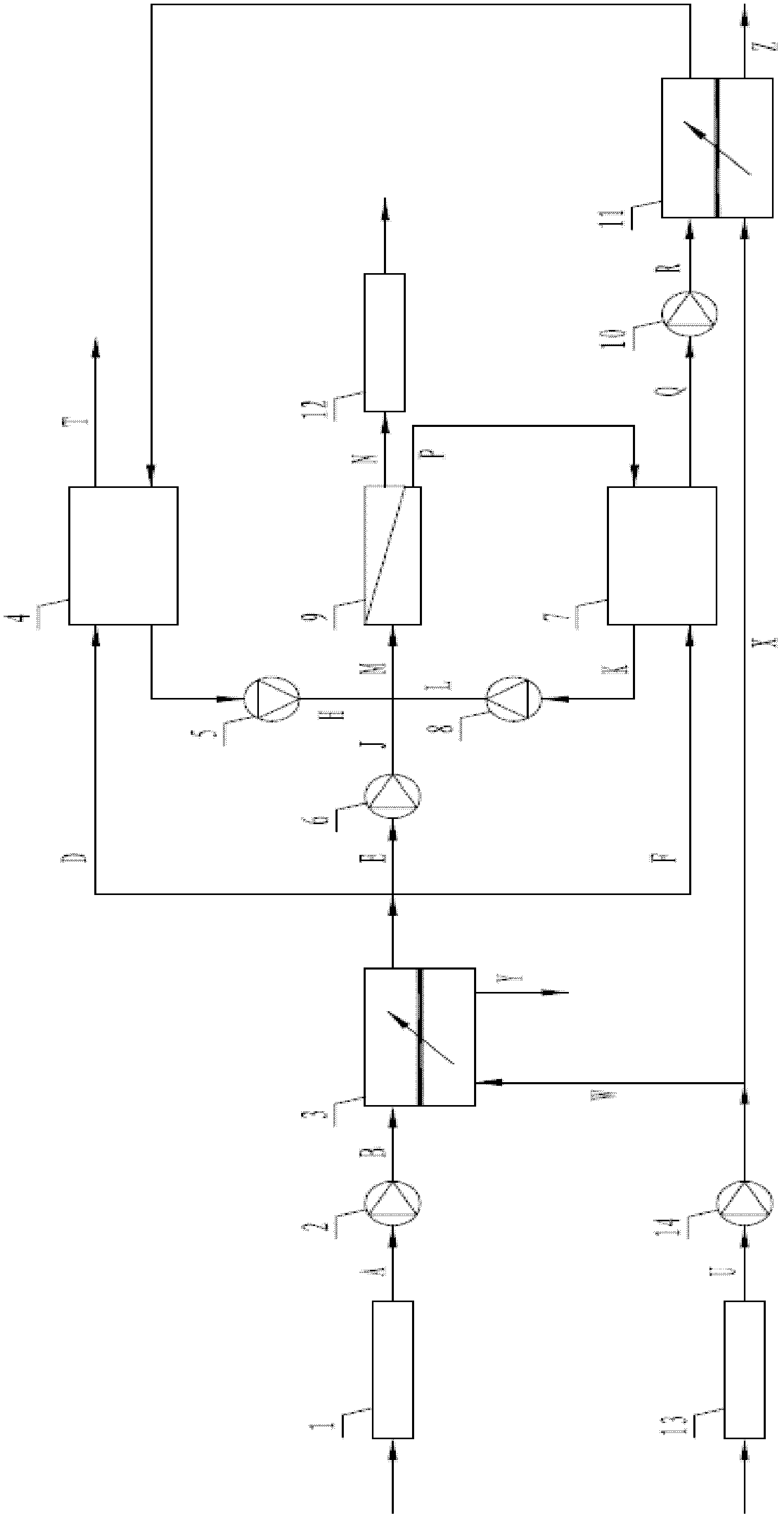

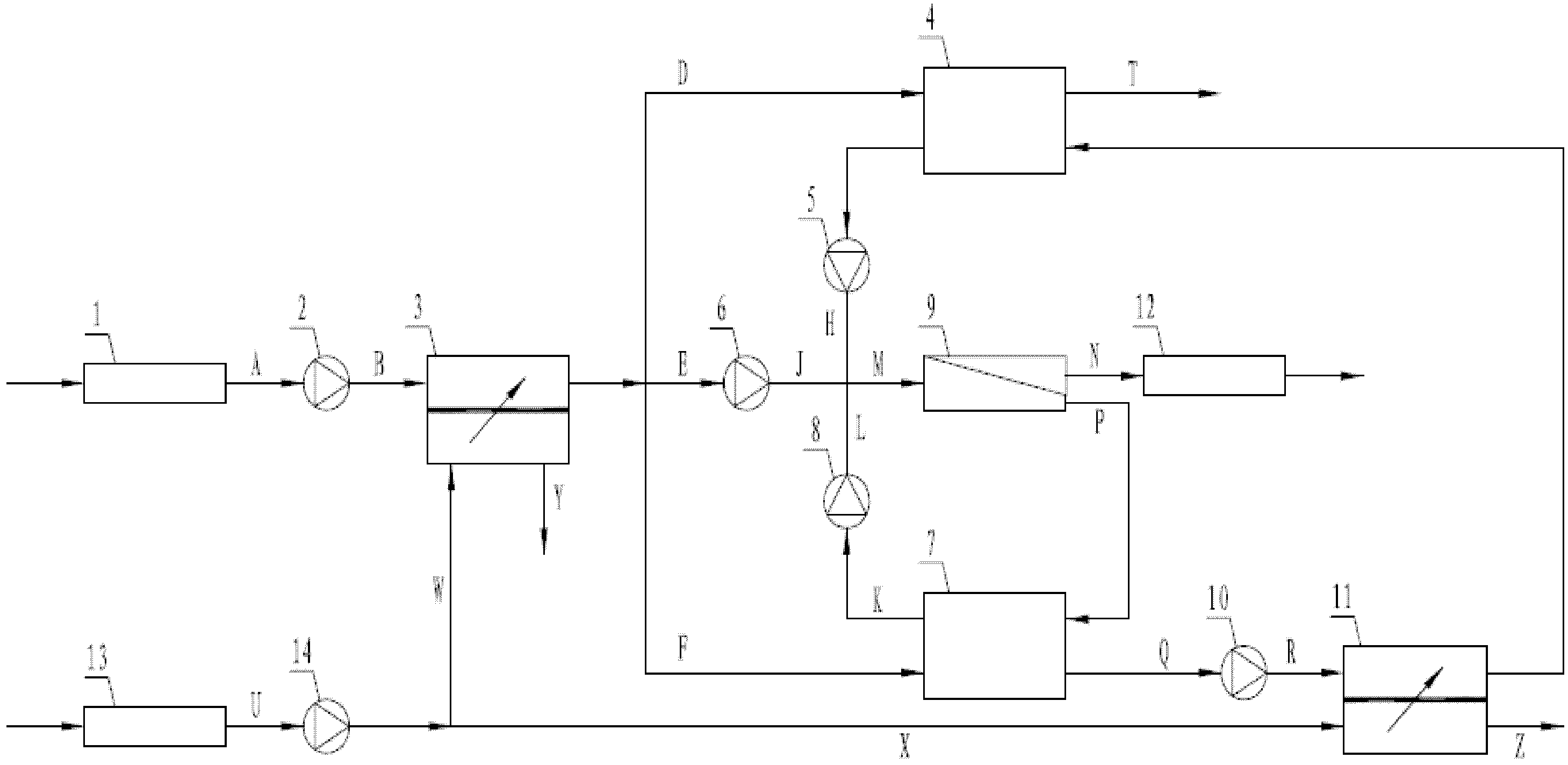

Pressure delay osmosis/reverse osmosis combined desalination method

InactiveCN102442715AHigh recovery rateHigh water recoveryGeneral water supply conservationSeawater treatmentEnergy absorptionReverse osmosis

The invention discloses a pressure delay osmosis / reverse osmosis combined desalination method, which comprises the following steps of: pressurizing pretreated sewage flow U, successively inputting into first and second pressure delay osmosis devices; pressurizing pretreated seawater flow A, entering into the first pressure delay osmosis device, outputting three flows D, E and F, inputting the flow D into a first energy recovery device for energy absorption, inputting into a first booster pump for supercharging, inputting the flow E into a second booster pump for supercharging, inputting the flow F into a second energy recovery device for energy absorption, inputting into a third booster pump for supercharging, merging the three flows, inputting into a high-pressure membrane module, outputting a strong brine flow P from the membrane module, inputting the flow P into the second energy recovery device to release energy, inputting into a fourth booster pump for supercharging, inputting into the second pressure delay osmosis device, inputting into the first energy recovery device to release energy, outputting product water out from the membrane module, and processing the product water for usage. The method provided by the invention is used to raise energy utilization rate, decrease energy consumption, save desalination cost and reduce discharge load of the strong brine.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

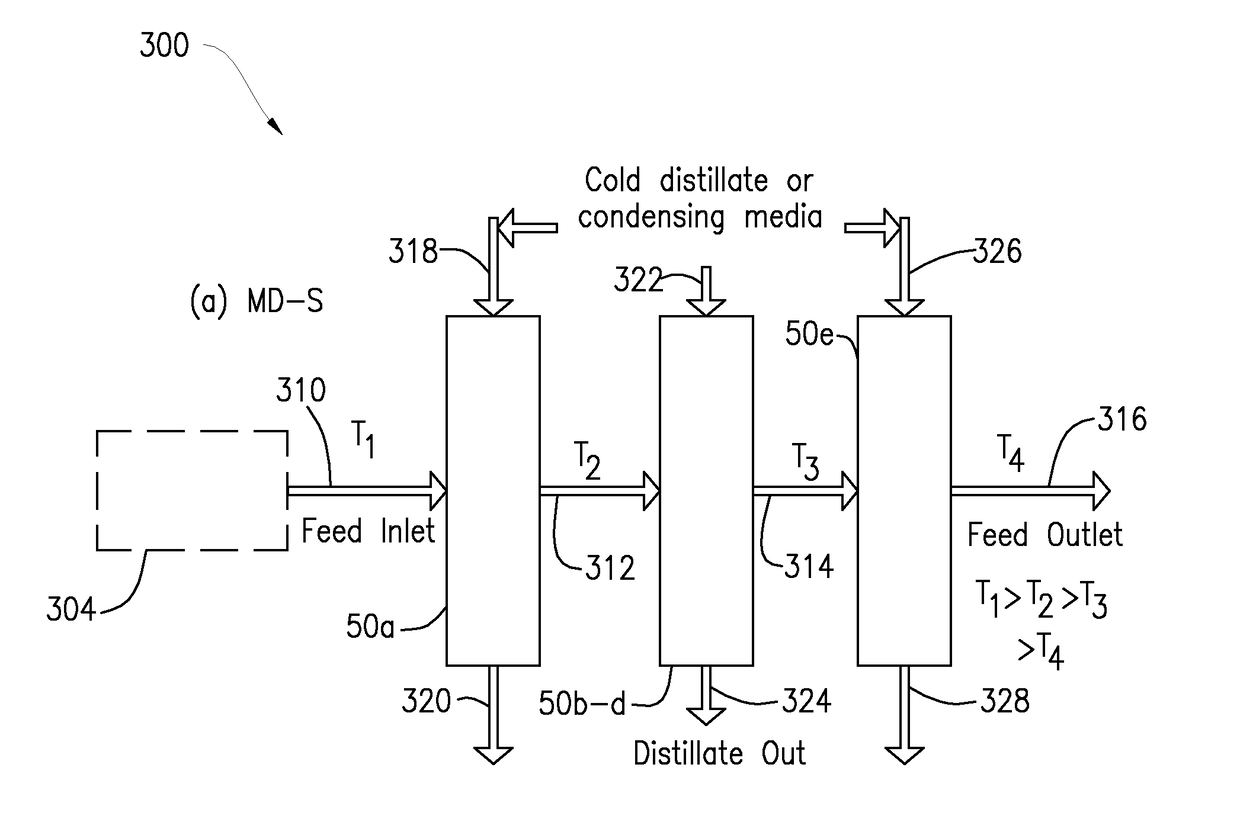

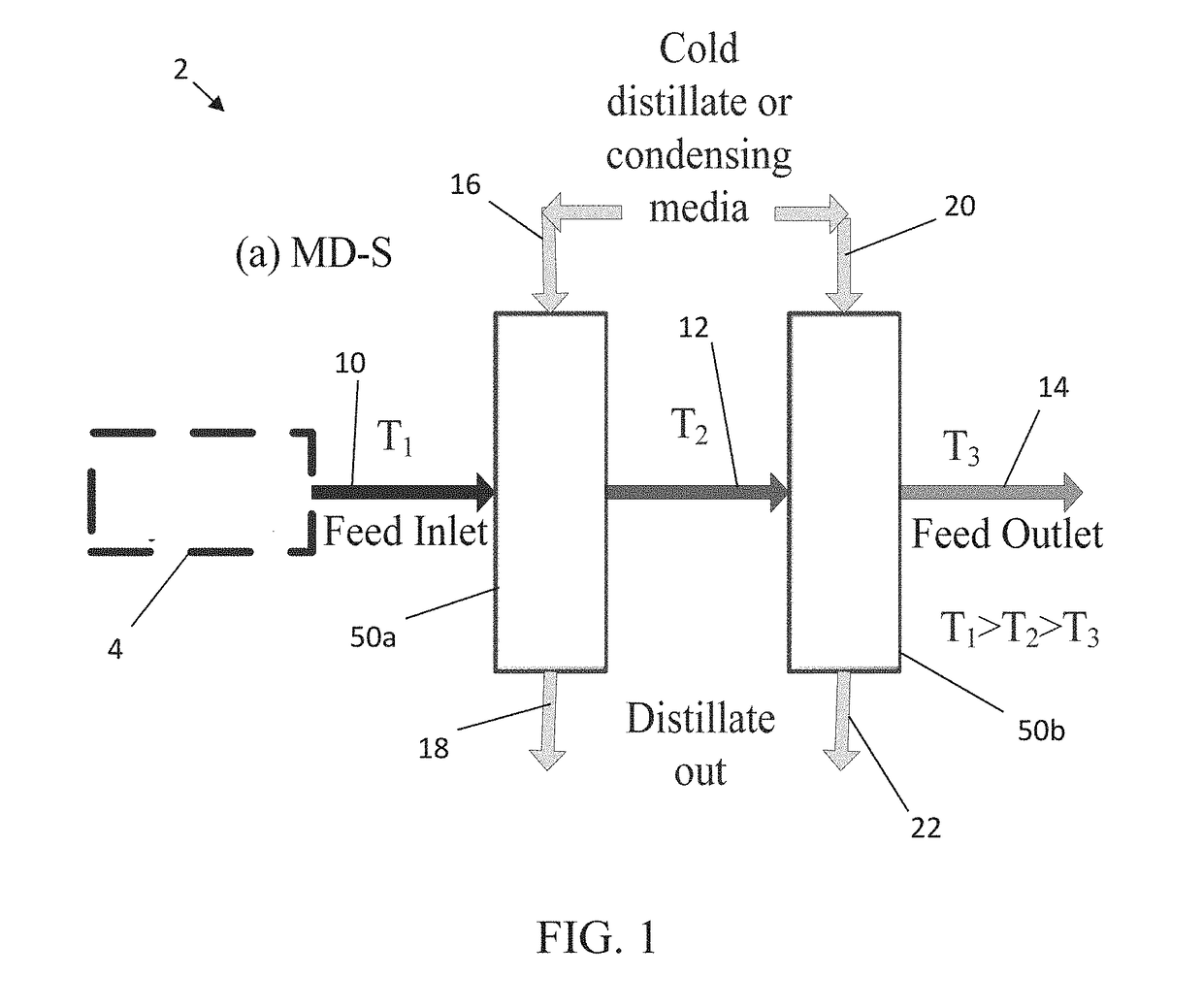

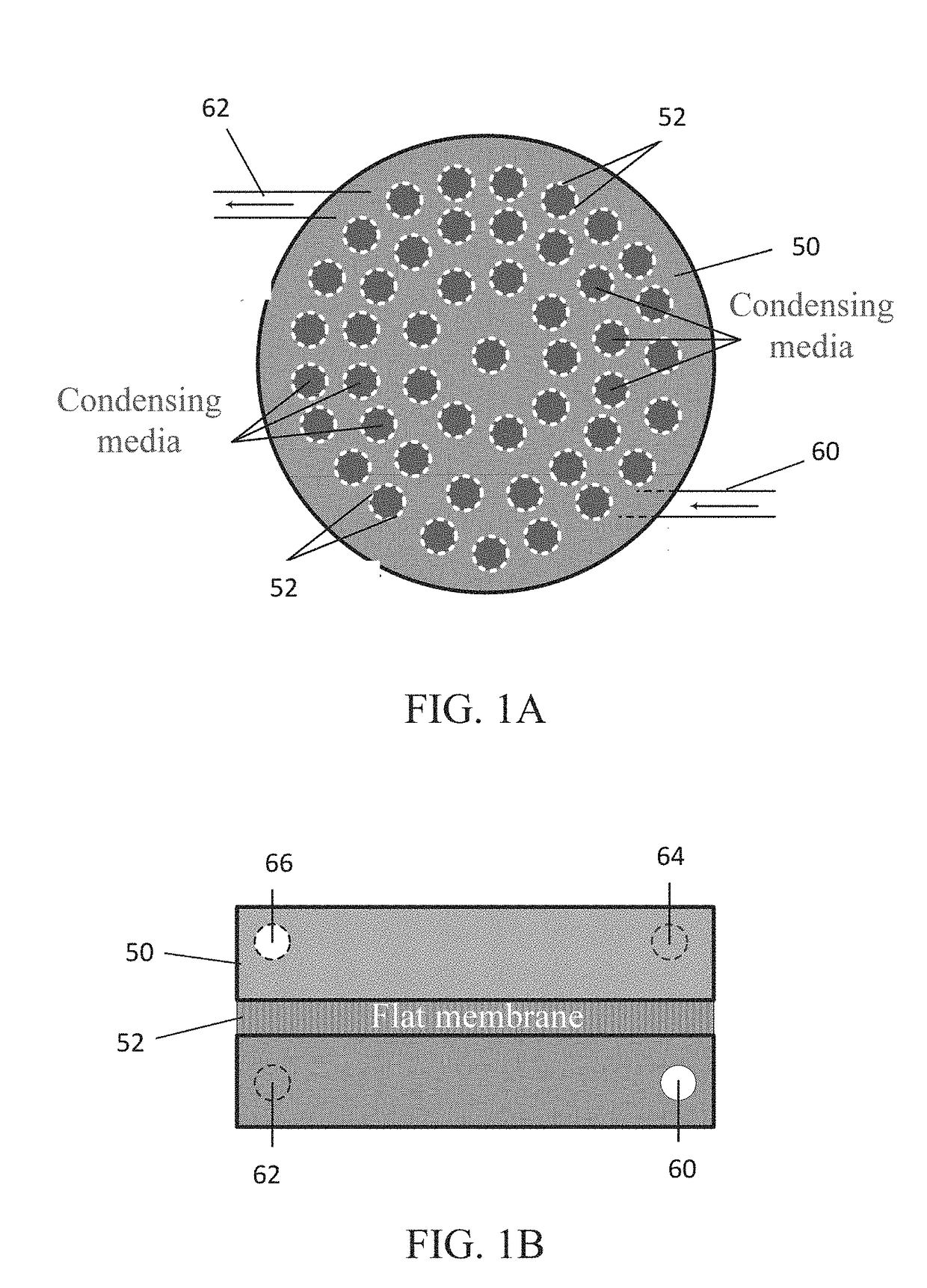

Systems and methods for maximizing recovery in membrane distillation

ActiveUS20170368506A1High water recoveryHigh yieldMembranesSeawater treatmentComputer moduleMembrane distillation

Membrane distillation (MD) systems include at least two MD modules arranged in series, each of at least two MD modules including a condensing media inlet operable to receive a condensing media and a condensing media outlet, a feed inlet operable to receive a feed media and a feed outlet, and a first heating element positioned and operable to heat a feed prior to or upon introduction of the feed to a first of the at least two MD modules, wherein a stream exiting the feed outlet of the first of the at least two MD modules is introduced to the second of the at least two MD modules. Other MD systems include at least two MD modules arranged in parallel.

Owner:ROY SAGAR +1

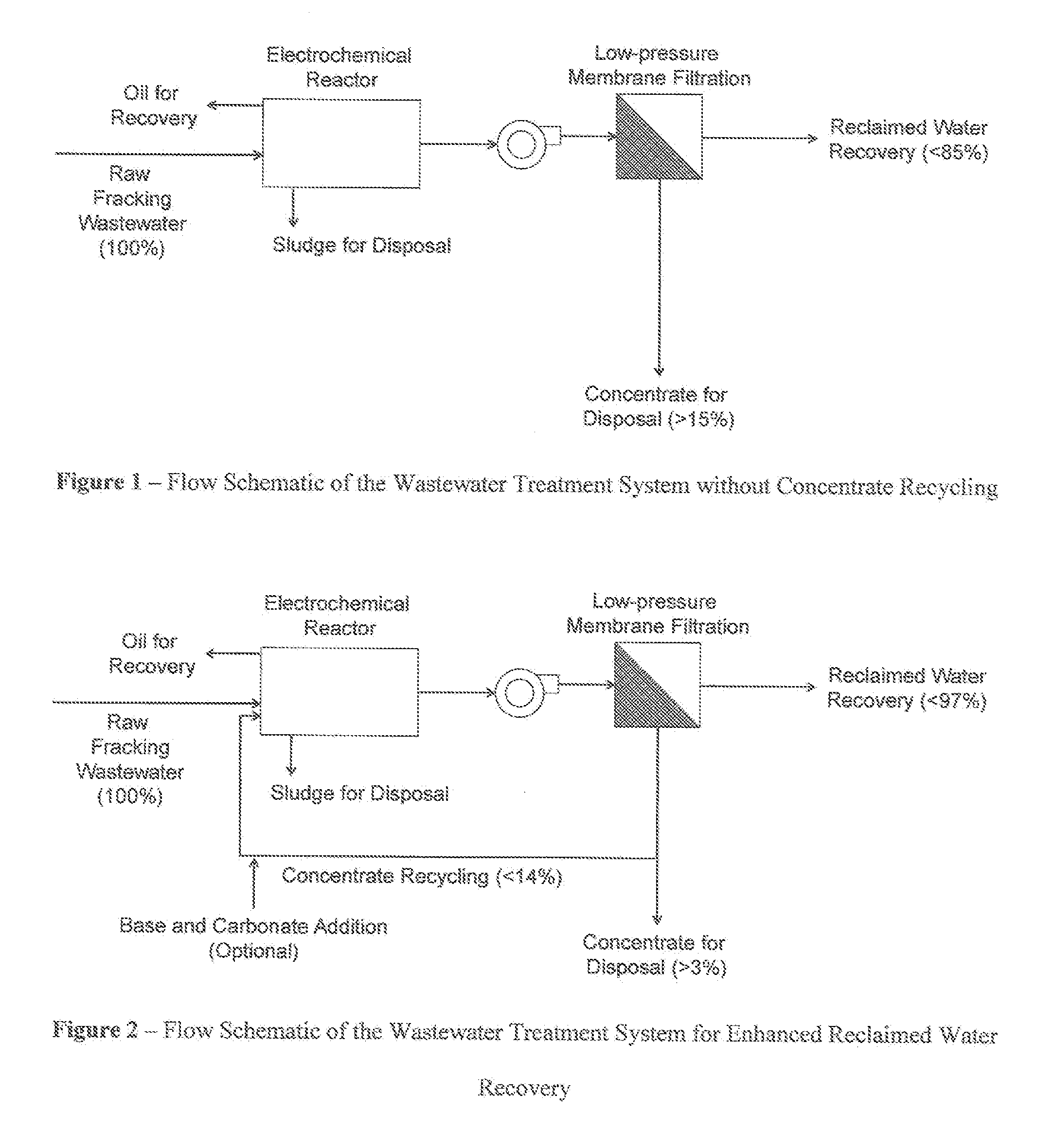

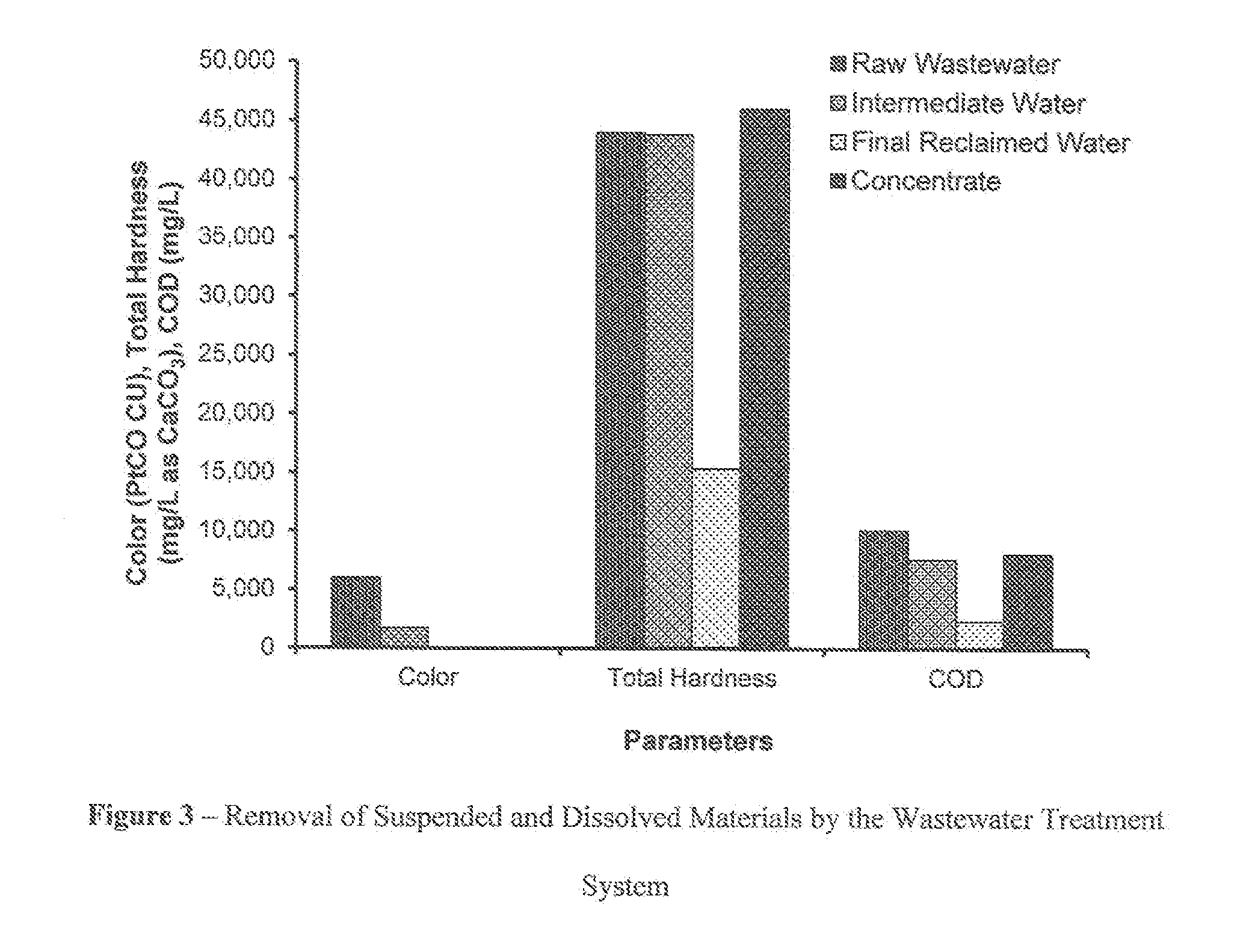

System for enhanced reclaimed water recovery

InactiveUS20150083663A1Reduce probabilityIncrease overall reclaimed water recoveryWaste water treatment from quariesDialysis systemsFiltrationReclaimed water

An apparatus for treating wastewater, such as high-solids contend wastewater from a fracking operation, includes a solids-oil-water separation apparatus coupled to a low-pressure membrane filtration apparatus, with a wastewater recycling conduit coupled at one end to the low-pressure membrane filtration apparatus and coupled at a second end to the solids-oil-water separation apparatus, whereby progressive recycling of membrane concentrate from the low-pressure membrane filtration apparatus through the wastewater recycling conduit, into the solids-oil-water separation apparatus, provides recovery of as much as 97% of the water from a raw wastewater stream.

Owner:PACIFIC ADVANCED CIVIL ENG

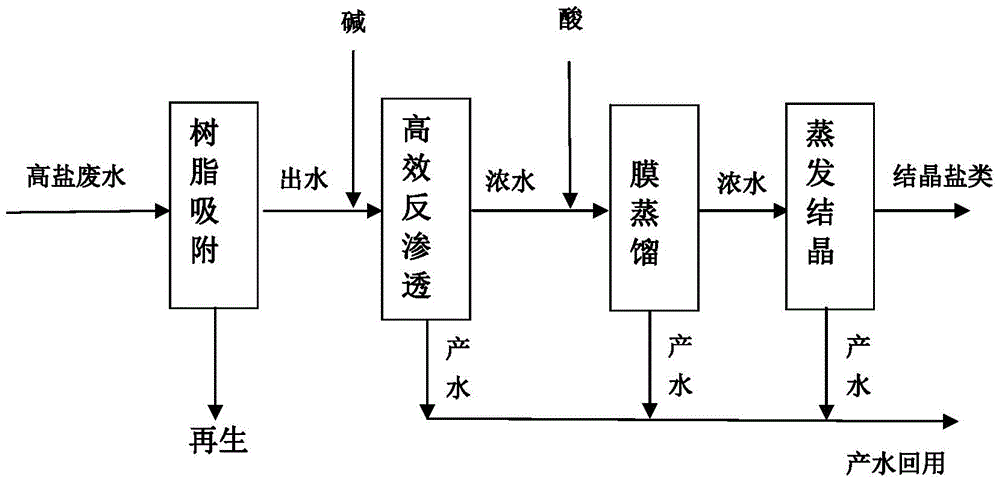

High-salinity wastewater zero-discharging method

ActiveCN105198142ARealize in-depth treatment and even zero discharge problemsReduce pollutionMultistage water/sewage treatmentWater resourcesReverse osmosis

The invention relates to the field of industrial wastewater treatment, in particular to a high-salinity wastewater zero-discharging method. According to the method, a 'resin adsorption + efficient reverse osmosis + membrane distillation + evaporative crystallization' method is adopted to treat high-salinity wastewater. Firstly, resin adsorption is adopted to remove hardness and a little amount of organic matter in the high-salinity wastewater, then efficient reverse osmosis is adopted to further concentrate the high-salinity wastewater without hardness so as to obtain efficient reverse osmosis producing water and efficient reverse osmosis concentrated water, deep concentration is conducted on the efficient reverse osmosis concentrated water through membrane distillation to obtain membrane-distillation producing water and membrane-distillation concentrated water, evaporative crystallization treatment is further conducted on the membrane-distillation concentrated water to enable salt solids in the concentrated water to crystallize out, and centralized drying disposal is performed. The efficient reverse osmosis producing water, the membrane-distillation producing water and evaporative-crystallization producing water produced in the treating process can be reused for a production process, water resources are recycled to the most degree while the problem of wastewater discharging is solved, and zero discharging of high-salinity wastewater is basically achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

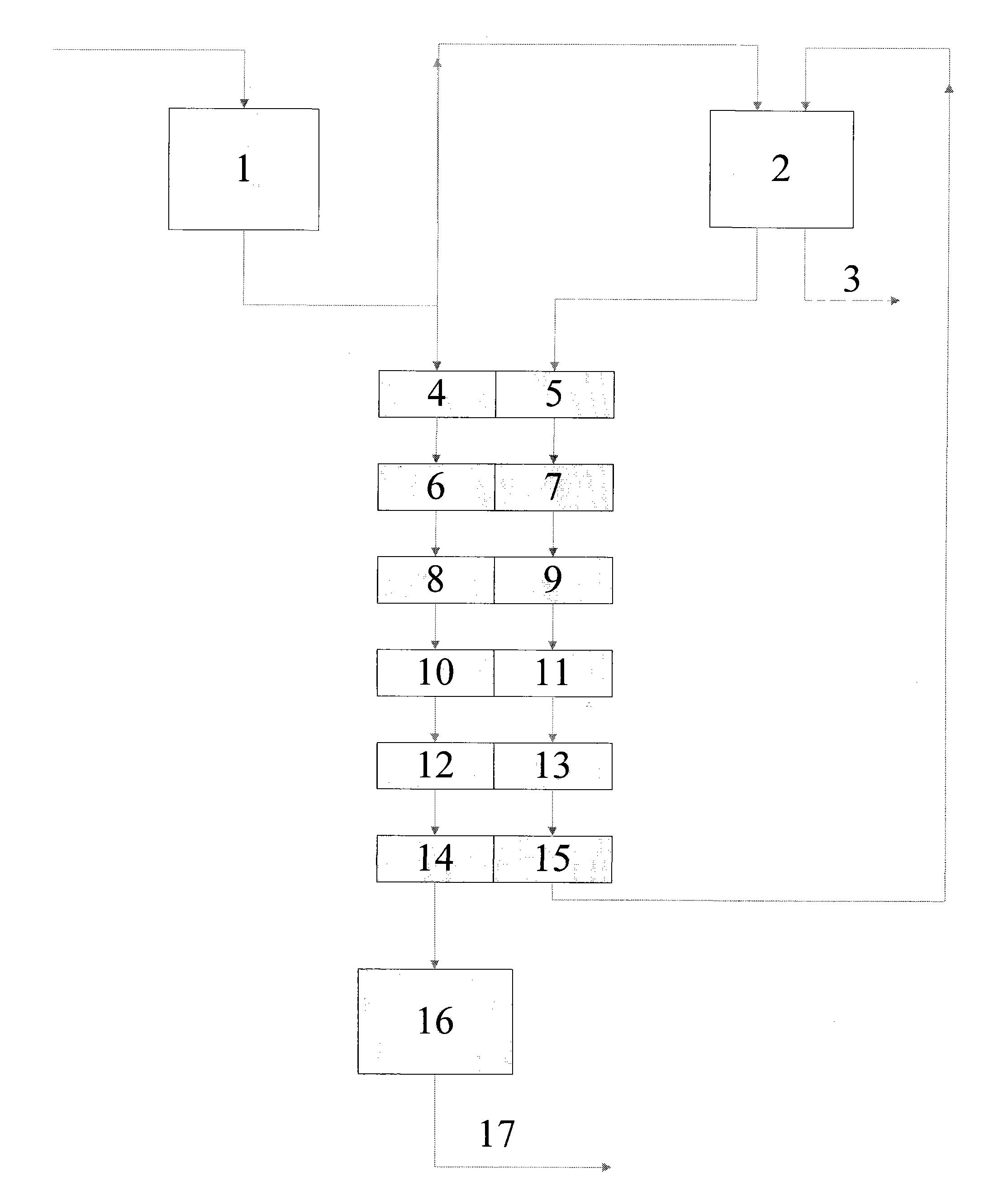

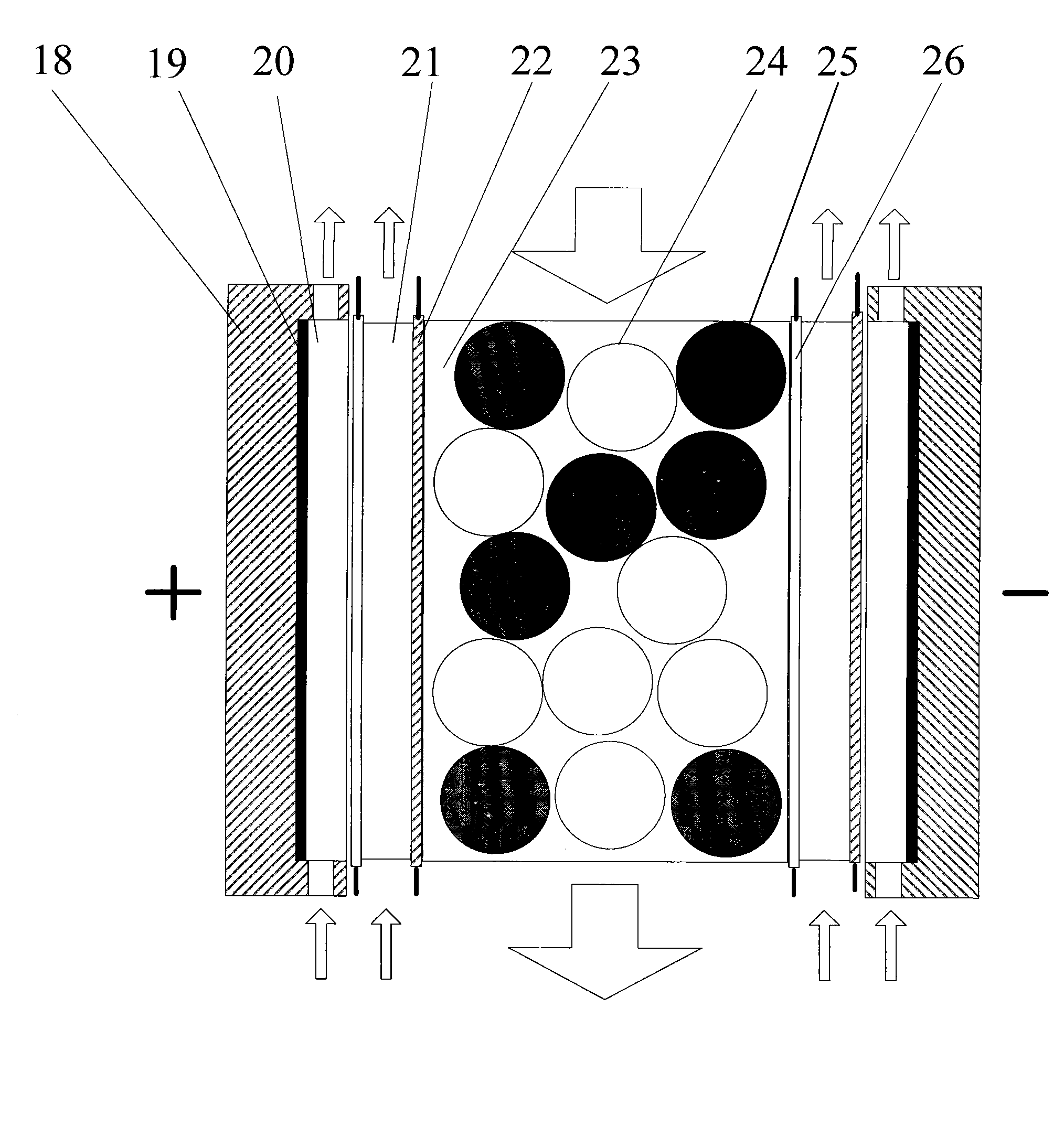

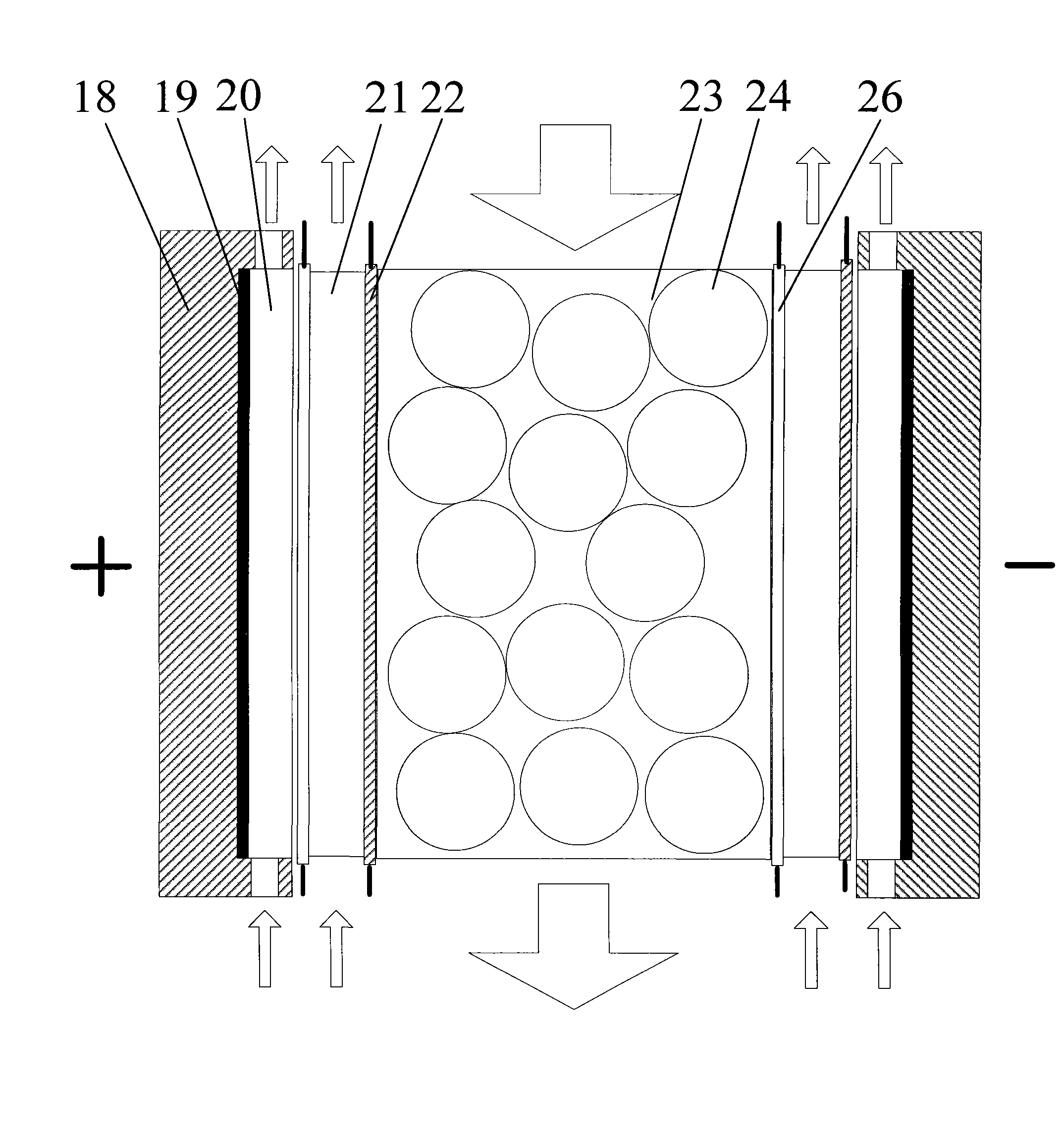

Electro-deionization method and electro-deionization device for recycling ammonia nitrogen waste water

ActiveCN101648738ASimple processReduce processing costsDispersed particle separationAmmonium salt preparationAmmoniacal nitrogenEnvironmental engineering

The invention discloses an electro-deionization method and an electro-deionization method for recycling ammonia nitrogen waste water, wherein the electro-deionization method comprises the following steps: a plurality of modules which are connected in series or in parallel are selected to form a set of electro-deionization device according to the water quantity of waste water to be processed and the mass concentration of ammonium salt of the waste water, wherein inlet water of the device is ammonia nitrogen waste water that is preprocessed and accordant with requirements, producing water is process pure water, does not contain nitrogen-containing compounds and can be recycled; in addition, ammonium salt thickening solution is obtained by a thick water circulated thickening method, and the mass concentration of the ammonium salt reaches an expected requirement of 1-25 percent; and the thickening solution is evaporated, concentrated and crystallized to obtain the solid ammonia nitrogen product. The invention not only can reach the zero emission requirement of the system, but also simultaneously recycle the ammonium salt thickening solution and the process pure water. The invention hasadvanced process, low cost, low energy consumption and simple operation.

Owner:王方

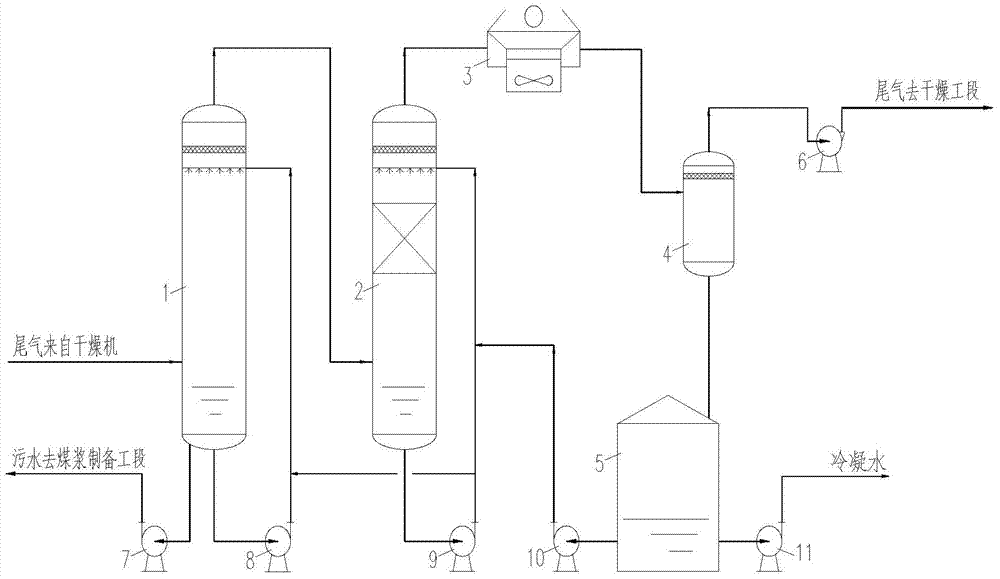

Method for recovering water from hot carrier gas for lignite drying

ActiveCN103537112ARecycled water is of good qualityLow running costUsing liquid separation agentVapor condensationGas phaseWater quality

The invention discloses a method for recovering water from hot carrier gas for lignite drying, which comprises the following steps: feeding drying hot carrier gas from a drying unit into a washing tower under the action of a blower, and performing two-stage heat-insulated washing; feeding the tail gas after washing into an air cooler, and indirectly cooling with environmental air; performing gas-liquid separation, feeding the liquid phase into a water recovery tank, and performing simple treatment to ensure that the liquid phase meets the water standard for industrial circulating water; and returning the gas phase to the drying unit for recycling through a circulating tail gas blower. The system disclosed by the invention has the characteristics of low operating cost, favorable quality of recovered water, high water recovery rate and the like.

Owner:EAST CHINA ENG SCI & TECH

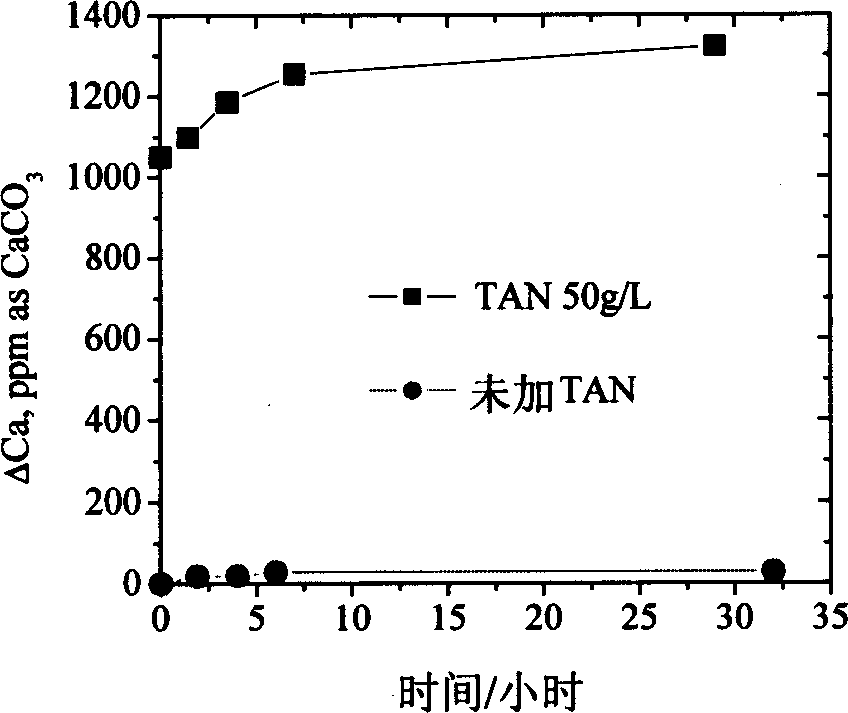

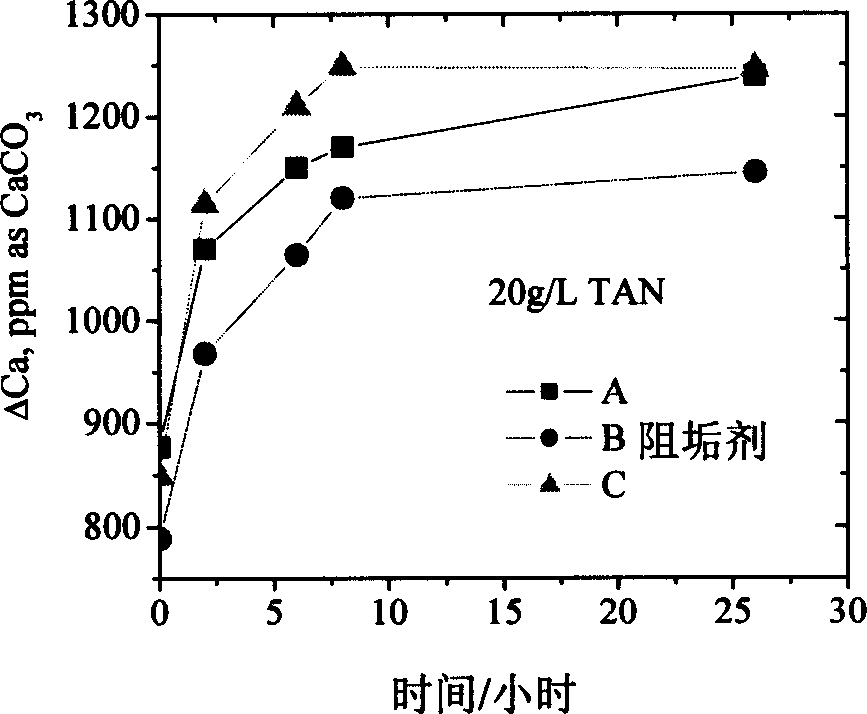

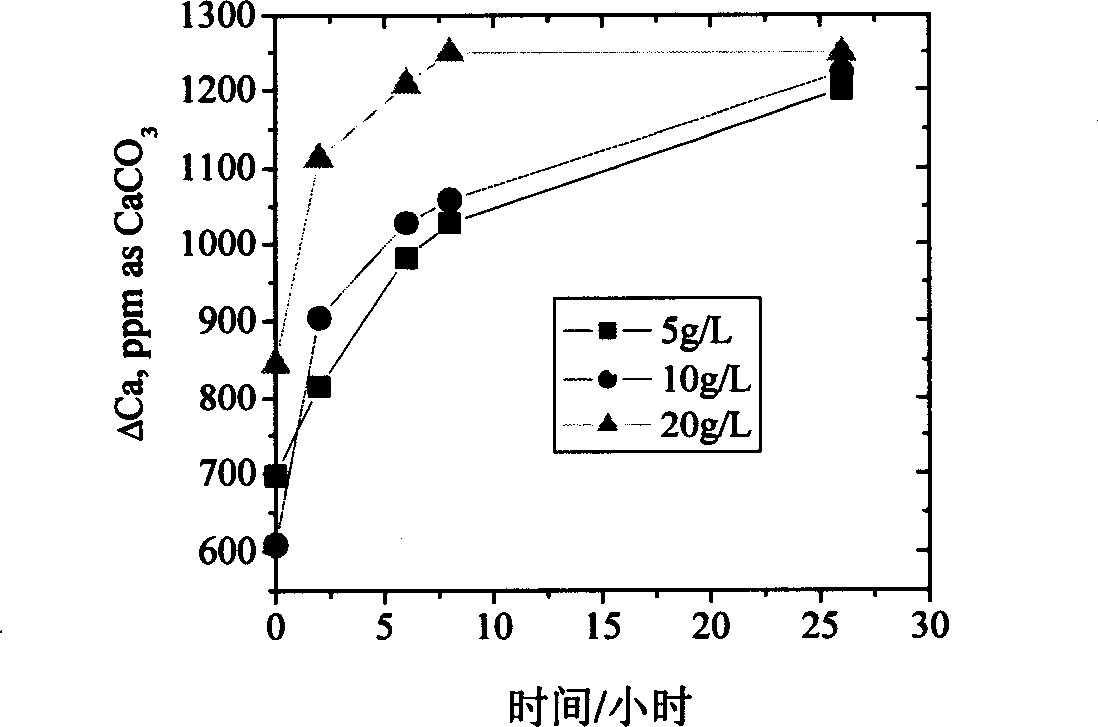

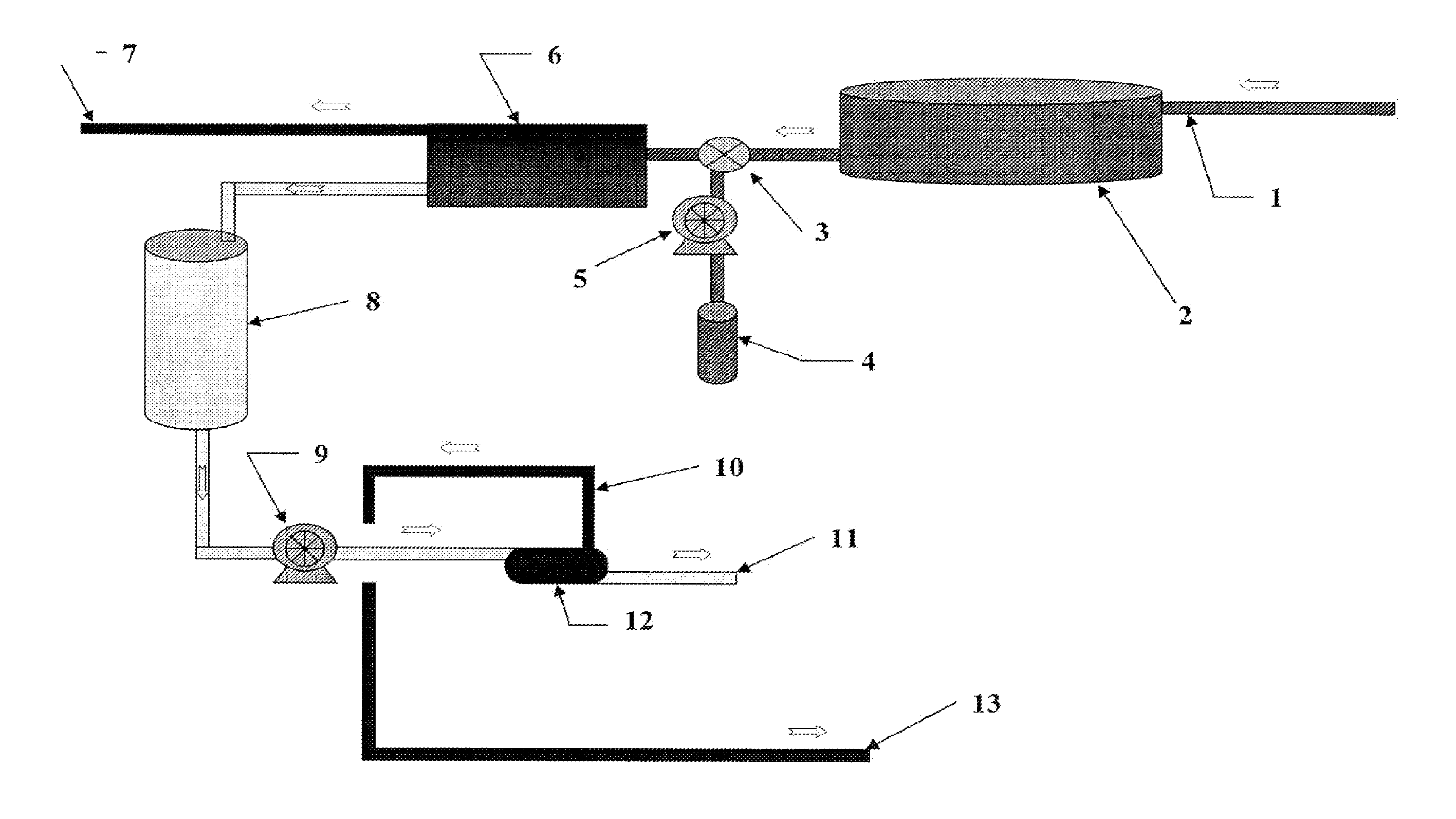

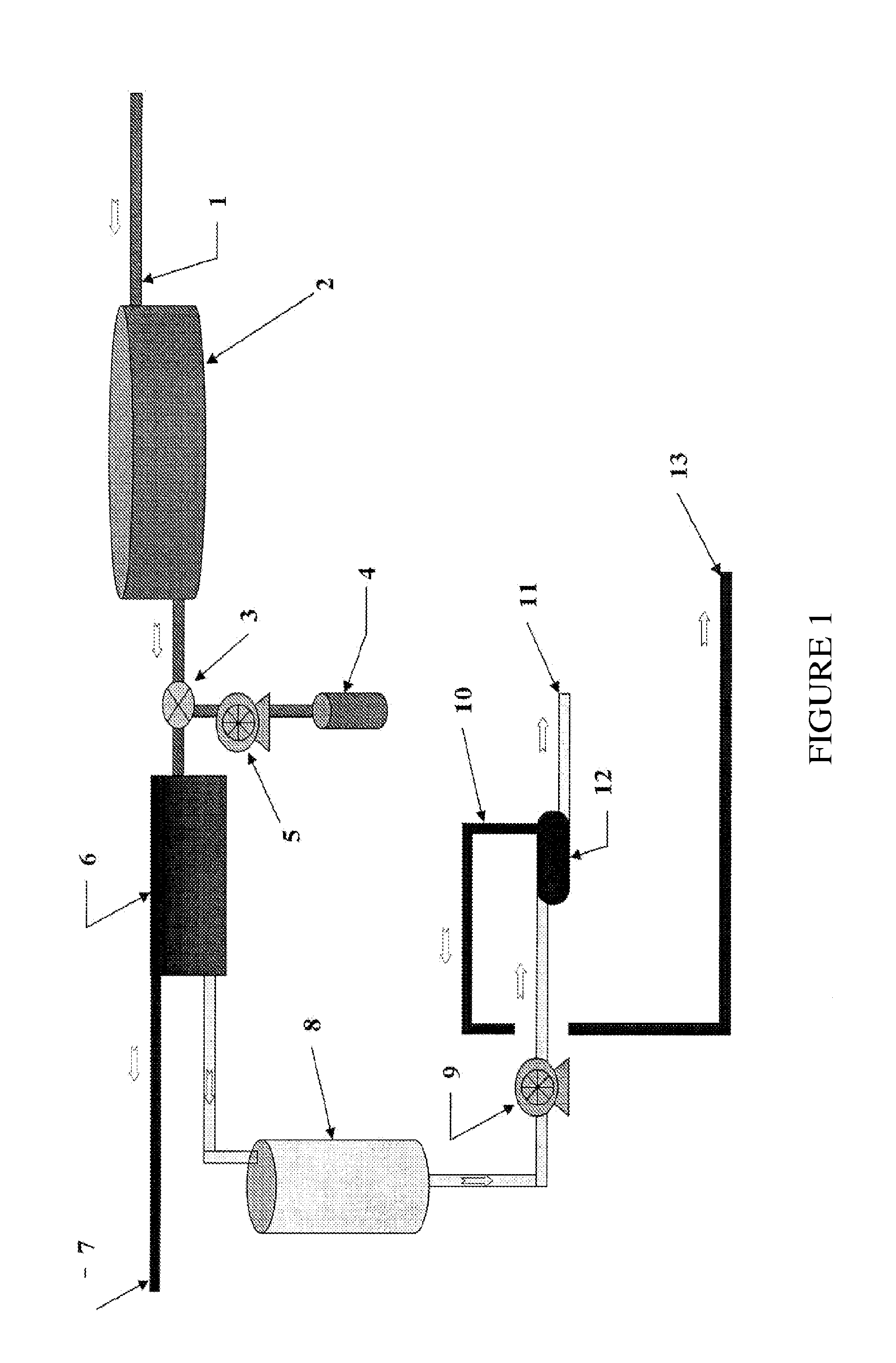

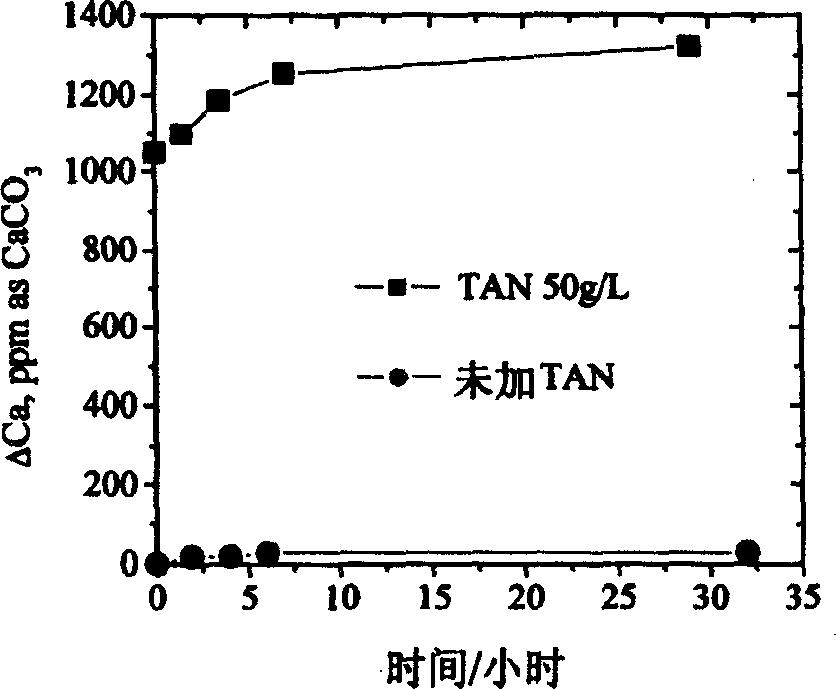

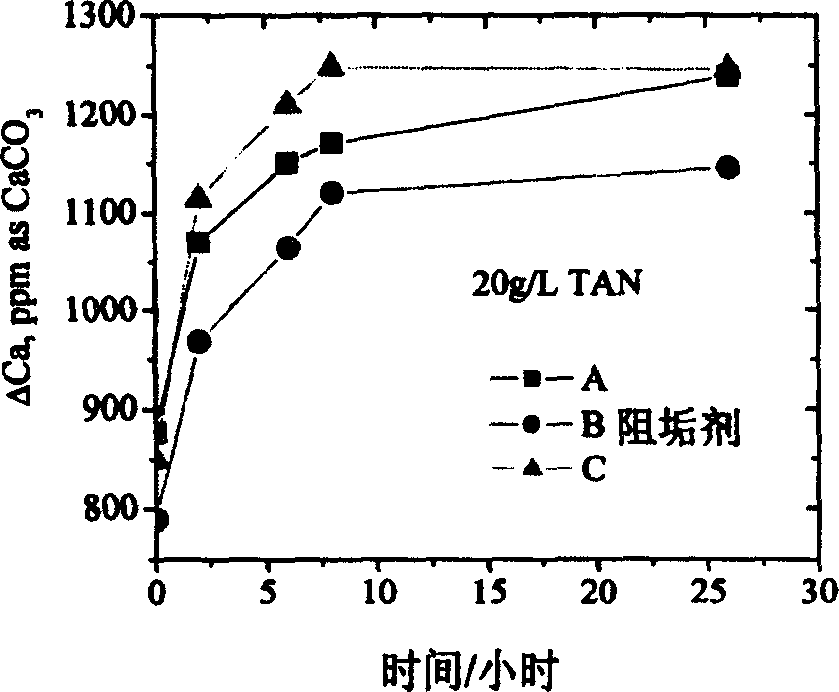

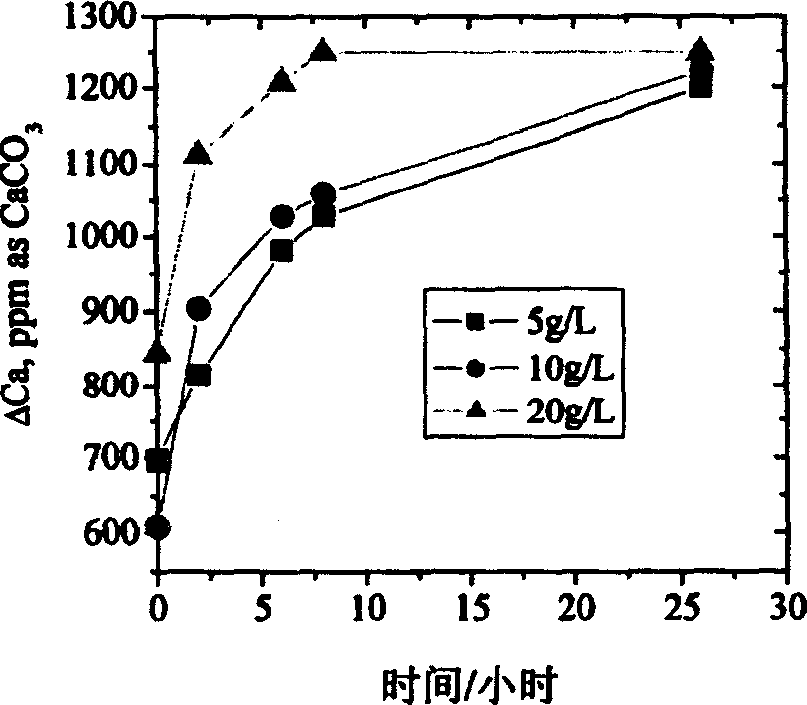

Inorganic inducing treatment for reverse osmosis concentrate

InactiveCN1636886ARealize resourcesHigh water recoveryWater/sewage treatment bu osmosis/dialysisWater/sewage treatment by flocculation/precipitationHazardous substanceReverse osmosis

During inorganic inducing treatment of reverse osmosis concentrate, dolomite with CaMg(CO3)2 as main component is used as inorganic inducing agent TAN to treat the reverse osmosis concentrate containing universal antiscale. The inorganic inducing agent reacts with Ca2+, Mg2+ and HCO3- ion to make the high saturated scaling ion deposit out; then aluminum sulfate is added through stirring to coagulate; and the solution is filtered and deposited to obtain treated reverse osmosis concentrate. The inorganic inducing agent is cheap and non-toxic, the treating process is low in cost and environment friendly, and the treated concentrate may be reused as useful resource to raise the water recovering rate of reverse osmosis system.

Owner:SHANGHAI JIAO TONG UNIV

Method for treatment of salt-containing wastewater by forward osmosis membrane distillation

ActiveCN110627284AReduce energy consumptionHigh water recoveryWater contaminantsMultistage water/sewage treatmentChemistryDistillation

Belonging to the field of chemical wastewater treatment, the invention relates to a method for treatment of salt-containing wastewater, in particular to a method for treatment of salt-containing wastewater by forward osmosis membrane distillation. The method utilizes high-salt concentration water generated by membrane distillation as a draw solution in forward osmosis, combines forward osmosis andmembrane distillation, recycles water resources and salt at the same time, and realizes regeneration of the draw solution in the forward osmosis process. The method provided by the invention can recycle water resources and salt in the high-salt wastewater while treating high-salt wastewater, the two processes are carried out simultaneously, and promote each other. The technical scheme provided bythe invention can be applied to treatment of high-salt wastewater and the like to realize zero-pollution emission and resource recycling.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

High recovery drinking water process

ActiveUS9199866B2High water recoveryEliminate needIon-exchanger regenerationOrganic anion exchangersReverse osmosisIon exchange

Disclosed is a process that uses reverse osmosis (RO) or nanofiltration (NF) membranes and ion exchange (IX) water softening resins to maximize the production of drinking water, purified industrial service water or recycled purified municipal or industrial effluents. The membrane and ion exchange units are configured in a manner that enables operation of the system at high permeate recoveries in the range 90% to 99%, thus producing purified drinking water with a minimum volume of wastewater to drains and a very low membrane cleaning or membrane replacement frequency. The process mitigates membrane fouling and scale formation and minimizes the use of water treatment chemicals including acidic and alkali solutions and sodium chloride salt that is normally required to regenerate the IX resin.

Owner:AL SAMADI RIAD A

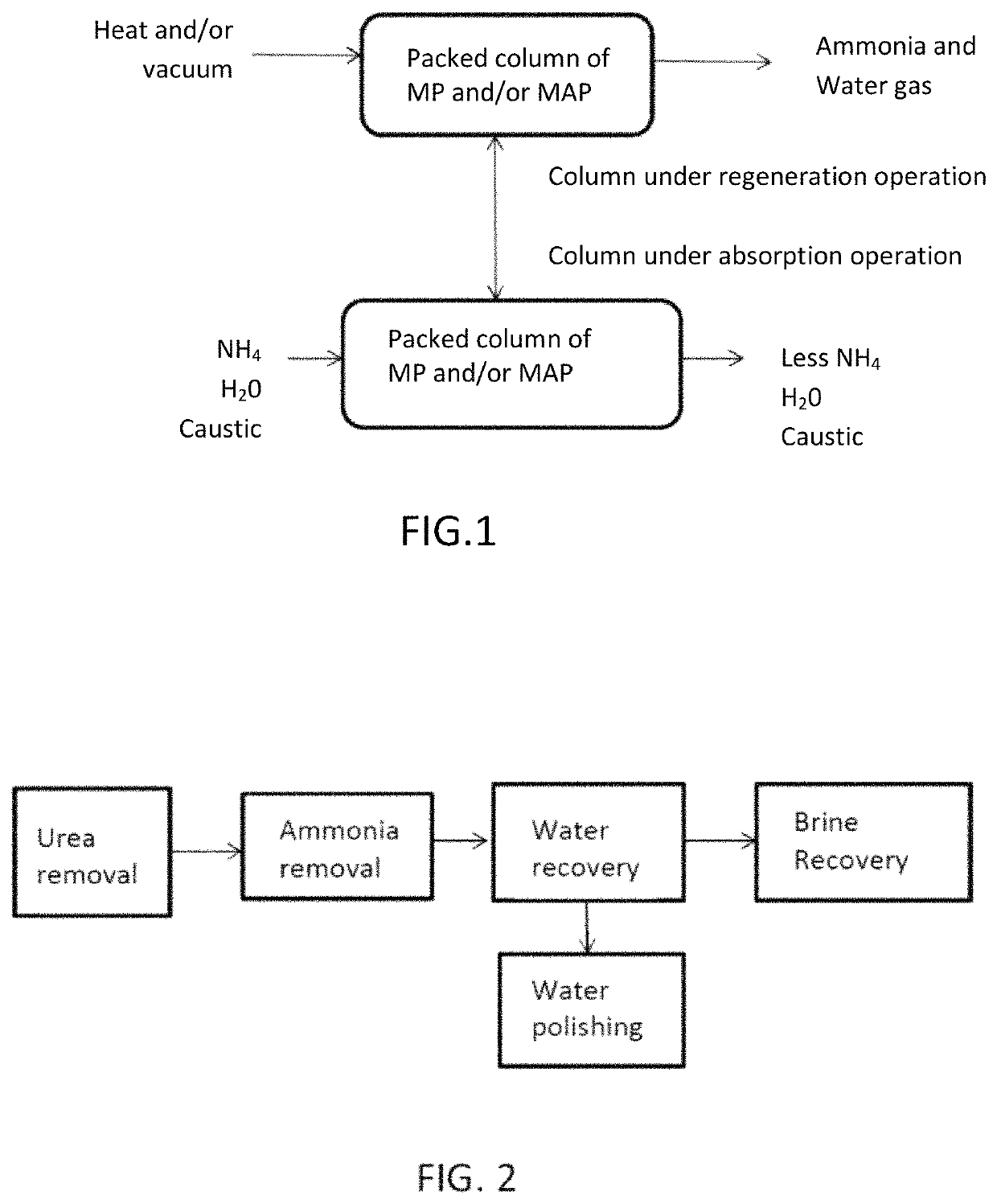

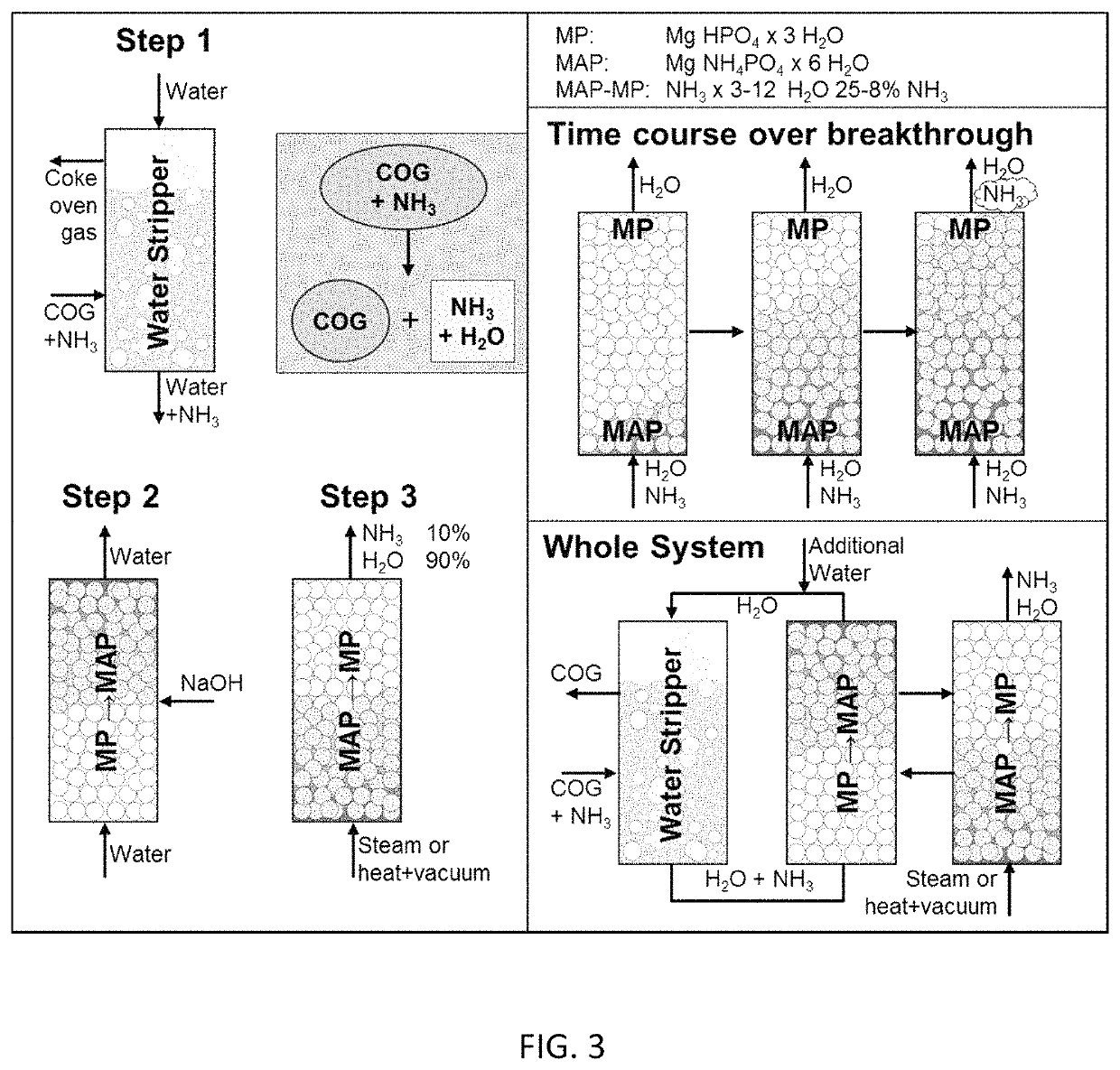

Ammonia capture and recovery system and method for removing ammonia from a wastewater stream

ActiveUS10676374B1Reduce system complexityEasy to controlWater treatment parameter controlSpecific water treatment objectivesMagnesium phosphateMagnesium orthophosphate

A wastewater stream including ammonia and water is fed to at least one packed column including packing material having a surface of solid magnesium phosphate or solid magnesium ammonium phosphate or both. Each of the packed columns is capable of cycling between an ammonia absorption operation and an ammonia regeneration operation. The magnesium phosphate compound reacts with the water and ammonia to form a magnesium ammonium phosphate compound. In one embodiment, this system provides for the regeneration of the magnesium ammonium phosphate compound for further use as an ammonia sorber. In another embodiment, the magnesium ammonium phosphate compound is used as fertilizer. Additionally, the ammonia capture and recovery system may be used in conjunction with other unit operations in an overall wastewater treatment system.

Owner:NASA

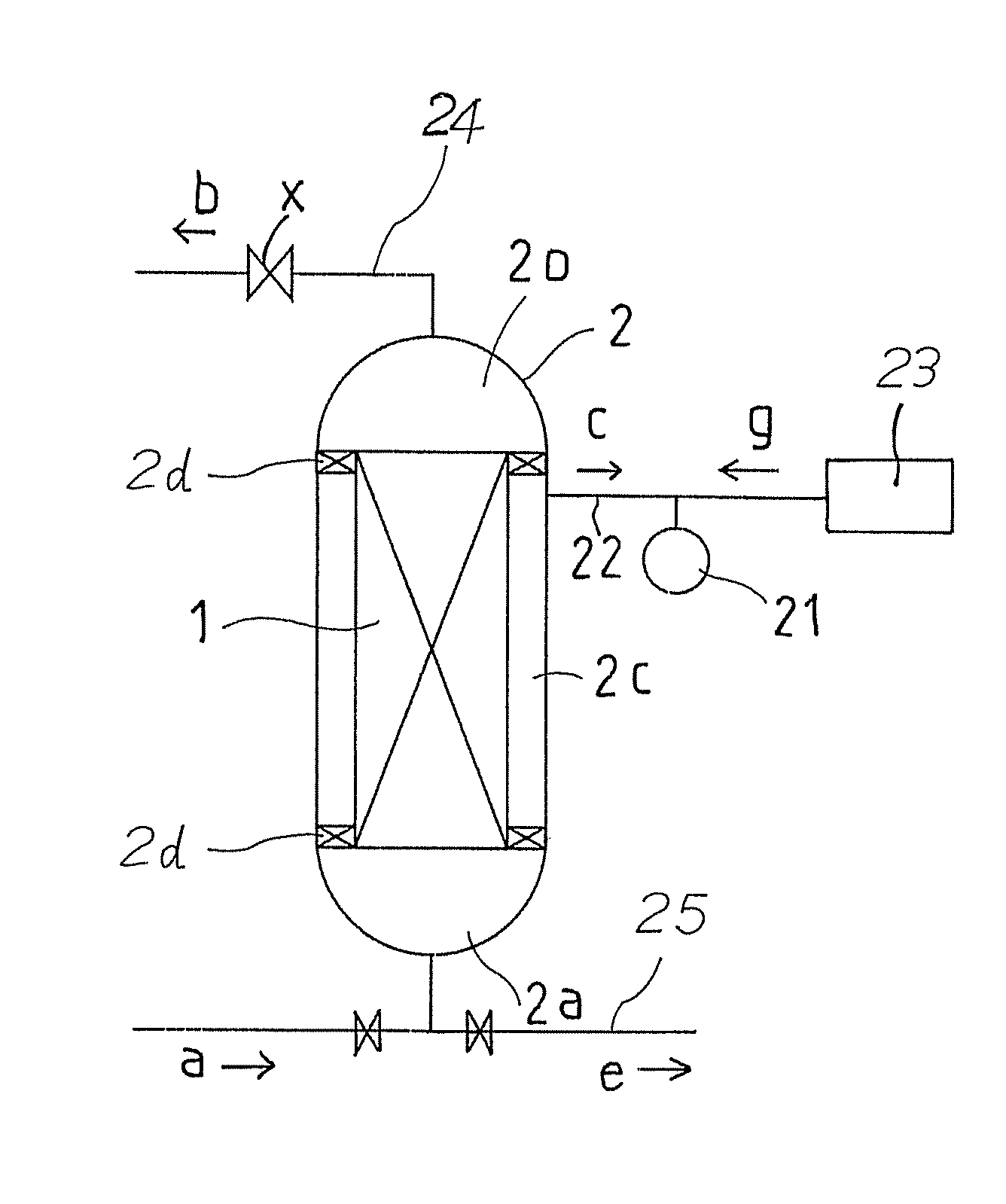

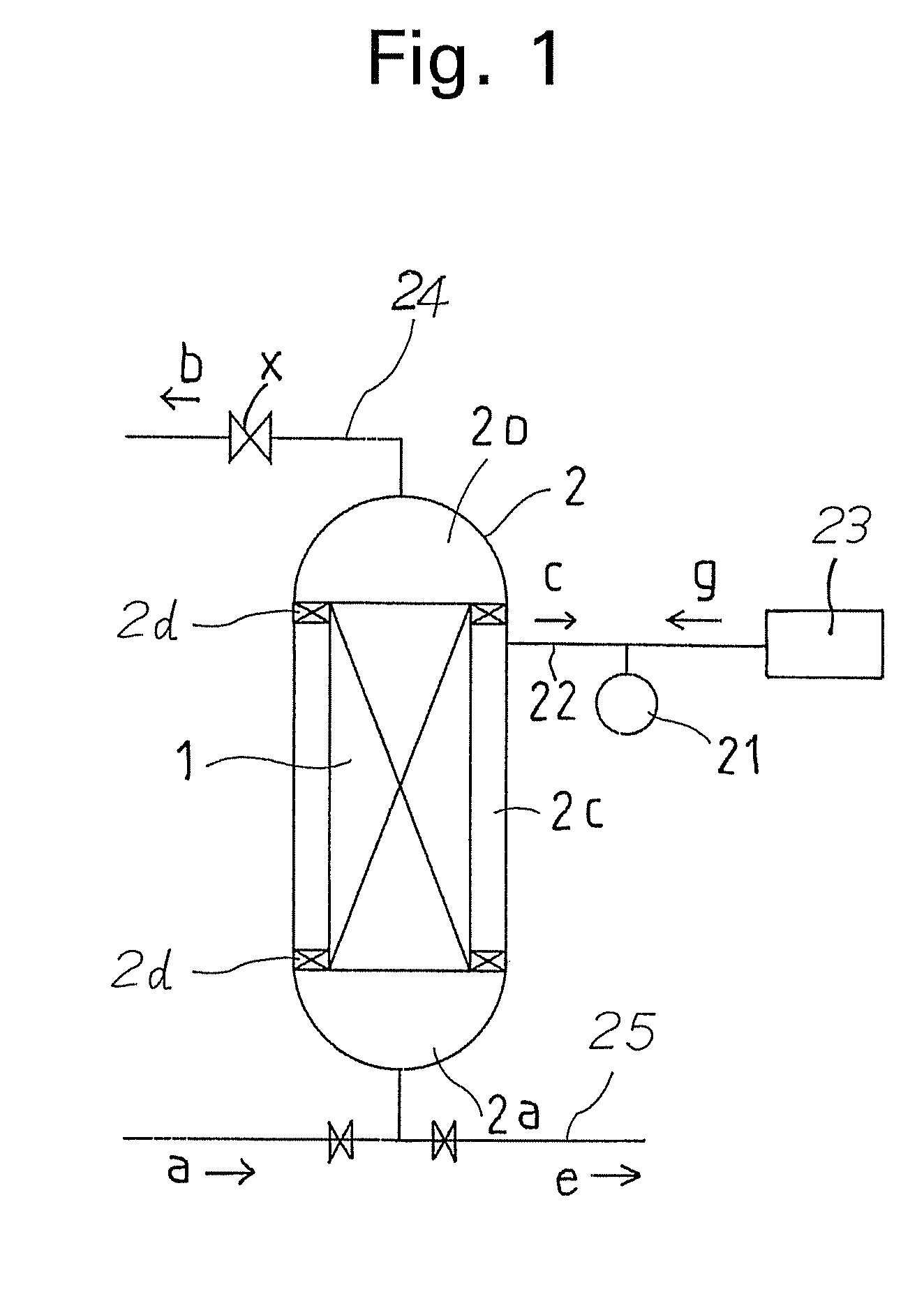

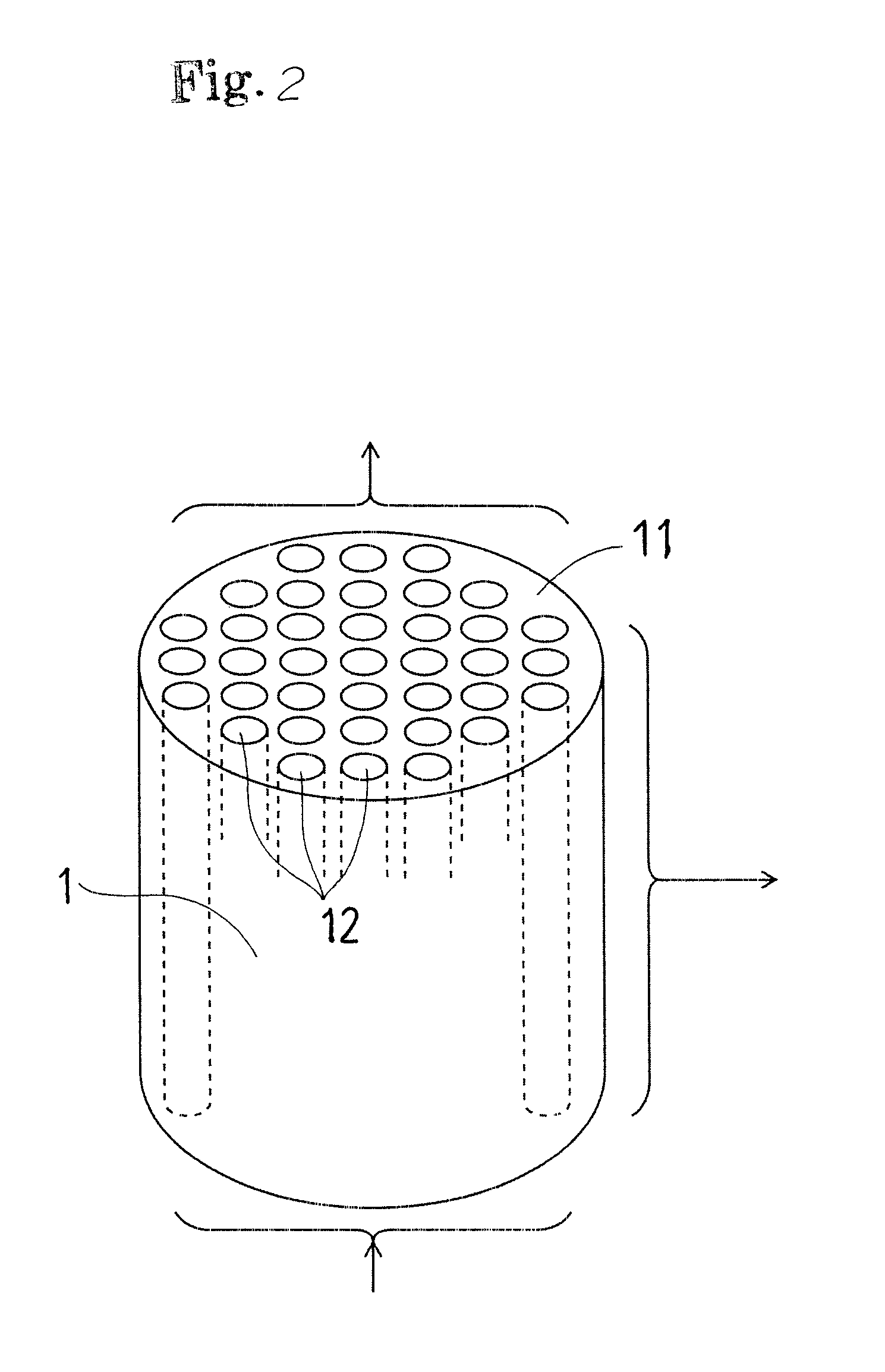

Method for membrane backwashing and backwashing apparatus

ActiveUS8641904B2Increase flexibilityReduced effectivenessSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisBasal laminaFiltration membrane

A backwashing method incorporating a membrane filtration apparatus in which a ceramic filtration membrane including a substrate layer 11b having an extremely large number of filtration pores and a separating layer 11a having filtration pores smaller than those of the substrate layer is accommodated in a casing. Air controlled to a pressure p1 is supplied to the secondary side of the filtration membrane so as to drain the filtrated water in the membrane filtration apparatus gradually toward the primary side. After that, air pressure is increased to p3 so as to push the water in the filtration membrane toward the primary side together with the air, thereby peeling off any fouling substances. Unlike in conventional cases, a large amount of backwashing drain water is at no time drained at any one time, and thus, without reducing the effectiveness of backwashing, a backwashing drain pipe can be designed to have a small diameter. As a result, equipment can be reduced in size and the flexibility of equipment can be enhanced.

Owner:METAWATER CO LTD

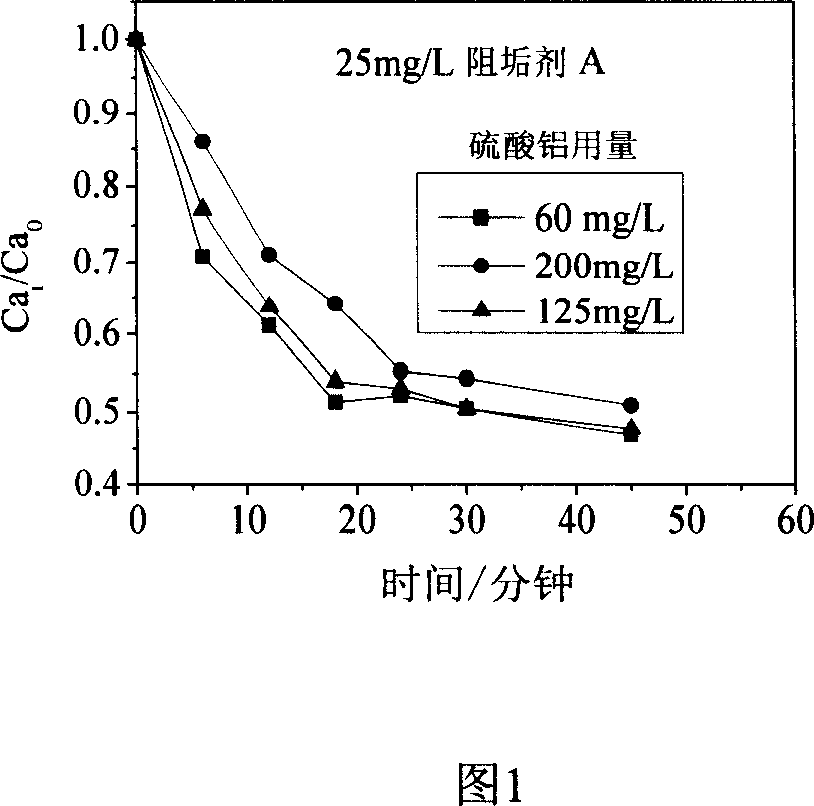

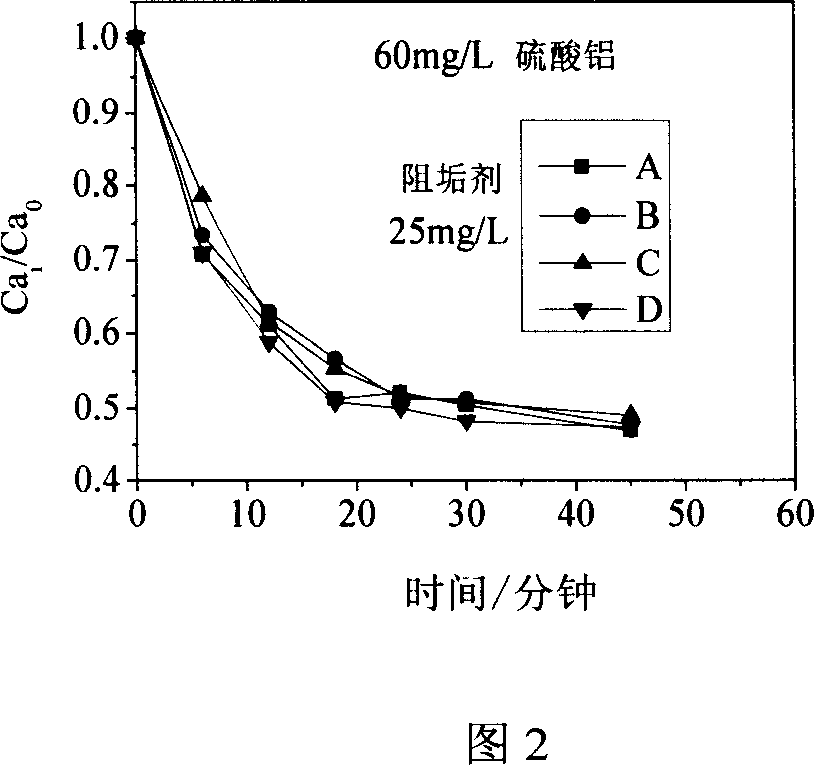

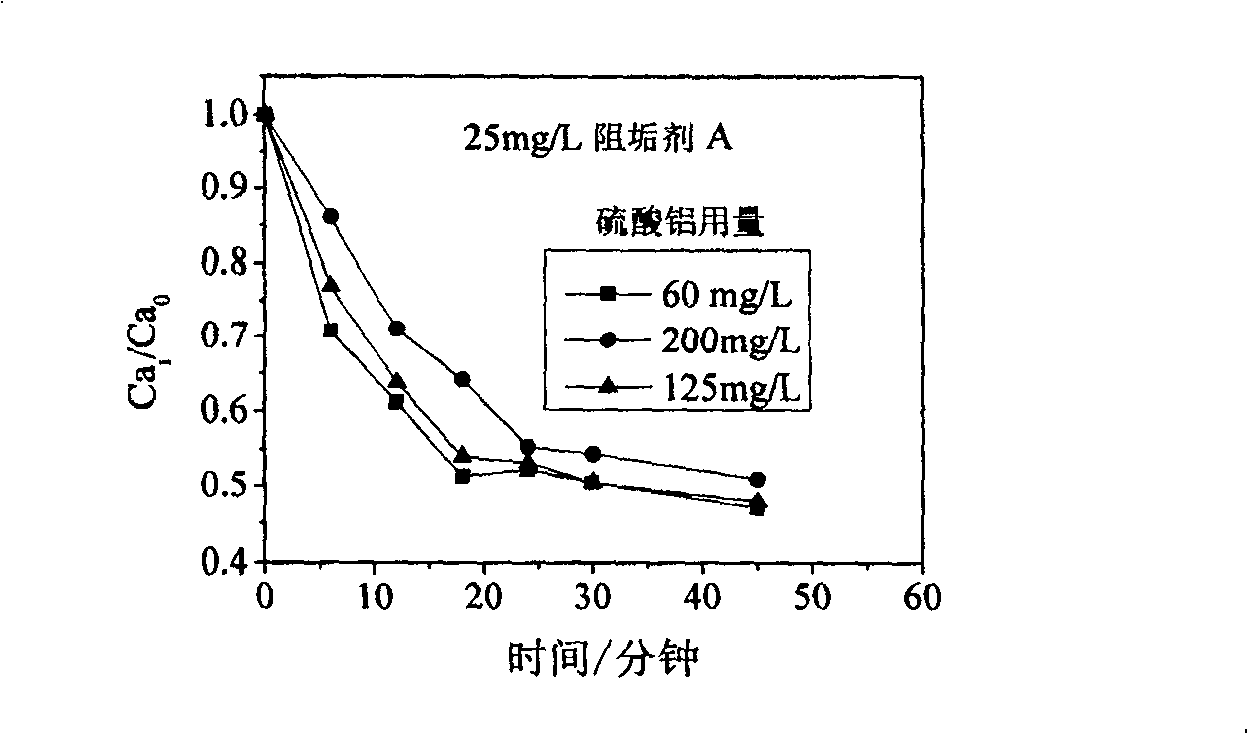

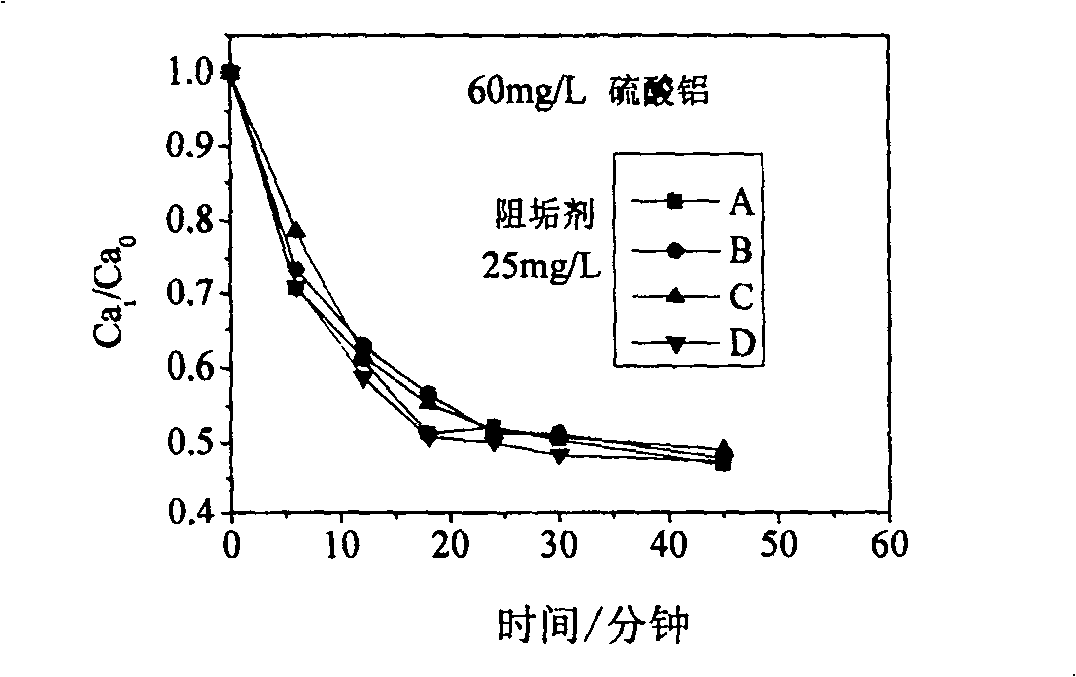

Coagulating removing method of calcium sulfate fouling in reverse osmosis concentrated liquid

InactiveCN1927734ARealize resourcesHigh water recoveryWater/sewage treatment bu osmosis/dialysisTreatment using complexing/solubilising chemicalsAluminium sulfateHazardous substance

The present invention relates to waste water treating technology, and is especially the method of eliminating scaled calcium sulfate salt in reverse osmosis concentrate. Coagulant capable of coagulating the nanometer particle formed by scaling ions Ca2+ and SO42- in the concentrate is used in treating the reverse osmosis concentrate to deposit oversaturated scaling ions. The deposit is then eliminated through filtering, and the concentrate with less scaling may be reused in the reverse osmosis, reaching raised water recovering rate of the reverse osmosis system. The present invention has aluminum sulfate used as the coagulant, low treating cost, environment friendship and raised water recovering rate.

Owner:浙江凯锐环保股份有限公司

Bicarbonate conversion assisted ro treatment system for natural gas flowback water

InactiveUS20140091040A1High water recoverySpeed up the processSemi-permeable membranesMembranesSodium bicarbonateReverse osmosis

Bicarbonate conversion assisted reverse-osmosis (RO) treatment systems for treatment of contaminated water, particularly natural gas flowback water. The systems and processes provide for simultaneous conversion of the primary salt in gas production flowback waters from sodium bicarbonate to sodium sulfate, and flotation removal of organic contaminants, for the enhanced water recovery by RO of these waters. In the systems and processes, RO processes are enhanced by lowering the osmotic potential of the water being processed, by converting the bicarbonate ions to sulfate ions.

Owner:HYDRATION SYST

Inorganic inducing treatment for reverse osmosis concentrate

InactiveCN1275882CRealize resourcesHigh water recoveryWater softeningWater/sewage treatment bu osmosis/dialysisHazardous substanceReverse osmosis

Owner:SHANGHAI JIAOTONG UNIV

Coagulating removing method of calcium sulfate fouling in reverse osmosis concentrated liquid

InactiveCN100415659CRealize resourcesHigh water recoveryWater/sewage treatment bu osmosis/dialysisTreatment using complexing/solubilising chemicalsAluminium sulfateHazardous substance

The present invention relates to waste water treating technology, and is especially the method of eliminating scaled calcium sulfate salt in reverse osmosis concentrate. Coagulant capable of coagulating the nanometer particle formed by scaling ions Ca2+ and SO42- in the concentrate is used in treating the reverse osmosis concentrate to deposit oversaturated scaling ions. The deposit is then eliminated through filtering, and the concentrate with less scaling may be reused in the reverse osmosis, reaching raised water recovering rate of the reverse osmosis system. The present invention has aluminum sulfate used as the coagulant, low treating cost, environment friendship and raised water recovering rate.

Owner:浙江凯锐环保股份有限公司

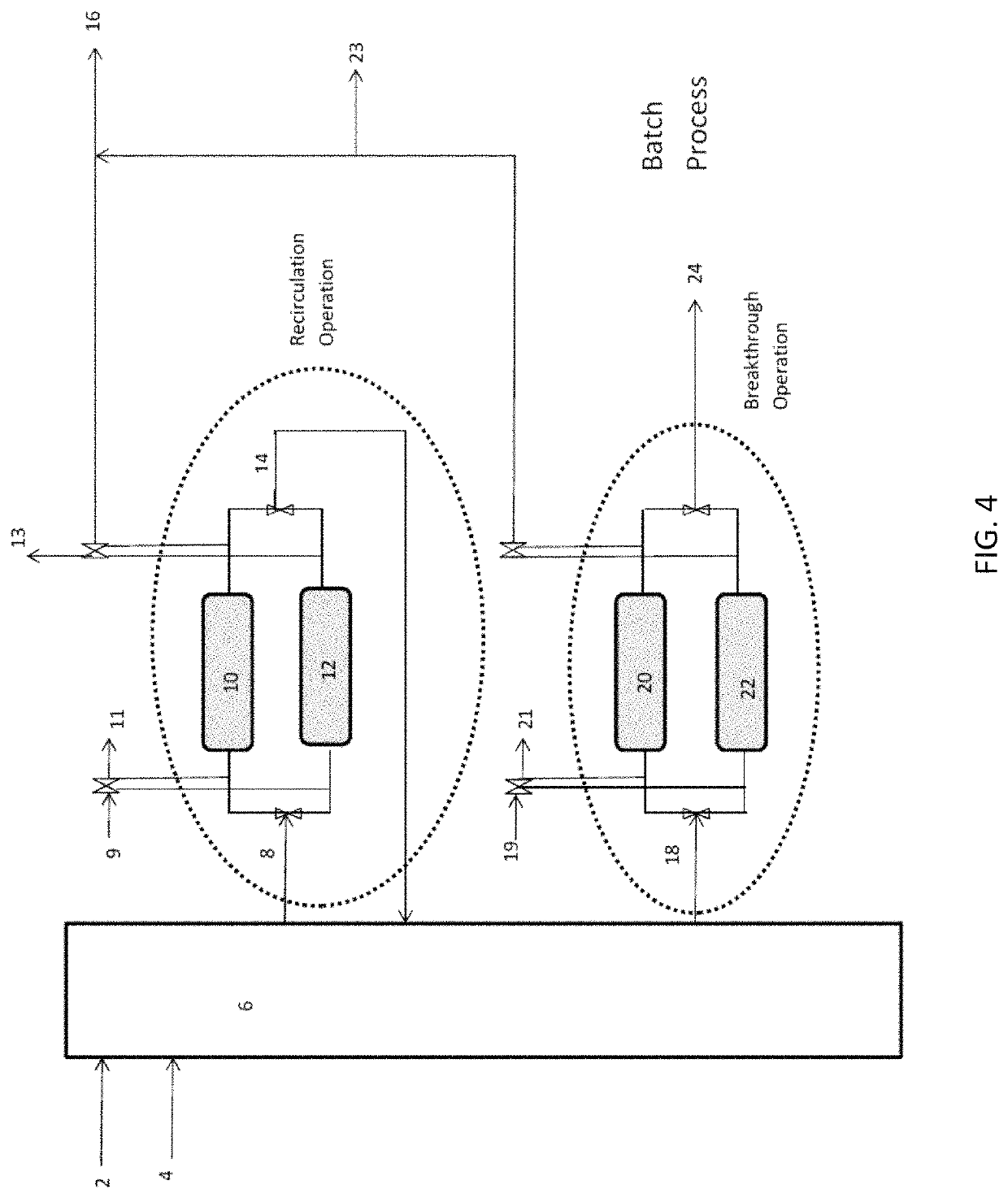

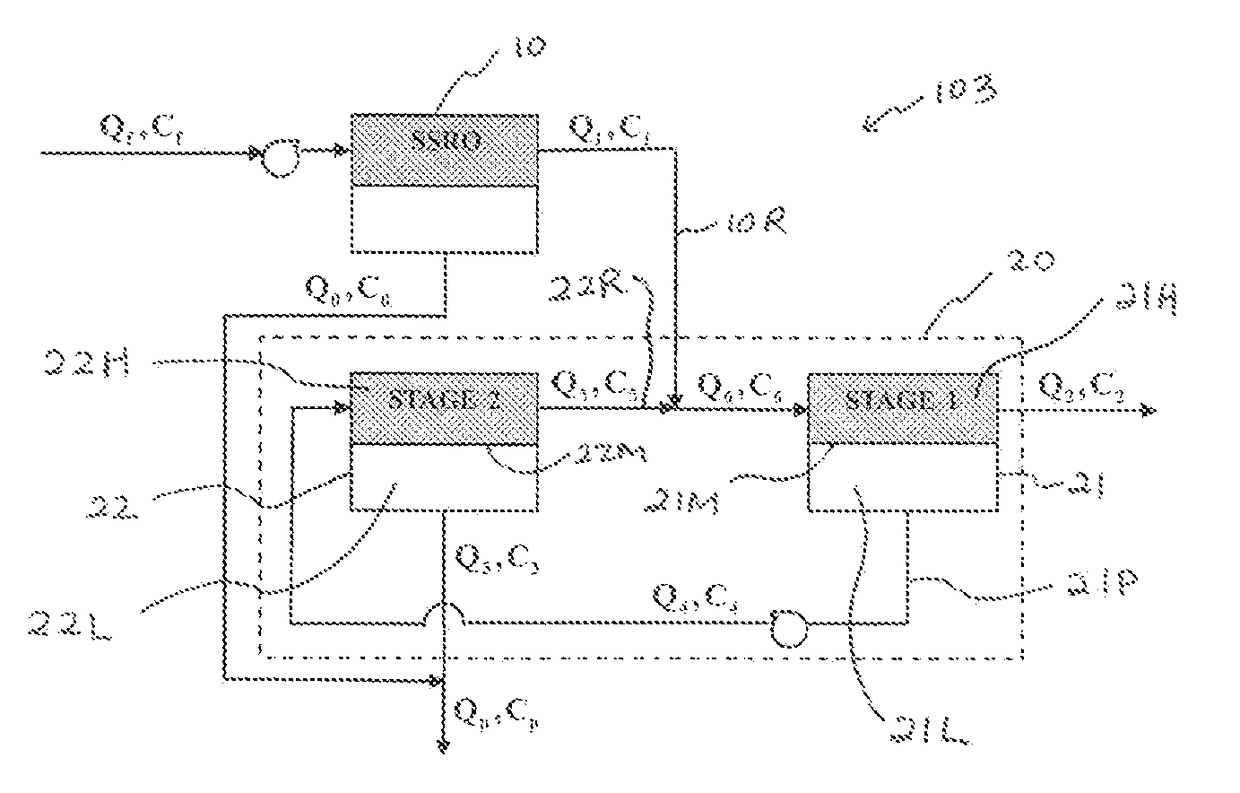

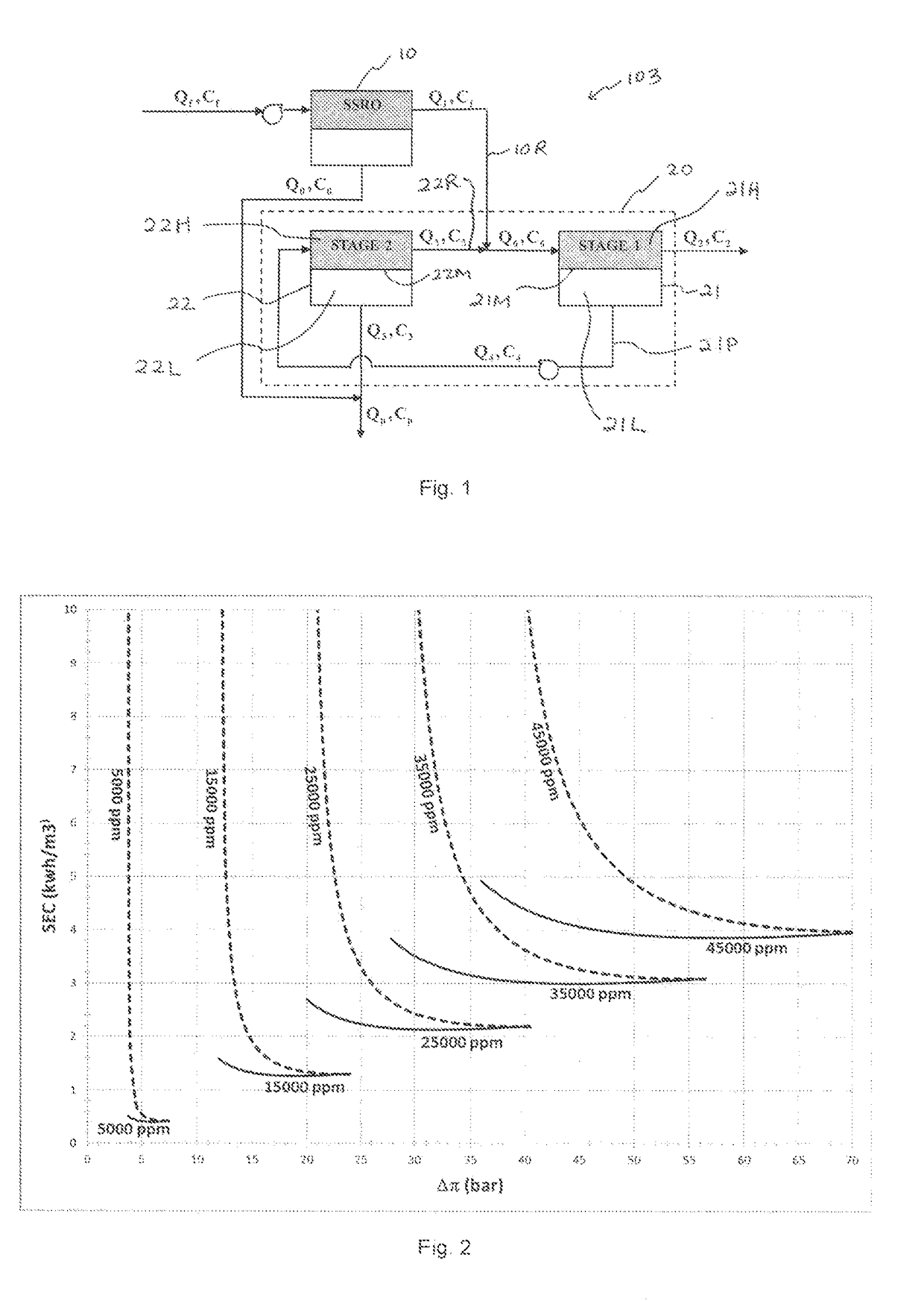

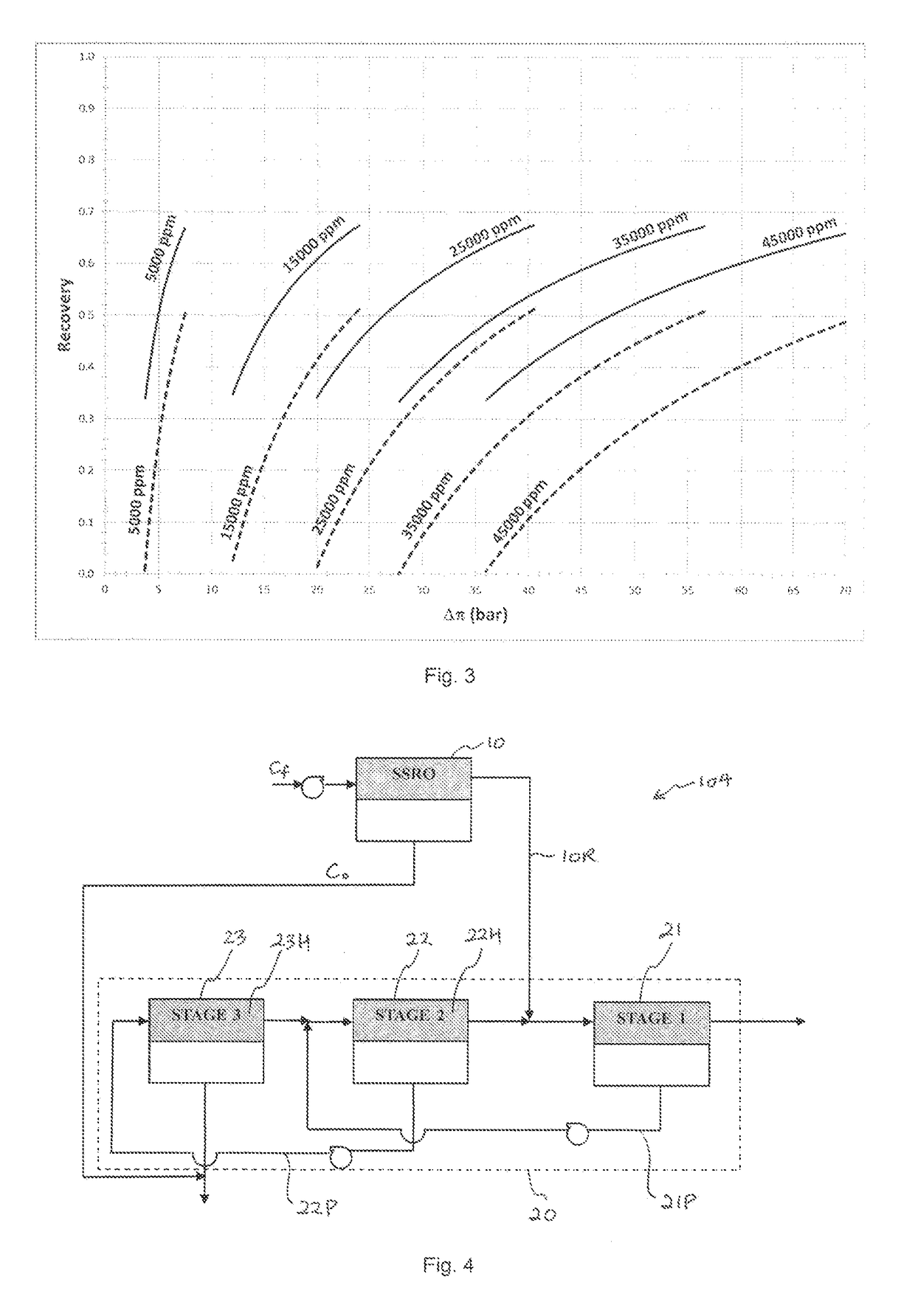

Apparatus and method for reverse osmosis

ActiveUS20180243694A1High product recovery rateReduce energy consumptionMembranesGeneral water supply conservationSingle stageReverse osmosis

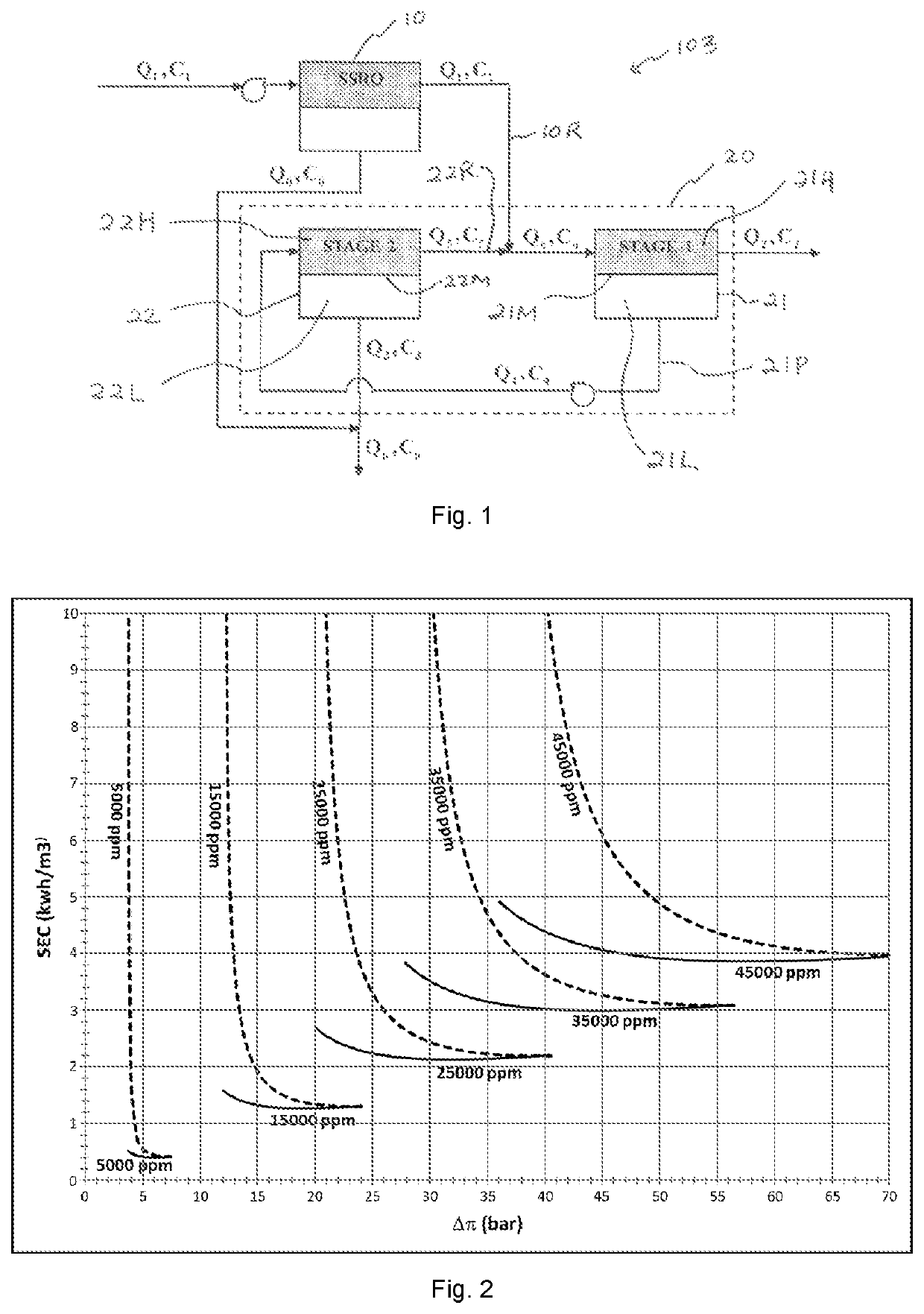

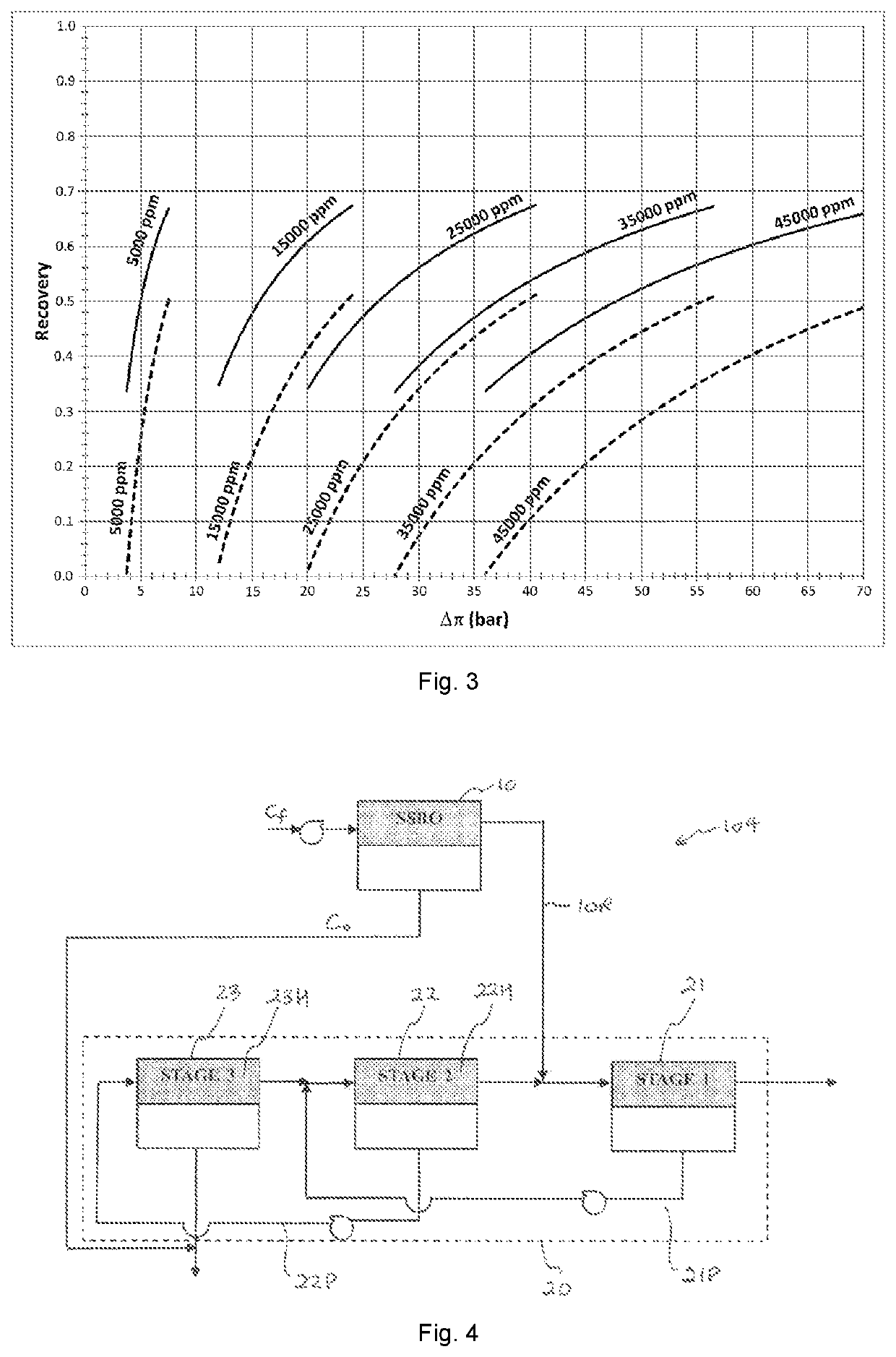

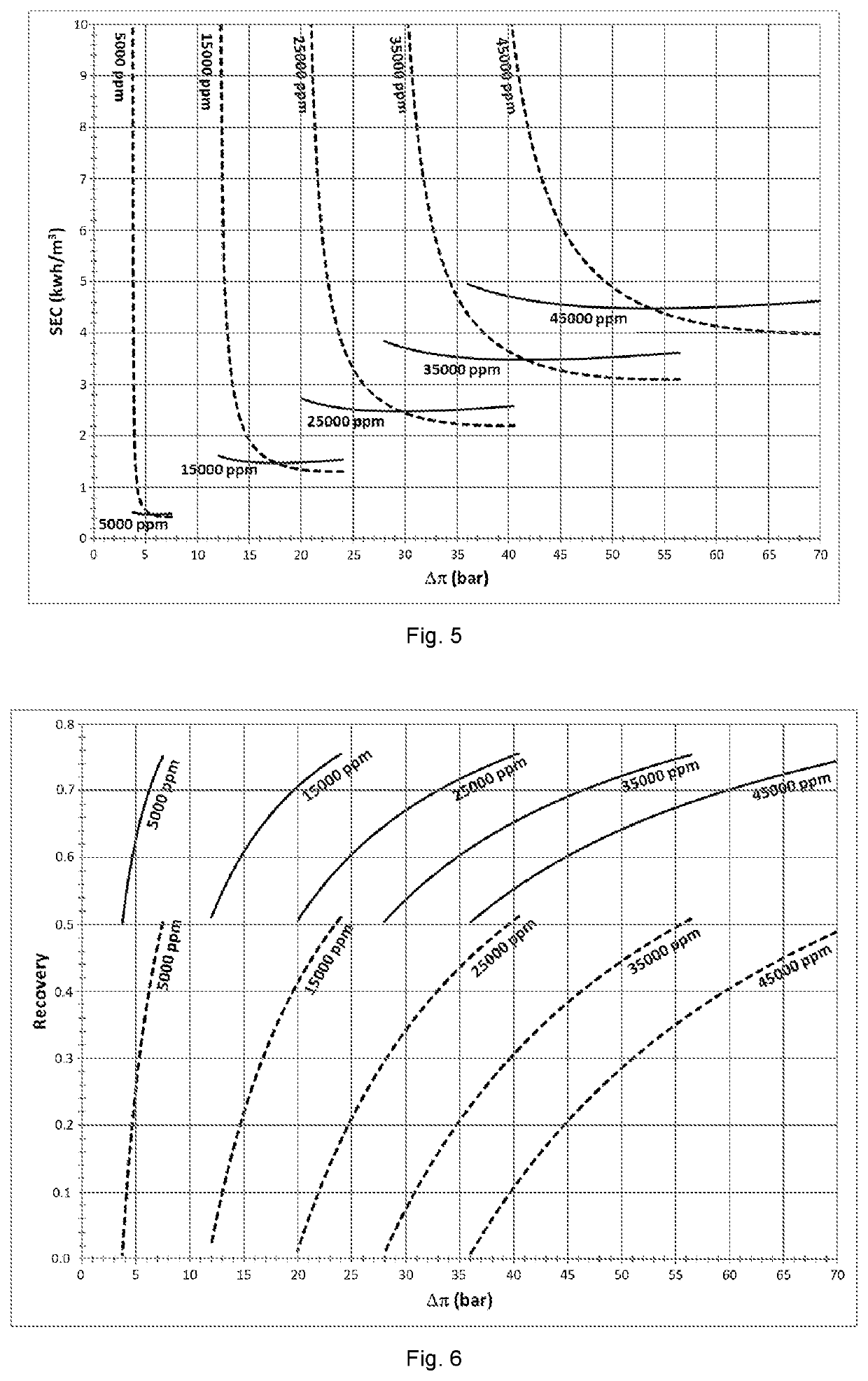

An apparatus for reverse osmosis, the apparatus comprising: a single-stage reverse osmosis (SSRO) unit; and a counter-current membrane cascade with recycle (CMCR) unit comprising a plurality of stages of reverse osmosis including at least a first stage and a second stage wherein permeate from the first stage is configured to be introduced as feed to the second stage; wherein retenate from the SSRO unit is configured to be introduced as feed to the first stage, and wherein product obtained using the apparatus comprises permeate from the SSRO unit and permeate from a last stage of the CMCR unit.

Owner:NANYANG TECH UNIV

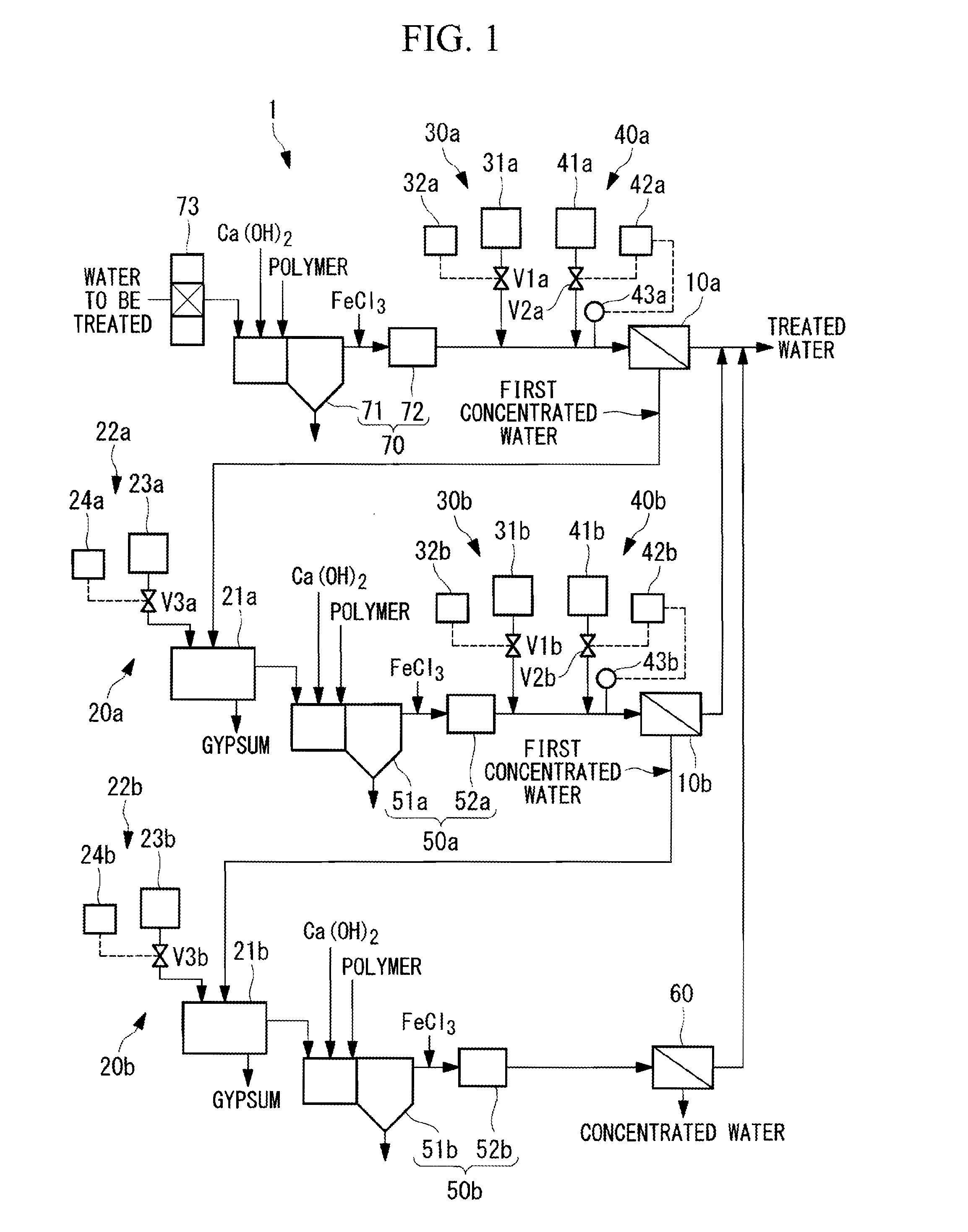

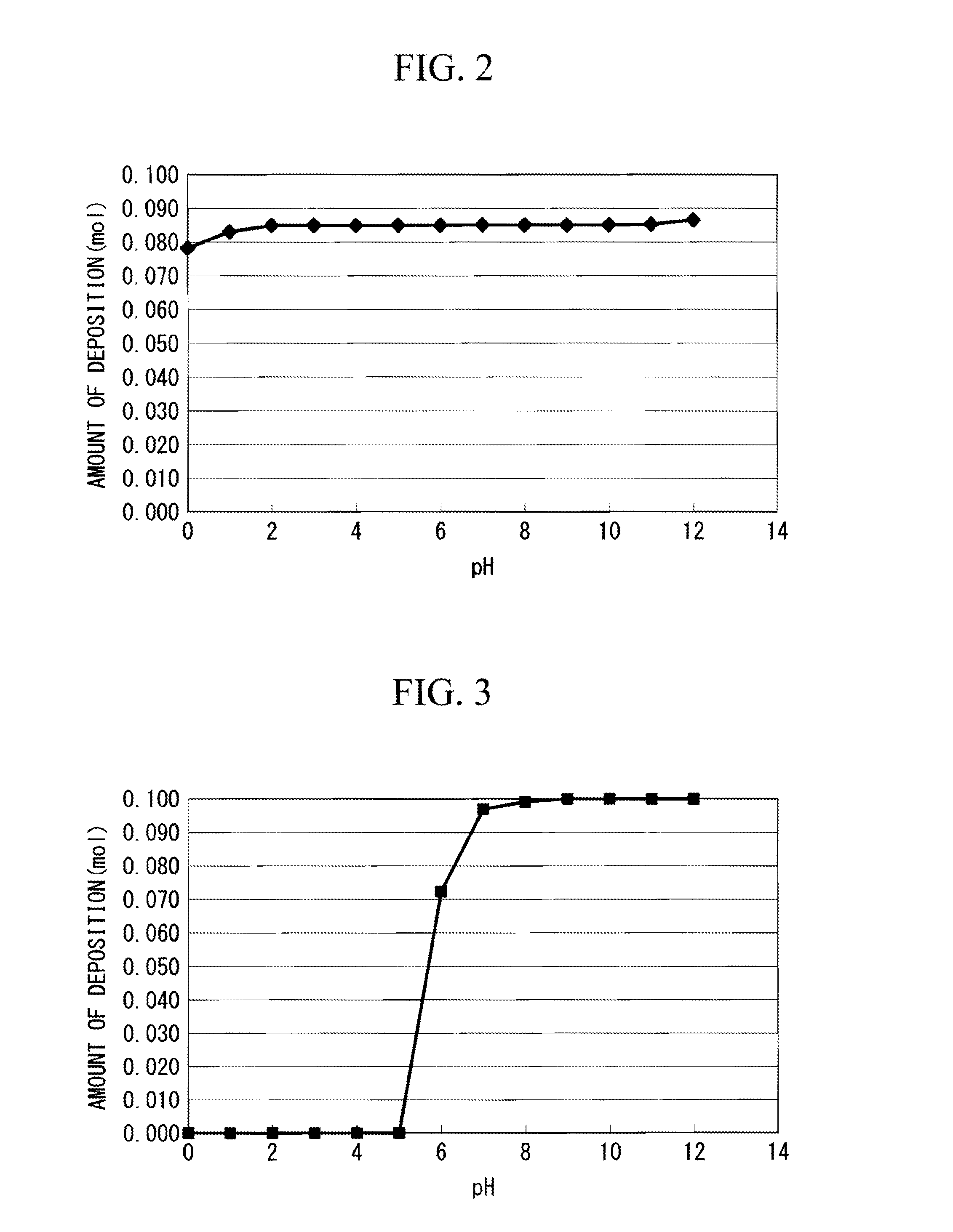

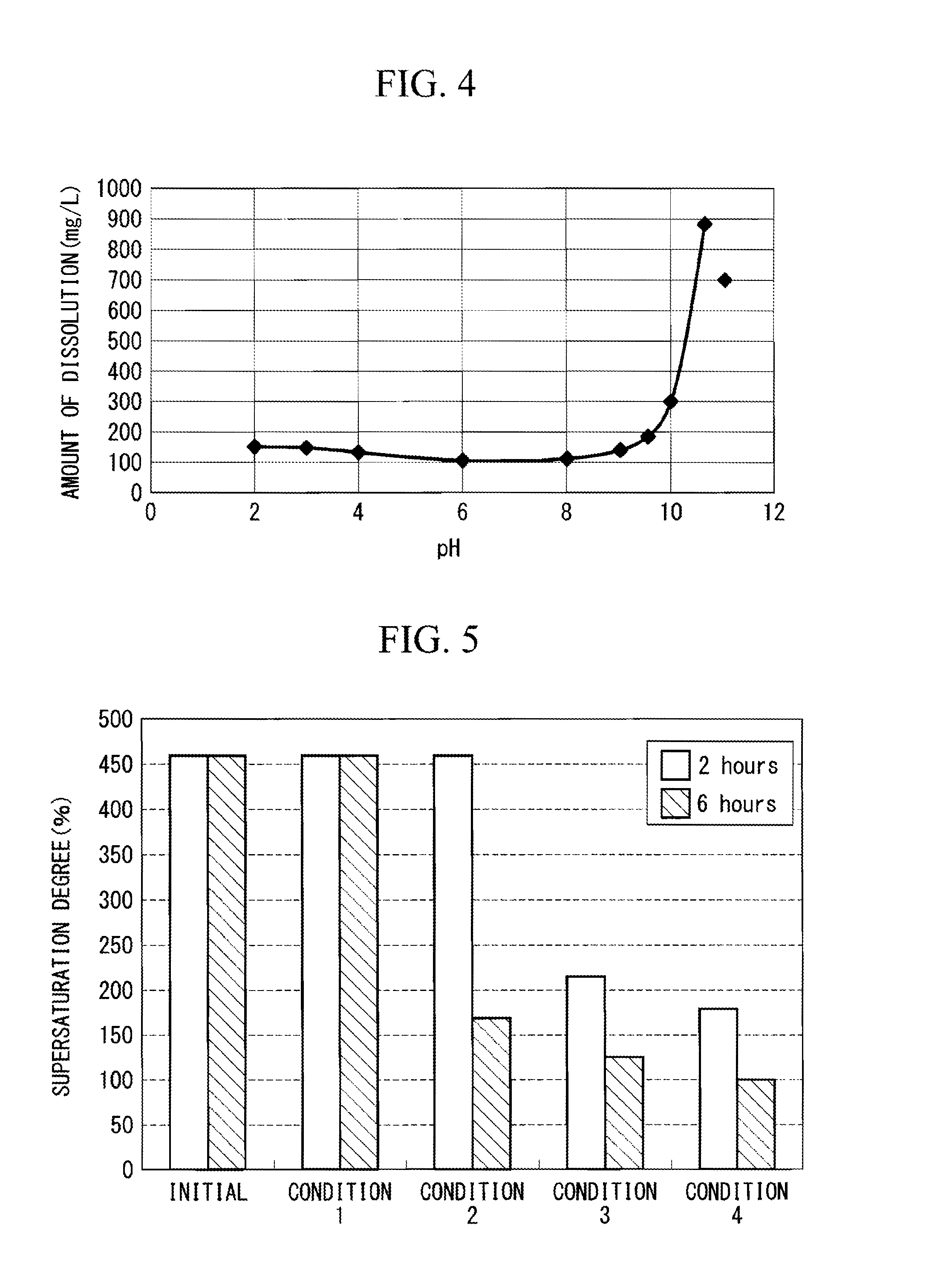

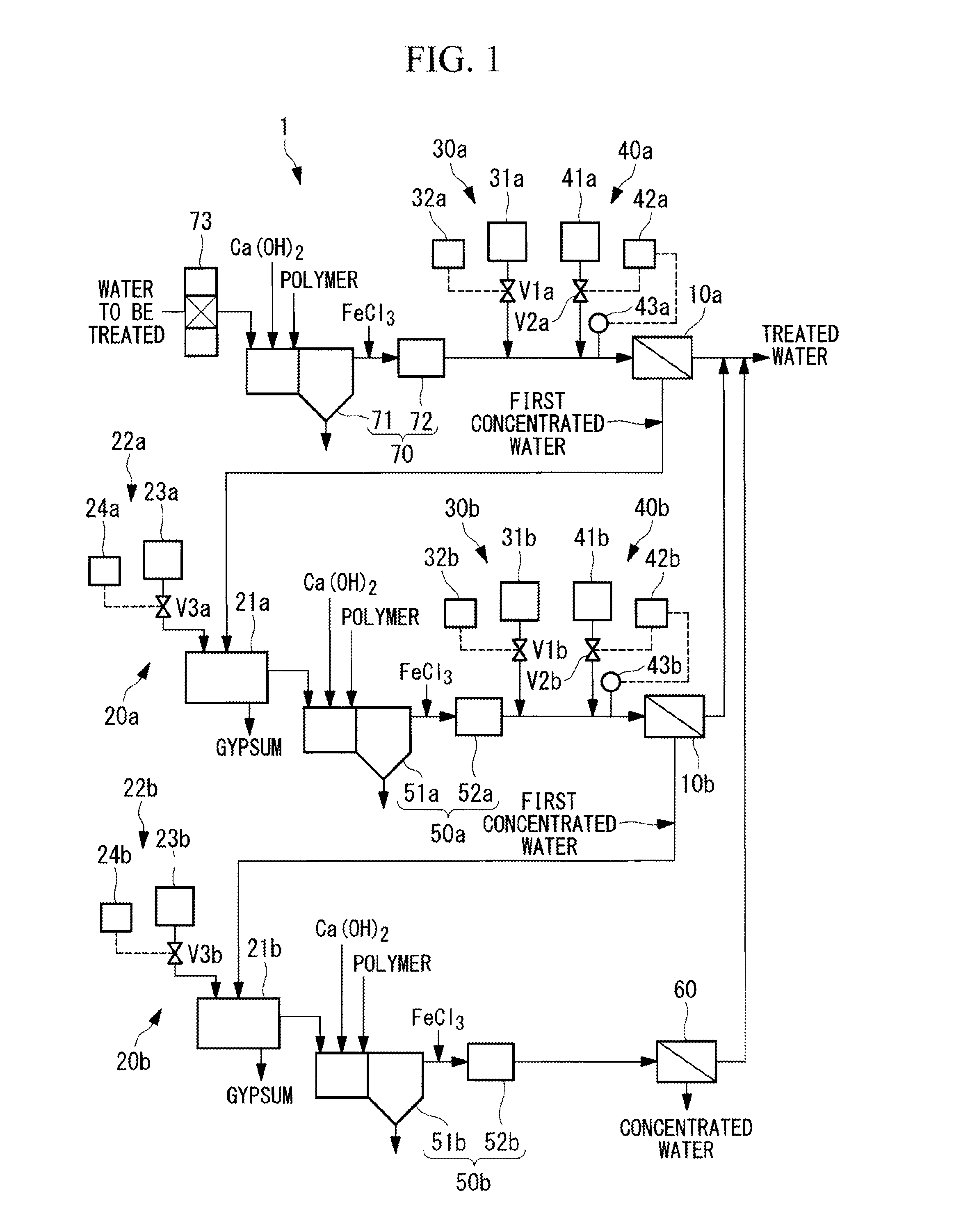

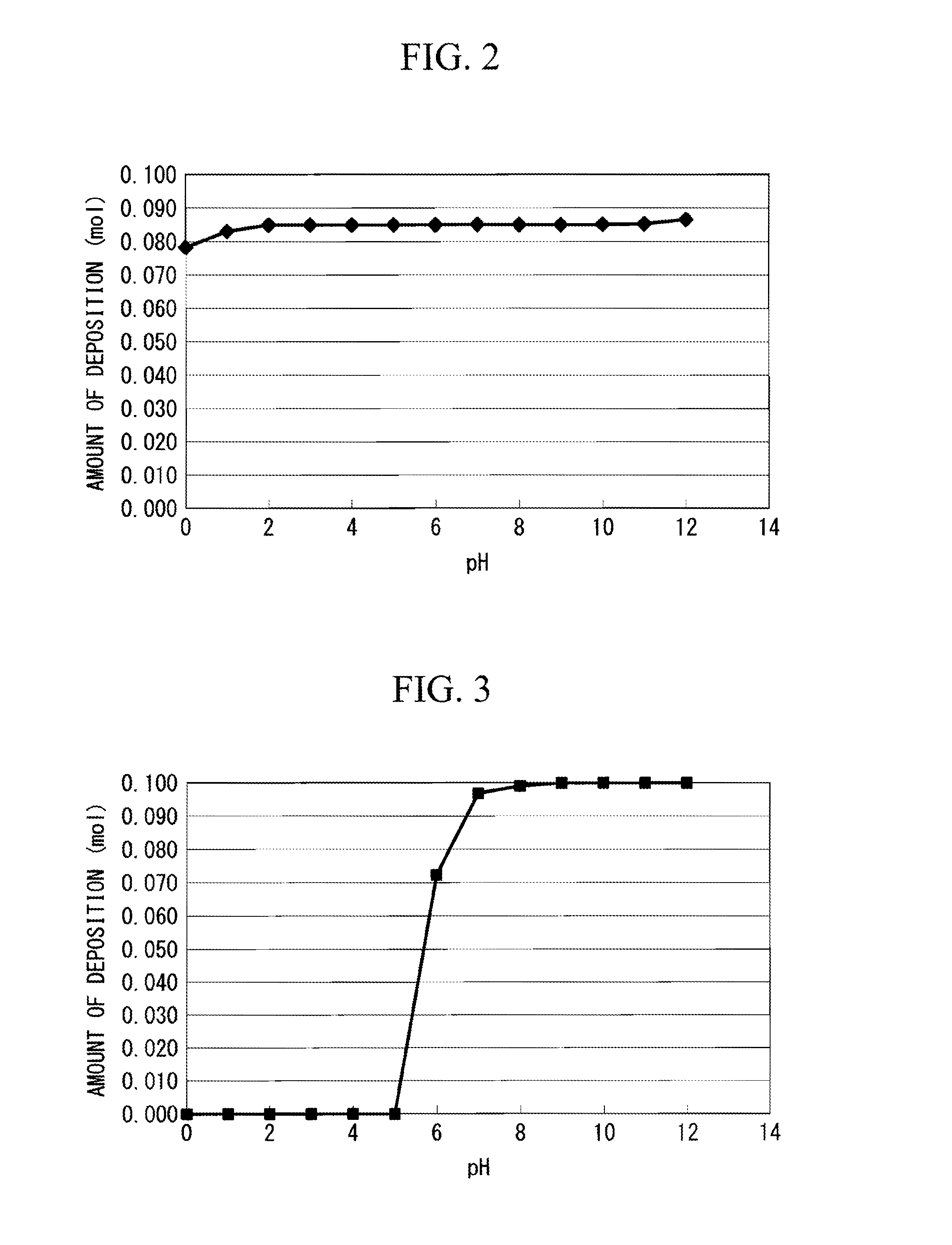

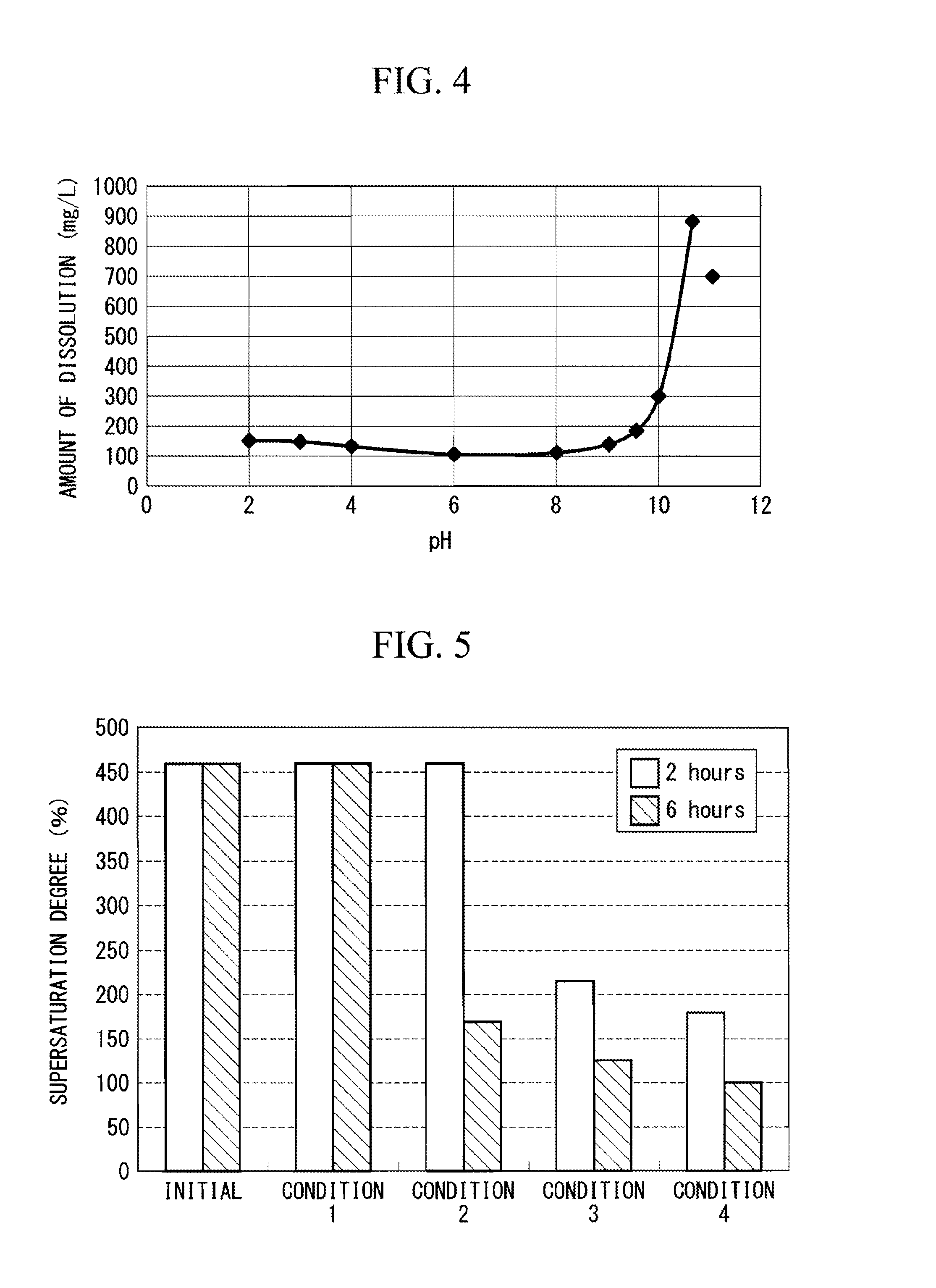

Water treatment process and water treatment system

InactiveUS20150203382A1High water recoveryInhibit productionLiquid degasification with auxillary substancesGeneral water supply conservationWater treatment systemSilicon dioxide

In a water treatment system and a water treatment process, a scale inhibitor is supplied to water to be treated containing Ca ions, SO4 ions, carbonate ions, and silica, and the water to be treated is adjusted to a pH at which silica is soluble. The pH-adjusted water containing the calcium scale inhibitor is separated in a first demineralizing section into concentrated and treated water. In a first crystallizing section, seed crystals of gypsum are supplied to the first concentrated water, whereby gypsum is crystallized and removed from the first concentrated water. Silica in the water to be treated is removed from the first concentrated water on the downstream side of the first crystallizing section. Calcium carbonate in the water to be treated is removed from the first concentrated water on the upstream side of the first demineralizing section or the downstream side of the first crystallizing section.

Owner:MITSUBISHI HEAVY IND ENG LTD

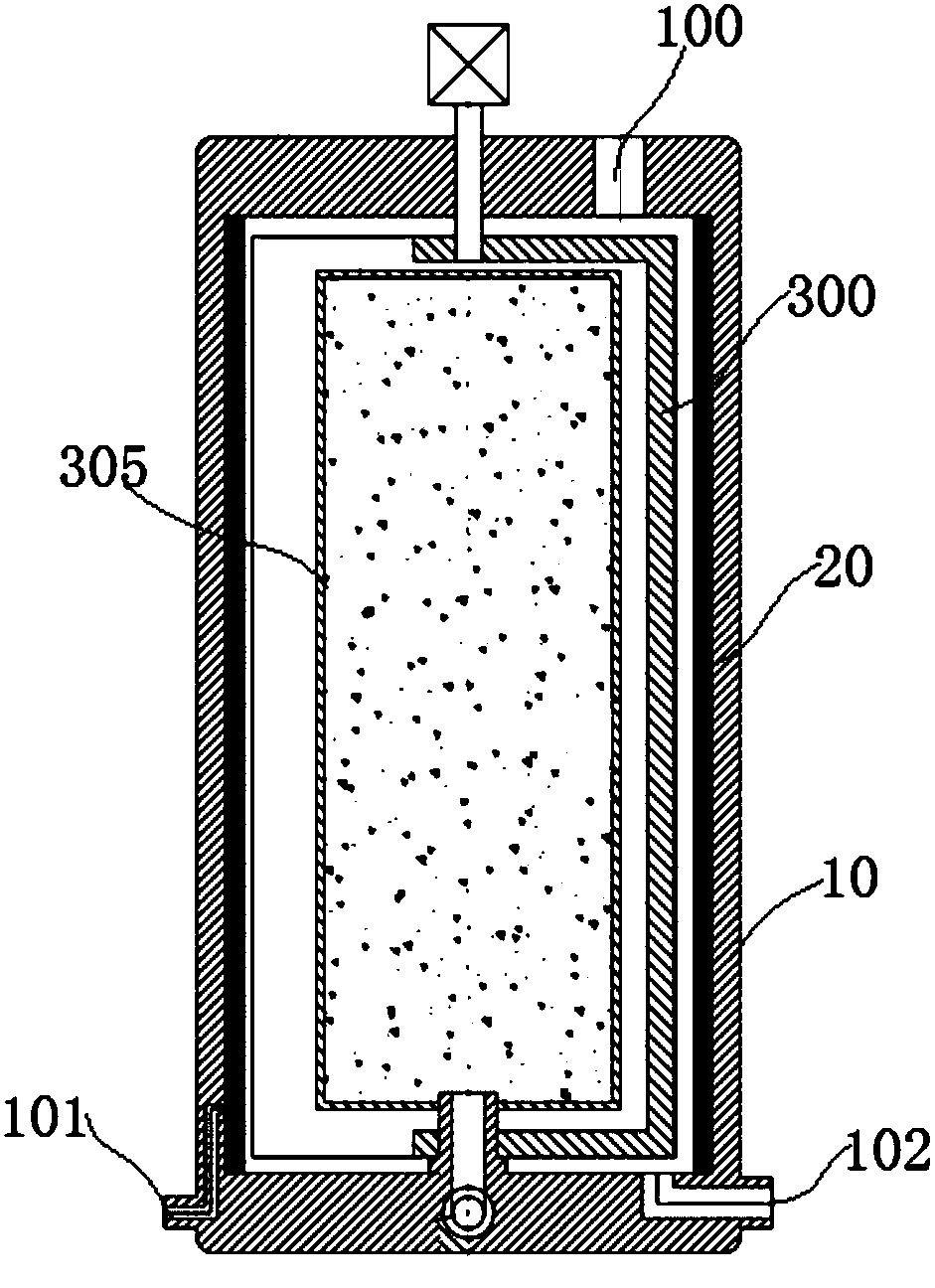

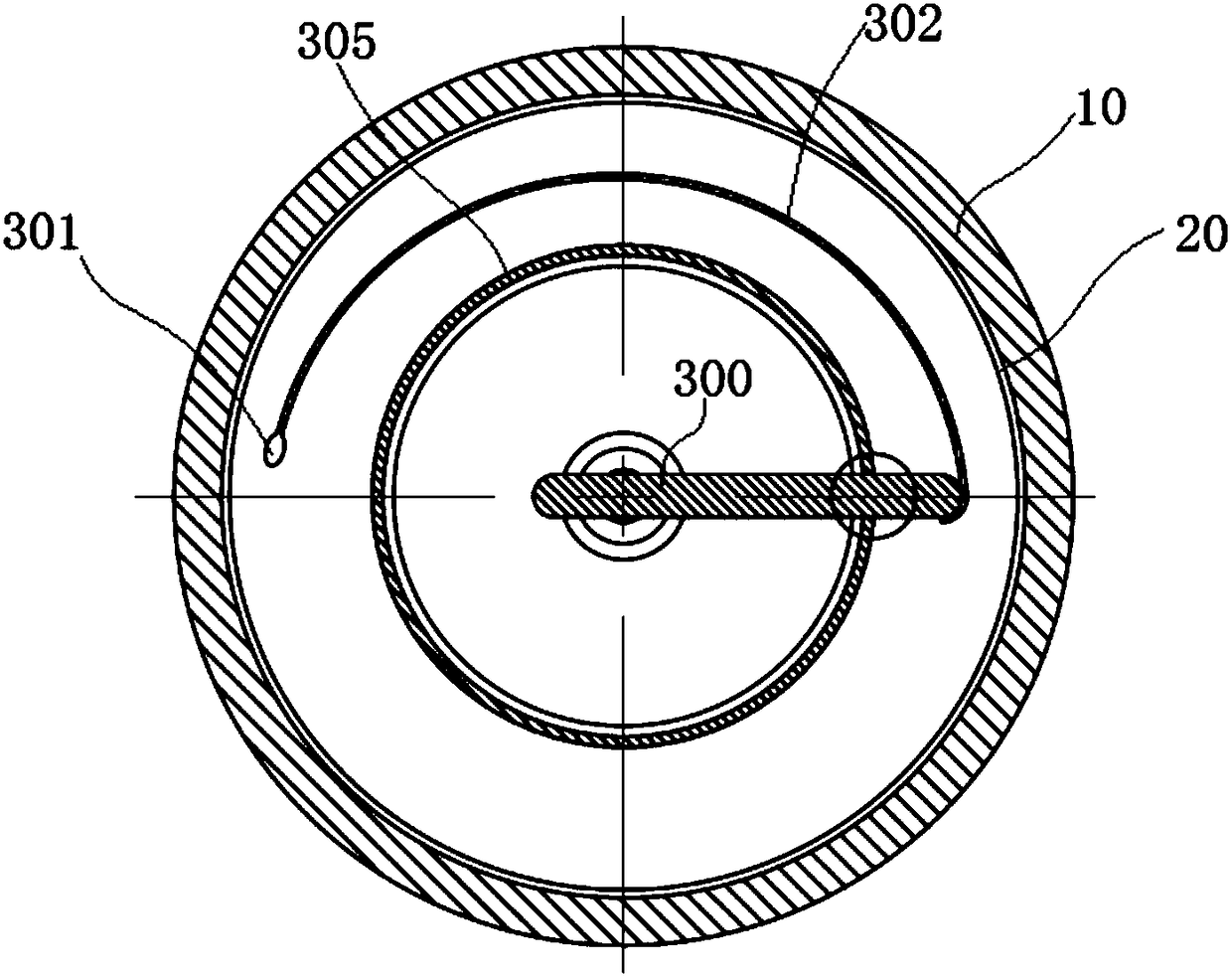

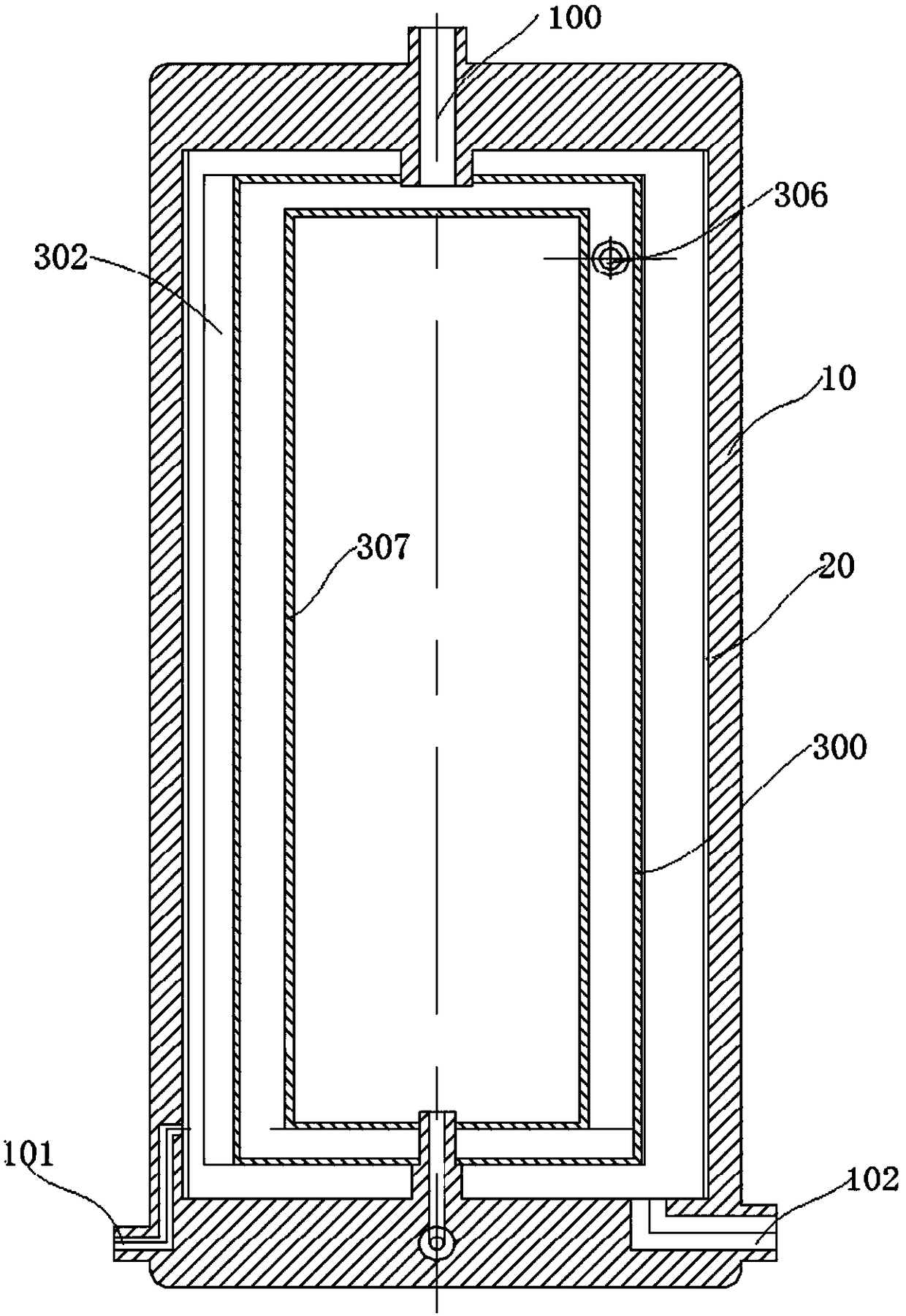

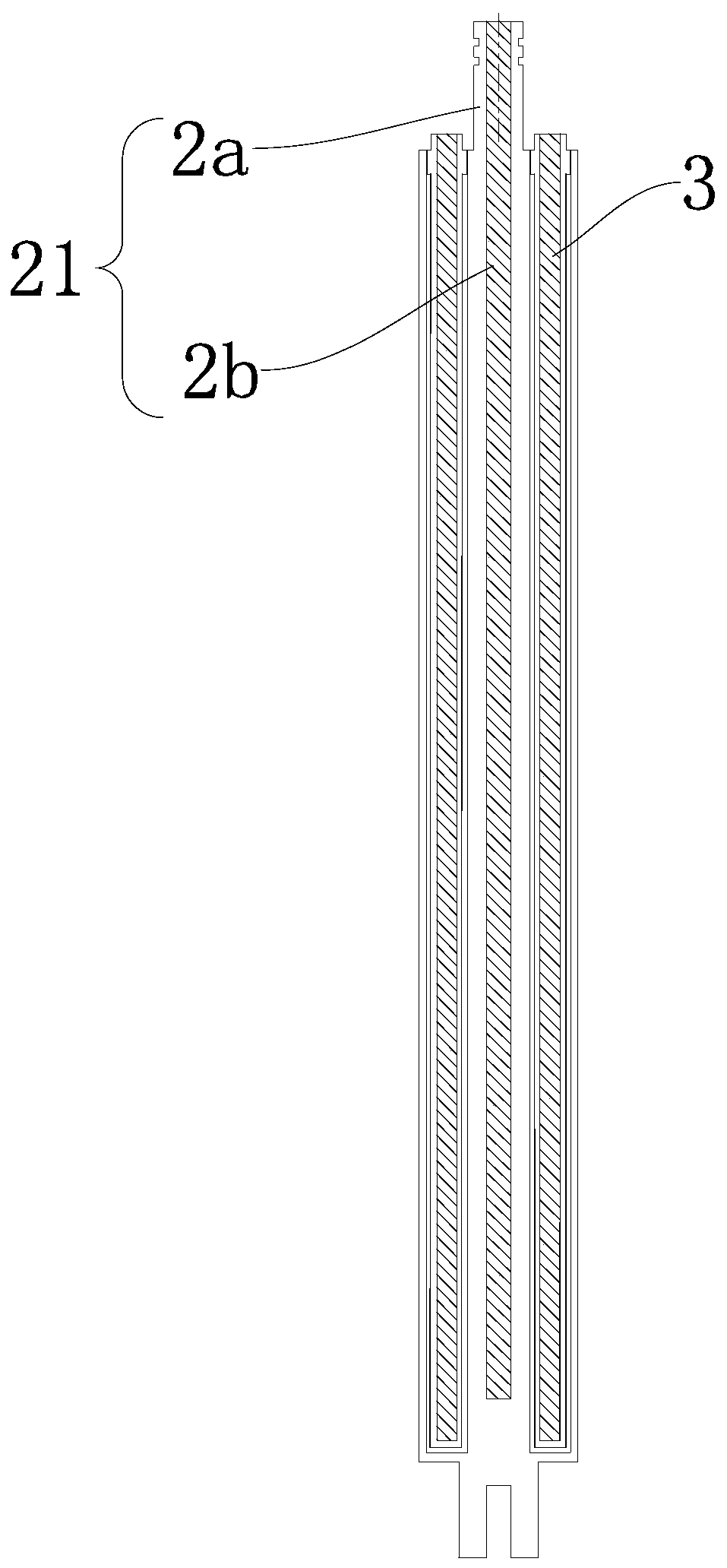

Filter and water purification apparatus

InactiveCN108434991AIncrease the concentration ratioHigh water recoveryWater/sewage treatment bu osmosis/dialysisReverse osmosisFiltrationSoft water

The present invention relates to the technical field of liquid separation, and discloses a filter and a water purification apparatus. The filter comprises a shell (10) and a membrane separation unit (20) arranged on the inner wall of the shell (10) and used for filtration, wherein a liquid inlet (100), a passing liquid outlet (101) for allowing a liquid penetrating through the membrane separationunit to pass, and a concentrated liquid outlet (102) for allowing a liquid impermeable to the membrane separation unit (20) are arranged on the shell (10), the filter further comprises a scrubbing unit (30) for scrubbing the surface of the membrane separation unit, and the scrubbing unit comprises a scrubbing head (301) and is arranged for making the scrubbing head selectively contact the membraneseparation unit. According to the present invention, the filter can remove contaminants on the surface of the separation membrane, and has uniform scrubbing friction; and the filter can be inserted into the softening water agent tank to form the water purification apparatus for preparing non-drinking soft water for washing rooms and soft water meeting drinking water standard, and the advantages of low cost, high water recovery rate and the like can be achieved.

Owner:佛山市亿玖电器科技有限公司

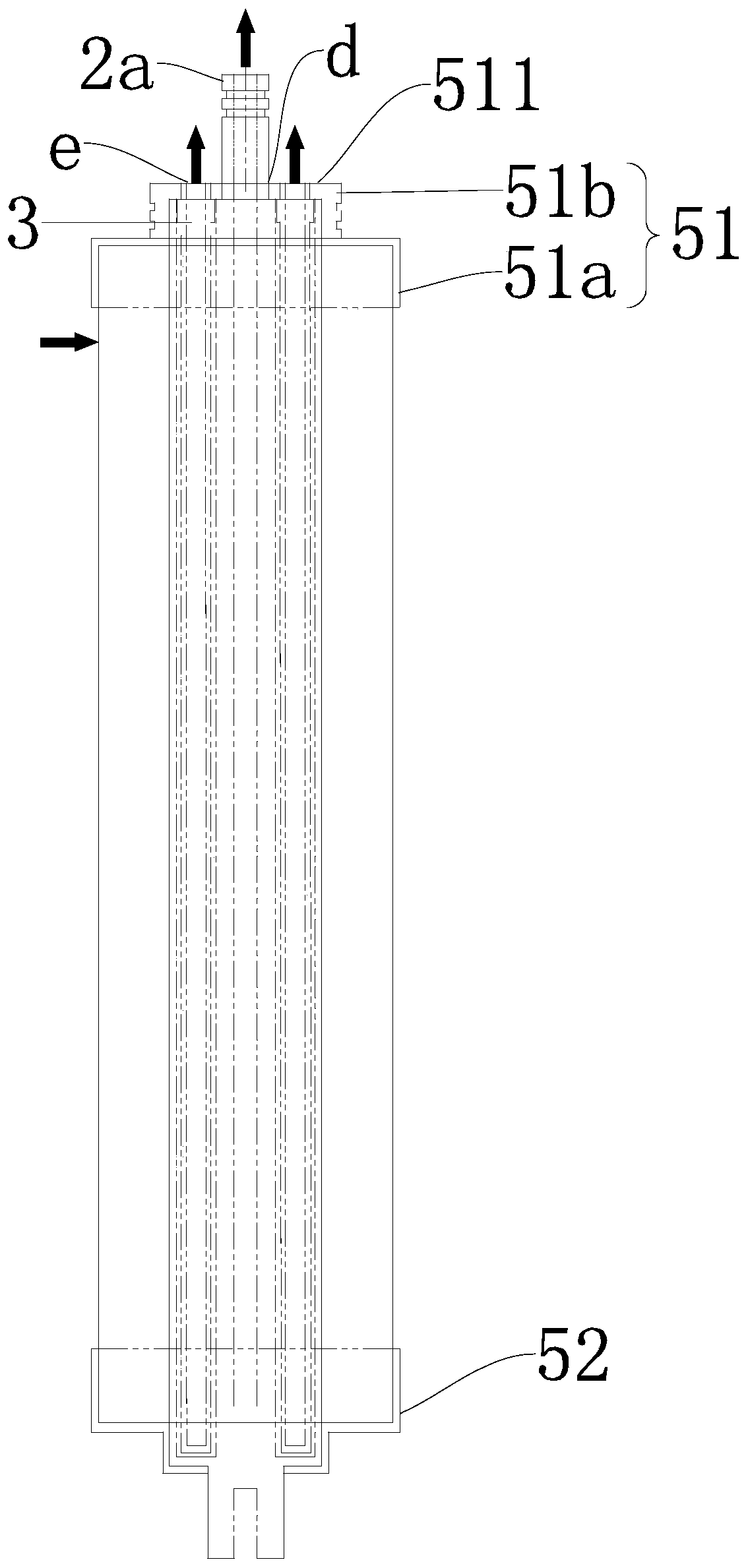

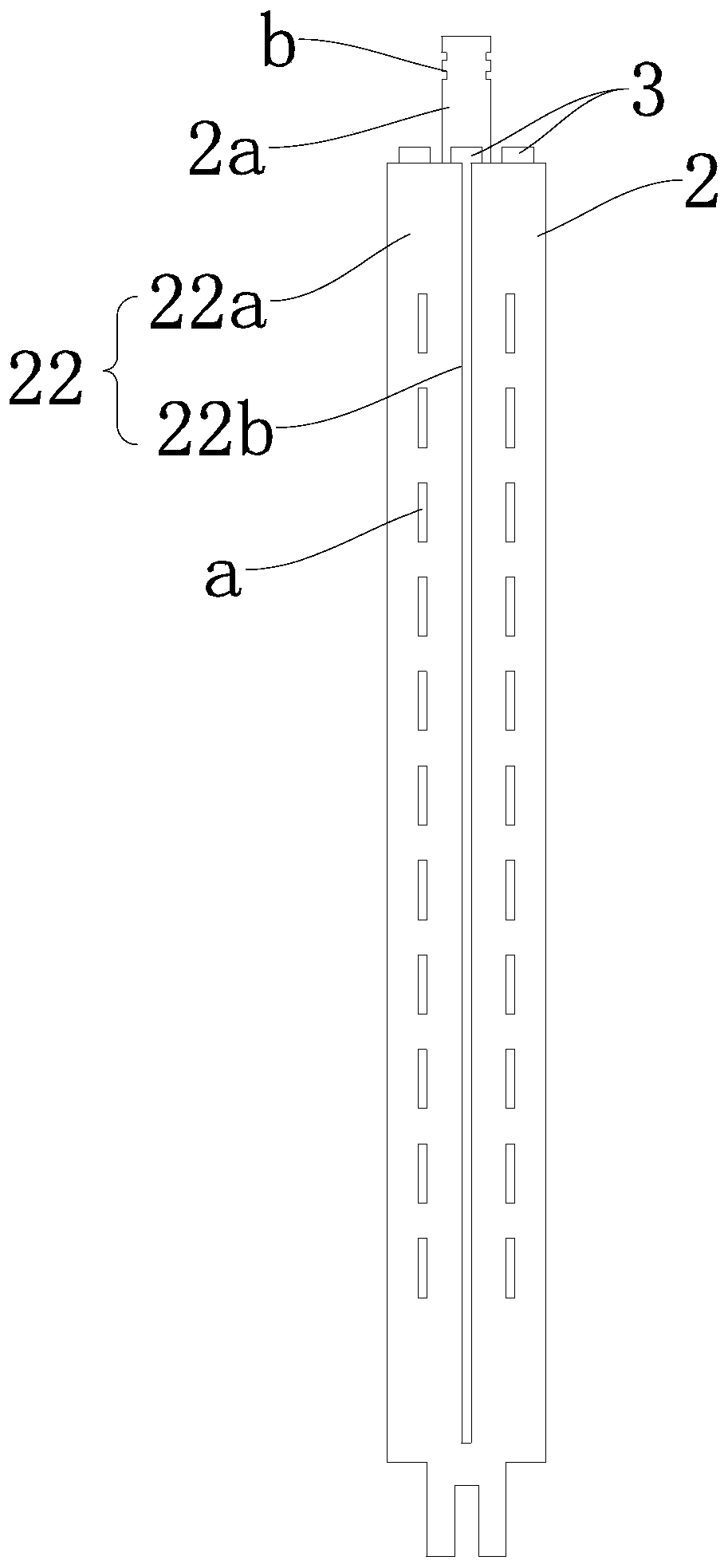

Reverse osmosis membrane element realizing water inflow from side surface

PendingCN110433659AIncrease surface velocityImprove anti-pollution performanceReverse osmosisWater/sewage treatment bu osmosis/dialysisConcentration polarizationWastewater

The invention discloses a reverse osmosis membrane element realizing water inflow from a side surface. The reverse osmosis membrane element comprises a reverse osmosis membrane group, a central tube member and a pure water pipeline. Raw water is fed from the side surface of the reverse osmosis membrane group; the reverse osmosis membrane group is bidirectionally wound to form a pure water flow channel and a water inflow channel respectively located in and out of the reverse osmosis membrane group, and a pure water pipeline is located in the pure water flow channel; the central tube member includes a wastewater outlet channel and a body arranged around the wastewater outlet channel; the wastewater outlet channel is located in water inflow channel; the body includes a main body portion and anotch; the side surface of the main body portion is provided with a plurality of wastewater passing holes communicating with the wastewater outlet channel; and the pure water pipeline is arranged inthe notch, and the side surface of the pure water pipeline is axially provided with a number of pure water passing holes. The design of the reverse osmosis membrane element realizing water inflow fromthe side surface in the invention can well improve the surface flow velocity of a membrane, reduce the phenomenon of concentration polarization of an RO membrane, improve the anti-pollution ability of a household RO membrane element and the water recovery rate of the RO membrane, and prolong the service life of the reverse osmosis membrane group.

Owner:XIAMEN BAILIN WATER PURIFICATION TECH CO LTD

Water treatment process and water treatment system

InactiveUS20150203381A1Inhibit productionHigh water recoveryLiquid degasification with auxillary substancesGeneral water supply conservationWater treatment systemTreated water

Provided are a water treatment system and a water treatment process, which are capable of reproducing water containing salts with high water recovery. A water treatment system 100 comprises a second demineralizing section 210a, 210b that separates water to be treated containing Ca ions, SO4 ions and carbonate ions into concentrated water in which the Ca ions and the SO4 ions are concentrated and treated water; a crystallizing section which is positioned on a downstream side of the second demineralizing section 210a, 210b and which includes a second crystallizing tank 221a, 221b that crystallizes gypsum from the concentrated water and a seed crystal supplying section that supplies seed crystals of gypsum to the second crystallizing tank 221a, 221b; and a separating section that is positioned on a downstream side of the crystallizing section and separates the gypsum from the concentrated water.

Owner:MITSUBISHI HEAVY IND ENG LTD

Apparatus and method for reverse osmosis

ActiveUS11097223B2High recovery rateReduce energy consumptionMembranesGeneral water supply conservationReverse osmosisProcess engineering

An apparatus for reverse osmosis, the apparatus comprising: a single-stage reverse osmosis (SSRO) unit; and a counter-current membrane cascade with recycle (CMCR) unit comprising a plurality of stages of reverse osmosis including at least a first stage and a second stage wherein permeate from the first stage is configured to be introduced as feed to the second stage; wherein retenate from the SSRO unit is configured to be introduced as feed to the first stage, and wherein product obtained using the apparatus comprises permeate from the SSRO unit and permeate from a last stage of the CMCR unit.

Owner:NANYANG TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com