Method for recovering water from hot carrier gas for lignite drying

A water recovery and drying technology, which is applied in separation methods, chemical instruments and methods, steam condensation, etc., can solve problems such as environmental pollution, increased coal consumption, and increased smoke exhaust loss, and achieves low device investment and low floor space. Small size and high water recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

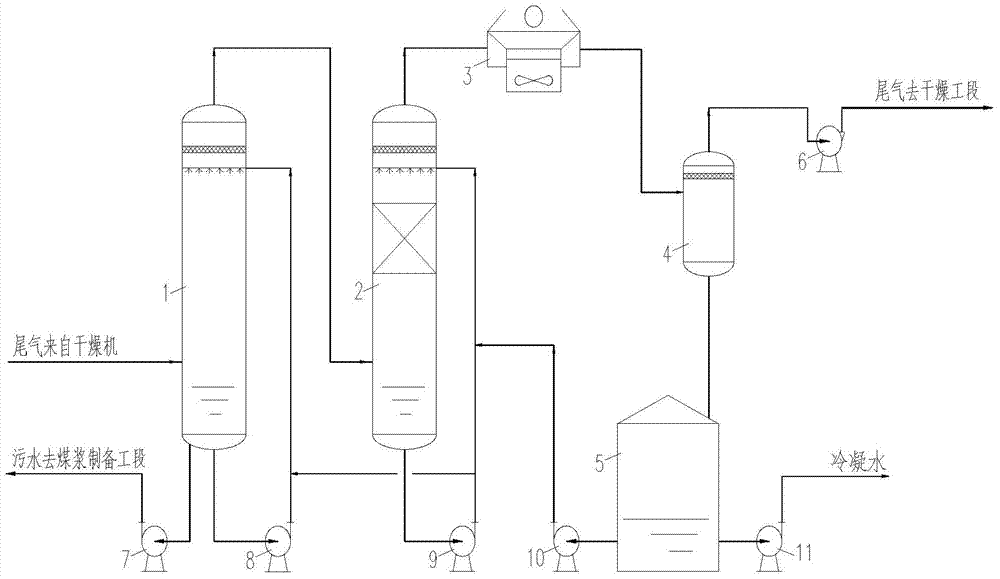

[0018] Such as figure 1 shown. figure 1 Among them, 1 is the primary washing tower; 2 is the secondary washing tower; 3 is the air cooler; 4 is the separator; 5 is the water recovery tank; 6 is the exhaust fan; 7 is the waste water discharge pump; 8 is the circulating water pump A; 9 Circulating water pump B; 10 is a replenishment pump; 11 is a recovery water discharge pump.

[0019] The invention discloses a method for recovering water from lignite drying hot carrier gas. Before entering the washing tower, the dry hot carrier gas used as tail gas is superheated, and the dust is removed by adiabatic washing in the washing tower, and the hot carrier gas is condensed by an air cooler to achieve recovery. For the purpose of water, the process is as follows:

[0020] The 110°C superheated tail gas from the lignite drying unit enters the washing tower under the action of the fan; the washing process is completed by a two-stage washing tower, and is washed with circulating water a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com