Antioxidant reverse osmosis membrane and preparation method thereof

A reverse osmosis membrane, anti-oxidation technology, applied in chemical instruments and methods, reverse osmosis, semi-permeable membrane separation, etc., can solve the problems of short service life, limited tolerance of oxidative substances, limited application, etc. Receptivity and separation performance, good water quality for wastewater recovery, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

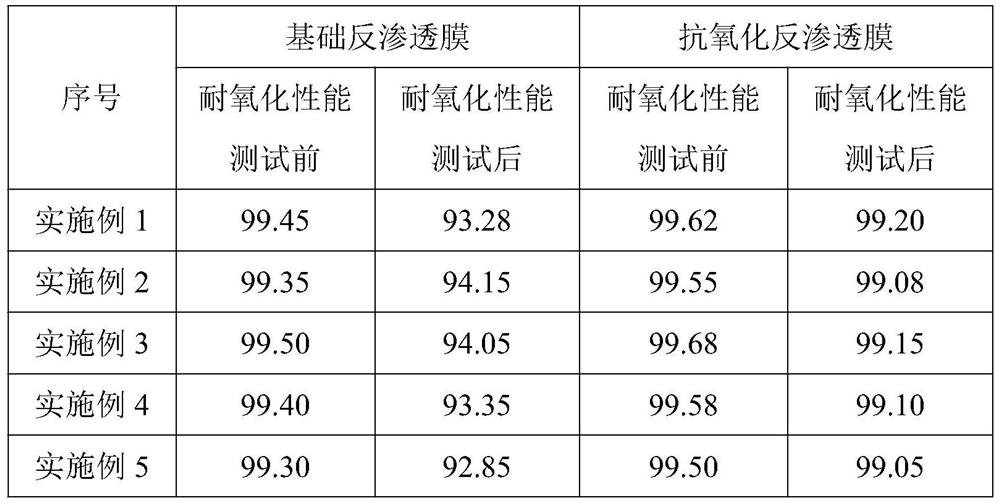

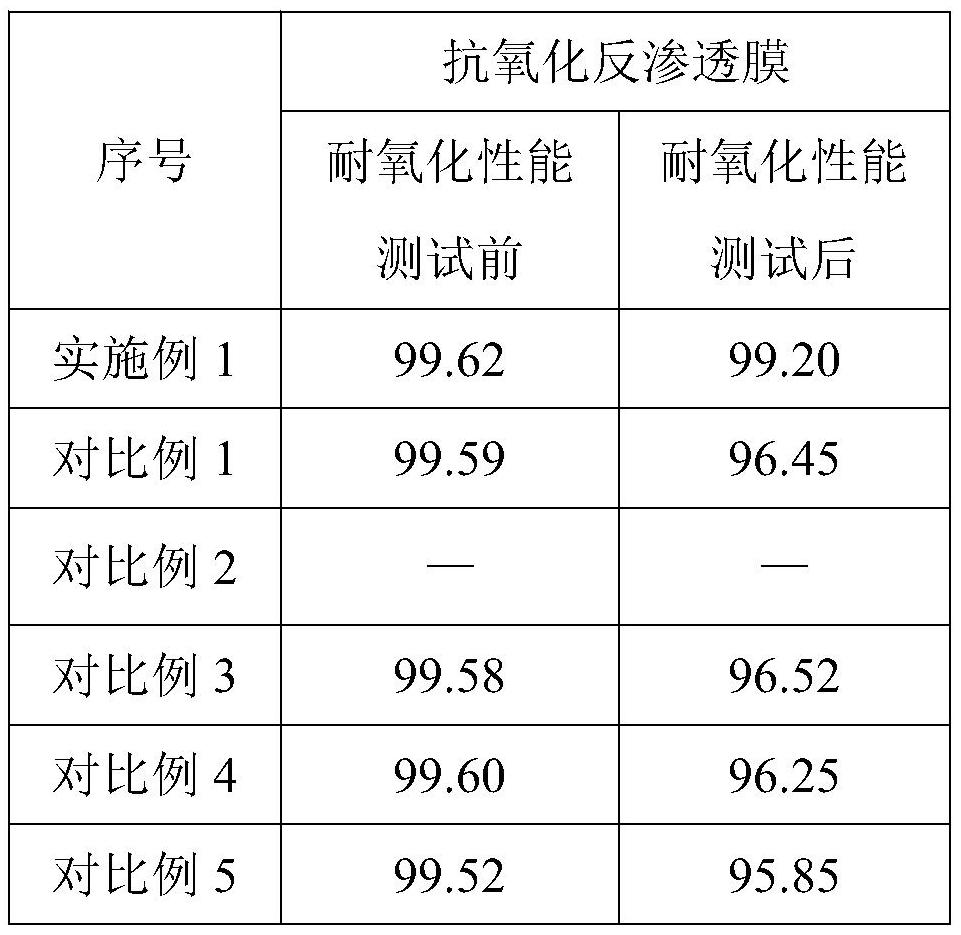

Examples

preparation example Construction

[0023] A method for preparing an anti-oxidation reverse osmosis membrane, comprising the following steps:

[0024] Step 1) The base layer is prepared, and a polyamide desalination layer is formed on the surface of the base layer through the interfacial polymerization reaction between the polyamine solution and the polyacid chloride solution to obtain a basic reverse osmosis membrane.

[0025] The polyamine is at least one of p-phenylenediamine, m-phenylenediamine, o-phenylenediamine liquid, diethylenetriamine and triethylenetetramine, and the polyacyl chloride is isophthaloyl chloride, terephthaloyl At least one of formyl chloride, phthaloyl and trimesoyl chloride. The concentration of the polyamine solution is 0.5-5 wt%, and the concentration of the polyacyl chloride solution is 0.2-4 wt%.

[0026] Step 2) Select suitable polyvinyl alcohol, cross-linking agent, acid catalyst and anti-oxidation substance to configure anti-oxidation coating solution, coat the anti-oxidation co...

Embodiment 1

[0032] In this embodiment, the reverse osmosis membrane product is prepared by the above-mentioned method, wherein the interfacial polymerization reaction is carried out by using p-phenylenediamine aqueous solution and trimesoyl chloride solution, the degree of polymerization of polyvinyl alcohol is 700, the degree of alcoholysis is 82%, and the crosslinking agent It is glyoxal, the acid catalyst is hydrochloric acid, the antioxidant substance is sodium thiosulfate, the heat treatment temperature is 65°C, and the time is 3min.

Embodiment 2

[0034] In this embodiment, the reverse osmosis membrane product is prepared by the above-mentioned method, wherein the interfacial polymerization reaction is carried out by using p-phenylenediamine aqueous solution and isophthaloyl chloride solution, the degree of polymerization of polyvinyl alcohol is 500, the degree of alcoholysis is 78%, and the cross-linking The agent is malondialdehyde, the acid catalyst is sulfuric acid, the antioxidant substance is sodium dithionite, and the heat treatment temperature is 50° C. and the time is 4 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com