Patents

Literature

128 results about "Microbial pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Indoor microbial air pollution is caused by excessive growth of bacteria, fungi, or algae in warm, wet materials including lumber, ceiling tiles, books and papers, insulation, or hay.

Film-forming agent composition and starchiness vegetable adhesive containing the composition

InactiveCN101245157APromote digestion and absorptionReduce breakage rateMicroballoon preparationMicrocapsule preparationMicrobial pollutionAdhesive

The invention provides a film forming compound with modified starch as the main component, a film forming material containing the compound, and more particularly a hard-shell natural capsule made from the compound. The compound contains no or very little animal protein such as gelatin, etc. The compound can partially or completely replace the gelatin from animals for producing natural hard-shell capsules. The prepared natural capsule shell product has the advantages of excellent film forming property, high strength, good flexibility, high transparency, decomposability and microbial pollution resistance. The main component of the compound, modified starch, has stable quality and highly controllable performance.

Owner:长春大成特用玉米变性淀粉开发有限公司

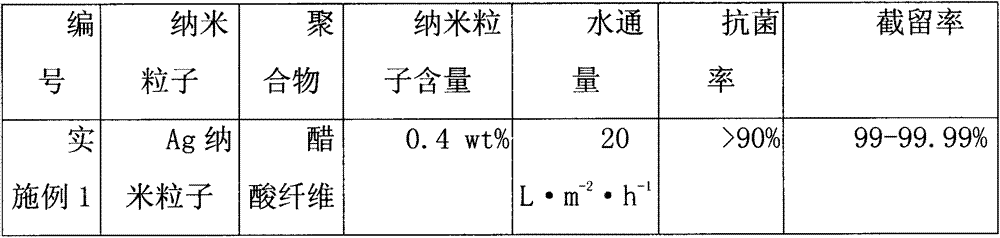

Polymer separation membrane with on-line antibiosis and self-cleaning functions and preparation method thereof

InactiveCN101785976ASimple preparation processEasy to industrializeSemi-permeable membranesSolventSalivation Stimulation

The invention belongs to the preparation field of high molecular functional membrane materials, in particular to a polymer microporous filter membrane with the on-line anti-microbial pollution and self-cleaning functions and a preparation method thereof. The membrane is prepared from a casting solution by the phase inversion method, and can be prepared into a flat membrane or a hollow fiber membrane. The casting solution is composed of polymers, nano oxide particles, a pore forming agent and an organic solvent, and is scraped into the flat membrane by the salivation method or prepared into the hollow fiber membrane through a spinneret, the flat membrane or the hollow fiber membrane is then coagulated in de-ionized water or water solution containing the organic solvent to form a primary membrane, and then the primary membrane is soaked in a weak solvent to obtain the polymer separation membrane with the on-line antibiosis and self-cleaning functions. The membrane has favorable elasticity and mechanical strength, and the surface of the membrane has the antibiosis and self-cleaning functions. Besides, since the pore diameter of the membrane is sensitive to the pressure, the de-ionized water flux and the trapped relative molecular mass of the membrane can be controlled by controlling the operation pressure.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

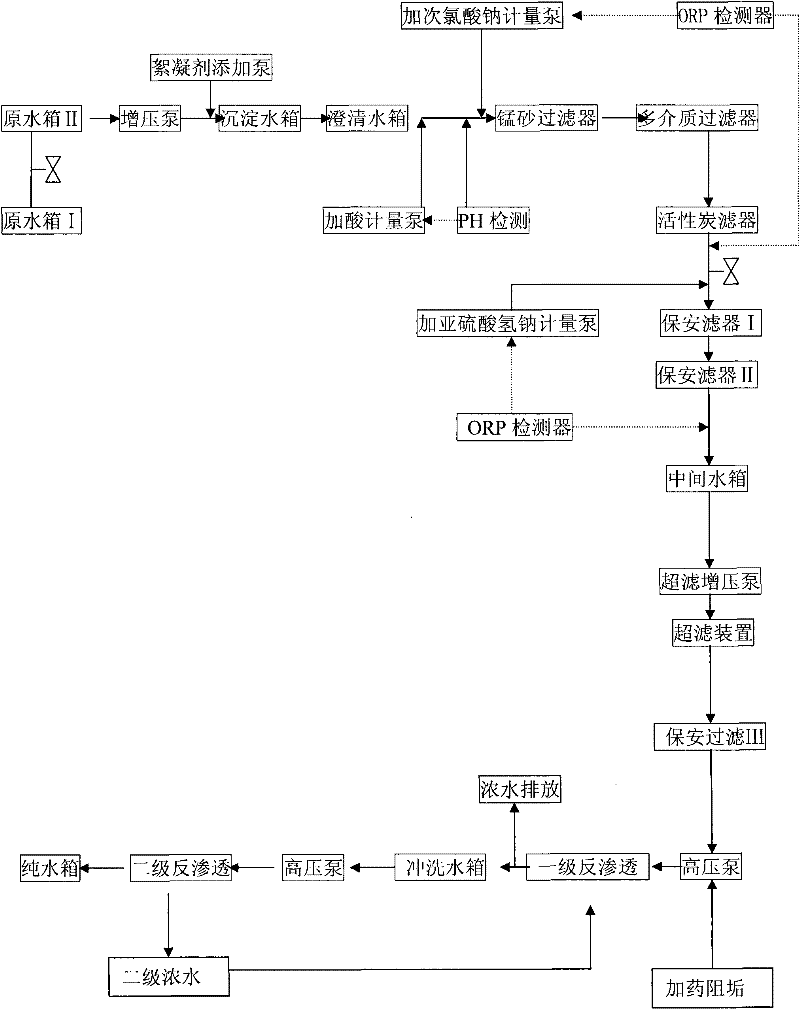

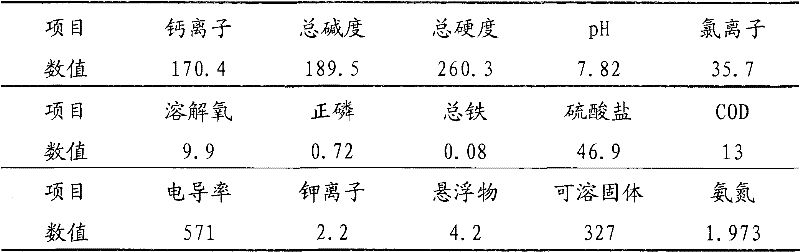

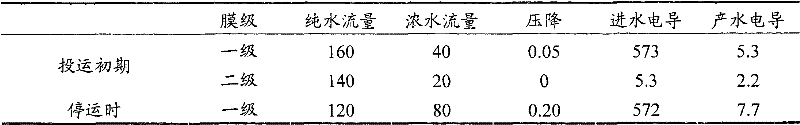

A cleaning method for a reverse osmosis system

ActiveCN102285705AReduce pressure differenceAvoid pollutionReverse osmosisWater/sewage treatment bu osmosis/dialysisMeth-Active agent

The invention relates to a method for cleaning a reverse osmosis system. The method comprises a step of cleaning a reverse osmosis membrane by using reverse osmosis system cleaning liquid, wherein the cleaning liquid is cleanser-containing aqueous solution; the pH value of the cleaning liquid is controlled to be 11.0+ / -0.5; the cleanser consists of a chelating agent, an anionic surfactant and a polymer dirt dispersion agent; the chelating agent is at least one selected from polyphosphates and ethylenediamine tetraacetic acid; the anionic surfactant is at least one selected from C8-C16 alkylbenzene sulfonate and N-oleoyl-N-methyl taurine; and the polymer dirt dispersion agent is at least one selected from acrylate homopolymer and acrylate copolymer. By cleaning the reverse osmosis membrane with the method provided by the invention, the problems of colloid, organic and microbial pollution and the like which slowly occur on the reverse osmosis membrane can be intensively solved; the salinity of water produced by the reverse osmosis system can be effectively reduced; the water yield of the reverse osmosis system can be increased; and the pressure difference before and after the reverse osmosis membrane can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP

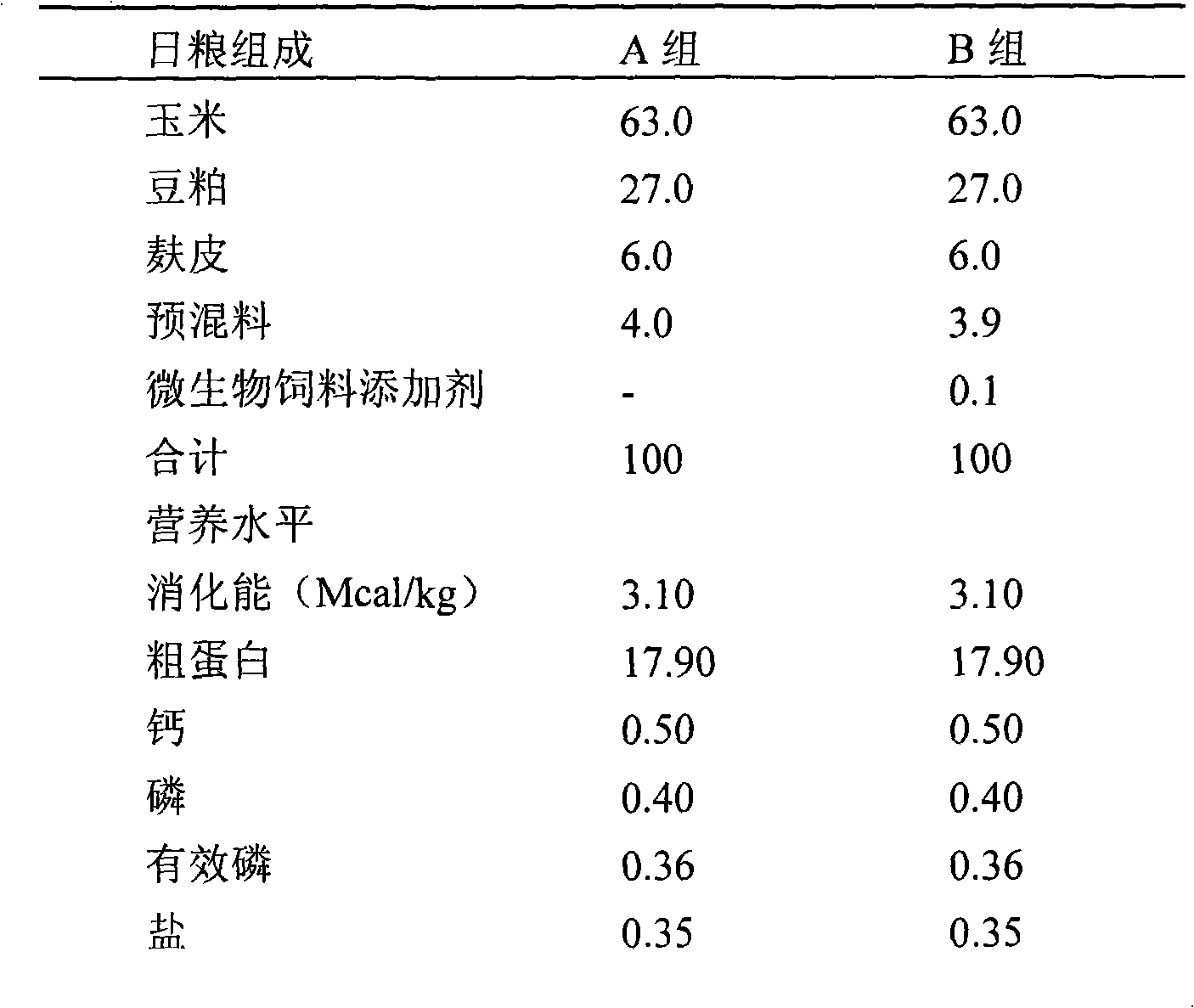

Novel microbial feed additive and method of producing the same

ActiveCN101278702AIncrease payImprove qualityBacteriaAnimal feeding stuffBiotechnologyBacterial strain

The invention relates to a novel microorganism feed additive, in particular to a microorganism feed additive which contains bacterial strain that can produce conjugated linoleic acid and a preparation method thereof, which belongs to the microorganism feed additive technical field. The preparation method of the microorganism feed additive is that plant lactobacillus and enterococcus faecalis are respectively processed by zymotic liquid which is cultured by liquid deep-layer high-density fermenting and are made into powder by a micro-capsule peridum spray drying method and a frozen-dried preparation method. The microorganism feed additive transforms linoleic acid into the conjugated linoleic acid in the intestinal tracts of poultry and livestock, which takes effects of promoting the growth performance of the poultry and the livestock, reducing fat, increasing meat factor and regulating immunity reaction, etc., and the microorganism feed additive also solves the problem of the high expense caused by adding the conjugated linoleic acid into the feed directly. The microorganism feed additive prepared by the method has the advantages of high viable bacteria content, long holding period and little microbial pollution.

Owner:BEIJING DABEINONG TECH GRP CO LTD +2

Disease-suppression antibacterial beautiful sealant and preparation technology thereof

InactiveCN105969046AReduce pollutionReduce pollution sourcesAntifouling/underwater paintsPaints with biocidesDiseaseEpoxy

The present invention provides a disease-suppressing and antibacterial beautifying agent and a preparation process thereof, wherein the disease-suppressing and antibacterial beautifying agent includes components A and B; component A includes: 50-90 parts of epoxy resin, benzyl alcohol 1-5 parts, 0.2-1.2 parts of defoaming agent, 1-9 parts of fumed silica, 0.3-1.2 parts of thixotropic agent, 0.2-0.8 parts of silver antibacterial agent, 0.5-1.2 parts of ultraviolet absorber, and 1 part of water repellent ‑6 parts, 3‑40 parts of toner, 1‑20 parts of flexibility additive; component B includes: 10‑20 parts of polyetheramine, 9‑35 parts of alicyclic amine, 25‑45 parts of epoxy resin, benzyl alcohol 20-40 parts, 0.5-2 parts of defoamer, 0.5-4 parts of fumed silica, 1-5 parts of thixotropic agent, 0.2-0.9 parts of silver antibacterial agent. The invention can fill the gaps to bring aesthetics, and at the same time, suppress live viruses and bacteria existing in the gaps, and reduce indoor microbial pollution sources.

Owner:苏州久居环保科技有限公司

Anti-pollution separation membrane and preparation method

ActiveCN102728241AStrong bindingImprove anti-pollution performanceSemi-permeable membranesMethacrylateMethyl carbonate

The invention discloses an anti-pollution separation membrane and a preparation method, wherein aiming at the shortages of a preparation technology for the present anti-pollution PVDF (polyvinylidene fluoride) separation membrane, the invention provides a novel method for preparing an anti-microbial pollution PVDF separation membrane. The novel method provided by the invention comprises the following steps of: synthesising the random copolymer with a zwitterionic structure, of MMA (methl methacrylate), DMC (dimethyl carbonate) and AMPS (2-acrylamido-2-methylpropane sulfonic acid) via free radical polymerization at first, adding the copolymer and a porogenic agent, i.e., polyethylene glycol (PEG) in PVDF, and preparing the anti-pollution separation membrane by using N,N-dimethyl formamide (DMF) as a solvent and using water as a coagulating agent through a phase inversion method. Electropositive quaternary amine group and electronegative sulfonic group exist in the structure of the copolymer simultaneously, and have a binding capacity for water molecules which is much stronger than the binding capacity of traditional polyethylene glycol and the derivatives of the traditional polyethylene glycol, and the formed hydration layer is more stable; therefore, the prepared novel PVDF membrane is lasting in anti-pollution performance.

Owner:TIANJIN POLYTECHNIC UNIV

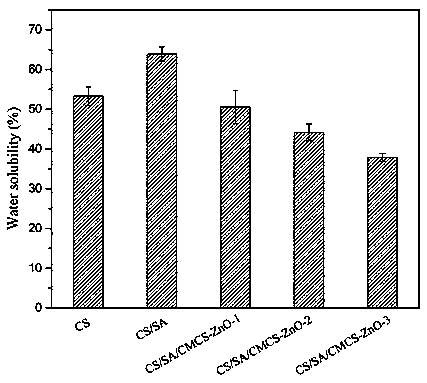

ZnO-containing chitosan/sodium alginate antibacterial cling film and preparation method thereof

InactiveCN109294003ALow water solubilityLow water vapor transmission coefficientSolubilityWater vapor

The invention discloses a ZnO-containing chitosan / sodium alginate antibacterial cling film and a preparation method thereof. The preparation method comprises the following steps: preparing ZnO nano particles by taking starch as a dispersing agent and a stabilizer and taking Zn(NO3)2.6H2O as a zinc source; dissolving chitosan in a 1% acetic acid solution, and adding glycerol to prepare a chitosan film solution; dispersing the ZnO nano particles into deionized water, adding sodium alginate and glycerol, carrying out stirring, carrying out ultrasonic dispersion, carrying out standing, and carrying out ultrasonic degassing to obtain a sodium alginate film liquid; and casting the chitosan film liquid into a film, carrying out drying, then casting the sodium alginate film liquid into a film on the surface of the chitosan film, carrying out drying, finally, casting the chitosan film liquid into a film, carrying out drying, and uncovering the film to obtain the antibacterial cling film. The chitosan / sodium alginate / starch-ZnO (CS / SA / SH-ZnO) antibacterial cling film prepared by the method has relatively low water solubility and water vapor permeability coefficient, the antibacterial property is good, and excessive loss of water and microbial pollution in transportation, storage and processing processes of fruits and vegetables can be avoided.

Owner:TAIYUAN UNIV OF TECH

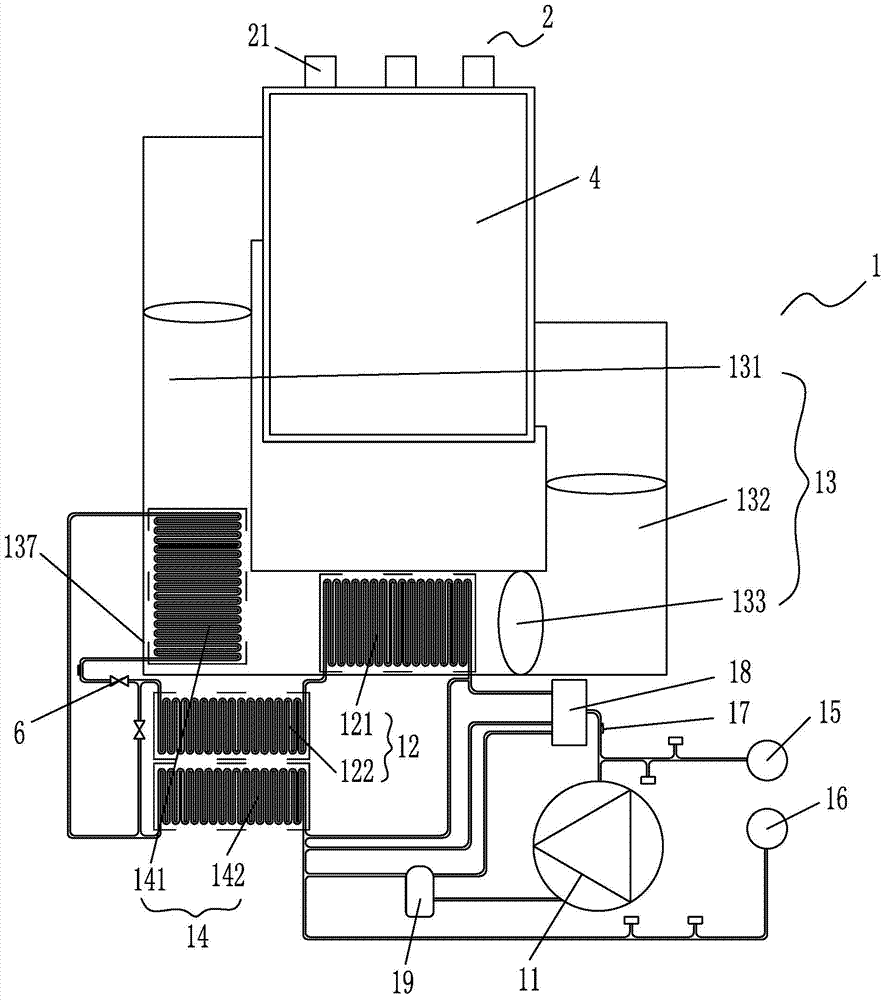

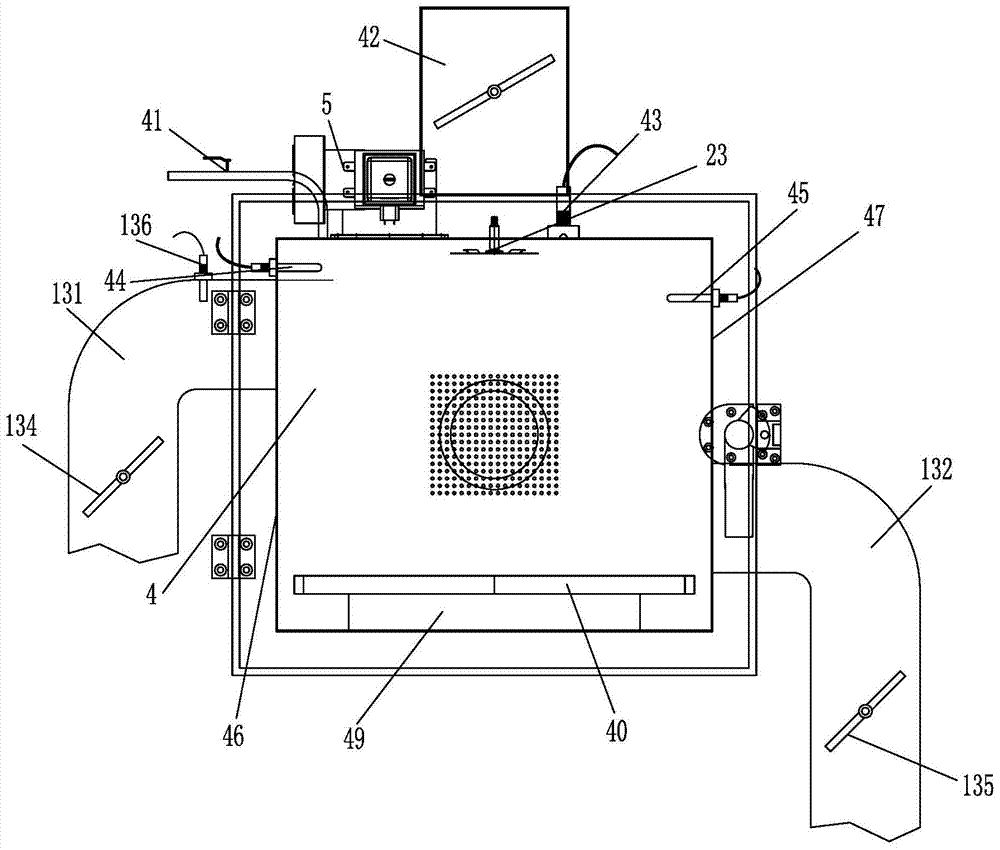

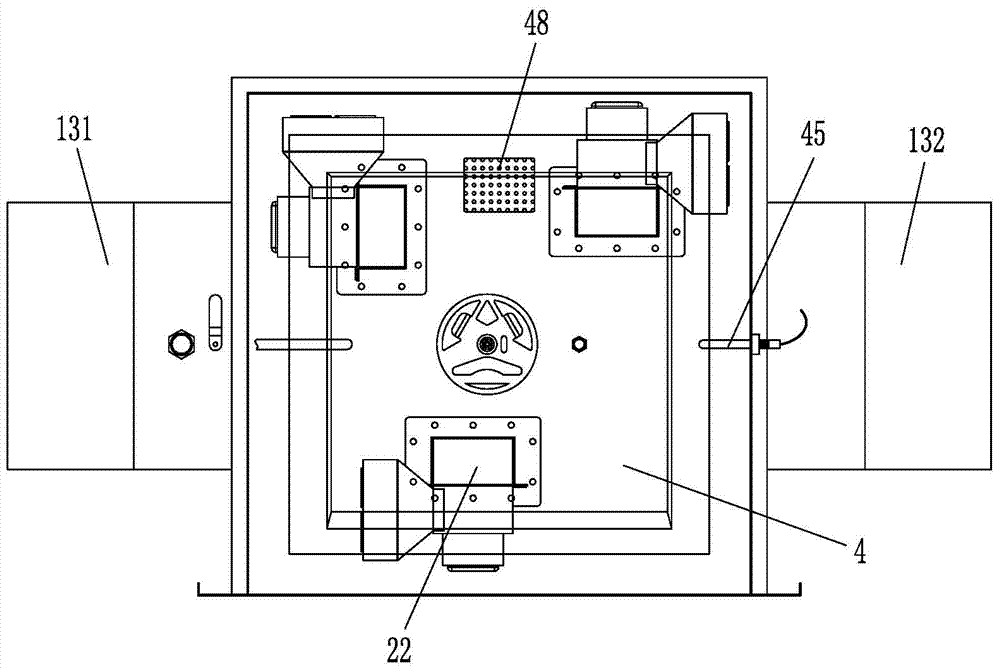

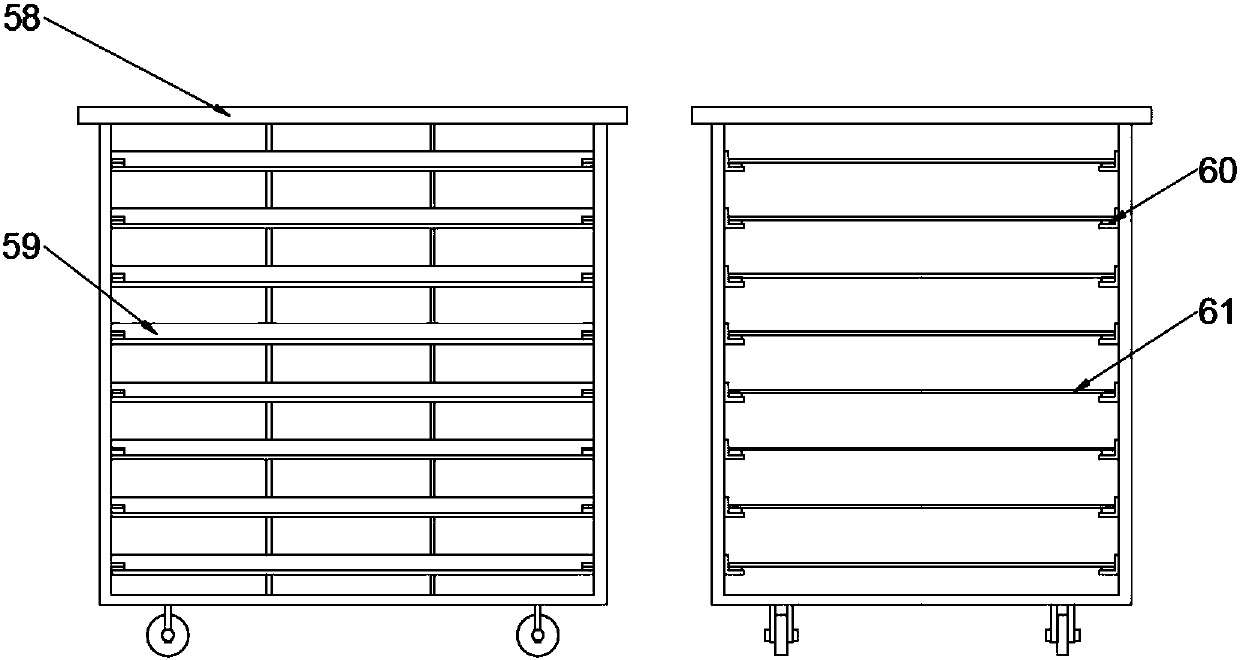

Heat pump-microwave combined drying device

ActiveCN103900355AReduce heat loadOvercoming problems that hinder the movement of internal moisture to the outsideDrying solid materials with heatChemical industryChemical industryMicrowave

A heat pump-microwave combined drying device comprises a heat pump system, a microwave system and a control system. The heat pump assembly and the microwave system share a drying chamber, the microwave system is installed on the top of the drying chamber, the heat pump system is connected with the drying chamber through a circulating air duct, and the control system is connected with the heat pump system and the microwave system, used for setting and adjusting drying conditions and online monitoring drying parameters, and capable of selecting microwave drying and / or heat pump drying according to the characteristics of materials and finished product requirements so that high water content materials with different shapes and different water contents or under high-humidity conditions can be dried. The heat pump-microwave combined drying device is reasonable in structural layout, easy to use, maintain and repair, uniform in drying, large in processing capacity, efficient, free of microbial pollution and capable of saving energy, the process is advanced, and the quality of dried products is good. The heat pump-microwave combined drying device is especially suitable for drying fruit and vegetables, drying marine products and drying materials which are high in heat sensitivity and prone to oxidization, and applied to the biological industry, the pharmaceutical industry, the chemical industry and the like.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

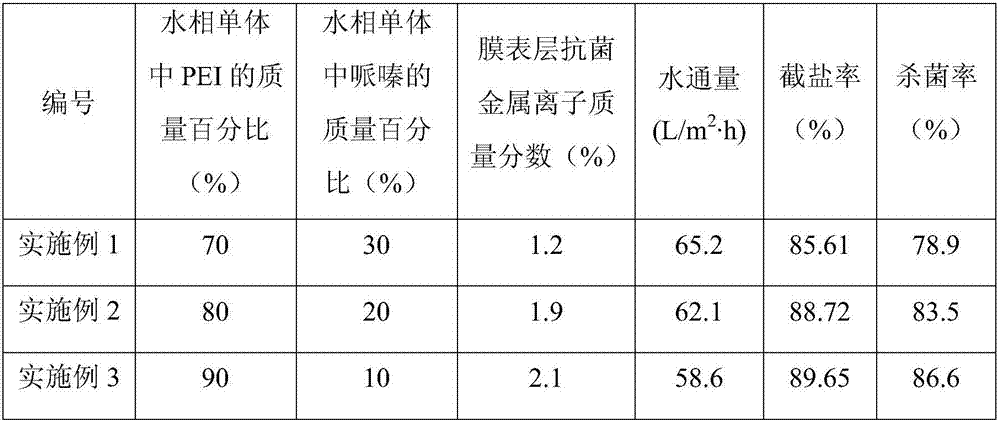

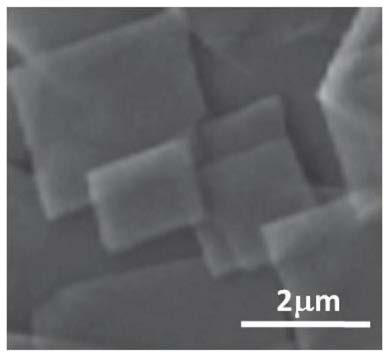

Antibacterial composite nanofiltration membrane and preparation method thereof

ActiveCN107983158AImprove antibacterial propertiesExtended service lifeMembranesSemi-permeable membranesSurface layerMicrobial pollution

The invention provides an antibacterial composite nanofiltration membrane. The antibacterial composite nanofiltration membrane comprises a porous support membrane bottom layer and an antibacterial surface layer complexed with antibacterial metal ions on the surface. The preparation method of the antibacterial composite nanofiltration membrane comprises the steps as follows: the bottom layer is impregnated with an aqueous phase solution containing aqueous phase monomers, and a bottom layer coated with the aqueous phase monomers is obtained; the bottom layer coated with the aqueous phase monomers is impregnated with an oil phase solution containing oil phase monomers, and a bottom layer coated with the aqueous phase monomers and the oil phase monomers is obtained; the bottom layer coated with the aqueous phase monomers and the oil phase monomers is subjected to thermal treatment, and a composite nanofiltration membrane with a polyamide functional layer is prepared; the composite nanofiltration membrane is impregnated with a metal salt solution containing antibacterial metal ions and the antibacterial composite nanofiltration membrane is obtained, wherein the aqueous phase monomers comprise polyethyleneimine. The antibacterial performance, particularly the microbial pollution resistance, of the antibacterial composite nanofiltration membrane is improved while the high permeabilityis kept; the antibacterial composite nanofiltration membrane has lasting antibacterial performance, long service life and good application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

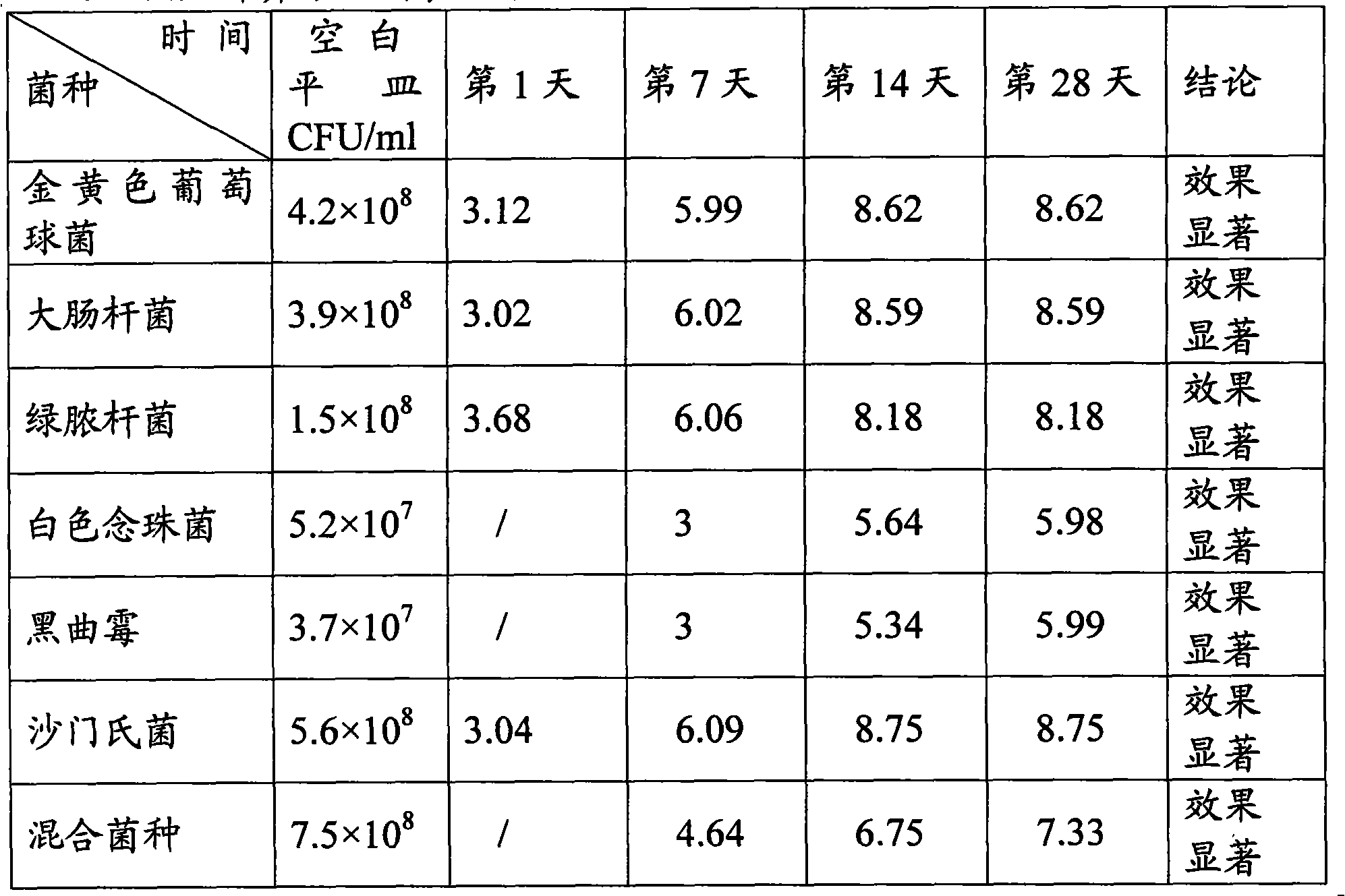

Method for testing and evaluating capacity of corrosion prevention system of cosmetic

InactiveCN101550438AReal life situationTrue response to living conditionsMicrobiological testing/measurementMicroorganism based processesEscherichia coliBacillus pyocyaneus

The present invention relates to a method for resting and evaluating capacity of corrosion prevention system of cosmetic. The invention selects micrococcus pyogenes, bacillus coil, bacillus pyocyaneus, candida albicans, aspergillus niger and salmonella as evaluating strain. The product is grafted into the cosmetic sample solution through the six pathogens and the mixed strains composed of the six pathogens for executing culture experiment. The corrosion prevention capacity of cosmetic is evaluated through comparing and identifying data. The risk resistance capacity of cosmetic for resisting the microbial pollution is effectively evaluated. As the six pathogens have wide representativeness and typical reference value, the six pathogens are used as the typical representative sample strains for evaluating. If the corrosion prevention capacity test is passed, the pollution of product by the microorganism can be effectively prevented, and the possibility of product pollution caused by the reproduction of microorganism can be effectively suppressed. The safety risk caused by product and the cost for frequently executing microbiological examination can be reduced through the basic product formula checked by the corrosion prevention capacity test or all products extended from the basic product formula. The effect is extraordinarily remarkable.

Owner:TIANJIN TIANSHI BIOLOGICAL DEV +2

Forward-osmosis organic-inorganic composite membrane and preparation method thereof

InactiveCN103657433AImprove hydrophilicityIncrease water fluxSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisMicrobial pollutionPolymer

The invention discloses a forward-osmosis organic-inorganic composite membrane. The forward-osmosis organic-inorganic composite membrane comprises at least one bottom membrane layer, wherein the at least one bottom membrane layer contains polymers and nano particles dispersed in the at least one bottom membrane layer; and the water flux of the forward-osmosis organic-inorganic composite membrane is larger than 12L*m<-2>*h<-1>. The invention further discloses a preparation method of the forward-osmosis organic-inorganic composite membrane. The forward-osmosis organic-inorganic composite membrane has the larger contact area with water and has the better hydrophilicity, so that the water flux of the forward-osmosis organic-inorganic composite membrane is increased to a greater degree. Besides, the antibacterial property of the forward-osmosis membrane can be improved remarkably, so that the defect that traditional forward-osmosis organic-inorganic composite membranes are prone to microbial pollution in water treatment environments is overcome, the service life of the forward-osmosis membrane is prolonged, and the membrane is a new forward-osmosis organic-inorganic composite membrane with the wide application potential.

Owner:NINGBO LIANHUA ENVIRONMENTAL SCI & TECH

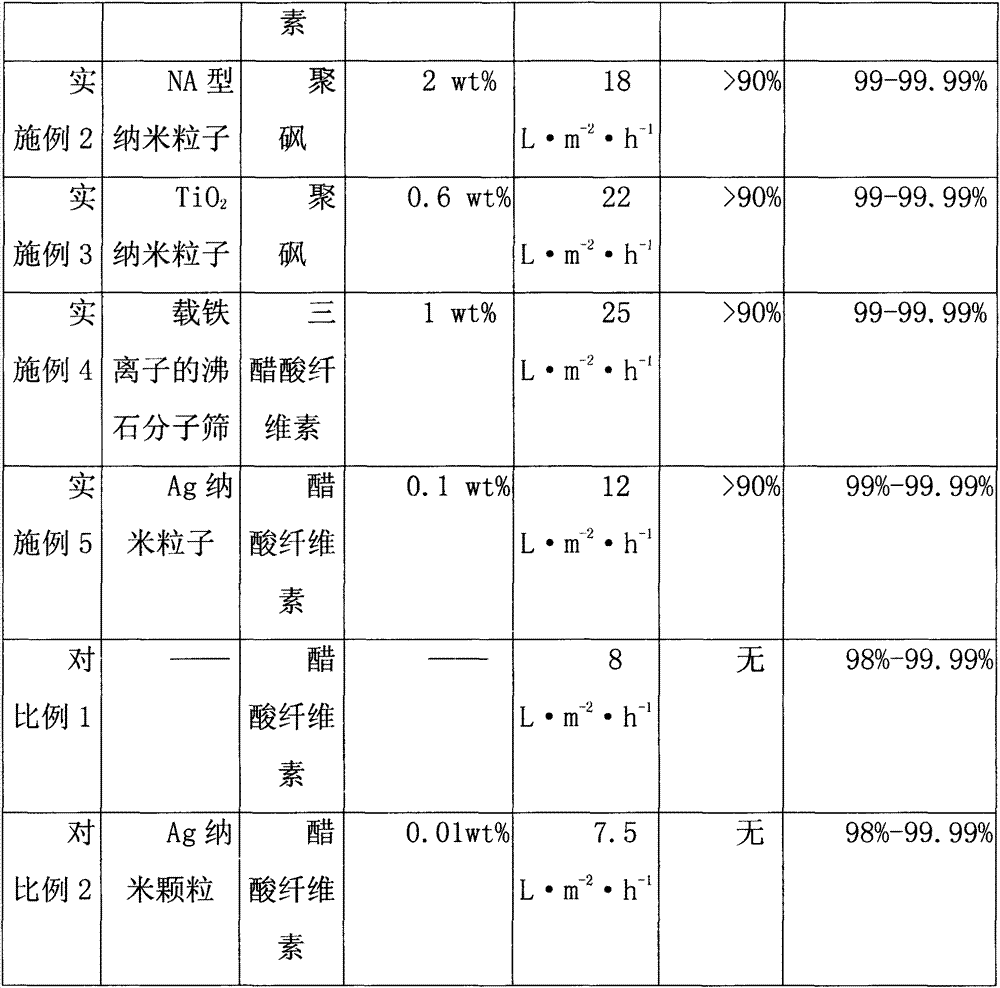

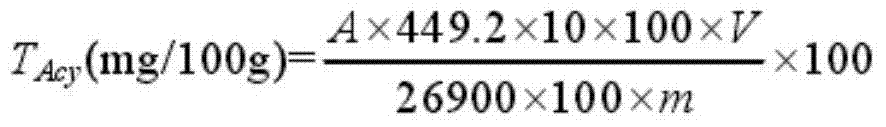

Method for producing blueberry fruit cake by utilizing blueberry residues

InactiveCN103892154AAvoid churnAvoid exposure to oxidationFood freezingFood thermal treatmentFreeze thawingFruit cake

The invention provides a method for developing fruit cakes by utilizing blueberry juice residual residues as a raw material. The method comprises the following steps: directly performing vacuum freezing chopping treatment on frozen blueberry residues without melting and pulping, accelerating the dissolution of active ingredients in a manner of combining ultrasonic emulsification treatment with proper heat treatment, wherein the manner replaces a traditional boiling process, performing high-pressure pasteurization, and finally cooling and molding. Part of macromolecular hydrophilic colloid is added before sterilization, and the gel strength and the shape maintenance are improved. The method is simple to operate, low in heat treatment strength and short in time, and repeated freeze thawing and high-strength heat treatment of a product are avoided. Therefore, the method has the advantages that the microbial pollution probability is low, the retention rate of the effective active ingredients is high, the sensory quality is excellent, the shape maintenance at the temperature of 37-42 DEG C is good and the like.

Owner:ZHEJIANG UNIV OF TECH +1

Environment-friendly alcohol-free fountain solution for offset printing and preparing method thereof

InactiveCN104960354AMeet high viscosity requirementsControl and prevent pollutionPrinting pre-treatmentEthylenediamineBetaine

The invention discloses an environment-friendly alcohol-free fountain solution for offset printing and a preparing method thereof. The solution is prepared from, by weight, 4-7 parts of lauryl polyoxyethylene, 6-8 parts of coconut diethanolamide, 3-5 parts of petroleum sodium sulfonate, 4-6 parts of potassium pyrophosphate, 10-14 parts of trisodium citrate, 8-10 parts of Arabic gum, 4-5 parts of dodecyl polyglucoside, 2-4 parts of hydroxyethyl ethylenediamine, 7 parts of dimethyl dodecyl amine oxide, 2-3 parts of di-o-tolyl-thiourea, 1-2 parts of sodium carboxymethylcellulose, 0.6-0.8 part of methylisothiazolinone, 4-5 parts of Turkey red oil, 0.8-1.2 parts of ethylene diamine tetraacetic acid tetrasodium, 0.6-0.8 part of tea saponin, 3-5 parts of dipropylene glycol methyl ether, 3-4 parts of dodecyl betaine type phosphate, 2-3 parts of sodium hexametaphosphate, and 120-140 parts of deionized water. According to the fountain solution, alcohol of any kinds is not added, no volatile harmful substance is contained, environment friendliness is realized completely, no harm can be done to the human body, a quite strong microorganism killing effect can be realized, microbial pollution of the fountain solution can be controlled and prevented, metal parts can be prevented from being corroded, and a printing plate and a printing machine are prevented from being damaged by early water.

Owner:李子健

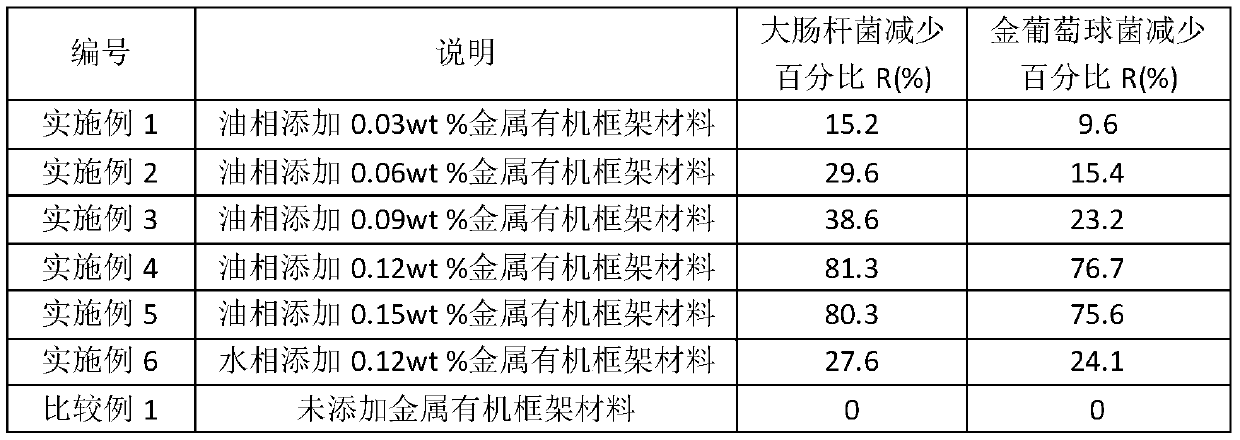

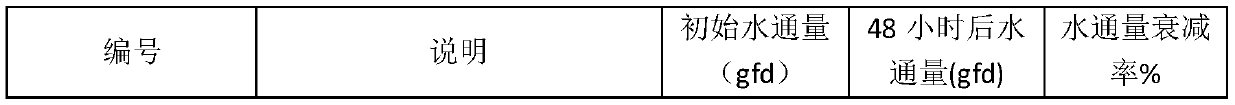

MOF-modified antipollution composite reverse osmosis membrane and preparation method thereof

InactiveCN110449046APlay a bactericidal effectImprove hydrophilicityGeneral water supply conservationWater contaminantsMicrobial pollutionMetal-organic framework

The invention belongs to the technical field of seawater desalination, and particularly relates to an MOF-modified antipollution composite reverse osmosis membrane and a preparation method thereof. The composite reverse osmosis membrane comprises a polysulfone support layer and a desalination layer, the desalination layer is a polyamide composite membrane loaded with a copper-1,4-benzenedicarboxylate metal organic framework material, and the copper-1,4-benzenedicarboxylate metal organic framework material has a pore size of 0.52 nm. The invention also provides the preparation method of the MOF-modified antipollution composite reverse osmosis membrane. The MOF-modified antipollution composite reverse osmosis membrane prepared in the invention effectively reduces organic pollutants adsorbedto the surface of the composite reverse osmosis membrane, and copper ions on the surface of the membrane have a sterilization effect, so that the composite reverse osmosis membrane has the function ofresisting organic pollution and microbial pollution; and the water flux of the composite reverse osmosis membrane increases significantly while keeping the desalination rate unchanged.

Owner:恩泰环保科技(常州)有限公司

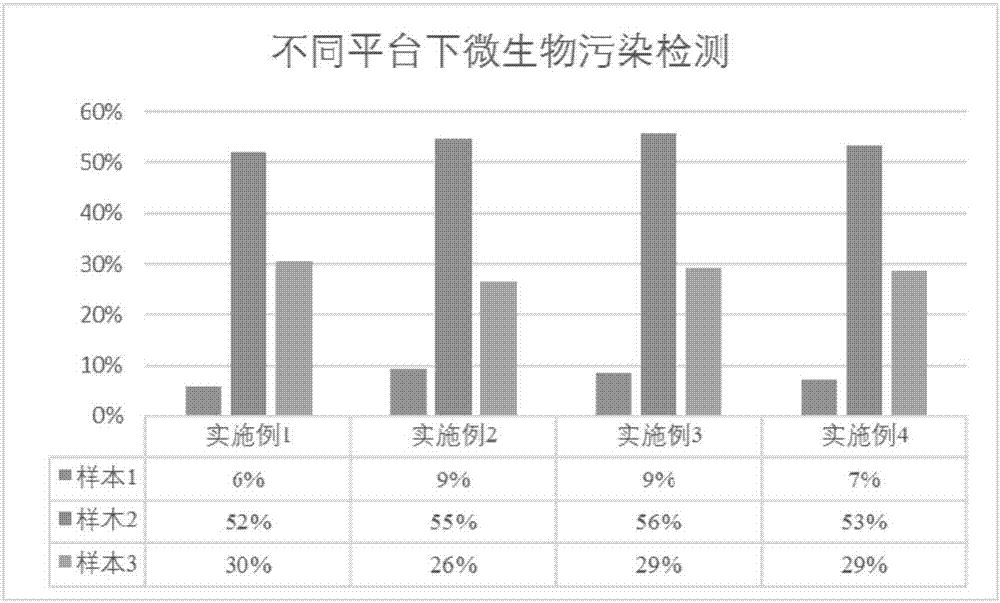

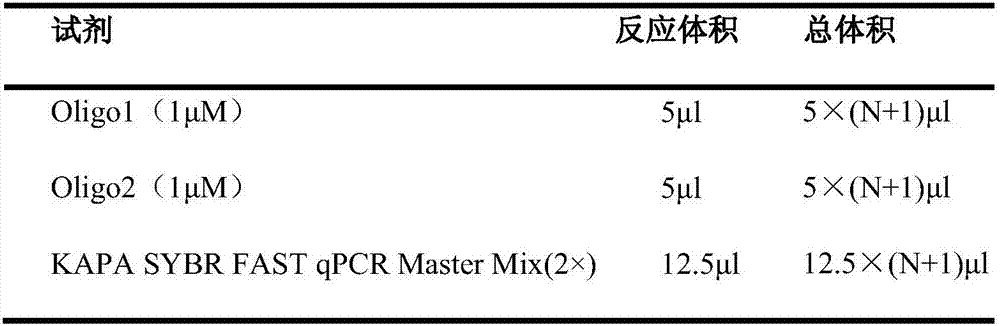

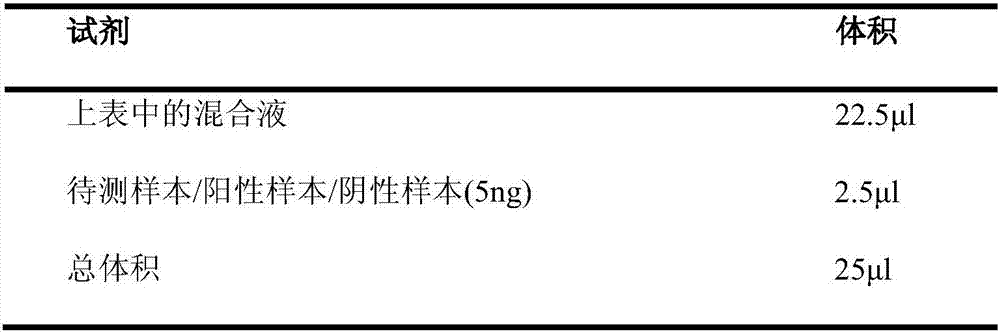

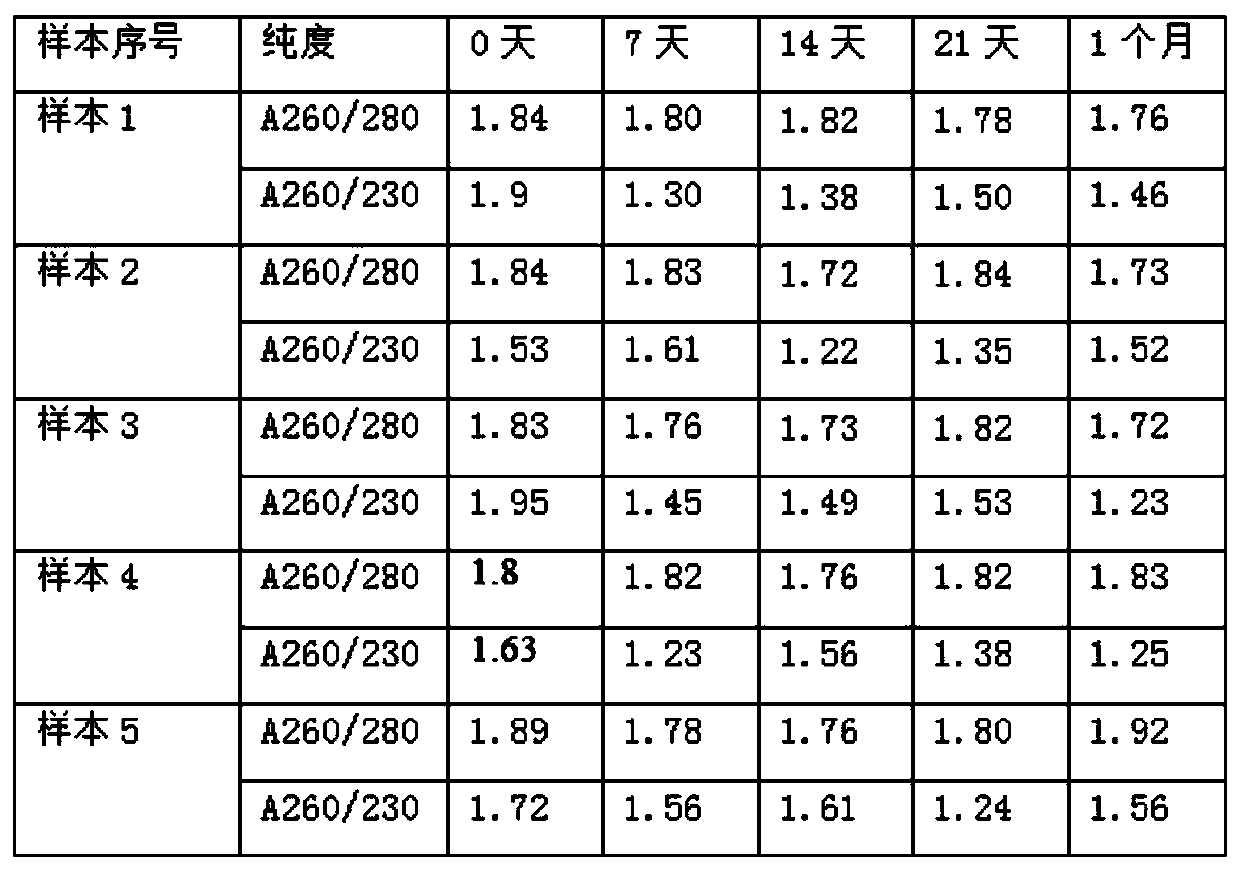

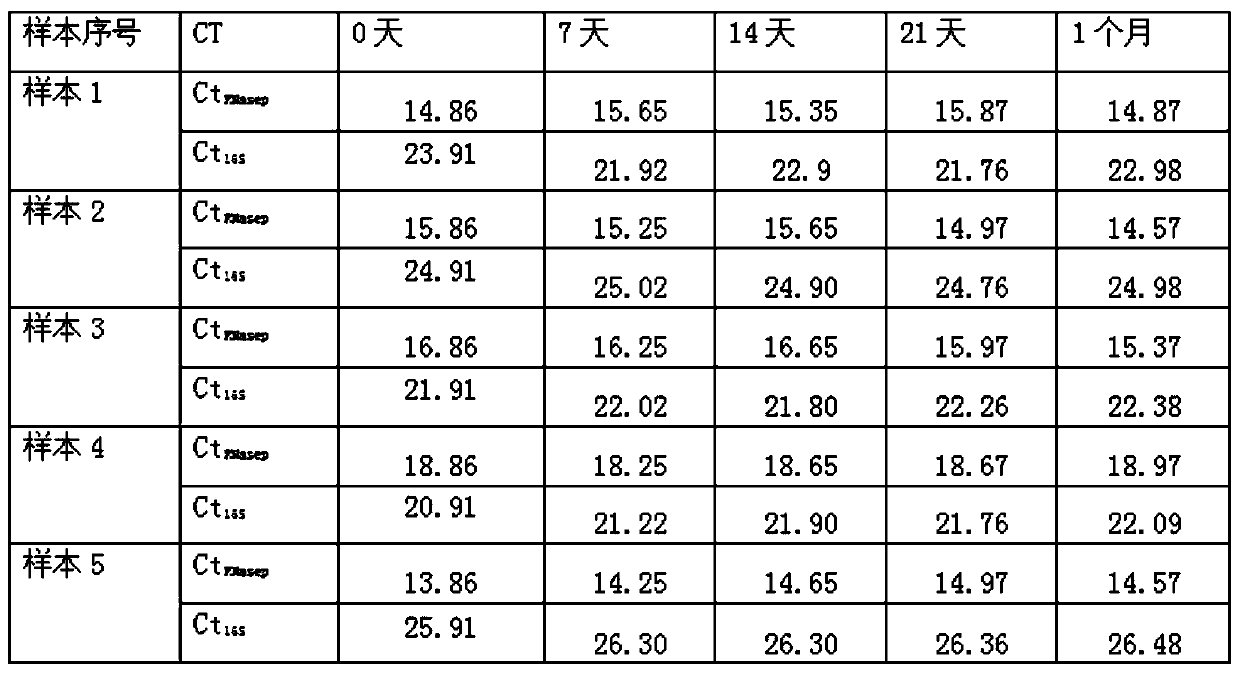

Reagent and kit for quickly detecting microbial pollution of saliva DNA, and application thereof

InactiveCN106916889AEffective detection of contamination levelsGuaranteed reliabilityMicrobiological testing/measurementMicroorganismMicrobial pollution

The invention discloses a reagent and a kit for quickly detecting microbial pollution of saliva DNA, and applications thereof. The reagent includes a first primer and a second primer. A detection method includes the steps of: 1) providing the reagent or the kit for quickly detecting microbial pollution of saliva DNA; 2) uniformly mixing a to-be-detected saliva DNA sample, the reagent for quickly detecting the microbial pollution of saliva DNA and a regular component for PCR amplification detection, and performing PCR amplification. The reagent has simple configuration, is simple in operation and short in time consumption, is low in cost, is free of special technical training and special instruments and devices, can effectively detect the degree of the microbial pollution in saliva DNA, effectively guarantees reliability of application of a next-generation sequencing targeted capturing technology in medical examination, and greatly reduces experiment and cost risks due to failure of subsequent experiment, which is caused by the microbial pollution of a saliva DNA sample, thereby ensuring that the saliva DNA is used for downstream molecular biological detection.

Owner:SUZHOU ZHONGXIN BIOTECH

Cooling method capable of quickly reducing center temperature of postmortem pig carcass

InactiveCN102308868AFood processingMeat/fish preservation by freezing/coolingMicrobial pollutionEngineering

The invention relates to a new method capable of quickly reducing center temperature of postmortem pig carcass through two-stage cooling. The method comprises the following steps of: in the first stage, placing a pig half carcass, which is slaughtered, cut into a half and washed ultrasonically to reduce bacteria, into a large-scale vacuum cooling machine; starting a refrigerating system and a vacuum pump of the vacuum cooling machine; performing vacuum cooling for 20 to 30 minutes under the vacuum degree of more than 610 Pa, so that the center temperature of the half carcass is reduced to about 20 DEG C quickly; taking out from the vacuum cooling machine; and entering the second stage to perform conventional air cooling, namely cooling in an air cooling storage for 2 to 16 hours under the conditions of temperature of between 0 and 4 DEG C, air speed of about 0.5 to 1 m / s to reduce the center temperature of the half carcass to 0 to 4 DEG C, wherein water supplementation (spraying 1 to 3 percent of cold tap water at the temperature of between 0 and 4 DEG C) is necessary before and after vacuum cooling and in the vacuum cooling process so as to make up for water loss of the pig half carcass in the vacuum cooling process. In the treatment method, the vacuum cooling method adopted in the first stage has the effects of effectively reducing cooling time, saving energy consumption, reducing occurrence rate of pale, soft and exudative (PSE) pork, improving processing efficiency and reducing microbial pollution, so the method is safe, sanitary and environment-friendly.

Owner:QINGDAO AGRI UNIV +1

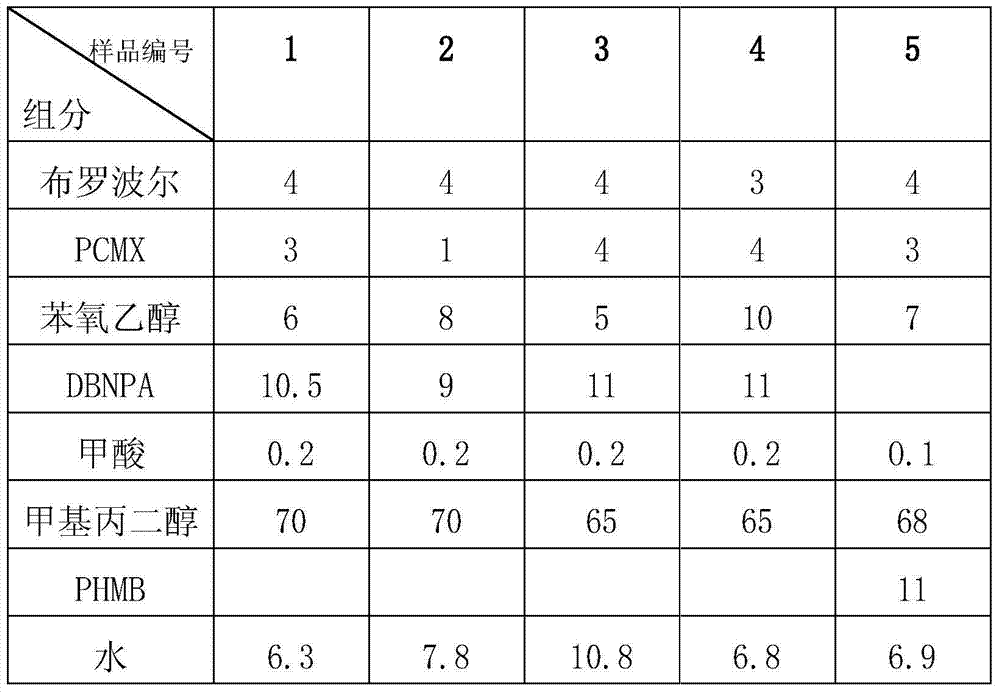

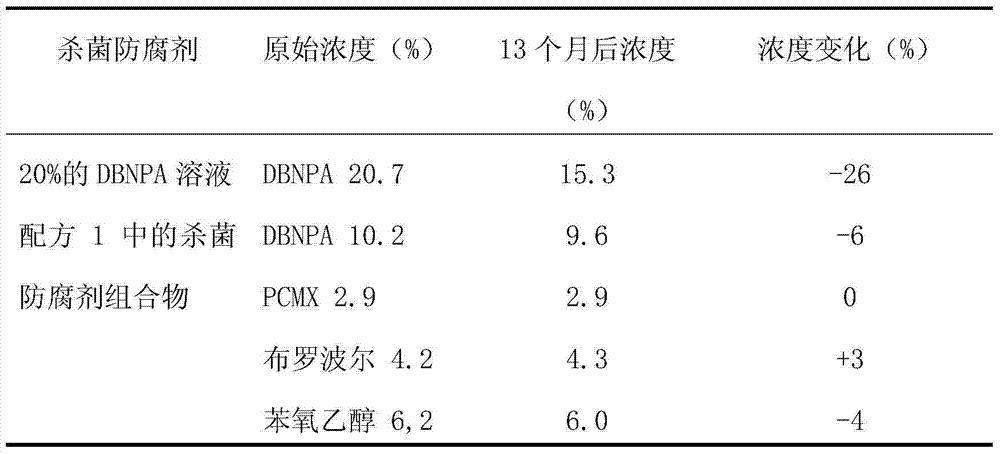

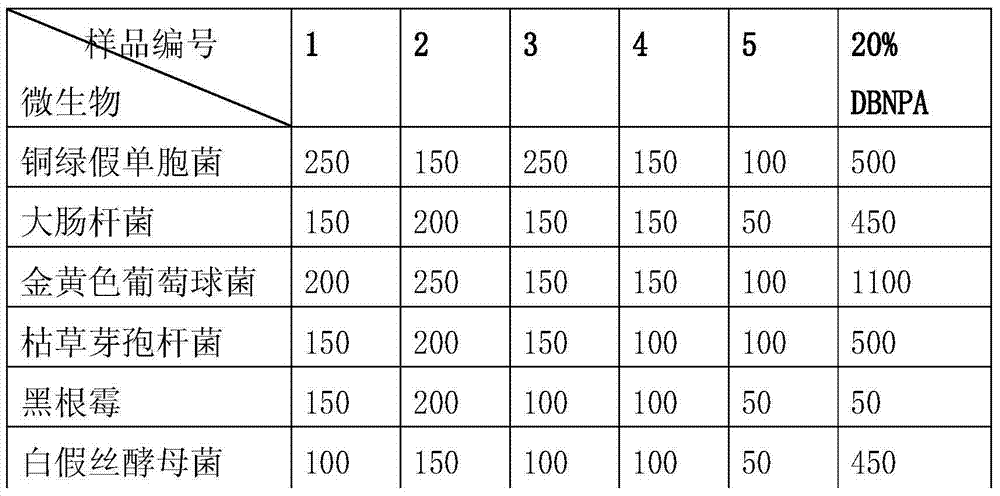

Bactericidal and preservative agent combination for repair-regeneration of microbial pollution products

The invention relates to a bactericidal and preservative agent combination for the repair-regeneration of microbial pollution products, which comprises the following active ingredients: a preservative agent A, a preservative agent B, a bactericide, solvents, additives and water, wherein the preservative agent A is formed by bronopol, the preservative agent B is formed by parachlorometaxylenol PCMX and a phenoxyethanol mixture, and the bactericide is formed by 2,2-dibromo-3-nitrilo-propionamide DBNPA or polyhexamethylene biguanidine hydrochloride PHMB. Through one-time addition, the bactericidal and preservative agent combination disclosed by the invention has strong synergistic, preservative and bactericidal effects, and can concurrently have the functions of bactericidal repair and corrosion and mildew prevention in the period of re-storage, thus most of industrial water-based products metamorphosed by microbial pollution are reused. The bactericidal and preservative agent combination disclosed by the invention has the advantages of reasonable formula, advanced process, high cost performance, low toxicity, good operational feasibility, bactericidal and preservative effect, and the like, and is verified through a lot of industrial practices.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

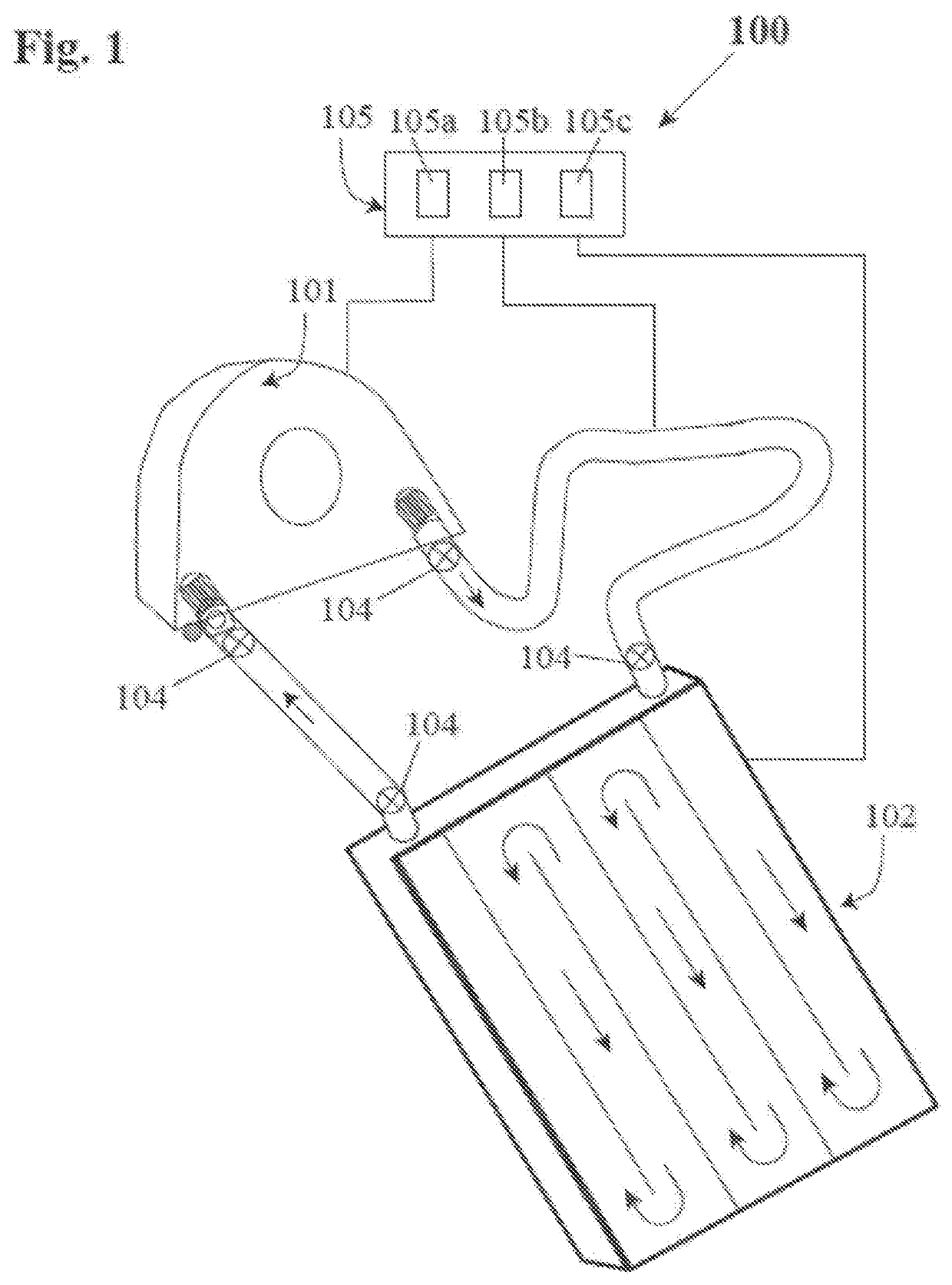

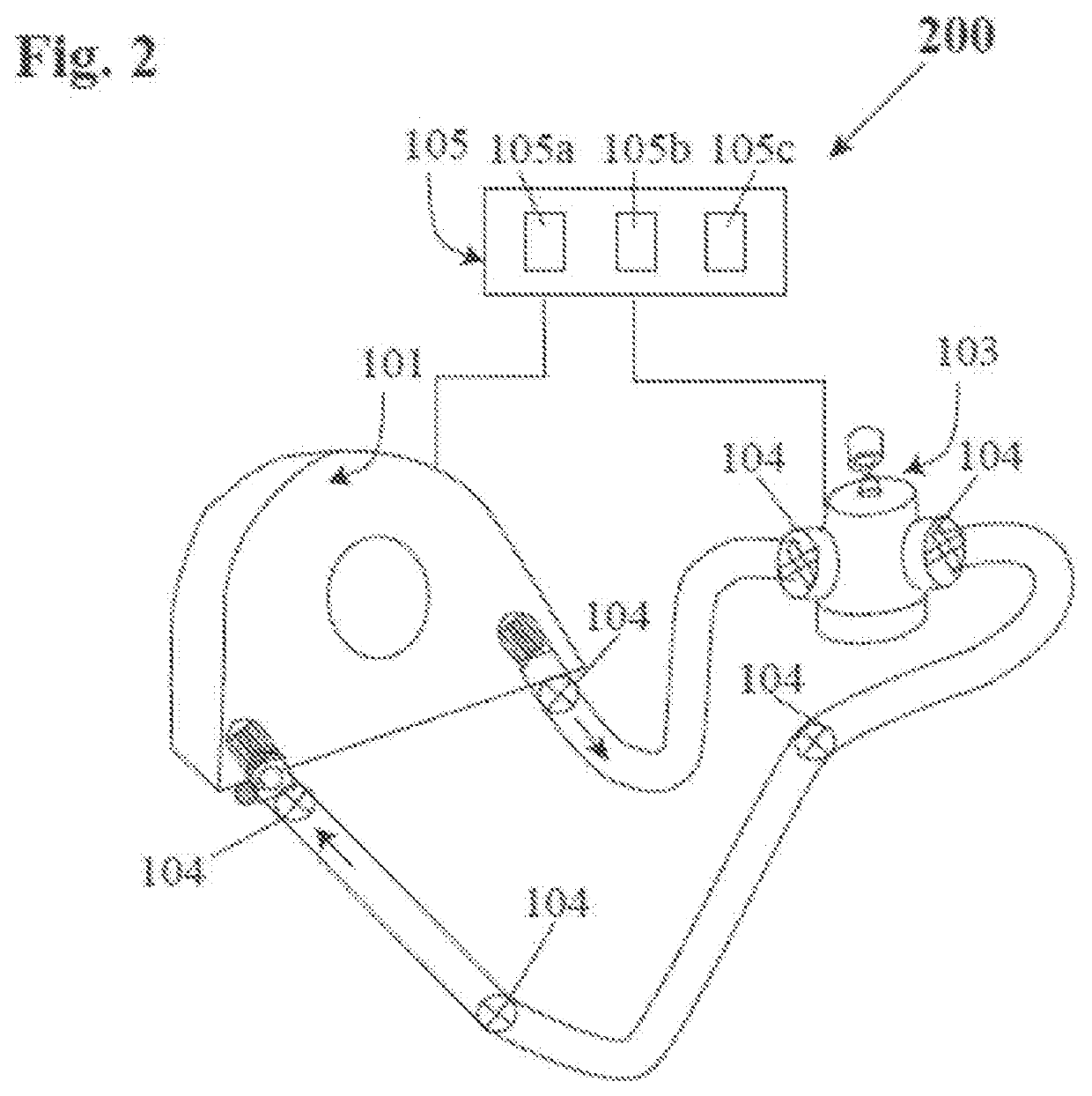

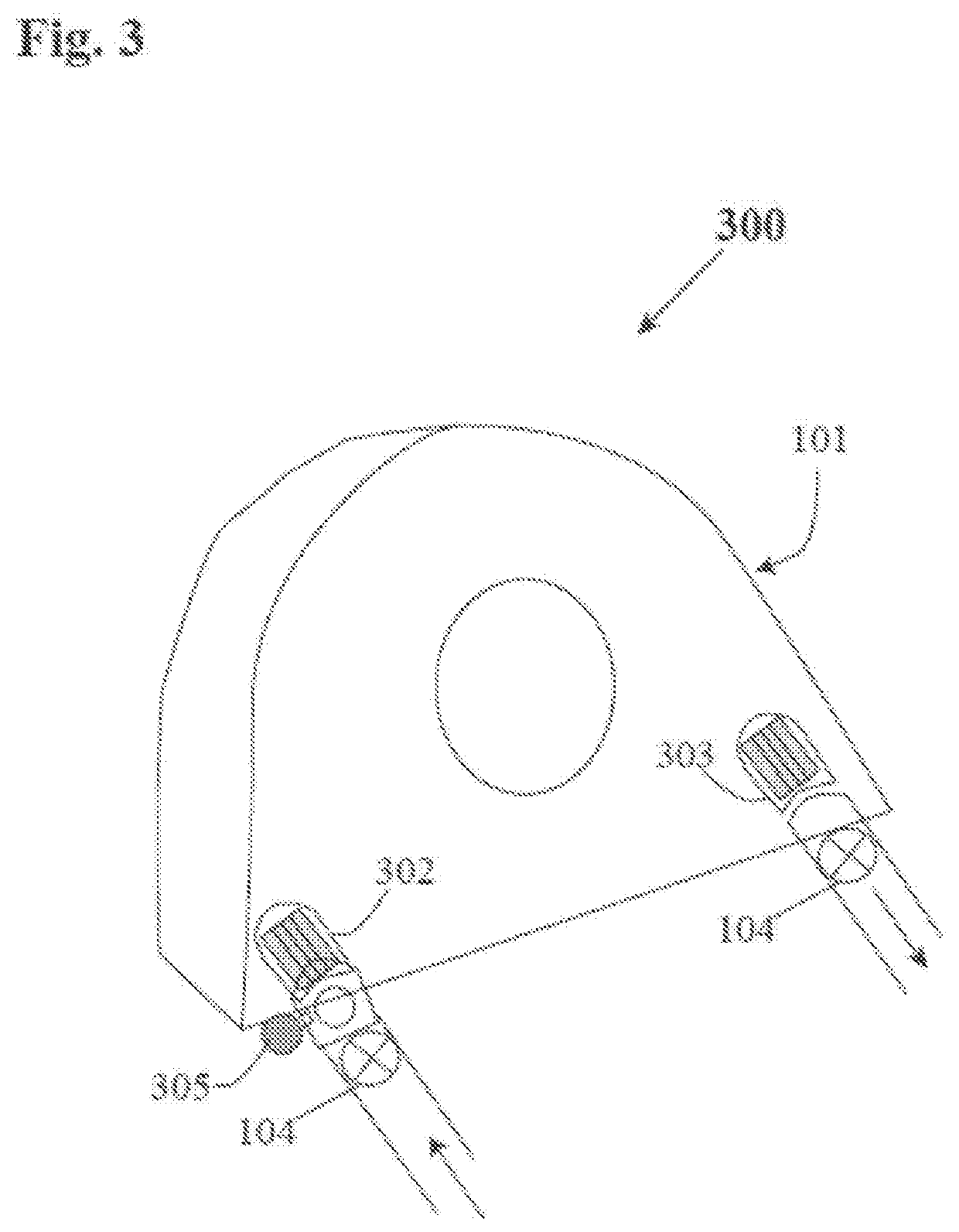

Mist generator for sterilizing forced air systems

PendingUS20200345885A1Improve sterilityReduce Microbial ContaminationRespiratorsMedical devicesAir cycleUltraviolet lights

A mist generator is a standalone device that improves the internal sterility of controlled forced air systems. Sterilizing mist is generated when forced air circulates above or through a liquid disinfectant. The disinfectant is taken up into the circulating air and distributed throughout the internal structure of the system, sterilizing its internal surfaces. The mist generator contains no ionizers, atomizers, ultraviolet lamps, or other electric or mechanical devices.In one embodiment, the mist generator has a chamber with an inlet adapted for attachment to a blower or duct delivering forced air into the chamber. The chamber also includes an output duct or aperture adapted for attachment to a second hose which, in turn, is adapted for attachment to the inlet of the blower for delivery of disinfectant-misted air through internal components of the blower. Alternatively, there is used a disinfectant filter formed as a sterilizing grid having a screen coated with a soft porous surface material impregnated with a liquid disinfectant. The soft porous surface material releases said liquid disinfectant when forced air moves through the filter and through the system. In both embodiments, sterile water can be introduced to take up residual disinfectant and the vapor is captured in a dry filter or desiccant material and removed from the system.In the alternative embodiment, the sterilizing mist produced by the uptake of liquid disinfectant into circulating air and distributed throughout the forced air system can be formed when air from a blower or air handler is circulated across a sterilizing screen with a porous surface material impregnated with a liquid disinfectant. The antimicrobial mist is distributed throughout the system and acts to disinfect the internal surfaces and components. Additional water may be added to the sterilizing screen and distributed similarly by the forced air. A dry, desiccating filter, remote from the blower, traps the water and any residual disinfectant as it exits from the system. A dehumidifier, if installed, may also be used to remove water and can be readily emptied.The mist generator improves the sterility of the blower and mitigates microbial contamination of forced-air delivery systems.

Owner:LEWIS RANDALL J

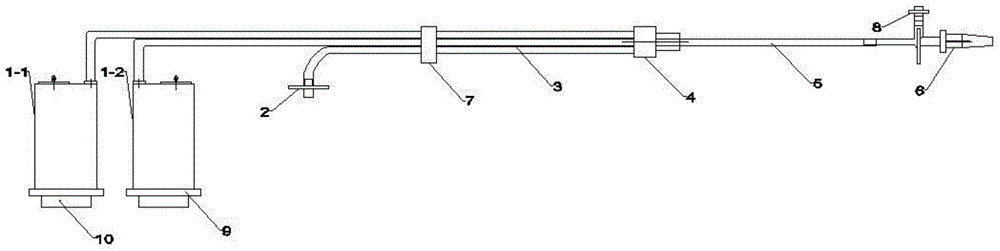

Fully closed membrane filter for sterile examination of sterile packaging interlayer and detection method of fully closed membrane filter

ActiveCN105670916AReduce secondary pollutionLow costBioreactor/fermenter combinationsBiological substance pretreatmentsTest articleMicrobial pollution

The invention relates to the field of sterile detection, in particular to a fully closed membrane filter for sterile examination of a sterile packaging interlayer and a detection method of the fully closed membrane filter. The fully closed membrane filter comprises two bacterium collecting incubators and an air filter device, wherein the two bacterium collecting incubators and the air filter device are connected to one end of a three-phase circulator by virtue of a conduit; the other end of the three-phase circulator is connected to a sterile sampling needle by virtue of a detection tube; and an intercepting clip is arranged on the part, close to the three-phase circulation valve (the three-phase circulator), of the conduit. By virtue of the fully closed membrane filter disclosed by the invention, secondary pollution on leaching liquor during operating is reduced, a microorganism detection rate is improved and an experimental result is better guaranteed. The circulation of medicine liquid in a sealed space is achieved and the medicine liquid is prevented from getting into contact with external side, so that the fully closed membrane filter plays a great role in the prevention of microbial pollution. Meanwhile, as for operation time, the experimental operation time is shortened by half, the detection efficiency of test article sterile examination is greatly improved, and a detection pollution rate is reduced to be less than 5% from original 20-25%.

Owner:HUAREN PHARMACEUTICAL CO LTD

Novel saliva preserving fluid as well as preparation method and application thereof

PendingCN111020001AEasy to storeStable weak alkaline environmentMicrobiological testing/measurementSodium acetateSodium sorbate

The invention relates to a novel saliva preserving fluid comprising the following components: 1-10mmol / L of EDTA, 1-50mmol / L of Tris-HCl, 10-100 mmol / L of sodium chloride; 0.1-3% (w / v) of sodium sorbate, 0.1-3% (w / v) of sodium diacetate, 0.01-0.1% (v / v) of proclin 300, 0.1-1% (v / v) of TWEEN20, 0.1-1% (w / v) of NP40 and 0.1-2% (w / v) of SDS. The novel saliva preserving fluid is used for preservingsaliva samples, can effectively inhibit nuclease activity, prevent microbial pollution, guarantee DNA fragment integrity and purity, simplify pretreatment steps, is suitable for centrifuge-free and low-temperature environments, can guarantee transport stability of samples among different places, and is suitable for molecular epidemiological large-scale population investigation and research.

Owner:申友基因组研究院(南京)有限公司

Processing method of freshly brewed pear wine

InactiveCN101974387AIncrease the sugar contentEasy to keepAlcoholic beverage preparationMicroorganism based processesFlavorMicrobial pollution

The invention discloses a processing method of freshly brewed pear wine, which comprises the following steps: selecting fresh pears as raw materials, washing and selecting the pears with excellent quality for secondary washing; crushing and pulping the pears after secondary washing to obtain pear pulp; enzymolyzing the pear pulp; extracting and cleaning juice of the enzymolyzed pear pulp to obtain pear juice; freezing, dehydrating and concentrating the pear juice; fermenting the pear juice; separating wine sediments from the fermented pear juice to obtain bulk pear wine; and clarifying and filtering the bulk pear wine to obtain the finished product of the pear wine. In the method, the raw juice is dehydrated by a freeze concentration technology, thus increasing the sugar content of the pear juice; the pear juice is fermented at a low temperature of not more than 15 DEG C for a short time of about 10 days, thus being beneficial to keeping pear flavor and enhancing typicality of the product; and a small amount of nisin from streptococcus lactis is added to prevent microbial pollution.

Owner:潘万财

Method for reducing microbial pollution in indoor air

InactiveCN104436271AQuality improvementReduce pollutionAtomized substancesMicroorganismElectrolysed water

The invention discloses a method for reducing microbial pollution in indoor air. The method comprises the following steps: atomizing slightly acidic electrolyzed water for 15-120 minutes, and jetting the slightly acidic electrolyzed water into the air at a flow rate of 200-300 mL / h, wherein the effective chlorine concentration of the slightly acidic electrolyzed water is 10-30 mg / L, the pH is 4.5-6.5, and the oxidation reduction potential is 700-900 mV. The method disclosed by the invention can be used for indoor sterilizing with people and effectively reducing microbial pollution in the air without corroding furniture, so that no additional protection measure is carried out on indoor decorations, and in addition, the method can also be used for achieving the function of a traditional air humidifier to perfect the indoor air quality by adjusting the relative humidity of the indoor air; the method disclosed by the invention is convenient, efficient and is conducive to promotion and application.

Owner:ZHEJIANG UNIV

Anti-fouling separation membrane and preparation method thereof

ActiveCN102728241BStrong bindingImprove anti-pollution performanceSemi-permeable membranesMethacrylateMethyl carbonate

The invention discloses an anti-pollution separation membrane and a preparation method, wherein aiming at the shortages of a preparation technology for the present anti-pollution PVDF (polyvinylidene fluoride) separation membrane, the invention provides a novel method for preparing an anti-microbial pollution PVDF separation membrane. The novel method provided by the invention comprises the following steps of: synthesising the random copolymer with a zwitterionic structure, of MMA (methl methacrylate), DMC (dimethyl carbonate) and AMPS (2-acrylamido-2-methylpropane sulfonic acid) via free radical polymerization at first, adding the copolymer and a porogenic agent, i.e., polyethylene glycol (PEG) in PVDF, and preparing the anti-pollution separation membrane by using N,N-dimethyl formamide (DMF) as a solvent and using water as a coagulating agent through a phase inversion method. Electropositive quaternary amine group and electronegative sulfonic group exist in the structure of the copolymer simultaneously, and have a binding capacity for water molecules which is much stronger than the binding capacity of traditional polyethylene glycol and the derivatives of the traditional polyethylene glycol, and the formed hydration layer is more stable; therefore, the prepared novel PVDF membrane is lasting in anti-pollution performance.

Owner:TIANJIN POLYTECHNIC UNIV

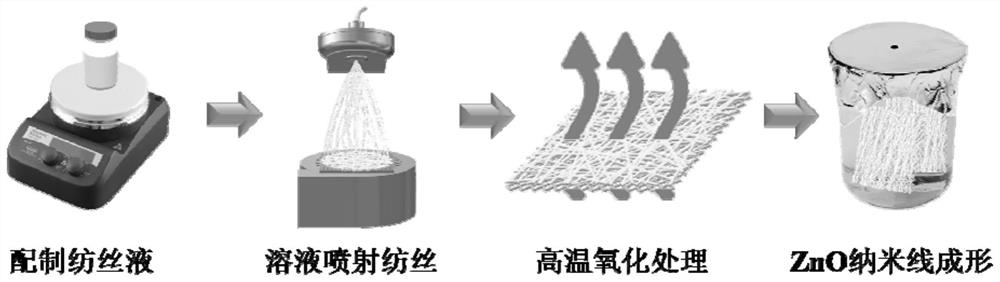

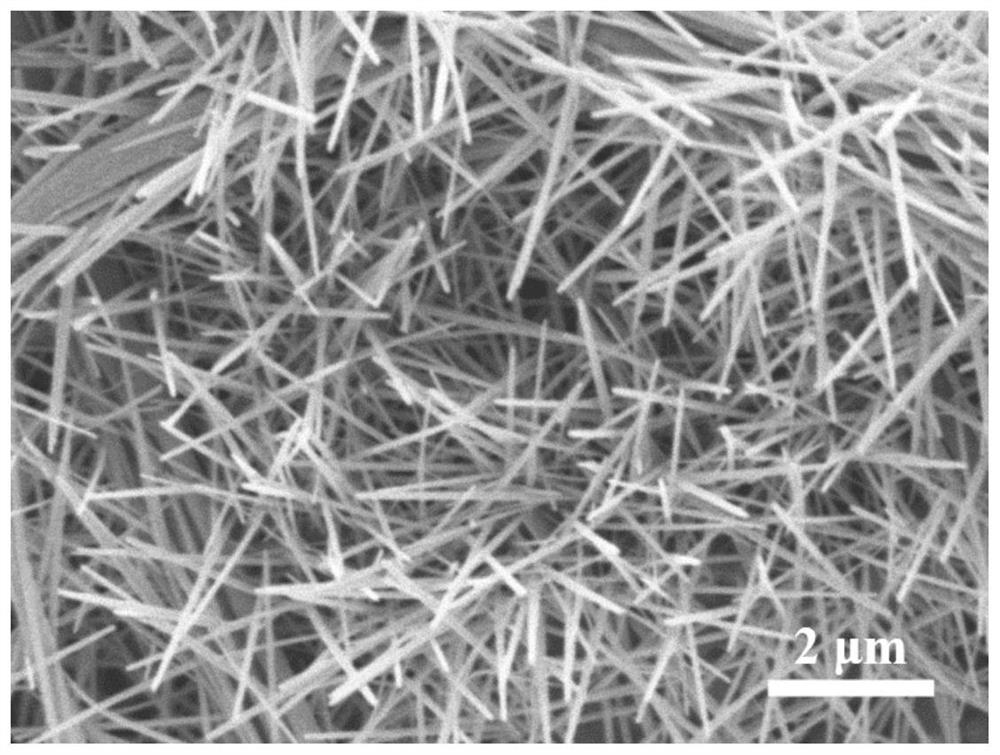

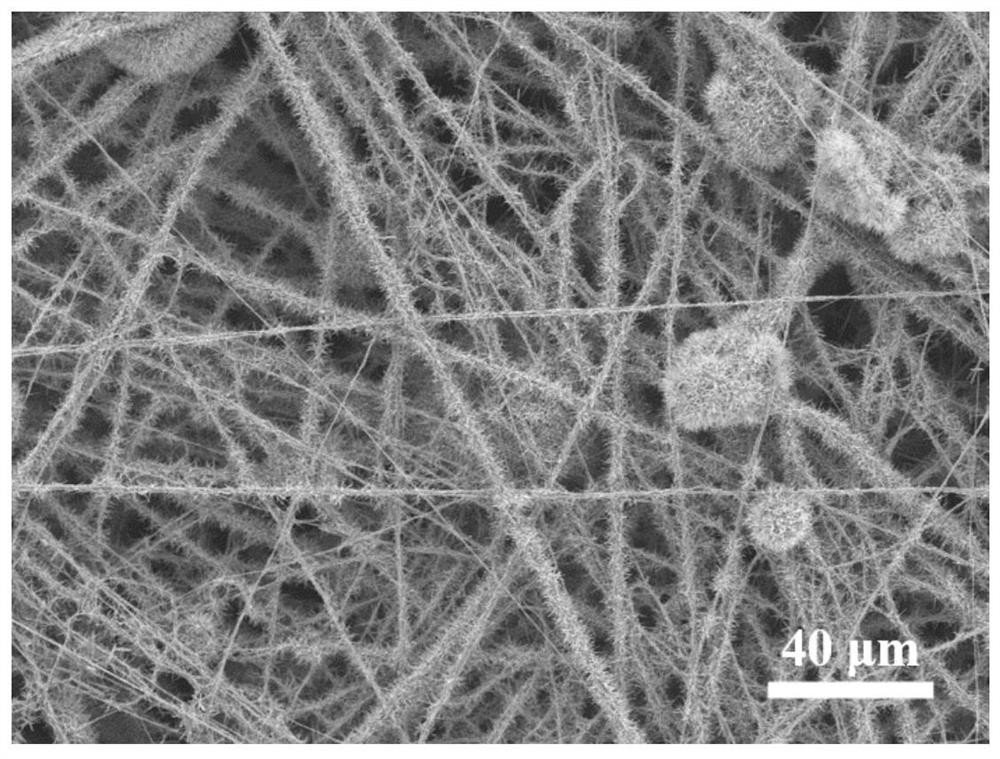

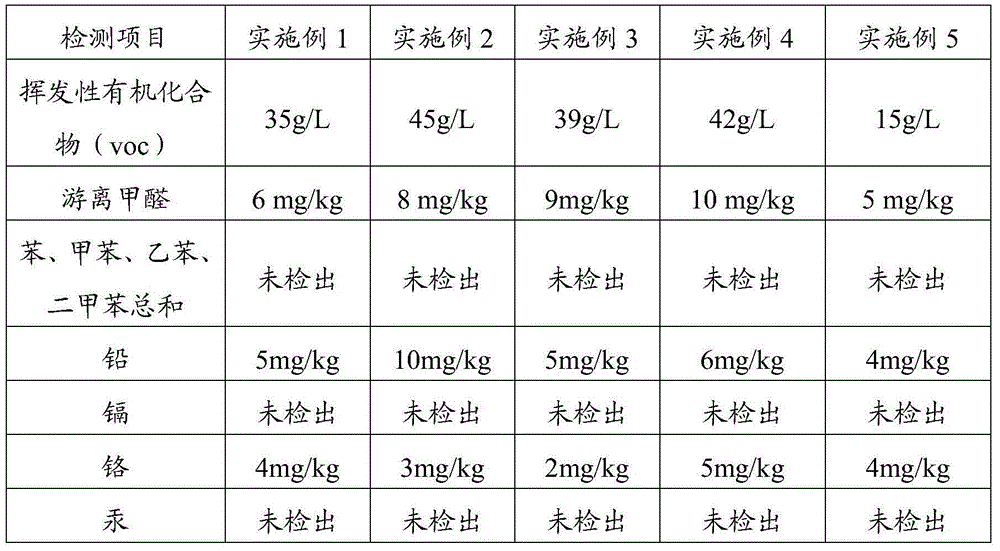

Preparation method of zinc oxide nanowire modified nanofiber filtering membrane

ActiveCN114073897AWettabilityGood antimicrobial performanceMembranesSemi-permeable membranesSpinningAnti bacteria

The invention discloses a preparation method of a zinc oxide nanowire modified nanofiber filtering membrane, and belongs to the field of textile materials. The specific preparation method comprises the steps of dissolving thermal decomposition zinc salt, antibacterial metal salt and a high polymer in an organic solvent, and obtaining a spinning solution; preparing a nanofiber membrane from a spinning solution obtained by solution jet spinning; then drying the nanofiber membrane at a high temperature lower than the viscous flow temperature of a high polymer to obtain a nanofiber membrane loaded with zinc oxide seed crystals; and dissolving thermal decomposition zinc salt and alicyclic amine substances in water to obtain a growth solution, regulating and controlling the pH value, then immersing the obtained nanofiber membrane loaded with the zinc oxide crystal seeds in the growth solution, conducting heating, and obtaining the zinc oxide nanowire modified nanofiber filtering membrane. The zinc oxide nanowire modified nanofiber filter membrane prepared by the method has super-hydrophilic / underwater oleophobic wettability, has stable high temperature resistance and alkali resistance, can resist microbial pollution, and can be used in the fields of oil-water separation, catalysis, industrial waste gas filtration and desulfurization and the like.

Owner:JIANGNAN UNIV

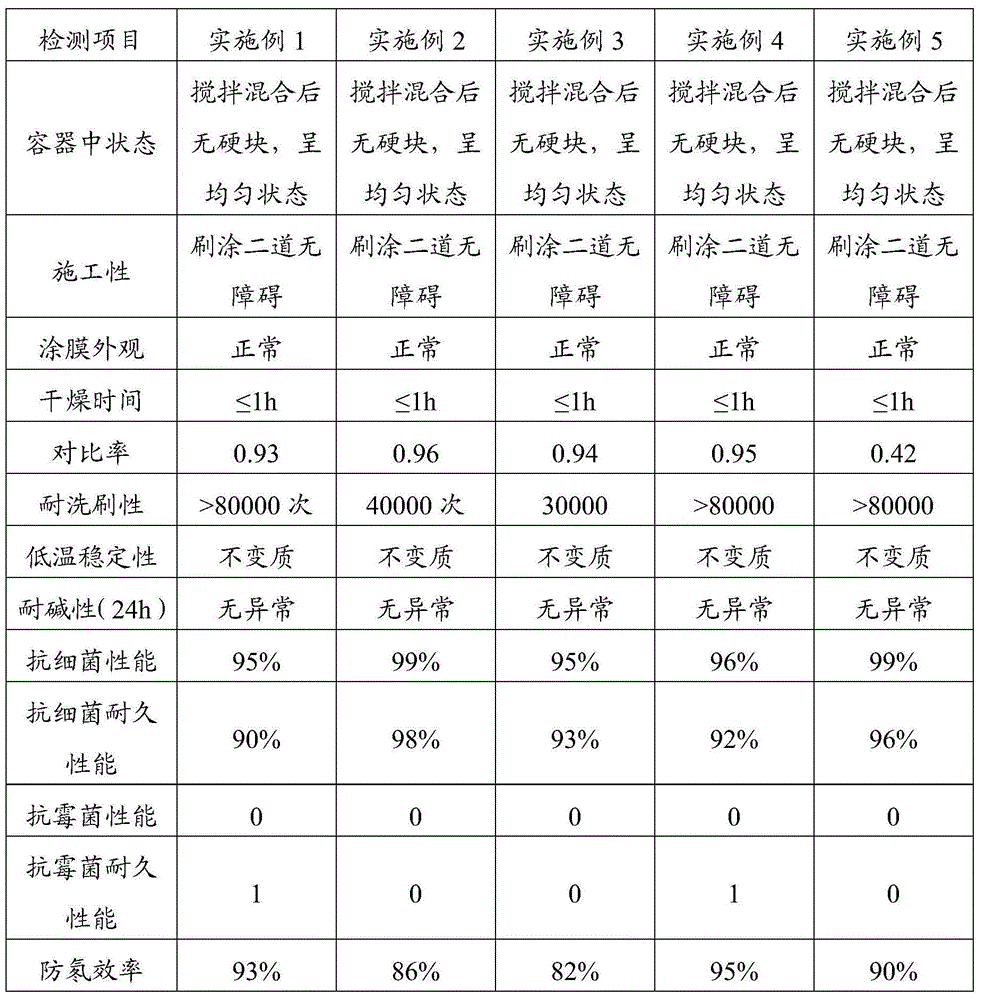

Coating and preparation method thereof

ActiveCN103980770APromote environmental protectionGood scrub resistanceAntifouling/underwater paintsPaints with biocidesEmulsionMicrobial pollution

The invention provides a coating, comprising the following raw materials in parts by weight: 8-18 parts of water, 0.3-1 part of a dispersant, 1-2 parts of a coalescing agent, 1-4 parts of a moldproof antibacterial agent, 0.1-0.5 parts of a defoamer, 2-5 parts of nanometer antibacterial powder, 6-10 parts of a nano adsorbent, 30-50 parts of styrene-acrylic nanometer emulsion, 5-9 parts of nanometer silicone-acrylic emulsion and 0.1-0.3 parts of a pH modifier. The coating provided by the invention forms a shielding film which is poor in breathability and watertight by the styrene-acrylic nanometer emulsion, escape of a radon gas is prevented, meanwhile, the nano adsorbent can absorb radon ions, escape of the radon gas is further reduced, and the nanometer antibacterial powder and the moldproof antibacterial agent act with each other, so that the coating provided by the invention can effectively reduce the concentration of bacteria, and prevent microbial pollution. Therefore, the coating provided by the invention has the antibacterial and radon-proof functions.

Owner:福州展辰新材料有限公司

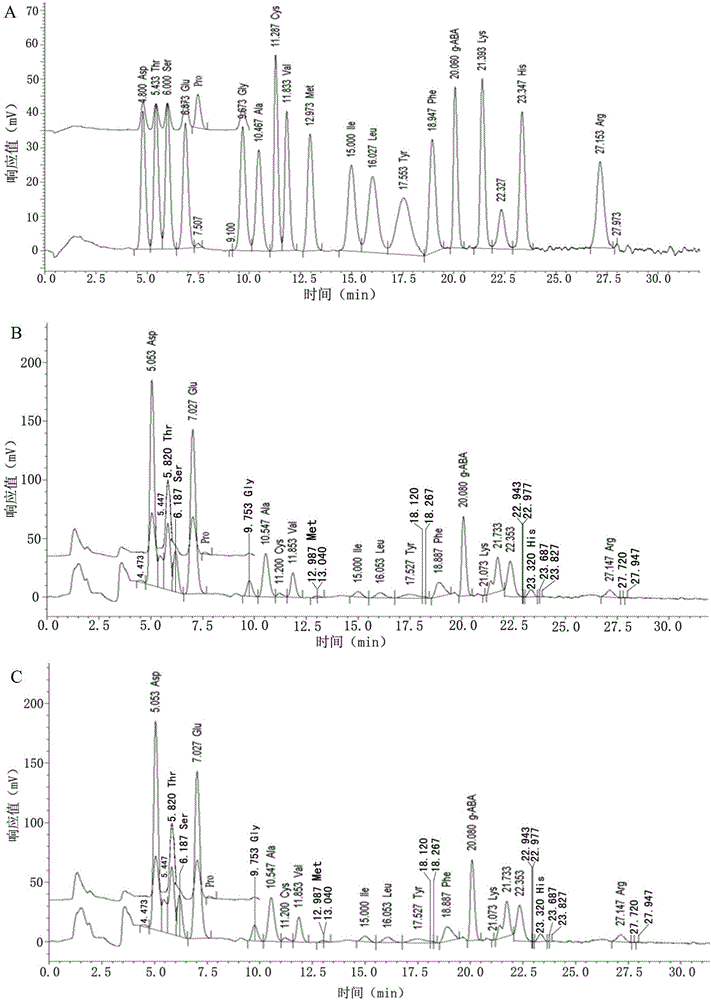

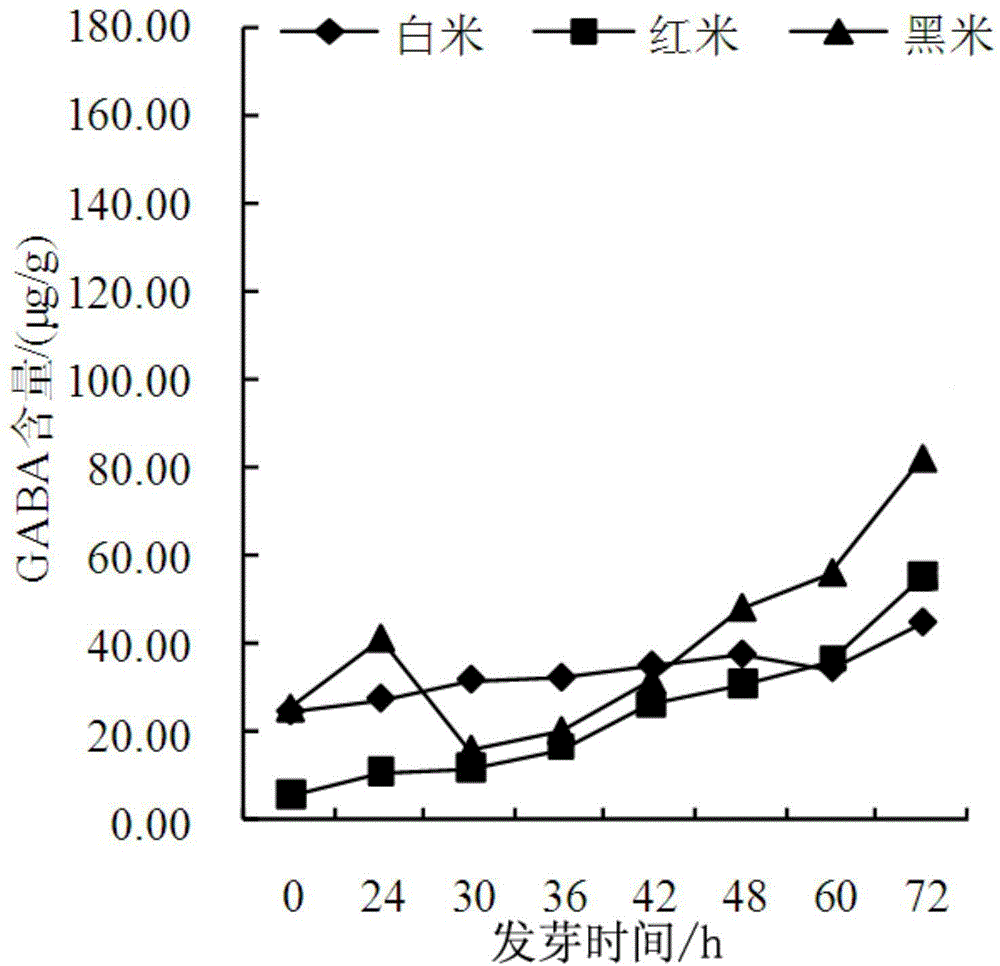

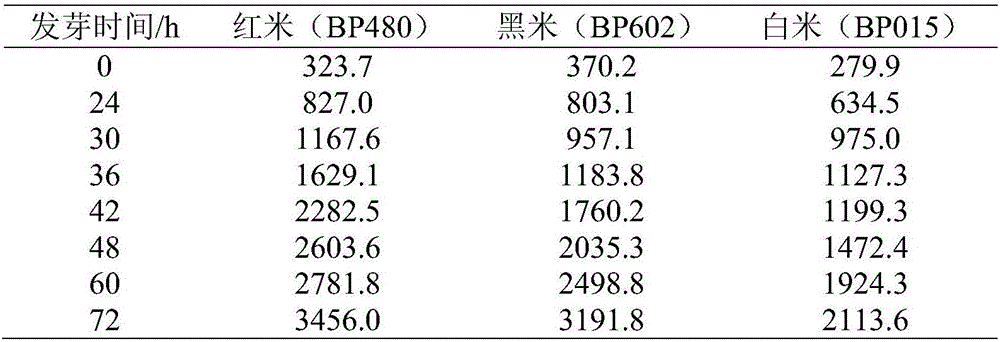

Preparation method of germinated brown rice

The invention discloses a preparation method of germinated brown rice. The preparation method includes the following steps that (1), brown rice is subjected to sterilization processing; (2), the sterilized brown rice is cleaned and then soaked with water at the temperature of 22-28 DEG C for 3-5 hours; (3), the soaked brown rice is germinated for 48-72 hours under the conditions that the temperature is 26-30 DEG C, and relative humidity is larger than 95%; (4), the germinated brown rice is dried, and the germinated brown rice is obtained. According to the preparation method of the germinated brown rice, the brown rice is soaked and germinated after being subjected to sterilization processing, and finally the germinated brown rice is obtained after being dried. By means of the preparation method of the germinated brown rice, the pigment loss can be reduced, microbial pollution is lowered, the content of FAAs is improved, and nutrition quality is improved.

Owner:ZHEJIANG UNIV

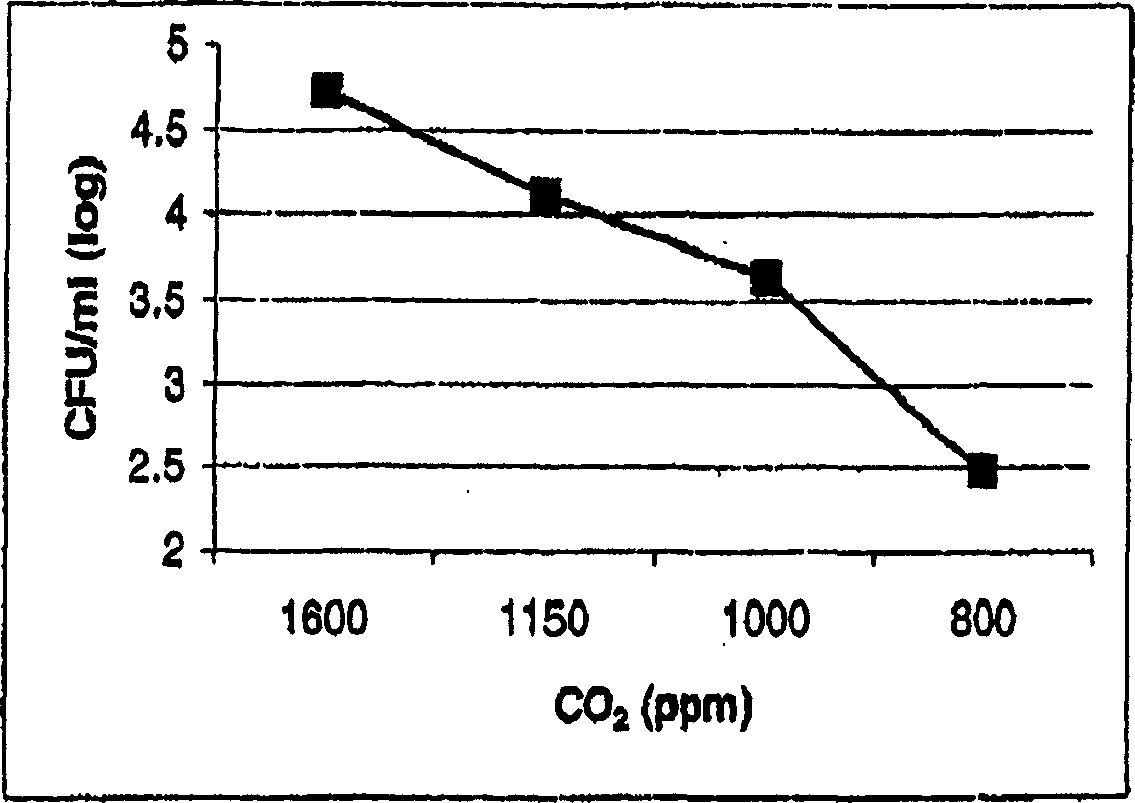

Improved method for controlling polymerized emulsion microbial pollution by using carbon dioxide detection

InactiveCN1495426AAnalysis using chemical indicatorsMicrobiological testing/measurementEmulsionMicrobial pollution

This invention relates to an improved process for the control of biocontamination in aqueous based polymeric emulsions contained in vessels having a headspace. The improvement comprises monitoring the carbon dioxide concentration in the headspace of the vessel using a direct reading carbon dioxide probe; and, then adding biocide when a preselected concentration of carbon dioxide above the atmospheric carbon dioxide concentration is reached.

Owner:AIR PRODS POLYMERS

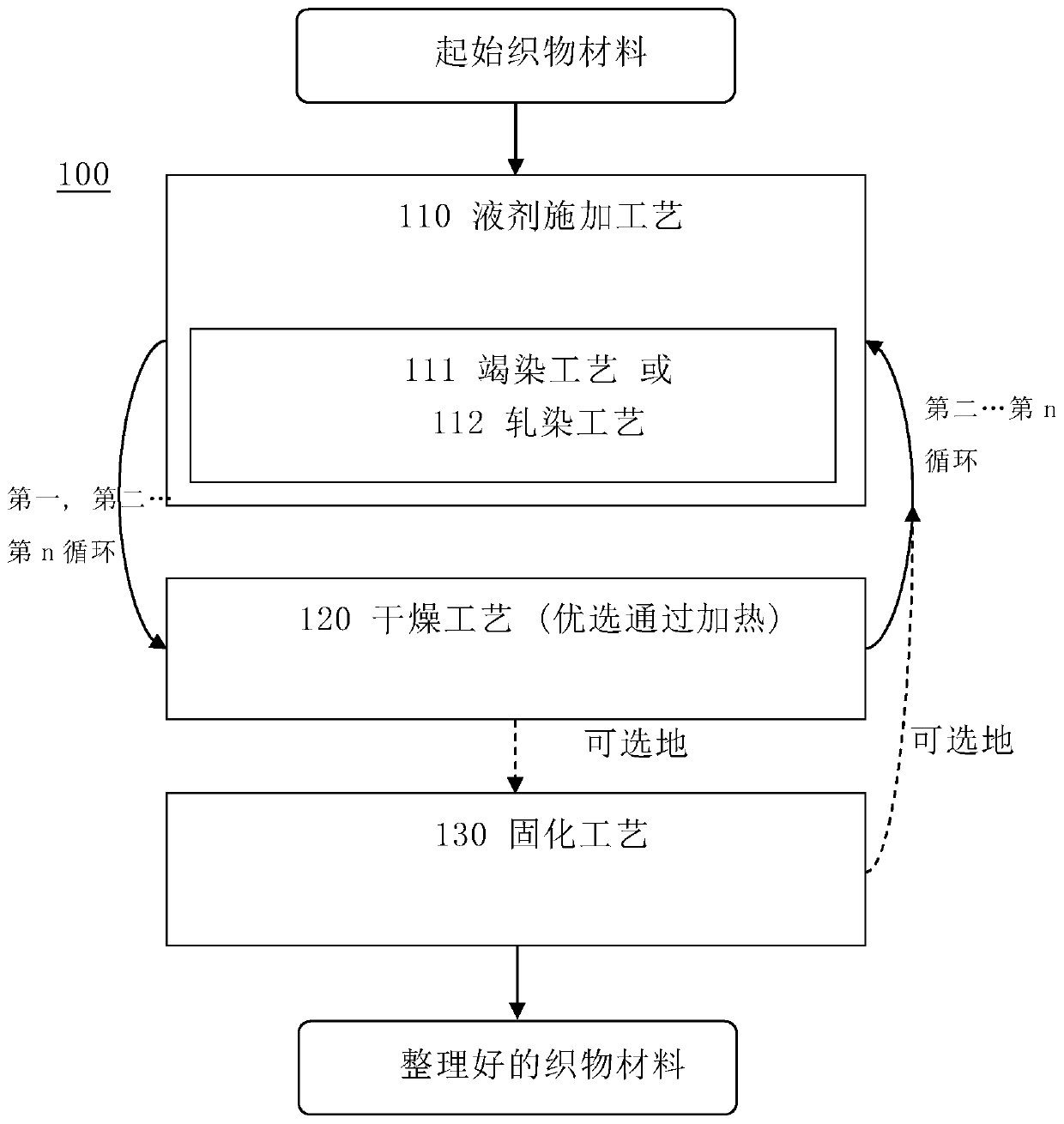

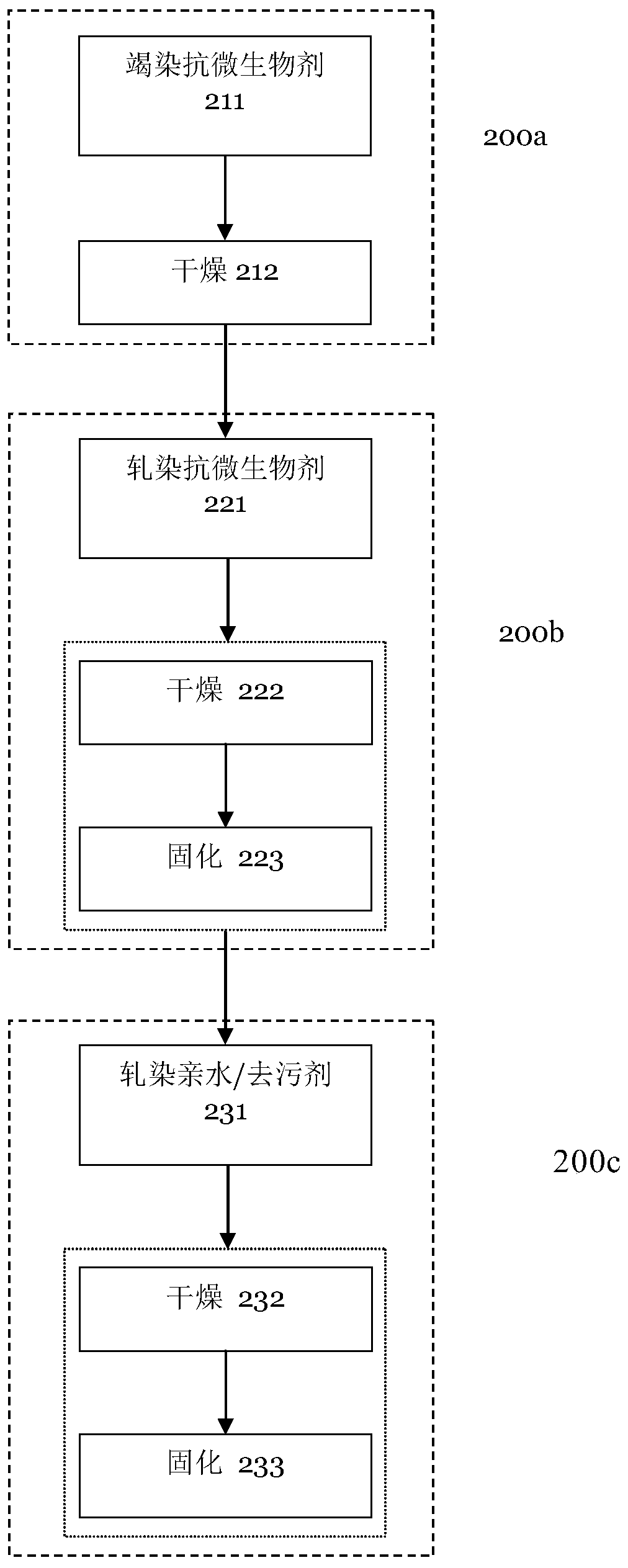

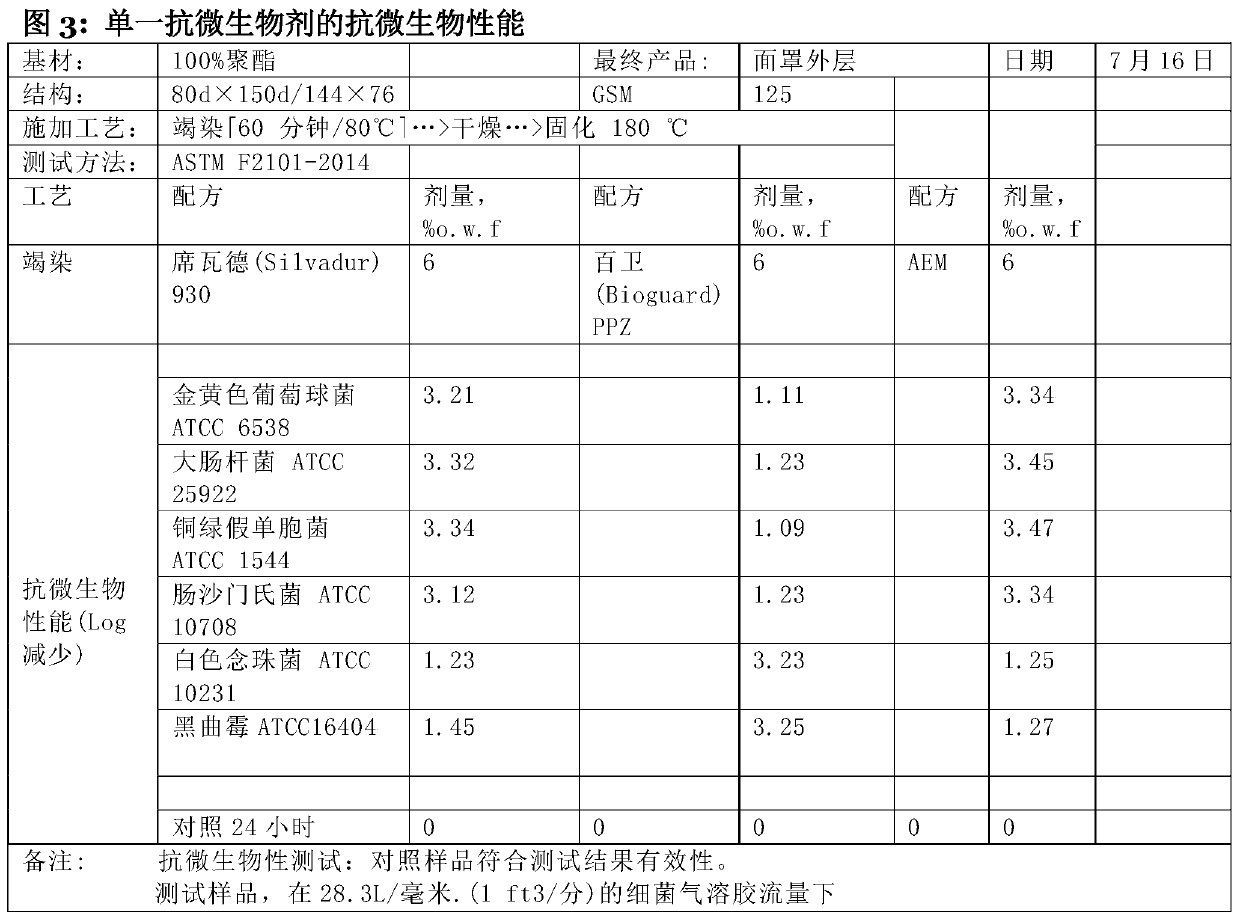

Wash-durable face mask with antimicrobial properties and/or improved washability

InactiveCN109862798AReduce high filtration efficiencyReduce filtration efficiencyBiocideCosmetic preparationsParticulatesEngineering

The present invention is directed to a face mask comprising a multi-layer filter material. One or more antimicrobial and / or hydrophilic and / or stain release agents are adhered to a textile material that forms the outer layers of the multi-layerfilter material. The agent(s) is / are adhered to the textile material in such a manner that they are not released from the textile material even if the facemask is washed, so that the face mask as such is re-usable. The particular arrangement of textile layers of the face mask according to the present invention also allows that the face mask can be washed. That is, the textile and the overall structure of the face mask is preserved albeit the physical stress applied during washing. In preferred embodiments, where one or more antimicrobial agents areadhered to the textile material, the face mask can be used to protect the wearer against airborne particulate and microbial pollution, and, in particular, sanitize the inhaled air. Likewise, the environment, such as other persons, are protected from particles and microbes that are exhaled by the wearer of a face mask according to the present invention. Washability and / or usability of the textile material within the multi-layerfilter material of the face mask is / are improved when one or more hydrophilic and / or stain release agents are adhered to the textile material, which is particularly advantageous to ensure that the face mask is rendered as clean as possible during wash, i.e. that absorbed or adsorbed stains are released from the textile. The invention further relates to a method of finishing a textile material by applying and binding antimicrobial and / or hydrophilic and / or stain release agents to the textile material so that the agents are essentially irreversibly adhered to the finished textile material.

Owner:LIVINGUARD AG

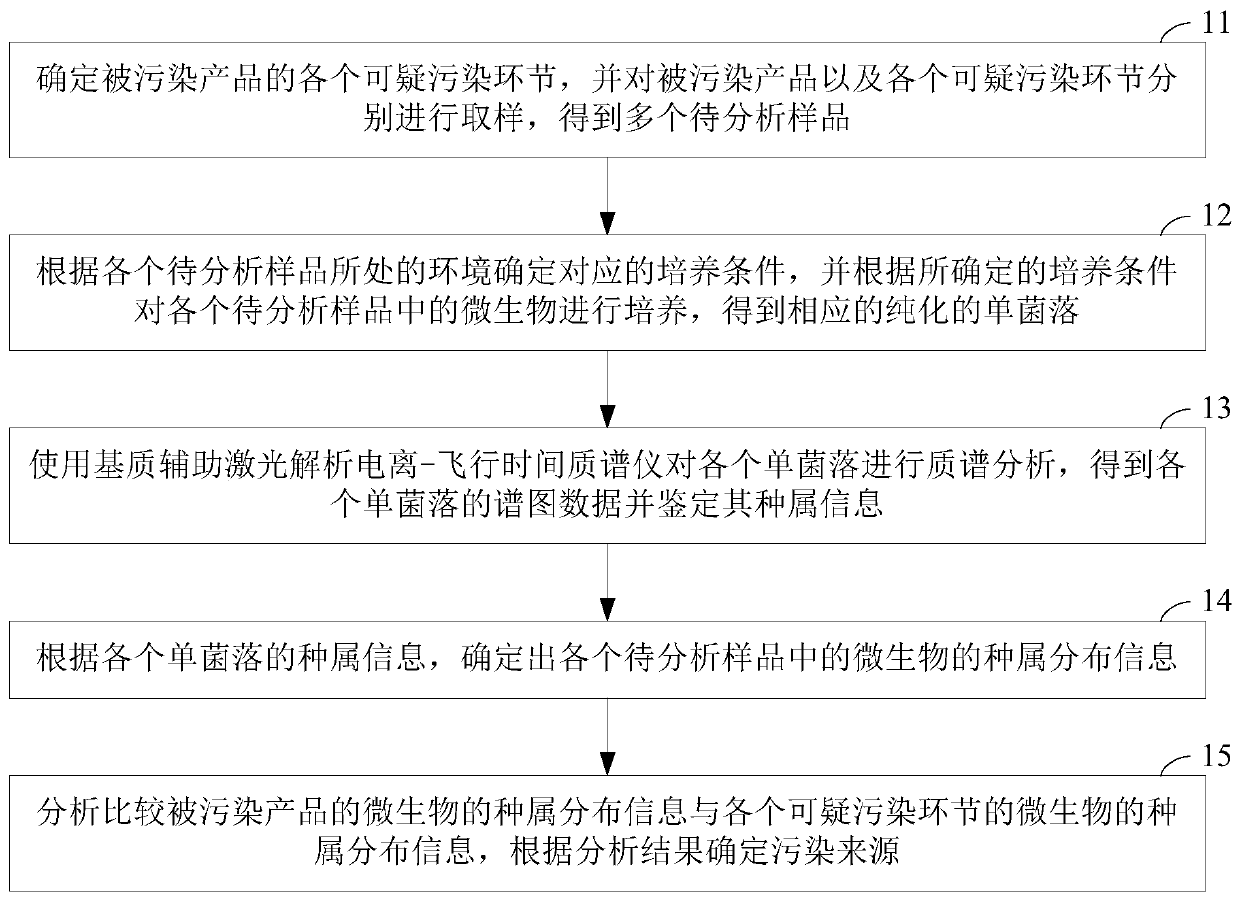

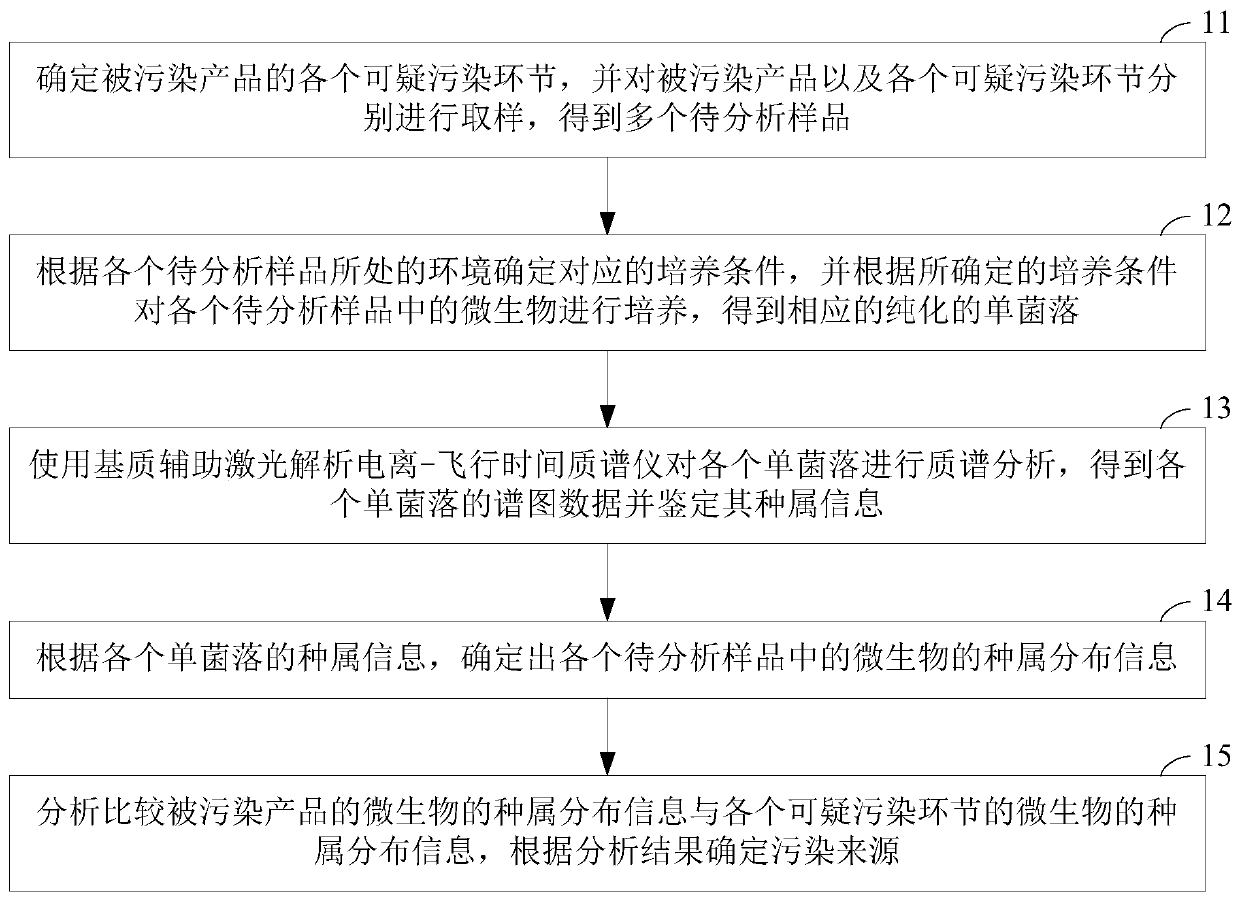

Microbial pollution source tracing method

PendingCN111122689ARealize traceabilityRealization of pollution source traceabilityMaterial analysis by electric/magnetic meansMicroorganismMicrobial pollution

The invention provides a microbial pollution source tracing method. The method comprises the following steps: determining each suspicious pollution link of a polluted product, and respectively carrying out sampling to obtain a plurality of samples to be analyzed; determining corresponding culture conditions according to the environment where each sample to be analyzed is located, and culturing microorganisms in each sample to be analyzed according to the determined culture conditions to obtain corresponding purified single colonies; performing mass spectrometric analysis on each single colonyby using a matrix-assisted laser desorption ionization-time-of-flight mass spectrometer to obtain spectrogram data of each single colony and identify species information of each single colony; determining species distribution information of microorganisms in each sample to be analyzed according to the species information of each single colony; and analyzing and comparing the species distribution information of the microorganisms of the polluted product with the species distribution information of the microorganisms of each suspicious pollution link, and determining a pollution source accordingto an analysis result. According to the invention, microbial pollution source tracing can be rapidly and efficiently realized.

Owner:北京鑫汇普瑞科技发展有限公司

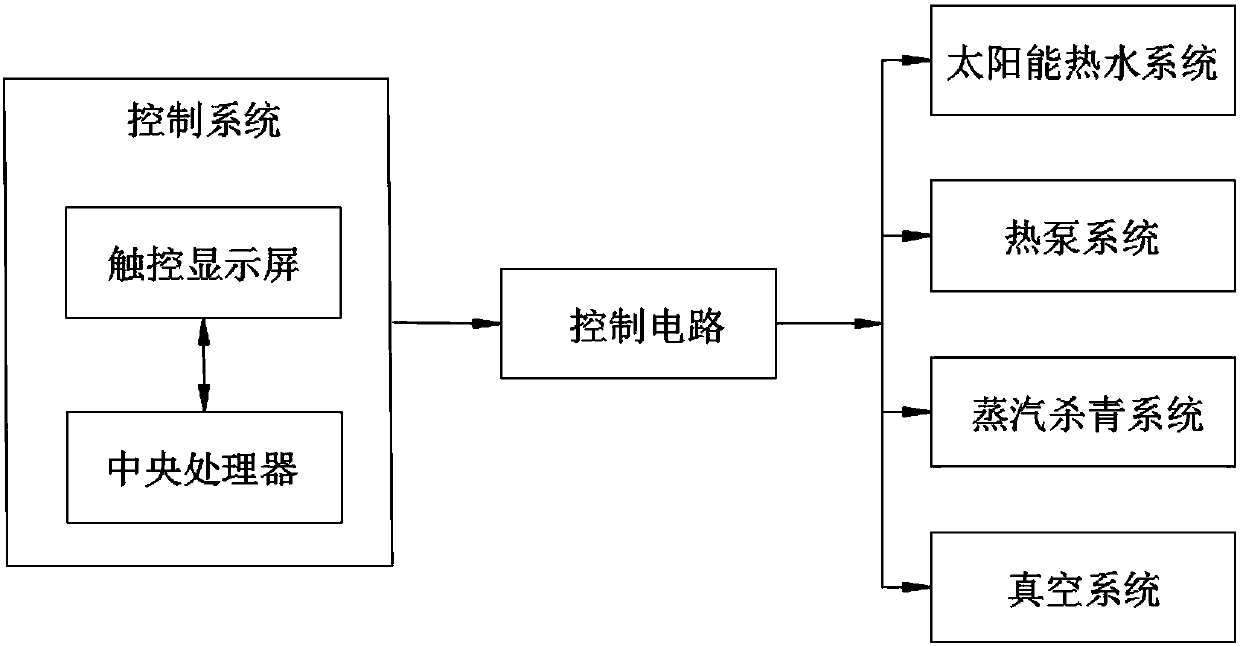

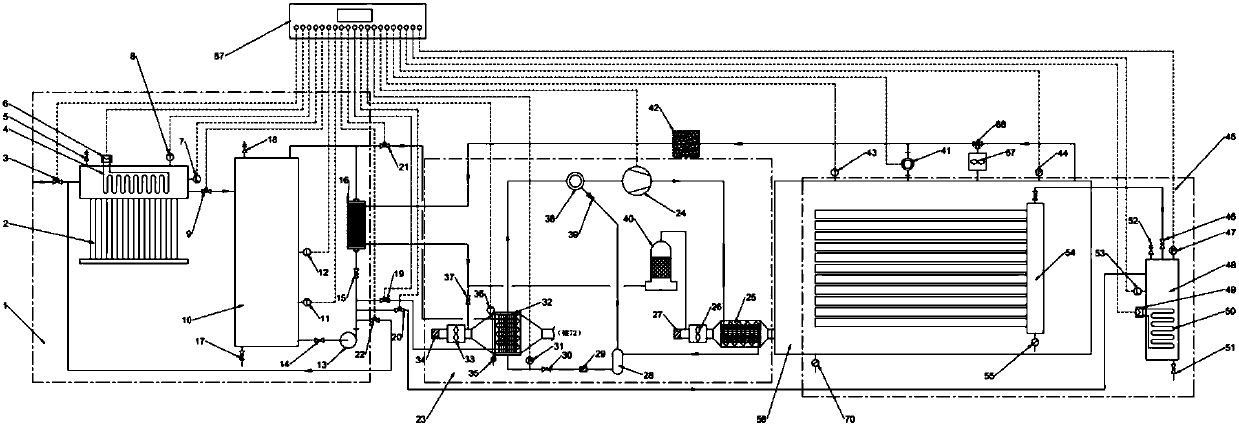

Vacuum coupling steam enzyme deactivation drying device with solar auxiliary heat pump for flos chrysanthemi

PendingCN107549407AUse of economic valueIncrease profitDrying solid materials without heatTea substituesThermodynamicsGas heater

The invention discloses a vacuum coupling steam enzyme deactivation drying device with a solar auxiliary heat pump for flos chrysanthemi. The vacuum coupling steam enzyme deactivation drying device comprises a solar hot-water system, a heat pump system, a vacuum system, a steam enzyme deactivation system, a control system, a spiral tube heat exchanger, a gas heater and a gas drying tower, whereinthe heat pump system, the vacuum system and the steam enzyme deactivation system shares the same drying box. The vacuum coupling steam enzyme deactivation drying device can be used for forming the advantage complementary integration of two methods of solar auxiliary heat pump drying and vacuum drying; the drying processes of the saturated steam enzyme deactivation, the heat pump drying, the softening and the vacuum drying of the flos chrysanthemi are realized; meanwhile, essential oil volatilized in the drying procedure of the flos chrysanthemi is recovered. The vacuum coupling steam enzyme deactivation drying device is energy-saving and high-efficiency, is uniform in drying and has no microbial contamination; a dried product of the flos chrysanthemi is high in quality; the visual real-time monitoring can be realized and the economic value of the flos chrysanthemi is furthest utilized.

Owner:CHUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com